Patents

Literature

118 results about "Glassine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glassine is a smooth and glossy paper that is air, water, and grease resistant. It is usually available in densities between 50–90 g/m². It is translucent unless dyes are added to color it or make it opaque. It is manufactured by supercalendering: after pressing and drying, the paper web is passed through a stack of alternating steel and fiber-covered rolls called a supercalender at the end of the paper machine such that the paper fibres flatten facing in the same direction.

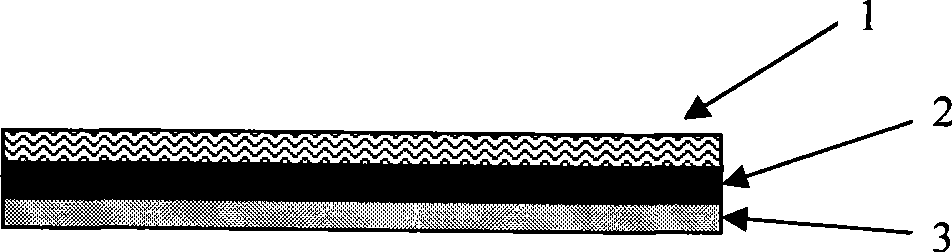

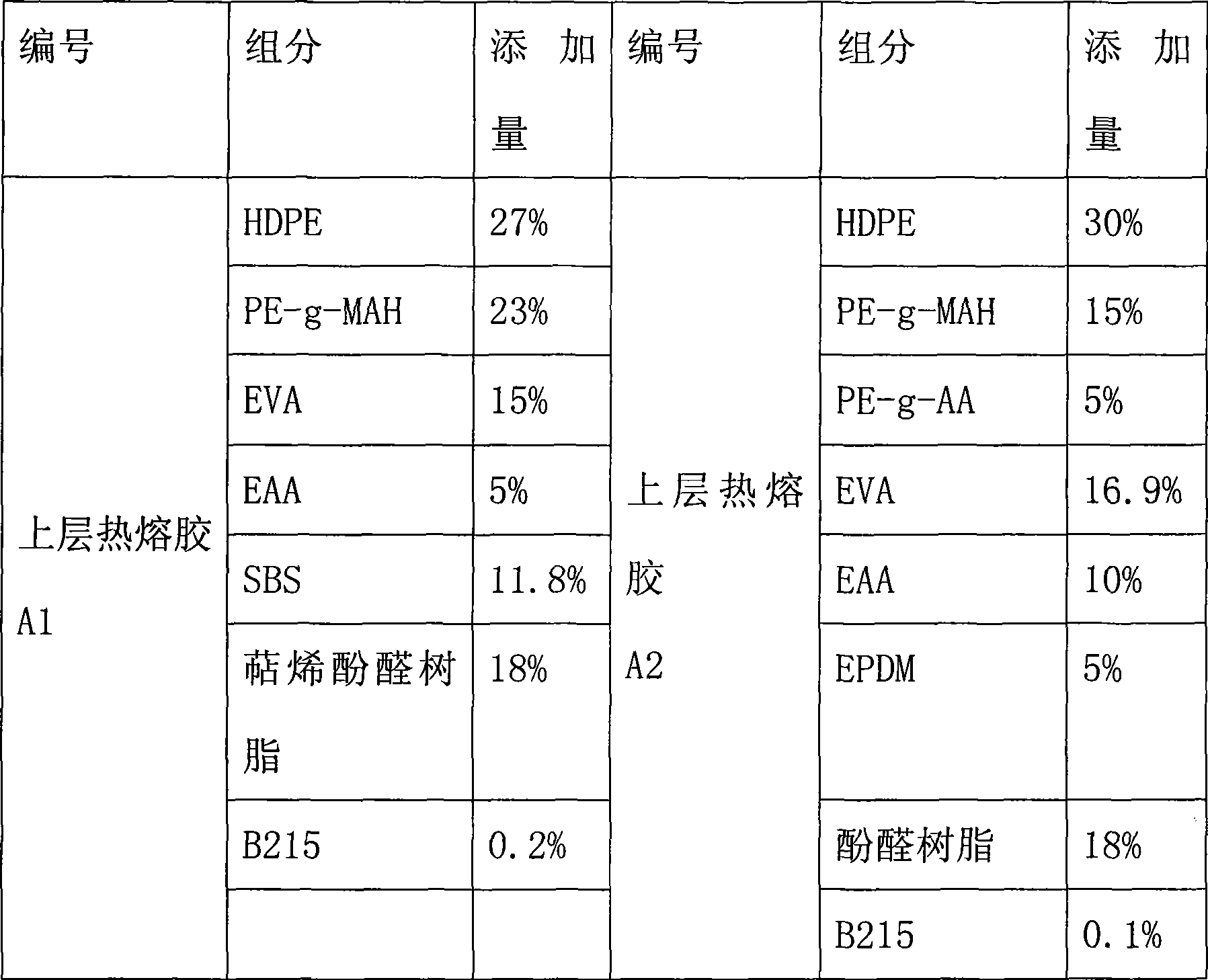

Double-layer composite hot melt adhesive film for bonding metal and plastic

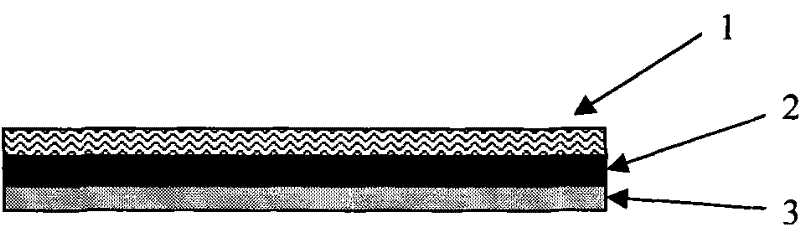

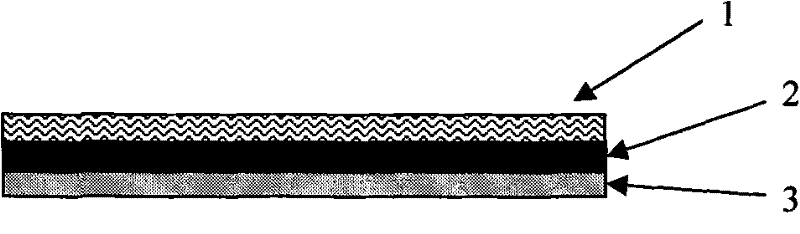

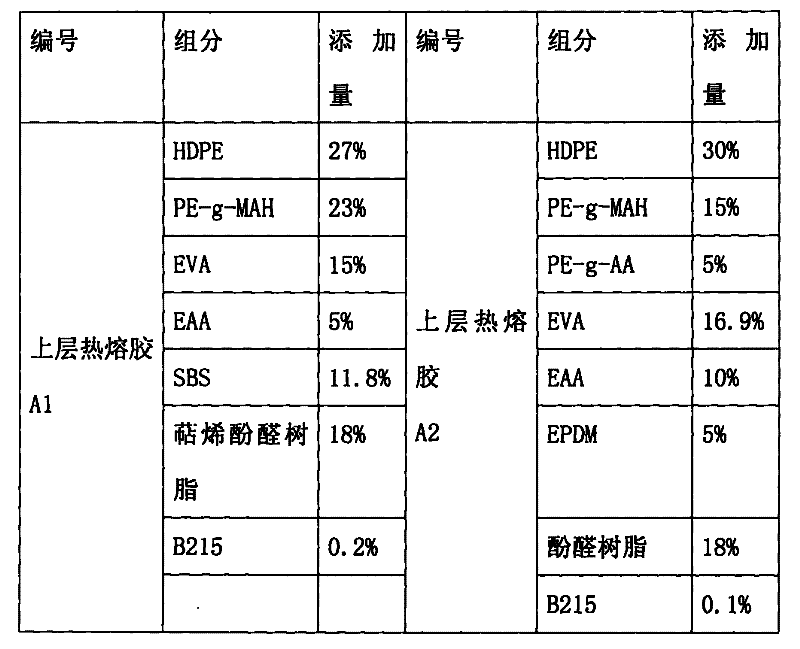

The invention discloses a double-layer composite hot melt adhesive film adhering metal and plastic, which is formed by compounding an upper adhesive film layer and a lower adhesive film layer, wherein the lower adhesive film layer is attached to a piece of release paper, the thickness of the composite adhesive film is 0.05 to 0.20 millimeter, the upper adhesive film layer is a hot melt adhesive layer adhered with the metal, the thickness of the upper adhesive film layer is 30 to 60 percent of the thickness of the composite film, the lower adhesive film layer is a hot melt adhesive layer adhered with the plastic, the thickness of the lower adhesive film layer is 40 to 70 percent of the thickness of the composite film, and the lower adhesive film layer is attached to a piece of glassine release paper. The double-layer composite hot melt adhesive film directly compounds two modified hot melt adhesives with different adhesive properties, is adhered with the release paper to prevent rolling from adhering and the adhesive film from being damaged, reduces application of a middle isolating layer, reduces the thickness of the composite adhesive film, and is prepared by once casting through coextrusion casting equipment or twice casting through common coextrusion casting equipment. The double-layer composite hot melt adhesive film can be used for composite adhesion of metallic materials such as aluminum, stainless steel and the like and plastic such as ABS, PVC, PET and the like, is particularly suitable for mutual adhesion between sheets, plates and films of the metal and the plastic, and has simple and convenient operation and no pollution.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

