Patents

Literature

130results about How to "Improve paste quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

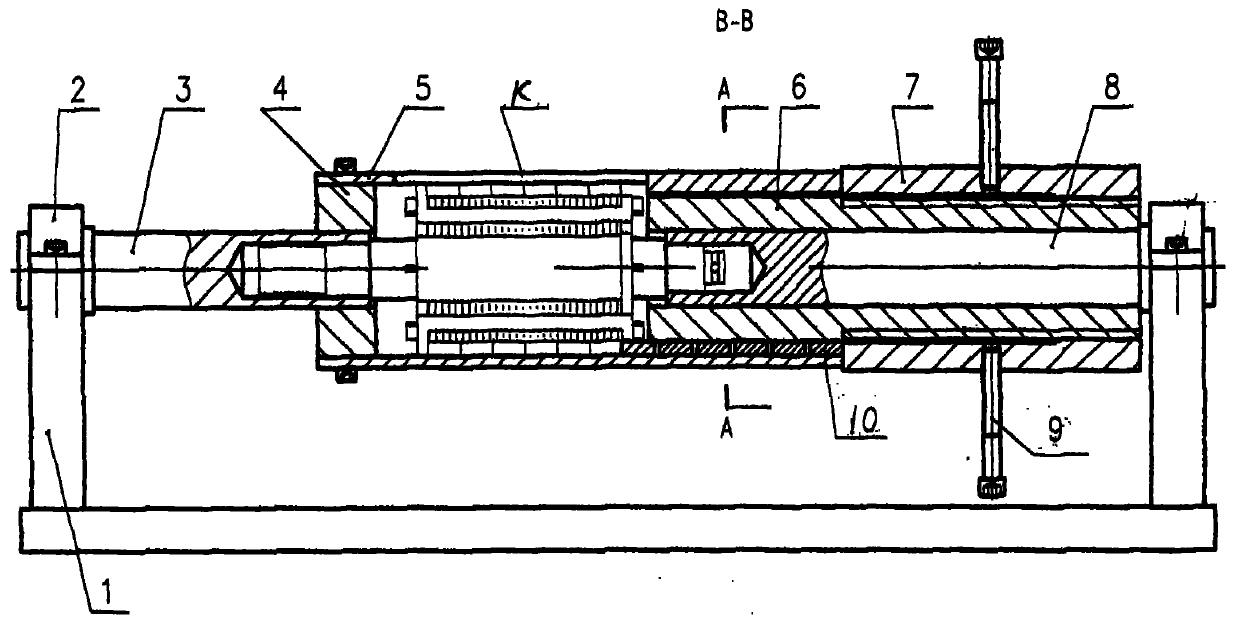

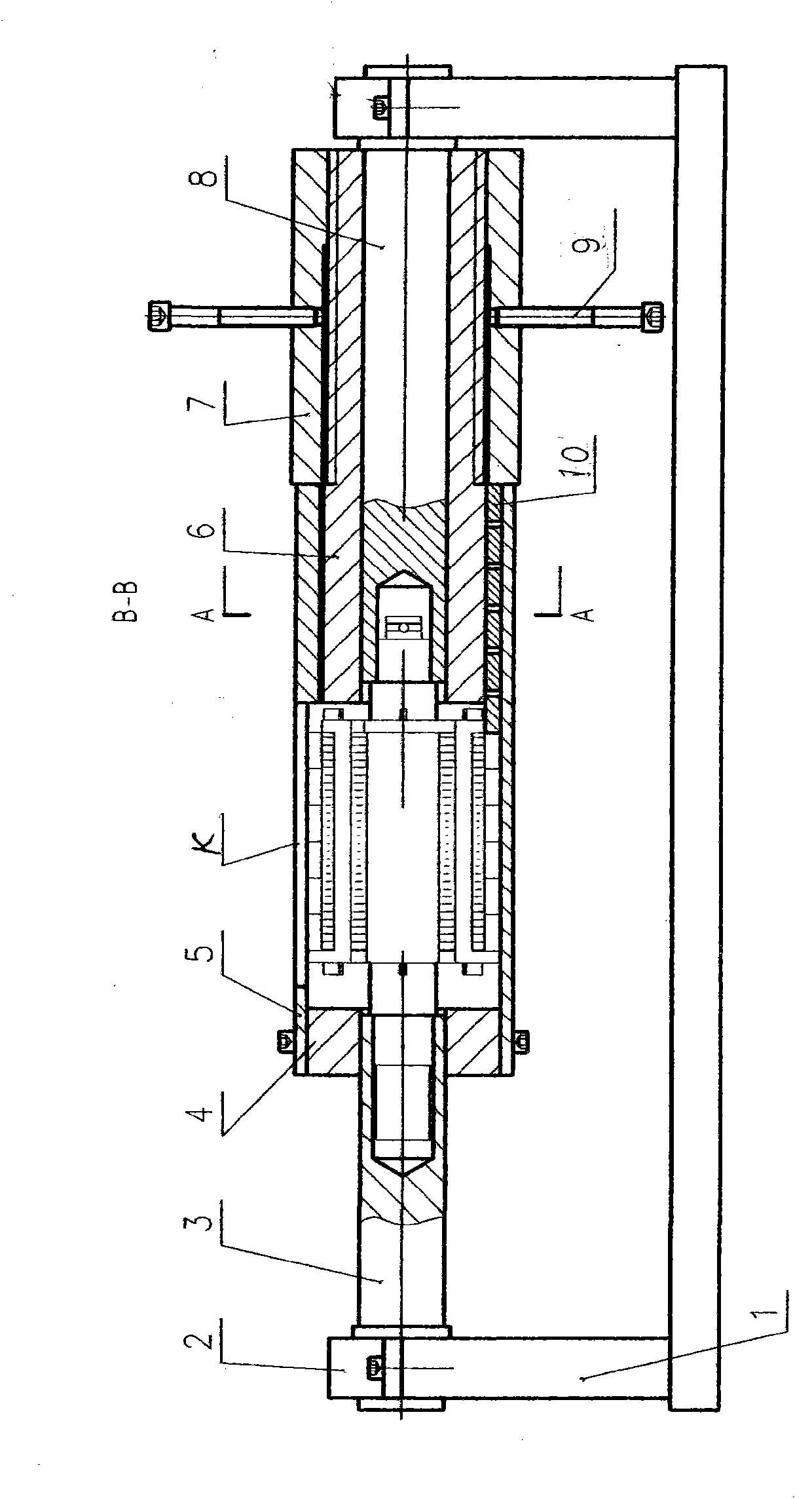

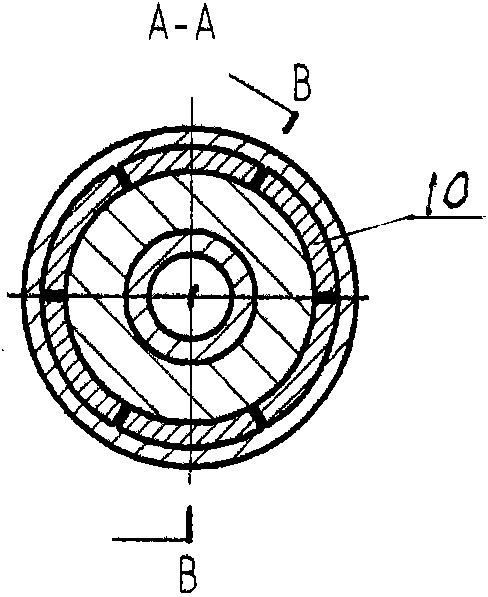

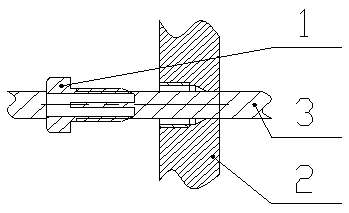

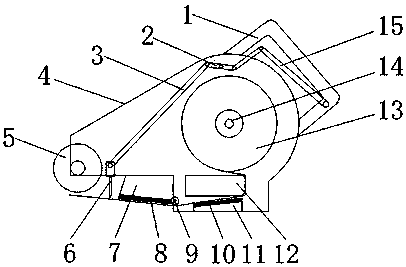

Process and device thereof for sticking magnetic steel on rotor of high-power permanent magnet motor for vehicles

InactiveCN101908798ANovel ideaCompact structureManufacturing stator/rotor bodiesElectric machineMagnetic poles

The invention provides a process and a device thereof for sticking magnetic steel on a rotor of a high-power permanent magnet motor for vehicles, relating to a permanent magnet motor, in particular to a process device and a process for sticking the magnetic steel on the rotor of the permanent magnet motor. The device comprises a support, a press plate, supporting sleeves, an auxiliary guide supporting block, a mold sleeve, a guide supporting sleeve, a nut pushing block and a locking screw. The process comprises the following steps of: assembling a motor rotor to be stuck with the magnetic steel with the left supporting sleeve, the right supporting sleeve, the auxiliary guide supporting block, the mold sleeve, the guide supporting sleeve and the nut pushing block into a whole in the process for sticking the magnetic steel on the rotor of the permanent magnet motor and then supporting on the support; and coating viscose glue on an opening of the mold sleeve, placing the magnetic steel in an axial positioning slot, rotating the nut pushing block, then pushing the mold sleeve and the magnetic steel to move ahead, and then sticking the magnetic steel on the outer circle of the motor rotor to form magnetic poles. The device has the advantages of novel concept, compact structure, easy fabrication and convenient use, and 36 blocks of magnetic steel are stuck once so that the sticking process is simplified, the sticking quality is improved, the efficiency is improved, the cost is reduced, and the process and the device are suitable for batch production. The invention can be widely applied to production enterprises of the permanent magnet motor.

Owner:湖北华声机电股份有限公司

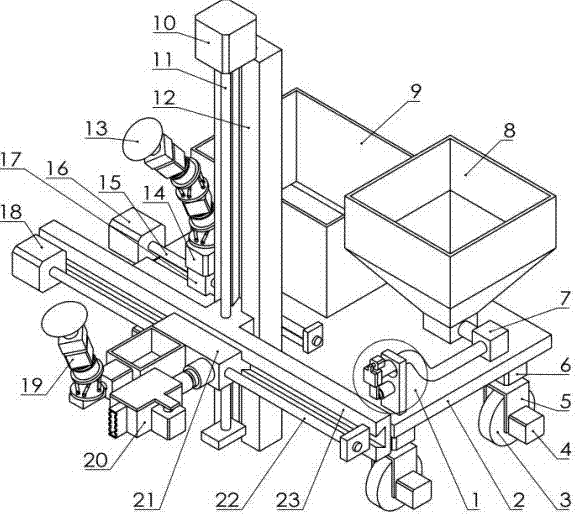

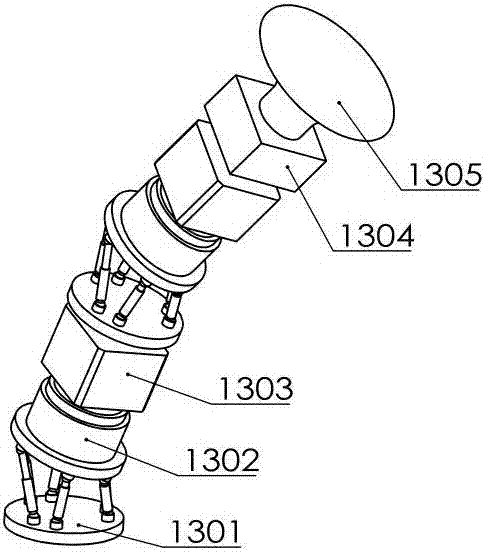

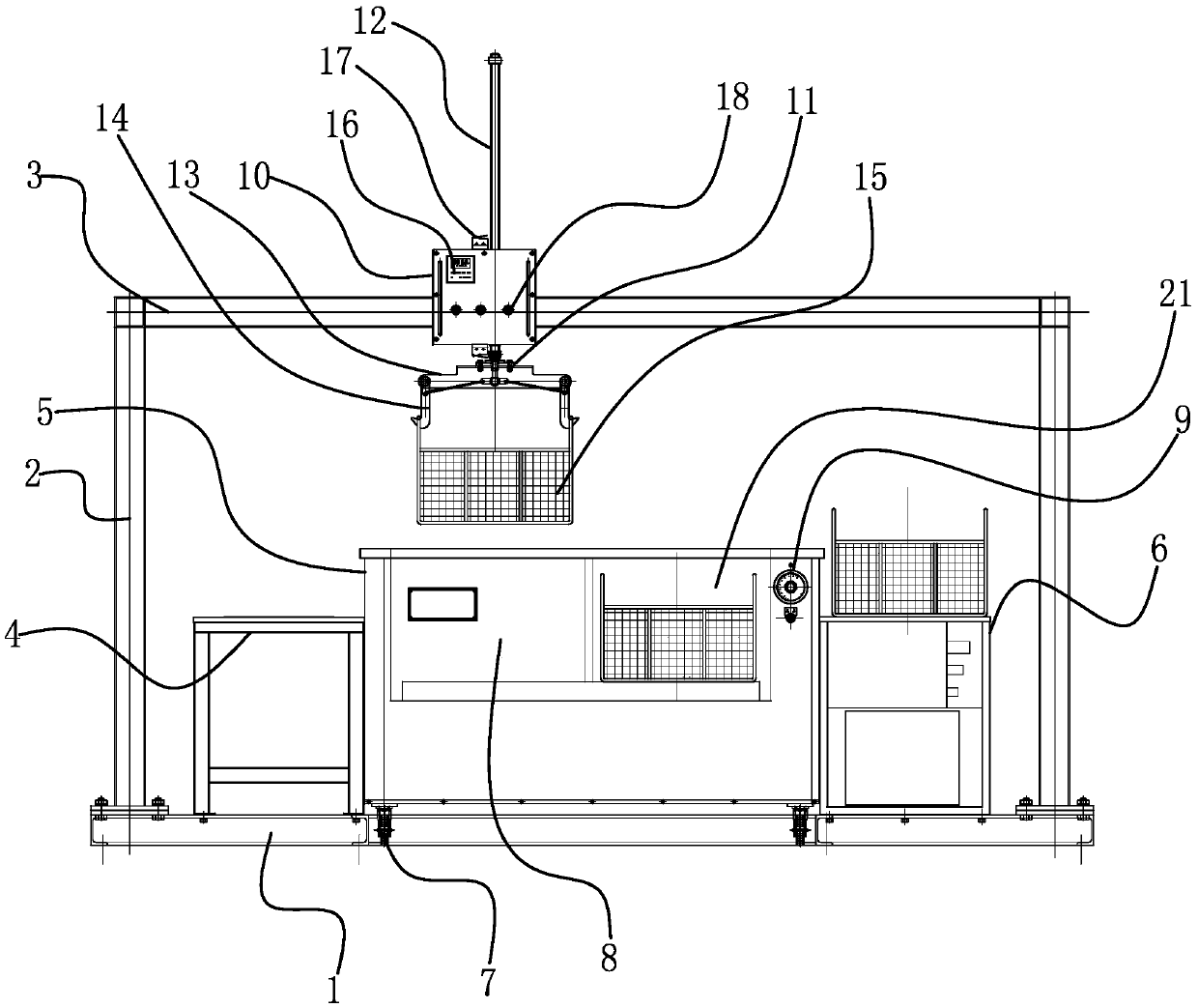

Intelligent wall tile attaching robot

Provided is an intelligent wall tile attaching robot. The robot comprises a pipe head assembly, a bottom plate, four wheels, four first stepping motors, four wheel carriers, four first servo motors, a cement pump, a cement storage box, a tile storage box and the like. By the adoption of technical scheme, the intelligent wall tile attaching robot has the advantages that the robot moves up, down, left and right flexibly through a movable tile box assembly designed specially, and a mechanical arm and a vacuum chuck which have ultrahigh flexibility are adopted to grasp tiles, which is safe, efficient and stable in work; cement can be evenly spread on a wall through a special cement spreading tool, which greatly improves the attachment quality; the tile storage box is arranged, meanwhile tiles are added into the movable tile box assembly through the mechanical arm, the cement storage box is arranged, and meanwhile cement is added into the cement spreading tool through the cement pump, which greatly liberates the manpower and improves the work efficiency.

Owner:韩朝锋

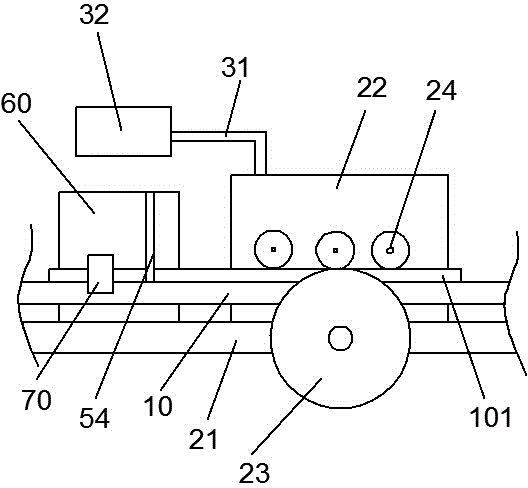

Tile fixing machine capable of preventing hollowing and large vertical flatness errors

InactiveCN108560889ANo hollowingImprove paste qualityBuilding constructionsArchitectural engineeringEngineering

The invention relates to the technical field of building equipment and discloses a tile fixing machine capable of preventing hollowing and large vertical flatness errors. The tile fixing machine comprises a base, wherein support pipes are fixedly connected to two sides of the top of the base, the top ends of the two support pipes are movably sleeved with a rotating shaft, two ends of the rotatingshaft is fixed sleeved with reels which are located in the two support pipes, a support plate is fixedly connected to the top of the side surface of one support pipe, and a driving motor is fixedly mounted at the top of the support plate. According to the tile fixing machine, a tile is adsorbed through a suction disc, two sides of the tile are clamped through tension forces of two second tension springs, cement mortar is added to the tile, and the cement mortar on the tile is paved to be level with one ends of side plates on two sides and is uniformly distributed, so that a hollowing phenomenon is avoided after the tile is fixed to a wall, and the adhesion quality of the tile is improved.

Owner:北京鼎翰科技有限公司

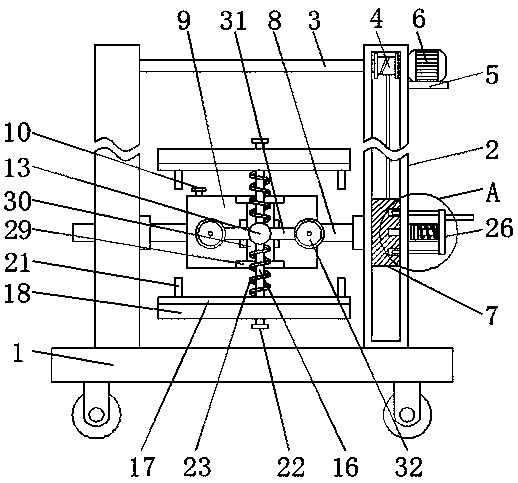

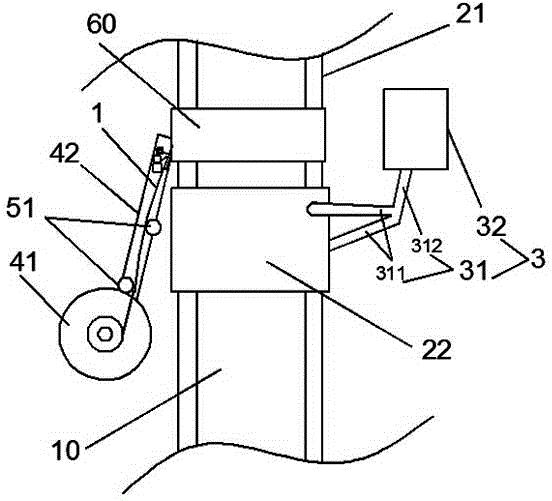

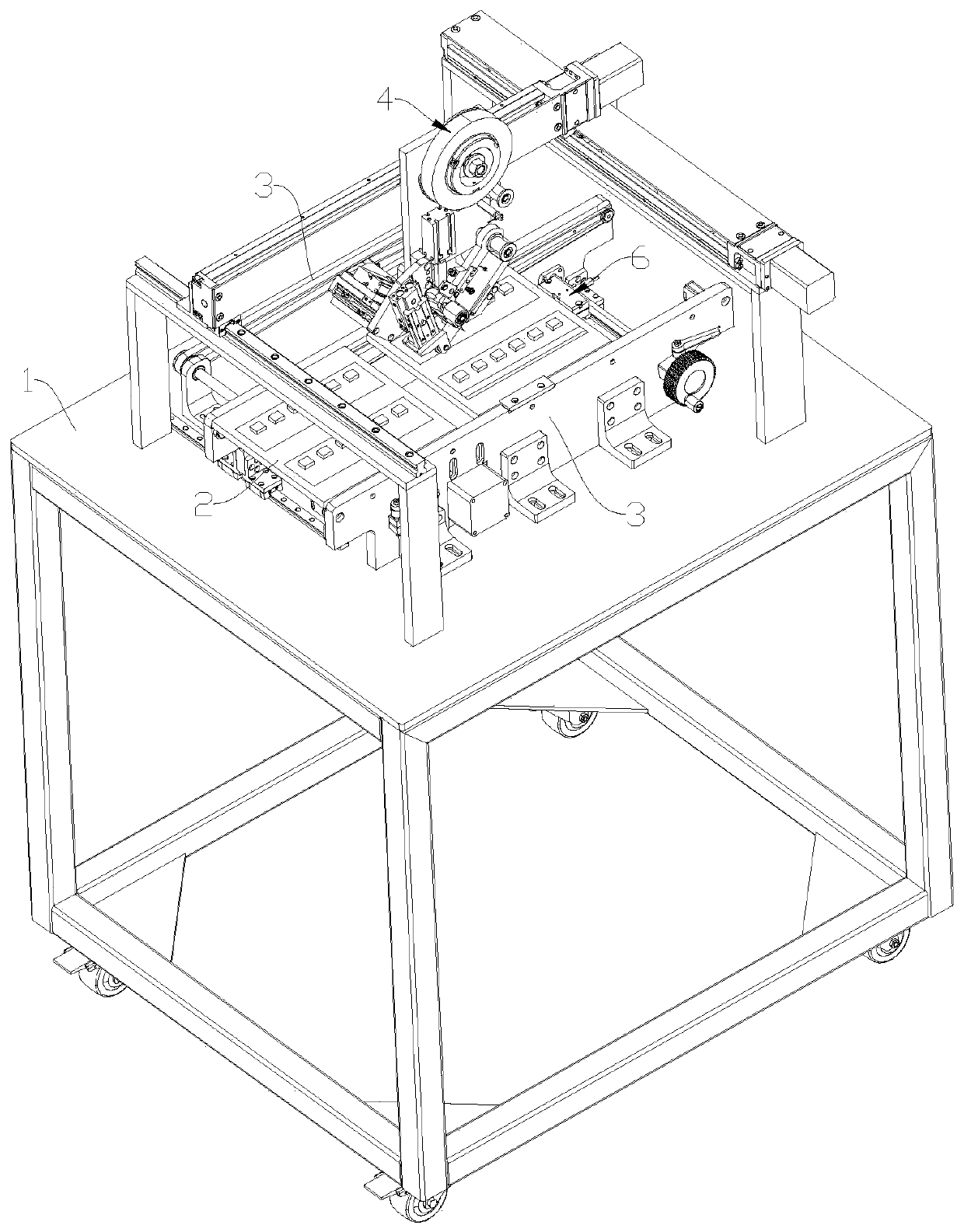

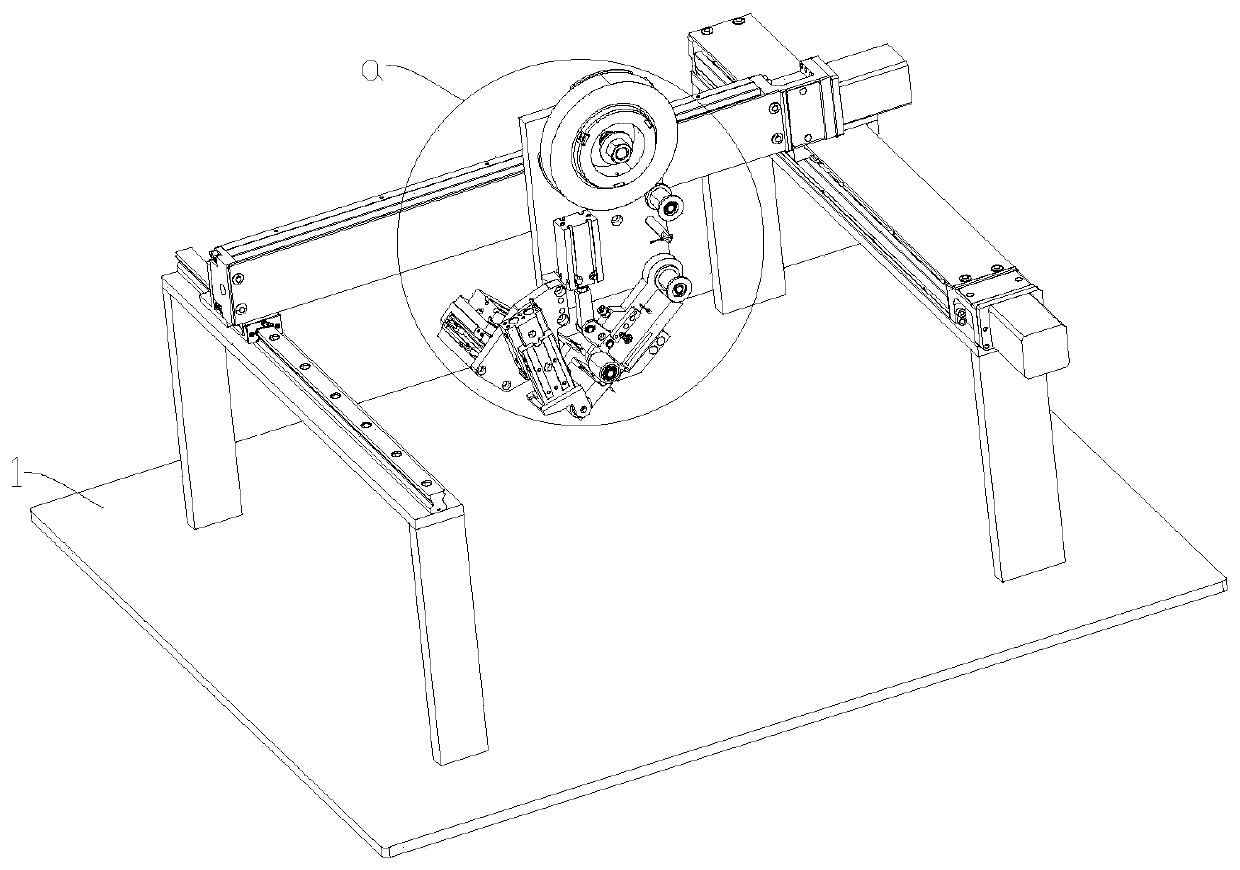

Semi-automatic pasting machine for wallpaper pasting

InactiveCN106985597AGuaranteed linear flatnessAvoid the problems of unstable quality, time-consuming and labor-intensive manual pastingPaperhangingSemi automaticDrive motor

