Patents

Literature

193results about How to "Improve pasting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

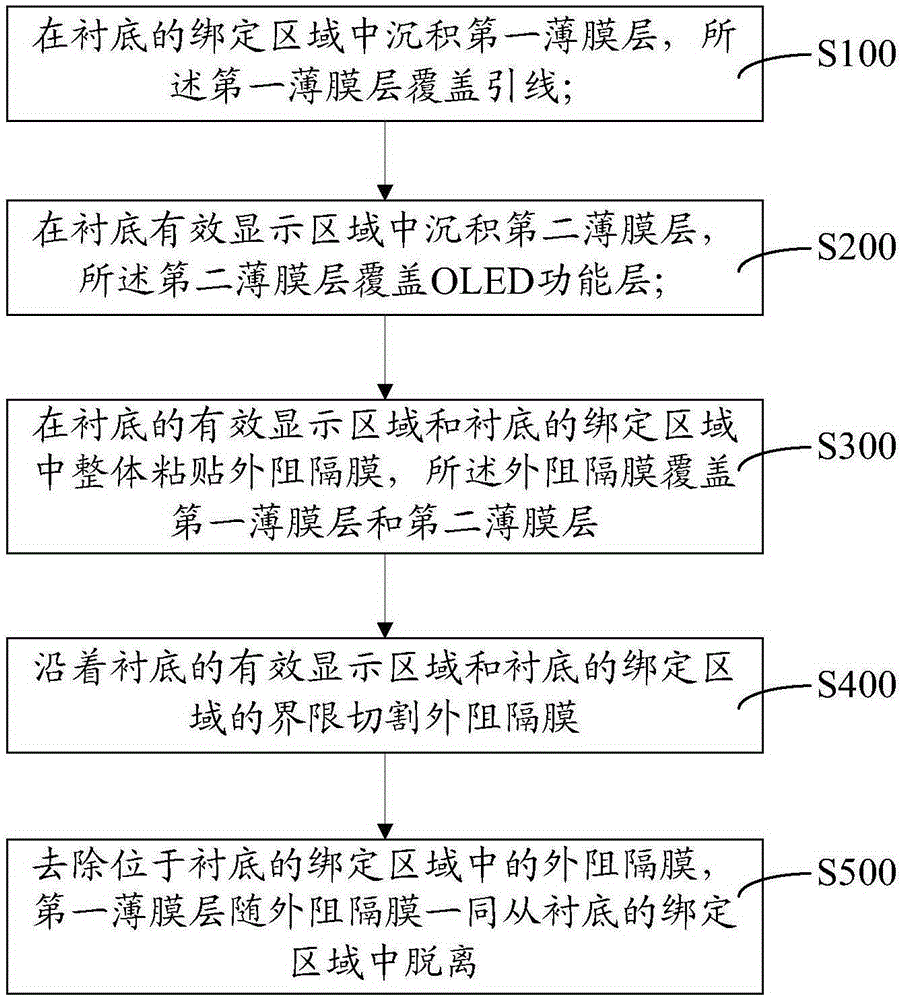

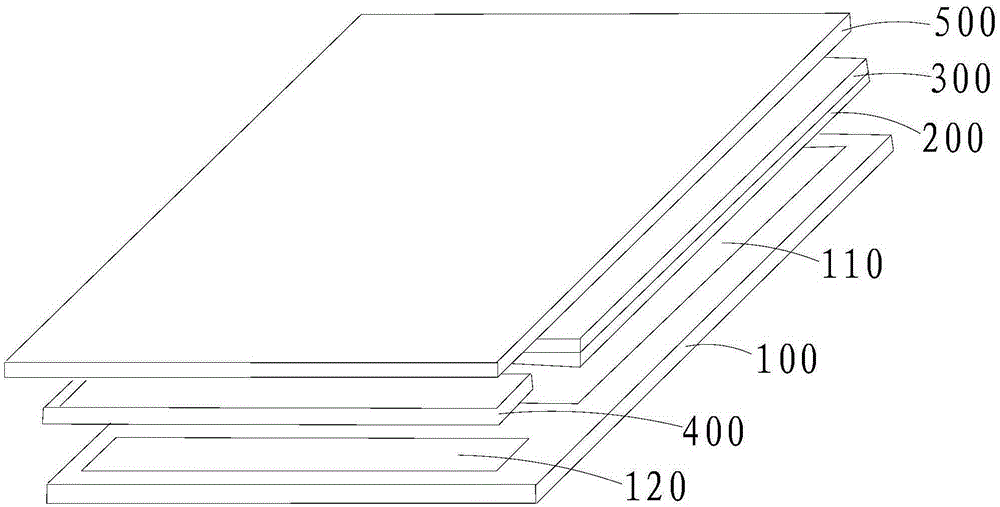

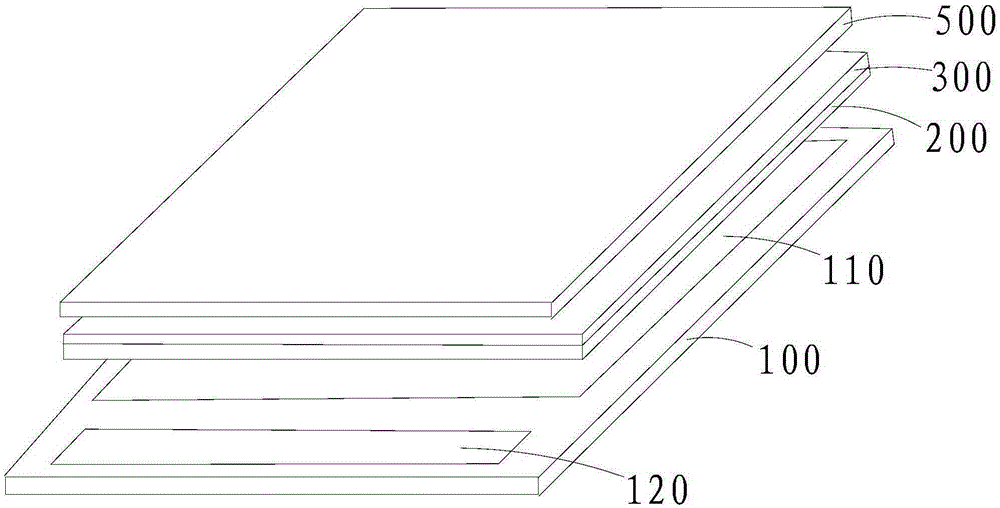

Packaging method of OLED (organic light emitting diode) display panel

ActiveCN105322104AImprove production efficiencyExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeSeparation process

The invention discloses a packaging method of an OLED (organic light emitting diode) display panel. The method comprises the following steps: depositing a first film layer in a binding area of a substrate, wherein the first film layer covers a lead; depositing a second film layer in an effective display area of the substrate, wherein the second film layer covers an OLED functional layer; integrally adhering an outer obstruction film in the effective display area of the substrate and the binding area of the substrate, wherein the outer obstruction film covers the first film layer and the second film layer; cutting the outer obstruction film along a boundary of the effective display area and the binding area of the substrate; and removing the outer obstruction film in the binding area of the substrate, wherein the first film layer is separated from the effectively display area along with the obstruction film. The outer obstruction film is adhered in an integral pasting manner, so that the adhesion efficiency and adhesion precision of the outer obstruction film are effectively improved, damage on the lead in the binding area during the separation process of the outer obstruction film is avoided, the service life of the OLED display panel is prolonged, and the application safety is improved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

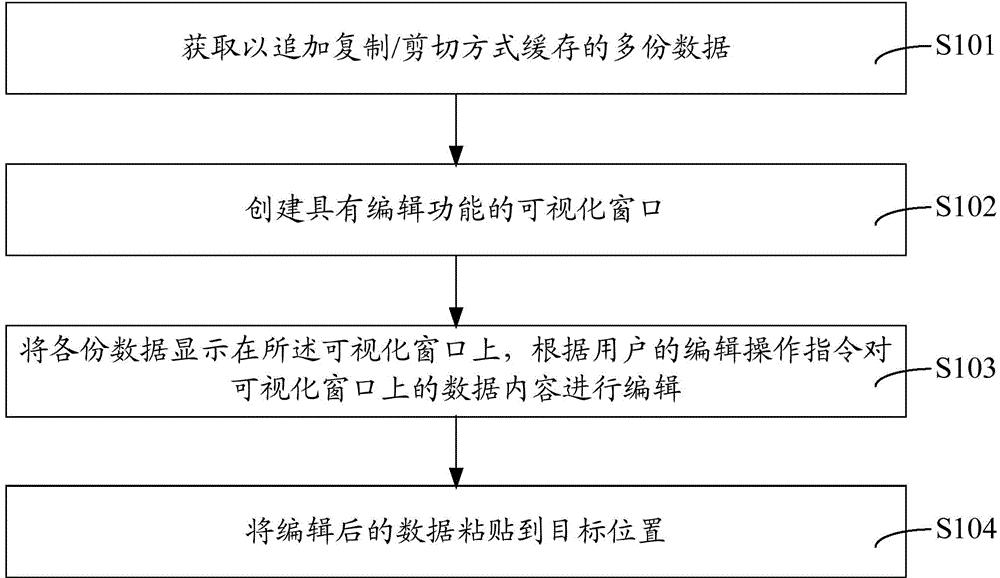

Method and system for copying/ cutting and pasting data

ActiveCN105302784ARealize visual displayEasy to viewSpecial data processing applicationsData displayComputer graphics (images)

The invention discloses a method for copying / cutting and pasting data. The method comprises the following steps: obtaining multiple pieces of data which is cached in an appending copying / cutting way; creating a visual window with an editing function; displaying each piece of data on the visual window, and editing data contents on the visual window according to an editing operation instruction of a user; and pasting the edited data to a target position. The scheme of the invention also provides a system for copying / cutting and pasting data. The scheme of the invention obtains multiple pieces of data cached in the appending copying / cutting way, after the visual window with the editing function is created, each piece of data is displayed on the visual window, and data visualization can be realized so as to bring convenience for users to check whether wrong appending or missing appending exists or not. According to the editing operation instruction of the user, the data contents on the visual window can be edited and pasted to a target position. Therefore, appended data can be processed before the data contents are pasted, and copying / cutting and pasting efficiency can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

