Patents

Literature

49 results about "Geometric symmetry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

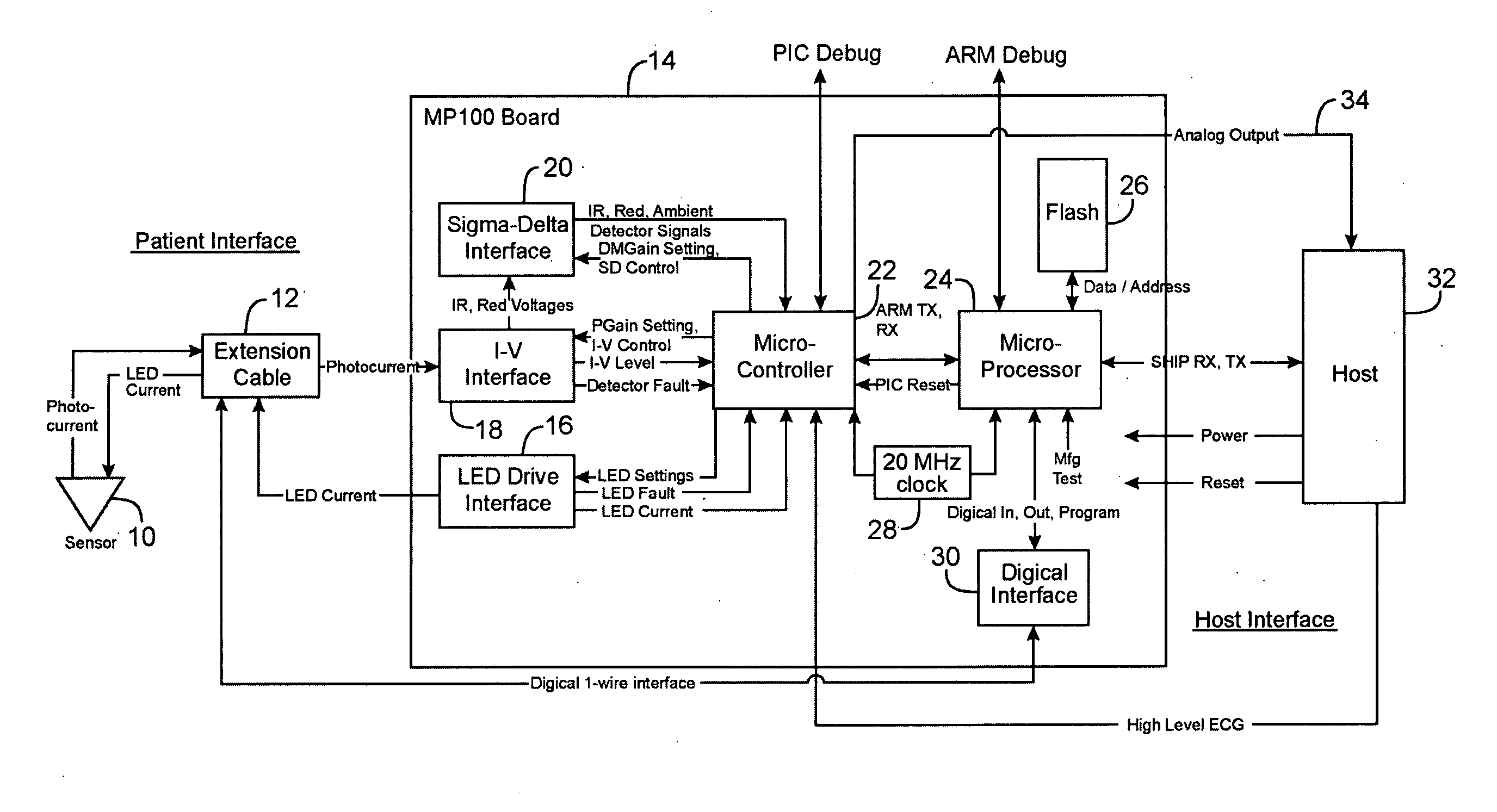

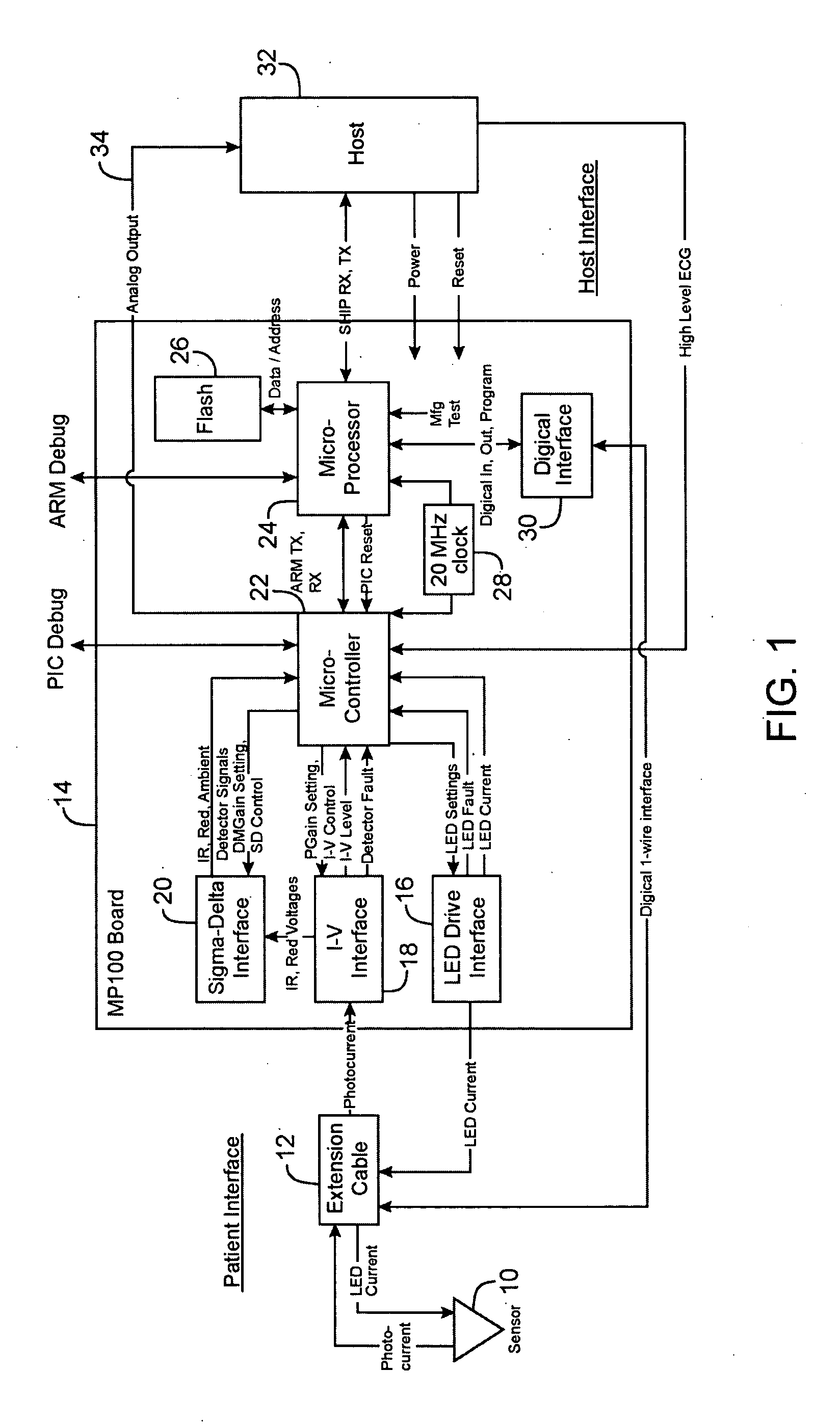

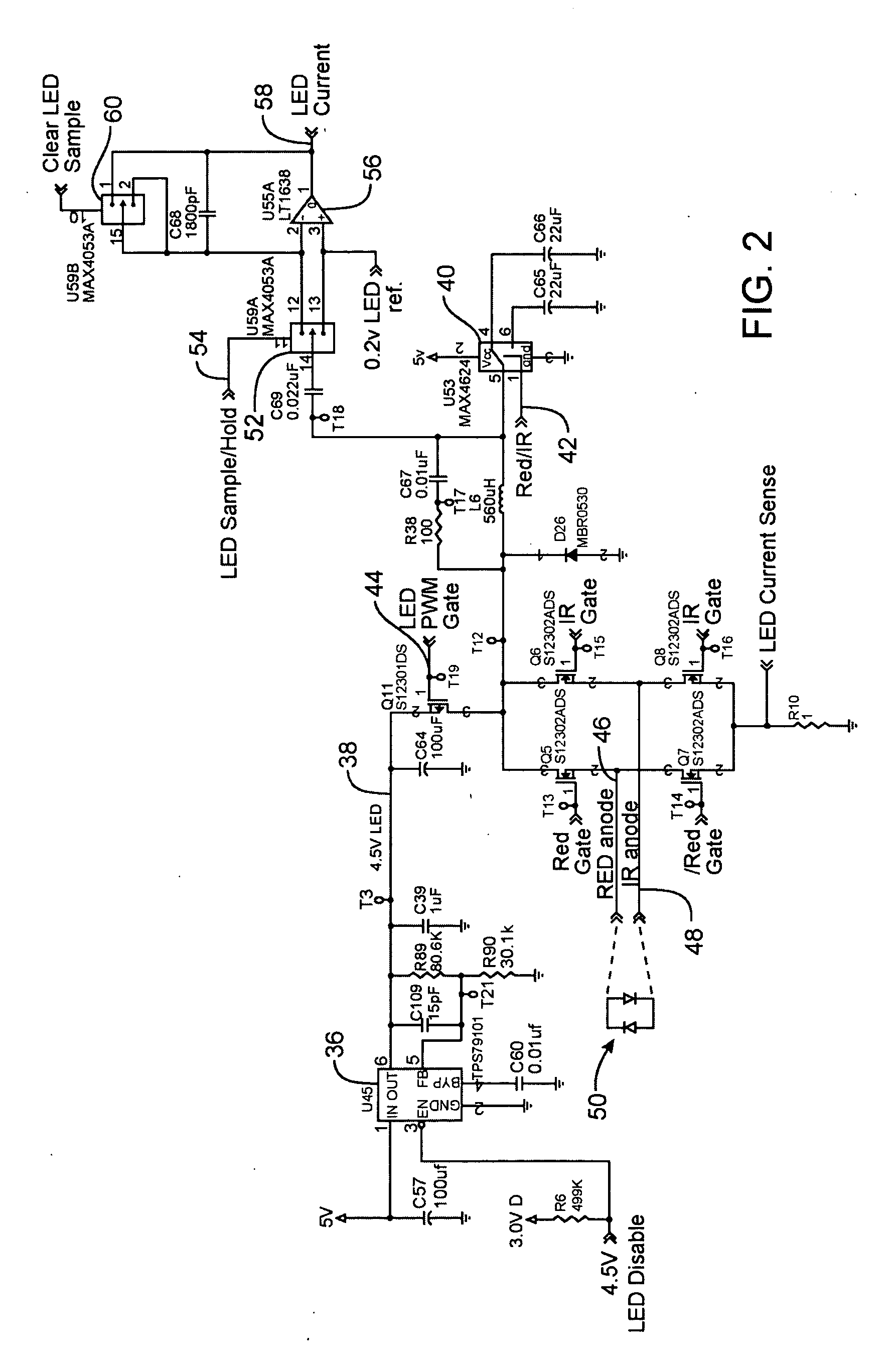

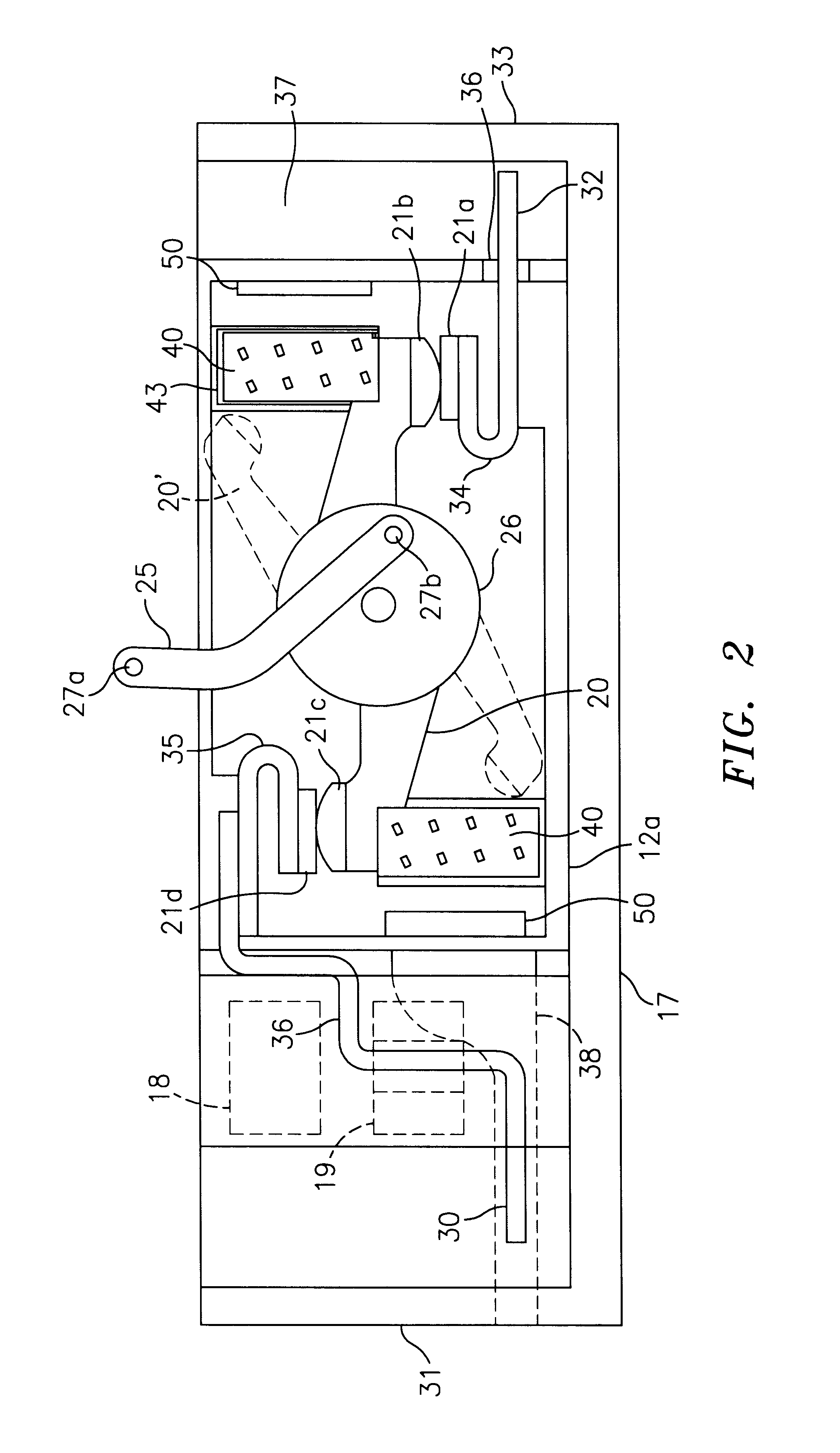

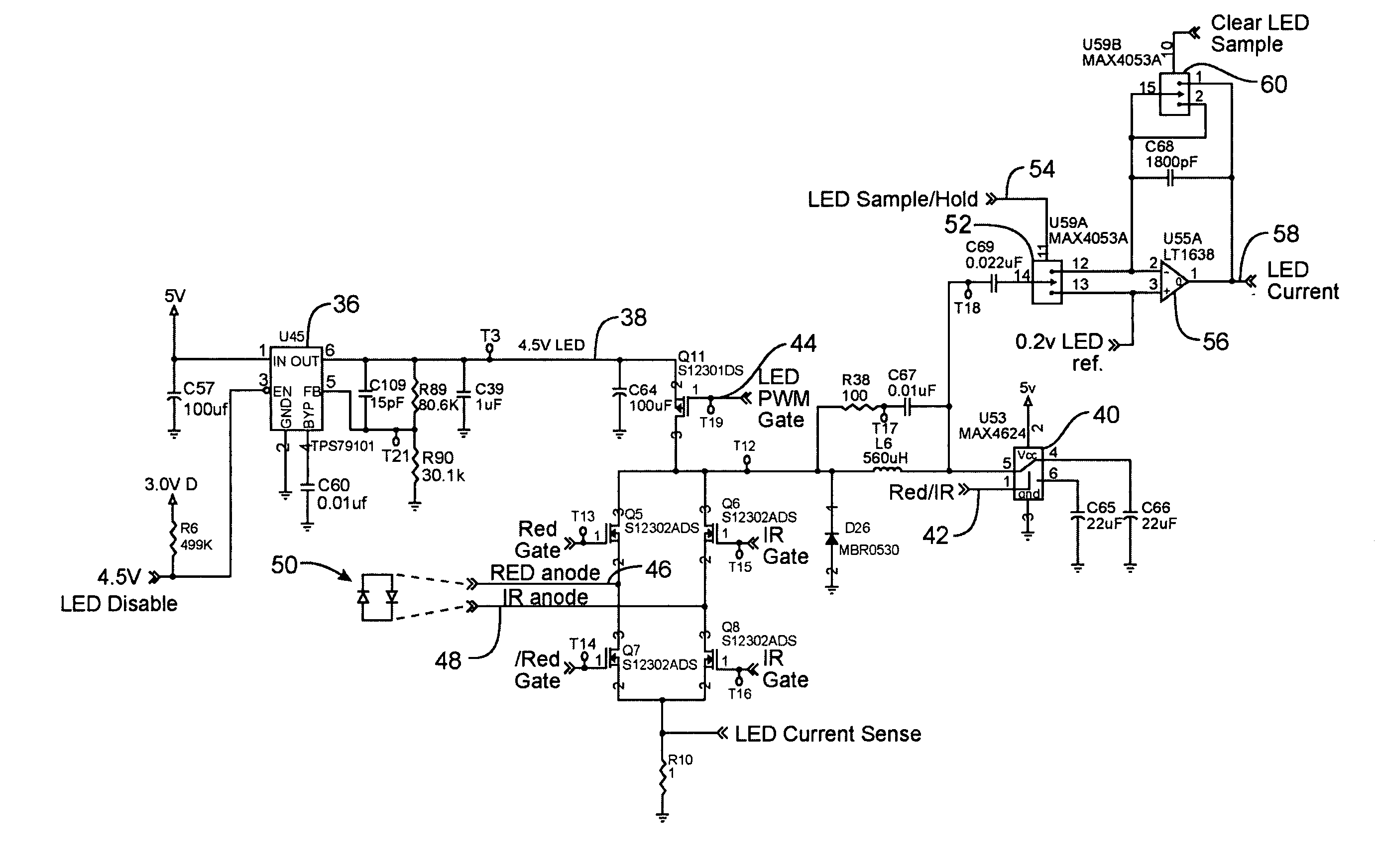

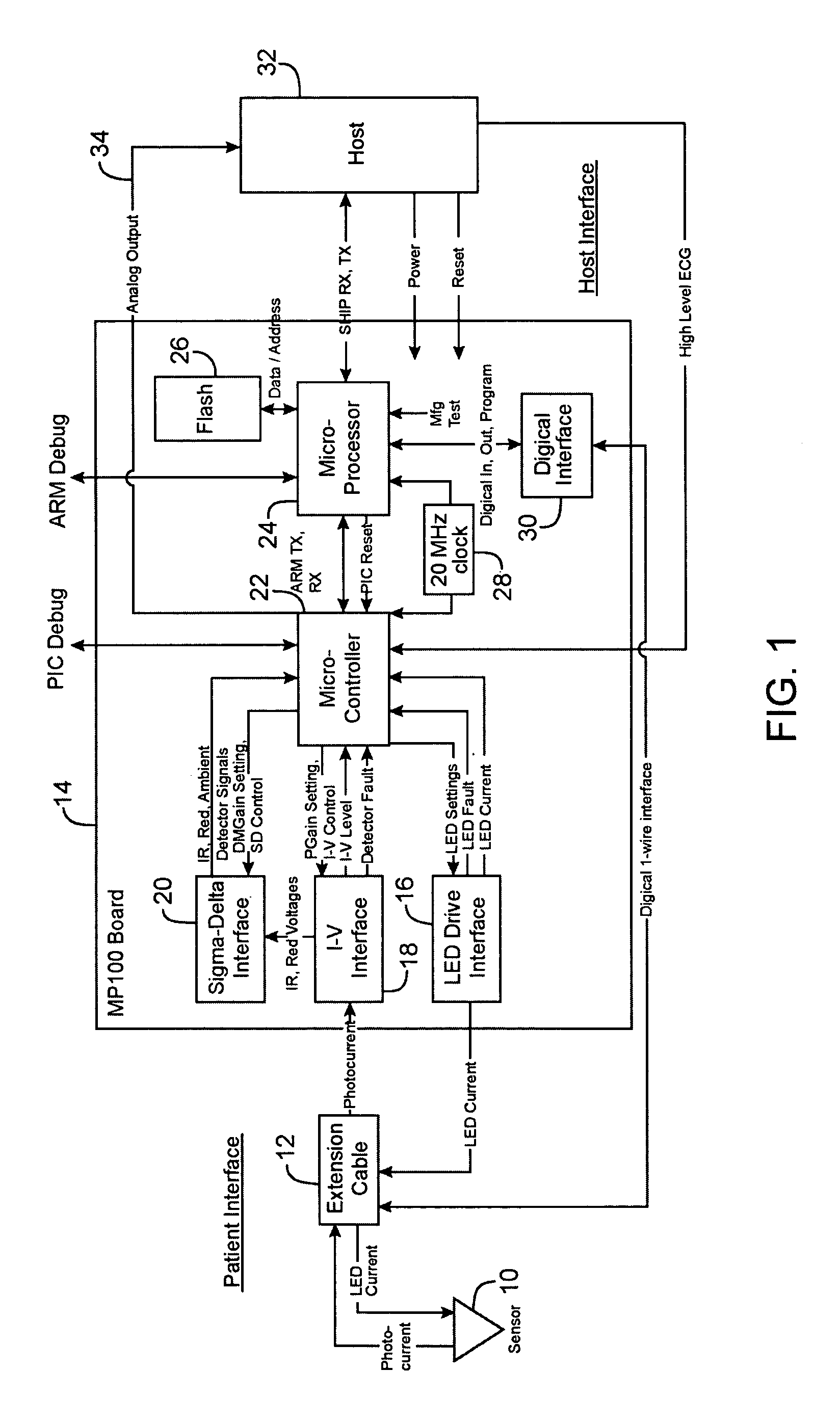

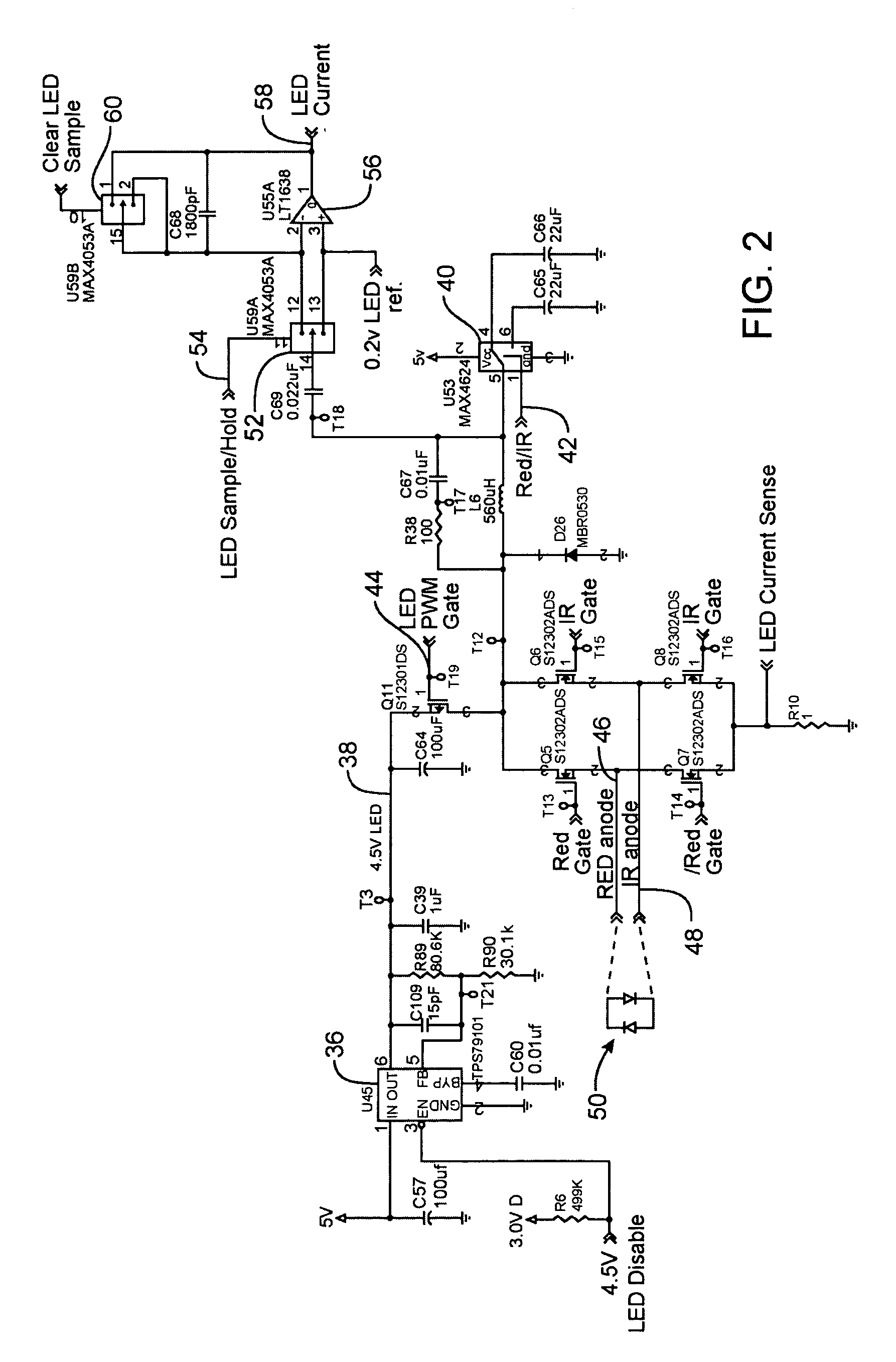

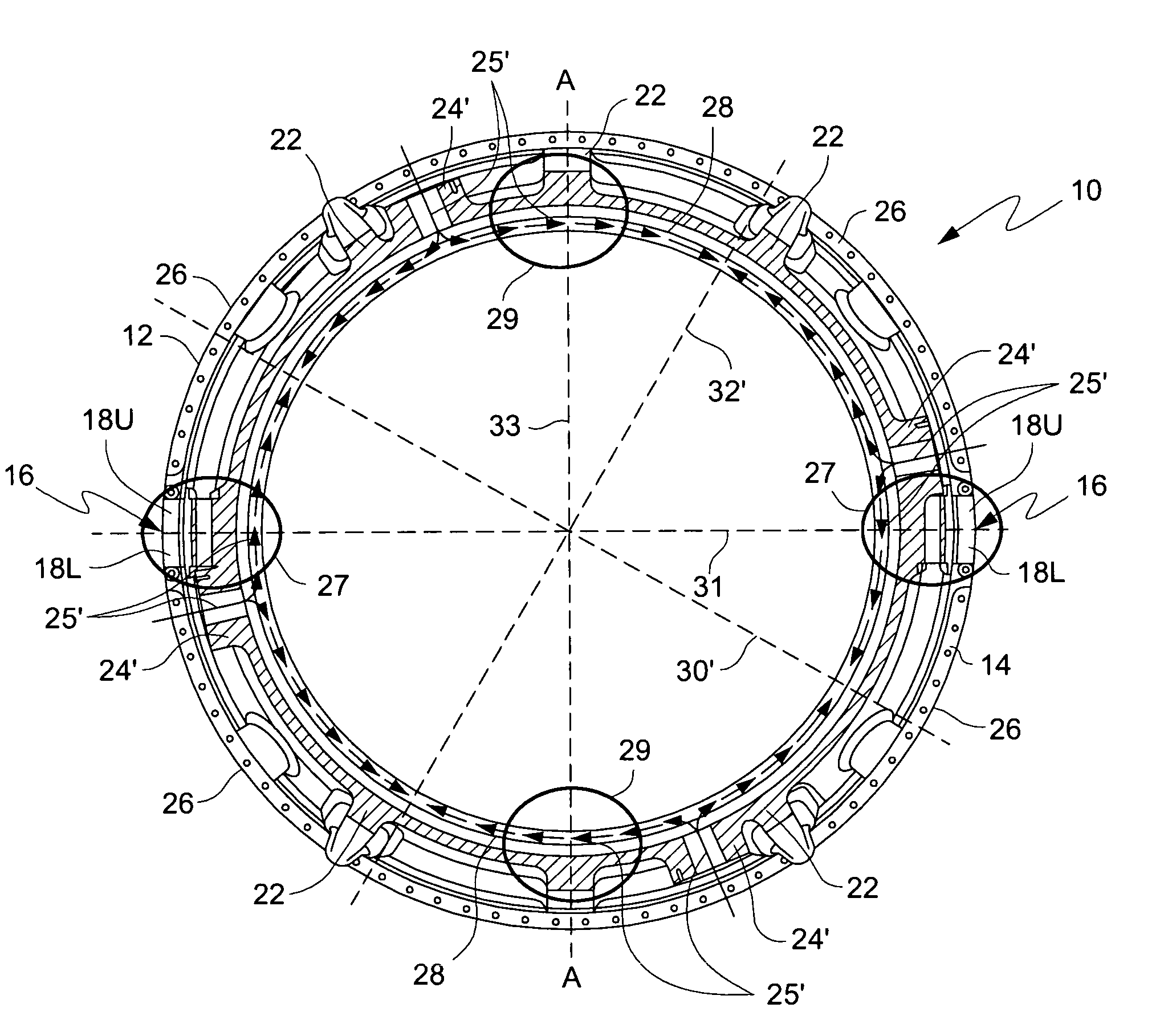

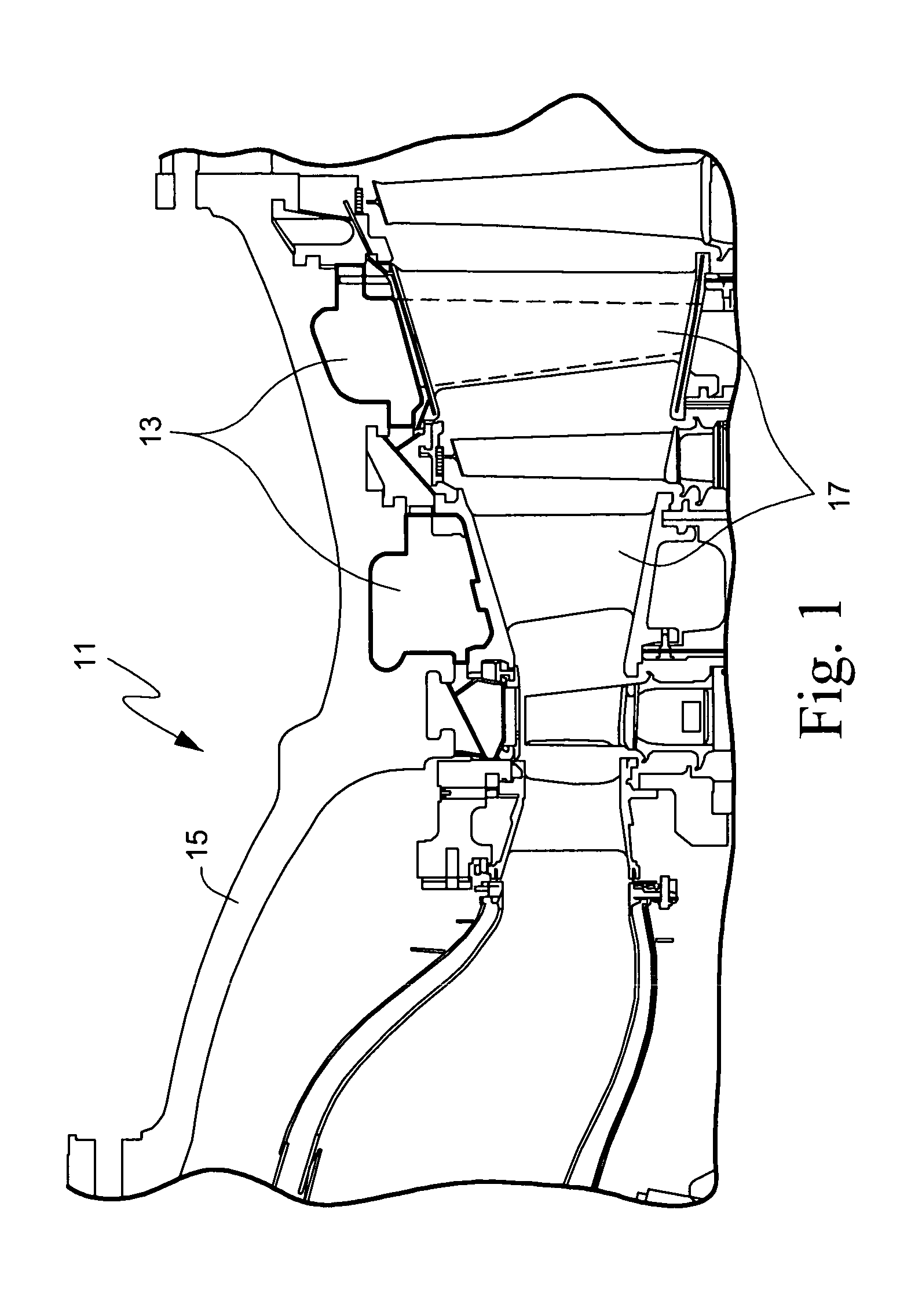

Switch-mode oximeter LED drive with a single inductor

ActiveUS20050187447A1Low magnetic susceptibilityCancellation effectElectric light circuit arrangementDiagnostic recording/measuringMagnetic susceptibilityBobbin