The invention discloses a semi-automatic pasting machine for wallpaper pasting. The semi-automatic pasting machine comprises a bottom plate which is flattened against the ground and the wall surface for positioning, and an installation seat fixedly connected to the bottom plate; the installation seat is provided with a wallpaper winding shaft around which wallpaper is wound, the bottom plate is furthermore fixedly provided with two parallel sliding rails perpendicular to the bottom plate, and a wallpaper pasting mechanism is slidably connected between the sliding rails; the end heads of the ends, away from the bottom plate, of the sliding rails are provided with synchronous wheels, the synchronous wheels are sleeved with belts, and the belts are driven by a drive motor installed on the bottom plate; and the belts are detachably and fixedly connected with the wallpaper pasting mechanism. Through the arrangement of the sliding rails and a tackle matched with the sliding rails, the wallpaper is pasted through relatively linear sliding, and linear flatness of wallpaper pasting can be guaranteed; and the drive motor is utilized to drive the tackle, so that the problems that quality is unstable through fully manual pasting, and time and labor are consumed are solved.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

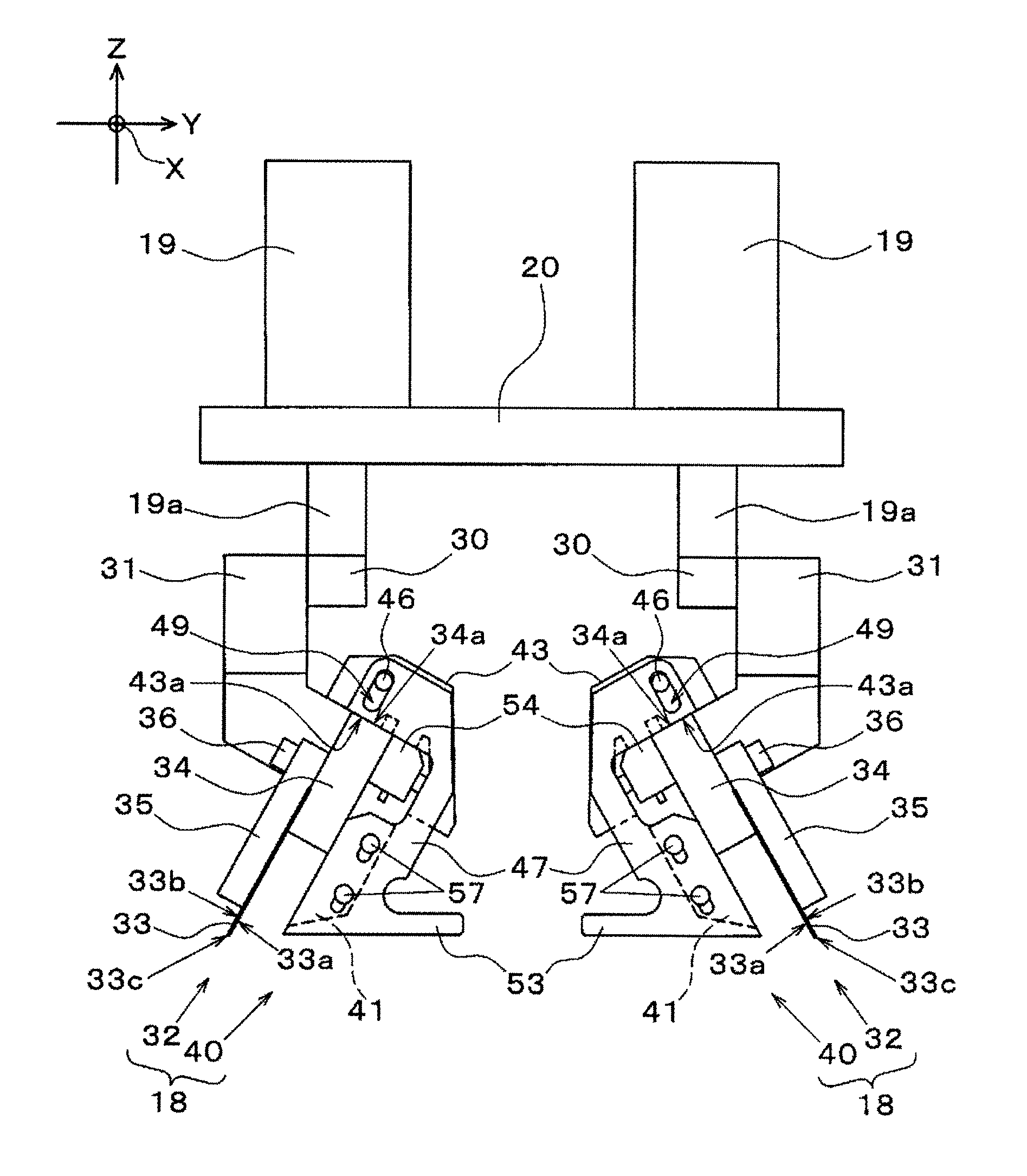

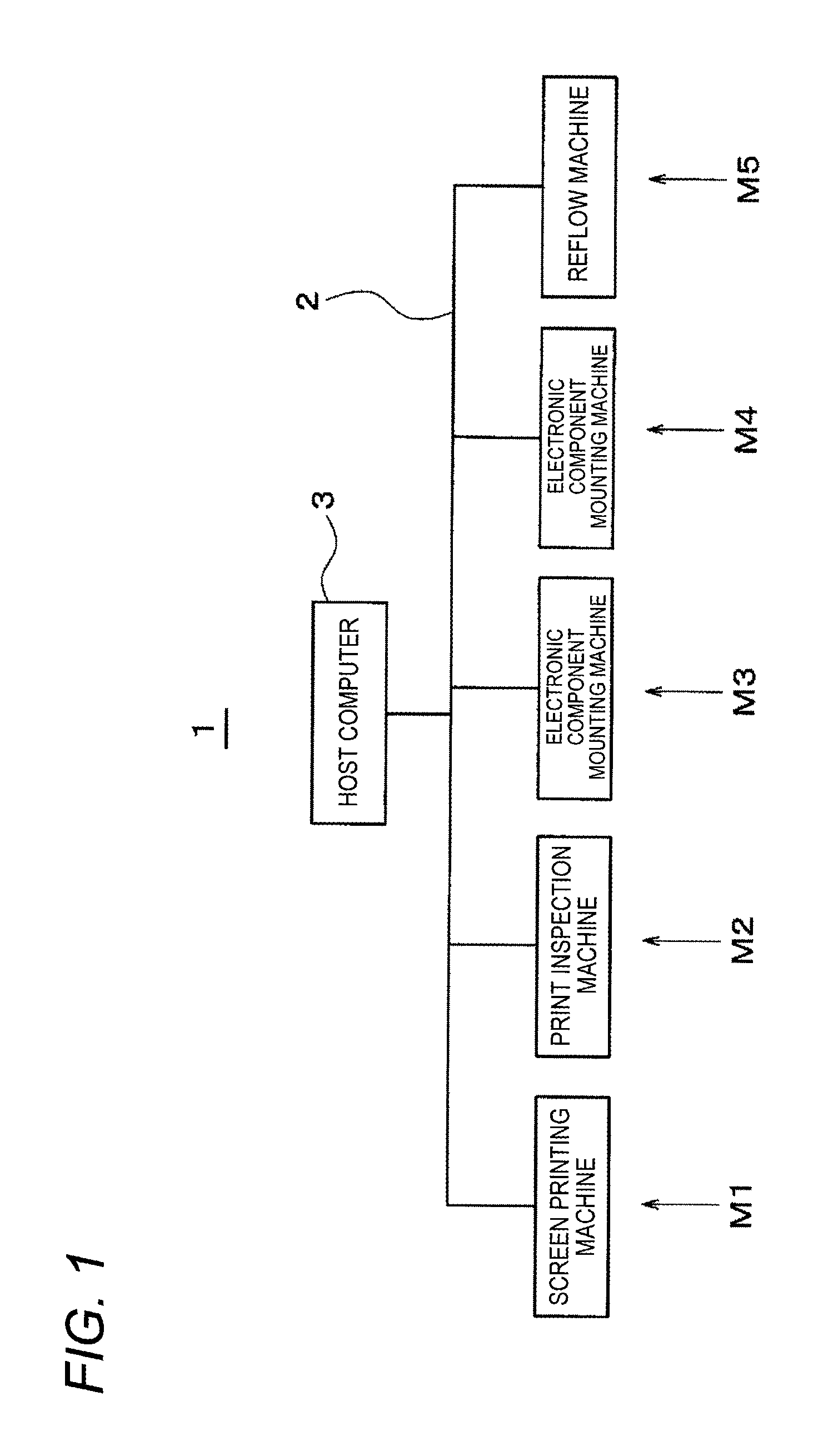

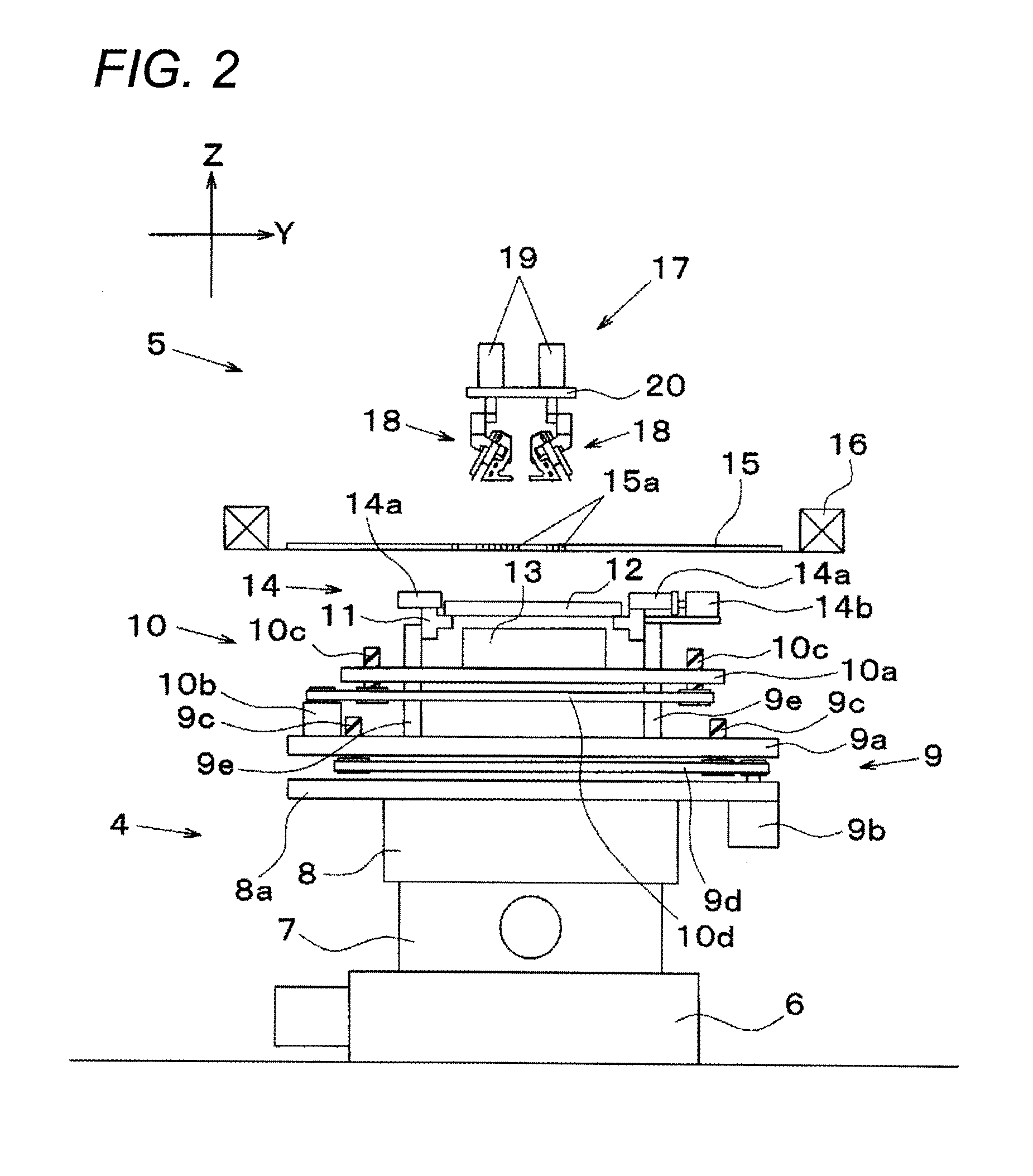

Screen printing machine and electronic component mounting system

ActiveUS9352409B2Simple configurationLow costPrinted circuit assemblingScreen printersEngineeringElectronic component

A screen printing machine for forming a print of paste supplied to a mask plate having pattern holes, includes: a filling squeegee which is held to have a given clearance with respect to the mask plate, and which fills the pattern holes with the paste by moving the filling squeegee relative to the mask plate in a printing direction; and an urging member which urges the filling squeegee toward the mask plate such that at least the given clearance is maintained. The screen printing machine further includes a scraping squeegee which is held to maintain a given interval from the filling squeegee in the printing direction, and which scraps off paste remaining on the mask plate after passage of the filling squeegee by moving the scraping squeegee together with the filling squeegee in the printing direction.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

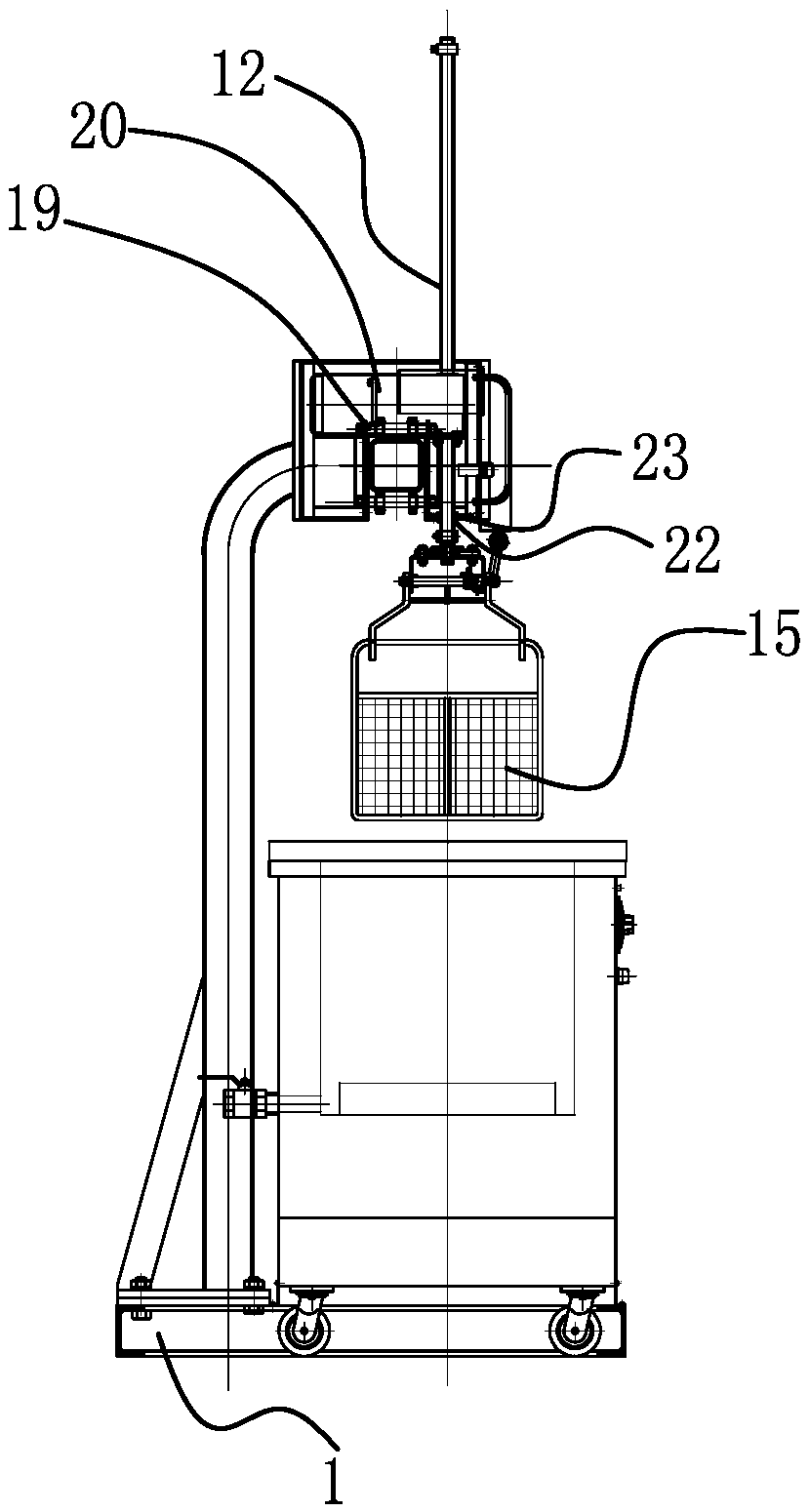

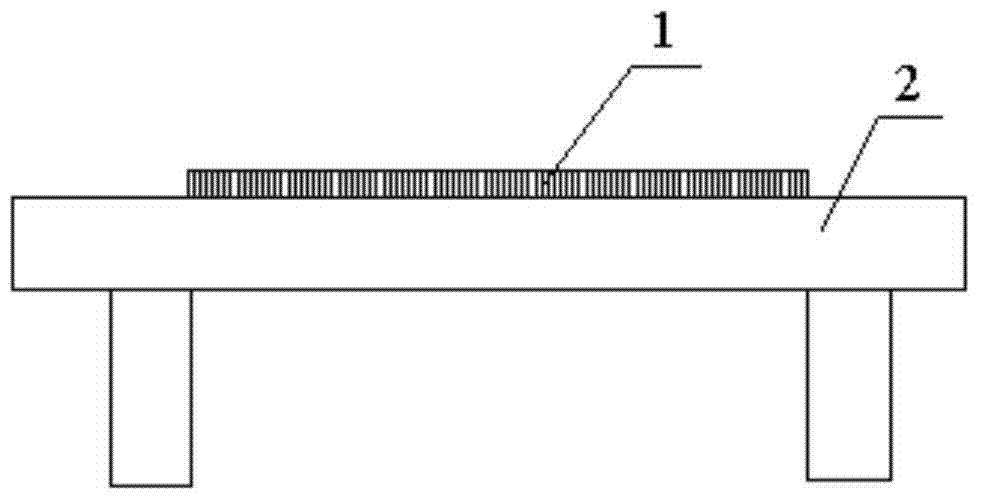

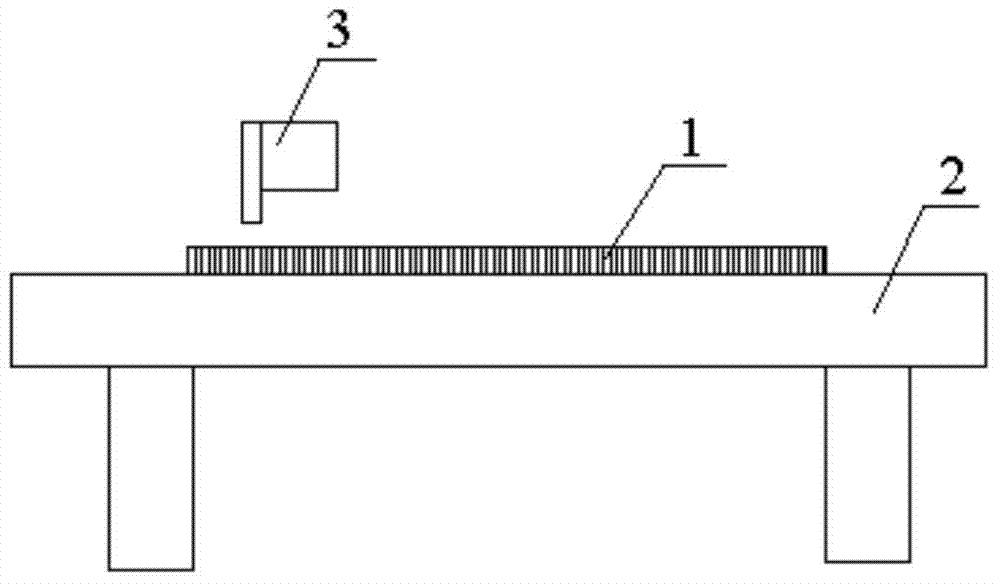

Ultrasonic washing device of high-performance storage battery plate grid

InactiveCN105499208AImprove paste qualityEfficient and quick removalCleaning using liquidsElectrical batteryMegasonic cleaning

The invention relates to an ultrasonic washing device of a high-performance storage battery plate grid. The ultrasonic washing device comprises an engine base, supporting rods arranged at the left and right ends of the engine base, and a bracket arranged at the upper ends of the supporting rods, wherein the engine base is provided with a worktable, an ultrasonic washing chamber and an electric control working chamber from left to right; universal wheels are arranged at the bottom of the ultrasonic washing chamber; the ultrasonic washing chamber is connected onto the engine base through the universal wheels in a sliding manner; the ultrasonic washing chamber comprises a washing groove and a drying groove, which are arranged in the ultrasonic washing chamber, and an ultrasonic controller arranged outside the ultrasonic washing chamber. The ultrasonic washing chamber and the electric control working chamber are arranged, and a movable trolley is used for carrying out washing and drying treatment on the plate grid, so that de-molding oil stain, dust and fine and small burrs on the surface of the plate grid can be rapidly and efficiently cleaned; de-molding oil and impurities entering a battery are reduced, and the bonding strength of the plate grid and active substances is increased; the washing efficiency is improved, the plastering quality of the plate grid is improved, an electrochemical performance of the storage battery is improved, and the service life of the battery is prolonged.

