Mechanism capable of realizing lifting and rotating integrated movement of furnace door

A furnace door lift, linkage mechanism technology, applied in the furnace, crystal growth, furnace components and other directions, can solve the problems of high cost, complex structure, large volume and weight, etc., to achieve the effect of simple control, improved motion efficiency, and simplified control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

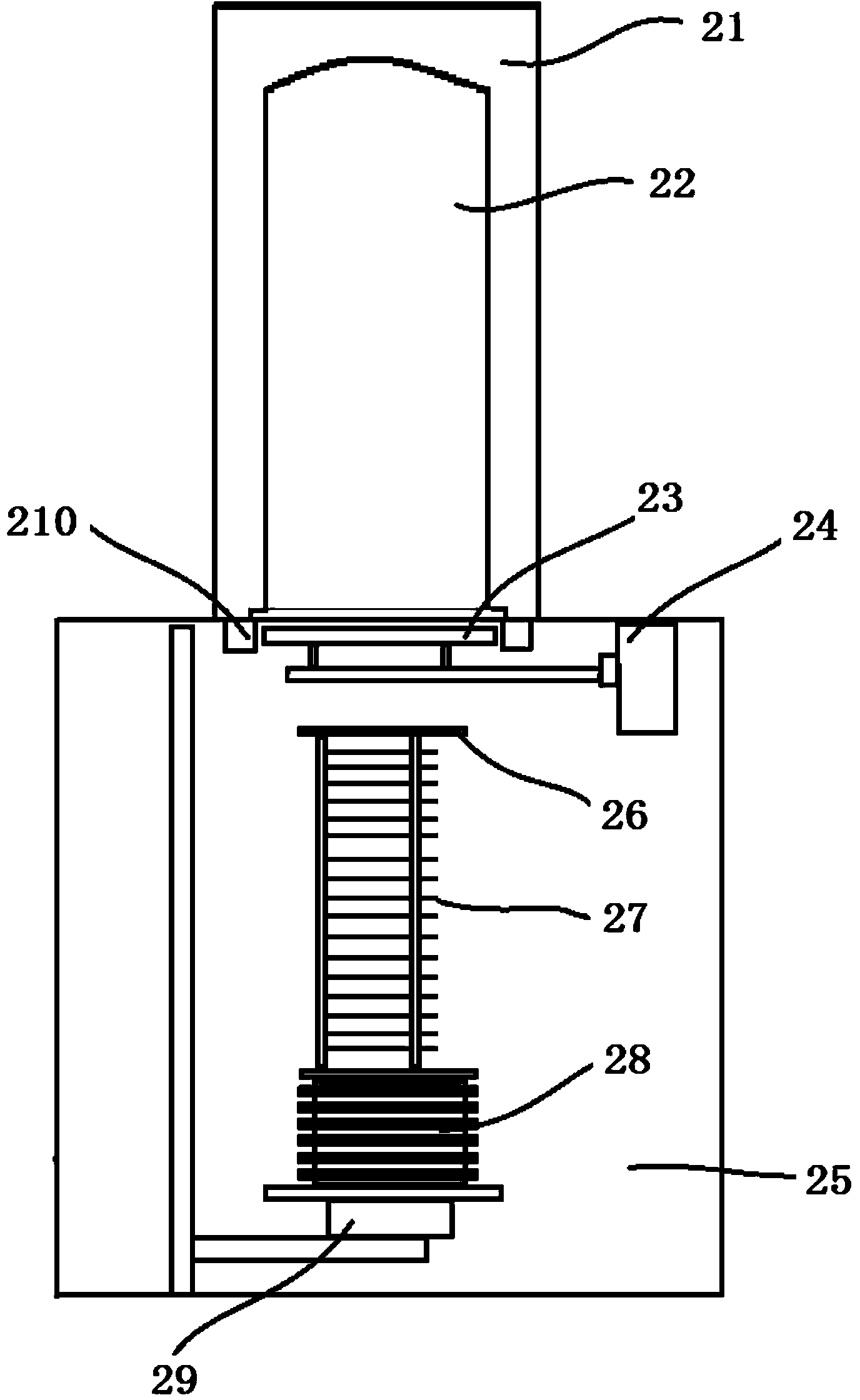

