Patents

Literature

219results about How to "Realize the limit function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

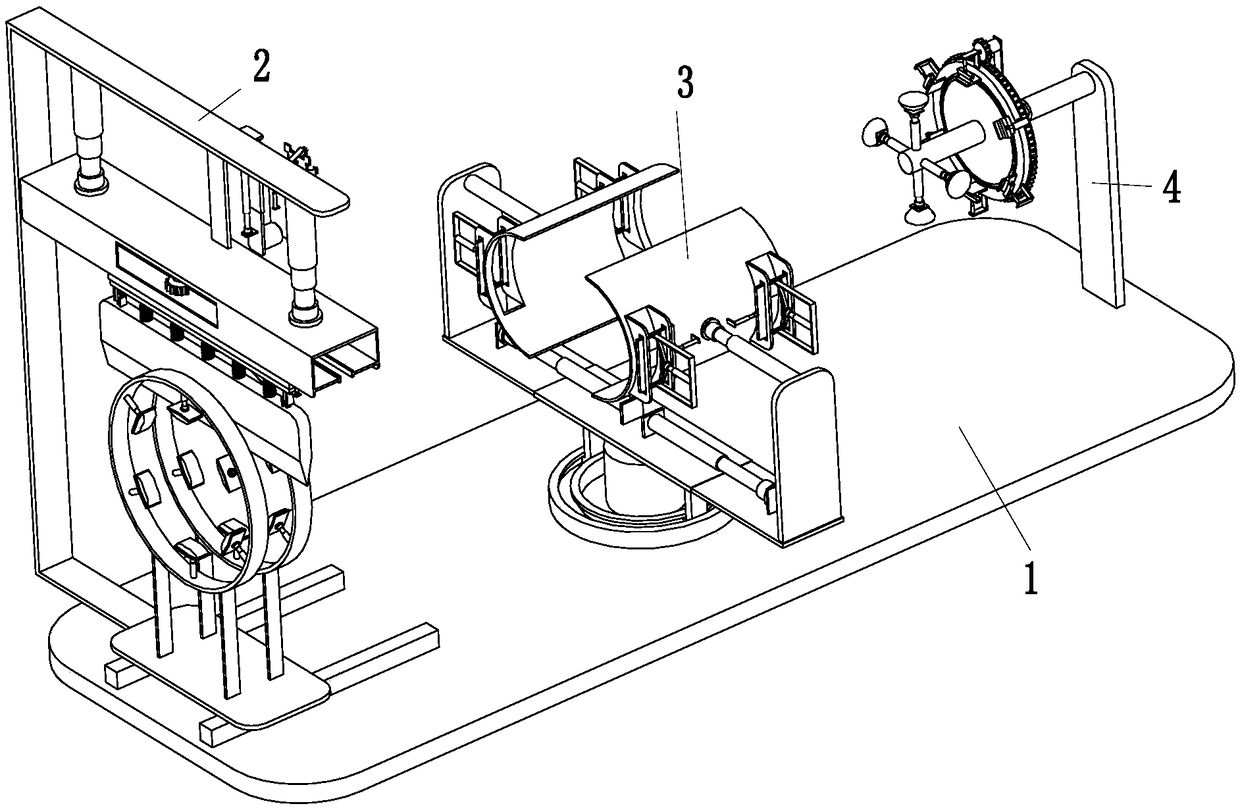

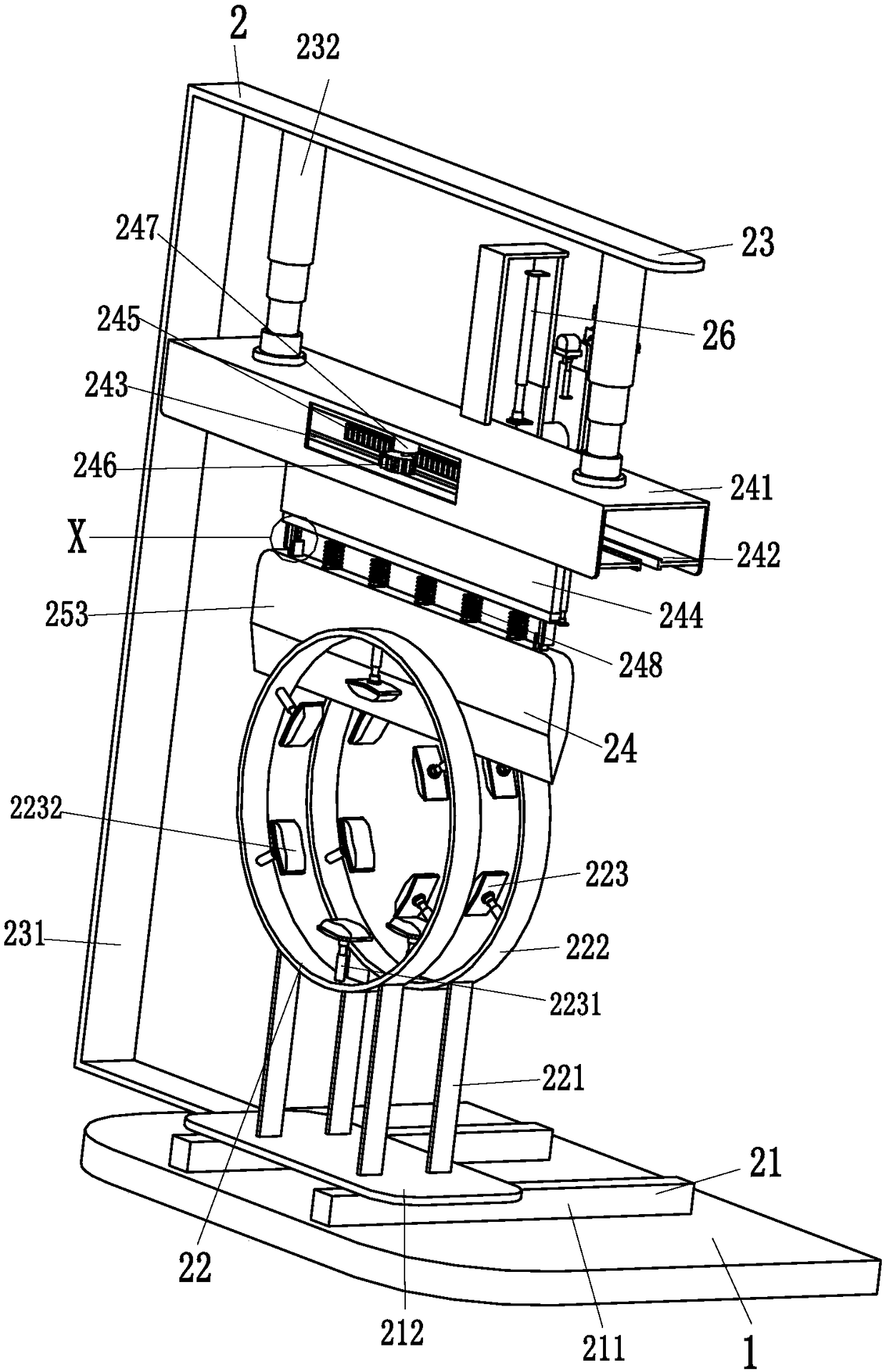

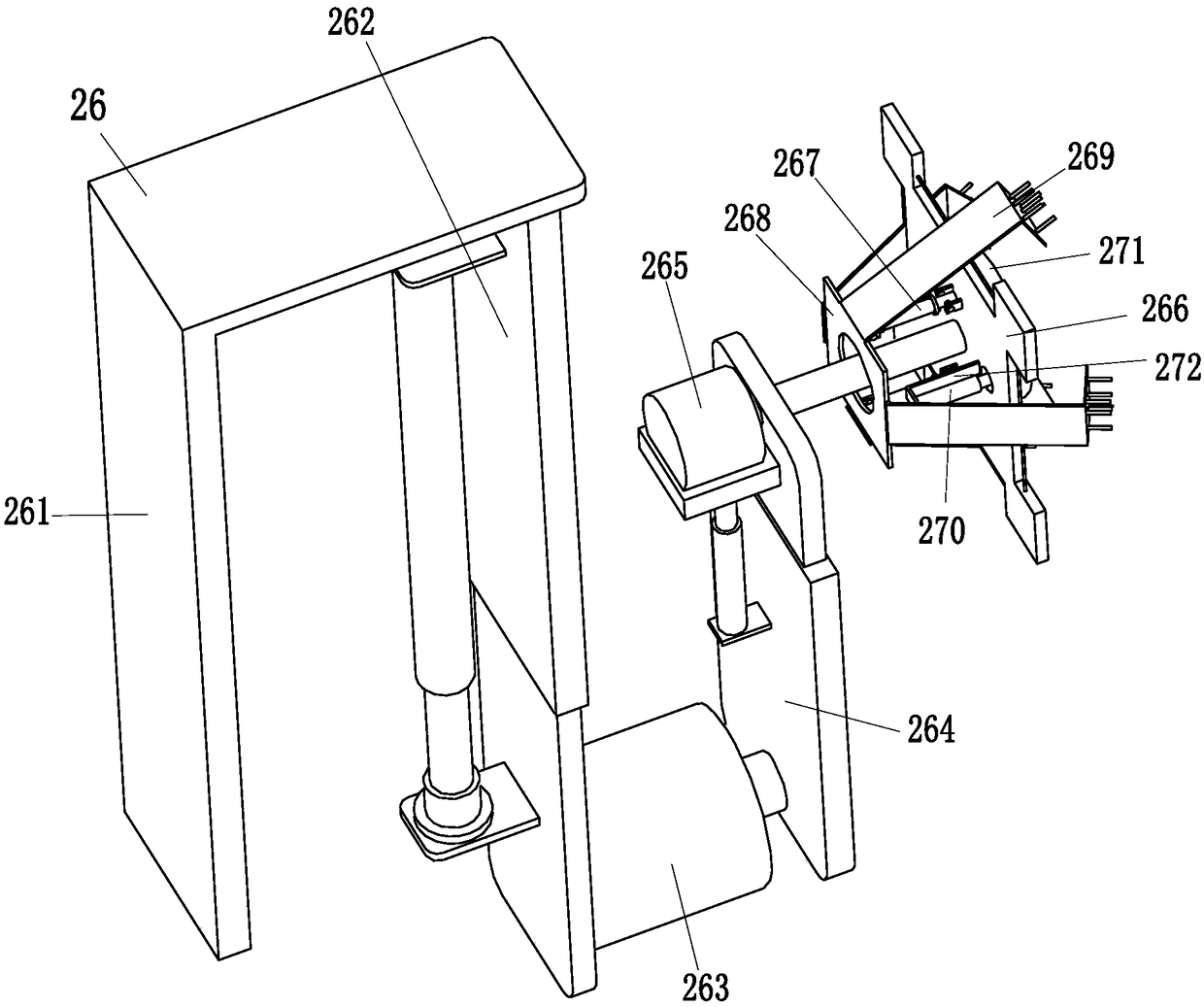

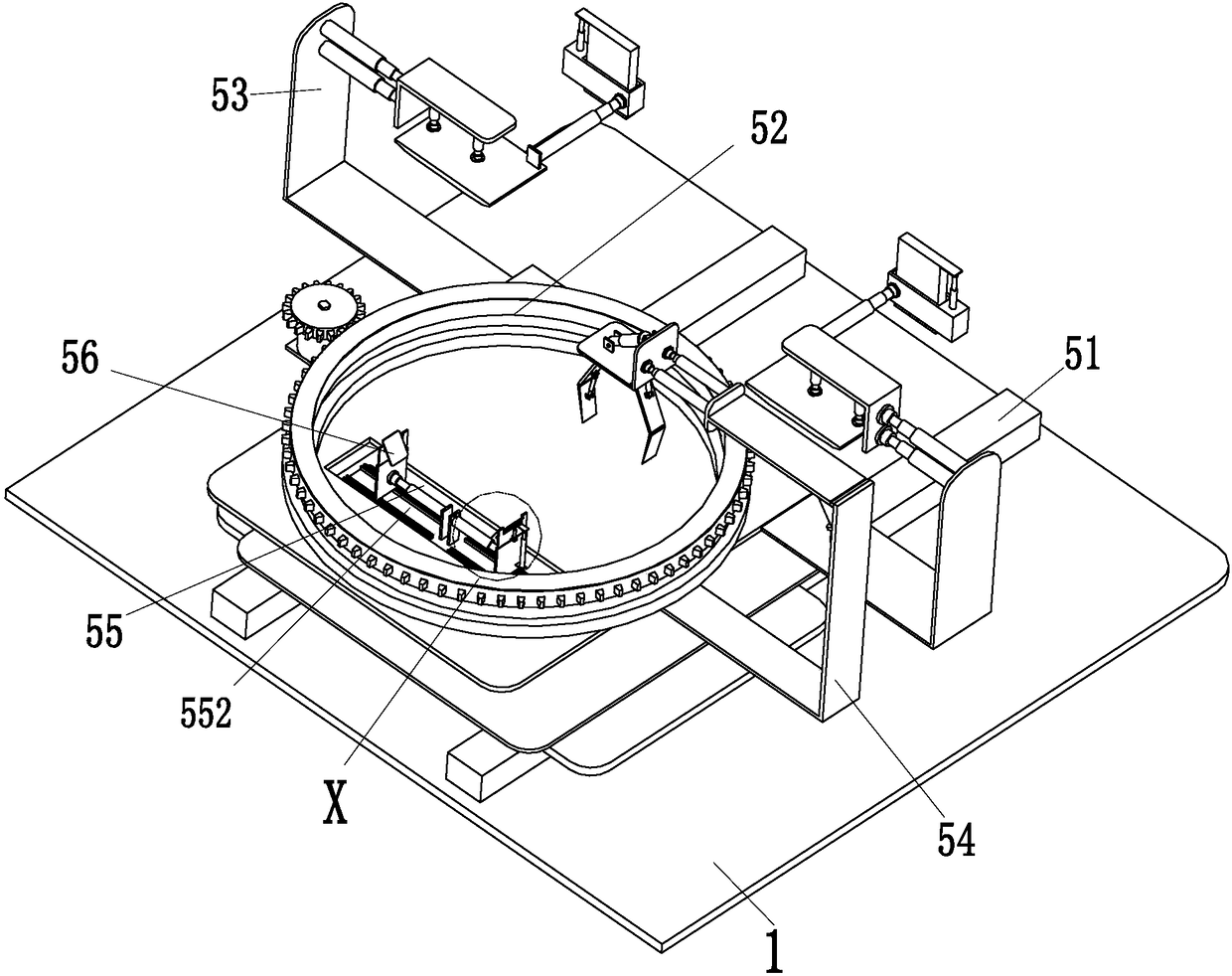

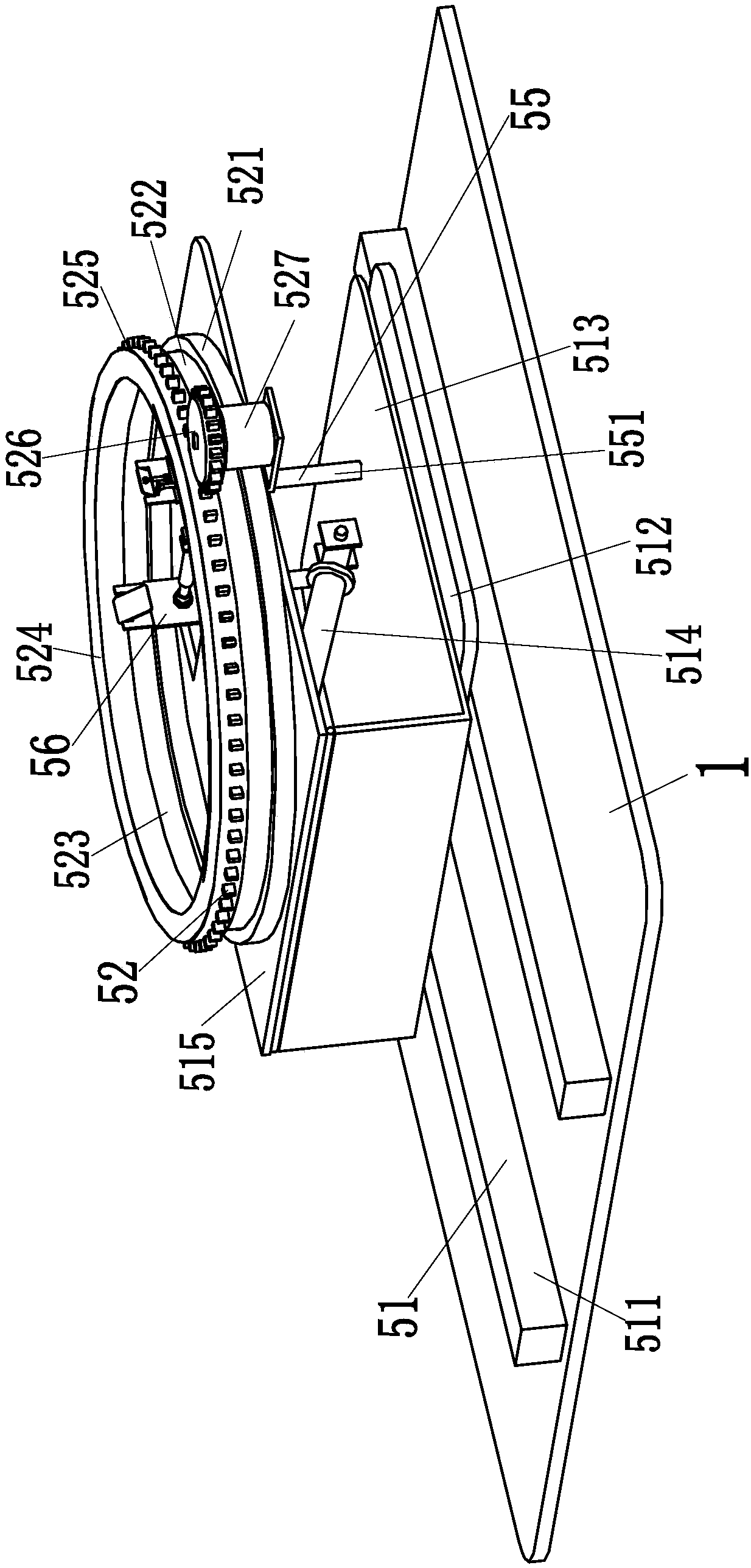

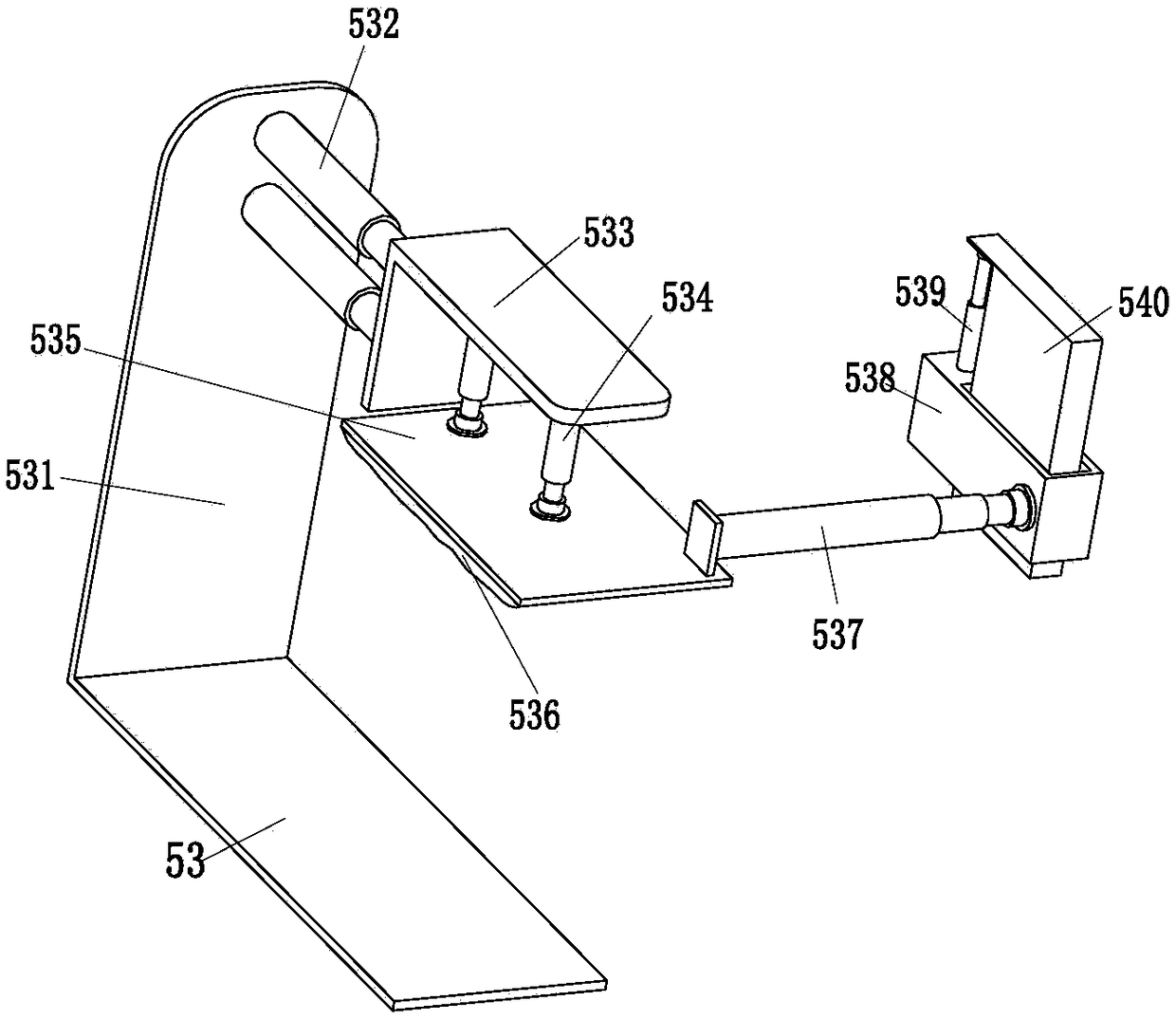

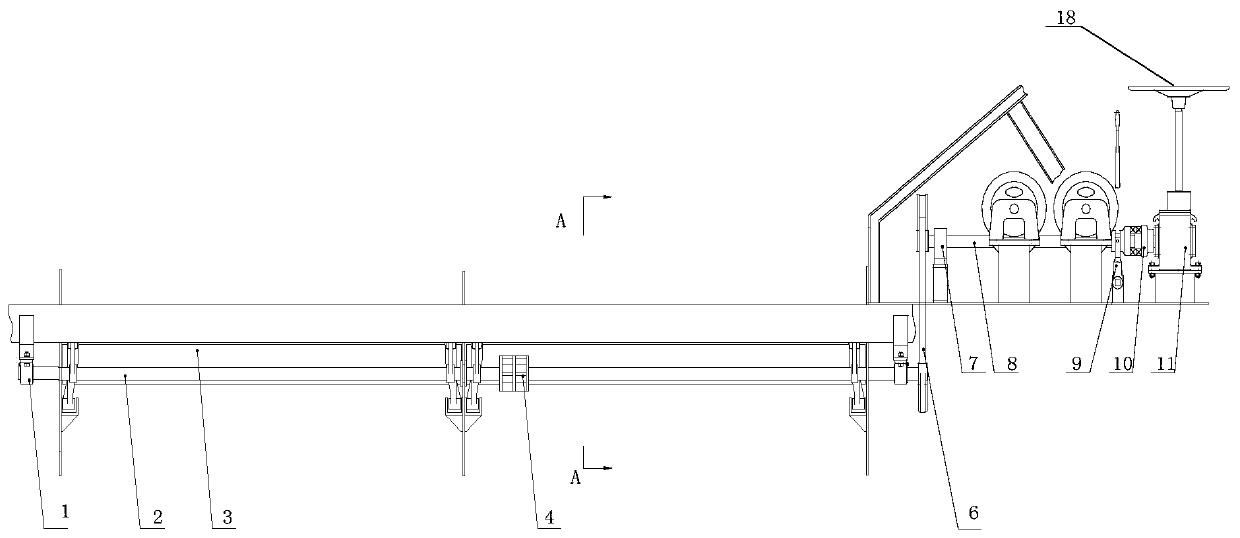

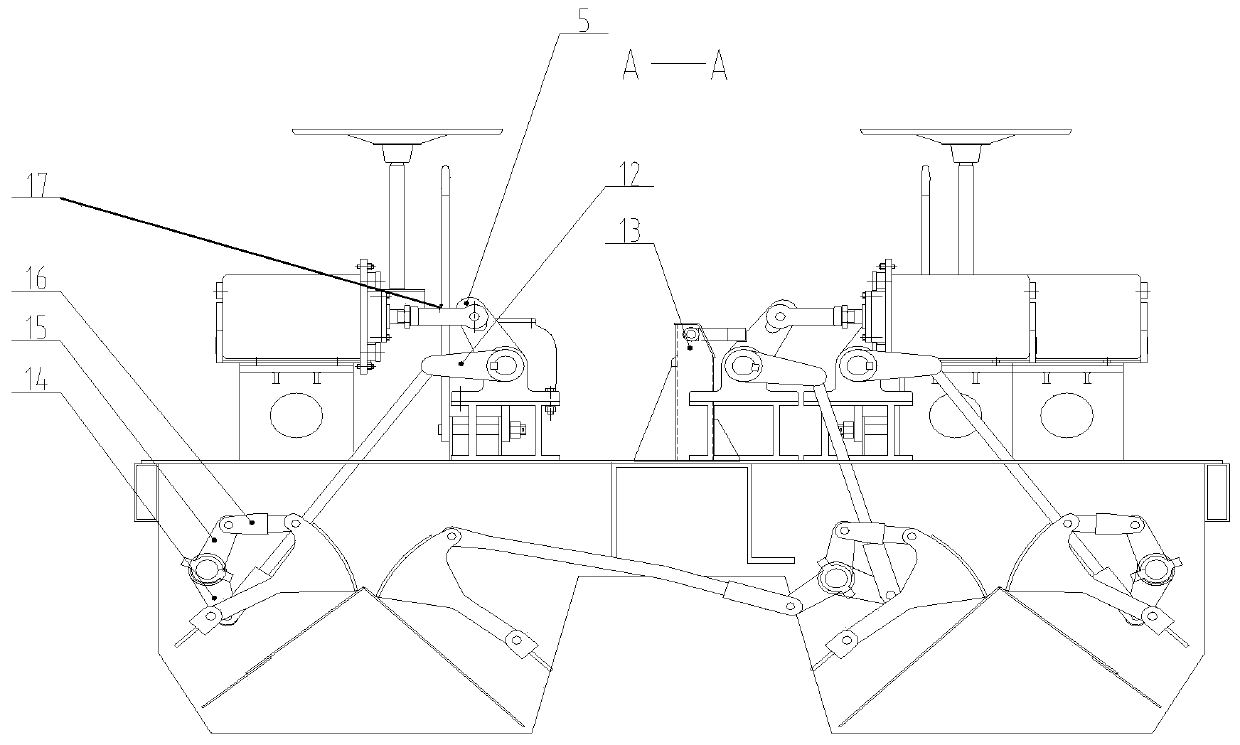

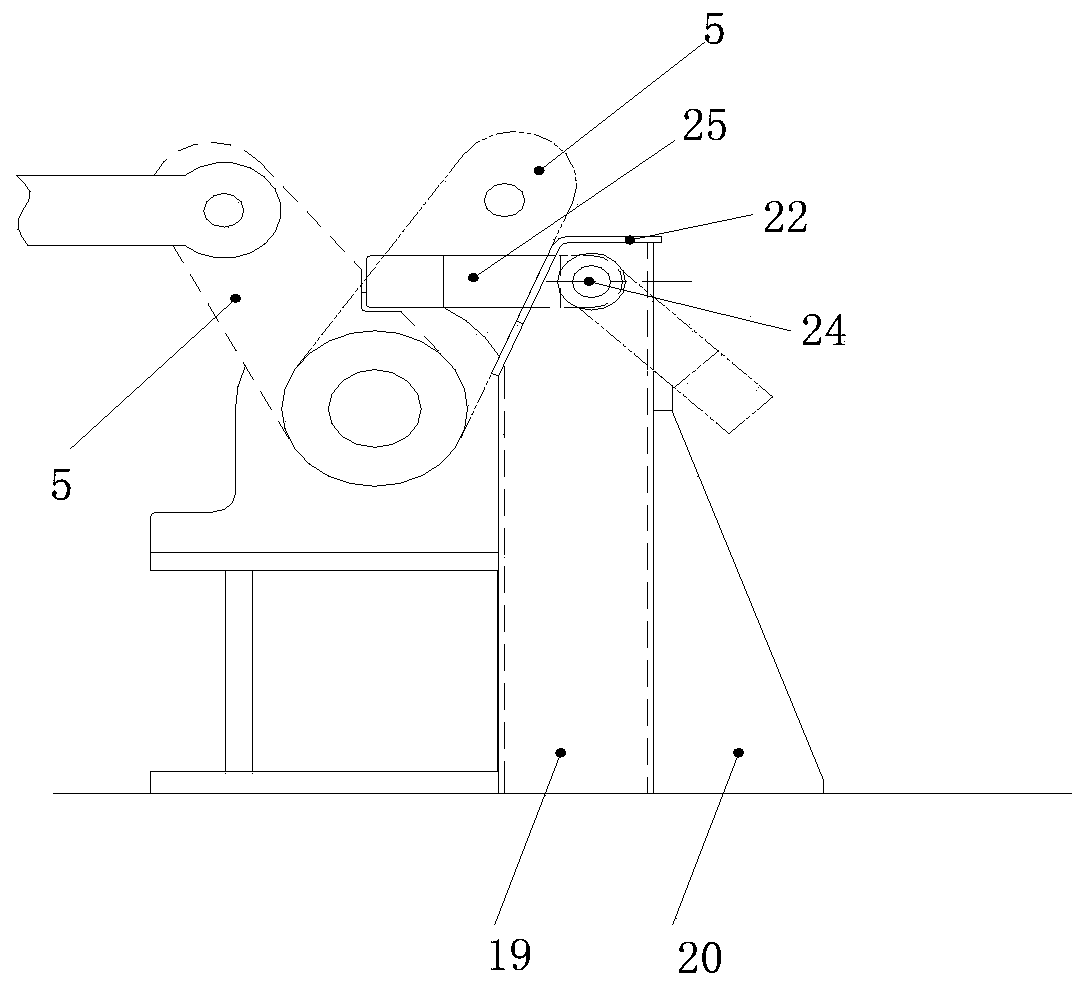

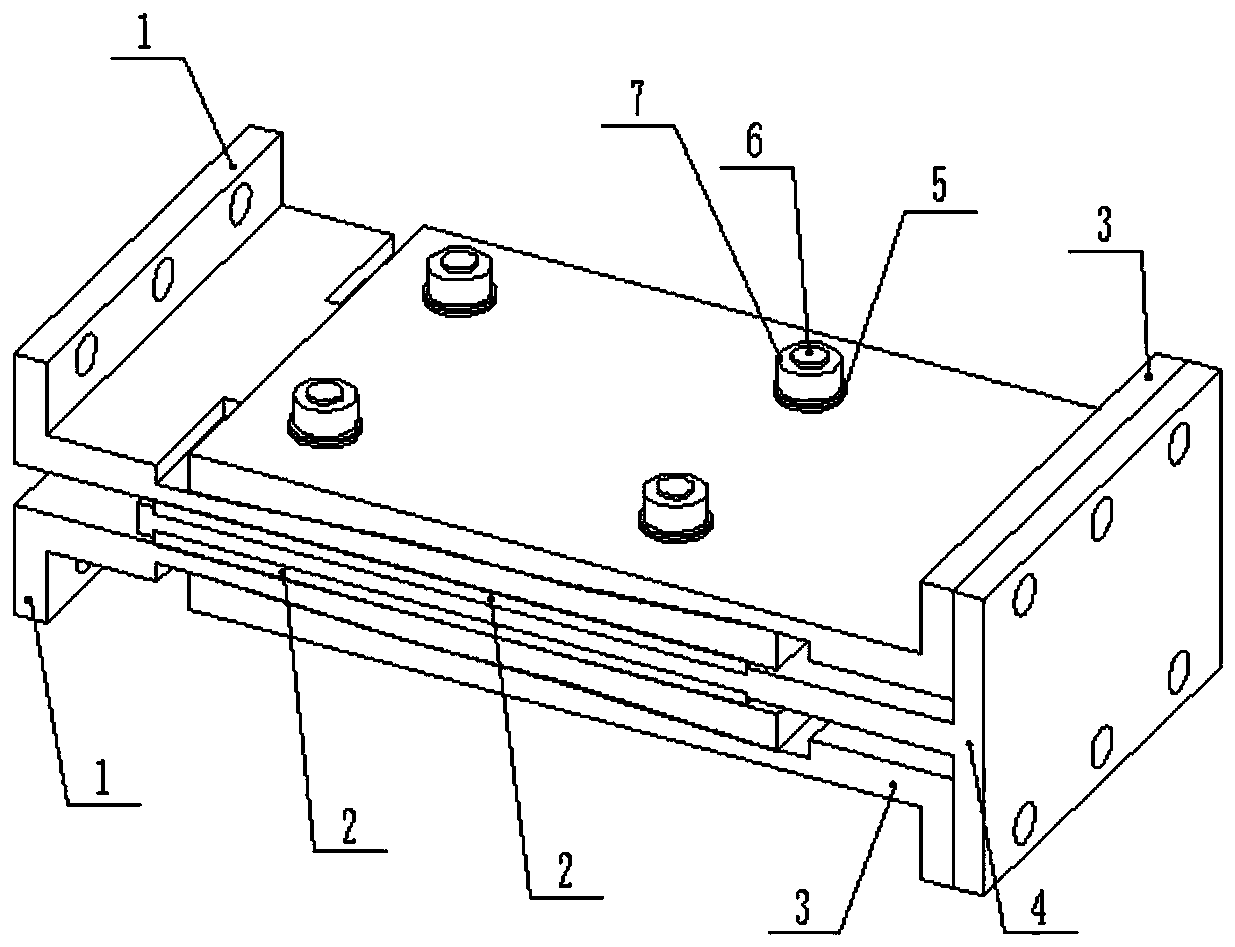

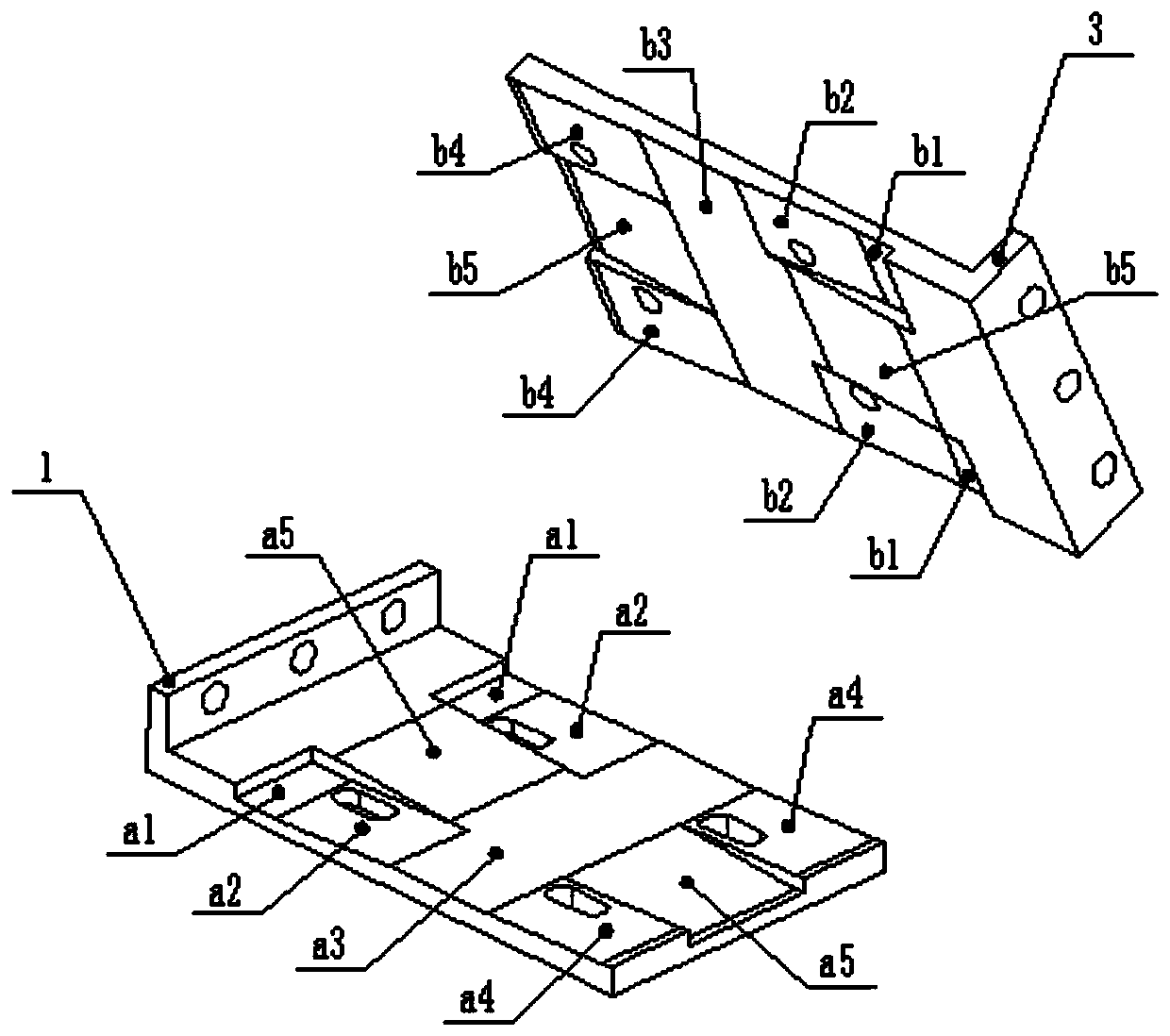

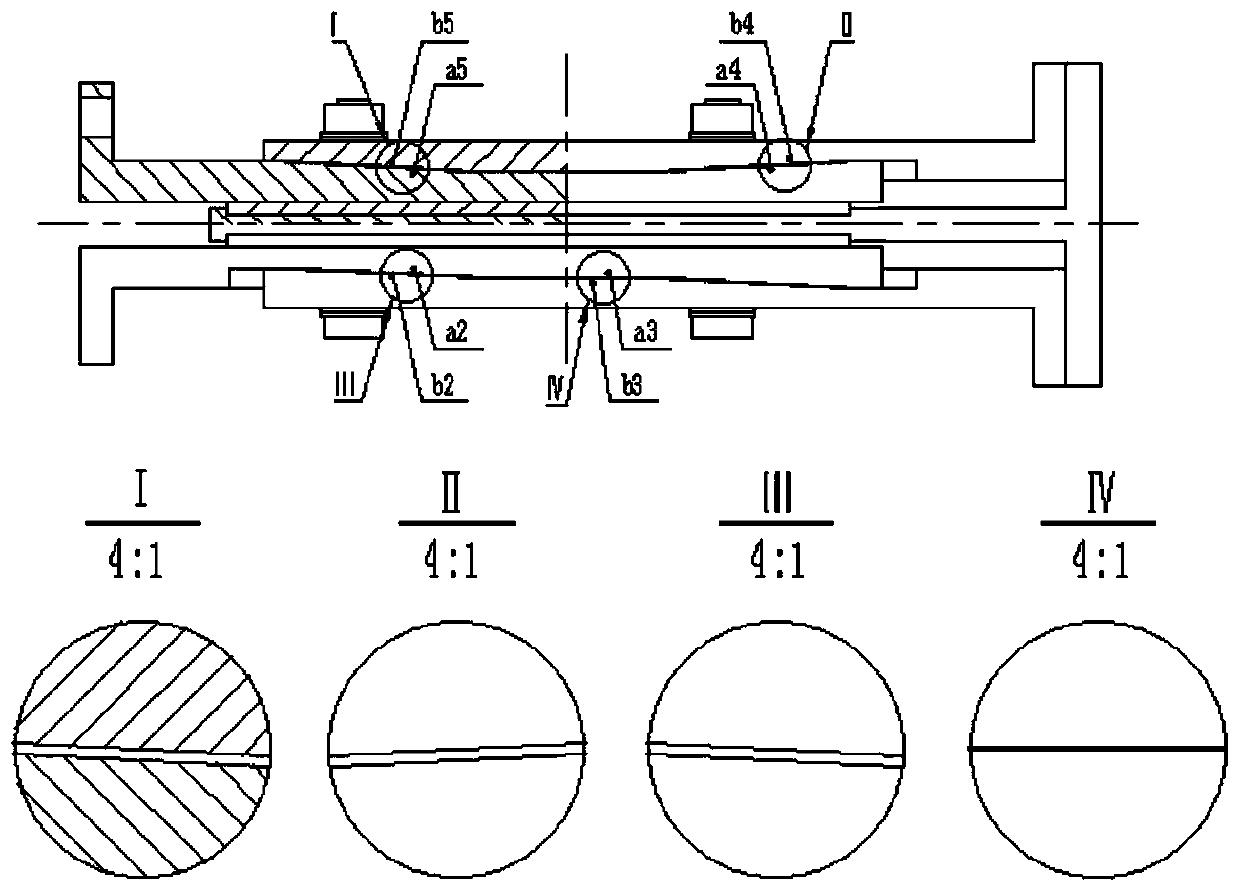

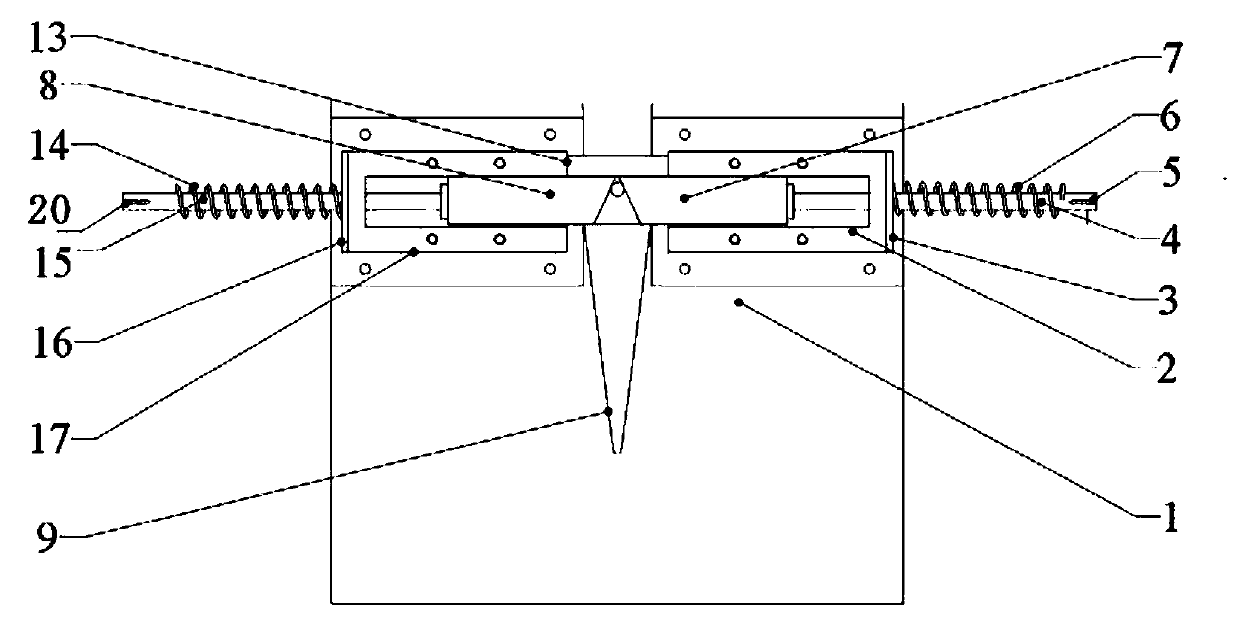

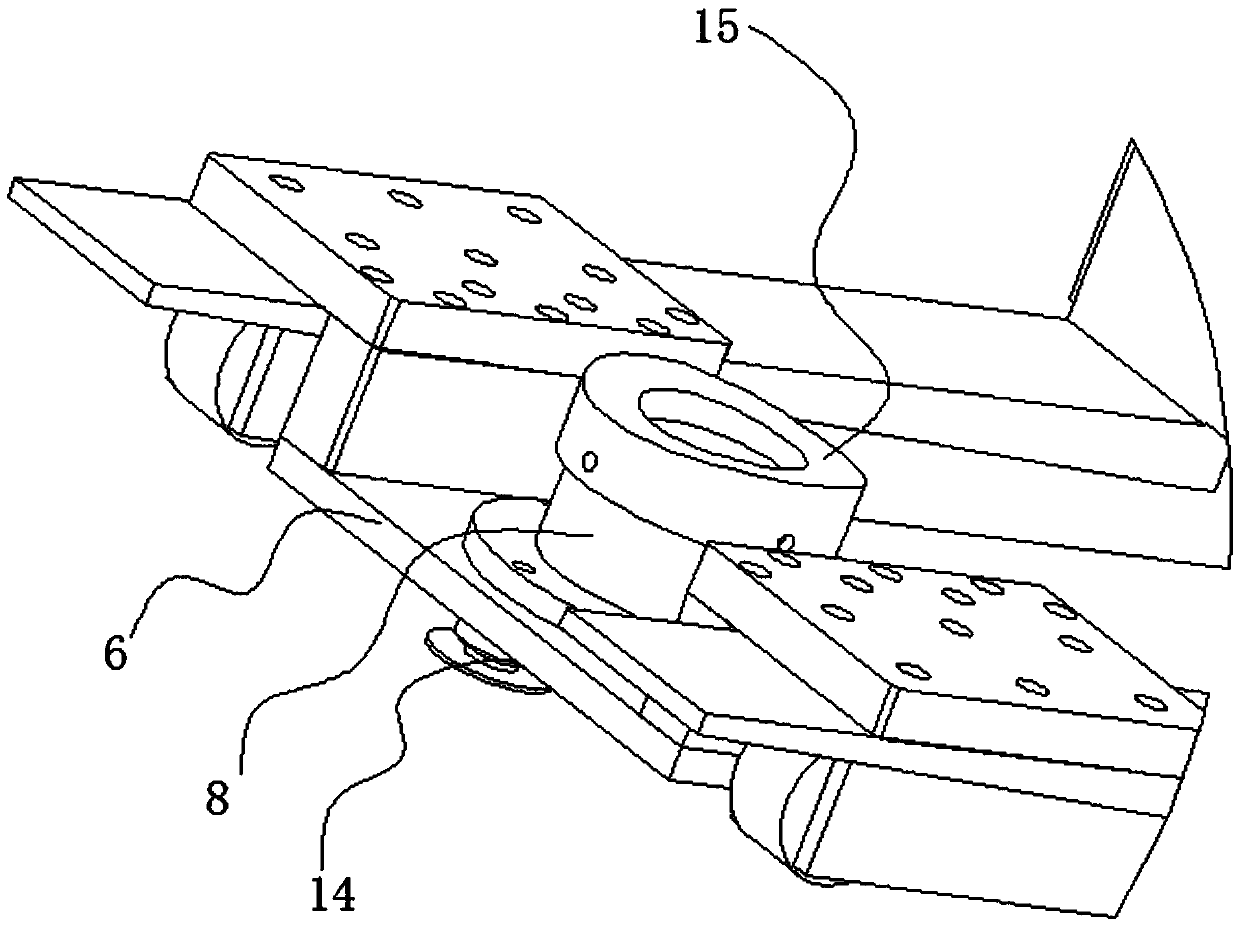

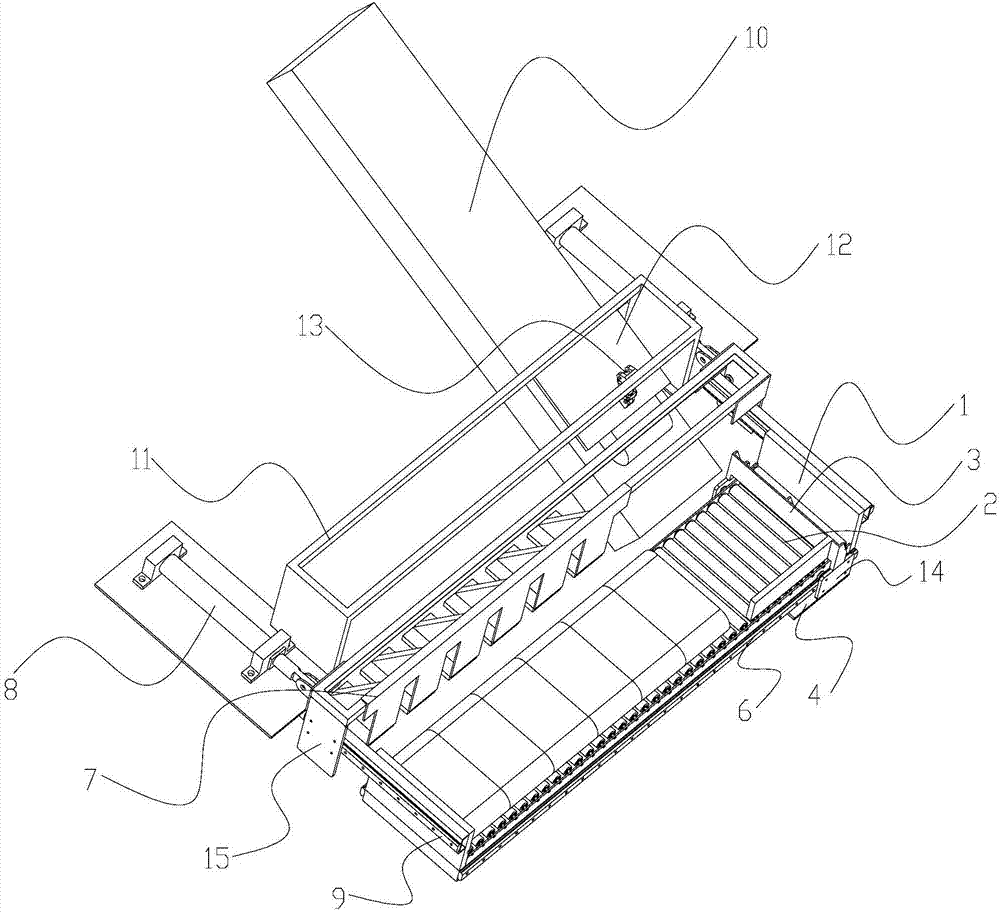

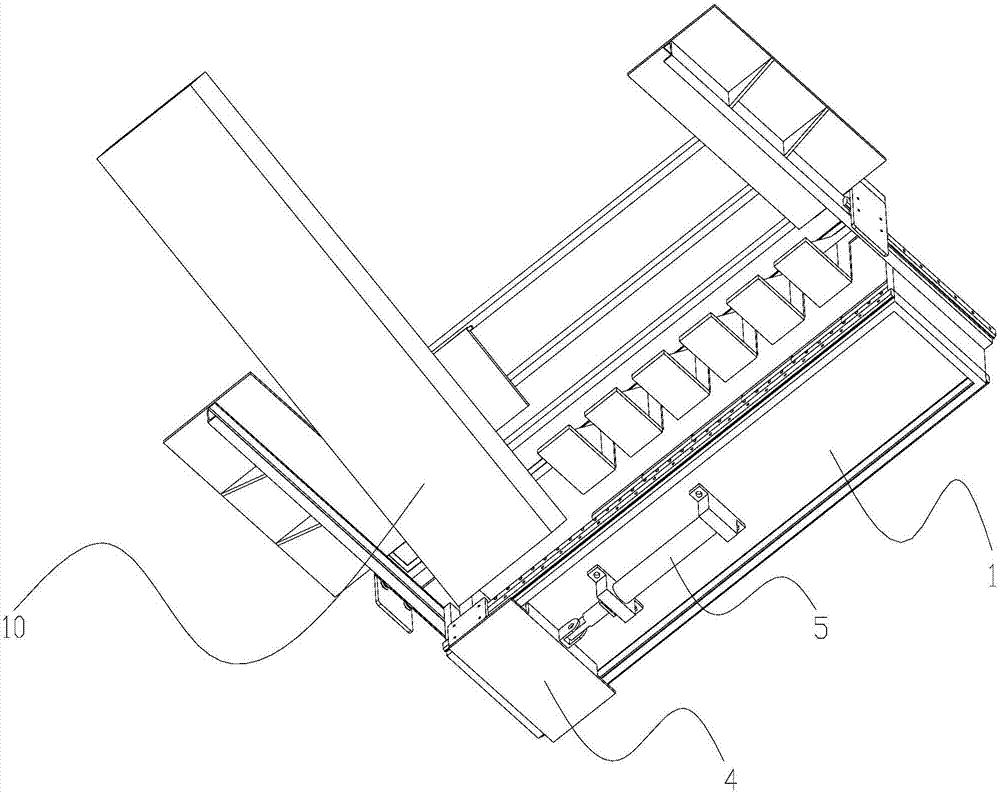

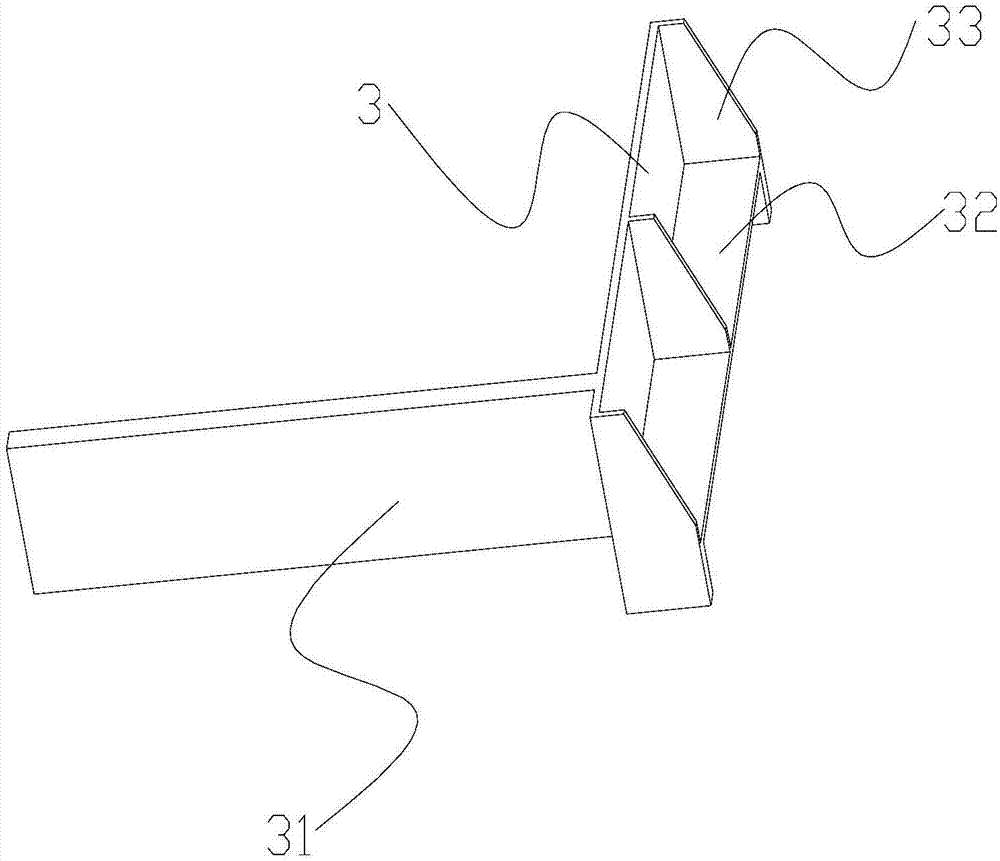

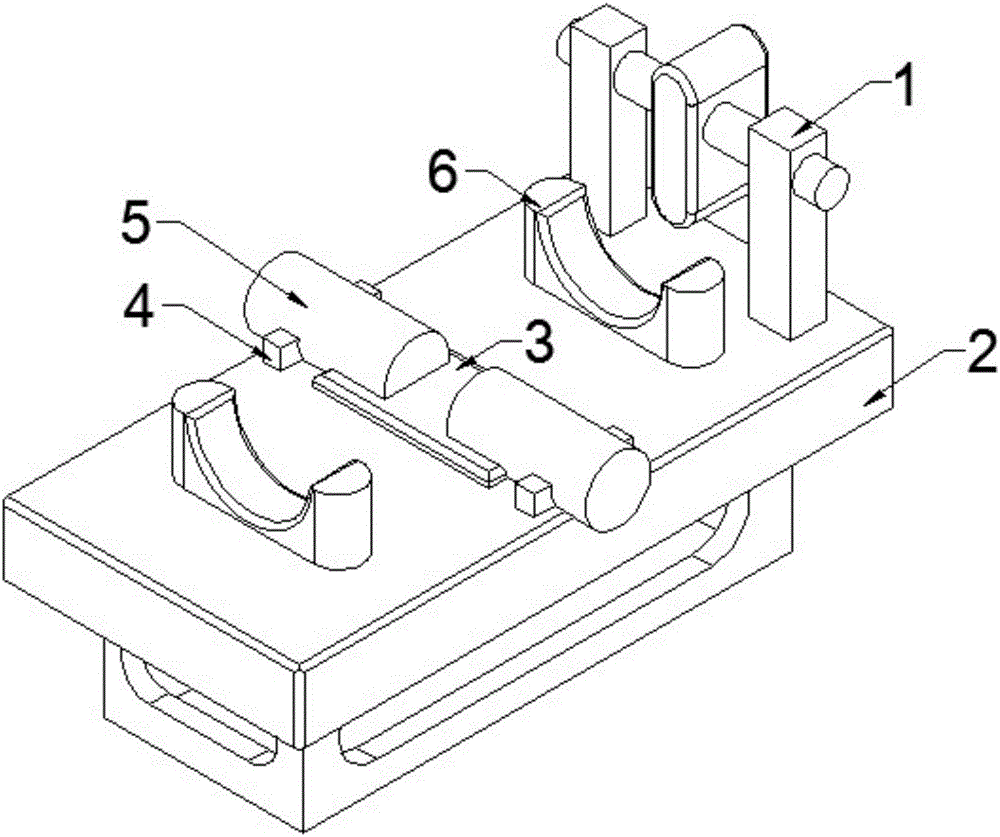

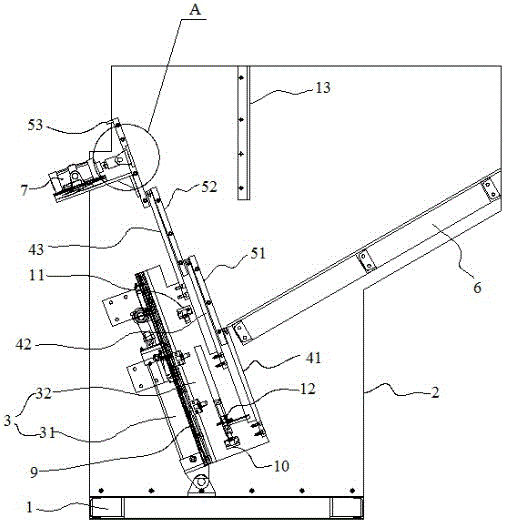

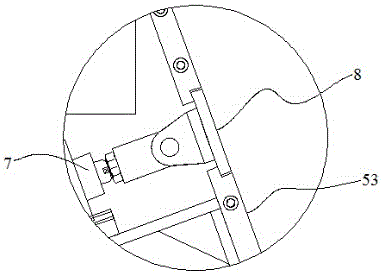

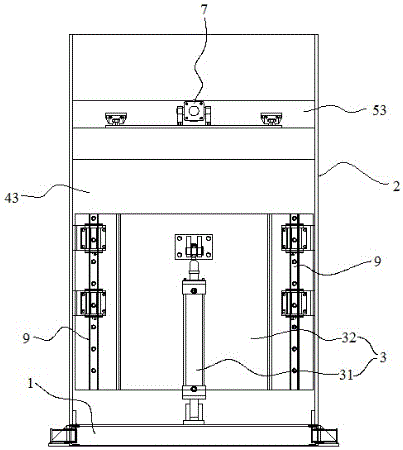

Machining equipment for communication cable

ActiveCN108515564AEasy to operateShort costEdge grinding machinesMetal working apparatusMachining processMotherboard

The invention relates to machining equipment for a communication cable. The machining equipment comprises a main plate, a cutting and deburring device, a middle limiting device and an end limiting device, the cutting and deburring device is installed at the front end of the main plate, the middle limiting device is installed in the middle of the main plate, and the end limiting device is installedat the back end of the main plate. According to the machining equipment for the communication cable, the problems that in the existing communication cable sleeve machining process, communication cable sleeves need to be manually limited and then cut, the process is tedious and complex, when the communication cable sleeves are limited, workers need to grab the communication cable sleeves with different structures in different modes, manual grabbing is single and unstable, when cutting is conducted, sleeve openings are likely to be uneven due to the fact that the positions are prone to deviating when manual cutting is conducted, burrs can be generated after cutting, the time consumed by the process is long, the labor intensity is high, and the efficiency is low can be solved, and the automatic limiting and cutting functions on the communication cable sleeves can be achieved.