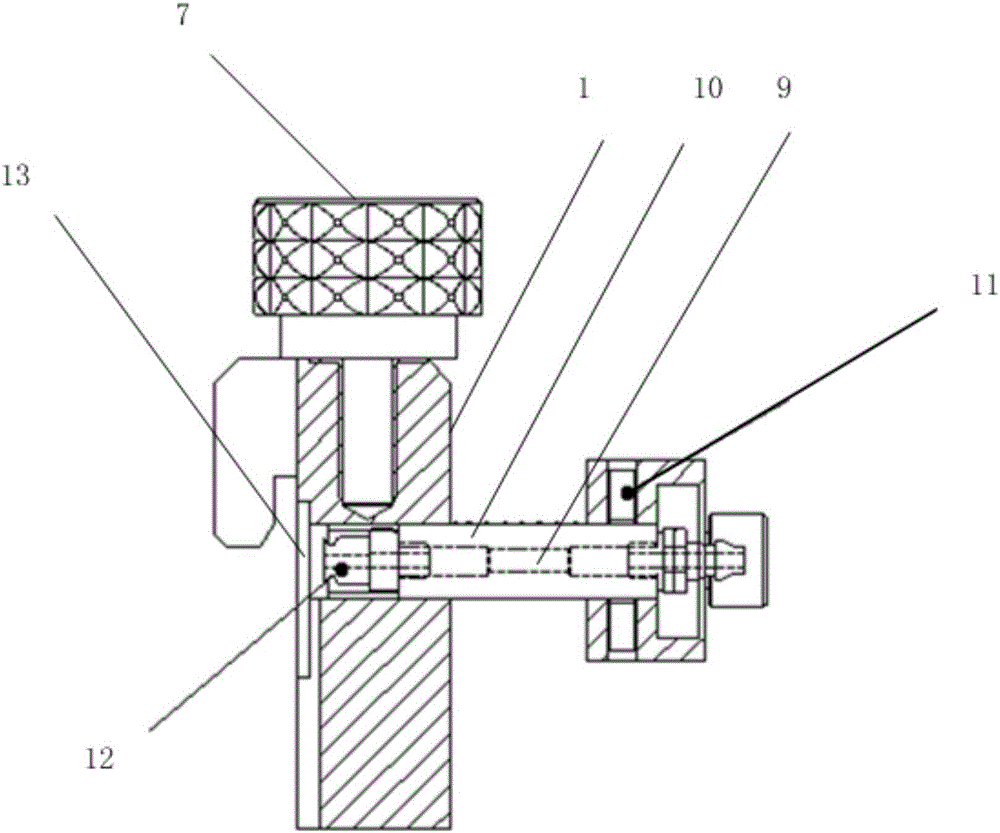

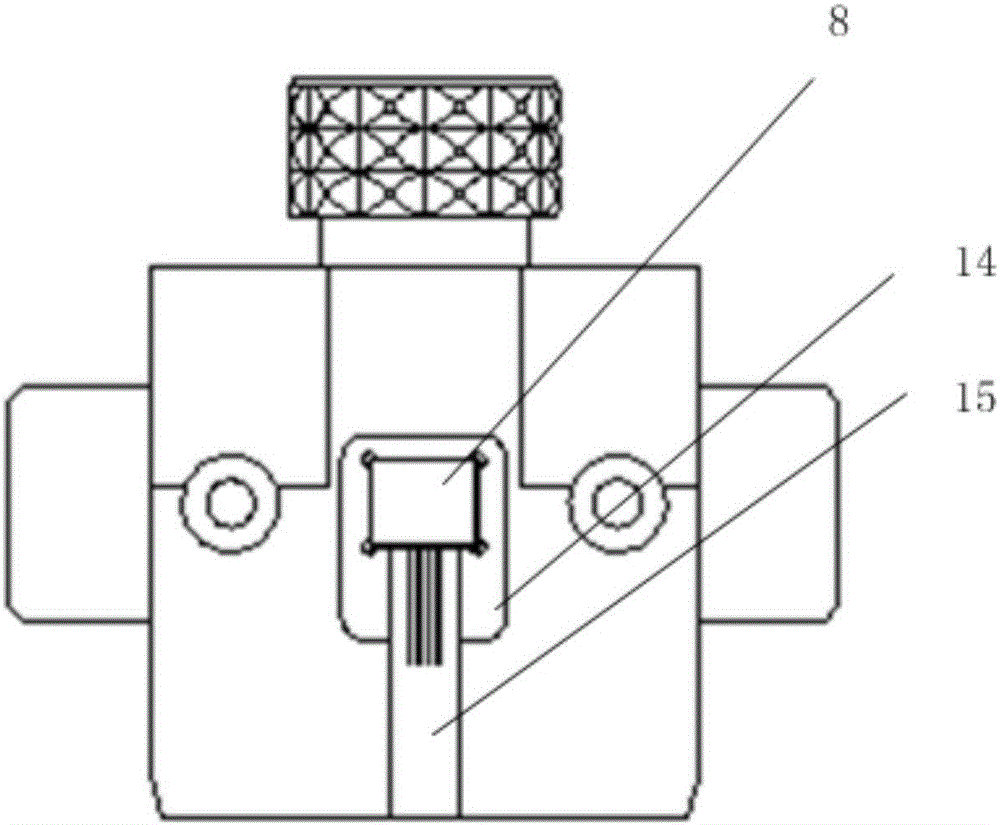

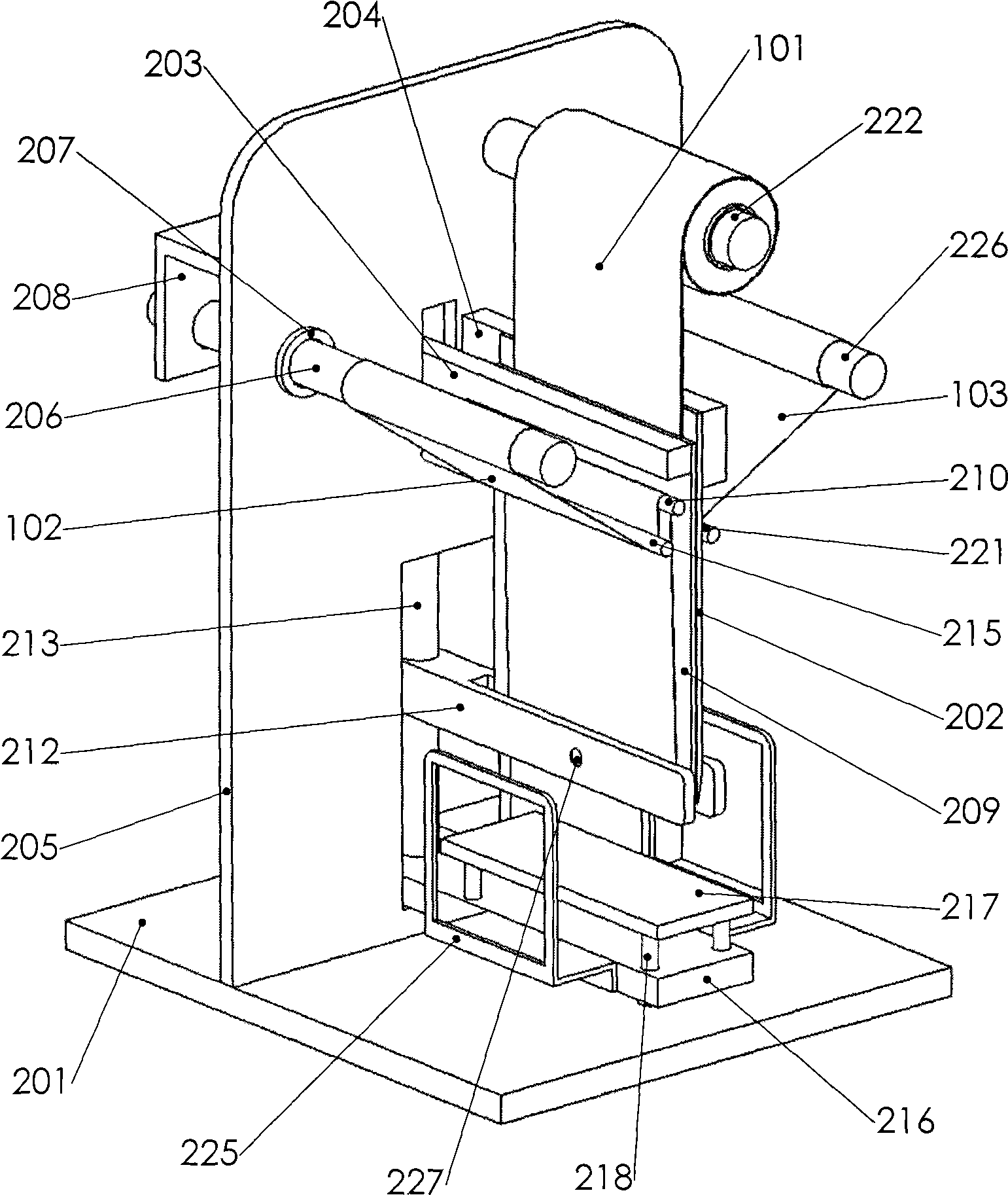

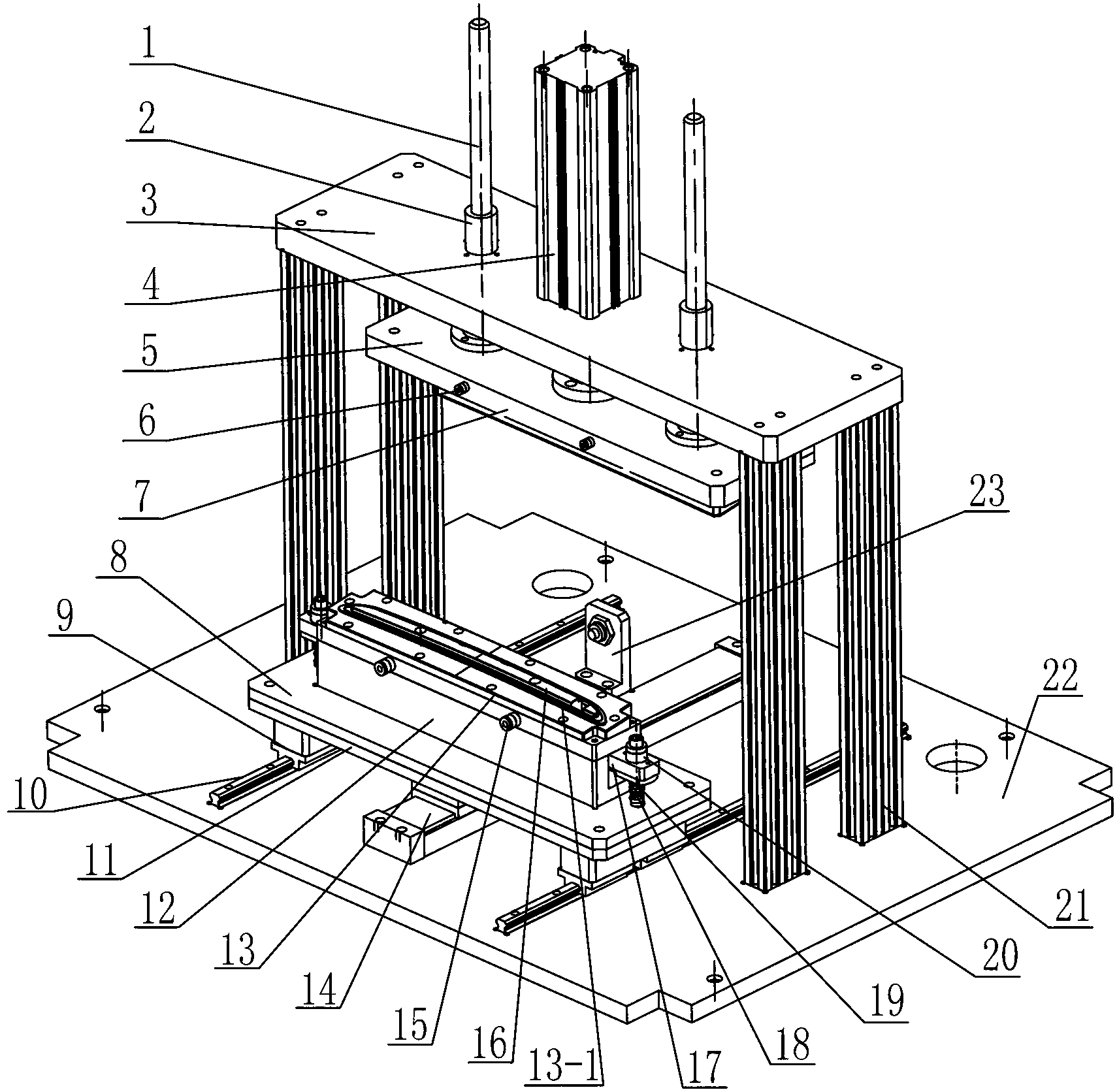

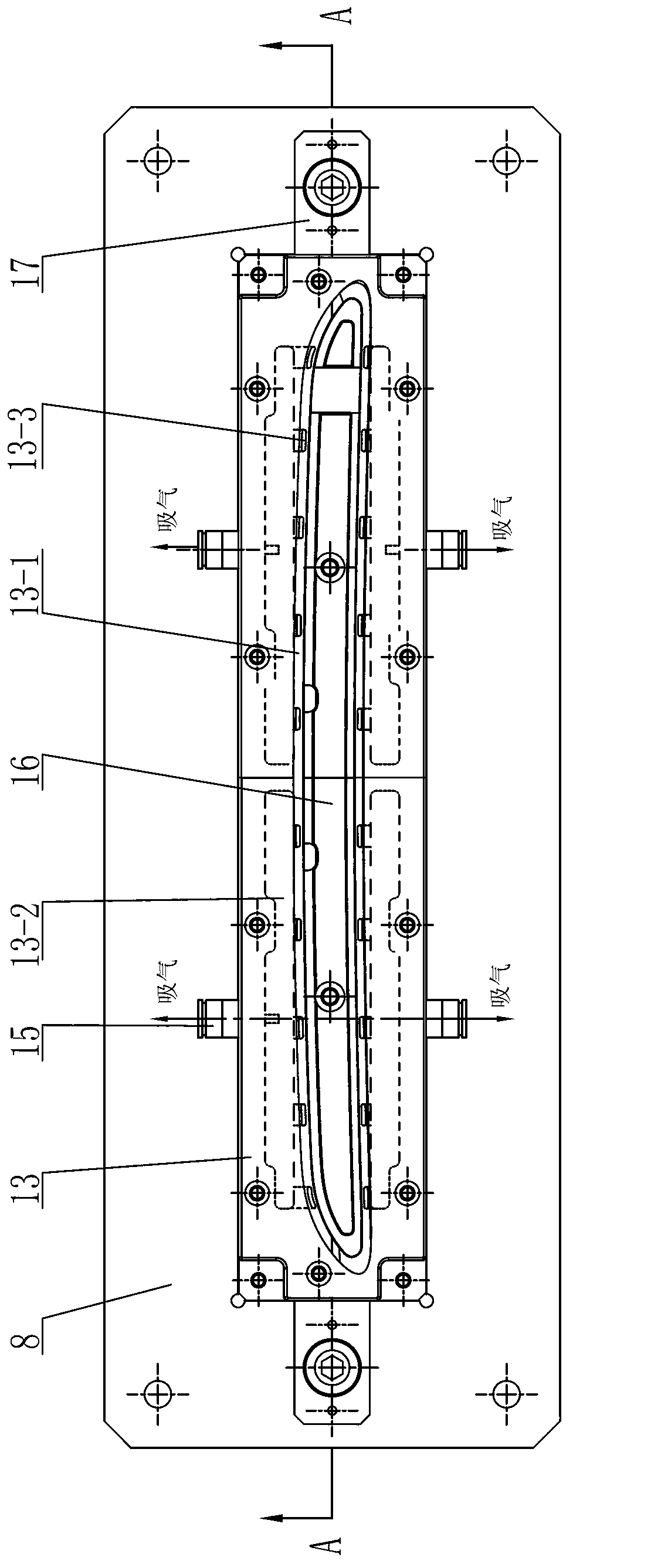

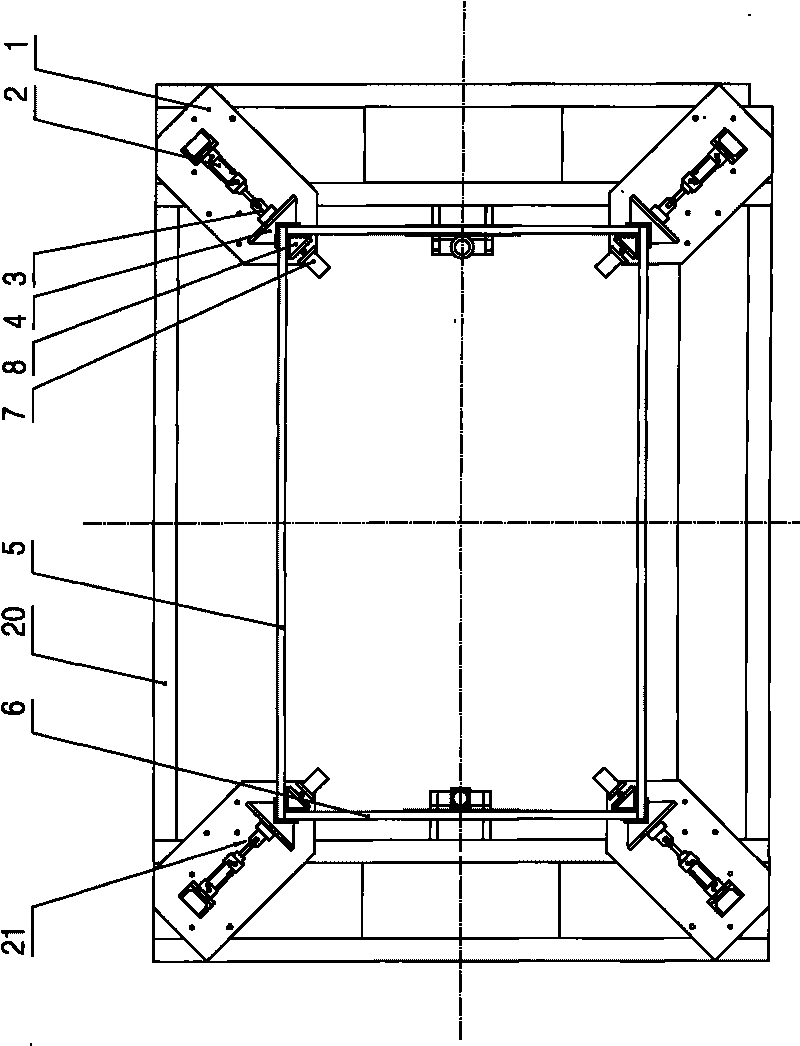

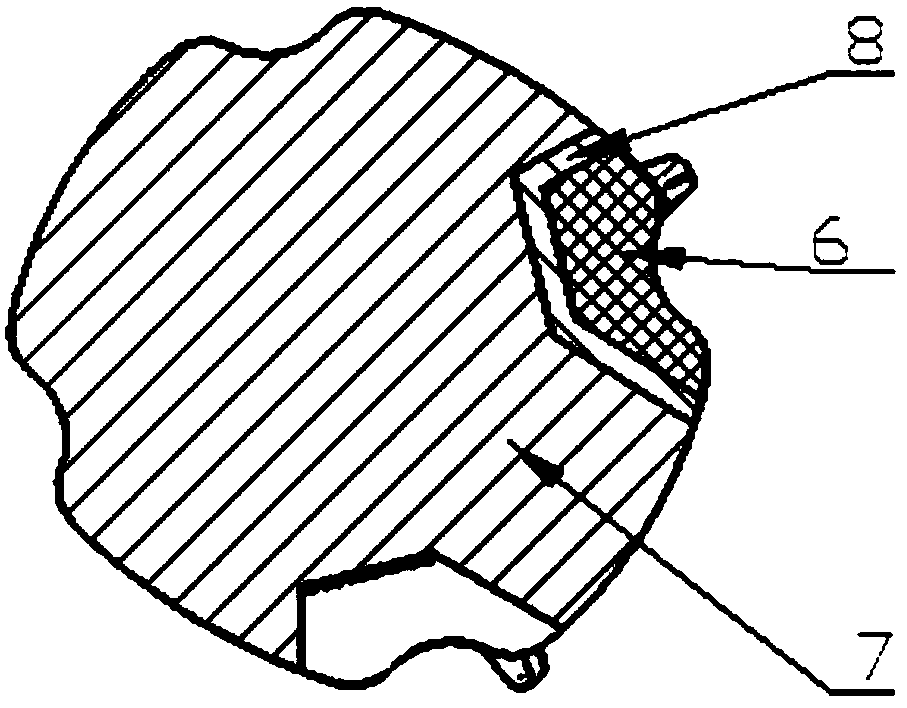

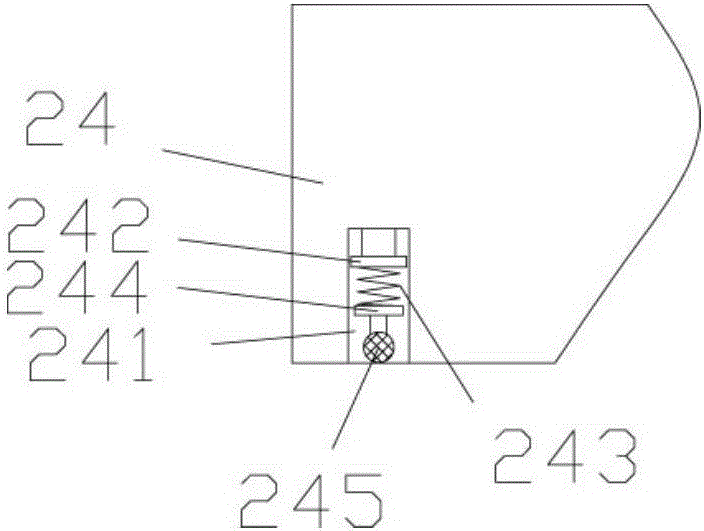

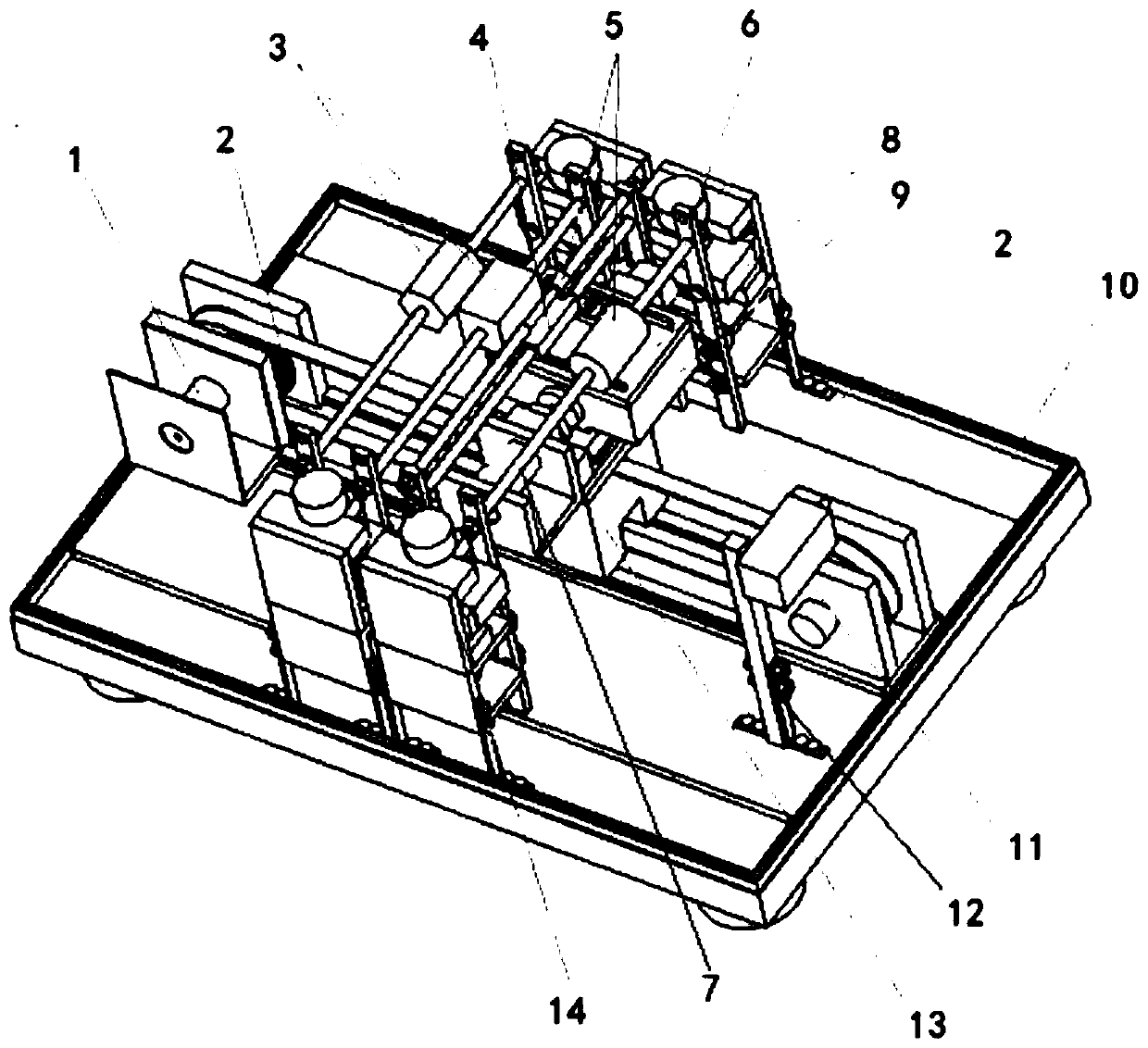

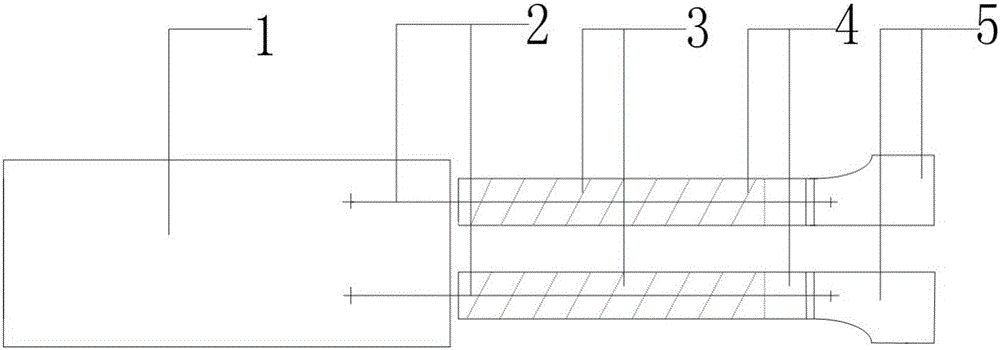

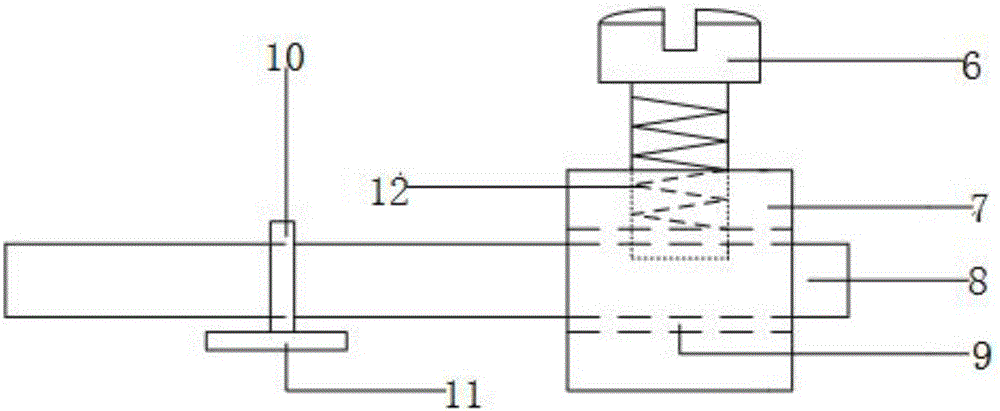

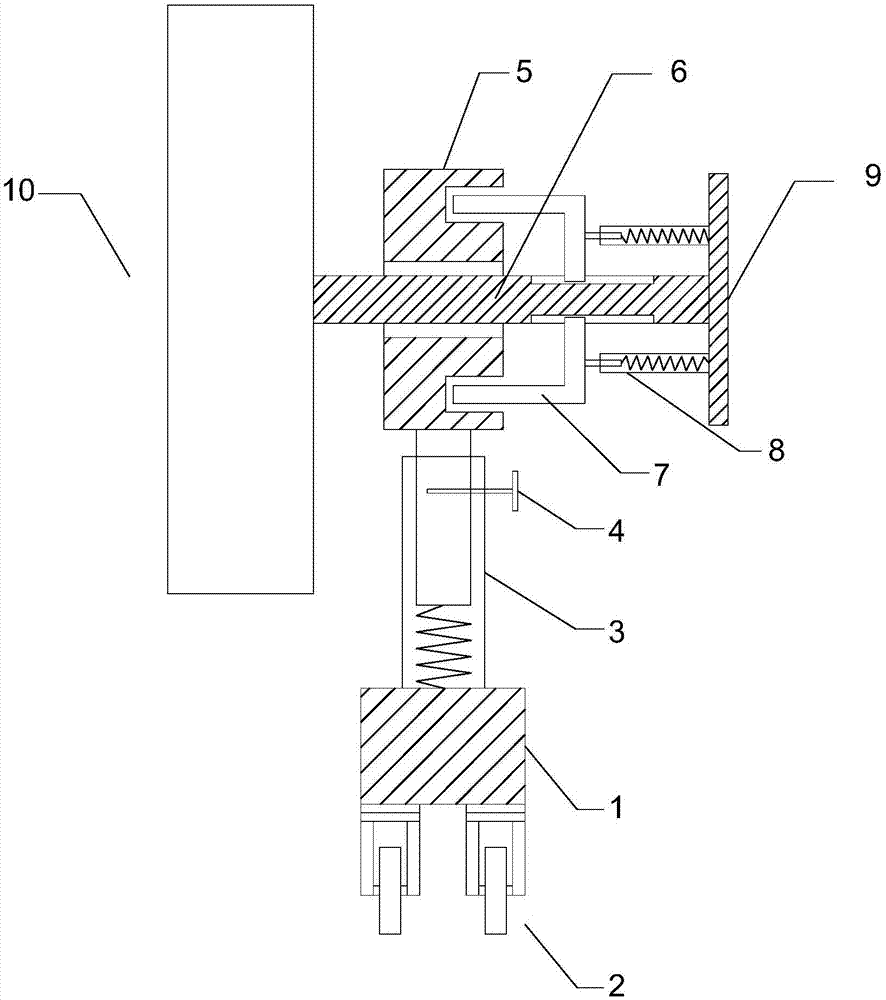

Strain gage pasting device

ActiveCN105065397APlace stableImprove pasting efficiencyFastening meansPulp and paper industryStrain gauge

The invention discloses a strain gage pasting device which is used for pasting a strain gage to a to-be-pasted area. The strain gage pasting device comprises a positioning plate, a compression mechanism and a sucking disc assembly, wherein a strain gage positioning groove and a strain gage line guiding groove are formed in the front end of the positioning plate, and a through hole is formed in the positioning plate and communicated with the strain gage positioning groove; the compression mechanism comprises a pressing plate, a pressing block and a guide column, the guide column is connected to the back end of the positioning plate, the pressing plate is connected to the guide column in a sliding manner, the pressing block is connected to the through hole in a sliding manner, and the back end of the pressing block is connected with the pressing plate; the back end of the pressing block does not exceed the strain gage positioning groove, and a containing hole is formed inside the pressing block; and the sucking disc assembly comprises a vacuum sucking disc, a connecting pipe and a connecting joint, the vacuum sucking disc is fixed to the front end of the containing hole, the connecting joint is fixed to the back end of the containing hole, and a connecting pipe is used for connecting the vacuum sucking disc with the connecting joint and located in the containing hole. By means of the pasting device, the strain gage can be sucked to be accurately pasted into the to-be-pasted area.

