Patents

Literature

46results about How to "Avoid turnover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for tunneling extrahard rock by means of hydraulic fracturing technology and tunneling machine

ActiveCN107083967AAvoid turnoverEffective controlHydro energy generationTunnelsEngineeringHydraulic fracturing

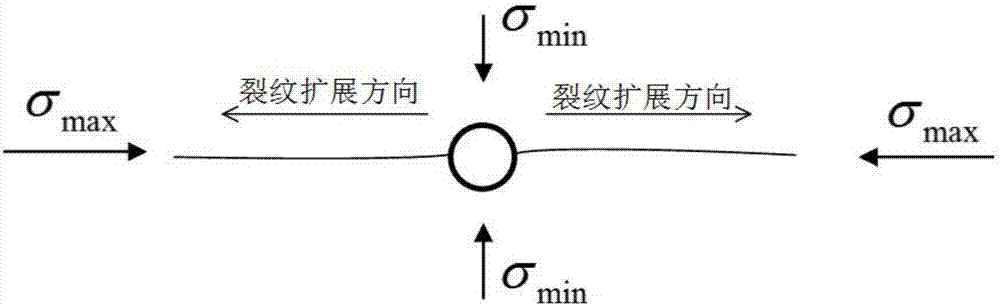

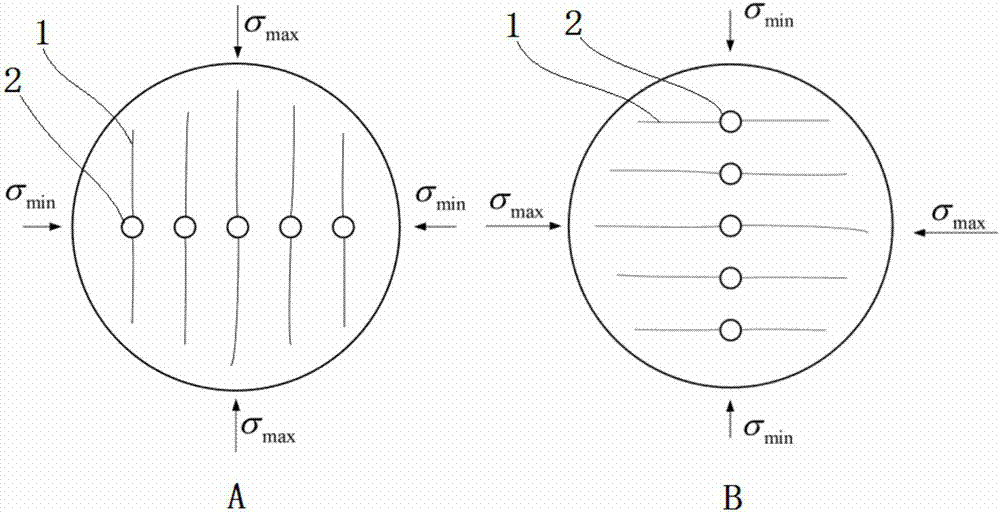

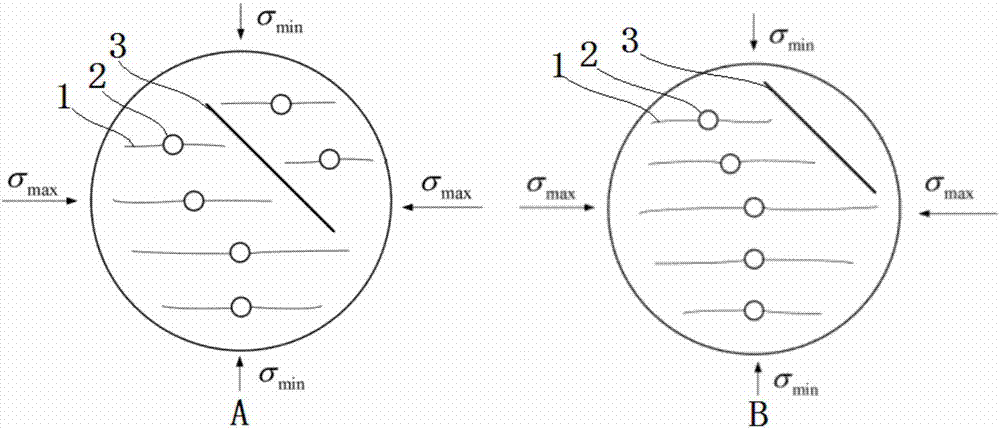

The invention relates to a method and system for tunneling extrahard rock by means of a hydraulic fracturing technology and a tunneling machine. By means of the hydraulic fracturing technology, the extrahard complete rock generates cracks, and therefore the rock integrity is lowered; according to the formation condition, the drilled hole position and the fracturing sequence of a face are designed, a drill rod stretches out of a hole to perform perpendicular punching in sequence on the face, a to-be-fractured section inside the drilled hole is sealed through a packer, high-pressure water is pumped into the to-be-fractured section, the hydraulic pressure is increased continuously, after the hole wall is fractured, cracks are expanded, and pressurizing is stopped after the cracks are expanded to the preset length, the packer together with other fracturing devices is taken out, and the tunneling machine begins tunneling. According to the method and system, the integrity of the rock within the construction range is lowered, the tool abrasion during tunneling is reduced, and the tunneling efficiency is improved.

Owner:WUHAN UNIV

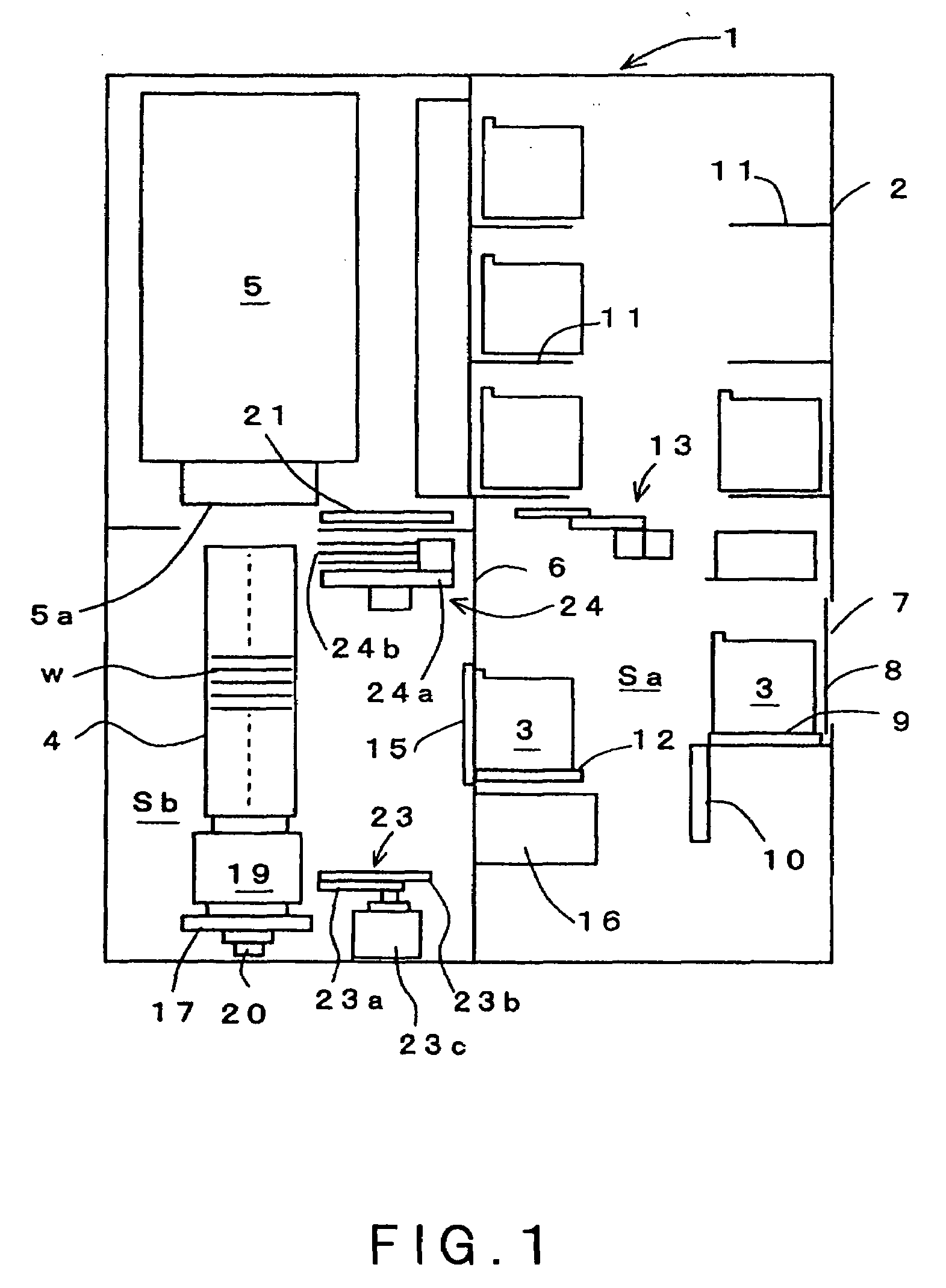

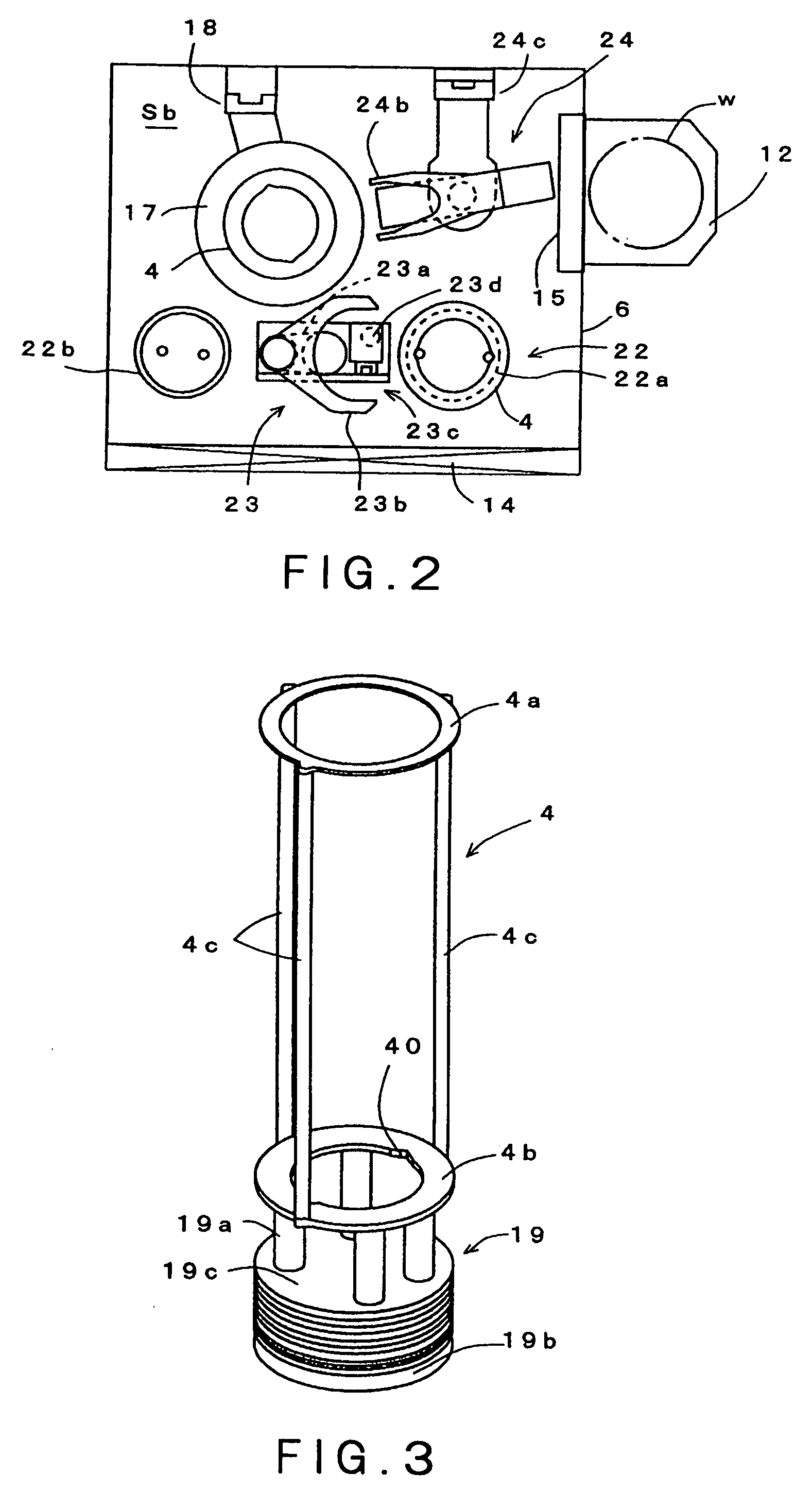

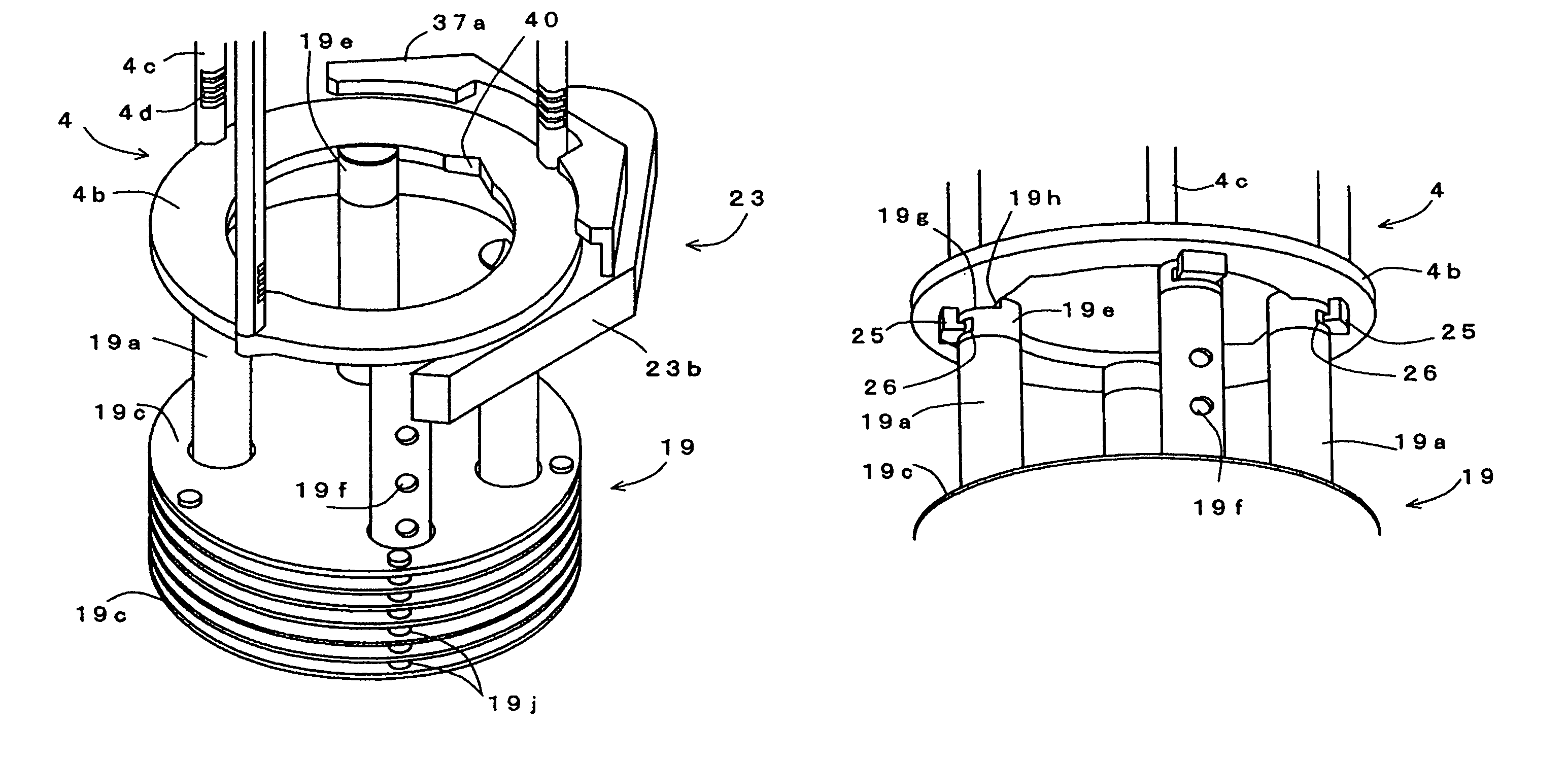

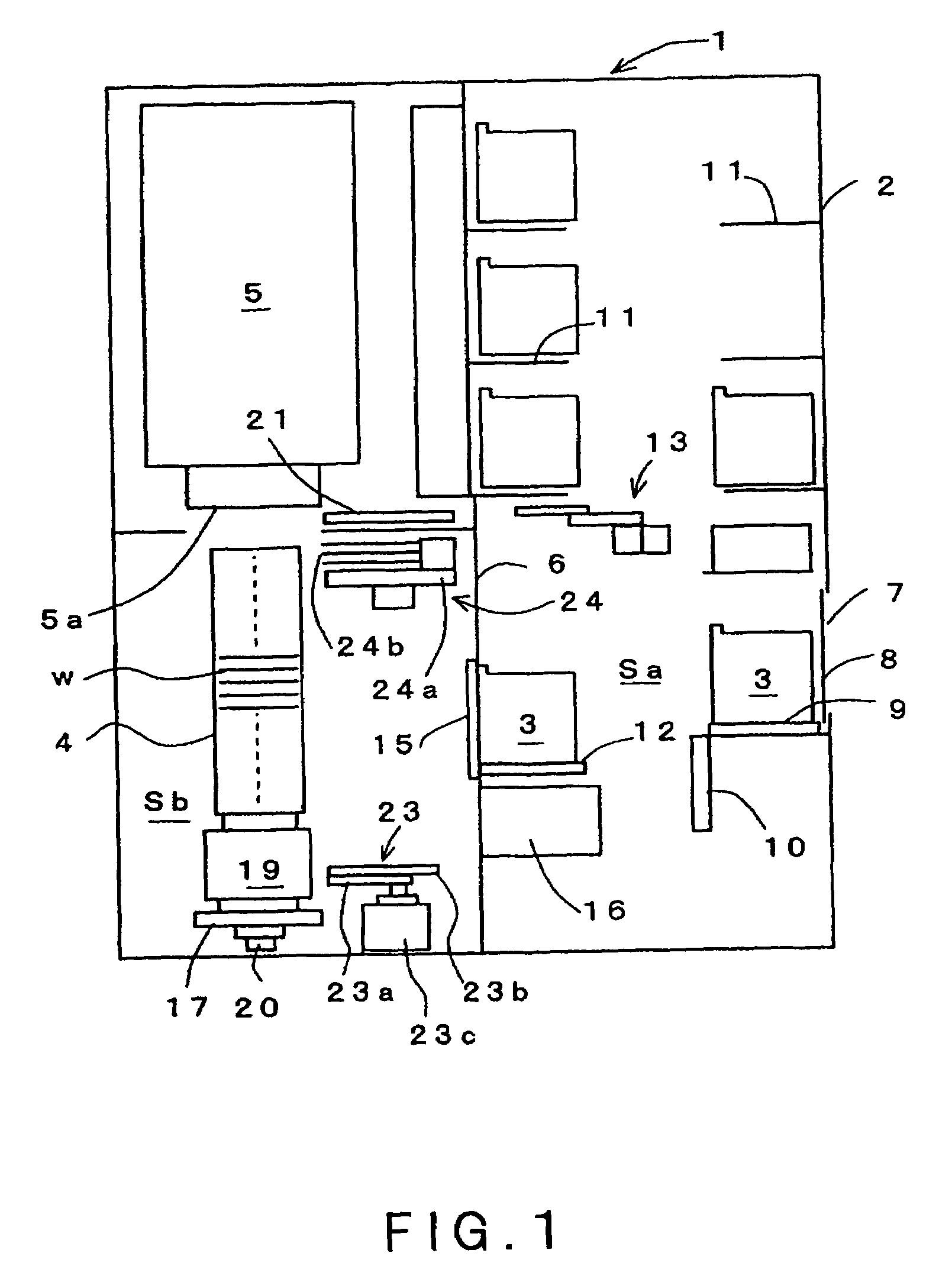

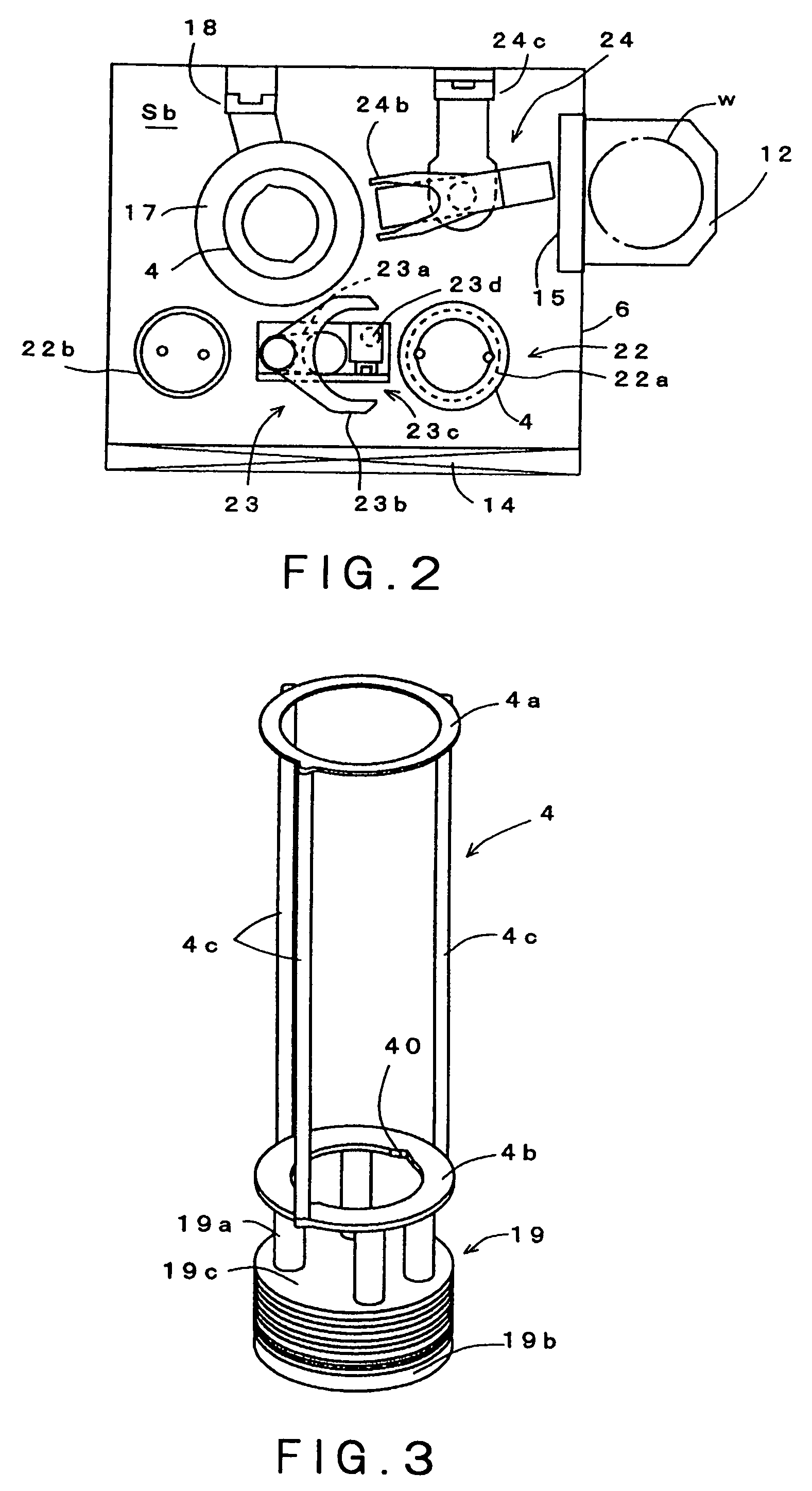

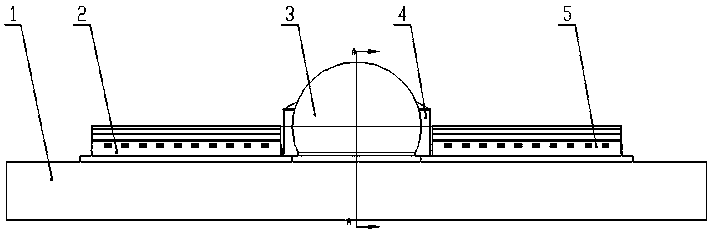

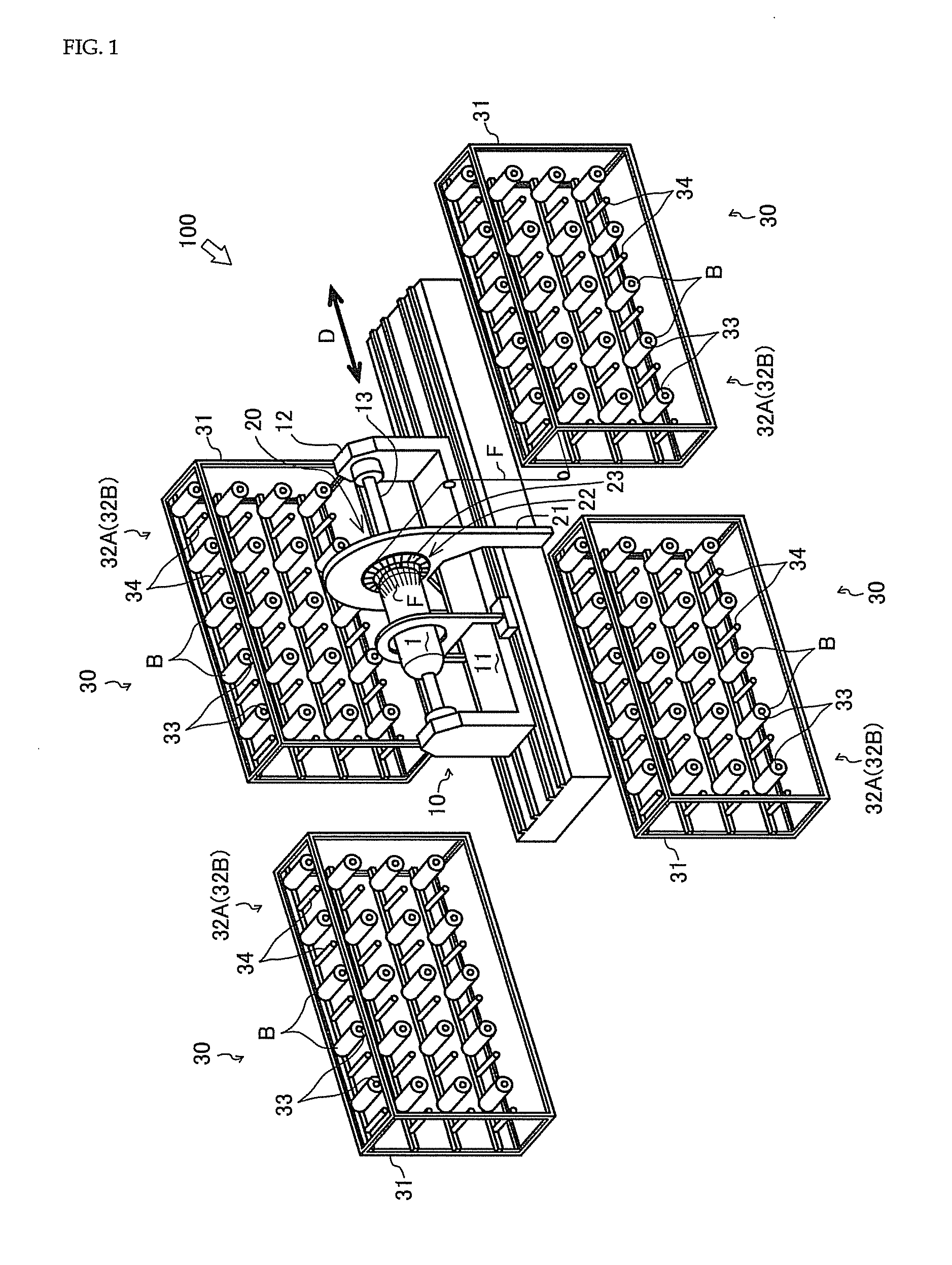

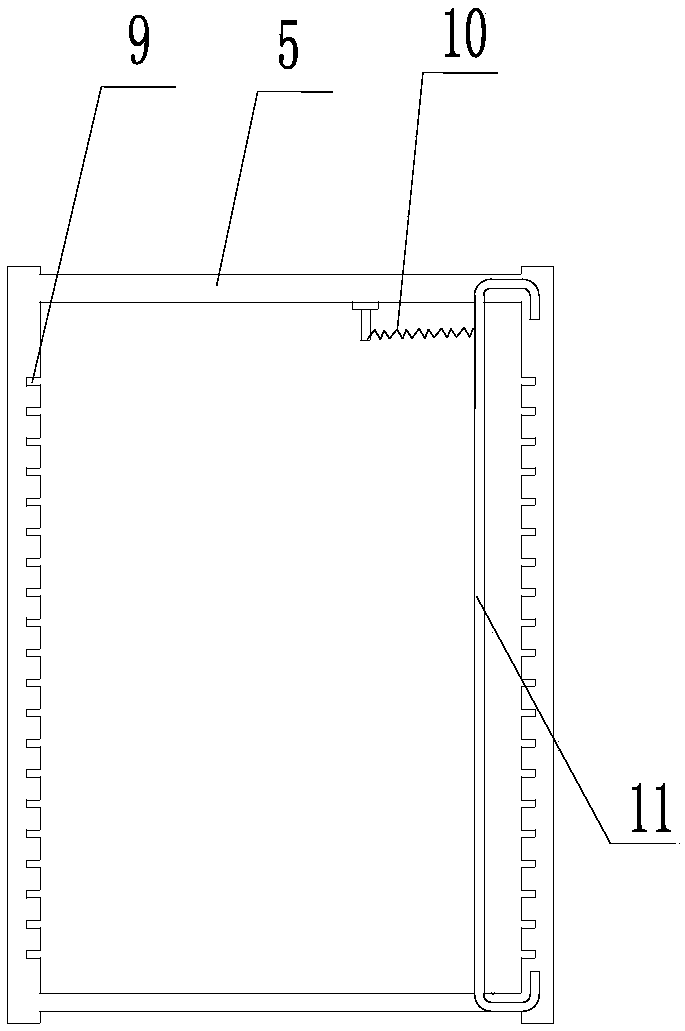

Vertical heat processing apparatus and heat processing method using the vertical heat processing apparatus

