Dual-component adhesive coating device

A glue-coating, two-component technology, which is applied to the surface coating device, spray device, coating, etc., can solve the problems of wasting manpower, inconvenience, affecting the beauty of the workpiece, etc., and achieve uniformity and structure. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

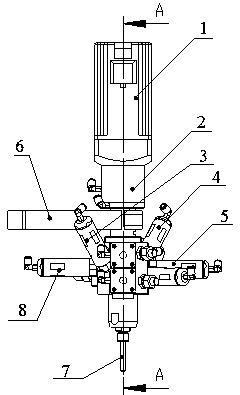

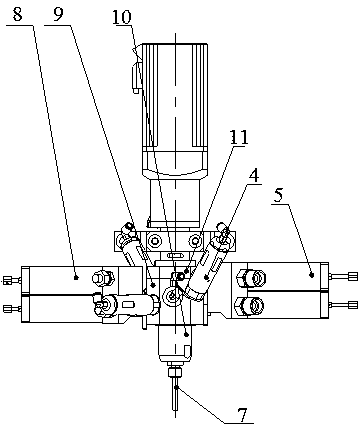

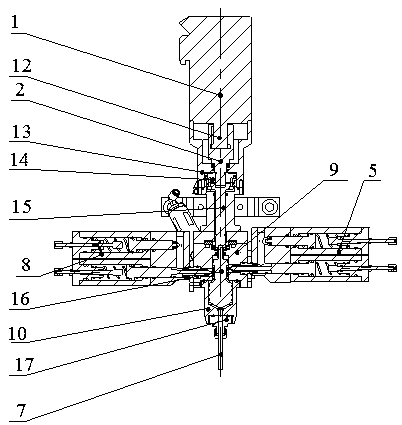

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a two-component glue application device includes a glue application pipe 7, a glue valve A8, a glue valve B5, a feed chamber 9 and a stirring chamber 10 communicated with the feed chamber (the stirring chamber is threadedly connected with the feed chamber ), the glue pipe 7 and the mixing chamber 10 are threaded through the glue pipe mounting seat 17 and the glue pipe 7 is connected to the stirring chamber 10; the glue valve A8 and the glue valve B5 are connected to the feed chamber 9 through the positioning block 11; the glue valve A8 Both the outlet and the outlet of the glue valve B5 communicate with the feeding chamber 9 .

[0026] The water inlet cylinder 4 and the air blowing cylinder 3 are connected to the feed chamber 9 by threads, and the feed chamber 9 communicates with the water inlet cylinder 4 and the air blow cylinder 3 .

[0027] A stirring hub 16 is arranged in the stirring ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com