Owner:ZHEJIANG PINGHU HUALONG IND CO LTD

Door plate processing mechanism

InactiveCN104960070AGreat suctionAvoid Paste EffectsDomestic articlesBark-zones/chip/dust/waste removalEngineeringMechanical engineering

The invention belongs to the field of door processing technology, and relates to a door plate processing mechanism. The door plate processing mechanism comprises a door plate conveying platform, a trimming device used for trimming a door plate, a strip binding device used for binding edge sealing strips on the trimmed door plate, and a feed device used for feeding edge sealing strips to the strip binding device. The trimming device comprises a support disposed under the conveying platform, a trimming chamber mounted on the support, and trimming disc disposed on a sidewall of the trimming chamber and driven by a motor. The conveying platform penetrates the trimming chamber, and the trimming chamber is provided with a wood chip suction structure. By adopting the door plate processing mechanism, wood chips generated when doorframes are trimmed can be sucked up, so the wood chips can be prevented from influencing on adhering connection between the edge sealing strips and the doorframes, the adhering quality of the edge sealing strips can be raised, a trimming point can be aligned, so the wood chips can be effectively sucked up. The edge sealing strips can be quickly and stably conveyed, and a plurality of conveying positions of the edge sealing strips are finely adjusted, the conveying quality can be ensured, so the edge sealing strips can be adhered in high quality in the later process.

Owner:浙江采丰木业有限公司

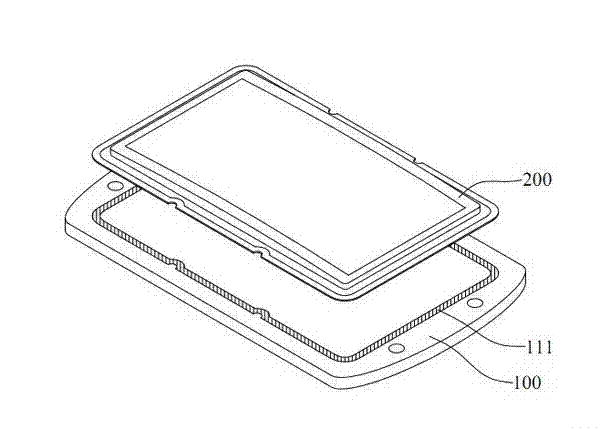

Mobile phone film pasting equipment and method thereof

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI +1

Automatic adhesive tape pasting equipment

PendingCN110459490AReasonable designAvoid manual inputSemiconductor/solid-state device manufacturingWork in processEngineering

The invention provides a piece of automatic adhesive tape pasting equipment, which relates to the technical field of chip production. The equipment includes a frame, clamps used to carry semi-finishedchips, a pair of conveying mechanisms used to intermittently convey the clamps and an adhesive tape pasting mechanism used to paste adhesive tapes onto the pins of the semi-finished chips. The conveying mechanisms are installed in parallel on the frame. The adhesive tape pasting mechanism can be connected to the frame by sliding along the conveying direction of the conveying mechanisms and is located above the conveying mechanisms. The equipment is reasonable in design, can automatically paste adhesive tapes onto chip pins and avoid manual input, and has high pasting efficiency and excellentand stable pasting quality.

Owner:MIANYANG WEICHENG TECH CO LTD

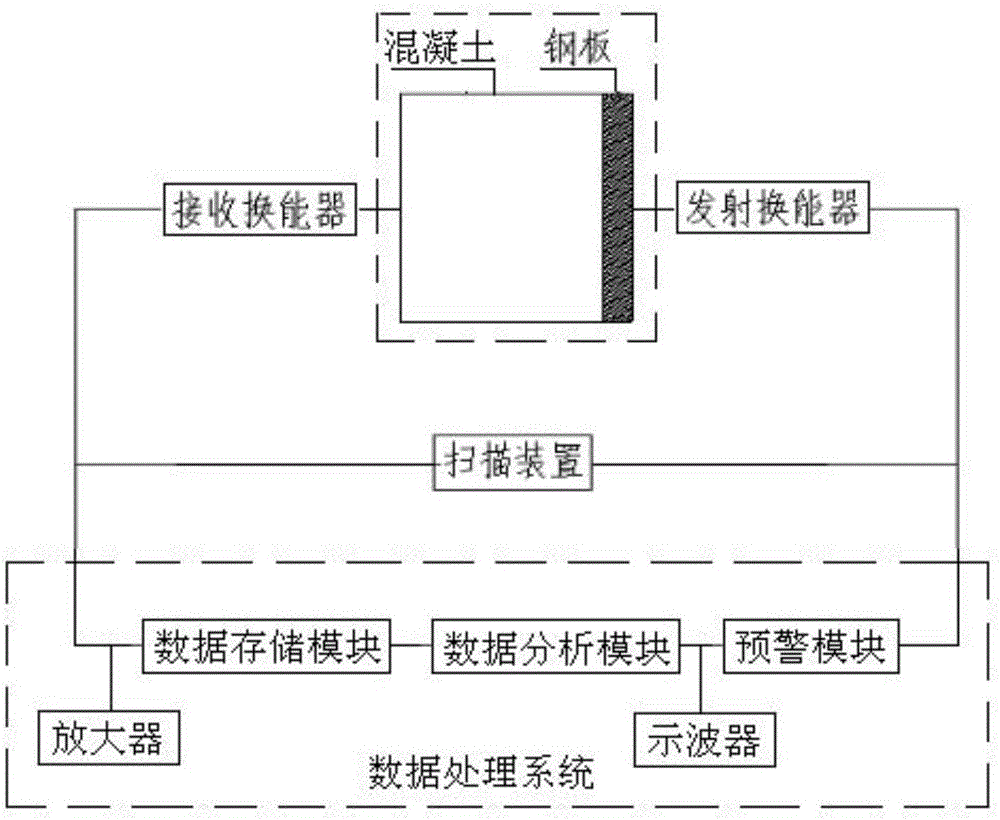

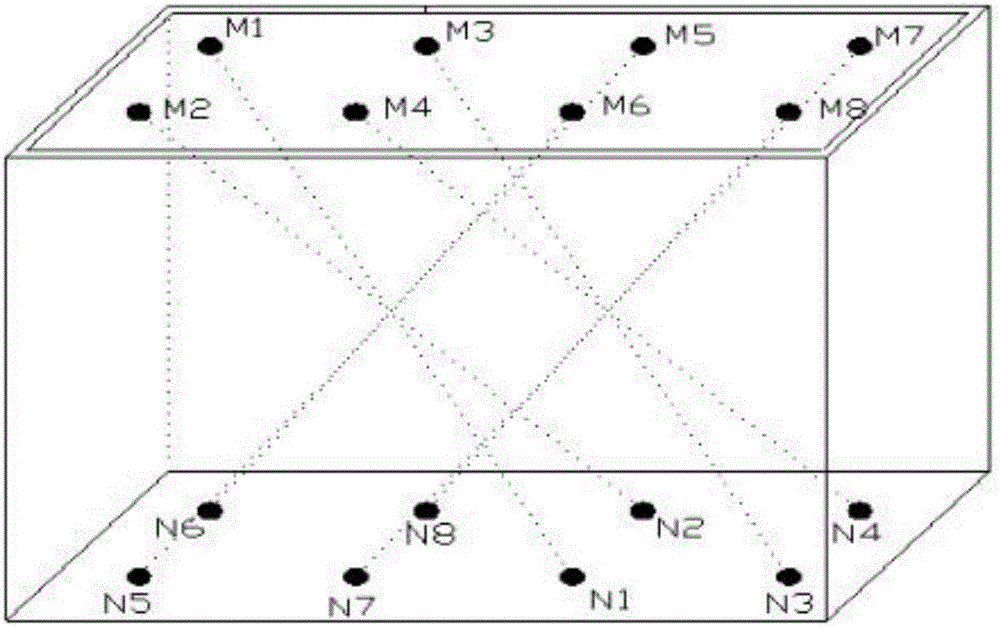

Device and method for detecting sticking compactness of steel plate

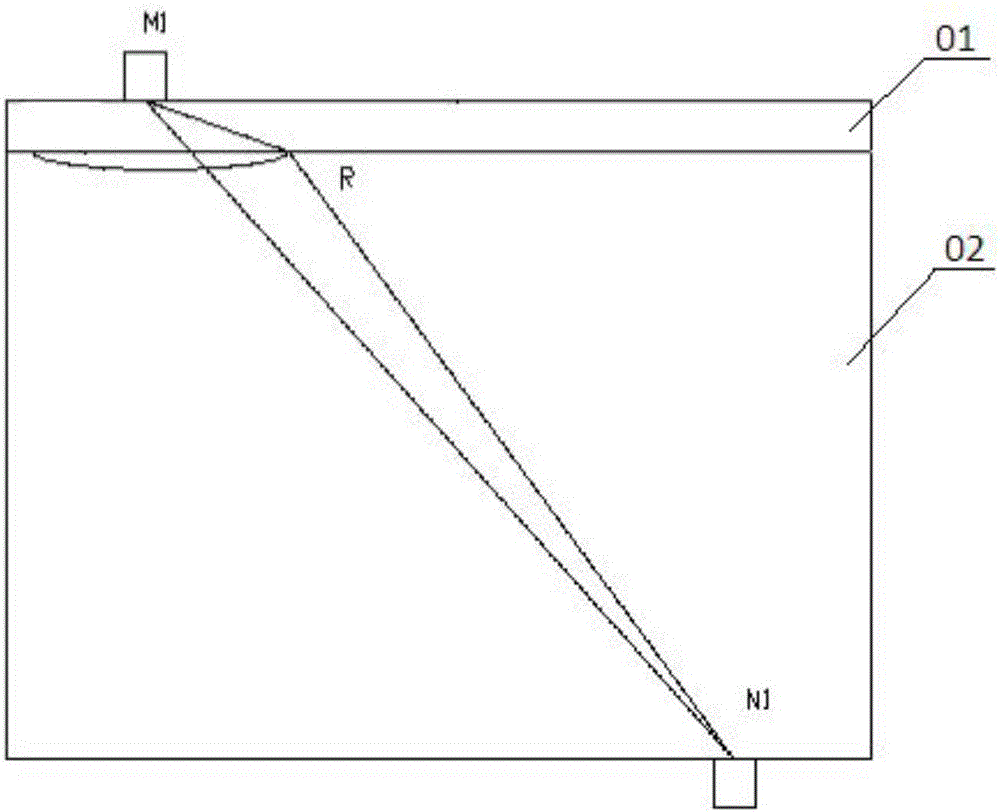

InactiveCN105866247AGood detectionWell repairedAnalysing solids using sonic/ultrasonic/infrasonic wavesSteel platesSheet steel

The invention provides a device and method for detecting sticking compactness of a steel plate. The device comprises a plurality of transmitting transducers used for transmitting ultrasonic waves, a plurality of receiving transducers used for receiving ultrasonic waves, a scanning device and a data processing system, wherein the transmitting transducers, the receiving transducers and the data processing system are sequentially connected, the scanning device is connected with the data processing system in parallel, and the data processing system comprises an amplifier used for amplifying signals received by the receiving transducers and an oscilloscope used for graphic display of data. By the adoption of the device and method, components are not damaged, detection is reliable, work load is small, working efficiency is high, and vacancy degree can be detected qualitatively and quantitatively.

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH

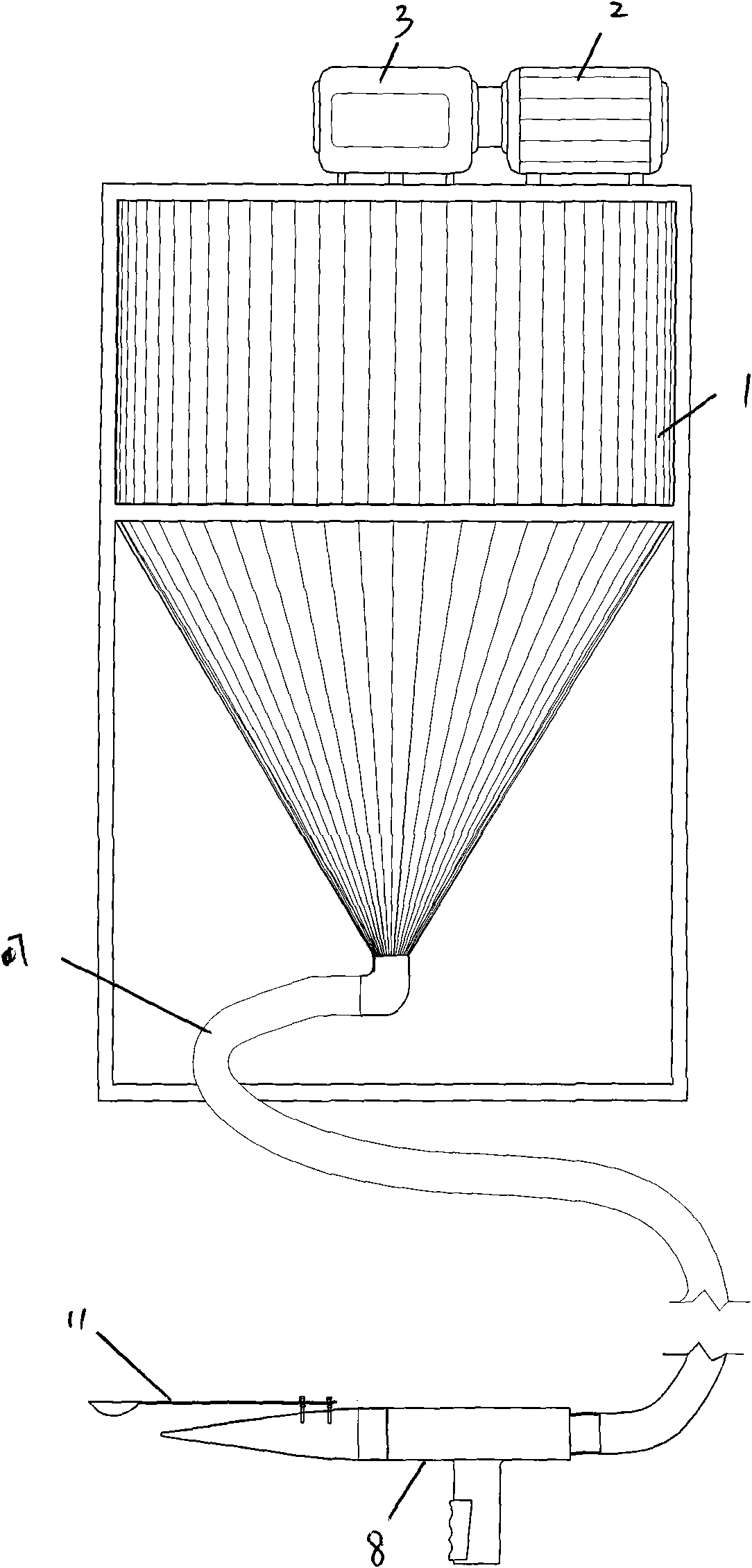

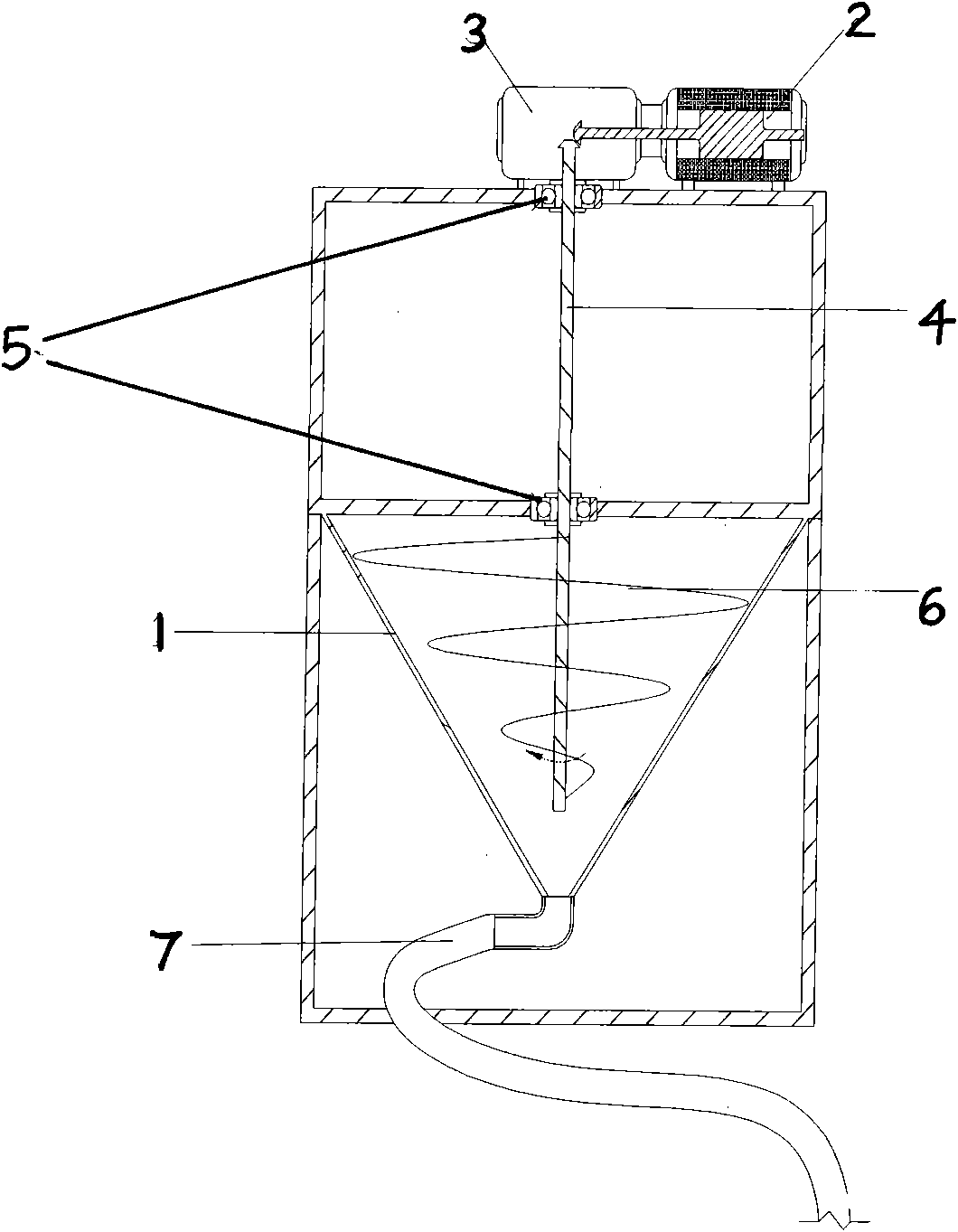

Caulking device and caulking method for building facing bricks

InactiveCN101597954AImprove paste qualityImprove the decorative effectBuilding constructionsSocial benefitsSEMI-CIRCLE

The invention discloses a caulking device and a caulking method for building facing bricks, which are suitable for sticking construction of various building exterior wall facing bricks and outdoor paving bricks. The device comprises a mortar stirring and pressing device, a conveying hose and a caulked joint mouth. After the exterior wall facing bricks are stuck, stirred caulking mortar is poured into the mortar stirring and pressing device and conveyed to the caulked joint mouth by the hose with the rotation of the mortar stirring and pressing device; a handheld switch controls mortar output; the caulked joint mouth is aimed at a brickwork joint at an angle of 45 degrees to shove mortar to caulk the brickwork joint; and a mortar pressing spring arranged on the caulked joint mouth presses the mortar into a smooth semi-circle groove. The device and the method can caulk compact and beautiful facing brick brickwork joint, improve the waterproof performance of the exterior wall, and solve the technical problems of difficult cleaning of the facing bricks, environmental pollution and facing brick pollution which are caused by the prior full plastering caulking. The method has the advantages of simple process, convenient construction, great cleaning water and labor conservation, environmental protection, construction cost conservation, excellent economic, environmental-protection and social benefits.

Owner:湖北全洲扬子江建设工程有限公司

Trimming device for fireproof door frame

InactiveCN104985670AImprove paste qualityGood suctionDomestic articlesBark-zones/chip/dust/waste removalEngineeringElectrical and Electronics engineering

The invention belongs to the field of fireproof door machining, and relates to a trimming device for a fireproof door frame. The trimming device comprises a support, a door board conveying platform arranged on the support and a trimming disc which is mounted on the support and driven by a motor; an auxiliary structure is further arranged on the support, and comprises a supporting rod fixed to the support and auxiliary blocks fixed to the supporting rod; each auxiliary block comprises an upper auxiliary block and a lower auxiliary block opposite to the upper auxiliary block; the door frame penetrates the position between the upper auxiliary block and the lower auxiliary block; and the auxiliary blocks are connected with a suction structure for sucking saw dust generated by trimming. According to the device, the saw dust generated during trimming of the door frame is sucked, and the influence of the saw dust on bonding between a sealing strip and the door frame is avoided; the bonding quality of the sealing strip is improved, the device is aligned with the trimming point, and the sucking effect on the saw dust is good.

Owner:浙江采丰木业有限公司

Full-automatic sole adhering equipment and sole adhering method

ActiveCN110464082APrecise positioningIncrease productivityShoe gluingSoftware engineeringEngineering

Owner:YANSHAN UNIV

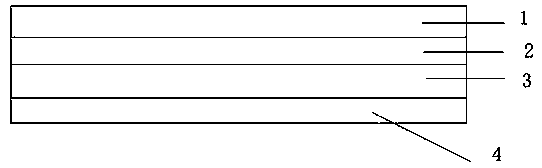

Composite function film capable of measuring surface deformation and internal damage, and application method thereof

ActiveCN105352426AReduce lossesImprove paste qualityElectrical/magnetic solid deformation measurementRubber layered productsThermal insulationGradient material

The invention discloses a composite function film capable of measuring surface deformation and internal damage, and an application method thereof, and belongs to a damage measurement composite function film and the application method therefor. The function film consists of a thermal insulation layer and a measurement layer. The thermal insulation layer consists of a double-layer film, wherein the center of the double-layer film is provided with an air interlayer, and each layer of the double-layer film is formed by the mixing and laying of a material B. The measurement layer is made of materials A and B, and the materials A and B are laid layer by layer from the third layer to the fifth layer. The center of a contact surface of a first laying layer of the measurement layer with a hollow cylinder is provided with a plurality of flexible electrodes, and a conductive black - silicone rubber strip is disposed between the first laying layer and a second laying layer. The double silicone rubber film with the center being provided with the air interlayer can effectively reduce the heat conductivity coefficient, and achieves the improvement of horizontal temperature gradient control precision. The measurement layer employs a function gradient material idea to achieve the close gluing and synchronous deformation with the surface of a tested sample, and assists the plurality of flexible electrodes and conductive rubber strip, thereby completing the distribution measurement of a surface deformation field of the hollow cylinder and the internal resistivity in a temperature gradient direction.