Owner:以太龙精密机械江苏有限公司

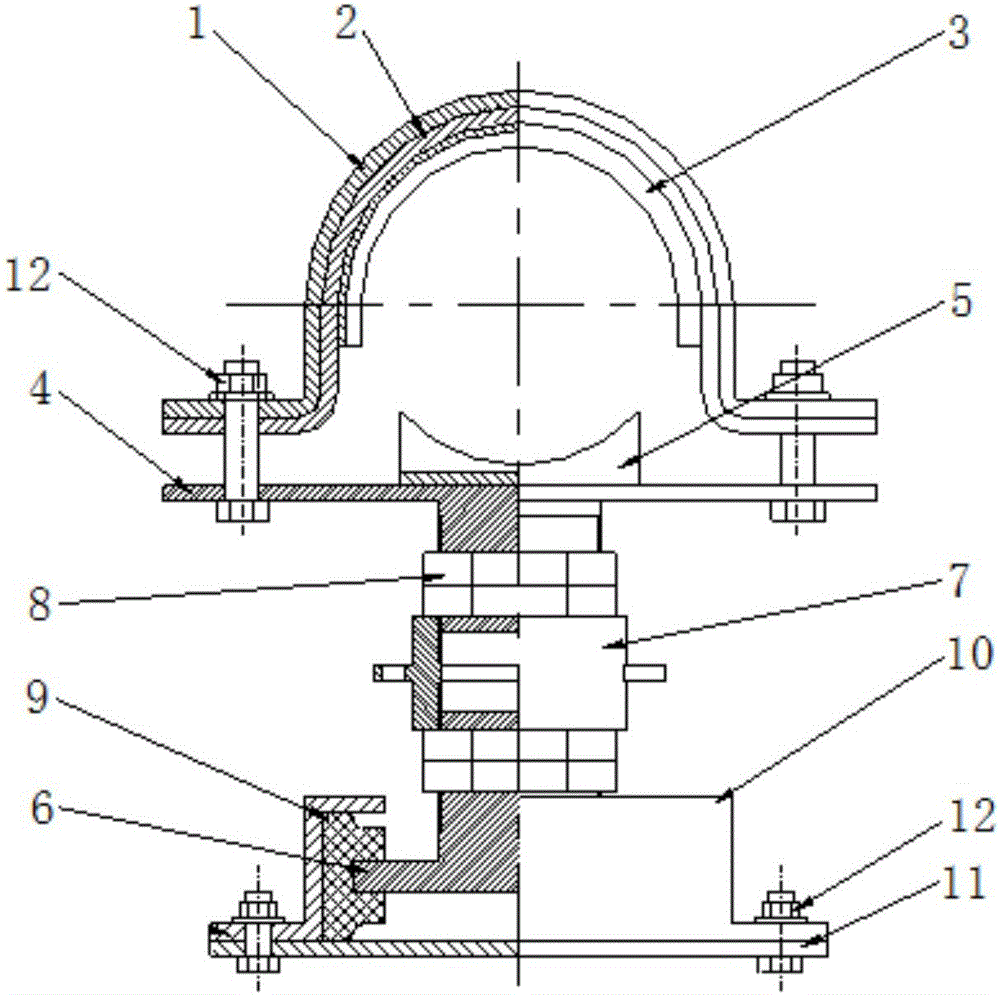

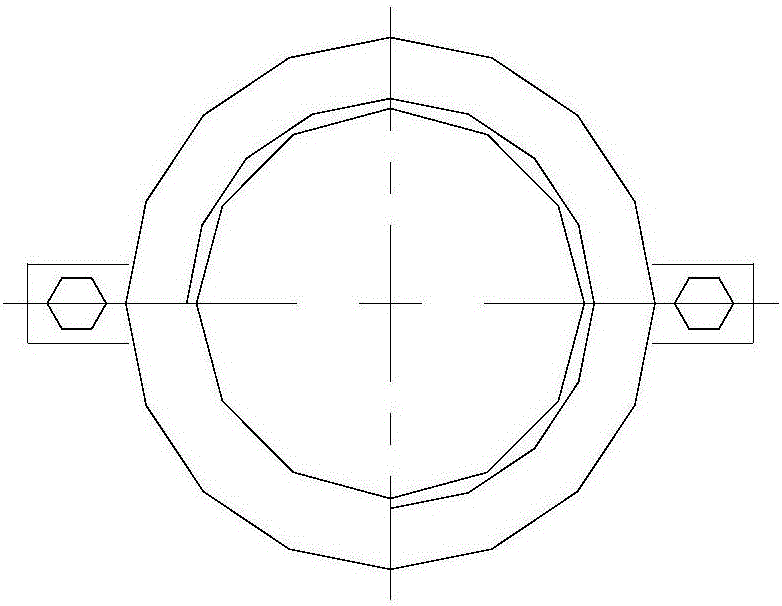

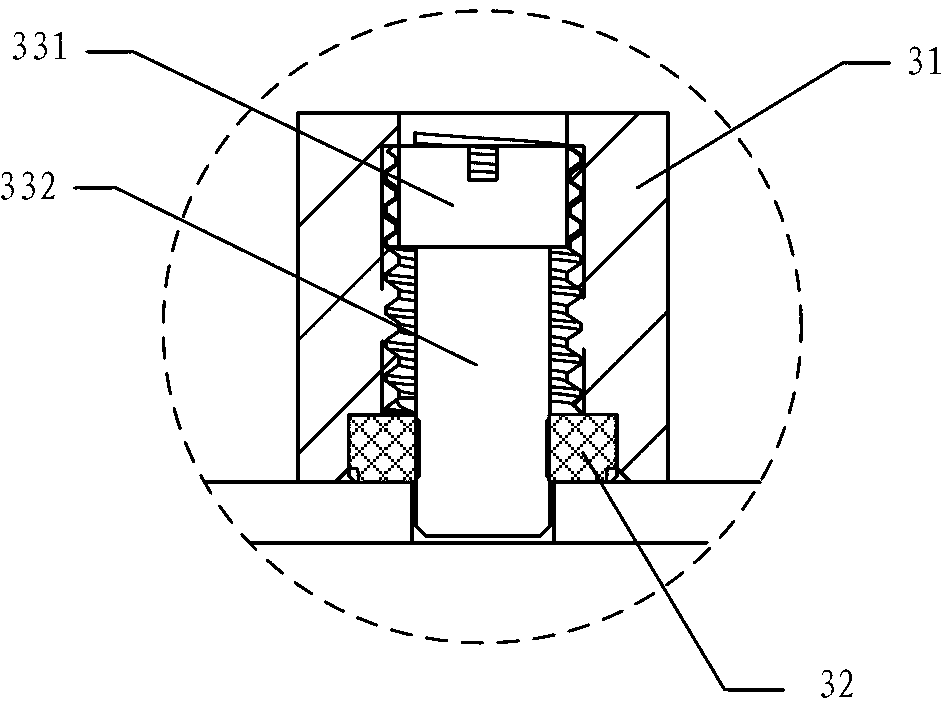

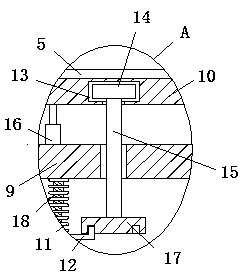

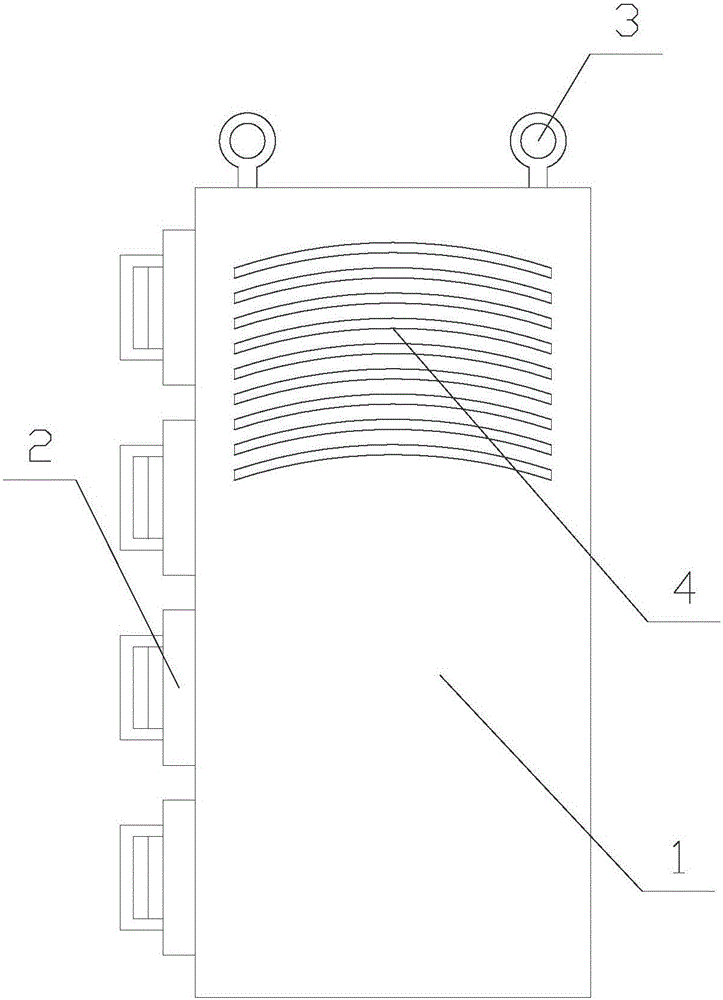

Adjustable elastic pipeline support and hanger with limiting function

InactiveCN106122597AAchieve elastic vibration isolationRealize the limit functionPipe supportsNon-rotating vibration suppressionNoise controlElastic vibration

The invention relates to an adjustable elastic pipeline support and hanger with a limiting function, and belongs to the technical field of vibration noise control. The support and hanger comprises a composite hoop, a backing board, a cushion block, an intermediate block, a bidirectional threaded sleeve, a locknut, an elastic rubber layer, a sleeve and a base, wherein an external pipeline is fixed through the composite hoop, the cushion block and the backing board; two ends of the bidirectional threaded sleeve are in threaded connection with the backing board and the intermediate block respectively, height adjustment of the support and hanger is realized by adjusting the bidirectional threaded sleeve, and the adjusting range is controllable and accurate; the intermediate block is in support transmission with the sleeve and the base through the elastic rubber layer, and elastic vibration isolation is realized through reasonable design of the elastic rubber layer. The adjustable elastic pipeline support and hanger is reasonable in structural design, compact in structure and convenient to mount and has larger mounting advantages under the condition of arrangement with high space requirement.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

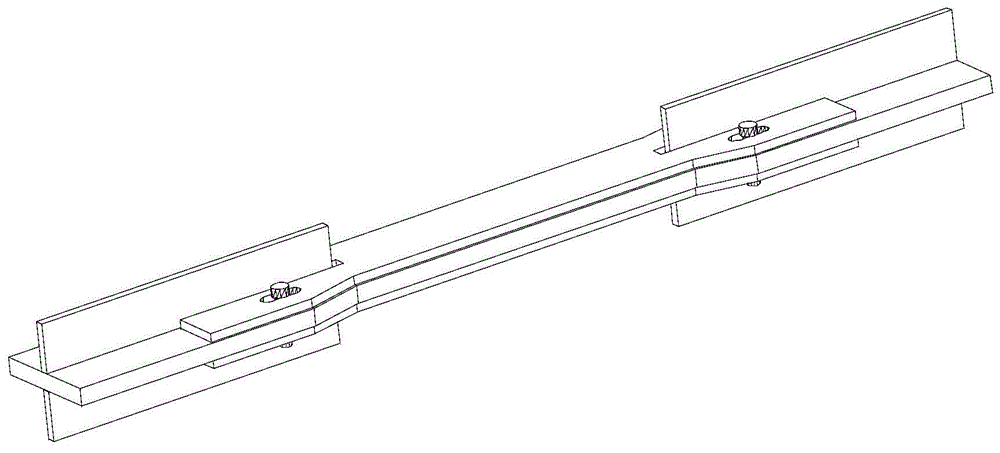

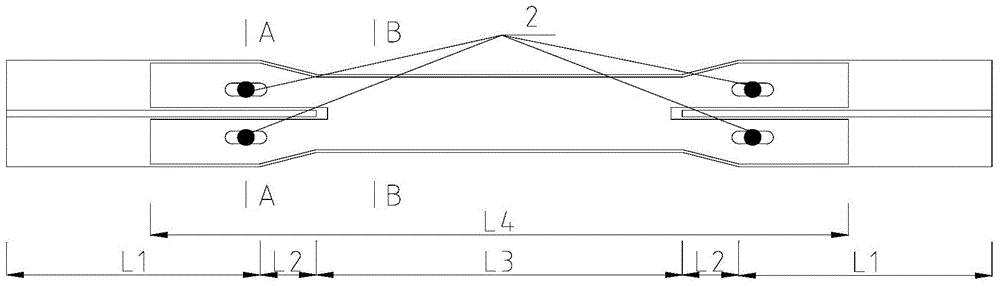

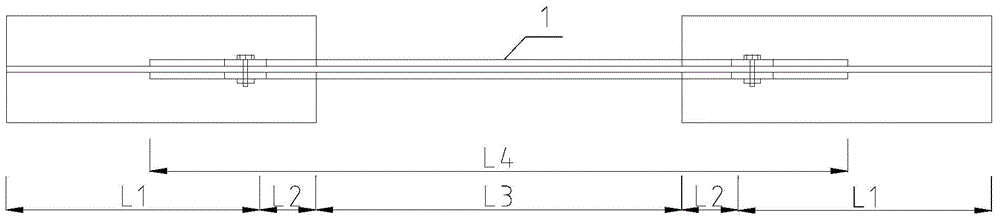

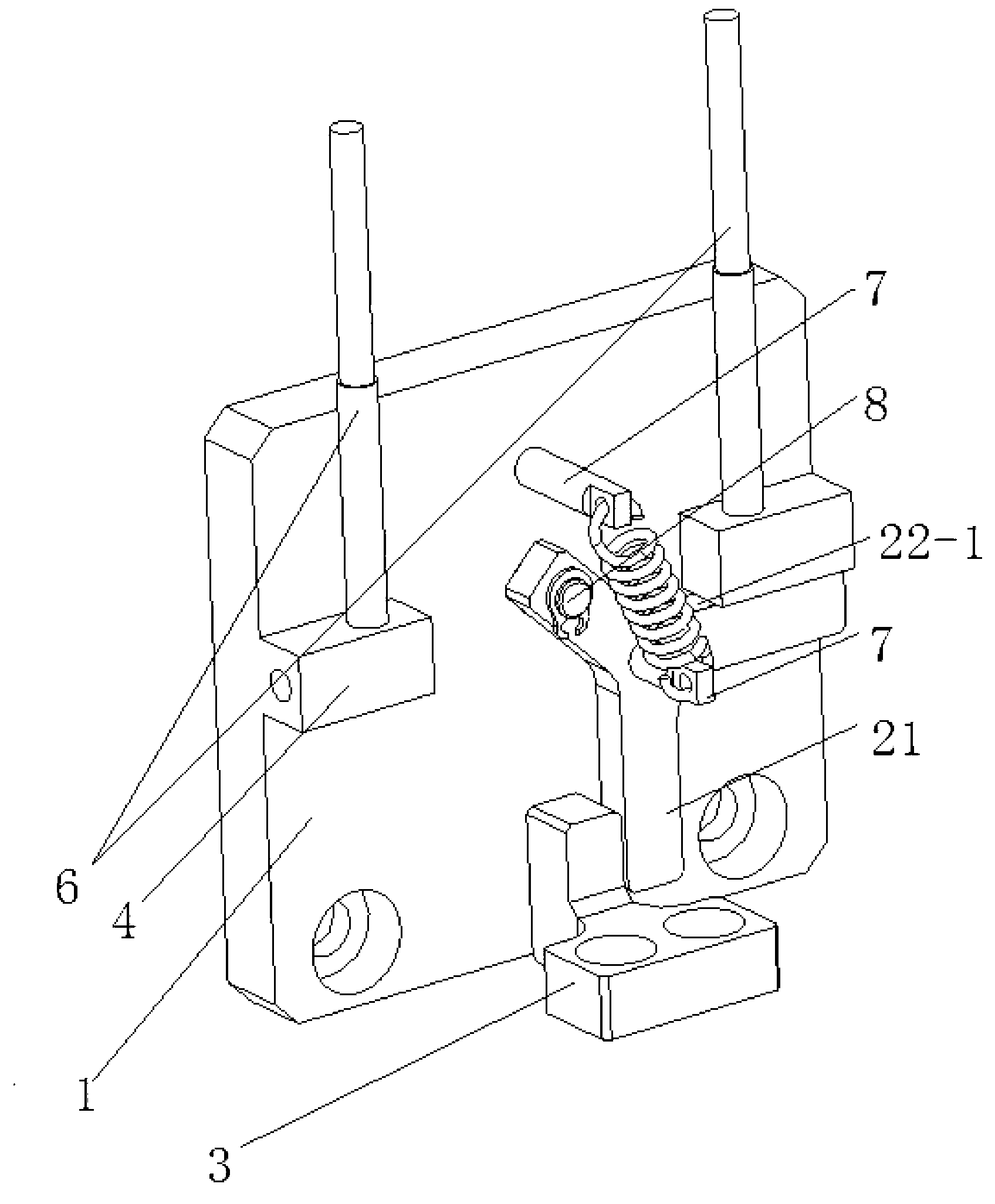

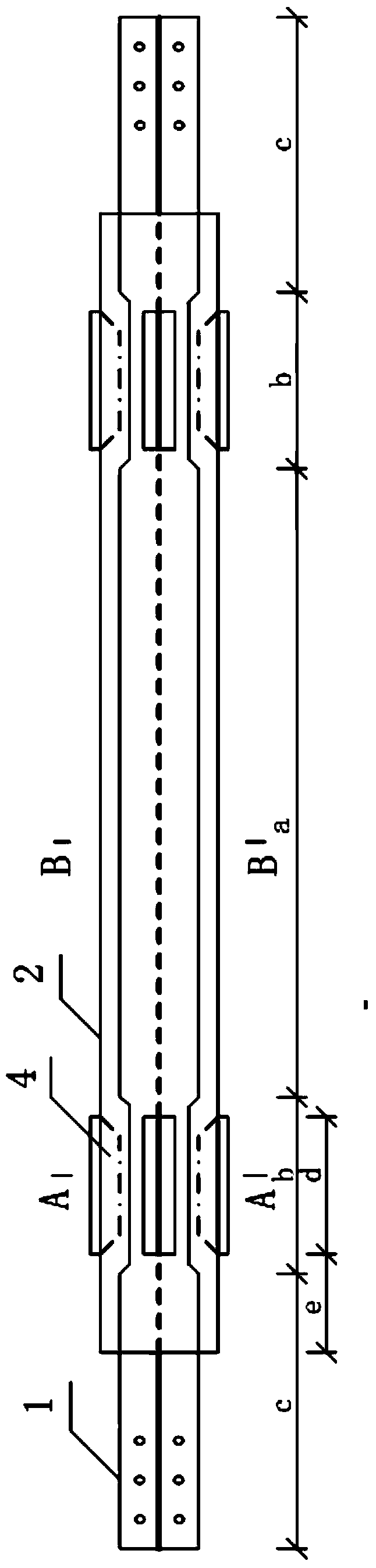

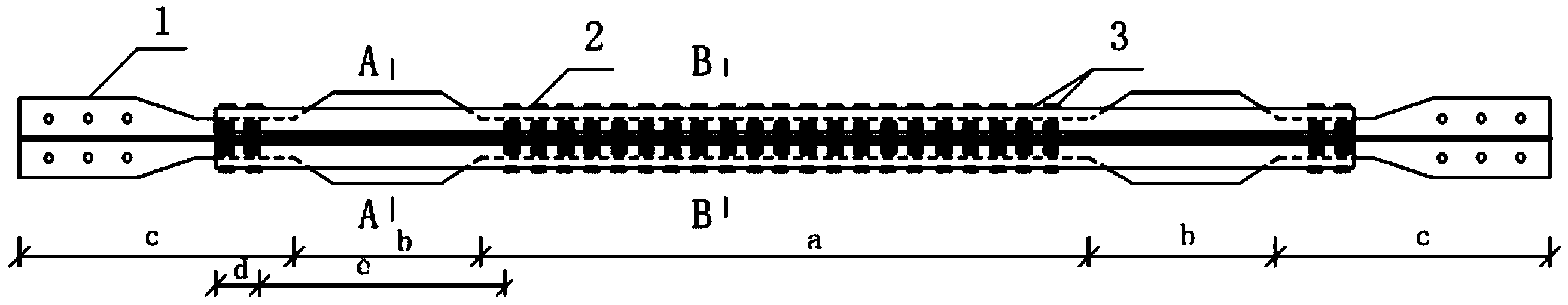

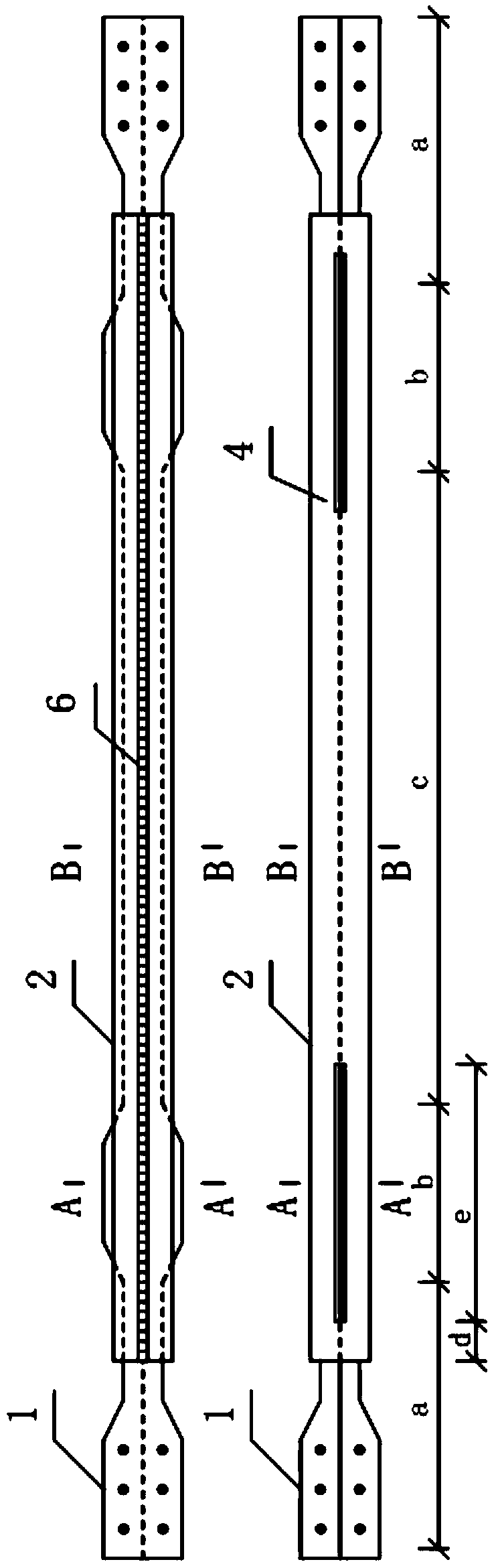

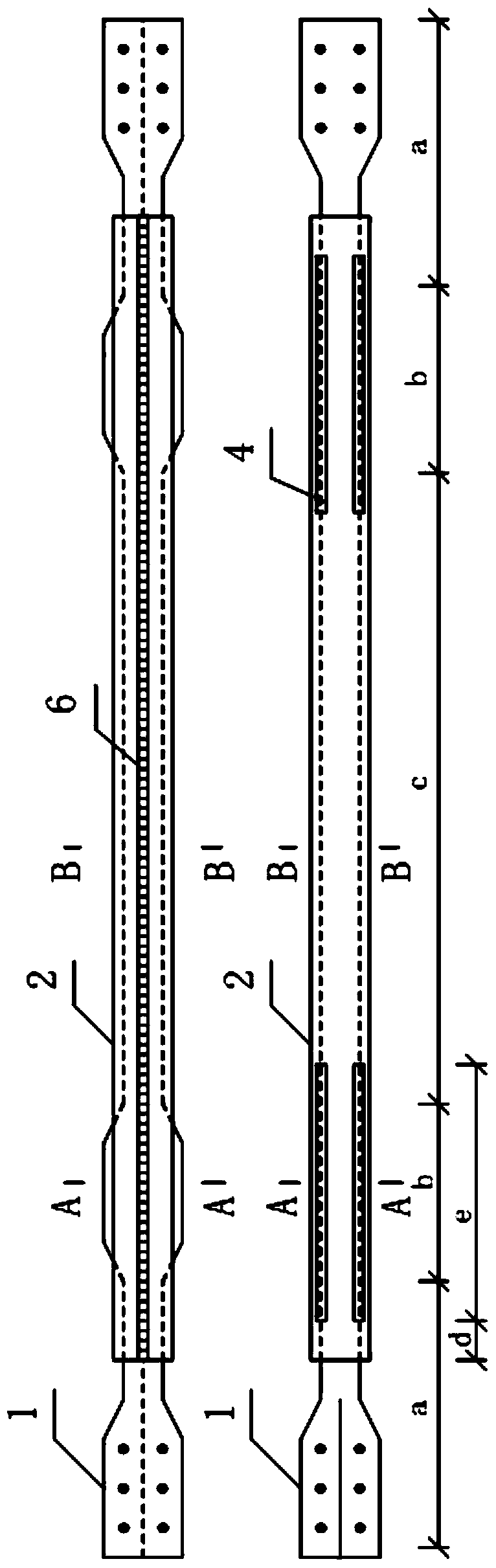

Anti-buckling limit support member for reinforcing post-yield stiffness

The invention discloses an anti-buckling limit support member for reinforcing a post-yield stiffness, which belongs to the technical field of building construction. The anti-buckling limit support member comprises a two-order yield steel core and an outer constraint steel tube, wherein the two-order yield steel core comprises a first-level yield steel core and a vertically-covering steel plate; the first-level yield steel sequentially comprises a connection section L1, transition sections L2 and a yield working section L3 from the both ends to the middle, the connection section L1 and the transition sections L2 are cross sections, the yield working section L3 is an inline section, and the yield working section L3 is located between the two transition sections L2; bolts are arranged on connection sections at the both sides of the first-level yield steel core; the lengths of the first-level yield steel core and the vertically-covering steel plate are L4, the steel plate is connected to the upper surface and the lower surface of the first-level yield steel core by the bolts at the both ends, grooves are opened in thee both ends of the steel plate, the cross sections of the first-level yield steel core stretch into the grooves, and the two-order yield steel core is located in the outer constraint steel tube. The anti-buckling limit support member disclosed by the invention is convenient to take materials, definite in force transfer, and capable of being widely applied to energy dissipation and seismic mitigation, and limit control for buildings.

