Patents

Literature

37results about How to "Control gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

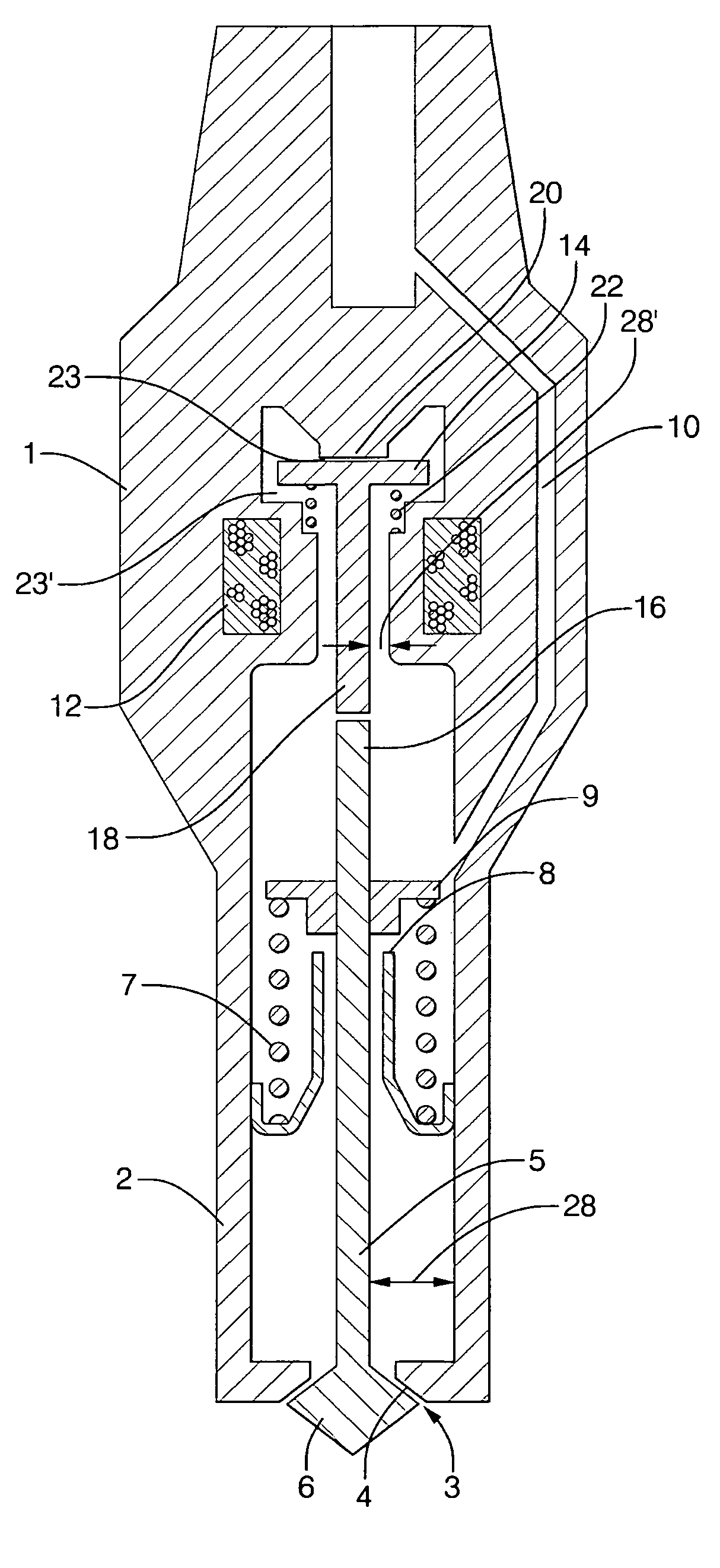

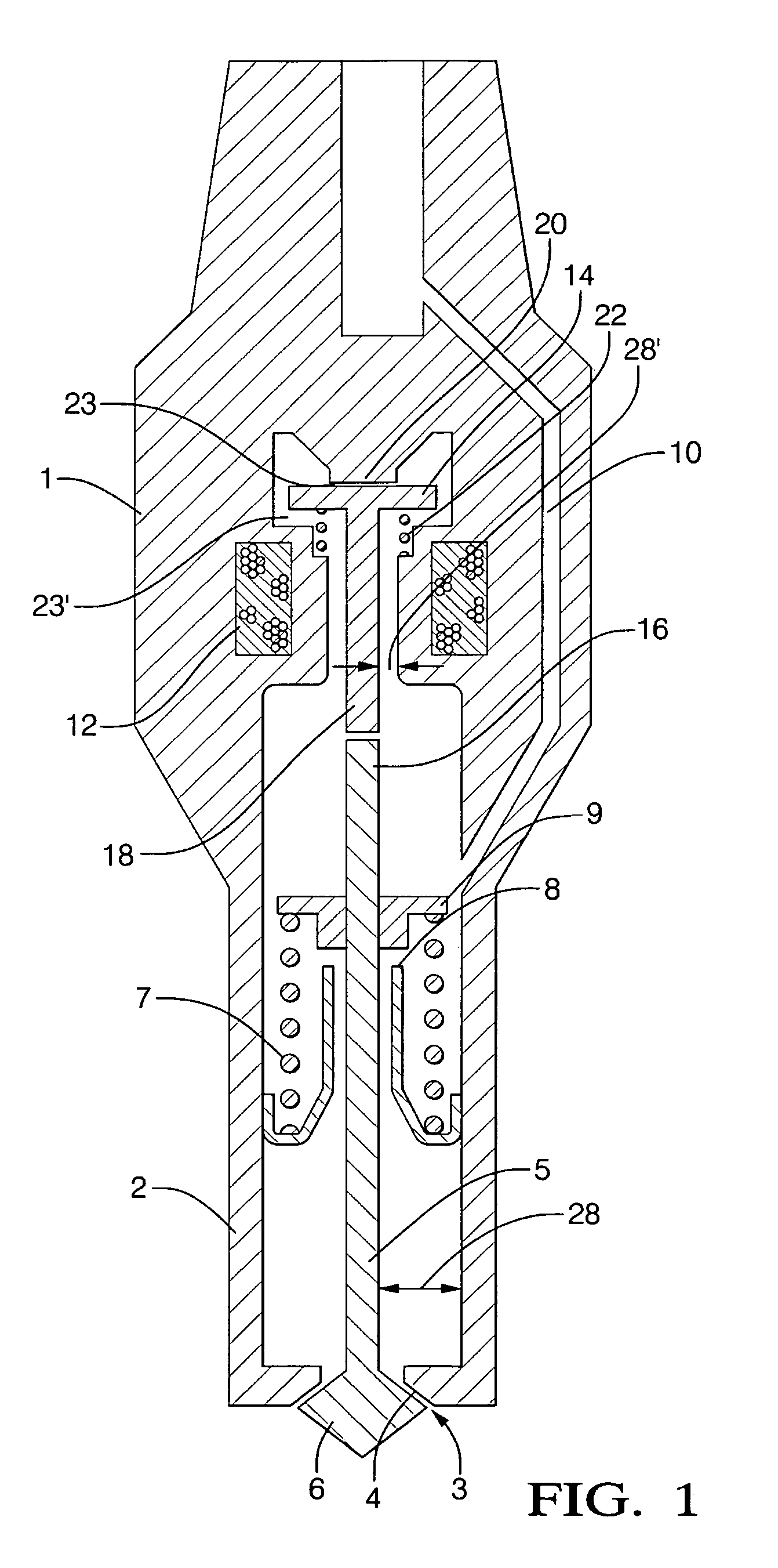

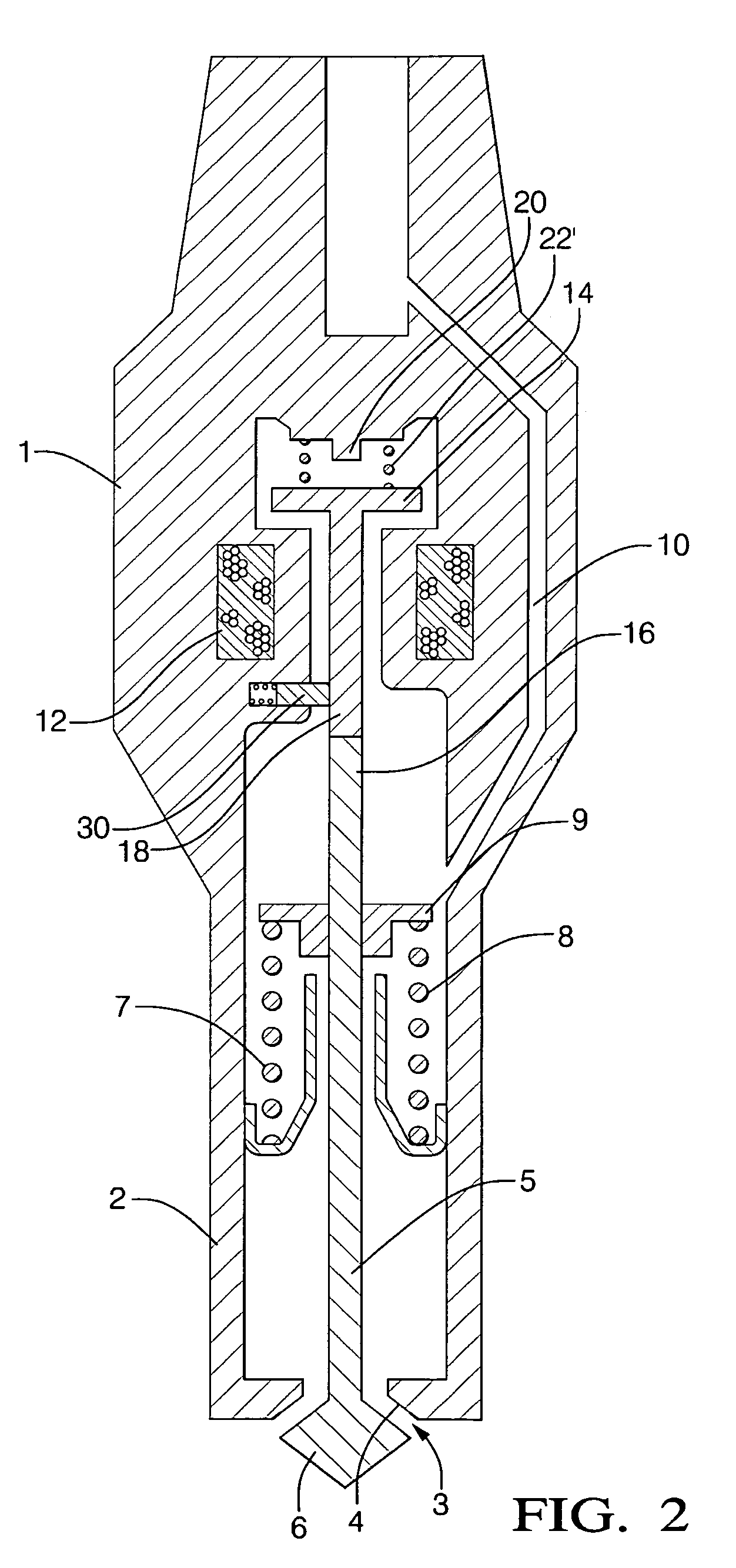

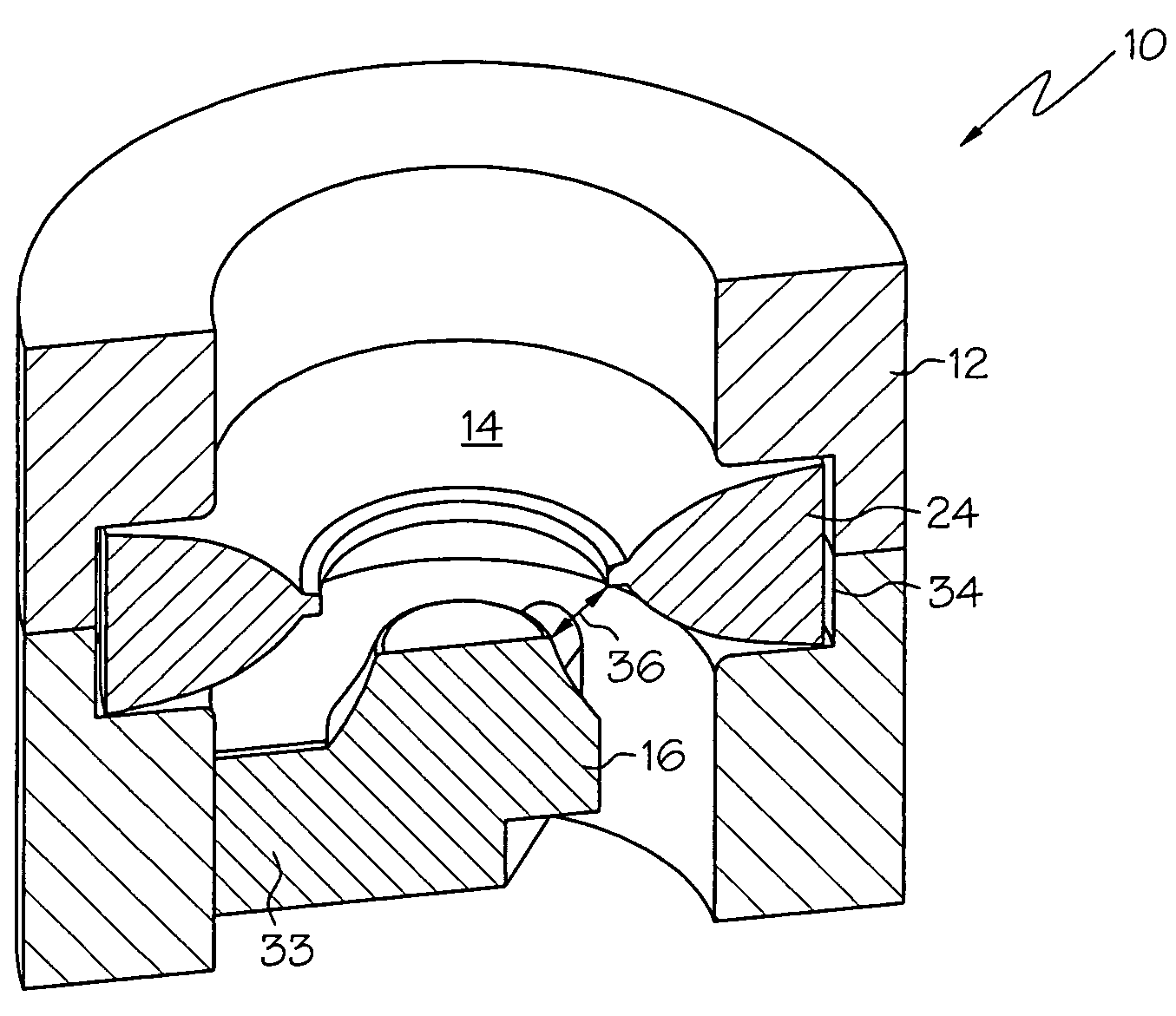

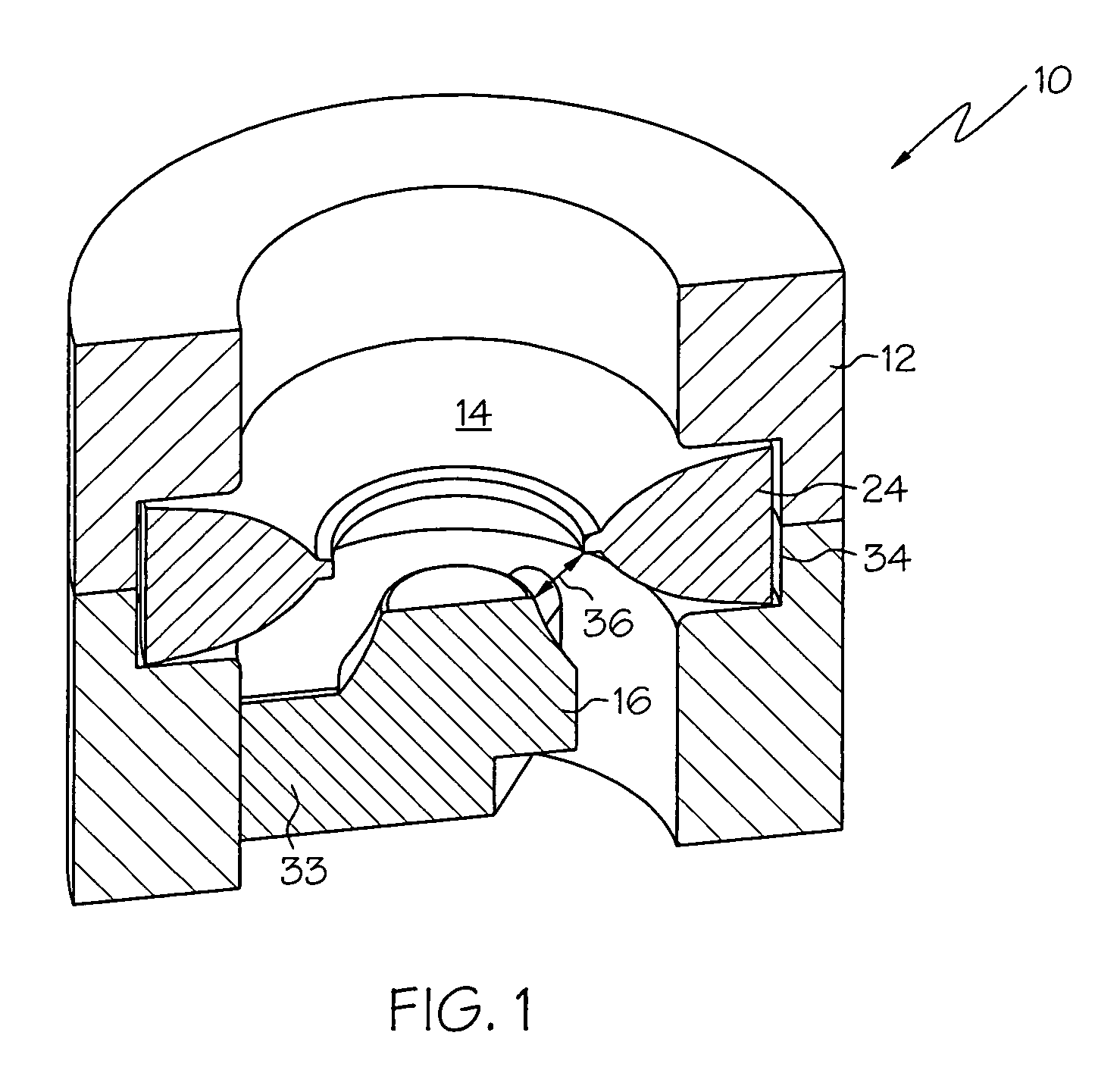

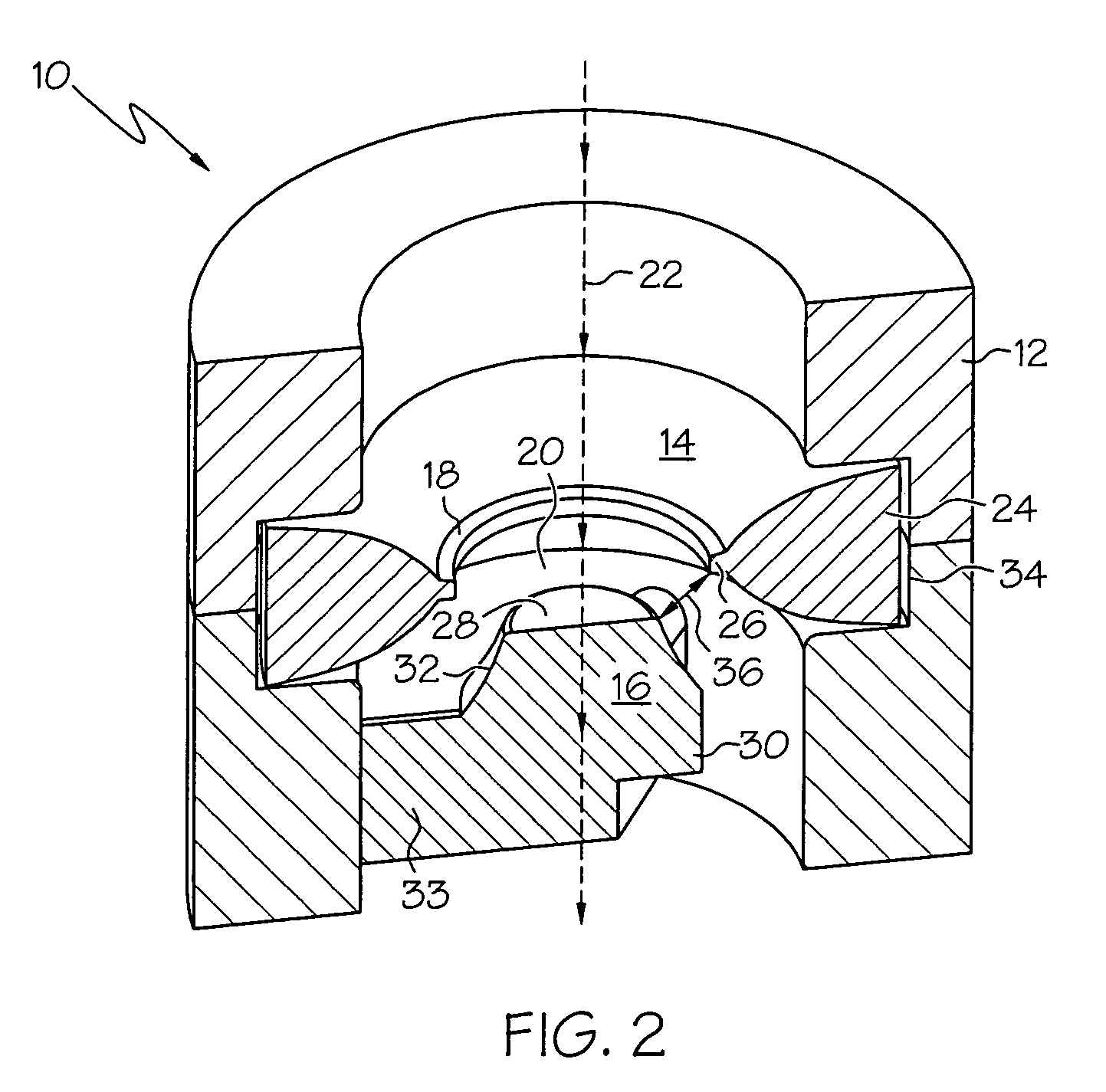

Fuel injector having a separable armature and pintle

ActiveUS7422166B2Control gapInertia of the pintle is greatly reducedSpray nozzlesFuel injection apparatusEngineeringElectromagnetic coil

A fuel injector comprises an injector body having a tip portion defining a spray aperture; a pintle extending within the tip portion for axial movement between an extended position and a retracted position, the pintle having a head portion engageable with the spray aperture to close the spray aperture when the pintle is in its retracted position; biasing means being provided for biasing the pintle towards its retracted position; and solenoid means for selectively moving the pintle into said extended position; said solenoid means comprising an electromagnetic coil and a moveable armature capable of being acted upon by the coil to urge the pintle towards its extended position; wherein the pintle and armature are separable from one another whereby the armature can decouple from the pintle when the pintle moves from its extended position to its retracted position.