ActiveUS20080199818A1Simple structureAvoid turnoverCharge supportsSemiconductor/solid-state device manufacturingHeat processingElectrical and Electronics engineering

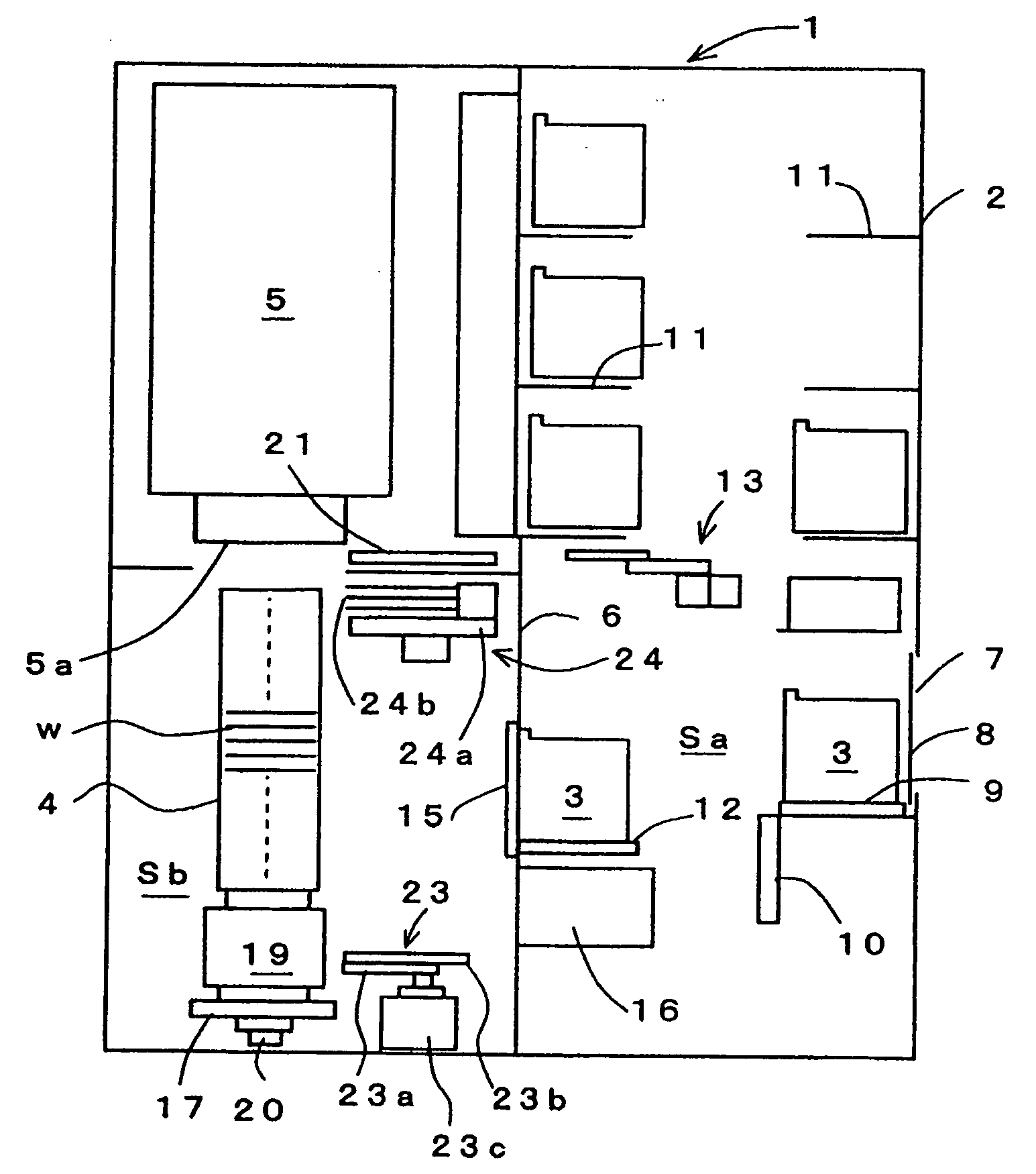

The present invention is a vertical heat processing apparatus comprising: a heat processing furnace having a furnace opening; a lid member for closing the furnace opening of the heat processing furnace; a first substrate holder and a second substrate holder, each of which is capable of holding a plurality of substrates in a tier-like manner and of being alternately placed on the lid member through a heat retention tube; an elevating mechanism that vertically moves the lid member to load one of the substrate holders into the heat processing furnace, and to unload the one of the substrate holders from the heat processing furnace; a holder table configured to be placed thereon the other of the substrate holders for transfer of the substrates, when the one of the substrate holders is in the heat processing furnace; and a holder conveying mechanism configured to convey the respective substrate holders between the holder table and the heat retention tube; wherein the holder table is provided with a holder gripping mechanism for gripping the substrate holder to prevent turnover thereof.

Owner:TOKYO ELECTRON LTD

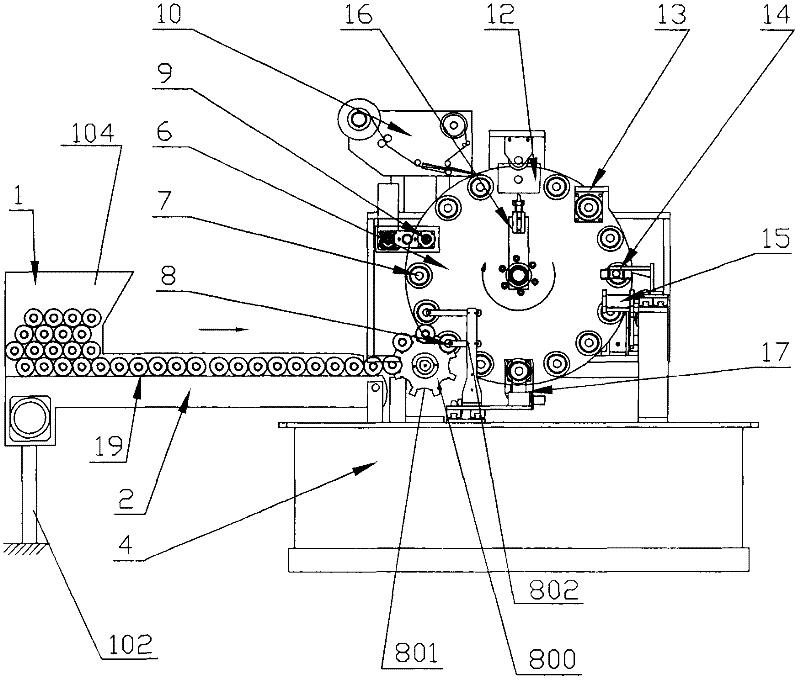

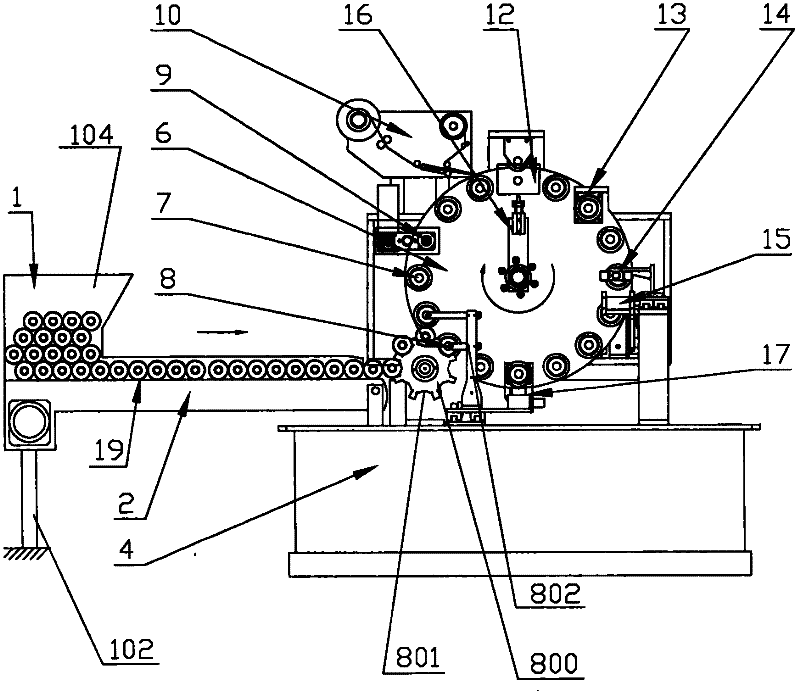

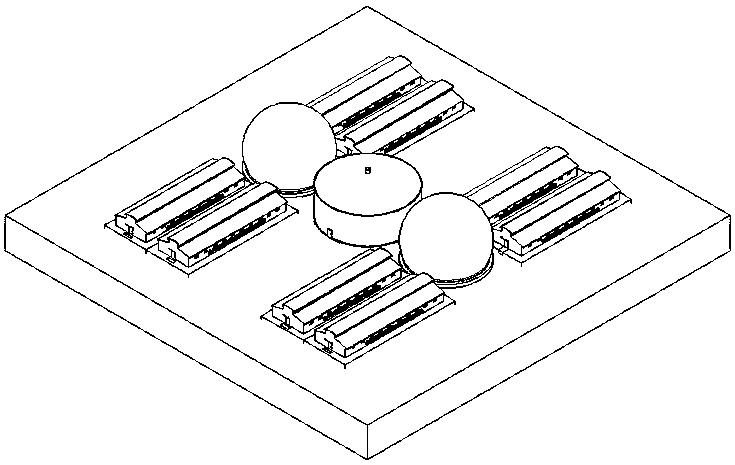

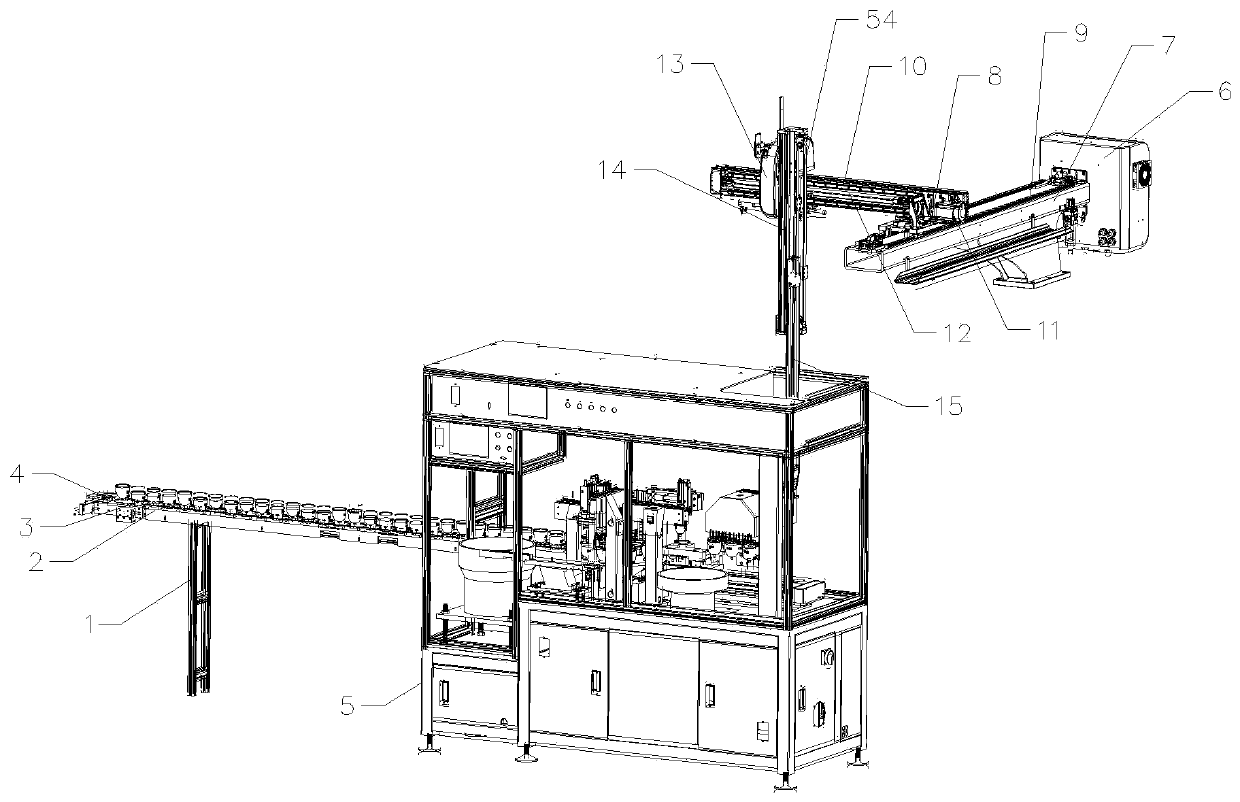

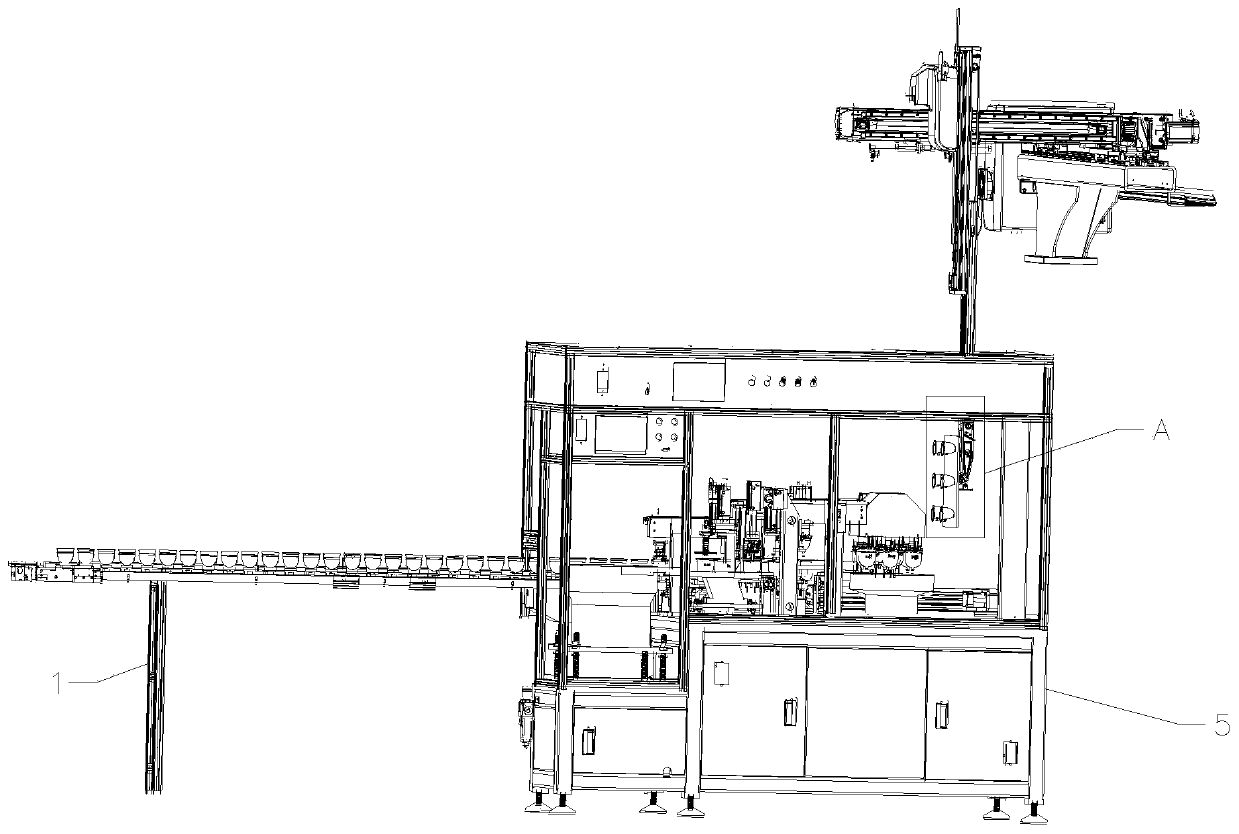

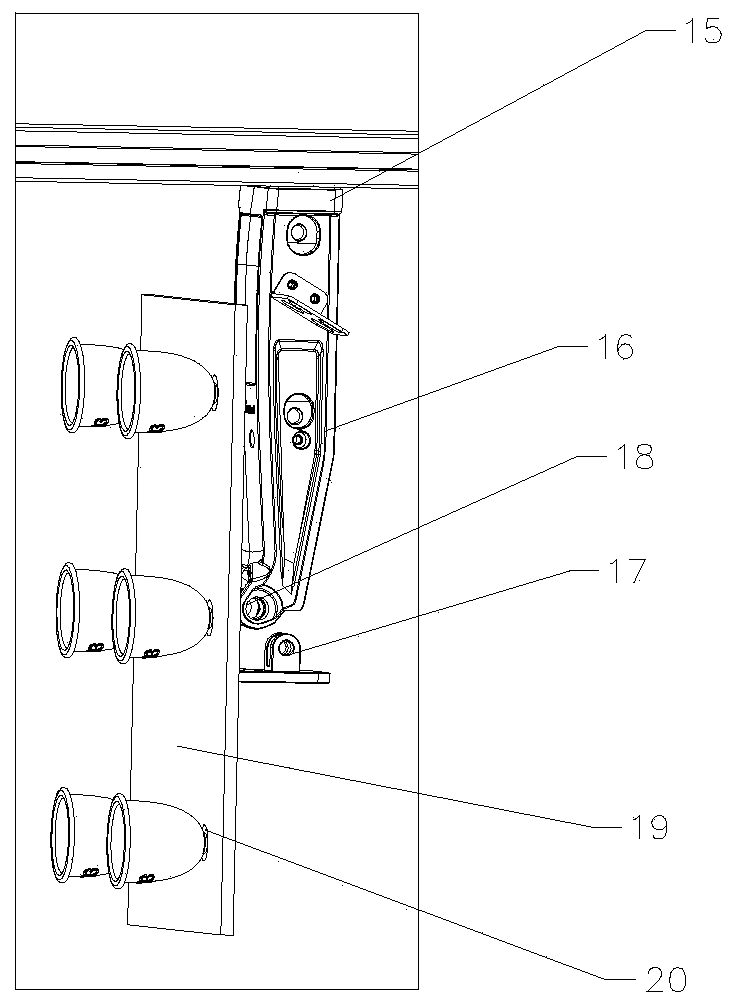

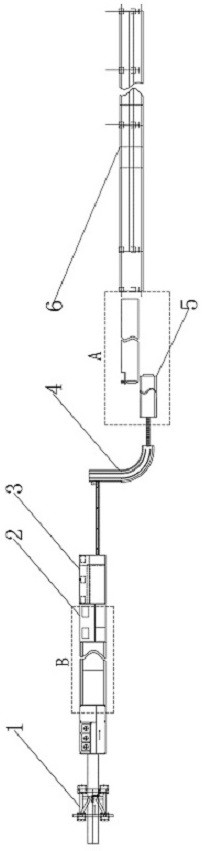

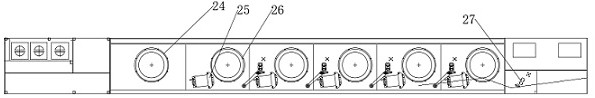

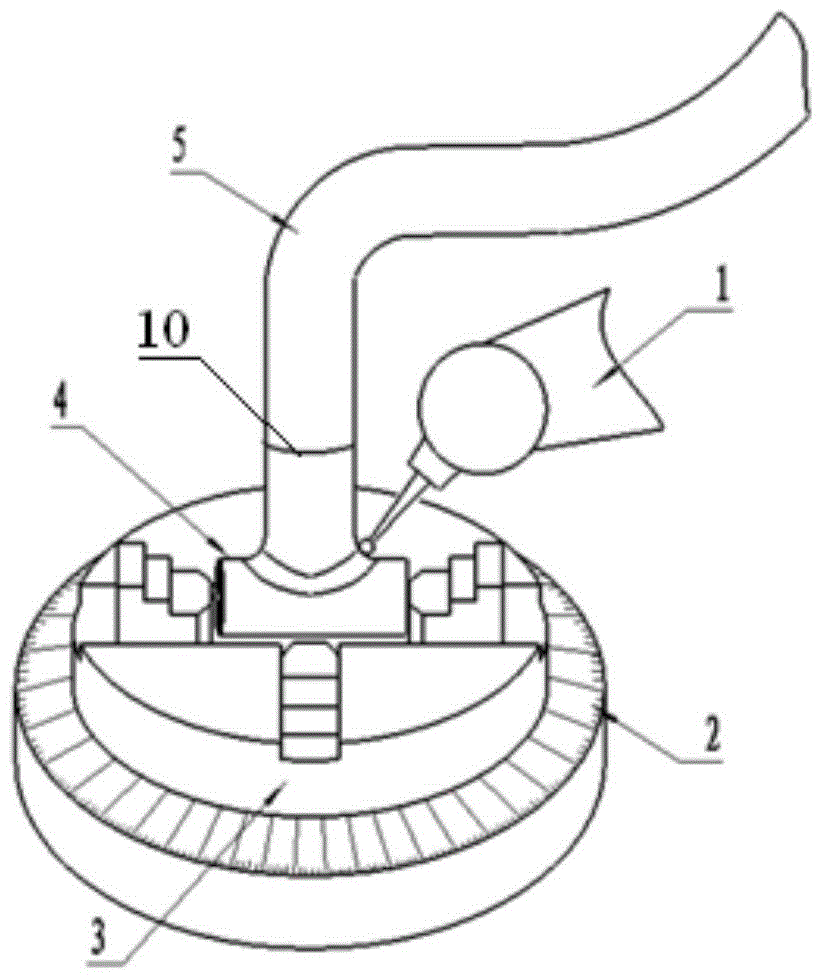

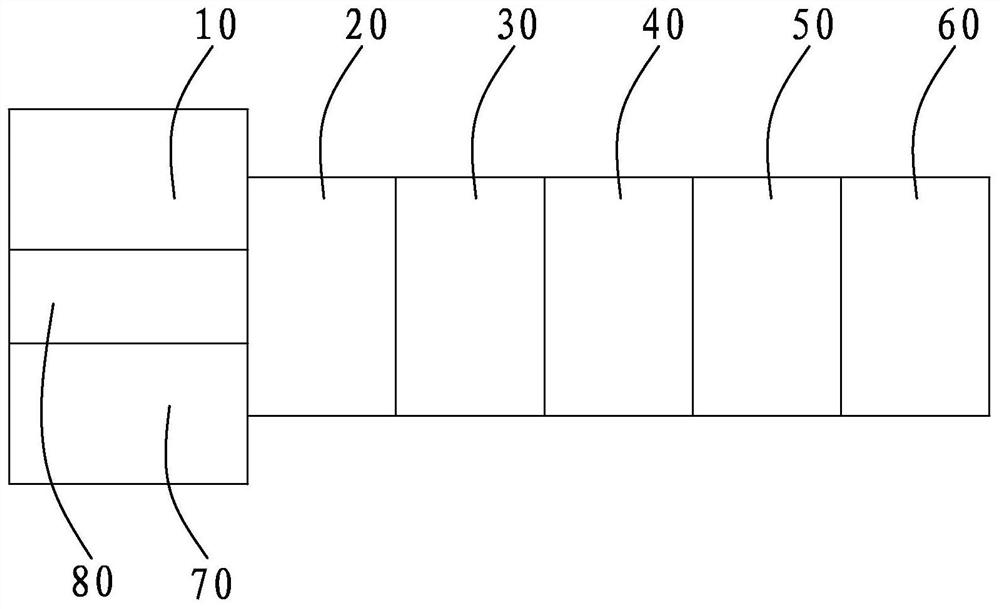

Device for production of packaging hose and use method thereof

The invention relates to a device for production of a packaging hose and a use method of the device. The device comprises a bracket, a rotary disc arranged on the bracket, a printing core arranged on the rotary disc, a hose feeding mechanism, a sealing mechanism, a labeling mechanism, a capping mechanism, a cap fastening mechanism, a blowing and discharging mechanism, a discharge transfer belt, a hose cutting mechanism, a waste discharging mechanism and a circuit control system. The hose feeding mechanism, the sealing mechanism, the labeling mechanism, the capping mechanism / the hose cutting mechanism, the blowing and discharging mechanism, the discharge transfer belt and the waste discharging mechanism are arranged orderly along the circumferential direction of the rotary disc and are controlled by the circuit control system. The device has the multifunction of integrating hose feeding, sealing, labeling, capping, hose cutting, cap fastening, hose discharging, waste discharging and the like, avoids the turnover among cockamamie steps, is beneficial to saving manpower cost and can improve the production efficiency.