Owner:BEIJING UNIV OF TECH

Rotation limitation and orientation identification mechanism and limiting and identifying method thereof

ActiveCN103324242ARealize the limit functionIngenious designLimiting/preventing/returning movement of partsHome positionEngineering

The invention discloses a rotation limitation and orientation identification mechanism and a limiting and identifying method of the rotation limitation and orientation identification mechanism. The rotation limitation and orientation identification mechanism comprises a bottom plate, a rotating plate, a rammer, two stop blocks and an elastic piece. The upper end of the rotating plate is connected with the bottom plate in a rotating mode. The lower end of the rotating plate is provided with a left limiting plate and a right limiting plate, wherein one end of the left limiting plate and one end of the right limiting plate are connected, and an included angle is formed between the other end of the left limiting plate and the other end of the right limiting plate. The included angle between the limiting edge located on the outer side of the left limiting plate and the limiting edge located on the outer side of the right limiting plate is 90 degrees. The rammer is connected with a rotating shaft and is driven by the rotating shaft to rotate. The rammer and the bottom plate are located on two planes respectively, and the two planes are perpendicular to each other. The starting position of the rammer is in the middle of the included angle formed between the left limiting plate and the right limiting plate of the rotating plate. The rammer can make contact with the left limiting plate or the right limiting plate in the rotating process. The two stop blocks are fixed on the bottom plate, located on two sides of the rotating plate, and matched with the limiting edges respectively to restrict the rotating amplitude of the left limiting plate and the rotating amplitude of the right limiting plate. The elastic piece provides upward tensile force for the rotating plate. The rotation limitation and orientation identification mechanism can be used for limiting a rotating mechanism or the rotating shaft by + / -360 degrees, and is ingenious in design and simple to use.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

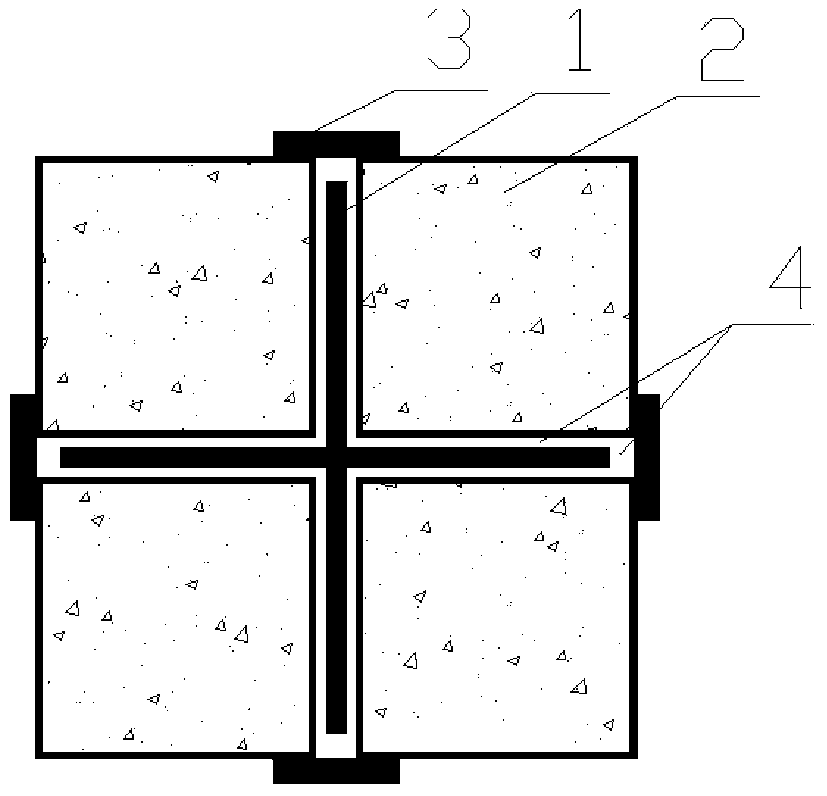

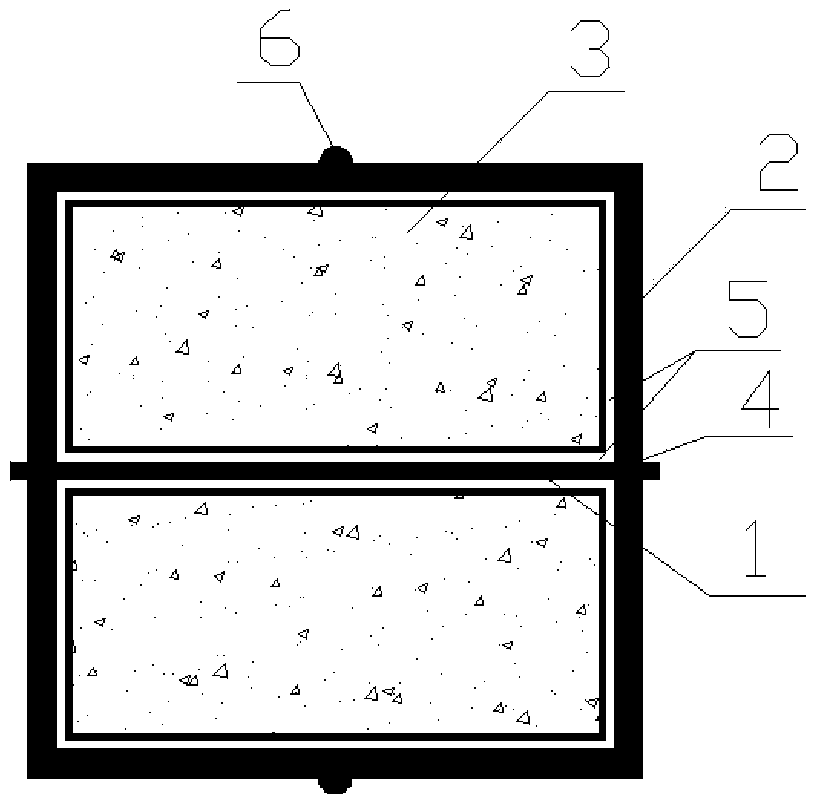

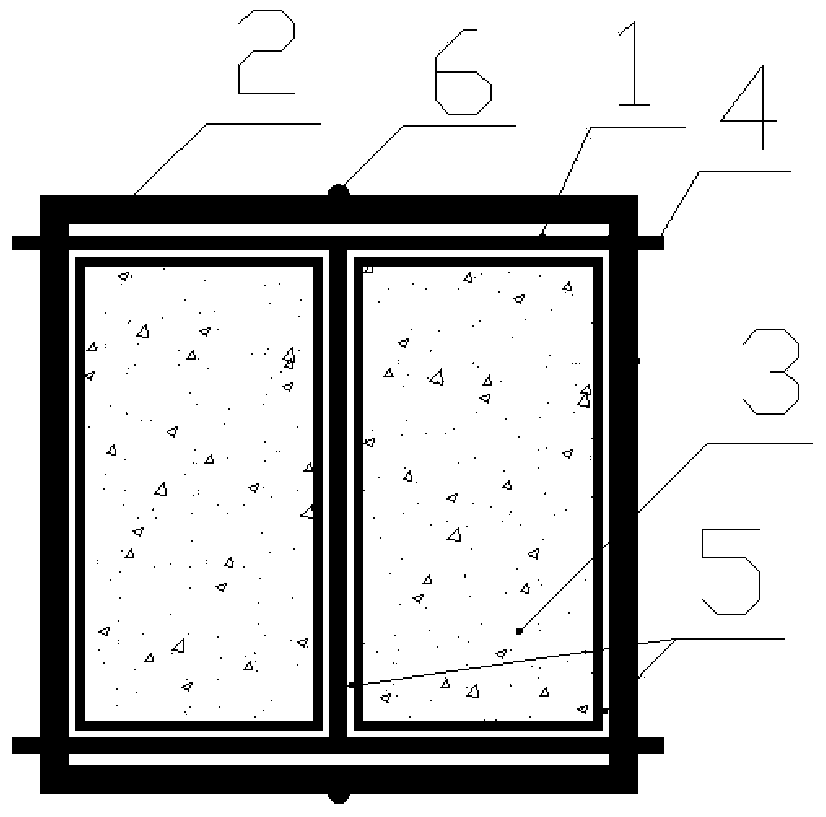

Rectangular steel tube variable-cross-section steel core anti-buckling limiting energy dissipation supporting member assembled with bolt shaped like Chinese character 'tian'

InactiveCN103711216ALimited lateral movementReach the limit effectShock proofingChinese charactersMaterials science

The invention relates to a rectangular steel tube variable-cross-section steel core anti-buckling limiting energy dissipation supporting member assembled with a bolt shaped like a Chinese character 'tian', and belongs to the technical field of anti-buckling supporting. The anti-buckling limiting energy dissipation supporting member comprises a cross-shaped steel core and an outer limiting body, the cross-shaped steel core is located in the outer limiting body, and four spaces defined by the steel core and the outer limiting body are respectively filled with a light-gauge steel section concrete filled steel tube. The anti-buckling limiting energy dissipation supporting member is characterized in that the partial cross section of the steel core becomes large, a limiting groove (3) is formed in the position, corresponding to a partial cross section largened section c, of the outer limiting body, the groove length of the limiting groove (3) is slightly larger than the section length of the corresponding partial cross section largened section, and the portion, located on a partial cross section largened section b, of the cross-shaped steel core outwards extends out of the outer limiting body through a corresponding limiting groove. After the steel core is deformed and buckled, an outer limiting steel tube and the axial stiffness of the buckled steel core are used for limiting the whole displacement of the structure to achieve the limiting target.

