Patents

Literature

359 results about "Steelmaking continuous casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

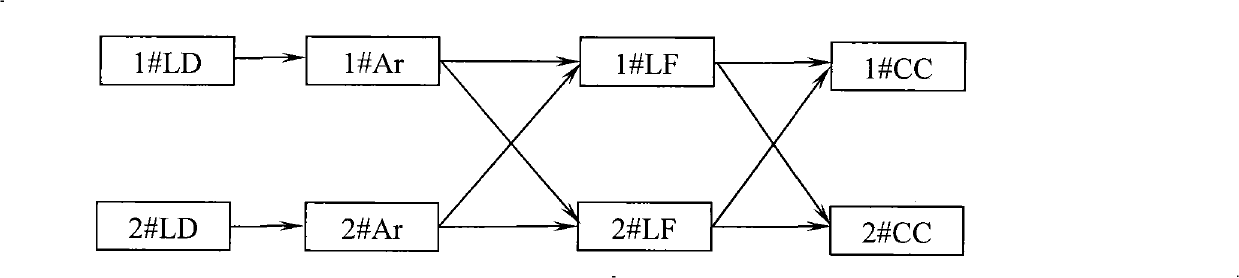

Steelmaking-continuous casting scheduling method utilizing priority policy hybrid genetic algorithm

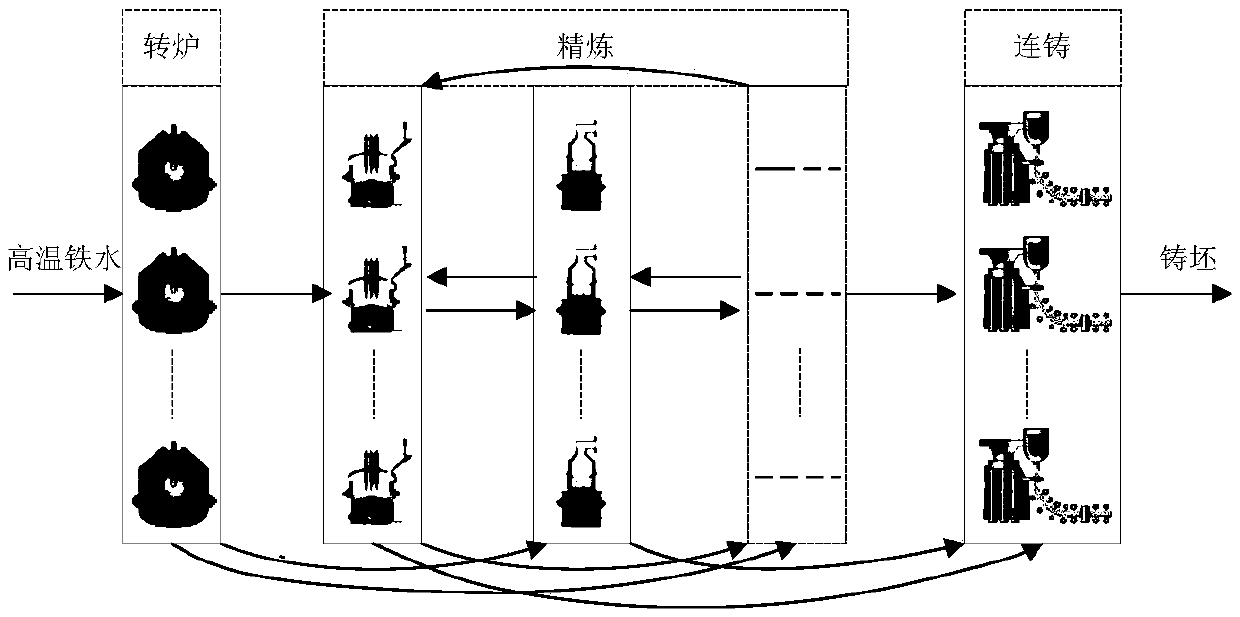

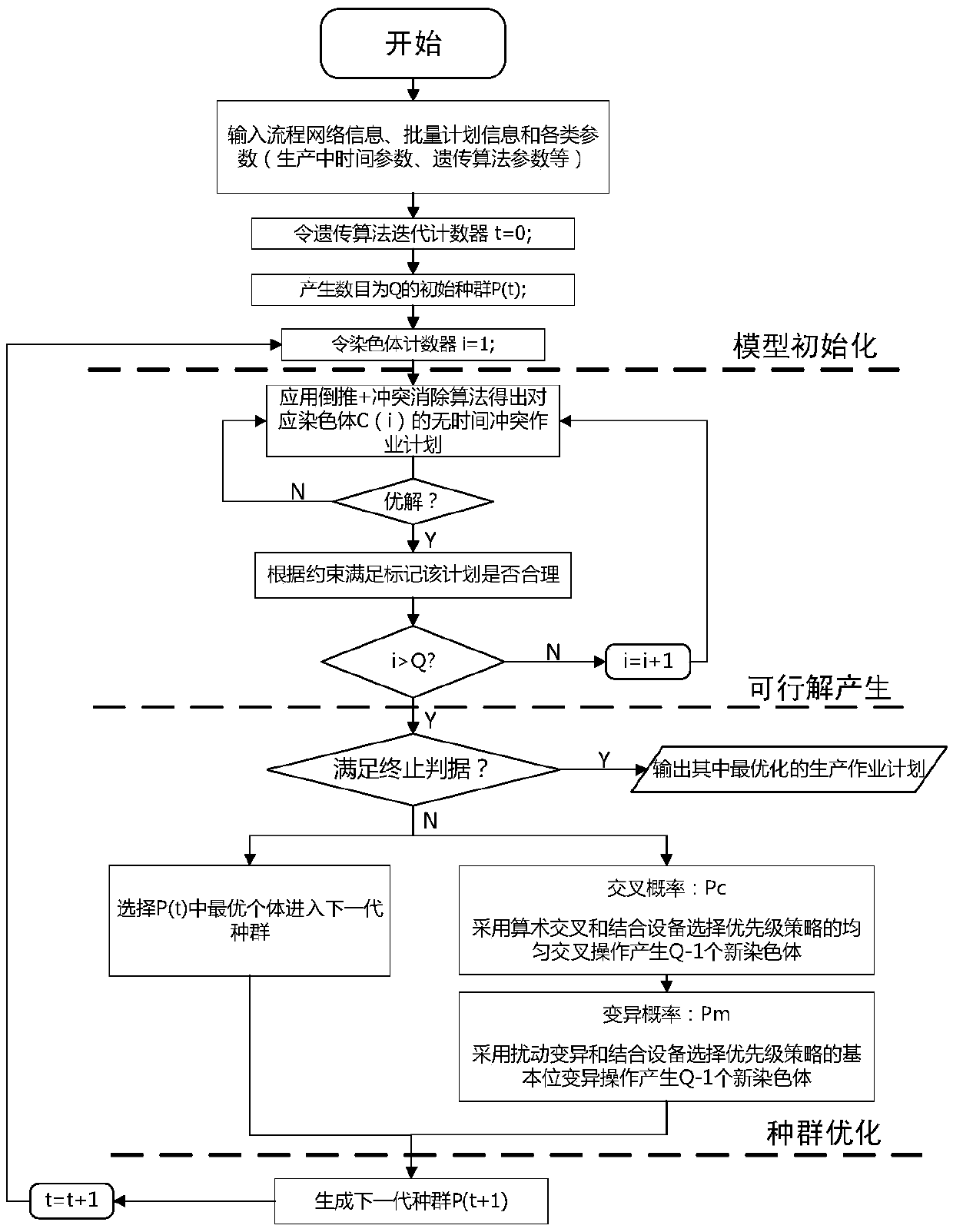

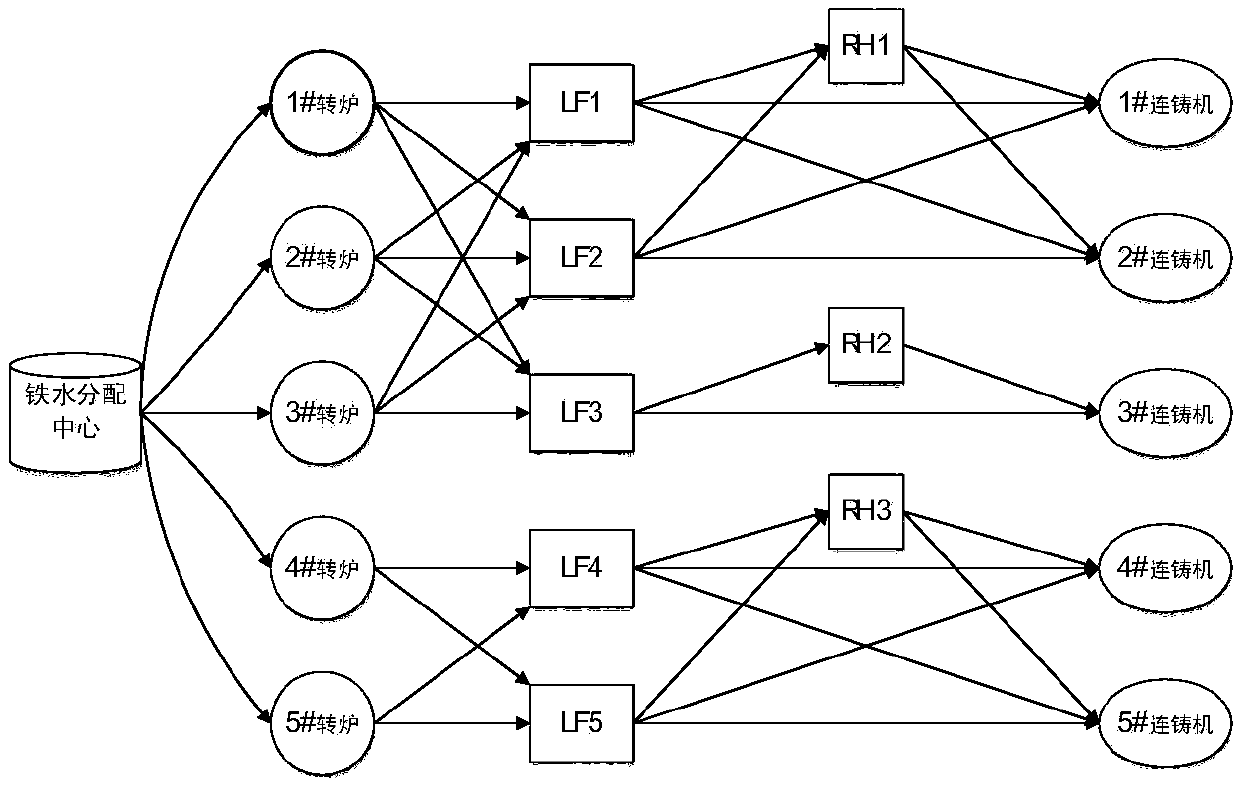

The invention proposes a steelmaking-continuous casting scheduling method utilizing a priority policy hybrid genetic algorithm. The method comprises the following steps: establishing a production scheduling plan target function; establishing a constraint condition set; performing iterative calculation on the target function by utilizing the priority policy hybrid genetic algorithm; and calculating decision variables. The calculation of the decision variables specifically comprises the steps of performing model initialization; calculating a feasible solution: designing a segmented combined real number code composed of casting time information of a continuous casting machine and information of a heat machining device, randomly generating operation time according to a distribution law, and obtaining a time conflict-free scheduling plan by backward inference calculation and conflict elimination methods; and performing population genetic optimization: quantitatively describing a matching relationship among machining devices in reality by using processing weight assignment of a task executable device, and introducing the matching relationship to genetic operation in the form of a device selection priority policy to perform population evolution. The method can solve the problem of uncertainty of device selection and operation time in production to obtain an optimized executable production scheduling plan.

Owner:CHONGQING UNIV

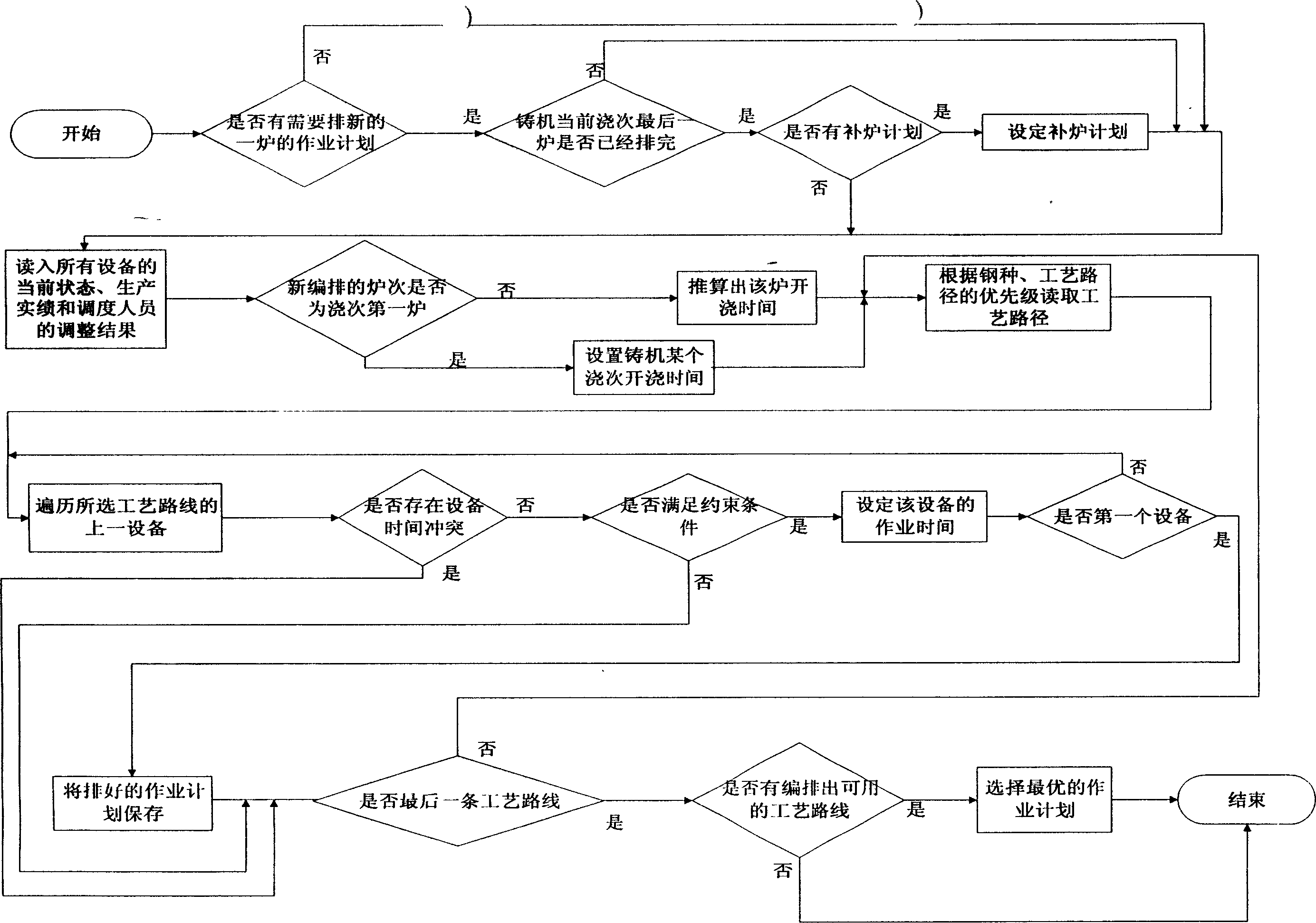

On-line dynamic dispatching method for continuous steel casting production

InactiveCN1614618AReduce cumulative time errorEasy production organizationSpecial data processing applicationsComputerized systemWorkstation

An on-line dynamic dispatching method for continuous production of steel making includes applying distributed computer system; working out a dynamic operation plan suitable for current production state by collecting data from site process and equipment, combining the set of dispatcher and using roll search mode; following the plan to carry out operation by operation station and feeding back regulation request to dispatching room for used as basis of next dispatch.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

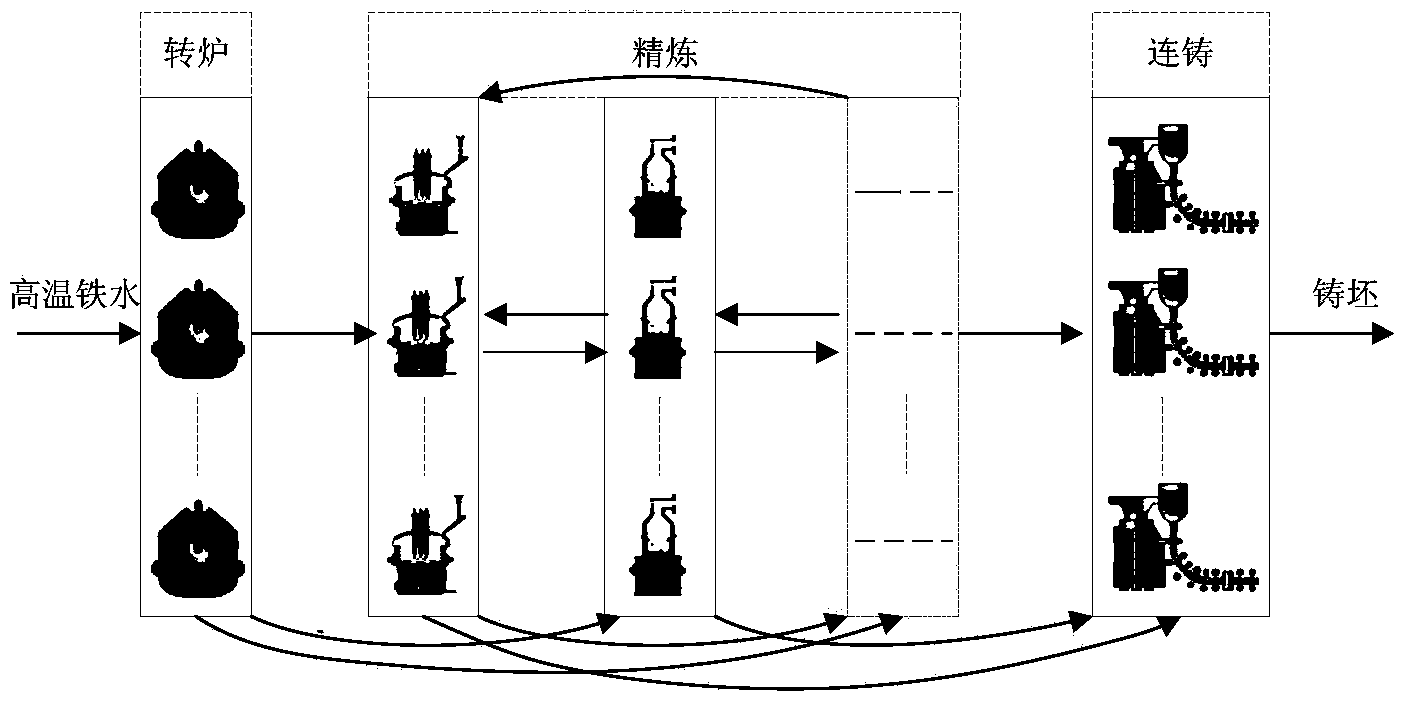

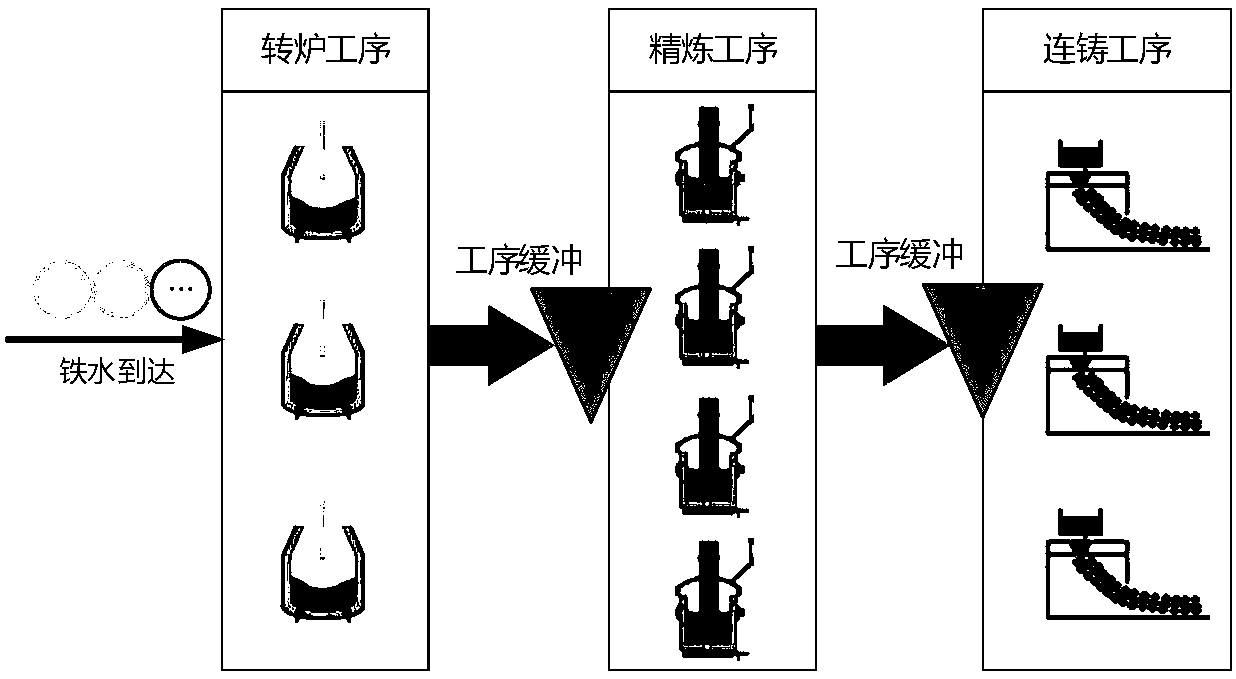

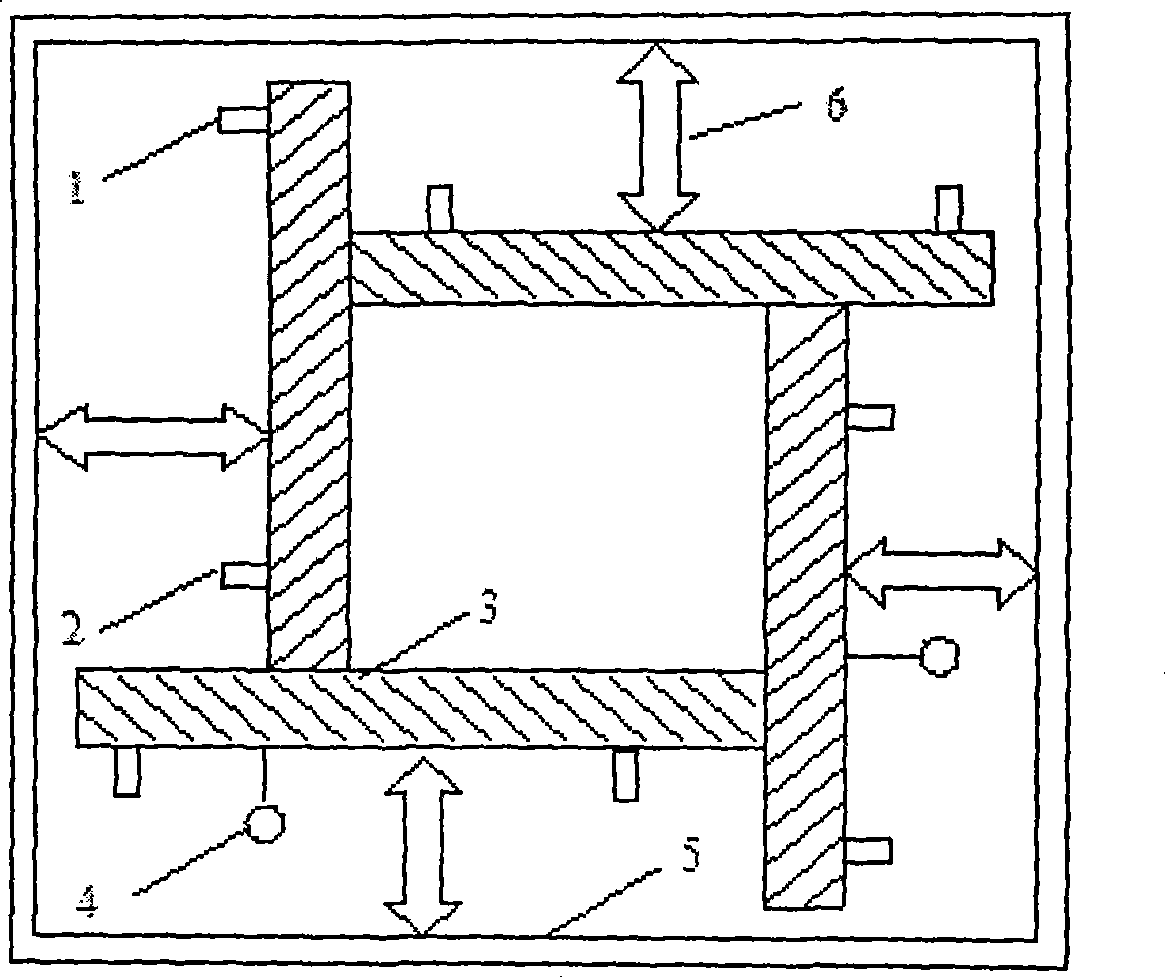

Iron-making and steel-making continuous casting integrated dispatching system

InactiveCN101908092ASolve the integrated scheduling problem of ironmaking-steelmaking-continuous castingFast Online SchedulingSpecial data processing applicationsData acquisitionSteelmaking continuous casting

The invention discloses an iron-making and steel-making continuous casting integrated dispatching system, and belongs to the planning and dispatching field of iron-making and steel-making continuous casting production. The dispatching system comprises system implementing conditions and four sub-modules, wherein the system implementing conditions comprise equipment state and data acquisition programs, a database server, a database management program, database software and a client application program; and the four sub-modules comprise a torpedo ladle and foundry ladle dispatching planning and blast furnace area-converter area molten iron planning matching model module, an iron-steel interface molten iron dispatching framework module, a molten iron pretreatment-continuous casting dispatching module and an information communication module. Iron-steel interface torpedo ladle dispatching is implemented by monitoring the equipment state, judging the abnormal condition of the production, recording the operation performance, combining the setting parameters of dispatching personnel and establishing a blast furnace area-converter area molten iron planning matching model; static dispatching of a molten iron pretreatment-continuous casting section is generated by adopting a heuristic algorithm, and dynamic dispatching is implemented by using a hybrid genetic algorithm; and quick and flexible on-line dispatching of the molten iron pretreatment-continuous casting section is implemented.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL +2