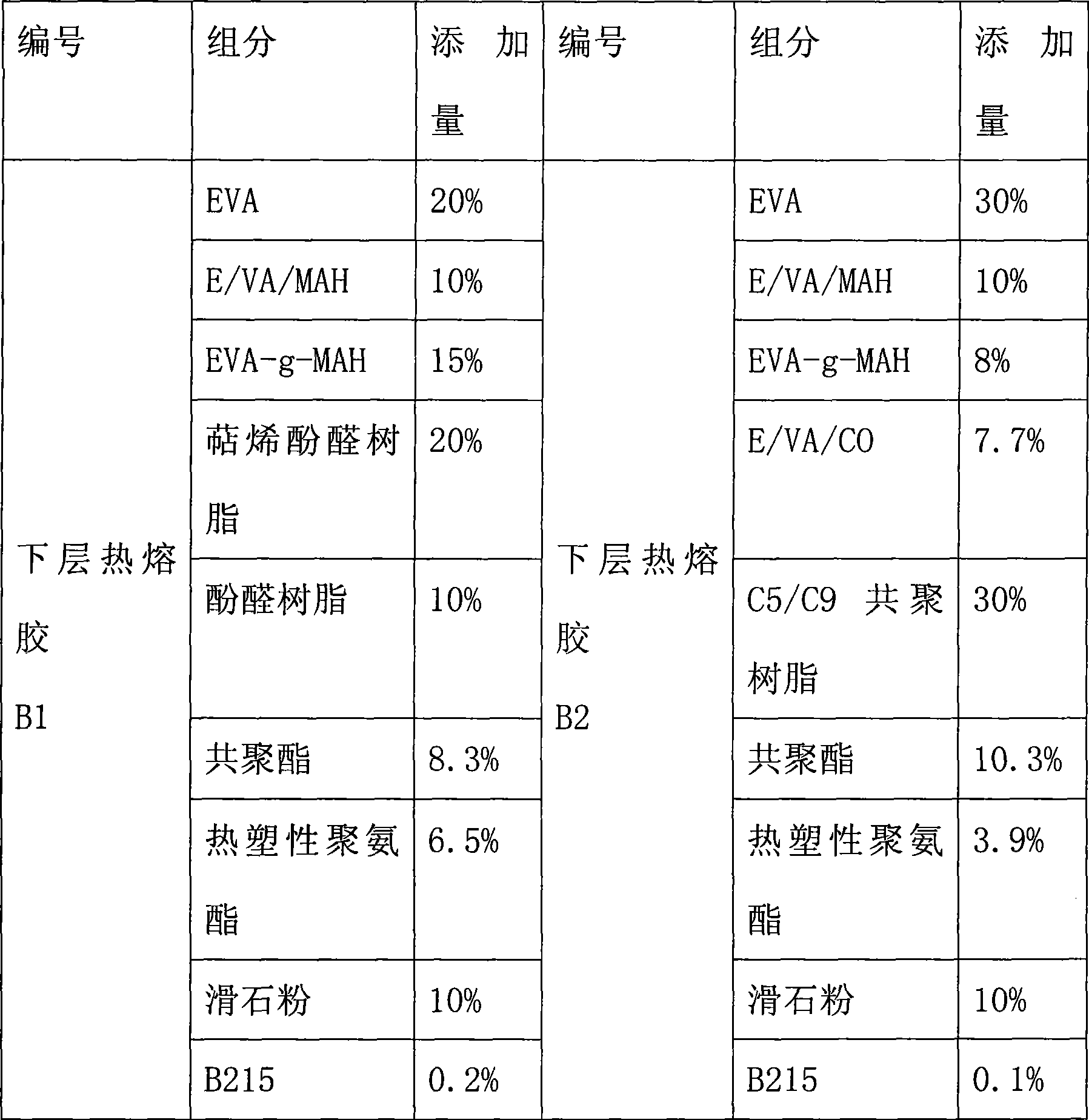

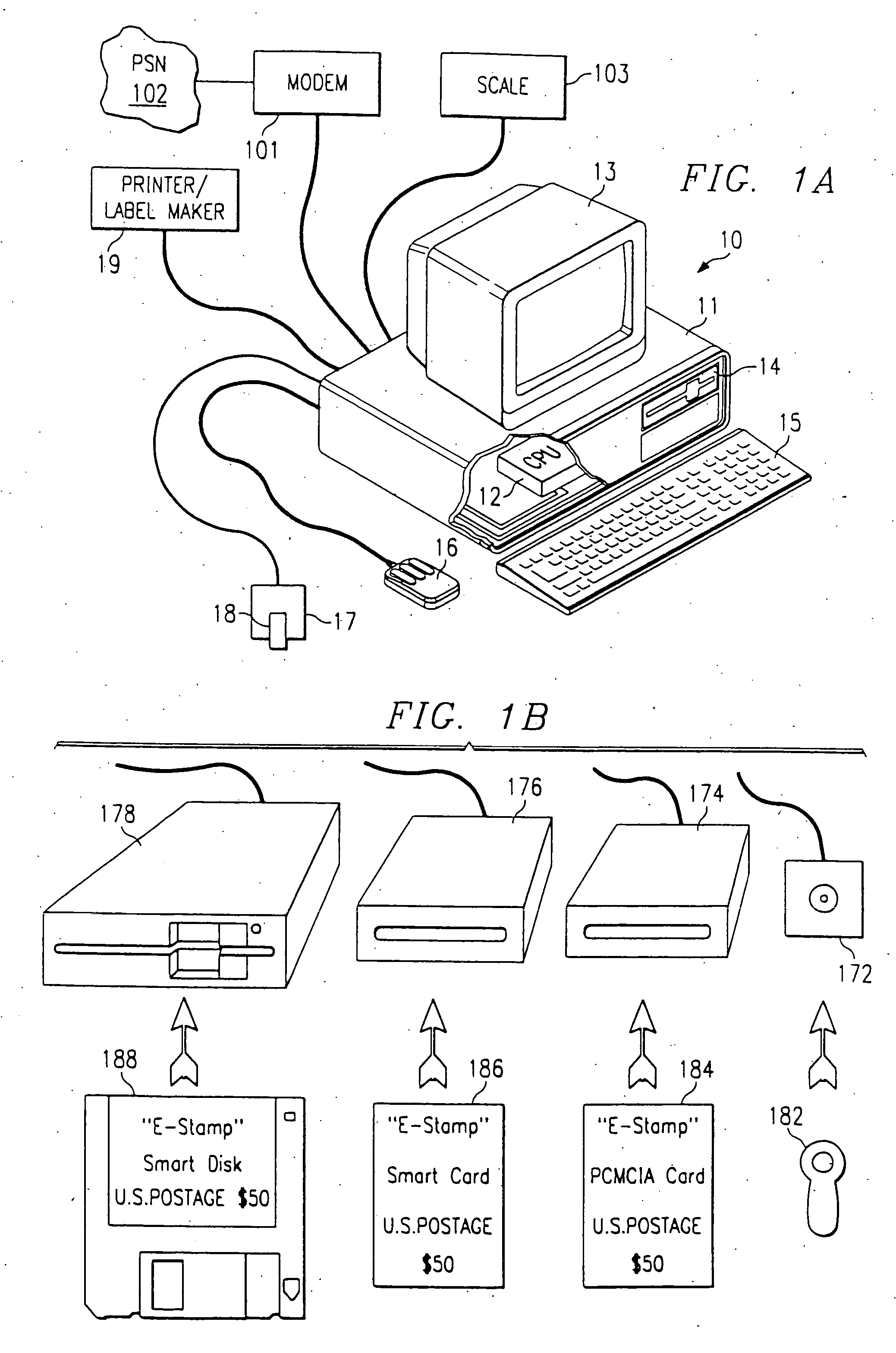

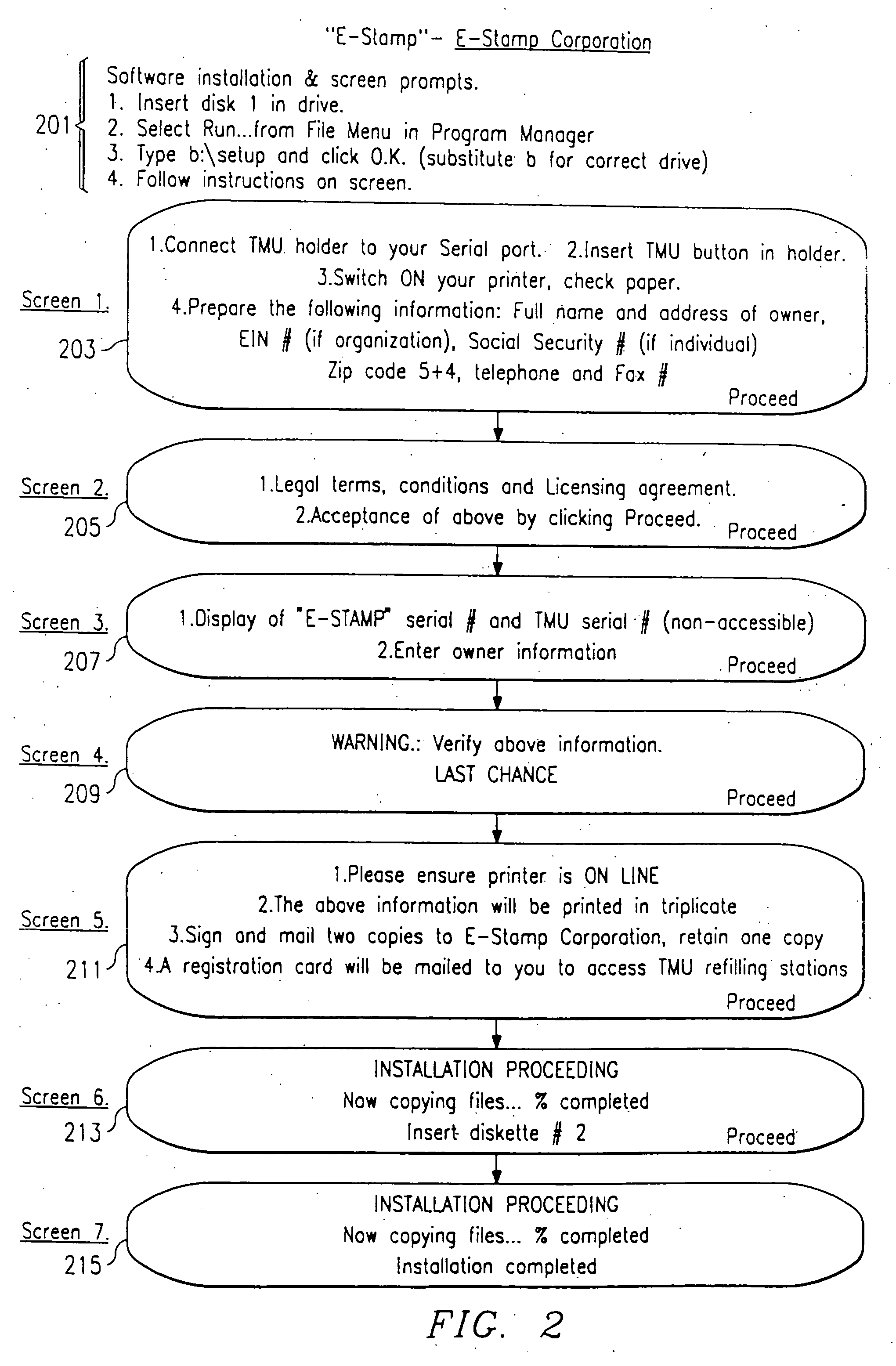

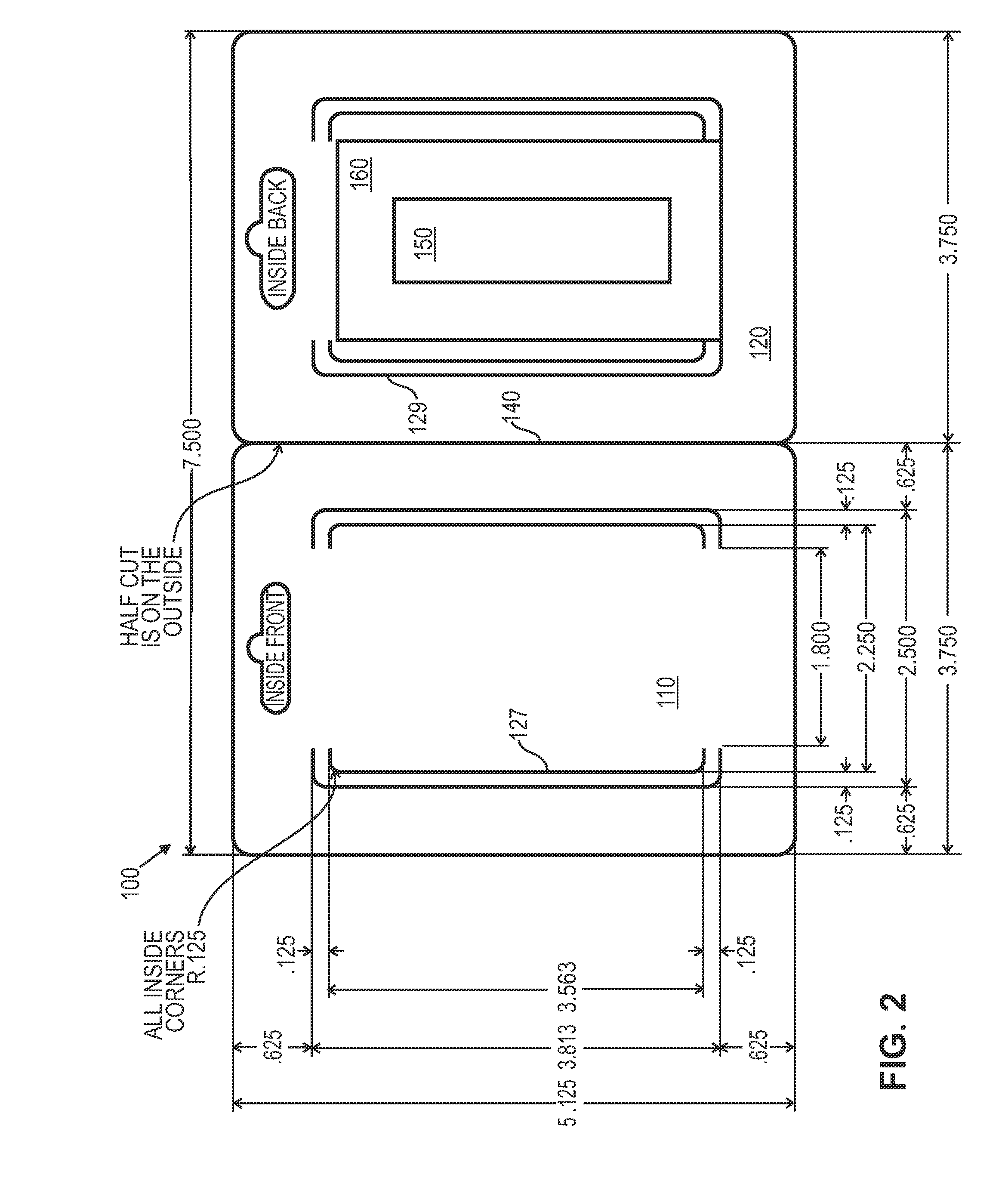

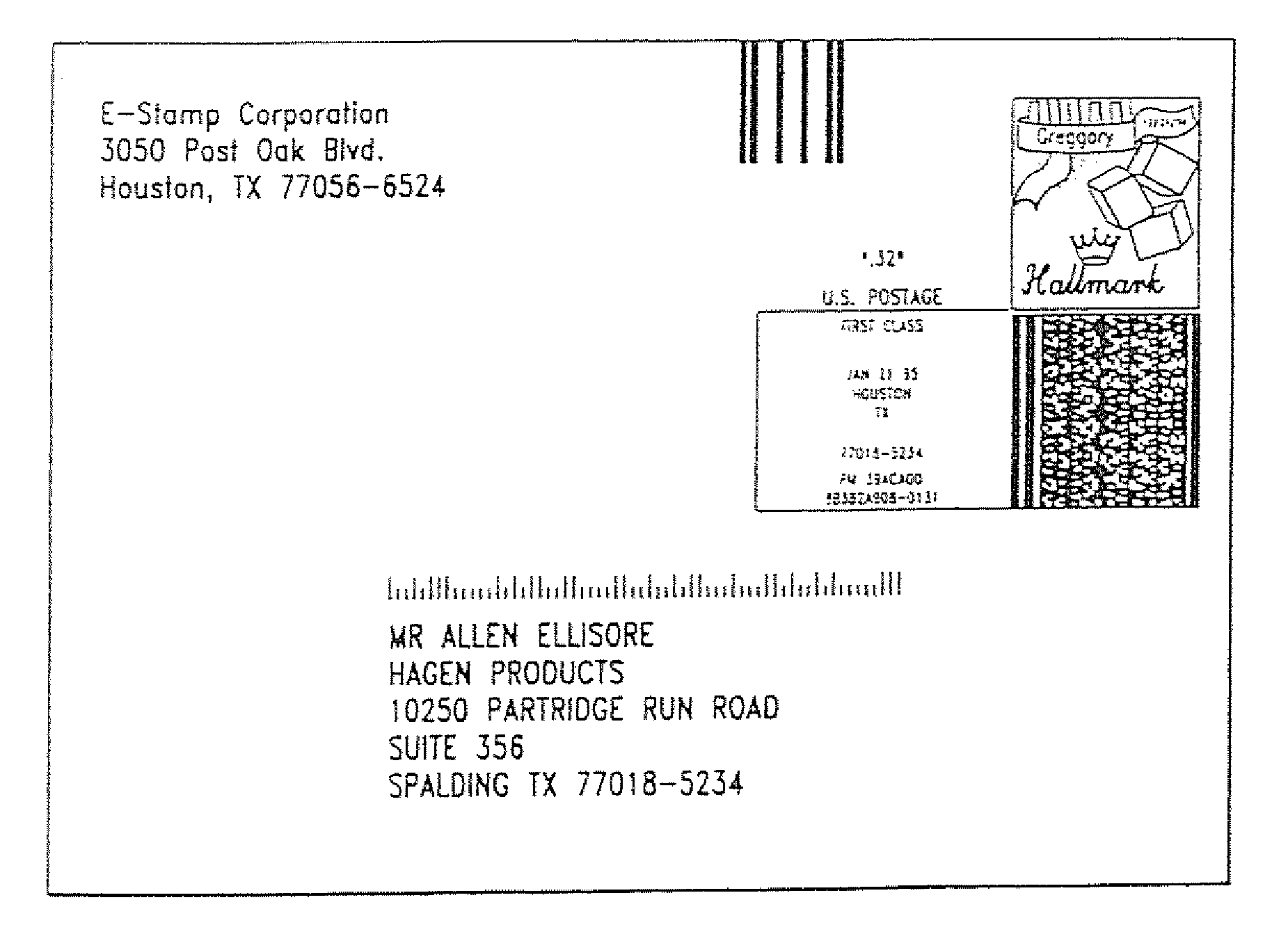

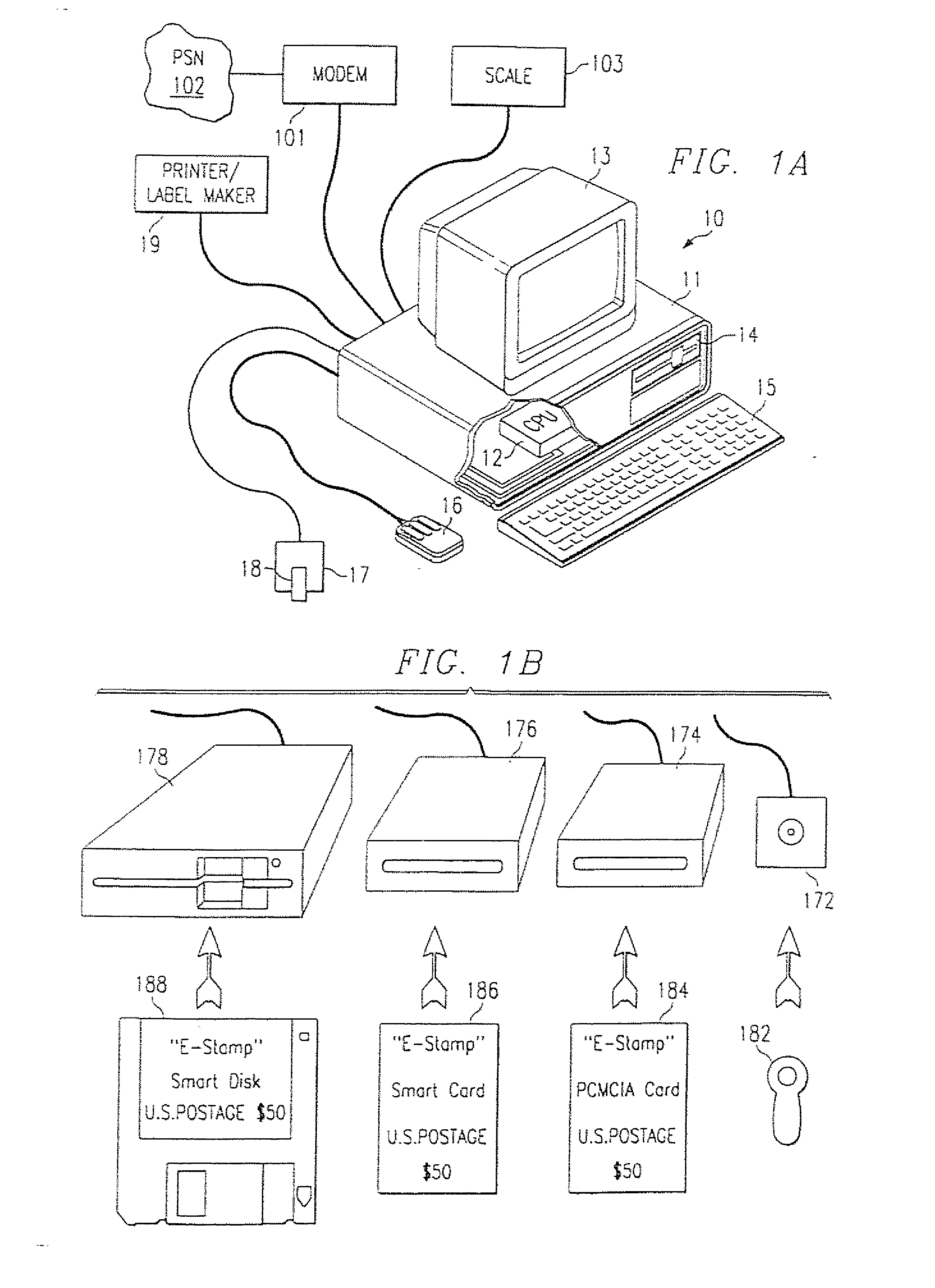

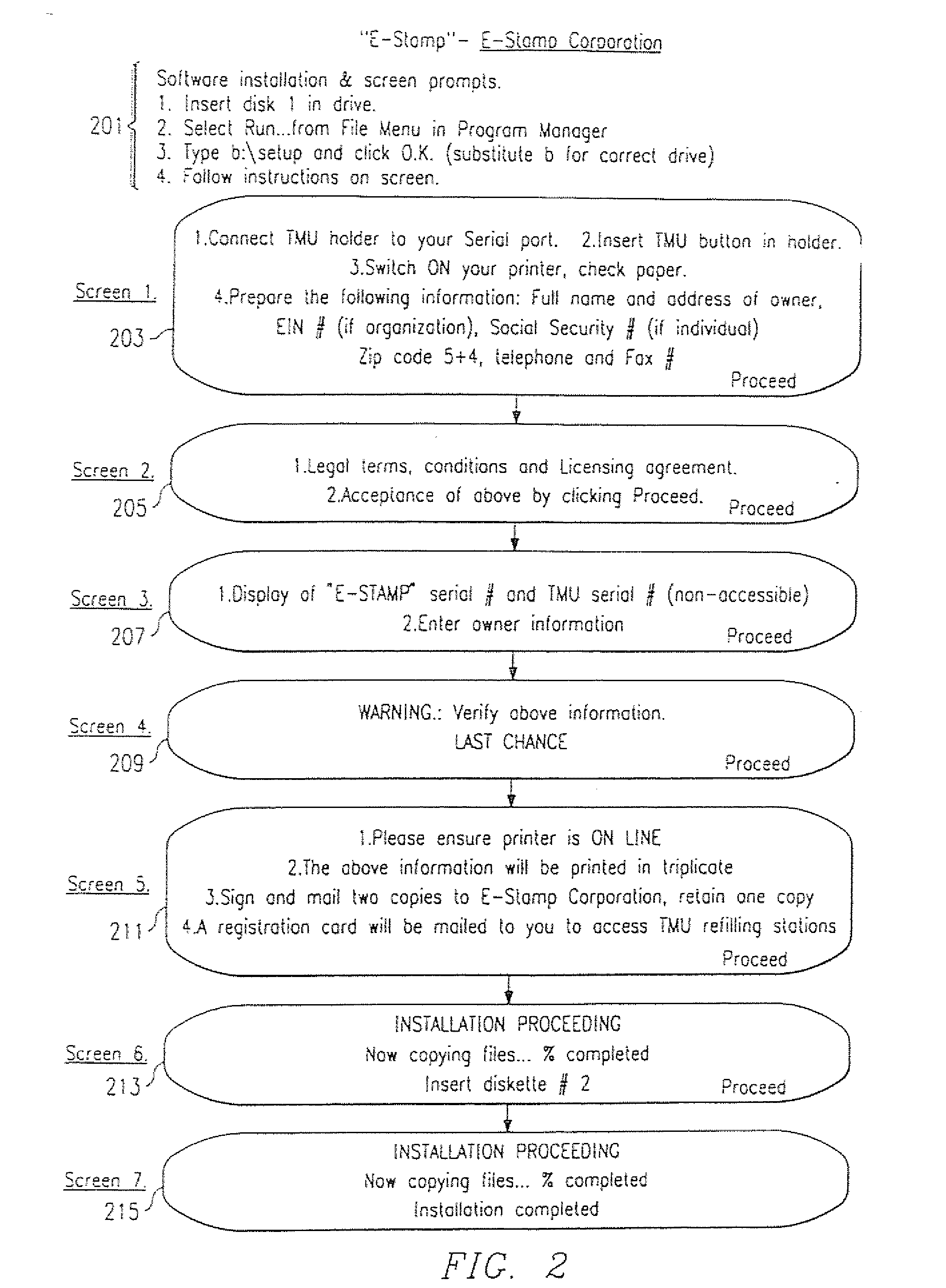

System and method for printing multiple postage indicia

InactiveUS20060173796A1Franking apparatusSpecial data processing applicationsPaper documentDocument preparation