Owner:SHENZHEN BEAUTY STAR

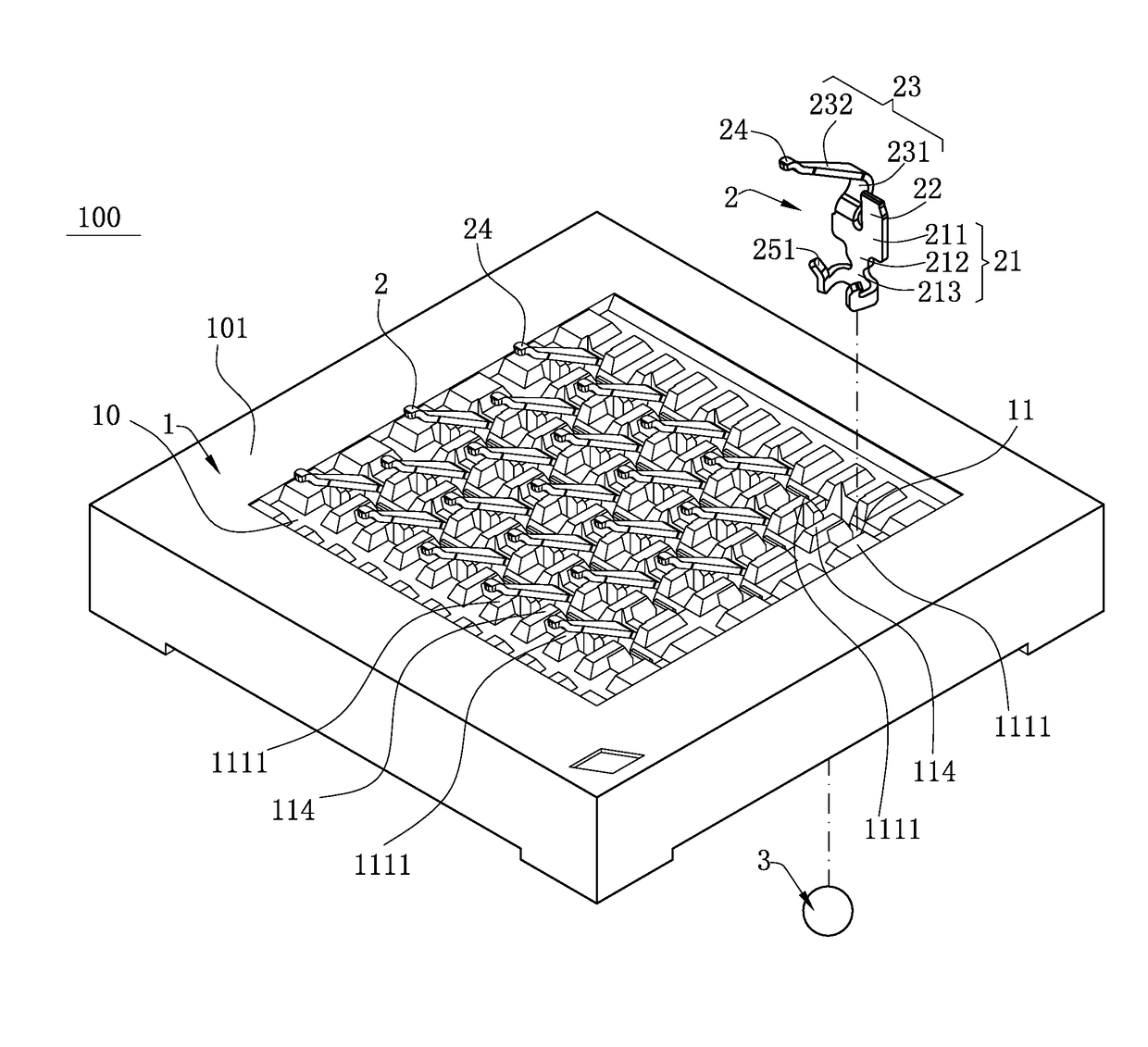

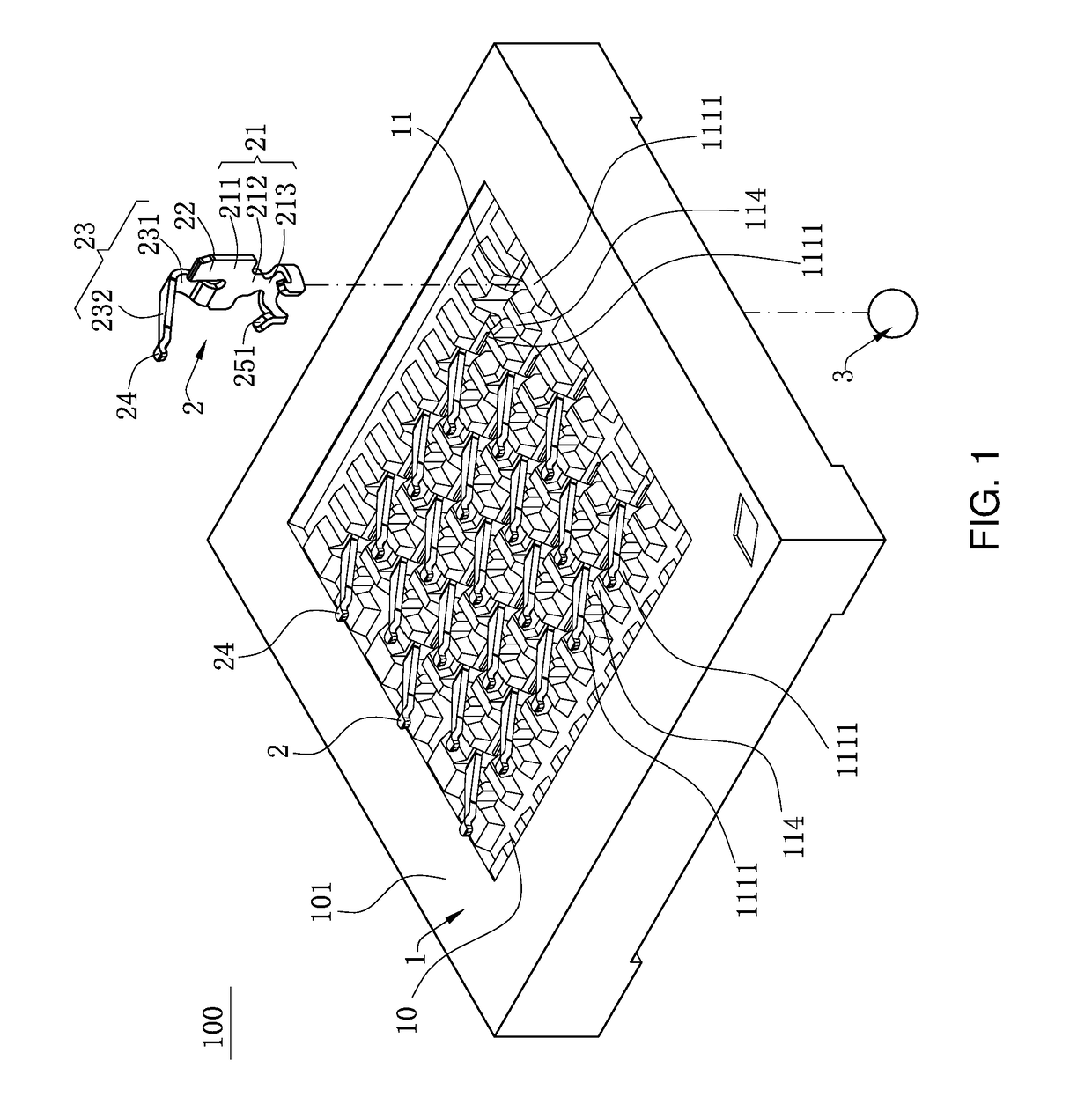

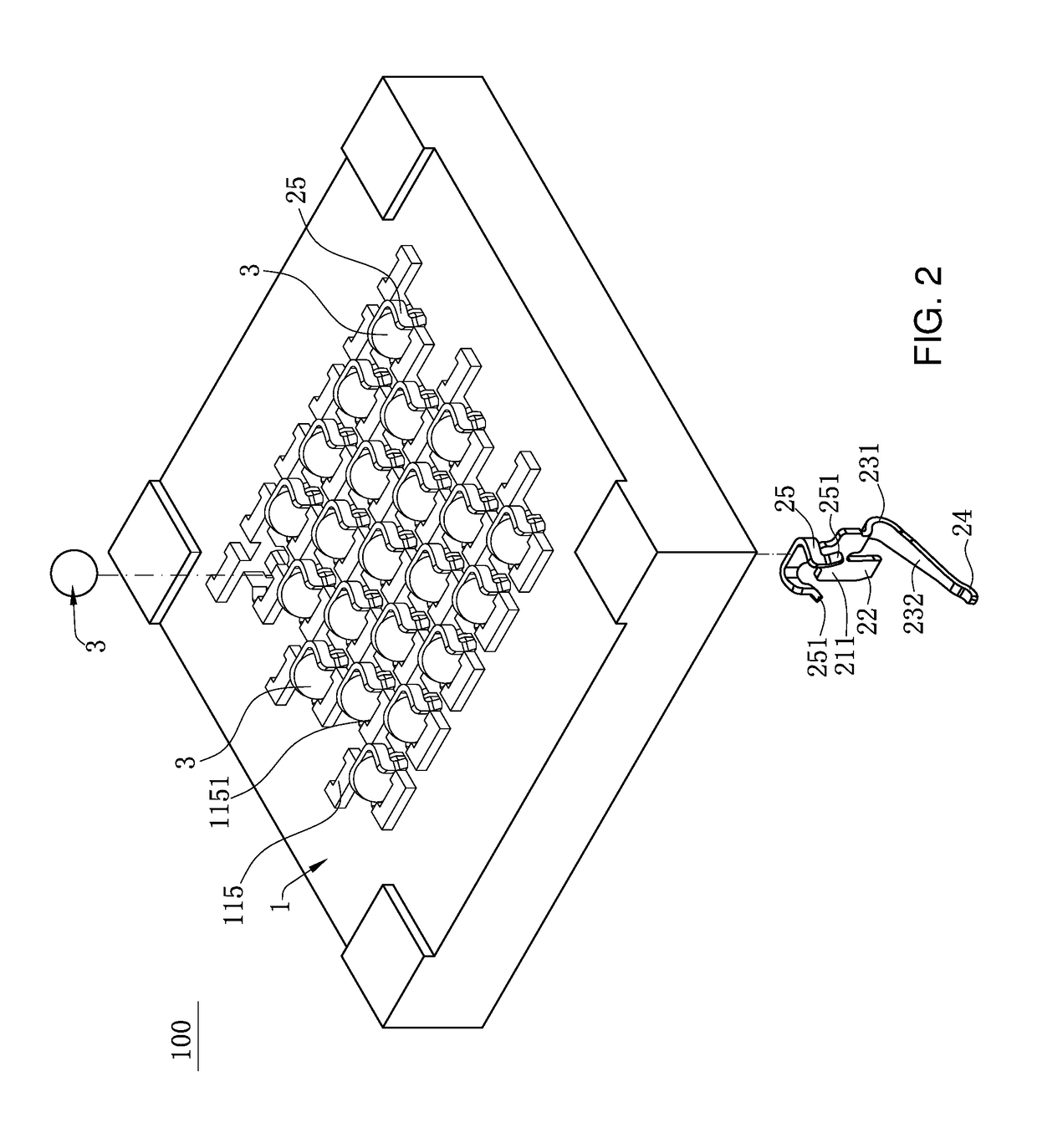

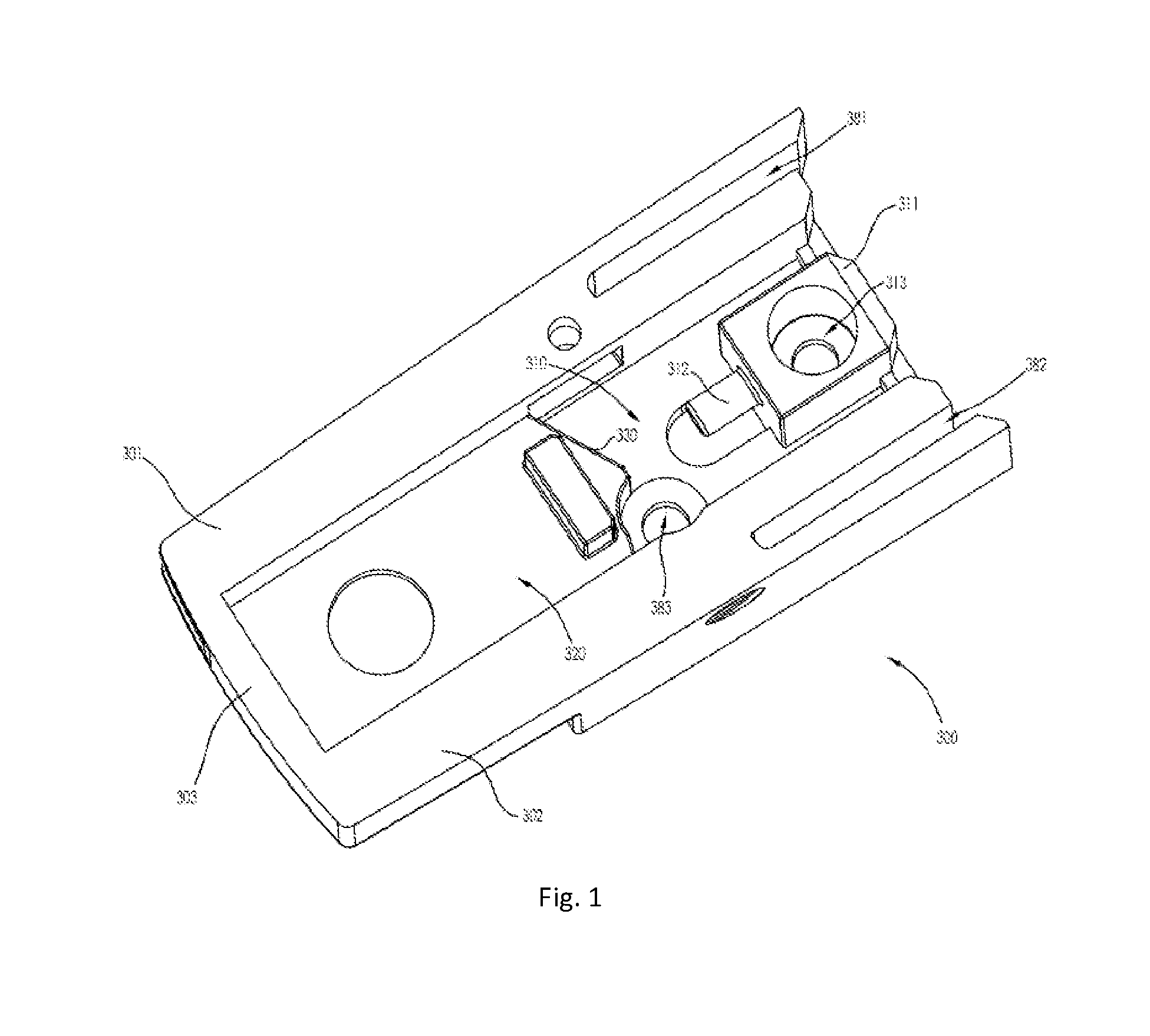

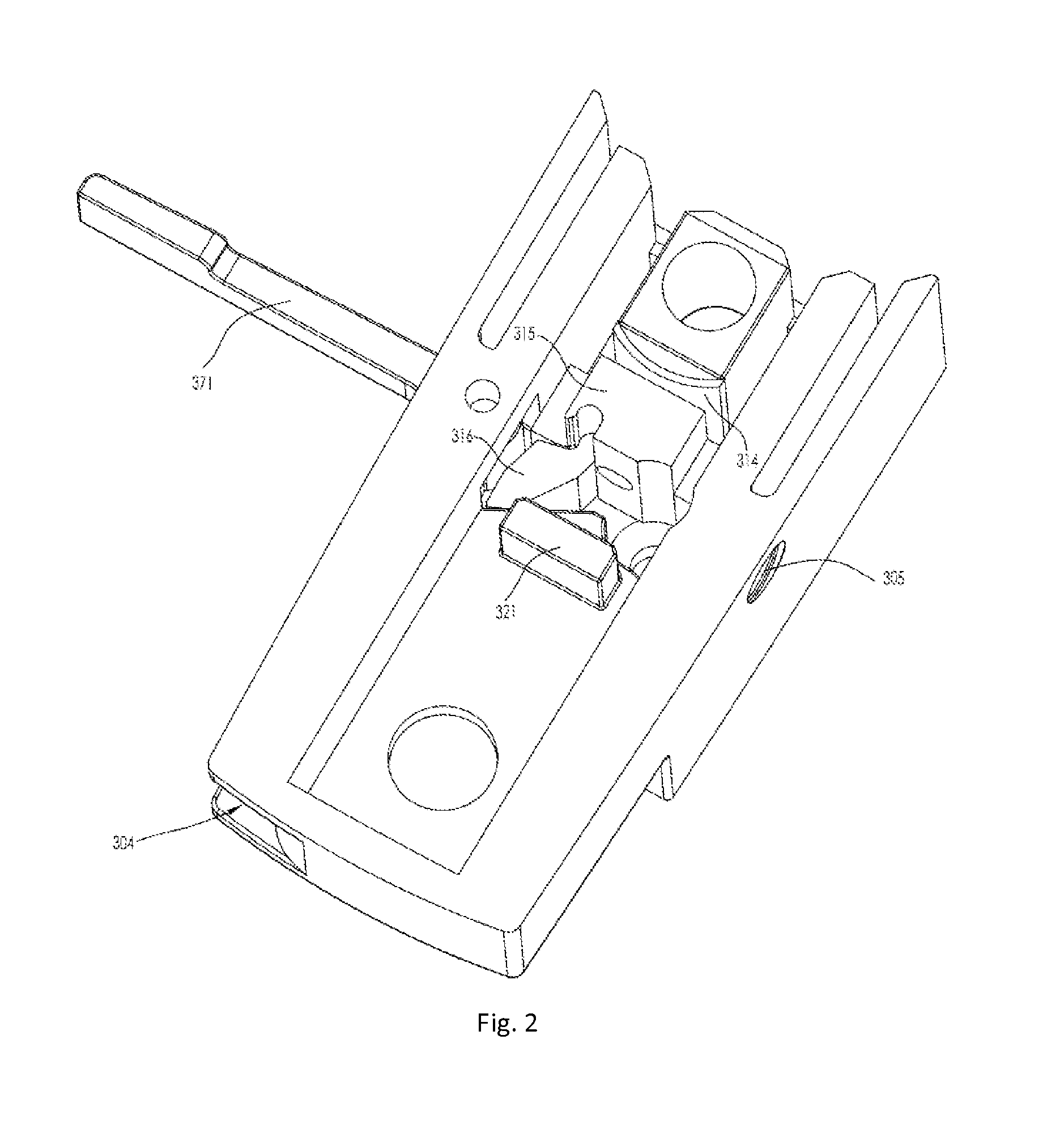

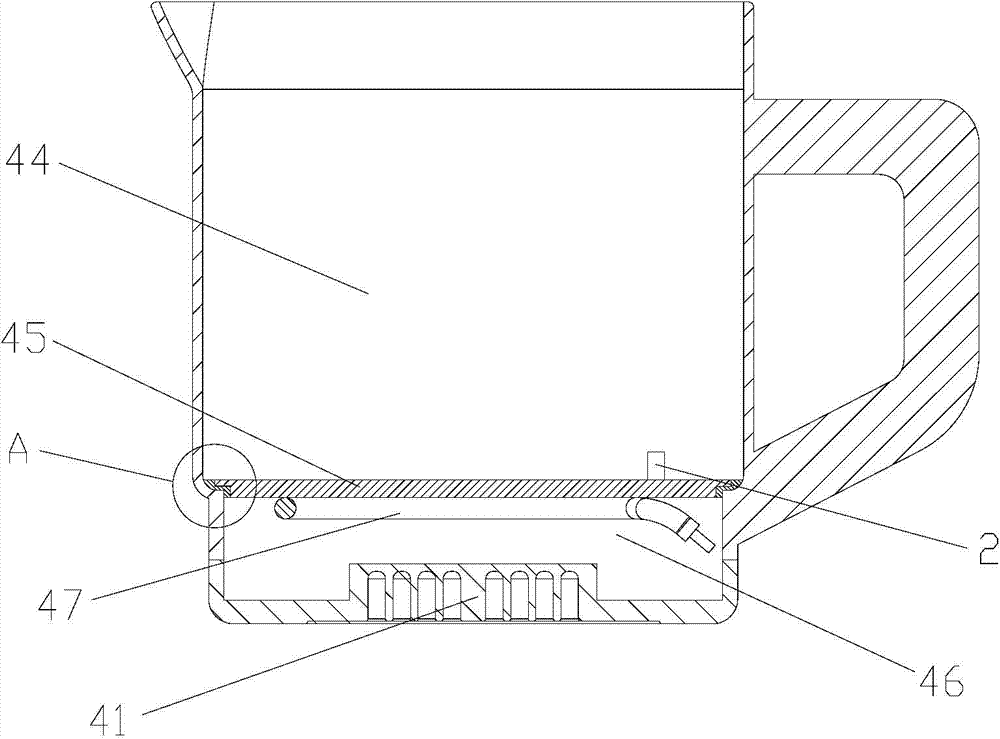

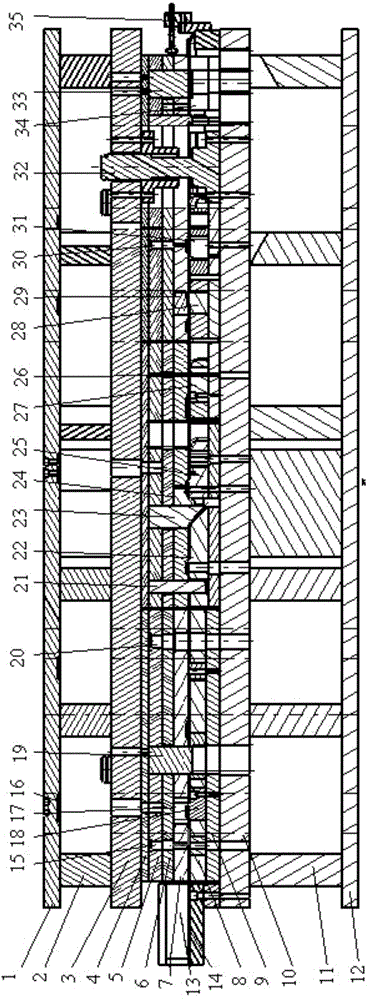

Electrical connector

ActiveUS9806444B1Improve production yieldSimple terminal structureCoupling contact membersFixed connectionsElectrical connectorMechanical engineering

An electrical connector includes an insulating body having a bottom plate with receiving slots and multiple terminals received in the receiving slots. Each receiving slot has two opposite first side walls, and a second and third side walls connecting the first side walls. A protruding block protrudes from the second side wall toward the third side wall. Each terminal has a plate portion, an elastic arm and a material connecting portion extending upward from the plate portion, a contact portion at a top end of the elastic arm to urge a chip module, and two clamping portions bending and extending from two opposite sides of the plate portion horizontally. The plate portion and the material connecting portion are limited between the protruding block and the third side wall. Tin balls are fixed between the clamping portions, and soldered to a circuit board. The tin balls are below the protruding block.

Owner:LOTES

Vertical heat processing apparatus and heat processing method using the vertical heat processing apparatus

ActiveUS7896648B2Simple structureAvoid turnoverCharge supportsSemiconductor/solid-state device manufacturingEngineeringHeat processing

The present invention is a vertical heat processing apparatus comprising: a heat processing furnace having a furnace opening; a lid member for closing the furnace opening of the heat processing furnace; a first substrate holder and a second substrate holder, each of which is capable of holding a plurality of substrates in a tier-like manner and of being alternately placed on the lid member through a heat retention tube; an elevating mechanism that vertically moves the lid member to load one of the substrate holders into the heat processing furnace, and to unload the one of the substrate holders from the heat processing furnace; a holder table configured to be placed thereon the other of the substrate holders for transfer of the substrates, when the one of the substrate holders is in the heat processing furnace; and a holder conveying mechanism configured to convey the respective substrate holders between the holder table and the heat retention tube; wherein the holder table is provided with a holder gripping mechanism for gripping the substrate holder to prevent turnover thereof.

