Patents

Literature

234 results about "Cellophane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellophane is a thin, transparent sheet made of regenerated cellulose. Its low permeability to air, oils, greases, bacteria, and water makes it useful for food packaging. Cellophane is highly permeable to water vapour, but may be coated with nitrocellulose lacquer to prevent this.

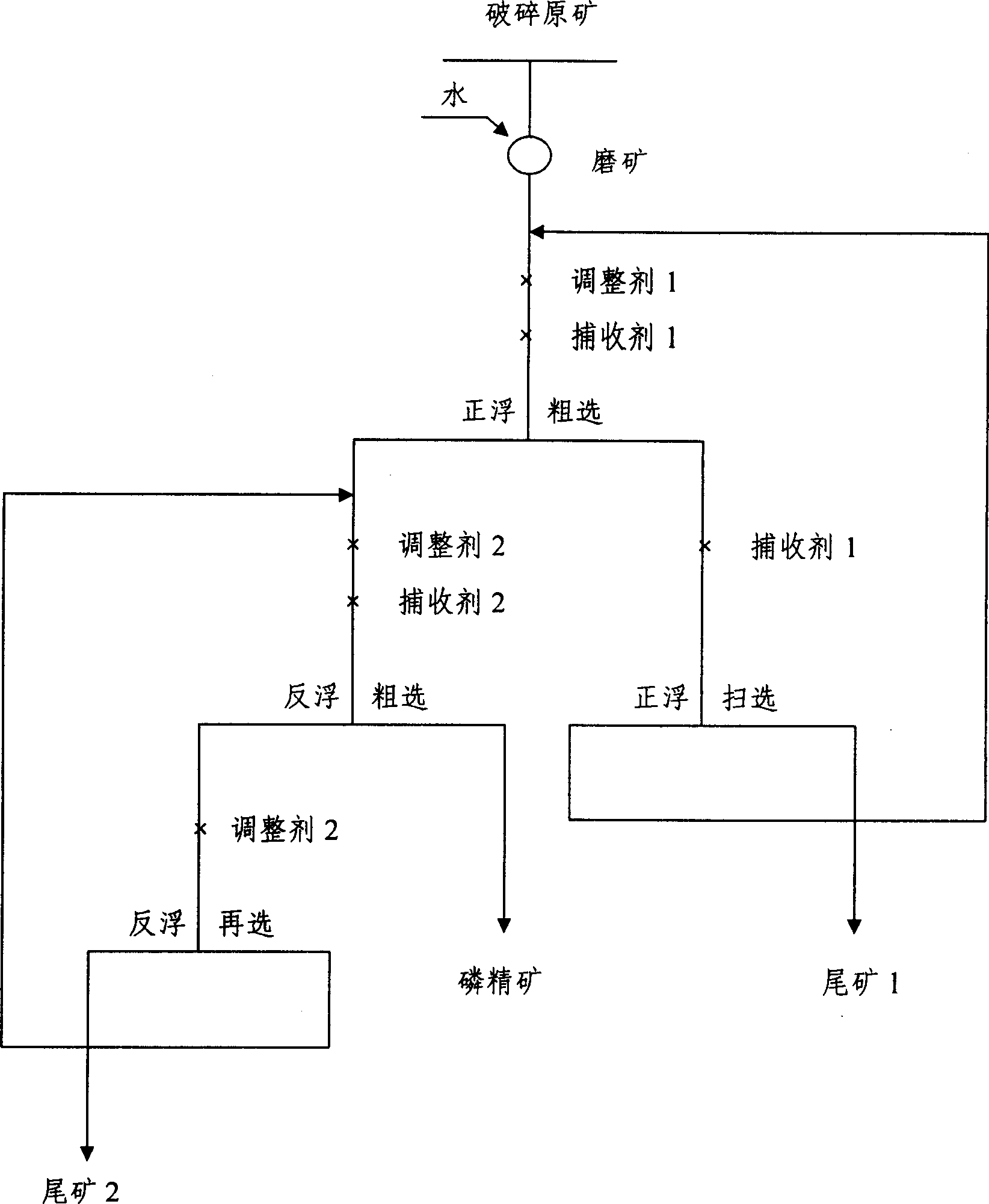

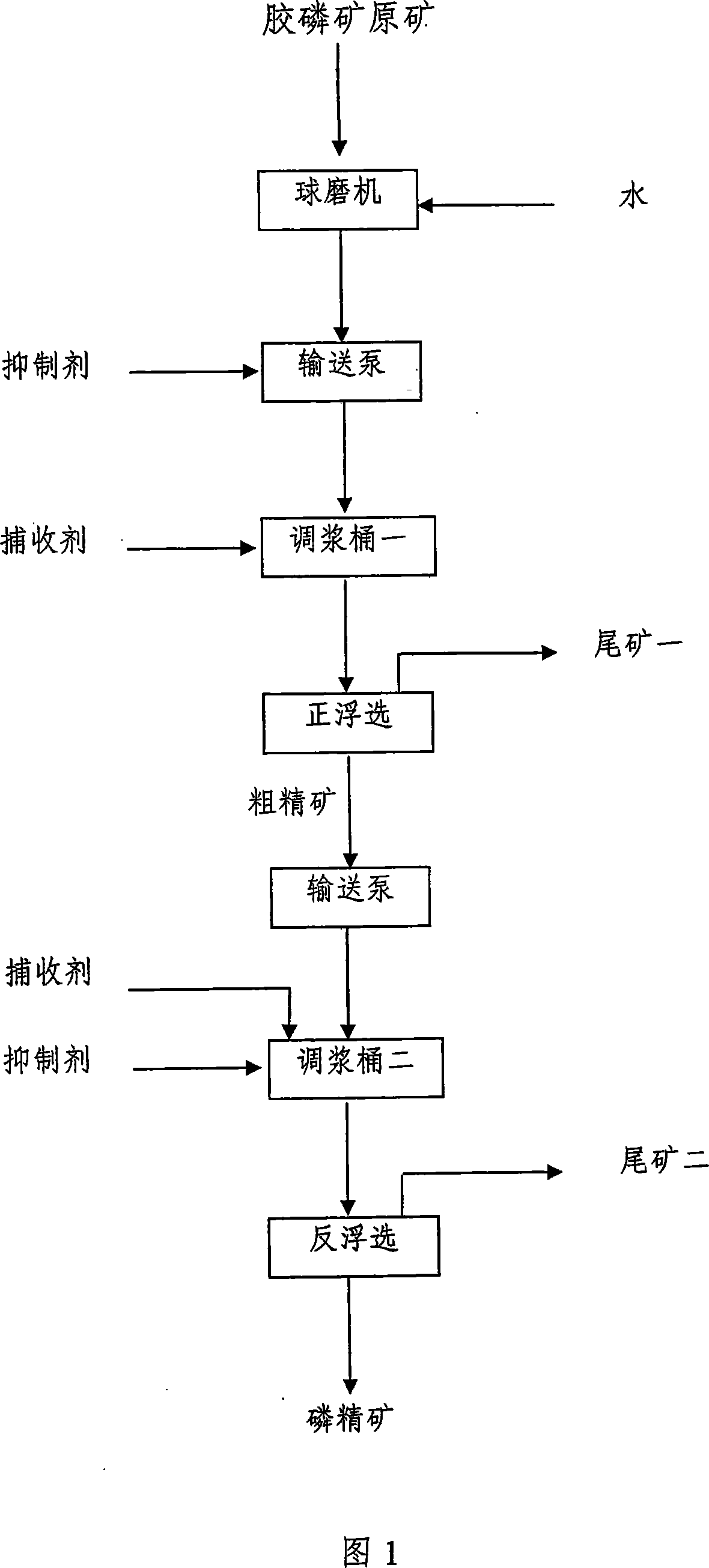

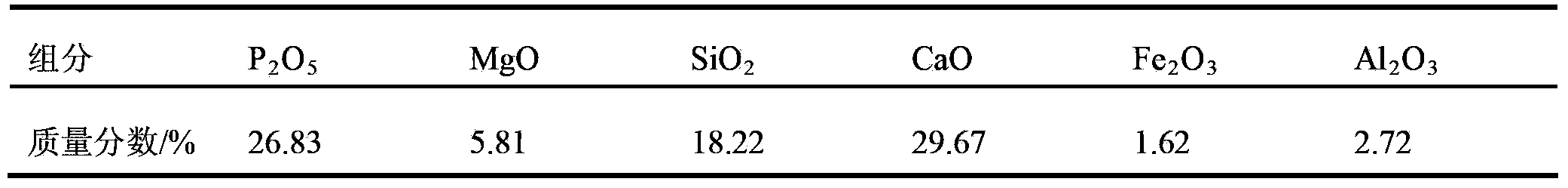

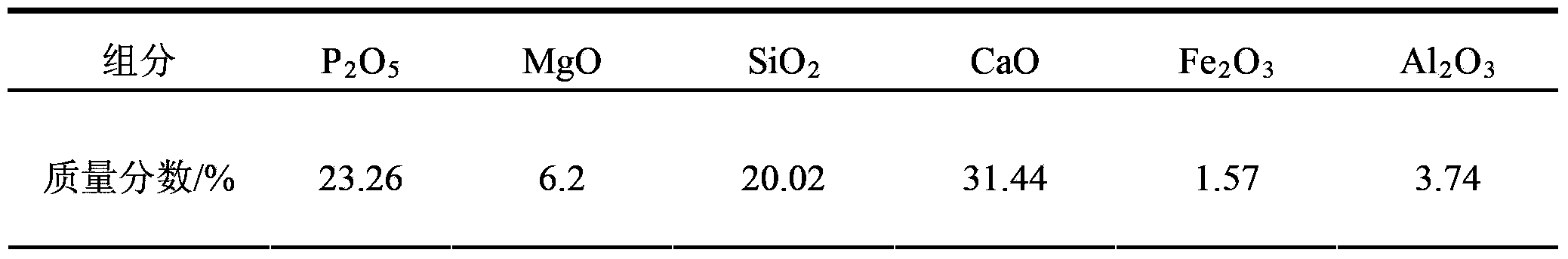

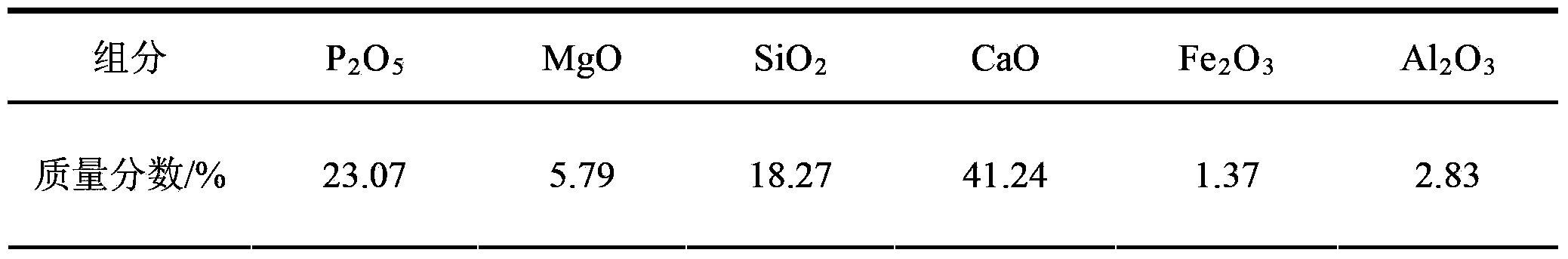

Collophanite direct flotation and reverse flotation technique

The invention relates to a positive-negative floatation technology for cellophane, which comprises the following steps: subjecting siliceous-calcareous collophane ore to breaking and grinding process to dissociate ore monomer; adding water to it get ore pulp with concentration of 20 -50%; Leading the mixture to agitated tank; adding modifying agent sodium silicate and positive collector agent to ore pulp; processing the mixture in positive floating system to get foamed product; adding negative floatation agent inorganic acid and collector agent to the foamed product in negative flotation agitated tank; processing the mixture in negative floating system with carbonate vein mineral negative flotation to get foamed product as negative flotation debris and product in tank as clean ore. The invention can simplify process, deduce cost and recycle the water.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

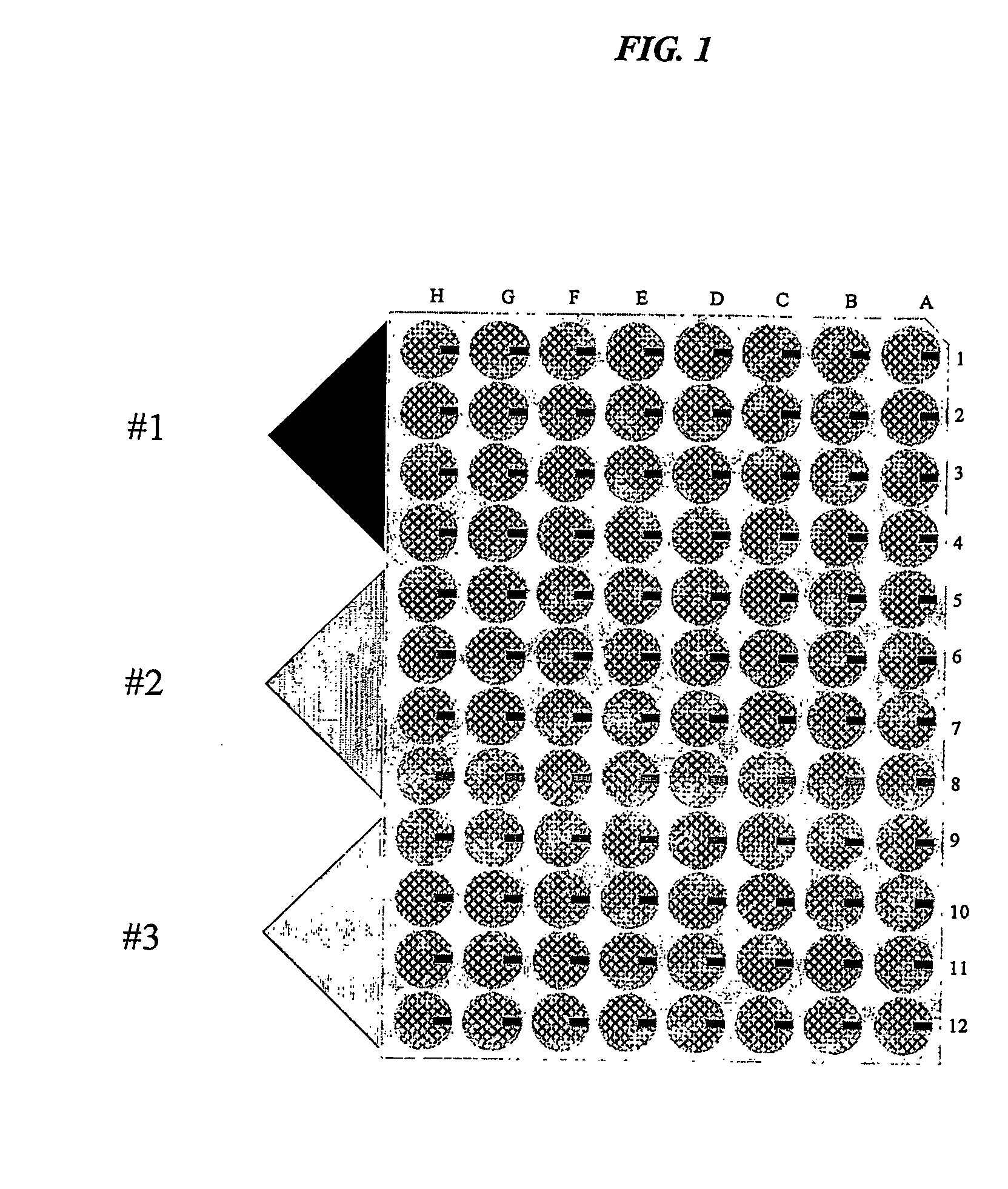

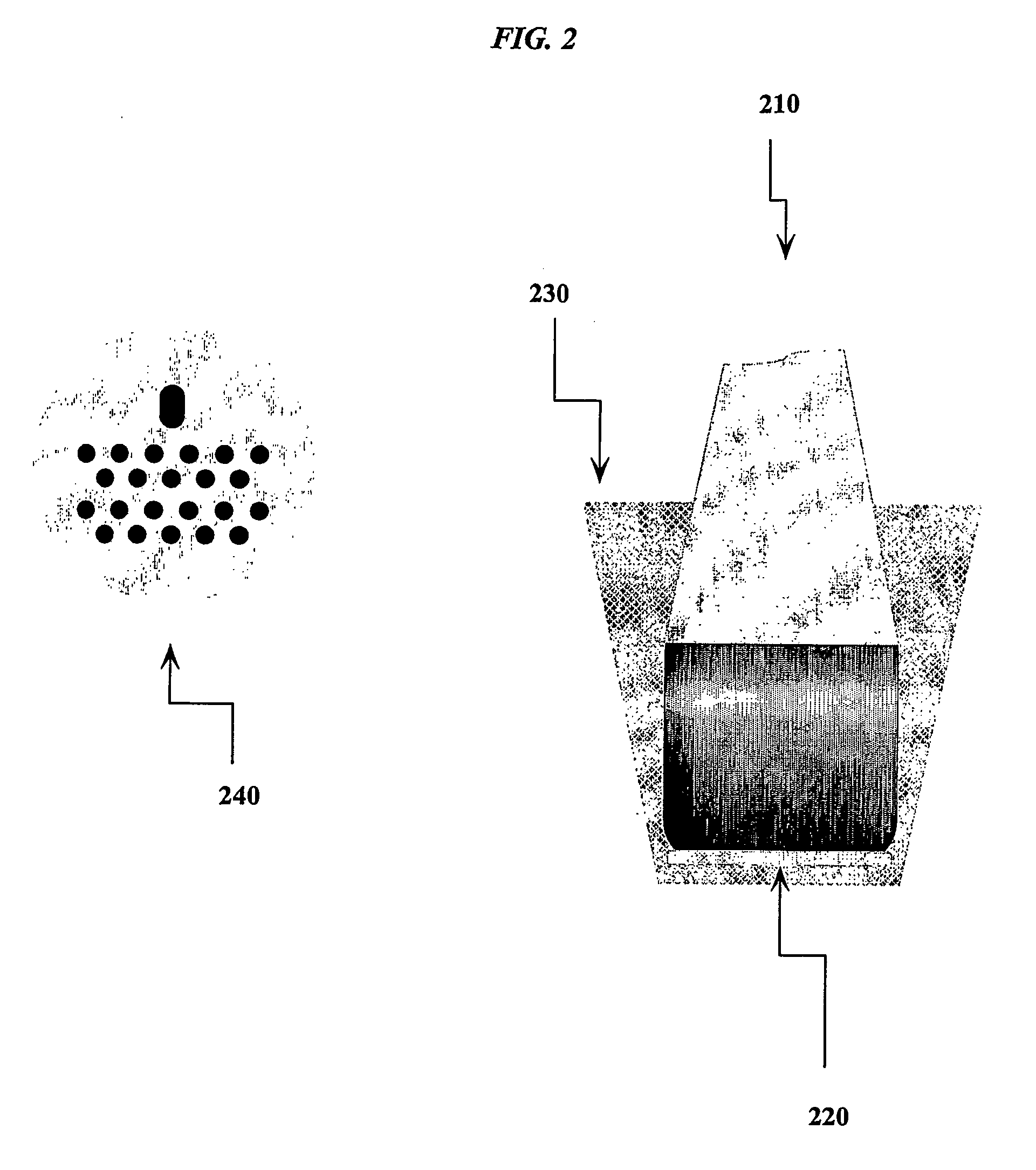

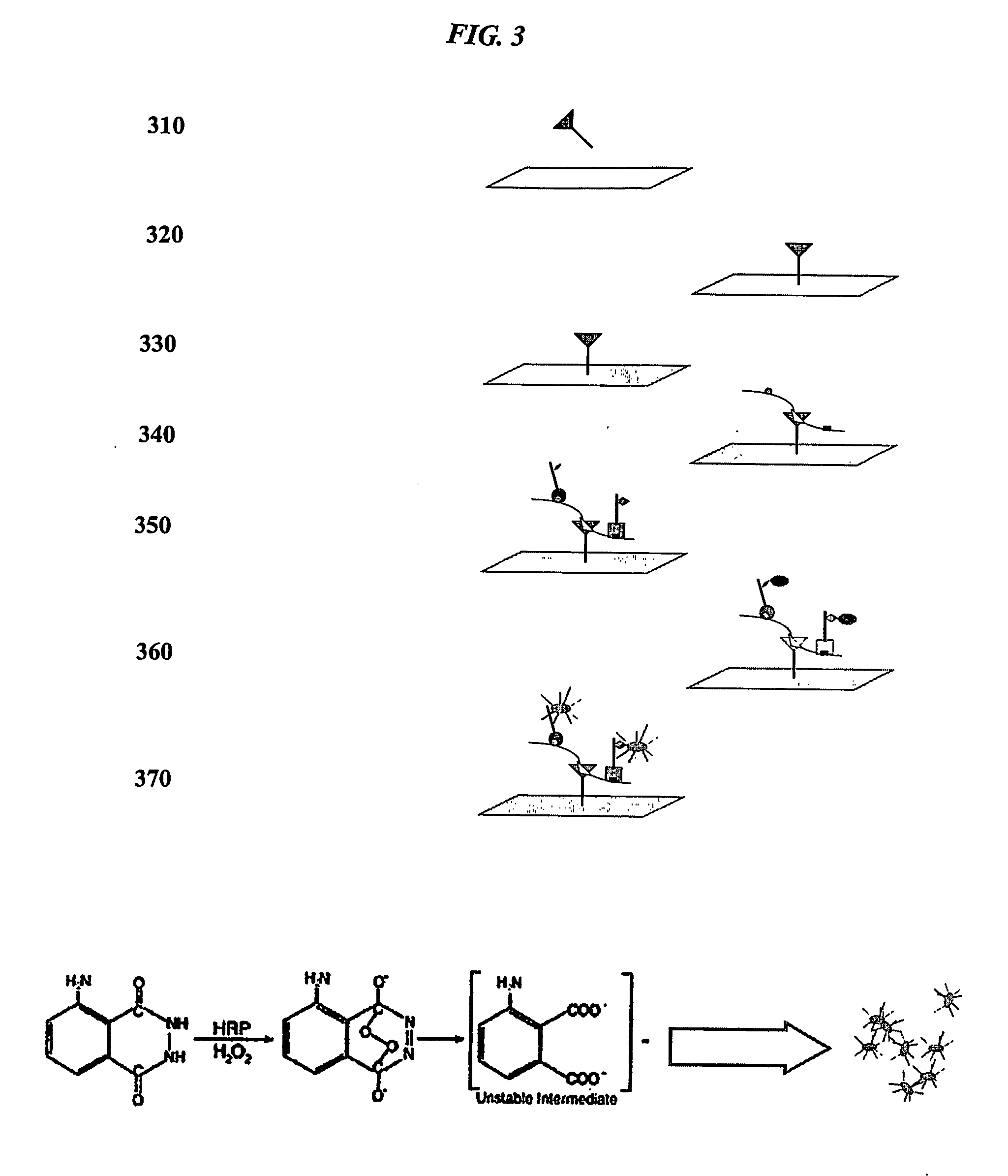

Translucent solid matrix assay device dor microarray analysis

InactiveUS20060211044A1Low production costImprove the level ofBioreactor/fermenter combinationsImage enhancementNitrocelluloseCellophane

The present invention concerns methods and compositions relating to translucent matrix arrays. In certain embodiments, the arrays are reconfigurable. Reconfigurable arrays may be produced using small linker molecules, such as aptamers or affibodies, which preferably bind to an IgG specific portion of antibodies. Such arrays may be used to detect any target that binds selectively or specifically to an IgG. Translucent matrix arrays may utilize cellophane, rayon or a translucent, colloidal form of nitrocellulose to coat the substrate. Other embodiments concern methods of data analysis and apparatus for analyte detection. Certain embodiments concern a total optical assay device (TOAD™), which may be used with GRABBER™ slides and / or FOOTPAD™ microtiter well assay devices.