An envelope having a window for allowing a printed postage indicia to show through is shown. According to a preferred embodiment, the postage indicia window may be provided with a glassine covering. Preferably the postage indicia may be put in a corner of a document to be mailed and the document placed in the envelope so that the postage indicia shows through the postage indicia window.

Owner:STAMPS COM

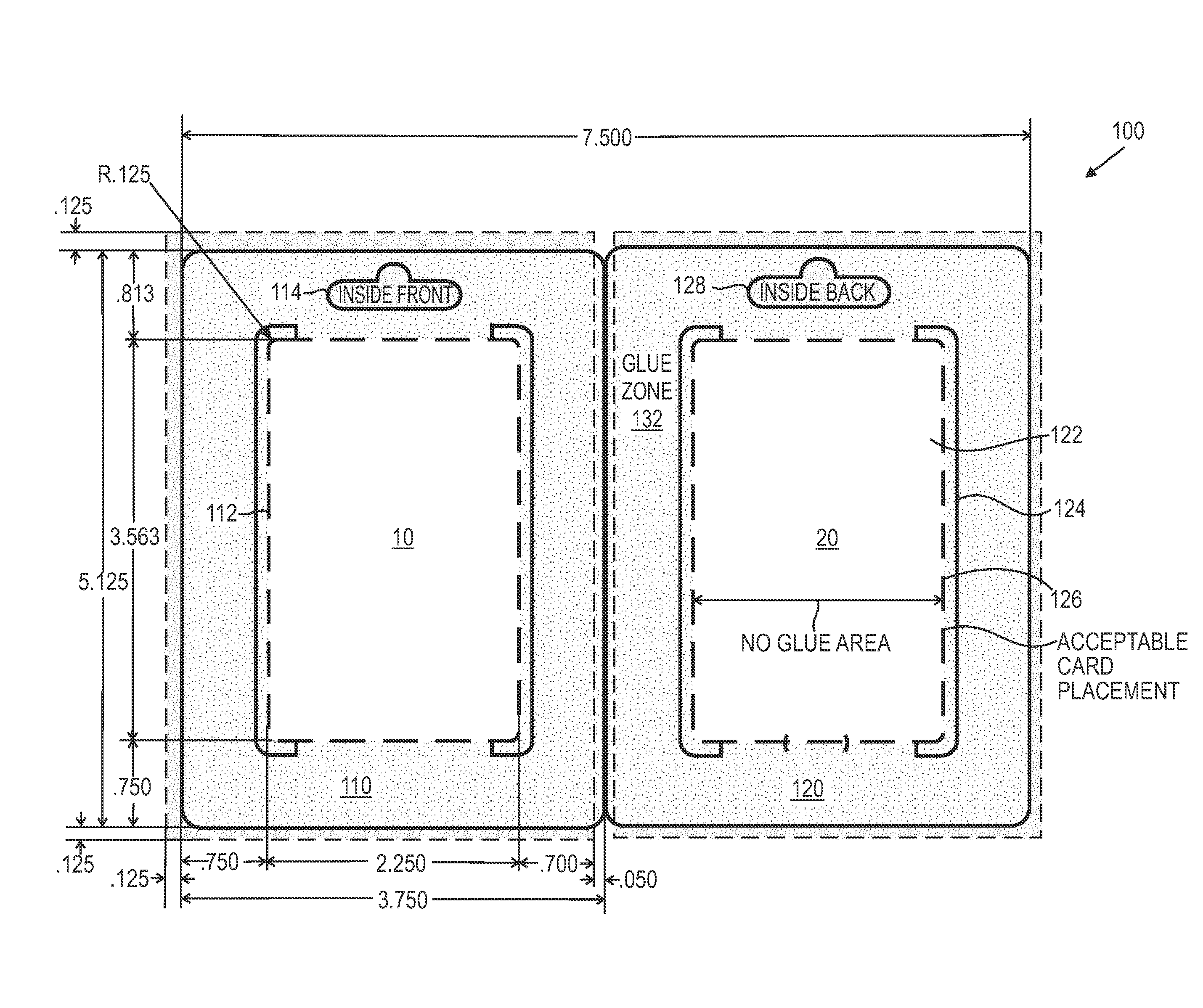

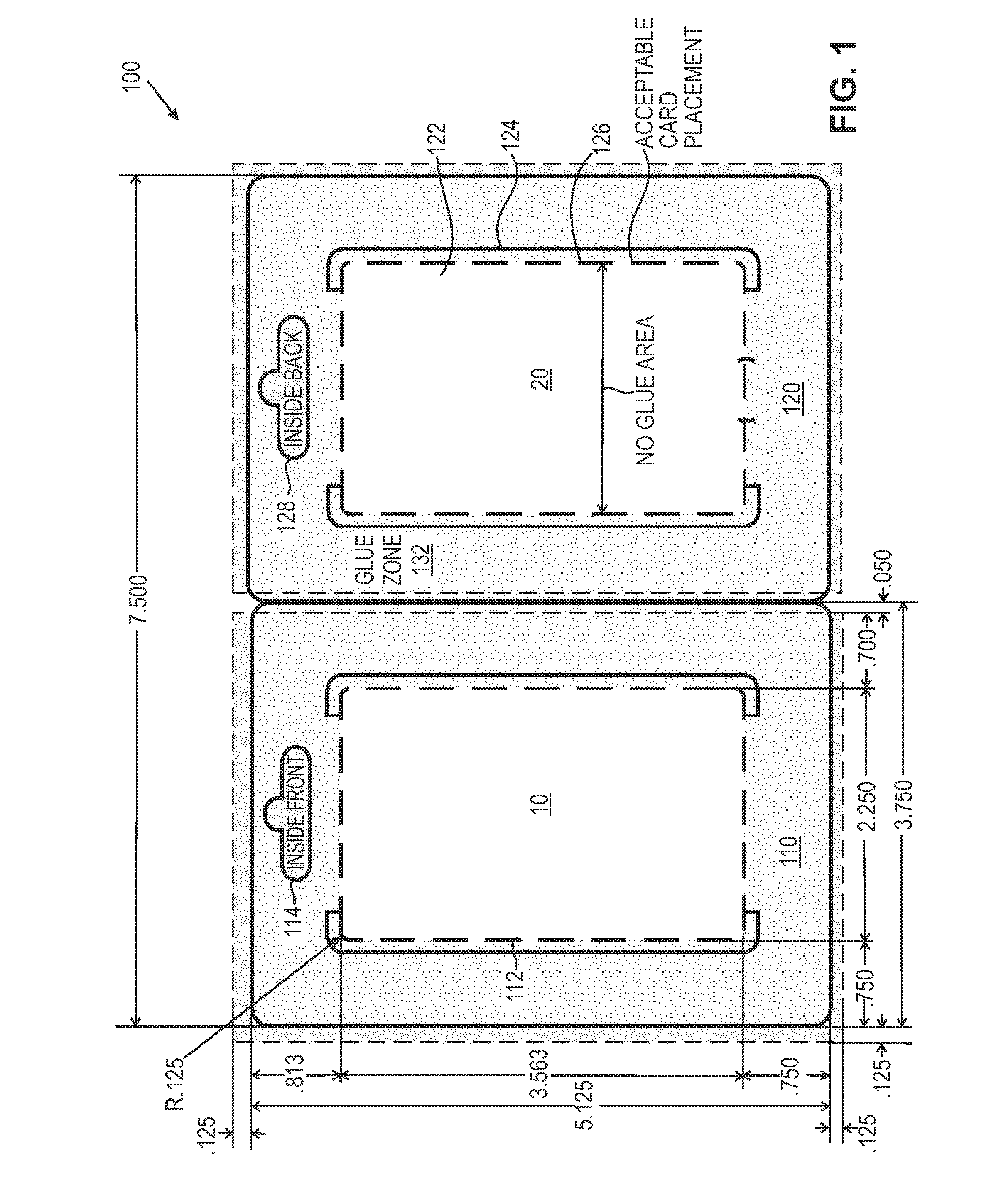

Methods and Apparatus for Prepaid Card Packaging

Techniques for providing cost effective and tamper evident prepaid card packaging are described. By forming a cutout in a panel of the prepaid card packaging, covering the cutout with a material such as red glassine, and aligning an activation bar code or other indicia on the card with the cutout when mounting the card within the packaging, the security of the activation indicia can be better maintained. After purchase, the bar code can be scanned through the red glassine but prior to purchase, the red glassine prevents photocopying.

Owner:IDEMIA AMERICA CORP

Method for producing glassine paper

InactiveCN102493284AReduce energy consumption for beatingReduce energy billsSpecial paperWater-repelling agents additionSulfateCellulase

The invention relates to a method for producing glassine paper, which is characterized by comprising the following steps: a. respectively carrying out pulping on bleached sulfate needle wood chemical pulp and bleached sulfate broadleaf wood chemical pulpboard, respectively adding an beater auxiliary agent modified cellulase in the pulp for beating; b. preparing the pulp according to weight ratio, adding a sizing agent for mixing, forming by net part dehydration, carrying out shoe pressing and drying; c. passing the paper through at least 3 pressing areas when superpressing. The method of the present invention saves beating energy consumption by 10-15% and steam consumption by 5%.

Owner:YUEYANG FOREST & PAPER CO LTD

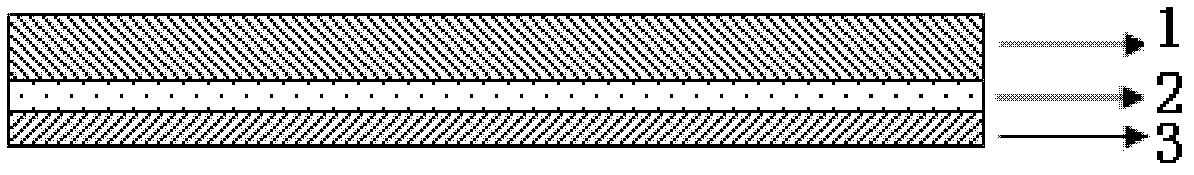

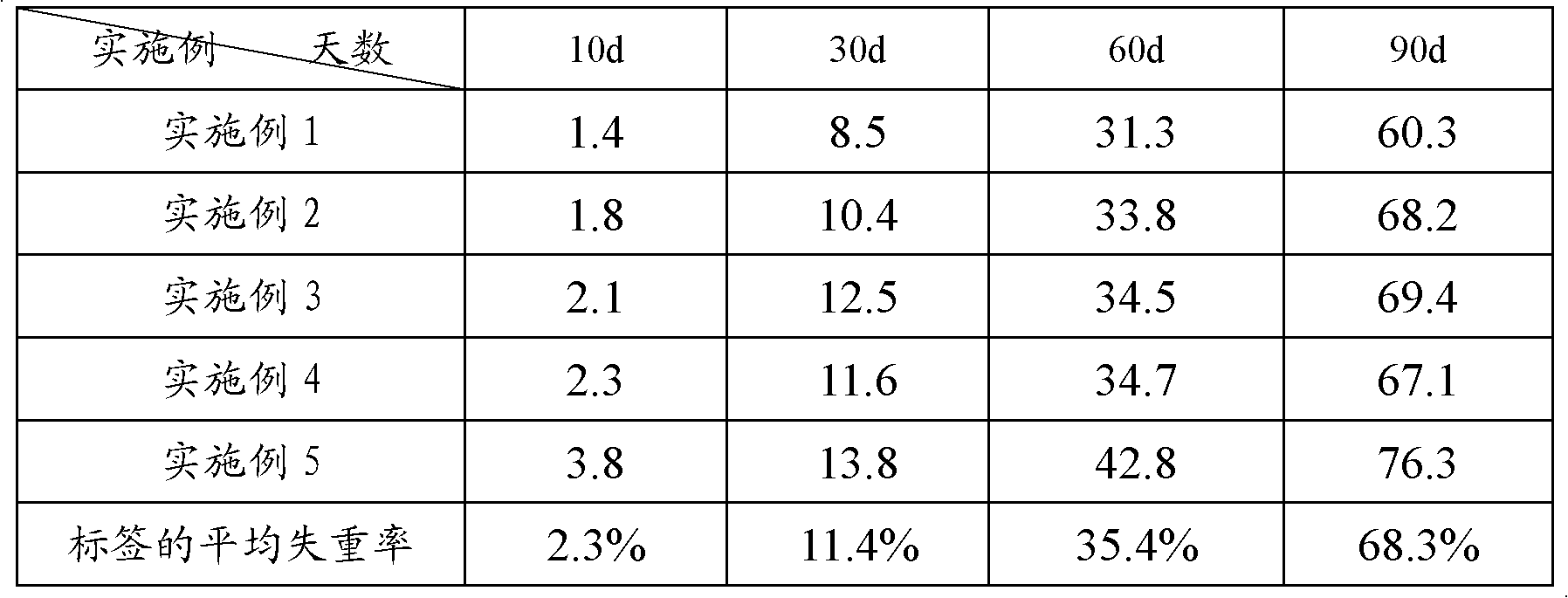

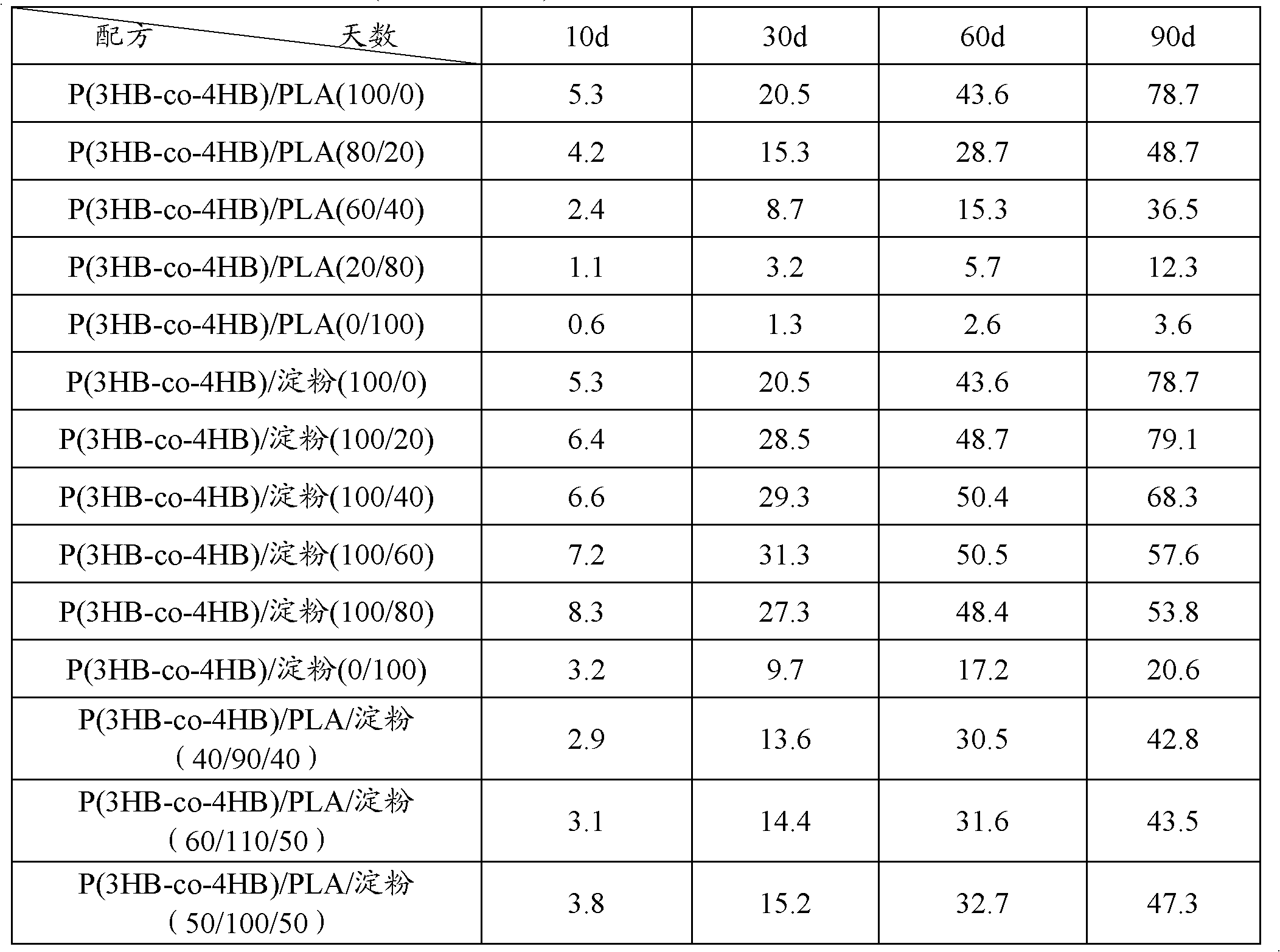

Biodegradable adhesive sticker label

ActiveCN102867459AImprove mechanical propertiesSimple structureStampsLamination ancillary operationsAdhesion strengthMechanical property