Owner:BORGWARNER LUXEMBOURG OPERATIONS SARL +1

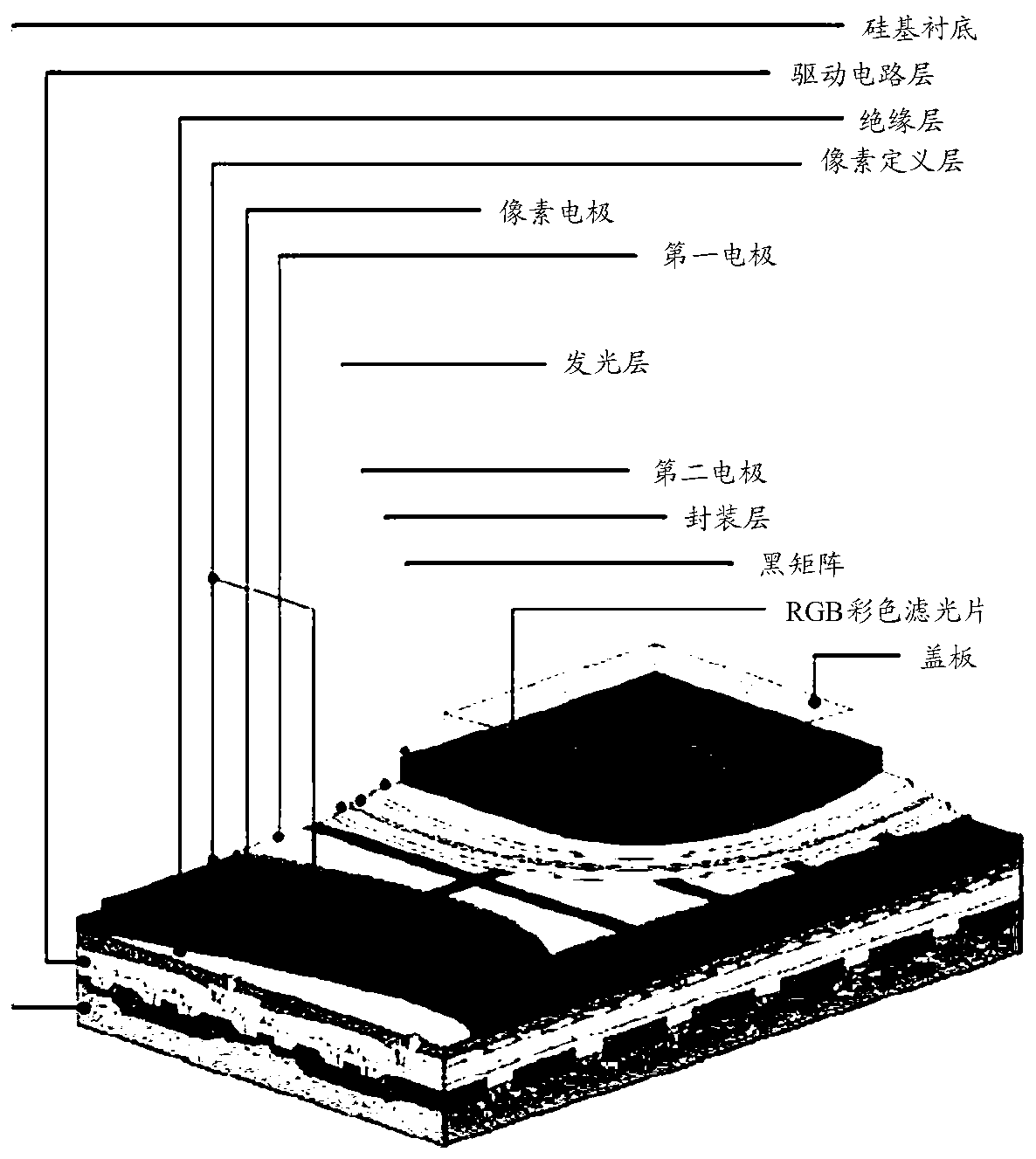

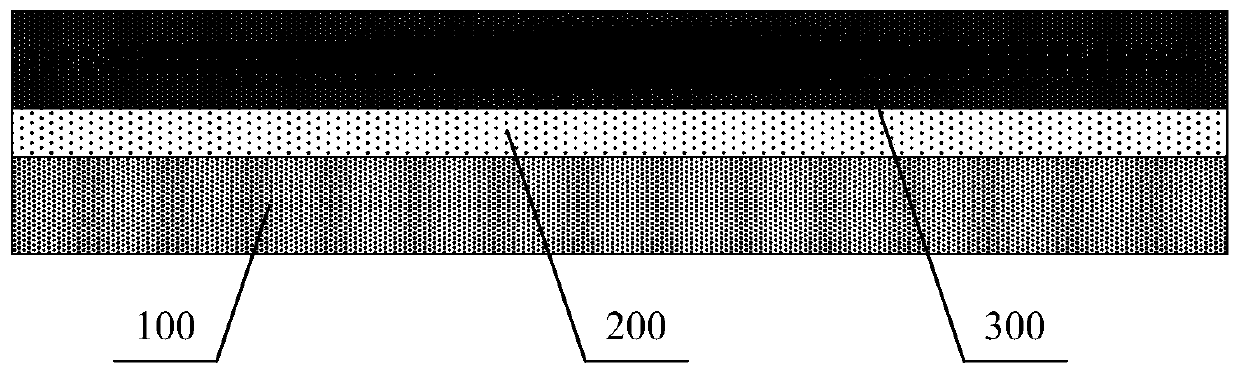

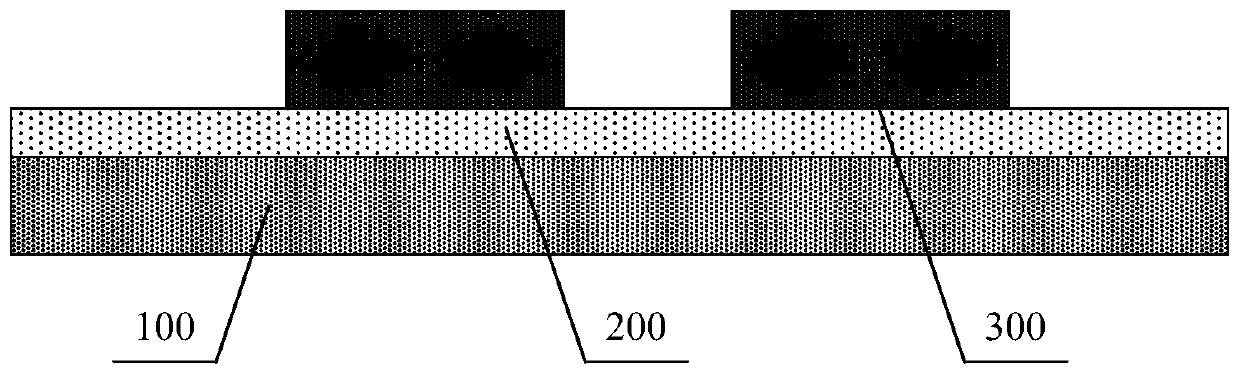

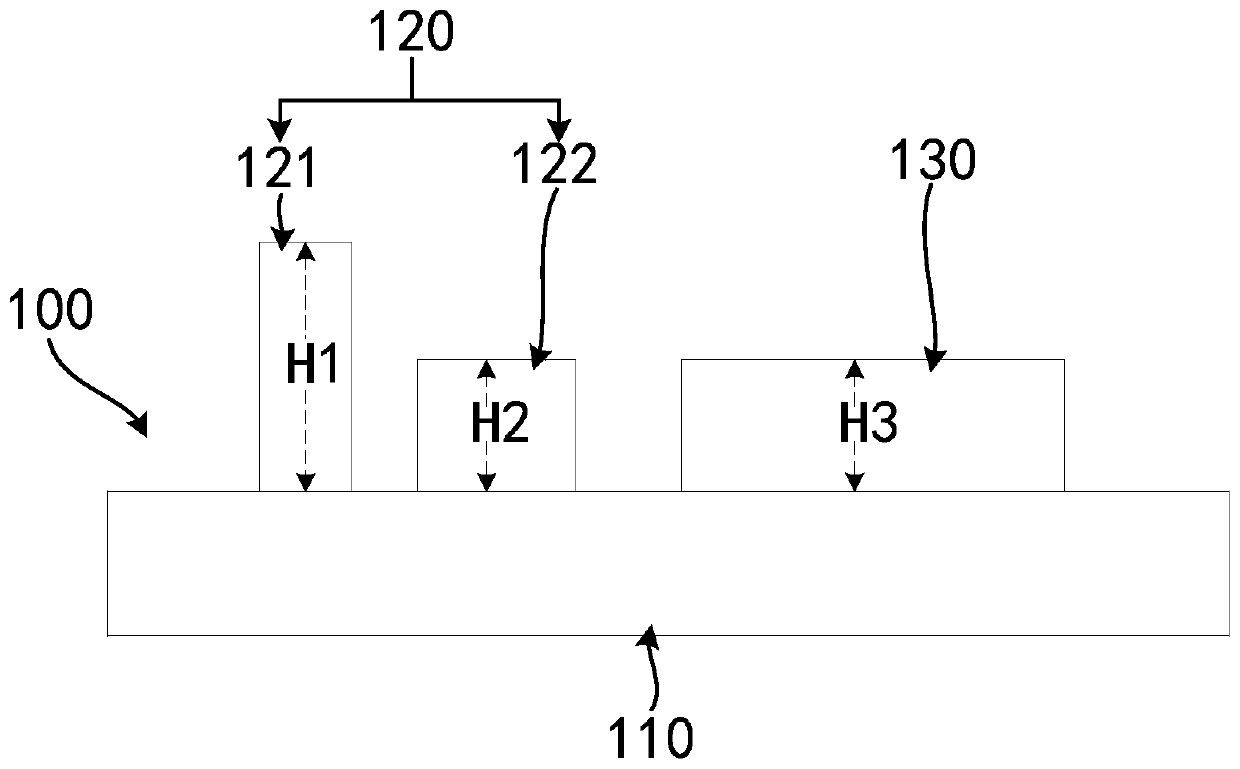

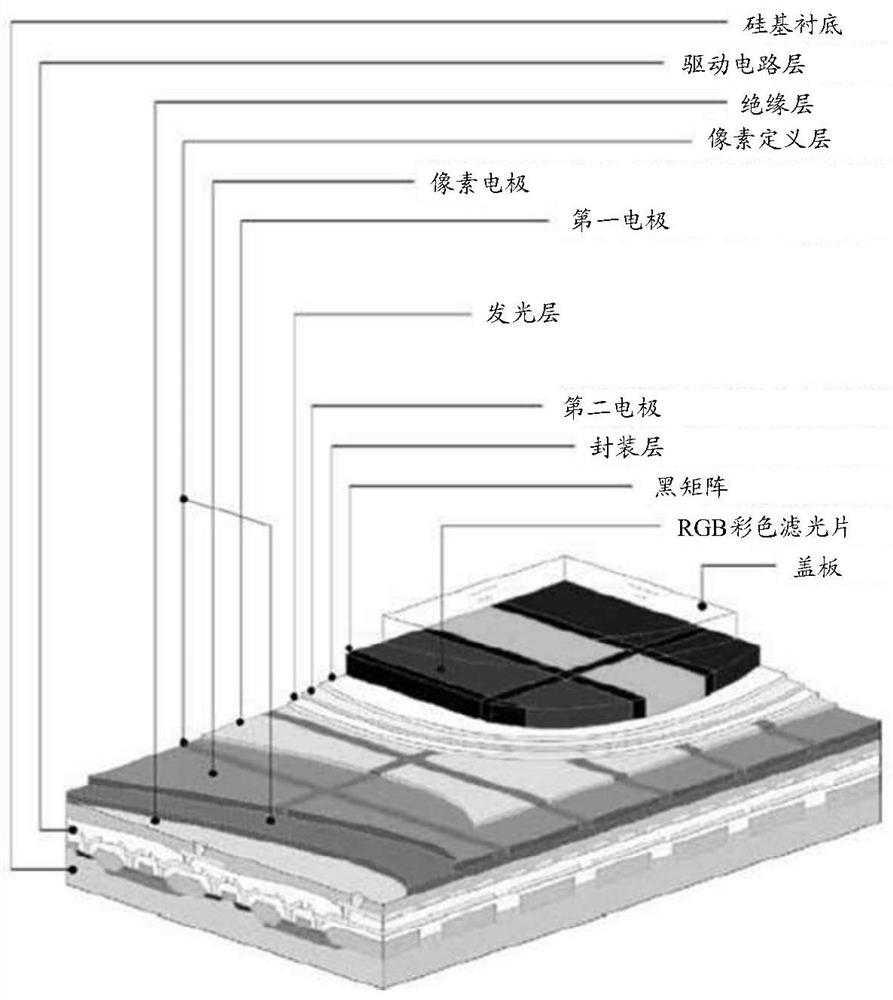

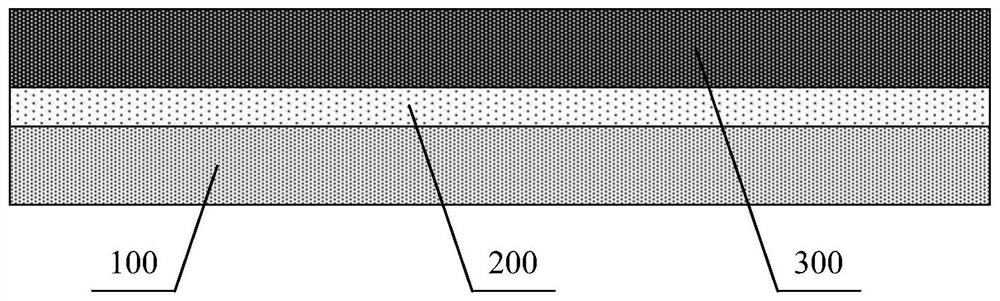

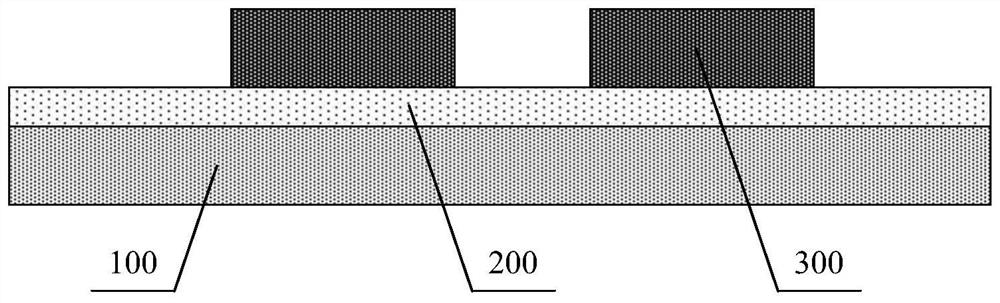

Display substrate and preparation method thereof and display device

ActiveCN110610975AControl gapGuaranteed flatnessSolid-state devicesSemiconductor devicesDisplay deviceEvaporation

The invention provides a display substrate and a preparation method thereof and a display device. The display substrate comprises a micro-cavity structure layer and a light-emitting structure layer which are arranged in a stacked mode. A reflection electrode is arranged in the micro-cavity structure layer. A groove is formed in the surface of the micro-cavity structure layer. The light-emitting structure layer comprises a first electrode arranged in the groove, and the first electrode is connected with the reflection electrode. According to the invention, because the groove is formed in the micro-cavity structure layer and the first electrode of the light-emitting structure layer is arranged in the groove, the offset between the first electrode and the micro-cavity structure layer is controlled, the problem that a cathode and an anode are short-circuited in the preparation process of an existing silicon-based OLED micro-display is solved, and the surface flatness and uniformity requirements of subsequent evaporation are met.

Owner:BOE TECH GRP CO LTD

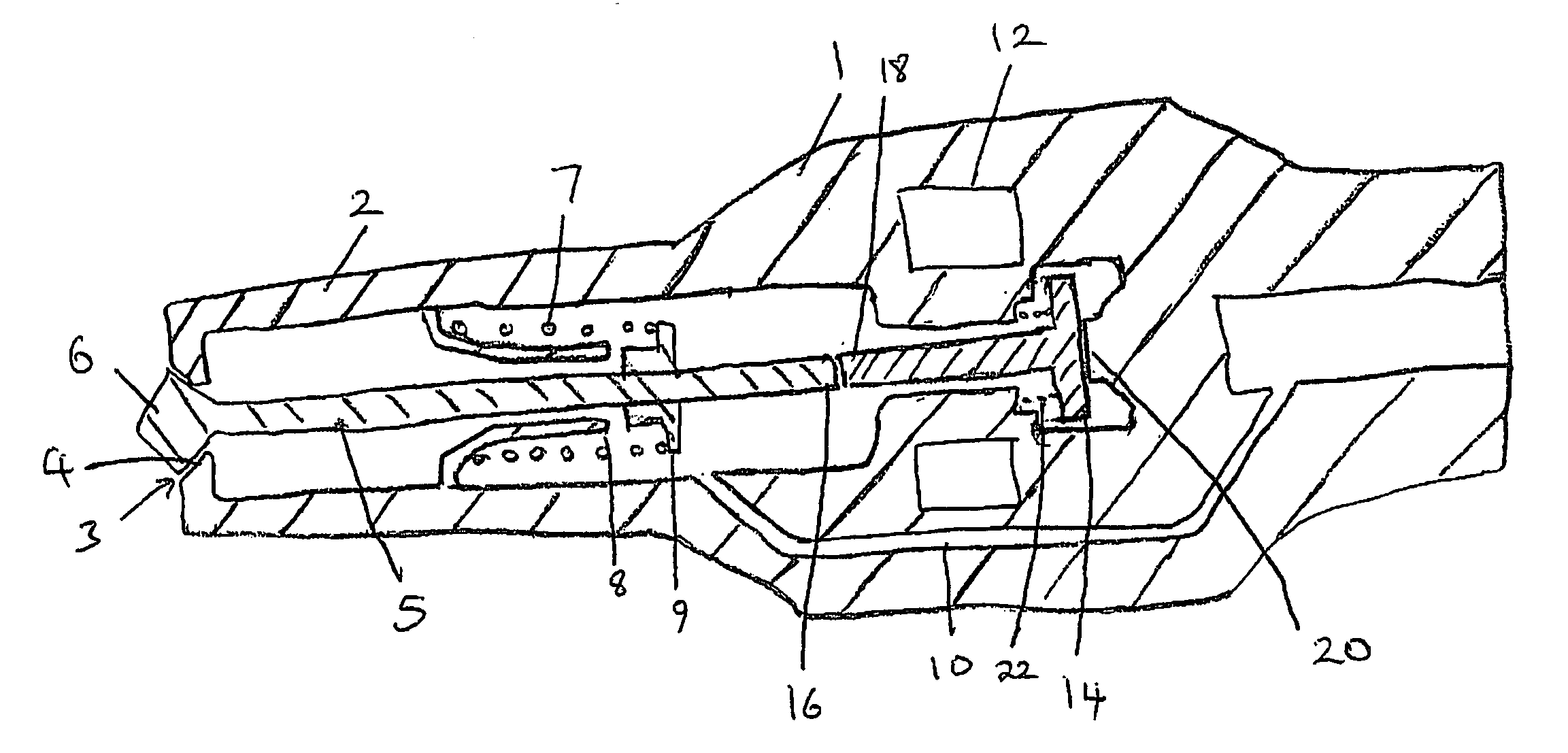

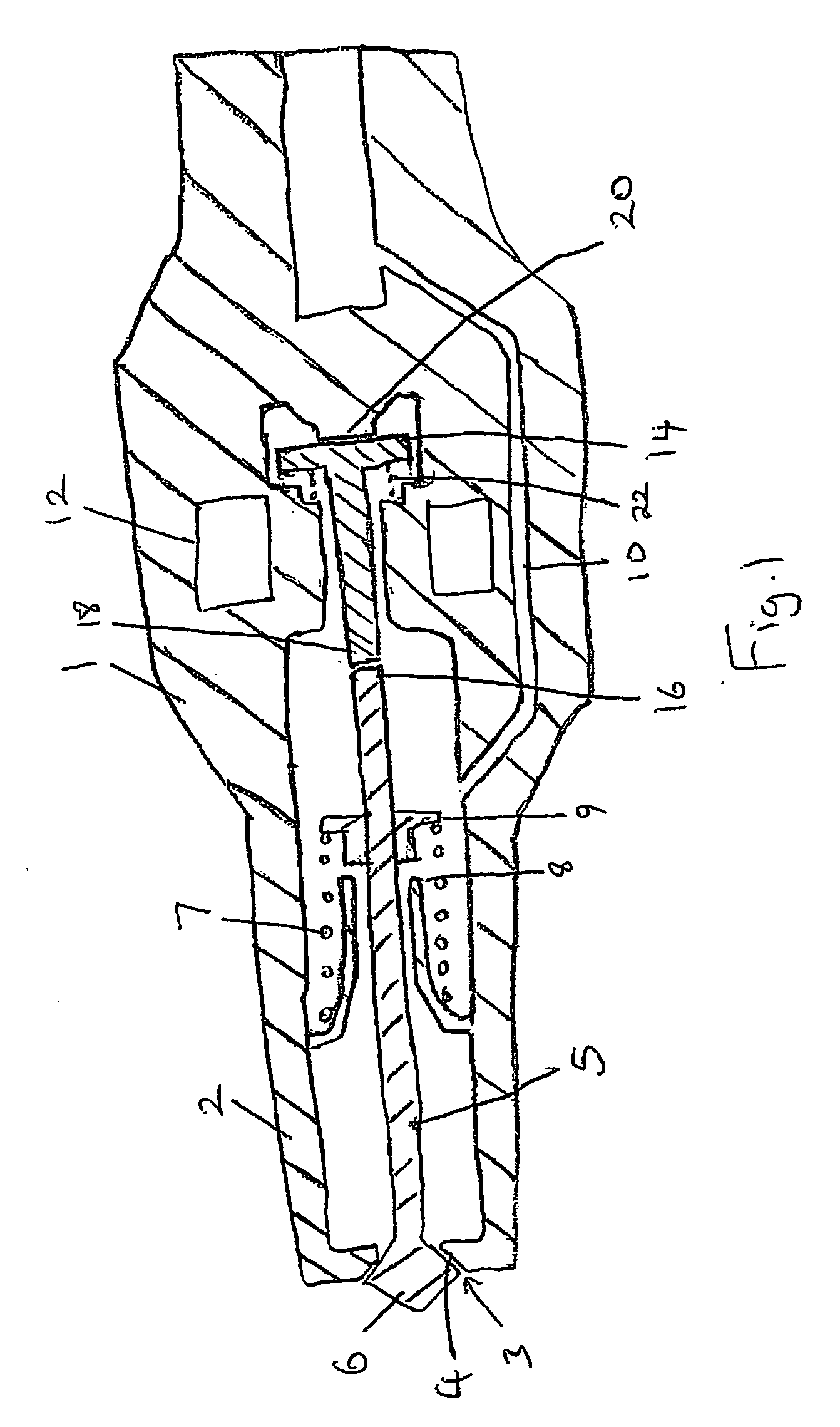

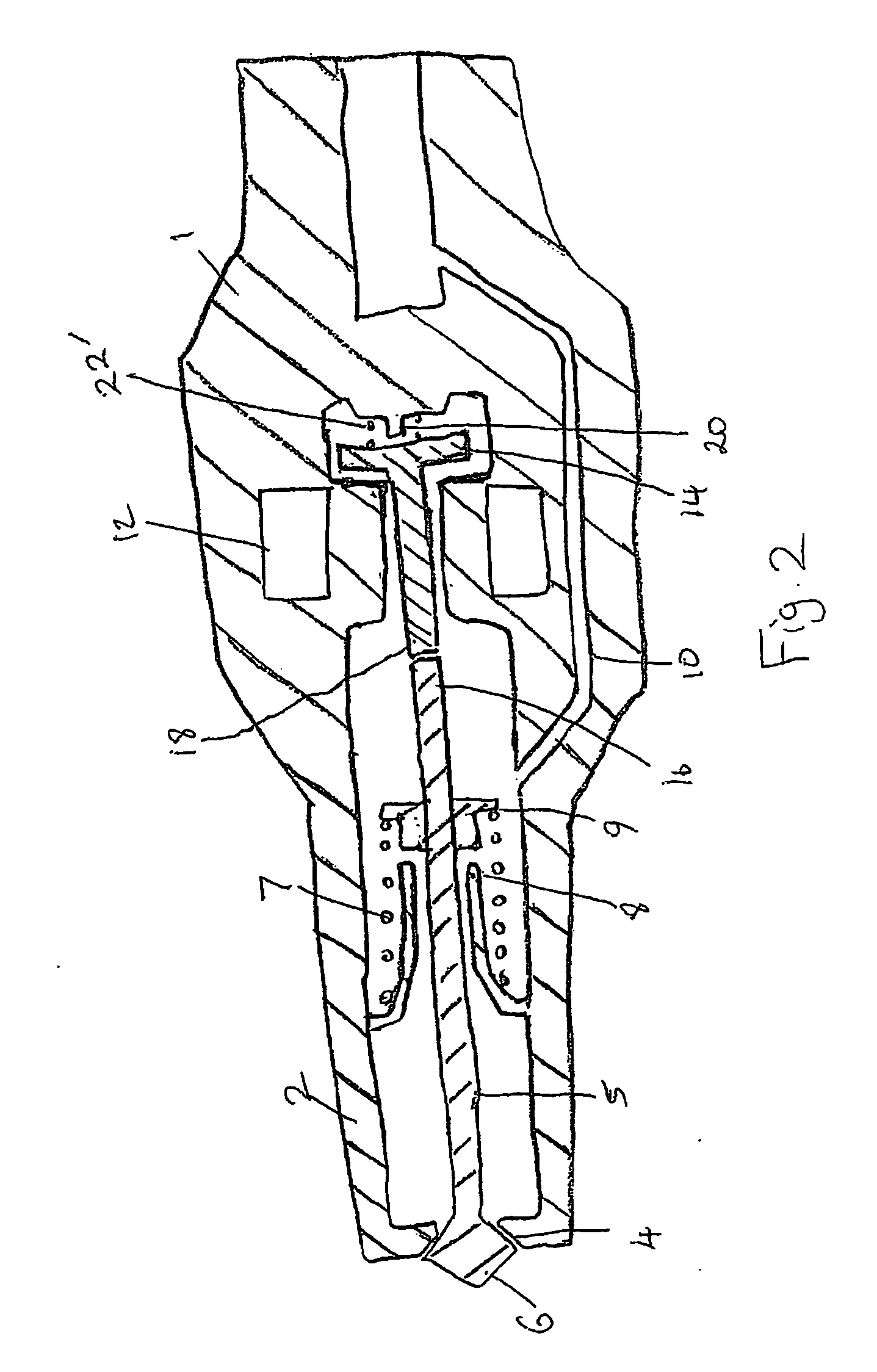

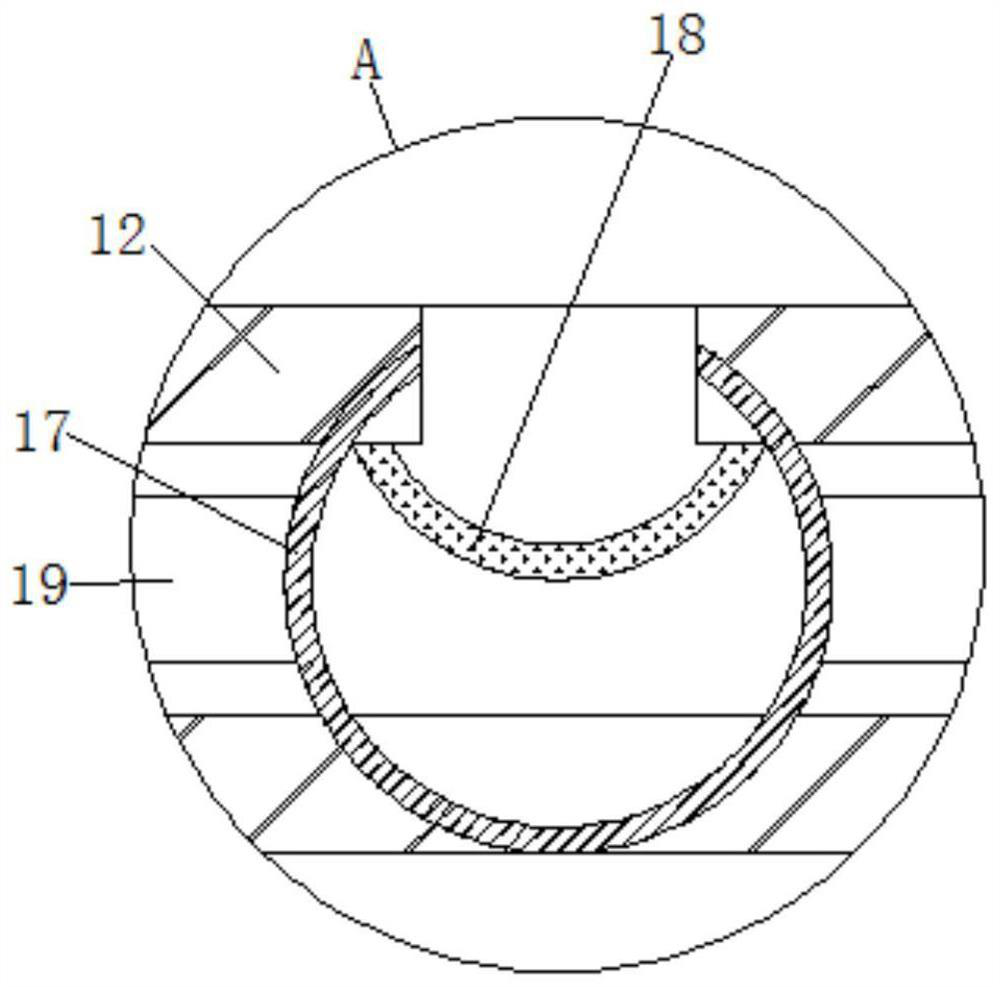

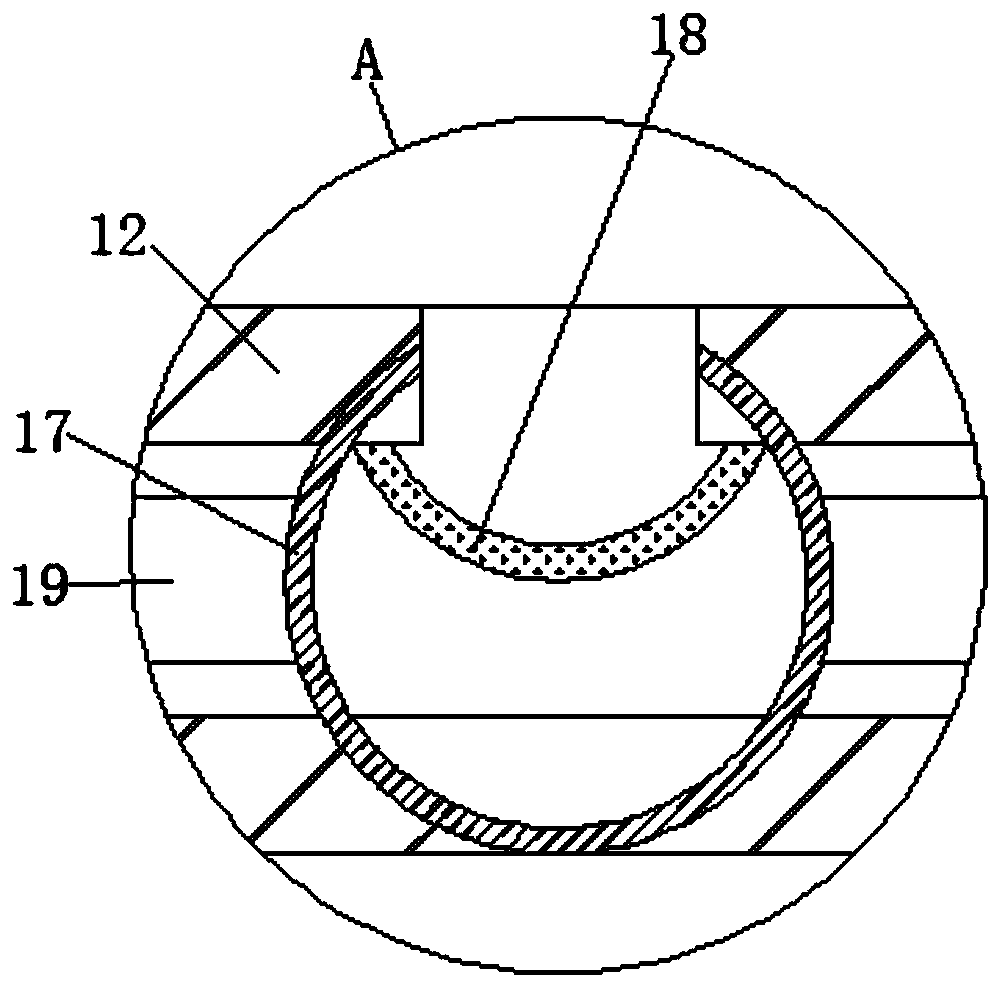

Internal post flow control

ActiveUS7222643B2Control gapConstant flowPipe elementsFlow control without auxillary powerEngineeringFluid pressure

A flow control including an annular flexible member and an internal post disposed downstream of the flexible member is described. The annular flexible member has a deflectable inner edge that defines a passage channel and the annular flexible member and internal post define a control gap therebetween wherein the deflectable inner edge of the annular flexible member deflects axially under increasing fluid pressure to reduce the control gap and consequently control fluid flow.

