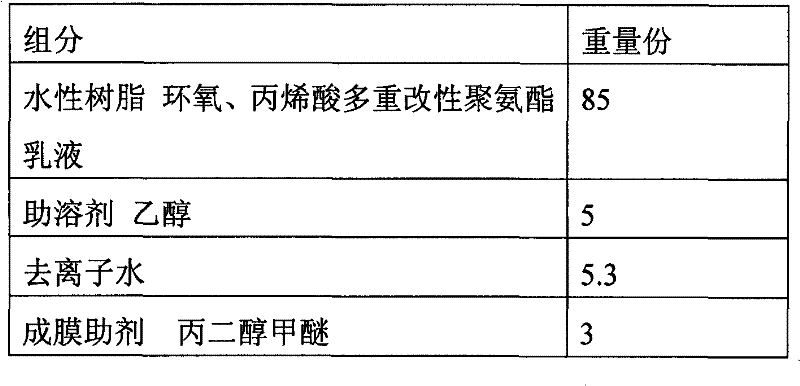

Patents

Literature

712results about "Defoamers addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

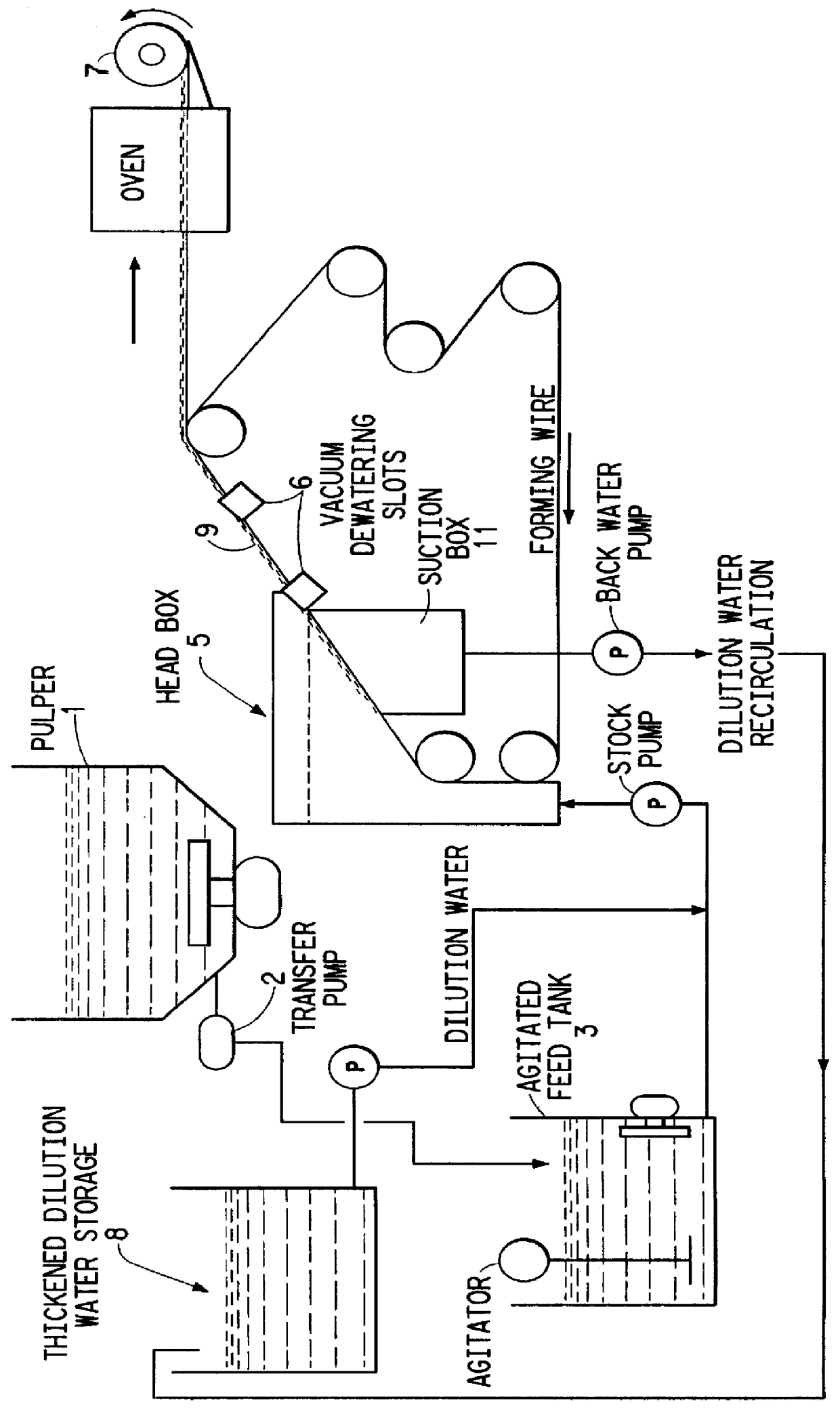

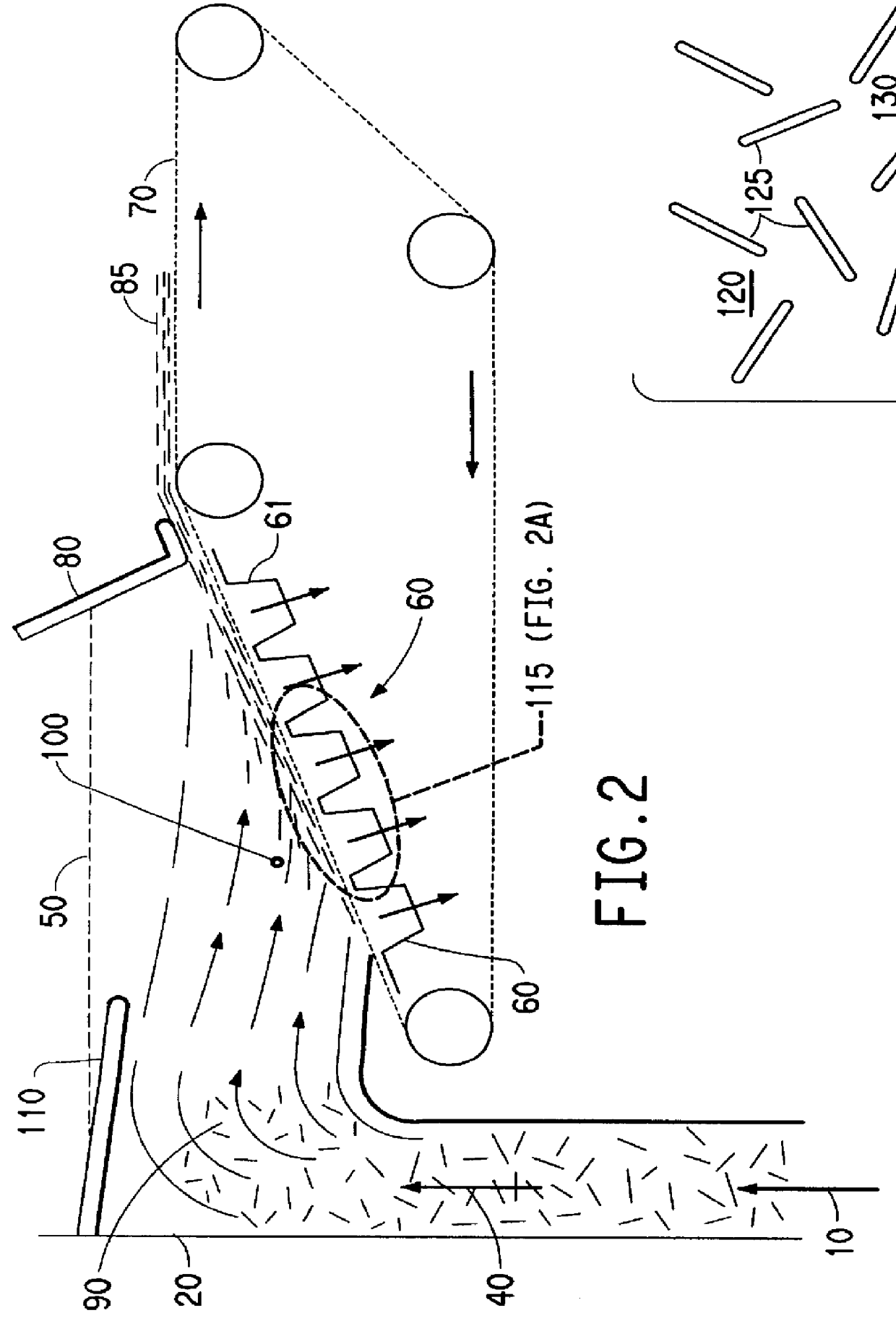

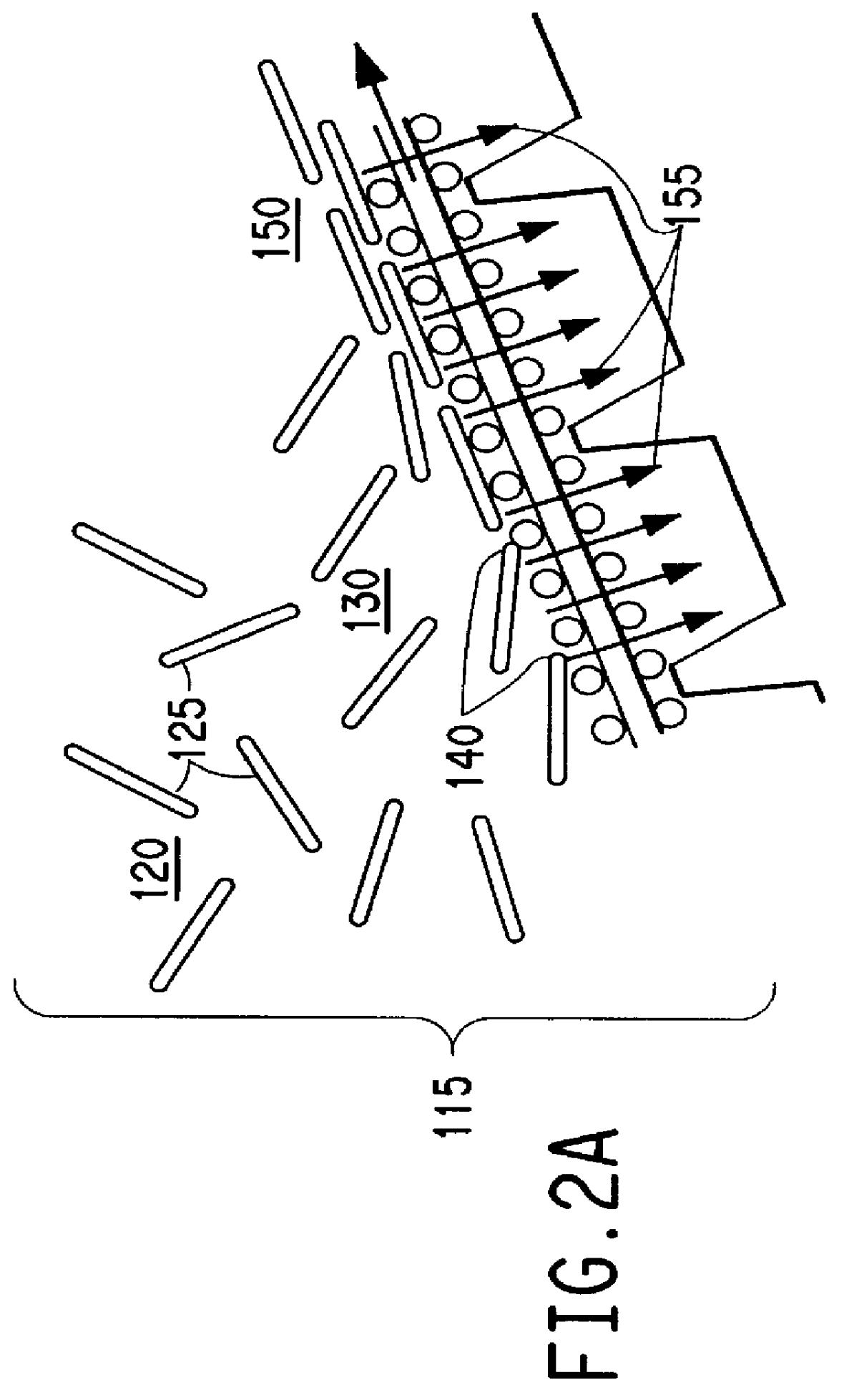

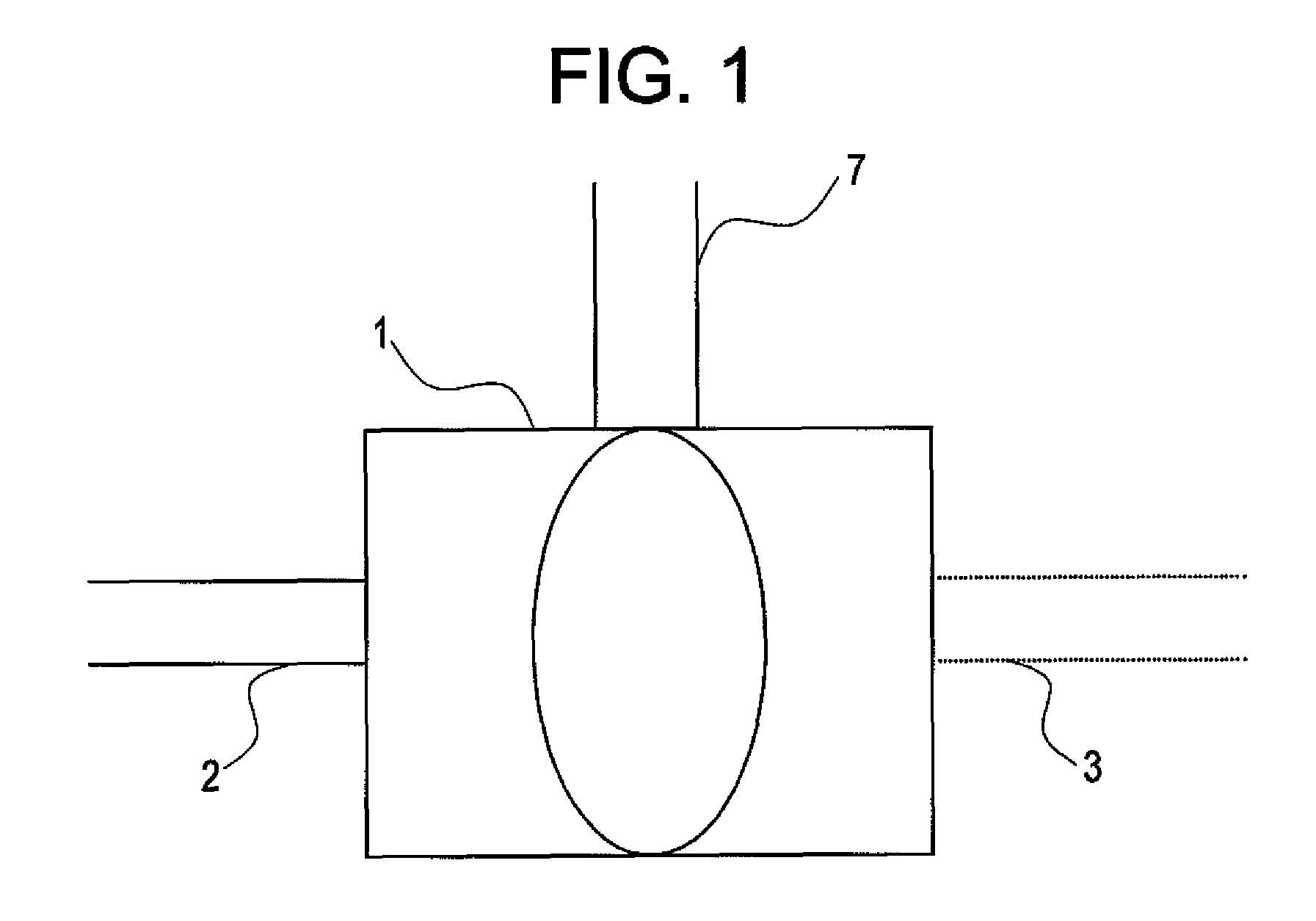

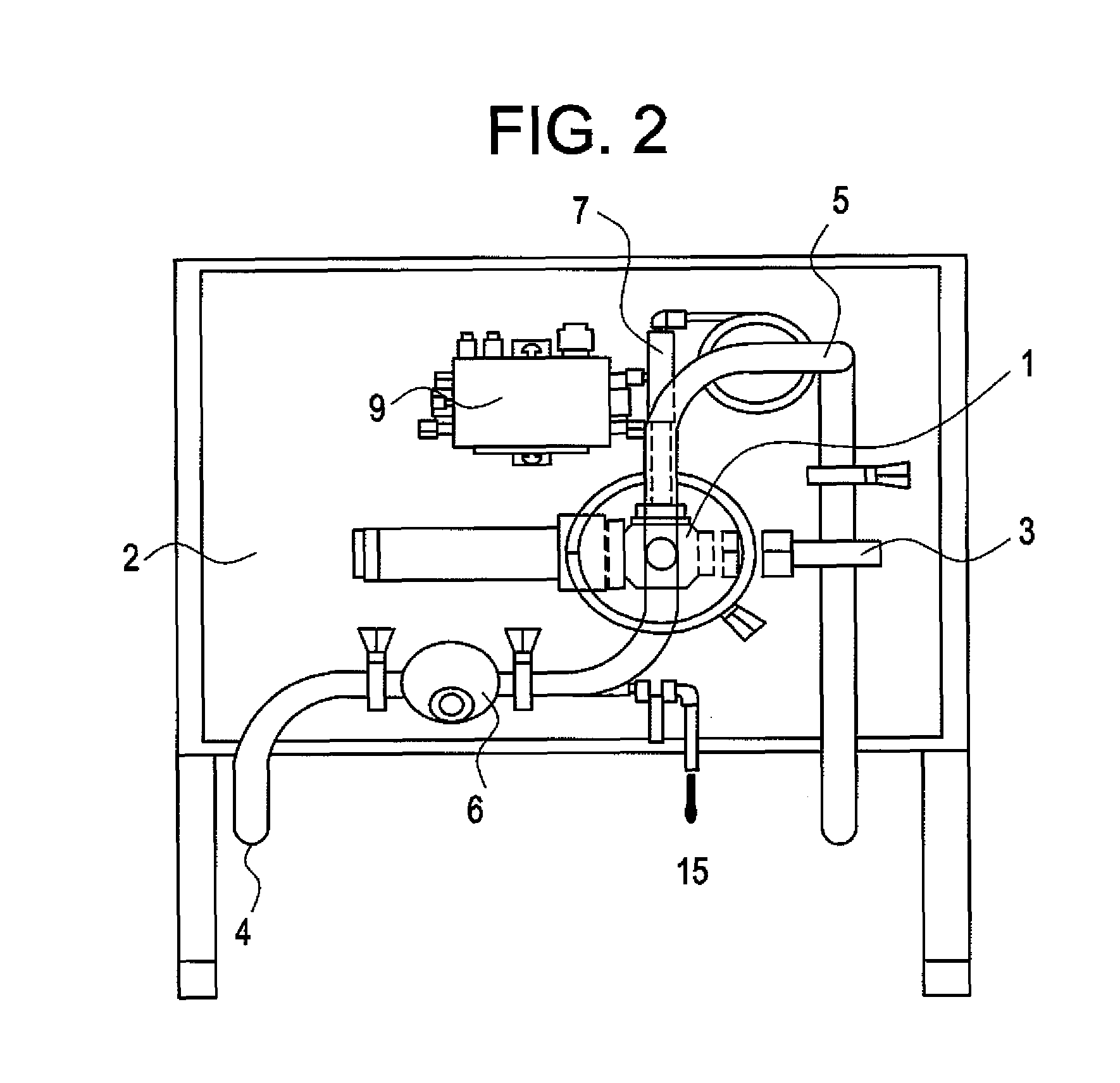

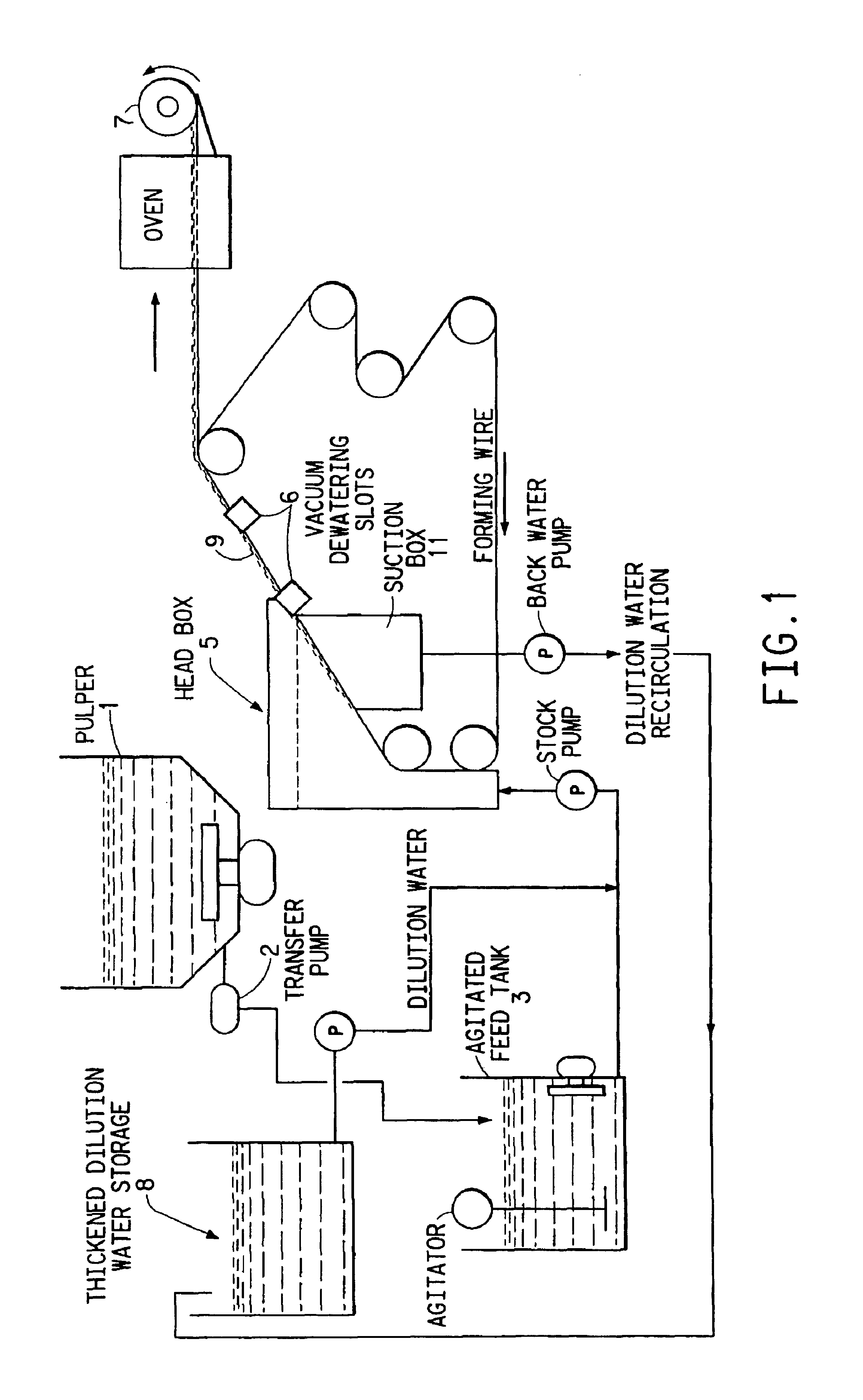

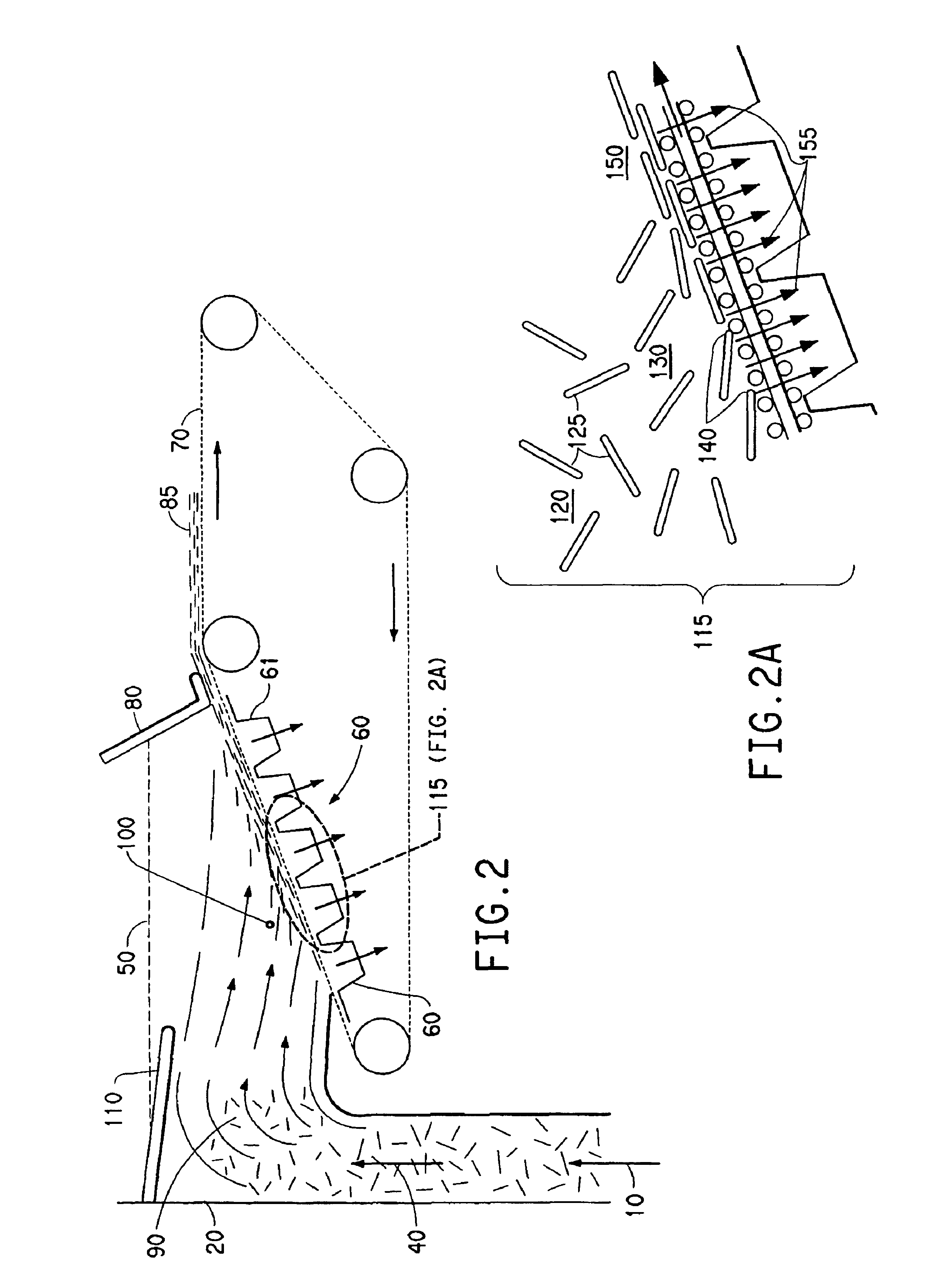

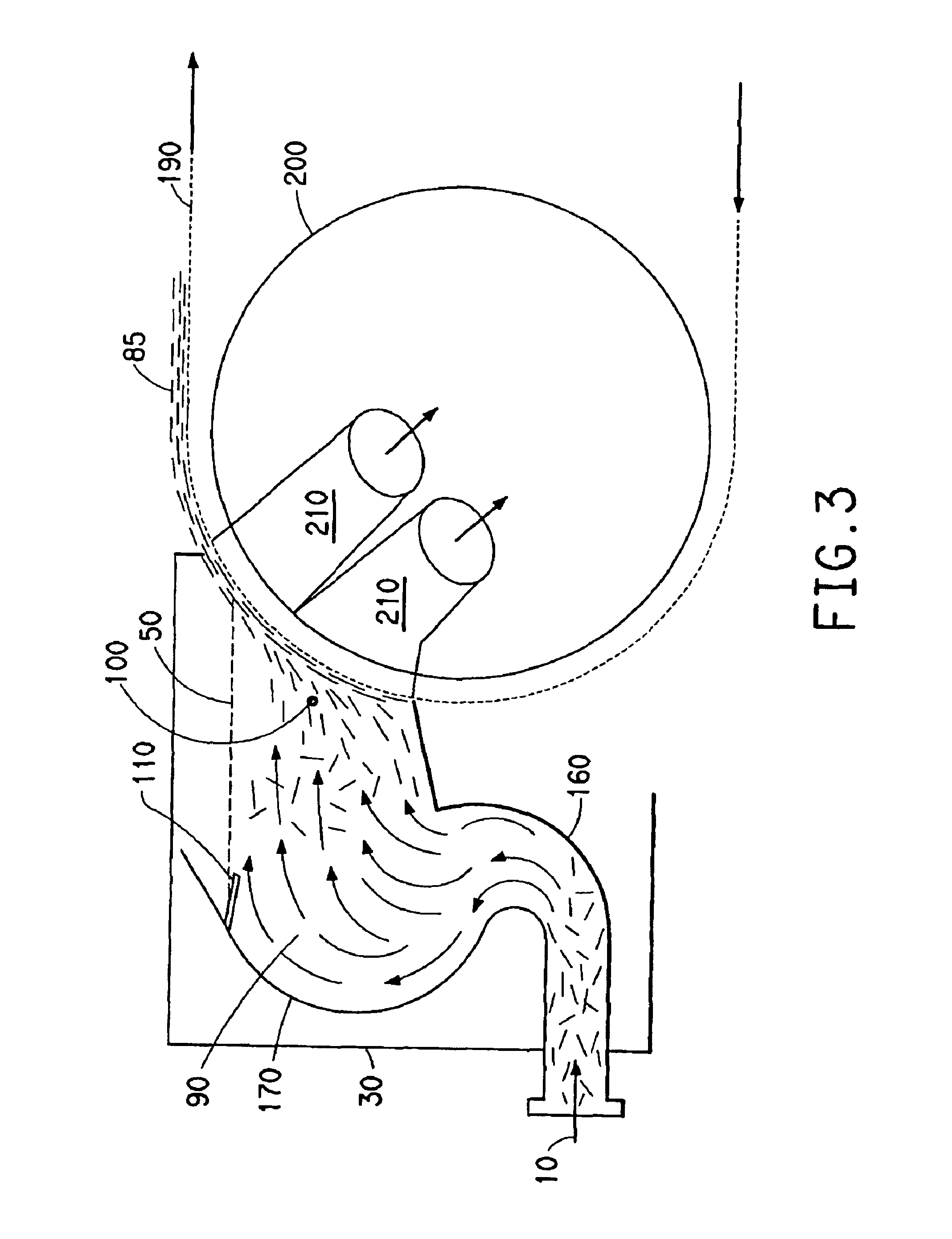

Wetlay process for manufacture of highly-oriented fibrous mats

A mat containing highly machine direction oriented (90% or greater), discontinuous reinforcement fibers, is produced on inclined wire or rotary paper making machinery. Fibers are first uniformly dispersed in an aqueous medium containing thickeners and wetting agents. In one embodiment, antifoaming agents are also added to prevent floating fibers which entangle and reduce orientation. Thermoplastic fibers or particles may also be included. Stock is brought into an open headbox in a flow pattern which allows the fibers to decelerate before approaching the porous suction belt (wire). As the fibers approach the suction belt, the fibers begin to turn and align in the streamline so as to present one end toward the suction wire. The leading ends of the fibers are gripped by the moving belt which drags the fibers out of the dispersion stock in a straight line. The porous mat produced may be dried and bonded through hot air, heat and / or pressure, or chemical binders. Stacks of such mats may be compressed partially to produce porous structures, or fully to produce

