Laser ray spacing measurement method for robot self-calibration

A measurement method and self-calibration technology, applied in the field of robot calibration, can solve the problems of low efficiency and achieve high efficiency and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

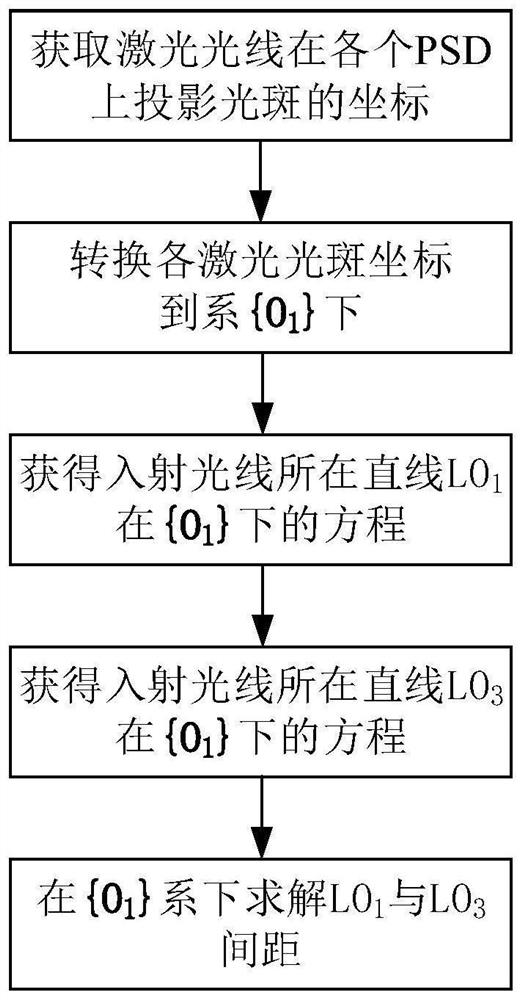

[0050] Laser beam distance measurement method for robot self-calibration, such as figure 1 shown, including the following steps:

[0051] Step 1. Obtain the coordinates of the laser light spot projected on each PSD

