Patents

Literature

32 results about "Femur condyle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

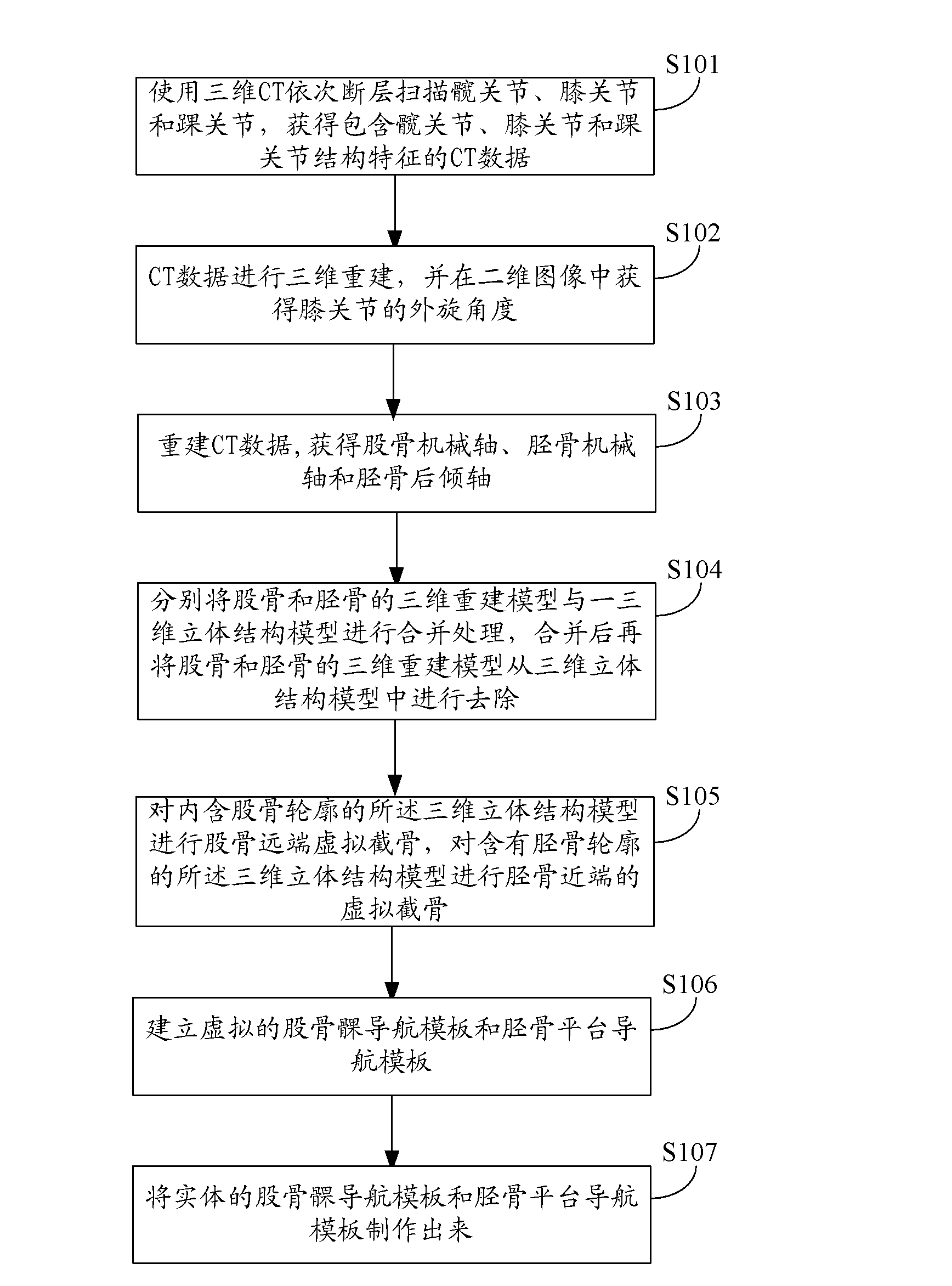

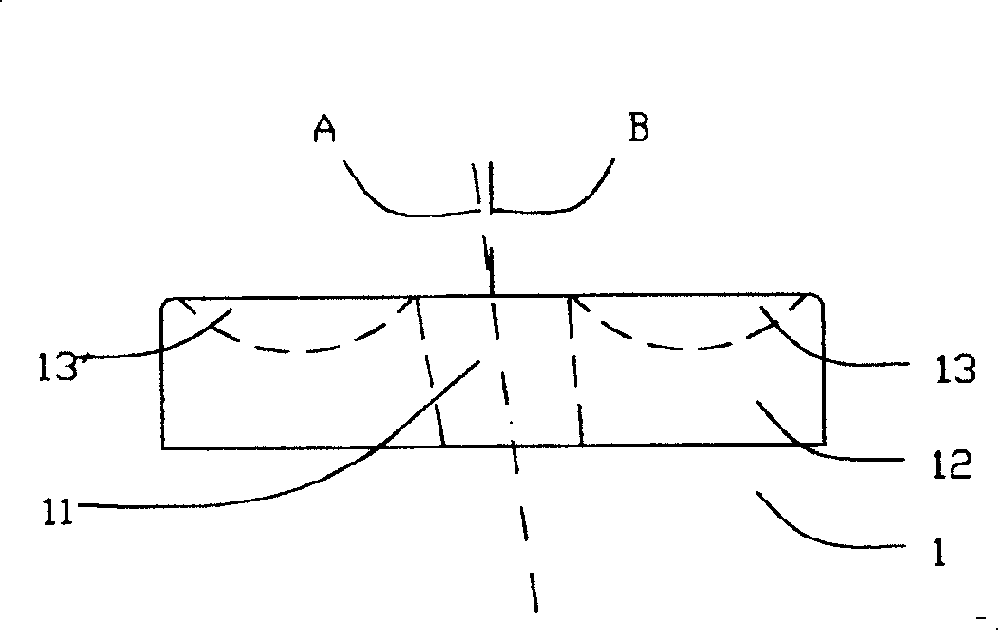

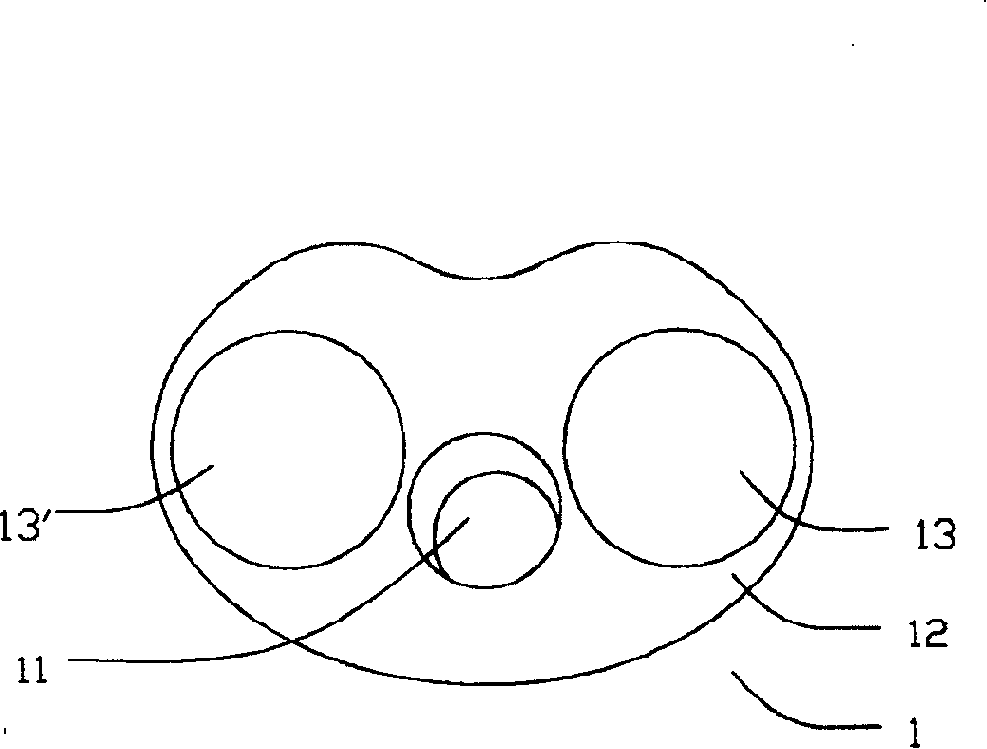

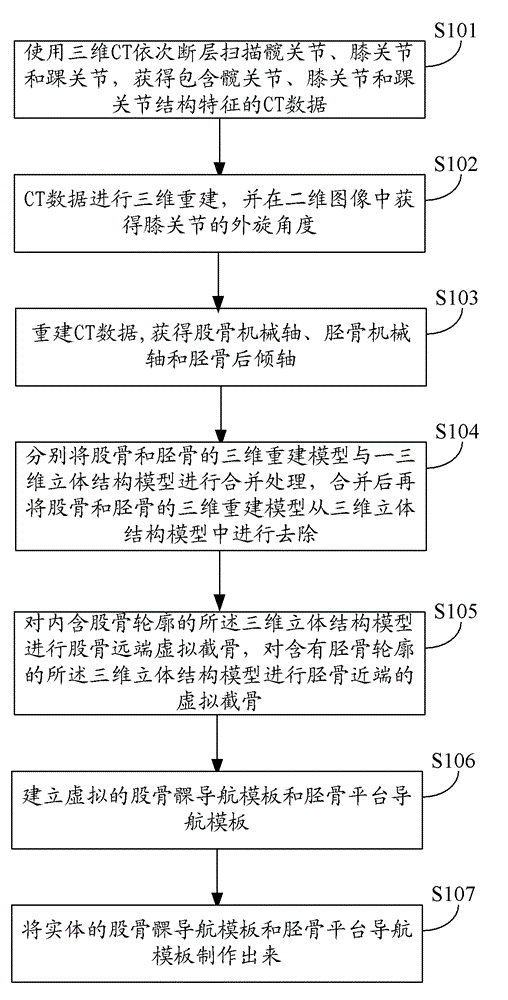

Method for manufacturing navigation template for knee replacement, and navigation template

ActiveCN102760199AAvoid offsetImprove the effect of long-term follow-upDiagnosticsSurgeryThighComputing tomography

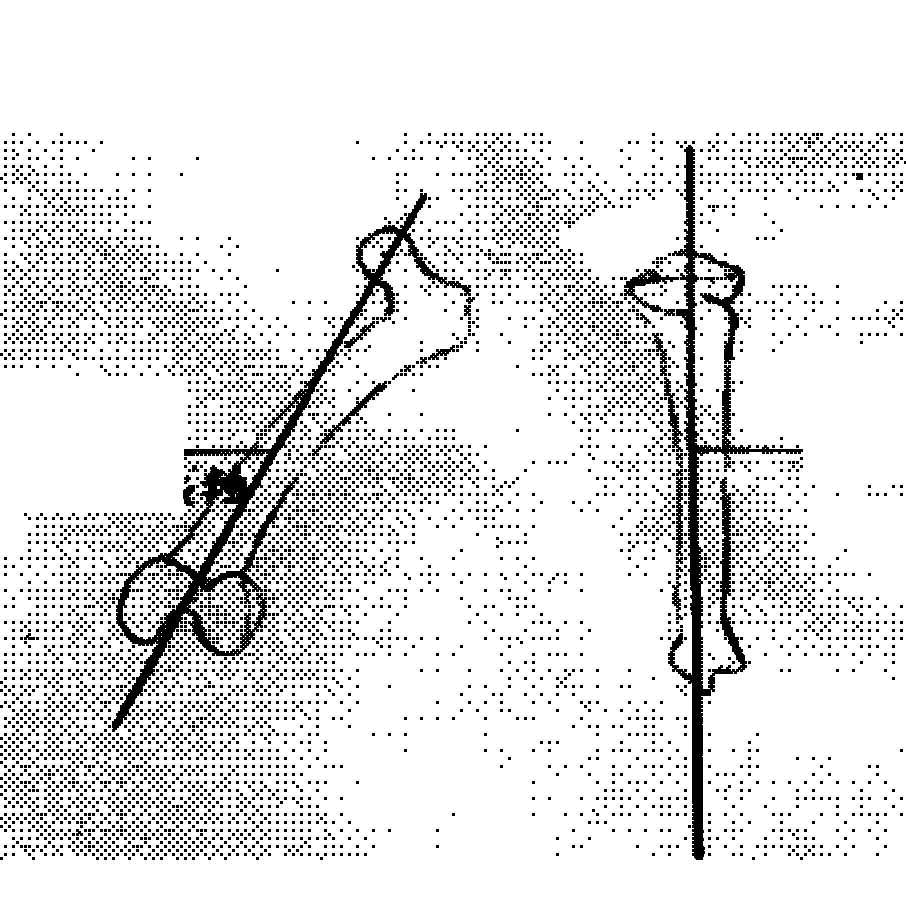

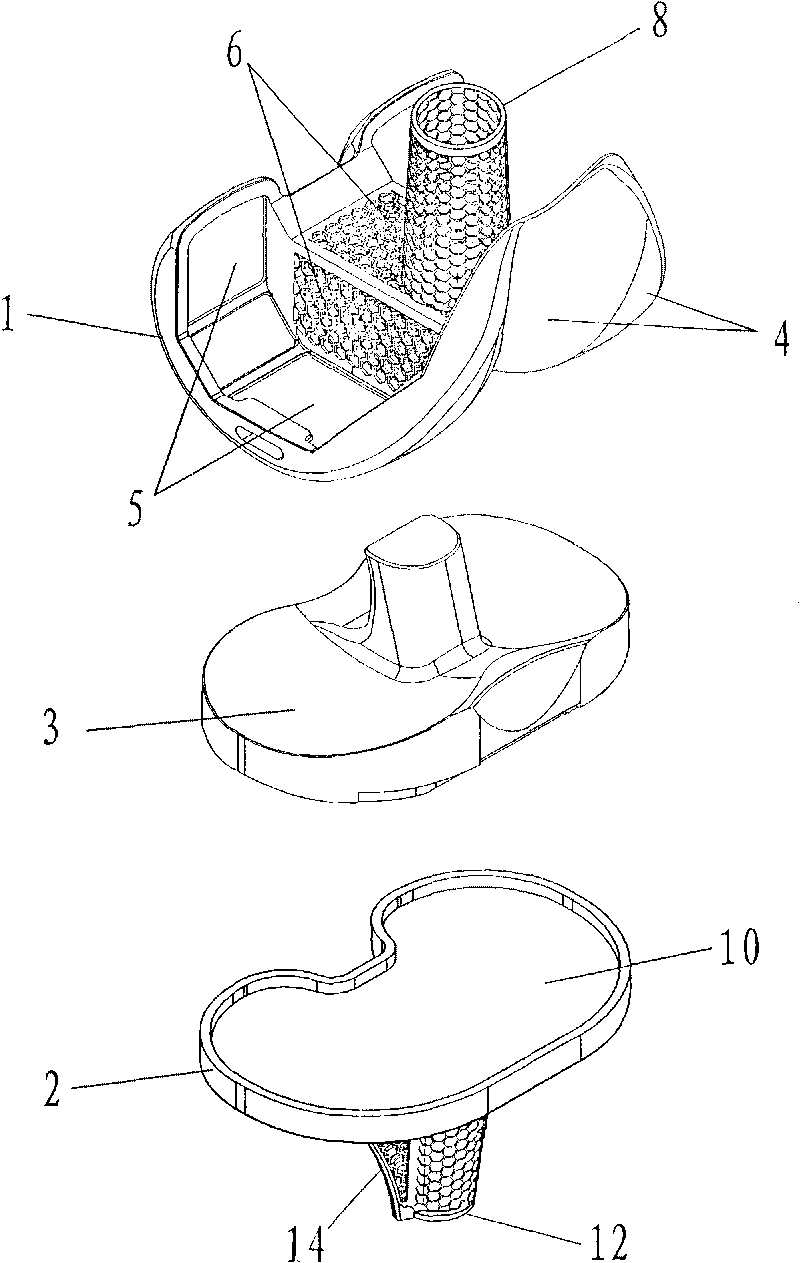

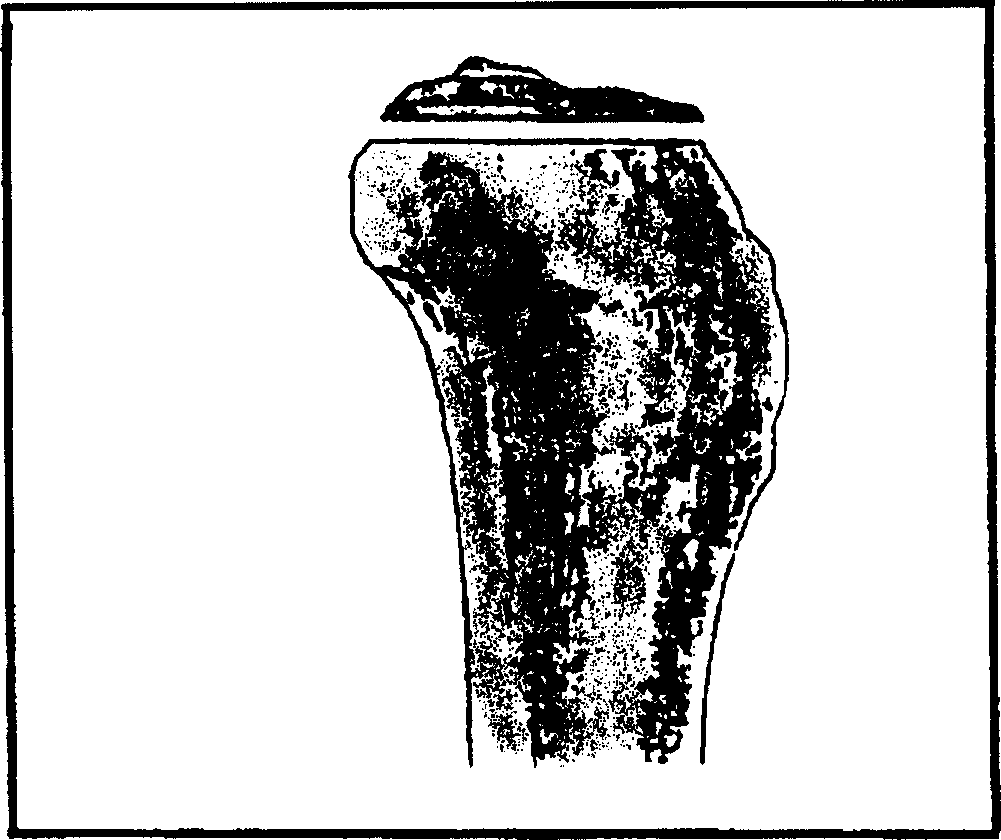

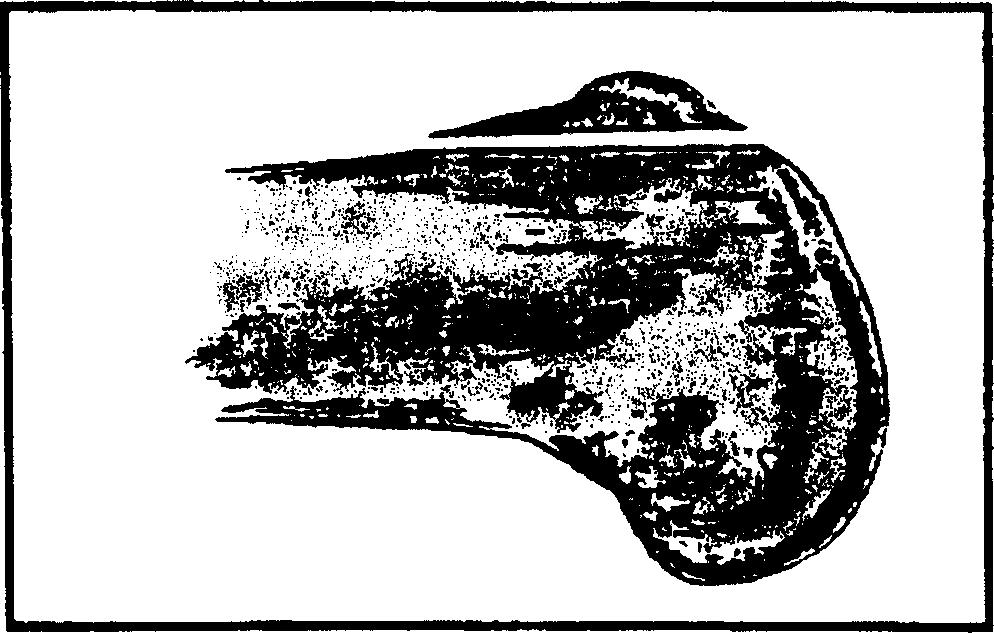

The invention relates to a method for manufacturing a navigation template for knee replacement. The method comprises the following steps of: scanning a hip joint, a knee joint and an ankle joint through computed tomography (CT) to obtain CT data, and establishing three-dimensional reconstruction models of femur and tibia according to the CT data; respectively carrying out combination on the three-dimensional reconstruction models of thigh bone and shin bone with a three-dimensional structure, and respectively removing the three-dimensional structure models of femur and tibia from the three-dimensional structure; according to the knee replacement process, carrying out distal femoral virtual osteotomy on the three-dimensional structure model containing the femur contour, and carrying out proximal tibia virtual osteotomy on the three-dimensional structure model containing the tibia contour; and establishing virtual femur condyle navigation template and a virtual tibia platform navigation template, and manufacturing an entity condyle navigation template and an entity tibia platform navigation template. The individual navigation template manufactured by the invention be used for carrying out positioning of osteotomy and a rotating axis on the affected knee femur condyle and tibia platform, thus realizing individual precise osteotomy.