Owner:BEIJING UNIV OF TECH

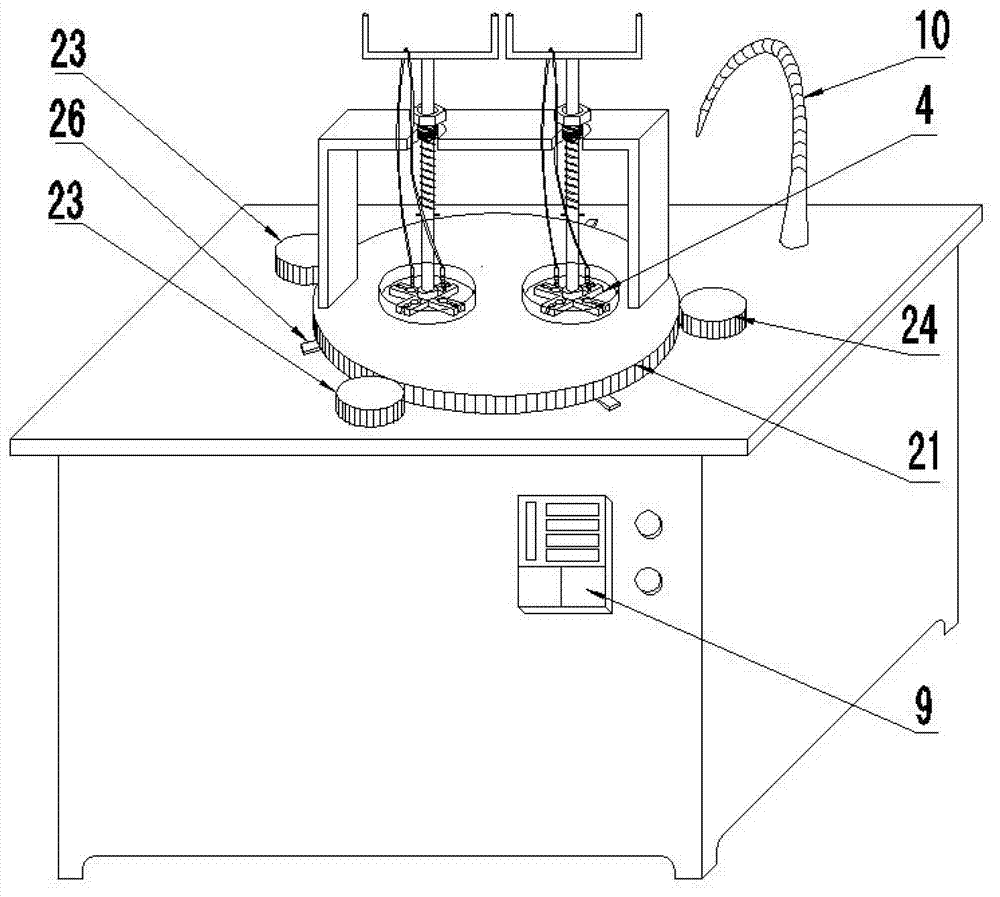

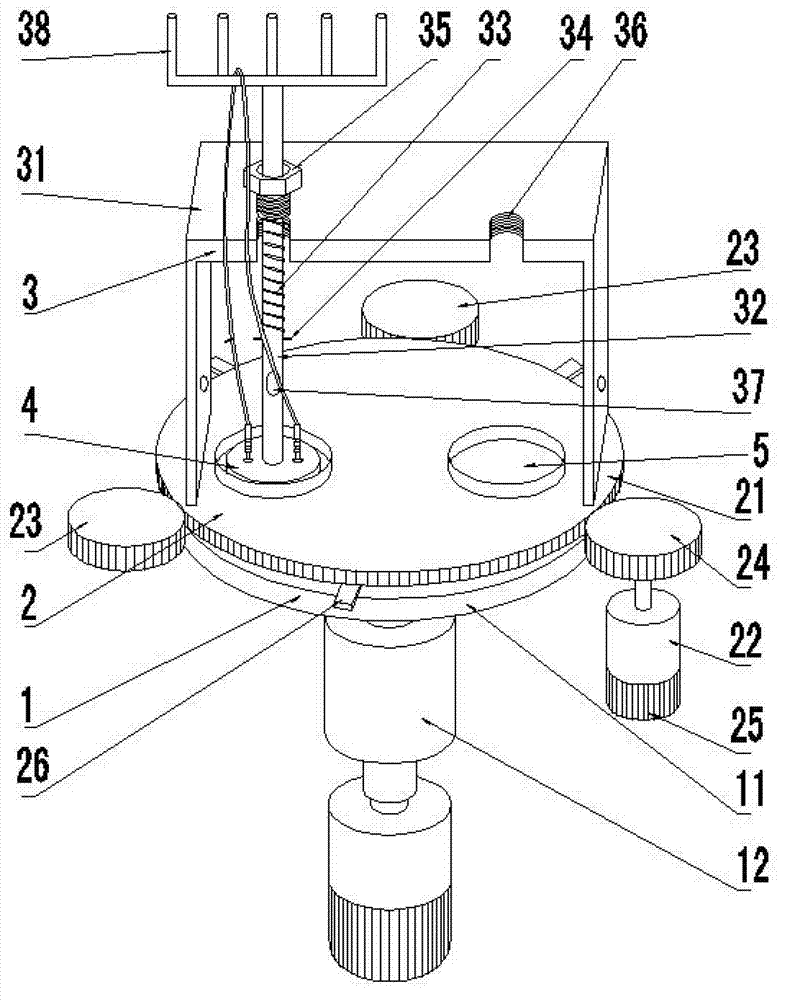

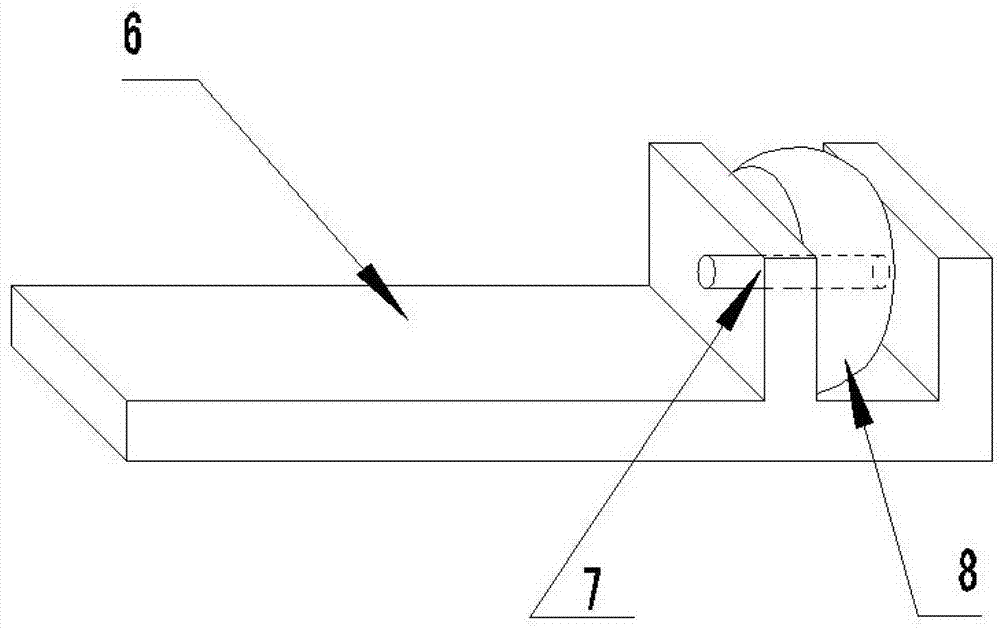

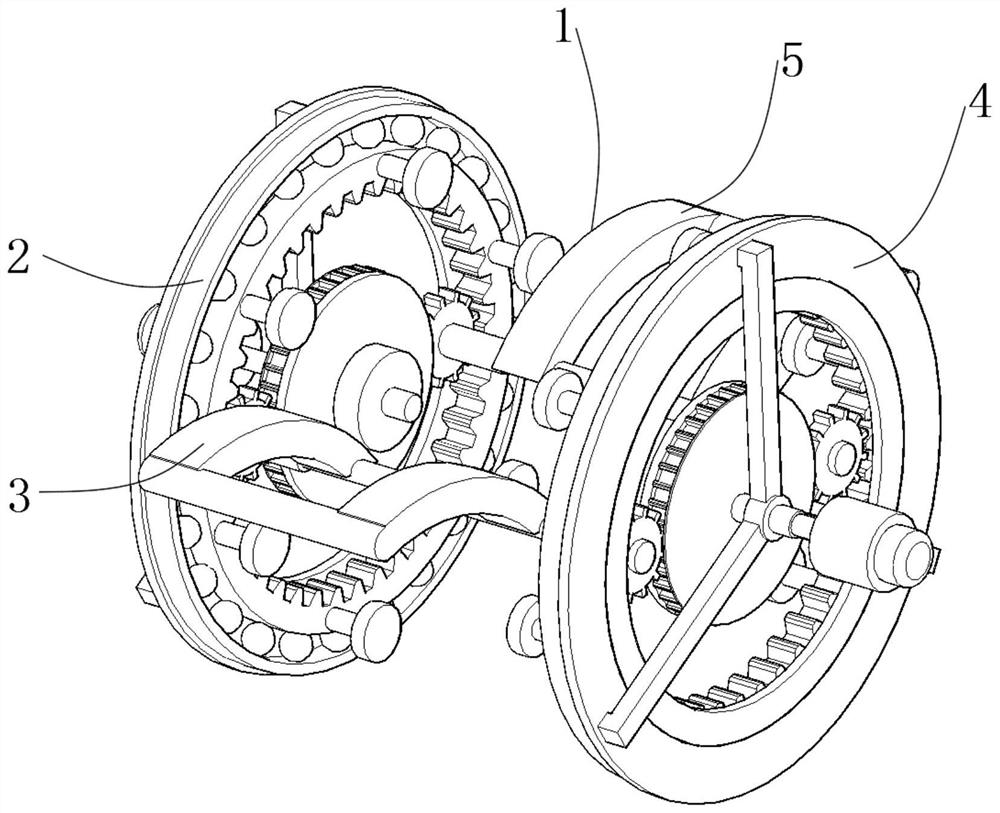

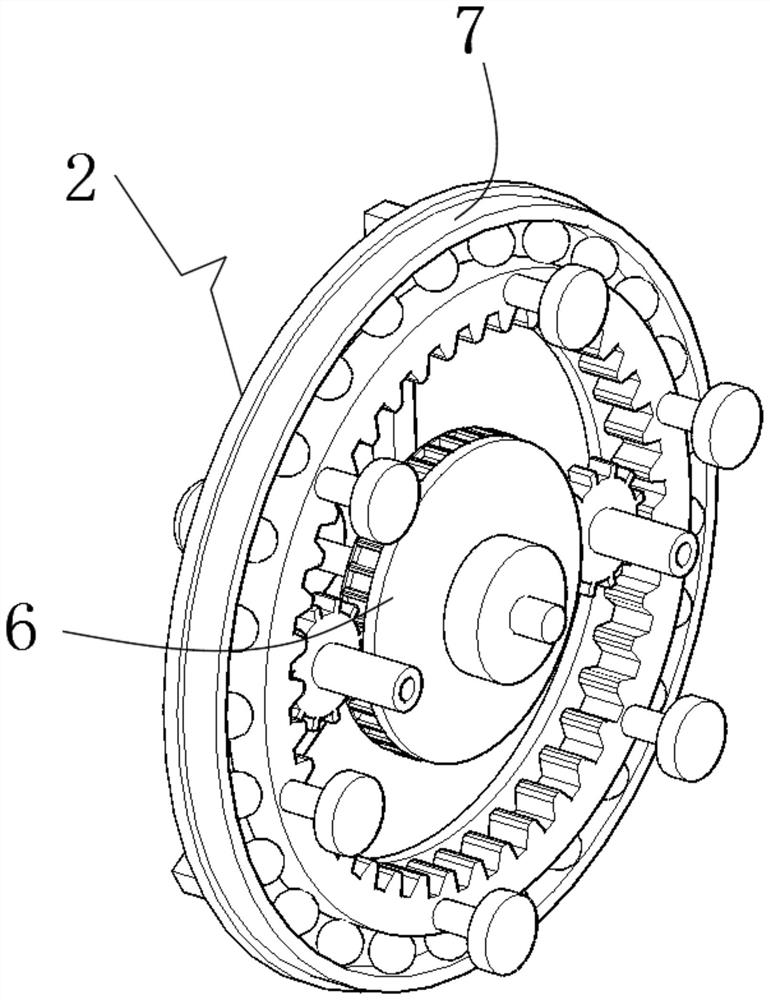

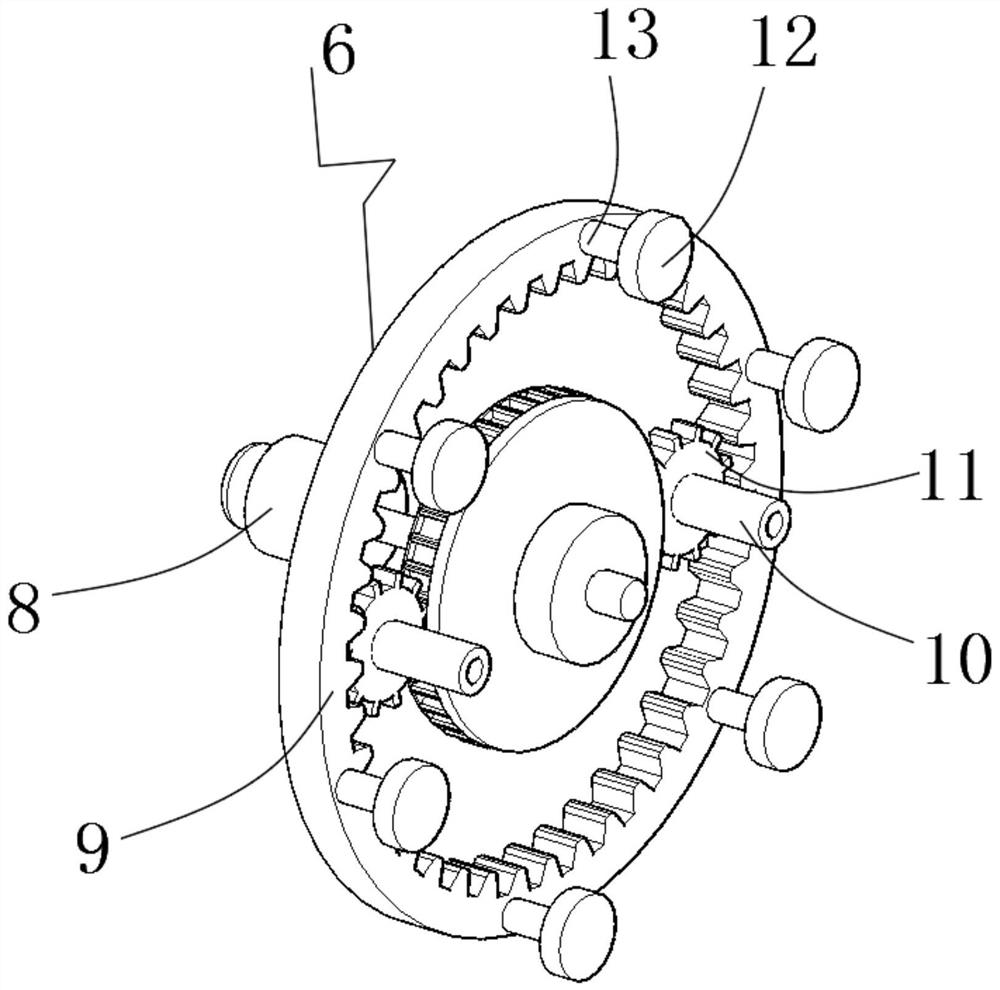

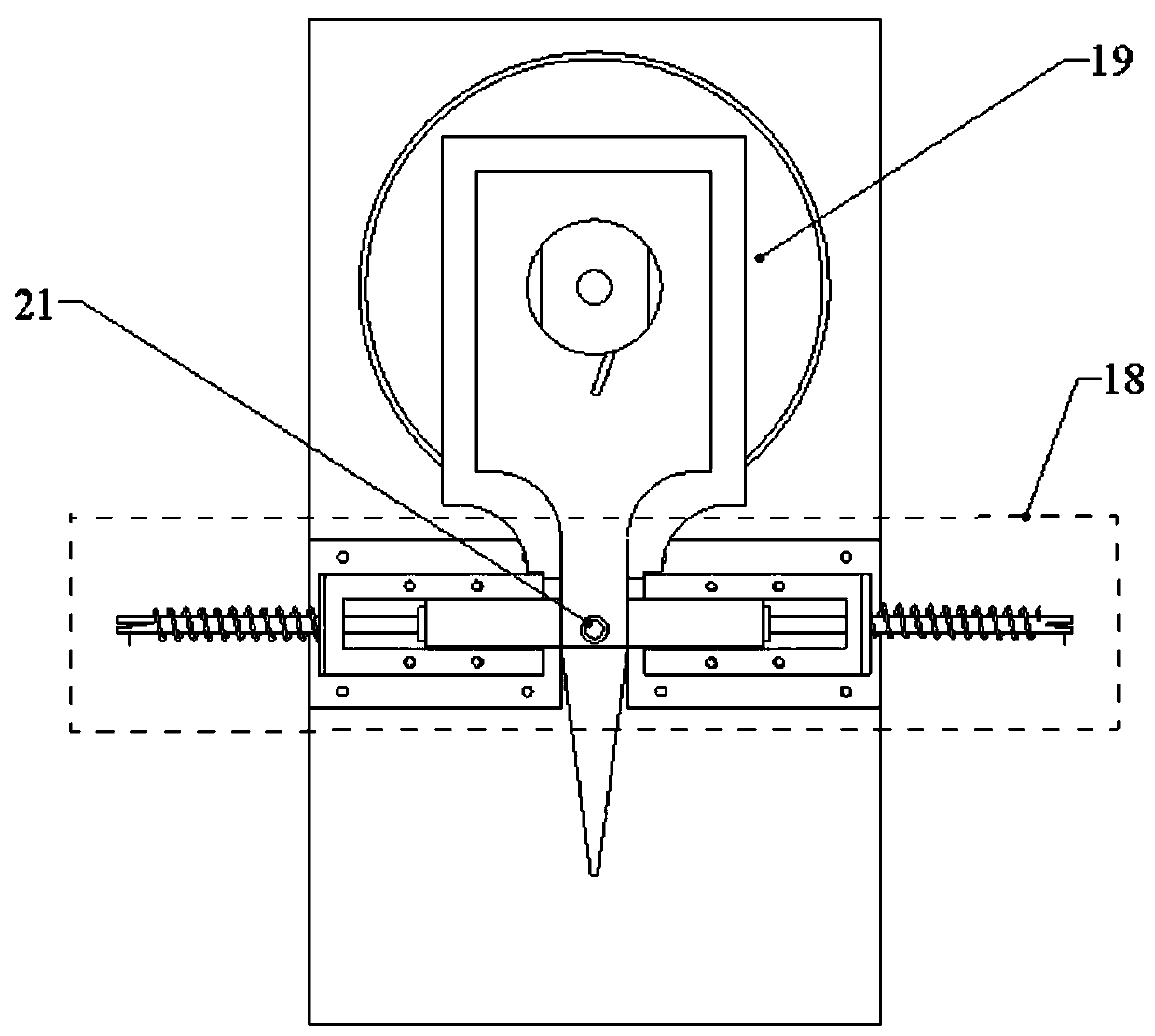

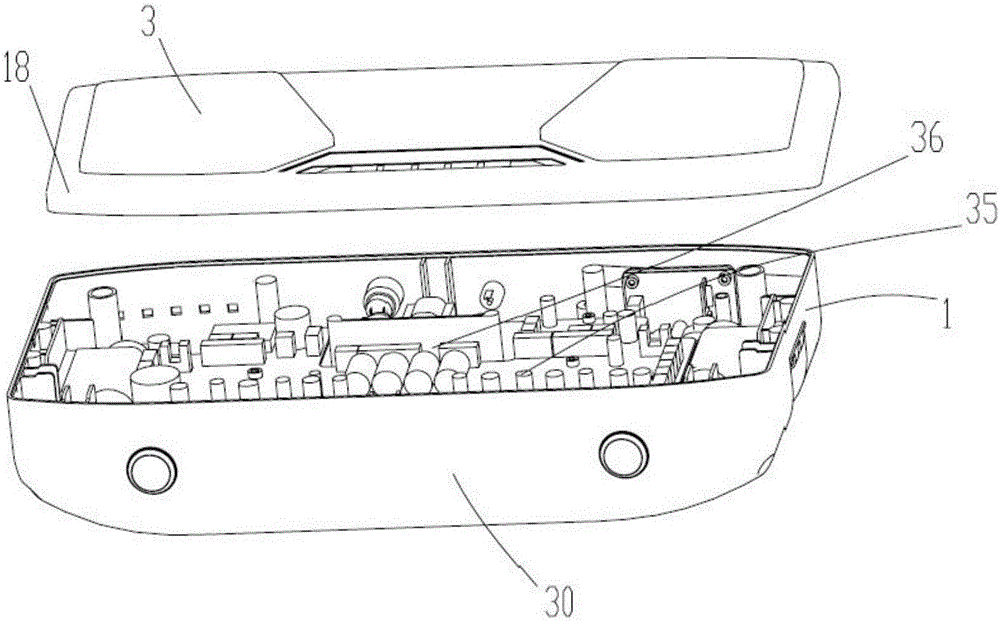

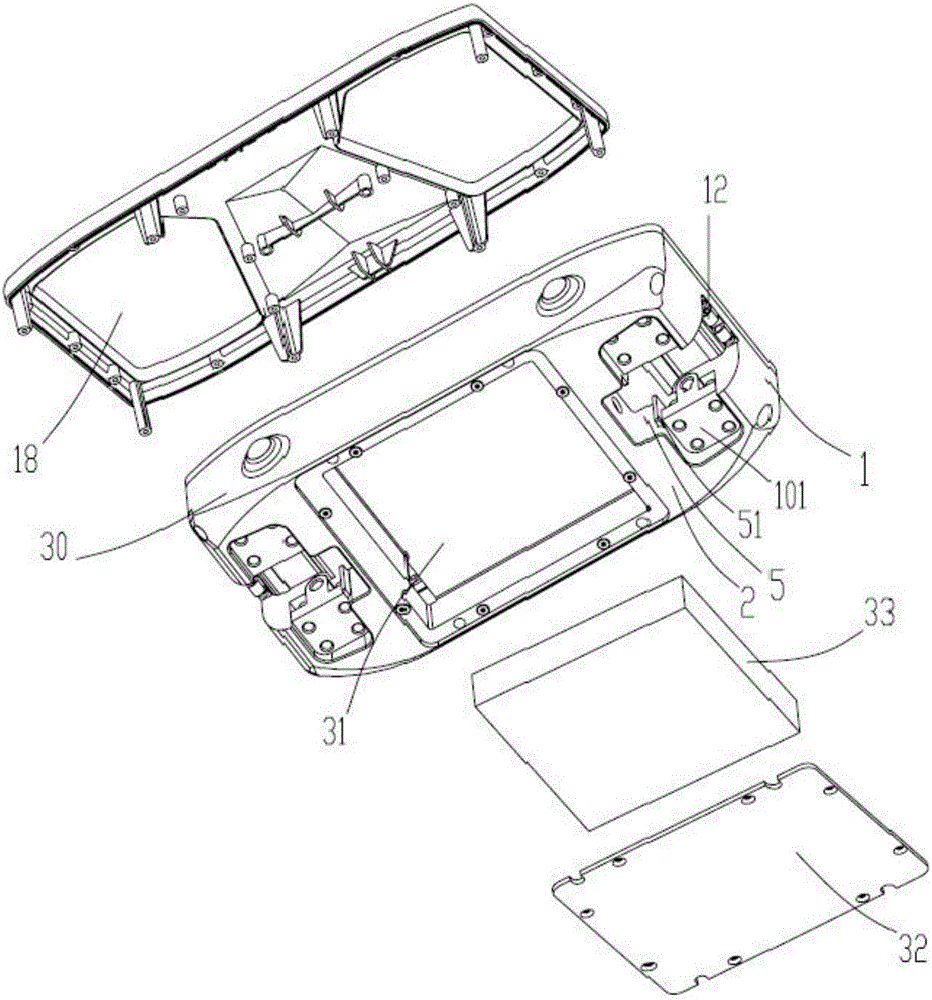

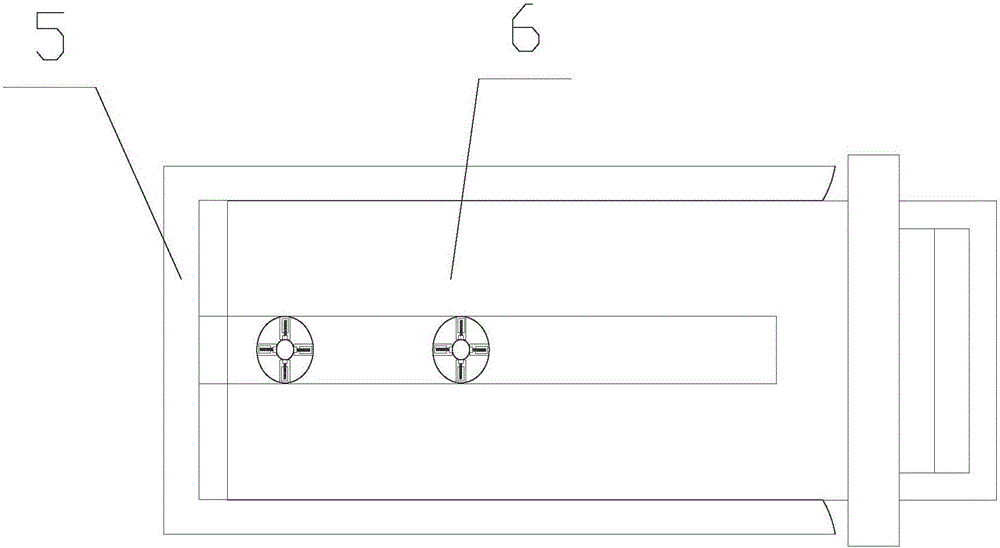

Automatic grinding and polishing device for end surfaces of optical fibers and cables

ActiveCN102922383AAutomatic grinding and polishingHardwiredGrinding work supportsPlane surface grinding machinesDrive wheelEngineering

The invention discloses an automatic grinding and polishing device for end surfaces of optical fibers and cables. The automatic grinding and polishing device comprises a machine case, a grinding and polishing assembly and an electric control unit. The grinding and polishing assembly comprises a plane grinding and polishing mechanism, an emulational hand assembly, a grinding and polishing clamp and an elastic boosting device, wherein the emulational hand assembly comprises a working disc, a driving wheel, a transmission motor, a driven wheel and a working disc rotating booster; the driven wheel and the driving wheel are in external meshing with the working disc; the elastic boosting device comprises a grinding and polishing clamp connection rod and a working disc gantry base; the grinding and polishing clamp connection rod is connected with the working disc gantry base; the working disc gantry base is arranged on the working disc, the grinding and polishing clamp connection rod is connected with the grinding and polishing clamp, and the grinding and polishing clamp is assembled in a working hole; and the working disc rotating booster is respectively connected with the working disc and the plane grinding and polishing disc. The automatic grinding and polishing device for end surfaces of the optical fibers and cables can perform automatic grinding and polishing, can stimulate human hands to exert force on the grinding and polishing clamp of the optical fibers and cables, and is high in grinding and polishing efficiency, stable in grinding and polishing quality and safe and reliable to operate.

Owner:NANJING CHUNHUI SCI & TECH IND

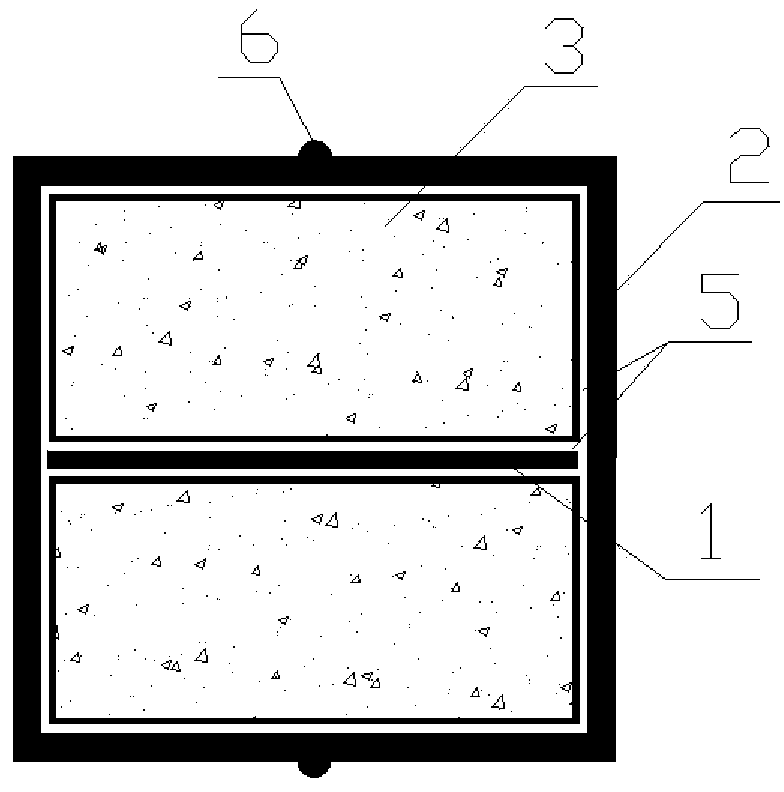

Bending-prevention limiting energy-dissipation supporting component with steel pipe with baffles inside and cross-shaped inward contracting type variable-section steel core

InactiveCN103711219ATake full advantage of axial stiffnessImprove performanceShock proofingSteel tubeEngineering

The invention discloses a bending-prevention limiting energy-dissipation supporting component with a steel pipe with baffles inside and a cross-shaped inward contracting type variable-section steel core, and belongs to the technical field of bending-prevention limiting energy-dissipation supporting components. The cross-shaped steel core sequentially includes a non-variable-section section a, section-decreasing sections b and a connecting section c from the two ends to the middle, wherein the non-variable-section section a is located between the two section-decreasing sections b, the section-decreasing sections b are near the two ends of the external limiting steel pipe respectively, limiting grooves correspond to the section-decreasing sections b of the cross-shaped steel core, a T-shaped-section baffle is welded to each limiting groove, a wing edge plate of each T-shaped-section baffle is welded to the outer surface of the outer limiting steel pipe, a web plate is vertically inserted into each limiting groove, an interval is reserved between each web plate with and each section-decreasing section b of the cross-shaped steel core, the two ends of each section-decreasing section b of the cross-shaped steel core contracts inwards at the rope angle of 60 degrees, the end of the web plate of each T-shaped-section baffle also contracts inwards at the rope angle of 60 degrees and is parallel with the ends of the section-decreasing sections b of the steel core. The bending-prevention limiting energy-dissipation supporting component with the steel pipe with the baffles inside and the cross-shaped inward contracting type variable-section inner core can be widely applied to energy dissipation, seismic mitigation and limiting control of a building.

Owner:BEIJING UNIV OF TECH

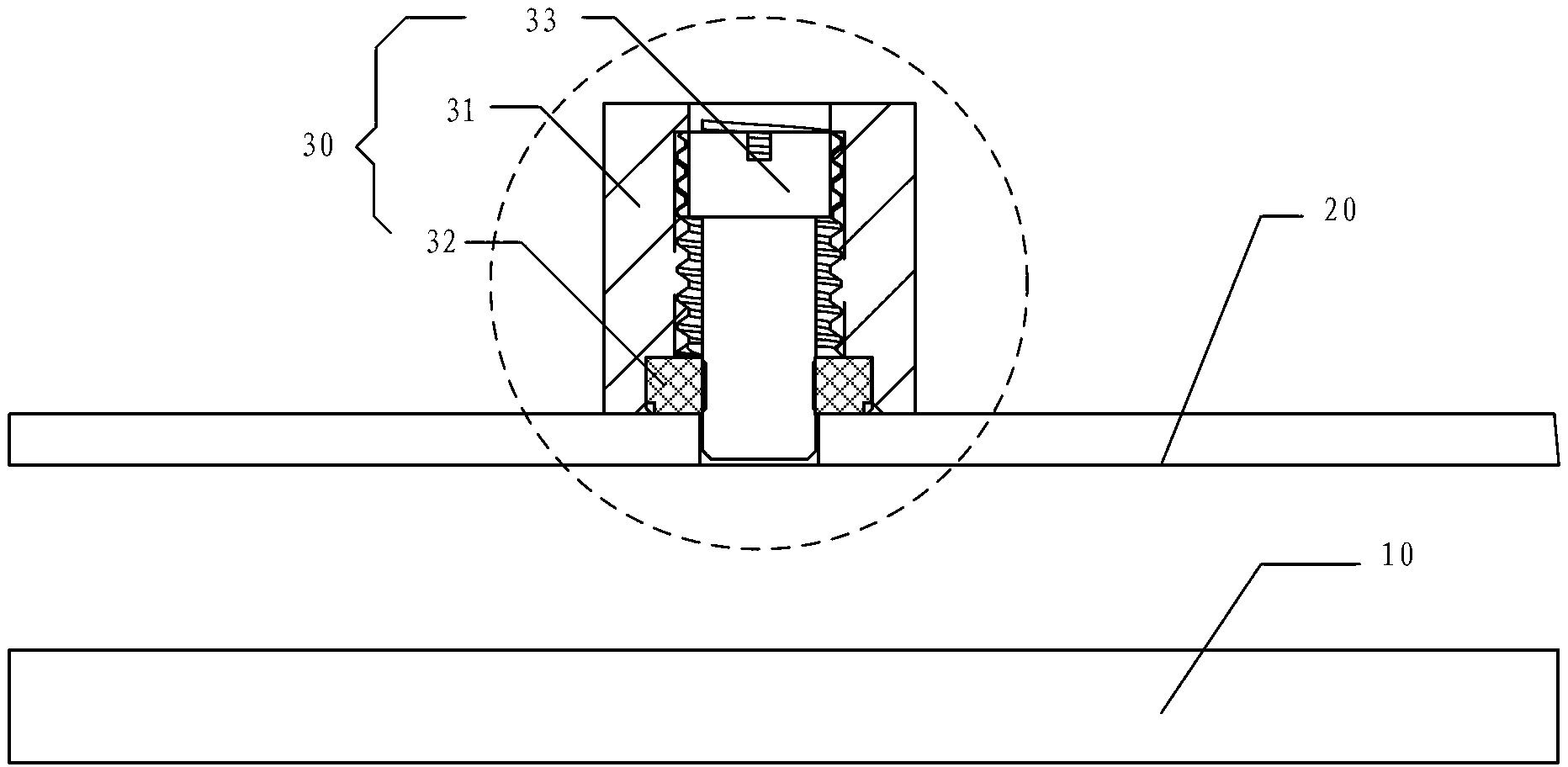

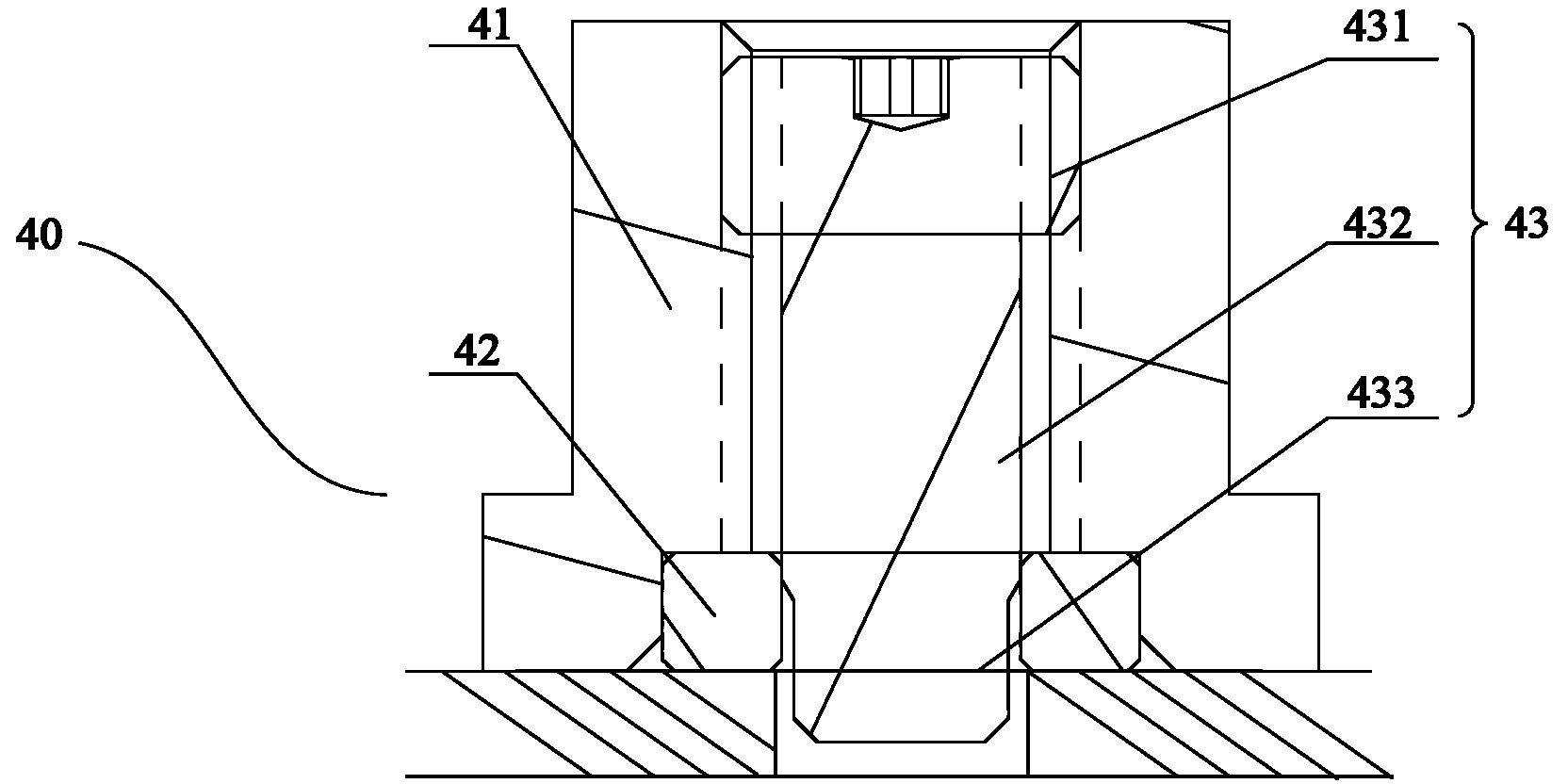

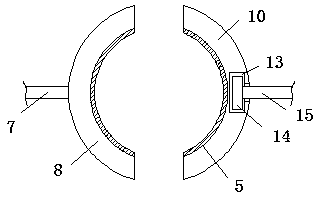

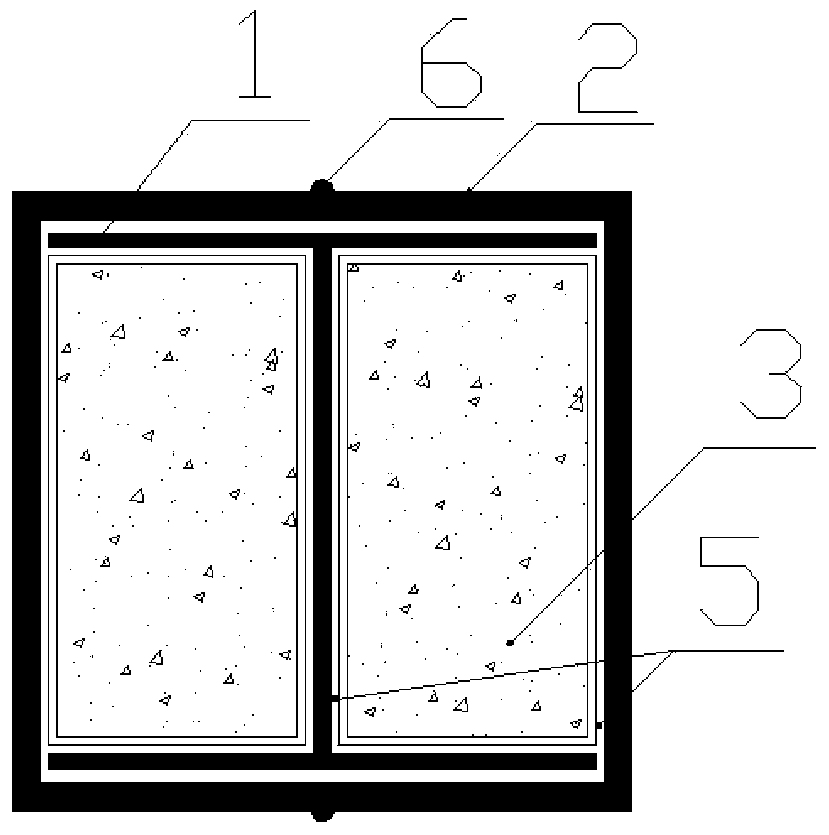

Coupling device, cavity filter and communication radio frequency equipment

ActiveCN103219573AWith limit functionShort circuit will not causeCoupling devicesInterference fitElectrical conductor

The invention discloses a coupling device, a cavity filter and communication radio frequency equipment. The coupling device comprises a signal transmission main rod and a coupling body which is used for acquiring a signal of the signal transmission main rod, wherein the coupling body is connected to a printed circuit board in parallel to the signal transmission main rod. The coupling device is characterized in that the coupling body comprises a coupling outer conductor which is connected to the printed circuit board, and a coupling inner conductor which is arranged in the coupling outer conductor, wherein one end of the coupling inner conductor is positioned in a through hole of the printed circuit board; the coupling inner conductor comprises a threaded part and is in threaded fit with the coupling outer conductor through the threaded part; an elastic fixing block is arranged between the coupling outer conductor and the coupling inner conductor; and the coupling inner conductor is in interference fit with the elastic fixing block and is fixed in the through hole of the coupling outer conductor. The coupling device can be conveniently installed, has limiting and self-locking functions, is free of short-circuit, and is high in safety.