Owner:CHINA UNIV OF MINING & TECH

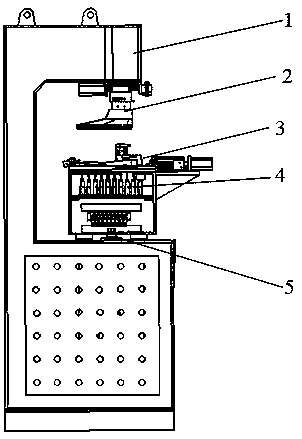

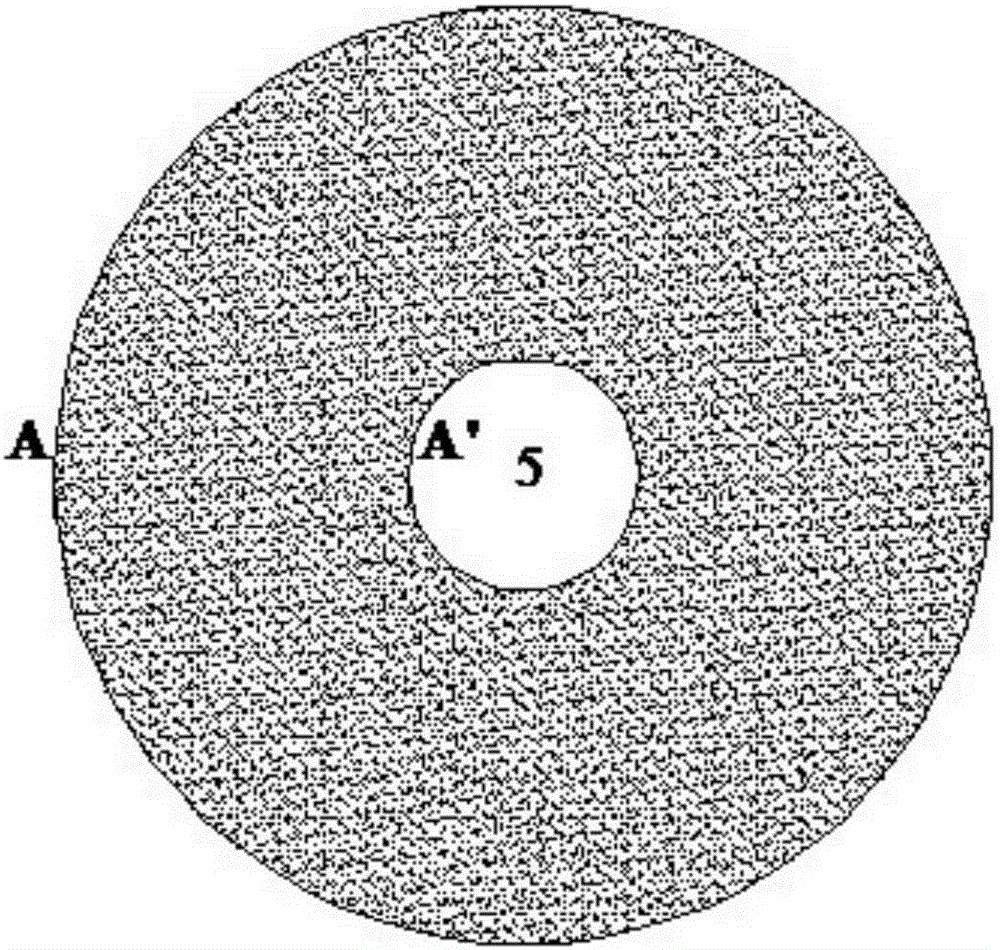

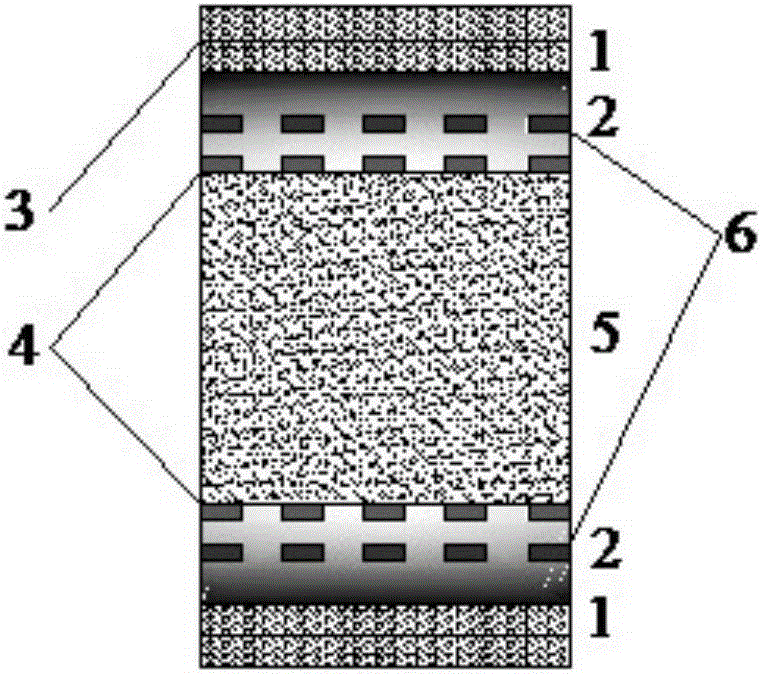

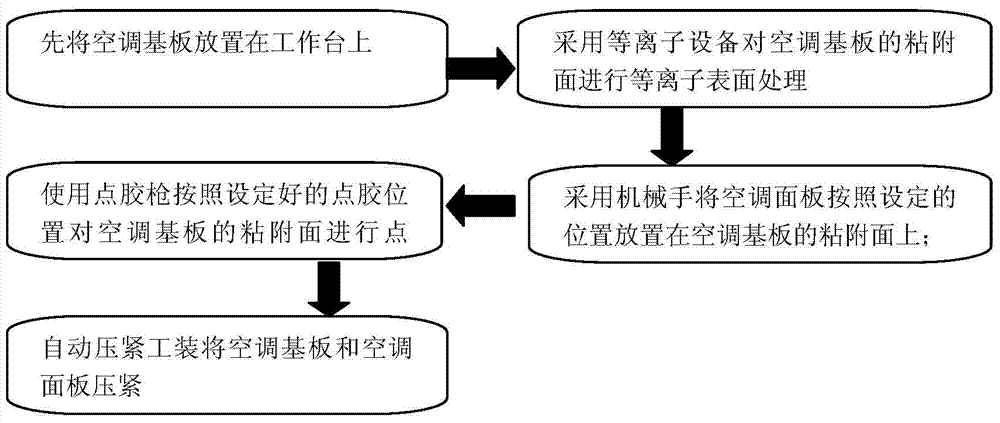

Air-conditioner panel adhesion process and air conditioner

ActiveCN104494277AAdhesive environmental protectionLow priceLamination ancillary operationsHeating and ventilation casings/coversPolyurethane adhesiveAdhesion process

The invention relates to the technical field of air conditioning equipment and in particular relates to an air-conditioner panel adhesion process. The air-conditioner panel adhesion process comprises the step of adhering an air-conditioner base plate subjected to plasma treatment and an air-conditioner panel by adopting a structure adhesive, wherein the structure adhesive refers to a polyurethane adhesive or silica gel. The invention also provides an air conditioner which comprises an air-conditioner panel adhered to the air-conditioner base plate by adopting the air-conditioner panel adhesion process. With the adoption of the structure adhesive and the plasma treatment technology, the adhesion between the air-conditioner panel and the air-conditioner base plate is environmentally friendly, the price is low, and the air conditioner has high safety, stability and reliability. Automatic flow-line production is adopted, and the working efficiency and the adhesion quality are greatly improved. The invention further provides an air conditioner. According to the air-conditioner panel adhesion process, the production cost is reduced, and the adhesion is firm.

Owner:GREE ELECTRIC APPLIANCES INC

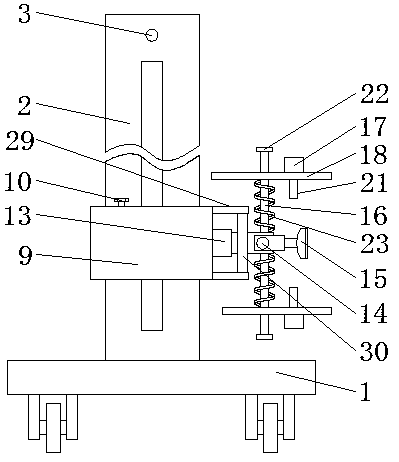

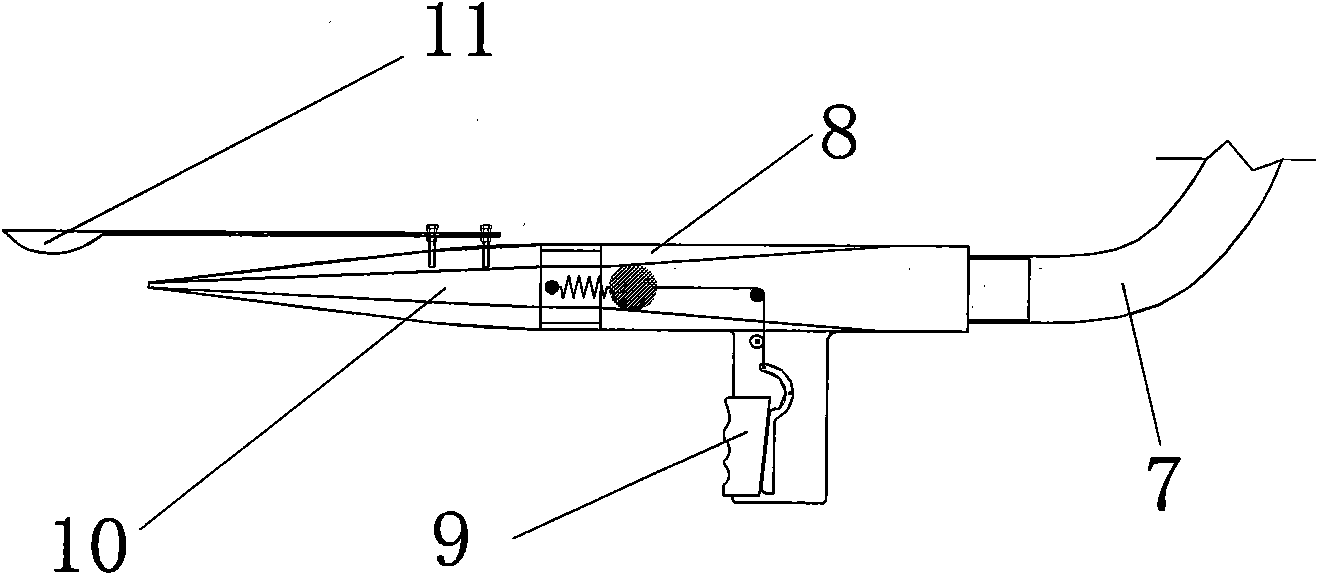

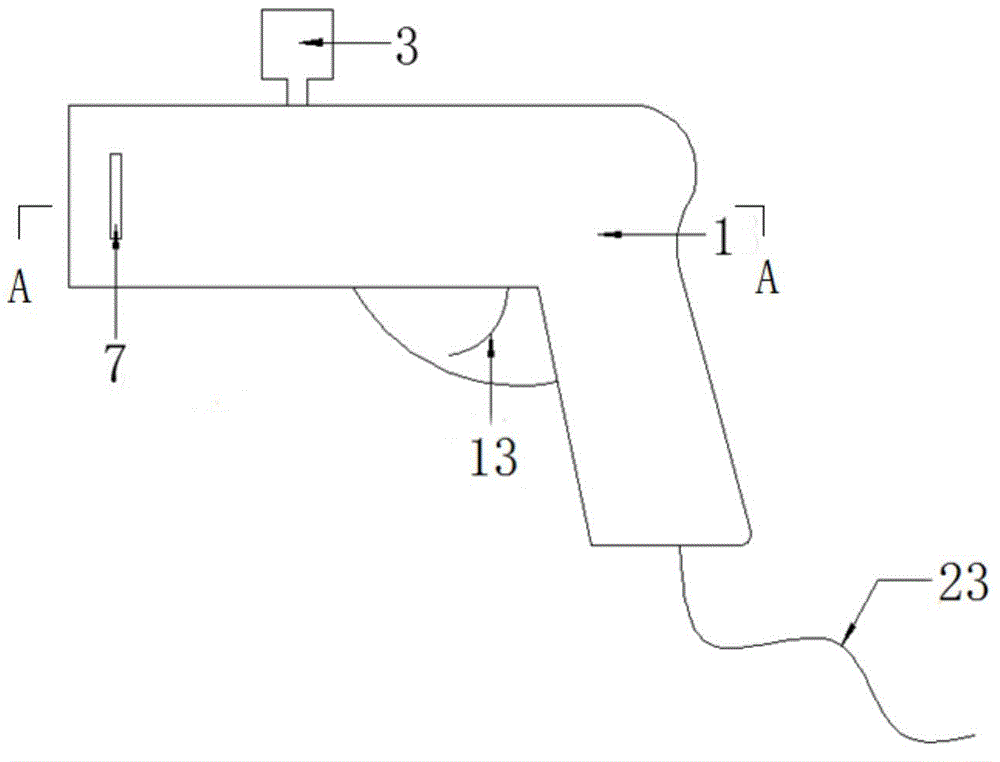

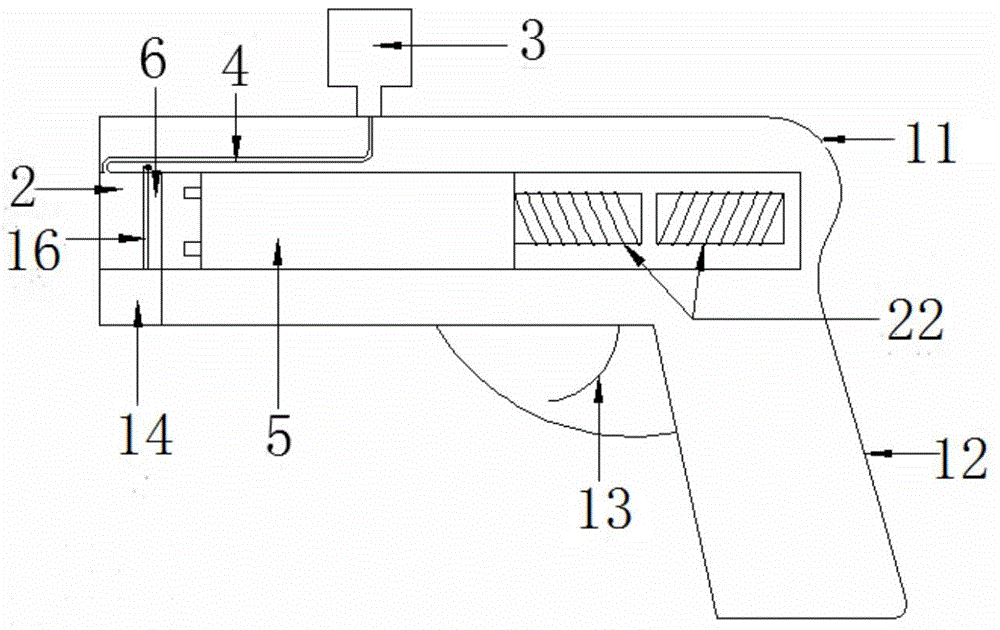

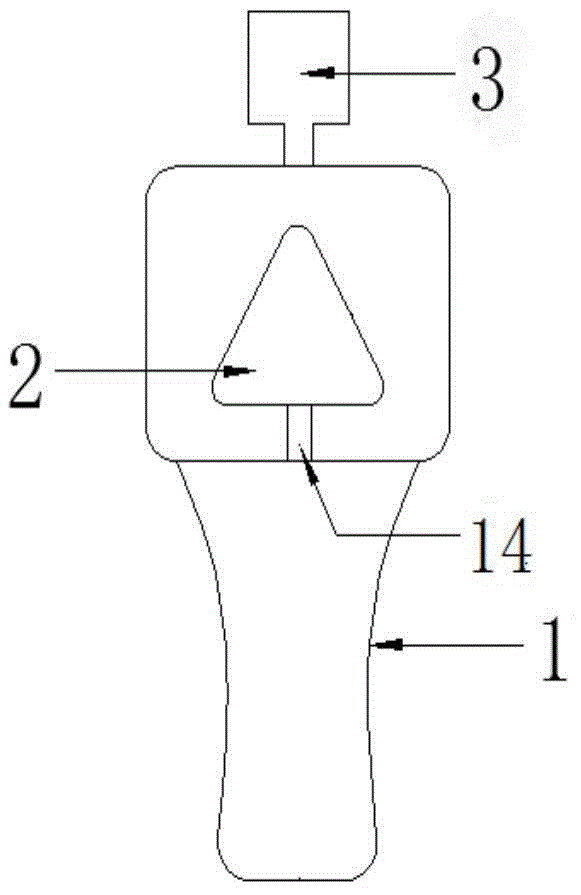

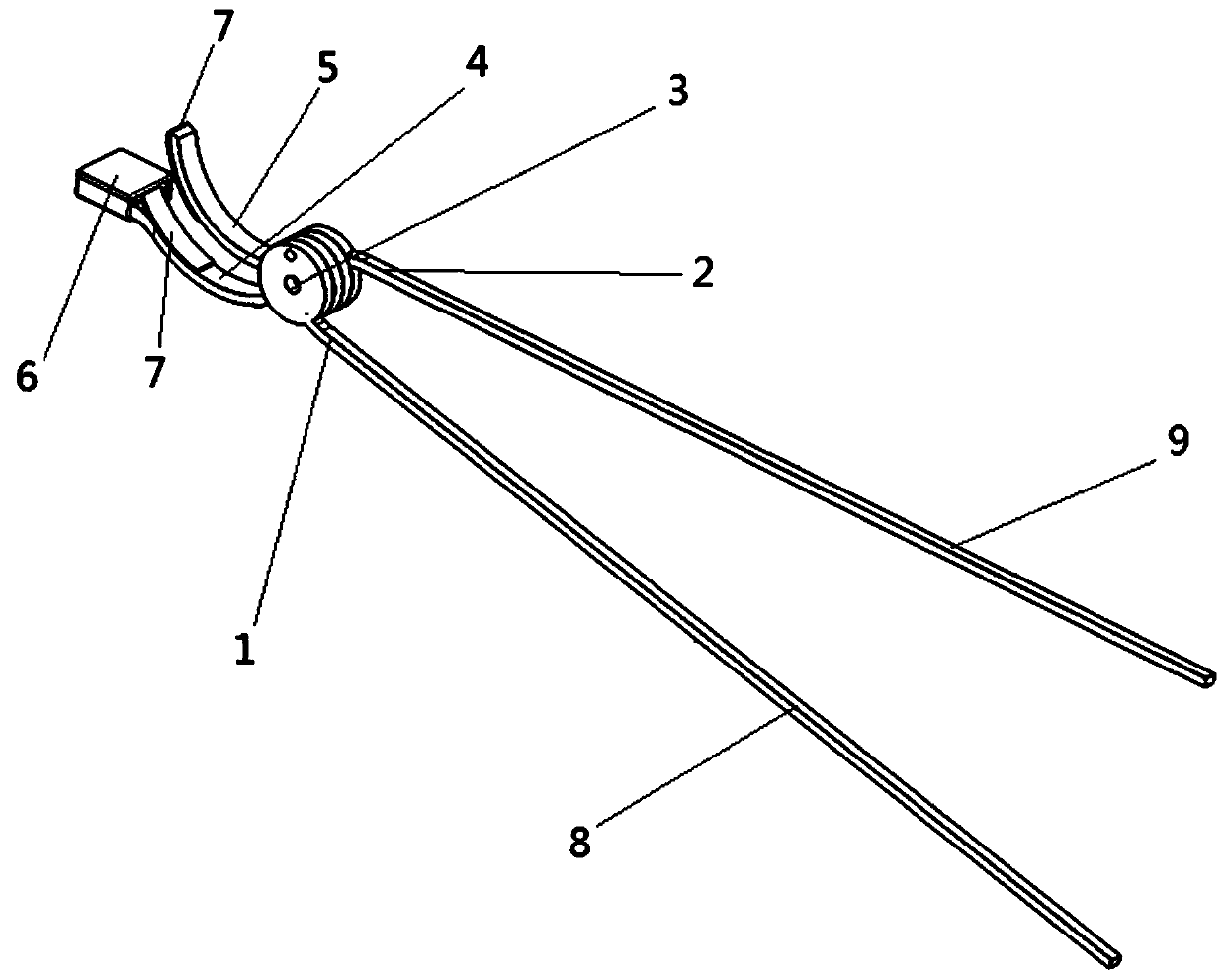

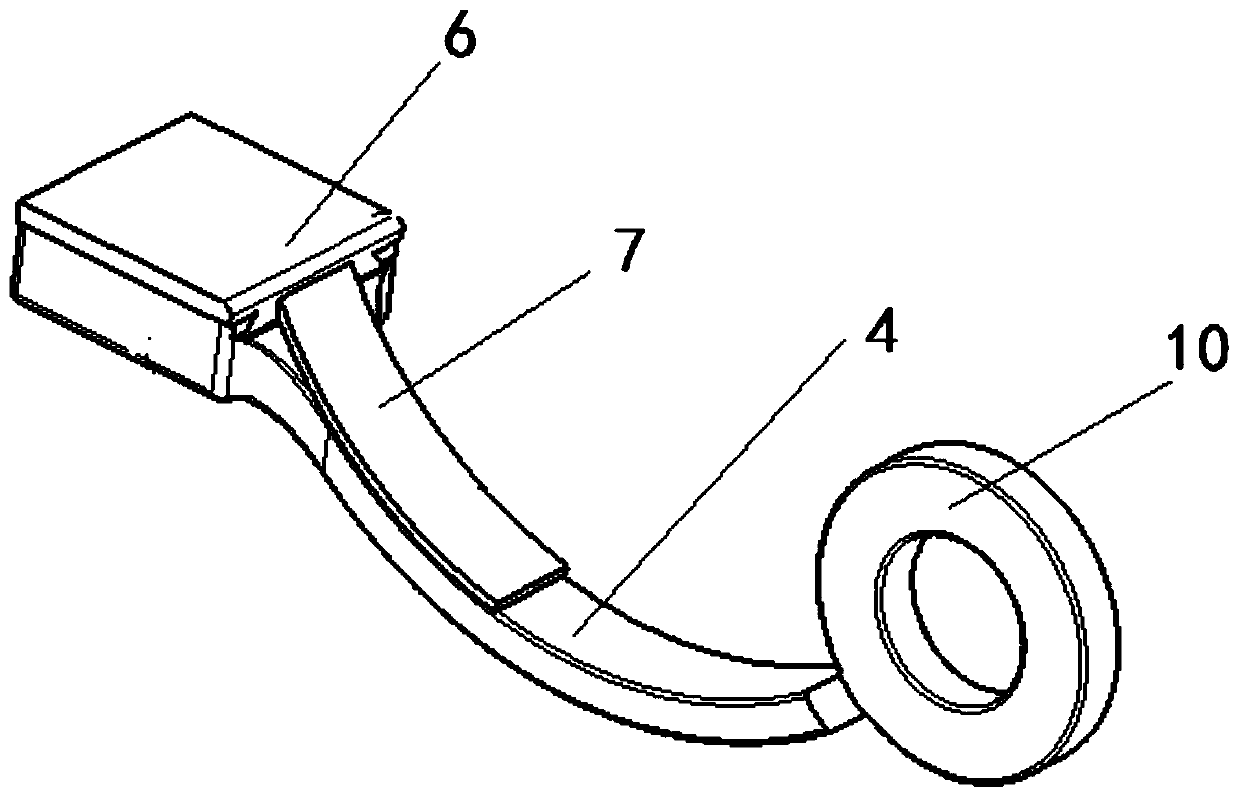

Strain gauge automatic welding and pasting device

InactiveCN104917027ALocation pinpointingImprove paste qualityLine/current collector detailsMaterial gluingStrain gaugeAutomatic testing

