Patents

Literature

246results about How to "Implement the rotation function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

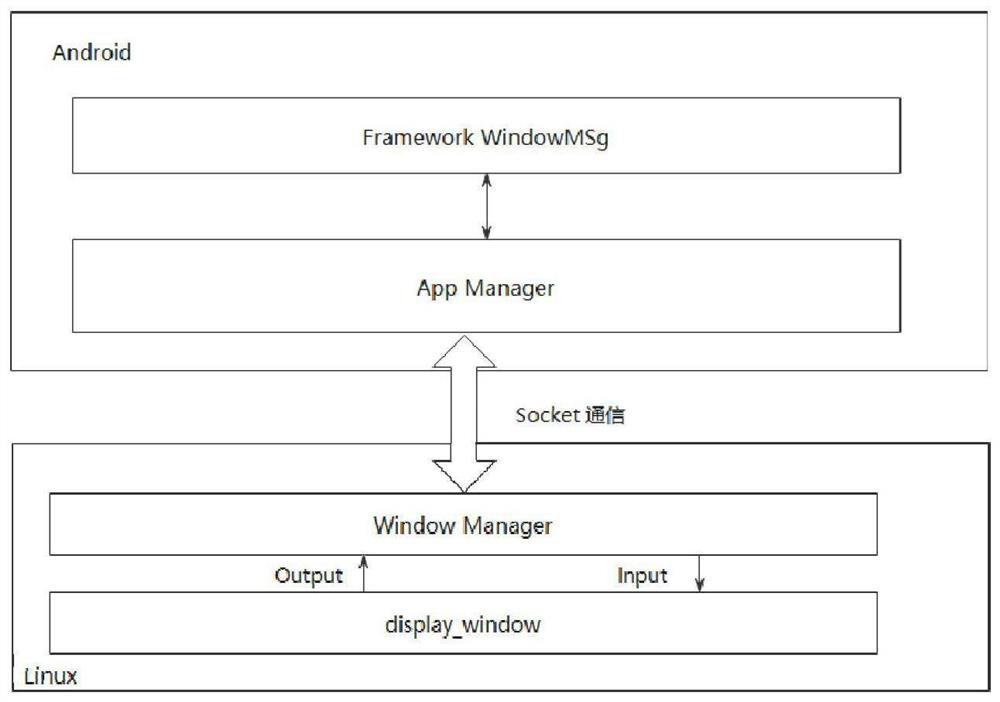

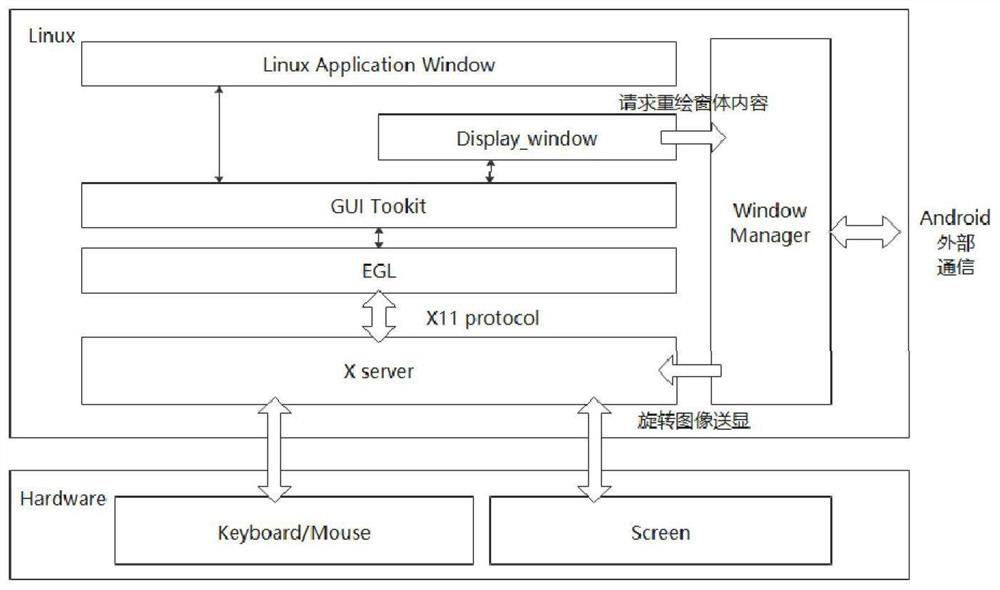

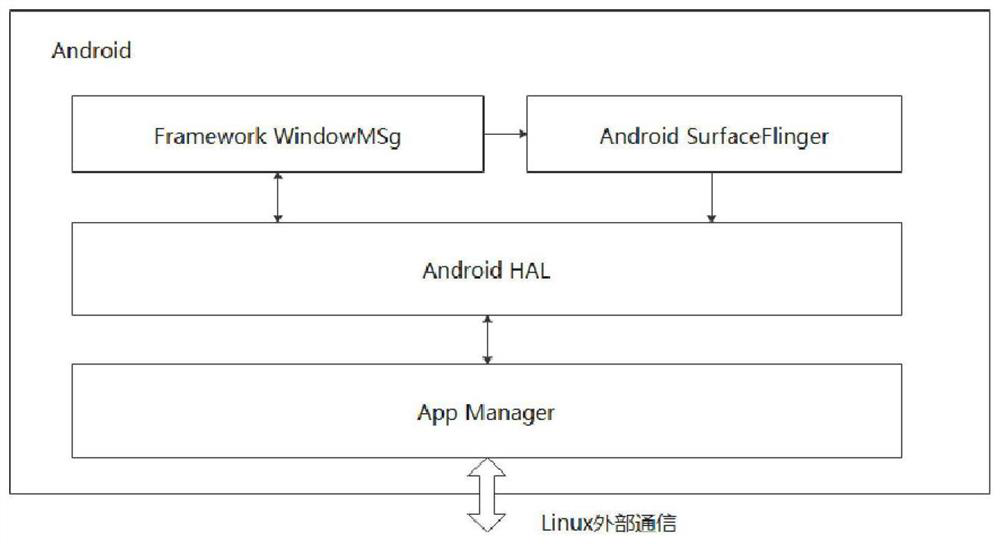

Window interaction method and device for compatibly running Android application on Linux

ActiveCN112269604ARealize soft keyboard inputImplement the rotation functionProgram loading/initiatingExecution for user interfacesCommunication interfaceSoft keyboard

The invention discloses a window interaction method and device for compatibly running an Android application on Linux, and belongs to the technical field of computers. The method comprises the steps of compatibly operating an Android application in a Linux operating system in a container mode, and establishing a Socket communication interface between the Linux side and the Android side of a container; capturing a window body operation on an Android application display window by the Linux side, and updating and displaying the window body; and sending information, needing to be updated and displayed, of the corresponding image in the window to the Android side through the Socket communication interface, updating an internal image by the Android side, and sending the internal image to the Linux side for display, thereby achieving synchronous updating of the window body of the display window and the internal image, and realizing interactive operation of the window. The main purpose is to solve the problem that in the prior art, for an Android running environment compatibly running on a Linux system in a container form, a current standard Linux window cannot support window operation commonly used by an Android application window, such as window rotation, a soft keyboard and window rollback, and improve the smoothness of operating an Android application by a user in a heterogeneous system.

Owner:北京技德系统技术有限公司

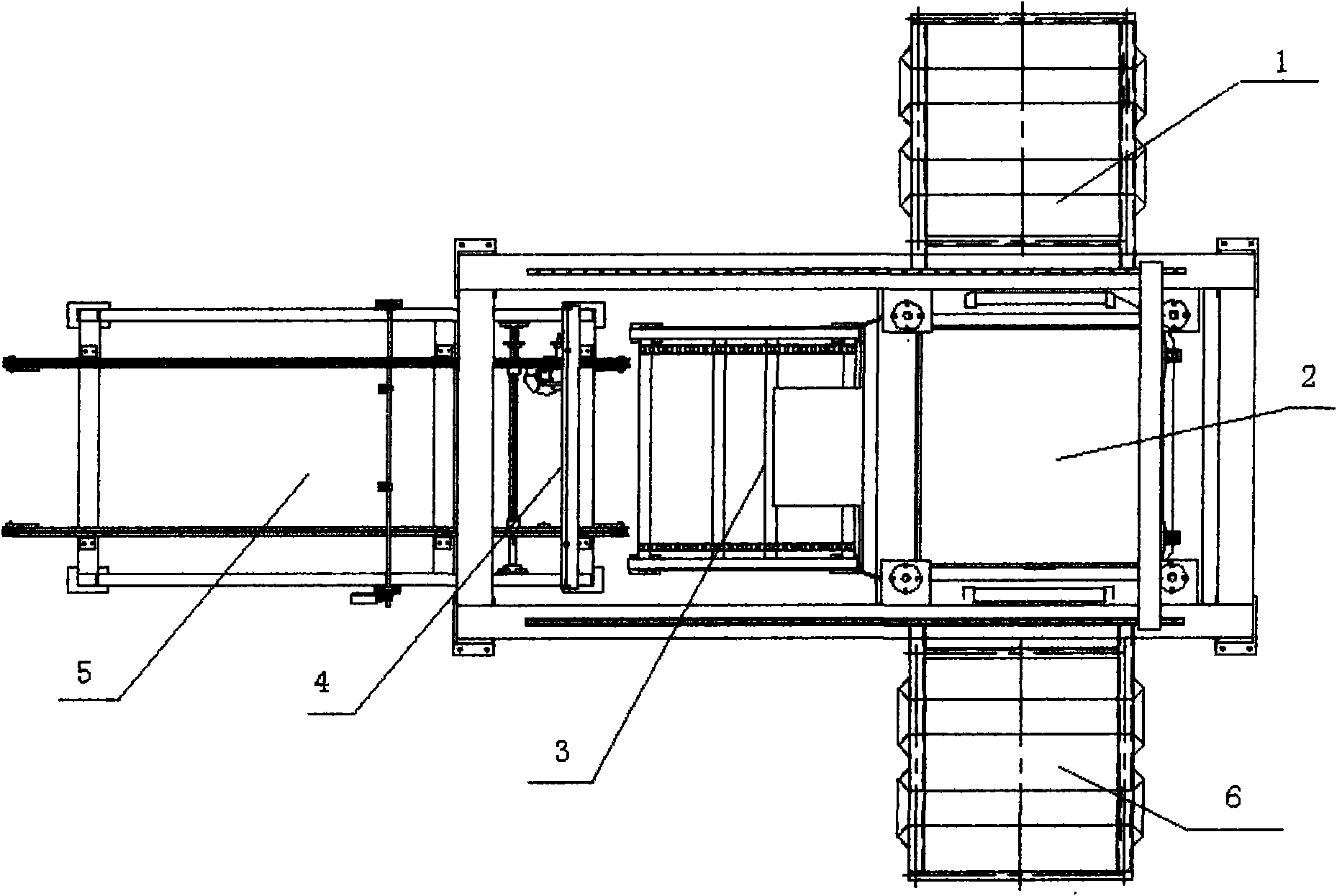

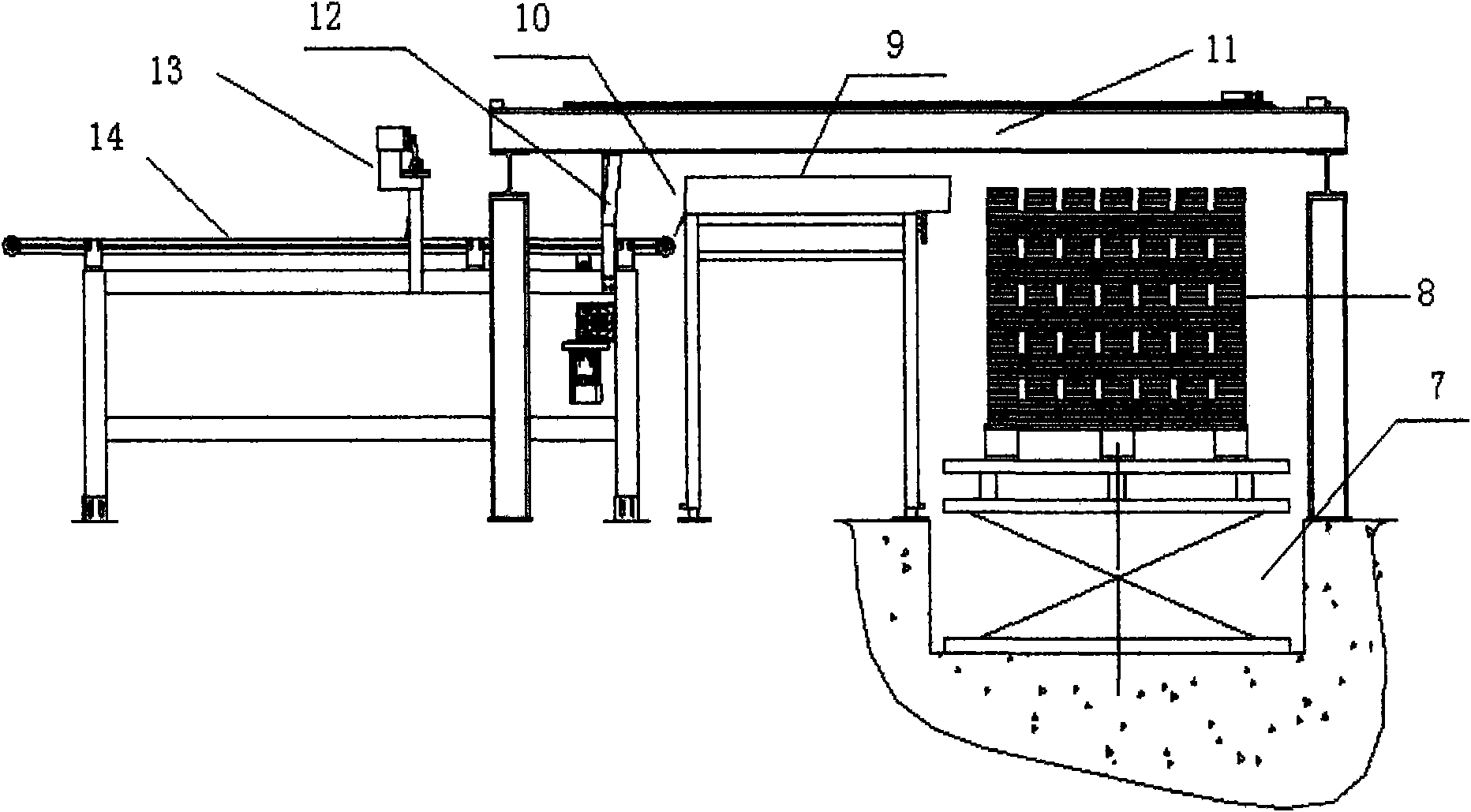

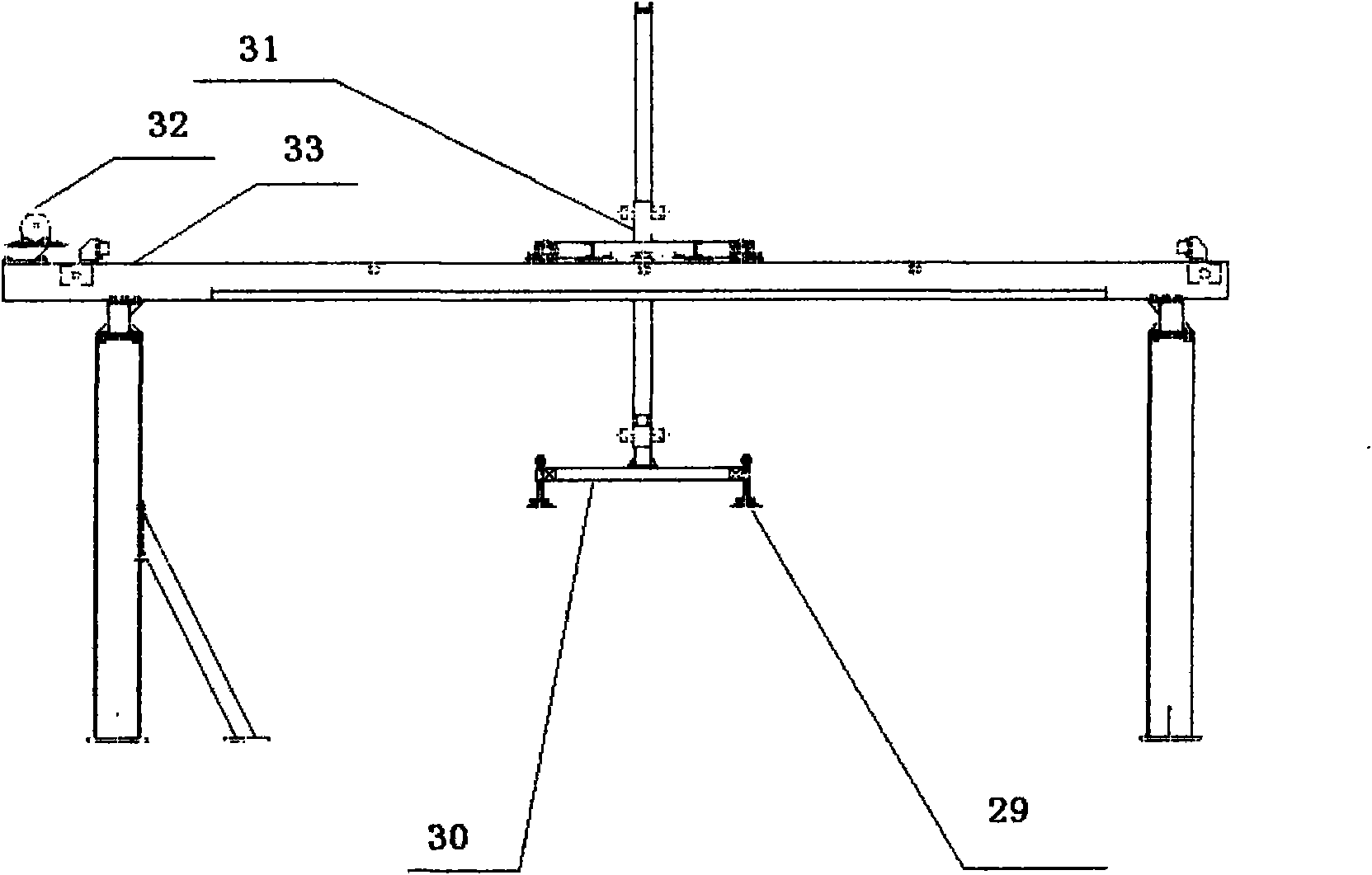

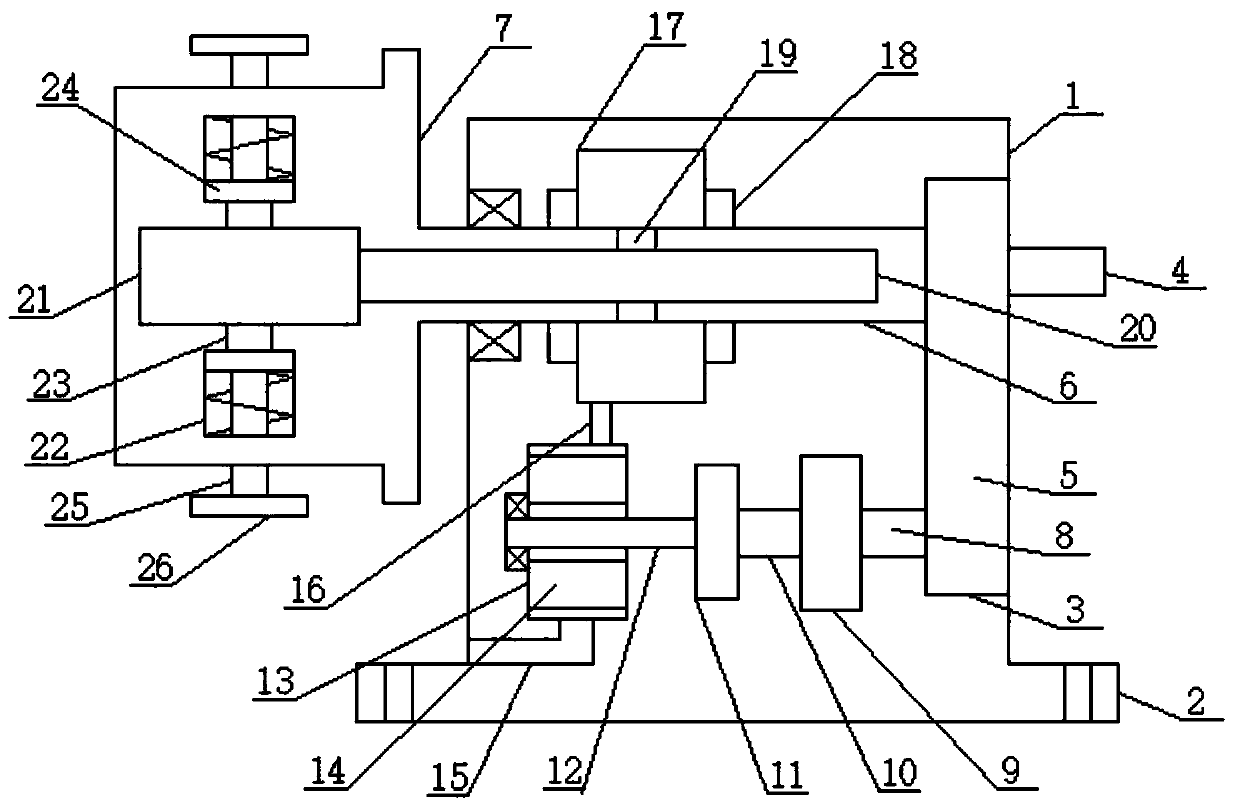

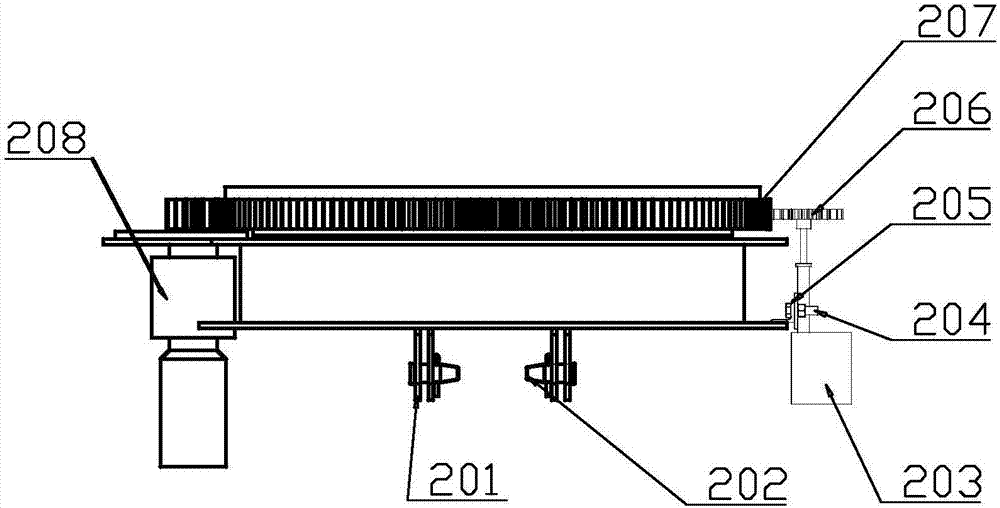

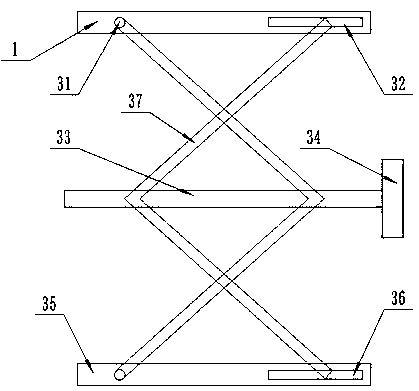

Automatic loading device for plates to be milled and loading material method thereof

InactiveCN101830013AAchieve mechanical propertiesFully automatedWood mortising machinesWood slotting machinesAutomatic controlEngineering

The invention discloses an automatic loading device for plates to be milled, which is suitable for delivering wood floor strips in a production process. The device consists of a feeding and discharging conveyor, a hydraulically lifted steering platform, a plate pusher or a plate absorbing carriage system, a lift-up roller and a turning and conveying mechanism, wherein the feeding and discharging conveyor is used for conveying a tray inside and outside; the hydraulically lifted steering platform is used for lifting the tray and steering the tray at an right angle horizontally; the plate pusher is used for pushing a plate blank onto the lift-up roller; the plate absorbing carriage system absorbs the plate blank and transfers the plate blank to the turning and conveying mechanism; and the turning and conveying mechanism turns the designated plate blank. The invention also discloses an automatic loading method for the plates to be milled, which comprises the following steps of: conveying the tray to the feeding and discharging conveyor; transferring the plate blank (lapped in a single manner) on the top layer onto the lift-up roller by using the plate pusher and conveying the plate blank onto the turning and conveying mechanism; or absorbing the plate blank and transferring the plate blank on the turning and conveying mechanism by using the plate absorbing carriage system; and turning over the designated plate blank by using a turning hook and conveying the designated plate blank into a two-end mill. The automatic loading device and the automatic loading method thereof adopt automatic control, are convenient to operate, reduce labor intensity and save materials.

Owner:苏州伍得人造板设备有限公司

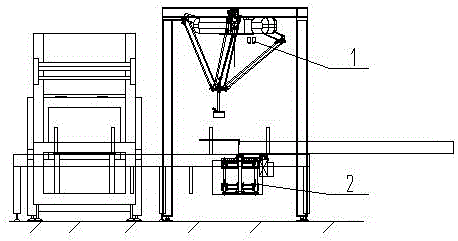

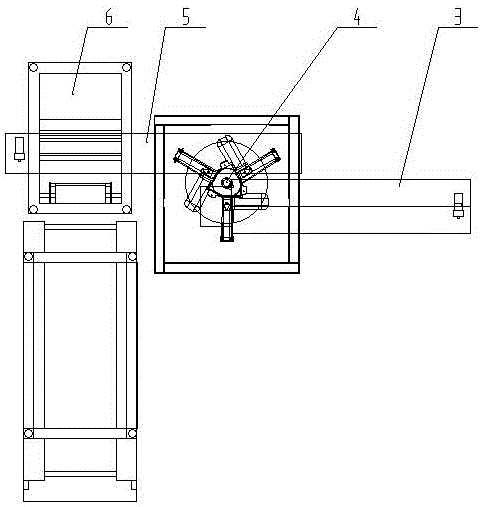

Special-shaped tobacco carton automatic stacking and packing method

InactiveCN106742281AImplement the rotation functionReduce run pathConveyorsControl devices for conveyorsCartonOrder form

The invention discloses a special-shaped tobacco carton automatic stacking and packing method. The method comprises the following steps: 1) order data is read, and a corresponding relation between a stacking manipulator and sorting system real-time orders is set; 2) tobacco cartons are conveyed to the end part of a tobacco carton conveying device and stopped on a baffle plate; 3) a camera and a light source are triggered to shoot; and data of the tobacco cartons is transmitted to the stacking manipulator; 4) according to the orders and the tobacco carton size data, the stacking manipulator grabs the tobacco cartons to stack on a lifting mechanism in sequence; and tobacco stacks are lifted to reach a chain conveyor; 5) the chain conveyor conveys the tobacco stacks to a packing machine for plastic packing; and 6) a labeling machine prints information of the tobacco cartons and labeling time. The method has the following advantages: the method can realize automatic detection, automatic stacking and automatic packing of the special-shaped tobacco cartons according to real-time sorting data; the stacking manipulator can realize the grabbing stability and efficiency; the lifting mechanism shortens the path of the stacking manipulator to improve the stacking efficiency; and the chain conveyor adopts a poking plate form to convey the tobacco stacks, and is provided with multiple poking plates for improving the stacking efficiency.