Owner:中国人民解放军联勤保障部队第九二〇医院

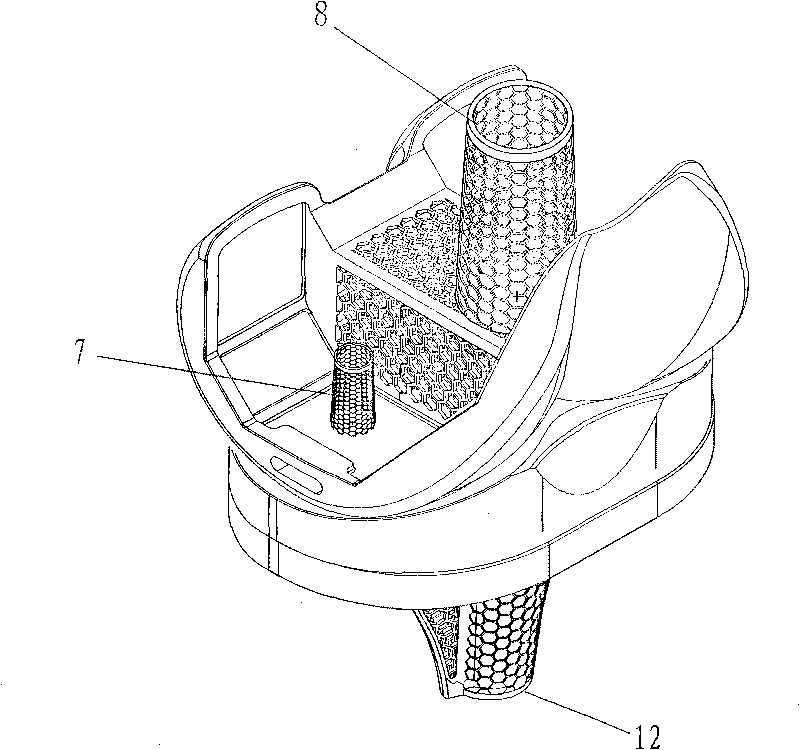

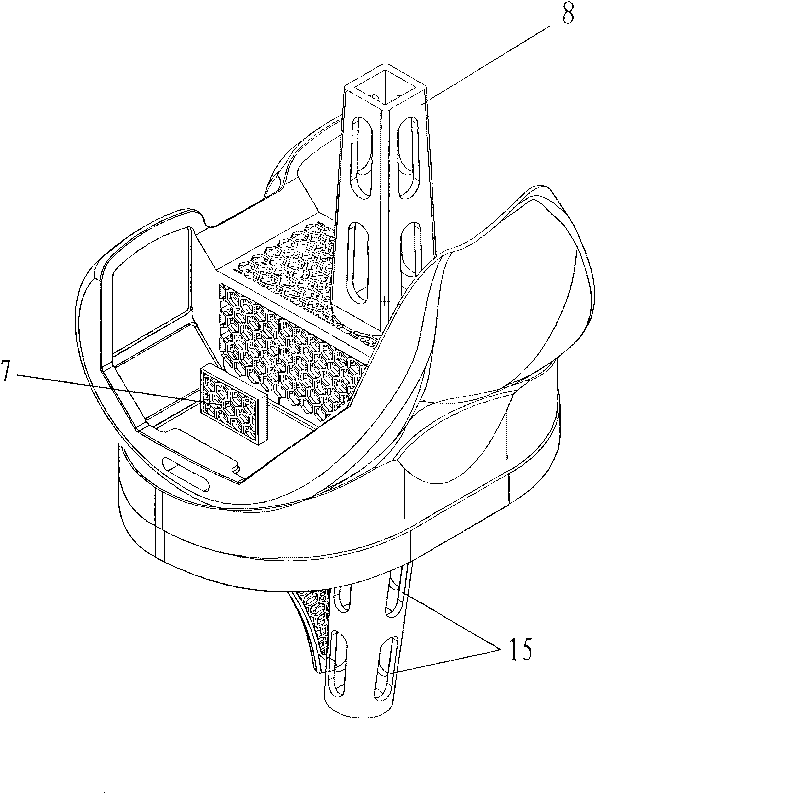

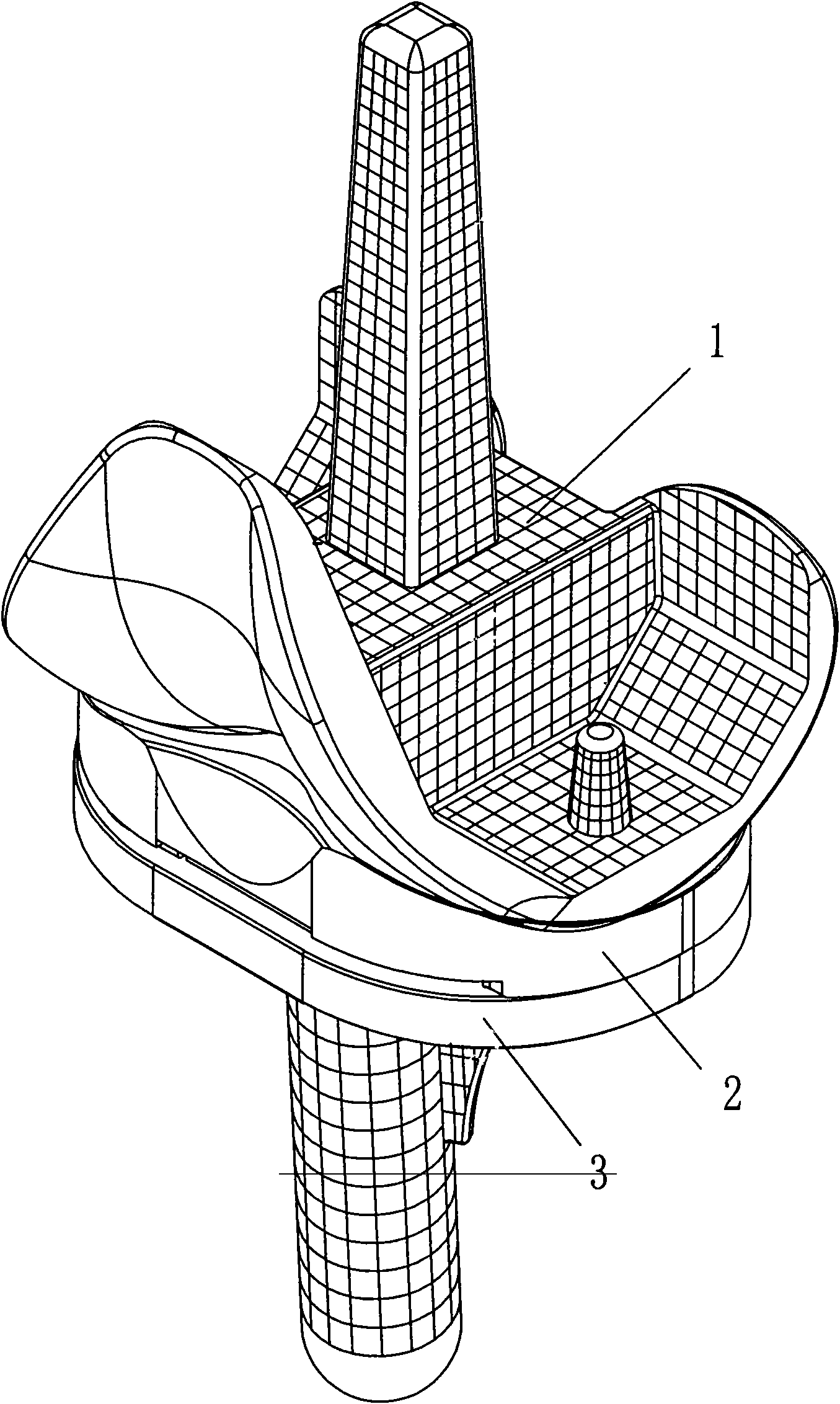

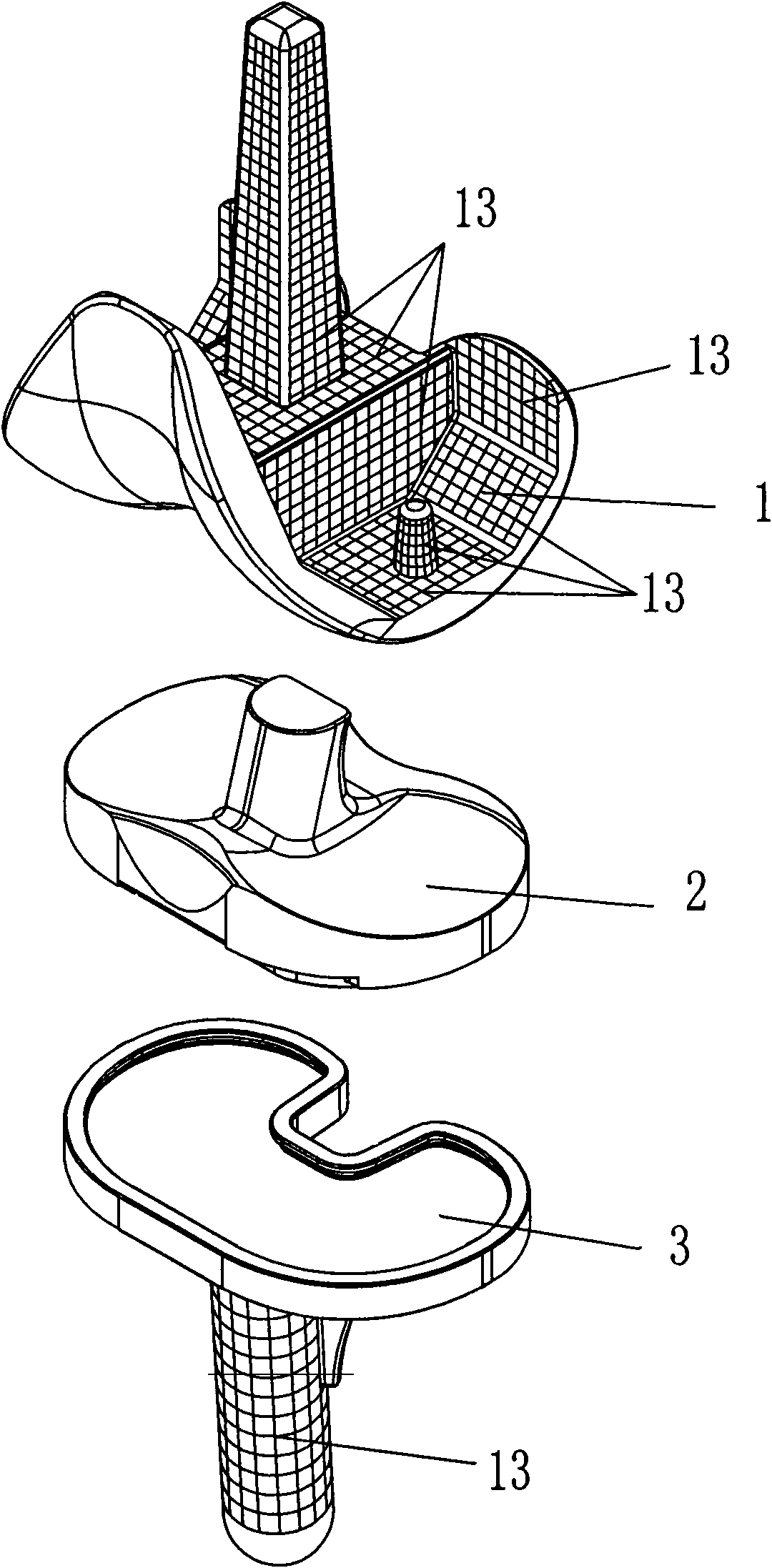

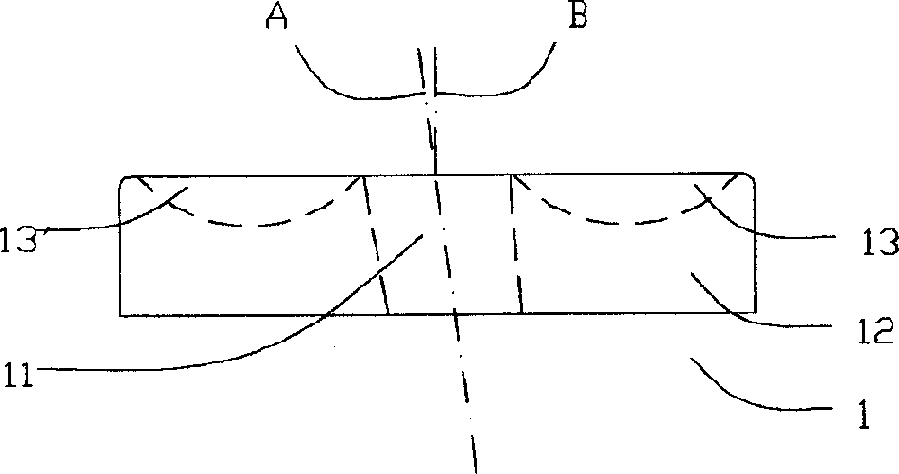

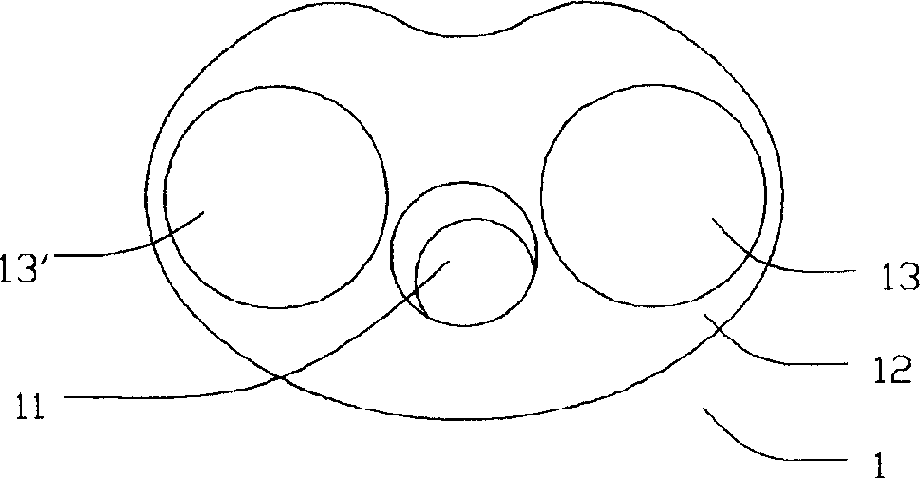

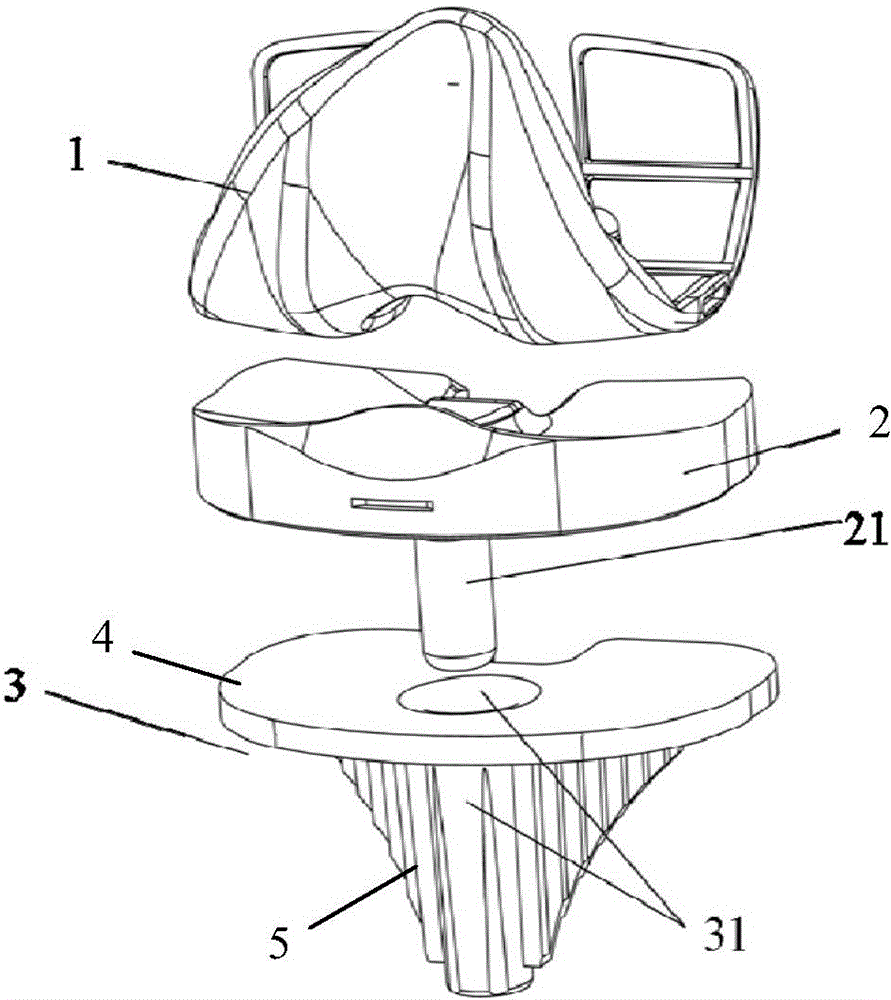

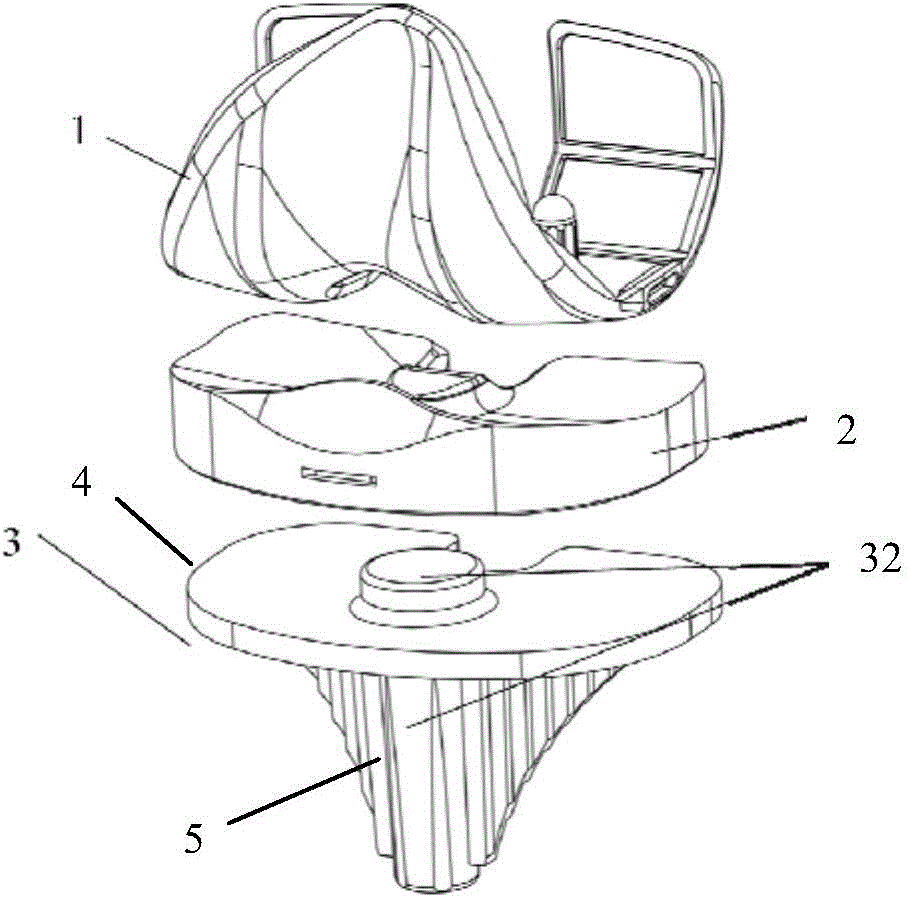

Artificial knee joint bone fusion prosthesis

InactiveCN101708138AGuaranteed connectivityPrevent looseningJoint implantsCoatingsTarsal JointBone particle

The invention relates to an artificial knee joint bone fusion prosthesis. The artificial knee joint bone fusion prosthesis comprises a femur condyle prosthesis, a tibia platform prosthesis and a joint pad, wherein the femur condyle prosthesis comprises a joint surface, a condyle combination surface, a intercondylar combination surface, a positioning body, a femur intramedullary stem and a femur intramedullary extending stem; the tibia platform prosthesis comprises a platform body, a tibia combination surface, a wing plate or a positioning body, a tibia intramedullary stem and a tibia intramedullary extending stem; the femur intramedullary stem, the femur intramedullary extending stem, the tibia intramedullary stem and the tibia intramedullary extending stem are hollow, the surfaces of the intramedullary stems and the extending stems have porous or mesh structure so as to ensure that the hollow parts in the stem body can be communicated with the external part; when in use, autograft or allograft crushed bone particles are filled in the hollow parts of the intramedullary stems and the intramedullary extending stems, and after the external bone tissue fuses and grows together with the crushed bone particles filled in the intramedullary stems, the overall elastic modulus can be very close to that of the human bone, thus reaching the aim of effectively preventing the loose between the artificial knee joint bone fusion prosthesis and the sclerotin for long time.

Owner:BEIJING AKEC MEDICAL

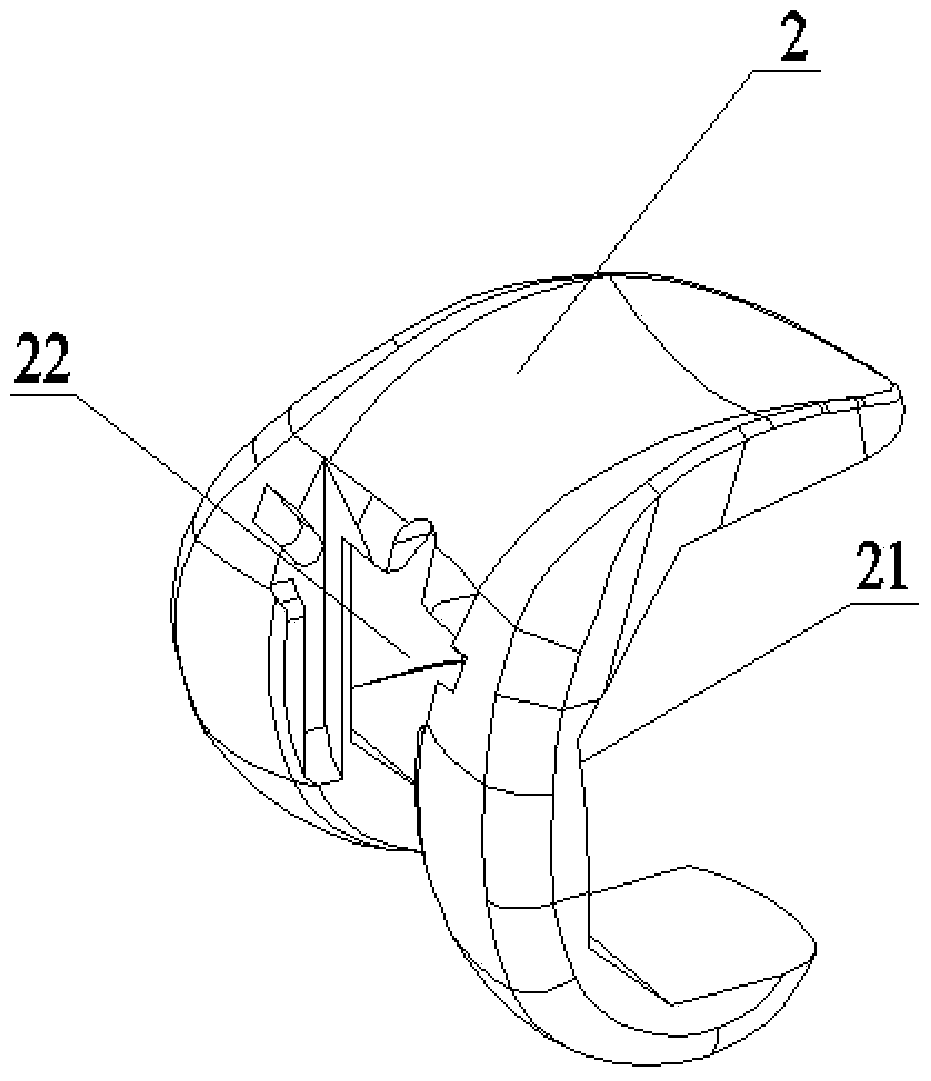

Customized artificial semi-knee-joint and method of producing the same

InactiveCN101278866AReduce wearJoint implantsComputerised tomographsArticular surfacesArticular surface

Customized hemi-knee joint prosthesis and a preparation method thereof are provided. Firstly, the normal side knee joint femur condyle data of a patient is extracted by CT for the medical image three-dimensional image reconstruction. The three-dimensional anatomy model of patient femur condyle is obtained by an antagonizing model. A metal femur condyle joint is obtained according to the three-dimensional anatomy model. Then, a rolling pillar is arranged in the metal femur condyle joint. The two sides of the rolling pillar are respectively opened with a cylindrical groove. A rolling combined station is sheathed on the rolling pillar. The two sides of the rolling combined station are respectively equipped with a side-push plate with a lug boss. The lug bosses of the side-push plates are inserted in the grooves of the rolling pillars. As the rolling pillar is arranged inside the articular surface of the metal femur condyle of the hemi-knee joint prosthesis, the prosthesis upper part, namely the rolling combined station, and the lower part, namely the articular surface of the metal femur condyle, which are fixed on a femoral shaft move relatively within a certain angle. Being corresponding to a tibia platform, the lower part is static during the period. Therefore, the whole process of the knee joint bending is finished and the abrasion of the prosthesis on the cartilage surface of the joint is reduced.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Artificial knee joint

The invention relates to an artificial knee joint comprising a femur condyle prosthesis, a tibial plateau prosthesis and a joint pad. The femur condyle prosthesis is provided with a joint surface, a condyles jointing surface, an inter-condyles jointing surface, a positioning pin and an intramedullary handle. The tibial plateau prosthesis is provided with a plateau body, a tibia jointing surface, a positioning piece and a tibia intramedullary handle. The condyles jointing surface, the inter-condyles jointing surface, the surface of the positioning pin, the surface of the intramedullary handle, the tibia jointing surface, the surface of the positioning piece and the surface of the tibia intramedullary handle together constitute an osseous jointing surface. Part or all of the osseous jointing surface is integrated into a whole so as to form a three-dimensional net body. The surface of the three-dimensional net body is provided with a plurality of holes extending from the surface to the inside. Horizontal passages communicated with part or all of the holes are arranged inside the three-dimensional net body. The horizontal passages of the three-dimensional net body are single-layer or multi-layer passages. The artificial knee joint has the advantage of long-time looseness prevention.

Owner:曼德卡姆有限公司

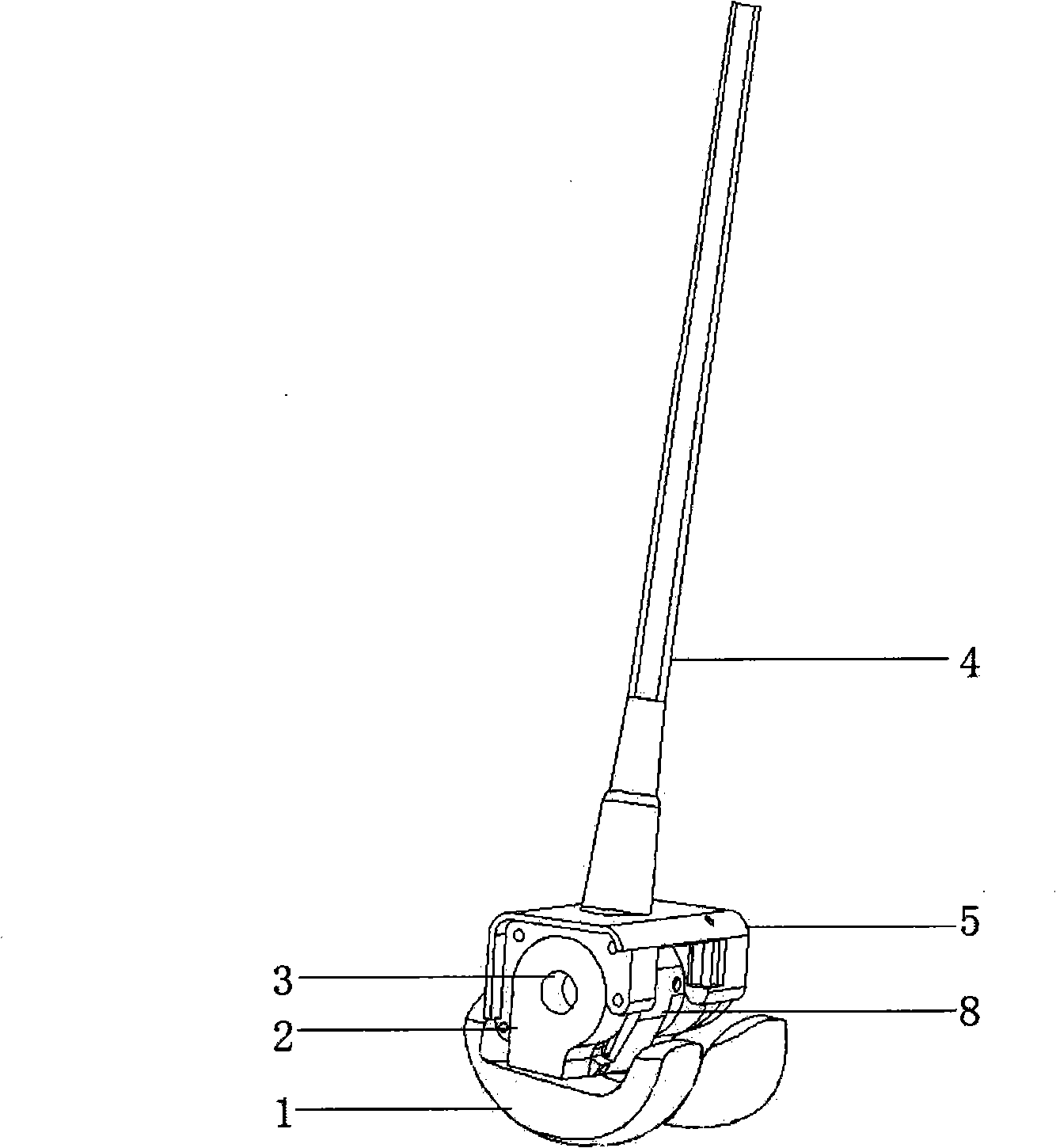

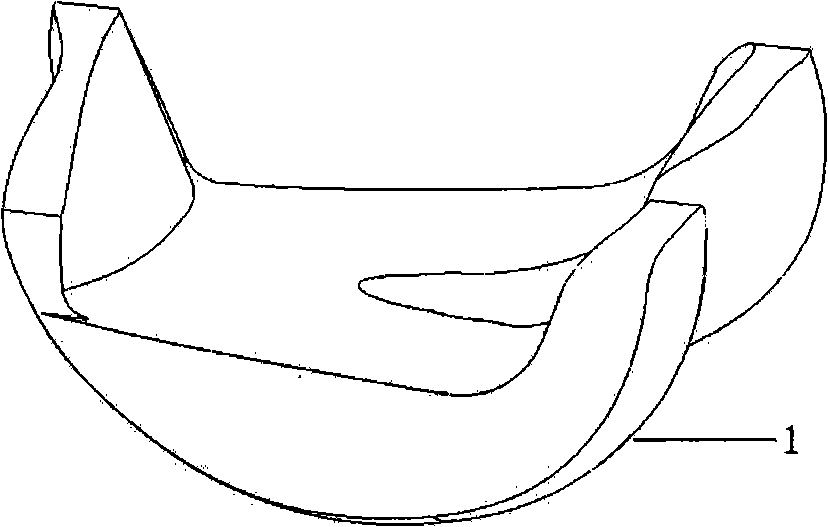

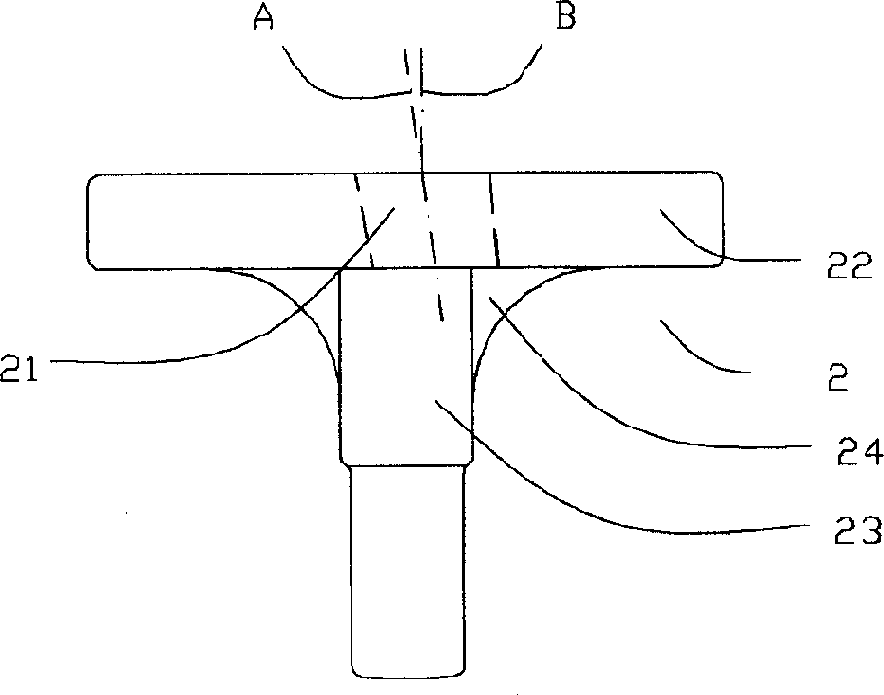

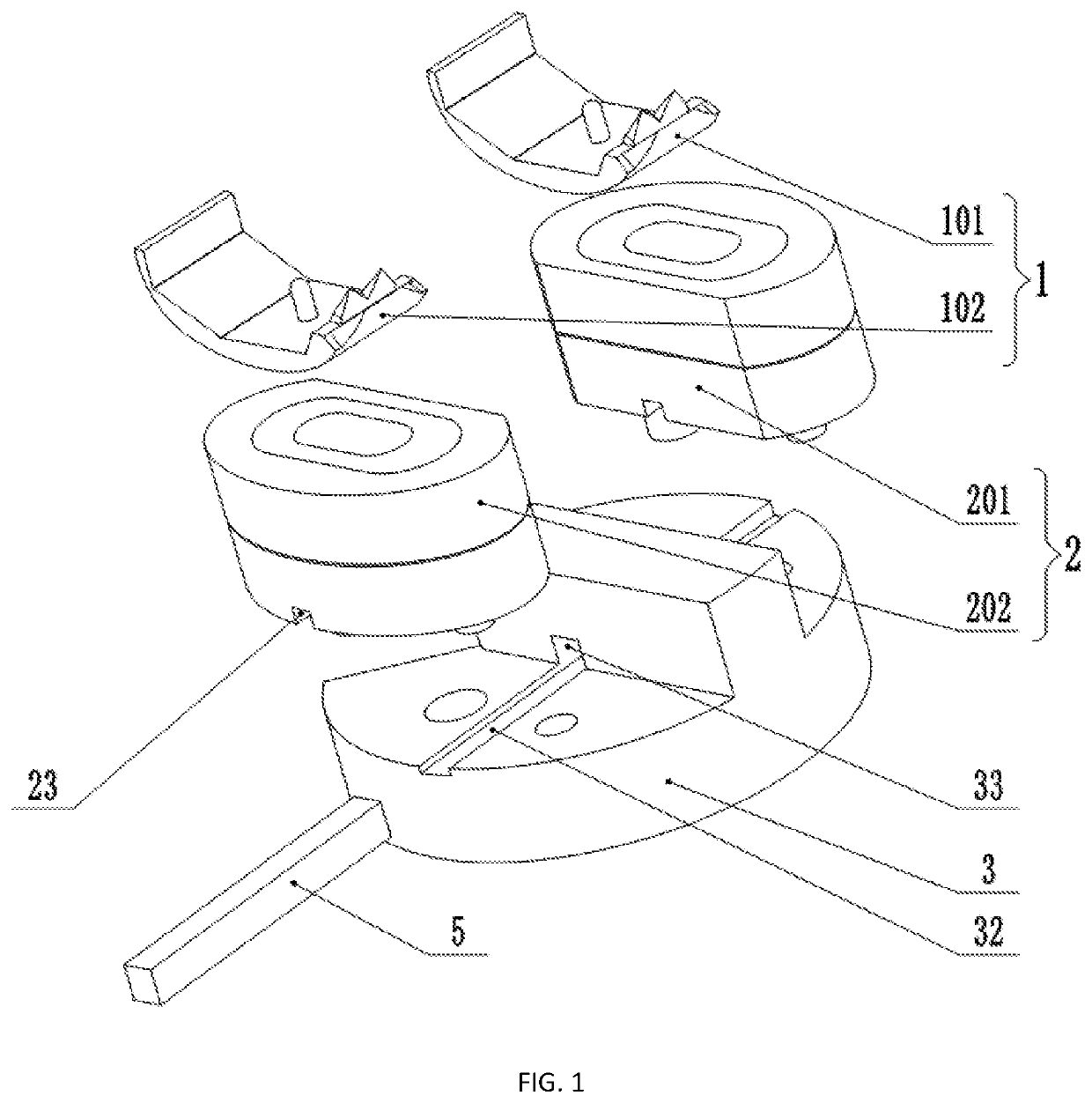

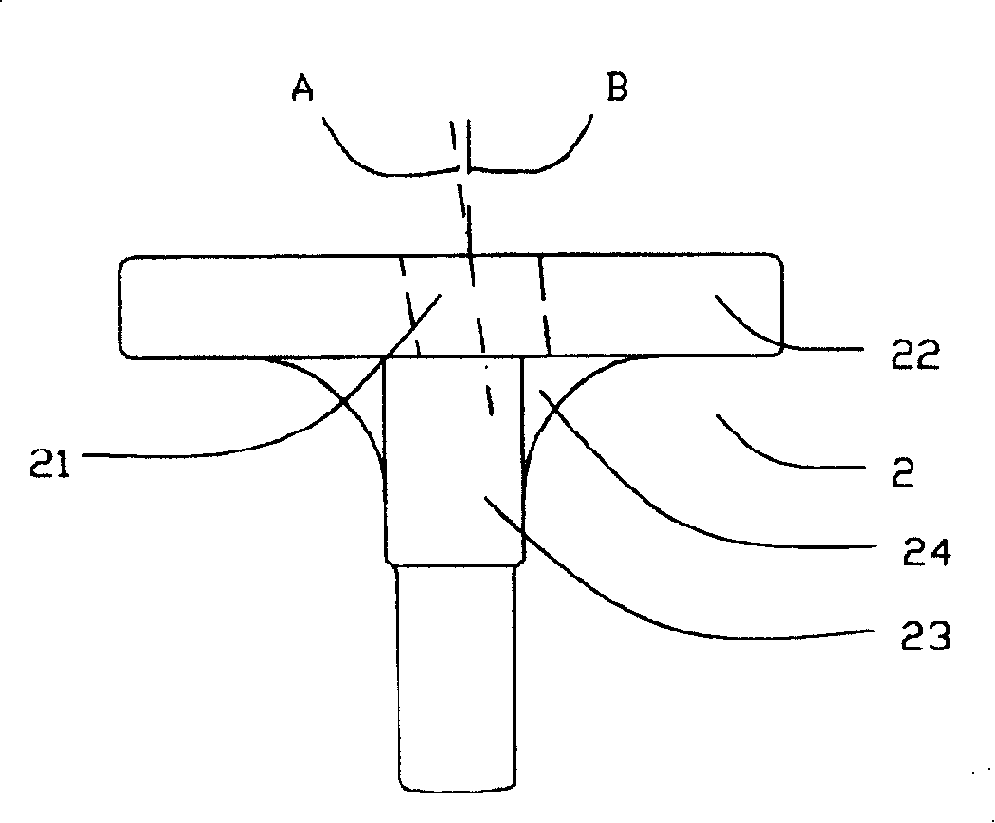

New axial center type knee joint prosthesis

ActiveCN101584615AMeet needsIncrease contact surfaceJoint implantsKnee jointsPhysical medicine and rehabilitationProsthesis