Owner:TOKYO ELECTRON LTD

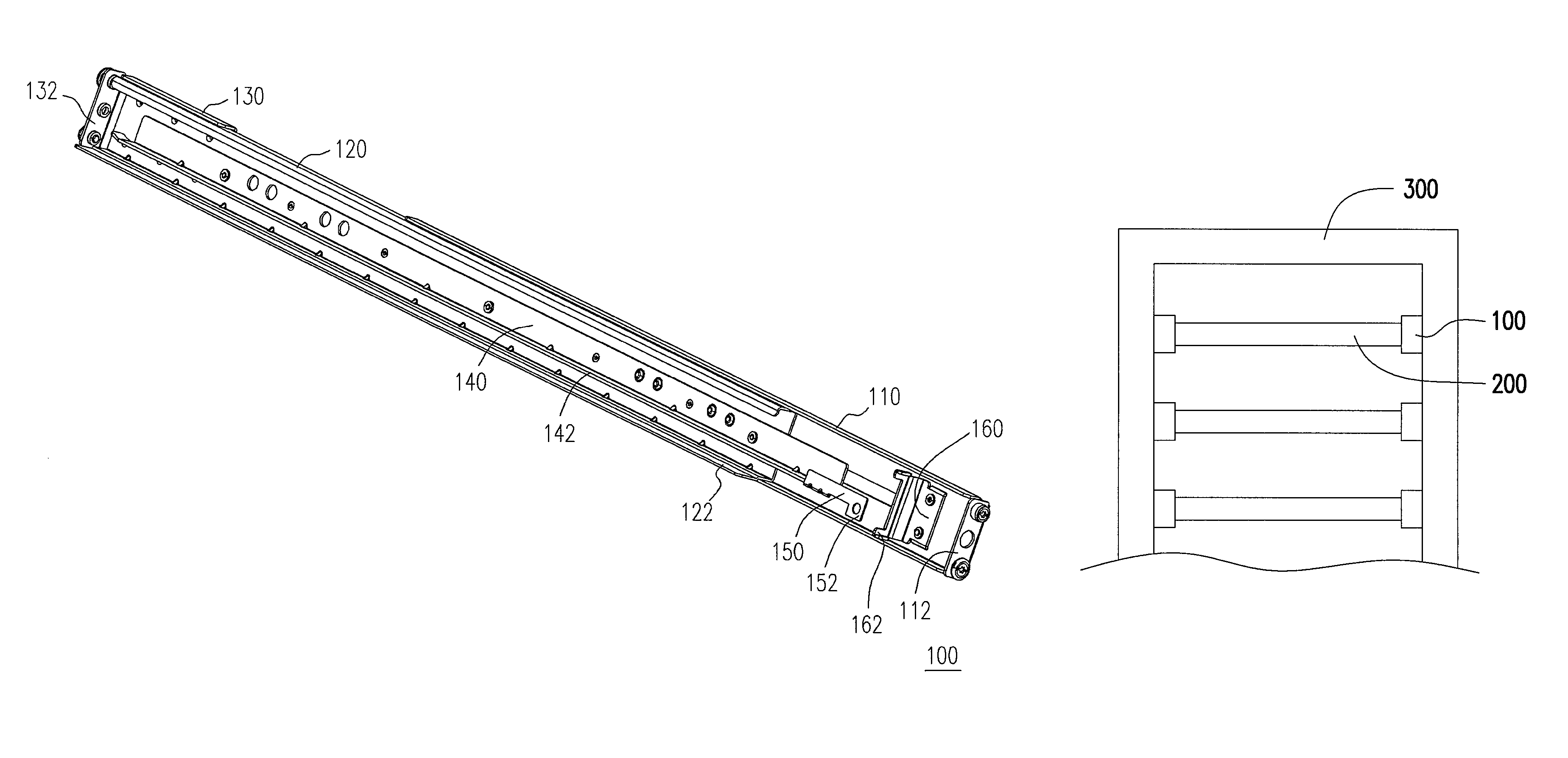

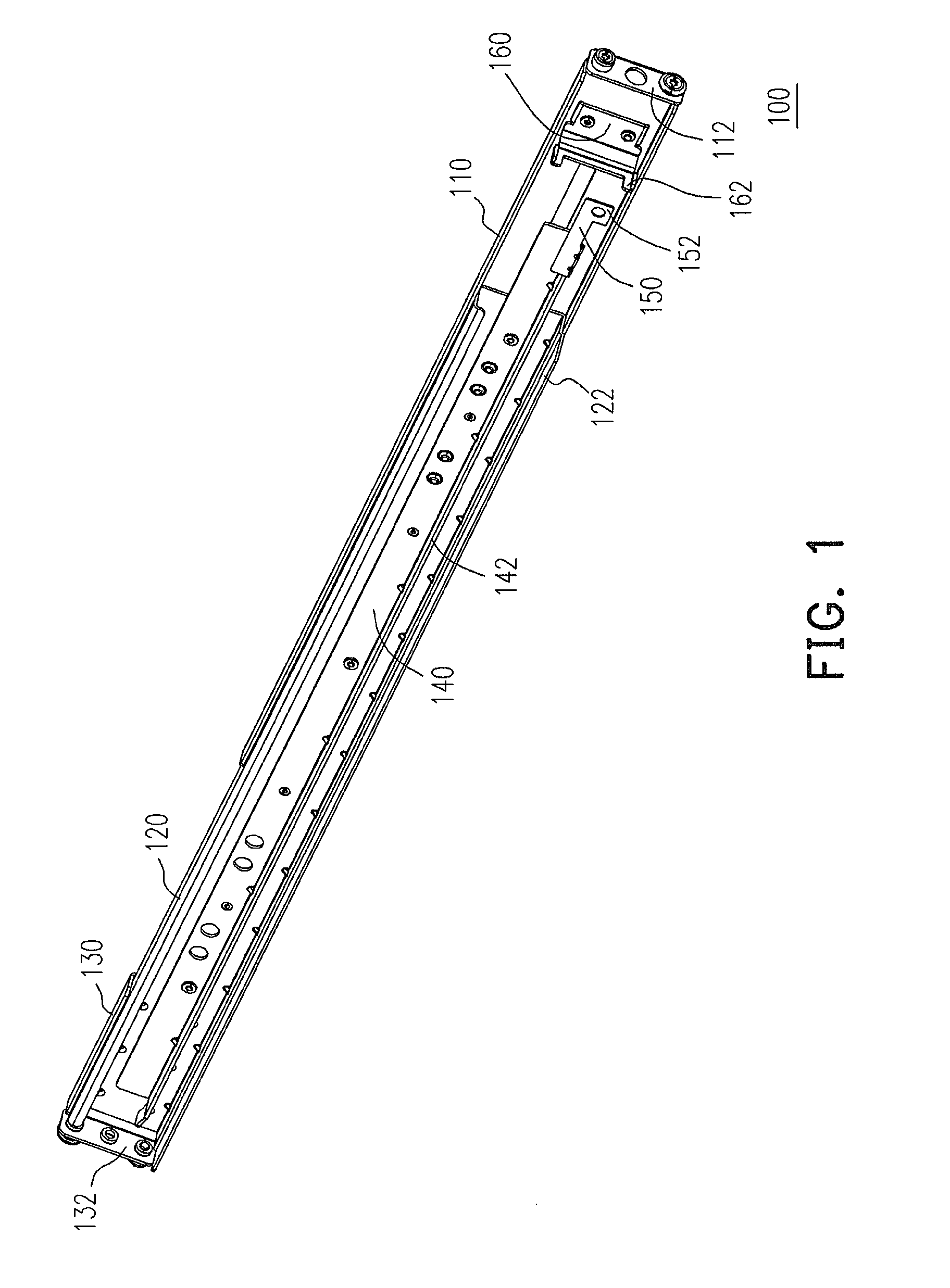

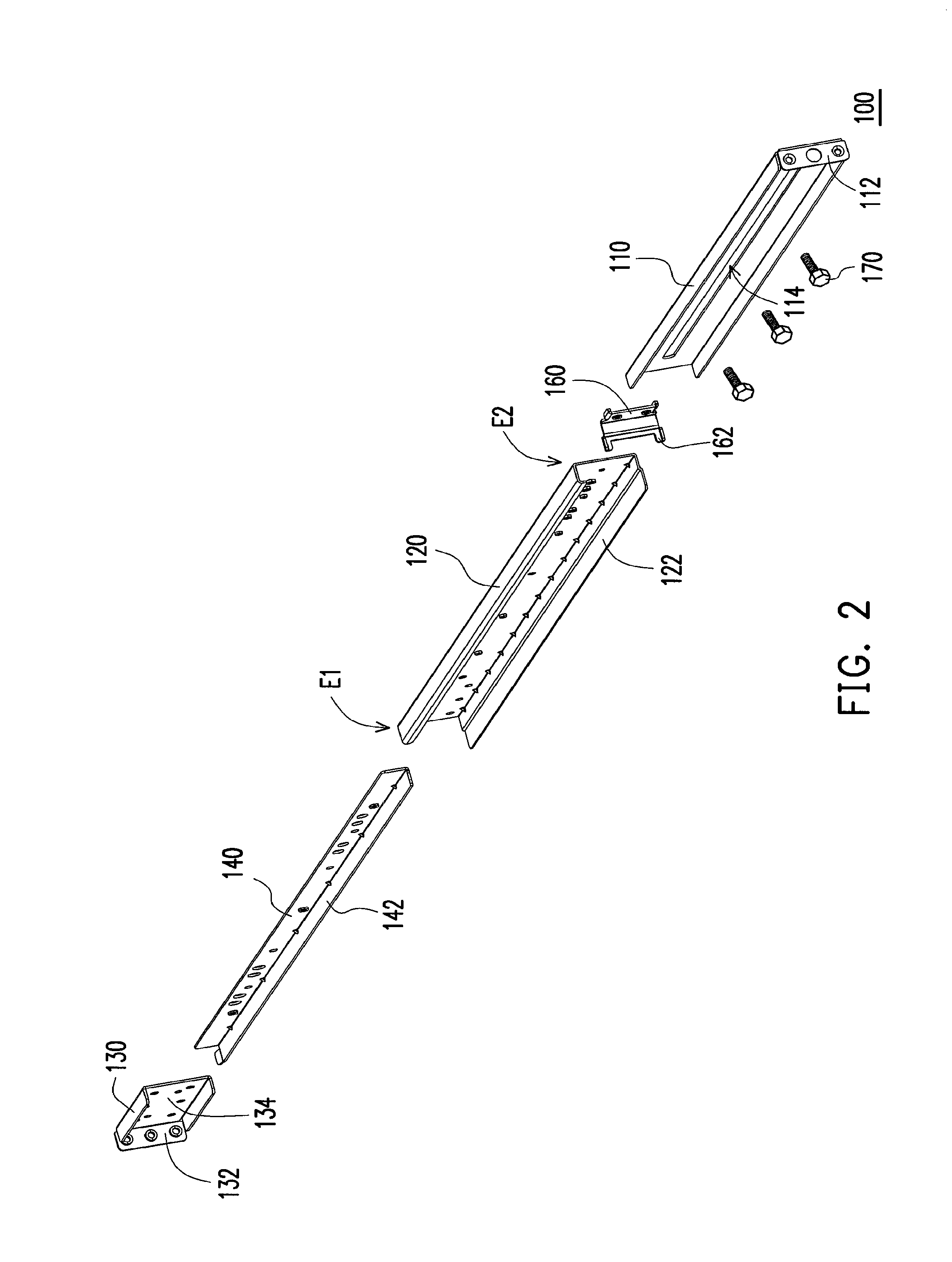

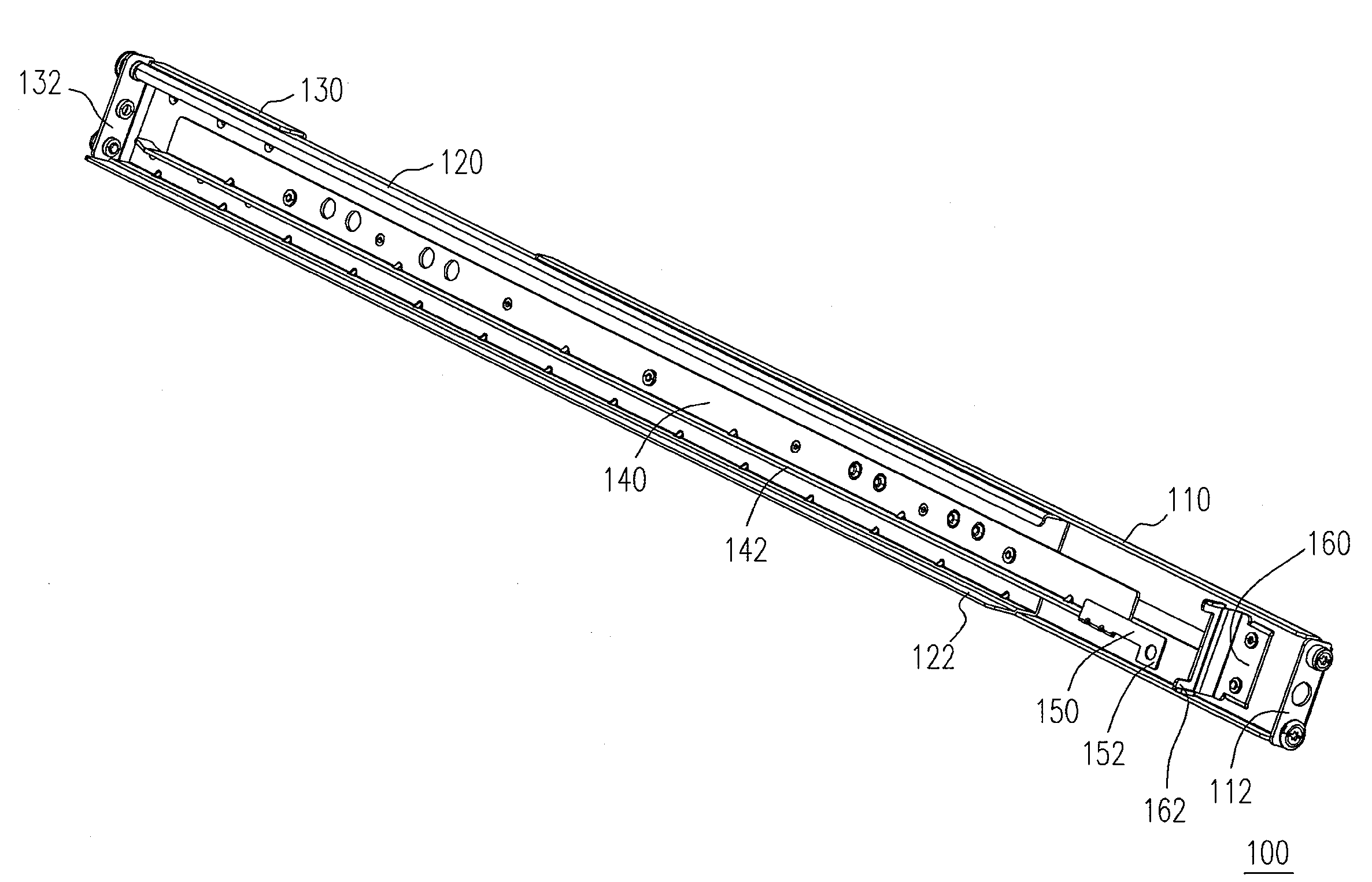

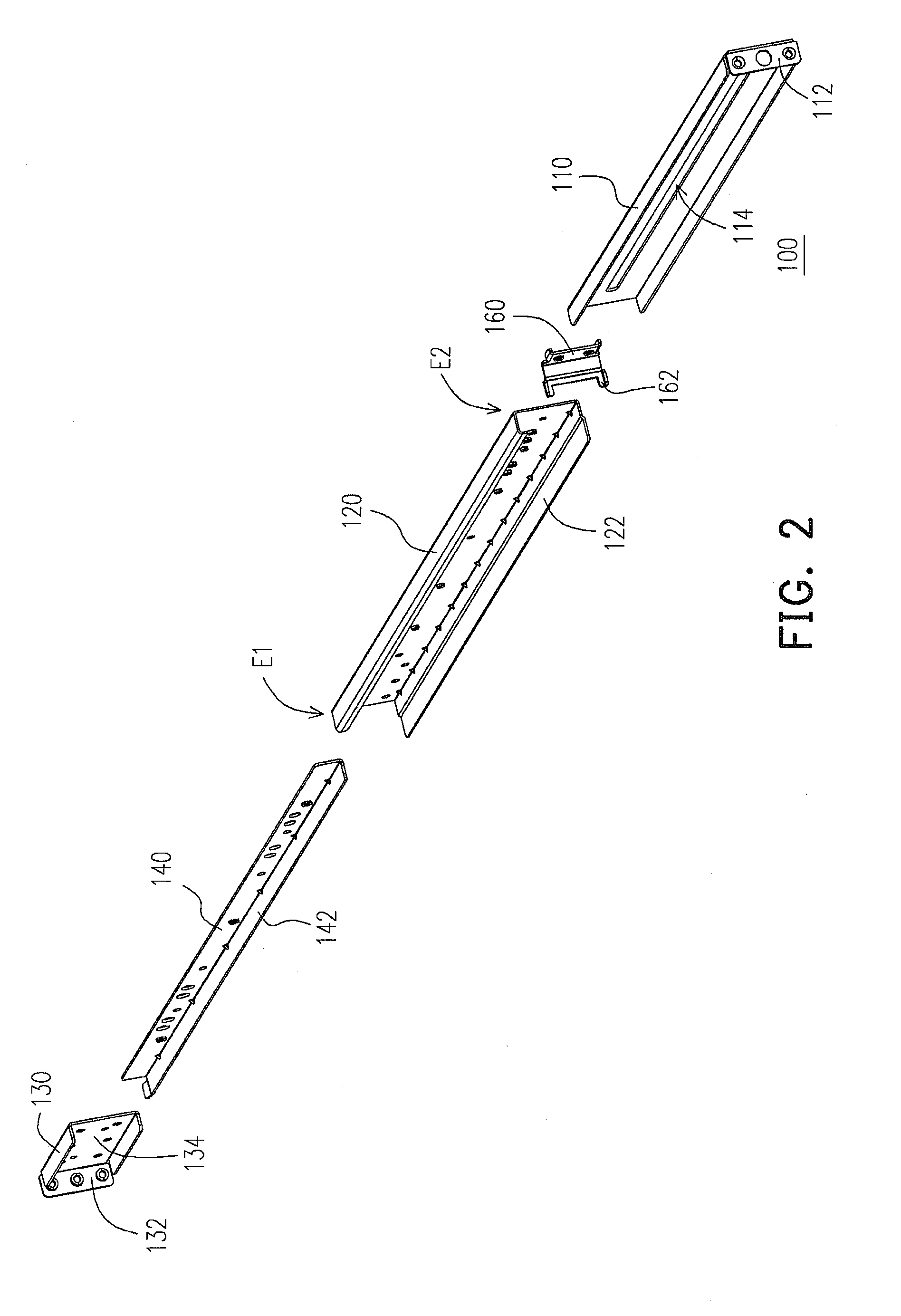

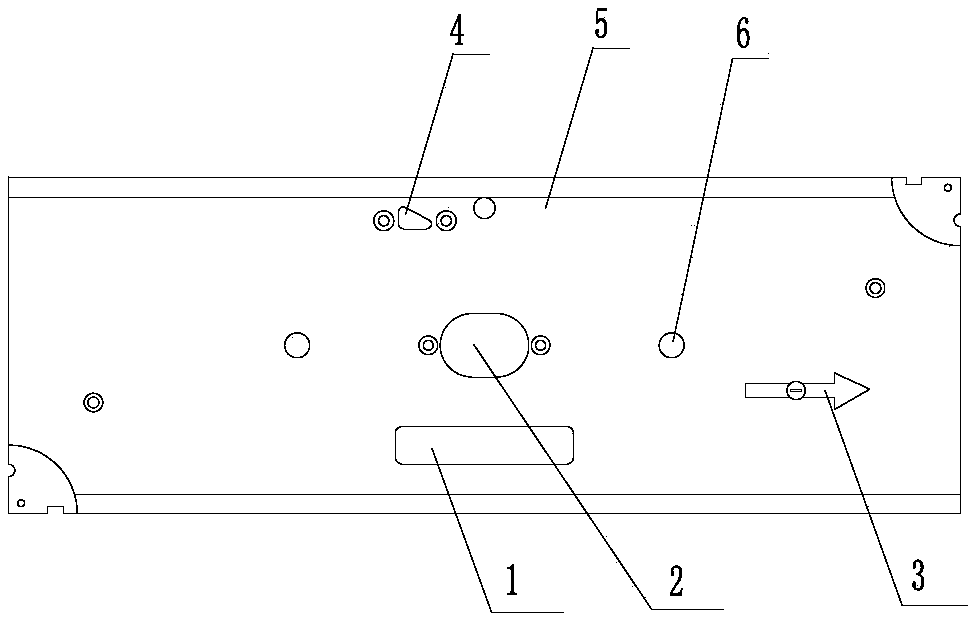

Slide rail structure

ActiveUS8226181B2Small widthTurnover of the computer case can be avoidedServersDrawersEngineeringMechanical engineering

A slide rail structure is provided. The slide rail structure is disposed between a computer case and a rack, and includes a first slide rail and a second slide rail. The first slide rail is fixed to the rack. The second slide rail has a first end, a second end and a carrying part. The second slide rail is fixed to the rack via the first end, and is connected to the first slide rail via the second end. The carrying part contacts a bottom plate of the computer case for sliding the computer case on the carrying part.

Owner:INVENTEC CORP

Slide rail structure

A slide rail structure is provided. The slide rail structure is disposed between a computer case and a rack, and includes a first slide rail and a second slide rail. The first slide rail is fixed to the rack. The second slide rail has a first end, a second end and a carrying part. The second slide rail is fixed to the rack via the first end, and is connected to the first slide rail via the second end. The carrying part contacts a bottom plate of the computer case for sliding the computer case on the carrying part.

Owner:INVENTEC CORP

METHODS OF MODULATING PROTEIN HOMEOSTASIS, METABOLIC SYNDROME, HEAVY METAL INTOXICATION AND Nrf2 TRANSCRIPTION FACTORS

InactiveUS20100086531A1Reduce and eliminate conditionPrevent degradationBiocidePeptide/protein ingredientsDiseaseAdjuvant therapy

Phthalazinediones that function as intracellular redox modulators in the redox therapy of certain stressed cells are provided. By buffering aberrant redox states, phthalazinediones enable cellular processes essential for survival and augment medical treatments. The phthalazinediones of the invention can modulate functions related to cell growth, differentiation, activity, or death, to correct aberrations and restore homeostasis, and can serve as adjunctive therapy in treating various disease conditions.

Owner:BACH PHARMA

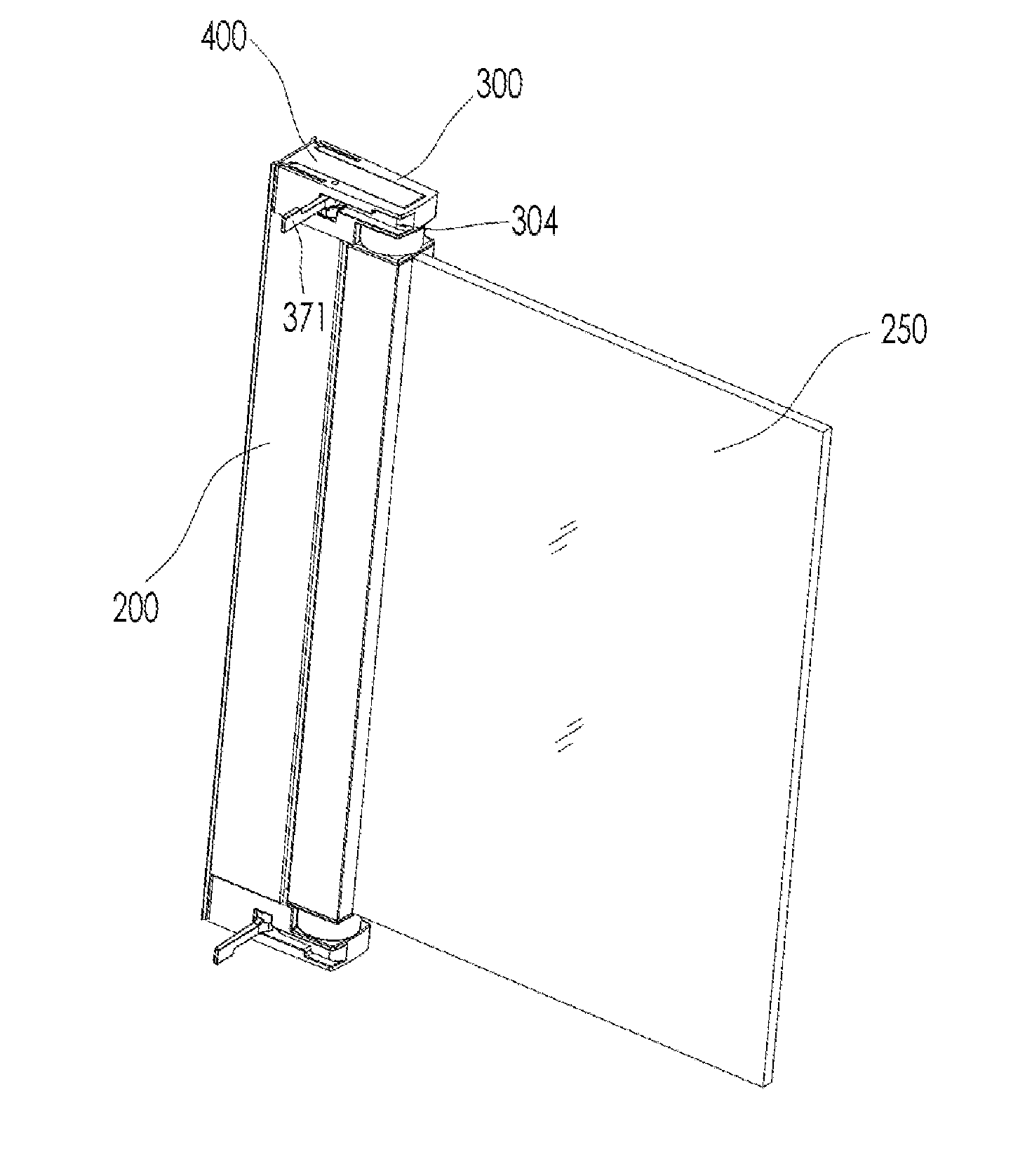

Shower door assembly for fast assembling and adjustment

A shower door assembly with at least one adjustment assembly has an adjustment device and a locking device. The locking device includes a blocking element, a pressing element and an elastic element between the blocking element and the pressing element. The elastic element is arc-shaped when unlocked. An inclined surface projects to the blocking element. The curvature of the elastic element is thus reduced until it engages with the adjustment device. A driving device includes a cam mechanism and a sliding element having one end in contact with the pressing element and the other end sliding along with the inclined surface when driven by the cam mechanism so as to push the pressing element toward the blocking element, and thus reduce the curvature of the arc-shaped elastic element until the elastic element is engaged with the adjustment device.

