Patents

Literature

2034 results about "DISC assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fertilizer injector wing for disc openers

InactiveUS7004090B2High speed useReduce distractionsTill seedingDirect liquid fertiliser deliverySeederAgricultural engineering

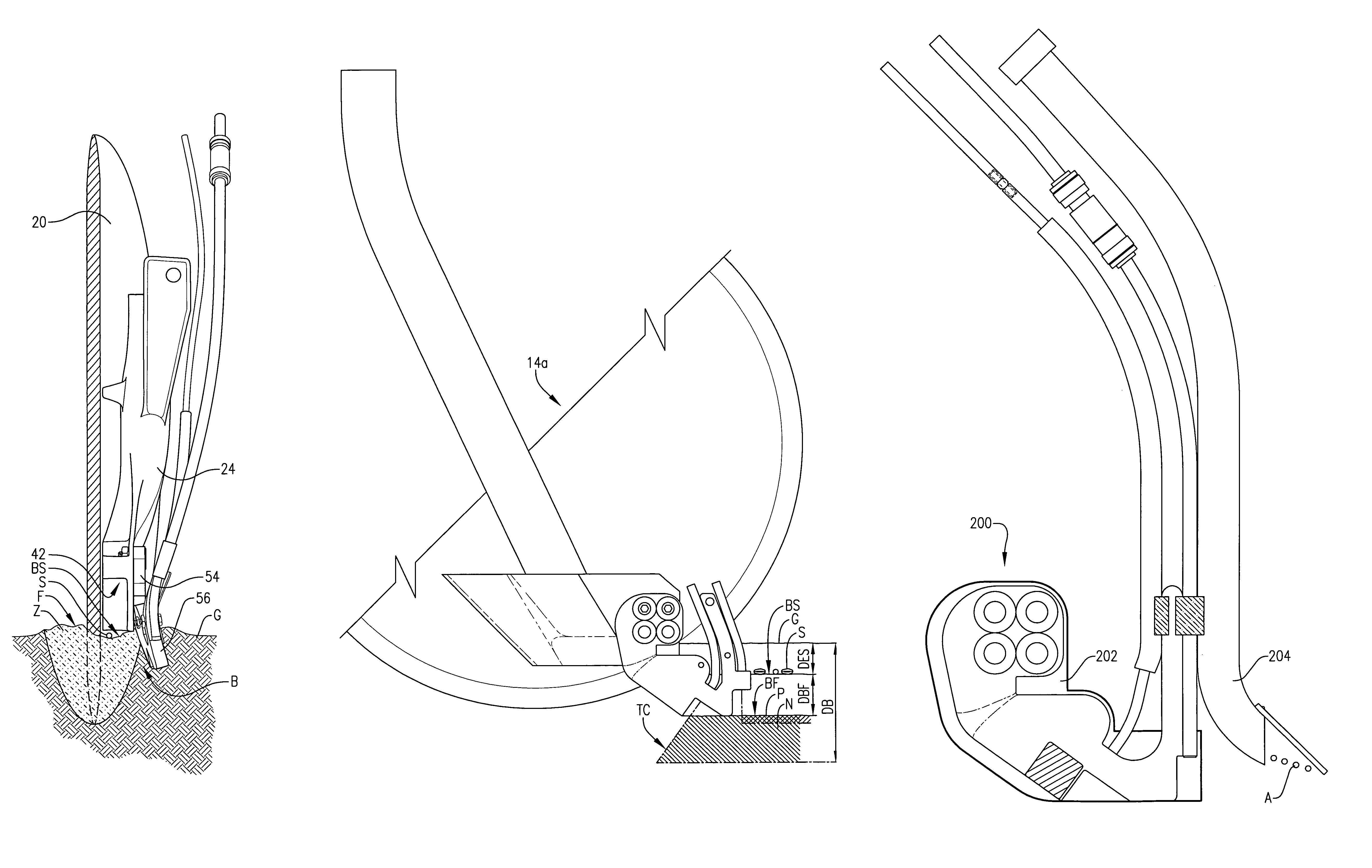

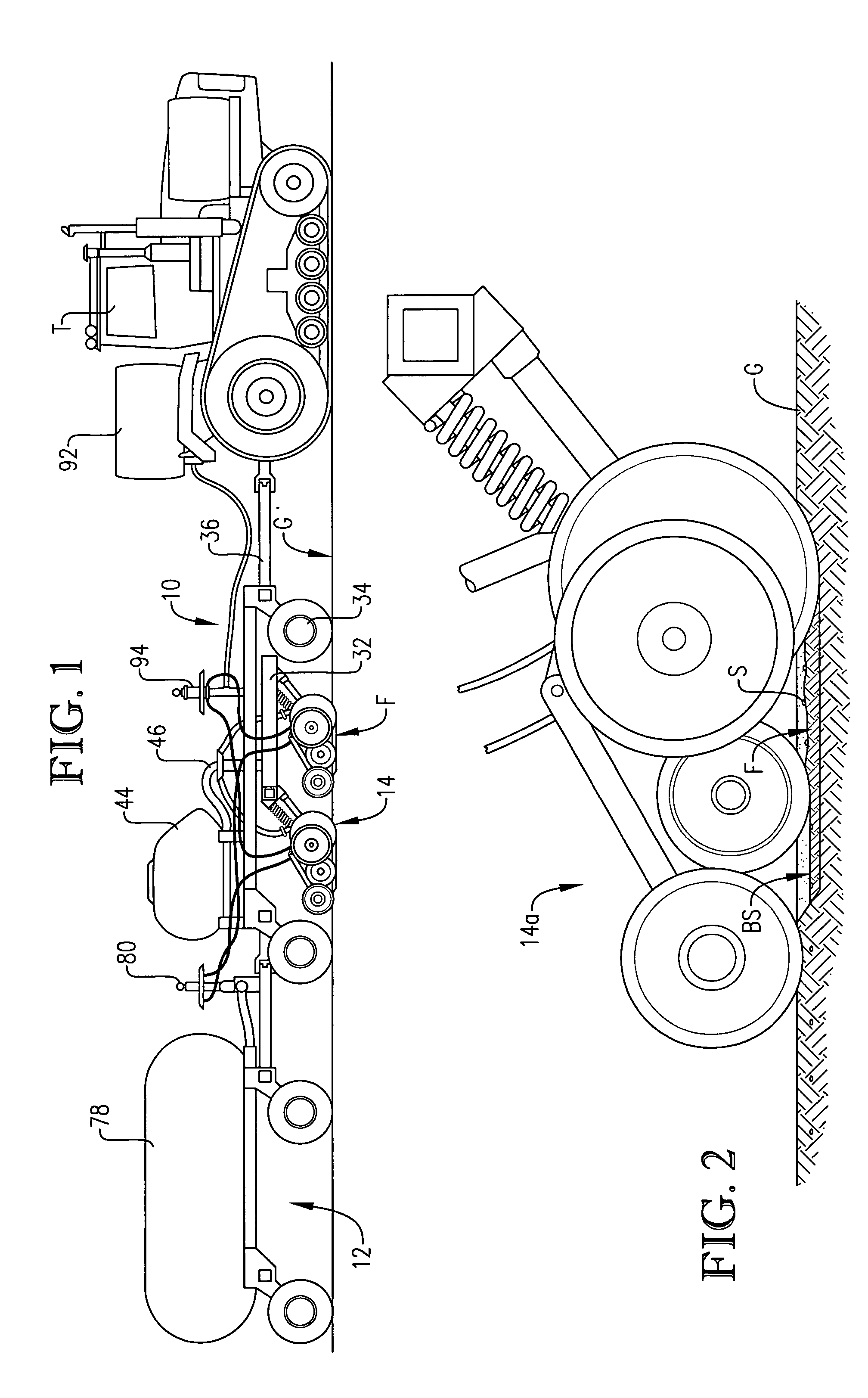

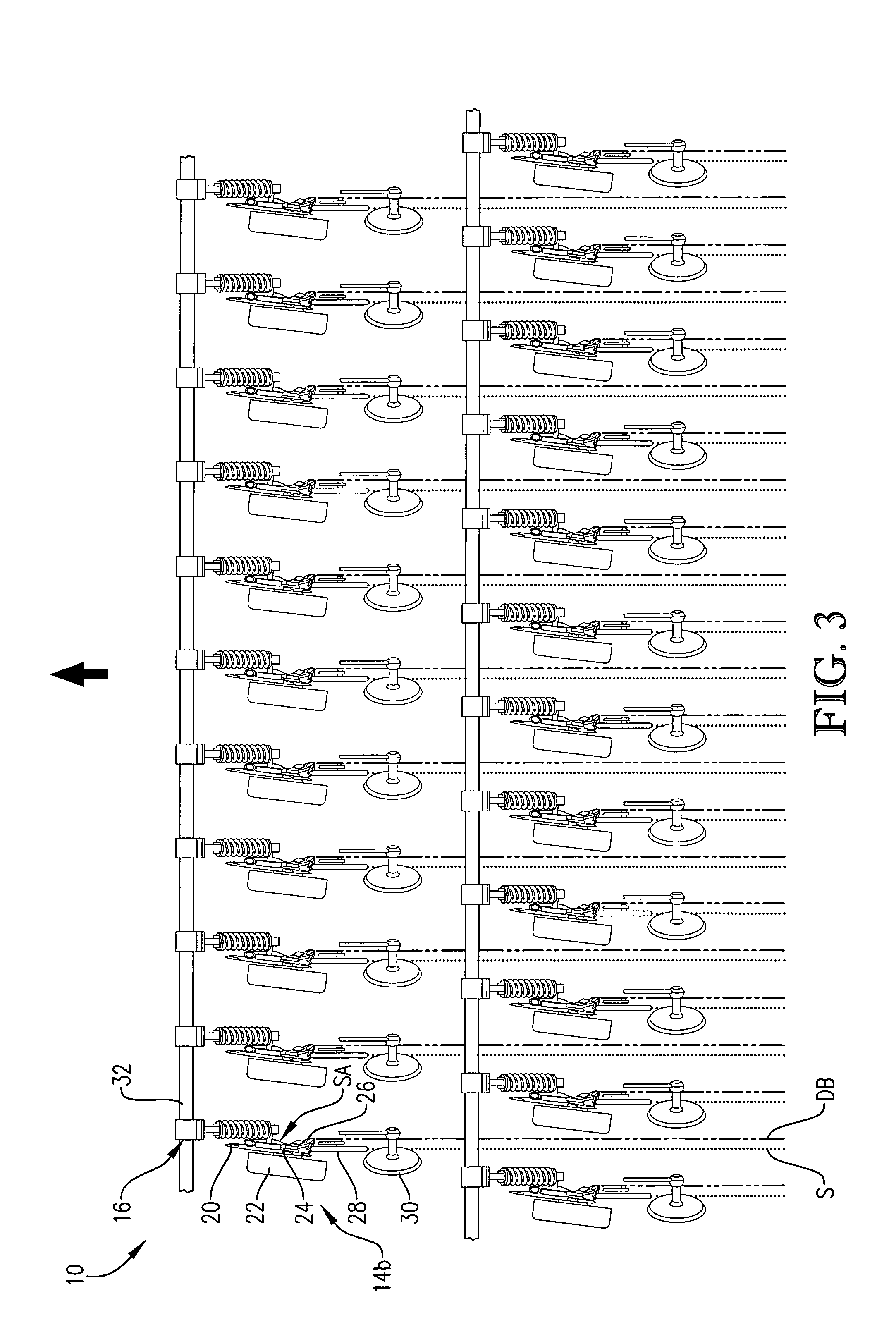

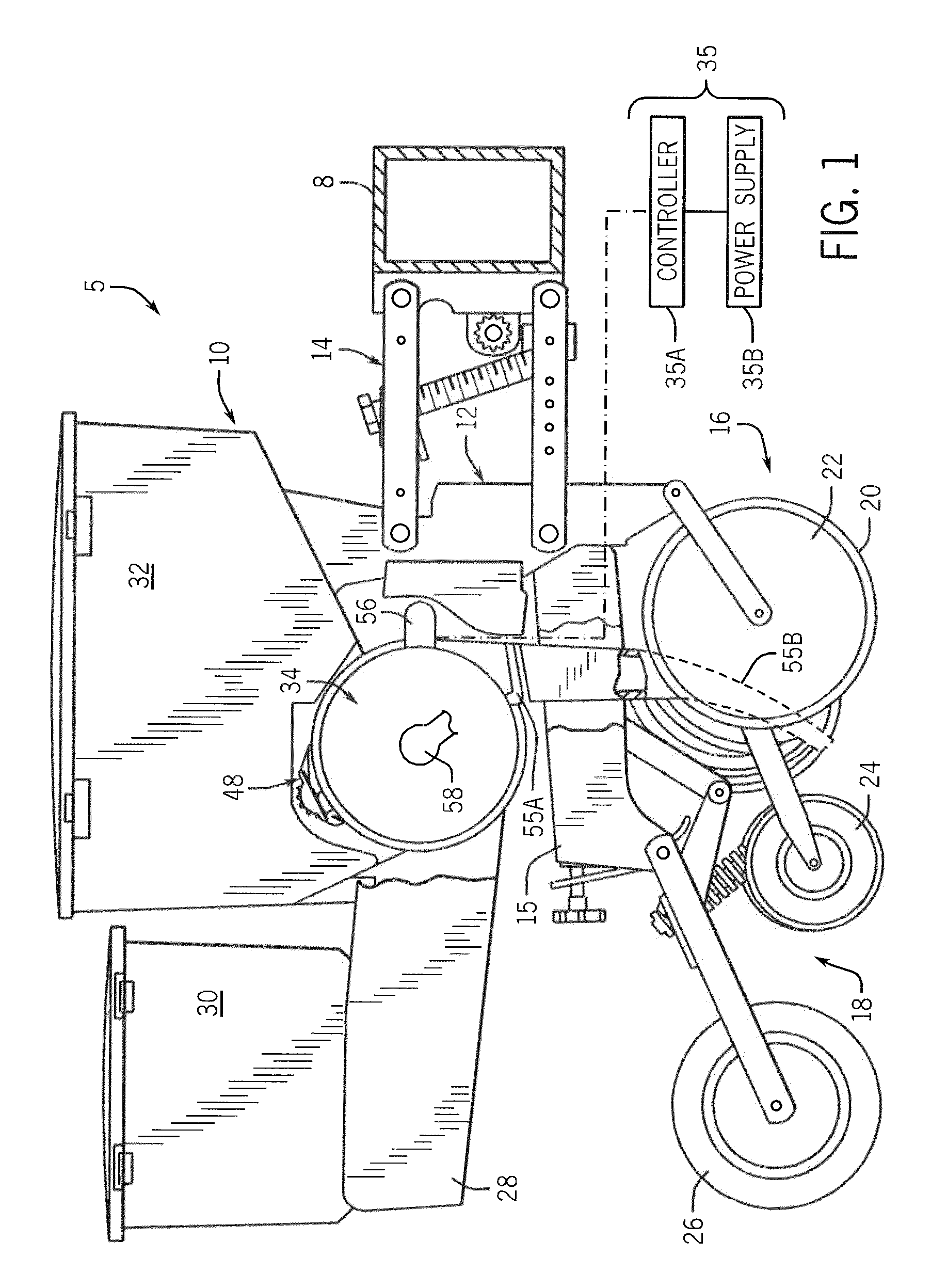

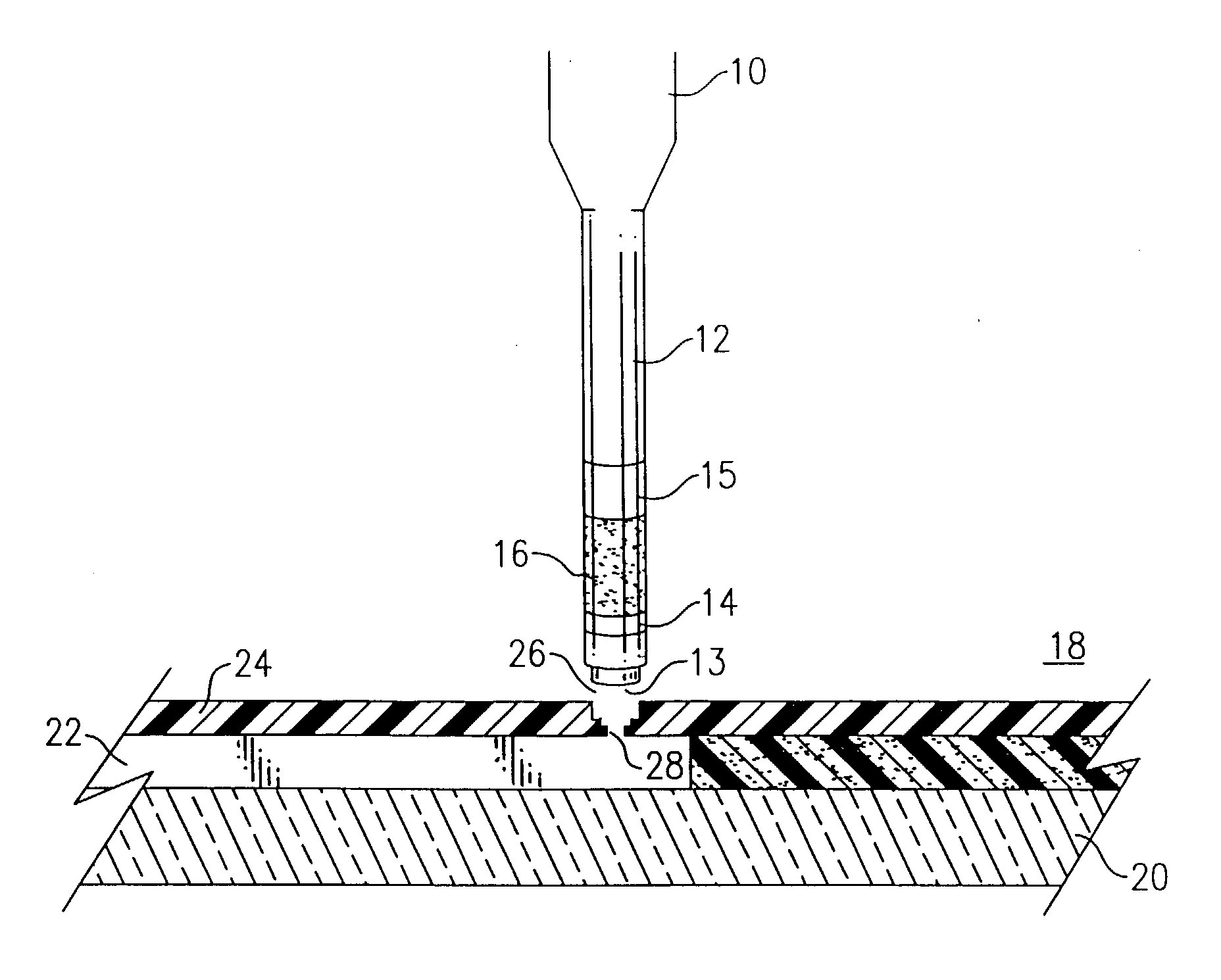

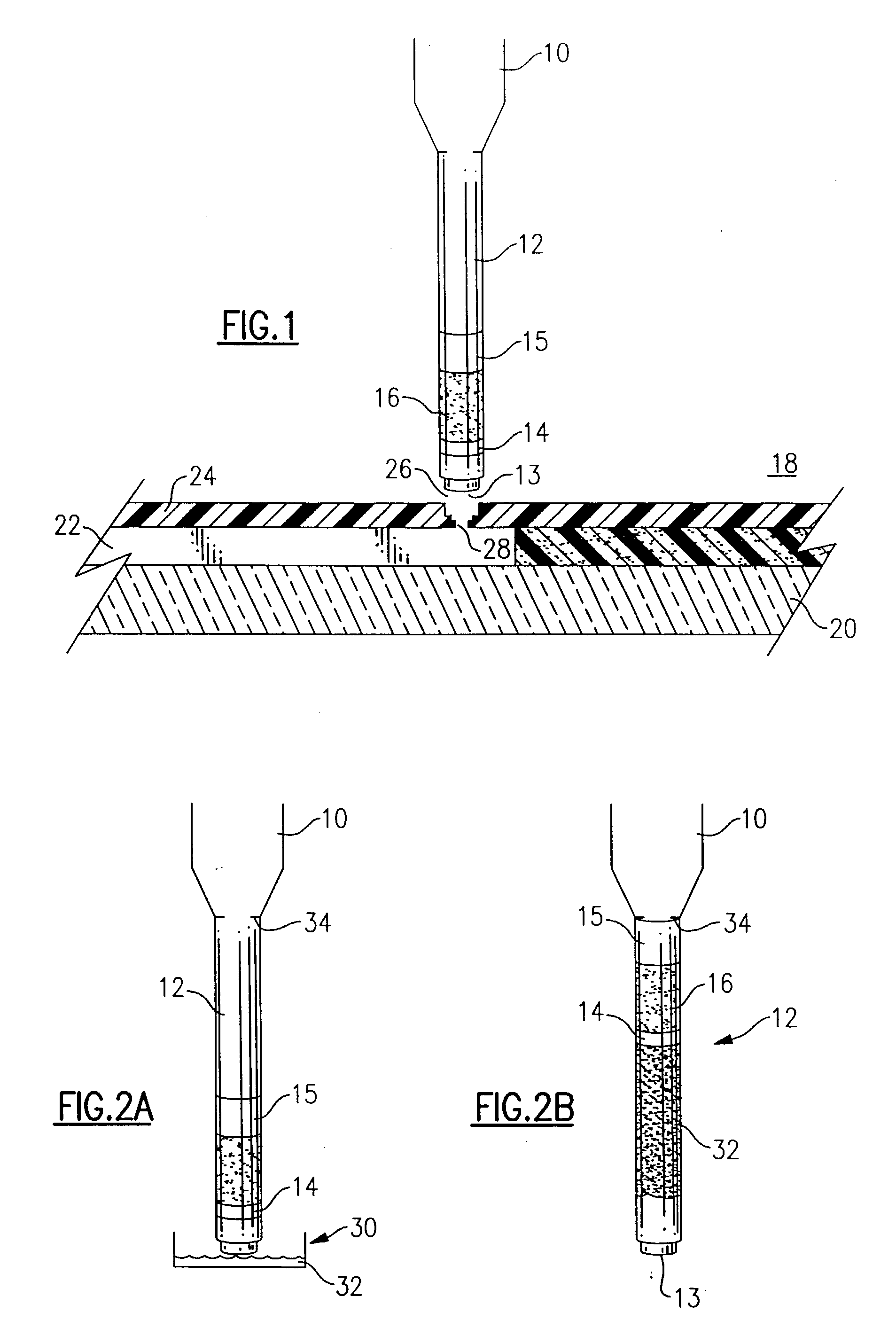

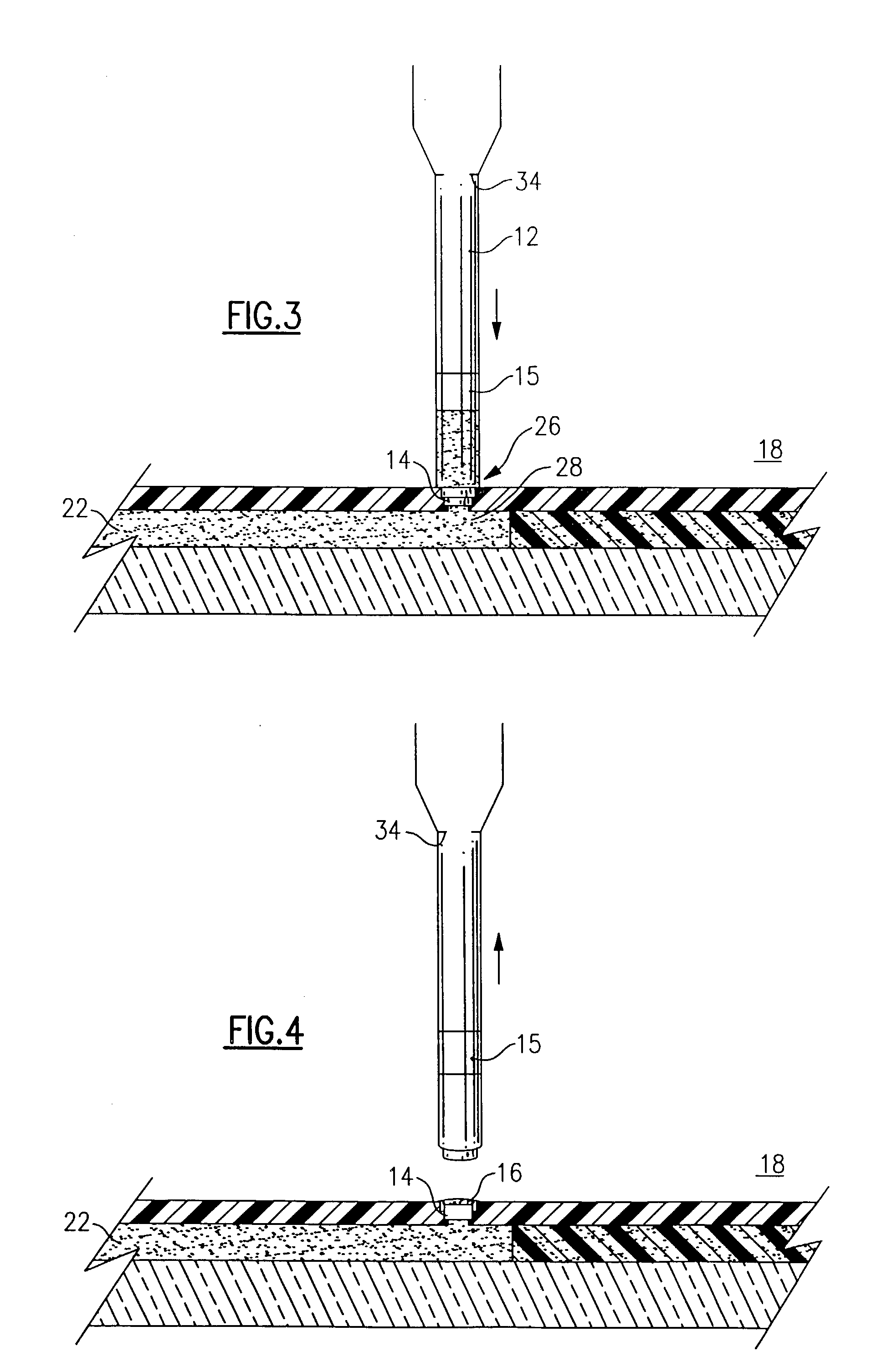

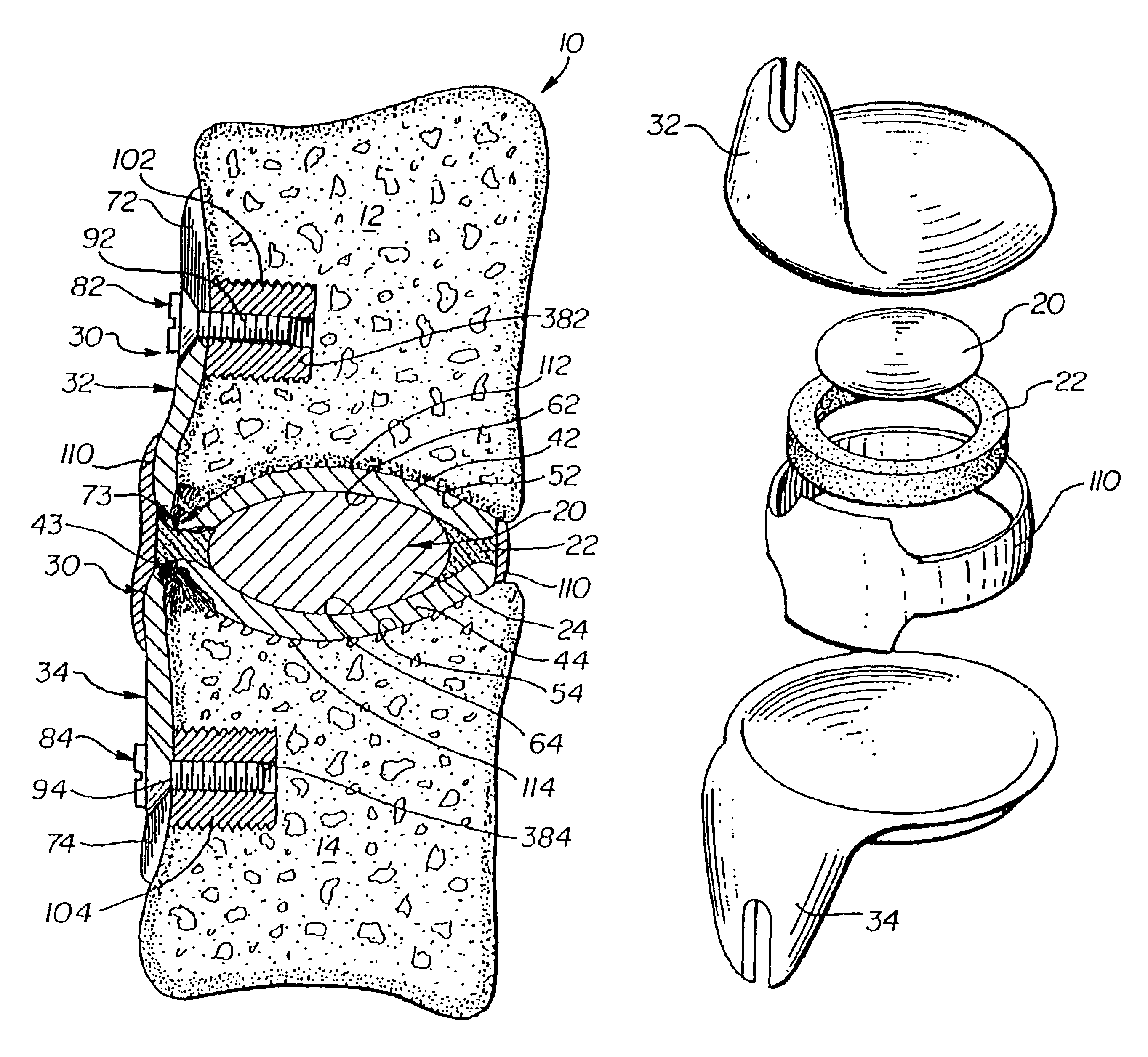

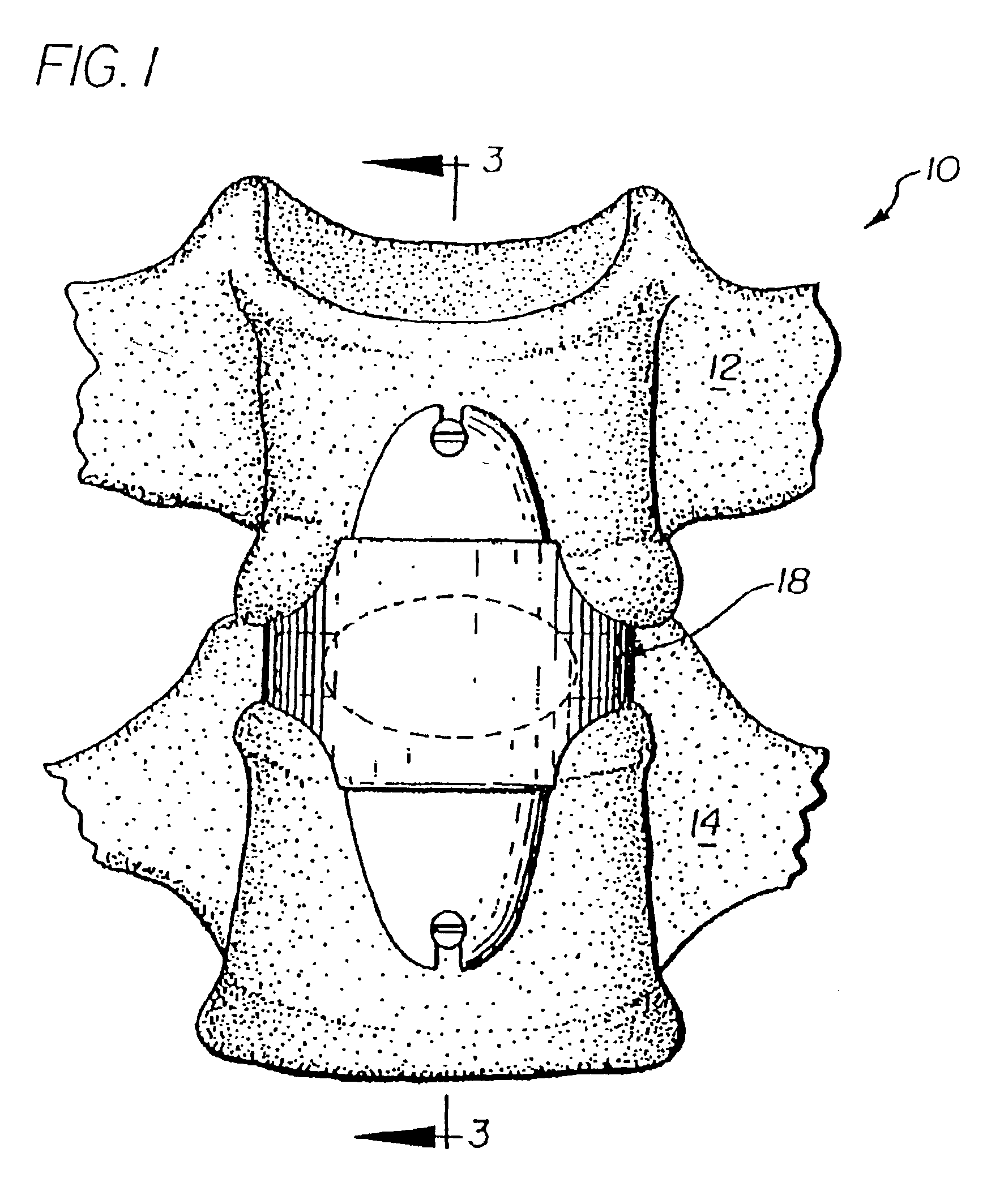

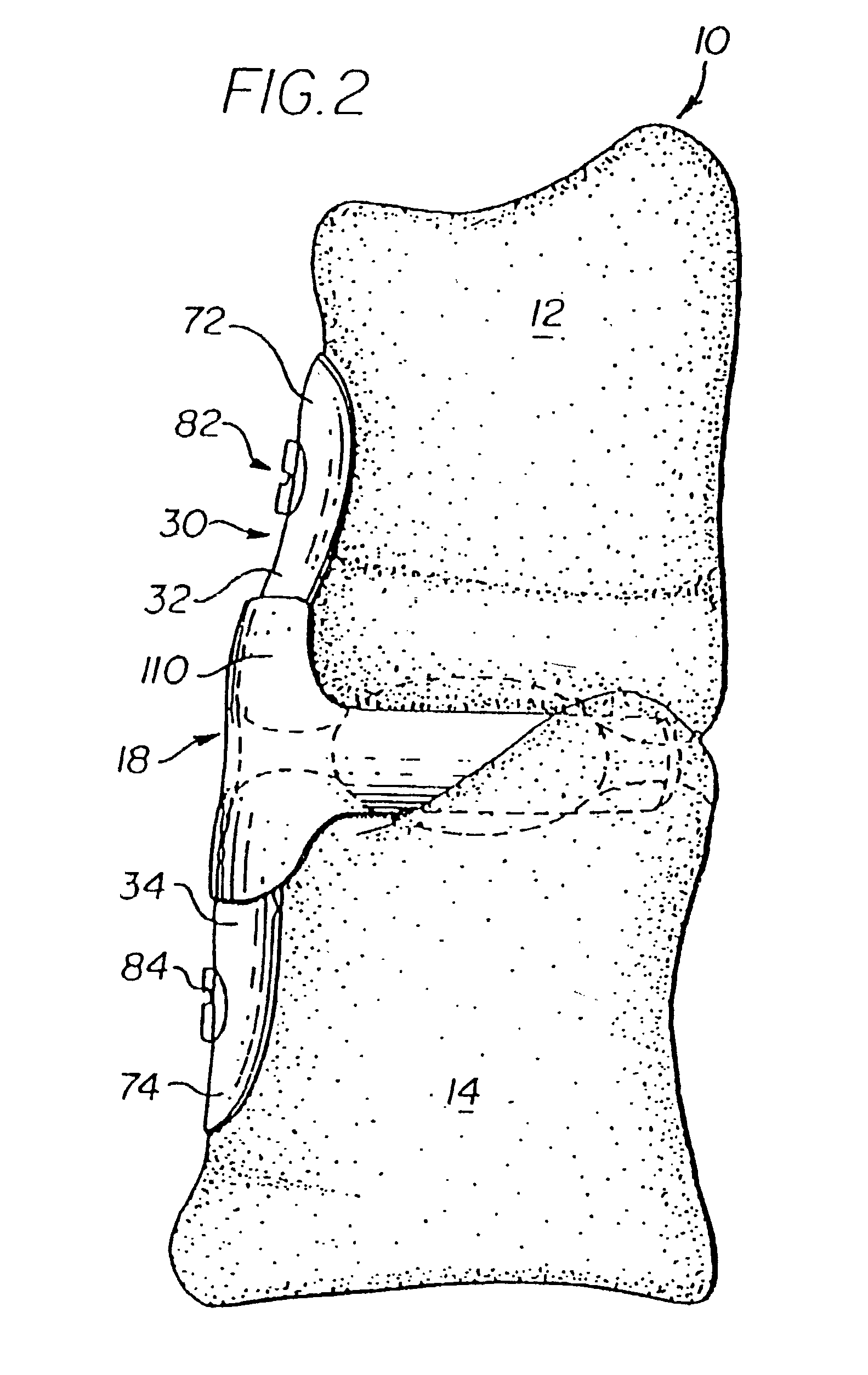

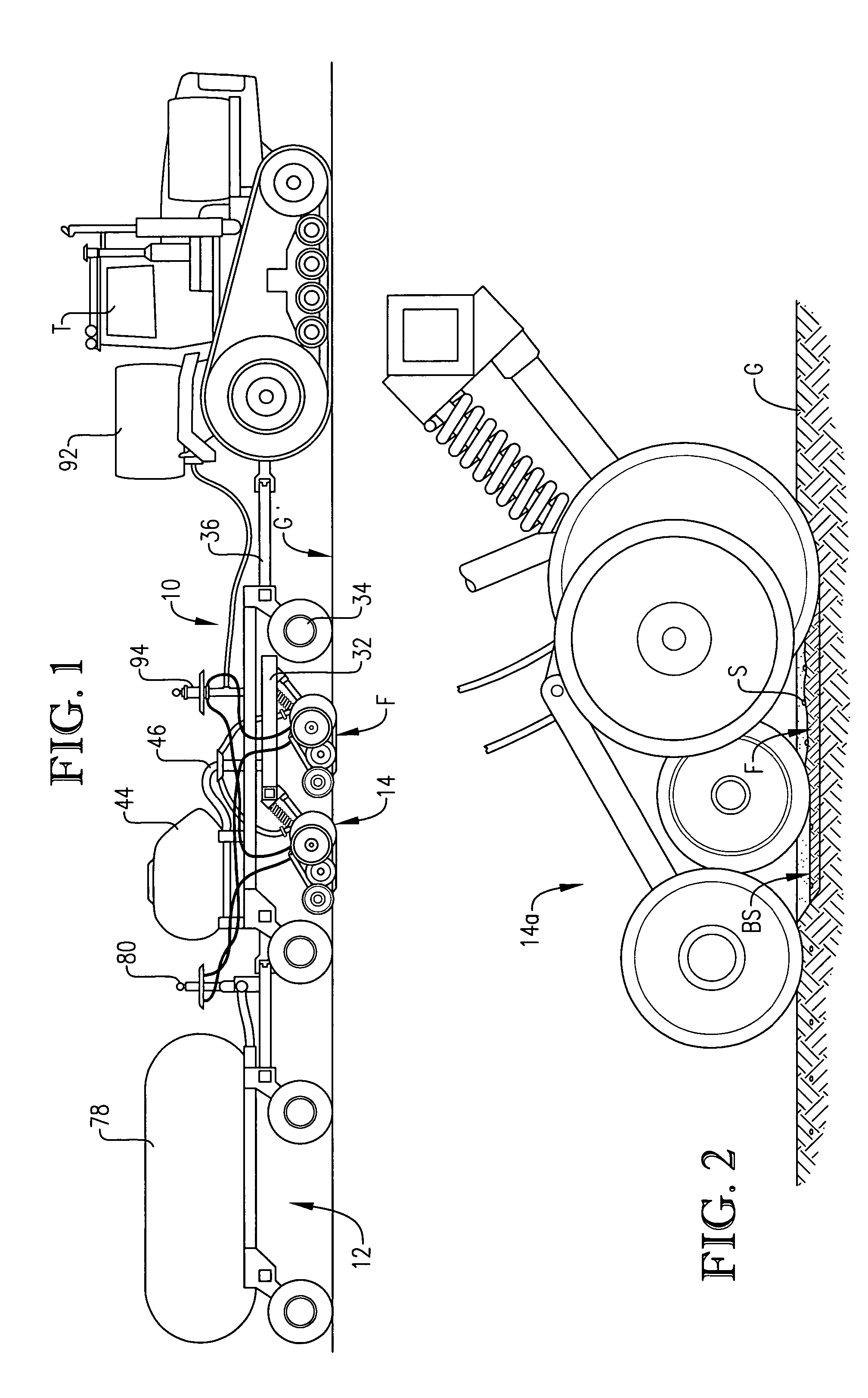

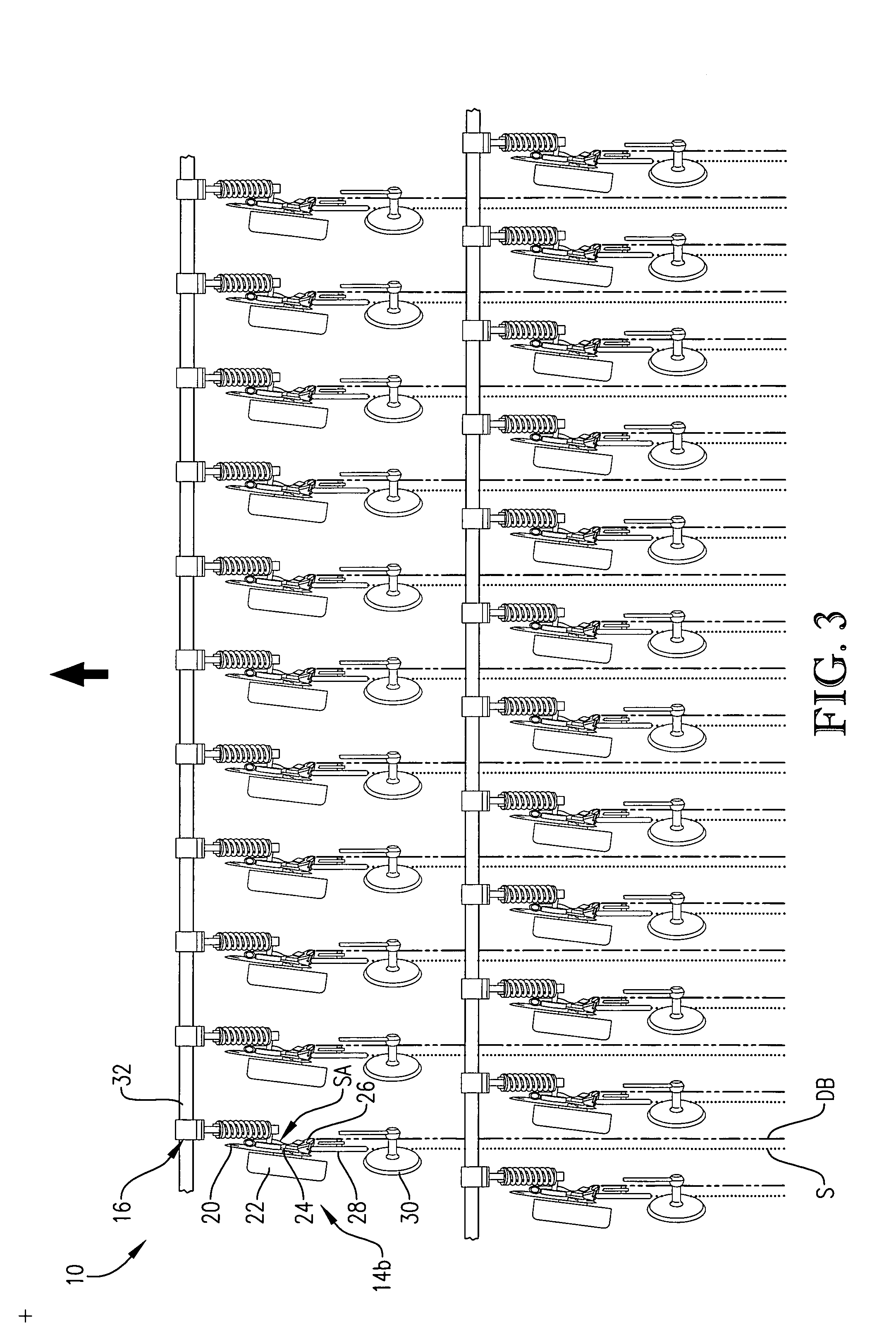

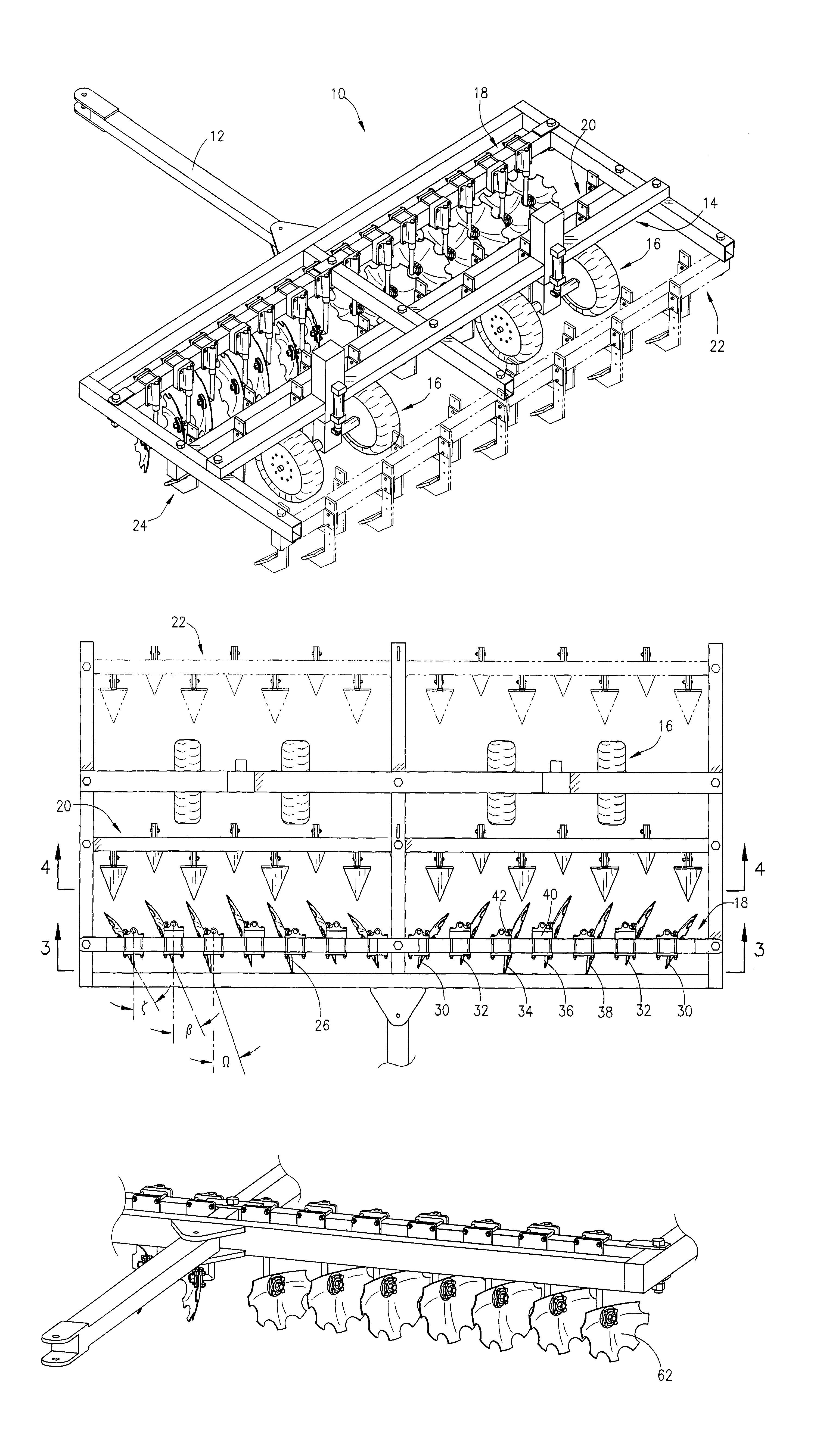

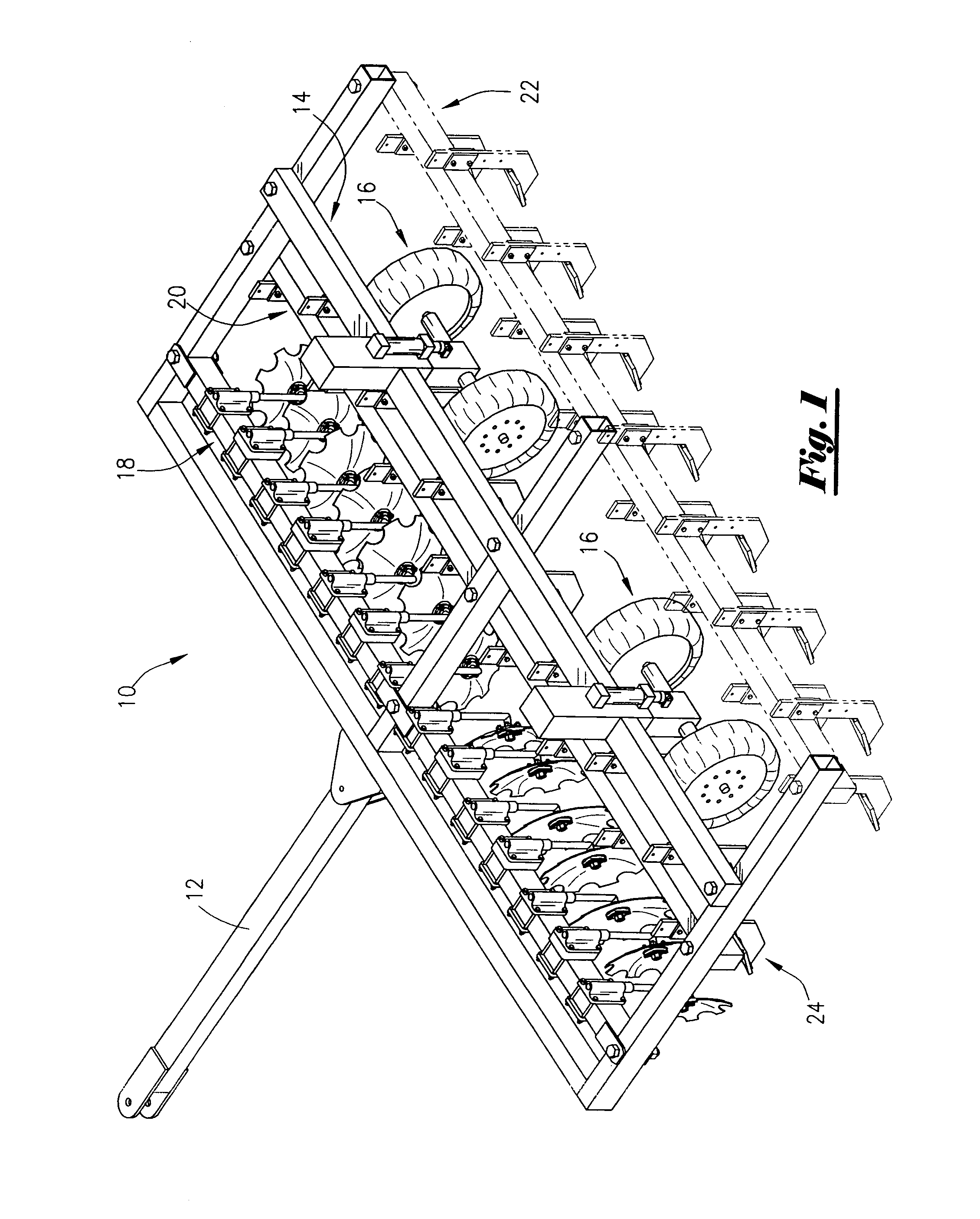

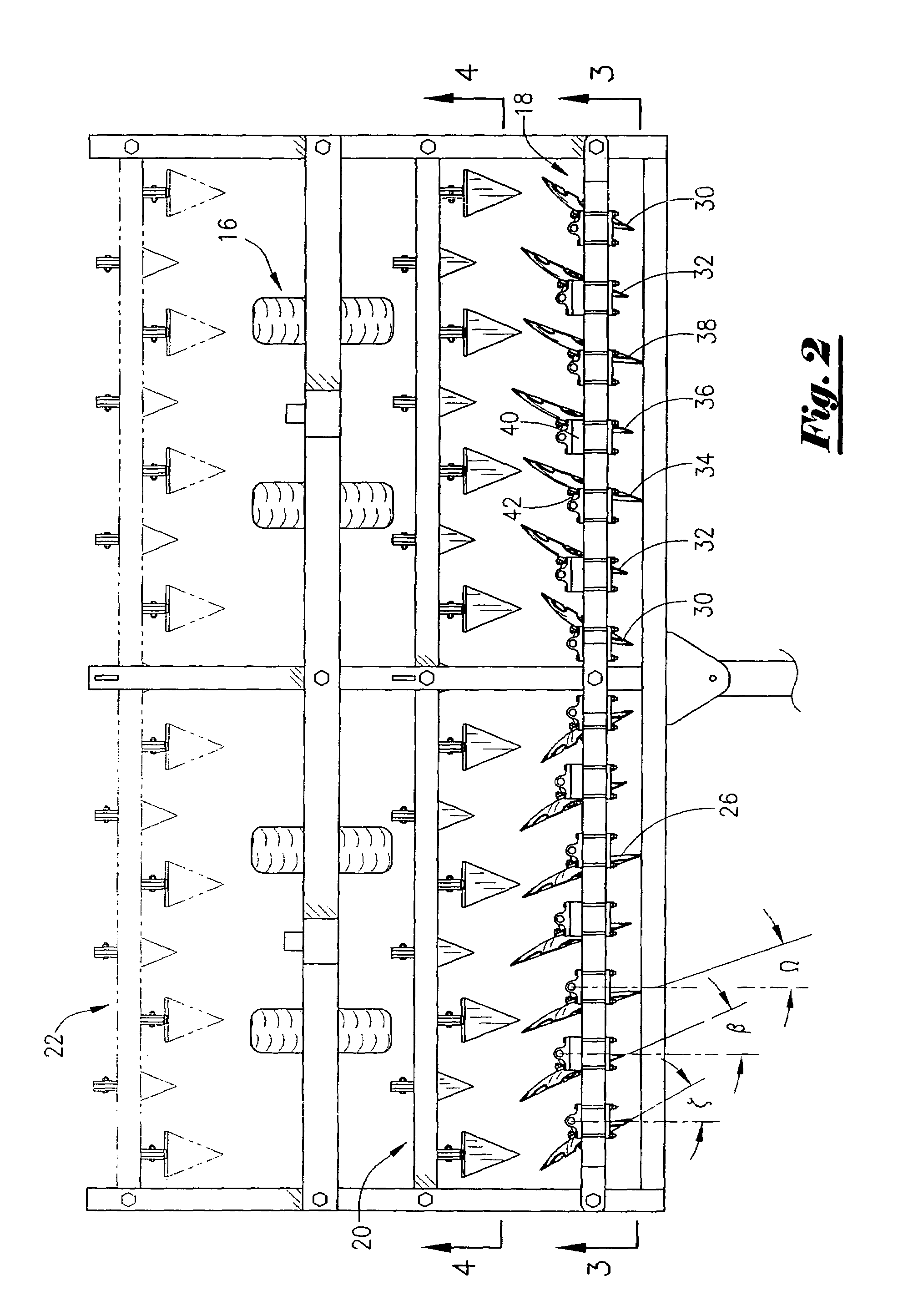

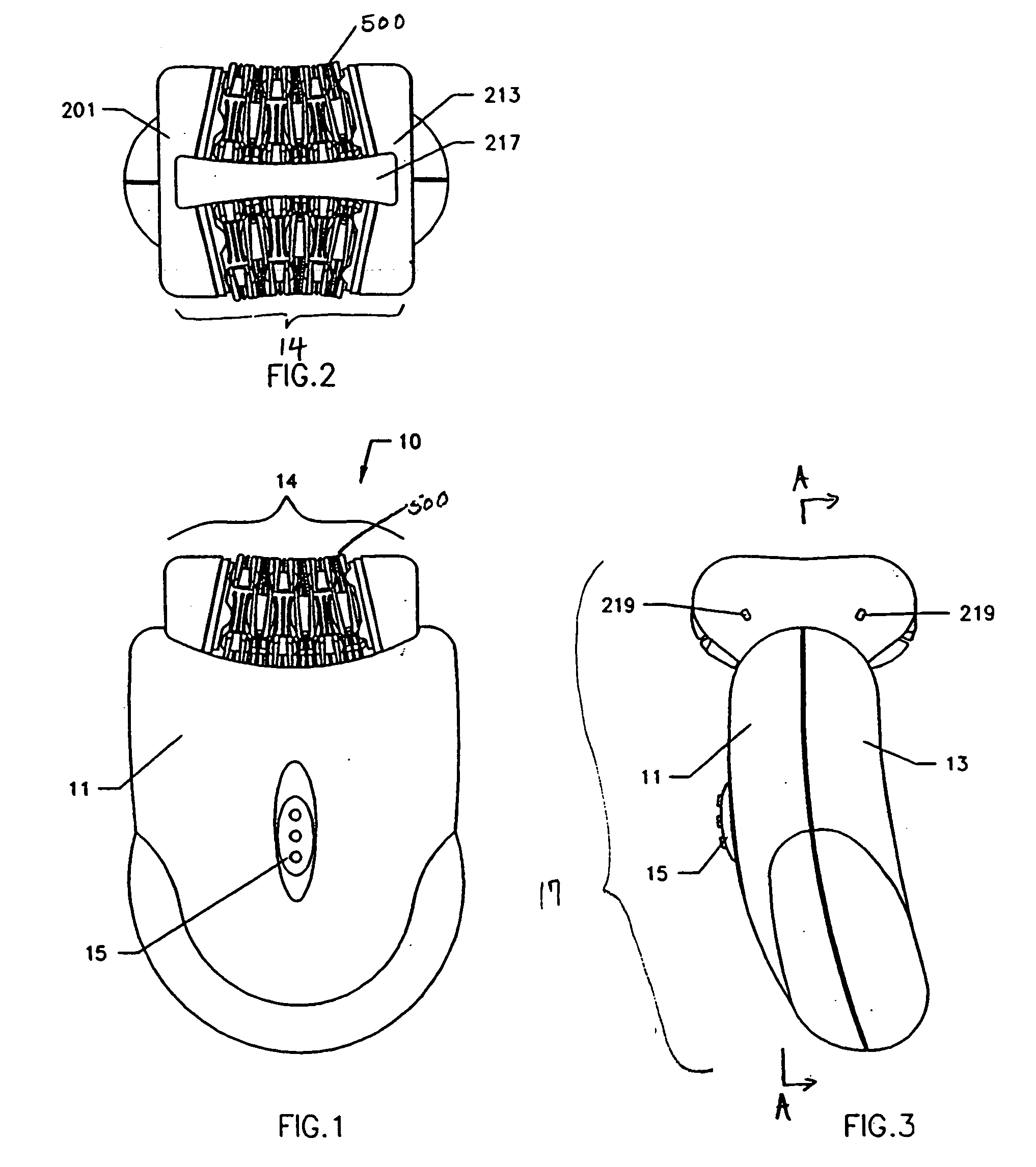

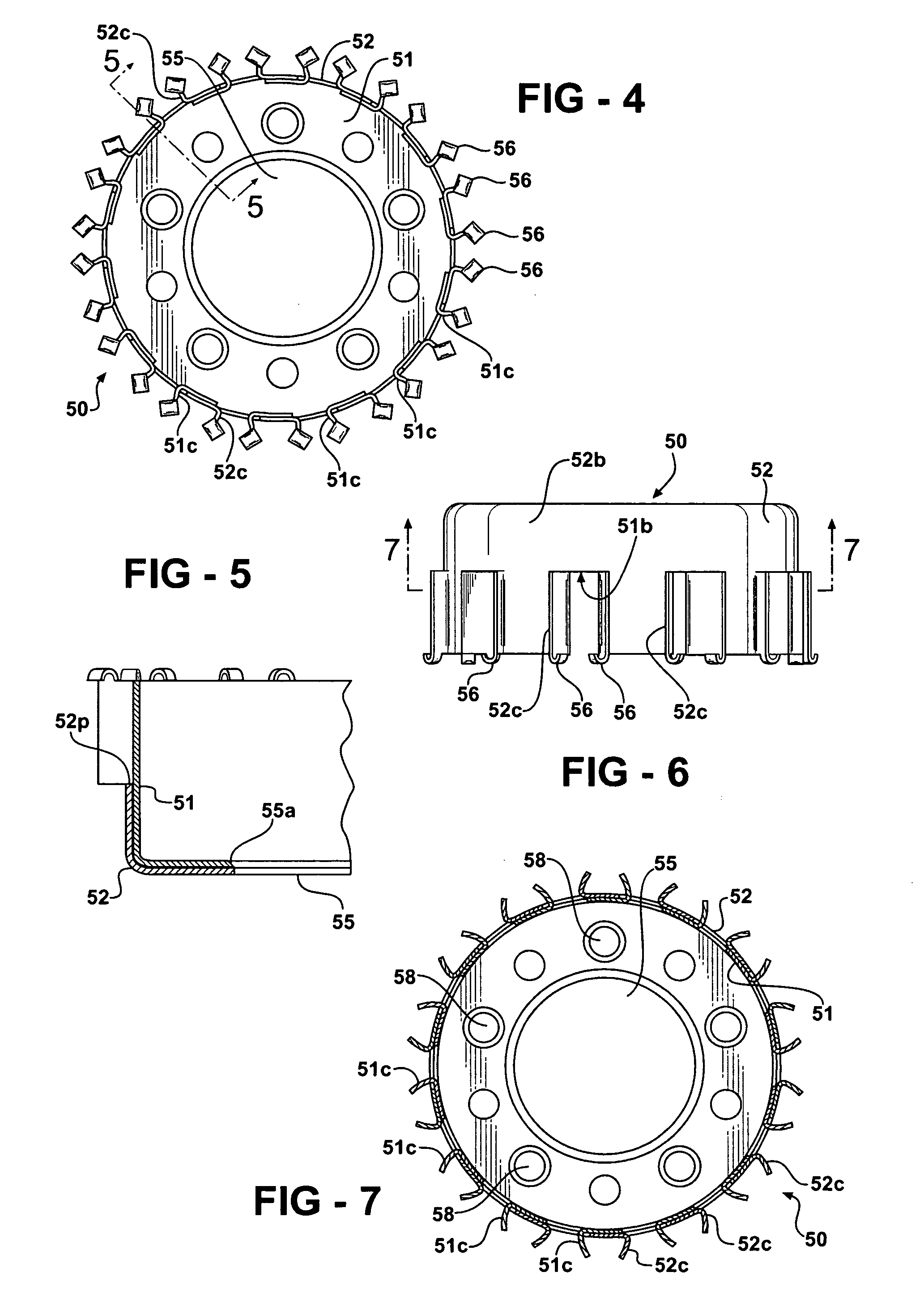

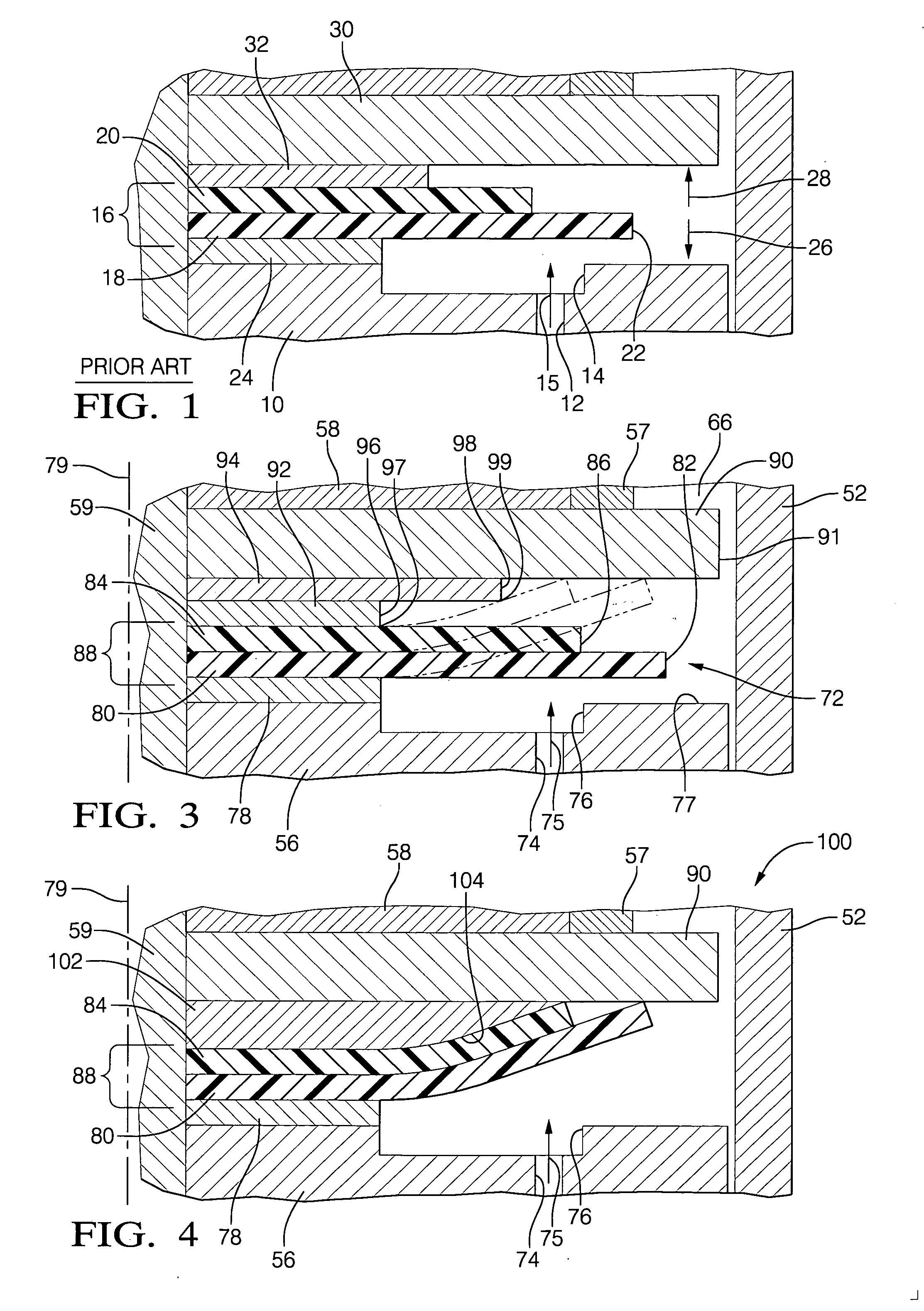

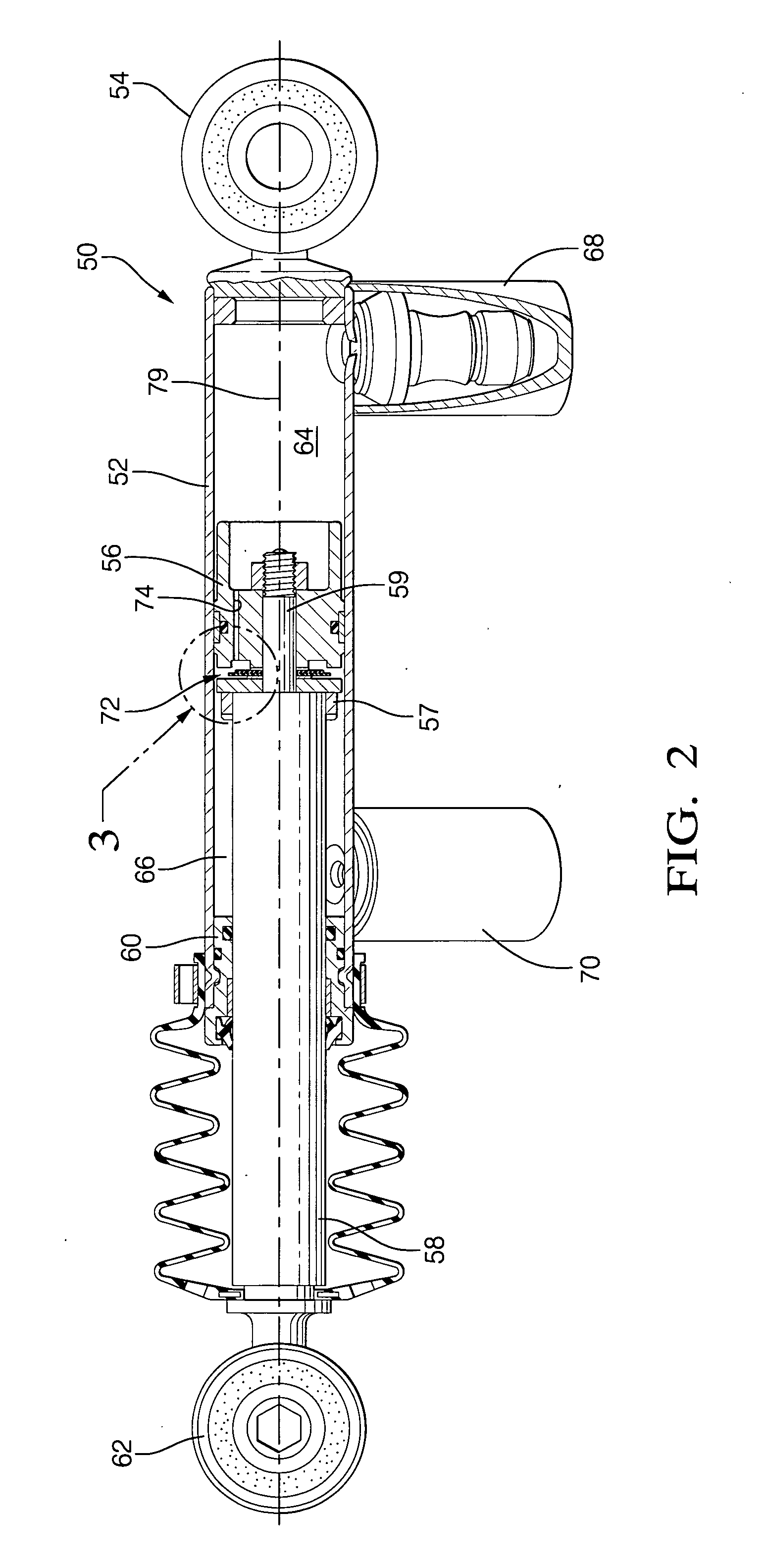

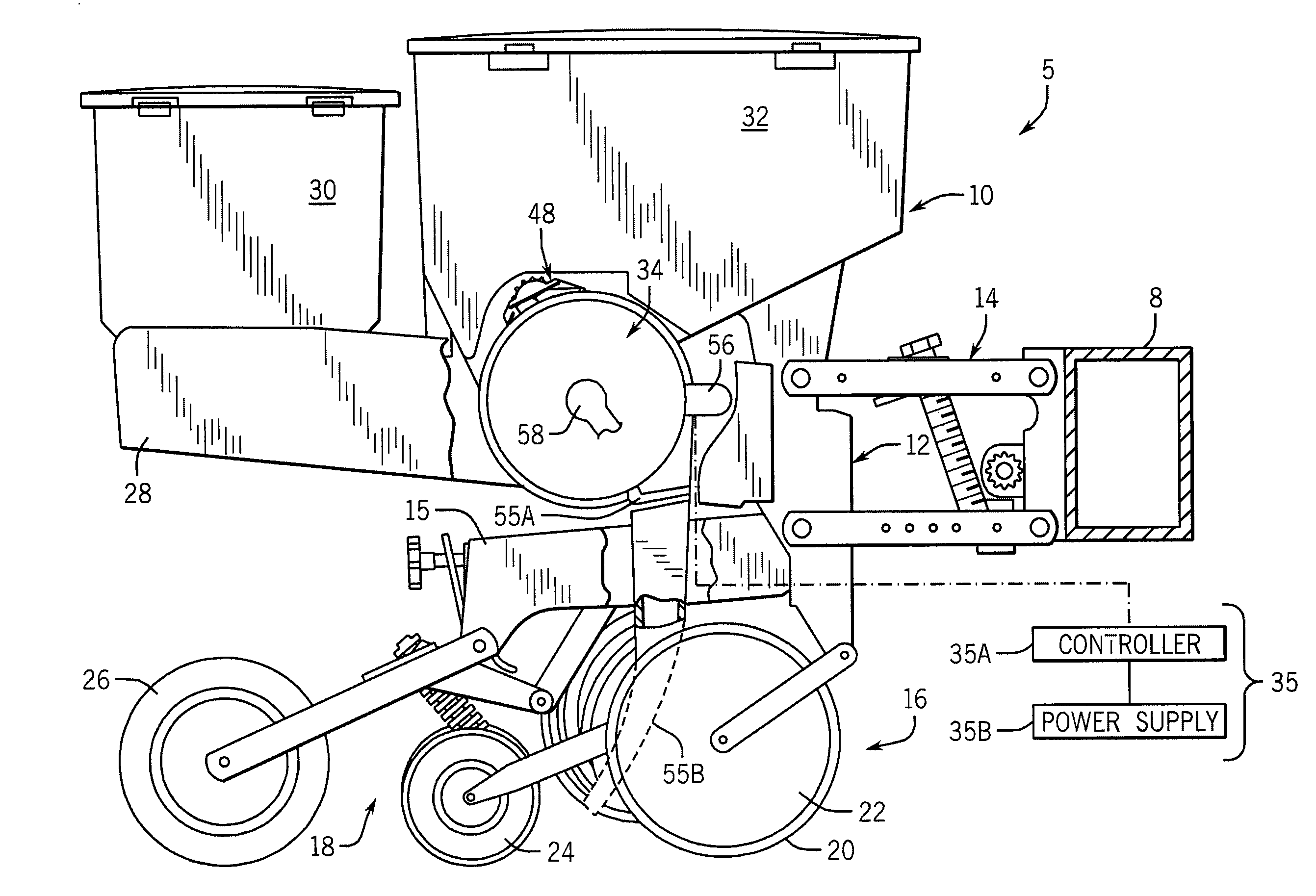

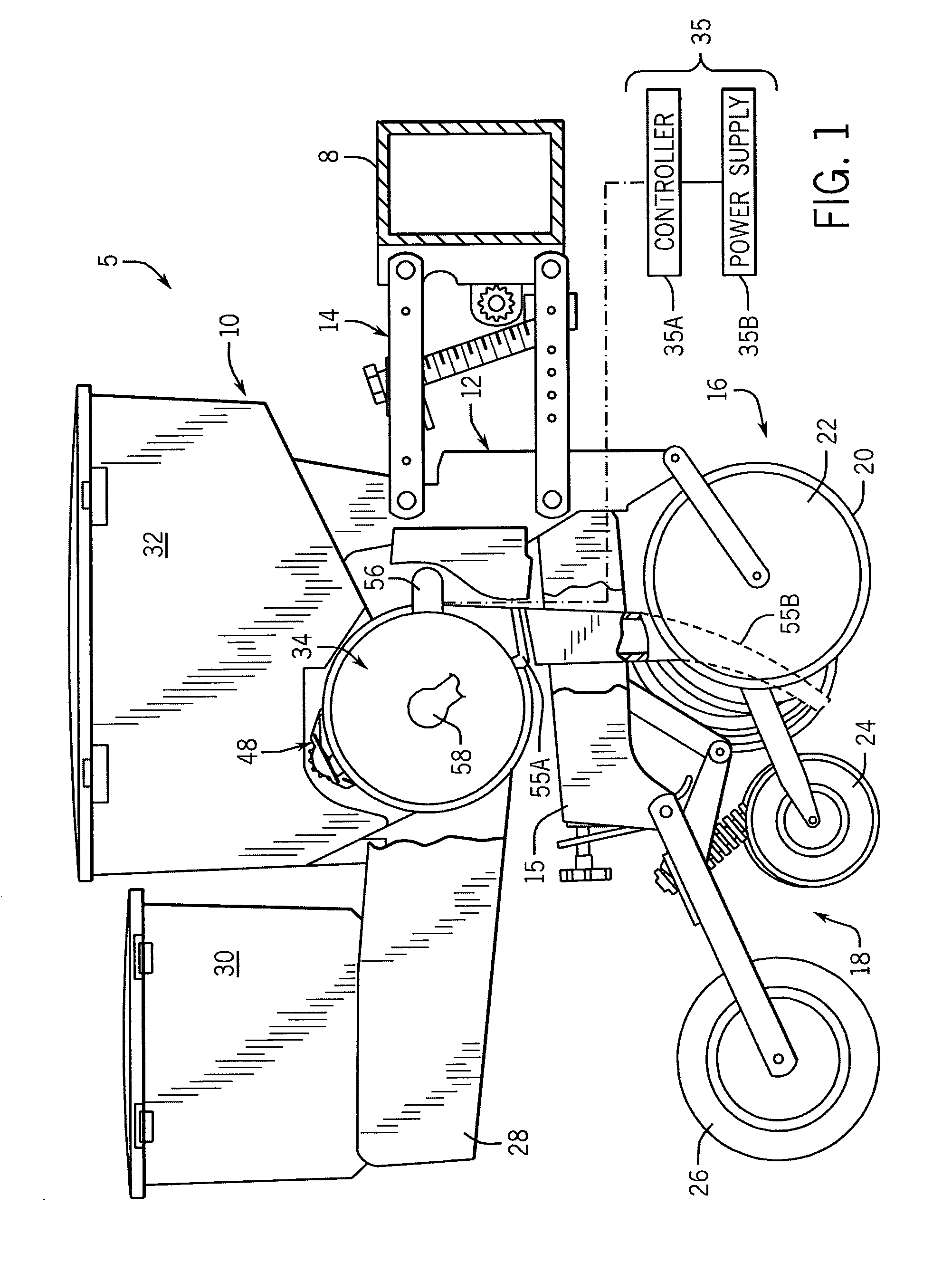

