Novel aluminum-free lining paper coating for cigarette package and preparation method thereof

A technology for lining paper and coating, applied in paper coating, coating, papermaking and other directions, can solve the problem that the hardness of the coating film and the resistance to folding can not be balanced, the water resistance and hot water immersion performance of the coating film is poor, and it cannot meet the requirements of paper coating. Cloth requirements and other issues, to achieve excellent airtightness, reduce enterprise costs, save aluminum foil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

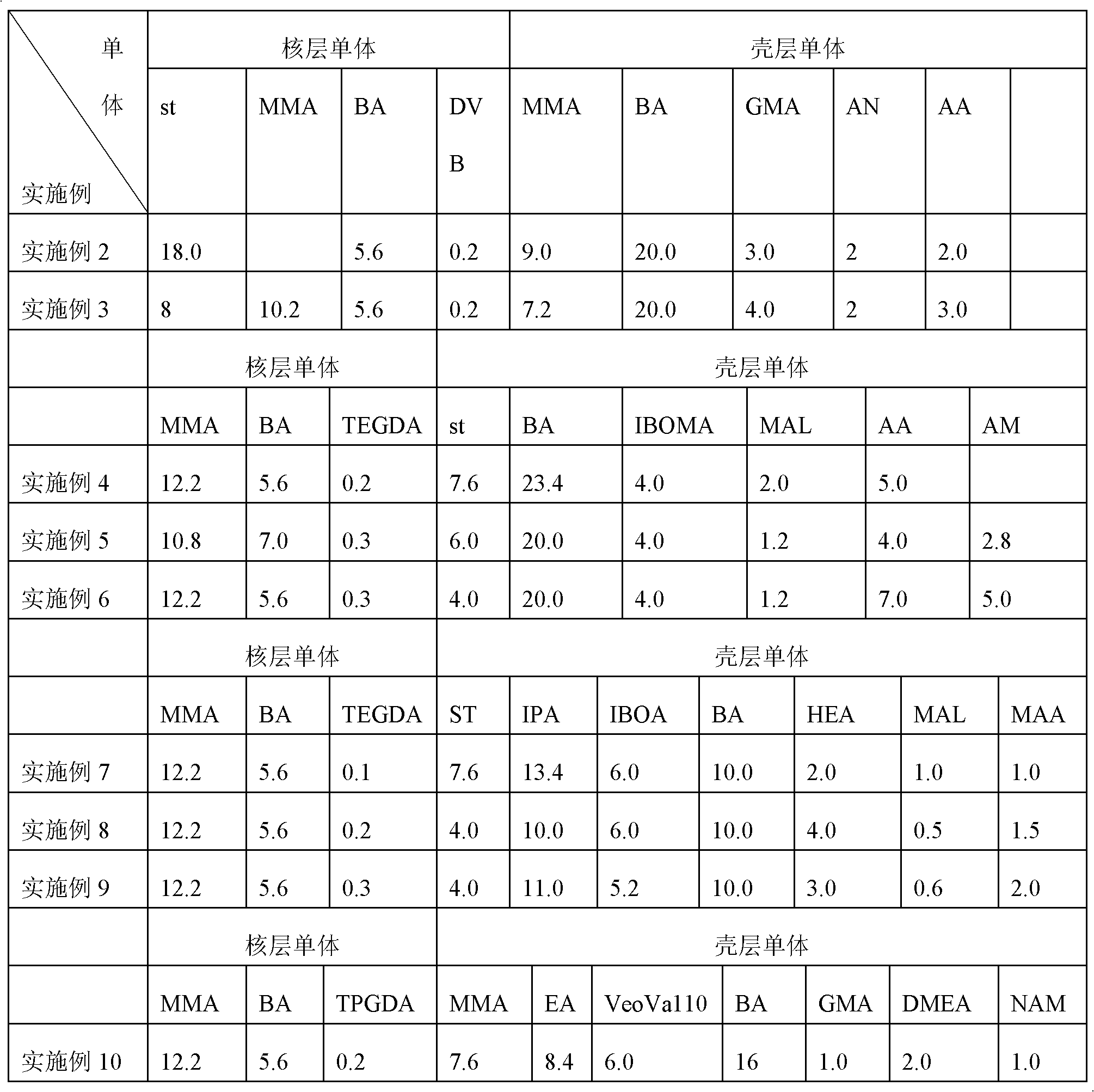

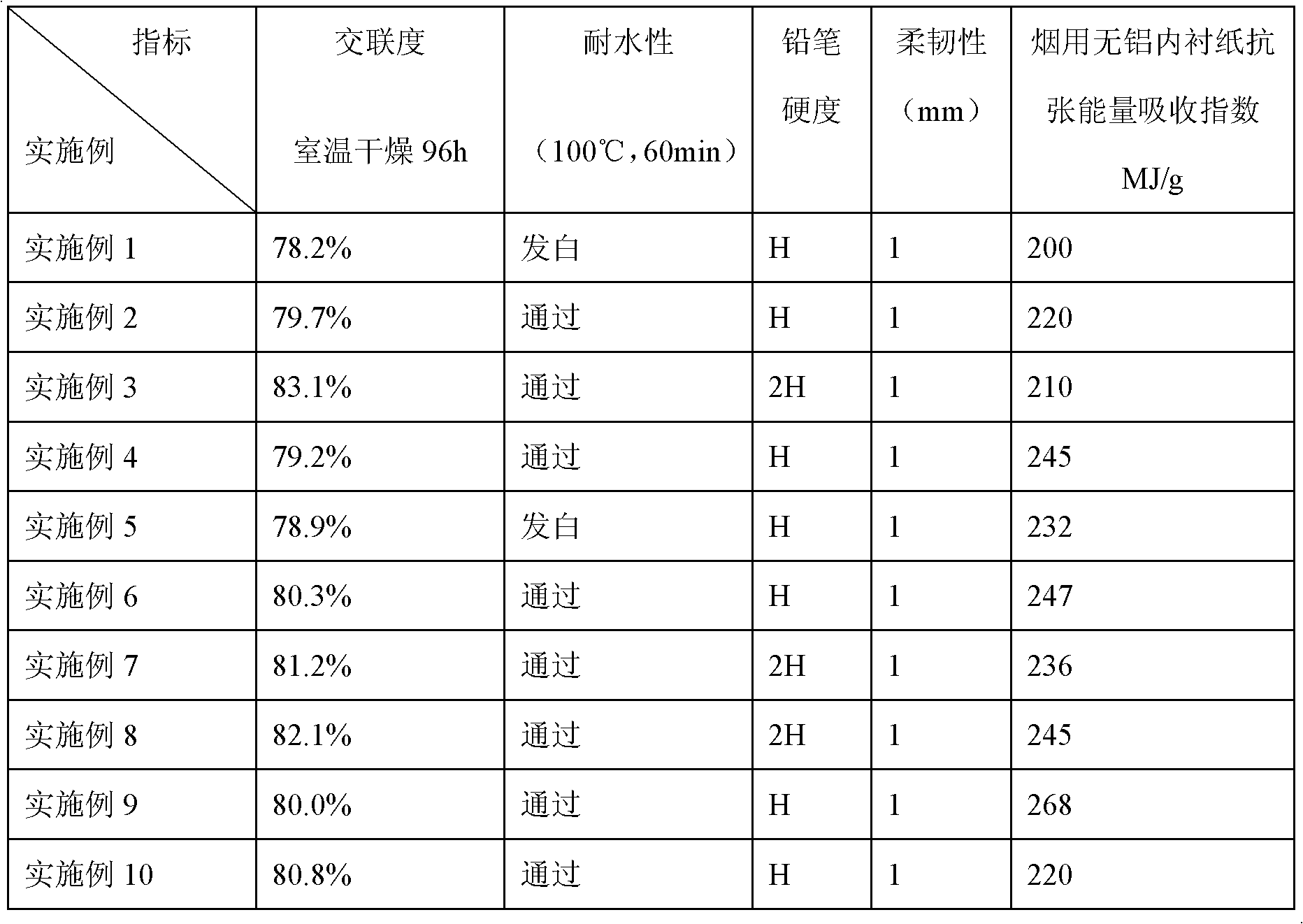

Examples

Embodiment 1

[0030] A preparation method of a novel cigarette aluminum-free lining paper coating, comprising the steps of:

[0031] (1) Synthesis of core-shell structure cross-linked polyacrylate emulsion

[0032] Add 55.5 kg of deionized water, 1.79 kg of reactive emulsifier allyl polyethoxysulfonate (SEN-10), 20 kg in a 200-liter reactor with condensed water, stirring, thermometer, and dropping device Methacrylic acid (MAA), 5 kg of butyl acrylate (BA), 0.25 kg of divinylbenzene (DVB), stirred and emulsified at 1000 rpm for 20 