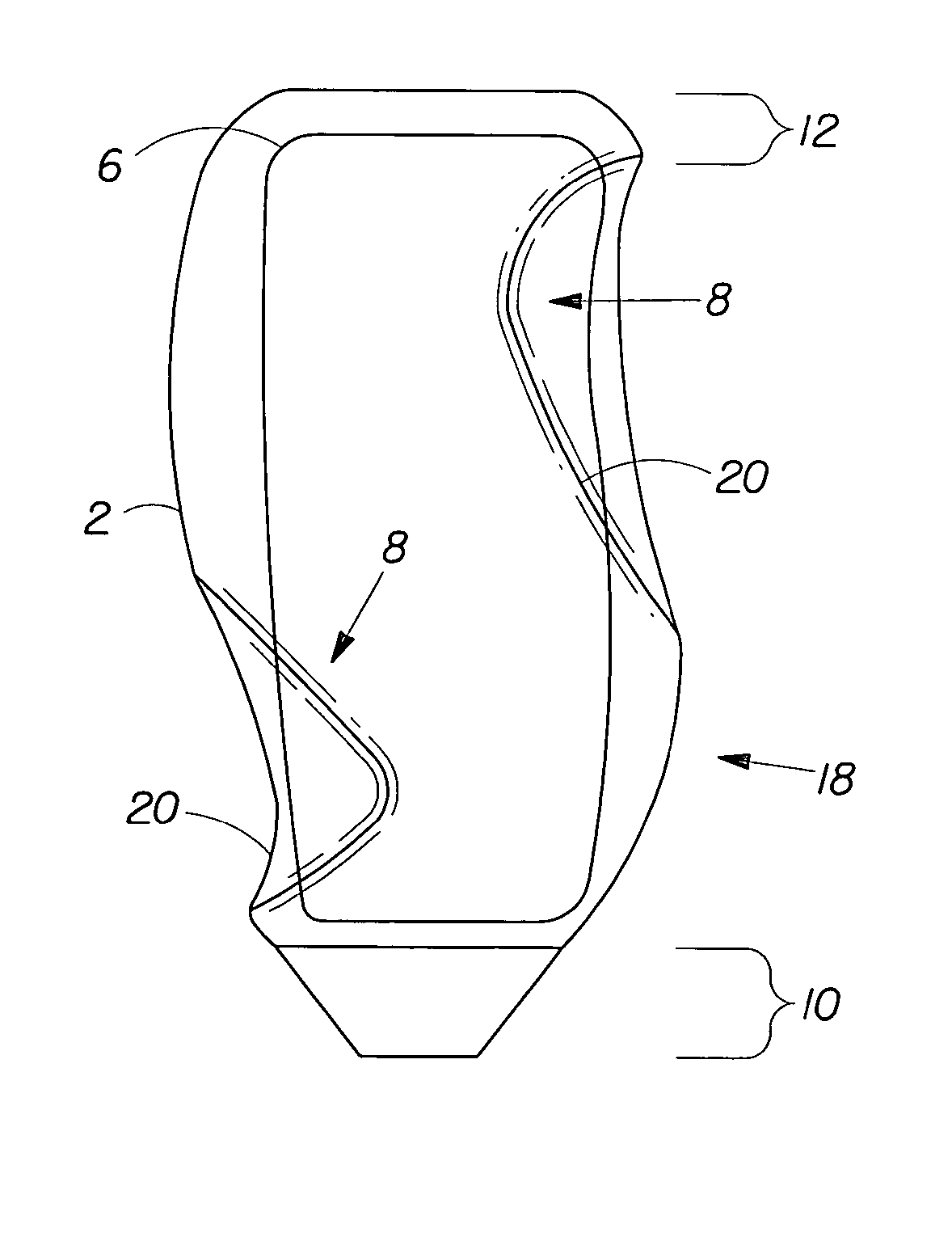

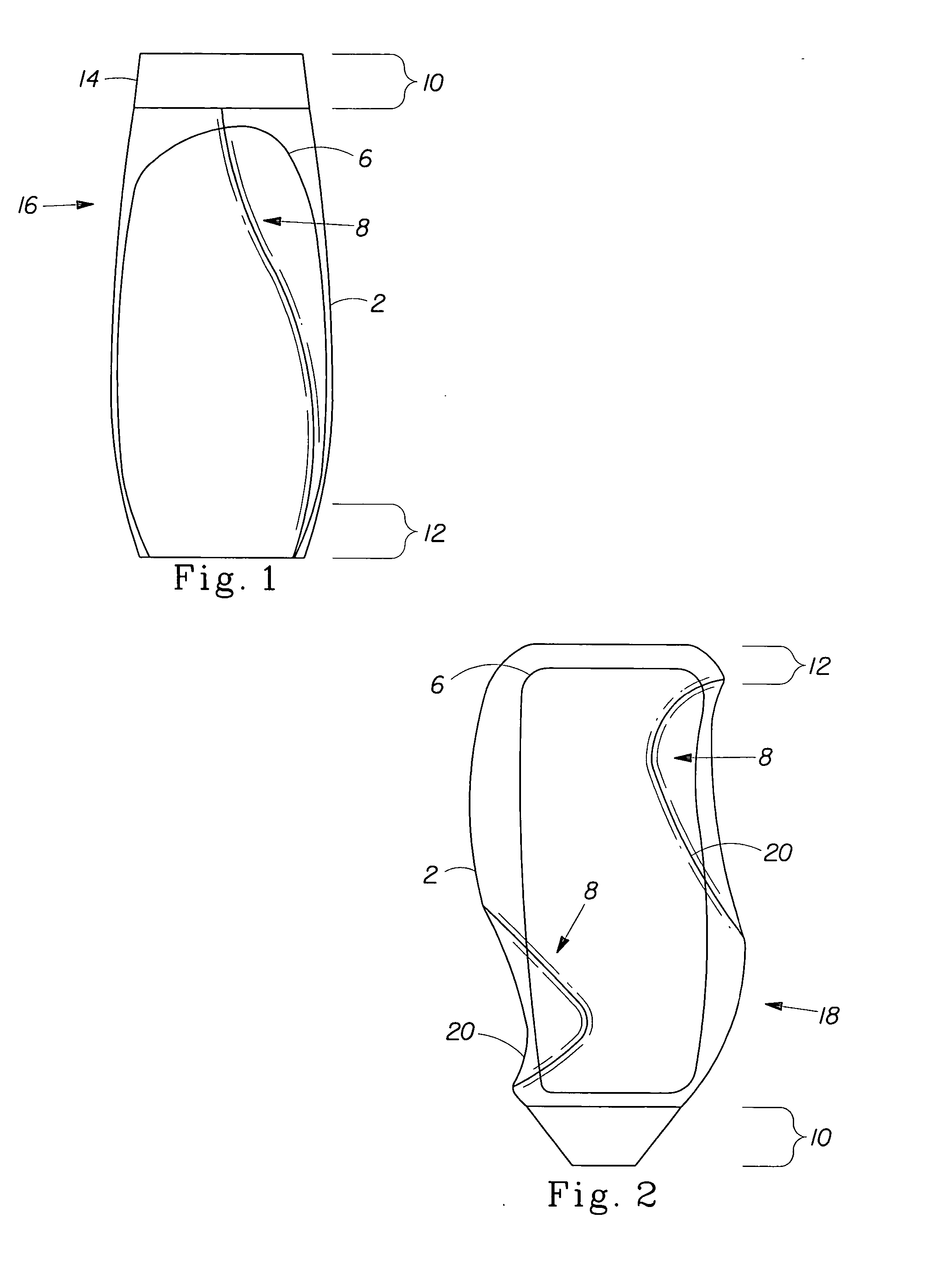

Container comprising an in-mold label positioned proximate to a surface topography

a container and surface topography technology, applied in the field of containers, can solve the problems of increasing the cost of manufacturing of containers, difficult to squeeze, and not liking containers with thick plastic walls, and achieve the effect of increasing the resiliency of containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The term “ambient conditions” as used herein, unless otherwise specified, refers to surrounding conditions at one (1) atmosphere of pressure, 50% relative humidity, and 25° C.

[0013] The term “bottle” as used herein, is a hollow rigid or semi-rigid container having a comparatively narrow dispensing end (neck or mouth). The dispensing end (neck or mouth) is typically the end where the bottle's contents is filled into and dispensed from.

[0014] The term “liquid composition” as used herein, unless otherwise specified, refers to the compositions of the present invention, wherein the compositions are intended to include, but are not limited to, compositions for topical application to the skin, hair, teeth, body, surfaces, and fabric fibers. Such compositions can include, but are not limited to, shampoos, conditioners, tooth cleansers, hair styling products, cleaners, soaps, cosmetics, foundations, antiperspirants, deodorants, lotions, creams, ointments, kitchen and bathroom cleans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com