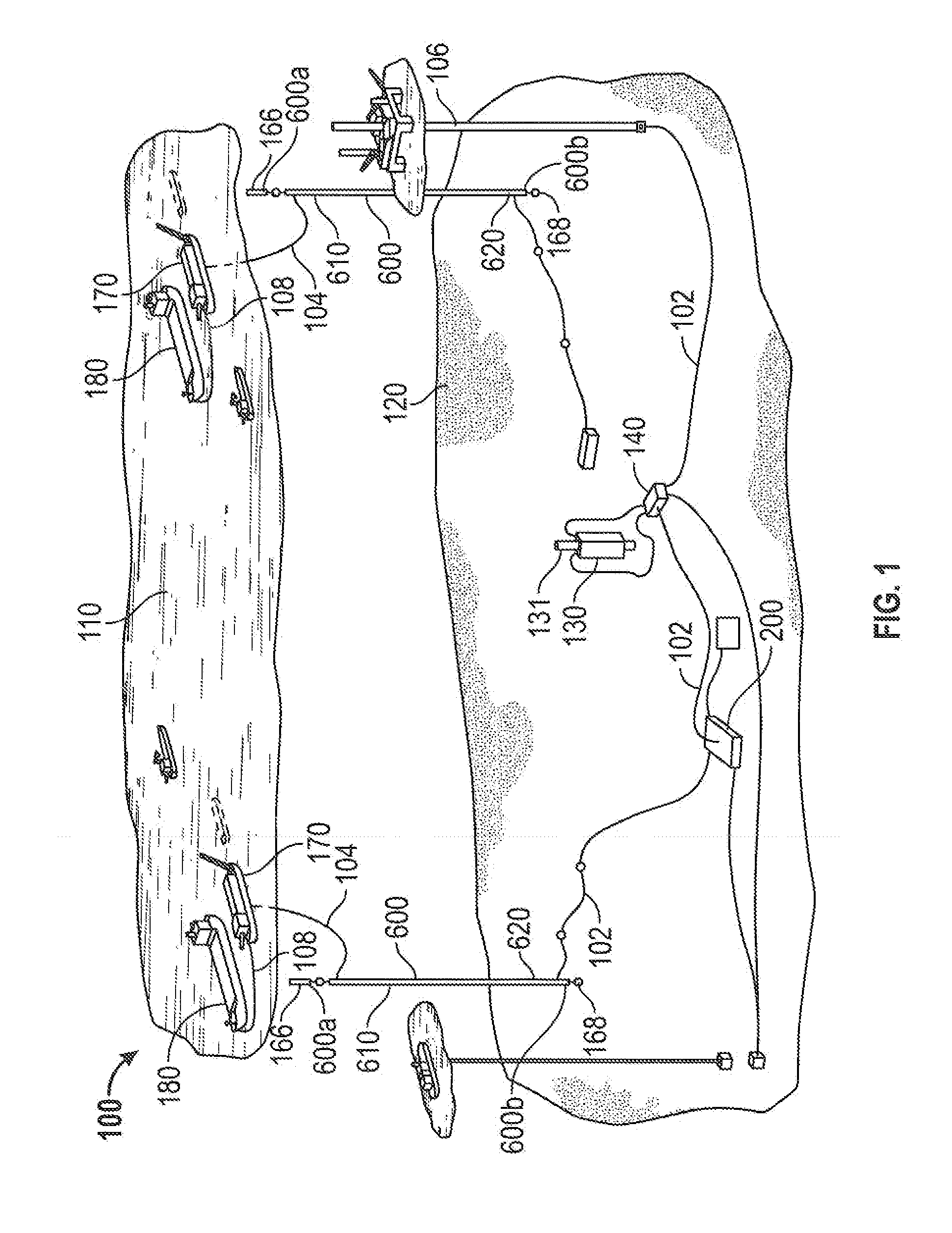

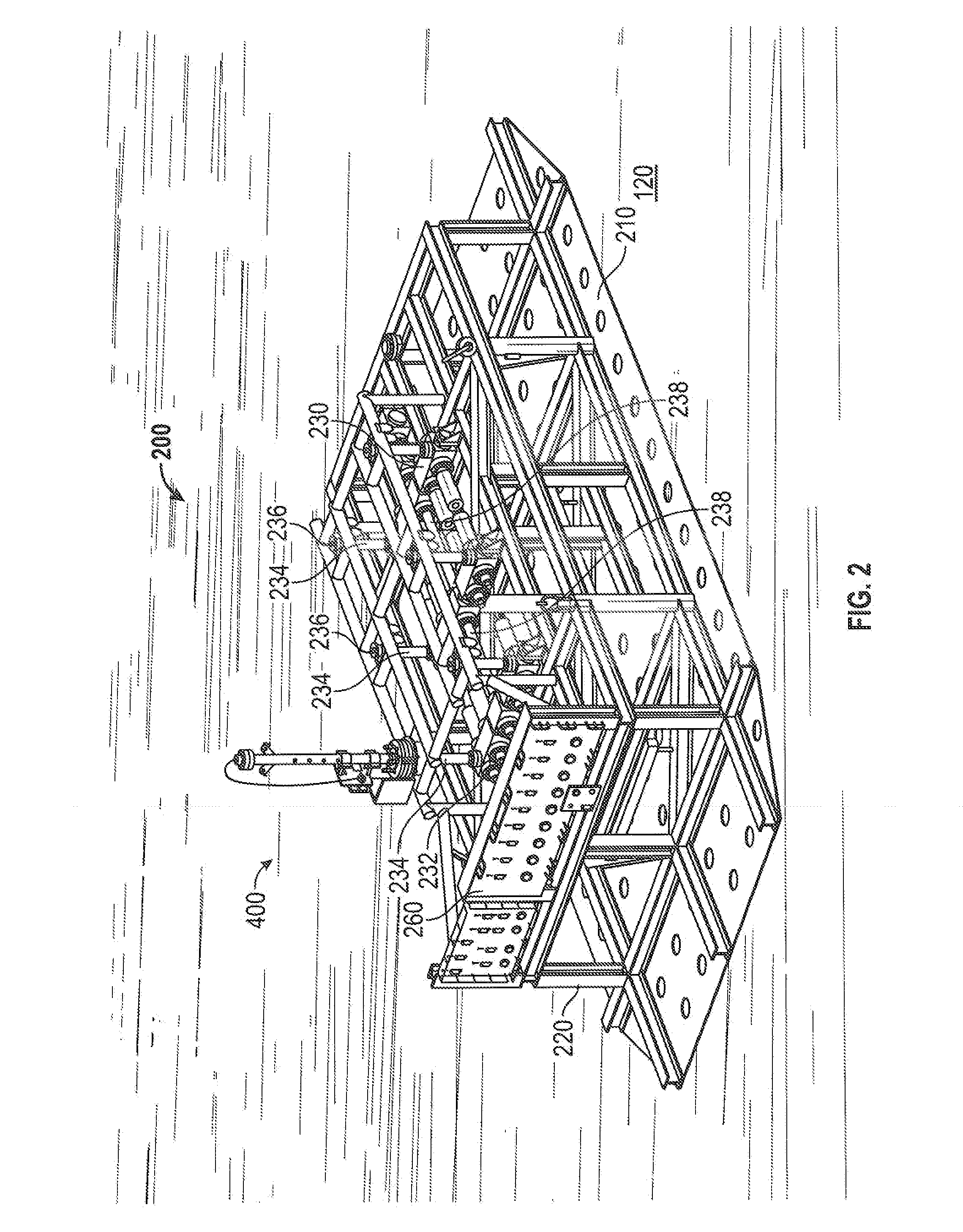

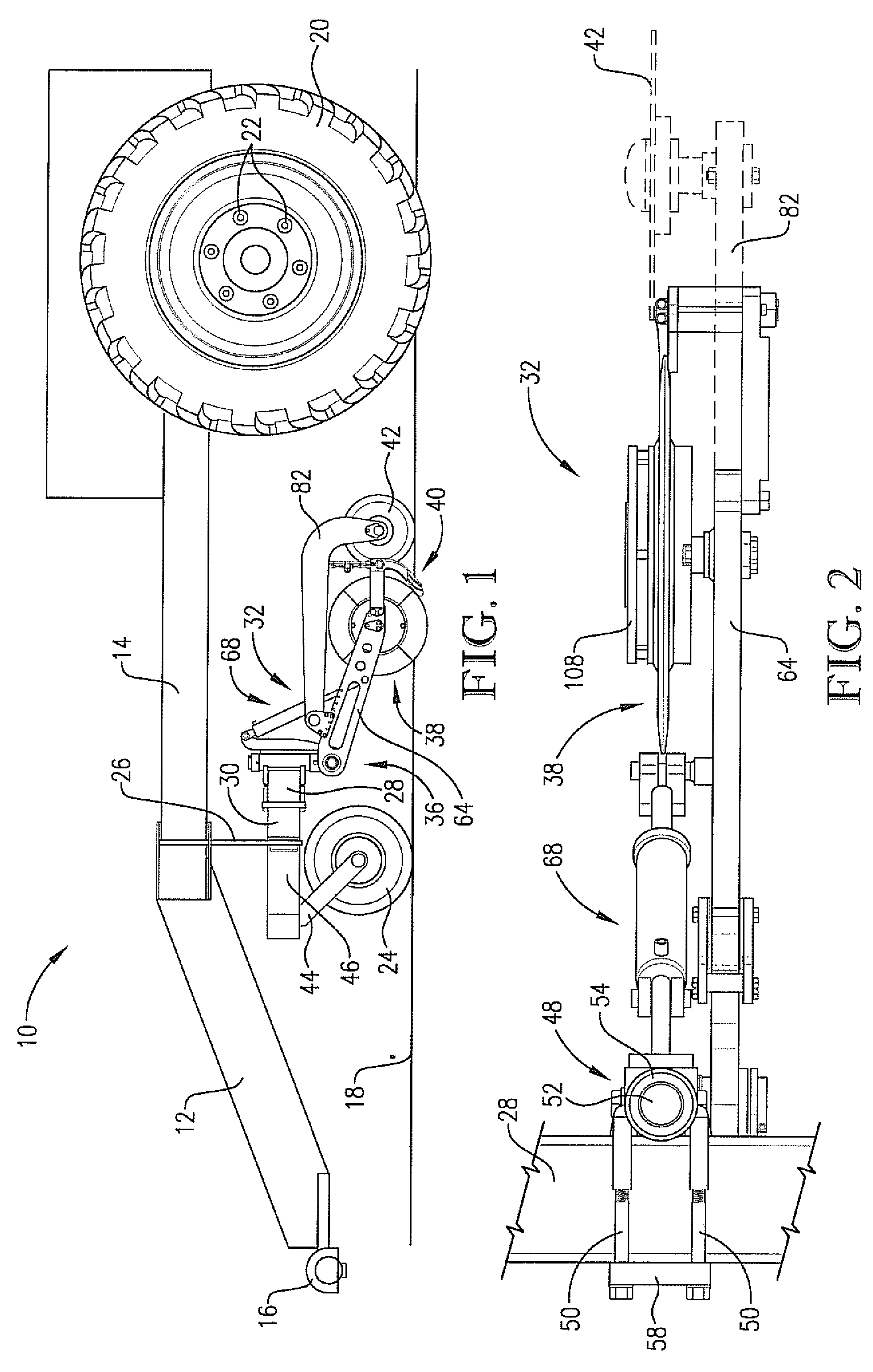

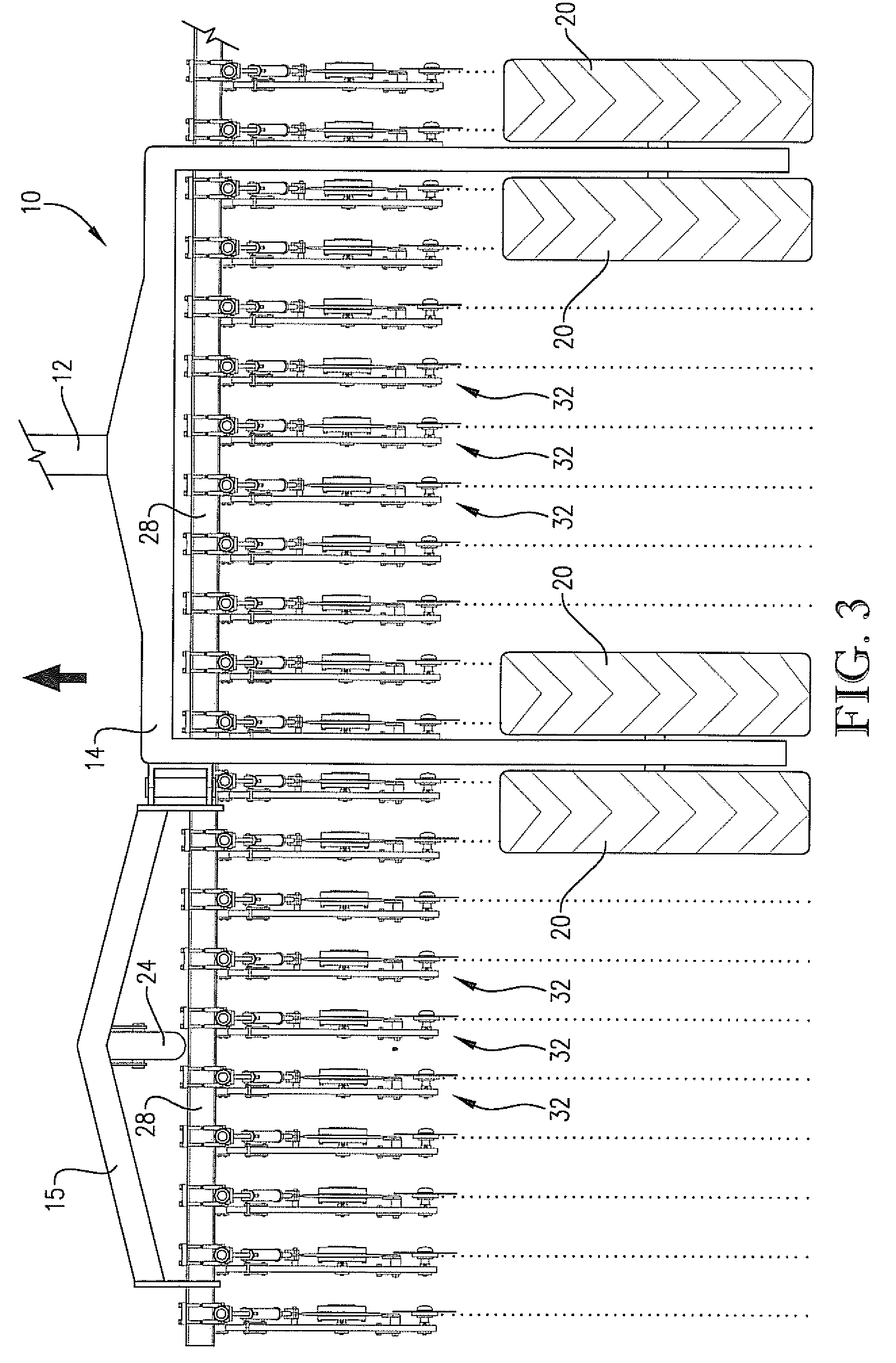

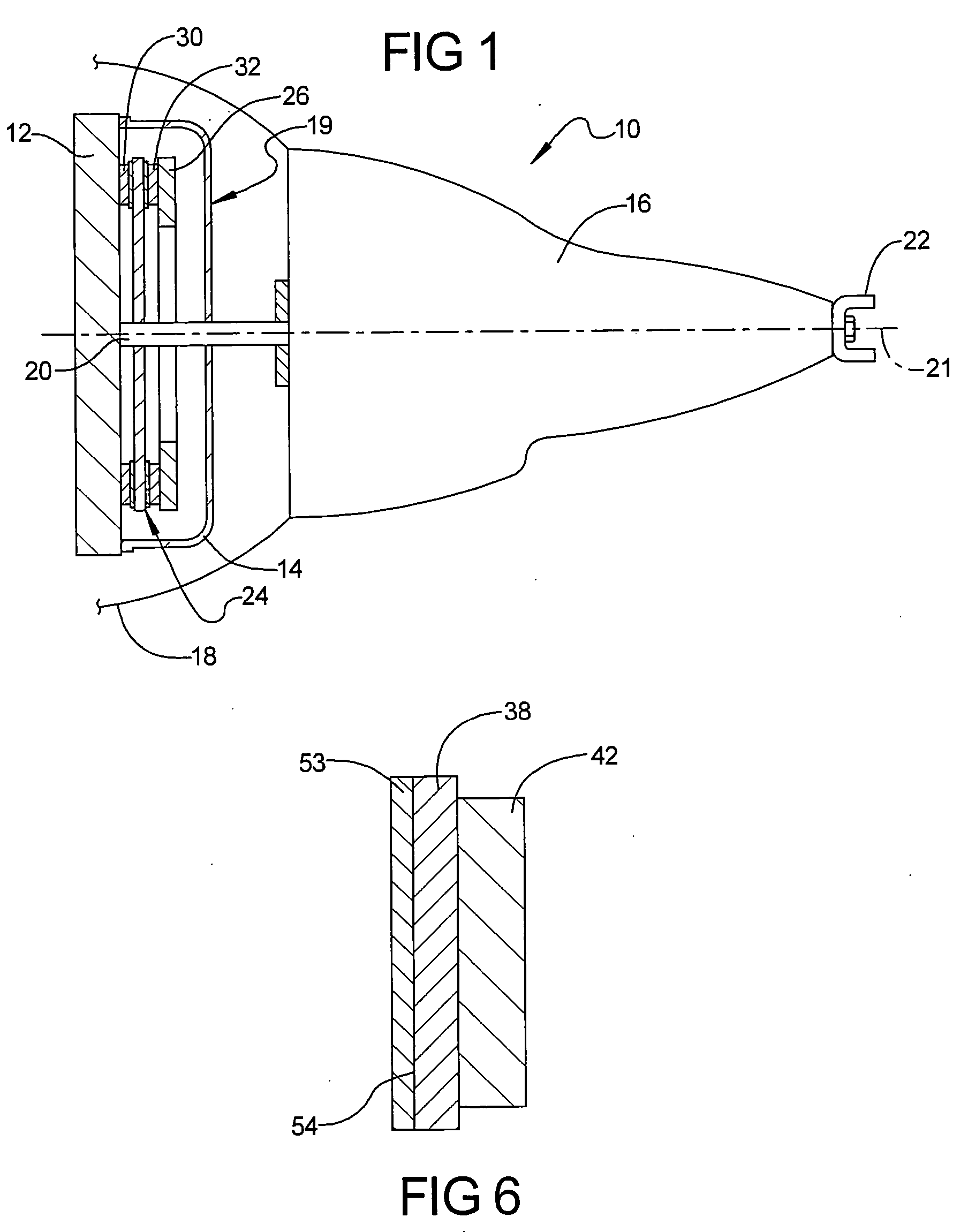

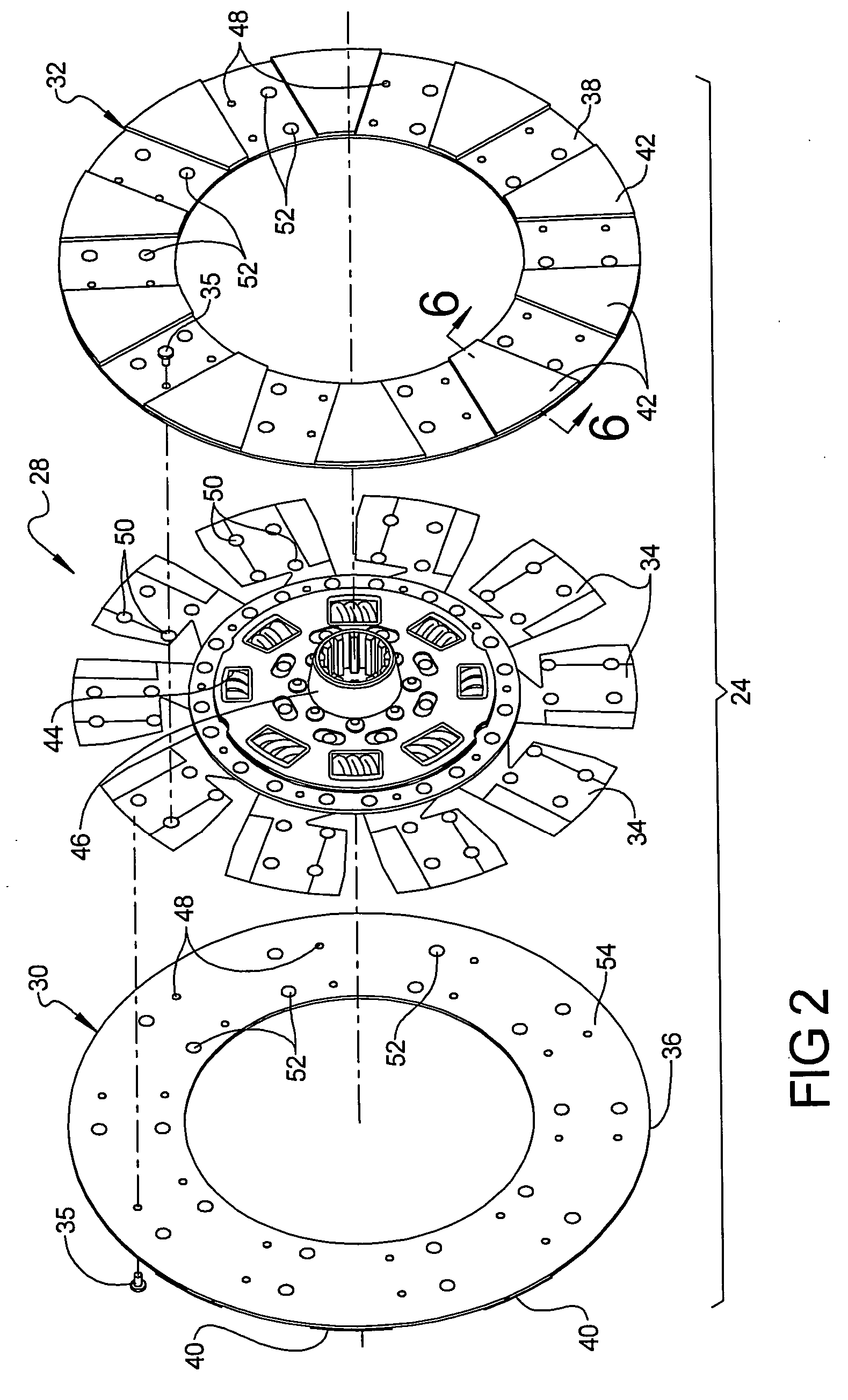

Disc openers (14) for use with an air seeder (10), are configured for seeding and fertilizing a field (G). The opener (14b) broadly includes a drawbar assembly (16), a disc assembly (18) including a coulter disc (20) and a gauge wheel (22), a seed boot (24), a fertilizer injector wing (26), a firming wheel assembly (28), and a closing wheel assembly (30). The fertilizer injector wing (26) is configured for fixed attachment to the seed boot (24) and broadly includes a body (48), including an angled outboard portion (56), a toxic fertilizer injector (50), and a non-toxic fertilizer injector (52). The opener (14b) with the fertilizer injector wing (26) is configured to place the seed row (S) and the dedicated fertilizer band (DB) at an optimum geometric positional alignment relative to the seed row (S), in a single, low soil disturbing planting pass without disrupting the seed bed (BS).

Owner:EXACTRIX

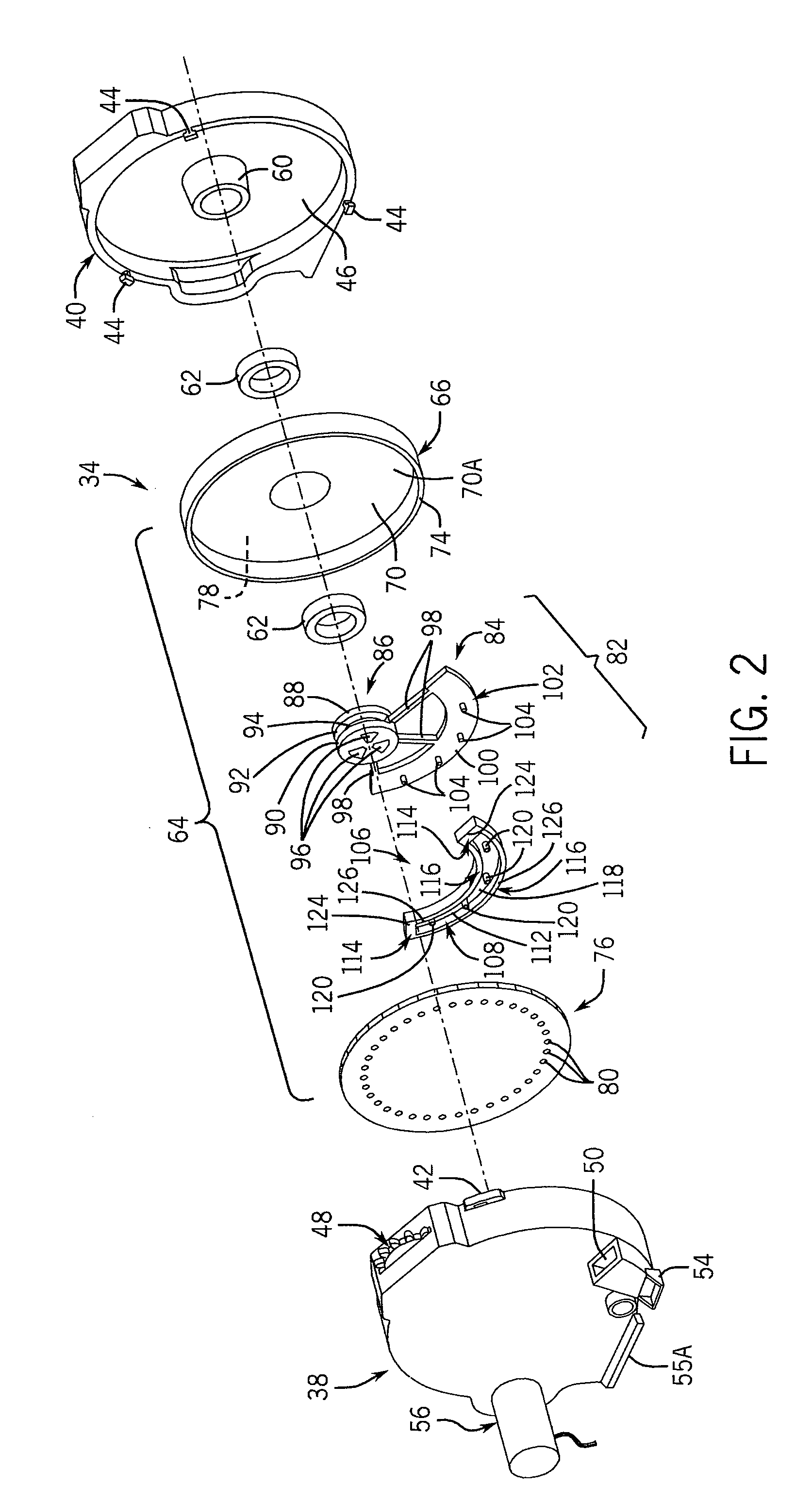

