Layout for reducing aberration sensitiveness, light shield manufacture and graphic method

A technology of layout method and manufacturing method, which is applied in the direction of photoplate making process, optics, and originals for photomechanical processing on the pattern surface, which can solve the problems of reducing the sensitivity of the lithography system to aberrations and achieve the best critical size Consistency, reduced aberration sensitivity, improved density distribution and uniformity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

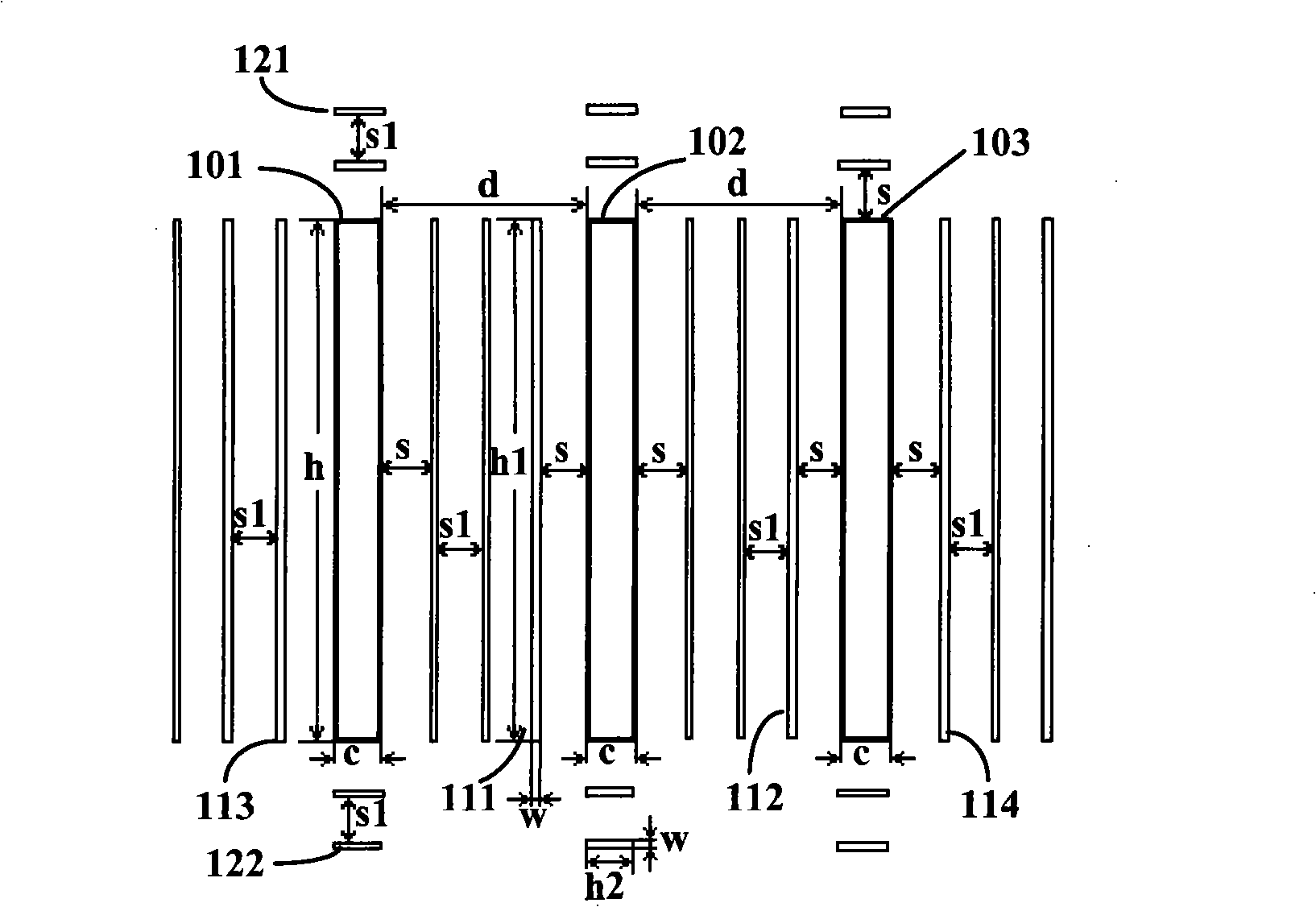

[0025] Please refer to figure 1 , figure 1 It is a schematic diagram of adding layout auxiliary graphics to one-dimensional layout patterns in the layout method for reducing aberration sensitivity described in the present invention. As shown in the figure, the layout patterns 101, 102, 103 parallel to each other form a one-dimensional layout pattern, and the width c of the layout patterns 101, 102, 103 is 1CD. According to the distance between the layout graphics 101, 102, 103, the layout graphics can form a one-dimensional dense pattern, a one-dimensional semi-dense pattern, or a one-dimensional isolated pattern. The dense pattern means that the distance between the layout graphics is equal to 1CD, semi-dense A pattern means that the distance between the layout graphics is greater than 1CD and less than or equal to 3CD, and an isolated pattern means that the distance between the layout graphics is greater than 3CD. In this embodiment, the spacing d of the layout patterns 10...

