Counter-rotating sealing coal sample sampler and application method thereof

A sampler and coal sample technology, applied in the direction of sampling devices, etc., can solve the problems of coal seam gas content measurement error, gas loss, softness and other problems, and achieve accurate determination of gas content, reduction of gas loss, and reduction of gas loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. For ease of description, "up" and "down" hereinafter are consistent with the up and down directions in the accompanying drawings, but during use, the device is used horizontally, and the direction of "up" is towards the coal seam.

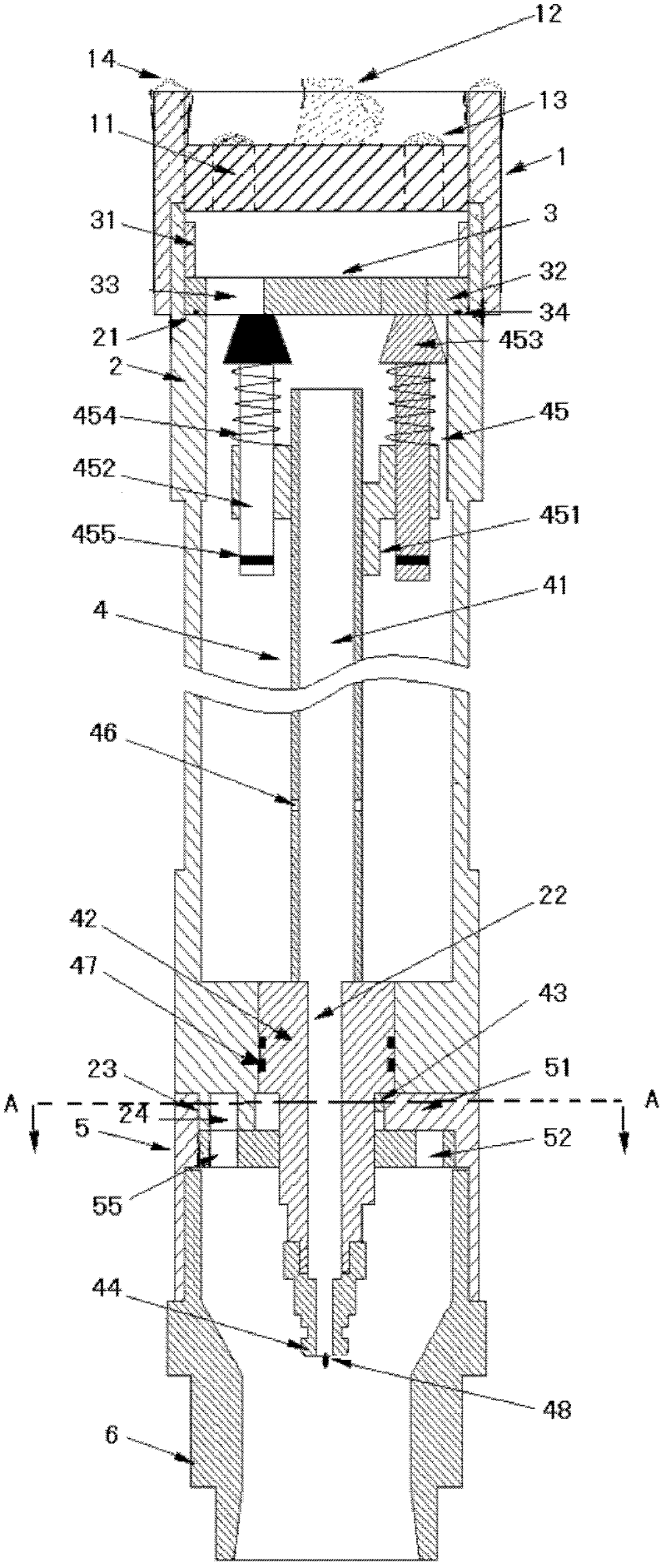

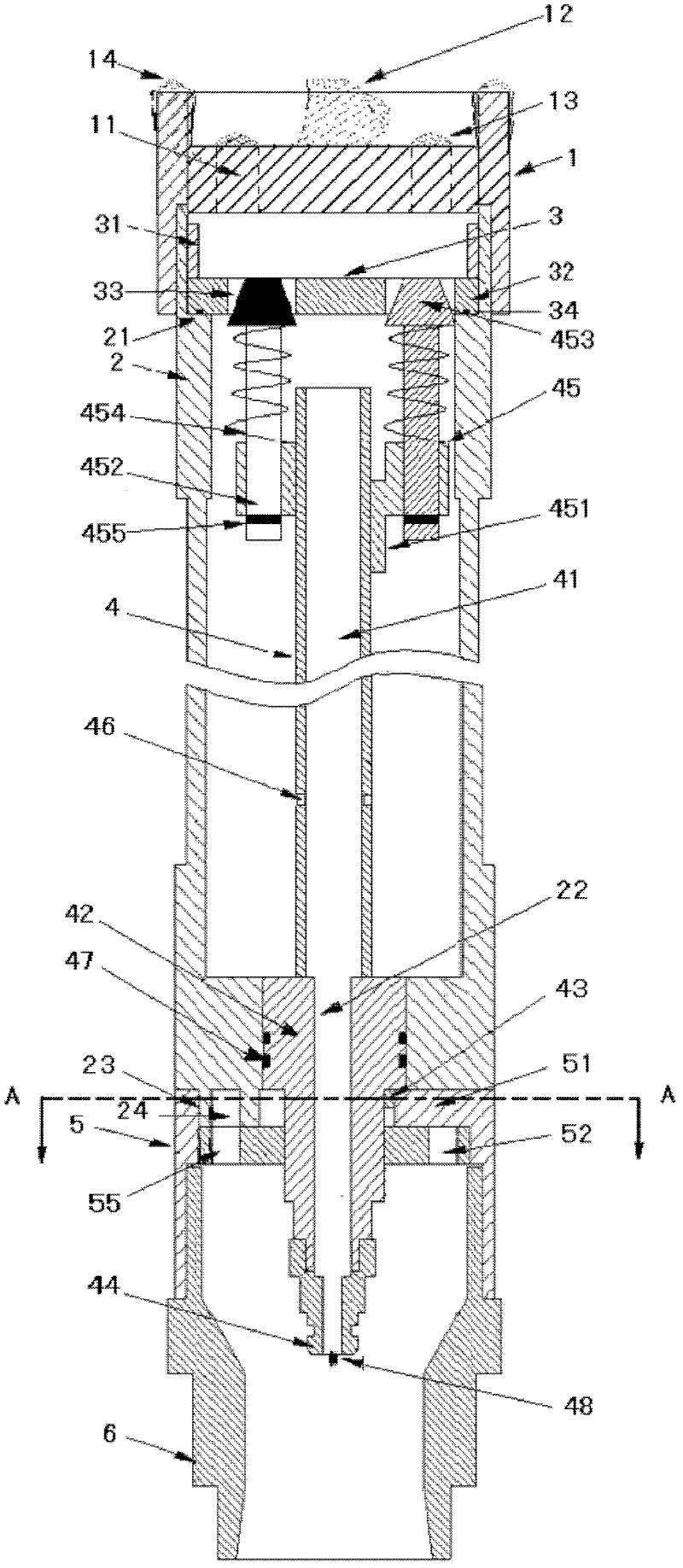