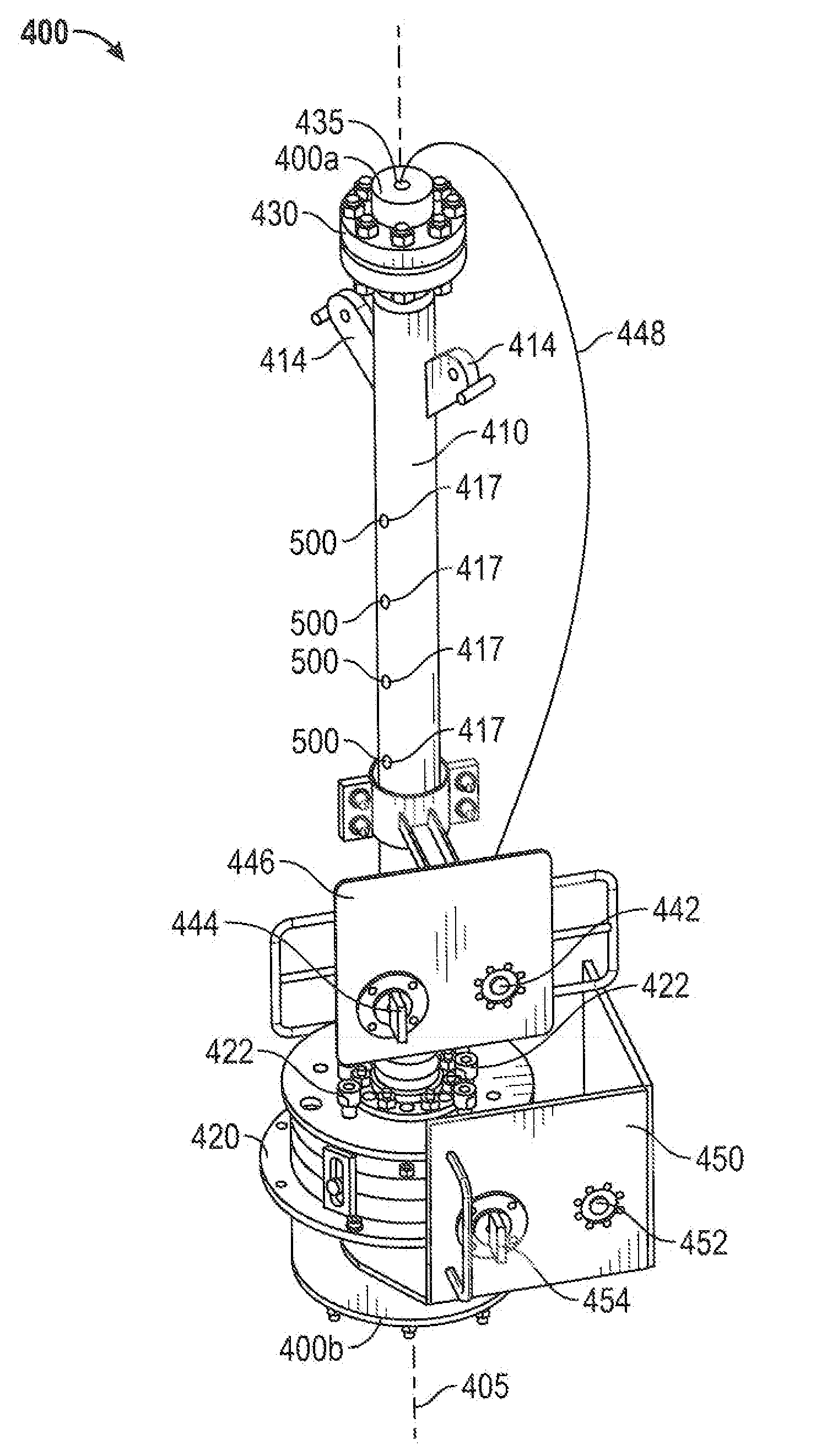

Low torque and vacuum seed meter

ActiveUS8925471B2Improve uniformityLess input vacuum pressurePotato plantersFurrow making/coveringVacuum pressureEngineering

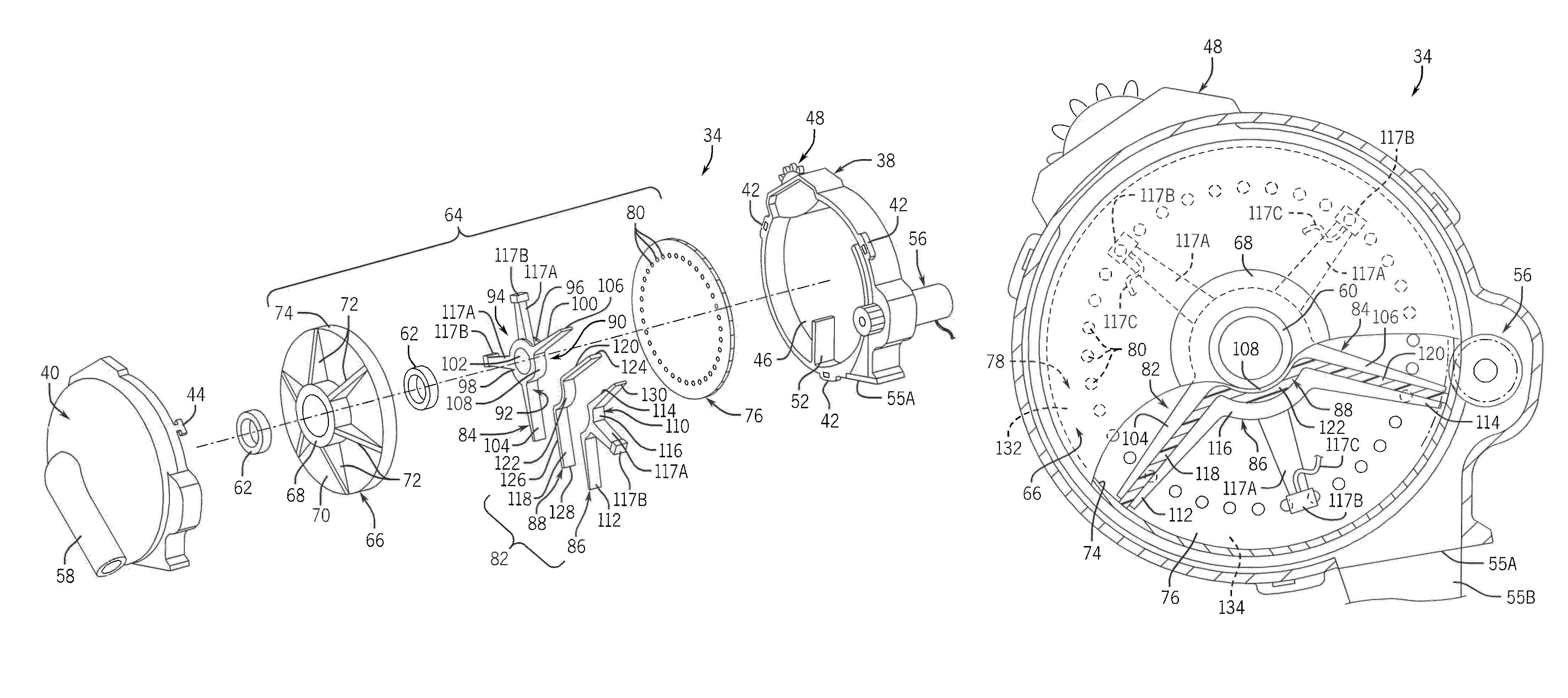

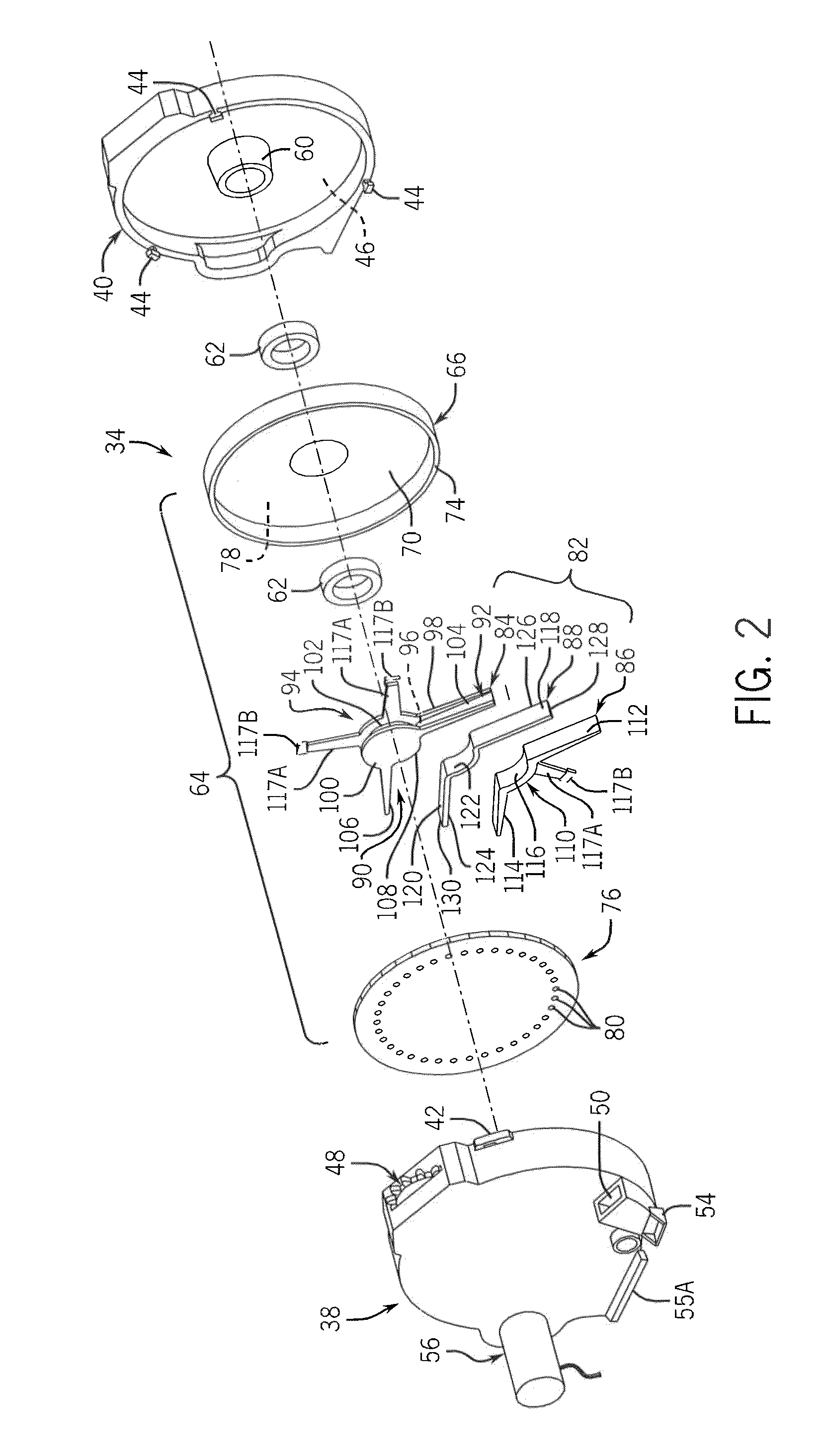

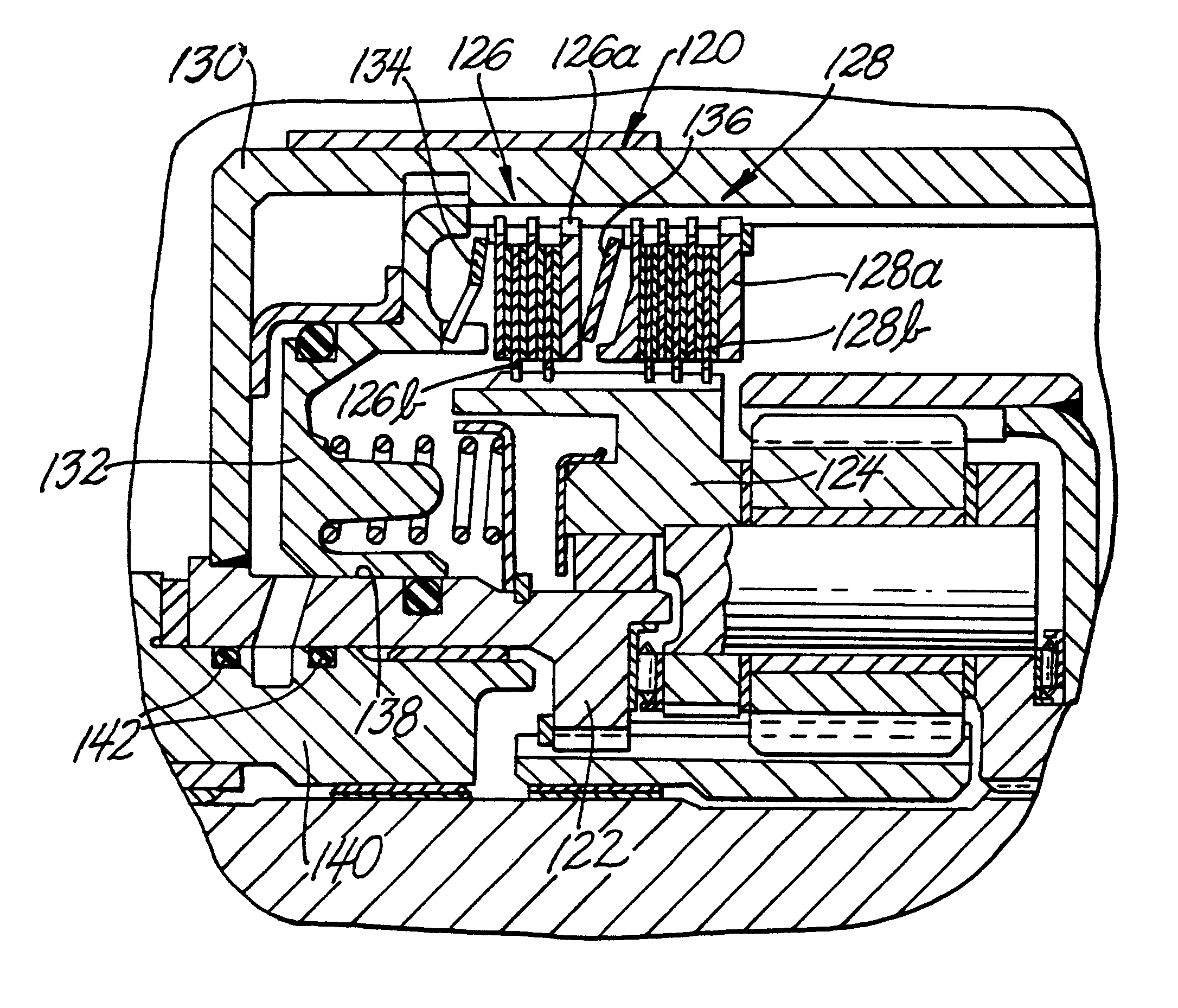

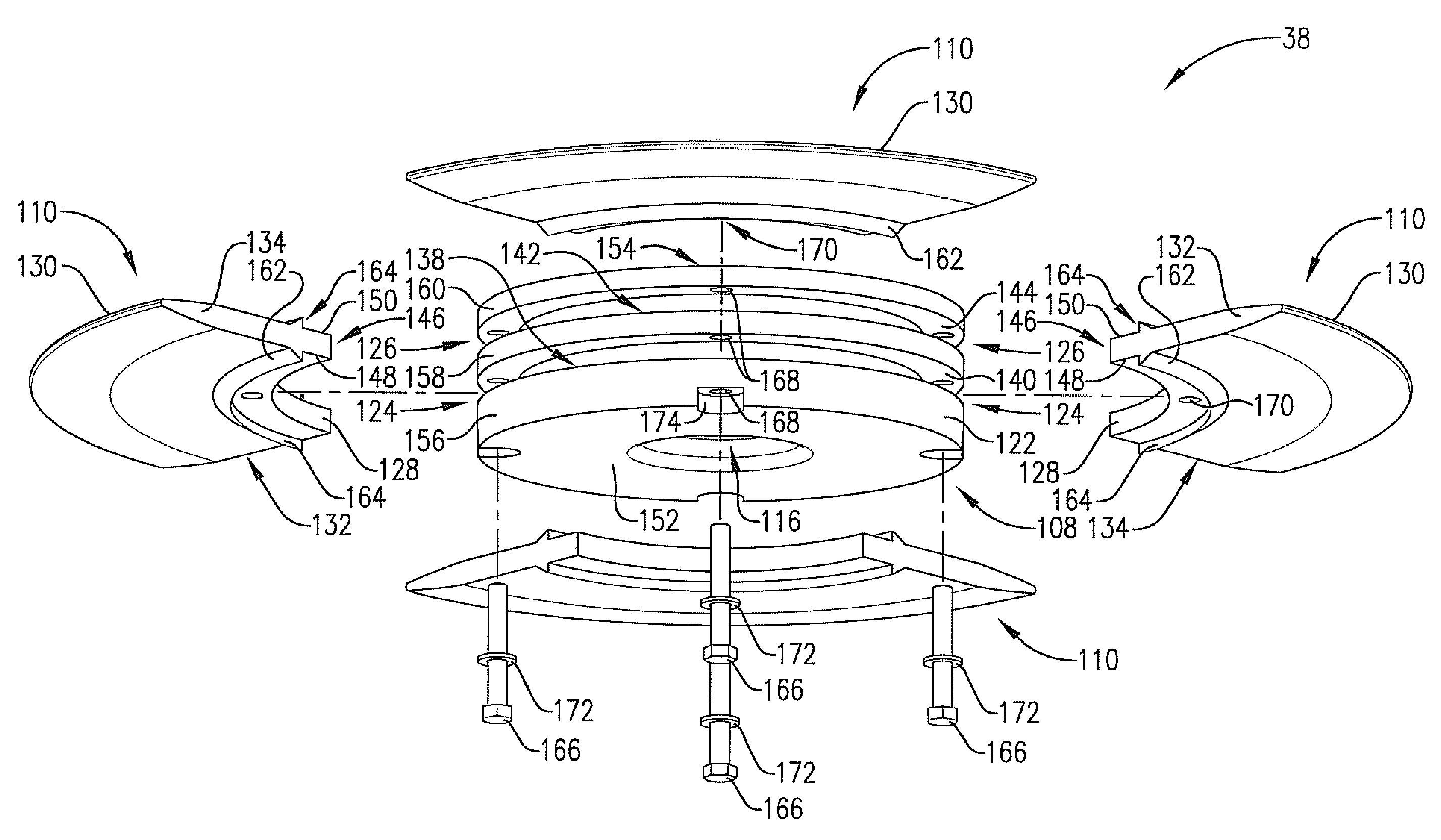

A seed meter is provided for use with a row crop planter or seed planter that includes a seed disk assembly that rotates within a meter housing cavity and that has a seed disk assembly cavity in which a vacuum pressure is applied for pulling seeds into seed pockets of a seed disk of the seed disc assembly. The vacuum pressure is applied to the seed disk assembly by pulling a vacuum airflow through a spindle that supports the seed disk assembly. A wiper seal is arranged in a fixed position within the seed disk assembly cavity and seals against the seed disk assembly as a support plate and seed disk of the seed disk assembly rotate over the wiper seal, so that the wiper seal creates a boundary between a vacuum zone and a non-vacuum zone inside of the seed disc assembly cavity.

