A kind of method for salting out of trimethyl borate

A trimethyl borate and salting-out technology, which is applied in the field of mixture analysis and purification, can solve the problems of high cost, cumbersome operation, and long time consumption, and achieve the effects of high yield, simple process, and avoiding strict requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

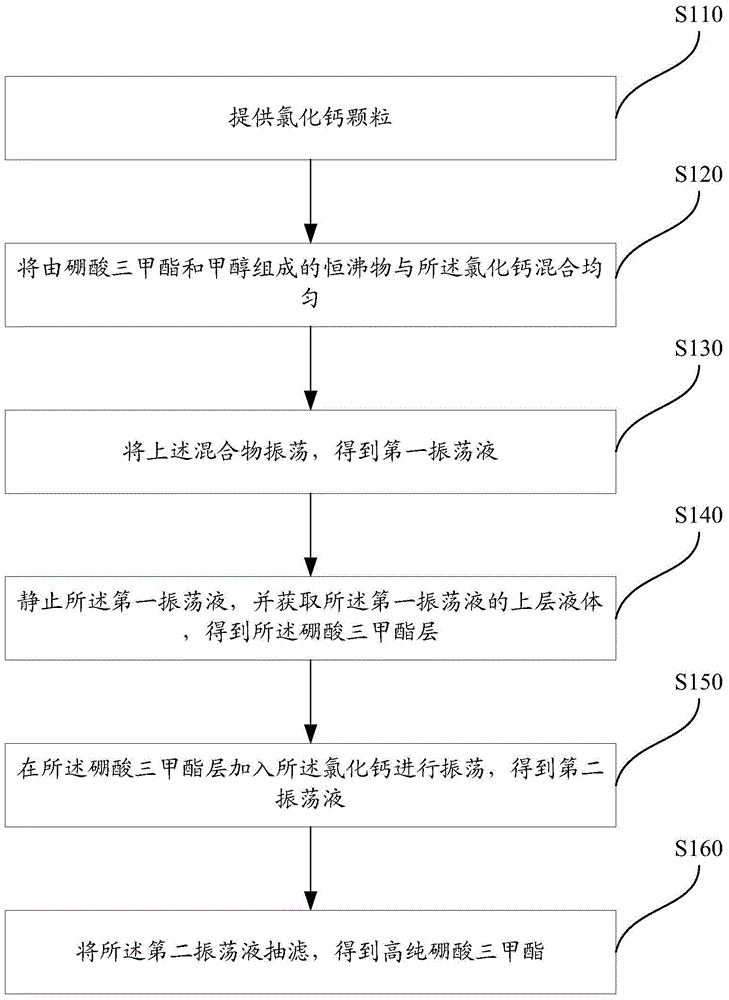

Image

Examples

Embodiment 1

[0052] Weigh 2.0g of 20-80 mesh mixed mesh powder calcium chloride in a 100ml iodine measuring bottle; mix the azeotrope composed of trimethyl borate and methanol with the calcium chloride evenly, wherein trimethyl borate The mass ratio of ester to methanol is 70%: 30%; the above mixture is oscillated, wherein the oscillating ambient temperature is 20°C, the oscillating time is 10min, and the oscillating speed is 280r / min to obtain the first oscillating liquid; The liquid is transferred to a separatory funnel, and separated after standing for 30 minutes. The upper layer is a trimethyl borate layer, and the lower layer is a salt and alcohol layer. The upper layer and the lower layer are titrated to analyze the purity of trimethyl borate. The purity of trimethyl borate in the upper layer is 91.64 And the yield is 83.12, the quality of the lower layer is 12.9, which contains 36.90% of trimethyl borate.

Embodiment 2

[0054] Weigh 4.0g of 20-80 mesh mixed mesh powder calcium chloride in a 100ml iodine measuring bottle; mix the azeotrope composed of trimethyl borate and methanol with the calcium chloride evenly, wherein trimethyl borate The mass ratio of ester to methanol is 70%: 30%, wherein the ambient temperature of oscillation is 30°C, the oscillation time is 20min, and the oscillation speed is 300r / min to obtain the first oscillation liquid; Liquid funnel, separate liquid after standing for 30 minutes, the upper layer is a trimethyl borate layer, the lower layer is a salt and alcohol layer, take the upper layer and the lower layer to titrate and analyze the purity of trimethyl borate, the upper layer trimethyl borate has a purity of 93.40 and a yield of 89.30, The lower mass 13.2 contains trimethyl borate 23.11%.

Embodiment 3

[0056] Weigh 1.0g of 20-80 mesh mixed mesh powder calcium chloride in a 100ml iodine measuring bottle, and mix the azeotrope composed of trimethyl borate and methanol with the calcium chloride evenly, wherein trimethyl borate The mass ratio of ester to methanol is 70%: 30%, wherein, the ambient temperature of oscillation is 30°C, the oscillation time is 30min, and the oscillation speed is 320r / min to obtain the first oscillation liquid; the first oscillation liquid is static, and Obtain the upper liquid of the first oscillating liquid to obtain the trimethyl borate layer, wherein the resting time is 20 min; add the trimethyl borate layer to the calcium chloride for oscillation to obtain the second oscillating liquid, Among them, the oscillation is under the same conditions as the first oscillation; the second oscillation liquid is transferred to the separatory funnel, and the oscillation is over. Since the solution is no longer stratified, suction filtration is selected, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com