Patents

Literature

32results about How to "The pasting position is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

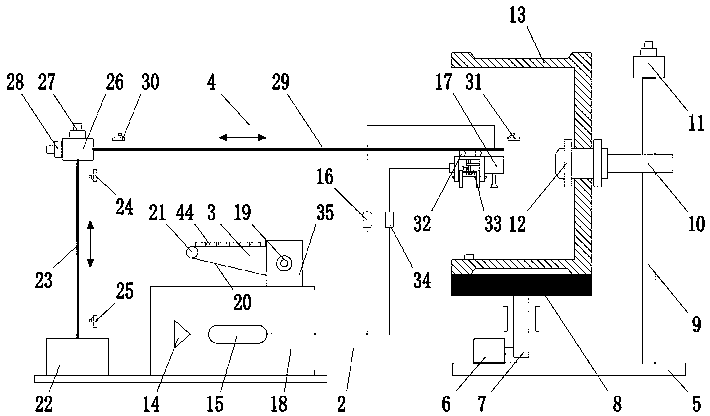

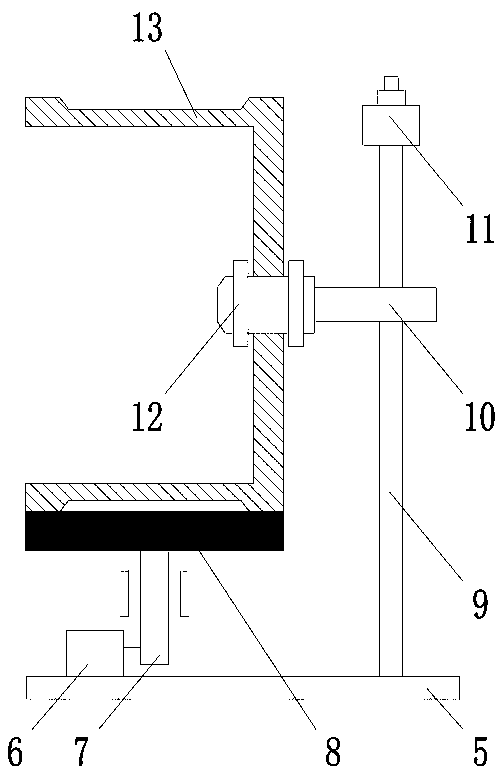

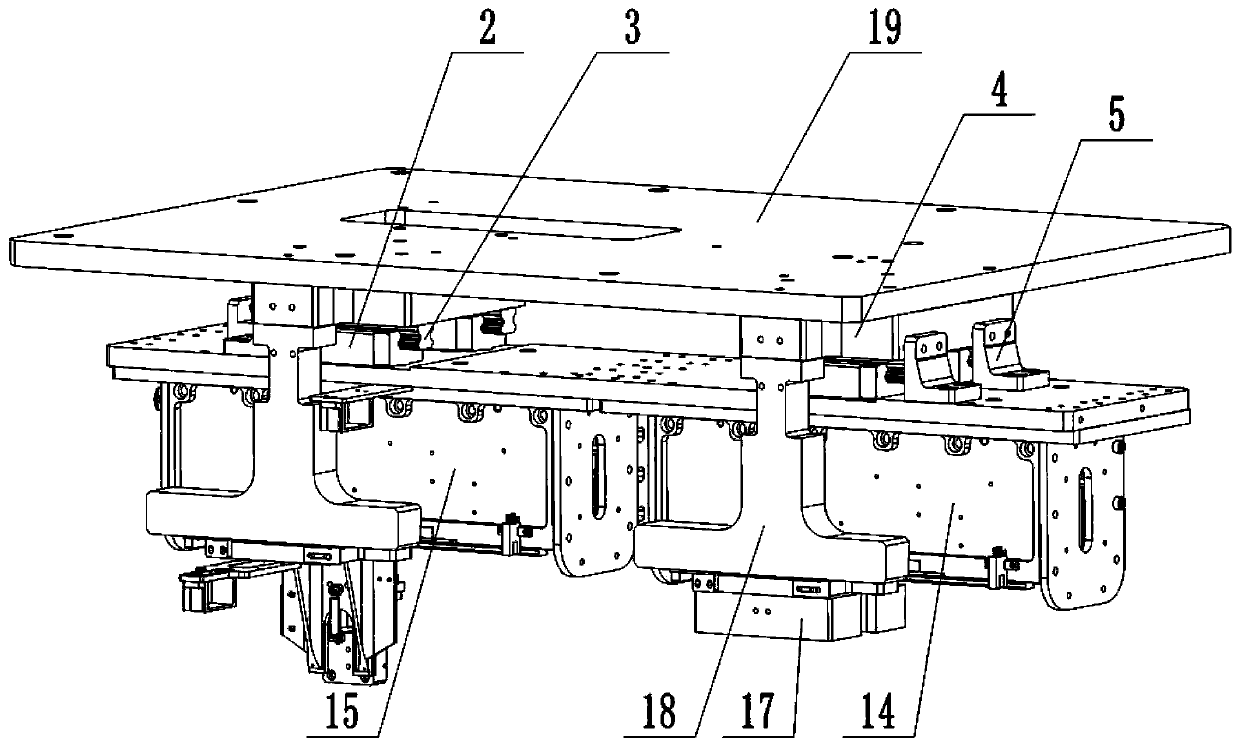

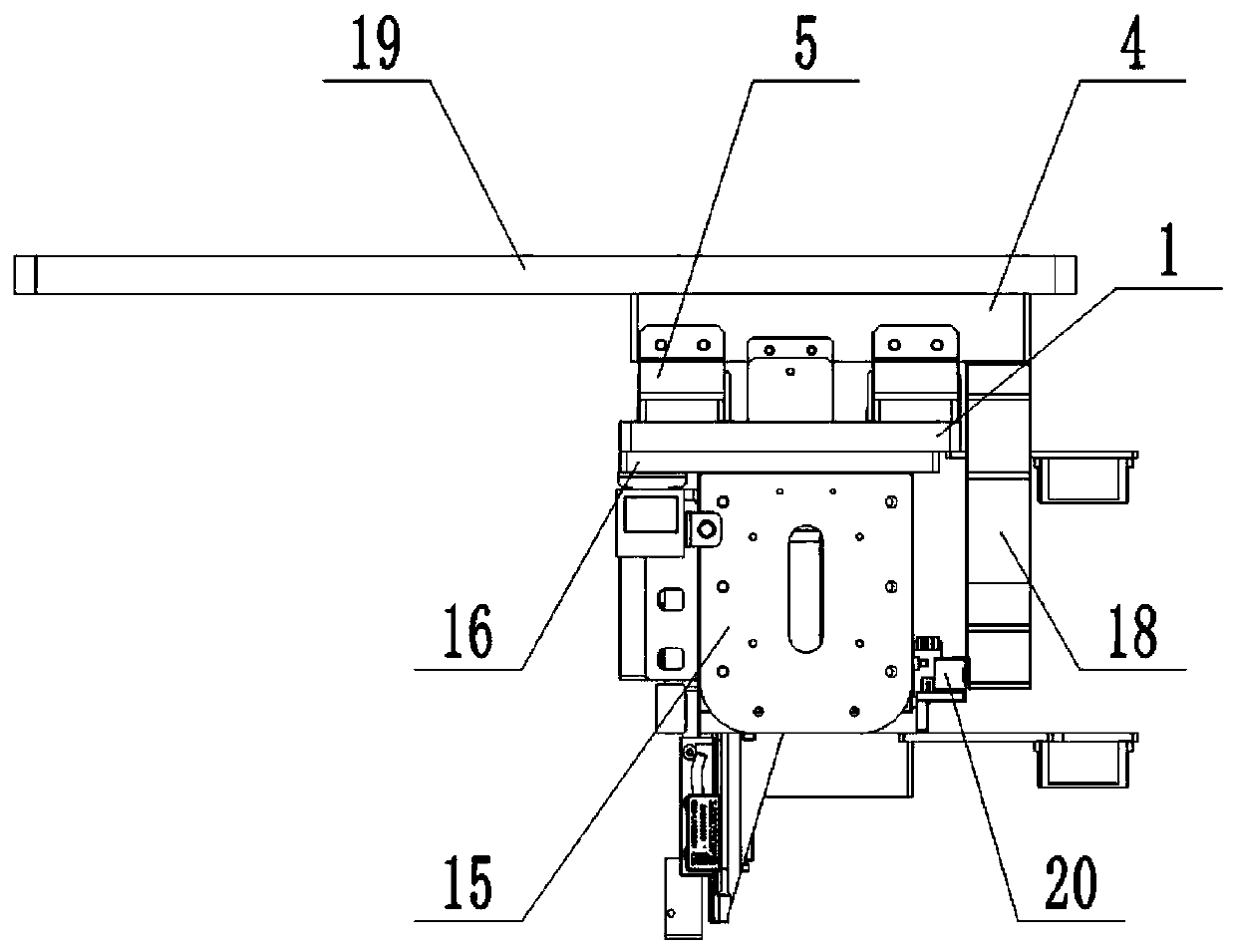

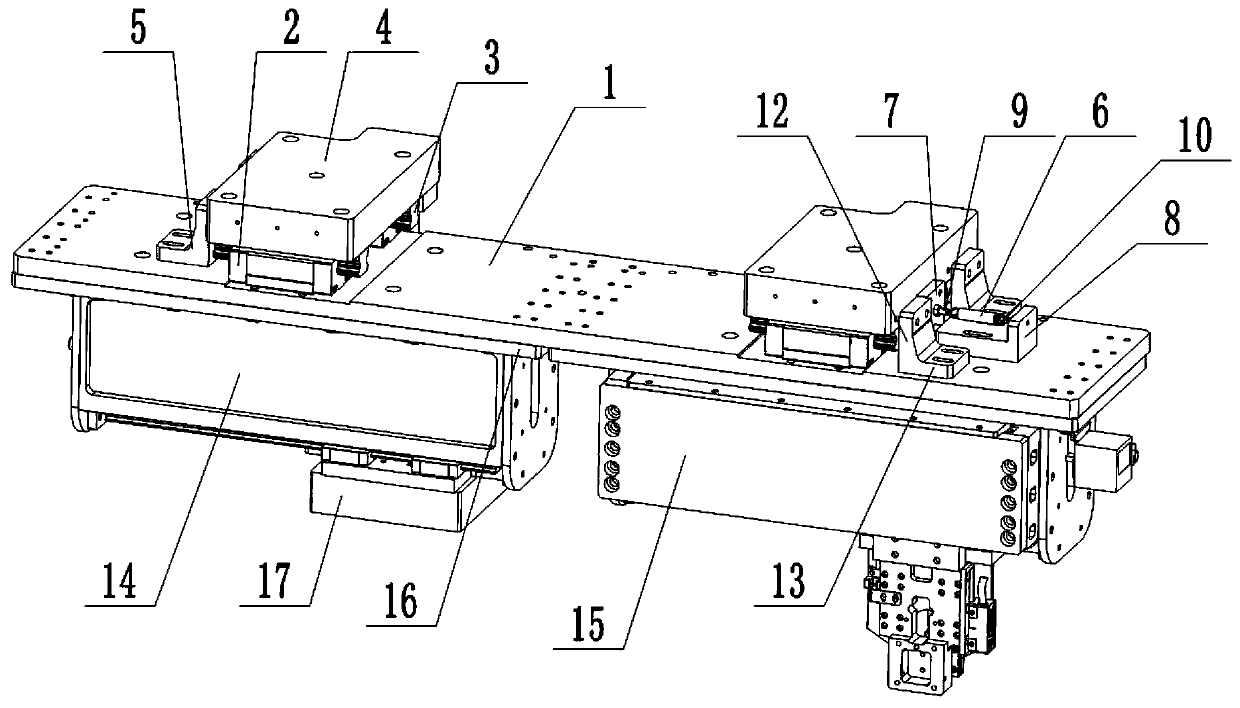

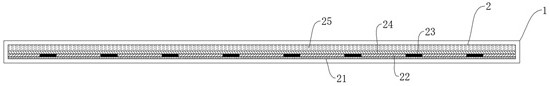

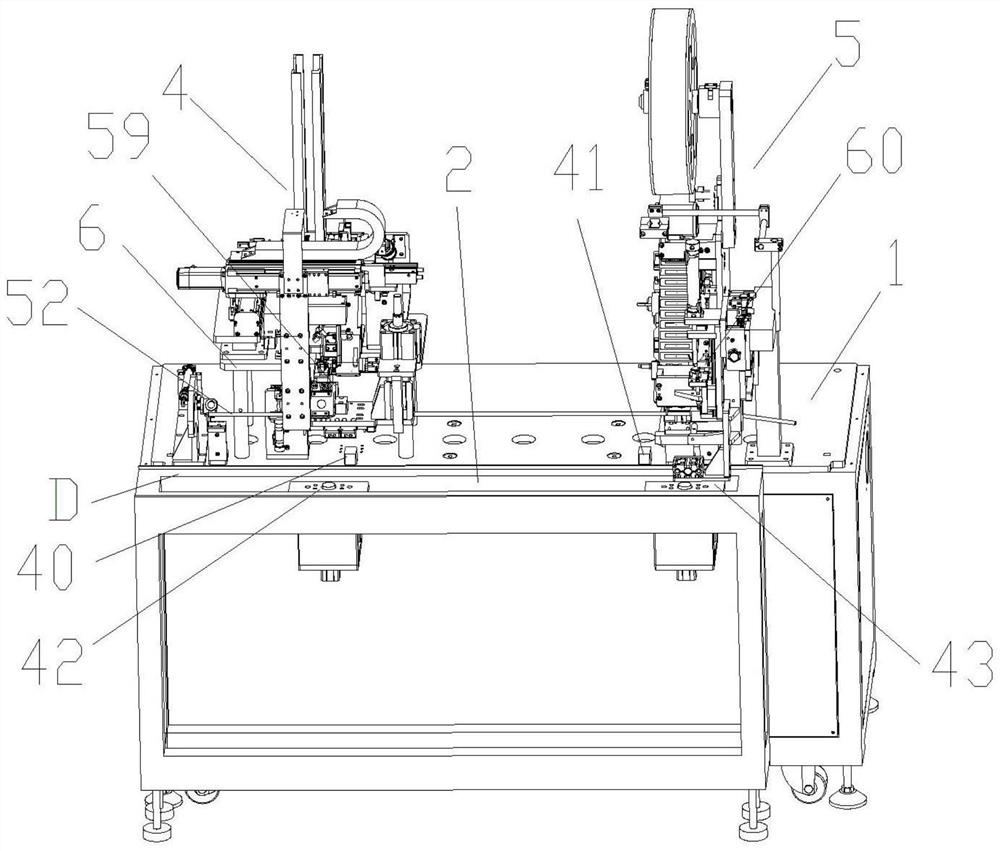

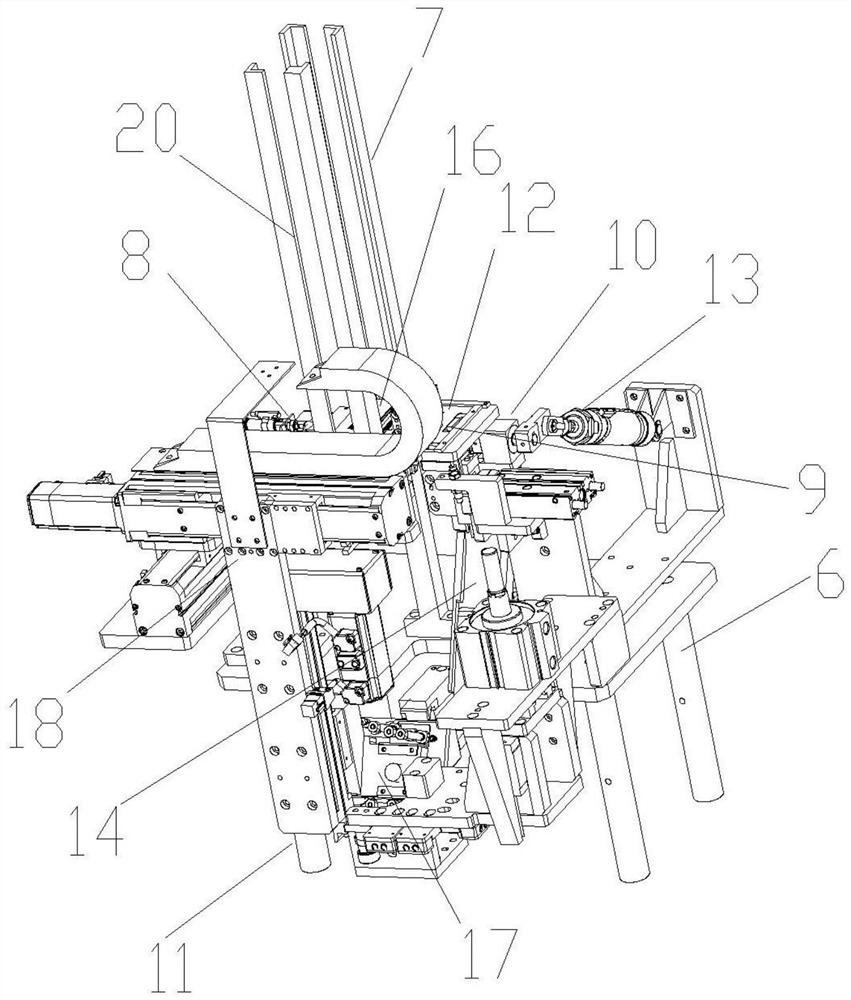

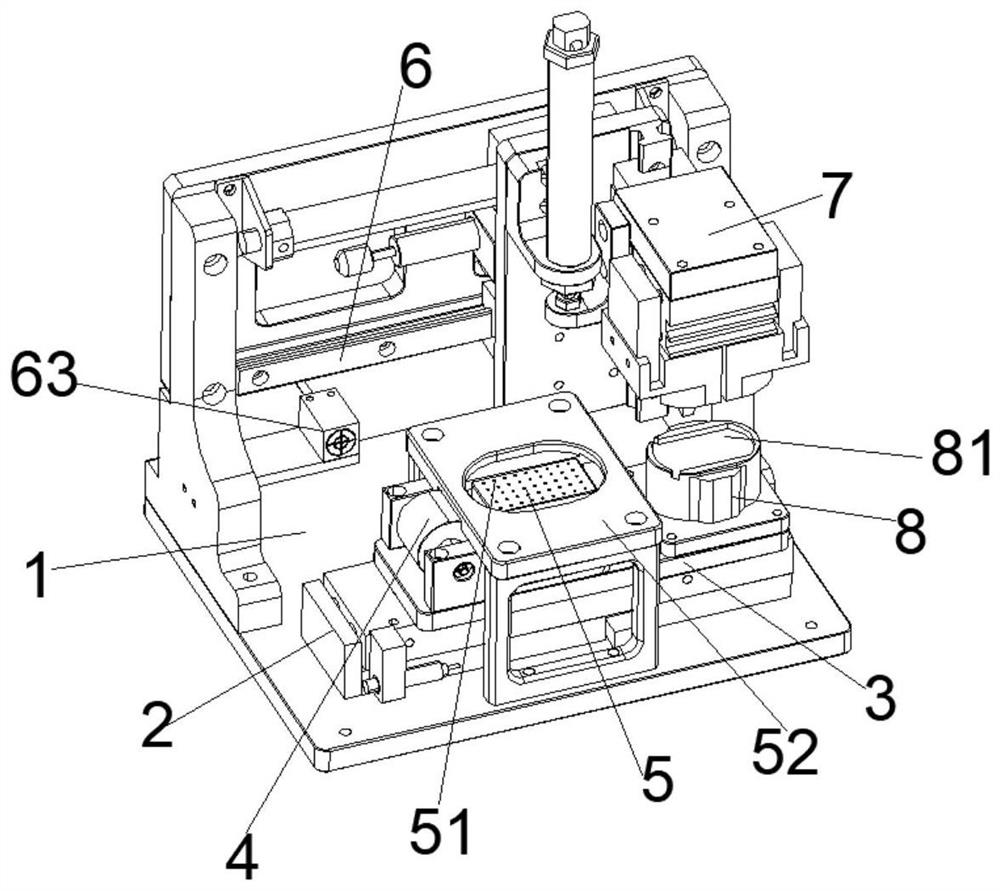

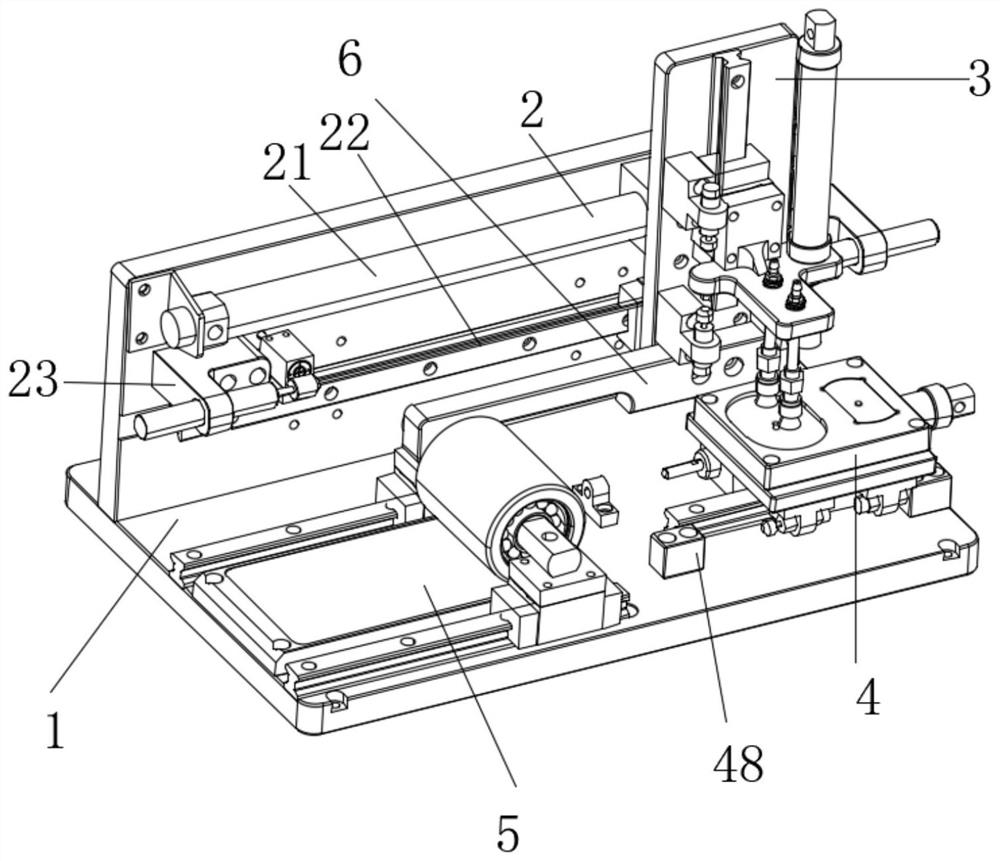

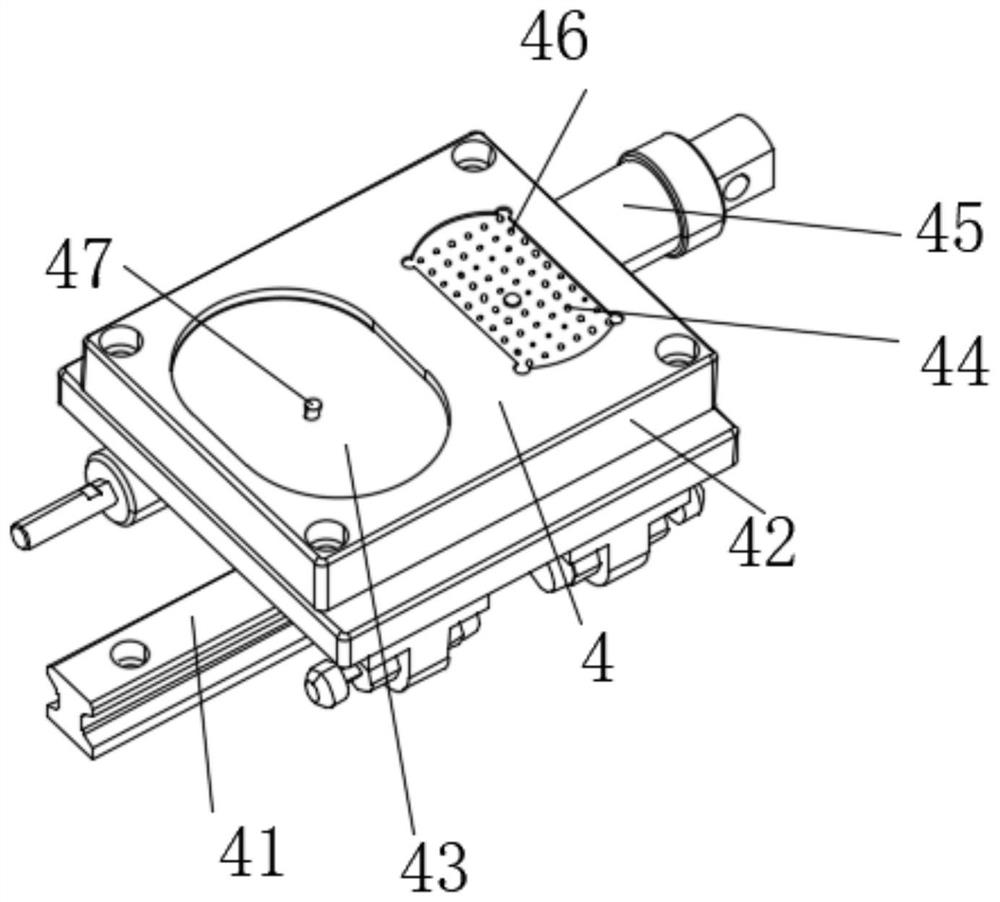

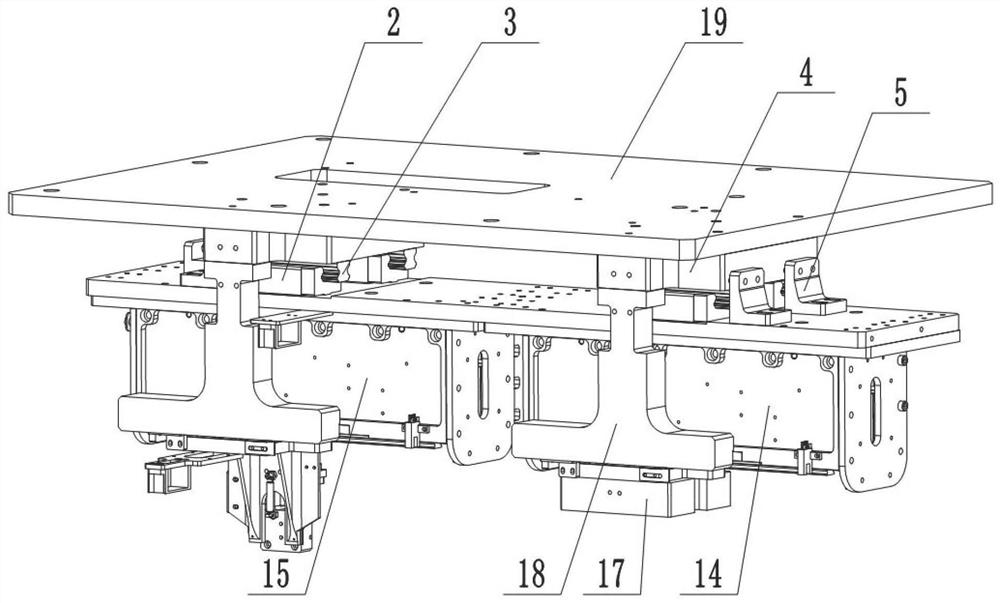

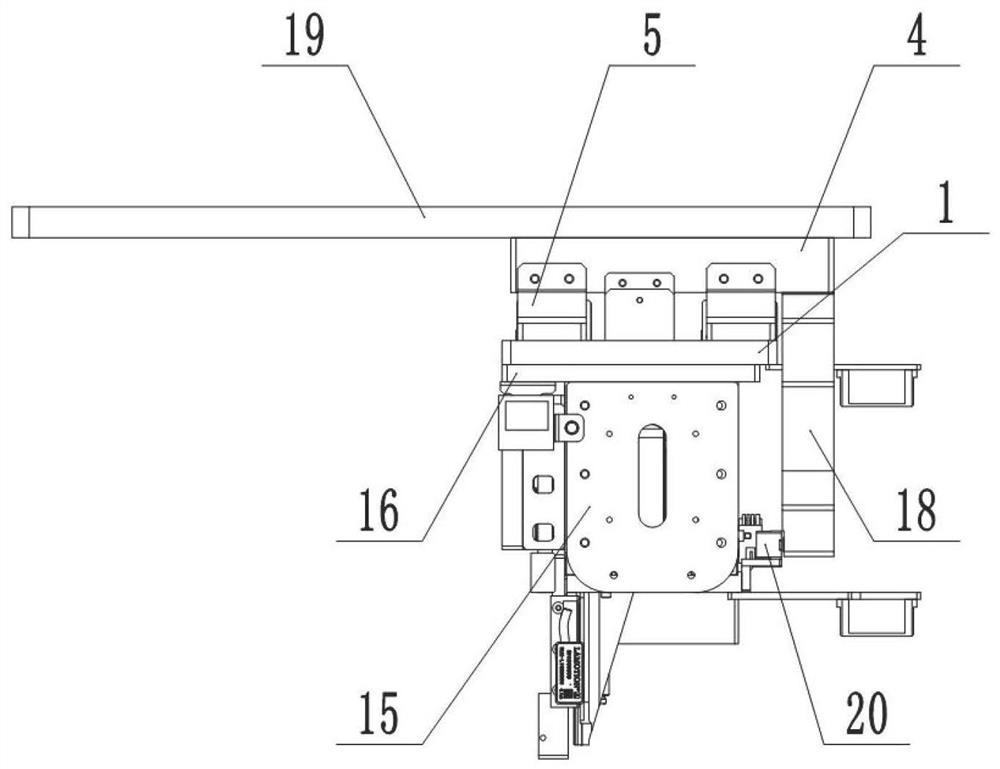

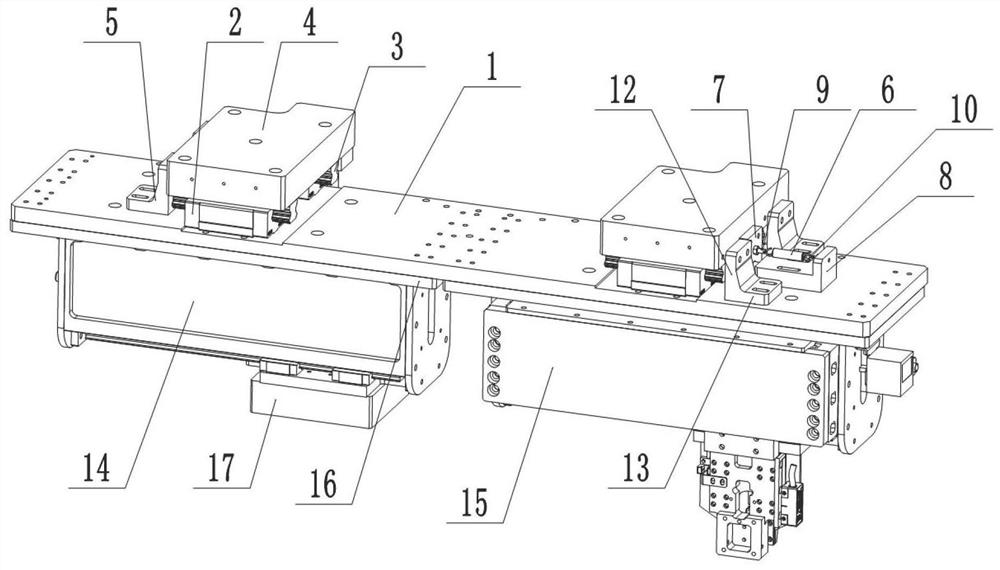

Vacuum laminating fixture and method for 3D curved surface glass and explosion-proof film

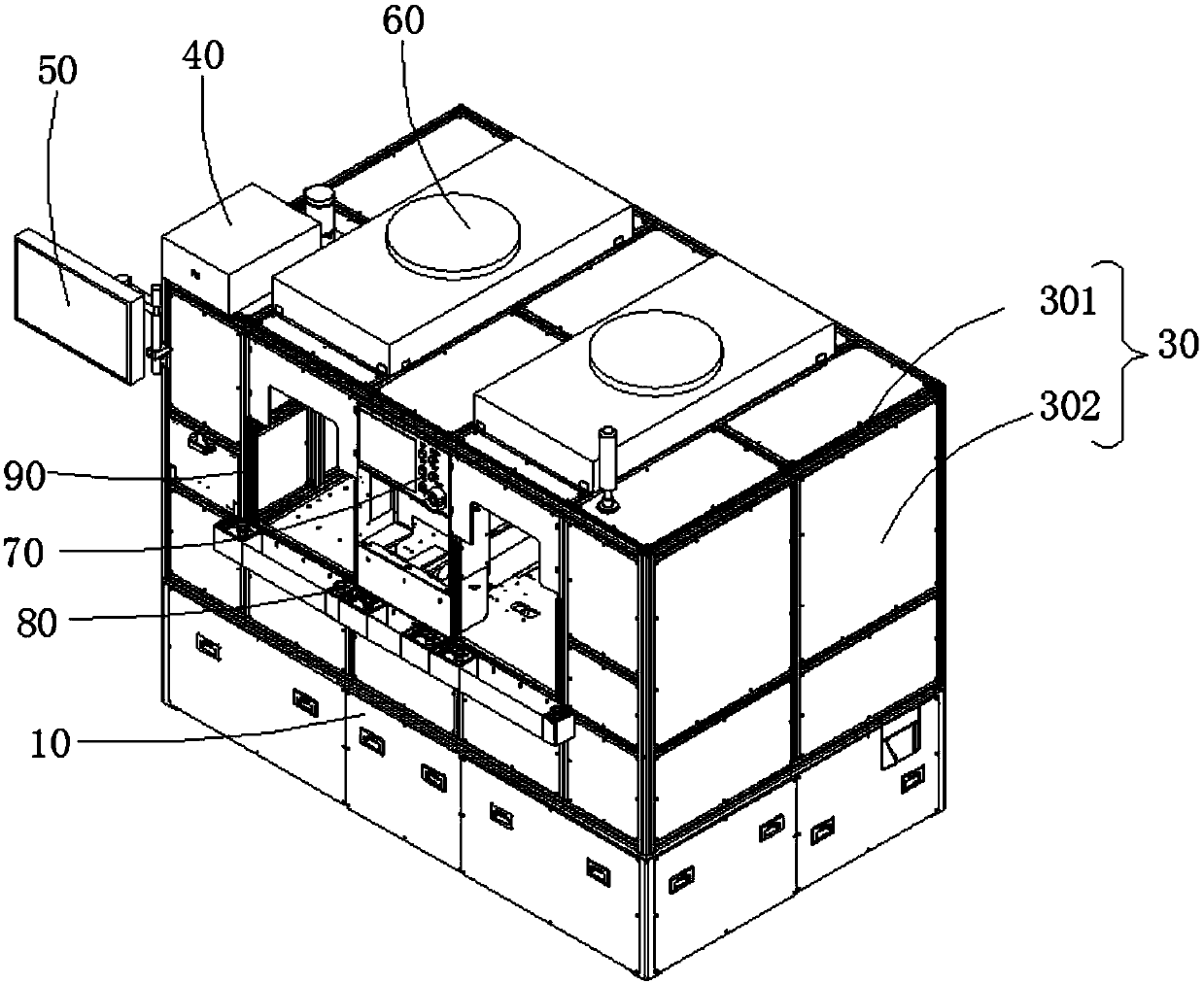

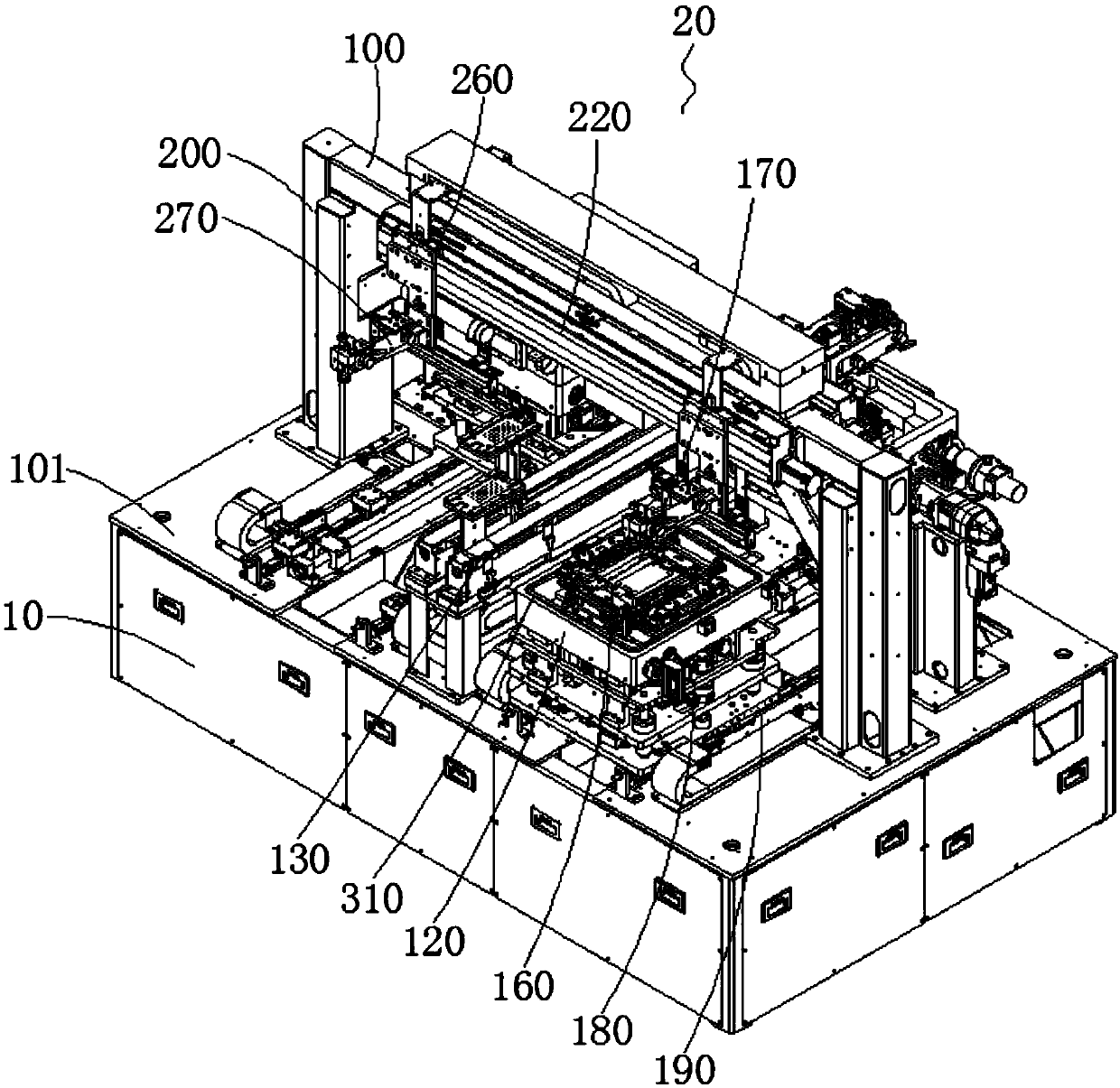

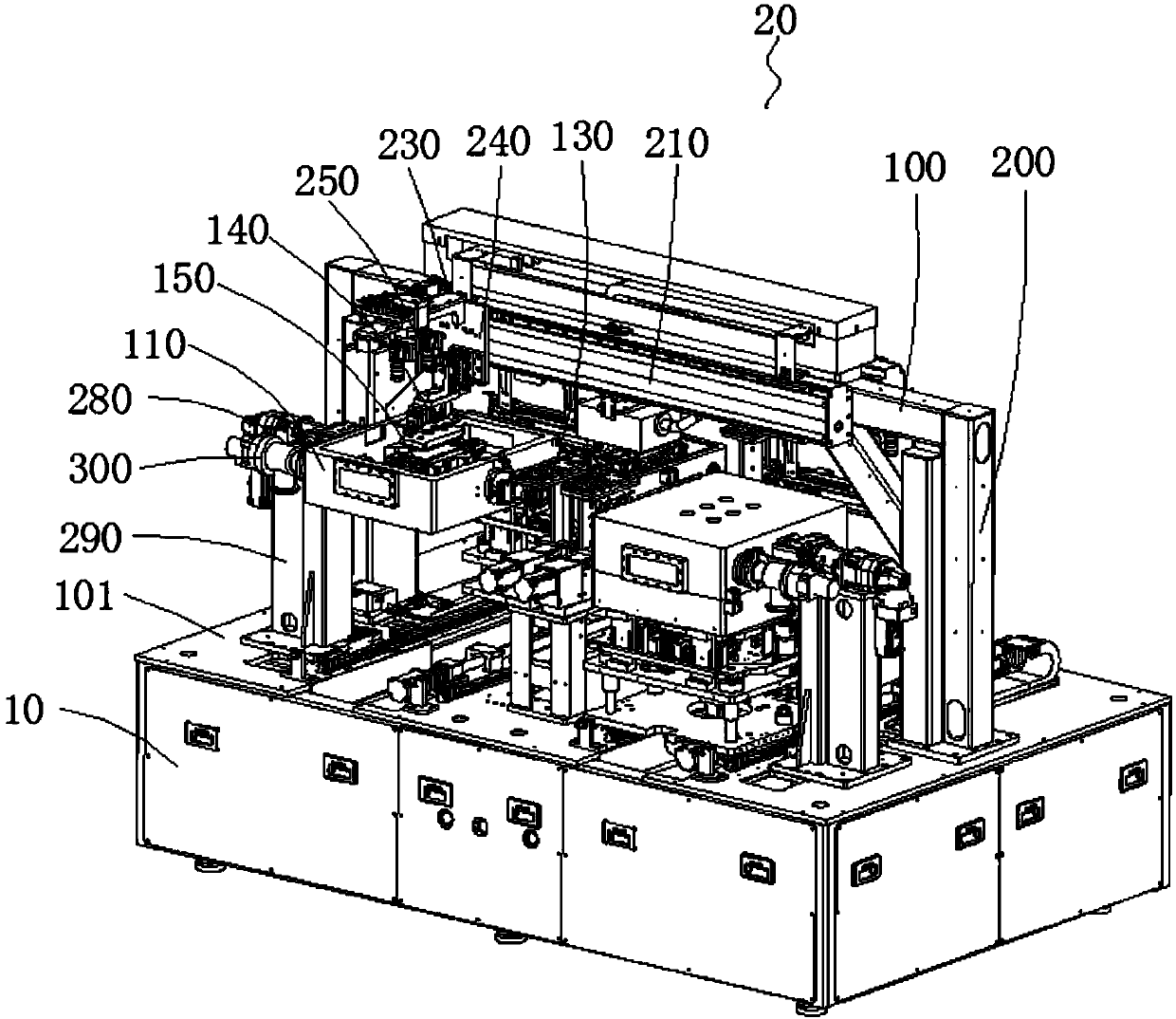

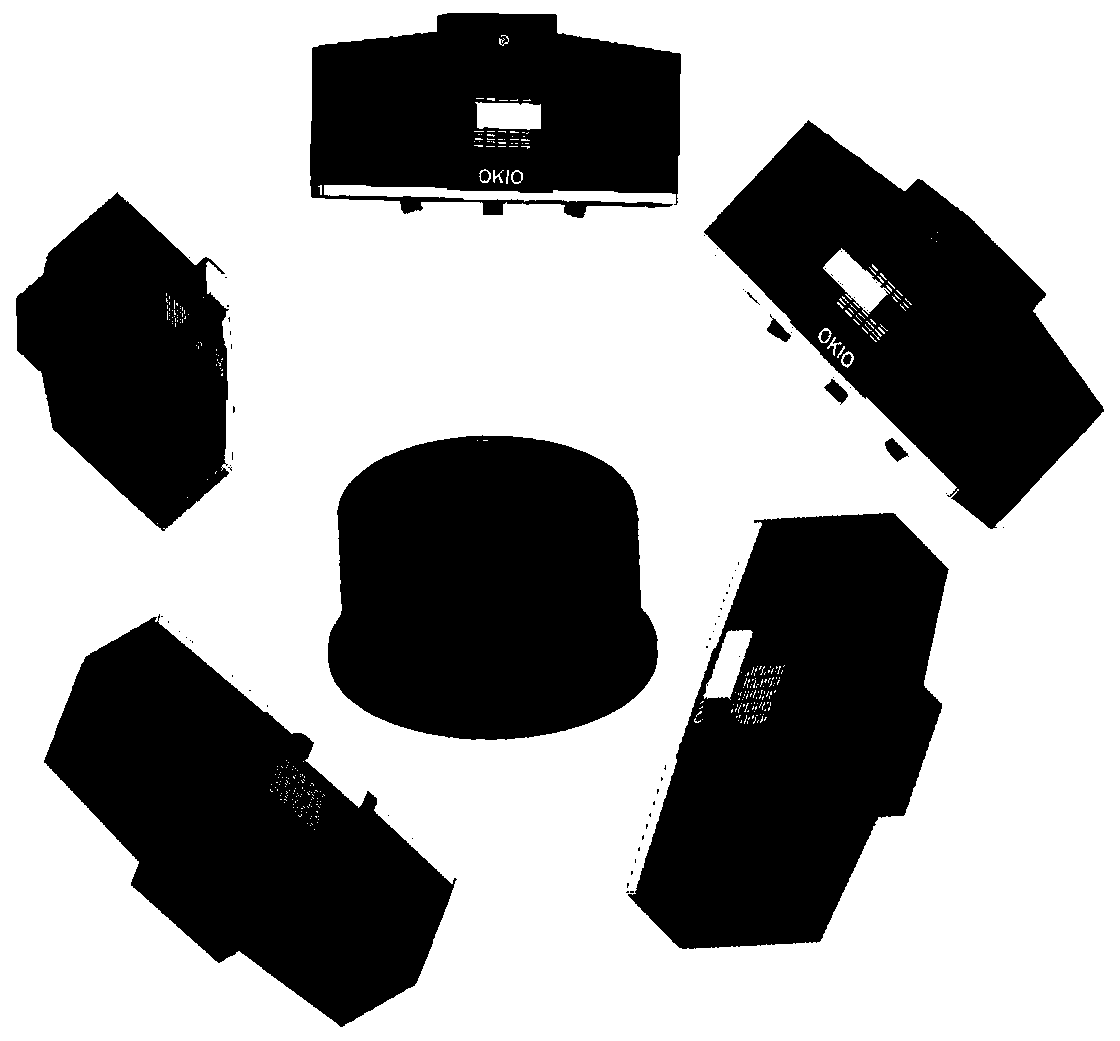

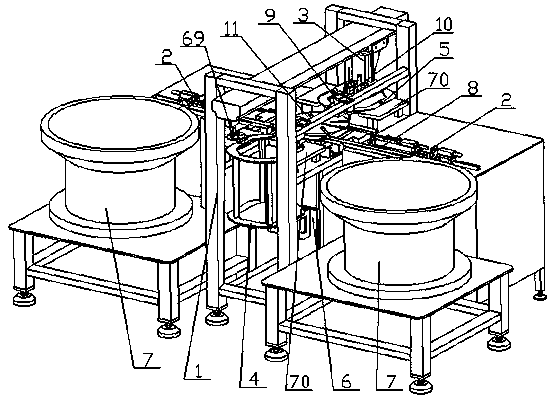

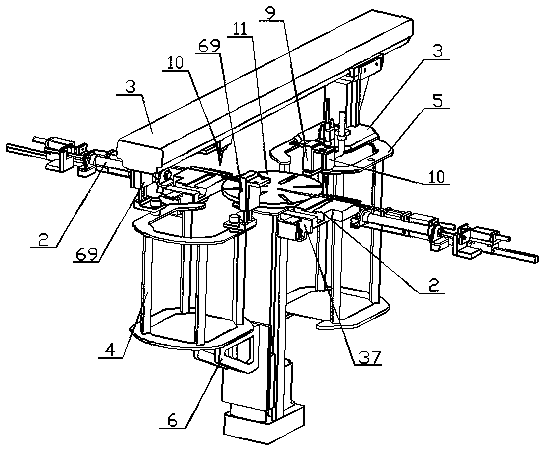

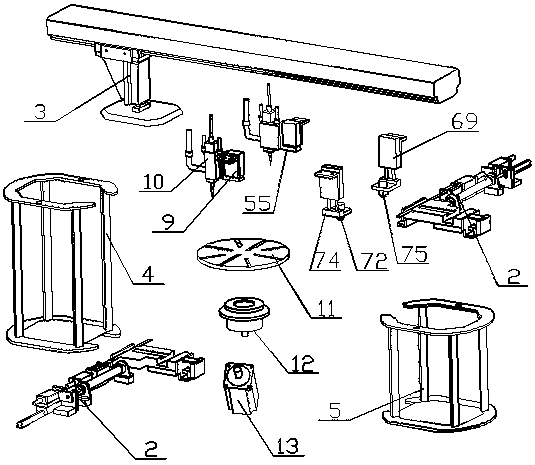

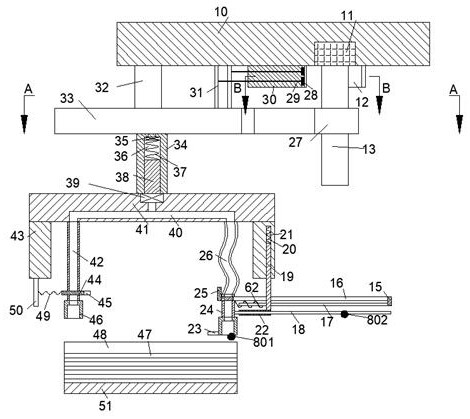

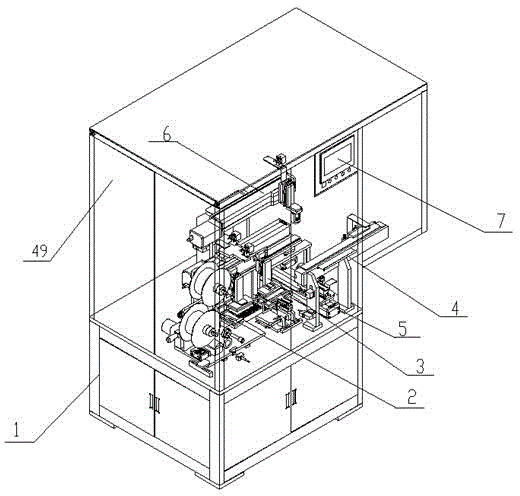

