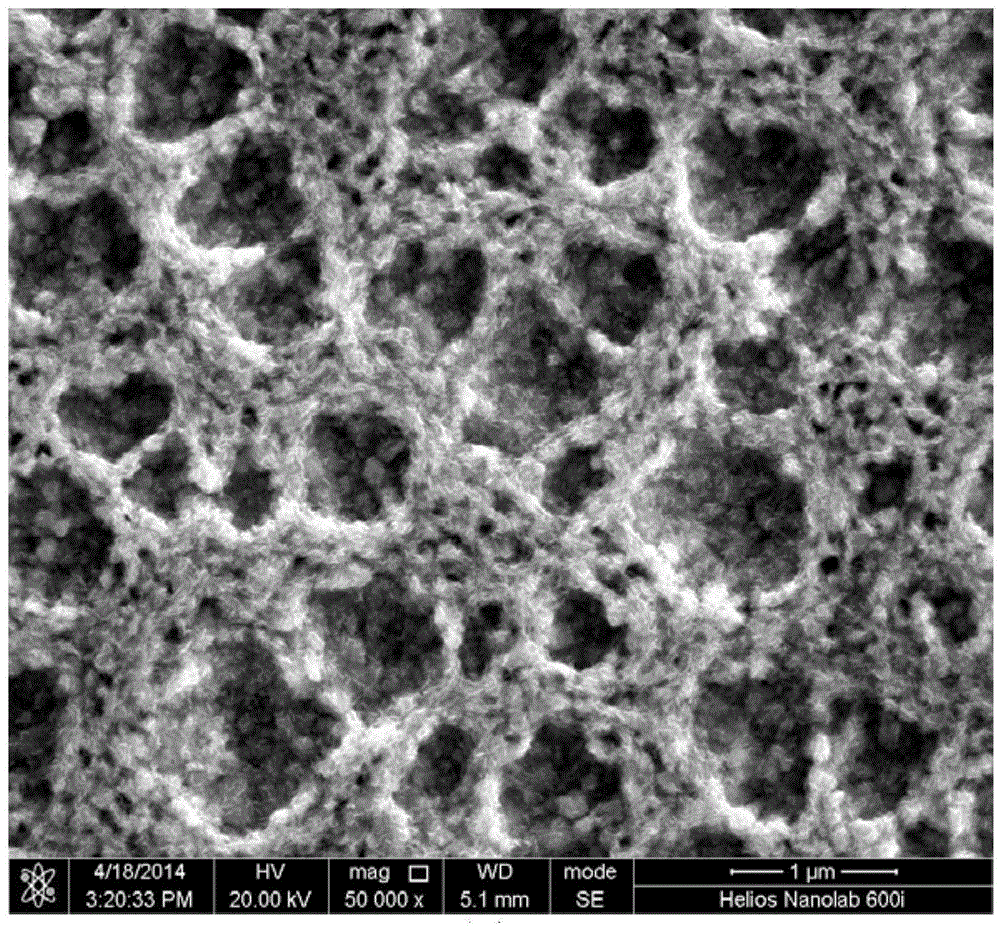

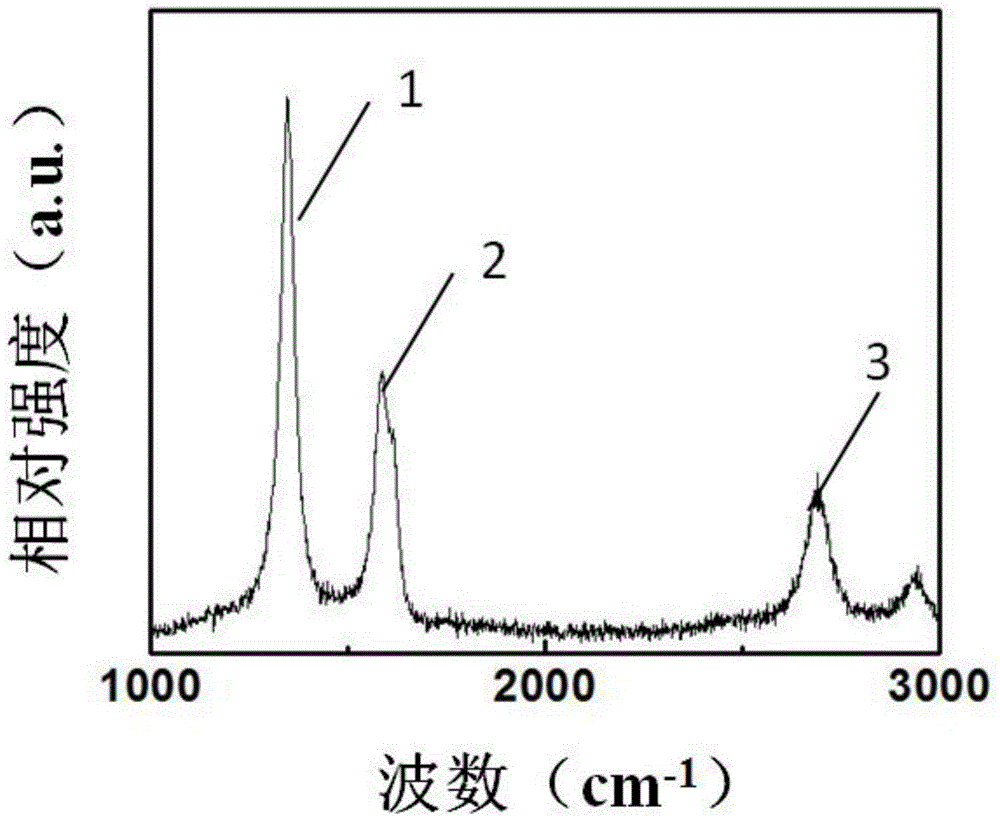

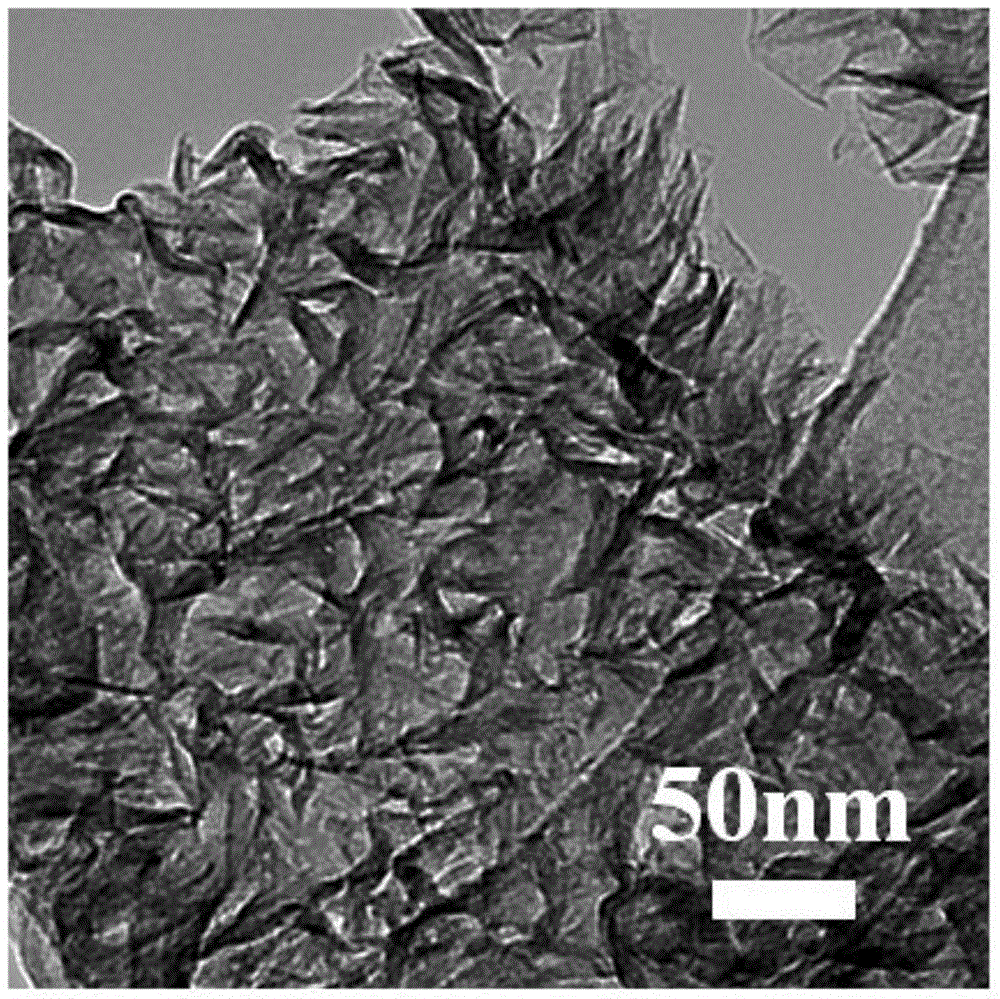

Preparation method of 3D bowl-shaped graphene super capacitor electrode material of mixed nanometer structure

A technology of supercapacitors and nanostructures, applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problem that the effective specific surface area of electrode materials cannot continue to increase, the effective area of charge conduction and storage decreases, and the probability of charge annihilation increases and other problems, to achieve the effect of reducing the probability of charge annihilation, reducing the porosity effect, and increasing the storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment one: the preparation method of a kind of 3D bowl-shaped mixed nanostructure graphene supercapacitor electrode material described in this embodiment, specifically is carried out according to the following steps:

[0021] 1. Put the substrate material in the plasma-enhanced chemical vapor deposition vacuum device, evacuate to a pressure below 5Pa, feed argon gas with a gas flow rate of 65sccm-95sccm, and adjust the vacuuming speed to put the plasma-enhanced chemical vapor deposition vacuum device The medium pressure is controlled at 100Pa~300Pa, and under the pressure of 100Pa~300Pa and argon atmosphere, the temperature is raised to 700℃~900℃ at a heating rate of 30℃ / min;

[0022] 2. Anneal the base material at a temperature of 700°C to 900°C, a pressure of 100Pa to 300Pa and an argon atmosphere, and the annealing time is 15min to 60min;

[0023] 3. Introduce carbon source gas, adjust the gas flow rate of carbon source gas to 5sccm-35sccm, and the gas ...

specific Embodiment approach 2

[0031] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the base material in step 1 is Pt / Ti / SiO 2 / Si multilayer hybrid substrate material. Others are the same as in the first embodiment.

[0032] The base material described in this specific embodiment can be used as a current collector of a supercapacitor.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and one of specific embodiments one or two is: the thickness of the Pt layer is 150nm-200nm; the thickness of the Ti layer is 20nm; the SiO 2 The layer thickness was 300 nm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com