The invention relates to a new axial center type knee joint prosthesis comprising a femur intramedullary pin, a femur condyle, connecting components and a tibia intramedullary pin, also comprsing a tibia platform and a femur sleeve, wherein, the femur condyle is provided with a positioning slot and is fixed at lower part of the femur intramedullary pin; the tibia platform is provided with a centre hole and is fixed at the upper part of the tibia intramedullary pin for holding the femur condyle; the connecting components are T-shaped and comprise a transverse shaft and a vertical shaft, the vertical shaft is inserted into the centre hole of the tibia platform, the transverse shaft is rotatable arranged through the lower part of the femur condyle; the femur sleeve is sleeved at the lower part of the femur intramedullary pin and are butted with the positioning slot of the femur condyle. The new axial center type knee joint prosthesis of the invention can completely recovery the functions of extending and bending, and inward and outward rotating of the knee joint and adopt the bionic molding, the stability is good, the movement requirement of the patient can be satisfied sufficiently under the precondition of protecting limbs, the patient can recovery the movement freely like originally.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

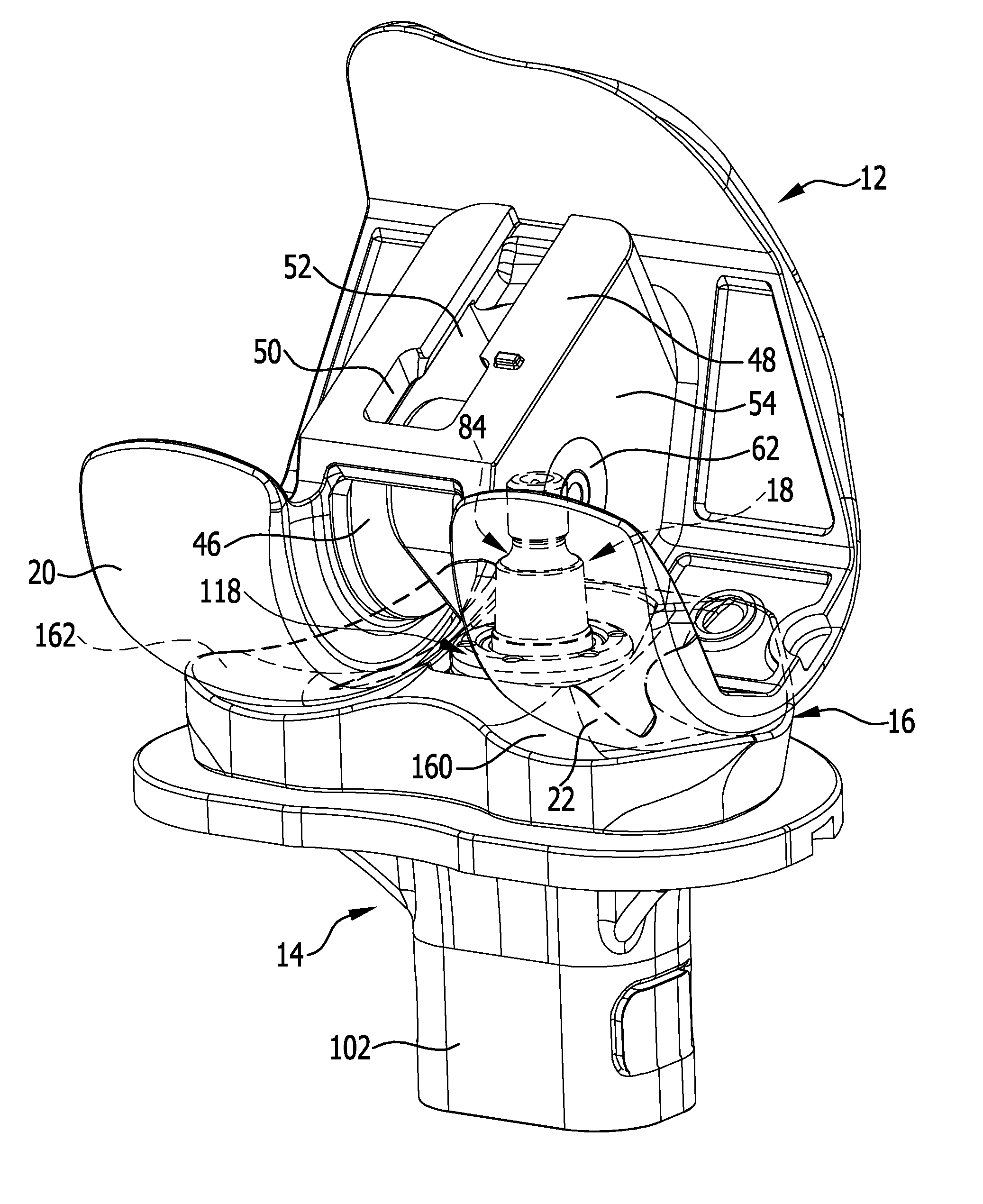

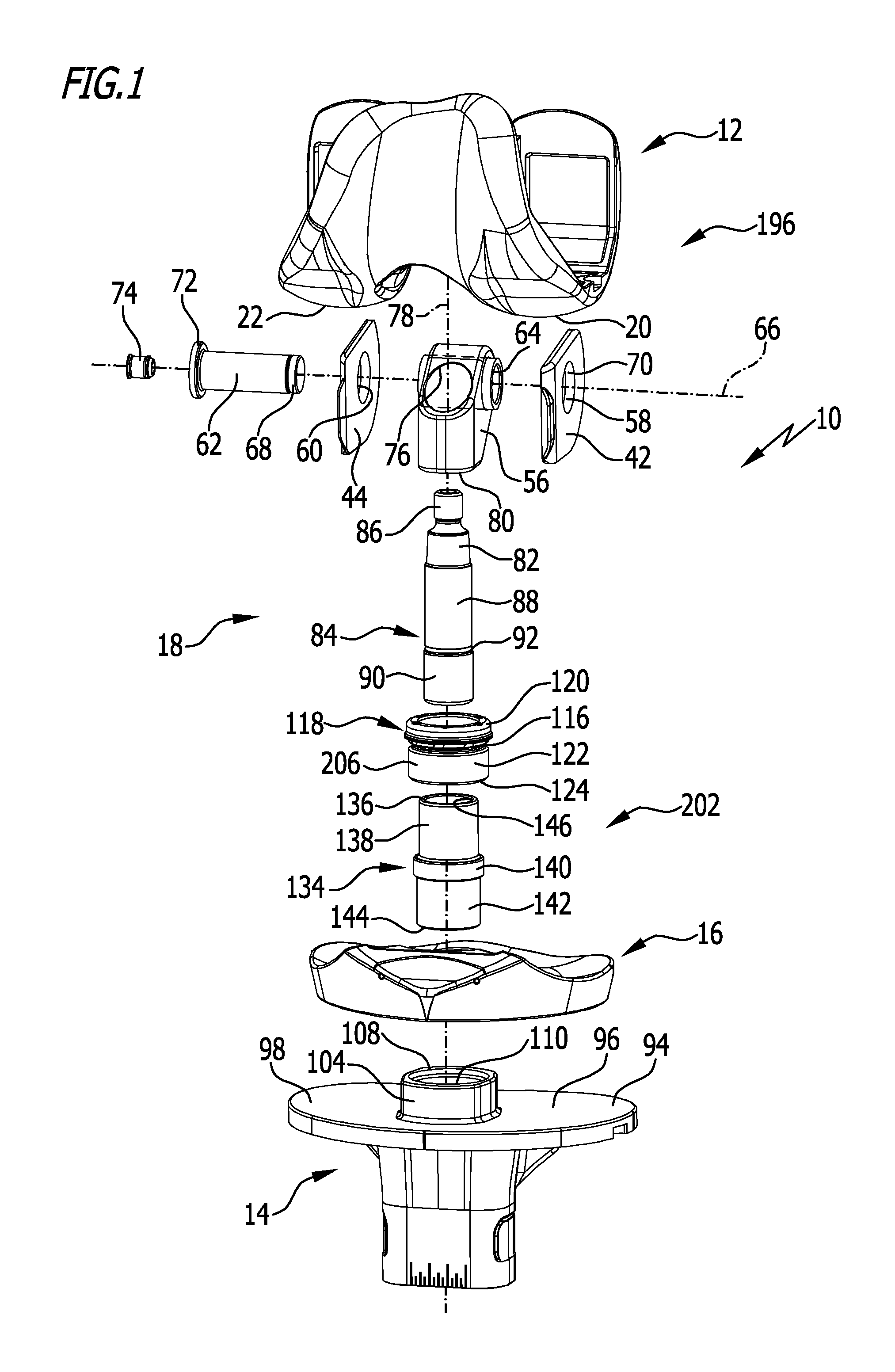

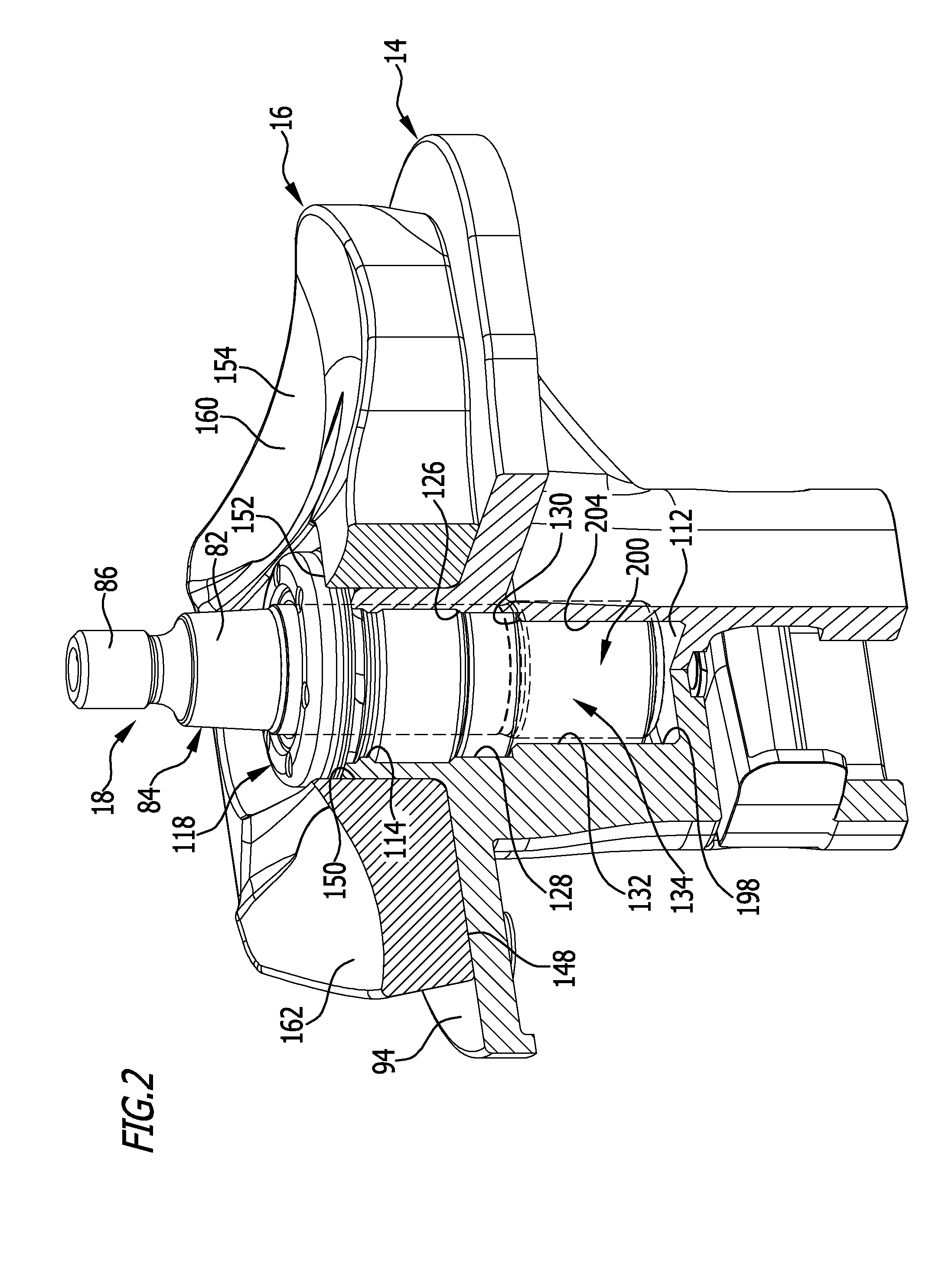

Femur formation and cutting center

A cutting center for shaping the femur condyle is composed of a speed variator, a main drive shaft in said speed variator, a main drive gear installed to said main drive shaft, at least one driven gear matched with said main drive gear and installed to the first driven shaft in said speed variator, and a cutter installed to the extended end of the first driven shaft.

Owner:BEIJING MONTAGNE MEDICAL DEVICE

Knee joint endoprosthesis

The invention relates to a knee joint endoprosthesis has a tibia part, a femur part, a meniscus part arranged on the tibia part in mutually non-rotatable manner and a connecting device for connecting the tibia part to the femur part in articulated manner. Said femur part comprises at least one femur condyle having a femur condyle surface. Said meniscus part comprises at least one upper surface which faces the femur part and has at least one meniscus joint surface which touches the femur condyle surface of the at least one femur condyle. Said femur part and the tibia part are mounted such as to be rotatable relative to each other about a rotational axis.

Owner:AESCULAP AG

Knee joint prosthesis

PendingCN111184598AAvoid transverse shear stressAddresses susceptibility to wear due to shear stressJoint implantsKnee jointsKnee arthrodesis prosthesisFEMORAL CONDYLE

The invention provides a knee joint prosthesis, which comprises a tibia platform, a femur condyle component and a spacer component, wherein the femur condyle component is positioned above the tibia platform and comprises an inner condyle joint surface and an outer condyle joint surface, and the inner condyle joint surface and an outer condyle joint surface have a height difference H; the spacer component is positioned between the tibia platform and the femur condyle part and comprises an inner side spacer cooperated with the inner condyle joint surface, and an outer side spacer cooperated withthe outer condyle joint surface; a position, which corresponds to the outer side spacer, on the upper surface of the tibia platform is provided with a first spherical convex surface; the outer side spacer is movably arranged on the prosthesis platform; and in addition, the lower surface of the outer side spacer is provided with a first spherical concave surface cooperated with the first sphericalconvex surface. According to the technical scheme of the invention, the problem in the relevant art that the knee joint prosthesis is likely to abrade can be effectively solved.

Owner:BEIJING AKEC MEDICAL

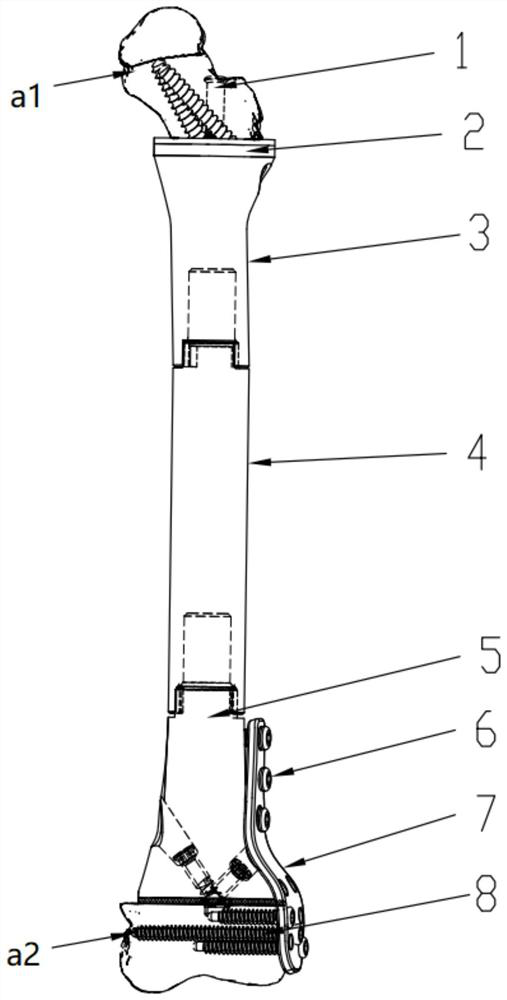

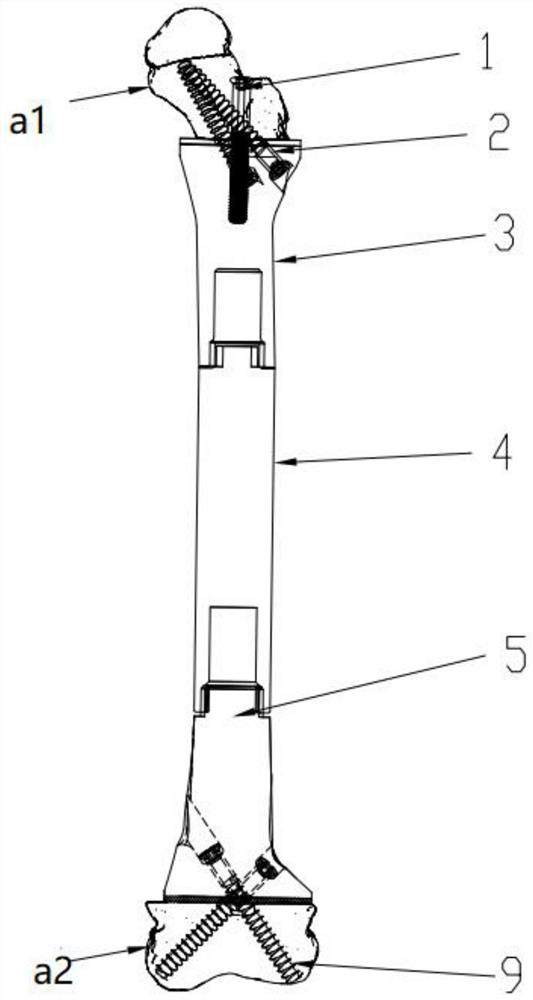

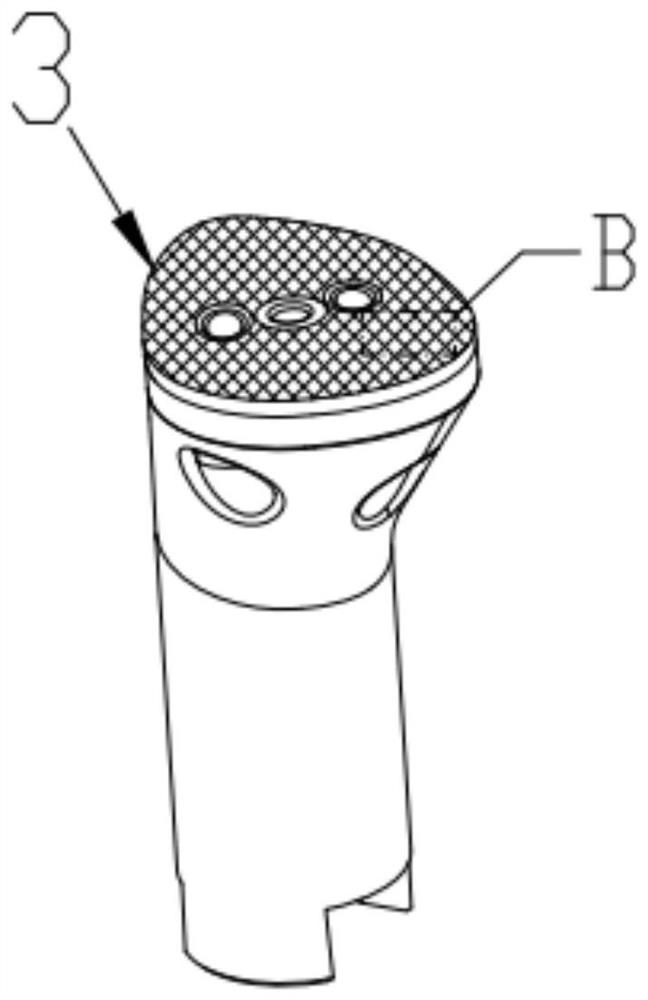

Children type tumor joint prosthesis reserving femur neck and knee joint surface

InactiveCN111789702APreserve bone growth functionImprove stabilityJoint implantsFemoral headsEngineeringFEMORAL CONDYLE

The invention provides a children type tumor joint prosthesis reserving a femur neck and a knee joint surface. The children type tumor joint prosthesis reserving a femur neck and a knee joint surfacecomprises a backbone extension segment, wherein a femur near end prosthesis and a femur far end prosthesis are respectively assembled and connected to two ends of the backbone extension segment; porous structure grooves having bone trabecula are formed in the junction surface of the femur near end prosthesis and a femur and the junction surface of the femur far end prosthesis and femur condyle; afemur outside steel plate is in dismountable connection to the outer side of the femur far end prosthesis; and a femur near end central pulling force nail and femur near end assistant nail are connected with the femur near end prosthesis and the femur, and locking nails and spongy bone pulling force nails are connected with the femur far end prosthesis and the femur condyle. The prosthesis is connected with metaphyseal dysplasia tissue of a femur upper segment and a femur far end, and the bone growth function of a child patient is reserved. The situation that the skeleton growth of a postoperative child patient is not limited by the steel plate can be guaranteed, after the prosthesis and bone tissue form reliable biological fixation, the femur outside steel plate can be demounted, and theincreased spongy bone pulling force nails crossed inside and outside can further improve the stability and the reliability of the prosthesis.

Owner:BEIJING LIDAKANG TECH

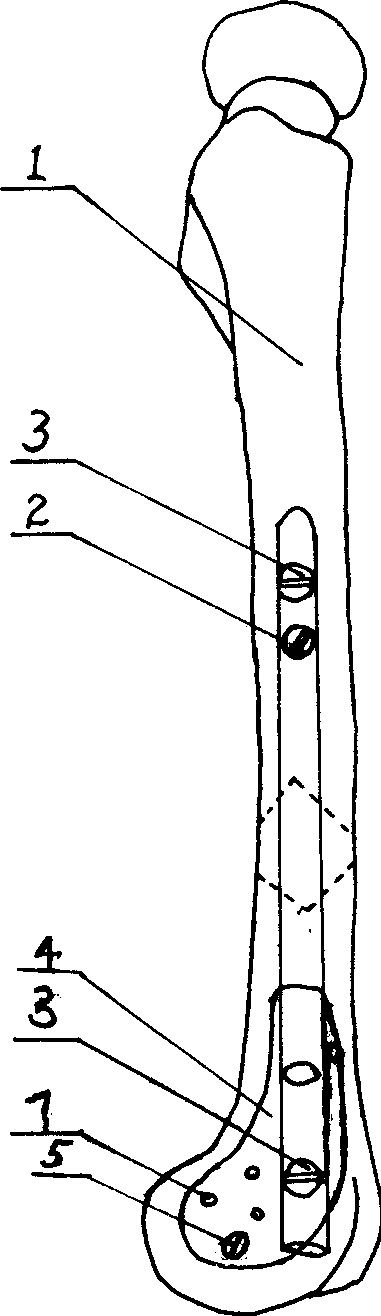

Artificial complete knee joint substitute prosthesis capable of reconstructing anterior cruciate ligament

ActiveCN1663541AEasy to manufactureEasy to installJoint implantsKnee jointsTotal knee replacementProsthesis

The present invention is one kind of artificial total knee replacement prosthesis of rebuildable anterior cruciate ligament, which comprises tibia plant holder piece and pad; tibia plant holder piece comprises horizontal plant and member bar fastened together, top surface of pad has double horizontal spaced spherical concave surface to receive separated one part of femur condyle. Designing a pore path both on pad and tibia plant holder piece, which penetrate separated the horizontal plants of pad and tibia plant holder piece and connect to each other, makes anterior cruciate ligament can cross the pore path and be fixed of two ends separated femur external malleolus and tibia down horizontal plant of tibia plant holder piece, realizes rebuilding of anterior cruciate ligament in artificial total knee replacement.

Owner:王岩

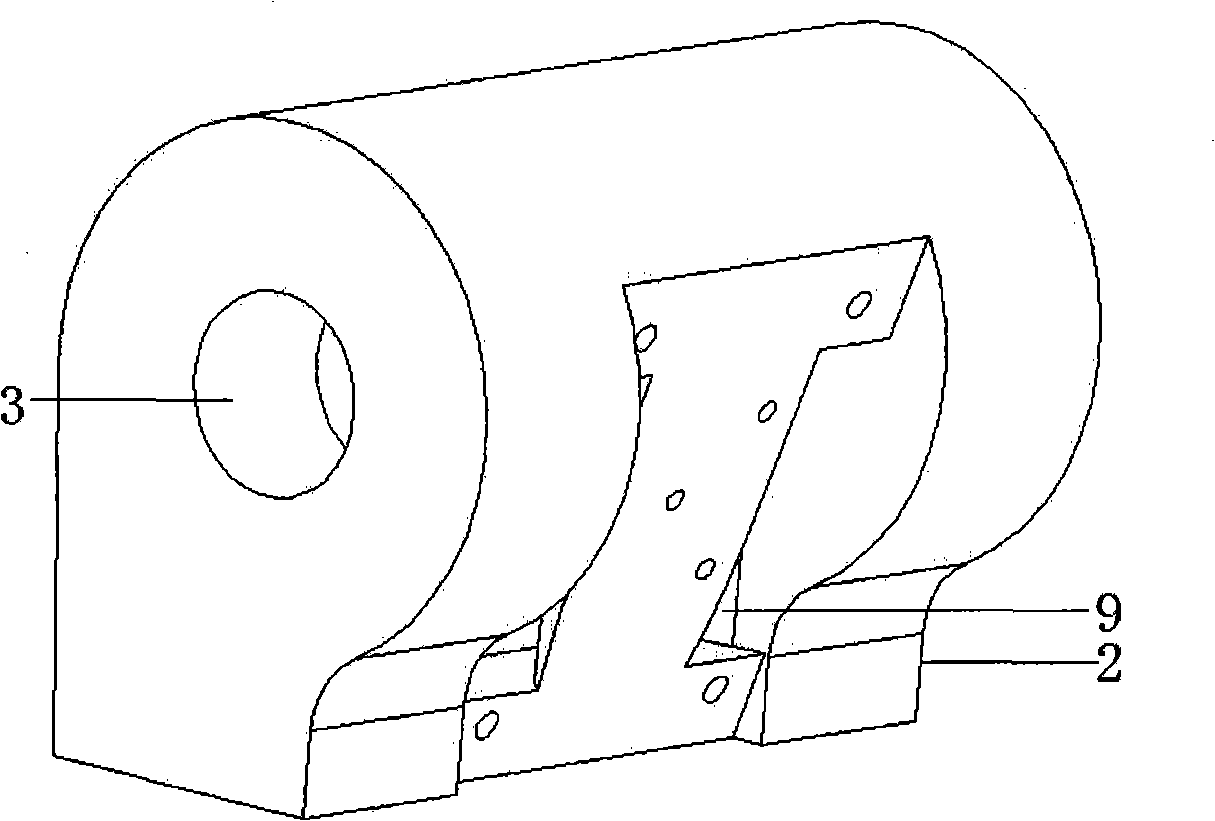

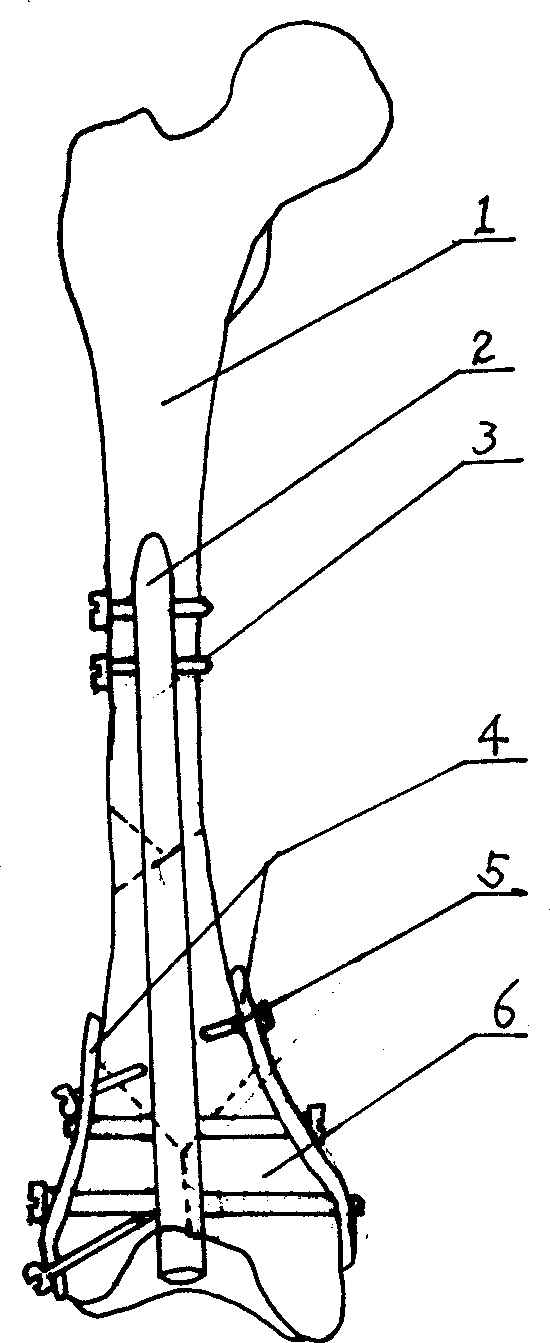

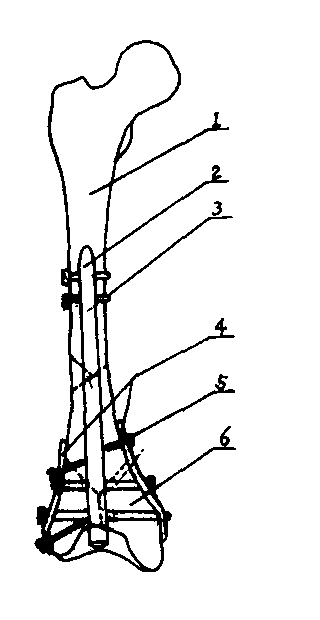

Internal fixator of interamedullary nail jined with steel plate

InactiveCN1329878AGood medical effectPromote recoveryInternal osteosythesisIntramedullary rodSheet steel

An internal fixator of intramedullary nail joined with steel plate is disclosed. Said intramedullary nail has two screw holes at its near and far ends. A locking nail has spiral thread and is matched with said two screw holes of intramedullary nail for locking them together after it passes through femur, femur condyle and two steel plate. Its advantages include good mechanical stability, high effect on preventing shift between fractural bone segments, and promoting healing.