Owner:VERNAY LAB

Fuel injector having a separable armature and pintle

ActiveUS20070095955A1Reduce riskReduce usageSpray nozzlesFuel injection apparatusEngineeringElectromagnetic coil

A fuel injector comprises an injector body having a tip portion defining a spray aperture; a pintle extending within the tip portion for axial movement between an extended position and a retracted position, the pintle having a head portion engageable with the spray aperture to close the spray aperture when the pintle is in its retracted position; biasing means being provided for biasing the pintle towards its retracted position; and solenoid means for selectively moving the pintle into said extended position; said solenoid means comprising an electromagnetic coil and a moveable armature capable of being acted upon by the coil to urge the pintle towards its extended position; wherein the pintle and armature are separable from one another whereby the armature can decouple from the pintle when the pintle moves from its extended position to its retracted position.

Owner:BORGWARNER LUXEMBOURG OPERATIONS SARL +1

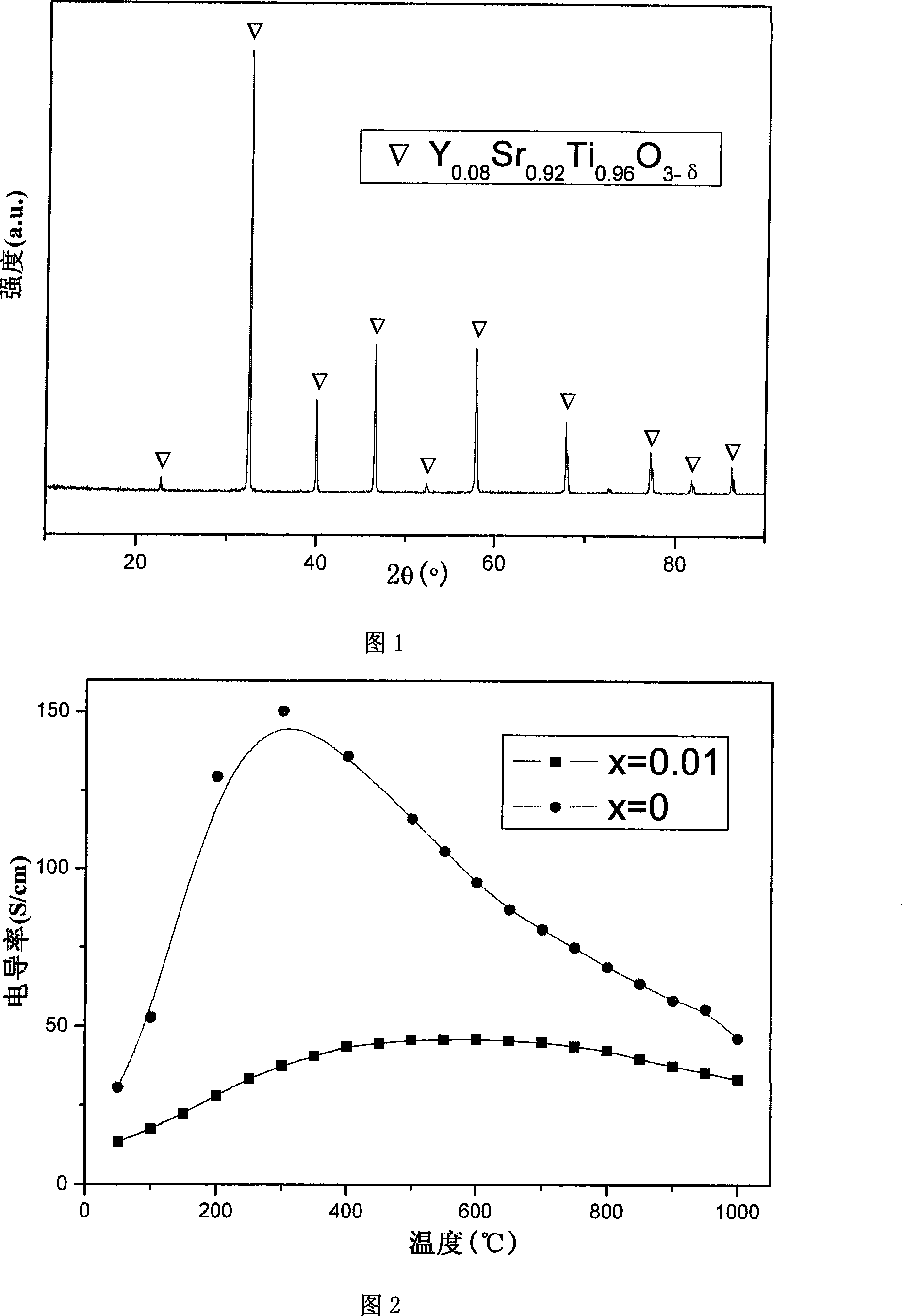

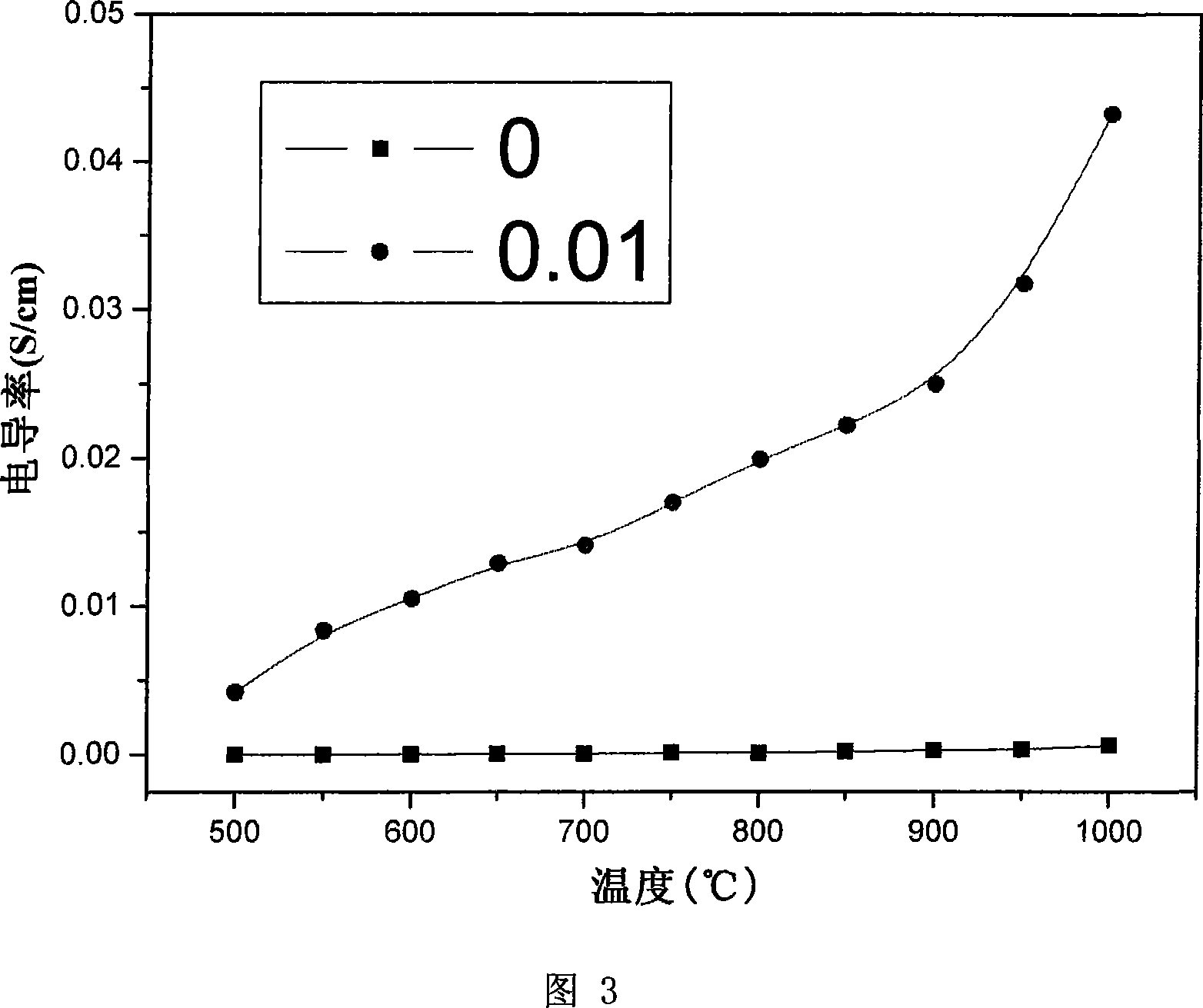

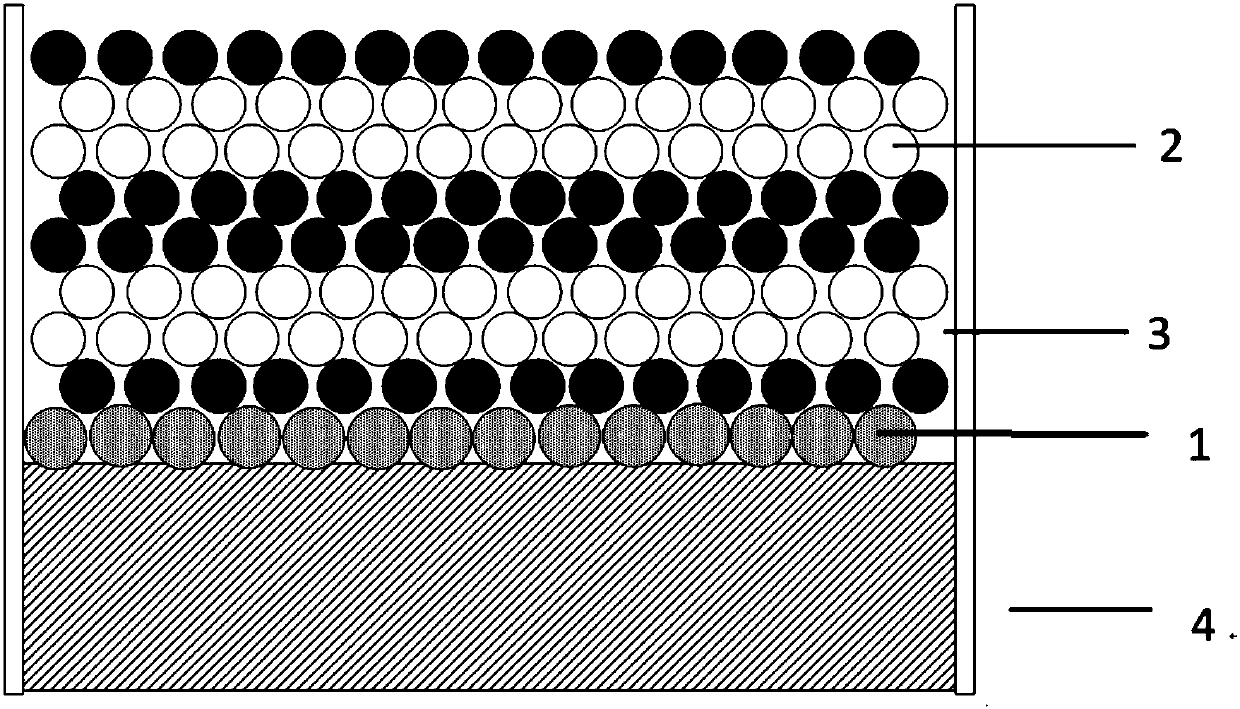

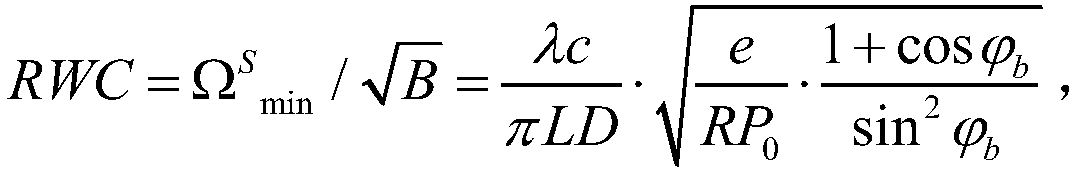

B-position omission perovskite anode material used for solid-oxide fuel battery

InactiveCN101222059AImprove performanceGood chemical compatibilityCell electrodesFuel cell detailsFuel cellsIonic conductance

The invention relates to a B-site omission perovskite anode material used for a solid oxide fuel cell, belonging to the fuel cell field. The invention is characterized in that: an A site of perovskite SrTiO3 is adulteration of Y (8 mole percent); Ti omission exists on a B site; molecular formula after omission adulteration is Y0.08Sr0.92Ti1-xO3-delta, wherein, x is equal to 0 to 0.05; a transition element for A-site adulteration is yttrium. The omission adulteration anode material prepared by the invention can be used for the solid oxide fuel cell and has stable performance and good chemical compatibility with electrolyte YSZ and LSGM, and ionic conductivity of the material is greatly improved. Compared with data of a material Y0.08Sr0.92TiO3-delta which has no omission adulteration, the ionic conductivity is raised by two order of magnitudes, thereby working performance of the anode material is improved and foundation is laid for practicality of the SOFC.

Owner:UNIV OF SCI & TECH BEIJING

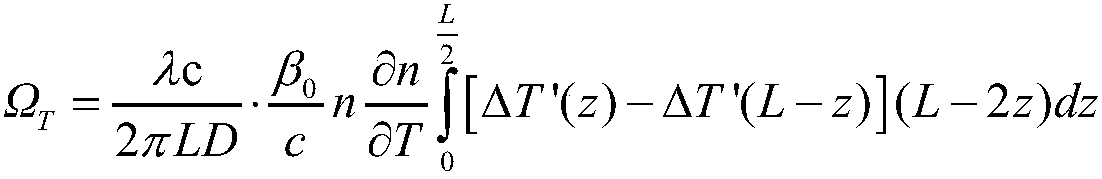

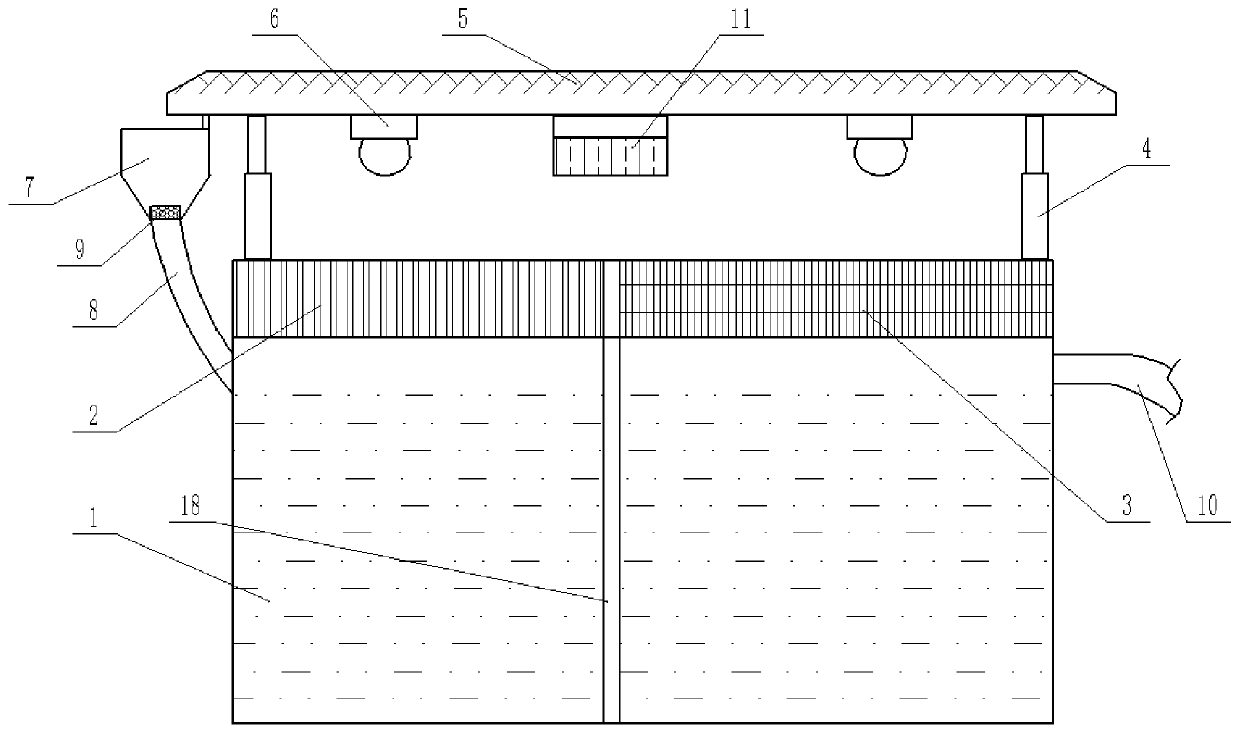

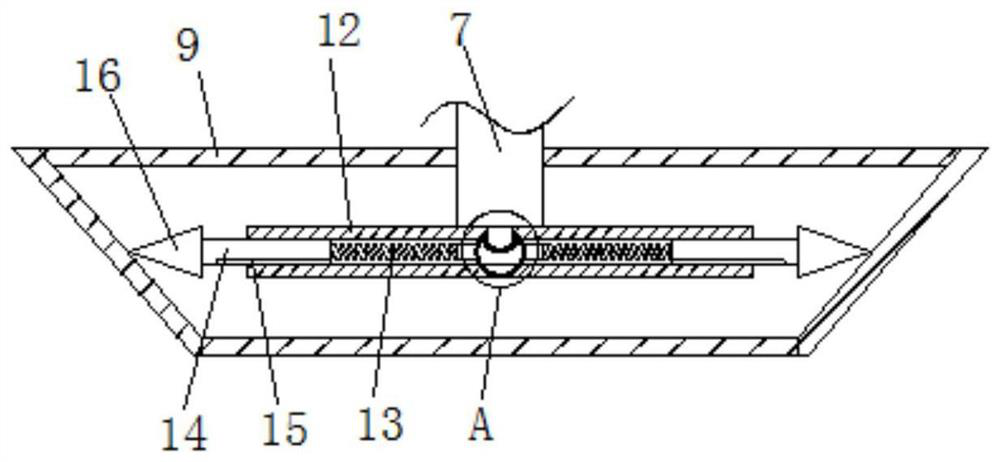

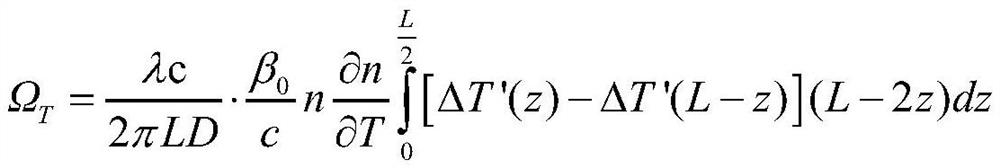

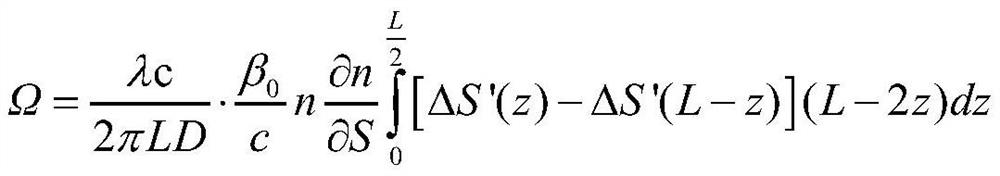

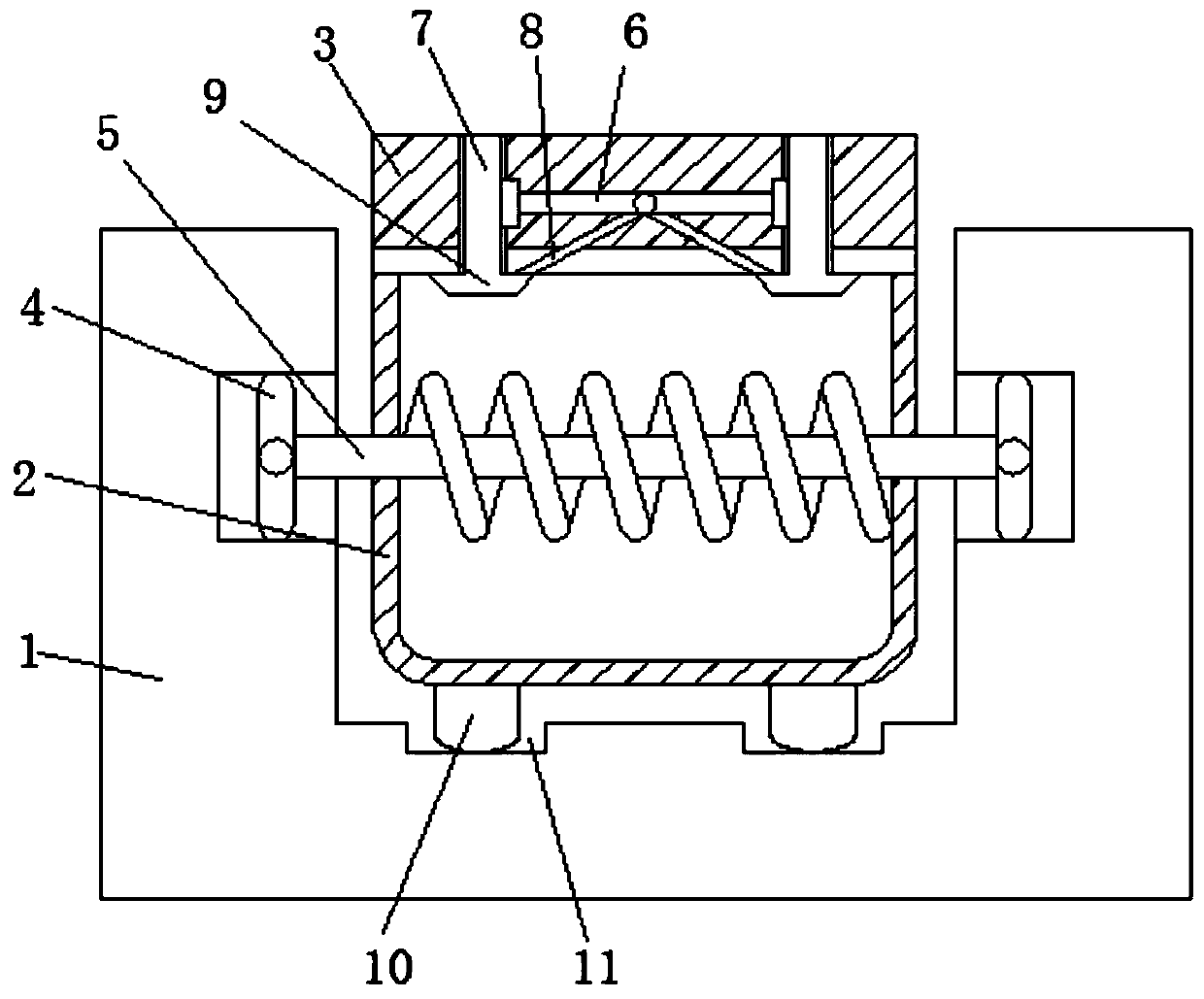

Optical fiber ring precision winding method

ActiveCN108088466AControl gapGuaranteed potting effectSagnac effect gyrometersGyroscopePolarization-maintaining optical fiber

The invention belongs to the technical field of manufacturing of an optical fiber ring of an optical fiber gyro, and in particular relates to an optical fiber ring precision winding method. The methodcomprises the following steps: determining the length of optical fiber and the structure of the optical fiber ring; processing winding tooling; selecting suitable polarization maintaining optical fiber; winding single mode optical fiber; and winding the polarization maintaining optical fiber. The method needs to solve the problems that when a large-length optical fiber ring is wound, the existingoptical fiber winding method cannot guarantee the geometric symmetry of the optical fiber ring, the zero-drift amount of the optical fiber ring under the variable temperature condition is too large,and the precision of an inertial gyroscope is influenced. By customizing of the special-sized single-mode optical fiber and winding tooling, the gap between the optical fiber can be controlled when the polarization-maintaining optical fiber is wound, and the number of turns of the optical fiber in each layer is fixed. Based on a four-pole symmetrical winding method, the geometric symmetry of the optical fiber is finally ensured, the zero-drift amount of the optical fiber ring under the variable temperature condition is reduced, and the precision of the inertial gyroscope is improved.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Method and device for positioning single-phase ground faults in star-shaped three-phase ungrounded system

InactiveCN106771881AFast positioning timeEasy to FeedbackTransmission systemsFault location by conductor typesInjection pointThree-phase

The invention relates to a method and a device for positioning single-phase ground faults in a star-shaped three-phase ungrounded system. The method includes sequentially injecting abnormal-frequency current signals different from a power grid frequency into a midpoint of a three-phase line when the line is in ground fault, and detecting current signal intensities on two sides of the injection point so as to determine a fault phase; continuing to inject the abnormal-frequency current signals at the end of the fault phase, and indicating that a single-phase fault point is positioned between A and the other end of a fault-phase line if the abnormal-frequency current signals can be detected at the midpoint A of the fault-phase line; acquiring a midpoint B between the A and the other end of the fault-phase line, and indicating that the single-phase ground fault point is positioned between the A and the B if the abnormal-frequency current signals cannot be detected; repeating the above steps until the single-phase ground fault point is positioned within a visual range distance of human eyes. The method is capable of accelerating positioning of single-phase ground fault points effectively and accurate in positioning.