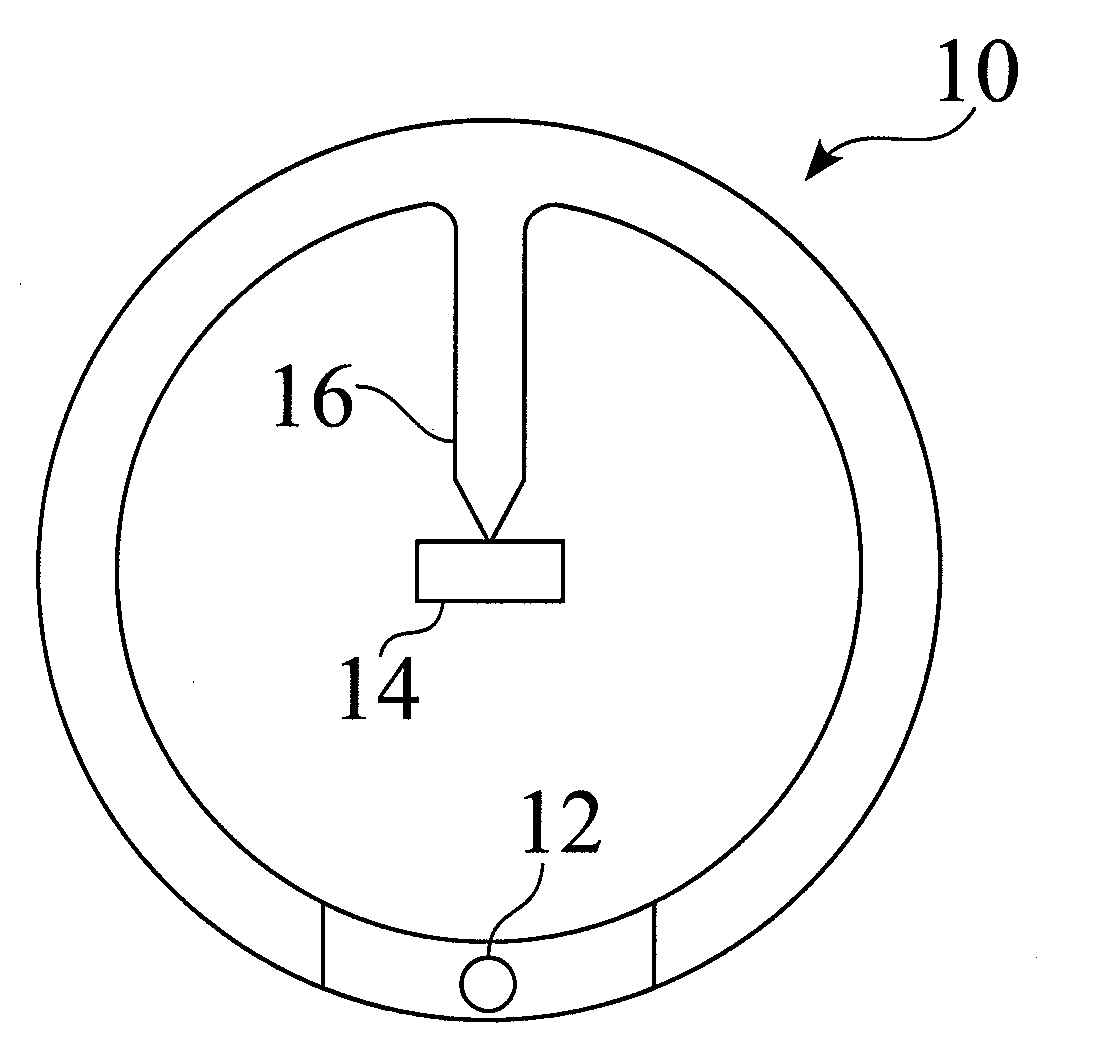

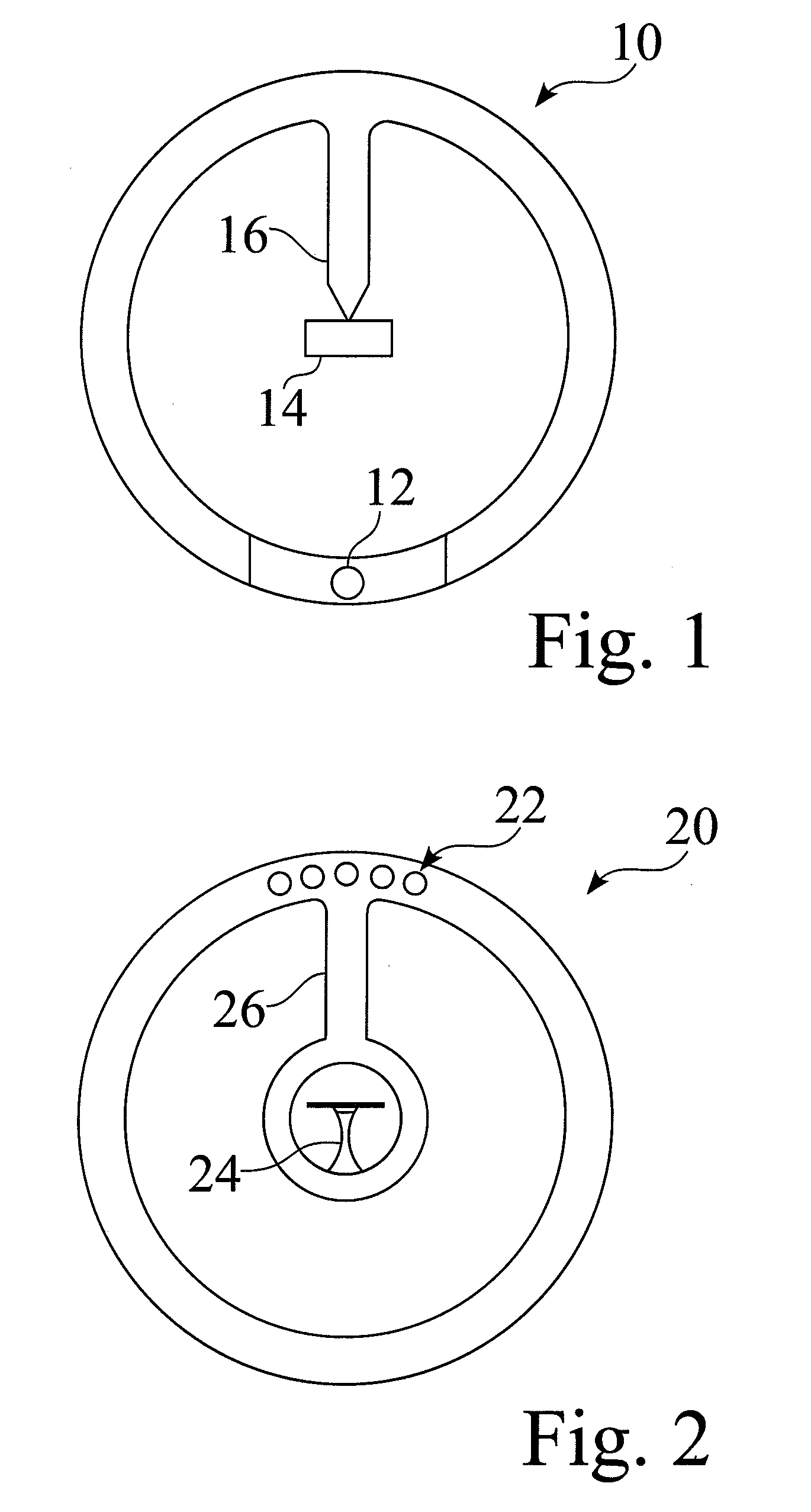

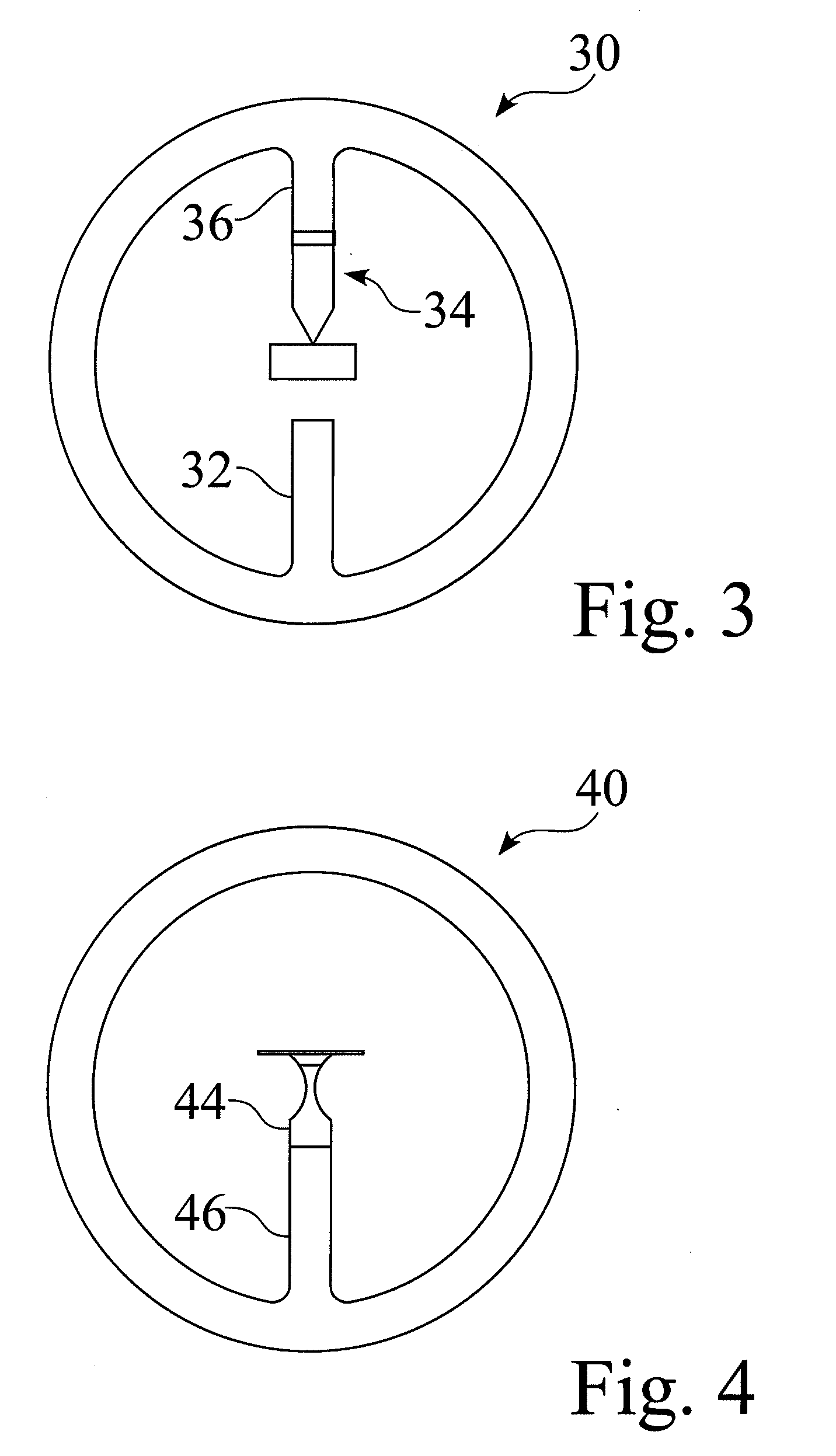

A light emitter drive circuit for an oximeter which utilizes a single inductor for driving multiple light emitters. The inductor is connected to a switching circuit to multiple energy storage circuits, such as capacitors. These are alternately charged up, using the same inductor. Subsequently, the capacitors are alternately discharged for their corresponding light emitters through the same inductor. Also, the magnetic susceptibility of the LED drive circuit is reduced by using magnetic flux canceling in the inductor. In one embodiment, a toroidal inductor is used with geometric symmetry and its magnetic flux. In another embodiment, a dual core closed bobbin shielded inductor is used.