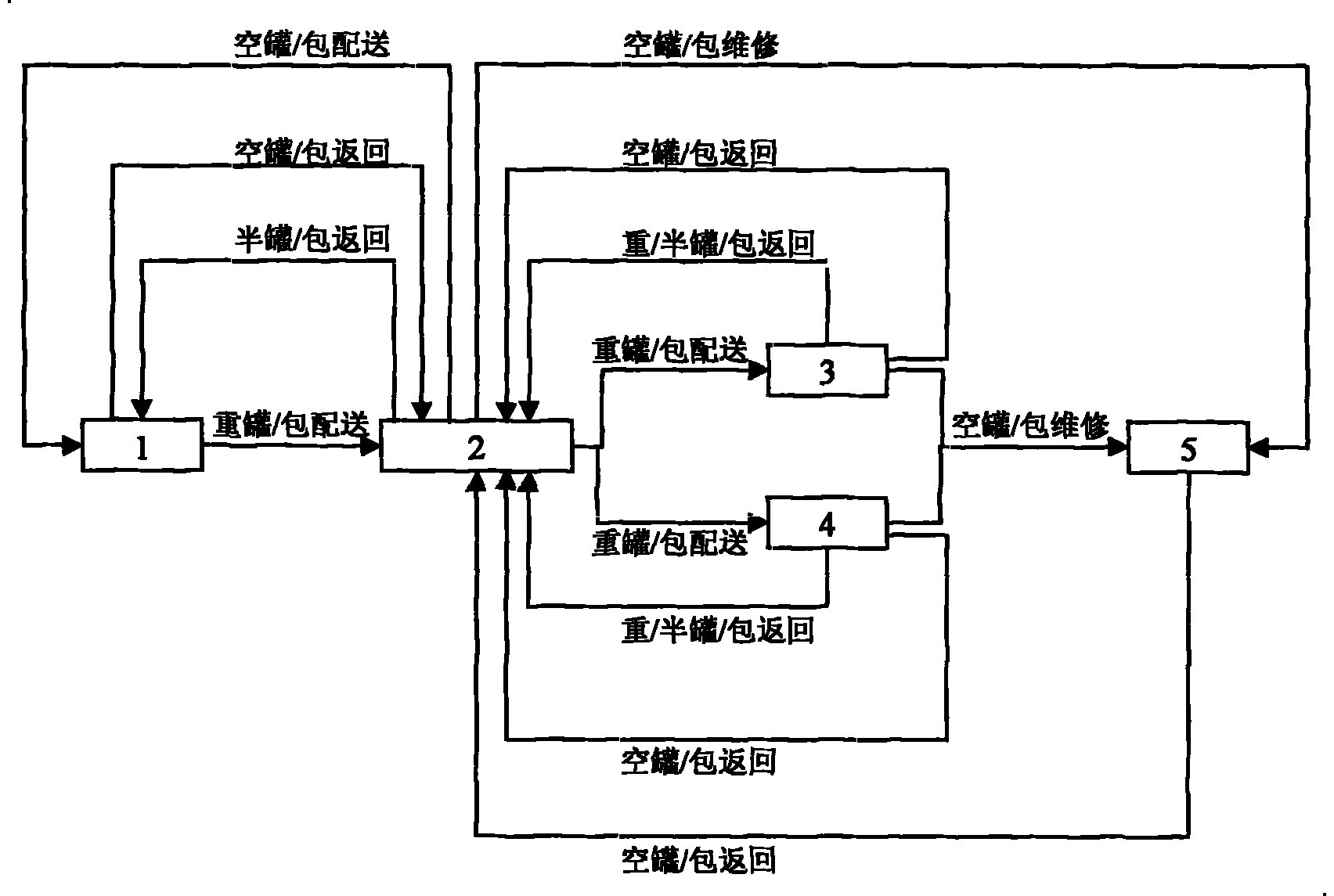

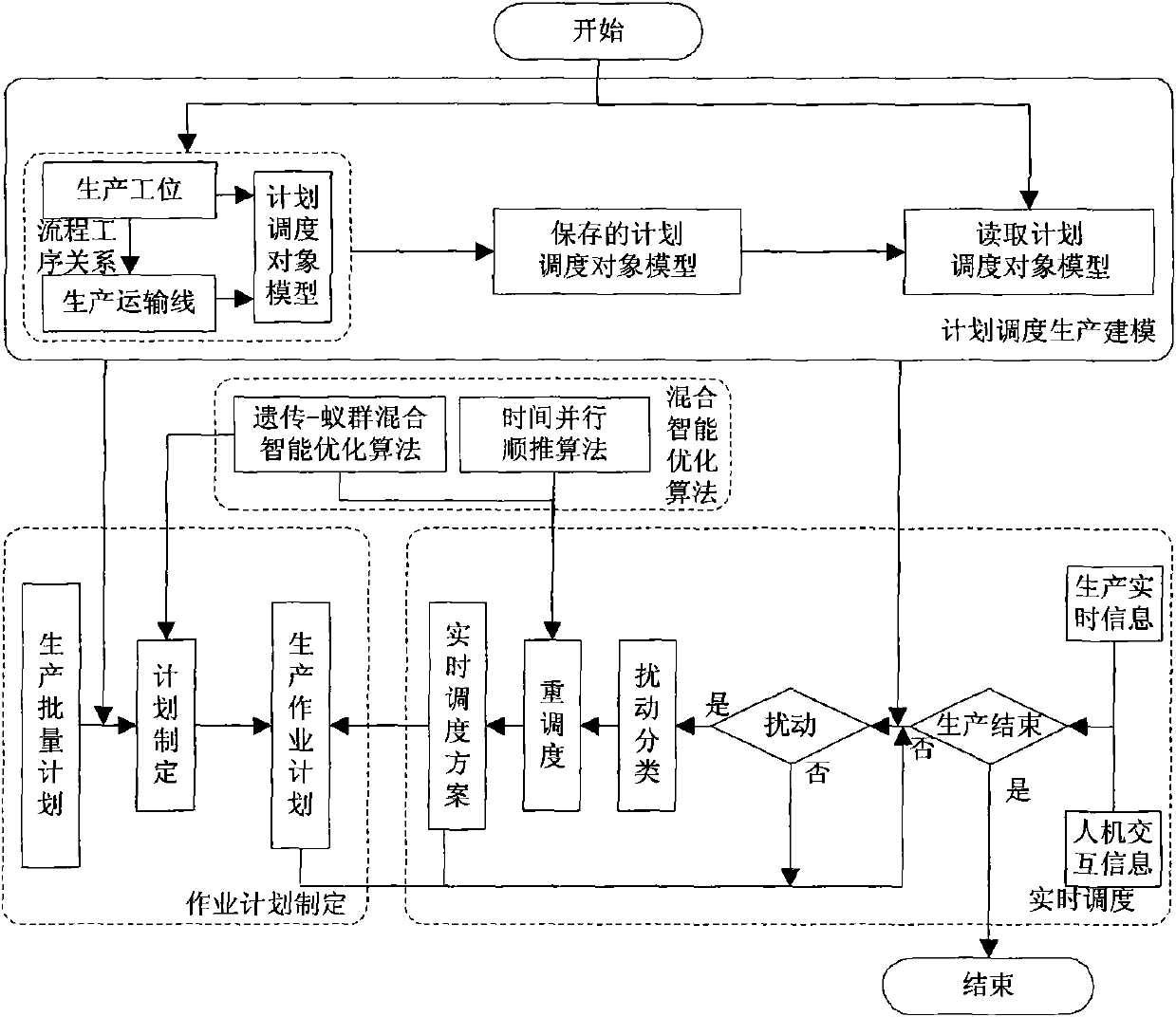

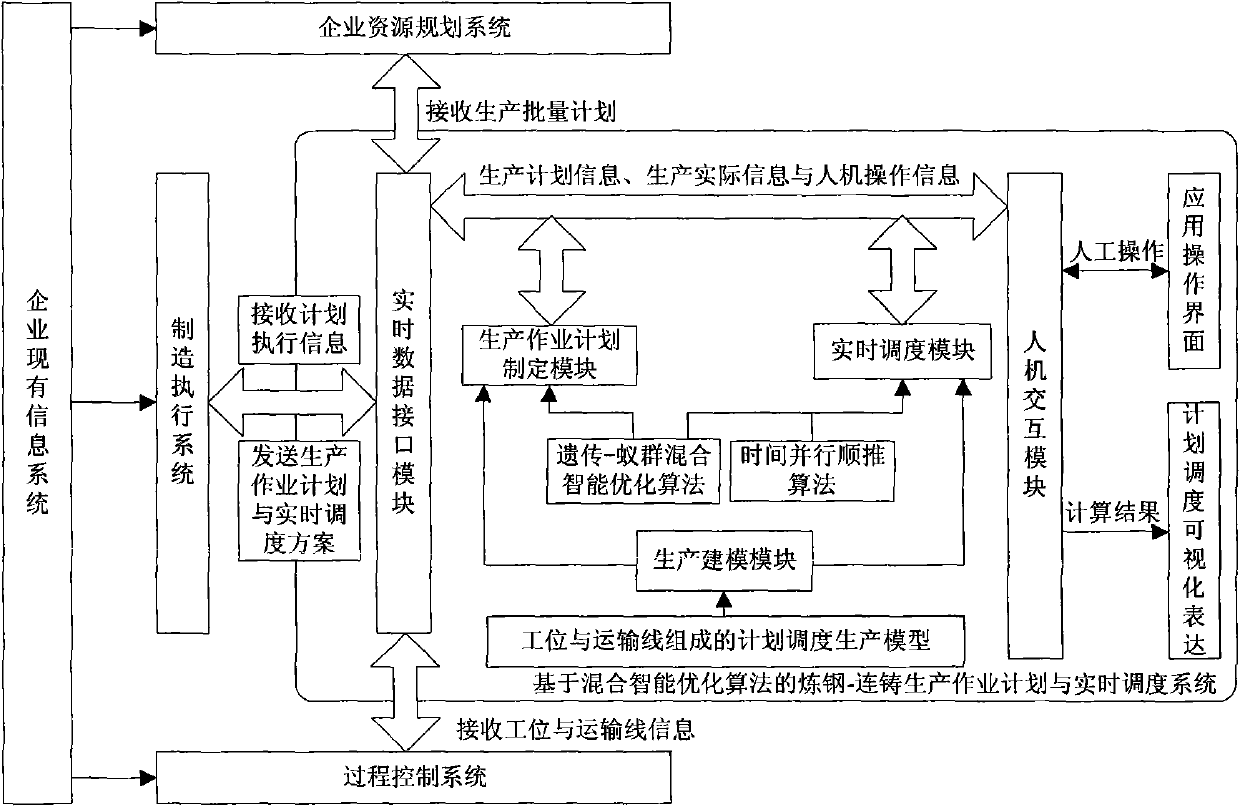

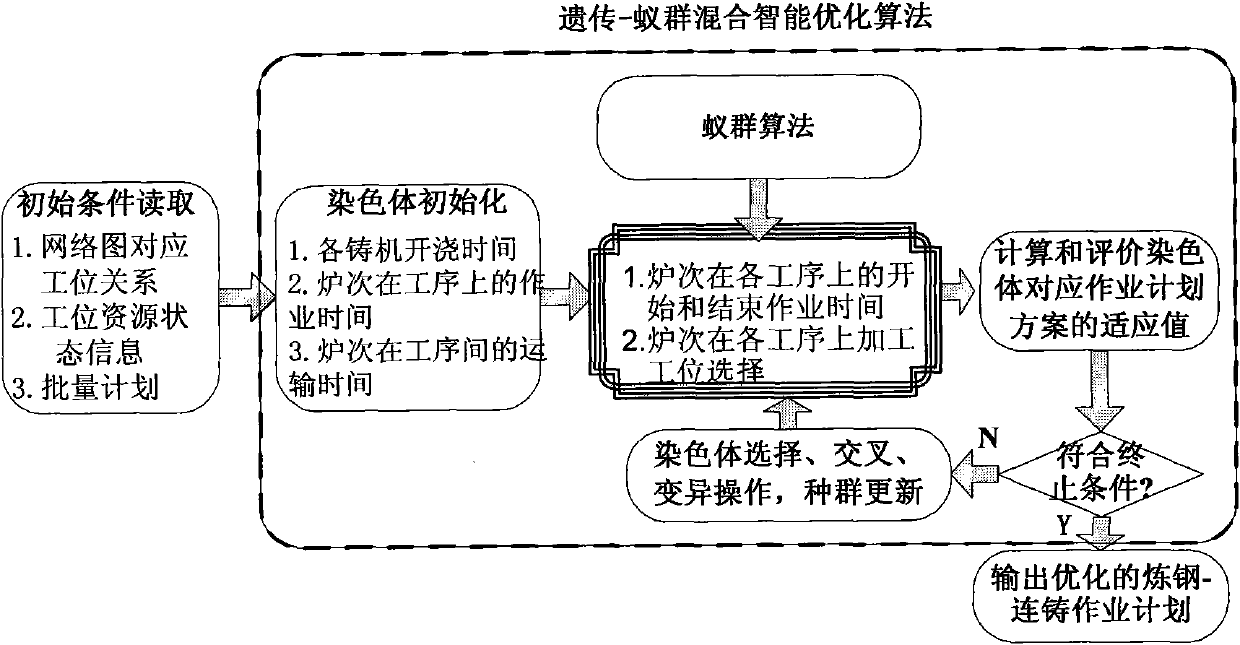

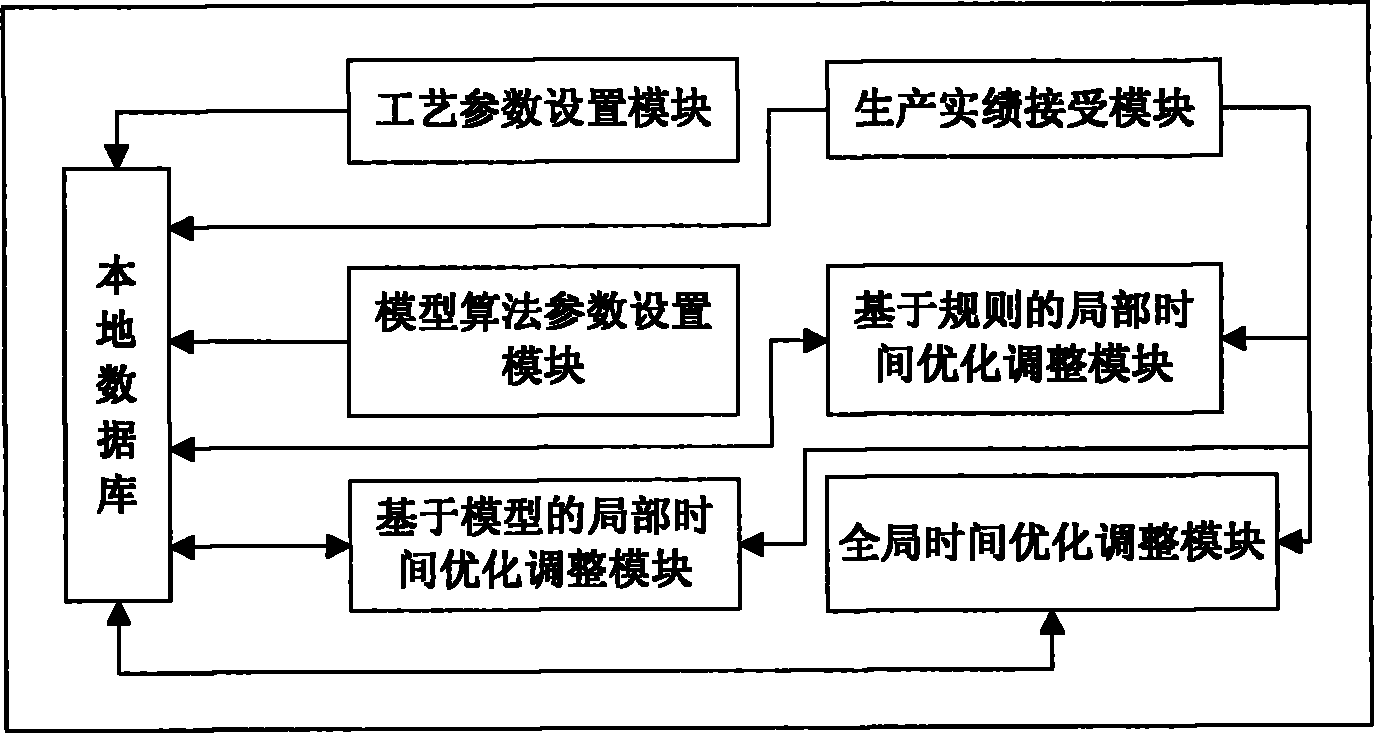

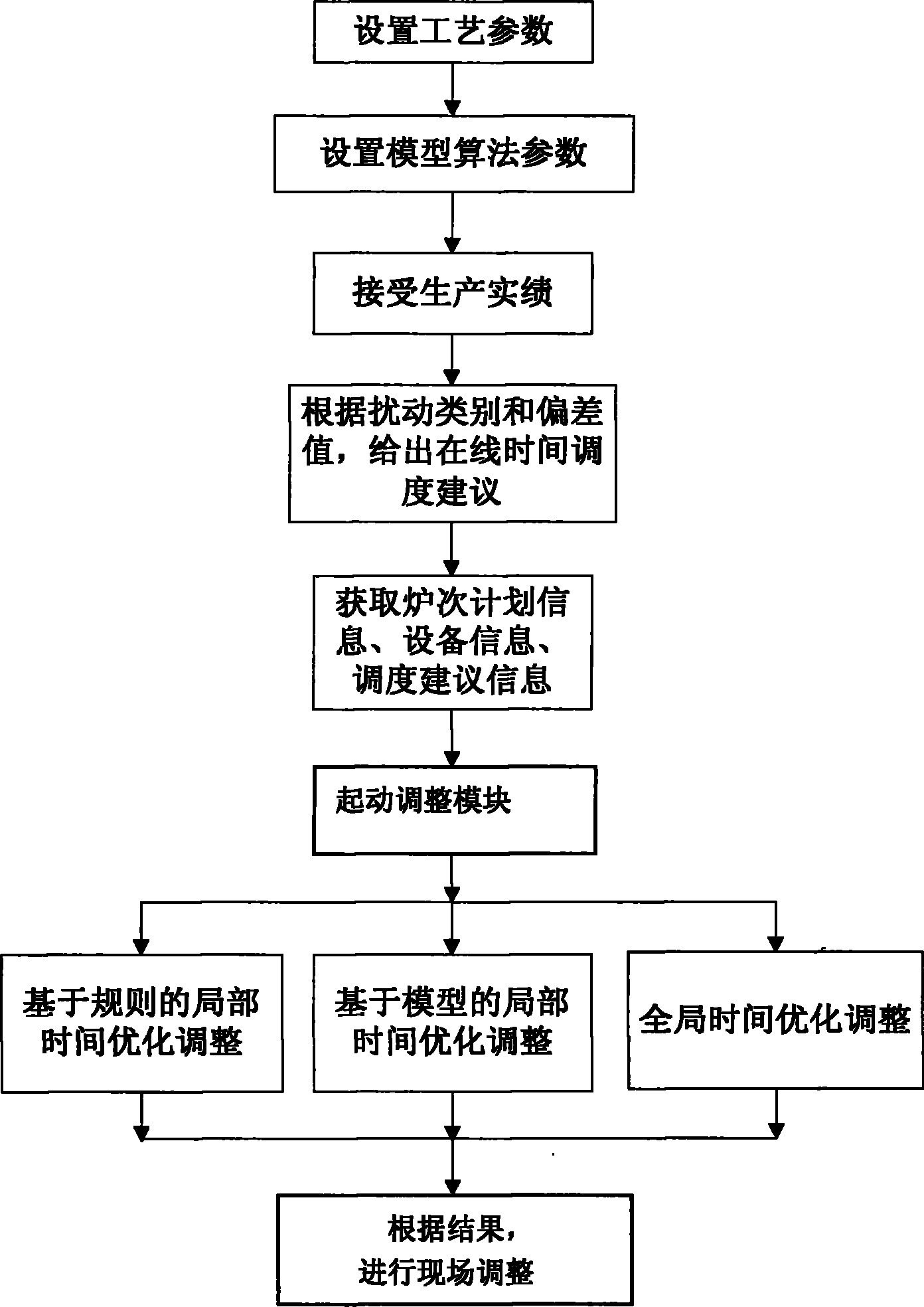

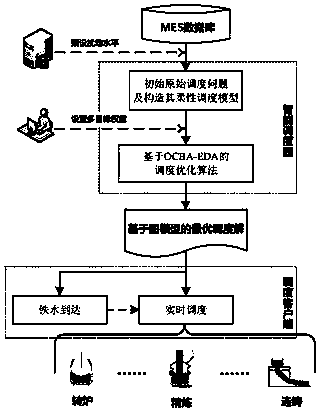

Steelmaking-continuous casting production operation plan and real-time dispatching optimization method and system based on mixed intelligent optimization algorithm

InactiveCN101770615AQuick buildOptimize production scheduleResourcesManufacturing computing systemsProcess mechanismModel method

The invention provides a steelmaking-continuous casting production operation plan and a real-time dispatching optimization method and a system based on a mixed intelligent optimization algorithm. The method comprises the following steps: establishing a production operation plan and an original dispatching proposal by the mixed intelligent optimization algorithm according to a production batch plan; detecting the perturbation in the production process through the established real-time data and a human-computer interaction interface; adopting the mixed intelligent optimization algorithm for remaking the plan on operating plans and unoperated plans; classifying the main perturbation in the production process; and establishing processing mechanisms corresponding to each kind of perturbation. The invention provides the re-planning and re-dispatching functions under the condition of changed production environment, and brings convenience for dispatching personnel to regulate the dispatching proposals according to personnel experience. The method considers the possible conflicts between equipment and the furnace sequence during the generation of the production operation plan and the dispatching proposal, so the calculation results are feasible. Because of the real-time dispatching function, the model method has strong system self organization performance, good adaptability and good universality.

Owner:CHONGQING UNIV

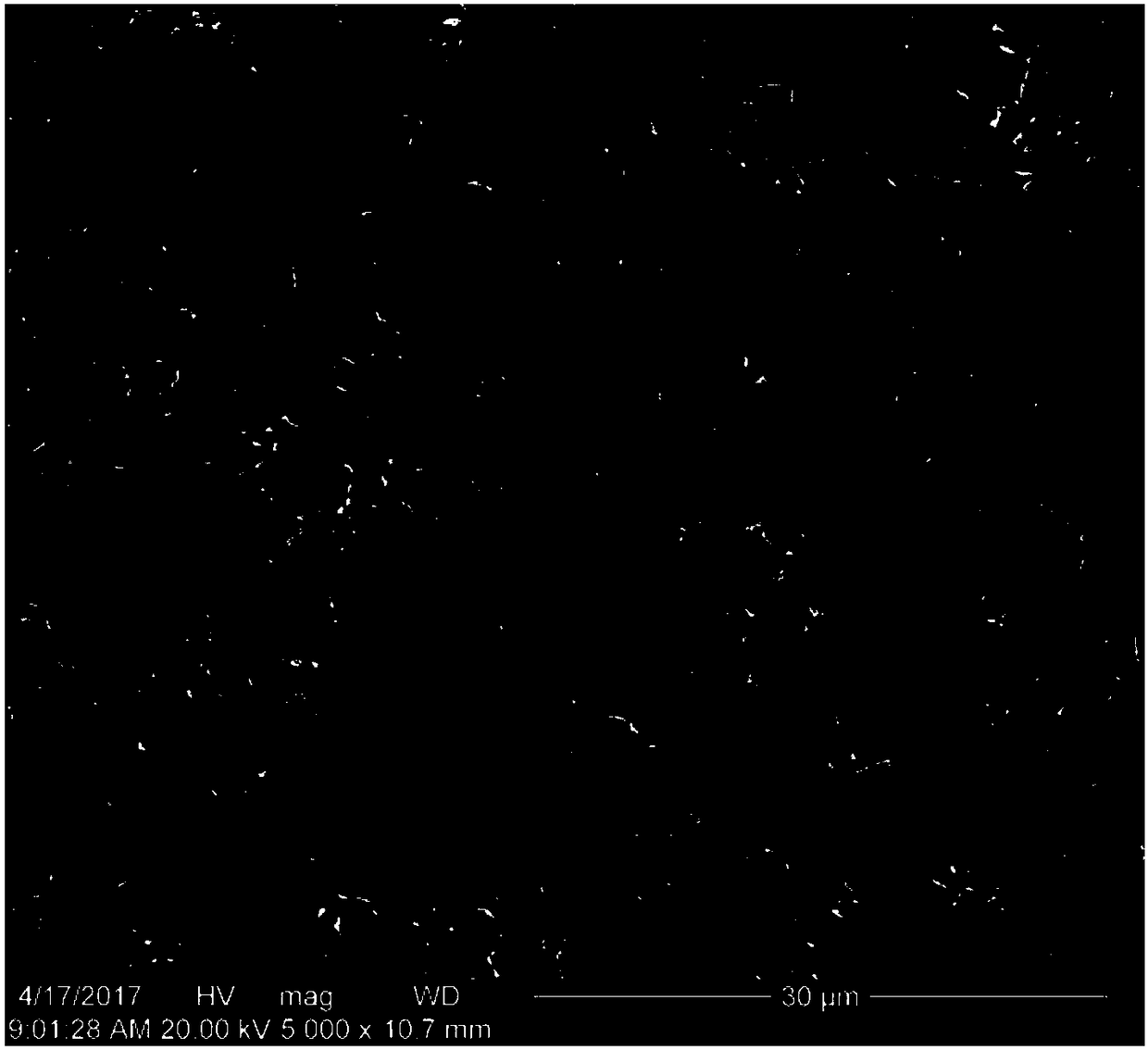

Fluorine free protecting slag for steelmaking and continuous casting and method for manufacturing same

A fruorine-free mold flux for the continuous casting of steel and method for producing the same relates to a mold flux for the continuous casting of new steel grade, which accord with the requirement of protecting natural environment. The characteristic is in that the mold flux contains the fellowing compositions and performance range: 23-40% SiO2, 20-4-% CaO, 0.5-10% MgO, 0.5-10% Al2O3, 0.5-10% MnO2, 2-15% Na2O, 5-15% B2O3, and 0.5-10% C; the melting point is 800-1200 DEG C, the viscosity is 0.2-5 pt, and the crystallizer rate is 0.1-30%. The advantages of the invention are in that the fruorine-free mold flux can alternatively act the role of the fluorine component, according with the continuous casting conditions (steel grade, casting speed, and the like). In this way, uniform fusing characteristic, fluidity and viscosity are improved or promoted, and the mold flux is contributed to the improvement of the operational stability and the product quality with the smooth workability in the continuous casting process by singly or in combination use.

Owner:SANYI METALLURGICAL MATERIAL

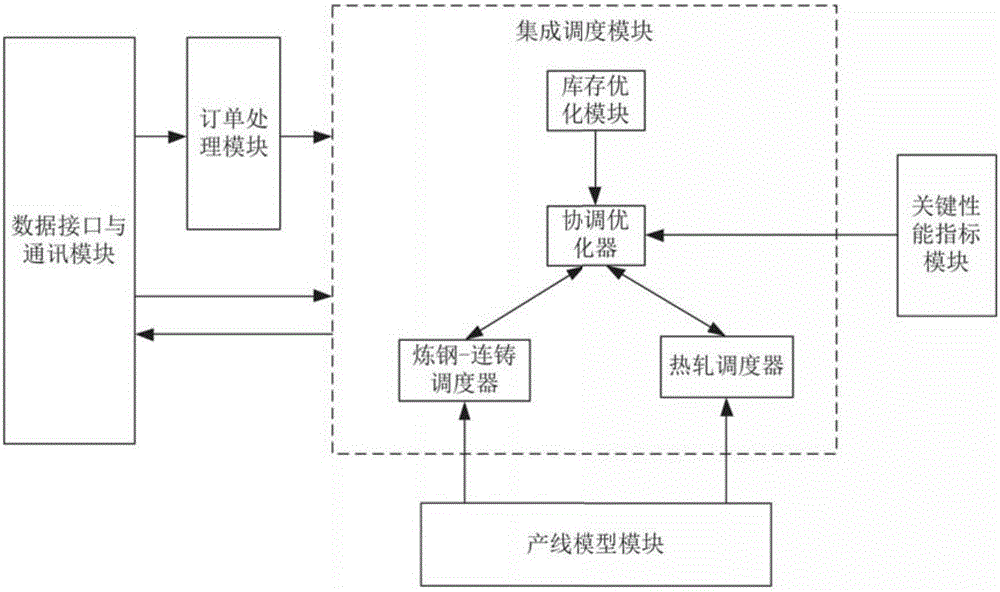

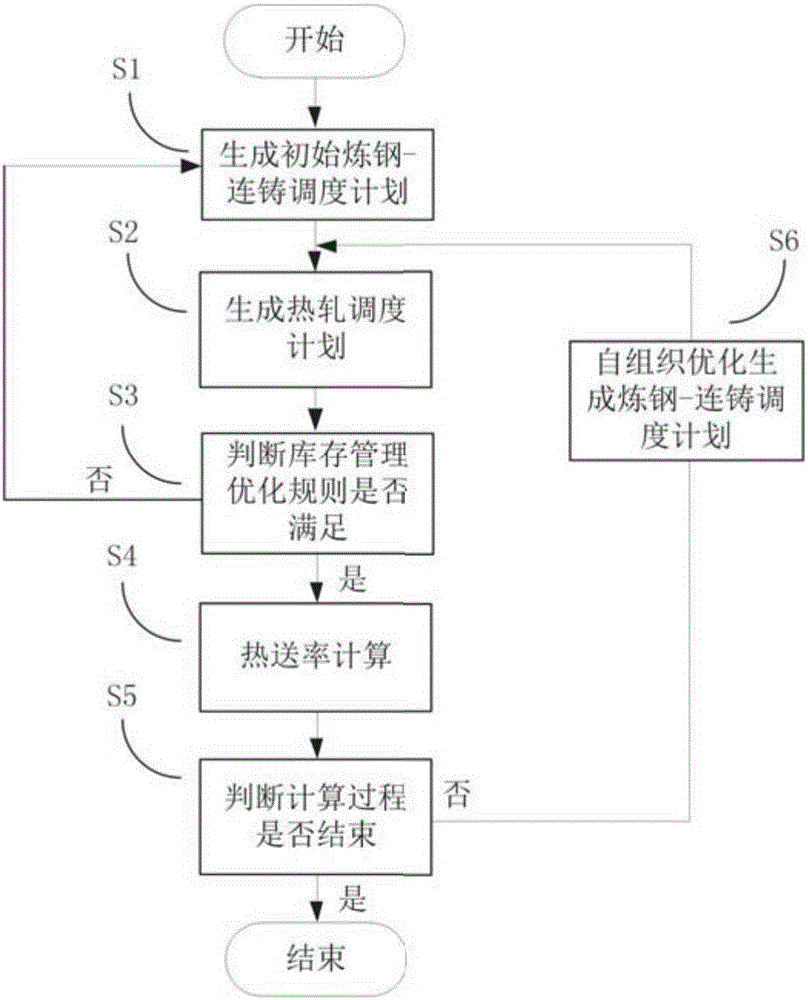

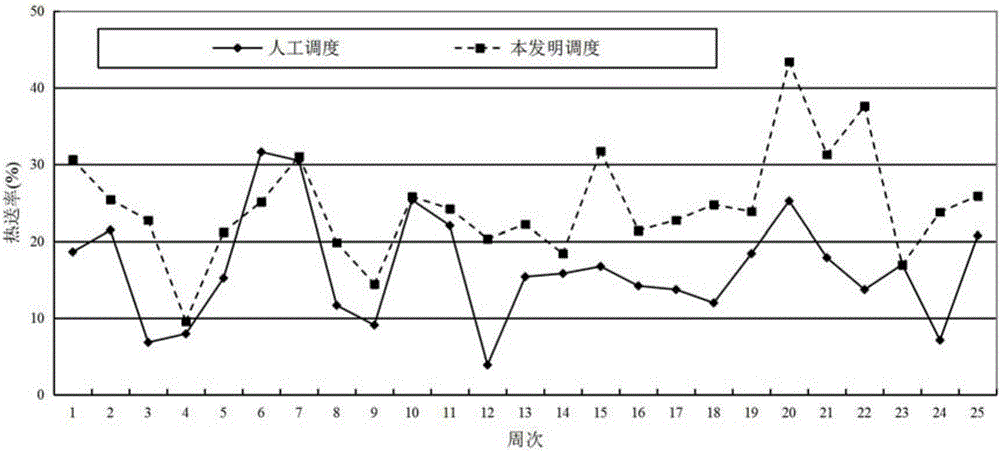

Steelmaking-continuous casting-hot rolling integrated scheduling method and system

ActiveCN106779220AAvoid confictImprove heat transfer rateForecastingResourcesProduction lineHardness

The invention provides a steelmaking-continuous casting-hot rolling integrated scheduling method and system. The method comprises the steps of S1, performing initialization to obtain a steelmaking-continuous casting scheduling plan; S2, obtaining a hot rolling scheduling plan according to the current steelmaking-continuous casting scheduling plan as well as a working order demand, a production line model, a current production rhythm, a rolling unit length constraint, and a rolling unit internal adjacent plate blank width, thickness and hardness jump constraint; S3, determining whether an inventory change situation meets a preset inventory optimization plan or not according to the current steelmaking-continuous casting scheduling plan and the hot rolling scheduling plan, and if the preset rule is met, entering the next step, otherwise, adjusting current parameters related to inventory optimization and returning to the step S1; S4, obtaining overall heat supply rate data according to the current steelmaking-continuous casting scheduling plan and the hot rolling scheduling plan; S5, judging whether an integrated scheduling stop condition is met or not, and if the stop condition is met, performing the scheduling plan, otherwise, performing the next step; and S6, performing re-optimization to generate the steelmaking-continuous casting scheduling plan, and returning to the step S2.