The invention relates to a biodegradable adhesive sticker label. The biodegradable adhesive sticker label comprises a surface material layer, an adhesive layer and backing paper, wherein the adhesive layer is positioned between the surface material layer and the backing paper, the backing paper adopts silicone oil-coated glassine paper, and the surface material layer comprises the following compositions in part by weight: 30-70 parts of PHA, 0-150 parts of polylactic acid, 0-50 parts of starch, 1-15 parts of plasticizer, 0.3-1 part of nucleating agent, and 1-10 parts of lubricating agent; the adhesive layer comprises the following compositions in part by weight: 20-60 parts of starch, 90-110 parts of water, 5-50 parts of PHA, 0.5-20 parts of alkaline matters, 0.5-10 parts of water-proofing agent, 0.1-5 parts of crosslinking agent, and 0.1-5 parts of bacteriostatic agent. Complete biodegradation can be realized without compost treatment; the adhesive sticker label has better mechanical property according to weight part proportion of all compositions, and the viscosity, the water resistance and the binding strength of oxidized starch can be effectively regulated and improved. In addition, the label has the characteristics of being simple in structure, simple and convenient in preparation process, and low in cost.

Owner:中国印刷科学技术研究院有限公司

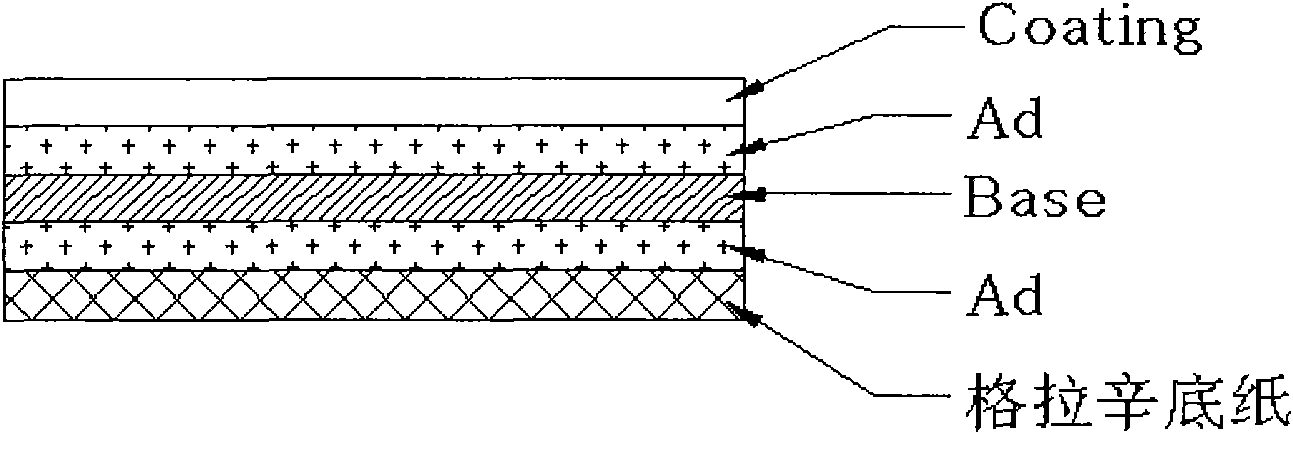

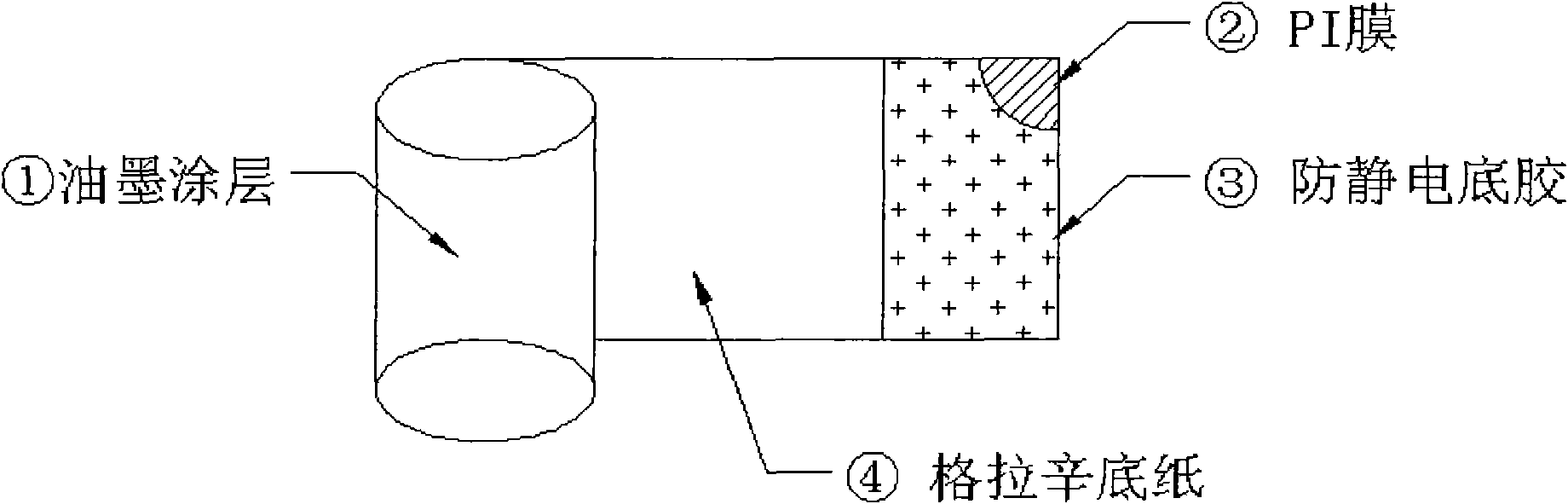

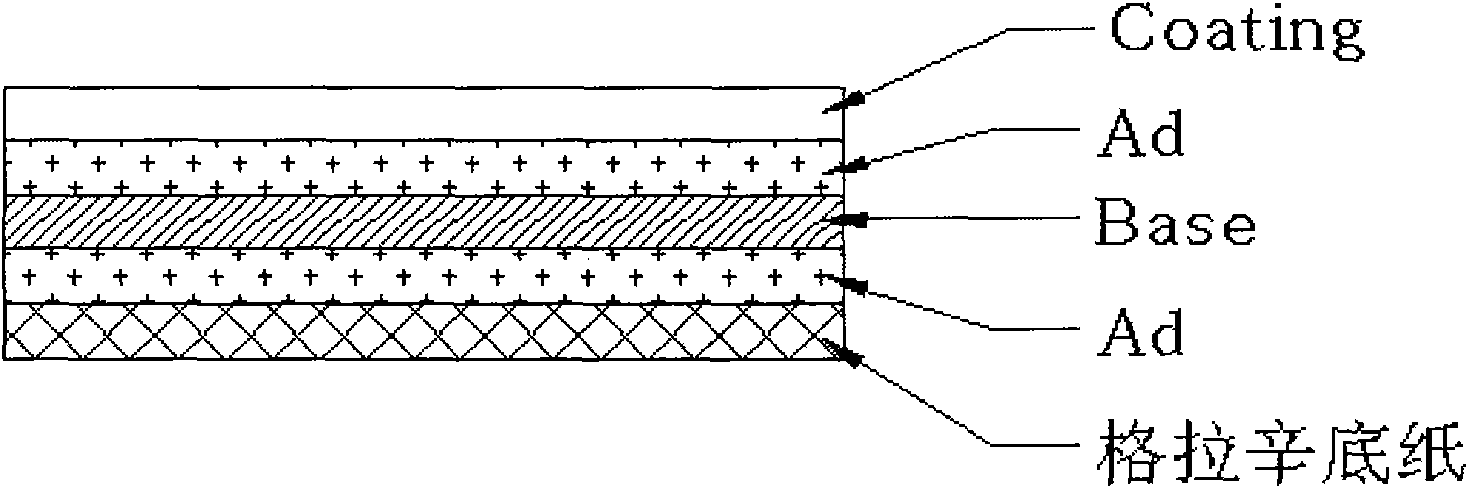

Electrostatic prevention temperature-resistant marking material and manufacturing method thereof

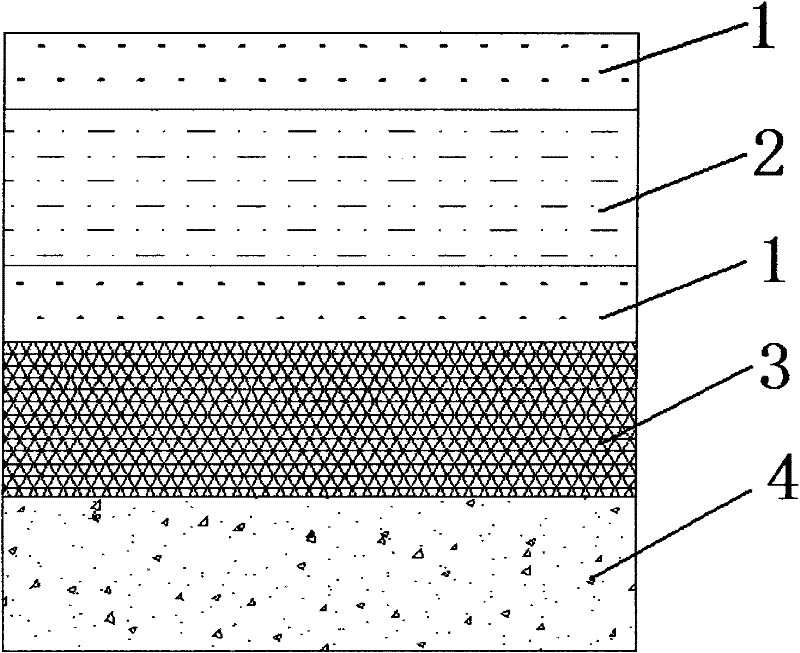

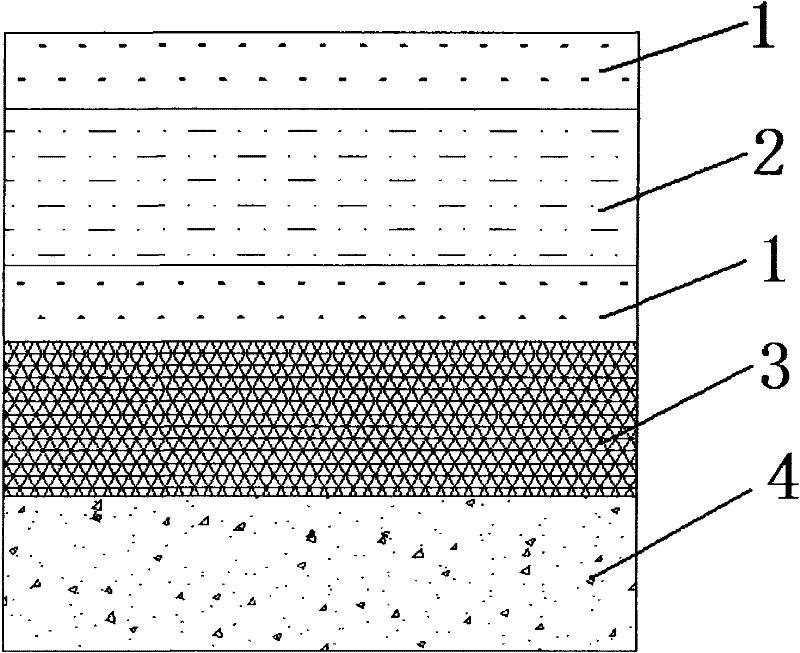

The invention relates to an electrostatic prevention temperature-resistant marking material which is mainly applied to tracing marking materials of integrated circuit surface mounting and chip encapsulation information, belonging to the technical fields of electronic and information application. The marking material of the invention takes a polyimide film (PI) as a substrate, electrostatic prevention permanent pressure-sensitive adhesive as a primer, special ink as a coating, and Glassine release paper as base paper. The manufacturing method of the invention comprises the following steps: firstly, carrying out surface electrostatic elimination treatment on the substrate; then coating the ink layer on one side of the substrate; then coating the primer on the Glassine base paper; and finally, compounding the glue surface of the Glassine base paper with the other side of the substrate to obtain the electrostatic prevention marking material (figure 1 and figure 2). The marking material comprises the following technical quality indexes: the temperature-resistant range of the material is -20 DEG C-320 DEG C (270 DEG C / 10min, 320 DEG C / 10S), the surface resistivity of adhesive is 104-108ohsm / sq, the sticky consistency is greater than or equal to 1000g, and the electrostatic discharge speed (time required for electrostatic discharge to 1%) is less than or equal to 0.01s; and the marking material resists certain acid, alkali, soldering flux and part organic solvents, is suitable for resin ribbon thermal transfer and UV ink printing, and is especially suitable for two-dimensional code marking, great application to chip encapsulation or special electrostatic discharge situations.

Owner:XIAMEN INNOV INFORMATION TECH

Biodegradable double-sided adhesive tape

InactiveCN103320036AReasonable material selectionSatisfy the initial viscosityFilm/foil adhesivesPolyesterMixed materials

The invention discloses a biodegradable double-sided adhesive tape. The double-sided adhesive tape comprises a base material layer, an adhesive layer and release paper, wherein the adhesive layer is positioned between the base material layer and the release paper, the release paper adopts glassine paper coated with silicone oil, the base material layer is a non-toxic and pollution-free mixed material layer, and the adhesive is a biodegradable quaternary random co-polyester adhesive. The invention discloses the biodegradable double-sided adhesive tape. The double-sided adhesive tape has the advantages of reasonable material selection, environmental friendliness and safety, can not only meet the requirements of initial adherence, sustained adherence and stripping strength, but also realize excellent biodegradable property, and further has great application prospects in the aspects of stickers, stationery, office supplies and the like.

Owner:KUNSHAN HANBAO TAPE TECH

Production method of glassine paper

ActiveCN101372822AShort processReduce energy billsSpecial paperWater-repelling agents additionSlurrySizing

The invention discloses a production method for Glassine which includes the technique steps of slurry beating, slurry preparing, shaping on a net, squeezing, front section drying, surface sizing, back section drying, excessive pressing, etc. The production method for Glassine can simplify the technique for producing the Glassine and reduce the production cost.

