Transparent super-hydrophobic spraying agent, and preparation method and application thereof

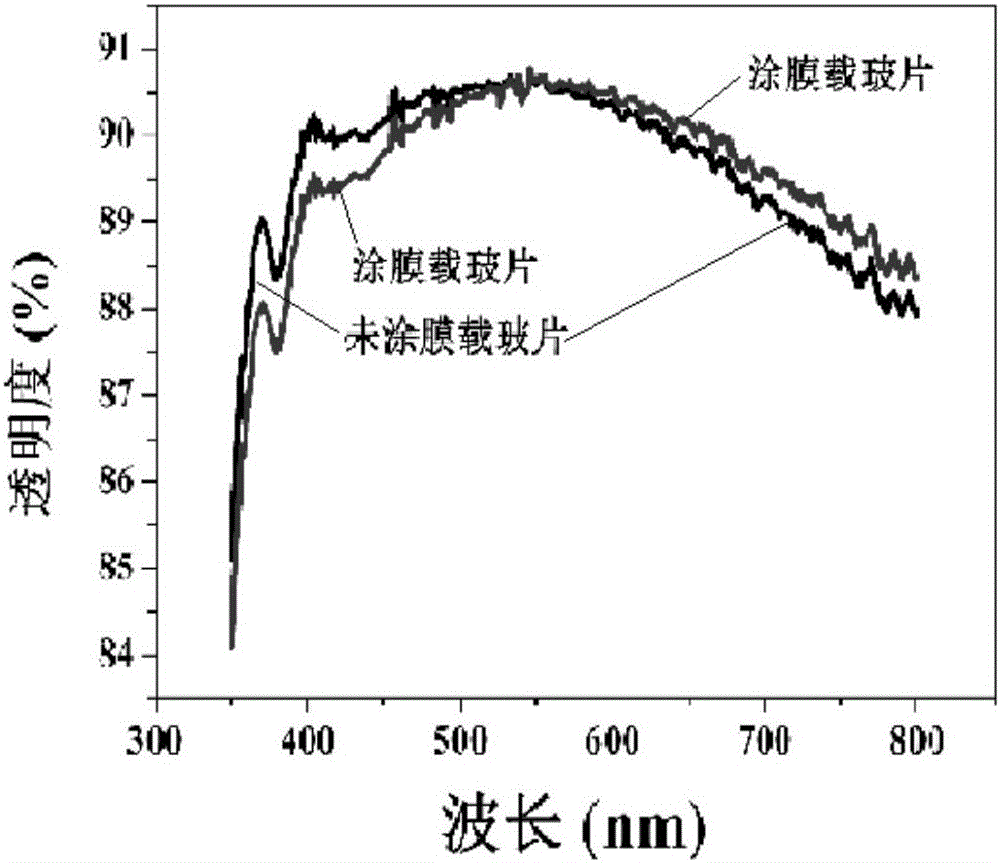

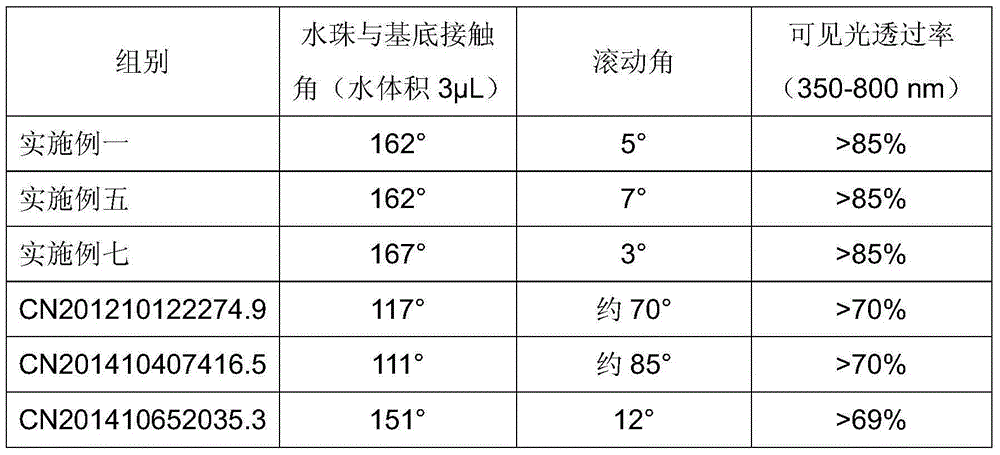

A super-hydrophobic and transparent technology, applied in the direction of coating, etc., can solve the problems of difficult decomposition, great harm, unfavorable civilian production, etc., and achieve the effect of good hydrophobic performance, convenient use, and high visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