Owner:TYCO HEALTHCARE GRP LP

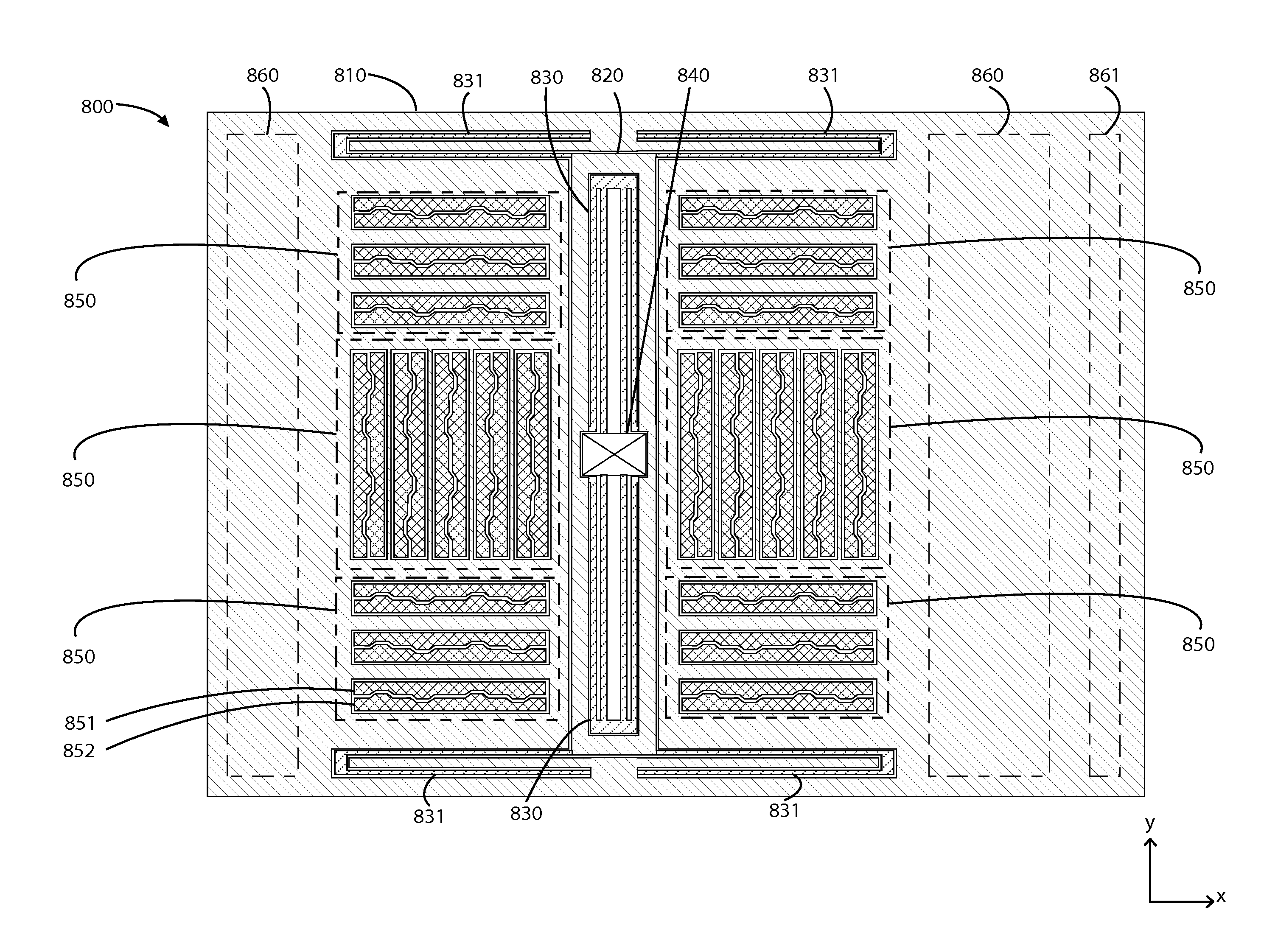

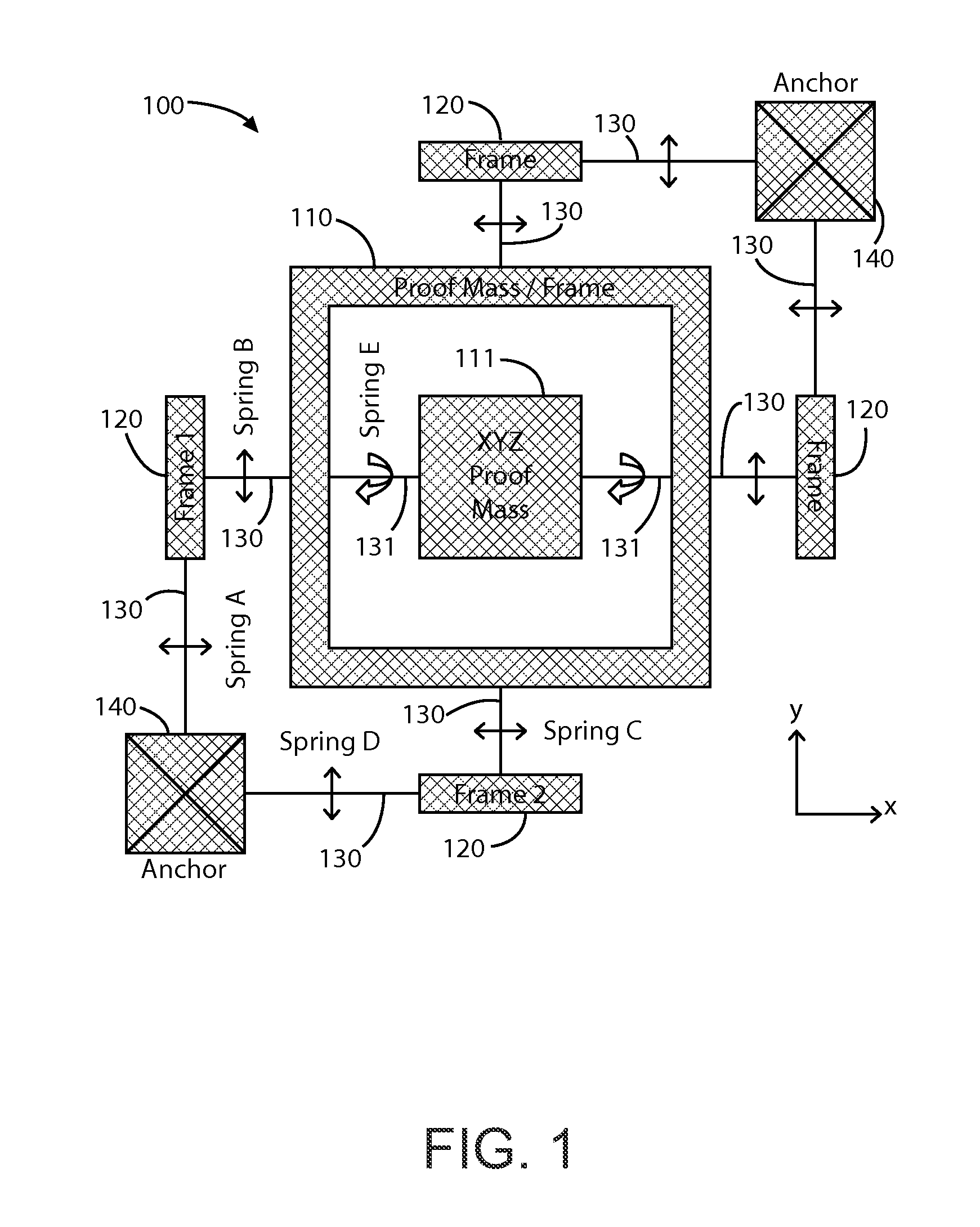

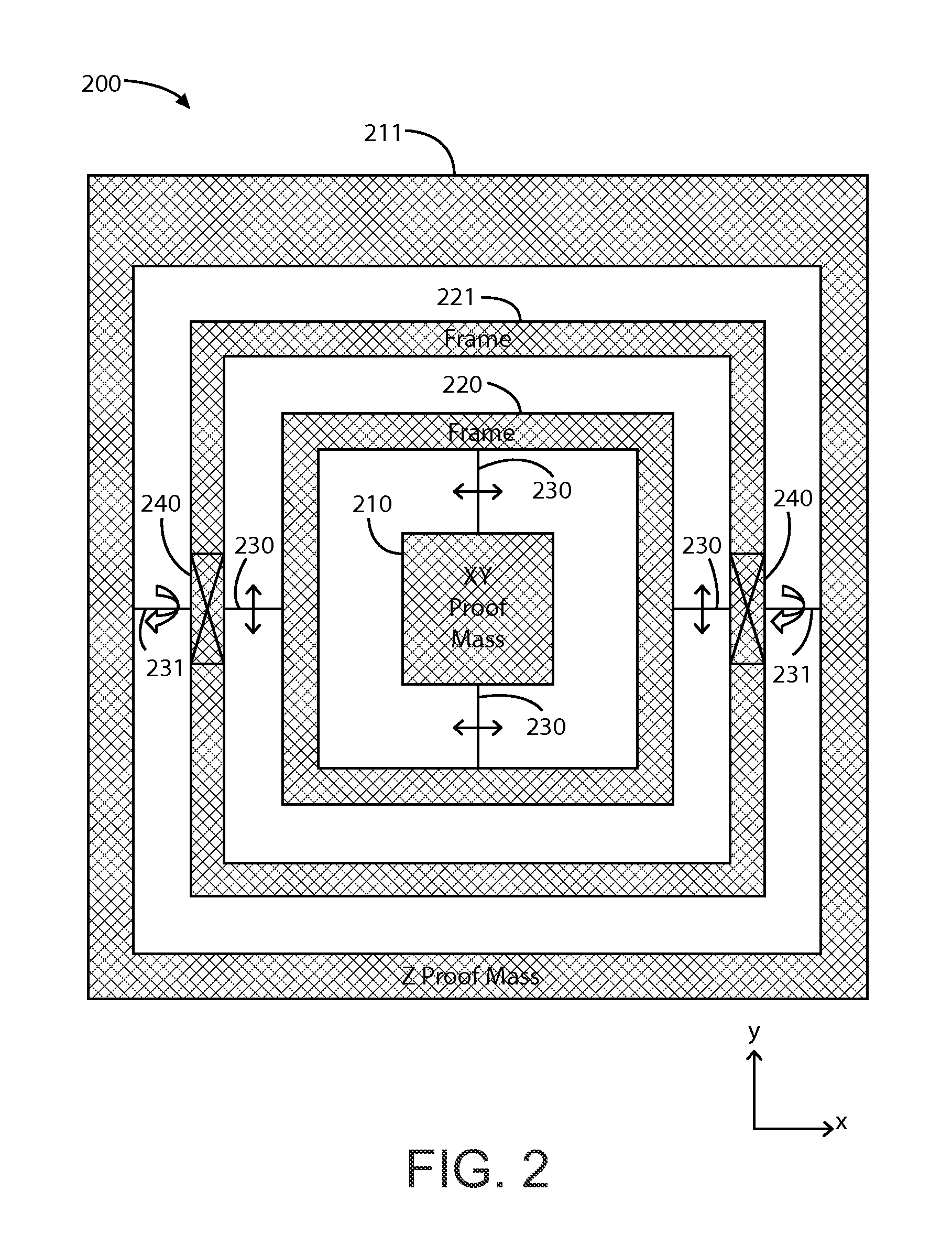

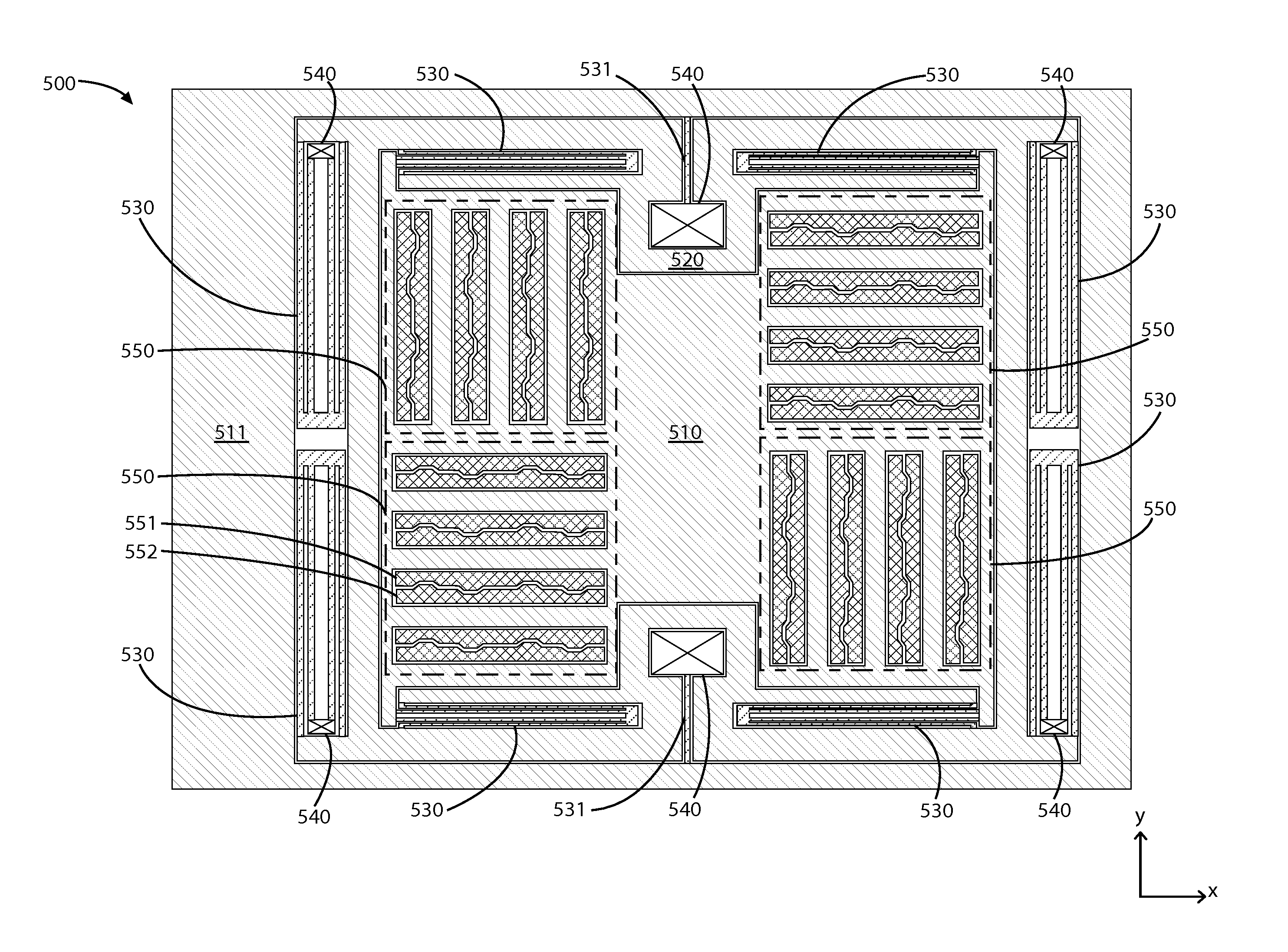

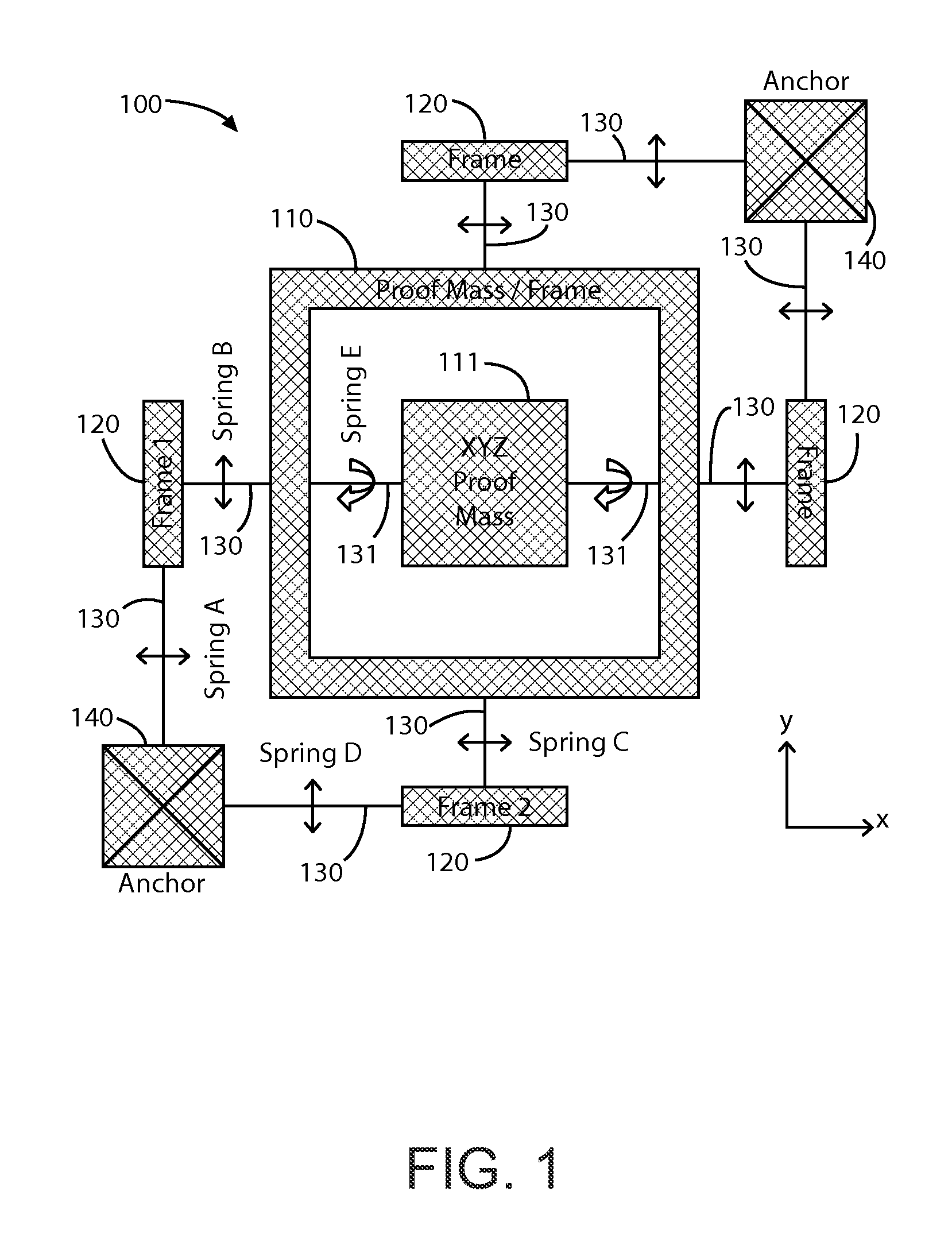

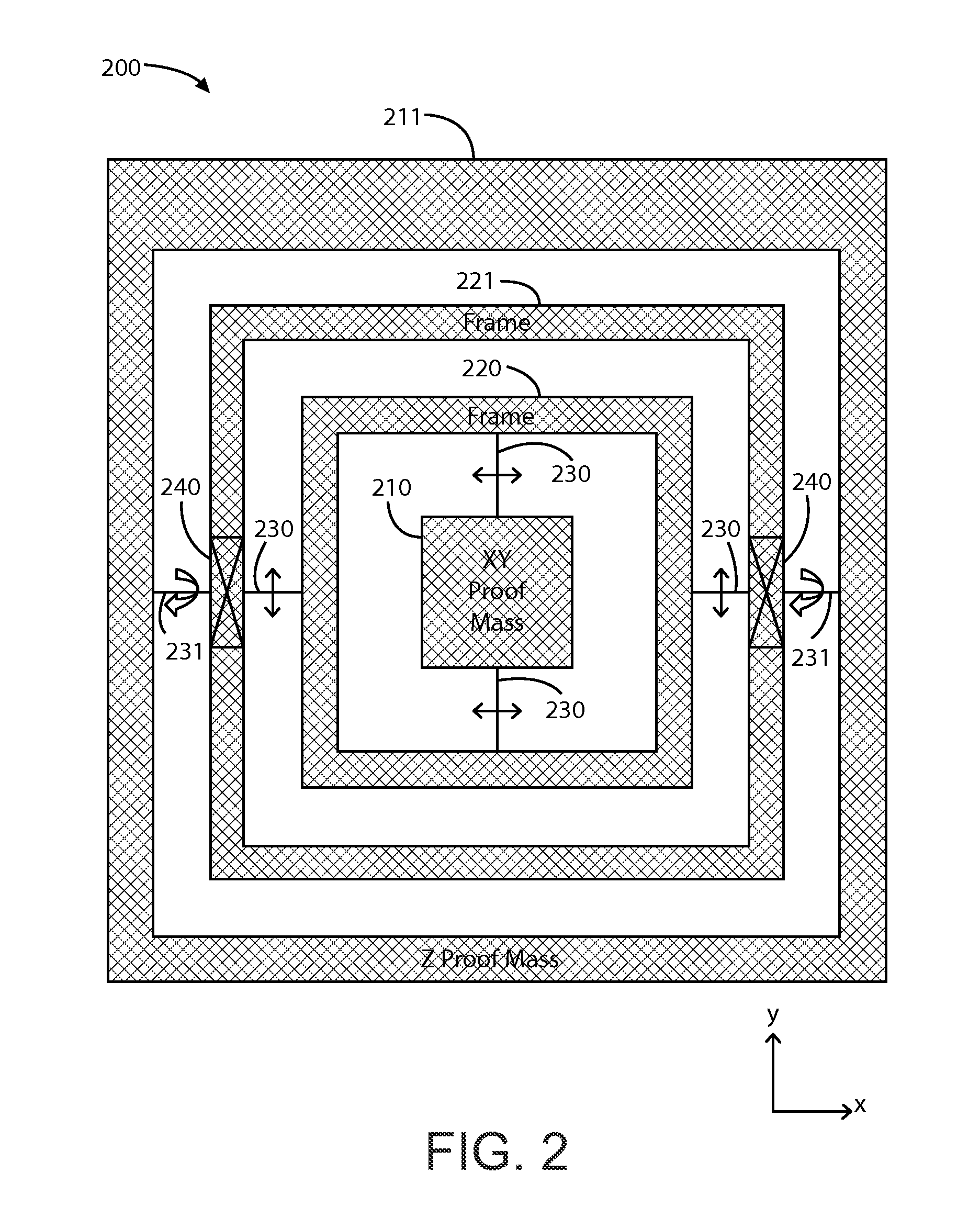

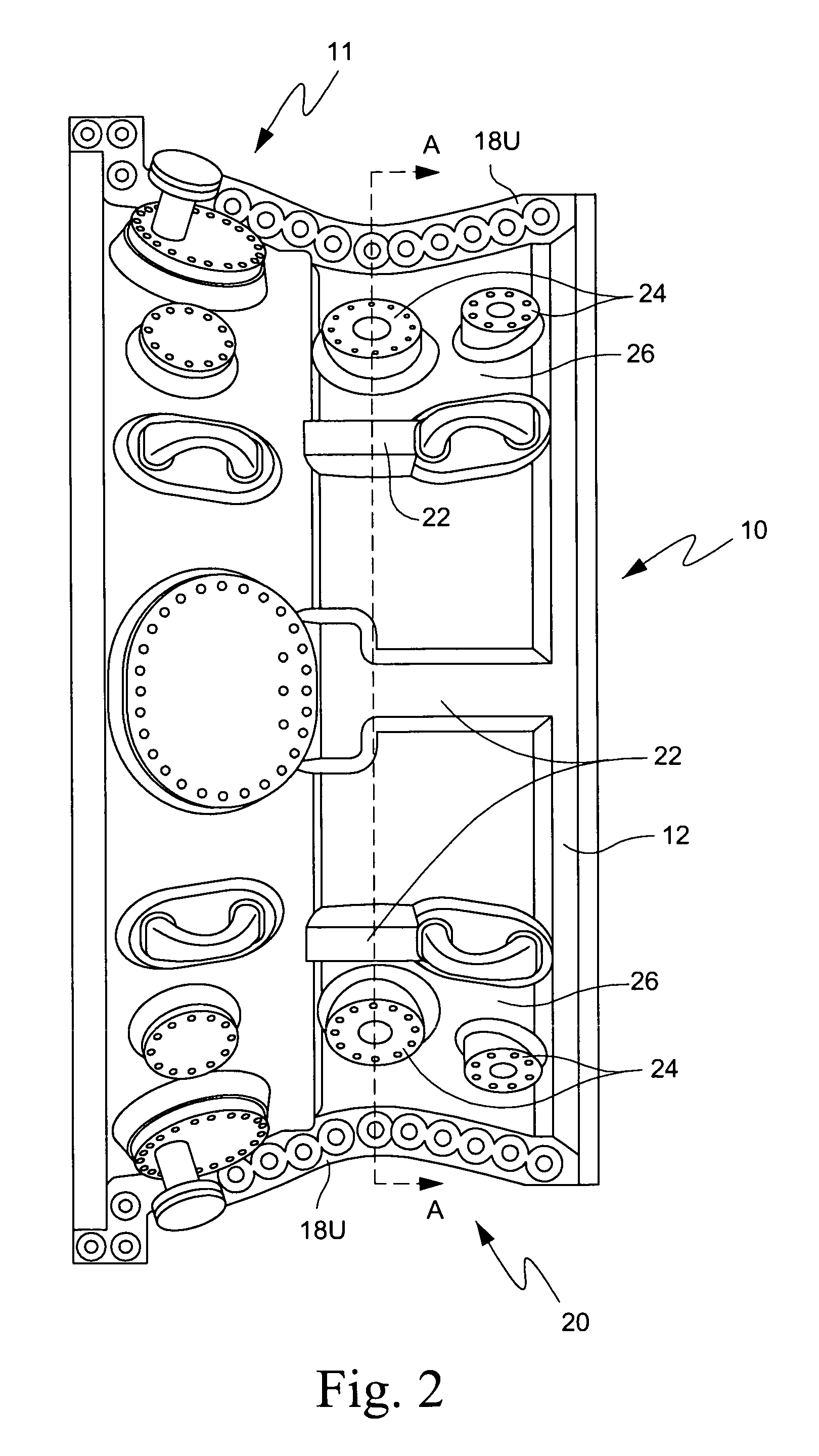

Mems-based dual and single proof-mass accelerometer methods and apparatus

ActiveUS20130214367A1Easy to measureMinimize, orAcceleration measurement using interia forcesSemiconductor devicesObservational errorEngineering

An integrated MEMS inertial sensor device includes one or more three-axis MEMS inertial sensor devices, such as accelerometers, with dual or single proof mass configurations. These designs can be compact and can decouple the motion of each axis to minimize the measurement errors due to cross-axis sensitivity. Some embodiments include a frame to decouple the motion of two axes and to provide geometric symmetry. Some embodiments also include double-folded springs. In a specific embodiment, the three axes of an integrated MEMS accelerometer device are entirely decoupled. Thus, the actuation of each axis, through a force due to acceleration, has little or substantially no effect on the other axes.

Owner:MOVELLA INC

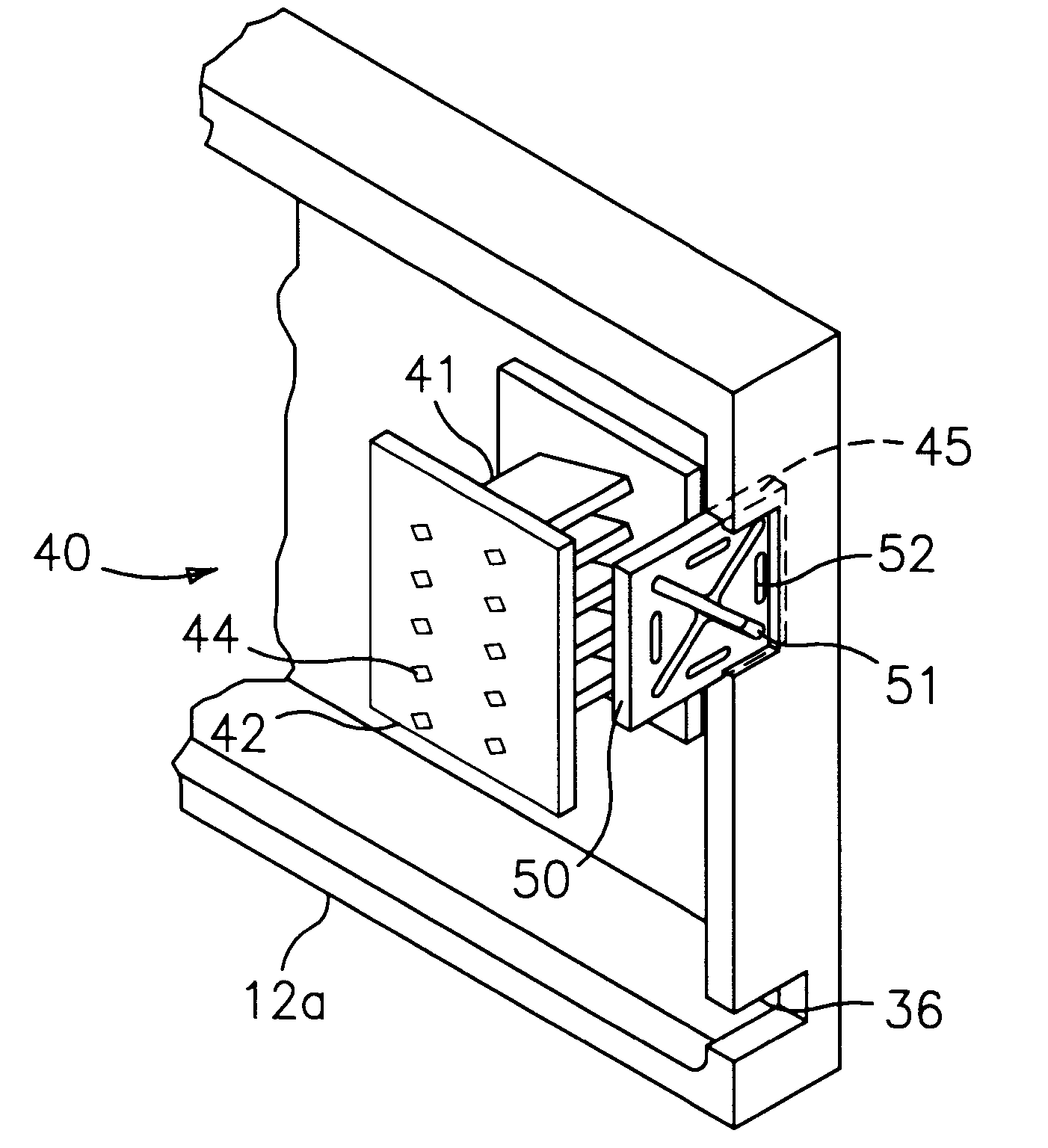

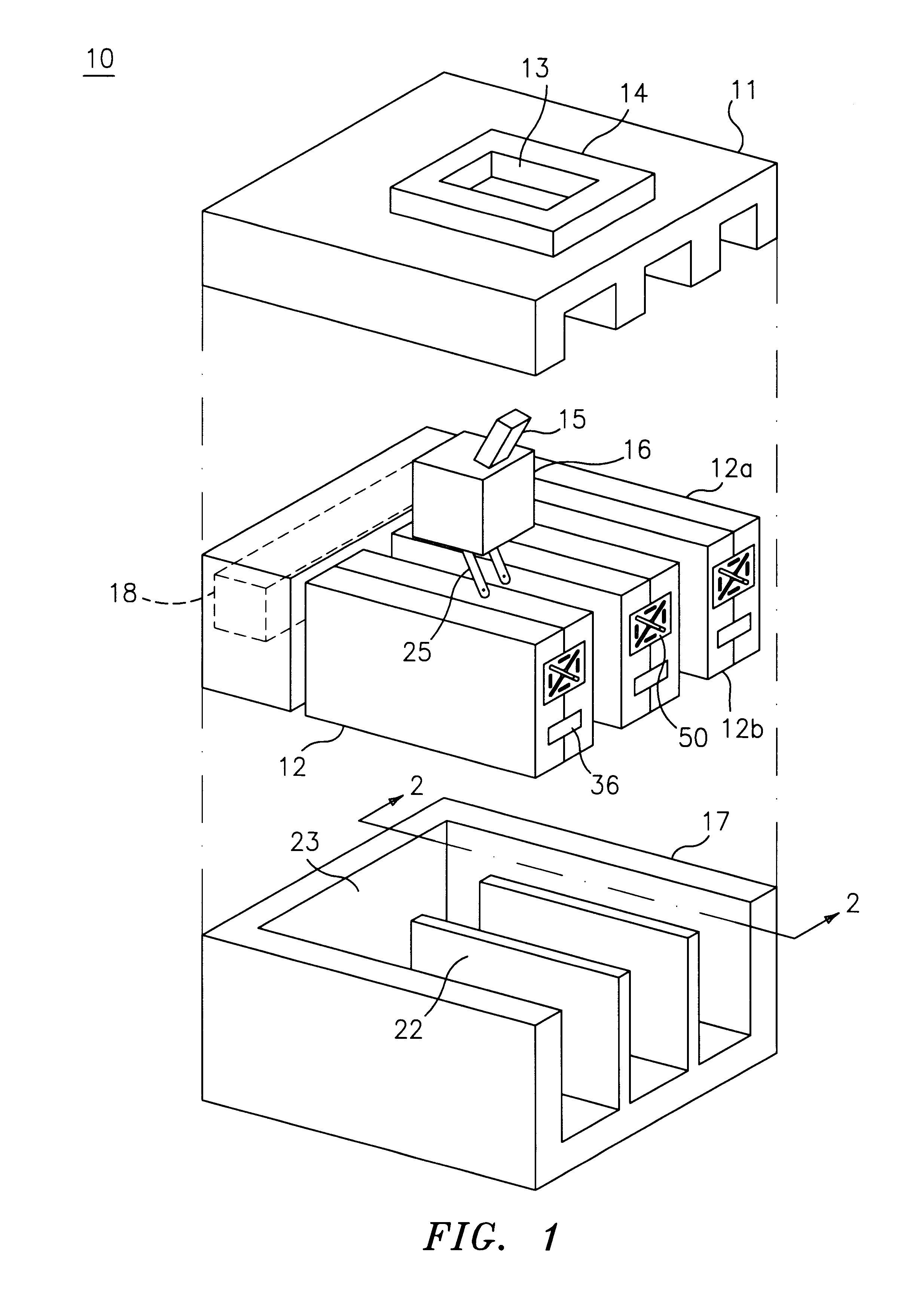

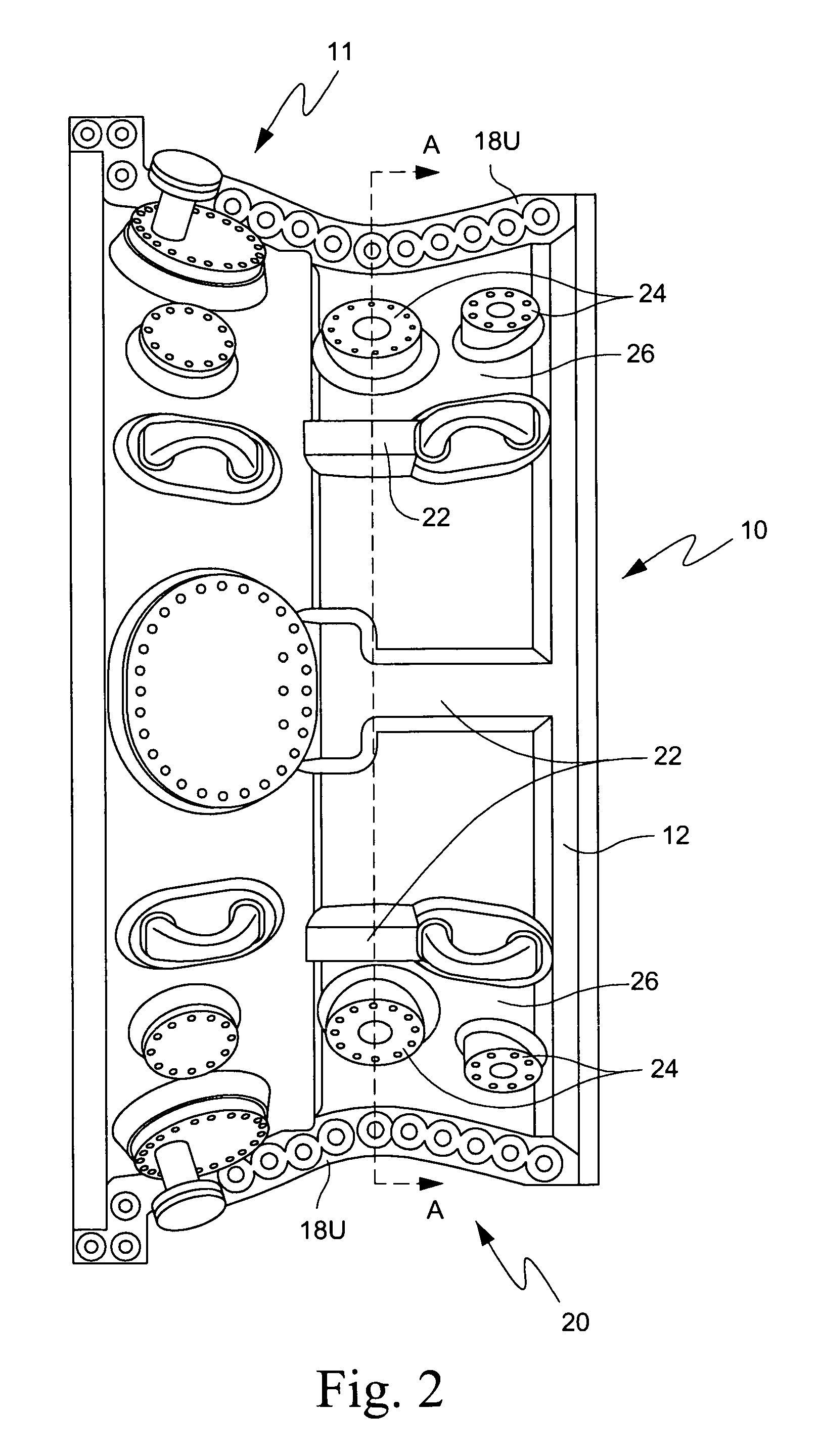

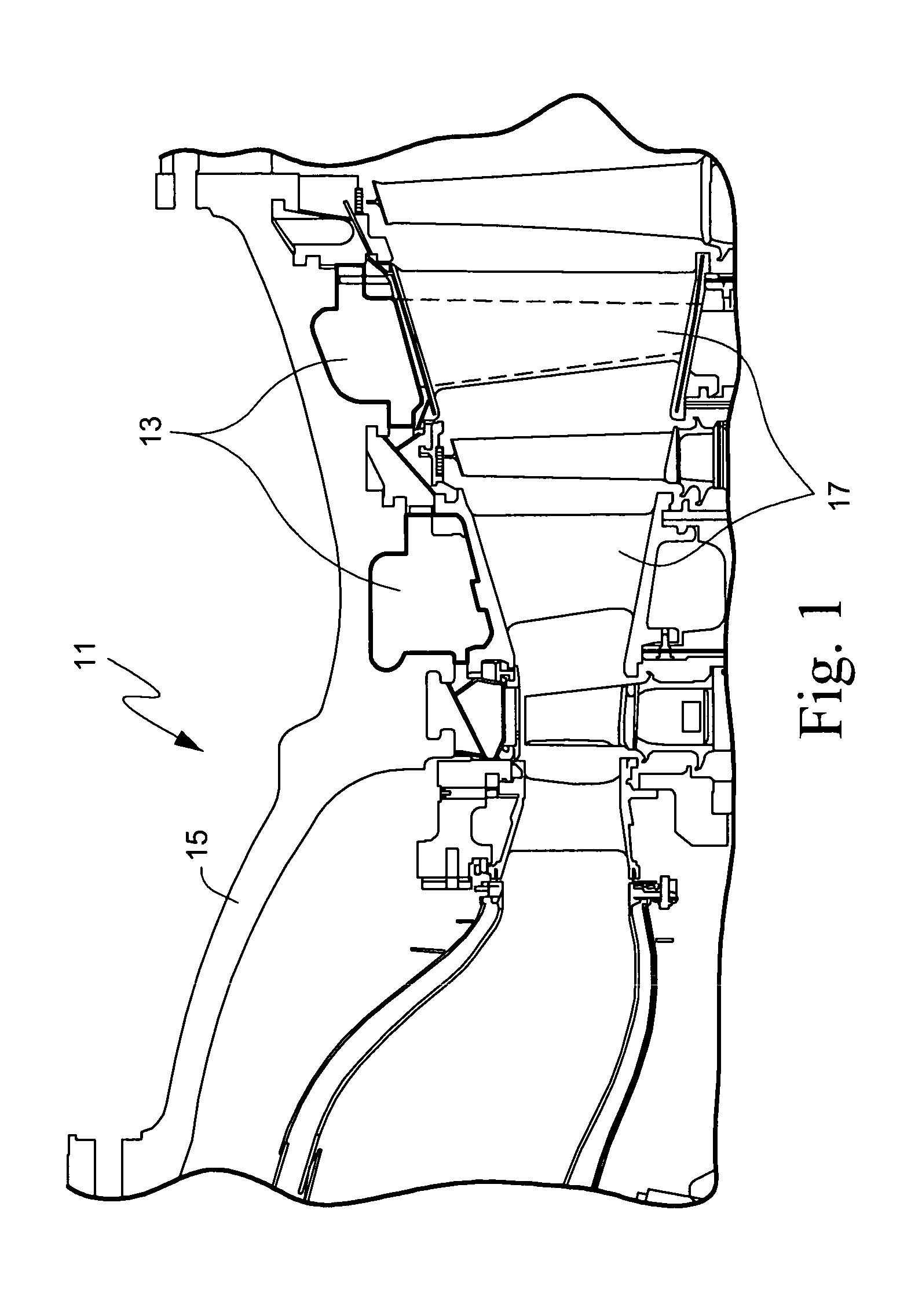

Circuit breaker arc exhaust baffle with variable aperture

InactiveUS6222147B1Reduce stressIncrease pressureProtective switch detailsHigh-tension/heavy-dress switchesCircuit breakerCircuit protection

An improved exhaust baffle for a circuit protective device such as a circuit breaker utilizes material having elastomeric characteristics to provide for variable apertures where the cross-sectional opening of the apertures is dependent on the pressure gradient across the exhaust baffle, thereby effectively controlling arc pressure and arc effluent during short circuit interruption. Fabrication of the exhaust baffle with geometric symmetry about one or more axes or planes also facilitates assembly during product construction.

Owner:ABB (SCHWEIZ) AG

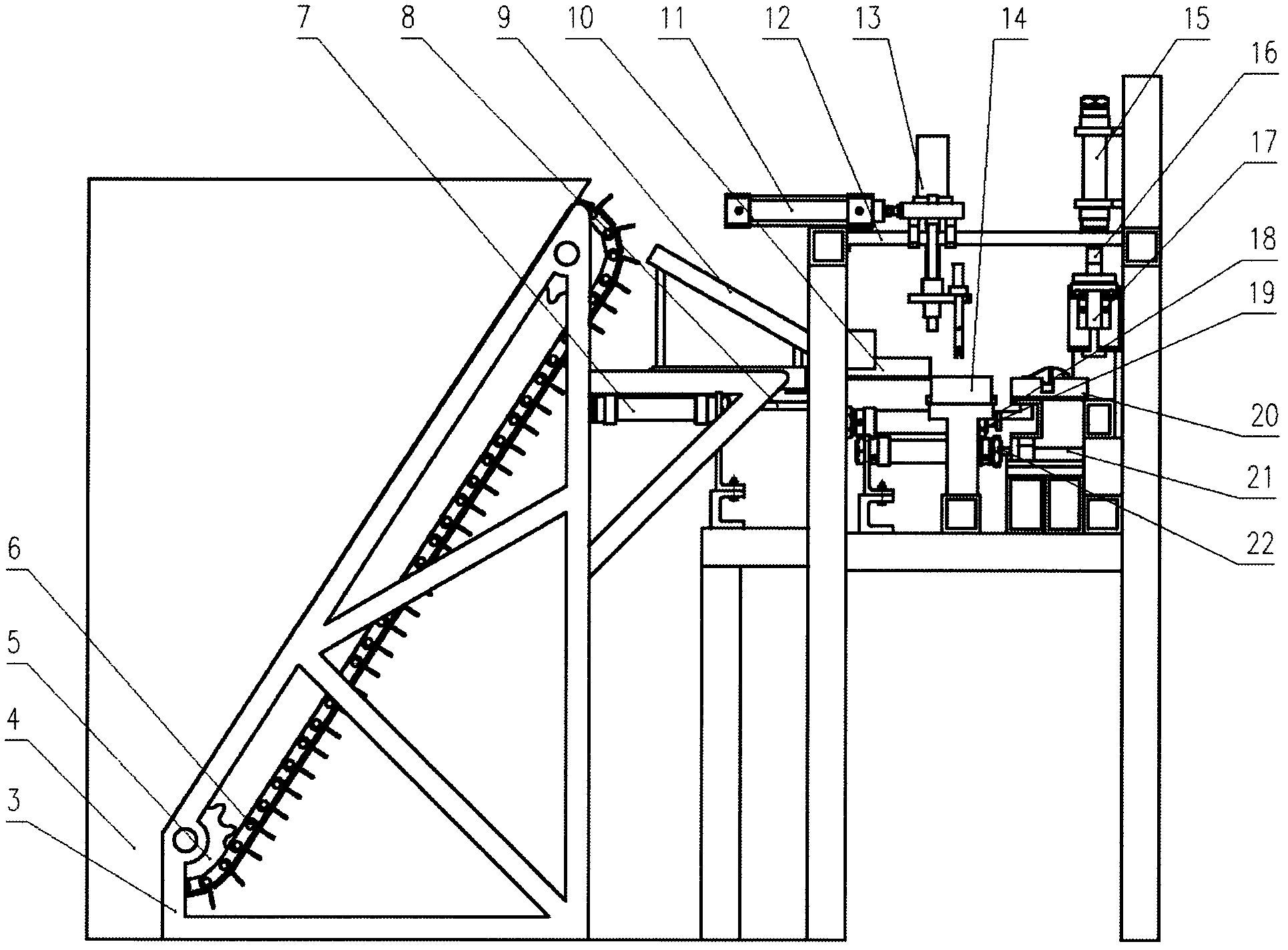

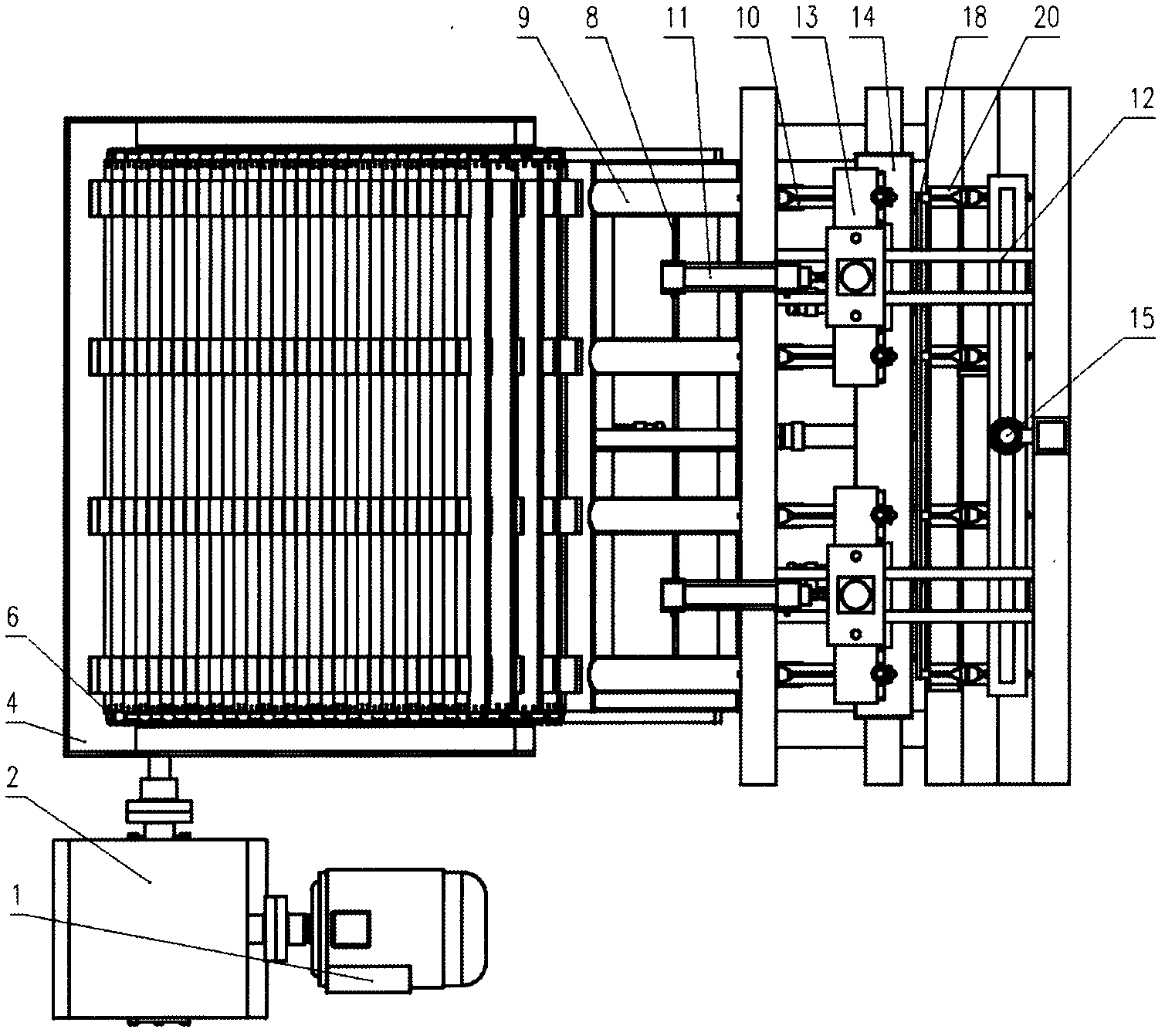

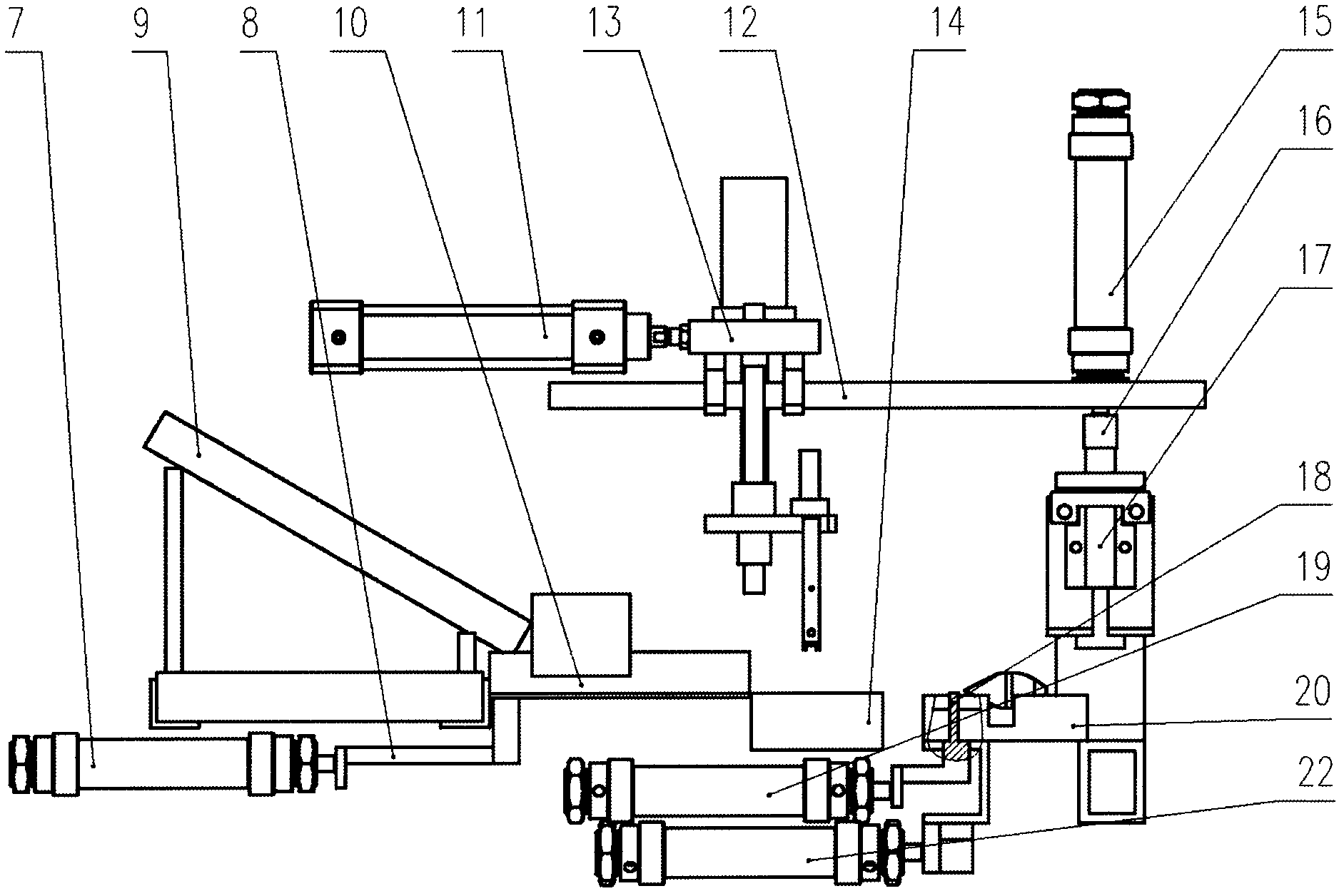

Betel nut slicing machine with positioning function

ActiveCN102490196ARealize automatic straighteningGuaranteed symmetryMetal working apparatusBetelEngineering

The invention relates to food processing equipment, in particular to a betel nut slicing machine with a positioning function. The betel nut slicing machine with the positioning function comprises a conveying device, a positioning device, a slicing device and a discharging device. Compared with the prior art, the betel nut slicing machine with the positioning function has the following advantages that the geometric symmetry planes of the betel nut can be found during slicing no matter the shape of the betel nut; the betel nut slicing machine with the positioning function has the advantages of being accurate to position, high in efficiency, reliable to act, safe to operate and the like, and can completely replace manual operation; and according to the combination of multiple groups of feeding plates, mechanical arms and slicing knives, the production capability is equivalent to the combination of various lines, the production efficiency is greatly improved, and the betel nut slicing machine with the positioning function is suitable for large-batch and full-automatic betel nut processing for the betel nut producing enterprises.