Owner:ANHUI TATFOOK TECH CO LTD

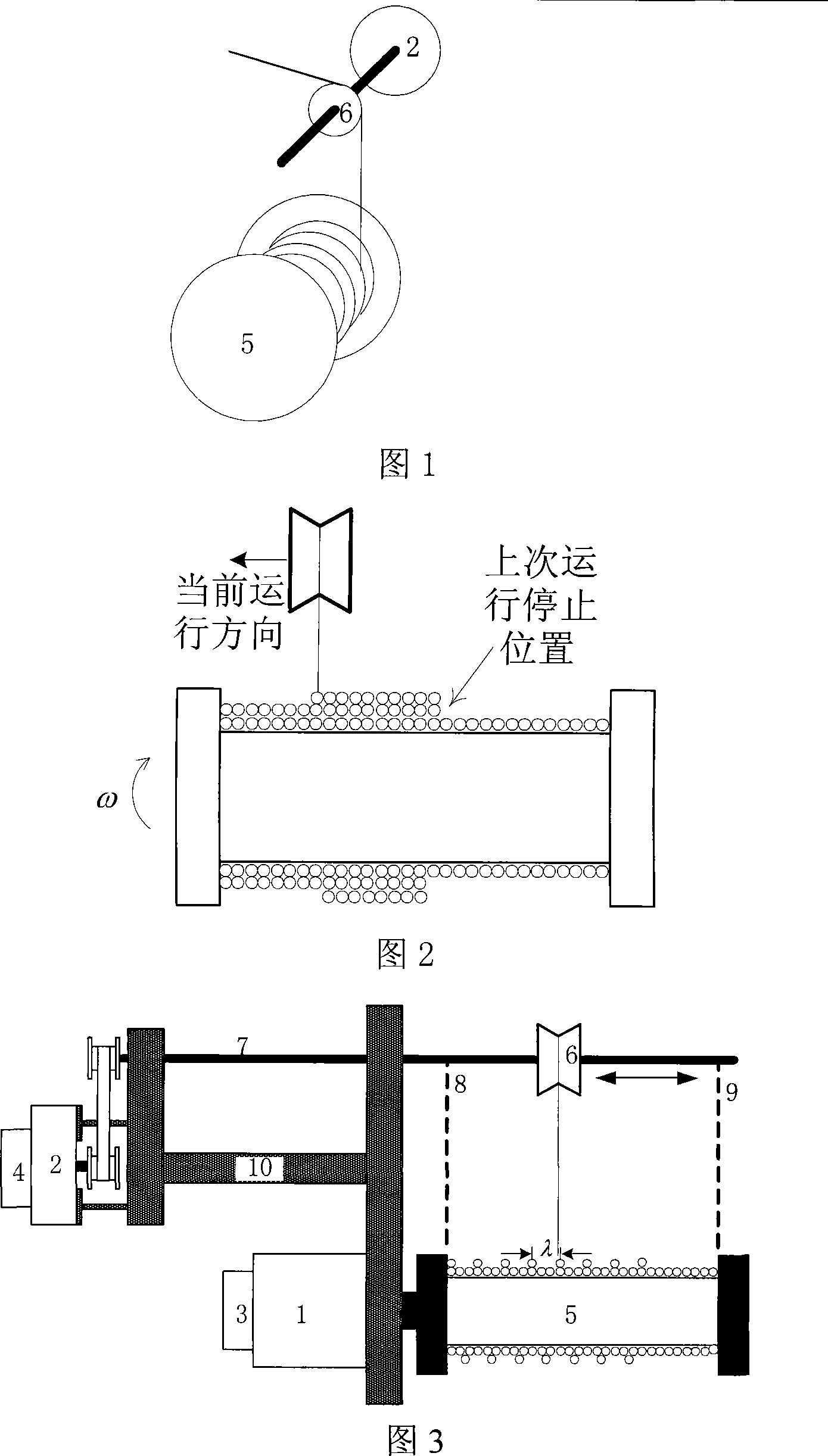

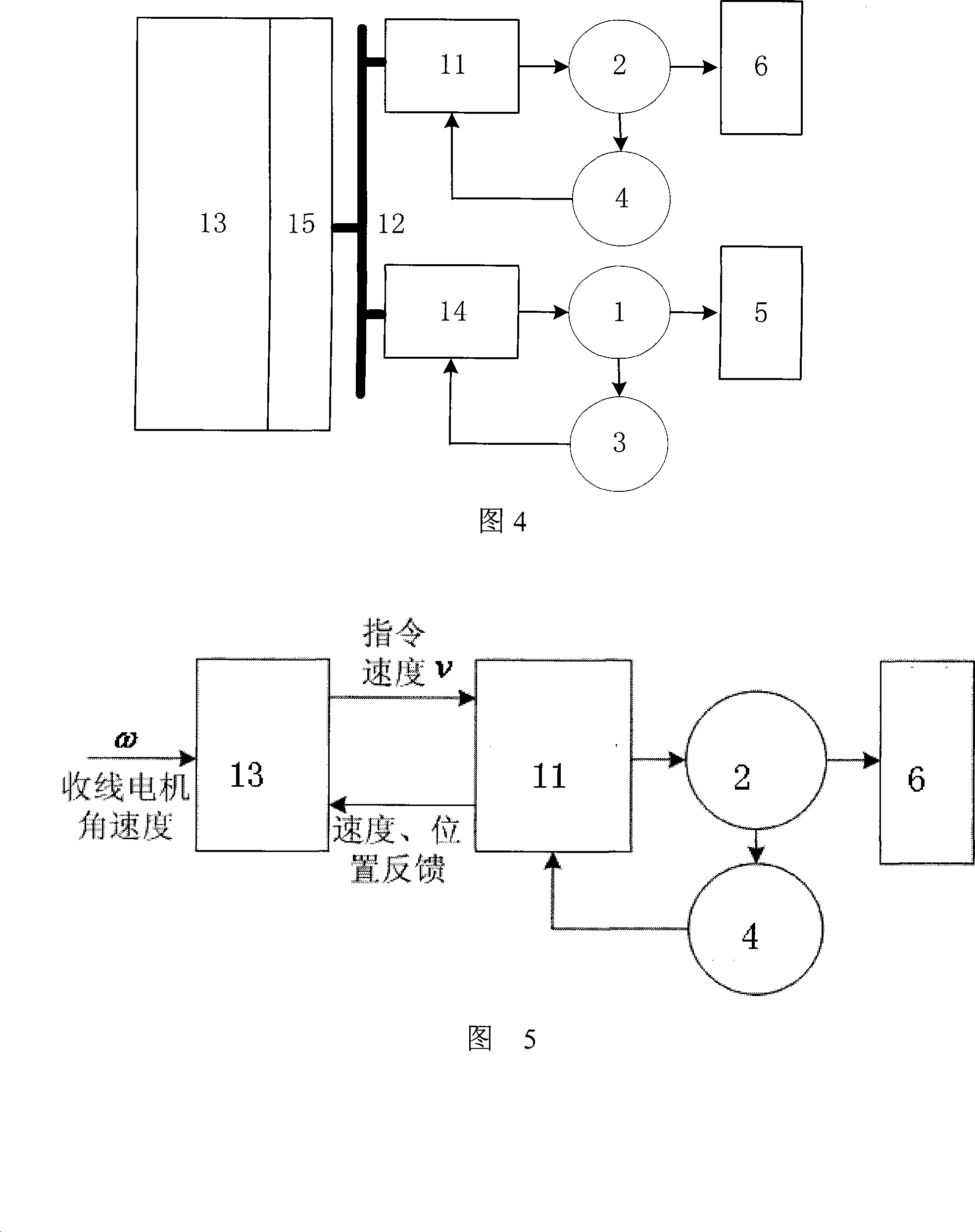

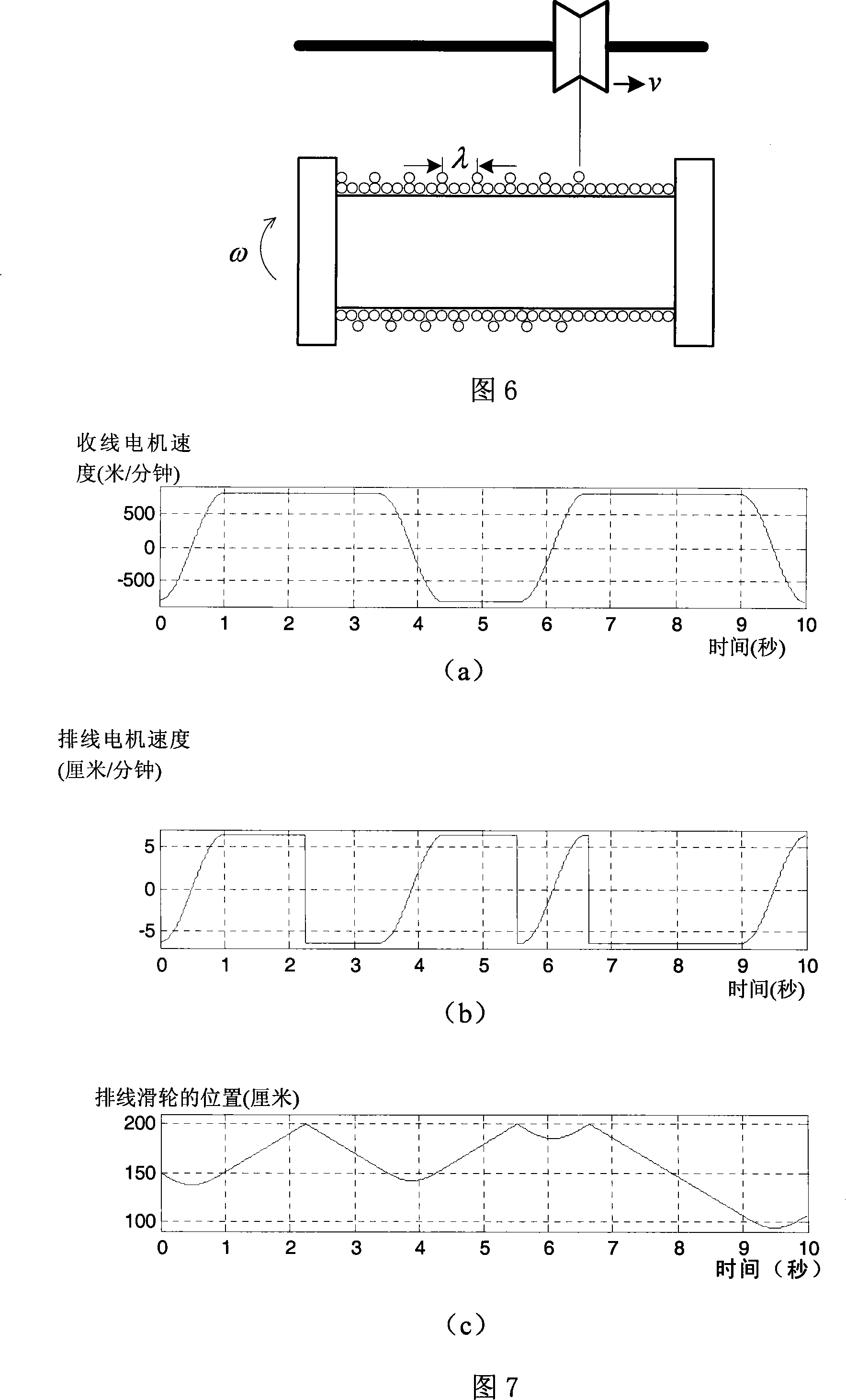

Wire arrangement control method based on servo- moto

ActiveCN101211161ARealize the limit functionLow costElectric controllersElectric machineAngular velocity

The invention discloses a wire arrangement controlling method based on an actuating motor, which comprises the following steps: using the origin of an absolute value encoder built in an wire arrangement motor as a coordinate system origin and using the deflection angle of the motor with respect to the origin as an independent variable to construct a position coordinate system of the wire arrangement motor; determining the position movement range of a wire arrangement pulley according to the positions at two sides of the inner edge of a wire-winding disc spool and real-time feeding the speed and position information of the wire arrangement motor back to a motion controller, and calculating the command speed of the wire arrangement motor in the next sampling period via the motion controller according to the speed and position information fed back from the wire arrangement motor and the angular velocity fed back from a wire-winding motor. The invention replaces a proximity switch and a variable motor with the absolute value encoder and the actuating motor, so as to remarkably improve the control precision; the spacing position can be randomly set, so as to ensure reliable performance; and the speed tracking control adopts advanced shaftless transmission technology, so that the speed control precision is high, and the wire arrangement is uniform and flat.

Owner:江苏双晶新能源科技有限公司

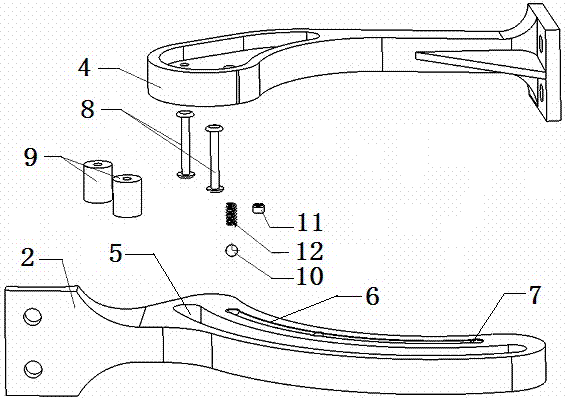

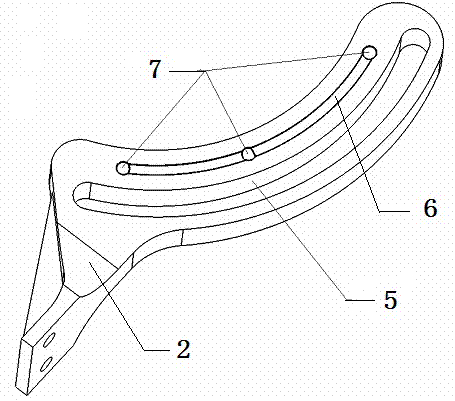

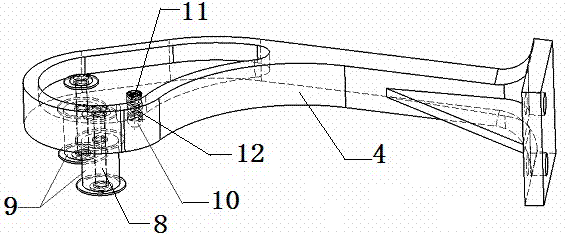

Automobile rotating door hinge

The invention discloses an automobile rotating door hinge, which comprises a fixed arm and a rotating arm, wherein the fixed arm is fixedly connected onto a door post of an automobile body; the rotating arm is fixedly connected onto the automobile body; the fixed arm is respectively provided with an arc-shaped roller guide slot and an arc-shaped limit chute; and at least two limit pits are arranged in the limit chute. The rotating arm is provided with a roller mechanism and a limit ball mechanism, wherein the roller mechanism corresponds to the roller guide slot, and the limit ball mechanism corresponds to the limit chute. The roller mechanism and the limit ball mechanism respectively do relative slip in the roller guide slot and the limit chute, and thus, the fixed arm and the rotating arm can be rotatablely and glidingly connected. According to the automobile rotating door hinge, the opening angle of the automobile door is increased to the maximum degree; the opening and closing and limit function of the automobile door is realized; the arrangement of the hinge is realized by using a smaller space, therefore, the weakening to the door post is reduced, and the strength of the door post is ensured. Castings are respectively adopted to serve as the fixed arm and the rotating arm, therefore, the cost is reduced.

Owner:SUZHOU AUTO TECH

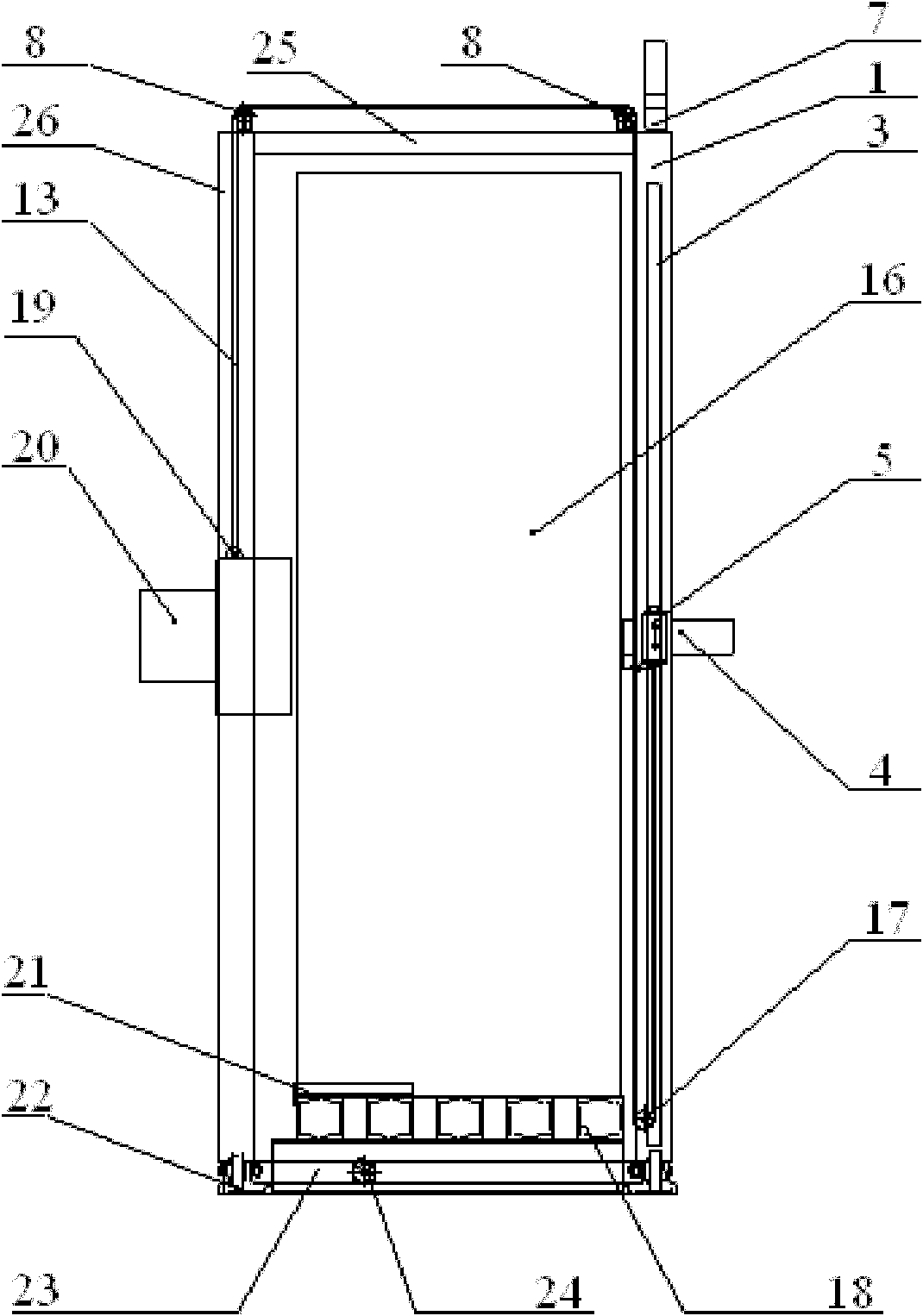

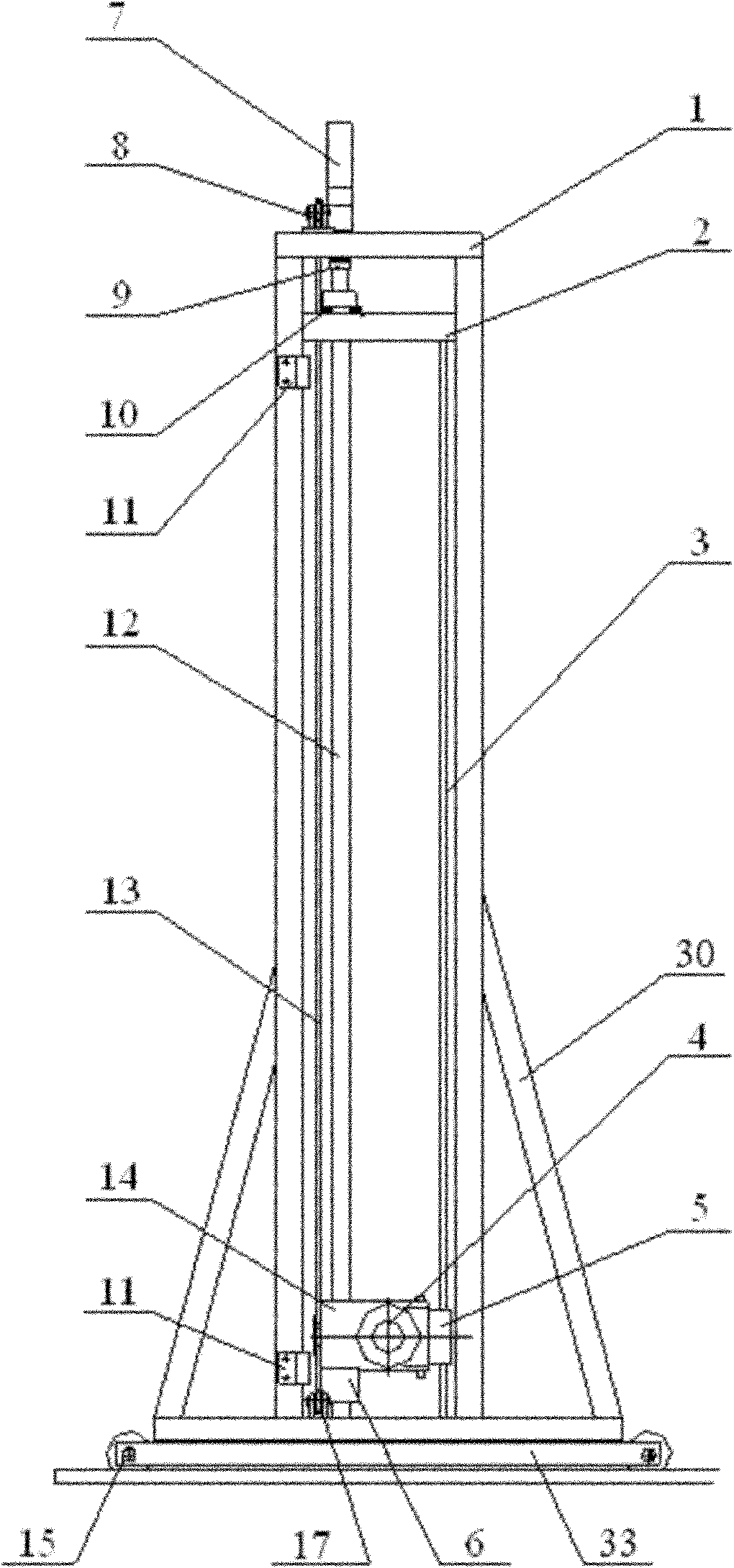

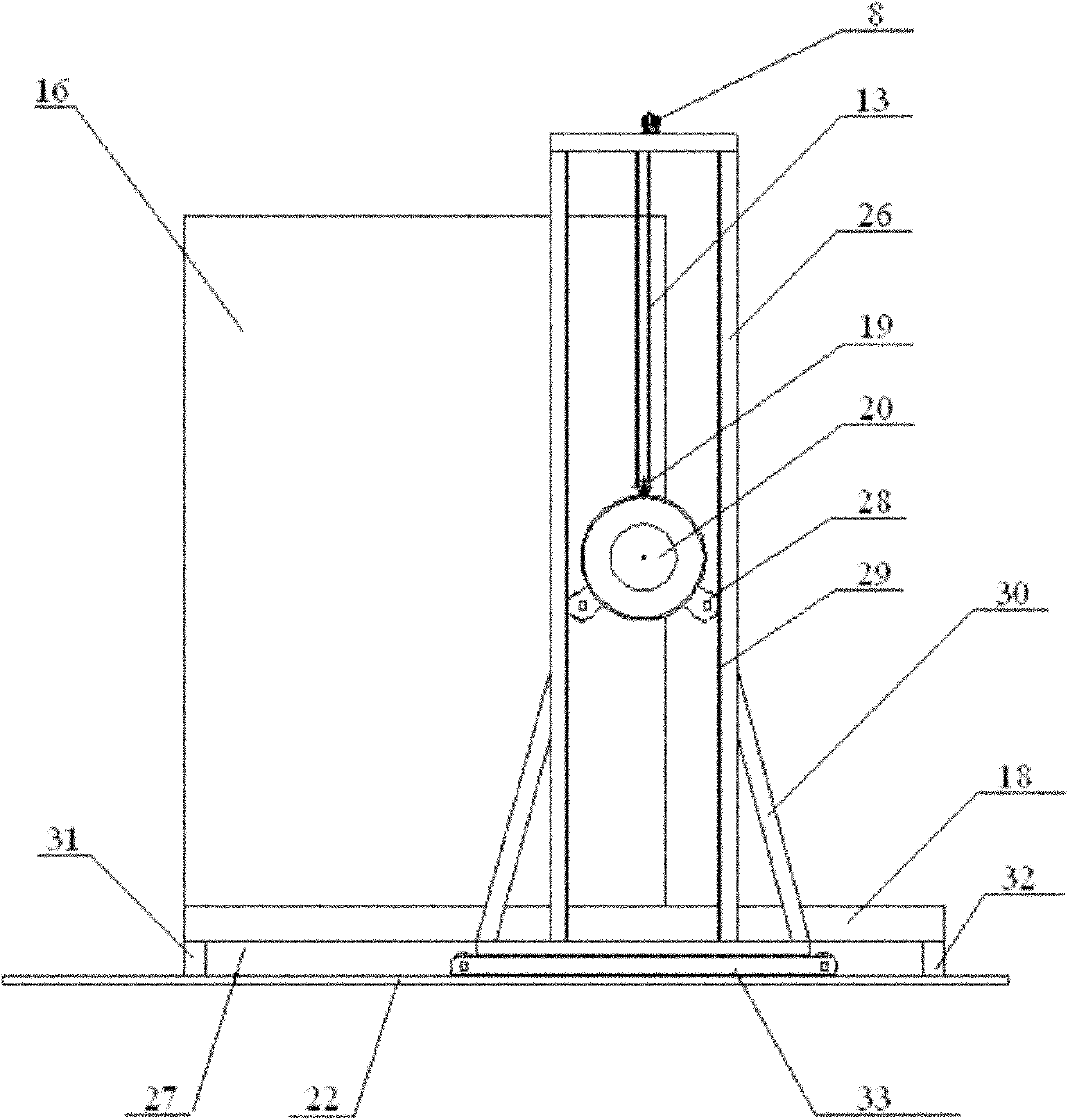

Electrical intelligent construction equipment

InactiveCN108193682ARealize the limit functionRealize the installation functionBulkheads/pilesSignsArchitectural engineeringElectric power

Owner:李猛

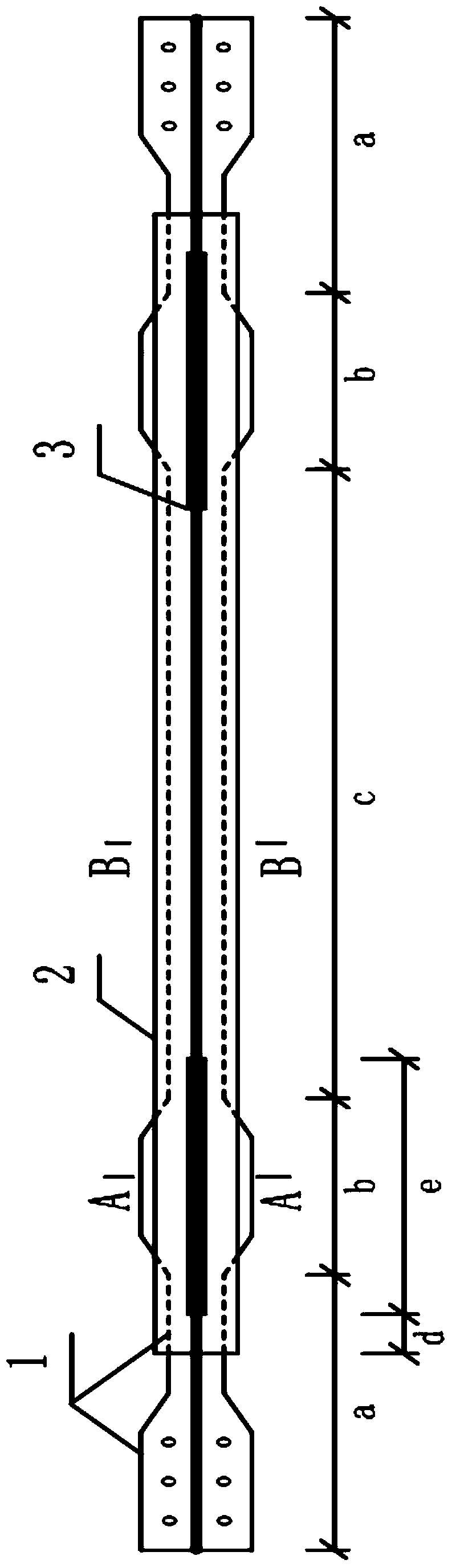

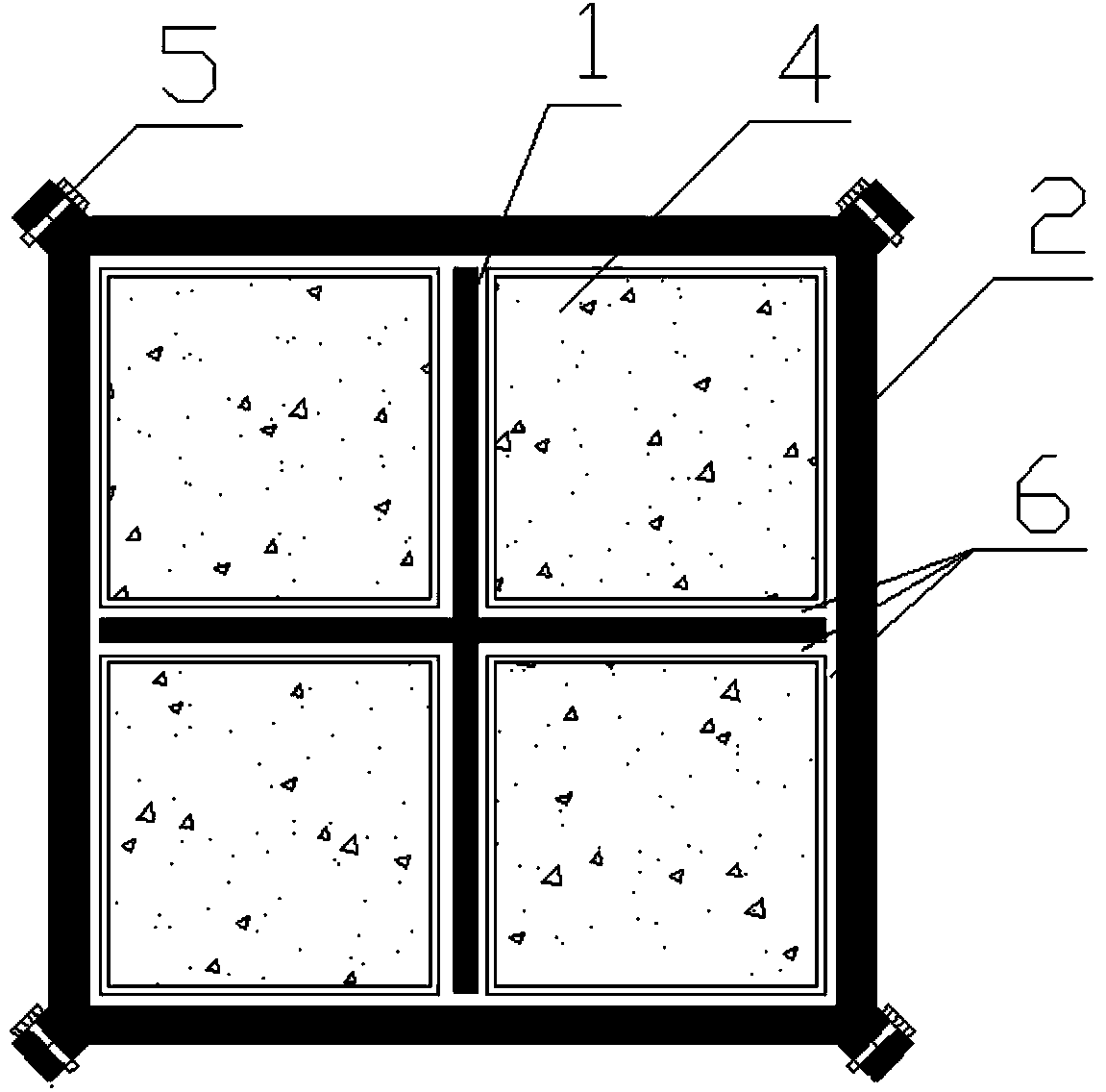

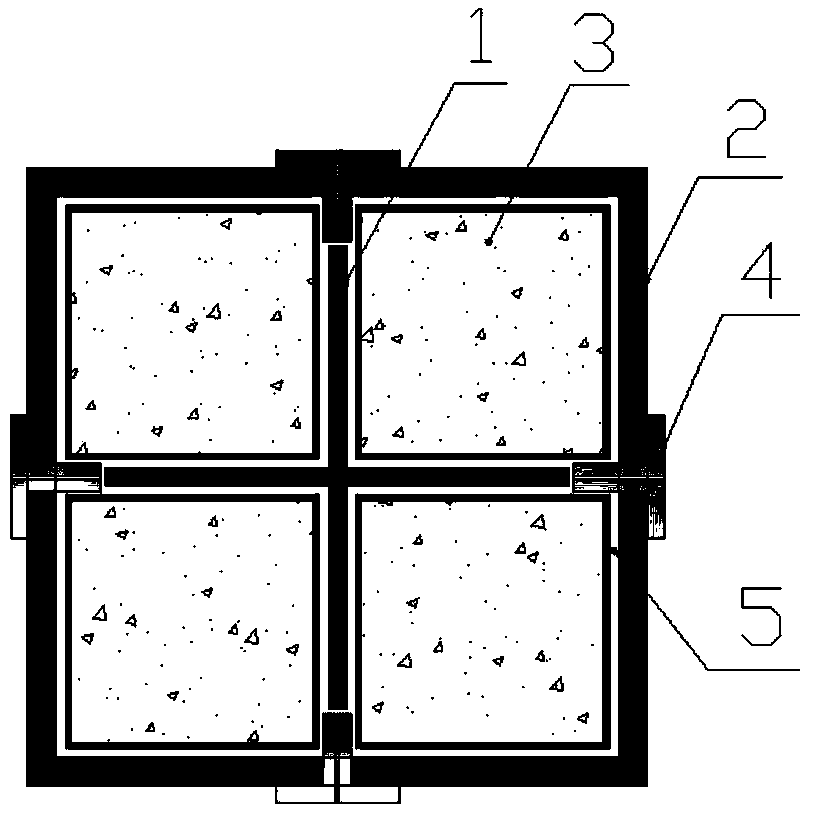

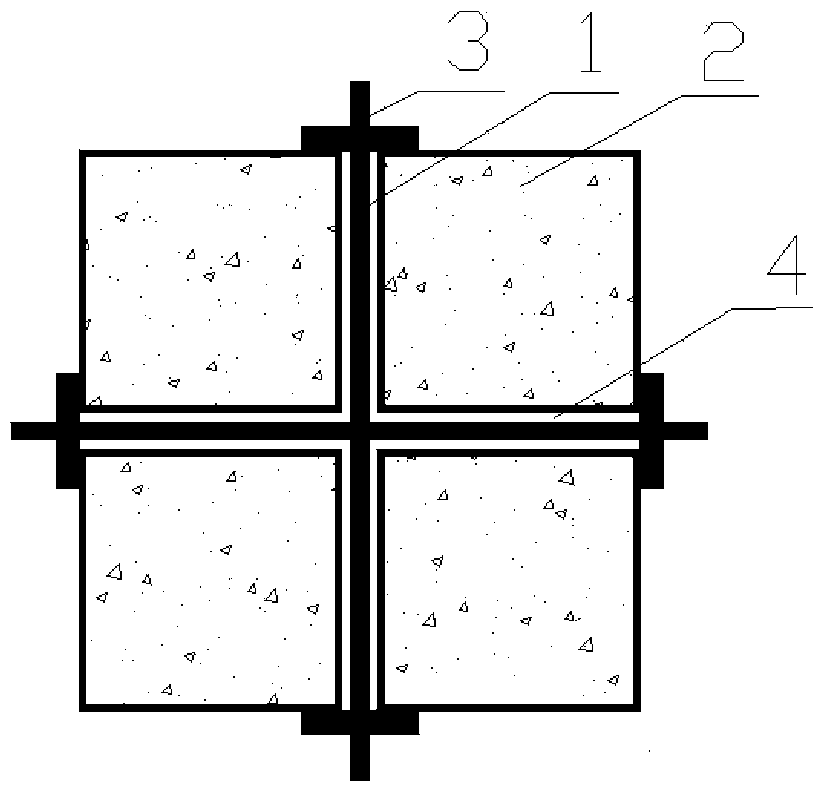

Four-steel-tube externally-attached decoration plate type cross-shaped variable-cross-section steel core energy dissipation limiting anti-buckling supporting member