Owner:PRITEST

Collophanite floatation method

The present invention discloses one kind of cellophane floating process, which has floatation columns applied for eliminate impurity and includes direct floatation to eliminate silicon and reverse floatation to eliminate magnesium. The cellophane floating process includes crushing crude cellophane, milling and grading to form 20-40 wt% concentration pulp; mixing the pulp with direct floatation reagent, and floatation in direct floatation columns to obtain foamed rough concentrate in the top and direct floated tailings in the bottom; mixing the foamed rough concentrate with reverse floatation reagent in one other mineralizing tank, and floatation in reverse floatation columns to obtain cellophane concentrate in the bottom and foamed reverse floated tailings. The process is simple and stable, and has easy control, high depurating effect, high concentrate quality, less phosphate loss and other advantages.

Owner:YUNNAN CHEM RES INST +1

Label having improved aesthetic appearance

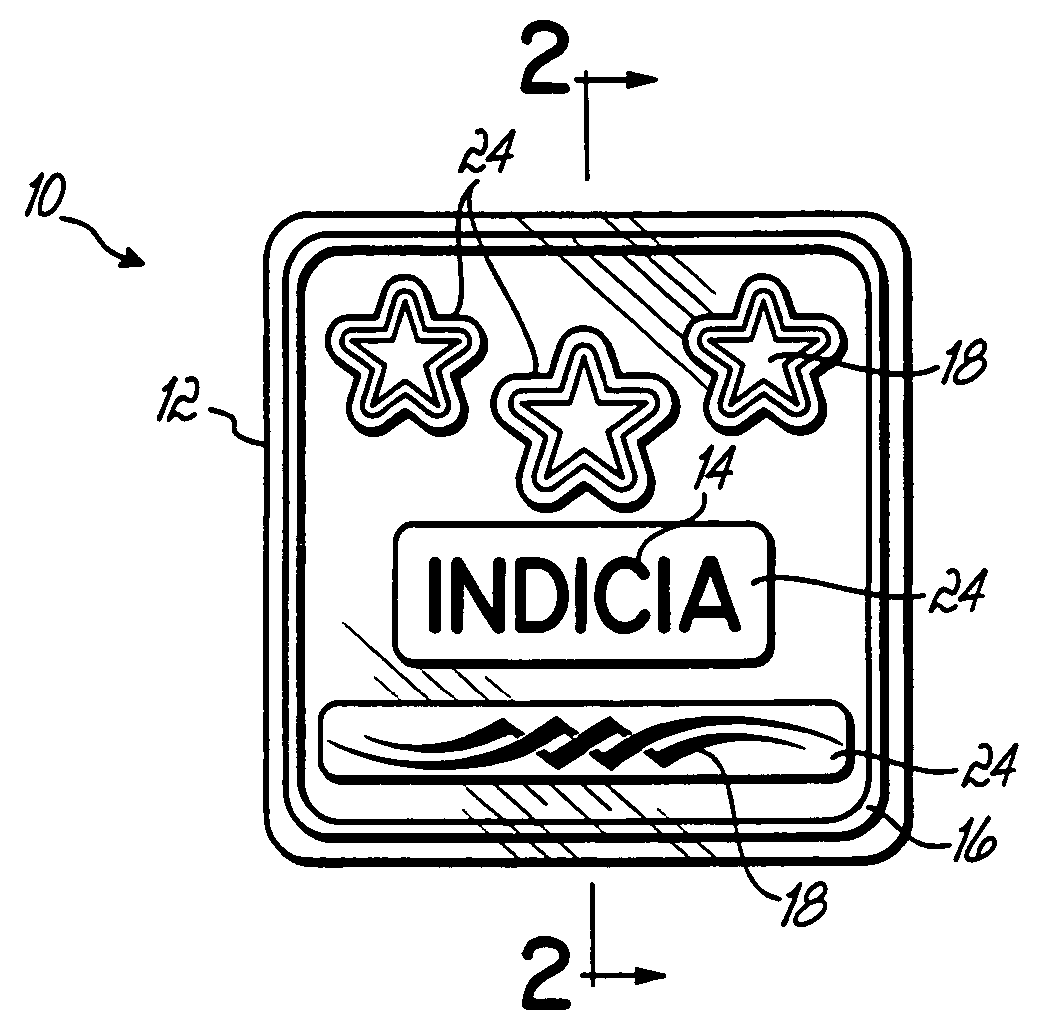

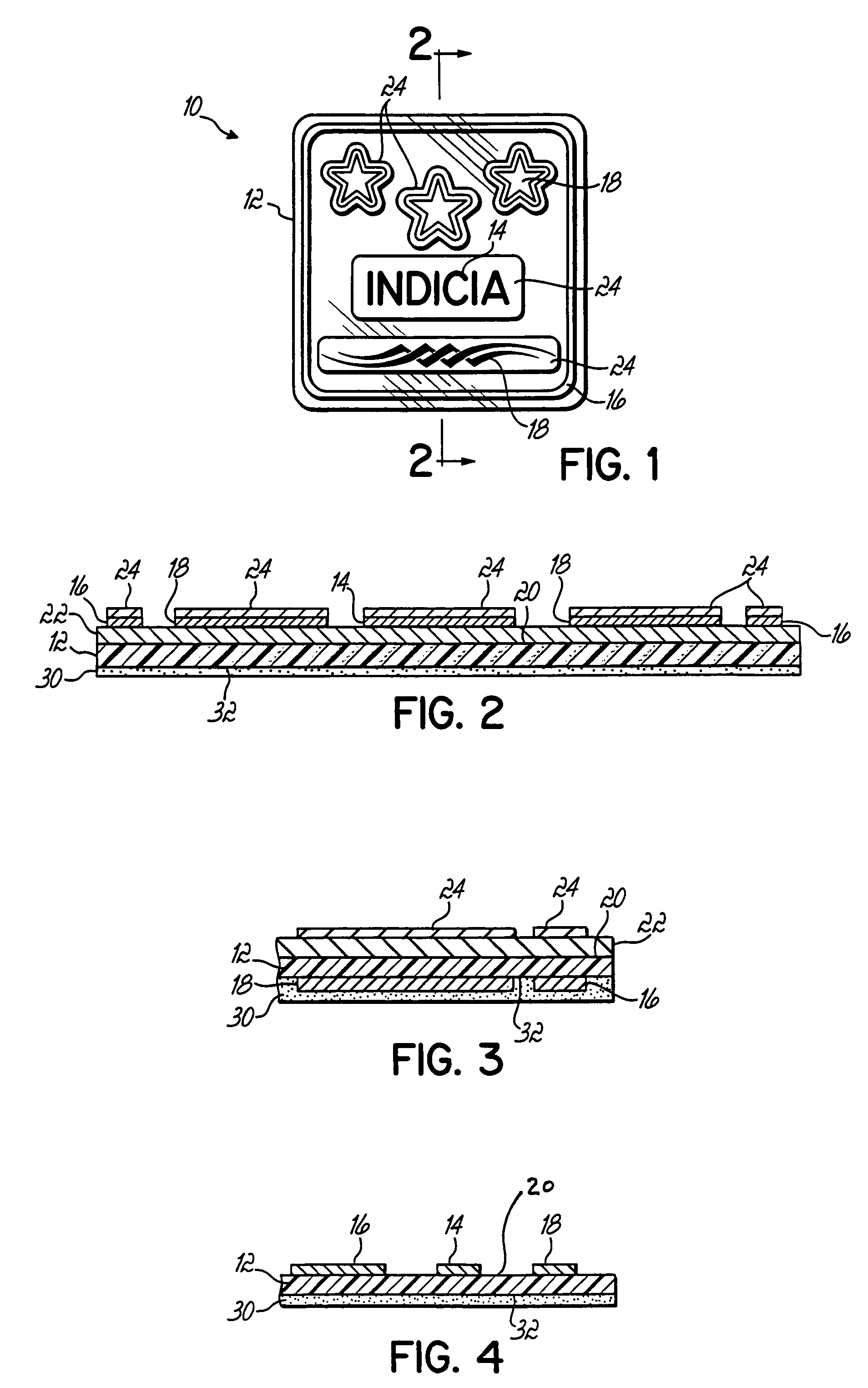

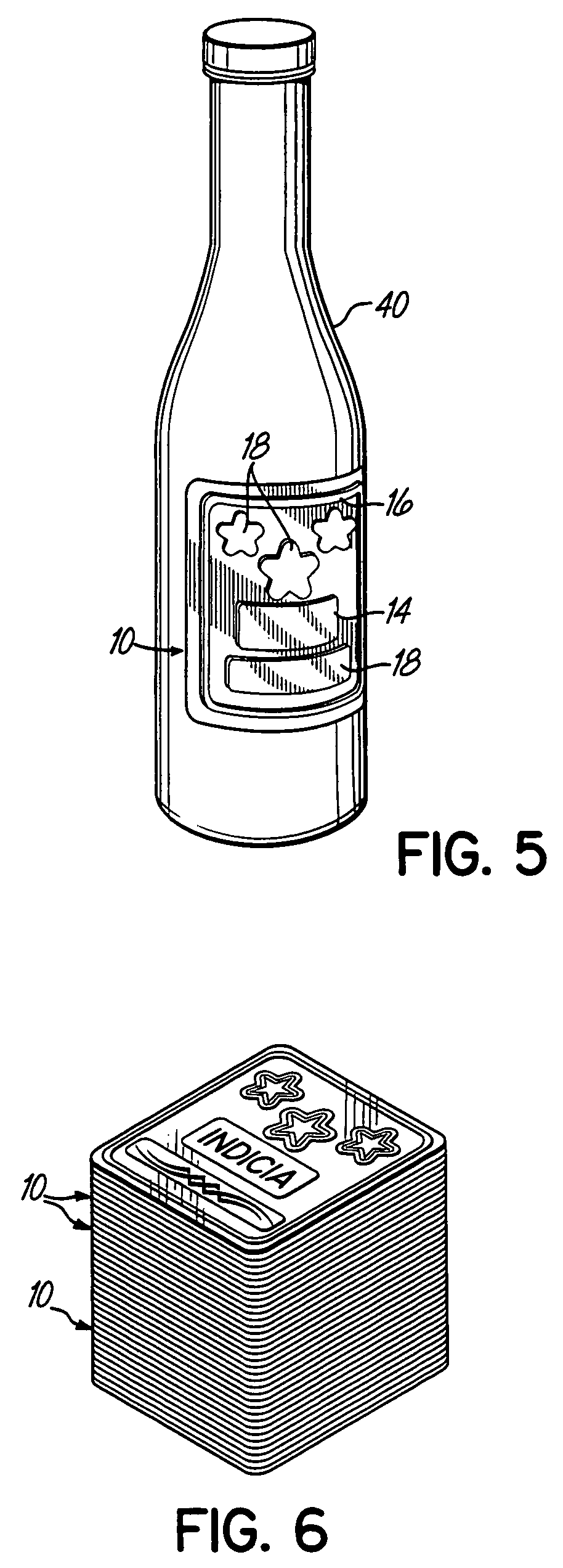

A label includes indicia disposed on a facestock comprising cellophane. In one embodiment, the indicia are screen printed onto the facestock. In another embodiment, the label may further include layers of tactile coating selectively applied to discrete areas of the facestock to create distinct raised portions on the label. The tactile coating may be applied to correspond to the location of the indicia, wherein the raised portions overlie the indicia. A separate layer of primer may be applied to the facestock to cover substantially an entire side of the facestock. A plurality of such labels may be provided in a stack to an automatic labeling machine for application to a series of containers. The label may be applied to a container and the raised portions of the label provide tactile feel which enhances the aesthetic qualities of the label and container.

Owner:SPEAR USA LLC

Process for preparing regenerated cellulose films and wires

The invention discloses a method for manufacturing cellulose film and silk. The cellulose is dissolved in mixed liquid 5-12wt% natrium oxyhydrogen and 8-20wt% ureophil, gets the cellulose liquid, then carries on film scratching and silk spraying to the cellulose, they are solidified in the solidifying bath, then the regenerated cellulose film and silk will be got after being cleaned. The cellulose thick liquid has excellent fiber textile performance and compactibiity of film, the regenerated cellulose has excellent light transmission and mechanical performance, the silk also has good mechanical performance. The method can obtain cellulose thick liquid by dissolving cellulose in room temperature. It has no contamination and its price is low, it is a kind of green manufacturing process.