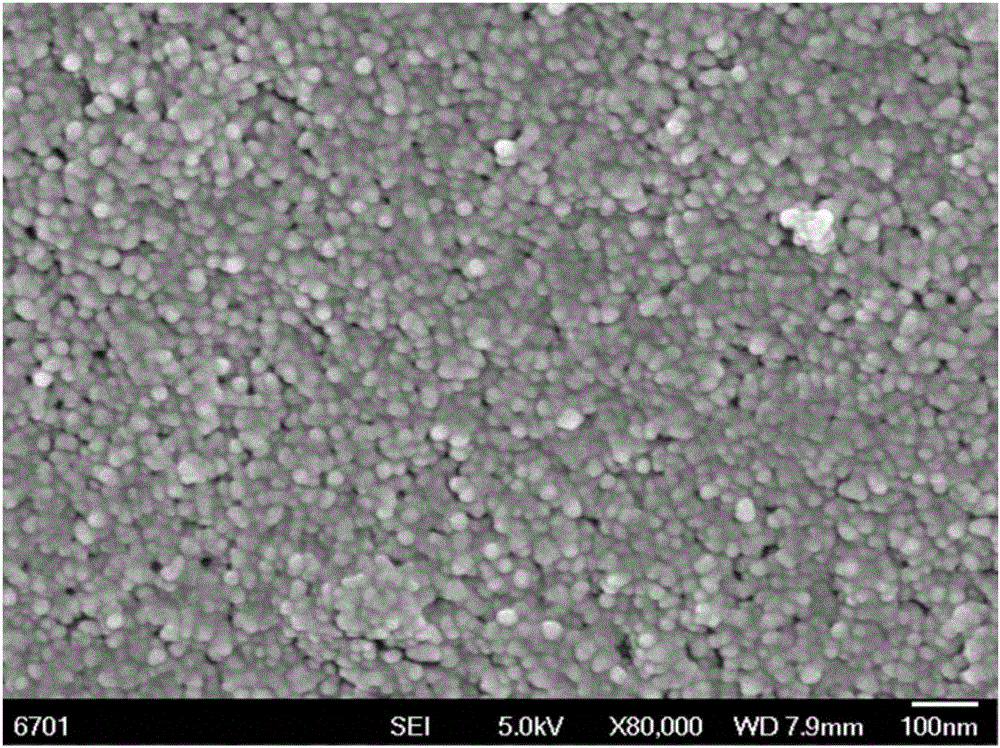

Image

Examples

preparation example Construction

[0019] The second aspect of the present invention provides a kind of preparation method of transparent superhydrophobic spray, it comprises the following steps:

[0020] (1) Preparation of sol: provide tetraethyl orthosilicate solution A and alkaline solution B, mix to obtain mixed solution C, add acidic solution, adjust PH to 1~3, and react to obtain silica sol with a solid content of 5- 30% silica sol;

[0021] (2) Preparation of gel: adding alkaline solution B to the silica sol obtained in step (1) to make its pH value 8-10 to obtain transparent silica gel;

[0022] (3) Modification of the gel: Mix the modifier with the dispersion medium to obtain the mixed solution D, and add the mixed solution D to the silica gel obtained in step (2), and react at 30-80°C for 1-24h , to obtain an alkylated silica gel;

[0023] (4) Dispersion of the gel and preparation of the spray: add a dispersion medium to the alkylated silica gel obtained in step (3), wash and disperse to obtain a di...

Embodiment 1

[0033] (1) Mix 4.7g ethyl orthosilicate and 7.9g methanol uniformly to obtain mixed solution A; mix 7.5g 0.02mol / L ammonia water and 7.9g ethanol uniformly to obtain mixed solution B. Mix mixed solution A and mixed solution B evenly to obtain mixed solution C. Add 3.5 g of 0.1 mol / L hydrochloric acid to the mixed solution C, and then ultrasonicate at 50 Hz for 2 hours to obtain a sol precursor, and the silicon dioxide content of ethyl orthosilicate is 28%;

[0034] (2) adding ammonia water with a mass fraction of 25%-28% to the sol precursor under the condition of high-speed stirring, so that the pH value is 8-10, and a transparent gel precursor is obtained;

[0035] (3) Mix 8 g of triethylchlorosilane and 48.5 g of n-hexane evenly to obtain a mixed liquid D. Add the mixed solution D to the gel precursor and react at 60°C for 16 hours to obtain an alkylated silica gel;

[0036](4) washing the alkylated silica gel with n-hexane and n-propanol, adding 20 g of n-propanol to the...

Embodiment 2

[0042] (1) Mix 4.7g ethyl orthosilicate and 7.9g ethanol uniformly to obtain mixed solution A; mix 7.5g 0.02mol / L ammonia water and 7.9g ethanol uniformly to obtain mixed solution B. Mix mixed solution A and mixed solution B evenly to obtain mixed solution C. Add 3.5 g of 0.1 mol / L hydrochloric acid to the mixed solution C, and then ultrasonicate at 50 Hz for 2 hours to obtain a sol precursor, and the silicon dioxide content of ethyl orthosilicate is 28%;

[0043] (2) adding ammonia water with a mass fraction of 25%-28% to the sol precursor under the condition of high-speed stirring, so that the pH value is 8-10, and a transparent gel precursor is obtained;

[0044] (3) Mix 6.5 g of trimethylchlorosilane and 48.5 g of n-hexane evenly to obtain a mixed liquid D. Add the mixed solution D to the gel precursor and react at 60°C for 16 hours to obtain an alkylated silica gel;

[0045] (4) washing the alkylated silica gel with n-hexane and n-propanol, adding 20 g of n-propanol to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com