The invention belongs to the field of engineering tests, and in particular relates to a strain gauge automatic welding and pasting device. The strain gauge automatic welding and pasting device comprises a gun-shaped main body, wherein the gun-shaped main body comprises a gun barrel, a handle is arranged under the rear end of the gun barrel, and a trigger is arranged at a joint of the front side top part of the handle and the gun barrel; a smoothbore is arranged inside the gun barrel, the smoothbore extends from the front end to the rear end of the gun barrel but does not penetrate the rear end, and the cross section of the smoothbore is a triangle; an electromagnetic power device, an extruding rod, a carrier and a curly welding baffle plate are arranged in the smoothbore from back to front in sequence; and a carrier hole groove is formed in one side of the front end of the gun barrel, the carrier hole groove penetrates the smoothbore vertically, a wiring sliding groove extends from the front end to the rear end of the bottom part of the gun barrel, and the wiring sliding groove penetrates the bottom wall. The strain gauge automatic welding and pasting device provided by the invention can position the location of a strain gauge accurately, realizes the automatic welding of wiring terminals and automatic pasting of the strain gauge, can effectively improve the pasting quality of the strain gauge, saves pasting time, and can be used by workers with or without manual pasting experience.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

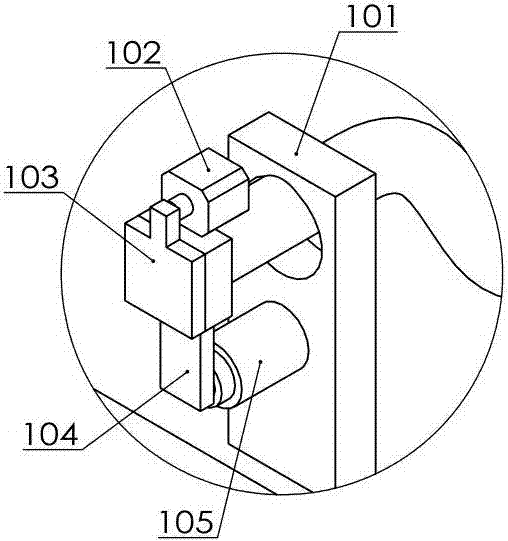

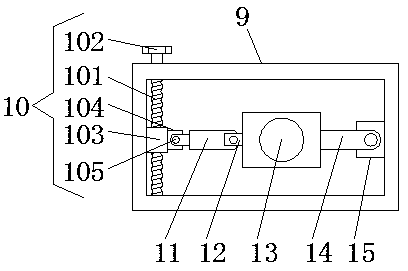

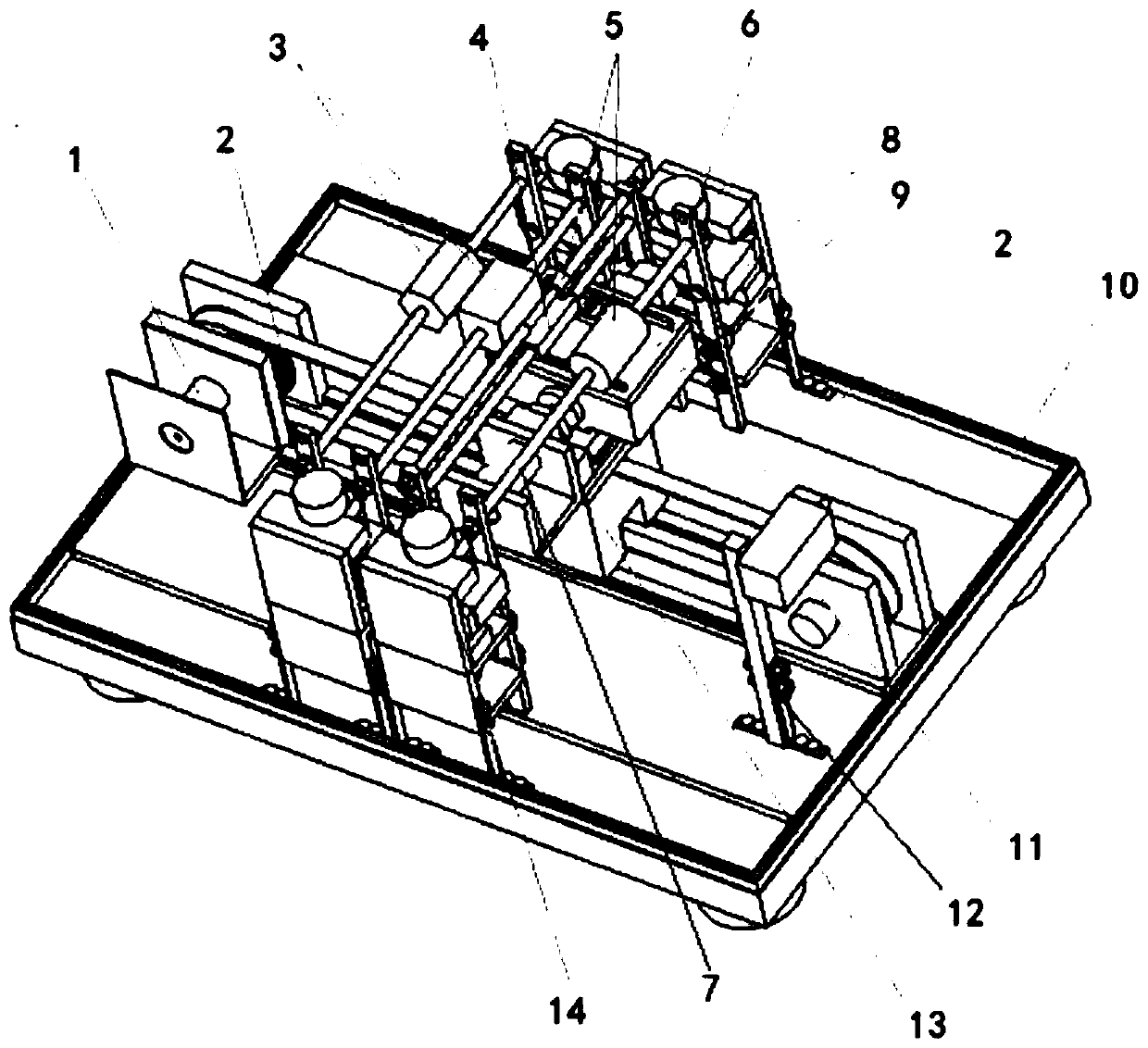

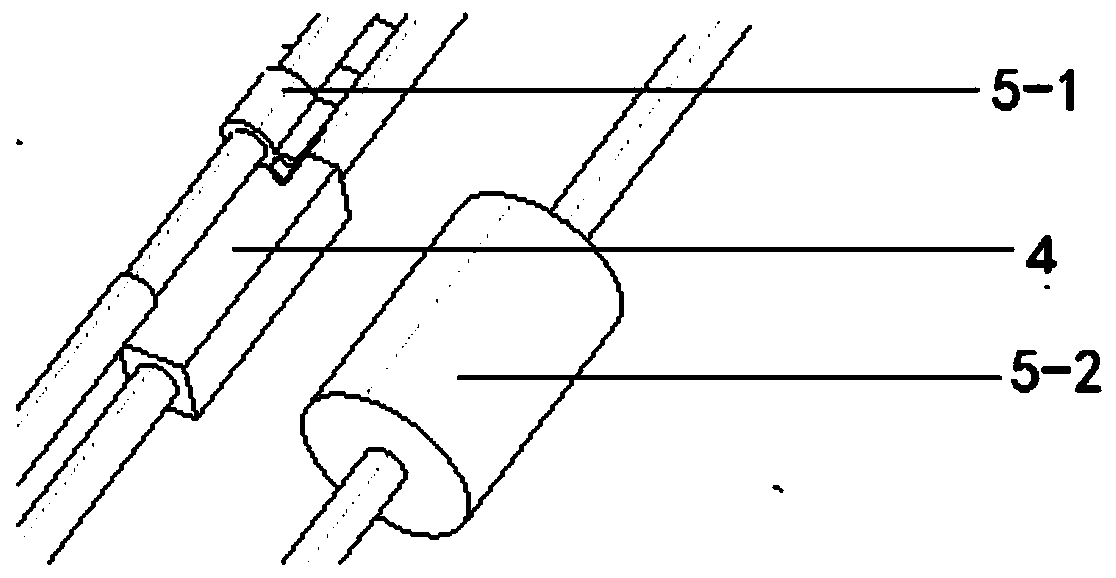

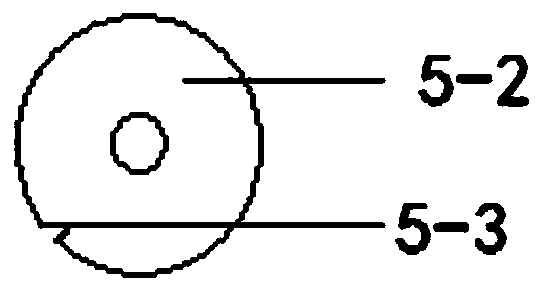

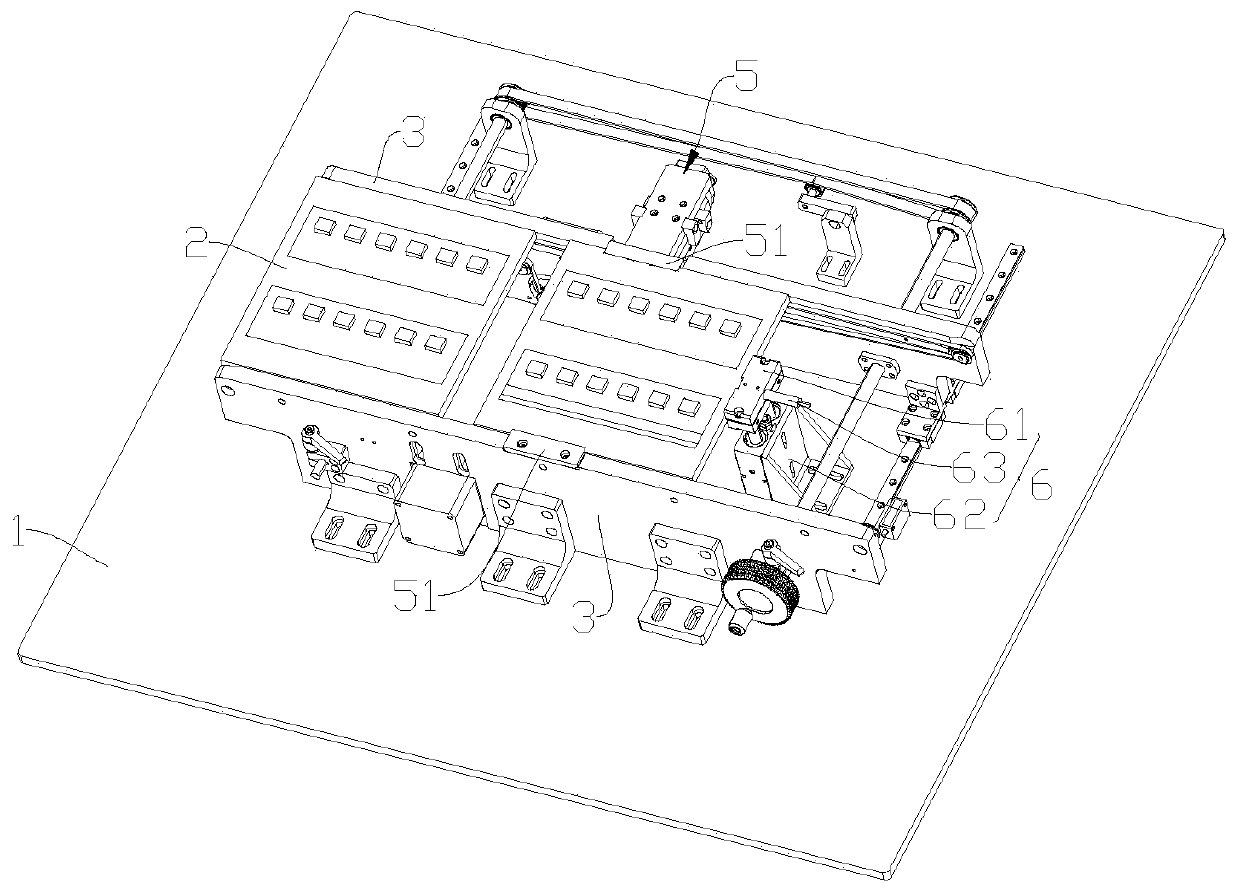

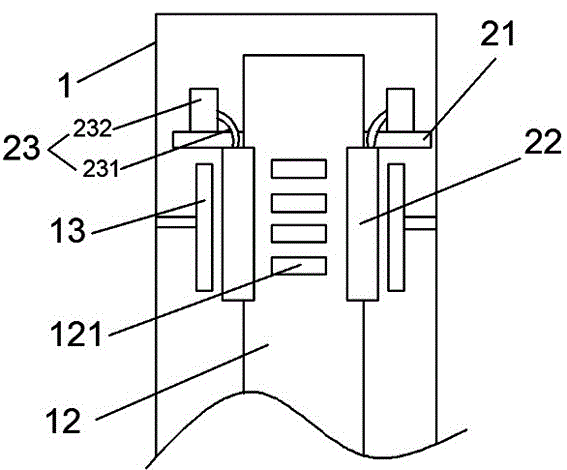

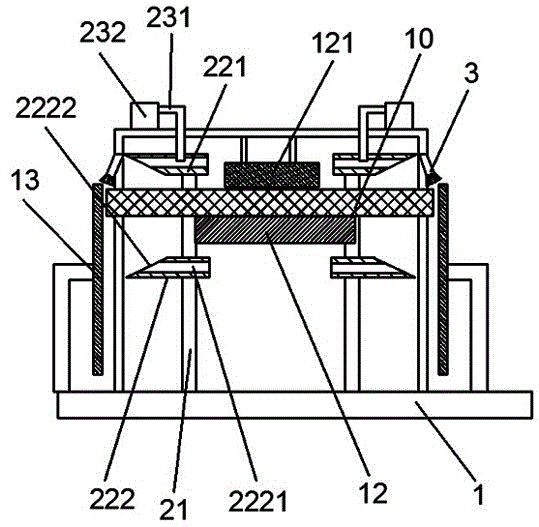

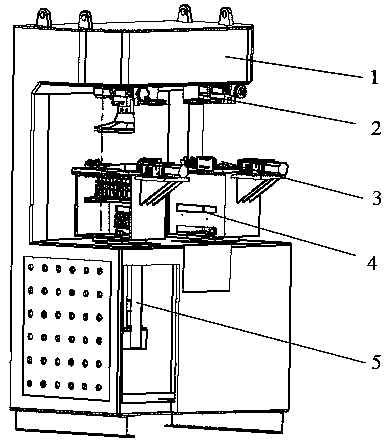

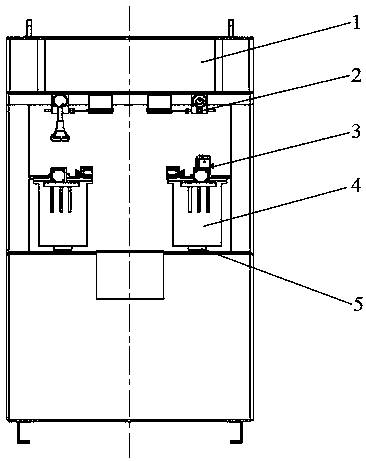

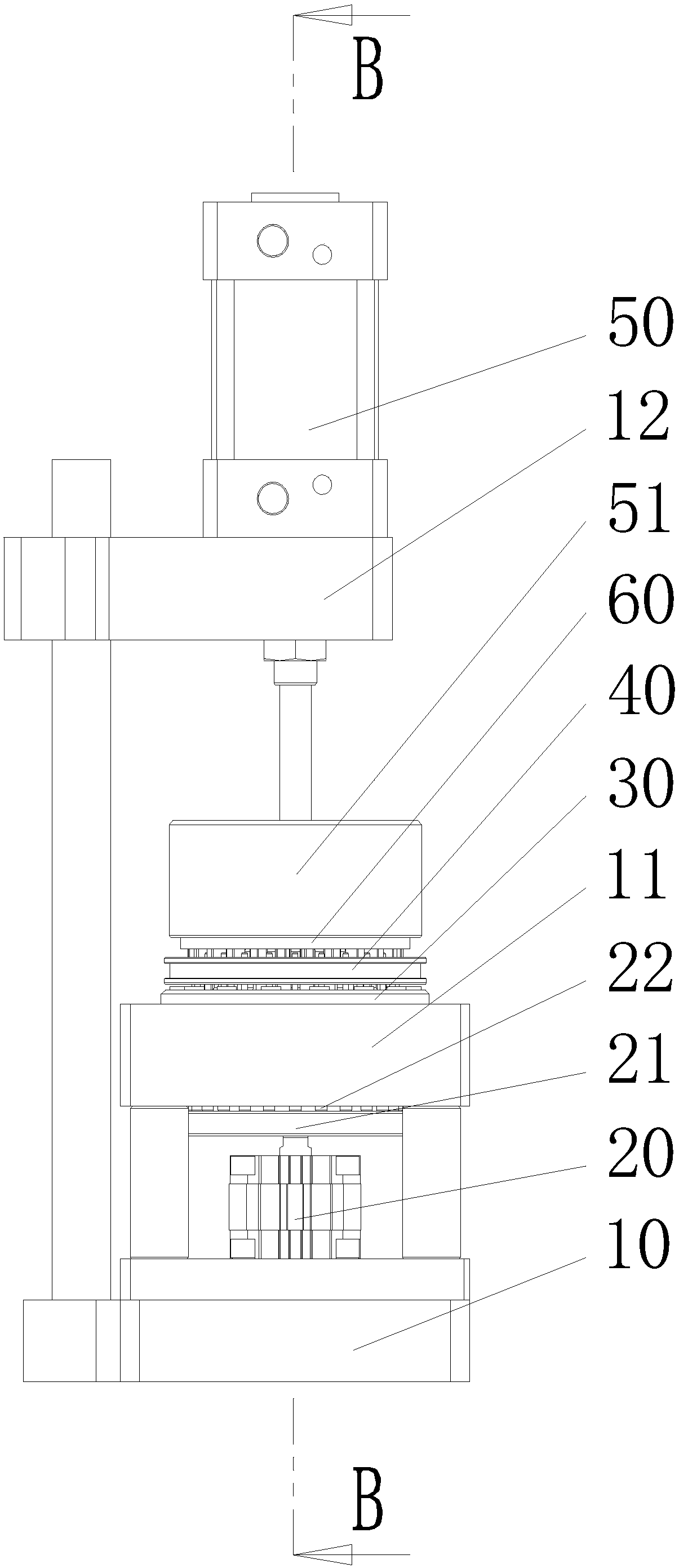

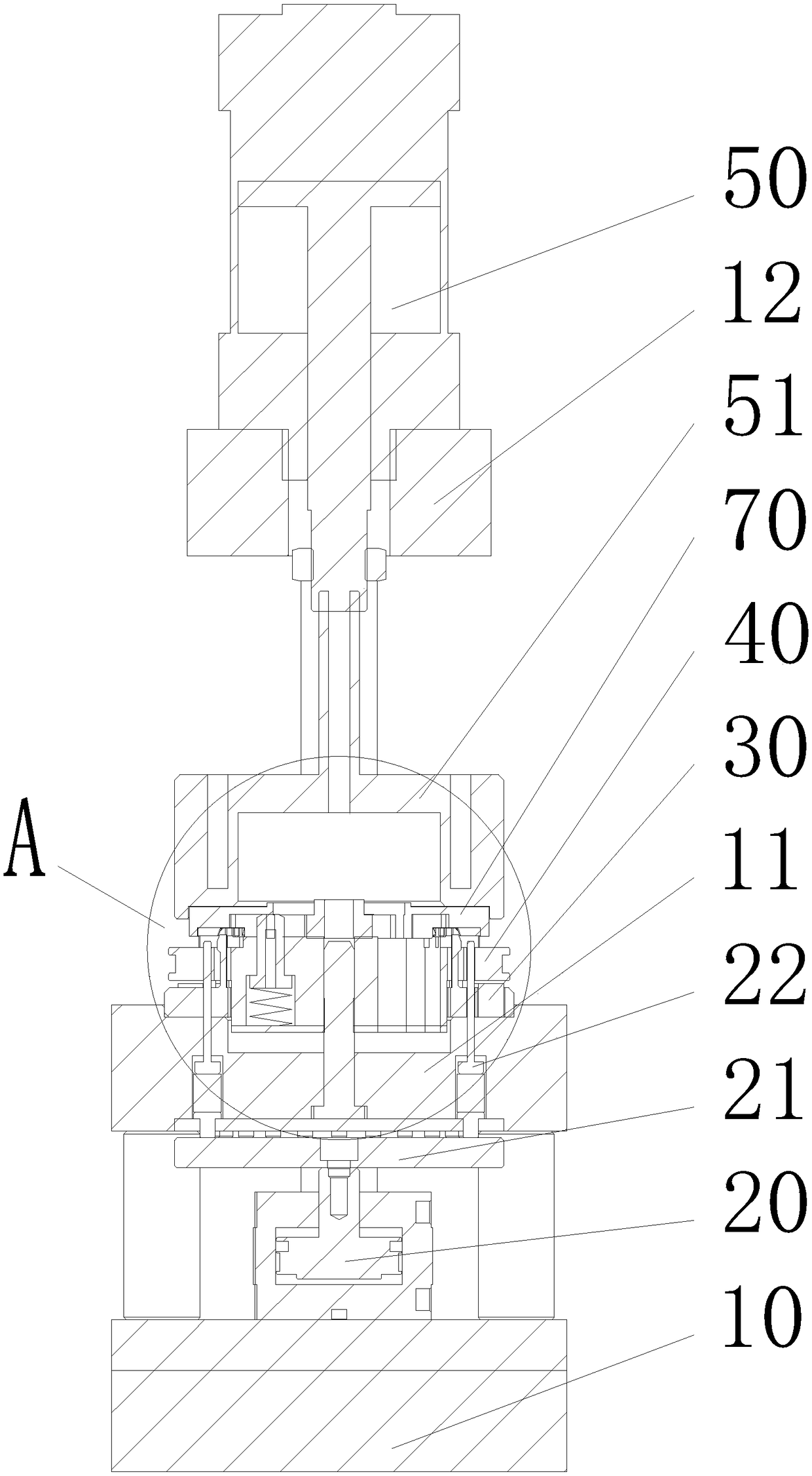

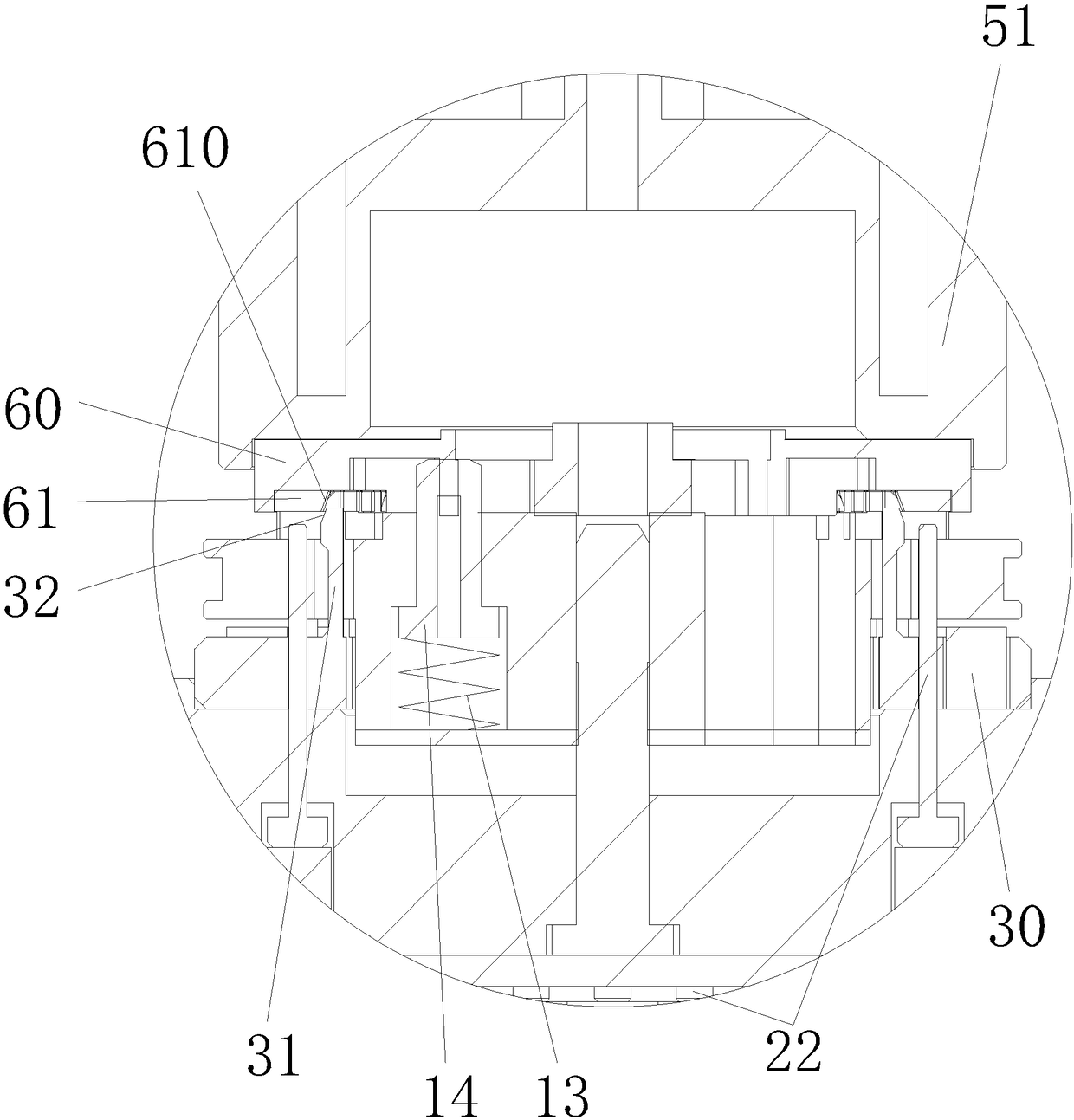

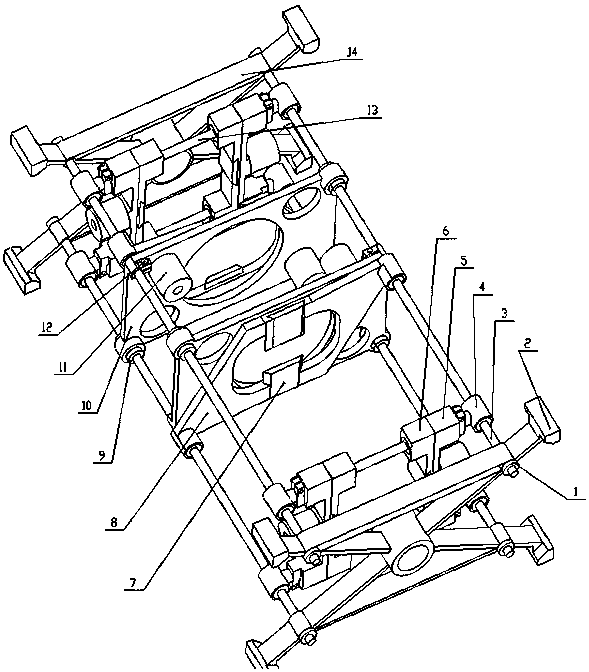

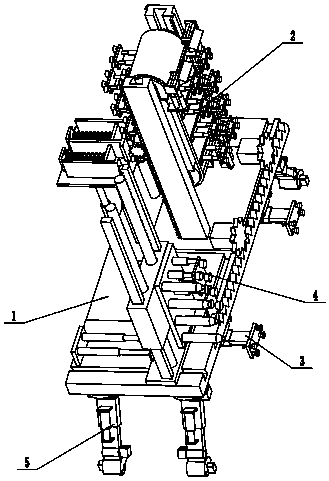

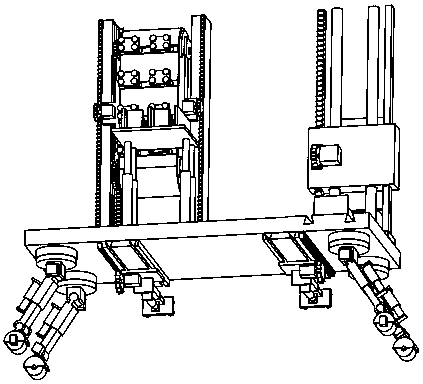

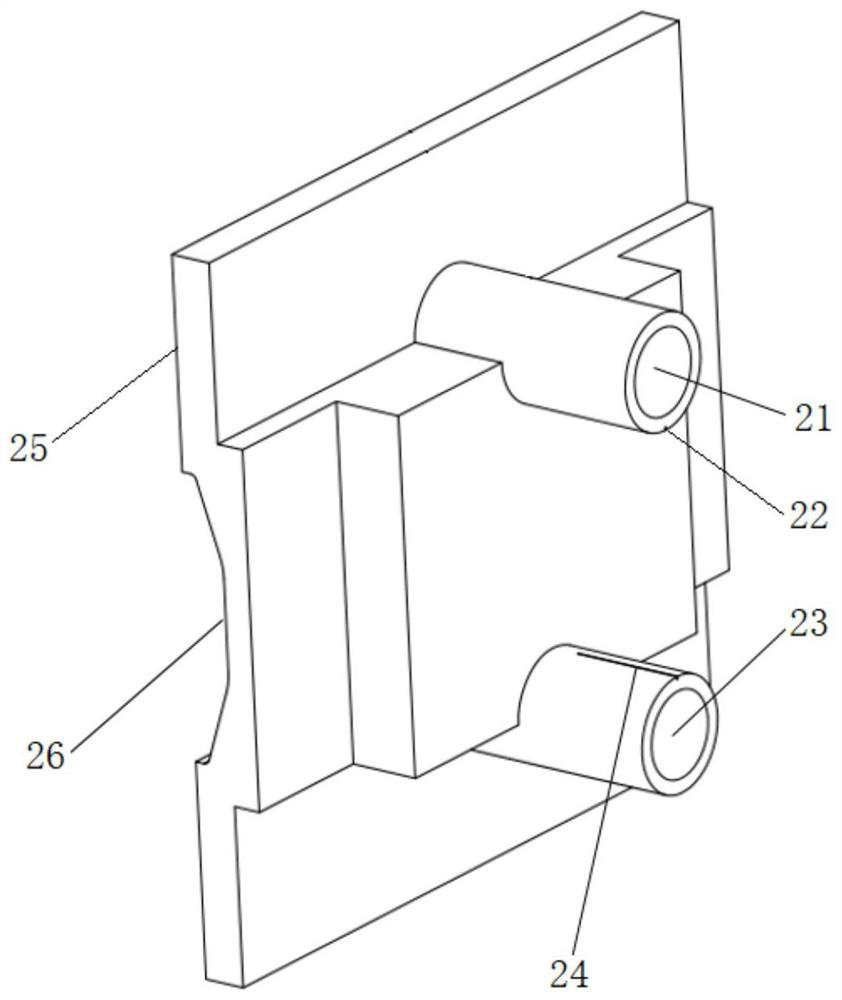

Flange-type magnetic steel pasting machine

ActiveCN108321994AImprove paste qualityConsistent spacingManufacturing stator/rotor bodiesEngineeringMechanical engineering

The invention discloses a flange-type magnetic steel pasting machine comprising a frame and upper and lower brackets disposed thereon. The upper bracket is provided with a vertically downward down-pushing driving source. The shaft end of the down-pushing driving source is provided with a suction cup. The lower bracket is provided with a spring and an expanded lobe disc. The spring is provided witha support column. The expanded lobe disc is provided with a vertically upward lobe the free end of which is provided with a radially protruding wedge surface protrusion. The expanded lobe disc is provided with a mother disc on which positioning protruding blocks and support holes which are equally distributed on the upper surface thereof are disposed. The positioning protruding blocks are provided with positioning baffles. The mother disc between the positioning protruding blocks is provided with a lobe hole penetrating through the mother disc. The wedge surface protruding blocks pass throughthe mother disc through the lobe hole, and a part of the wedge surface extends into the height of the positioning baffle. The support column is stuck in the support hole. The flange-type magnetic steel pasting machine can automatically push forward the magnetic steel, so that the pasting quality of the magnetic steel is higher, and the magnetic steel is not easily damaged, and the structure is simple and the cost is low.