The invention discloses a vacuum laminating fixture and method for 3D curved surface glass and an explosion-proof film. The vacuum laminating fixture comprises a machine frame base and a 3D curved surface glass laminating device arranged above the machine frame base, an outer cover is arranged on the surface of the 3D curved surface glass laminating device in a sleeving mode, the outer cover is fixedly connected with the machine frame base, the 3D curved surface glass laminating device comprises a supporting cross beam, an overturning upper box body, a movable lower box body, a curved surfaceglass sheet conveying mechanism, a curved surface glass sheet grabbing mechanism, a curved surface glass sheet positioning mechanism, a silica gel soft mold bearing mechanism, a back adhesive anti-explosion film sheet positioning mechanism, a back adhesive anti-explosion film sheet laminating lifting mechanism and a back adhesive anti-explosion film sheet conveying mechanism. The vacuum laminatingfixture and method for the 3D curved surface glass and the explosion-proof film has the advantages that the structure is simple, the use is convenient, pasting of a back adhesive of the curved surface glass product can be quickly realized, the error is within + / -0.05 mm, no bubbles and wrinkles exist between the back adhesive explosion-proof film sheet and the attaching surface of the curved surface glass sheet, so that the quality of the curved surface glass product is improved, meanwhile, the yield of the product is improved, and the production cost is greatly reduced.