InactiveCN103711224ALimited lateral movementReach the limit effectShock proofingSupporting systemChinese characters

The invention relates to a four-steel-tube externally-attached decoration plate type cross-shaped variable-cross-section steel core energy dissipation limiting anti-buckling supporting member, and belongs to the field of anti-buckling energy dissipation limiting supporting members. An outer limiting body is mainly formed by four square light-gauge steel section concrete filled steel tubes forming a shape shaped like a Chinese character 'tian', and the outer sides of the four square light-gauge steel section concrete filled steel tubes are limited by partially welding decoration plates; the welding decoration plates are not arranged on the short edge, corresponding to a cross section largened section b, of the outer limiting body, and the welding decoration plates are welded to the other edges. A steel core is located in a gap of a cross-shaped structure in the middles of the four square light-gauge steel section concrete filled steel tubes, the steel core comprises a buckling working section a, the cross section partial largened section b and a connecting section c, the position, where the decoration plates are not welded to an outer steel tube, of the cross section of the steel core is partially expanded with a 60-degree slope angle, the buckled steel core is in good connection with the outer limiting body, sliding dropping is prevented, and the limiting function is achieved through the axial stiffness of the outer limiting body. After the steel core is buckled, the axial stiffness of the outer limiting body serves as the auxiliary stiffness of a supporting system, and therefore the lateral displacement of the structure is easily limited.

Owner:BEIJING UNIV OF TECH

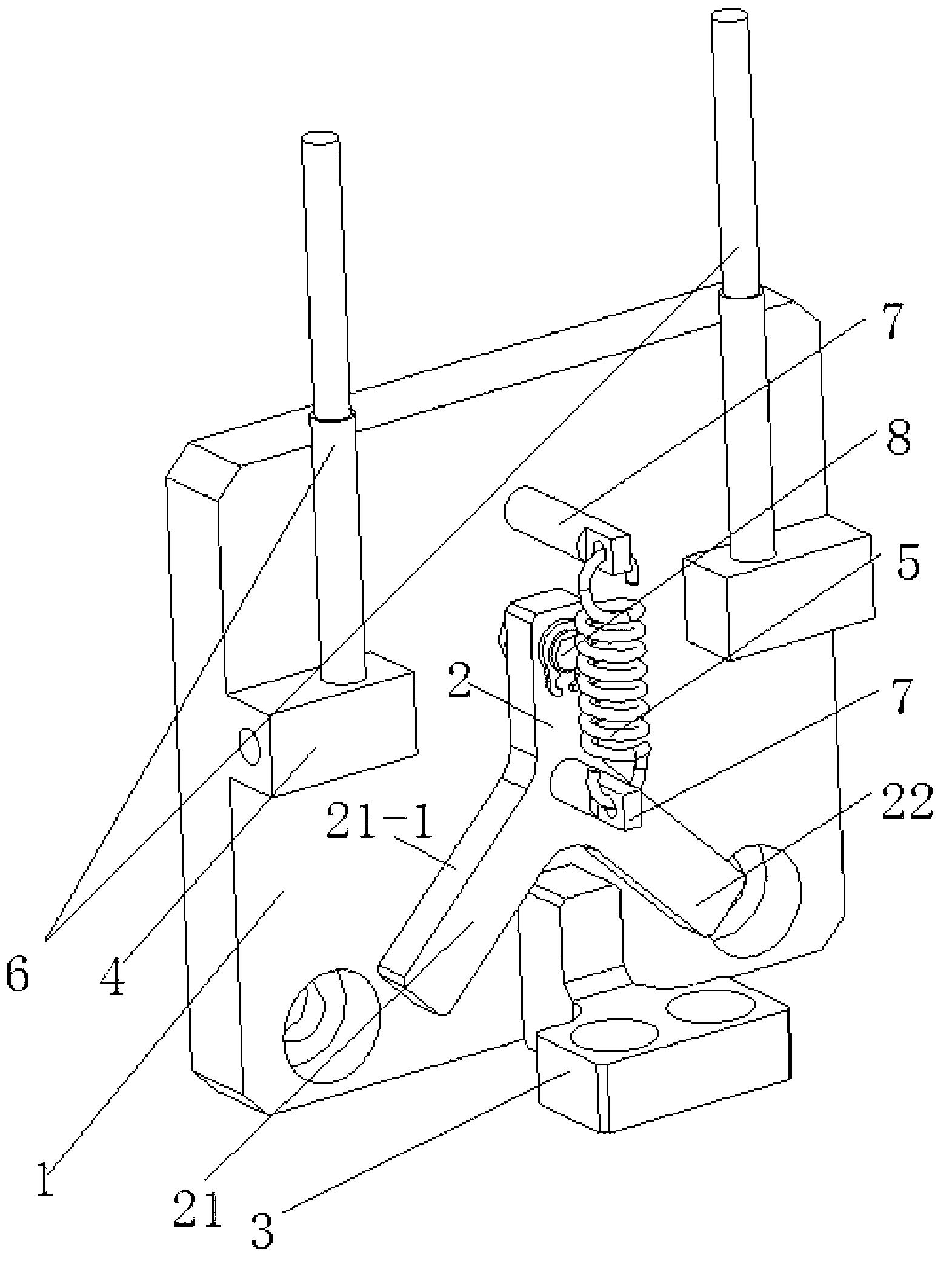

Limiting device for hopper vehicle bottom door opening and closing mechanism

PendingCN110466546APrevent the wrong rotation of the bottom door opening and closingImprove the efficiency of unloading operationsHopper carsEngineeringSpare part

Disclosed is a limiting device for a hopper vehicle bottom door opening and closing mechanism. The limiting device comprises a push rod mechanism and a limiting mechanism. The push rod mechanism comprises a push rod body capable of moving in the horizontal direction and connected with an upper transmission shaft. The limiting mechanism is used for limiting the movement range of the push rod body to limit the rotation angle of the upper transmission shaft and further to control the opening state of a bottom door conveniently. The upper transmission shaft drives the bottom door to be opened or closed through rotation, the range of movement of the push rod mechanism in the horizontal direction is limited through the limiting mechanism, and the push rod body is connected with the upper transmission shaft, so that the rotation angle of the upper transmission shaft is limited, the opening state of the bottom door is controlled, the limiting function of the opening angle of the bottom door isrealized, wrong rotation during bottom door opening and closing is avoided, requirements for controlling the unloading flow of a hopper vehicle are met, and the unloading operation efficiency of thehopper vehicle is improved. On the premise that spare parts of an original bottom door closing system are not changed, by means of the limiting device, the extra introducing and transformation of an existing hopper vehicle can be implemented, the transformation cost is low, the time is saved, the efficiency is high, and the economic efficiency is good.

Owner:CRRC TAIYUAN CO LTD

Barrier mechanism for mechanical transmission

InactiveCN111661635ARealize the limit functionAchieve a solid supportConveyor partsGear wheelEngineering

The invention discloses a barrier mechanism for mechanical transmission. The barrier mechanism comprises a barrier mechanism main body, a first driving frame is arranged on one side of the inner end of the barrier mechanism main body, a first barrier plate is connected to one end of the first driving frame in a gear meshing mode, a second barrier plate is connected to the other end position of thefirst driving frame in a gear meshing mode, and a second driving frame is connected to the side end positions of the first barrier plate and the second barrier plate in a meshing mode; the inner endof the first driving frame comprises a driving frame and a stable frame, the driving frame is rotatably connected at the central position of the first driving frame, the stable frame is fixedly connected at the side end position of the driving frame, the driving frame comprises a power shaft frame, a driven gear plate, a sleeve frame, a connecting gear plate, a pushing shaft and a fixed frame, andthe power shaft frame is arranged at the central position of the driving frame. According to the barrier mechanism for mechanical transmission, the purpose of inner end barrier is achieved through the arrangement of the first driving frame and the second driving frame.

Owner:杨发陆

Friction damper capable of achieving variable damping force output

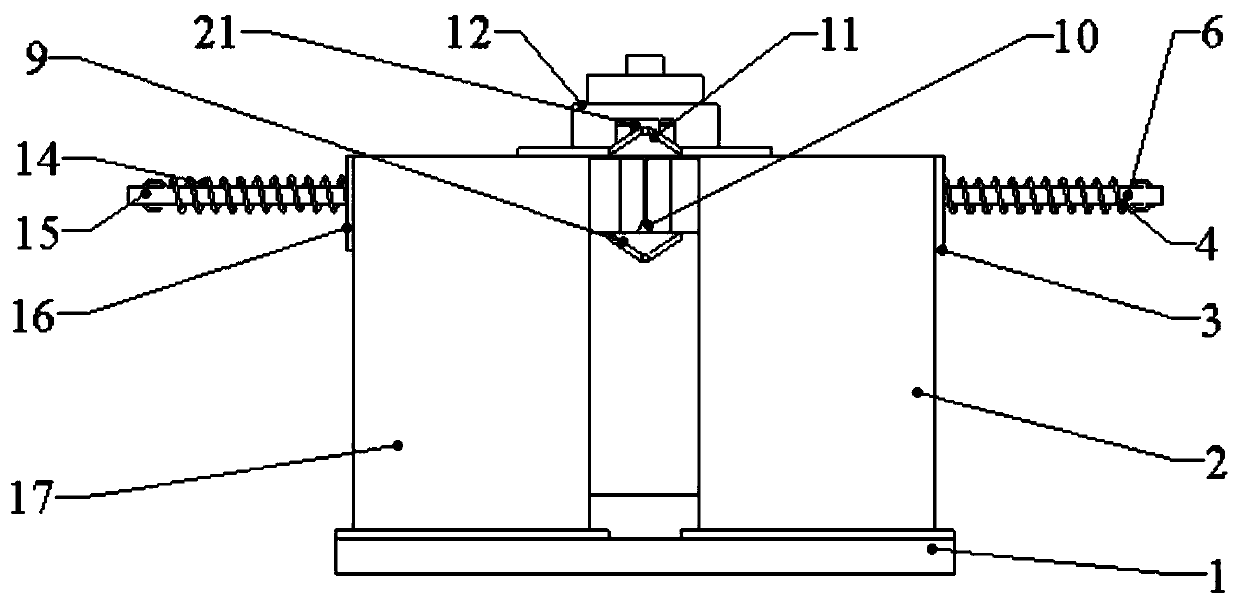

ActiveCN109826333AEven by forceEasy to realize variable damping force outputBridge structural detailsProtective buildings/sheltersSlide plateSnubber

The invention provides a friction damper capable of achieving variable damping force output, and belongs to the technical field of damping devices. The damper comprises sliding plates, friction plates, fixed plates, a core plate, a butterfly spring, pre-tightening nuts and pre-tightening bolts. The fixed plates, the sliding plates and the friction plates are all used in pairs, and are symmetrically mounted through the pre-tightening nuts and the pre-tightening bolts. The damper can generate certain damping force under the action of the pretightening force of the bolts; when the damper bears anexternal load, straight sections of the sliding plates make contact with straight sections of the fixed plates in advance and slide, and at the moment, the contact surfaces of the sliding plates andthe friction plates achieve friction energy consumption under the action of constant pressure. The characteristic that the damper outputs variable damping force along with the change of the external load can be achieved, and the damper can adapt to seismic loads under different intensities. The damper has the advantages of being symmetrical in structure, easy to install, convenient to use and capable of bearing offset loads, and the structure has a stroke limiting function.

Owner:UNIV OF SCI & TECH BEIJING

Side-feed supply device for pulsed plasma electric thruster

ActiveCN110469473AIncrease the areaIncrease ablation qualityMachines/enginesUsing plasmaElectricityEngineering

The invention discloses a side-feed supply device for a pulsed plasma electric thruster. The side-feed supply device comprises two sets of supply assemblies of symmetric structures, the supply assemblies are fixedly connected to a bottom plate of the electric thruster, the supply assemblies comprise a first supply bracket, a first tension spring, a first push rod, a first supply blocking sheet, afirst solid propellant, a second supply bracket, a second tension spring, a second push rod, a second supply blocking sheet and a second solid propellant, the opposite ends of the first solid propellant and the second solid propellant are of bevel structures which constitute a V-shaped discharge groove, an opening of the V-shaped discharge groove faces the tail end of an electrode plate, and a cone limiting table is arranged at the position, at the included angle of the V-shaped discharge groove, of the inner side of an anode plate. According to the side-feed supply device, the two solid propellants can be fed, a V shape is constituted by the ablation end faces of the propellants in a discharge room, thus the area swept by an electrical discharge arc can be increased, and the ablation quality of single pulse under the same condition is also improved.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

Loading and unloading forklift

PendingCN108017020ARealize lifting functionImplement the rotation functionLifting devicesEngineeringMechanical engineering

Owner:DONGGUAN CLIMAX SEAL TECH

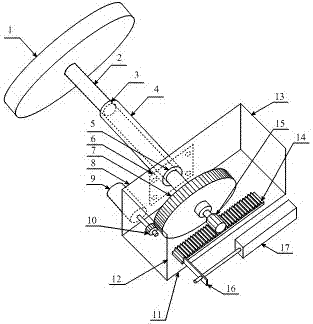

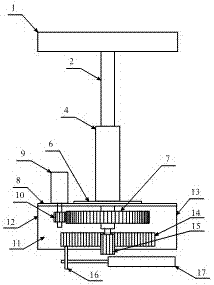

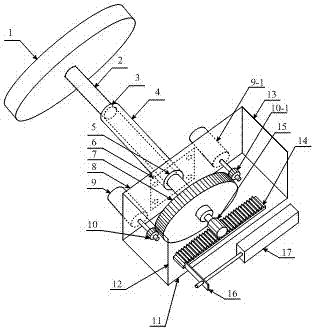

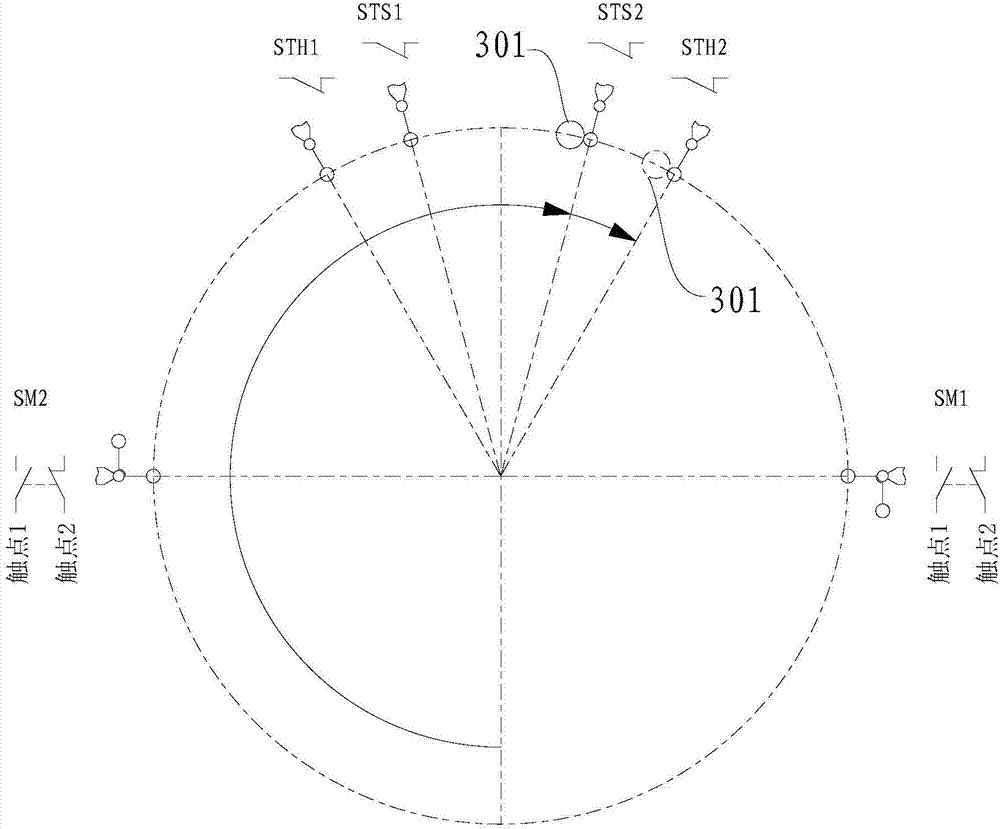

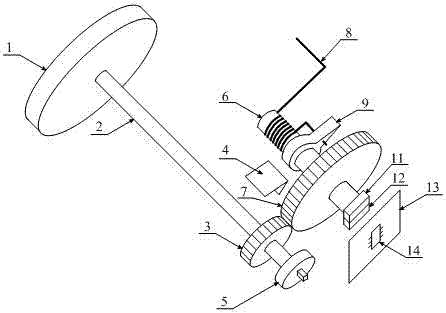

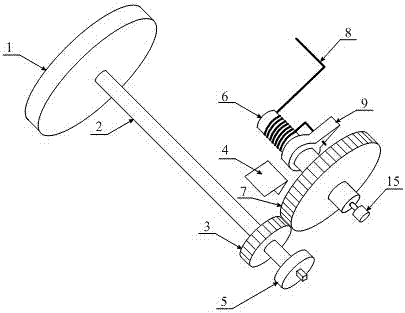

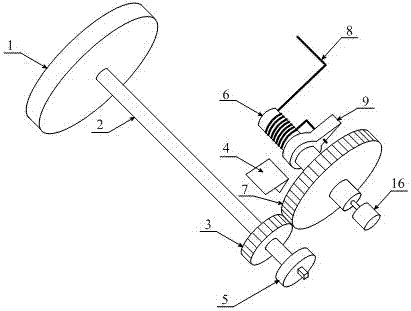

Driving simulator steering device of rack spacing and displacement measurement

InactiveCN107507487ARealize the limit functionRealize steering wheel angle measurement functionCosmonautic condition simulationsSimulatorsSteering wheelAgricultural engineering

A driving simulator steering device with rack limit and displacement measurement, which includes a steering wheel, a rotating shaft, first and second bearings, bearing sleeves, bearing sleeve fixing plates, first, second, and third gears, steering Device frame front plate, bottom plate, left side plate, right side plate, rack, sensor connector, motor, displacement sensor. The front plate, bottom plate, left side plate, and right side plate of the steering gear frame are used to form the main body of the steering gear frame, and the bearing sleeve, the bearing sleeve fixing plate and the first and second bearings are used to install the rotating shaft, and the rotating shaft is sequentially fitted with The steering wheel, the first gear, and the third gear are connected. The second gear is installed on the front shaft end of the motor and meshes with the first gear. The rack is arranged under the third gear and meshes with the third gear. One end of the rack is connected through a sensor. Connect the displacement sensor. The third gear and the rack realize the limit, the motor realizes vibration and return to alignment, and the displacement sensor is used for angle measurement.

Owner:NANCHANG MONI SOFTWARE

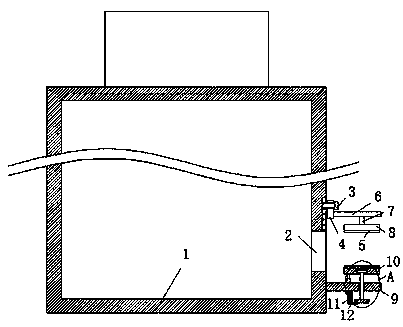

Cement bag transportation buffer machine

InactiveCN107416489ARealize the push effectRealize the limit functionLoading/unloadingConveyor partsEngineeringMechanical engineering

The invention relates to a cement bag transportation buffer machine, comprising: a transportation assembly, a pushing assembly, a horizontal pushing assembly and a downhill conveyor, the transportation assembly includes a transportation frame and several rollers, and several rollers are rotatably arranged on the surface of the transportation frame ; The pushing component is used for pushing longitudinally on the track formed by the roller, and the horizontal pushing component is used for pushing horizontally on the track formed by the roller. The downhill conveyor is arranged on one side of the second push plate and the slope bottom of the downhill conveyor communicates with the track formed by several rollers. First of all, the bagged cement is pushed horizontally to one station through the pushing component, and after each bag of cement is pushed from one station to several stations, the horizontal pushing effect is realized through the horizontal pushing component, and it is pushed to the installation equipment In the process of pushing, the position is limited by the action of the first push plate and the stop plate, and the correction is realized through the gap between the push plates on the second push plate. The process is simple, fast, and efficient. The error rate is low.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Transformer primary input lead position structure of high-voltage frequency converter

InactiveCN109510441ARealize the clamping functionInhibit sheddingPower conversion systemsTransformerEngineering

The invention discloses a transformer primary input lead position structure of a high-voltage frequency converter. The transformer primary input lead position structure comprises a cabinet body; a wire incoming hole is formed in the outer side wall of the bottom of the cabinet body; the cabinet body is connected with a first supporting column through a fixing mechanism; and the first supporting column is connected with a first clamping block through a supporting rod. According to the transformer primary input lead position structure of the high-voltage frequency converter of the invention, thefirst supporting column, a second supporting column, the supporting rod, the first clamping block, a second clamping block, a threaded rod, a first telescopic rod and a rotating block are matched with one another, so that the threaded rod can be rotated to drive the second clamping block to move toward the first clamping block, and therefore, the first clamping block and the second clamping blockcan clamp a high-voltage cable entering the wire incoming hole; a spring, a second telescopic rod, an L-shaped insertion pin, and a fixing disc are matched with one another, so that the spring pullsthe L-shaped insertion pin to be plugged into an insertion slot in the fixing disc, and therefore, the limiting function of the threaded rod is realized.

Owner:山东迈易特传动有限公司

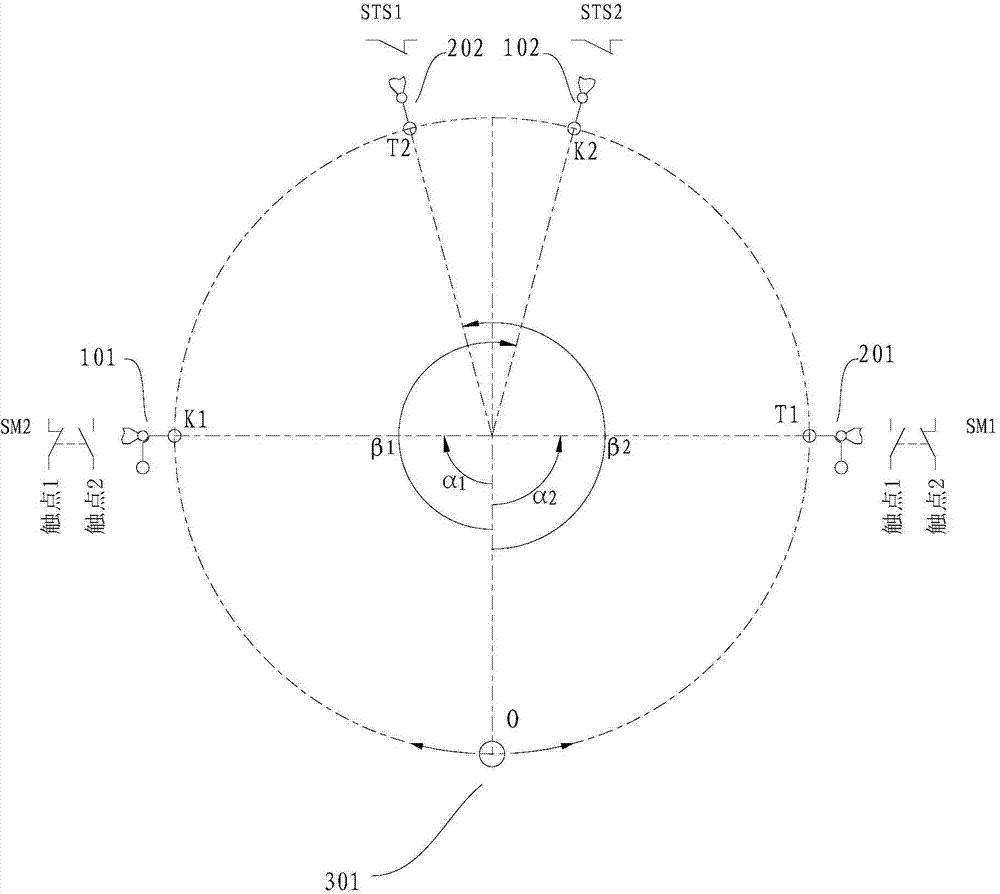

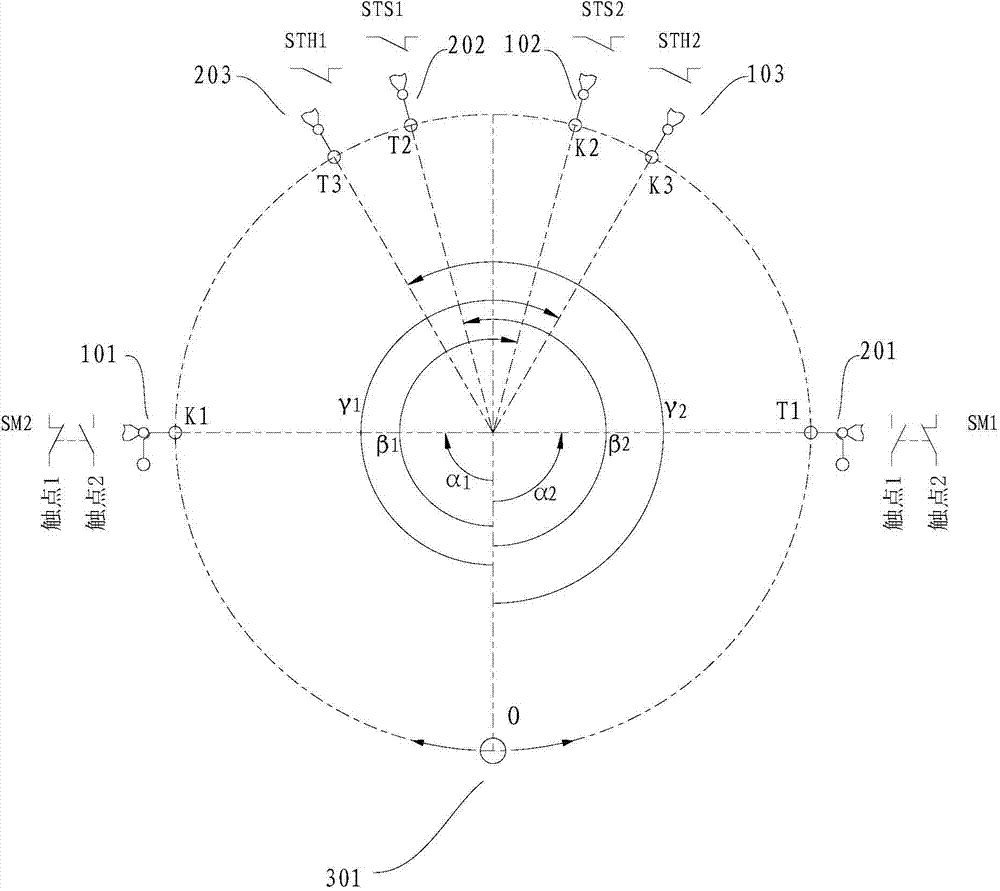

Rotating member limiting device used for medical equipment and medical equipment comprising same

ActiveCN103536307AAvoid excessive rotation in one directionReliable limitComputerised tomographsTomographyEngineeringMedical equipment

The invention discloses a rotating member limiting device used for medical equipment and the medical equipment comprising the same. The rotating member limiting device comprises a machine frame, a rotating member, a first clockwise switch, a second clockwise switch, a first anticlockwise switch, a second anticlockwise switch and a controller. The rotating member is rotationally arranged on the machine frame and is provided with a triggering part, the first clockwise switch and the second clockwise switch are fixed on the first clockwise position and the second clockwise position of the machine frame respectively, the first anticlockwise switch and the second anticlockwise switch are fixed on the first anticlockwise position and the second anticlockwise position of the machine frame respectively, the first clockwise position corresponds to the position where a triggering pin clockwise rotates the angle alpha1 from the zero position, the second clockwise position corresponds to the position where the triggering pin clockwise rotates the angle beta1 from the zero position, the first anticlockwise position corresponds to the position where the triggering pin anticlockwise rotates the angle alpha2 from the zero position, and the second anticlockwise position corresponds to the position where the triggering pin anticlockwise rotates the angle beta2 from the zero position of the triggering pin, and the controller is used for controlling the rotating member. The rotating member limiting device has reliable electrical limitation, can achieve double-direction limitation of the rotating member, and is reliable in limitation.