Owner:VIRGINIA TECH FOUND

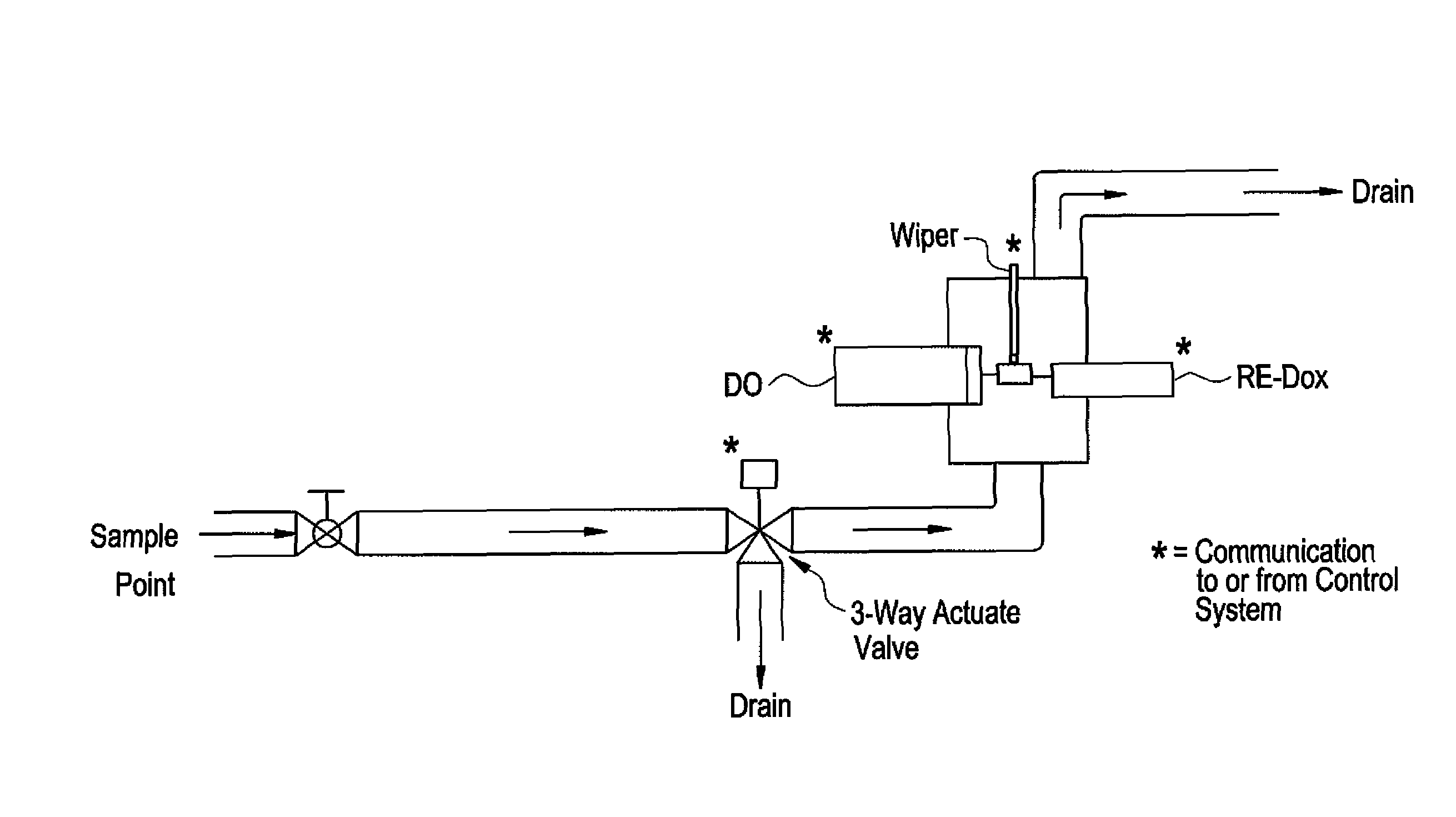

Method of monitoring surface associated microbiological activity in process streams

Owner:ECOLAB USA INC

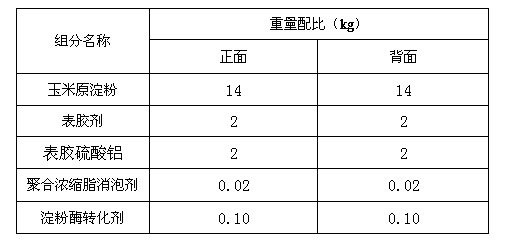

Foam control formulations

ActiveUS20150080273A1Lower Level RequirementsInhibition formationDewatering/demulsification with chemical meansDefoamers additionProcedure AgentsWater insoluble

The invention provides a foam control formulation in the form of a microemulsion, the formulation comprising: (a) from S to 70% w / w of primary surfactant, this surfactant having an HLB of from 1 to 12 and / or a cloud point of from 20 to 70° C.; (b) from 2 to 40% w / w of water-insoluble organic carrier liquid; and (c) water. Also provided is the use of this formulation to prevent and / or reduce foam in a fluid system, or as a processing aid to control foam production in a fluid system. The formulation may be used in an aqueous fluid system, such as an oilfield.

Owner:ENERGY SOLUTIONS (US) LLC

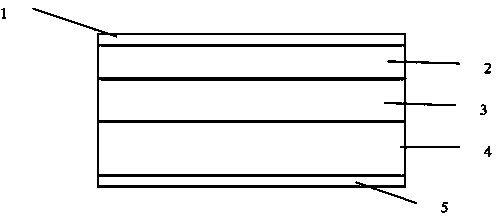

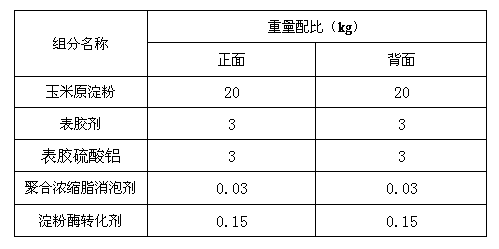

White craft paper and production method thereof

ActiveCN103437242AImprove retentionHigh whitenessDefoamers additionSpecial paperManufacturing technologyProcess engineering

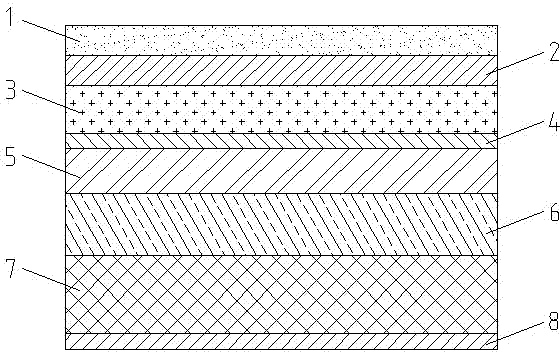

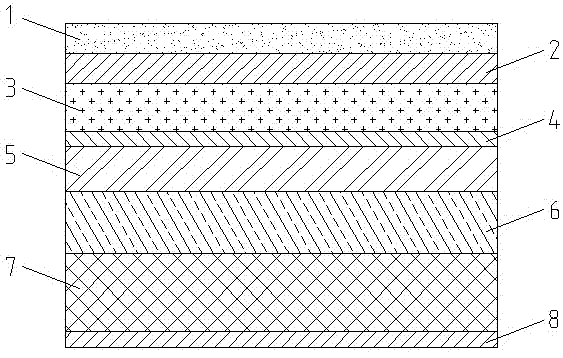

The invention relates to a white craft paper and a production method thereof, and belongs to the pulping papermaking production field. The white craft paper comprises a surface layer, a core layer, a substrate and surface gluing layers (comprising a right-side gluing layer and a wrong-side gluing layer). The quantitative range of the white craft paper is 125-200g / m<2>, wherein the weight ranges of the surface applying layers, the surface layer, the core layer and the substrate are 2-5g / m<2>, 20-24g / m<2>, 30-35g / m<2> and 75-150g / m<2>. The invention also relates to the making method of the white craft paper which is a gluing squeezing making technology. The white craft paper produced through the making technology has the advantages of high whiteness, high strength, good printing performance, low cost and environmental protection, and can satisfy clients' requirements.

Owner:JIAN GRP

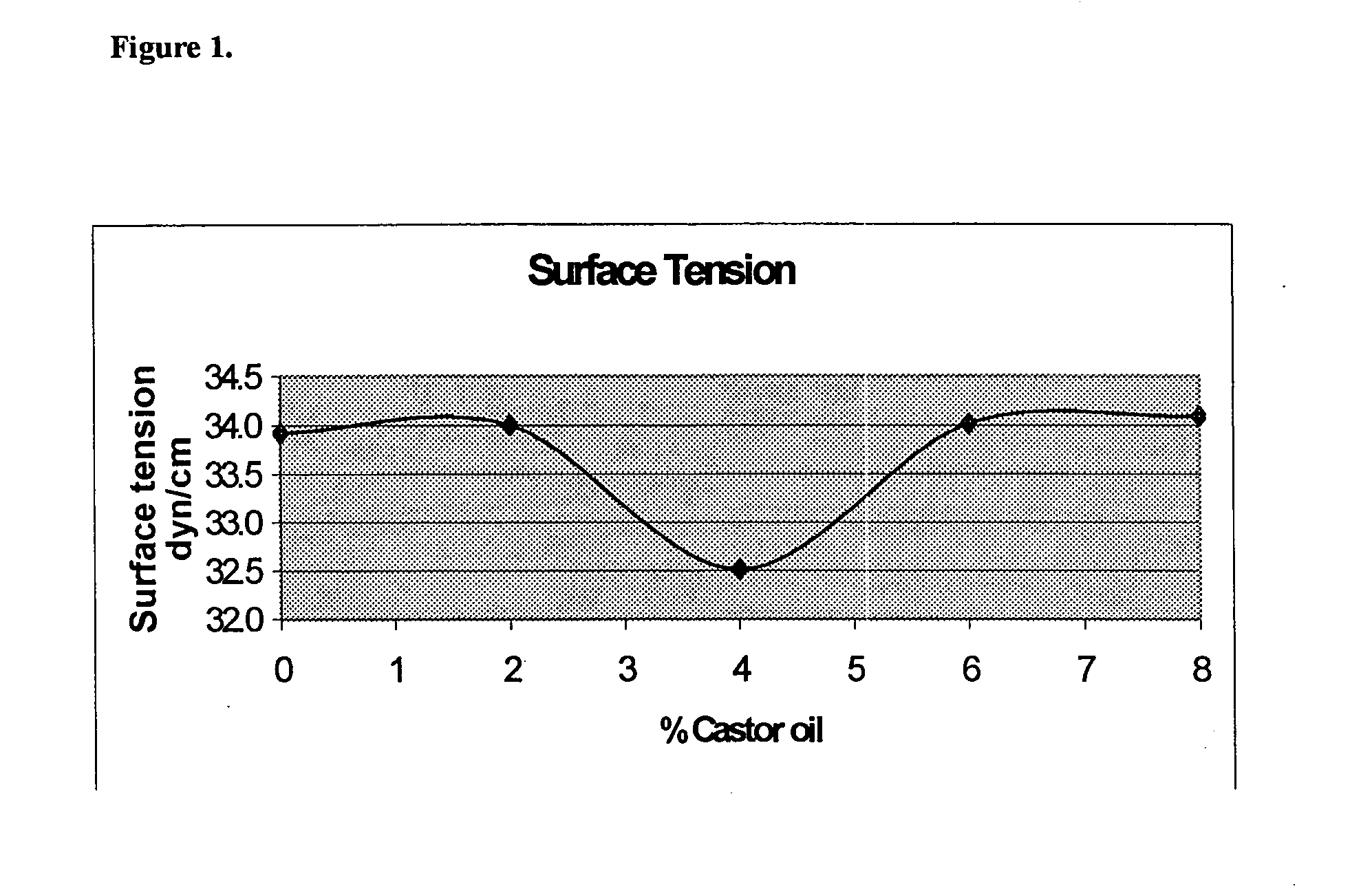

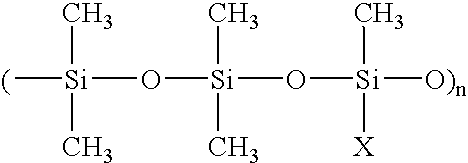

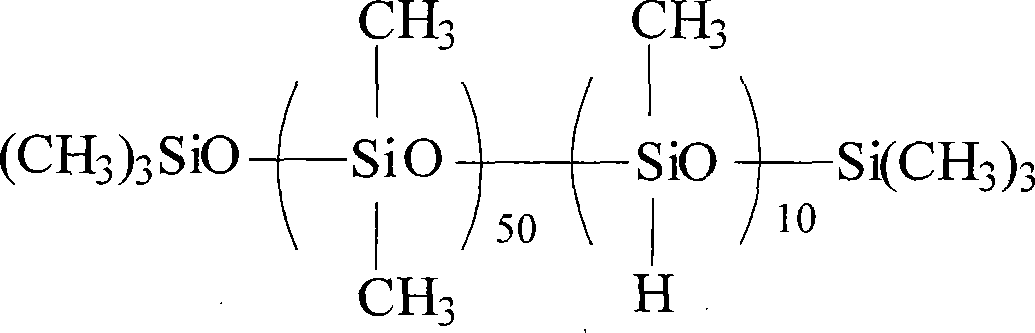

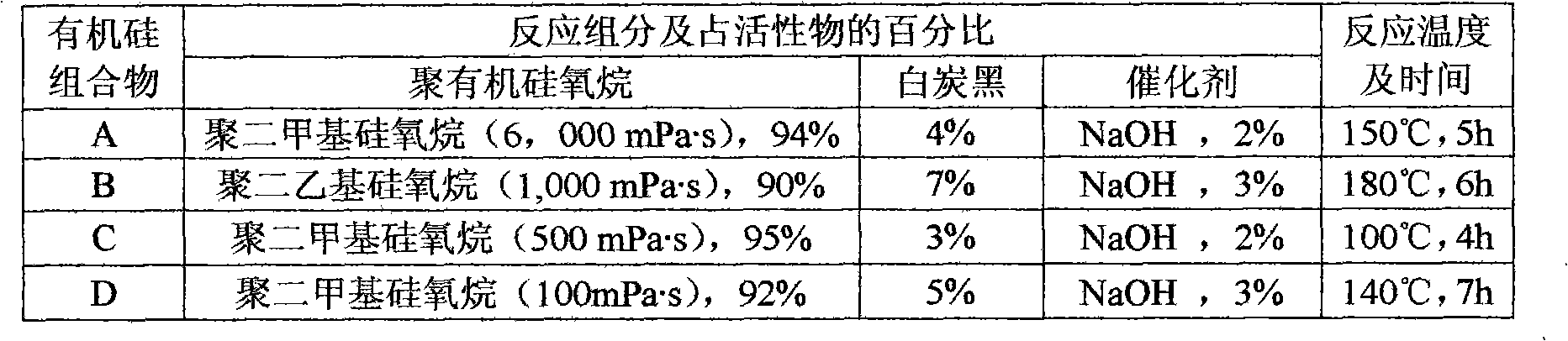

Silicone defoaming agent for papermaking and pulping and preparation method thereof