Owner:IDEAL SANITARY WARE CO LTD

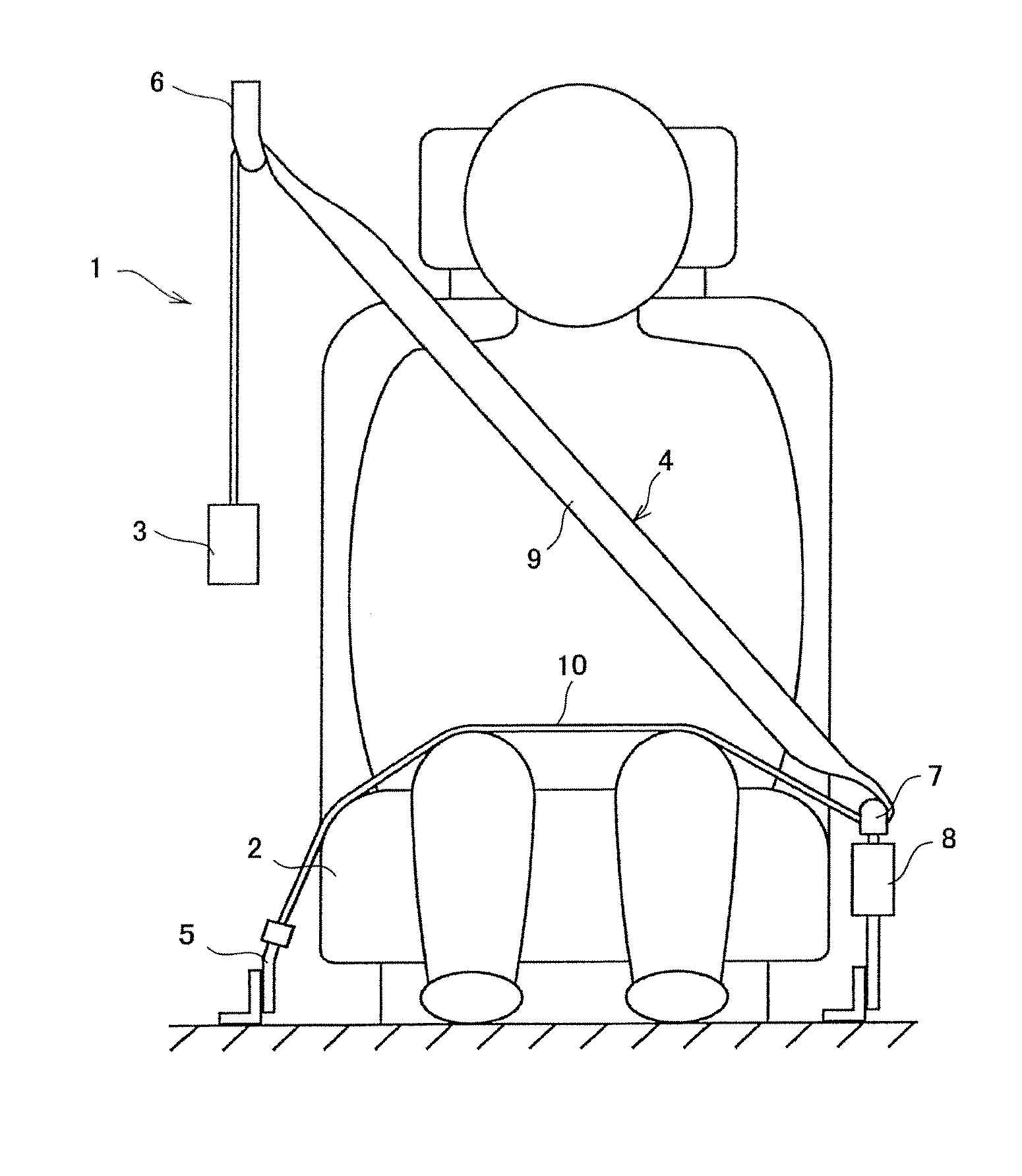

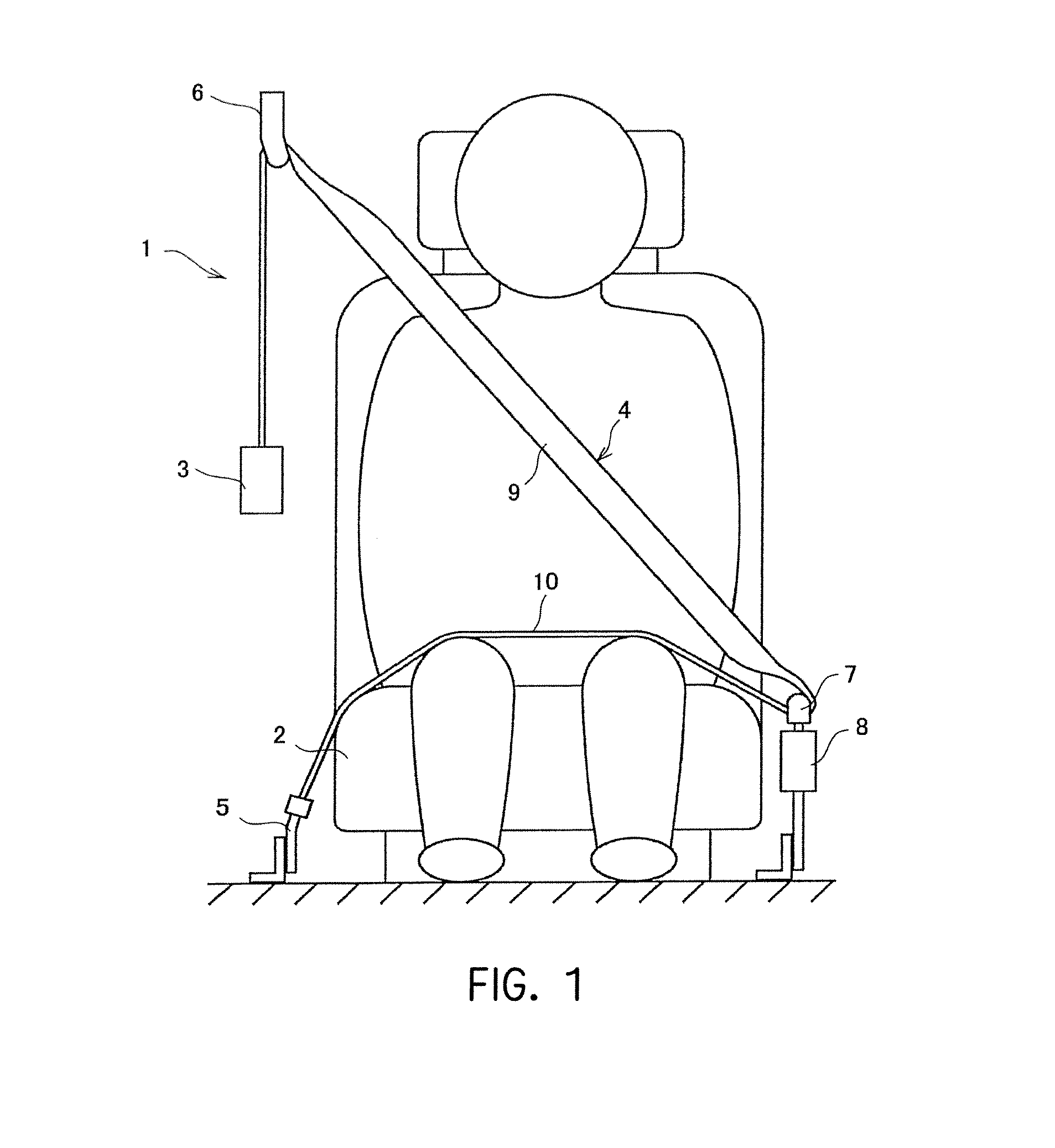

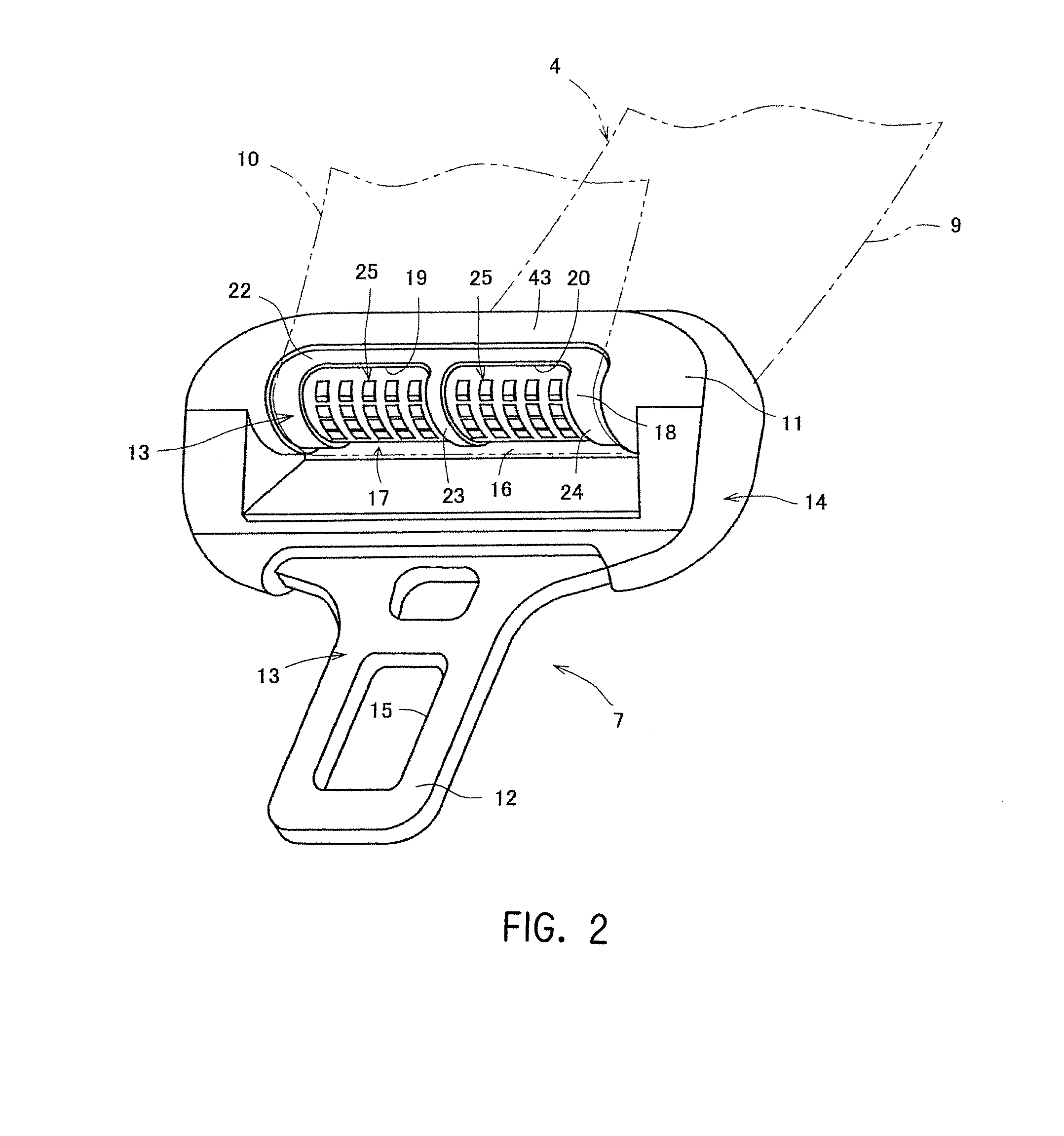

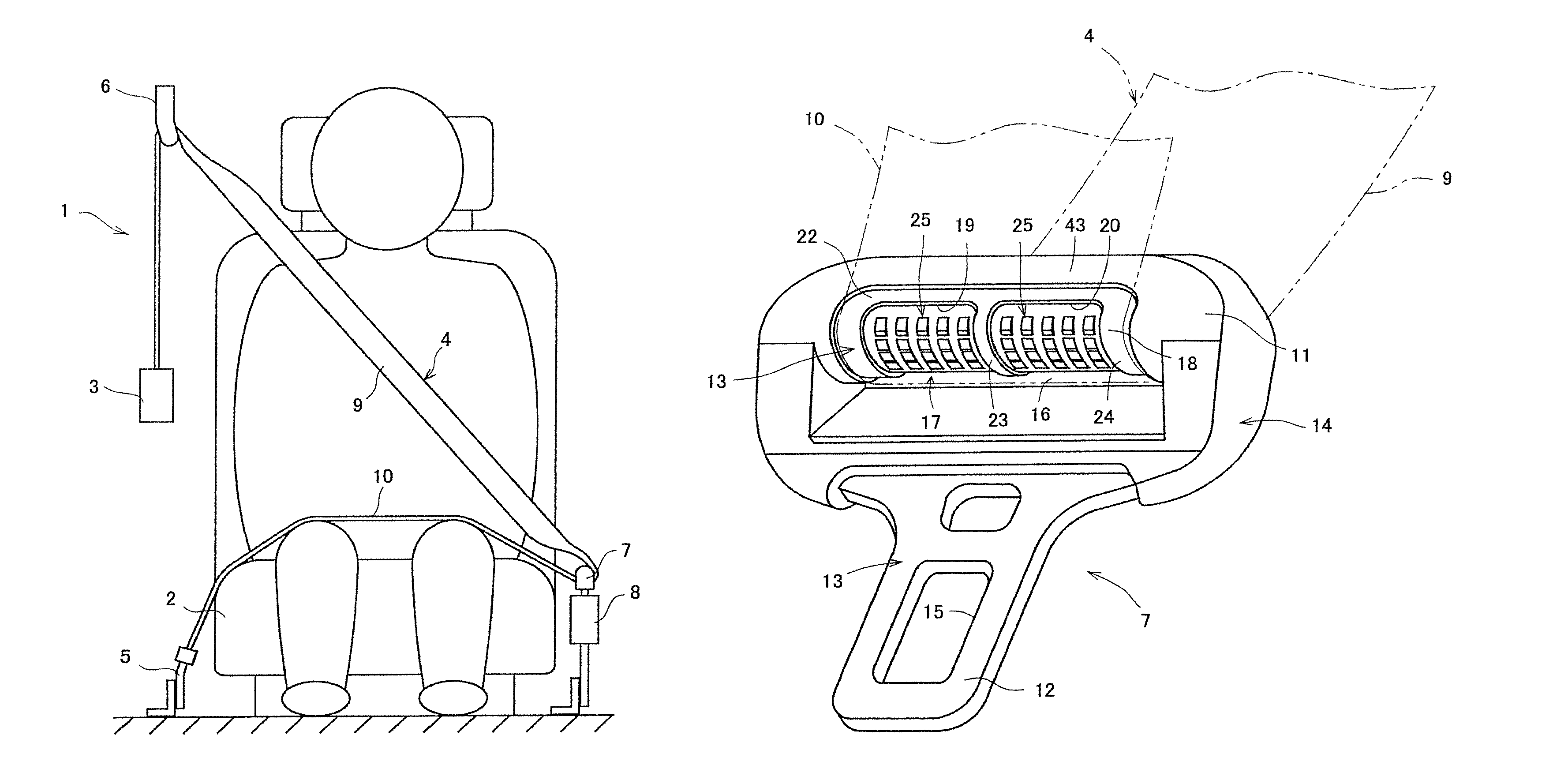

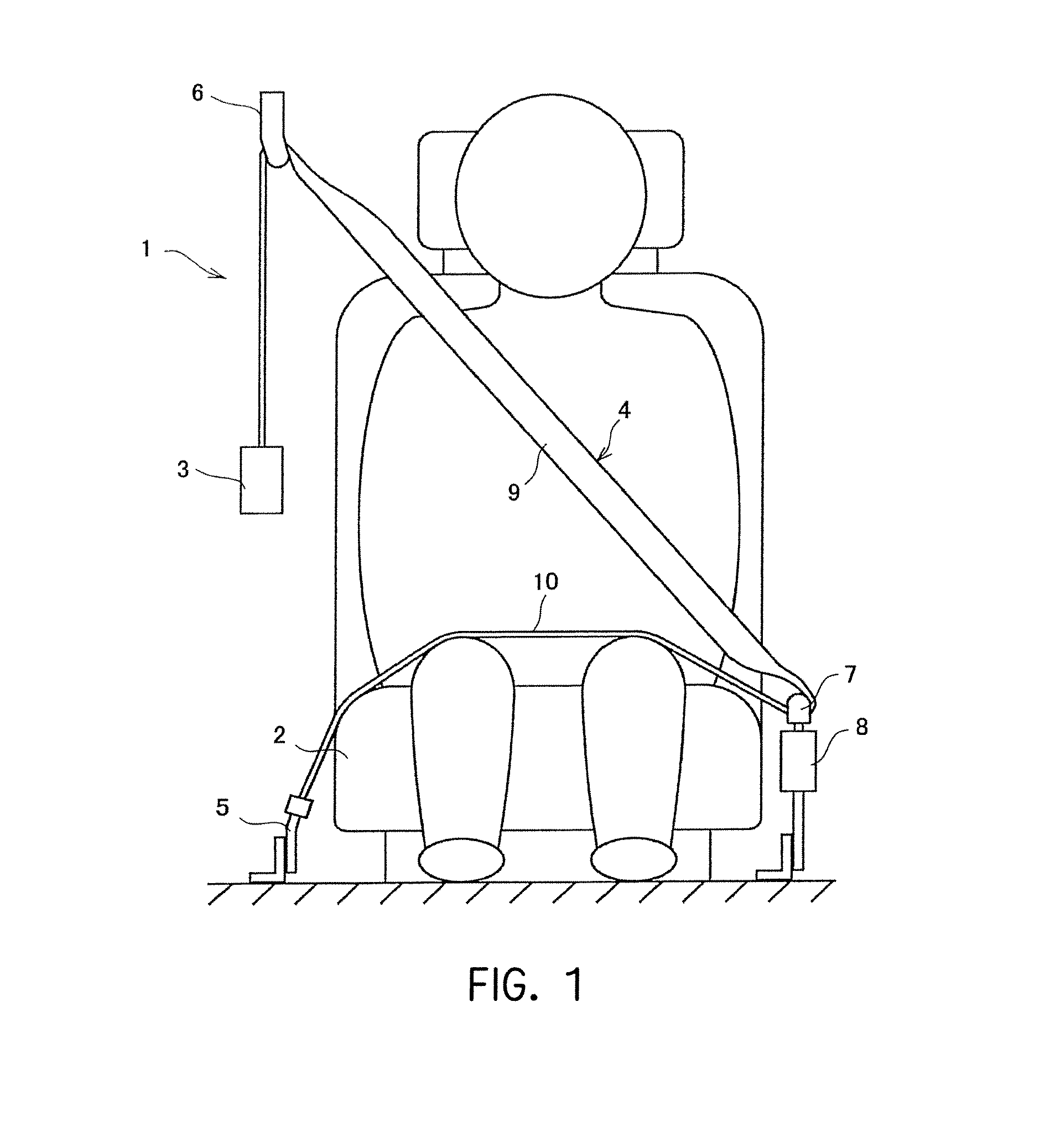

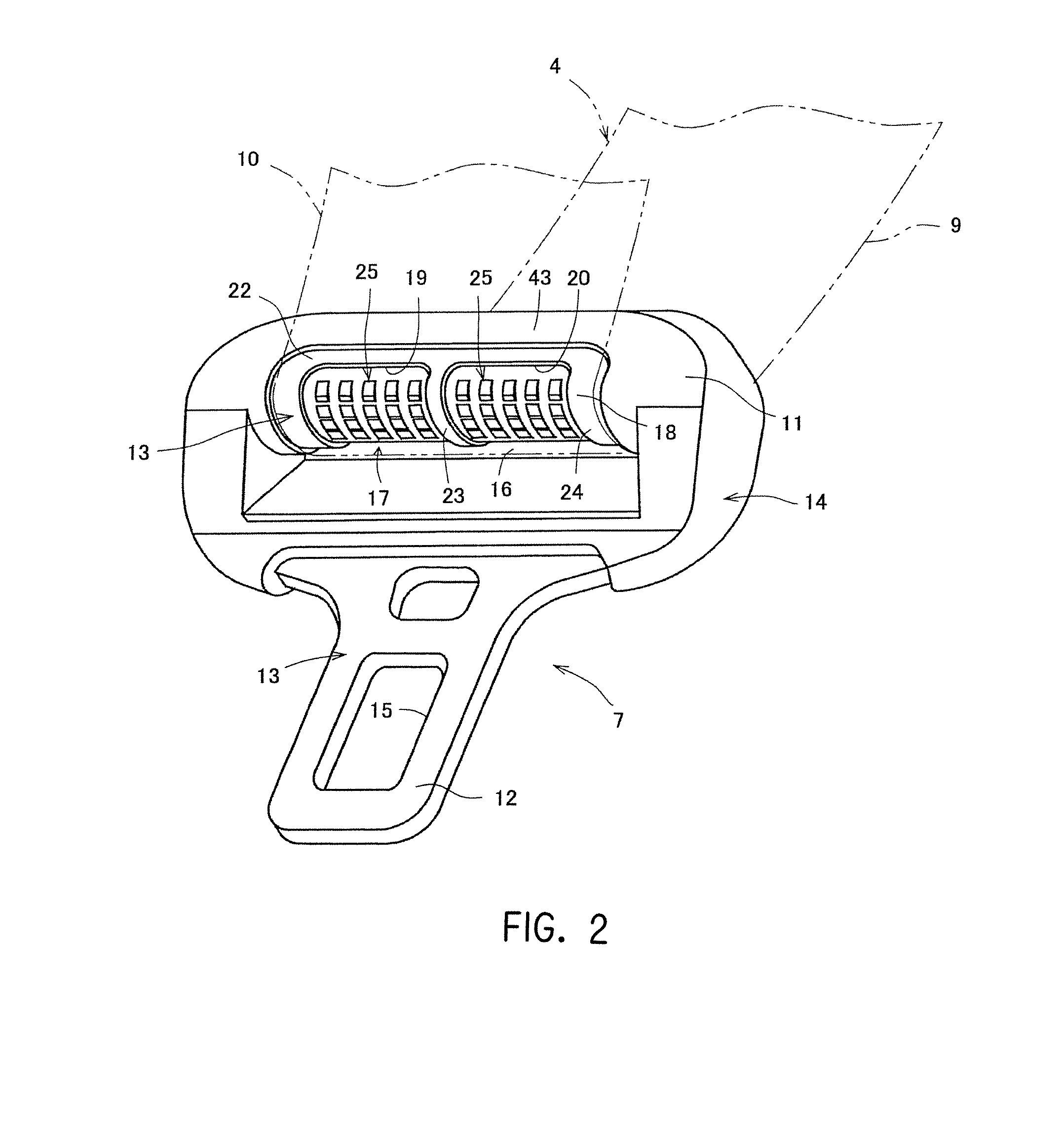

Tongue and seat belt apparatus using tongue

InactiveUS20140070596A1Easy to operateReduce tensionSlide fastenersBelt retractorsEngineeringSTI Outpatient

A tongue for a seat belt system. The tongue is configured to allow a seat belt to smoothly slide thereon at normal times and that is capable of preventing stretch of a lap belt in the event of emergency. The seat belt sliding unit includes a predetermined number of the protrusions disposed in the first and second concave portions and. The first protrusion has a flat or substantially flat end surface on the shoulder belt side, a flat or substantially flat end surface on the lap belt side, and an arc-like top end. An angle formed by the imaginary line between the topmost end of the protrusion and an arc center of an outer peripheral surface of the concave portions and the end surface on the shoulder belt side is less than an angle formed by the imaginary line and the end surface on the lap belt side.

Owner:JOYSON SAFETY SYST JAPAN KK

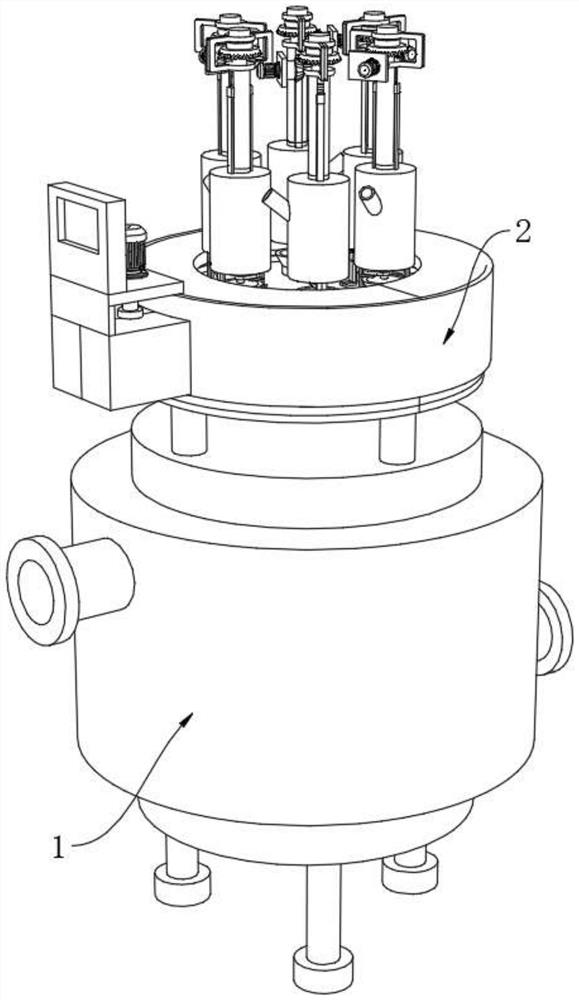

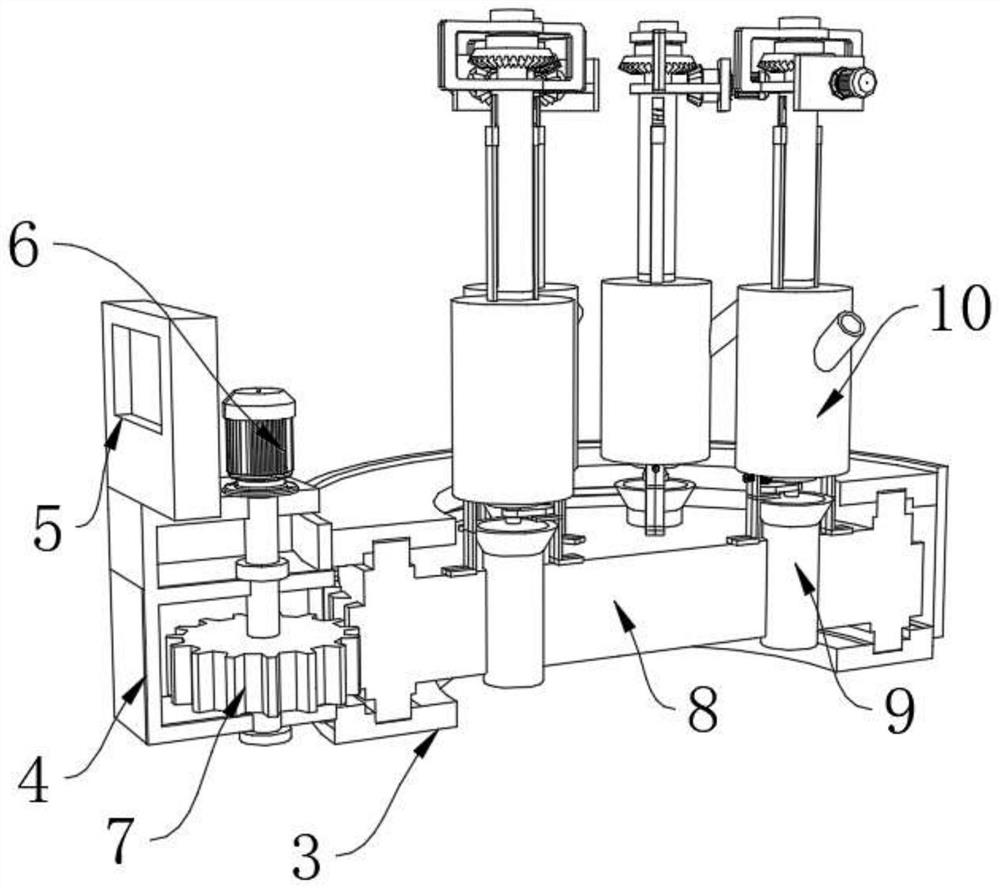

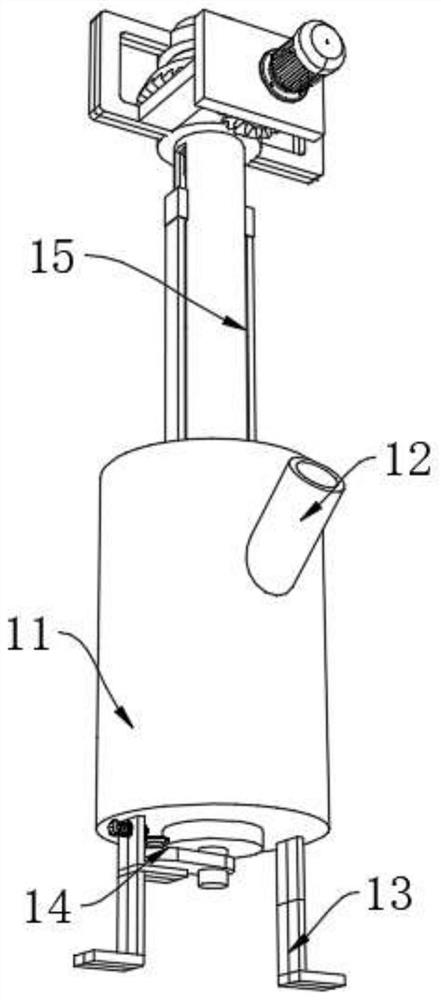

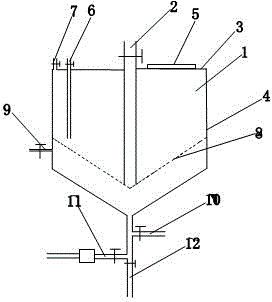

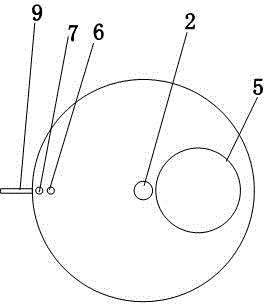

Batching and stirring integrated dry film production device convenient for quantitative feeding in batches

InactiveCN113522154AEasy to automate feedingImprove convenienceShaking/oscillating/vibrating mixersMixer accessoriesProcess engineeringHeat losses

The invention discloses a batching and stirring integrated dry film production device convenient for quantitative feeding in batches, and relates to the technical field of novel dry film production devices. The device comprises a heat-loss-preventing uniform stirring tank structure and a batched quantitative feeding structure, wherein the top end of the heat-loss-preventing uniform stirring tank structure is fixedly connected with the batched quantitative feeding structure. Through the design of a batch quantitative feeding structure, the device can automatically feed raw materials according to different feeding time and doses of different raw materials, the feeding convenience and stability are improved, through the design of a heat loss prevention uniform stirring tank structure, the device can conveniently heat ingredients through high-heat steam, and the production efficiency is improved. According to the present invention, the non-uniform electric heating temperature is avoided, the stirring efficiency of the whole ingredient fusion is improved by using the matching design of the rotary stirring and the lifting stirring, and the turnover of the ingredient processing is avoided through the integrated design of the batch quantitative feeding structure and the heat loss prevention uniform stirring tank so as to improve the whole molding efficiency.

Owner:江西力征材料有限公司

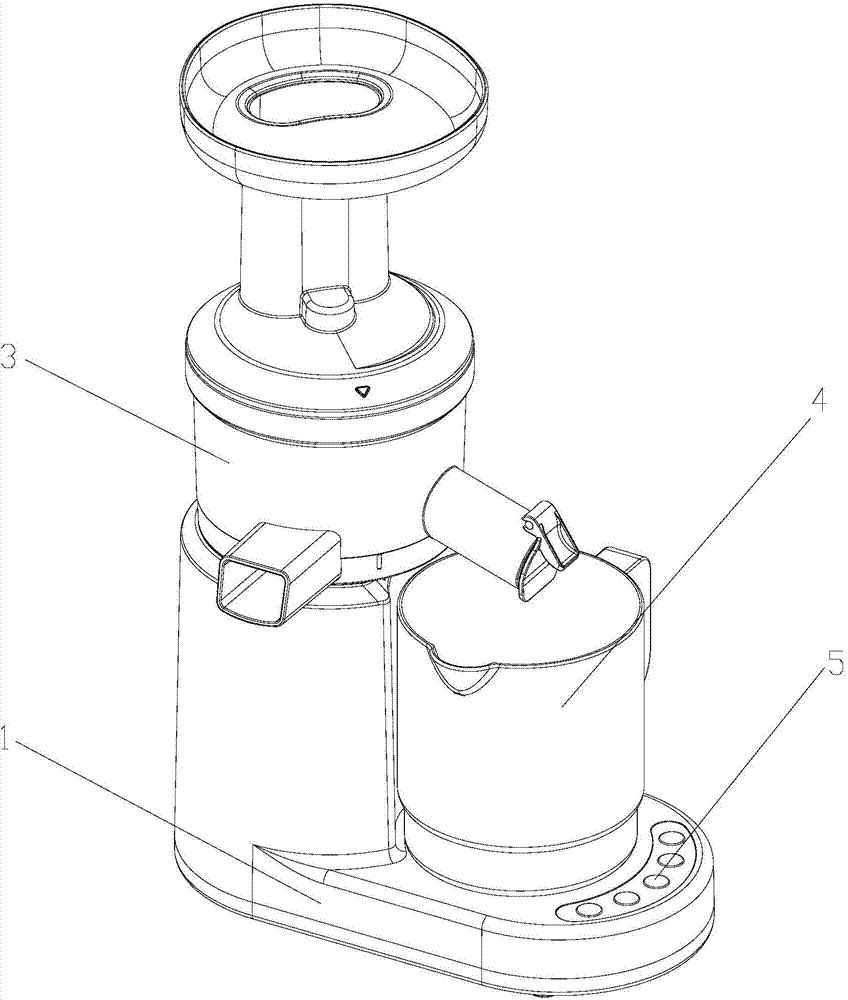

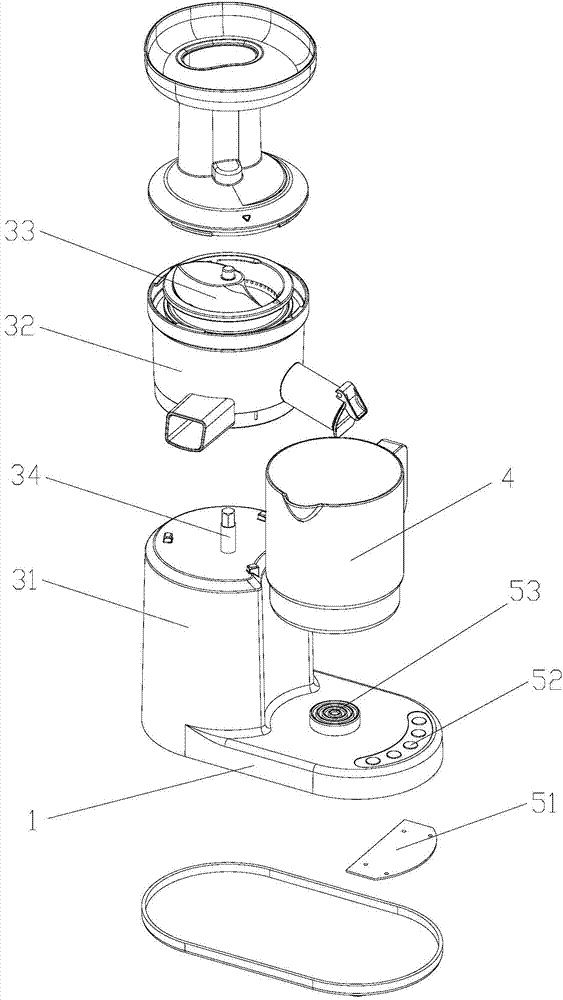

Multifunctional juicer

The invention discloses a multifunctional juicer which comprises a juicing device, a control device, a juice container and a heating element for heating the juice container, wherein the juicing device comprises a base; a juicing cup is arranged on the base; a juicing system is arranged in the juicing cup; a driving unit capable of driving the juicing system to rotate is arranged in the base; the base extends to one side to form a control base; the control device and the juice container are located on the control base; the control device comprises a control panel and a control circuit board electrically connected with the control panel; and the control circuit board is electrically connected with the driving unit and the heating element. With the structure, the multifunctional juicer integrates juicing and heating of fruit and vegetable juices, achieves multiple functions, and is creative, simple in structure and convenient to use; and meanwhile the multifunctional juicer avoids extra purchase of various small kitchen electrical appliances so as to save purchase cost, greatly reduce space usage, avoid idle equipment and improve the utilization ratio of electrical appliances. Therefore, the multifunctional juicer can better serve a family or a single person.

