Preparation method of iron runner castable containing graphene oxide

An iron trench castable and oxide stone technology, which is applied in the field of iron trench castables, can solve the problems that graphite is not easy to disperse evenly, is not suitable for large-scale production, and the strength of the sample is reduced, so as to improve the structural strength and corrosion resistance, and reduce the structure. spalling and cracking, porosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

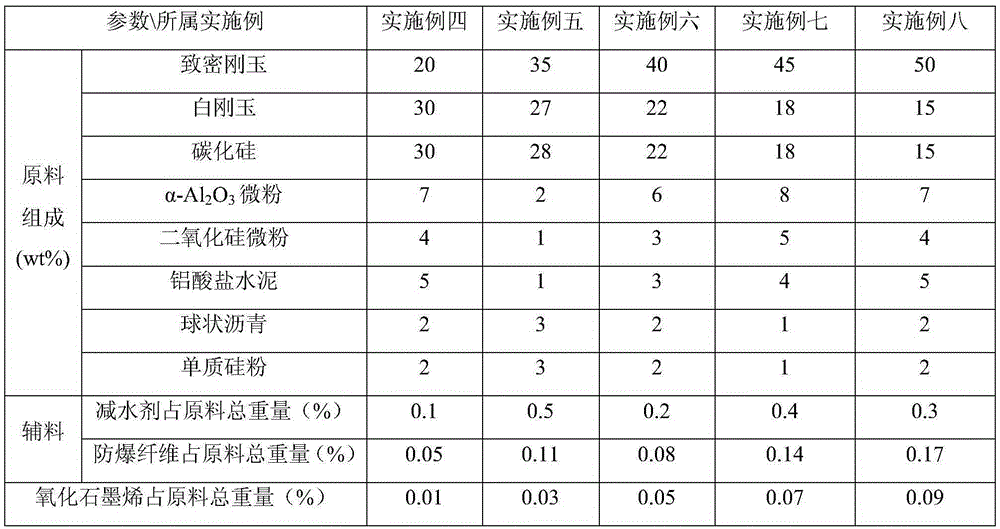

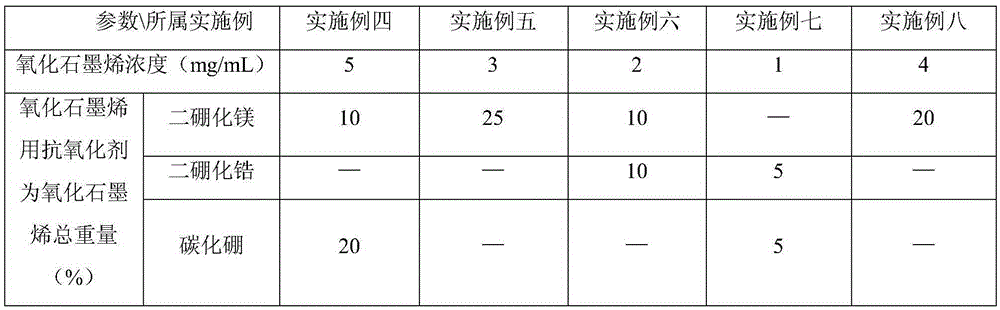

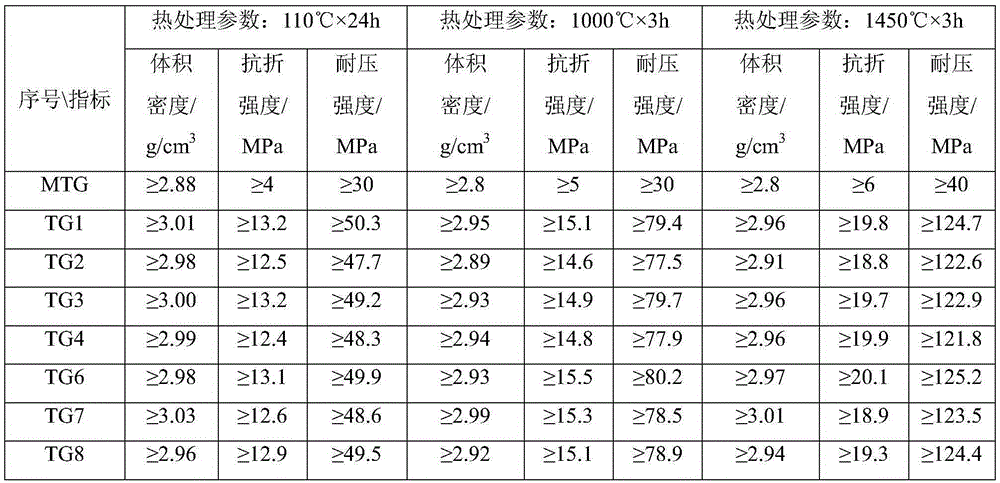

Examples

Embodiment 1

[0034] A kind of preparation method of iron channel castable containing graphene oxide, add by weight percentage by 43% dense corundum, 20% white corundum, 20% silicon carbide, 7% α-Al 2 o 3 Micropowder, 3% silica powder, 3% aluminate cement, 2% spherical asphalt and 2% elemental silica fume are used as raw materials, adding 0.1% water reducer and 0.1% of the total weight of the raw materials The auxiliary material that the anti-explosion fiber of above-mentioned raw material gross weight 0.05% is formed, adds graphene oxide solution and graphene oxide antioxidant (the consumption of graphene oxide in graphene oxide solution is described raw material gross weight 0.05%, the graphene oxide solution The concentration is 3 mg / mL, and the amount of antioxidant for graphene oxide is 20% of the amount of graphene oxide).

[0035] The antioxidant for graphene oxide is magnesium diboride, and the water reducer is sodium tripolyphosphate.

[0036] The mass content of aluminum oxide i...

Embodiment 2

[0044] A preparation method of iron trench castable containing graphene oxide, adding 50% dense corundum, 10% white corundum, 15% silicon carbide, 10% α-Al in weight percentage 2 o 3 Micropowder, 5% silicon dioxide micropowder, 5% aluminate cement, 3% spherical asphalt, 2% elemental silicon powder are used as raw materials, and 0.5% of the water reducer and 0.5% of the total weight of the raw materials are added. The auxiliary material that the above-mentioned raw material gross weight 0.2% explosion-proof fiber constitutes, adds the graphene oxide that accounts for described raw material gross weight 0.01% and the graphene oxide antioxidant of described graphene oxide consumption 10-30%, adds raw raw material gross weight 3 % water.

[0045] The antioxidant for graphene oxide is zirconium diboride, and the water reducer is sodium polyacrylate.

[0046] The above-mentioned graphene oxide was added as a graphene oxide solution with a concentration of 5 mg / mL. The preparation...

Embodiment 3

[0053] A preparation method of iron trench castable containing graphene oxide, adding 30% dense corundum, 30% white corundum, 30% silicon carbide, 3% α-Al in weight percentage 2 o 3 Micropowder, 1% silica micropowder, 4% aluminate cement, 1% spherical asphalt, and 1% elemental silicon powder are used as raw materials, and 0.5% of the total weight of the raw materials is added to the water reducer and the raw materials 0.1% of the total weight of explosion-proof fiber constitutes the auxiliary material, adding 0.1% of the total weight of the raw material graphene oxide and 10% of the graphene oxide antioxidant, adding 1% of the total weight of the raw material water.

[0054] The antioxidant for graphene oxide is boron carbide, and the water reducer is sodium hexametaphosphate.

[0055] The above-mentioned graphene oxide was added as a graphene oxide solution with a concentration of 1 mg / mL. The preparation method of the graphene oxide solution refers to Example 1.

[0056] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com