Sound absorption coefficient field measurement apparatus and method

A technology for on-site measurement and sound absorption coefficient, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc. It can solve the problem of undesigned test devices, sound absorption details that cannot match the application conditions, and expensive reverberation chamber construction costs, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

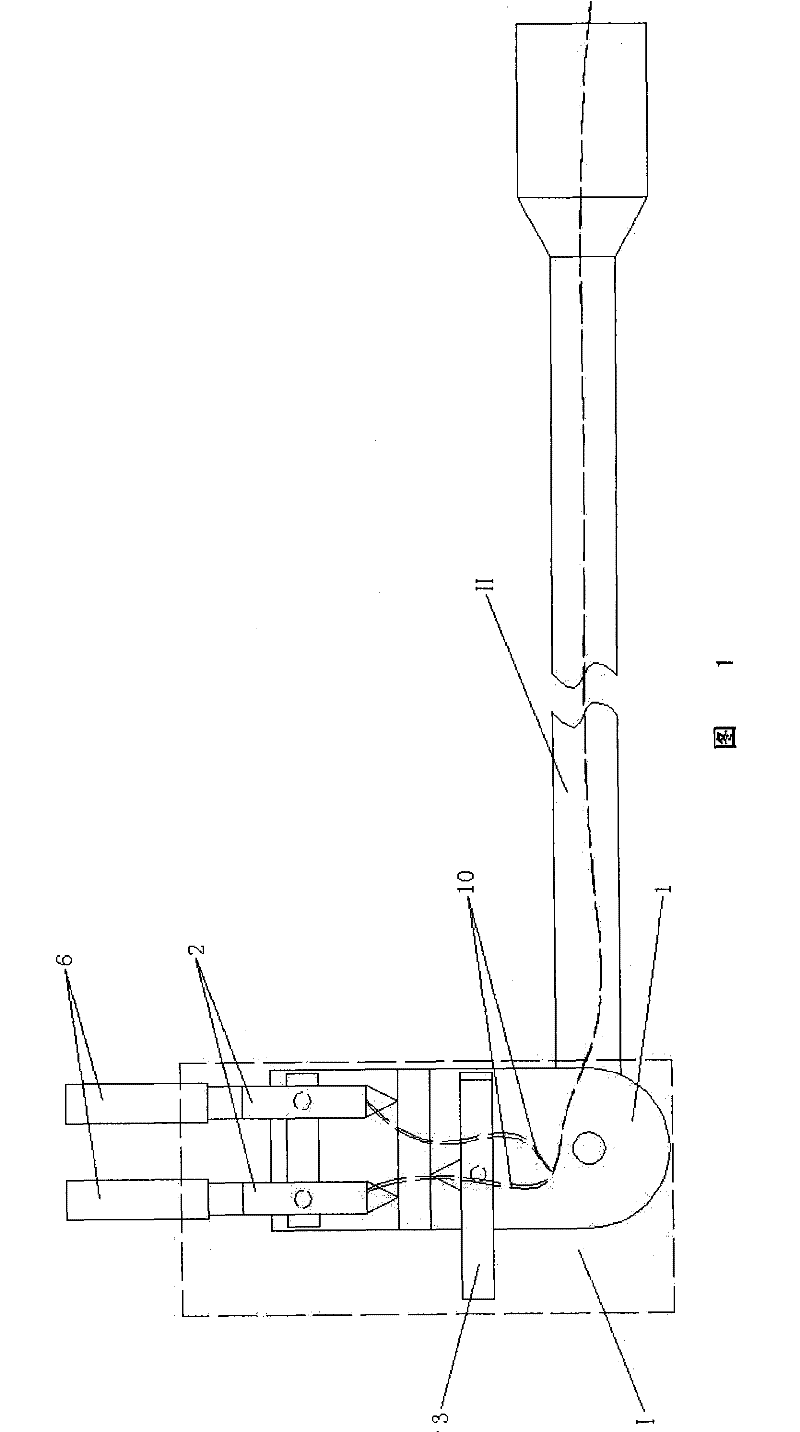

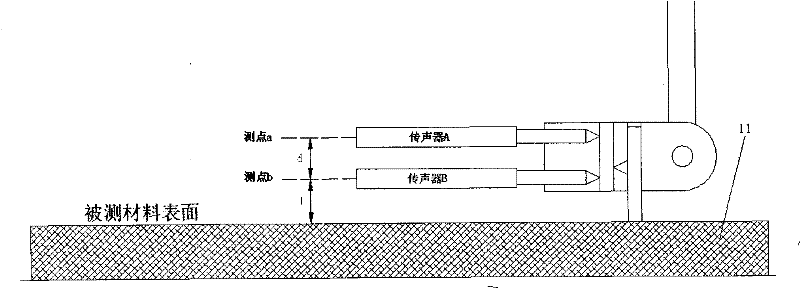

[0025] As shown in FIG. 1, the measuring device of the present invention includes a measuring probe I and a hollow fixed handle II. The measuring probe 1 includes a probe base 1, two microphone measuring probes 2 and a material spacing measuring probe 3.

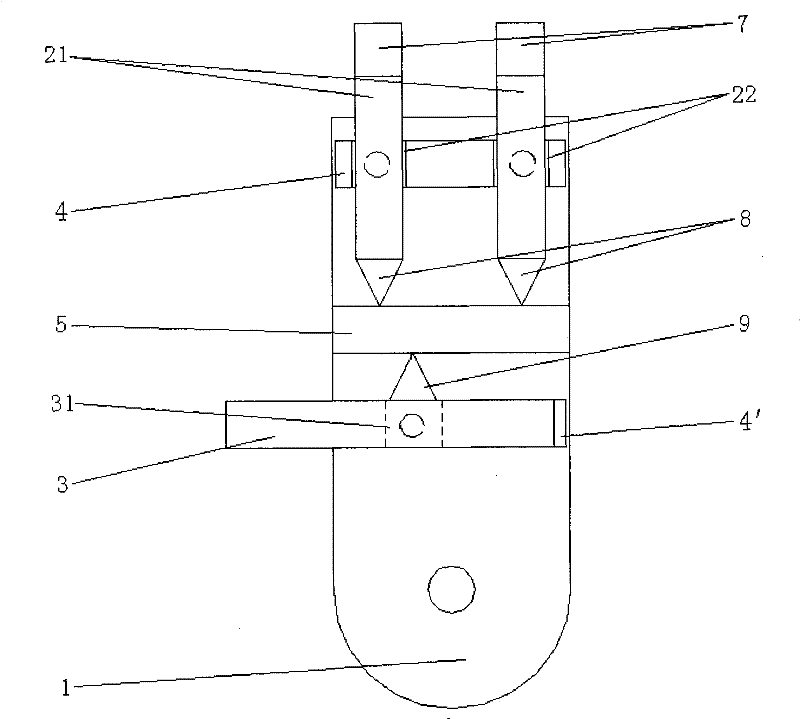

[0026] Such as figure 2 As shown, the probe base 1 is a metal plate with a rectangle at one end and a semicircle at the other end, which is used to fix the microphone measuring probe 2 and the material distance measuring probe 3 . A sliding slot 4, 4' is opened on the probe base 1 near the rectangular end and in the middle, and a position measuring ruler 5 is arranged laterally on the probe base 1 between the two sliding slots 4, 4'. The round end of the probe base 1 is pivotally connected to the fixed handle II through bolts and fixed nuts, and the fixed handle II can be held for measurement.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com