Owner:ZHEJIANG SUPCON RES

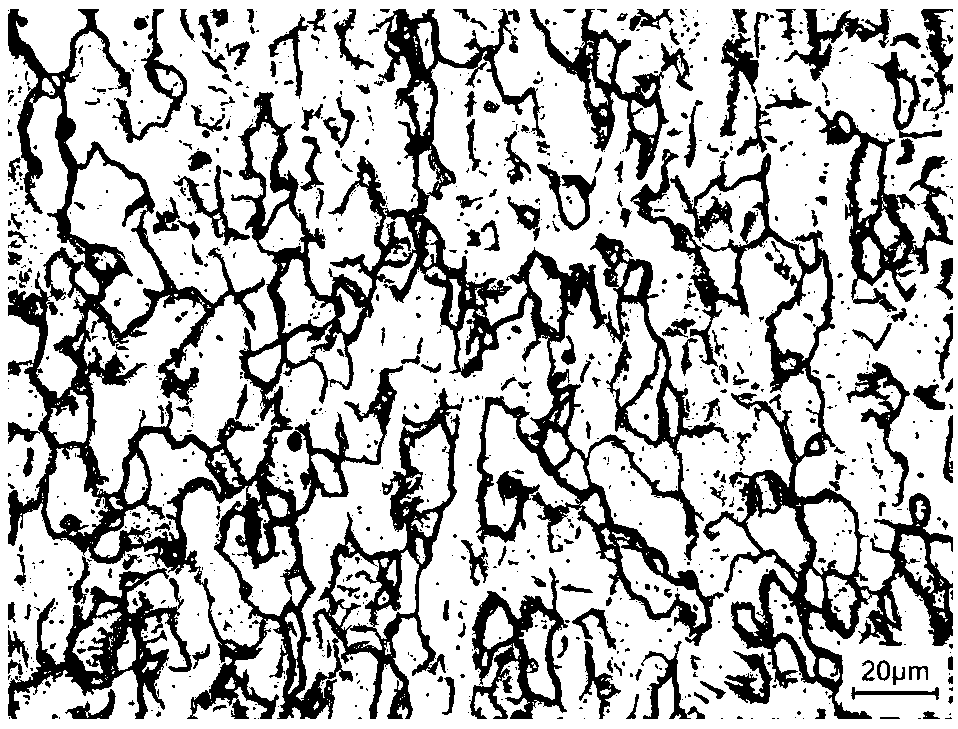

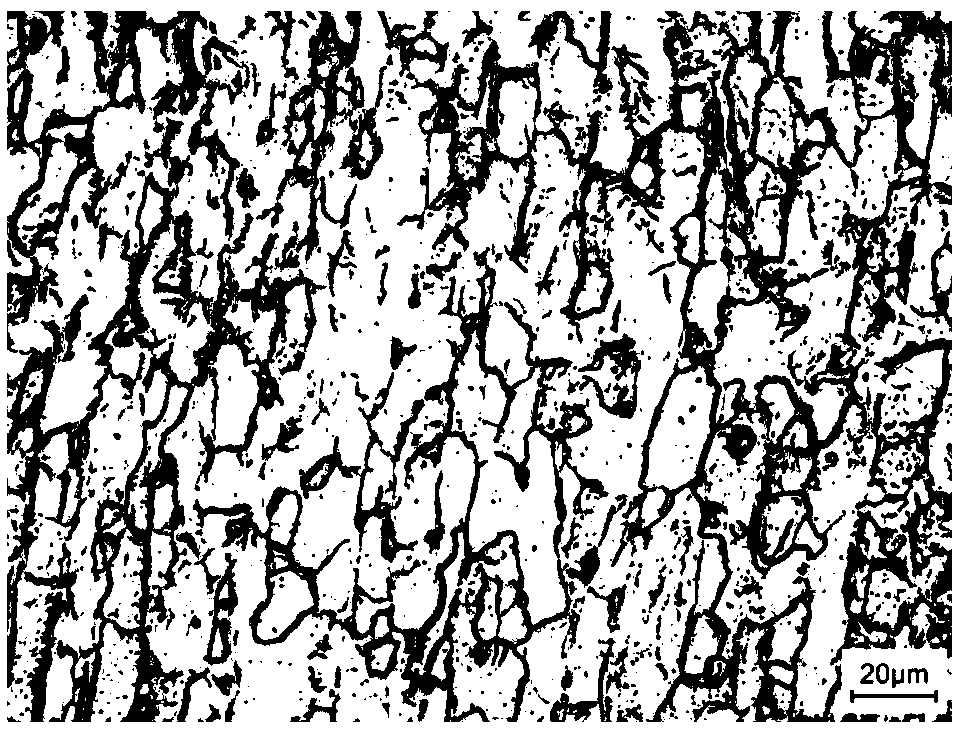

Cold rolling hot-dip galvanizing high-strength steel with extension strength being 1,000 MPa and preparation method of cold rolling hot-dip galvanizing high-strength steel

The invention discloses a cold rolling hot-dip galvanizing high-strength steel with extension strength being 1,000 MPa and a preparation method of the cold rolling hot-dip galvanizing high-strength steel. The cold rolling hot-dip galvanizing high-strength steel with extension strength being 1,000 MPa comprises the following chemical components including, by mass percent, 0.06%-0.11% of C, 0.30%-0.50% of Si, 1.0%-3.0% of Mn, 0.2%-0.5% of Cr, 0.10%-0.30% of Mo, 0.03%-0.06% of Als, 0.015% or less of P, 0.004% or less of S, 0.005% or less of N, at least one of (a) 0.18% or less of Nb+Ti+V and (b)0.005% or less of B and the balance Fe and unavoidable impurities. By coordinating with reasonable steelmaking, continuous casting, hot rolling, cover retreating, acid rolling and continuous annealinghot-dip galvanizing process, the hot-dip galvanizing high-strength steel with the 1,000 MPa-level high elongation is obtained, the yield strength of the hot-dip galvanizing high-strength steel is 550MPa-700 MPa, the extension strength is larger than or equal to 980 MPa, the ductility A50 is larger than or equal to 14%, and good plating quality is achieved.

Owner:MAGANG (GROUP) HOLDING CO LTD

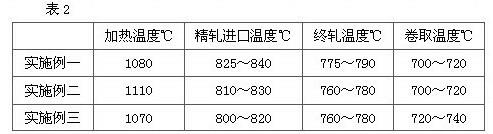

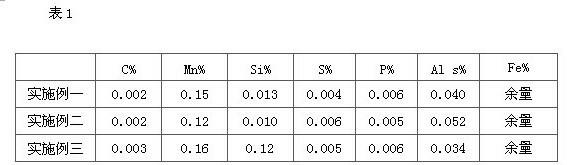

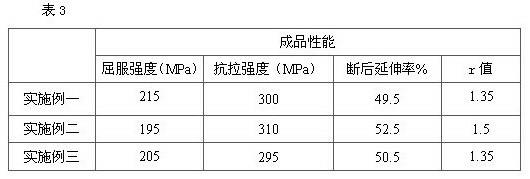

Processing method for producing low-cost high-formability IF (interstitial-free) steel

InactiveCN102581008AHigh drawabilityIncrease productivityTemperature control deviceMetal rolling arrangementsSlow coolingWater cooling

The invention relates to a processing method for producing low-cost high-formability IF (interstitial-free) steel, which is based on thin-slab continuous casting and rolling and adopts a ferrite rolling process to produce the IF steel, belonging to the technical field of IF steel production. The processing method comprises the following working procedures of steelmaking, continuous casting, heating, rolling, cooling and coiling. A thin-slab continuous casting machine is adopted, the thickness of a continuous casting slab is at most 100mm, and the charging temperature is at least 880 DEG C. During hot rolling, a roughing mil and a finishing mill keep a continuous rolling relationship and keep micro-tension control, and water cooling equipment is used between the roughing mil and the finishing mill and is used for uniformly reducing the temperature of an intermediate slab with a thickness of 12-25mm from the temperature at least 950 DEG C of the outlet of the roughing mil into the range of 750-850 DEG C. Finish rolling is carried out in a ferrite area, and a lubrication rolling technology is adopted. The coiling temperature is higher and is 680-760 DEG C, slow cooling is carried out after coiling, and thereby an annealing process is finished. The invention provides a method for obtaining high-formability hot rolled sheets without cold rolling and cover annealing. The method has the advantages of being simple in process, low in cost, high in production efficiency, short in flow and the like, and the formability of products is higher.

Owner:HEBEI IRON AND STEEL

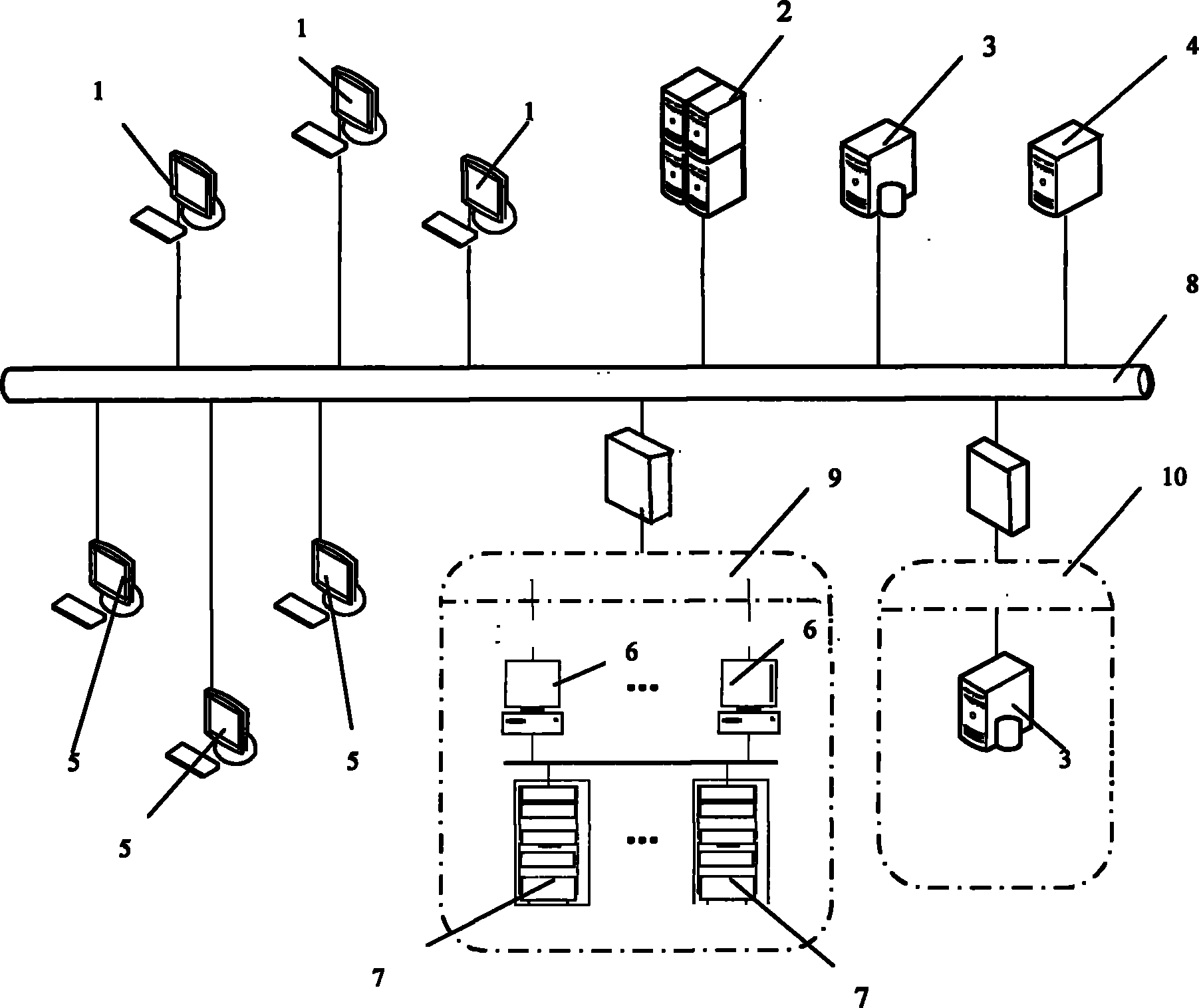

Online steelmaking continuous casting control method

ActiveCN101786146AReduce redundant wait timeQuick solveTotal factory controlProgramme total factory controlNetwork connectionSystem configuration

The invention relates to an online steelmaking continuous casting control method, belonging to the technical field of steelmaking continuous casting; the method comprises the following steps: an interface management server is in network connection with a site controller, and stores the acquired various state information and process data in a database after data processing and format conversion, and also stores the production method delivered by the upper system in the database; a database server stores the production site real-time process data, planning data and various system configuration data in the database; an application server executes the steelmaking continuous casting production online control method, acquires data from the database server and stores the regulation result in the database; a client workstation displays various data, conducts the query of routine data, stores the data in a local computer and accordingly realizes the offline analysis of data; the online steelmaking continuous casting control method has high solving speed, higher automation degree, can preciously adjust to minutes, reduce the manual adjusting times and molten steel redundant waiting time.

Owner:NORTHEASTERN UNIV

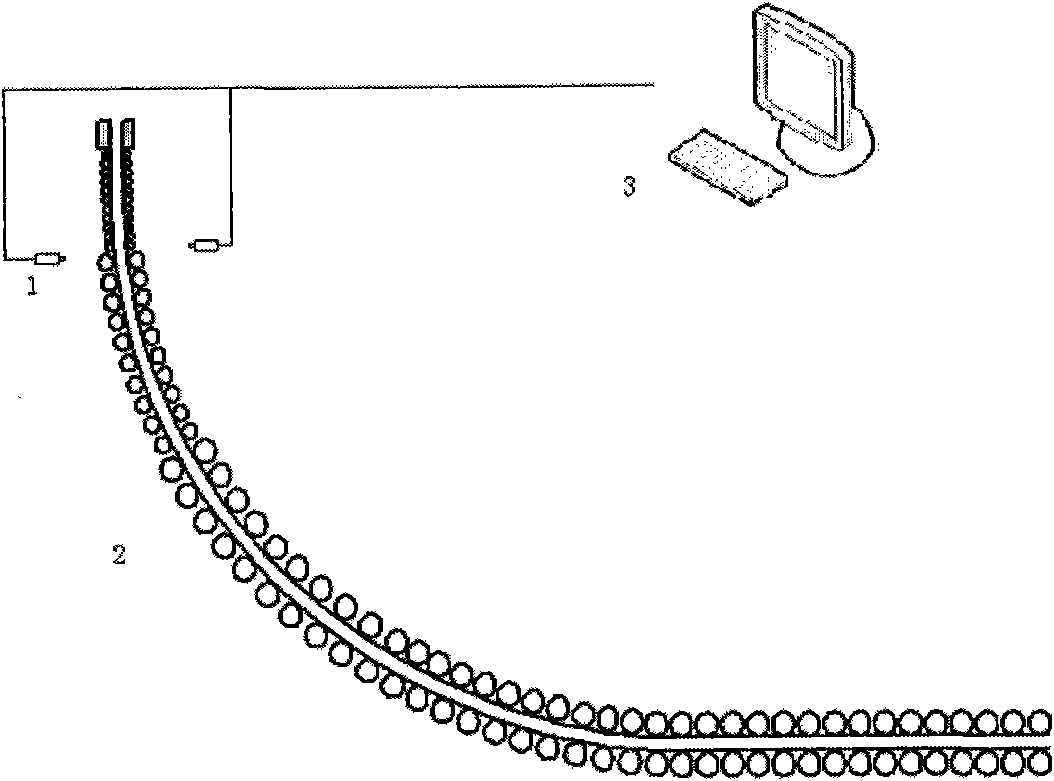

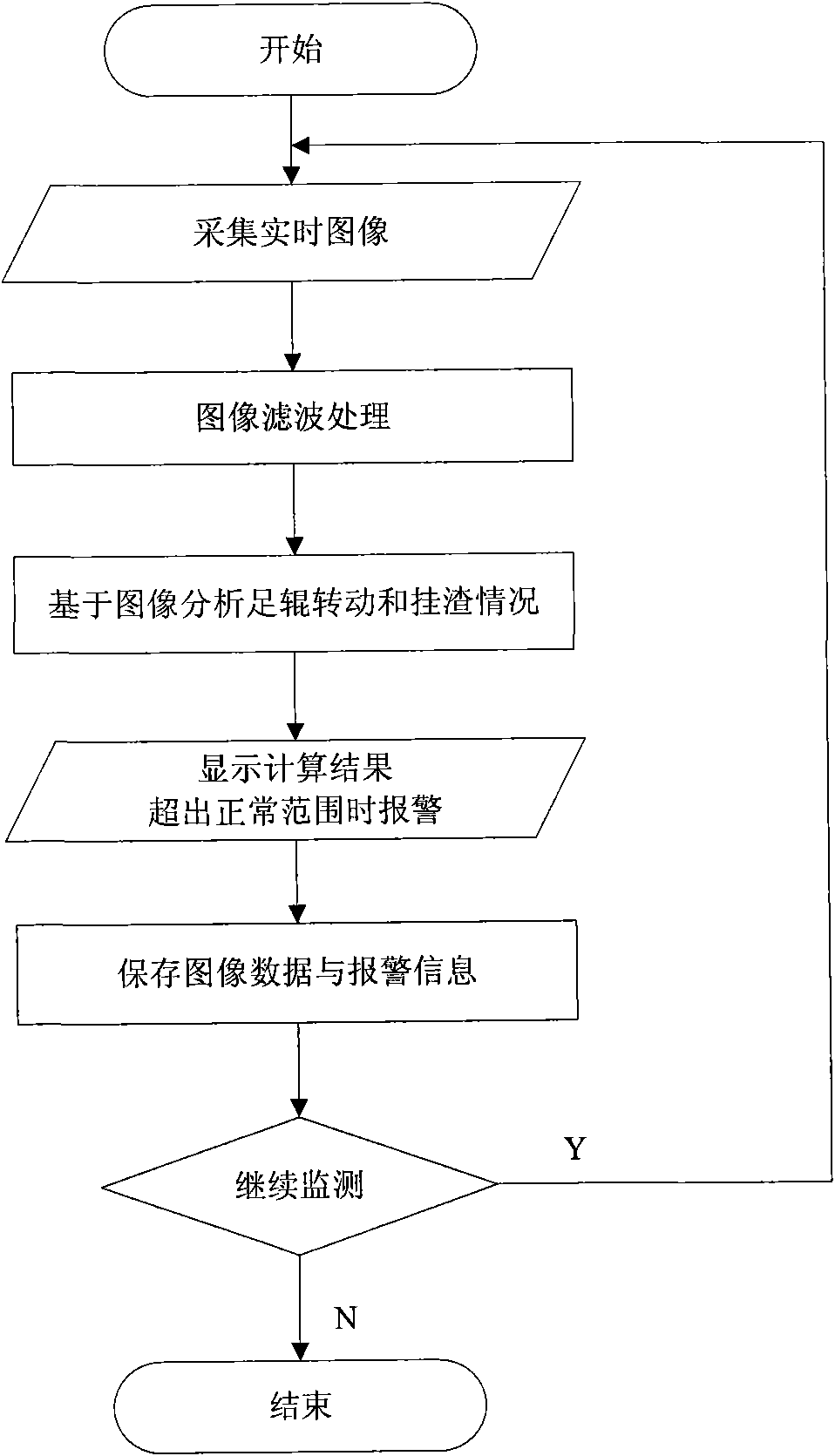

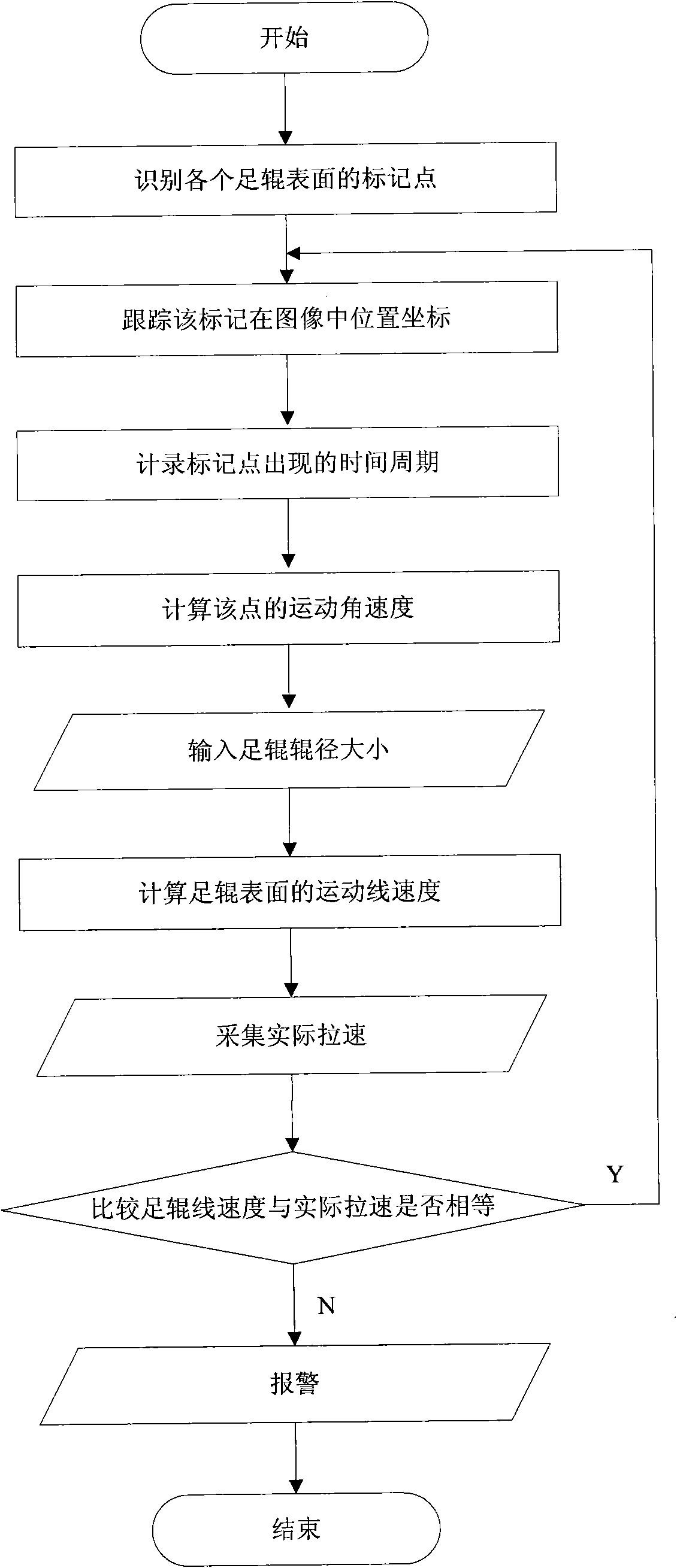

Online monitor of continuous casting machine crystallizer foot roll working state and monitoring method thereof

The invention belongs to the technical field of steelmaking continuous casting, in particular to an online monitor of a continuous casting machine crystallize foot roll working state and a monitoring method thereof. The monitor comprises minitype CCD cameras, a video image acquiring module and an industry computer, wherein the minitype CCD cameras are arranged at the inner arc side and the outer arc side of a continuous casting machine foot roll area and is used for acquiring bi-dimensional image information; the video image acquiring module is used for receiving and storing the bi-dimensional image information; and the industry computer is used for processing and analyzing the bi-dimensional image information and display the final result. By installing the CCD cameras at the inner arc side and the outer arc side of the foot roll area and adopting the computer image processing technology to perform online image analysis on foot roll rotation condition and slag adhering condition, the working state of the foot roll can be monitored in real time, and alarm or corresponding fault treatment can be carried out timely based on the characteristics of abnormal conditions in necessity. The invention has the advantages of simple device structure, wide application range, realized remote monitoring by the image pickup technology, lowered labor intensity and danger level for field workers and improved whole automation level and intelligence level of the continuous casting machine.