Owner:NINEBOT (CHANGZHOU) TECHCO LTD

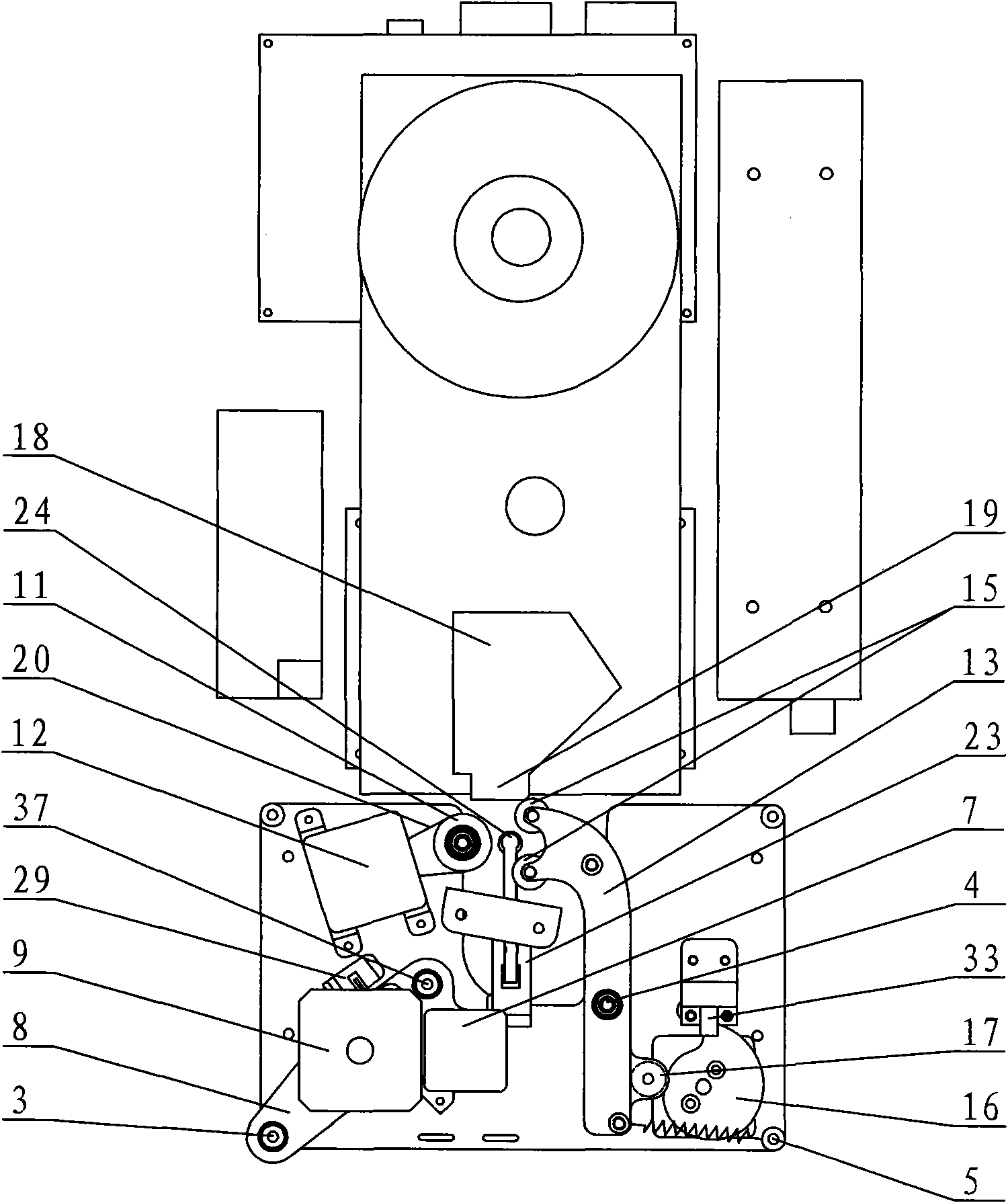

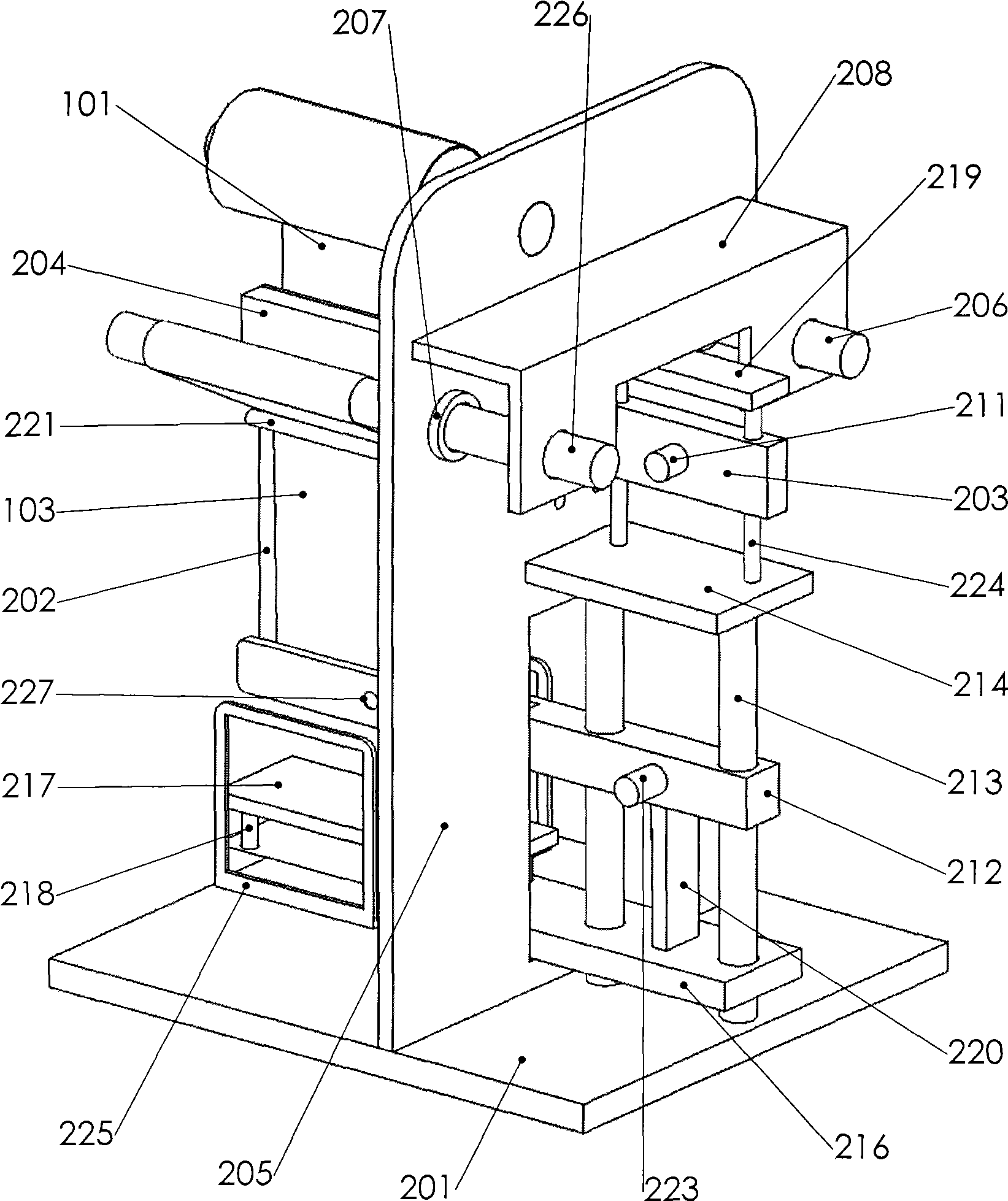

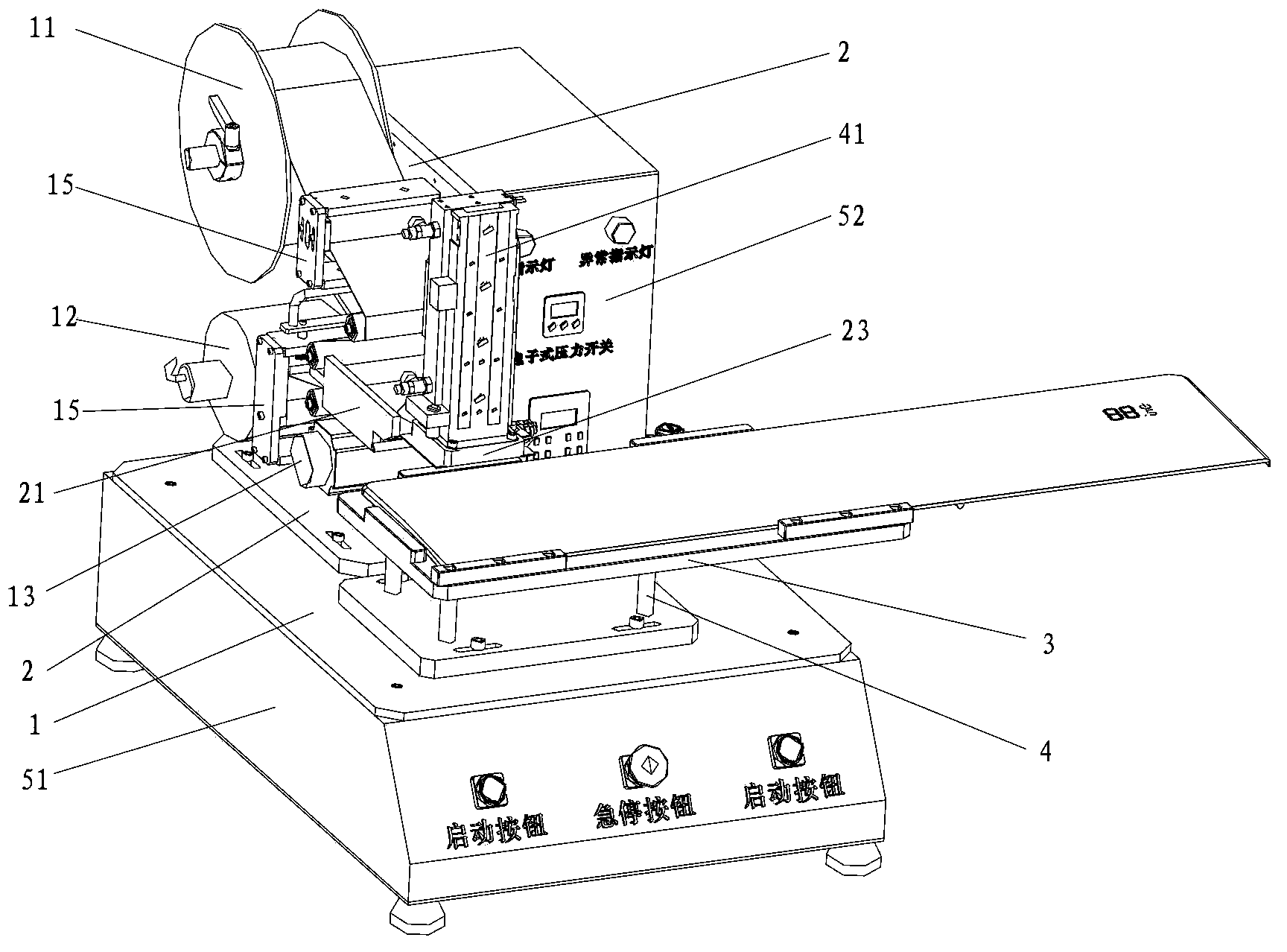

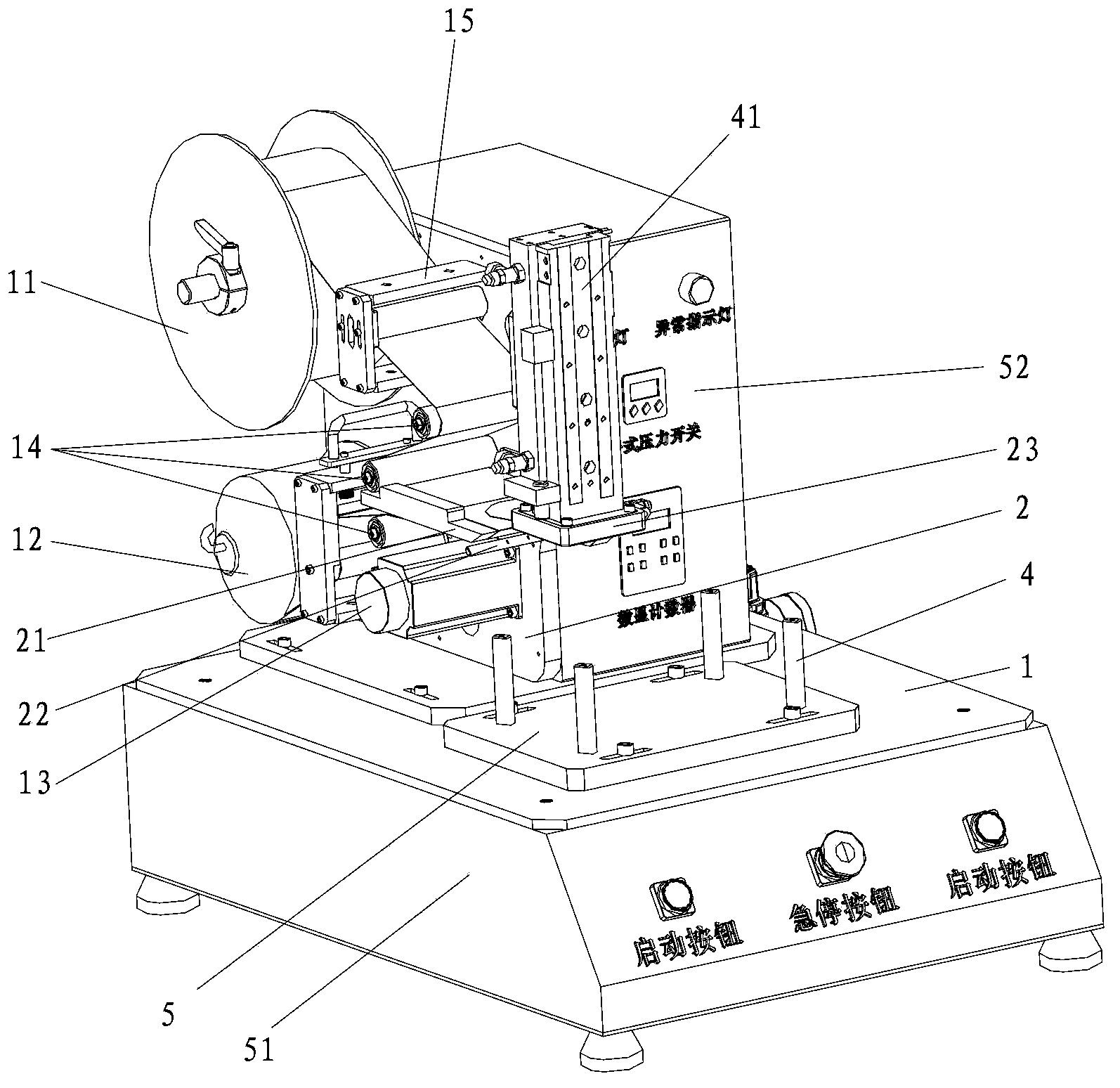

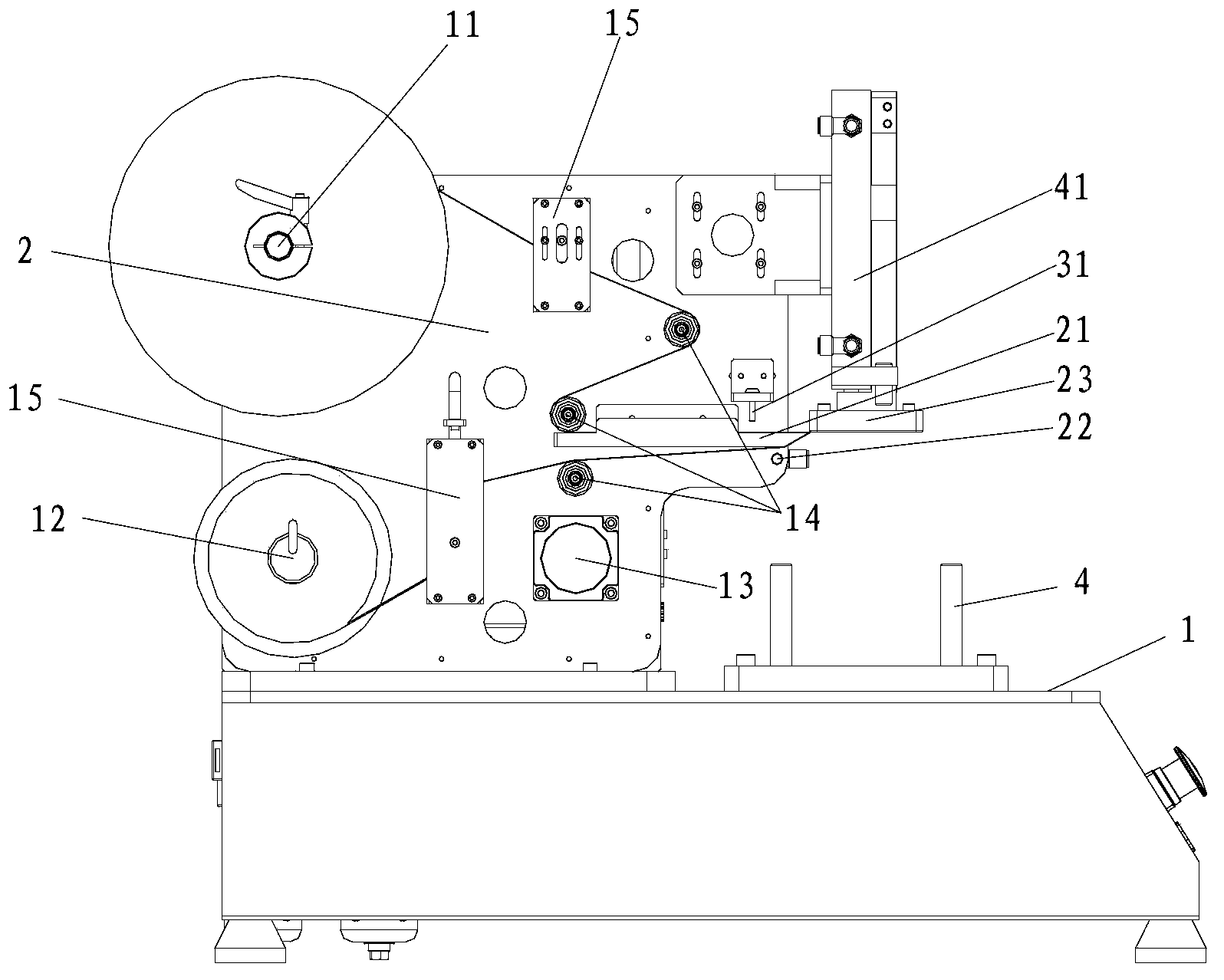

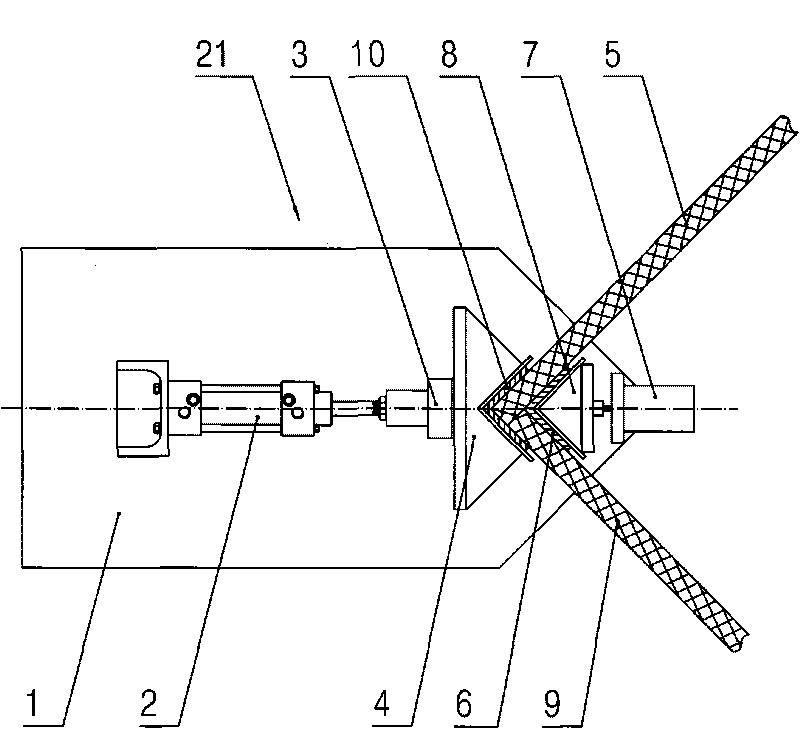

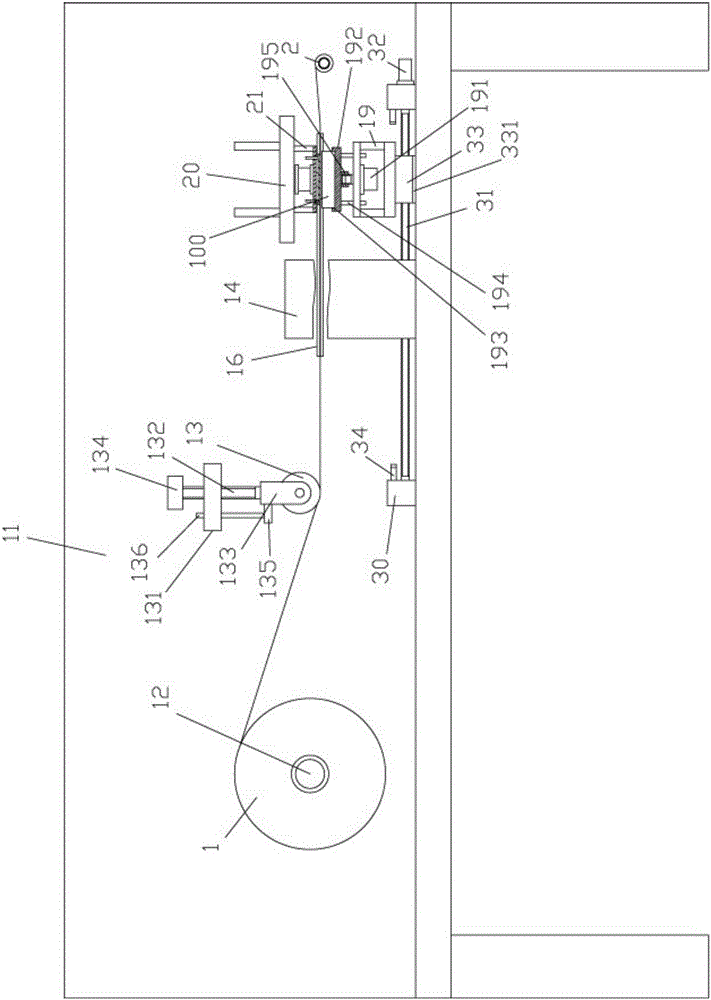

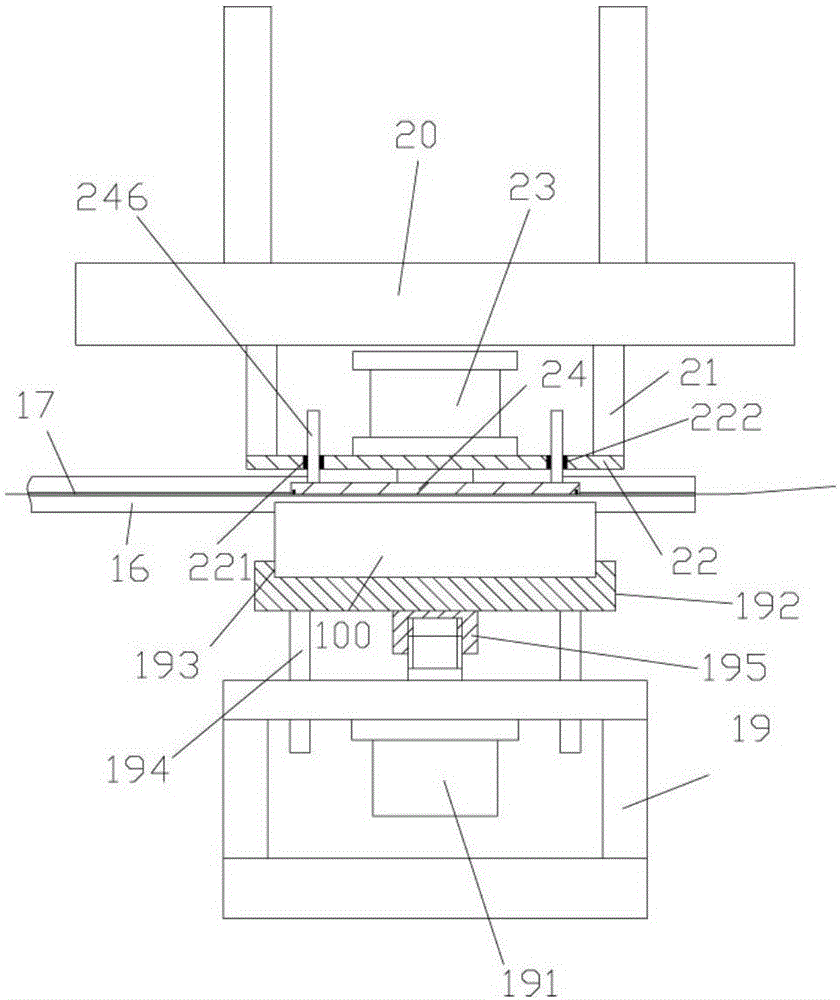

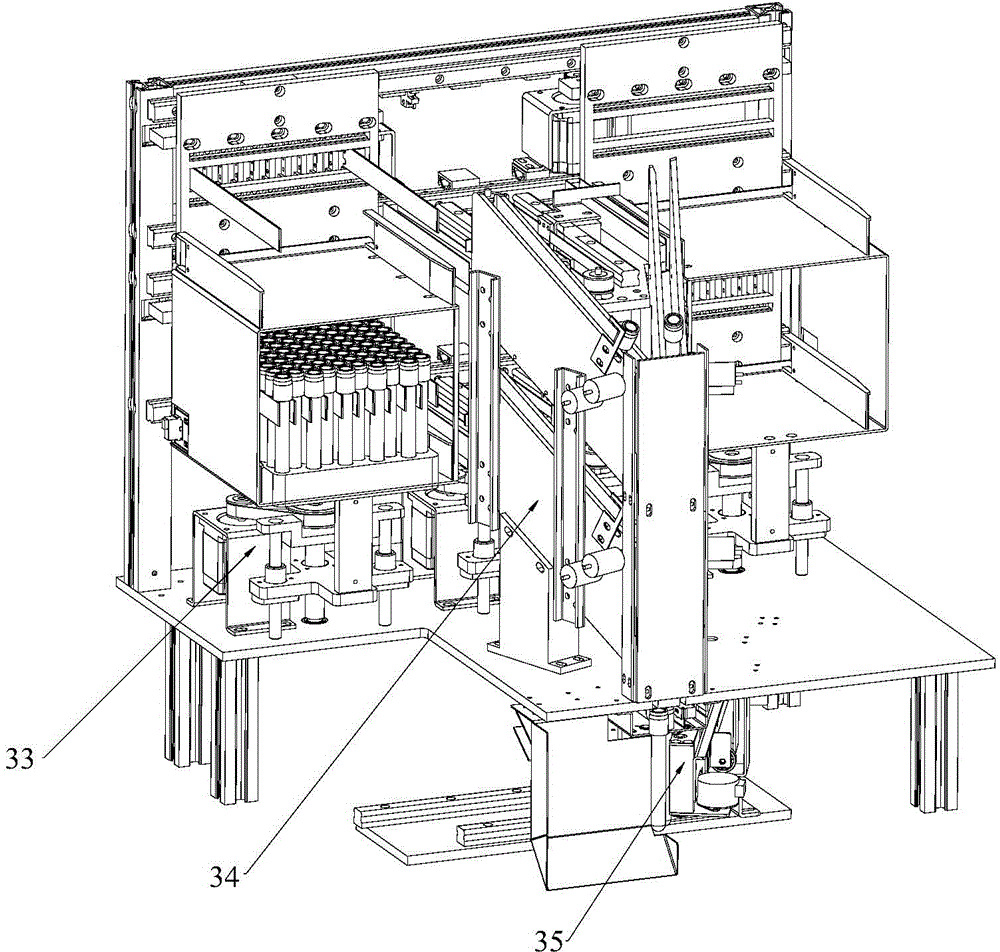

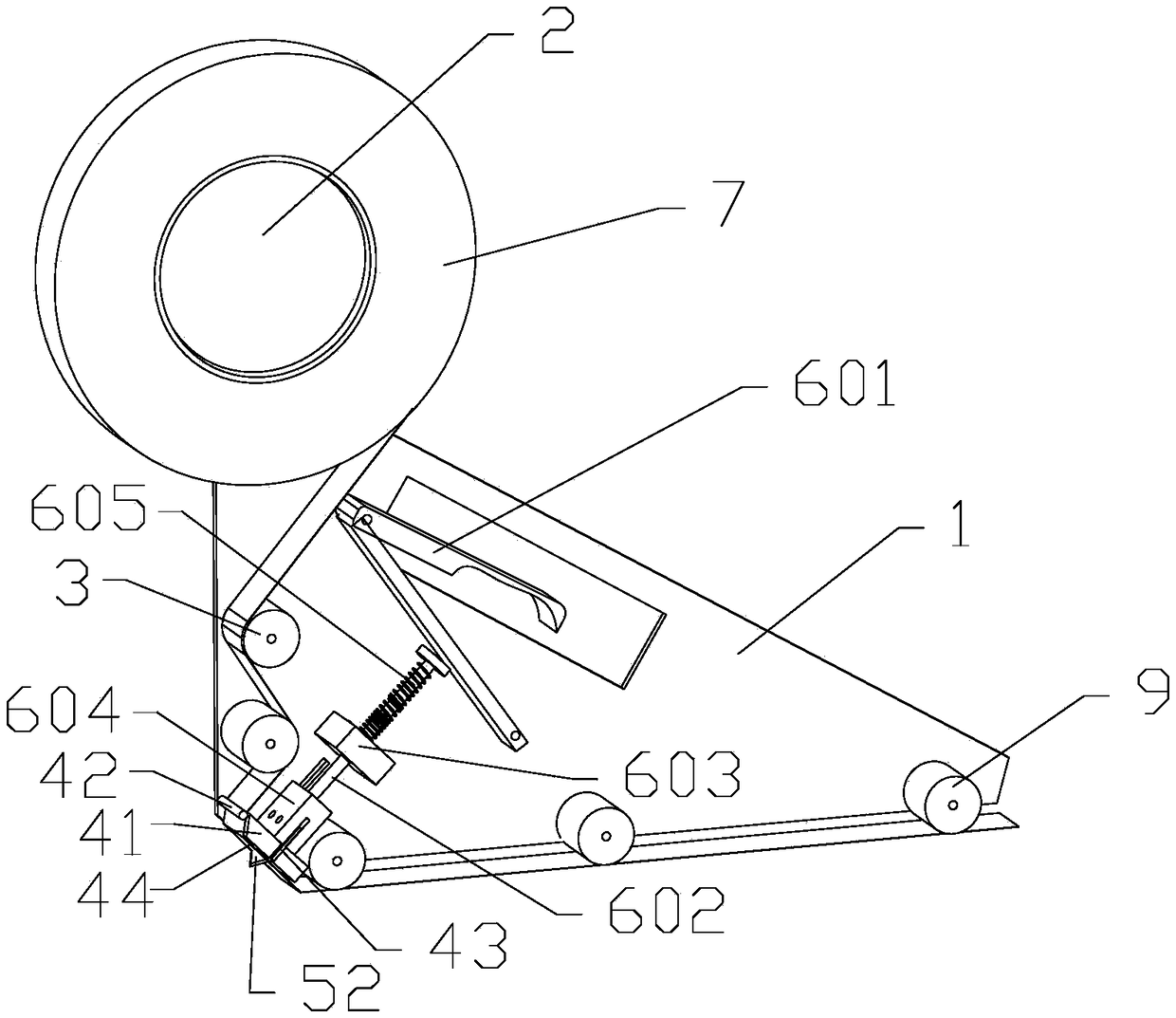

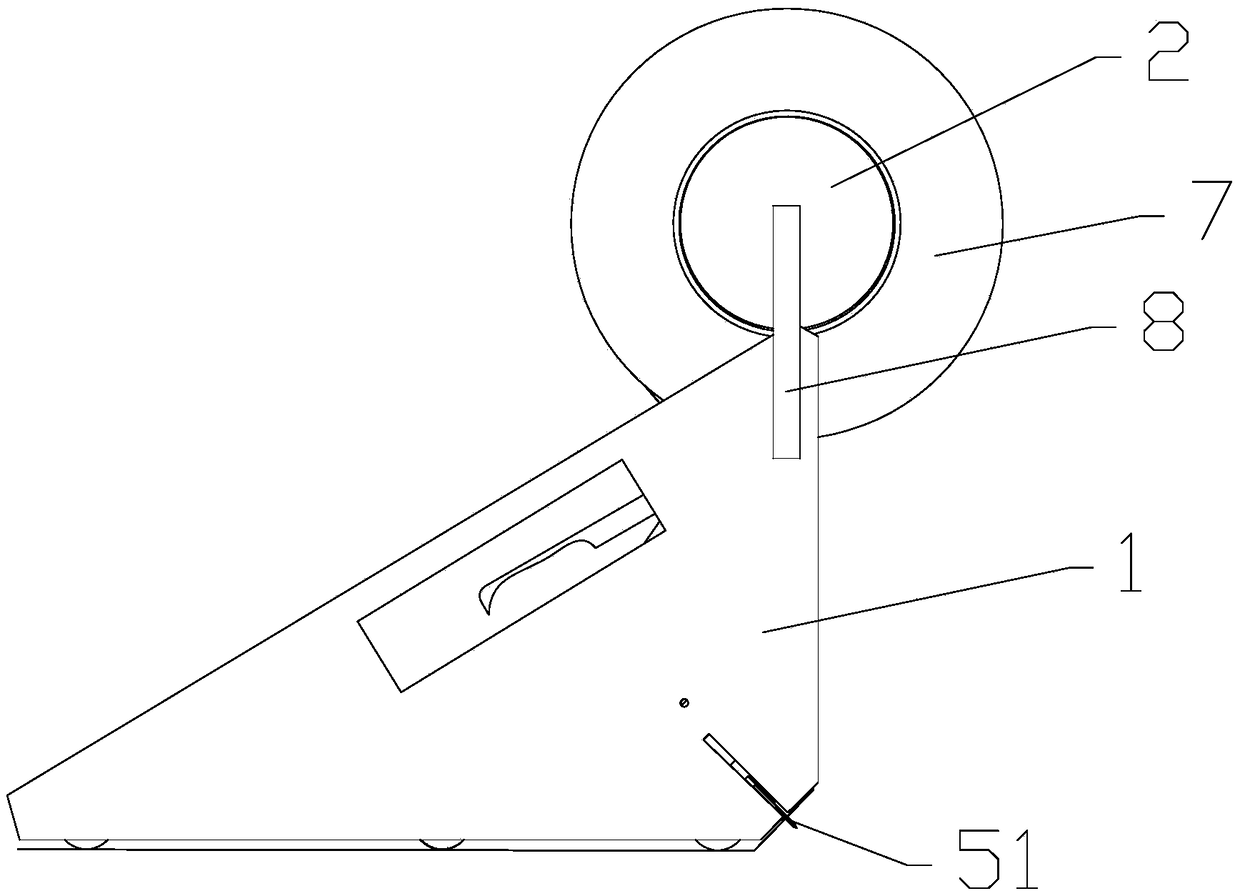

Test tube bar code gluing machine

ActiveCN101811586AEasy to readImprove pasting efficiencyManual label dispensersWithdrawing sample devicesEngineeringTest tube

The invention provides a test tube bar code gluing machine, relates to a machine for gluing a label on a test tube, and aims to provide a test tube bar code gluing machine with simple structure, tidy gluing and high efficiency. The test tube bar code gluing machine comprises a frame and an execution part, wherein the execution part is arranged on the frame, and comprises a test tube clamping device, a test tube supporting device, a test tube rotating device and a bar code printing and gluing device; the test tube clamping device, the test tube supporting device, the test tube rotating device and the bar code printing and gluing device comprise a corresponding power part respectively; the power part drives the execution part to execute the following actions: a, the test tube supporting device executes or cancels axial support to the test tube, and adjusts the height of the test tube; b, the test tube clamping device executes or cancels clamping to the test tube; c, the test tube rotating device drives the test tube to circumferentially rotate; and d, the bar code printing and gluing device glues the bar code on the wall of the test tube.

Owner:SHANGHAI JINYU LUOBO ELECTRONICS TECH

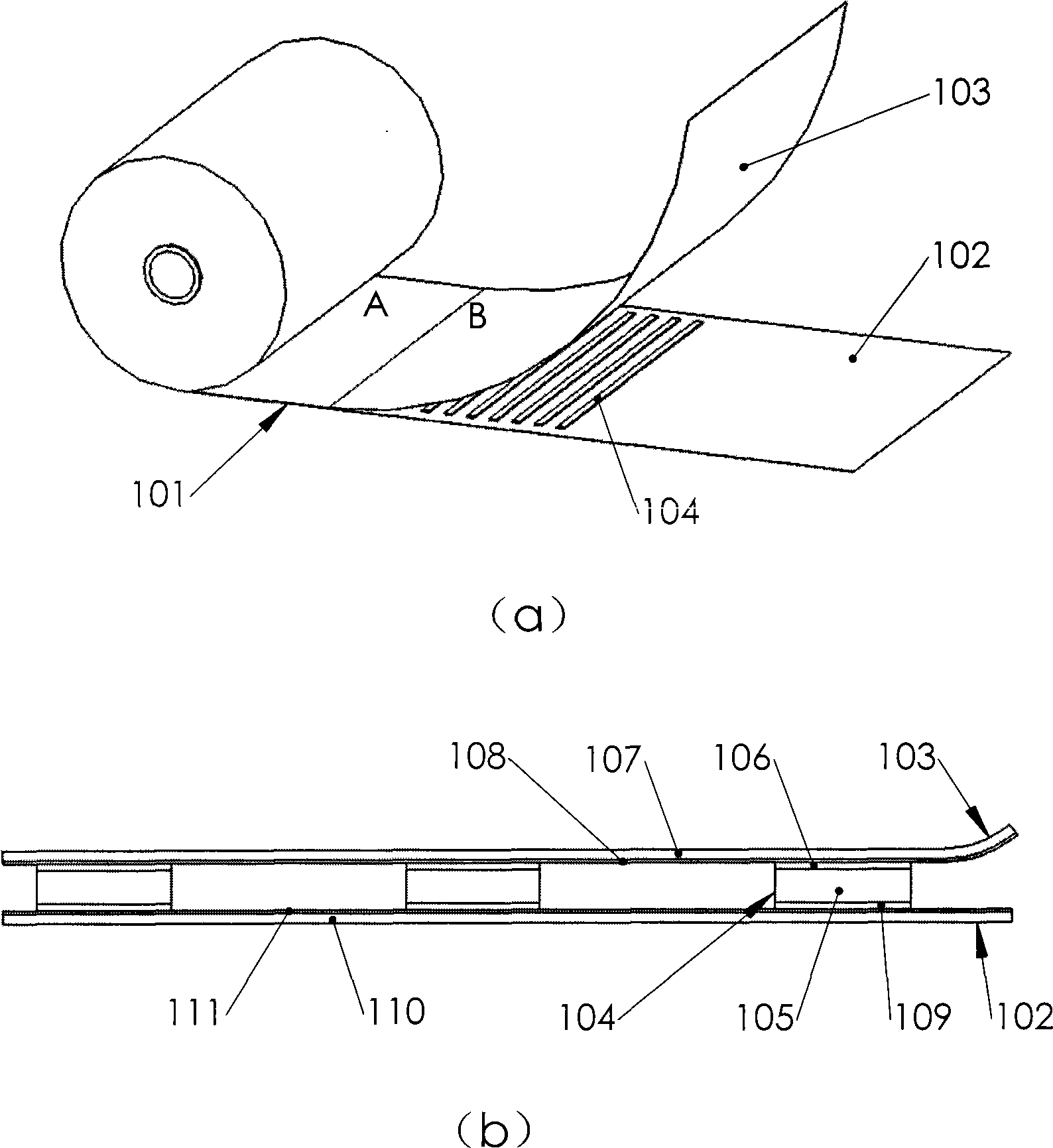

Method and device for pasting book labels, and label band used thereby

InactiveCN101519140AGood flexibilityGood light transmissionFlexible coversWrappersEngineeringViscose fiber

The invention provides a method and a device for pasting book labels, and a label band used thereby. The device comprises a pasting fixture, a label-band drawing mechanism, a device for drawing / loosing a lining band of a fixture movable plate, a mechanism for moving the fixture movable plate, and an inserting-pushing mechanism. The pasting method adopts the following steps that: (1) the blank lining band is drawn to convey a first label of the label band to a pasting-edge appointed position of the pasting fixture; (2) the pasting edge of the pasting fixture comprising the label band is inserted into a book seam of an opened book; (3) a fixture fixed plate and the lining band on one side of the fixed plate are kept still; the fixture movable plate is withdrawn; and the lining band on one side of the movable plate is lifted towards the outside of the book seam so as to peel the lining band on one side of the movable plate from a label viscose layer on the pasting edge of the fixture; and (4) the pasting edge of the fixture, together with the lining band, is separated from the book seam, and a viscose layer on the other side of the label is peeled from the lining band on one side of the fixture fixed plate. The method and the device have the advantages of pasting labels more reliably and more deeply into the book seam, leaving out individual mechanism and step of passing the labels and improving pasting efficiency.