Owner:BLUE LEAF I P INC

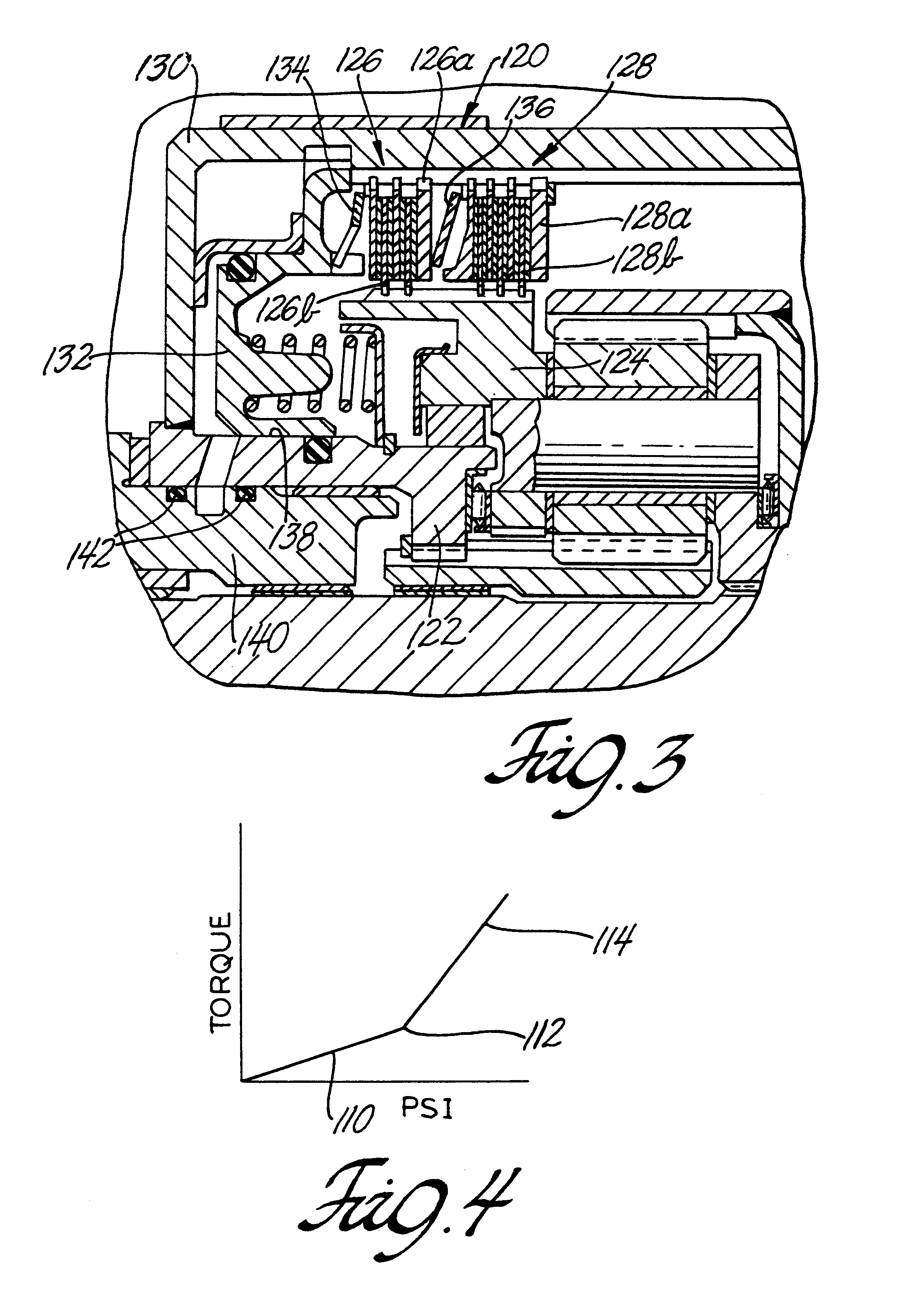

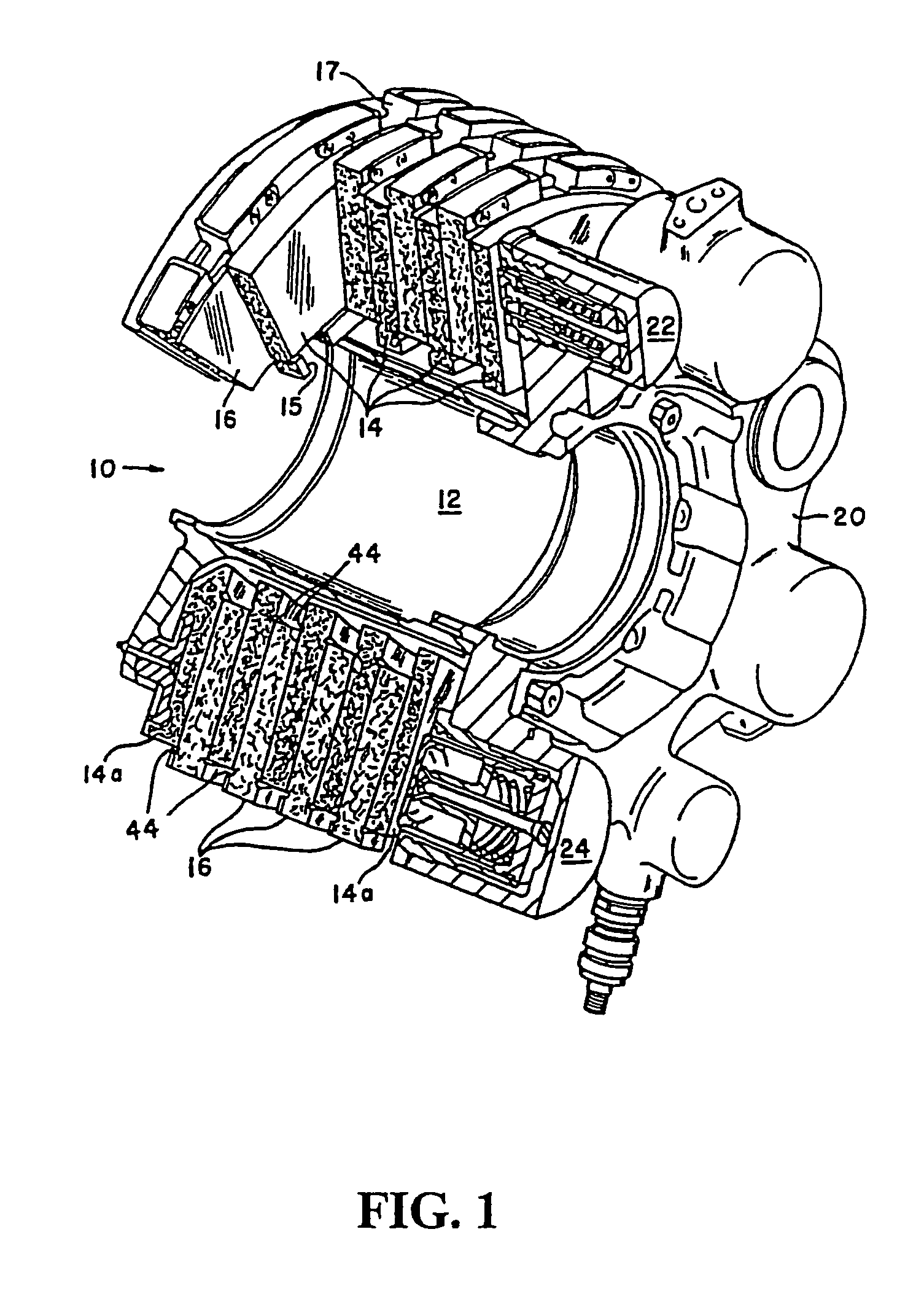

Automatic transmission with dual gain multi-disk friction device

InactiveUS6227340B1Suitable for useReduce widthFluid actuated brakesFluid couplingsAutomatic transmissionCoupling

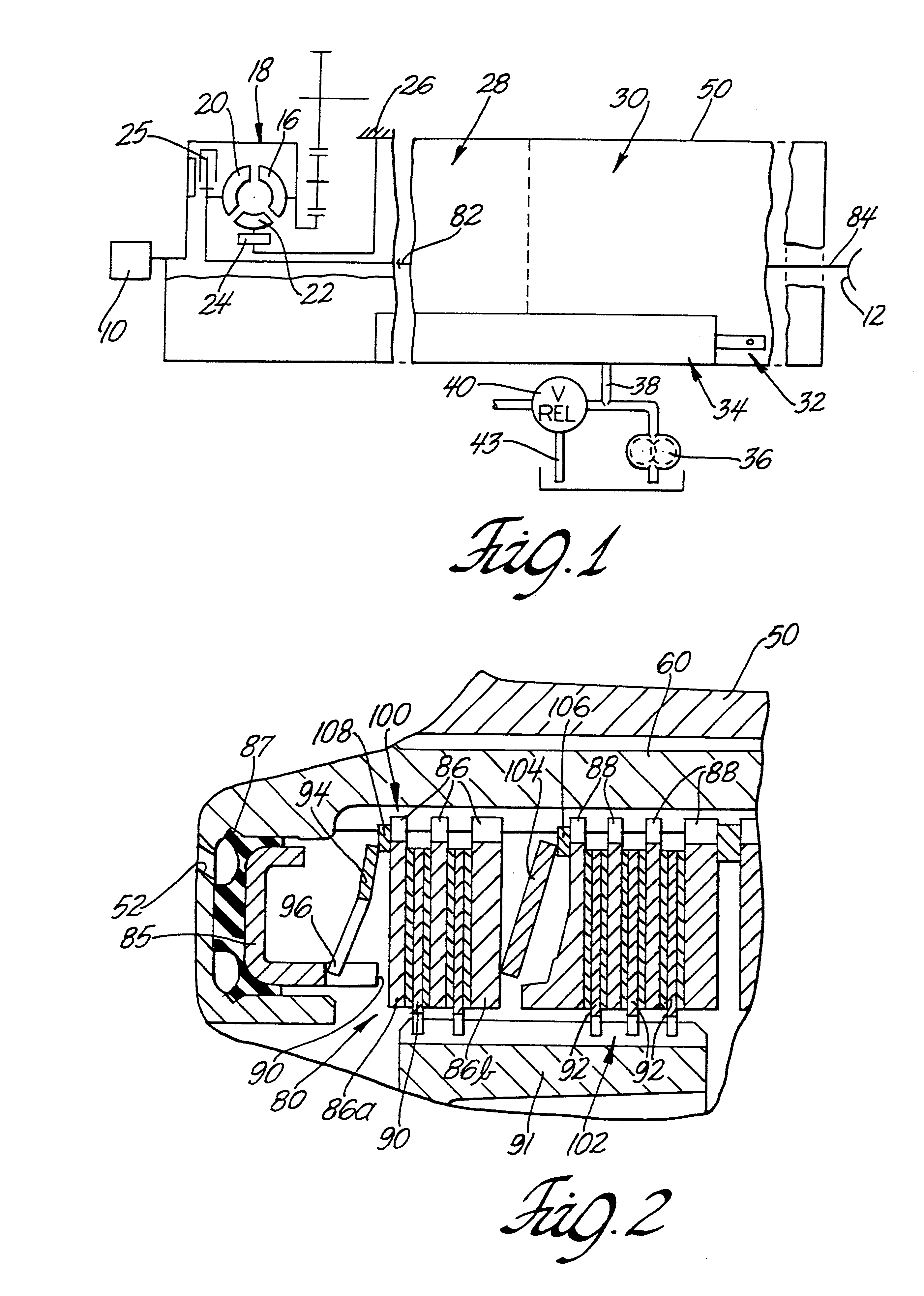

A fluid pressure operated friction coupling comprising a multiple friction disc assembly having a single piston actuator and having first and second springs operatively configured and arranged in response to pressurization of the piston actuator to selectively engage first and second sets plates and friction components for varying the gain of the coupling.

Owner:BORGWARNER INC

Bio-safe dispenser and optical analysis disc assembly

InactiveUS20050176059A1Simple and quick on-disc processingSmall sample volumeBioreactor/fermenter combinationsBiological substance pretreatmentsCircular discTest sample

A liquid sample dispenser for use with an optical analysis disc. The dispenser includes a body portion, a tip portion connected to the body portion, first and second retainer members moveably supported within the tip portion, and a sealant contained between the first and second retainer members. One of the retainer members also functions as an inlet stopper. The associated optical analysis disc includes a substrate and a channel layer associated with the substrate. The disc further includes a cover portion located so that the channel layer is positioned between the substrate and the cover portion. An inlet port formed in the cover portion is adapted to receive a test sample from the tip portion of the dispenser. The sample is loaded form the dispenser into the disc followed by the inlet stopper and sealant to seal the sample in the disc. Related methods for loading a biological sample into the analysis disc through the dispenser, and sealing the disc inlet are also provided. Kits including the disc and dispenser or the disc and one-use dispenser tips are also provided.

Owner:NAGAOKA

Human spinal disc prothesis with hinges

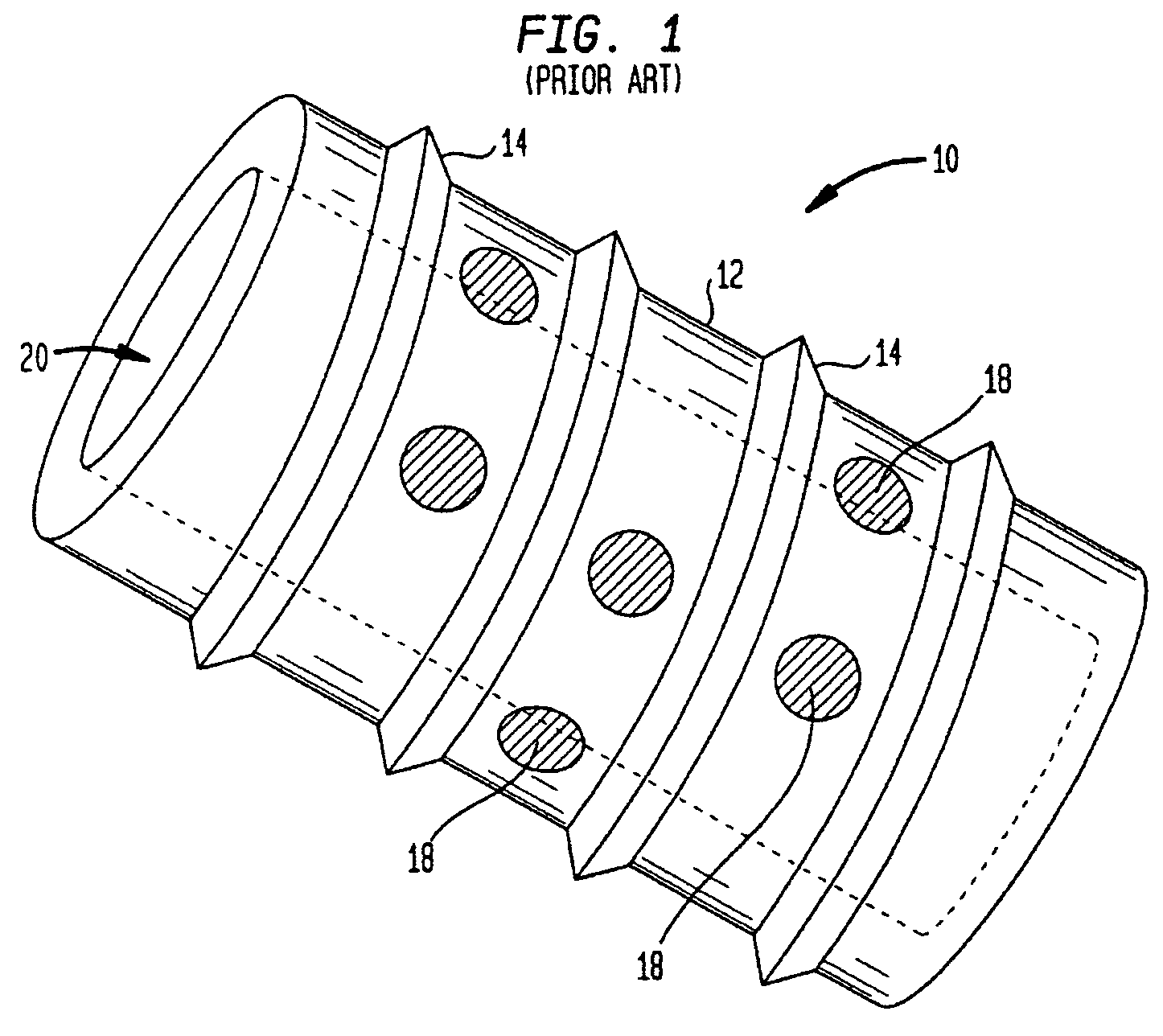

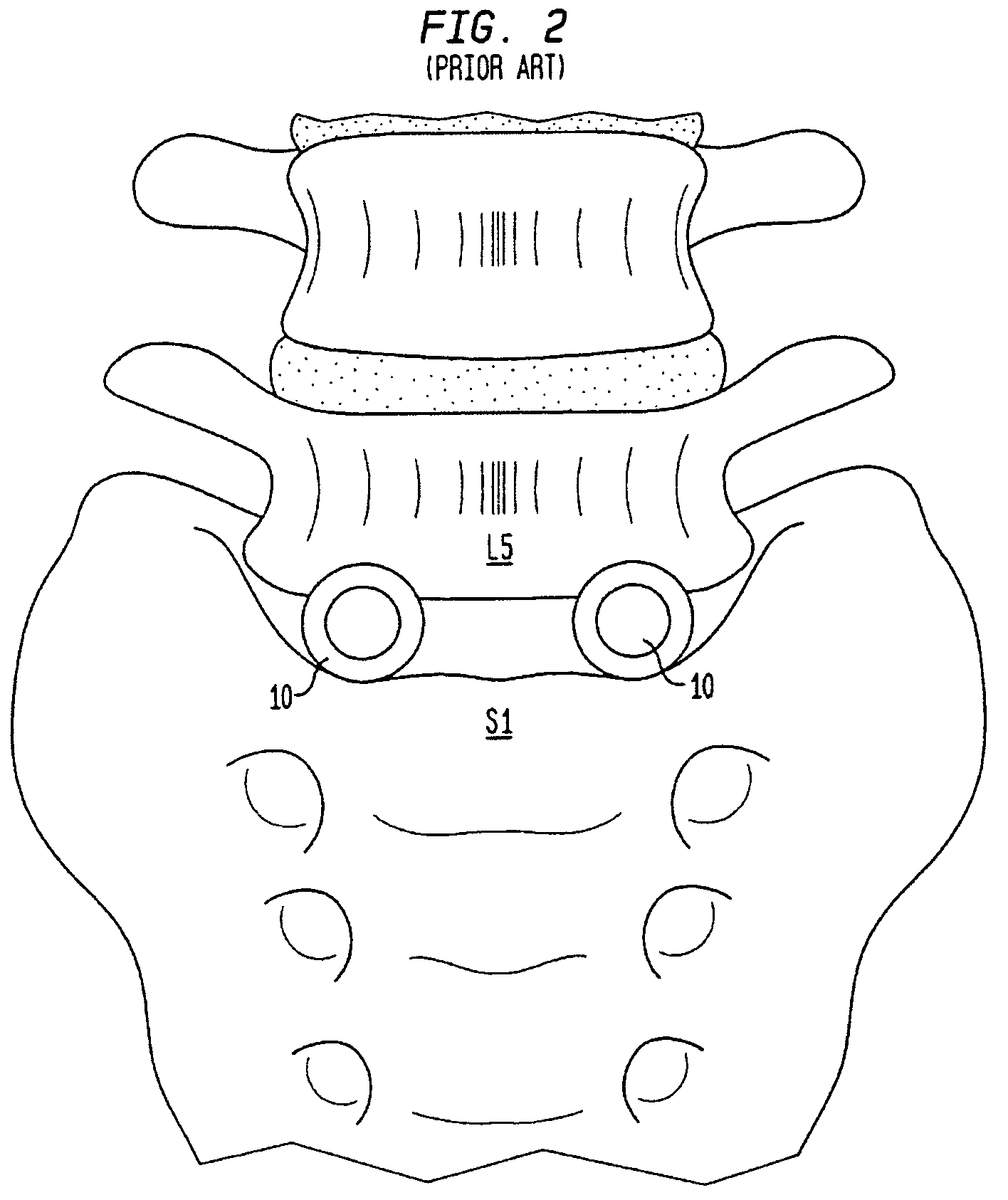

The invention relates to a spinal disc endoprosthesis. The endoprosthesis has a resilient body formed of one or more materials which may vary in stiffness from a relatively stiff exterior annular gasket portion to a relatively supple central nucleus portion. Concaval-convex elements at least partly surround that nucleus portion so as to retain the nucleus portion and gasket between adjacent vertebral bodies in a patient's spine. Assemblies of endoprosthetic discs, endoprosthetic vertebral bodies, and endoprosthetic longitudinal ligaments may be constructed. To implant this endoprosthesis assembly, information is obtained regarding the size, shape, and nature of a patient's damaged spine. Thereafter, one or more prosthetic vertebral bodies and disc units are constructed in conformity with that information. Finally, the completed and conformed vertebral body and disc assembly is implanted in the patient's spine.

Owner:WARSAW ORTHOPEDIC INC

Fertilizer injector wing for disc openers

InactiveUS20050051068A1Eliminate needHigh speed useTill seedingDirect liquid fertiliser deliverySeederCircular disc

Disc openers (14) for use with an air seeder (10), or other no-till drill and the like, configured for seeding and fertilizing a field (G) for crop production are disclosed. The representative opener (14b) broadly includes a drawbar assembly (16), a disc assembly (18) including a coulter disc (20) and a gauge wheel (22), a seed boot (24), a fertilizer injector wing (26), a firming wheel assembly (28), and a closing wheel assembly (30). The inventive fertilizer injector wing (26) is configured for fixed attachment to the seed boot (24) and broadly includes a body (48), including an angled outboard portion (56), a toxic fertilizer injector (50), and a non-toxic fertilizer injector (52). The opener (14b) with the unique fertilizer injector wing (26) is configured to place the seed row (S) and the dedicated fertilizer band (DB) at an optimum geometric positional alignment relative to the seed row (S), in a single, low soil disturbing planting pass without disrupting the seed bed (BS). The inventive wing (26) enables a toxic charge (TC) of the fertilizer (N,P)—a charge containing the optimum nutrient package to sustain season long growth of the crop—to be placed sufficiently close to the seed (S) while minimizing soil disturbance so that weed growth and moisture loss are minimized and crop yield is maximized.

Owner:EXACTRIX

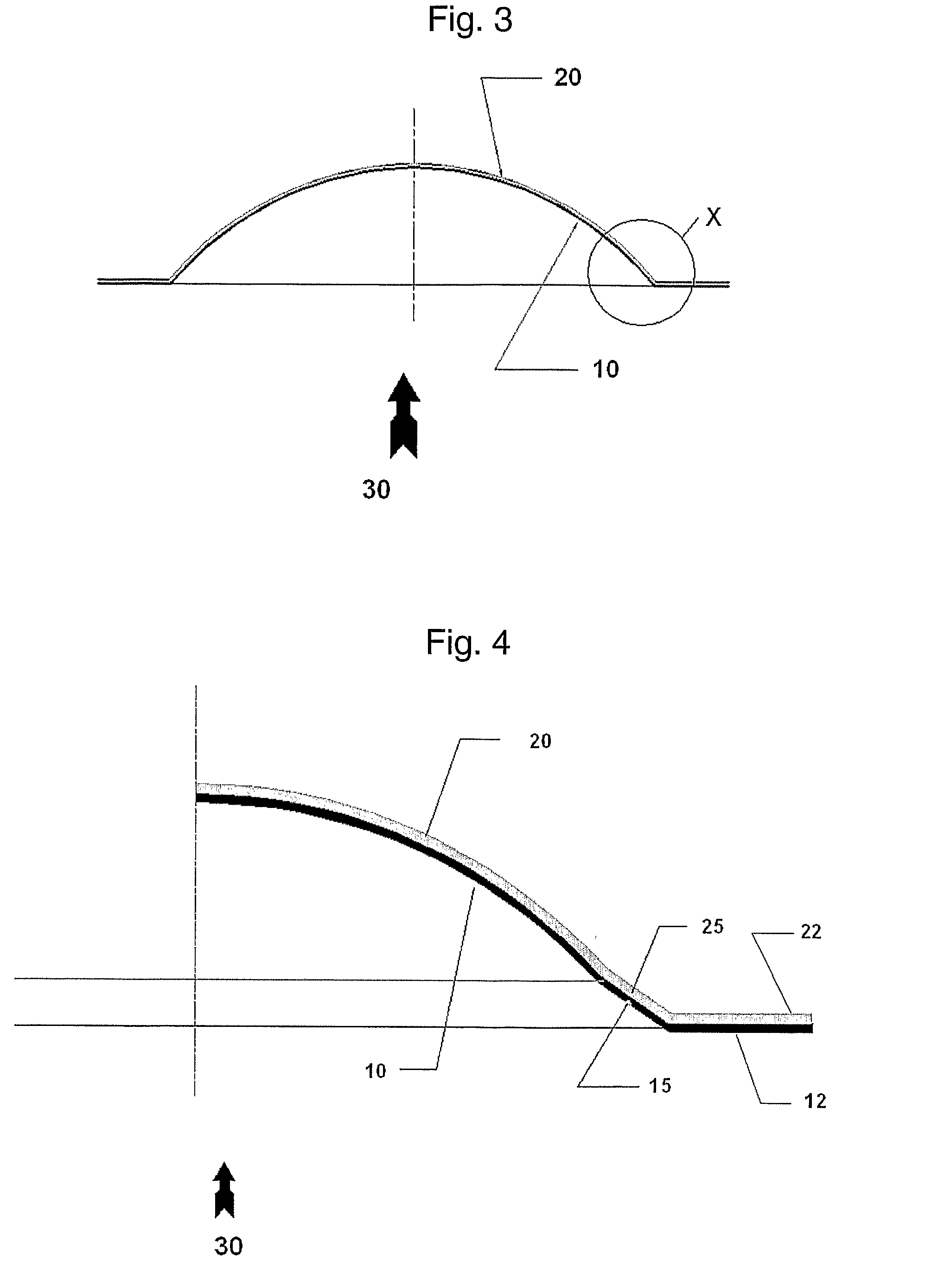

Bursting Disc Assembly

ActiveUS20080202595A1Easy to controlHigh strengthLarge containersEqualizing valvesBursting strengthDISC assembly

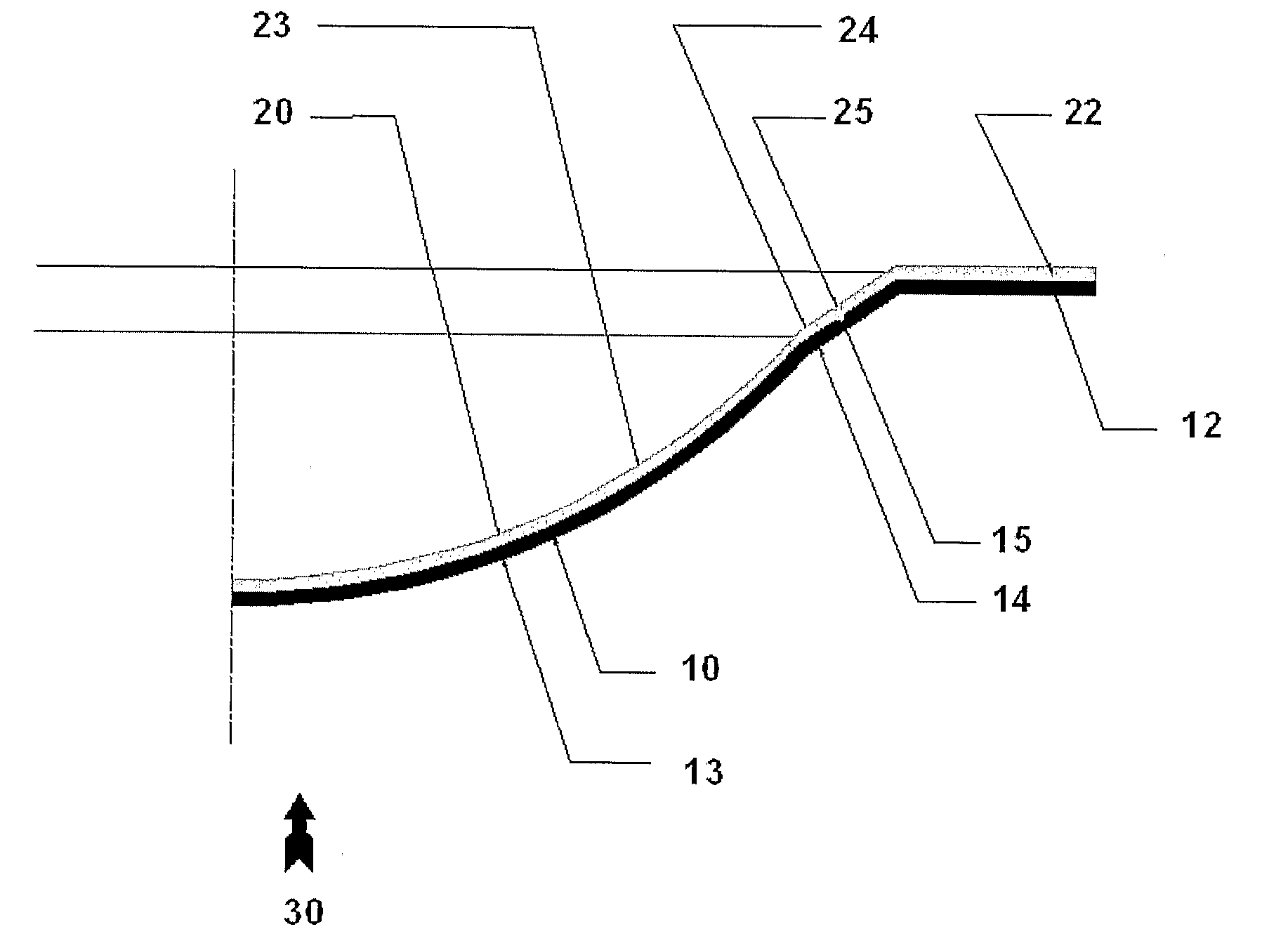

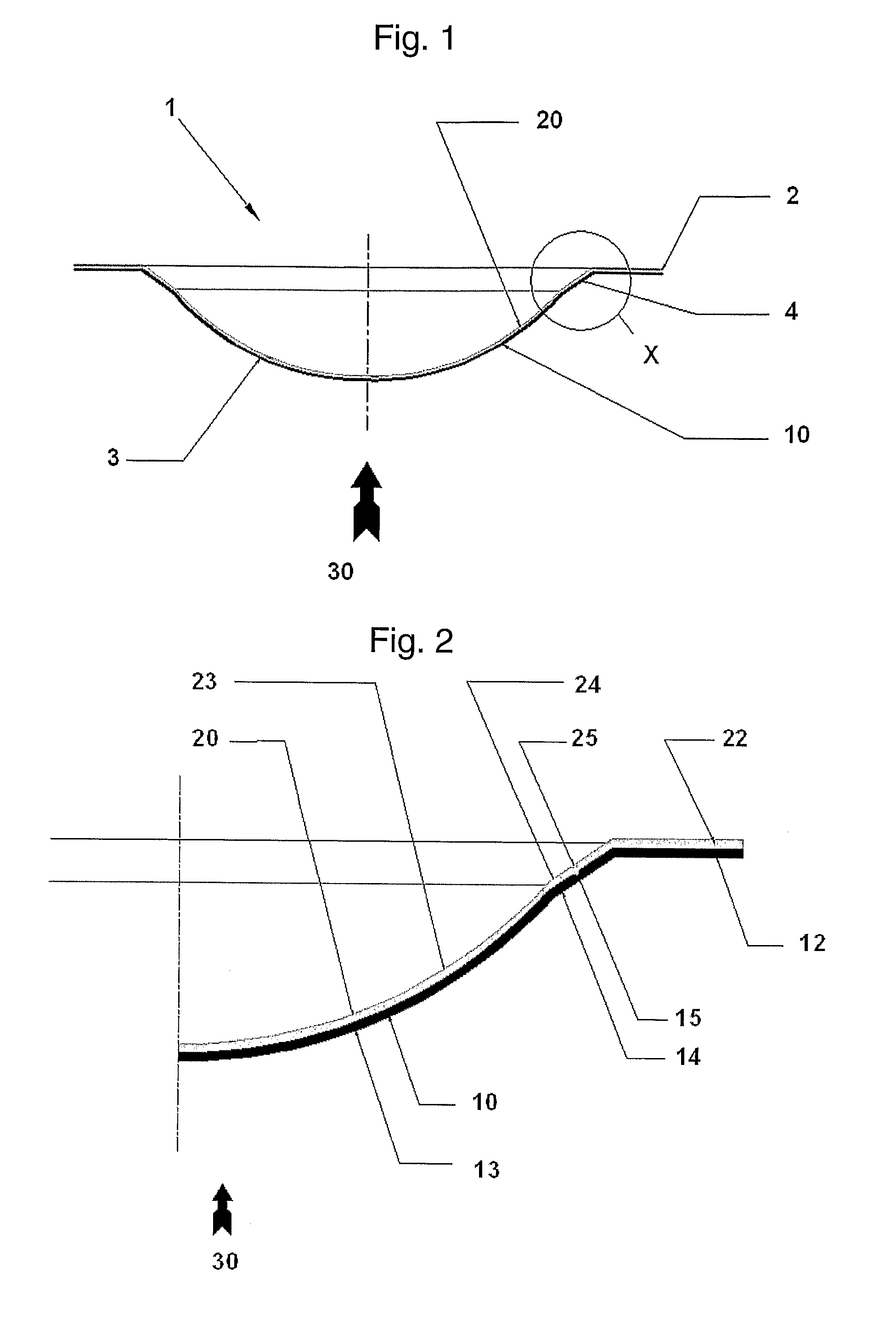

The bursting disc assembly has a primary bursting disc (10) and a secondary bursting disc (20) immediately behind and supporting the primary bursting disc. Each of the said discs (10,20) is made of metal and is gas impermeable, and the bursting strength of the assembly is derived from both of the bursting discs acting in combination. The primary and secondary bursting discs are in contact over the whole of the operating area of the disc, and are shaped together as a pair The materials of the two discs can be chosen suitably for their functions. The primary disc is for example corrosion-resistant.

Owner:ELFAB LTD

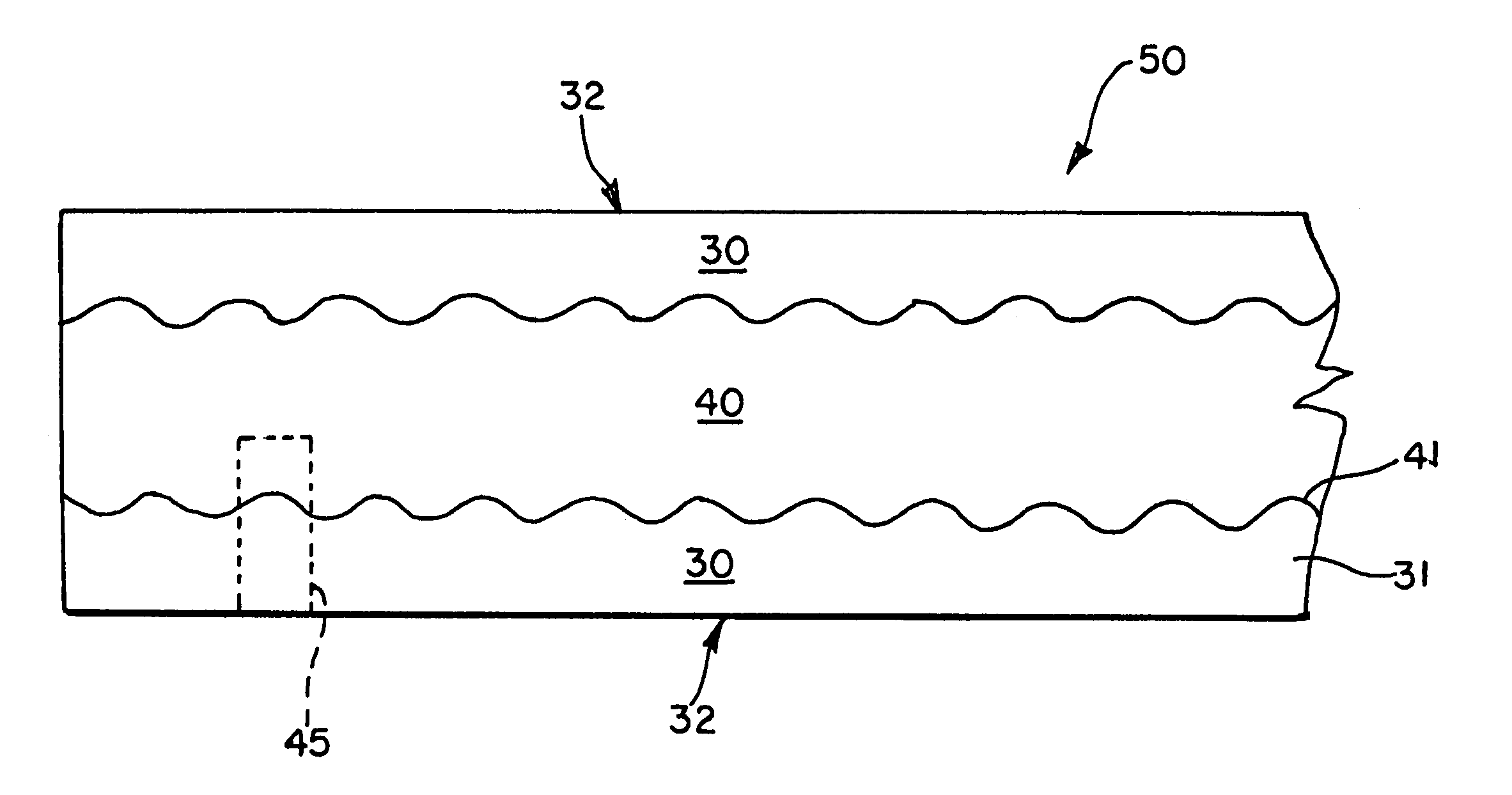

Composite friction disc with structural core and refurbishable lining elements

InactiveUS7090057B2Easy transferImproves Structural IntegrityBraking element arrangementsAxially engaging brakesCarbon compositesUltimate tensile strength

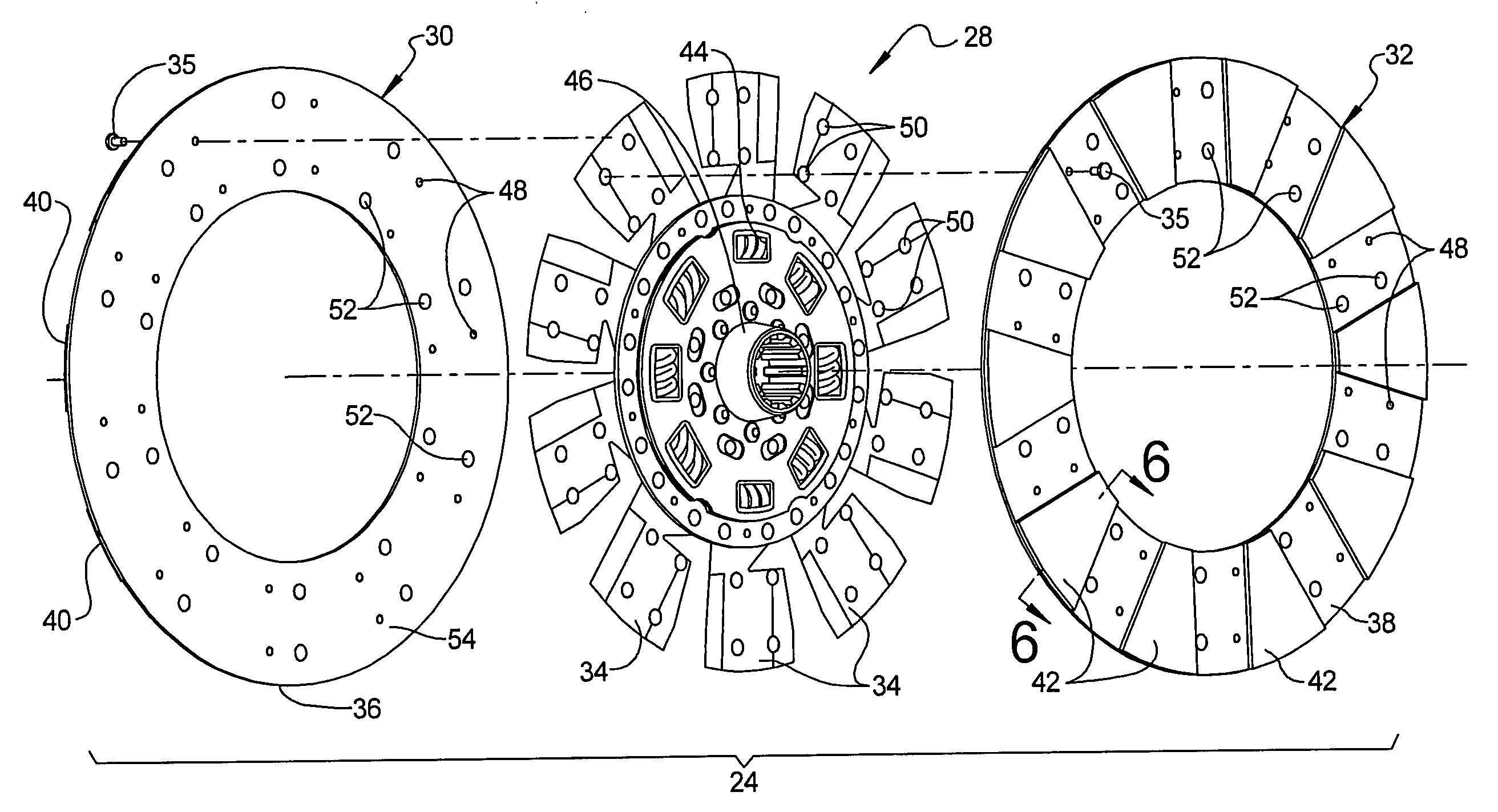

A friction disc assembly having an annular structural core (40) and at least one friction lining disc (30). The annular structural core (40) is made from a strength-optimized carbon carbon composite and the friction lining discs (30) from a friction-optimized carbon carbon composite. Each friction lining disc (30) is provided with a mounting surface (31) and a wear surface (32). The structural core (40) includes at least one mounting surface (41). The mounting surfaces (31,41) may include corresponding sinusoidally-shaped wave patterns for increasing the surface area of a contact zone between the friction lining discs (30) and a reusable structural core (40).

Owner:HONEYWELL INT INC

Agricultural disc harrow and method

An agricultural implement consisting primarily of a towed frame supported on retractable wheels, the frame having a plurality of independently adjustable spindles for setting height and angle of attack for various size rotatable discs. Each disc is staggered to reduce resistance and clogging. Each group of discs further includes descending diameter discs at each end with the angle of attack increasing with each decrease in diameter while spacing between the discs decreases as the diameters are reduced. The implement further including harrow teeth or picks located at strategic points adjacent the discs to ensure uniform soil disruption, the disc assembly being convertible from single gang to double gang assembly and may include conventional harrow teeth sets and or unique soil leveler attachments.