Owner:苏继承 +2

A combined organic polymer material artificial knee joint

ActiveCN104887354BReduce stress shieldingReduce wearJoint implantsTissue regenerationOrganic polymerUltra-high-molecular-weight polyethylene

A combined organic polymer material artificial knee joint, including femoral condyle and tibial support of polyetheretherketone (PEEK) or its derivatives and tibial liner of ultra-high molecular weight polyethylene (UHMWPE), wherein the tibial support includes a platform and The positioning part of the stabilizer wing perpendicular to it; the upper end and the lower end of the tibial liner are respectively engaged with the femoral condyle and the platform; the femoral condyle has a buffer for the sliding surface of the tibial liner; The sliding surface against the tibial liner matches the fretting of the tibial tray against the tibial liner. The main parts of all implant parts of the present invention are made of polymer materials, which reduces the allergies and toxicity problems that metals and their corrosion may cause; the elastic modulus of PEEK matches the natural bone, which reduces the stress shielding problem; the PEEK femoral condyle and The tibial tray combines the sliding surface and the fixed surface of the UHMWPE tibial liner with micro-movement, which greatly reduces the wear problem. At the same time, the reinforcement and development parts are added to further improve the practicality.

Owner:SUZHOU SINOMED BIOMATERIALS CO LTD

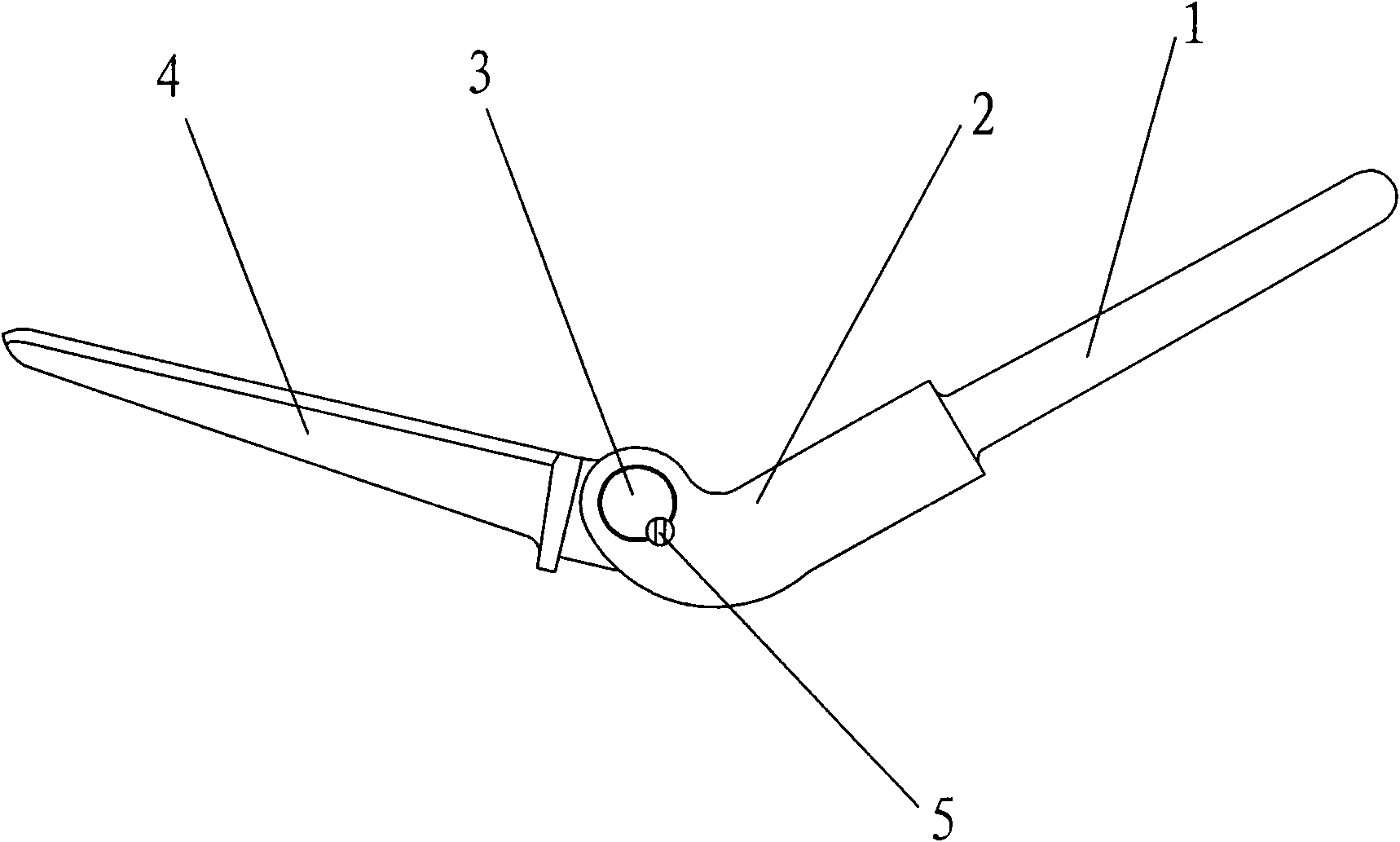

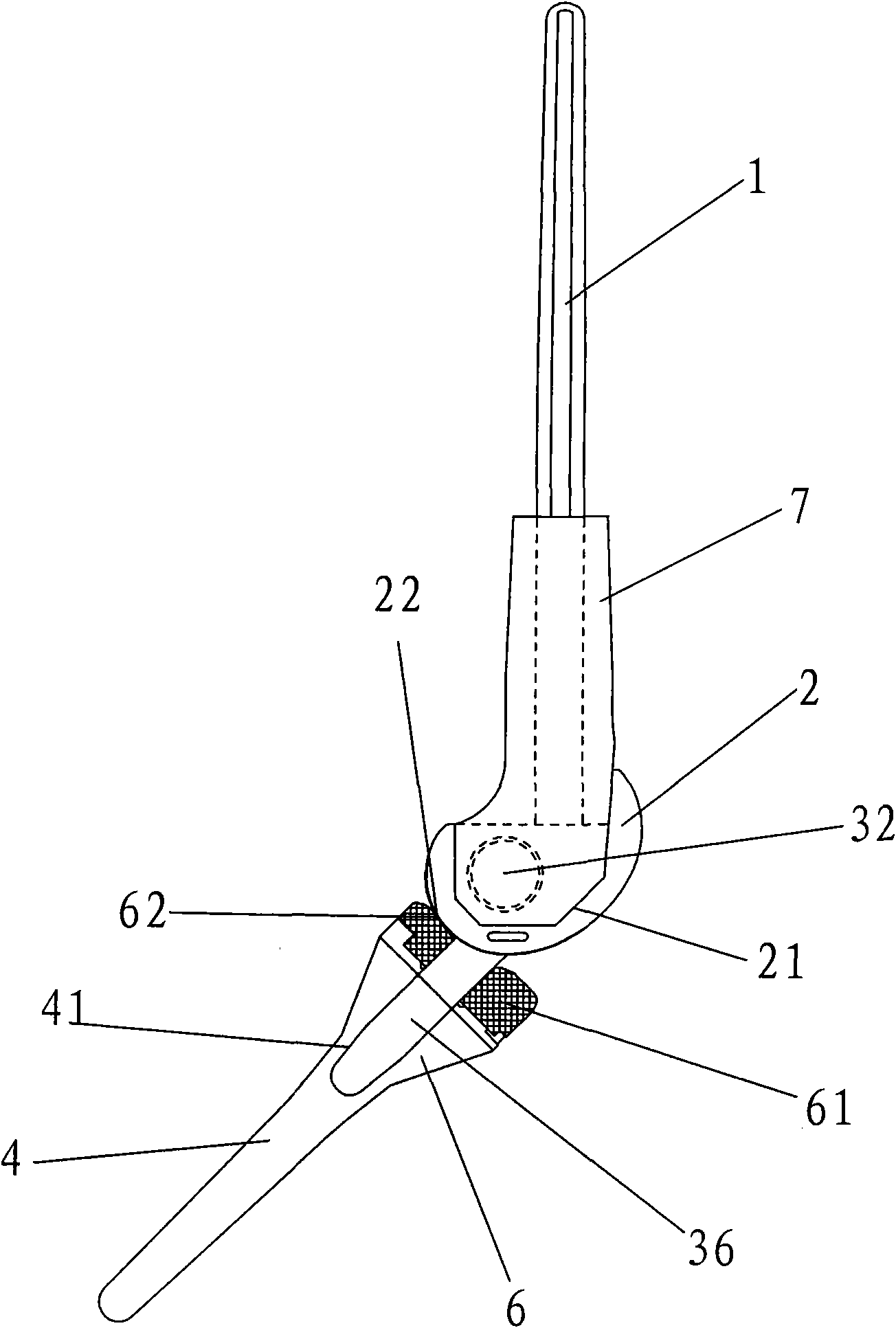

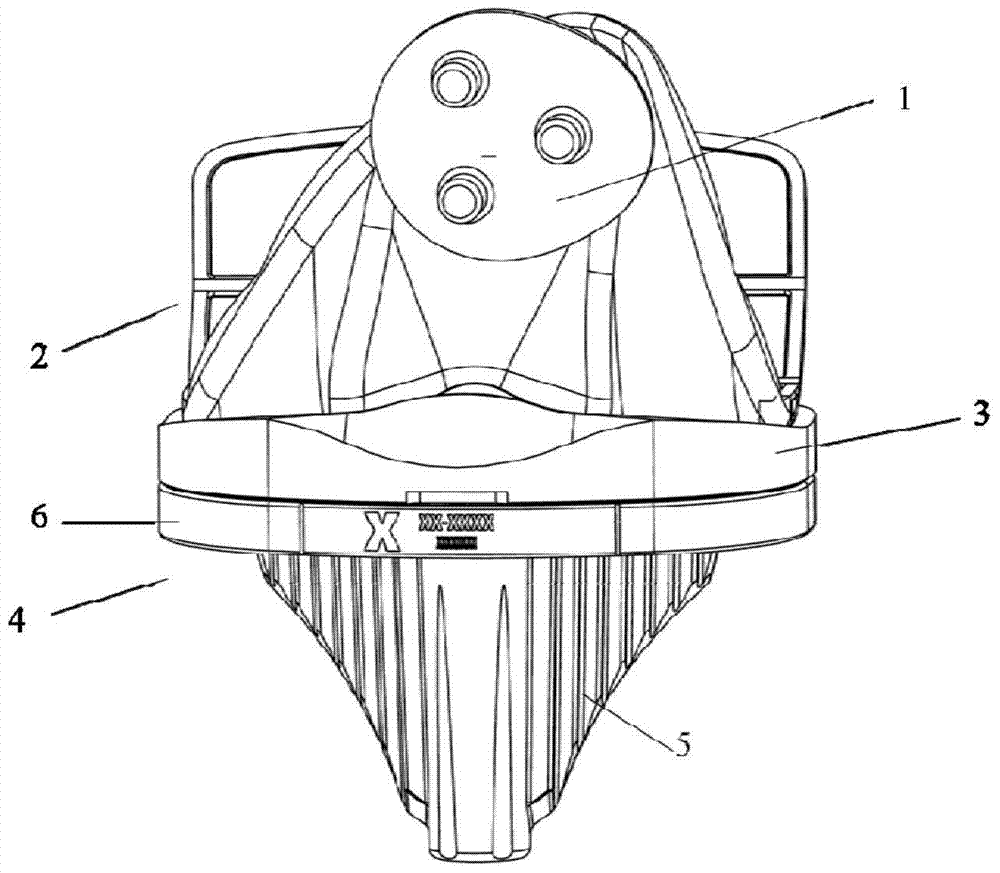

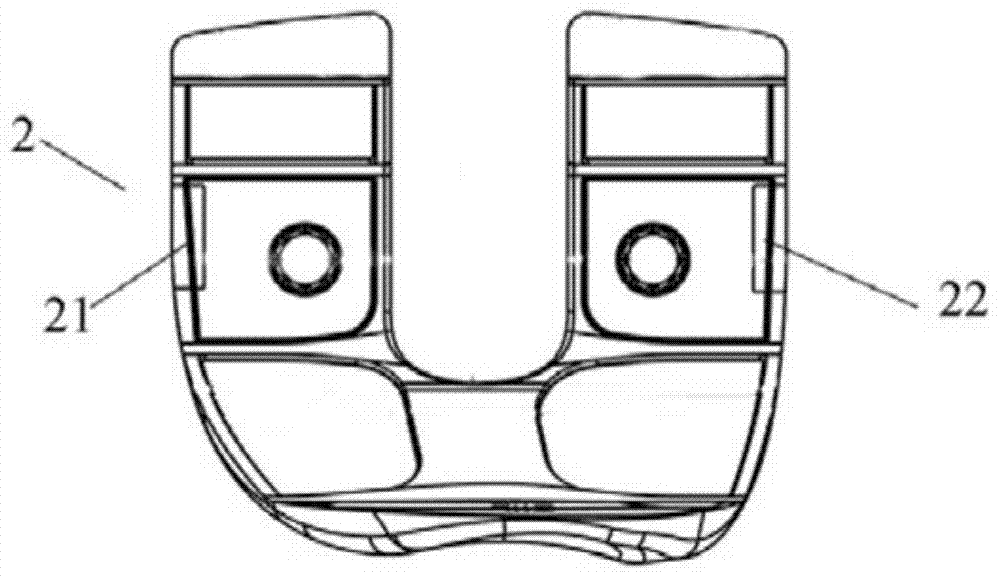

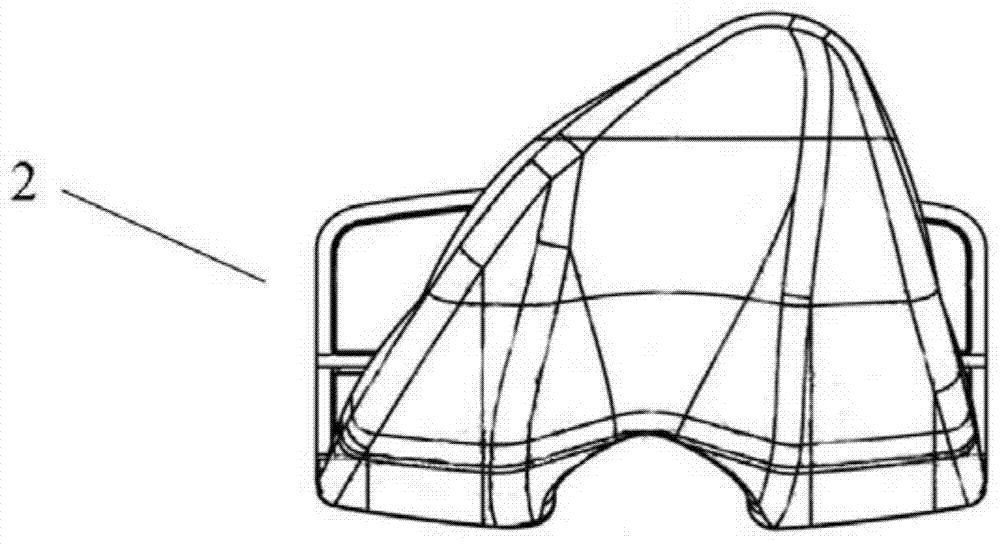

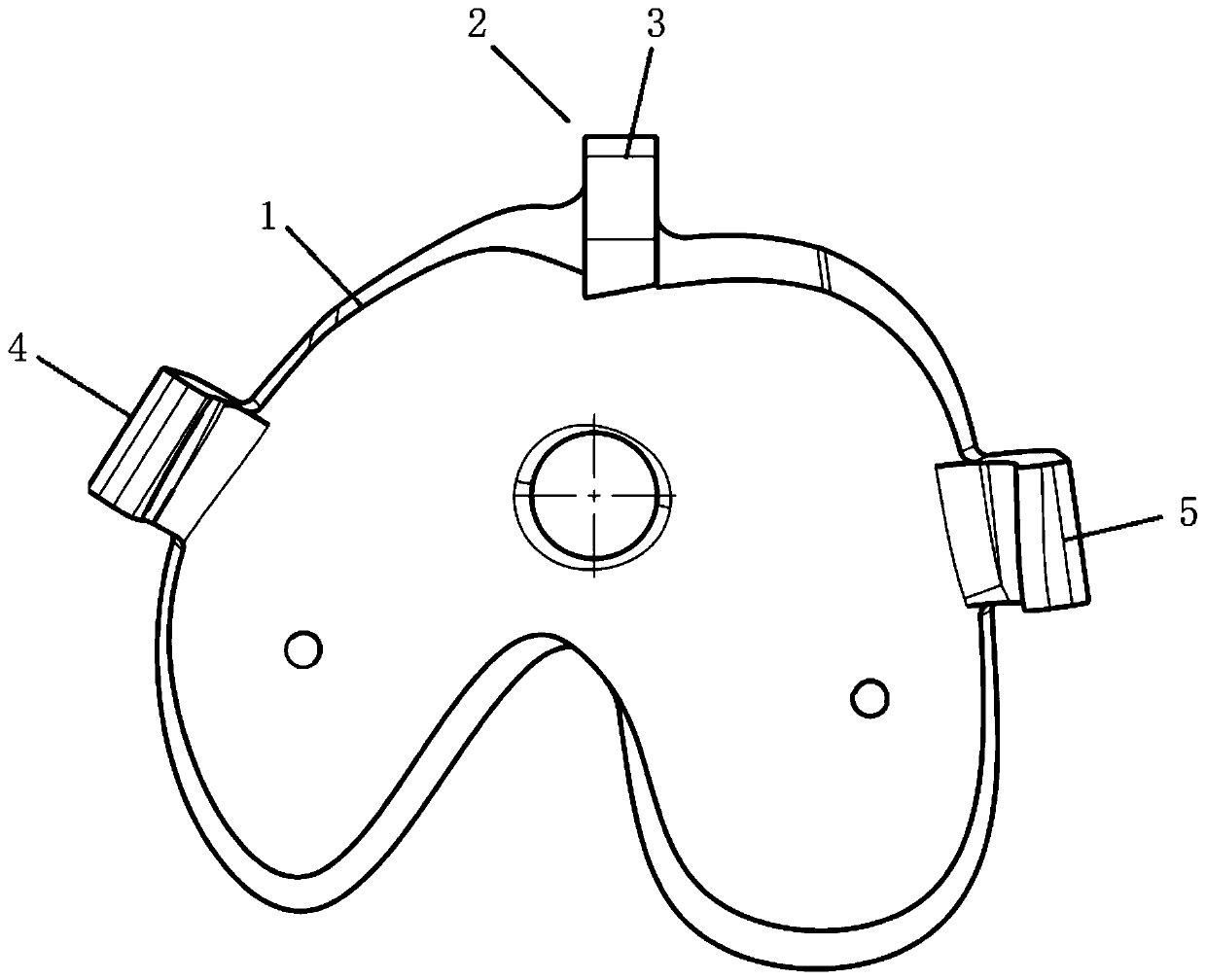

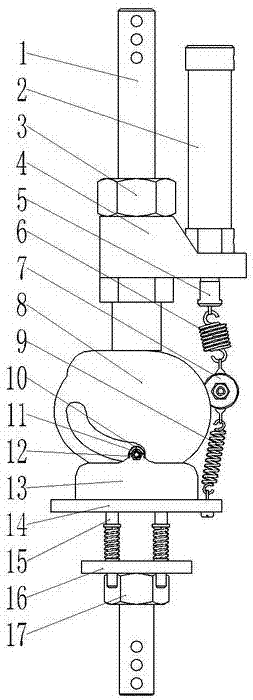

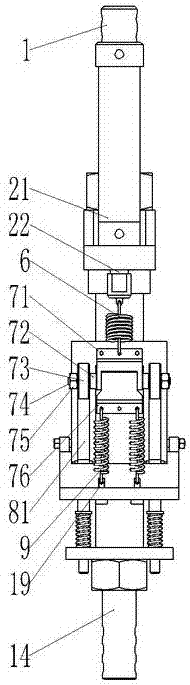

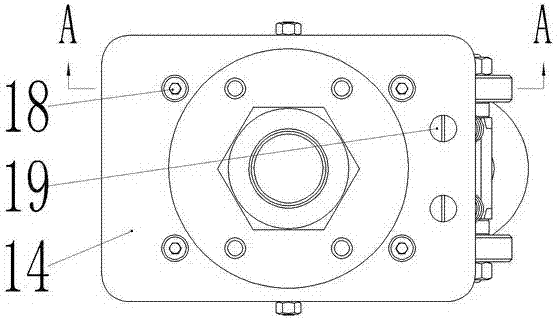

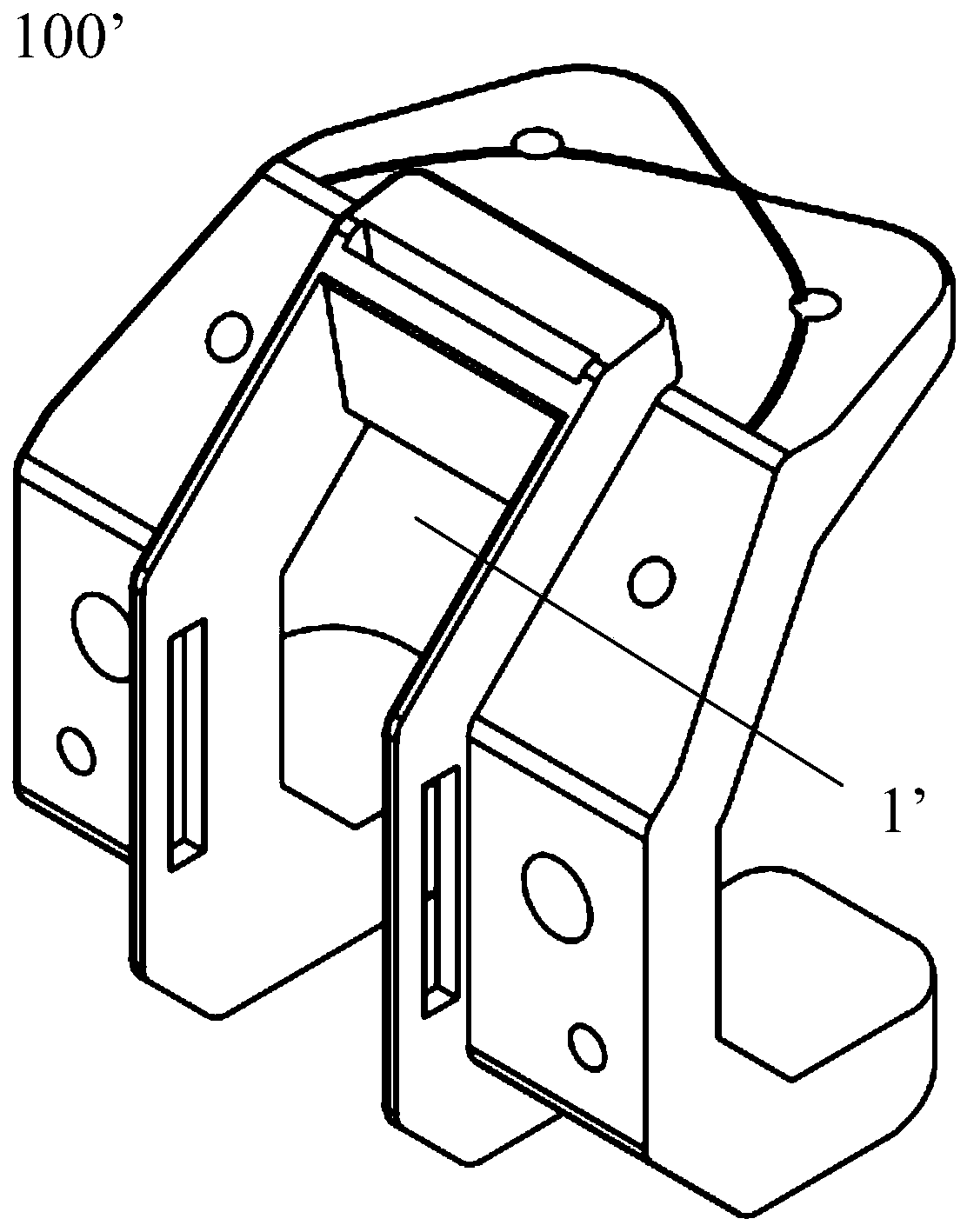

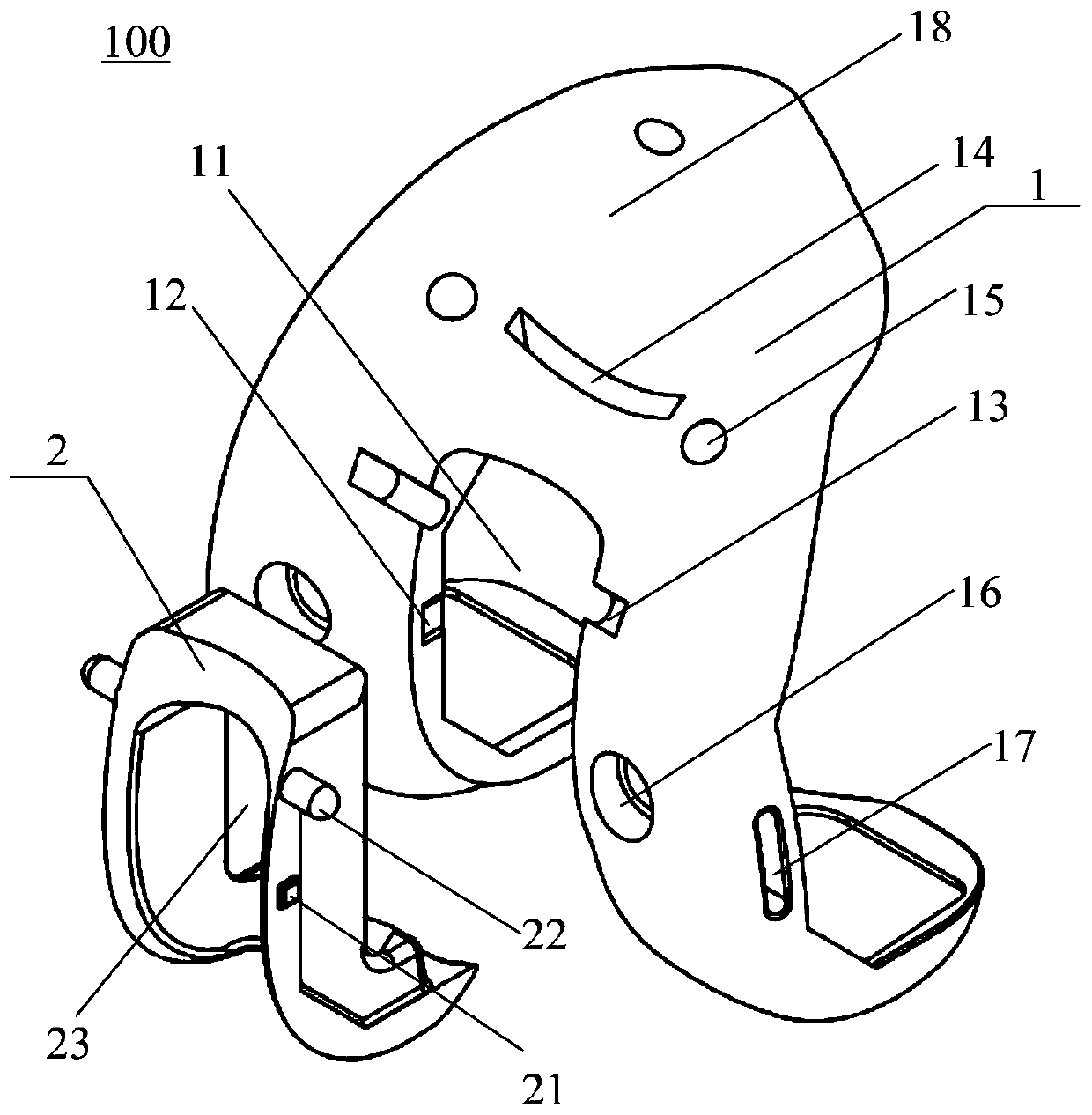

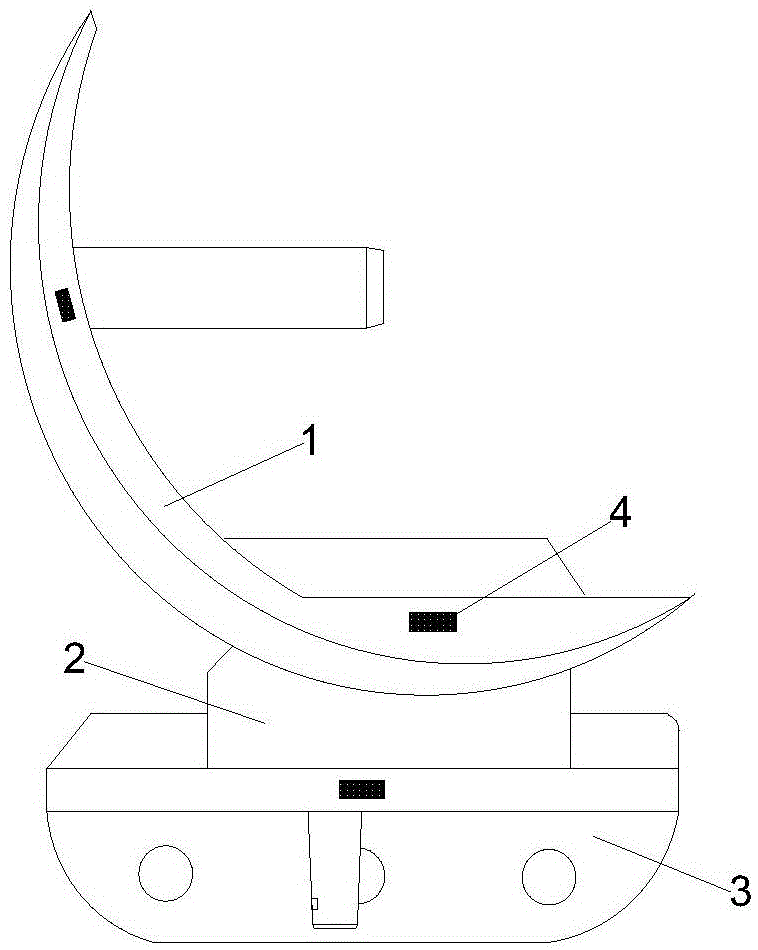

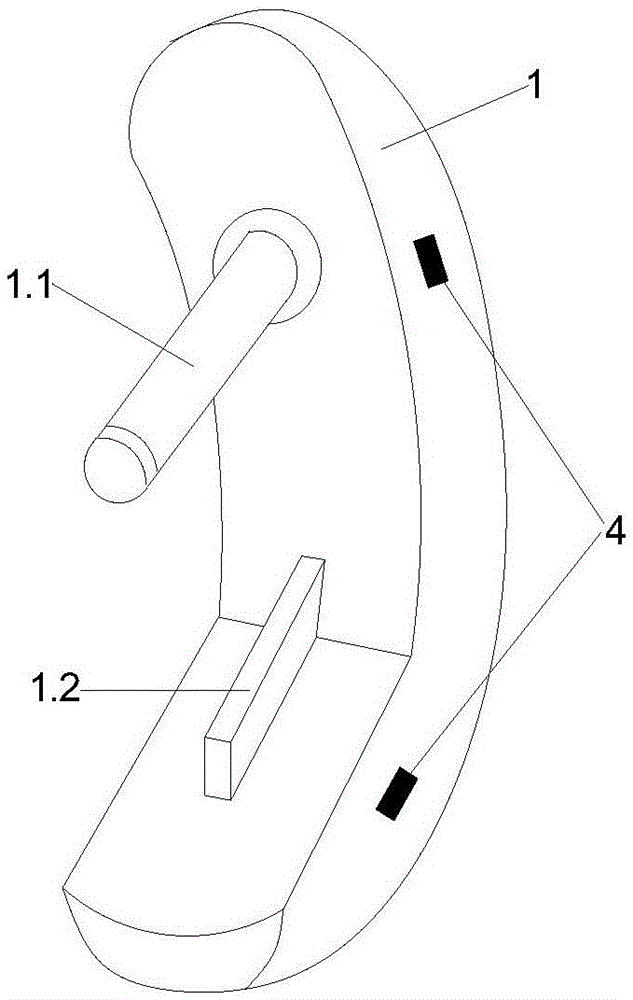

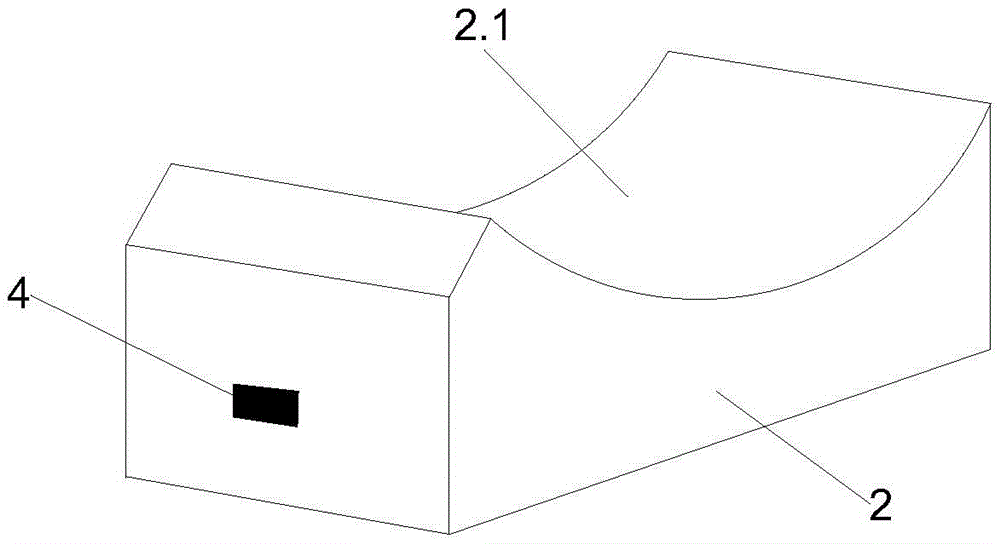

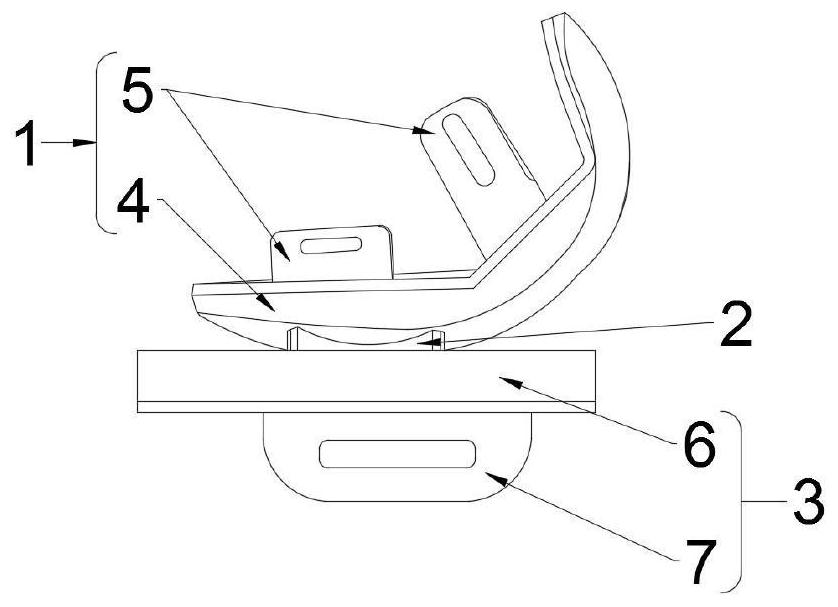

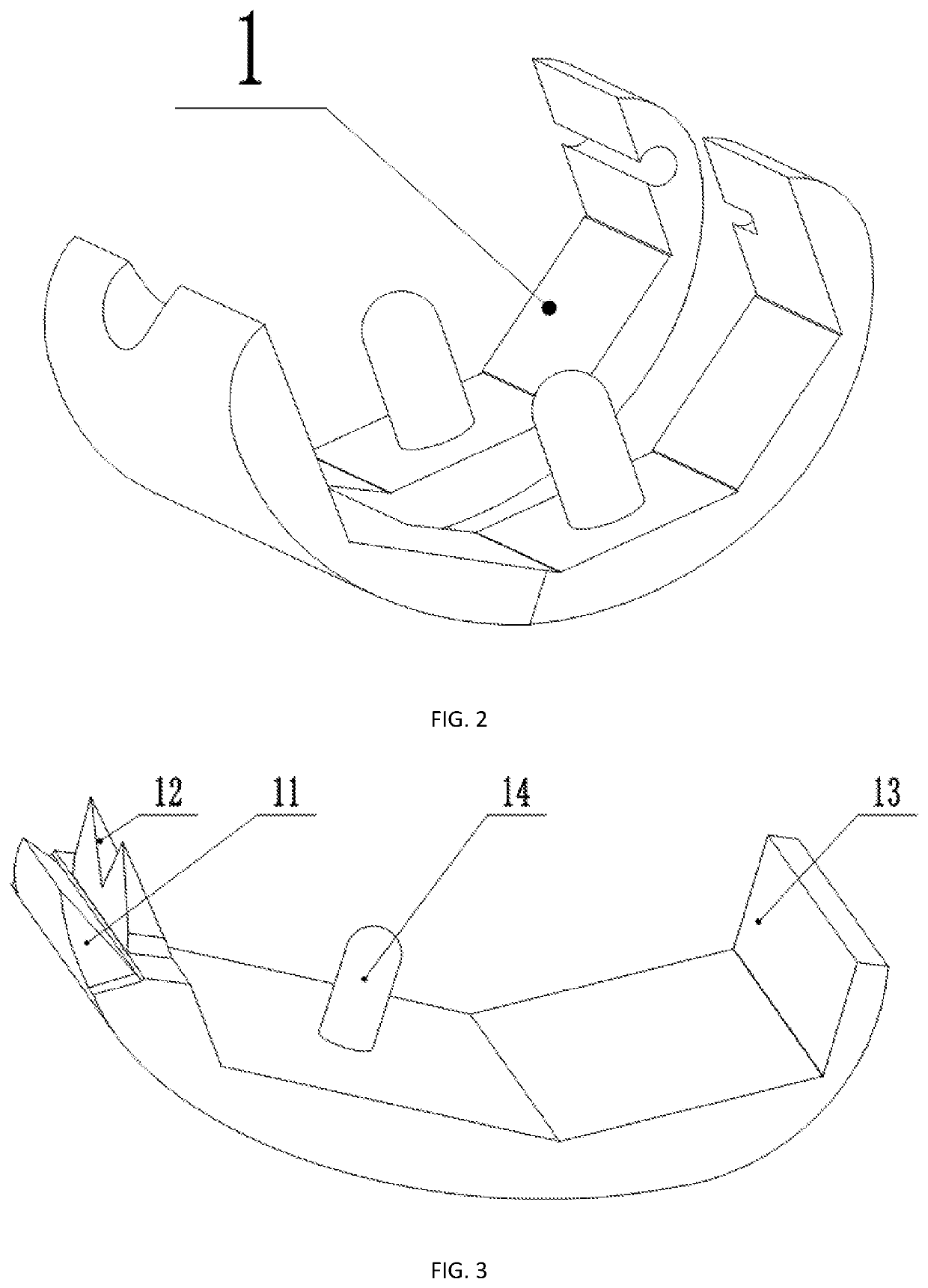

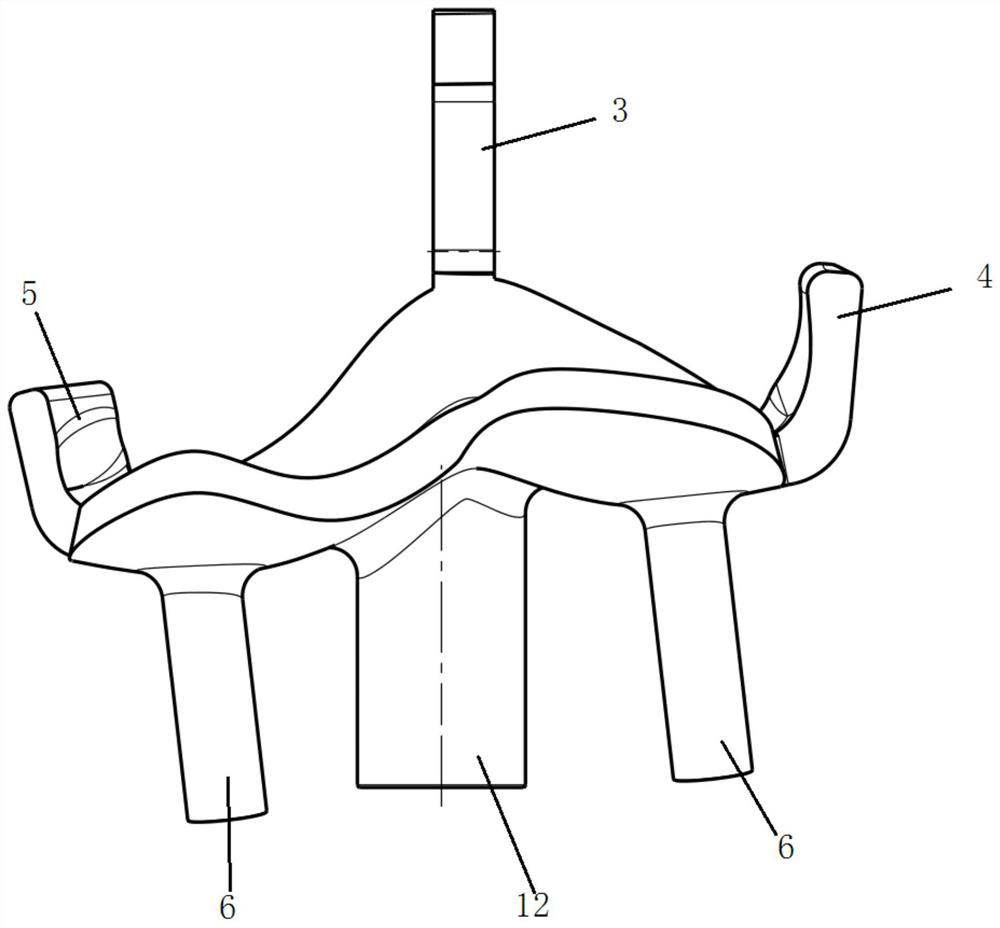

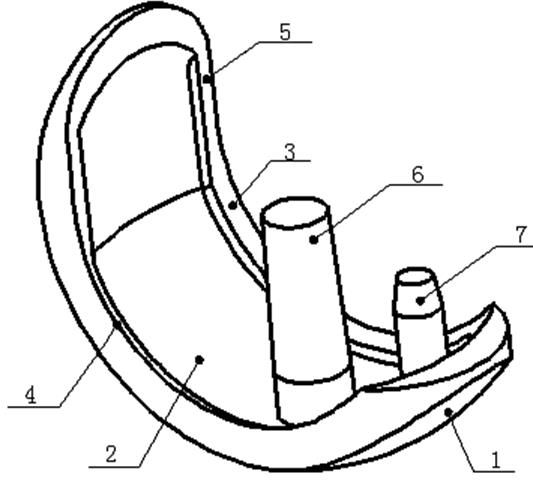

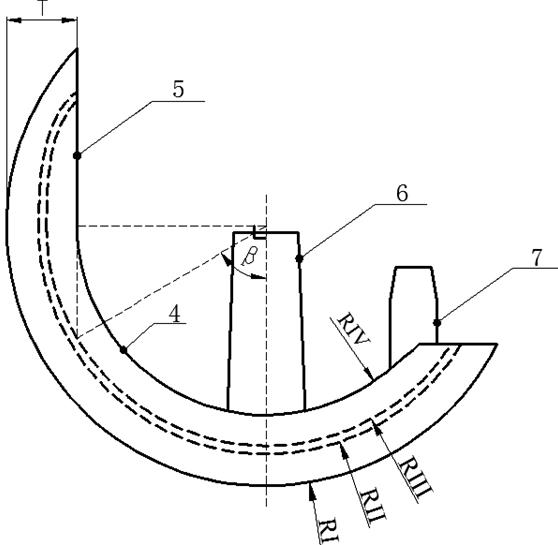

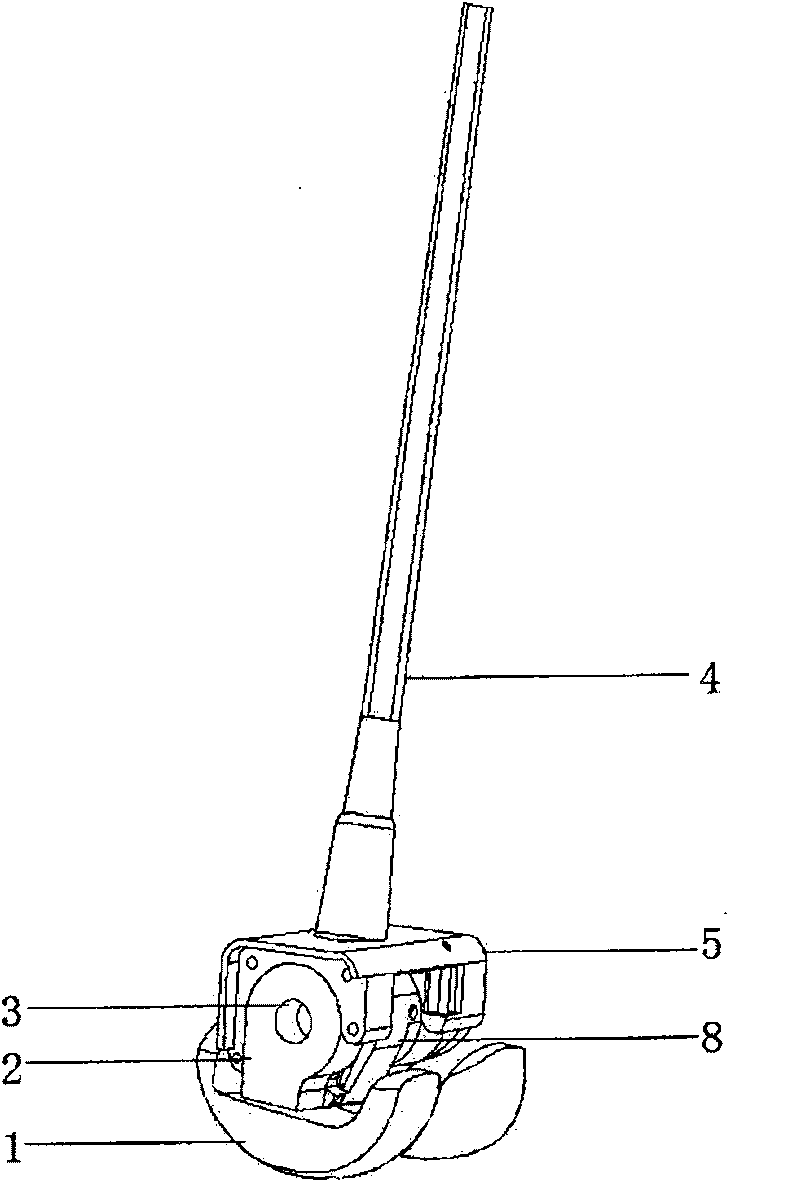

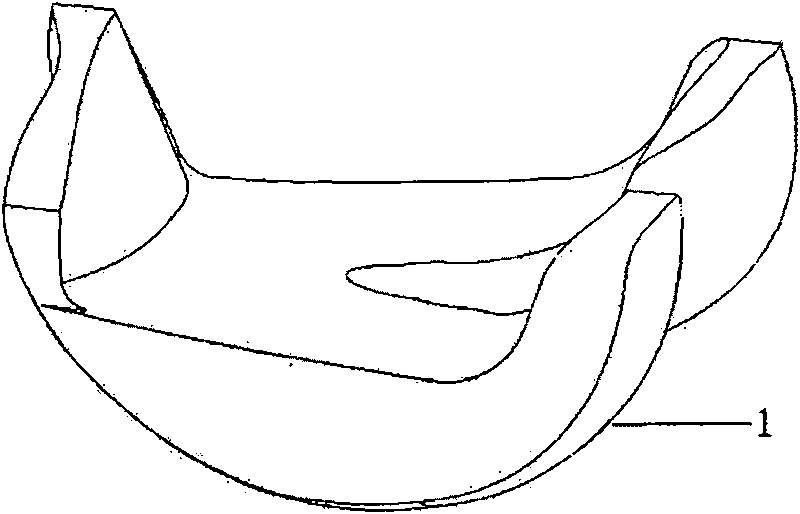

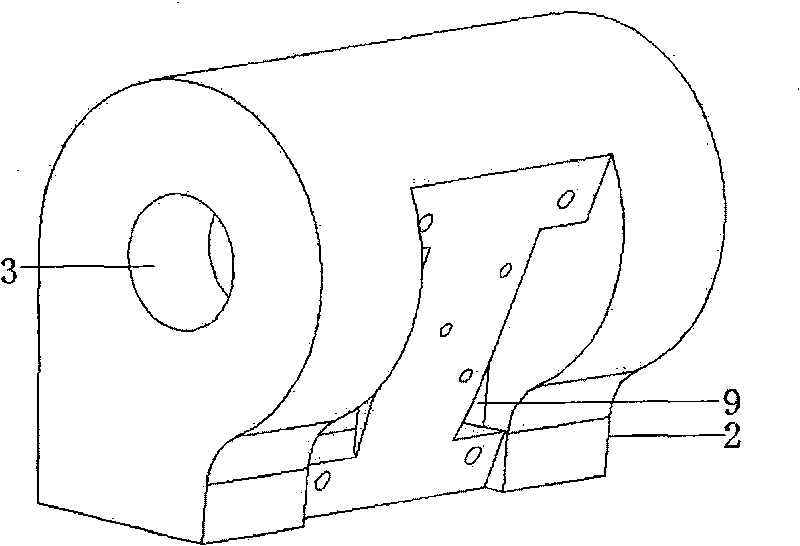

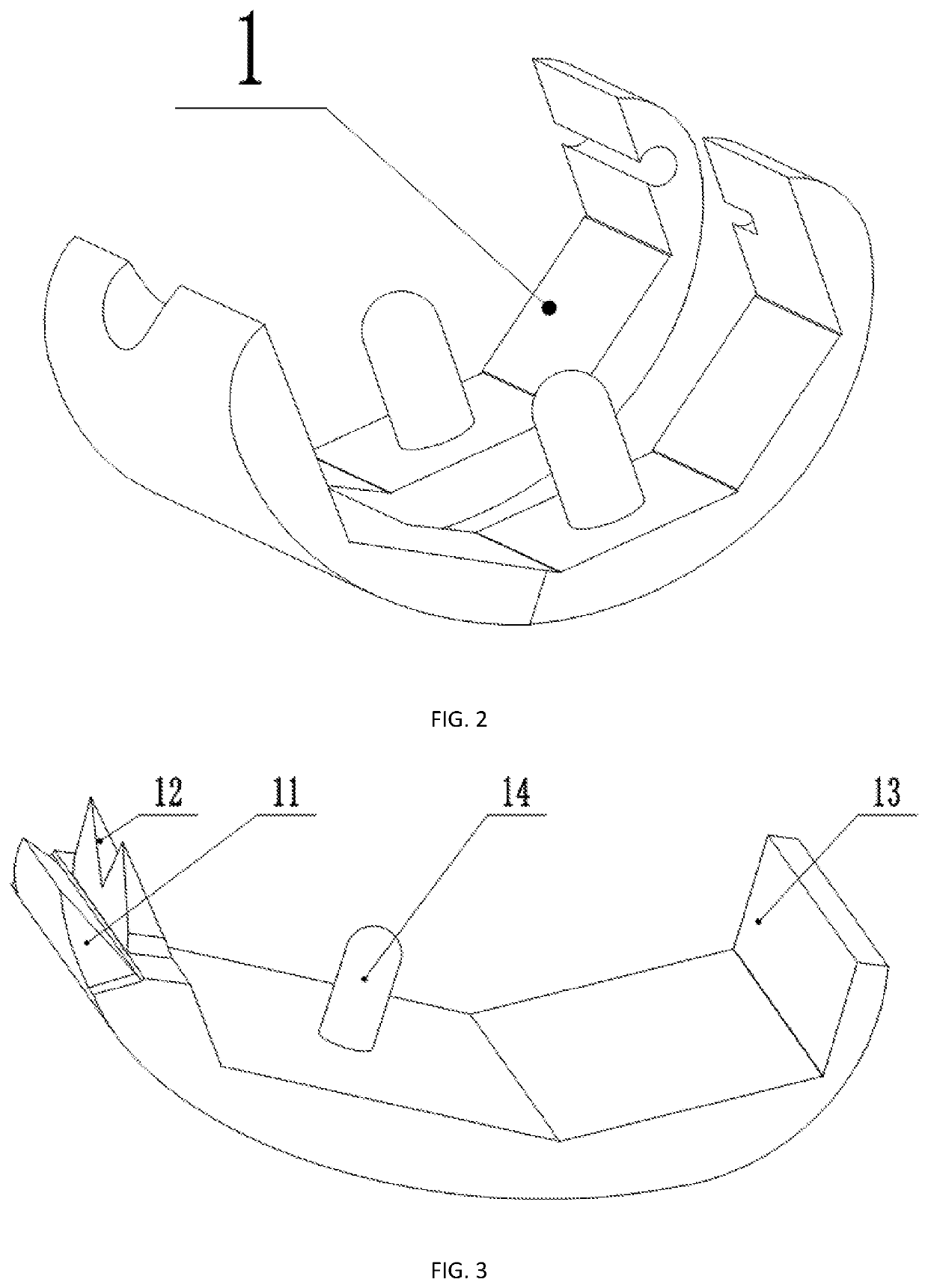

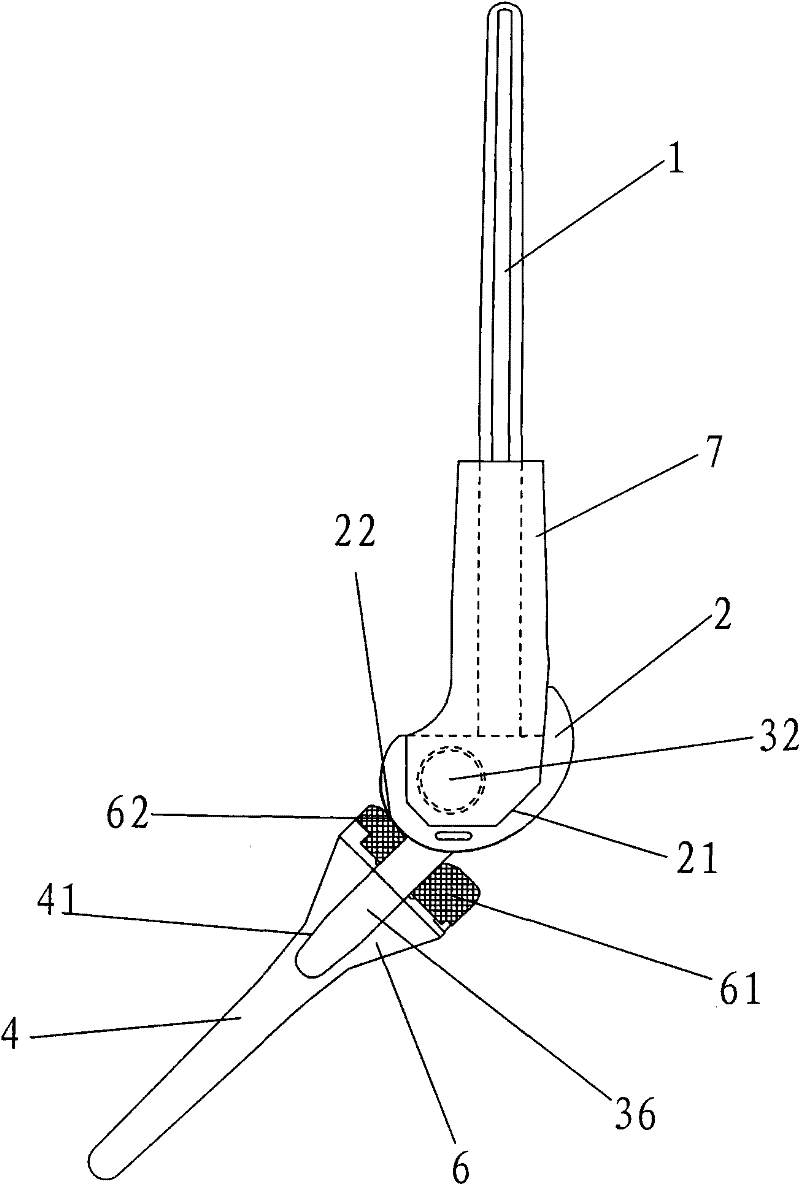

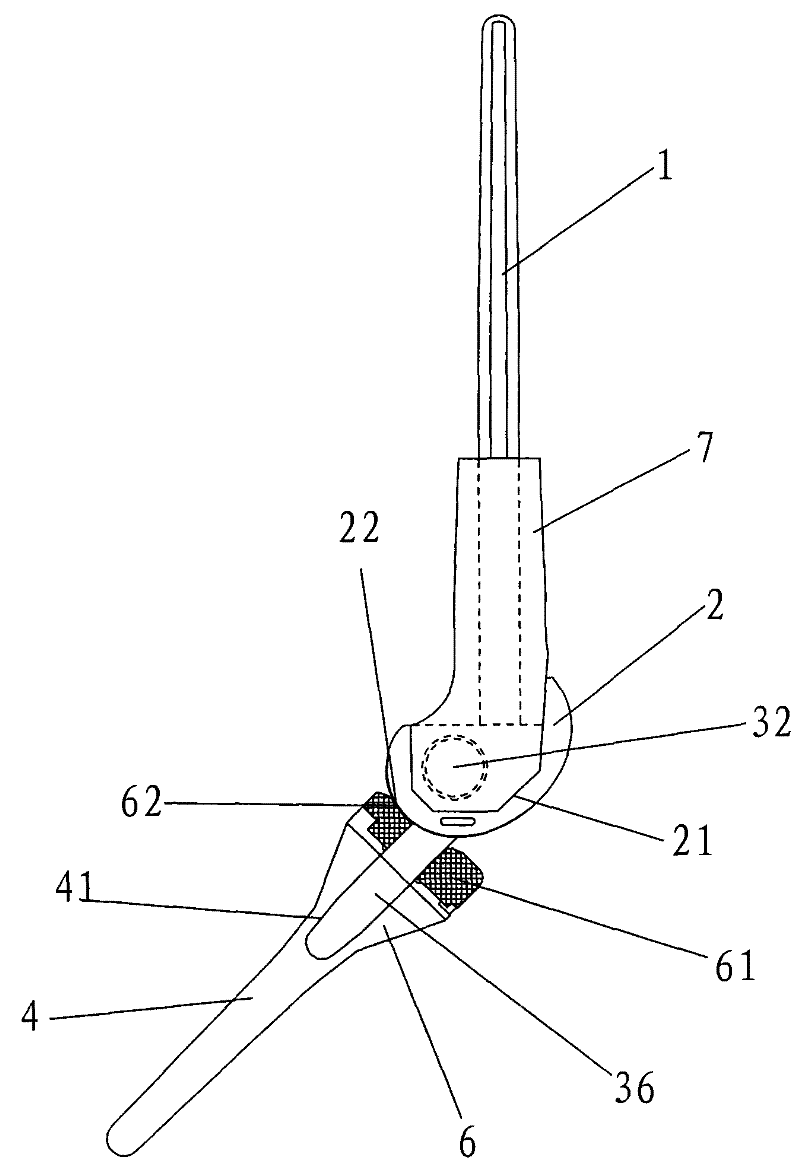

Osteotomy navigation device for total knee arthroplasty

ActiveCN110432948AEasy to grasp the actual situationAccurate guidanceSurgical navigation systemsBone drill guidesOsteotomyMarine navigation