Owner:张明昊

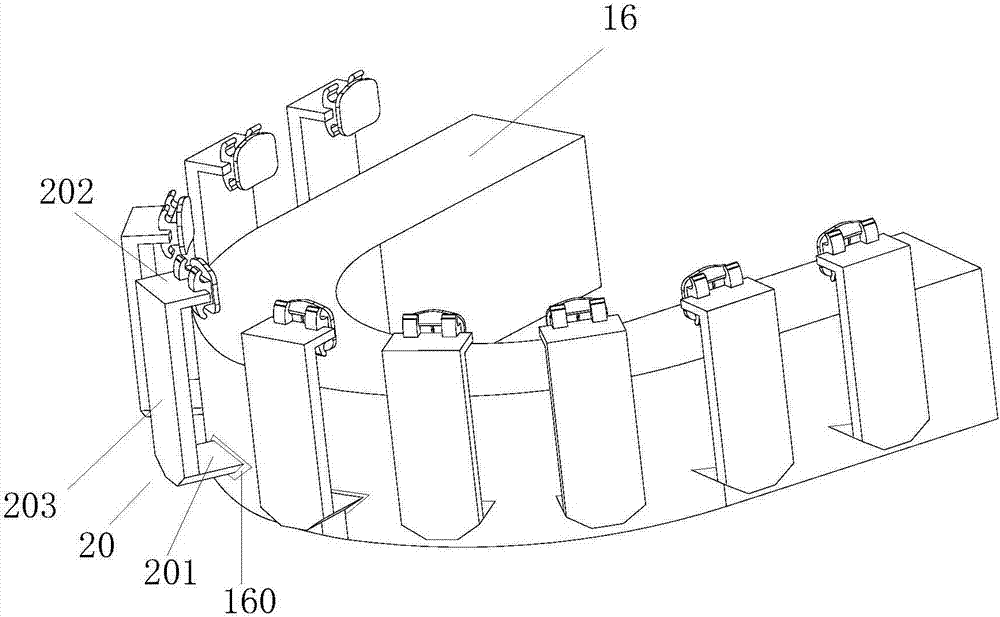

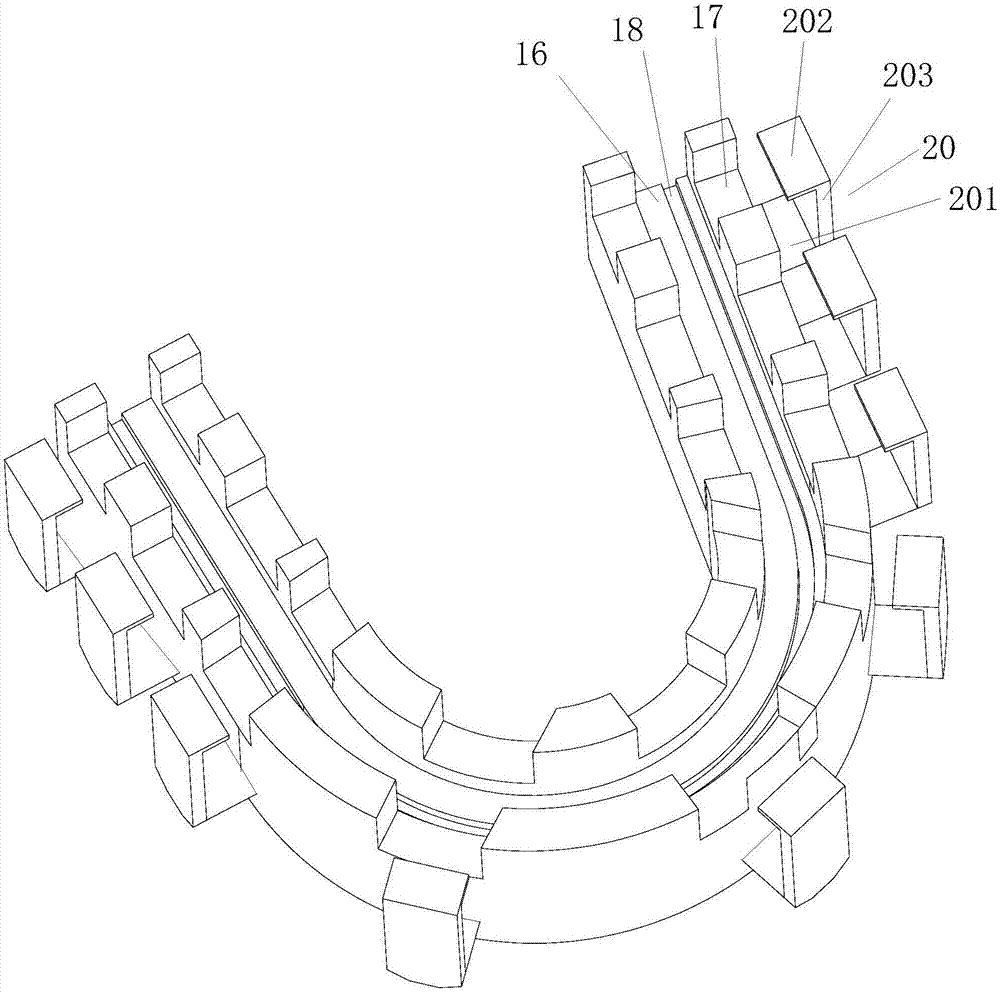

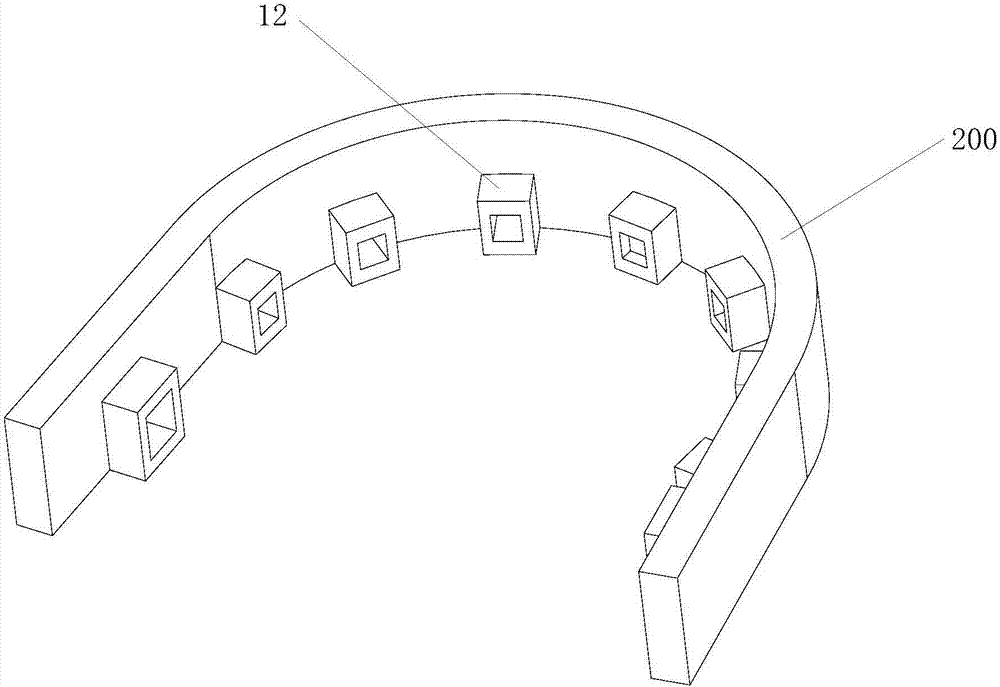

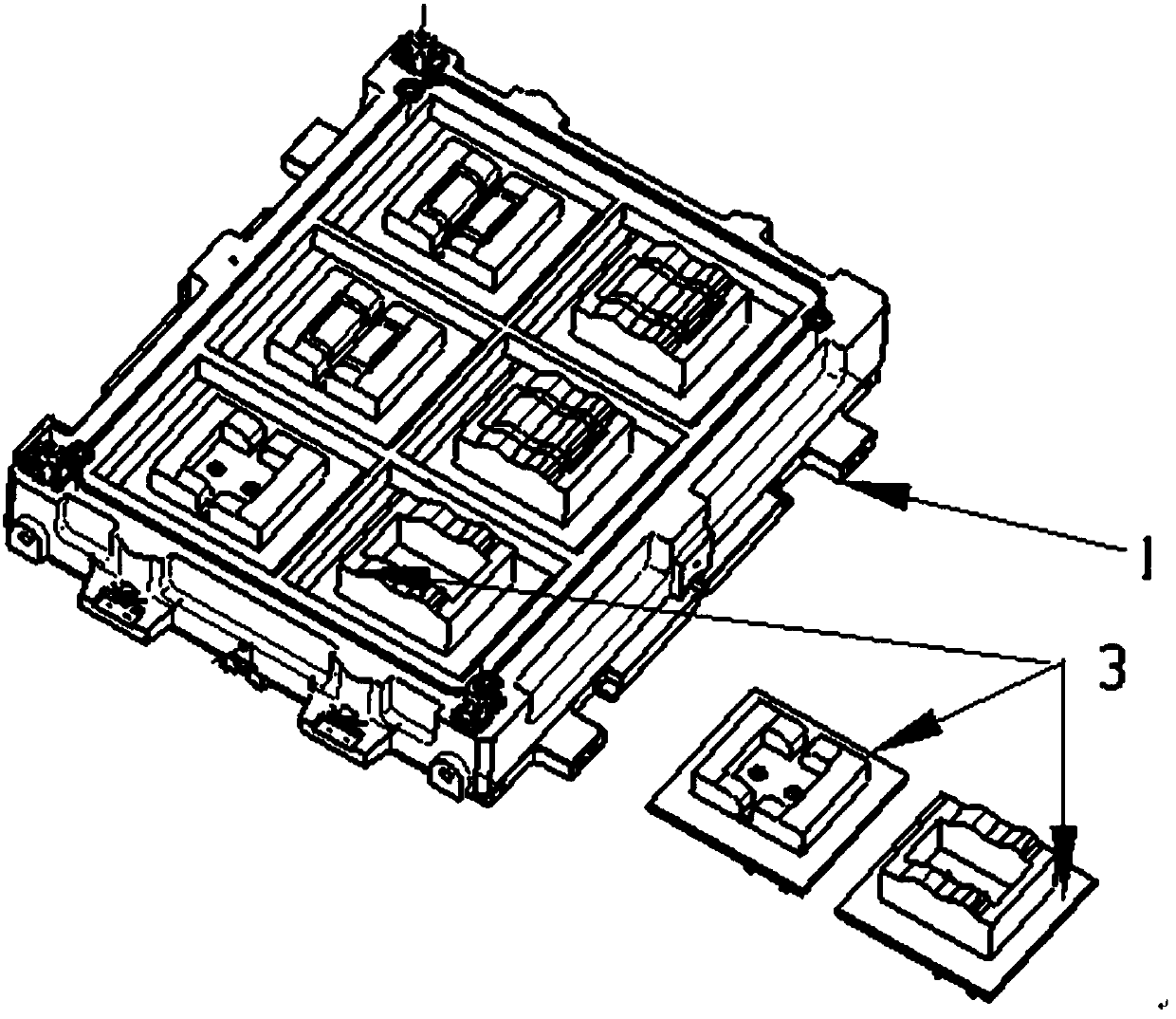

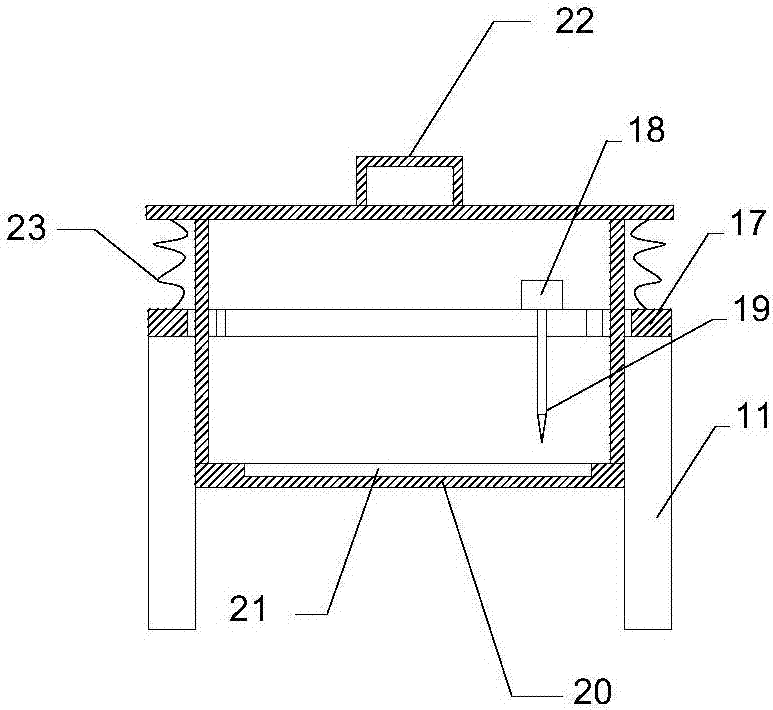

Bracket bonding locator, manufacturing method thereof and bracket locating method

ActiveCN107874849AReduce discomfortImprove the treatment environmentArch wiresBracketsCorrosionEngineering

The invention relates to the field of orthodontics and discloses a bracket bonding locator, a manufacturing method thereof and a bracket locating method. The bracket bonding locator comprises an occlusion plate (16) used for occluding upper and lower oral teeth, wherein a bracket locating rack (20) used for transferring the bracket is arranged on the occlusion plate (16); the bracket locating rack(20) is inserted into the occlusion plate (16); and the bracket locating rack (20) slides in the occlusion plate (16) to transfer the bracket to be bonded onto the tooth surface. Simulated creation of a personalized bracket bonding locator and an acid etching locating plate is performed by utilizing a computer, so that the personalized acid etching locating plate is matched with the teeth, accurate bonding of the bracket is ensured, and the operation is convenient and simple. Meanwhile, the bracket bonding locator disclosed by the invention has the advantages of being high in acid etching synchronicity, low in tooth corrosion, simple in operation and the like.

Owner:浙江日盛医疗科技股份有限公司

Automatic gluing device for lampshade double-side-glued seal gaskets

The invention relates to an automatic gluing device for lampshade double-side-glued seal gaskets. The automatic gluing device comprises a bottom plate, a lower mould assembly, and an upper mould assembly. A lower positioning plate of the lower mould assembly is mounted on a lower mould fixing plate through a bearing block, two guide shafts are mounted on the lower mould fixing plate, two sides of a floating block are mounted on the guide shafts, one end of a spring wrapping each guide shaft is connected with one floating block while the other end of every spring is abutted to the lower mould fixing plate, a flexible moving block passes through the bearing block and the lower positioning plate, the top of the lower positioning plate is provided with a seal gasket positioning groove in the outer periphery of an upper cavity and a closed gas cavity inside, and the gas cavity is communicated with the seal gasket positioning groove through at least four suction holes. A lifting cylinder of the upper mould assembly is mounted on an upper mould fixing plate while a moving side of the lifting cylinder is connected with a top plate, the upper positioning plate is mounted below the top plate, at least two vacuum suckers are mounted on the top plate, and suction holes of the vacuum suckers are located in a lampshade cavity of the upper positioning plate. The automatic gluing device for lampshade double-side-glued seal gaskets is convenient to operate and enables assembly quality and production efficiency to be improved.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

Label sticking device and label sticking method

InactiveCN104276316AReduce labor intensityImprove accuracy and efficiencyLabelling machinesData miningMass Consistency

The invention discloses a label sticking device and a label sticking method. The label sticking device comprises a working platform, a rack and a product positioning component are arranged on the working platform, and a sending / receiving component, a label stripping and adsorption component, a label positioning component and a label sticking component are arranged on the rack. By virtue of a series of action of the sending / receiving component, the label stripping and adsorption component, the label positioning component and the label sticking component, a label can be precisely stuck onto a product. Therefore, by virtue of the label sticking device and the label sticking method, the product label can be stuck mechanically, the labor intensity is lowered, the label sticking efficiency and the label sticking precision are improved, and the consistency of product label sticking quality is further enhanced.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

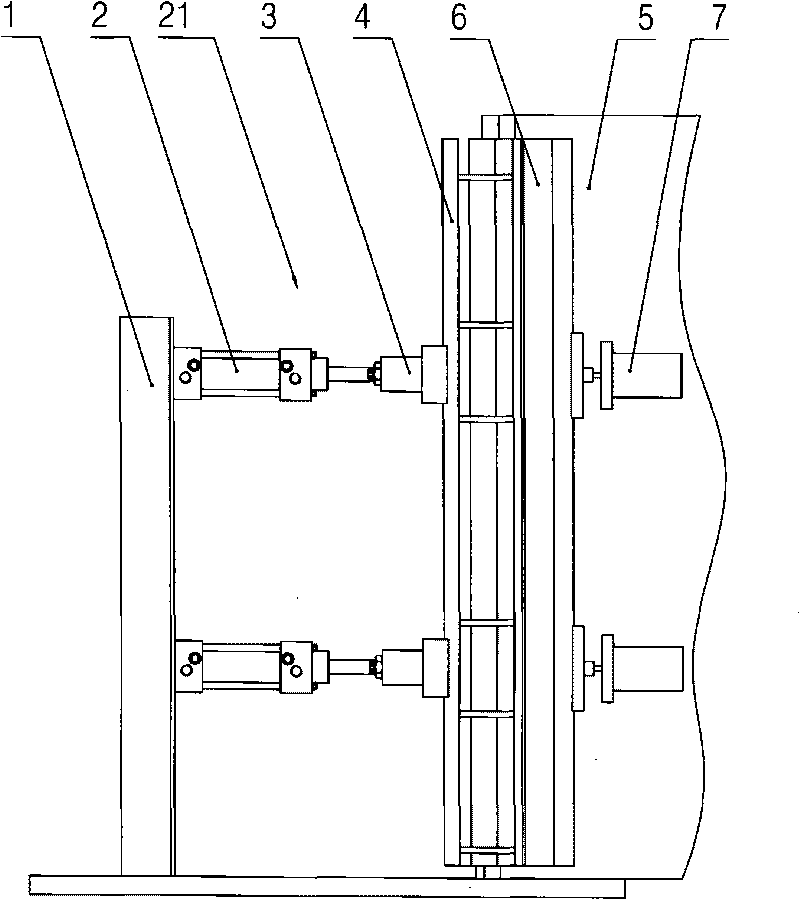

Carton splicing machine

InactiveCN101746078AImprove pasting efficiencyGuaranteed strengthContainer making machineryCartonPiston rod

The invention discloses a carton splicing machine capable of increasing the splicing speed and firmness, which comprises a machine base on which at least one paper corner protector splicing device. The structure of carton splicing machine comprises a chassis on which a pressure cylinder and an apical plate which form a fitting with each other are arranged, a pressure plate is arranged on the end part of the piston rod of the pressure plate cylinder, an apical plate is arranged on the end part of the piston rod of the apical plate cylinder, corner protector grooves and corner protector tappetsforming a fitting with the corner protector grooves are respectively arranged on respective side parts of the pressure plate which are adjacent to the apical plate. Through mechanized operation, the carton splicing machine not only ensures the splicing force application to reliably ensure the splicing firmness but also greatly increases the splicing efficiency. In addition, the carton splicing machine can splice four corners of a carton in one go so as to further increase the carton splicing efficiency.

Owner:ZHANGJIAGANG DESHUN MACHINERY

Sand core and core shooting universal mold for cold box and manufacturing method thereof

ActiveCN107745087ASolve productivitySolve efficiency problemsAdditive manufacturing apparatusFoundry mouldsMaterials scienceProcess engineering

Owner:四川共享铸造有限公司

Process of preparing adhesive for building materials

The invention relates to a process of preparing adhesive for building materials, characterized in that the adhesive is prepared from ethane-vinyl acetate copolymerized resin, polyvinyl alcohol solution, ethanol or ethylene alcohol, water, lime stone powder, tricresyl phosphate through charging water into lime stone powder, agitating till moistening, charging aqueous solution of polyvinyl alcohol and VAE copolymerized emulsion, finally charging ethanol, tricresyl phosphate, fully mixing the constituents and grinding.

Owner:陈晓光

Automatic feeding type cutting and labelling mechanism

ActiveCN106628471AImprove pasting efficiencyGuaranteed paste effectLabelling machinesWebs handlingPulp and paper industryLabelling

The invention discloses an automatic feeding type cutting and labelling mechanism. The mechanism comprises a rack; a main supporting plate is fixed on the top surface on the back side of a top plate of the rack; a main rotating shaft is hinged to the front wall surface of the left side of the main supporting plate; a label roll is mounted on the main rotating shaft; an adjusting plate is fixed on the front wall surface of the main supporting plate on the right side of the main rotating shaft; an adjusting screw is in threaded connection with the adjusting plate; the lower end of the adjusting screw is hinged to a roller body connecting frame; a tensioning roller is hinged in the roller body connecting frame; the lower end of the tensioning roller extends out of the roller body connecting frame; a rotating part is fixed at the top end of the adjusting screw; a side connecting part is fixed on the left side wall of the roller body connecting frame; a limiting rod is fixed at the top of the side connecting part and is sleeved with the adjusting plate in an inserted manner; a front supporting plate is fixed at the front part of the top plate of the rack on the right side of the tensioning roller; and a front guiding strip is fixed on the inner side wall of the front supporting plate. According to the mechanism, the label roll without release paper bonded is adopted, a label is cut and bonded automatically, the cost is reduced, waste is reduced, and the bonding efficiency is high.

Owner:贵阳渝冠技术服务中心

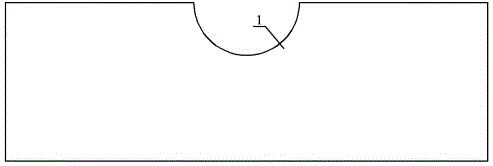

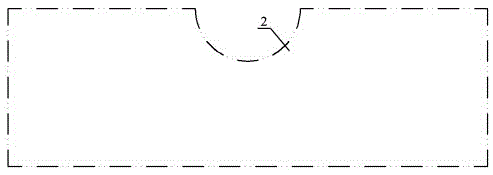

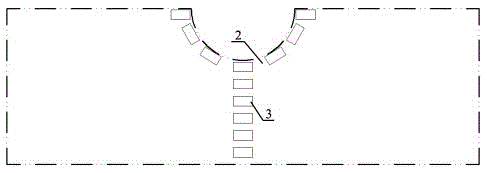

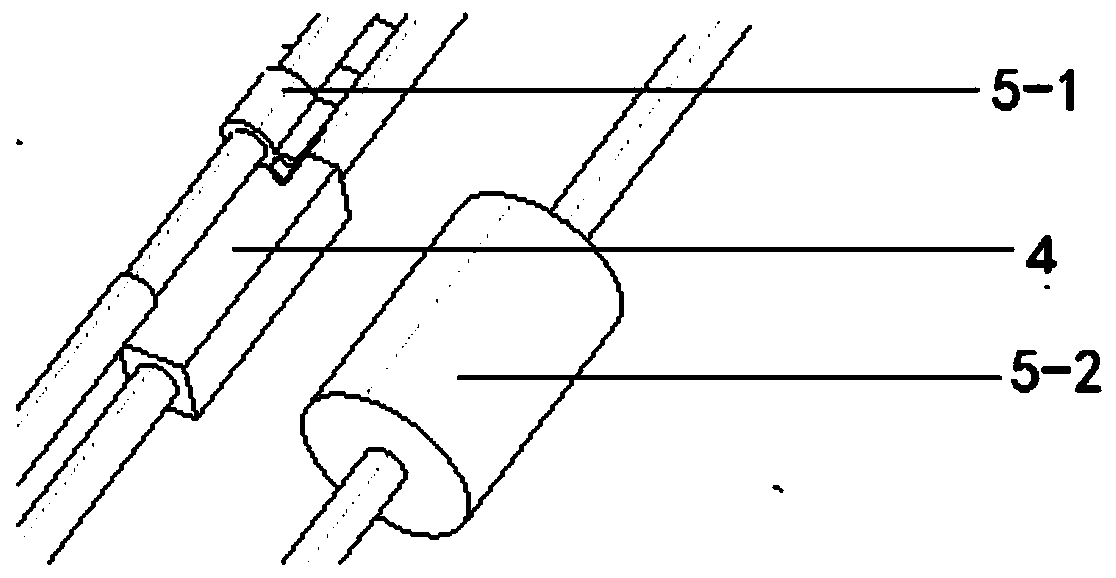

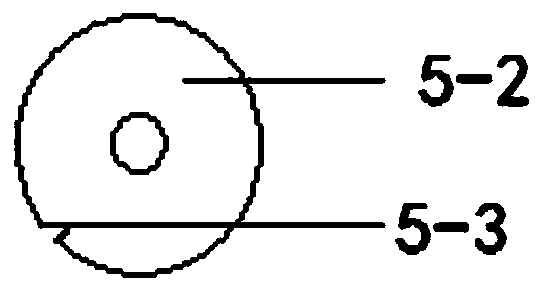

Batch strain gauge pasting method

ActiveCN105605054ARealize batch pasteImprove pasting efficiencyMaterial gluingTest articleStrain gauge

The invention discloses a batch strain gauge pasting method. The method comprises the main steps that an outline skeleton map of a sample is drawn firstly, strain gauge position mark frames and outline skeleton position locating mark points are marked on the outline skeleton map, and then a drawing is printed to transparent adhesive sticker printing paper; strain gauges are sequentially pasted into the strain gauge position mark frames of the adhesive face of the transparent adhesive sticker printing paper; a base of each strain gauge is uniformly smeared with glue; the transparent adhesive sticker printing paper on which the strain gauges are pasted is pasted onto the sample, and the strain gauges are pressed to exhaust bubbles between the strain gauges and the sample; after the glue is solidified completely, the transparent adhesive sticker is torn off, and batch pasting of the strain gauges is completed. The method has the advantages of being simple, easy to implement and suitable for test articles in various shapes, and the multiple strain gauges with positions and angles distributed unevenly can be pasted effectively.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

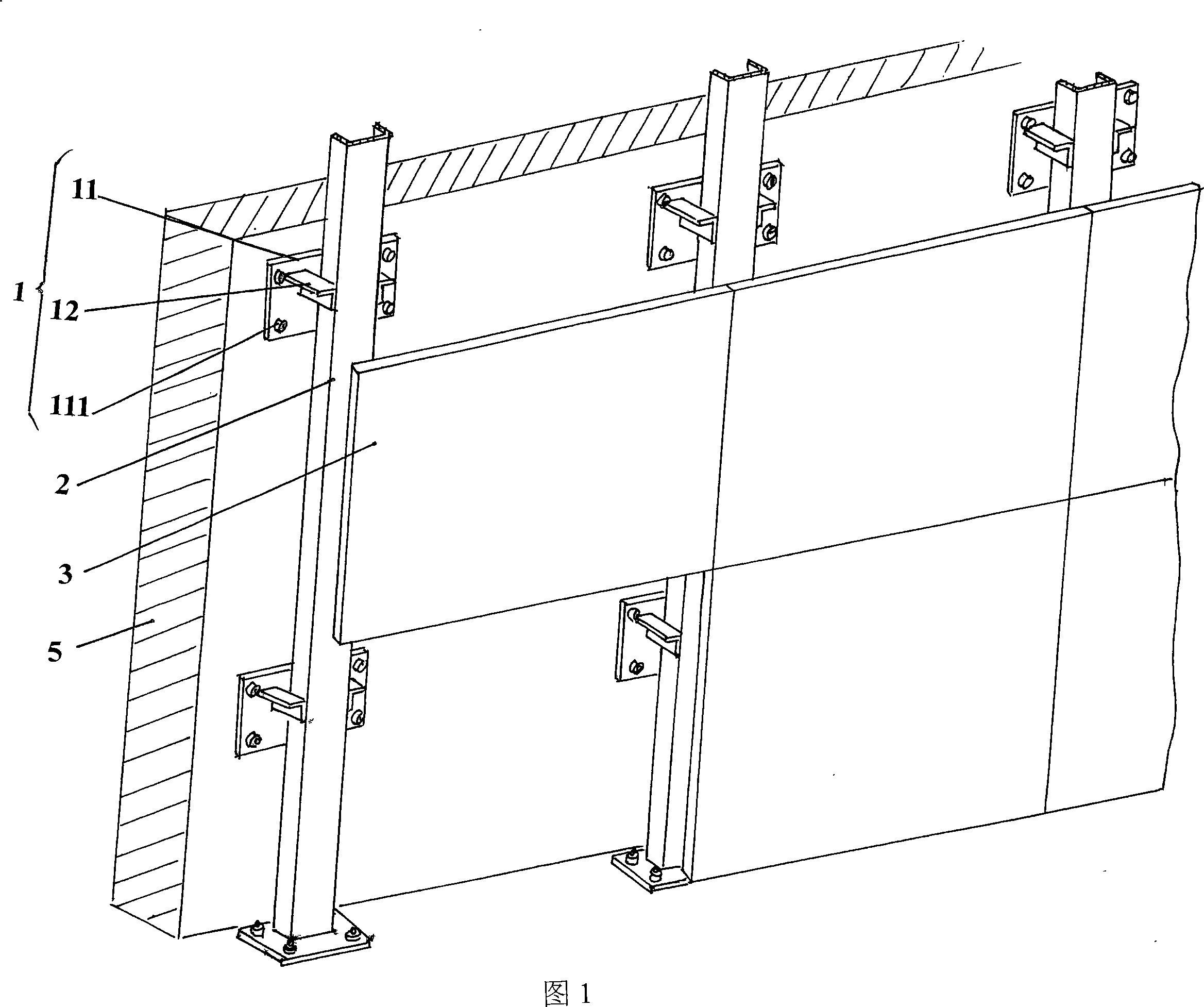

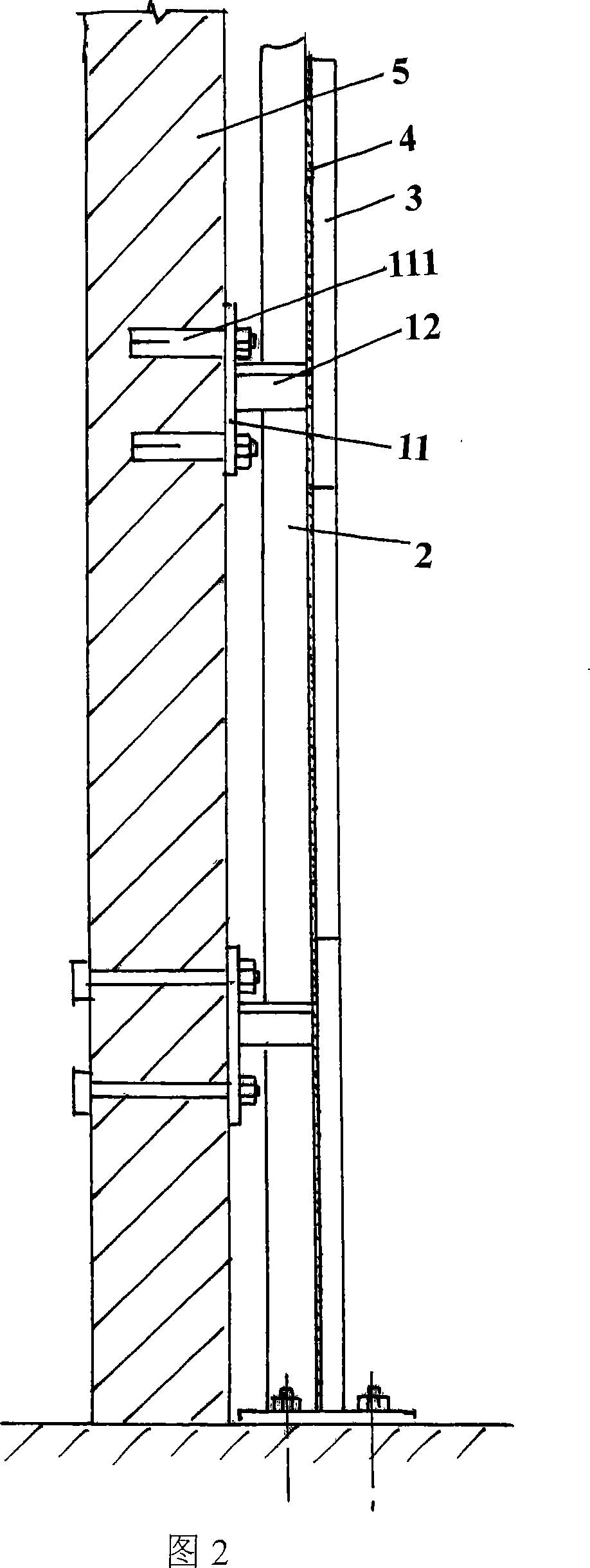

Sticking method for decorative brick

The invention relates to a method for adhering facing tiles, and belongs to the architectural decoration technical field. The method comprises the following steps: firstly, first holding pieces protruding the surface of a wall are arranged on the wall at intervals; secondly, second holding pieces are fixed and connected on the first holding pieces; thirdly, the facing tiles are adhered on the second holding pieces by using adhesion agent; fourthly, joint pointing treatment is performed to the joint positions among the facing tiles; fifthly, the surfaces of the facing tiles are cleaned finally. The invention has the advantages that the wet method adhesion in the prior art is changed into the dry method adhesion, the cement slurry and dust pollution is not existed in an operation site, thereby ensuring the environment of the construction site to be clean and sanitary; the adhering efficiency is improved by three times than the prior art; the adhering effect is ideal, and the post cleaning is simple.