InactiveCN101798781ANovel production formulaRaw materials are easy to getDefoamers additionCoatingsEmulsionPapermaking

The invention provides a silicone defomaing agent for papermaking and pulping and a preparation method thereof, which belong to the papermaking chemicals, and mainly comprise silicon grease mixture, silicon oil mixture, emulsifier, thickener and water. In the defoaming agent emulsion, silicon grease mixture and silicon oil mixture account for 70 to 90 percent of the active matter content, wherein total active matter content accounts for 5 to 30 percent of total content of emulsion, and the rest medium is water. The anti-foaming performance is improved through the silicon grease mixture, the defoaming performance is improved through the silicon oil mixture, the viscosity of the silicon grease is reduced by adding the emulsifier, and the emulsion effect is improved. The silicone defoaming agent has novel formula composition and good defoaming and anti-foaming performance, and has excellent performance in the papermaking pulping work procedure and partial water systems.

Owner:XIAN SUNY FINE CHEM

Water-based calcium stearate dispersion for papermaking and preparation method thereof

InactiveCN102094356AImprove performanceSmall particle sizeDefoamers additionCoatings with pigmentsWater basedRoom temperature

The invention relates to a water-based dispersion and a preparation method thereof, wherein the water-based dispersion takes calcium stearate as the main component and is used for papermaking; and the dispersion is mainly used as an auxiliary, a functional auxiliary and a coating lubricant in the papermaking and coating processes. The dispersion is formed by processing the calcium stearate, an emulsifier A, an emulsifier B, an auxiliary, a dispersing agent, a defoamer, a fungicide and water; and the production comprising the steps of: adding the calcium stearate, the emulsifier A, the emulsifier B, the auxiliary, the dispersing agent, the defoamer, the fungicide and the water into a high-pressure reaction kettle according to a certain proportion; sealing the high-pressure reaction kettle and heating to 160-190DEG C; mixing the materials at a constant temperature for 1h; and then rapidly cooling to the room temperature so as to obtain the target product. According to the proportion and the method, the viscosity range of the prepared water-based calcium stearate dispersion is 90-680mPa.S, the particle size range is 0.45-5.0 microns and the solid content is 39-75wt%. The water-based calcium stearate dispersion has the advantages of simple process, high efficiency, no color reversion of the product, no odor, no pollution and the like; and the particle size, the solid content and the viscosity are adjustable.

Owner:DONGGUAN CHNV TECH CO LTD

Defoamer emulsion compositions for pulp mill applications

InactiveUS20060128816A1Reduce usageLow costNatural cellulose pulp/paperDefoamers additionPulp millHydrophobic silica

An oil-in-water emulsion useful as a defoamer for pulp and paper mill applications is described. The defoamer has an oil blend (of a triglyceride oil or a mixture of triglyceride oils and silicone), a stabilizing agent (to make the oil blend stable in the emulsion), hydrophobic silica particles, surfactants, dispersants, and other components. The emulsion is usable directly at low concentrations to control foam.

Owner:SOLENIS TECH CAYMAN

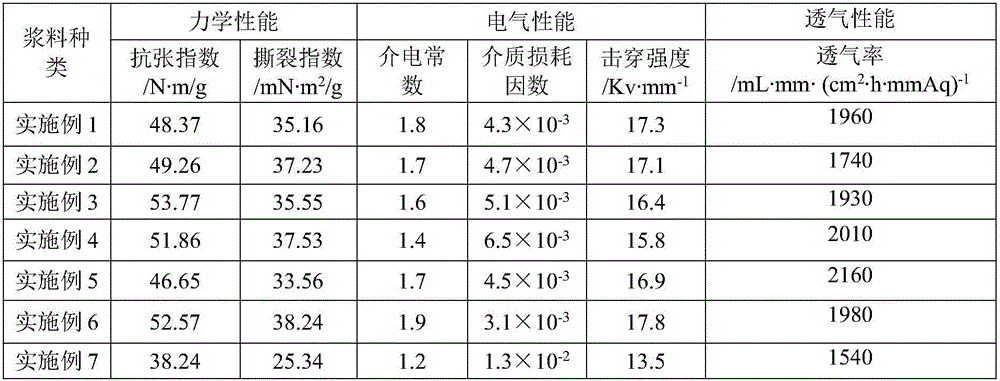

Preparation method of polyimide fiber paper

ActiveCN106436441AHigh surface energyIncrease roughnessDefoamers additionPaper/cardboardFiberPapermaking

The invention discloses a preparation method of polyimide fiber paper, and belongs to the field of paper-making industries and materials. The method comprises the steps that polyimide chopped fiber is treated by a chemical reagent, the treated fiber is washed to be neutral, then, the fiber, a binder and a dispersing agent M are mixed according to a certain mass ratio, the fiber raw materials are dispersed into a pulp suspension, papermaking is performed through a paper making machine to obtain raw polyimide fiber paper, and finally hot pressing is performed through a hot press to obtain the polyimide fiber paper. According to the preparation method, the fiber is subjected to modification treatment, fiber surface active groups are added, the fiber surface energy and roughness are improved, the binding force of components in paper pages can be improved, the binder flows in the paper pages to achieve the effect of viscose fiber through hot pressing and melting, the preparation method can remarkably reduce chemical auxiliaries added in the polyimide fiber raw paper making process, environmental pollution caused in the paper making process can be reduced, and the mechanical performance, the electrical performance and the gas permeability of the polyimide fiber paper can be effectively improved.

Owner:JIANGNAN UNIV +2

Coating and coating used coated paper

ActiveCN103590282AHigh glossReduce the risk of bad printsDefoamers additionCoatings with pigmentsStrong acidsPaper sheet

The invention provides a coating used in the papermaking field. The coating contains nanometer microcrystalline cellulose, a pigment, a latex, an assistant and water, and the nanometer microcrystalline cellulose is highly-crystallized cellulose having a length of 100-500nm and a width of 3-100nm obtained by hydrolyzing a cellulose raw material in a strong acid; and the bone dry mass parts of the nanometer microcrystalline cellulose, the pigment, the latex, the assistant and water in the coating are 0.02-10, 75-95, 5-15 and 0.35-10 respectively. The invention also provides a coated paper made by using the coating. The coating is coated on the surface of paper to effectively improve the glossiness, the post-print glossiness and the roughness of the coated paper in order to improve the paper quality.

Owner:GOLD EAST PAPER JIANGSU

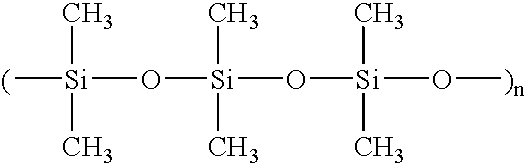

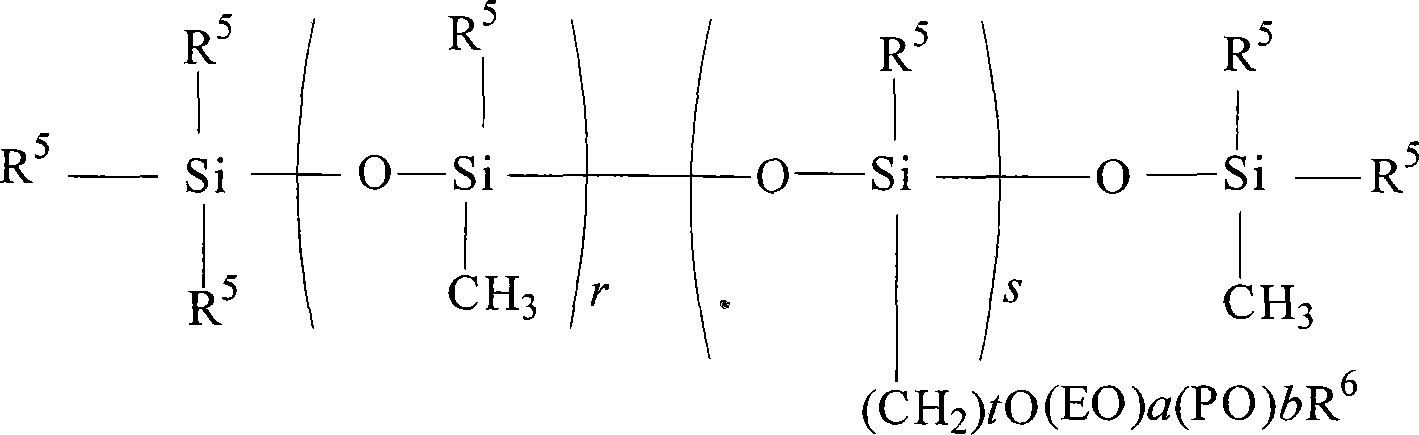

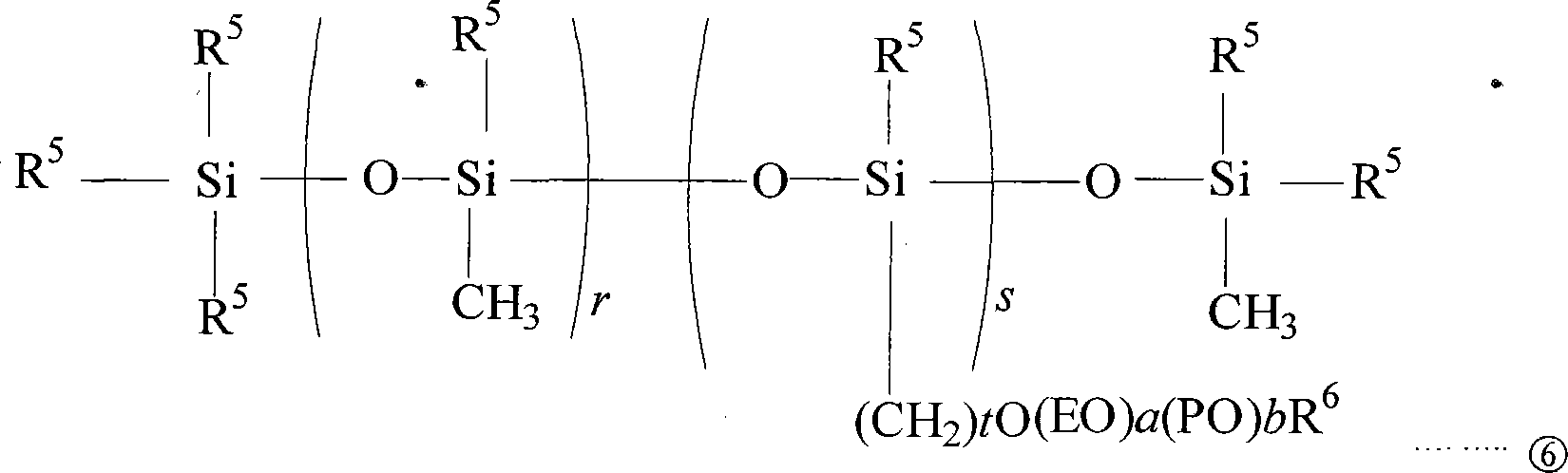

Defoamer Formulations

InactiveUS20110021688A1Efficient defoaming formulationStable to hydrolysisDefoamers additionOther chemical processesHydrosilylationBonds hydrogen

(A) Siloxane-based antifoams and(B) silicone polyethers prepared by reactingorganopolysiloxanes (1) containing 0.05% to 1.6% by weight of Si-bonded hydrogen atomswith unsaturated polyethers (3) of the formulae:CH2═CR1—(CH2)aO(C2H4O)bR1 (Ia)CH2═CR1—(CH2)aO(C2H4O)b(C3H6O)cR1 (Ib)CH2═CR1—(CH2)aO(C3H6O)cR1 (Ic),whereR1 is a hydrogen or a C1-6 hydrocarbon radical,a is 0 to 16,b is 1 to 50, andc is 1 to 50,wherein the sum b+c is ≧10 and at least two different polyethers (Ia), (Ib) and (Ic) are used, andoptionally further reacting the reaction productwith organopolysiloxanes (2) containing from 0.01% to 0.5% by weight of Si-bonded hydrogen atoms,wherein the first and second step reactions take place with a hydrosilylation catalyst, and the weight ratio of Si-bonded hydrogen in organopolysiloxane (1) to Si-bonded hydrogen in organopolysiloxane (2) is at least 1.5.

Owner:WACKER CHEM GMBH

Waterproof high-gloss waterborne gloss oil for corrugated case and preparation method thereof

ActiveCN102517982AImprove waterproof performanceHigh glossDefoamers additionPaper coatingWaxPolymer science

The invention discloses a waterproof high-gloss waterborne gloss oil for a corrugated case and a preparation method thereof. The gloss oil is prepared from the following raw materials by mass: 50 to 69% of organosilicon modified styrene-acrylic acid ester emulsion, 16 to 30% of styrene-acrylate resin liquid, 3 to 8% of high gloss wax emulsion, 1 to 3% of waterproof wax emulsion, 5 to 10% of water and 0.1 to 0.3% of an antifoaming agent. The preparation method comprises the following steps: at normal temperature, adding the organosilicon modified styrene-acrylic acid ester emulsion at first, then at a rotating speed of 800 to 900 r / min, slowly adding the styrene-acrylate resin liquid, the high gloss wax emulsion, the waterproof wax emulsion and water in sequence under stirring, adjusting the rotating speed to be 400 r / min in 5 min, adding the antifoaming agent and carrying out dispersing for 5 min so as to allow all the raw materials in a system to be uniformly dispersed. The waterborne gloss oil has high water resistance, high gloss and wear resistance, is applicable to glazing of a variety of corrugated cases and enables the corrugated cases to meet requirements for beautiful appearance, moisture resistance and wear resistance.