Owner:湖南宾之郎实业集团有限公司

MEMS-based dual and single proof-mass accelerometer methods and apparatus

ActiveUS9246017B2Minimize, orSubstantially error-freeAcceleration measurement using interia forcesSemiconductor devicesObservational errorAccelerometer

An integrated MEMS inertial sensor device includes one or more three-axis MEMS inertial sensor devices, such as accelerometers, with dual or single proof mass configurations. These designs can be compact and can decouple the motion of each axis to minimize the measurement errors due to cross-axis sensitivity. Some embodiments include a frame to decouple the motion of two axes and to provide geometric symmetry. Some embodiments also include double-folded springs. In a specific embodiment, the three axes of an integrated MEMS accelerometer device are entirely decoupled. Thus, the actuation of each axis, through a force due to acceleration, has little or substantially no effect on the other axes.

Owner:MOVELLA INC

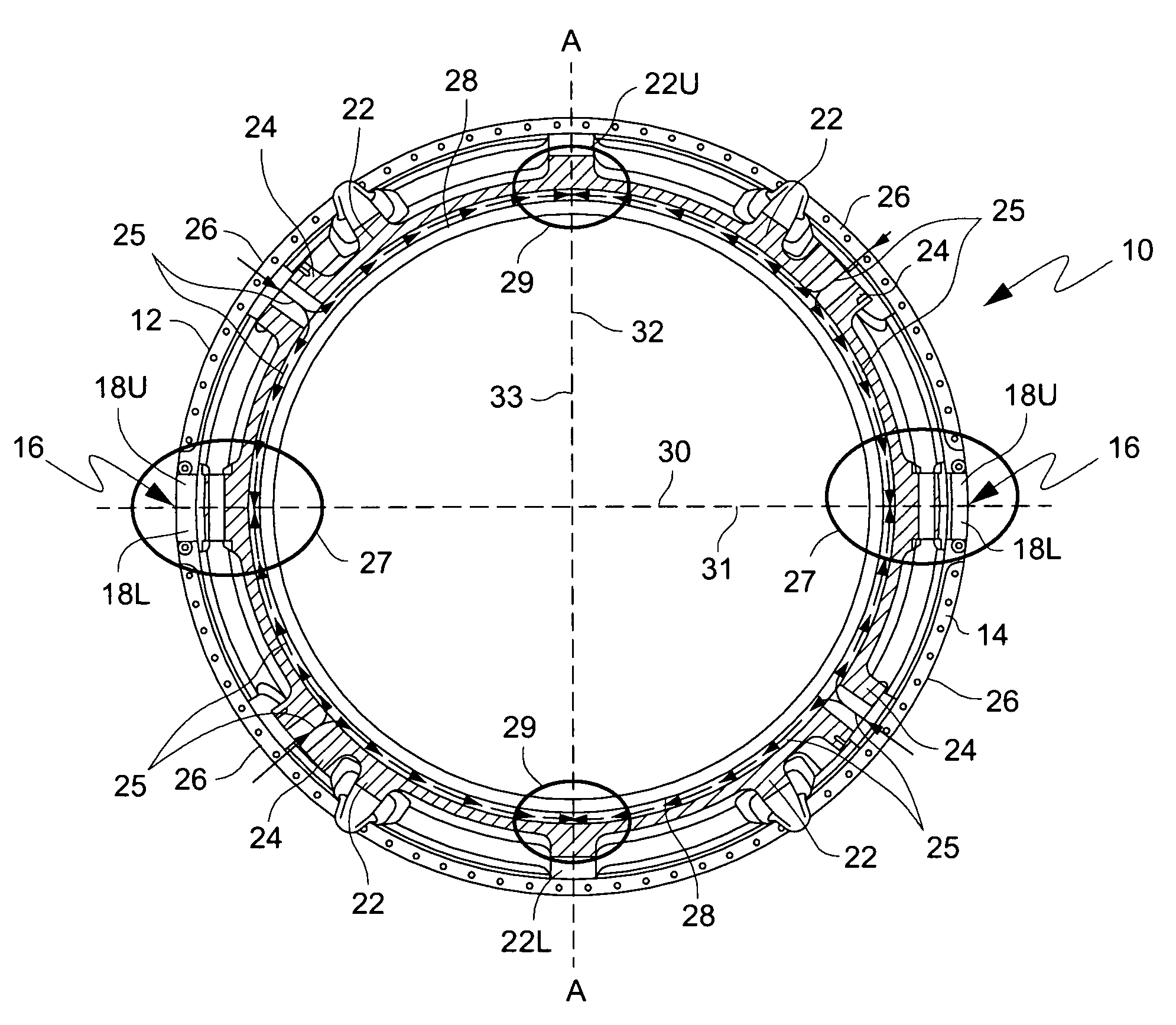

Switch-mode oximeter LED drive with a single inductor

ActiveUS7120479B2Reduce susceptibilityCancellation effectElectric light circuit arrangementDiagnostic recording/measuringMagnetic susceptibilityBobbin

A light emitter drive circuit for an oximeter which utilizes a single inductor for driving multiple light emitters. The inductor is connected to a switching circuit to multiple energy storage circuits, such as capacitors. These are alternately charged up, using the same inductor. Subsequently, the capacitors are alternately discharged for their corresponding light emitters through the same inductor. Also, the magnetic susceptibility of the LED drive circuit is reduced by using magnetic flux canceling in the inductor. In one embodiment, a toroidal inductor is used with geometric symmetry and its magnetic flux. In another embodiment, a dual core closed bobbin shielded inductor is used.

Owner:TYCO HEALTHCARE GRP LP

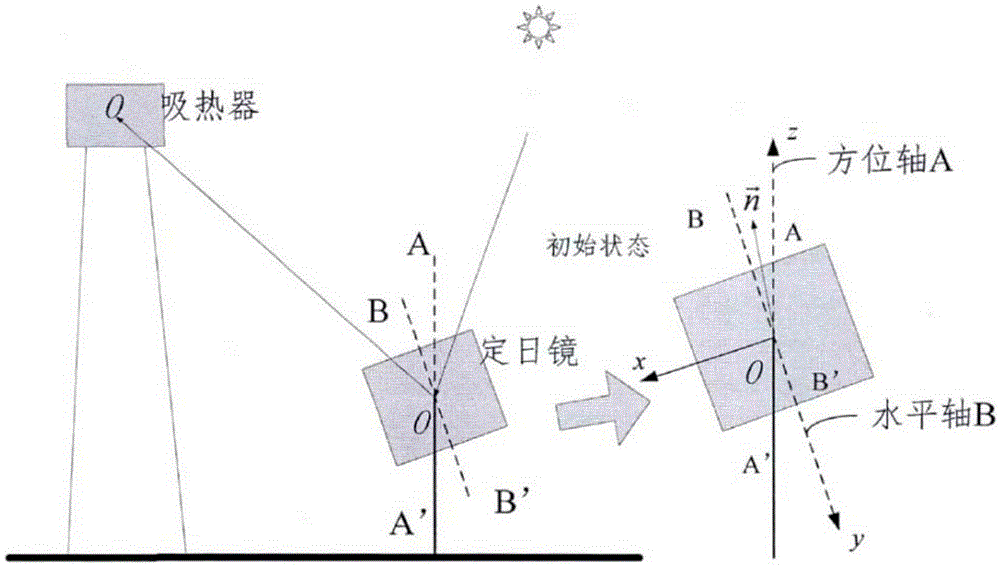

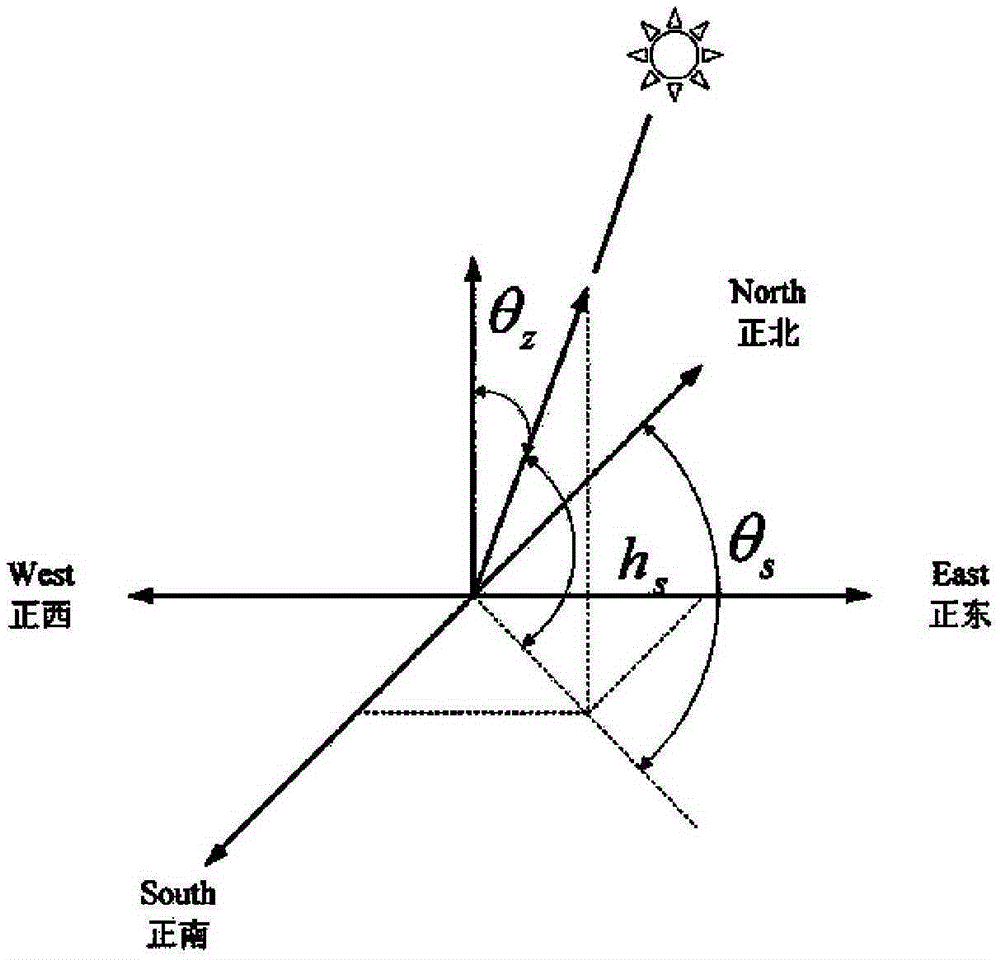

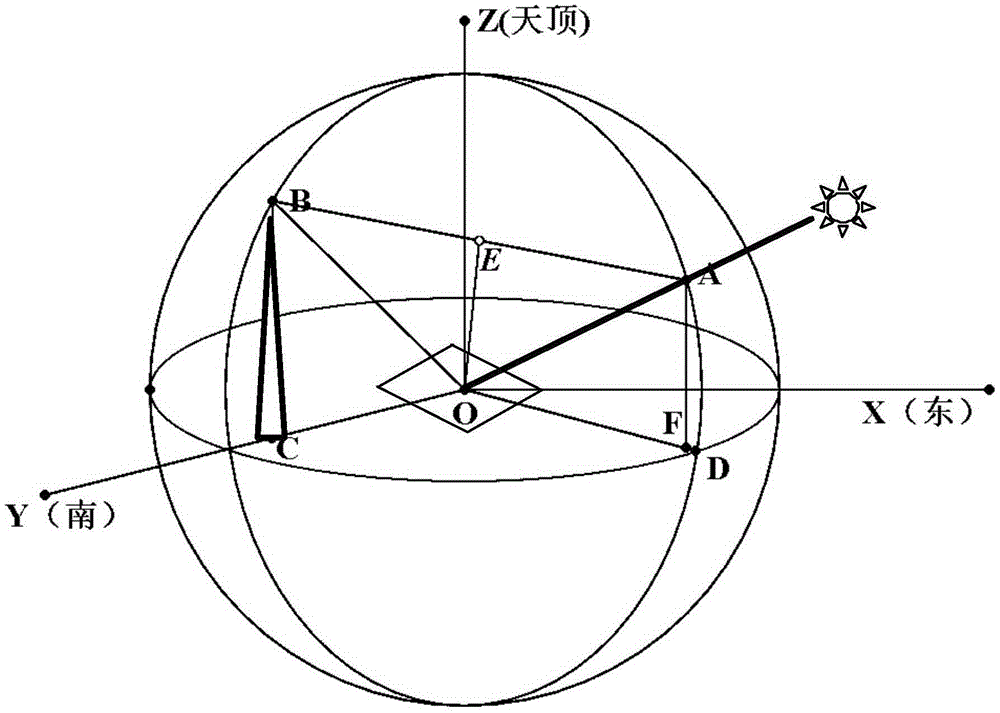

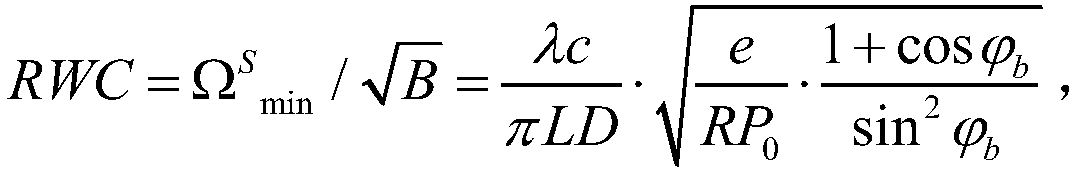

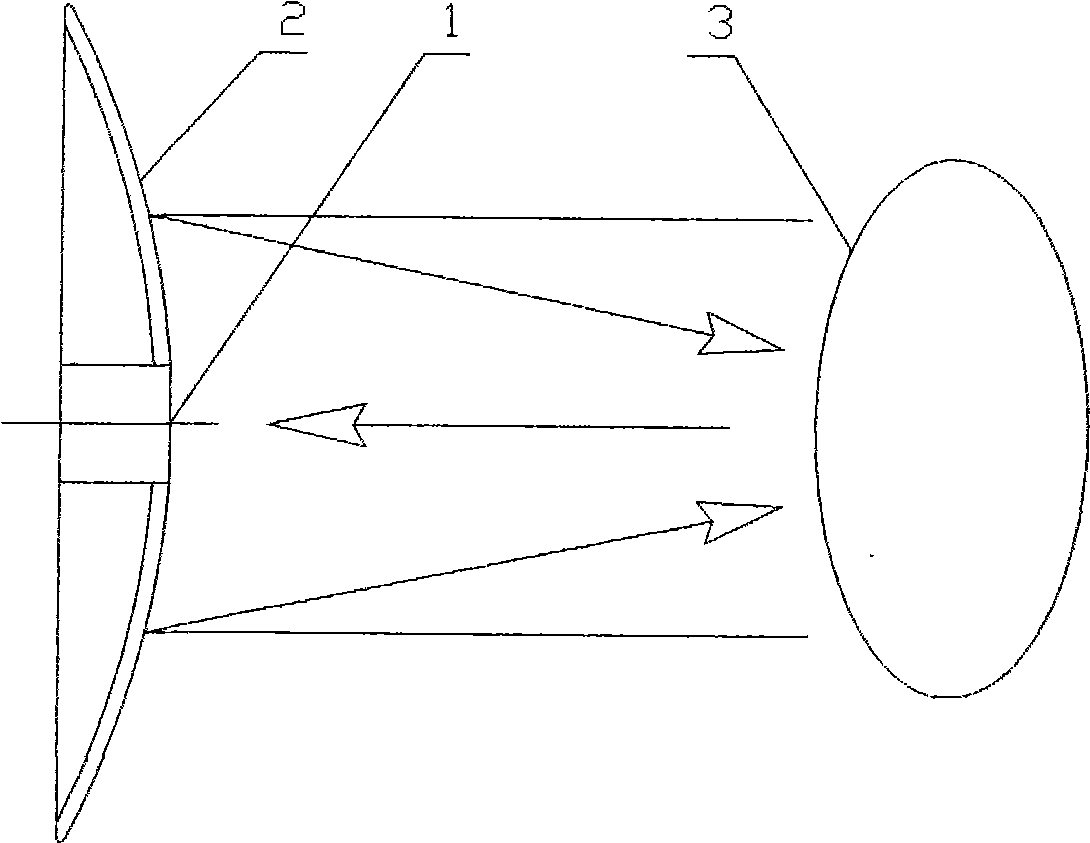

Efficient heliostat sun tracking method

ActiveCN105425833AImprove computing efficiencyRealize tracking and tracking controlControl using feedbackSun trackingGeometric symmetry

The invention provides an efficient heliostat sun tracking method, wherein a solar elevation angle hs and a solar azimuth angle Thetas of the position of a heliostat at a current moment are calculated; and a simplified formula takes the place of an SPA solar position algorithm published by NREL so as to realize calculation of the solar elevation angle and the solar azimuth angle, a sun tracking position of the heliostat is calculated according to optical reflection principles and geometric symmetry principles, and an instruction is sent to a stepping motor to control rotation of the heliostat so as to realize sun tracking control of the heliostat. The calculation method for the solar elevation angle and the solar azimuth angle is simple, has high calculation efficiency, can realize programming easily and is high in practicability and reliability.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

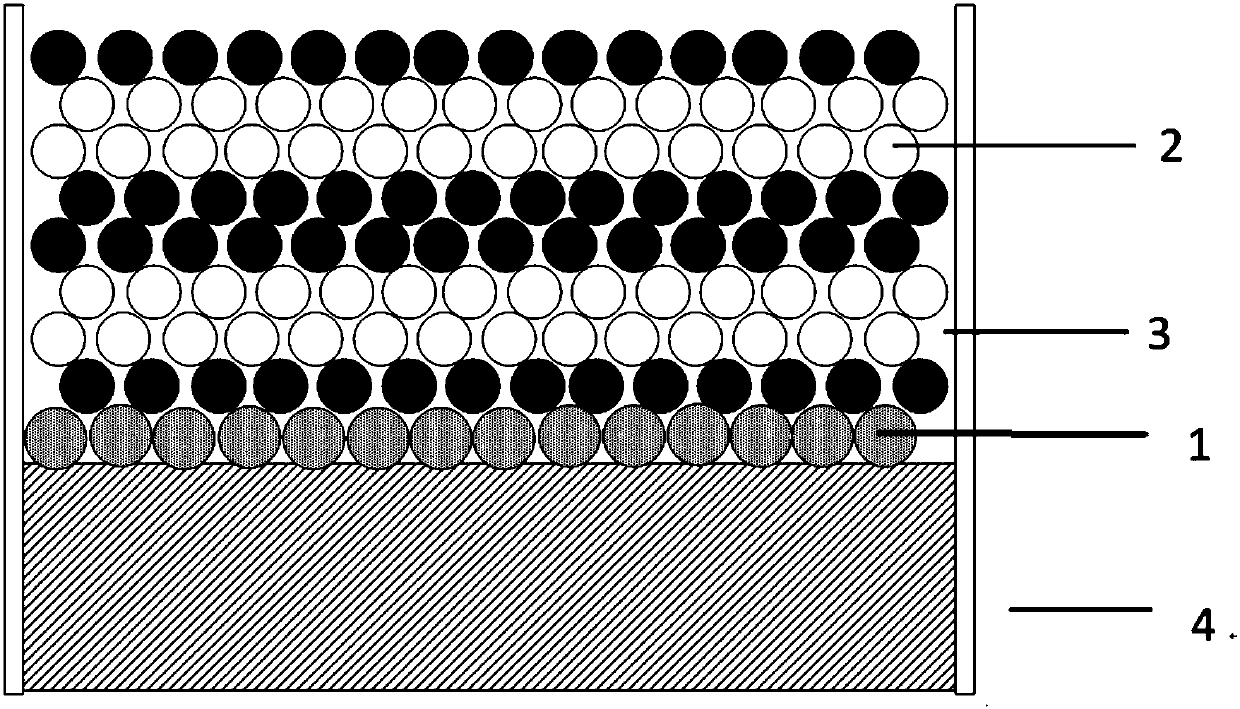

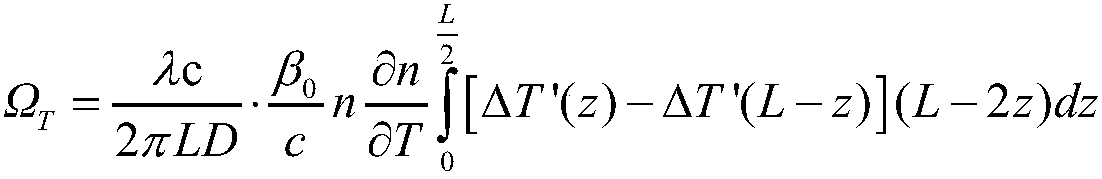

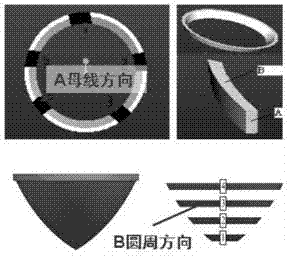

Optical fiber ring precision winding method

ActiveCN108088466AControl gapGuaranteed potting effectSagnac effect gyrometersGyroscopePolarization-maintaining optical fiber

The invention belongs to the technical field of manufacturing of an optical fiber ring of an optical fiber gyro, and in particular relates to an optical fiber ring precision winding method. The methodcomprises the following steps: determining the length of optical fiber and the structure of the optical fiber ring; processing winding tooling; selecting suitable polarization maintaining optical fiber; winding single mode optical fiber; and winding the polarization maintaining optical fiber. The method needs to solve the problems that when a large-length optical fiber ring is wound, the existingoptical fiber winding method cannot guarantee the geometric symmetry of the optical fiber ring, the zero-drift amount of the optical fiber ring under the variable temperature condition is too large,and the precision of an inertial gyroscope is influenced. By customizing of the special-sized single-mode optical fiber and winding tooling, the gap between the optical fiber can be controlled when the polarization-maintaining optical fiber is wound, and the number of turns of the optical fiber in each layer is fixed. Based on a four-pole symmetrical winding method, the geometric symmetry of the optical fiber is finally ensured, the zero-drift amount of the optical fiber ring under the variable temperature condition is reduced, and the precision of the inertial gyroscope is improved.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

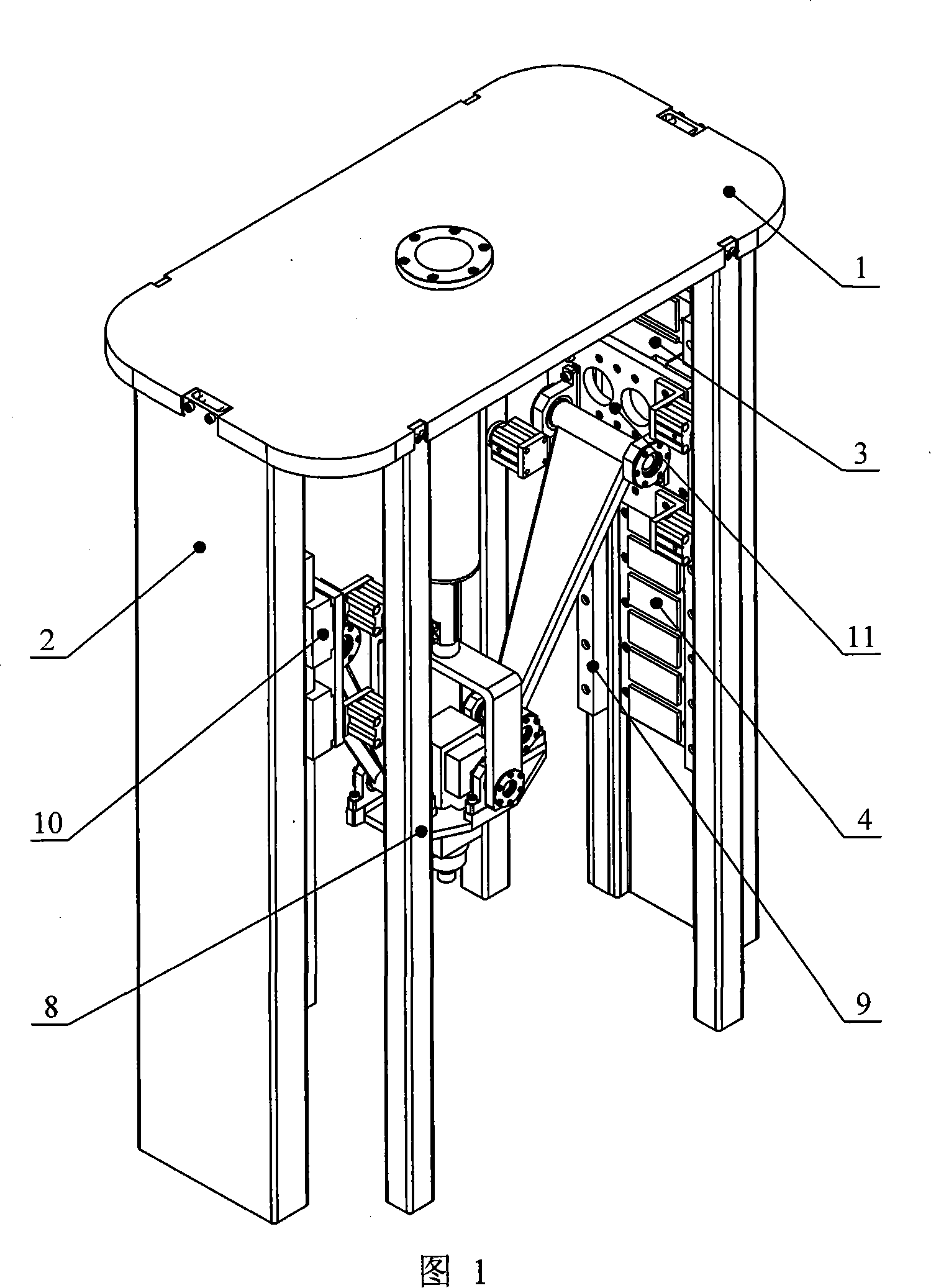

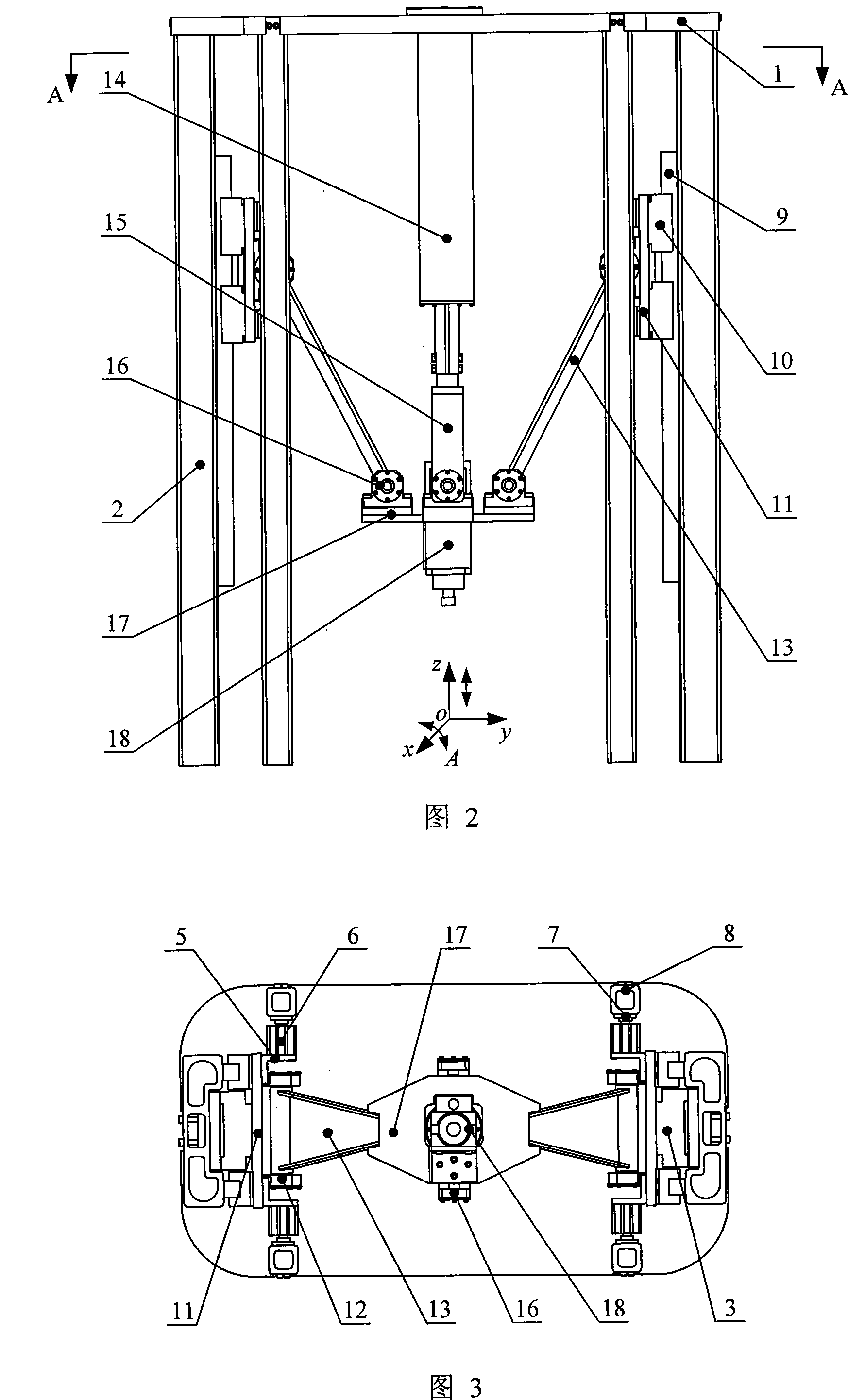

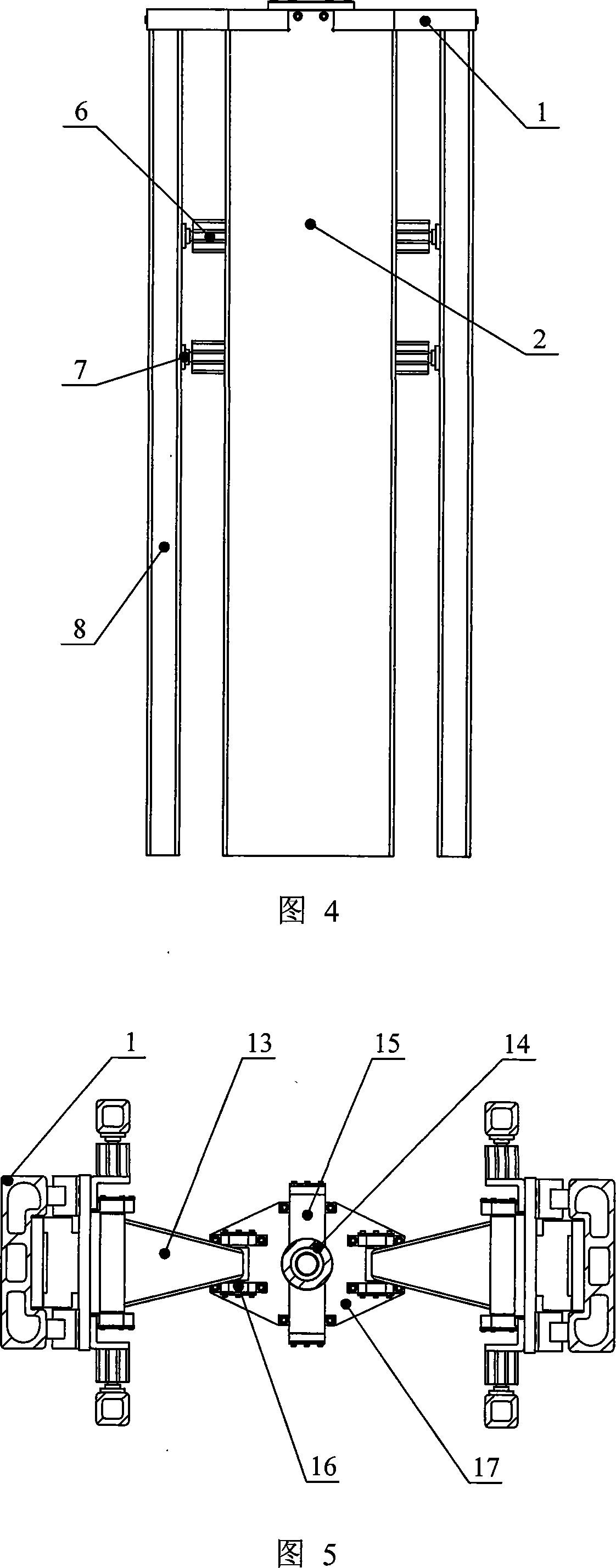

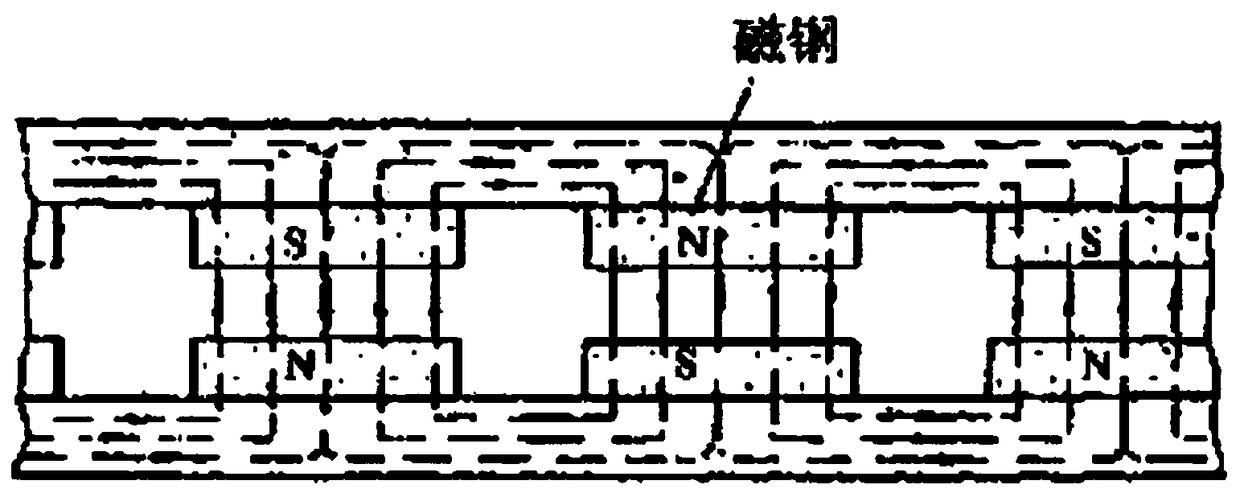

Platform of principal axis with paralleled Z, A two degrees of freedom driven by linear motor