Owner:WUHAN UNIV

Decorative material

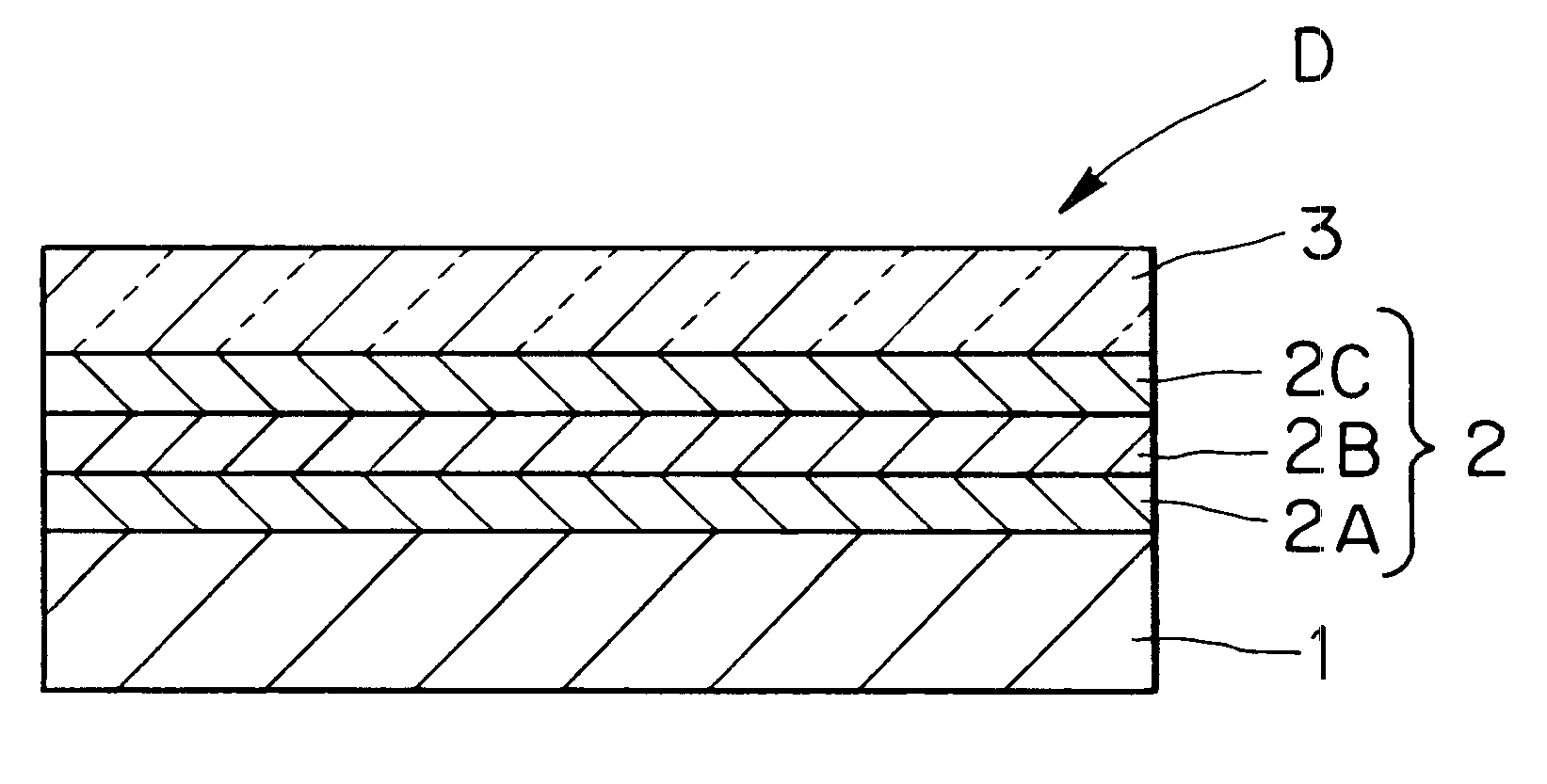

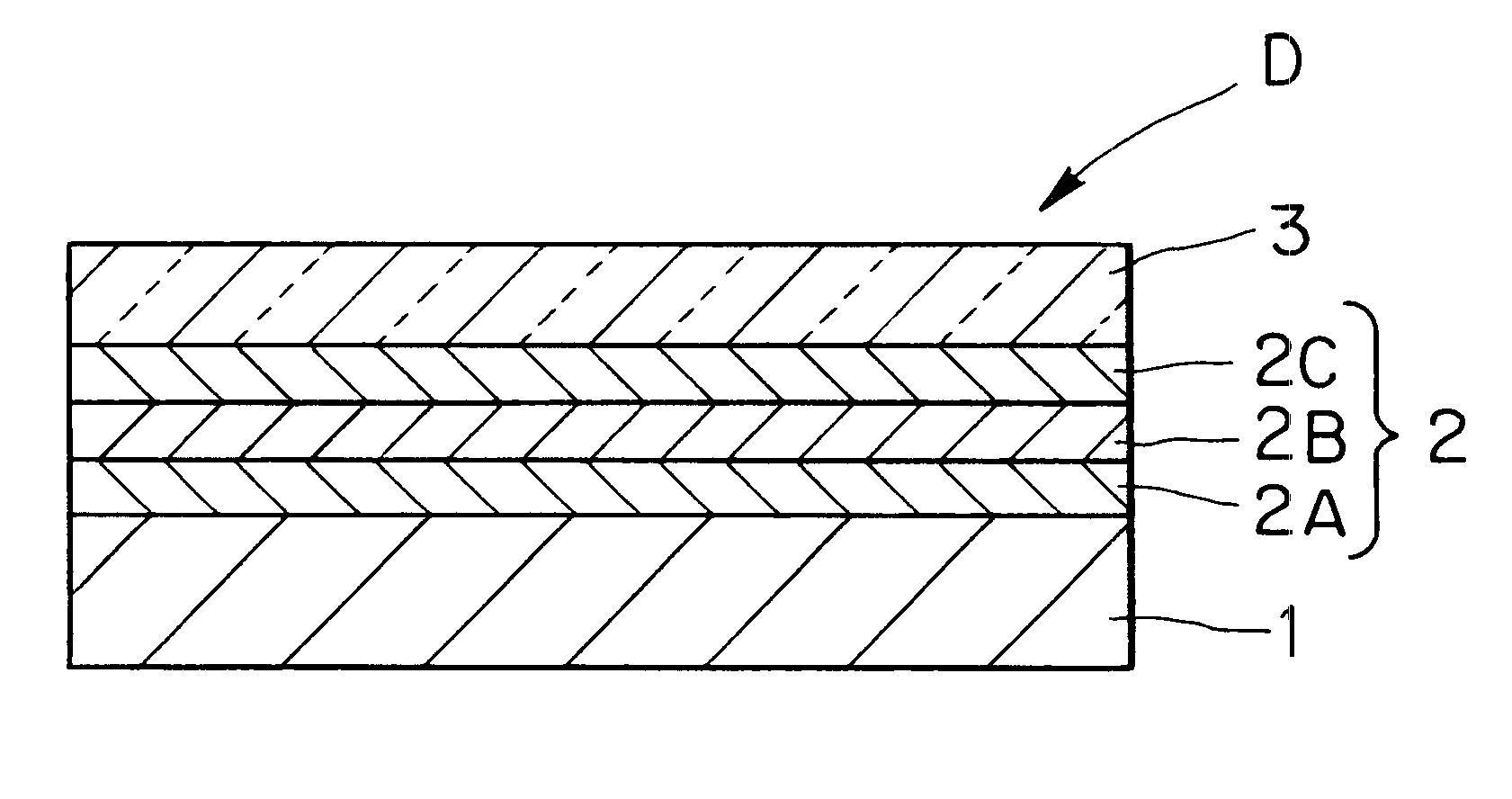

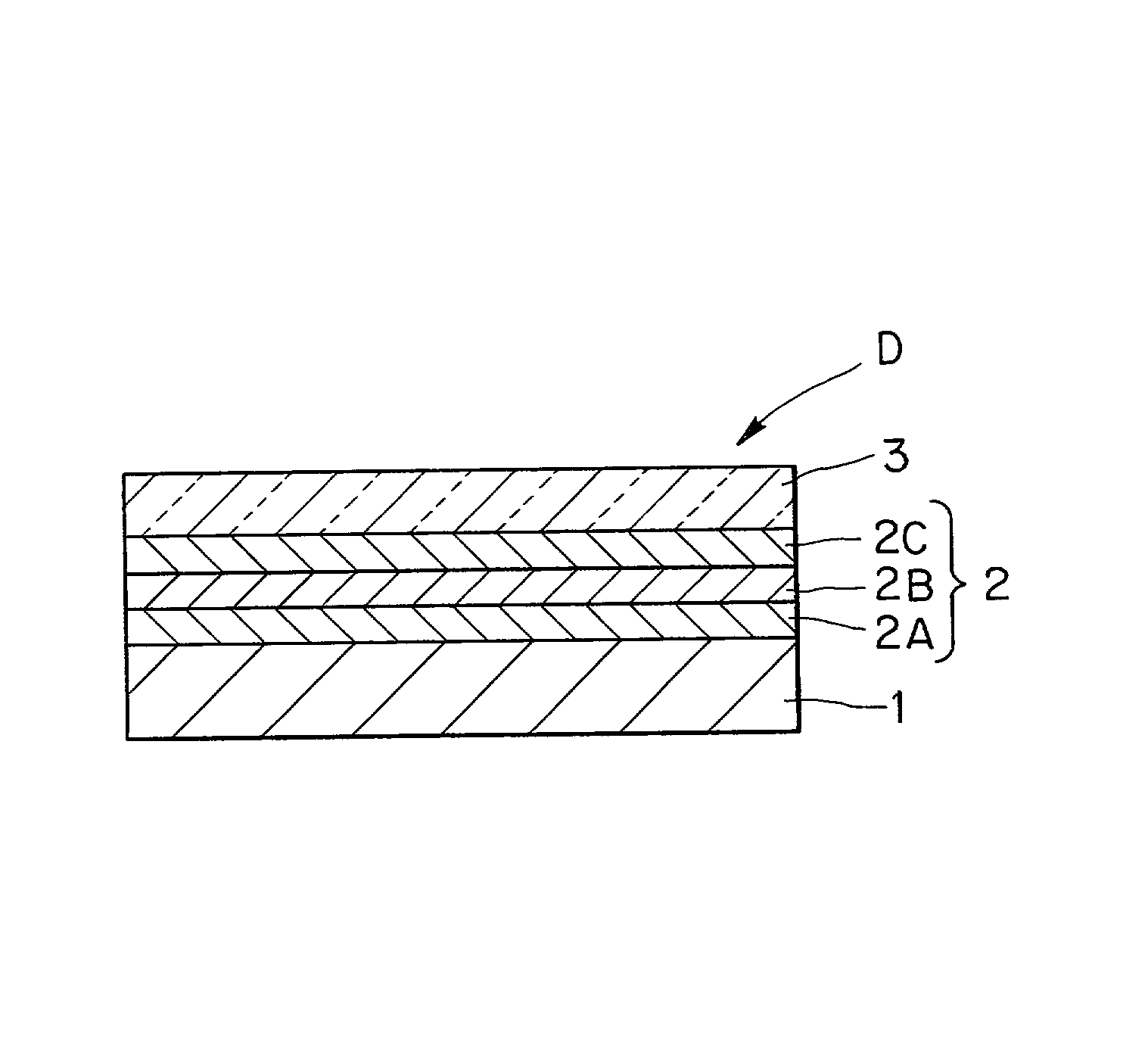

InactiveUS6558799B2Low costImprove surface propertiesOther plywood/veneer working apparatusDecorative surface effectsHydrogenCellophane

Owner:DAI NIPPON PRINTING CO LTD

Decorative material

InactiveUS20010049022A1Low costImprove surface propertiesOther plywood/veneer working apparatusDecorative surface effectsHydrogenVolumetric Mass Density

A decorative material is provided which possesses excellent surface properties, such as excellent staining resistance, marring resistance, scratch resistance, abrasion resistance, and anti-transferability to a cellophane pressure-sensitive adhesive tape, and can be produced at low cost. This decorative material comprises: a substrate having at least on its surface an active hydrogen-containing polar functional group; and, provided on the substrate, a two-component cured urethane resin layer and a surface resin layer of a crosslinked coating formed from a ionizing radiation curable acrylate resin, the two-component cured urethane resin layer having a structure of at least three layers, the crosslinking density of the intermediate layer being lower than that of each layer provided on both sides of the intermediate layer.

Owner:DAI NIPPON PRINTING CO LTD

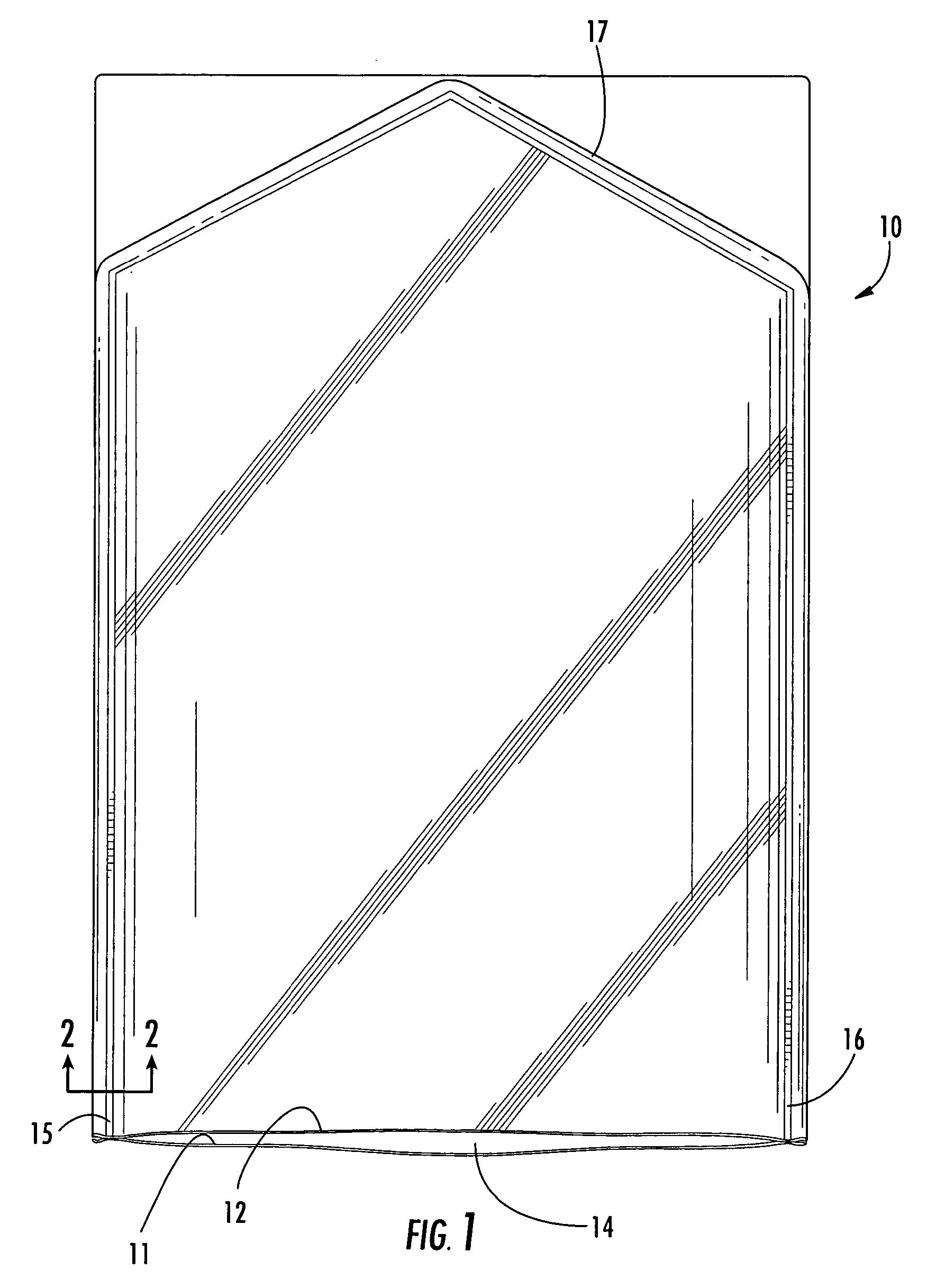

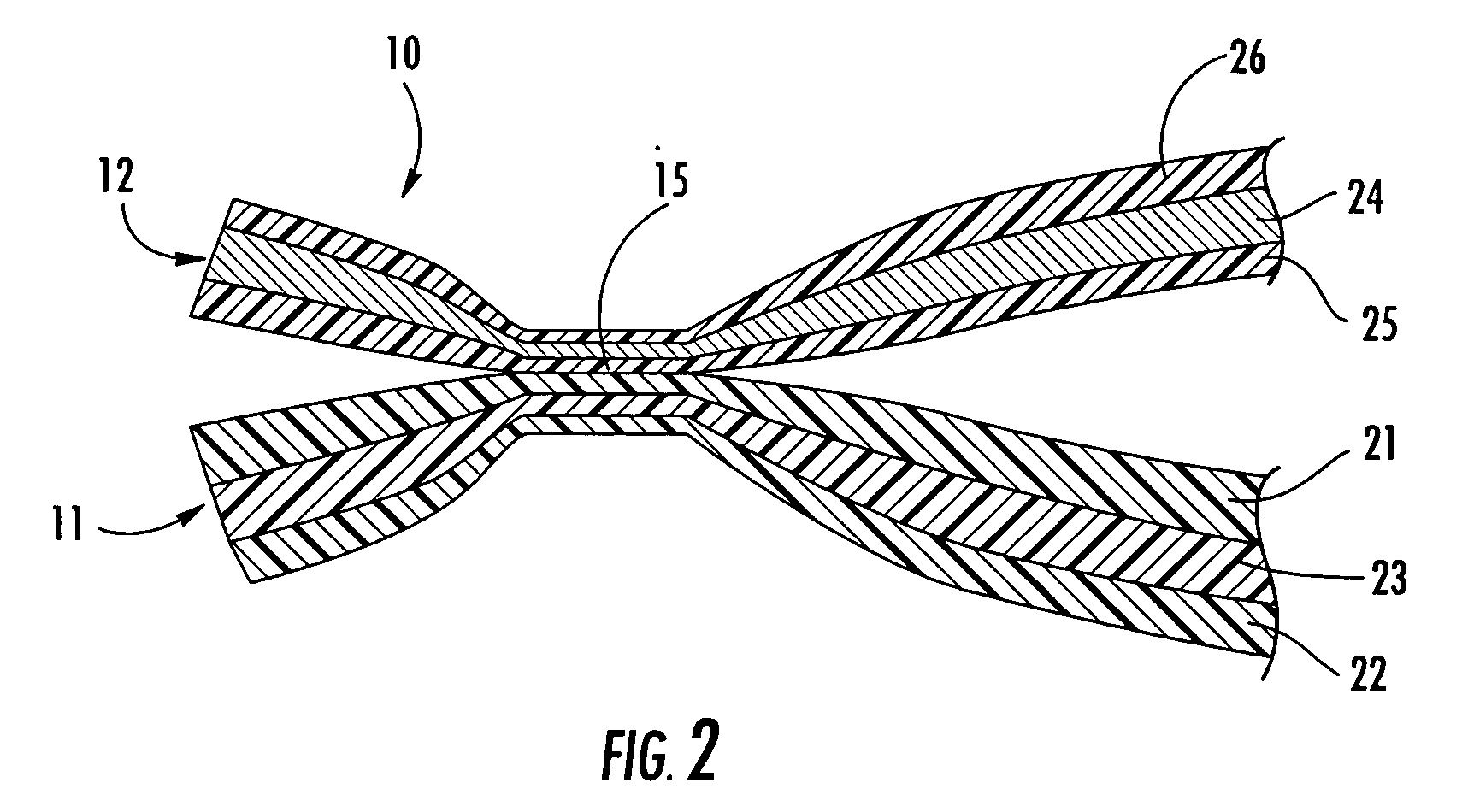

Transparent autoclavable bag

InactiveUS20060016708A1Improve barrier propertiesSufficient barrier propertySurgical furnitureDiagnosticsPolyethylene terephthalatePolyolefin

An autoclavable sterilization bag is provided having first and second composite film laminates positioned in opposing relation and sealed to one another to form a pouch. At least the first laminate comprises a heat sealable transparent thermoplastic polymer inner layer forming an inner surface of the laminate and a transparent polymer film outer layer. A transparent barrier layer is located between the inner and outer layers and formed of molecularly oriented polychlorotrifluoroethylene (PCTFE). In advantageous specific embodiments of the invention, the heat sealable transparent thermoplastic polymer inner layer is a polyolefin film, and the transparent polymer outer layer is a film selected from the group consisting of polyethylene terephthalate, nylon, polypropylene, polyethylene and cellophane.

Owner:AMCOR FLEXIBLES INC

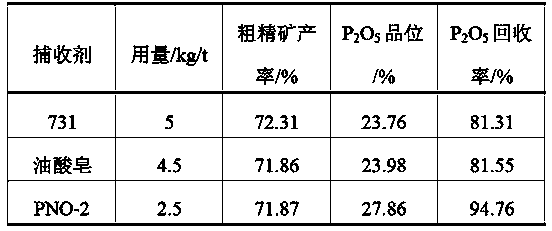

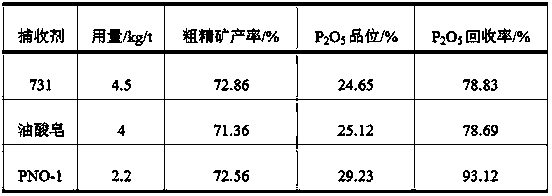

Collophanite direct flotation collector, and preparation method, purposes and application method thereof

The invention provides a cellophane direct flotation collector. The collophanite direct flotation collector comprises, by weight, 75 parts to 80 parts of fatty acid soap, 10 parts to 15 parts of fatty acid monoethanolamine and 3 parts to 8 parts of non-ionic surface active agents, and the non-ionic surface active agents are selected from one or more of octylphenol ethoxylate, nonylphenol polyeothoxylates and fatty alcohol polyoxyethylene ether. The invention further discloses a preparation method of the cellophane direct flotation collector, illegal cooking oil serves as raw materials, and the cellophane direct flotation collector is obtained after deodorization and decoloring. The collophanite direct flotation collector is good in selectivity and high in collecting capacity. According to the method, the illegal cooking oil harmful to the environment serves as the raw materials, waste is turned into wealth, the carboxylic acid derivative collector containing hydroxyl and amide polar groups is prepared, and the collector has great actual significance in development and utilization of medium and low grade collophanite.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Reverse flotation collecting agent of cellophane and preparation method thereof

InactiveCN103357509AEfficient removalImprove complexation abilityFlotationCellophaneReverse flotation

The invention relates to a reverse flotation collecting agent of collophane, and particularly to the collecting agent manufactured by the compounding and combination of modified fatty acid, strong alkali solution, and fatty acid, and a preparation method thereof. The method comprises the following steps: mixing raw materials of 1-5 parts of Alpha-hydroxy oleinic acid, 0.2-1.5 parts of strong alkali A, 0-1 parts of oleinic acid, and 1 parts of saturated higher fatty acid in parts by weight, wherein the temperature is controlled between 60-95 DEG C, and the mechanical stirring is 2-5 hours, so as to obtain basic materials; when in use, adding water to preparing 2 wt%-50 wt% water solution. The combination collecting agent obtained by the compounding of Alpha-hydroxy oleinic acid, strong alkali, oleinic acid, and saturated higher fatty acid has the advantages that the ordinary temperature selectivity is strong, the dispersivity is good, the medicine dosage is small, the cost is low, the beneficiation overall efficiency is obviously improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

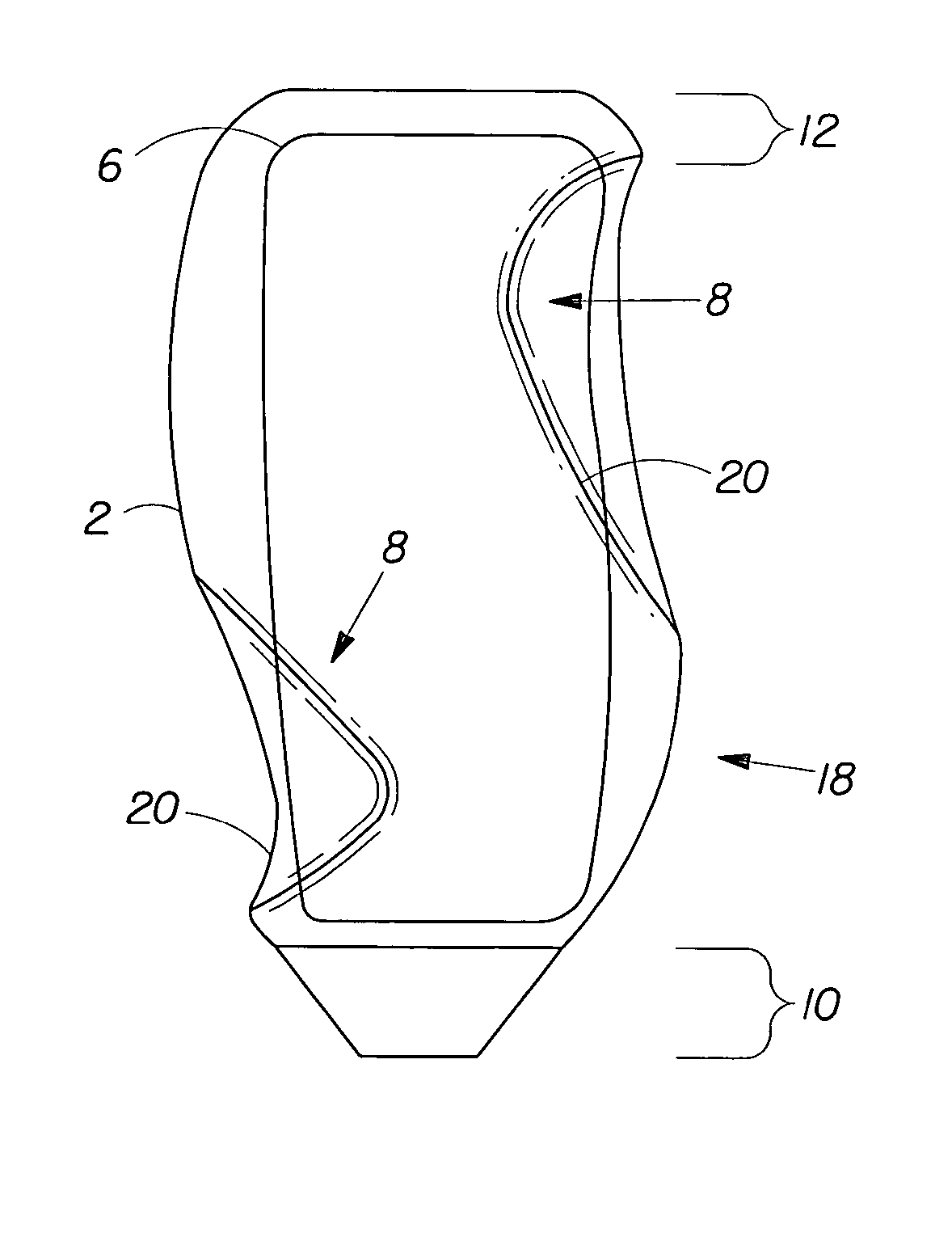

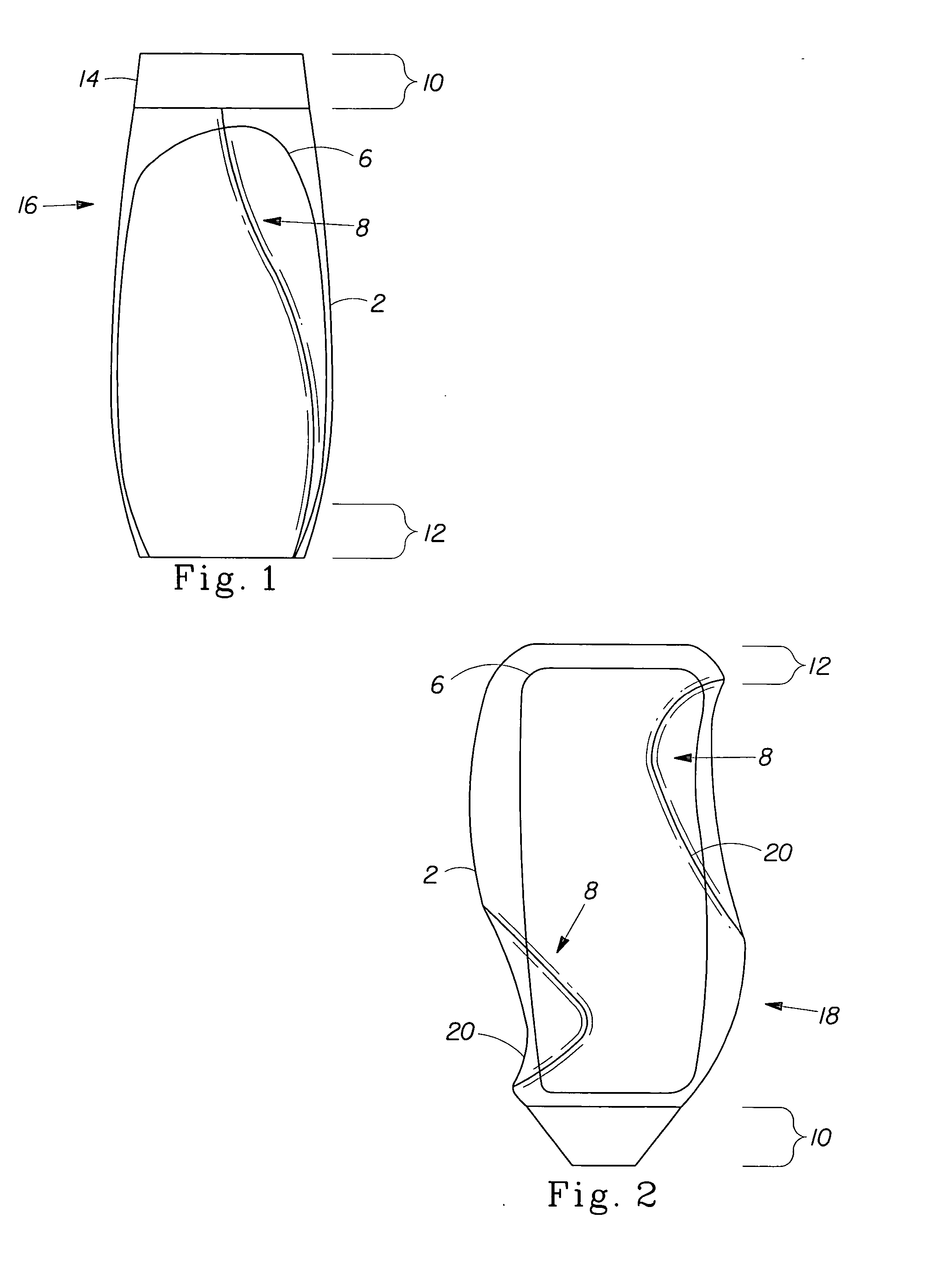

Container comprising an in-mold label positioned proximate to a surface topography

A container for liquid compositions including a reservoir including a liquid composition a surface topography and an in-mold label positioned proximate to the surface topography to improve the resilience of the container. The surface topography is selected from the group consisting of ridges, valleys, grooves, dimples, depressions, bumps, convexity, concavity, ribs, protrusions, curves, raised surfaces or other surface topography. The in-mold label has a thickness of at least 4.5 mils; wherein the in-mold label is made from a material selected selected from the group consisting of polyethylene, copolymers of polyethylene, polypropylene, copolymers of polypropylene, nylon, polyester, copolymers of polyester, polylactic acid, cellophane, polyvinyl chloride, ionomers, ethylene-acrylic acid copolymers, metallocene polyethylene, metallocene polypropylene, and mixtures thereof.