Owner:DEZHOU POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

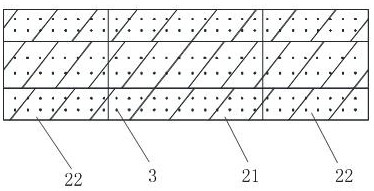

Construction method for bonding face bricks with tile glue in washy room

Provided is a construction method for bonding face bricks with tile glue in a washy room. The construction method for bonding face bricks with tile glue in a washy room forms a new construction technology for bonding face bricks in a washy room through brick laying modeling, wall base layer cleaning and waterproofing treatment, perpendicular line hanging and square setting and flatness and perpendicularity determining, tile glue mixing and stirring in proportion, auxiliary inlaying of face bricks by using tile glue and by combining a wedge leveling device and an infrared level gauge, finishedproduct protection, and the like. The construction method for bonding face bricks with tile glue in a washy room gets rid of a traditional technique which takes cement mortar as a bonding agent, has the advantages of high bonding strength, high flexibility, high water resistance, high freeze-thaw resistance, high aging resistance and convenient construction, and has good workability, so that the tile glue can effectively penetrate into the gaps on the surface of the base layer to enable the molded face bricks to have good bonding performance, thus reducing the working time, being the construction method is simple, and being easy to control. Besides, the construction method for bonding face bricks with tile glue in a washy room can quickly adjust and maintain the flatness between a tile anda tile, can prevent the tiles from shifting during the solidification of the cement or tile glue, and can control the tile gap by means of the wedge leveling device.

Owner:NO 9 METALLURGICAL CONSTR

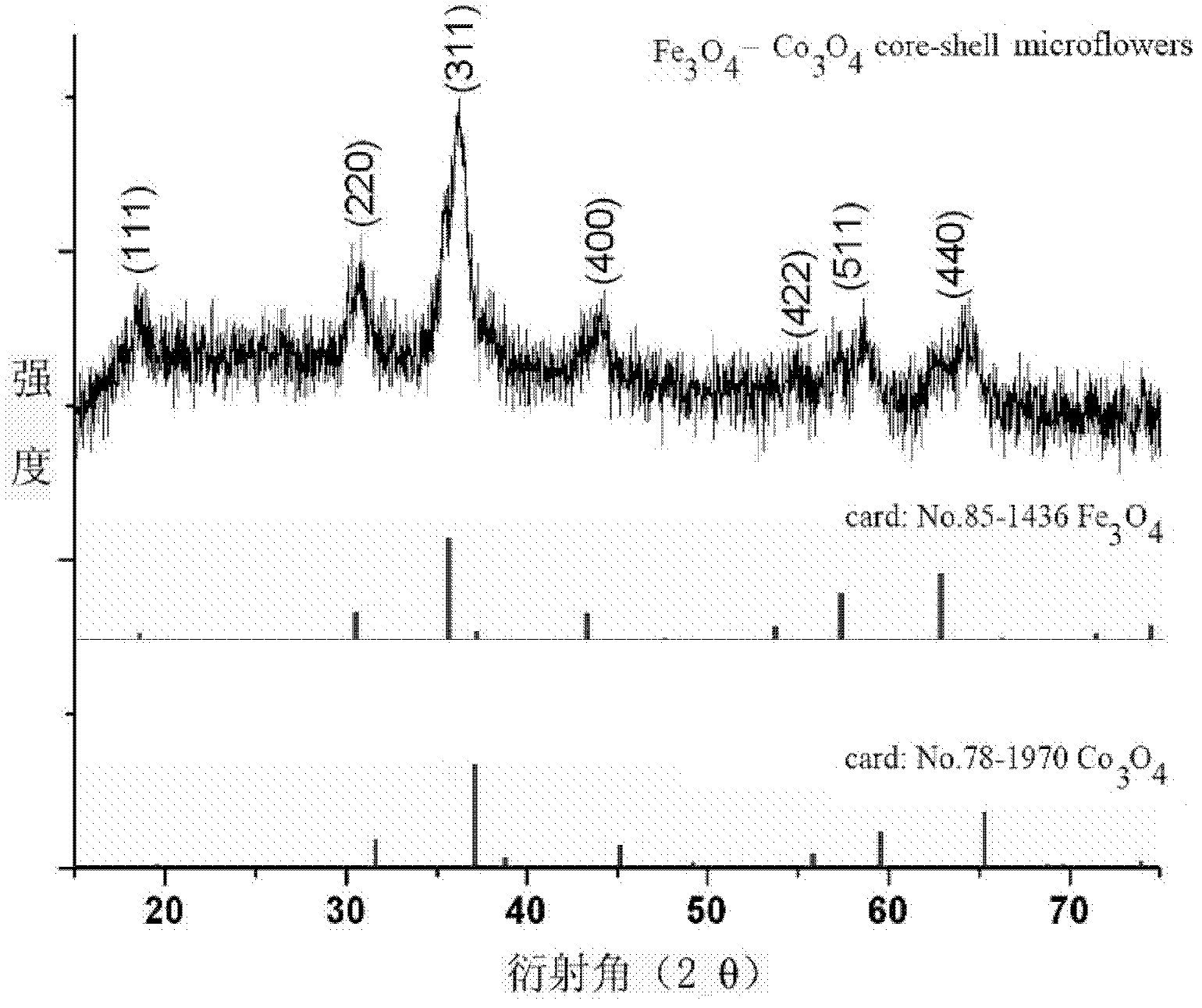

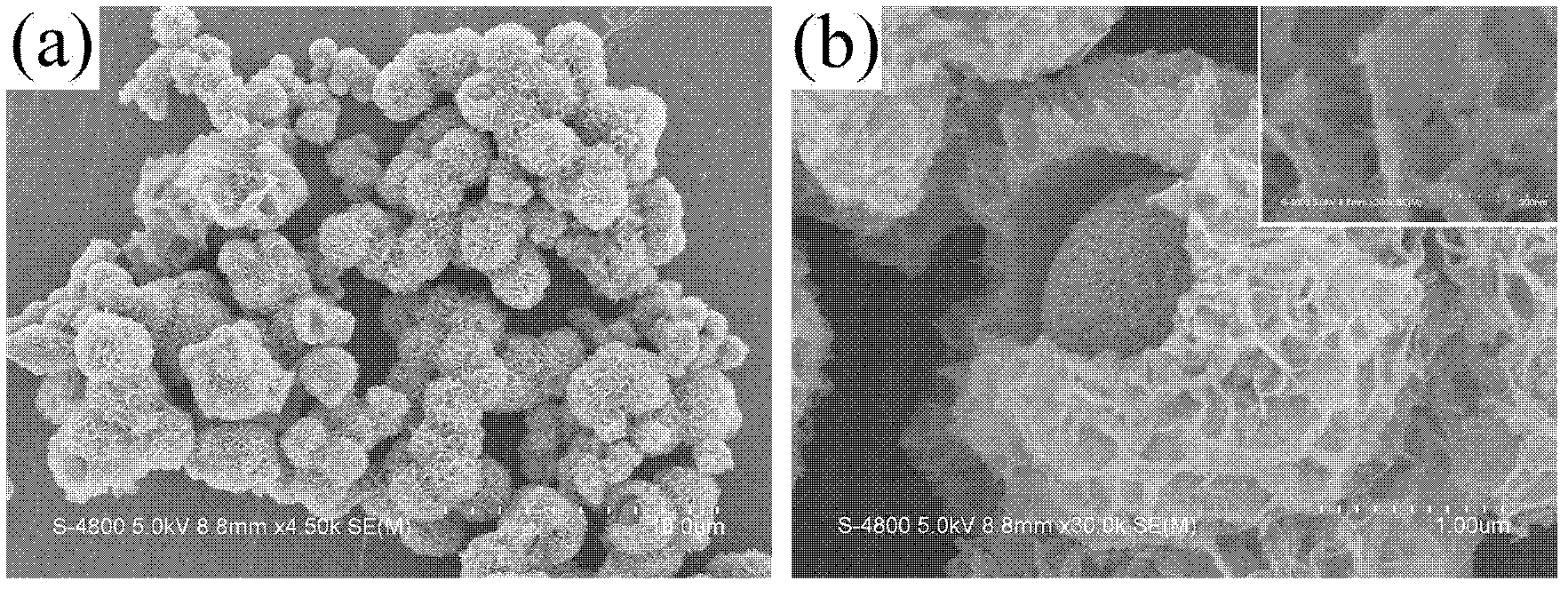

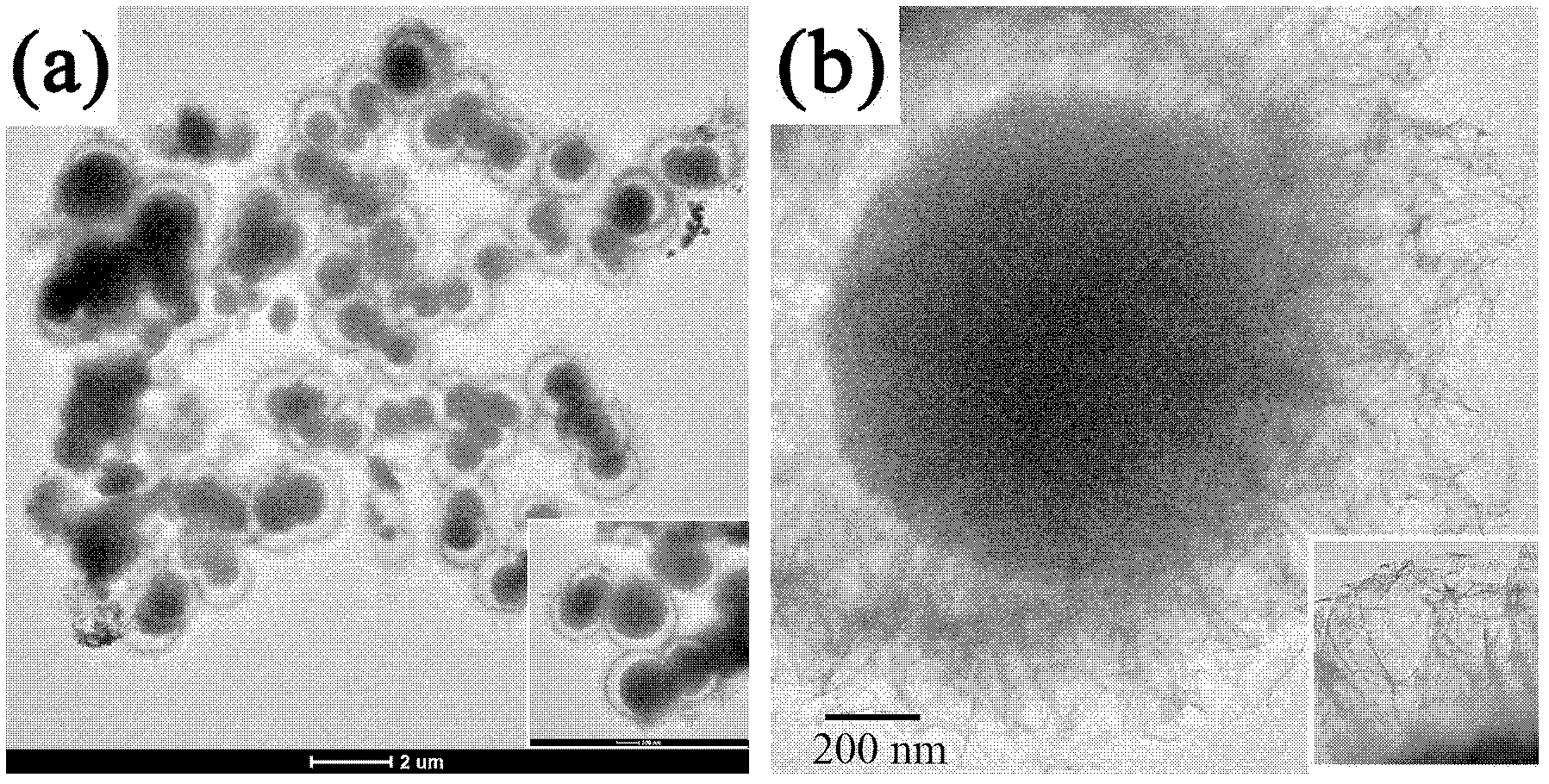

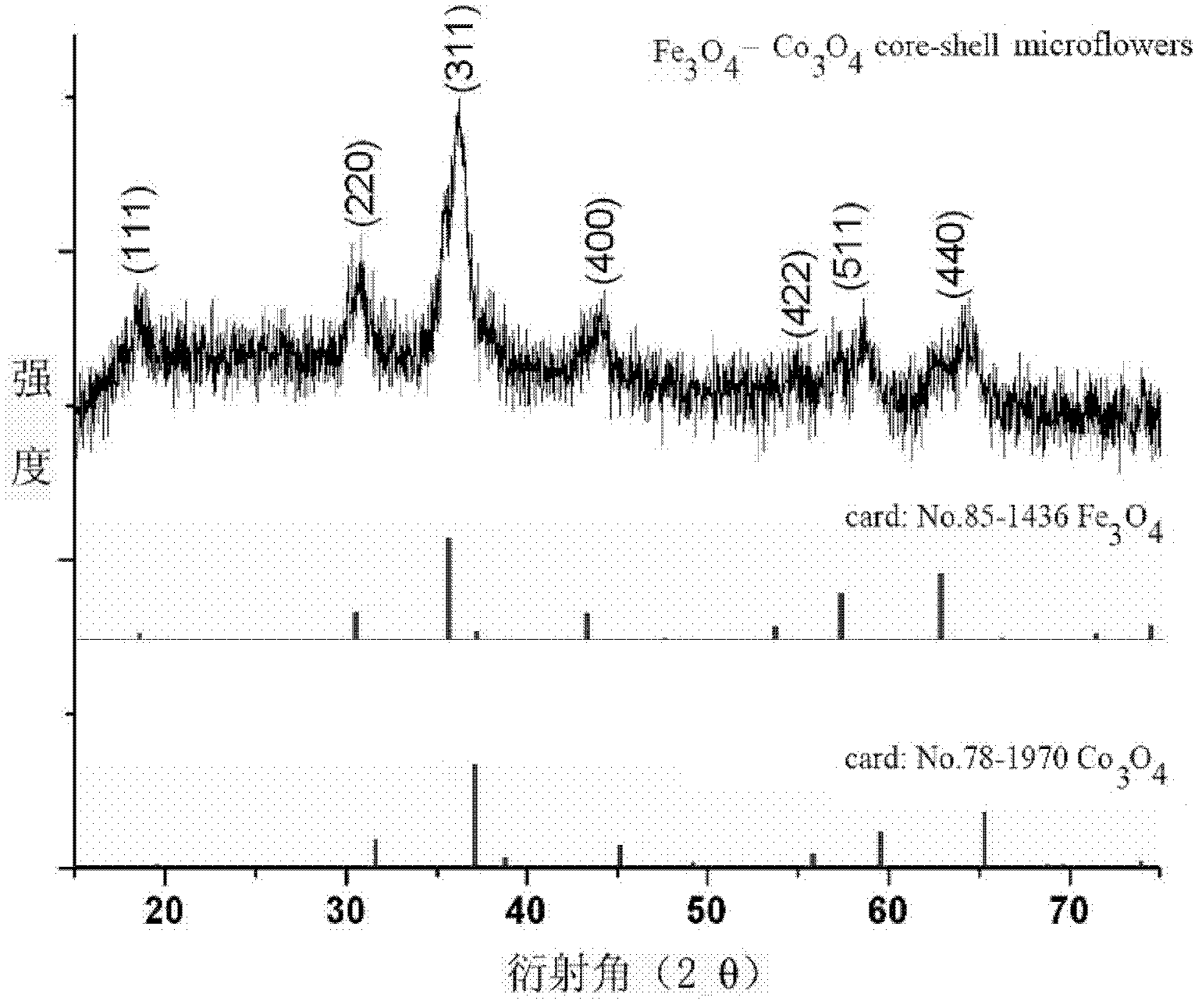

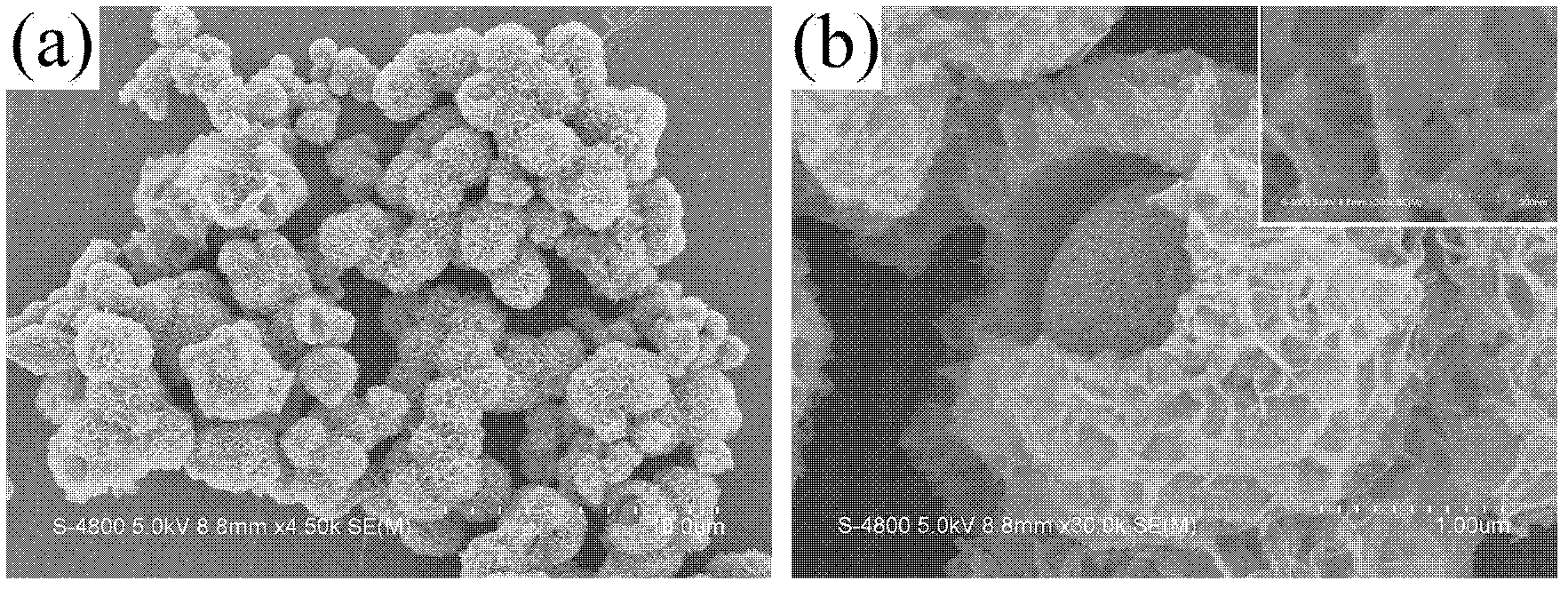

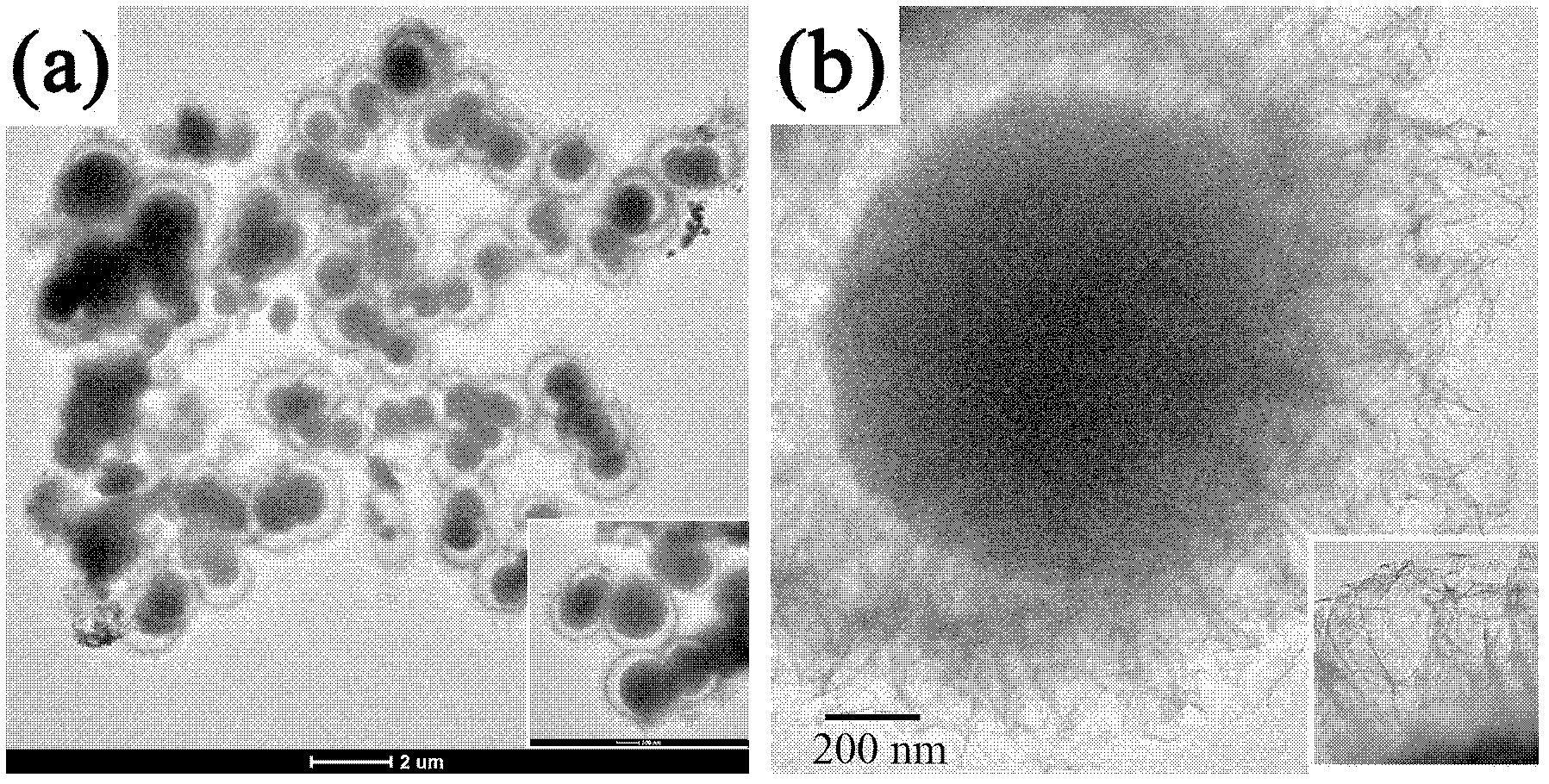

Preparation method and application of Fe3O4-Co3O4 porous magnetic composite material

The invention discloses a preparation method of a Fe3O4-Co3O4 porous magnetic composite material. The preparation method comprises the following steps of (a) blending, (b) heating, (c) drying and (d) calcining. In comparison with the prior art, the invention has the following advantages: (1) other oxides are not found in the product, and the product is a heterogeneous material and has uniform particle size, special morphology, high activity, simple one-step synthesis method, large apparent density, and good magnetic performance; (2) the method has high yield, low cost, short production flow and is convenient in scale-up experiment; (3) the method is simple and controllable, and has low demand for equipment, so that the method is suitable for industrial production; and (4) the magnetic material with a heterogeneous oxide core-shell structure provided by the invention can be effectively applied to lithium-ion and fuel cell materials.