Owner:BOLLICH GERALD

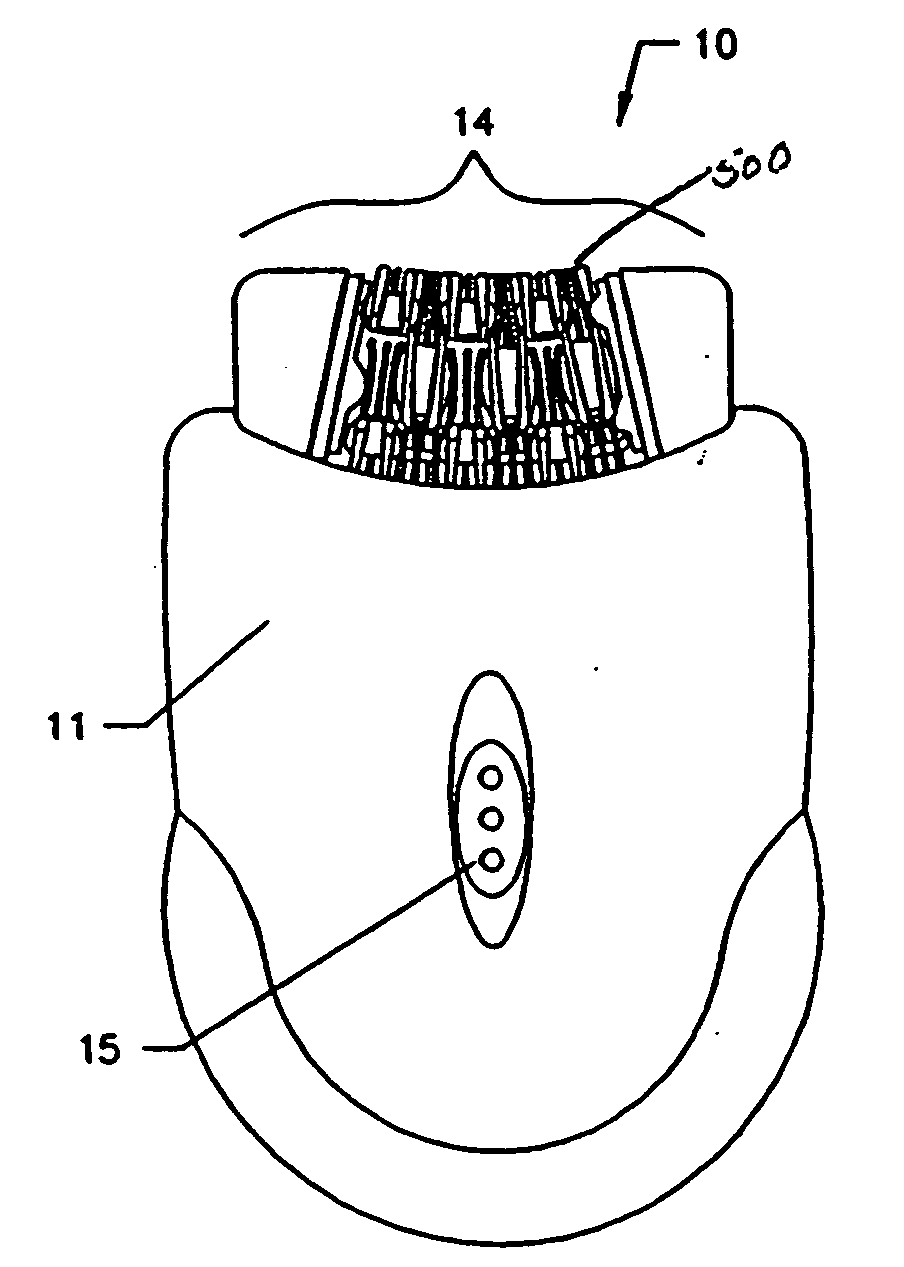

Hair removal device with disc and vibration assemblies

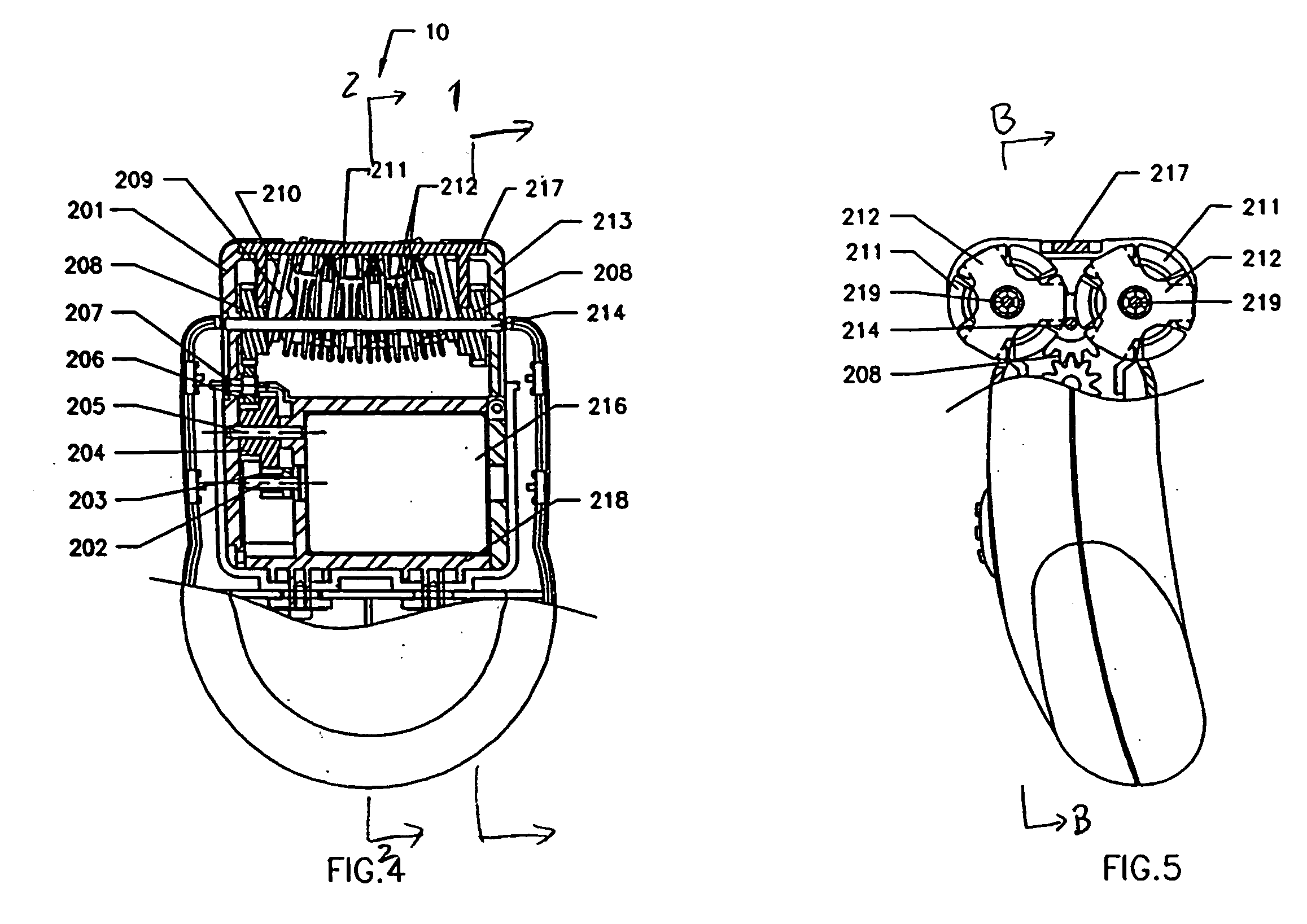

A device for removing unwanted hair, including a hair-plucking assembly, and a vibration assembly, a driving assembly, and a housing. The hair-plucking assembly includes two groups of disc assemblies that remove hair as they rotate. As the hair-plucking assembly removes hair, the vibration assembly vibrates to massage the area of hair removal to minimize discomfort associated with the hair removal.

Owner:SOFT LINES

Brake disc assembly and method of construction

A brake disc assembly comprises a rotor and a hat assembly. The hat assembly is comprised of two hat portions, each having a plurality of curved projections. The curved projections interact with radial recesses formed in the rotor to ensure a secure connection between the hat assembly and the rotor over a wide range of operating conditions.

Owner:FEDERAL MOGUL WORLD WIDE

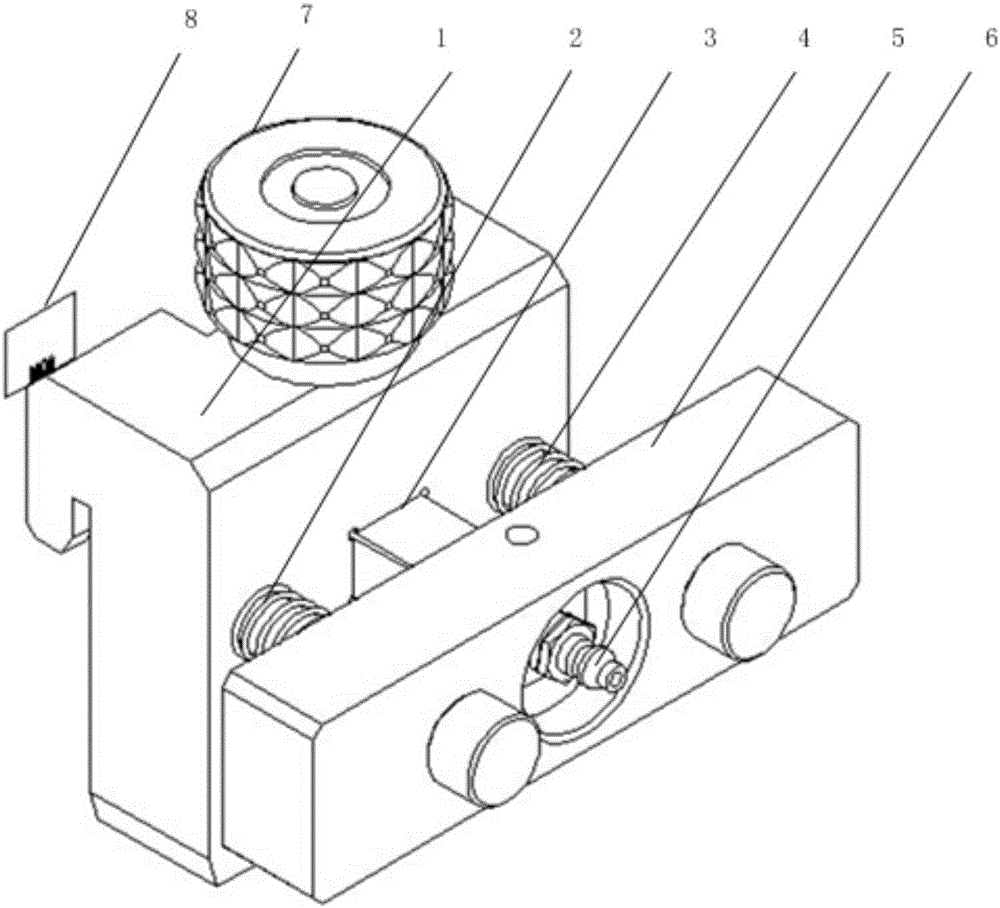

Full-automatic oil press production line capable of automatic material feeding and discharging

InactiveCN105665503AAchieve separationRealize the collectionMetal-working feeding devicesStripping-off devicesProduction lineEngineering

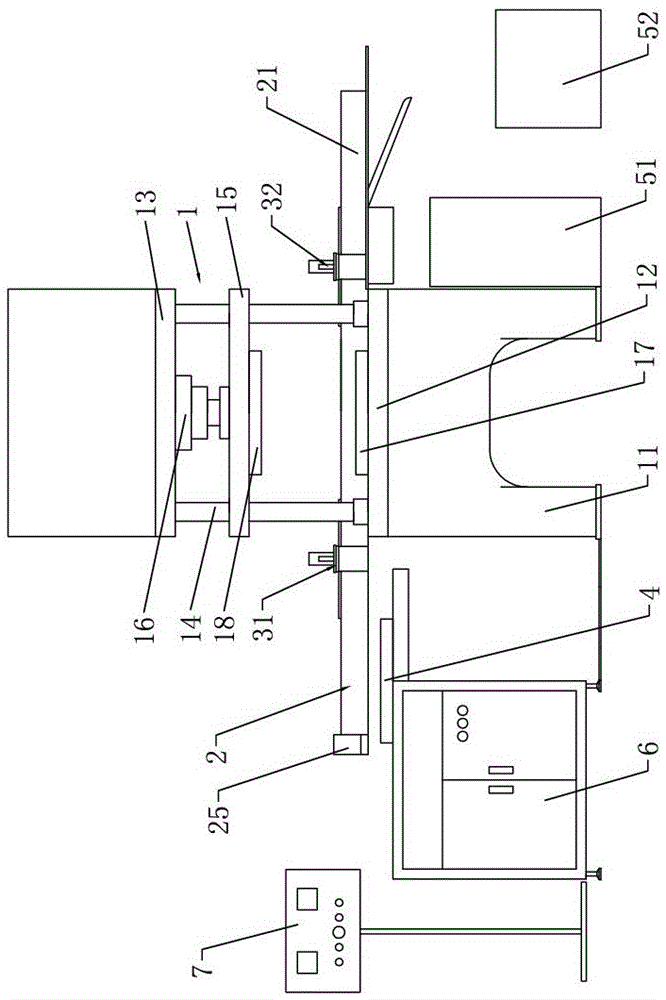

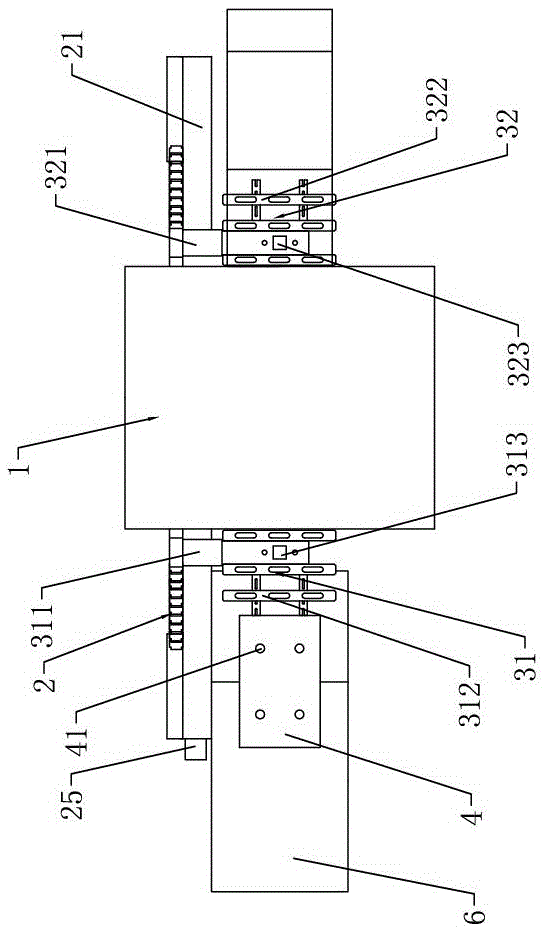

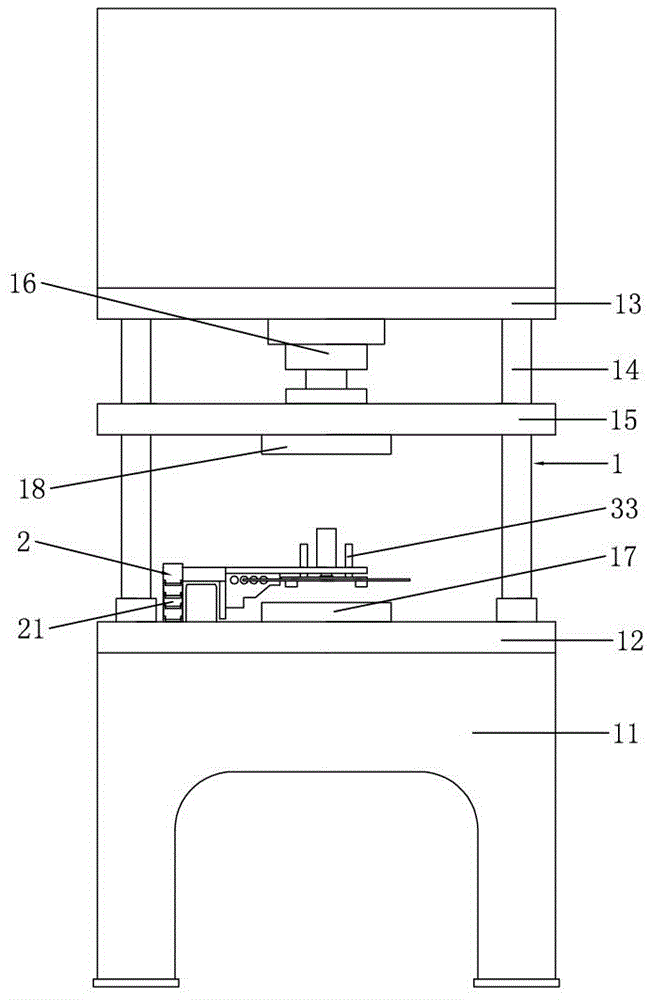

The invention discloses a full-automatic oil press production line capable of automatic material feeding and discharging. The full-automatic oil press production line comprises an automatic oil press, a control cabinet, a horizontal diving linear module, a material feeding manipulator, a material discharging manipulator, a material feeding module table, a finished product containing box and a scrap containing box; the automatic oil press comprises an oil press machine table, a lower end fixing assembly plate, an upper end fixing assembly plate, a movable assembly plate, a driving oil cylinder, a compression moulding lower mould and a compression moulding upper mould; the horizontal driving linear module comprises a linear module shell, a driving synchronous belt pulley, a driven synchronous belt pulley, a transmission synchronous belt and a servo driving motor; the material feeding manipulator comprises a material feeding assembly rack, a material feeding suction disc assembly rack, a material feeding suction disc and a material feeding side driving cylinder; and the material discharging manipulator comprises a material discharging assembly rack, a material discharging suction disc assembly rack, a material discharging suction disc and a material discharging side driving cylinder. The full-automatic oil press production line disclosed by the invention has the advantages that the design is novel; the automation degree is high; the production efficiency is high; the safety is high; manual cost can be effectively reduced; and finished products and scraps can be automatically separated and collected.

Owner:DONGGUAN YINTONG MACHINERY TECH

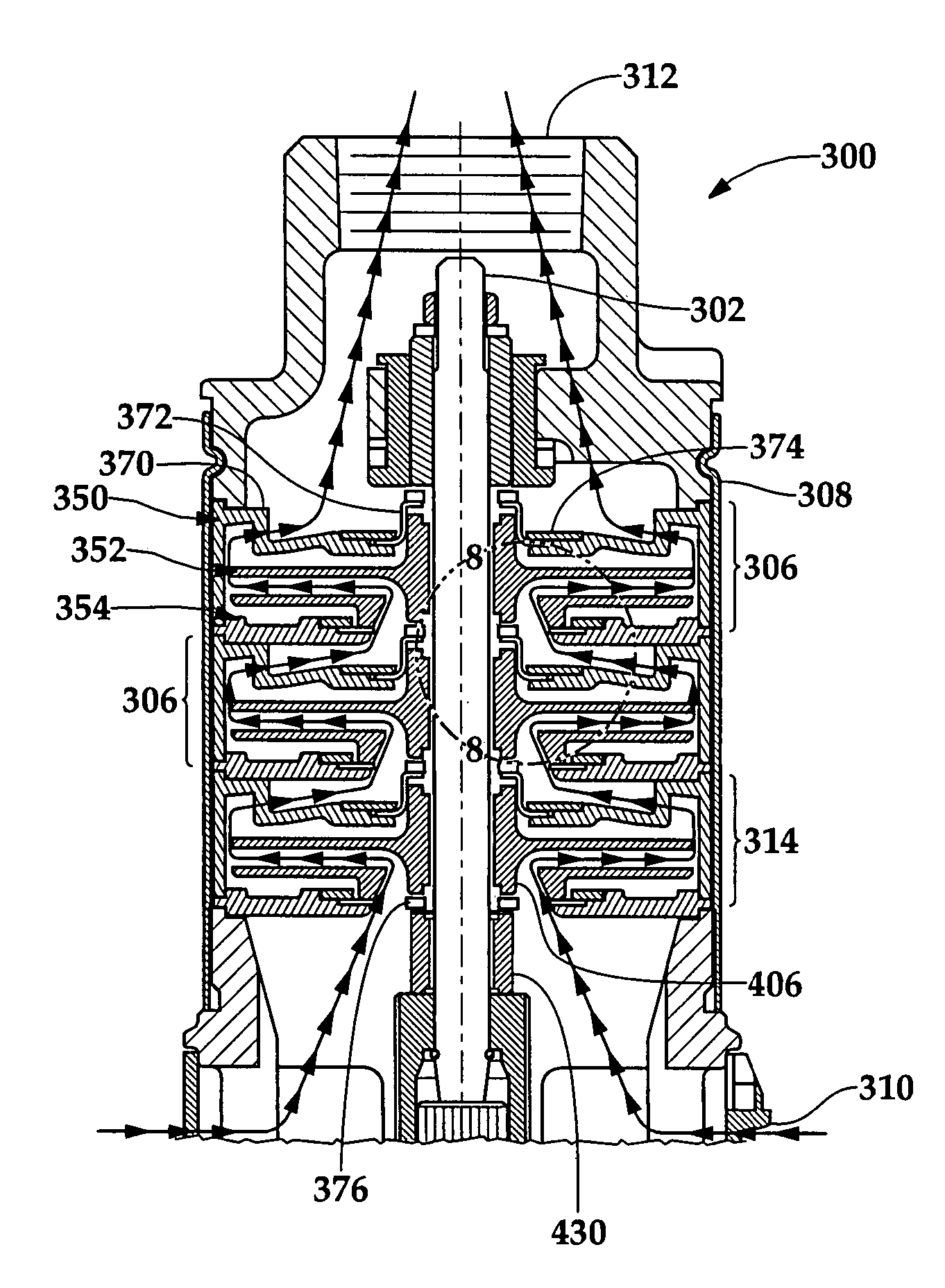

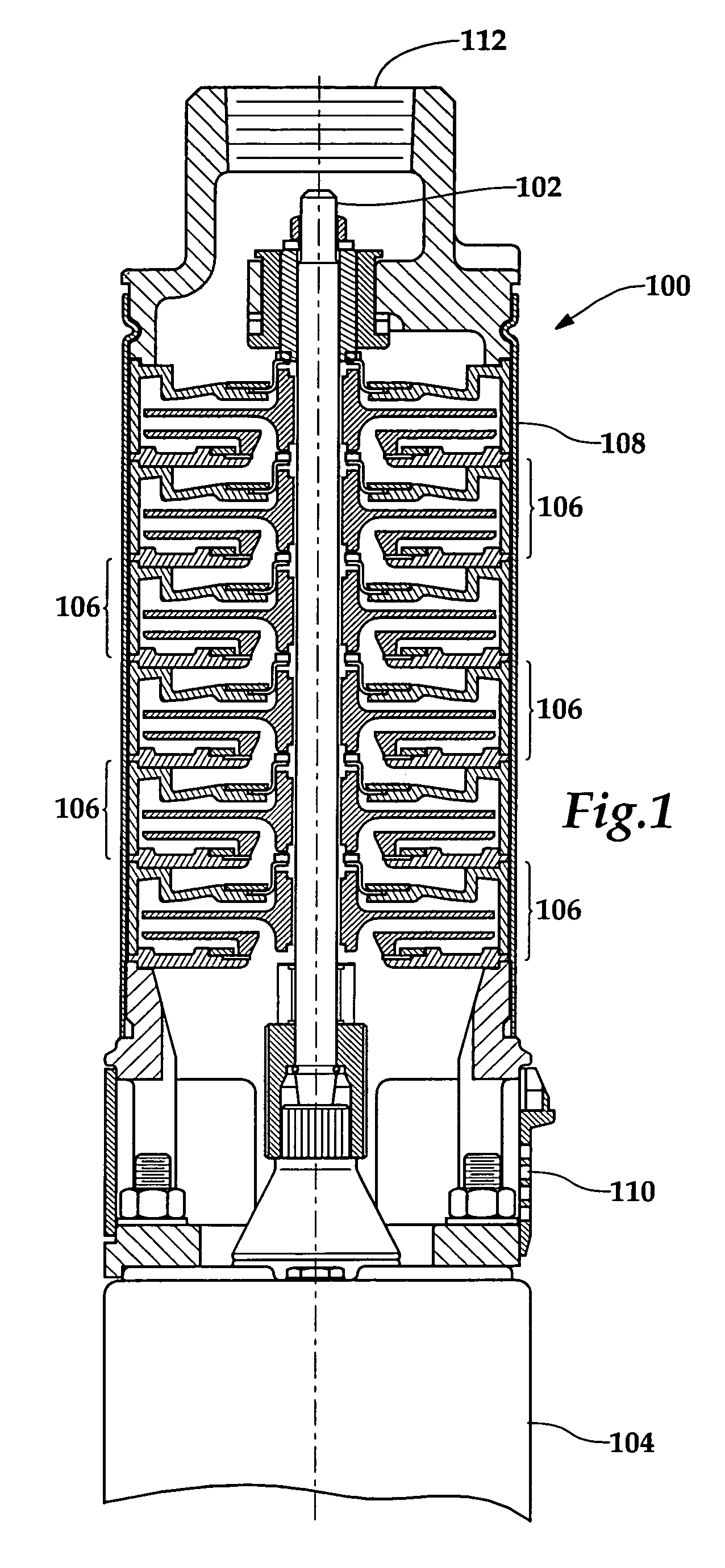

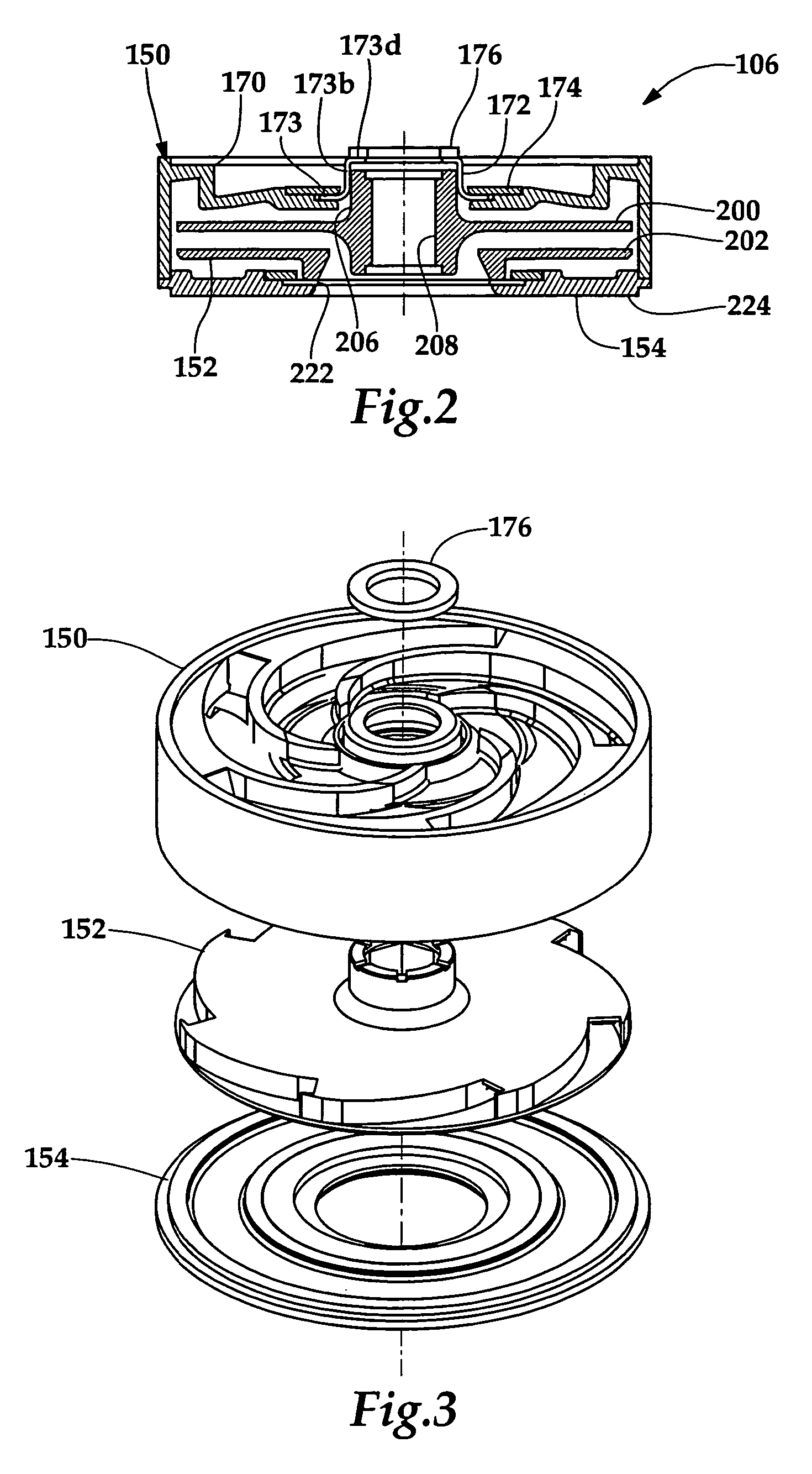

Multistage pump

A centrifugal pump includes plural pump stages, each comprising an impeller assembly, a stationary disc assembly and a diffuser assembly, all disposed about an impeller shaft. A floating impeller hub seal is supported by a diffuser assembly to minimize fluid recirculation. A thrust washer is disposed around the impeller shaft and is engageable with an impeller hub and the hub seal. A wear ring is secured to a disc assembly and engageable with a wear surface on the impeller.

