Environment-friendly curbstone for landscape architecture construction and production method therefor

A production method and technology of curb stones, applied in the field of garden landscape, can solve the problems of quality dependence, single source of materials, large production process, etc., and achieve the effects of protecting the environment, simplifying the preparation process steps, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

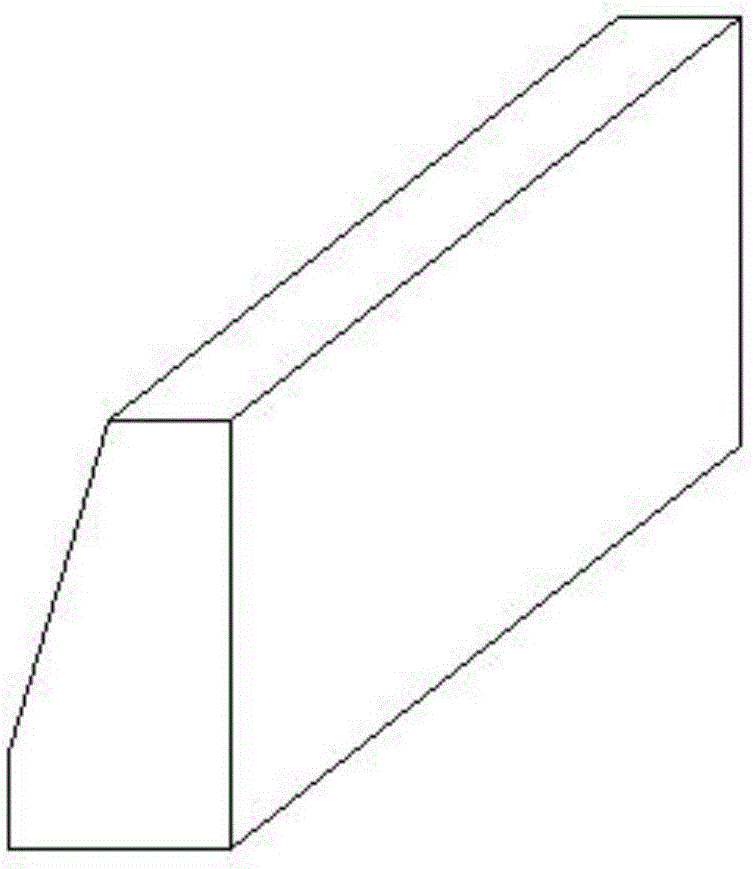

[0016] A kind of environment-friendly roadside stone for landscape garden construction, see figure 1 , consists of the following raw materials in parts by weight: 20 parts of fly ash, 16 parts of clay, 10 parts of polypropylene fiber, 3 parts of epoxy resin, 14 parts of silica fume, 1 part of foaming agent, 24 parts of yellow sand, 35 parts of cement parts, 36 parts of water.

[0017] The production steps of the environment-friendly roadside stone for landscape garden construction are:

[0018] Mix the fly ash with water for 1 hour, mix uniformly to form a slurry, and keep the temperature of the slurry at 55°C; mix clay, yellow sand and cement to form a dry material; separate the polypropylene fiber, epoxy resin and microsilica powder Add it to the slurry mixture twice, then add the dry material, after fully stirring, add the foaming agent, and stir for 20 minutes to form a mixed slurry, keep the temperature at 50°C, and control the fluidity of the slurry at 30cm ; Pour the ...

Embodiment 2

[0020] An environmentally friendly roadside stone for landscape garden construction, which is composed of the following raw materials in parts by weight: 15 parts of fly ash, 22 parts of clay, 8 parts of polypropylene fiber, 5 parts of epoxy resin, 10 parts of micro-silica fume, and a foaming agent 2 parts, yellow sand 18 parts, cement 48 parts, water 28 parts.

[0021] The production steps of the environment-friendly roadside stone for landscape garden construction are:

[0022] Mix the fly ash with water for 2 hours, mix uniformly to form a slurry, and keep the temperature of the slurry at 50°C; mix clay, yellow sand and cement to form a dry material; separate the polypropylene fiber, epoxy resin and microsilica powder Add it to the slurry mixture twice, then add the dry material, after fully stirring, add the foaming agent, and stir for 20 minutes to form a mixed slurry, keep the temperature at 55°C, and control the fluidity of the slurry at 30cm ; Pour the slurry into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com