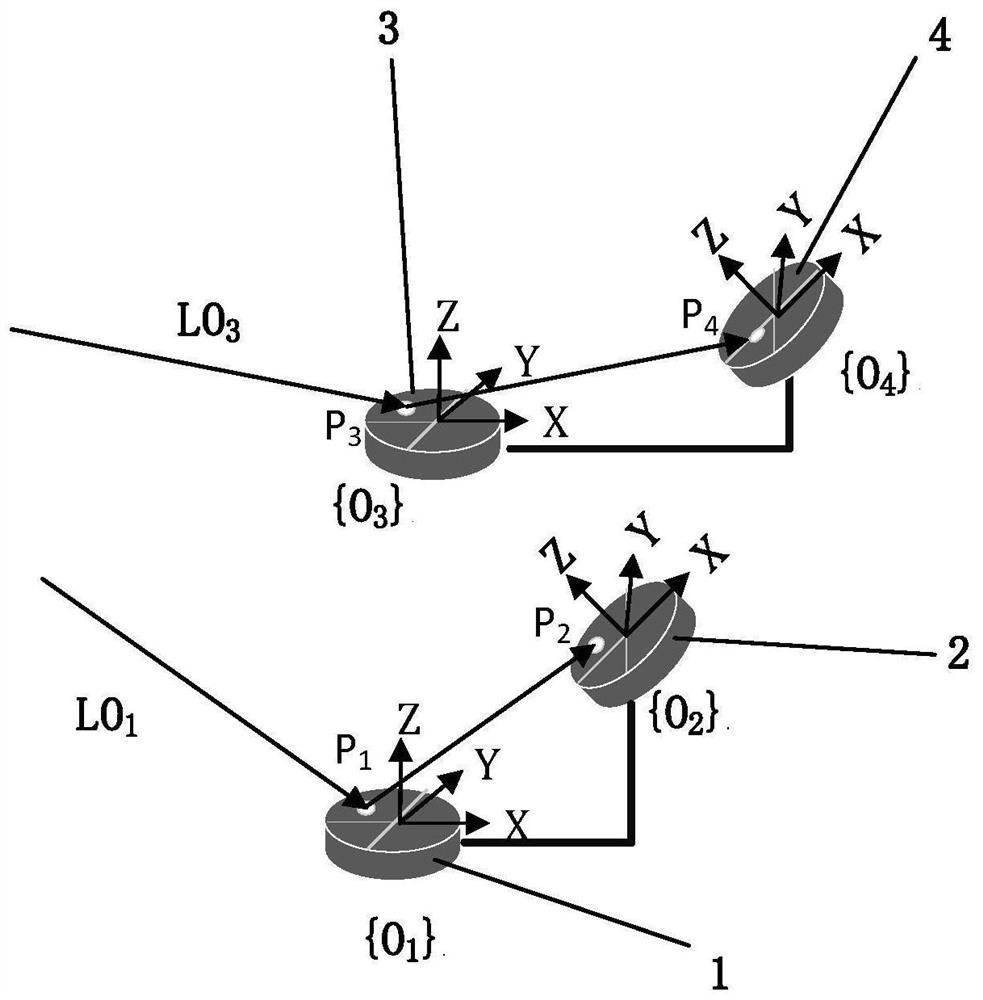

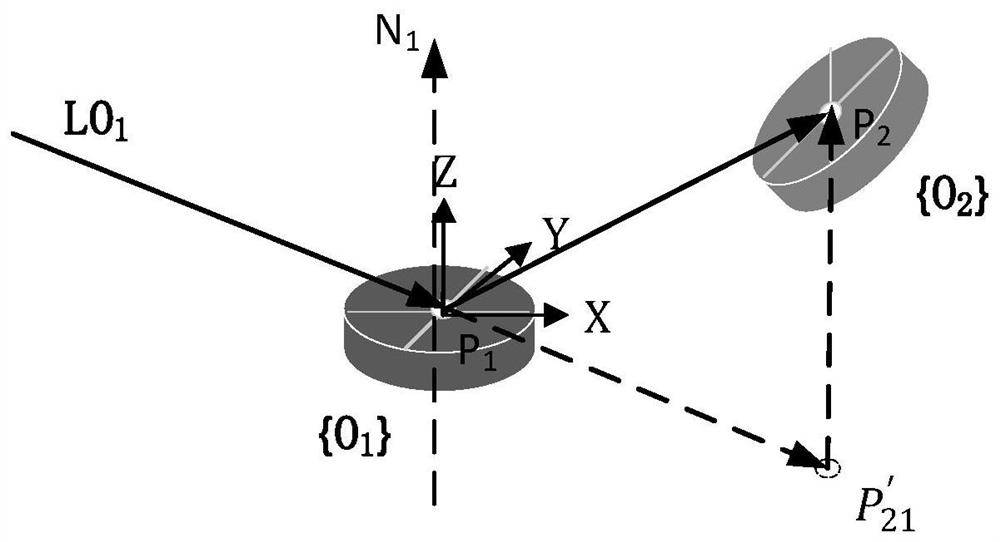

[0052] Such as figure 2 As shown, let the PSD 1 1 The coordinate system is {O 1}, PSD 2 2 The coordinate system is {O 2}, PSD 3 3 coordinate system is {O 3}, PSD 4 4 The coordinate system is {O 4}, {O 1}, {O 2}, {O 3}, {O 4} rigidly fixed together. Department {O 2} relative to the system {O 1}’s pose transformation matrix is Department {O 3} relative to the system {O 1}’s pose transformation matrix is Department {O 4} relative to the system {O 1}’s pose transformation matrix is is known; make the laser light LO 1 via PSD 1 1 center area reflection to PSD 2 2 central area, at this time incident to the system {O 1} Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com