Owner:常熟市金龙装饰有限责任公司

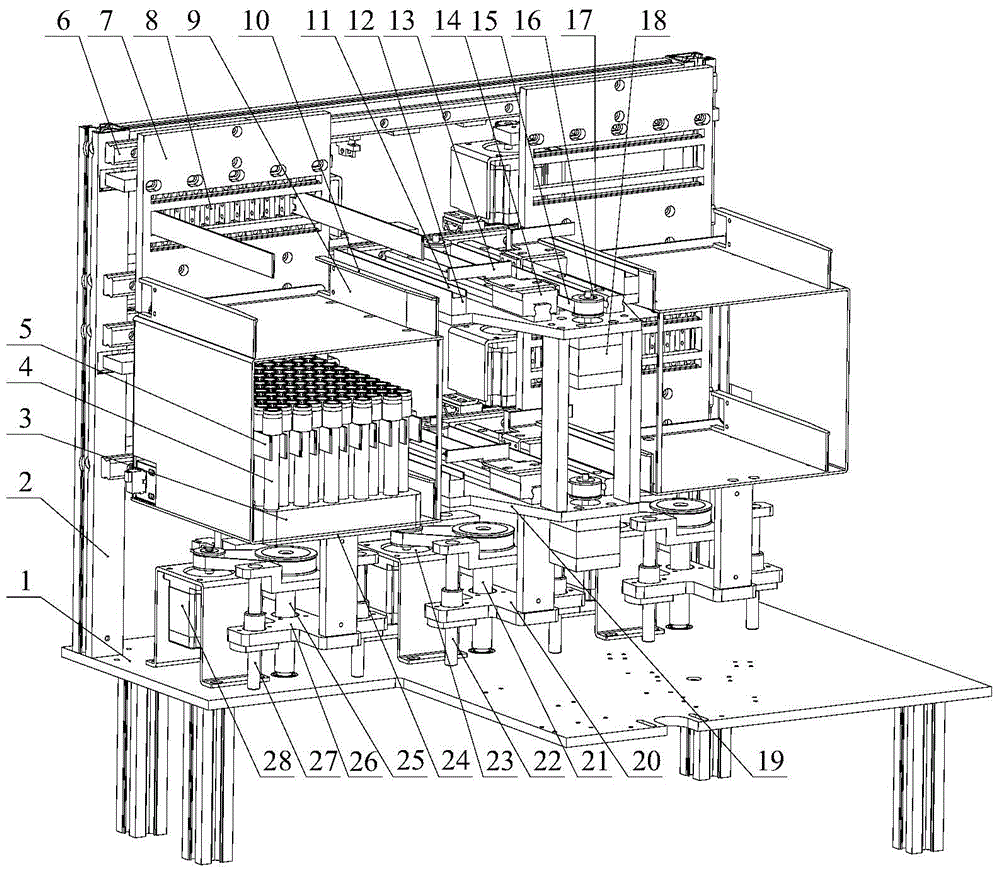

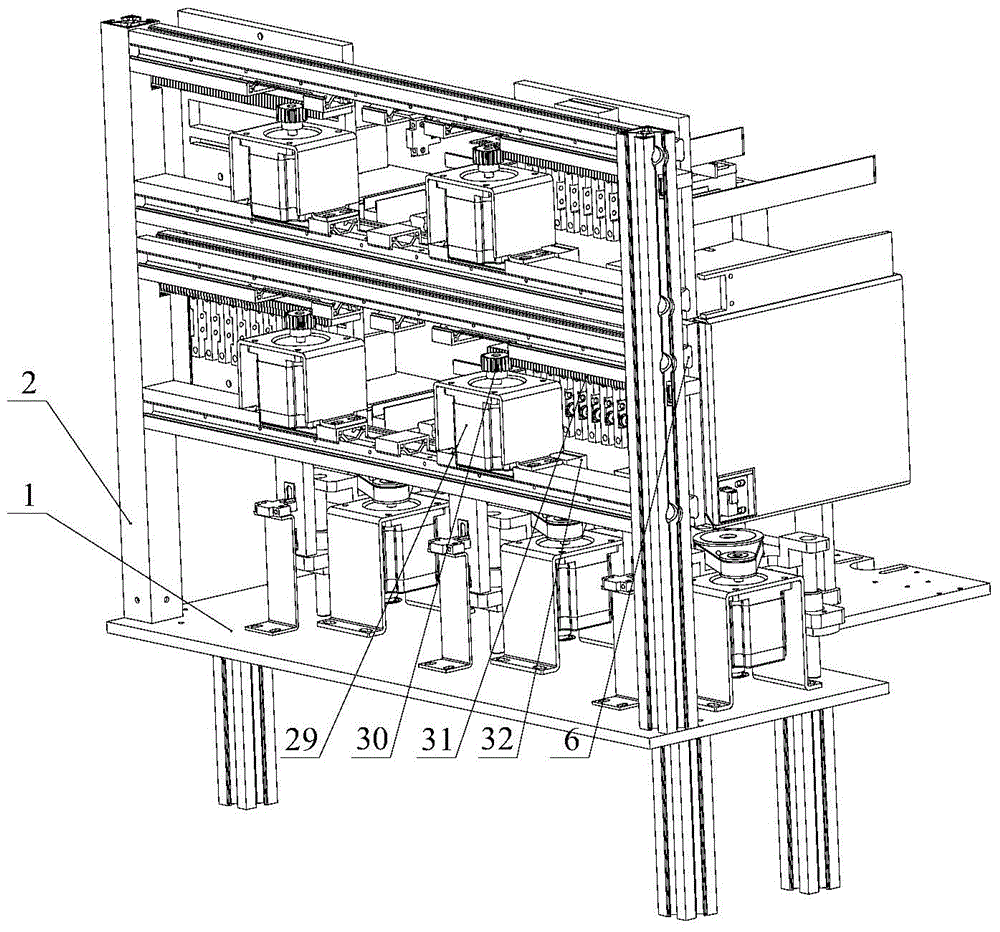

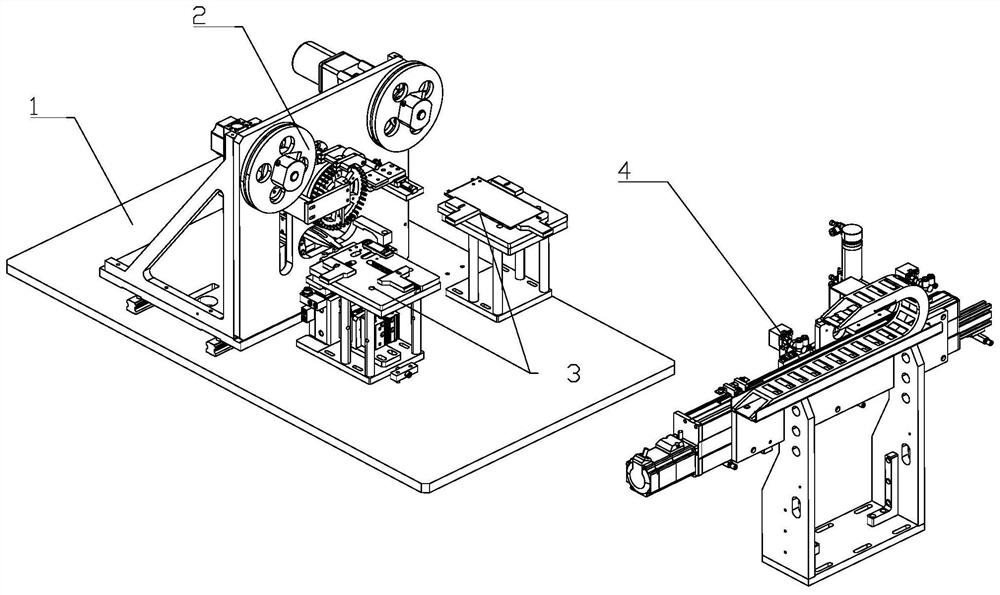

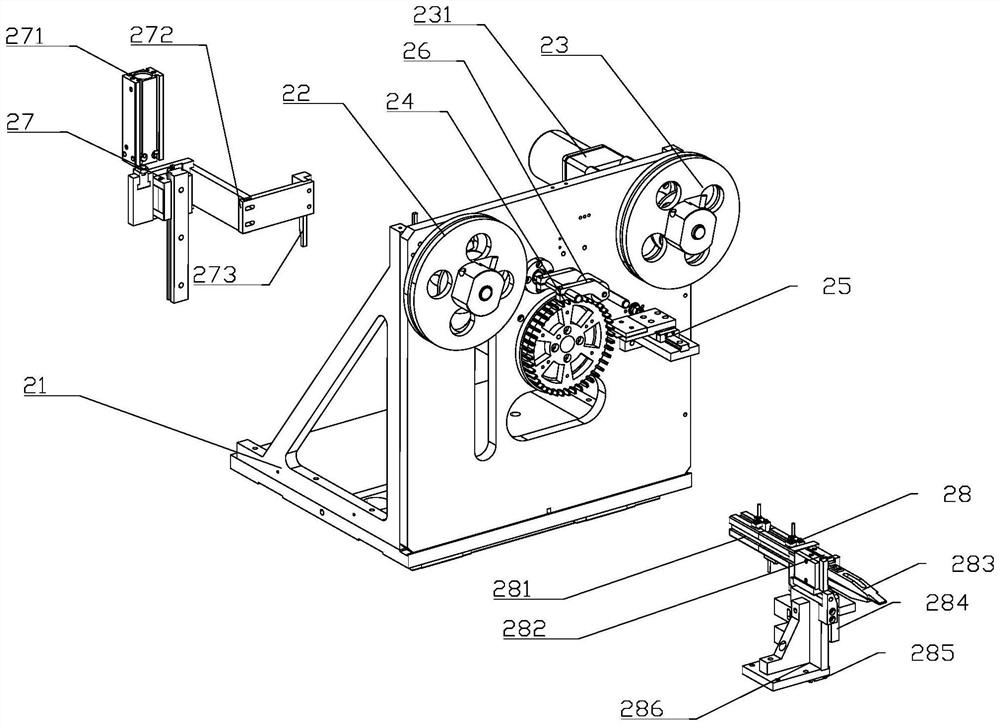

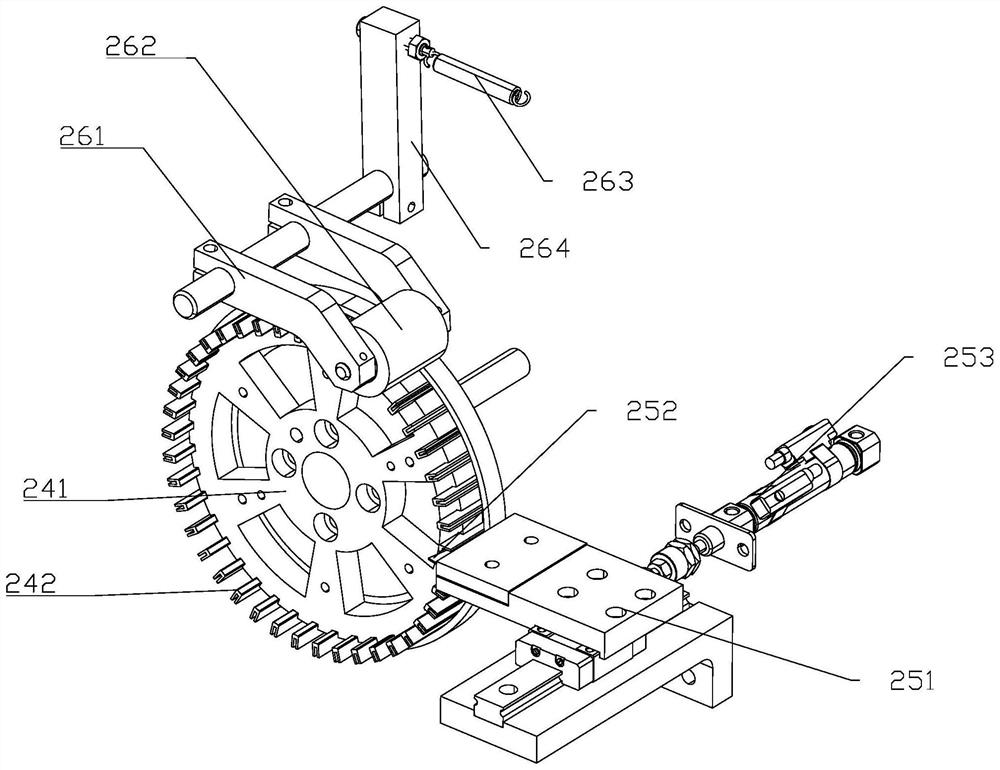

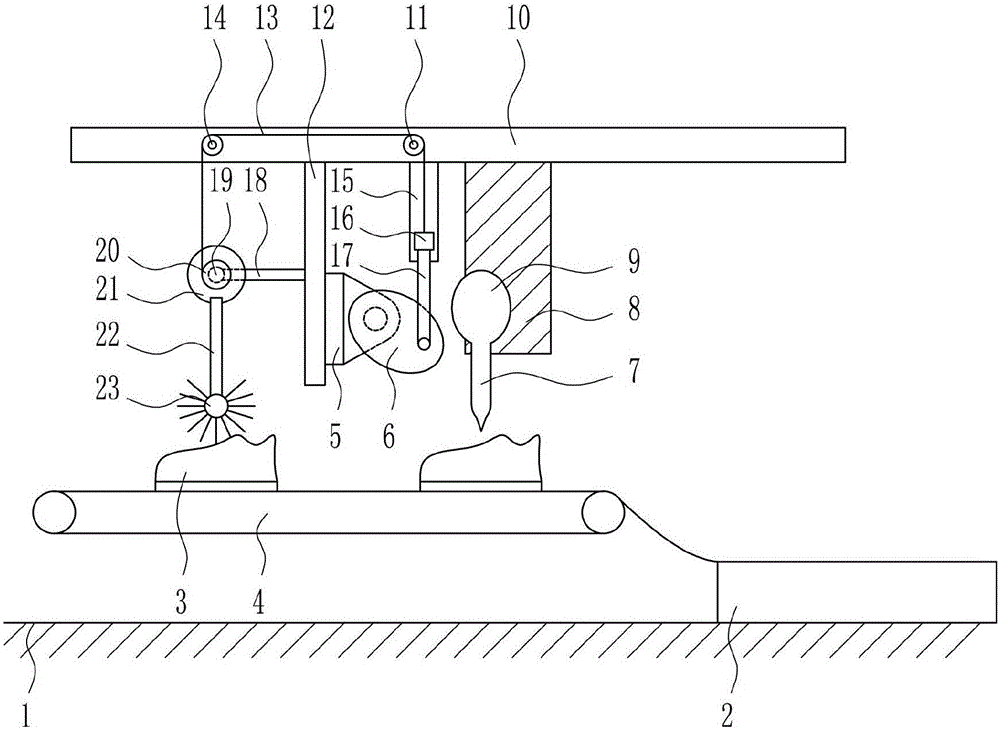

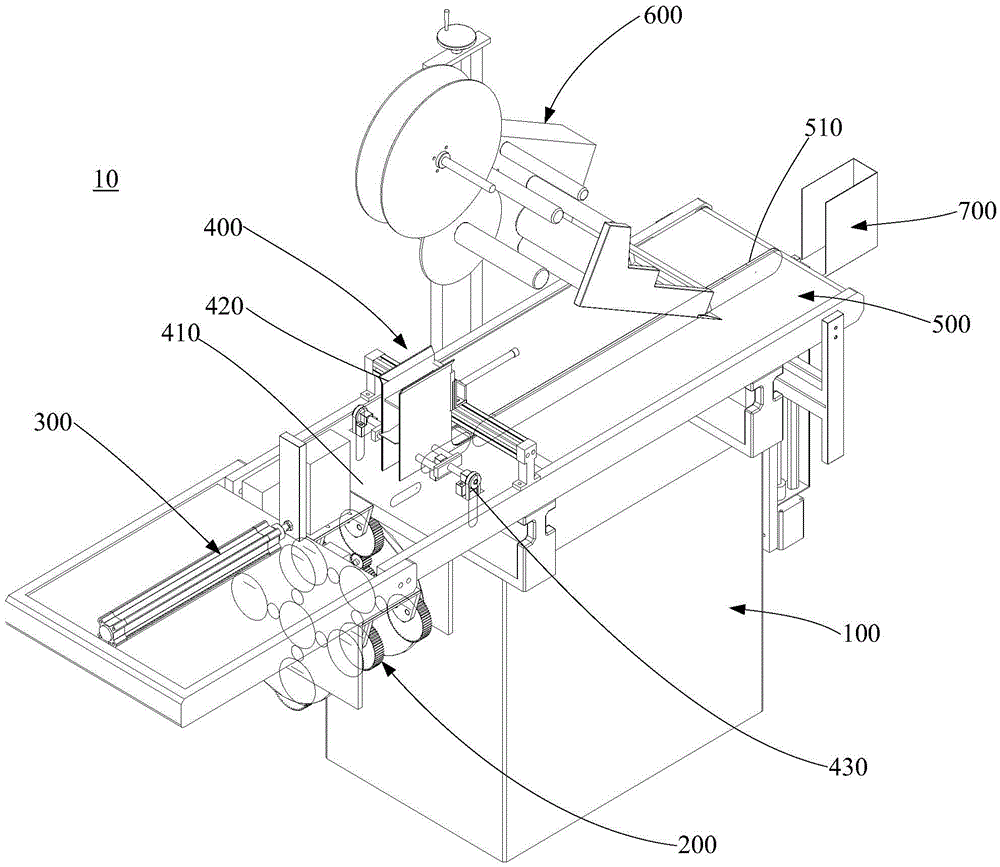

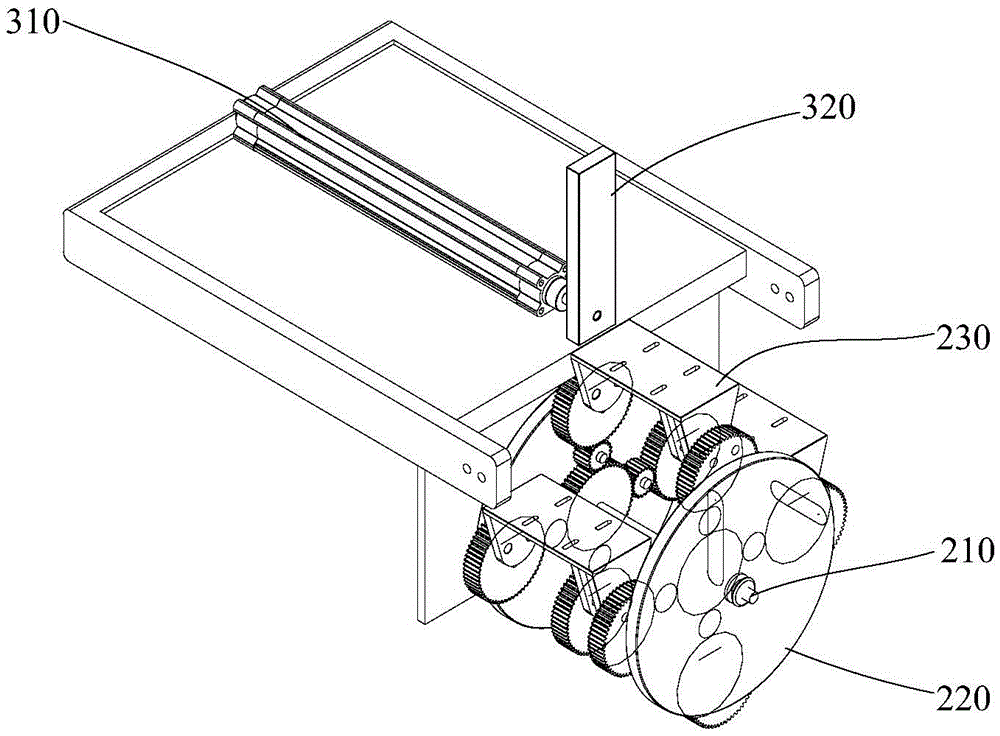

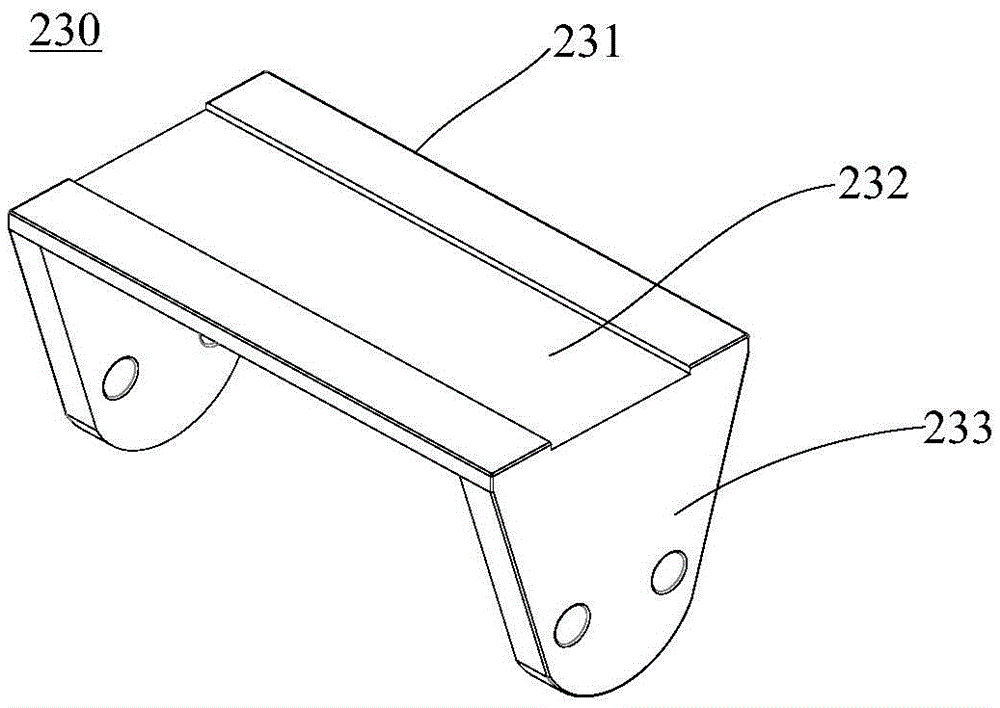

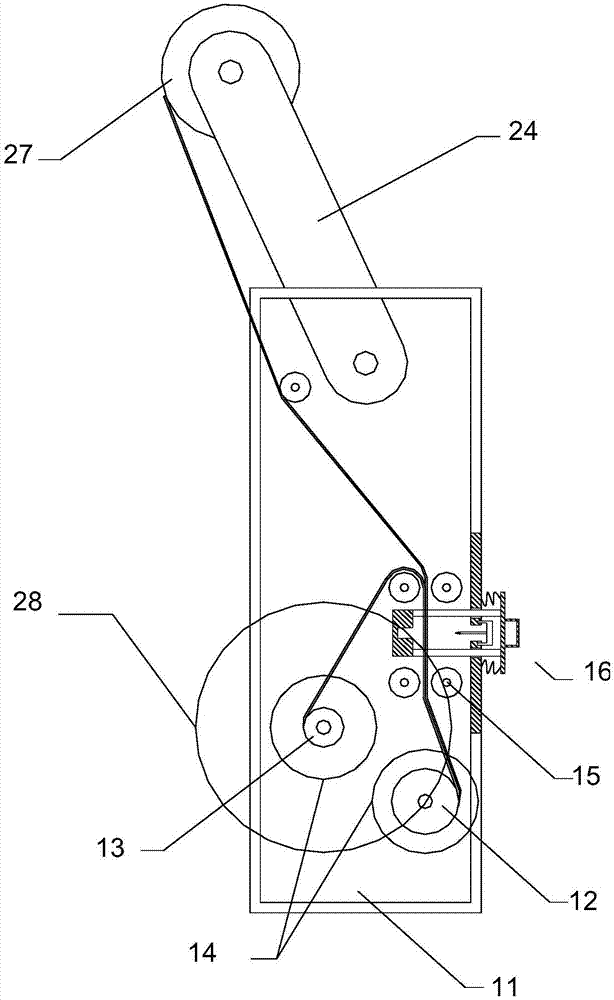

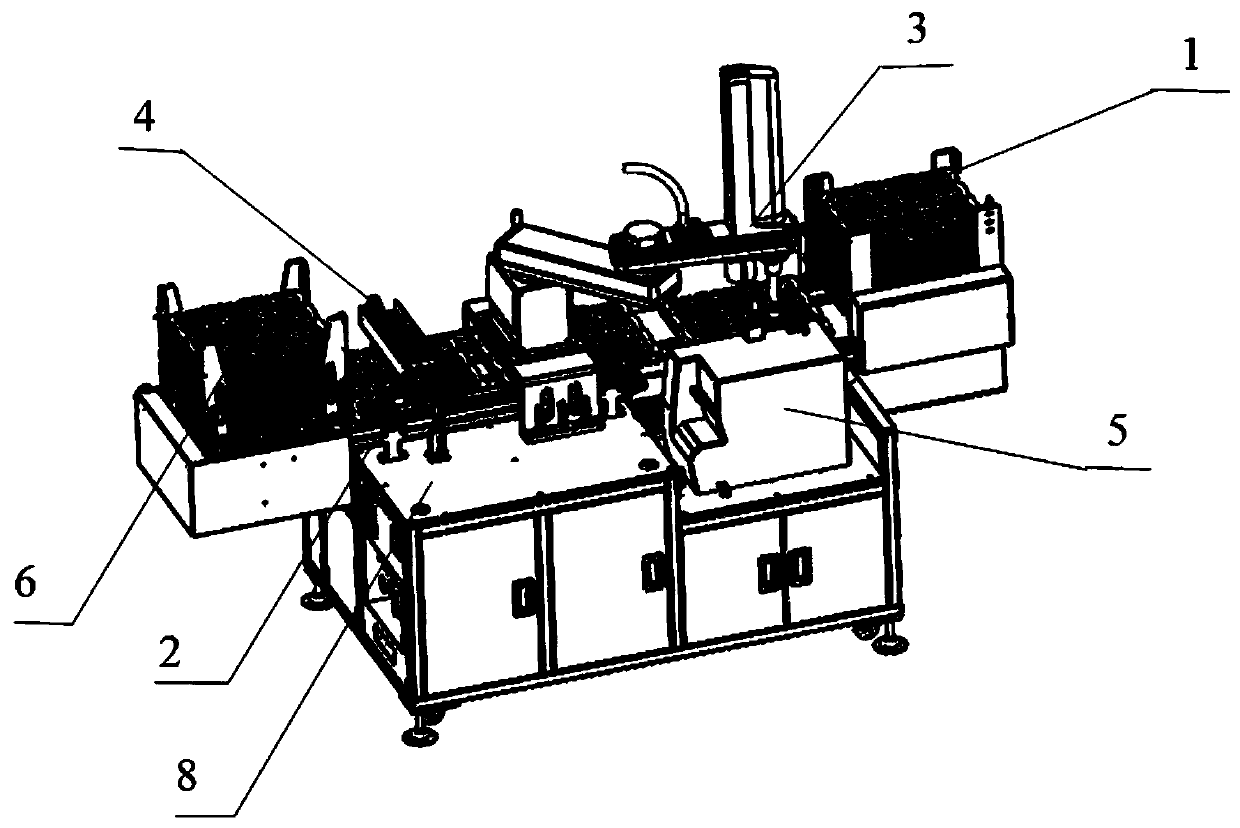

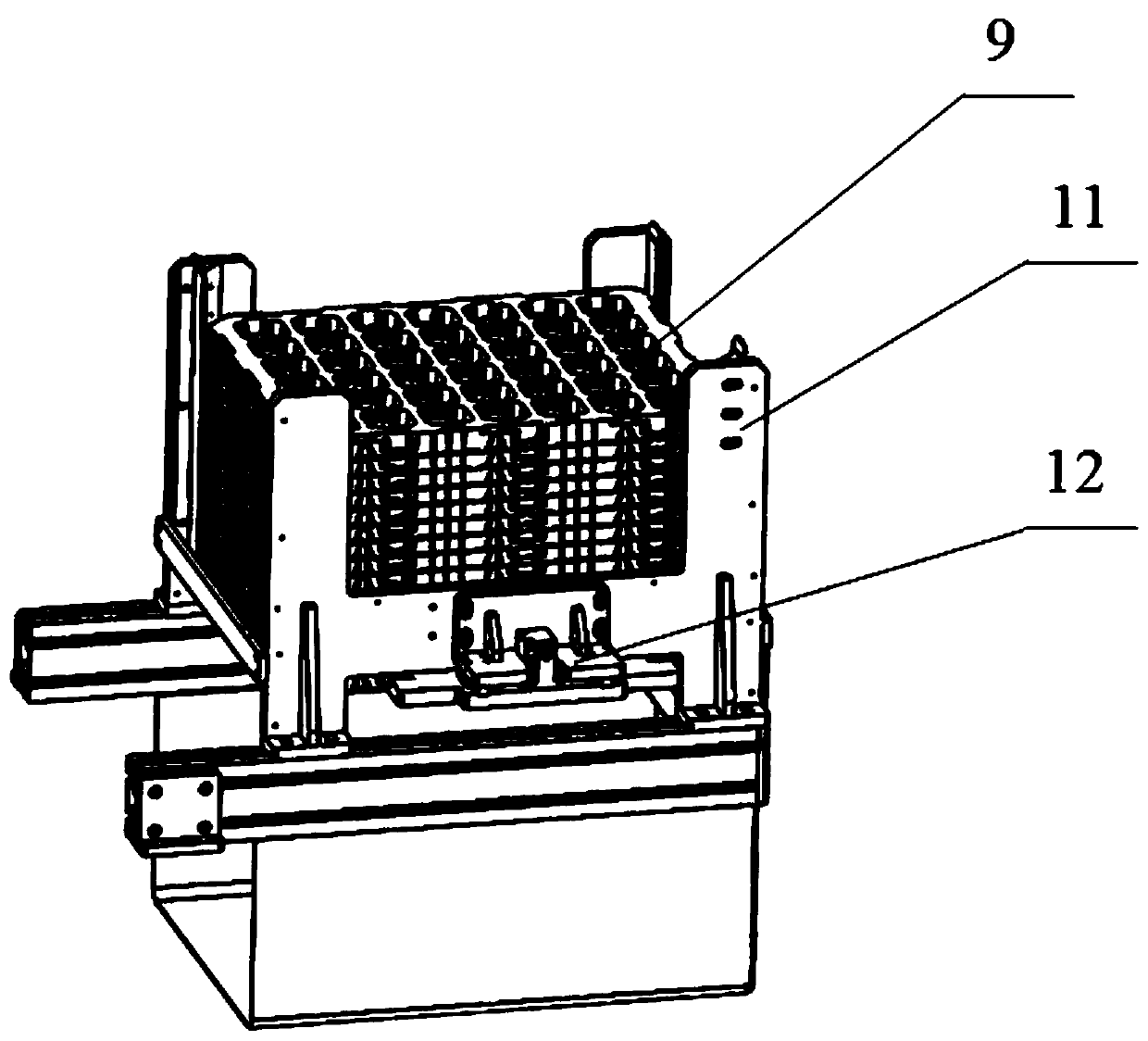

Test tube bar code pasting machine

ActiveCN104528087AImprove pasting efficiencyImprove clamping efficiencyLabelling short rigid containersLabelling machinesEngineeringTransfer mechanism