Owner:UNIV OF SCI & TECH BEIJING

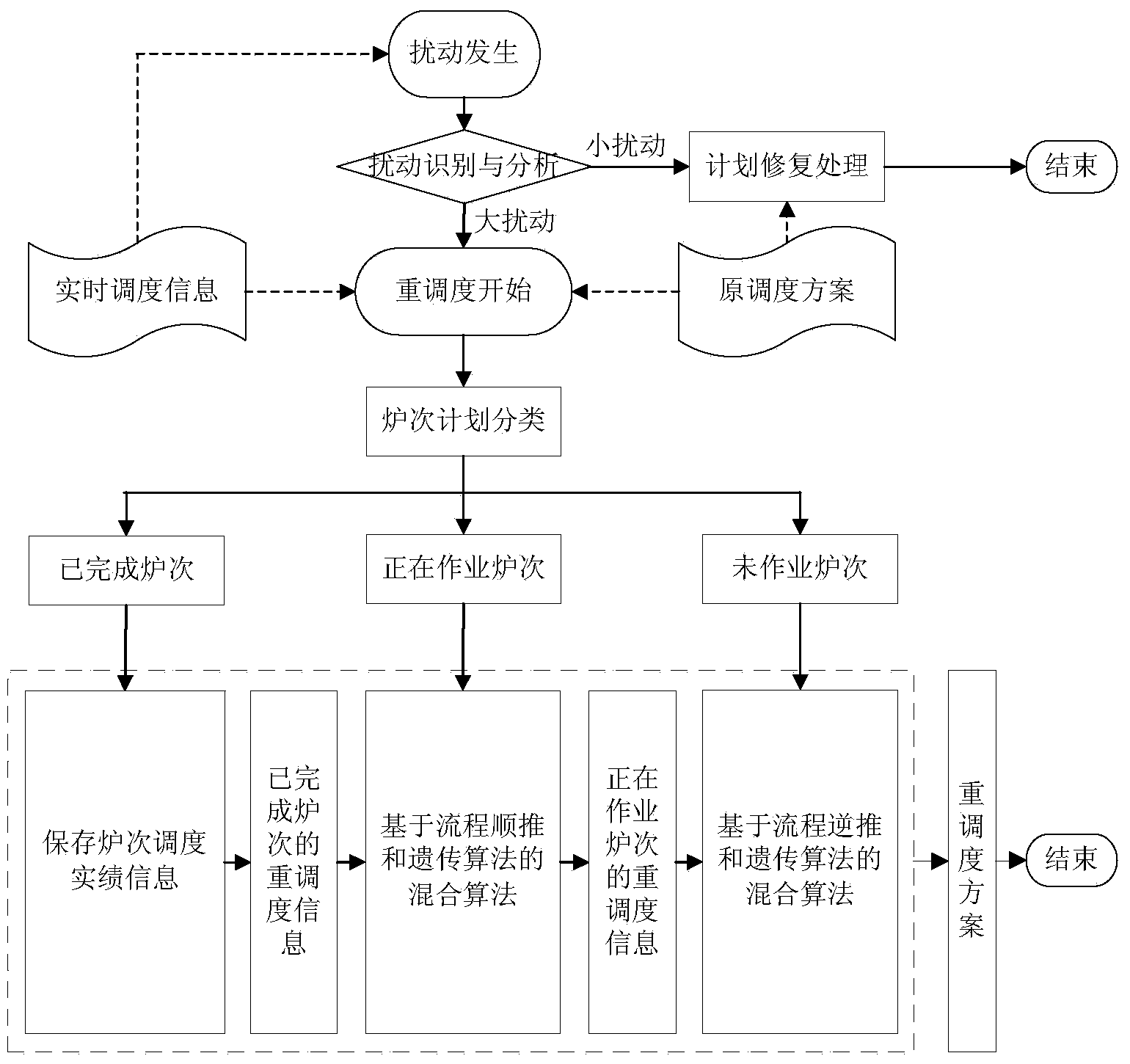

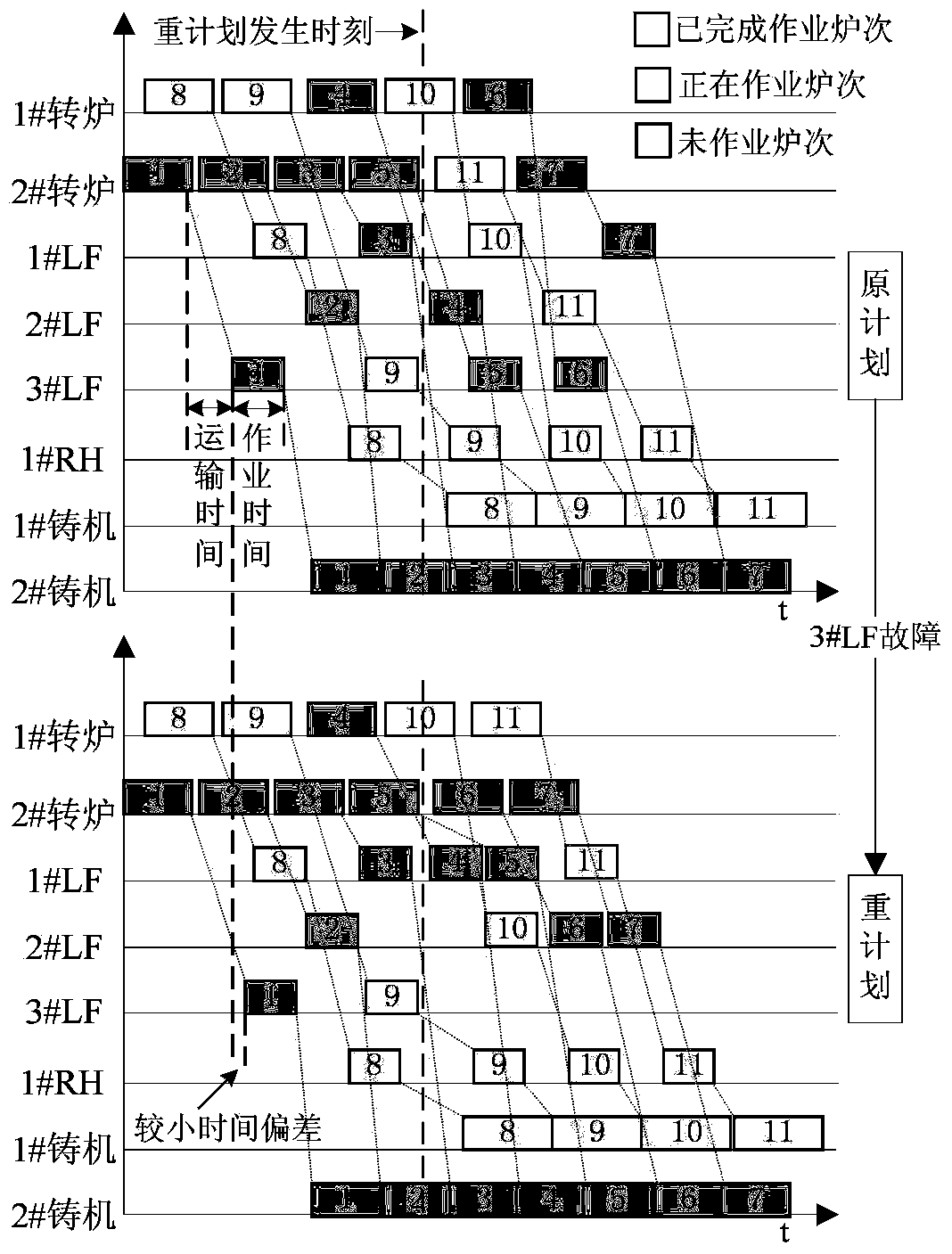

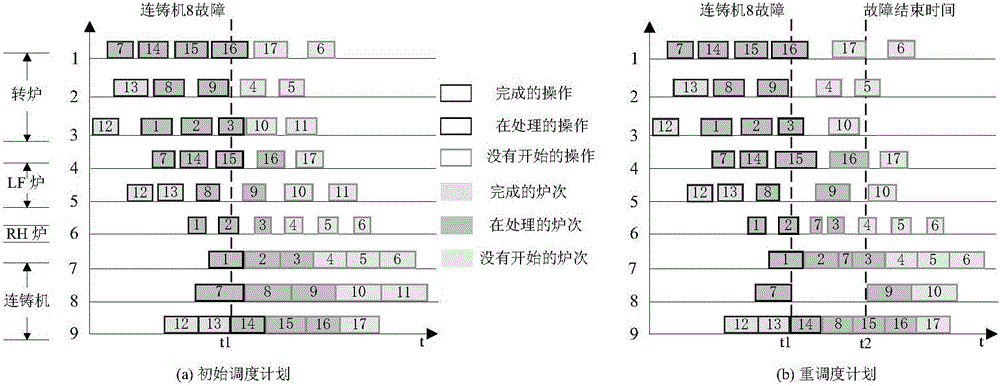

Rescheduling method and rescheduling system of steel making and continuous casting on basis of genetic algorithm

ActiveCN103631243AGuaranteed reasonablenessEffective connectionTotal factory controlProgramme total factory controlTime scheduleMetallurgy

The invention provides a rescheduling method and a rescheduling system of steel making and continuous casting on the basis of a genetic algorithm. The rescheduling method comprises the following steps: by virtue of the rescheduling system, acquiring a production batch plan, the current scheduling scheme and real-time scheduling data of a steel making and continuous casting system, carrying out disturbance identification and analysis, adjusting the current scheduling scheme in small disturbance, carrying out rescheduling in large disturbance; for all furnaces in the operation-finished furnace set, adopting actual scheduling information as a rescheduling subscheme of all the furnaces in the set; for all the furnaces in an operating-furnace set, on the basis of the actual scheduling information and a rescheduling target of the operation-finished furnace set, solving according to a hybrid algorithm of flow direct and a genetic algorithm; for all the furnaces in a stopped-furnace set, on the basis of the rescheduling subscheme of the operation-finished furnace set and the rescheduling subscheme of the operating-furnace set, solving according to the hybrid algorithm of the flow direct and the genetic algorithm. The rescheduling method and rescheduling system provided by the invention have the advantages that the problem of rescheduling under random disturbance in the process of steel making and continuous casting production can be solved.

Owner:CHONGQING UNIV

Low-cost aging resistant household appliance color coated sheet and production method thereof

The invention discloses a low-cost aging resistant household appliance color coated sheet. The color coated sheet is made of, by weight, 0.010-0.030% of C, no more than 0.030% of Si, 0.015-0.35% of Mn, no more than 0.020% of P, no more than 0.020% of S, 0.020-0.060% of A1s, 0.005-0.020% of Ti, no more than 0.0040% of N, and the balance Fe and other unavoidable impurities. The invention further discloses a production method of the household appliance color coated sheet. The method comprises the steps of molten iron steelmaking, continuous casting, hot rolling, acid pickling, cold rolling, hot galvanizing, finishing, pulling correcting and color coating. In the hot galvanizing step, the continuous annealing temperature is 785-795 DEG C. The sum of the ductility of the finishing step and the ductility of the pulling connecting step is 1.0-1.2%. The low-cost aging resistant household appliance color coated sheet and the production method thereof are simple in technology, high in strength and rigidity, good in stamping property, aging resistant, low in cost, and capable of being widely used in the technical field of the iron and steel smelting technology.

Owner:武汉钢铁有限公司

Cold-rolled steel strip for high-drawing-performance flux-cored wire, and making method thereof

The invention belongs to the technical fields of cold-rolled steel strips for a flux-cored wire, and making methods thereof, and concretely relates to a cold-rolled steel strip for a high-drawing-performance flux-cored wire, and a making method thereof. The cold-rolled steel strip for a high-drawing-performance flux-cored wire comprises 0.0035wt% or less of C, 0.03wt% or less of Si, 0.10-0.25wt% of Mn, 0.008wt% or less of P, 0.005wt% or less of S, 0.005wt% or less of N, 0.02-0.04wt% of Alt, and the balance Fe and other inevitable impurities. The making method of the cold-rolled steel strip for high-drawing-performance flux-cored wire comprises the steps of steelmaking, continuous casting, hot rolling, reeling, cold rolling, annealing, and flattening. The making method reduces the contents of C, Si, P and S, improves the drawing performance of the cold-rolled steel strip for the flux-cored wire, and improves the performances of the heat affected zone of a wedding material; and the appropriate control of the Mn content guarantees the stability of the whole cold-rolled steel strip for the flux-cored wire, and the enough elasticity of the finally-made cold-rolled steel stripe.

Owner:JIGANG GRP

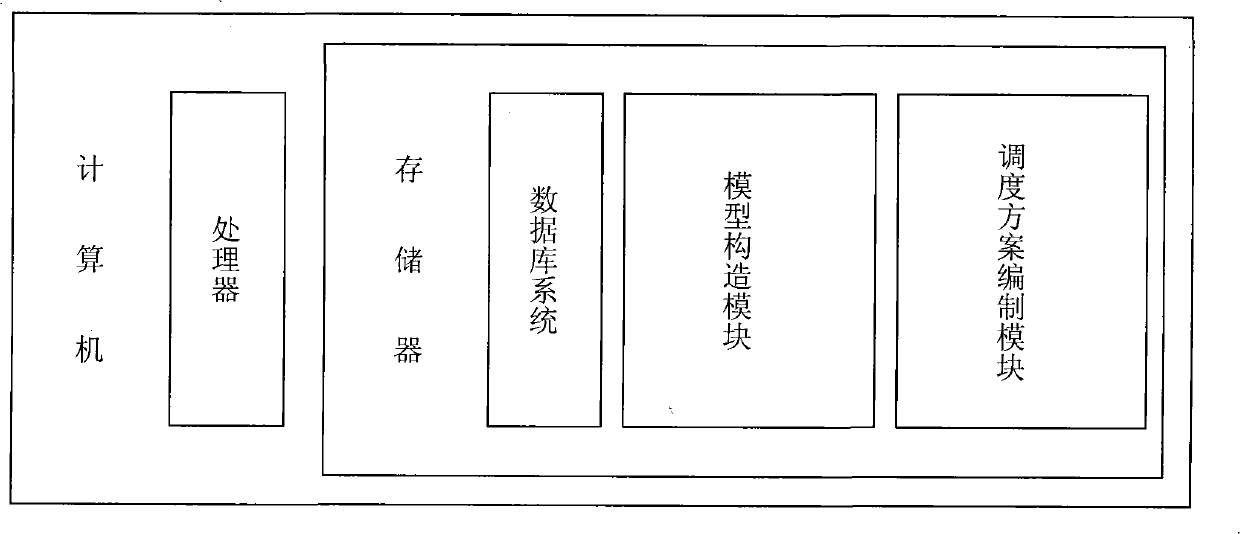

Steel-smelting continuous casting production scheduling method for taking molten steel residency time limit into account

The invention provides a method used for steelmaking continuous casting production scheduling, which considers the dwell time of molten steel; the invention belongs to information technology filed and relates to the application of the construction of mathematical model and the solution algorithm in schedule scheme compilation. The invention is characterized in that the method consists of a model construction module, a schedule scheme compilation module and a database system. During the model construction process, the constraint of the steelmaking continuous casting production process is considered, the dwell time of molten steel is considered especially, as normal punishment is given to the dwell time of the molten steel within the limit of the dwell time and more punishment is given to the part exceeding the limit, the waiting time of every heat is balanced, and the molten steel rhythm qualified rate is improved. The method of the invention solves the problem existing in the background technology, by adopting the single parent genetic algorithm a steelmaking continuous casting production plan which is better than any existing scheduling method can be obtained, the online adjusting times are reduced, the energy and material consumption is reduced, and the method can be applied to the steelmaking continuous casting production scheduling system in iron and steel enterprises.

Owner:苏志雄

Quick and thinning stamping processing new energy automobile battery shell steel and method for producing same

InactiveCN109136444AComposition is stableImprove cleanlinessJackets/cases materialsFurnace typesSteelmakingChemical composition

The invention discloses quick and thinning stamping processing new energy automobile battery shell steel and a method for producing the same. The quick and thinning stamping processing new energy automobile battery shell steel comprises chemical components including, by weight, 0.0030-0.0060% of C, 0.10-0.20% of Mn, less than or equal to 0.03% of Si, 0.050-0.090% of Als, 0.050-0.070% of Ti, less than or equal to 0.015% of P, less than or equal to 0.012% of S, less than or equal to 0.0040% of N, the balance Fe and inevitable impurities. The method includes steelmaking, continuous casting, hot rolling, reeling, cold rolling, continuous annealing and flattening working procedures. The quick and thinning stamping processing new energy automobile battery shell steel and the method have the advantages that the quick and thinning stamping processing new energy automobile battery shell steel produced by the aid of the method can adapt to quick stamping and thinning stamping processing requirements, and the problem of poor forming properties of low-carbon battery shell steel can be solved by the aid of the quick and thinning stamping processing new energy automobile battery shell steel andthe method; control points of technologies for producing the quick and thinning stamping processing new energy automobile battery shell steel are clear and definite, and the quick and thinning stamping processing new energy automobile battery shell steel and the method are good in implementation and low in production cost.

Owner:TANGSHAN IRON & STEEL GROUP +1

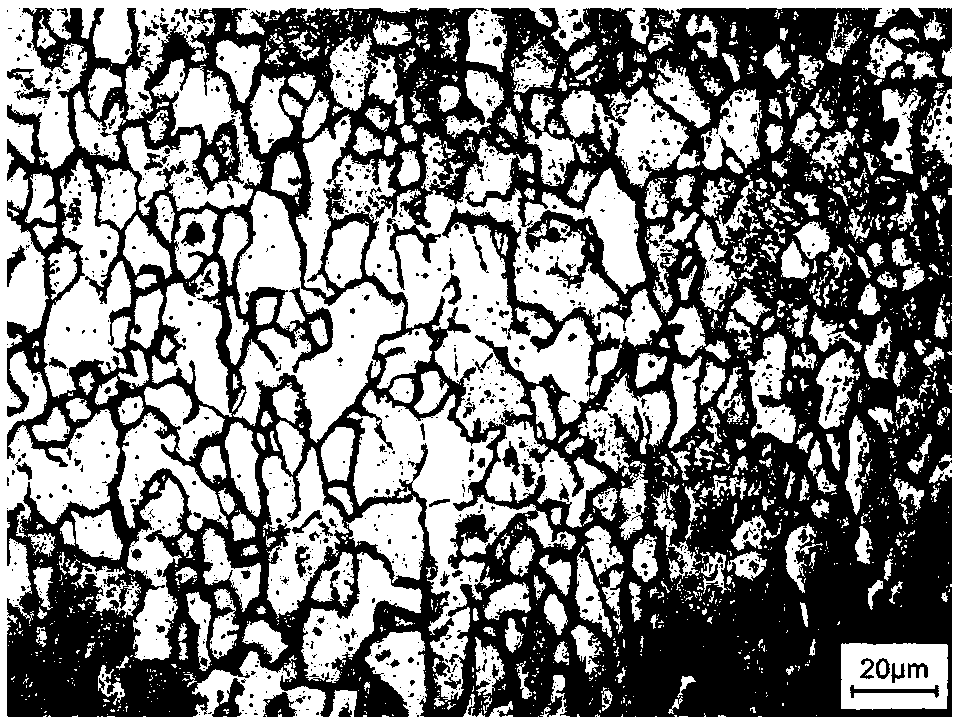

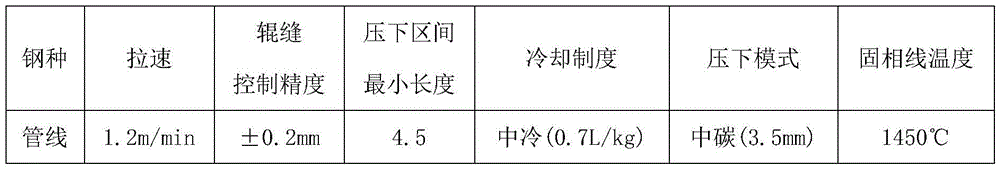

Control method for typical middle cracks and center segregation during pipeline steel slab continuous casting

ActiveCN105562642AGood compatibilityImproved Heat Tracking AccuracyMetallurgySteelmaking continuous casting

The invention belongs to the technical field of steelmaking continuous casting, and relates to a control method for typical middle cracks and center segregation during pipeline steel slab continuous casting. The control method comprises the steps that a roll gap of a casting machine is subjected to offline calibration and online detection, and it is guaranteed that precision is + / -0.2 mm; steel grade grouping is carried out, and matching of steel grades and thermophysical parameters is enhanced; the degree of superheat is strictly controlled, the proportion of equiaxed grains is increased, and developed columnar grains are avoided; a pulling rate and a secondary cooling process are adjusted, and basic roll gap control in the casting slab solidification process is optimized; and the soft press quantity is optimized, two or three segments of press are selected to the greatest extent according to the continuous casting process, and a large press quantity difference is avoided in press distribution between different sector segments. The control method has the beneficial effects that the internal quality of the casting slab is improved, and the product competitiveness is enhanced.

Owner:SHOUGANG CORPORATION

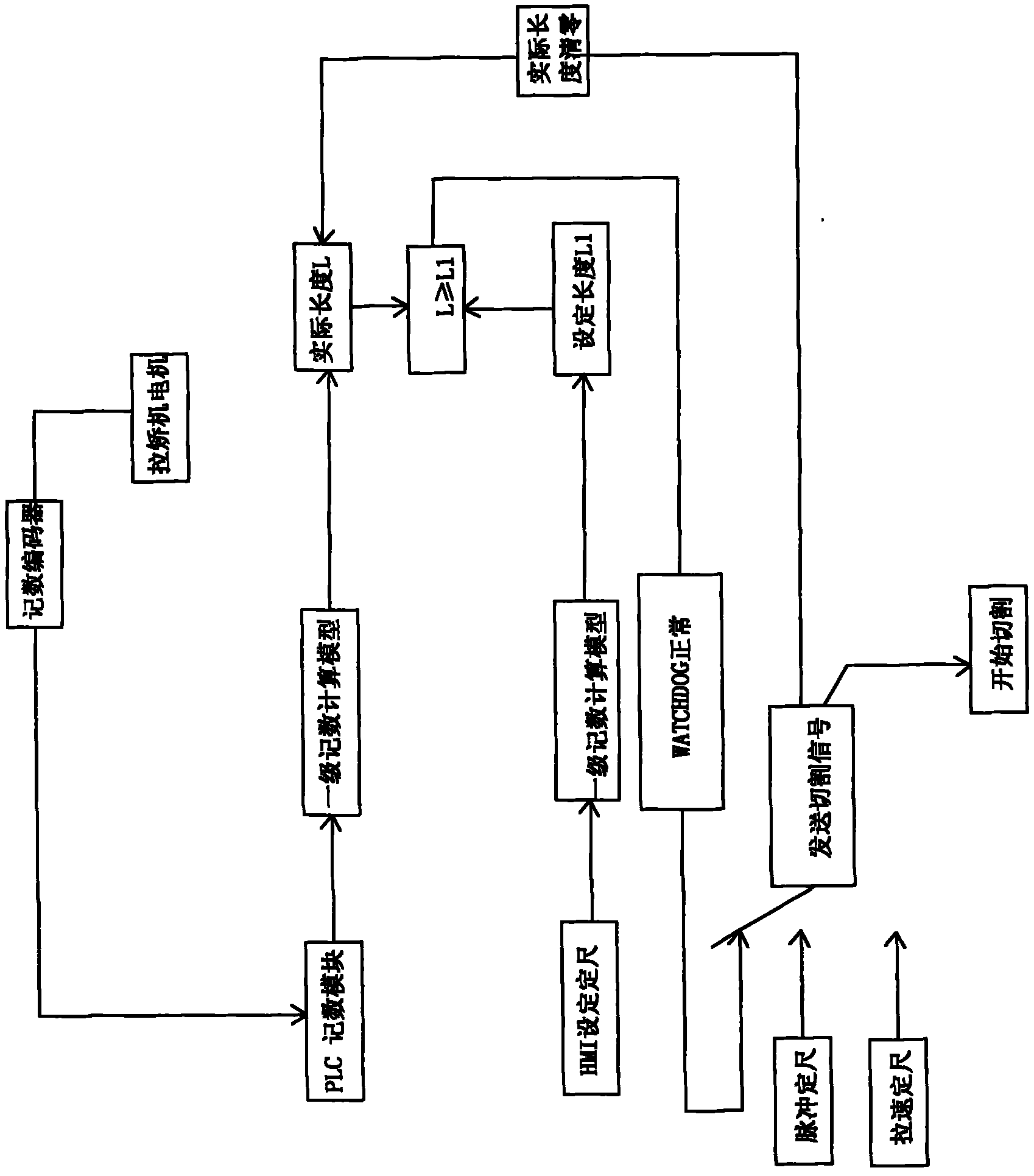

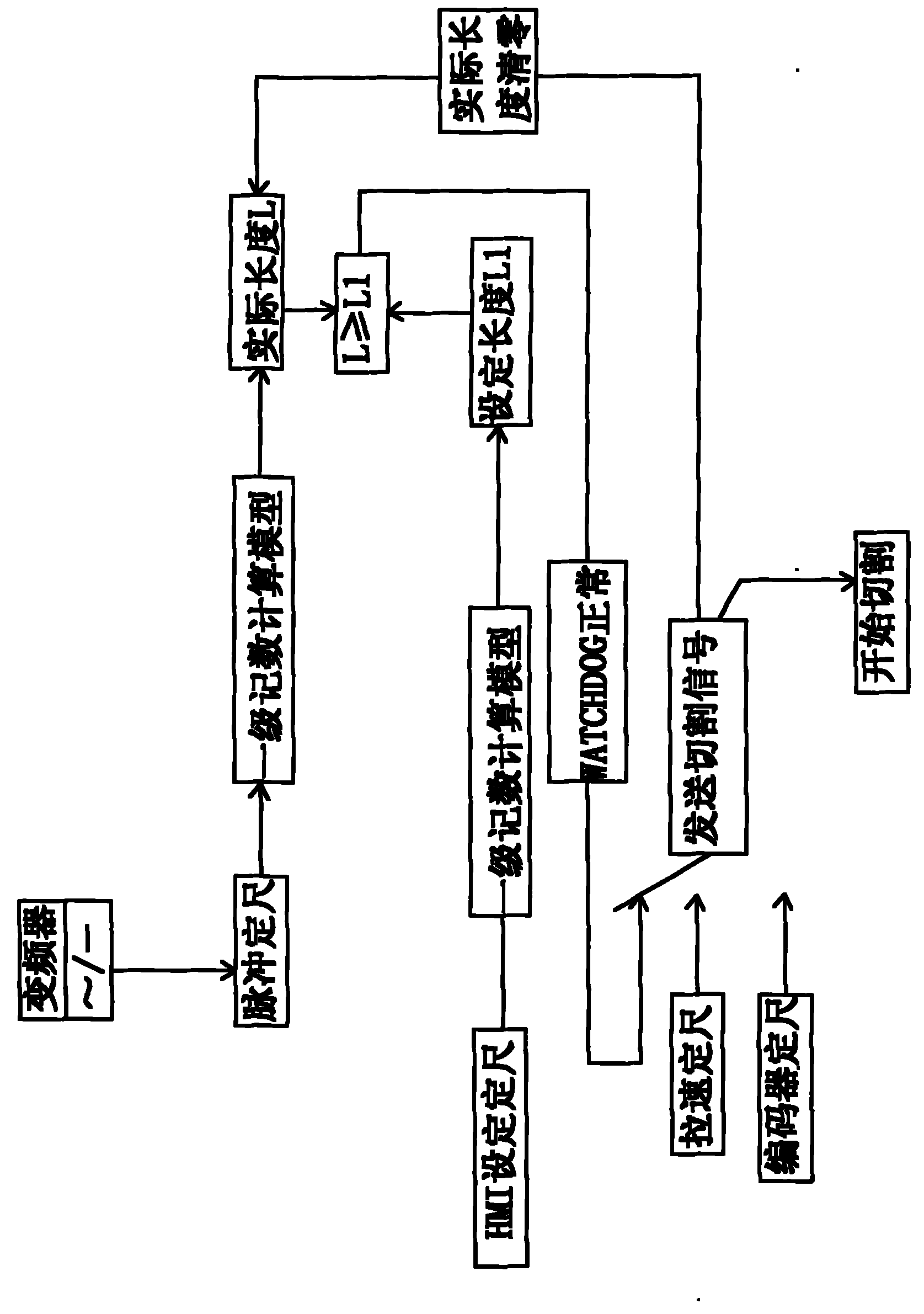

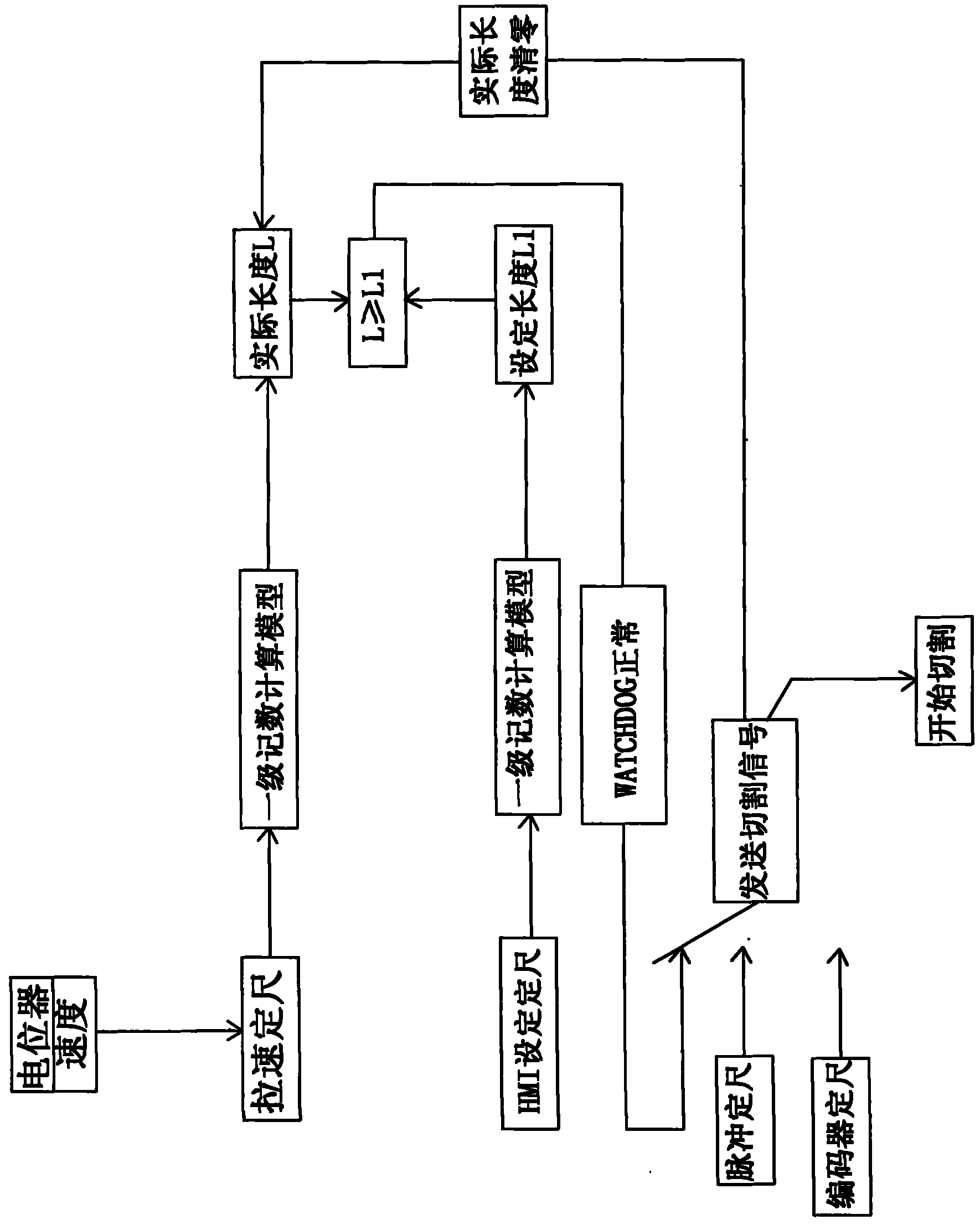

Steelmaking square billet encoding and sizing method

The invention relates to a method for accurately sizing a casting billet on a steelmaking continuous casting production line, in particular to a steelmaking square billet encoding and sizing method which comprises the following steps: mounting an increment rotary encoder on a roll of a withdrawal and straightening machine, establishing communication between an upper computer and a PLC by a network, and sending a cutting and sizing plan command from the upper computer to the PLC; when the PLC receives the signal, carrying out data trace calculation and comparison on the accumulated calculation length for sizing of the increment rotary encoder, the radian track of a dummy bar in accordance with a continuous casting process and the planed length of the upper computer; when the casting machine starts casting until stripping is finished, storing the current radian trace data of the dummy bar; and when the accumulated length of the encoder is greater than or equal to the planed length, the PLC sending a screwdown cutting command signal to a cutting vehicle, and simultaneously setting the accumulated length of the encoder to zero to carry out the next trace calculation of the sizing length. By using the withdrawal and straightening roll as a measuring roll, the invention realizes that the encoder can carry out trace calculation and measurement on the sizing data of the casting billet, thereby achieving the advantages of cost saving and accurate measurement.

