Fin, heat exchanger with fin and refrigerator

A technology of fins and joints, applied in the field of heat dissipation, can solve problems such as single structure, low heat transfer efficiency, and slow refrigeration speed of refrigerators, and achieve the effects of improving heat transfer efficiency, increasing heat transfer area, and improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

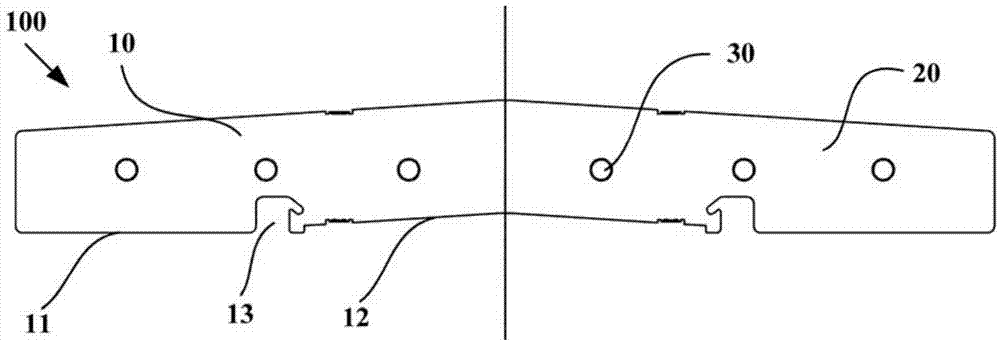

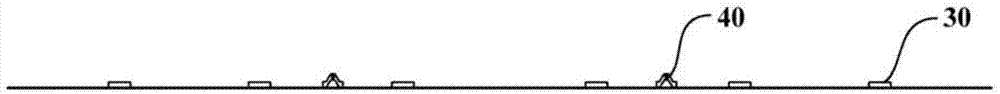

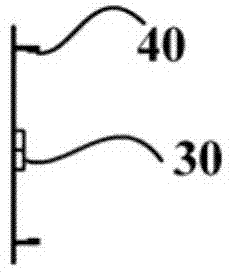

[0044] figure 1 is a schematic front view of a fin according to an embodiment of the present invention; figure 2 yes figure 1 Schematic bottom view of the fin shown; image 3 yes figure 1 Schematic left side view of the fin shown; Figure 4 yes figure 1 Schematic perspective view of the fin shown. Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a fin 100 with a novel structure, which has a first half 10 and a second half 20 that are symmetrical about a geometric axis of symmetry. In particular, the inner angle and the outer angle formed by the first half 10 and the second half 20 at the junction of the geometric symmetry axis are both larger than 120°. The length of the geometric connection line between the inner edge endpoint of the extended end of the first half 10 and the inner edge endpoint of the extended end of the second half is greater than the outer vertex at the junction of the first half 10 and the second half 20 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com