Automatic gasketing device for induction cooker coil production

A technology for induction cooker and gasket, which is applied in the field of gasket sticking device and electromagnetic cooker gasket sticking device, which can solve the problems of uneven glue application, low sticking efficiency, time-consuming and laborious, etc. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

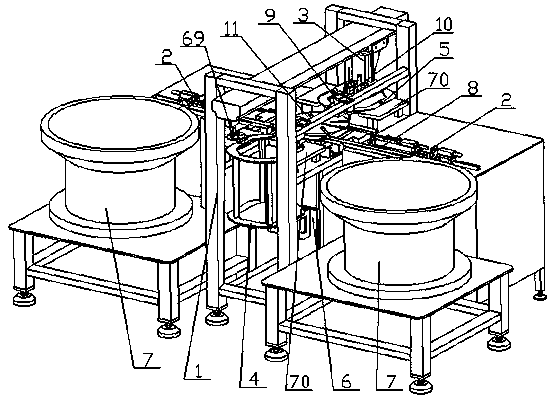

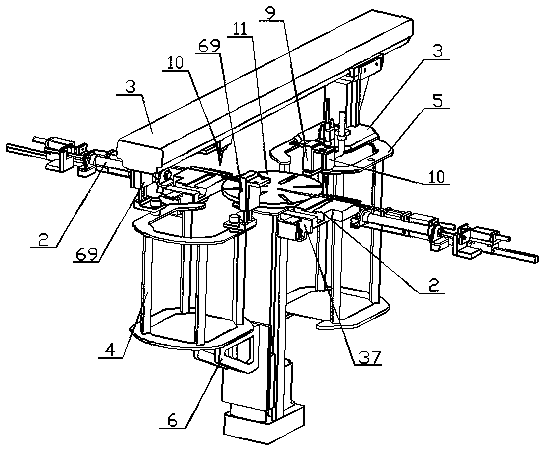

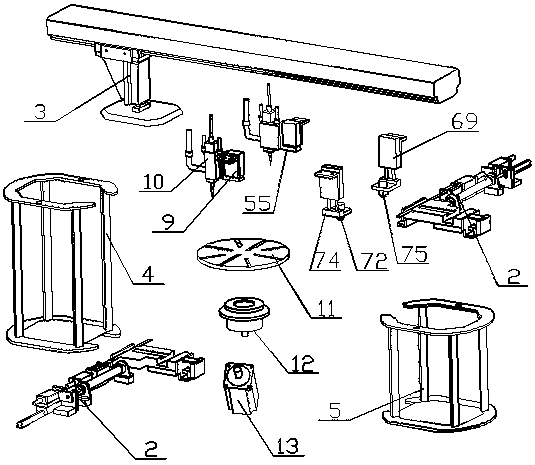

[0021] Depend on figure 1 , figure 2 and image 3 As shown, the automatic gasketing device for induction cooker coil production mainly includes a frame 1, a pair of gasket transmission devices 2, a robot mechanism 3, mica feeding bin 4, mica discharging bin 5, and mica feeding bin Mechanism 6, paired positioning cylinders 69, paired vibrating trays 7, feed pipes 8, side rail cylinders 9, glue guns 10, gasket distribution trays 11, bearing housings 12 and distribution motors 13. The material distribution motor 13 is installed on the bottom of the frame 1, the bearing seat 12 is installed on the middle part of the frame 1, the bearing seat 12 is connected with the material distribution motor 13, and the gasket distribution plate 11 is fixedly installed on the bearing On the seat 12, the pad material distribution disc 11 can be driven to rotate by the material distribution motor 13.

[0022] Depend on Figure 14 As shown, the gasket chute 11 is provided with a divergent gask...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com