Owner:GUANGDONG YINGKE GRP CO LTD

Defoaming agent for linerboard paper making

InactiveCN101158131AEffective controlMeet actual needsDefoamers additionALUMINUM STEARATESPapermaking

The invention provides a defoaming agent for a boxboard paper making, which belongs to the field of chemical preparation special for papermaking, and is characterized in that the invention consists of the following components. (1) 5 to 40 percent organic hydrocarbon defoaming mixture consists of organic hydrocarbon and superfine particles consisting of hydrophobic inorganic particles, a surface area of which is bigger than 50m2 / g, and organic particles such as ethyl pillared double stearic amide (EBS), aluminum stearate, MQ silicone resin and so on; (2) 1 to 30 percent fatty alcohol; (3) 5 to 70 percent fatty alcohol polyether; (4) 5 to 50 percent fatty alcohol polyether; (5) 5 to 60 percent common group modified polyether; (6) 1 to 10 percent polyether organic silicon modification, also simply called 'silicon polyether'. The invention is a cheap and high-efficiency defoaming agent for a linerboard paper making, improves the performance by complex and increasing effect of the components, and further solves the problem of the foams in the boxboard production system.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Water-based halogen-free flame-retardant paper and preparation method thereof

InactiveCN102619139ASolve the disadvantage of flammabilityImprove flame retardant performanceDefoamers additionPaper/cardboardWater basedPolyvinyl alcohol

The invention discloses water-based halogen-free flame-retardant paper and a preparation method thereof, aiming to provide a non-toxic and pollution-free water-based halogen-free flame-retardant paper with no influence on the environment caused by combustion products and good flame retardant property and a preparation method thereof. A flame-retardant layer is coated on the surface of the raw paper of the flame-retardant paper, the flame-retardant layer is obtained by drying flame-retardant solution, the flame-retardant solution is composed of flame retardant, glue solution and defoaming agent, the flame retardant is composite flame retardant compounded from two of magnesium hydroxide, aluminium hydroxide, antimonous oxide and micron-sized or nanoscale hydrotalcite or antimonous oxide is used as the flame-retardant layer, the glue solution is mixed by polyvinyl alcohol and carboxymethylcellulose, single-face paper coating weight of the flame retardant is 16-30g / m<2>, and the defoaming agent accounts for 0.1wt% of the total weight of the polyvinyl alcohol and carboxymethylcellulose. The flame-retardant paper disclosed by the invention takes mixed solution of water-based polyvinyl alcohol and carboxymethylcellulose as the glue solution, and halogen-free flame retardant is added, thus the flame-retardant paper is non-toxic and environmentally friendly; meanwhile, the combustion product produces no influence on the environment, and the flame-retardant paper has good flame retardance.

Owner:TIANJIN UNIV OF COMMERCE

Carbon fiber shielding paper preparing process

InactiveCN101265676AImprove shielding effectGuaranteed lightweightDefoamers additionPaper/cardboardCarbon fibersPlant fibre

A process for preparing carbon fiber screening paper is provided. The invention includes the following steps: mixing chopped carbon fiber and plant carbon fiber in a certain proportion, adding certain amounts of a dispersant and a defoaming agent, dispersing on a fluffer, and papermaking in a paper former. While the light weight of material is guaranteed, the paper is endowed with good screening performance and easy process, which make full use of the advantages of large scale production in the papermaking industry. Furthermore, the paper electric conductive screening performance can be controlled by adjusting and quantifying the amount of the carbon fiber. The carbon fiber screening paper, which is an electric conductive material with high performance, replaces the conventional electric conductive screening material and covers the shortages thereof. The prepared screening paper has good screening performance of electromagnetic waves, the screening effectiveness at 100KHz-1500MHz is more than 30dB and the maximum is 50dB, thereby being generally applicable to radiation protection and anti-interference of common commercial or electronic products.

Owner:SHAANXI UNIV OF SCI & TECH

Manufacturing method of high-bulk coating printing paper

ActiveCN102877365AReduce smoothnessDegree of reductionDefoamers additionCoatings with pigmentsColor printingPulp and paper industry

The invention discloses a manufacturing method of high-bulk coating printing paper. In the method, high proportion chemical pulp is adopted for coating body paper, light calcium carbonate is used as filler, and high bulk is achieved. A door roller coating machine is used for coating the body paper, and the coating paint adopts plastic paint with a given proportion and a hollow structure, so that the bulk of the coat and the formed paper brightness can be effectively improved. Meanwhile, a soft calender is used for pre-calendering and polishing the coated body paper, so that the fineness of the paper surface is greatly improved while the thickness of the original paper is maintained. The bulk of the high-bulk coating printing paper manufactured through the method is 1.3 to 1.5 cm<3> / g and is far better than that of the ordinary copper paper and light coating paper; and meanwhile, the surface of the paper is smooth and fine, so that printed patterns are full and rich in color, image dots are clear and strong in three-dimensional impression, and the paper is applicable to top-grade color printing.

Owner:MCC PAPER YINHE

Anti-foaming agent for papermaking system

InactiveCN102154939AEliminate effectiveNot affected by performanceDefoamers additionPaper/cardboardFoaming agentPapermaking

The invention provides an anti-foaming agent for a papermaking system. The anti-foaming agent consists of advanced fatty alcohol, advanced fatty alcohol polyether, aliphatic ester, organic silicon composition, emulsifying agent and water. The anti-foaming agent can effectively eliminate the harmful foam in the processes of papermaking, coating, pulp washing, sewage treatment and the like in the industries of coating and starch processing and the like and the papermaking industry, the performance of the anti-foaming agent is not affected by temperature, and the problem of foam elimination under the jointed foam stabilizing condition of multiple surfactants can be well solved.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

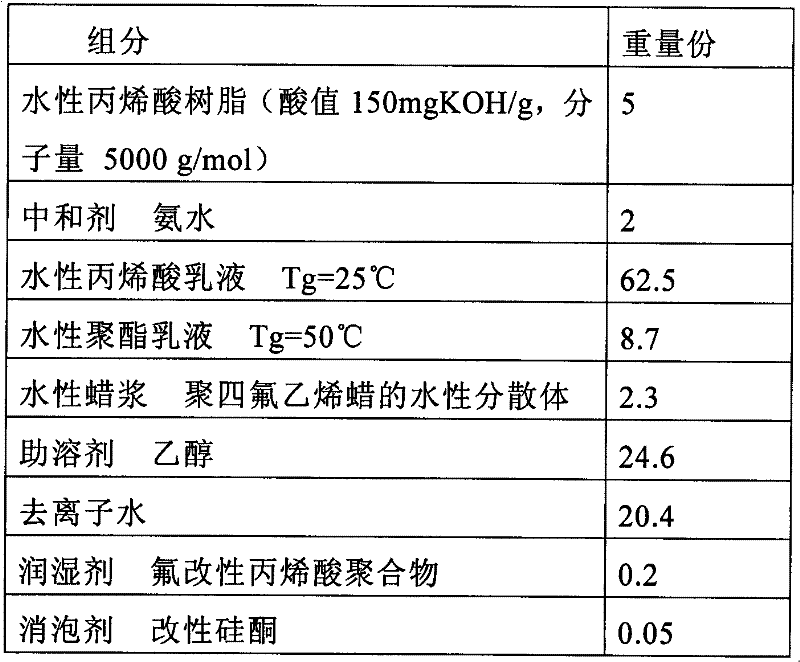

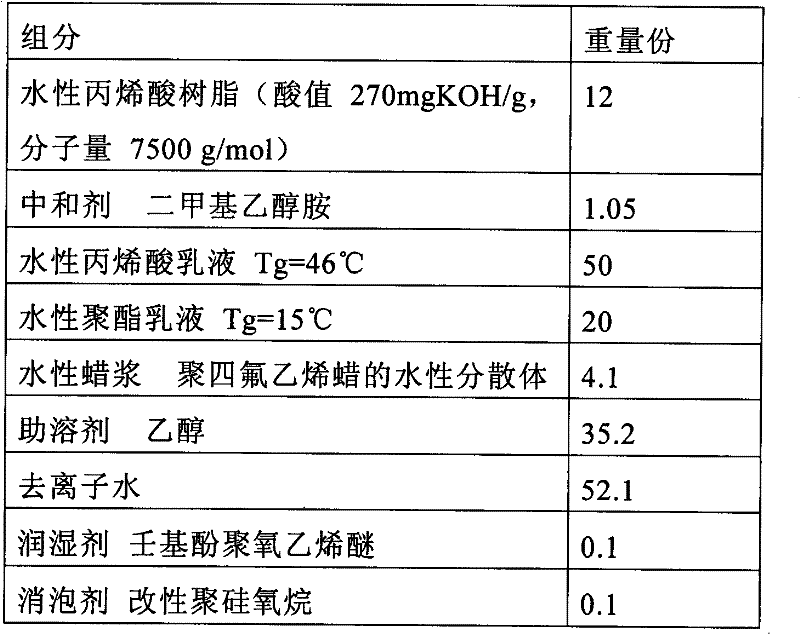

Environmentally-friendly aqueous matte aluminized paper undercoating paint and preparation method as well as application thereof

ActiveCN102363933AGood matte effectImprove wear resistanceDefoamers additionCoatingsEnvironmental resistancePolyester

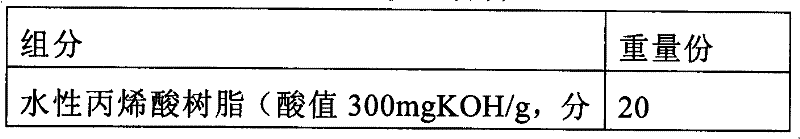

The invention relates to an environmentally-friendly aqueous matte aluminized paper undercoating paint and a preparation method as well as application thereof. The paint comprises the following component raw materials in parts by weight: 5-20 parts of aqueous acrylic resin, 0.5-8 parts of neutralizing agent, 50-70 parts of aqueous acrylic emulsion, 10-20 parts of aqueous polyester emulsion, 1-5 parts of aqueous wax slurry, 20-45 parts of cosolvent, 20-80 parts of de-ionized water, 0.1-0.3 part of moistening agent, 0-0.2 part of rheological control agent and 0.05-0.2 part of defoaming agent, and can be used for surface treatment of cigarette inner lining paper. Compared with the prior art, the paint has the advantages of aqueous environmental friendliness, high metal glossiness, superior coverage and wear resistance; and the problem that directly plated paper made by the conventional paint cannot achieve effects of metal feeling and flatness of a matte aluminum foil is solved.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