Owner:MINFENG SPECIAL PAPER

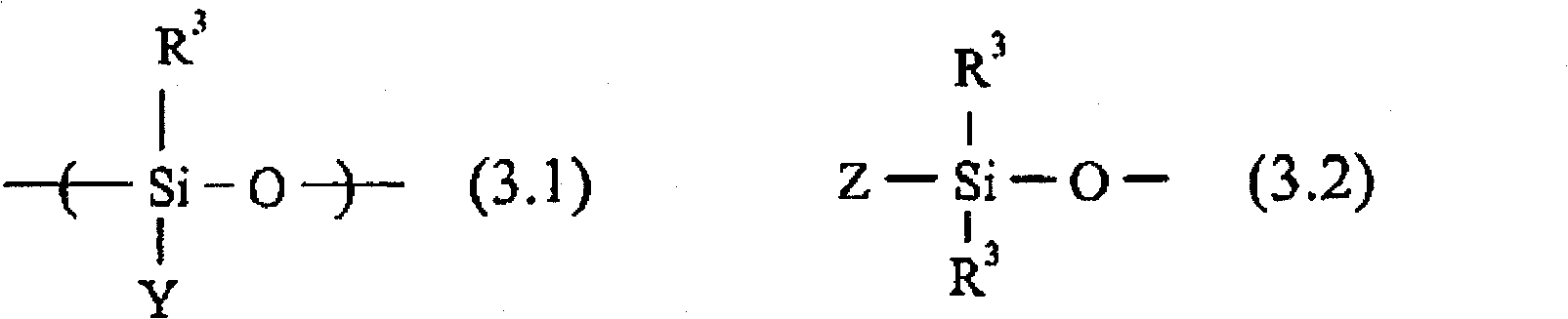

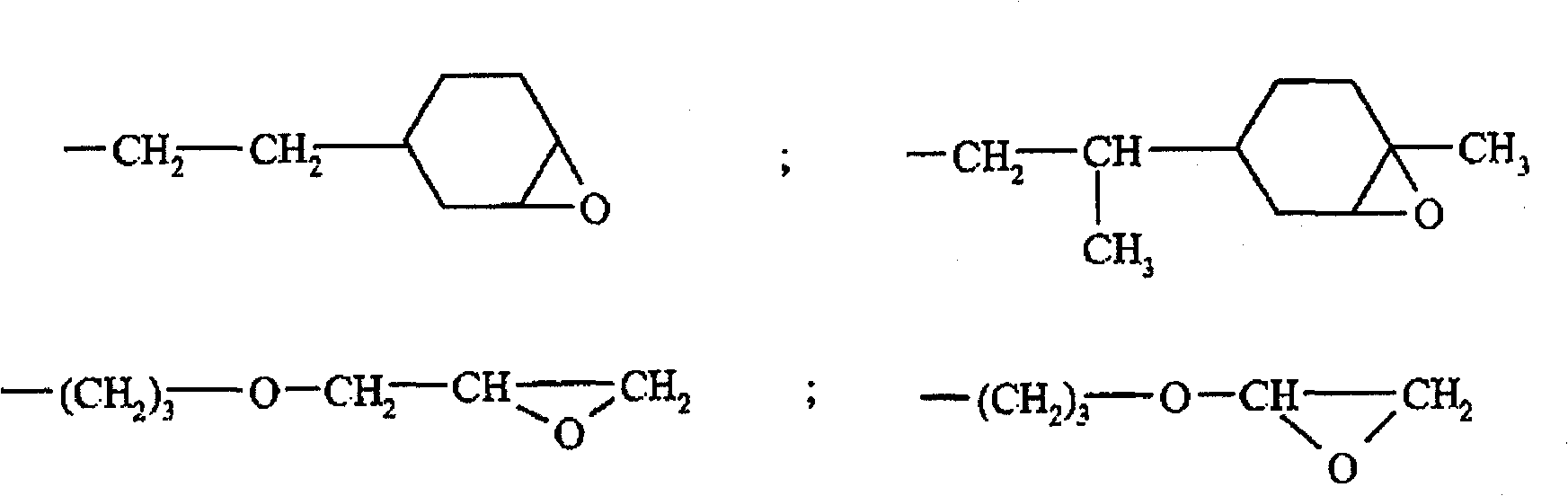

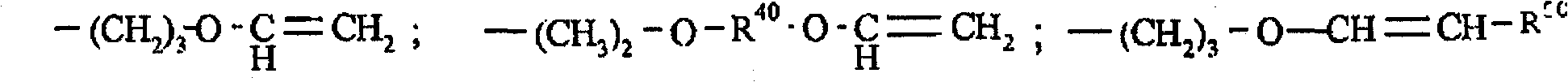

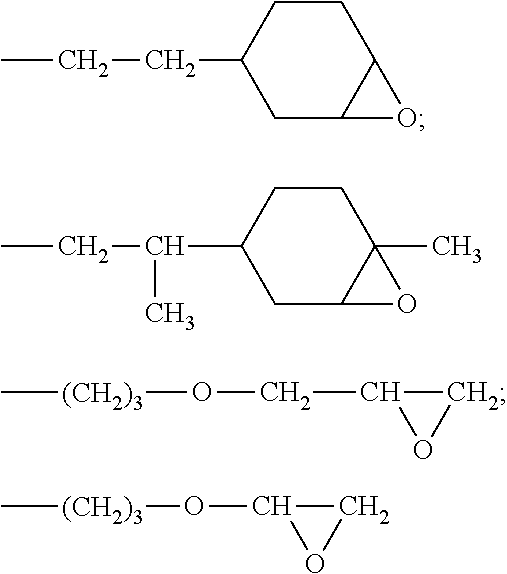

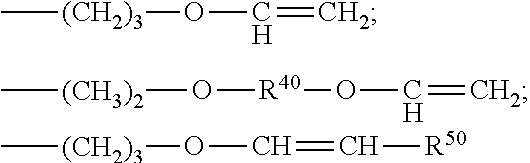

Silicone composition for coating a flexible support intended to form a crosslinked coating having increased attachment, mechanical strength and reactivity

The invention relates to crosslinkable or crosslinked silicone compositions capable of being used to form a water-repellent and release coating for a flexible support made of paper or of polymer, in particular that is heat-sensitive. These compositions are of the type of those comprising crosslinking polyorganosiloxanes (POSs) bearing =Si-H units and unsaturated, preferably =Si-Vi, vinyl-containing POSs, capable of reacting with the crosslinker by polyaddition, in the presence of platinum in order to form the crosslinked release coating on the flexible support.; The targeted objective is to enable the coating composition to crosslink instantaneously in order to produce, on all types of flexible supports (paper, e.g. glassine, or polymer, e.g. polyester such as polyethylene terephthalate PET), a crosslinked silicone coating endowed, in particular, on leaving the coating machine, with excellent attachment (adhesion) and mechanical strength or cohesion - "Rub-off" - properties. In order to achieve this objective, the invention proposes the use, per 100 parts by weight of silicone base, of 1 to 40 parts by weight of an additive comprising from 1 or 5 to 80% by weight of particulate filler, preferably nanoscale filler, in a silicone oil capable of reacting with the crosslinker. The supports and the high-speed coating processes are targeted. Applications: silicone release coatings obtained by crosslinking / polyaddition for flexible supports.

Owner:BLUESTAR SILICONES FRANCE SAS

Dual-use heat-transfer paper for ink-jet or laser printing

ActiveCN102381069AMeet individual market demandsLow costSynthetic resin layered productsCoatingsKetoneThermal transfer

The invention relates to a manufacturing process of heat-transfer paper for ink-jet or laser printing. The manufacturing process comprises the following steps: glassine paper, CCK (clay-coated kraft) paper or PEK (Polyether ketone) paper is selected as a paper base; organic-silicon release treatment or Tropsch-process micronization is carried out on the surface of the paper base so as to form wax, and the peeling strength needs to be controlled between 100g / inch and 150g / inch; a first heat-transfer glue layer is uniformly coated on the paper base; a second heat-transfer glue layer is coated at the upper part of the first heat-transfer glue layer; then an absorbing medium layer of ink-jet ink or laser carbon powder is uniformly coated at the upper part of the second heat-transfer glue layer; and after being dried thoroughly, all the layers are cut according to the needed size. The heat-transfer paper for ink-jet or laser adopted by the manufacturing process not only can be used for an ink-jet printing machine, but also can be used for a laser printing machine to print drawn images freely, and then is transferred on any textile by a hot-pressing tool.

Owner:FUZHOU AIRUI DIGITAL IMAGING

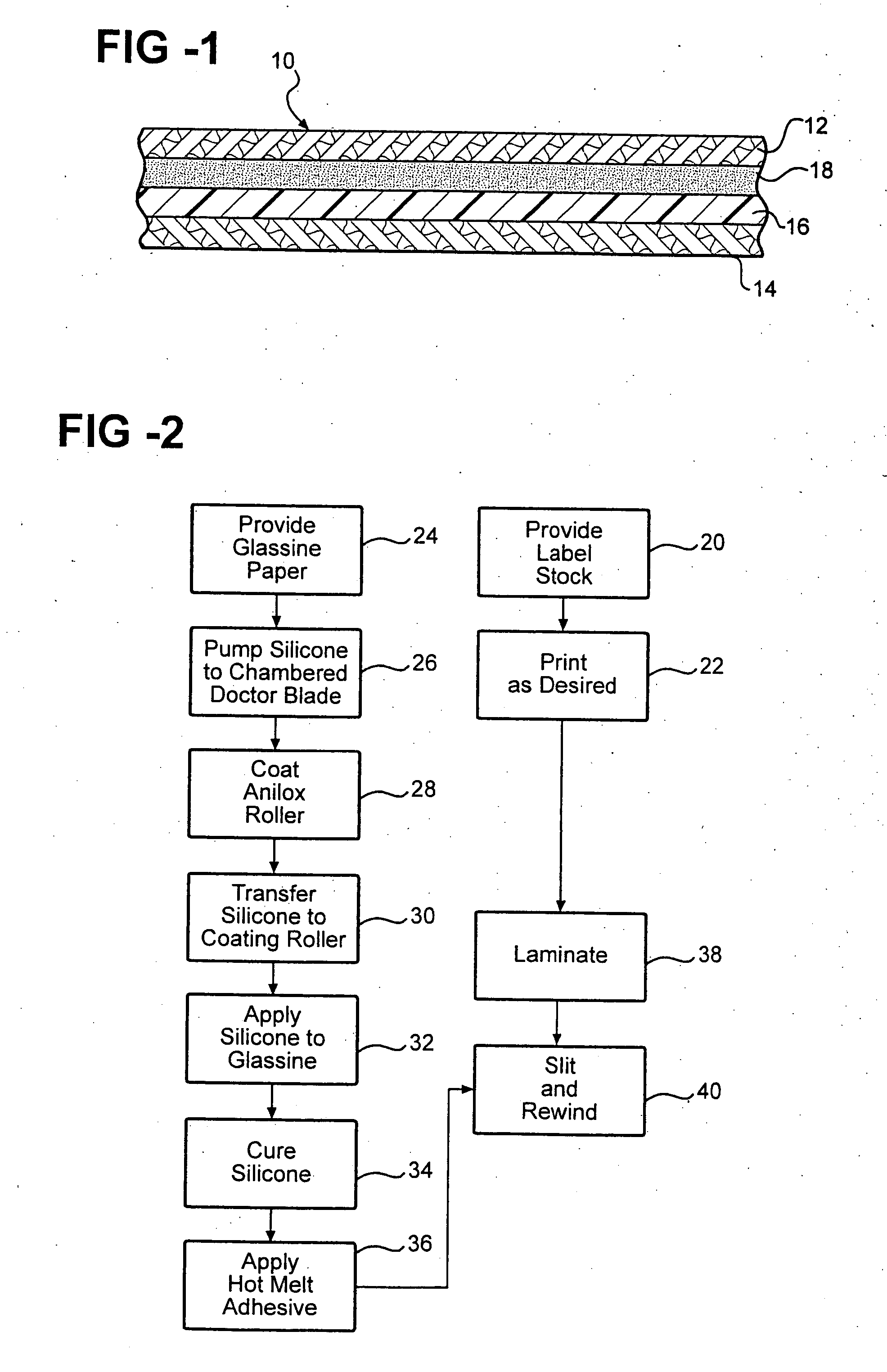

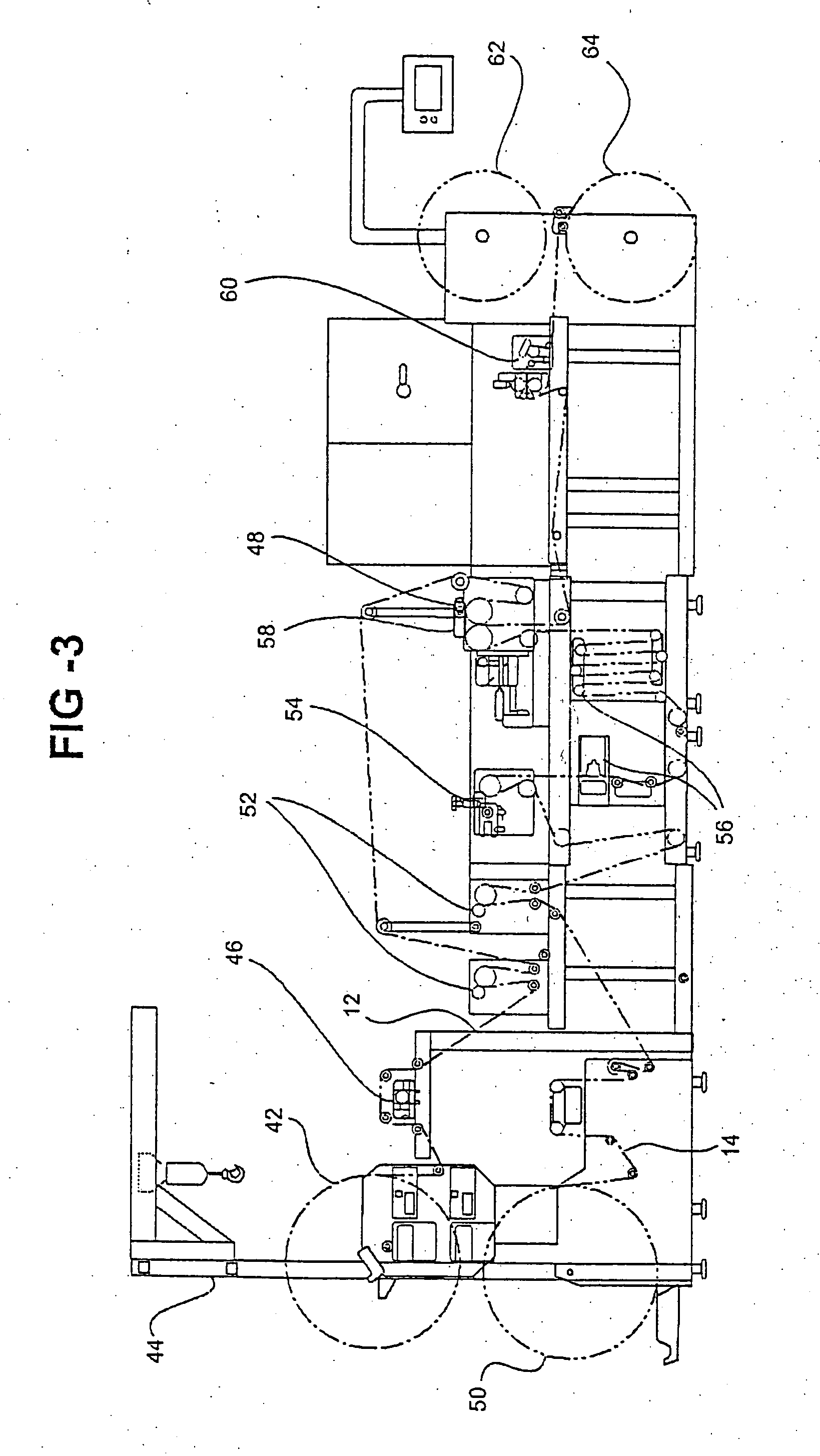

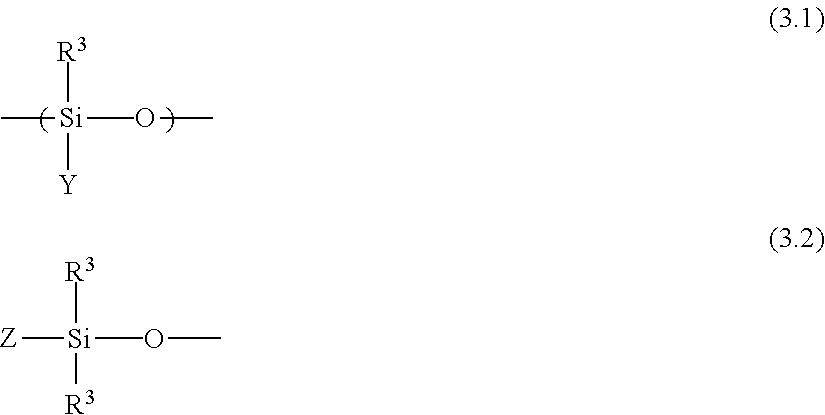

Method and apparatus for manufacturing pressure sensitive adhesive label stocks with printing under adhesive and product produced thereby

InactiveUS20050089662A1Simpler and more expeditious to carry-outRule out the possibilityStampsAdhesive processesEngineeringSilica gel

A method and apparatus for making adhesive-backed labels. Glassine paper stock is unwound from a roll, coated with photo-cationic silicone and exposed to wavelength-controlled illumination to cure. Hot melt adhesive is applied over the silicone. Simultaneously, label stock is fed with the coated glassine paper to laminating rollers where the two are joined. Illumination is provided by a dichroic reflector.