Owner:深圳市义鹏技术有限公司

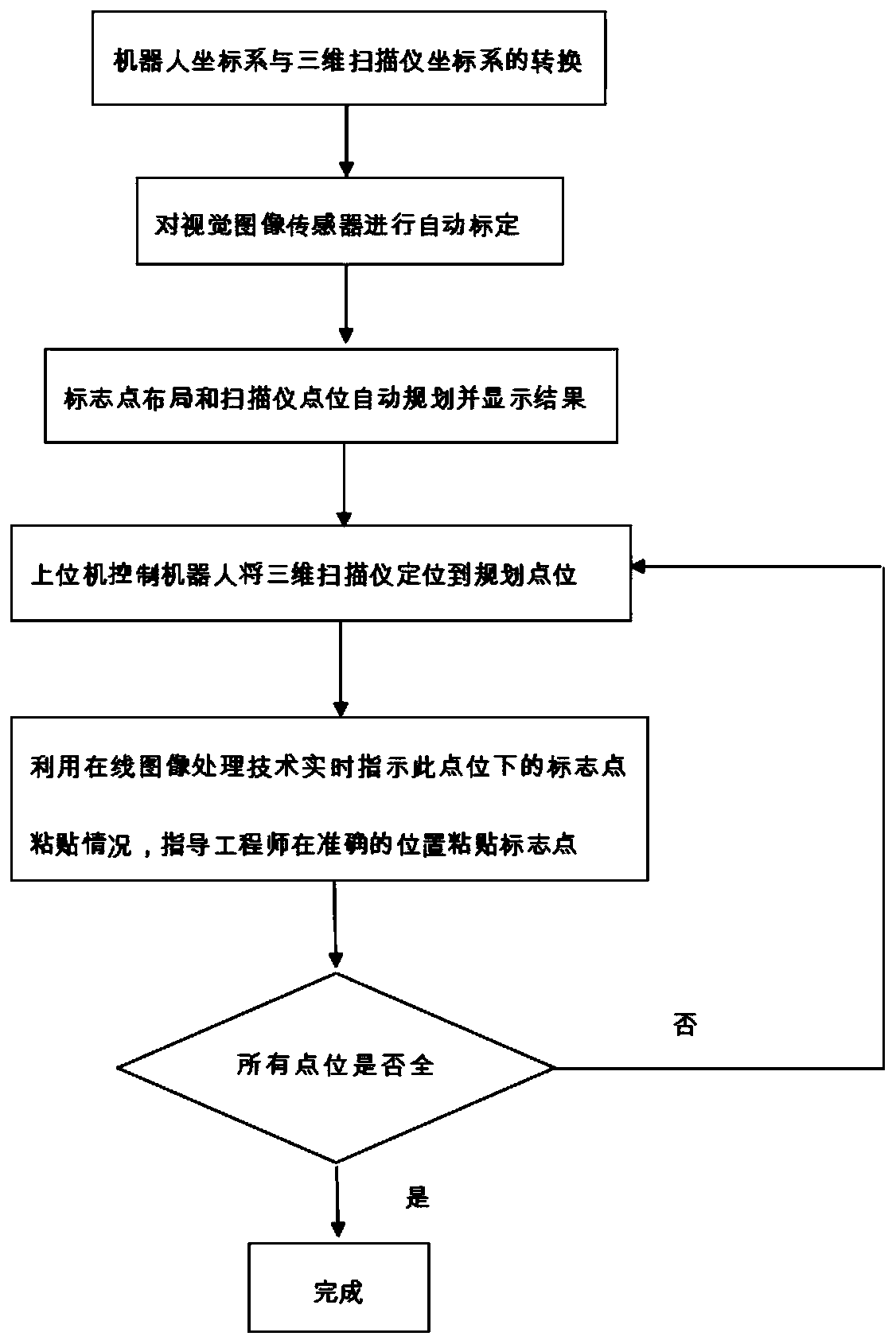

Pasting indication method for mark point orienting to three-dimensional scanning and based on on-line image processing

InactiveCN109916300AImprove ease of useQuick Paste LocationImage analysisUsing optical meansImaging processing3d scanning

The invention provides a pasting indication method for a mark point orienting to three-dimensional scanning and based on on-line image processing. After a virtual layout position of the mark point required for the three-dimensional scanning is calculated according to digital-analog information of a measured object and parameter information of a three-dimensional scanner, it is judged by an onlineimage technology whether a current coordinate position is pasted with the mark point, passing processing is performed on the pasted mark point, a warning treatment is utilized by a coordinate positionof an unpasted mark point to guide a technical engineer to perform pasting work of the mark point in real time, and the fluency of a later three-dimensional scanning process is ensured. The method isbased on a reliable online image processing technology, brings great convenience and accuracy to the pasting work of the mark point in a three-dimensional scanning process, avoids influence of humanobjective factors on a pasting layout of a position of the mark point, and provides great convenient conditions for automation f the three-dimensional scanning and development of process standardization.

Owner:TENYOUN 3D(TIANJIN)TECH CO LTD

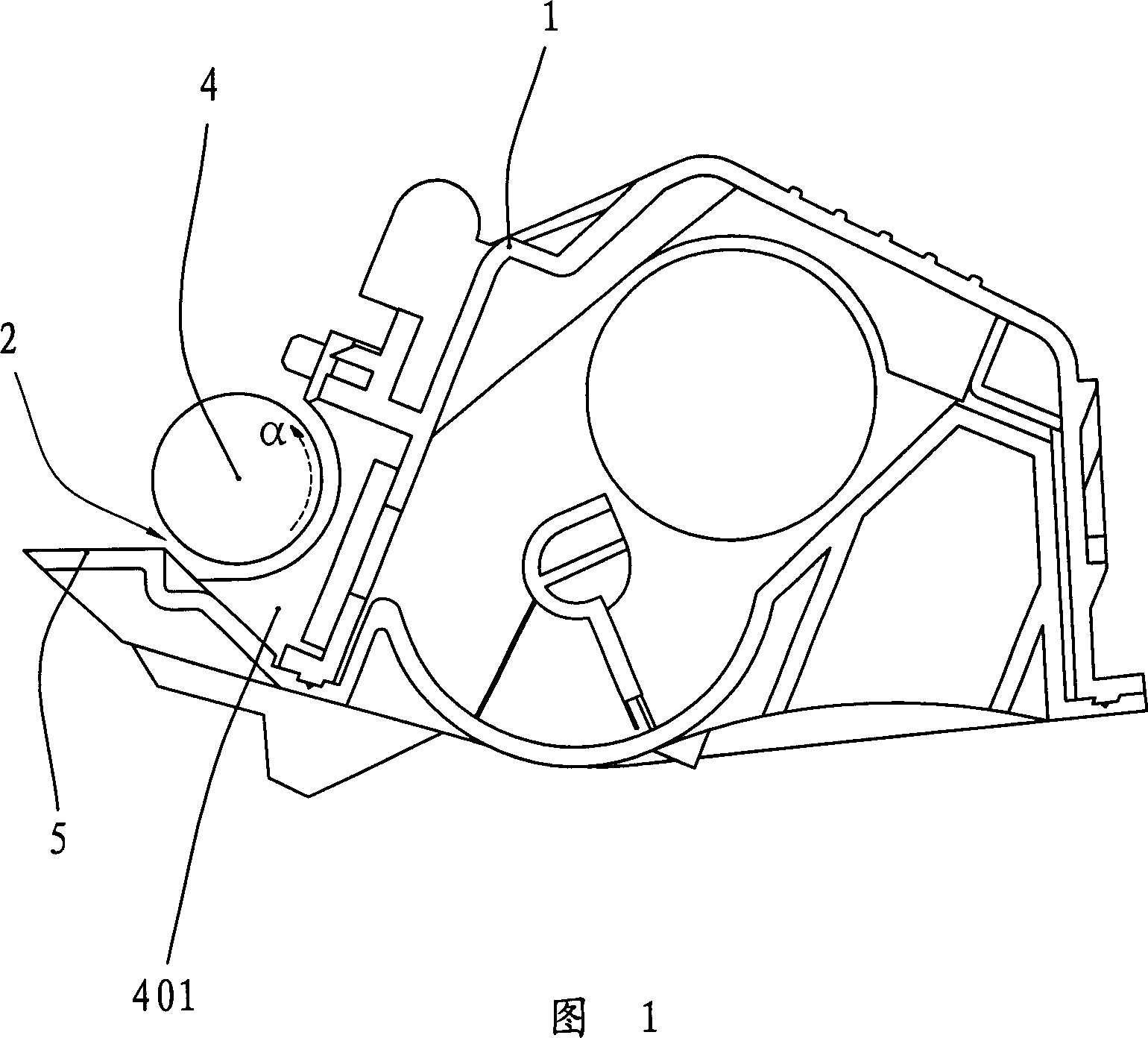

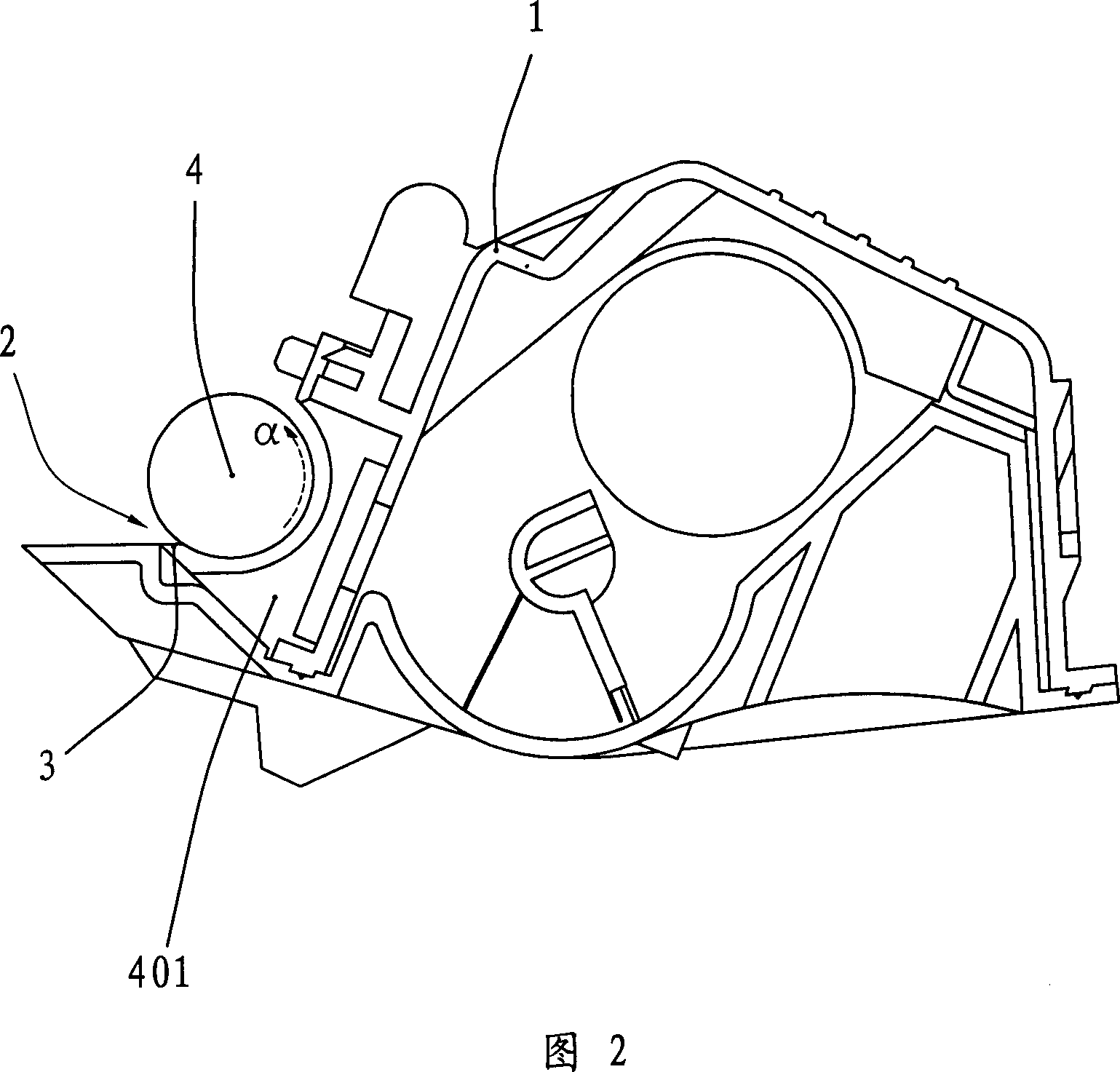

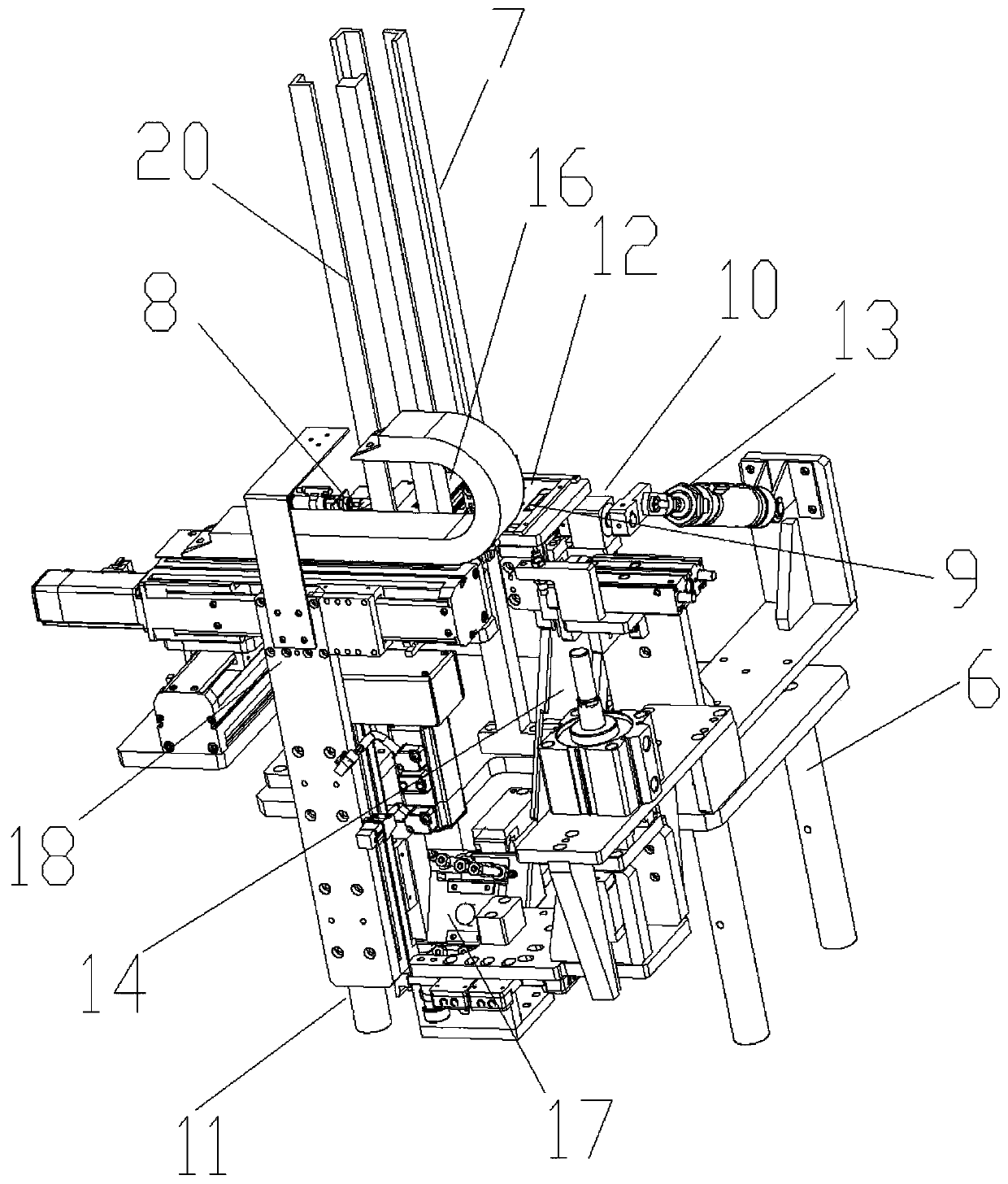

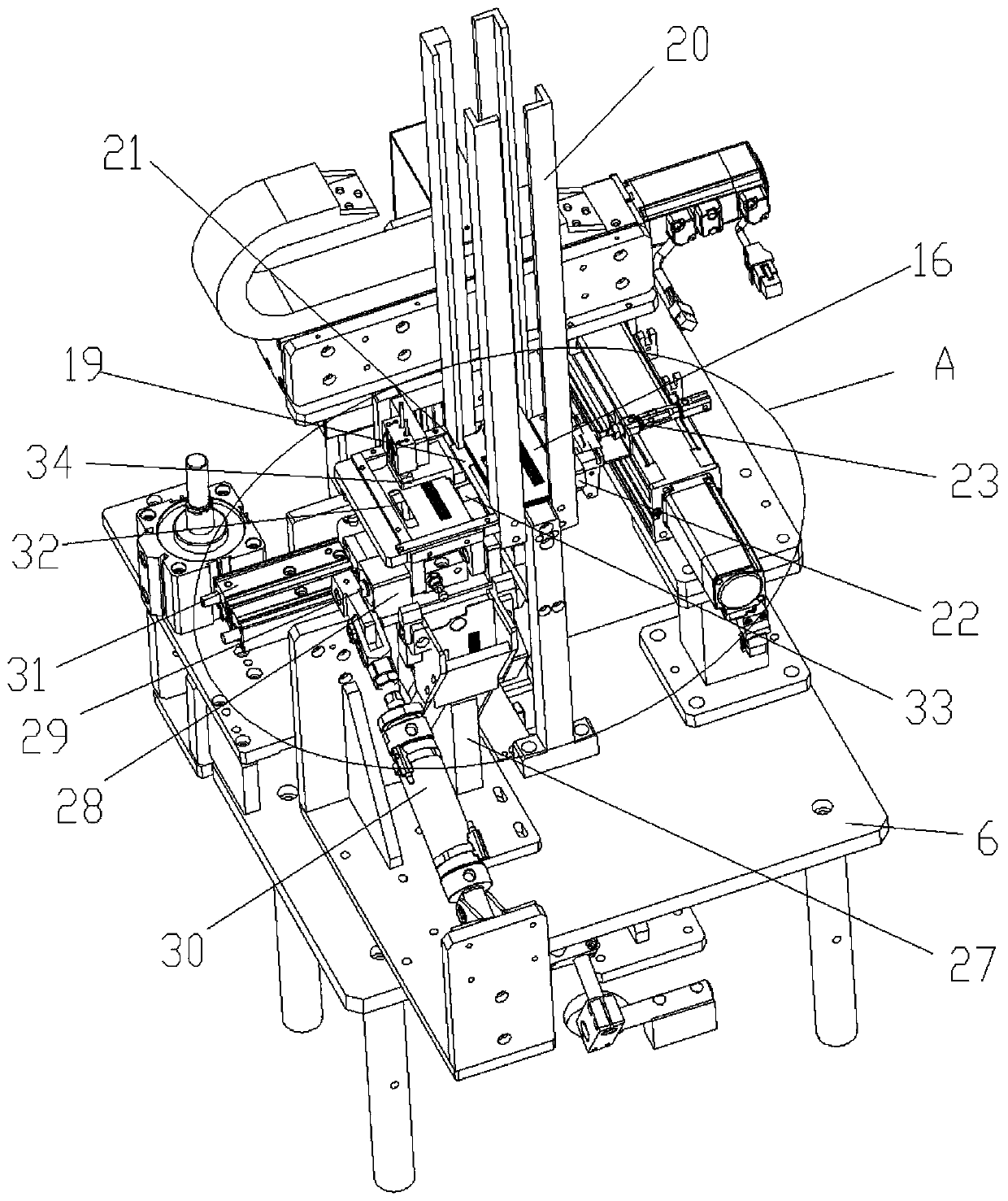

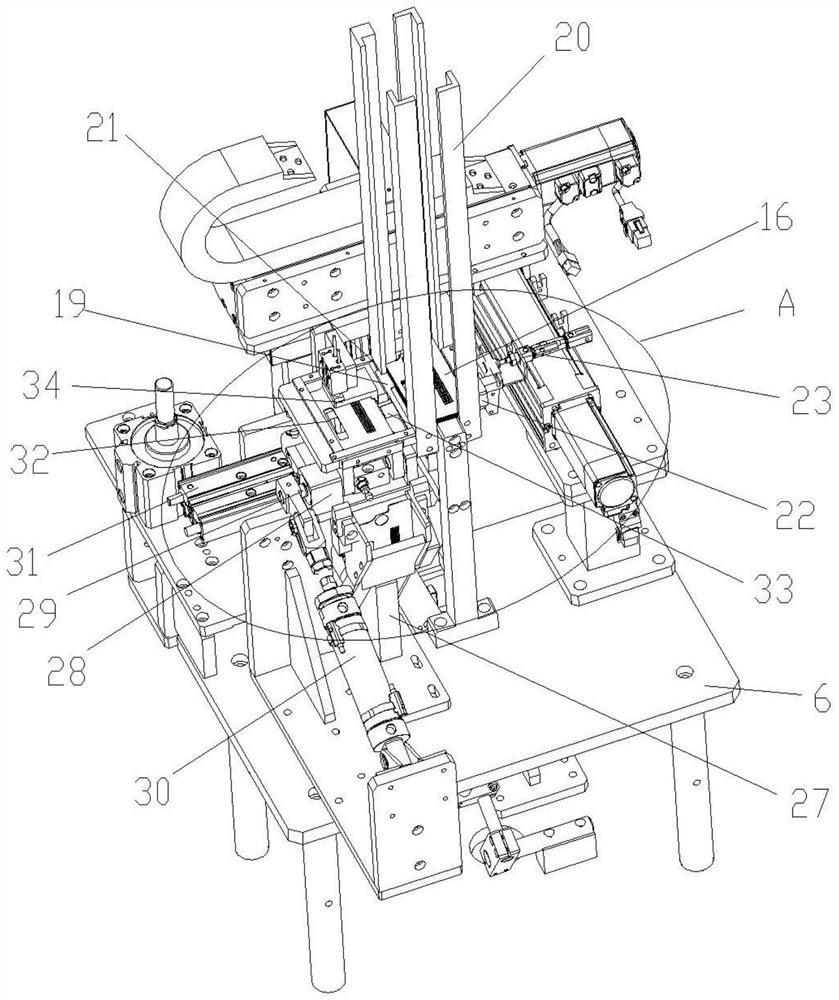

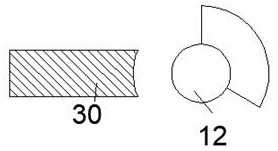

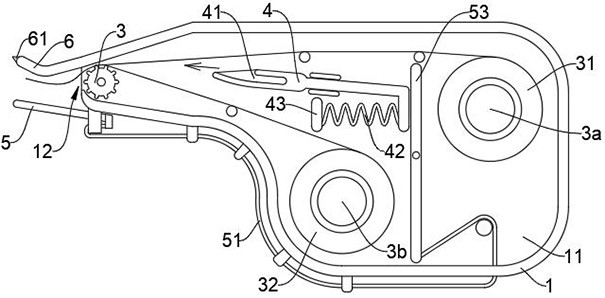

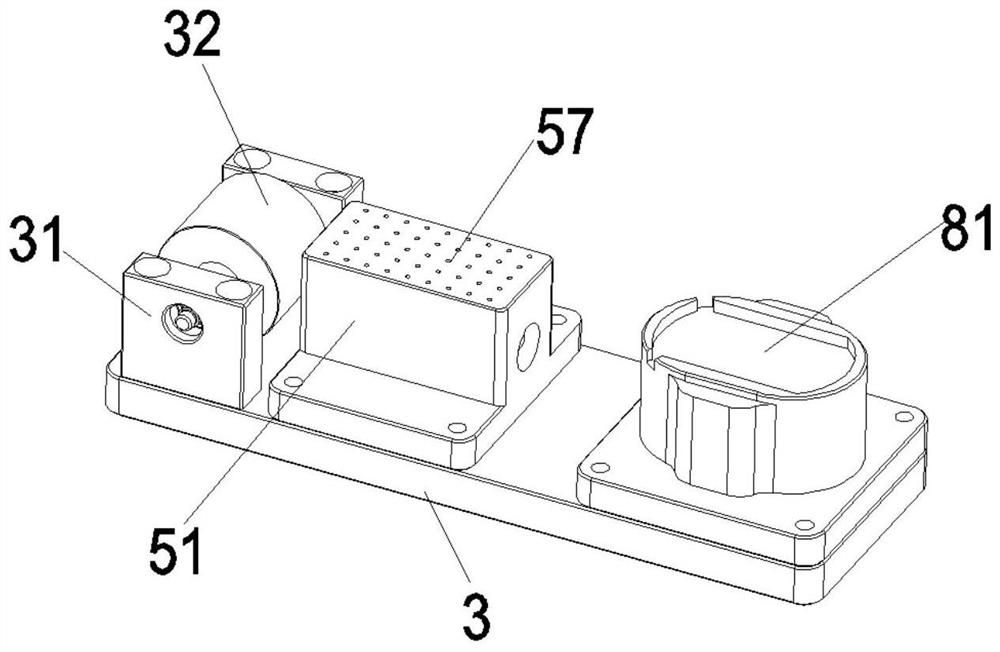

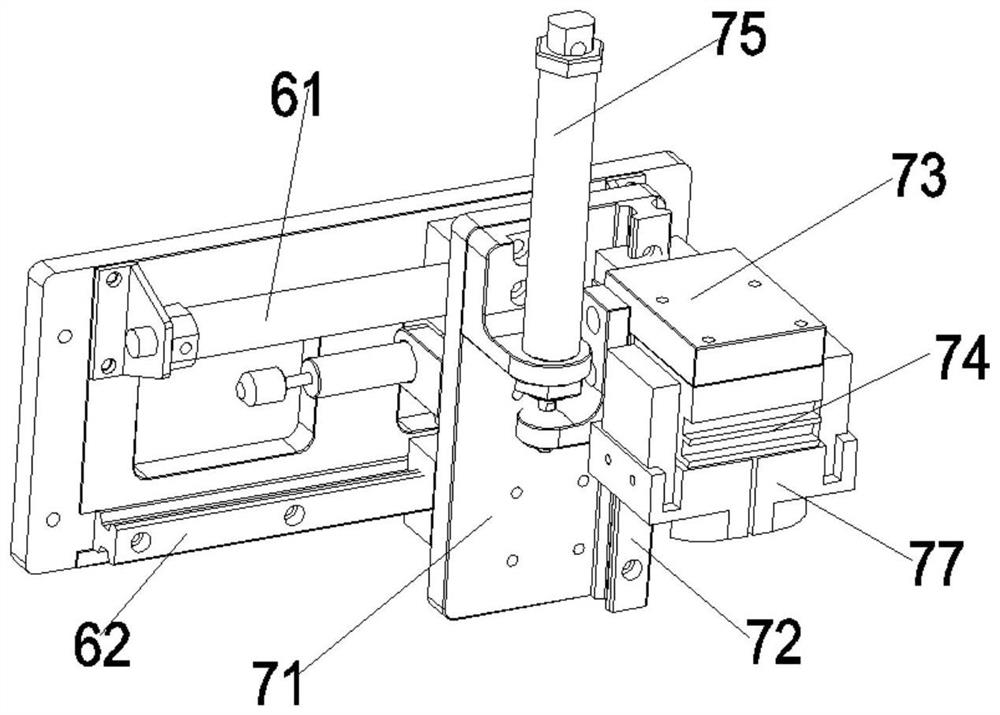

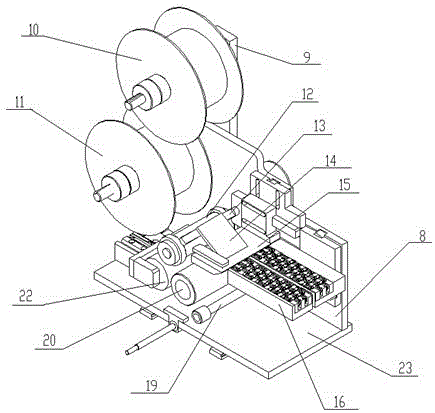

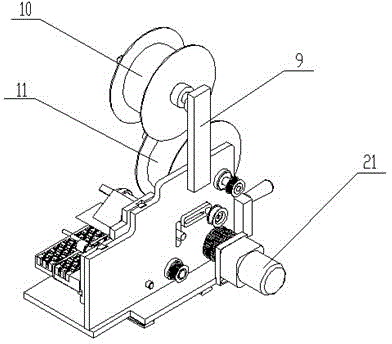

Laser printer developing device sealing sheet adhesion device

InactiveCN101086649AImprove pasting efficiencyThe pasting position is accurateElectrographic process apparatusMechanical engineeringLaser