Owner:ETABONG QINGDAO TOBACCO MACHINERY

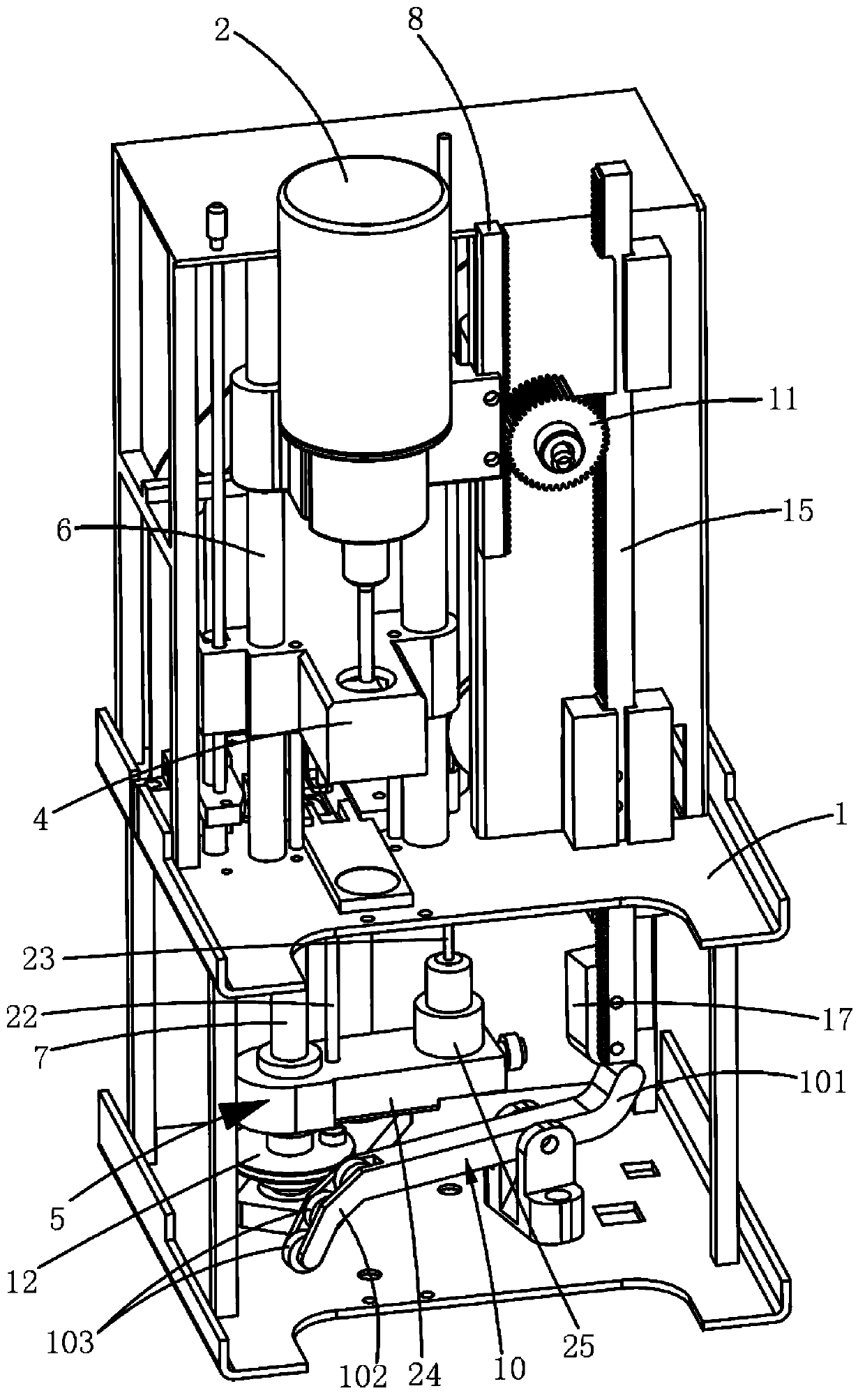

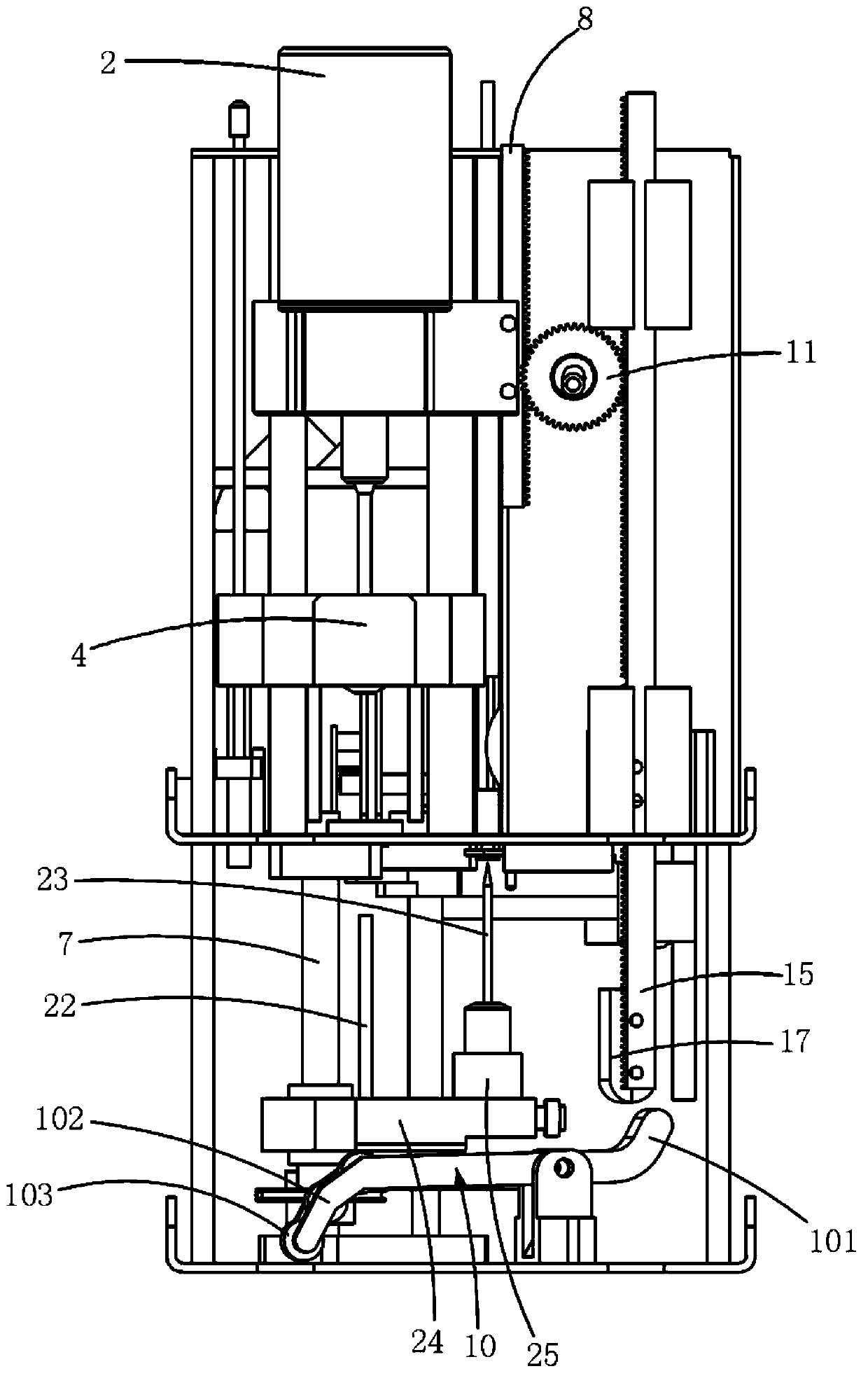

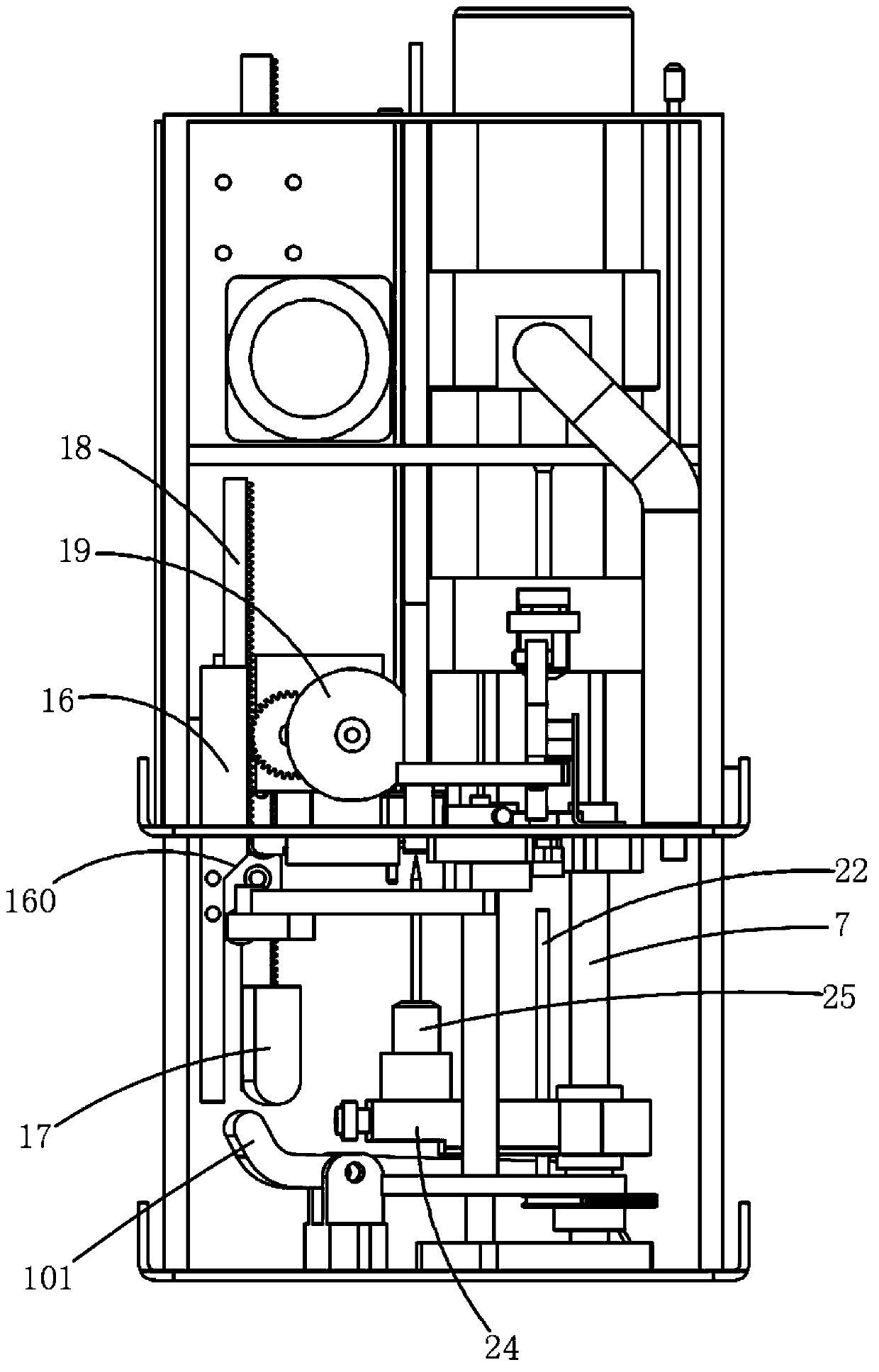

Fully automatic binding machine

ActiveCN103465672AImplement the rotation functionRealize lifting functionSheet bindingElectric machineryEngineering

The invention discloses a fully automatic binding machine. A motor is connected with a drilling rack and a driving rack set for driving a lower heating component to rotate and lift; a rotating shaft is connected with the driving rack set through a steel wire and a transmission mechanism; a rack is pivotally connected with a lever; a first end of the lever extends to the space below the driving rack set, and a second end of the lever extends to the space below the rotated lower heating component; after the lower heating component is rotated to a pressing rivet position, the driving rack set is butted against the first end of the lever in a descending process of the driving rack set, so that the lower heating component is lifted up to a heating riveting position by the second end of the lever. A drilling tool is driven by the drilling motor to drill in a rotary mode; a rotary function of the lower heating component, a lifting function of the lower heating component, a rubber pipe delivery function and a pipe cutting function are simultaneously realized by using the motor; the fully automatic binding machine has the advantages of simple structure, low cost, stable action and higher reliability.

Owner:曹东华

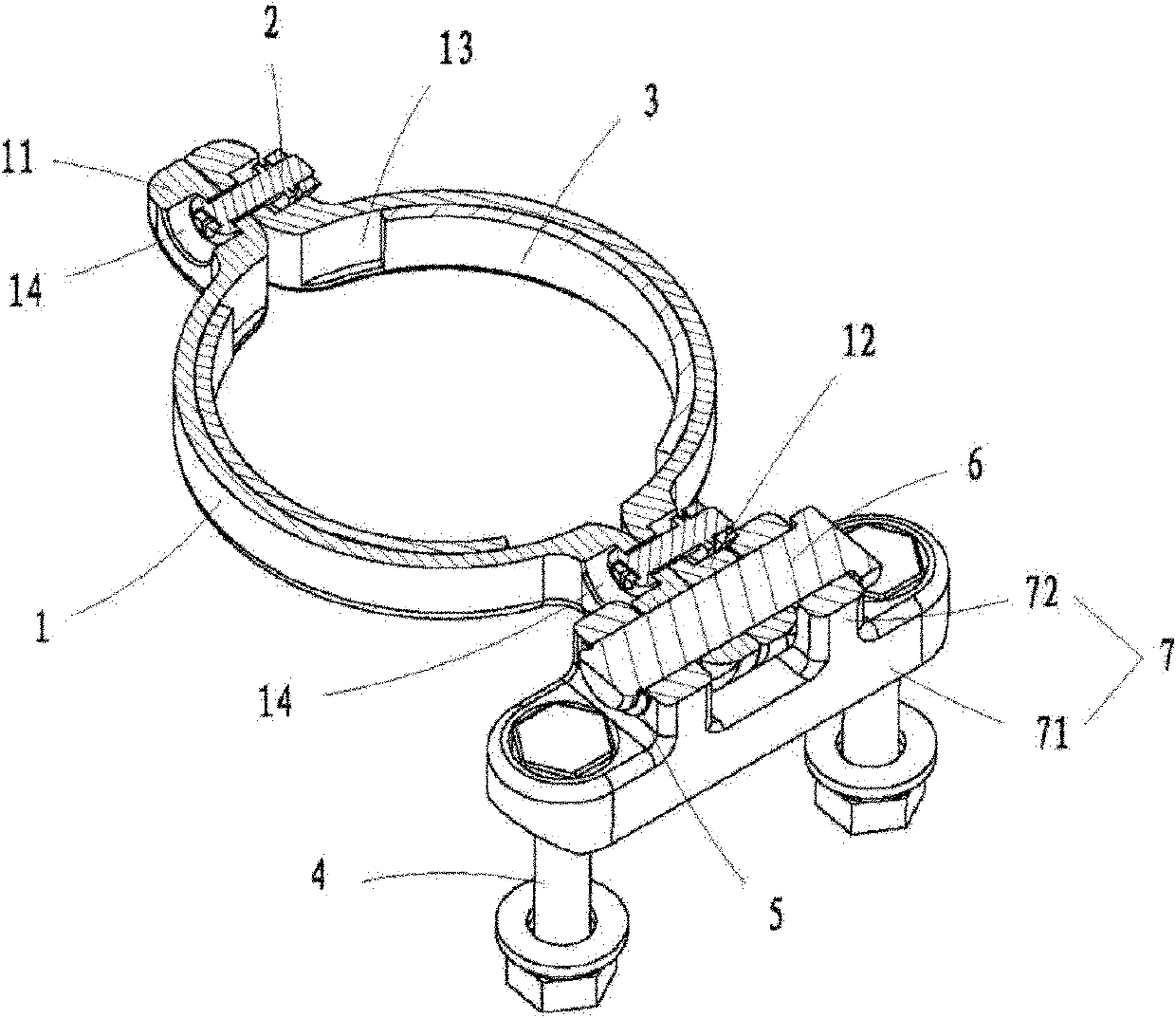

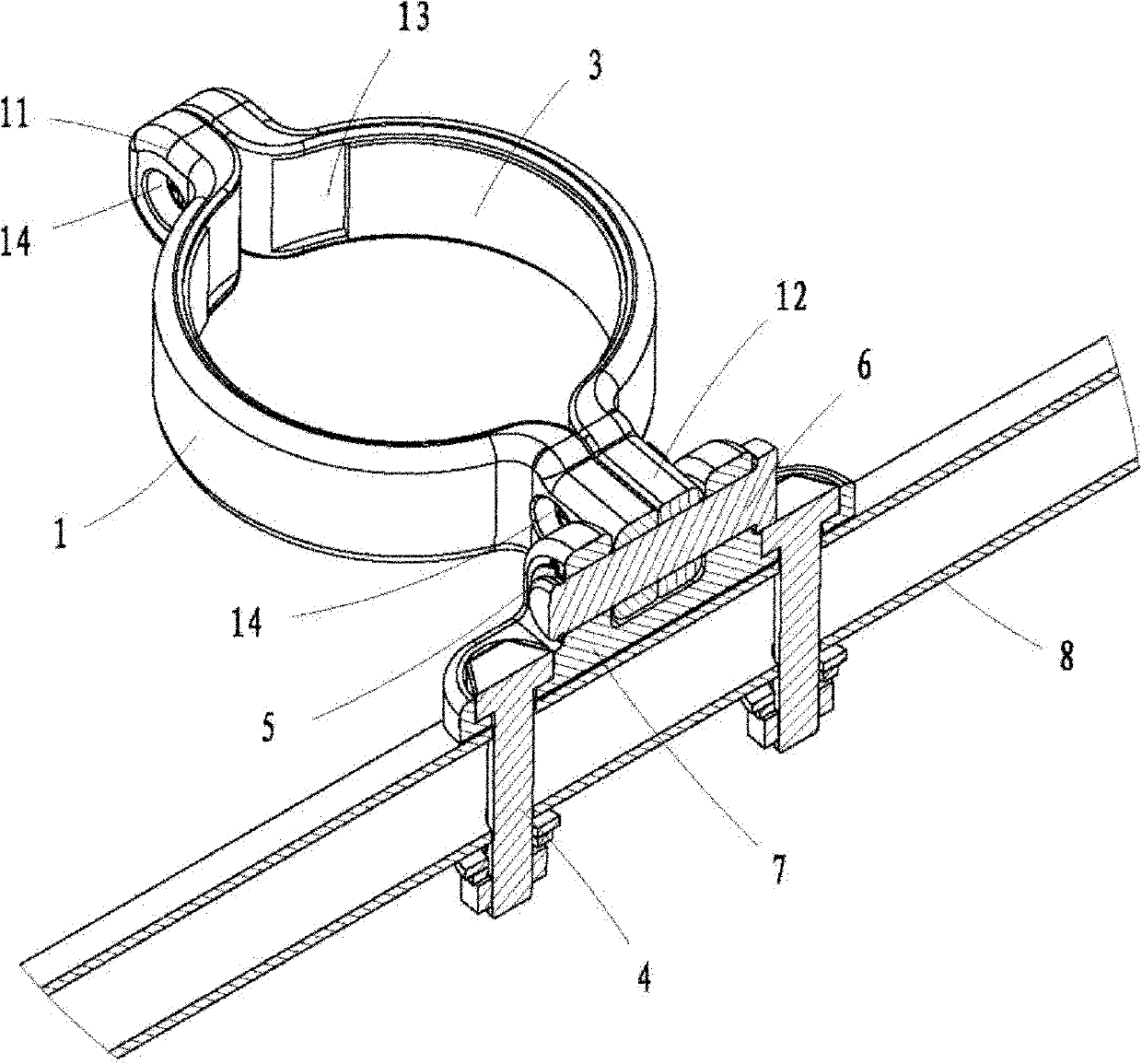

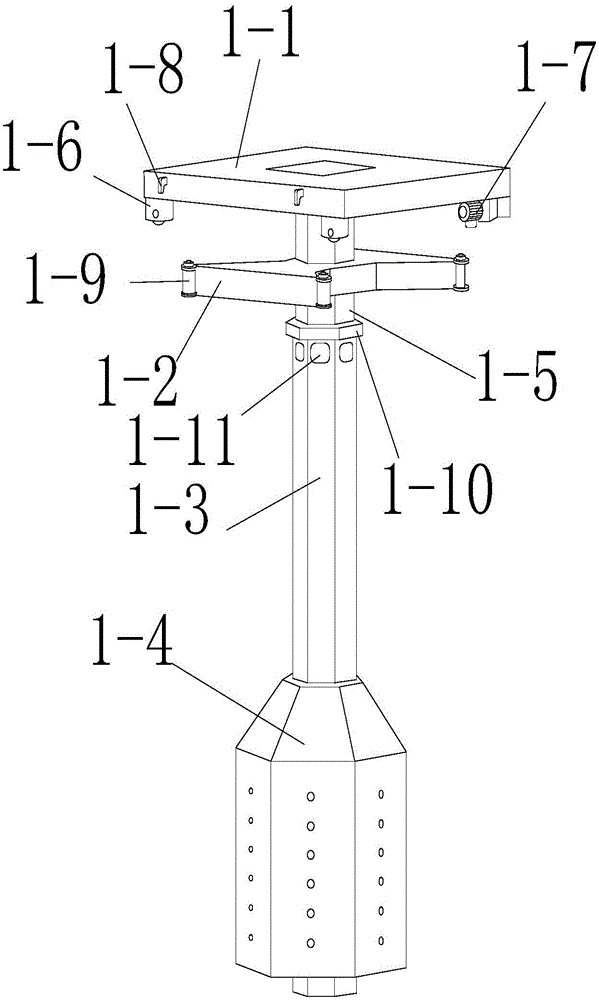

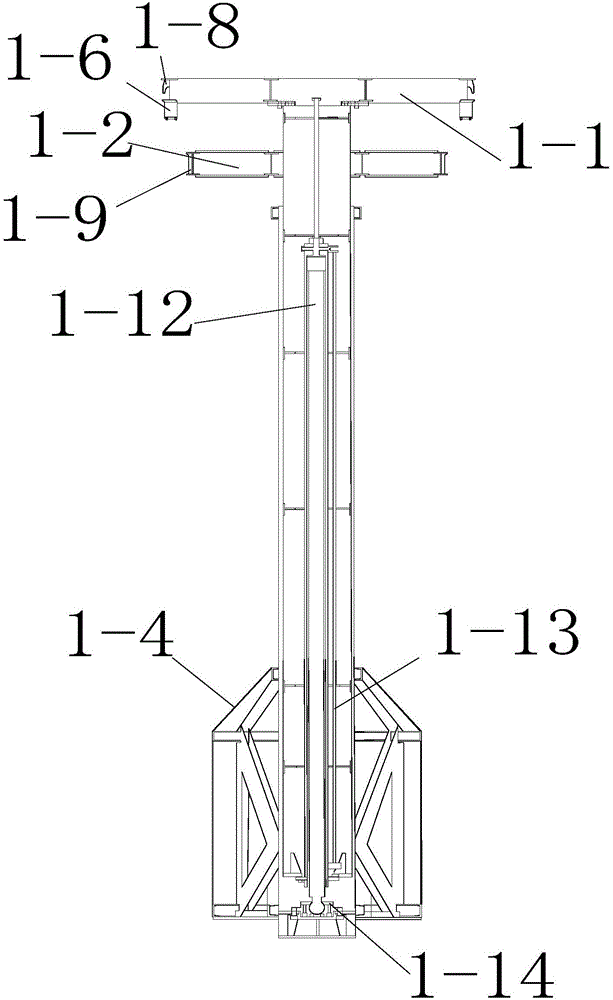

Locking structure capable of rotating lamp pole

InactiveCN102563302AImplement the rotation functionEasy to carryStands/trestlesEngineeringMechanical engineering

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

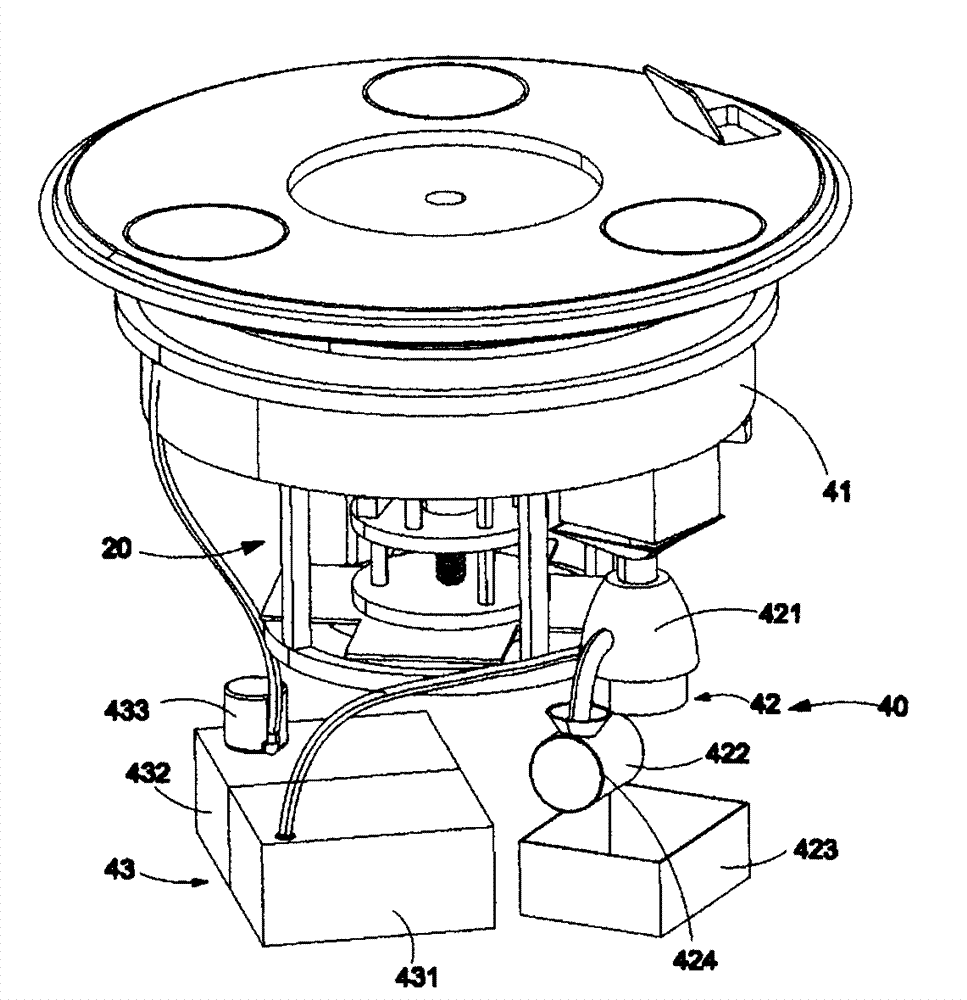

Full-automatic dinner table

InactiveCN102824030ASolve problems that require additional workRealize lifting functionServing tablesVariable height tablesAnimal feedEngineering

The invention provides a full-automatic dinner table. The full-automatic dinner table comprises a dinner table main body, a lifting device, a rotary device and a feed production device, wherein a rotary disc capable of lifting or rotating is arranged on the dinner table main body; the lifting device is arranged in the dinner table main body and connected with the rotary disc; the rotary disc is driven by the lifting device to lift relative to the dinner table body; the rotary device is fixedly arranged on the lower side surface of the rotary disc and used for driving the rotary disc to rotate relative to the dinner table body; and the feed production device comprises a food residue recycler, a treating device and a circulating water supply device. The lifting and rotating functions can be performed by the rotary disc, and food residues can be made into animal feeds through the feed production device, so that the dining function of the people can be achieved, the problem of additional treatment of the existing food residues can be also solved, and the effect of directly collecting the food residues and processing the food residues into the feeds is obtained.

Owner:肖冬成

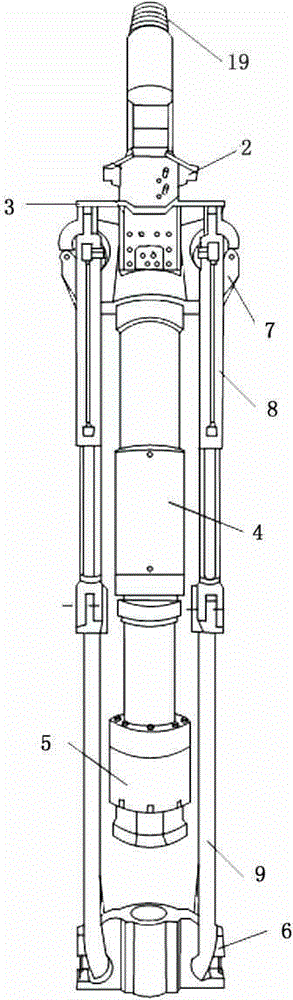

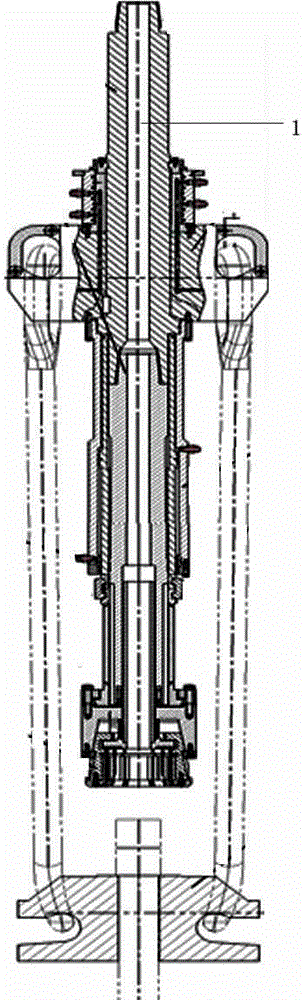

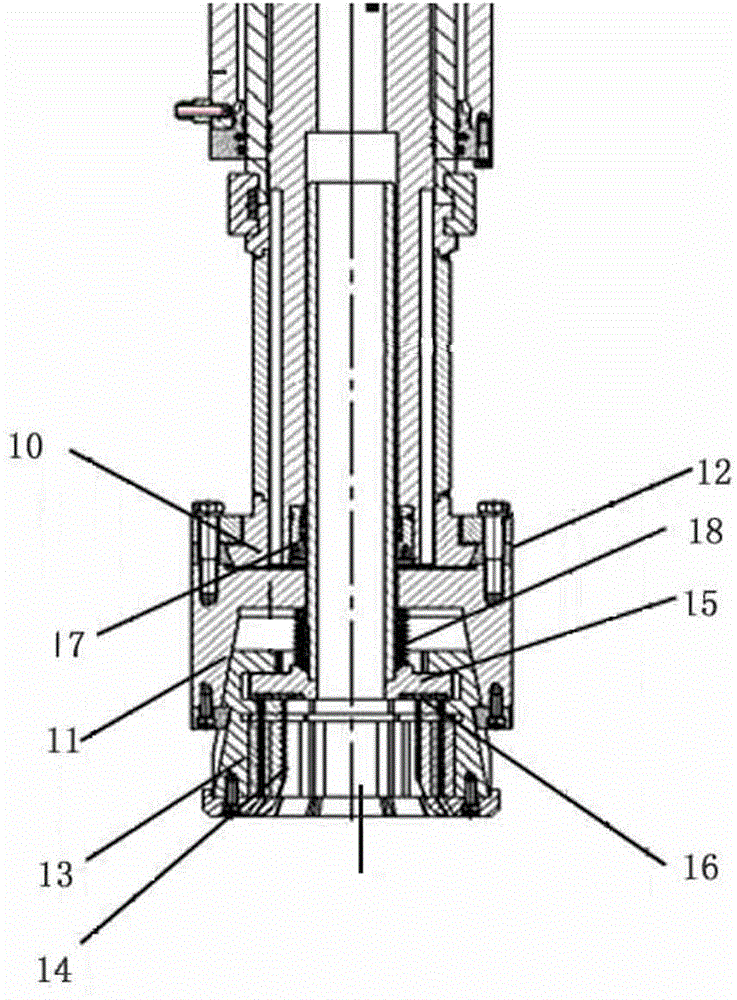

Top drive drilling device coupling clamping type sleeve lowering device and application method thereof

ActiveCN104131781AEffective size controlImplement the rotation functionDrilling rodsDrilling casingsHydraulic cylinderTop drive

The invention relates to a top drive drilling device coupling clamping type sleeve lowering device and an application method of the top drive drilling device coupling clamping type sleeve lowering device. The top drive drilling device coupling clamping type sleeve lowering device comprises a top drive hydraulic system. A central pipe is arranged below the top drive hydraulic system. A rotating sealing connecting plate, a suspended supporting base, a main hydraulic cylinder and a pincers head body are sequentially arranged on the central pipe from top to bottom. A sleeve hanging clamp is arranged below the pincers head body. A suspended body is arranged at the lower end of the suspended supporting base. The lower end face of the suspended body is fixedly connected with a hanging ring. The lower end of the hanging ring is connected with the sleeve hanging clamp. A hanging ring inclined hydraulic cylinder is arranged on the surface of the hanging ring. The central pipe is connected with the top drive device, the hydraulic cylinder provides main power so as to drive the central pipe to drive the pincers head body, the pincers head body firmly grasps a sleeve through coordination of two wedge-shaped flange inclined faces, the sleeve can be appropriately buckled in a rotating mode and pressed downwards in the sleeve lowering process while the sleeve is prevented from falling, and therefore the drilling tool jamming phenomenon is prevented, the top drive drilling device coupling clamping type sleeve lowering device is safe and reliable, work efficiency is improved, and the labor amount of workers is decreased.