The invention relates to an osteotomy navigation device for total knee arthroplasty and belongs to the technical field of surgical instruments. The osteotomy navigation device comprises a substrate fit with femur condylar bone surfaces, a marrow entering sleeve and positioning sleeves arranged on the outer side of the substrate as well as a limit wall arranged on the inner edge of the substrate and extending outwards, the inner hole axis of the marrow entering sleeve coincides with the center of femur marrow cavity, one positioning sleeve is arranged on each of two sides of the lower side of the marrow entering sleeve, the two positioning sleeves are fixed on the femur condylar bone surfaces, the connection line of centers of end surfaces of the two positioning sleeves coincides with the rotating axis of the femur condyle, the limit wall at least comprises an inner side front end wall, an inner side left end wall and an inner side right end wall. By initial limit and connection and fixation of the positioning sleeves and the femur condylar bone surfaces, a guide is firmly connected and fixed with the femur condylar bone surfaces, the axis of the marrow entering sleeve coincides with the center of the femur marrow cavity and the connection line of centers of end surfaces of the two positioning sleeves coincides with the rotating axis to construct a real-time coordinate system toprovide basis reference for surgery.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

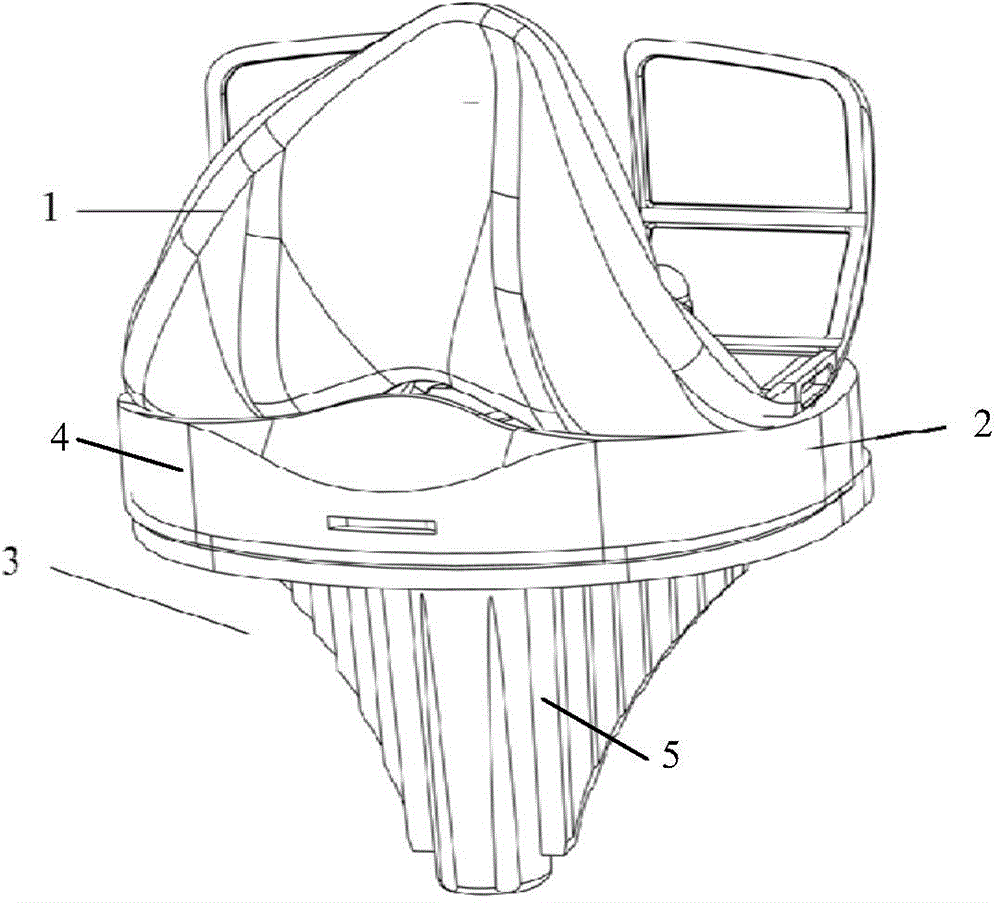

An energy-saving shock-absorbing bionic knee joint for a biped walking robot

The invention discloses an energy saving damping bionic knee joint for a biped walking robot; the energy saving damping bionic knee joint comprises a bionic femur, a bionic tibia and a bionic kneecap; a cylinder is fixedly connected on a femur condyle connector through a cylinder support; leg extension motions of the knee joint is completed by cylinder active acting; the bionic femur condyle makes contacts with a third roller through a first slide rail, so a meniscus assembly can support and guide the bionic femur condyle; a second roller rolls in a second slide rail so as to simulate mankind knee joint instant center change motions; the second slide rail has two motion limit positions so as to limit the knee joint motion scope; a kneecap assembly uses the motions of the first roller in the first slide rail to simulate mankind kneecap, thus increasing an acting force arm of the cylinder output force in the leg extension motions, and saving energy; the bionic femur condyle, bionic kneecap and meniscus assembly are employed to realize knee joint instant center change motions, low energy consumption, and high buffer performance.

Owner:JILIN UNIV

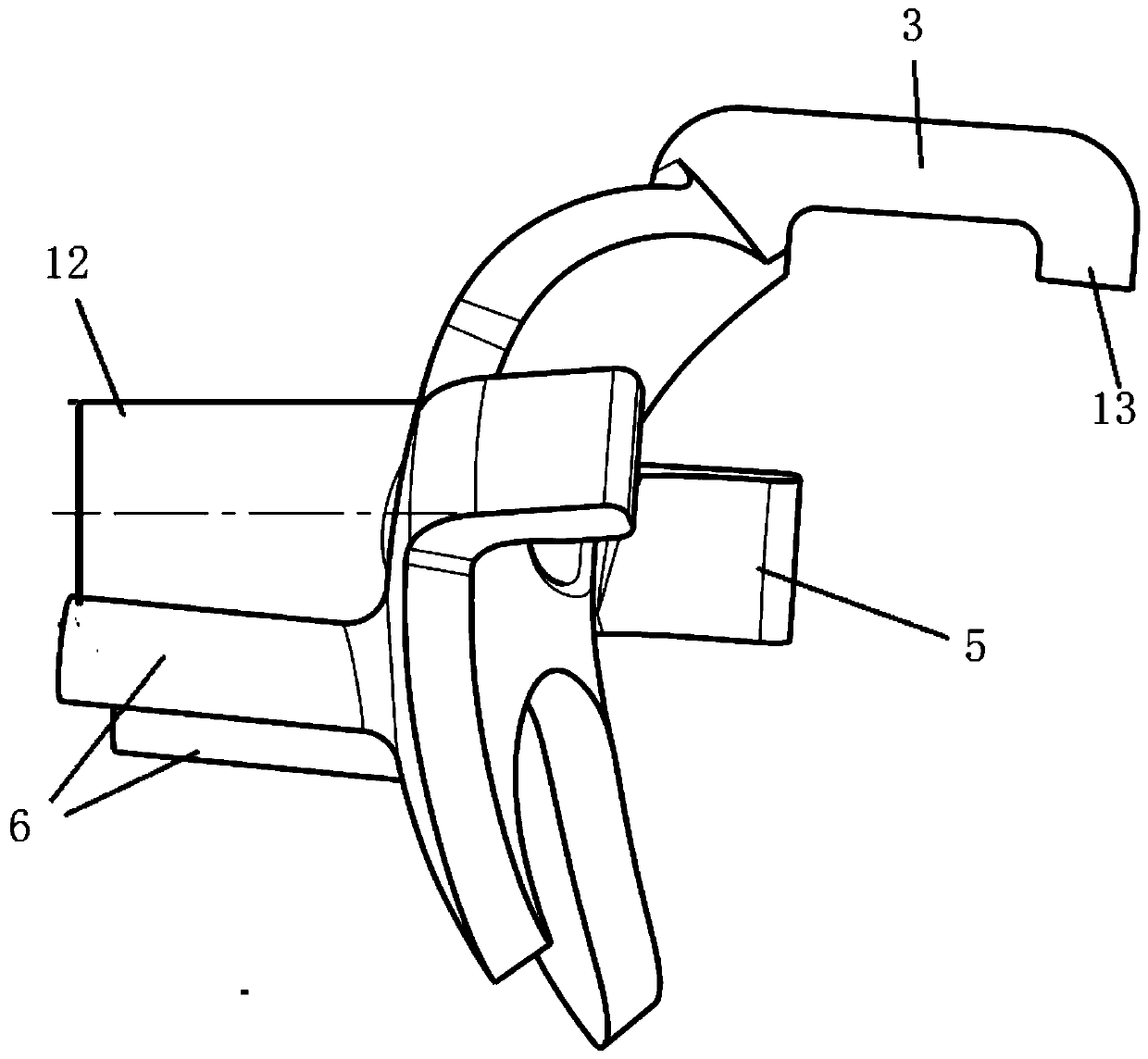

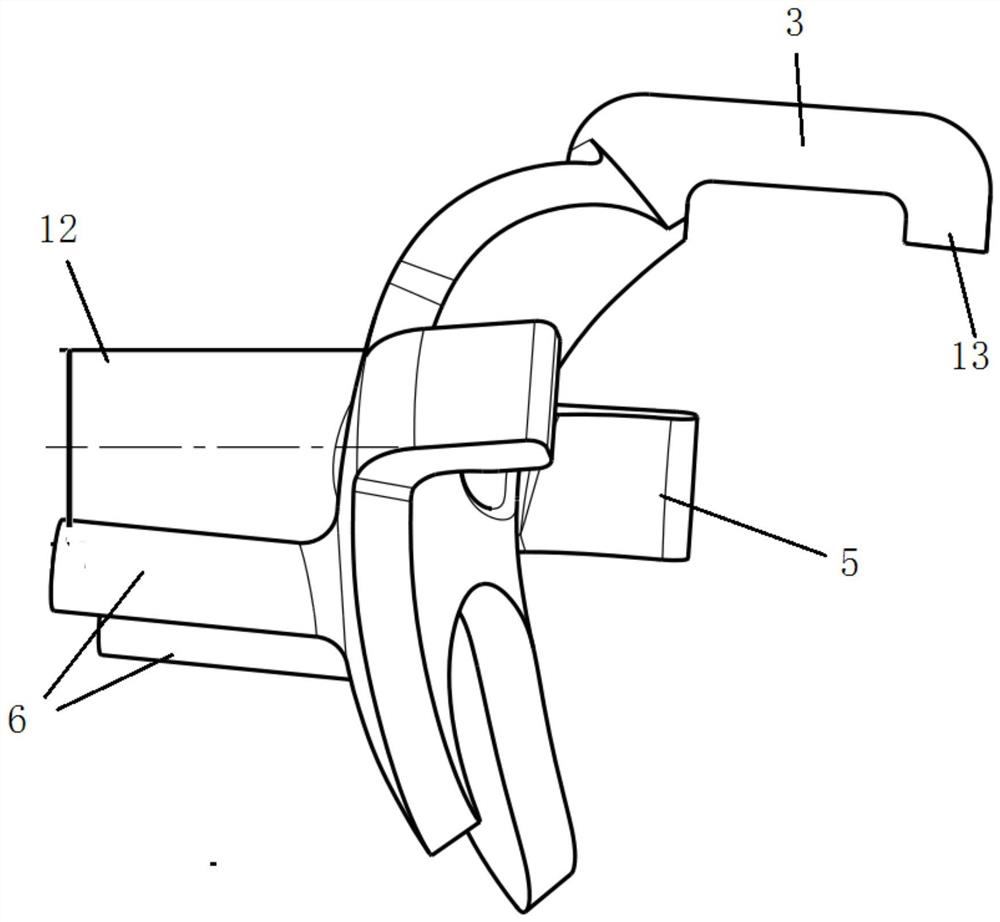

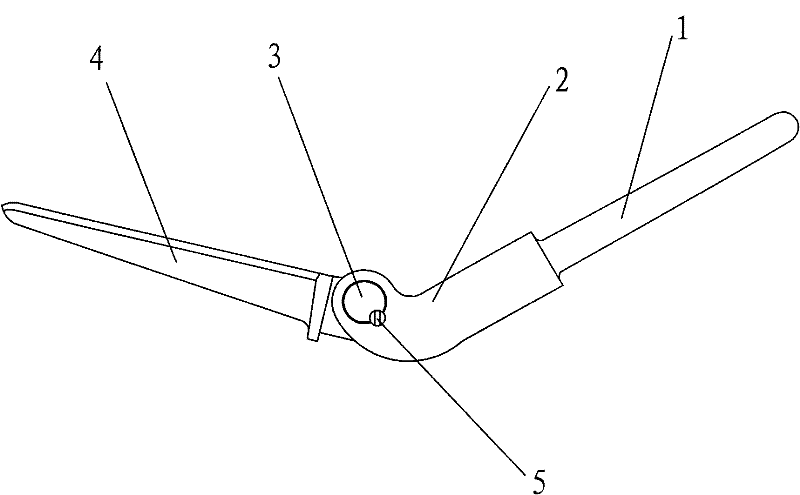

Intercondylar osteotomy module

The invention belongs to the field of medical apparatuses, and discloses an intercondylar osteotomy module. The intercondylar osteotomy module comprises an osteotomy module and a positioning module, wherein a notch part is formed at the bottom of the osteotomy module, and the positioning part can be fixed in the notch part in a dismountable manner, so that when the positioning module is fixed in the notch part, the shape jointly formed by the osteotomy module and the positioning module is consistent with that of a preset femur condyle prosthesis, and when the positioning module is removed fromthe notch part, the notch part can be used as an osteotomy opening. The intercondylar osteotomy module disclosed by the invention can improve the accuracy of an intercondylar osteotomy position and osteotomy quantity so as to avoid repeated osteotomy amendment during subsequent femur condyle prosthesis mounting due to inaccurate osteotomy position or inaccurate osteotomy quantity.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

Organic polymer material dual-slide artificial knee joint

InactiveCN105030382AReduce stress shieldingSolve clamping problemsJoint implantsKnee jointsNatural boneTibial tray

An organic polymer material dual-slide artificial knee joint comprises a femur condyle and tibia holder made of PEEK or derivative thereof, and a tibia liner made of UHMWPE; the tibia holder comprises a platform and a stable wing positioning portion with certain cross section; the stable wing positioning portion is arranged below the platform and vertical to the platform; the top and bottom of the tibia liner are respectively jointed with the femur condyle and the platform of the tibia holder; the tibia liner is a dual-slide tibia liner, a slide surface of the femur condyle against the tibia liner and a slide surface of the tibia holder against the tibia liner are respectively a smooth surface. All implants of the organic polymer material dual-slide artificial knee joint contain no metal material, so no allergy problem will be caused by metal and metal corrosion; PEEK elastic modulus is matched with a natural bone so as to reduce stress shield problem; a wearing problems of a main slide friction surface of the PEEK femur condyle against the UHMWPE tibia liner can be reduced; a latent wearing problem of a secondary slide interface of the PEEK femur condyle against the UHMWPE tibia liner can be further reduced.