Owner:苏州市翔耀精密自动化设备有限公司

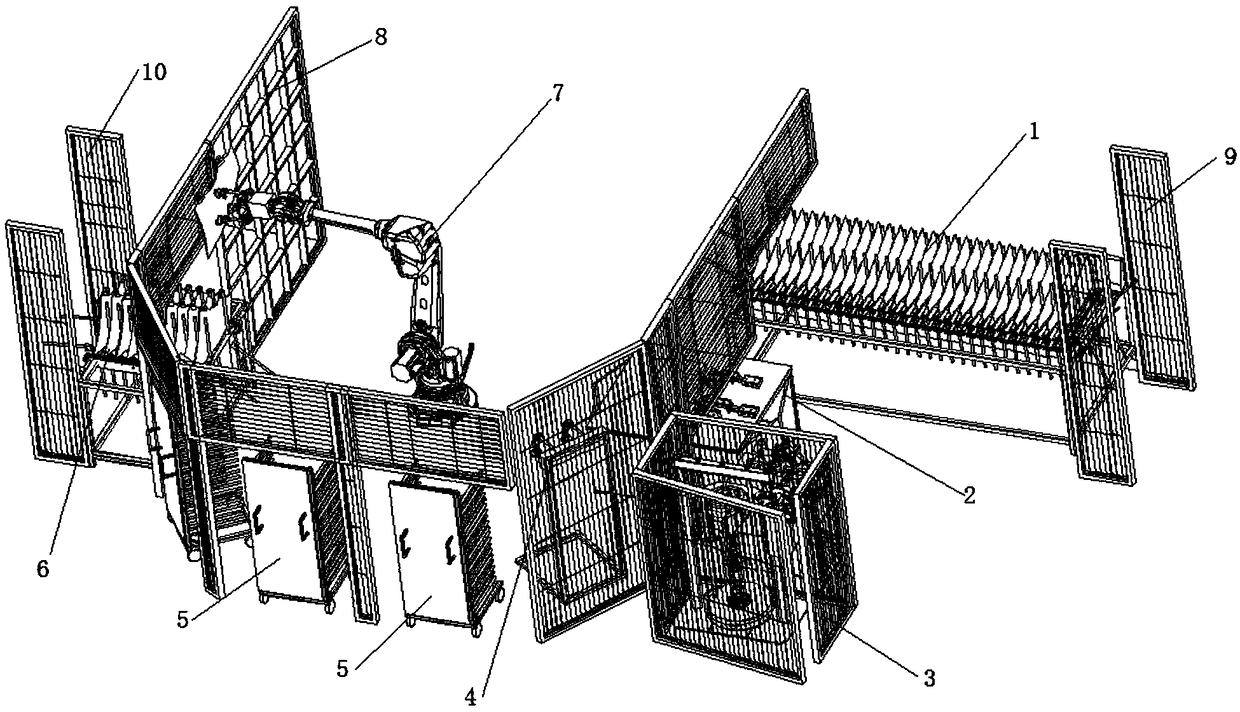

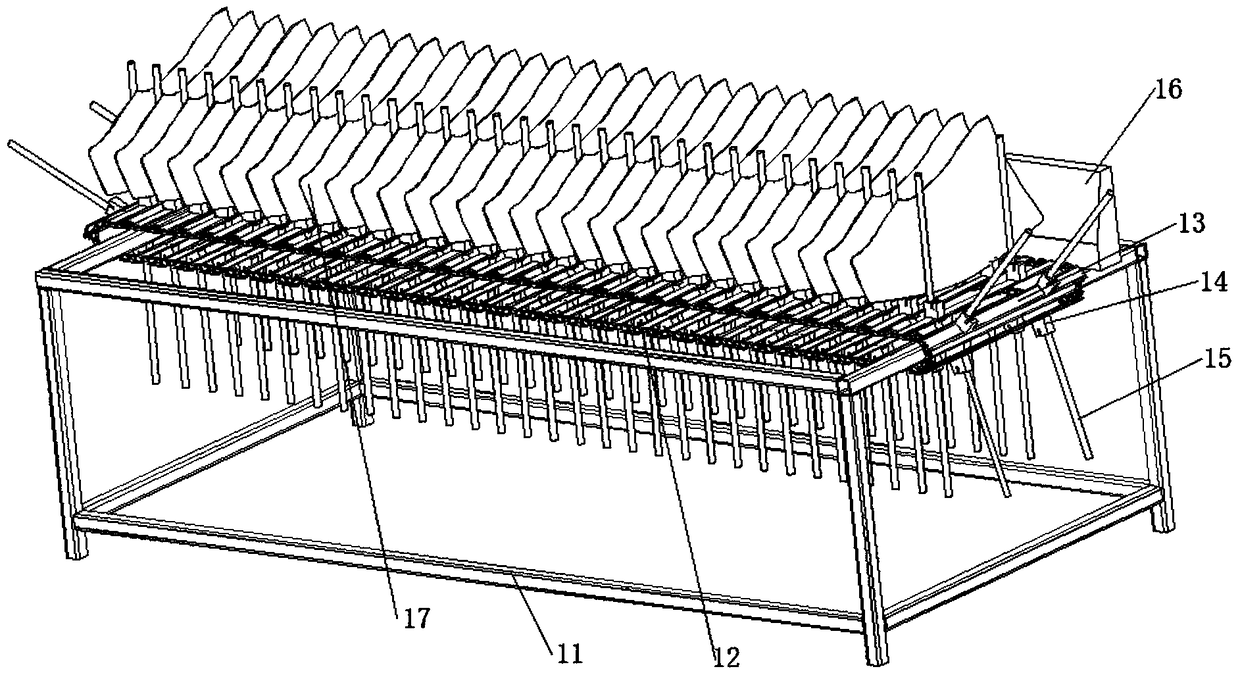

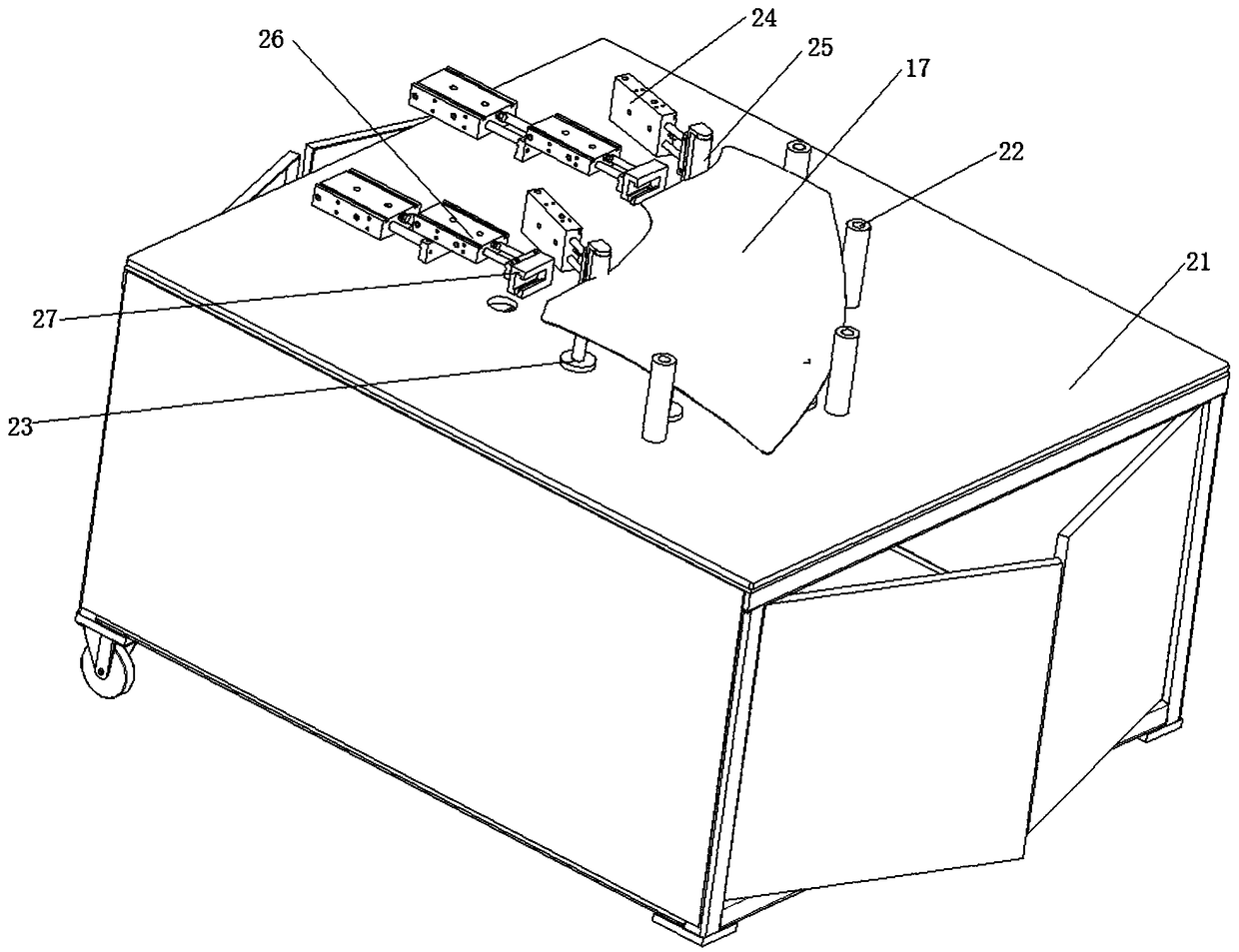

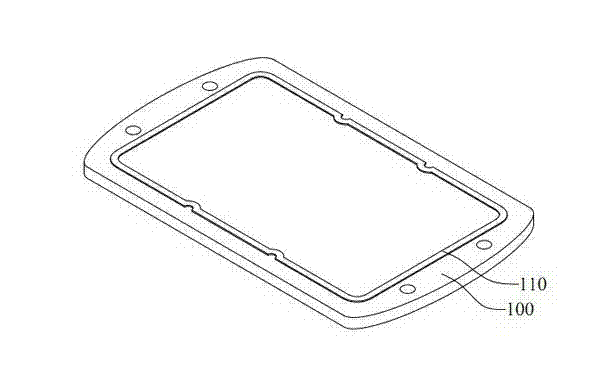

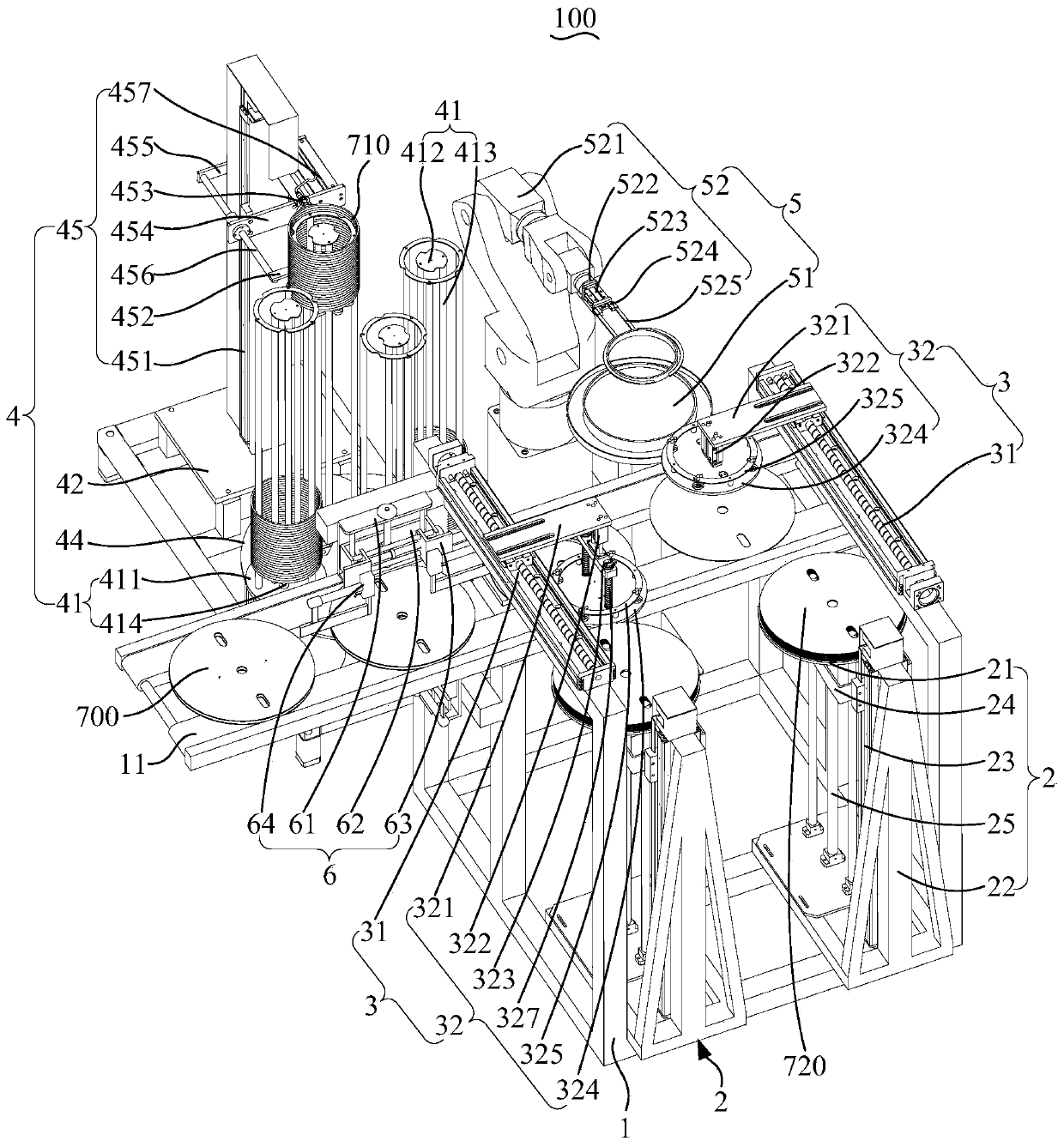

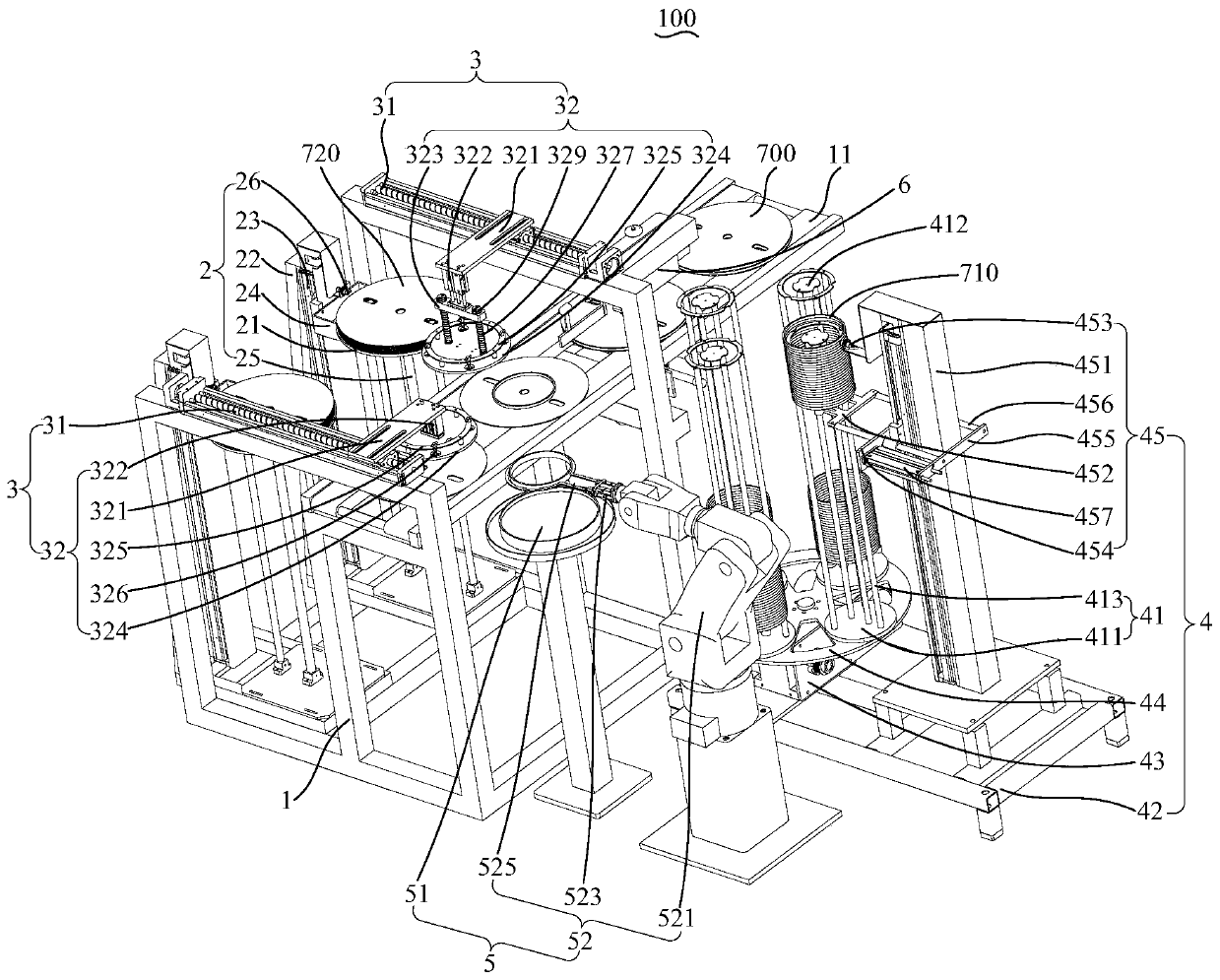

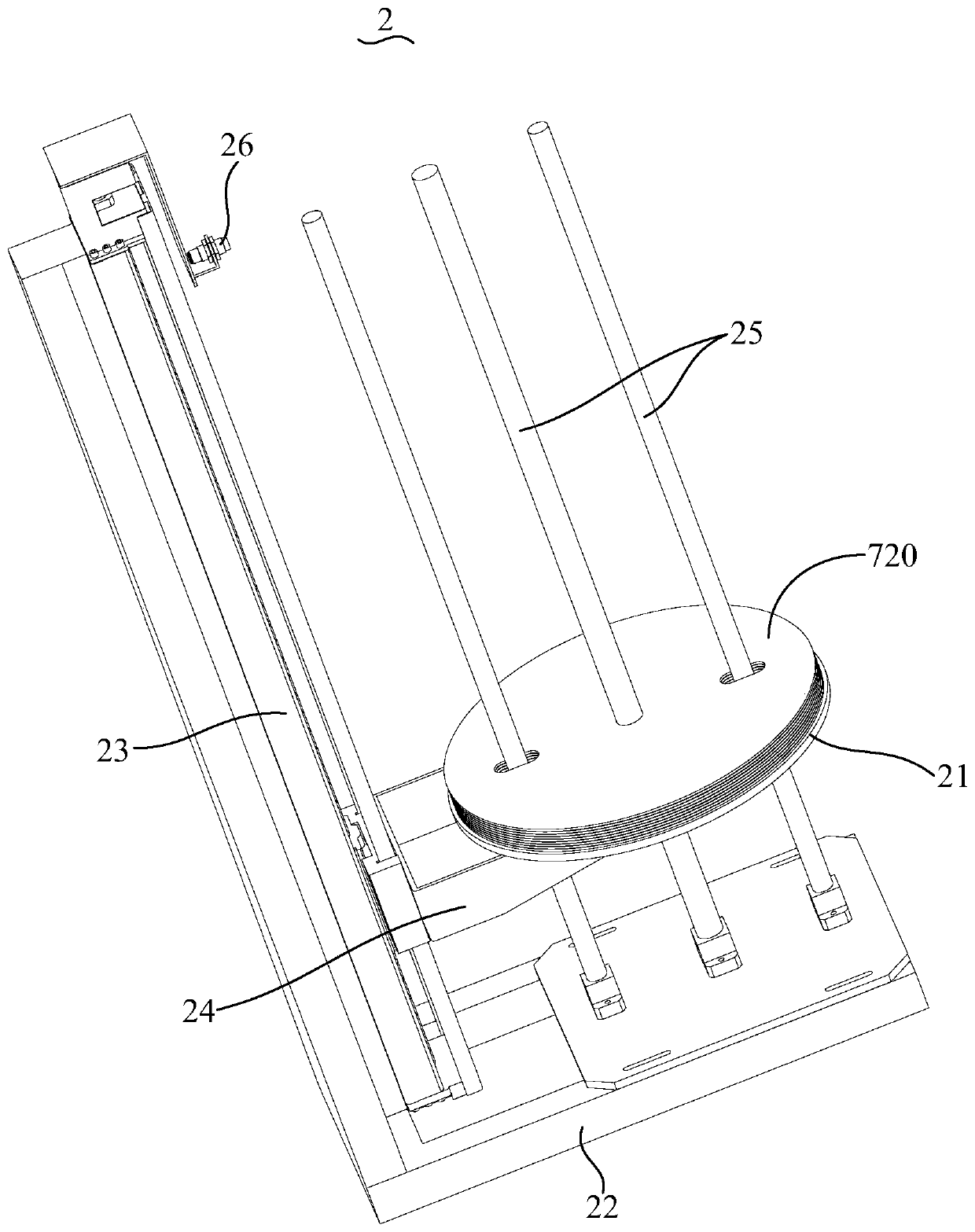

Glass assembly line

PendingCN108860372AImplement automatic assemblyImprove paste qualityVehiclesAssembly lineUltimate tensile strength

The invention relates to the technical field of automotive glass production, in particular to a glass assembly line. A feeding device herein feeds glass; a carrying robot carries the glass to a door holder assembly device for the purpose of mounting a door holder; after the door holder assembly device fits the door holder, the carrying robot carries the glass to a discharging device that discharges the glass; automatic assembly of the door holder can be achieved, door holder binding quality is greatly improved, door holder assembly reliability is enhanced, capacity of an enterprise is greatlyimproved, labor intensity is reduced, and production efficiency is improved.

Owner:KUNSHAN SPEED AUTO MACHINERY CO LTD

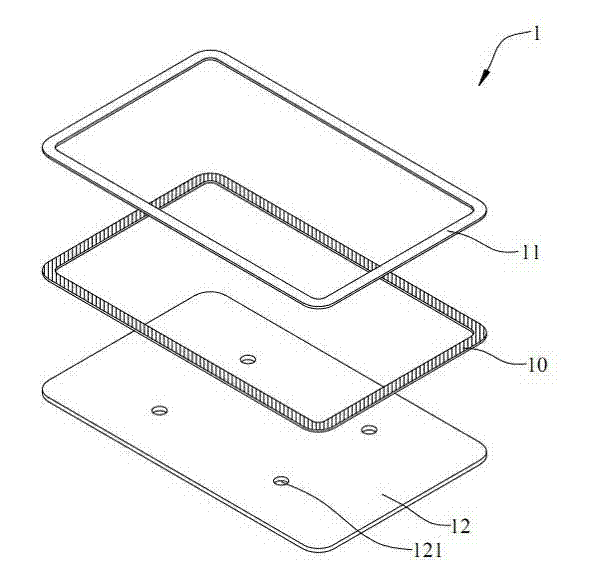

Adhesive tape, adhering device and adhering method thereof

InactiveCN103241447AImprove good rateAchieve positioning effectFlexible coversWrappersBiomedical engineeringDe bonding

The invention discloses an adhesive tape which is formed by stacking of a first de-bonding layer, an adhering layer and a second de-bonding layer. The second de-bonding layer is provided with a positioning portion, and the total area of the second de-bonding layer is larger than that of the first de-bonding layer. In addition, the invention further discloses an adhering device and an adhering method thereof. A base of the adhering device is provided with an accommodating groove and a positioning unit, and the adhesive tape is arranged in the accommodating groove of the base so as to enable the positioning portion of the adhesive tape and the positioning unit of the base to be positioned. A supporting member is provided, the first de-bonding layer is removed to expose the adhering layer, and the supporting member is adhered with the