Owner:ANSHAN ZHENGFA SURFACE TECHN & ENG CO LTD

Method for realizing rotation of handheld device screen pictures by 90 degrees and 270 degrees simultaneously

ActiveCN101958112AReduce usageEasy to useCathode-ray tube indicatorsHand held devicesRotation control

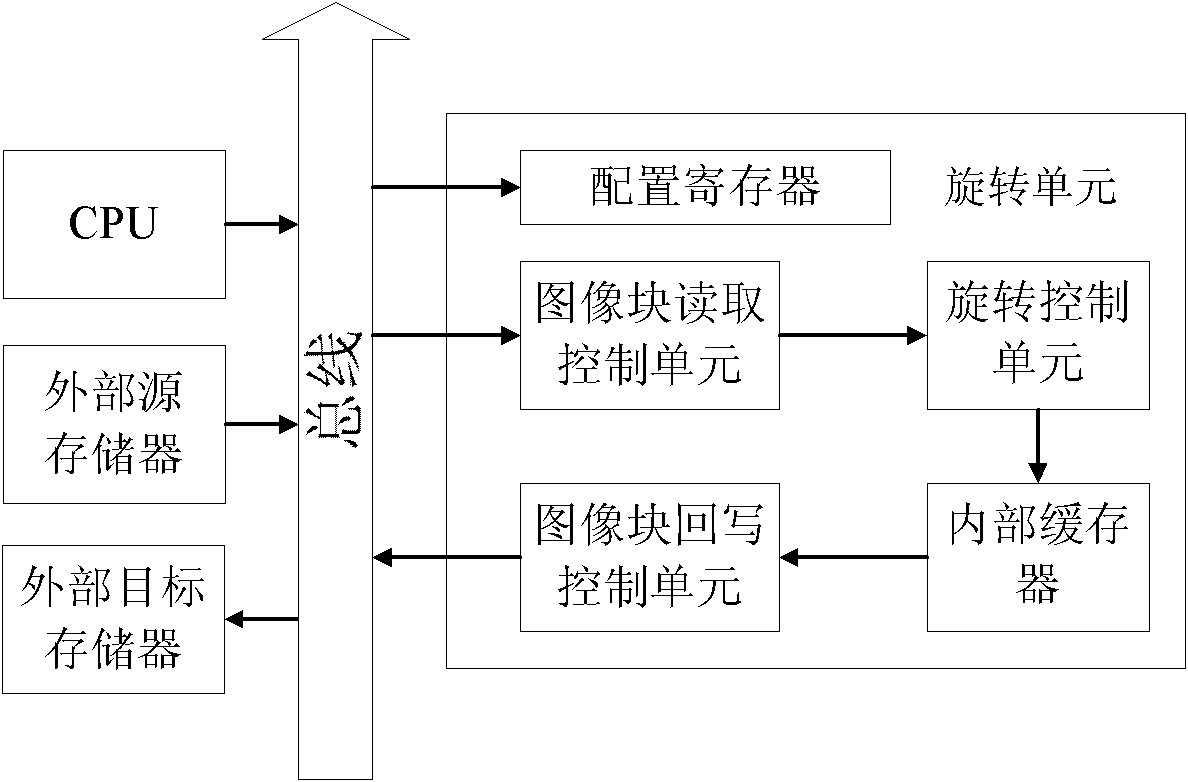

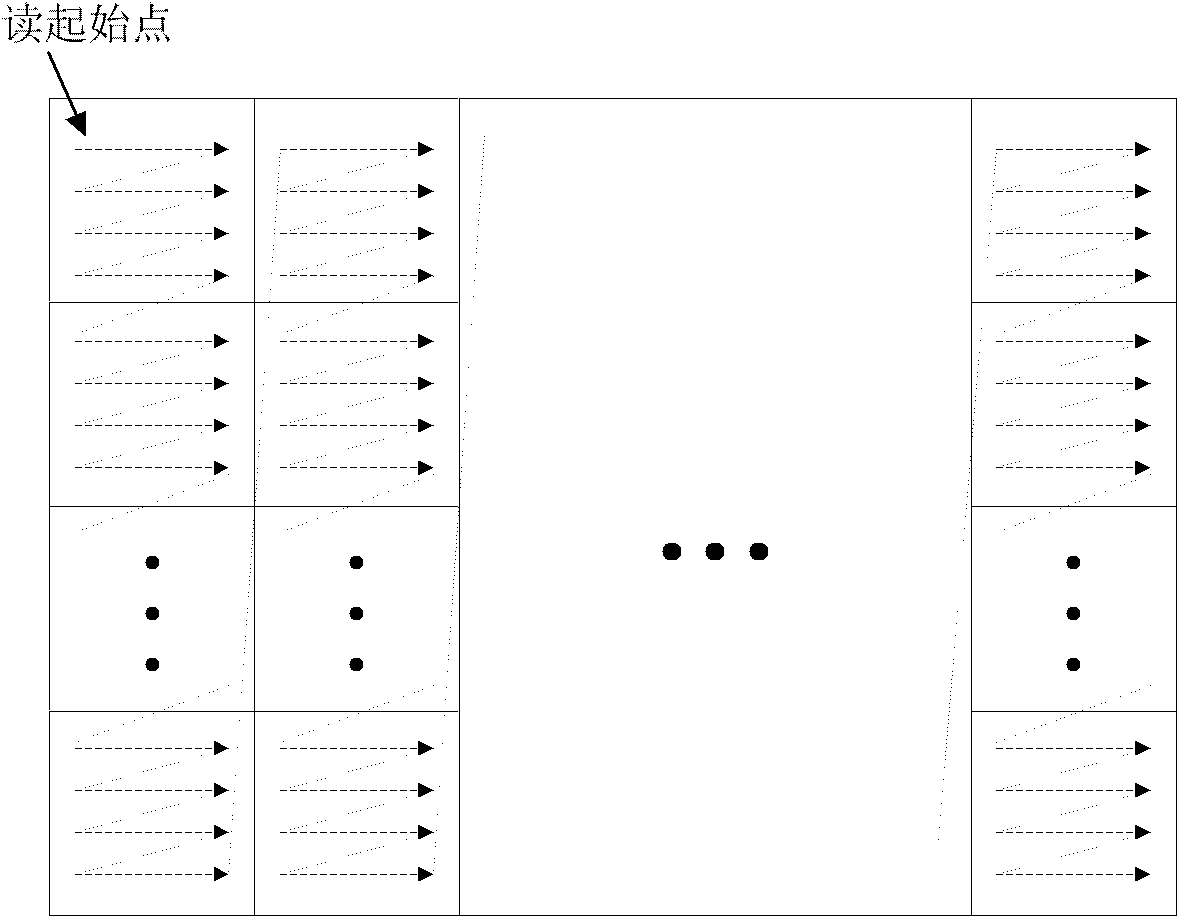

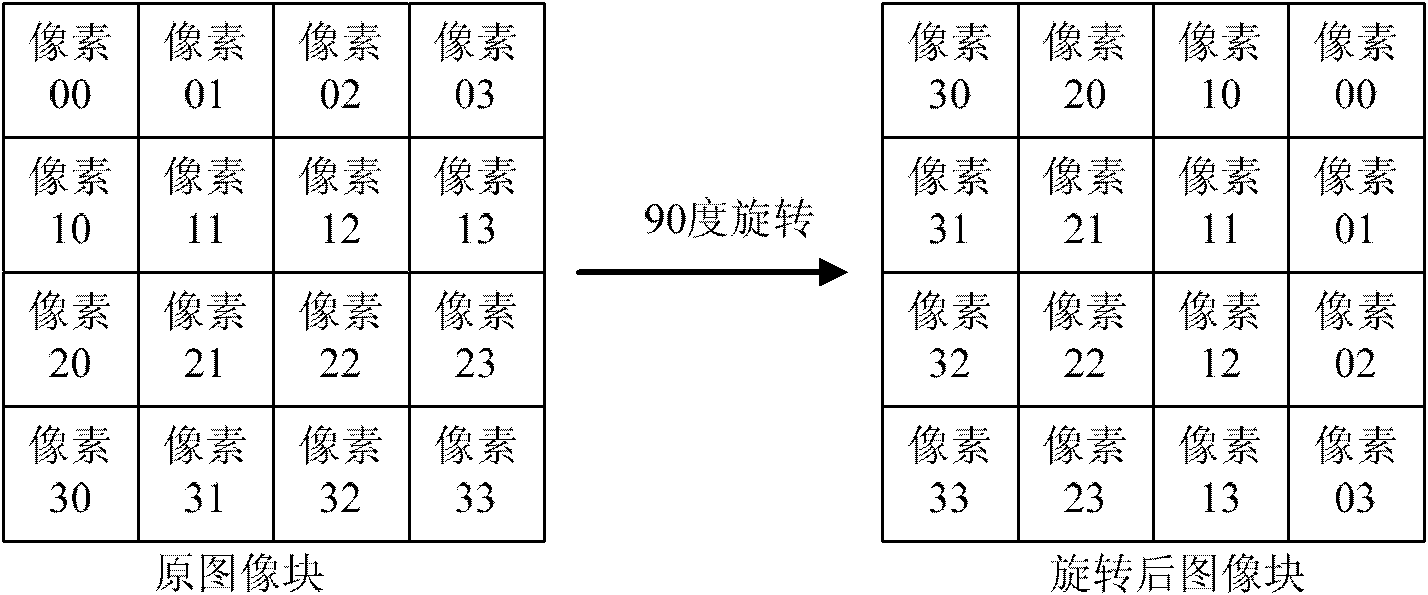

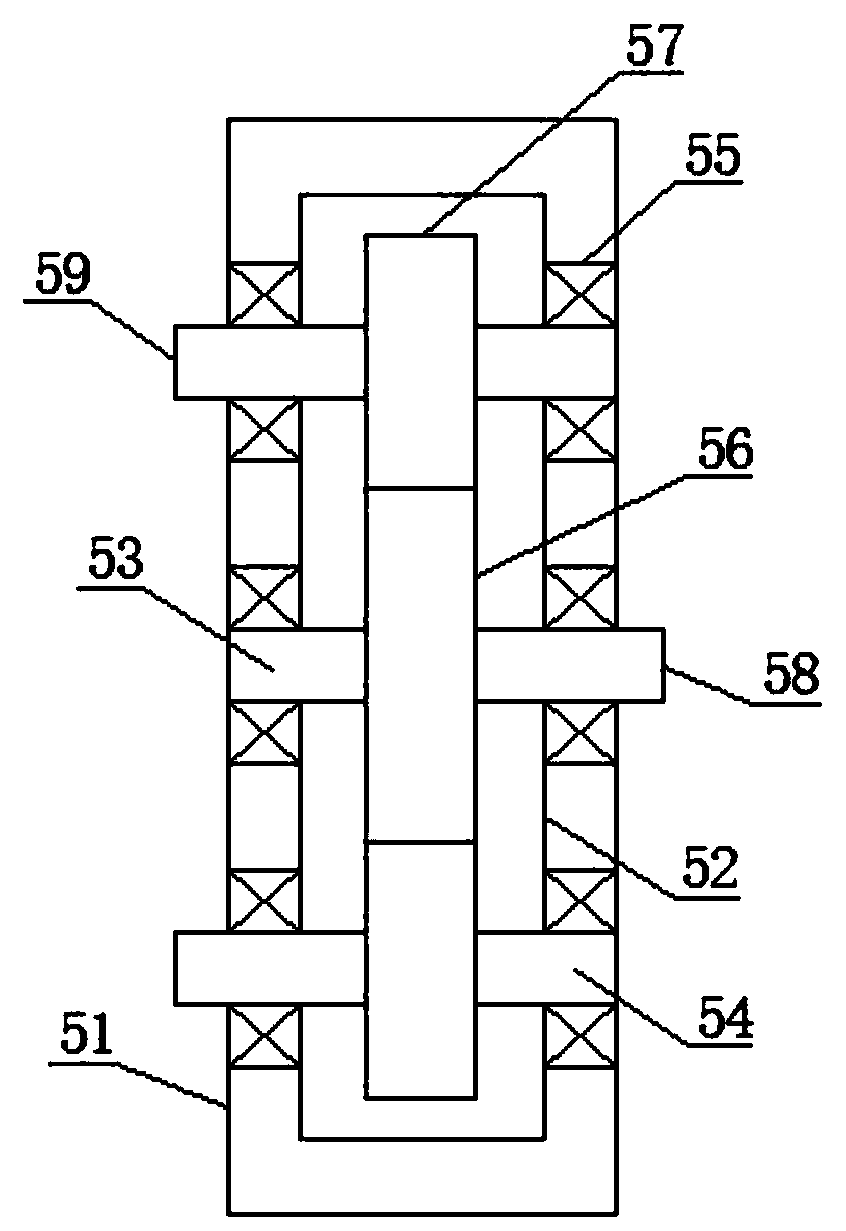

The invention relates to a method for realizing the rotation of handheld device screen pictures by 90 degrees and 270 degrees simultaneously. A rotary circuit structure is designed, which comprises an external source memory, a CPU, a bus, an external target memory and a rotary unit, wherein the external source memory, the CPU and the external target memory are respectively connected to the bus; the bus is connected with the rotary unit; the rotary unit comprises a configuration register, an image block reading unit, a rotary control unit, an internal buffer and an image block write-back control unit; the image block reading unit is connected with the rotary control unit; the rotary control unit is connected with the internal buffer; the internal buffer is connected with the image block write-back control unit; and the image block reading unit and the image block write-back control unit are respectively connected to the bus. In the method, only a small buffer capacity is needed, and the circuit realization area is saved to the maximum extent; and circuits with different functions can be used repeatedly, thereby reducing the circuit realization area greatly.

Owner:FUZHOU ROCKCHIP SEMICON

New axial center type knee joint prosthesis

ActiveCN101584615AMeet needsIncrease contact surfaceJoint implantsKnee jointsPhysical medicine and rehabilitationProsthesis

The invention relates to a new axial center type knee joint prosthesis comprising a femur intramedullary pin, a femur condyle, connecting components and a tibia intramedullary pin, also comprsing a tibia platform and a femur sleeve, wherein, the femur condyle is provided with a positioning slot and is fixed at lower part of the femur intramedullary pin; the tibia platform is provided with a centre hole and is fixed at the upper part of the tibia intramedullary pin for holding the femur condyle; the connecting components are T-shaped and comprise a transverse shaft and a vertical shaft, the vertical shaft is inserted into the centre hole of the tibia platform, the transverse shaft is rotatable arranged through the lower part of the femur condyle; the femur sleeve is sleeved at the lower part of the femur intramedullary pin and are butted with the positioning slot of the femur condyle. The new axial center type knee joint prosthesis of the invention can completely recovery the functions of extending and bending, and inward and outward rotating of the knee joint and adopt the bionic molding, the stability is good, the movement requirement of the patient can be satisfied sufficiently under the precondition of protecting limbs, the patient can recovery the movement freely like originally.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

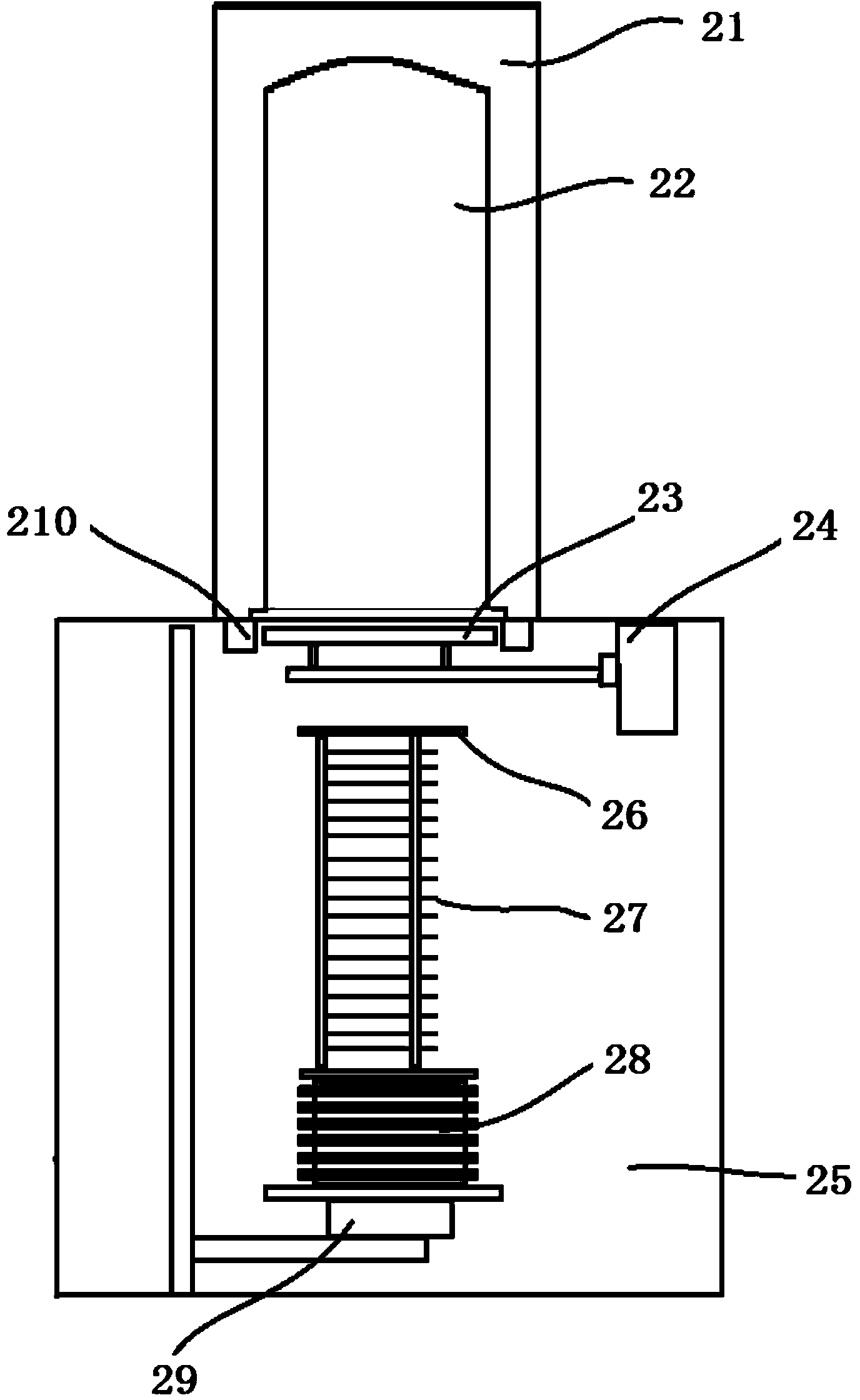

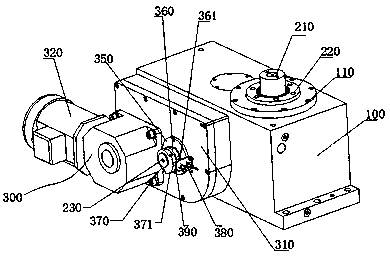

Mechanism capable of realizing lifting and rotating integrated movement of furnace door

ActiveCN103710761AImplement the rotation functionRealize lifting functionPolycrystalline material growthAfter-treatment detailsEngineeringCantilever

The invention discloses a mechanism capable of realizing a lifting and rotating integrated movement of a furnace door. One section of transmission thread is processed on each of the outer surface of a fixed threaded rod with limit and guide functions and the inner surface of an outer pipe of a movable threaded rod, the transmission threads are correspondingly matched, a drive device drives threads of outer pipes of the threaded rods through bearing assemblies to screw with thread grooves of the threaded rods and enables the outer pipes of the threaded rods to go up and down along the grooves of the threaded rods, the outer pipes of the threaded rods drive a furnace door to go up and down and rotate through a cantilever, and thus the furnace door is accurately controlled to open and close. According to the mechanism, through one drive source, by using the screwing function of the threaded rods and one section of transmission thread pair designed on the outer pipes of the threaded rods and using the limit and guide functions of the grooves of the threaded rods, the realization of the lifting and rotating integrated movement of the furnace door can be simply controlled, and thus the movement reliability is ensured, the movement time is shortened, the process efficiency is increased, and thereby the cost is saved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

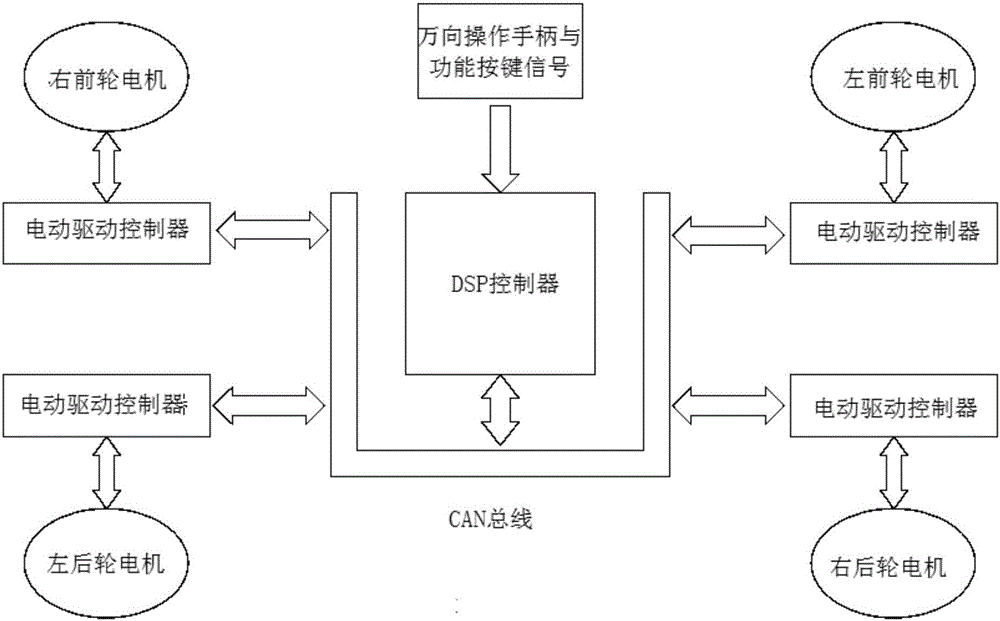

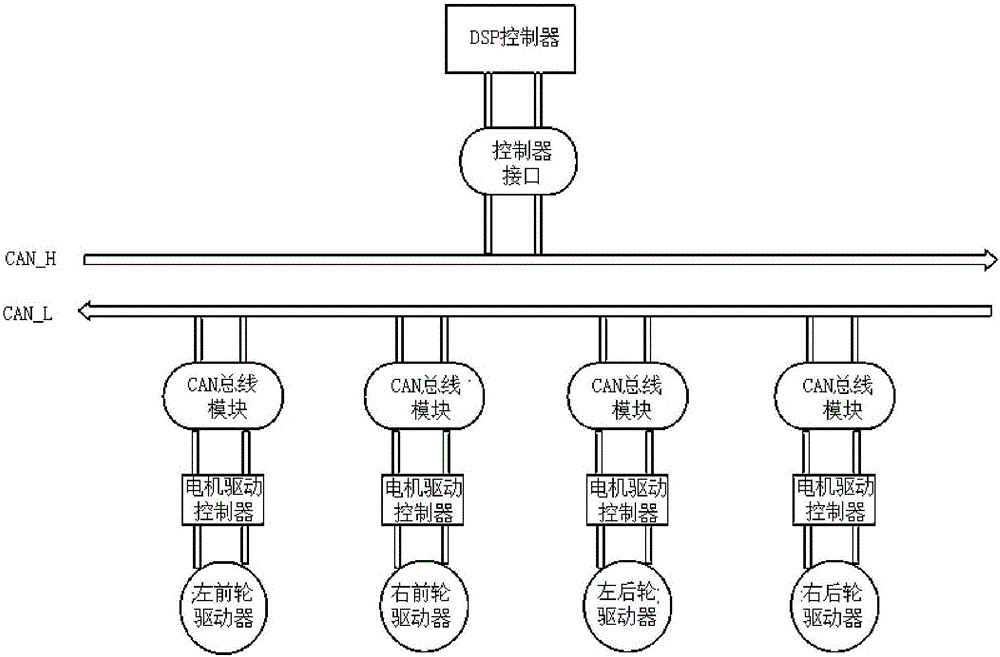

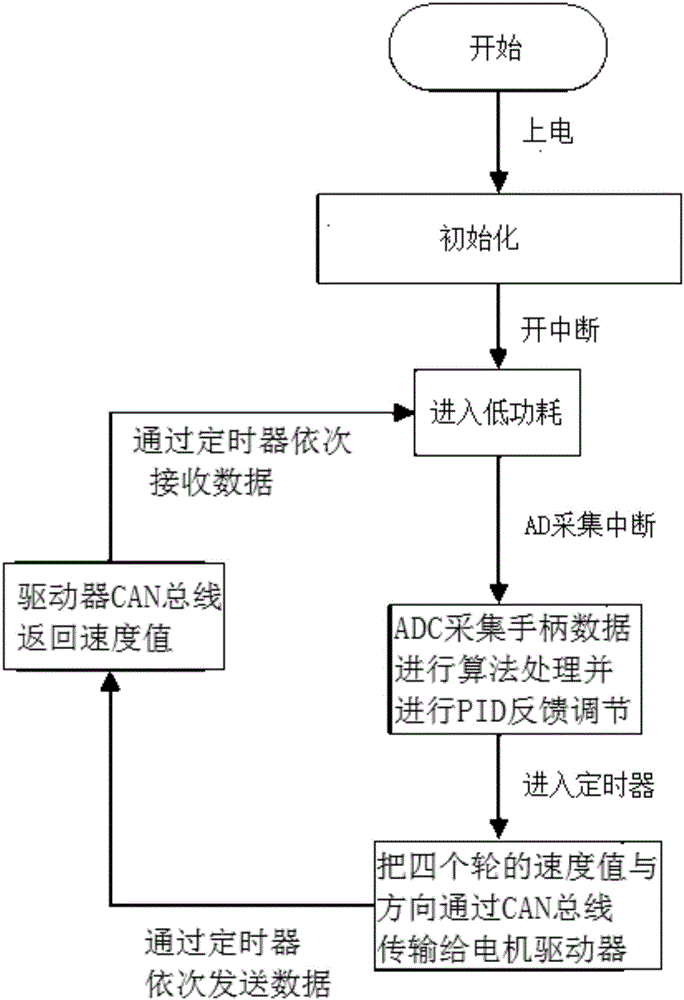

Four-wheel independent driving control system of electric wheelchair

InactiveCN106038103AReduce slippageReduce rollingWheelchairs/patient conveyanceTravel modeArea network

The invention relates to a four-wheel independent driving control system of an electric wheelchair. The four-wheel independent driving control system comprises a universal operation handle, a function button, a DSP (digital signal processor) controller and four electric driving controllers respectively controlling left rear, right rear, left front and right front wheel motors; the electric driving controllers are connected with the DSP controller by CAN (controller area network) buses, and the DSP controller is connected with the universal operation handle electrically; the function button comprises a power source switch, a wheelchair movement mode selecting button for realizing control on traveling or autorotation of the wheelchair, an autorotation mode selecting button for realizing control on anticlockwise or clockwise autorotation of the wheelchair, and a traveling mode selecting switch for realizing control on advancing or backing of the wheelchair. Judgment and calculation of speed and direction are completed through the DSP controller according to setting of the operation handle and the function button, output information is sent to the driving controllers through the CAN buses, and the driving controllers control four hub motors through torque and speed dual-loop PID (proportion integration differentiation) to enable wheels to collaboratively output different directions and speeds.