Owner:BEIJING NOVEL MEDICAL EQUIP LTD

Car driving simulator steering device straightened using single spring

InactiveCN107346623ASimple structureLow costCosmonautic condition simulationsSimulatorsTurn angleSteering wheel

The invention provides a steering device for a car driving simulator with a single spring returning to normal, which comprises a steering wheel, a first rotating shaft, a first gear, a triangular limit block, a rotating damper, a second rotating shaft, a second gear, a spring , Triangular limit knob, angle measurement sensor. The invention can realize the functions of position limiting, centering and rotation angle measurement of the steering wheel. The rotary damper is used to reduce the speed of the steering wheel returning to the center, so as to obtain a better steering wheel feel and more safety. A spring is used to return the steering wheel, and the return effect is good, the structure is simple, and the cost is low. The spring is sleeved on one end of the second rotating shaft, which is convenient for disassembly and replacement. The angle measurement sensor can use a Hall angle sensor, a potentiometer, a photoelectric encoder, an angular displacement sensor, etc., to measure the steering wheel angle. The limit knob and the limit block are used to realize the limit function of the steering wheel, and a triangular structure is adopted, the contact area is large, and the limit block is not easy to be damaged.

Owner:NANCHANG MONI SOFTWARE

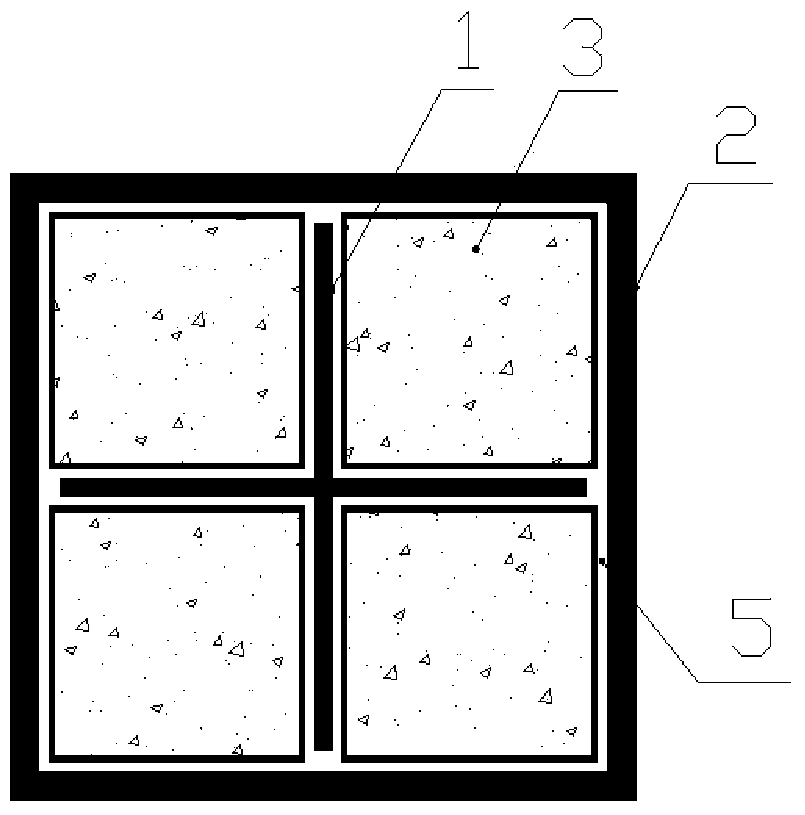

Box iron grooving type linear variable-cross-section steel core buckling-prevention limiting and energy-consumption supporting component

InactiveCN103711218ALimited lateral movementAxial rigidity fully utilizedShock proofingSquare cross sectionSlope angle

The invention discloses a box iron grooving type linear variable-cross-section steel core buckling-prevention limiting and energy-consumption supporting component and belongs to the technical field of buckling-prevention limiting and energy-consumption supporting components. Connection segments, cross section local enlarging sections and a buckling working section are sequentially arranged from the two ends of a linear steel core to the middle of the linear steel core. The buckling working section is located between the two cross section local enlarging sections, and the cross section local enlarging sections are close to the two ends of an outer constraint steel pipe respectively and extend out of the constraint steel pipe through limiting grooves. According to the outer constraint steel pipe, a square cross section is formed by welding box iron of two grooves in a butted mode, and positions, corresponding to the cross section local enlarging sections of the linear steel core, are provided with limiting grooves. The length of the limiting grooves is slightly larger than the length of the cross section local enlarging sections, and the two ends of the cross section local enlarging sections locally enlarge the cross section with the slope angles of 60 degrees till the cross section penetrates out of the limiting grooves, the steel core can be well connected with the outer constraint steel pipe after being pulled, pressed and buckled, the axial rigidity of the outer constraint steel pipe is used for achieving the limiting function. The limiting and energy-consumption supporting component can be widely applied to energy dissipation, seismic reduction and limiting control of buildings.

Owner:BEIJING UNIV OF TECH

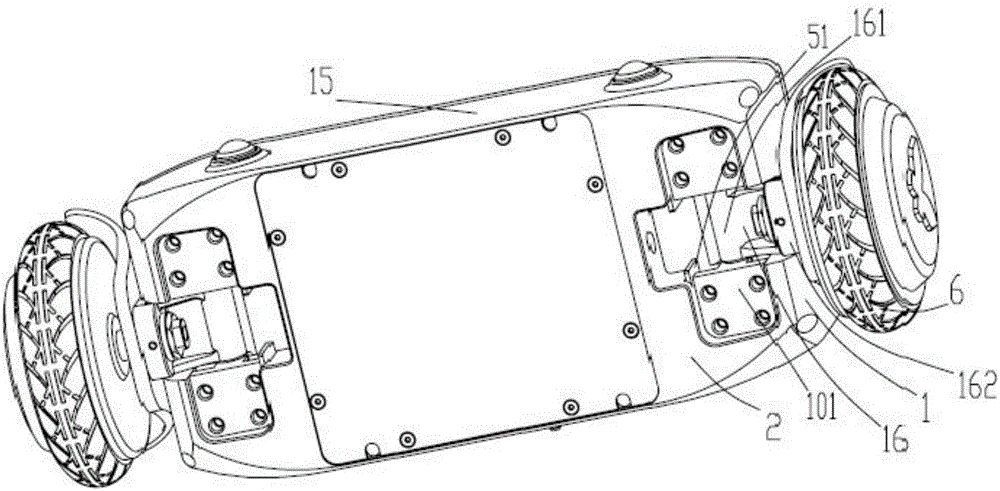

Intelligent balancing vehicle

InactiveCN106741412AAvoid interferenceEasy to placeFoldable cyclesBicyclesMechanical engineeringEngineering

Owner:CHANGZHOU MOBEN INTELLIGENT TECH

Box iron grooving type H-shaped variable-cross-section steel core buckling-prevention limiting and energy-consumption supporting component

InactiveCN103711221AAxial rigidity fully utilizedLimited lateral movementShock proofingSlope angleEngineering

The invention discloses a box iron grooving type H-shaped variable-cross-section steel core buckling-prevention limiting and energy-consumption supporting component and belongs to the technical field of buckling-prevention limiting and energy-consumption supporting components. Connection segments a, cross section local enlarging sections b and a buckling working section c are sequentially arranged from the two ends of a steel core to the middle of the steel core. The buckling working section c is located between the two cross section local enlarging sections b, and four wing positions, corresponding to the cross section local enlarging sections b of the H-shaped steel core, of an outer constraint steel pipe are provided with limiting grooves. The length of the limiting grooves is slightly larger than the length of the cross section local enlarging sections b, and four wings of the cross section local enlarging sections b extend out of the outer constraint steel pipe through the limiting grooves, the cross section of the H-shaped steel core is locally enlarged at the limiting grooves with the slope angle of 60 degrees till the cross section penetrates out of the limiting grooves of the outer constraint steel pipe. In the early stage of load bearing, the variable-cross-section steel core consumes energy and buckles, when deformation reaches the constrained point of the limiting grooves, the outer constraint steel pipe and the buckled steel core commonly provide axial rigidity, the constraint structure is integrally deformed, and the function of limiting displacement is achieved.

Owner:BEIJING UNIV OF TECH

D-shaped pipe molding device

ActiveCN104259235ASimple structureEasy to operateExtrusion profiling toolsEngineeringRefrigerated temperature

The invention provides a D-shaped pipe molding device. The D-shaped pipe molding device comprises a fixed part and a movable part, wherein the fixed part comprises a fixed frame and a fixed piece; the fixed piece is fixed in the fixed frame and the side wall of the fixed piece is provided with a semicircular containing groove; a circular pipe can be contained in the semicircular containing groove; the movable part comprises a movable frame and a movable piece; the movable piece is fixed in the movable frame; the movable part is arranged in the fixed frame of the fixed part and can move relative to the fixed frame; the semicircular containing groove is formed in one side close to the movable piece of the fixed piece; and when the movable part gets close to the fixed piece of the fixed part, the movable piece can extrude the circular pipe on the fixed piece so that the circular pipe in the semicircular containing groove is extruded into a D-shaped pipe. With the adoption of the technical scheme, the D-shaped pipe molding can be realized rapidly and simply; and the D-shaped pipe is applied to a refrigerator so that the energy is saved and the consumption is reduced.

Owner:HEFEI HUALING CO LTD +1

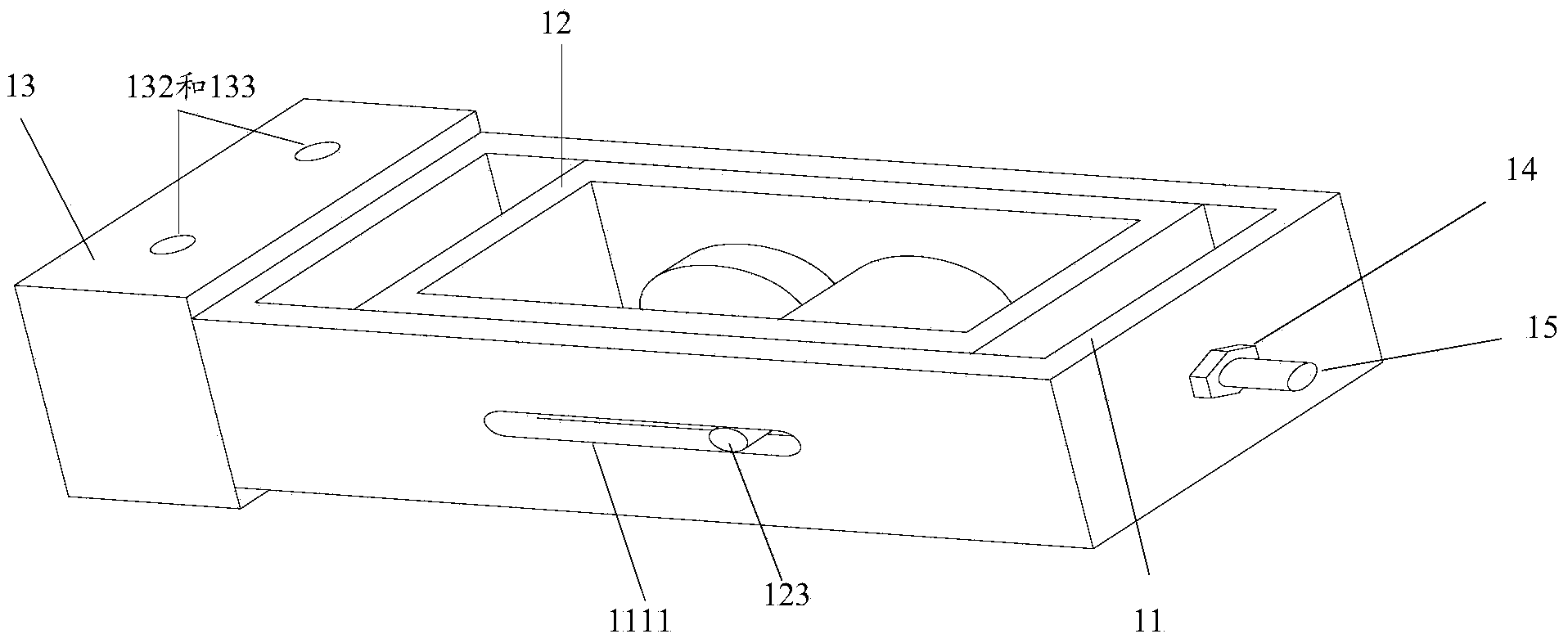

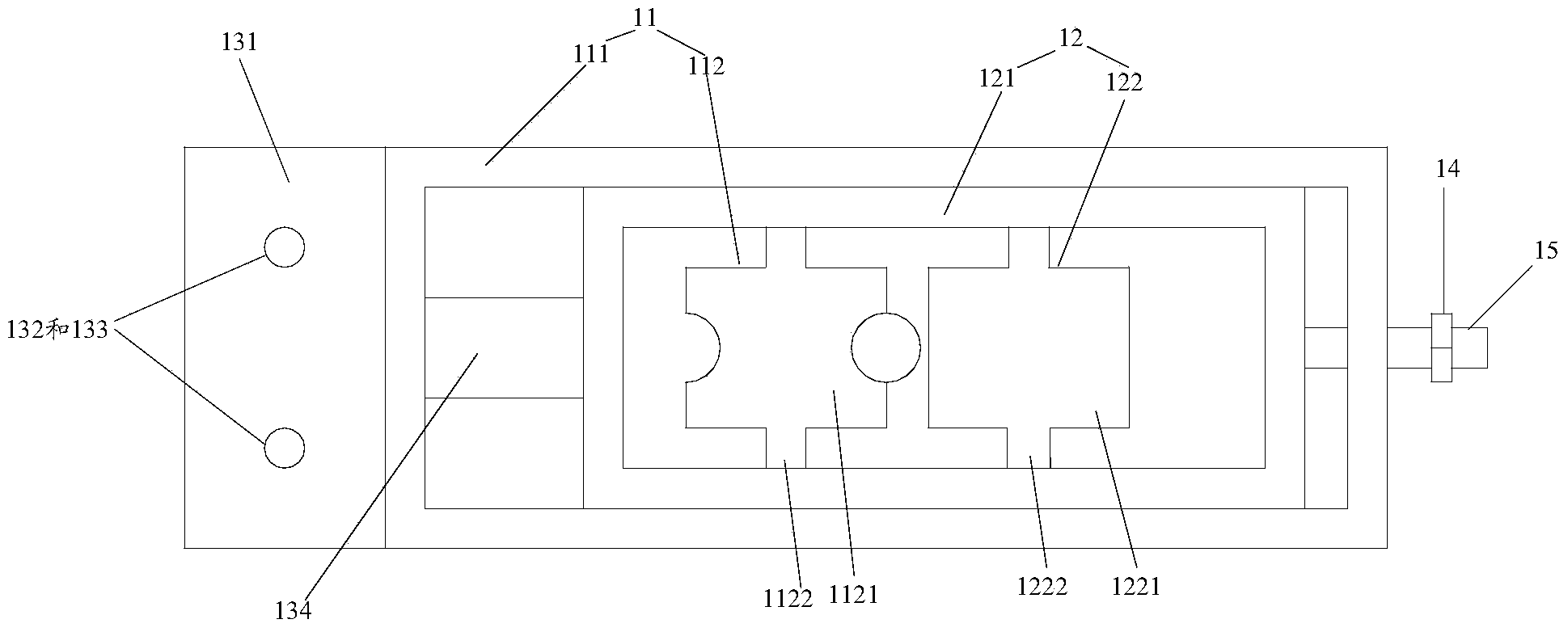

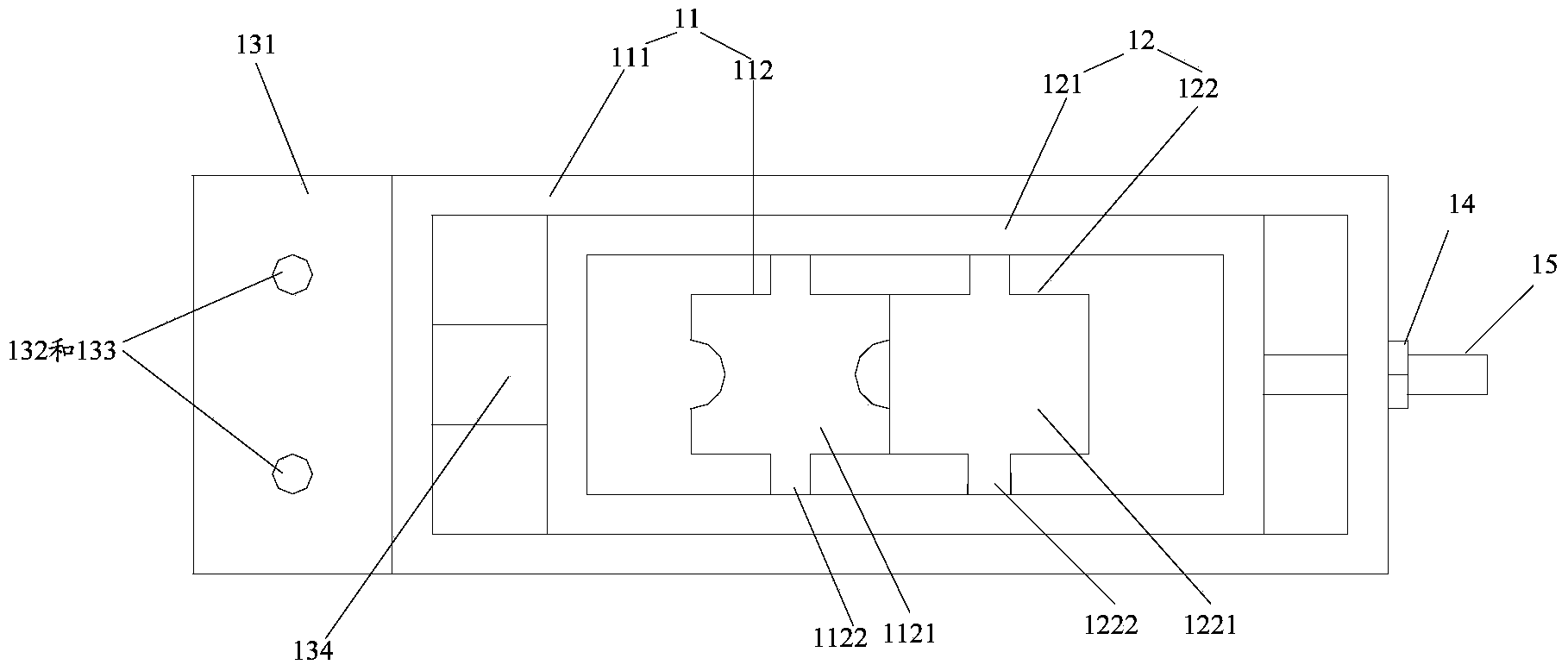

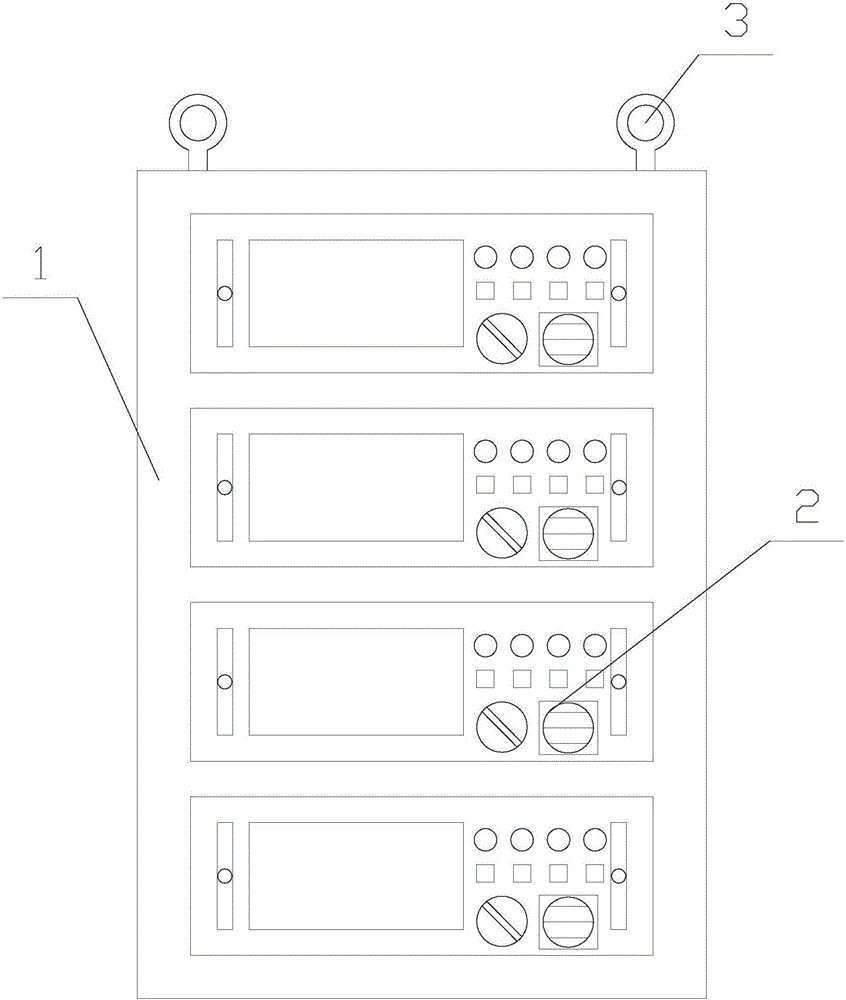

Intelligent drawer cabinet for power system

ActiveCN106025860AImprove accuracyGuaranteed stabilitySwitchgear with withdrawable carriageSubstation/switching arrangement cooling/ventilationElectric power systemDrive motor

The invention relates to an intelligent drawer cabinet for a power system. The intelligent drawer cabinet comprises a cabinet body, the front surface of the cabinet body is provided with a plurality of drawer cabinet units, and the side surface of the cabinet body is provided with a plurality of thermovents. According to the intelligent drawer cabinet for the power system, sleeves are enabled to be moved outside grooves through rotation of driving motors in fixation units, projecting parts are formed on rollers, the rollers are prevented from movement, accordingly, drawer boxes are fixed, a limiting function is realized, besides, in a digital temperature measurement circuit, through transmission of analog signals in the form of digital signals, the stability and the reliability of signal transmission are ensured, and the interference immunity of temperature measurement and the accuracy of a measurement result are improved.

Owner:广东稳峰电力科技有限公司

Fixing platform for bicycles

InactiveCN106425262AImprove welding qualityEasy flat welding operationWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

The invention provides a fixing platform for bicycles. The fixing platform comprises an operation platform, wherein a bracket is fixedly arranged in the position, close to the edge part, of the upper end face of the operation platform; a mounting shaft is arranged on the bracket; a top plate is arranged on the mounting shaft in a sleeving manner; the top plate performs rotation motion, with the mounting shaft adopted as the center line; guide blocks are symmetrically arranged in the positions, on one side of the top plate, in the operation platform, with the geometric center line of the operation platform adopted as the symmetry axis; a base plate is arranged between the symmetrically distributed guide blocks; limiting rods are further arranged on the base plate parallel to the guide blocks; the limiting rods and the operation platform are connected in a sliding manner; and the limiting rods comprise locating blocks used for limiting positions of the limiting rods. The fixing platform has the beneficial effects that two to-be-welded bicycle steel pipes are successfully subjected to butt joint through the arranged guide blocks, the two to-be-welded bicycle steel pipes are reinforced through the arranged limiting rods, and the problem that a weld joint is increased due to shaking during the welding process is avoided; and in the design, through well limiting the steel pipes, the flat welding quality is greatly improved.

Owner:天津瑞阳运动器材有限公司

Short-section bar feeding mechanism

ActiveCN106002443AAvoid manual adjustmentRealize the limit functionConveyorsMetal working apparatusMechanical engineeringEngineering

The invention discloses a short-section bar feeding mechanism. The mechanism comprises a base, a rack, a driving device, a pushing plate assembly, a fixed plate assembly and a feeding plate arranged in an inclined manner, wherein the rack, the driving device, the pushing plate assembly and the fixed plate assembly are located on the base; and the driving device is fixed to the base, the driving device and the feeding plate are located on the two sides of the pushing plate assembly, and the driving device is used for pushing the pushing plate assembly to move in a reciprocating manner between the first position and the second position. According to the short-section bar feeding mechanism, short-section bars can be conveyed in a unified posture, and the feeding efficiency is improved.

Owner:西安博大感应科技有限公司

Nondestructive inspection equipment of casting

ActiveCN102565094APrevent overreachingHigh precisionMaterial analysis using wave/particle radiationEngineeringNondestructive testing

The invention belongs to the technical field of industrial nondestructive inspection, and more particularly relates to nondestructive inspection equipment of a casting. The nondestructive inspect equipment comprises a gantry assembly, a Y-direction lifting assembly, a probe shielding assembly, a source application assembly, pulley assemblies, an underframe assembly and an X-direction moving assembly, wherein the gantry assembly comprises a right gantry frame and a left gantry frame; the source application assembly and a ray receiving assembly are respectively arranged on the right gantry frame and the left gantry frame; the pulley assemblies are respectively arranged on the right gantry assembly and the left gantry assembly of the gantry assembly; the X-direction moving assembly which is used for horizontally moving the gantry assembly is arranged below the gantry assembly; and the underframe assembly is erected above the X-direction moving assembly and used for supporting a casting subjected to flaw detection. The nondestructive inspection equipment disclosed by the invention solves the technical problem that the ultra-thick casting cannot subjected to flaw detection and achieves the technical effect of carrying out nondestructive flaw detection on the ultra-thick casting.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com