Owner:FRANKLIN ELECTRIC CO INC

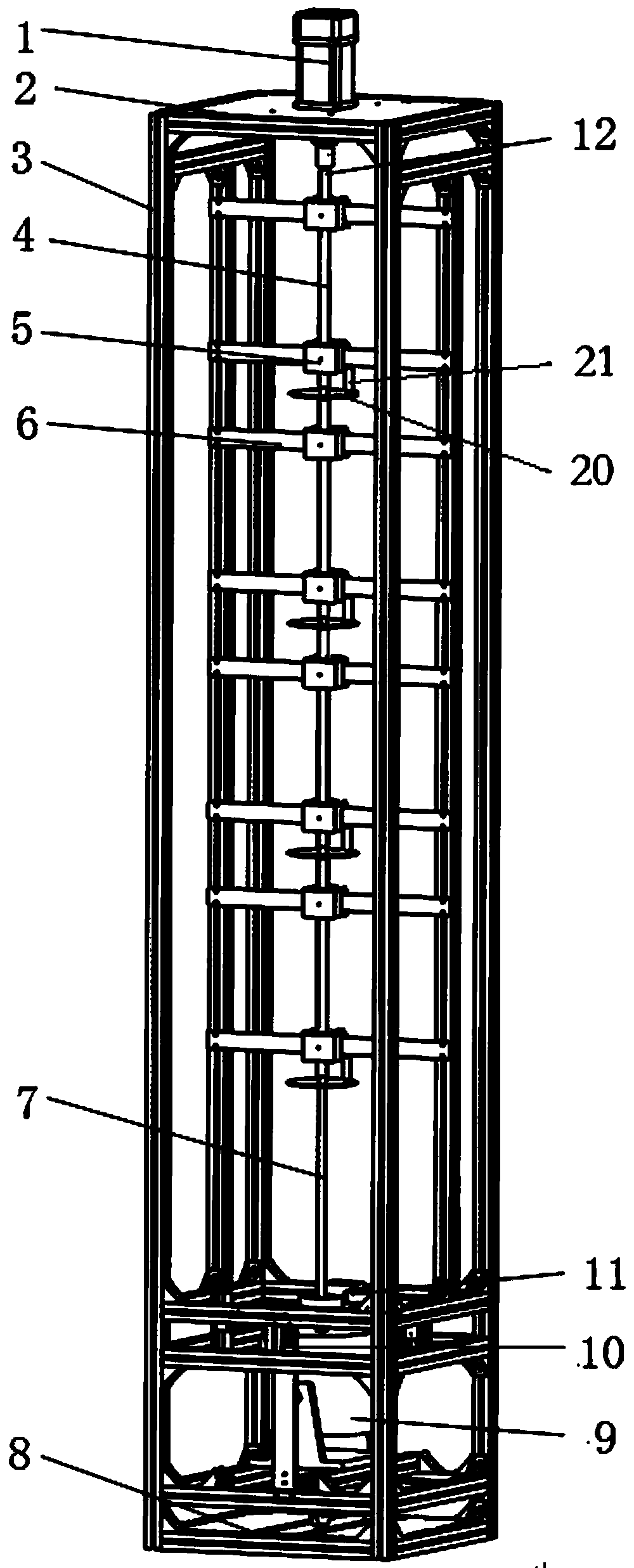

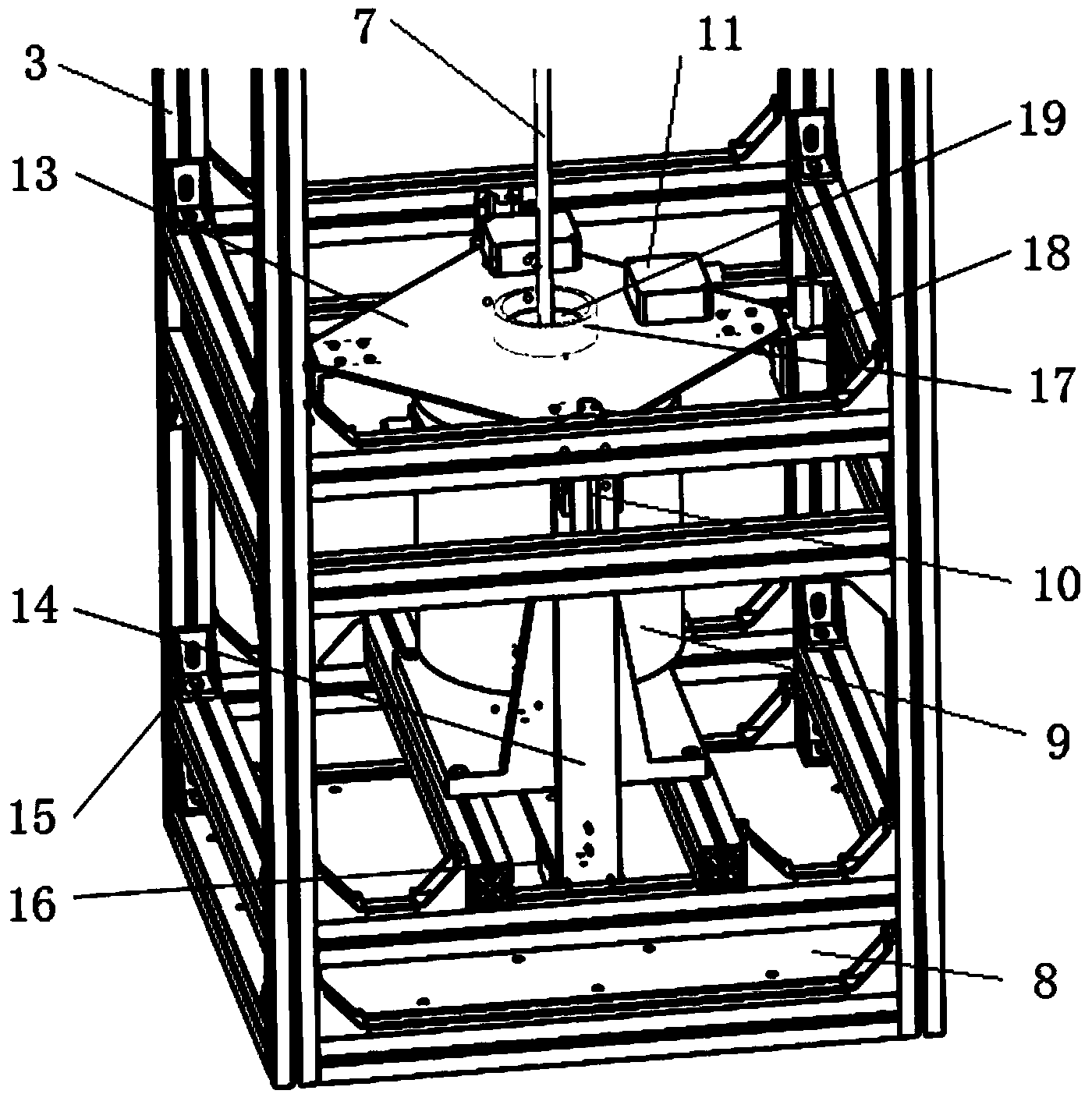

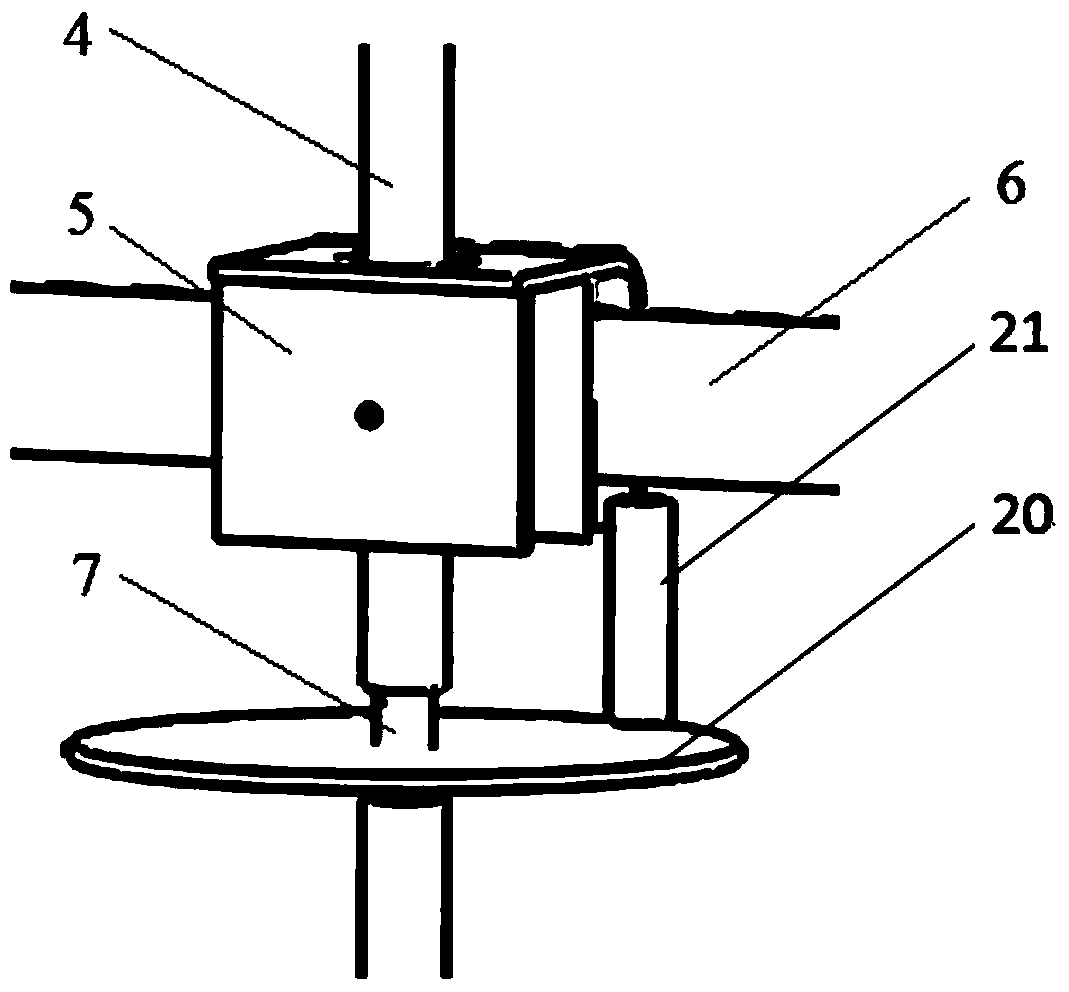

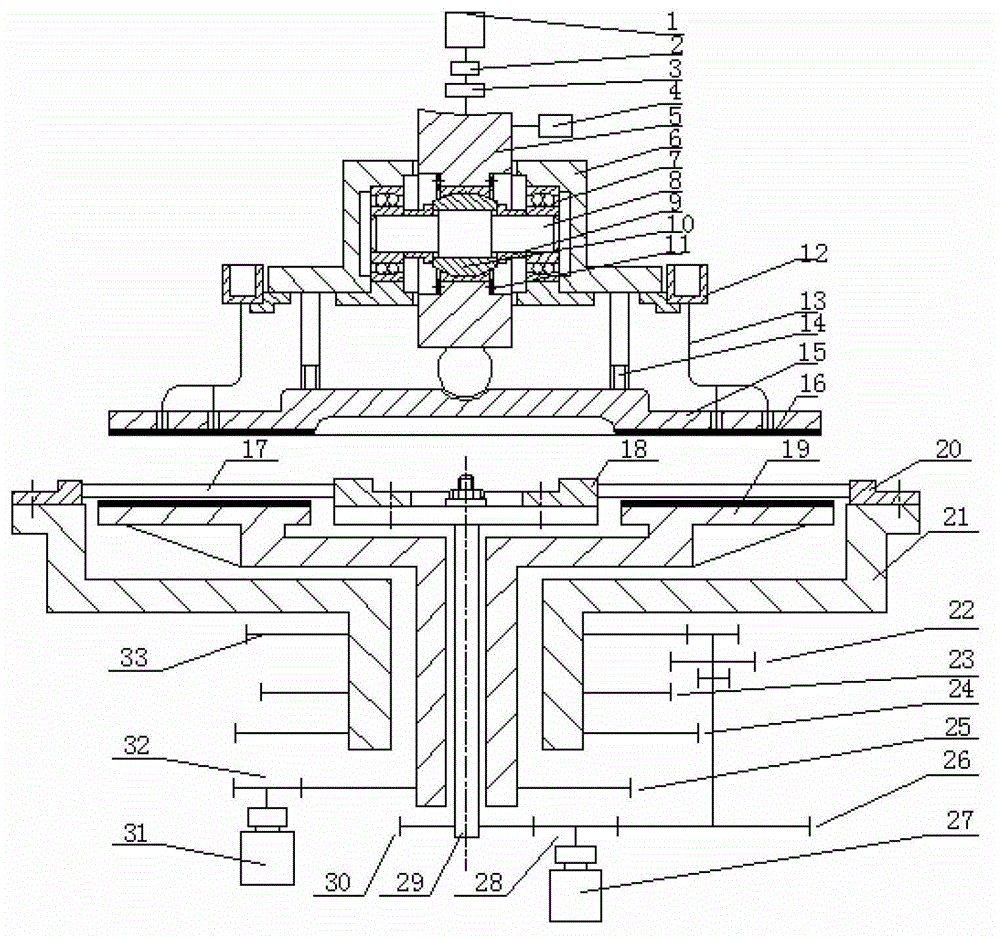

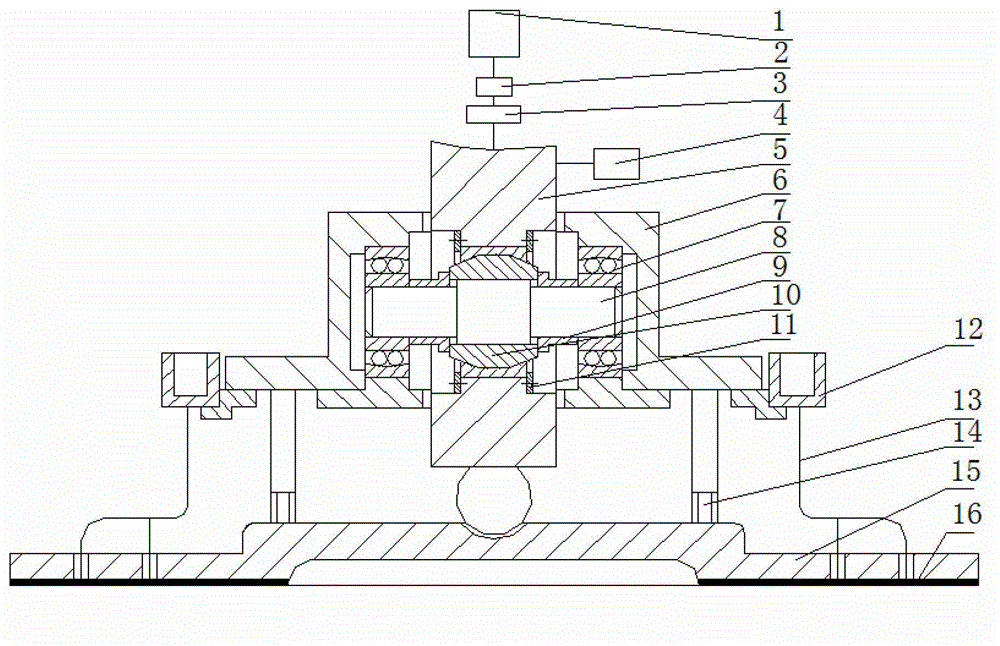

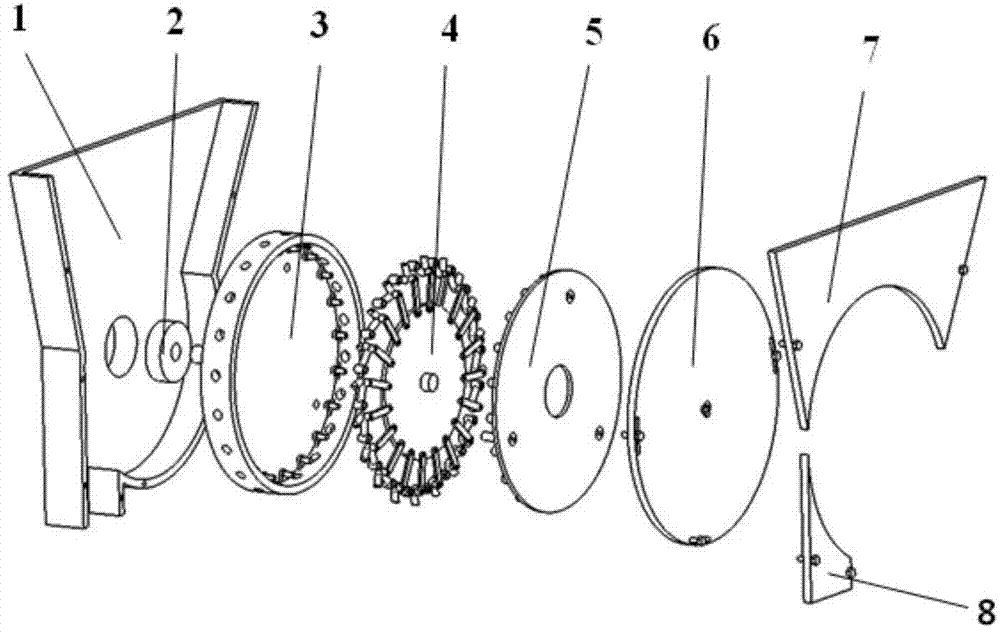

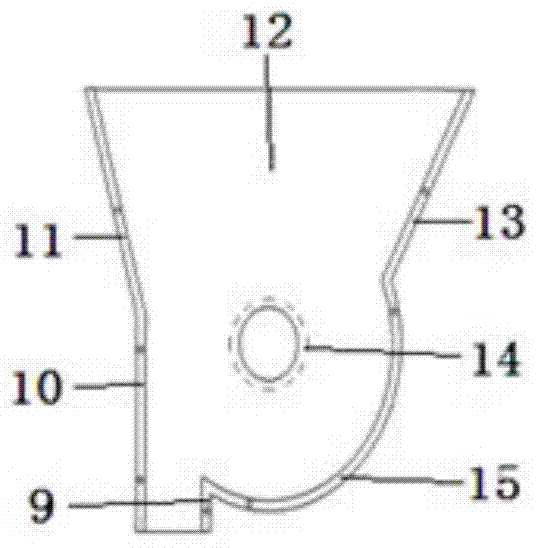

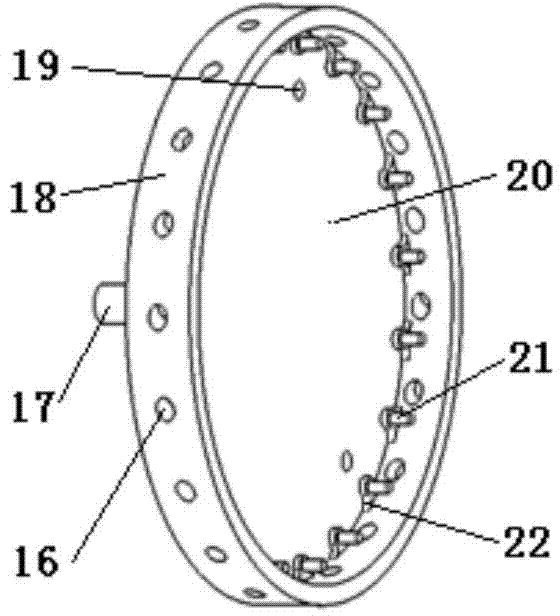

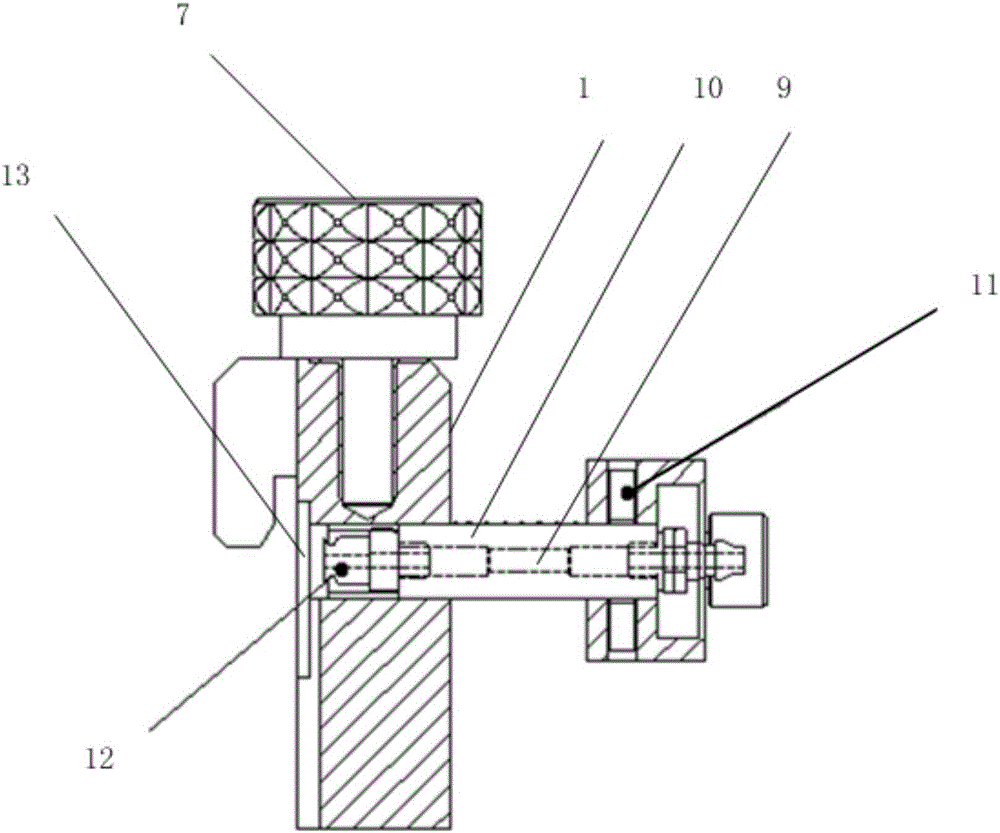

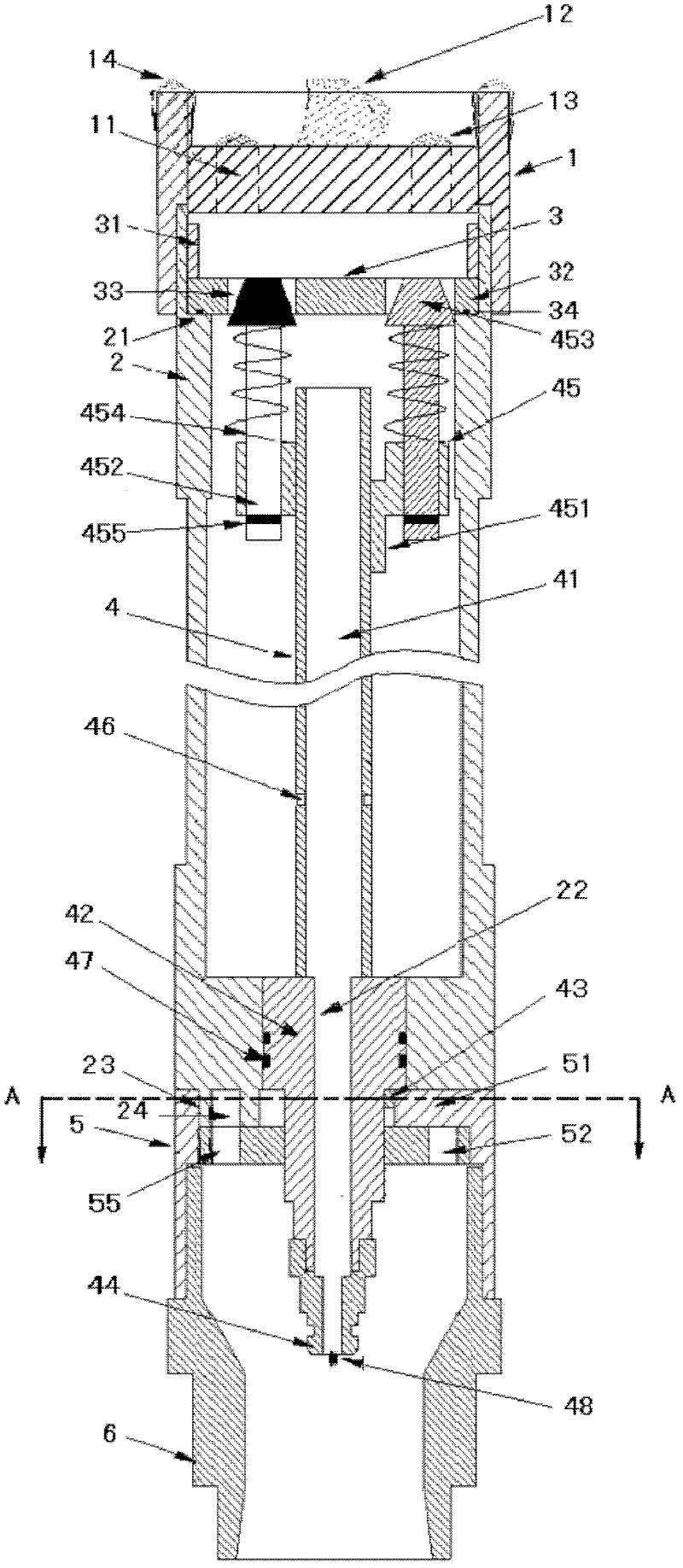

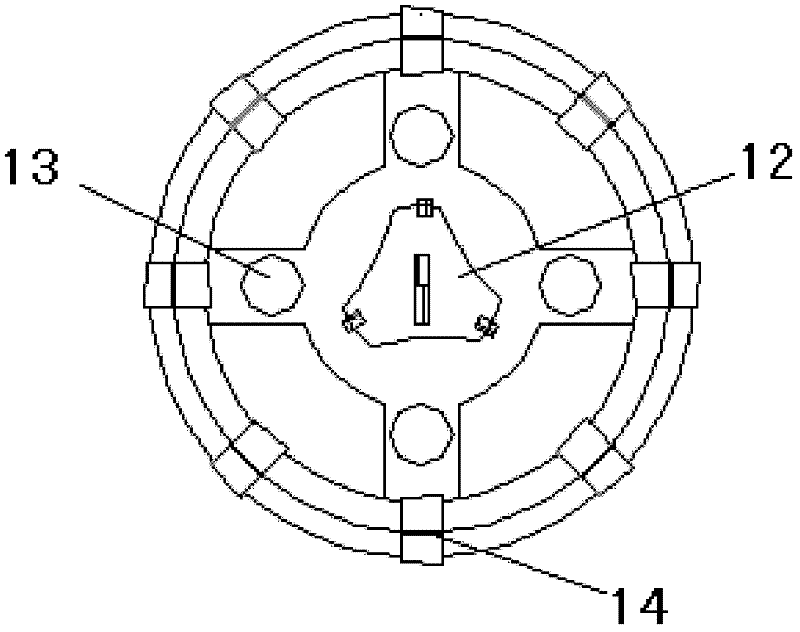

Experimental device for researching drill column dynamic characteristic

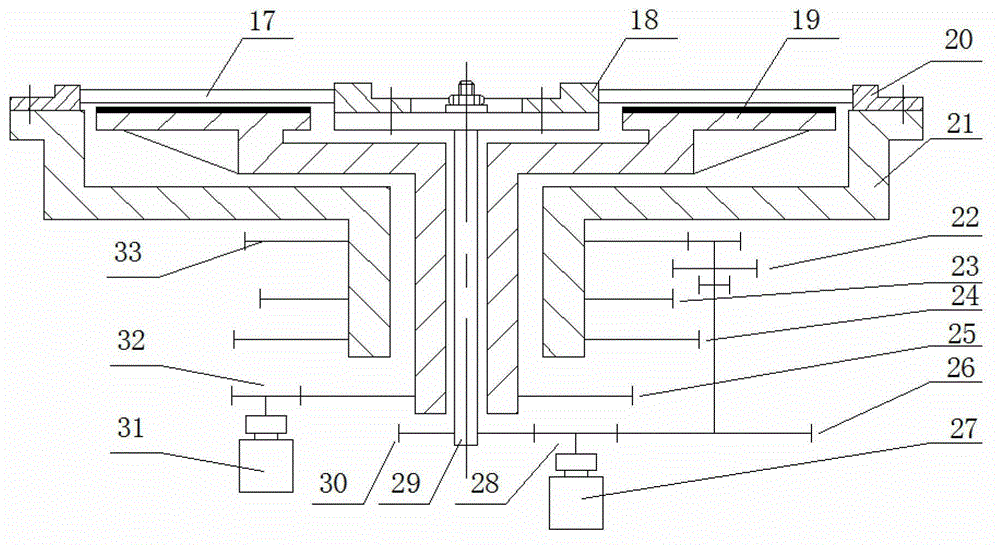

InactiveCN103712790AResearch is accurate and feasibleMachine part testingCircular discElectric machinery

The invention relates to an experimental device for researching a drill column dynamic characteristic. The experimental device comprises a main machine frame, a well-wall-simulating assembly, a rotary assembly, a disc assembly, an excitation assembly, a weighing assembly and a detecting device. The well-wall-simulating assembly comprises an organic glass tube, a fixing clamping and a clamp mounting plate. The rotary assembly is provided with a motor, a driver, a coupler, a thin steel column and a top mounting plate, the rotary assembly penetrates through the whole main machine frame, the disc assembly comprises a disc and a cylinder, the disc is arranged on a floating platform, and the disc conducts rotary movement in the cylinder. An exciter in the excitation assembly excites the bottom of the disc according to the input signal type to simulate interaction of a drill head and rocks at the bottom of a borehole. The detecting device comprises a whirling motion track and a transverse vibration and longitudinal vibration detecting device. The experimental device for researching the drill column dynamic characteristic can simulate the vibration and deformation situations of a drill column and determine the parameters of the rotating speed, the bit pressure similarity ratio and the like according to the dynamic similarity ratio and the geometric similarity ratio.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

High-precision electric servo double-faced grinding machine

InactiveCN103331661AImprove grinding precisionIncrease productivityOptical surface grinding machinesPlane surface grinding machinesThree stageDISC assembly

A high-precision electric servo double-faced grinding machine comprises an upper grinding disc assembly and a lower grinding disc assembly, wherein the upper grinding disc assembly comprises a servo electric cylinder, an upper spindle, an upper grinding disc servo motor, an upper grinding disc seat and an upper grinding disc; the servo electric cylinder is connected with the top end of the upper spindle; the upper grinding disc servo motor is connected with the upper spindle; the upper grinding disc seat is fixed on the upper spindle; the upper grinding disc is connected with the upper grinding disc seat; the lower grinding disc assembly consists of a lower grinding disc, a lower grinding disc driving system and a lower grinding disc speed governing system; a lower grinding disc shaft is concentrically matched with shafts of the lower grinding disc speed governing system; and the lower grinding disc speed governing system can realize large-torque three-stage speed change of an outer gear ring. The high-precision electric servo double-faced grinding machine has the advantages that the upper grinding disc can swing universally, the machine is applicable to processing various workpieces with different thicknesses, the lower grinding disc realizes the large-torque multistage speed change, the upper grinding disc and the lower grinding disc rotate simultaneously for grinding, the grinding precision is high, the production efficiency is high, and the machine is applicable to optical plane grinding, particularly precision processing of special glass.

Owner:YANSHAN UNIV

Execution time dependent command schedule optimization

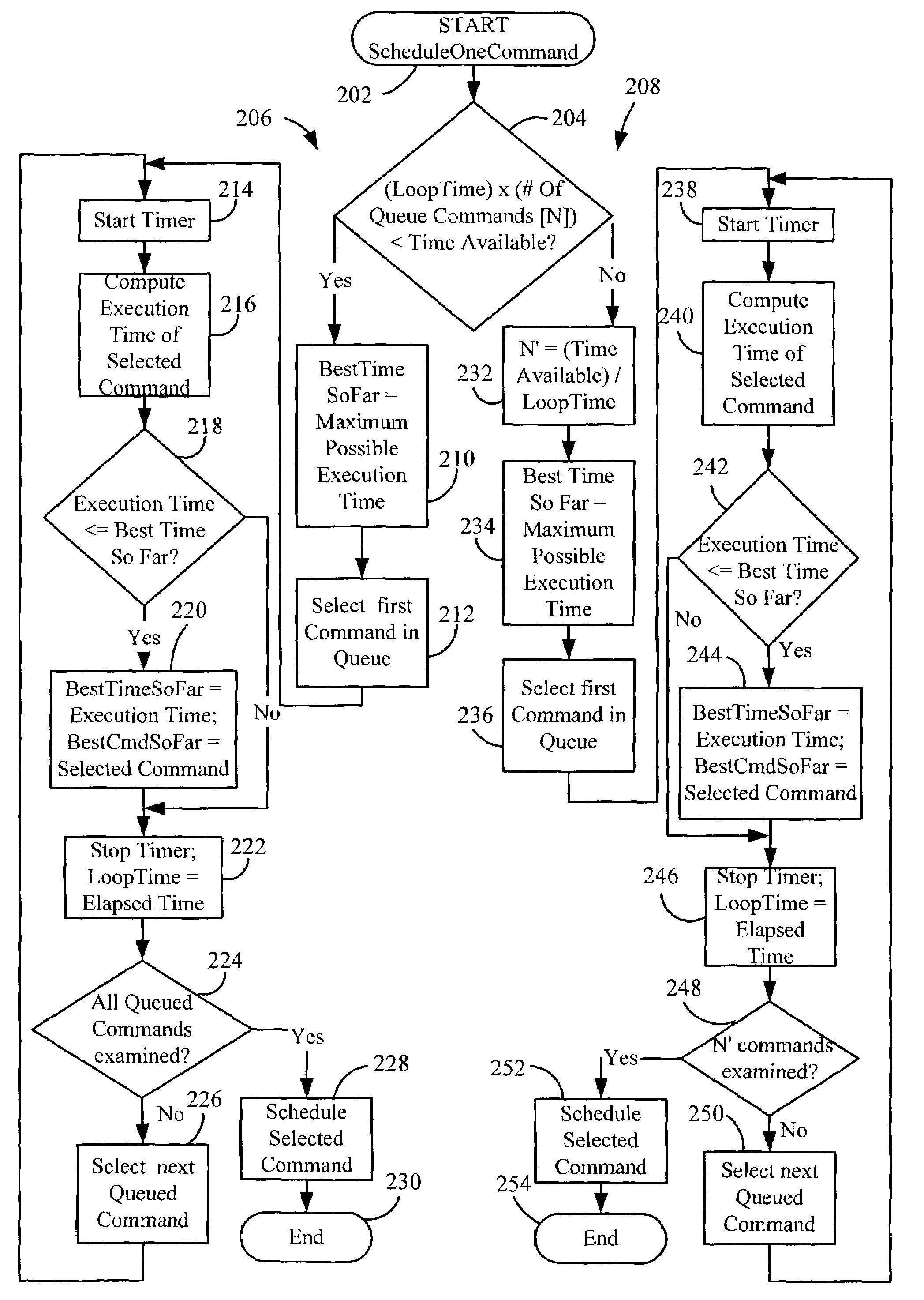

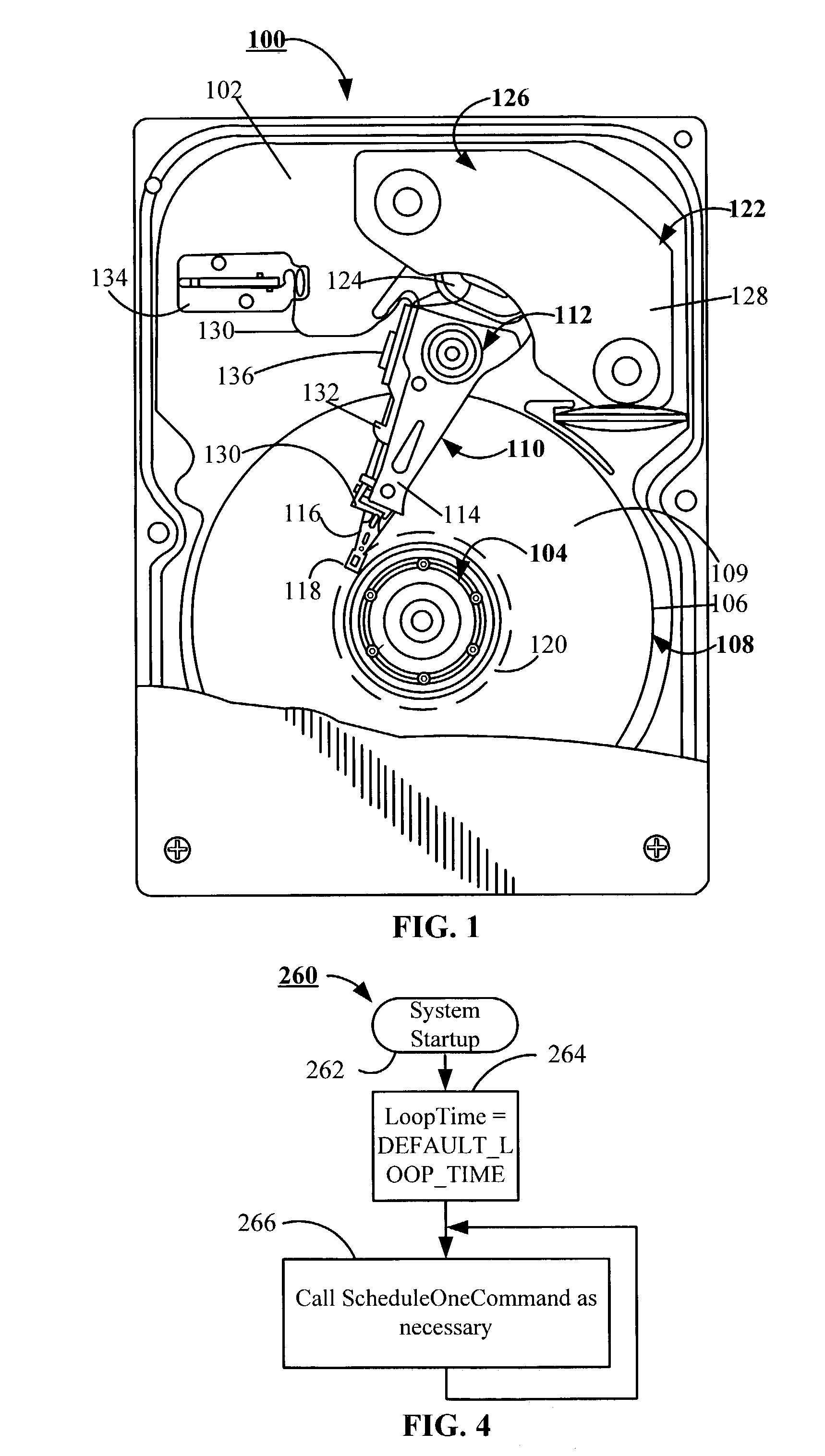

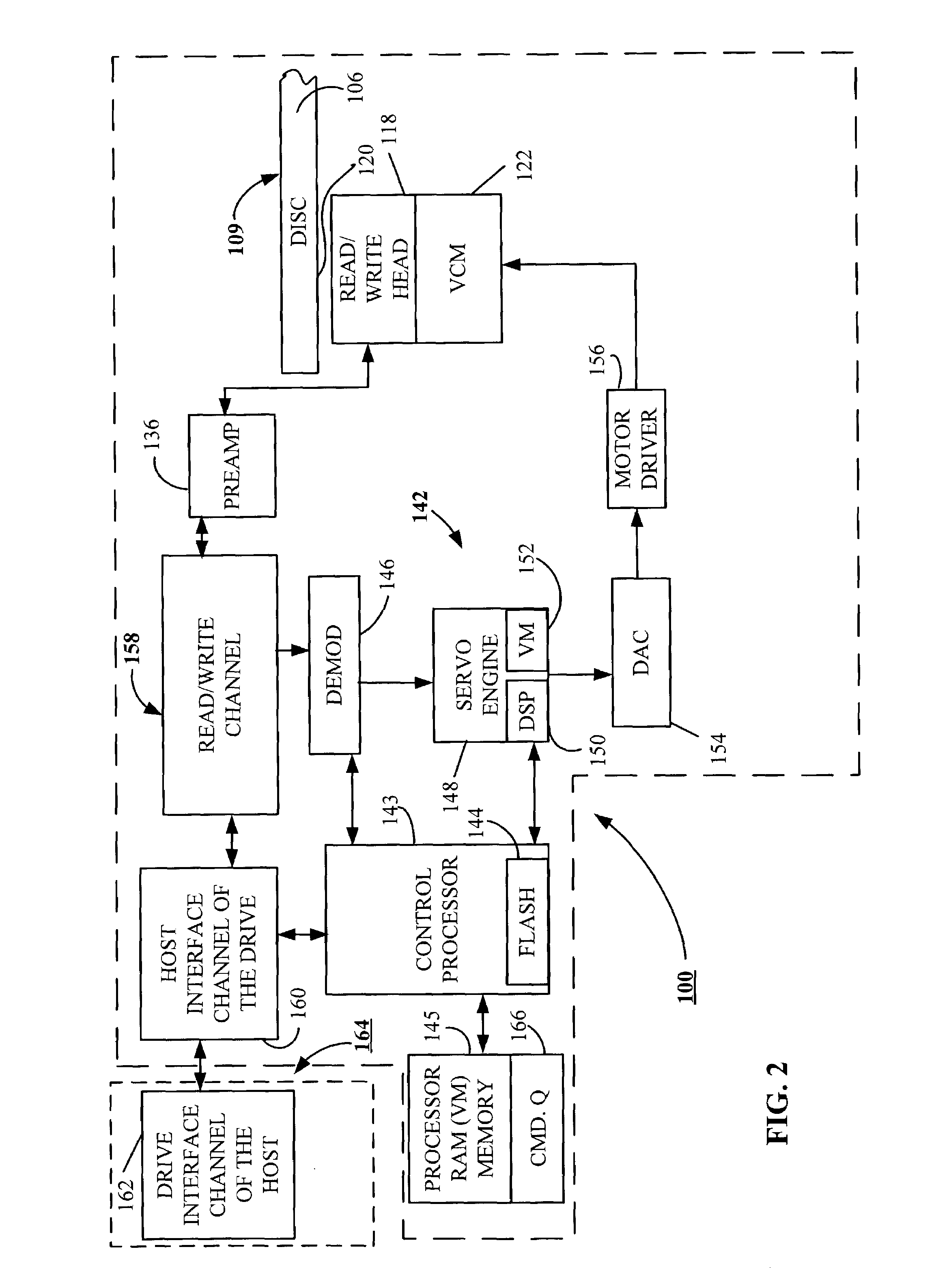

InactiveUS7003644B2Improve data throughputInput/output to record carriersMemory systemsProcessor schedulingParallel computing

A disc drive with a control processor programmed with an execution time dependent command schedule optimization method to effect data throughput with a host device. The disc drive includes a head disc assembly executing commands scheduled by the control processor. The control processor selects and schedules a next optimum command from among commands analyzed by the control processor during a time the head disc assembly is executing a current command. The steps utilized by the control processor to select and schedule the next optimum command include executing a first command with the head disc assembly, determining a computation time for a second command, storing the computation time as a computation time estimate, and using the stored computation time estimate to determine the number of commands in a command queue for analysis to provide a level of command schedule optimization commensurate with the available time.

Owner:SEAGATE TECH LLC

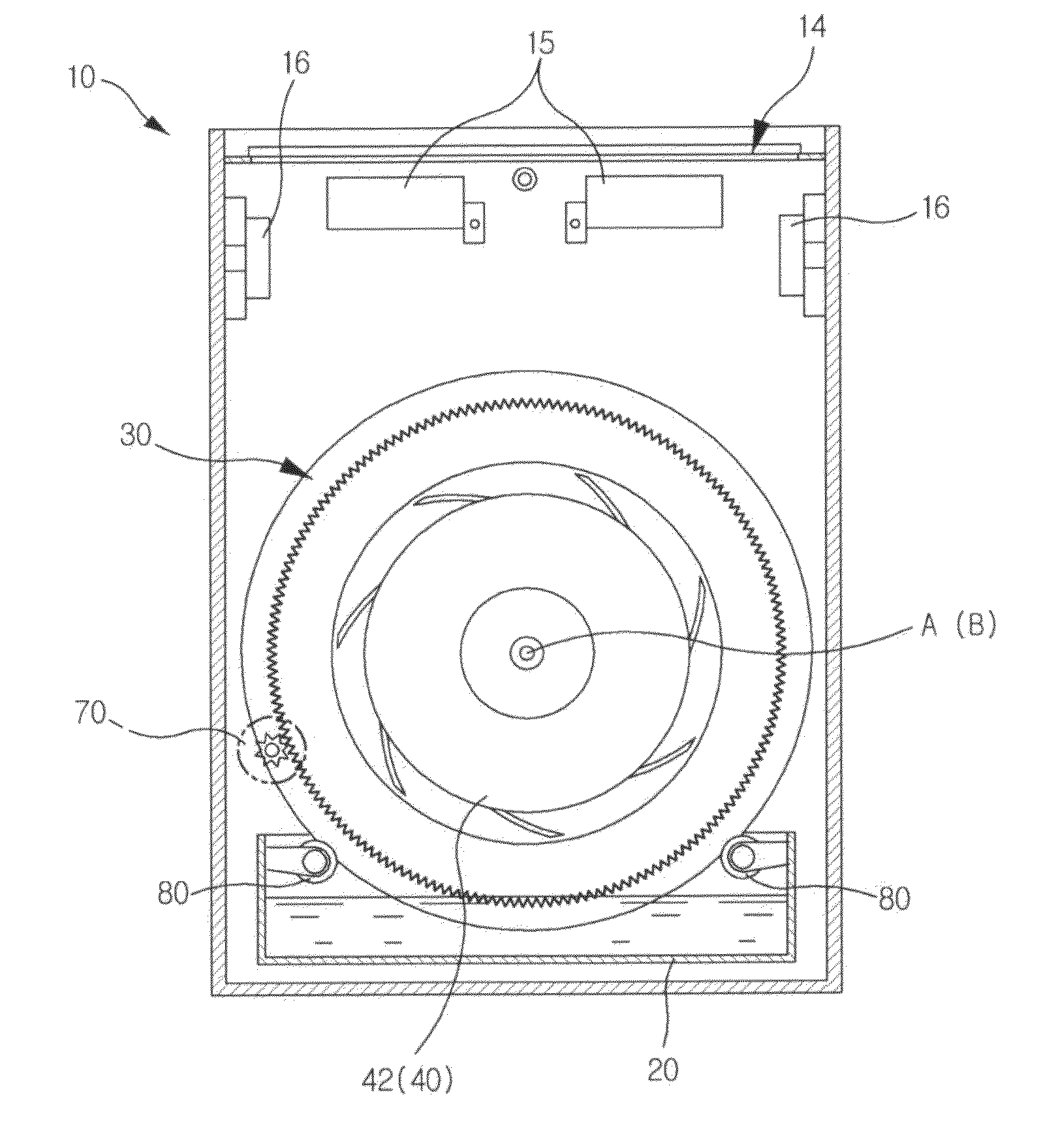

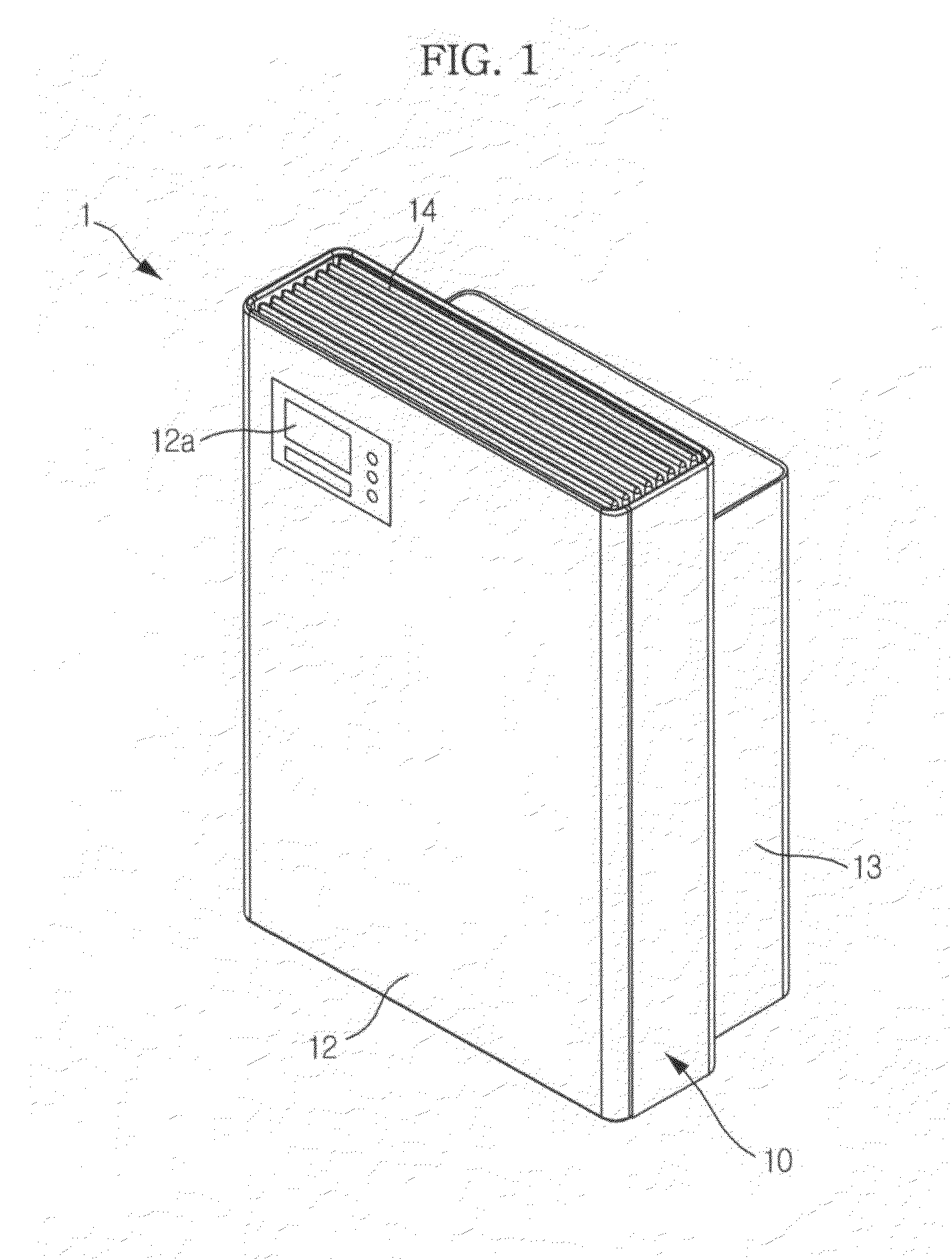

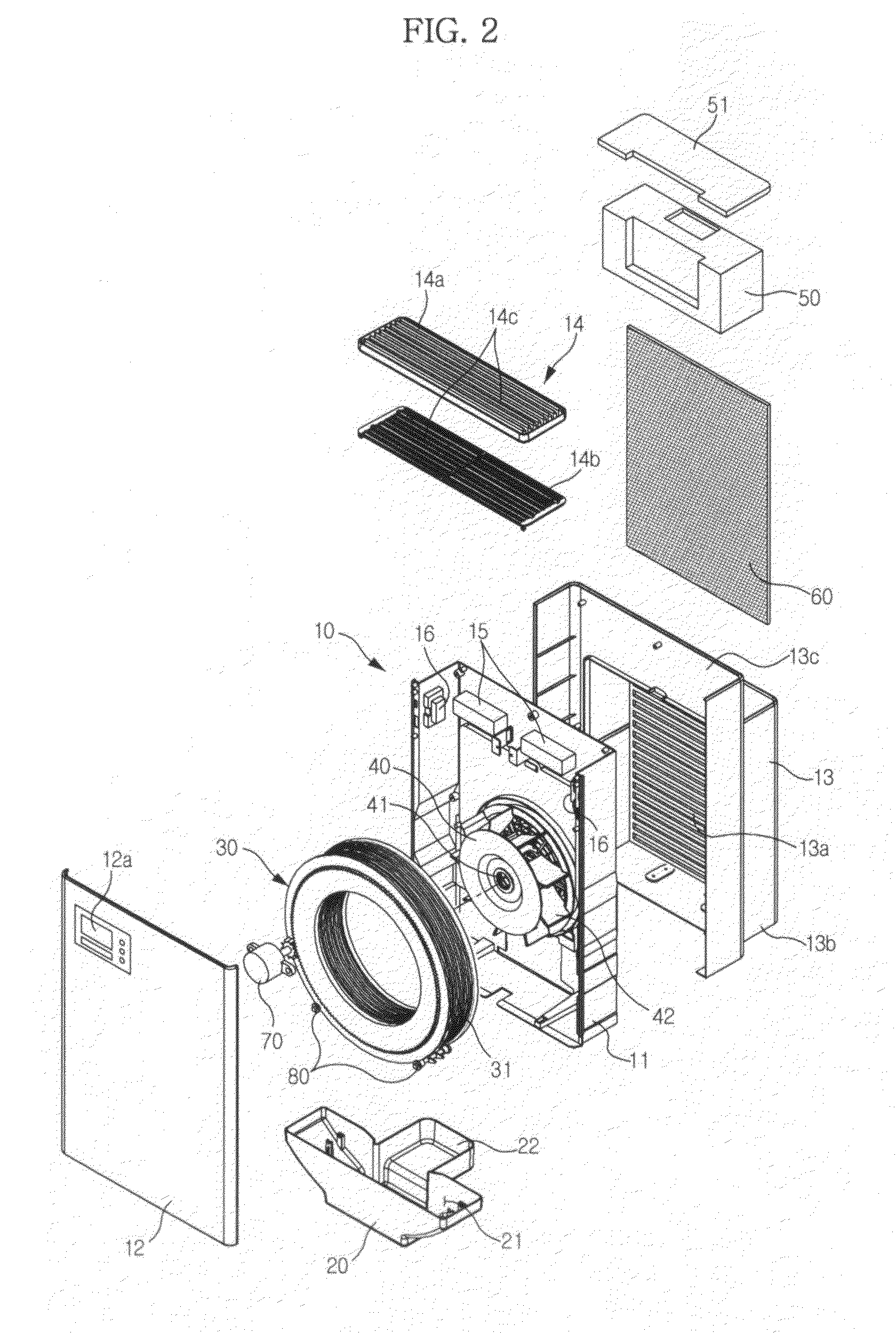

Air cleaning humidifier and disc assembly thereof

ActiveUS20110084415A1Easy to assembleLighting and heating apparatusUsing liquid separation agentAir cleaningEngineering

Disclosed herein is an air cleaning humidifier having a disc assembly performing a purifying function and a humidifying function of indoor air, and a disc assembly thereof. The air cleaning humidifier includes a main body, a tub provided in the main body, an air blower fan generating an air current in the tub, and a rotatable disc assembly having a part of the disc assembly being disposed in the tub, and including a plurality of stacked discs, each of at least two of the discs including a body, a plurality of assembly parts defined through a surface of the body, first protrusion parts protruded from one surface of the body, and second protrusion parts protruded from the other surface of the body, the body being divided into a plurality of sectors by the plurality of assembly parts, and the first protrusion parts and the second protrusion parts being alternately formed in even-numbered regions, into which each of the plurality of sectors is divided.