Owner:THE PROCTER & GAMBLE COMPANY

Acylation cellophane and producing method thereof

InactiveCN1526754AImprove adhesionGood optical performanceSynthetic resin layered productsCellulosic plastic layered productsSurface layerLiquid-crystal display

In a multi-layer structure of a cellulose acylate film, the averaged degree of acylation of surface layers is controlled in the range of 0.5 to 2.8 by mixing several sorts of cellulose acylates having different averaged degrees of acyation. One of the surface layers is formed on a substrate by casting a solution containing cellulose acylate made of cotton linter. Lubricant particles are added to a solution for the surface layers, and emission compounds to a solution for the inner layers. The obtained cellulose acylate film is excellent in adhesive property to the hydrophobic material without saponification, and adequately used for the polarizing filter, an optical compensation sheet, and liquid crystal display.

Owner:FUJIFILM CORP +1

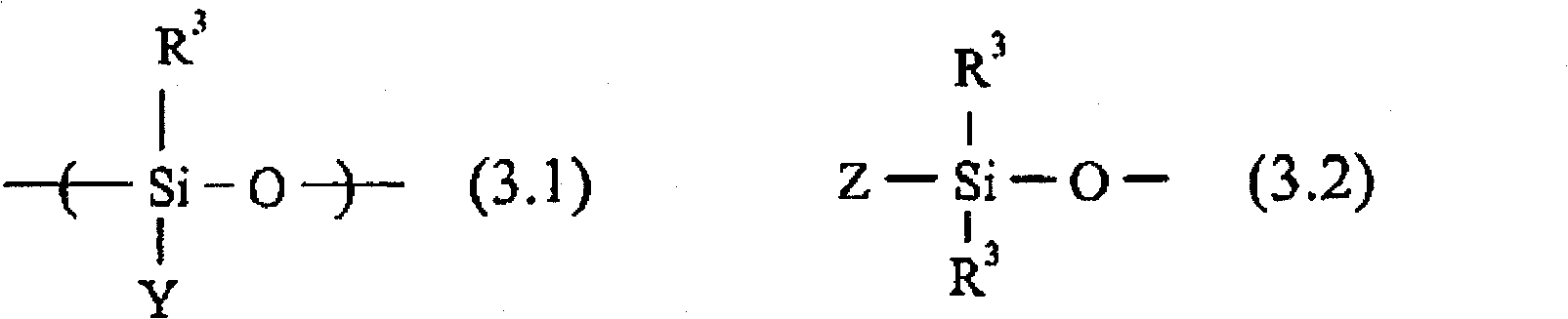

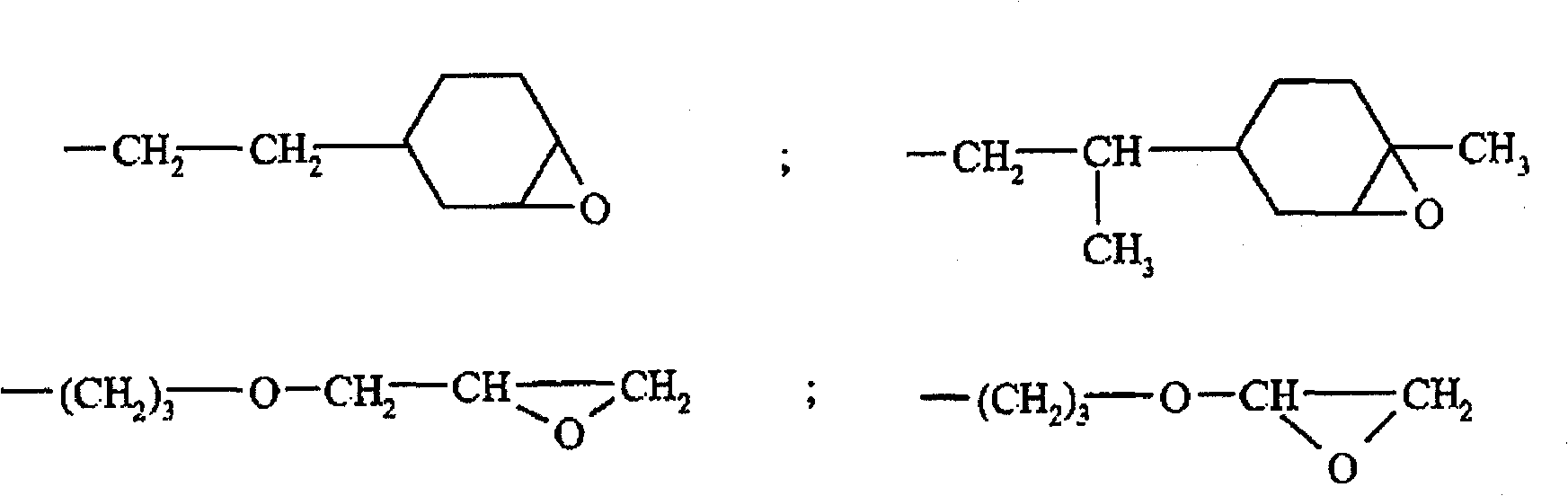

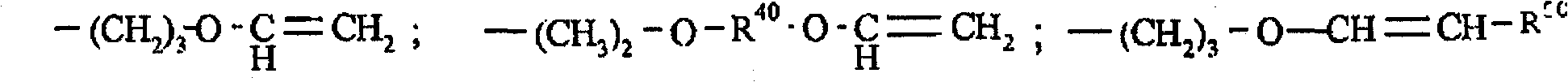

Silicone composition for coating a flexible support intended to form a crosslinked coating having increased attachment, mechanical strength and reactivity

The invention relates to crosslinkable or crosslinked silicone compositions capable of being used to form a water-repellent and release coating for a flexible support made of paper or of polymer, in particular that is heat-sensitive. These compositions are of the type of those comprising crosslinking polyorganosiloxanes (POSs) bearing =Si-H units and unsaturated, preferably =Si-Vi, vinyl-containing POSs, capable of reacting with the crosslinker by polyaddition, in the presence of platinum in order to form the crosslinked release coating on the flexible support.; The targeted objective is to enable the coating composition to crosslink instantaneously in order to produce, on all types of flexible supports (paper, e.g. glassine, or polymer, e.g. polyester such as polyethylene terephthalate PET), a crosslinked silicone coating endowed, in particular, on leaving the coating machine, with excellent attachment (adhesion) and mechanical strength or cohesion - "Rub-off" - properties. In order to achieve this objective, the invention proposes the use, per 100 parts by weight of silicone base, of 1 to 40 parts by weight of an additive comprising from 1 or 5 to 80% by weight of particulate filler, preferably nanoscale filler, in a silicone oil capable of reacting with the crosslinker. The supports and the high-speed coating processes are targeted. Applications: silicone release coatings obtained by crosslinking / polyaddition for flexible supports.

Owner:BLUESTAR SILICONES FRANCE SAS

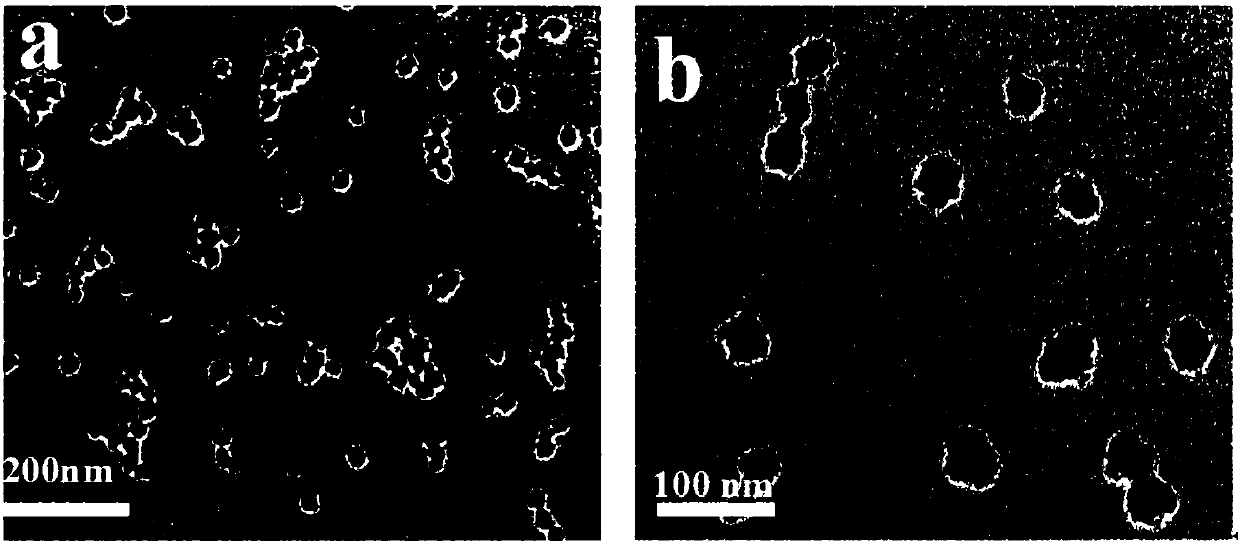

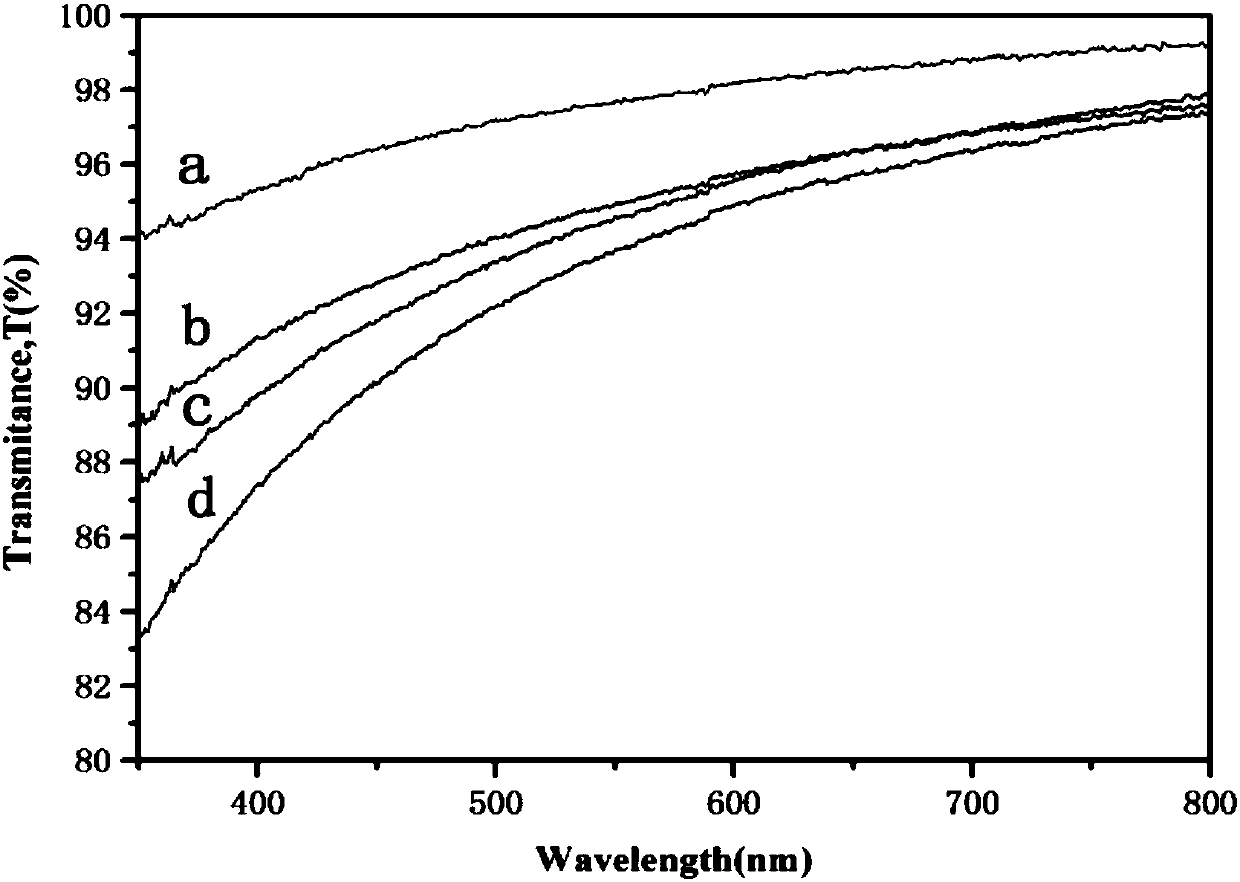

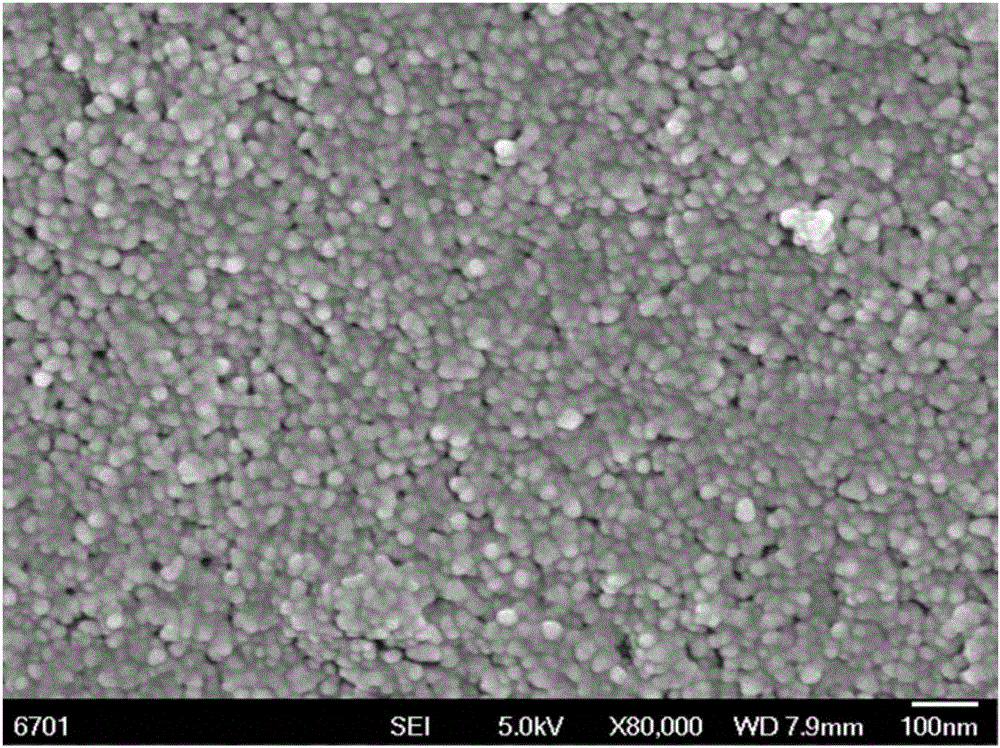

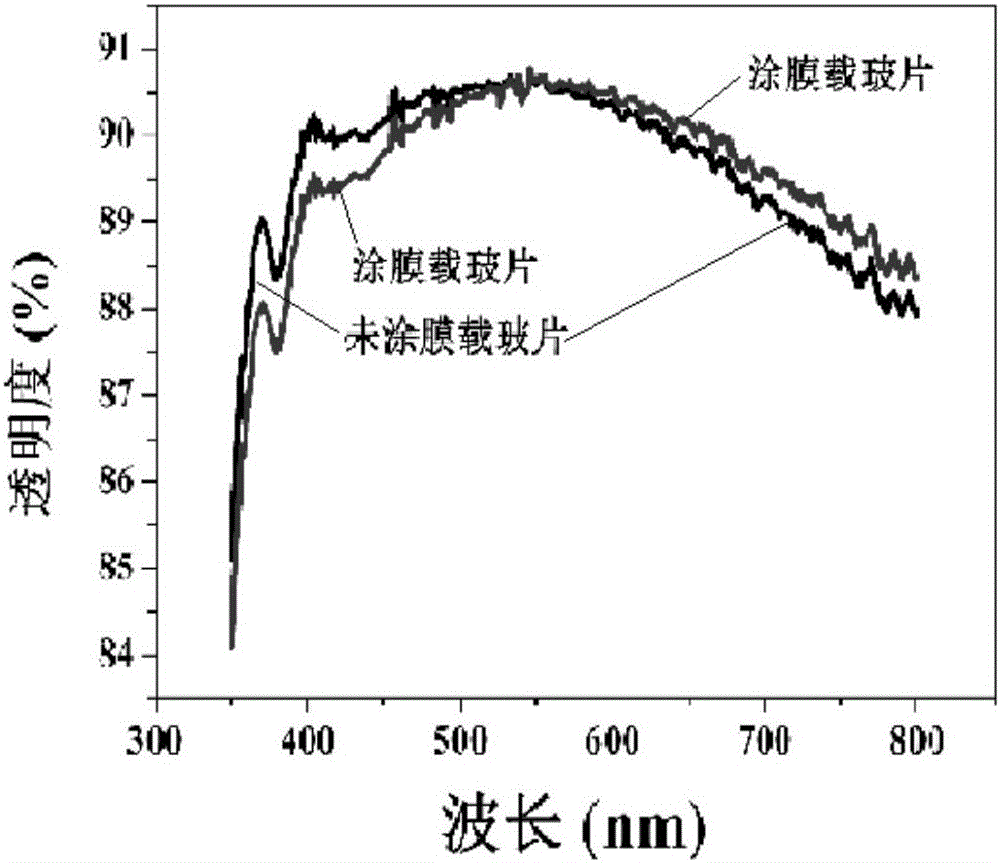

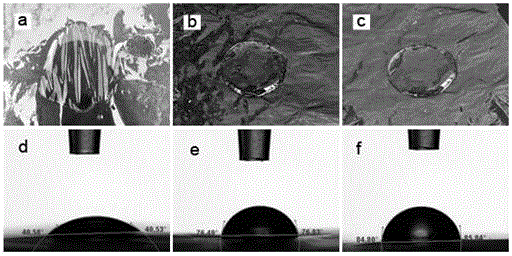

Superhydrophobic coating preparation method, coating prepared therethrough, and application of coating in production of highly-transparent superhydrophobic coating layer

The invention discloses a superhydrophobic coating preparation method, a coating prepared therethrough, and an application of the coating in the production of a highly-transparent superhydrophobic coating layer. The superhydrophobic coating preparation method comprises the following steps: adding a certain volume of a solvent, a cosolvent and a catalyst into a container one time, stirring the added substances at a certain rotating speed for a period of time, adding a certain volume of silicate ester and fluorine-containing siloxane, and continuously reacting all above substances at room temperature for a certain period of time to obtain the coating. The superhydrophobic coating prepared in the invention can be sprayed, dip-spread or dip-coated on glass, sheet paper, steel or other different substrates, and the transmittance of the produced coating layer in a visible light range reaches 92% or more. Compared with coating layers in the prior art, the produced coating layer has the advantages of simple production method, low cost, and facilitation of large-scale industrial production, has multiple uses in window glass, skyscraper light curtains, mobile phone screens and computer screens, and has great commercial values.