Owner:TIANJIN POLYTECHNIC UNIV

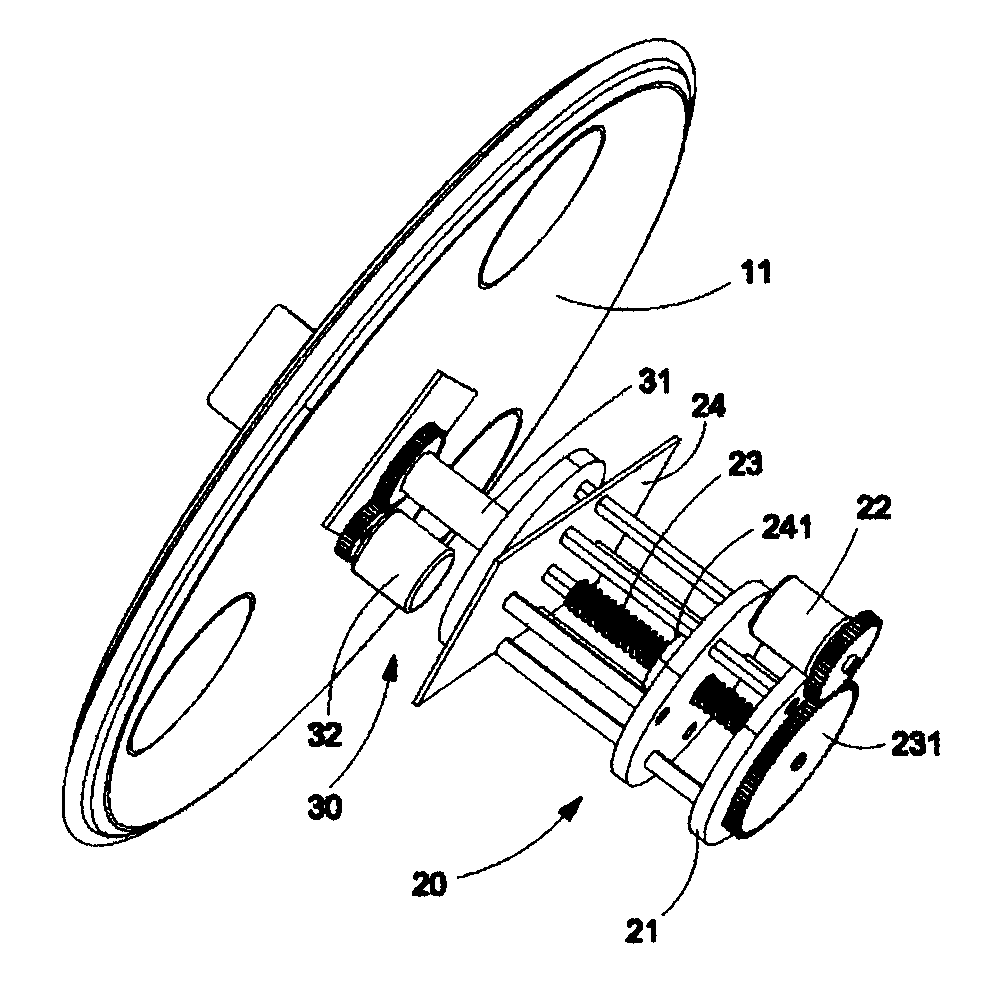

Multi-purpose electric wire winding driving device

InactiveCN110642087AAvoid negative effectsAchieve fixationFilament handlingGear wheelElectric machine

The invention discloses a multi-purpose electric wire winding driving device which comprises a main body shell. According to the multi-purpose electric wire winding driving device, a power source, namely a driving motor is utilized, the necessary rotating function during winding can be achieved, the fixing effect on a winding wheel during electrical wire winding can also be achieved, fixing has the controlling effect, the maximum rotating strength can be controlled autonomously, the effect of controlling the longest guiding wire winding length is also achieved, control performance is high, thepart utilization rate is high, furthermore, the multi-purpose electric wire winding driving device is provided with a gear combination type rotating state dividing-into-two mechanism, a driving statecan be differentiated, thus the driving effects of different functions are achieved, in addition, the multi-purpose electric wire winding driving device is provided with a gear engagement type rotating speed increasing mechanism, the rotating speed can be increased, the air pressure is enhanced, in addition, the multi-purpose electric wire winding driving device is provided with an annular arrayspiral spring abutting type maximum rotating strength controlling mechanism, the maximum resistance during rotating can be controlled, and the negative effects caused by excessively-large air power assistance on the driving motor are effectively prevented.

Owner:胡立泉

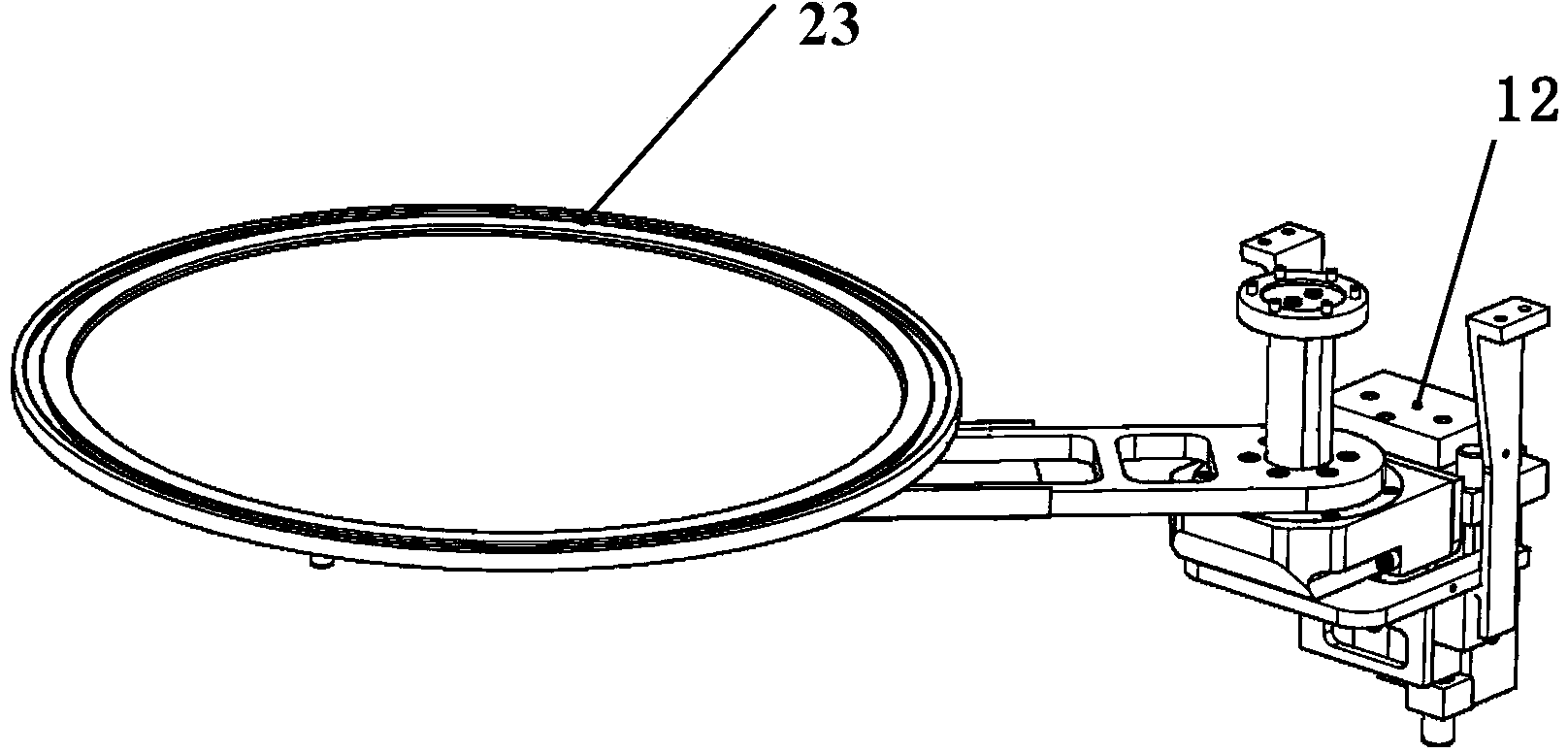

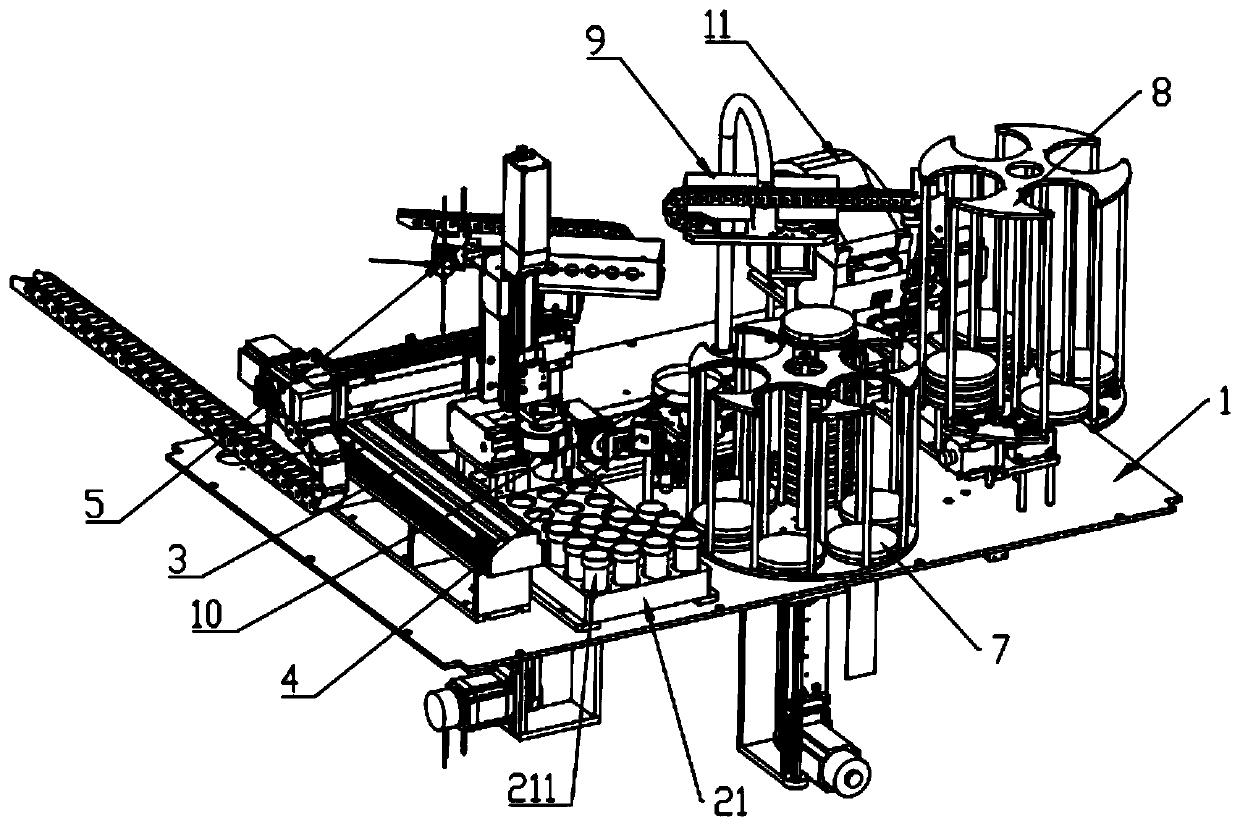

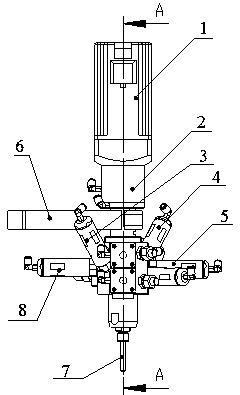

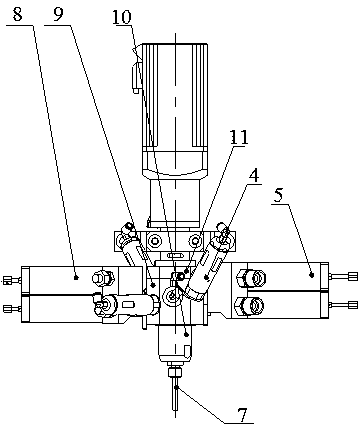

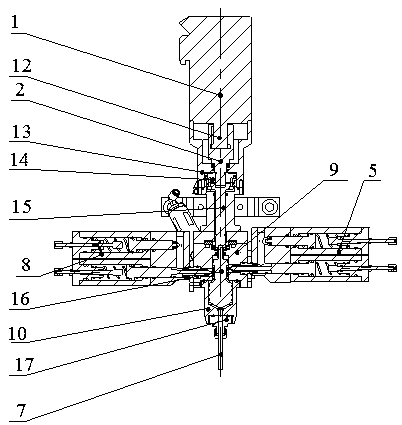

Microbial sample inoculation device

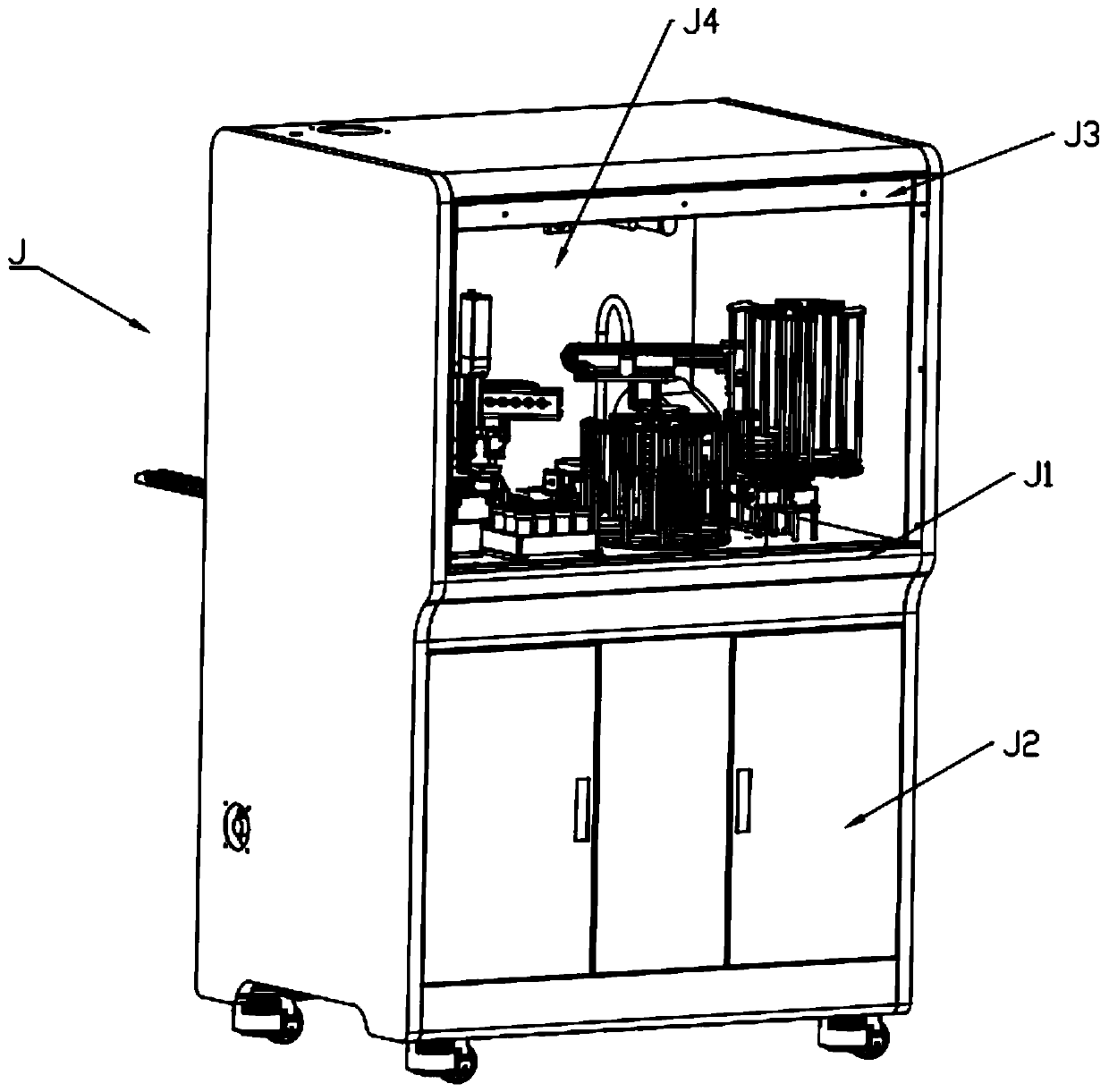

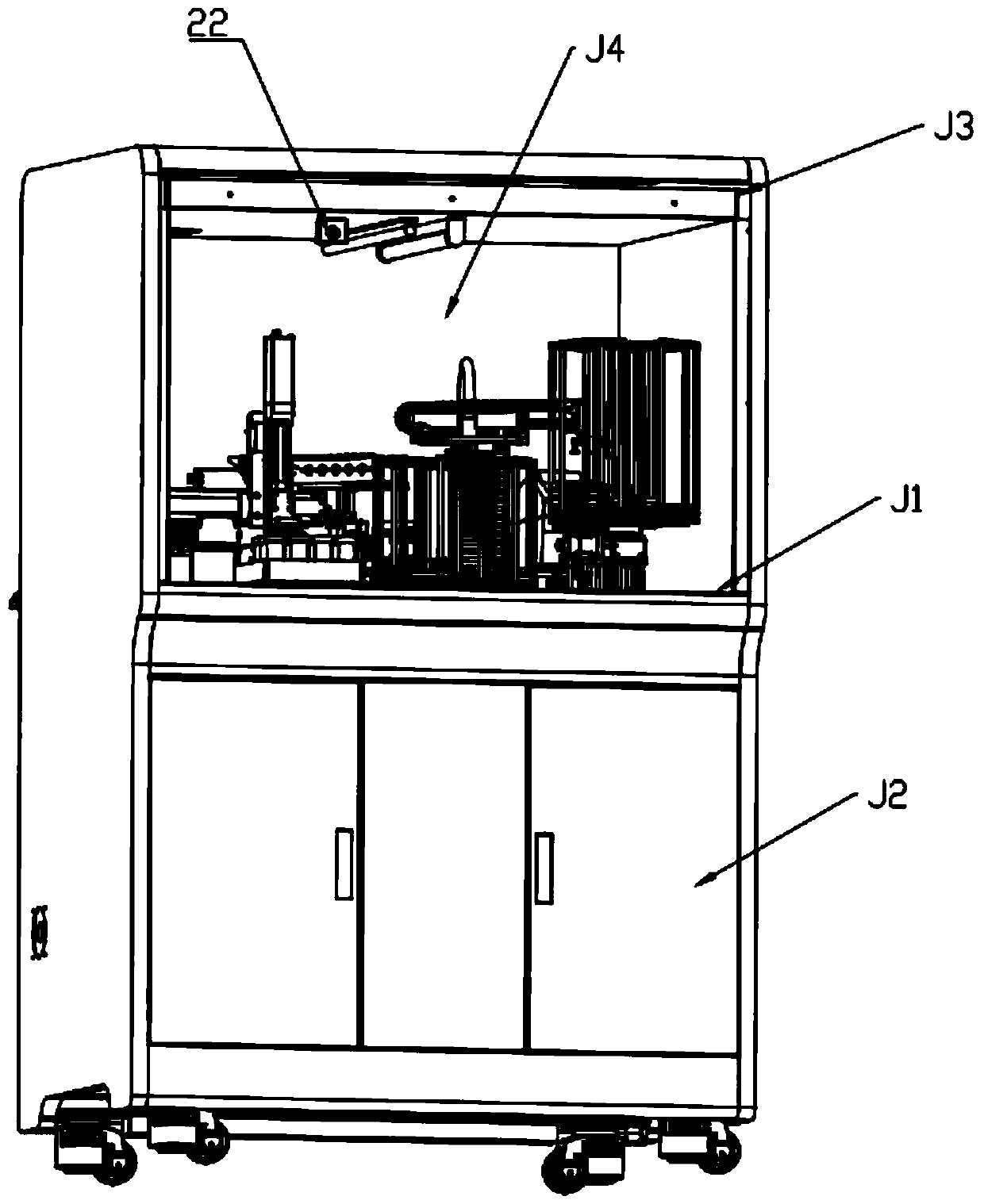

PendingCN111286458AImprove work efficiencyLow costBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicrobial inoculation

The invention relates to a microbial sample inoculation device. The technical problem that adverse effects are caused when microorganism inoculation is conducted in an existing manual streaking mode is solved. Meanwhile, the structure of the existing intelligent robot for treating the microorganism sample is simplified; the device of the invention comprises a rack; a sample test tube recognition mechanism, a sample test tube grabbing mechanism, a scanning device, a sampling mechanism, a sterilization device, a culture dish containing mechanism, a culture dish recycling mechanism, a culture dish grabbing mechanism, a culture dish moving mechanism, a label pasting mechanism, a culture dish conveying mechanism and a controller are fixedly connected to the rack. The invention is widely appliedto the technical fields of microorganism inoculation, clinic, chemistry, environment and the like. Meanwhile, through mutual cooperation of the simplified mechanisms, the whole operation of test tubescanning, cover removing, cover installing, culture dish automatic cover removing and installing, automatic scribing, automatic labeling and the like is completed in a full-automatic mode, the working efficiency is improved, and the cost is reduced.

Owner:WEIHAI SHILI ELECTRONICS TECH

Dual-component adhesive coating device

ActiveCN105381930ASimple structureEasy to useLiquid surface applicatorsSpraying apparatusAdhesiveEngineering

The invention discloses a dual-component adhesive coating device and belongs to the field of adhesive coating equipment. In the use process of the coating device, liquid adhesives pass through a feeding chamber and a stirring free hub and enter a stirring cavity through an adhesive valve A and an adhesive valve B, specifically, the liquid adhesives enter the stirring cavity via a spiral channel of the stirring free hub and are stirred and mixed to be even under high-speed rotation of the stirring free hub; the stirring free hub is driven by an air cylinder to ascend, the stirring cavity is opened, the evenly-mixed liquid adhesives enter an adhesive coating pipe, and then adhesive coating is performed; the adhesive valve A and the adhesive valve B are reset and closed after adhesive coating is completed; a water inlet air cylinder is started to clean the feeding chamber, the stirring free hub and the stirring cavity with high pressure; after cleaning is completed, an air blowing air cylinder is started to blow air so as to dry the feeding chamber, the stirring free hub and the stirring cavity; after air blowing is completed, a spline air cylinder is vented, a spline shaft moves downwards and drives the stirring free hub to move downwards, and the stirring free hub seals the adhesive coating pipe so that the liquid can be prevented from dropping off.