Owner:TANGSHAN GUOFENG IRON & STEEL

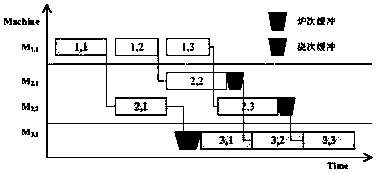

Graph-model-based uncertain steelmaking-continuous casting flexibility optimization scheduling method and system

ActiveCN108376315AImprove evaluation efficiencyExtended waiting timeDesign optimisation/simulationResourcesAlgorithmOptimal computing budget allocation

The invention discloses a graph-model-based uncertain steelmaking-continuous casting flexibility optimization scheduling method and system. The method comprises: a flexibility scheduling model is constructed, a flexibility decision-making mode of a scheduling solution is described by using a graph model according to features of a steelmaking-continuous casting production process, and time buffer is set to protect the performance index and feasibility of the scheduling solution under an uncertain condition; optimized solution solving based on a distribution estimation algorithm is carried out,and an association relationship between decision-making variables is described by using a procedure-association-based probability model to generate a high-quality new population, and an expectation performance of the flexibility scheduling solution is evaluated by using a stochastic simulation method. During the simulation process, the limited computing resources are allocated dynamically based onthe optimal computational allocation technique, so that the evaluation efficiency of the population is improved. Therefore, optimization of the waiting time of the steelmaking-continuous casting scheduling process and the expected value of the discontinuous casting ratio in the uncertain environment is realized.

Owner:CHONGQING UNIV

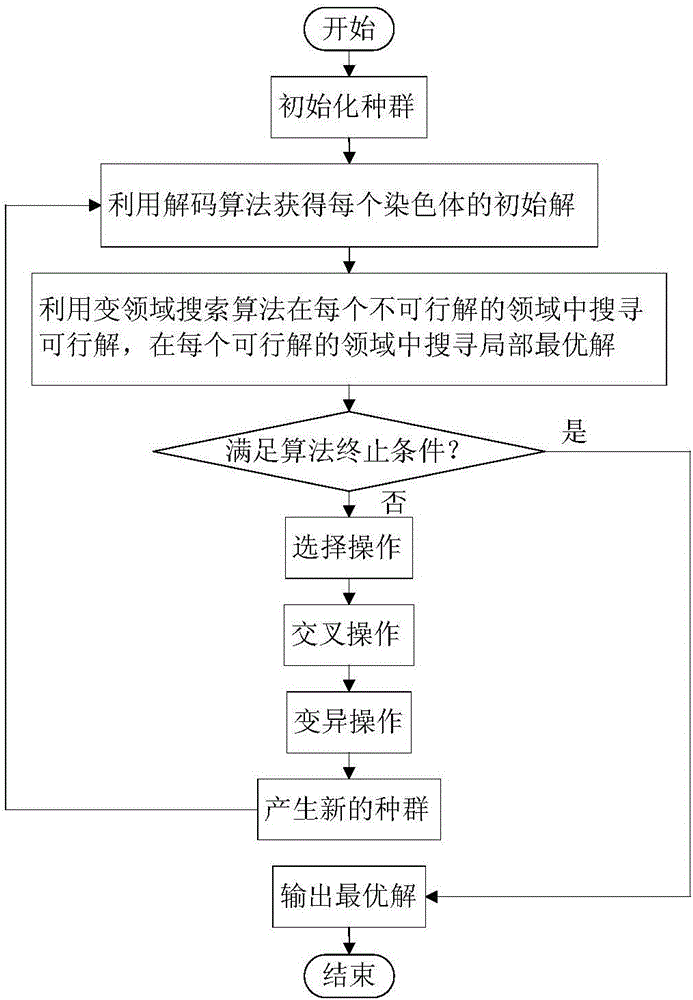

Steelmaking-continuous casting rescheduling method for solving continuous casting machine fault

ActiveCN106611221AIncrease flexibilityImprove rationalityResourcesGenetic algorithmsSteelmaking continuous castingDevice failure

The continuous casting machine fault problem involves the casting characteristics of casting times, so that the conventional rescheduling method of steelmaking-continuous casting production for processing equipment faults is difficult to apply. The invention provides a steelmaking-continuous casting rescheduling method for solving a continuous casting machine fault, specifically comprising the steps of: establishing a rescheduling optimization model according to the difference of rescheduling strategies of different heat processes treatment after the continuous casting machine fault on the rescheduling process; and designing a new hybrid algorithm having the advantages of global searching ability of a comprehensive genetic algorithm and local searching ability of a variable neighborhood searching algorithm to perform iterative optimization of an optimal solution. The algorithm has the main characteristics: initial solutions of chromosomes are quickly obtained by using a decoding heuristic algorithm on the premise of complex constraint at the slack; and the quality of each initial solution is improved by using the variable neighborhood searching algorithm before population crossover mutation, wherein different neighborhood structures are designed for non-feasible solutions and feasible solutions. The method can effectively solve the rescheduling problem under the continuous casting machine fault.

Owner:CHONGQING UNIV

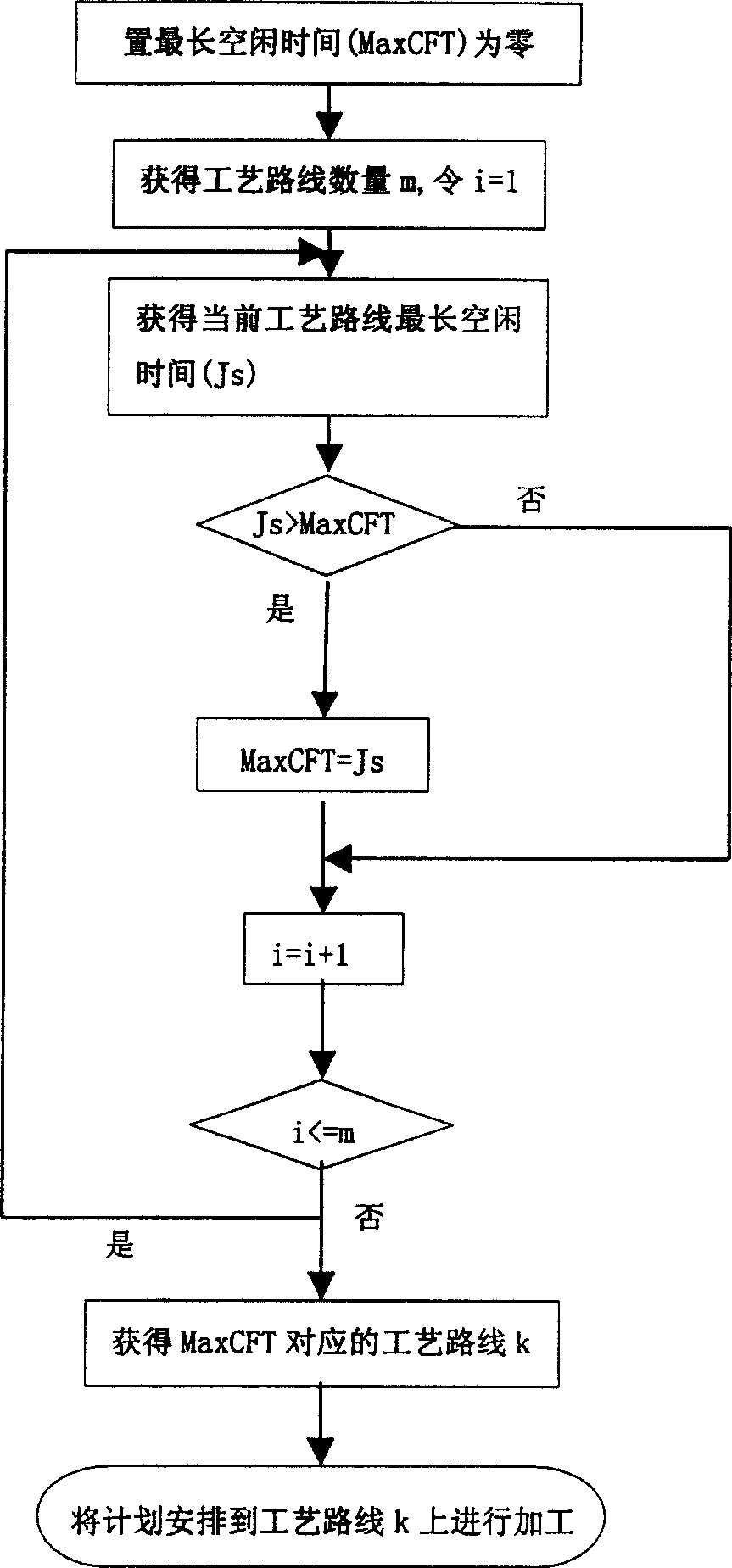

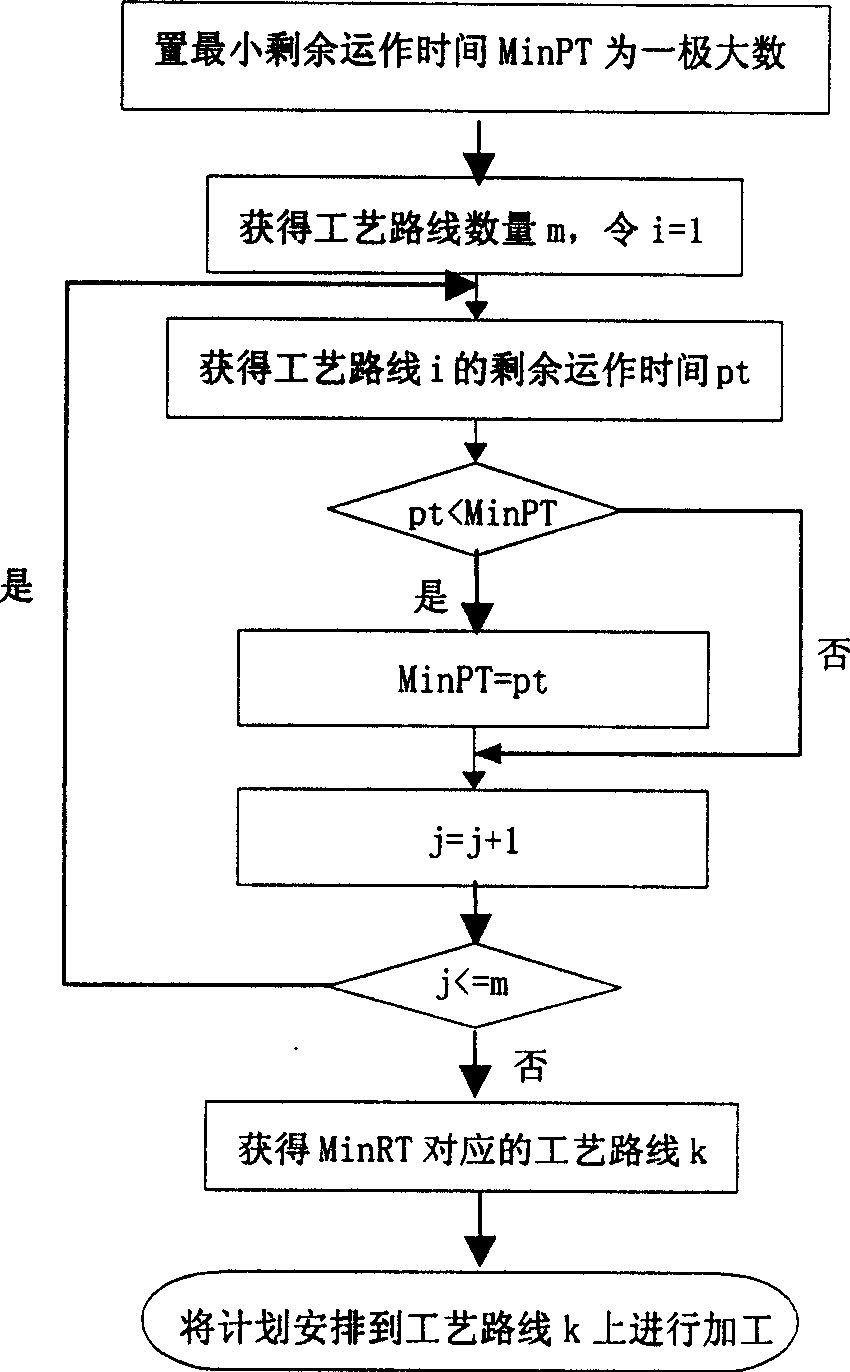

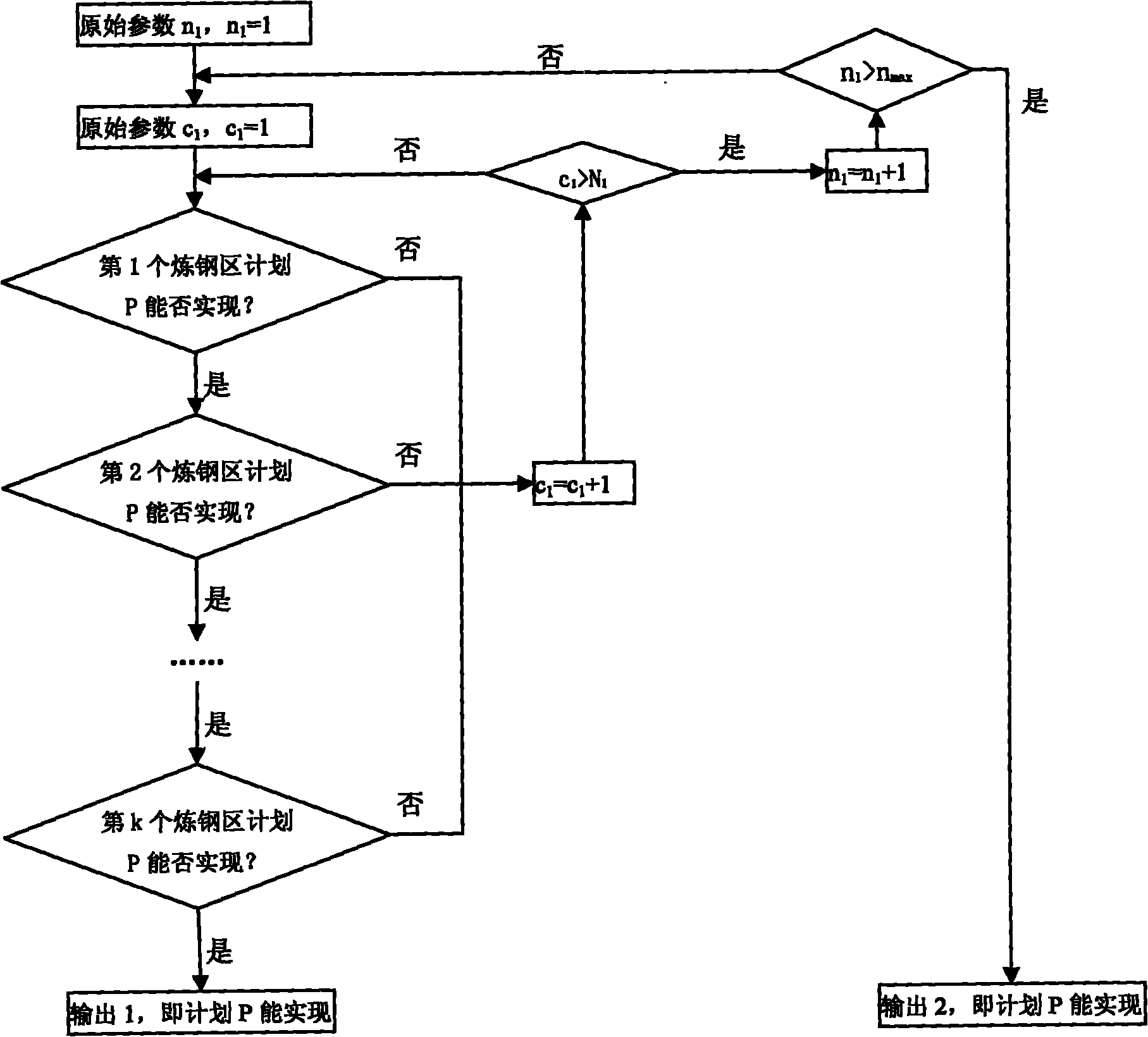

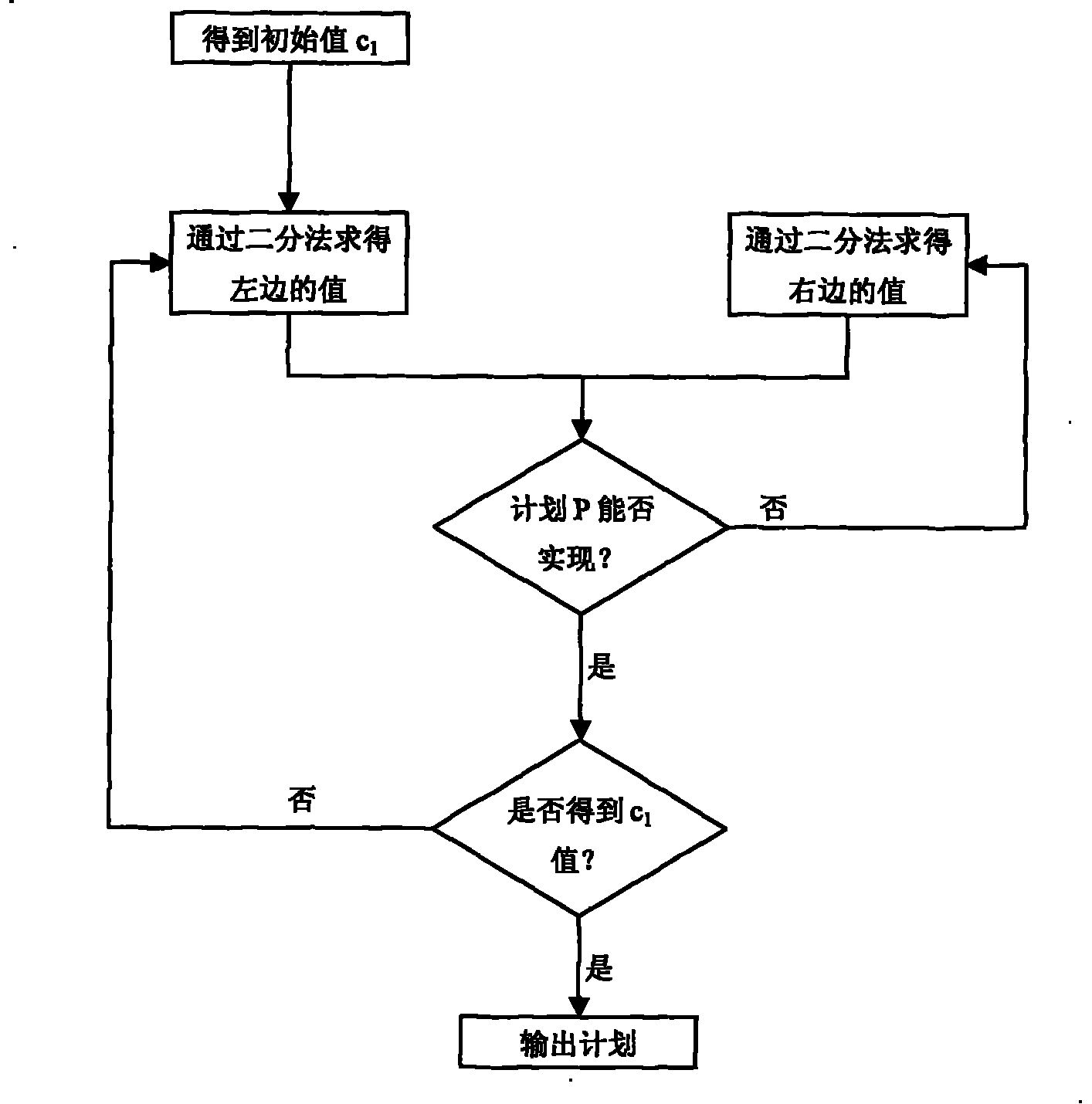

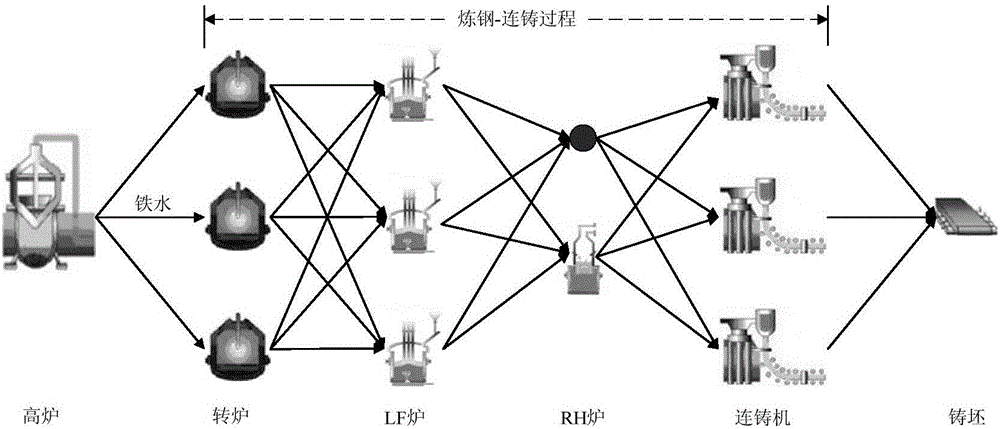

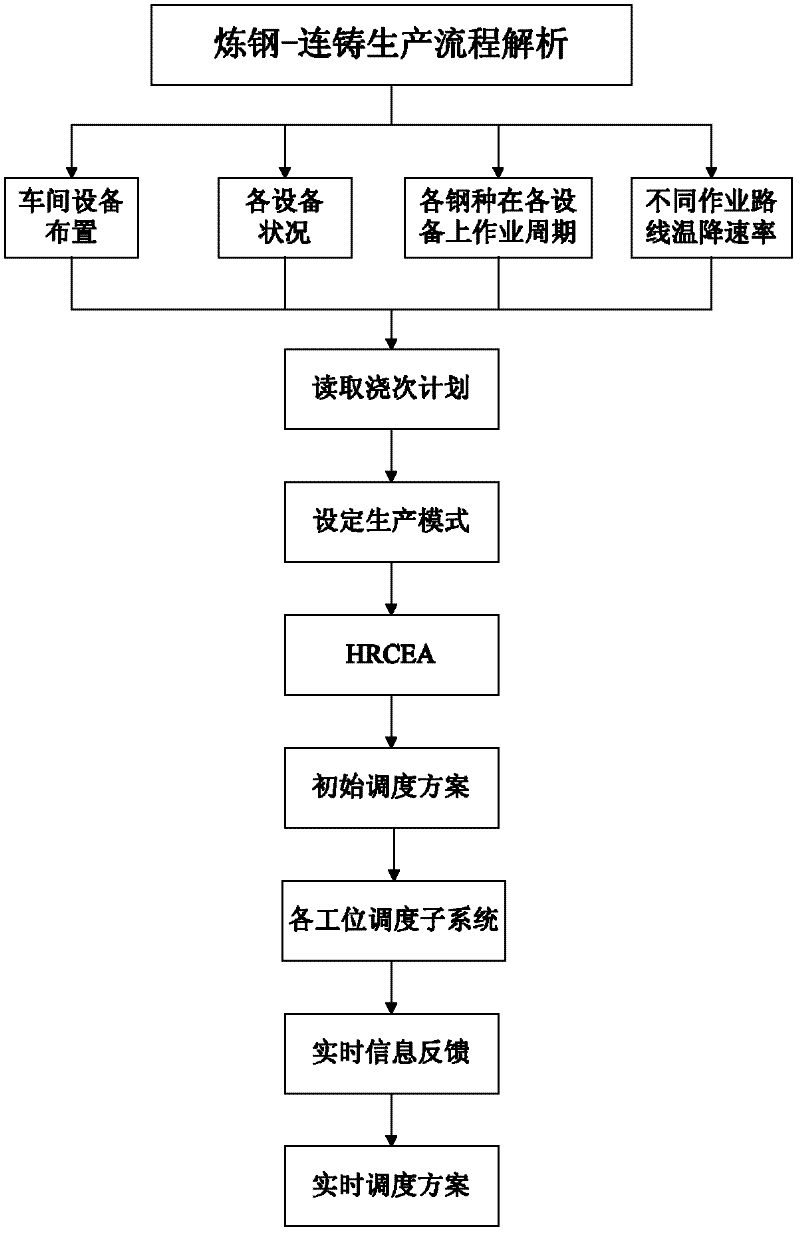

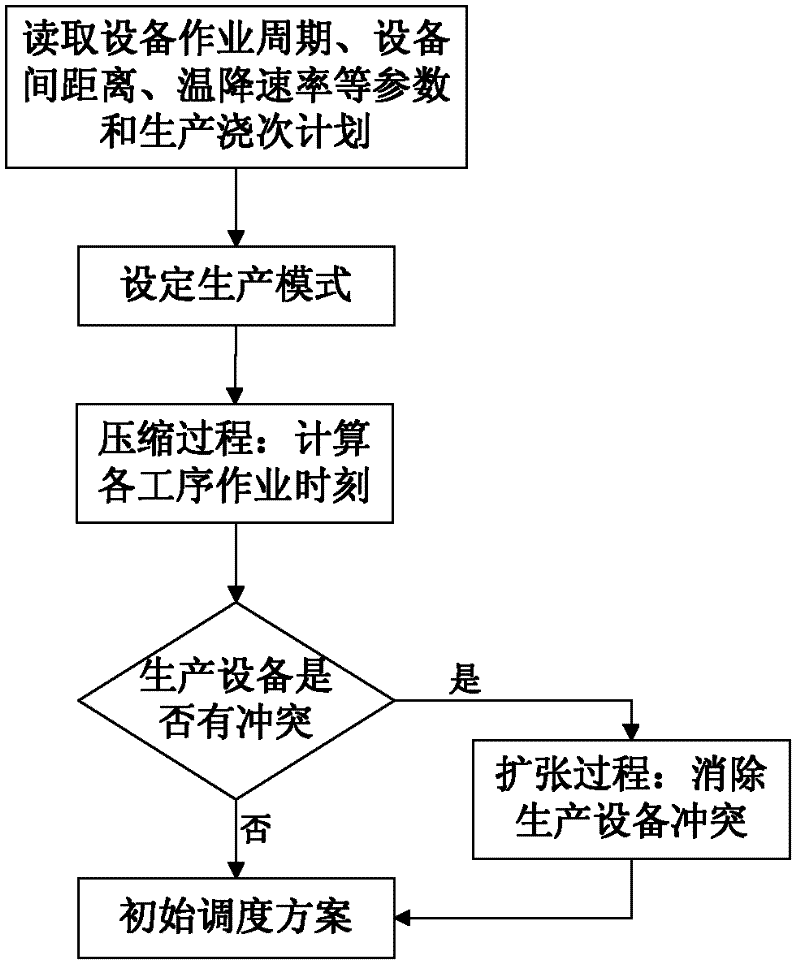

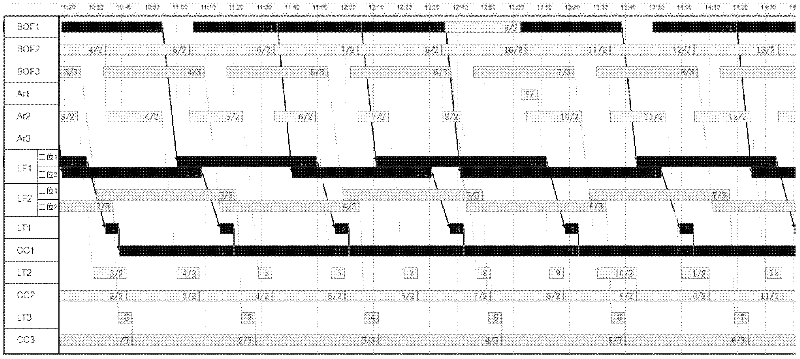

HRCEA (hybrid of rules and compression-extensive algorithm)-based steel making-continuous casting production scheduling method for special steel mill

InactiveCN102419581ASmall amount of calculationImprove efficiencyTotal factory controlProgramme total factory controlReal-time dataSteel mill

The invention provides a HRCEA (hybrid of rules and compression-extensive algorithm)-based steel making-continuous casting production scheduling method for a special steel mill. In the scheduling method, model and algorithm parameters are obtained by analyzing a steel making-continuous casting production flow; according to a known production casting times plan, an initial production scheduling plan is worked out by adopting the HRCEA; and all subsequent furnace working plans are adjusted by using the HRCEA according to an established scheduling rule and fed-back real-time data so as to realize dynamic scheduling. According to the HRCEA-based steel making-continuous casting production scheduling method disclosed by the invention, with the aims of reasonably quickening production rhythms and shortening production process time, equipment conditions of the steel mill, produced steel grades and temperature requirements of the produced steel grades are considered; an executable production scheduling plan can be quickly worked out, thus schedulers are facilitated on adjusting the scheduling plan in real time; and the production scheduling of the steel making-continuous casting process is optimized.