Owner:江门市贝尔斯顿电器有限公司

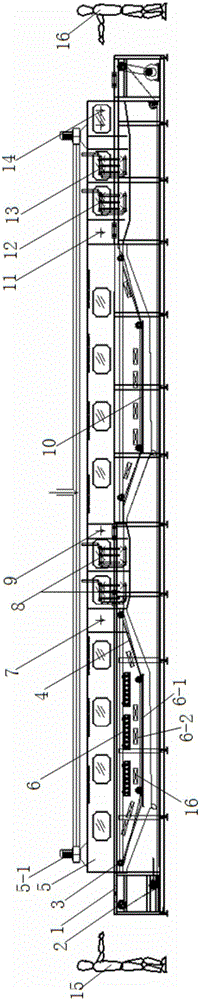

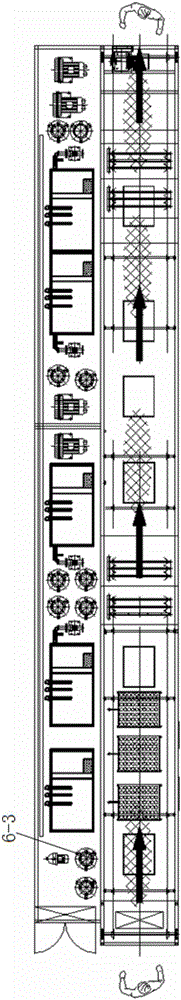

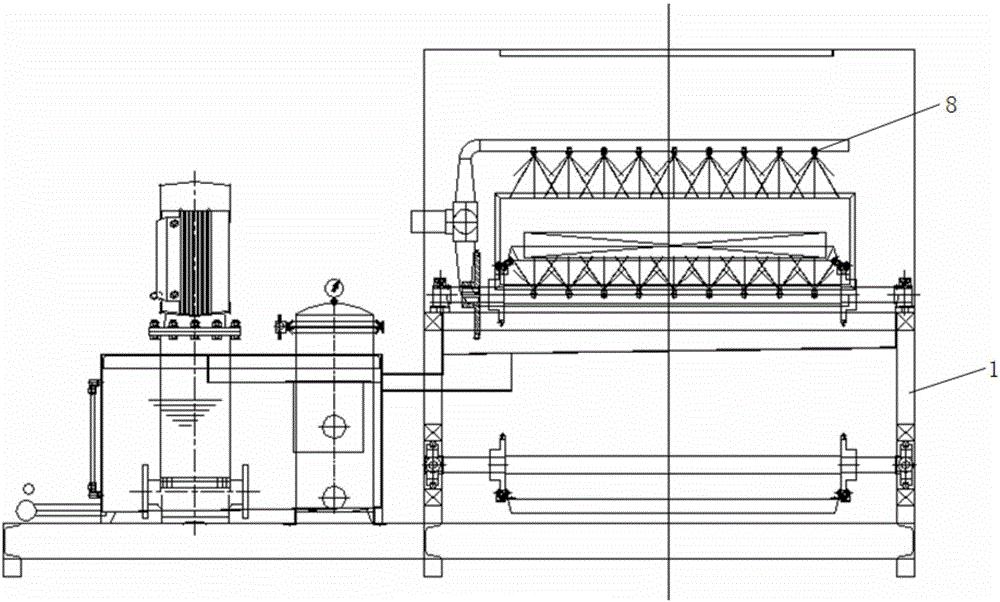

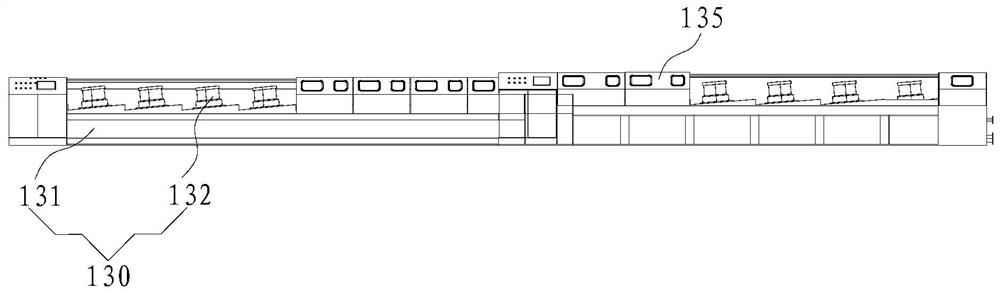

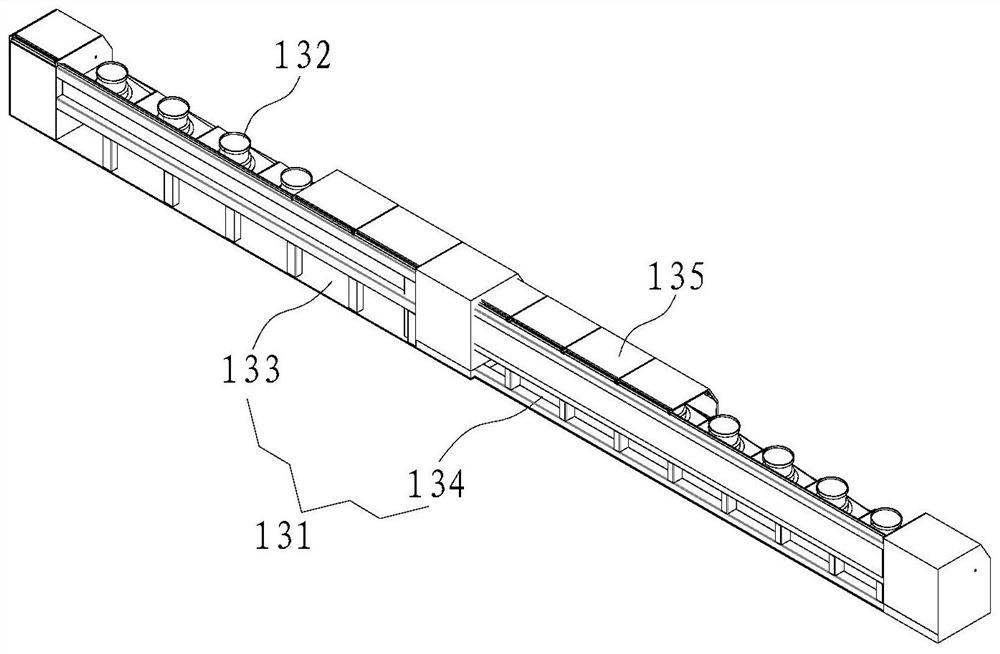

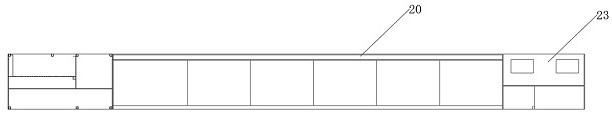

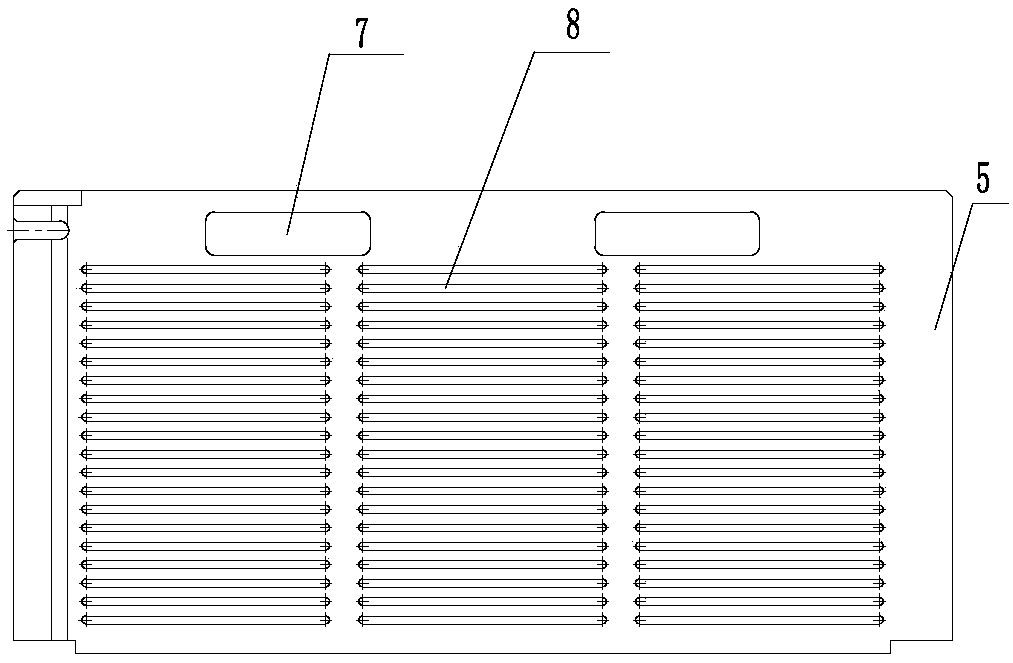

Full-automatic mesh belt pass-type ultrasonic spraying cleaning machine

InactiveCN106391562AAvoid handlingAvoid turnoverMetallic material coating processesCleaning using liquidsMegasonic cleaningWind shear

The invention relates to finned evaporator cleaning passivating equipment, in particular to a full-automatic mesh belt pass-type ultrasonic spraying cleaning machine. The full-automatic mesh belt pass-type ultrasonic spraying cleaning machine comprises a machine frame, and a motor and a roller shaft which are arranged on the machine frame; a mesh belt is mounted on the roller shaft and passes through a fog exhausting system, an ultrasonic immersion cleaning device, a first water shearing spraying head, a first tap water spraying rinsing spraying head, a second water shearing spraying head, a passivating tank, a third water shearing spraying head, a second tap water spraying rinsing spraying head, a pure water spraying rinsing spraying head and a wind shear which are arranged on the machine frame in sequence from front to back under the driving of the motor. By adopting the above structure, the full-automatic mesh belt pass-type ultrasonic spraying cleaning machine has the following advantages: firstly, cleaning and passivating are connected together, so that a one-flow production mode is realized, and the appearance quality of a product is improved; secondly, workpieces are automatically and uniformly fed into an ultrasonic cleaning tank under the action of the mesh belt, ultrasonic waves act on each of the workpieces without being sheltered, and each of the workpieces can be cleaned within a very short time, and the cleaning efficiency is high.

Owner:HEFEI TAITONG REFRIGERATION TECH CO LTD

Tongue and seat belt apparatus using tongue

Owner:JOYSON SAFETY SYST JAPAN KK

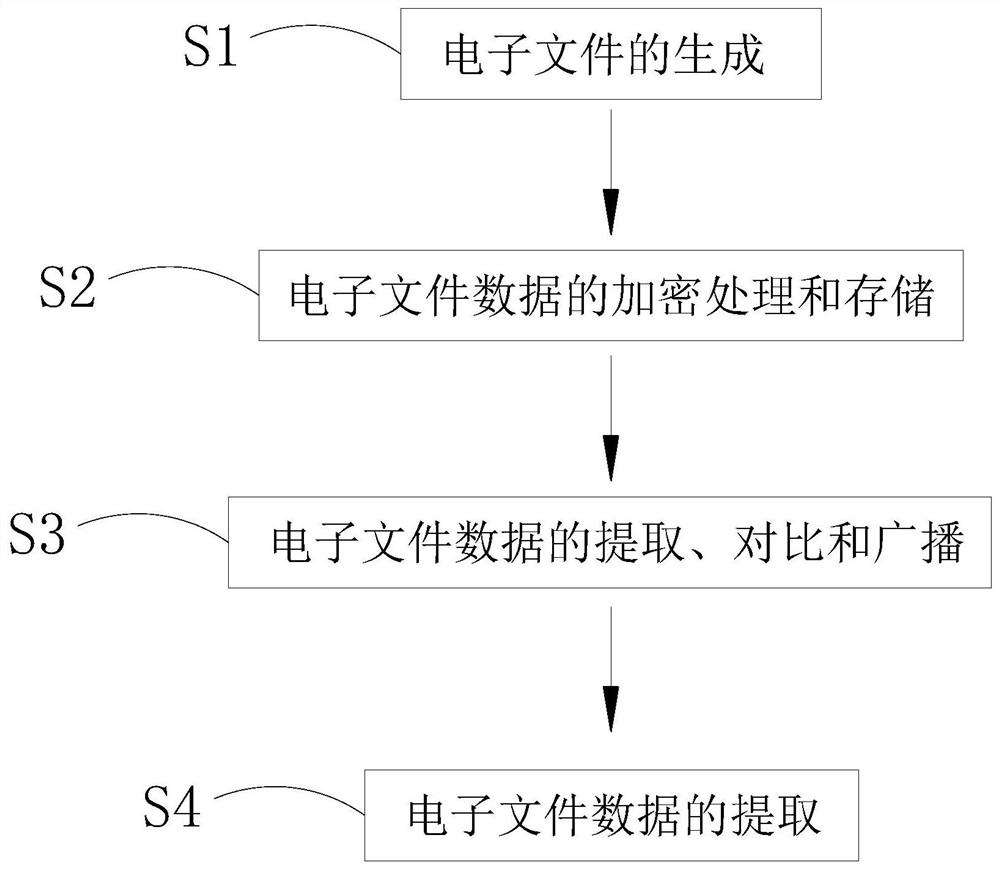

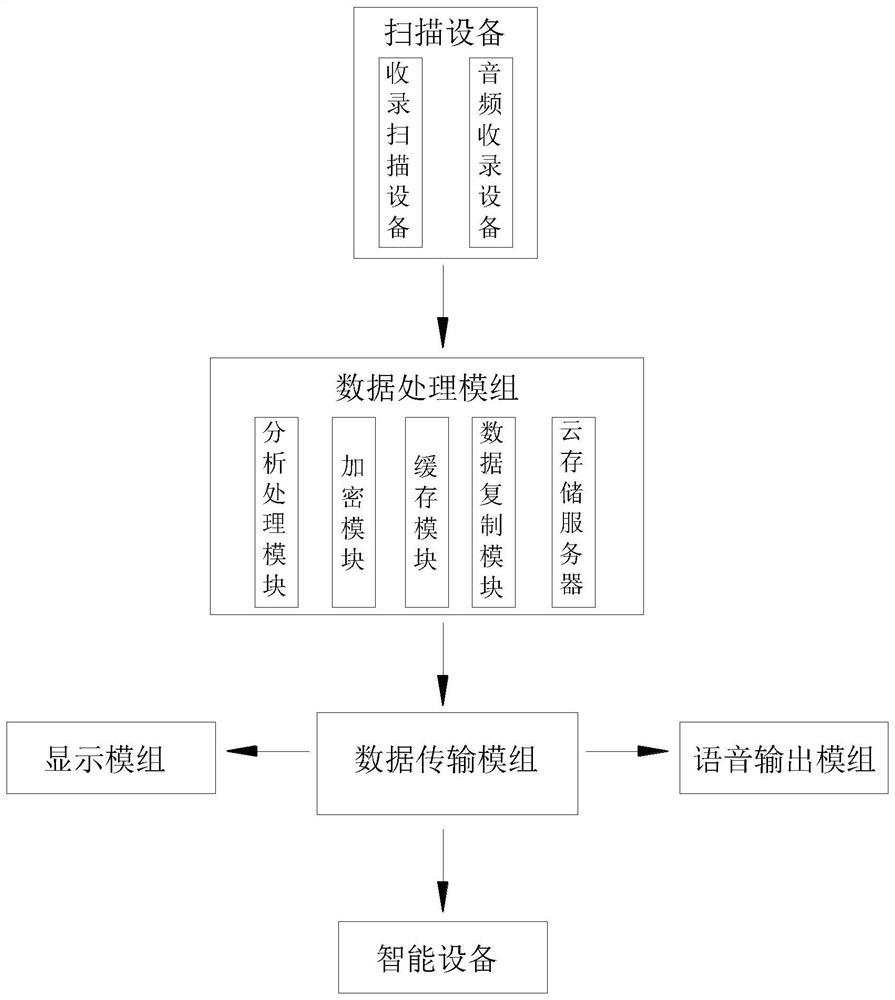

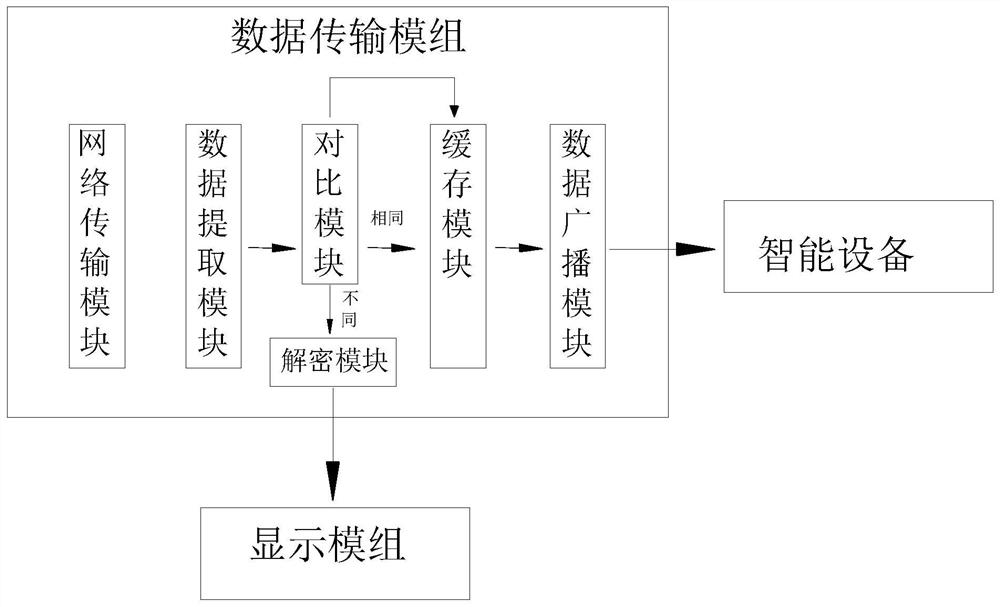

Electronic file circulation tamper-proofing method and device

The invention relates to the technical field of electronic file circulation tamper-proofing, in particular to an electronic file circulation tamper-proofing method and device. The electronic file circulation tamper-proofing method comprises the following steps: generating an electronic file; encrypting and storing electronic file data; extracting, comparing and broadcasting electronic file data; and extracting electronic file data. According to the invention, electronic file data is copied, and then a data hash value is extracted. One of the two data hash values is stored in the same cloud server, and the other data hash value is distributed and stored in a plurality of different cloud servers. The different storage modes of the two data are beneficial to confusing lawbreakers. After a lawbreaker changes the hash value of any one piece of data, before circulation, the two pieces of data need to be compared; and if the two pieces of data are different, the file cannot be broadcasted, so that the situation that the data is transferred after being tampered is avoided, and the security of the electronic file is guaranteed.

Owner:苏州优炫智能科技有限公司

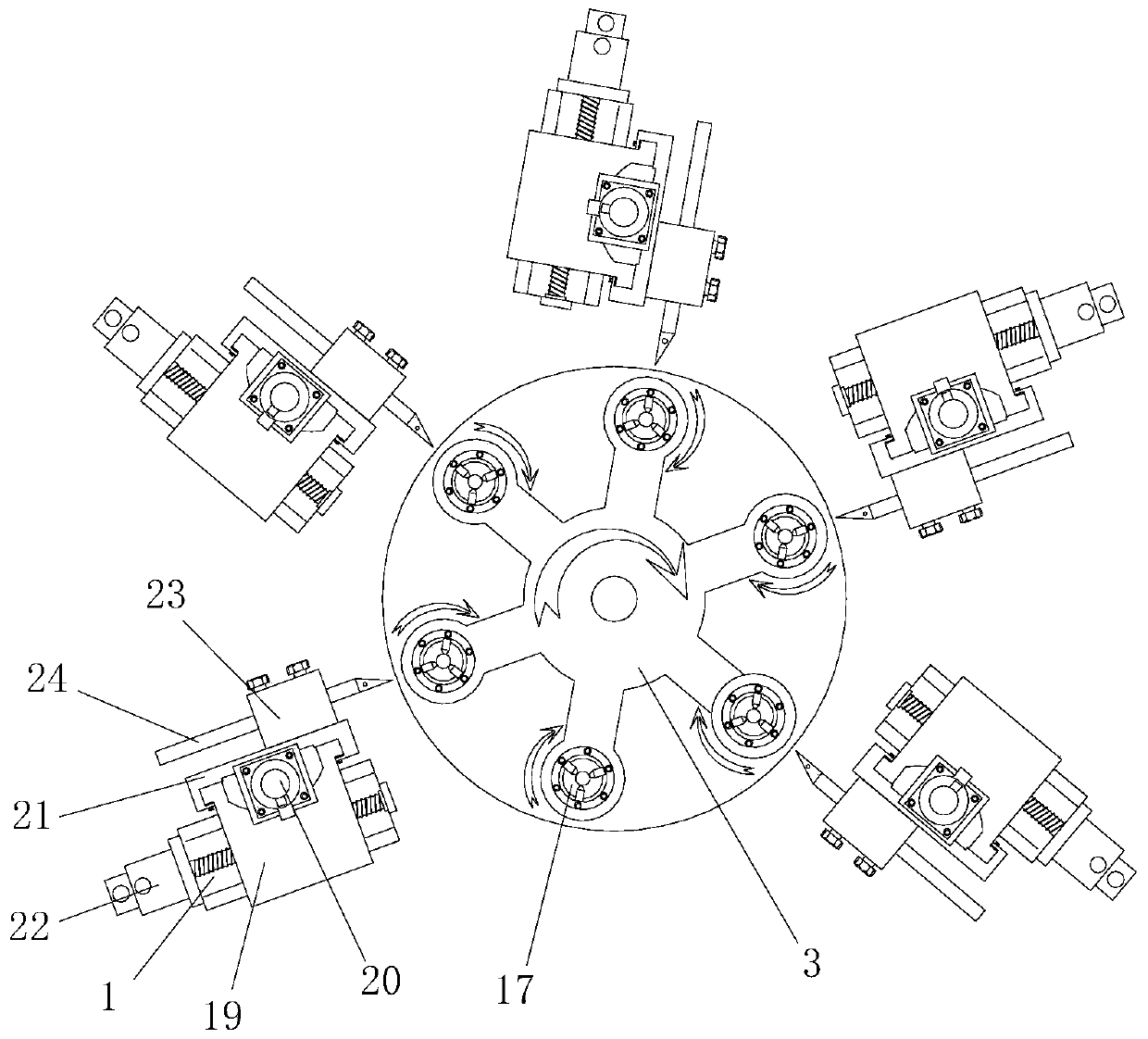

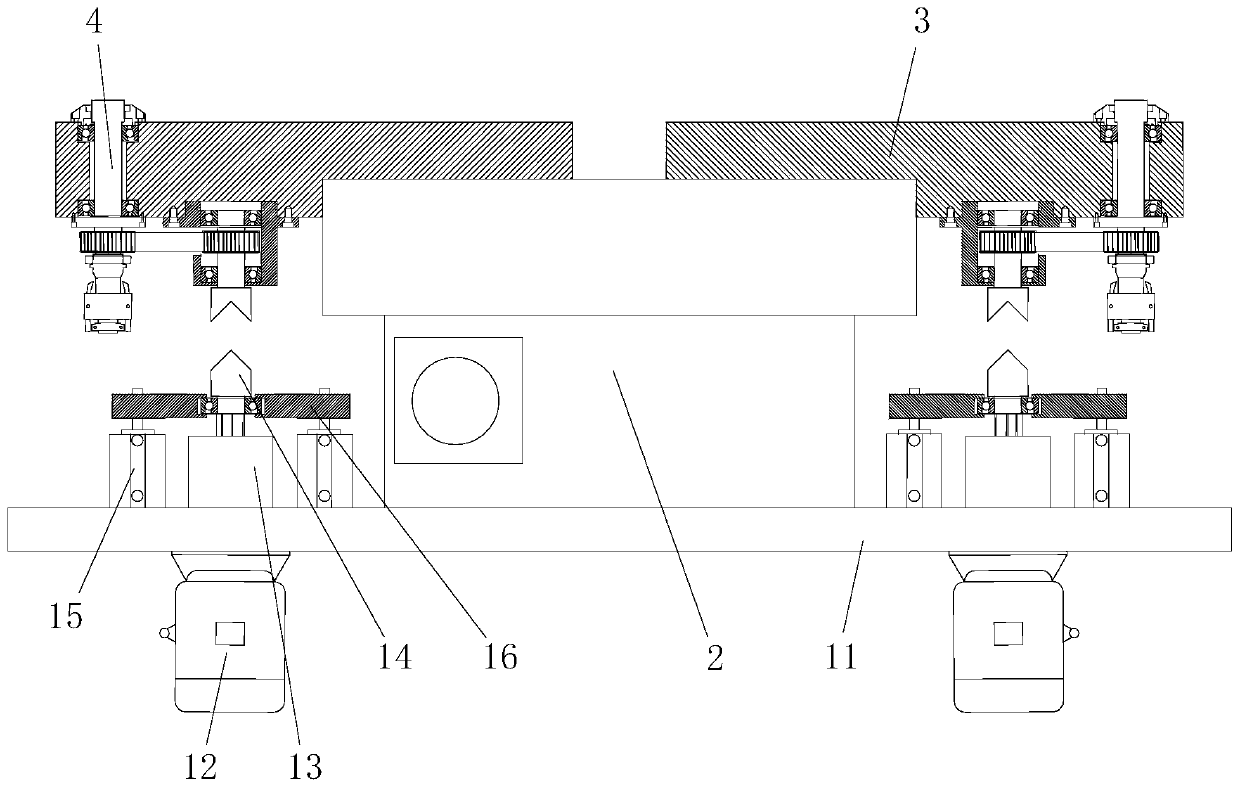

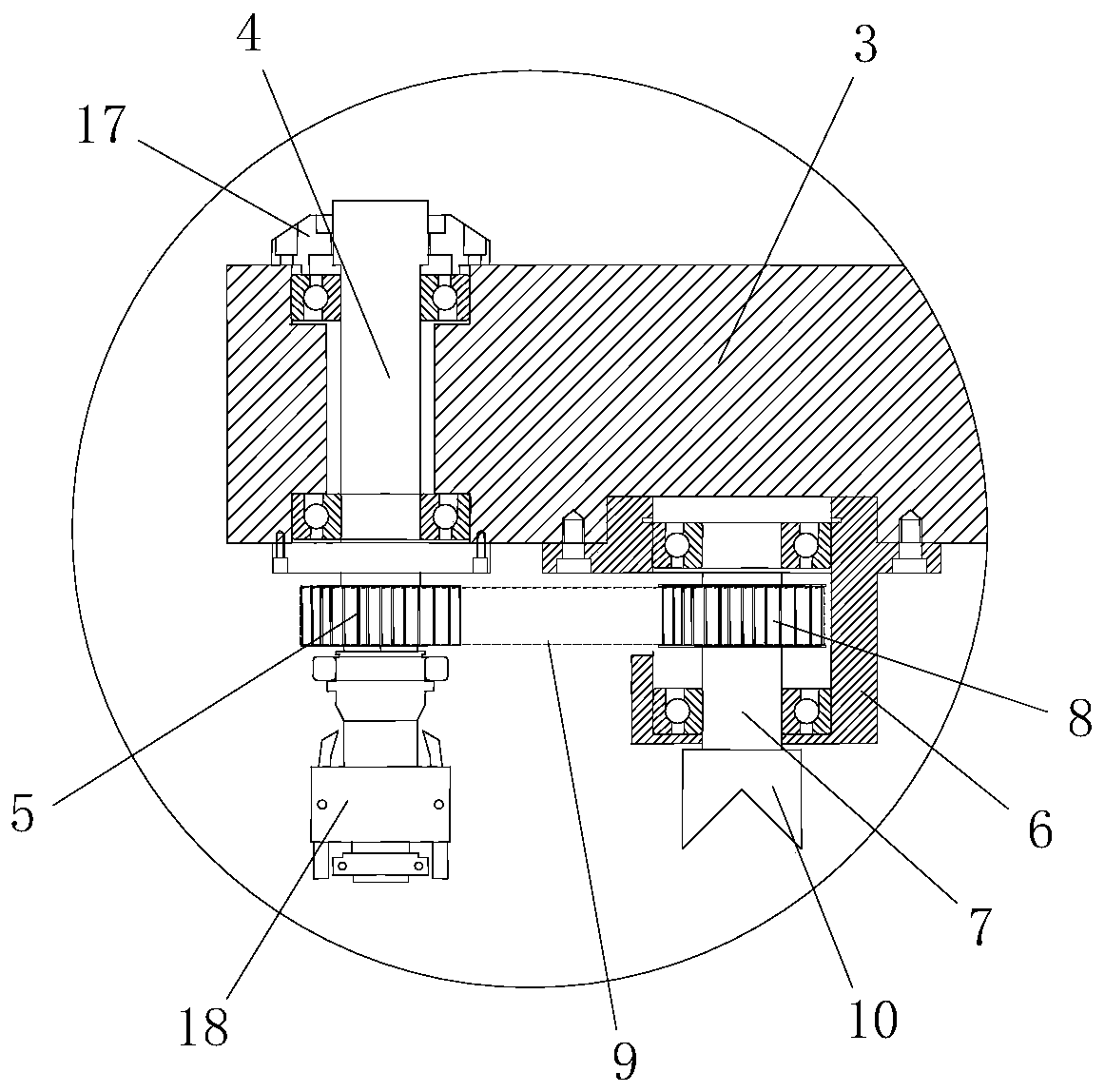

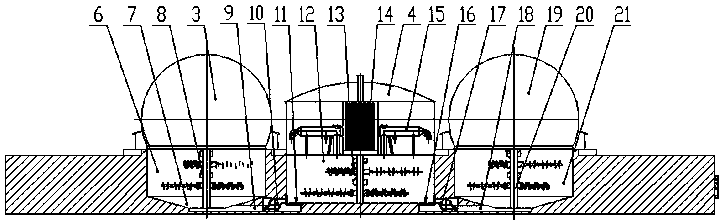

Multi-station lathe

PendingCN110293234AImprove processing efficiencyImprove efficiencyLarge fixed membersTurning machinesEngineeringMaterial resources

The invention discloses a multi-station lathe. The lathe comprises a lathe main body and a dividing plate installed on the lathe main body, the dividing plate comprises a main disc body and a rotatingdisc body which is connected with the main disc body in a matched mode, the lathe is characterized by further comprising a plurality of independently-rotatable lathe spindles uniformly distributed along the circumferential direction of the rotary disc body, clamping devices used for clamping workpieces is arranged on the lathe spindles. The multi-station lathe has the advantages that a pluralityof cutters correspond to a plurality of different working procedures respectively, a plurality of cutters can simultaneously process a plurality of workpieces at the same time, and the workpiece machining efficiency is improved; a plurality of cutters are used for simultaneously processing a plurality of workpieces at the same time, then the rotary disc body is rotated to enable each workpiece toenter the next working procedure for further processing, so that the workpiece with multiple procedures can be completed on one lathe bed; the workpiece turnover between the lathe and the lathe is avoided, so that a lot of manpower and material resources are saved; a plurality of working procedures do not need to be carried out on a workpiece and a plurality of lathes do not need to be placed, resources and space are saved, and management is facilitated.