Owner:SAMSUNG ELECTRONICS CO LTD

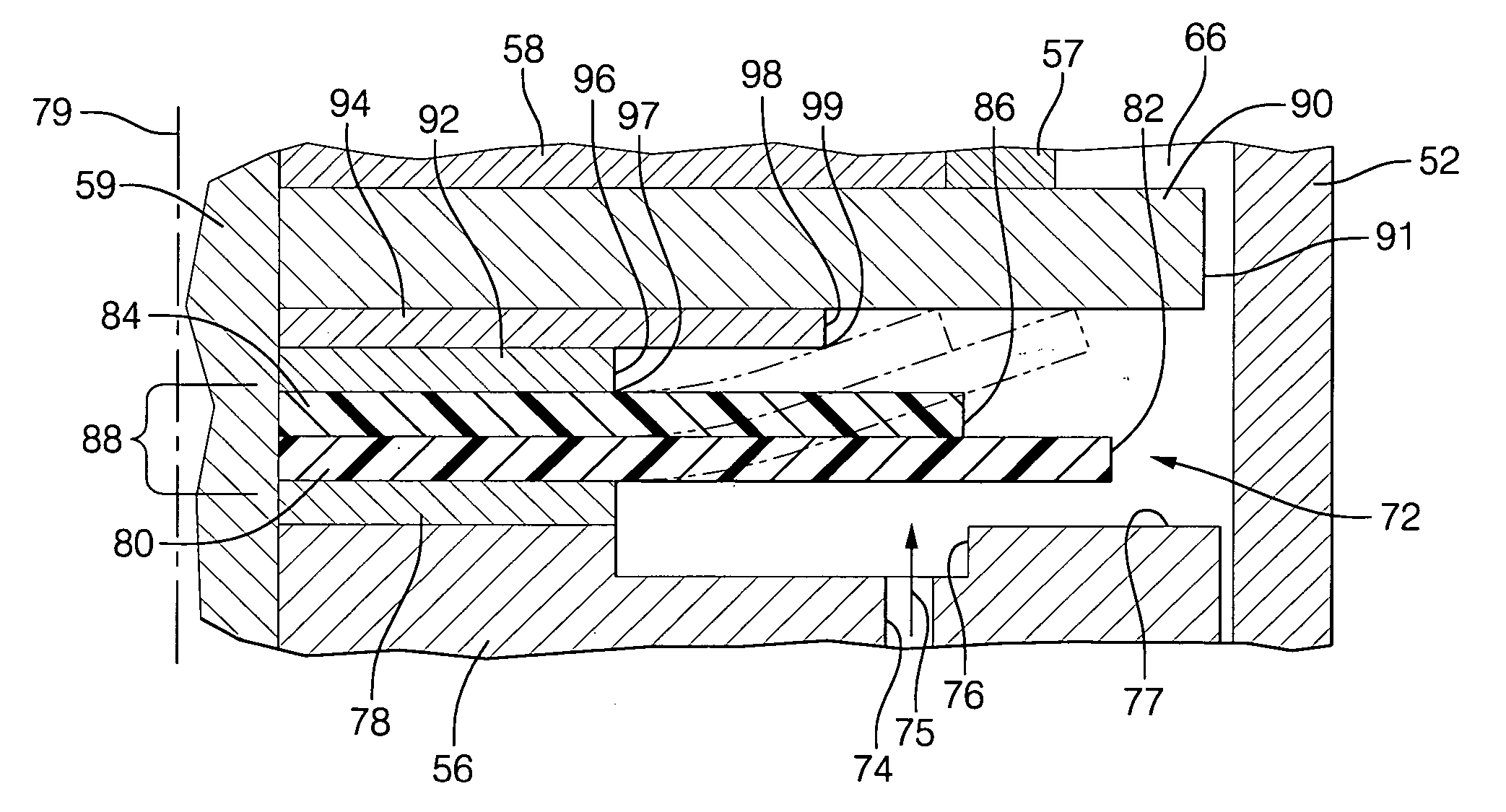

Hydraulic actuator having disc valve assembly

ActiveUS20050211087A1Reduces stress build-upExtended service lifeSpringsServomotor componentsEngineeringHydraulic fluid

A hydraulic actuator comprises piston that divides the interior into a piston chamber and a rod chamber and a valve disc assembly to regulate flow of hydraulic fluid between the piston chamber and the rod chamber through a passage in the piston. The disc valve assembly includes a washer, a valve pack that includes at least one flexible disc valve, and a spacer arrangement spacing the valve pack apart from the washer. During operation, the valve pack flexes to open and close the passage. The spacer arrangement includes a first support point supporting the valve pack relative to the washer and at least one second support point spaced apart from the flexible portion of the disc valve pack. In the open position, the valve pack engages the second support point to reduce stress build-up at the first support point, thereby reducing work fatigue of the valve disc and extending the useful life of the hydraulic actuator.

Owner:DELPHI TECH INC +1

Low Torque And Vacuum Seed Meter

ActiveUS20140182496A1Improve uniformityImprove efficiencyPotato plantersFurrow making/coveringVacuum pressureEngineering

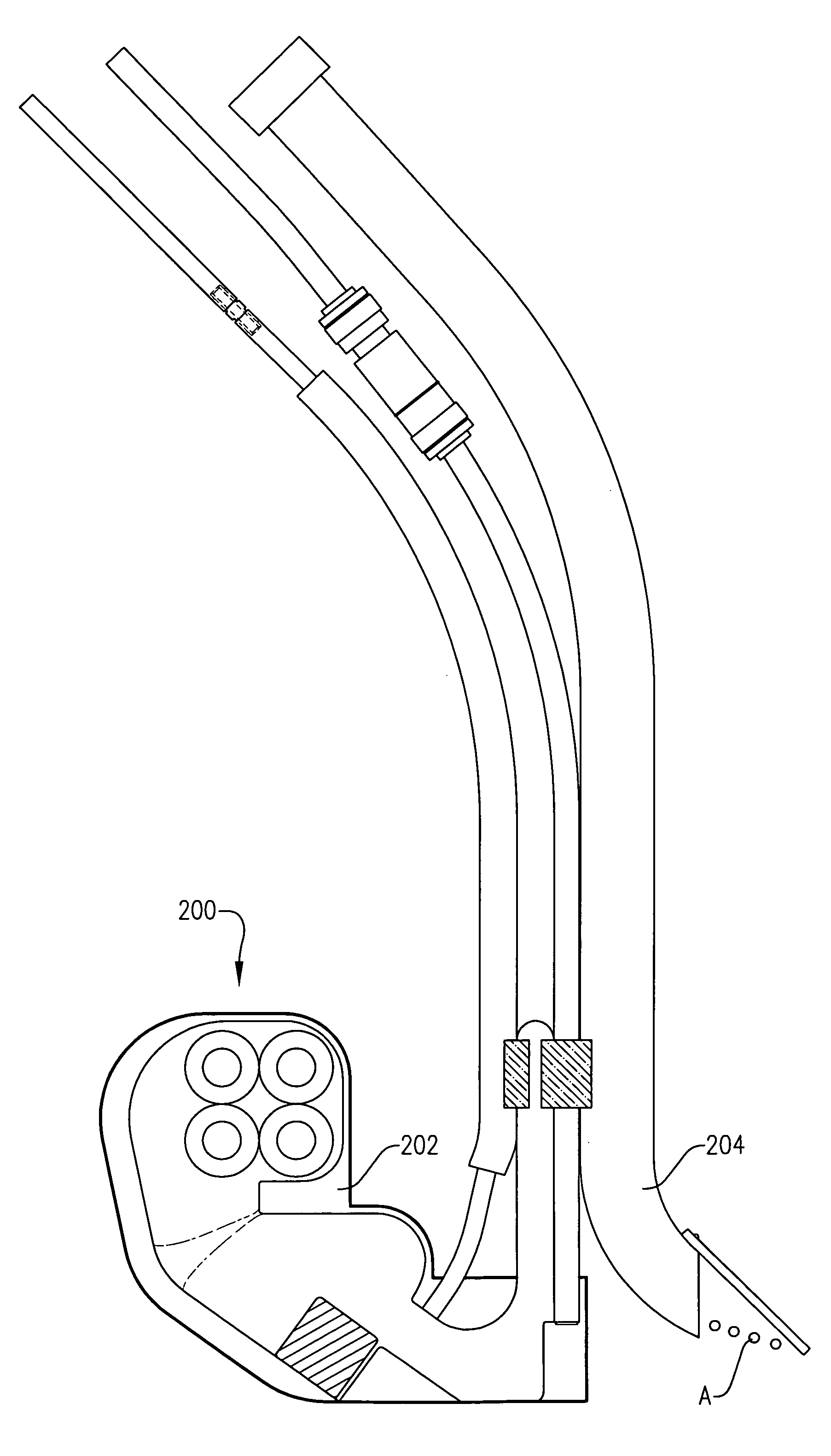

A seed meter is provided for use with a row crop planter or seed planter that includes a seed disk assembly that rotates within a meter housing cavity and that has a seed disk assembly cavity in which a vacuum pressure is applied for pulling seeds into seed pockets of a seed disk of the seed disc assembly. The vacuum pressure is applied to the seed disk assembly by pulling a vacuum airflow through a spindle that supports the seed disk assembly. A wiper basket is arranged in a fixed position within the seed disk assembly cavity and seals against the seed disk assembly as a support plate and seed disk of the seed disk assembly rotate over the wiper basket, so that side walls of the wiper basket create a boundary between a vacuum zone and a non-vacuum zone inside of the seed disc assembly cavity.

Owner:BLUE LEAF I P

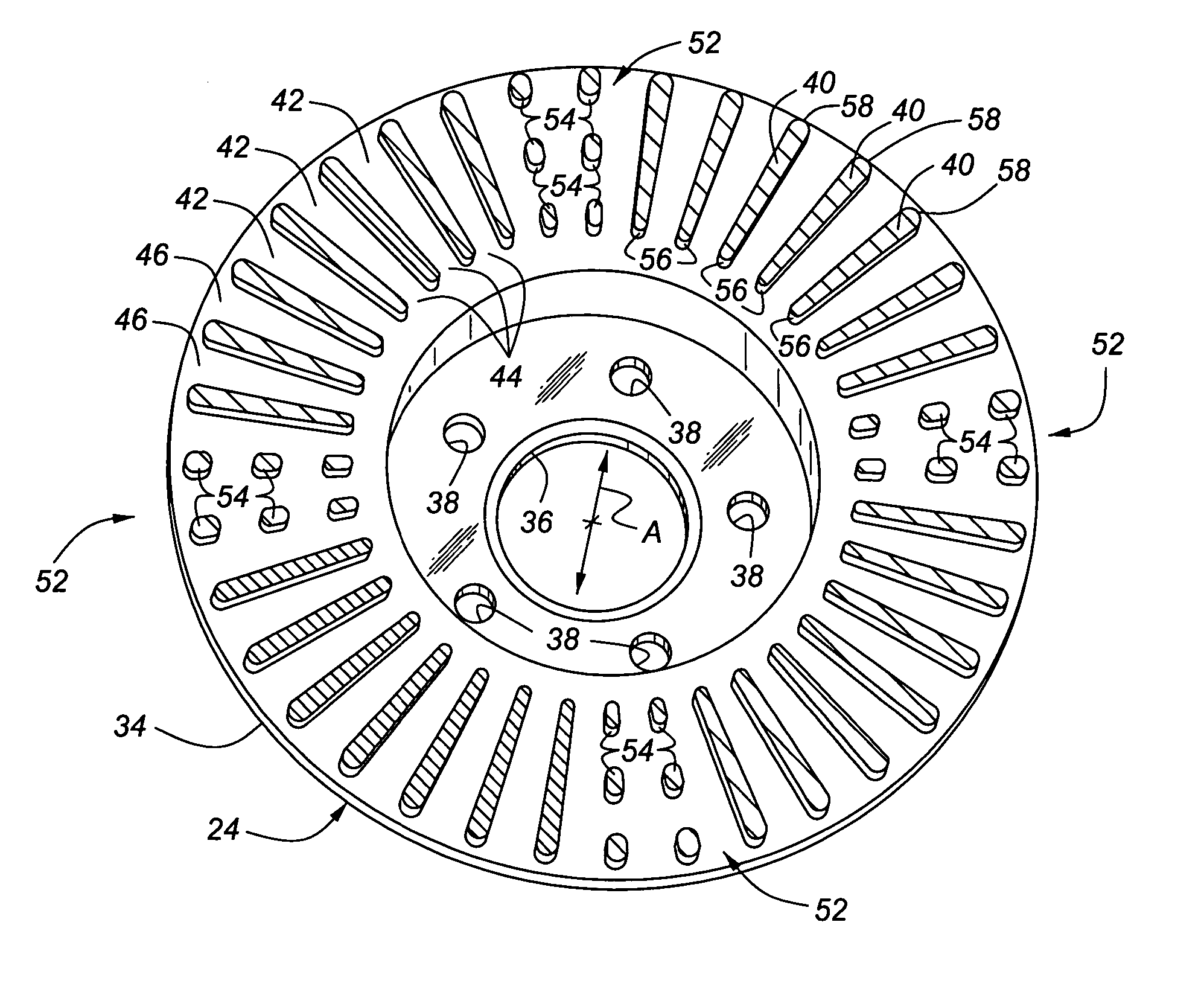

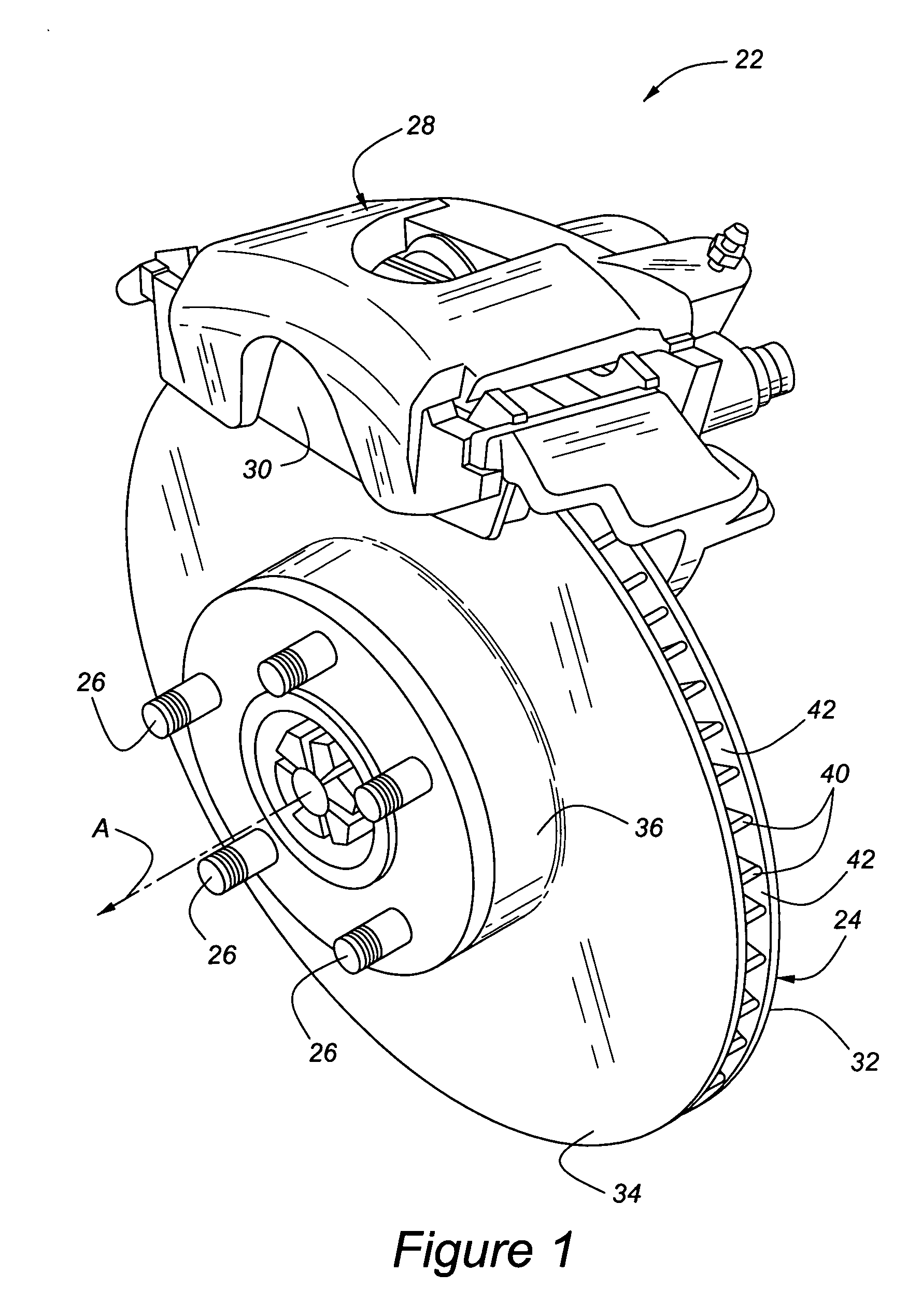

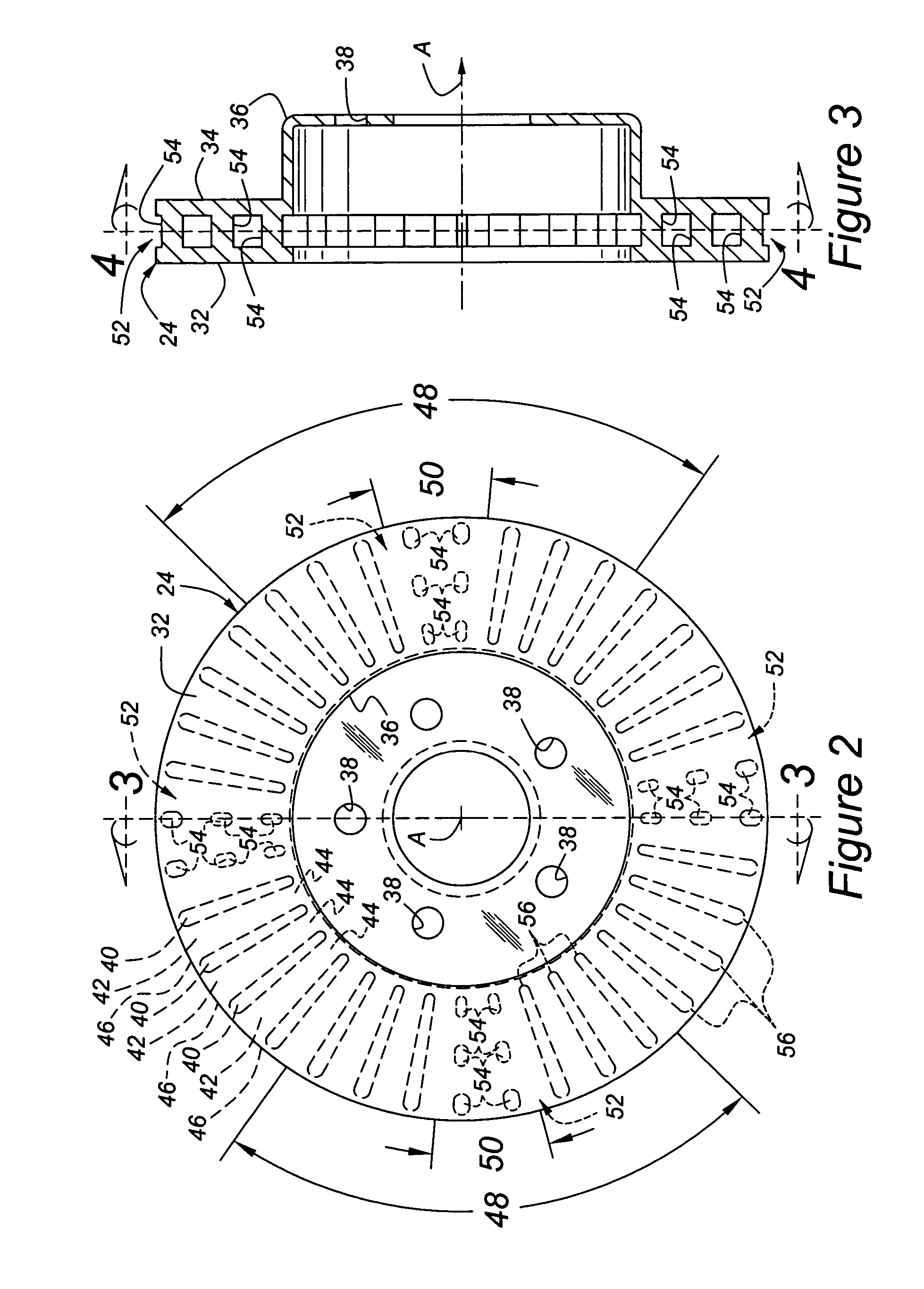

Vented disc brake rotor

ActiveUS20060219500A1Reduce the possibilityEasy to implementBraking discsSlack adjustersEngineeringDISC assembly

A brake disc assembly (22) for a vehicle includes a ventilated rotor (24) defined by vent holes (42) between inboard (32) and outboard (34) friction plates. The vent holes (42) are separated by ribs (40) spaced in regular circumferential increments about the rotor (24). The rib pattern (40) is divided into two or more sectors (48) of equal angular measure. Within each sector (48), an attenuation region (50) interrupts two or more ribs (40) by replacing the ribs (40) with a cluster of individual pins (54) which may be arranged in radial and circumferential rows. The pins (54) can have consistent circular or varying cross-sectional configurations. Each attenuation region (50) spans a territory within each sector (48) that is preferably at least 20% and less than 55% of the sector (48) real estate. The rotor (24) completely or at least substantially eliminates vibration modes in objectionable, audible frequencies without adversely affecting the structural integrity, cooling capabilities or functional attributes of the disc brake assembly (22).

Owner:FEDERAL MOGUL WORLD WIDE LLC

Type hole volume variable type precision seed metering device

InactiveCN104255139AReduce the chance of injurySatisfy broadcasting requirementsSeed depositing seeder partsInterference fitCircular disc

The invention discloses a type hole volume variable type precision seed metering device, belonging to the technical field of agricultural machines. A bearing outer ring is in interference fit with a bearing seat of a seed box, a bearing inner ring is in interference fit with a power input shaft of a type hole disc, a pin shaft hole of a V-shaped seed pushing rod in a driving disc assembly is movably connected with a pin shaft of the type hole disc, a side cover of the type hole disc is fixedly connected with the type hole disc by virtue of countersunk head screws, a boss on the side cover of the type hole disc covers the top of the pin shaft of the type hole disc, a driving disc shaft of a driving disc in the driving disc assembly is movably connected with a driving disc shaft base of a disc II in an adjustment disc, and the adjustment disc is connected with a left lower vertical plate and an arc plate of the seed box by virtue of adjustment holes through screws. By adopting the type hole volume variable type precision seed metering device disclosed by the invention, the damaging probability of seeds caused by the seed metering device in seed filling, seed cleaning and seed charging processes can be reduced, the volume of type holes generated when the type holes rotate to a seed cleaning area can be changed by adjusting the adjustment disc, and the precision seeding requirements of seeds with a wider size range can be met without changing the type hole disc.

Owner:JILIN UNIV

Subsea pressure relief devices and methods

A device for relieving pressure in a subsea component comprises a housing including an inner cavity, an open end in fluid communication with the inner cavity, and a through bore extending from the inner cavity to an outer surface of the housing. In addition, the device comprises a connector coupled to the open end. The connector is configured to releasably engage a mating connector coupled to the subsea component. Further, the device comprises a burst disc assembly mounted to the housing within the through bore. The burst disc assembly is configured to rupture at a predetermined differential pressure between the inner cavity and the environment outside the housing.

Owner:BP CORP NORTH AMERICA INC +1

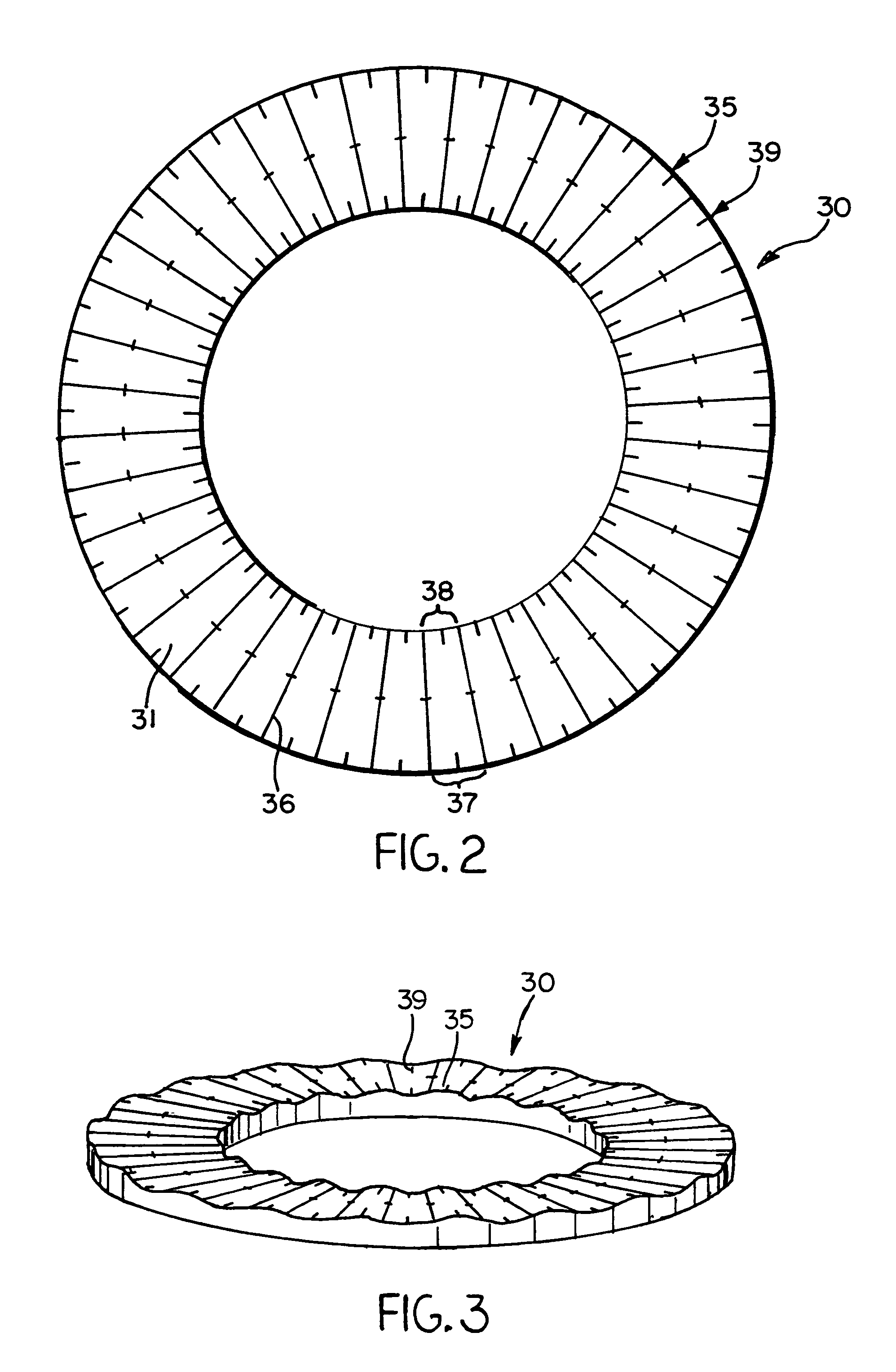

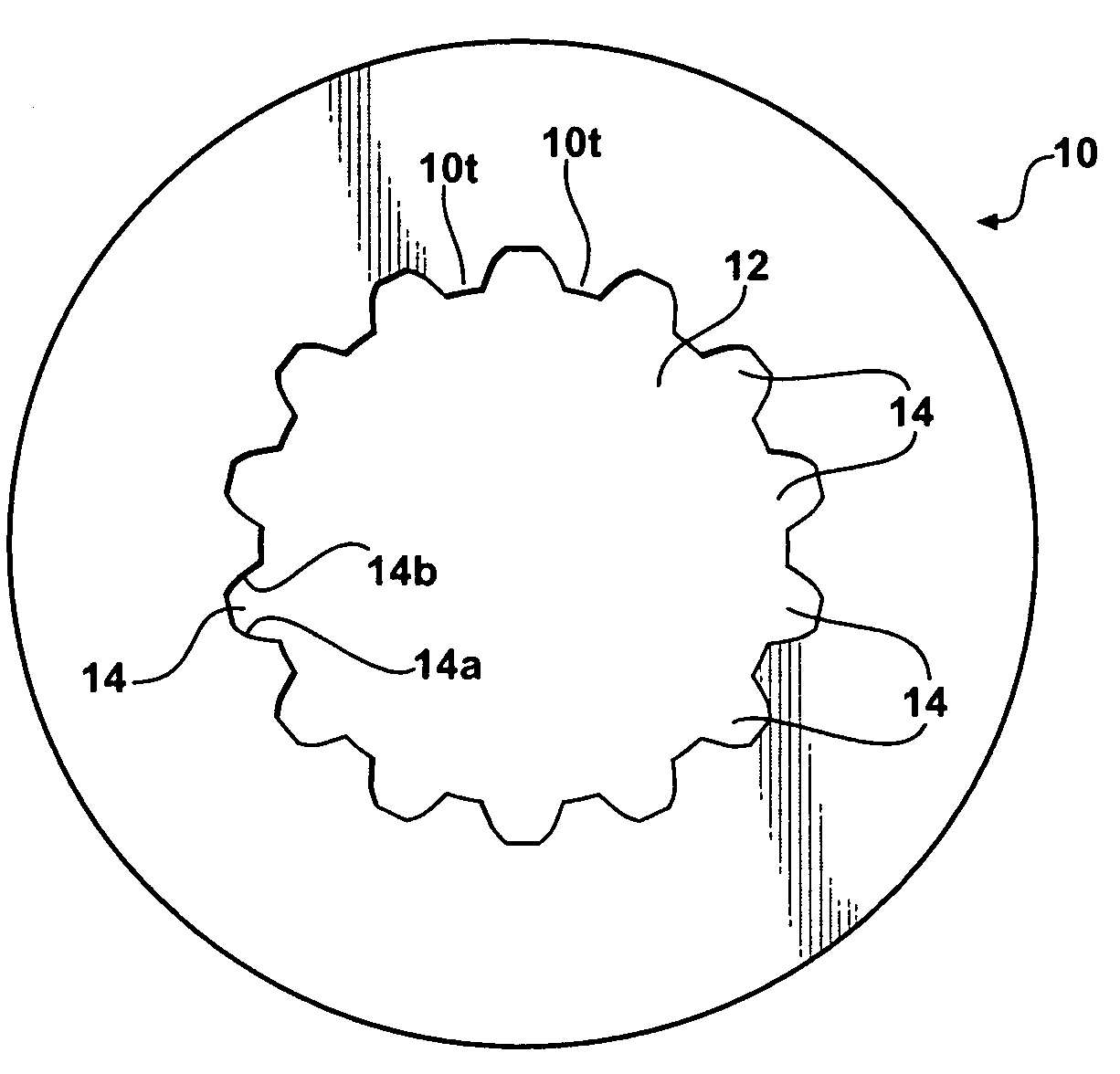

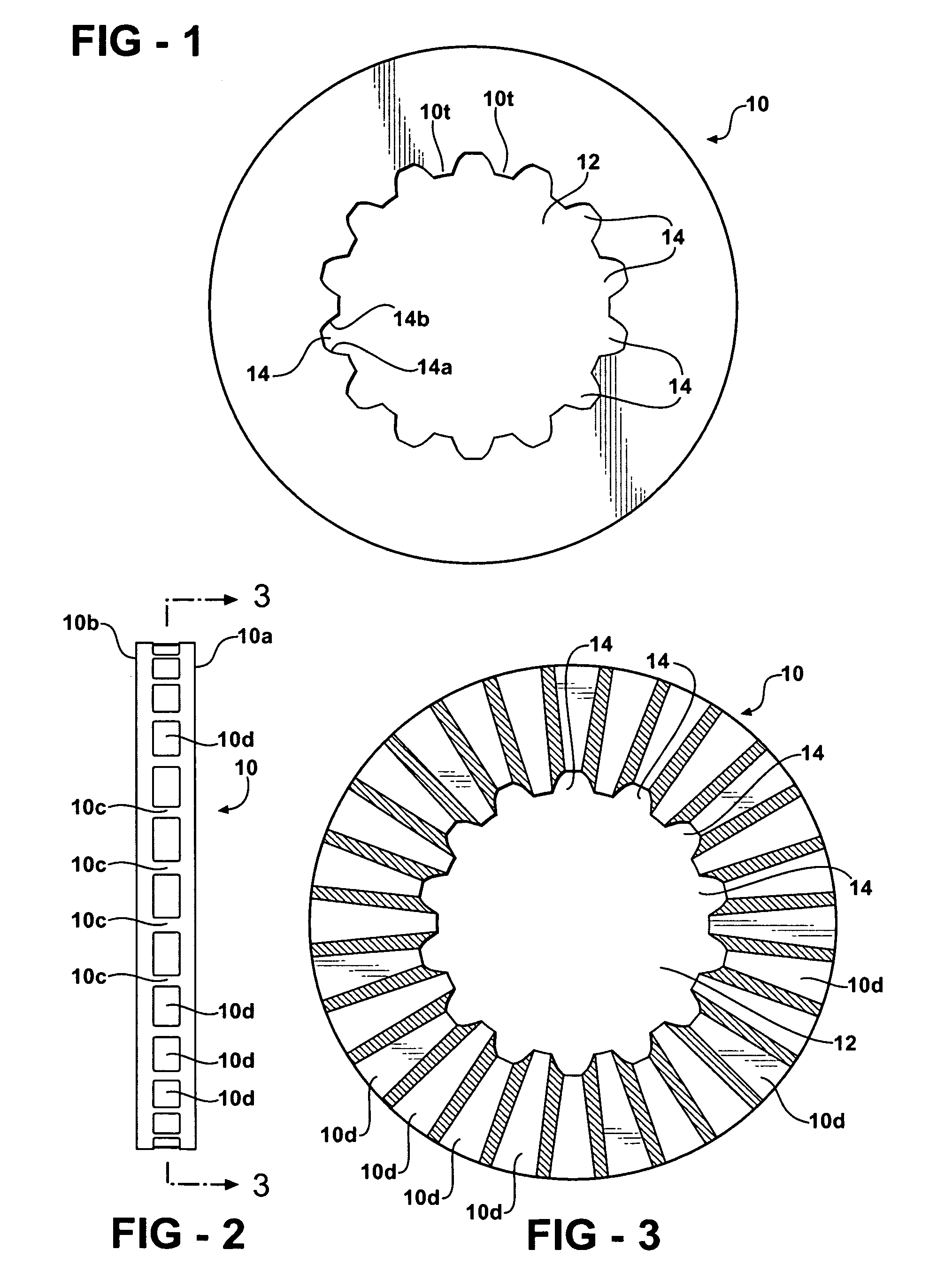

Sectored disc for opener

A sectored disc assembly, removable disc sector, and method of replacing a disc sector are disclosed for use with a soil opener that uses a disc assembly to open the soil prior to injection of a fertilizer or seed into the ground. The sectored disc assembly includes a rotatable hub and a plurality of disc sectors cooperatively forming a substantially continuous disc around the hub. Connectors, such as bolts, secure each of the disc sectors to the hub. The disc sector includes a body with radially inner and outer margins and side margins that are configured for continuous abutment with adjacent side margins of other disc sectors. The method of replacing a disc sector includes removing the connector securing the disc sector to the hub, moving the disc sector radially outwardly away from the hub, placing a replacement disc sector into contact with the hub, and inserting the connector.