Owner:UNIV OF SCI & TECH BEIJING

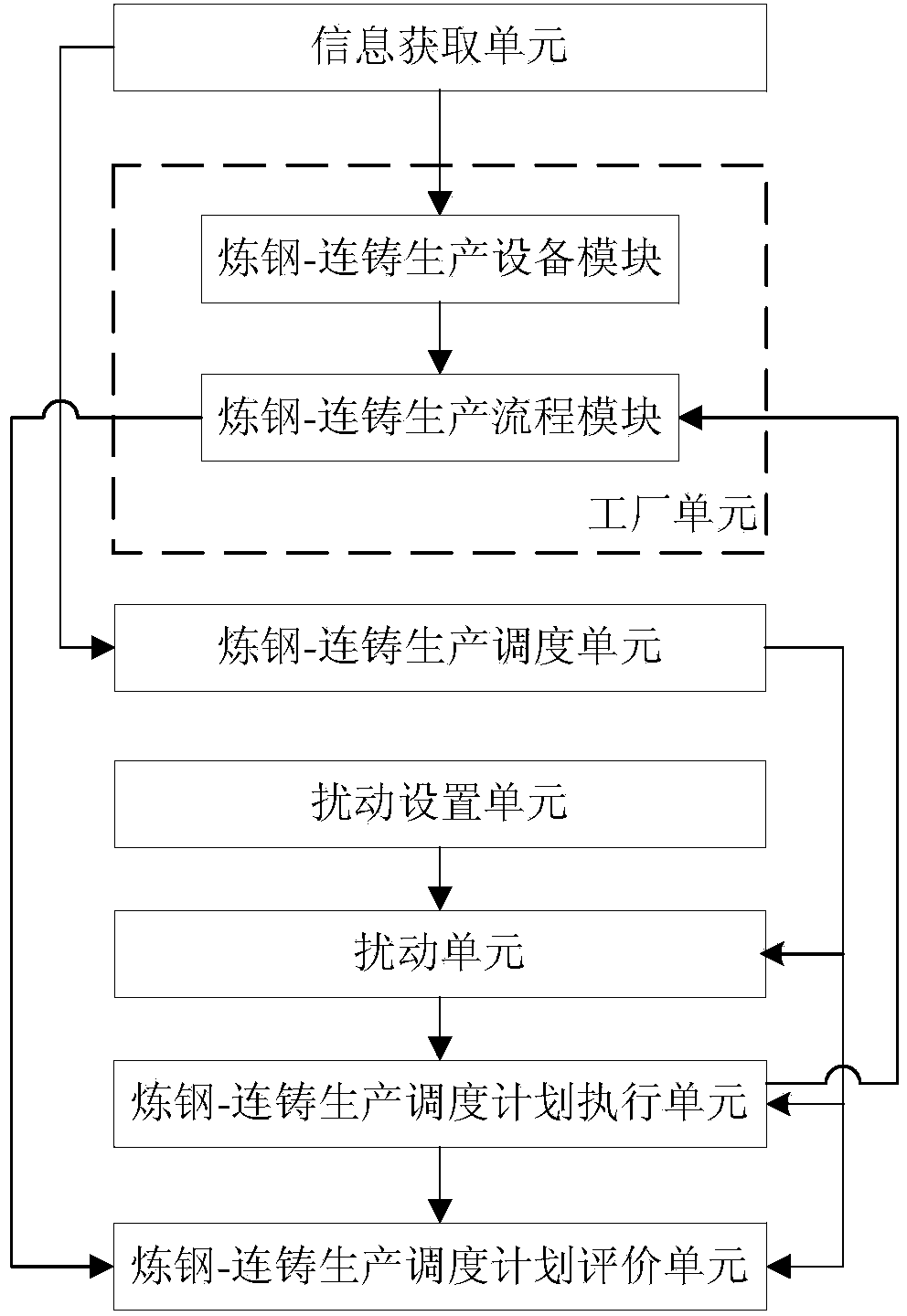

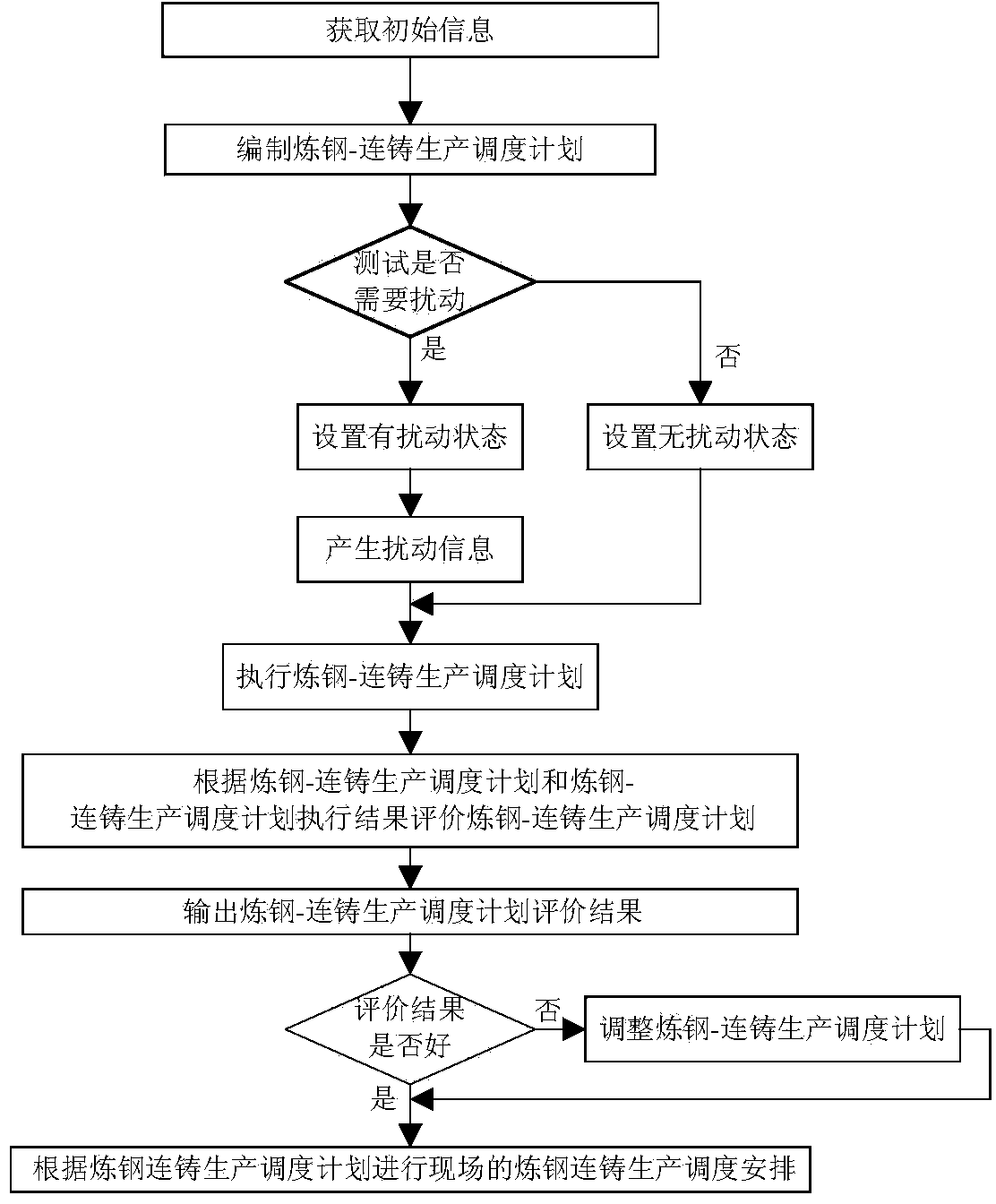

Scheduling system and method for steel making and continuous casting production

InactiveCN103996146AImprove adaptabilityImprove effectivenessData processing applicationsManufacturing computing systemsEvaluation resultProcess engineering

Provided is a scheduling system and method for steel making and continuous casting production. The system comprises an information obtaining unit, a factory unit, a scheduling unit of steel making and continuous casting production, a disturbance setting unit, a disturbance unit, a scheduling plan execution unit of steel making and continuous casting production and a scheduling plan evaluation unit of steel making and continuous casting production. The method comprises the steps of 1) obtaining initial information; 2) planning a scheduling plan of steel making and continuous casting production; 3) setting a disturbance state; 4) determining whether disturbance information is generated, if yes, generating the disturbance information, and if no, not generating the disturbance information; 5) executing the scheduling plan of steel making and continuous casting production; 6) evaluating the scheduling plan of steel making and continuous casting production; 7) outputting an evaluation result of the scheduling plan; and 8) carrying out scheduling of steel making and continuous casting production onsite. The scheduling system and method can improve the adaptability of the scheduling plan in practical production and enhance of the effectiveness of the scheduling plan in guiding practical production.

Owner:NORTHEASTERN UNIV

Cold-rolling steel belt for flux-cored wire and manufacture method thereof

The invention discloses a cold-rolling steel belt for a flux-cored wire and a manufacture method thereof. The manufacture method for the cold-rolling steel belt for a flux-cored wire successively comprises: steelmaking, continuous casting, hot rolling, coiling, cold rolling and annealing, wherein in the step of hot rolling, the rough rolling temperature is 1120-1160 DEG C, the finish rolling temperature is 1030-1060 DEG C, and the final rolling temperature is 920-960 DEG C; in the step of low-temperature coiling performed after the step of hot rolling, the coiling temperature is 500-520 DEG C; and in the step of annealing, the annealing temperature is 700-740 DEG C, and the holding time is more than 10 hours. The method provided by the invention can be used for manufacturing the cold-rolling steel belt for a flux-cored wire, which has low yield ratio, high elongation rate, simple production technology, stable performance and low production cost.

Owner:SHANDONG IRON & STEEL CO LTD

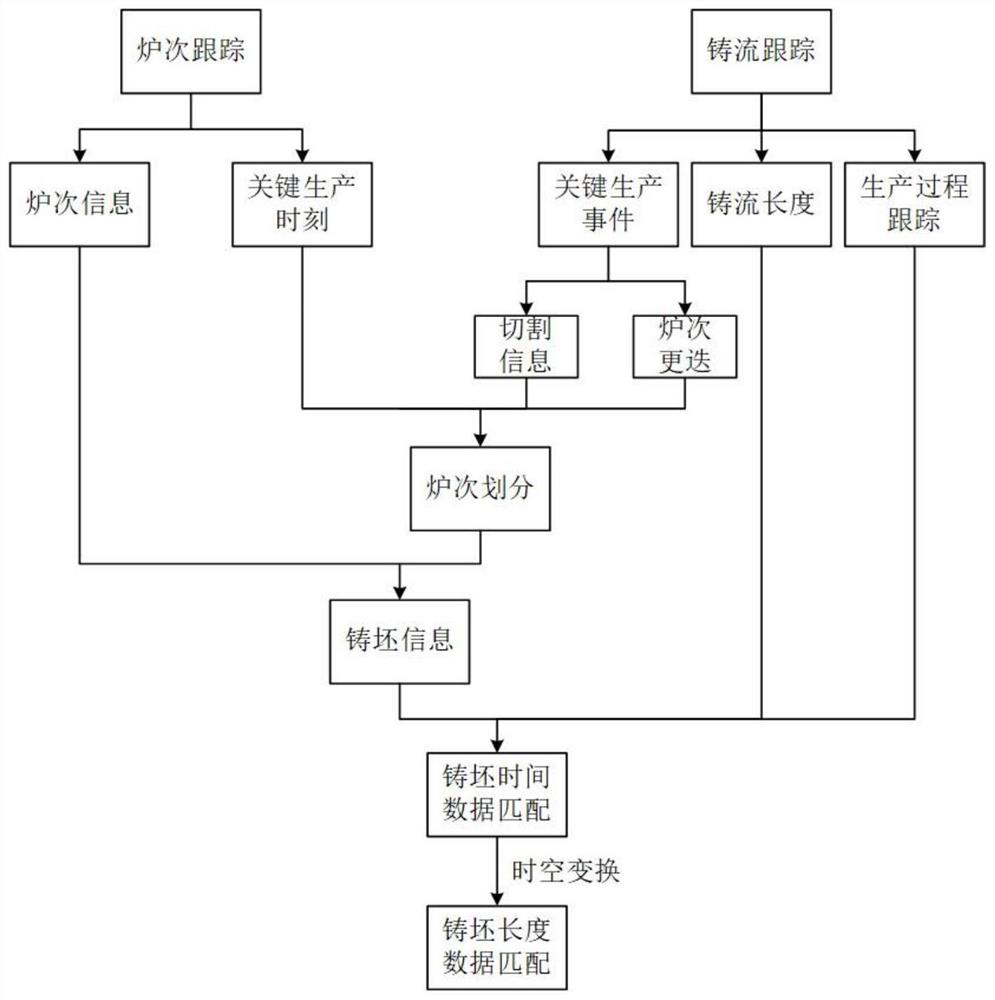

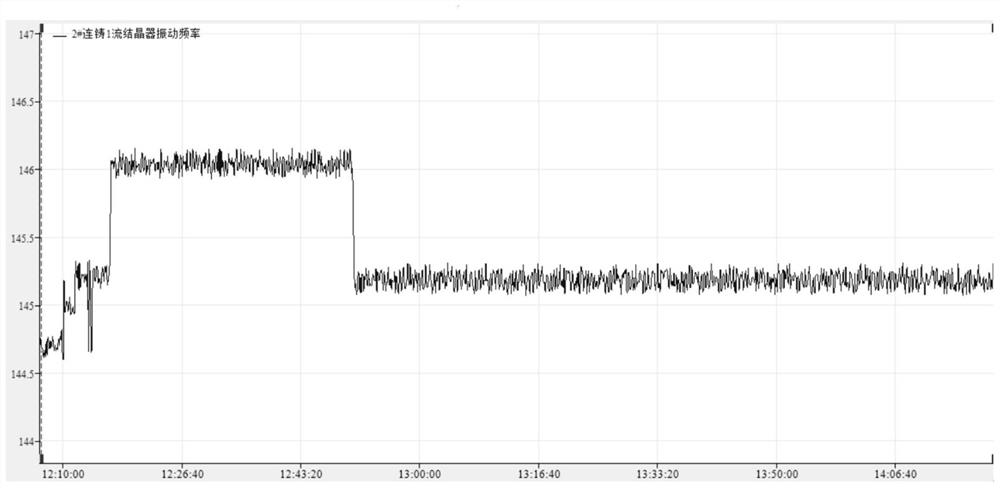

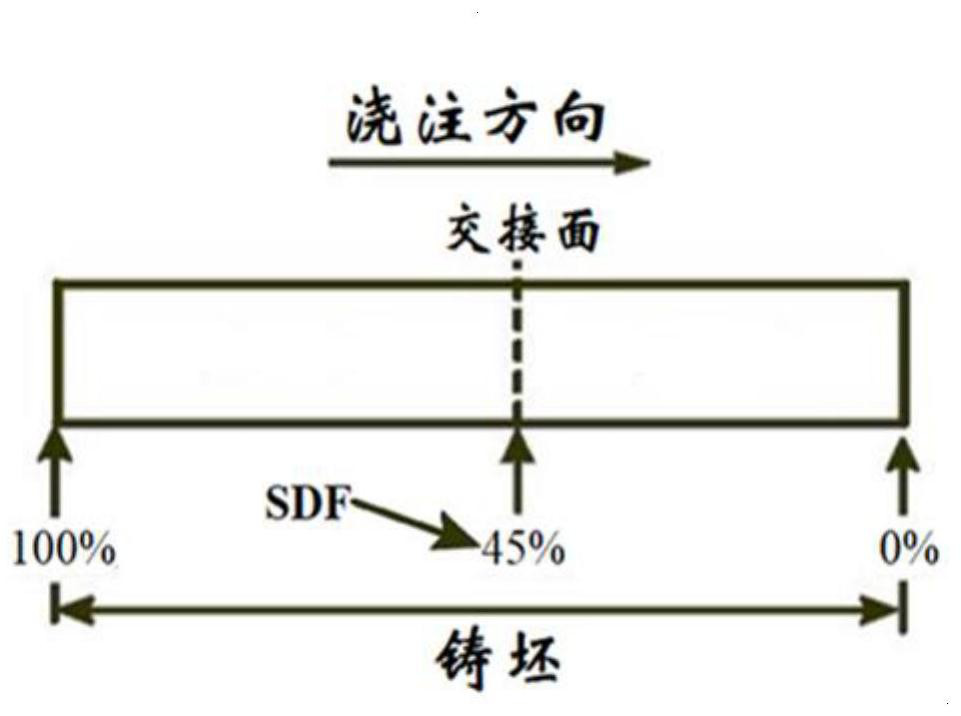

Continuous casting data space-time matching method based on heat tracking and casting flow tracking

ActiveCN112417217AQuick matchExact matchOther databases indexingResourcesTime transformationData space

The invention provides a continuous casting data space-time matching method based on heat tracking and casting flow tracking, and belongs to the technical field of steelmaking continuous casting. Themethod comprises the following steps: recording furnace number, casting flow production process data, key production time and key production events in real time, calculating the casting flow length inreal time through encoding, performing furnace number division on a just cut casting blank by utilizing the casting flow length, cutting information and the like, endowing the casting blank with furnace number information and casting blank number information, calculating a time window of the casting blank in each continuous casting device according to the casting flow length, matching the production process data of the time window with the time direction of the casting blank, and finally carrying out space-time transformation to finish the matching of the production process data with the length direction of the casting blank. According to the method, matching of the continuous casting production process and the casting blank can be rapidly and accurately completed, and data support is provided for continuous casting blank quality prediction and continuous casting production optimization control.

Owner:UNIV OF SCI & TECH BEIJING

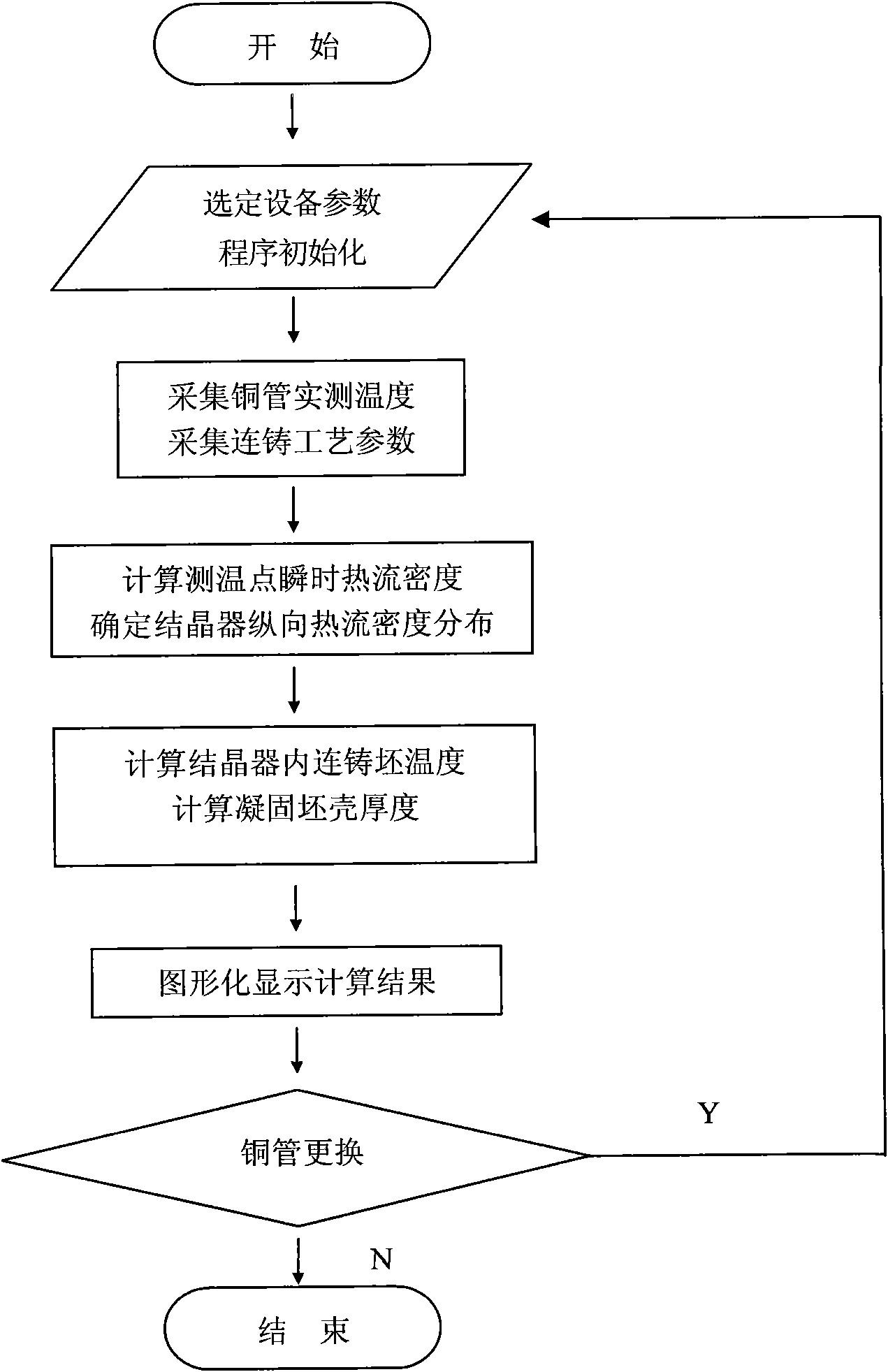

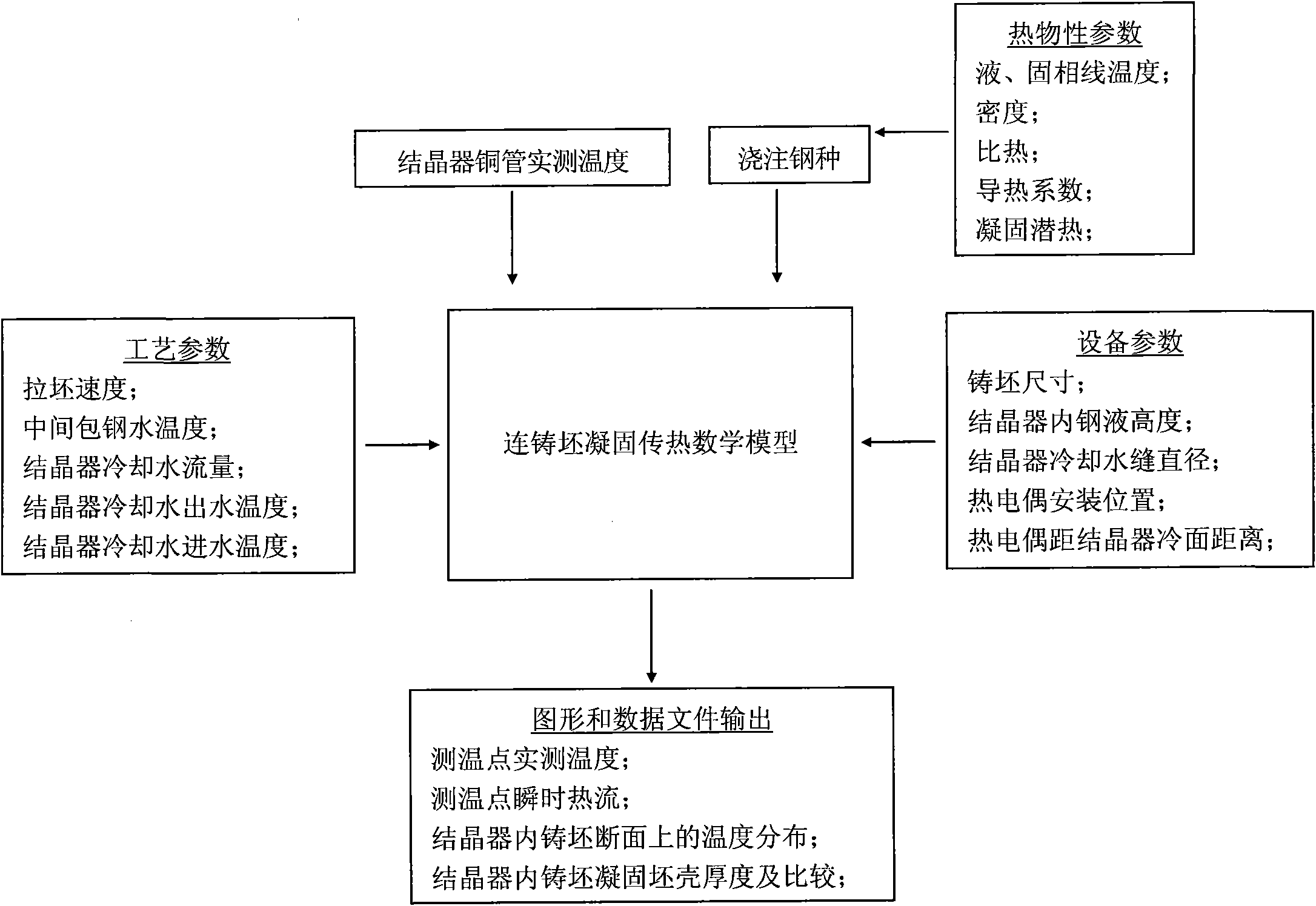

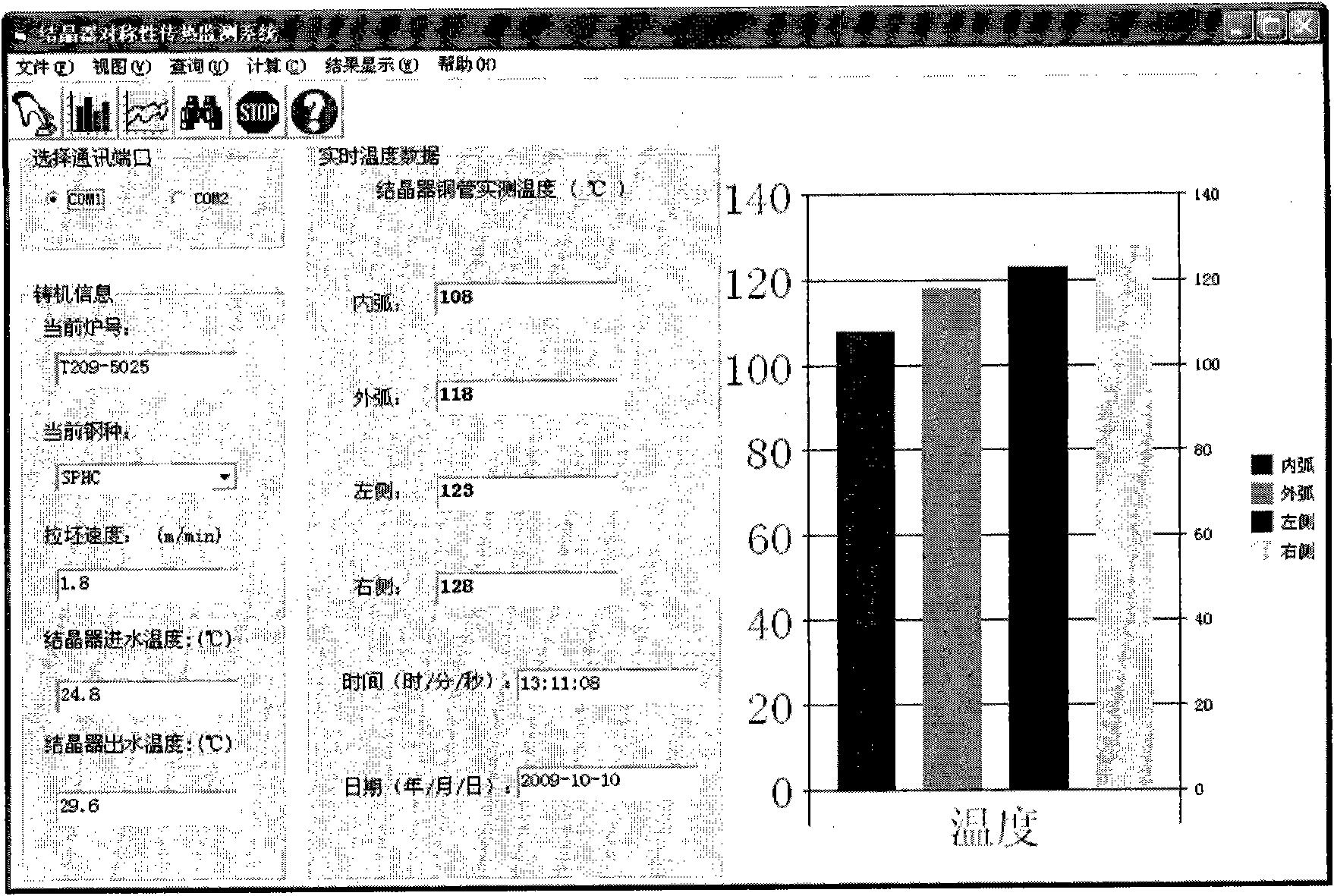

On-line thermal monitoring system of heat transfer symmetry of crystallizer copper pipe and method thereof

InactiveCN101879583ACalculate Heat FluxSimple structural designMaterial heat developmentThermal monitoringProcess optimization

The invention belongs to the technical field of steelmaking continuous casting, and relates to an on-line thermal monitoring system of heat transfer symmetry of a crystallizer copper pipe on a continuous casting machine. The system comprises the crystallizer copper pipe which can monitor the heat transfer symmetry, a temperature data collection and storage module and an industrial control computer. The on-line thermal monitoring system is characterized in that a plurality of temperature measuring elements are embedded at the back of the copper pipe, and the temperature measuring elements are distributed in a 'cross' shape and in a symmetrical form based on the central section of the copper pipe. The invention comprehensively utilizes on-site actual measuring data and a computer numerical simulation technology, researches the heat transfer symmetry of a crystallizer by monitoring the surface temperature of the copper pipe, determines longitudinal distribution of heat flow of the crystallizer according to the transient heat flow calculated by the temperature of the copper pipe, calculates the temperature field of a continuous casting billet and the shell thickness of a solidification billet through a heat transfer mathematical model, and finally compares the situation of symmetrical surfaces. The invention can provide a basis for structural design of the crystallizer copper pipe and production process optimization of the crystallizer so as to promote the continuous casting billet to uniformly grow in the crystallizer.