Owner:上海非圆科技有限公司

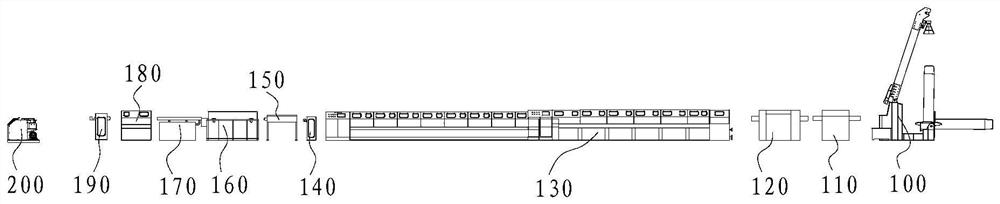

Full-process automatic welding wire production line

PendingCN112170532AHigh degree of automationIncrease productivityWelding/cutting media/materialsExtrusion cleaning devicesWire rodWinding machine

The invention discloses a full-process automatic welding wire production line. The full-process automatic welding wire production line comprises a pay-off machine around which a wire rod is wound. A husking machine, a derusting machine, a drawing all-in-one machine, a front tension box, a mixed cleaning machine, a high-speed plating tank, a high-speed cleaning tank, a high-speed polishing tank, arear tension box and a layer winding machine which allow the wire rod to penetrate through are sequentially arranged behind the pay-off machine. The drawing all-in-one machine comprises a box body andmultiple drawing rollers arranged on the box body, the multiple drawing rollers incline towards the same side of the box body and have the same inclination angle, and the multiple drawing rollers have the same height in the vertical direction. The drawing all-in-one machine in the scheme comprises the multiple drawing rollers so that the wire rod can be drawn into finished welding wires of various different specifications, the functions of a rough drawing machine and a fine drawing machine are integrated in the equipment, turnover of the wire rod between the rough drawing machine and the finedrawing machine can be avoided, thus, machine halt caused by frequent turnover of spools is avoided, and the stability of the product quality can be ensured.

Owner:德州市立尊焊丝有限公司

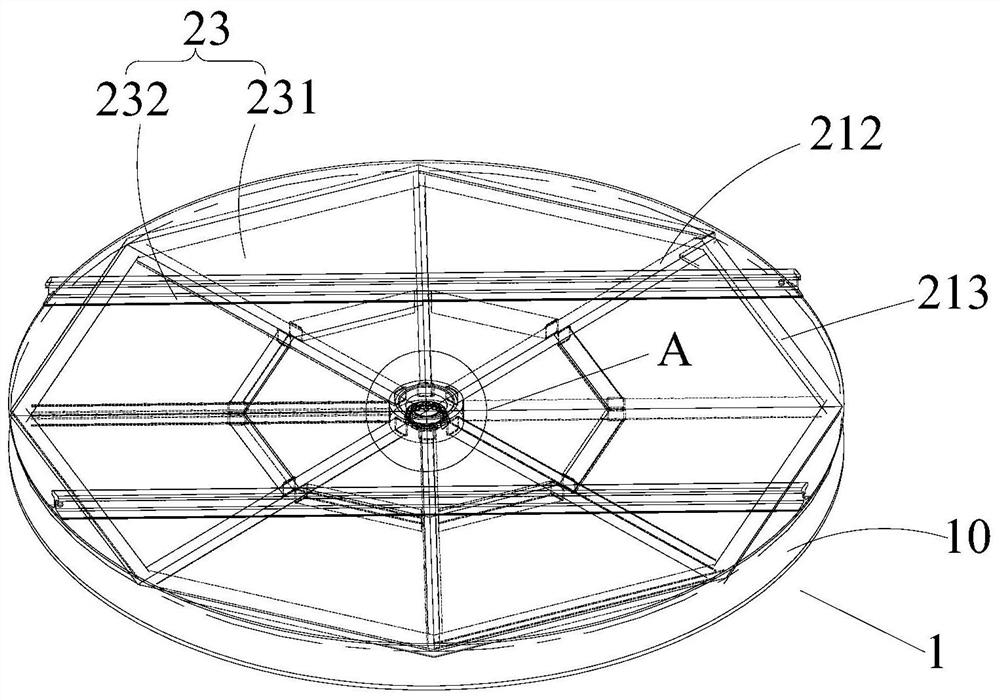

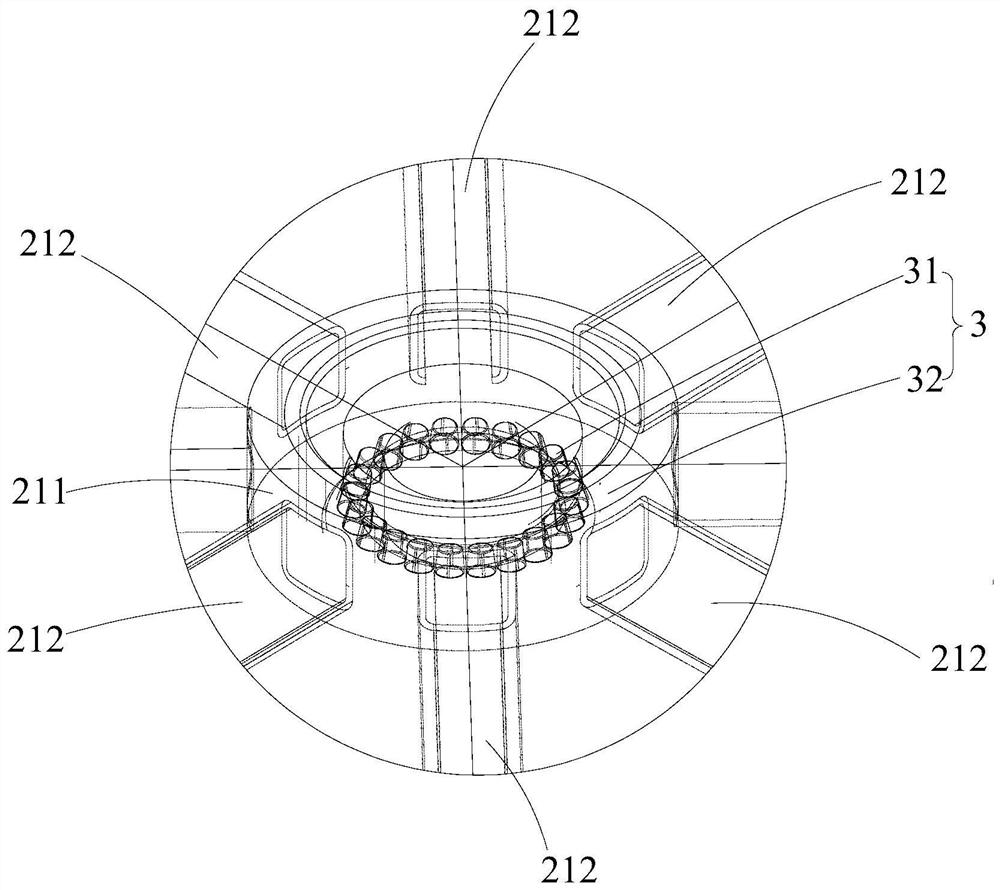

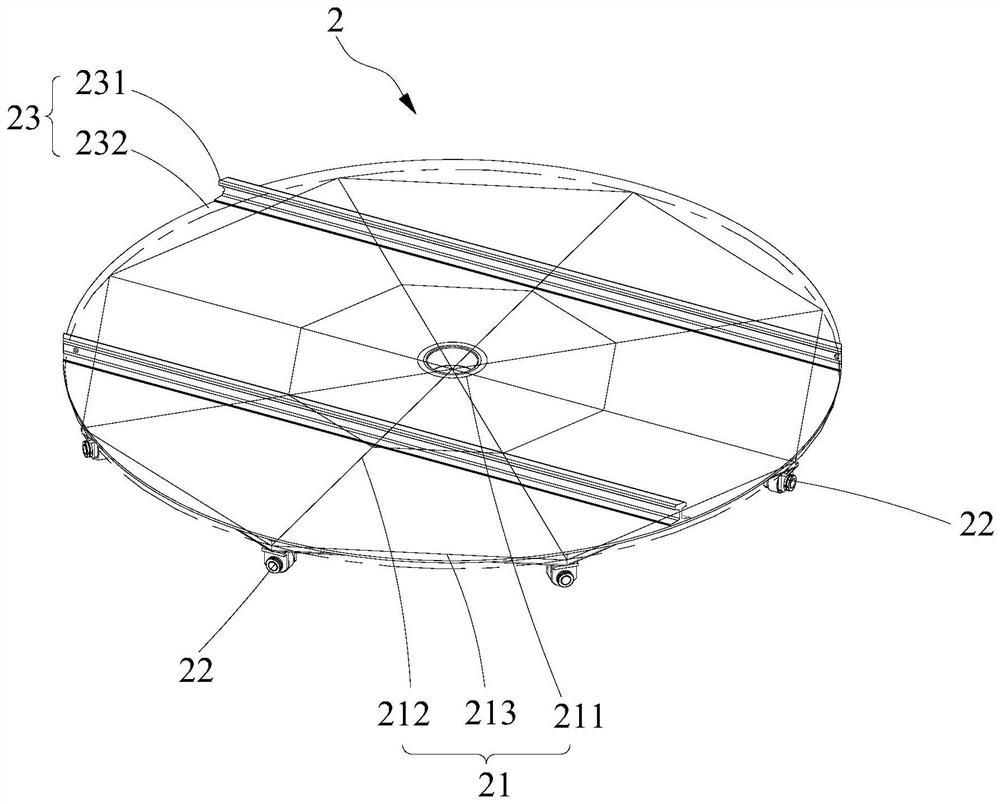

Glass trolley bearing and rotating device

PendingCN111846959AEasy to moveAvoid turnoverCharge manipulationConveyor partsEngineeringGlass production

The invention is suitable for the technical field of glass production equipment, and provides a glass trolley bearing and rotating device. The glass trolley bearing and rotating device comprises a base, a rotating disc assembly rotationally installed on the base and a bearing assembly arranged on the base. The rotating disc assembly comprises a rotating disc framework, a plurality of rolling wheels installed on one side of the rotating disc framework and a guide rail assembly arranged on the other side of the rotating disc framework; and the rotating disc framework is arranged on the bearing assembly in a sleeved mode. The rotating disc framework is arranged on the rotating disc assembly, the plurality of rolling wheels are arranged at the bottom end of the rotating disc framework, and theguide rail assembly is arranged on the rotating disc framework so that a glass trolley can be pushed onto the guide rail assembly, then the glass trolley can move along the guide rail assembly, and the rotating disc framework is rotated according to actual requirements; and at the moment, the glass trolley can be guided to other rails for turnover operation, the production efficiency is improved,turnover of the glass trolley through crane or forklift hoisting is avoided, and therefore potential safety hazards are reduced.

Owner:XINYI GLASS (TIANJIN) CO LTD

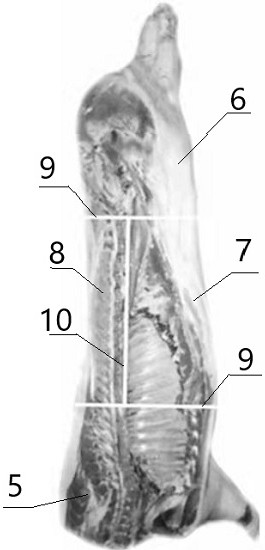

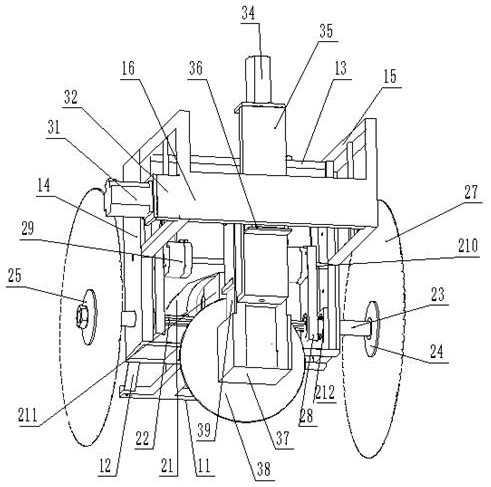

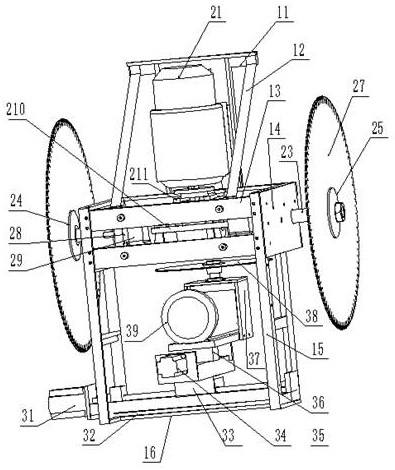

Cutting device for demi-carcass pork

ActiveCN114514939AReduce processAvoid turnoverSlaughtering accessoriesMetal working apparatusPork meatElectric machinery

The invention discloses a demi-carcass pork cutting device. The demi-carcass pork cutting device comprises an assembling frame, a double-saw-blade cutting mechanism and a single-saw-blade cutting mechanism. The assembling frame comprises a bottom frame, two side frames, a hoisting plate and a rear mounting frame. The side frames are vertically fixed on two sides of the rear mounting frame; the hoisting plate and the bottom frame are oppositely fixed between side edges of the two side frames; the double-saw-blade cutting mechanism comprises two transverse cutting saw blades, a shaft, a transverse cutting motor, a speed reducer and a supporting frame. A bearing is arranged on the support frame; the shaft is mounted in the two bearings, and the end part of the shaft extends out of the two side frames; the two transverse cutting saw blades are fixed to the two ends of the shaft respectively. The transverse cutting motor drives the shaft to rotate through the speed reducer. The single-saw-blade cutting mechanism comprises a disc-shaped longitudinal cutting saw blade, a longitudinal cutting motor and a longitudinal cutting motor mounting frame; the longitudinal cutting motor mounting frame is arranged on the rear mounting frame and can move left and right relative to the shaft; and the longitudinal cutting motor is connected with the longitudinal cutting saw blade. According to the demi-carcass pork cutting device, demi-carcass pork can be cut into eight parts at a time, and the working efficiency is high.

Owner:HENAN INST OF SCI & TECH

Filter-dryer

InactiveCN104457188ALess investmentReduce labor costsDrying gas arrangementsDrying machines with progressive movementsEngineeringThermal water

The invention relates to a filter-dryer, in particular to filtering and drying integrated equipment for powdery materials. The filter-dryer comprises a machine body and a material pumping pipe. Proper filter cloth is laid on a supporting frame and fixed, then materials are fed through a feeding pipe, a valve of a vacuumizing pipe is opened for vacuumizing after materials are fed, water in the materials is pumped away through the filter cloth to achieve dryness of the materials, hot water is fed through the feeding pipe for washing, the process is carried out repeatedly, after the materials are washed clean, a valve of a steam pipeline is opened, steam is introduced for drying, and after drying, a valve of the material pumping pipe is opened for vacuum material pumping. The filter-dryer is safe, efficient, low in cost and small in energy consumption, achieves integration of material filtering, washing, drying and discharging, and has great popularization significance.

Owner:GUANGXI UNIV

Fully-automatically recycling ecological breeding system

InactiveCN109644880AAvoid pollutionSave land resourcesClimate change adaptationExcrement fertilisersLand resourcesNew energy

The invention provides a fully-automatically recycling ecological breeding system. The fully-automatically recycling ecological breeding system comprises an automatic feeding system, a manure recycling system, a biogas fermentation system, an organic fertilizer fermentation system and a finished product production system, wherein the manure recycling system comprises a manure recycling ditch arranged under the automatic feeding system, a manure integrally recycling device is arranged inside the manure recycling ditch, a plurality of floor drains are arranged above the manure integrally recycling device, the manure integrally recycling device is connected with a manure reservoir A and a manure reservoir B, and the manure reservoir A is communicated with a biogas fermentation tank A of the biogas fermentation system through a pneumatic feeding pump. The fully-automatically recycling ecological breeding system can fundamentally overcome environmental pollution of existing breeding industry, greatly save land resources and water resources, greatly improve the surrounding working environment and the natural environment, increase the working quality and efficiency, reduce the workload ofworkers, produce a large amount of new energy and ensure multiple economic benefits.

Owner:周垟

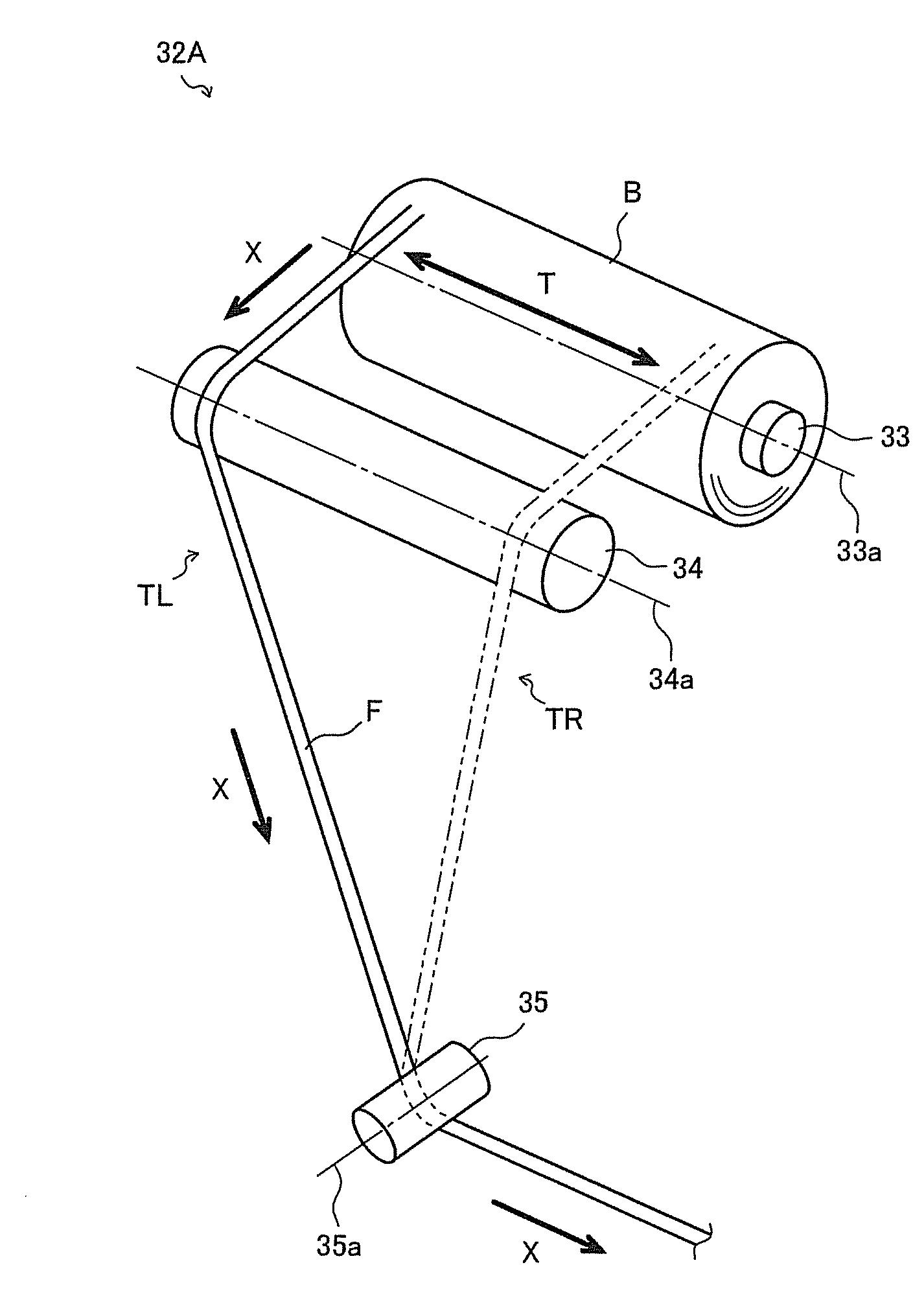

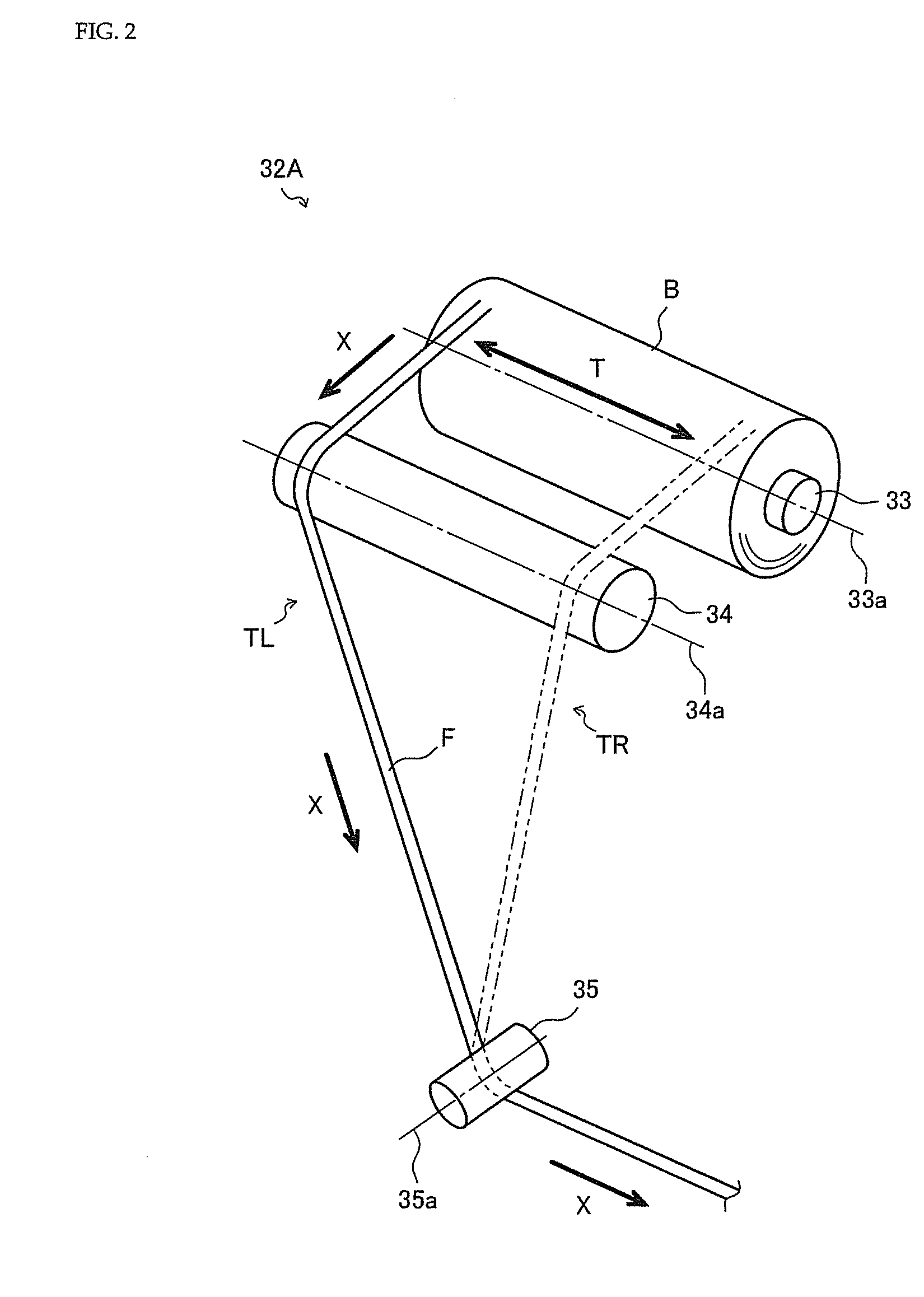

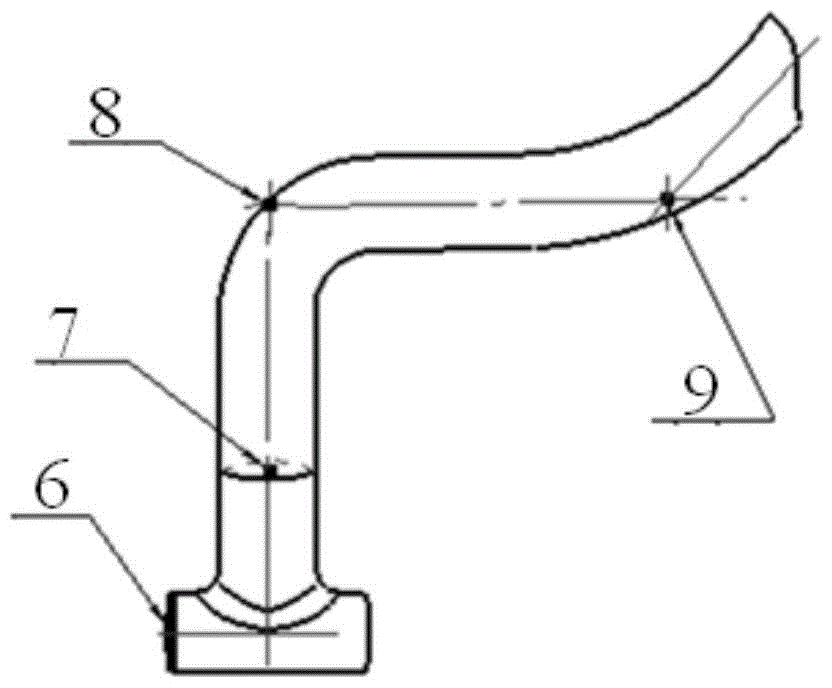

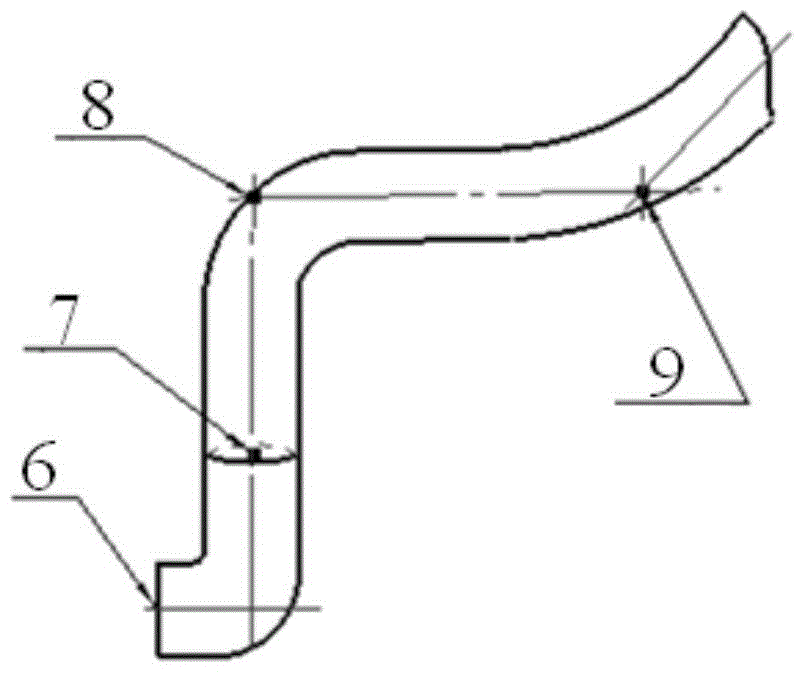

Bobbin unwinding device of filament winding device

ActiveUS20140346271A1Effect is exertedAvoid turnoverFilament handlingWebs handlingFiber bundleBobbin

This bobbin unwinding device (32A (32B)) is provided with a bobbin support shaft (33) which rotatably supports a bobbin (B) around which a band-like fiber bundle (F) is wound, a fixed guide (35) which changes the running direction of the fiber bundle (F) unwound from the bobbin (B), and an auxiliary roller (34) arranged between the bobbin (B) and the fixed guide (35), wherein the fixed guide (35) is arranged such that the shaft center of the fixed guide (35) is substantially perpendicular to the shaft center of the bobbin support shaft (33), and the auxiliary roller (34) is arranged such that the shaft center of the auxiliary roller (34) is parallel or substantially parallel to the shaft center of the bobbin support shaft (33).