The invention discloses a test tube bar code pasting machine. The test tube bar code pasting machine comprises a test tube clamping mechanism, a separating mechanism, a transfer mechanism, a jacking mechanism, a pushing mechanism, a conveying mechanism, a pasting mechanism and a popup mechanism, wherein the test tube clamping mechanism is used for clamping test tubes; the separating mechanism is used for separating the test tubes from test tube foam seats; the transfer mechanism is used for driving the test tube clamping mechanism to a designated position; the jacking mechanism is used for jacking the test tubes on the test tube clamping mechanism; the pushing mechanism is used for pushing the test tubes jacked by the jacking mechanism away from the test tube clamping mechanism; the conveying mechanism is used for receiving and conveying the test tubes pushed out by the pushing mechanism; the pasting mechanism is used for pasting bar codes onto the test tubes conveyed by the conveying mechanism; the popup mechanism is used for making the test tubes pasted with the bar codes leave the test tube bar code pasting machine. According to the test tube bar code pasting machine, the test tube clamping mechanism and the separating mechanism can automatically make the test tube foam seats separate from the test tubes, so that the clamping efficiency is greatly improved; an operator just needs to push the test tube foam seats into the test tube clamping mechanism, and the other mechanisms of the test tube bar code pasting machine can automatically paste the bar codes onto the test tubes and output the test tubes pasted with the bar codes.

Owner:HANGZHOU ZHONGGUAN HANMING TECH

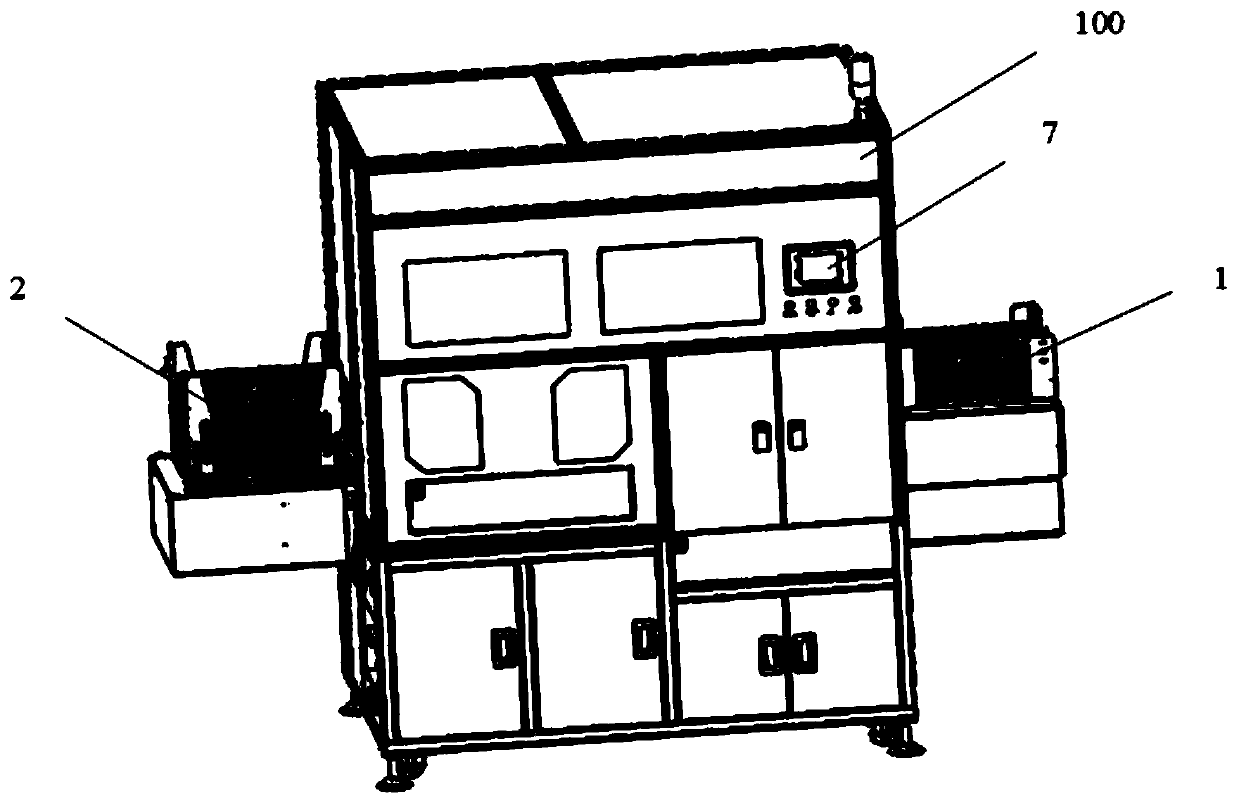

Mobile phone film pasting equipment and method thereof

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI +1

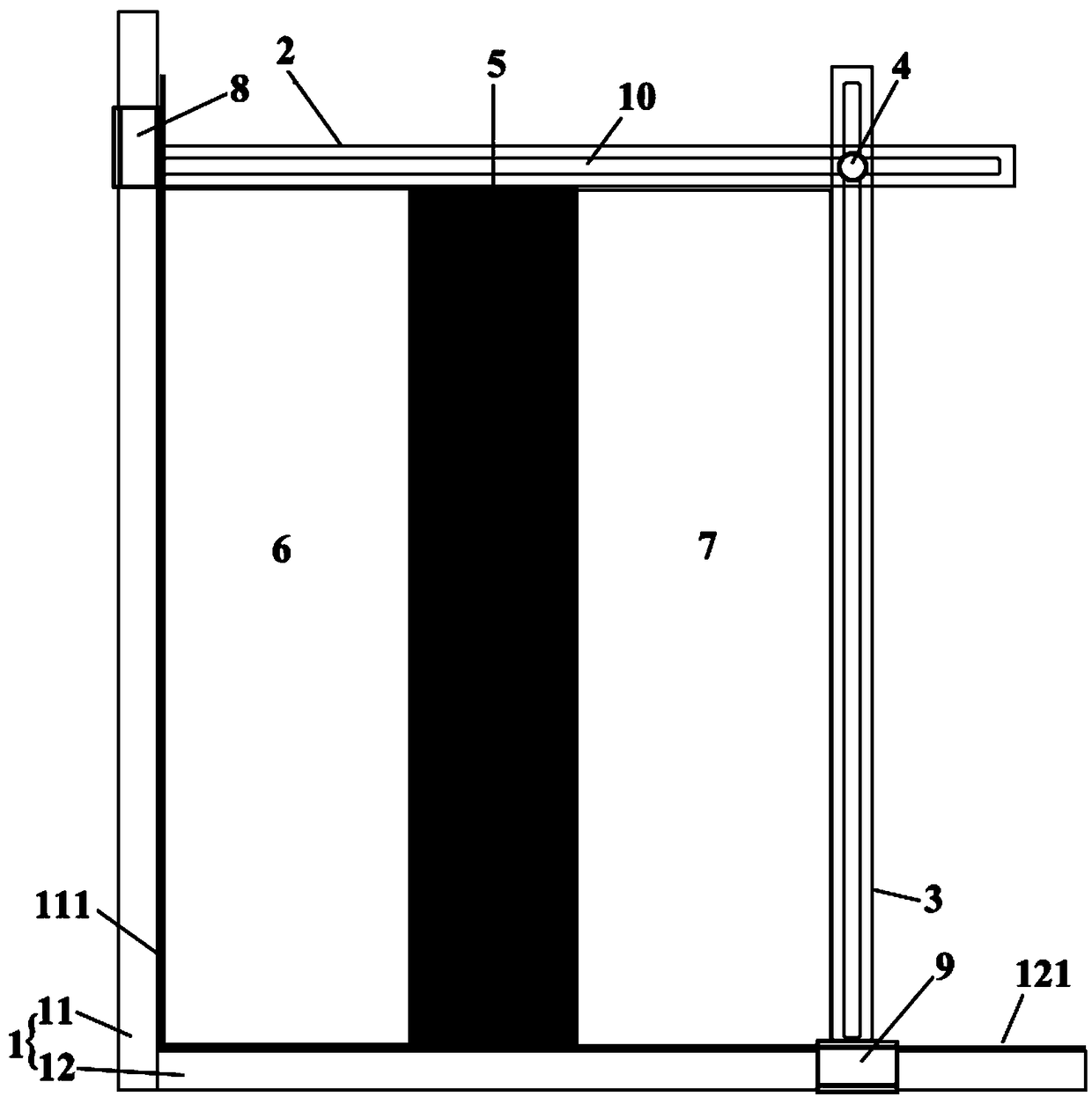

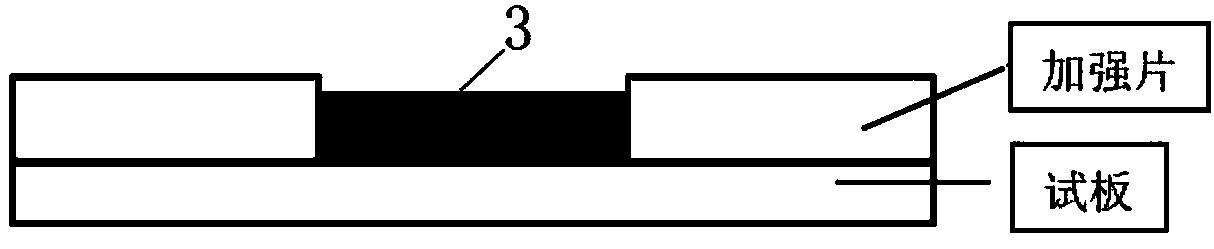

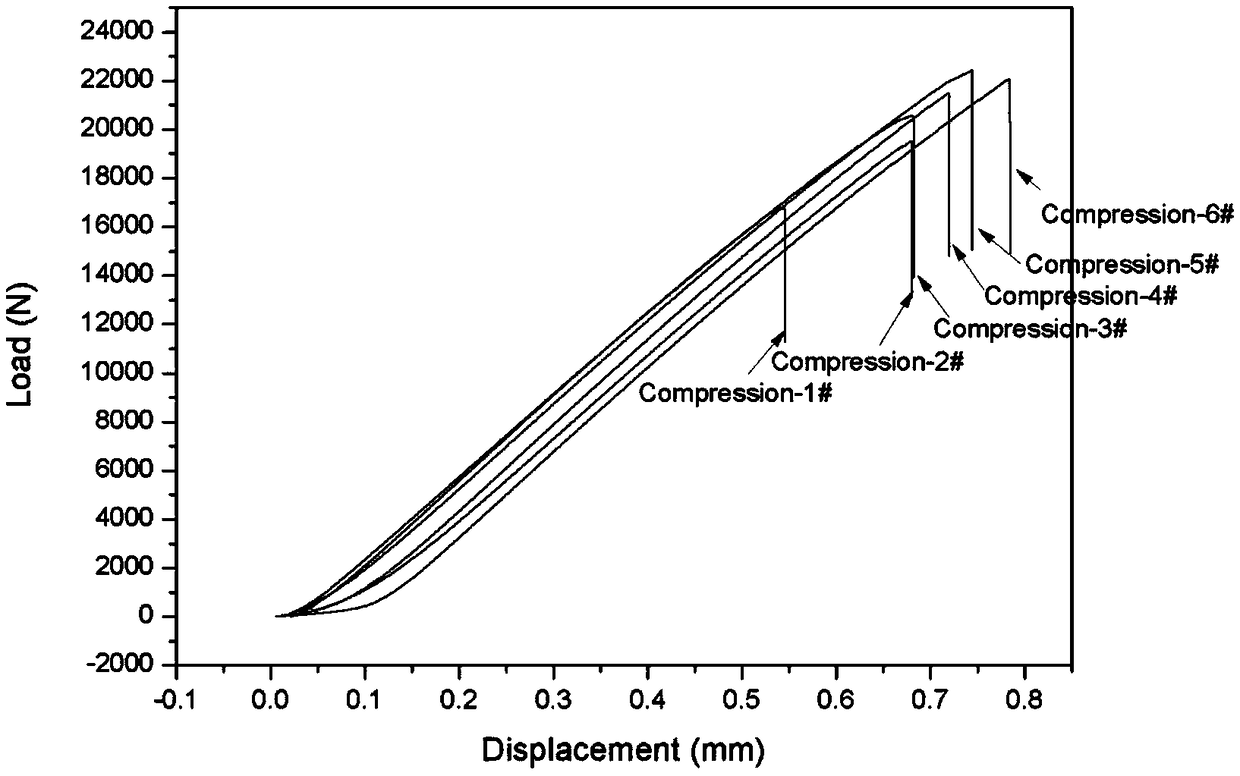

Universal tool for pasting reinforcing sheets and using method and application thereof

PendingCN109085037ASimplify the pasting processPaste implementationPreparing sample for investigationSoftware engineeringGauge length

The invention belongs to the field of universal tools, and particularly relates to a universal tool for pasting reinforcing sheets and a using method and application thereof. The universal tool comprises an L-shaped right-angle main positioning arm, a first sliding arm perpendicular to one side of the right-angle main positioning arm, a second sliding arm perpendicular to the other side of the right-angle main positioning arm, a positioning slide knob for connecting the first sliding arm and the second sliding arm, and a limiting block for positioning the reinforcing sheets and ensuring the gauge length of a tested test piece, wherein the limiting block is arranged in a rectangle formed by the right-angle main positioning arm, the first sliding arm and the second sliding arm. The universaltool can be used for pasting reinforcing sheets on composite test pieces which have different types and specifications and can assist in rapid preparation of the test pieces with the reinforcing sheets, so that the reinforcing sheet pasting procedure is simplified, the reinforcing sheet pasting tool cost is lowered, and pasting efficiency and the test piece machining dimension precision are improved.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

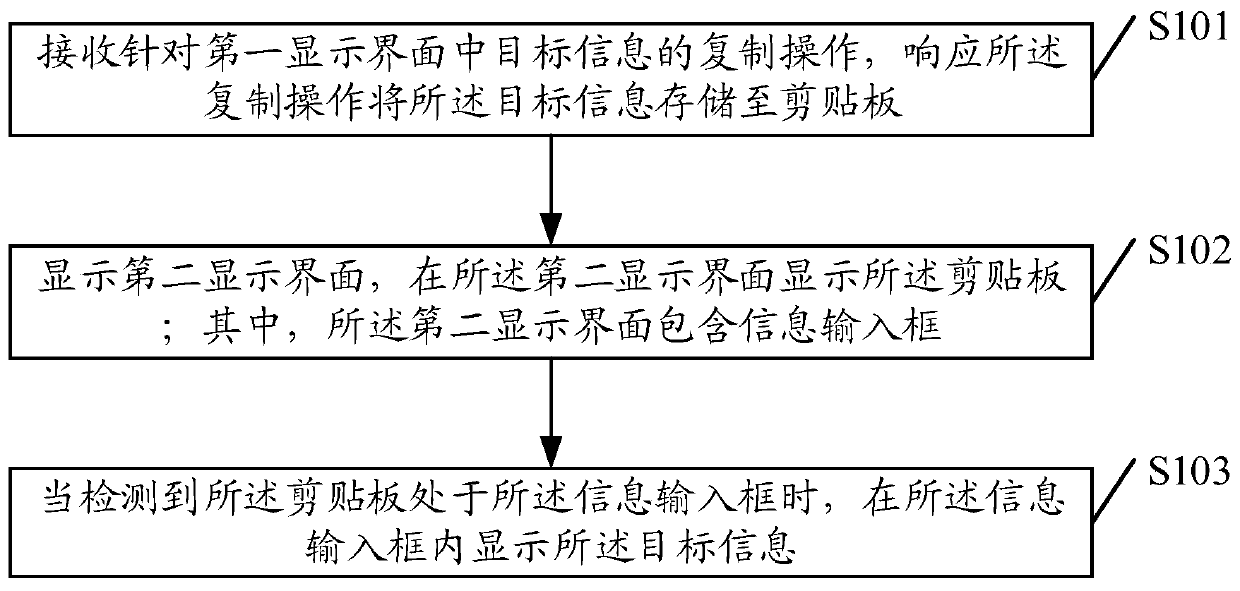

Information processing method and device, storage medium and electronic device

InactiveCN110489039AImprove pasting efficiencyImprove experienceInterprogram communicationInput/output processes for data processingInformation processingWorld Wide Web

The embodiment of the invention discloses an information processing method and device, a storage medium and an electronic device, and the method comprises the steps: receiving a copy operation for target information in a first display interface, and storing the target information to a clipboard in response to the copy operation; displaying a second display interface, and displaying the clipboard on the second display interface; wherein the second display interface comprises an information input box; and when it is detected that the clipboard is located in the information input box, displayingthe target information in the information input box. Therefore, by adopting the embodiment of the invention, a user only needs to move the clipboard into the information input box to paste the copiedcontent, the operation is simple and quick, and the information pasting efficiency is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

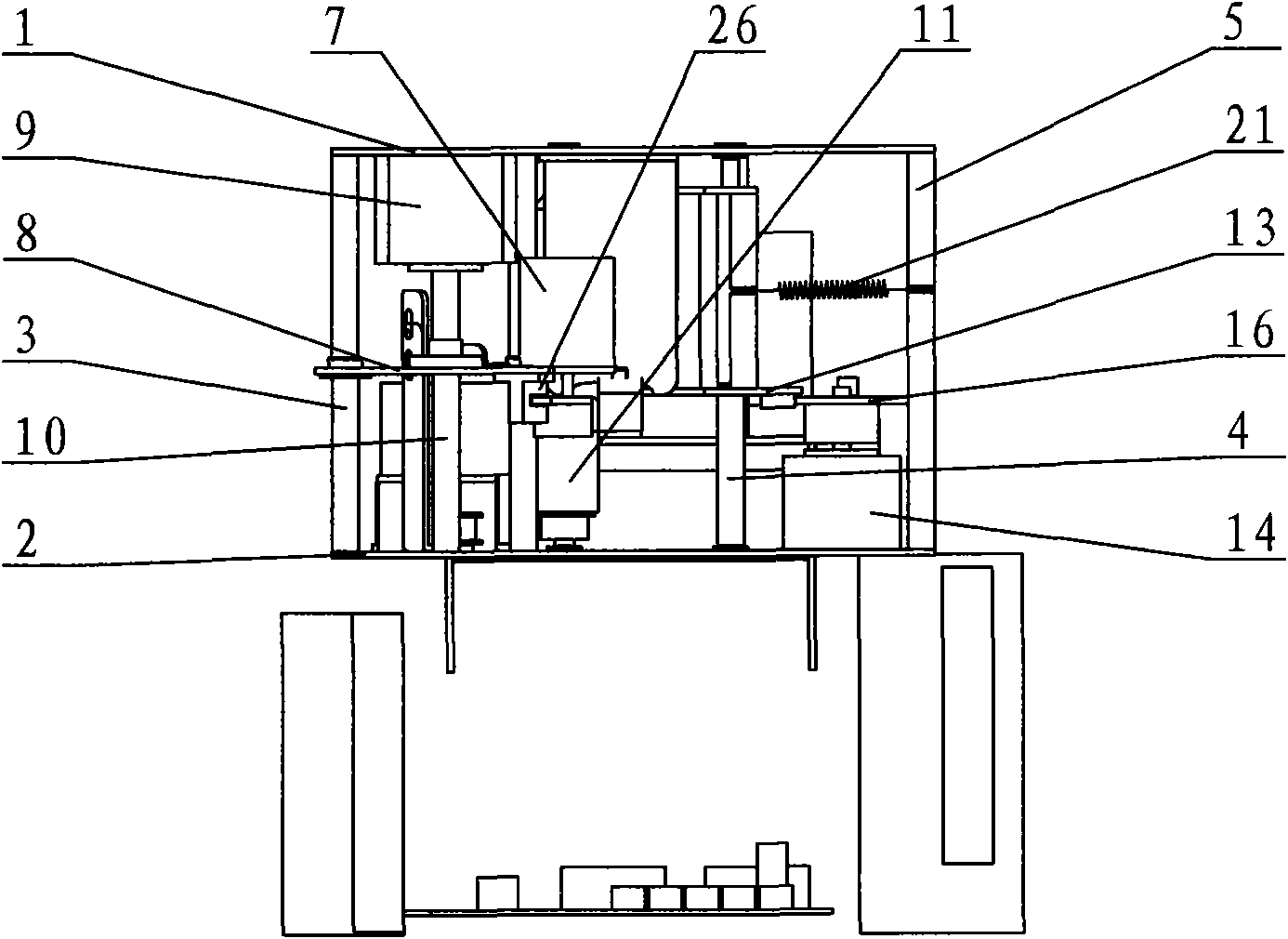

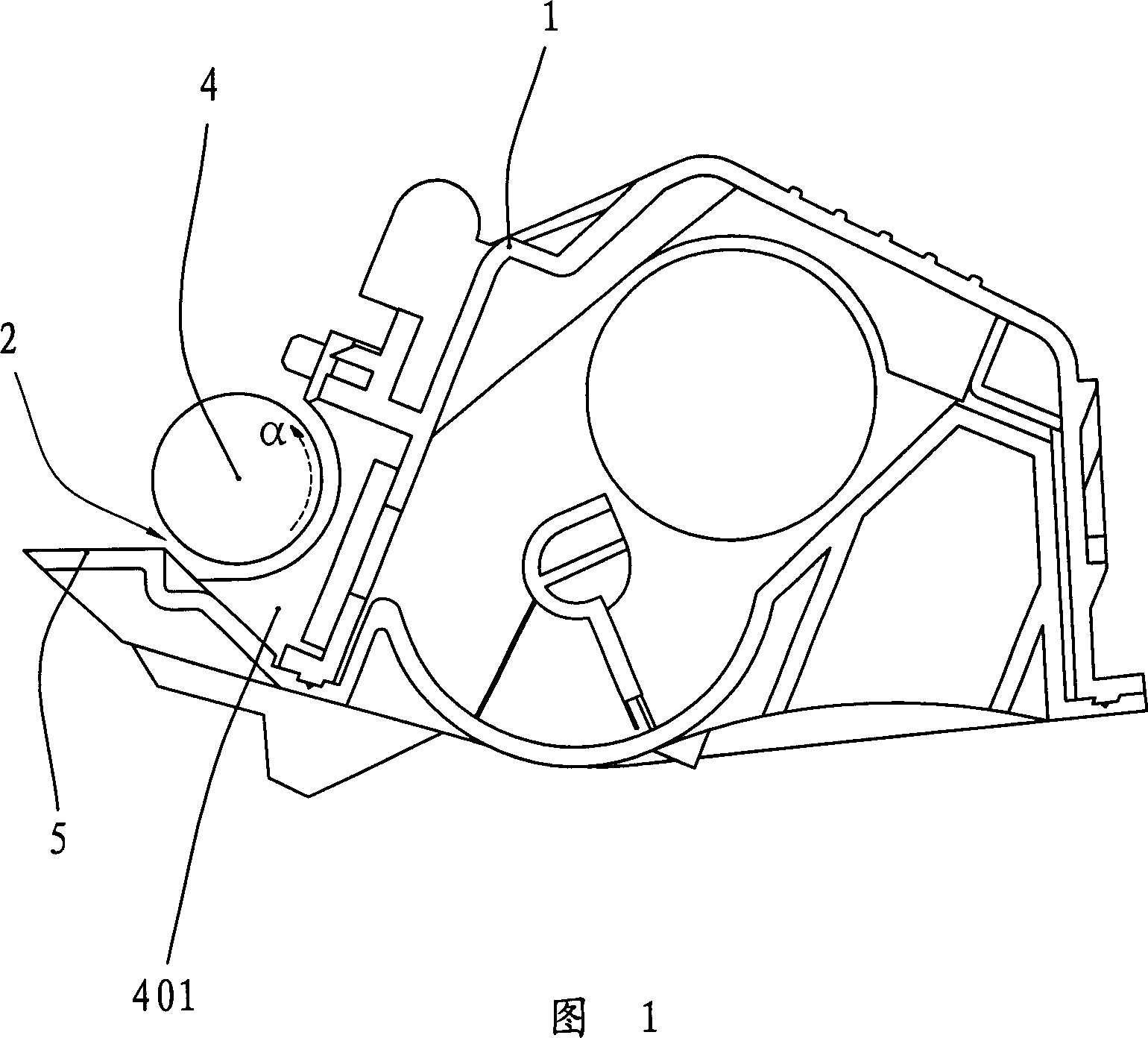

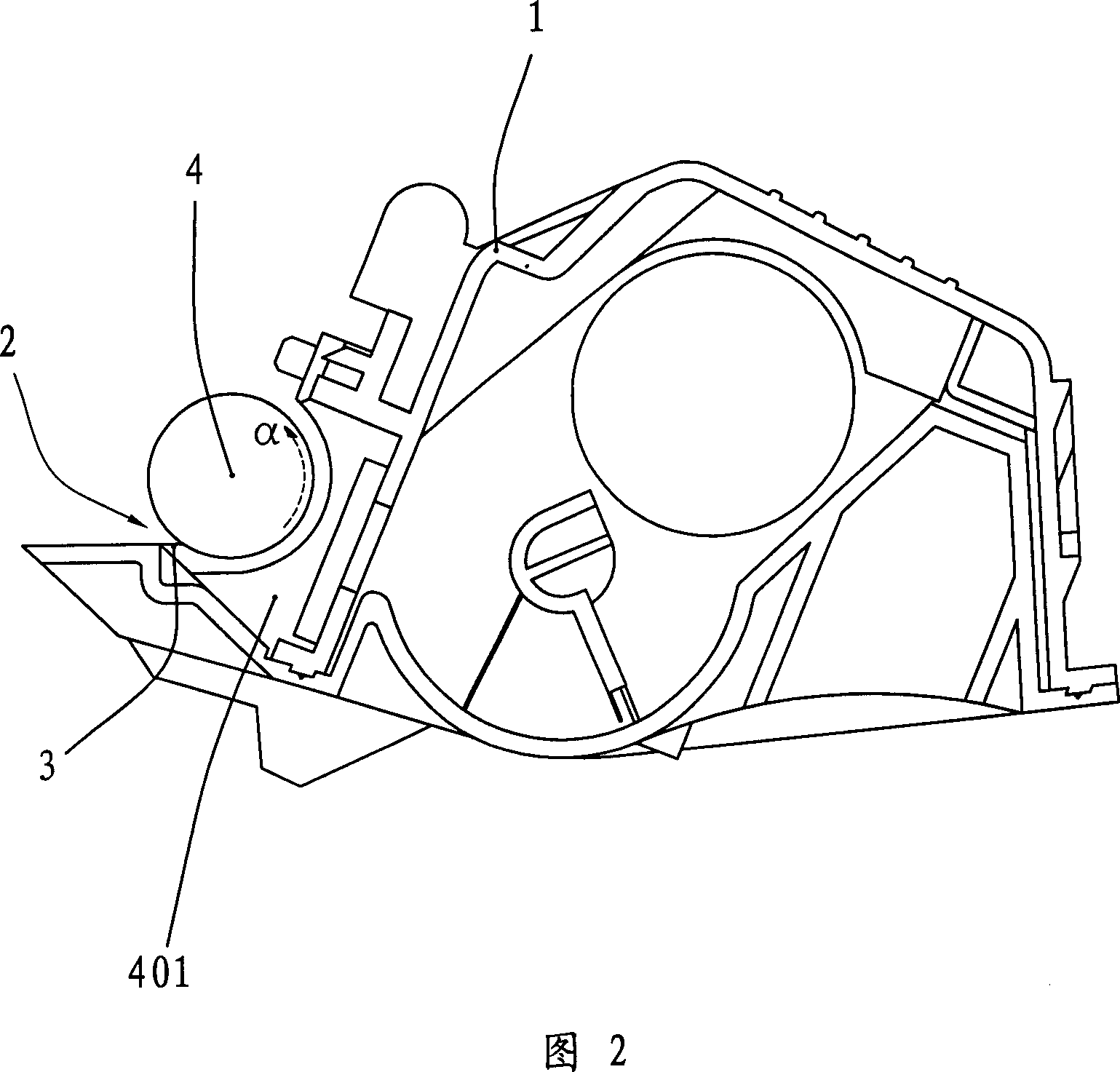

Laser printer developing device sealing sheet adhesion device

InactiveCN101086649AImprove pasting efficiencyThe pasting position is accurateElectrographic process apparatusMechanical engineeringLaser

The stick device for seals of a laser printer developing device comprises the base and installation platform on it. It also comprises the seal sticking structure, paper and glue separation structure, seal cutting structure and the seal sticking structure. The seal sticking structure binds the seal on the glue of the double glue paper, tearing off the coated paper through the paper glue separation device, cutting the seal plate based on the preset length and move to the corresponding position of the developing device, and sticking the seal to the corresponding part of the developing device. It has high precision in matching the seal with the developing device with fastness, and better flatness.

