Method for preparing copy sheet used for sealing gasket

A sealing gasket and plate technology, which is applied in the direction of fiberboard, inorganic fiber/sheet, synthetic cellulose/non-cellulose material pulp/paper, etc., can solve the problems of poor strength and oil resistance, high price, and difficulty in leading products, etc. , to achieve the effect of reasonable selection and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

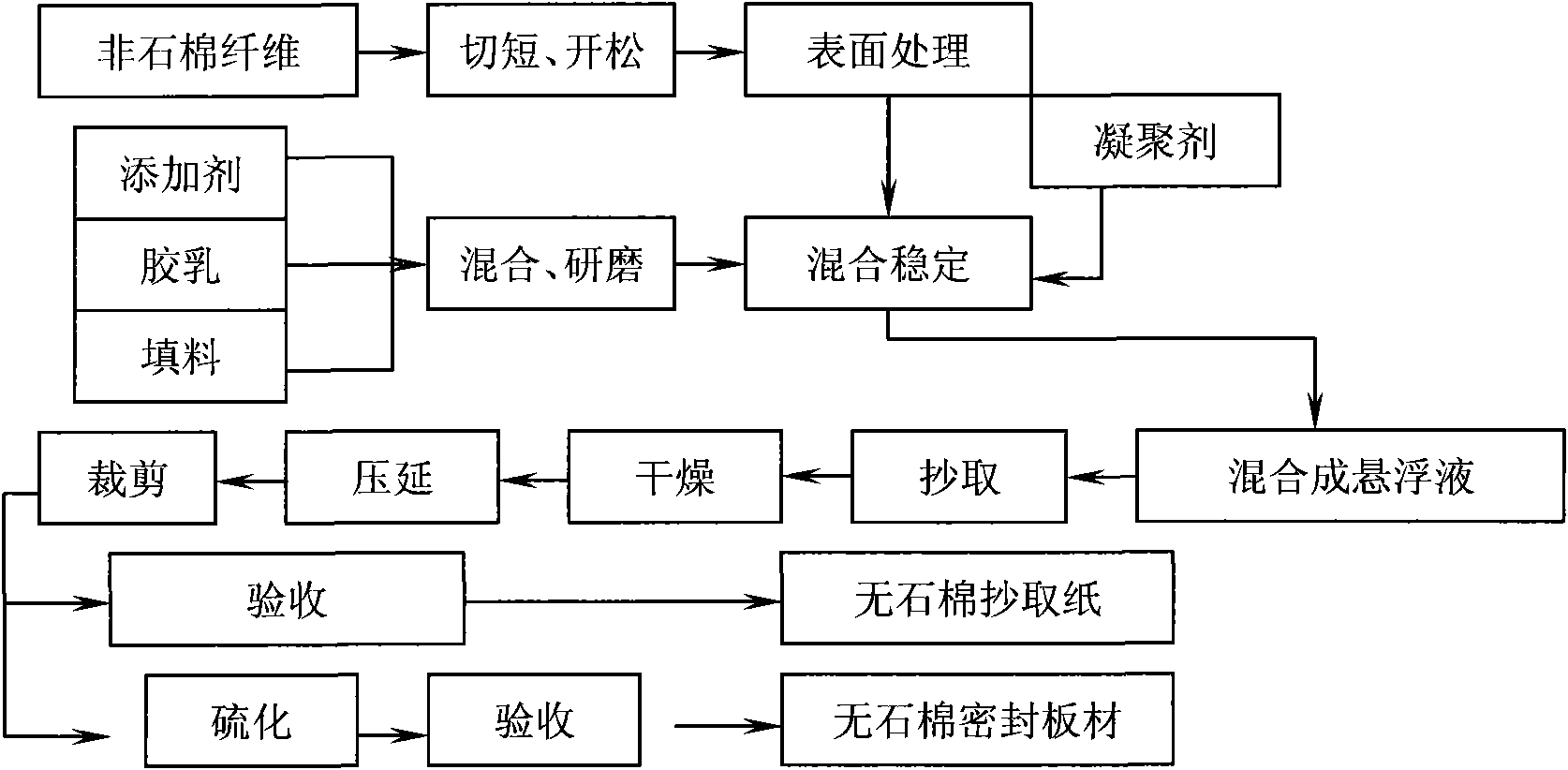

Method used

Image

Examples

Embodiment