no. 2 example

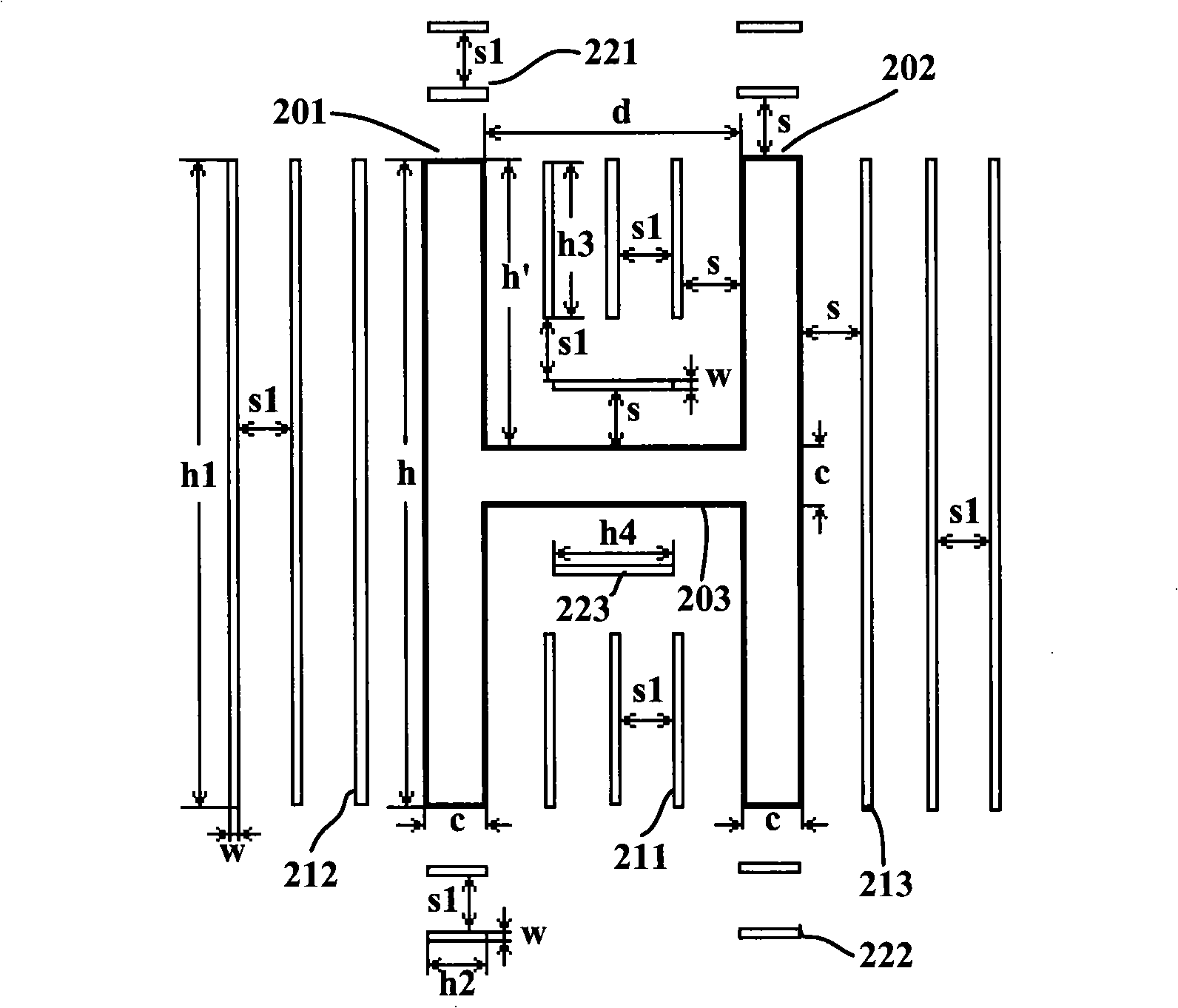

[0030] Please refer to figure 2 , figure 2 It is a schematic diagram of adding layout auxiliary graphics to two-dimensional layout patterns in the layout method for reducing aberration sensitivity described in the present invention, wherein it is the same as figure 1 The same symbols represent the same or similar meanings. As shown in the figure, the layout pattern 203 is perpendicular to and connects the layout patterns 201 and 202, that is, constitutes a two-dimensional layout pattern. The width c of the layout patterns 201, 202 and 203 is 1CD. According to the distance between the layout graphics 201 and 202, the layout graphics can form a two-dimensional dense pattern, a two-dimensional semi-dense pattern or a two-dimensional isolated pattern. The dense pattern means that the distance between the layout graphics is equal to 1CD, and the semi-dense pattern means The distance between the layout graphics is greater than 1CD and less than or equal to 3CD, and the isolated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com