Owner:JIANSU OKANI MEDICAL TECH CO LTD

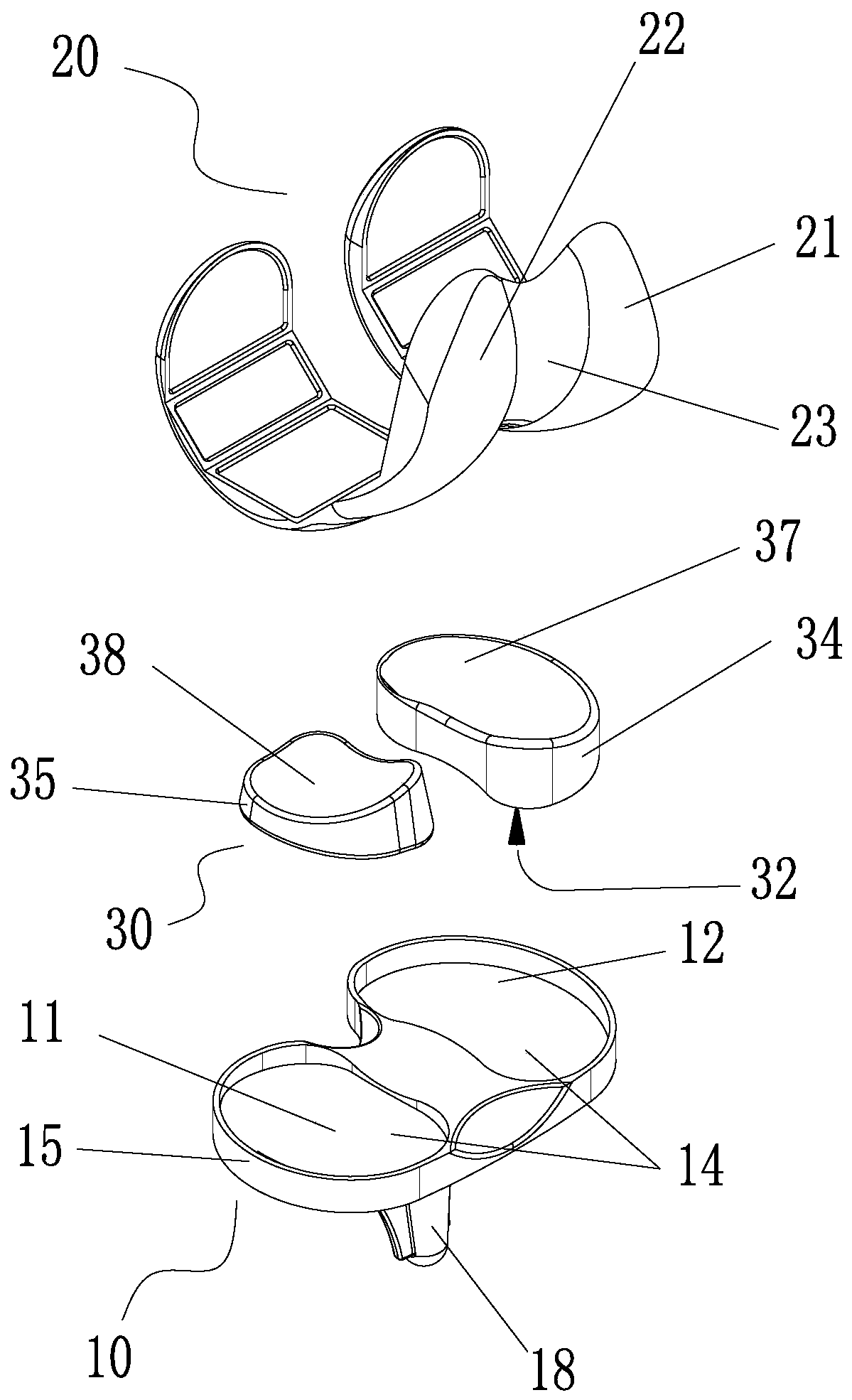

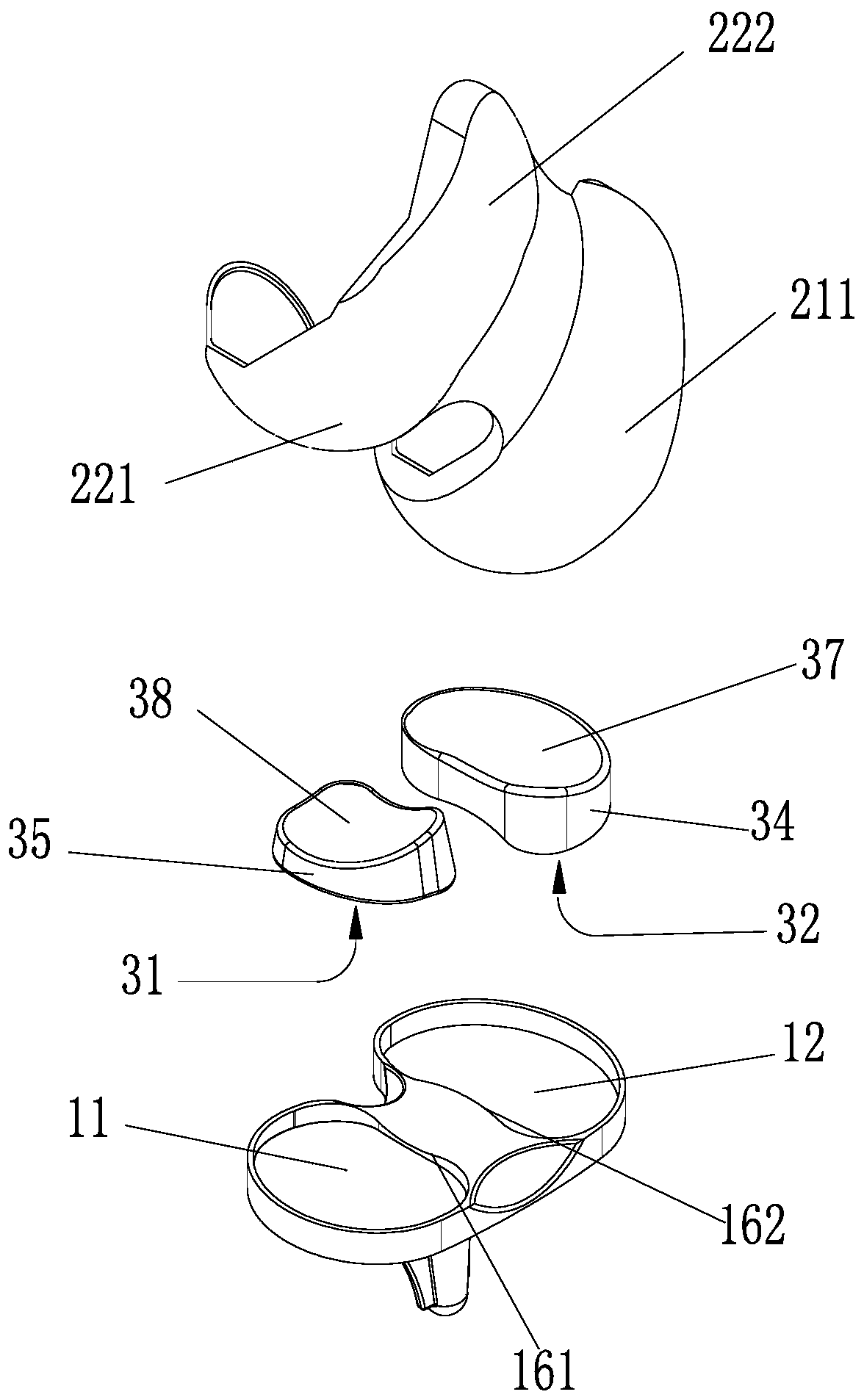

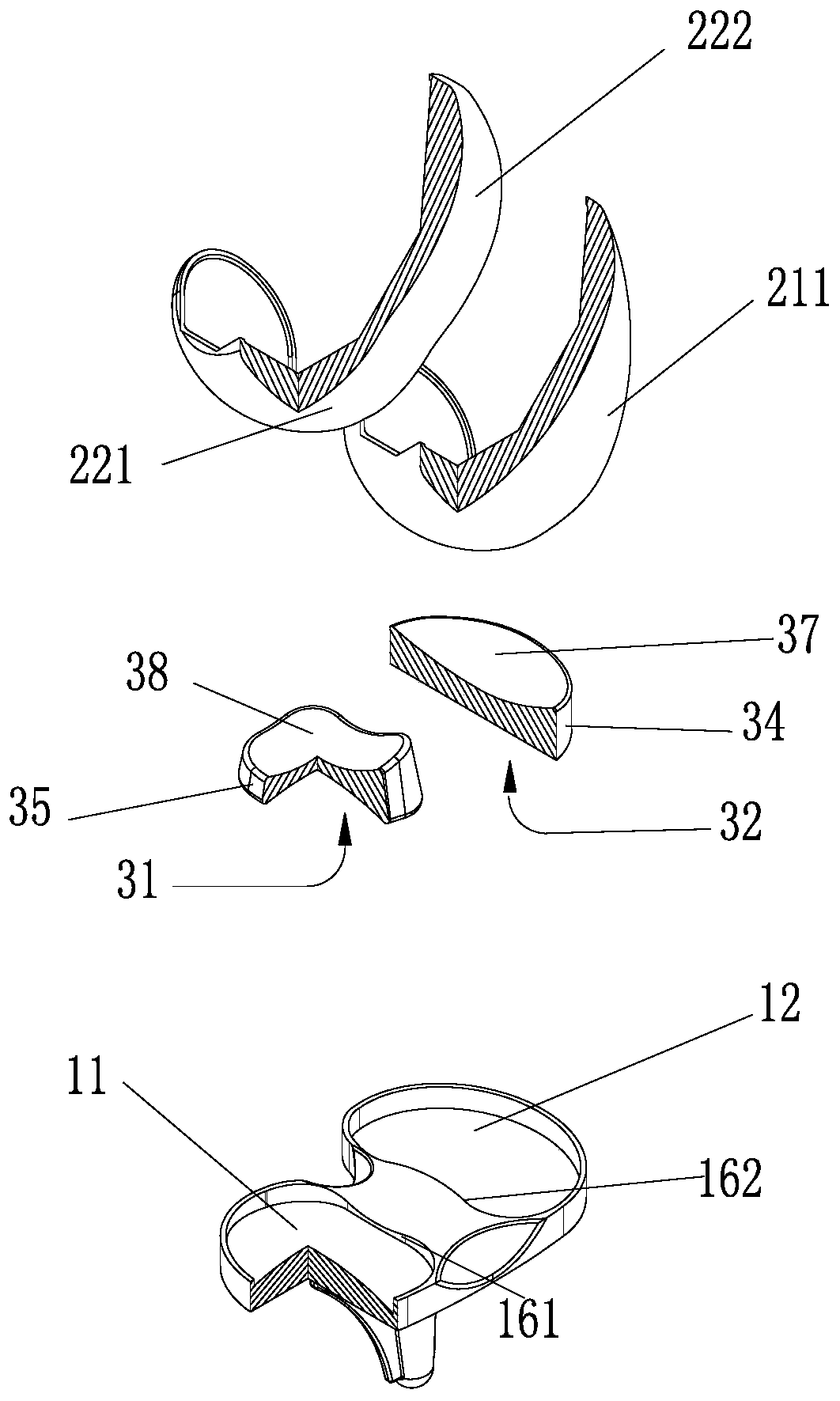

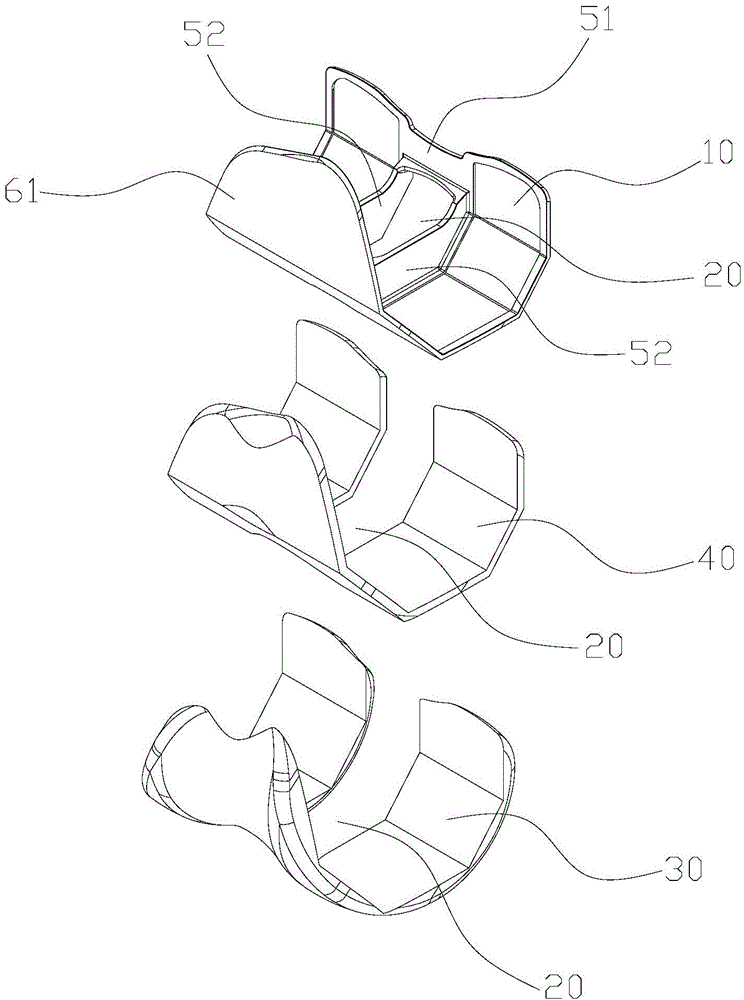

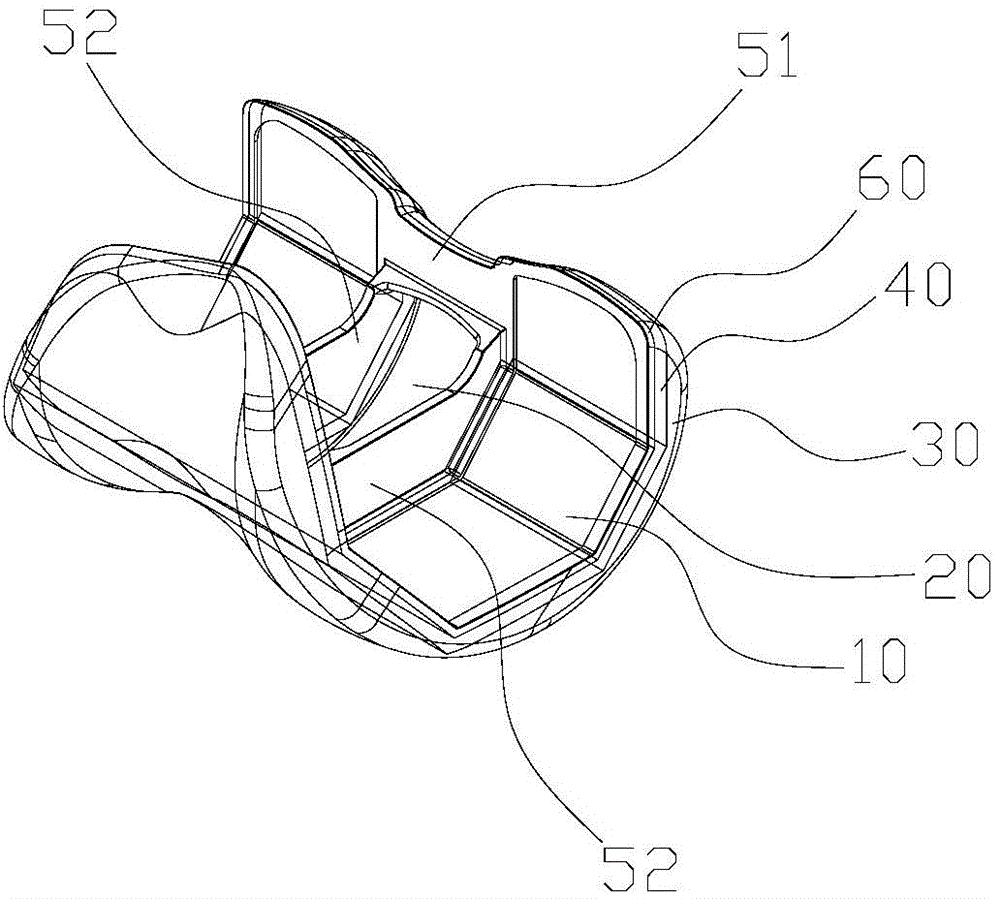

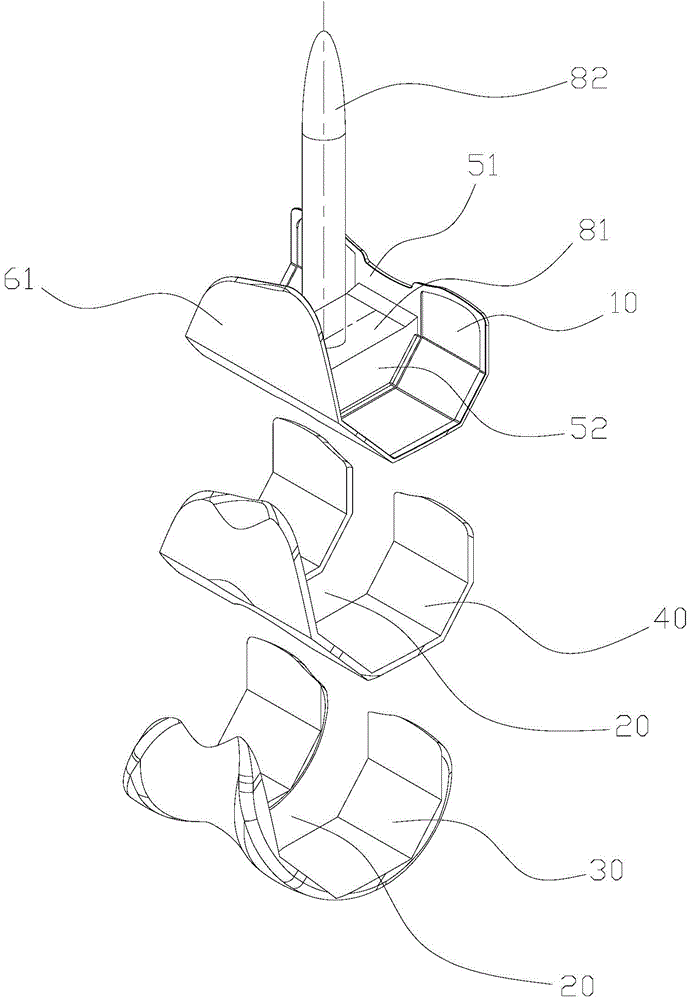

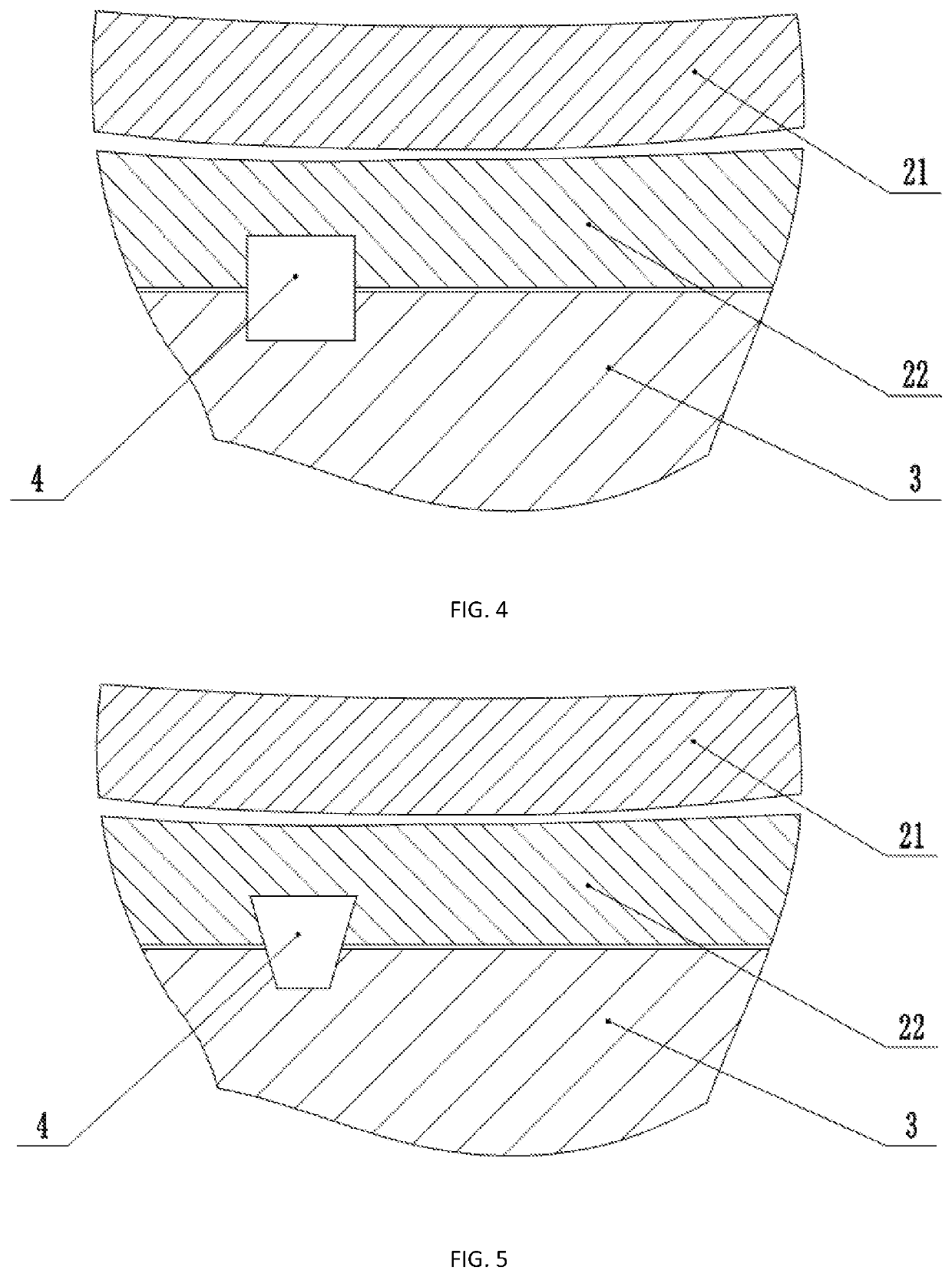

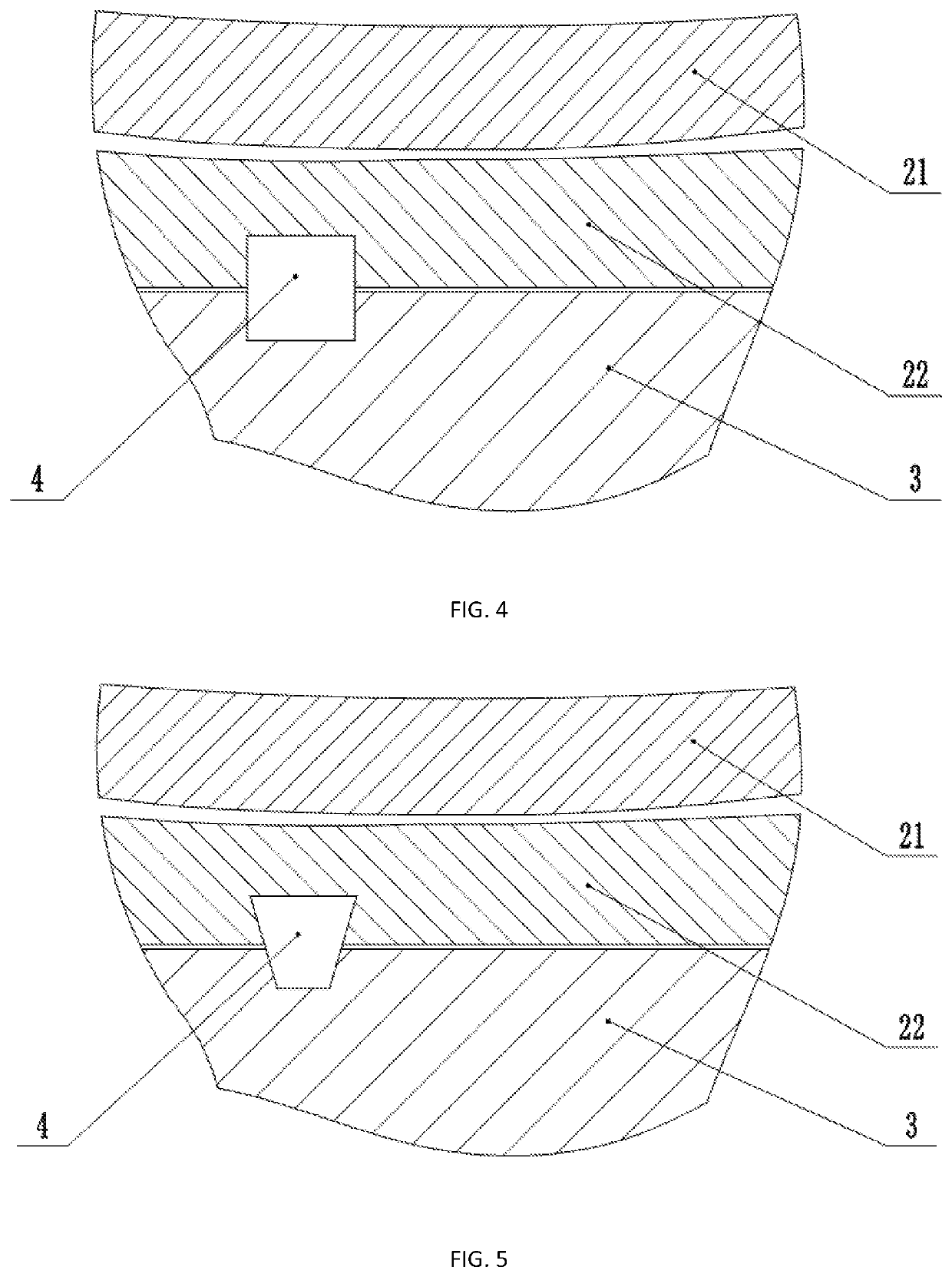

Femur condyles prosthesis component

InactiveCN104825255AGuarantee the stability of useAvoid chippingJoint implantsKnee jointsProsthesisBody of femur

The invention provides a femur condyles prosthesis component. The femur condyles prosthesis component comprises a prosthesis base body part and a limiting part arranged on the prosthesis base body part. The prosthesis base body part is provided with a receding notch part (20) used for being matched with a central stand column of a tibial plateau prosthesis. The limiting part comprises a transverse limiting part (51) arranged at the opening end of the receding notch part (20). The prosthesis base body part comprises a bone combining layer (10), a ceramic layer (30) arranged above the bone combining layer (10), and a buffering layer (40) arranged between the bone combining layer (10) and the ceramic layer (30). According to the technical scheme, the problems that in the prior art, a femur condyles prosthesis component cannot be compatible with the implanting stability and the indication application range can be effectively solved.

Owner:BEIJING AKEC MEDICAL

Single-condyle artificial knee joint

InactiveCN105640671AExtended service lifeReduce the overhaul rateJoint implantsKnee jointsNMR - Nuclear magnetic resonanceMedicine

The invention discloses a single-condyle artificial knee joint which comprises a femur condyle, a liner and a tibia support which are sequentially connected. The upper surface of the liner is in sliding fit with the joint face of the femur condyle. The lower surface of the liner is in sliding fit with the surface of the tibia support. The femur condyle, the liner and the tibia support are all made from poly(ether ether ketone) or derivatives of poly(ether ether ketone). The single-condyle artificial knee joint has high wear resistance, high biocompatibility and good buffer performance, the biolotical properties of normal knee joints can be better simulated, the subjective feeling of patients can be improved, the single-condyle artificial knee joint is long in service life and low in overhaul rate, metal ion toxicity and anaphylactic reaction can not be generated, and perspective developing and nuclear magnetic resonance imaging can not be influenced.

Owner:TONGJI HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI TECH

Unicompartmental knee joint prosthesis and manufacturing method thereof

PendingCN112472370AEasy to integrateImprove securityJoint implantsCoatingsKnee arthrodesis prosthesisBone tissue

The invention discloses a unicompartmental knee joint prosthesis and a manufacturing method thereof. The unicompartmental knee joint prosthesis comprises a femur condyle, a gasket and a tibial plateau, wherein a first porous structure is arranged on the inner surfaces, making contact with a host bone, of a femur connecting column and a femur condyle body, and a second porous structure is arrangedon the surfaces, making contact with the host bone, of a tibia connecting column and the tibial plateau body. The invention discloses a manufacturing method of the unicompartmental knee joint prosthesis. The manufacturing method comprises the steps of S1, additive manufacturing of a femur condyle, S2, hot isostatic pressing treatment of the femur condyle, S3, machining of the femur condyle, S4, additive manufacturing of a tibial plateau, S5, hot isostatic pressing treatment of the tibial plateau, S6, machining of the tibial plateau and S7, surface modification. According to the invention, theporous structure provides space for ingrowth of human bone tissue so as to improve stability of the prosthesis; the tibial plateau is endowed with a bioactive function through the in-situ membrane layer, so that bone induction and bone ingrowth of the tibial plateau can be rapidly achieved in the early stage of implantation; and the prosthesis is endowed with good mechanical properties through thehot isostatic pressing process, so that long-term safety and effectiveness of the prosthesis are facilitated.

Owner:天衍医疗器材有限公司

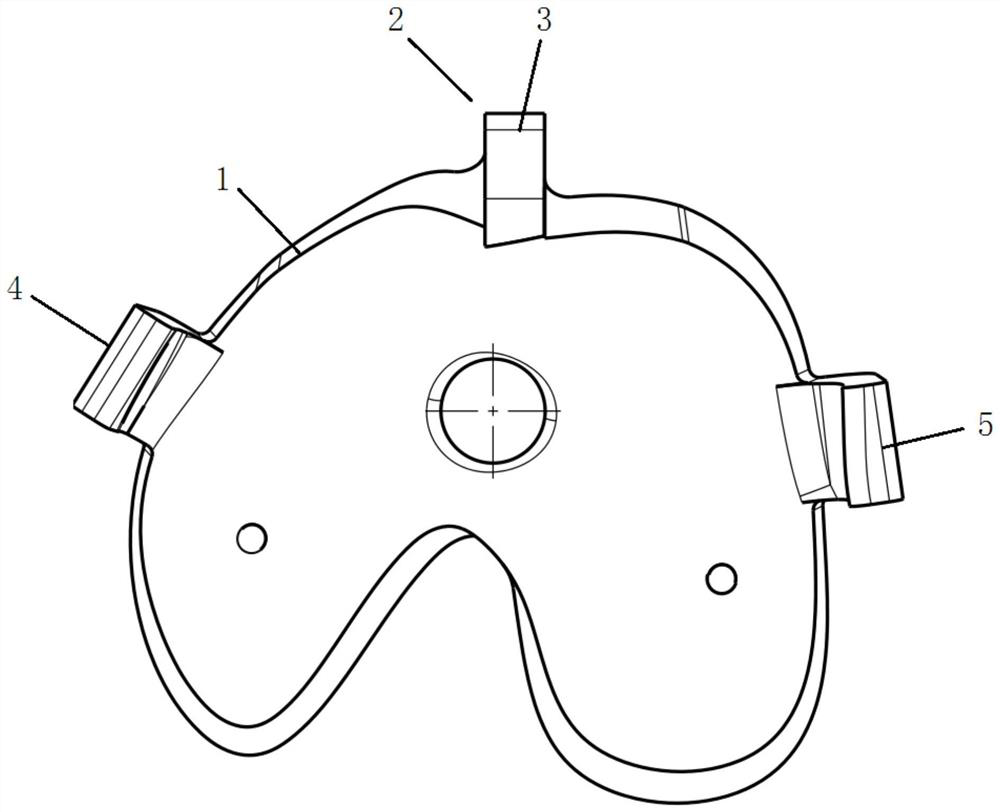

Artificial knee joint

ActiveUS20200383795A1Simulates its functionBalanced forceJoint implantsKnee jointsFemoral boneAnatomy

The invention describes an artificial knee joint, which includes a femoral condyle prosthesis and a tibial plateau prosthesis, and said tibial plateau prosthesis includes a medial tibial plateau prosthesis and a lateral tibial plateau prosthesis respectively disposed at both sides of the tibial plateau intercondylar eminence. The artificial knee joint further includes a locating pin for fixing the tibial plateau prosthesis. The bottom surface of said tibial plateau prosthesis is provided with a prosthetic notch, and the tibia below said tibial plateau prosthesis is provided with a tibial notch. Said prosthetic notch corresponds to said tibial notch, together forming a limiting hole for accommodating the locating pin. The cooperation between the locating pin and the limiting hole can ensure relative position stability and balance between the medial tibial plateau prosthesis and the lateral tibial plateau prosthesis.

Owner:ZHU HONGWEN

Osteotomy Navigation Device for Total Knee Arthroplasty

ActiveCN110432948BEasy to grasp the actual situationAccurate guidanceSurgical navigation systemsBone drill guidesRotational axisFEMORAL CONDYLE

The invention relates to an osteotomy navigation device for total knee arthroplasty and belongs to the technical field of surgical instruments. The osteotomy navigation device comprises a substrate fit with femur condylar bone surfaces, a marrow entering sleeve and positioning sleeves arranged on the outer side of the substrate as well as a limit wall arranged on the inner edge of the substrate and extending outwards, the inner hole axis of the marrow entering sleeve coincides with the center of femur marrow cavity, one positioning sleeve is arranged on each of two sides of the lower side of the marrow entering sleeve, the two positioning sleeves are fixed on the femur condylar bone surfaces, the connection line of centers of end surfaces of the two positioning sleeves coincides with the rotating axis of the femur condyle, the limit wall at least comprises an inner side front end wall, an inner side left end wall and an inner side right end wall. By initial limit and connection and fixation of the positioning sleeves and the femur condylar bone surfaces, a guide is firmly connected and fixed with the femur condylar bone surfaces, the axis of the marrow entering sleeve coincides with the center of the femur marrow cavity and the connection line of centers of end surfaces of the two positioning sleeves coincides with the rotating axis to construct a real-time coordinate system toprovide basis reference for surgery.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

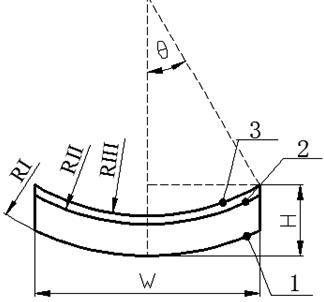

Single-condyle prosthesis matched with posterior condyle of femur

PendingCN114159194AReduce the amount of osteotomyPrecisely Balanced TensionJoint implantsKnee jointsFacial boneOsseointegration

The invention relates to the field of medical instrument design, in particular to a unicompartmental prosthesis matched with a posterior condyle of a femur, which comprises a joint friction surface, a bone cement binding surface, a distal condyle binding surface and a posterior condyle binding surface of the femur condyle which are integrally formed, the joint friction surface, the bone cement binding surface and the distal condyle binding surface of the femur condyle are three concentric spherical surfaces with different radiuses, the curvature radius RI of the joint friction face is larger than the curvature radius RII of the bone cement binding face, the curvature radius RII of the bone cement binding face is larger than the curvature radius RIII of the femoral condyle far-end binding face, and the femoral condyle posterior condyle binding face is a vertical plane and intersects with the femoral condyle far-end binding face to form an osseointegration face to be matched with a matched bone. According to the product provided by the invention, by changing the design of the bone binding surface of the single-condylar prosthesis, the movable single-condylar prosthesis is more adaptive to the posterior condyle of the femur, and the flexion and extension balance of the knee joint is more accurate, so that postoperative complications are reduced.

Owner:JIASITE HUAJIAN MEDICAL EQUIP (TIANJIN) CO LTD

Customized artificial semi-knee-joint and method of producing the same

InactiveCN101278866BReduce wearJoint implantsComputerised tomographsArticular surfacesArticular surface

Customized hemi-knee joint prosthesis and a preparation method thereof are provided. Firstly, the normal side knee joint femur condyle data of a patient is extracted by CT for the medical image three-dimensional image reconstruction. The three-dimensional anatomy model of patient femur condyle is obtained by an antagonizing model. A metal femur condyle joint is obtained according to the three-dimensional anatomy model. Then, a rolling pillar is arranged in the metal femur condyle joint. The two sides of the rolling pillar are respectively opened with a cylindrical groove. A rolling combined station is sheathed on the rolling pillar. The two sides of the rolling combined station are respectively equipped with a side-push plate with a lug boss. The lug bosses of the side-push plates are inserted in the grooves of the rolling pillars. As the rolling pillar is arranged inside the articular surface of the metal femur condyle of the hemi-knee joint prosthesis, the prosthesis upper part, namely the rolling combined station, and the lower part, namely the articular surface of the metal femur condyle, which are fixed on a femoral shaft move relatively within a certain angle. Being corresponding to a tibia platform, the lower part is static during the period. Therefore, the whole process of the knee joint bending is finished and the abrasion of the prosthesis on the cartilage surface ofthe joint is reduced.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Artificial knee joint

An artificial knee joint comprises a femoral condyle prosthesis and a tibial plateau prosthesis; wherein the tibial plateau prosthesis includes a medial tibial plateau prosthesis and a lateral tibial plateau prosthesis disposed at both sides of the tibial plateau intercondylar eminence, respectively. The artificial knee joint further comprises a locating pin for fixing the tibial plateau prosthesis. The bottom surface of the tibial plateau prosthesis is provided with a prosthetic notch, and the tibia below the tibial plateau prosthesis is provided with a tibial notch. The prosthetic notch corresponds to the tibial notch, together forming a limiting hole for accommodating the locating pin. The cooperation between the locating pin and the limiting hole can ensure relative position stability and balance between the medial tibial plateau prosthesis and the lateral tibial plateau prosthesis.