Owner:ANHUI NORMAL UNIV

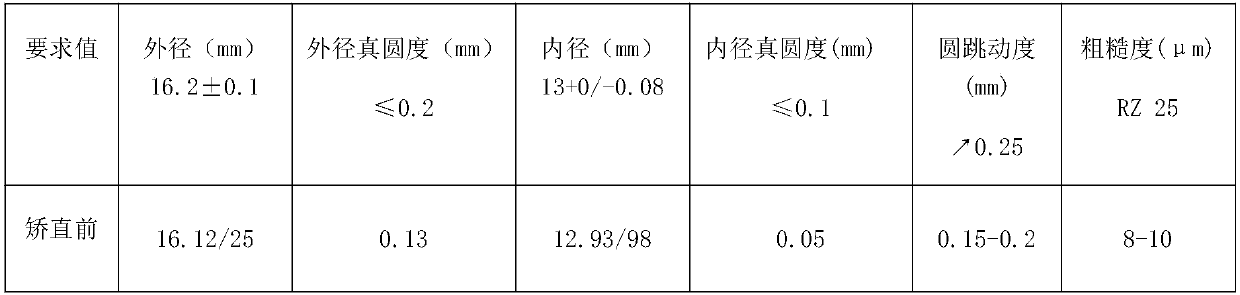

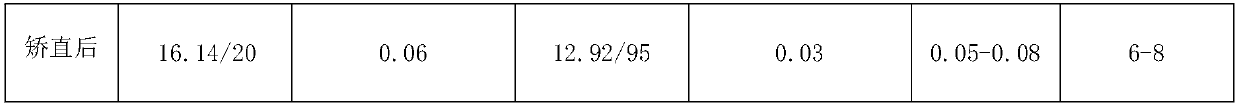

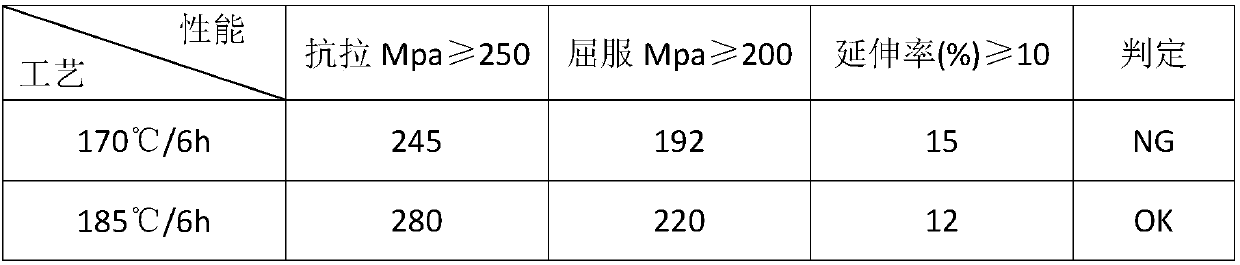

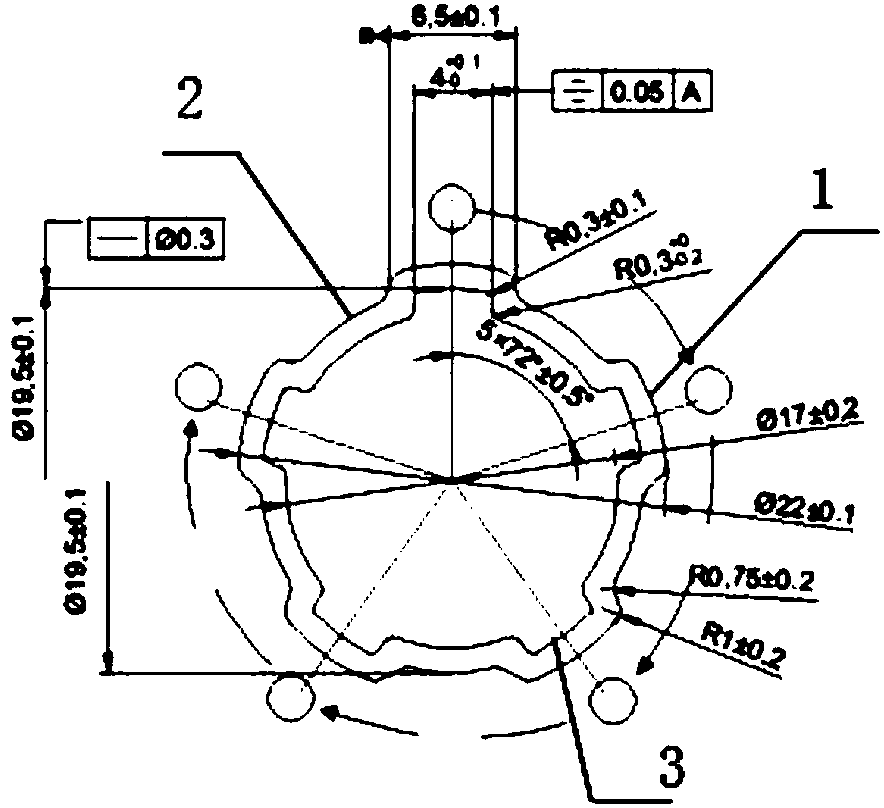

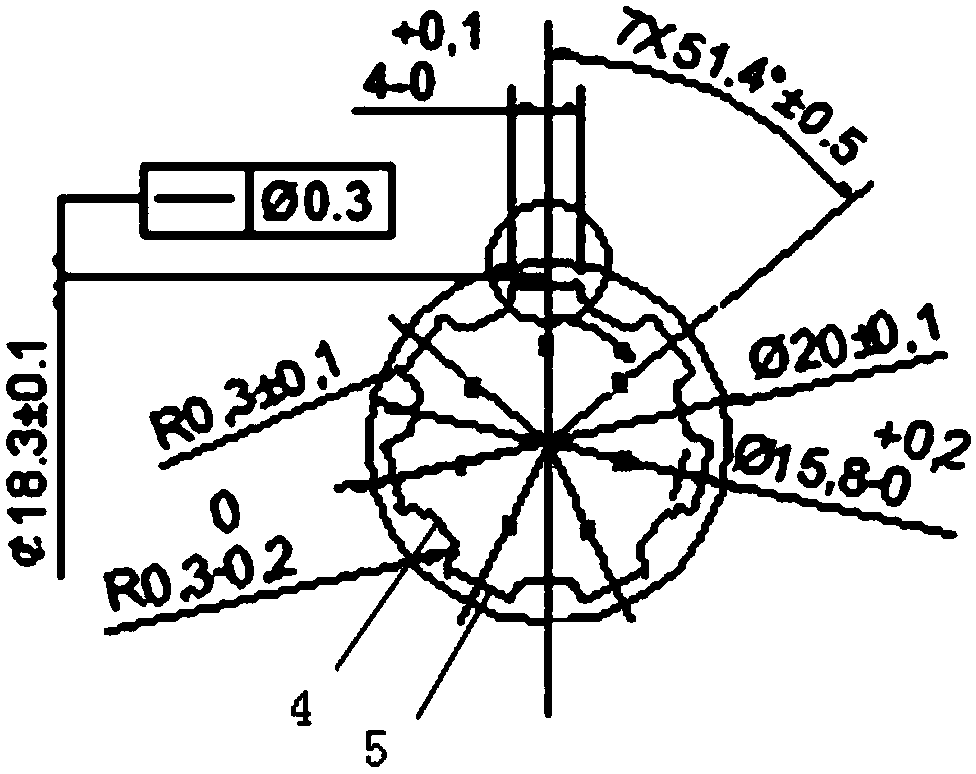

Manufacturing method of novel circular aluminium alloy tube for automobile gas spring

ActiveCN107739908AControl gapGuaranteed performance requirements for plastic processingGas springHigh surface

The invention discloses a manufacturing method of a novel circular aluminium alloy tube for an automobile gas spring. Raw materials comprise alloy elements in percentage by mass as follows: 0.48%-0.52% of Si, 0.16%-0.20% of Fe, less than or equal to 0.05% of Cu, less than or equal to 0.05% of Mn, 0.51%-0.55% of Mg, less than or equal to 0.05% of Cr, less than or equal to 0.05% of Zn, 0.15%-0.25% of Ti, 0.004%-0.01% of Pb, 0.001%-0.002% of Ca+Na, less than or equal to 0.05% of other individual elements, less than or equal to 0.15% of the total amount of other elements and the balance of Al; andan aluminium rod comprising the components is prepared through procedures including hot extrusion, drawing, finishing, finished product sawing, cleaning, aging treatment, machining and the like. Theproduct prepared with the method has the advantages of good plasticity and mechanical property, high machining precision and high surface quality, has the tensile strength ranging from 280 Mpa to 320Mpa, has the yield strength ranging from 220 Mpa to 260 Mpa and has the elongation ranging from 12% to 15%.

Owner:CYMA PRECISION ALUMINUM

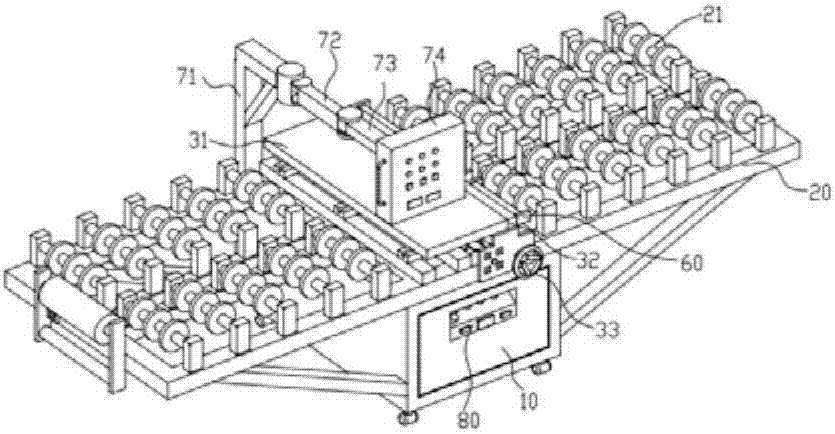

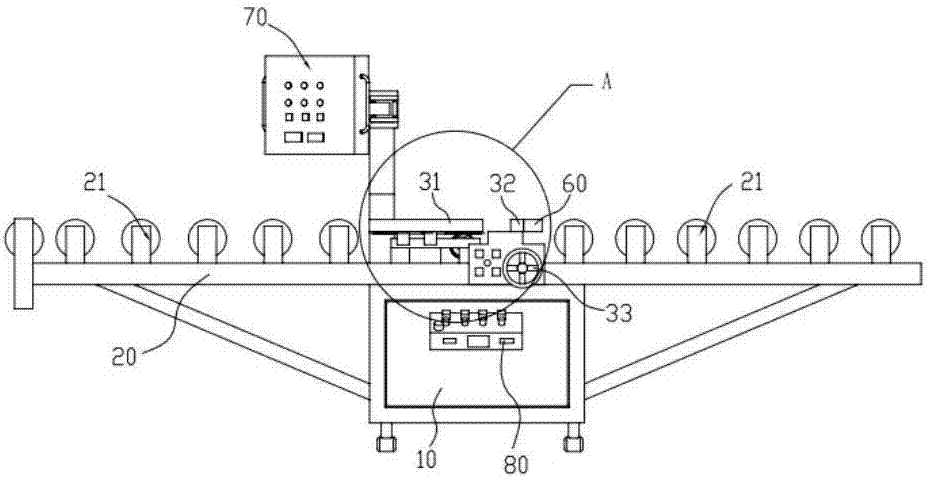

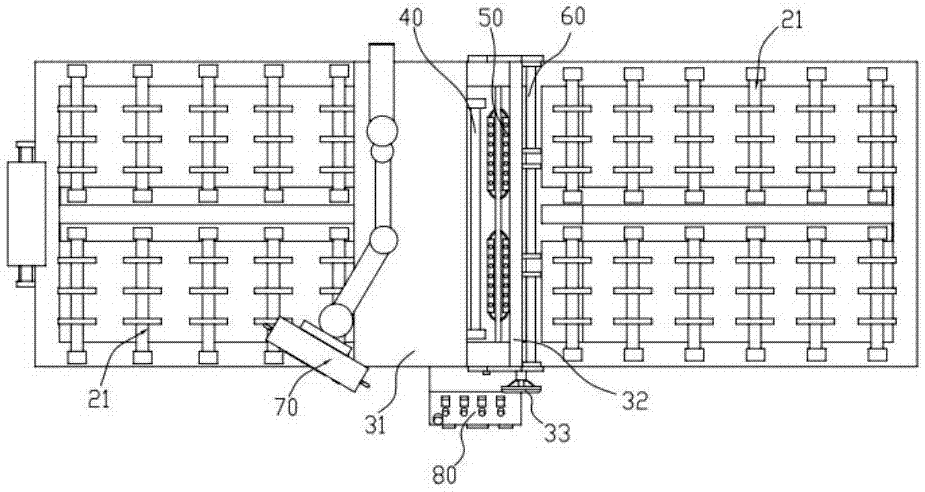

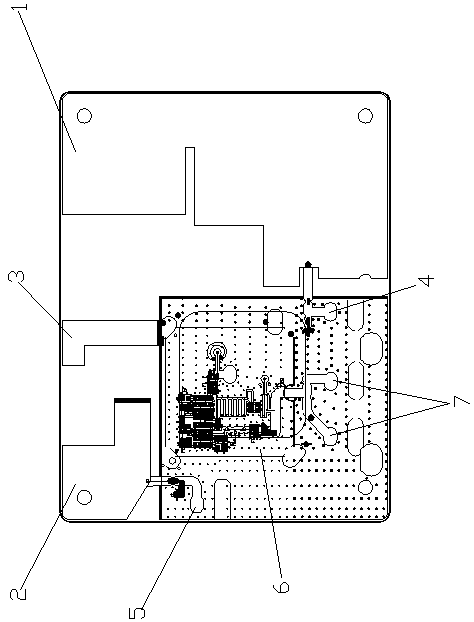

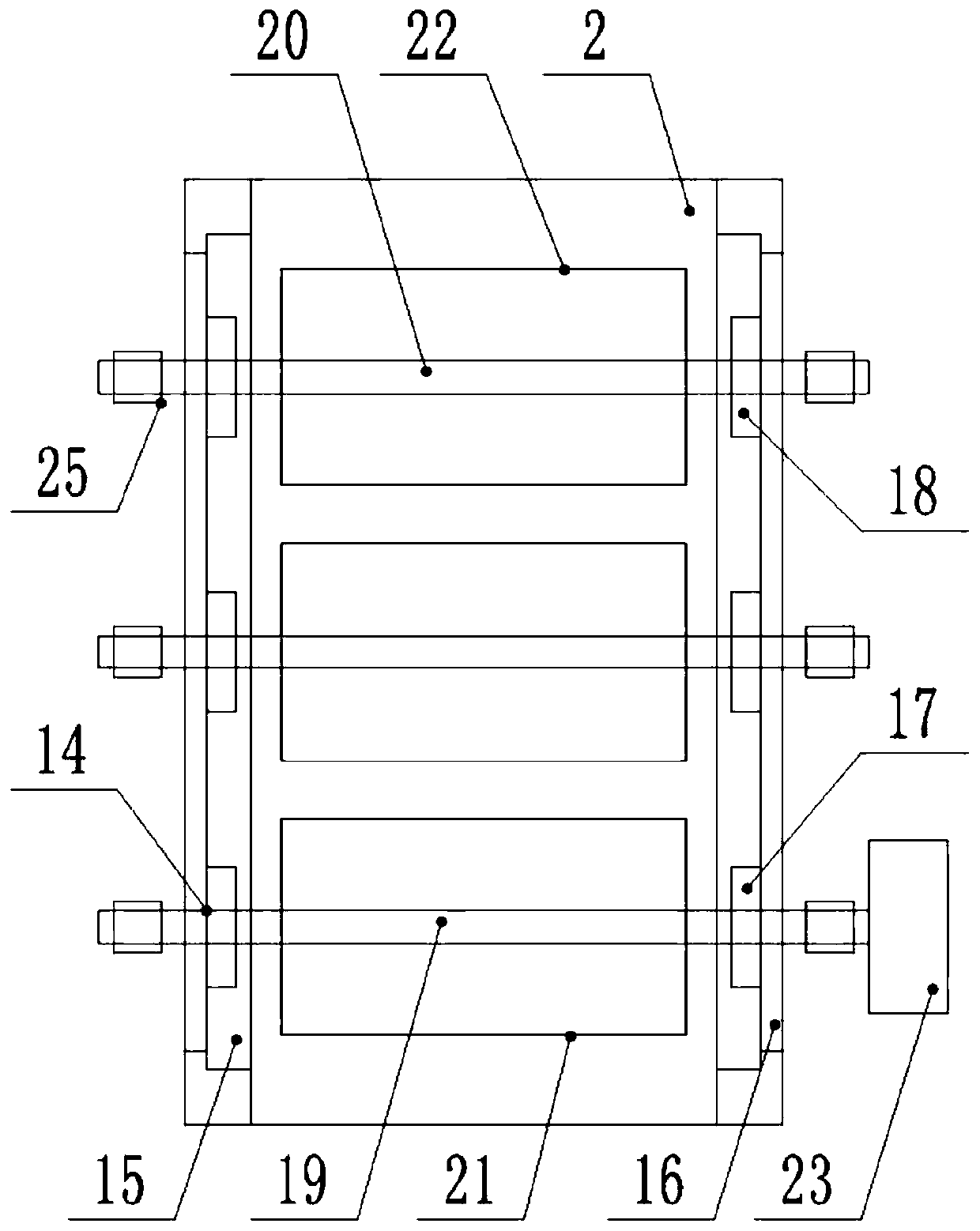

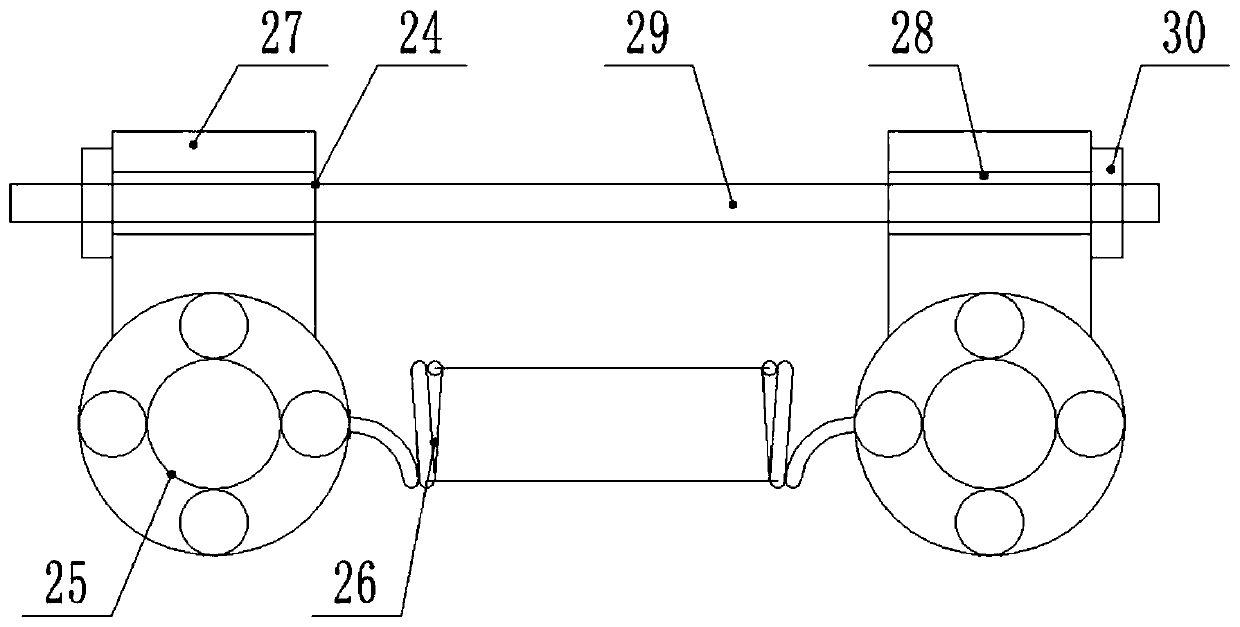

Improved polaroid stripping machine

ActiveCN107966837AControl gapImprove stripping efficiencyNon-linear opticsWorkbenchStatic electricity

An improved polaroid stripping machine includes a base cabinet, a support frame, a workbench unit, a rotating shaft unit, a heating device, a destaticizing device, a first control cabinet unit and a second control cabinet; the support frame is fixedly arranged on the base cabinet, the workbench unit includes a material placement table, an inspection conveyor and a rotating disk mechanism, the material placement table is arranged on the support frame, the inspection conveyor is fixedly arranged on the support frame and matched with the material placement table, and the rotating disk mechanism is used for driving the material placement table to horizontally move; the rotating shaft unit is fixedly arranged on the top of the base cabinet and located below the workbench unit, the heating device is fixedly arranged on the top of the base cabinet and located on one side of the rotating shaft unit, the destaticizing device is fixedly arranged on one side of the workbench unit, the first control cabinet unit is arranged on the base cabinet, and the second control cabinet is movably arranged on the base cabinet. The rotating disk mechanism can accurately and conveniently control the gap between the material placement table and the inspection conveyor, and the polaroid stripping quality and efficiency are thus improved.

