On-line thermal monitoring system of heat transfer symmetry of crystallizer copper pipe and method thereof

A technology for a crystallizer copper tube and a monitoring system, which is applied in the field of steelmaking and continuous casting, can solve the problems of non-specificity, inconsistency, discount of calculation accuracy, etc. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

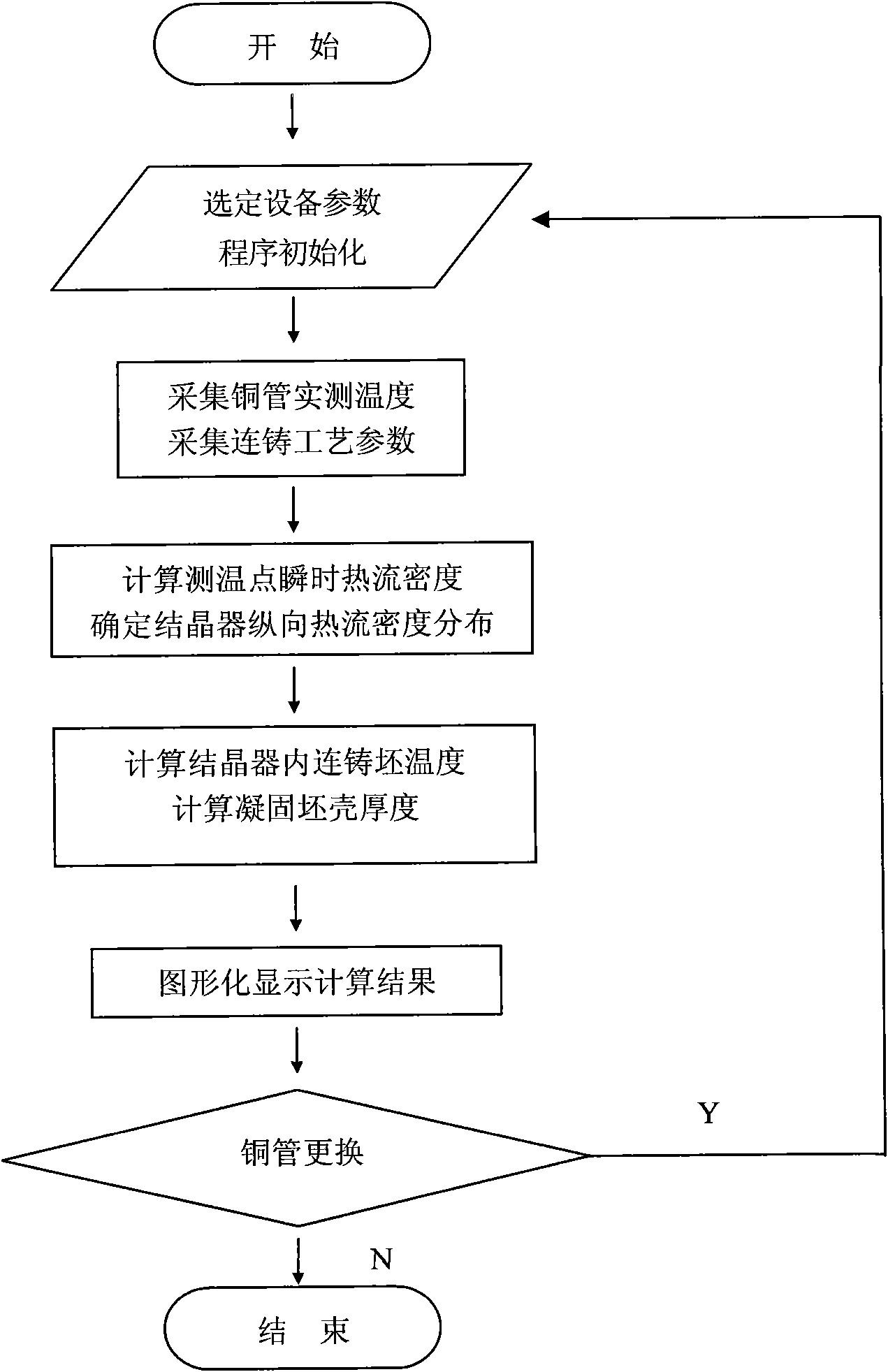

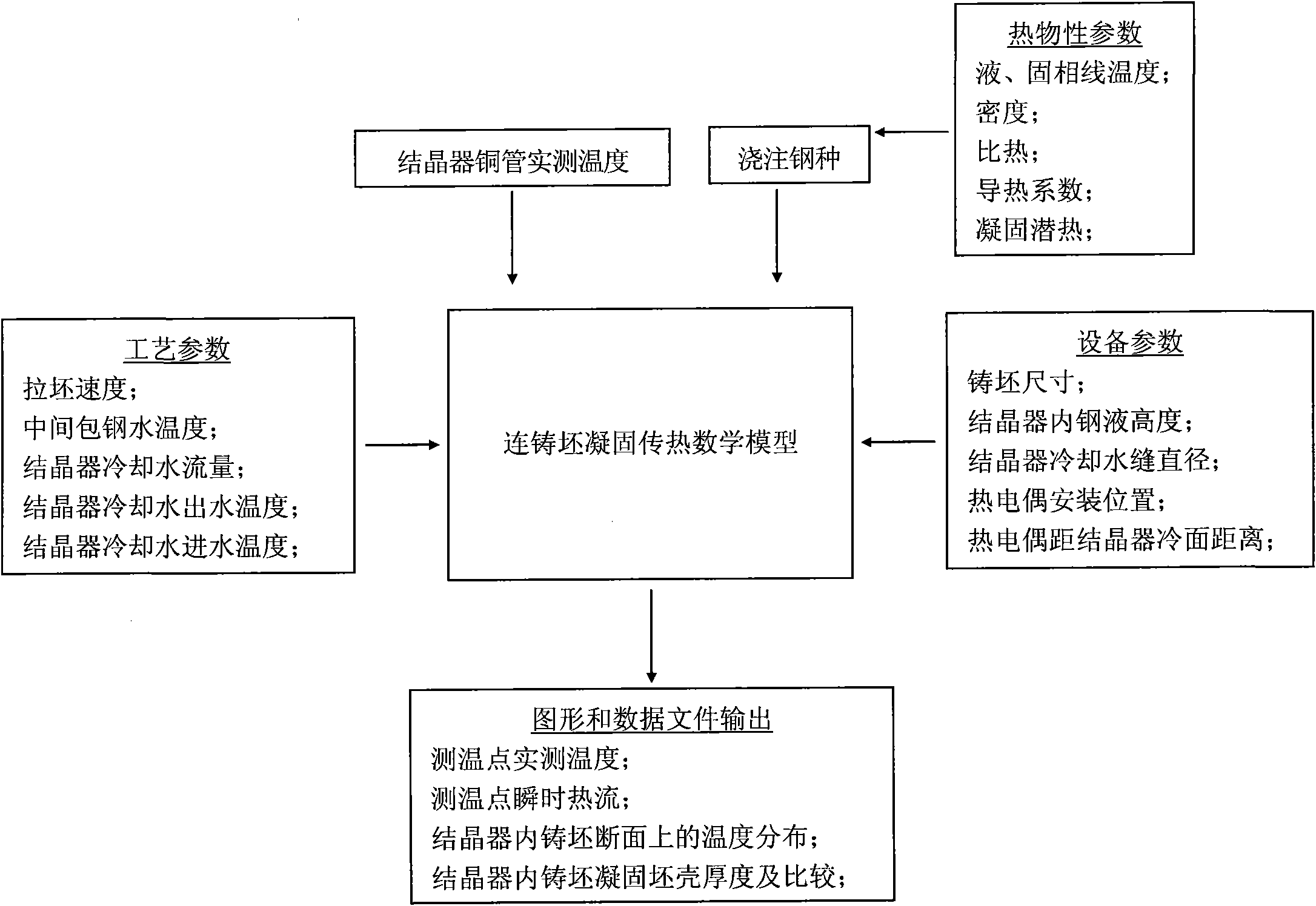

Method used

Image