Owner:BAYZELON FRANCOIS +2

Silicone composition for coating a flexible support intended to form a crosslinked coating having increased attachment, mechanical strength and reactivity

ActiveUS20110183566A1High mechanical strengthQuick SetupNon-fibrous pulp additionCoatings with pigmentsParticulatesPolyester

Crosslinkable or crosslinked silicone compositions, forming water-repellent and release coating for a flexible heat sensitive support of paper or polymer, and comprising crosslinking polyorganosiloxanes (POSs) bearing ≡Si—H units and unsaturated, preferably ≡Si-Vi, vinyl-containing POSs, capable of reacting with the crosslinker by polyaddition, in the presence of platinum in order to form the crosslinked release coating on the flexible support. The object is enabling the coating composition to crosslink instantaneously to produce, on various flexible supports (paper, e.g. glassine, or polymer, e.g. polyester such as polyethylene terephthalate PET), a crosslinked silicone coating leaving the coating machine, with excellent attachment (adhesion) and mechanical strength or cohesion—“Rub-off”—properties. The invention uses, per 100 parts by weight of silicone base, of 1 to 40 parts by weight of an additive comprising from 1 or 5 to 80% by weight of particulate filler, preferably nanoscale filler, in a silicone oil reacting with the crosslinker.

Owner:BLUESTAR SILICONES FRANCE SAS

Novel povidone-iodine antibacterial hydrocolloid dressing and preparation method thereof

InactiveCN103143053AAvoid side effectsKeep the wound moistAbsorbent padsBandagesCellulosePolymer science

The invention provides a novel povidone-iodine antibacterial hydrocolloid dressing and a preparation method thereof. The preparation method comprises the following steps of: (a) adding styrene-isoprene segmented copolymer and mineral oil (medical-grade white oil) into an internal mixer at a temperature of between 120 and 170 DEG C, and softening for 5 to 10 minutes; (b) dosing tackifying resin and an antioxidant into the softened styrene-isoprene segmented copolymer, and mixing to obtain premix; (c) adding hydrocolloid particles, sodium carboxymethylcellulose and carboxymethyl chitosan into the premix; (d) uniformly spraying povidone-iodine into the mixture obtained in step (c) by using a povidone-iodine complex device; and (e) applying to a copolymer film or non-woven fabric, namely coating the hydrocolloid layer to a back-lining layer. The copolymer film or glassine paper is coated on the prepared hydrocolloid layer, which means that a release layer is coated on the hydrocolloid layer to obtain the povidone-iodine antibacterial hydrocolloid dressing. The povidone-iodine antibacterial hydrocolloid dressing has the advantages of reducing the side effect of antibiosis and improving the effect of constant antibiosis.

Owner:SHANDONG KANGLI MEDICAL EQUIP TECH

Novel pressure-sensitive adhesive composite material and preparation method thereof

InactiveCN103374864AIncrease speedMeet security requirementsLamination ancillary operationsSpecial paperHealth riskAging resistance

The invention relates to the field of composite materials and particularly discloses a novel pressure-sensitive adhesive composite material and a preparation method thereof. The novel pressure-sensitive adhesive composite material comprises a body paper layer and a face paper layer, wherein the body paper layer comprises Glassine body paper as well solvent-free solution and an environment-friendly adhesive which are sequentially coated on one surface of the Glassine paper. The preparation method comprises the following steps of: after processing the Glassine body paper by utilizing the solvent-free solution, coating the environment-friendly adhesive, immediately covering one glued face of body paper with the face paper after drying the Glassine body paper to a certain degree, carrying out press fit by utilizing a rubber roller and a rolling drum, and drying so as to obtain the novel composite material. According to the novel pressure-sensitive adhesive composite material and the preparation method, since the body paper is processed by utilizing a PE (polyethylene)-free film and silica paper is processed by utilizing the solvent-free solution, the production is safe, the health risk is avoided, the energy can be saved, and the vehicle speed of the coating can be increased; besides, the composite material is good in heat resistance and ageing resistance and hardly tilts in a use process, and phenomena such as shrinkage, corrugation, deformation and yellowing do not appear at the high and low temperatures, so that the service life of the composite material is long.