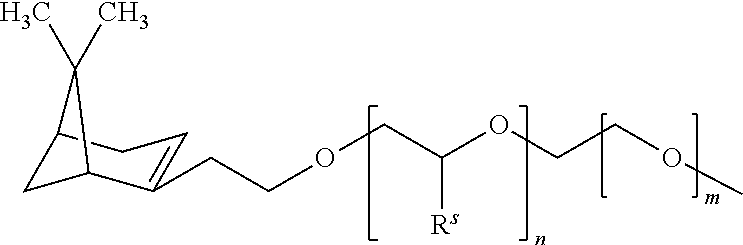

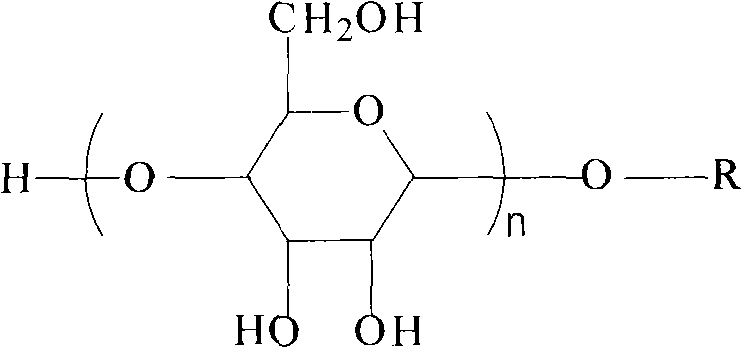

Novel papermaking wet part deformer

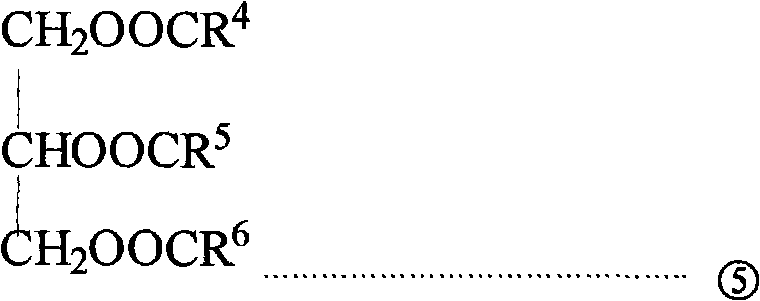

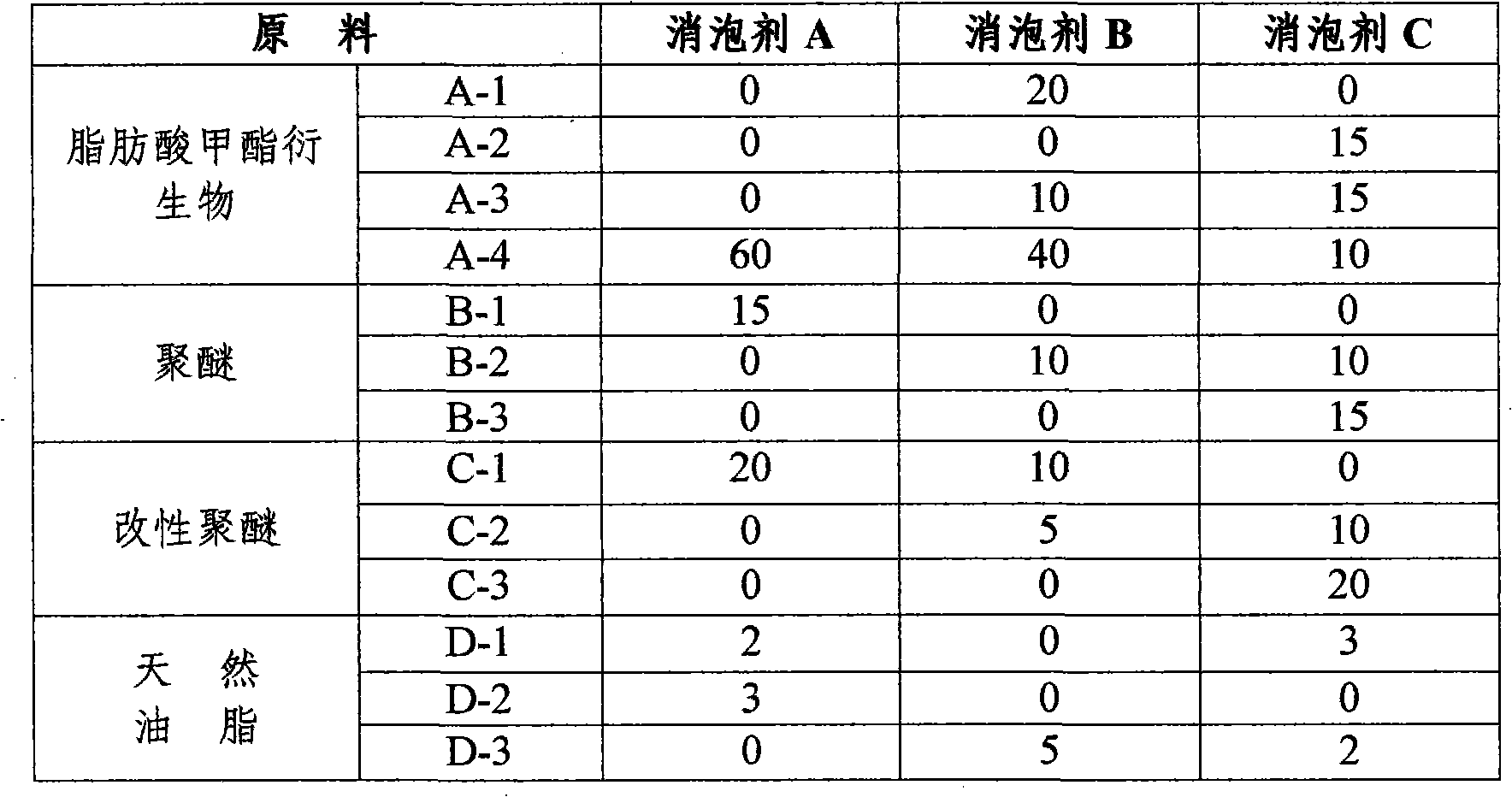

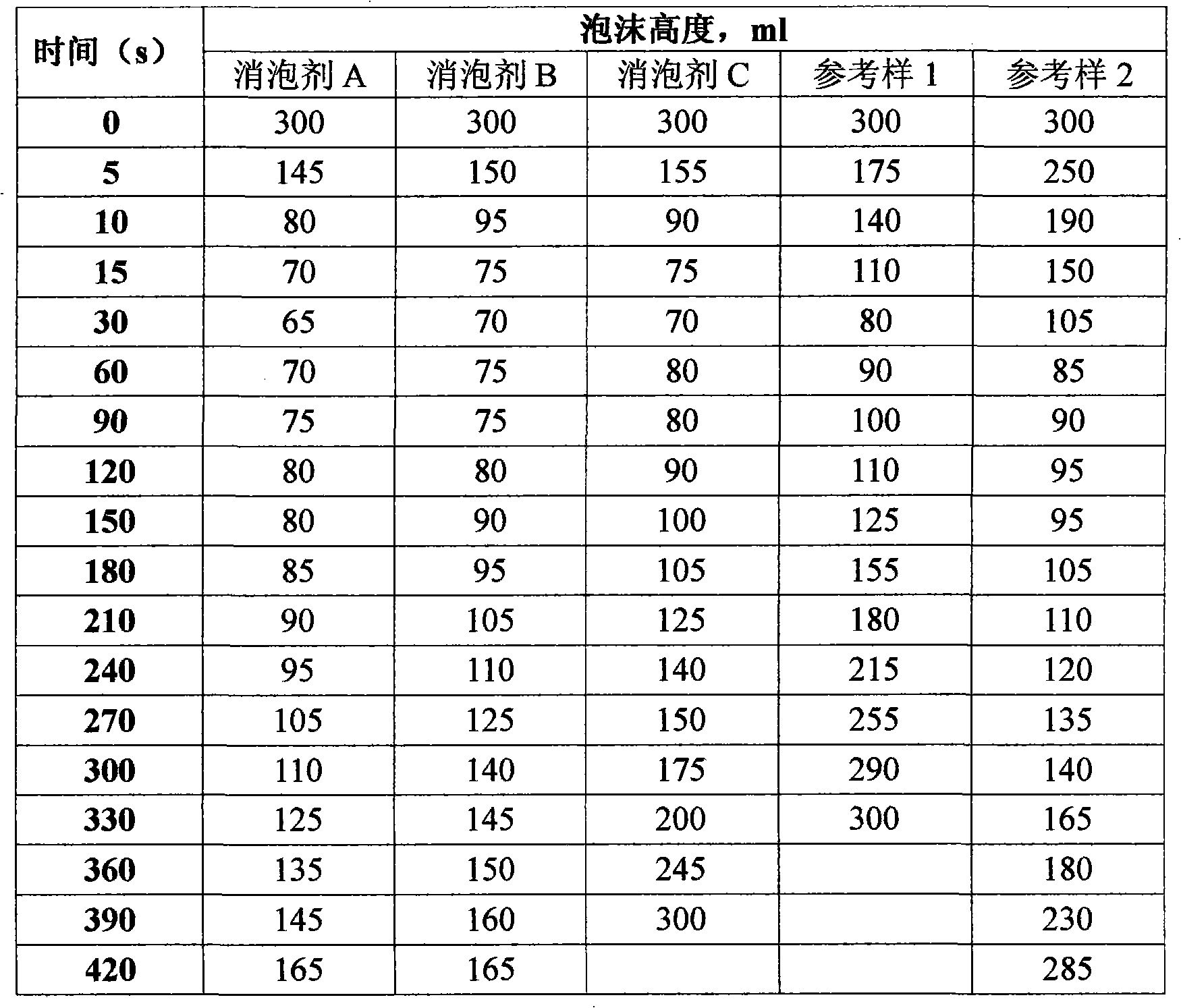

The invention relates to a preparation method of a novel papermaking wet part deformer, belonging to the field of special chemical preparations for papermaking. The novel papermaking wet part deformeris characterized by comprising the following components: 5-99 percent of fatty acid methyl ester derivative (1), 0.1-80 percent of polyether (2), 0.1-70 percent of modified polyether (3) and 0.1-20 percent of natural oil (4), wherein the fatty acid methyl ester derivative has a general structure formula of R<1>CO(EO)x(PO)yOCH3, a molecular weight of 300-3000 and a cloud point of 20-80 DEG C and is a product prepared by an addition reaction of ethylene oxide (EO) and propylene oxide (PO) under the action of a catalyst by using fatty acid methyl ester as an initiator; the polyether has a structural general formula of R<2>(M(EO)m(PO)nH)a, a molecular weight of 500-8,000 and a cloud point of 10-80 DEG C; and the modified polyether has a structural general formula of R<2>(M(EO)m(PO)nR<3>)a. The novel papermaking wet part deformer is not only suitable for a papermaking wet part working procedure, but also suitable for the treatment of papermaking waste water and the elimination of other water-phase foams.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Coated natural kraft and manufacturing method thereof

ActiveCN102199898AHigh strengthIncreased ring compressive strengthDefoamers additionWater-repelling agents additionSurface layerPulp and paper industry

The invention relates to coated natural kraft and a manufacturing method thereof. The traditional coated kraft does not have the advantages of attractive appearance, environment friendliness, high strength and good printing performance. The coated natural kraft disclosed by the invention comprises natural kraft, a surface sizing layer and a surface coating layer and is characterized in that a bottom layer comprises OCC (Old Corrugated Case) waste paper pulp and a core layer comprises waste paper; a surface layer comprises natural wood pulp and waste paper pulp, wherein the weight percentage of the natural wood pulp is 30% to 90% and the balance is the waste paper pulp; the surface sizing layer comprises a front sizing layer and a back sizing layer; and the surface coating layer comprises a bottom coating layer, a middle coating layer and a surface coating layer. The manufacturing method for the coated natural kraft sequentially comprises a natural kraft preparing working procedure, a sizing working procedure, a coating working procedure and a molding working procedure. The coated natural kraft has the advantages of reasonable structure design, attractive appearance, environment friendliness, high strength, good printing performance, simple preparation technology, low production cost and good quality.

Owner:JIAN GRP

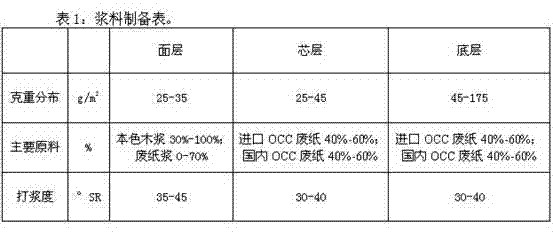

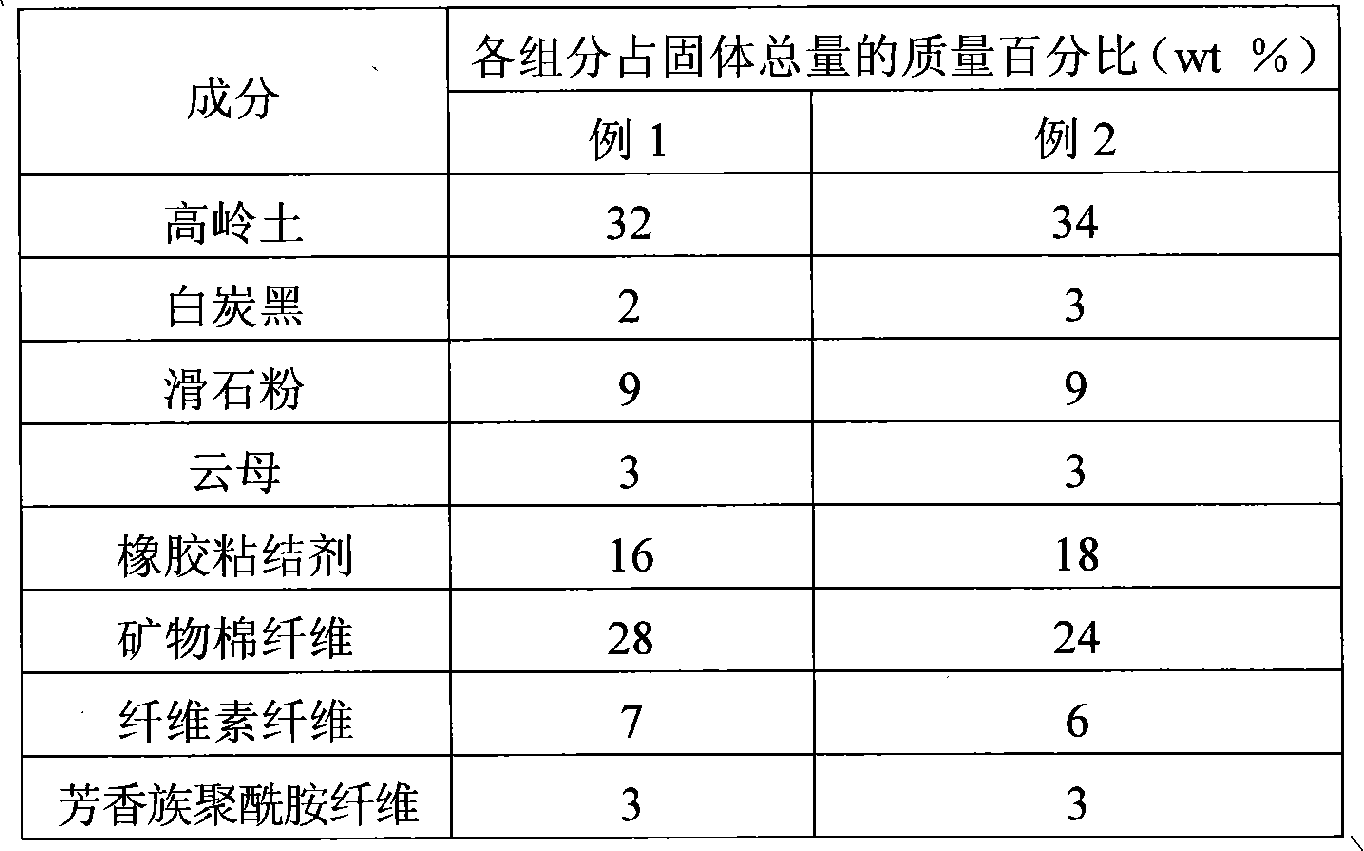

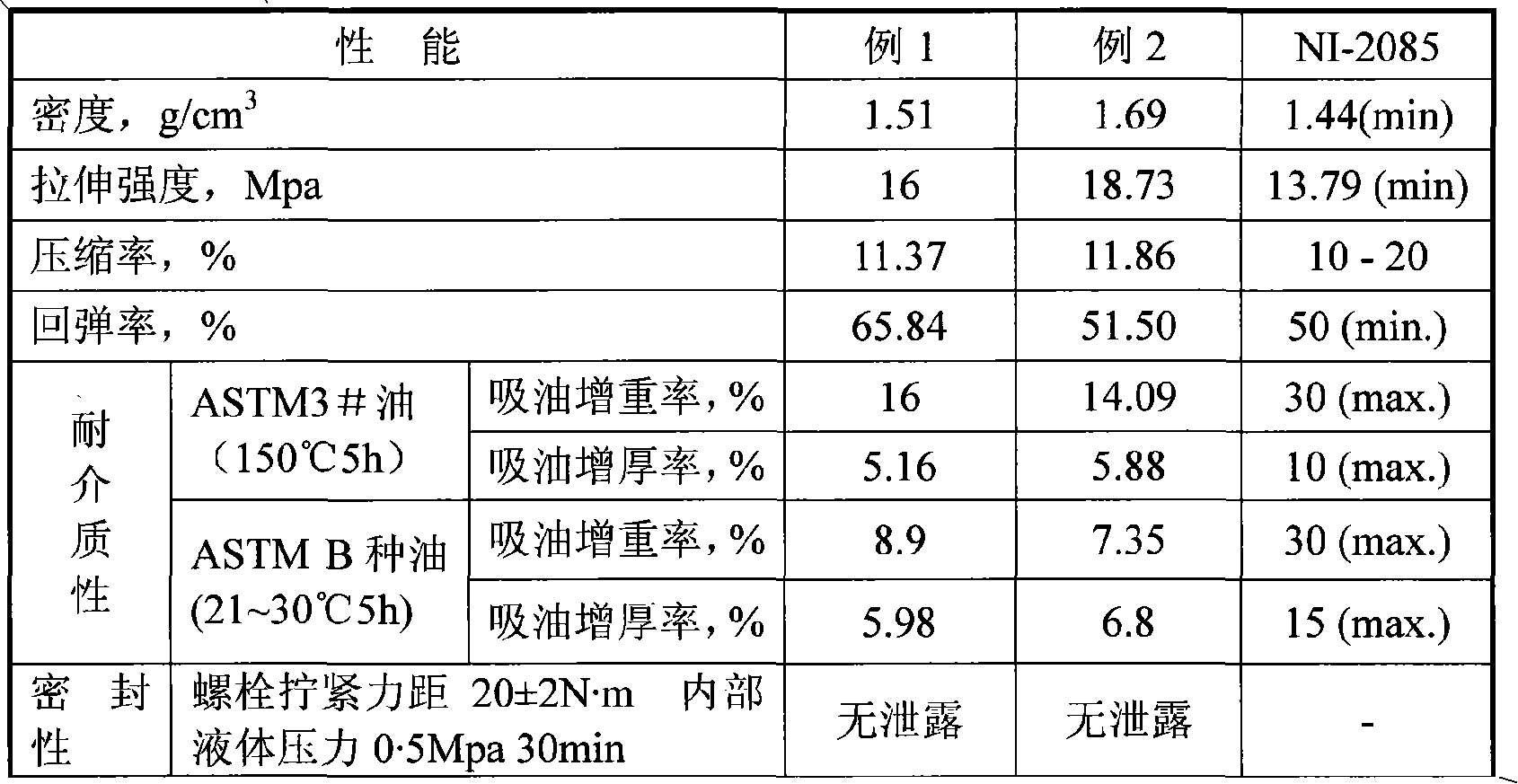

Method for preparing copy sheet used for sealing gasket

InactiveCN101575829AReasonable choiceNo pollution in the processFibreboardInorganic fibres/flakesAsbestos sheetVulcanization

The invention relates to a method for manufacturing a sealing gasket, in particular to a method for preparing a copy sheet used for a sealing gasket which does not contain asbestos fiber, belonging to the field of sealing materials. The copy sheet contains the main components of mineral cotton fiber, cellulose fiber, aromatic polyamide fiber, rubber cement and kaoline; the components are mixed to a dispersed system containing water, then a paper-making technique is adopted to dehydrate gradually and form a layer, and a finished product of the copy sheet is manufactured by compression, drying and vulcanization. The sealing gasket manufactured by the sheet has tensile strength, compression resilience performance, medium resistance and sealing performance and the like equivalent to that of the copying asbestos sealing gasket and can completely replace asbestos sheets for manufacturing the sealing materials of the gasket and the like.