[0017] Such as figure 1 As shown, the sampler of the present invention includes a combined drill bit 1 , a coal sample cylinder 2 , a sealing disc assembly 3 , a sealing shaft assembly 4 , a sealing dial assembly 5 and a reducing joint 6 .

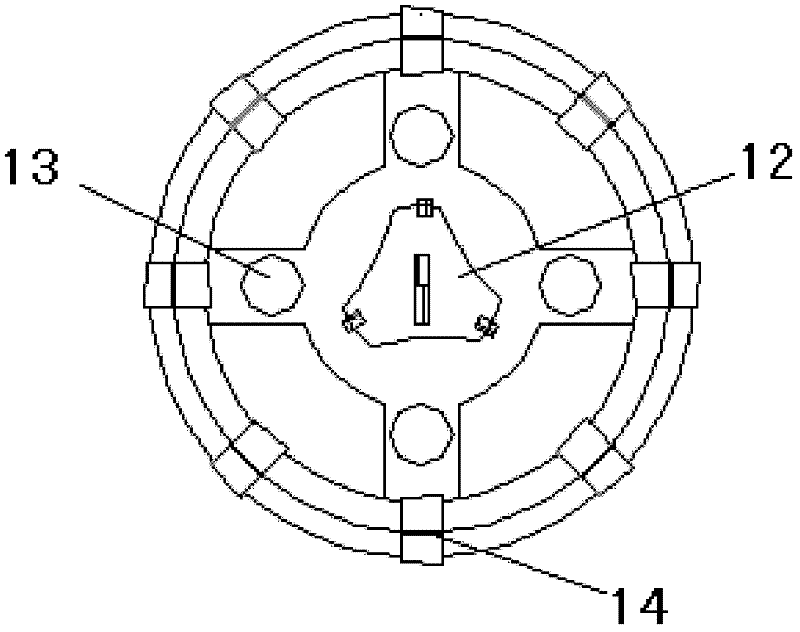

[0018] Such as figure 1 , image 3 As shown, the combined drill bit 1 of the present invention comprises a cylindrical drill seat 11, a central drill bit 12 is arranged at the center of the drill seat 11, and four holes are evenly arranged on the same circumference of the drill seat 11 with the central drill bit 12 as the center. Small drill bits 13 are evenly arranged with eight smal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com