Owner:JINAN CJR ELECTRICS CO LTD

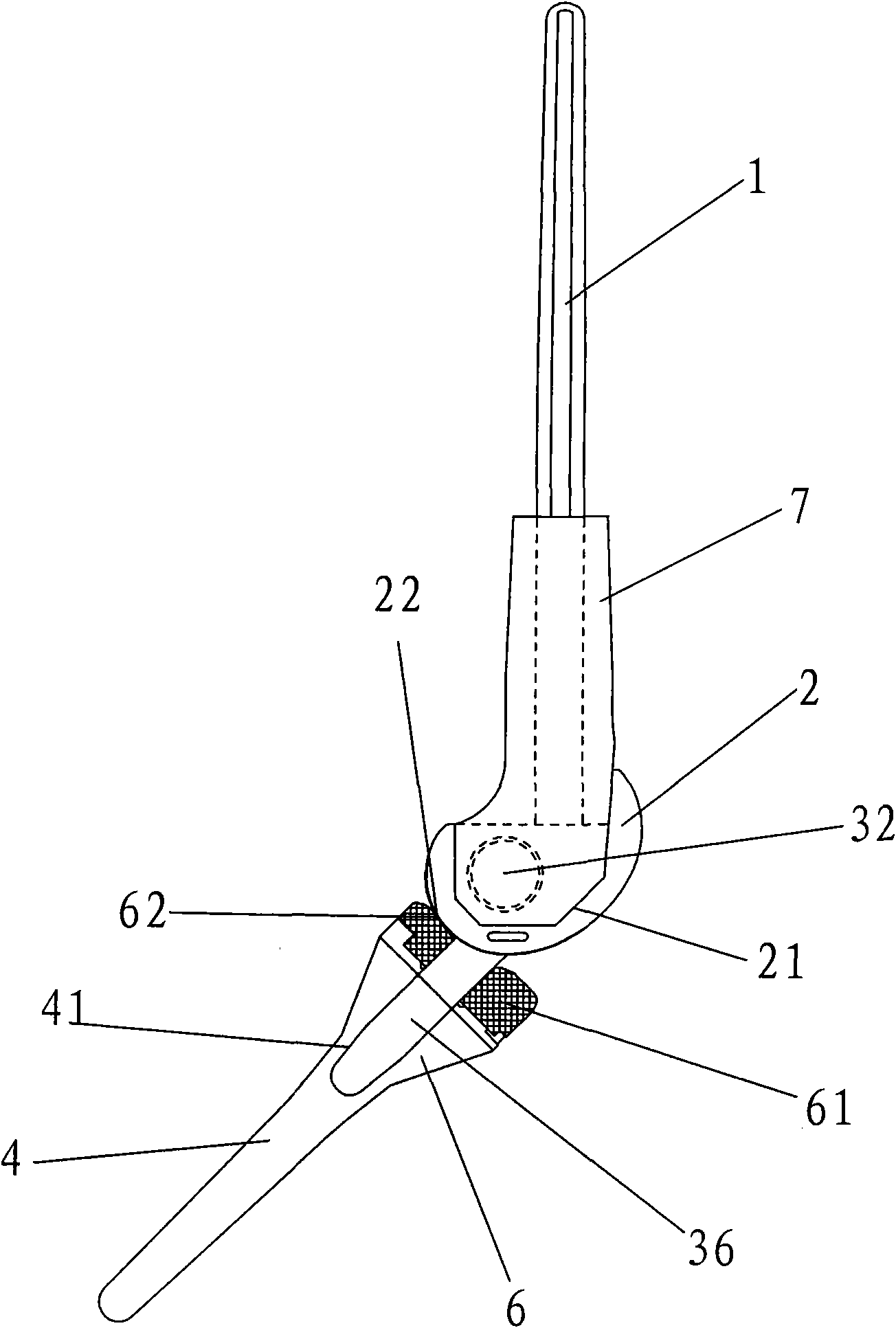

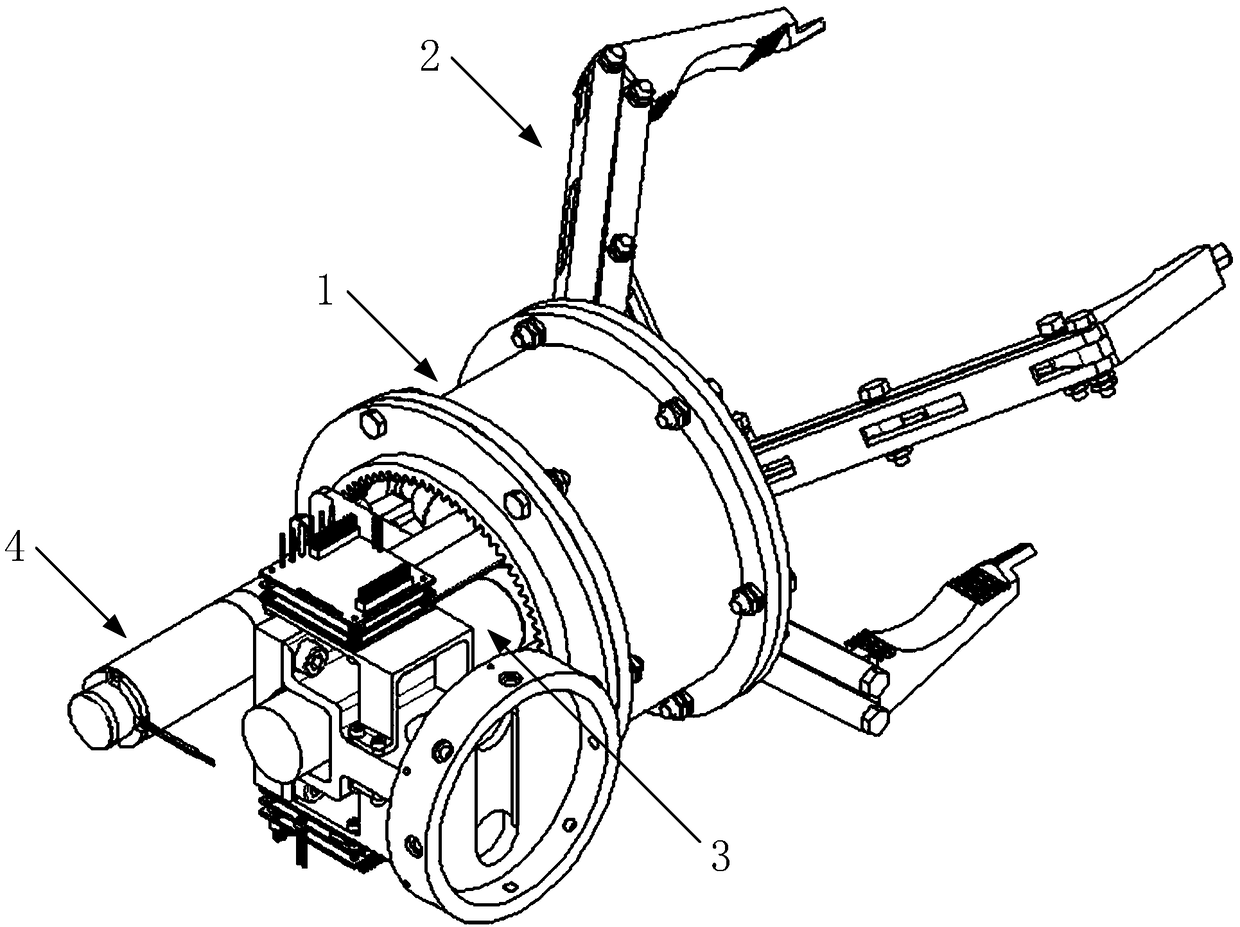

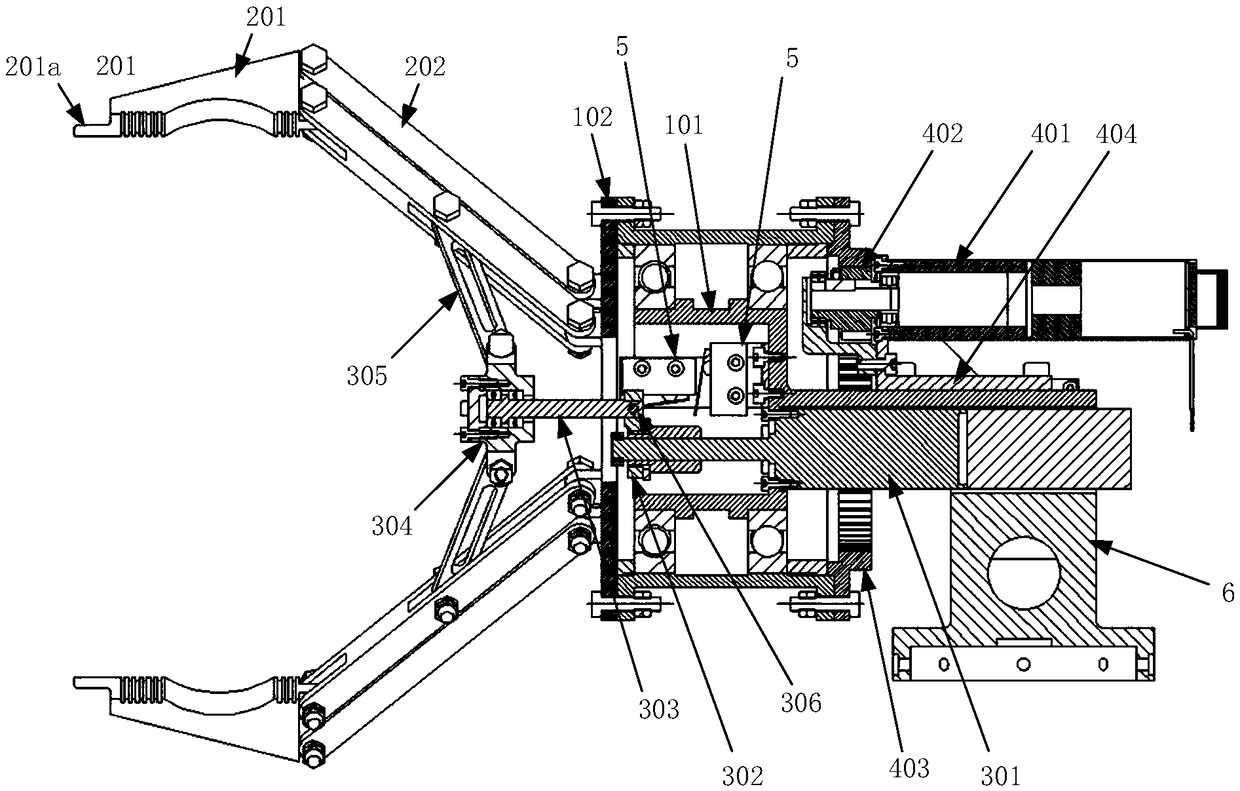

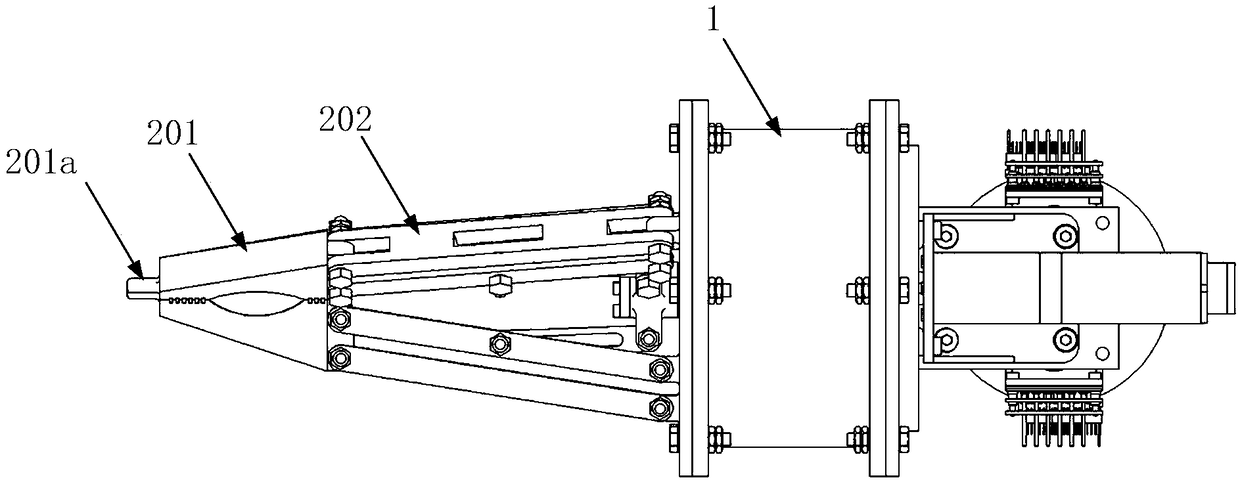

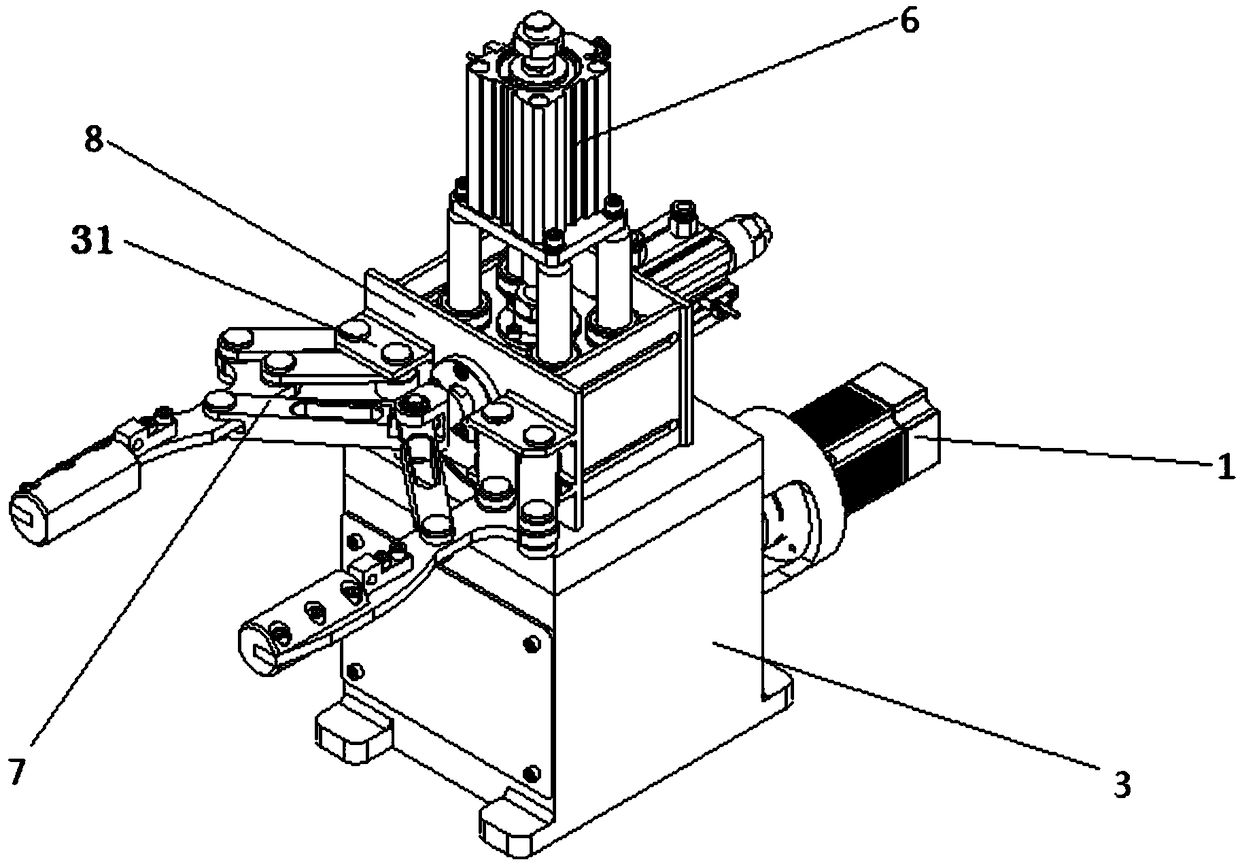

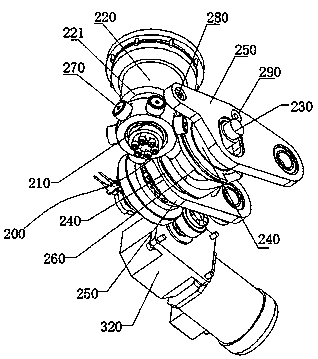

Continuous rotation multifunctional three-finger mechanical paw

ActiveCN108656146AImplement the rotation functionRealize the tightening functionGripping headsControl systemEngineering

The invention discloses a continuous rotation multifunctional three-finger mechanical paw. A physical mechanical structure comprises a wrist part and a paw part. On the basis of the physical mechanical structure, a control system and a sensing system of the three-finger mechanical paw are constructed. The wrist part comprises a rotation freedom degree and is used for rotation of the three-finger paw. The paw part comprises an opening and closing freedom degree and is used for opening and closing of the three-finger paw. The control system of the three-finger mechanical paw comprises two motordrivers. The sensing system is composed of two touch switches, and the paw opening and closing extreme position is detected. Through the finger tip part mechanical structure design, the function similar to the function that an inner hexagon wrench screws an inner hexagon screw can be achieved. The continuous rotation multifunctional three-finger mechanical paw has the beneficial effects that the grabbing, operating and continuous rotating functions are combined, and the operation functions of inner hexagon screw and outer hexagon nut screwing can be achieved.

