Method for producing layered material wrinkles

A layered material and fold technology, which is applied in the field of rapid preparation of layered material folds, can solve the problems of high difficulty, high energy consumption, and cumbersome methods, and achieve the effects of low cost, low energy consumption, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) with 4×4cm 2 PDMS membrane as the substrate.

[0048] (2) Use tweezers to pick up highly oriented pyrolytic graphite (HOPG) crystals purchased from Nanjing Xianfeng Nano Co., Ltd., adhere to the surface of the PDMS film, and use multiple PDMS films of the same size to repeatedly cleavage, that is Thin-layer graphene was obtained on PDMS membrane.

[0049] (3) Put the PDMS film sample with graphene into liquid nitrogen to quench quickly, stay for 5 seconds, take it out quickly and place it in room temperature environment, and then the graphene wrinkle structure can be obtained on the surface of the PDMS film.

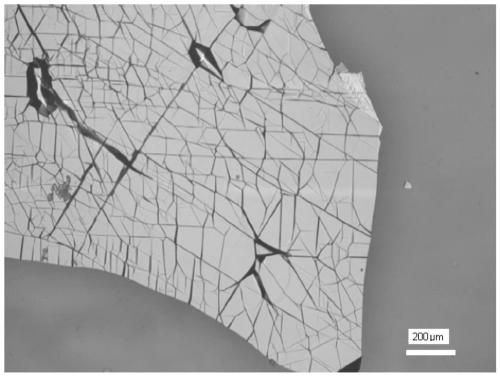

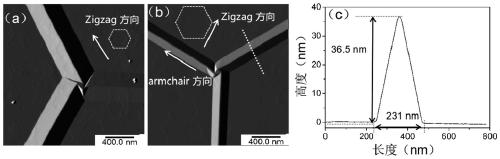

[0050] (4) Repeat step (3) many times to obtain more wrinkled structures. The obtained folds can be directly observed by an optical microscope, and the folds form a converging network structure, and the pitch of the folds is usually in the range of 1 to 20 microns. The height and width of the wrinkles can be characterized by atomic force microscopy. The di...

Embodiment 2

[0053] (1) in 1×1cm 2 silica gel membrane as the substrate.

[0054] (2) Pick up MoS purchased from Nanjing Xianfeng Nano Co., Ltd. with tweezers 2 Crystals, adhered to the surface of the silica gel membrane, and repeatedly cleaved with multiple silica gel membranes of the same size, that is, a thin layer of MoS was obtained on the silica gel membrane. 2 .

[0055] (3) will have MoS 2 The silica gel film sample is quickly put into liquid nitrogen to quench, stay for 10 seconds, quickly take it out and place it at room temperature, and MoS can be obtained on the surface of the silica gel film. 2 wrinkled structure.

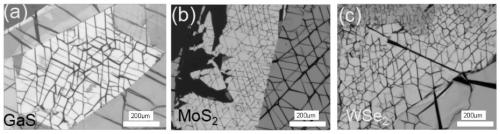

[0056] (4) Repeat step (3) many times to obtain more wrinkled structures. The obtained folds can be directly observed by an optical microscope, and the folds form a converging network structure, and the pitch of the folds is usually in the range of 1 to 20 microns. figure 2 (b) is the multilayer MoS on the silica gel substrate that embodiment 2 makes 2 wrin...

Embodiment 3

[0058] (1) in 1×1cm 2 silica gel membrane as the substrate.

[0059] (2) Use tweezers to pick up WSe purchased from hq-graphene company 2 Crystals, adhered to the surface of the silica gel membrane, and repeatedly cleaved with multiple silica gel membranes of the same size, that is, a thin layer of WSe was obtained on the silica gel membrane. 2 .

[0060] (3) will have WSe 2 The silica gel membrane sample is quickly put into liquid nitrogen to quench, stay for 10 seconds, quickly take it out and place it at room temperature, and then WSe can be obtained on the surface of the silica gel membrane. 2 wrinkled structure.

[0061] (4) Repeat step (3) many times to obtain more wrinkled structures. The obtained folds can be directly observed by an optical microscope, and the folds form a converging network structure, and the pitch of the folds is usually in the range of 1 to 20 microns. figure 2 (c) is the multilayer WSe on the silica gel substrate that embodiment 3 makes 2 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com