Collophanite floatation method

A collophosphate and flotation technology, applied in flotation, solid separation and other directions, can solve the problem of not meeting the requirements of wet phosphoric acid production, and achieve the effects of saving pharmaceutical dosage, large processing capacity and small installed capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

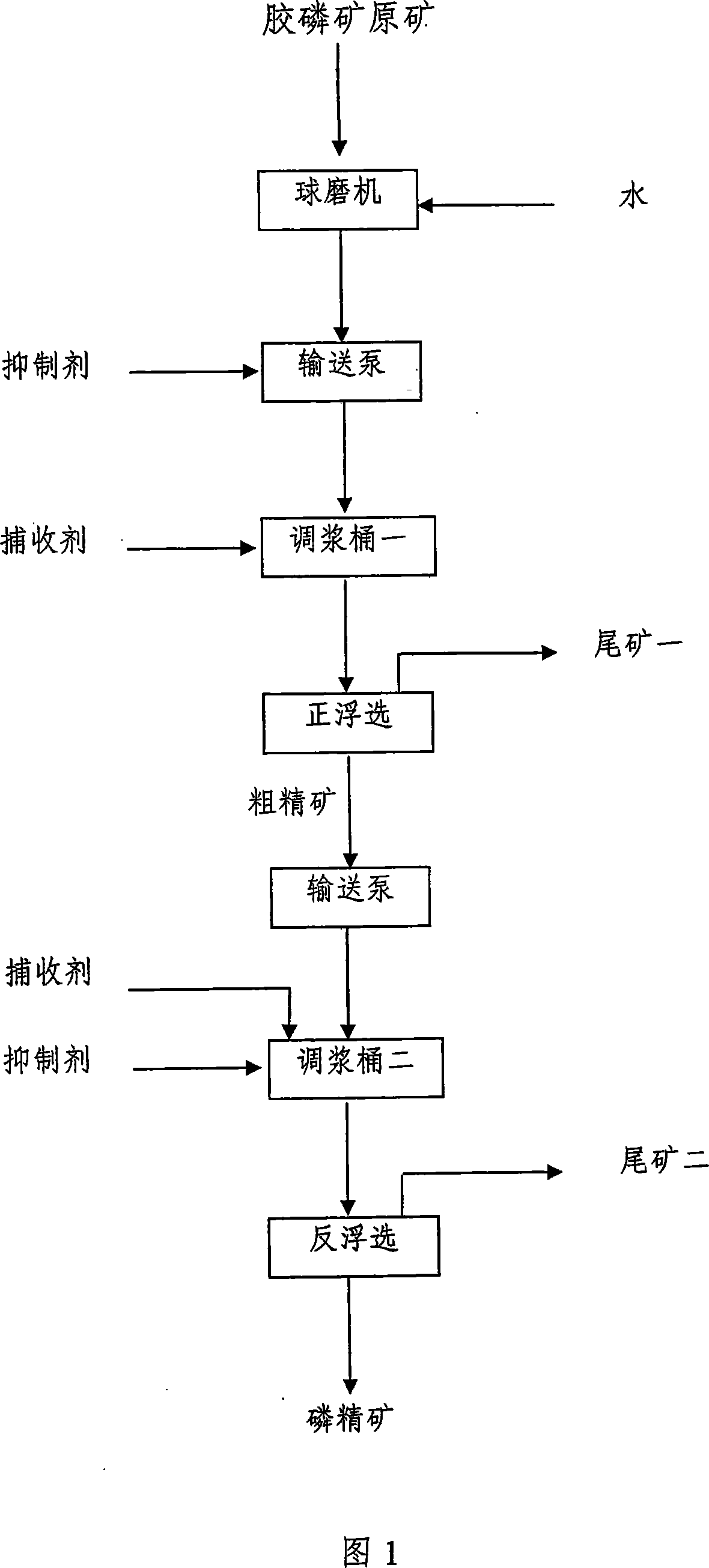

Method used

Image

Examples

Embodiment 1

[0039] Ore sample from a mining area in Anning, Yunnan, raw ore P 2 o 5 The grade is 22.30%, and the MgO content is 2.42%. The process adopts the positive and negative flotation process: the grinding fineness is -200 mesh 94%, the grinding concentration is 32%, and the flotation temperature is normal temperature. Positive flotation agent dosage: water glass 7.0kg / t, collector 3.0kg / t. The positive flotation froth product enters the reverse flotation system. Reverse flotation agent dosage: sulfuric acid 7.0kg / t, collector 0.4kg / t. Phosphorus concentrate P after reverse flotation 2 o 5 Grade 29.47%, MgO content 0.68%, P 2 o 5 The recovery rate reached 84.58%, and the MgO removal rate reached 82.02%.

Embodiment 2

[0041] Ore sample from a mining area in Kunyang, Yunnan, raw ore P 2 o 5 The grade is 23.01%, and the MgO content is 5.12%. The process adopts the positive and negative flotation process: the grinding fineness is -200 mesh 90%, the grinding concentration is 30%, the flotation temperature is normal temperature, and the dosage of positive flotation agents is: water glass 6.0kg / t, collector 3.0kg / t. The foam product of positive flotation enters the reverse flotation system, and the dosage of reverse flotation agent is: sulfuric acid 7.0kg / t, collector 0.4kg / t. Its P 2 o 5 Grade 30.22%, MgO content 0.96%, P 2 o 5 The recovery rate reached 86.6 8%, and the MgO exclusion rate was 87.6 3%.

Embodiment 3

[0043] Ore sample from a mining area in Dongchuan, Yunnan, raw ore P 2 o 5 The grade is 21.76%, and the MgO content is 4.08%. The process adopts the positive and negative flotation process: the grinding fineness is -200 mesh 93%, the grinding concentration is 31%, the flotation temperature is normal temperature, and the dosage of positive flotation agents is: water glass 8.0kg / t, collector 3.2kg / / t. The positive flotation foam enters the reverse flotation system, the dosage of reverse flotation reagents: sulfuric acid 8.0kg / t, collector 0.6kg / t, after reverse flotation, phosphorus concentrate is obtained, and its P 2 o 5 Grade 29.84%, MgO content 0.89%, P 2 o 5 The recovery rate reached 85.02%, and the MgO removal rate was 86.48%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com