Owner:佑仁电子科技(苏州)有限公司

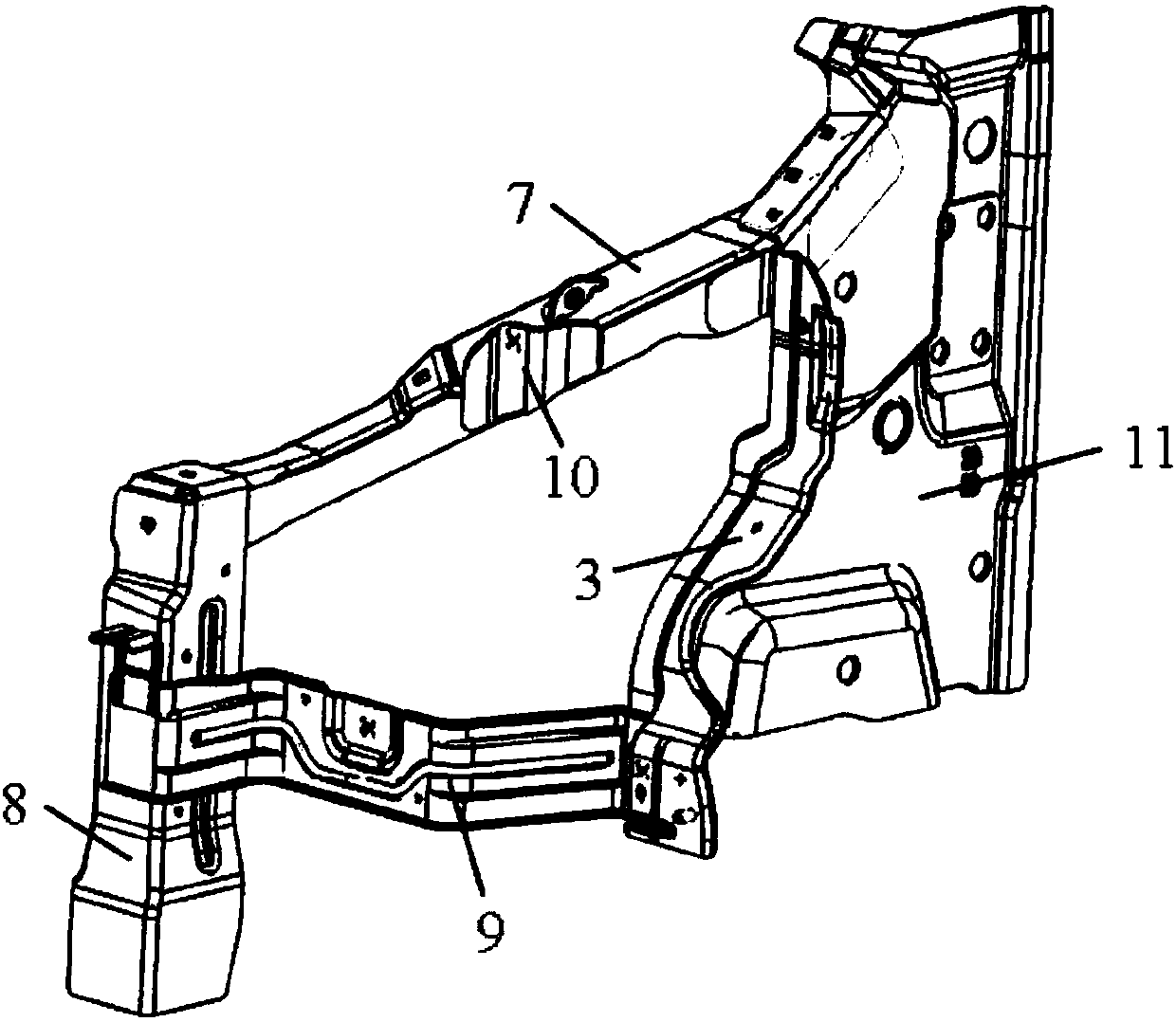

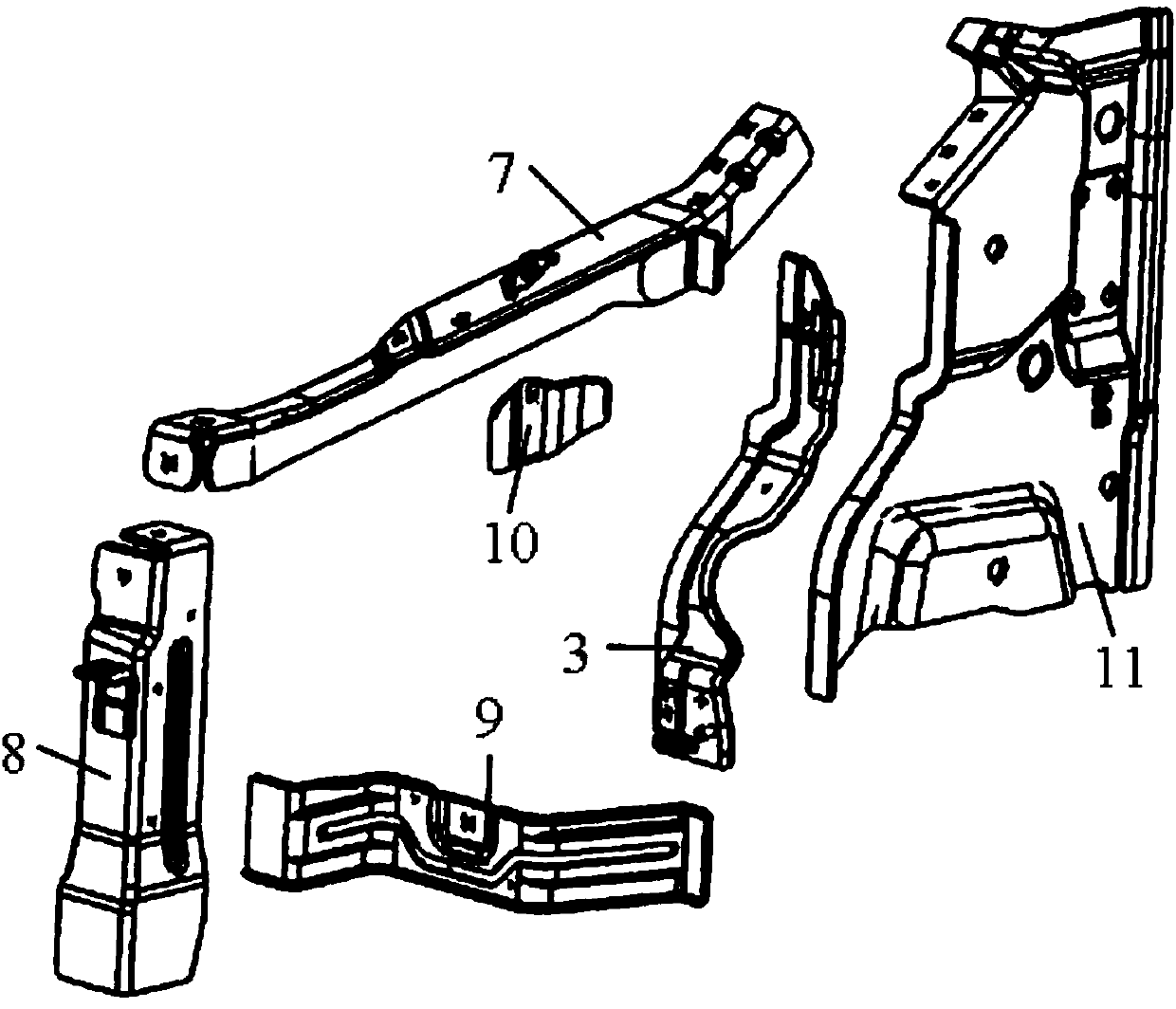

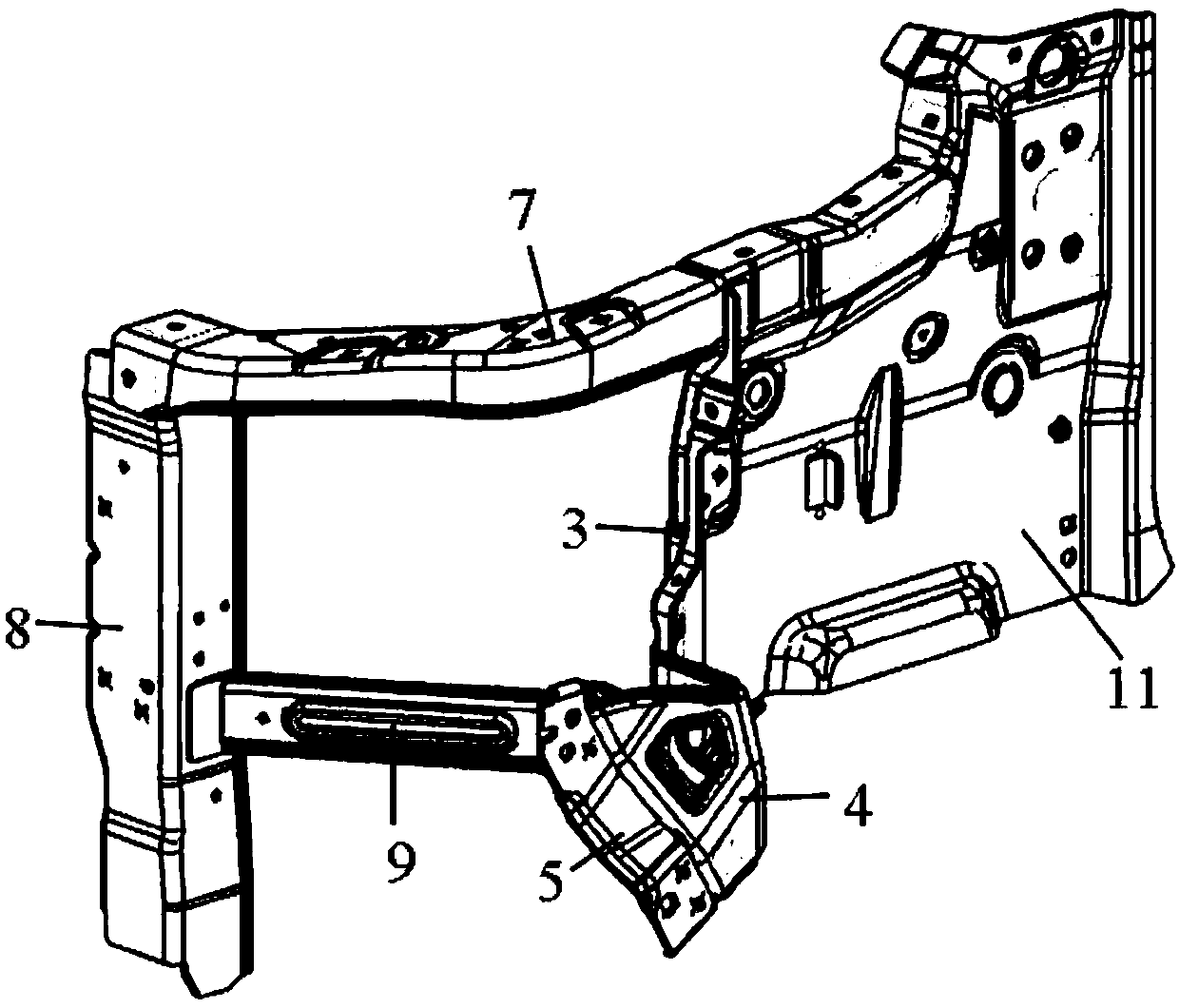

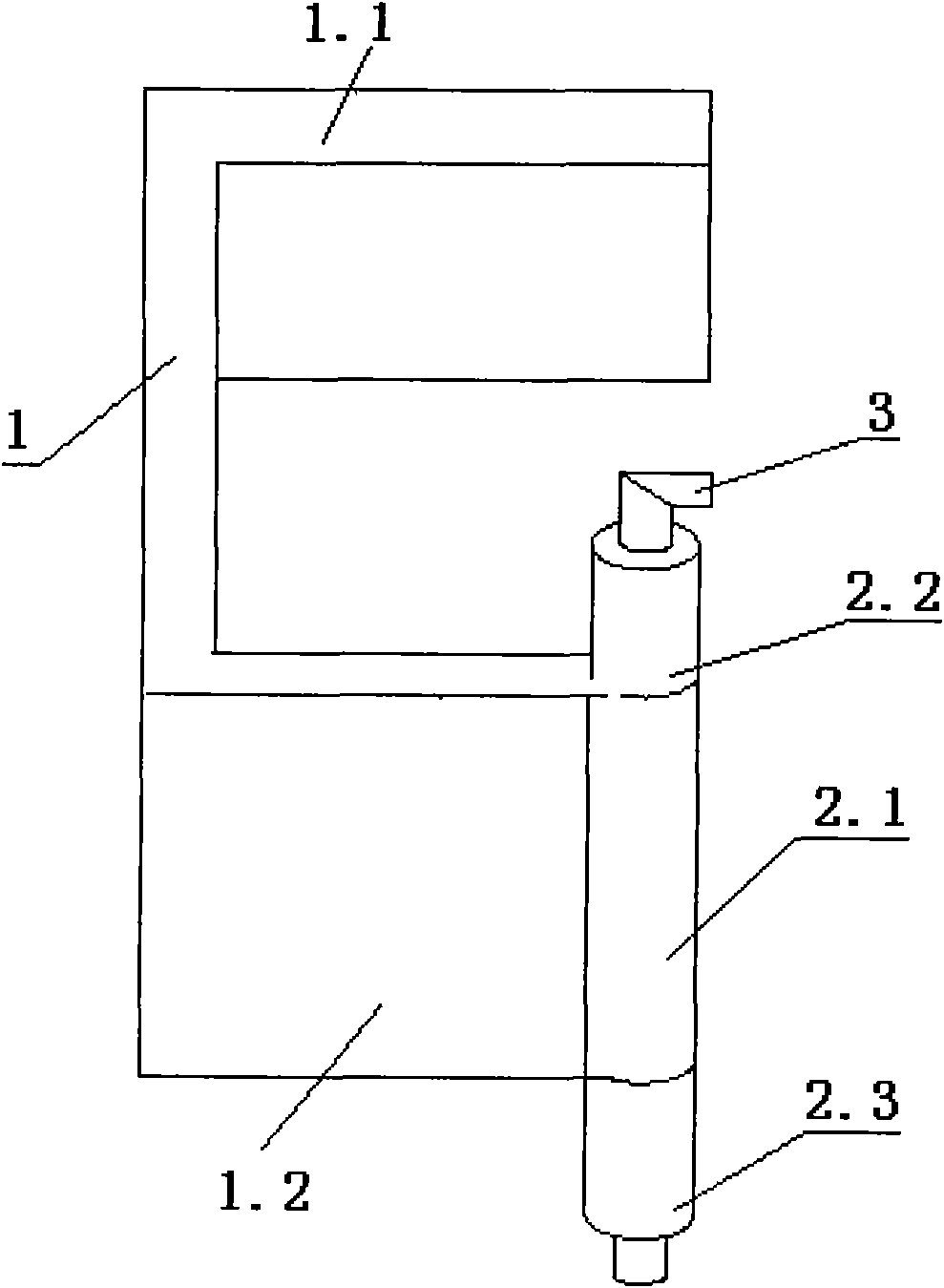

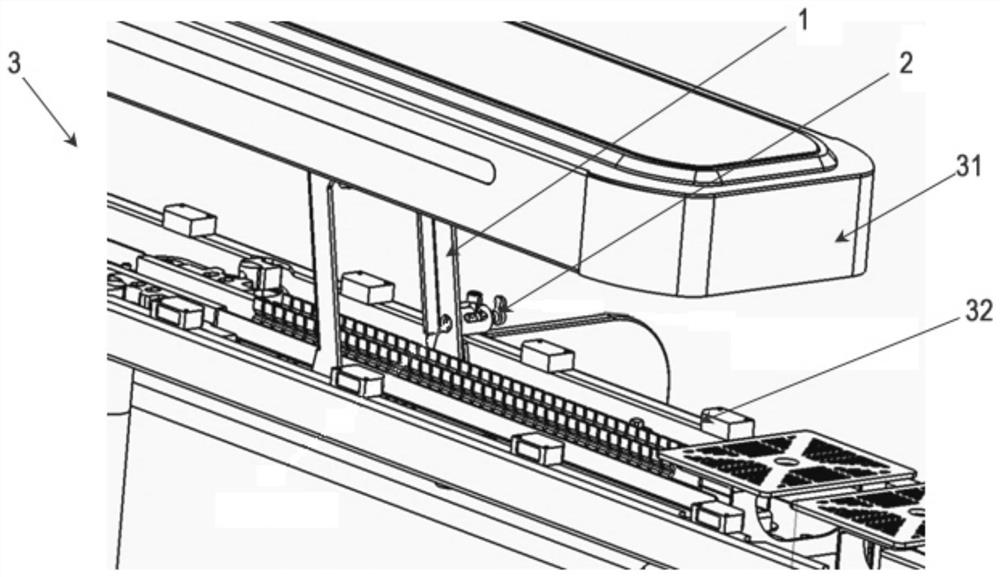

Mounting assembly of headlamp and fender

PendingCN110341581AReduce welding errorsThe installation structure is stableSuperstructure subunitsOptical signallingEngineering management

The invention discloses a mounting assembly of a headlamp and a fender. The mounting assembly comprises a front connecting plate, a headlamp mounting beam assembly, a fender mounting reinforcing plateand a fender mounting bracket; the front connecting plate is fixedly arranged on a front plate, the headlamp mounting beam assembly is fixedly connected with the front connecting plate, the fender mounting reinforcing plate is fixedly connected with the lower portion of the front connecting plate, the fender mounting bracket fixed on the fender mounting reinforcing plate in a position adjustablemode, a headlamp is respectively fixedly connected with the headlamp mounting beam assembly, the front connecting plate and the fender mounting bracket, and a fender body is fixedly connected with theheadlamp mounting beam assembly and the fender mounting bracket respectively. According to the mounting assembly of the front headlamp and the fender in the invention, the segment gap clearance between the fender body and the headlamp can be effectively controlled and quickly adjusted.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

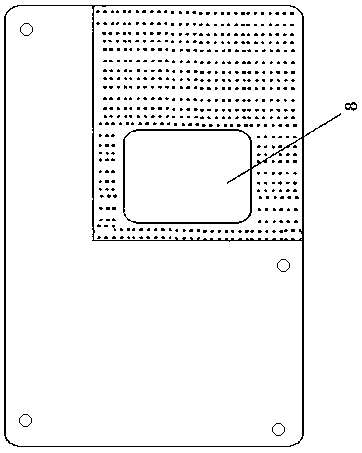

Vehicle-mounted multimode antenna

InactiveCN107611563AReduce diversity energy leakageIncrease trace areaAntenna supports/mountingsRadiating elements structural formsCouplingSatellite

The invention relates to a vehicle-mounted multimode antenna, and the antenna comprises a PCB, a satellite antenna which is disposed on the PCB and is used for receiving a GPS signal, an LTE main antenna and an LTE diversity antenna, wherein the LTE main antenna and the LTE diversity antenna are disposed on the PCB. The LTE main antenna and the LTE diversity antenna are disposed at corners of thePCB, and the feed layout of the LTE main antenna and the LTE diversity antenna is of a diagonal type. The LTE main antenna and the LTE diversity antenna are set in a manner of an extending branch node. The antenna achieves the more high-frequency modes through coupling, improves the isolation degree, is very high in overall efficiency, is simple in structure, and is easy to manufacture.

Owner:HUIZHOU SPEED WIRELESS TECH CO LTD

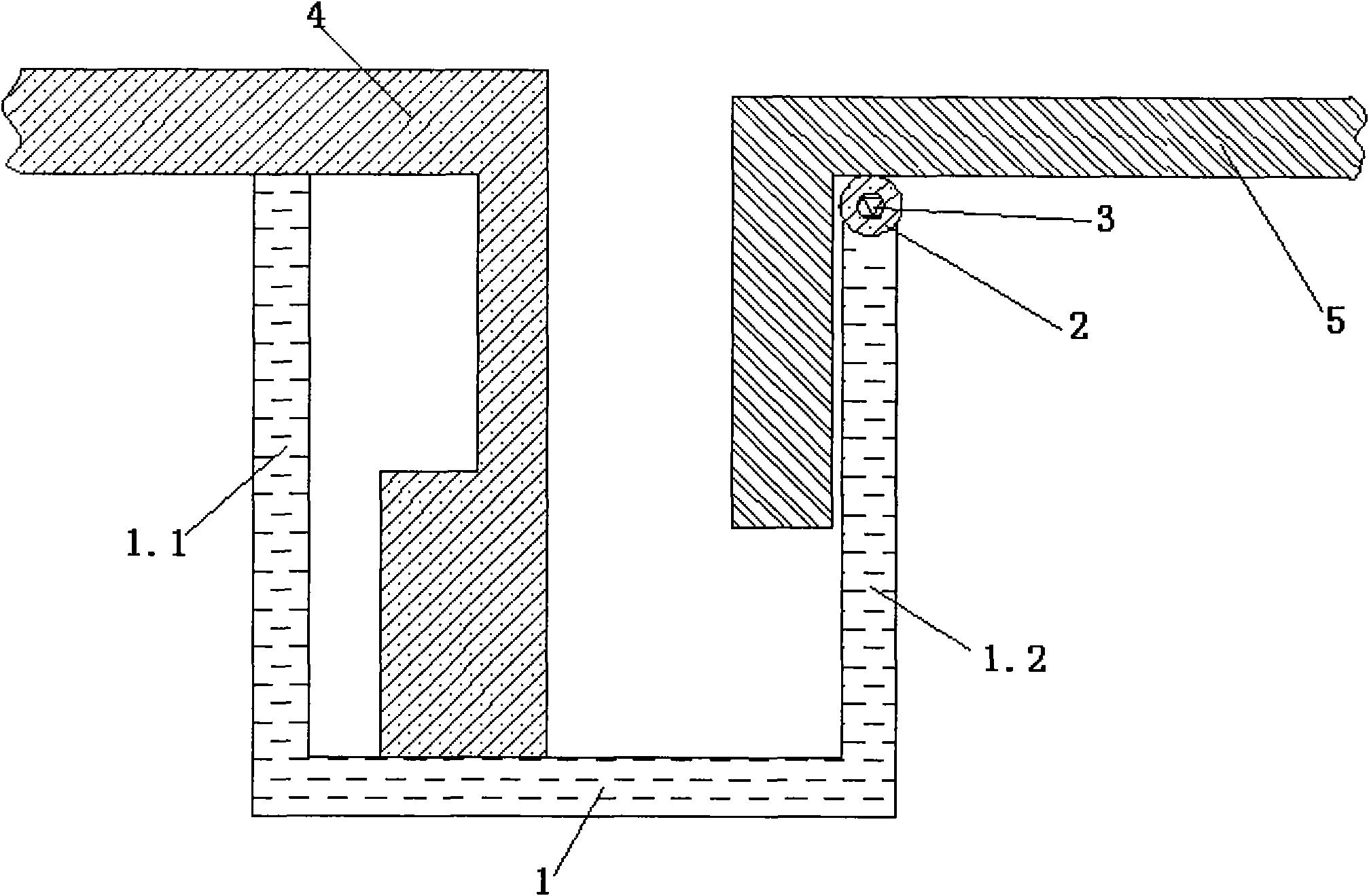

Power distribution cabinet hinge with limiting function

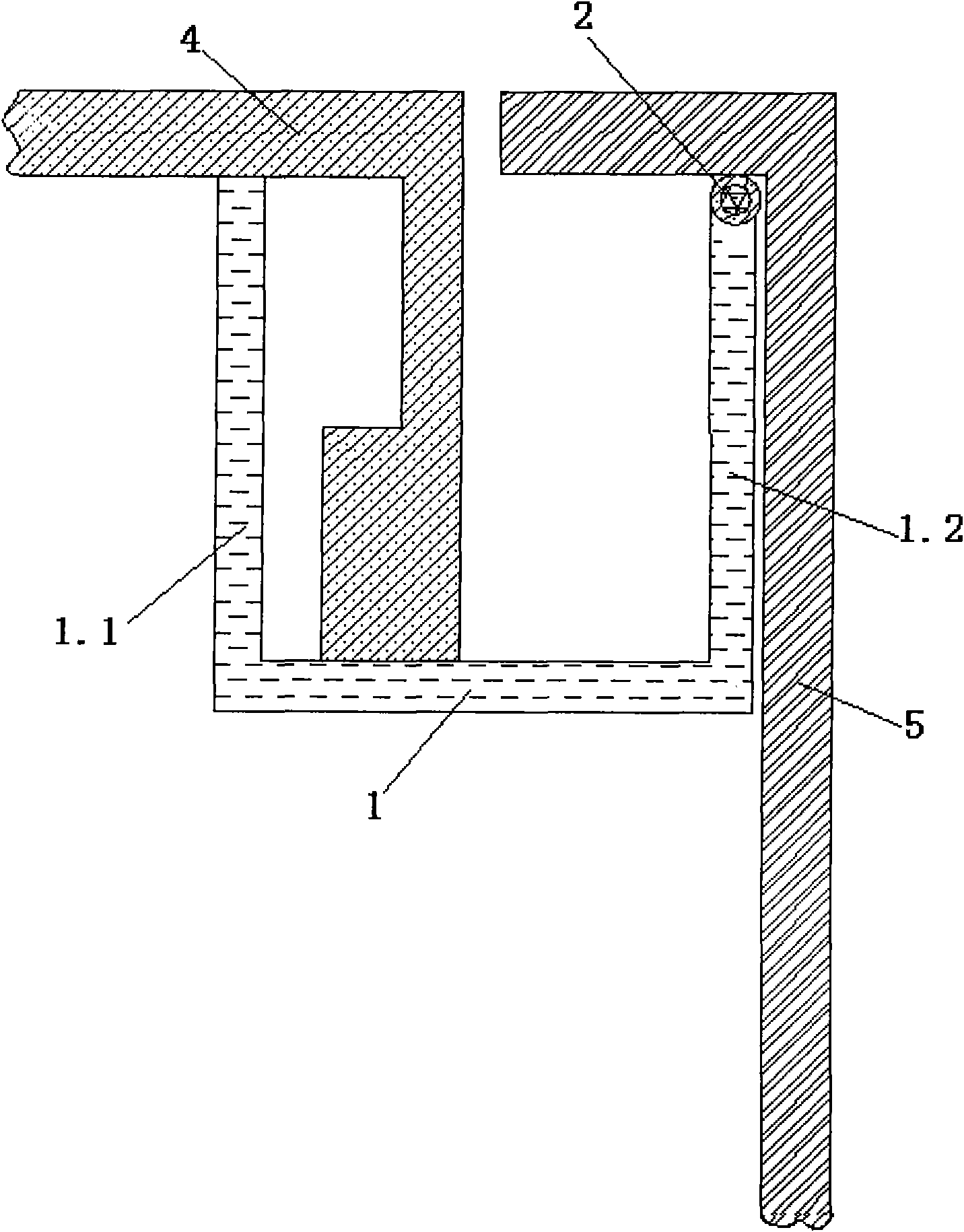

InactiveCN101567524AControl gapRealize the limit functionSubstation/switching arrangement detailsLeft wallElectrical and Electronics engineering

The invention discloses a hinge device for a power distribution cabinet, which comprises a stator block, rotary rings and rotary shafts, and is characterized in that the stator block is concave; the left wall surface of the stator block is arranged on a cabinet body; the rotary rings are arranged on the upper right of the stator block, namely the upper part of the right wall surface of the concave stator block, and a corner of a J-shaped cabinet door; and the rotary shafts are arranged on the rotary rings on the stator block and the cabinet door. Due to the design of the J-shaped cabinet door, the gap between the power distribution cabinet and the cabinet door can be effectively controlled. The hinge device for the power distribution cabinet has a simple structure, only consists of the stator block, the rotary rings, the rotary shafts and other components, and realizes the function of limiting the opening of the power distribution cabinet door through the improvement of the cabinet door and other components so as to reduce the cost. Due to the unique structural design, the gap between the power distribution cabinet and the cabinet door is effectively controlled.