Owner:ZHUHAI TIANWEI TECH DEV CO LTD

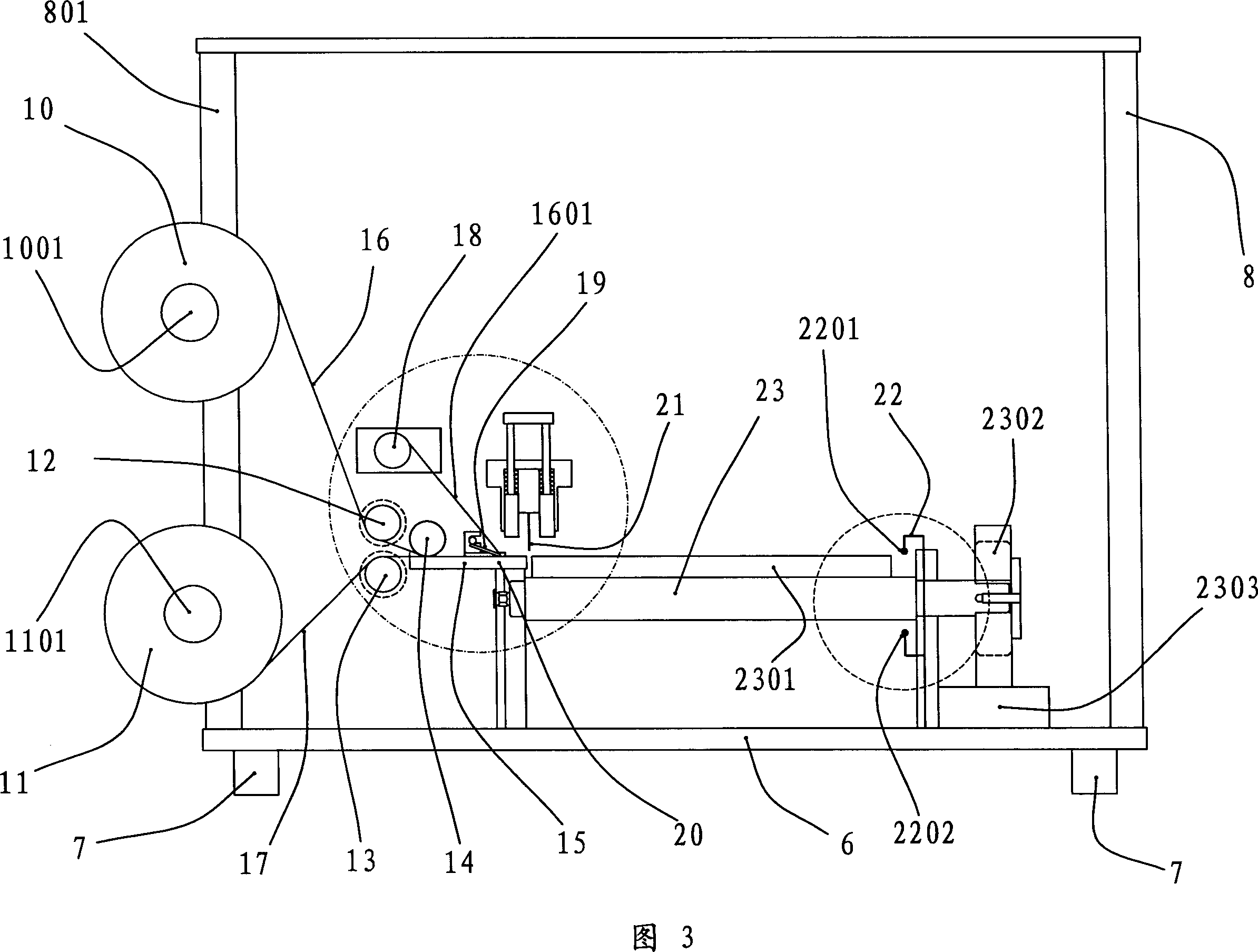

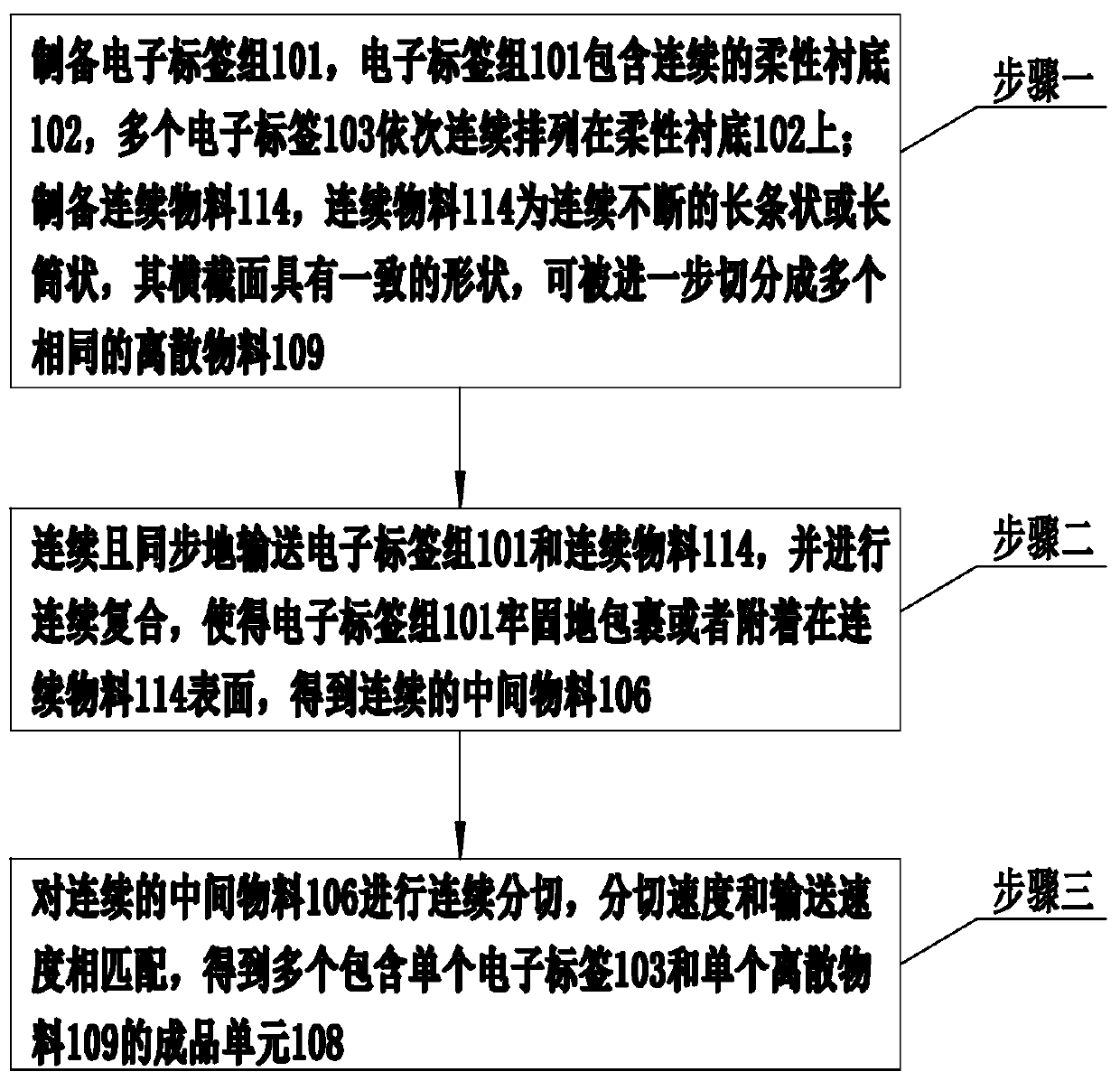

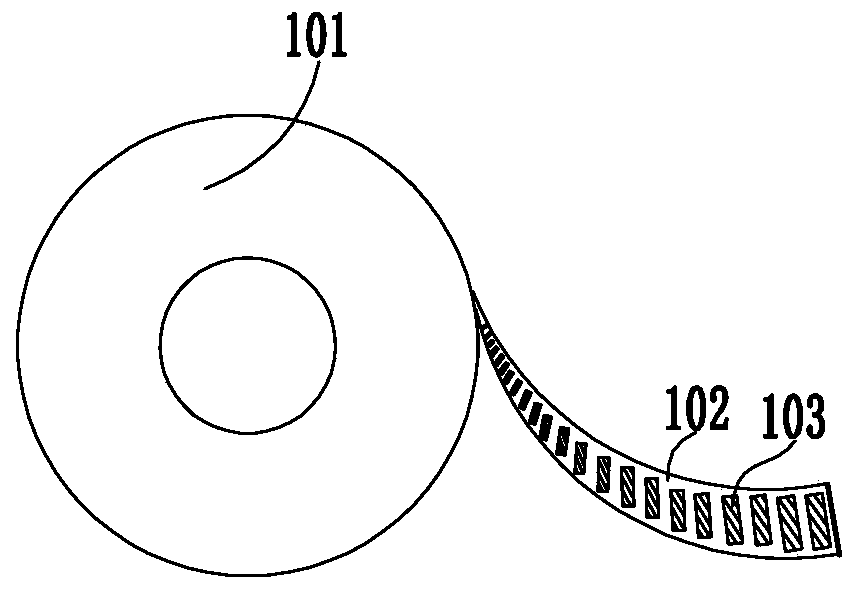

Method and system for pasting electronic tags at high speed

InactiveCN111516952AOvercome limitationsContinuous high-speed stable operationLabelling machinesElectronic taggingEngineering

The invention discloses a method and system for pasting electronic tags at high speed and belongs to the technical field of automatic pasting. The method comprises the steps that an electronic tag setis prepared, wherein the electronic tag set comprises a continuous flexible substrate, and the plurality of electronic tags are sequentially and continuously arranged on the flexible substrate; a continuous material set is prepared, wherein the continuous material set is in a continuous long-strip shape or long-barrel shape, the cross sections of materials are consistent in shape, and the continuous material set can be further cut into a plurality of identical discrete materials; the electronic tag set and the continuous material set are continuously and synchronously conveyed and continuously compounded, so that the electronic tag set firmly wraps or is firmly attached to the surface of the continuous material set to obtain a continuous intermediate material set; and the continuous intermediate material set is continuously cut to obtain a plurality of finished product units which each contains one electronic tag and one discrete material. According to the method and system for pasting the electronic tags at high speed, continuous high-speed operation can be achieved, the pasting efficiency of the electronic tags is improved, the use cost of the electronic tags is reduced, and favorable conditions are created for the application of the radio frequency identification technology in a larger range.

Owner:李可夫

Lithium battery pack tab adhesive tape pasting machine and adhesive tape pasting method

InactiveCN112259924AEasy to pasteAchieve circulationAssembling battery machinesFinal product manufactureEngineeringMechanical engineering

The invention discloses a lithium battery pack tab adhesive tape pasting machine. The lithium battery pack tab adhesive tape pasting machine comprises a rack, and an adhesive tape pasting device, a positioning device and a carrying device which are mounted on the rack, wherein the adhesive tape pasting device corresponds to the position above the positioning device, and the carrying device and theadhesive tape pasting device are located on the two sides of the positioning device respectively; the adhesive tape pasting device is used for cutting adhesive tape and pasting the adhesive tape to tabs of the lithium battery packs in the positioning devices, and the carrying device is used for feeding and discharging the lithium battery packs and carrying the lithium battery packs between the positioning devices. The machine has the advantages of being high in adhesive tape pasting efficiency, accurate in adhesive tape pasting and automatic in feeding and discharging.

Owner:周俊英

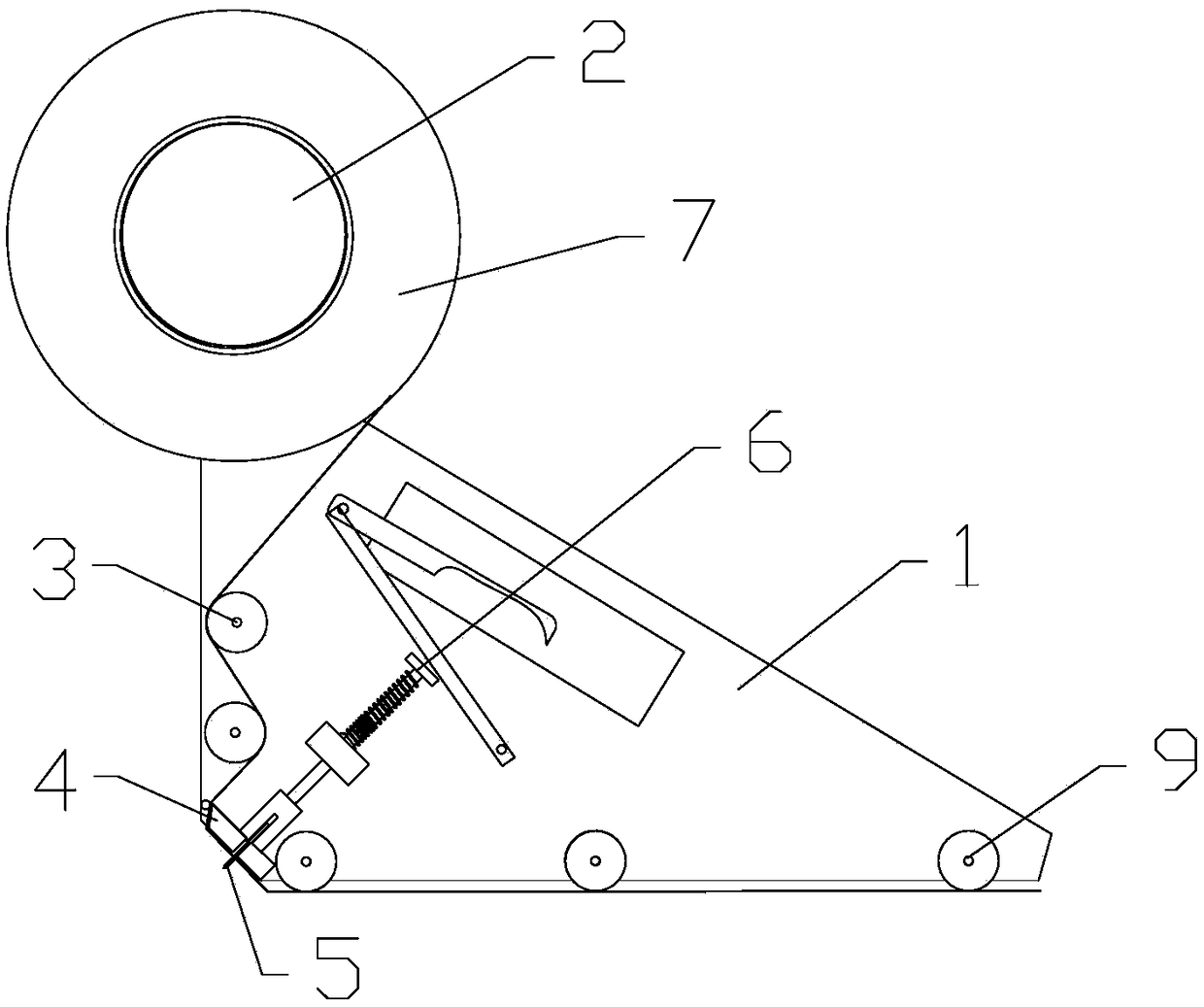

Adhesive tape pasting device

The invention discloses an adhesive tape pasting device. The adhesive tape pasting device comprises a support, an adhesive tape wheel, several conveying wheels, a cutting platform, a cutting mechanismand a control mechanism, the adhesive tape wheel is arranged on the support and is used for containing an adhesive tape, the conveying wheels are rotatably arranged on the support and are used for conveying the adhesive tape on the adhesive tape wheel to the cutting platform, the cutting platform comprises a tape pressing table and a traction roller, the traction roller is arranged on one side ofthe tape pressing table and cooperates with the tape pressing table to guide the free end of the adhesive tape to the tape pressing table for pasting, the cutting mechanism comprises a cutter used for cutting the adhesive tape, and the control mechanism is connected with the cutting mechanism so as to control the cutting mechanism to cut the adhesive tape on the tape pressing table. The providedadhesive tape pasting device has the advantages that the operation is simple and rapid, the adhesive surface is flat and clean, the free end of the adhesive tape does not return to paste other parts of the adhesive tape while the adhesive tape is cut off, then the head of the adhesive tape can be convenient to pull, and the pasting efficiency and the utilization rate of the adhesive tape are greatly improved.

Owner:杭州奥方科技有限公司

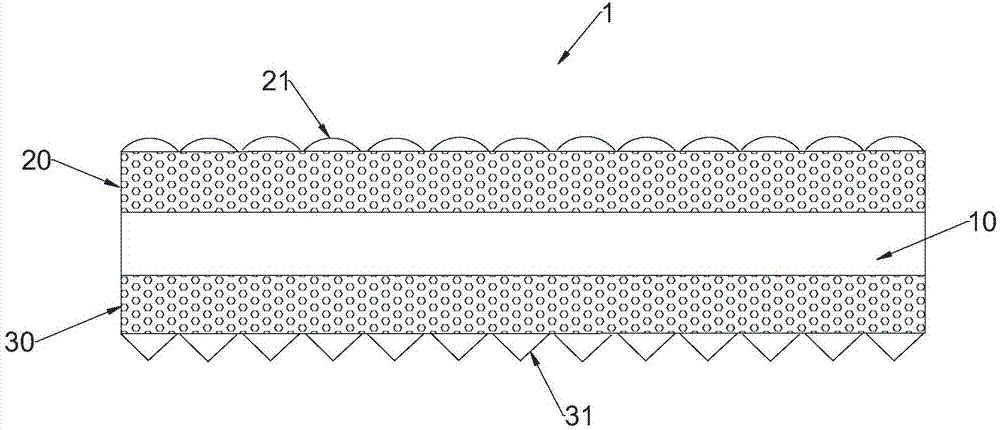

Novel energy saving and environment-friendly tile bonding material

InactiveCN107035094AImprove pasting efficiencyEasy to useCovering/liningsSynthetic resin layered productsEpoxyPolymer science

The invention discloses a novel energy saving and environment-friendly tile bonding material comprising a polytetrafluoroethylene fiber layer. A macroporous sponge layer is arranged on one face of the polytetrafluoroethylene fiber layer. Epoxy group acrylic ester emulsion are imbibed fully in the macroporous sponge layer. A plurality of wall surface engaged strips are arranged on the surface of the macroporous sponge layer. A microporous sponge layer is arranged on the other face of the polytetrafluoroethylene fiber layer. Acrylic emulsion and superpolymers are imbibed fully in the microporous sponge layer. A plurality of tile engaged strips are arranged on the surface of the microporous sponge layer. The novel energy saving and environment-friendly tile bonding material is integrally of a platy structure. When the novel energy saving and environment-friendly tile bonding material is used, a protecting film on the surface of the material is torn off, and the bonding material is attached on the wall face or ground; then a tile is attached on the bonding material to be compacted; and the material is similar to double-side tape, using is quite convenient in the process of tile sticking, and the sticking efficiency of the tile can be greatly improved.

Owner:江苏君成建材科技有限公司

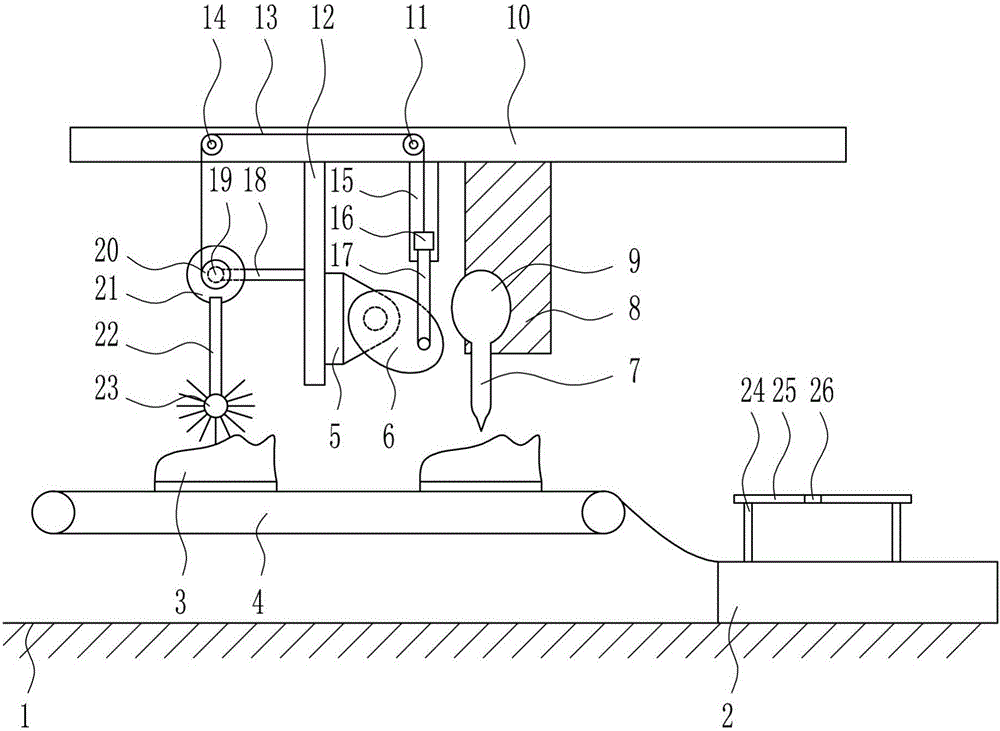

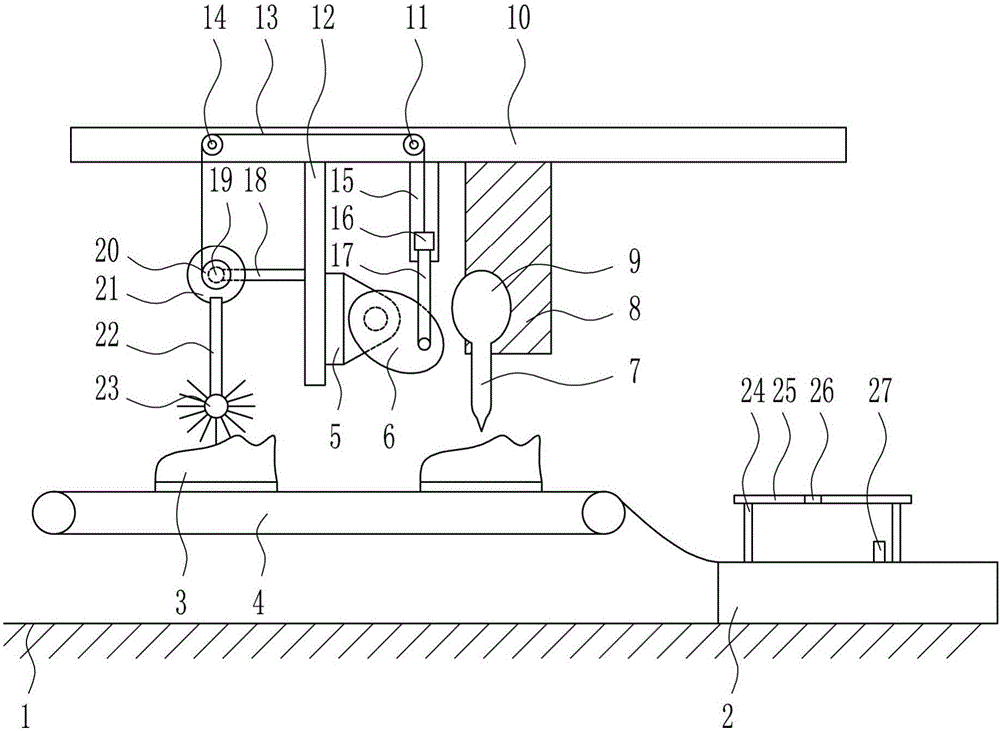

Ornament adhesion device for shoe making

The invention relates to an ornament adhesion device and especially relates to an ornament adhesion device for shoe making. The technical problem to be solved by the invention is to provide the ornament adhesion device for the shoe making, wherein adhesion efficiency is high and ornament adhesion is accurate. In order to solve the technical problem, the invention provides the ornament adhesion device for the shoe making. The device comprises a working table, a transmission device, a sway base, an ellipsoid cam, an adhesive dripping bottle, a fixation trough, an adhesive cap, a top plate, a second fixed pulley, a fixation plate, a pull wire, a first fixed pulley, a slide rail, a slide block, a connecting rod, a first strut, an electric motor, a winding wheel, a round disk, a sway rod and a duster, wherein the transmission device and the working table are disposed on the ground, and the transmission device is located above the left part of the working table. According to the invention, ornaments can be adhered on a shoe rapidly; by a limiting block, a second strut and a positioning plate, the ornaments can be adhered on the shoe more easily; and ornament adhesion positions are more accurate.

