High-frequency copper foil substrate and composite material used thereby

A technology of composite materials and high-frequency circuits, which is applied in the direction of circuit substrate materials, synthetic resin layered products, layered products, etc., can solve the problems of large wear of drill pins, low dielectric constant, low solubility, etc., and achieve cost saving, Low signal loss, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

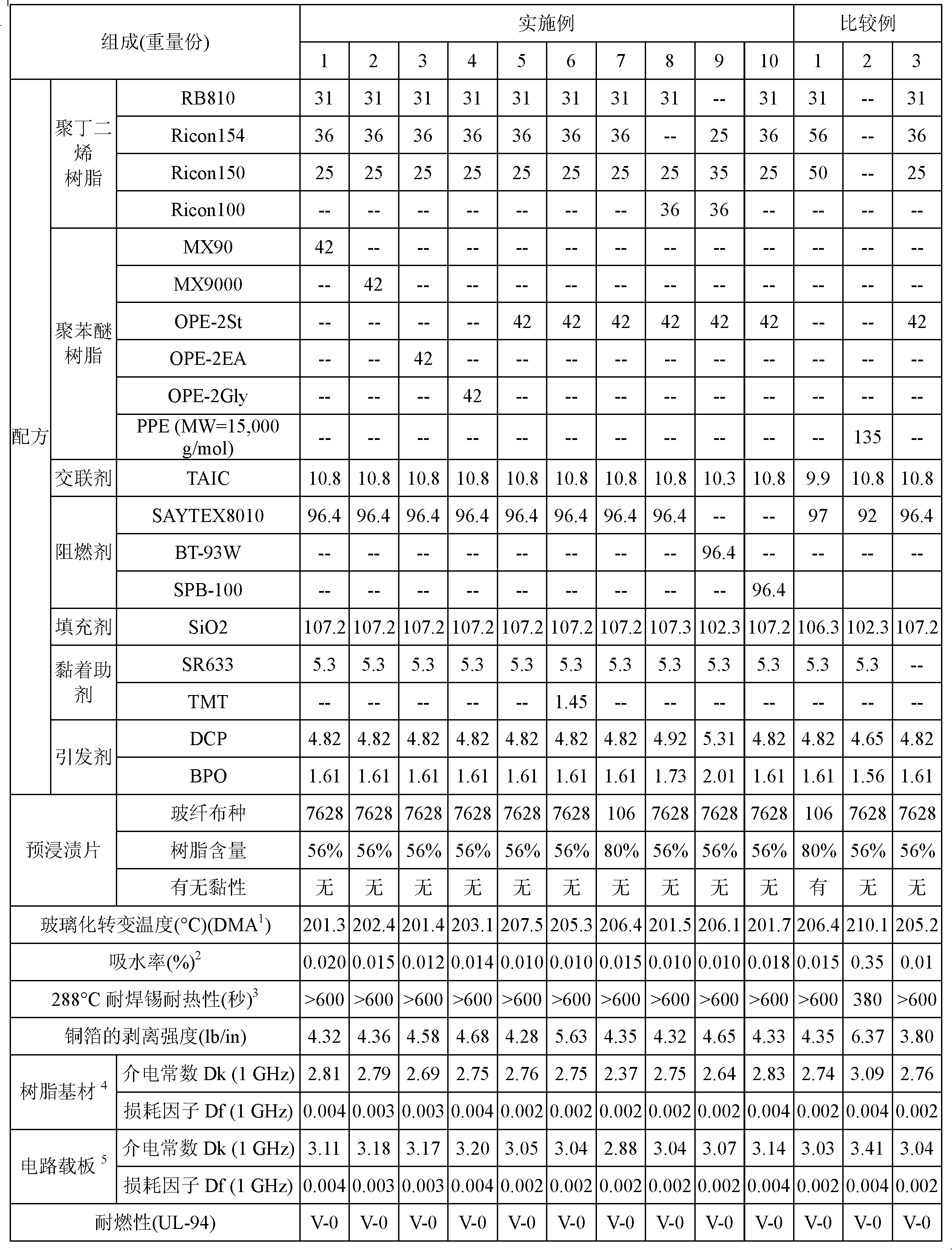

Embodiment 1

[0054] Get 31 parts by weight RB810 (polybutadiene) resin (Japanese JSR company product), 36 parts by weight Ricon154 (polybutadiene) resin (U.S. Sartomer Company company product), 25 parts by weight Ricon150 (polybutadiene) resin ( U.S. Sartomer Company product), and 42 parts by weight of MX90 modified polyphenylene ether (modified groups at both ends are hydroxyl, Saudi Arabian businessman SABIC company product) etc. add appropriate amount of toluene and stir under normal temperature; Then mix in 5.3 parts by weight SR633 adhesion aid, and add 107.2 parts by weight of silica filler, and 96.4 parts by weight of SAYTEX8010 brominated flame retardant, 10.8 parts by weight of TAIC crosslinking agent, 4.82 parts by weight of DCP hardening initiator, 1.61 parts by weight of BPO hardening initiator After mixing evenly, impregnate the above resin solution with Nanya glass fiber cloth (Nanya Plastic Company, cloth type 7628) at room temperature, and then dry it at 110°C (impregnating ...

Embodiment 2

[0057] The method is the same as in Example 1, but the components of the polyphenylene ether resin are replaced by MX9000 modified polyphenylene ether (the modified groups at both ends are acryloyl groups, manufactured by SABIC Company in Saudi Arabia).

[0058] The physical properties of the prepared copper foil substrate were tested, and the results are shown in Table 1.

Embodiment 3

[0060] The method is the same as in Example 1, but the polyphenylene ether resin components are replaced by OPE-2EA modified polyphenylene ether (modified groups at both ends are acryloyl groups, manufactured by Nissho MGC Co., Ltd.).

[0061] The physical properties of the prepared copper foil substrate were tested, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Copper foil peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com