Owner:SOUTHEAST UNIV

Transparent super-hydrophobic spraying agent, and preparation method and application thereof

ActiveCN105038338AImprove hydrophobicityHigh visible light transmittanceCoatingsLiquid stateRoom temperature

The invention provides a transparent super-hydrophobic spraying agent, and a preparation method and an application thereof. The transparent super-hydrophobic spraying agent is colorless and is in a liquid state at room temperature. A layer of super-hydrophobic film can be formed on a substrate surface via spraying the agent, wherein the transparent super-hydrophobic film formed from the transparent super-hydrophobic spraying agent has a contact angle less than 150 degrees, a rolling angle less than 10 degrees, and a 550nm light transmission rate of 90-99% at a visible light area. The transparent super-hydrophobic spraying agent provided in the invention is convenient to use and can be widely applicable to hydrophobic treatment of ceramic, glass, paper, wood, stone, metal, or polymer surfaces.

Owner:HUBEI UNIV

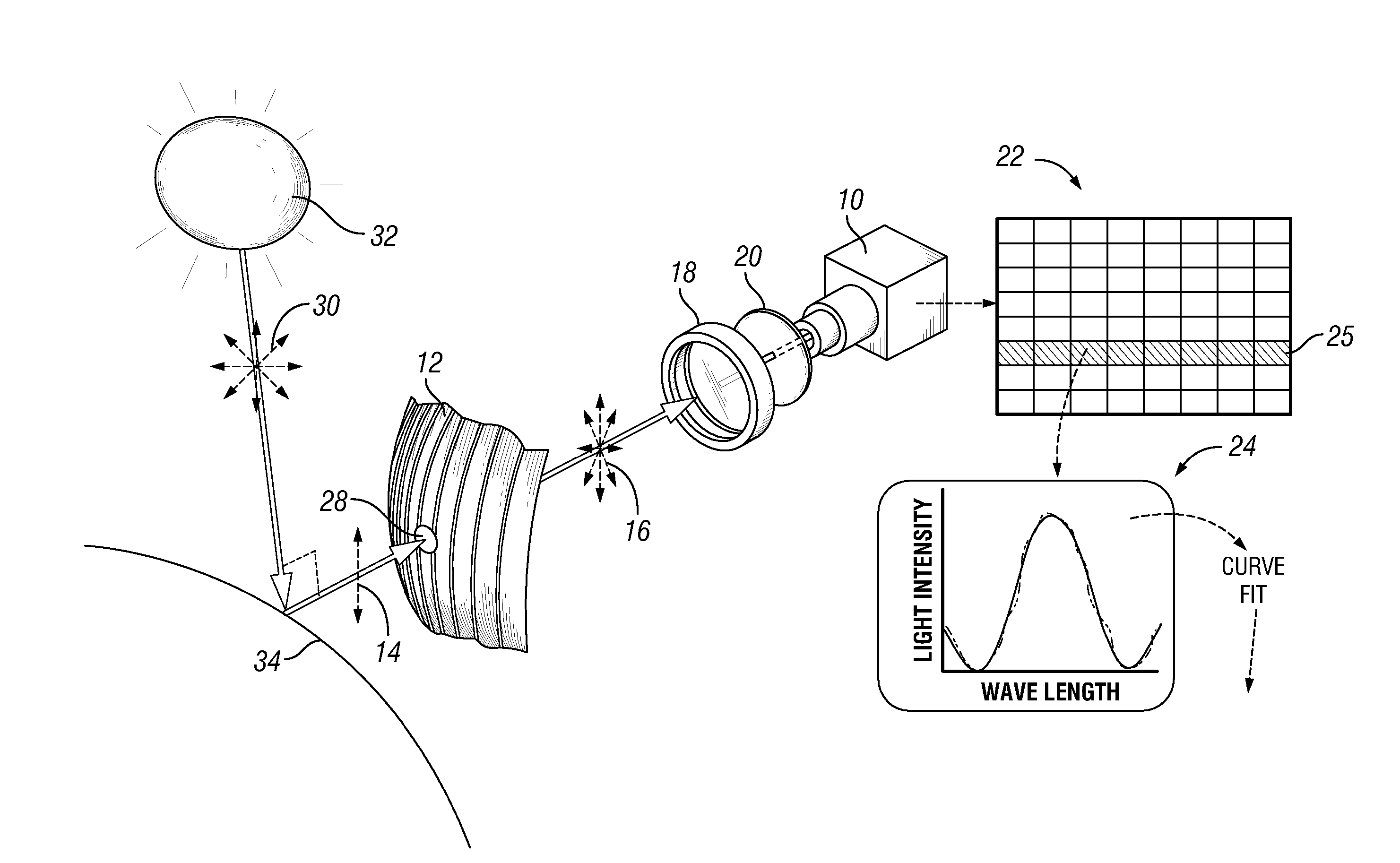

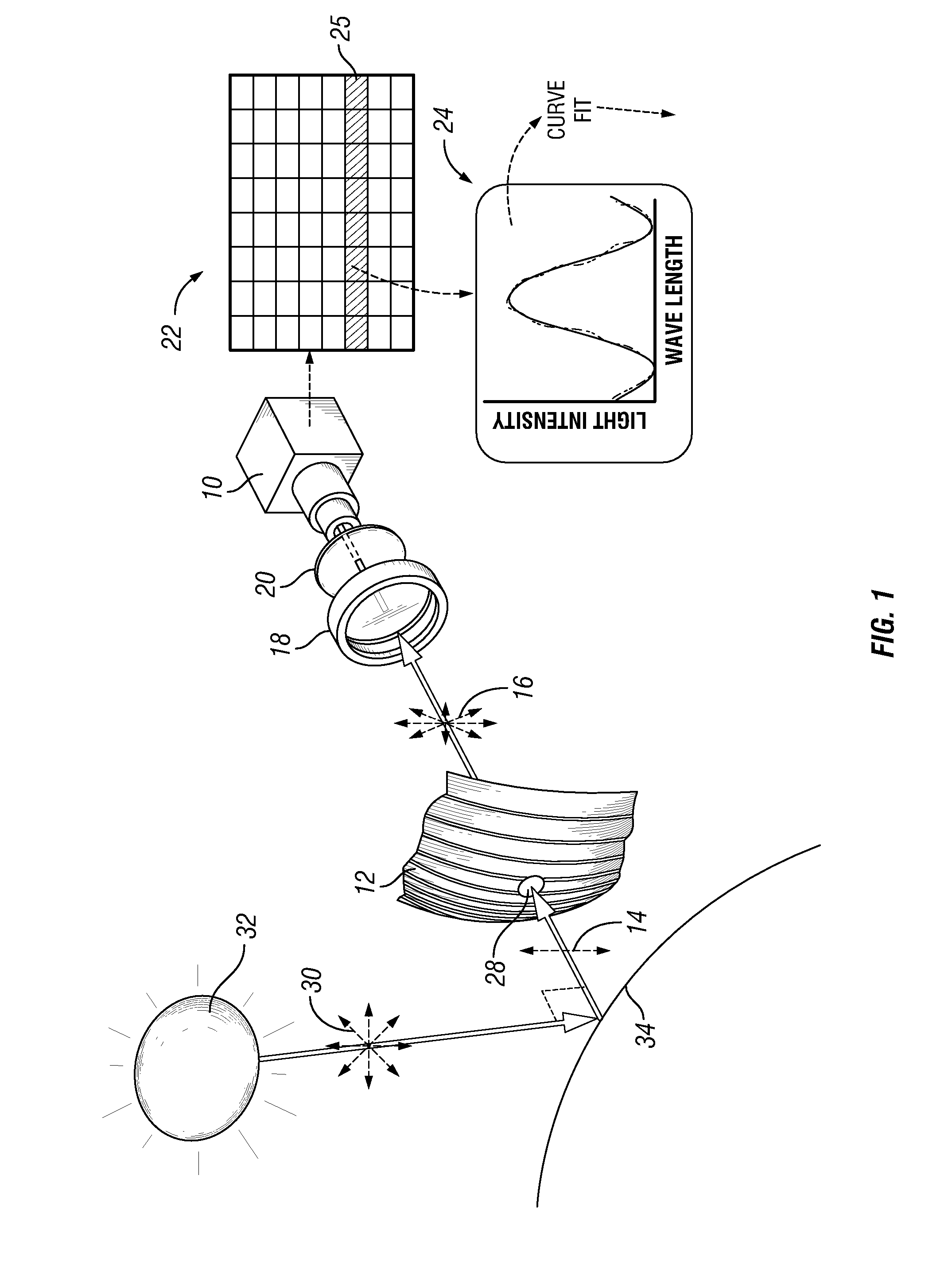

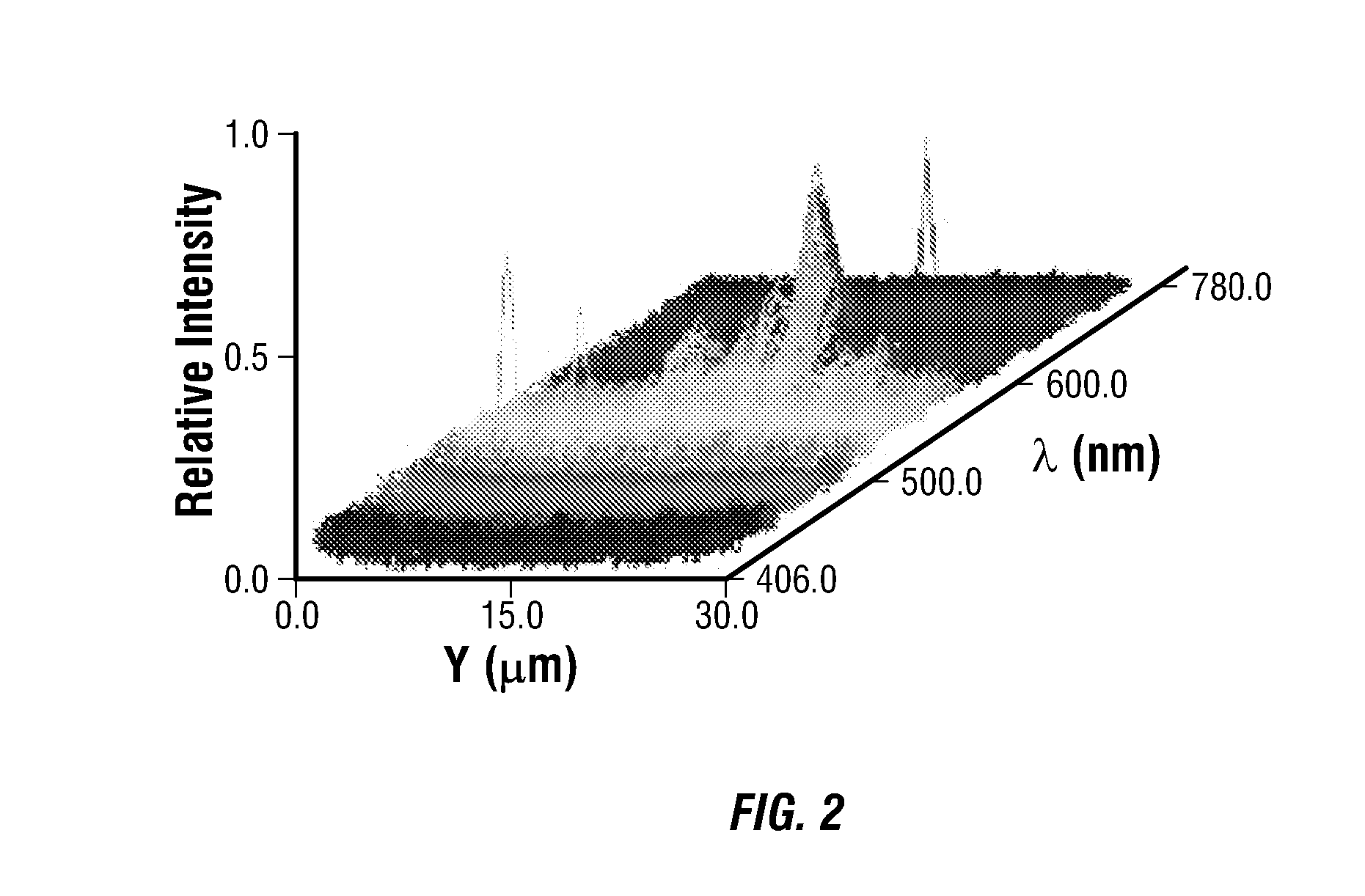

Detecting strain in birefringent materials using spectral polarimetry

InactiveUS20080094609A1Polarisation spectroscopyUsing optical meansPolyesterLow-density polyethylene

A method, computer program product and system for analyzing multispectral images from a plurality of regions of birefringent material, such as a polymer film, using polarized light and a corresponding polar analyzer to identify differential strain in the birefringent material. For example, the birefringement material may be low-density polyethylene (LDPE), high-density polyethylene (HDPE), polypropylene, polyethylene terephthalate (PET), polyvinyl chloride (PVC), polyvinylidene chloride, polyester, nylon, or cellophane film. Optionally, the method includes generating a real-time quantitative strain map.

Owner:LYNNTECH

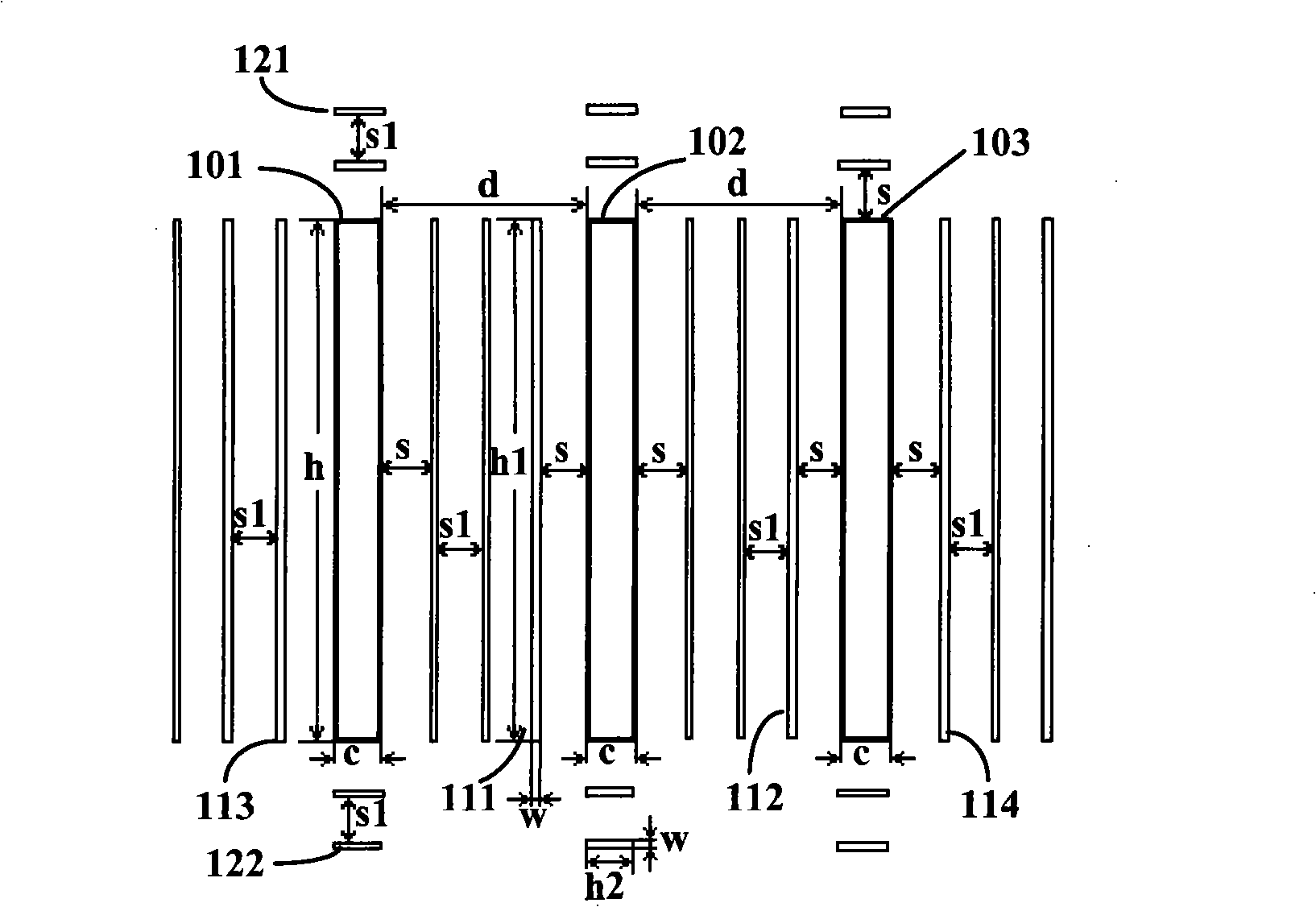

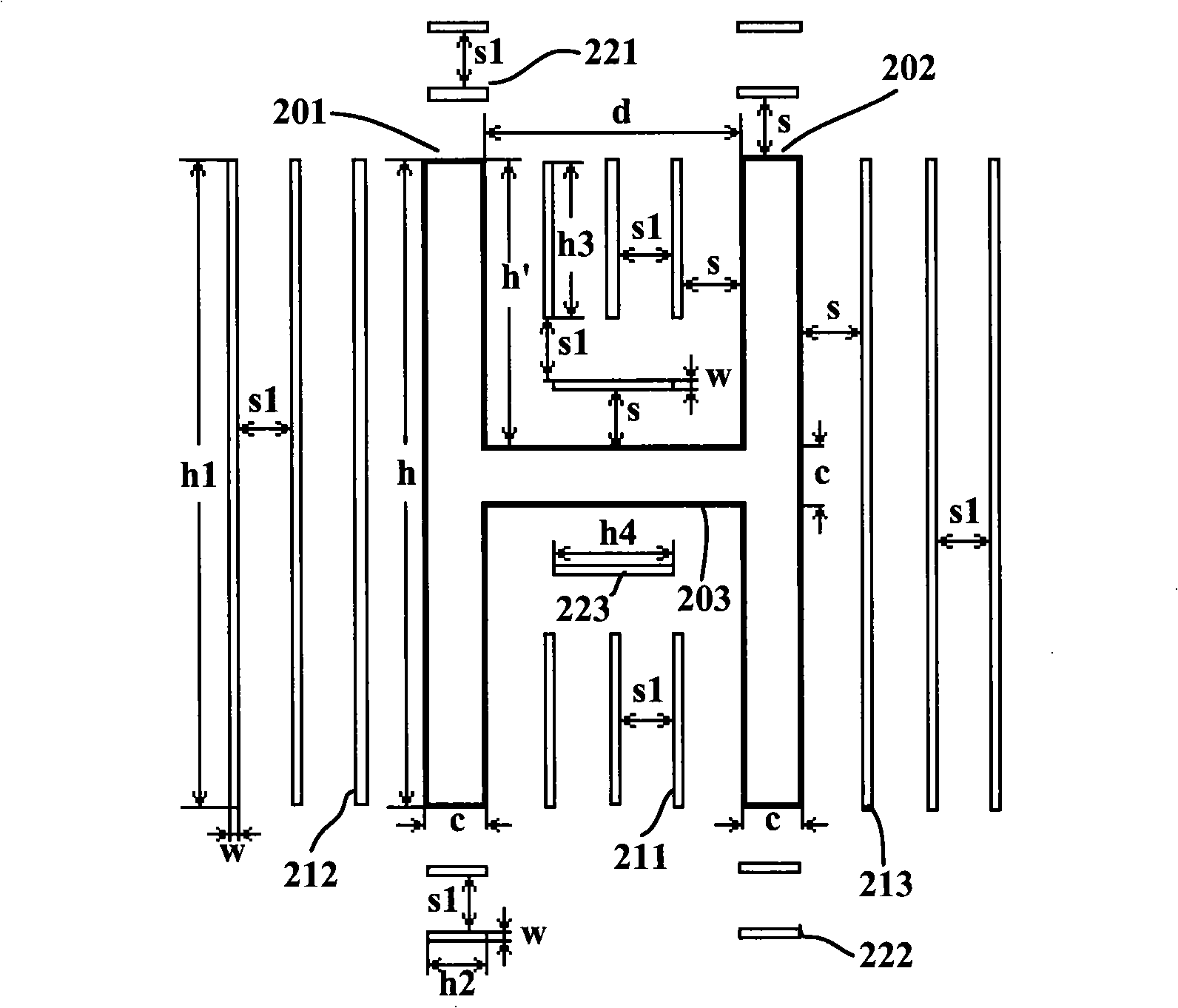

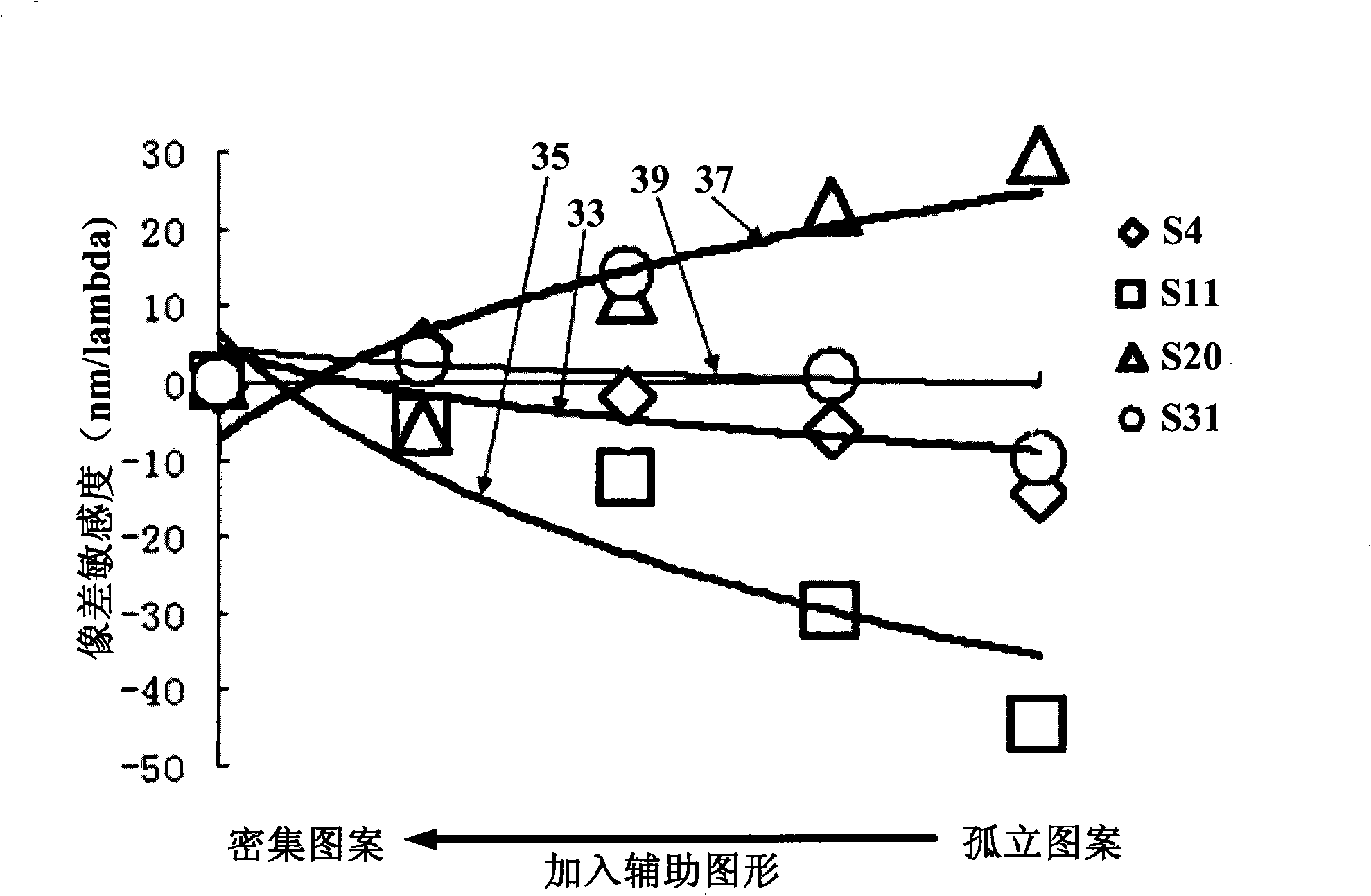

Layout for reducing aberration sensitiveness, light shield manufacture and graphic method