Owner:KUNSHAN POWER SUPPLY CO LTD OF JIANGSU ELECTRICPOWER +1

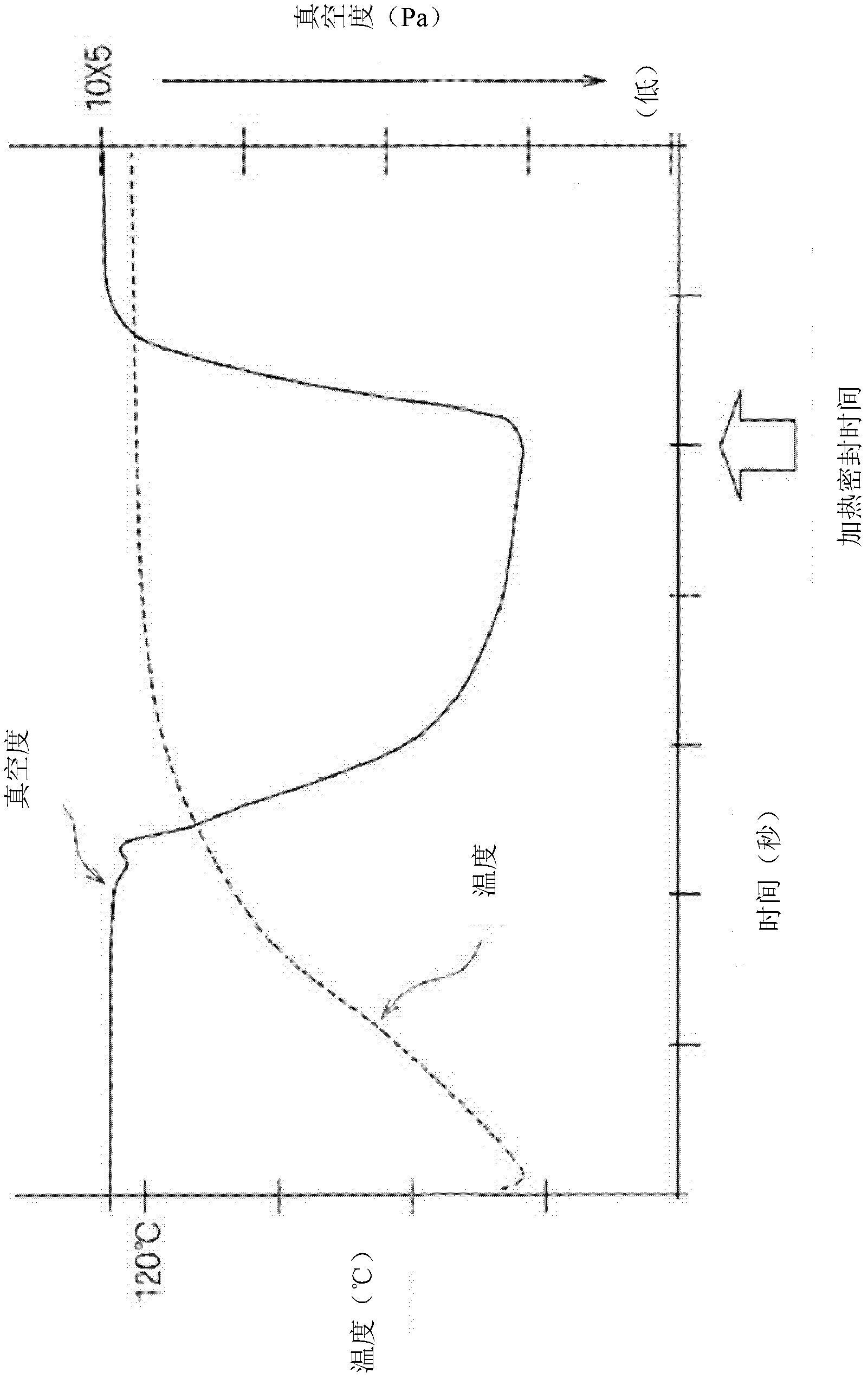

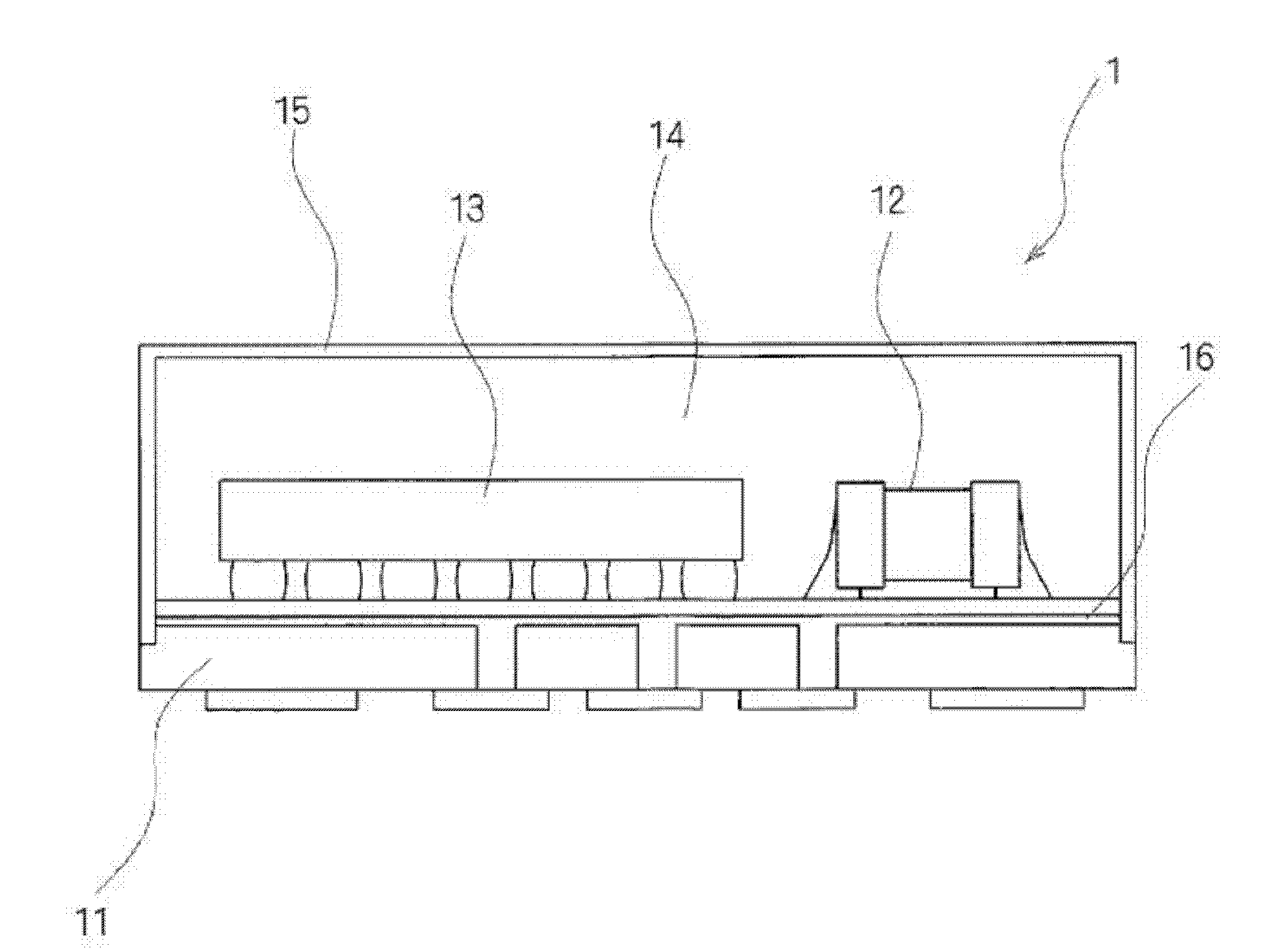

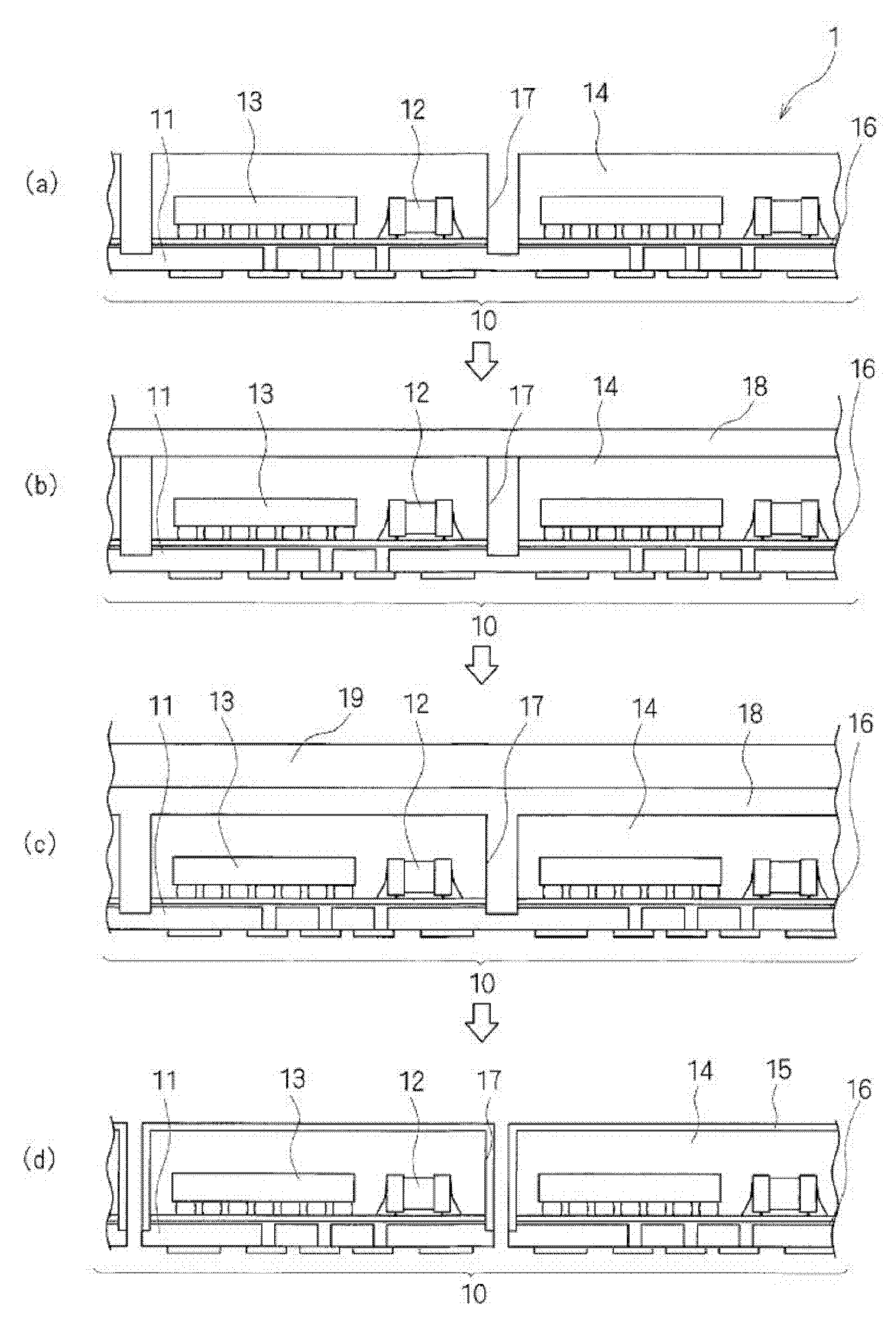

Manufacturing method of electronic parts module

ActiveCN102203926BAchieve thin filmAchieve thinningSemiconductor/solid-state device detailsCross-talk/noise/interference reductionMiniaturizationElectronic component

Owner:MURATA MFG CO LTD

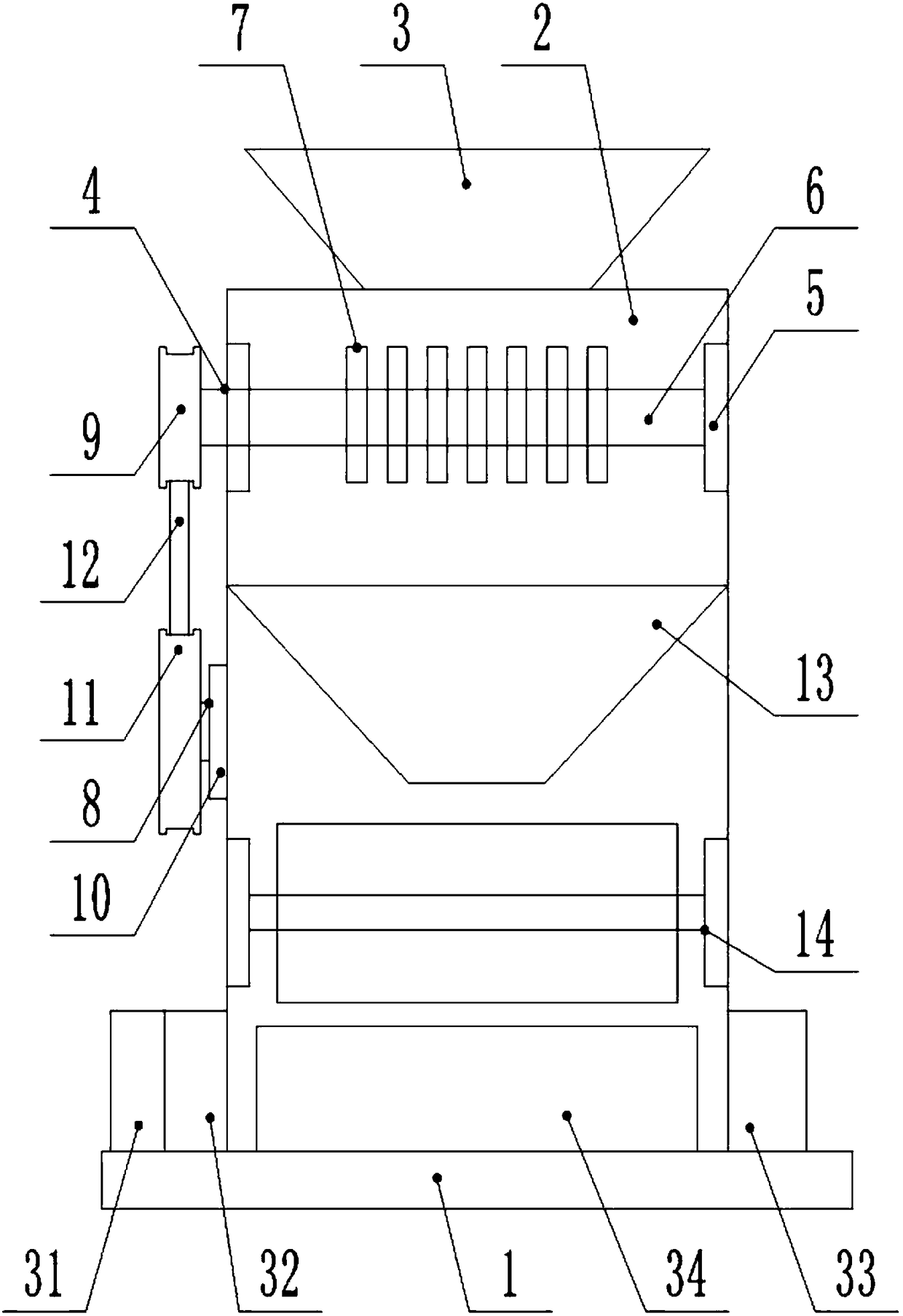

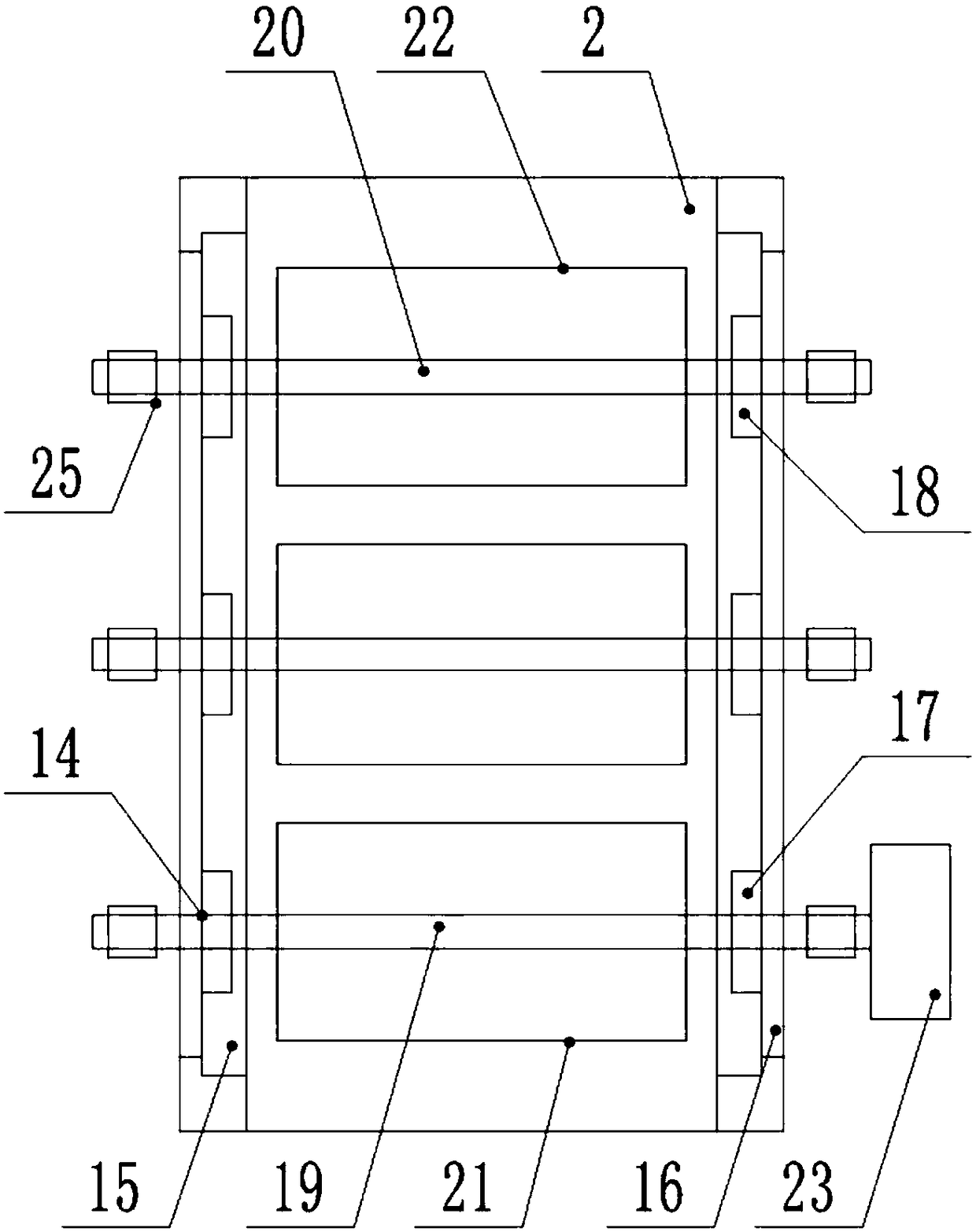

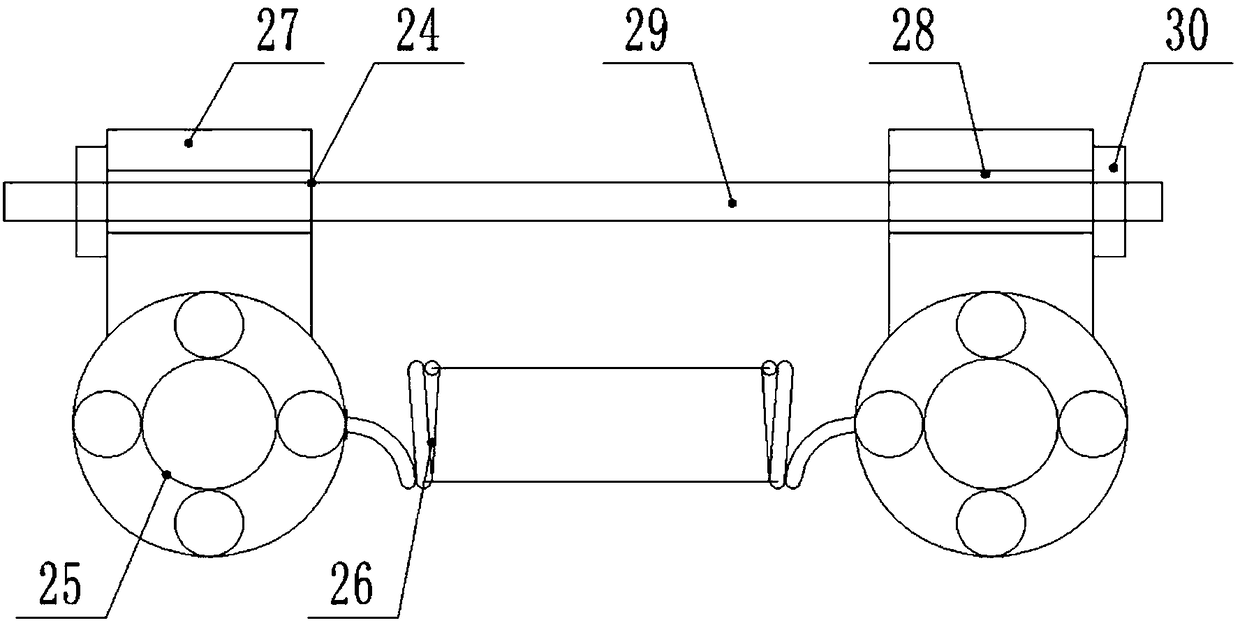

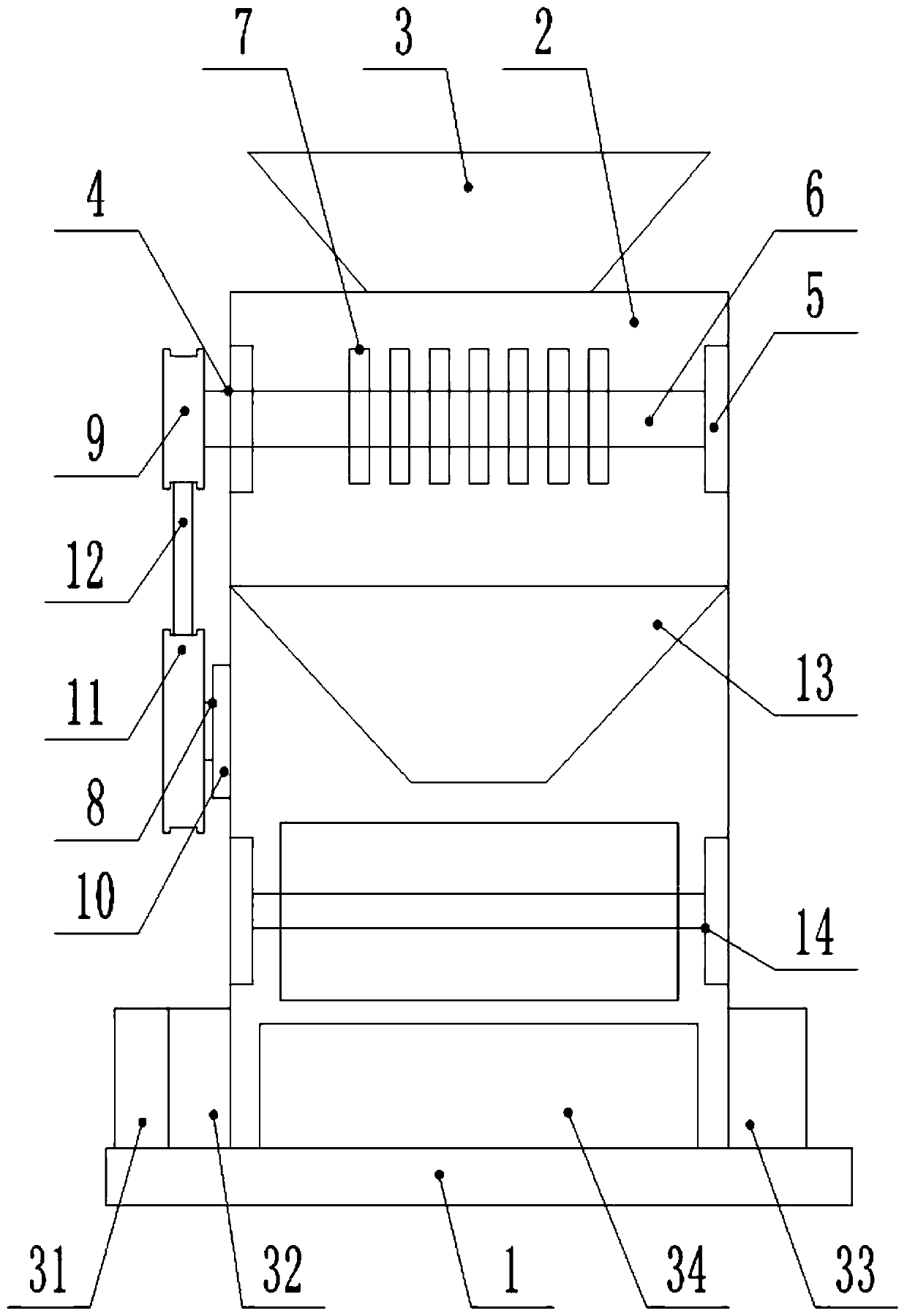

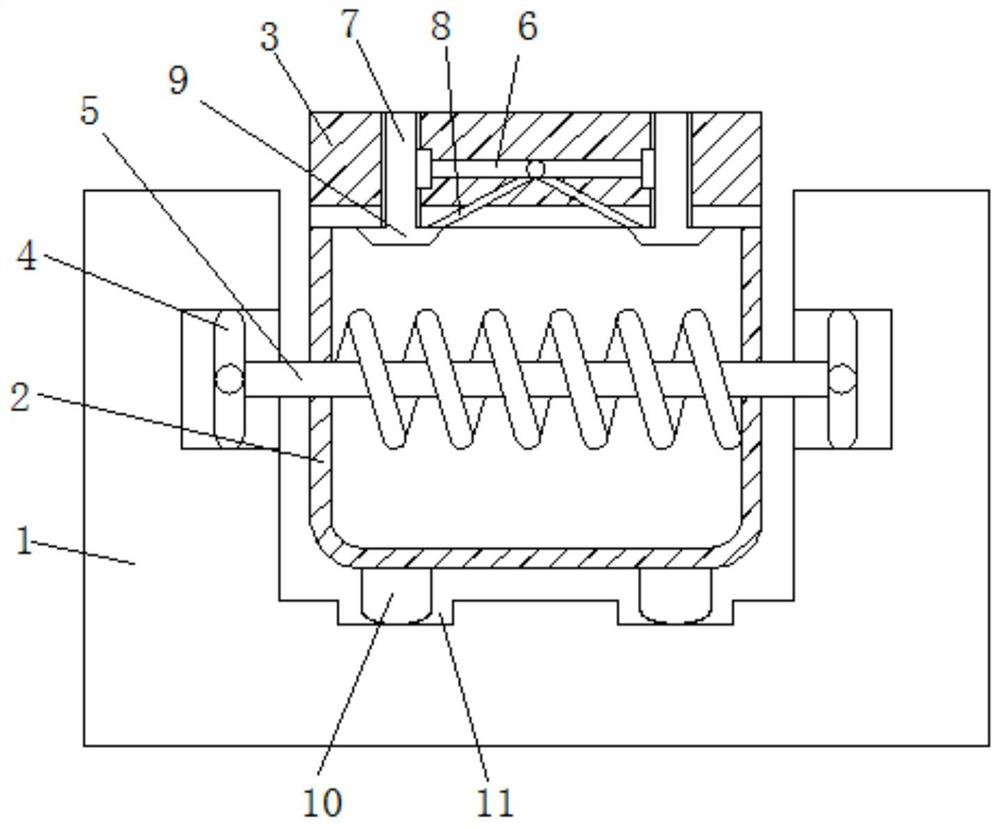

Crusher device used for water conservancy project

The invention discloses a crusher device used for a water conservancy project. The crusher device comprises a foundation rectangular base and a foundation rectangular crushing box body. A primary crushing device is arranged at the upper end of an inner cavity of the foundation rectangular crushing box body and composed of first fixing bearings, a rolling shaft, crushing blades and a driving device. A prismatic-table-shaped collecting chamber is formed in the inner cavity of the foundation rectangular crushing box body, and a secondary crushing device is arranged below the prismatic-table-shaped collecting chamber and composed of rectangular grooves, rectangular through grooves, second fixing bearings, sliding bearings, rotating shafts, rollers, a driving assembly and roller displacement adjusting devices. The roller displacement adjusting devices are composed of movable connection assemblies, compressing springs, locking seats, thread through holes, adjusting screws and adjusting nuts.A control device and an operation panel are arranged at the upper end of the foundation rectangular base. The crusher device has the beneficial effects of simple structure and high practicability.

Owner:奥特贝(天津)机器人有限公司

Manufacturing method of aluminum alloy combined pipe for automobile gas spring

ActiveCN107813104AControl gapGuaranteed performance requirements for plastic processingPipe fittingGas spring

The invention discloses a manufacturing method of an aluminum alloy combined pipe fitting for an automobile gas spring. The aluminum alloy combined pipe is composed of an aluminum alloy special-shapedpipe for the automobile gas spring and an aluminum alloy circular pipe for the automobile gas spring, wherein one end of the aluminum alloy circular pipe for the automobile gas spring is fixedly welded in the aluminum alloy special-shaped pipe for the automobile gas spring in a sleeved mode, and the aluminum alloy special-shaped pipe for the automobile gas spring has two structures that an outercontour is of a five-tooth pattern structure and an inner contour is of a seven-tooth pattern structure. According to the manufacturing method, a prepared product has the advantages of good plasticityand mechanical properties, high machining precision and good surface quality, technical indexes such as the tensile strength, the yield strength, the elongation rate, the outer diameter true roundness and the inner diameter true roundness of the product are superior to those of the requirement values, the product has been sold to medium and large automobile manufacturers in Europe, in America, athome and at abroad, so that blanks at home and abroad are filled in for aluminum alloying of the gas spring.

Owner:CYMA PRECISION ALUMINUM

Preparation method and application of Fe3O4-Co3O4 porous magnetic composite material

Owner:ANHUI NORMAL UNIV

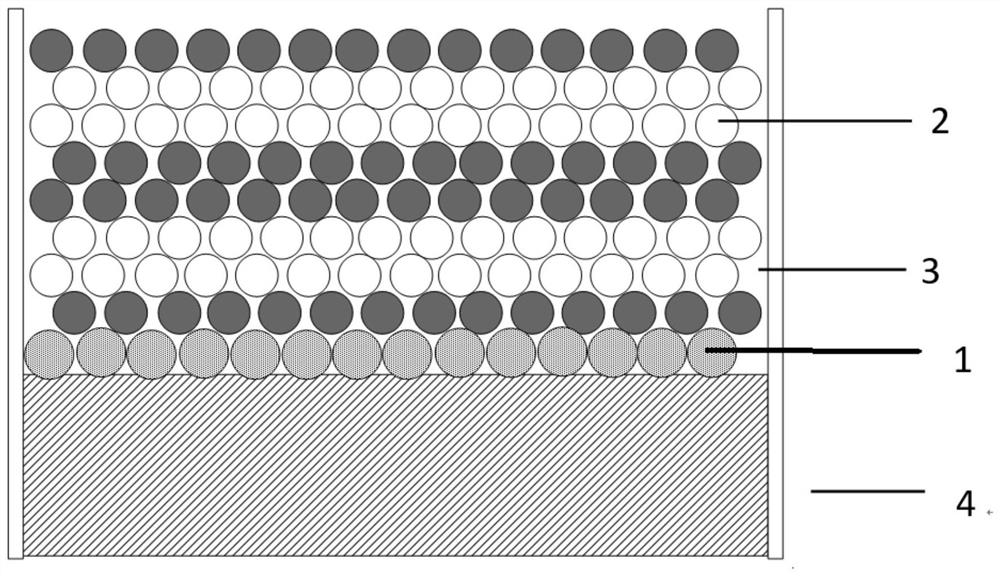

Display panel, display panel manufacturing process and photomask

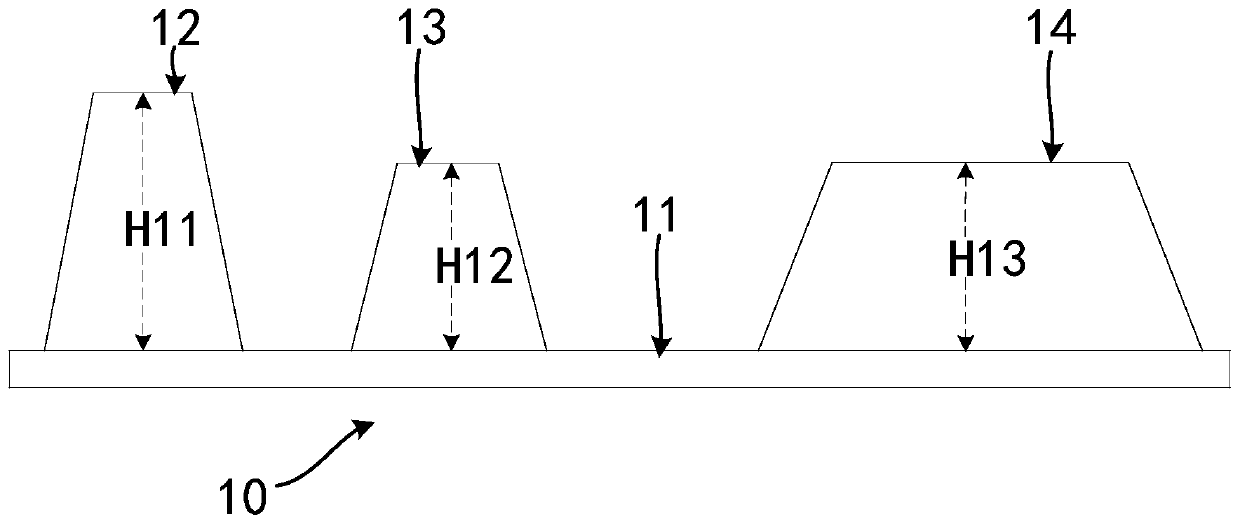

ActiveCN106773345BReduce processing technologyControl gapPhotomechanical apparatusOriginals for photomechanical treatmentEngineeringColloid

The invention discloses a display panel, a manufacturing process of the display panel and a photomask, wherein the manufacturing process of the display panel comprises the following steps: doping a photoinitiator in the colloid for making spacers; coating the colloid on the substrate Spacers are formed, and light-shielding objects are arranged on the same layer; the corresponding spacers are respectively irradiated with light of at least two different wavelengths, so as to control the photoinitiator so that different spacers have different shrinkage amounts. In the present invention, the spacer and the light-shielding object are arranged on the same layer, and the spacer and the light-shielding object are simultaneously processed in the same manufacturing process, which saves the manufacturing process of the display panel. Disposing the photoinitiator on the spacer can control the shrinkage of the spacer by light with a predetermined wavelength, thereby controlling the height of the spacer.