minutes, raised the temperature to 80°C, and added dropwise 0.8 kg of potassium persulfate ( Dissolved with 0.8 kg of deionized water) to initiate the polymerization reaction for 1 hour, and then make core layer particles, and the reaction temperature of the system is kept at 80±2°C.

[0033] Preparation of the shell polymer: mix 9 kg of methyl methacrylate (MMA), 20 kg of butyl acrylate (BA), 3.5 kg of glycidyl methacrylate (GMA), 2 kg of acrylonitrile (AN) , 2 ...

Embodiment 2

[0042] A preparation method of a novel cigarette aluminum-free lining paper coating, comprising the steps of:

[0043] (1) Synthesis of core-shell structure cross-linked polyacrylate emulsion

[0044] Add 59.7 kg of deionized water, 2.985 kg of reactive emulsifier allyl polyethoxysulfonate (SEN-10), 18 kg in a 200-liter reactor with condensate, stirring, thermometer, and dropping device Methacrylic acid (MAA), 5.6 kg of butyl acrylate (BA), 0.10 kg of divinylbenzene (DVB), stirred and emulsified at 1500 rpm for 20 minutes, raised the temperature to 75°C, and added dropwise 0.0237 kg of potassium persulfate ( Dissolved with 0.12 kg of deionized water) to initiate the polymerization reaction for 1 hour, and make core layer particles, and the reaction temperature of the system is kept at 80±2°C.