adhering layer mutually. By increasing the area of the second de-bonding layer, the problem that the shape of an existing adhesive tape is too narrow is solved, positioning fixation of the adhesive tape and the supporting member during adhering is achieved through the positioning portion, time and effort are saved, operation error rate is reduced simultaneously, and sticking quality is improved further.

Owner:ASKEY TECH JIANGSU +1

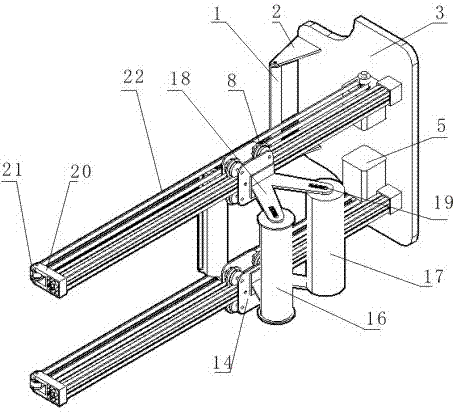

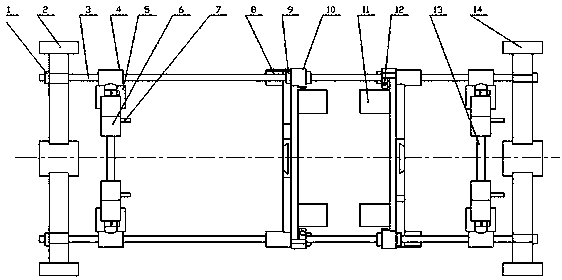

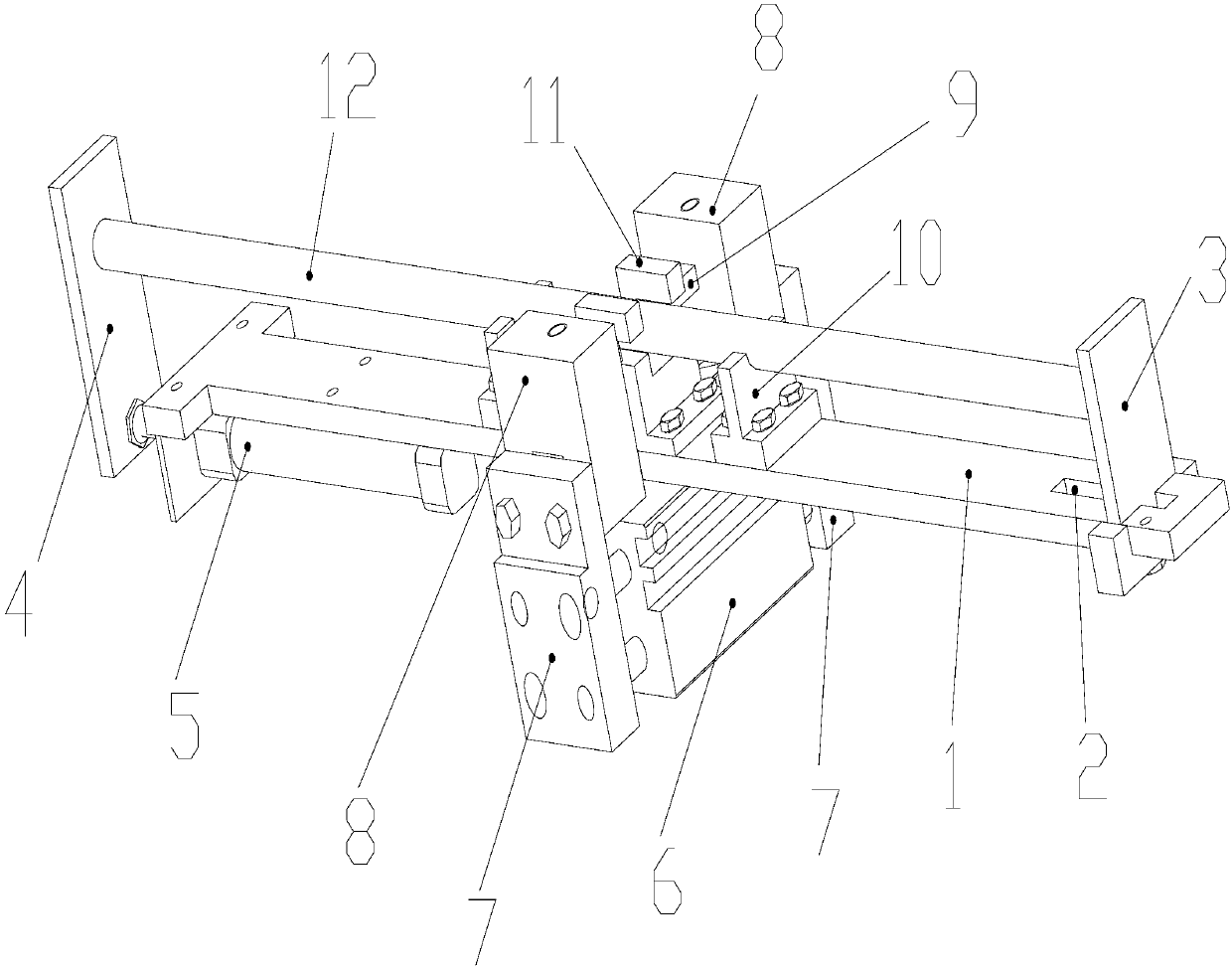

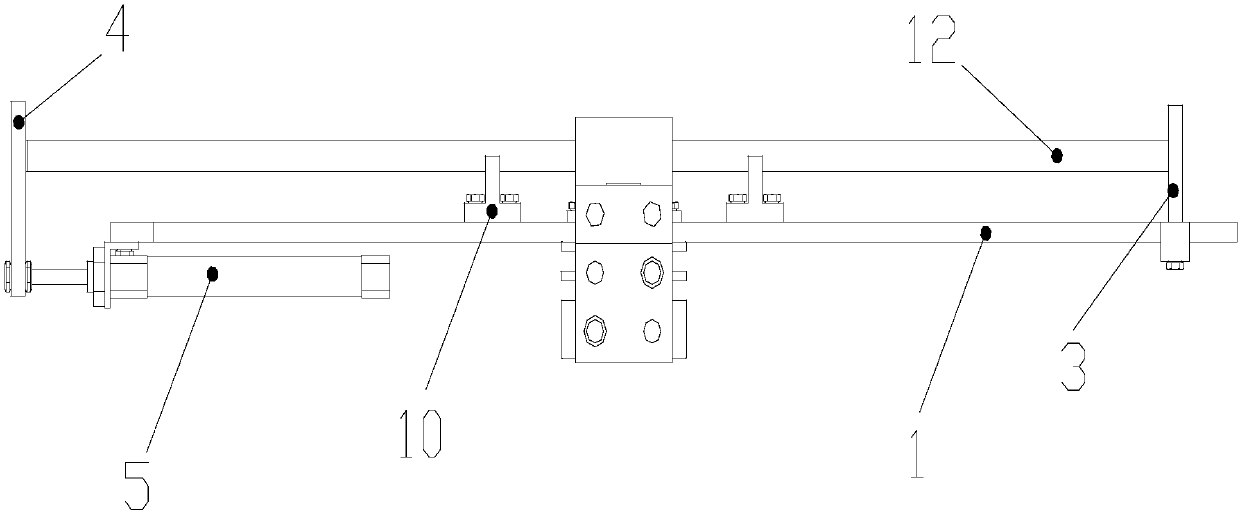

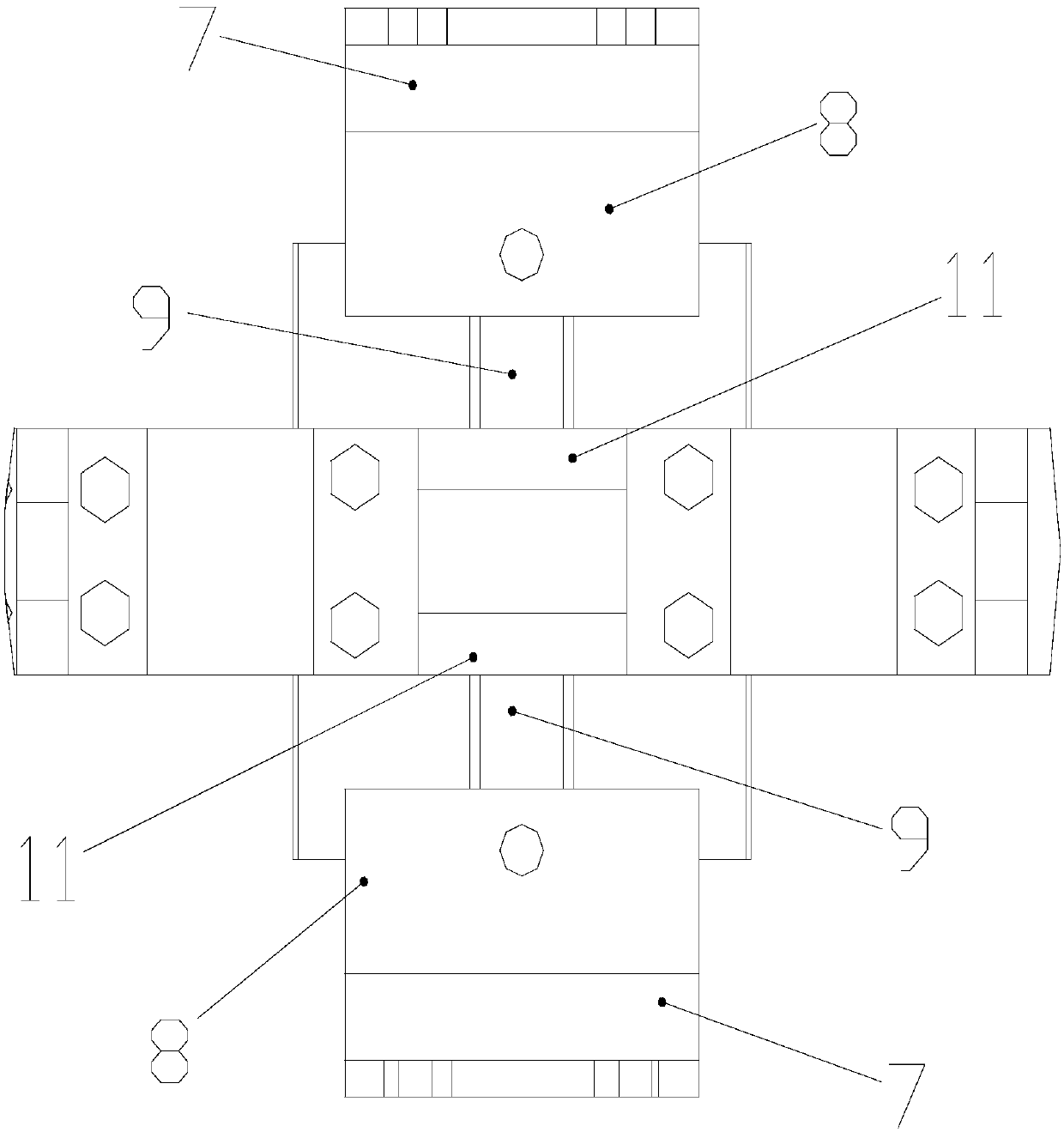

Universal quantitative pressure application system for pasting rod type wind tunnel strain balance

ActiveCN107796593AImprove versatilitySolve the problem of insufficient single pressurizationAerodynamic testingAxial forceEngineering

The invention discloses a universal quantitative pressure application system for pasting a rod type wind tunnel strain balance. The universal quantitative pressure application system is characterizedby comprising a supporting and connecting part, radial force application parts and an axial force application part; the quantitative pressure application control is used as an idea; the stable performance of an integrated frame structure is used; the influence of the temperature on the integral deformation is fully considered in material selection; the quantitative pressure application control onall weights in the process of pasting and curing the strain balance is ensured. Through the universal pressure application system, the problem that a pressure application value cannot be quantified inthe pasting process of the rod type wind tunnel strain balance is solved; meanwhile, the problems of low universality and the insufficient one-time pressure application weight of a pasting clamp aresolved; the inconvenience caused by frequently assembling and disassembling is avoided; the pasting quality and efficiency of the rod type wind tunnel strain balance are improved; meanwhile, the production cost of the pasting clamp is reduced; the quality and the benefit of wind tunnel test are favorably improved.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