InactiveCN101329505AIncrease distribution densityImprove distribution uniformityOriginals for photomechanical treatmentSpecial data processing applicationsGraphicsCellophane

The invention relates to a layout method for reducing aberration sensitivity, which is characterized in that at least one layout auxiliary graph is added around a layout graph, the layout auxiliary graphs are not intersected mutually, the layout auxiliary graphs and the layout graph are not intersected mutually, the distance between the neighboring layout auxiliary graphs is longer than or equal to one time of the critical dimension of the layout graph, and shorter than or equal to three times of the critical dimension of the layout graph. The invention also discloses a manufacturing method of a photomask for reducing the aberration sensitivity, and an imaging method. By applying the methods provided by the invention, the aberration sensitivity of a photoetching system can be reduced, which causes the graphs formed on the photoetching cellophane of a semiconductor substrate to obtain better critical dimension uniformity.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Base fabric material for embroidery and embroidery thread

The invention relates to a base fabric material for embroidery and an embroidery thread. The base fabric material is characterized by comprising following paper base fabrics: writing paper, copying paper, decorating paper, newspaper, coated paper, offset paper, halftone paper, plate paper, cellophane, one-side / two-side transparent glazed paper, synthetic fabric paper, cast coated paper, coating paper, cartridge paper, wallpaper, brown paper, parchment, foaming paper, packaging paper, honeycomb paper, waterproof paper, fireproof paper and mothproofing paper; and following paperboard base fabrics: a case board, a straw board, a white board, a binding paperboard, compound multi-layer paper and a corrugated board. The embroidery thread comprises a plant fibre thread, an animal fiber thread, a chemical fiber thread, a metal fiber thread and a mixed fiber thread. An embroidery product manufactured by the base fabric material and the embroidery thread can be used for decorating and finishing walls, table-boards, ground and furniture, can be used permanently or temporally, has waterproof, mothproof and fireproof performances, is durable, is long in service life, and has good environmental performance.

Owner:单虹岩

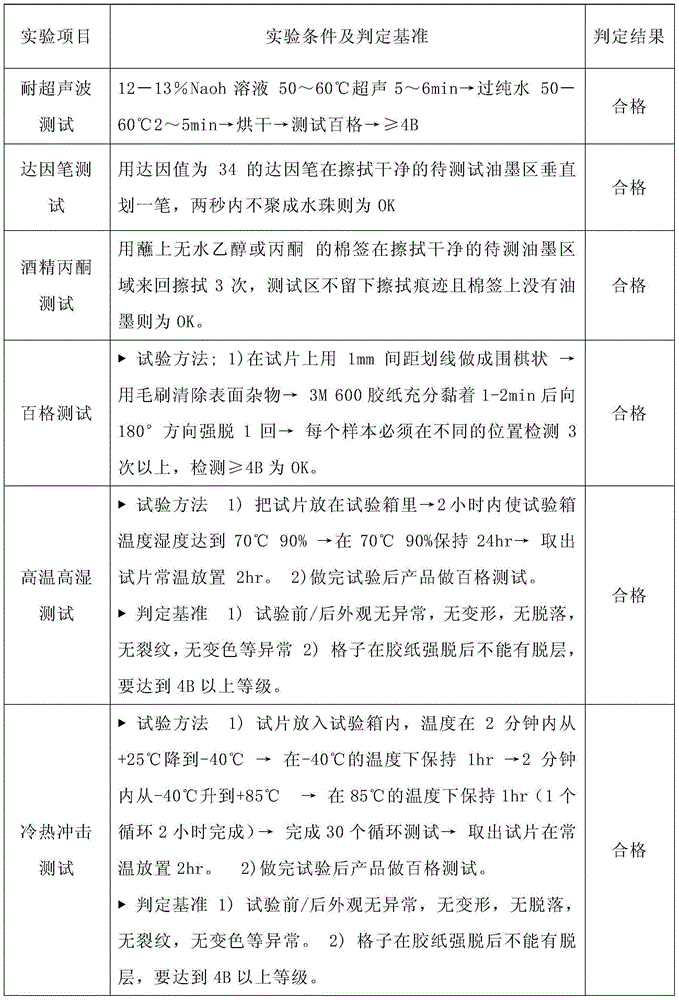

Mirror surface golden ink for glass cover plates

The invention discloses a mirror surface golden ink for glass cover plates, which comprises the following components in percentage by weight: 15-25 parts of silver powder, 60-70 parts of mirror surface gloss oil, 5-10 parts of diluter, 3-8 parts of red color paste, 2-6 parts of yellow color paste, 1-5 parts of accelerator, 0.5-1.5 parts of defoaming agent, 5-10 parts of curing agent, 1-2 parts of cellophane anchoring agent, 1.5-2.5 parts of anionic starch and 0.5-1.5 parts of acramoll W paste. Compared with the prior art, by adding the silver powder, mirror surface gloss oil, red color paste, yellow color paste, accelerator, defoaming agent, curing agent, diluter and other components and mixing with the especially added cellophane anchoring agent, anionic starch and acramoll W paste, the ink has the advantages of favorable adhesion, high reliability, ultrasonic cleaning resistance, acid / alkali resistance, solvent resistance, scrubbing resistance, high adhesion, high brightness, favorable color and stable silk screen printing effect, and can resist 220-DEG C high temperature without discoloration.

Owner:蓝思旺科技(深圳)有限公司

Method for manufacturing polystyrene torsion film

InactiveCN101096129AExcellent mechanical propertiesHigh glossSynthetic resin layered productsFlat articlesEngineeringHigh intensity

The invention discloses a producing method for no-rebound polystyrene torsion film used for food package. Polystyrene resin, high impact polystyrene resin or modified polystyrene resin is mixed with toughening agent and so on in plasticization. The mixture is melted and extruded out to form single-layer or multiple-layer film. The film is drawn in horizontal and vertical direction to become finished product. The torsion film is provided with better mechanical characteristic, high intensity, big rigidity, no rebound elasticity. The torsion film is a better torsion film and can take the place of PVC torsion film, glass paper or PET torsion film as packaging material.