The invention relates to a Z-A two degree of freedom parallel main shaft platform driving by linear motor. It includes static platform, vertical shaft, linear motor stator and mover, self locking device, moving fit device, rotating fit assembly A, B, connecting rod assembly, expansion link component, moving platform component and main shaft component. The static platform has plane shaped, and vertical shaft is slot shaped. Linear motor stator is set on vertical shaft and mover is connected to moving fit device. The self locking device has cylinder, cylinder base, friction plate, and friction column. The moving fit component has linear guide rail, slider and moving base. Rotating fit assembly is rotating component. Connecting rod assembly has V shape, and expansion link component has expansion link and U shaped shifter. Moving platform component has geometric symmetry polygon. The connecting relationship is that: vertical shaft connects to static platform; moving fit component is located on vertical shaft; connecting rod assembly connects to moving fit device and moving platform through rotating fit assembly A and B; one end of expansion link connects to static platform and the other end connects to moving platform assembly. The main shaft section is set on moving platform assembly.

Owner:BEIHANG UNIV

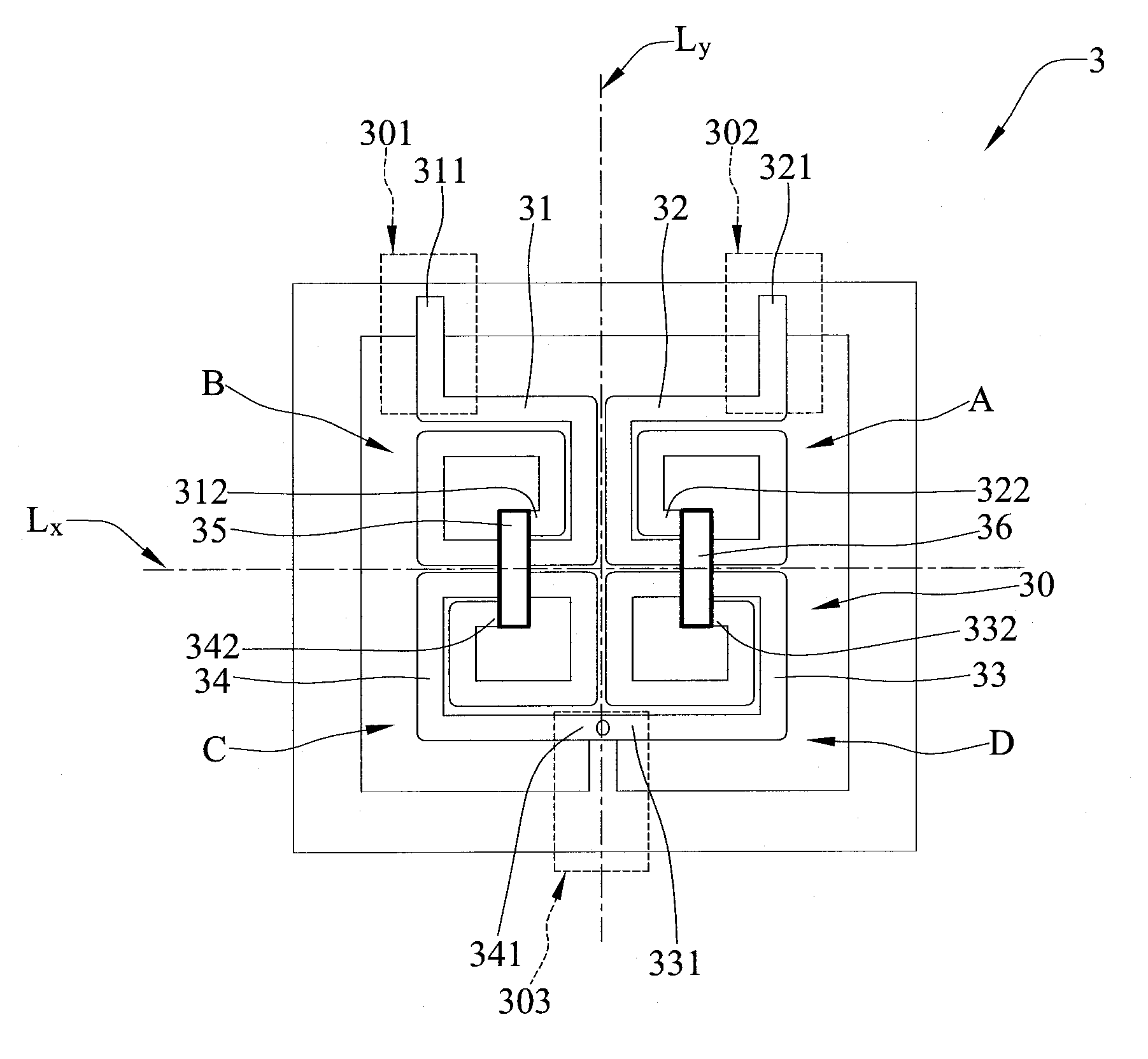

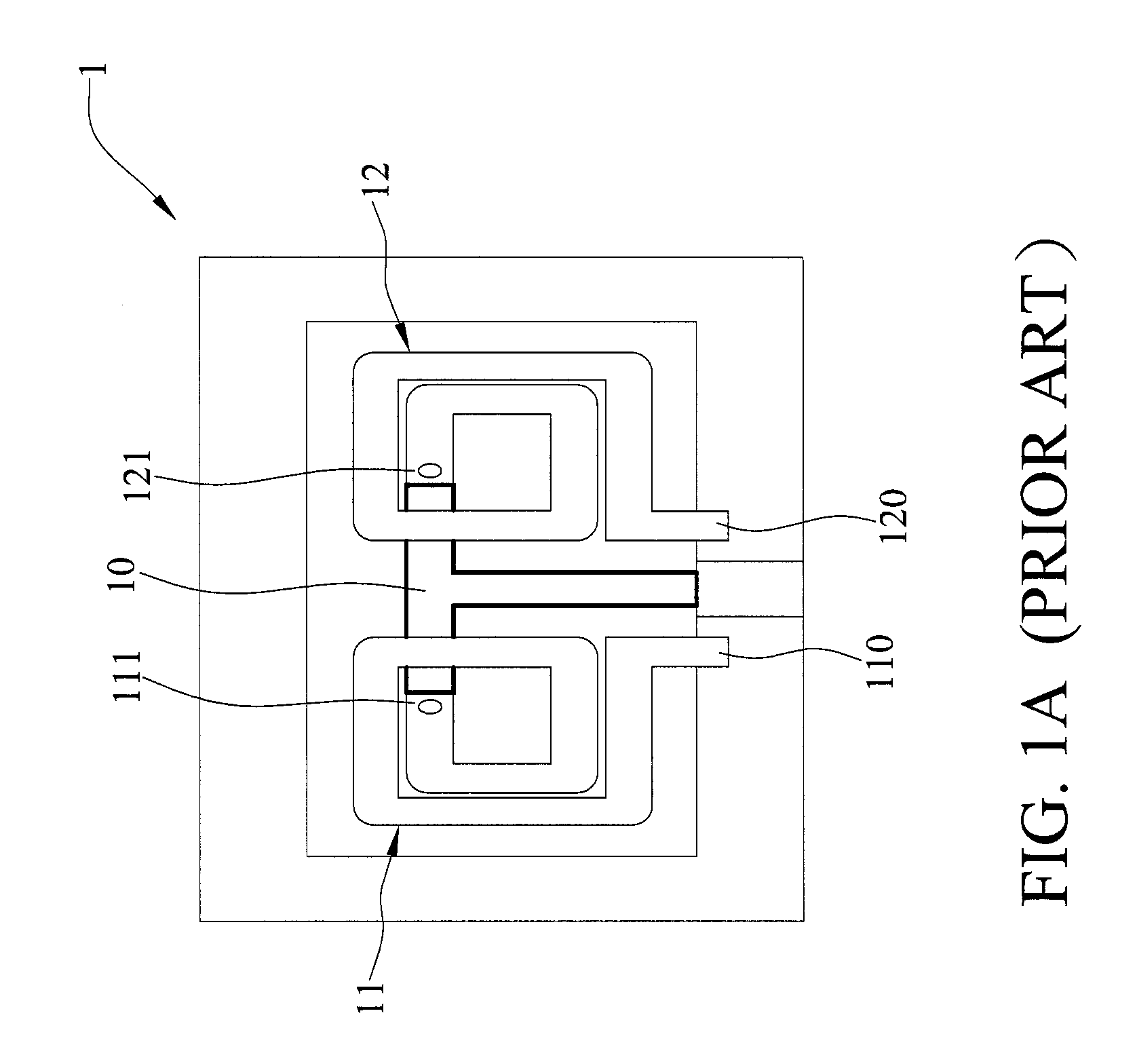

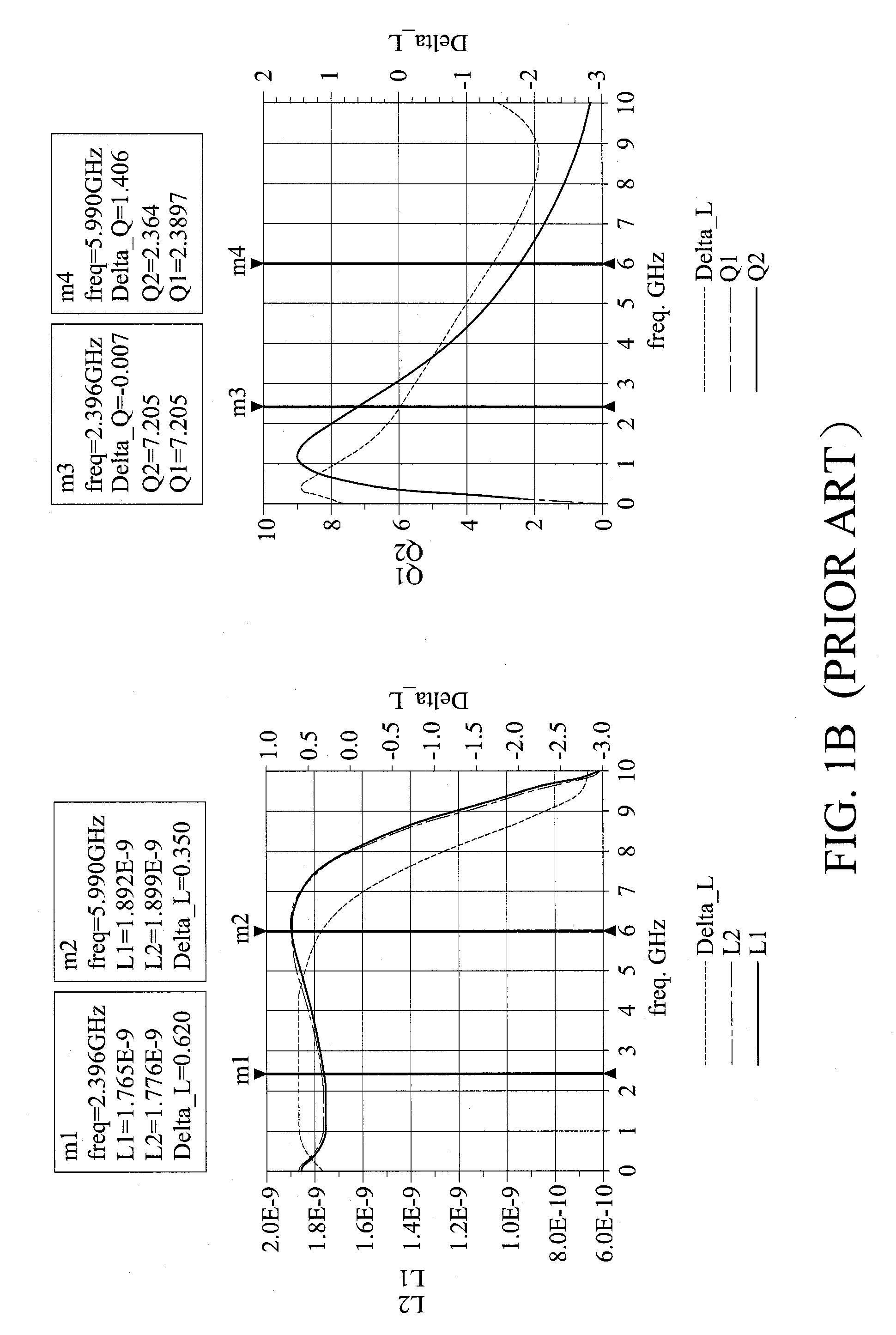

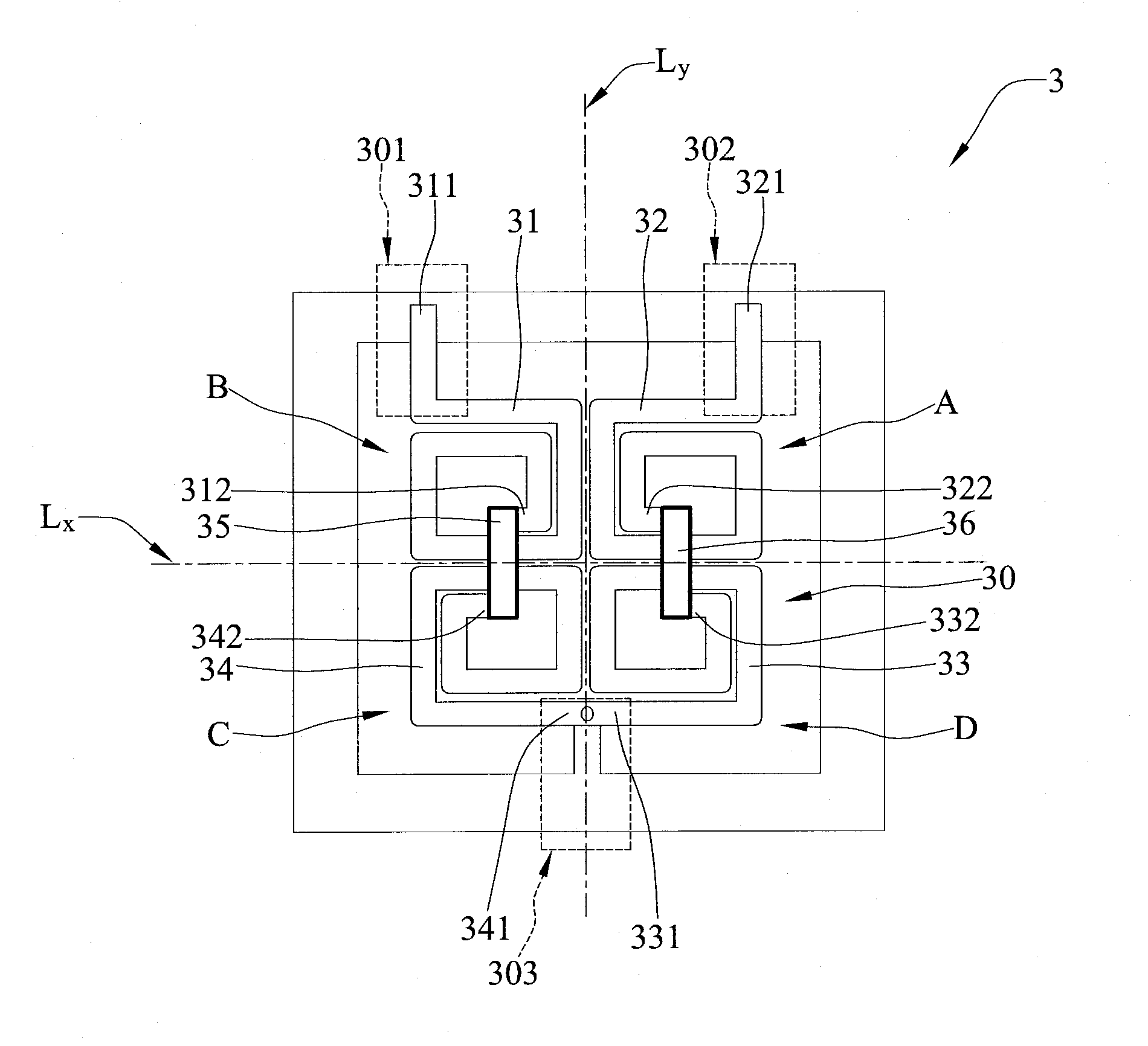

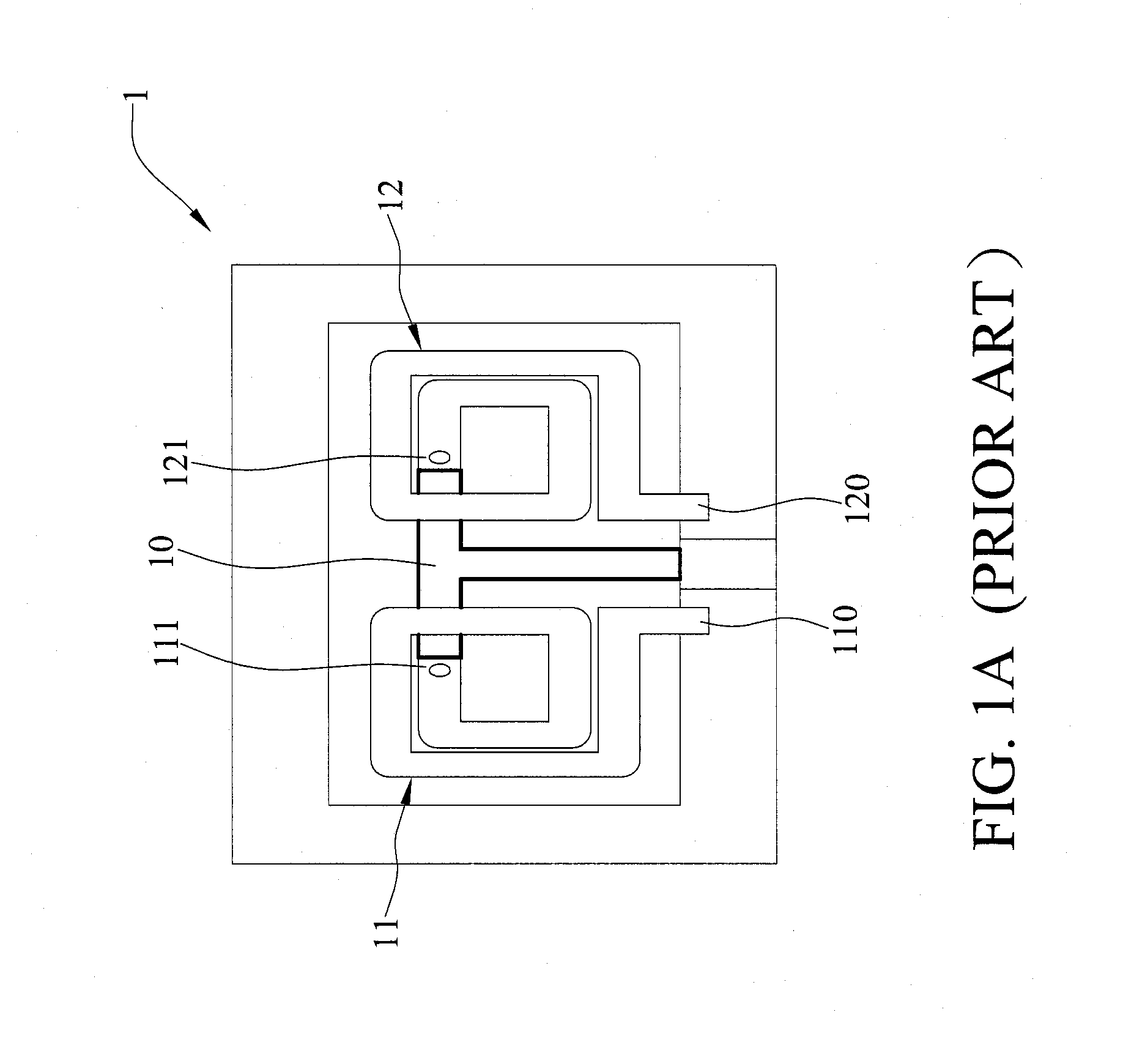

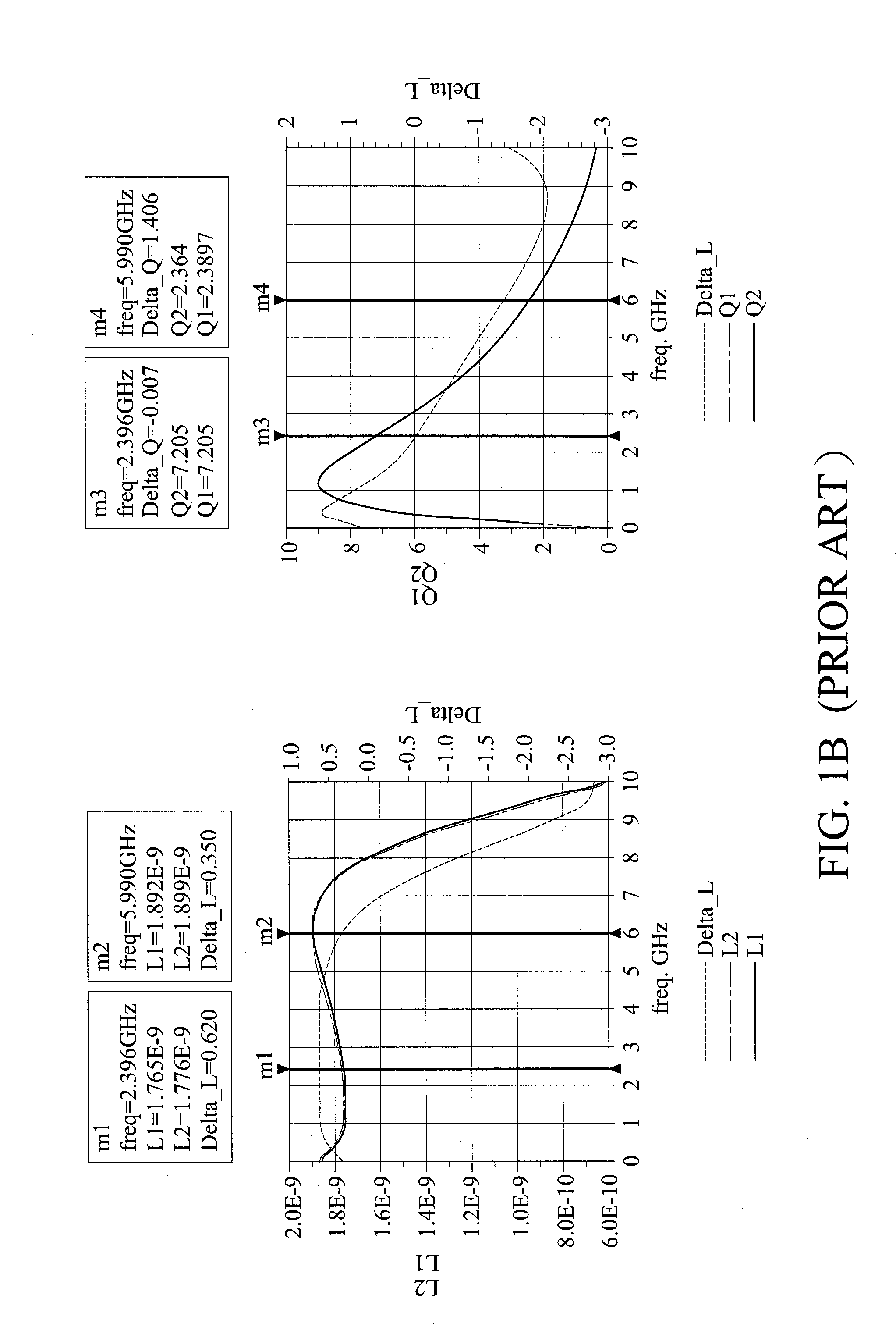

Symmetric differential inductor structure

ActiveUS8305182B1Increase product profitHigh yieldSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsFour quadrantsInductor

A symmetric differential inductor structure includes first, second, third and fourth spiral conductive wirings disposed in four quadrants of a substrate, respectively. Further, a fifth conductive wiring connects the first and fourth spiral conductive wirings, and a sixth conductive wiring connects the second and third spiral conductive wirings. The first and second spiral conductive wirings are symmetric but not intersected with one another, and the third and fourth spiral conductive wirings are symmetric but not intersected with one another. Therefore, the invention attains full geometric symmetry to avoid using conductive wirings that occupy a large area of the substrate as in the prior art and to thereby increase the product profit and yield.

Owner:SILICONWARE PRECISION IND CO LTD

Asymmetrical gas turbine cooling port locations

ActiveUS20100111679A1Improve heat transfer performanceQuality improvementPump componentsTurbine/propulsion engine coolingTurbineHorizontal and vertical

A method is disclosed for improving a turbine's thermal response during transient and steady state operating conditions in which the flow of cooling fluid in the turbine's casing is caused to be asymmetrical relative to the horizontal and vertical symmetry planes of the casing so that the turbine's cooling symmetry planes are rotated relative to its geometric symmetry planes and thereby the heat transfer at locations in the casing with increased mass is increased.