Owner:KUNMING UNIV OF SCI & TECH +1

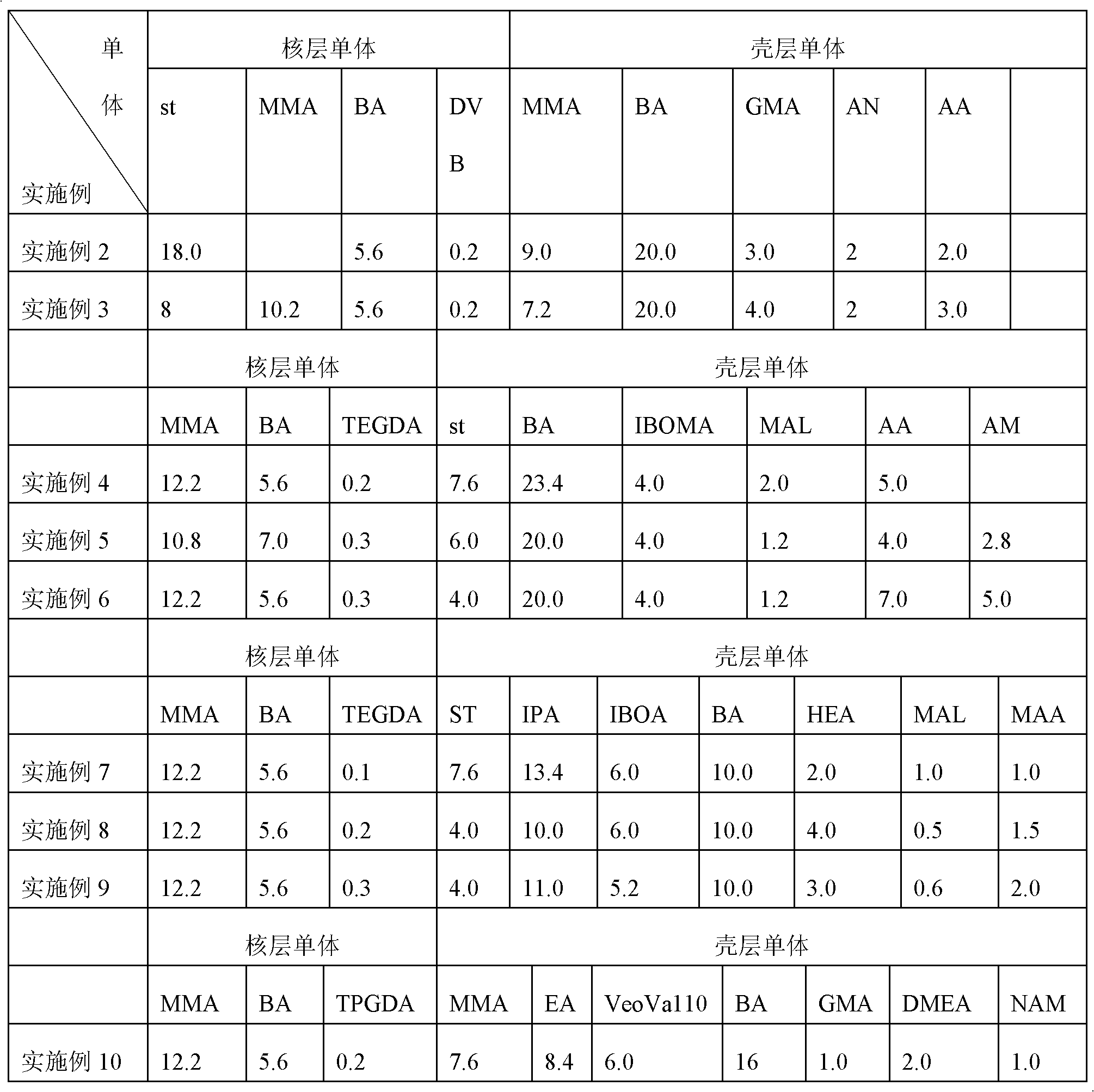

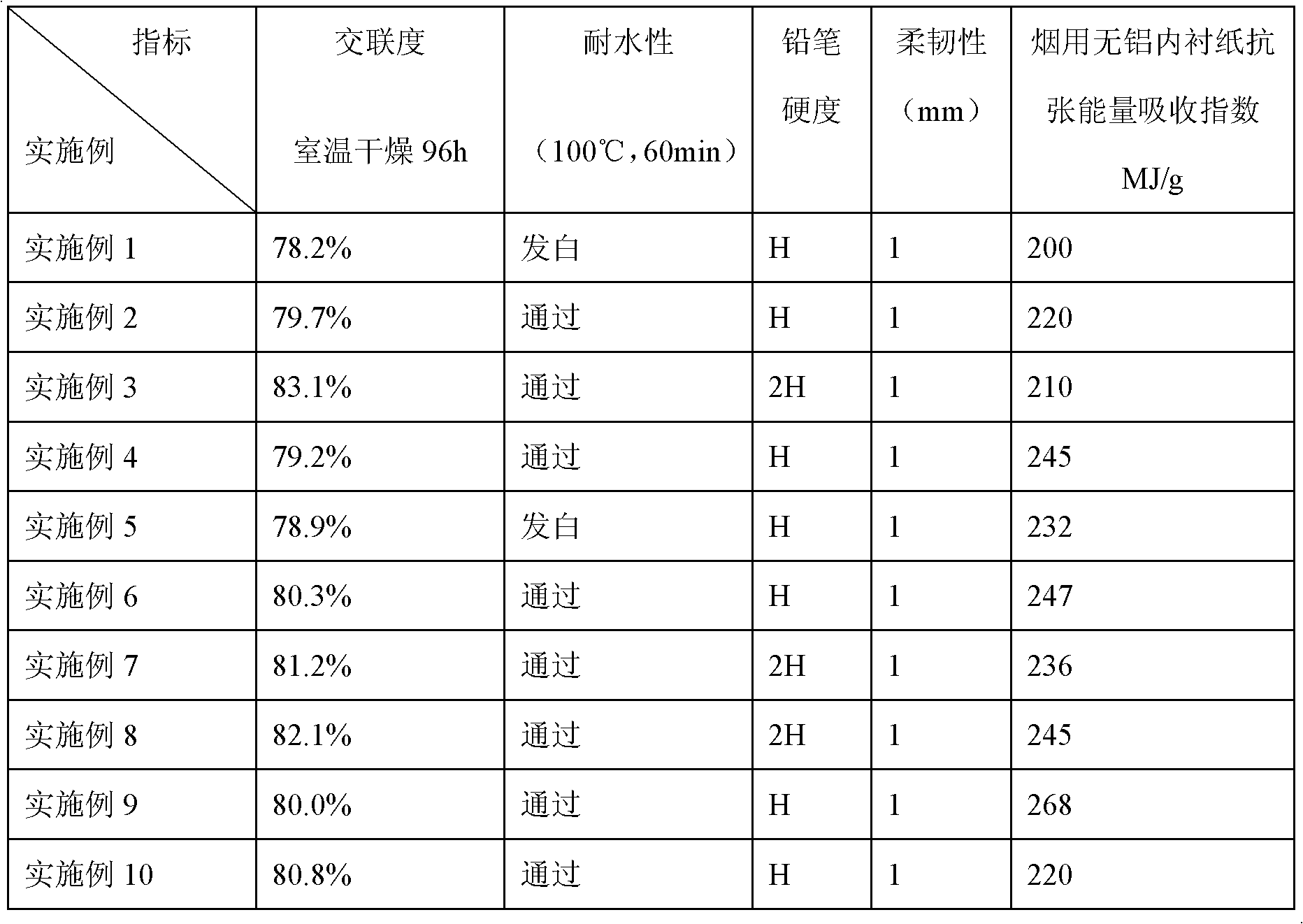

Novel aluminum-free lining paper coating for cigarette package and preparation method thereof

InactiveCN102619135AIncrease crosslink densityHigh hardnessDefoamers additionPaper coatingEmulsionAluminum foil

The invention discloses a novel aluminum-free lining paper coating for cigarette package and a preparation method thereof. The method includes preparation of core-shell structure cross-linking type polyacrylate emulsion and preparation of a novel cigarette aluminum-free lining paper coating. The method includes: adding deionized water, an emulsifying agent and a core layer monomer in a reaction kettle, stirring and emulsifying, heating to 75-80 DEG C, adding water solution of an initiating agent dropwise, leading polymerization reaction, and manufacturing core layer particles; simultaneously adding a core layer olefin monomer and the water solution of the initiating agent which are mixed well in a core layer particle reaction system dropwise, and adding tert-butyl hydroperoxide water solution after reaction; cooling, filtering, and discharging to obtain the core-shell structure cross-linking type polyacrylate emulsion. The obtained novel cigarette aluminum-free lining paper coating is suitable for being coated on aluminum-free paper, the paper can replace aluminum foil composite paper to be applied to the cigarette package after being dried, and the novel aluminum-free lining paper coating has the advantages of being high in strength, good in tightness and water resistance and the like.

Owner:GUANGDONG RONGYU INDAL

Coated paper coating containing nano particle modified adhesive and preparation method thereof

ActiveCN104594121AGood optical performanceImprove surface printabilityDefoamers additionCoatings with pigmentsAdhesivePigment particle

The invention relates to a coated paper coating containing a nano particle modified adhesive and a preparation method thereof. The coating dislcosed by the invention is composed of Kaolin, heavy calcium carbonate, modified styrene acrylic emulsion, sodium carboxymethyl cellulose, sodium hexametaphosphate, a water repellent agent, a lubricant, an anti-foaming agent, ammonium hydroxide and water. The preparation method comprises the following steps: firstly, adding the dispersing agent into water and stirring evenly, adding pigment particles, stirring for 30min at speed of 2000r / min, after slowing down the stirring speed to 1000r / min, adding the adhesive nano calcium carbonate modified styrene-butyl acrylate emulsion, water repellent agent, lubricant and anti-foaming agent, continuing to perform shearing dispersion at the speed of 1000r / min for 10min, regulating pH to 8.0, and finally, filtering a coarse material through a 200-mesh screen to get the coated paper coating. The coating obtained by the preparation method has the characteristics of high solid content, low viscosity, good water retention capacity and low production cost.

Owner:ZHEJIANG SCI-TECH UNIV

Wallpaper base paper capable of adsorbing formaldehyde and production method thereof

ActiveCN104746382AImprove breathabilityHas the function of absorbing formaldehydeDefoamers additionCoatings with pigmentsFiberAdsorption effect

The invention discloses wallpaper base paper capable of adsorbing formaldehyde which is made by using a special process, and wall paper prepared by the wallpaper base paper has a function of adsorbing indoor free formaldehyde. Functional fibers are added into pulp of wallpaper base paper capable of adsorbing formaldehyde, so that the air permeability and the adsorption capability of the paper are improved; formaldehyde adsorbent and calcined diatomaceous earth are added into a coating solution so that an adsorption effect is improved. The base paper provided by the invention can further comprise a thin additional coating having a formaldehyde adsorption function with strong directivity; the wallpaper base paper adhered with the coating is suitable for being used in places in which a large amount of formaldehyde needs to be removed. The invention aims to protect the wallpaper base paper capable of adsorbing formaldehyde, and the wallpaper base paper capable of adsorbing formaldehyde is prepared from the following raw materials in percentage by weight: 30-80 percent of wood pulp, 15-60 percent of a functional fiber, and 5-10 percent of an auxiliary.