Owner:GUANGDONG HUAYE PACKING MATERIAL

Smart Packaging for Any Type of Product

Owner:ANHEUSER BUSCH INBEV SA

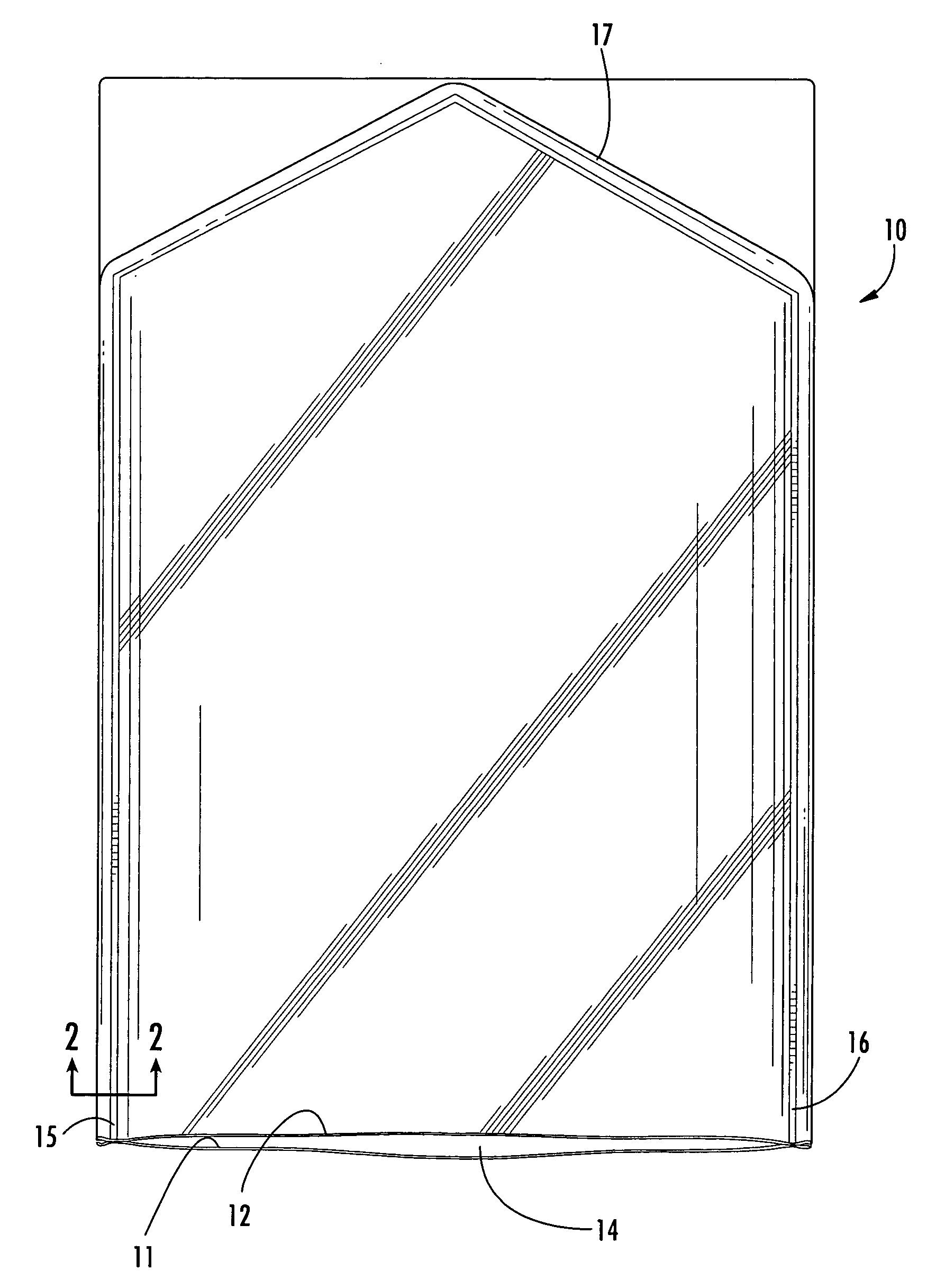

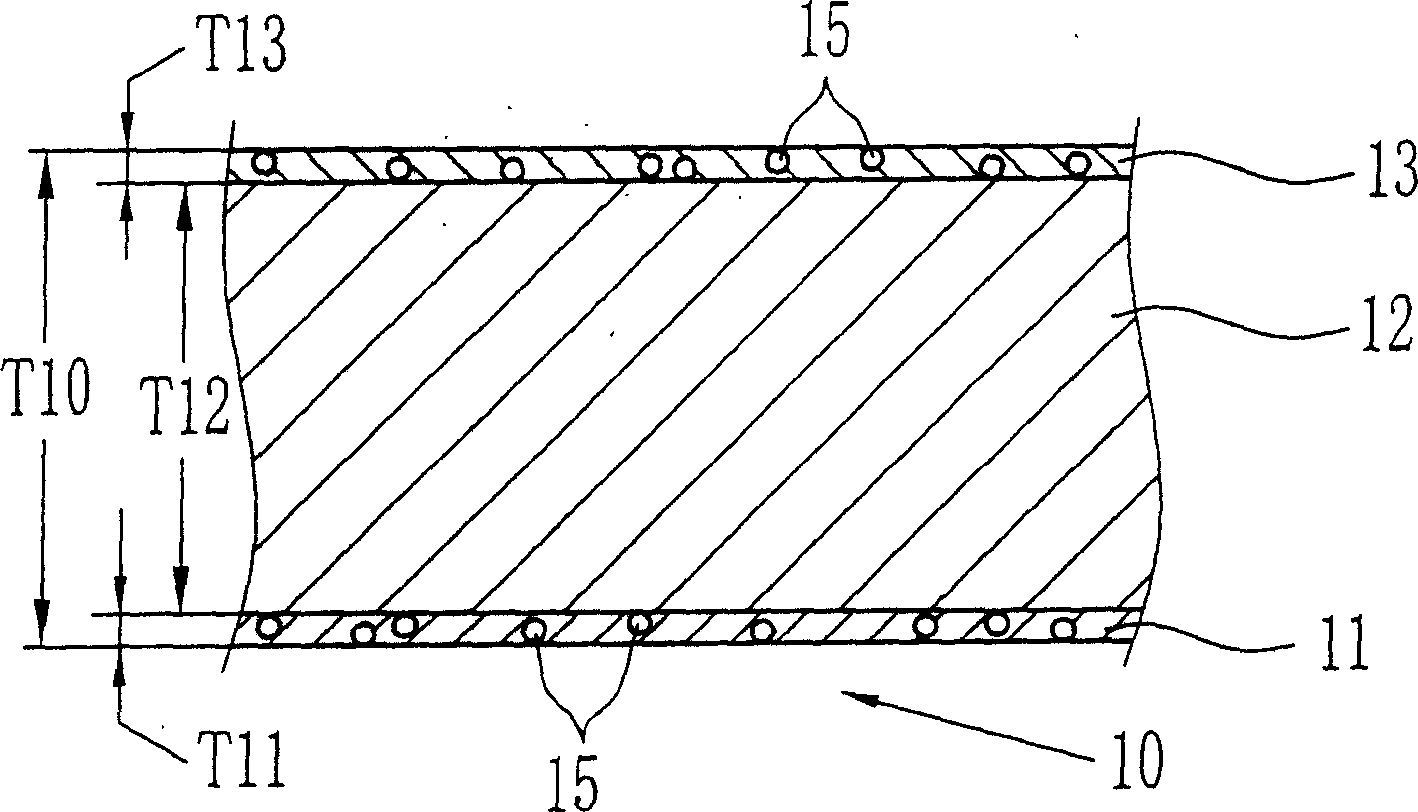

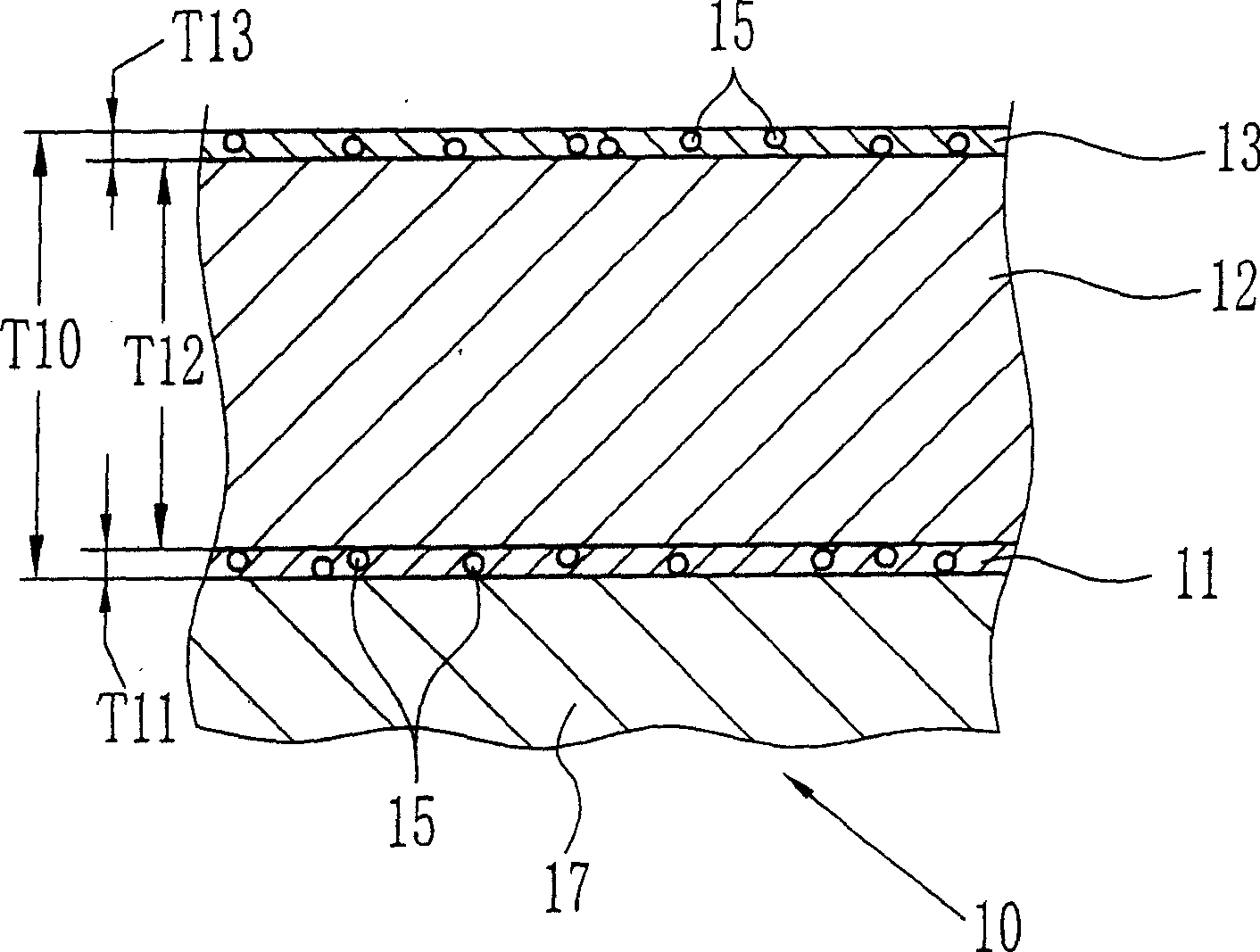

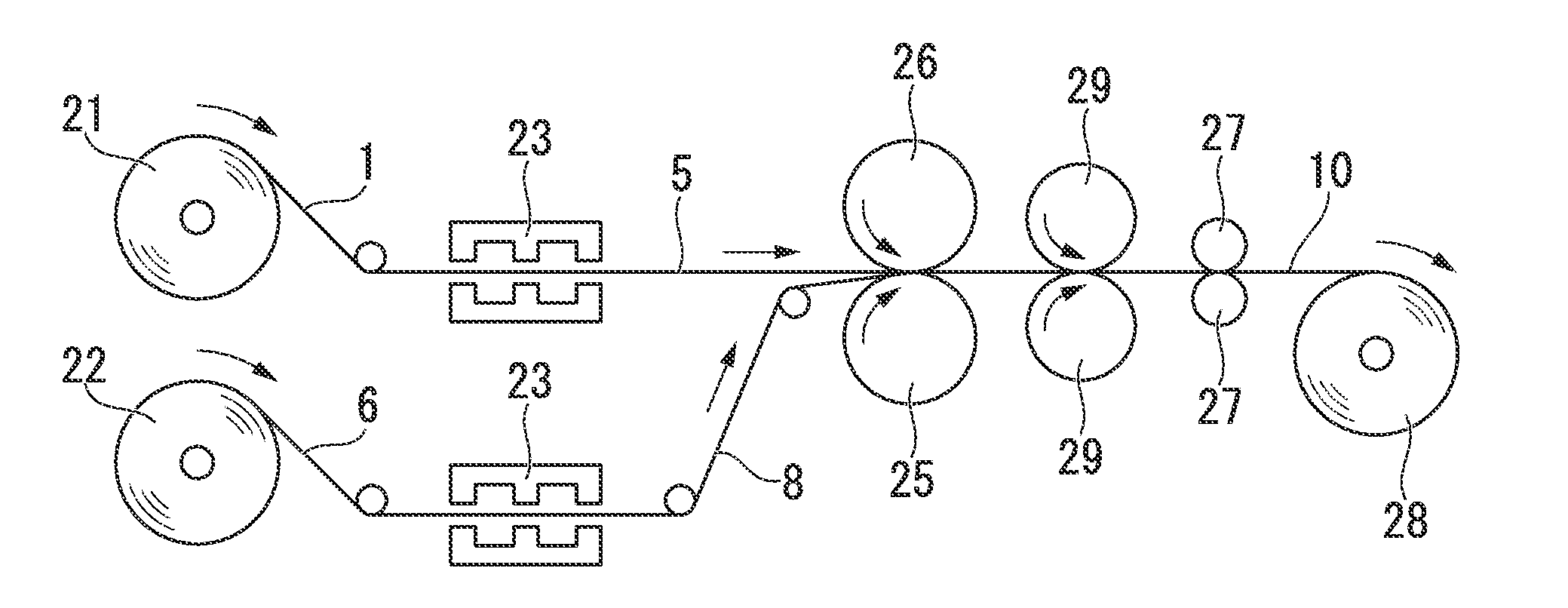

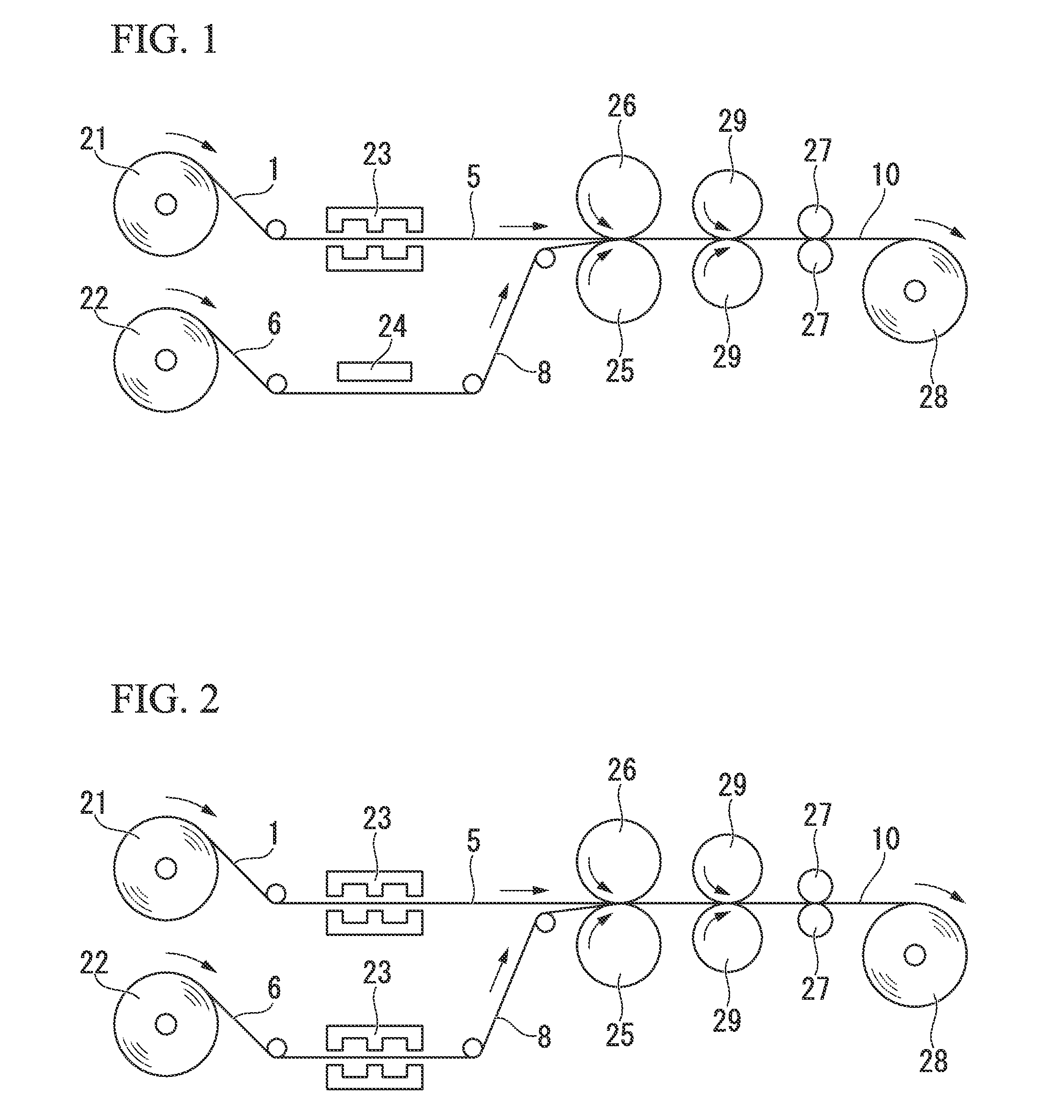

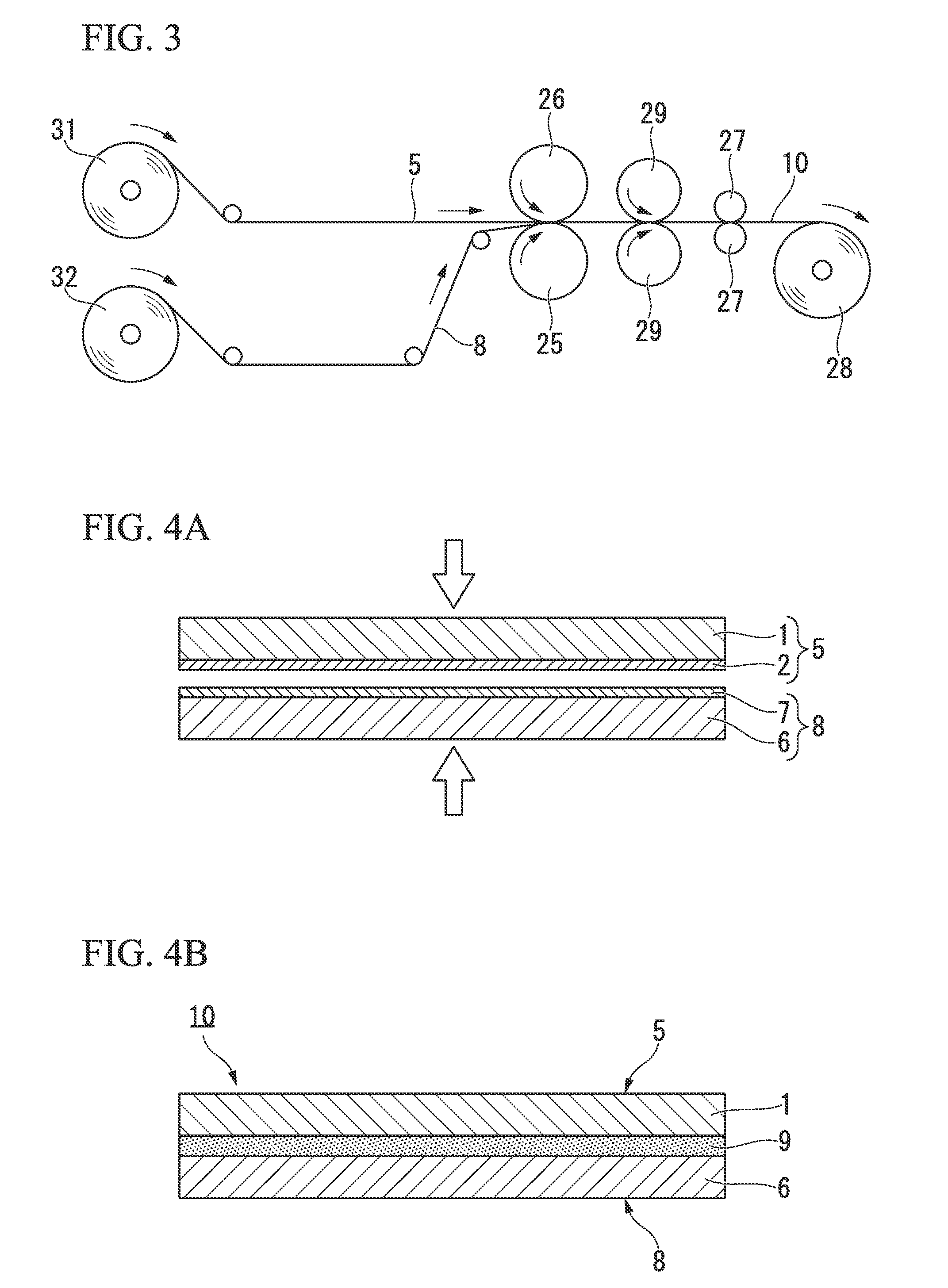

Laminate production method, laminate, and packaging container using same

InactiveUS20120205387A1Improve handlingGood energyLamination ancillary operationsLayered product treatmentAdhesiveCellophane

A substrate which is either a first substrate or a second substrate consisting of a different kind of thermoplastic resin film or cellophane film, and which is drawn out from rolled films where the first substrate and the second substrate are rolled respectively. The substrate has a surface of the hot gluing reforming layer which was formed with the surface modification with an atmospheric pressure plasma processor, and the other substrate has a surface with which an air corona processor is possessed. And the substrate and the other base member are opposed, and are attached together with a heating roll with spreading neither an adhesive nor an anchor agent.

Owner:FUJIMORI KOGYO CO LTD

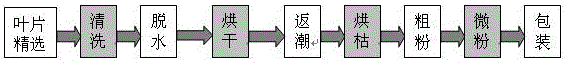

Preparation method of dry Premna microphylla leaf powder

InactiveCN106262112AThe solution is not suitable for long-term storageAddress limitationsFood sciencePremna microphyllaCellophane

A preparation method of dry Premna microphylla leaf powder is characterized in that the dry Premna microphylla leaf powder is prepared from Premna microphylla leaves through steps including cleaning, dehydration, drying, moisture regain, baking to dryness, coarse powder preparation and micronization. The dry Premna microphylla leaf powder prepared with the method retains green the same as the fresh leaves and effectively retains effective components such as chlorophyll and the like of the fresh leaves; the prepared dry powder has high pectin content which is basically identical to that of the fresh Premna microphylla leaves; Premna microphylla leaf curd, noodles and cellophane noodles prepared from the dry powder have high quality, materials are saved, and 60 jin or more of Premna microphylla leaf curd can be prepared from 1 jin of the dry Premna microphylla leaf powder, while only 20 jin of Premna microphylla leaf curd can be prepared from 1 jin of the dry Premna microphylla leaf powder with a conventional general process; the dry Premna microphylla leaf powder tastes fine and smooth, has the fresh scent of the Premna microphylla leaves and effectively guarantees the nutritive and medical values of the fresh Premna microphylla leaves.

Owner:杨兴才 +1

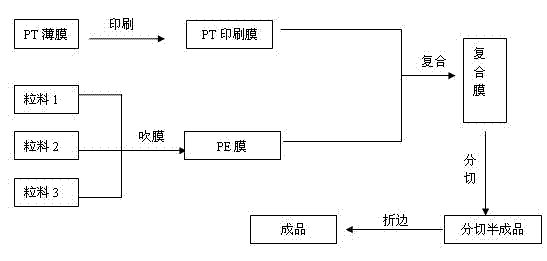

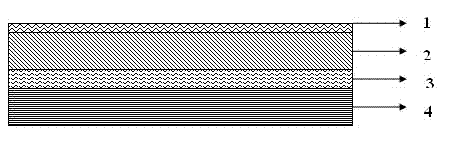

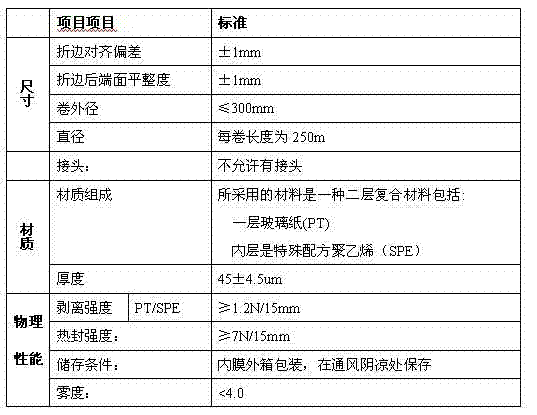

Easily-torn flanged compound film with good transparency and preparation method thereof

ActiveCN102765236AGuaranteed flatnessFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

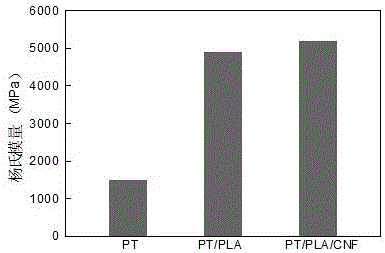

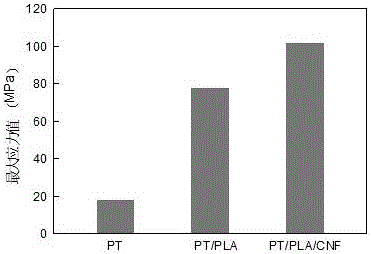

The invention relates to an easily-torn flanged compound film with good transparency and a preparation method of the compound film. The compound film comprises an outer layer and a heat seal layer from top to bottom, wherein the outer layer is a cellophane (PT) film surface layer; the heat seal layer is a polyethylene film formed by co-extruding a composite layer, a core layer and the heat seal layer from top to bottom, and the materials of the composite layer, the core layer and the heat seal layer are formed by mixing low-density polyethylene with linear low-density polyethylene according to a weight ratio of 1 to 2; and the cellophane (PT) film surface layer is compounded with the polyethylene film layer through a polyurethane rubber layer. The prepared flanged compound film is good in transparency and can serve as a packing material for a full-automatic drug packing machine.

Owner:JIANGYIN BAOBO PACKING

Food packaging film

In the present invention, there is provided a food packaging film which is excellent in workability, processability, productivity, gas barrier properties, low-temperature heat sealing properties, safety and mechanical strengths, which can be used as an alternative film to generally used cellophane / wax films, and can be suitably used as a packaging film for melting cheese. The food packaging film according to the present invention comprises at least five layers of a heat seal layer / an adhesive layer / a gas barrier layer / an adhesive layer / a heat seal layer, which heat seal layer comprises an olefin-based resin and melts at not lower than 60° C. and lower than 90° C.