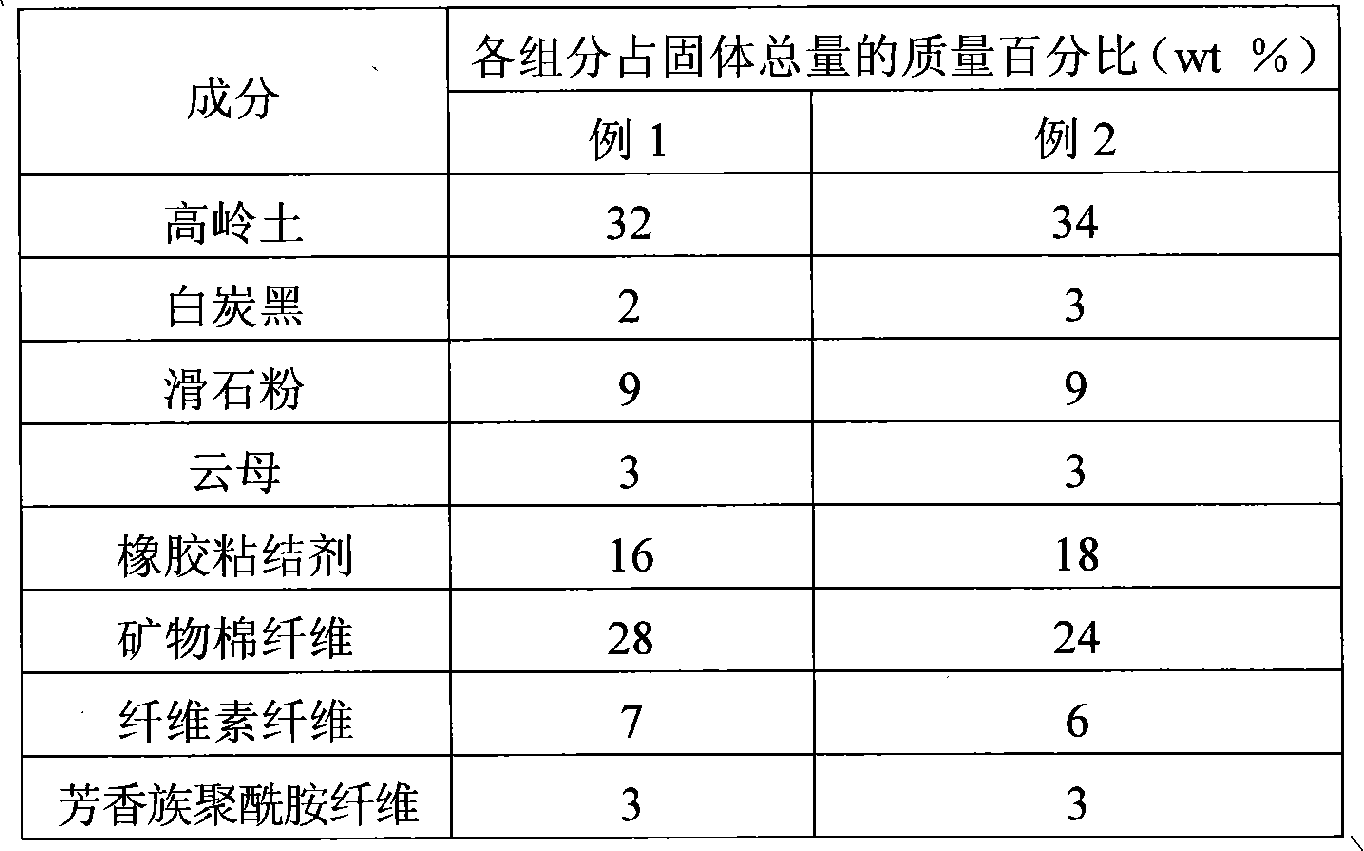

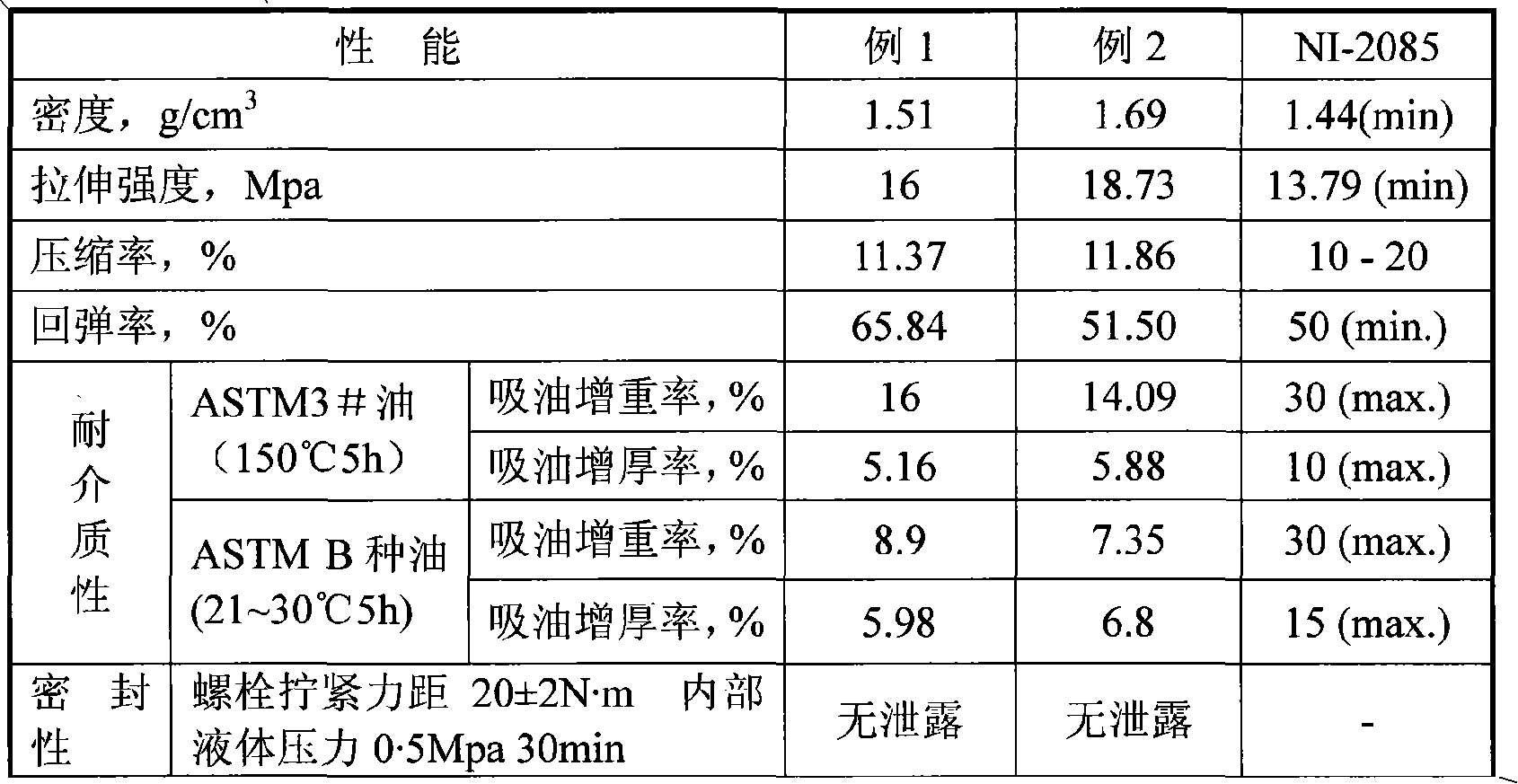

[0023] The present invention has preferred two formulas, which can be further illustrated by the following examples:

[0024]

[0025] First, aramid pulp, cellulose fiber and active agent are pulped at a speed of 6000 rpm for about 6 minutes, then fillers are added, stirred for 5 minutes, mixed into a slurry, dispersed evenly, and finally mineral wool fibers are added and pulped 5 minutes. Dilute the suspension after pulping with water, gradually add nitrile latex and styrene-butadiene latex through slow stirring, dilute with water 5 times its own capacity, and continue stirring until a good suspension is formed, and the latex is completely absorbed .

[0026] The pH in the slurry can be lowered to 4.5 by adding paper alum (aluminum sulfate). The upper liquid in the mixture became clear after the agitation was stopped, which indicated that the dispersed particles of latex had been deposited on the fine particles of fibers and fillers. Additional water was added and stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com