Owner:GENERAL ELECTRIC CO

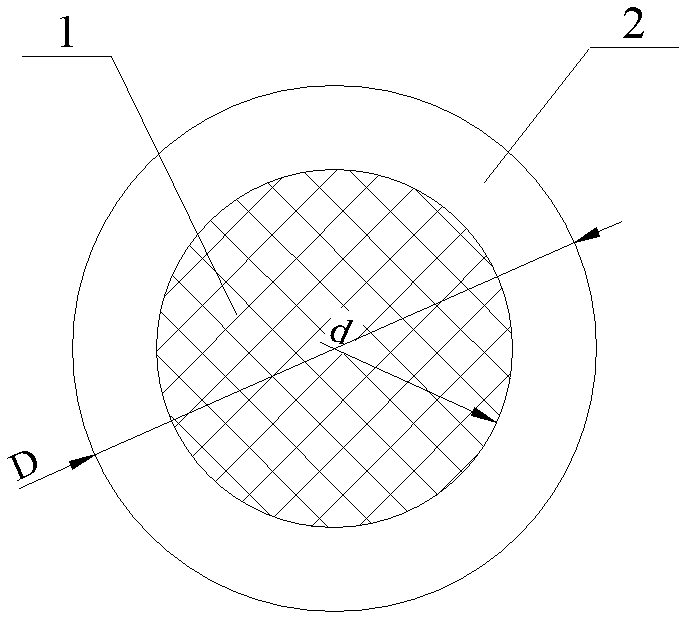

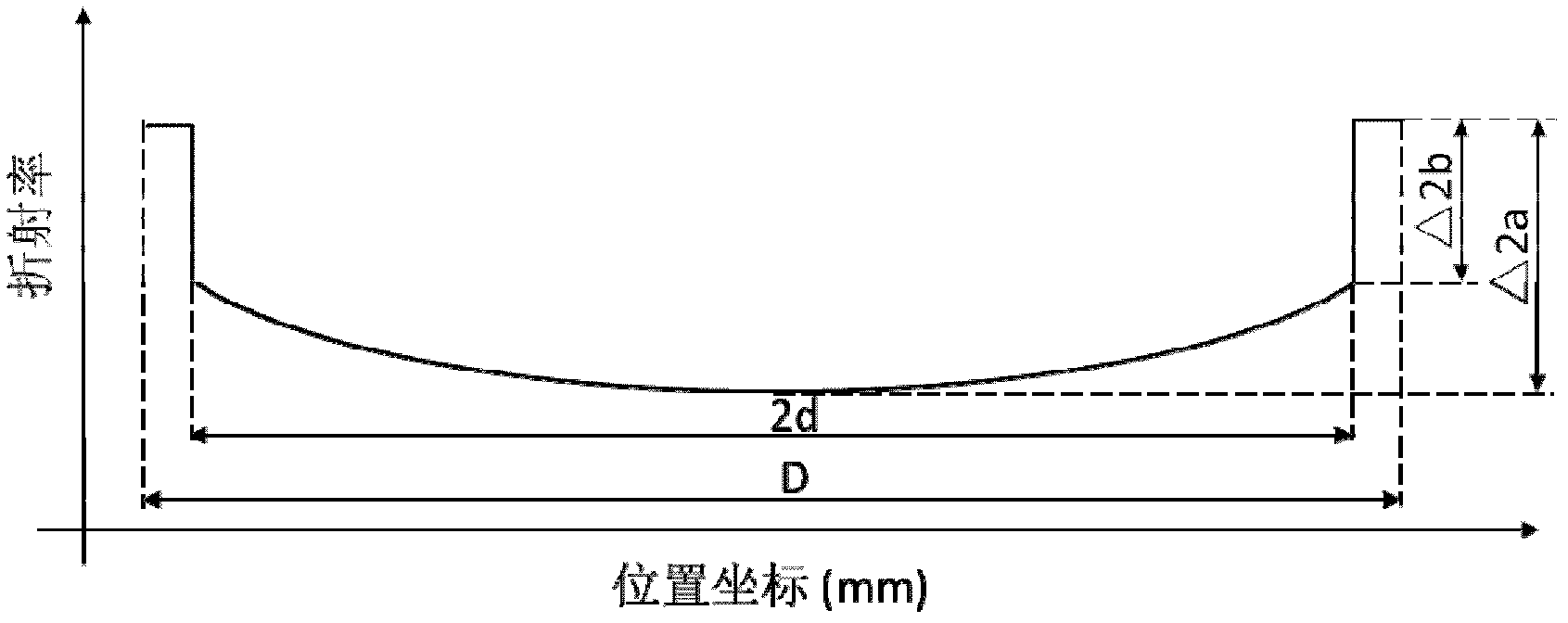

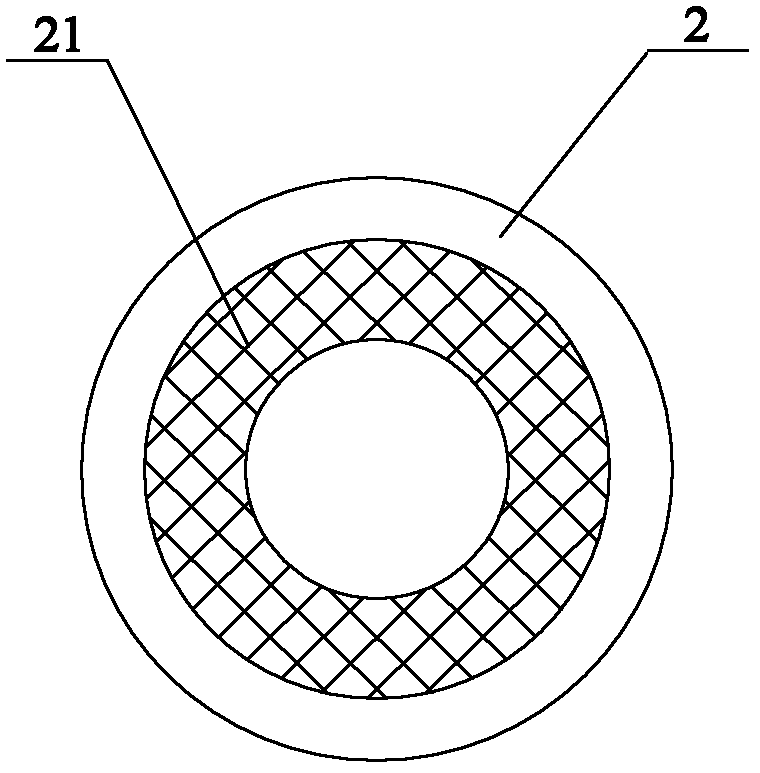

Boron-doped stress bar for manufacturing polarization-preserving fiber and manufacturing method for boron-doped stress bar

ActiveCN102531378AIncrease profitIncrease the doping concentrationGlass making apparatusGlass fibre productsFiberChloride

The invention discloses a boron-doped stress bar for manufacturing a polarization-preserving fiber and a manufacturing method for the boron-doped stress bar. The manufacturing method comprises the following steps of: A10, depositing a boron doping area on the inner wall of a quartz liner tube by using a plasma chemistry vapor deposition (PCVD) process to obtain a prefabricated member, namely introducing mixed gas into one end of the quartz liner tube, and discharging the mixed gas through the other end of the quartz liner tube, wherein the mixed gas comprises silicon tetrachloride vapor with the flow of 700-1,900sccm, high-purity oxygen with the flow of 1,600-5,000sccm and boron chloride with the flow of 70-1,100sccm; and A20, performing high temperature collapsar on the deposited prefabricated member into a solid boron-doped stress bar. BCl3 and SiCl4 are used as raw materials, the boron doping area is deposited at high speed and high efficiency by the PCVD process, and the utilization rate of the raw materials and the doping concentration are improved; and moreover, gradient doping is adopted, so that the problem that the boron stress bar is easily broken and twisted in the processing can be solved, the geometric symmetry of the doping area is improved, the probability of panda eye and cladding breakage in the cutting is reduced, and the welding efficiency of the fiber is improved.

Owner:RUIGUANG TELECOMM TECH CO LTD

Preparation method of uniform low-stress value cone-shaped charge cover

ActiveCN108004491AGuaranteed dimensional accuracyQuality assuranceExplosive chargesAmmunitionShaped chargePressure stress

The invention provides a preparation method of a uniform low-stress value cone-shaped charge cover. The preparation method comprises the steps: multi-pass extrusion moulding, vibrating ageing treatment and deep cooling treatment, wherein the multi-pass extrusion moulding is 4-8 pass extrusion deformation under the action of three-directional pressure stresses and deformation rates of 5-10mm / s, wherein the deformation amount of each pass is 5-50%. The uniform low-stress value cone-shaped charge cover prepared by the method provided by the invention is high in dimensional precision, good in geometric symmetry and low in stress value, is good in dimensional stability in precise cutting machining and using processes, and can enhance the penetration ability and the stability of the cone-shapedcharge cover of a armor penetration warhead remarkably.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Asymmetrical gas turbine cooling port locations

ActiveUS8047763B2Improve heat transfer performanceQuality improvementPump componentsBlade accessoriesTurbineHorizontal and vertical

A method is disclosed for improving a turbine's thermal response during transient and steady state operating conditions in which the flow of cooling fluid in the turbine's casing is caused to be asymmetrical relative to the horizontal and vertical symmetry planes of the casing so that the turbine's cooling symmetry planes are rotated relative to its geometric symmetry planes and thereby the heat transfer at locations in the casing with increased mass is increased.

Owner:GENERAL ELECTRIC CO

Processing technique of roots pump fan blade

The invention relates to a processing technology of Roots pump fan blade, comprising testing roughcast, milling the upper and lower big surfaces of a fan blade roughcast, grinding a big surface of a fan blade roughcast as the base level, using the grinded bug surfaces as the main shaft hole and the reducing hole base fan blade, grinding the left and right ends of the fan blade roughcast, planing keyway of the fan blade roughcast, planing the shape of the fan blade rudely, making the main shaft and pressing the fan blade main shaft into the main shaft hole, planing the external circle of the upper and lower surface of the fan blade and the left and right ends rudely, grinding the upper and lower external circle of the fan blade, the left and right ends and every external circle, and planing the external circle surface of the fan blade and the left and right ends well. The processing technology has the advantages of high size precision and shape precision of the fan blade, good geometric symmetry, no small problems such as nonuniform space and small compression ration generated in meshing the fan blade.

Owner:无锡市四方真空设备有限公司

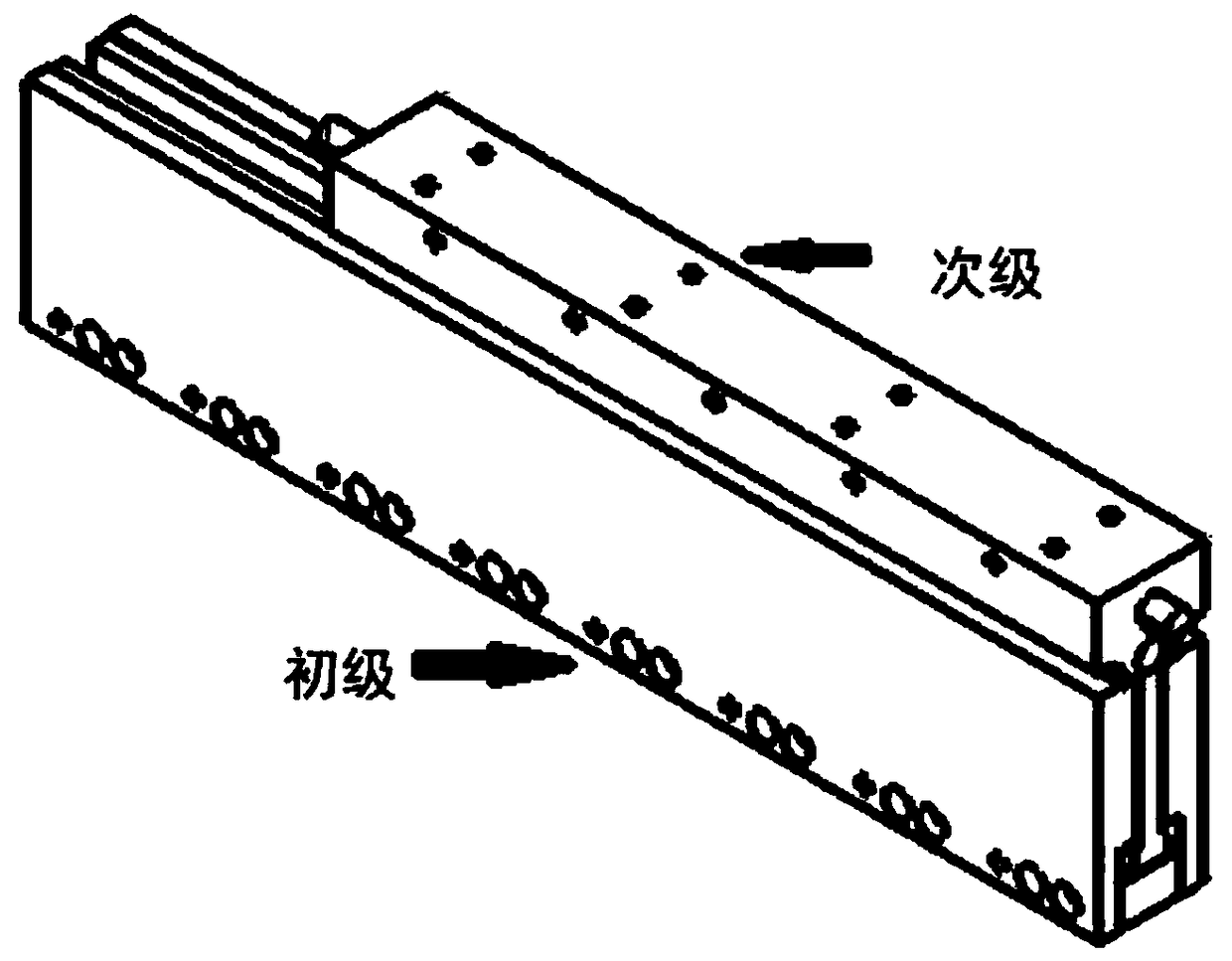

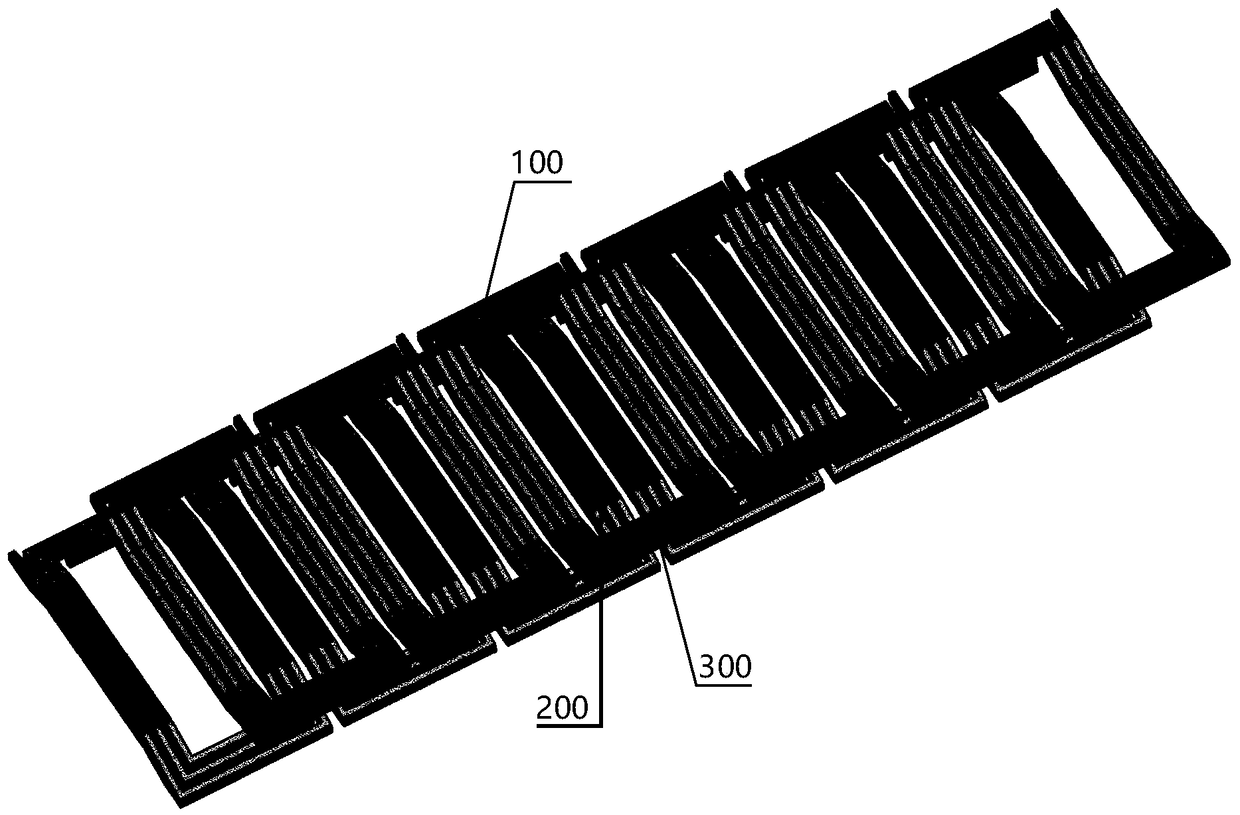

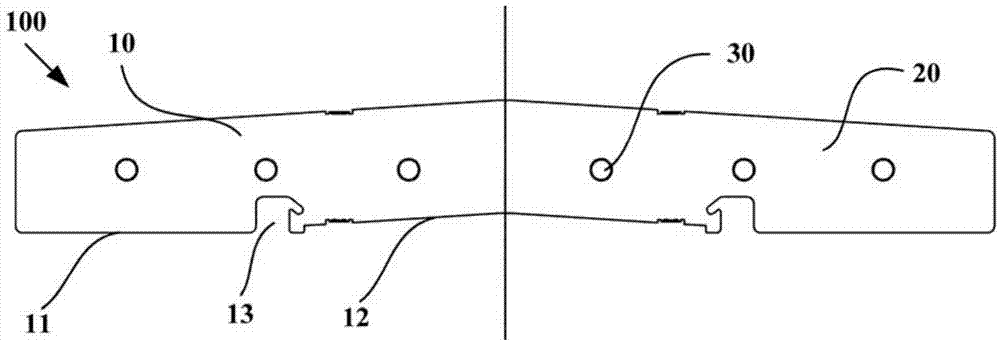

Linear coreless winding, preparation technology and linear permanent magnet motor with winding

InactiveCN109474159AImprove power densityReduce weightManufacturing dynamo-electric machinesPropulsion systemsElectric machineEddy current

The invention discloses a linear coreless winding. A wire of the winding is a strip-shaped copper sheet with the section long edge perpendicular to the movement direction of the linear motor, the strip-shaped copper sheets are concentrically wound to form a coil, and a plurality of coils are arranged adjacent to each other so as to form a linear winding structure; a concentrated winding can be adopted in the structure, and interference-free arrangement of end parts of the coils can be realized; or the coils are obtained through further processing, wherein the end parts of the coils are all located on one side of an effective part, and the coils are called an upper coil (100); the upper coil is overturned by 180 degrees along a geometric symmetry line to obtain lower coils (200, 300); the upper coil (100) and the lower coils (200, 300) are alternately arranged with each other to form the linear winding. The invention further discloses a preparation method of the winding and a linear permanent magnet motor with the winding. According to the linear coreless winding disclosed by the invention, an eddy current path is effectively cut off, the eddy current loss of the winding is inhibited, the copper cross section ratio in the air gap space is obviously improved, the power density of the motor is effectively improved, and the weight of the motor is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

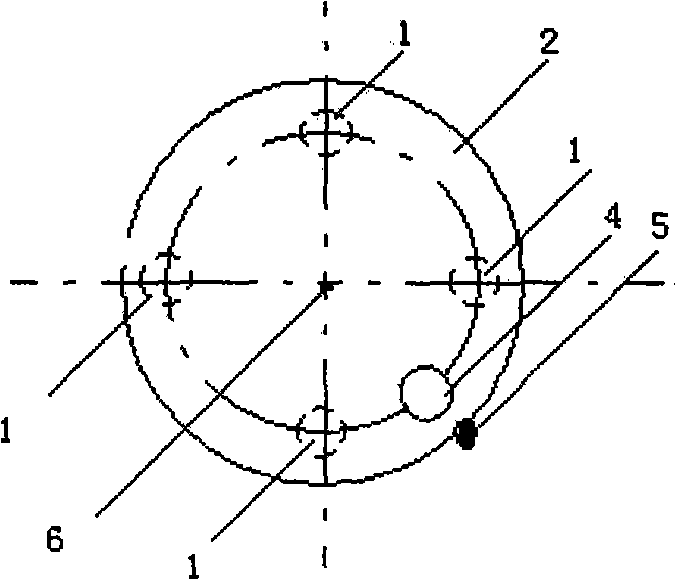

Non-contact type direction key

InactiveCN101299603ARealize blind operationImprove work efficiencyElectronic switchingElectronic switchEngineering

The invention belongs to the field of the instrument and meter, relating to the operating keyboard of the instrument and meter, particularly to the direction key in the interactive instrument and meter operating keyboard, characterized in that, a rotatable blanking disk 2 is arranged at the lower middle part of the four transparent photic windows 1 of the four direction keys, wherein the axle center 6 of the blanking disk is arranged at the geometric symmetry center of the four transparent photic windows 1, arranged on the same arc using the axle center 6 of the blanking disk as the center; the arc is provided with a photic hole 4. When the photic hole 4 of the blanking disk 2 rotates to the photic windows 1 of the light sensitive transistor, the light sensitive transistor turns on, which realizes an electronic switch action; when the photic hole 4 of the blanking disk 2 does not rotate to photic windows of the blanking disk, all the light sensitive transistor turnes off.

Owner:上海海想自动控制技术有限公司

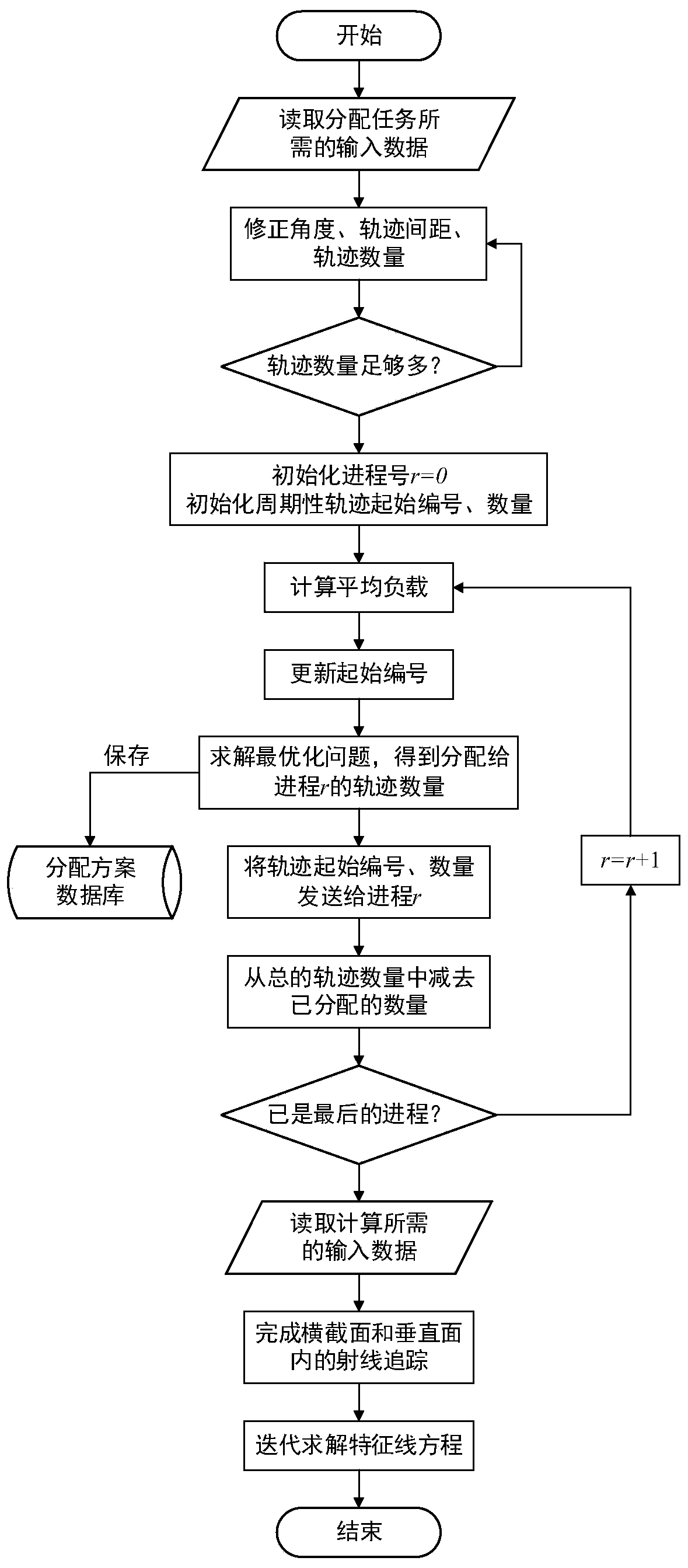

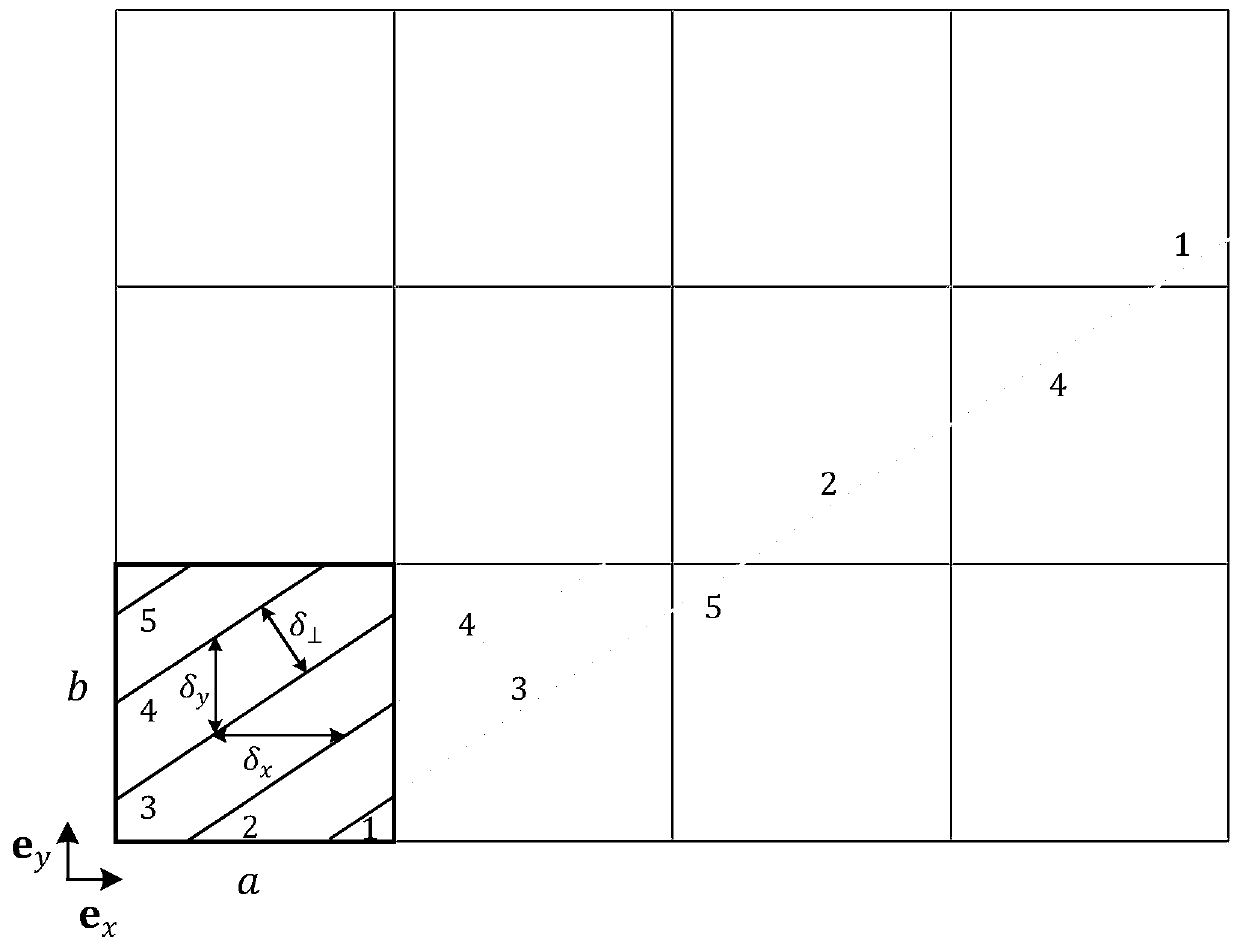

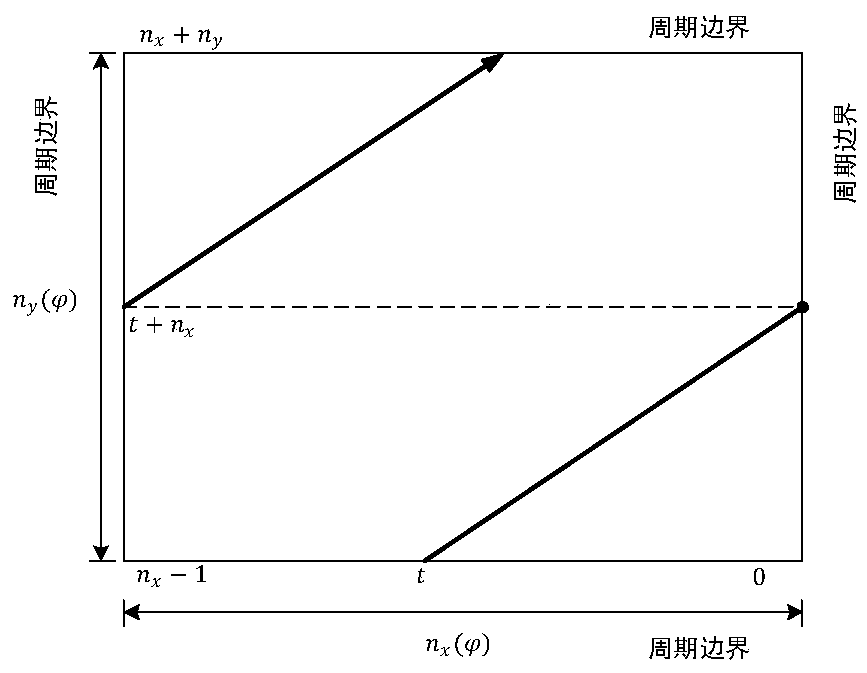

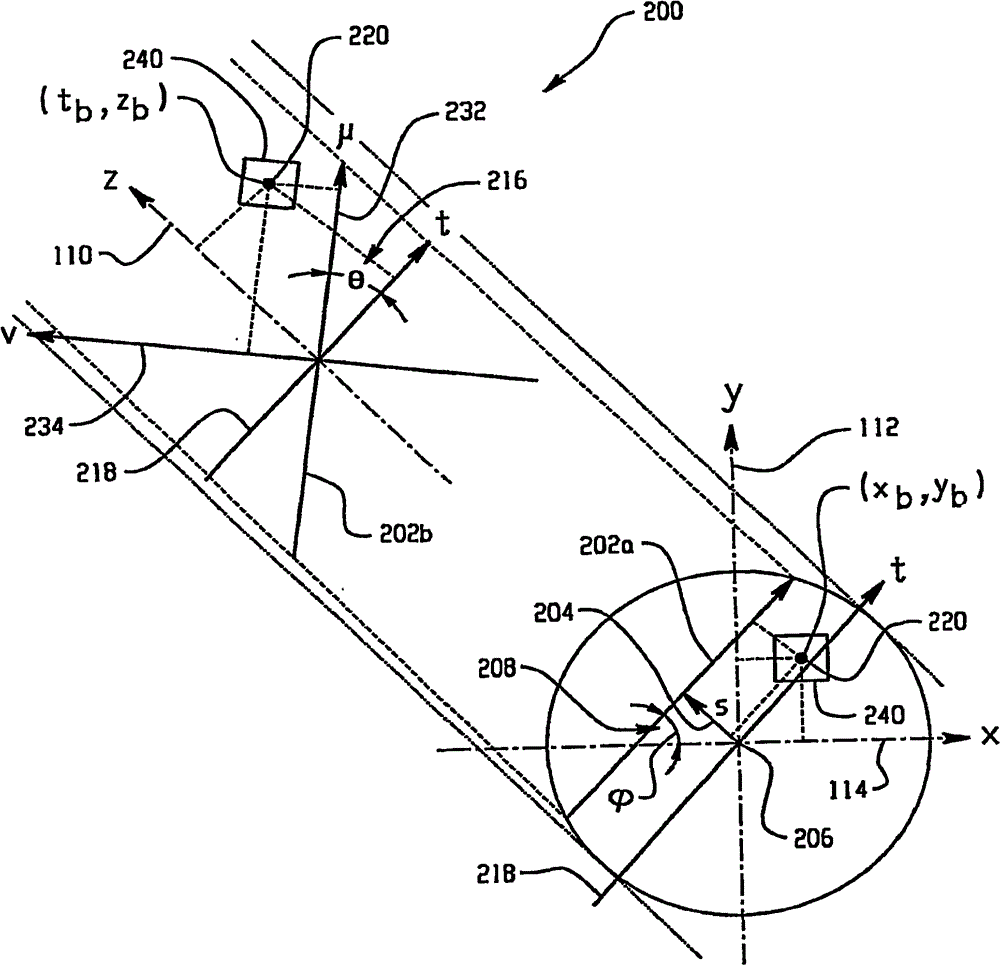

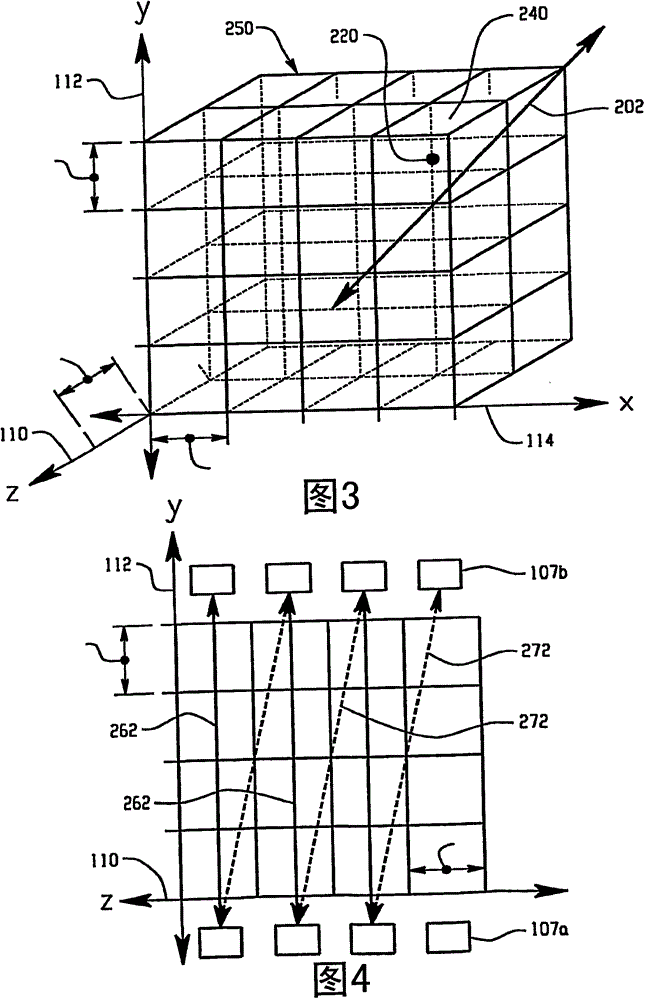

Load balancing parallel method of three-dimensional neutron transport characteristic line method