Owner:BEIHANG UNIV +1

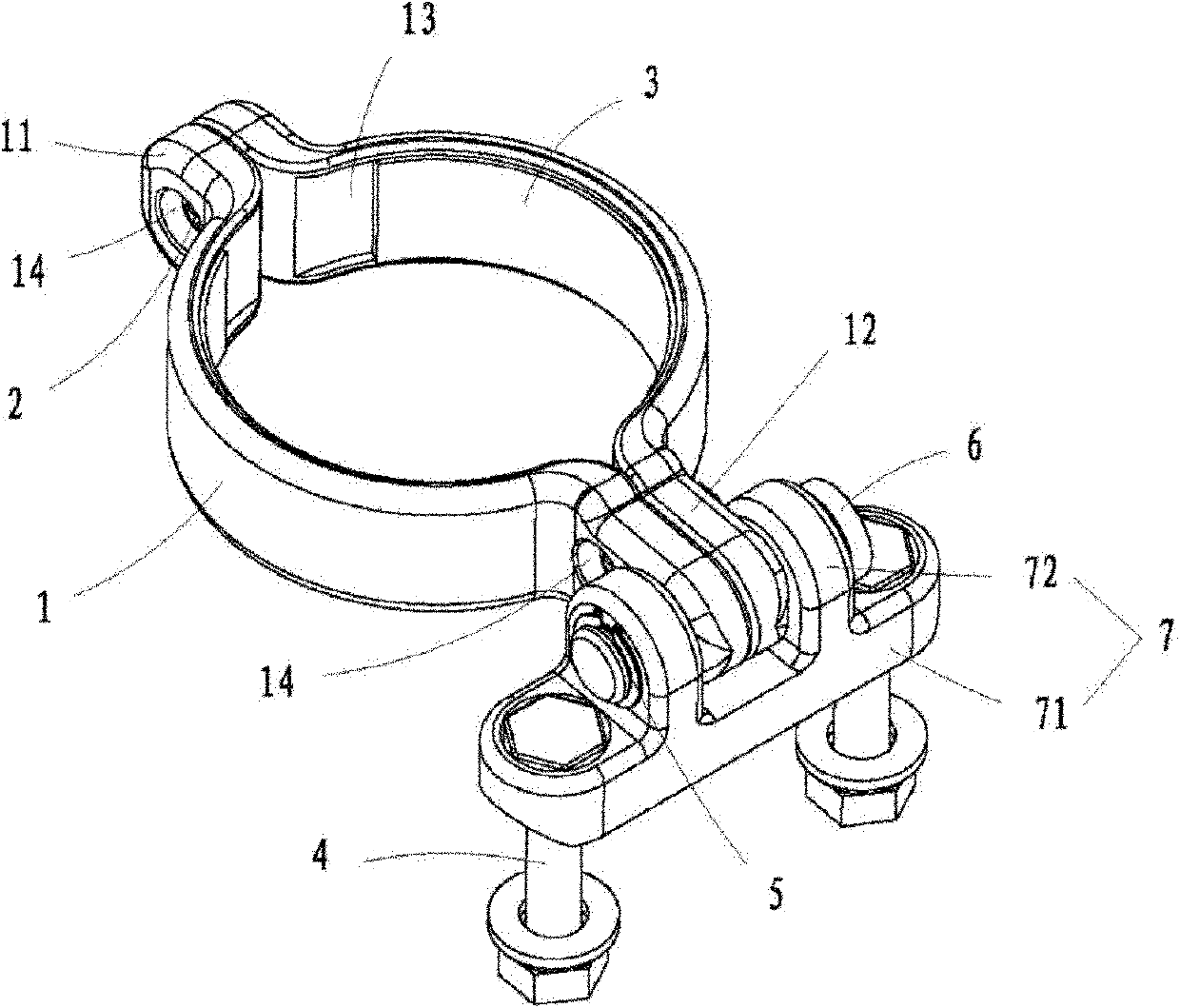

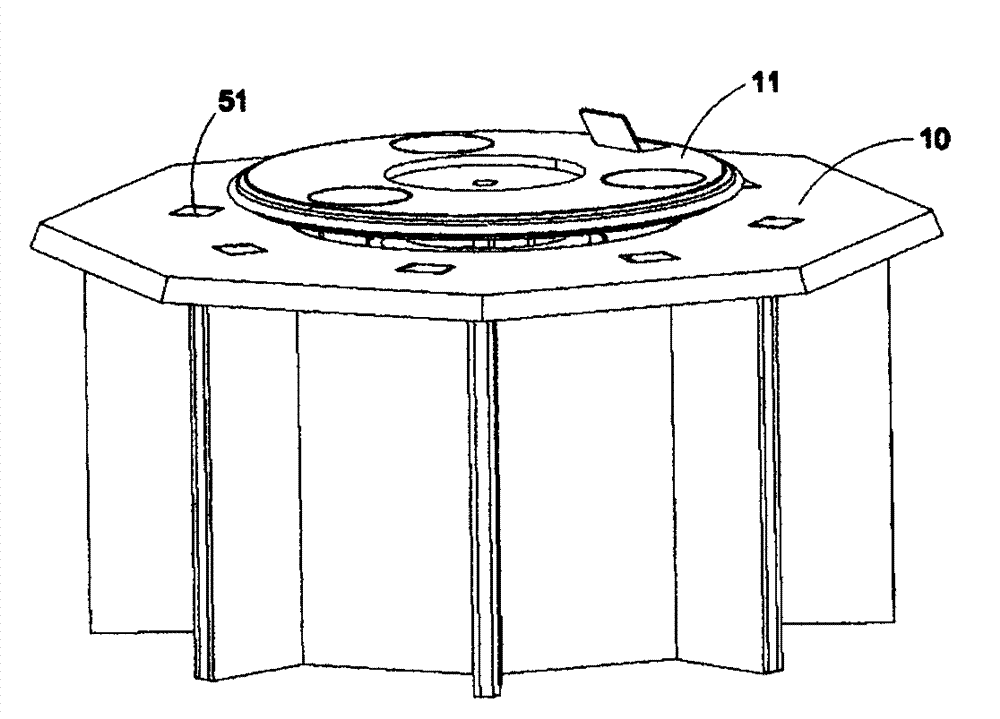

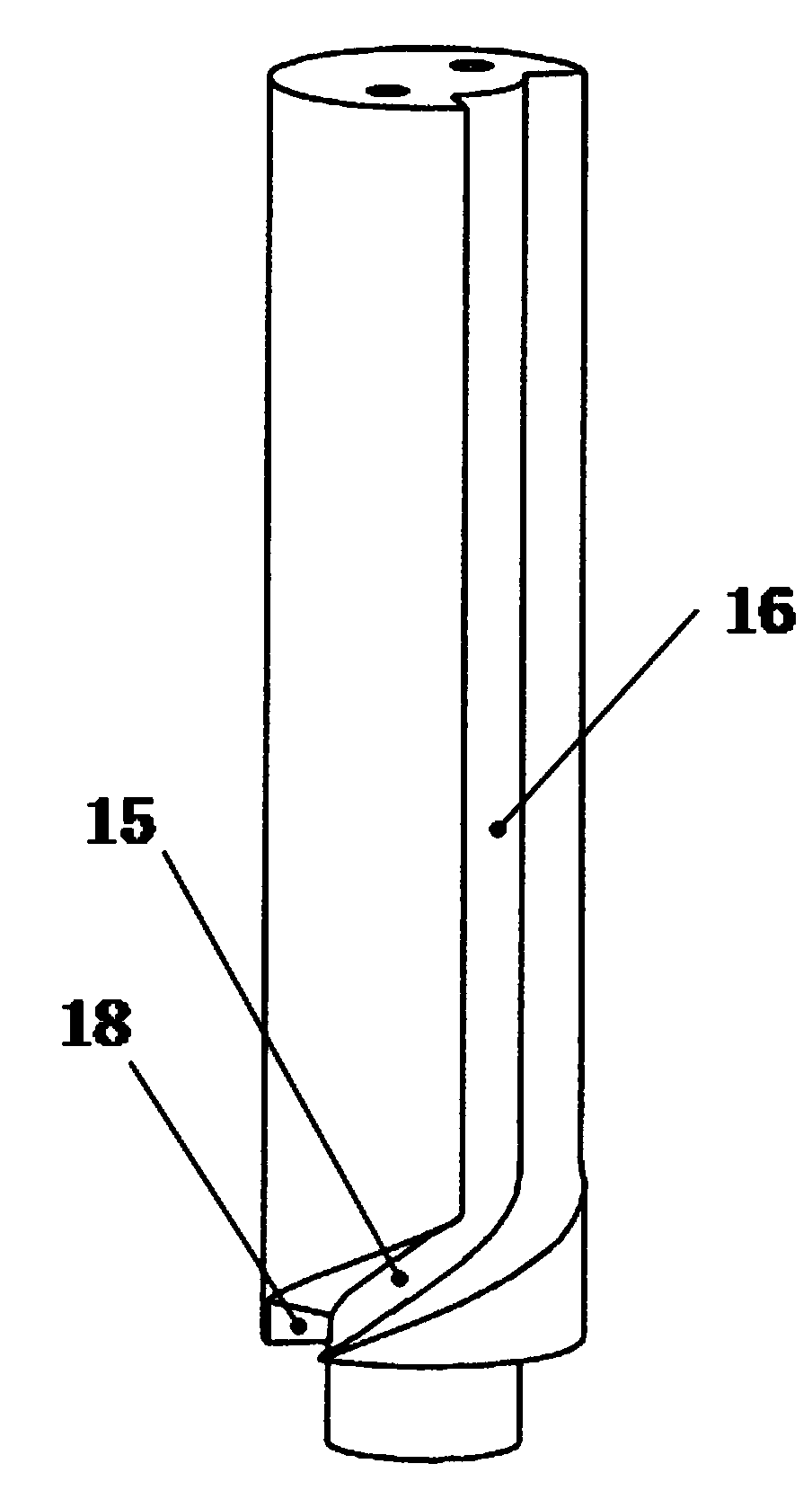

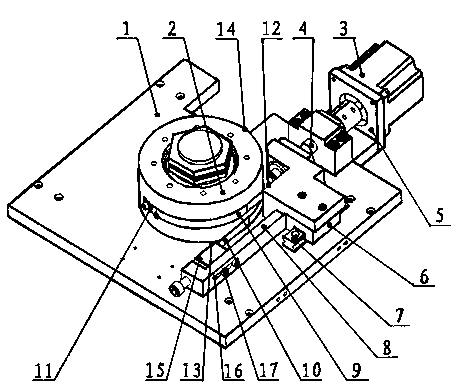

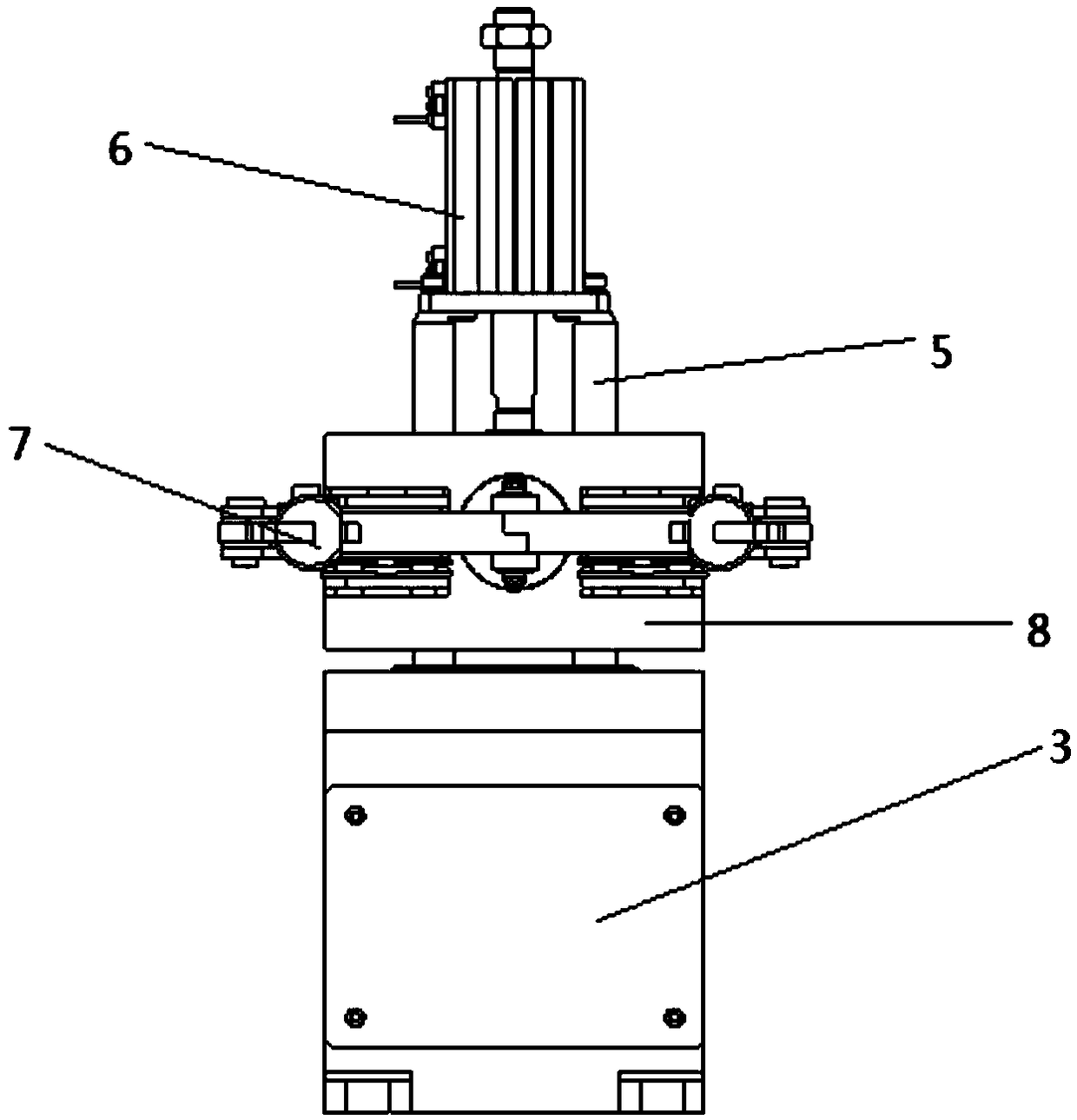

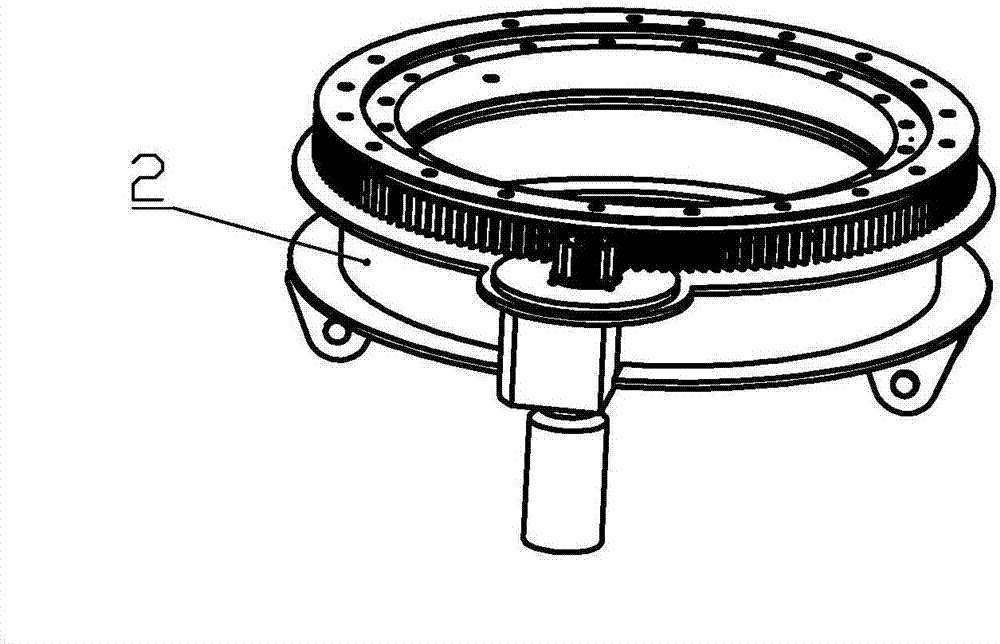

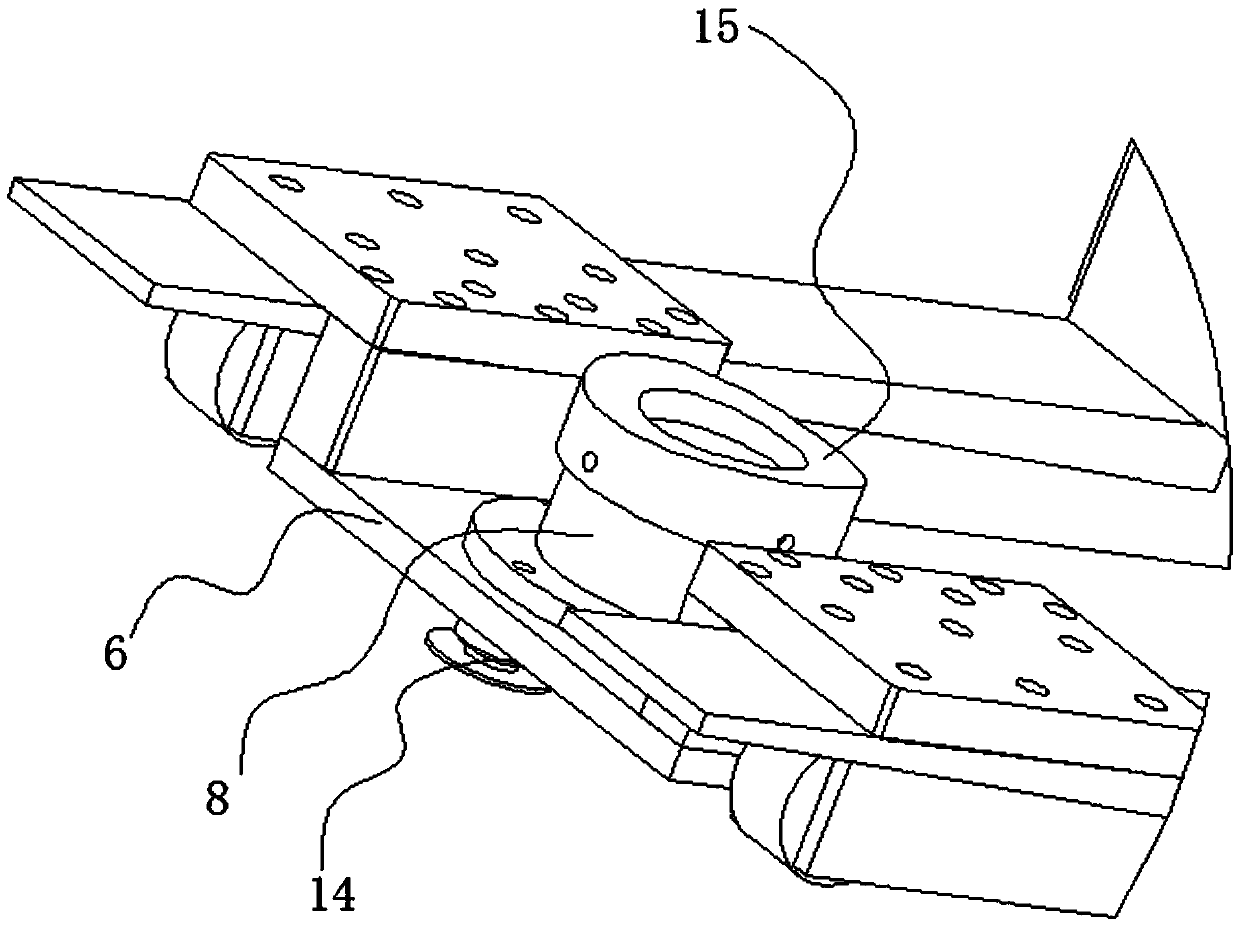

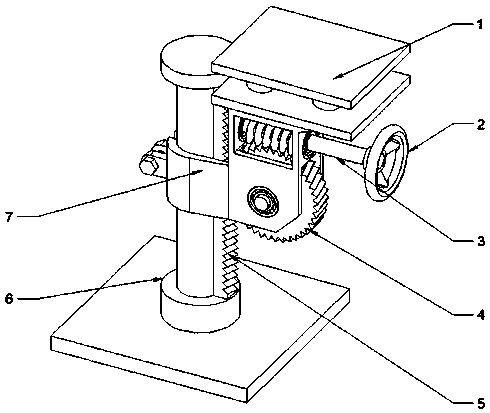

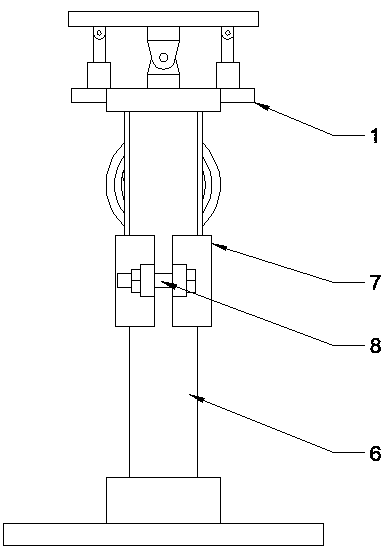

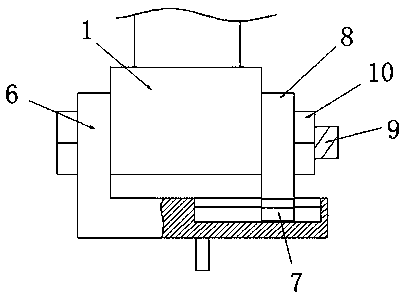

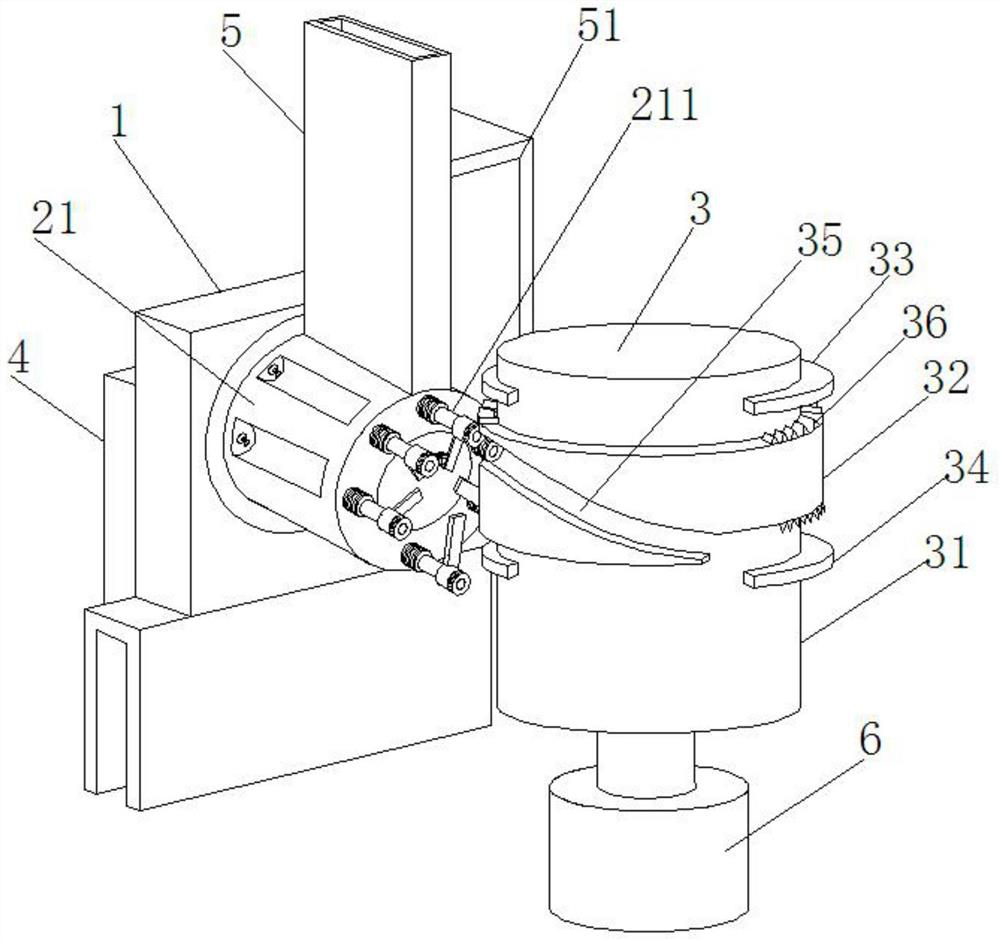

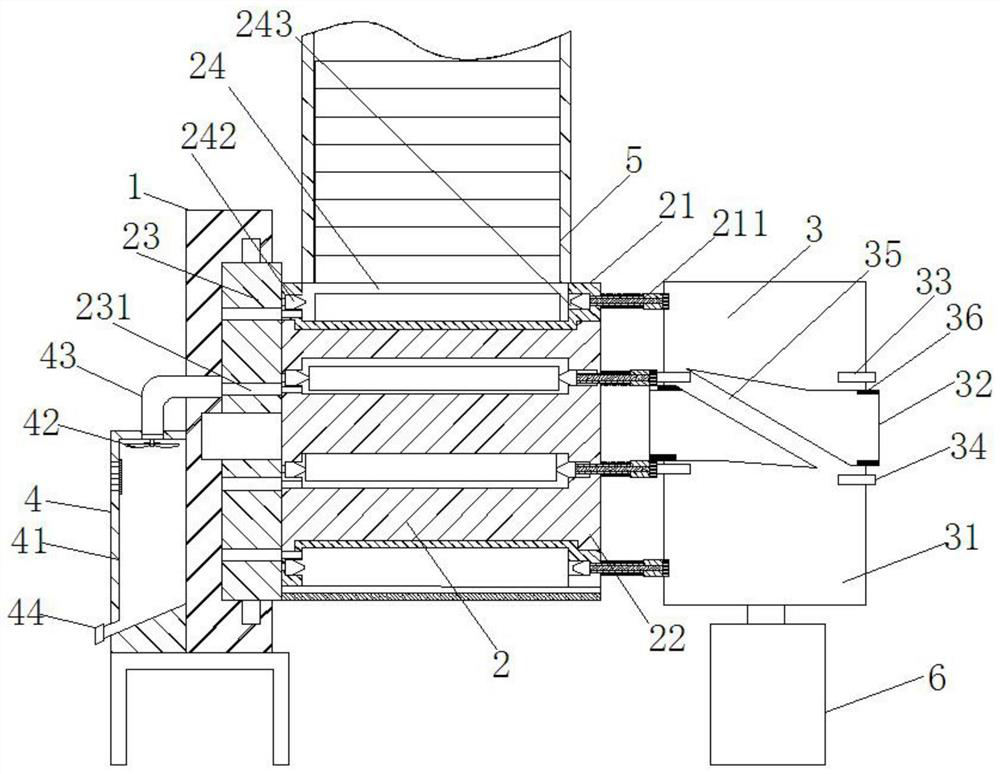

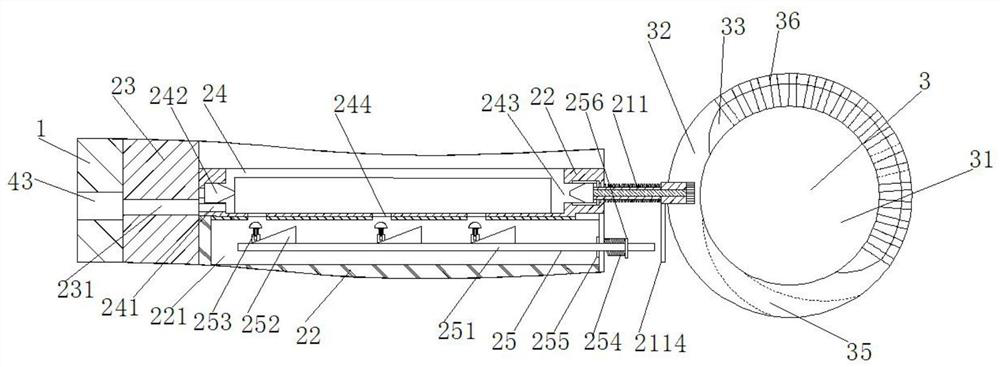

Compact small angle precision rotating mechanism

ActiveCN103639818AImplement the rotation functionSimple structureFeeding apparatusLarge fixed membersEngineeringLeaf spring

The invention discloses a compact small angle precision rotating mechanism which solves the problem that for existing equipment, cost of precision rotating and positioning in a narrow space is high. The compact small angle precision rotating mechanism comprises a PLC and a base plate (1), a lead screw motor base (5) and a slider guide rail (7) are arranged on the portion, on one side of a cylindrical rotary table (2), of the base plate, a stretching block (8) is arranged on a lead screw nut (6), an adjusting block (15) is arranged at the front end of the stretching block, the side faces of the cylindrical rotary table (2) are provided with a lower leaf spring fixing screw (14) and an upper leaf spring fixing screw (11) respectively, one end of a lower leaf spring (10) is connected with a lower leaf spring fixing pin, the other end (13) of the lower leaf spring (10) is connected with the adjusting block, one end of an upper leaf spring (9) and an upper leaf spring fixing pin are connected together, the other end (12) of the upper leaf spring and a slider nut are connected together, both the plane where the lower leaf spring is located and the plane where the upper leaf spring is located are parallel to the top face of the cylindrical rotary table, and the PLC is electrically connected with a lead screw driving motor (3). The compact small angle precision rotating mechanism is simple in structure, small in occupied space, high in control precision and low in cost.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 2 RES INST

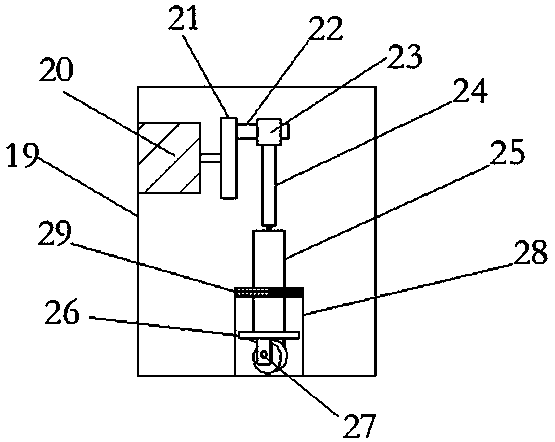

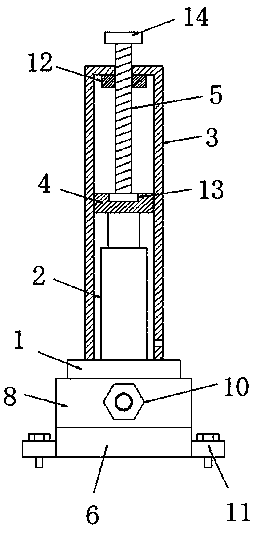

Rotatable lifting type pneumatic clamping device

The invention relates to the field of clamping mechanisms of automation equipment and provides a rotatable lifting type pneumatic clamping device. The rotatable lifting type pneumatic clamping devicecomprises a helical gear shaft, a stepped shaft, a second helical gear which is mounted on the stepped shaft, a first box body, a second box body, a first air cylinder, guide rail rods, a second air cylinder and a clamping mechanical arm; the helical gear shaft is connected with a motor; a first helical gear on the helical gear shaft is engaged with the second helical gear; the guide rail rods arecoaxially fixed to the top end of the stepped shaft; the second box body sleeves the guide rail rods; the second air cylinder is fixedly connected with the top ends of the guide rail rods; a second push rod of the second air cylinder is fixedly connected with the second box body; and the clamping mechanical arm is mounted on the second box body and controlled by the first air cylinder. The rotatable lifting type pneumatic clamping device can realize the functions of rotating, lifting, material taking, discharging and the like in an article clamping process, and the article clamping reliability and efficiency are improved.

Owner:JIANGSU UNIV

Computer auxiliary supporting device

InactiveCN108061224AImplement the rotation functionImprove stabilityNon-rotating vibration suppressionDigital data processing detailsComputer-aidedRadiation

The invention discloses a computer auxiliary supporting device which comprises a base. A first rotary motor is fixedly arranged in the base. The output end of the top of the first rotary motor is movably connected with a supporting table through a first ball bearing. Multiple circularly-distributed cylindrical grooves are formed in the upper surface of the base, the tops of the cylindrical groovesand the top of the base are through, and an electric push rod is fixedly arranged on the inner wall of the bottom of each cylindrical groove. A limiting block is fixedly arranged at the top of each electric push rod. Multiple limiting grooves corresponding to the limiting blocks are formed in the bottom of the supporting table. Second rotary motors are fixedly arranged at the four corners of thetop of the supporting table. An output shaft of the top of each second rotary motor is fixedly connected with a screw through a coupling, each screw is in threaded connection with a lifting barrel, and a containing plate is fixedly arranged at the top ends of the four lifting barrels. The computer auxiliary supporting device is simple and reasonable in structural design and convenient to operate,the computer rotating and lifting functions can be achieved, safety is high, the heat radiation efficiency is improved, and device movement is facilitated.

Owner:广州容骏信息科技有限公司

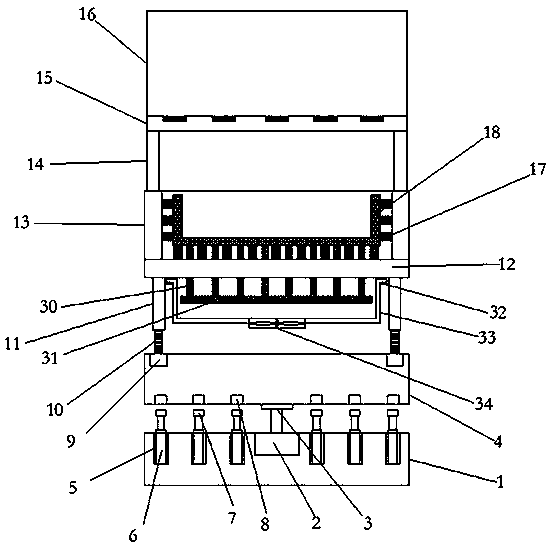

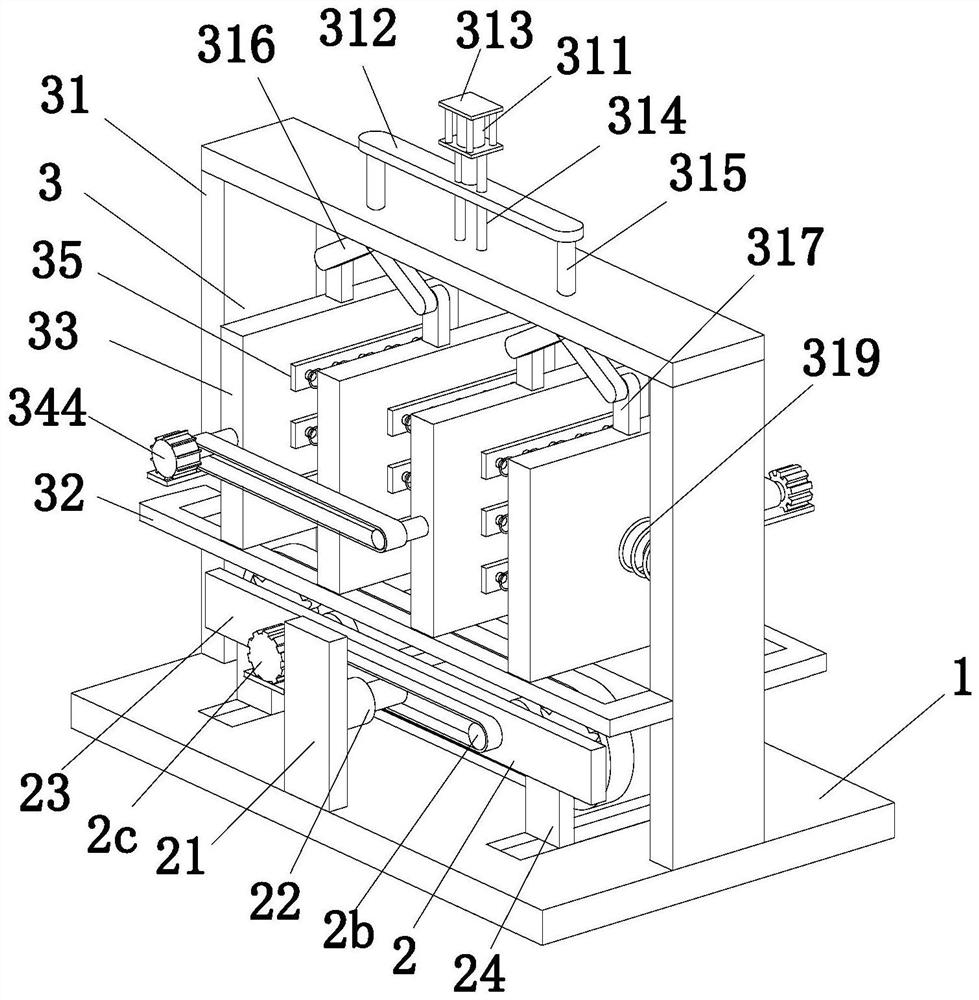

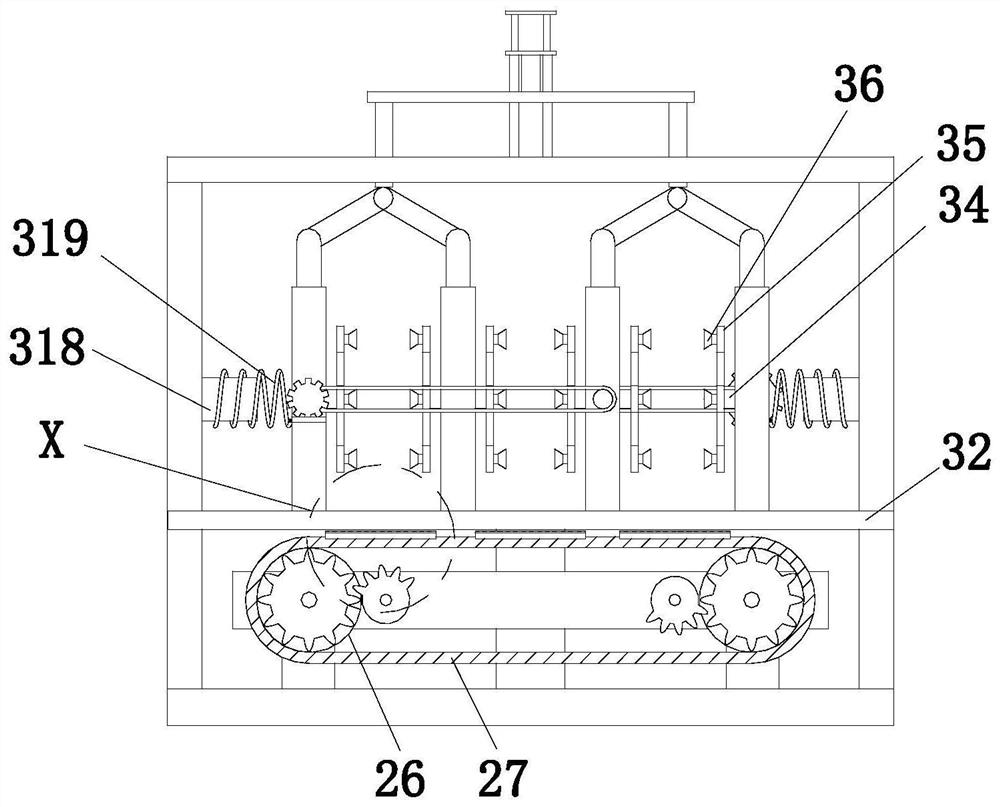

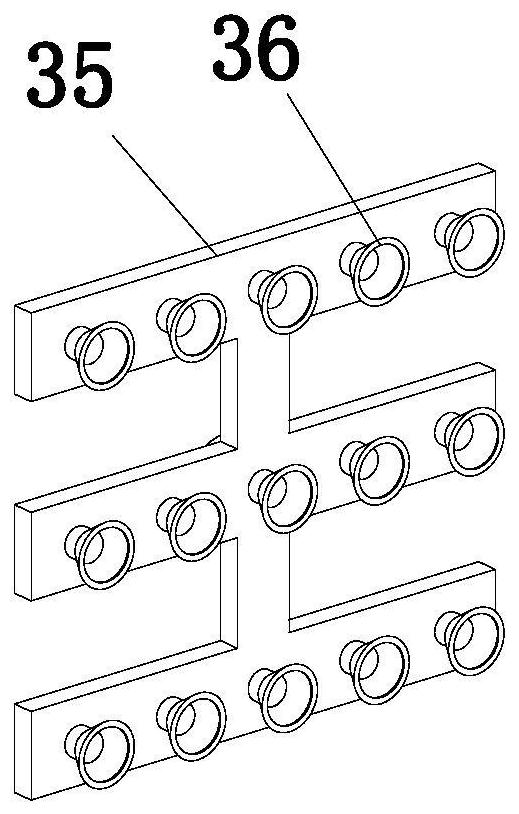

Batch treatment system for glass panels of liquid crystal display screens

ActiveCN112355825AIncrease profitReduce processing costsGrinding drivesBelt grinding machinesLiquid-crystal displayEngineering

The invention relates to a batch treatment system for glass panels of liquid crystal display screens. The batch treatment system for the glass panels of the liquid crystal display screens comprises abottom plate, a grinding device and a fixing device, wherein the bottom plate is fixedly installed on the existing ground; the grinding device is installed at the upper end of the bottom plate; and the fixing device is arranged above the grinding device. According to the invention, the design concept that a plurality of groups of glass panels are ground at the same time is adopted for carrying outbatch treatment on the glass panels of the liquid crystal display screens, the grinding device arranged in the batch treatment system for the glass panels of the liquid crystal display screens realizes linear reciprocating motion of a grinding belt through stretching and retracting of a first air cylinder, and therefore the function of carrying out reciprocating grinding on the corners of the glass panels of the liquid crystal display screens is realized; and moreover, the grinding degree can be controlled by controlling the reciprocating frequency, and then the utilization rate of the devicecan be increased.