Owner:ZHU HONGWEN

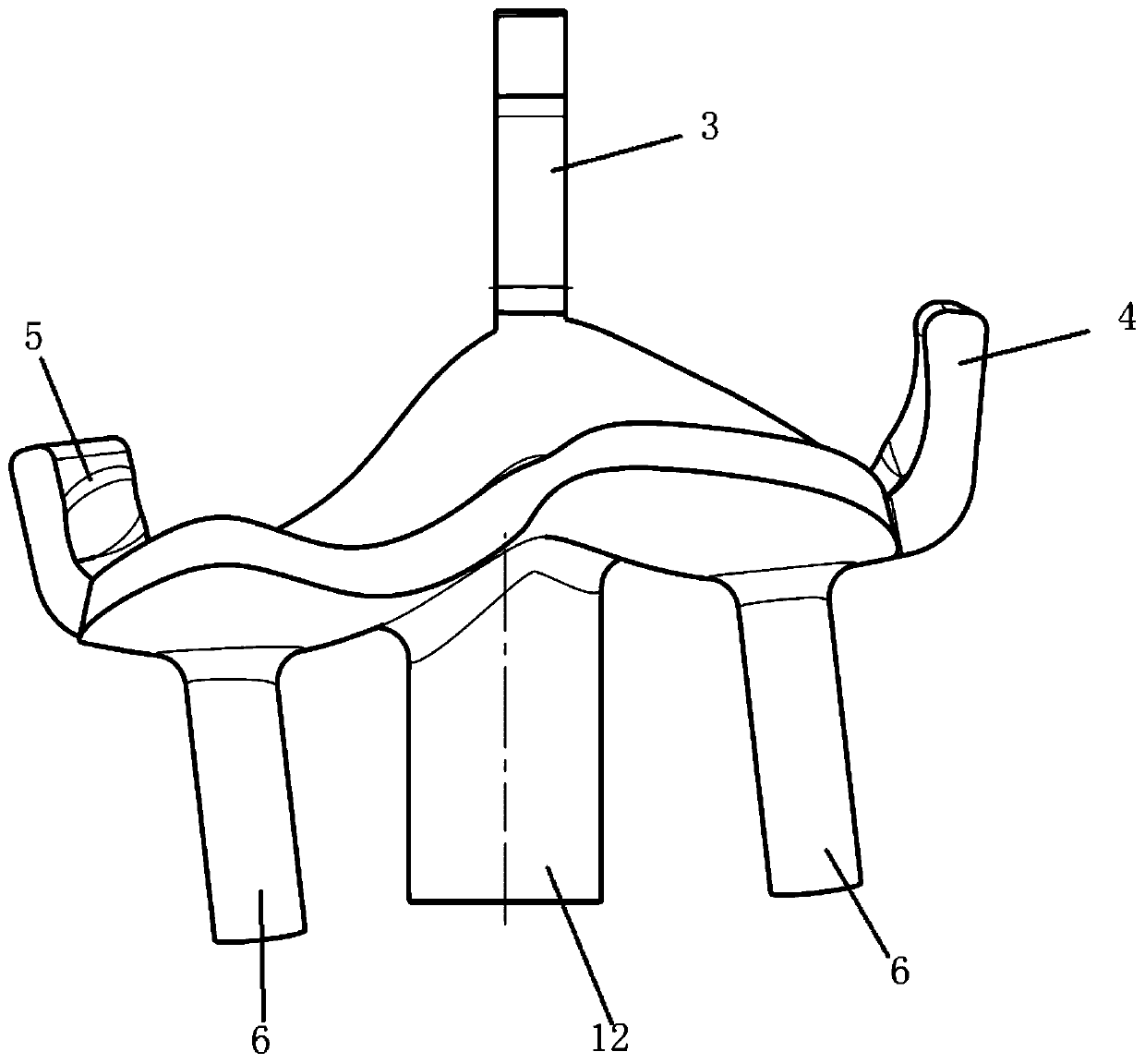

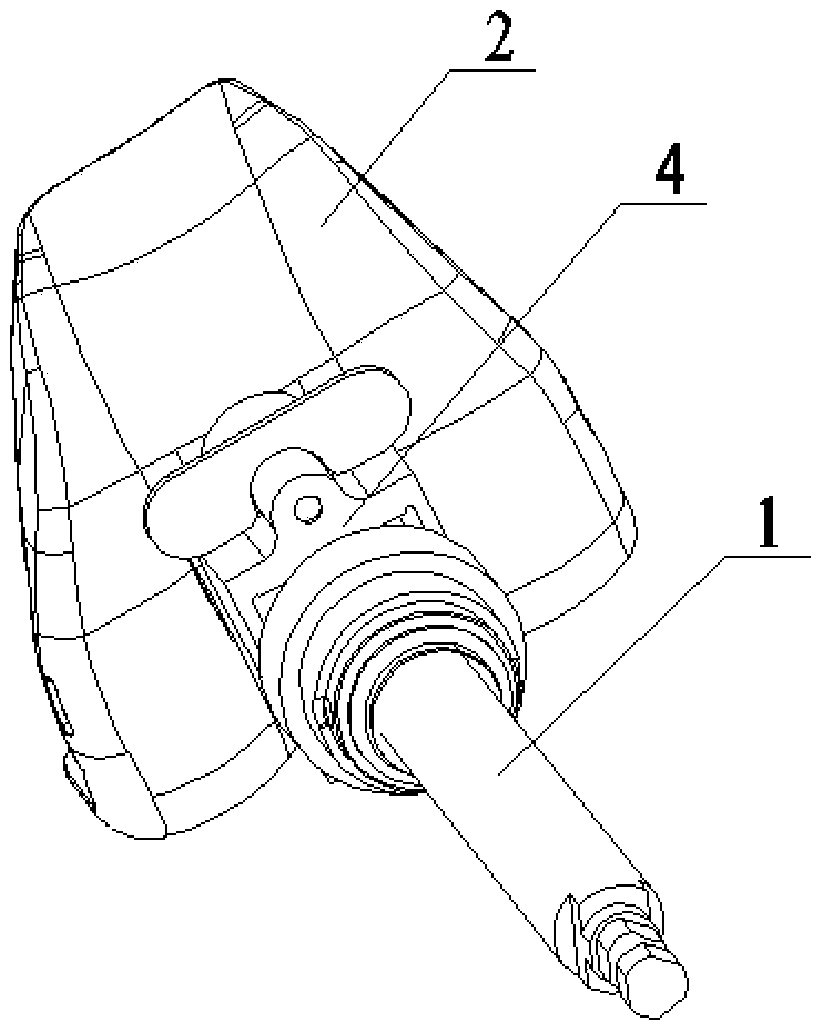

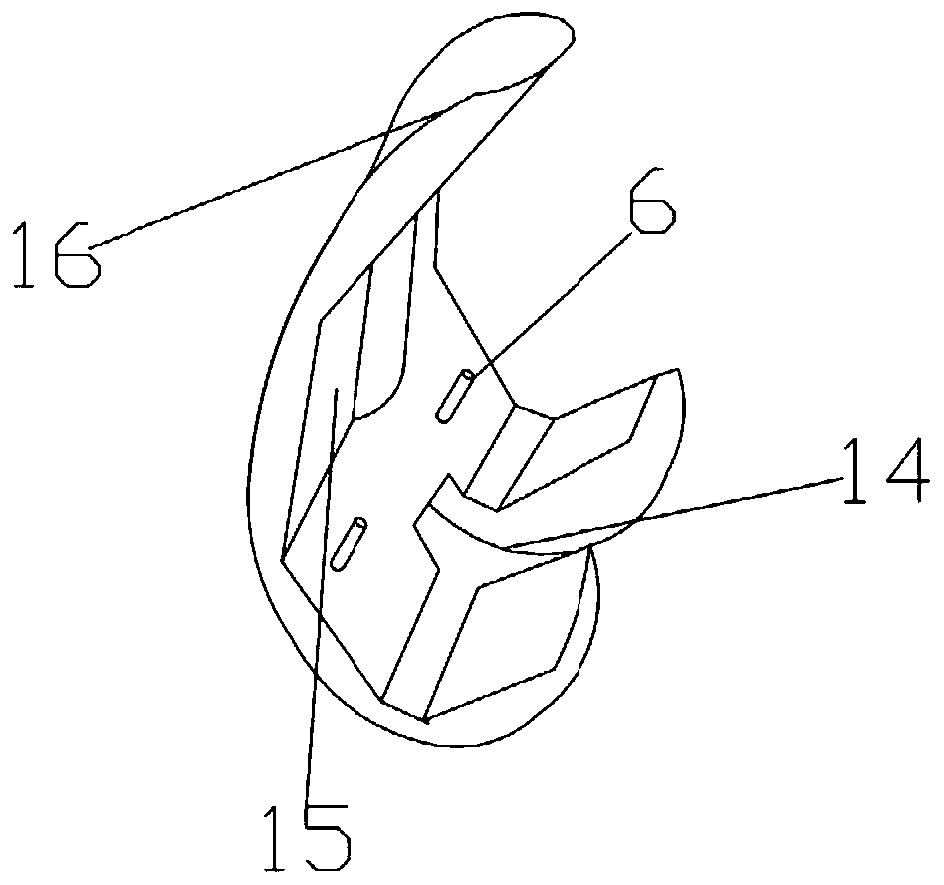

A cr-type and ps-type femoral condyle test mold and an integrated structure of the intercondylar processor

ActiveCN105342727BRealize integrated designReduce in quantitySurgeryJoint implantsMilling cutterMedicine

Owner:JIASITE HUAJIAN MEDICAL EQUIP (TIANJIN) CO LTD

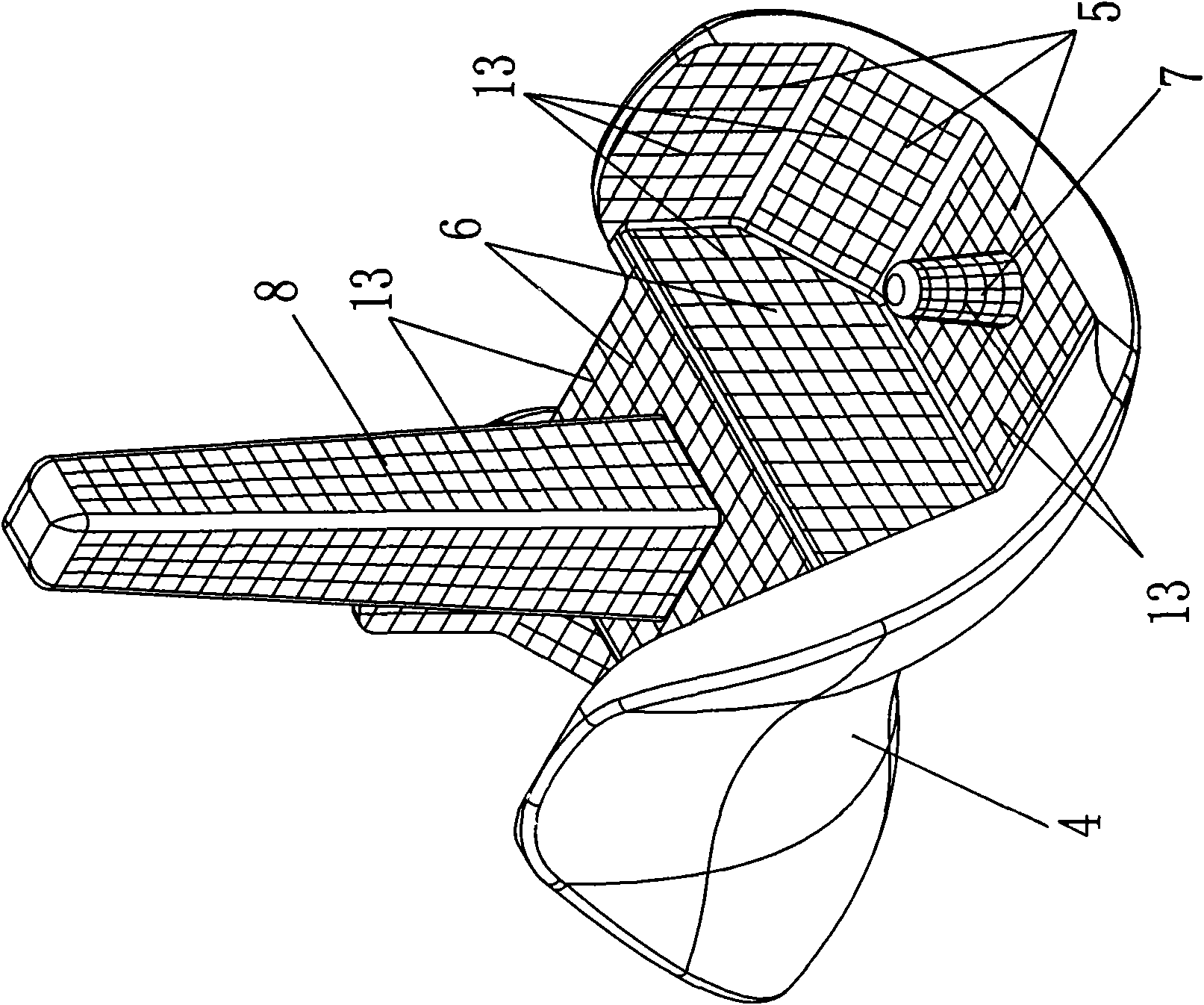

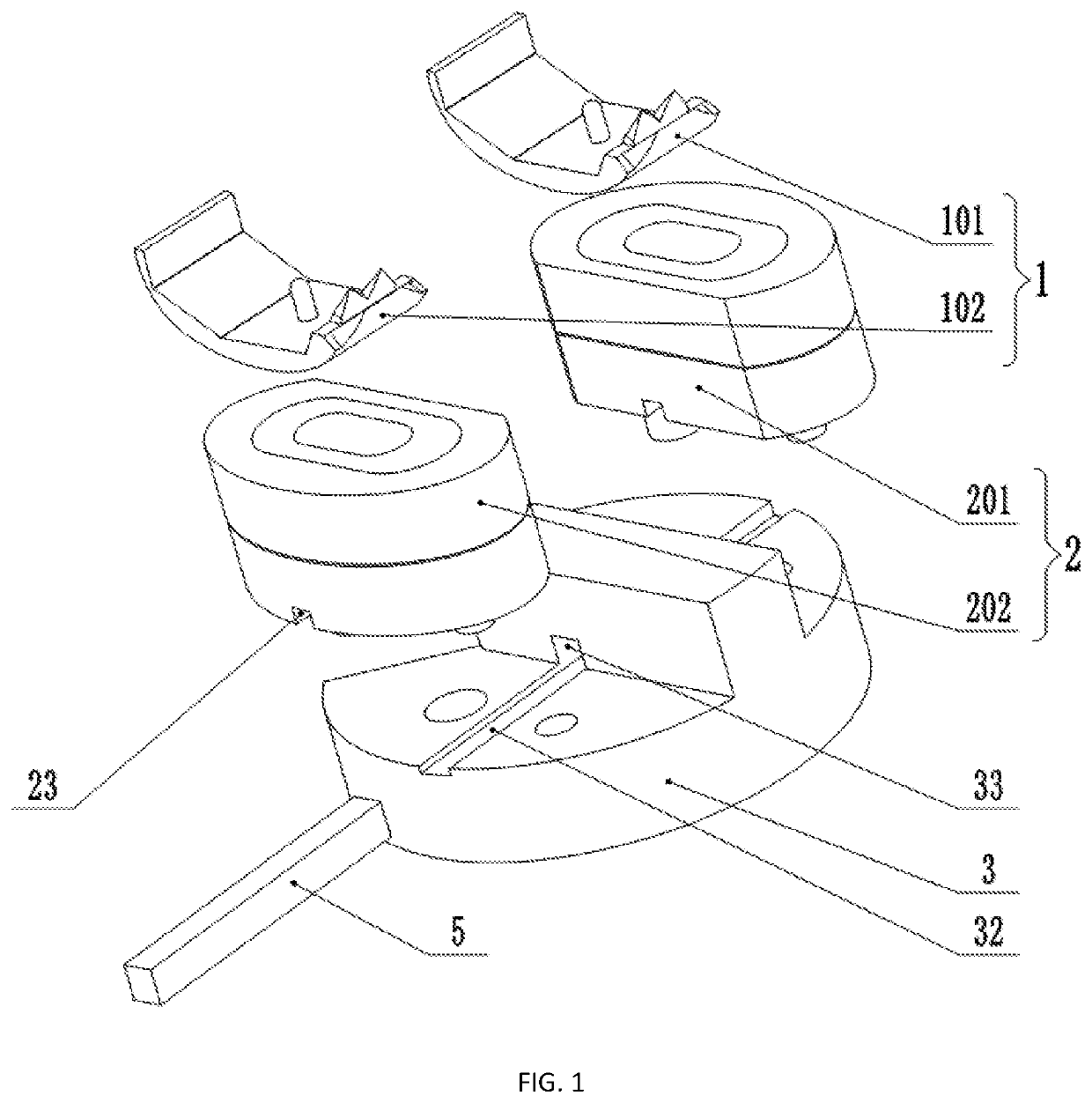

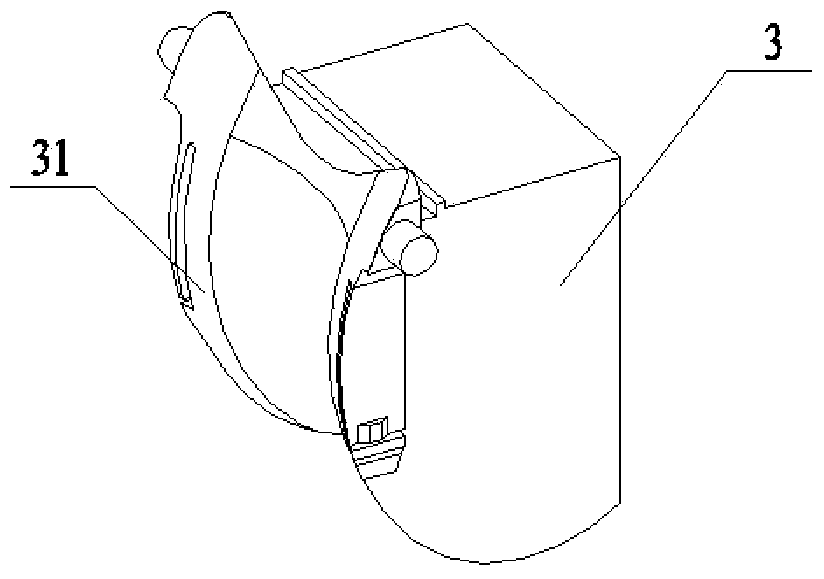

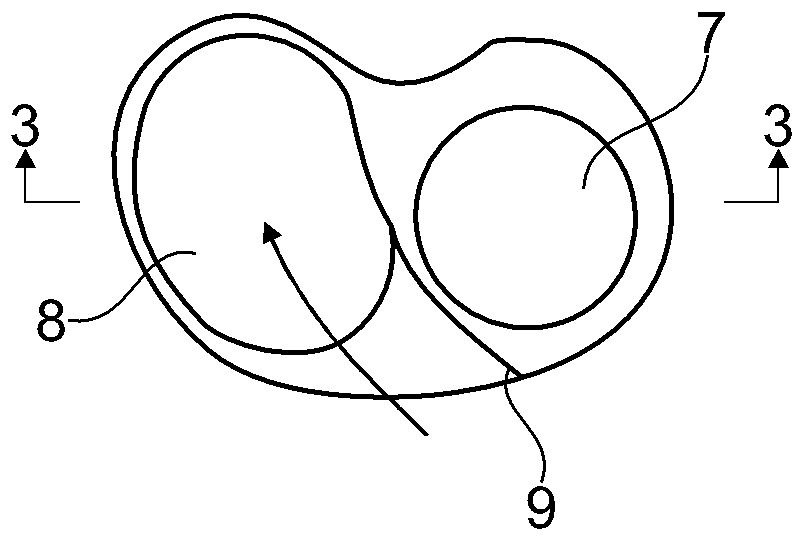

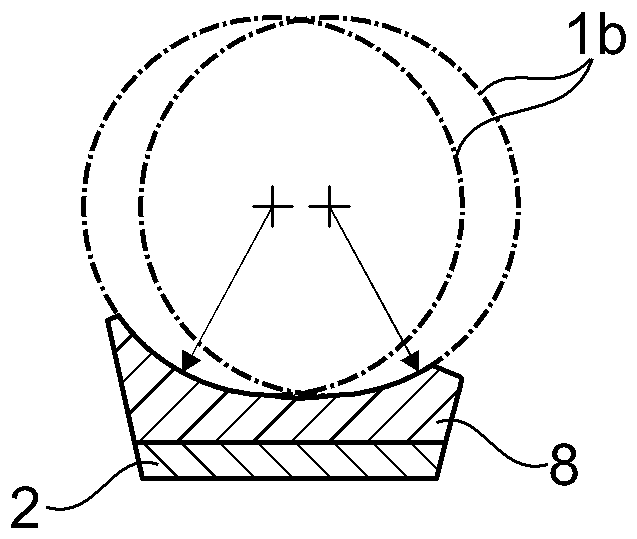

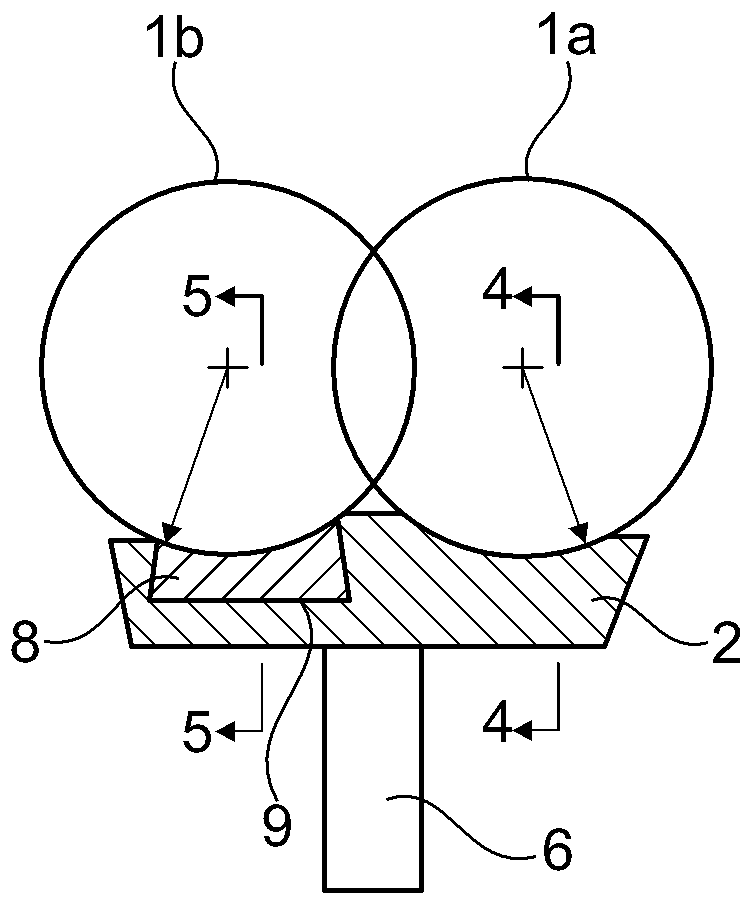

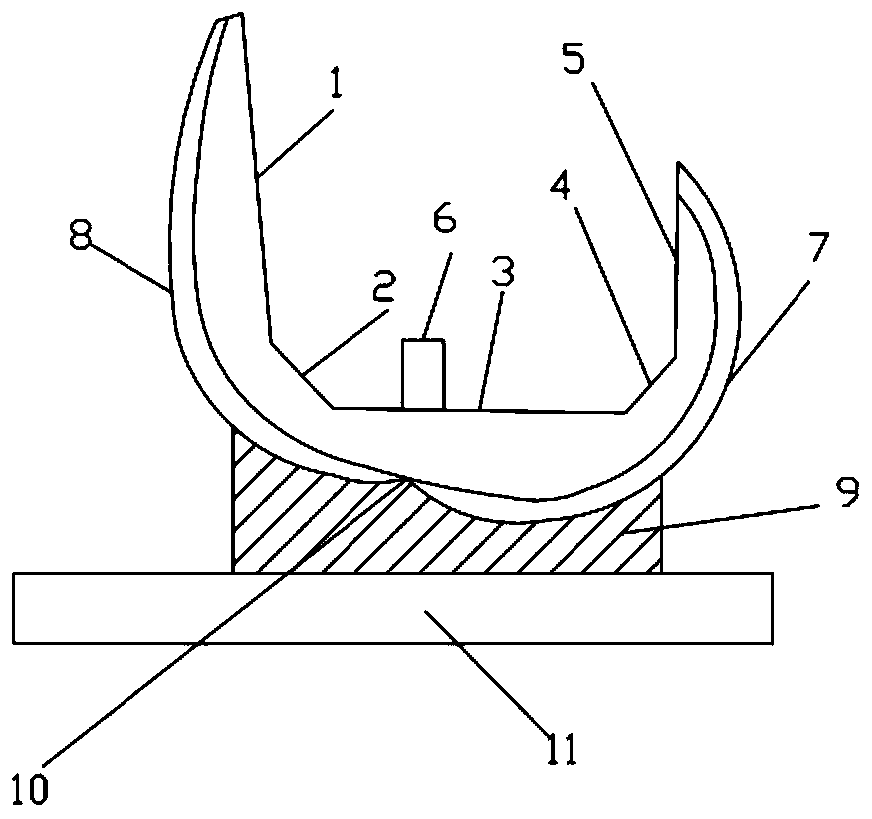

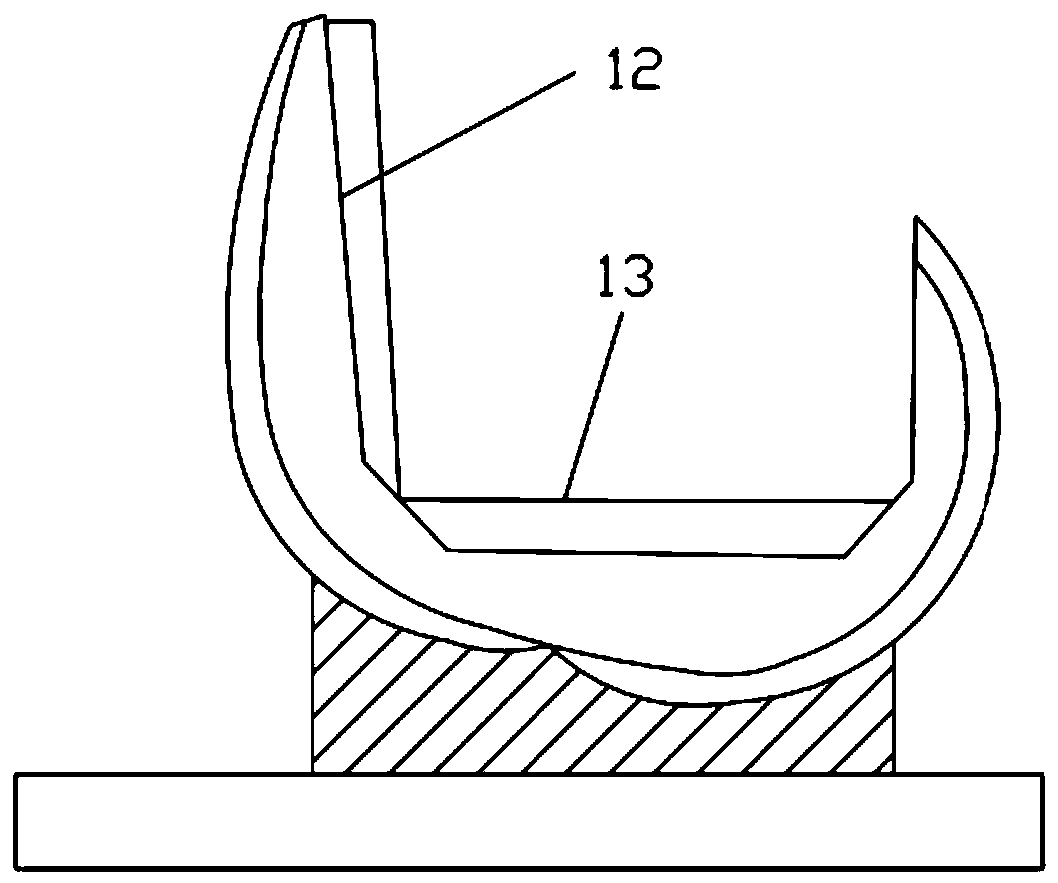

Knee endoprosthesis for replacing at least parts of the knee joint

The invention relates to a knee endoprosthesis comprising a femoral component (1) which has two condyle surfaces (1a, 1b) for anchoring on the distal femur, comprising a tibial component (2) for anchoring on the proximal tibia, and comprising sliding surfaces between the two components (1, 2). The aim of the invention is a knee endoprosthesis which has as little abrasion as possible while optimally reproducing the anatomical and kinematic properties of the natural knee joint, in particular by means of suitable combinations of materials and by reducing the abrasion-generating surfaces. This isachieved in that the entire femoral component (1), but at least the condyle surfaces (1a, 1b) thereof, for articulating with the tibial component (2) consists of a rigidly sintered ceramic, and the tibial component (2) comprises a tibial baseplate (11) consisting of a rigidly sintered ceramic, said baseplate having a medial spherical bearing shell (7) on the baseplate upper face facing the femoralcomponent (1). The medial spherical bearing shell (7) is an integral component of the tibial baseplate (11) and is integrally formed with the tibial baseplate, and the articulation surface of the medial femur condyle (1a) is likewise spherically shaped and together with the medial spherical bearing shell (7) constitutes a congruent ball joint. A bearing shell (8) which allows the rotation of thefemoral component (1), is made of multiple radii in the anterior-posterior direction, and is arranged non-congruently with the femur condyle (1b) is arranged laterally adjacent to the medial sphericalbearing shell (7), said bearing shell (8) either being formed integrally with the tibial baseplate (11) or being an inlay which is movable relative to the tibial baseplate (11).

Owner:CERAMTEC

Artificial complete knee joint substitute prosthesis capable of reconstructing anterior cruciate ligament

ActiveCN100405992CAchieve reconstructionSimple designLigamentsJoint implantsTotal knee replacementProsthesis

Owner:王岩

Method for manufacturing navigation template for knee replacement, and navigation template

The invention relates to a method for manufacturing a navigation template for knee replacement. The method comprises the following steps of: scanning a hip joint, a knee joint and an ankle joint through computed tomography (CT) to obtain CT data, and establishing three-dimensional reconstruction models of femur and tibia according to the CT data; respectively carrying out combination on the three-dimensional reconstruction models of thigh bone and shin bone with a three-dimensional structure, and respectively removing the three-dimensional structure models of femur and tibia from the three-dimensional structure; according to the knee replacement process, carrying out distal femoral virtual osteotomy on the three-dimensional structure model containing the femur contour, and carrying out proximal tibia virtual osteotomy on the three-dimensional structure model containing the tibia contour; and establishing virtual femur condyle navigation template and a virtual tibia platform navigation template, and manufacturing an entity condyle navigation template and an entity tibia platform navigation template. The individual navigation template manufactured by the invention be used for carrying out positioning of osteotomy and a rotating axis on the affected knee femur condyle and tibia platform, thus realizing individual precise osteotomy.

Owner:中国人民解放军联勤保障部队第九二〇医院

New Axial Knee Prosthesis

ActiveCN101584615BMeet needsIncrease contact surfaceJoint implantsKnee jointsPhysical medicine and rehabilitationFemur condyle

The invention relates to a new axial center type knee joint prosthesis comprising a femur intramedullary pin, a femur condyle, connecting components and a tibia intramedullary pin, also comprsing a tibia platform and a femur sleeve, wherein, the femur condyle is provided with a positioning slot and is fixed at lower part of the femur intramedullary pin; the tibia platform is provided with a centre hole and is fixed at the upper part of the tibia intramedullary pin for holding the femur condyle; the connecting components are T-shaped and comprise a transverse shaft and a vertical shaft, the vertical shaft is inserted into the centre hole of the tibia platform, the transverse shaft is rotatable arranged through the lower part of the femur condyle; the femur sleeve is sleeved at the lower part of the femur intramedullary pin and are butted with the positioning slot of the femur condyle. The new axial center type knee joint prosthesis of the invention can completely recovery the functions of extending and bending, and inward and outward rotating of the knee joint and adopt the bionic molding, the stability is good, the movement requirement of the patient can be satisfied sufficiently under the precondition of protecting limbs, the patient can recovery the movement freely like originally.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

Distal femur prosthesis

InactiveCN111084678AEnhanced TrackingReduce paradoxical shiftJoint implantsKnee jointsArticular surfaceEntire knee joint

The present invention provides a distal femur prosthesis and relates to the technical field of medical devices. The distal femur prosthesis comprises a femur condyle, a tibia support component and a tibia platform; the femur condyle is positioned on the tibial support component, the tibial support component is positioned on the tibial platform, and the femur condyle is characterized by comprisinga narrow groove and a condyle area; the narrow groove divides the condyle area into two condyles; the condyle area comprises a condyle internal joint surface and a joint surface, the condyle internaljoint surface and the joint surface are designed into a whole, and a connecting surface formed by the two condyles and the joint surface jointly forms a patella joint curved surface matched with a patella component. Matching of a groove of the patella joint curved surface and a projection on the tibial support component provides stability to the femur prosthesis, also helps reduce abnormal displacement or translation of entire knee joints and also facilitates enhancing tracking of patellofemoral joints.

Owner:BEIJING LIDAKANG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com