Owner:UNIV OF SCI & TECH BEIJING

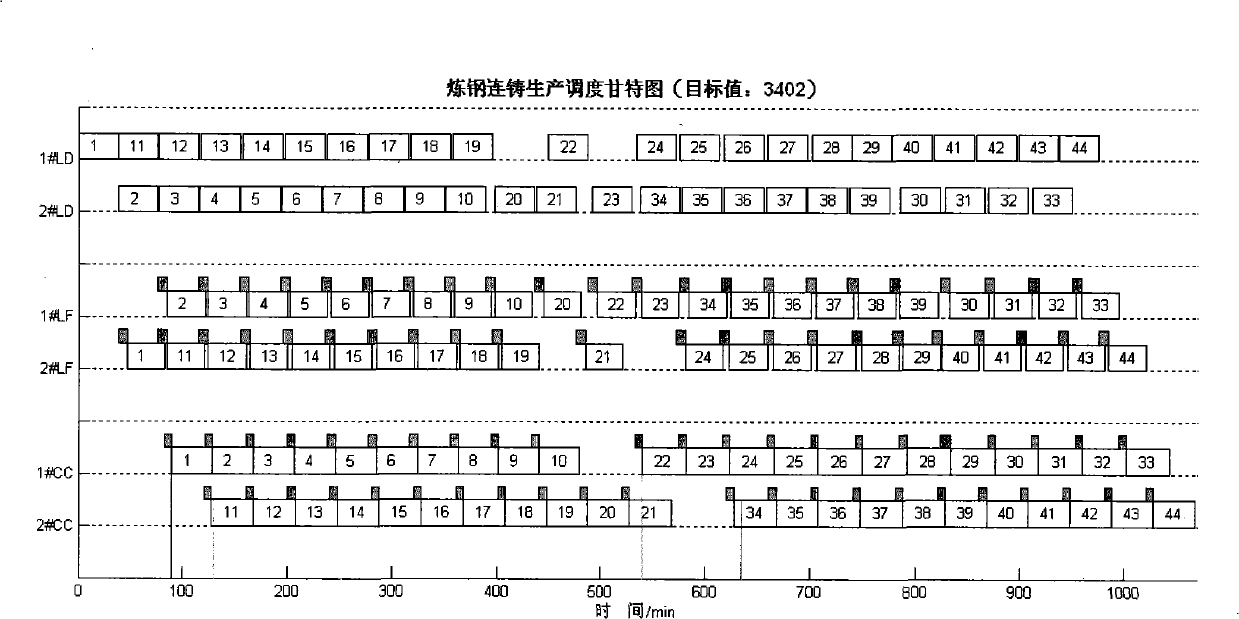

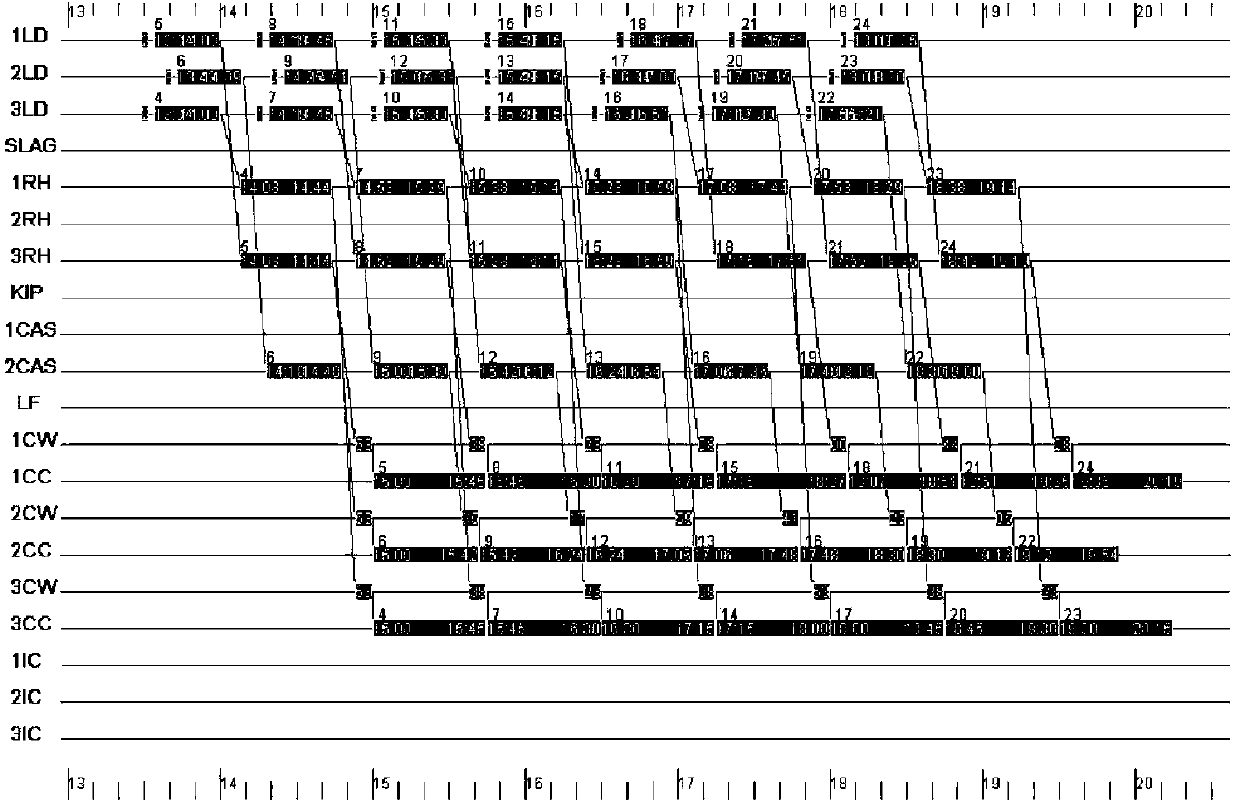

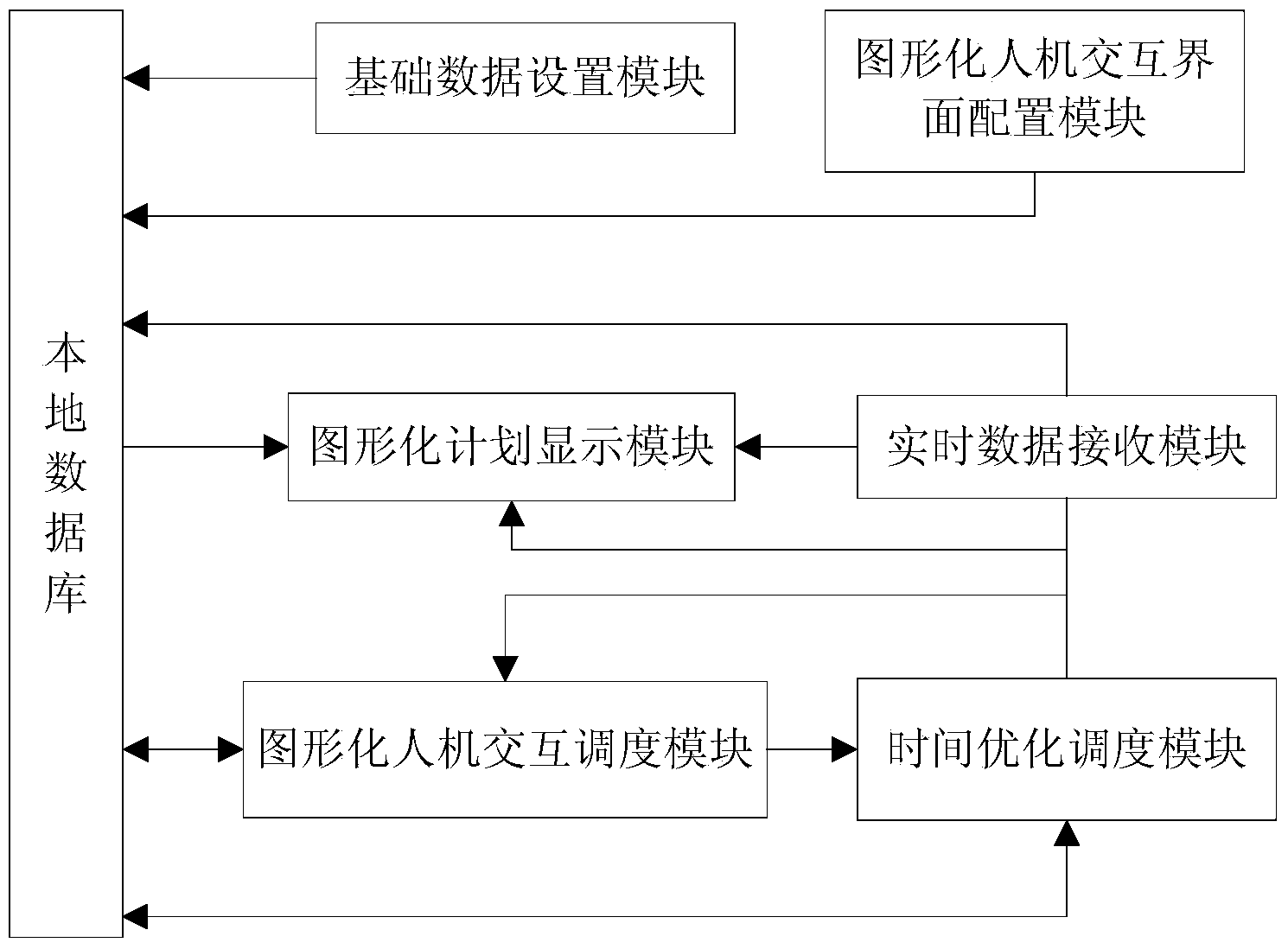

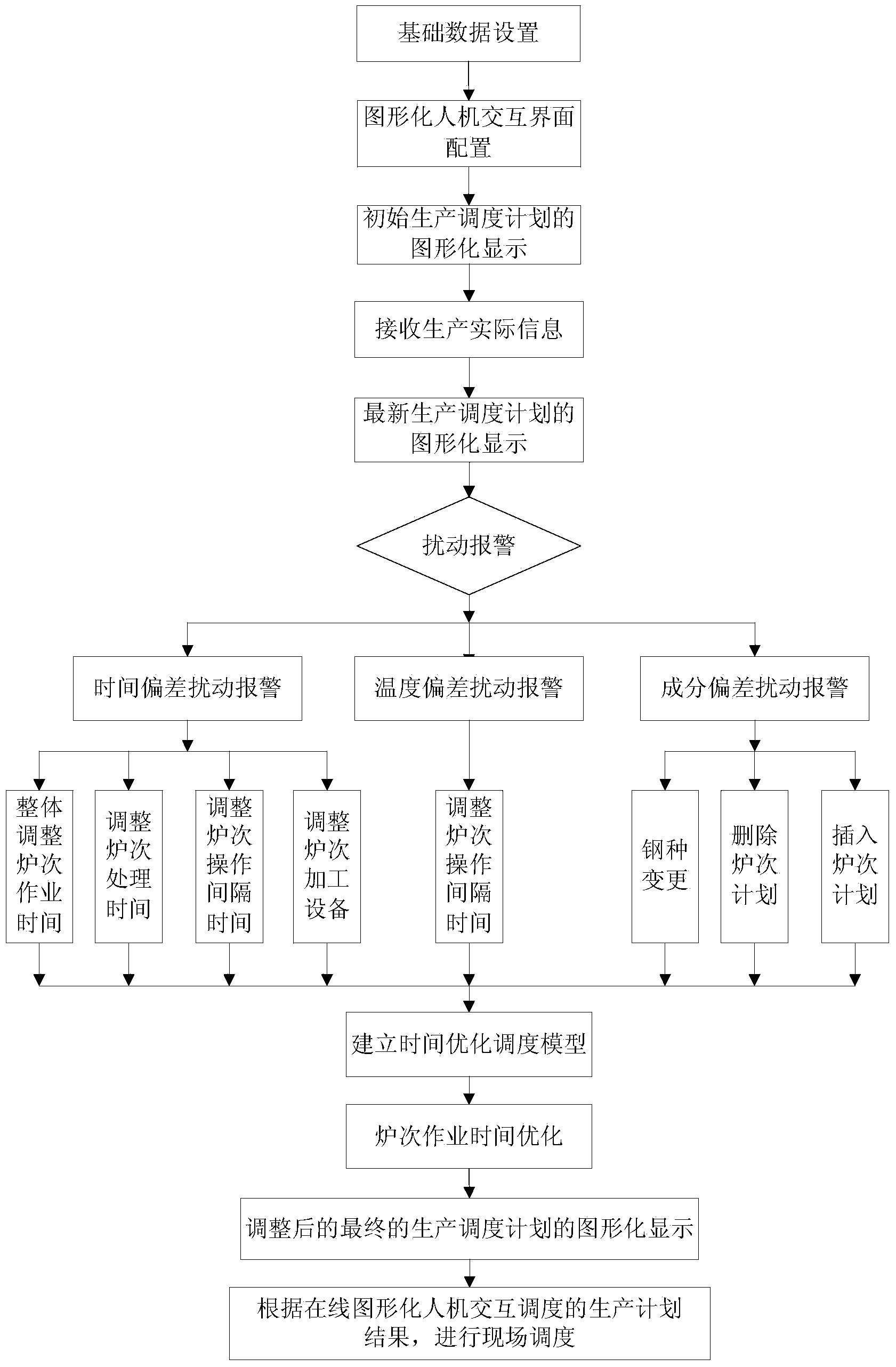

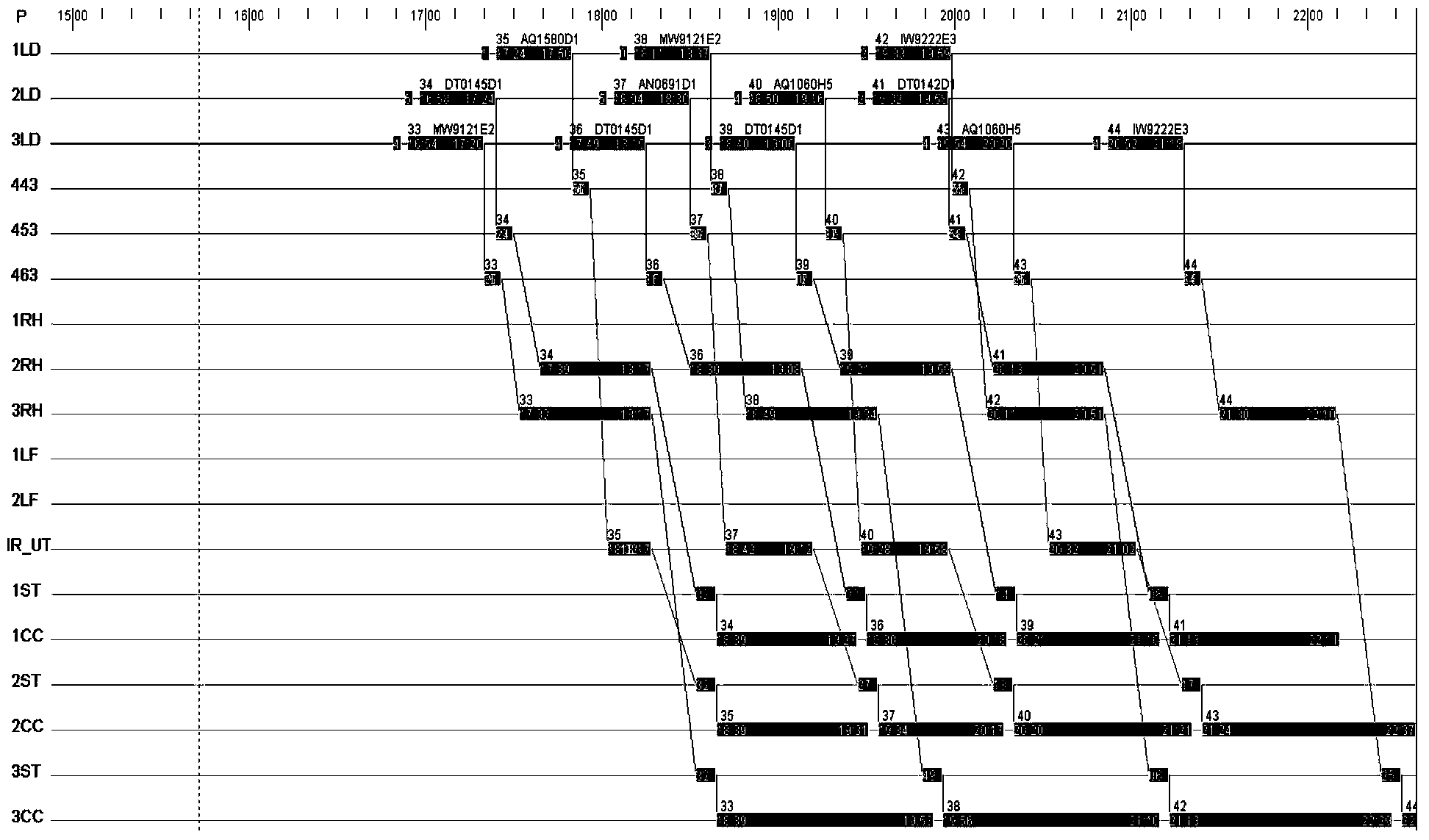

Online imaging man-machine interaction scheduling method for steel making and continuous casting production process

InactiveCN103646098AImprove optimization effectSpeed up dynamic schedulingSpecial data processing applicationsInput/output processes for data processingTime deviationGantt chart

The invention provides an online imaging man-machine interaction scheduling method for a steel making and continuous casting production process, and relates to the technical field of steel making and continuous casting. The method comprises steps as follows: initial steel making and continuous casting production scheduling plan data are acquired and displayed on a two-dimensional Gantt chart; actual production information of the steel making and continuous casting production process is acquired, and the disturbance condition is judged according to the actual production information of the steel making and continuous casting production process; and the initial steel making and continuous casting production scheduling plan data are adjusted according to time deviation disturbance, temperature deviation disturbance and ingredient deviation disturbance information, displayed in a two-dimensional Gantt chart manner and issued to a site for guiding production. In order to solve the problems that the plan adjustment speed is slow and the plan adjustment optimization degree is low due to the fact that the plan adjustment is manually entered by a scheduling worker of a steel making and continuous casting production scheduling system, an imaging man-machine interaction adjustment method based on the two-dimensional Gantt chart and online optimization of a time optimization scheduling model are combined, so that the online adjustment function of a scheduling plan is enhanced, and the scheduling plan optimization effect is improved.

Owner:NORTHEASTERN UNIV

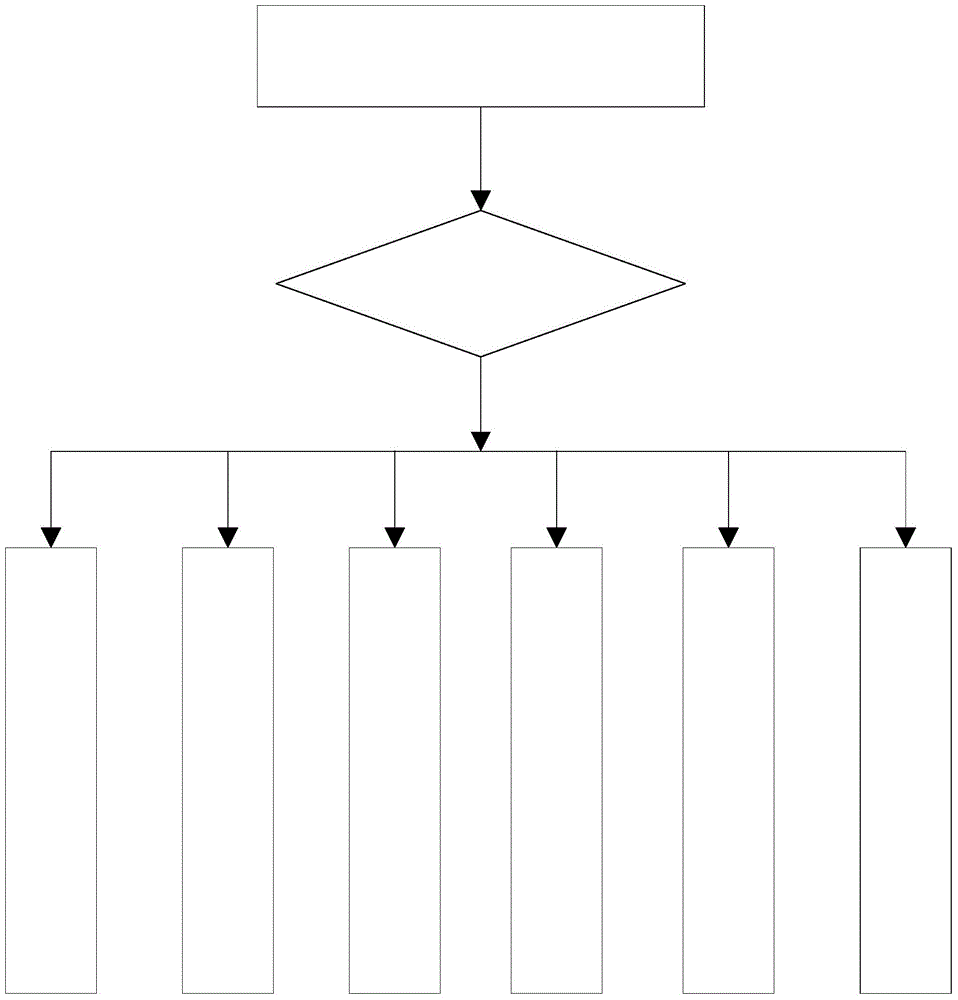

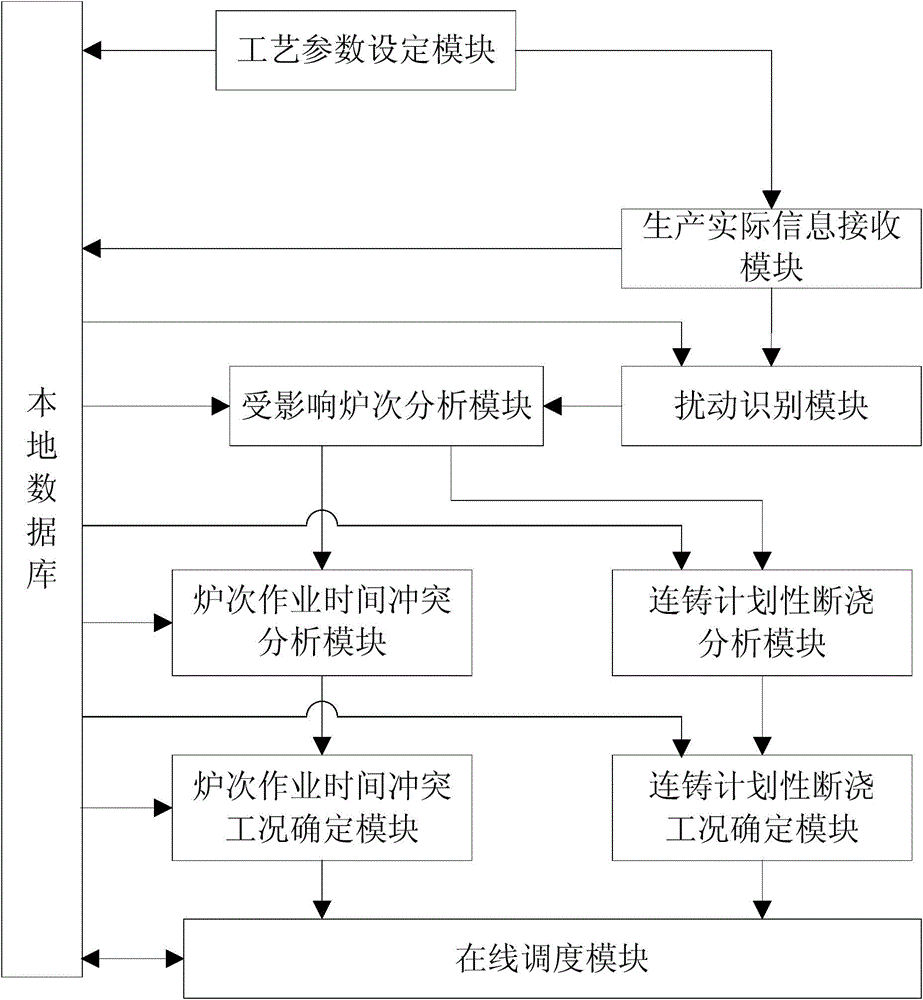

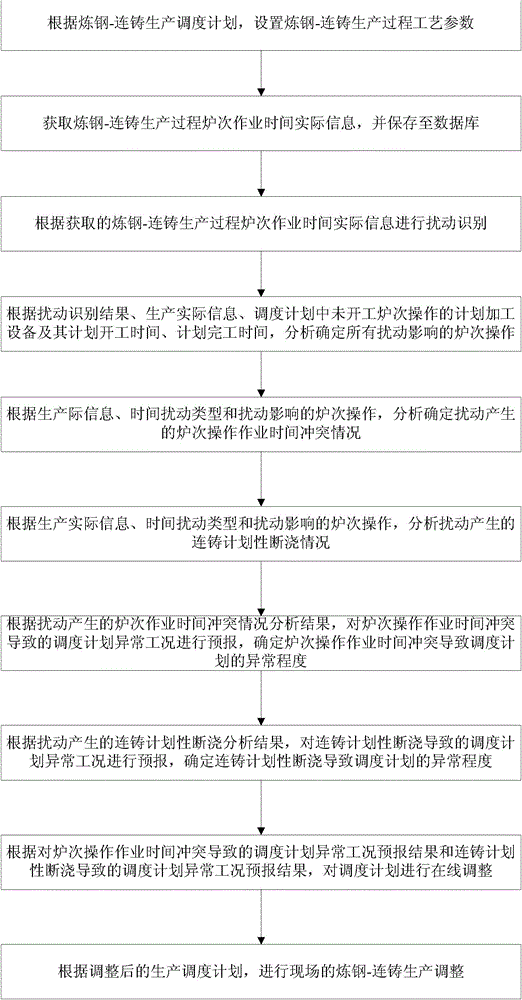

Online control method and system capable of maintaining steel-making and continuous casting production stability

ActiveCN103955173AImprove continuityImprove stabilityTotal factory controlProgramme total factory controlBusiness forecastingWork time

The invention provides an online control method and system capable of maintaining steel-making and continuous casting production stability. The method comprises: arranging a technological parameter of a steel-making and continuous casting production process; obtaining actual production information of the steel-making and continuous casting production process; performing disturbance identification; determining the furnace operation of all disturbance influences; determining furnace operation work time conflict situations generated by disturbance; determining continuous casting planned casting break situations generated by the disturbance; forecasting scheduling plan abnormity conditions caused by furnace operation work time conflicts; forecasting scheduling plan abnormity conditions caused by continuous casting planned casting break; performing online adjustment on a scheduling plan; and performing on-site steel-making and continuous casting production adjustment. According to the invention, the continuity and stability of the scheduling plan are improved based on disturbance identification, disturbance influence furnace analysis, furnace operation time conflict analysis, continuous casting planned casting break analysis, furnace operation time conflict condition determining, continuous casting planned casting break condition determining and online scheduling.