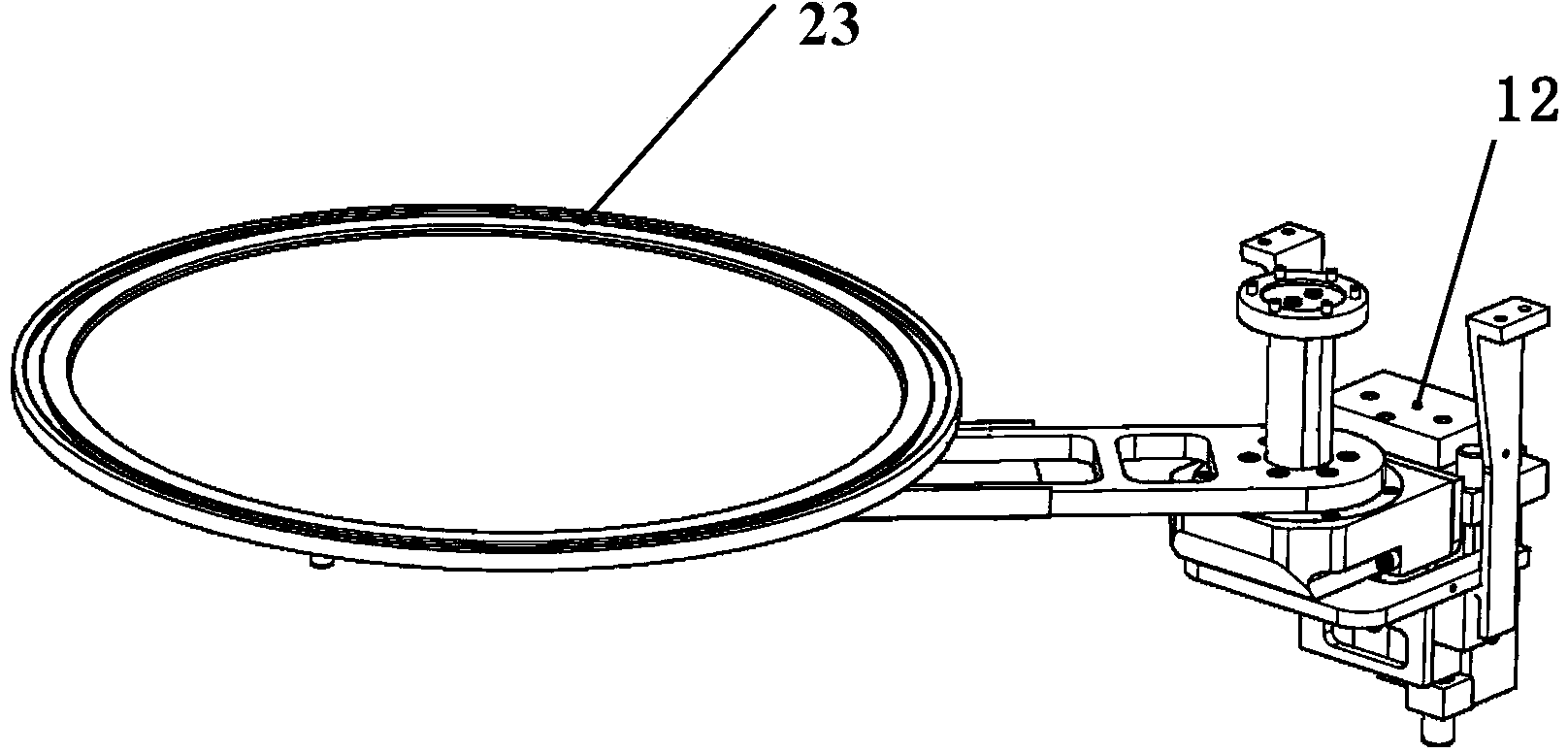

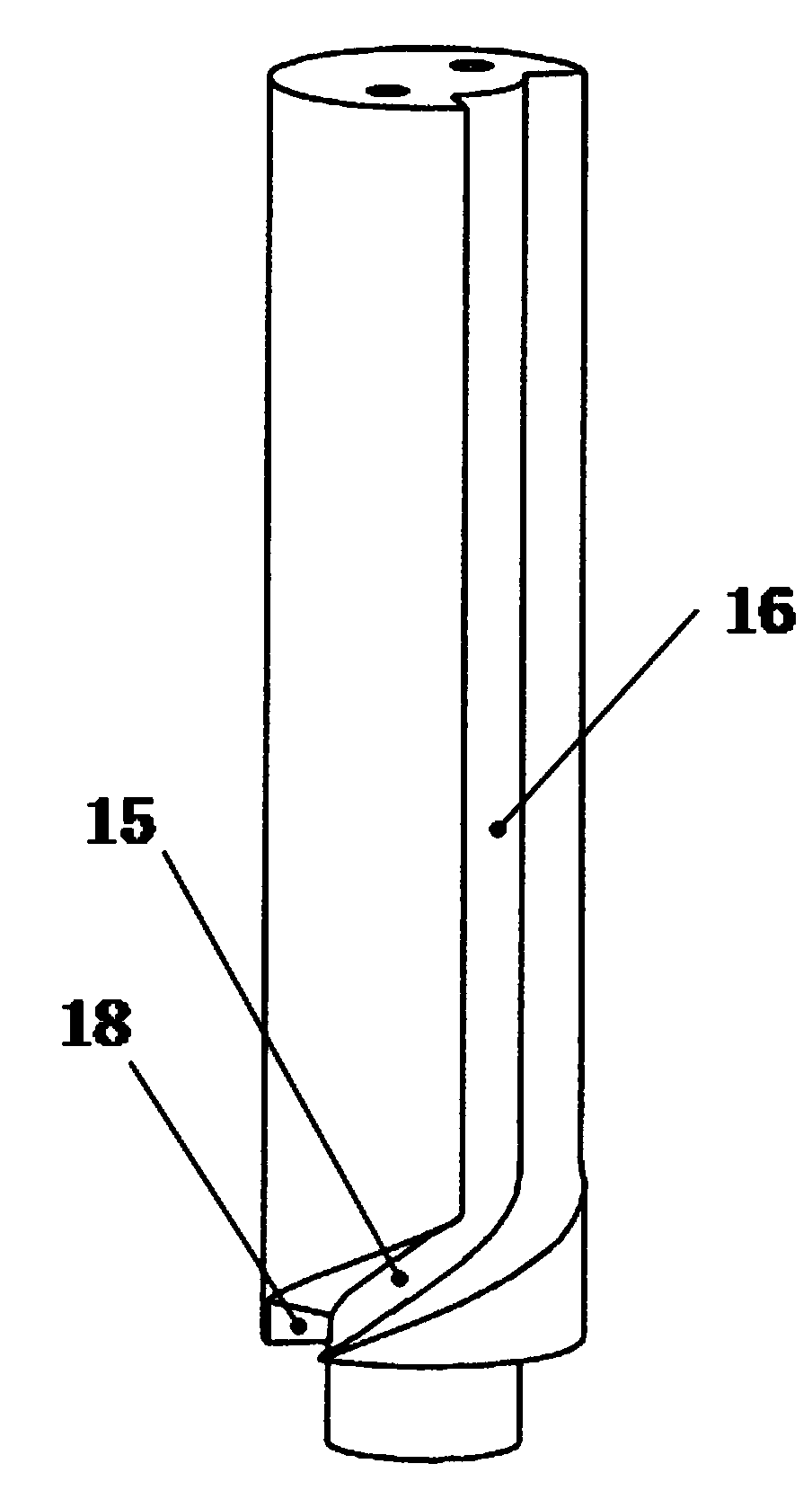

[0040] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0041] First of all, let me introduce the installation position and process requirements of the furnace door in the usual semiconductor vertical heat treatment equipment. Semiconductor vertical heat treatment equipment may include, for example, vertical oxidation furnaces, LPCVD furnaces, vertical annealing furnaces, etc. The function of the furnace door is to close the heating chamber of the equipment and isolate it from the outside world. Before the semiconductor vertical heat treatment equipment starts the process, that is, before the quartz boat and silicon wafer are sent into the heating chamber, the furnace door needs to be opened; after the process is completed, that is, after the quartz boat and silicon wafer are moved out of the heating chamber, The furnace door needs to be closed to insulate the heat and so on.

[0042] s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com