Owner:SWANSON GUY J

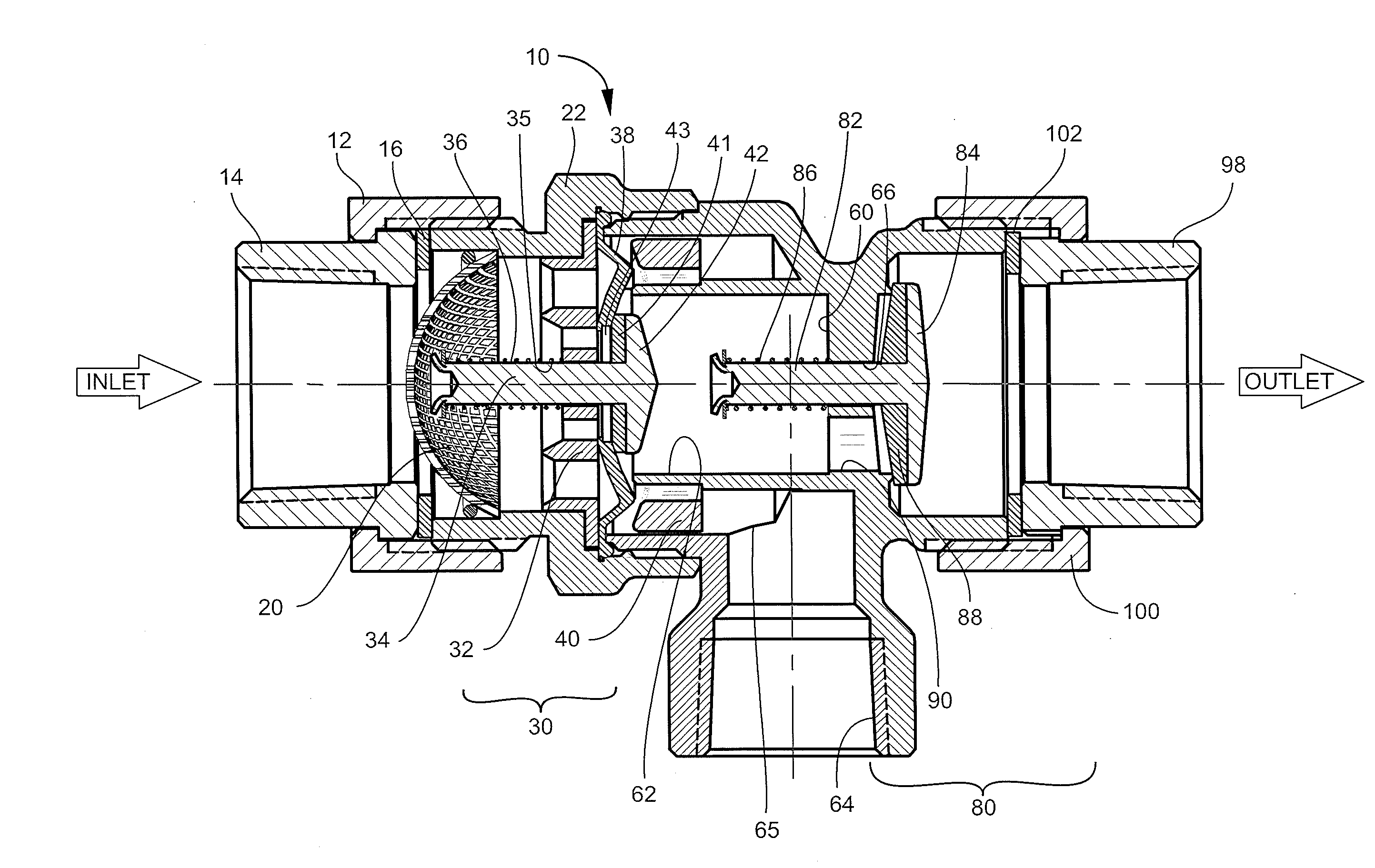

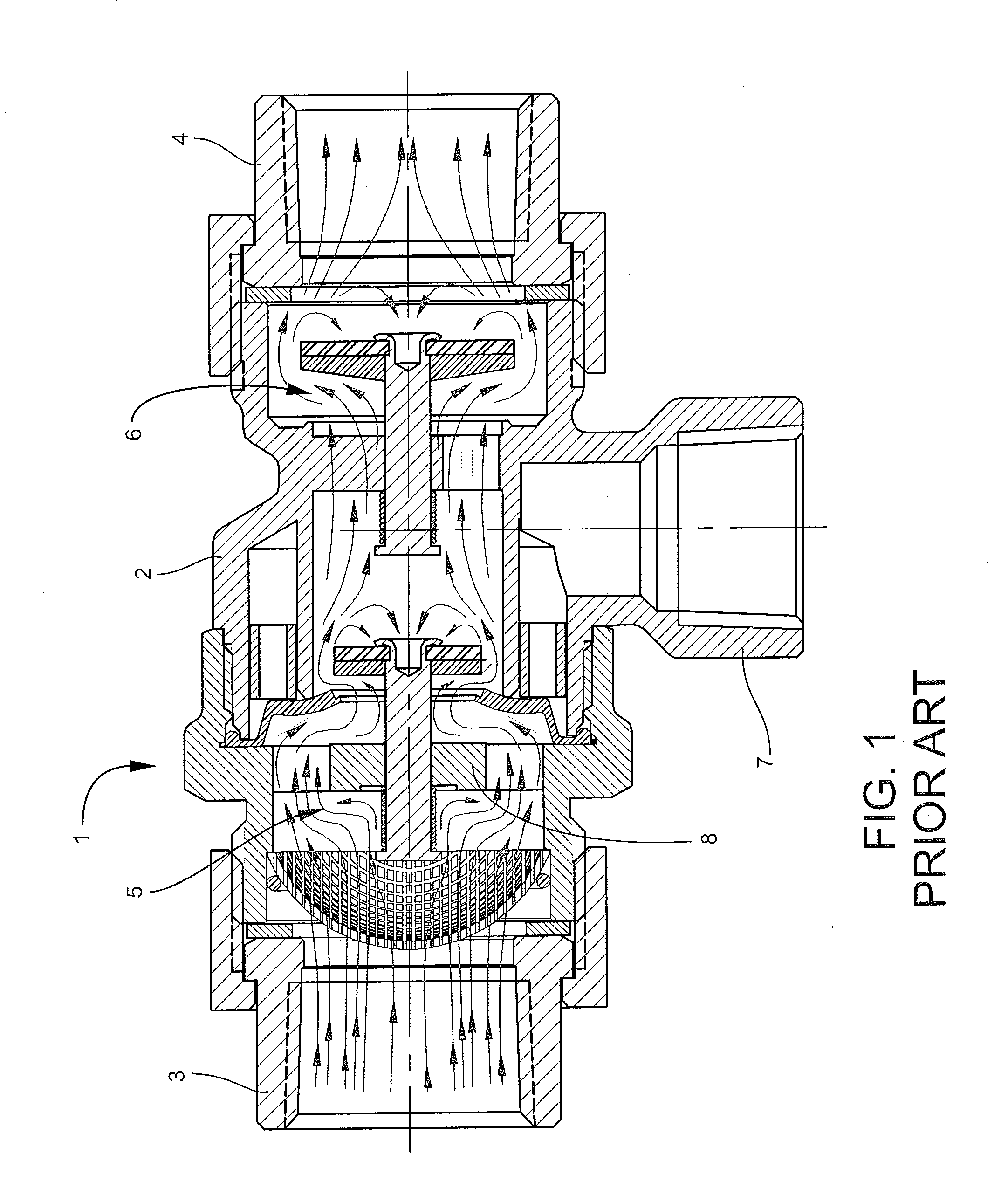

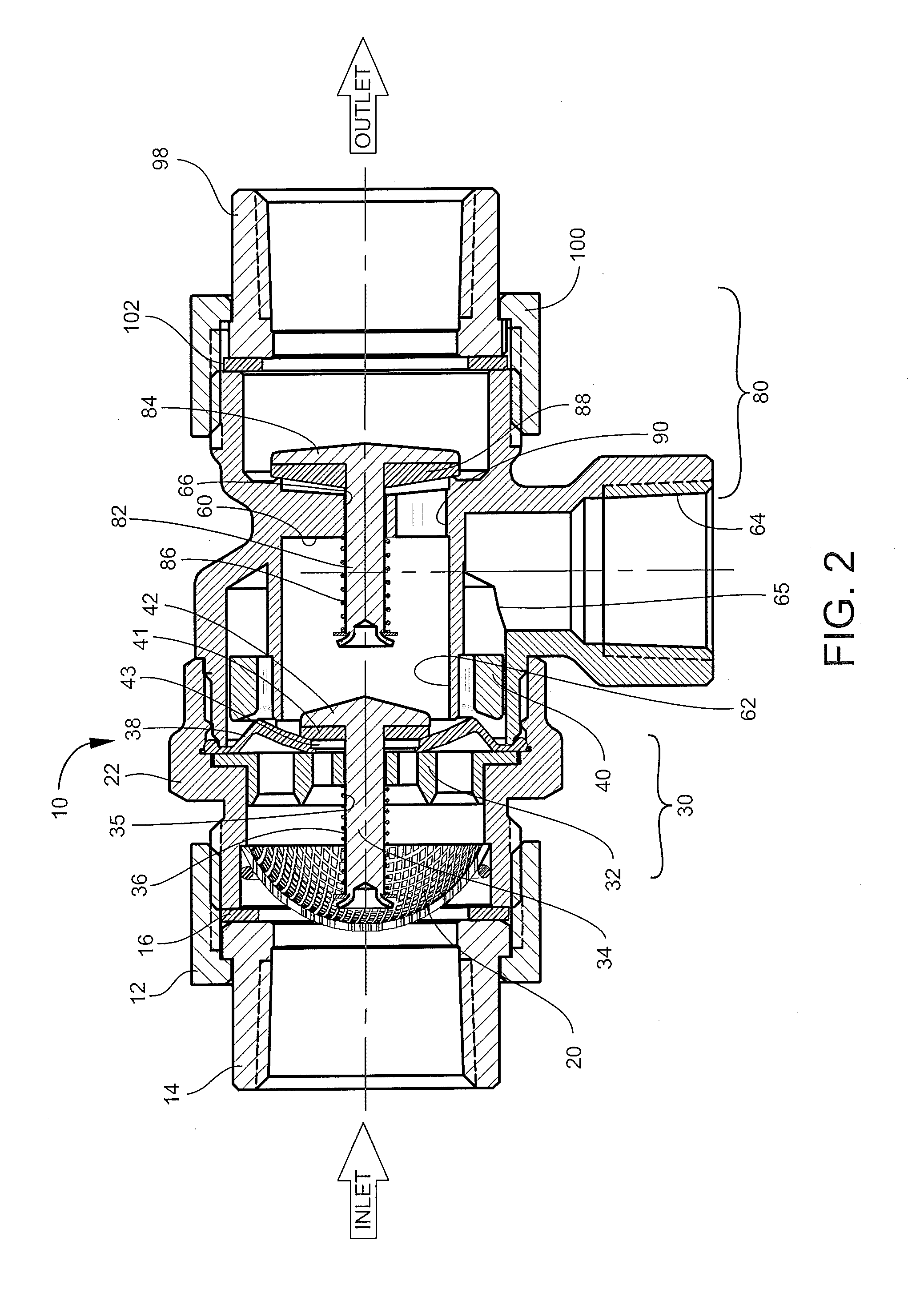

Dual check backflow preventer

ActiveUS20160178076A1Reduce flow turbulenceIncrease pressureCheck valvesDomestic plumbingBackflow prevention deviceEngineering

A backflow preventer that includes a housing having an inlet and an outlet adapted to be mounted in a liquid flow configuration in a liquid supply circuit. An upstream check disc assembly is positioned in the housing downstream of the inlet, and includes an upstream check plate supporting a downstream diaphragm. An upstream check disc is positioned downstream of the diaphragm and integrally formed with an upstream stem mounted in an aperture in a central hub formed in the check plate for movement between a normally open, flow position and a closed position preventing backflow of liquid through the inlet. A downstream check disc assembly is positioned in the housing downstream from the upstream check disc assembly. A vent discharges liquid to atmosphere upstream of the downstream check disc assembly.

Owner:CONBRACO IND

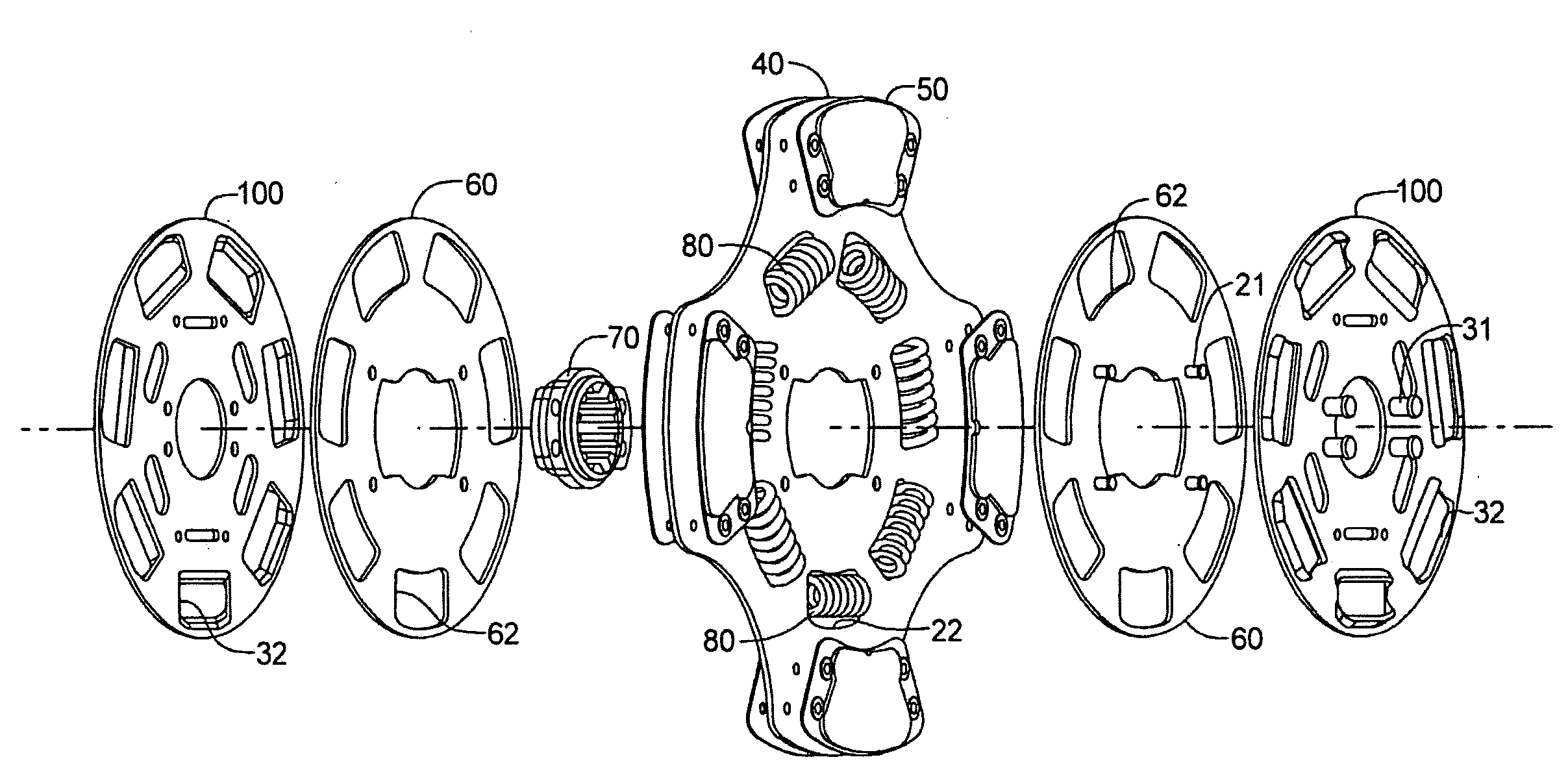

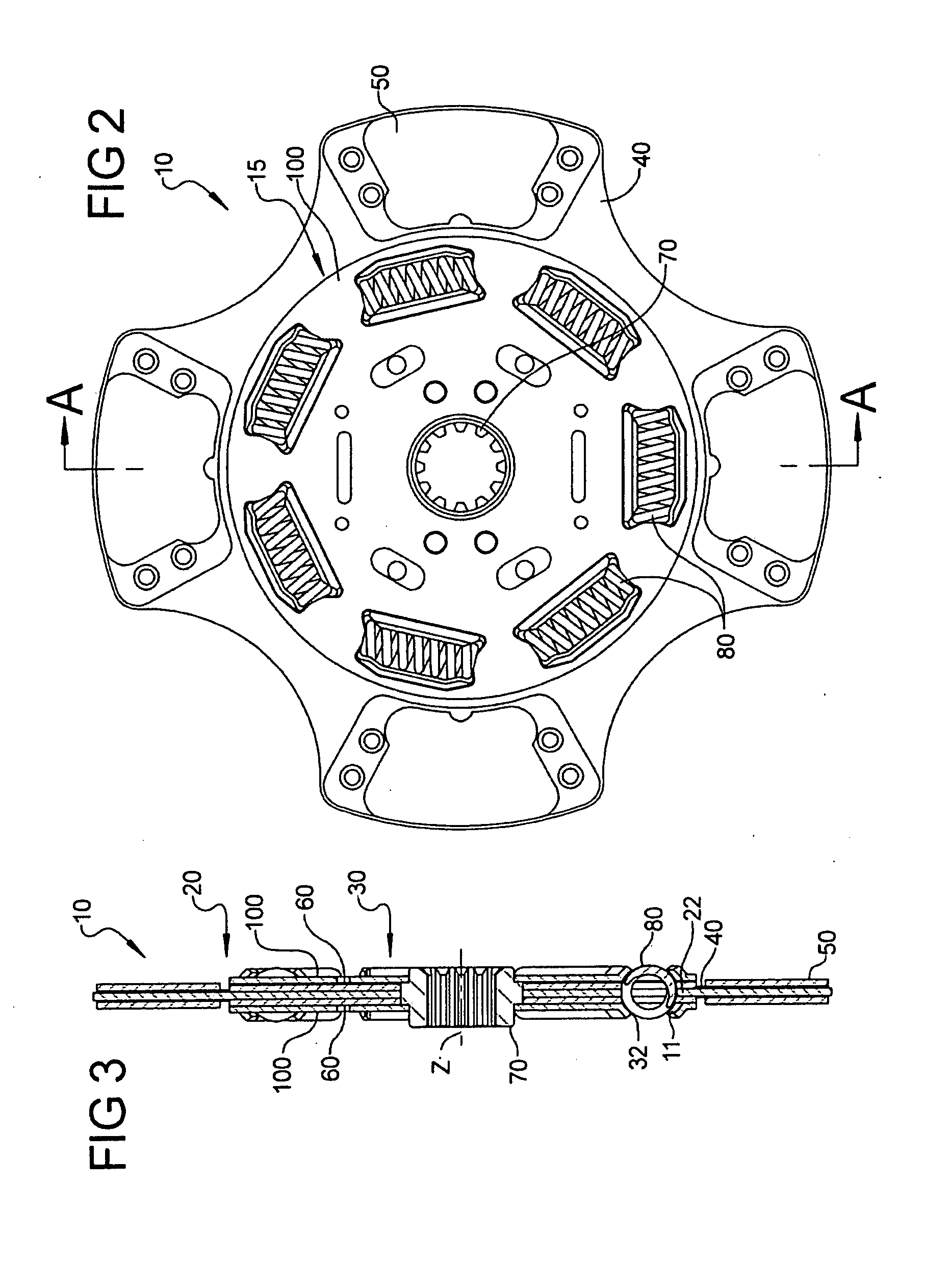

Clutch Damper Spring Pocket Improvement

A torsional damper with a hub assembly and a disc assembly has coil springs disposed therebetween. The coil springs are disposed in pockets defined in part by apertures in opposed cover plates. The apertures have sharply angled end portions providing deflection relief near the ends of the coil springs.

Owner:EATON INTELLIGENT POWER LIMITED

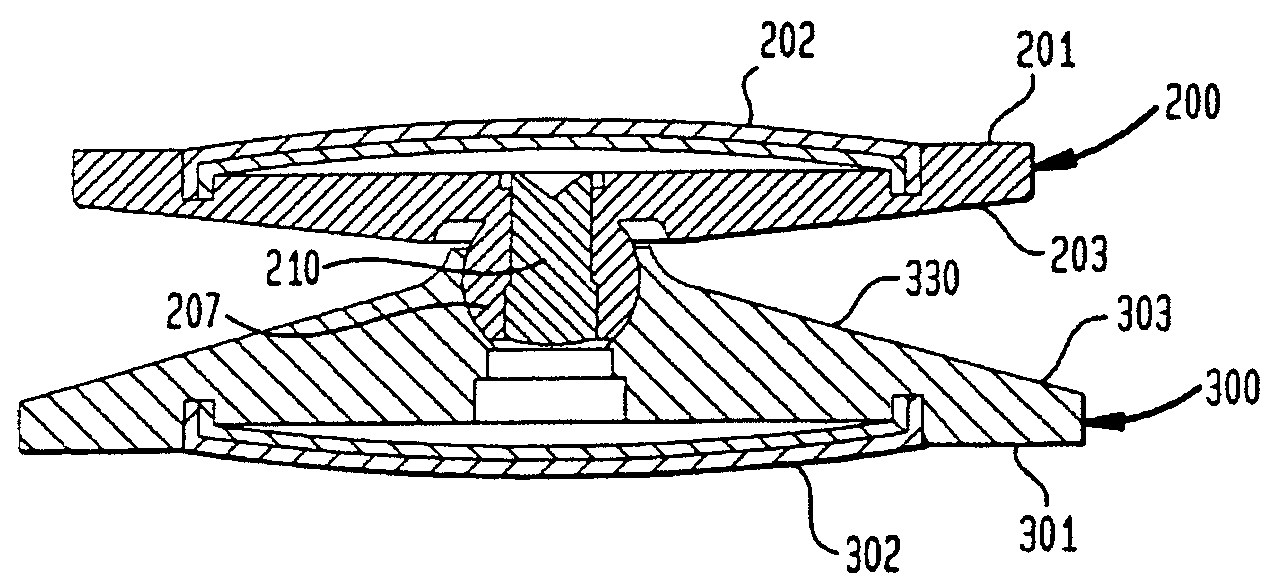

Artificial intervertebral disc utilizing a ball joint coupling

Owner:HOWMEDICA OSTEONICS CORP

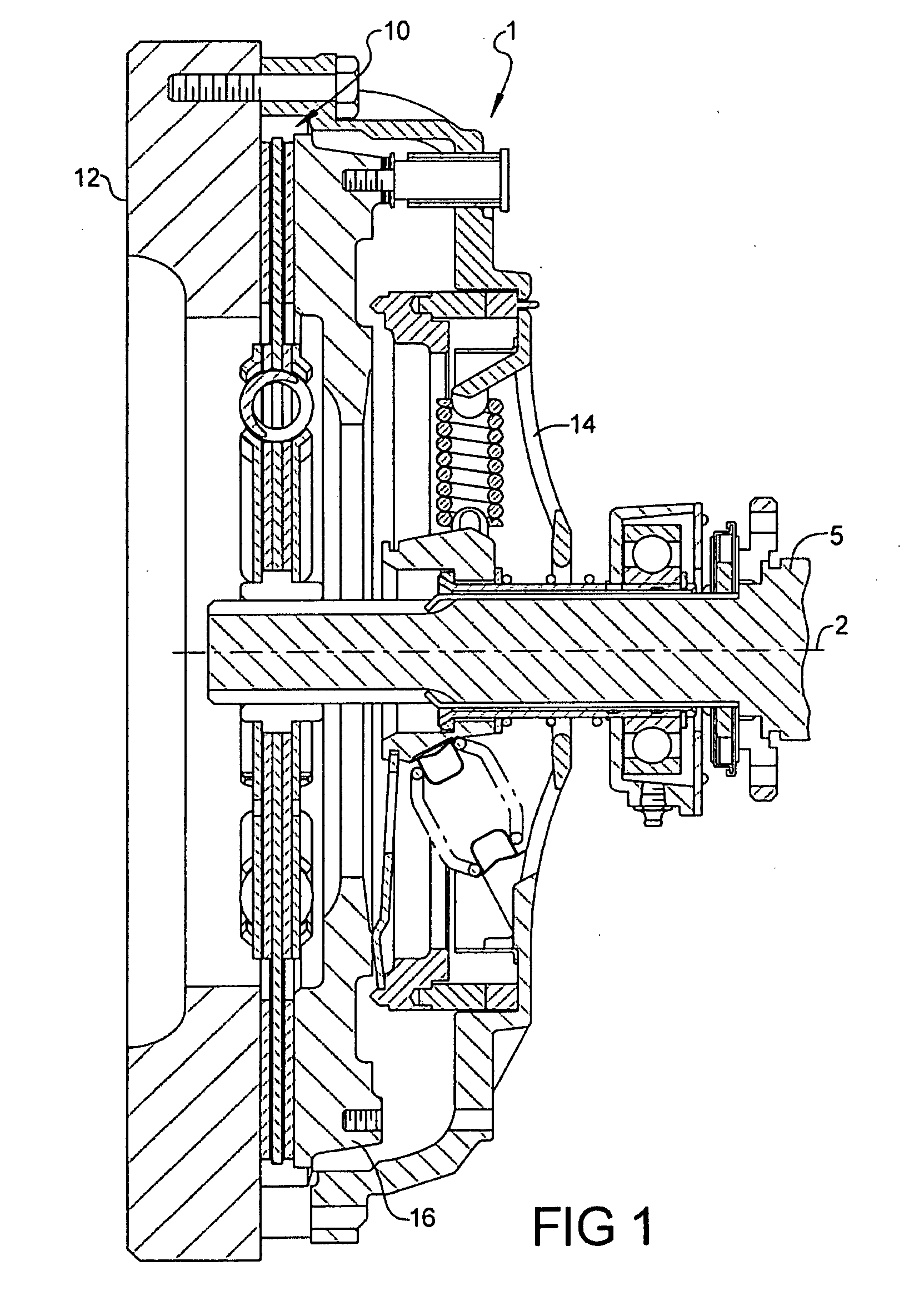

Clutch disc assembly with direct bond ceramic friction material

A clutch disc assembly for a friction torque device has a clutch damper assembly which includes a hub defining an axis of rotation. The damper assembly includes a plurality of cushion elements extending radially outwardly away from the axis of rotation. A first friction ring includes a backer plate fixed to the cushion elements by circumferentially distributed rivets. At least one ceramic friction element is bonded to the backer plate.

Owner:EATON CORP

Magnetic-dielectric assemblies and methods of fabrication

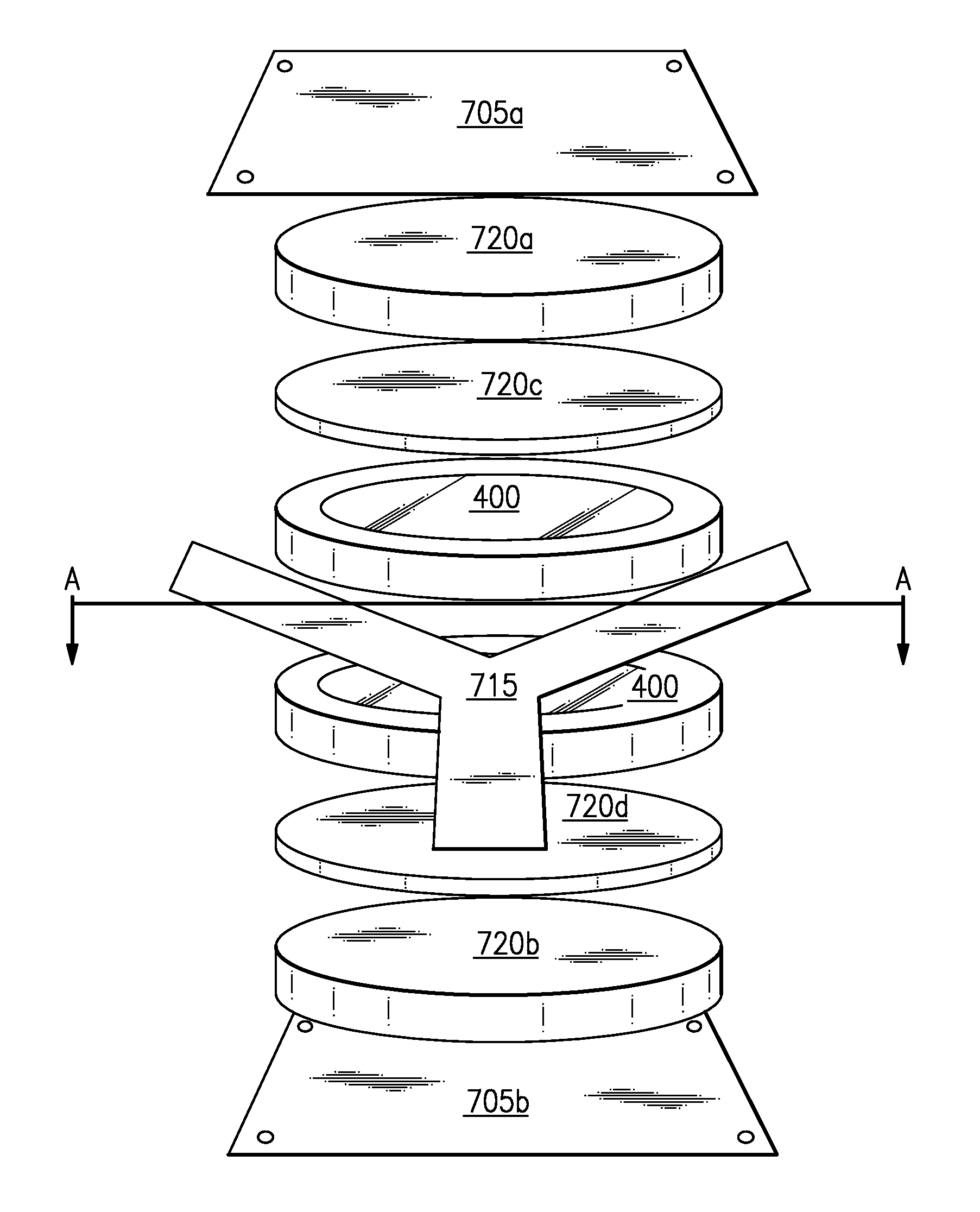

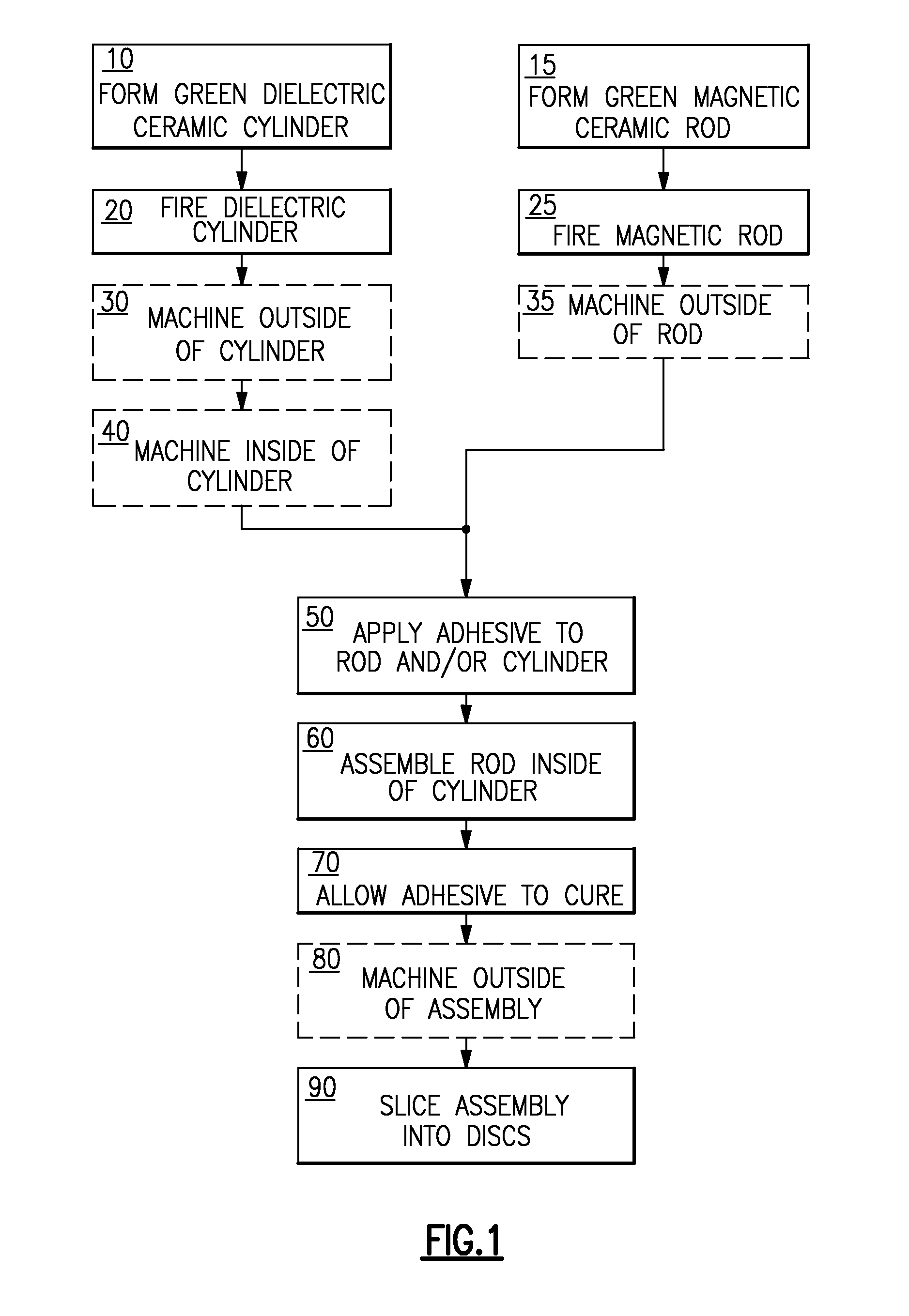

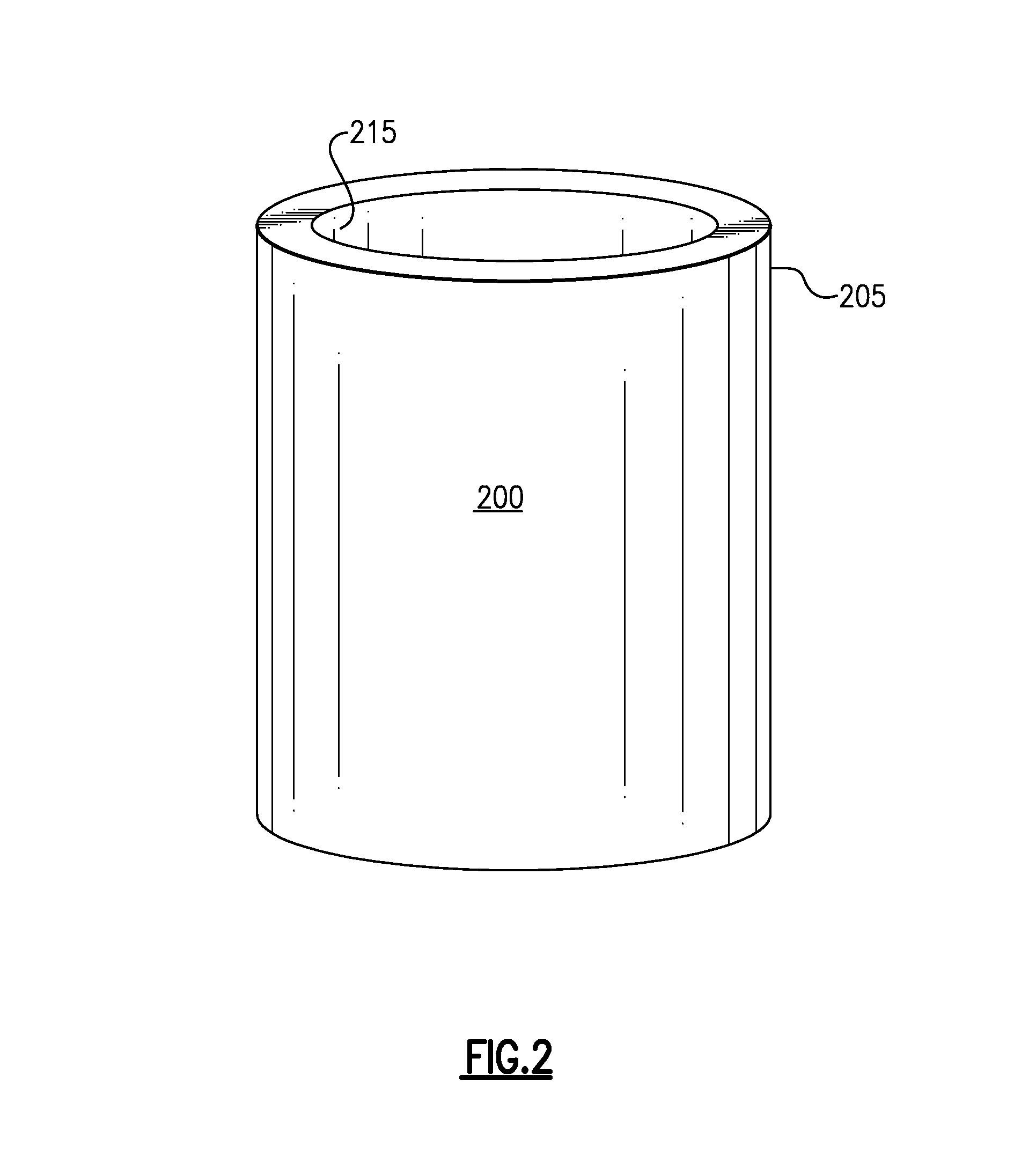

ActiveUS8282763B2Magnetic and electric loss tangentEasy to optimizeLamination ancillary operationsLaminationDielectricAdhesive

A method for making a composite magnetic-dielectric disc assembly includes forming a dielectric ceramic annular cylinder, forming a magnetic ceramic rod, assembling the magnetic ceramic rod coaxially inside the dielectric ceramic cylinder, joining the magnetic ceramic rod to the dielectric ceramic cylinder using an adhesive comprising a ceramic material to form a rod-and-cylinder assembly, and slicing the rod-and-cylinder assembly to form a plurality of composite magnetic-dielectric disc-shaped assemblies. The magnetic-dielectric disc assemblies can be used as components of, for example, circulators, isolators, or similar electrical assemblies.

Owner:ALLUMAX TTI LLC

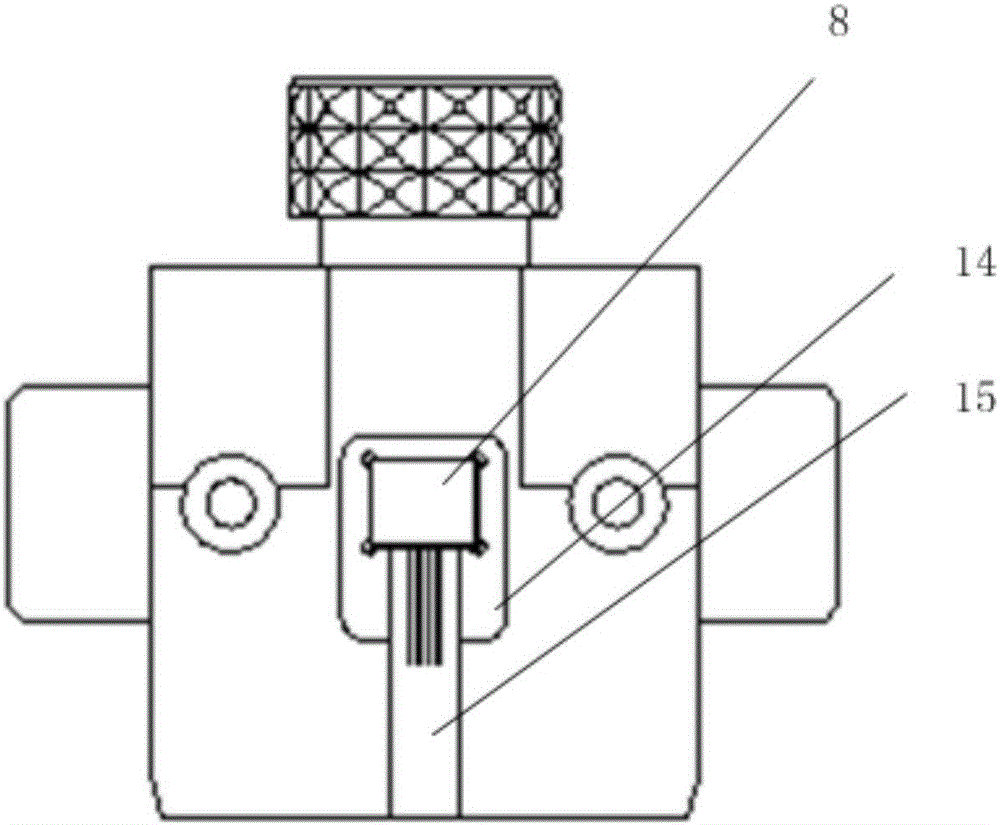

Strain gage pasting device

ActiveCN105065397APlace stableImprove pasting efficiencyFastening meansPulp and paper industryStrain gauge

The invention discloses a strain gage pasting device which is used for pasting a strain gage to a to-be-pasted area. The strain gage pasting device comprises a positioning plate, a compression mechanism and a sucking disc assembly, wherein a strain gage positioning groove and a strain gage line guiding groove are formed in the front end of the positioning plate, and a through hole is formed in the positioning plate and communicated with the strain gage positioning groove; the compression mechanism comprises a pressing plate, a pressing block and a guide column, the guide column is connected to the back end of the positioning plate, the pressing plate is connected to the guide column in a sliding manner, the pressing block is connected to the through hole in a sliding manner, and the back end of the pressing block is connected with the pressing plate; the back end of the pressing block does not exceed the strain gage positioning groove, and a containing hole is formed inside the pressing block; and the sucking disc assembly comprises a vacuum sucking disc, a connecting pipe and a connecting joint, the vacuum sucking disc is fixed to the front end of the containing hole, the connecting joint is fixed to the back end of the containing hole, and a connecting pipe is used for connecting the vacuum sucking disc with the connecting joint and located in the containing hole. By means of the pasting device, the strain gage can be sucked to be accurately pasted into the to-be-pasted area.

Owner:NINEBOT (CHANGZHOU) TECHCO LTD

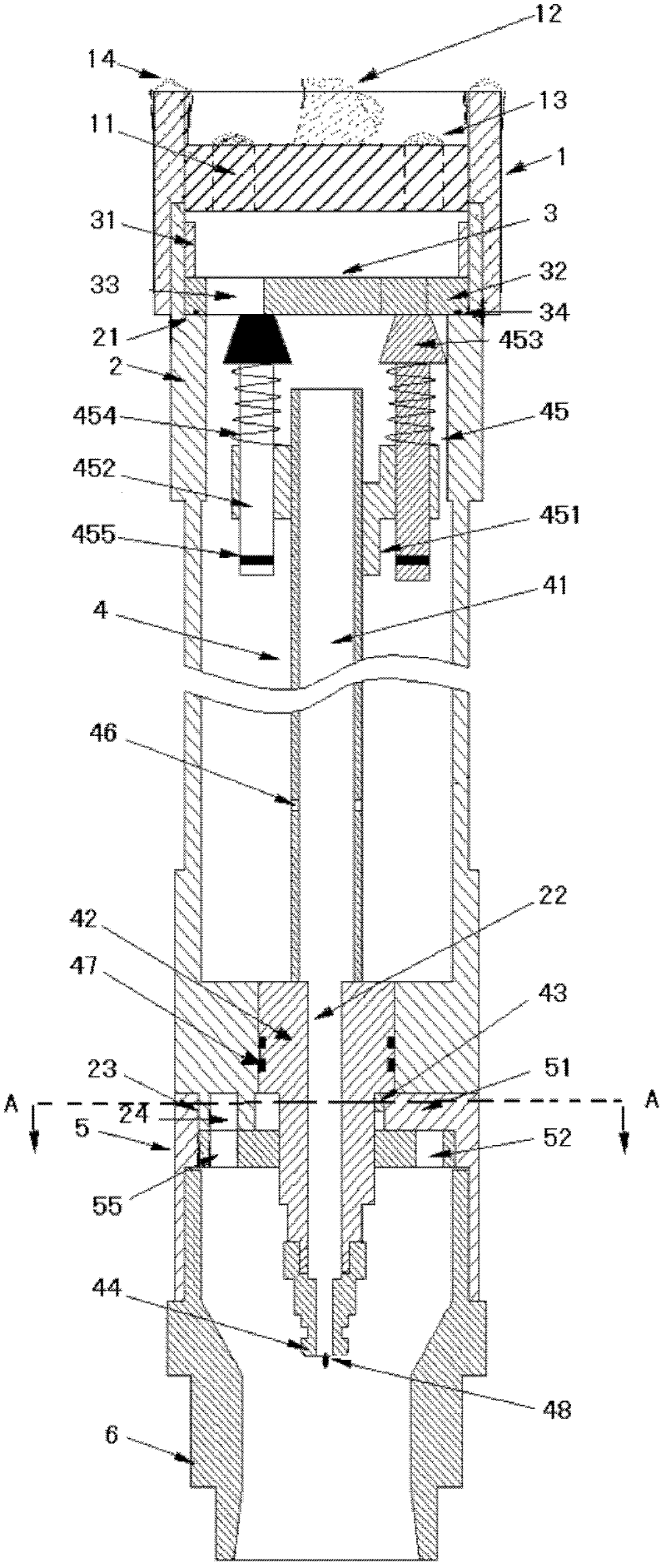

Counter-rotating sealing coal sample sampler and application method thereof

InactiveCN102384860AReduce exposure timeReduce lossesWithdrawing sample devicesDesorptionEngineering

The invention relates to a counter-rotating sealing coal sample sampler and an application method thereof; the sampler of the invention comprises a combined drill, a coal sample cylinder, a sealing disc assembly, a sealing shaft assembly, a hole-sealing drive-plate assembly and a diameter-variable joint; The combined drill is connected with the upper end of the coal sample cylinder; a pressure plate of the sealing disc assembly presses a sealing disc on a concave plateform of the coal sample cylinder; a coal inlet is disposed on the sealing disc; a sealing sleeve of the sealing shaft assemblyis connected inside a through hole of the coal sample cylinder; a drive plate of the hole-sealing drive-plate assembly drives the coal sample cylinder to rotate by cooperating with a drive block at the bottom of the coal sample cylinder; a arc-shaped key groove drives the sealing shaft assembly to rotate by cooperating with a drive block on the sealing sleeve; the whole sampler is connected to a drilling rod by the diameter-variable joint; when the drilling machine performs counter-rotation, a sealing head enters the coal inlet of the sealing disc to complete coal sample sealing; gas in the coal sample enters a gas desorption device through a rapidly-connected device at the end of the sealing shaft assembly, and an underground on-site gas desorption test is performed. The sampler of the invention is widely applicable to determination and detection of coal mine coal seam gas content.

Owner:NORTH CHINA INST OF SCI & TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com