Owner:麒麟电子(深圳)有限公司

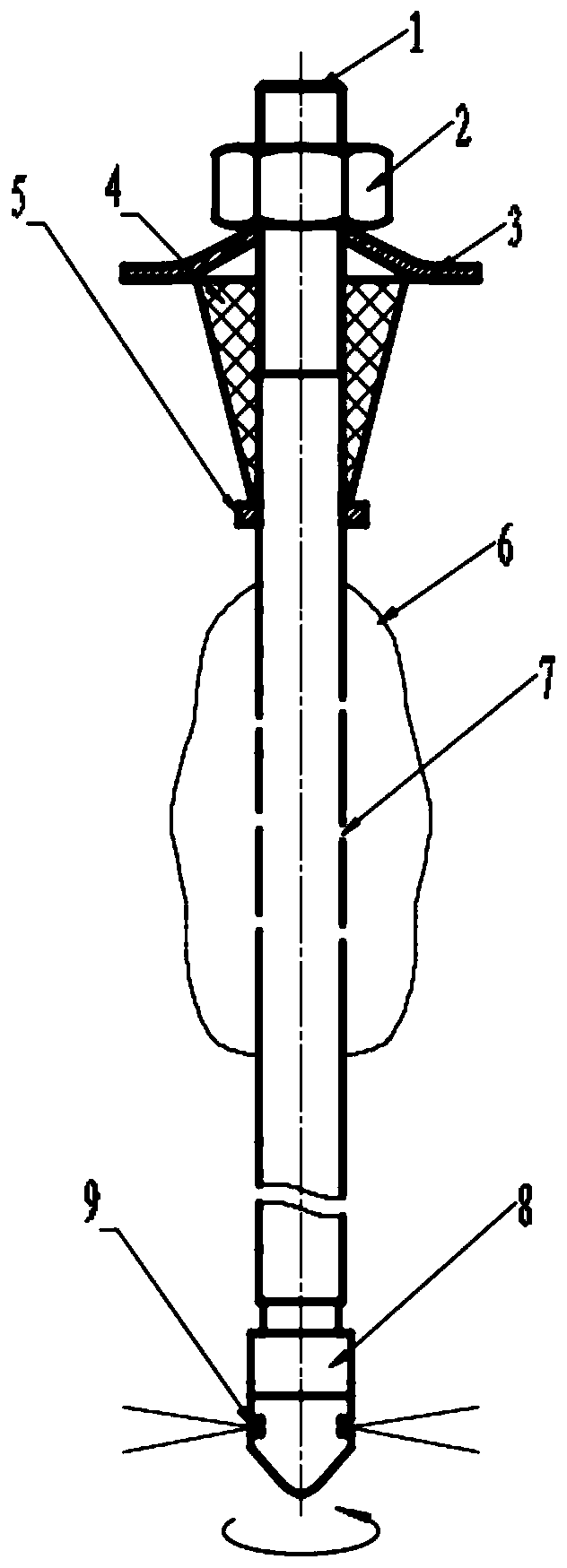

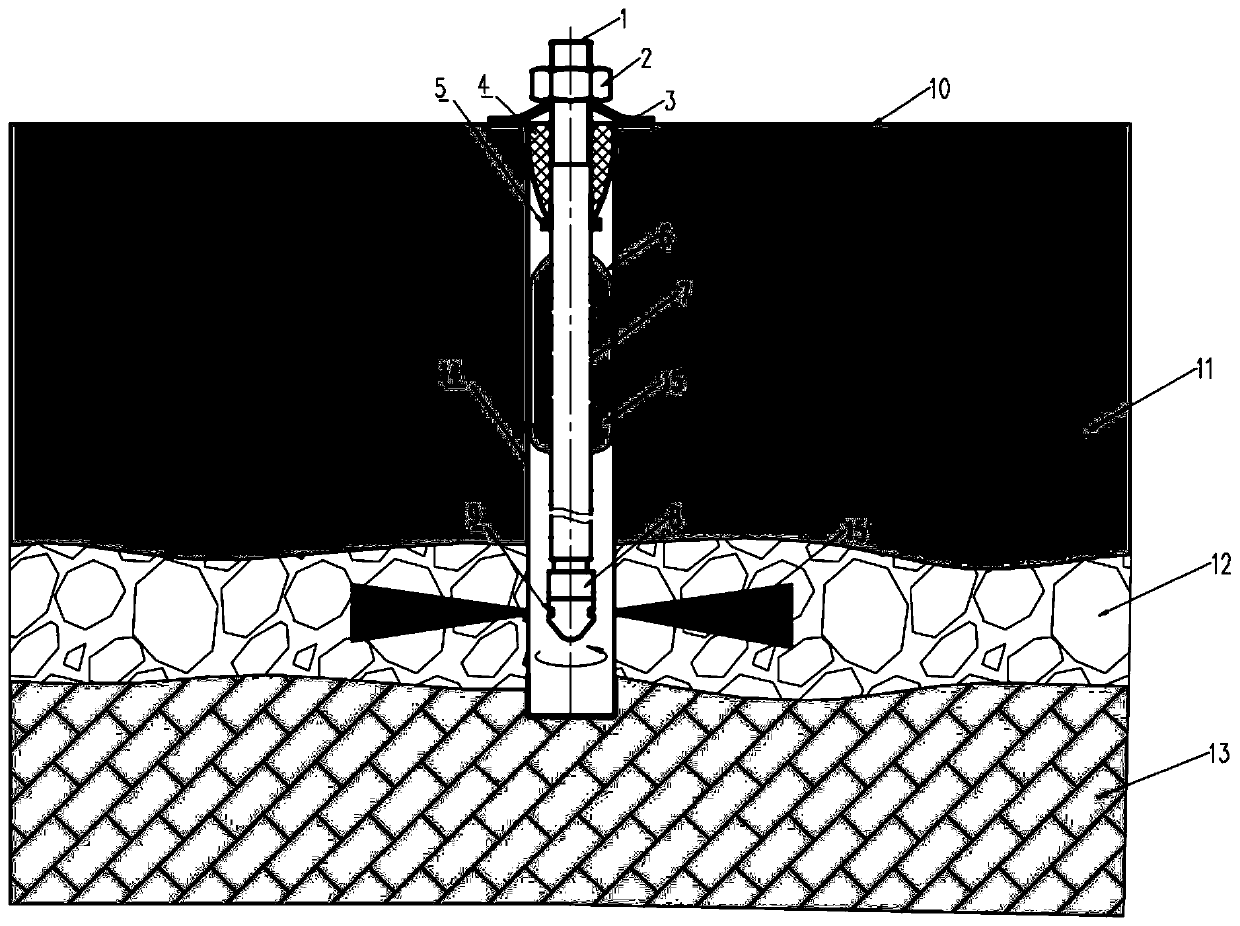

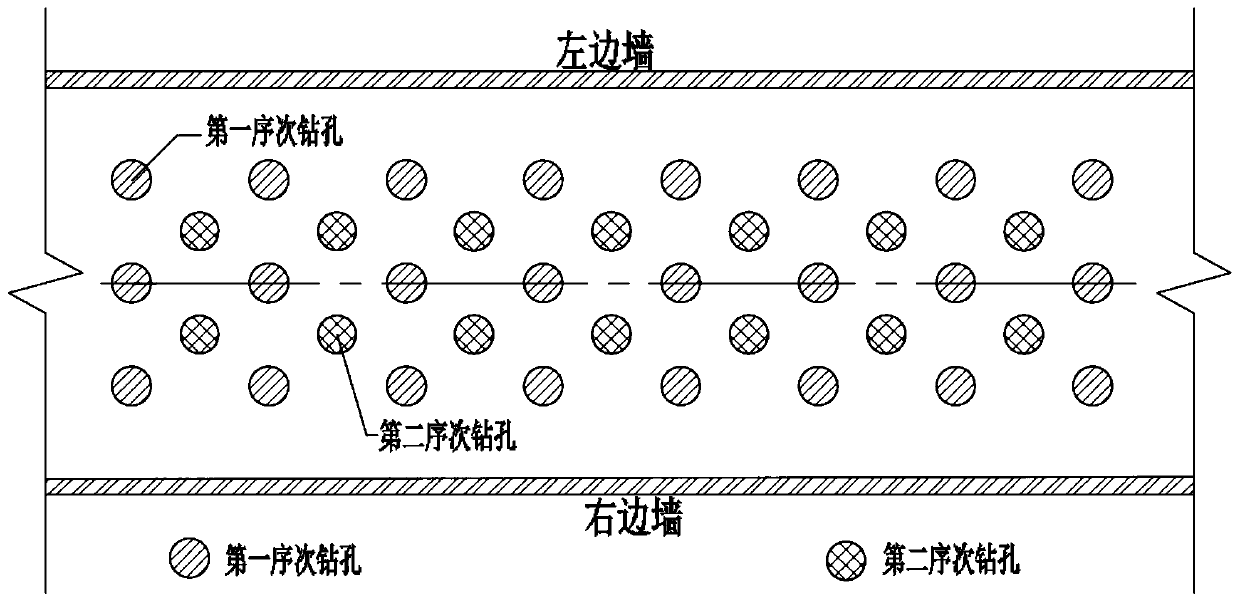

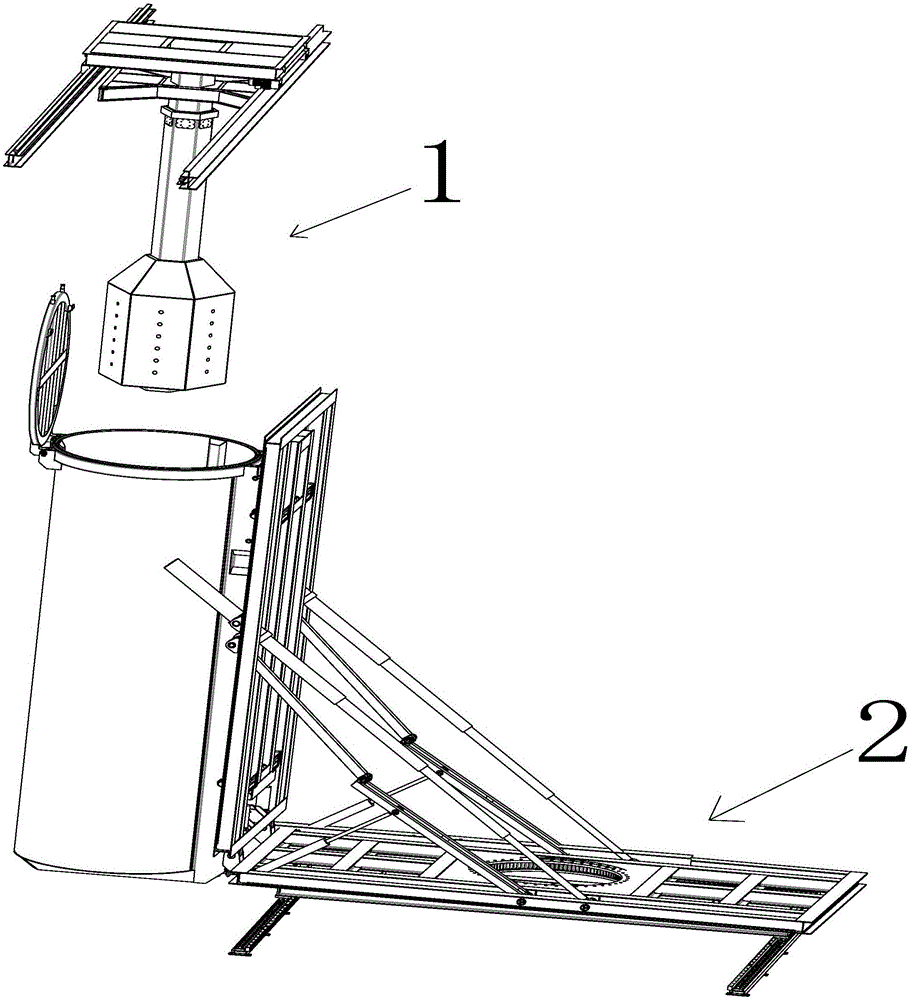

Karst tunnel operation period base plate separation layer rotary spraying grouting technology and grouting device

ActiveCN110017153AStrong orientationSpread evenlyUnderground chambersTunnel liningWater storageSprayer

The invention belongs to the technical field of tunnel and underground engineering disaster treatment, and particularly relates to a Karst tunnel operation period base plate separation layer rotary spraying grouting technology and a grouting device. The technology comprises the following steps: A, physical exploration of a separation layer of a base plate: determining the depth, the spatial rangeand the characteristics of the separation layer, and providing a decision basis for the design of a grouting treatment scheme; B, treatment scheme design: determining a treatment area, and completingscheme design, including slurry parameters, grouting parameters and drilling parameters; C, drilling construction: designing and arranging hole sites on site according to the scheme; and D, grouting reinforcement of the separation layer of the base plate: lowering the nozzle end of a separation layer plate rotary spraying grouting device into a drill hole, enabling a rotary sprayer to be located at the depth of the separation layer, and then conducting rotary spraying grouting on broken surrounding rock and holes in the separation layer. By means of the method, directional quick-setting grouting can be conducted on the position of the separation layer, circular diffusion is even, the reinforcing effect is better, and the method is not affected by the tunnel gradient and separation layer cavity water storage.

Owner:SHANDONG UNIV

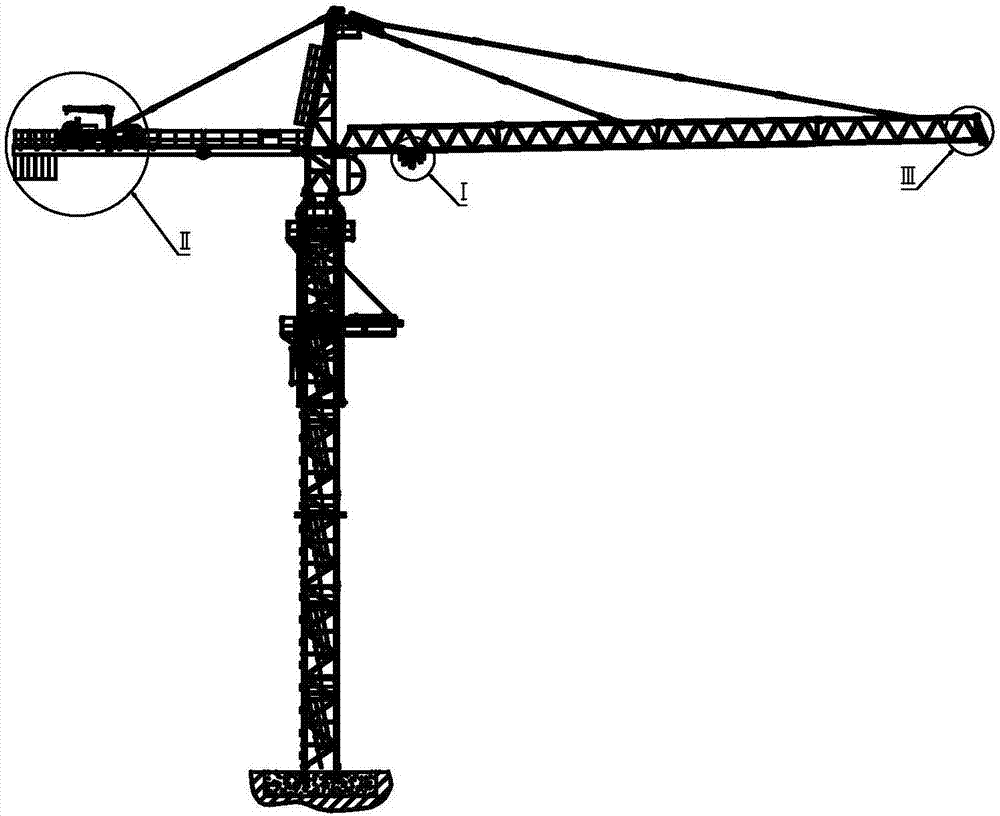

Tower crane with function of adjusting spatial position of lifting component omnidirectionally

ActiveCN106927377AImprove work efficiencyWith adjustmentLoad-engaging elementsCranesRotation functionLimiter

A tower crane with the function of adjusting the spatial position of a lifting component omnidirectionally belongs to the technical field of tower cranes. The tower crane comprises two parallel lifting mechanisms and a trolley with a slewing gear; the two parallel lifting mechanisms are installed back and forth on balance arms of the tower crane in the axis direction; the trolley is connected to a lower chord member of a crane jib, and slides along the crane jib; lifting steel wire ropes on the two lifting mechanisms are connected to wedged joints of the crane jib through a guide rope pulley block on a tower head, a lifting weight limiter, a trolley center guide rope pulley block, a slewing beam guide pulley block on the trolley and a lifting pulley block as well as a guide pulley block of the slewing beam, a central guide rope pulley block and two anti-twisting device pulleys at the end of the crane jib; the lift or decent of the lifting pulley blocks is controlled through the lifting mechanisms. In the invention, the + / - 90 DEG rotation function of the lifting component can be achieved, and the spatial position of the lifting component can be adjusted omnidirectionally; different lifting components can be rotated and adjusted in place on a construction side, and the efficiency and construction quality are improved in the lifting process.

Owner:SHENYANG JIANZHU UNIVERSITY

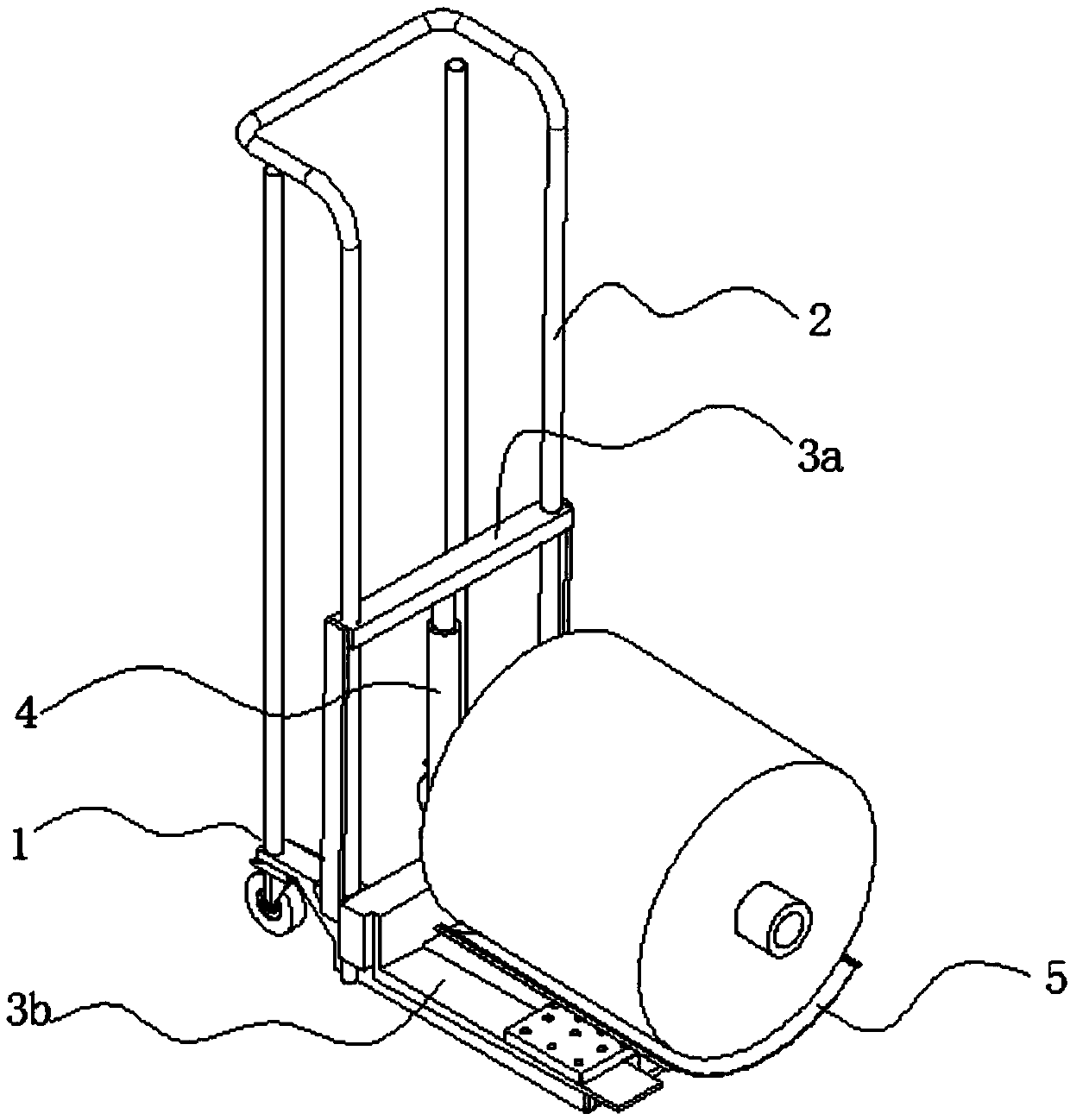

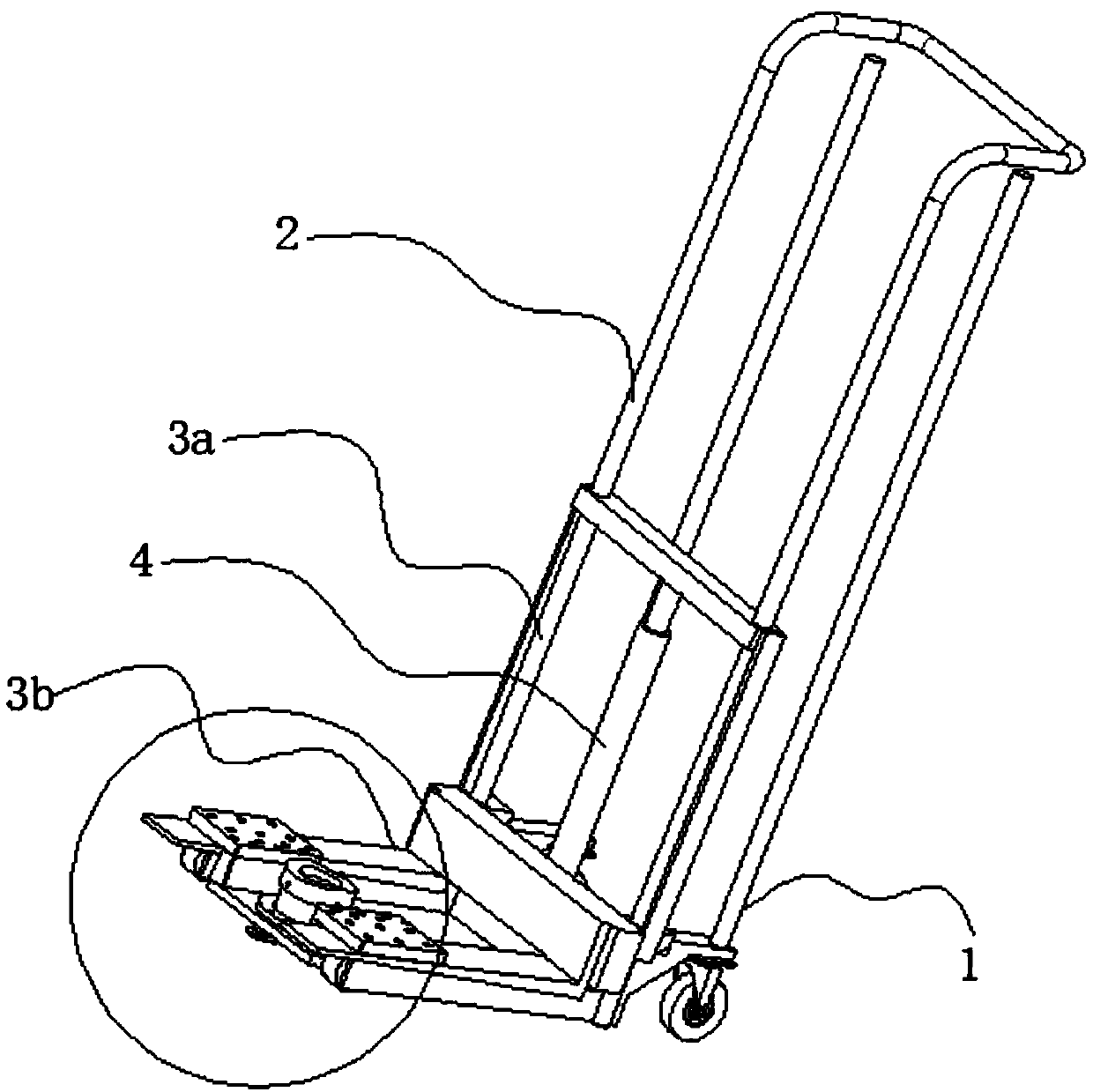

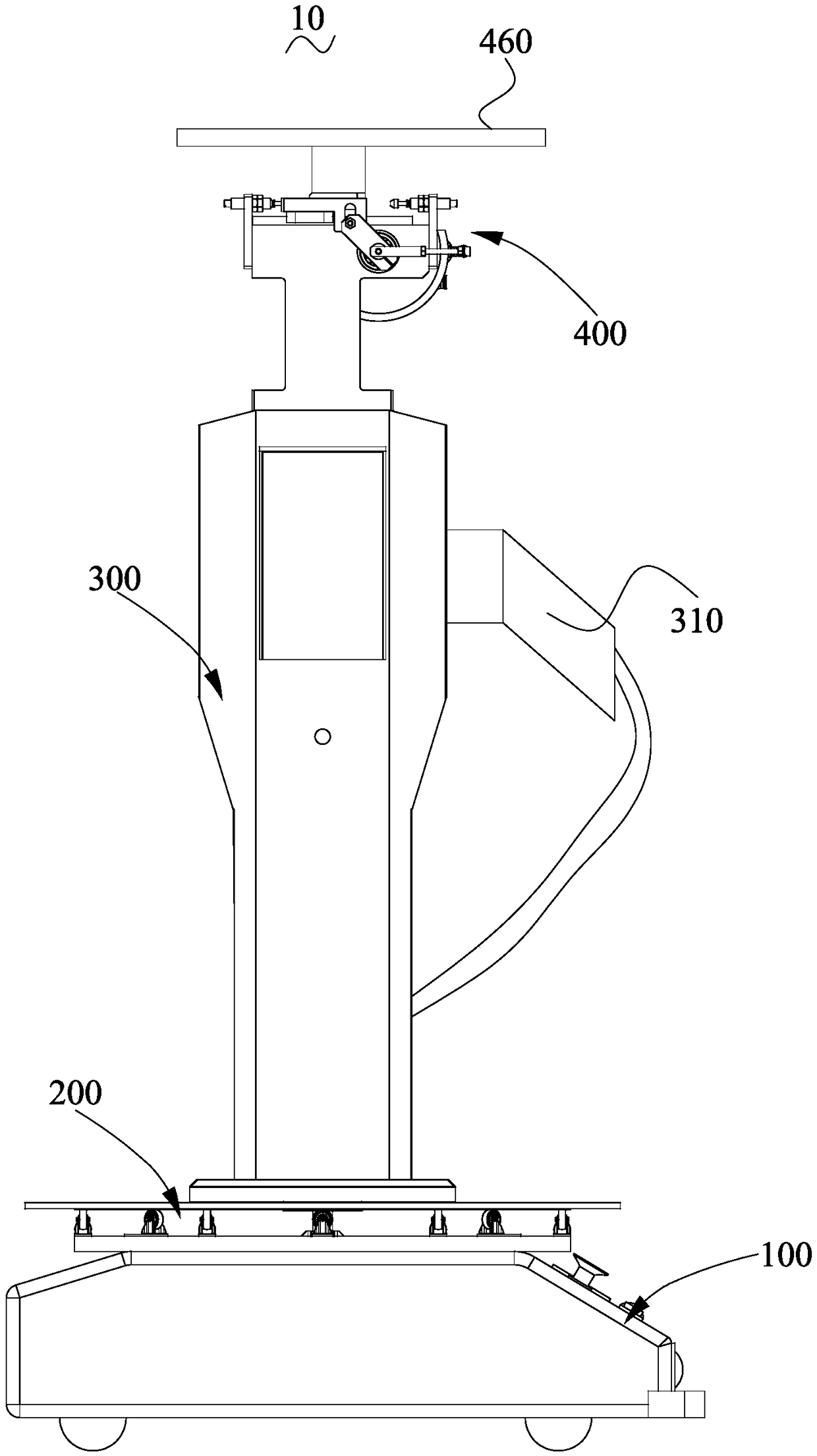

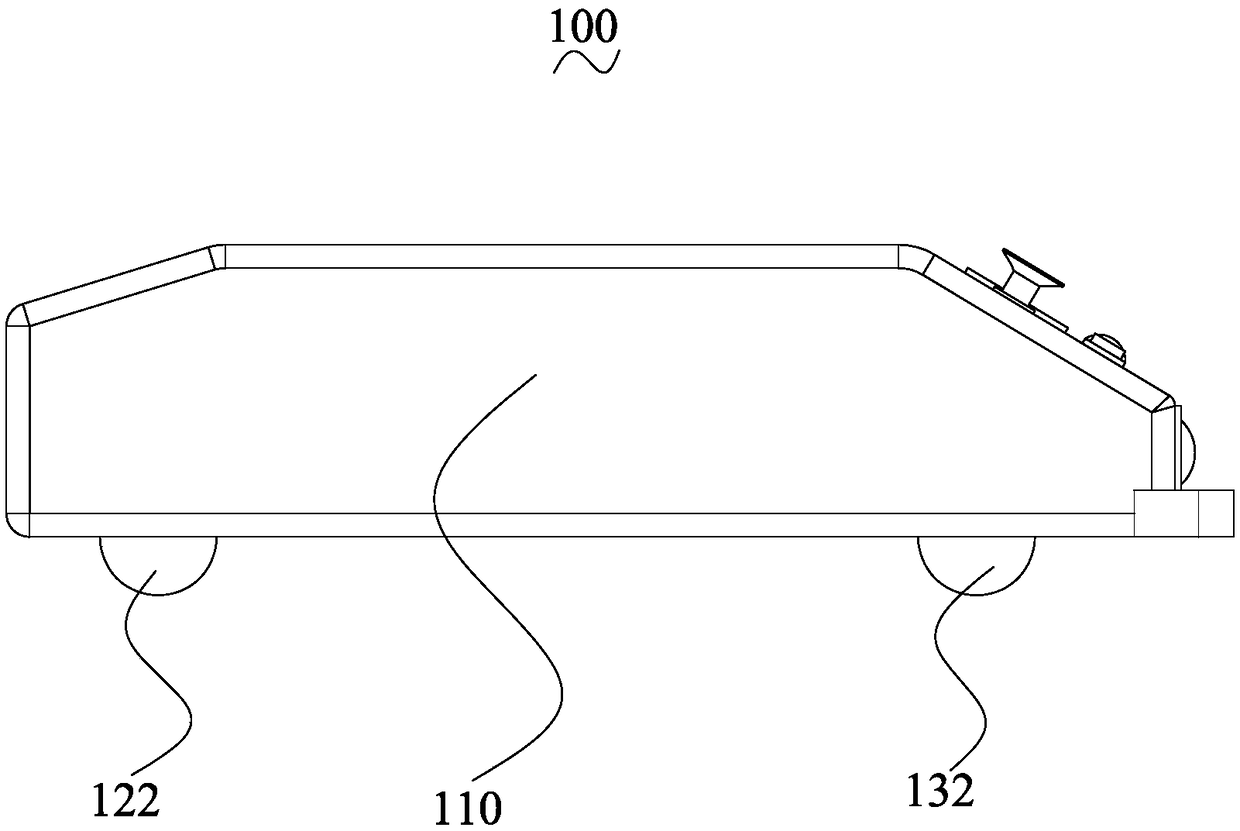

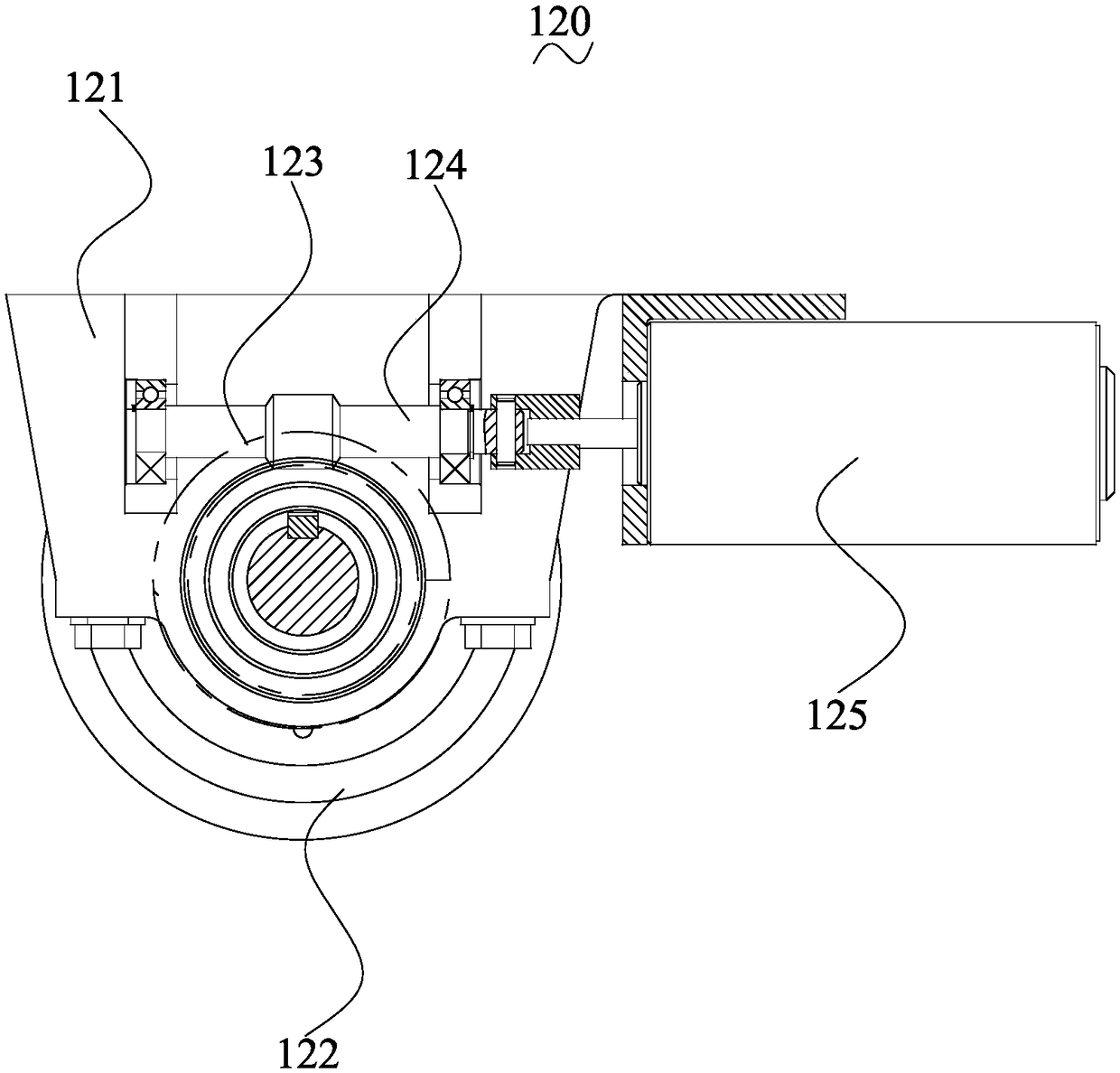

Loading and unloading forklift

PendingCN108017020ARealize lifting functionImplement the rotation functionLifting devicesEngineeringMechanical engineering

Owner:DONGGUAN CLIMAX SEAL TECH

Electric saw installation seat with adjustable position

InactiveCN110788398AAchieve angle adjustmentMeet cutting requirementsMetal sawing accessoriesControl engineeringElectric machinery

The invention discloses an electric saw installation seat with an adjustable position. The electric saw installation seat with the adjustable position comprises an installation base, wherein a rotarysupport is fixedly arranged at the bottom of the installation base; the rotary support is rotationally installed on a fixed pedestal, and fixed through a locking nut; a transmission assembly is further arranged in the rotary support; and a drive assembly is arranged on the transmission assembly in a linkage manner. According to the electric saw installation seat with the adjustable position, through the mutual engagement of a worm wheel, a worm and a skew rack, high transfer power, long life, stable working and high reliability are achieved, self-locking of the worm is benefited, and the stability is enhanced; through the mutual cooperation of the worm wheel and the worm, and the mutual cooperation of the worm wheel and the skew rack, the lifting and rotating functions of the installationbase are realized, the need of cutting for many materials is met, and a wide application range is achieved; the installation base with an adjustable angle is adopted, and angle adjustment for an electric saw device is realized through an adjustment oil cylinder and an adjustment piston rod, so that high flexibility is achieved; and the two working modes of manual operation and motor drive are adopted, and selected according to the actual condition, so that high practicability is achieved.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Telescopic rotary type hydraulic cylinder

InactiveCN111102266ARealize the function of telescopic rotationImplement the rotation functionFluid-pressure actuatorsHydraulic cylinderClassical mechanics

The invention discloses a telescopic rotary type hydraulic cylinder. The telescopic rotary type hydraulic cylinder comprises a base, wherein a hydraulic cylinder is fixedly arranged at the upper end of the base, the upper end of the base is fixedly provided with a protective shell located outside the hydraulic cylinder, a moving block is fixedly arranged at the tail end of a piston rod of the hydraulic cylinder, the upper end of the moving block is vertically and rotationally connected with a screw rod, a first threaded hole is formed in the upper end of the protective shell, the rod wall of the screw rod is in threaded connection with the protective shell through the first threaded hole and the upper end of the screw rod extends to the outside of the protective shell, a L-shaped supporting plate is arranged below the base, a T-shaped sliding groove is transversely formed in the upper end of the horizontal part of the L-shaped supporting plate, the inner part of the T-shaped sliding groove is slidably connected with a T-shaped sliding block, the upper end of the T-shaped sliding block is fixedly connected with a clamping plate, the base is located between the L-shaped supporting plate and the clamping plate, and the base is in fastening connection with the L-shaped supporting plate and the clamping plate through bolts and nuts. According to the telescopic rotary type hydrauliccylinder, the structure is simple, the use cost is reduced, and the practicability of the hydraulic cylinder is improved.