Owner:HKC CORP LTD +1

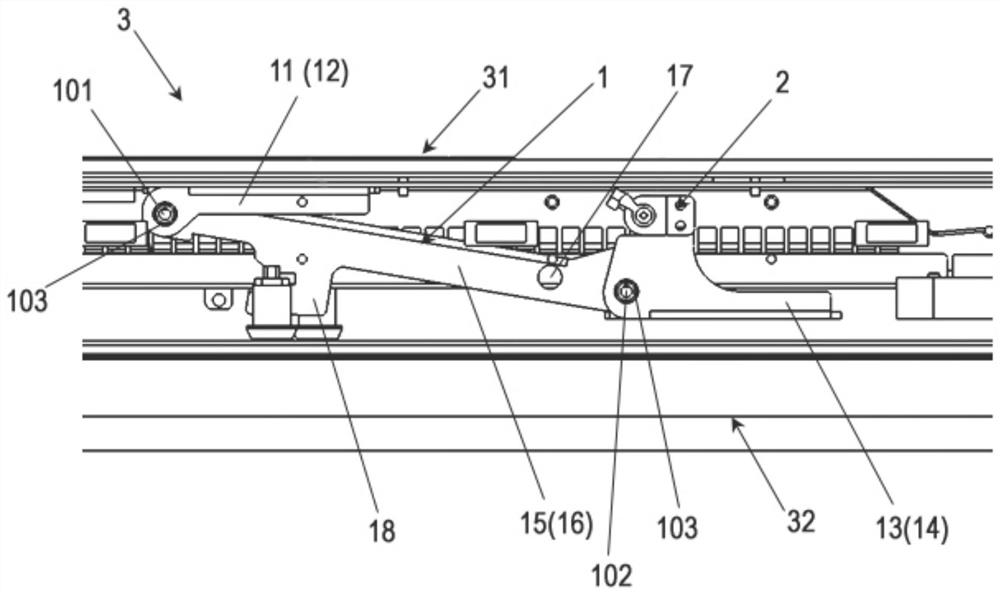

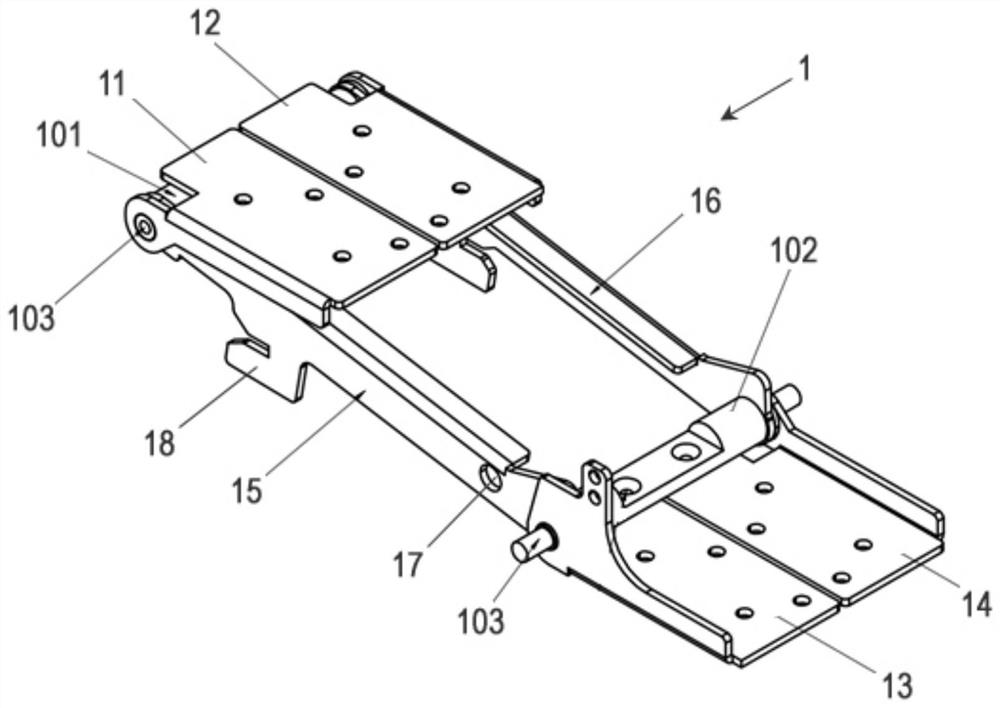

Up-lifting type supporting device for top cover of electric control passage gate of pedestrian entrance and exit

PendingCN114108516AEasy maintenanceControl openTraffic restrictionsStructural engineeringElectric control

The invention relates to the technical field of entrance and exit safety equipment and rail transit equipment. According to the lifting-up type supporting device for the top cover of the electric control passage gate of the pedestrian entrance and exit, when the gate is maintained, the top cover does not need to be taken down, the trouble of carrying the top cover is avoided, opening of the top cover can be well controlled so that the gate can be conveniently maintained, and gaps can be well controlled after the top cover is closed. The supporting device comprises a hinge mechanism and a locking mechanism. The hinge mechanism is installed and fixed to a gate top cover through a first top cover fixing base and a second top cover fixing base and installed and fixed to a gate body through a first body fixing base and a second body fixing base, and the two ends of a first hinge arm and the two ends of a second hinge arm are connected to the corresponding fixing bases through a top cover limiting rotating shaft and a body limiting rotating shaft correspondingly. The locking mechanism is fixed to the outer side of the machine body fixing base and comprises a hinge fixing block and a hinge fixing shaft.

Owner:GUNNEBO SECURITY SYST CHINA

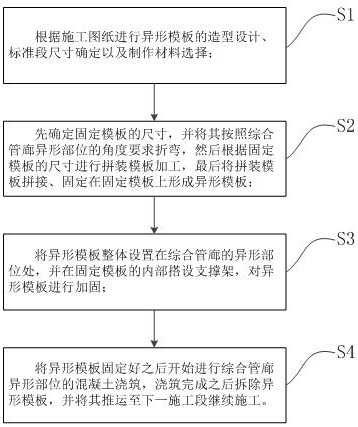

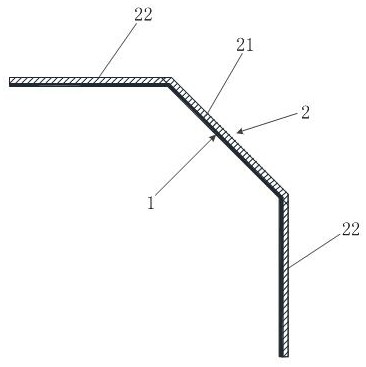

Construction method of special-shaped formwork for comprehensive utility gallery

ActiveCN108547317BReduce difficultyShorten the timeArtificial islandsUnderwater structuresConstruction engineeringShop drawing

Owner:CHINA MCC20 GRP CORP

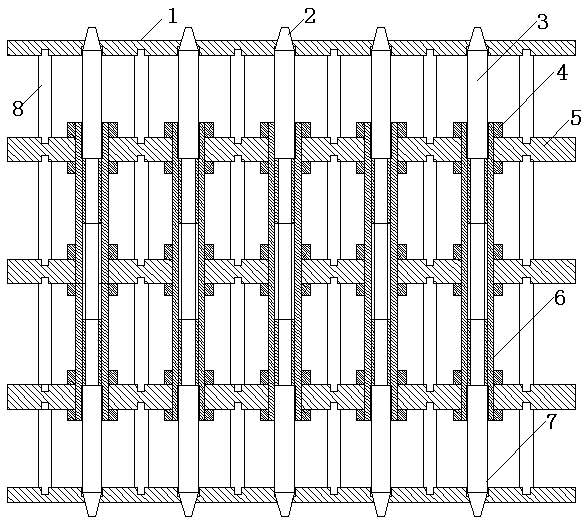

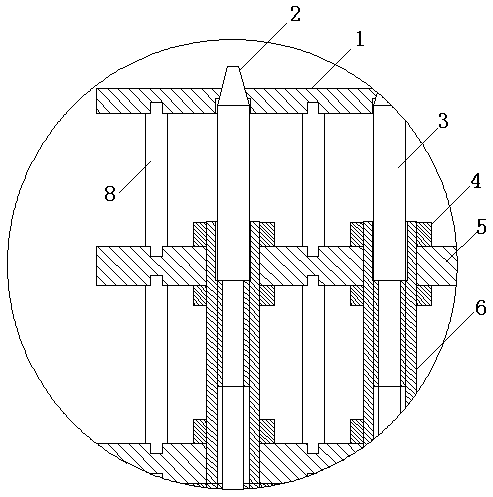

Protective safety net

The invention discloses a protective safety net. The protective safety net comprises a vertical rod group or a transverse rod group, and the vertical rod group or horizontal rod group consist of at least two vertical or horizontal rods. The vertical or horizontal rods include a vertical rod a or a transverse rod a, a vertical rod b or a transverse rod b, and connecting rods or connecting sleeves,and the vertical rod a or the transverse rod a, and the vertical rod b or the transverse rod b are separately provided with screw connection ends. The screw-into rotation direction of a threaded opening of the vertical rod a or the transverse rod a is the same as that of the vertical rod b or the transverse rod b, and the two ends of the connecting rods or the connecting sleeves are separately provided with threads suitable for the threaded openings of the vertical rod a or the transverse rod a and the vertical rod b or the transverse rod b. The vertical rod or the transverse rod is formed bythe vertical rod a or the transverse rod a and the vertical rod b or the transverse rod b through the connecting rods or the connecting sleeves, and the two ends of the vertical rod or the transverserod can be retracted or extended at the same time by the screwed connecting rods and the connecting sleeves.

Owner:郴州八方农林科技有限公司

A crusher device for hydraulic engineering

ActiveCN108187877BImprove work efficiencyReduce sizeGrain treatmentsFixed bearingHydraulic engineering

The invention discloses a crusher device used for a water conservancy project. The crusher device comprises a foundation rectangular base and a foundation rectangular crushing box body. A primary crushing device is arranged at the upper end of an inner cavity of the foundation rectangular crushing box body and composed of first fixing bearings, a rolling shaft, crushing blades and a driving device. A prismatic-table-shaped collecting chamber is formed in the inner cavity of the foundation rectangular crushing box body, and a secondary crushing device is arranged below the prismatic-table-shaped collecting chamber and composed of rectangular grooves, rectangular through grooves, second fixing bearings, sliding bearings, rotating shafts, rollers, a driving assembly and roller displacement adjusting devices. The roller displacement adjusting devices are composed of movable connection assemblies, compressing springs, locking seats, thread through holes, adjusting screws and adjusting nuts.A control device and an operation panel are arranged at the upper end of the foundation rectangular base. The crusher device has the beneficial effects of simple structure and high practicability.

Owner:奥特贝(天津)机器人有限公司

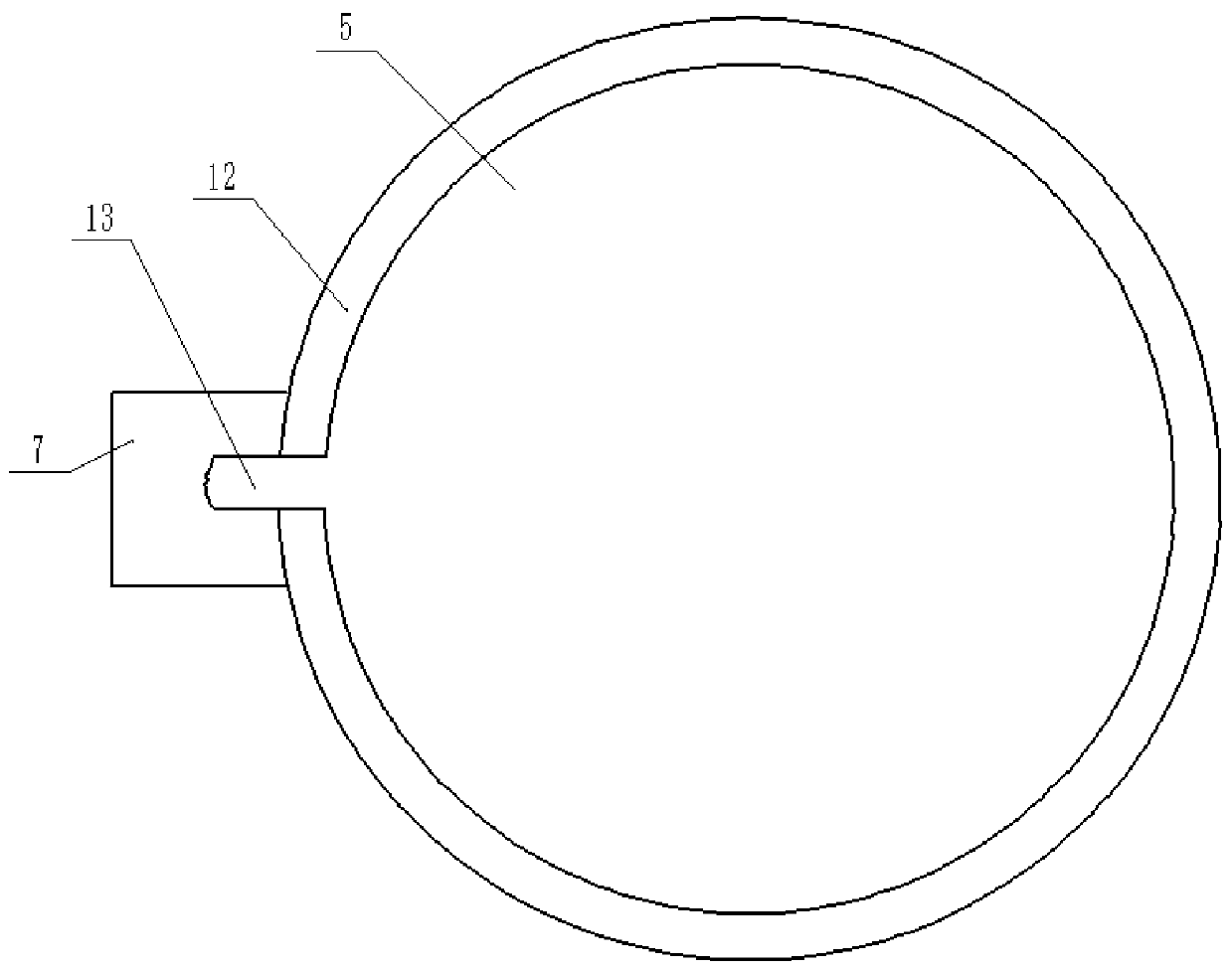

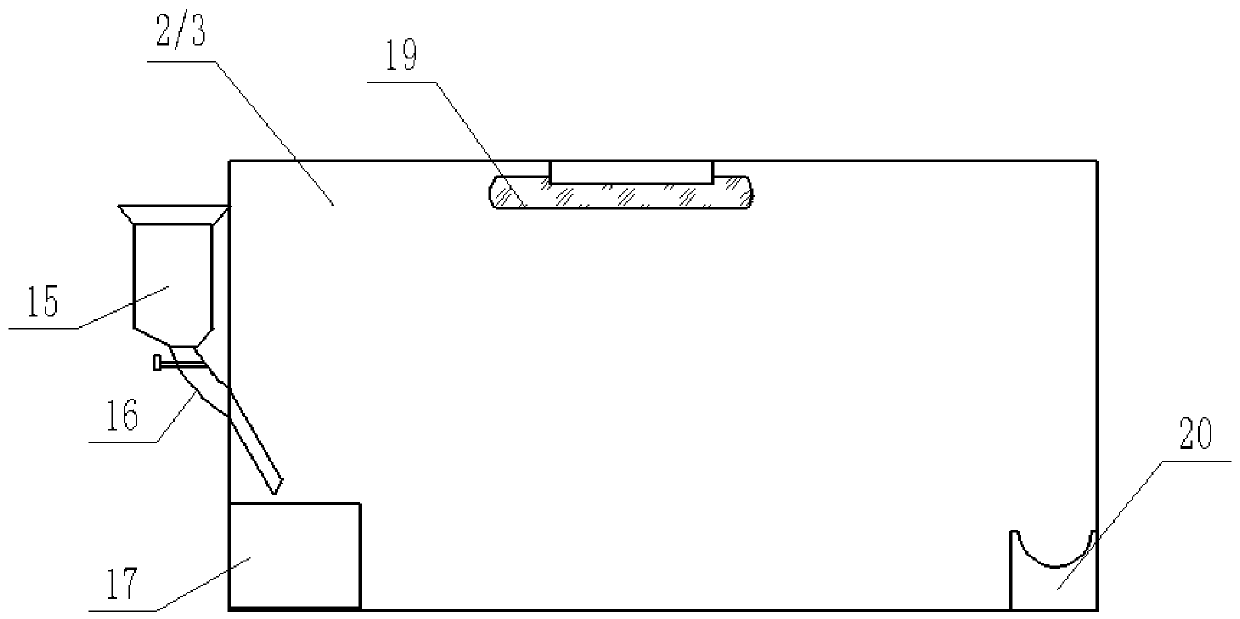

Safety composite culture system for animal husbandry

InactiveCN110268995AEasy to breedPromote growthBatteries circuit arrangementsGeneral water supply conservationFecesEutrophication

The invention discloses a safety composite culture system for animal husbandry. The system comprises a water tank, a duck shed, a birdcage and a ceiling. The duck shed and the birdcage are arranged above the water tank. A through hole is formed in a base plate of the duck shed. A partition plate net is arranged inside the water tank. An overflowing drainage pipe is arranged at the side wall of the water tank, supporting rods are arranged at the side walls of the top ends of the duck shed and the birdcage, the ceiling is arranged at the top ends of the supporting rods, and solar cell panels are evenly laid on the upper surface of the ceiling. Excrement generated by chicken and ducks can be adopted as feed for some fish cultured inside the water tank or eutrophication inside the water tank is added, growth of planktons in the water tank is more convenient, fish can eat planktons more conveniently, meanwhile, space is saved, the space is reasonably utilized, meanwhile, space composite culture of ducks, chickens and fish is achieved, relation between breeding industry is added, and use is convenient, the influence caused by rainwater and sunlight on duck and chicken culture is reduced, meanwhile, solar energy is converted into electric energy through the solar cell panels to be stored, electricity can be conveniently supplied to other components, resources are reasonably utilized, and use is convenient.

Owner:胡明雪

An Advanced Vacuum Kneading Machine Equipment

ActiveCN111264577BControl gapAvoid failureMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsGear wheelWater flow

The invention relates to the technical field of dough kneading machines, and discloses an advanced vacuum kneading machine equipment, which includes a fixed base, a kneading cylinder is movably installed on the inner side of the fixed base, and a cover is movably installed on the upper end of the kneading cylinder, and the fixed base is The inside of the cover is rotatably equipped with rotating gears, between the two rotating gears there is fixedly installed a kneading bar that runs through the kneading cylinder, and movable tubes are installed movably on the left and right sides of the inside of the cover. In the present invention, when it is necessary to add water to the inside of the device during the kneading process, the control device inside the fixed base controls the movable baffle to move up and down inside the ball plate, so that the water flow inside the movable tube can enter the fixed plate through the movable baffle At the same time, the movable intubation tube moves to the outside of the fixed plate, which can control the gap between the water delivery tank and the fixed plate, adjust the size of the water flow, control the amount of water added, and prevent the failure of the kneading work caused by excessive water addition.

Owner:惠民县宇东面粉有限公司

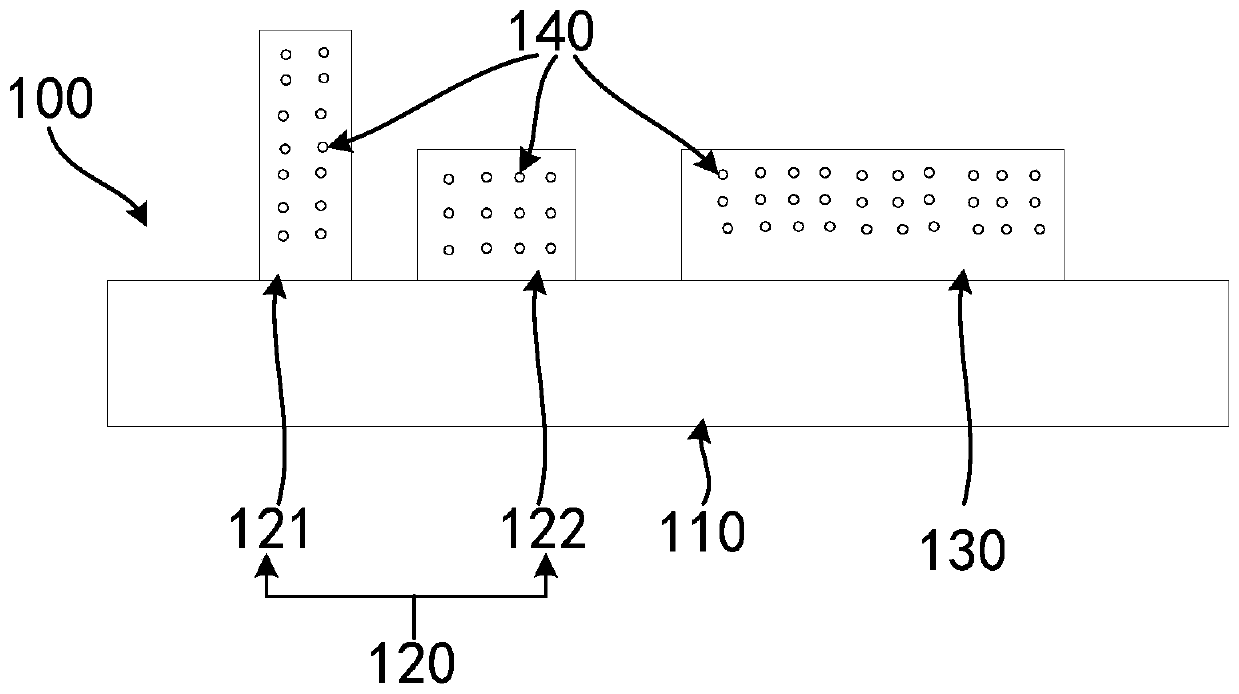

Display substrate, manufacturing method thereof, and display device

ActiveCN110610975BControl gapGuaranteed flatnessSolid-state devicesSemiconductor devicesDisplay deviceEngineering

The invention provides a display substrate, a preparation method thereof, and a display device. The display substrate includes a stacked microcavity structure layer and a light-emitting structure layer. Reflective electrodes are arranged in the microcavity structure layer, grooves are arranged on the surface of the microcavity structure layer, and the light-emitting structure layer includes The first electrode in the groove is connected to the reflective electrode. The present invention forms a groove on the microcavity structure layer, and the first electrode of the light emitting structure layer is arranged in the groove, effectively controlling the gap between the first electrode and the microcavity structure layer, and not only solves the problem of existing silicon-based There is a short-circuit problem between the cathode and the anode in the preparation process of the OLED microdisplay, and the surface flatness and uniformity requirements of the subsequent evaporation are guaranteed.

Owner:BOE TECH GRP CO LTD

A kind of manufacturing method of thinning fingerprint module with strong adhesion

ActiveCN108615000BReduce the gap widthGap does not existAcquiring/reconising fingerprints/palmprintsAdhesive glueEngineering

The invention discloses a manufacturing method of a thinned fingerprint module with strong adhesion, and relates to the field of fingerprint modules; it comprises the following steps: (1) packaging a fingerprint recognition chip on a PCB board through SMT technology; (2) packaging the fingerprint recognition chip on a PCB board; The side of the fingerprint chip is wrapped with elastic material; (3) laser square patterns on the bottom of the metal ring, apply underfill glue and perform defoaming baking, after baking, apply conductive silver glue and structural glue on the side of the metal ring for secondary baking; (4) Attach the processed metal ring to the elastic material and bake at constant pressure; (5) Lay the square pattern on the bottom of the PCB board and the upper part of the reinforcement board with structural glue and bake; (6) Dot structural glue on the cover plate, attach the cover plate on the fingerprint identification chip, and make the thinned fingerprint module with strong adhesion; the fingerprint module made by the present invention has a thinner thickness, and the metal ring The gap between the chip and the chip is more uniform and the gap becomes smaller.

Owner:蚌埠华特科技有限公司

A kind of precision winding method of optical fiber ring

ActiveCN108088466BControl gapSame lengthSagnac effect gyrometersPolarization-maintaining optical fiberEngineering

The invention is the field of optical fiber gyroscope fiber optic ring manufacturing technology, which involves a method of precision winding for fiber fiber ring.The method of the present invention includes the following steps: determine the length of the fiber and the structure of the fiber ring; the winding of the winding of the winding; select the applicable partial fiber; the single -mode fiber winding;When the present invention needs to solve the existing optical fiber surrounding method. When a large -length fiber ring is winding, the geometric symmetry of the fiber ring cannot be guaranteed, so that the zero drift of the fiber ring of the fiber ring is too large, which affects the technology of inertia.The problem, by customizing the single -mode fiber and winding workers with special sizes, ensure that the gap between the fiber can be controlled when preserving the optical fiber, and fix the number of fiber turns in each layer.The geometric symmetry of the ring reduces the zero drift of the fiber ring under the temperature of the fiber ring, and improves the accuracy of the inertial gyroscope.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Advanced vacuum dough mixer equipment

ActiveCN111264577AControl gapAvoid failureMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsGear wheelWater flow

The invention relates to the technical field of dough mixers. The invention further discloses advanced vacuum dough mixer equipment. The dough mixer equipment comprises a fixed base, a dough kneadingcylinder is movably installed in the inner side of the fixed base, a sealing cover is movably installed at the upper end of the dough kneading cylinder, rotating gears are rotatably installed in the fixed base, a dough kneading rod penetrating through the dough kneading cylinder is fixedly installed between the two rotating gears, and movable pipes are movably installed at the left side and the right side in the sealing cover. In the dough kneading process, the dough is kneaded; when water needs to be added into the device, a movable baffle is controlled by a control device in the fixed base to move up and down in a ball plate; and meanwhile, the movable inserting pipe moves towards the outer side of the fixed plate, the gap between a water conveying groove and the fixed plate can be controlled, the water flow can be adjusted, the water adding amount can be controlled, and the failure in dough kneading caused by excessive water adding can be prevented.

Owner:惠民县宇东面粉有限公司

A fingerprint module assembly method for improving the gap

ActiveCN108664898BReduce the gap widthGap does not existCharacter and pattern recognitionAdhesive glueMechanical engineering

Owner:蚌埠华特科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com