Owner:MURATA MASCH LTD +1

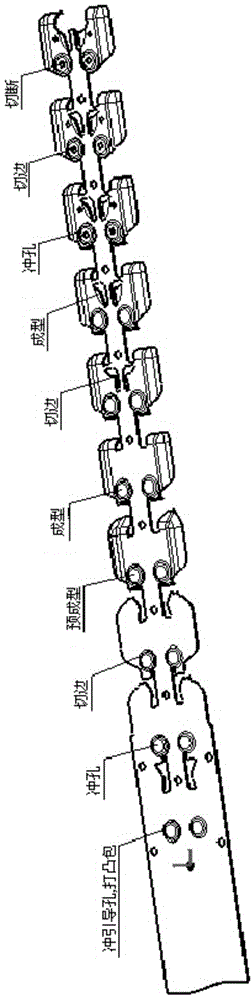

Continuous forming die for Audi B9U1 left/right rear brackets

The invention discloses a continuous forming die for Audi B9U1 left / right rear brackets. An upper bottom plate fixes an upper die holder through first padding legs, a lower bottom plate fixes a lower die holder through second padding legs, an upper padding plate is arranged on the lower side of the upper die holder, an upper fixing plate is arranged under the upper padding plate, a middle padding plate is arranged under the upper fixing plate, and a padding plate is arranged on the lower die holder. A female die plate and an above opposite first male punching die, a male raising die and an above opposite female raising die, a first male trimming die, and a first male forming die, a first female forming die and a male preforming die staggered, a second male forming die and a second female forming die staggered, a first female trimming die and a second male trimming die staggered, a third female forming die and a third male forming die arranged vertically, a second male punching die and a second female punching die arranged vertically and a second female trimming die and a third male trimming die staggered are sequentially arranged on the upper stripping end of the padding plate. By the continuous forming die, one-time forming can be realized, manpower and material resources are saved substantially, and precision is improved.

Owner:吉林博仁科技有限责任公司

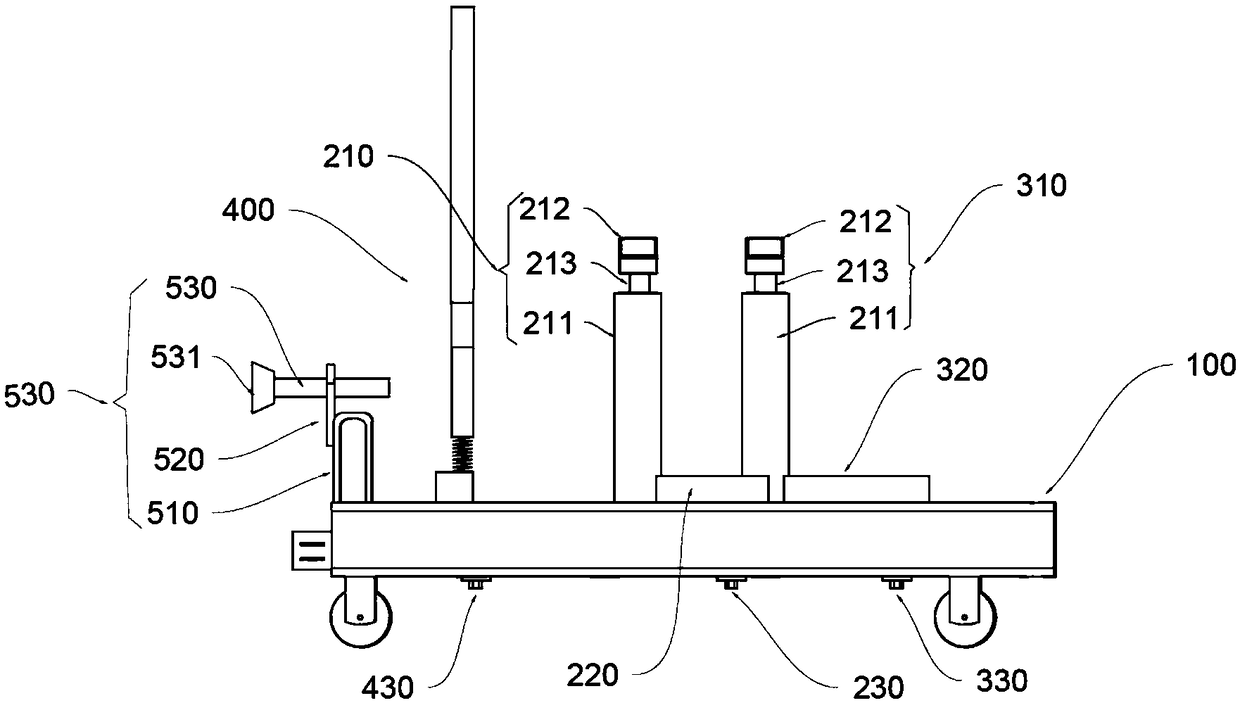

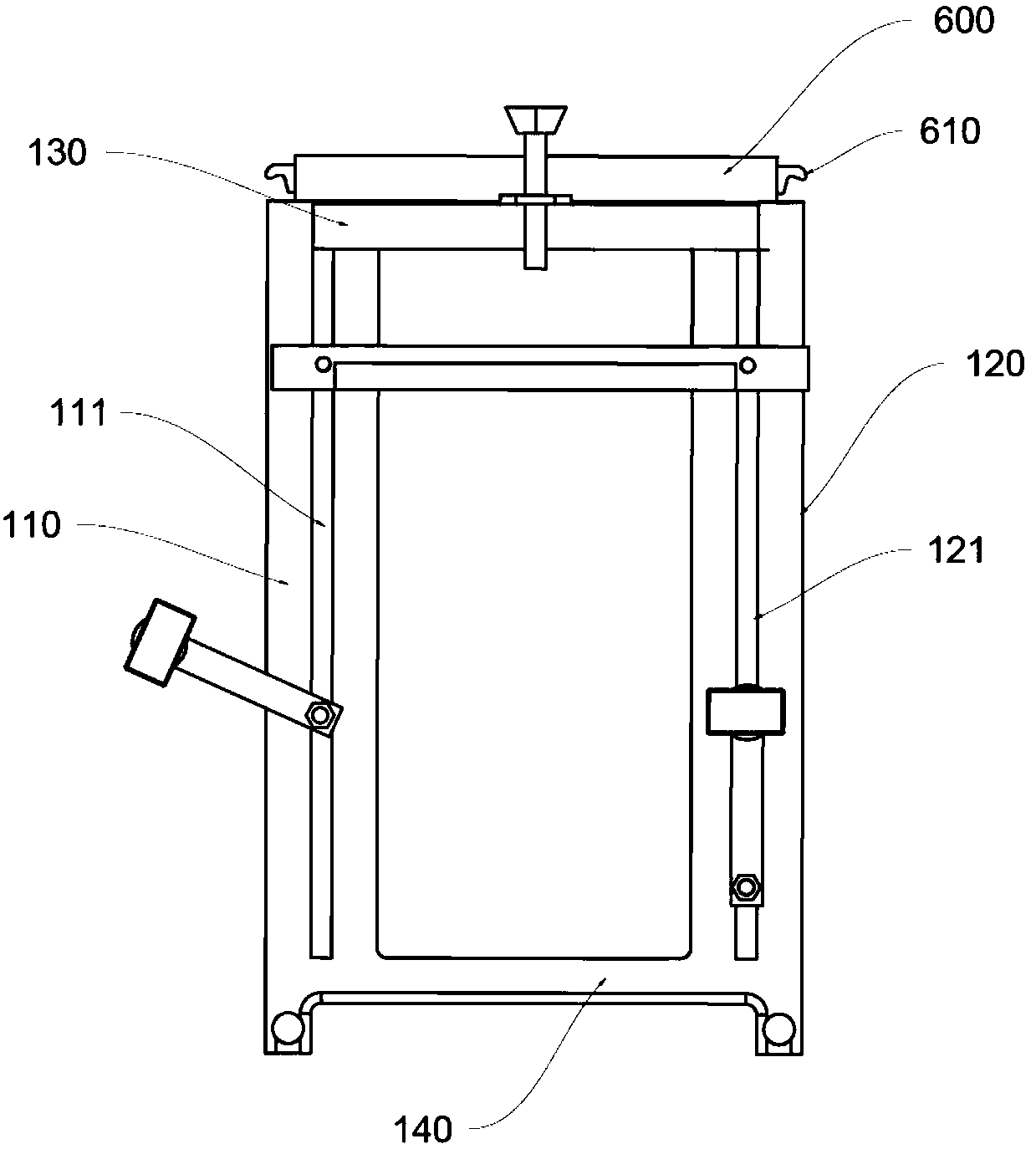

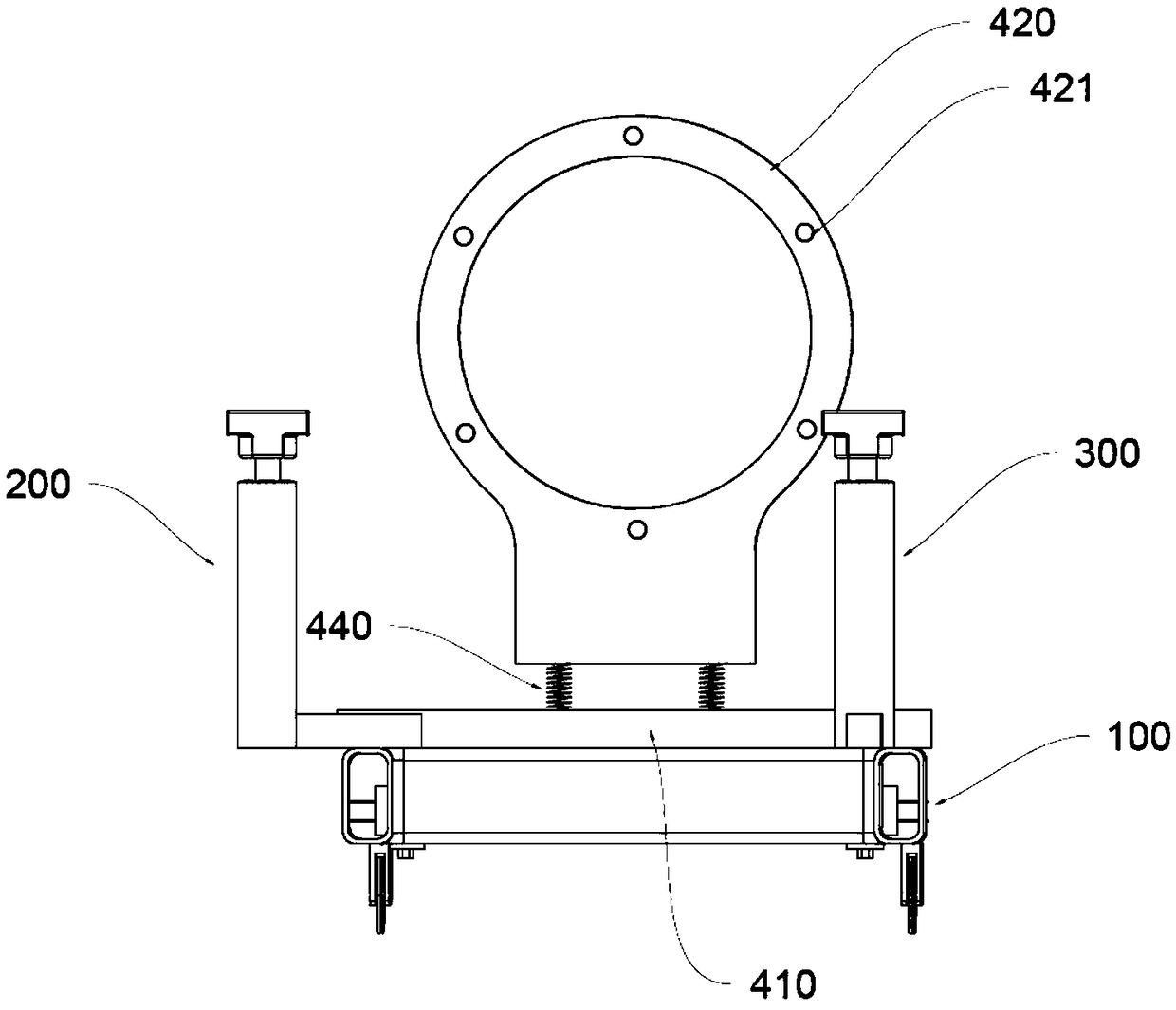

Universal docking trolley for testing automobile engines

PendingCN108407865ASimple structureEasy to useEngine testingHand carts with multiple axesEngineeringRolling chassis

The invention discloses an universal docking trolley for testing automobile engines. The universal docking trolley for testing the automobile engines comprises a chassis, a first supporting rod, a second supporting rod and an annular bracket, wherein rollers are mounted at the bottom of the chassis; the chassis comprises a first longitudinal beam, a second longitudinal beam, a first end beam and asecond end beam; a first oblong through hole is formed in the first longitudinal beam; a second oblong through hole is formed in the second longitudinal beam; the first supporting rod comprises a first vertical rod and a first cross rod and is integrally of an L shape; the first cross rod is mounted in the first oblong through hole through a first bolt; the second supporting rod comprises a second vertical rod and a second cross rod and is integrally of an L shape; the second cross rod is mounted in the second oblong through hole through a second bolt; the annular bracket comprises a supporting seat and an annular plate; a plurality of bolt through holes distributed in the form of an annular array are formed in the annular plate; and the two ends of the supporting seat are mounted in thefirst oblong through hole and the second oblong through hole through two third bolts in a sliding manner. The universal docking trolley for testing the automobile engines can be applicable to the engines with different models.

Owner:安妥驰(张家港)汽车零部件再制造有限公司

Full-automatic receiving and feeding mechanism

PendingCN111169999AAvoid product turnoverLabor savingMetal working apparatusConveyor partsElectric machineryPiston

The invention discloses a full-automatic receiving and feeding mechanism. A rotary table is installed on the periphery of a second motor, a plurality of fourth sucking cups are arranged on the circumference of the rotary table, a fourth air cylinder is further installed on the periphery of a main frame, a second hydraulic piston is installed on the fourth air cylinder, a connecting plate is installed on the second hydraulic piston, a fifth air cylinder is installed on the connecting plate, and a second claw hand is installed on the fifth air cylinder. An eighth air cylinder is installed at theposition, located on one side of the rotary table, at the upper end of a second bracket, a third sucking cup is installed on one side of the eighth air cylinder, a sixth installation plate is installed on one side of the main frame, a fourth guide rail is arranged on the sixth installation plate in the length direction, a ninth air cylinder is installed on the sixth installation plate, a third hydraulic piston is arranged on one side of the ninth air cylinder, a third sliding block is installed on the third hydraulic piston, the third sliding block slides on the fourth guide rail, a sixth aircylinder is installed at the lower end of the third sliding block, and a third claw hand is installed on the sixth air cylinder. According to the full-automatic receiving and feeding mechanism, manual direct contact with products is avoided, product turnover is avoided, and labor is reduced.

Owner:JINHUA CALET AUTOMATION TECH

A welding rod automatic production system

ActiveCN114055017BReduce configurationReduce investmentWelding/cutting media/materialsSoldering mediaWire cuttingIndustrial engineering

The invention provides an automatic production system for welding rods, including a wire feeding device, a drawing device, a wire cutting device, a buffer device, a wire feeding device, a powder feeding device and a drying device, a wire feeding device, a drawing device, a wire cutting device, and a buffering device , wire feeding device, powder feeding device and drying device are arranged in sequence along the welding rod preparation direction to prepare welding rods; the wire feeding device is set to transport the coiled welding core in a single form, and the drawing device is set to It is used to draw the welding core, the wire cutting device is set to cut off the drawn welding core, and the buffer device is set to buffer and turn over the cut welding core during the conveying process, and wire feeding The device is set to convey the welding core when the welding core is covered by the coating, the powder feeding device is set to coat the welding core, and the drying device is set to dry the prepared welding rod . The invention has the beneficial effects of reducing production personnel allocation, reducing equipment investment and maintenance costs.

Owner:天津市金桥焊材科技有限公司 +1

A Method for Digitized Angle Determination of Pipeline

ActiveCN105345382BRealize online detectionAvoid turnoverWelding/cutting auxillary devicesAuxillary welding devicesAngular deviationGuide tube

The invention discloses a method for digitally determining an angular direction of a pipeline. The method comprises the steps that a connector is clamped on a clamp with the indexing function; a matched guide tube is assembled on the connector according to any space angle; a tubular measurer is used for carrying out point collecting on the outer surface of the matched guide tube and the outer surface of the connector, a space data model is obtained through measurement of the tubular measurer, and the space data model is a model with the connector end assumed as the guide tube; data intercepted from UG modeling is used as standard data, data measured from the connector and the matched guide tube is used as correlation data, and therefore simulated data deviation is obtained; then angular deviation is calculated; measurement and adjustment are performed again after the angle is adjusted, and the assembling angle direction is marked on the connector and the matched guide tube till the measurement tolerance is within the allowed assembling tolerance range of the connector. The method can directly determine the angular direction of the connector of a part like the guide tube through UG modeling graphs, and is applicable to parts like guide tubes of any tube diameter, so that the parts are machined more easily, conveniently and efficiently with low cost.

Owner:AECC AVIATION POWER CO LTD

Integrated circuit package intelligentized tool structure

PendingCN107742615AEliminate the risk of manual identification errorsRealize automated productionSemiconductor/solid-state device manufacturingIntelligent lightingEngineering

The invention discloses an integrated circuit package intelligentized tool structure which comprises a tool body which comprises four side plates forming a rectangle. Matched grooves are formed in theinner surfaces of two opposite side plates, a set of positioning structures are arranged on the outer surface of the tool body, an RF recognition sensing module, an online recognition bar code and astarting point are arranged on the outer surfaces of the side plates, the side plates are further provided with a plurality of plasma cleaning runners for cleaning objects inside the tool body, and the cleaning runners correspond to the grooves one to one. Due to intelligent remote control RF recognition sensing, the risk of wrong artificial recognition in the production process is eradicated; dueto the sensing recognition and positioning structure and the tool positioning and robot grabbing structure, production automation can be achieved; due to the plasma cleaning runner structural design,the cleaning effect inside the tool of the structure can be effectively enhanced, and the structure is more comprehensively cleaned.

Owner:WUXI LINLI SCI & TECH CO LTD

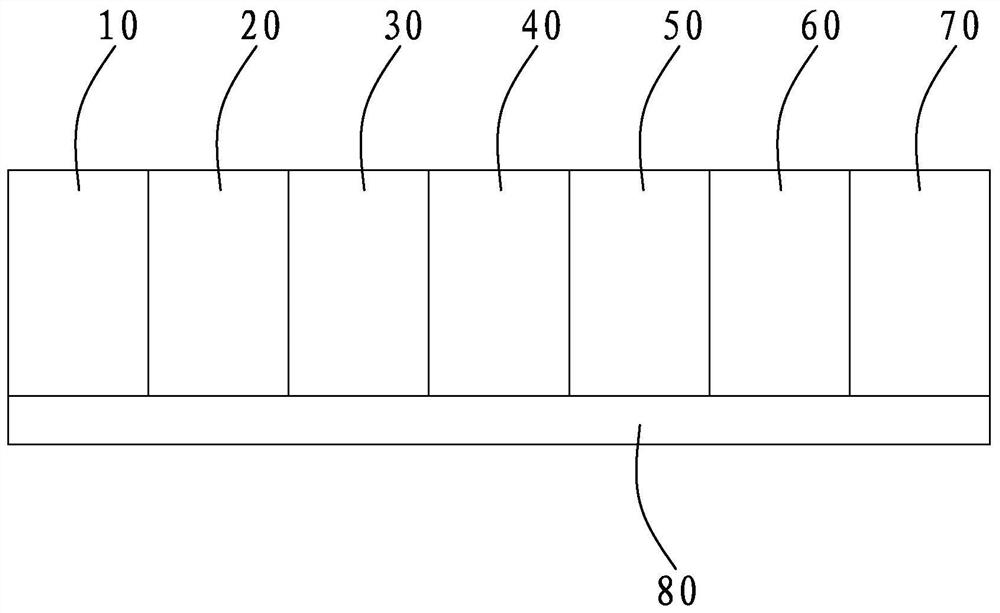

Plating device for AZO+SiN laminated protective film of solar cell

PendingCN112795872AReduce thicknessIncrease profitFinal product manufactureVacuum evaporation coatingAmorphous siliconSolar cell

The invention discloses a plating device for an AZO+SiN laminated protective film of a solar cell. The device comprises an AZO plating area, an SiN plating area and a chain type transmission mechanism corresponding to the AZO plating area and the SiN plating area, wherein the AZO plating area and the SiN plating area are sequentially arranged, and a carrier plate loaded with a silicon wafer is flatly laid on the chain type transmission mechanism and sequentially passes through the AZO plating area and the SiN plating area. AZO plating and SiN plating are simultaneously realized in the same device, thus the process integration degree is high, the process cycle is short, the equipment and labor cost input is greatly reduced, the production efficiency and product yield are effectively improved, and then the manufacturing cost of the solar cell is effectively reduced; and the AZO+SiN laminated protective film has good conductivity and light transmittance at the same time, the thickness of doped amorphous silicon can be reduced, so that the utilization rate of sunlight can be improved, the generating capacity can be increased, meanwhile, good ohmic contact with silver or other metals can be formed to reduce contact resistance, and further, the efficiency of the cell is improved.

Owner:CHANGZHOU BITAI TECH

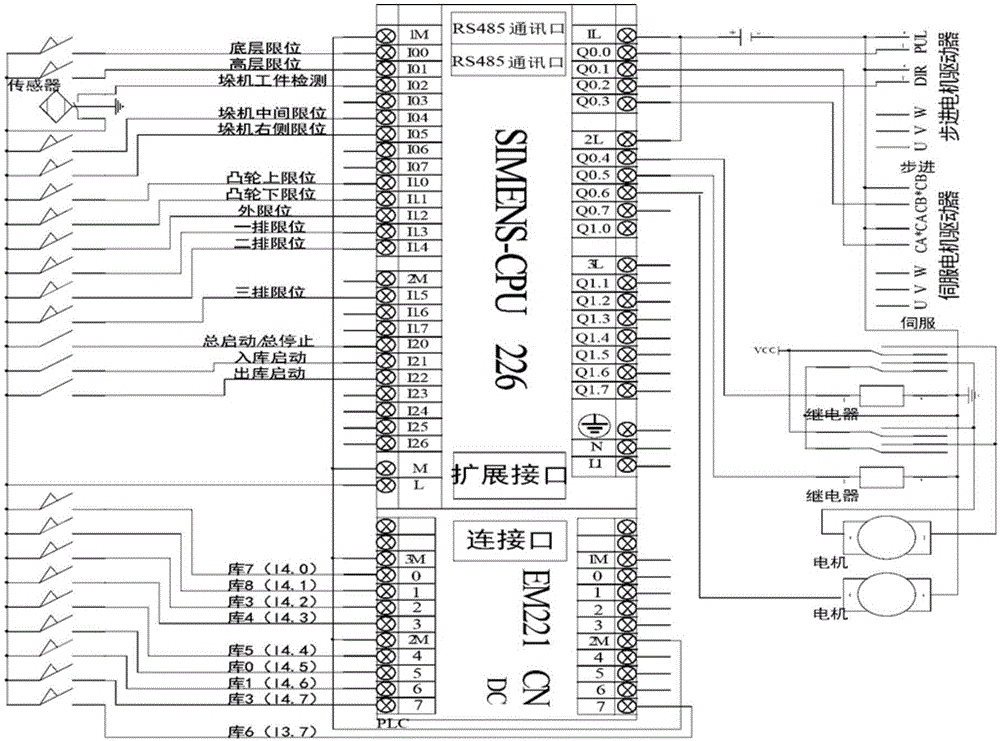

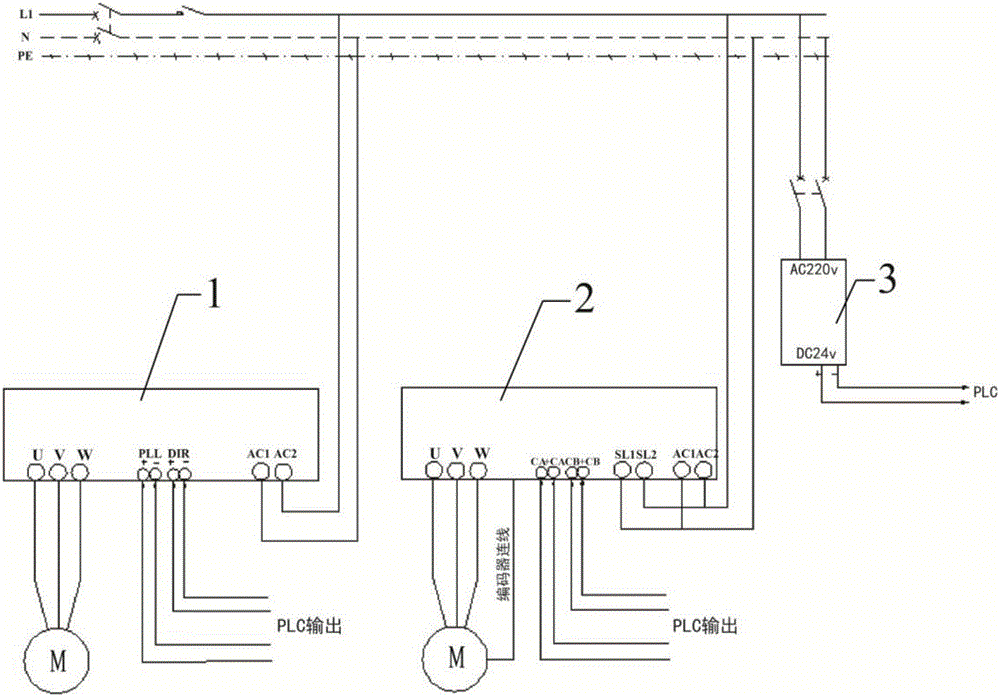

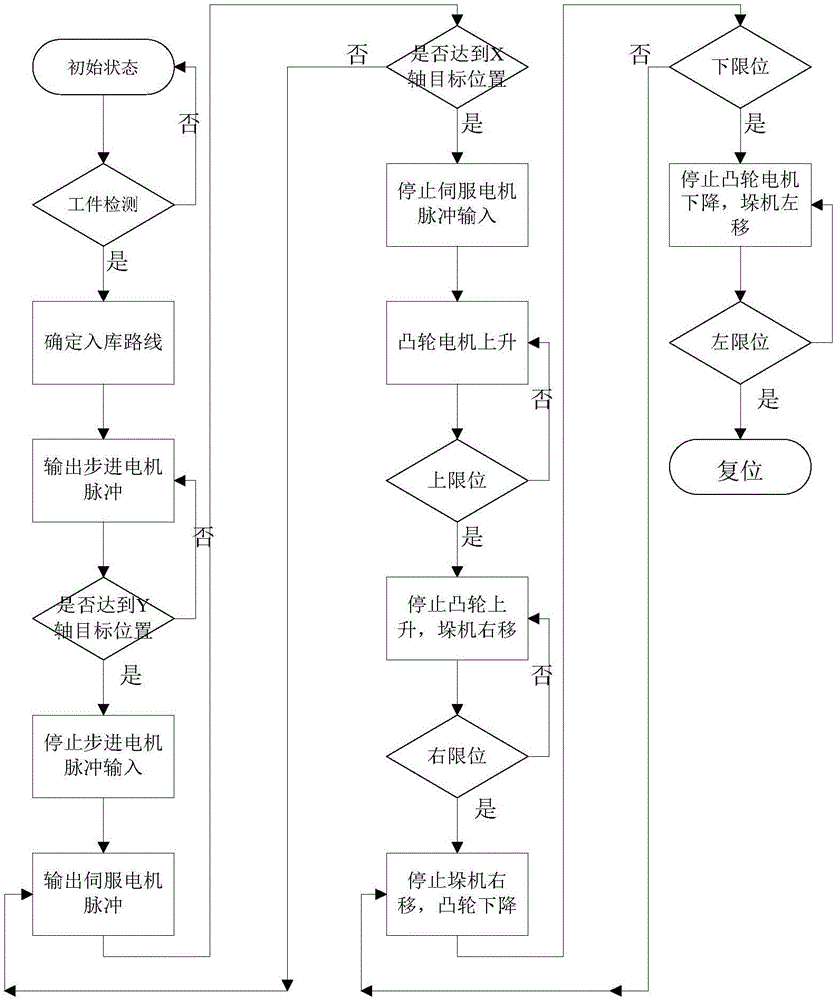

Method for wireless monitoring of space-parking system through adoption of Android intelligent terminal

InactiveCN106168787ASmall footprintLarge storageProgramme control in sequence/logic controllersWireless routerIp address

The present invention provides a method for wireless monitoring of a space-parking system through adoption of an Android intelligent terminal. The method comprises the following steps: S1, configuring the hardware of a space-parking system; S2, writing the PLC control program of a piler in an automation stereoscopic warehouse; S3, performing parameter setting of a wireless router, and connecting an Ethernet with control elements and the route; S4, setting parameters at the Android intelligent terminal, wherein the parameters must be completely consistent to the IP address, the port number and the device number in the control elements; S5, after the Android intelligent terminal powers on, receiving the signals emitted by the route through the Android intelligent terminal to monitor the running state of the space-parking system so as to solve the problems of the generation of the consumables of the wired monitoring and the inconvenient installation in the space-parking system and make the process monitoring convenient and more intelligent.

Owner:天津理工大学中环信息学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com