The stick device for seals of a laser printer developing device comprises the base and installation platform on it. It also comprises the seal sticking structure, paper and glue separation structure, seal cutting structure and the seal sticking structure. The seal sticking structure binds the seal on the glue of the double glue paper, tearing off the coated paper through the paper glue separation device, cutting the seal plate based on the preset length and move to the corresponding position of the developing device, and sticking the seal to the corresponding part of the developing device. It has high precision in matching the seal with the developing device with fastness, and better flatness.

Owner:ZHUHAI TIANWEI TECH DEV CO LTD

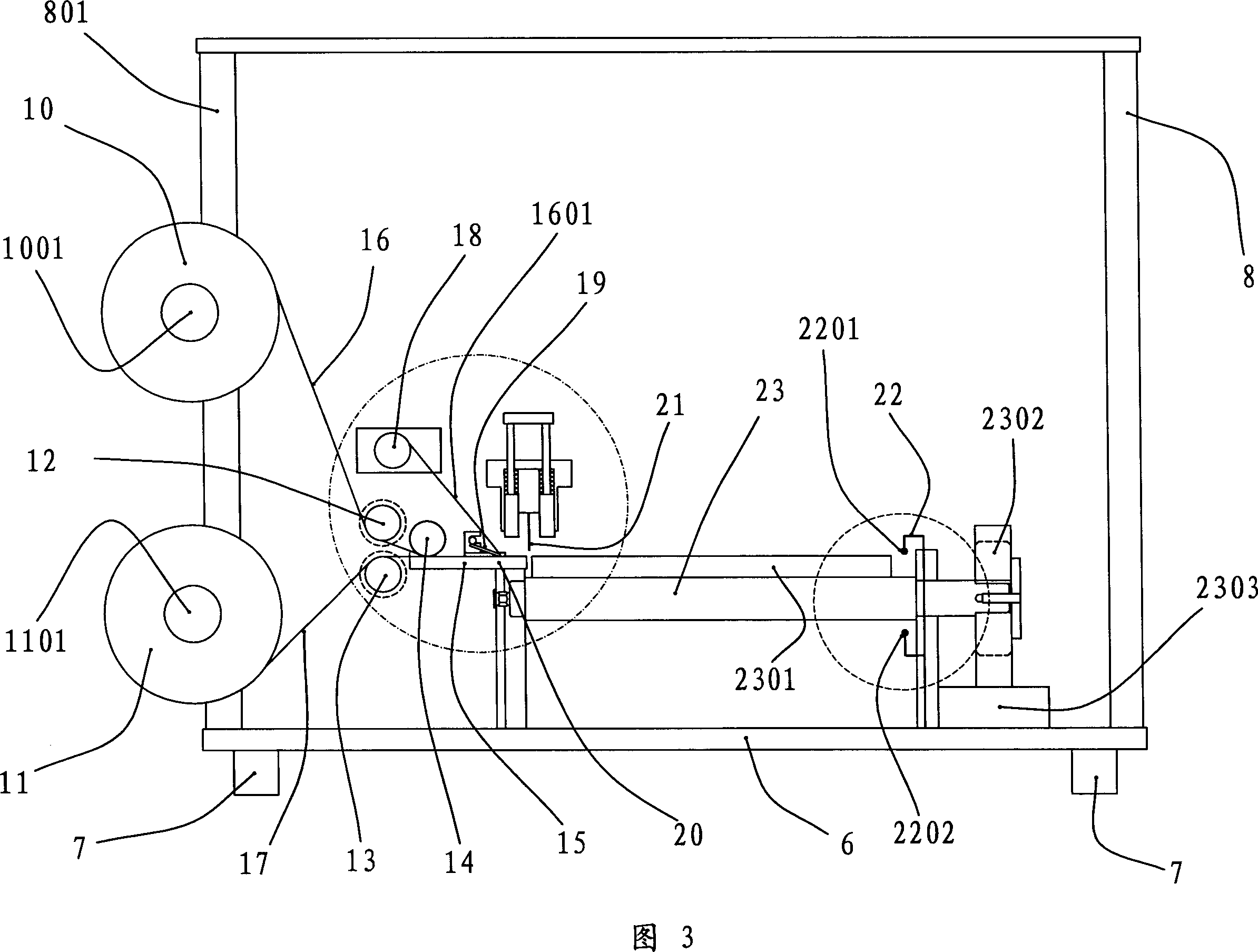

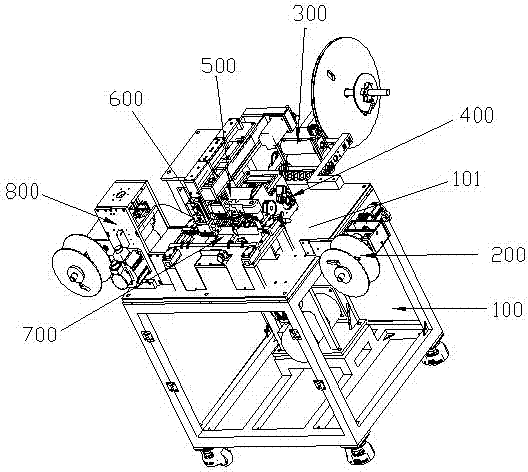

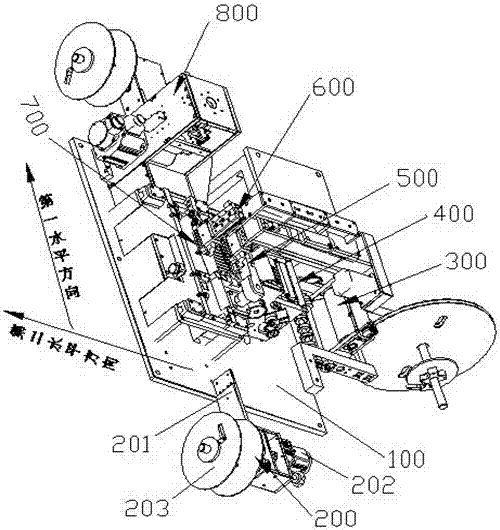

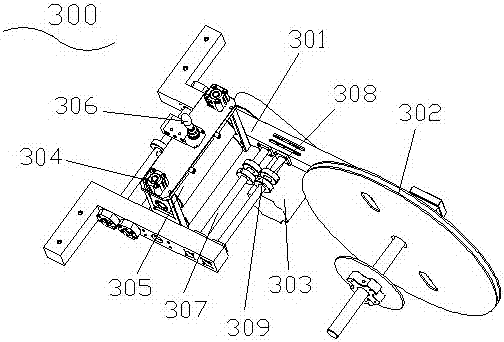

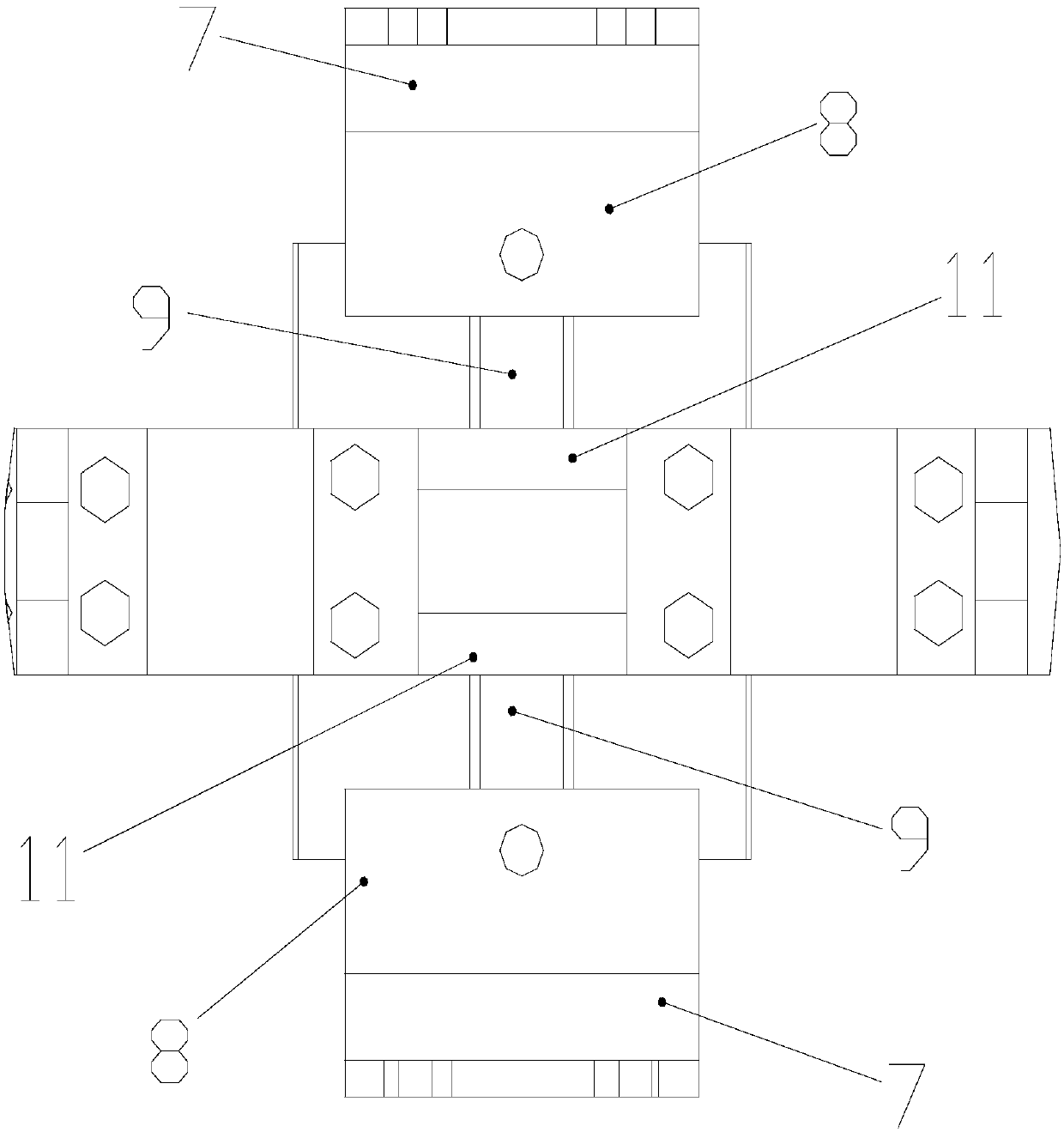

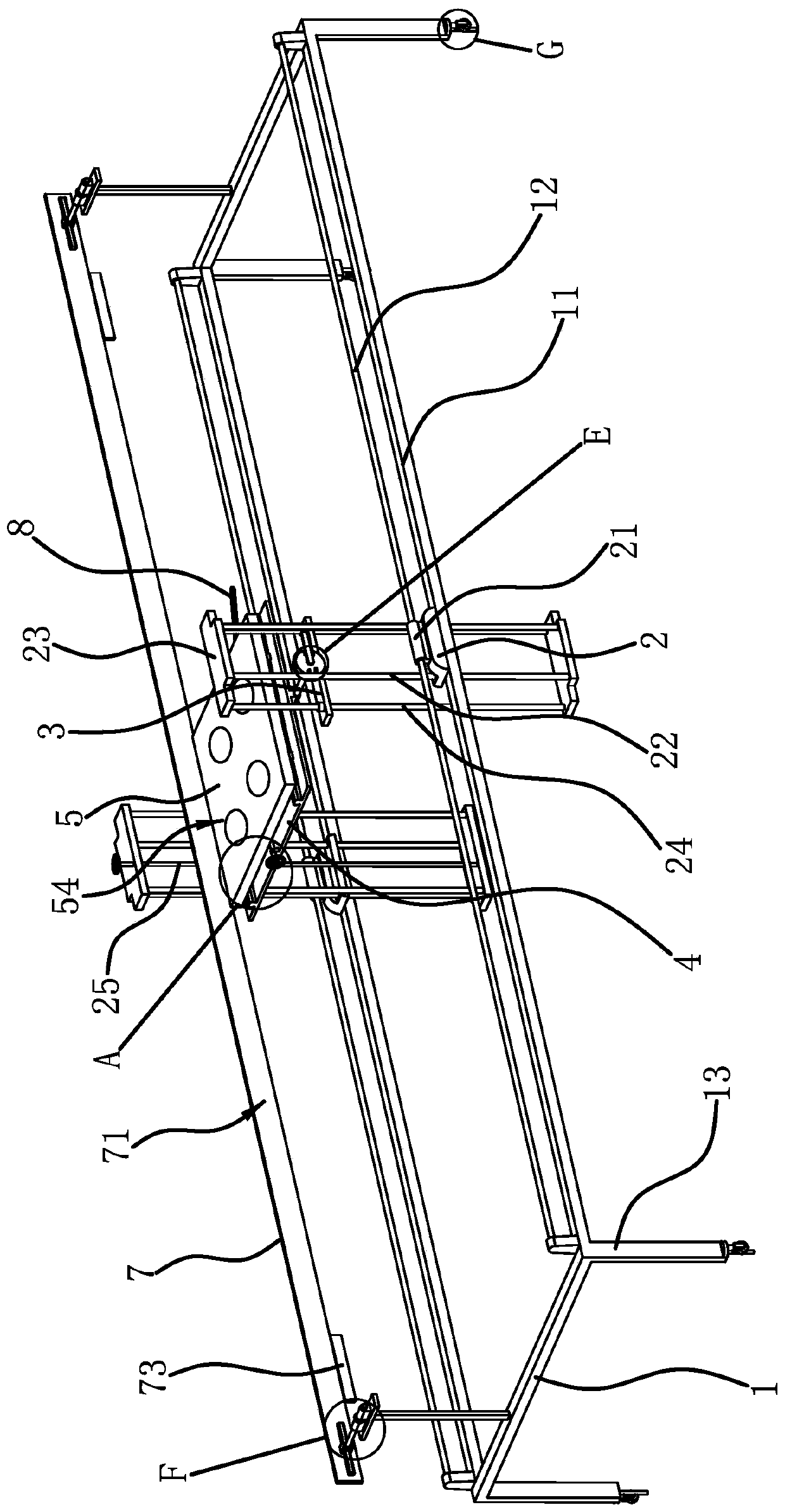

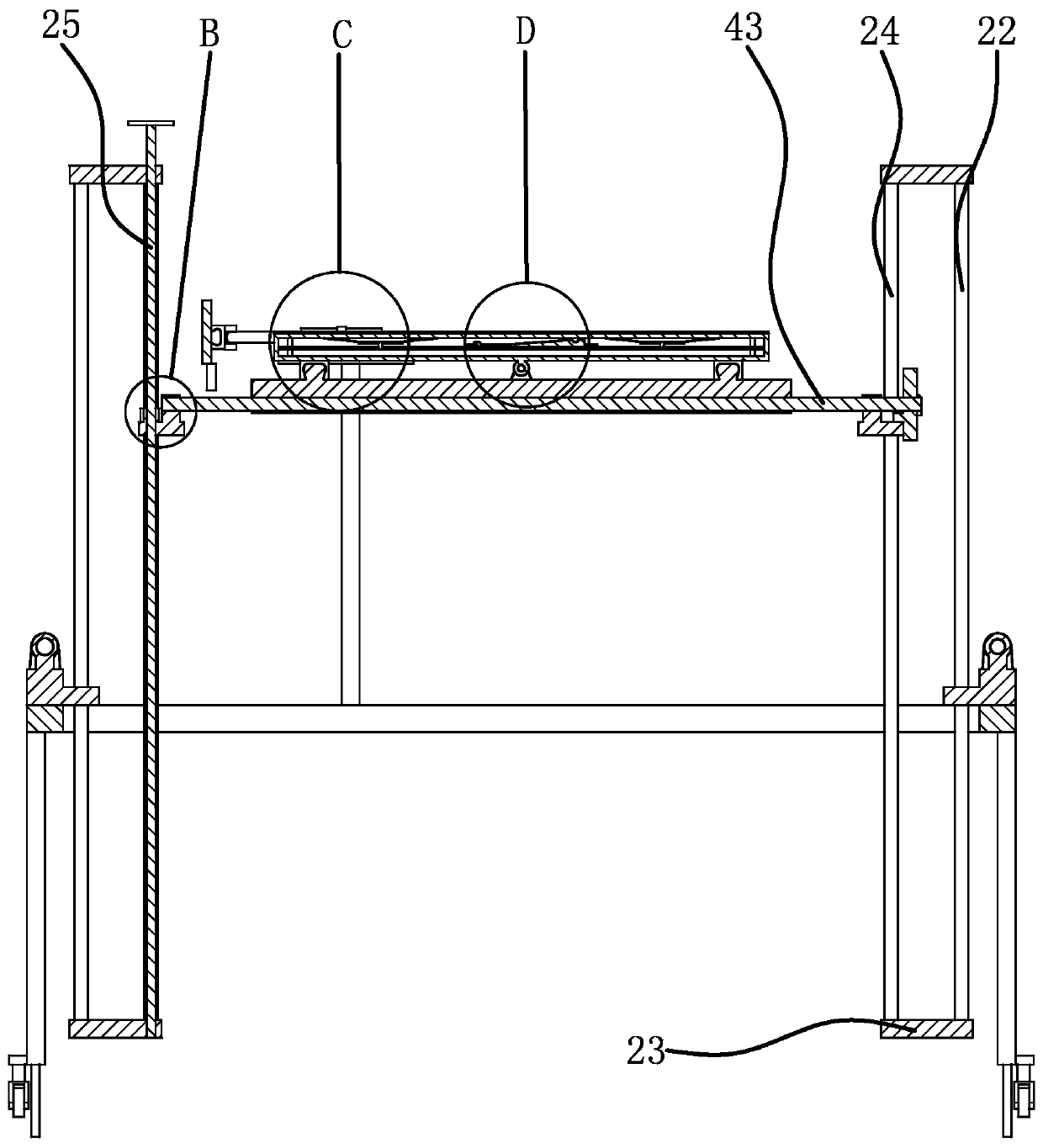

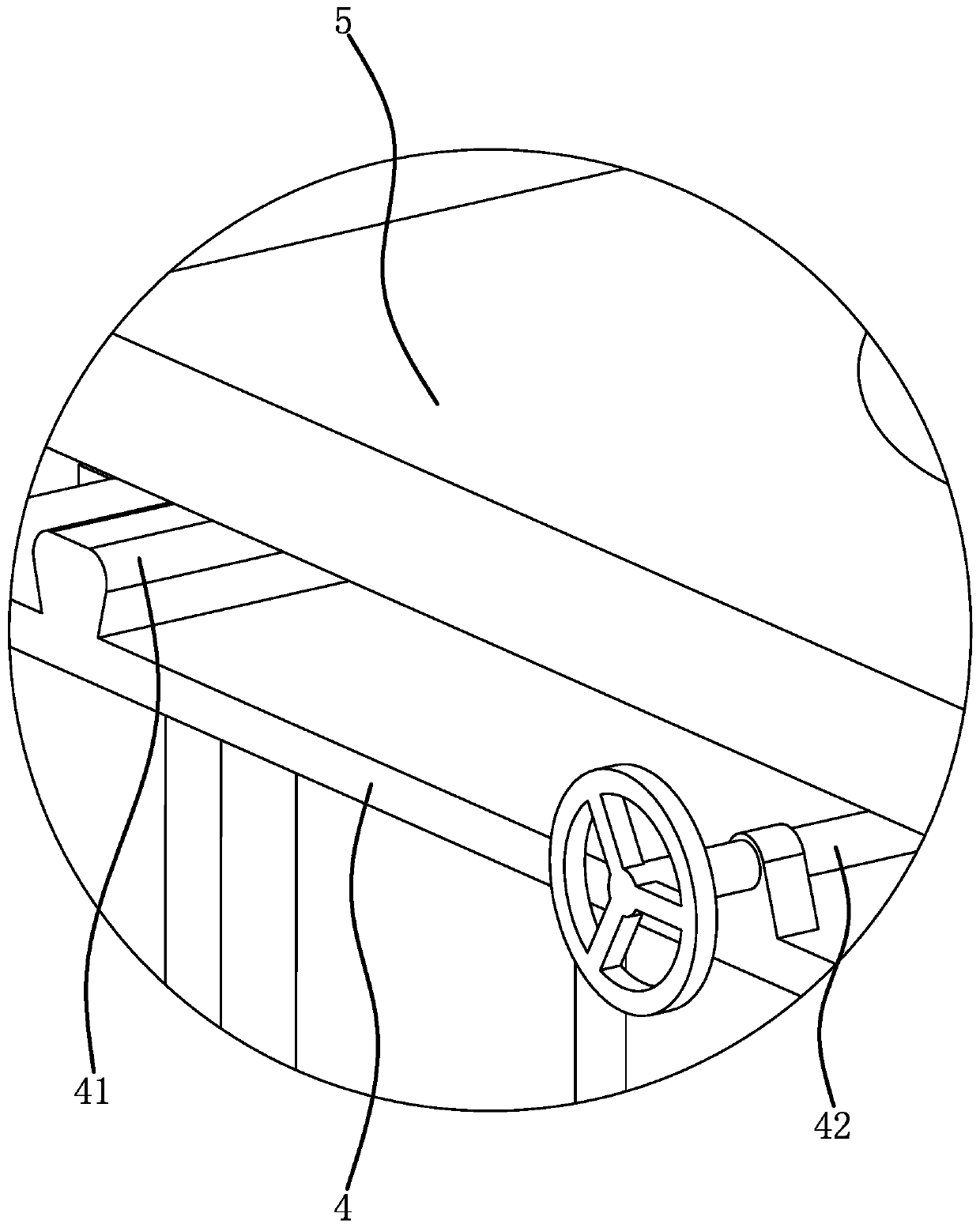

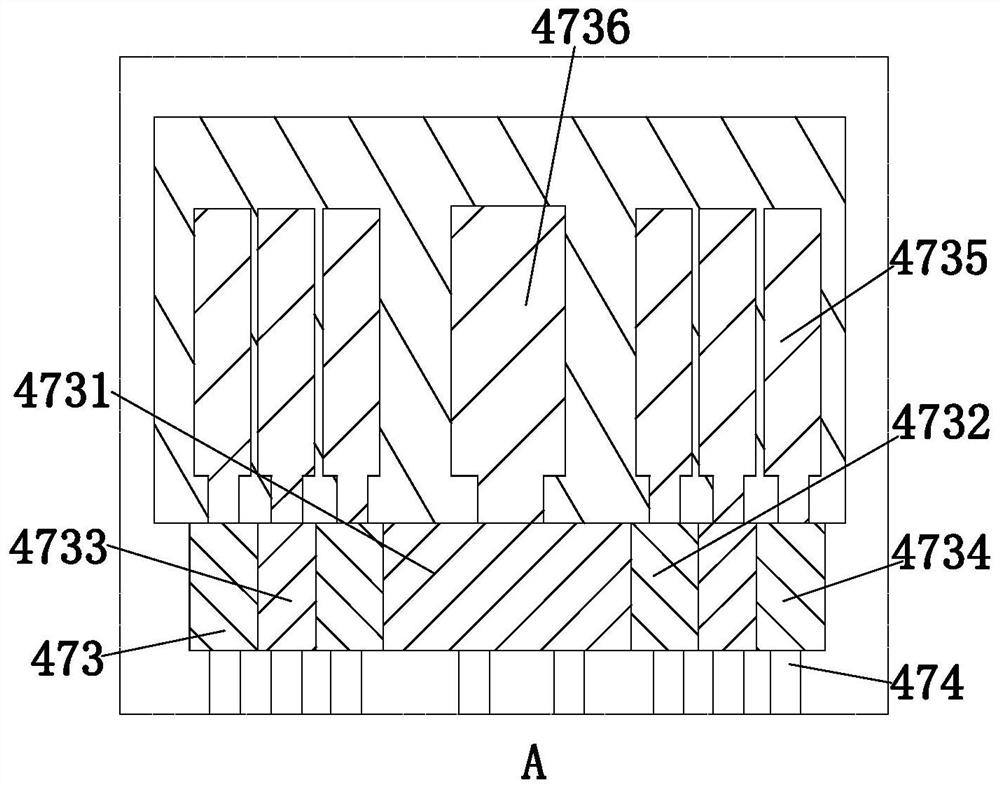

Automatic tubular product packaging equipment

PendingCN107416250APrecise cut sizeThe pasting position is accuratePackagingMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic tubular product packaging equipment which comprises a rack, a film band mechanism, a tube discharging mechanism, a tube feeding mechanism, a cutter mechanism, a tube adsorption mechanism, a tube pasting mechanism and a rolling mechanism, wherein the rack is provided with a horizontal fixed plate; the film band mechanism, the tube pasting mechanism and the rolling mechanism are sequentially fixed on the fixed plate in the first horizontal direction; and the tube feeding mechanism, the cutter mechanism, the tube adsorption mechanism and the tube pasting mechanism are sequentially fixed on the fixed plate in the second horizontal direction perpendicular to the first horizontal direction. When the automatic tubular product packaging equipment works, continuous tubular products stored in the tube discharging mechanism are cut into tubular product sections with specific length by the cutter mechanism, the tubular product sections are adsorbed by the tube adsorption mechanism and transmitted to the tube pasting mechanism to be pasted with film bands, and the film bands pasted with the tubular product sections are rolled by the rolling mechanism and transmitted to a disc to finish the automatic packaging process of tubular products.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