Owner:上海金大塑胶有限公司

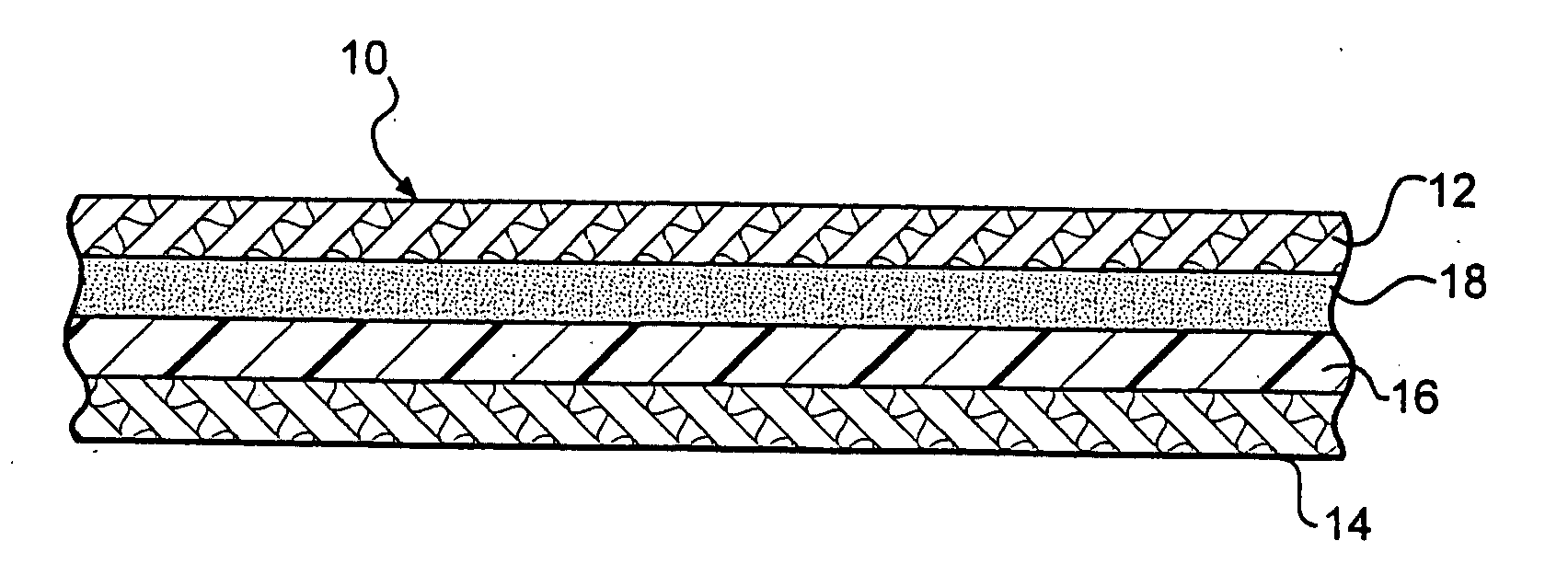

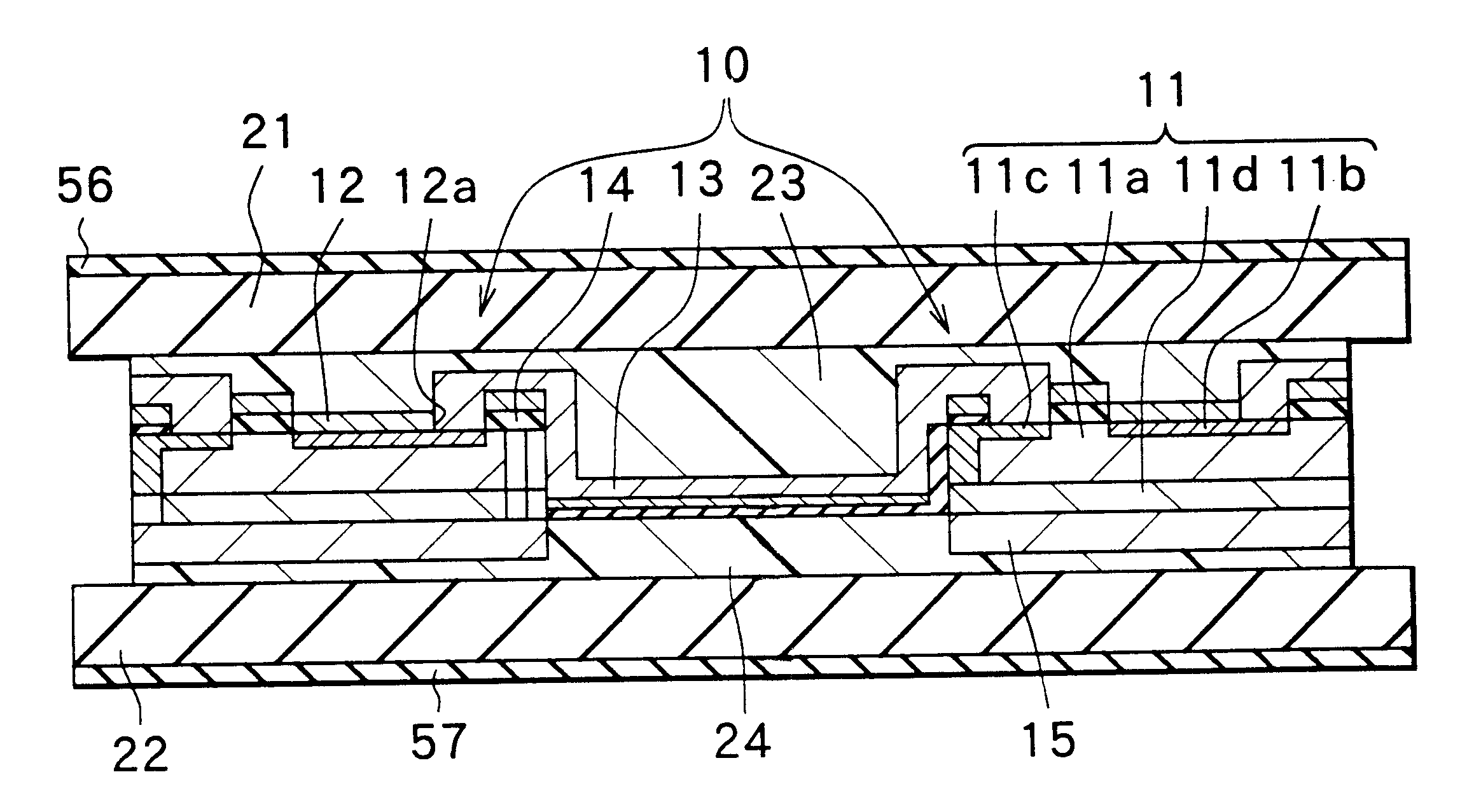

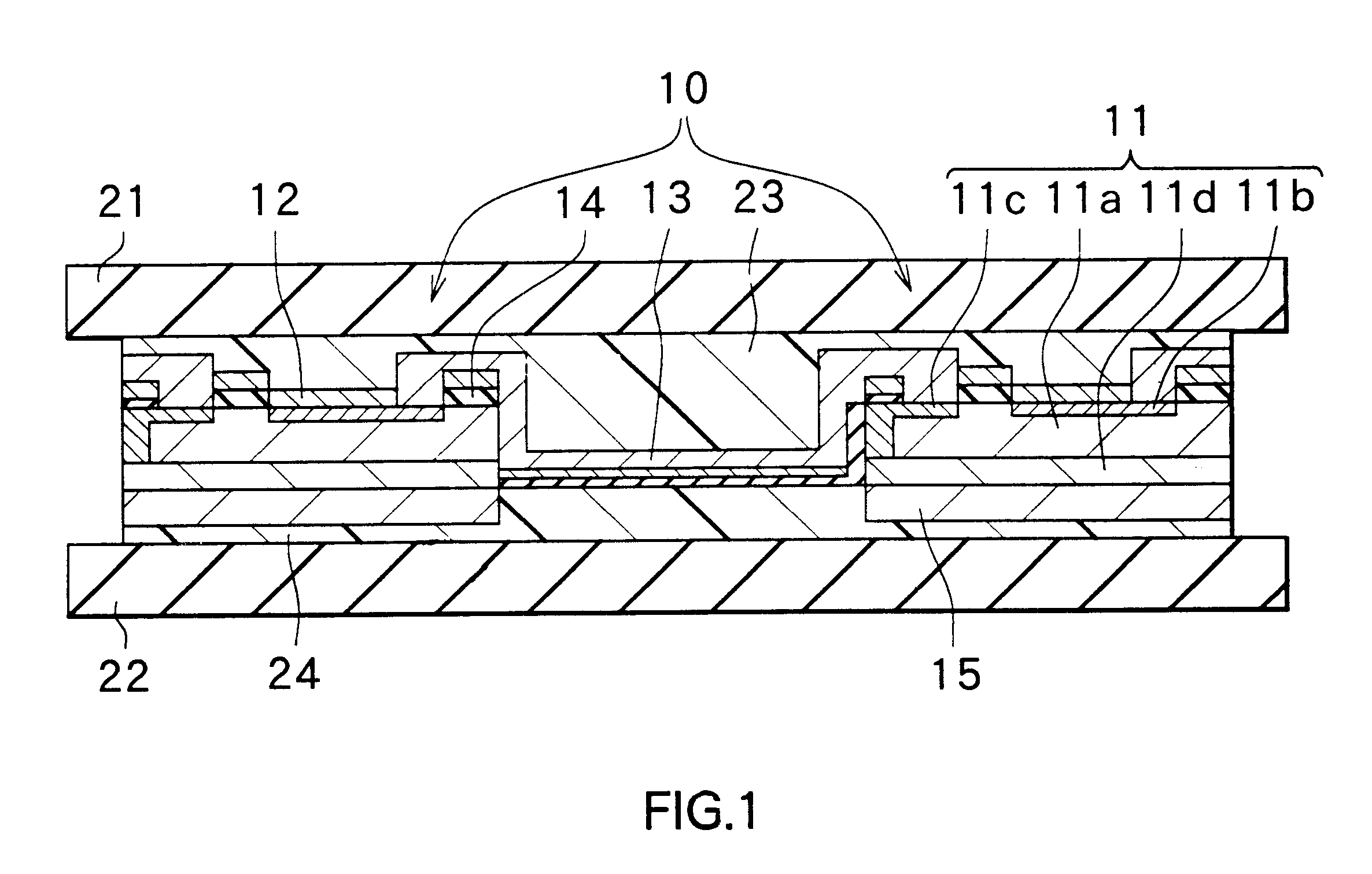

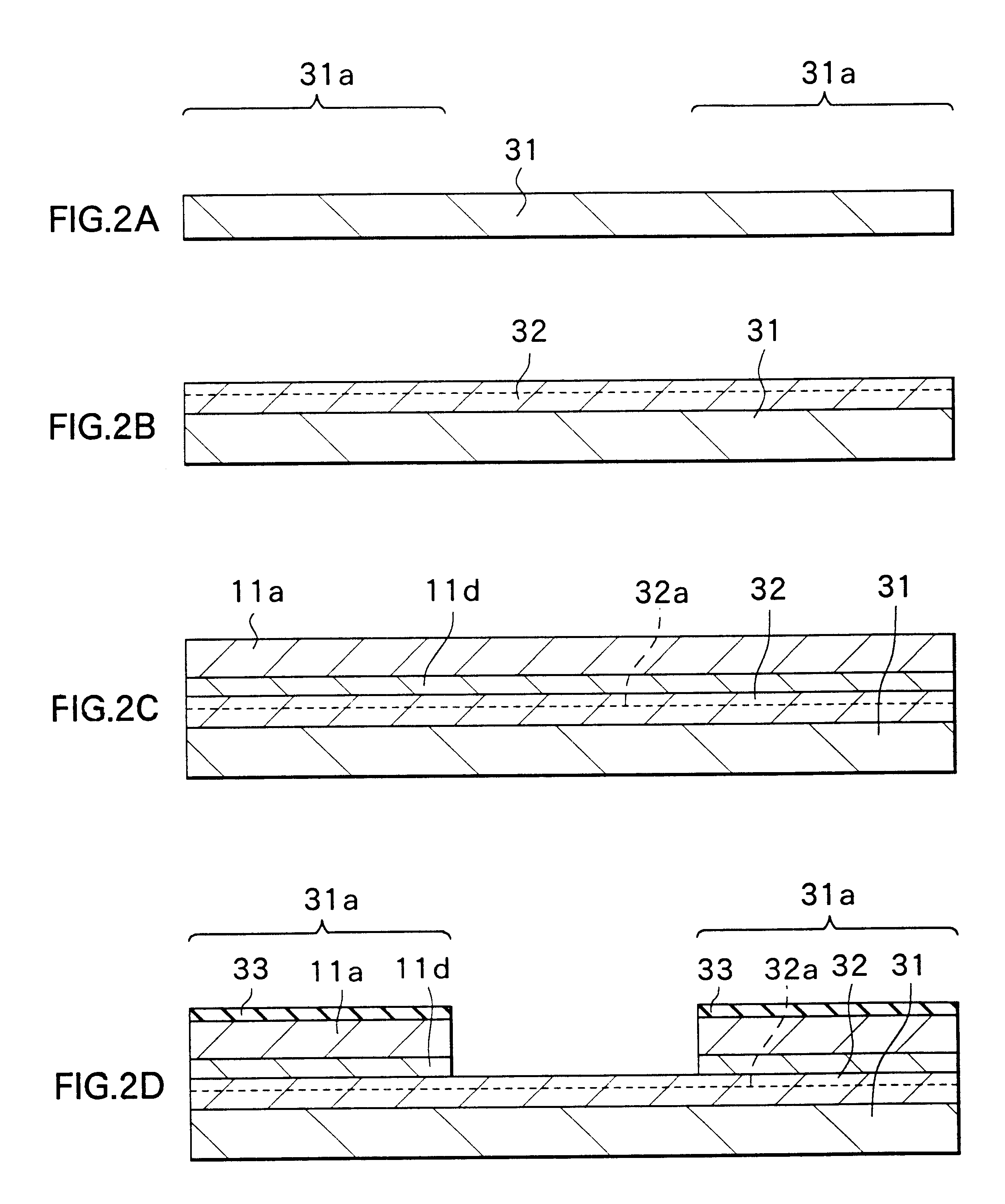

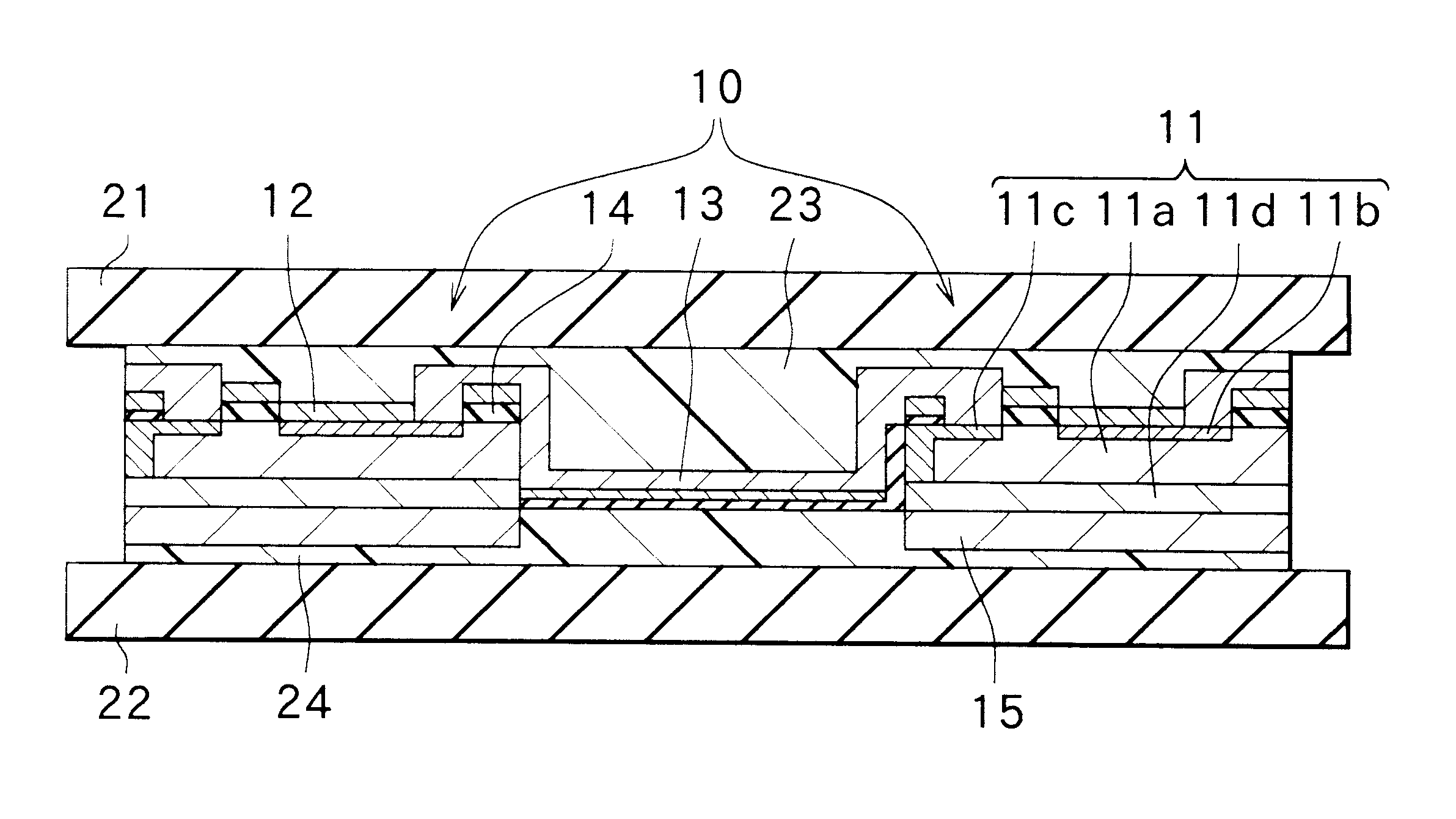

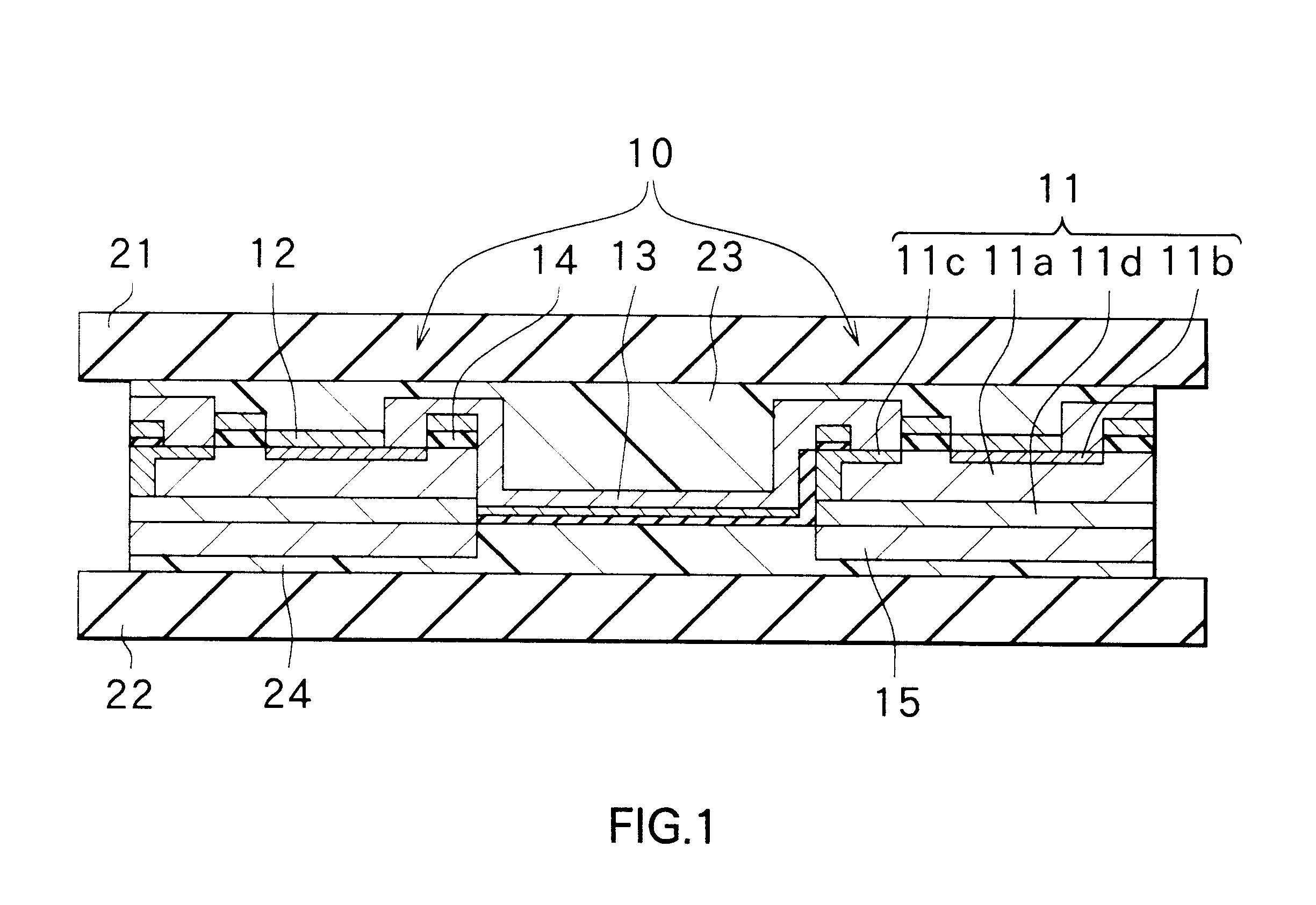

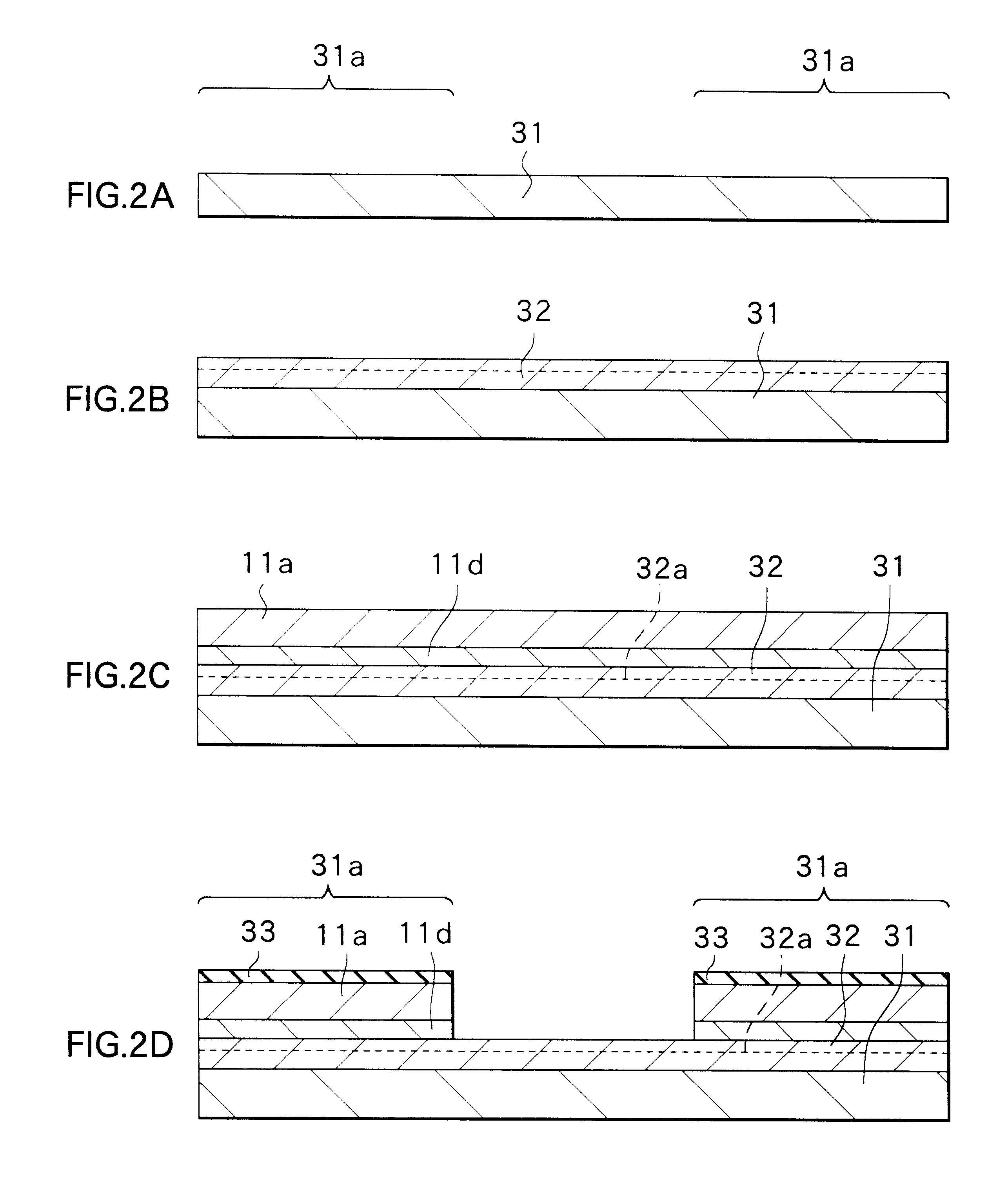

Method of manufacturing semiconductor device

InactiveUS6624050B2Semiconductor/solid-state device detailsSolid-state devicesEngineeringThermal expansion

A plurality of solar batteries are provided between a first substrate and a second substrate. The first substrate and the second substrate are formed of, for example, a paper or a non-woven cloth, which is a material including a natural fiber, cellulose, as the main component. Papers and silicon have relatively small difference in coefficient of thermal expansion so that warp caused by changes in the temperature is suppressed. Also, papers are light, easy to be processed and spontaneously decomposed so that disposing becomes easy. The first substrate is preferable to be transparent or semitransparent and preferable to be formed of cellophane paper, glassine paper, parchment paper, or Japanese paper. Oil may be included in the material. The second substrate is preferable to be opaque. A waterproof film may be formed on the first substrate and the second substrate.

Owner:SONY CORP

Making method for glassine paper

InactiveCN104947511AImprove penetration resistanceImprove smoothnessSpecial paperCalendersPulp and paper industryMachining system

The invention relates to field of paper making technology, and provides a making method for glassine paper. The tension between surface molecules of the glassine paper is high, and the glassine paper is good in oil resistance. The method includes the following steps: 1, body paper making; 2, coating and wetting, wherein a wetting machine is adopted for moisture adjustment, a heating device is installed in a wetting machine system, hot water is adopted for wetting, the temperature of the hot water is controlled within 30 DEG C-90 DEG C, the moisture content of the paper is controlled, and wetting is stopped when the moisture content of the paper reaches 20%-21%; 3, storage; 4, excessive calendaring, wherein a calender is adopted for calendaring, at least three calendaring areas are arranged on the calender, the pressure is 1000 KN / m<2>-1200 KN / m<2>, and the temperature is 180 DEG C-220 DEG C; 5, storage heat dissipation; 6, rewinding; 7, packaging and warehousing.

Owner:福建省晋江优兰发纸业有限公司

Biologically treated light-coated glassine paper and preparation method thereof

ActiveCN107401087AHigh transparencyHigh strengthSpecial paperMicroorganism/enzyme additionPapermakingSlurry

The invention discloses biologically treated light-coated glassine paper and a preparation method thereof. The method comprises the steps of material selection of selecting russia larix gmelini, fast-growing eucalyptus in the north sea and glass wool fiber as production materials; slurry preparation of larix gmelini, eucalyptus and wool fiber; and slurry preparation, biological treatment, papermaking and final paper forming operation. According to the preparation method of the biologically treated light-coated glassine paper, the transparency of the glassine paper is significantly improved by combining alkali treatment with bioenzyme treatment by selecting imported larix gmelini with excellent performance, cheap and available domestic eucalyptus and the glass wool fiber capable of improving the paper forming strength as the raw materials; meanwhile, the problems of linting and dusting of the surface of the glassine paper in the using process is solved through light coating; and the biologically treated light-coated glassine paper has excellent paper performance and relatively high market value.

Owner:浙江哲丰新材料有限公司

Ultrahigh strength glassine base paper and production technology thereof

ActiveCN107386002ASolve the short board that is fragile and fragileIncrease pulp yieldSpecial paperPulp beating methodsFiberPolyester

The invention discloses an ultrahigh strength glassine base paper and a production technology thereof. The production technology comprises the following steps: selecting Shanxi white bark pine, Linyi 3-5 year fast-growing triploid poplar, compounded chopped polyester fiber and alkali-free glass fiber as production raw materials; preparing the white bark pine, poplar, chopped polyester fiber and glass fiber into pulp; and preparing the pulp, making paper and lastly forming the paper. According to the production technology for the ultrahigh strength glassine base paper disclosed by the invention, the domestic white bark pine and poplar which are conveniently pulped and high in pulp yield and the chopped polyester fiber and glass fiber which can greatly promote the toughness, strength and rigidity of the end product of the paper are selected as the raw materials and the processes, such as, optimizing the pulp, preparing the pulp, making paper and post-processing, are performed, so that the physical properties of the glassine base paper are obviously promoted, the defect of easiness in breaking and cracking of the glassine in the use process of the product acquired by adopting the traditional raw materials and method can be overcome and the ultrahigh strength glassine base paper has excellent end-product paper properties and market value.

