Loading and unloading forklift

A forklift and material fork technology, applied in the field of loading and unloading forklifts, can solve the problems of inability to adjust the angle, material weight, troublesome handling and loading and unloading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

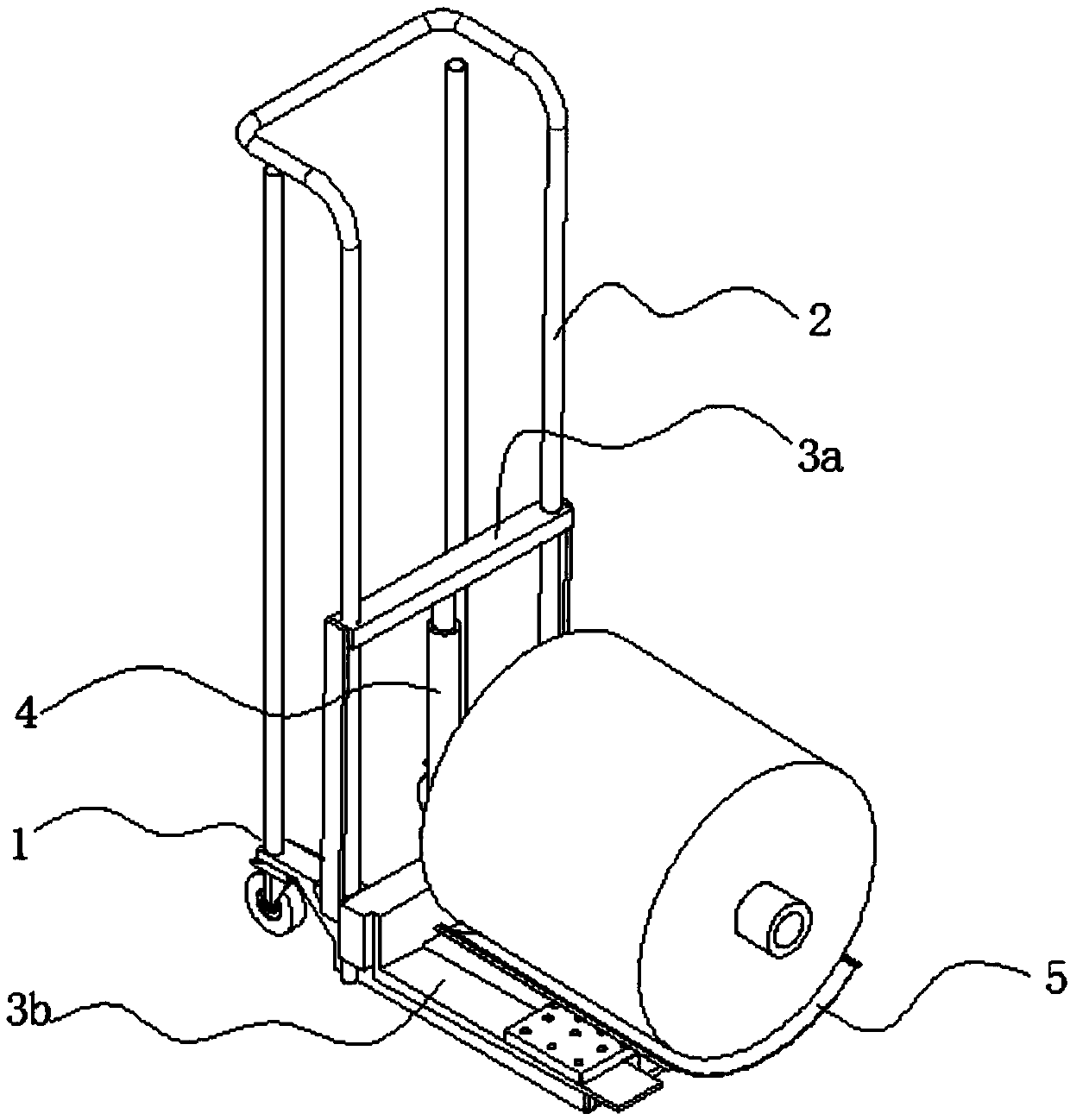

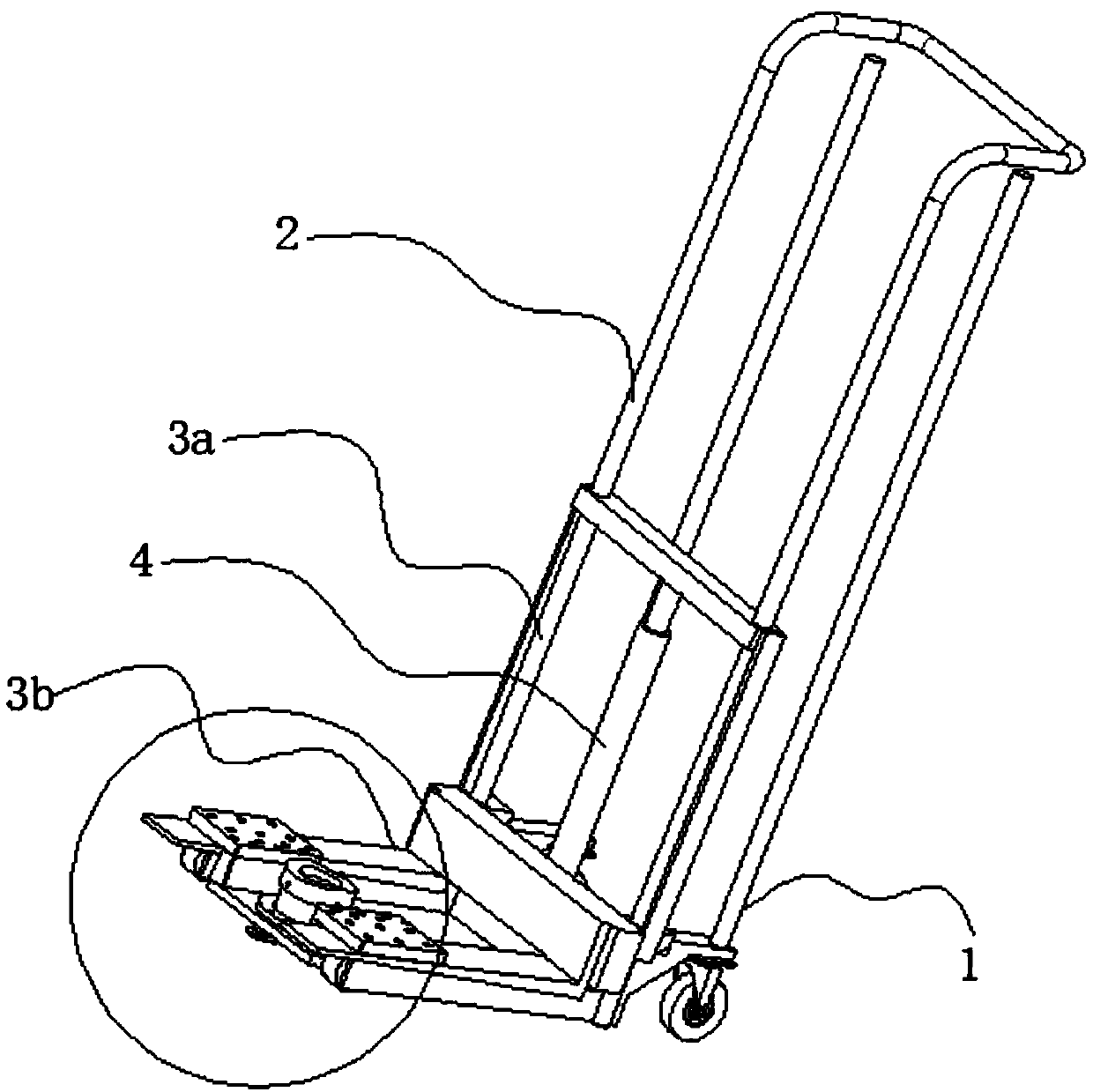

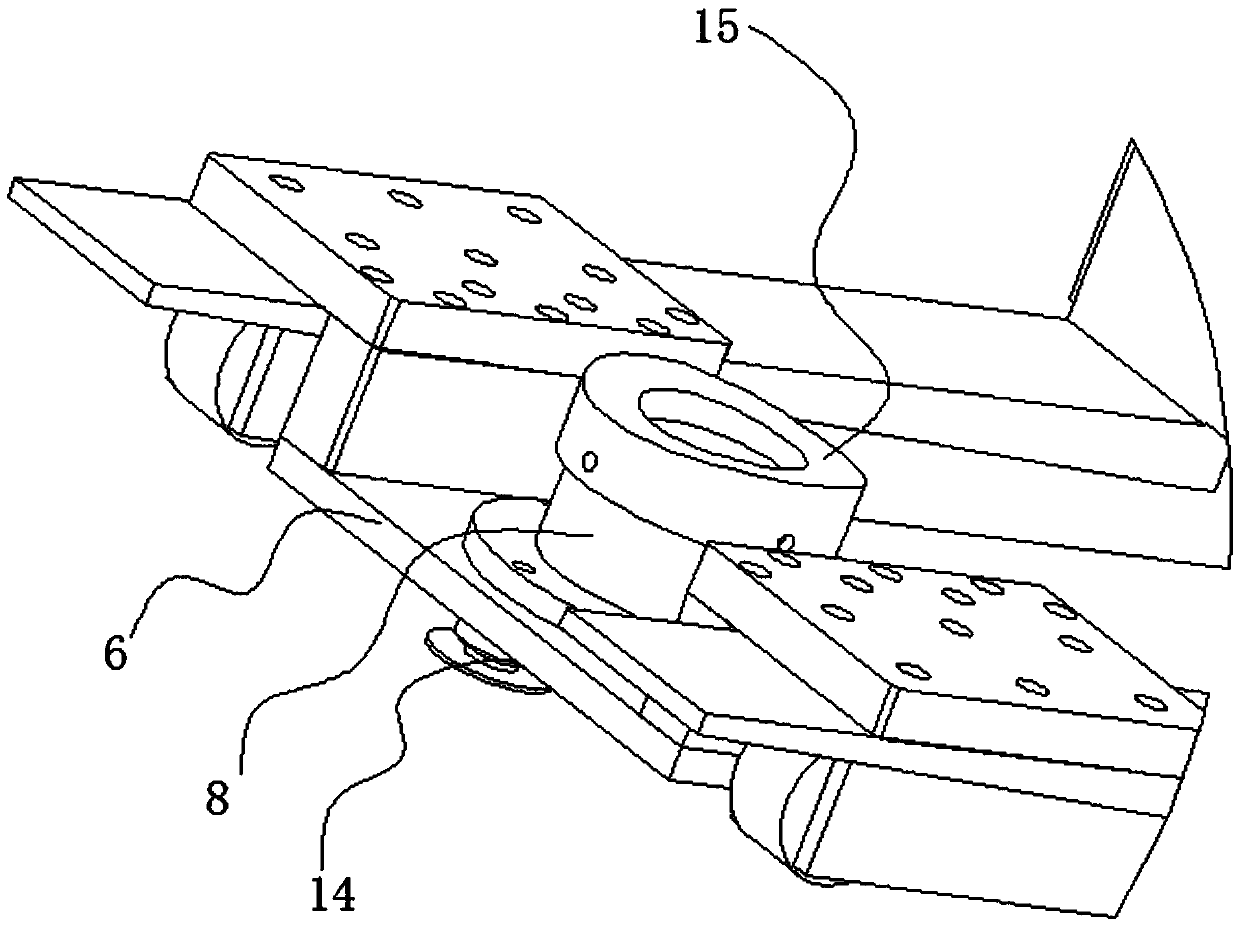

[0019] see Figures 1 to 6 , The loading and unloading forklift provided in this embodiment includes a forklift body, the forklift body 1 is provided with a lifting rod 2, the lifting rod 2 is provided with a lifting seat 3a, and the lifting seat 3a is provided with a supporting seat 3b, in addition, The forklift body 1 is also provided with a lifting drive device 4 (this embodiment adopts a hydraulic cylinder, which can also use a cylinder lifting mechanism, a motor lifting mechanism, etc.), and the lifting driving device 4 is connected with the lifting seat 3a to drive the lifting Seat 3a moves up and down on the lifting rod 2, and then drives the lifting seat 3b to obtain the expected height; the bearing plate 5 is arranged on the support seat 4 through a rotating positioning mechanism, and the rotating positioning mechanism includes a mounting base 6, and the mounting base 6 A rotating shaft 7 is provided, and the rotating shaft 7 is provided with a swivel seat 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com