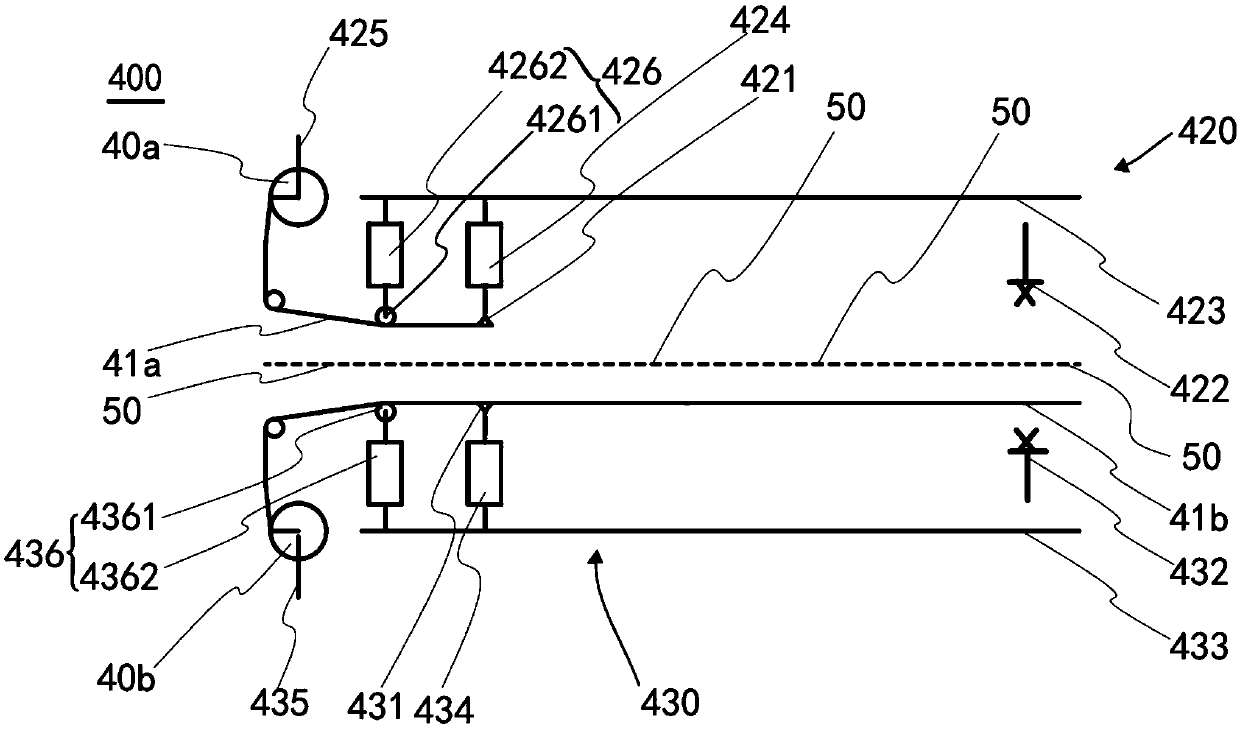

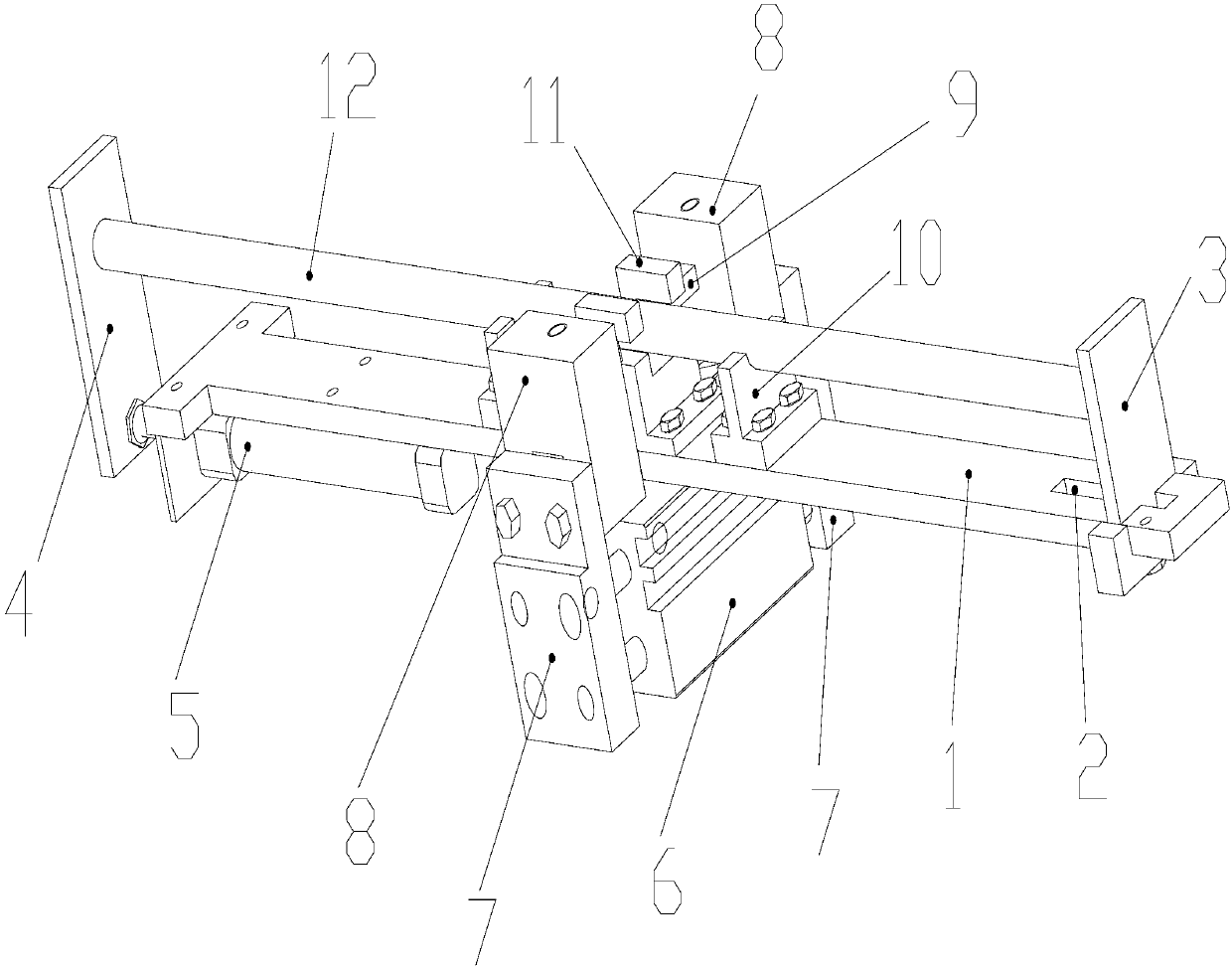

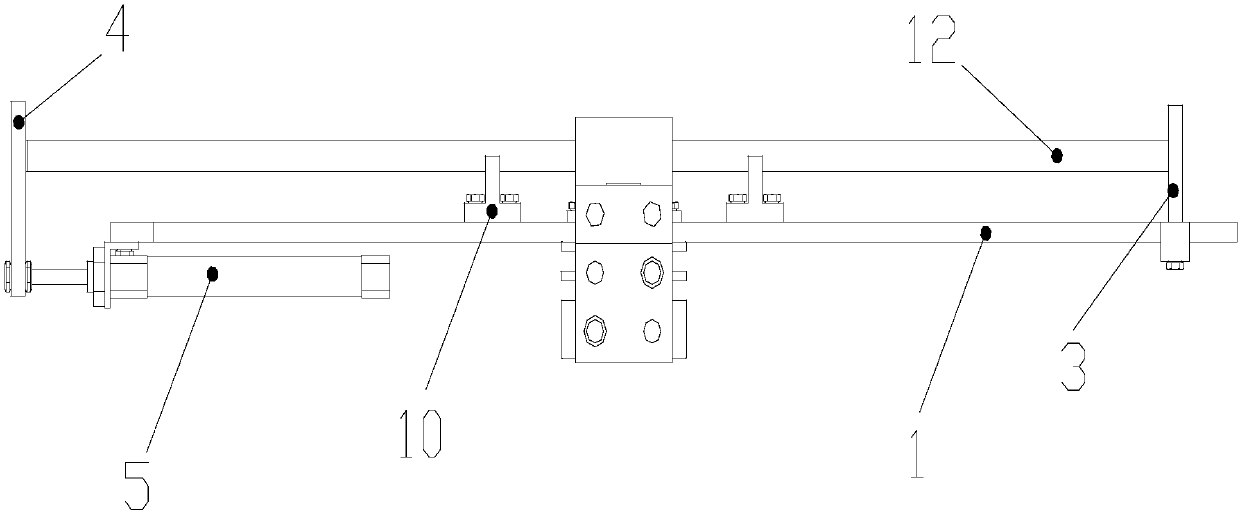

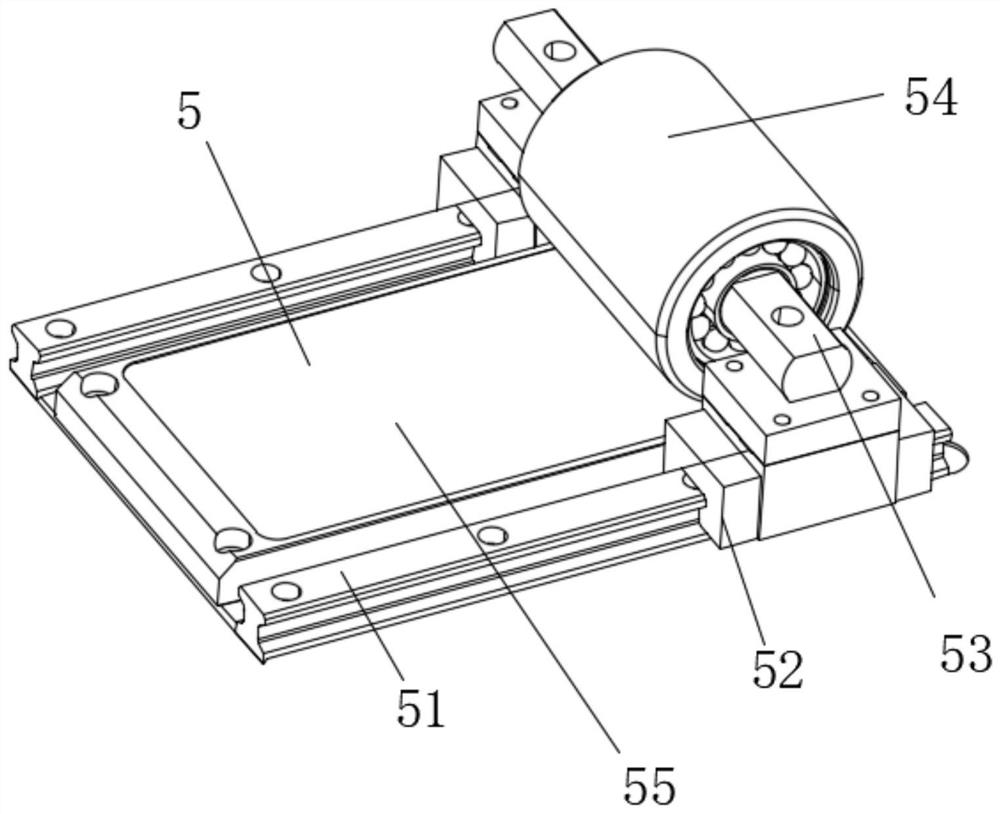

Automatic spinning equipment gluing mechanism, shaft transferring device and shaft transferring method

PendingCN109537122AImprove fixation efficiencyThe pasting position is accurateBeaming machinesOther manufacturing equipments/toolsYarnEngineering

The invention discloses an automatic spinning equipment gluing mechanism, a shaft transferring device and a shaft transferring method. The automatic spinning equipment gluing mechanism comprises a gluing bracket, a first gluing part and a second gluing part, wherein the first gluing part comprises a first driving part, a first shearing part and a first gluing guide part; the first shearing part isconnected to one end of the first gluing guide part; a glue coiling block is mounted at the other end of the first gluing guide part; the first driving part is connected with the first gluing guide part in a sliding manner to drive glue paper on the guide coiling block to move for a preset length; the second gluing part comprises a second driving part, a second shearing part and a second gluing guide part; the second gluing guide part and the first gluing guide part are oppositely arranged; the second shearing part is connected to one end of the second gluing guide part; the second driving part is connected with the second gluing guide part in a sliding manner to drive glue paper on the glue coiling block to move for a preset length. By adopting the automatic spinning equipment gluing mechanism, the purposes of high yarn fixing efficiency and precise glue paper pasting positions can be achieved.

