Non-oriented electrical steel sheet having superior magnetic properties and a production method therefor

A technology of oriented electrical steel sheet and magnetism, applied in the direction of magnetism of inorganic materials, can solve the problems of hindering domain wall migration, hindering grain growth, increasing hysteresis loss, etc., to achieve excellent magnetism, lower manufacturing unit price, and lower costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

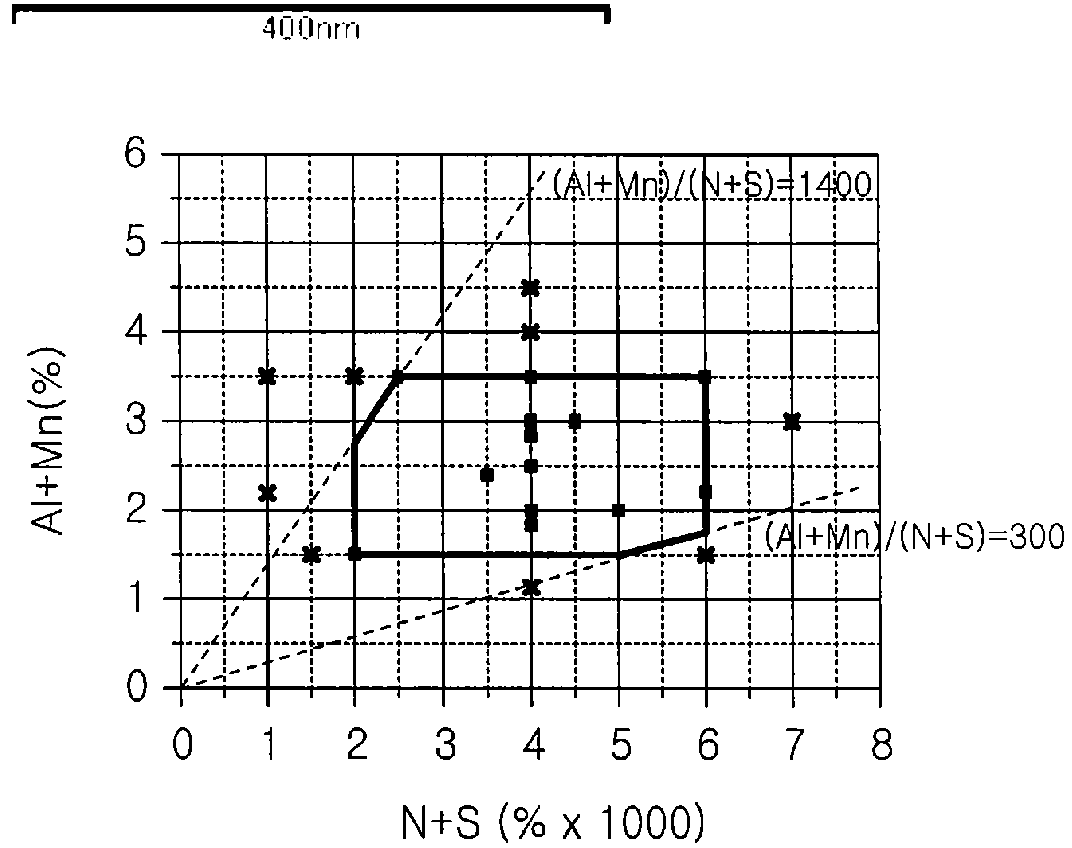

[0103] Vacuum melting was carried out in a laboratory to prepare steel ingots having the composition shown in Table 1 below. To this end, the content of the impurity elements C, S, N, and Ti of the raw materials is controlled at 0.002%, and 0.3~0.5% of Al is added to the molten steel to promote the formation of inclusions, and then the remaining Al and Si are added and Mn to produce steel ingots. Each ingot was heated to 1,150° C., and subjected to final hot rolling at 850° C. to manufacture a hot-rolled sheet having a thickness of 2.0 mm. The hot-rolled hot-rolled sheet was annealed at 1,050° C. for 4 minutes and then pickled. Subsequently, cold rolling was performed so that the thickness of the sheet material was formed to be 0.35 mm, followed by final annealing at 1,050° C. for 38 seconds.

[0104] The size and distribution density of inclusions, iron loss, magnetic flux density, and hardness of each sheet were measured. The results thereof are shown in Table 2 below. A...