Owner:广东亮丰达实业有限公司

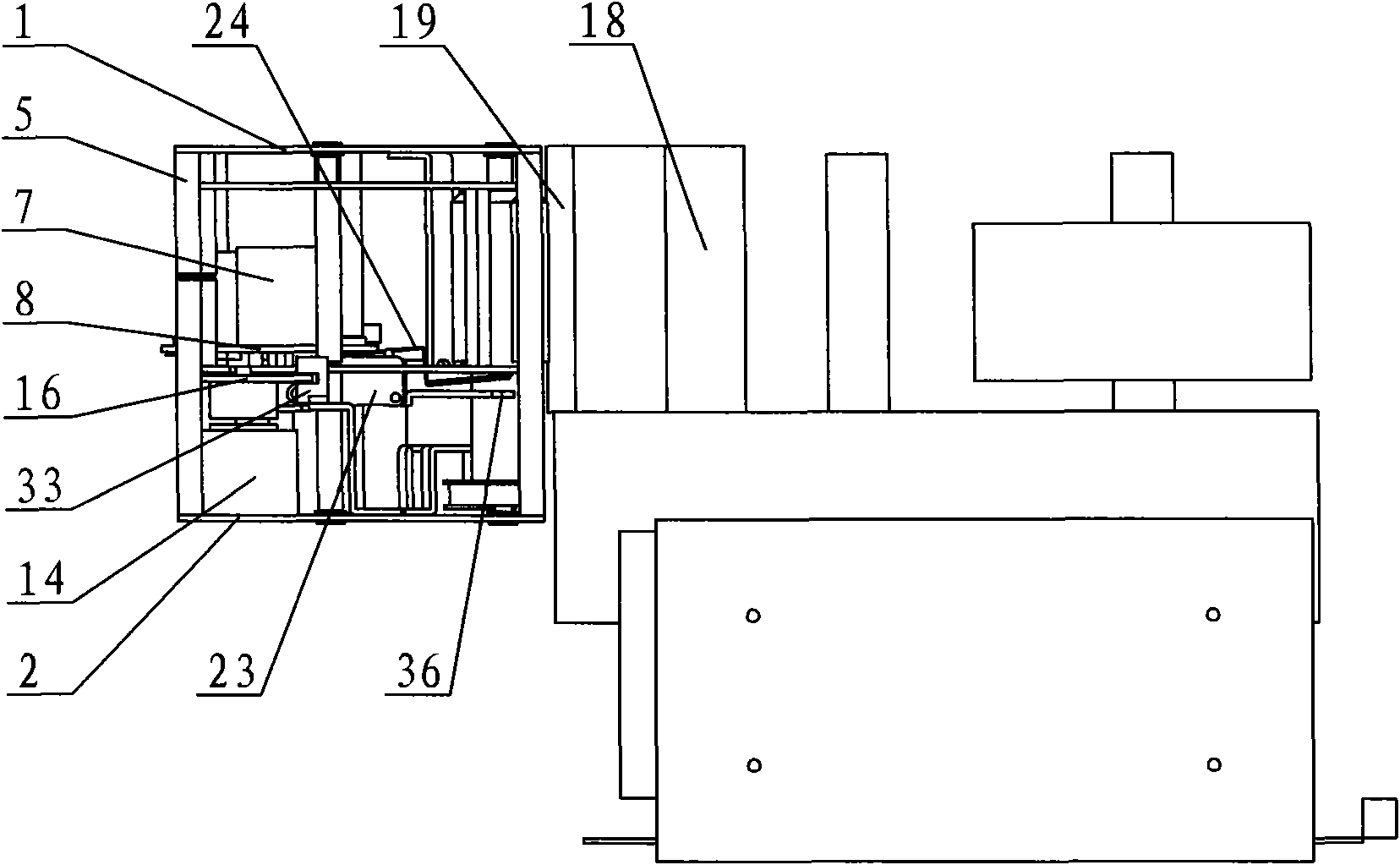

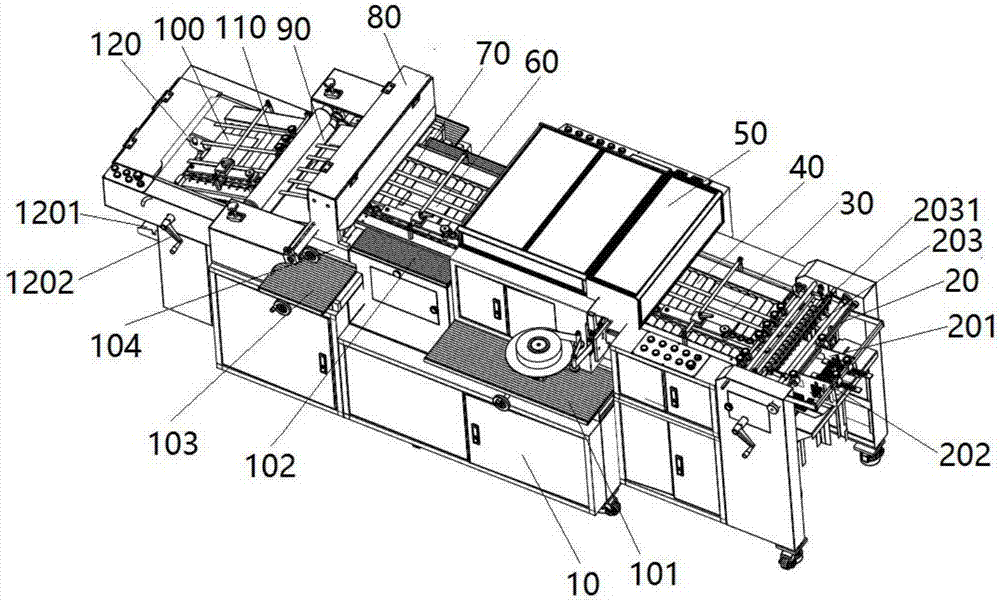

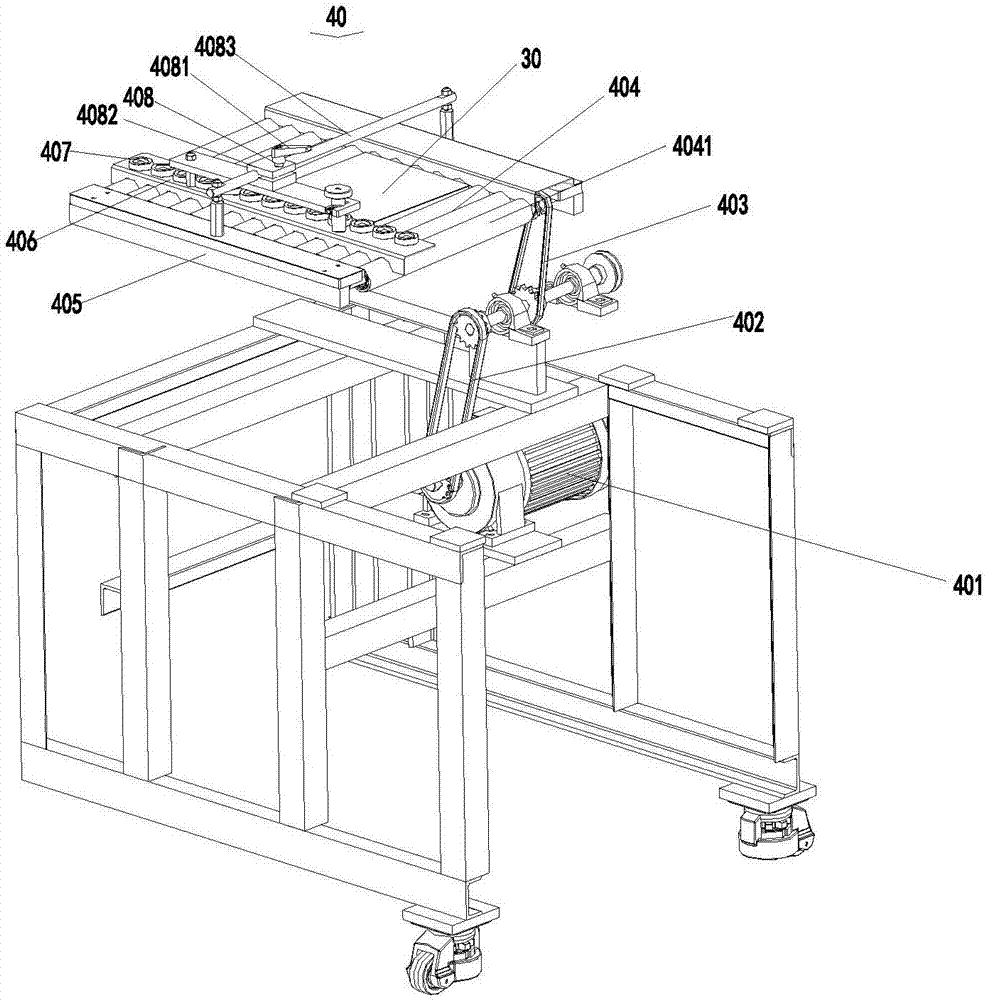

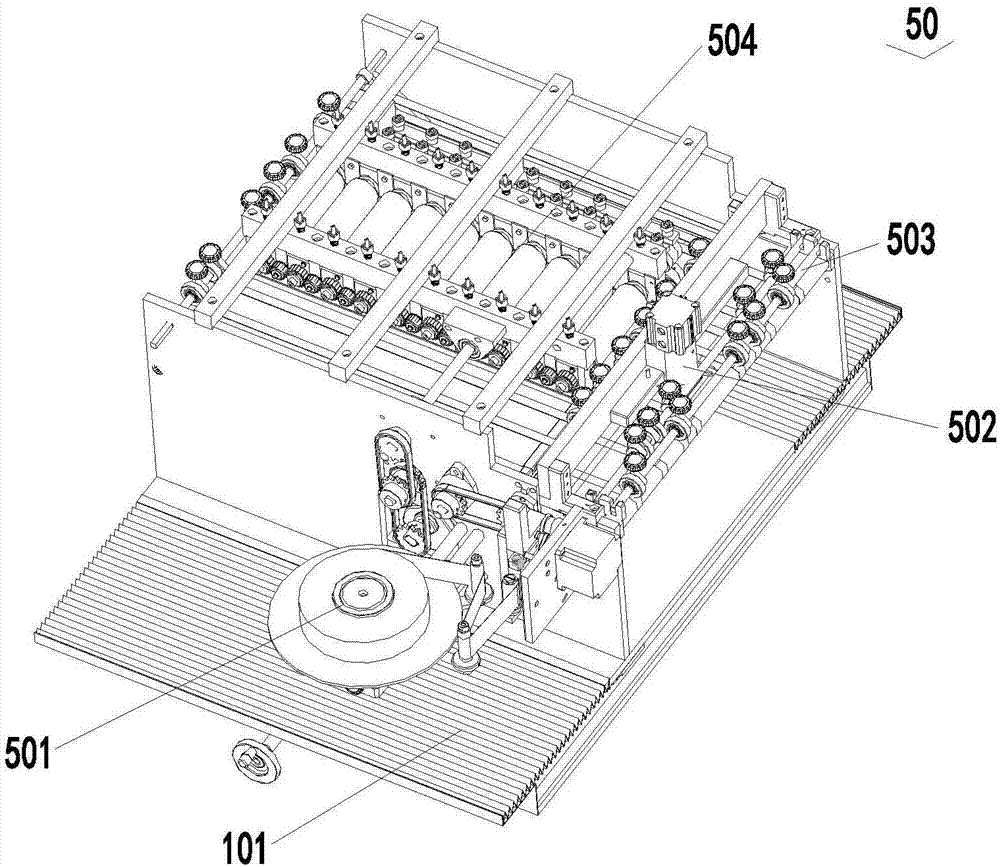

Paper film pasting, die cutting and forming equipment

PendingCN107571511AReduce manual workloadChange where to pasteMetal working apparatusPulp and paper industry

The invention discloses paper film pasting, die cutting and forming equipment. According to the main technical scheme, the paper film pasting, die cutting and forming equipment comprises a rack, a paper feeding mechanism, a paper first positioning and conveying mechanism, a film pasting mechanism, a paper second positioning and conveying mechanism, a film die cutting mechanism, a forming pressingroller mechanism, a paper collecting and positioning mechanism and a paper collecting mechanism, wherein the rack comprises a first moving platform arranged in the rack, a manual adjusting sliding platform arranged in the rack and a second moving platform arranged in the rack, and the second moving platform is provided with a third moving platform; the paper feeding mechanism is arranged at the front end of the rack; the paper first positioning and conveying mechanism is arranged on the rack and located behind the paper feeding mechanism; the film pasting mechanism is arranged on the first moving platform and located behind the paper first positioning and conveying mechanism; the paper second positioning and conveying mechanism is arranged on the manual adjusting sliding platform and located behind the film pasting mechanism; the film die cutting mechanism is located behind the paper second positioning and conveying mechanism; the forming pressing roller mechanism is located behind thefilm die cutting mechanism; the paper collecting and positioning mechanism is fixed to the rack and located behind the forming pressing roller mechanism; and the paper collecting mechanism is fixed to the rack and located behind the paper collecting and positioning mechanism.

Owner:毛以波

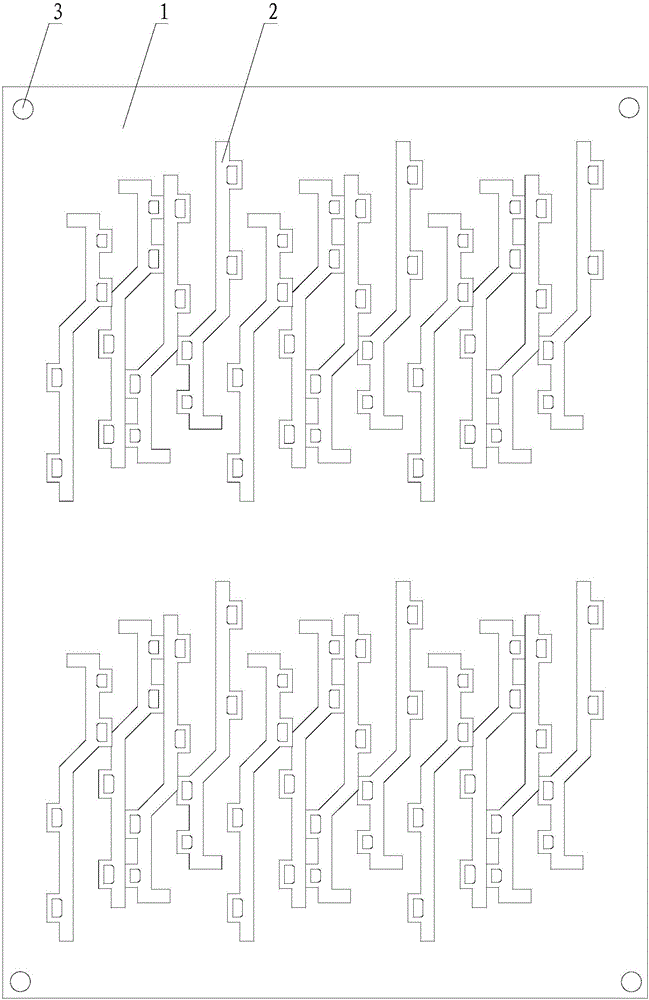

Shielding film and pasting method therefor

InactiveCN106163248AImprove pasting efficiencyReduce generationMagnetic/electric field screeningAdhesive processes with surface pretreatmentEngineeringRaw material

The invention discloses a pasting method for a shielding film. The method comprises the steps of punching an adhesive film, wherein the adhesive film comprises a film layer and an adhesive layer; punching and cutting the shielding film to form at least one shielding film unit; bonding one surface, provided with a protective film, of the at least one shielding film unit with the adhesive layer on the adhesive film according to an arrangement mode of a to-be-pasted product; pasting one surface, not provided with the protective film, of the shielding film unit bonded with the adhesive layer to the to-be-pasted product; pressing the to-be-pasted product pasted with the shielding film unit; and tearing off the adhesive film and removing the protective film on the shielding film unit. The invention furthermore provides the shielding film. The shielding film is prepared by the pasting method for the shielding film. According to the pasting method for the shielding film, provided by the invention, raw materials can be saved and the pasting effect is good.

Owner:深圳市玖联科技有限公司

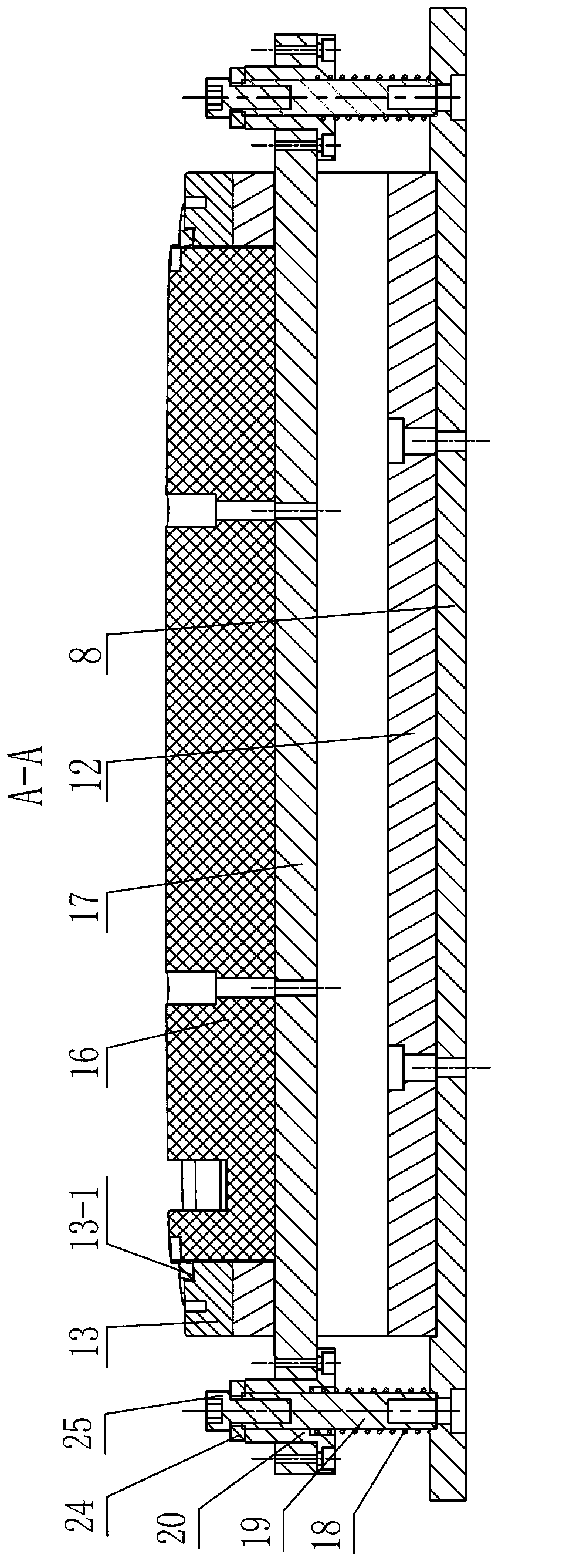

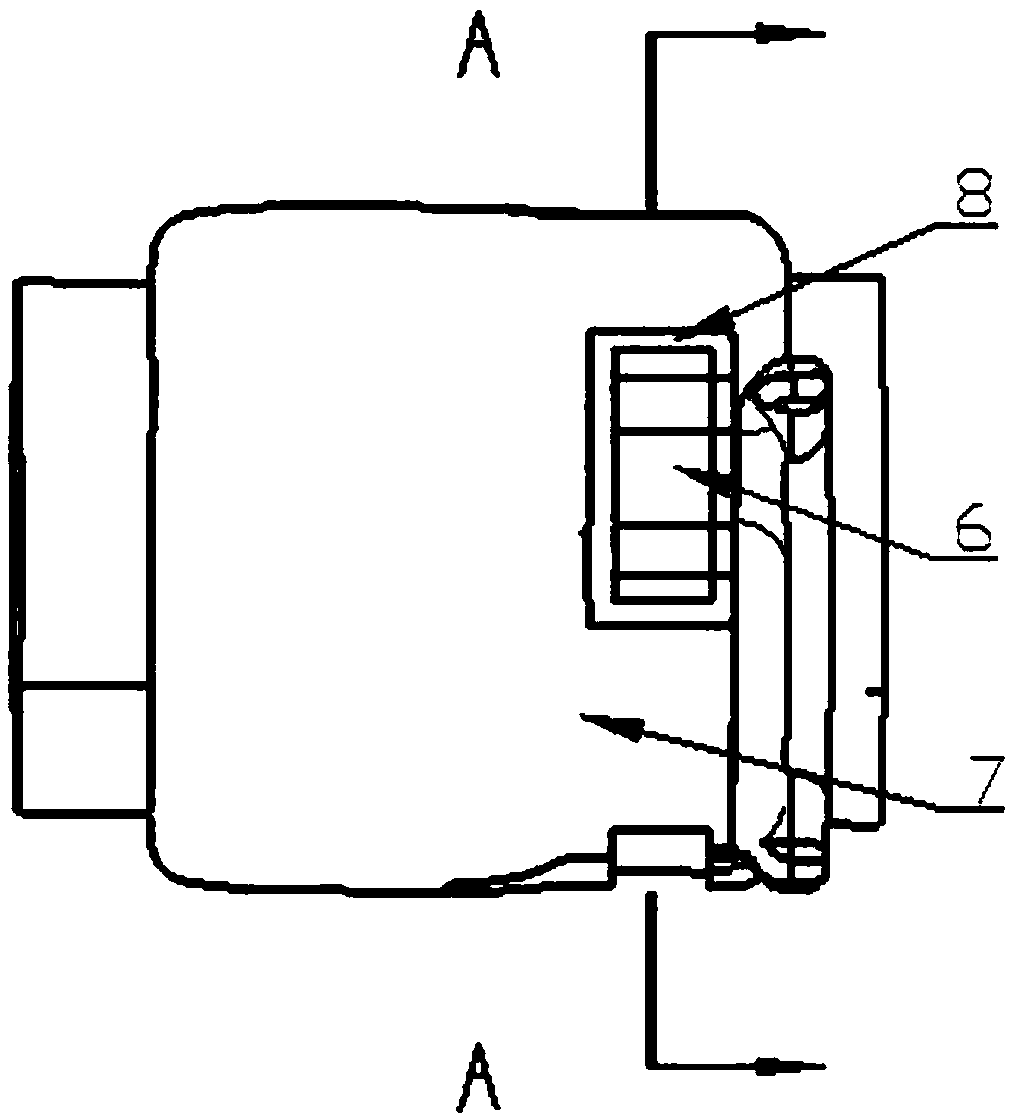

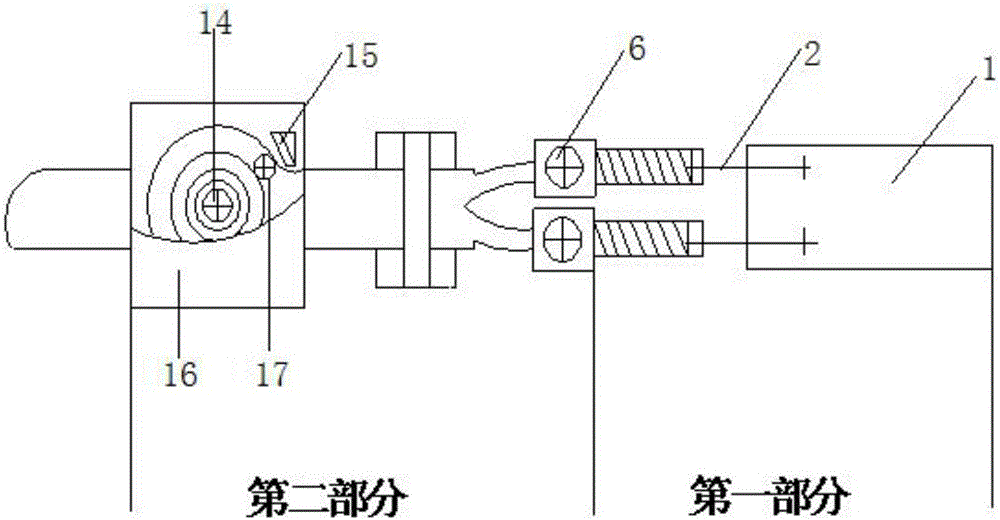

Lead and conductor connection device of strain gauge

InactiveCN105720397AReduce cumbersomeAvoid short circuitFluid pressure measurement using ohmic-resistance variationForce measurementStrain gaugeTriangular prism

The invention belongs to the technical field of a test device, and relates to a lead and conductor connection device of a strain gauge. The strain gauge is connected with two leads; the tail ends of the two leads are connected with arched soldering lugs; the backs of semitransparent cuboid gels are double sticky tapes; the tail ends of the semitransparent cuboid gels are connected with the arched soldering lugs; the upper half part of a fastening block is equipped with a threaded hole; the threaded hole is connected with a cup head cross-recess bolt; a conductor through hole is opened in the middle part of the fastening block; insulation paint is coated on the lower surface of the fastening block; the upper end of the fastening block is a circular fastening belt; the lower part of the fastening belt is an adhering sheet; the adhering sheet penetrates the fastening belt; the conductor at the outer side of each ring of spring sheet is winded on the spring sheet; one end of the spring sheet is clamped on a spring clamping shaft; the other end is located at the lower outlet of the conductor; the spring clamping slot is connected with an upper enclosure and a lower enclosure; and a triangular prism-shaped lock catch and a blocking shaft are mounted at the lower outlet of the conductor. The device is simple in structure, scientific and reliable in principle, flexible and convenient in operation and regulation mode and wide in application prospect.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Automatic labeling machine

ActiveCN105416735AImprove pasting efficiencyCompact structureLabelling deformable materialsLabelling machinesFeed driveEngineering

The invention relates to an automatic labeling machine used for pasting label paper on label stickers. The automatic labeling machine comprises a rack, a feeding mechanism, a pushing mechanism, a locating mechanism, a conveying mechanism and a labeling mechanism, can automatically paste label paper on label stickers, and adopts the feeding mechanism with a planetary gear set; a plurality of stacks of label stickers can be placed; during feeding, a feeding driving device returns the labels to a feeding station; the pushing mechanism pushes the label stickers to the locating mechanism; the locating mechanism performs locating and clamping; and the conveying mechanism conveys the label stickers to the labeling mechanism for label paper pasting. According to the automatic labeling machine, label paper pasting can be carried out on a plurality of stacks of label stickers, an electrical integration design is adopted, the structure is compact, the use is easy and convenient, and the pasting efficiency of label paper is improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Labor-saving high-efficiency self-adhesive wallpaper pasting device

InactiveCN107571678AImprove pasting efficiencyEfficient separationPaperhangingWorking environmentEngineering

The invention discloses a labor-saving high-efficiency self-adhesive wallpaper pasting device. The labor-saving high-efficiency self-adhesive wallpaper pasting device comprises a moving table, a pasting device body is arranged above the moving table, the pasting device body is provided with a fixing plate, the left side and the right side of the fixing plate are fixedly connected with symmetricalside plates, the side plates are rotationally connected with wallpaper rollers, gummed paper rollers are arranged above the wallpaper rollers, the side plates are rotationally connected with rotatingplates through second rotating shafts, and the rotating plates are rotationally connected with compressing rollers through rotating shafts. According to the labor-saving high-efficiency self-adhesivewallpaper pasting device, the wallpaper rollers and the gummed paper rollers which meshes with one another through transmission gears are arranged, so that gummed paper and a wallpaper body are separated efficiently, the gummed paper is collected, and the working environment is protected; by arranging a cutting device, a blade is driven by a sliding block cutter holder to linearly cut wallpaper, and a cutting opening is linearly neat; and by arranging a first rotating shaft and an inserting rod, the orientation of the pasting device body is adjusted, transverse construction and vertical construction can be realized, various construction requirements are accommodated, and labor saving an high efficiency are achieved.

Owner:SHENZHEN CHENGHONG ENTERPRISE MANAGEMENT CO LTD

Automatic online two-dimensional code printing and pasting equipment

PendingCN111598196AImprove pasting efficiencyImprove recognition efficiencyData processing applicationsCo-operative working arrangementsComputer printingProcess engineering

The invention relates to the technical field of code pasting equipment, in particular to automatic online two-dimensional code printing and pasting equipment. The system comprises a feeding mechanism,a feeding module, a code identifying and pasting mechanism, a code scanning and recording mechanism, a printer and a discharging mechanism, the feeding mechanism, the code identifying and pasting mechanism, the code scanning and recording mechanism and the discharging mechanism are sequentially arranged on the feeding module in the feeding direction from the upstream to the downstream, and the printer is arranged on one side of the feeding module. The feeding mechanism, the identifying and code pasting mechanism, the code scanning and recording mechanism and the discharging mechanism are arranged on the feeding station, the identifying and pasting station, the code scanning station and the discharging station in a one-to-one correspondence mode. According to the invention, the feeding mechanism is arranged; the feeding module and the discharging mechanism are matched to achieve differential transportation for different stations, two-dimensional code pasting and two-dimensional code recognizing and recording can be conducted on products through the code recognizing and pasting mechanism and the code scanning and recording mechanism, manual participation is not needed, and the beneficial effects of improving pasting and recognizing efficiency, reducing the reject ratio and the like are achieved.

Owner:东江精创注塑(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com