Owner:GUANGDONG ESQUEL TEXTILES

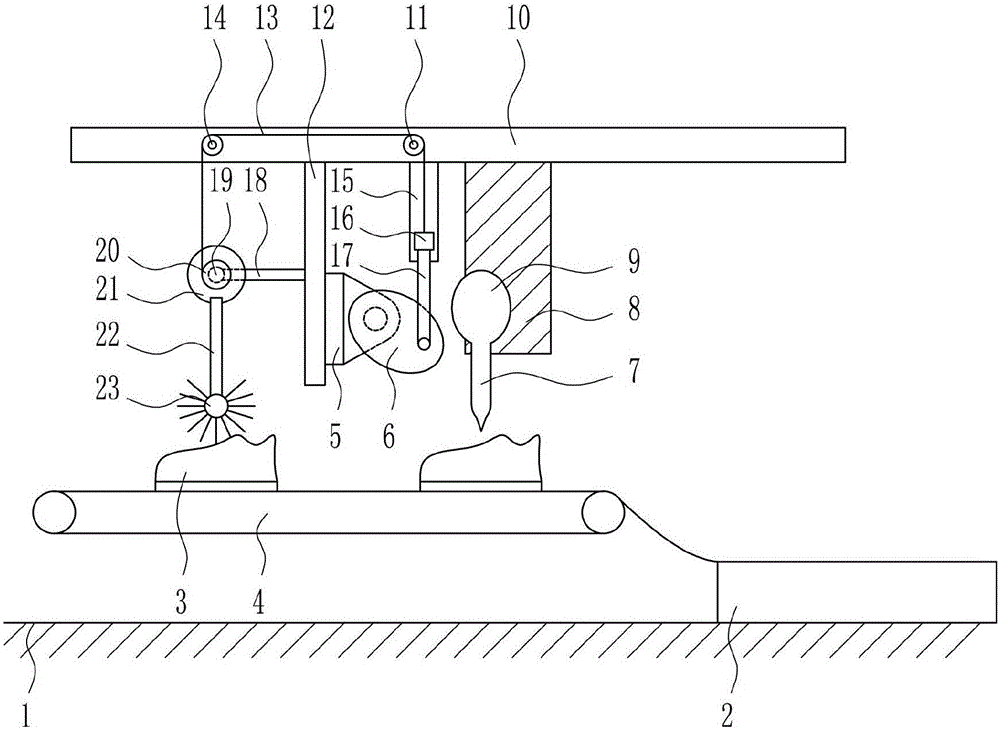

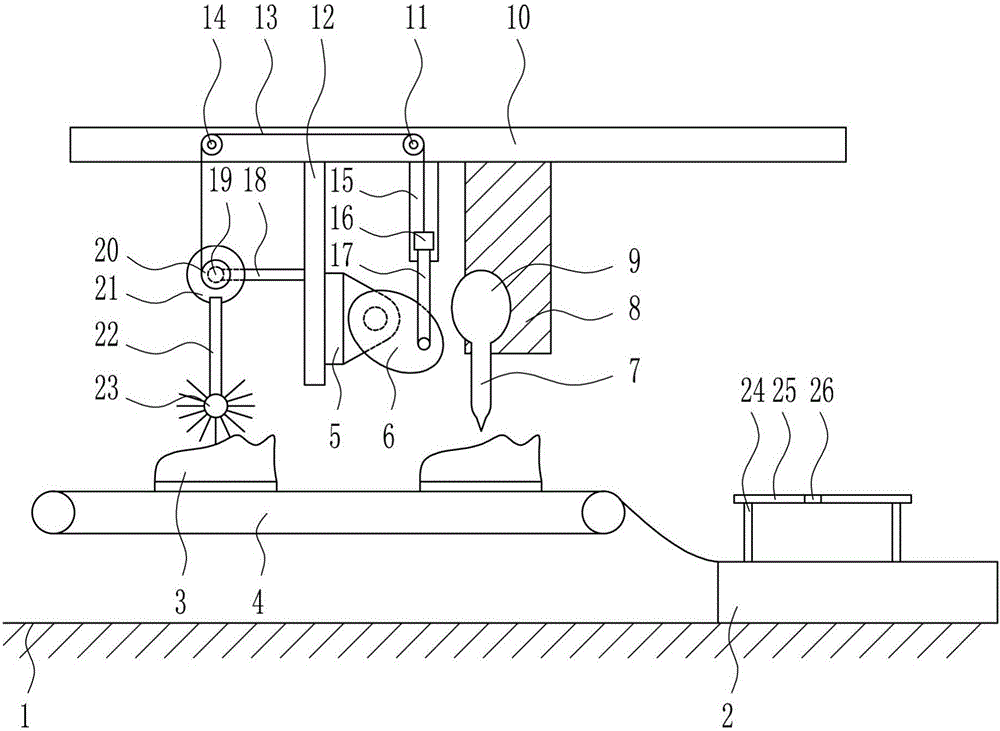

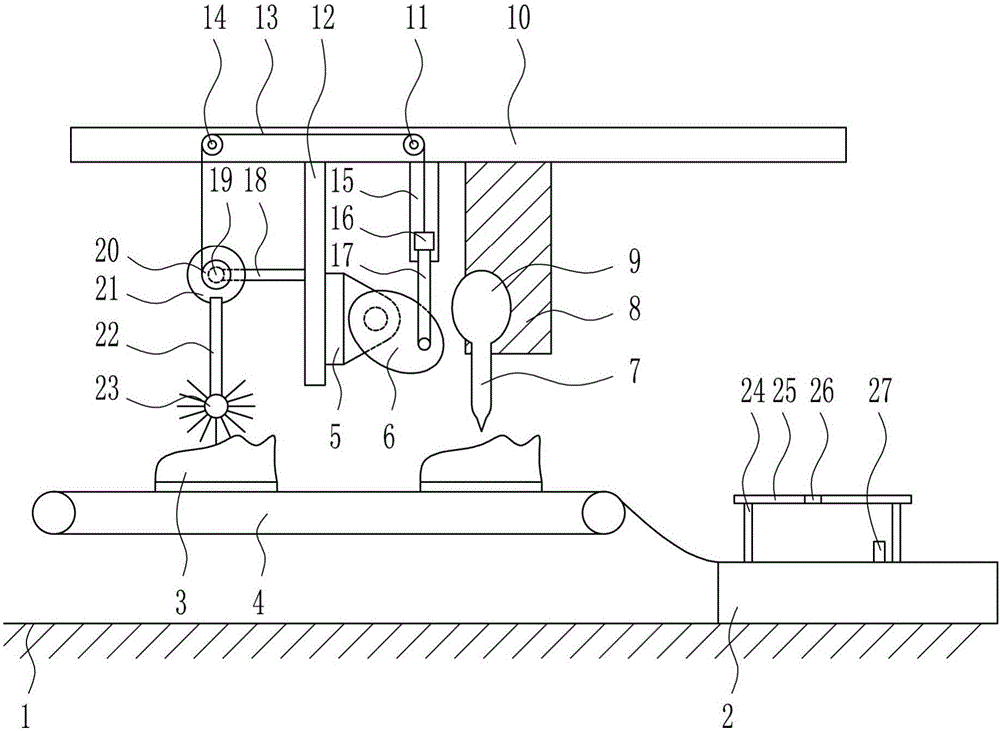

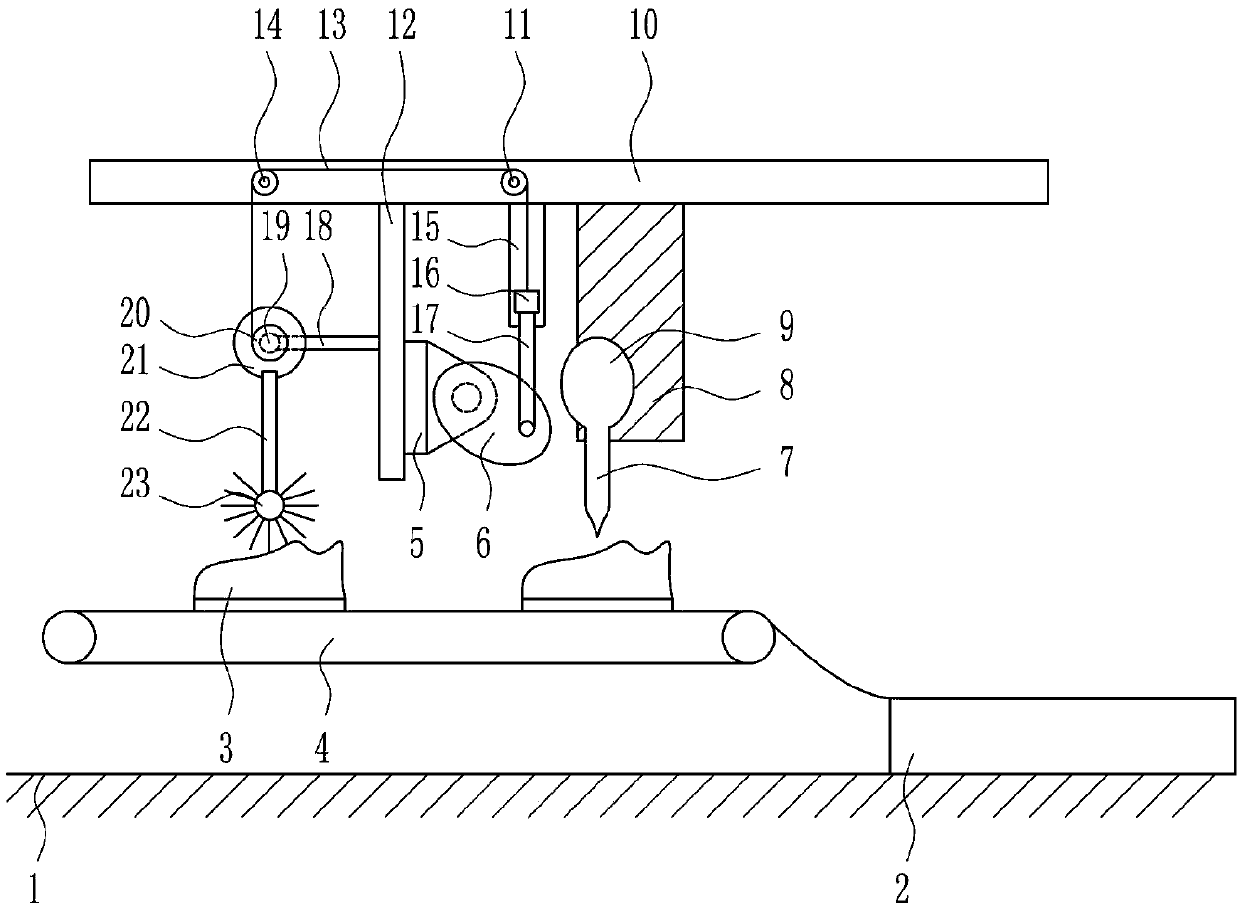

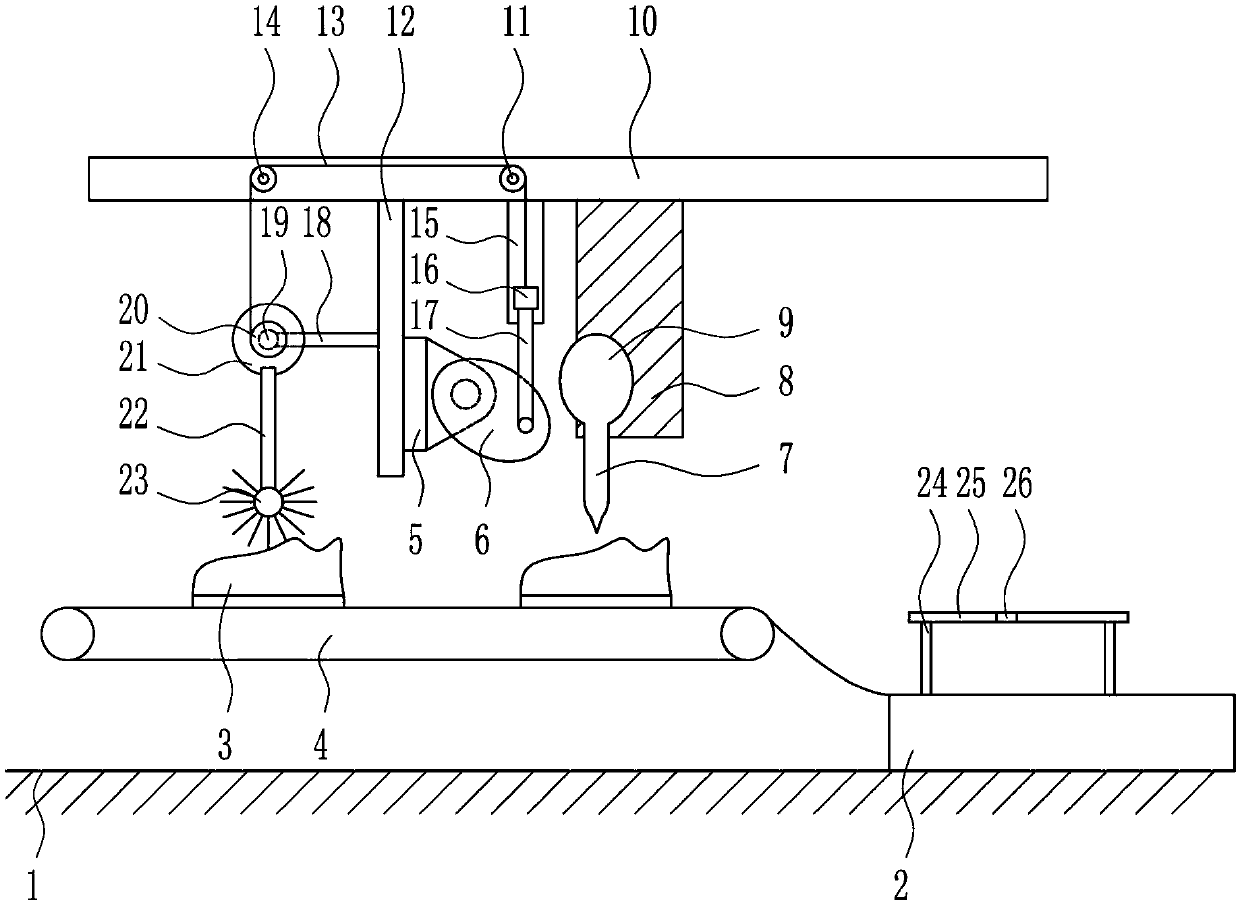

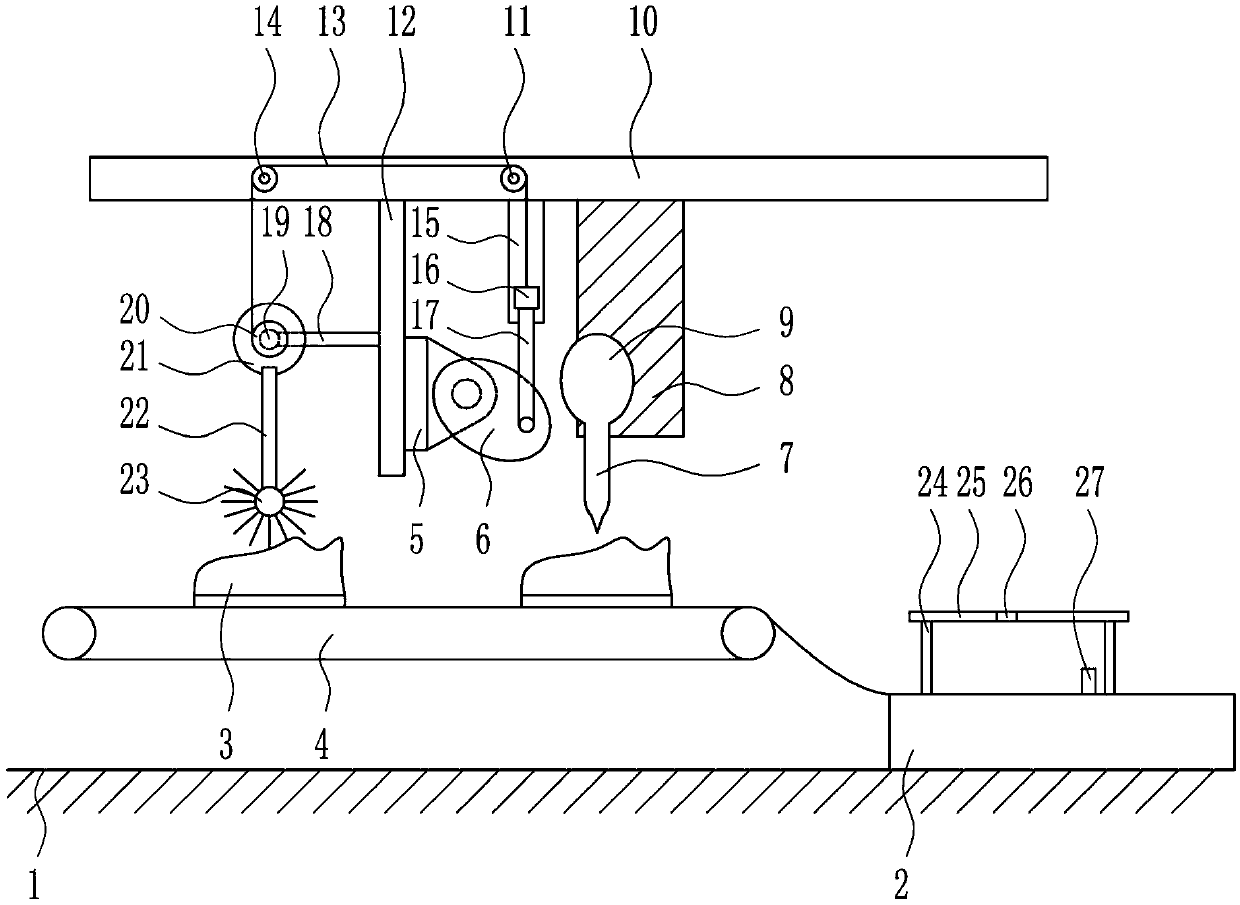

Ornament adhesion device for shoe making

The invention relates to an ornament adhesion device and especially relates to an ornament adhesion device for shoe making. The technical problem to be solved by the invention is to provide the ornament adhesion device for the shoe making, wherein adhesion efficiency is high and ornament adhesion is accurate. In order to solve the technical problem, the invention provides the ornament adhesion device for the shoe making. The device comprises a working table, a transmission device, a sway base, an ellipsoid cam, an adhesive dripping bottle, a fixation trough, an adhesive cap, a top plate, a second fixed pulley, a fixation plate, a pull wire, a first fixed pulley, a slide rail, a slide block, a connecting rod, a first strut, an electric motor, a winding wheel, a round disk, a sway rod and a duster, wherein the transmission device and the working table are disposed on the ground, and the transmission device is located above the left part of the working table. According to the invention, ornaments can be adhered on a shoe rapidly; by a limiting block, a second strut and a positioning plate, the ornaments can be adhered on the shoe more easily; and ornament adhesion positions are more accurate.

Owner:广东亮丰达实业有限公司

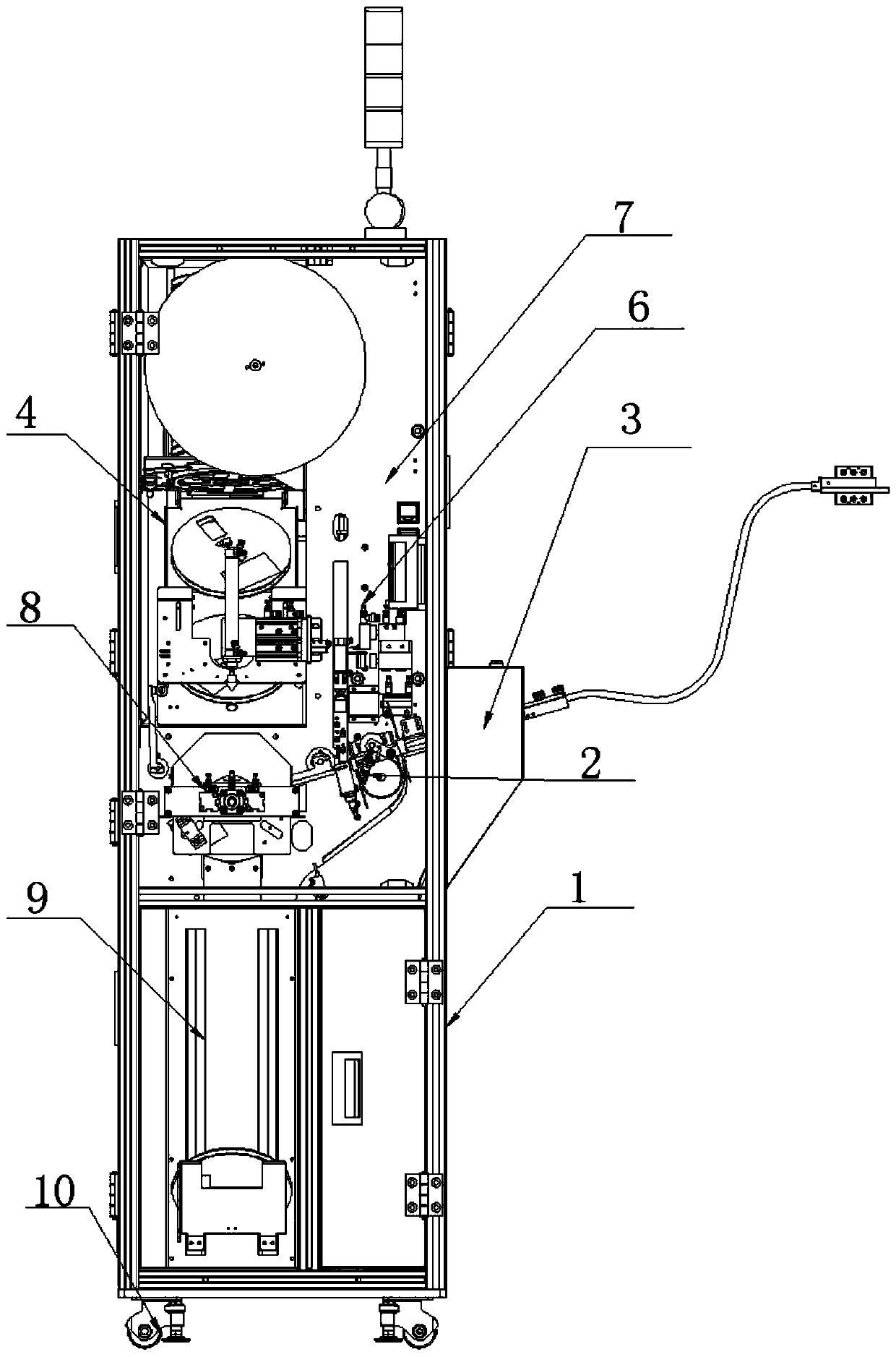

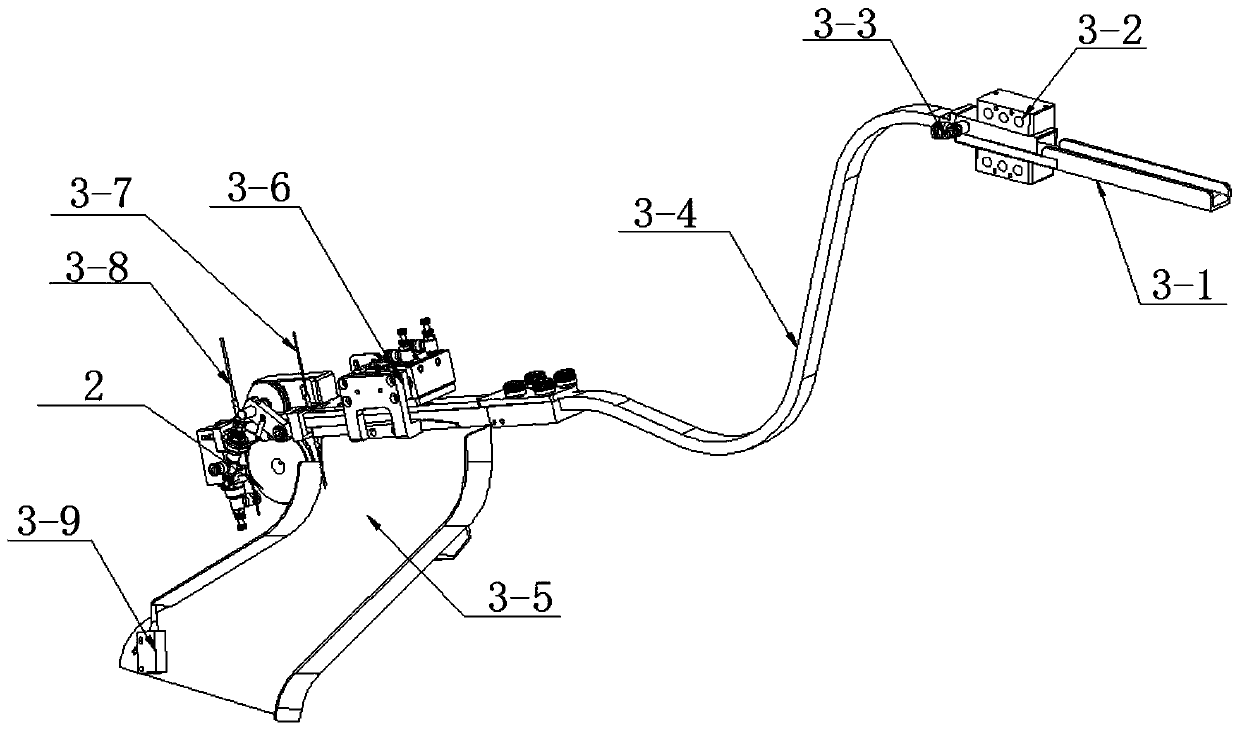

7-cun general full-automatic high-speed carrier band winding equipment

PendingCN110712785AAvoid interferenceEasy disk changePackagingArticle deliveryControl theoryMechanical engineering

The invention discloses 7-cun general full-automatic high-speed carrier band winding equipment, and relates to the technical field of carrier band packing equipment. The equipment comprises a frame, astorage mechanism, a tail glue bonding mechanism, a storage and emptying mechanism, a clamping mechanism and a caching mechanism; the storage and emptying mechanism is arranged on the upper side in the frame; the tail glue bonding mechanism is arranged in the frame on the right side of the storage and emptying mechanism; the storage mechanism is fixedly inserted in the right side wall of the frame; an output end of the storage mechanism is fixedly connected with a needle wheel guide mechanism; the clamping mechanism is fixedly arranged in the frame on the left side of the needle wheel guide mechanism; a feed end of the clamping mechanism is matched with a discharge end of the storage and emptying mechanism; and the caching mechanism is fixedly arranged in the frame on the lower side of the clamping mechanism. The equipment can accelerate the carrier band winding speed, improves the overall operation stability, and meanwhile, can be suitable for multiple products to achieve high generality and to reduce the cost investment.

Owner:深圳市恒峰锐机电设备有限公司

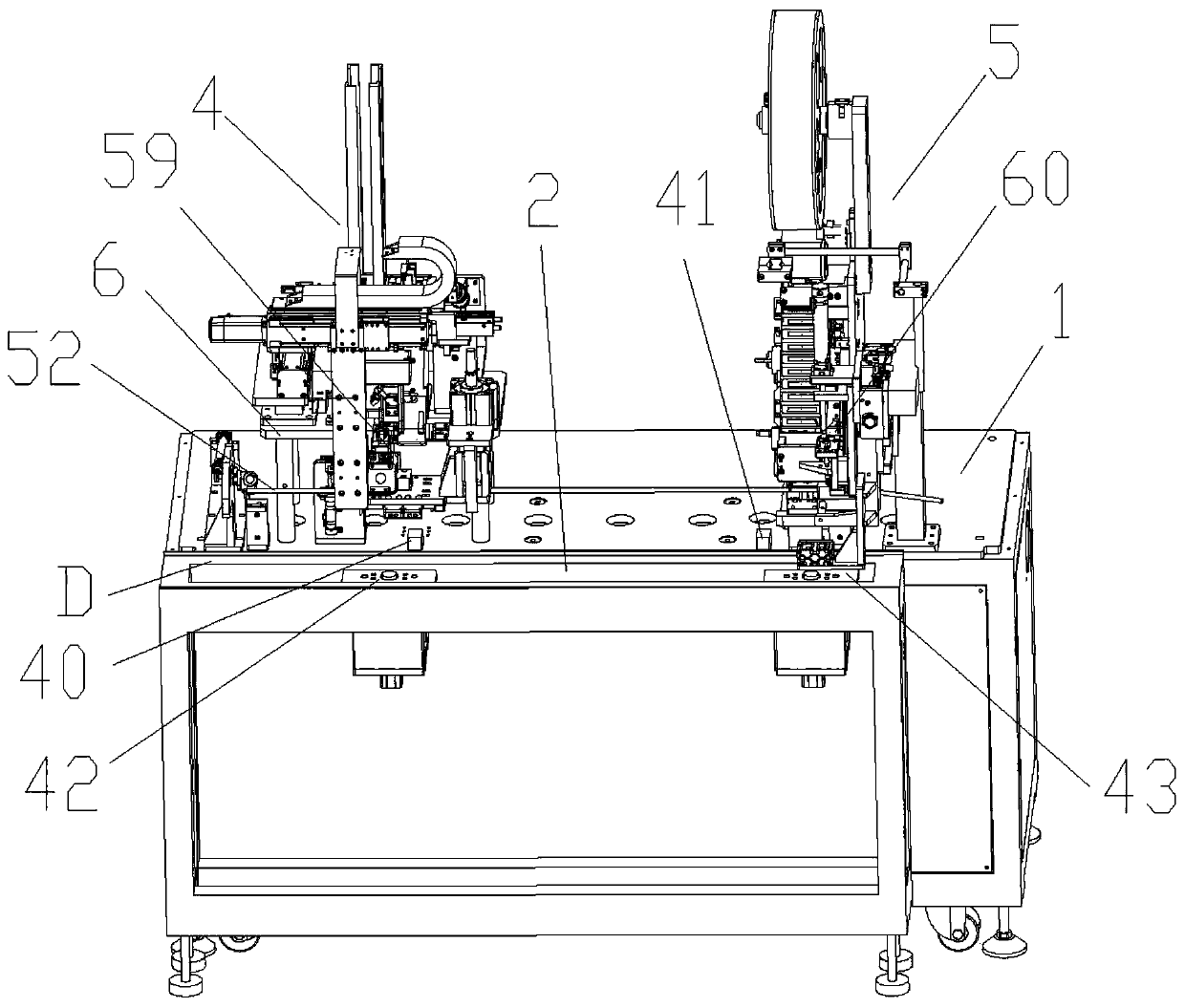

Device for mounting nameplates on electric meters

ActiveCN110127154ARealize automatic pasteThe pasting position is accurateMetal working apparatusLabelling machinesBarcodeAssembly line

The invention discloses a device for mounting nameplates on electric meters. The device is characterized by comprising a table body, an automatic assembly line and a nameplate back-side bar code pasting device, wherein the automatic assembly line is arranged on the table body and is used for conveying the electric meters, and the nameplate back-side bar code pasting device is arranged on the tablebody and is located on one side of the automatic assembly line; the device further comprises a limiting device, wherein the limiting device is arranged on the table body; the nameplate back-side barcode pasting device comprises a transmission roller assembly, a third vacuum adsorption device and a second XYZ three-axis driving device, the transmission roller assembly is arranged on the table body and is used for continuously conveying roll-type back-side bar codes, the third vacuum adsorption device is used for adsorbing the back-side bar codes, and the second XYZ three-axis driving device is used for driving the third vacuum adsorption device to move; a first bar code scanning gun used for scanning front-side bar codes of the nameplates and a second bar code scanning gun used for scanning the back-side bar codes on the transmission roll assembly are sequentially arranged on the table body along the advancing direction of the automatic assembly line. The device for mounting the nameplates on the electric meters is high in production efficiency and accuracy.

Owner:NINGBO SANXING INTELLIGENT ELECTRIC

Floor tile sticking assisting jig

ActiveCN107152157AThe construction process is labor-saving and convenientThe pasting position is accurateBuilding constructionsMechanical engineeringBuilding construction

Owner:临沂联泰新型建材合伙企业(有限合伙)

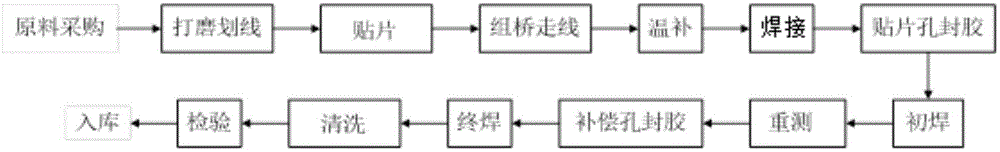

Production technology of small weighing sensor

InactiveCN106033004AHigh sensitivityImprove microscopic unevennessWeighing apparatus using elastically-deformable membersSpecial purpose weighing apparatusElastomerElastic component

The invention discloses a production technology of a small weighing sensor, and belongs to the technical field of sensor production. The production technology comprises procedures of grinding and scribing, surface-mounting, bridging and wiring, temperature compensation, welding, sealing of surface mounted holes, preliminary welding, re-measuring, sealing of compensation holes, final welding, cleaning, warehouse entry inspection and packaging. Patterns and an electroplating layer generated during processing of an elastomer are ground off, a reference line during surface mounting is drawn, a sensitive component is pasted to an elastic component, a strain gauge is connected to, a temperature compensation technology is carried out, a lead is welded to a circuit board, the surface-mounting and compensation holes of the sensor are sealed, the lead is welded to the circuit board, different indexes of a product are detected, the surface-mounting and compensation holes of the sensor are sealed, the lead is welded to the circuit board, the metal elastomer is cleaned, different parameters are tested, and the product is warehoused and classified when satisfying the requirement. According to the production technology of the small weighing sensor, the pasting position of the strain gauge is accurate, the sensitivity of the sensor is high, and output satisfies specific requirement.