Owner:NORTHEASTERN UNIV

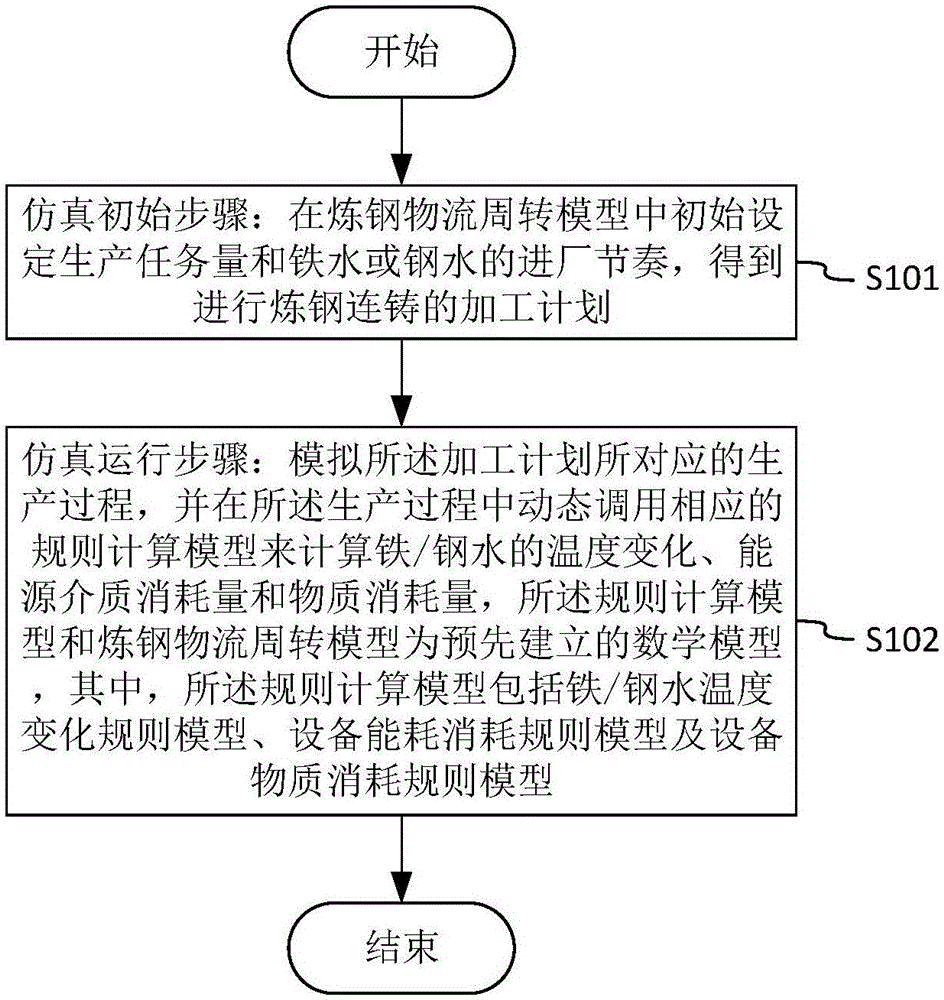

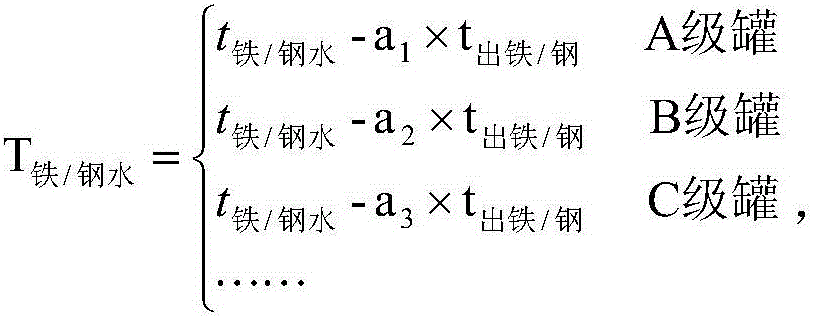

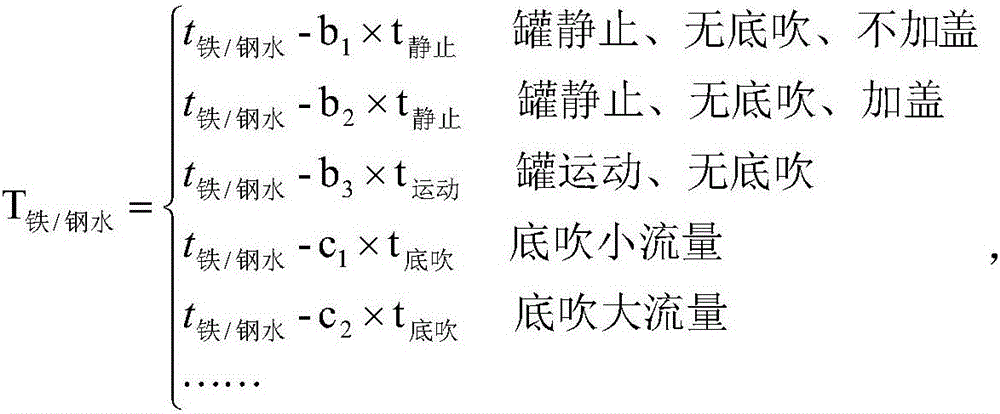

Simulation method for dynamic production run of steelmaking continuous casting workshop

ActiveCN106126842AAccurate dynamic reflectionData processing applicationsDesign optimisation/simulationLogistics managementMolten steel

The invention provides a simulation method for dynamic production run of a steelmaking continuous casting workshop. The method can be achieved through the following steps that firstly, according to the steelmaking process arrangement and logistics running characteristics, a corresponding steelmaking logistics circulation model is established; secondly, according to steelmaking continuous casting actual production, a molten iron / steel temperature change rule model, an equipment energy consumption rule model and an equipment matter consumption rule model are established; thirdly, the temperature change rule model, the equipment energy consumption rule model and the equipment matter consumption rule model in the second step are related with all equipment of the steelmaking logistics circulation model in the first step; fourthly, the simulation production task load and the molten iron / steel factory entering rhythm are set for logistics simulation calculation, and the corresponding rule models are dynamically called in the simulation process to calculate the temperature change, energy medium consumption amount and matter consumption amount of the molten iron / steel; fifthly, unit consumption of various kinds of matter under the production condition is obtained according to the simulation result, the unit price of the matter is set, and the production and running cost under different working conditions is calculated thereby.

Owner:CISDI ENG CO LTD

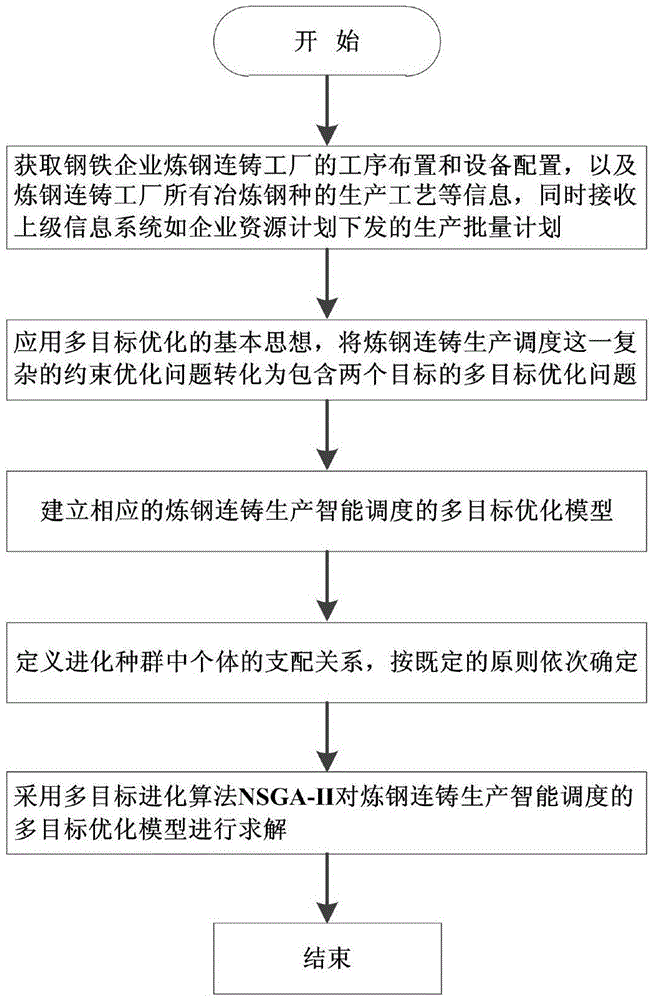

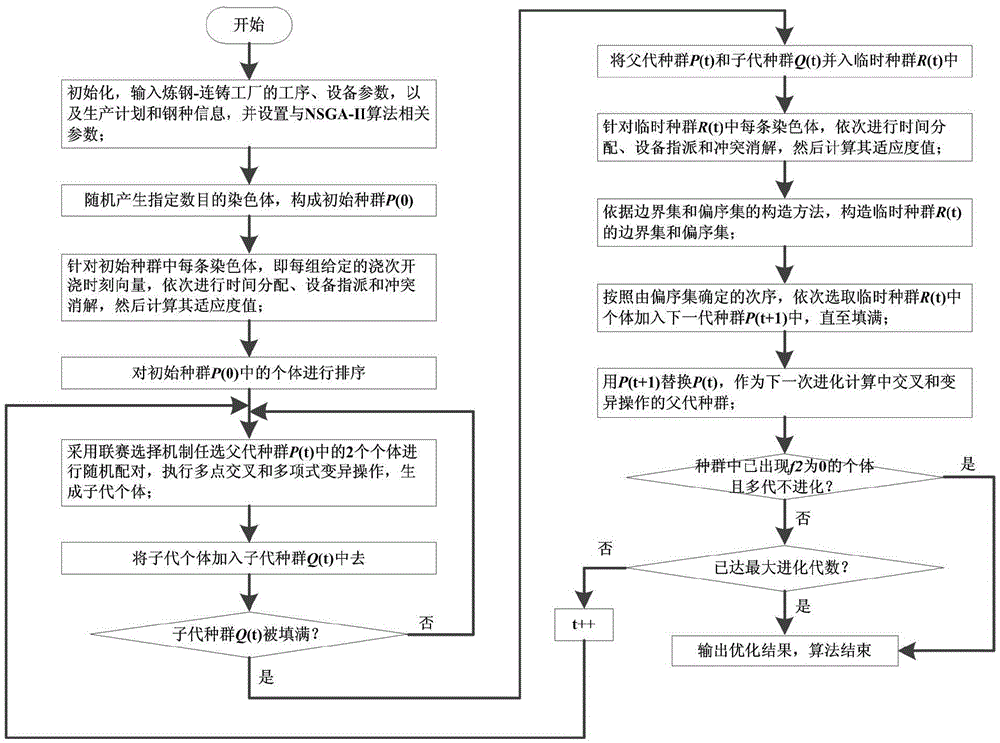

Multi-objective optimization method of steelmaking-continuous casting production scheduling based on NSGA-II

InactiveCN105550771AReduce iterative calculation loadImproves the likelihood of computational convergenceForecastingResourcesCompletion timeSteelmaking continuous casting

The invention is applicable to the field of steelmaking-continuous casting production process, and provides a multi-objective optimization method of steelmaking-continuous casting production scheduling based on NSGA-II. The method comprises the following steps: converting the constrained optimization problem of steelmaking-continuous casting production scheduling into a multi-objective optimization problem containing two objectives, wherein the first objective is to minimize the sum of the completion time of the whole factory and the waiting time of all furnaces, and the second objective is to minimize the sum of equipment conflict time; building a corresponding multi-objective optimization model of steelmaking-continuous casting production scheduling, wherein the multi-objective optimization model is characterized by minimizing first and second objective function values; defining the dominance relation between individuals in an evolution population; and adopting a multi-objective evolutionary algorithm NSGA-II to solve the multi-objective optimization model. By converting the complex constrained optimization problem of steelmaking-continuous casting production scheduling into the multi-objective optimization problem containing two objectives, hard-to-meet constraints during solving for the traditional method are relaxed, and the possibility of operation convergence is improved while the iterative computation load is reduced.

Owner:WISDRI ENG & RES INC LTD

Zinc-based coating thermoforming steel based on CSP process and preparation method thereof

InactiveCN108950160APrevent oxidationOxide layer, which can better prevent the volatilization of zincHot-dipping/immersion processesHot-dip galvanizationSteel plates

The invention discloses zinc-based coating thermoforming steel based on a CSP process and a preparation method thereof. The method comprises the following steps of (1) steelmaking; (2) CSP continuouscasting; (3) CSP hot rolling; (4) acid pickling; (5) cold rolling; (6) hot dip galvanizing; and (7) thermoforming. A steel plate comprises the following chemical components of, by weight, 0.10-0.4 ofC, 0.10-0.50 of Si, 0.50-3.50 of Mn, less than or equal to 0.03 of P, less than or equal to 0.03 of S, less than or equal to 0.10 of Al, 0.10-2.50 of Cr, 0.10-2.50 of Ni, less than or equal to 0.03 ofMo, 0.0004-0.01 of B, less than or equal to 0.01 of N, 0.01-0.10 of Ti, the balance Fe, and inevitable impurities. A thermoforming substrate is produced by using the CSP process in a low-cost manner,and a zinc liquid component containing the Al, the Mg and REM elements is coated on the substrate to form a coating layer; the coating which is subjected to thermoforming is good in corrosion resistance, volatilization and oxidation of the zinc can be well prevented, and an oxidation layer is good in adhesiveness during the thermoforming process.

Owner:MAANSHAN IRON & STEEL CO LTD

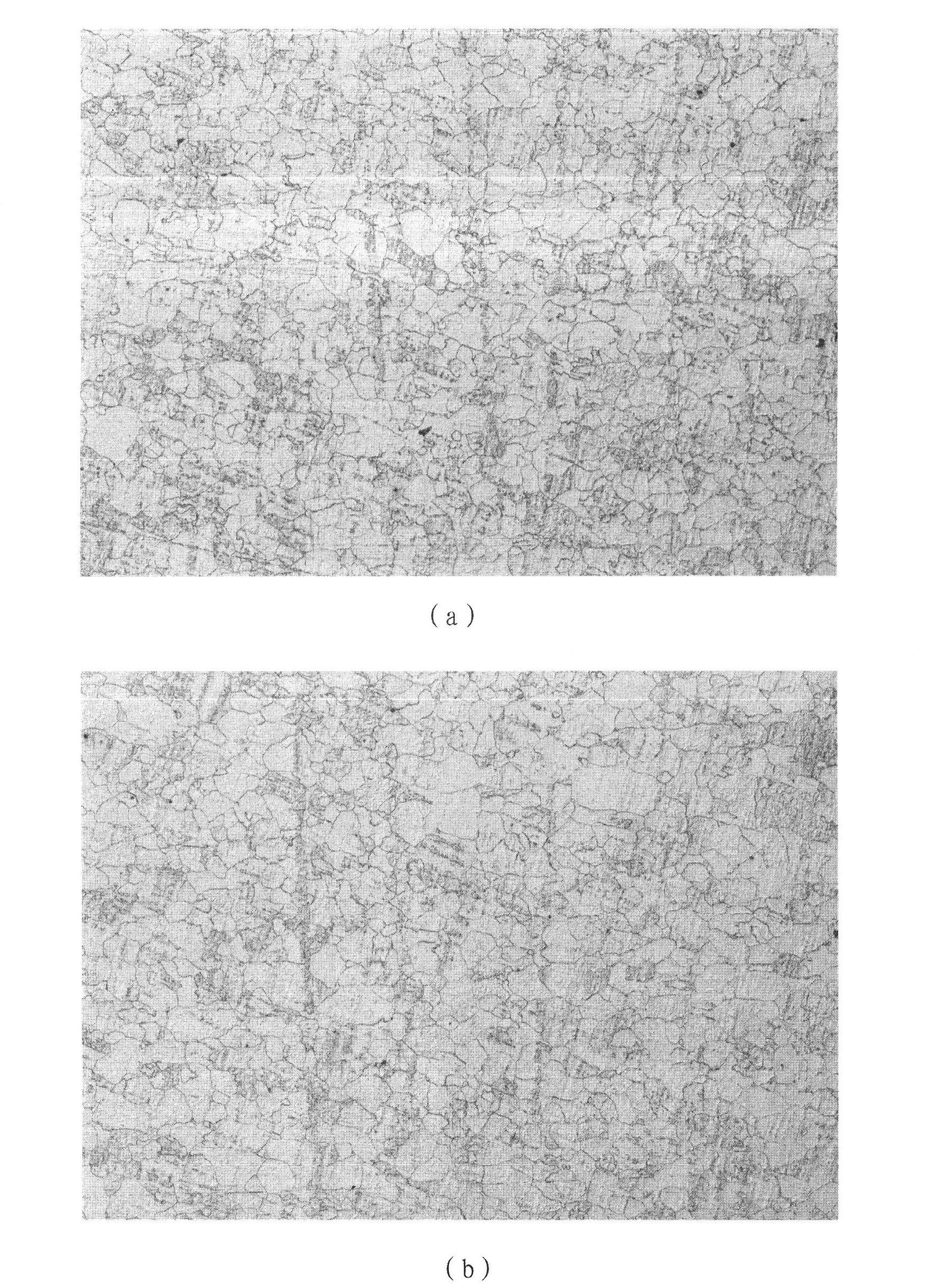

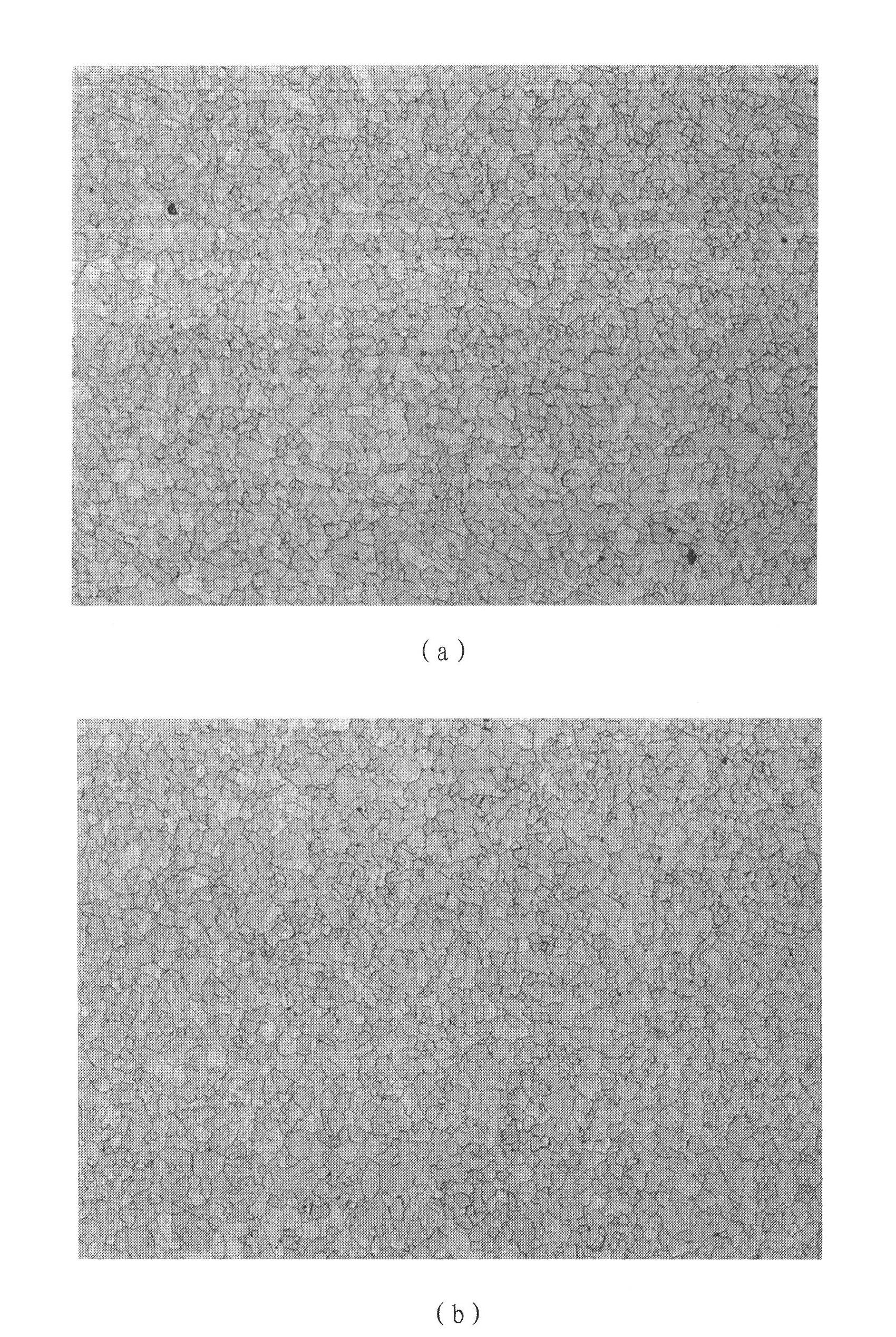

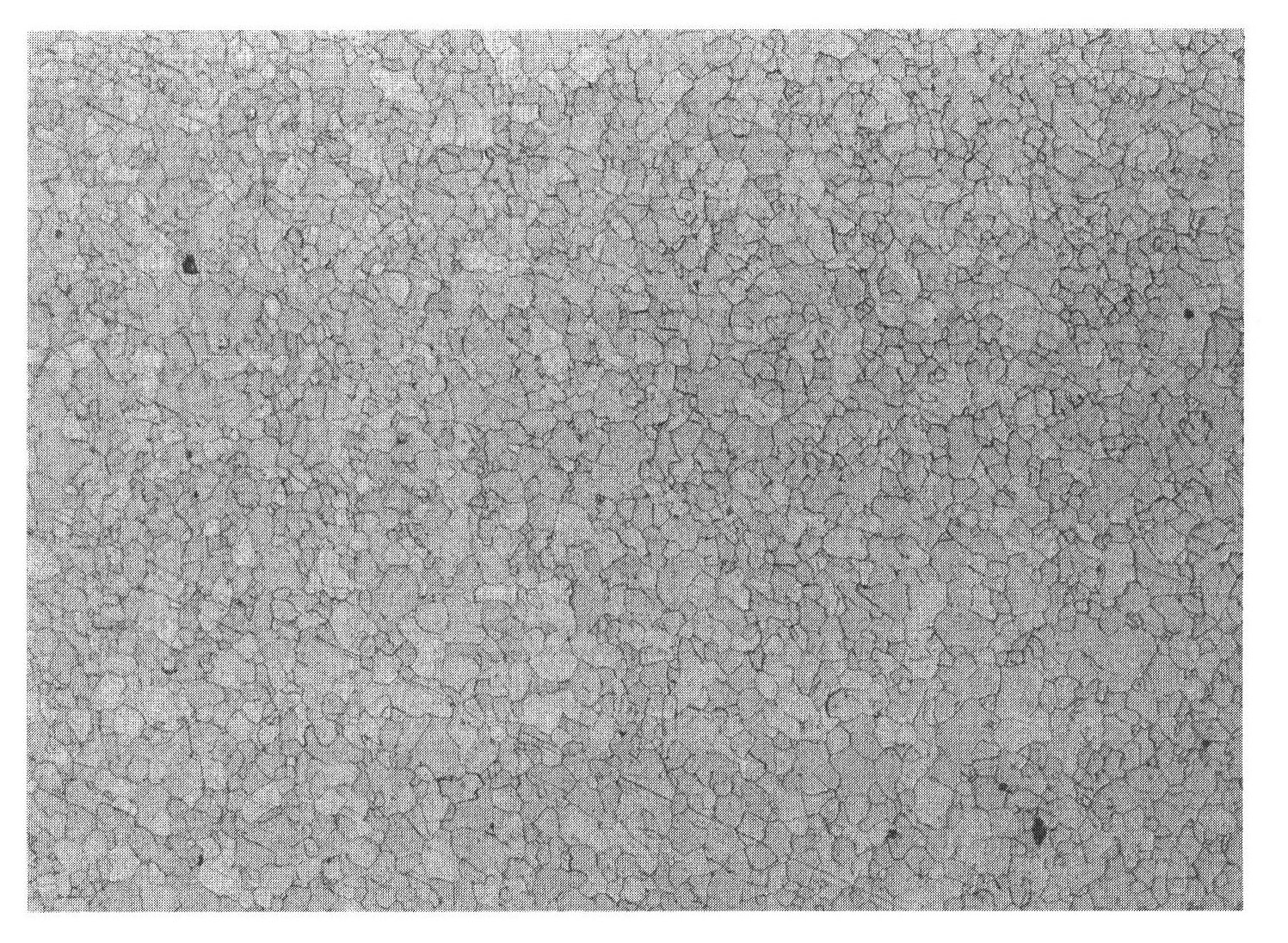

Casting mold experimental equipment for technology under simulating light press continuous casting blank and method

InactiveCN101363832ARich rheological theoryRich high temperature billetOptically investigating flaws/contaminationTesting metalsReduction rateCasting mold

The invention belongs to the steelmaking continuous casting technical field, and particularly provides a mold casting experimental device and a method thereof for simulating the soft-reduction technique of a continuous casting blank. The device is characterized in that the inner wall of a water-cooling copper mold can move; displacement signals can be acquired and recorded; and by the soft-reduction mold casting, the solidification process of the continuous casting blank under different soft-reduction process parameters can be stimulated. The structure evolution rule of the continuous casting blank is studied, and the influencing factors on the crack generation and central looseness of the casting blank are analyzed. During the experiment process, the macroscopic deformation rule of the continuous casting blank during the continuous casting process using the soft-reduction process is analyzed by the variation of the soft-reduction force, the soft-reduction total amount and the soft-reduction rate. By the metallurgical analysis, the action of the soft-reduction process on the enlargement of a central equiaxial crystal zone, the central looseness and segregation and the variation of the structure growth process is determined. By the soft-reduction experiments in different solid rate sections using the two-side and four-side soft-reduction processes, the reasonable soft-reduction process parameters during the continuous casting process are determined.

Owner:UNIV OF SCI & TECH BEIJING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com