Owner:江都区武坚兴业机械厂

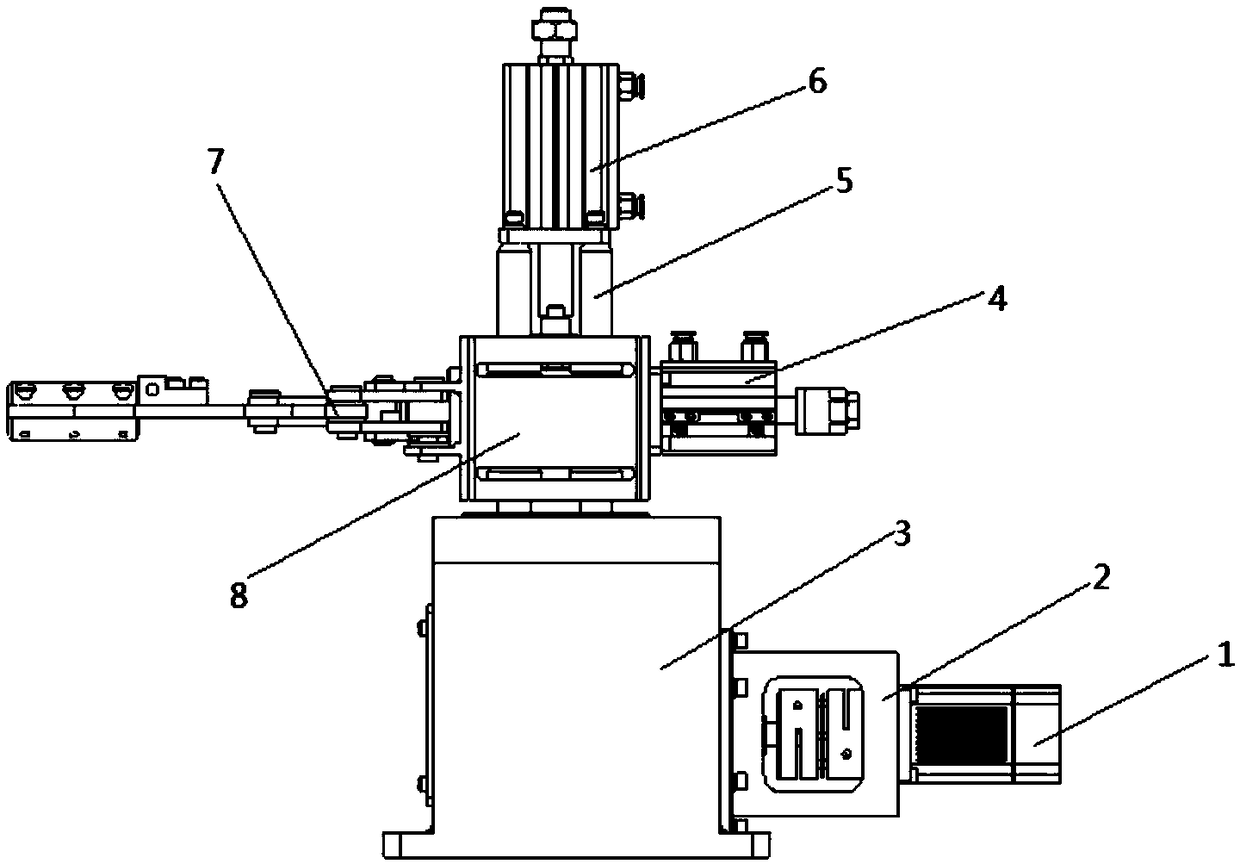

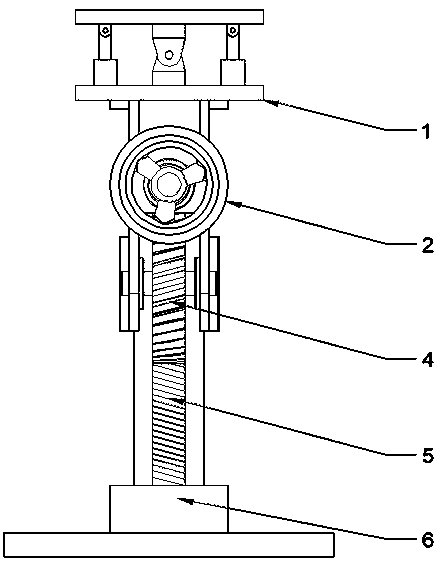

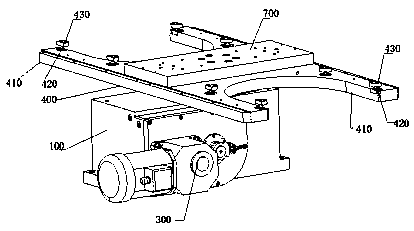

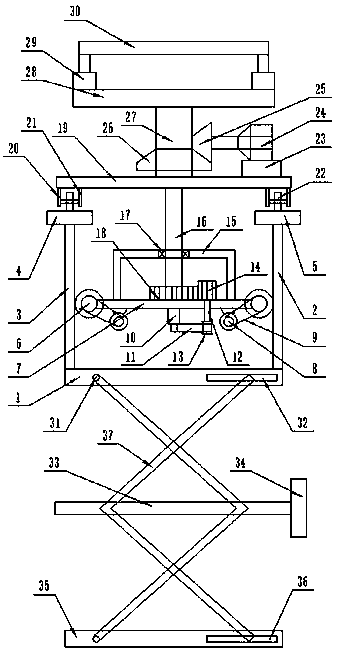

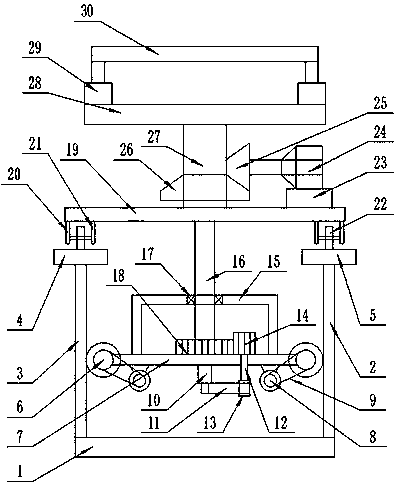

Lifting and rotating device for horizontal cam exchange table

PendingCN110977505AImprove work efficiencyRealize lifting functionLarge fixed membersRocker armEngineering

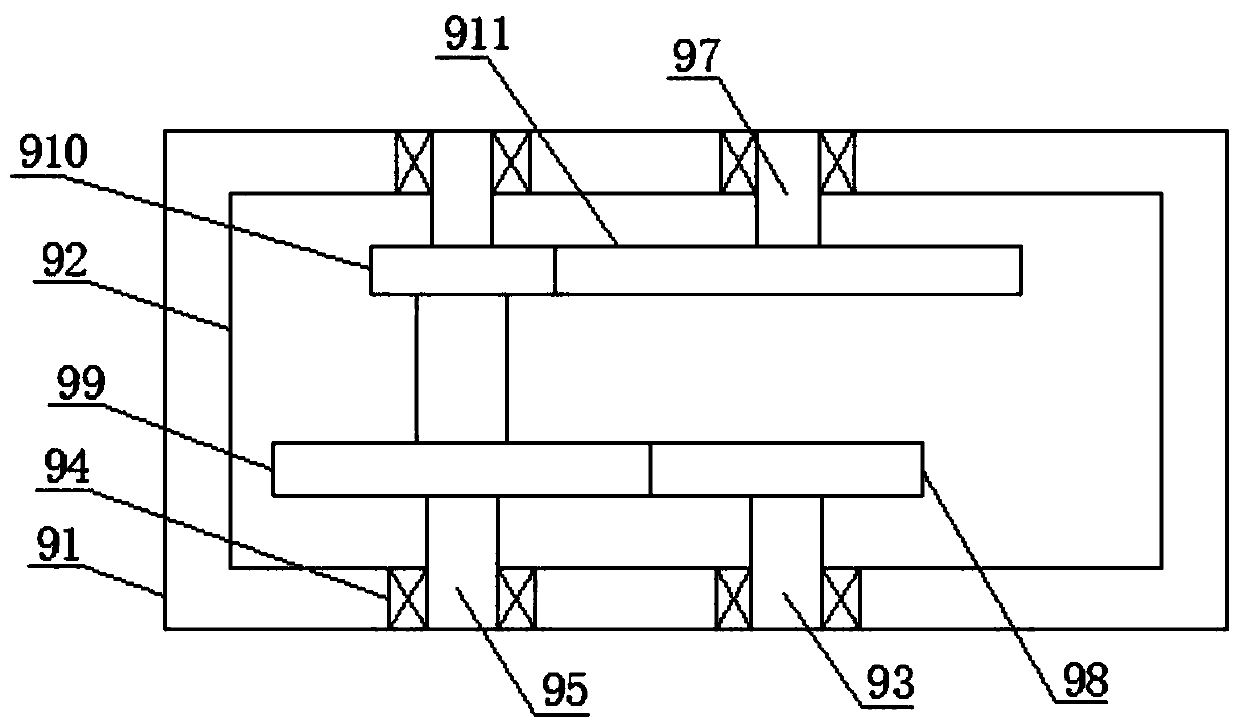

The invention discloses a lifting and rotating device for a horizontal cam exchange table. The lifting and rotating device comprises a box body, a cam transmission mechanism, a driving mechanism and arotating plate, the cam transmission mechanism is installed in the box body, and the cam transmission mechanism comprises a center shaft, an output shaft, a force input shaft, two flat cams, two rocker arms and a globoidal cam; the cam transmission mechanism realizes lifting and rotating functions; the driving mechanism is used for providing rotating power for the cam transmission mechanism; therotating plate is used for supporting and positioning a rotary workbench of a cam roller rotary table and a rotary workbench of a preparation tool, a jacking convex seat and a jacking concave seat arranged on the rotary plate are matched with each other, and the rotary workbench can be positioned at a U-shaped arm of the rotary plate in the lifting process and can be easily separated from the rotary workbench after rotating. The lifting and rotating functions are achieved, the sectional speed can be adopted for lifting and rotating, a hydraulic station does not need to be arranged, and the operation efficiency is greatly improved.

Owner:SUZHOU FURUTA AUTOMATION TECH

Solar charging pile

ActiveCN109159694AEasy to moveImplement the rotation functionPhotovoltaic supportsBatteries circuit arrangementsElectricityEngineering

The invention discloses a solar charging pile which comprises a mobile device, a rotating device, a charging pile body and a solar power generation device. The moving device comprises a moving bearingplate, a main driving mechanism and a steering mechanism. The main driving mechanism comprises a main driving bracket, a main driving wheel, a worm gear, a worm and a main driving power part. The rotating device comprises a disk support assembly, a rotating disk and a rotating driving part. The charging pile body is arranged on a rotating disk, the charging pile body is provided with a storage battery and a charging gun electrically connected with the storage battery, and the solar power generation device is electrically connected with the storage battery. The solar charging pile, on the onehand, the whole movement of the solar charging pile can be realized, so that the solar charging pile can be moved from one position to another according to the actual situation, and on the other hand,the rotating function of the charging pile body can be realized, so that the panel for displaying information arranged on the charging pile body can be adjusted according to the actual situation.

Owner:太原市中一嘉强环保科技开发有限公司

Machining equipment for traditional wooden building

InactiveCN112454559AImplement the rotation functionEasy to paintSpraying apparatusWood mortising machinesGear wheelConstruction engineering

The invention discloses machining equipment for a traditional wooden building. The machining equipment comprises a rack, wherein a conveying mechanism is mounted at on one side of the rack, a drivingmechanism is mounted at one end of the conveying mechanism, the conveying mechanism comprises a movable outer ring, a fixed cylinder is movably mounted in an inner cavity of the movable outer ring, one end of the fixed cylinder is fixedly connected with the rack, and a bearing is mounted at one end of the movable outer ring. The invention particularly relates to the field of wood machining. According to the machining equipment, by arranging the driving mechanism, the driving mechanism is matched with a jacking and clamping mechanism through a guide ring and a guide groove, and the function ofdriving the movable outer ring of the conveying mechanism to conduct rotary feeding is achieved; through matching arrangement of a tooth groove and a gear disc of the jacking and clamping mechanism, the function of driving fixed wood to rotate is achieved, and a grooving mechanism and a paint spraying mechanism can conveniently spray paint to the grooving position of the wood; and through matchingarrangement of a first convex ring, a second convex ring and the jacking and clamping mechanism, the function of automatically clamping and fixing the machined wood is achieved, machining is facilitated, and the working efficiency is improved.

Owner:姜志伟

Robot in garbage station

ActiveCN106364824AReasonable arrangementEasy to lockRefuse transferringLoading/unloadingEngineeringSmart control

A robot in a garbage station comprises a compression mechanism and a conveying mechanism. The conveying mechanism comprises a rotating and overturning device and a movable device. The rotating and overturning device is arranged on the movable device and comprises a first frame and a second frame. One end of the first frame is hinged to one end of the second frame. The second frame comprises an outer border, an inner supporting frame and an adjusting supporting assembly. The movable device comprises bases, sliding rails, a movable platform, a rotation platform, racks, a gear ring, a first gear, a second gear, a first power device and a second power device. The integral structure is simple, the functions of rotating and overturning can be achieved at the same time, the freedom degree is high, and intelligent control is achieved. The position of the adjusting supporting assembly arranged on the second frame is arranged reasonably, and the first frame can be conveniently supported.

Owner:江苏德昶环保科技有限公司 +2

Lifting and rotating device of mechanical arm of fire-fighting robot

InactiveCN108789393ASimple and reasonable structureReduce manufacturing costProgramme-controlled manipulatorEngineeringMotor drive

The invention discloses a lifting and rotating device of the mechanical arm of a fire-fighting robot. According to the device, the structure is reasonable and simple, the production cost is low, and the installation is convenient; the device can be used as a lifting and rotating device of the arm of the fire fighting robot, the lifting of the arm can be carried out on the premise that an ascendingtrack does not exist, and the rotation of degree can be carried out on the basis without the ascending track; a handle is rotated, a folding lifting frame is lifted under the action of a bolt rod, afirst motor drives a gear to rotate, the gear moves on a rack, and the adjustment of the height of a lifting plate is realized; a second motor drives a first rotating shaft to rotate, a pinion arranged on the first rotating shaft drives a main gear to rotate, and the rotation of the angle is achieved; and a third motor drives a first bevel gear to rotate, the first bevel gear drives a second bevelgear to rotate, and the rotation of the angle is achieved; and a fourth bottom plate is lifted by a hydraulic cylinder in height, by means of the technical means mentioned above, and the lifting androtating functions of the arm arranged on the fire-fighting robot are realized.

Owner:苗娥

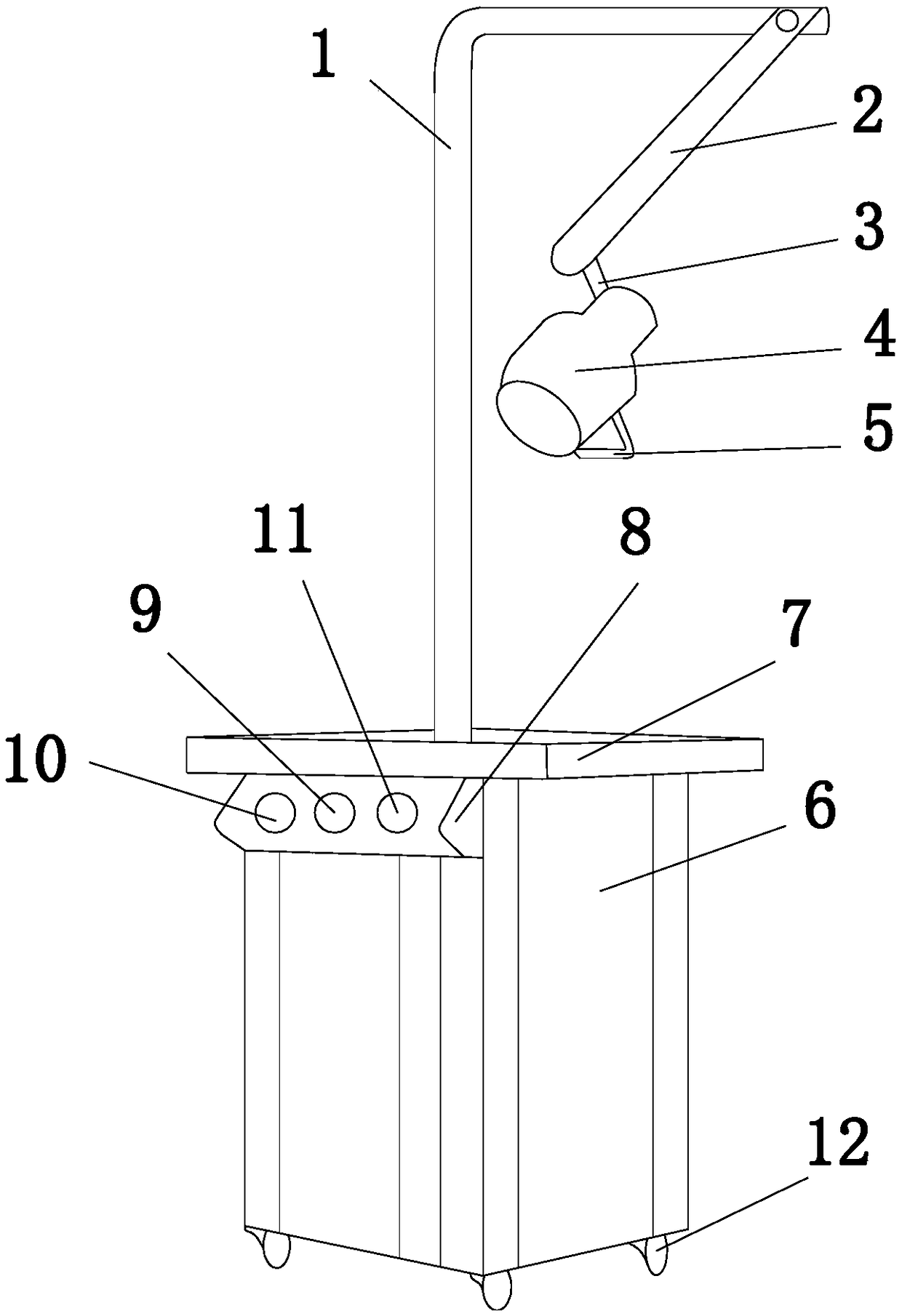

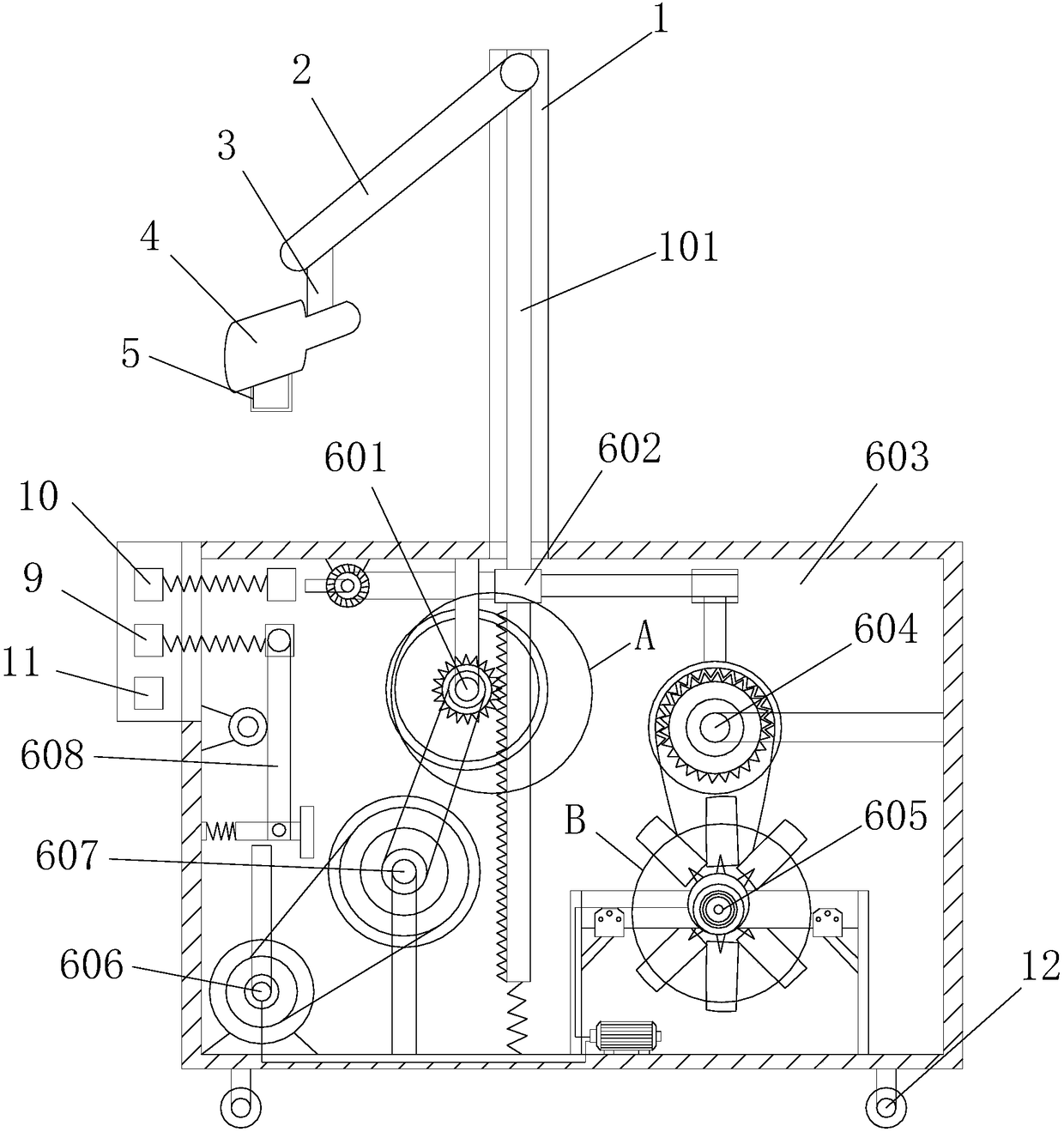

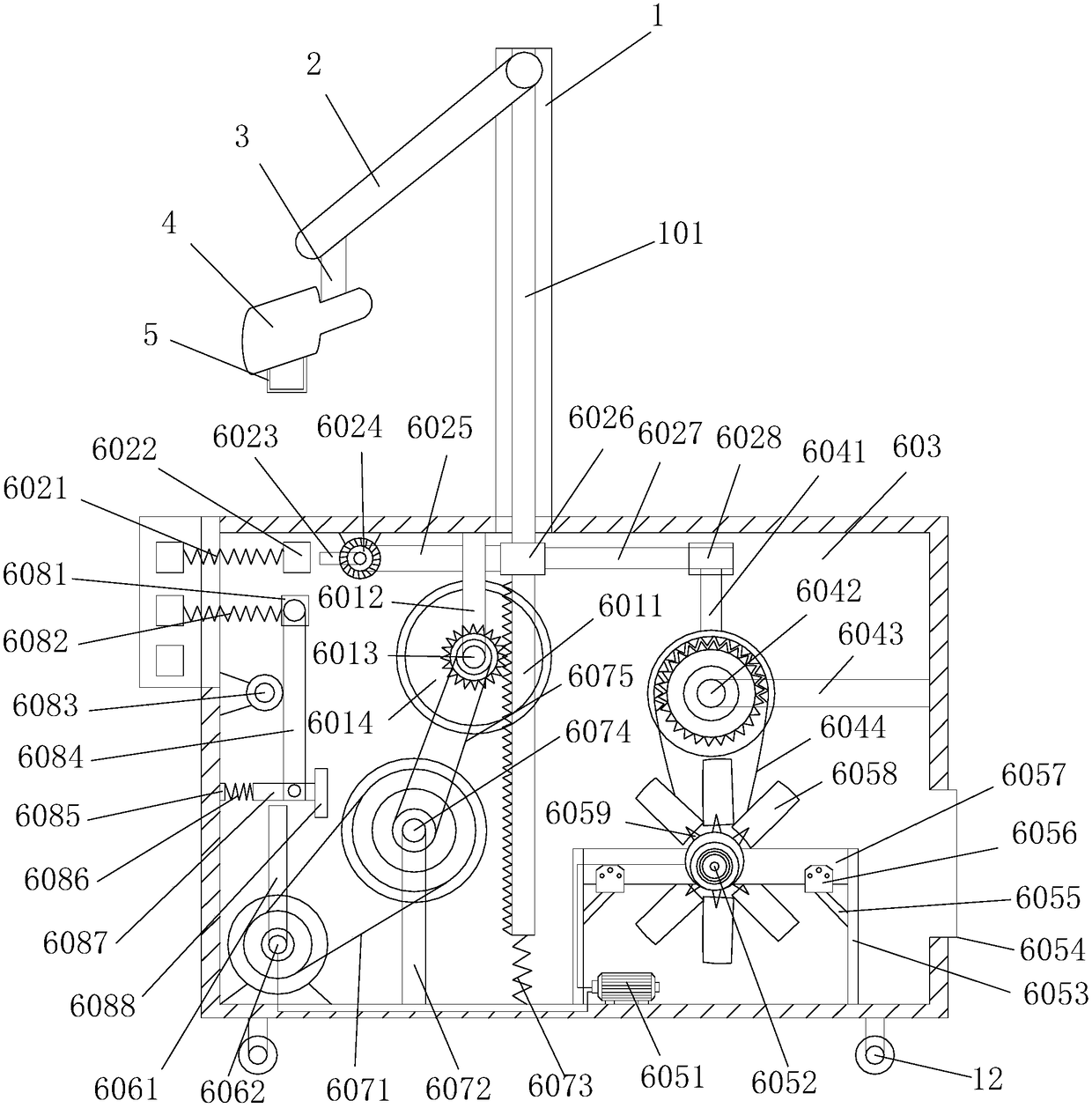

Radiology adjustable image viewing device

The invention discloses a radiology adjustable image viewing device. The structure of the device includes a supporting rod, a movable rod, a supporting bar, an illuminating lamp, a handle, a control box, a fixing base, a control panel, an elevating control button, a rotation control button, a power on button, and moving wheels. The control box consists of an elevating mechanism, a rotation mechanism, a control box chamber, a heat dissipation driving mechanism, a heat dissipation mechanism, a driving mechanism, a drop auxiliary transmission mechanism, and a lever driving mechanism. The supporting rod can be driven to elevate and rotate at the same time through the arranged elevating mechanism, rotation mechanism and heat dissipation mechanism, and so the angle of the image viewing device can be effectively adjusted. Elevating and rotation are combined with each other, and so the adjustment of the angle is flexible, which facilitates doctors to better observe a radiological image and carry out diagnosis and treatment.

Owner:TIANJIN BAODI HOSPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com