Owner:浙江哲丰新材料有限公司

Production technique for resin products with crystal peaks over peaks decorative design

The invention relates to the manufacturing process of a resin manufactured product with a transparent mountain fold, and relates to the manufacturing process of a resin manufactured product. Not only the color of the manufactured product manufactured with the process method is bright and transparent, but also the inner side of the manufactured product is provided with a vertical and transparent and beautiful design like the mountain fold. The manufactured product has the manufacturing process that the manufacture of a piece of glassine paper: the glassine paper is cut up into blocks, and gravity is used to kneading into a folding pile. The preparation of the mixed liquor of unpolymerized resin: unsaturated polyester resin is uniformly mixed with firming agent and energizing agent, and the mixed liquor of the unpolymerized resin is produced. The forming of the manufactured product: the glassine paper is arranged in a die assembly, the mixed liquor of the unpolymerized resin is injected, and then the glassine paper is taken out after being polymerized and solidified in the die assembly. Because the mixed liquid of the unpolymerized resin is slabby liquid during the forming process, the slabby liquid is polymerized and solidified after being dipped into the solid glassine paper, during the polymerizing and solidifying process, the interface can be generated in the mixed liquor of the unpolymerized resin and the interface of the glassine paper, the manufactured product formed with the light reflectance phenomenon of the interface is provided with the vertical and transparent design inside. The different die assemblies are adopted according to the requirement, and the various manufactured products wit ornamental can be manufactured.

Owner:崔朝

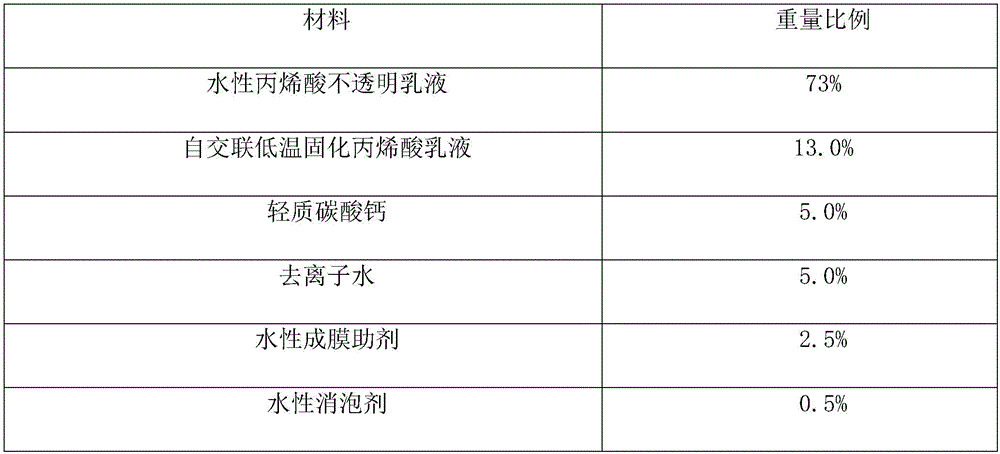

Novel water-based paint for environment-friendly glassine and preparation method of novel water-based paint

InactiveCN105887559AEmission reductionNon-toxicDefoamers additionCoatings with pigmentsWater basedEmulsion

The invention relates to novel water-based paint for environment-friendly glassine and a preparation method of the novel water-based paint, and provides the novel water-based paint and the preparation method which are mainly aimed at solving the problems that at present, water-based paint for glassine is not large enough in adhesion, too high in coating hardness, poor in coating folding endurance, not complete in coating transfer and not wide in printing adaptability. The novel water-based paint is prepared from, by weight, 60-80 parts of water-based acrylic acid opaque emulsion, 10-20 parts of self-crosslinking solidified acrylic acid emulsion, 3-8 parts of calcium carbonate, 5-10 parts of water, 1.0-3.0 parts of water-based coalescing agent, 0.3-0.8 part of water-based defoaming agent, 0.5-1 part of water-based dispersing agent and 0.5-1 part of water-based wetting agent. The novel water-based paint has the advantages of being environmentally friendly, good in film forming property, high in glossiness, wide in printing adaptability and the like.

Owner:ZHONGSHAN BOHAI SPECIAL CHEM CO LTD

Semiconductor device and method of manufacturing the same

InactiveUS6222118B1Semiconductor/solid-state device detailsSolid-state devicesEngineeringThermal expansion

A plurality of solar batteries are provided between a first substrate and a second substrate. The first substrate and the second substrate are formed of, for example, a paper or a non-woven cloth, which is a material including a natural fiber, cellulose, as the main component. Papers and silicon have relatively small difference in coefficient of thermal expansion so that warp caused by changes in the temperature is suppressed. Also, papers are light, easy to be processed and spontaneously decomposed so that disposing becomes easy. The first substrate is preferable to be transparent or semitransparent and preferable to be formed of cellophane paper, glassine paper, parchment paper, or Japanese paper. Oil may be included in the material. The second substrate is preferable to be opaque. A waterproof film may be formed on the first substrate and the second substrate.

Owner:SONY CORP

System and method for printing multiple postage indicia

InactiveUS20080021849A1Franking apparatusSpecial data processing applicationsPaper documentDocument preparation

An envelope having a window for allowing a printed postage indicia to show through is shown. According to a preferred embodiment, the postage indicia window may be provided with a glassine covering. Preferably the postage indicia may be put in a corner of a document to be mailed and the document placed in the envelope so that the postage indicia shows through the postage indicia window.

Owner:STAMPS COM

Manufacturing technology of thermal-insulation glassine release paper

InactiveCN108049248AMaintain propertiesExtended service lifePaper coatingCalendersSurface moistureManufacturing technology

The invention discloses a manufacturing technology of thermal-insulation glassine release paper. The manufacturing technology comprises the following steps of selecting glassine body paper as a raw material to be put on an overpressure machine again, compressing the glassine body paper under the condition of 40-50 DEG C, then using a smoothness detecting device to detect the surface smoothness ofthe glassine body paper, putting the glassine body paper under the condition of 70-90 DEG C, then smearing the surface of the treated glassine body paper with a thermal-insulation coating through a coating machine, smearing the surface of the coated glassine body paper with a release agent, then putting the glassine body paper under the condition of 70-90 DEG C to be dried, and immediately takingout the glassine body paper when the surface moisture of the body paper meets the requirements, so that the thermal-insulation glassine release paper is obtained. By means of the manufacturing technology of the thermal-insulation glassine release paper, thermal-insulation performance can be integrated into the release paper while original features of the release paper are guaranteed, so that the release paper has thermal-insulation performance, and the service life of the release paper is effectively prolonged.

Owner:WENZHOU XINFENG DECORATION MATERIAL

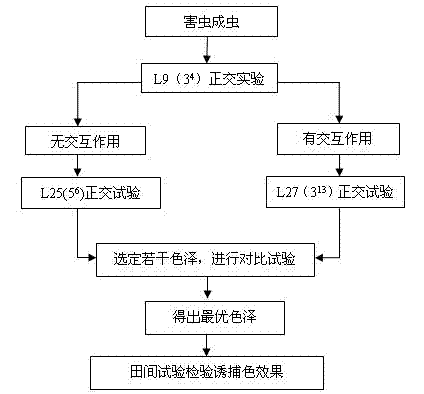

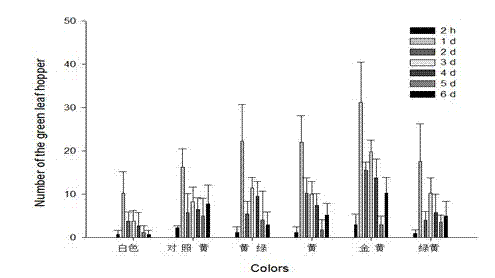

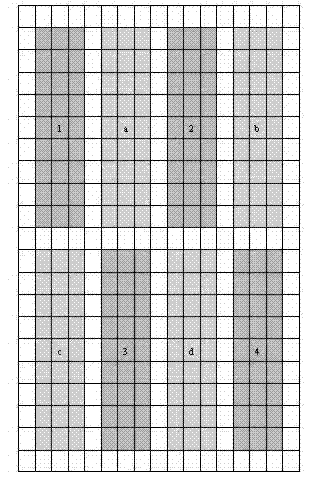

Empoasca vitis gothe trapping color screening and digitized standard color plate manufacture method

A empoasca vitis gothe trapping color screening and digitized standard color plate manufacture method belongs to the technical field of injurious insect pollution-free prevention and comprises the following processing steps of: 1) obtaining an empoasca vitis gothe best trapping color through orthogonal experiments, wherein the red, green, blue (RGB) value of the color is 255.215.0; 2) manufacturing a polypropylene (PP) plastic color plate main body provided with the empoasca vitis gothe best trapping color; and 3) coating sticky insect glue on the PP plastic color plate main body, controlling the coating volume to be 40-50g / m<2>, performing double-face coating, covering glassine release paper on the coated PP plastic color plate main body to serve as a protective film, then cutting and packaging coated slab rubber according to required specifications, and obtaining digitized standard color plates. The color plates obtained by the empoasca vitis gothe trapping color screening and digitized standard color plate manufacture method can improve the prevention effect of tea garden pollution-free empoasca vitis gothein tea gardens.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI +1

Medical polyurethane thin film and preparation method thereof

ActiveCN104436275AGood mechanical propertiesGood water vapor transmission rateAbsorbent padsBandagesPolymer scienceN dimethylformamide

The invention provides a medical polyurethane thin film and a preparation method thereof. The polyurethane thin film comprises the following raw materials: polyurethane, polyethylene, polyethylene glycol, ultra-fine chitosan powder, dihexyl phthalate, 4,5-epoxytetrahydrophthalate, epoxidized soybean oil, polymethylphenyl siloxane fluid, calcium carbonate, N-cyclohexylethanolamine, triphenyl phosphite, 1,4-dioxane and N,N-dimethylformamide. The preparation method comprises the following steps: firstly feeding each component into a mixing stirrer, uniformly mixing and stirring, then adding an obtained mixed material into a reaction kettle, heating, performing stirring reaction, finally pouring an obtained film preparing liquid into one side of a glassine paper matrix, uniformly pushing the liquid to the other side by using a coating machine, putting a coated film preparing liquid and the matrix into clear water together, taking out after film forming, washing, drying, and stripping off from the matrix to obtain the medical polyurethane thin film. The medical polyurethane thin film provided by the invention has excellent mechanical performance, and also has a very good water vapor transmission rate.

Owner:南通华盛高聚物科技股份有限公司

Double-layer composite hot melt adhesive film for bonding metal and plastic

The invention discloses a double-layer composite hot melt adhesive film adhering metal and plastic, which is formed by compounding an upper adhesive film layer and a lower adhesive film layer, wherein the lower adhesive film layer is attached to a piece of release paper, the thickness of the composite adhesive film is 0.05 to 0.20 millimeter, the upper adhesive film layer is a hot melt adhesive layer adhered with the metal, the thickness of the upper adhesive film layer is 30 to 60 percent of the thickness of the composite film, the lower adhesive film layer is a hot melt adhesive layer adhered with the plastic, the thickness of the lower adhesive film layer is 40 to 70 percent of the thickness of the composite film, and the lower adhesive film layer is attached to a piece of glassine release paper. The double-layer composite hot melt adhesive film directly compounds two modified hot melt adhesives with different adhesive properties, is adhered with the release paper to prevent rolling from adhering and the adhesive film from being damaged, reduces application of a middle isolating layer, reduces the thickness of the composite adhesive film, and is prepared by once casting throughcoextrusion casting equipment or twice casting through common coextrusion casting equipment. The double-layer composite hot melt adhesive film can be used for composite adhesion of metallic materialssuch as aluminum, stainless steel and the like and plastic such as ABS, PVC, PET and the like, is particularly suitable for mutual adhesion between sheets, plates and films of the metal and the plastic, and has simple and convenient operation and no pollution.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Manufacture technology of anti-folding Glassine release paper

InactiveCN108060615AImprove flexural performanceQuality improvementCoatings with pigmentsReinforcing agents additionSurface coolingManufacturing technology

The invention relates to the technical field of paper making, in particular to a manufacture technology of anti-folding Glassine release paper. The technology comprises the following steps: S1, preparing a piece Glassine paper as a base layer; S2, preparing a coated material; S3, forming a coated layer; S4, preparing an anti-wrinkle material: mixing 10 to 15 parts of resin, 0.5 to 1.5 parts of anantioxidant, 30 to 35 parts of polyethylene plastic particles, 5 to 8 parts of polybutadiene rubber particles, and 3 to 5 parts of polyvinyl chloride plastic particles in parts by weight, uniformly stirring, and then heating, so as to ensure that raw materials are completely molten; S5, forming an anti-wrinkle layer: uniformly spraying the anti-wrinkle material onto the outer surface of the coatedlayer with a spray gun, forming the anti-wrinkle layer after cooling, and then coating the surface of the anti-wrinkle layer with a release agent; S6, drying release paper obtained in the previous step, and then cutting the release paper into small pieces according to a specified specification. The technology can effectively improve the anti-folding capacity of the Glassine release paper, therebyimproving the overall quality, and is wide in application.

Owner:WENZHOU XINFENG DECORATION MATERIAL

Anti-electrostatic label paper and manufacture method thereof

InactiveCN102250580ADoes not affect stickinessEffective anti-staticStampsNon-fibrous pulp additionPolyethylene terephthalate glycolPolyvinyl chloride

The invention discloses an anti-electrostatic glue, and anti-electrostatic label paper manufactured from the anti-electrostatic glue. The anti-electrostatic glue is composed of voltage-sensitive resins and an electroconductive silver paste added to the voltage-sensitive resins. The label paper comprises a label substrate, an adhesive glue and a backing fabric covered on the glue; and the label paper is characterized in that the glue is the anti-electrostatic glue, the backing fabric is glassine paper, kraft paper or coated paper separately coated by dimethyl silicone oil, and the label substrate is PET (polyethylene terephthalate), PVC (polyvinyl chloride) or PP (polypropylene). The anti-electrostatic glue can effectively and permanently prevent static electricity, without influence on the adhesiveness; and the anti-electrostatic label paper manufactured from the anti-electrostatic glue can effectively isolate static influence during use.

Owner:朱向忠

Polyvinyl chloride protection film and production method thereof

InactiveCN106381085AIncreased compliance requirementsImprove adhesion stabilityFilm/foil adhesive primer layersEster polymer adhesivesTectorial membraneAdhesion force

The invention relates to the field of protection films, in particular to a polyvinyl chloride protection film. A polyvinyl chloride thin film is selected to be used as a base material; the upper and lower layers of the polyvinyl chloride thin film are attaching force coatings. The attaching force coatings concretely use a polyisocyanate silane coupling agent to form polyisocyanate attaching force coatings, wherein an adhesive layer is pasted under the attaching force coating positioned at the lower layer; glassine release paper is pasted under the adhesive layer; in order to be matched with the automatic production, the adhesion stability of the protection film needs to be high; an acrylic acid acryl adhesive emphasizes on the improvement of the initial adhesion force so that the protection film can be smoothly attached onto the surface of a mirror with a radian; the subsequent connection force is reduced, so that the smoothness degree of the subsequent protection film peeling by a mechanical arm cannot be influenced by the protection film due to the adhesion force enhancement along with the increase of attachment time; the polyisocyanate silane coupling agent is selected to be used as an intermediate medium of the polyvinyl chloride thin film and the acrylic acid acryl adhesive for enhancing the adhesion between the polyvinyl chloride thin film and the acrylic acid acryl.

Owner:TAICANG JIN YU ELECTRONICS MATERIALS

Preparation method of low-basis-weight high-strength glassine paper

InactiveCN112064411AQuantitative lowImprove toughnessDefoamers additionSpecial paperPolyesterPolymer science

The invention relates to the technical field of papermaking, and provides a preparation method of low-basis-weight high-strength glassine paper in order to solve the problem of low tear strength of low-basis-weight paper. The preparation method comprises the following steps of: (1) slurry preparation: carrying out biological treatment on raw material slurry, and then mixing the slurry with an auxiliary agent and pulping the mixture to obtain mixed slurry; (2) raw paper preparing: sequentially carrying out activation modification, net part papermaking, squeezing and pre-drying on the mixed slurry to obtain raw paper; (3) sizing: entering a surface sizing treatment procedure, and performing surface sizing on the raw material paper in the step (2) by adopting an unsaturated polyester sizing agent to obtain paper subjected to surface sizing treatment; and (4) paper forming: carrying out post-drying, calendaring, rolling and slitting on the paper sheet subjected to surface sizing treatmentto obtain a finished product. The prepared glassine paper is low in basis weight, good in toughness, high in thermal stability and good in tensile strength. The low-viscosity sizing agent with good film-forming property is introduced, so that the tear resistance of the sizing agent and the binding force between the sizing agent and the raw paper of the paper are improved.

Owner:浙江哲丰新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com