Owner:ANHUI KELI ELECTRIC MFG

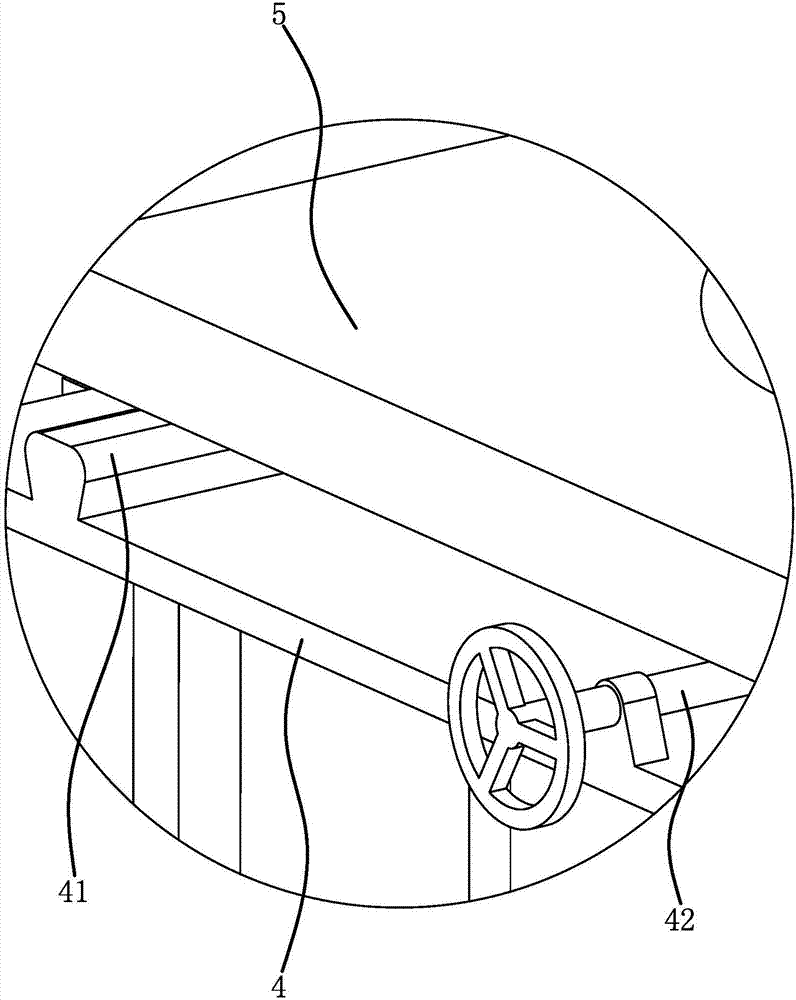

Shaft part strain gage sticking device

ActiveCN107676354AImprove paste qualityImprove pasting efficiencyMaterial gluingForce measurementEngineeringStrain gauge

Owner:GUANGZHOU UNIVERSITY

Machining technology of positive temperature coefficient sensor

InactiveCN109624194AImprove surface accuracyHigh sensitivityThermometers using electric/magnetic elementsUsing electrical meansPunchingWire cutting

The invention discloses a machining technology of a positive temperature coefficient sensor. The machining technology comprises the first step of wire cutting, the second step of outer skin peeling, the third step of metal plug pin punching, the fourth step of electroplating, the fifth step of terminal punching, the sixth step of metal plug pin welding, the seventh step of silicon wafer cleaning,the eighth step of metal plug pin injection molding, the ninth step of framework injection molding, the tenth step of circuit board installation and welding, the eleventh step of cover plate assembling, the twelfth step of detection and the thirteenth step of dispensing. The preparation process is simple and scientific, the surface precision of the patch area is high, the sticking position of a strain gauge is accurate, the sensitivity of the sensor is high, and electric signals can be input and output effectively; and the efficiency is greatly improved, the product quality is stable, the requirement of customers for the production capacity can be met, the product manufacturing cost can be reduced, cost advantages are obvious in the aspects of punching, electroplating and the like, the forming period can be greatly shortened, the yield is high, and the effect is obvious.

Owner:柳州国福科技有限公司

Automatic balance block pasting device

InactiveCN111120474AEasy to operateThe pasting position is accurateWheel-ballasting weightsMaterial gluingSprayerControl engineering

The invention discloses an automatic balance block pasting device. The automatic balance block pasting device comprises a fixed hub stepping module, a cleaning module, a balance block transmission module and a balance block clamping and pasting module, wherein the fixed hub stepping module comprises a fixed machine base; a motor is mounted on the fixed machine base and connected with one end of asynchronous belt, and the other end of the synchronous belt is connected with a roller; a lead screw is mounted on the other side of the fixed machine base and provided with a cantilever; a motor is arranged at the top end of the lead screw; a chuck is arranged at one end of the cantilever; the cleaning module is provided with an air pump; the air pump is connected with an air storage tank; and the air storage tank is connected with one end of a first electromagnetic valve, and the other end of the first electromagnetic valve is connected with an air nozzle sprayer. The automatic balance blockpasting device has the beneficial effects of being convenient to operate, accurate in pasting position, firm in pasting, high in work efficiency and the like.

Owner:CITIC DICASTAL

Vibration reducing mechanism of linear motor

ActiveCN110868007AEliminate tiny vibrationsPick up accuratelyPropulsion systemsSupports/enclosures/casingsElectric machineEngineering

The invention discloses a vibration reducing mechanism of a linear motor. The output ends of a Y-direction linear motor and a Y-Z-direction linear motor synchronously and reversely move in the Y direction, a balancing weight is arranged at the lower end of the Y-direction linear motor, a floating system is arranged at the upper end of a motor connecting plate, and a vibration reducing structure isarranged on the outer side of the floating system. The output ends of the Y-direction linear motor and the Y-Z-direction linear motor synchronously and reversely move in the Y direction, the vibration of the Y-direction linear motor and the Y-Z-direction linear motor in the Y direction is reduced, the weight difference between the Y-direction linear motor and the Y-Z-direction linear motor is counteracted by arranging the balancing weight, the balancing weight cannot accurately eliminate the weight difference of the two motors and tiny vibration exists, and the vibration reducing structure onthe outer side of the floating system eliminates the tiny vibration brought by the balancing weight. The vibration reducing effect in the Y direction is achieved through the combined action of the Y-direction linear motor, the balancing weight and the vibration reducing structure, and the chip picking and pasting positions of the Y-Z-direction linear motor are accurate.

Owner:大连佳峰自动化股份有限公司

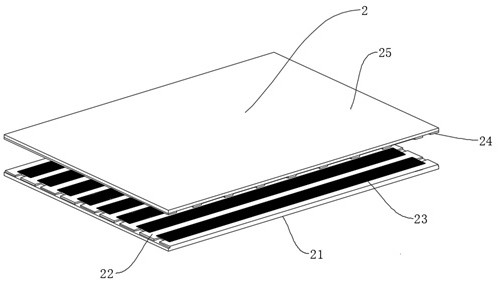

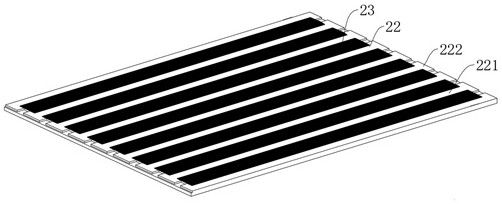

Magnetic stripe thin pad and production process thereof

PendingCN114129902AAutomatic and reliable pasting processThe pasting position is accurateStuffed mattressesSynthetic resin layered productsComposite materialEngineering

The invention discloses a magnetic stripe thin pad and a production process thereof.The magnetic stripe thin pad comprises a pad core and a cloth cover wrapping the pad core, the cloth cover and the pad core wrapped in the cloth cover, the pad core comprises a thin sponge layer, first fixing strips, magnetic stripes, second fixing strips and a high-density sponge layer, the first fixing strips are arranged on the upper surface of the thin sponge layer in an array mode, and the magnetic stripes are arranged on the lower surface of the thin sponge layer in an array mode; a clamping groove is formed between every two first fixing strips, the magnetic strips are arranged on the clamping grooves, the second fixing strips are arranged on the upper surfaces of the magnetic strips in an array mode, the length direction of the second fixing strips is perpendicular to the length direction of the first fixing strips, the high-density sponge layer is arranged above the second fixing strips, and the high-density sponge layer is arranged above the first fixing strips. The first fixing strips and the second fixing strips are detachably connected through the hook-and-loop fasteners, the magnetic strips can be taken out by detaching the hook-and-loop fasteners, the thin pad can be used as a common pad and can also be used as a magnetic therapy pad, and the thin pad is dual-purpose and more user-friendly in use.

Owner:HEYE HEALTH TECH CO LTD

A meter-mounted nameplate device

ActiveCN110127154BRealize automatic pasteThe pasting position is accurateMetal working apparatusLabelling machinesBarcodeStructural engineering

The invention discloses a device for mounting nameplates on electric meters. The device is characterized by comprising a table body, an automatic assembly line and a nameplate back-side bar code pasting device, wherein the automatic assembly line is arranged on the table body and is used for conveying the electric meters, and the nameplate back-side bar code pasting device is arranged on the tablebody and is located on one side of the automatic assembly line; the device further comprises a limiting device, wherein the limiting device is arranged on the table body; the nameplate back-side barcode pasting device comprises a transmission roller assembly, a third vacuum adsorption device and a second XYZ three-axis driving device, the transmission roller assembly is arranged on the table body and is used for continuously conveying roll-type back-side bar codes, the third vacuum adsorption device is used for adsorbing the back-side bar codes, and the second XYZ three-axis driving device is used for driving the third vacuum adsorption device to move; a first bar code scanning gun used for scanning front-side bar codes of the nameplates and a second bar code scanning gun used for scanning the back-side bar codes on the transmission roll assembly are sequentially arranged on the table body along the advancing direction of the automatic assembly line. The device for mounting the nameplates on the electric meters is high in production efficiency and accuracy.

Owner:NINGBO SANXING INTELLIGENT ELECTRIC

An auxiliary tooling for pasting floor tiles

ActiveCN107152157BThe construction process is labor-saving and convenientThe pasting position is accurateBuilding constructionsEngineeringMechanical engineering

Owner:临沂联泰新型建材合伙企业(有限合伙)

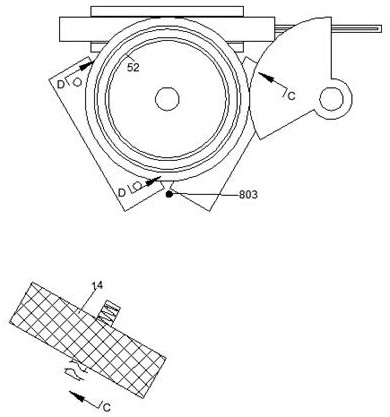

Automatic gasketing device for induction cooker coil production

InactiveCN106151196BRealize automatic pastingImprove pasting effectLiquid surface applicatorsMaterial gluingEngineeringInduction cooking

The invention discloses an automatic gasket sticking device used for induction cooker coil production. A distributing electrical motor is arranged on the lower portion of a rack; a bearing pedestal is arranged on the middle portion of the rack; the bearing pedestal is in transmission connection with the distributing electrical motor; a gasket distributing plate is fixedly arranged on the bearing pedestal; the gasket distributing plate is provided with gasket sliding grooves of a divergent shape; locating grooves are arranged inside the gasket sliding grooves; a mica feeding tank and a mica discharging tank are suspended on the rack and correspondingly placed on the front and back sides of the gasket distributing plate; a pair of vibrating plates is correspondingly arranged on the two side portions of the mica feeding tank; and the mica feeding tank and the mica discharging tank are each composed of a bottom board, a holder and an upper cover plate. The automatic gasket sticking device used for induction cooker coil production has the advantages that coil plate gaskets are stuck automatically; labor cost is highly saved; production efficiency is improved; glue is coated evenly through the device; the sticking position is precise; press fitting is conducted evenly; and the sticking effect of the coil plate gaskets is highly improved.

Owner:钟祥三富机电有限公司

Automatic pasting device for reflective film of traffic warning sign

InactiveCN111794142AReduce labor intensityThe pasting position is accurateTraffic signalsRoad signsTraffic signalElectric machine

The invention discloses an automatic pasting device for a reflective film of a traffic warning sign, which comprises a top plate, wherein the front side of the lower surface of the top plate is fixedly connected with a supporting plate fixedly connected to the ground, a motor is fixedly arranged in the lower surface of the top plate, the lower end of the motor is in power connection with a motor shaft, an arc-shaped block and an incomplete gear are fixedly connected to the motor shaft in sequence from top to bottom, the left side of the motor shaft is provided with a first rotating shaft rotationally connected to the lower surface of the top plate, and the first rotating shaft is fixedly connected with a gear capable of being connected with the incomplete gear in a meshed mode. Automatic pasting operation of the traffic signal board is realized step by step through intermittent motion between the incomplete gear and the gear; the labor intensity is much lower compared with manual operation, the pasting position is more accurate, the pasted reflective film can be perfectly attached to the upper surface of an aluminum plate without bubbles and wrinkles, and the pasting quality is better. Meanwhile, the pasting efficiency is greatly improved, and the pasting device is worthy of popularization.

Owner:绍兴柯桥凯歌电子有限公司

Labeling equipment with protection function

ActiveCN113998253AGuaranteed smoothEasy accessArticle deliveryLabelling machinesAdhesive beltLogistics management

The invention relates to the field of logistics equipment, in particular to labeling equipment with a protection function, which comprises a shell, an inner cavity is arranged in the shell, a first sleeve shaft is arranged on the side wall of the inner cavity, a first adhesive tape is sleeved on the first sleeve shaft, and an opening for the extension end of the first adhesive tape to extend out is arranged on one side of the inner cavity. An adhesive tape is sleeved with the shell in a coiled mode and is convenient to take and use, the adhesive tape is pulled out of the opening in the pasting process, the opening is aligned with the pasting position, it is guaranteed that the pasting position is accurate, and flatness of the adhesive tape is conveniently kept; a user only needs to put a label on the movable plate, the movable plate drives the label to be close to and make contact with the pasting face of the adhesive tape, then when the adhesive tape is pulled out, the label can be gradually attached to the adhesive tape along with movement of the adhesive tape, then the label and the adhesive tape can be conveniently pasted to the pasting face together, and the label is covered with the adhesive tape to achieve the protection effect.

Owner:ZHEJIANG BAISHI TECH

A pre-installation process of a small single-door refrigerator tank

ActiveCN105571254BGuaranteed service lifeService life will not be affectedDomestic cooling apparatusLighting and heating apparatusTemperature controlEngineering

Owner:CHUZHOU JIAJIAAI ELECTRICAL TECH

Pre-assembling technology of small single-door refrigerator container

ActiveCN105571254AGuaranteed service lifeService life will not be affectedDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

The invention discloses a pre-assembling technology of a small single-door refrigerator container. The pre-assembling technology comprises the following steps that S1, self inspection, wherein inner connecting lines and air returning coils inside a single-door refrigerator are subject to appearance quality detection, and it is ensured that the inner connecting line and the air returning coil are flat, and free of shaping, damaging and incompleteness; S2, line binding, wherein the qualified inner connecting lines in the S1 are taken, the portions away from ends of the inner connecting lines by 160 mm to 200 mm are wound and fixed by a belt, the length of the belt ranges from 320 mm to 380 mm, one face of the belt has glue foam, sealing of the inner connecting lines penetrating punched holes of a cold storage and temperature control box is facilitated, the sticking position of the rubber belt is correct, firm, in position, tight in seal and free of foam leaking, and the connecting lines are correctly bound up; and S3, the qualified inner connecting lines in the S1 are inserted into the punched holes of the temperature control box to the middle of the glued foam, and two 100 mm belts with glue foams on one faces are used for sealing and fixing the punched holes. The pre-assembling technology of the refrigerator container can preassemble a refrigerator well, the technology is simple, the structure is compact, and the technology is quite practical.

Owner:CHUZHOU JIAJIAAI ELECTRICAL TECH

A shoe decoration sticking device

The invention relates to an ornament adhesion device and especially relates to an ornament adhesion device for shoe making. The technical problem to be solved by the invention is to provide the ornament adhesion device for the shoe making, wherein adhesion efficiency is high and ornament adhesion is accurate. In order to solve the technical problem, the invention provides the ornament adhesion device for the shoe making. The device comprises a working table, a transmission device, a sway base, an ellipsoid cam, an adhesive dripping bottle, a fixation trough, an adhesive cap, a top plate, a second fixed pulley, a fixation plate, a pull wire, a first fixed pulley, a slide rail, a slide block, a connecting rod, a first strut, an electric motor, a winding wheel, a round disk, a sway rod and a duster, wherein the transmission device and the working table are disposed on the ground, and the transmission device is located above the left part of the working table. According to the invention, ornaments can be adhered on a shoe rapidly; by a limiting block, a second strut and a positioning plate, the ornaments can be adhered on the shoe more easily; and ornament adhesion positions are more accurate.

Owner:广东亮丰达实业有限公司

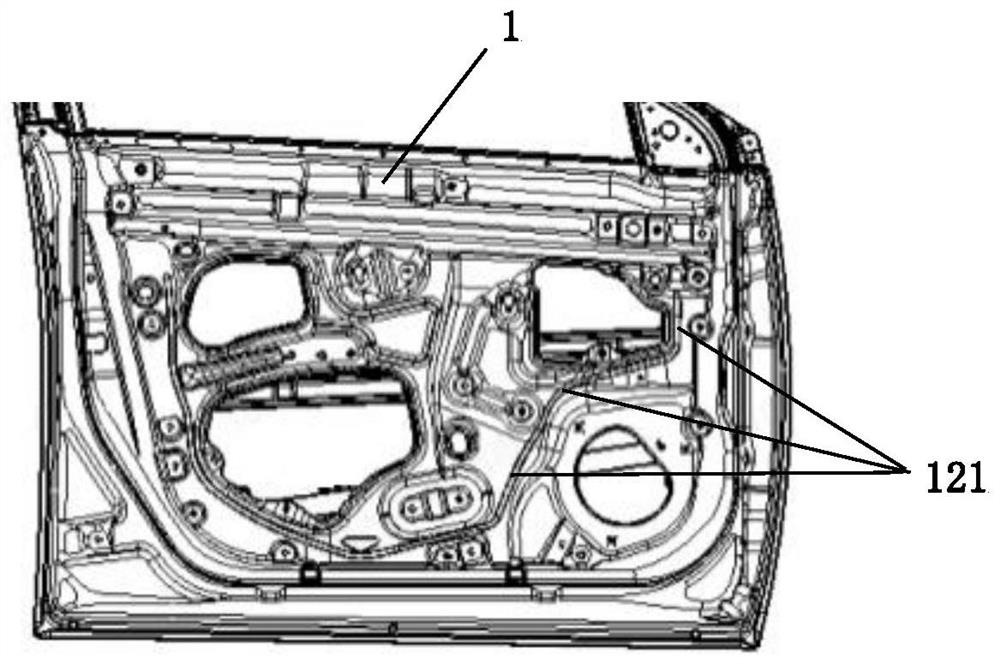

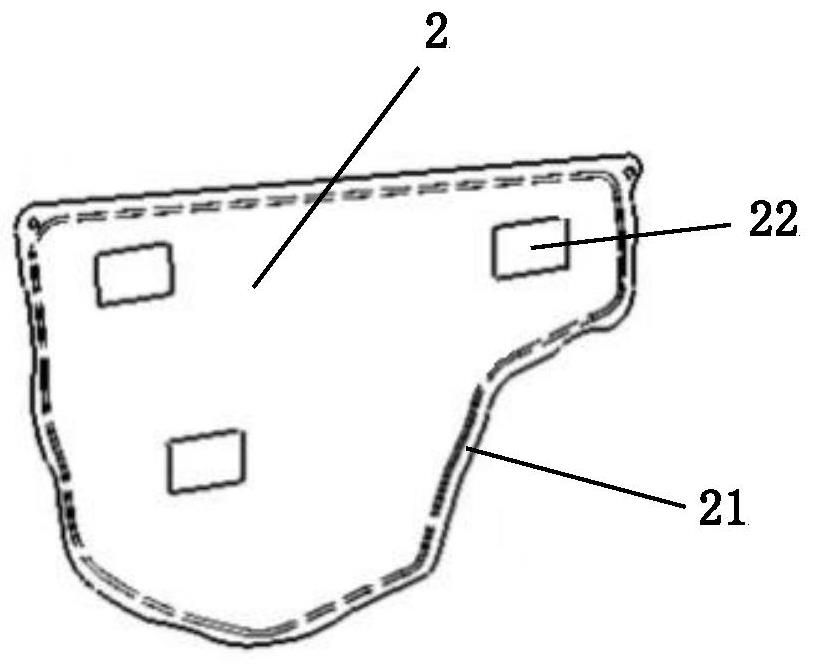

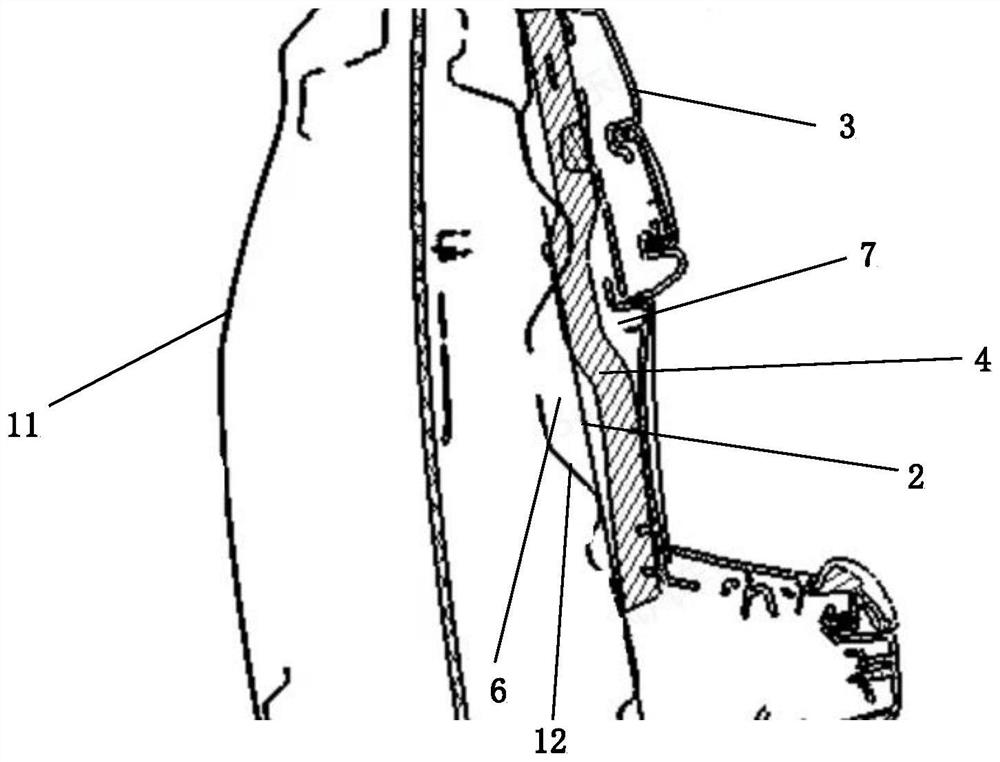

Automobile sound absorption door and installation method thereof

The invention discloses an automobile sound absorption door and an installation method thereof, and relates to the technical field of automobile sound insulation and noise reduction. The automobile sound absorption door comprises an automobile door inner metal plate having the inner surface provided with an adhesive contour line, a door protection plate fixedly installed on the inner surface of the automobile door inner metal plate, and having the face, facing the automobile door inner metal plate, provided with a plurality of clamping hooks, a waterproof film adhered to the automobile door inner metal plate along the adhesive contour line, and sound absorption cotton arranged between the waterproof film and the door protection plate; and all the clamping hooks penetrate through the sound absorption cotton to be hung and fixed. The sound absorption door further comprises strip-shaped sealing foam, and the sealing foam is arranged in a surrounding mode in the circumferential direction of the door protection plate and clamped between the door protection plate and the automobile door inner metal plate. The invention further discloses an installation method based on the automobile sound absorption door. According to the automobile sound absorption door and the installation method thereof, the noise control effect is good, the noise level in a cab is effectively reduced, and the comfort degree of passengers is improved.

Owner:DONGFENG MOTOR GRP

Automatic pasting device for skin fixing base production and working method

ActiveCN111772643AImprove yieldIncrease productivityMaterial gluingCatheterWrinkleManufacturing engineering

The invention discloses an automatic pasting device for skin fixing base production. The device comprises a first driving mechanism, a sliding plate, a rolling mechanism, a vacuum adsorption base, a clamping device, a first material placing base and a second material placing base, wherein a first material is clamped to the position 0.1-3mm away from the upper surface of a second material through the clamping device, then the sliding plate is pushed to move through the first driving mechanism, the rolling mechanism jacks up the second material in a moving process and carries out rolling and pasting on the lower surface of the first material, and the vacuum adsorption base stretches and fixes the part, not subjected to rolling and pasting, of the first material, so that a linear pasting process of pasting while pressing is achieved; air can be emptied in the pasting process; and compared with a traditional surface pasting process of directly pasting the first material and the second material and then flattening the first material and the second material through the rolling mechanism, the process has the advantages that the pasting degree and flatness of a finished product are higher,the phenomena of bubbles and wrinkles are avoided, and the finished product rate and the production efficiency are greatly improved.

Owner:ZHEJIANG POCTECH

Automatic pasting equipment for skin fixing seat production

The invention relates to automatic pasting equipment for skin fixing seat production. The automatic pasting equipment comprises a workbench, the inner side wall of the workbench is fixedly connected with a sliding rail mechanism. A clamping device is connected to the sliding rail mechanism in a sliding manner; the inner bottom of the workbench is fixedly connected with a fixing device and a flattening device in sequence in the sliding direction of the sliding rail mechanism. The fixing device is connected with the flattening device through a linkage rod; one end of the linkage rod is fixedly connected with the clamping device, the other end of the linkage rod is fixedly connected with the flattening device; the linkage connection between the clamping device and the flattening device is realized through a simple part, namely the linkage rod so that the extrusion between the non-woven adhesive tape and the double-sided adhesive tape is realized in the process of moving the clamping device, the fitting degree between the non-woven adhesive tape and the double-sided adhesive tape is increased, the failure rate of equipment is reduced, and the use stability is improved.

Owner:ZHEJIANG POCTECH

A Vibration Damping Mechanism for a Linear Motor

ActiveCN110868007BEliminate tiny vibrationsThe pasting position is accuratePropulsion systemsSupports/enclosures/casingsElectric machineLinear motor

The invention discloses a vibration reducing mechanism of a linear motor. The output ends of a Y-direction linear motor and a Y-Z-direction linear motor synchronously and reversely move in the Y direction, a balancing weight is arranged at the lower end of the Y-direction linear motor, a floating system is arranged at the upper end of a motor connecting plate, and a vibration reducing structure isarranged on the outer side of the floating system. The output ends of the Y-direction linear motor and the Y-Z-direction linear motor synchronously and reversely move in the Y direction, the vibration of the Y-direction linear motor and the Y-Z-direction linear motor in the Y direction is reduced, the weight difference between the Y-direction linear motor and the Y-Z-direction linear motor is counteracted by arranging the balancing weight, the balancing weight cannot accurately eliminate the weight difference of the two motors and tiny vibration exists, and the vibration reducing structure onthe outer side of the floating system eliminates the tiny vibration brought by the balancing weight. The vibration reducing effect in the Y direction is achieved through the combined action of the Y-direction linear motor, the balancing weight and the vibration reducing structure, and the chip picking and pasting positions of the Y-Z-direction linear motor are accurate.

