Tower crane with function of adjusting spatial position of lifting component omnidirectionally

A tower crane, all-round technology, applied in cranes, load hanging components, transportation and packaging, etc., can solve the problems of non-conformity, heavy weight, increase the labor intensity and work risk of hoisting workers, etc., to improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

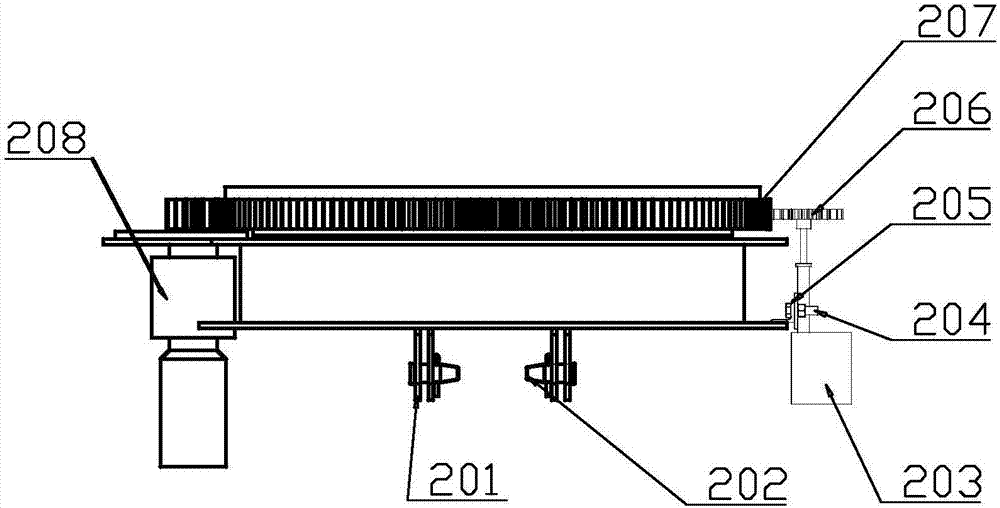

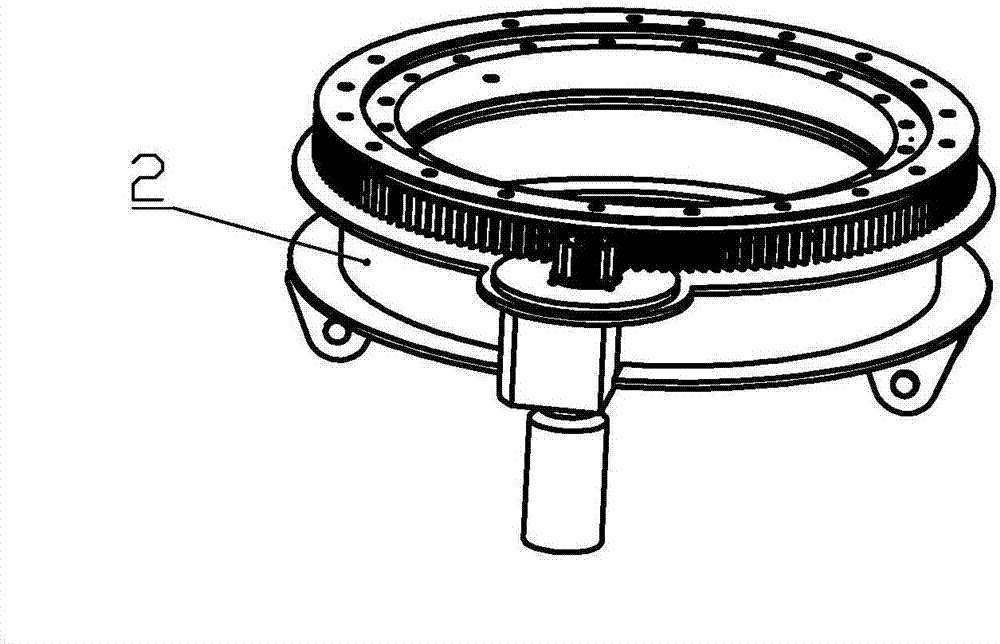

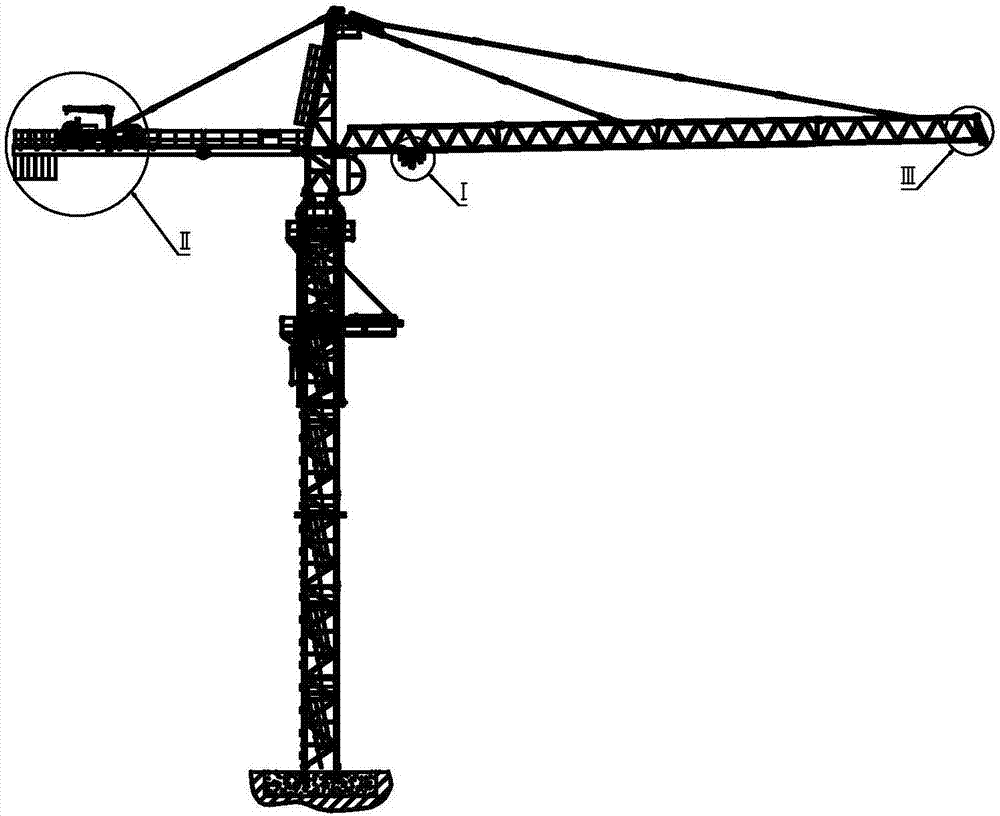

[0046] Example: such as figure 1 , Figure 14 , Figure 15As shown, the present invention is a tower crane with the function of all-round adjustment of the spatial posture of lifting parts, including two parallel hoisting mechanisms and luffing trolleys with slewing devices; the two parallel hoisting mechanisms are installed on On the balance arm of the tower crane, it is arranged forward and backward along the axial direction; the luffing trolley is connected to the lower chord of the boom and slides along the boom; The weight limiter, the center guide pulley block of the luffing trolley, the slewing beam guide pulley on the trolley, the hoisting pulley, and then return to the slewing beam guide pulley, the wedge joint connected to the boom end via the center guide pulley, are controlled by each lifting mechanism Lifting or lowering of the lifting block. The installation of the wedge-shaped joint: first install the swivel head through the swivel head bracket on the arm end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com