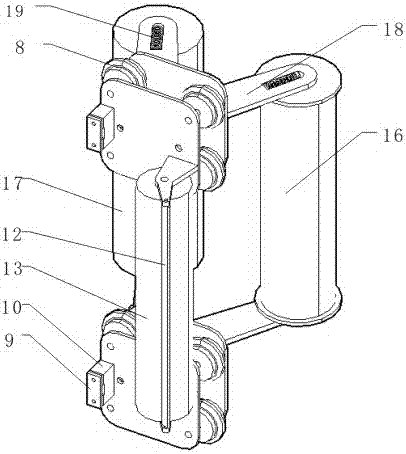

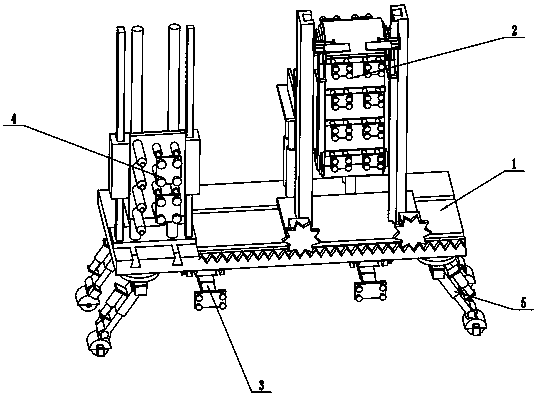

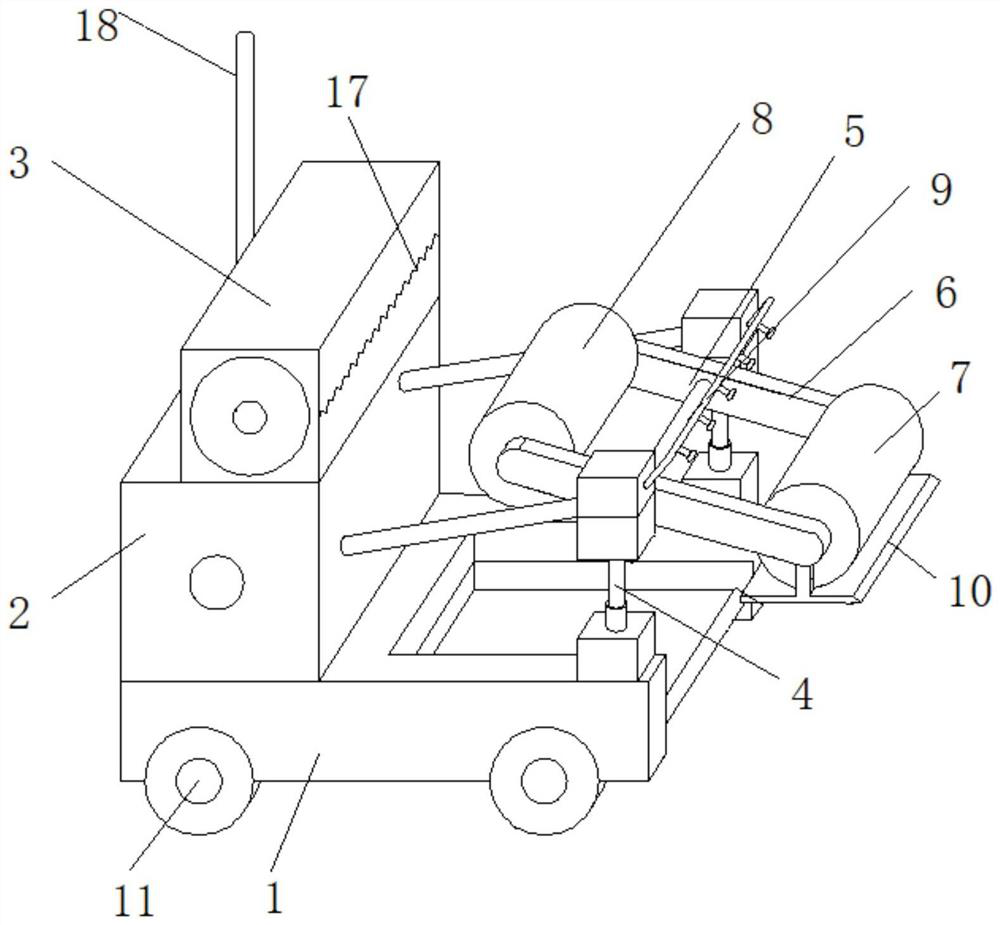

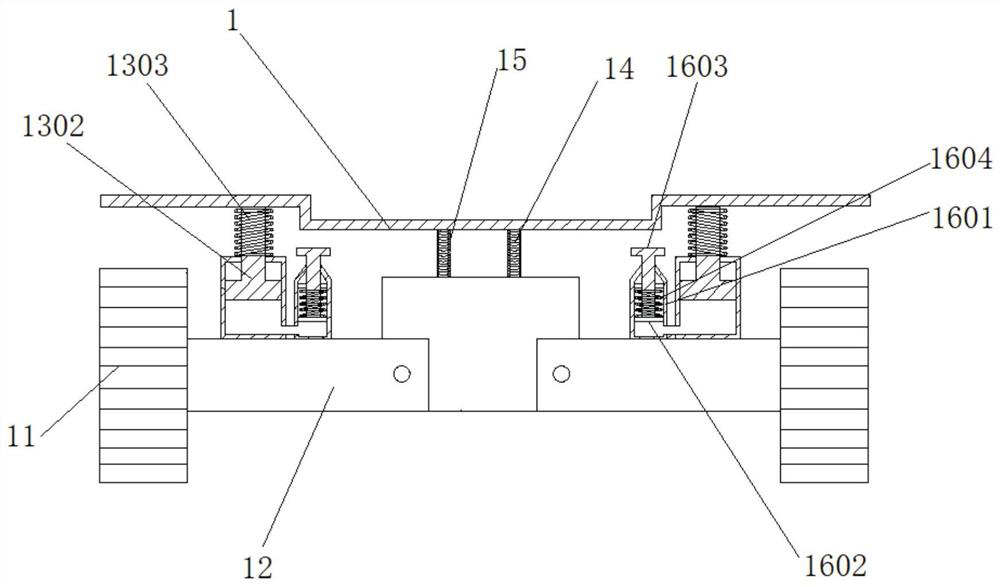

Mobile robot

ActiveCN108505736AImprove efficiencyQuality improvementBuilding constructionsEngineeringMechanical engineering

A mobile robot comprises a base, a wall tile pasting part, two fixing parts, a detection correcting part and four walking parts. The mobile robot is characterized in that two first sliding blocks of the wall tile pasting part are slidably mounted in two first dovetail grooves correspondingly, and two first gears are mutually engaged with first racks correspondingly; four second sliding blocks of the two fixing parts are slidably mounted in four third dovetail grooves correspondingly, and two fourth gears are mutually engaged with the two first racks; and four second round plates of the four walking parts are fixedly mounted on motor shafts of four first steering engines correspondingly, and four circular ring grooves are slidably mounted on four sets of rolling balls correspondingly. Through the wall tile pasting part, cement is automatically smeared, wall tiles are automatically pasted to walls, and the tile pasting efficiency and quality are improved; and the situation that the upperportions of the wall tiles are pasted well is detected through the detection correcting part, and the pasting quality is improved.

Owner:日照新睿招商发展有限公司

Paper plate bonding equipment

PendingCN109927349AIncrease productivityImprove paste qualityBox making operationsPaper-makingEngineeringManipulator

The invention discloses paper plate bonding equipment for paper plate machining. A paper plate comprises a plate core and a plate surface; the paper plate bonding equipment comprises a frame, a storage mechanism, a grabbing mechanism, a plate core treatment mechanism and a gluing mechanism, wherein the frame is provided with a conveying belt; the storage mechanism is arranged on the frame near theconveying belt, and comprises a storage disc for placing the plate surface; the grabbing mechanism comprises a translation module arranged on the frame and positioned above the conveying belt, and asucker module connected to the translation module; the translation module drives the sucker module to transfer a disc surface of the storage disc to the conveying belt; the plate core treatment mechanism comprises a plate core storage module arranged near the conveying belt; the plate core storage module is used for placing the plate core; the gluing mechanism comprises a glue disc arranged near the frame and a manipulator; and the manipulator transfers the plate core from the plate core storage module to the glue disc for gluing, and transfers the glued plate core to the conveying belt to bond the plate core with the plate surface. The paper plate bonding equipment not only can improve the production efficiency to realize automatic production, but also can improve the bonding quality.

Owner:深圳市沃尔热缩有限公司 +1

Adhesive tape pasting device

InactiveCN108216770AImprove paste speedShorten the timeWrapper twisting/gatheringEngineeringMechanical engineering

The invention relates to an adhesive tape pasting device, and belongs to the technical field of pasting devices. According to the device, adhesive tape is fixed inside the device through an adhesive tape fixing shaft, and the adhesive tape passes through and penetrates out of a gap between guide blocks to be adsorbed on the lower surface of an adsorption block; and when the device is used, a worker grasps a grip by hands, the adsorption block of the device is aligned with a box needing to be sealed, the adhesive tape is attached to the sealing part by pulling the grip, the adhesive tape is compacted on the surface of the box through a compaction roller, a pull rod inside the grip is pulled after the adhesive tape is pasted, a blade extends downwards to cut off the adhesive tape under the action of connecting rods and a hinge mechanism, and the cut-off adhesive tape is adsorbed on an electrostatic adsorption layer on the surface of the adsorption block to be conveniently used next time.

Owner:刘滨

Pasting device for pasting fiber composite material on surface of concrete structure

ActiveCN111701793AImprove pasting efficiencySimple structureLiquid surface applicatorsBuilding repairsFiberAdhesive glue

The invention discloses a pasting device for pasting a fiber composite material on the surface of a concrete structure. The pasting device comprises a glue storage box, a fiber composite material storage box and a bracket which are all mounted on a base. A rotating frame is rotatably arranged on the bracket, and a gluing roller and a pasting roller are arranged at the two ends of the rotating frame respectively. A glue spraying head is also arranged on the bracket, communicates with the glue storage box through a pipeline, and is arranged towards the gluing roller. The rotating frame is rotated to make the gluing roller contact the surface of the concrete structure, the glue spraying head sprays glue to the gluing roller, and when the base moves, the gluing roller smears the glue to the surface of the concrete structure. After gluing is completed, the rotating frame is rotated to make the pasting roller contact the surface of the concrete structure, the fiber composite material is introduced from a fiber composite material storage device to the bottom of the pasting roller, and the pasting roller is moved to paste the fiber composite material to the surface of the concrete structure coated with the glue. The pasting device is simple in structure, and the pasting efficiency and the pasting quality can be effectively improved.

Owner:SHANGHAI INST OF TECH

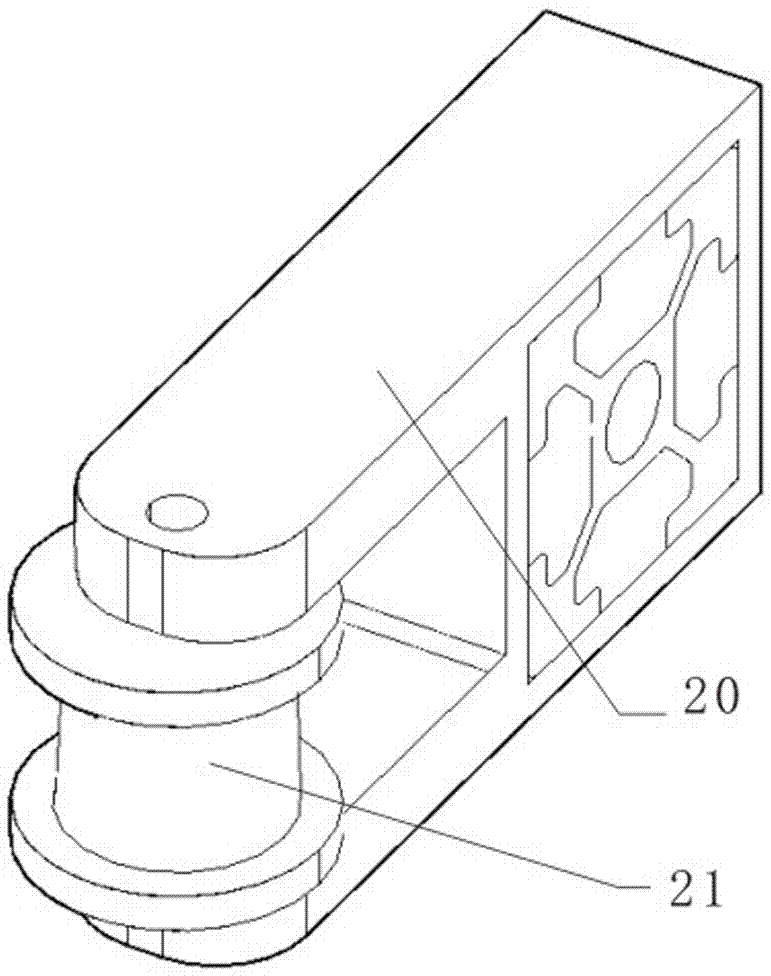

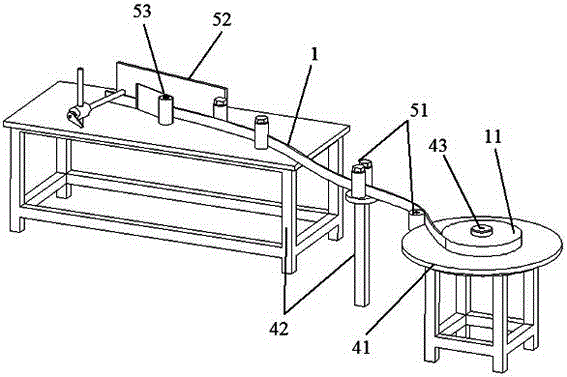

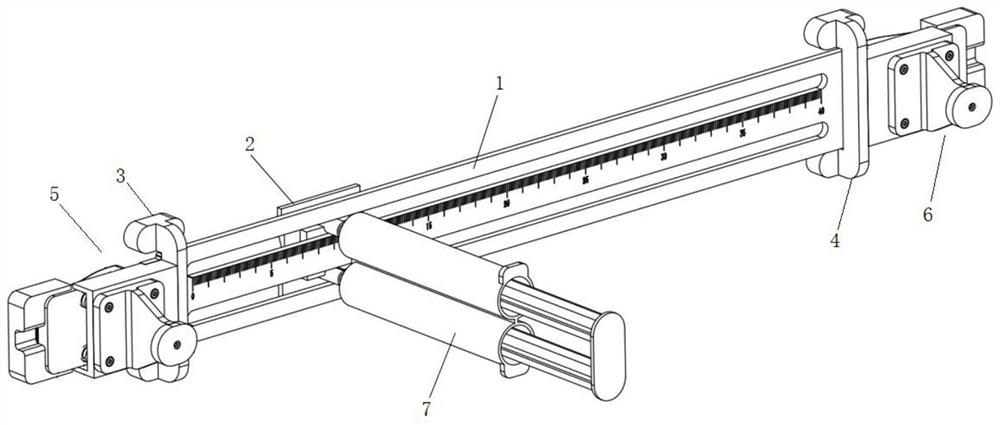

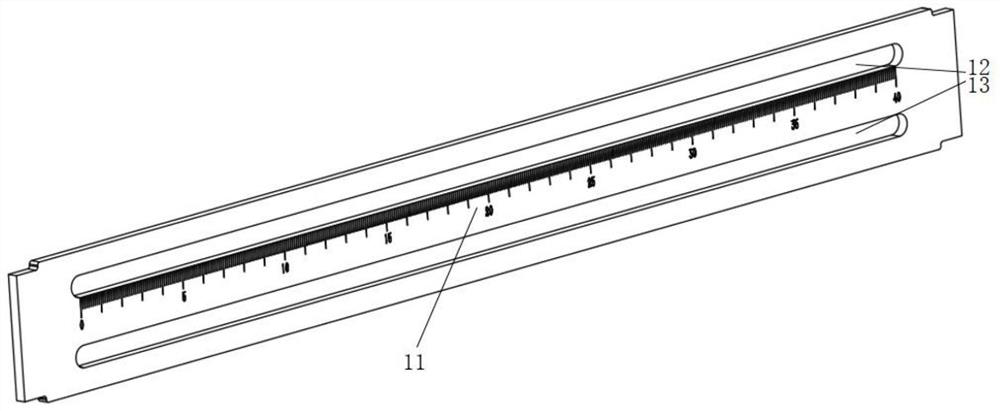

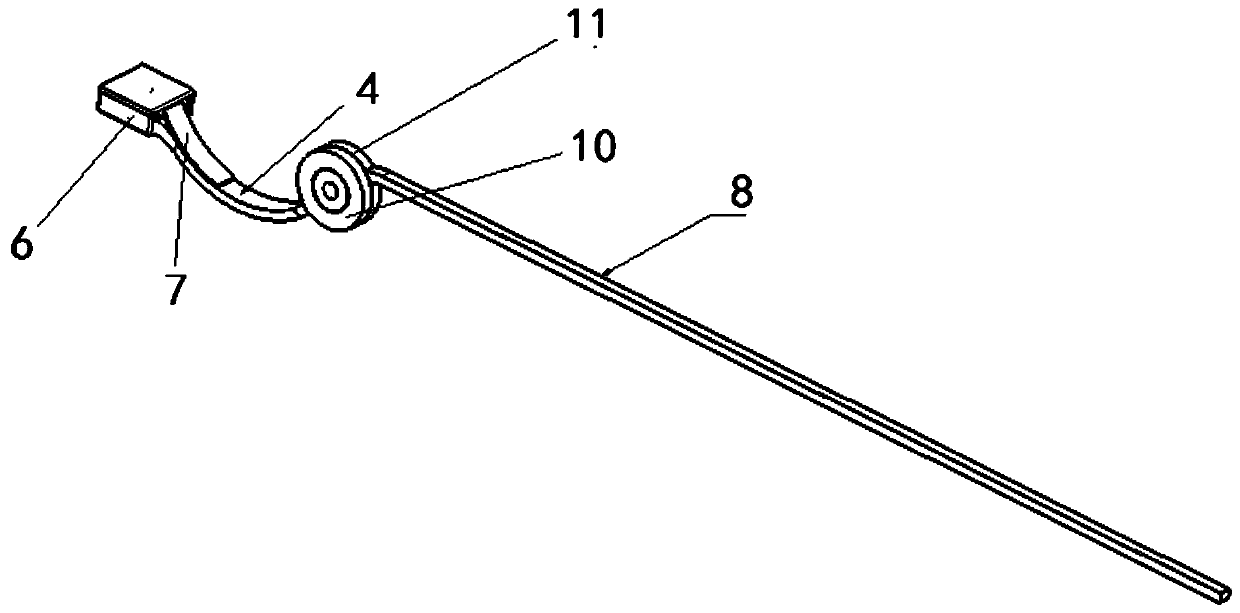

Rapid positioning and pasting device and method for fiber grating sensor

ActiveCN112439643AImplement fixed functionRapid positioningLiquid surface applicatorsMaterial gluingViscoseEngineering

The invention discloses a rapid positioning and pasting device and method for a fiber grating sensor, and relates to the technical field of fiber sensor installation. The device comprises a guide scale, a movable gluing head, a first fixing buckle, a second fixing buckle, a first supporting component and a second supporting component, wherein the guide scale comprises scale marks and is used for positioning the pasting position of the fiber grating sensor; the movable gluing head is movably connected with the guide scale and used for moving along the scale marks to enable the pasting positionof the fiber grating sensor to be coated with a gluing material; the first fixing buckle and the second fixing buckle are buckled on the surfaces of the two sides of the guide scale in a sleeving moderespectively and used for fixing the guide scale to the surface of a measured structure; and the first supporting component and the second supporting component are connected to the two ends of the guide scale respectively and used for fixedly supporting the two ends of the fiber grating sensor, so that the fiber grating sensor is straightened in the scale mark direction of the guide scale and tightly attached to the surface of the measured structure. The rapid positioning and pasting device and method have the advantages of being high in pasting speed, high in precision, good in quality, reliable in work and convenient to operate.

Owner:QINGDAO DMAR OCEAN ENG

Flexible paster of wave absorption material and preparation method and use method of flexible paster

InactiveCN108822752AEasy to manufactureEasy to operatePressure sensitive film/foil adhesivesFiberEpoxy

The invention discloses a flexible paster of a wave absorption material and a preparation method and a use method of the flexible paster. The flexible paster comprises a protection layer, a conductivebase material layer, an adhesive layer and a peel paper layer from top to bottom in sequence. The preparation method comprises the following steps: coating a single side of a nickel / silver plated conductive nylon fiber with an acrylic acid pressure sensitive adhesive or an organic silicon pressure sensitive adhesive, further pasting glass paper to the pressure sensitive adhesive, and coating theother side of the nylon fiber with any one of a polyurethane resin, an aqueous resin and an epoxy resin. By adopting the flexible paster, the defects of on-site cutting, tedious splicing, tedious construction, long production cycles and poor pasting appearance quality in the prior art can be overcome, rapid pasting can be carried out according to unknown shapes on a construction site, on-site cutting and splicing are reduced, the labor, materials and financial resources can be saved, and high pasting quality can be achieved; the preparation method is simple to operate, convenient in preparation, short in procedure and applicable to large-scale industrial production; and in addition, by adopting the use method, an optimal pasting quality state can be achieved for the flexible paster.

Owner:成都佳驰电子科技股份有限公司

Strain gauge pasting tool and pasting method

PendingCN110671404AWork conveniently and efficientlyImprove paste qualityMaterial gluingAirplaneStrain gauge

The invention discloses a strain gauge pasting tool and a pasting method, and belongs to the field of aircraft strength tests. The strain gauge pasting tool comprises a first handle and a second handle, wherein the near front ends of the first handle and the second handle are hinged; the front end of the first handle is a first clamping handle; the front end of the second handle is a second clamping handle; the first clamping handle is matched with the second clamping handle; a rubber pad is arranged on a pasting surface of the first clamping handle and the second clamping handle, and is usedfor clamping one end of a strain gauge; a pasting table corresponding to the strain gauge is arranged at the front end of the first clamping handle; and the size of the pasting table is matched with that of the strain gauge. According to the strain gauge pasting tool and the pasting method, the strain gauge achieves an ideal pasting effect, the pasting quality of the strain gauge is higher, and the pasting of the strain gauges at different angle inclined plane positions of a test piece can be realized by adjusting the angles of a handle rod and the clamping handles.

Owner:中航西飞民用飞机有限责任公司

Shaft part strain gage sticking device

ActiveCN107676354AImprove paste qualityImprove pasting efficiencyMaterial gluingForce measurementEngineeringStrain gauge

Owner:GUANGZHOU UNIVERSITY

Silver jewelry and processing method thereof

InactiveCN107502909AEfficient removalImprove production efficiencyJewelleryCelluloseDioxyethylene Ether

The invention provides a silver jewelry and a processing method thereof, and relates to the field of jewelry processing. The processing method of the silver jewelry comprises the following steps: silver is cast after melting, and is finished after preprocessing to obtain an initial sample; the qualified initial sample is polished to clean to obtain the silver jewelry; a cleaning agent is adopted to clean; the cleaning agent comprises 20-30 weight parts of hydroxyethyl cellulose with a concentration of 5%, 3-8 weight parts of borax, 50-60 weight parts of de-ionized water, 3-10 weight parts of silicon dioxide, 3-7 weight parts of polyoxyethylene lauryl ether, 2-3 weight parts of octadecyl sulfylpropionate, 1-2 weight parts of lauryl sodium sulfate, and 1-2 weight parts of white spirit; and the silver jewelry is excellent in gloss, is beautiful and elegant, and satisfies the demands of customers. The processing method of the silver jewelry is simple in processing process and convenient to operate.

Owner:贵州印象苗族银饰刺绣有限公司

Assembly process for magnetic cores and substrates of surface mounting type power inductors

ActiveCN102930970AJust pastedImprove paste qualityTransformers/inductances magnetic coresInductances/transformers/magnets manufactureInductorMagnetic core

The invention discloses an assembly process for magnetic cores and substrates of surface mounting type power inductors. The assembly process comprises the steps of filling the bottom of a container with auxiliary rods; pouring magnetic cores into the container; shaking the container to enable the magnetic cores to be arranged in grooves of the auxiliary rods; withdrawing the remaining magnetic cores; filling the magnetic cores in the empty cavities; rearranging the magnetic cores that are not arranged well; opening glue grooves of spreaders, and placing in and fixing the auxiliary rods; withdrawing and rearranging the whole auxiliary rods if the magnetic cores are inclined; shifting the glue to front ends of spreading blocks, and fixing the spreading blocks; spreading glue; arranging the auxiliary rods horizontally; pasting substrates; placing the auxiliary rods into grooves of pressing rod clamps; aligning and overlapping upper pressing rods with the auxiliary rods; placing the rods back into the grooves of the pressing rod clamps after the rods change positions up and down; taking up the auxiliary rods; performing visual inspection on the magnetic cores; and placing the upper pressing rods qualified through the visual inspection into a tunnel kiln for drying. Compared with the prior art, the assembly process for magnetic cores and substrates of surface mounting type power inductors solves problems of poor pasting quality and low production efficiency of prior manual magnetic core pasting on substrates.

Owner:广东昭信智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com