[0045] Preparation of the shell polymer: mix 9 kg of methyl methacrylate (MMA), 20 kg of butyl acrylate (BA), 3.0 kg of glycidyl methacrylate (GMA), 2 kg of acrylonitrile (AN) , 2 kil...

Embodiment 3

[0050] A preparation method of a novel cigarette aluminum-free lining paper coating, comprising the steps of:

[0051] (1) Synthesis of core-shell structure cross-linked polyacrylate emulsion

[0052] Add 72.2 kg of deionized water, 3.01 kg of reactive emulsifier allyl polyethoxysulfonate (SEN-10), 10.2 kg in a 200-liter reactor with condensate, stirring, thermometer, and dropping device Methacrylic acid (MAA), 8 kg of styrene, 5.6 kg of butyl acrylate (BA), 0.20 kg of divinylbenzene (DVB), stirring and emulsifying at 750 rpm for 20 minutes, raising the temperature to 80°C, adding dropwise within 15 minutes After 1.2 kg of ammonium persulfate (dissolved with 1.2 kg of deionized water) initiates the polymerization reaction for 1 hour, the nuclear layer particles are made, and the reaction temperature of the system is kept at 80±2°C.

[0053] Preparation of the shell polymer: mix 7.2 kg of methyl methacrylate (MMA), 20 kg of butyl acrylate (BA), 4.0 kg of glycidyl methacrylate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com