Ultrasonic washing device of high-performance storage battery plate grid

A battery board and cleaning device technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low cleaning efficiency and incomplete removal, so as to prolong the service life and improve paste application Quality, the effect of reducing release oil and impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

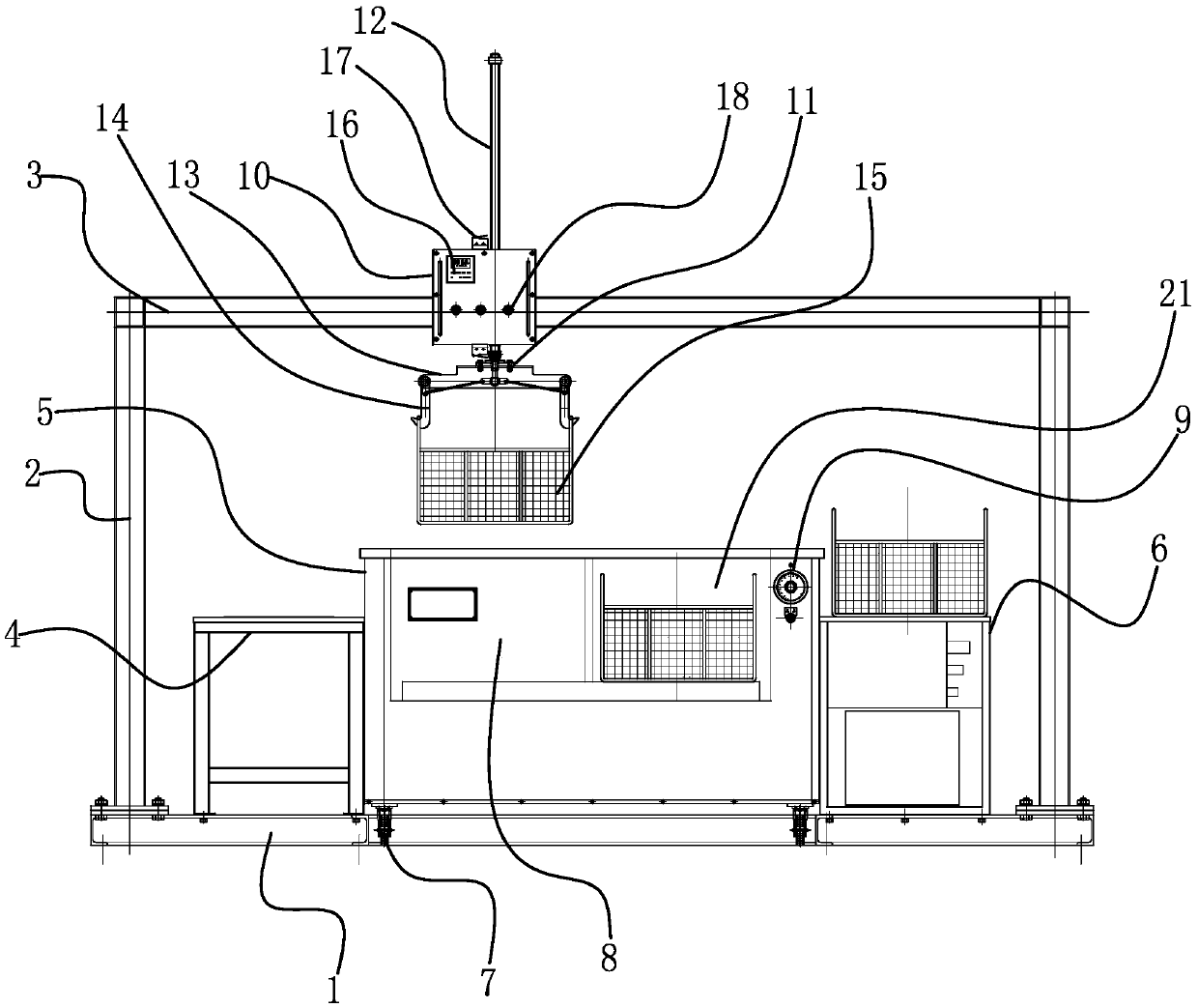

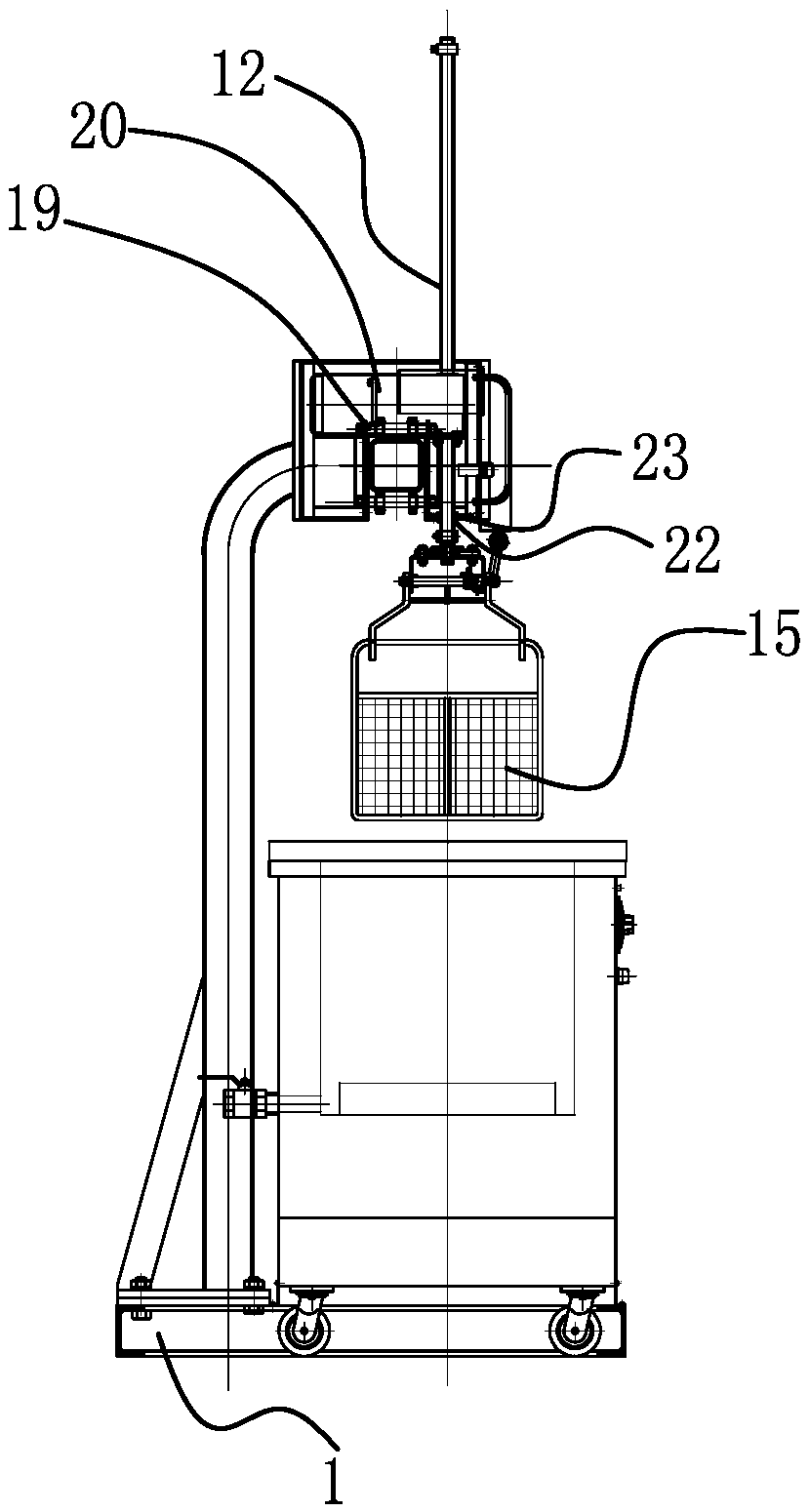

[0016] Example: such as Figure 1-2 As shown, the ultrasonic cleaning device for high-performance battery grids includes a machine base 1, a support rod 2 arranged at the left and right ends of the machine base 1, and a bracket 3 arranged at the upper end of the support rod 2; the machine base 1 is arranged from left to right There are a workbench 4, an ultrasonic cleaning chamber 5 and an electric control studio 6; the bottom of the ultrasonic cleaning chamber 5 is provided with universal wheels 7, and the ultrasonic cleaning chamber 5 is slidably connected to the base 1 through the universal wheels 7. The cleaning chamber 5 includes a cleaning tank 8 and a drying tank 21 arranged in the ultrasonic cleaning chamber 5, and an ultrasonic controller 9 arranged outside the ultrasonic cleaning chamber 5; Ultrasonic sliding device, ultrasonic sliding device comprises mobile trolley 10 and is located at the hoisting hook device 11 of mobile trolley 10 bottoms; Sliding up and down, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com