Owner:SHANDONG LUNAN NEW MATERIALS

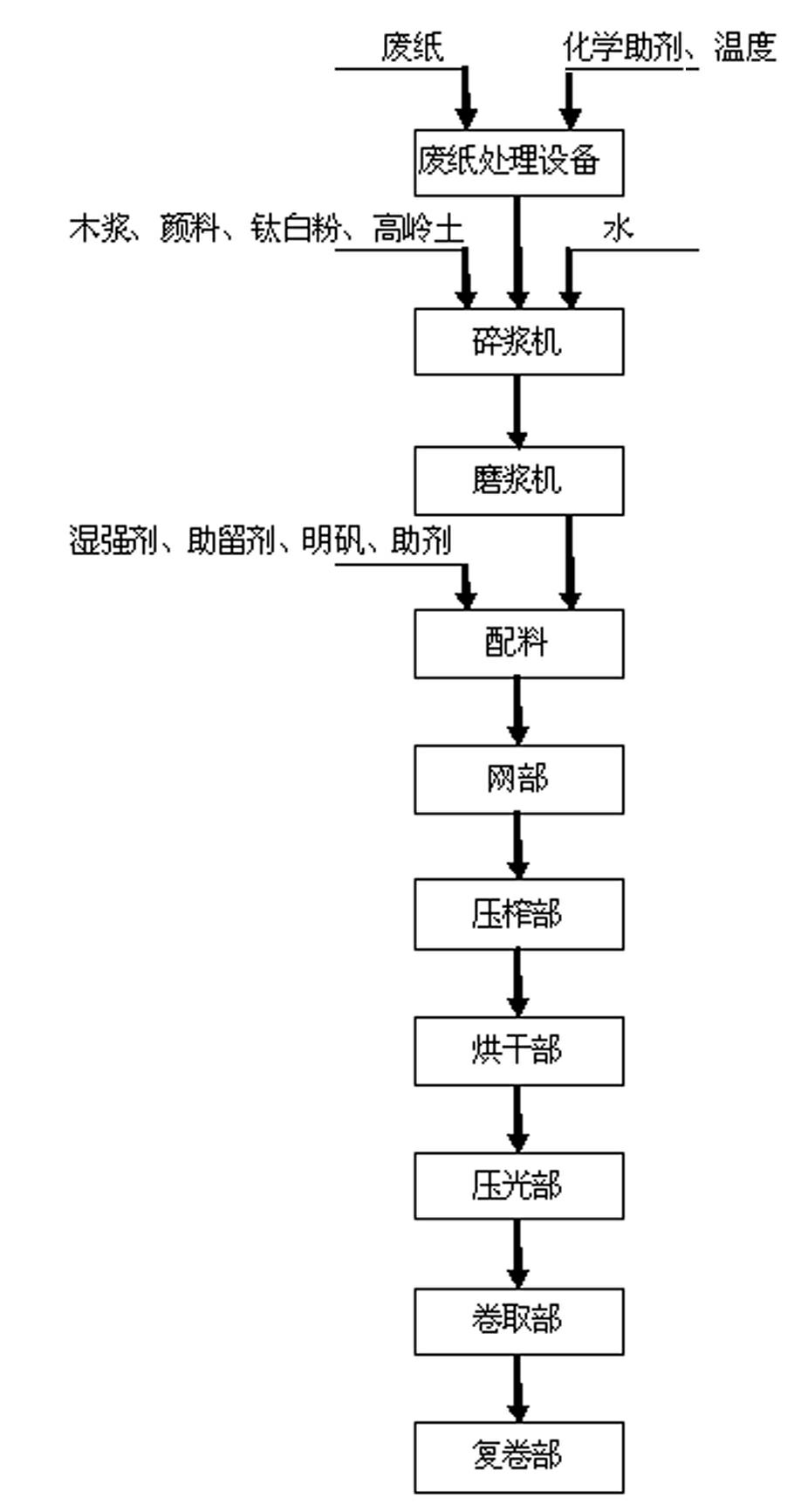

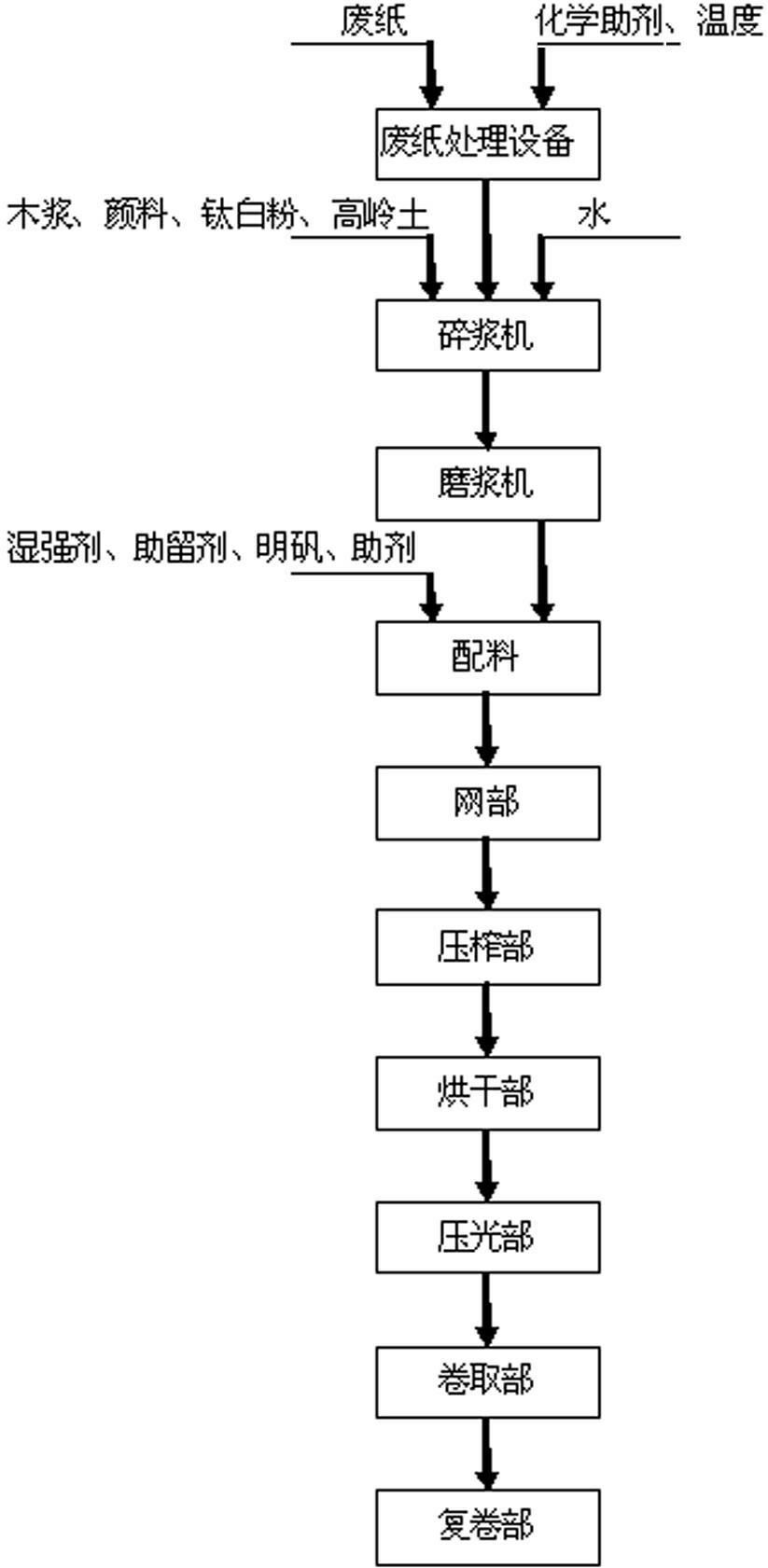

Process for producing printed decorative raw paper by using recycled waste paper

InactiveCN102174761AEmission reductionSolving Recycling ProblemsDefoamers additionPaper recyclingSocial benefitsPulp and paper industry

The invention relates to a process for producing printed decorative raw paper by using recycled waste paper. The process comprises the steps of waste paper treating, pulping, defibrinating, pulp preparing and papermaking, wherein the step of waste paper treating comprises the steps of mixing 80-90 wt% of waste paper and 10-20 wt% of chemical auxiliaries and then mixing with water at the temperature of 40-50 DEG C to prepare waste paper pulp with pH value being 8.0-9.0 and mass percent concentration being 6.0-8.0%; the step of pulping is characterized by mixing the waste paper pulp, wood pulp, kaolin, titanium dioxide, pigment and other raw materials with water to prepare pulp with a certain concentration; and the step of pulp preparing is characterized by adding a certain amount of a wet strength agent, a retention agent such as alum and an auxiliary to the defibrinated pulp to prepare pulp with a certain concentration. According to the invention, the treated waste paper and wood pulp are proportionally mixed to produce impregnated titanium oxide paper made from recycled waste paper; and all the quality indexes of the decorative raw paper can meet the requirements of the decorative raw paper; and the consumption and cost of the raw materials can be reduced and great economic and social benefits can be achieved.

Owner:杭州华旺新材料科技股份有限公司

Highly-oriented fibrous mats

A mat containing highly machine direction oriented (90% or greater), discontinuous reinforcement fibers, is produced on inclined wire or rotary paper making machinery. Fibers are first uniformly dispersed in an aqueous medium containing thickeners and wetting agents. In one embodiment, antifoaming agents are also added to prevent floating fibers which entangle and reduce orientation. Thermoplastic fibers or particles may also be included. Stock is brought into an open headbox in a flow pattern which allows the fibers to decelerate before approaching the porous suction belt (wire). As the fibers approach the suction belt, the fibers begin to turn and align in the streamline so as to present one end toward the suction wire. The leading ends of the fibers are gripped by the moving belt which drags the fibers out of the dispersion stock in a straight line. The porous mat produced may be dried and bonded through hot air, heat and / or pressure, or chemical binders. Stacks of such mats may be compressed partially to produce porous structures, or fully to produce impervious, rigid structural panels or shapes.

Owner:VIRGINIA TECH FOUND

Use of Aluminum Phosphate, Polyphosphate and Metaphosphate Particles in Paper Coating Applications

InactiveUS20100203318A1Avoid smudgingSimple compositionDefoamers additionCoatings with pigmentsMetallurgyPolyphosphate

Provided herein are coating compositions for paper comprising aluminum phosphate, aluminum metaphosphate, aluminum orthophosphate and / or aluminum polyphosphate pigments. Methods of making and using the compositions are described.

Owner:BUNGE AMORPHIC SOLUTIONS +1

Natural high class fatty alcohol emulsion and preparation method thereof

A natural high class fatty alcohol emulsion and a preparation method thereof belong to the technical field of fine chemical preparation. The natural high class fatty alcohol emulsion is characterized by comprising natural high class fatty alcohol, paraffin, polyether, alkyl polyglucoside (APG for short), thickening agent and water. The preparation method comprises the following steps: A. mixing natural high class fatty alcohol and paraffin in proportion, heating to 70-90 DEG C to obtain mixture (1); B. dissolving polyether and APG in hot water of 70 DEG C to obtain mixture (2); C. adding mixture (1) slowly into mixture (2), and then using an exorbitant shearing device to further emulsify to obtain a crude emulsion; D. supplementing corresponding water quantity to dilute into the required concentration; and E. using the thickening agent to adjust the viscosity of the product to 250-400mPa.s to obtain the natural high class fatty alcohol emulsion. The prepared natural high class fatty alcohol emulsion has good degasification performance in paper-dipping procedure of paper-making and excellent usage in paper-making industry.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

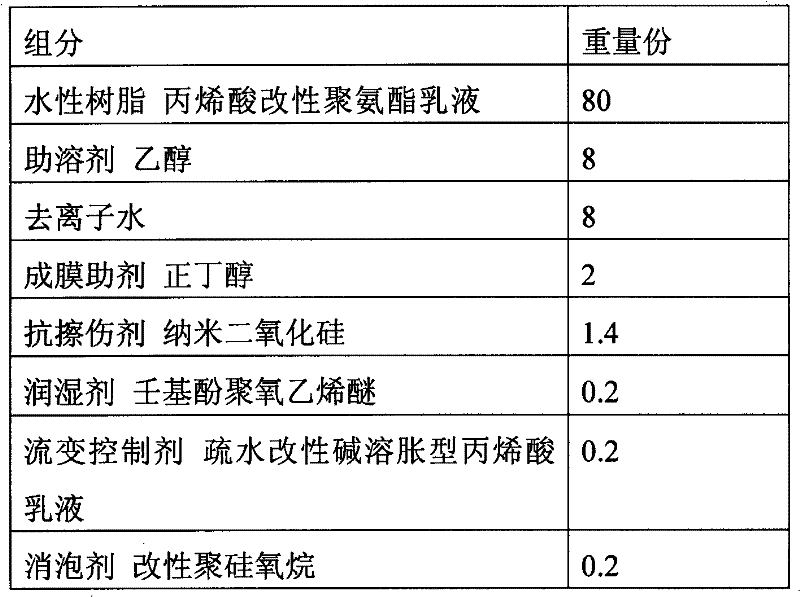

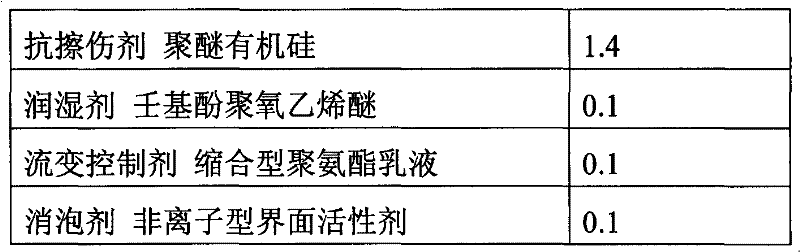

Environmentally-friendly quick drying aqueous glass imitation card transfer paint and preparation method as well as application thereof

InactiveCN102363934AFast dryingLow in volatile organic compounds (VOCs)Defoamers additionPaper coatingSolventCopper

The invention relates to an environmentally-friendly quick drying aqueous glass imitation card transfer paint and a preparation method as well as application thereof. The paint comprises the following component raw materials in parts by weight: 80-95 parts of aqueous resin, 0-8 parts of cosolvent, 0-8 parts of de-ionized water, 0-3 parts of filming auxiliary agent, 0-3 parts of anti-scratch agent, 0-0.5 part of moistening agent, 0-0.2 part of rheological control agent and 0-0.3 part of defoaming agent, and can be used for manufacturing glass imitation card paper or glass imitation copper plate paper. Compared with the prior art, the paint has the advantages of environmental friendliness, low smell, low VOC (Volatile Organic Compound), cost advantage, low production cot, high solid content, high drying speed, superior stripping property, high smoothness, high glossiness, simple application process, capability of recycling a transfer thin film for multiple times, no need of passing through a large-diameter mirror chromium plating drying cylinder like the conventional glass card and high printing adaptability.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

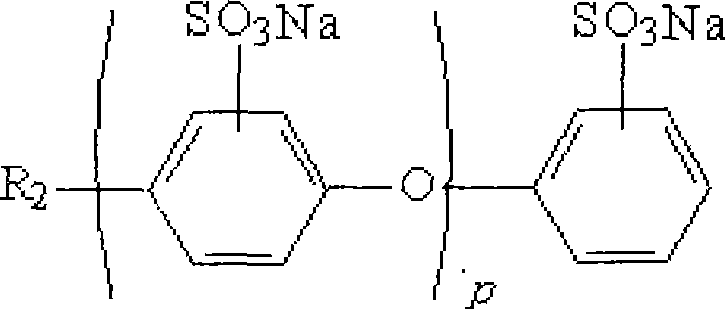

Method for dispersing higher fatty alcohol mixture

The invention discloses a method for dispersing a higher fatty alcohol mixture, which provides a method for dispersing a mixture of natural fatty alcohol and synthol into water, and belongs to the technical field of fine chemical preparations. A higher fatty alcohol emulsion prepared by the method contains the following components: (1) 1 to 30 percent of synthesized higher fatty alcohol with carbon number of between 14 and 30; (2) 1 to 15 percent of C12-18 saturated natural higher fatty alcohol; (3) 1 to 15 percent of paraffin; (4) 0.1 to 5 percent of non-ionic surfactant with MO(EO)m(PO)nH as a general formula; (5) 0.1 to 5 percent of one or more anionic surfactants selected from sulfonated ricinate, sulfonated fatty glyceride, alkyl sulfate, alkoxy sulfate, alkylaryl sulfonate and sodium polyoxyethylene alkyl ether sulfate; (6) 0.1 to 5 percent of thickening agent; and (7) 60 to 95 percent of dispersant (water), wherein M is an initiator group of the non-ionic surfactant, alkyl or an benzene ring. The method comprises the following realization steps that: (1) the synthesized higher fatty alcohol, the natural higher fatty alcohol, the paraffin, the non-ionic surfactant, and the anionic surfactants are mixed according to the proportion, and then the temperature is increased to be between 80 and 95 DEG C; (2) then the water with a temperature of between 60 and 80 DEG C is slowly added into the mixture to begin to emulsify, and the emulsification temperature is kept higher than 60 DEG C during the emulsification; (3) the obtained product passes through a colloid mill after the adding of hot water; and (4) finally the obtained product is cooled to be between 30 and 40 DEG C, then the thickening agent is added into the obtained product to be mixed evenly, thus the higher fatty alcohol emulsion is obtained.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com