Owner:SHIKOKU KAKOH CO LTD

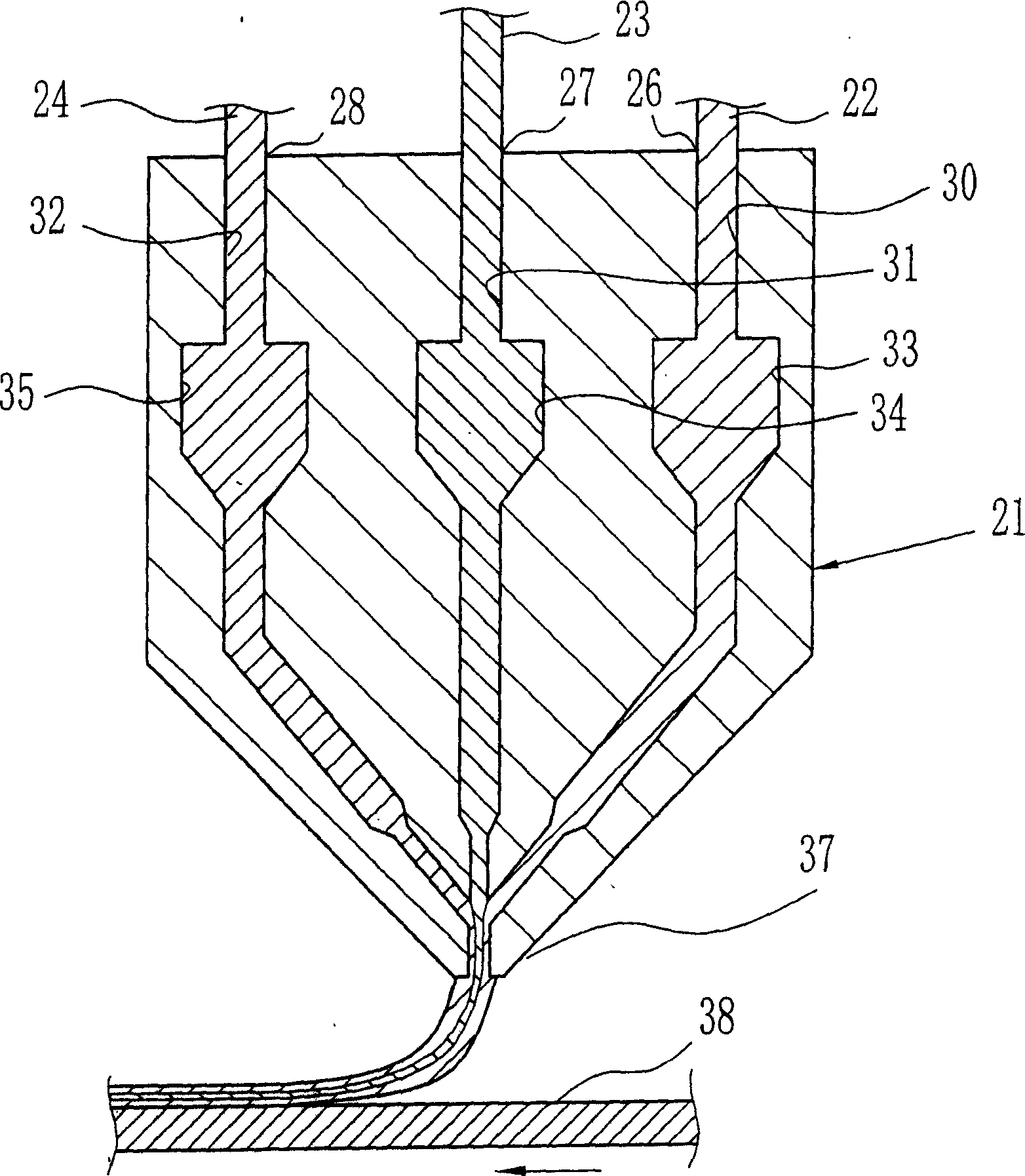

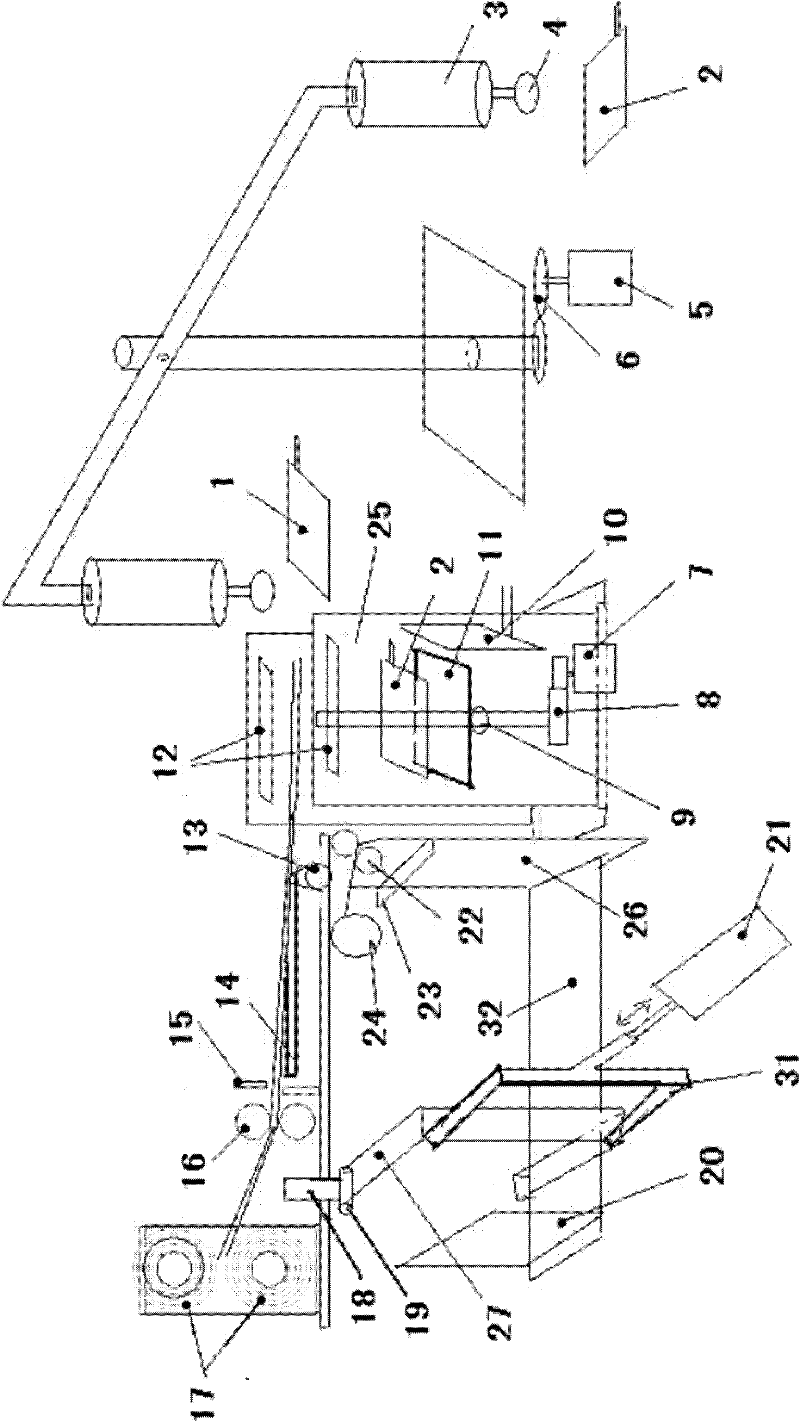

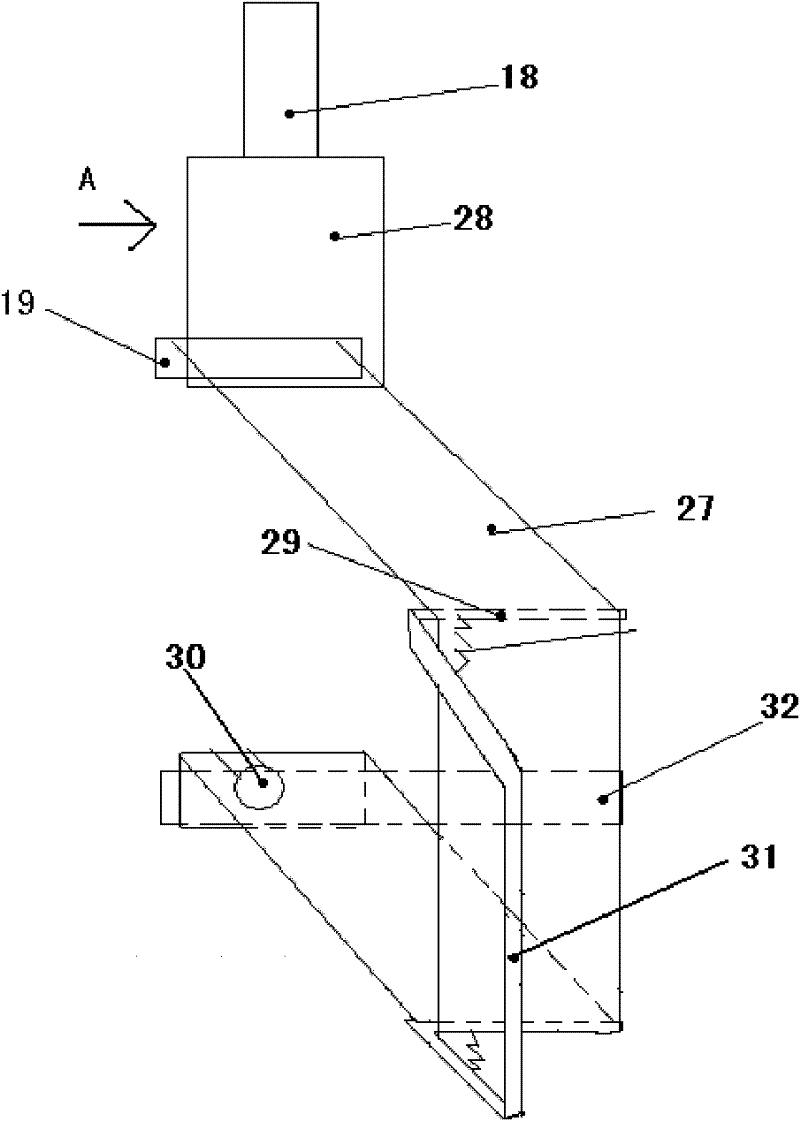

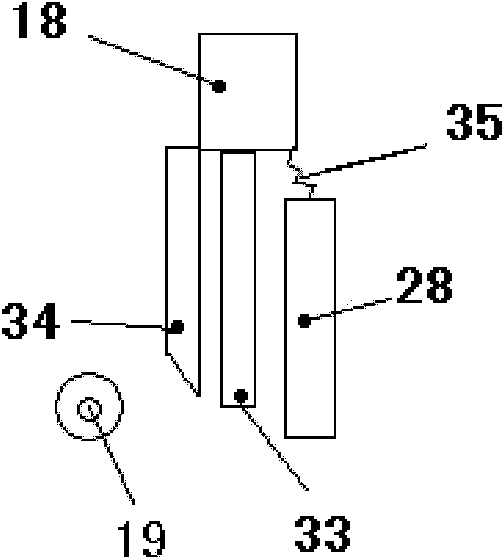

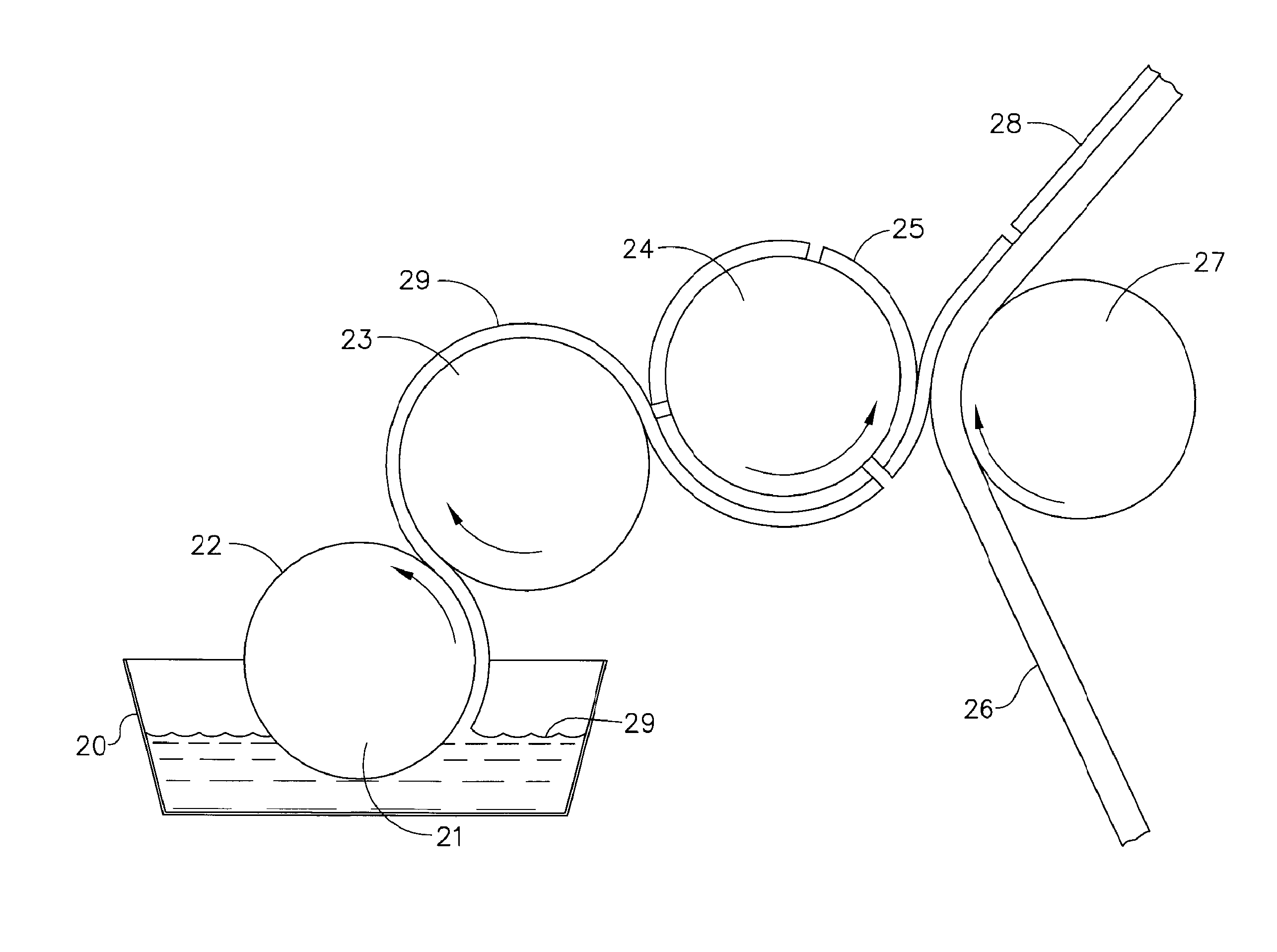

Automatic wrapping method for lead-acid battery production

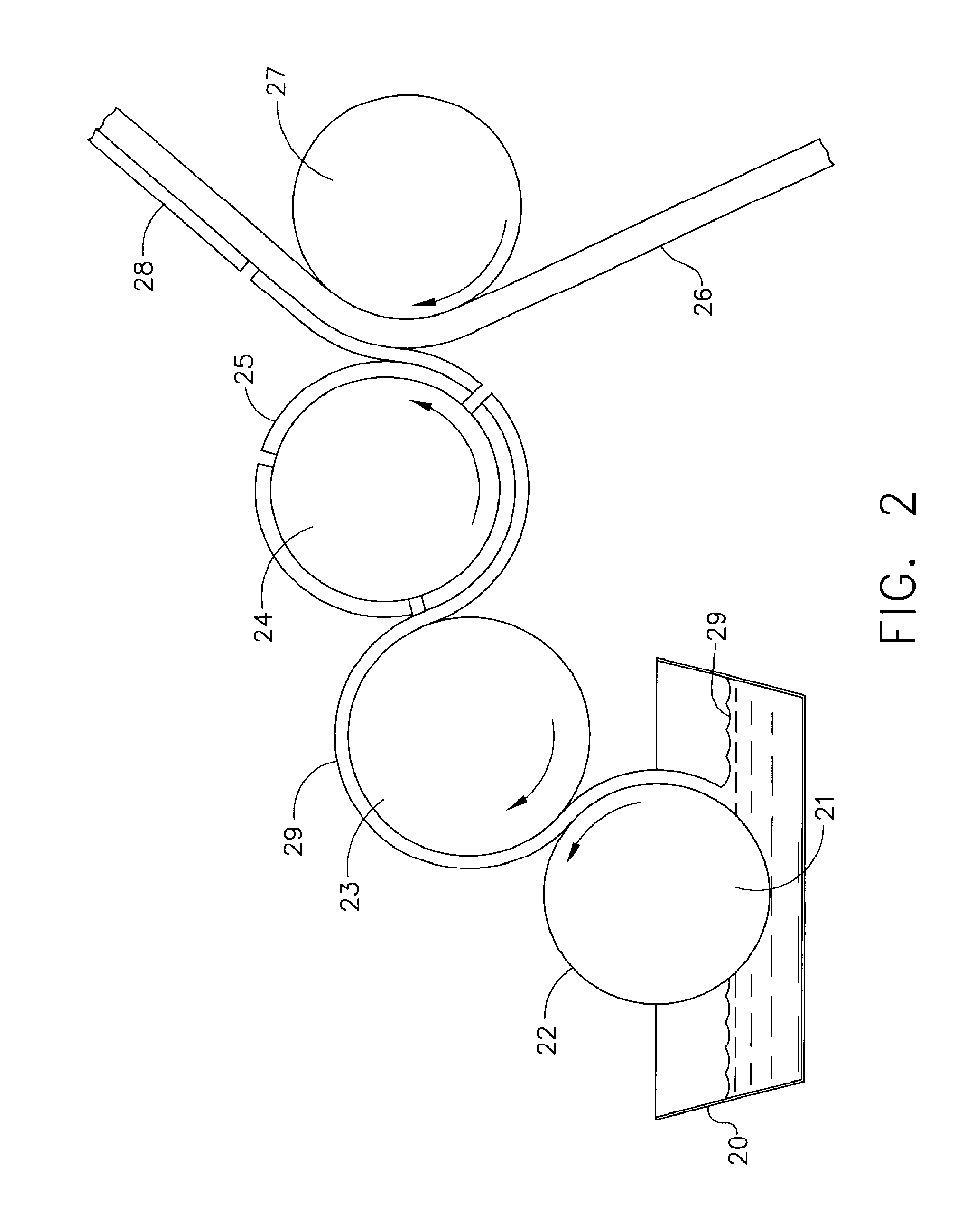

ActiveCN102263297AAvoid Lead ContaminationReduce labor intensityFinal product manufactureLead-acid accumulators constructionCellophaneEngineering

The invention belongs to an automatic plate-wrapping method with lower labor intensity and capability of preventing workers from lead pollution in lead-acid storage battery production. The method comprises the steps of: by adopting an automatic plate conveying device, respectively shifting anode plates and cathode plates which are in preset quantities out of an anode plate pile and a cathode plate pile and alternately stacking on a plate supporter one by one to form a rectangular cylinder-shaped plate pile; in the process of alternately stacking the anode plates and the cathode plates on the plate supporter one by one, arranging cellophanes for isolation among the anode plates and the cathode plates through a paper sending mechanism; and packing the plate pile through plastic paper by a packing mechanism after stacking the anode plates and the cathode plates which are in preset quantities, and finally, binding through a plastic tape by a binding mechanism.

Owner:路亚科消防车辆制造有限公司

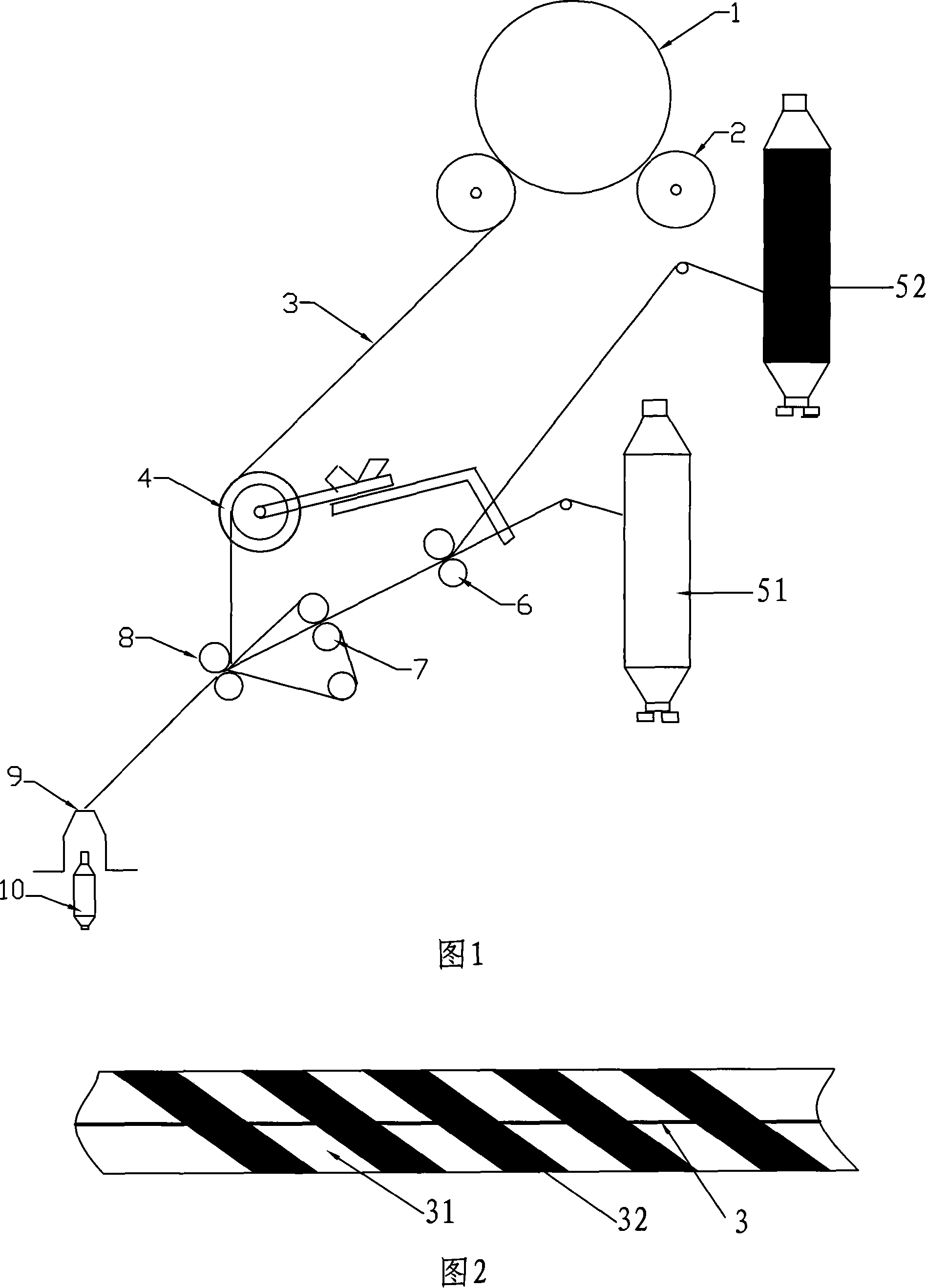

Siro-spinning spandex core-spun yarn

The present invention discloses a cellophane polyurethane fiber core-spun yarn. Said cellophane polyurethane fiber core-spun yarn is unique in style, possesses advantages of cellophane yarn and polyurethane fiber core-spun yarn simultaneously and can be used as high-grade textile face fabric. Its structure is characterized by that its center is polyurethane fiber yarn, and the exterior of said central polyurethane fiber yarn is covered with yarn fiber layer, and said yarn fiber layer is made up by using two strands of fiber through a certain winding and twisting process.

Owner:ZHANGJIAGANG TIANYI WEAVING

Film for food packaging

A film for food packaging which is excellent in workability, processability, productivity, gas-barrier properties, low-temperature heat sealability, safety, and mechanical strength. It can be a substitute for conventional cellophane / wax films, and is suitable for use as a packaging film for molten cheese, etc. The film for food packaging is composed of at least five layers, i.e., a fusion-bondable layer / adhesive layer / gas-barrier layer / adhesive layer / fusion-bondable layer, wherein the fusion-bondable layers are made of an olefin resin and melt at a temperature which is not lower than 60° C. and is lower than 90° C.

Owner:SHIKOKU KAKOH CO LTD

Preparation method of glass paper/polylactic acid/nanocellulose composite membrane

InactiveCN106633160ANot easy to layerImprove interface compatibilityCellulose coatingsPolyester coatingsFiberPolyethylene glycol

The invention discloses a preparation method of a glass paper / polylactic acid / nanocellulose composite membrane. The preparation method comprises the following steps: firstly, taking traditional glass paper as a base material; modifying the surface of the glass paper through an immersion manner, so as to improve the interface compatibility between the glass paper and a composite layer; secondly, compounding polylactic acid on the surface of the modified glass paper, so as to improve the waterproof performance and enhance the mechanical properties of the traditional glass paper to a certain extent; thirdly, uniformly dispersing cellulose nanofibers into a dichloromethane solution by adopting a method of compounding polyethylene glycol and mixing with a polylactic acid solution; forming the composite layer by the glass paper modified by immersion; finally, obtaining a high-intensity and waterproof glass paper / polylactic acid / nanocellulose composite membrane material. According to the preparation method disclosed by the invention, the problem that the polylactic acid in a lamination layer is easy to fall off is solved through carrying out interface modification and uniformly adding the cellulose nanofibers; the waterproof performance and the mechanical strength of the traditional glass paper are greatly improved and a process is simple so that industrialization is easier to realize.

Owner:NANJING FORESTRY UNIV

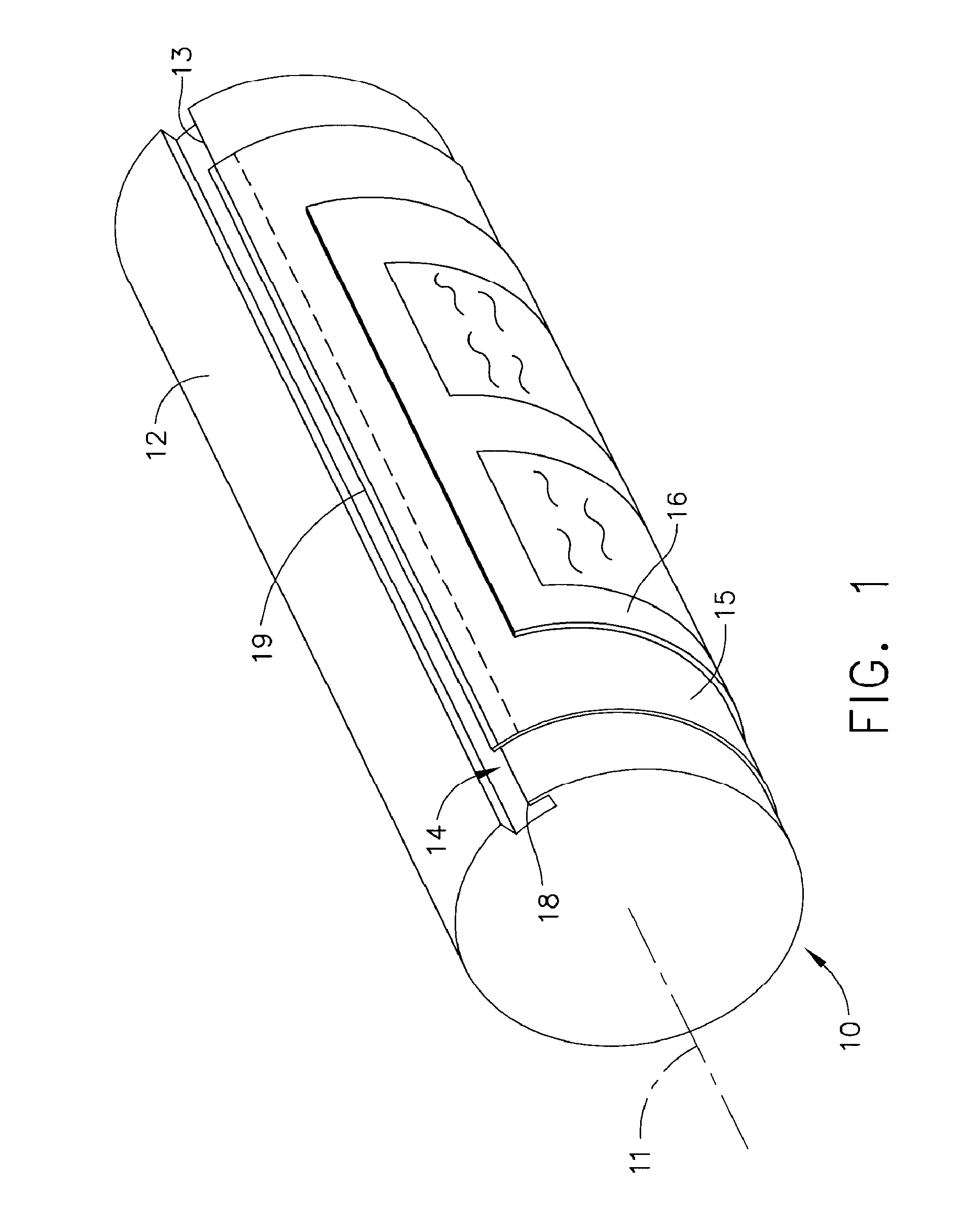

Label printing cylinder and process

A printing cylinder for printing at least two different designs on a continuous roll of a substrate. The printing cylinder has at least one printing plate secured to the surface of the cylinder, and each printing plate prints a different design. The substrate comprises vinyl, PVP, cellophane, wood pulp, or paper. The printing cylinder typically has at least two printing plates, that occupy the same arc or different arcs of the circumference of the printing cylinder. Also disclosed is a printing station comprising the printing cylinder, and a process for printing at least two different designs on a continuous roll of a substrate using the printing cylinder.

Owner:U S NONWOVENS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com