ActiveCN110472187AEliminate point-to-point communicationEasy to ensure load balancingChemical processes analysis/designComplex mathematical operationsMethod of characteristicsNeutron transport

The invention relates to a load balancing parallel method of a three-dimensional neutron transport characteristic line method. The method is based on geometric symmetry. The method comprises steps ofcalculating the number of angles needing to be considered; calculating the number and length of periodic tracks or reflective tracks at each angle; calculating the load of each process according to the length of the periodic or reflective track, the number of the processes and the number of the tracks, performing ray tracing on each process, and iteratively solving a characteristic equation according to the geometric grid information, completing the material data and the line segment information after ray tracing. According to the method, the periodic trajectory and the reflective trajectory are completely allocated to the threads, parallel tasks can be efficiently allocated, load balance is ensured, and point-to-point communication between the processes is eliminated.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

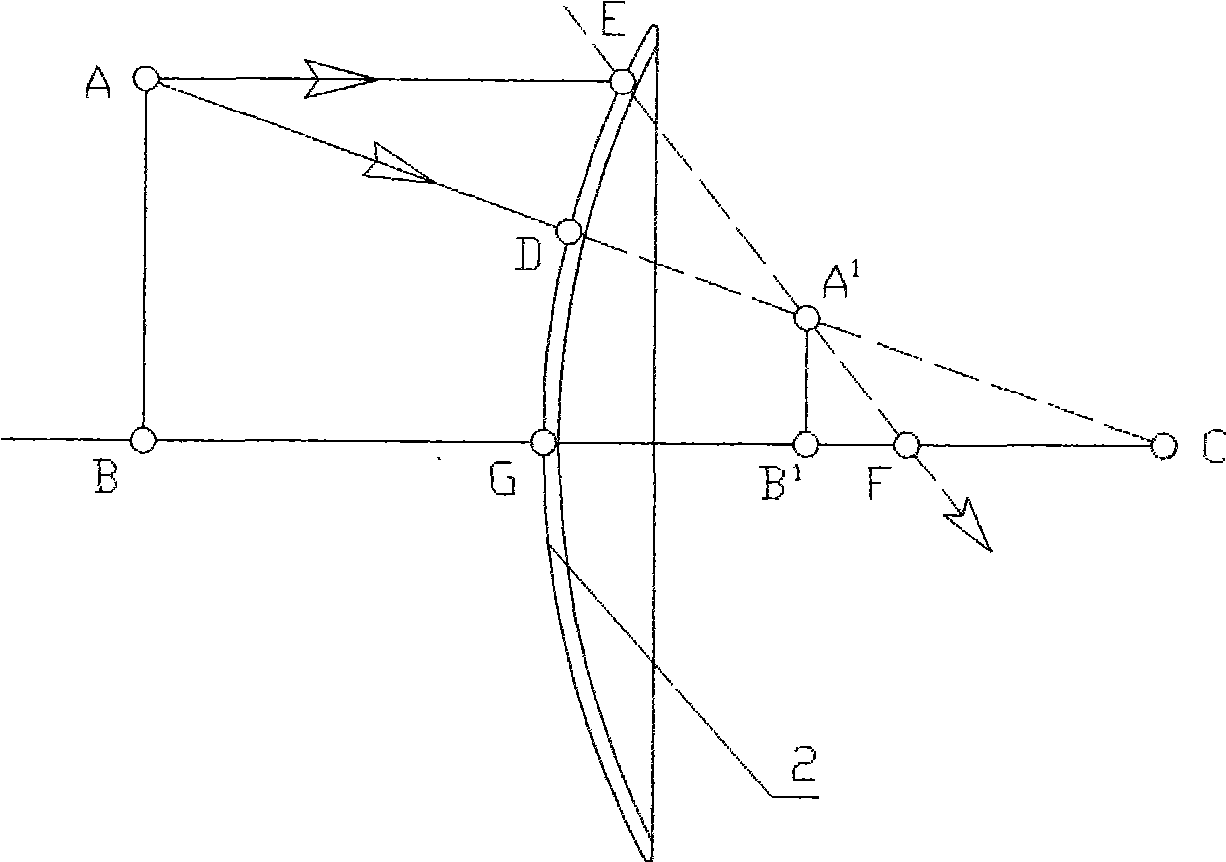

Auxiliary positioning method for acquiring sharp images

InactiveCN101477249AIncrease effective pixelsAdjust positioning intuitivelyCharacter and pattern recognitionMountingsCamera lensPositioning technology

The invention relates to an assisted positioning method for acquiring clear images. The method solves the problems of positioning technique for acquiring the clear images, and is particularly applicable to solving the positioning problem for acquiring the clear images in a human face identifying device. The technical proposal comprises that: a convex mirror is arranged in front of a camera lens; the convex mirror is fixed on the relative position of the camera lens; the convex mirror is provided with a viewing aperture of the camera lens; the axial line of the camera lens coincides with the geometric symmetry center line of the convex mirror; and the camera lens shoots after the relative positions, distances or gestures of the camera lens and the shot object are adjusted according to the size and position of an optical image of the shot object image formed in the convex mirror and whether the optical image is fully imaged in the designed area. The method has the advantages of visual, simple and convenient adjustment and positioning, and low cost, is particularly applicable to the human face identifying device and can greatly reduce the manufacturing cost of the human face identifying device.

Owner:SHENZHEN COBBER INTELLIGENT TECH

Enhanced compound pendulums and systems

ActiveUS20100128574A1Easy constructionGood compensationFrequency stabilisation mechanismEngineeringThermal expansion

Enhanced compound pendulums provide thermal compensation and / or barometric compensation, such as for a mechanical clock system. The enhanced compound pendulums are simple to construct, and can be more easily compensated than conventional, single-bob pendulums. The enhanced compound pendulums typically comprise material that is added above the point of rotation. Thermal expansion factors for components of the enhanced compound pendulums may preferably be chosen to provide thermal compensation to the first order. In some embodiments of enhanced compound pendulums, volume is added above the pivot to provide barometric compensation, such as by equalizing the moments above and below the pivot, or by providing geometric symmetry above and below the pivot, with a lower density above the pivot.

Owner:THE LONG NOW FOUND

Fin, heat exchanger with fin and refrigerator

ActiveCN104329976AImprove heat transfer efficiencyImprove performanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringRefrigerated temperature

The invention provides a fin. The fin is provided with a first half portion and a second half portion; the first half portion and the second half portion are symmetric about a geometric symmetry axis; the first half portion and the second half portion cross with each other at the combining position of the geometric symmetry axis to form an inner edge included angle and an outer edge included angle; the inner edge included angle and the outer edge included angle are larger than 120 degrees. The length of a geometric connecting line between the inner edge end point of the extending end of the first half portion and the inner edge end point of the extending end of the second half portion is larger than the distance between the top point outside the combination position of the first half portion and the second half portion and the geometric connecting line. In addition, the invention further provides a heat exchanger with the fin and the refrigerator. Due to the special fin structure of the fin, the heat exchanger with the fin and the refrigerator, the heat exchange efficiency of the fin is obviously improved, and the performance of the heat exchanger and the refrigerator is obviously improved.

Owner:HAIER GRP CORP +1

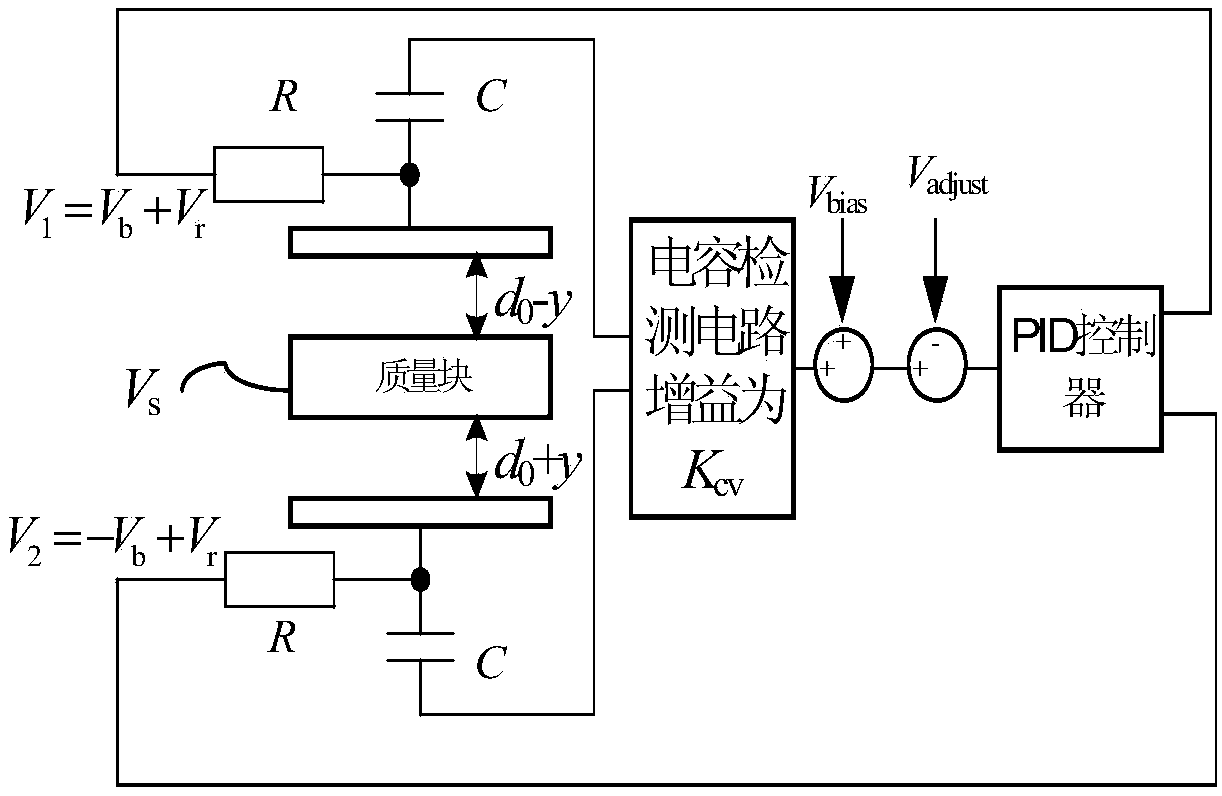

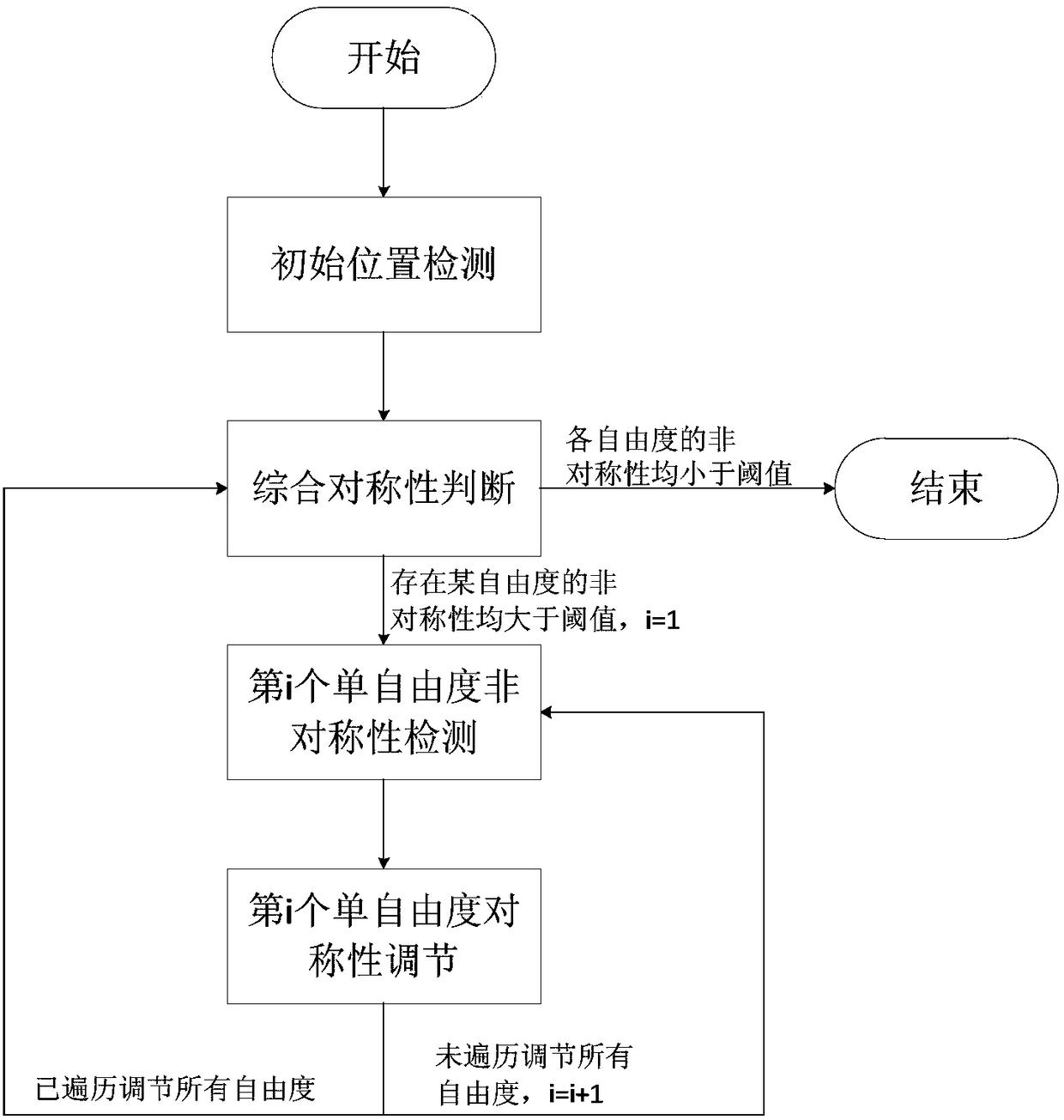

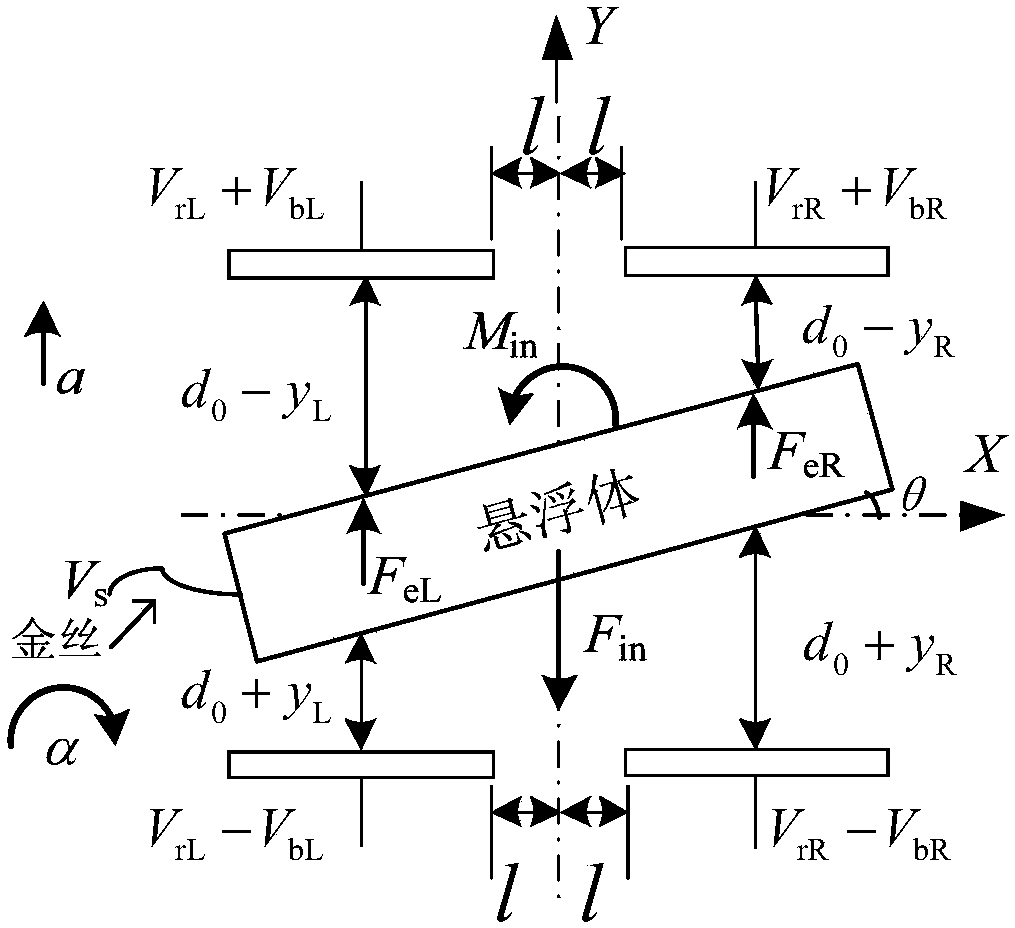

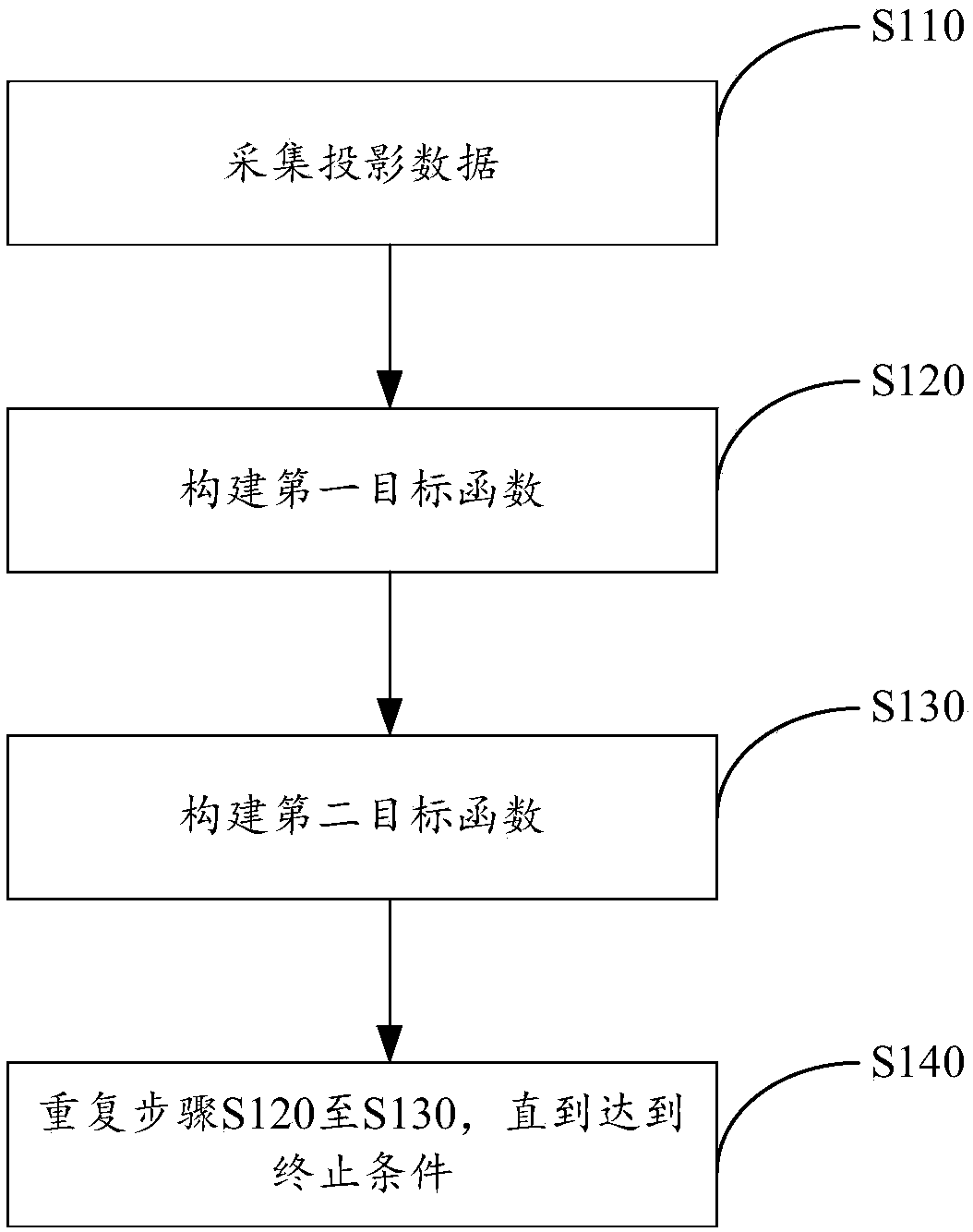

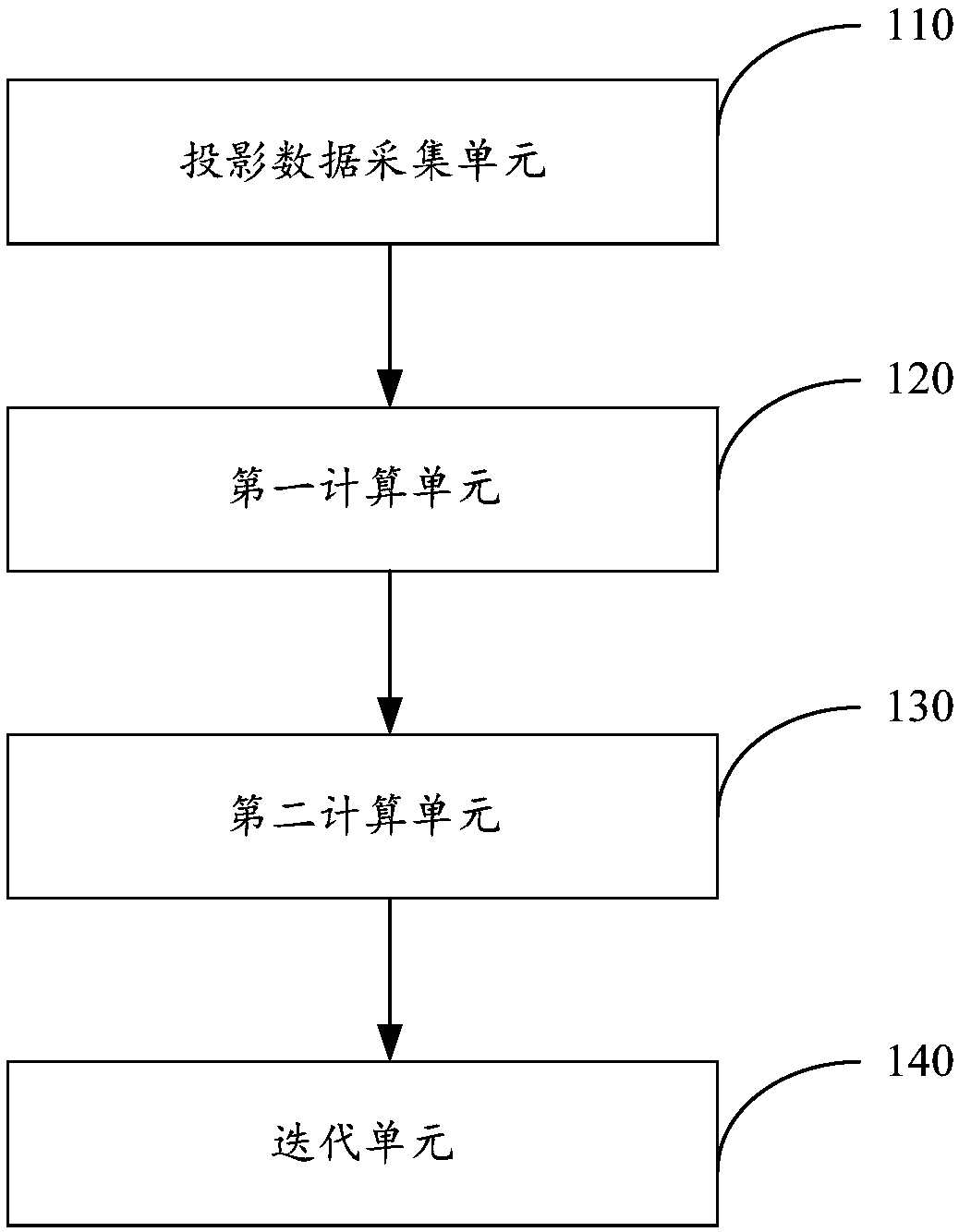

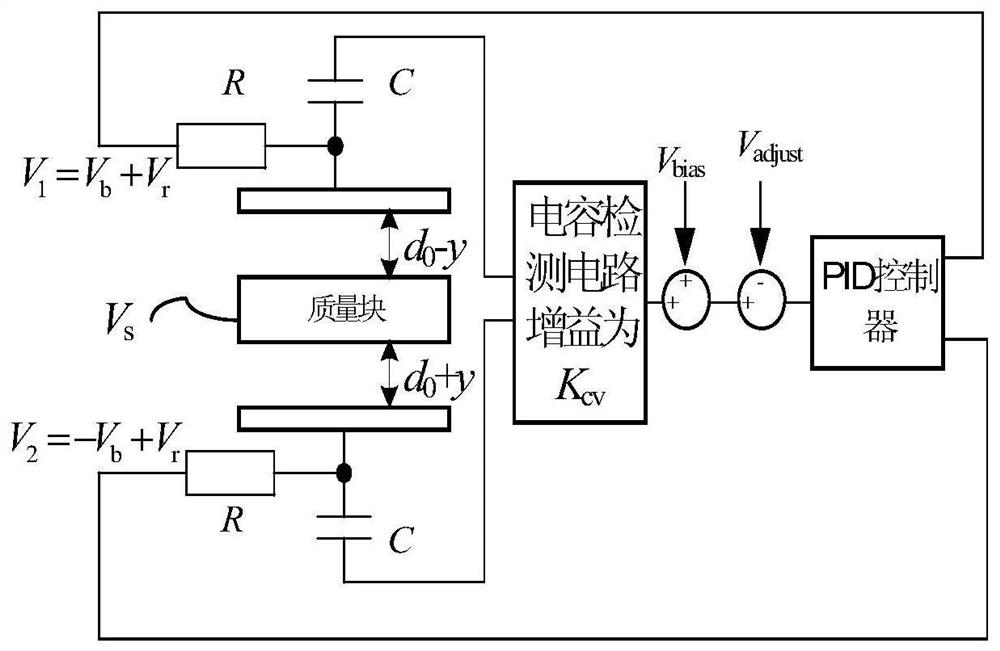

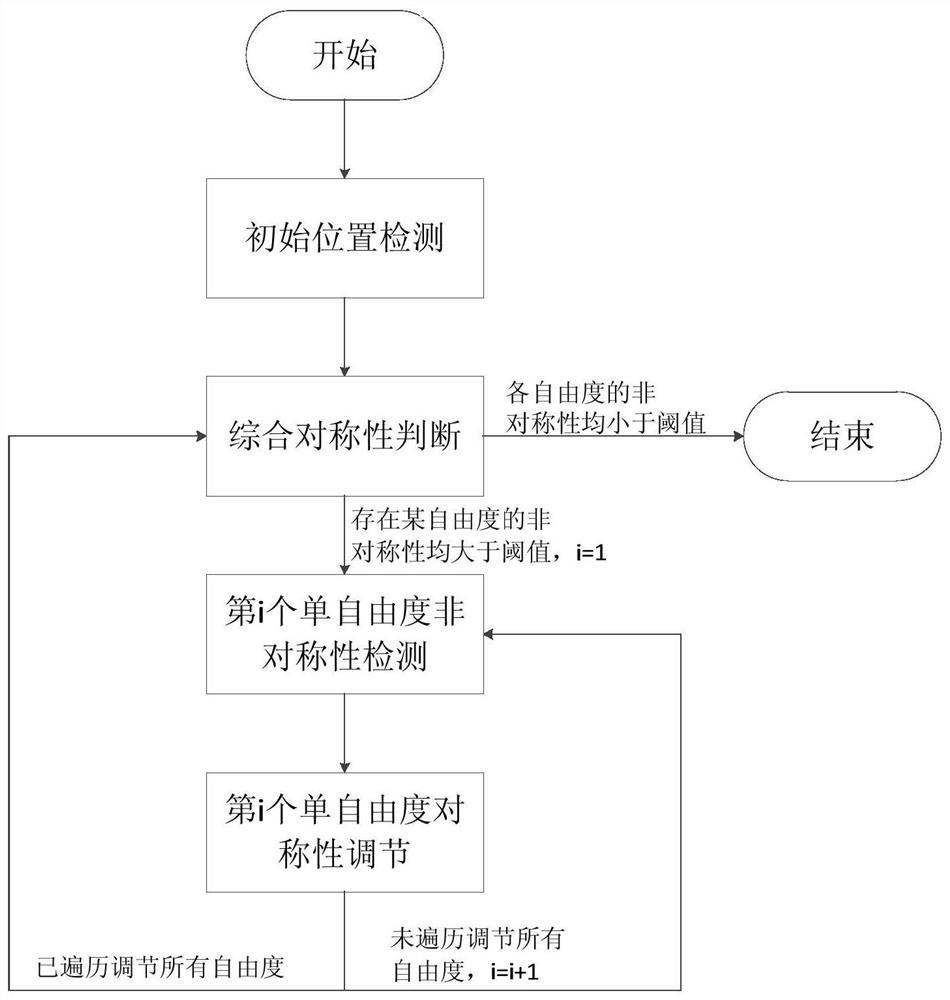

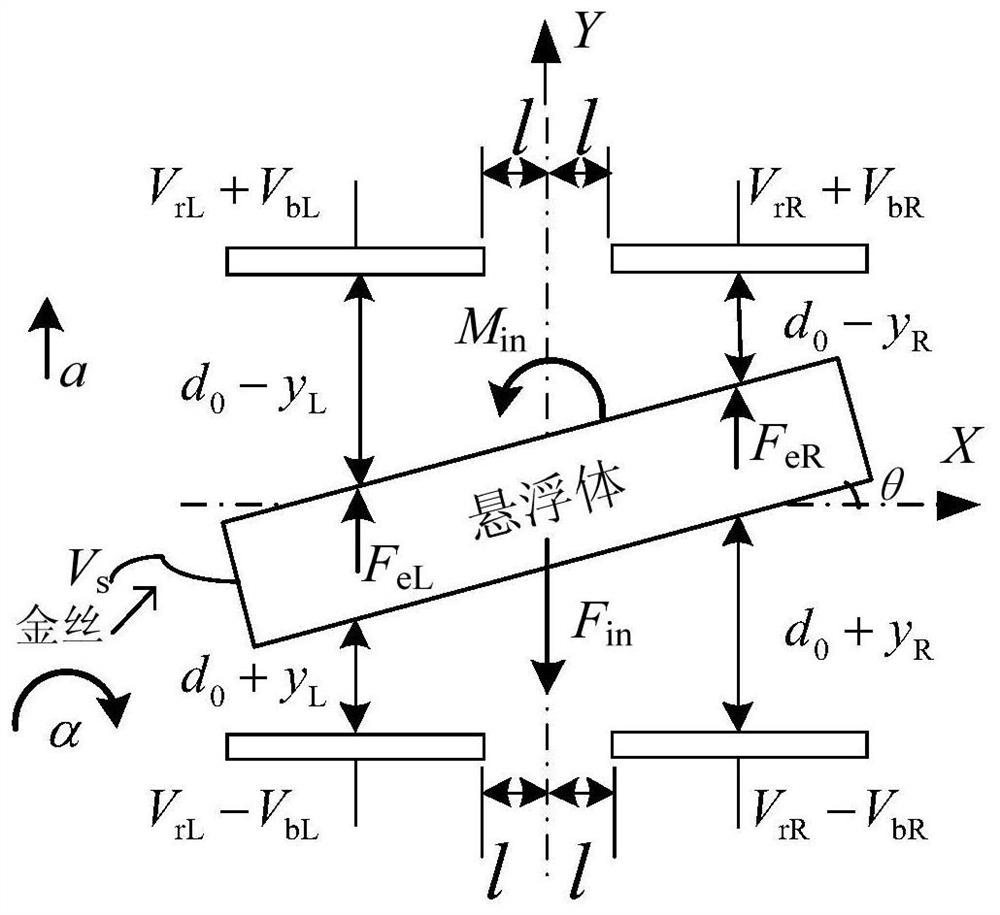

Geometric symmetry approximation method of multi-degree-of-freedom electrostatic suspension system based on iterative adjustment

InactiveCN108415244AEasy to adjustOvercome the influence of coupling forceAdaptive controlMulti degree of freedomEngineering

The invention provides a geometric symmetry approximation method of a multi-degree-of-freedom electrostatic suspension system based on iterative adjustment. In the method, horizontally moving-rotatingmulti-degree-of-freedom system is regarded as a plurality of independent translational freedom degrees, and a variable pre-load voltage method is adopted for carrying out sequential and circular iterative adjustment on the symmetry of each degree of freedom. A multi-degree-of-freedom suspension body can be adjusted to the geometric symmetry center of an electrode cage only through limited times of iteration. According to the invention, the influence of coupling force between multiple degrees of freedom can be overcome, and the whole process can be complete automatically. The method can be widely applied to high-precision sensing and ultra-precision vibration reduction control based on electrostatic suspension technology, so that the system has self-calibration and environment-adaptive capacity and the system can be retained at the optimal working point. In this way, precise instruments and the precise equipment can be ensured to play the required performance.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Symmetric differential inductor structure

ActiveUS20120299682A1Increase productionIncrease the areaSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsFour quadrantsInductor

A symmetric differential inductor structure includes first, second, third and fourth spiral conductive wirings disposed in four quadrants of a substrate, respectively. Further, a fifth conductive wiring connects the first and fourth spiral conductive wirings, and a sixth conductive wiring connects the second and third spiral conductive wirings. The first and second spiral conductive wirings are symmetric but not intersected with one another, and the third and fourth spiral conductive wirings are symmetric but not intersected with one another. Therefore, the invention attains full geometric symmetry to avoid using conductive wirings that occupy a large area of the substrate as in the prior art and to thereby increase the product profit and yield.

