Flexible paster of wave absorption material and preparation method and use method of flexible paster

A technology of absorbing materials and patches, applied in the field of flexible patches, can solve problems such as damage to the absorbing coating, and achieve the effects of short process, convenient preparation and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

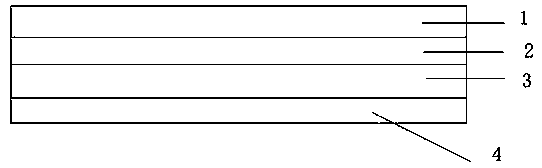

[0021] Embodiment 1: A kind of flexible patch of absorbing material, such as figure 1 As shown, it includes a protective layer 1, a conductive substrate layer 2, an adhesive layer 3 and a release paper layer 4 from top to bottom. The protective layer 1 is polyurethane resin 101, and the thickness of the protective layer 1 is 0.02mm. The conductive substrate layer is nickel-plated conductive nylon fiber, the thickness of the conductive substrate layer 2 is 0.05 mm, and the adhesive layer 3 is an acrylic pressure-sensitive adhesive, and the thickness of the adhesive layer 3 is 0.03 mm.

[0022] The preparation method of the flexible patch of the above-mentioned wave-absorbing material is to select nickel-plated conductive nylon fibers, apply acrylic pressure-sensitive adhesive to one side, then attach cellophane to the pressure-sensitive adhesive, and coat the other side of the nylon fiber with polyurethane resin.

Embodiment 2

[0023] Embodiment 2: A kind of flexible patch of absorbing material, such as figure 1 As shown, it includes a protective layer 1, a conductive substrate layer 2, an adhesive layer 3 and a release paper layer 4 from top to bottom. The protective layer 1 is a water-based resin 90, and the thickness of the protective layer 1 is 0.05mm. The conductive substrate layer is silver-plated conductive nylon fiber, the thickness of the conductive substrate layer 2 is 0.15 mm, and the adhesive layer 3 is a silicone pressure-sensitive adhesive, and the thickness of the adhesive layer 3 is 0.08 mm.

[0024] The preparation method of the flexible patch of the above-mentioned wave-absorbing material is to select silver-plated conductive nylon fibers, apply silicone pressure-sensitive adhesive to one side, then attach cellophane to the pressure-sensitive adhesive, and coat the other side of the nylon fibers with water-based resin.

Embodiment 3

[0025] Embodiment 3: a kind of flexible patch of absorbing material, such as figure 1 As shown, it includes a protective layer 1, a conductive substrate layer 2, an adhesive layer 3 and a release paper layer 4 from top to bottom. The protective layer 1 is epoxy resin, and the thickness of the protective layer 1 is 0.04mm. The conductive substrate layer is nickel-plated conductive nylon fiber, the thickness of the conductive substrate layer 2 is 0.10 mm, and the adhesive layer 3 is an acrylic pressure-sensitive adhesive, and the thickness of the adhesive layer 3 is 0.05 mm.

[0026] The preparation method of the flexible patch of the above-mentioned wave-absorbing material is to select nickel-plated conductive nylon fibers, apply acrylic pressure-sensitive adhesive to one side, then attach cellophane to the pressure-sensitive adhesive, and coat the other side of the nylon fiber with epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com