Novel water-based paint for environment-friendly glassine and preparation method of novel water-based paint

A glass cardboard and water-based coating technology, applied in paper coating, coating, papermaking, etc., can solve the problems of poor printing adaptability, incomplete coating transfer, poor folding resistance of coating, etc., and achieve excellent printing adaptability , Excellent transferability, high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

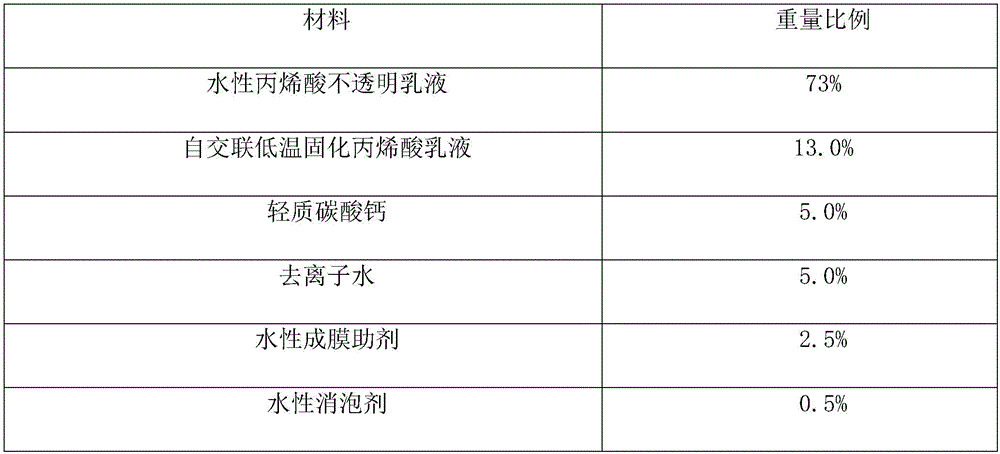

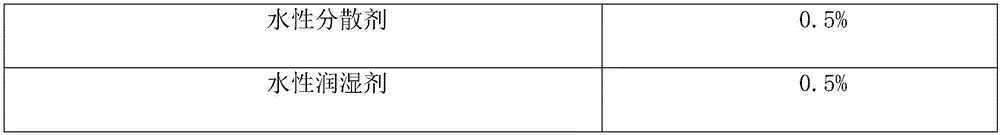

[0070] A new type of environmentally friendly water-based coating for glass cardboard, its formula consists of:

[0071]

[0072]

[0073] The preparation method of this novel environment-friendly glass cardboard water-based paint is as follows:

[0074] a) Add the water-based acrylic opaque emulsion into the dispersion tank according to the formula ratio, and start stirring at a speed of 300 rpm for 15 minutes;

[0075] b) Add water-based film-forming aids, water-based dispersants, and water-based wetting agents into the dispersion tank according to the formula ratio, and start stirring at a speed of 300 rpm for 15 minutes;

[0076] c) Slowly add the light calcium carbonate into the dispersing tank according to the formula ratio, be careful not to make the light calcium carbonate agglomerate, increase the speed to 500 rpm and stir for 30 minutes after adding;

[0077] d) Grind and disperse the dispersed materials with a 60L sand mill until the particle size is <2.5um, ...

Embodiment 2

[0085] A new type of water-based paint for environmentally friendly glass cardboard, its formula consists of:

[0086] Material weight ratio Waterborne Acrylic Opaque Emulsion 65.0% Self-crosslinking low temperature curing acrylic emulsion 21.0% light calcium carbonate 3.0% Deionized water 7.0% Water-based coalescent 1.5% Water-based defoamer 1% water-based dispersant 0.7% water-based wetting agent 0.8%

[0087] The preparation method of this novel environment-friendly glass cardboard water-based paint is as follows:

[0088] a) Add the water-based acrylic opaque emulsion into the dispersion tank according to the formula ratio, and start stirring at a speed of 250 rpm;

[0089] b) Add water-based film-forming aids, water-based dispersants, and water-based wetting agents into the dispersion tank according to the formula ratio;

[0090] c) Slowly add the light calcium carbonate into the dispersion tank according to ...

Embodiment 3

[0099] A new type of water-based paint for environmentally friendly glass cardboard, its formula consists of:

[0100] Material weight ratio Waterborne Acrylic Opaque Emulsion 70.0% Self-crosslinking low temperature curing acrylic emulsion 10.0% light calcium carbonate 7.0% pure water 8.0% Water-based coalescent 2.5% Water-based defoamer 1% water-based dispersant 1% water-based wetting agent 0.5%

[0101] The preparation method of this novel environment-friendly glass cardboard water-based paint is as follows:

[0102] a) The water-based acrylic opaque emulsion is added into the dispersion tank according to the formula ratio, and the stirring is started at a speed of 350 rpm;

[0103] b) Add water-based film-forming aids, water-based dispersants, and water-based wetting agents into the dispersion tank according to the formula ratio;

[0104] c) Slowly add the light calcium carbonate into the dispersion tank accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com