Owner:大连佳峰自动化股份有限公司

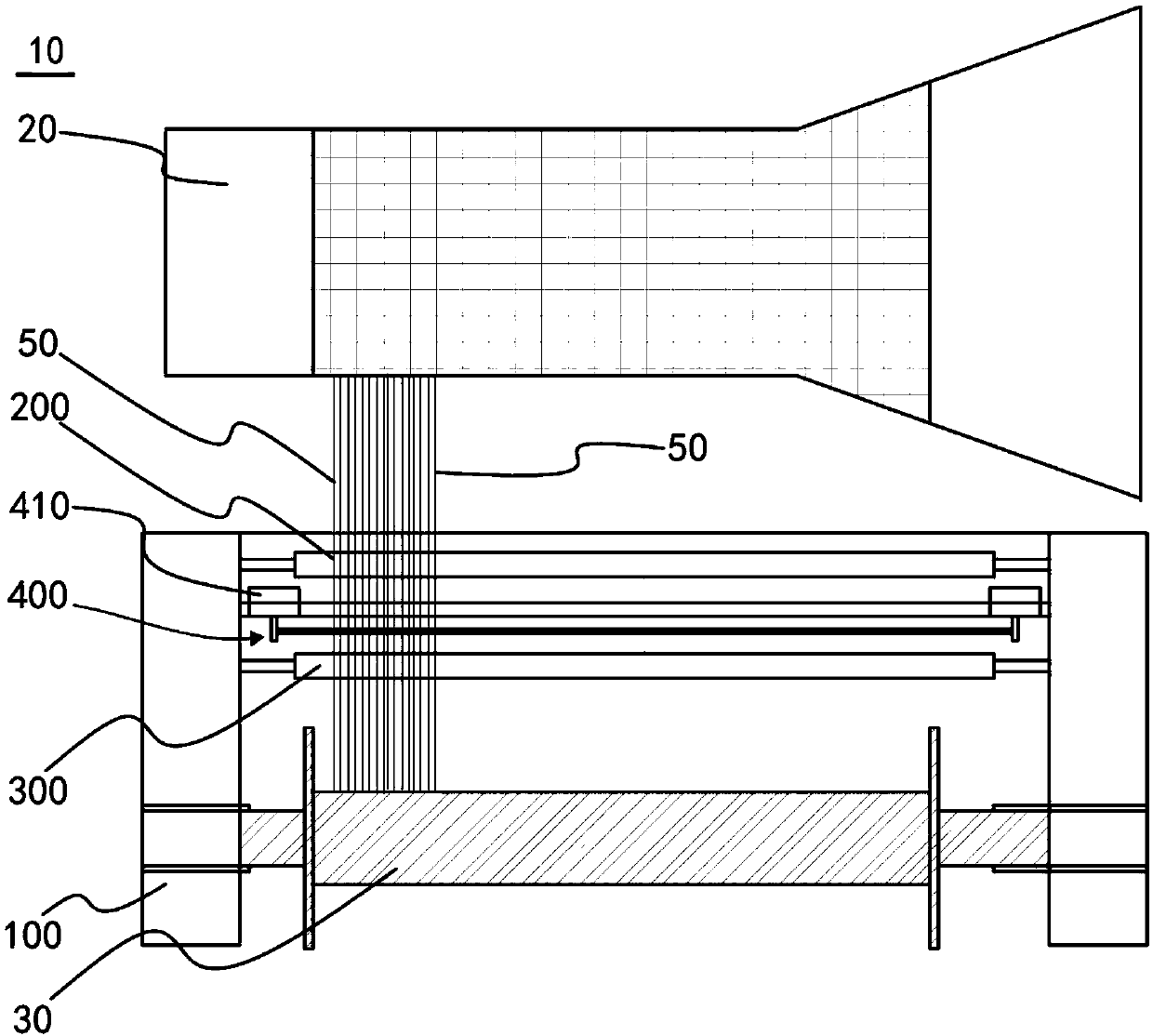

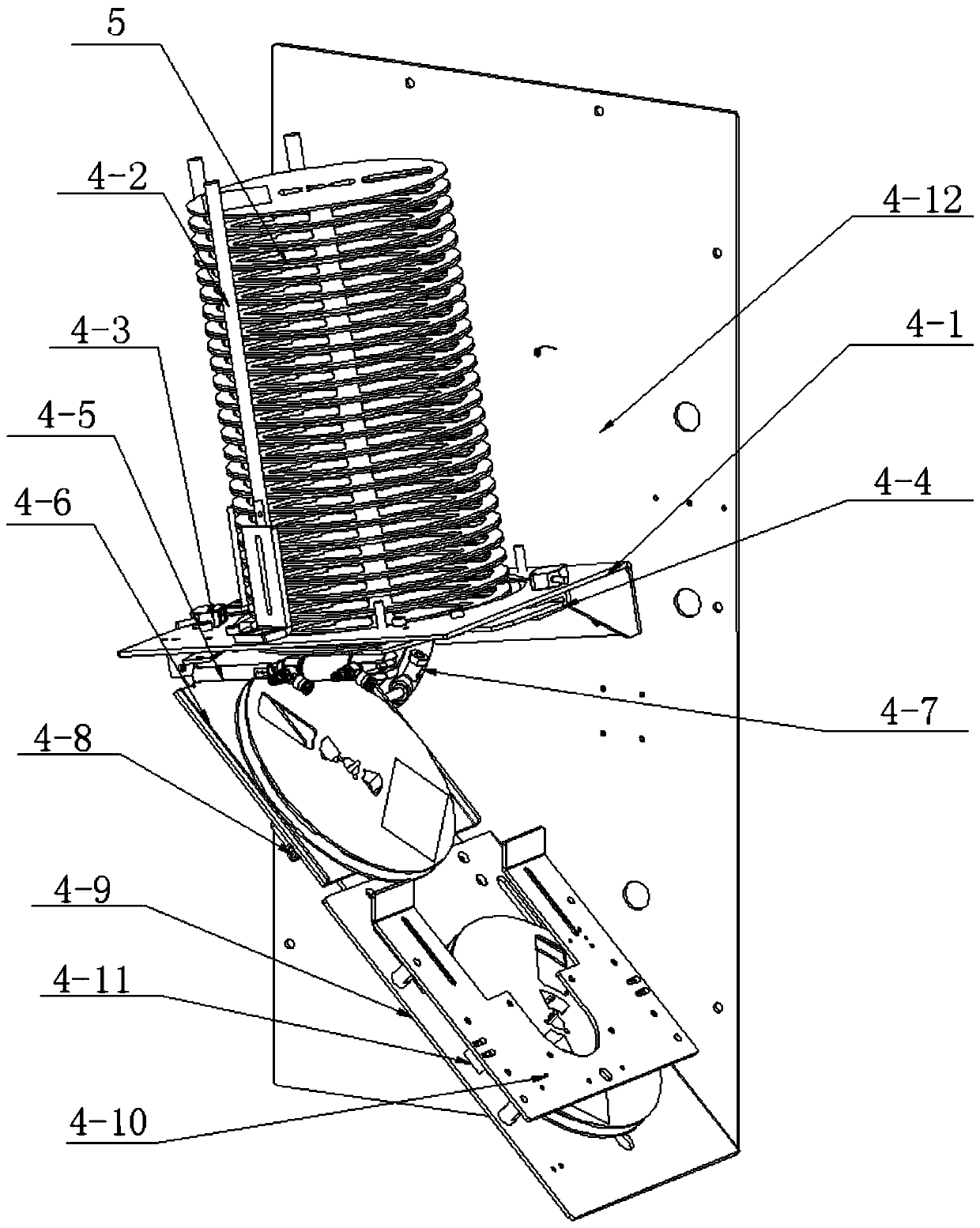

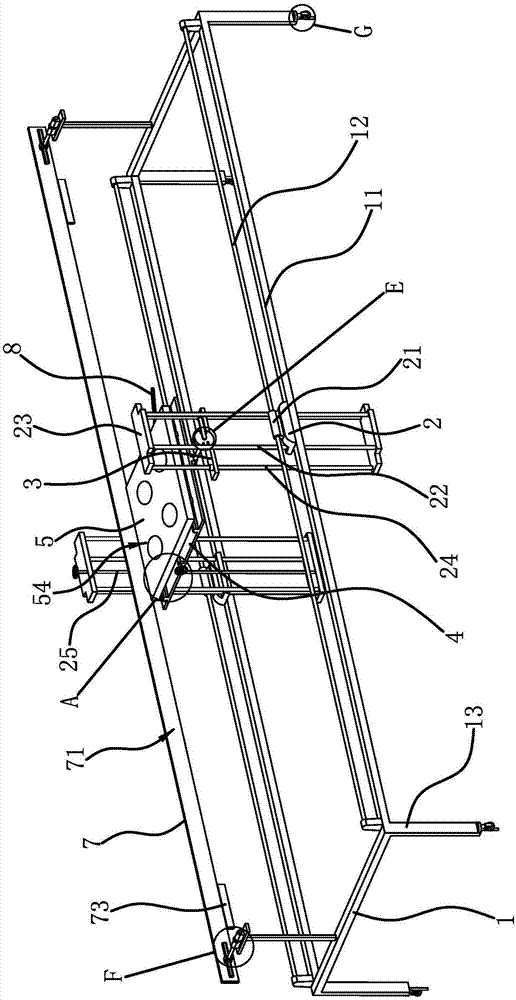

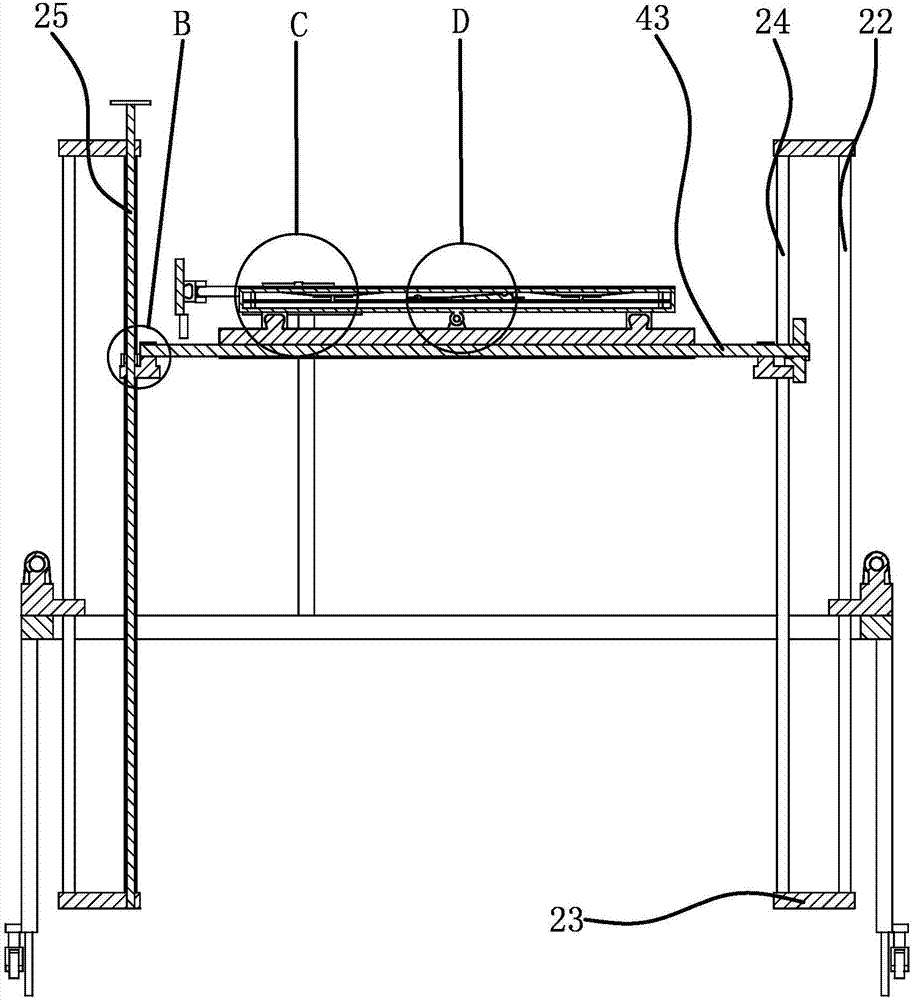

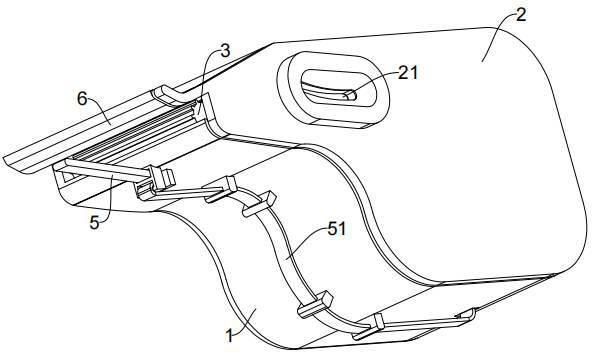

Full-automatic battery label sticking machine

ActiveCN103448969BShorten the action cycleIncrease productivityLabelling machinesLabelling elongated objectsNumerical controlDisplay device

The invention provides a full-automatic battery label sticking machine. The full-automatic battery label sticking machine comprises a rack, as well as a label and backing paper separating device, a label settling device, a battery picking device, a battery longitudinal moving device and a battery putting back device which are positioned on the rack; the label sticking machine is also connected with a numerical control display device. The full-automatic battery label sticking machine provided by the invention has the beneficial effects that a battery and a label are positioned accurately; the label sticking time is shortened by adopting a dual-suction-disc structure; multi-point positioning can be achieved by adopting an electric cylinder; the full-automatic battery label sticking machine is convenient to regulate and improves the product yield, a battery turnover device is saved, the integral structure is greatly simplified, and multiple purposes with one machine are realized.

Owner:滁州润度智能科技有限公司

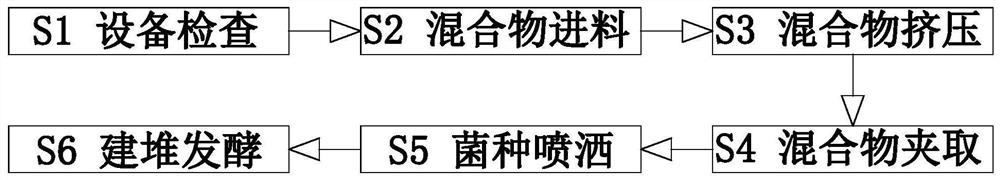

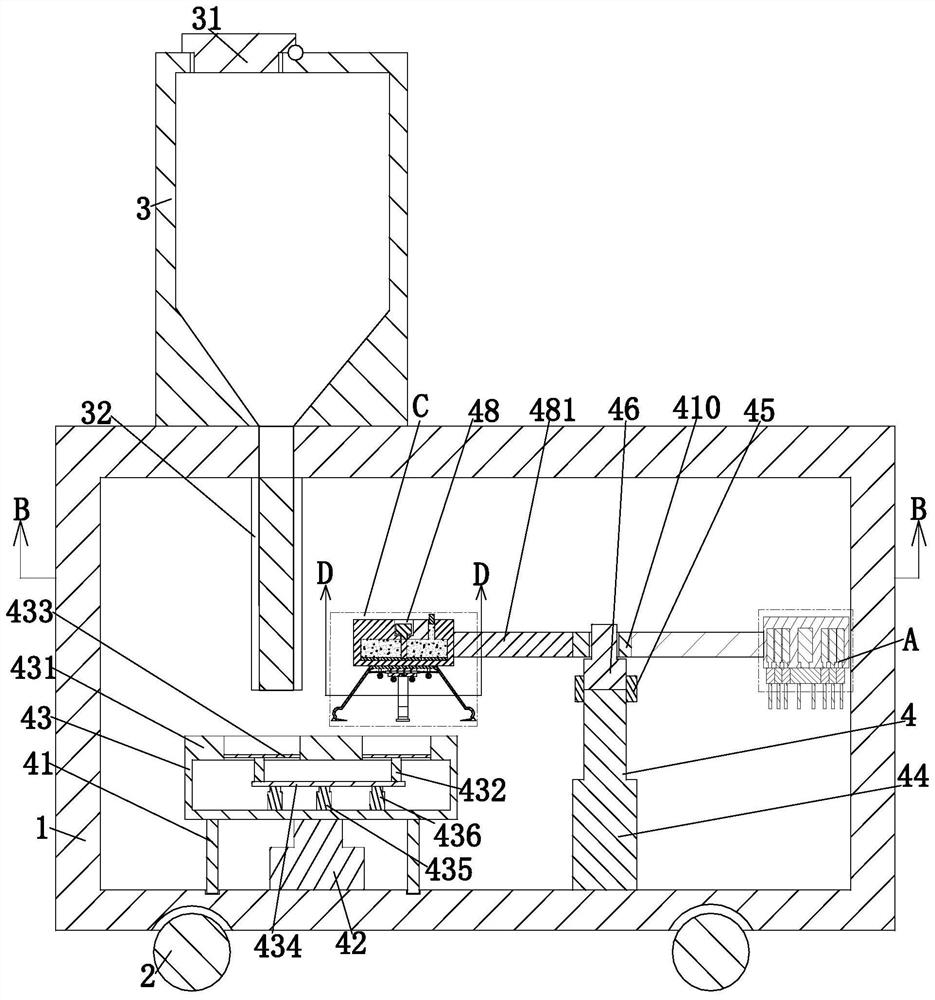

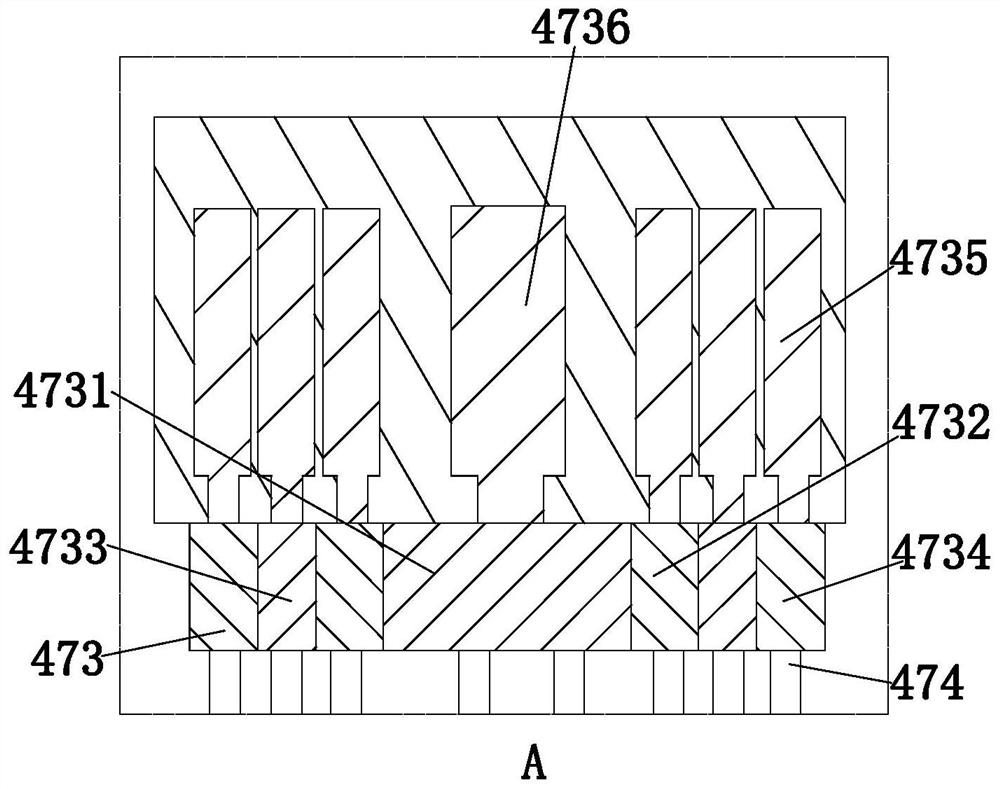

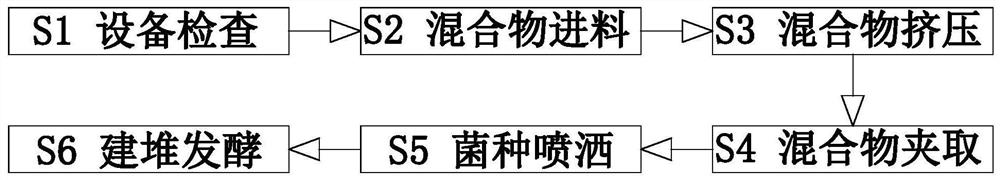

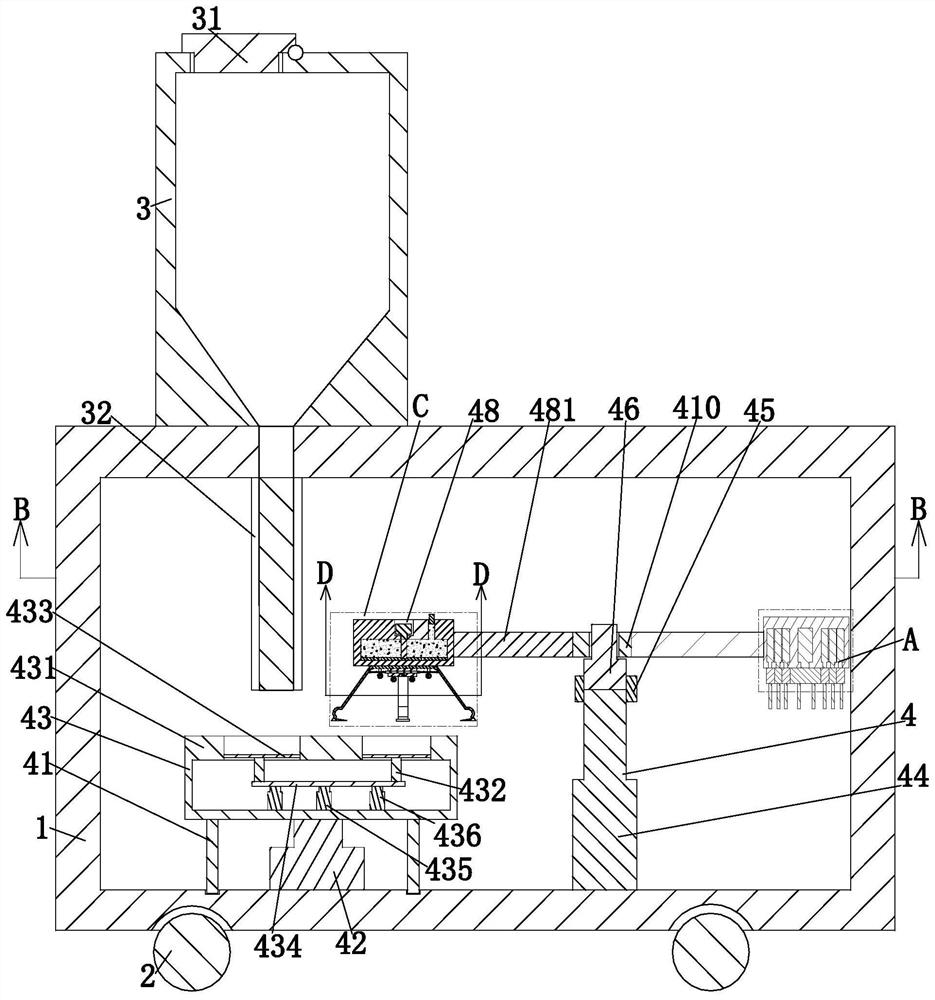

A kind of method of sludge fermentation to make organic fertilizer

ActiveCN112679248BChange the spraying areaFully fermentedBio-organic fraction processingOrganic fertiliser preparationAgricultural engineeringOrganic fertilizer

The invention relates to a method for producing organic fertilizer by fermentation of sludge. The method for producing organic fertilizer by fermentation of sludge adopts the following equipment for producing organic fertilizer by fermentation of sludge. Boxes and stacking devices; moving rollers are installed at equal distances on the left and right sides of the lower end face of the mobile carriage, a charging box is installed on the upper end face of the moving carriage, and a stacking device is installed inside the moving carriage. In the invention, the spraying unit cooperates with the clamping unit to spray the bacterial species on each cake-shaped mixture, so as to ensure the uniformity of the bacterial species spraying, so that the mixture can be fully fermented; Rotate the angle of the adjusting disc to adjust the overlap of the holes and the blanking holes according to different positions, and the spraying range of the spraying unit can be changed.

Owner:山东和众康源生物科技有限公司

Method for preparing organic fertilizer by sludge fermentation

ActiveCN112679248AChange the spraying areaFully fermentedBio-organic fraction processingOrganic fertiliser preparationAgricultural scienceAgricultural engineering

The invention relates to a method for preparing an organic fertilizer by sludge fermentation, the method for preparing the organic fertilizer by the sludge fermentation adopts the following equipment for preparing the organic fertilizer by the sludge fermentation, and the equipment for preparing the organic fertilizer by the sludge fermentation comprises a moving carriage, moving rollers, a charging box and a piling device; and moving rollers are equidistantly mounted on the left and right sides of the lower end face of the moving carriage, a charging box is mounted on the upper end face of the moving carriage, and a stacking device is mounted in the moving carriage. The spraying unit and the clamping unit are matched to spray strains to each cake-shaped mixture, so that the strain spraying uniformity is guaranteed, and the mixture can be fully fermented; and the spraying range of the spraying unit can be changed by rotating the angle of the adjusting disc according to cake-shaped mixtures with different diameters through the spraying unit and superposing the adjusting holes and the blanking holes according to different positions.

Owner:山东和众康源生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com