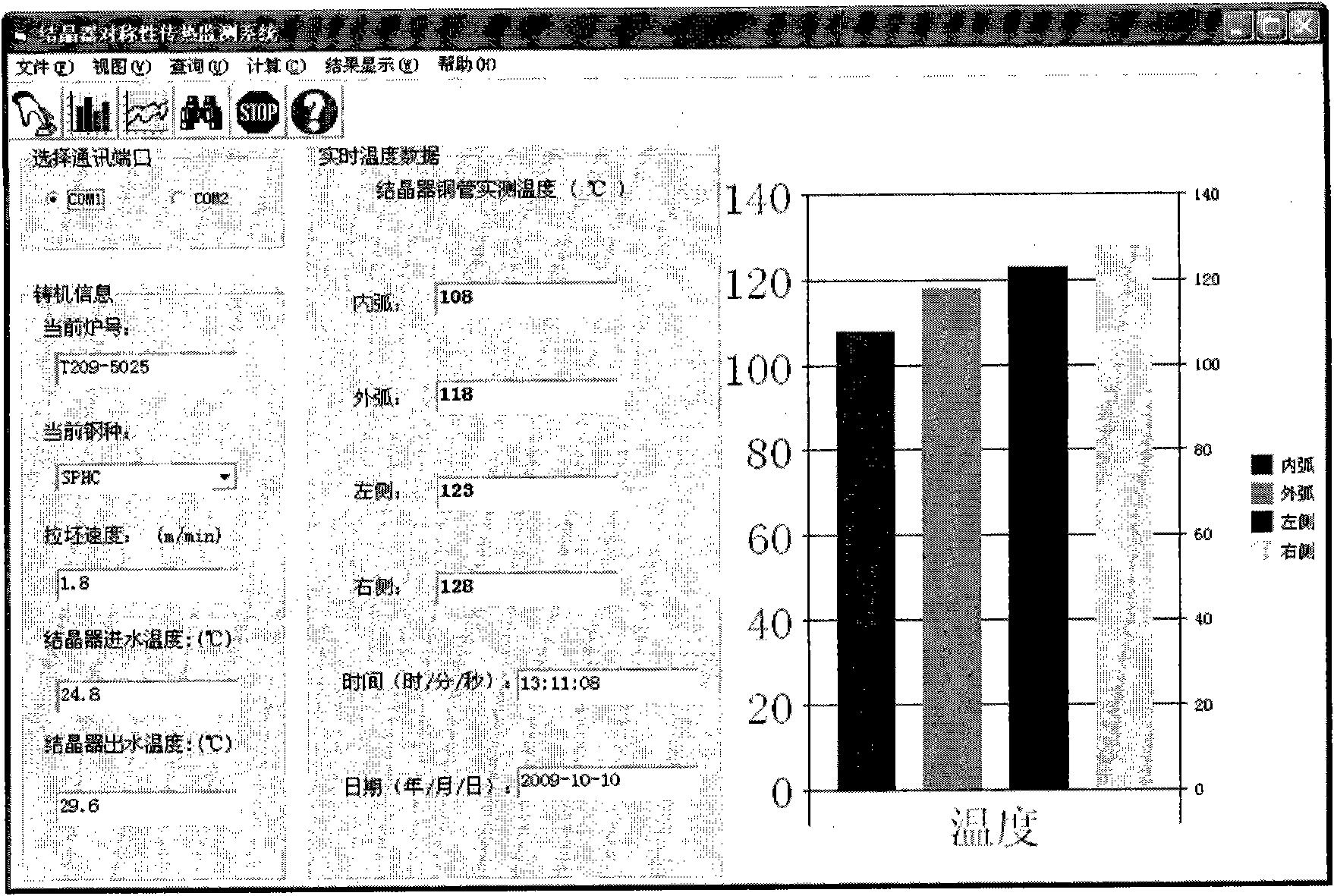

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with embodiment.

[0044] In order to minimize the number of temperature measurement points, the selection of temperature measurement points must be representative. Generally, 5 temperature measurement points are set on each side (face), distributed in the shape of a "ten", between the inner arc and the outer arc, on the east side The installation location must be exactly the same as the west side. For the billet crystallizer, the geometric center of each surface of the copper tube is determined as the central temperature measuring point, and other temperature measuring points are distributed equidistantly above and below these central temperature measuring points, directly to the left and directly to the right . Theoretically, each surface is required to have at least one temperature measurement point, so except for the central temperature measurement point, the other four temperature measurement poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com