Owner:SILICONWARE PRECISION IND CO LTD

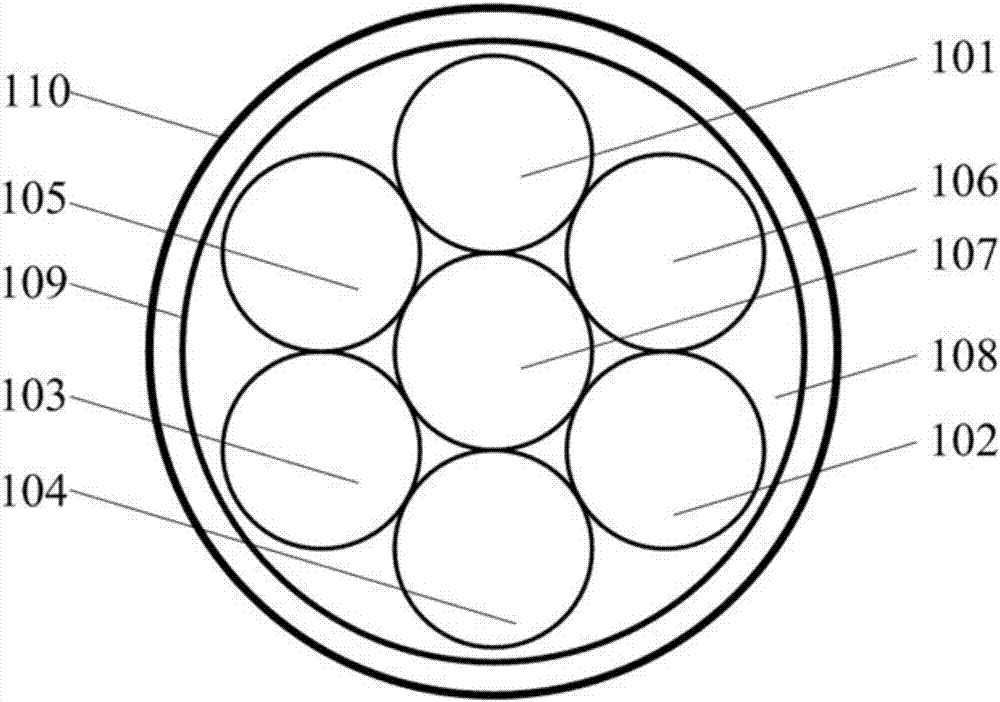

Power cable

InactiveCN106876019AExtended service lifeReduce the strength of the alternating magnetic fieldPower cables with screens/conductive layersInsulated cablesCapacitancePower cable

The invention discloses a power cable. The power cable comprises: an outer sheath; a shielding sheath placed in the outer sheath; six insulated phase wires and one ground wire placed in the shield sheath, wherein the six insulated phase wires are evenly distributed on the periphery of the ground wire and are arranged in a three phase geometric symmetry structure, wherein each phase is provided with two insulated phase wires which are symmetrically arranged at 180 degrees relative to the grounding wire; and a insulating filling material filled between the shielding sheath and the insulated phase wires. According to the invention, the electromagnetic interference, the distributed capacitance and the running temperature of the power cable can be reduced, the service life of the power cable can be prolonged. The power cable disclosed by the invention is suitable for the power cables of a frequency converter.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

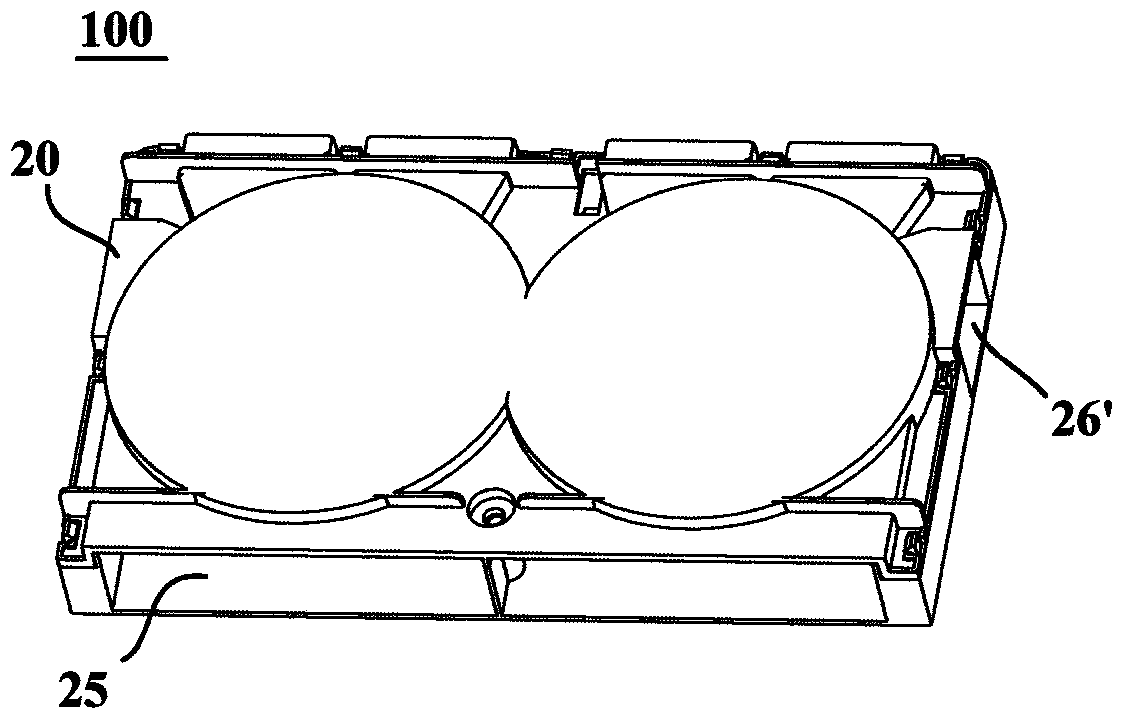

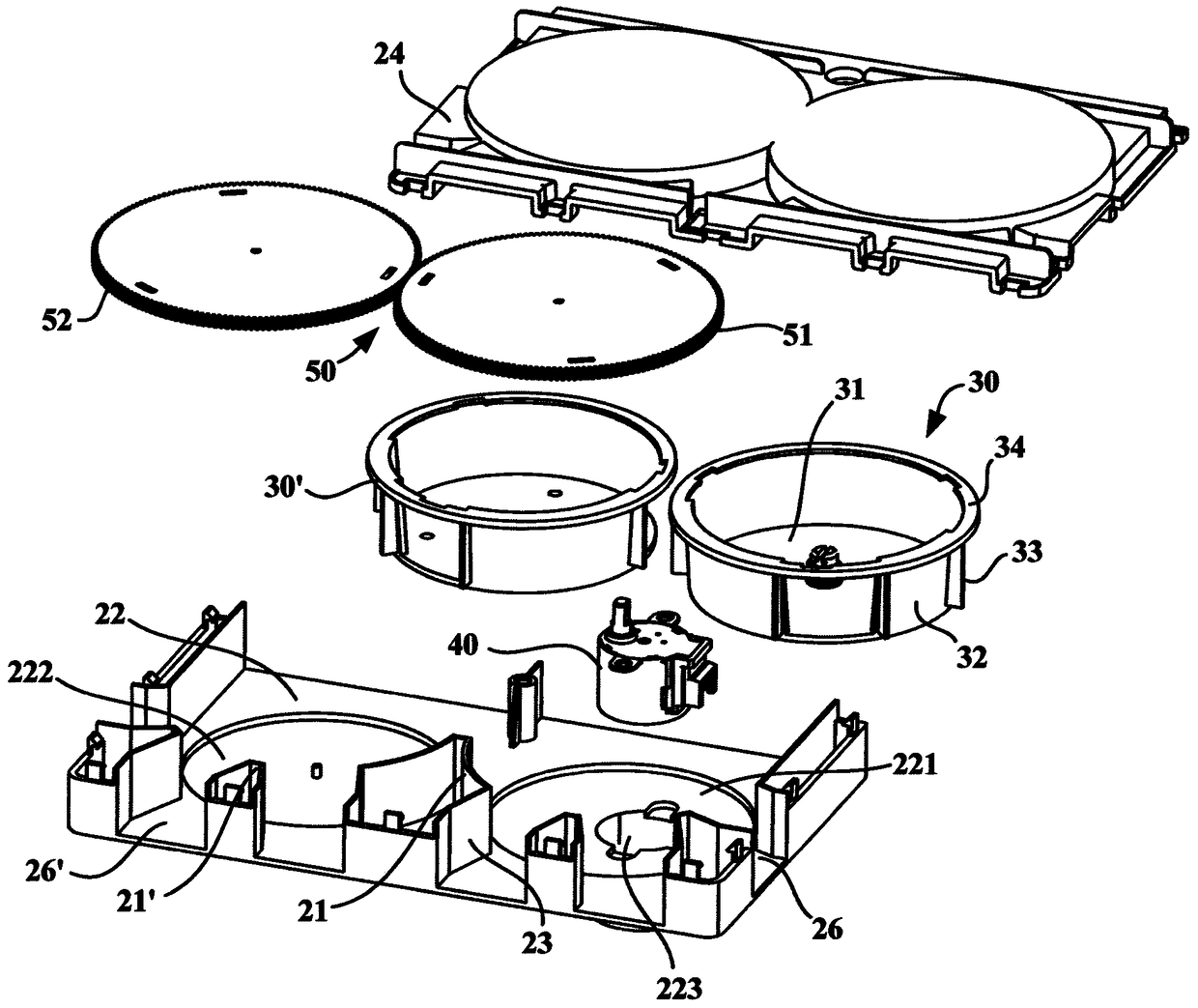

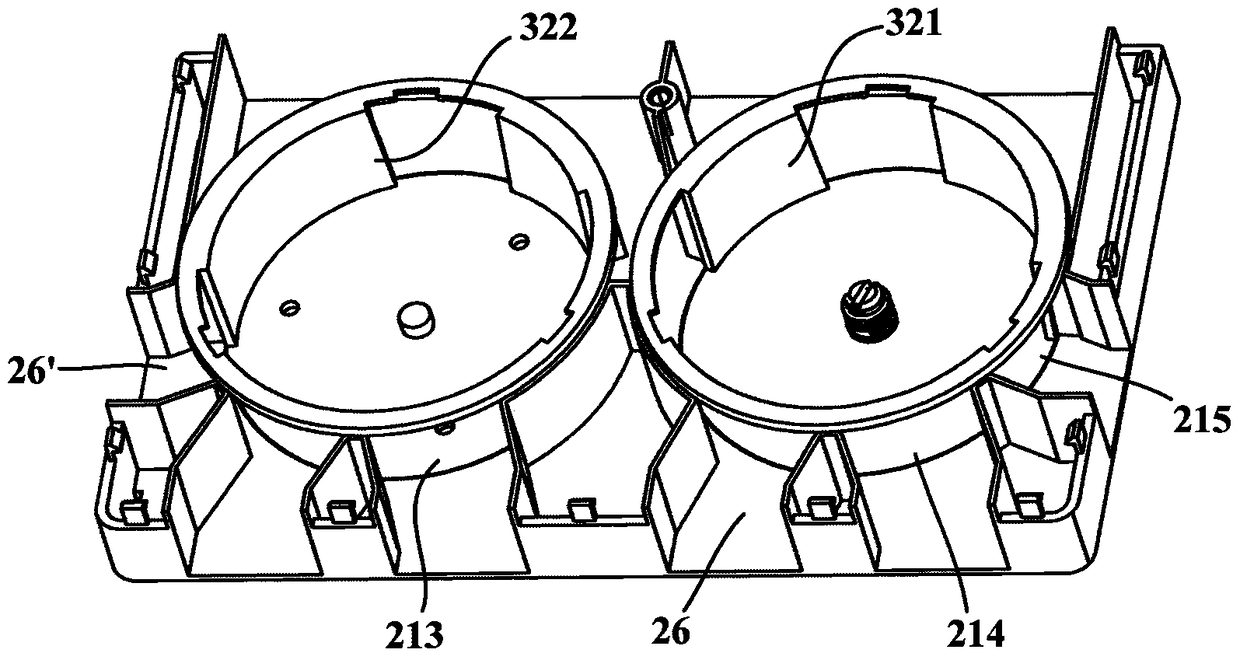

Branch air supply device and refrigerator with the branch air supply device

ActiveCN106196836BImprove efficiencyImprove operational efficiencyLighting and heating apparatusDomestic refrigeratorsShunt DeviceRefrigerated temperature

The invention relates to a branch air supply device and a refrigerator with the branch air supply device. Specifically, the present invention provides a branch air supply device, which includes: a casing having a first half and a second half symmetrical about a geometric symmetry plane, the first half and the second half are both There is at least one air inlet and a plurality of air outlets; the first adjusting member and the second adjusting member arranged symmetrically with respect to the geometric symmetry plane are used to adjust the air outlet area of each air outlet of the first half and the second half respectively ; a motor, the turntable portion of the first adjustment member is installed on the output shaft of the motor; and a transmission mechanism configured to synchronously and reversely transmit the rotational movement of the first adjustment member to the second adjustment member. In addition, the invention also provides a refrigerator with the branch air supply device. Since the turntable part of the first regulating part is installed on the output shaft of the motor, the first regulating part drives the second regulating part to rotate through the transmission mechanism, so that the branch air supply device has a compact structure, a small volume and fewer components.

Owner:HAIER SMART HOME CO LTD

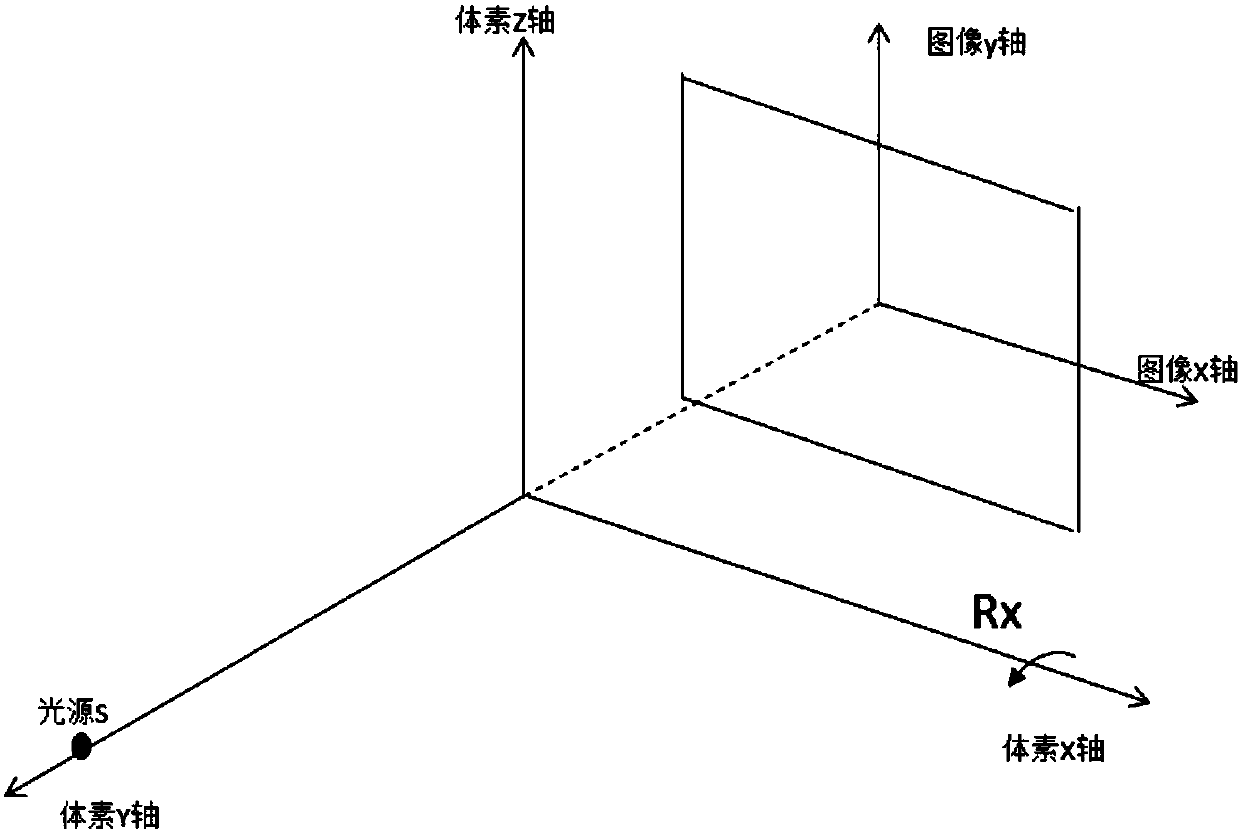

Cone beam CT three-dimensional reconstruction method and system

ActiveCN107784684ASmall amount of calculationGuaranteed reconstructed image quality2D-image generationImage generationVoxelReconstruction method

The invention provides a cone beam CT three-dimensional reconstruction method and system. A mode of GPU acceleration is adopted, at the same time, the amount of calculation is reduced by using geometric symmetry, a thread is established for a connection line between each pixel and a ray source, the length of the connection line in each voxel in volume data is calculated, thus an x optimal solutionis obtained through an iterative method, a purpose of efficient three-dimensional reconstruction is achieved, and the computational efficiency is greatly improved while the quality of a reconstruction image is guaranteed.

Owner:SHENZHEN INST OF ADVANCED TECH

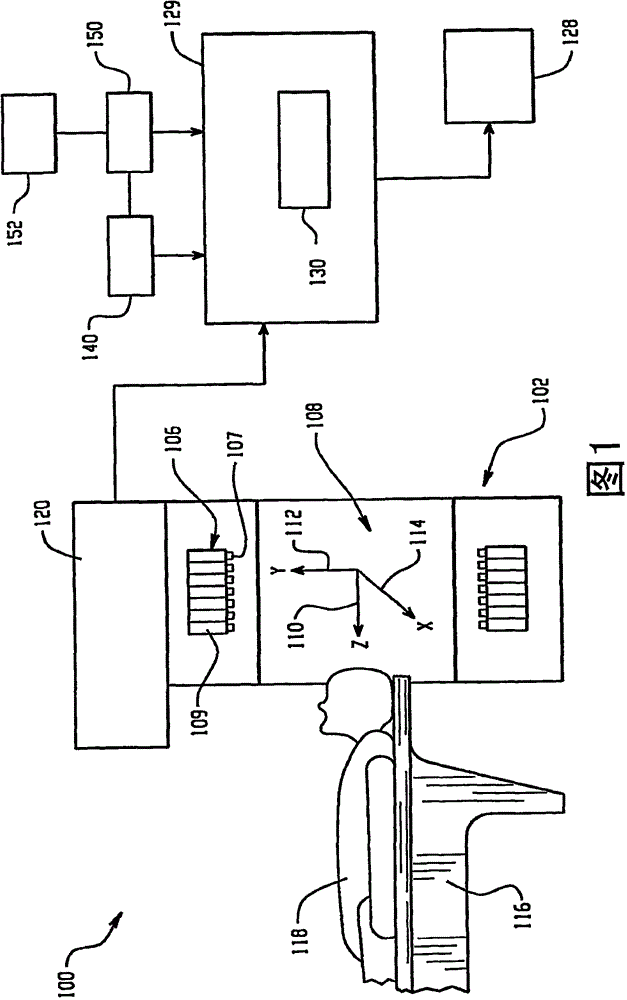

Image reconstruction using data sorting

InactiveCN101490712BReconstruction from projectionBiometric pattern recognitionSystem matrixEvent data

Methods, systems and apparatus for processing data associated with nuclear medicine imaging techniques are provided. Sort data in LUTs and memory structures. For a computer implementing aspects of the invention, an article of manufacture is provided. The data elements are sorted into a plurality of ordered data groups according to a spatial index order, and the data elements are retrieved and processed in the spatial index order. The data elements include sensitivity matrix elements, PET annihilation event data, and system and image matrix elements, grouping the data in an order corresponding to processing of the data. On the one hand, the geometric symmetry of the PET scanner FOV is used in sorting and processing the data. In one aspect, the system matrix LUT contains a total number of system matrix elements equal to the total number of image matrix elements divided by the total number of possible third index values.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

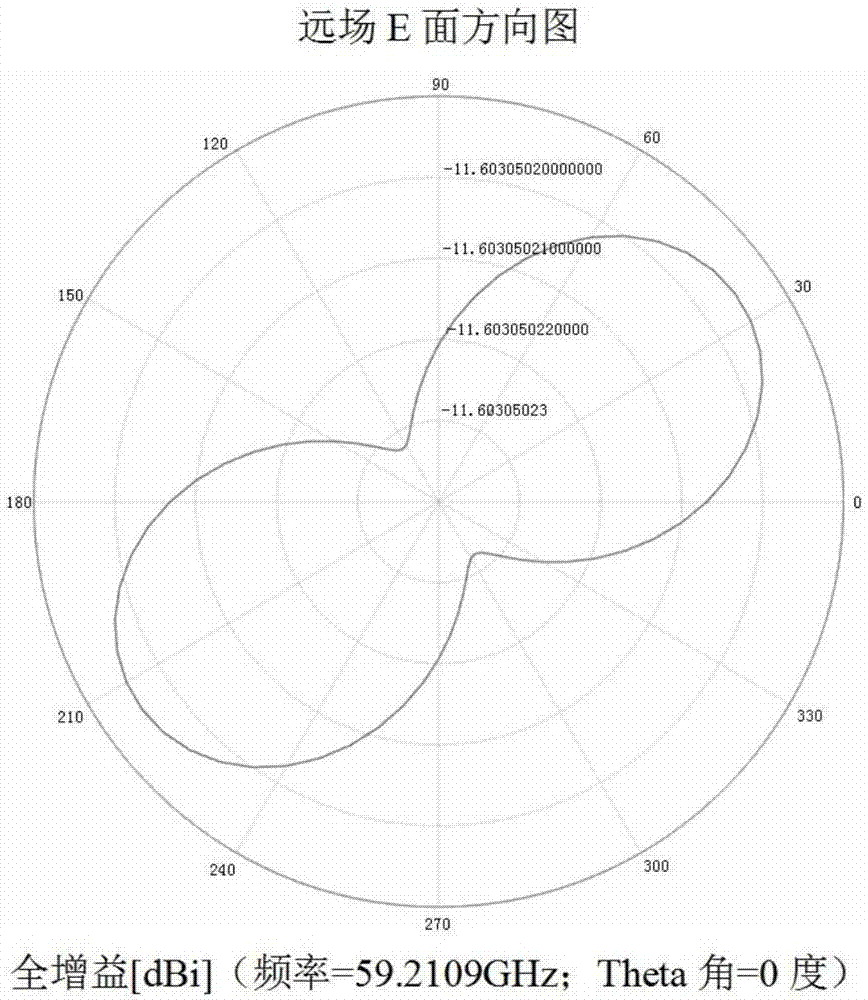

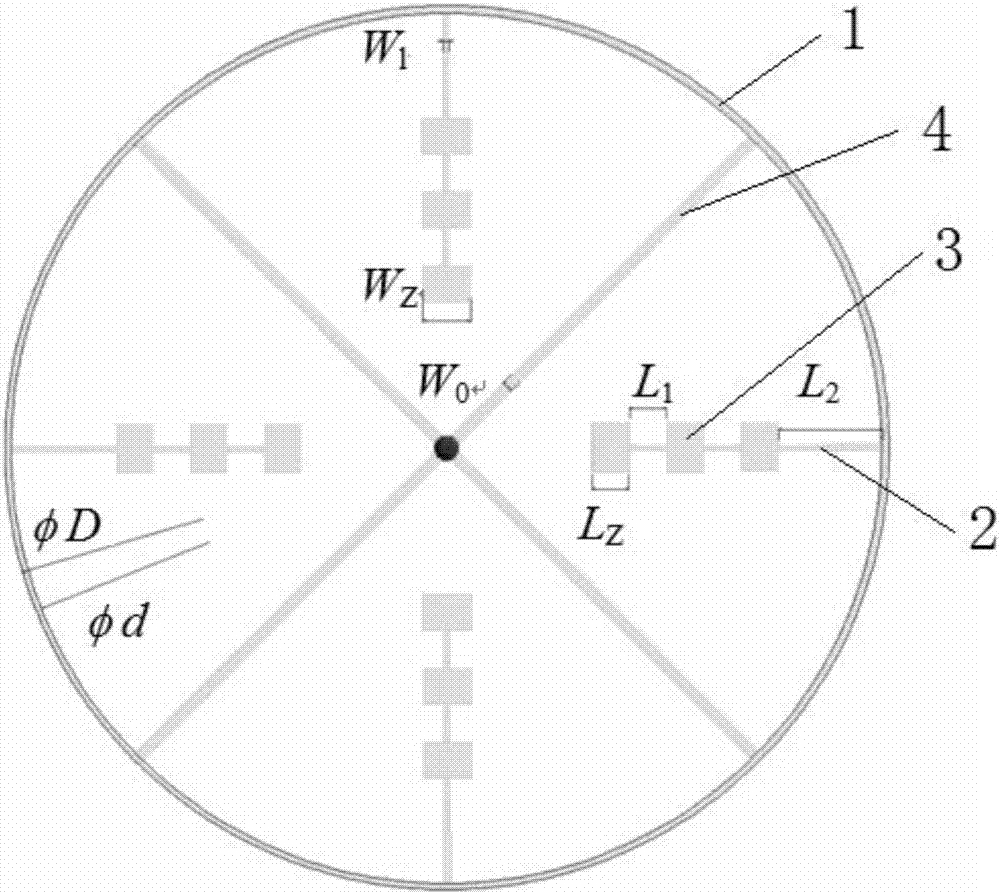

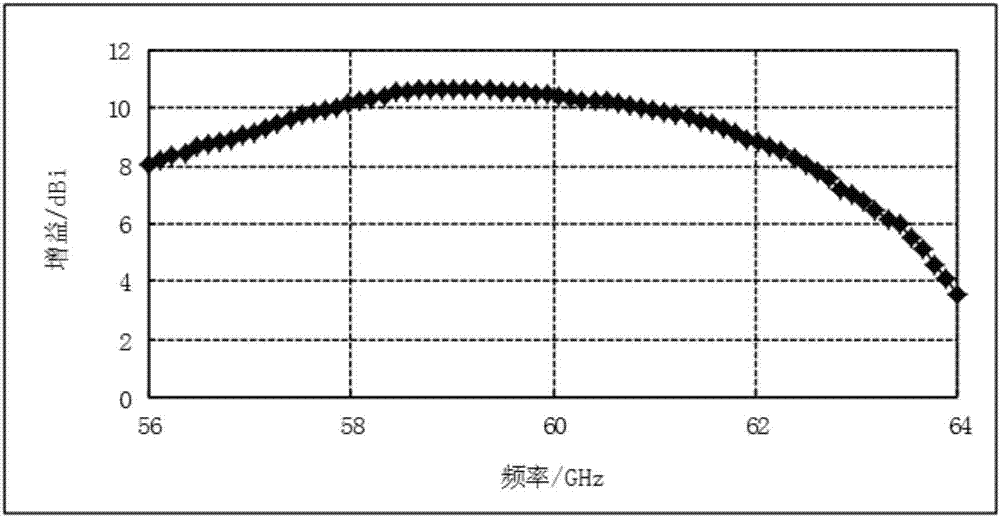

Millimeter-wave circumferential uniform radiation microstrip array antenna

ActiveCN107453054AUniform current distributionEnhanced current distributionRadiating elements structural formsAntennas earthing switches associationMicrostrip array antennaPower flow

The invention provides a millimeter-wave circumferential uniform radiation microstrip array antenna, which comprises a ring feeder, multiple array elements and inner feeders, wherein the ring feeder is an outer ring feeder with a circle center; one end of each of the multiple array elements is connected with the outer ring feeder and the other end is toward the circle center of the outer ring feeder; the multiple array elements are uniformly distributed in the circumferential direction; the inner feeders are equal to the array elements in quantity; one end of each inner feeder is connected with a middle point of a ring of connection points of the adjacent array elements and the outer ring feeder, and the other end is connected with the circle center of the outer ring feeder; and a feeding point is arranged at the circle center of the outer ring feeder. Through the design of the inner feeders with geometric symmetry, the feeding point is arranged at the circle center of the outer ring feeder, so that uniform current distribution of four array elements is ensured, current distribution on a non-main feed array antenna is strengthened, the directional radiation characteristic of the antenna is changed and high-gain radiation can be kept in multiple directions.

Owner:WUHAN UNIV OF TECH

A Method for Approximating the Geometric Symmetry of a Multi-DOF Electrostatic Levitation System

InactiveCN108415244BEasy to adjustOvercome the influence of coupling forceAdaptive controlEngineeringMechanical engineering

The invention provides a geometric symmetry approximation method of a multi-degree-of-freedom electrostatic suspension system based on iterative adjustment. In the method, horizontally moving-rotatingmulti-degree-of-freedom system is regarded as a plurality of independent translational freedom degrees, and a variable pre-load voltage method is adopted for carrying out sequential and circular iterative adjustment on the symmetry of each degree of freedom. A multi-degree-of-freedom suspension body can be adjusted to the geometric symmetry center of an electrode cage only through limited times of iteration. According to the invention, the influence of coupling force between multiple degrees of freedom can be overcome, and the whole process can be complete automatically. The method can be widely applied to high-precision sensing and ultra-precision vibration reduction control based on electrostatic suspension technology, so that the system has self-calibration and environment-adaptive capacity and the system can be retained at the optimal working point. In this way, precise instruments and the precise equipment can be ensured to play the required performance.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

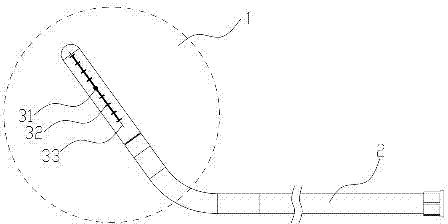

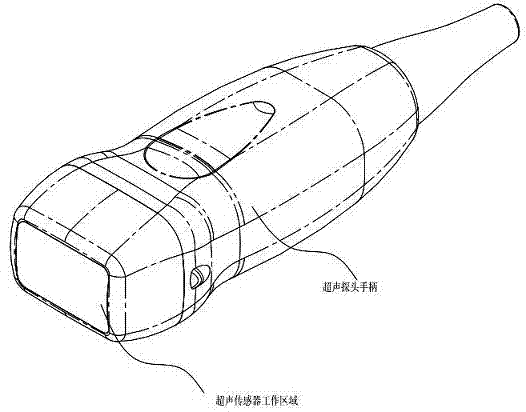

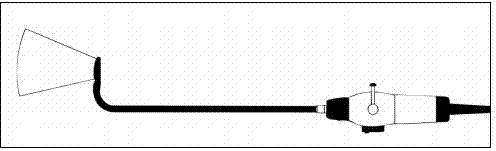

A laparoscopic ultrasound probe sensor and probe for improving physical positioning accuracy

ActiveCN103860205BImprove experienceFlexible and intuitive operationSurgeryCatheterTransducerProjection line

The invention provides a laparoscope ultrasonic probe sensor for improving the physical positioning accuracy. The laparoscope ultrasonic probe sensor comprises an outer casing and an internal main body structure of the outer casing, wherein the outer surface of the outer casing of the sensor is printed with a position calibration line in the axial direction, and the position calibration line at least comprises the following one position calibration line or the combination of several position calibration lines from a projection point geometric symmetry center projection point calibration line, a sound field focusing plane projection line and a uniform scale calibration line. The invention also provides a corresponding probe. When the technical scheme of the invention is adopted, the problem that the detecting region of the existing laparoscope ultrasonic probe cannot be accurately positioned in a human body is solved.

Owner:SONOSCAPE MEDICAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com