Embodiment 2

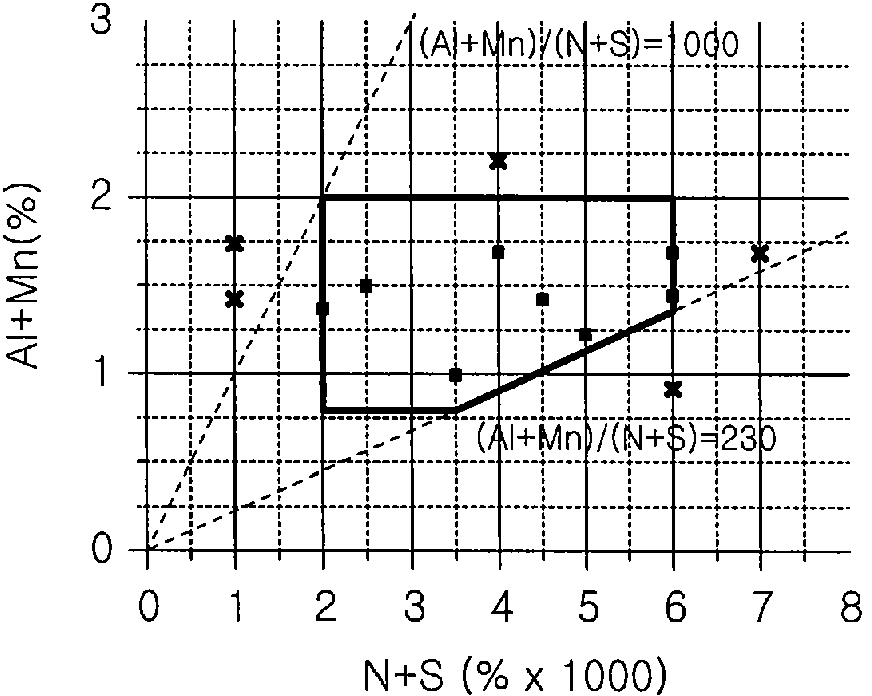

[0113] Vacuum melting was carried out in a laboratory, thereby preparing steel ingots having the compositions shown in Table 3 below. To this end, the composition of the steel is controlled while the amounts of impurity elements N and S are adjusted differently, and 0.3-0.5% of Al is added to the molten steel to promote the formation of inclusions, and then the remaining Al and Si and Mn are added Thereby producing steel ingots. Each ingot was heated to 1,150° C., and subjected to final hot rolling at 850° C. to manufacture a hot-rolled sheet having a thickness of 2.0 mm. The hot-rolled hot-rolled sheet was annealed at 1,050° C. for 4 minutes and then pickled. Subsequently, cold rolling was performed so that the thickness of the sheet material was formed to be 0.35 mm, followed by final annealing at 1,050° C. for 38 seconds.

[0114] The size and distribution density of inclusions, iron loss, magnetic flux density, and hardness of each sheet were measured. The results there...

Embodiment 3

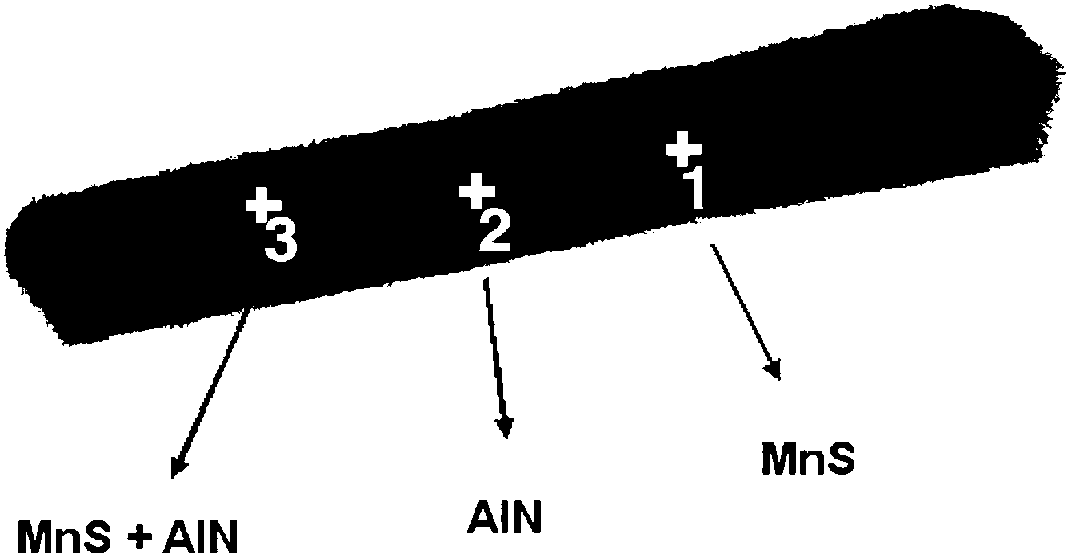

[0123] Vacuum melting was carried out in a laboratory to prepare steel ingots having the composition shown in Table 5 below. For this, 0.3~0.5% of Al is added to molten steel to promote the formation of inclusions, and thereafter the remaining Al and Si, Mn, and P are added to manufacture a steel ingot. Each ingot was heated to 1,150° C., and subjected to final hot rolling at 850° C. to manufacture a hot-rolled sheet having a thickness of 2.0 mm. The hot-rolled hot-rolled sheet was annealed at 1,050° C. for 4 minutes and then pickled. Subsequently, cold rolling was performed to form sheets having various thicknesses of 0.15˜0.35 mm, followed by final annealing at 1,050° C. for 38 seconds. Measure the iron loss and magnetic flux density of each sheet of different thickness. The results thereof are shown in Table 6 below. A sample for observation of inclusions was produced using a replica method commonly used in the steel industry, and a transmission electron microscope was u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com