Patents

Literature

75 results about "Knee arthrodesis prosthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

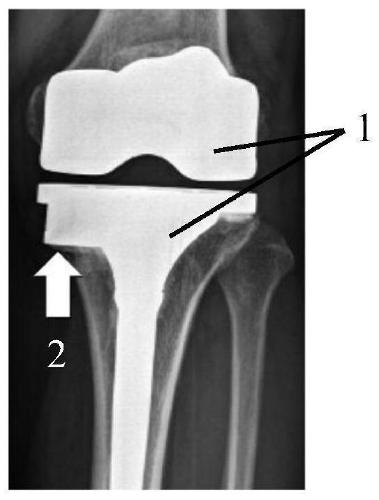

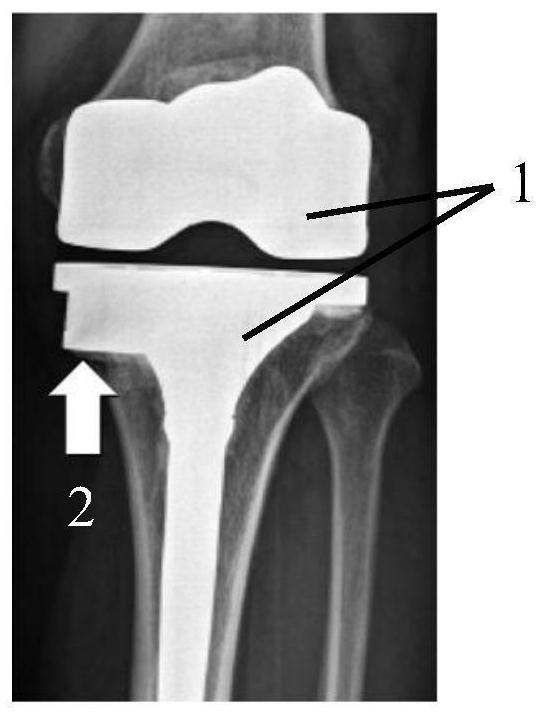

One prosthesis was revised though retained following a prosthetic fracture, and 1 patient underwent above-knee amputation for uncontrolled infection. We conclude that the Stanmore knee arthrodesis prosthesis provides reliable fusion in an otherwise difficult-to-treat group of patients.

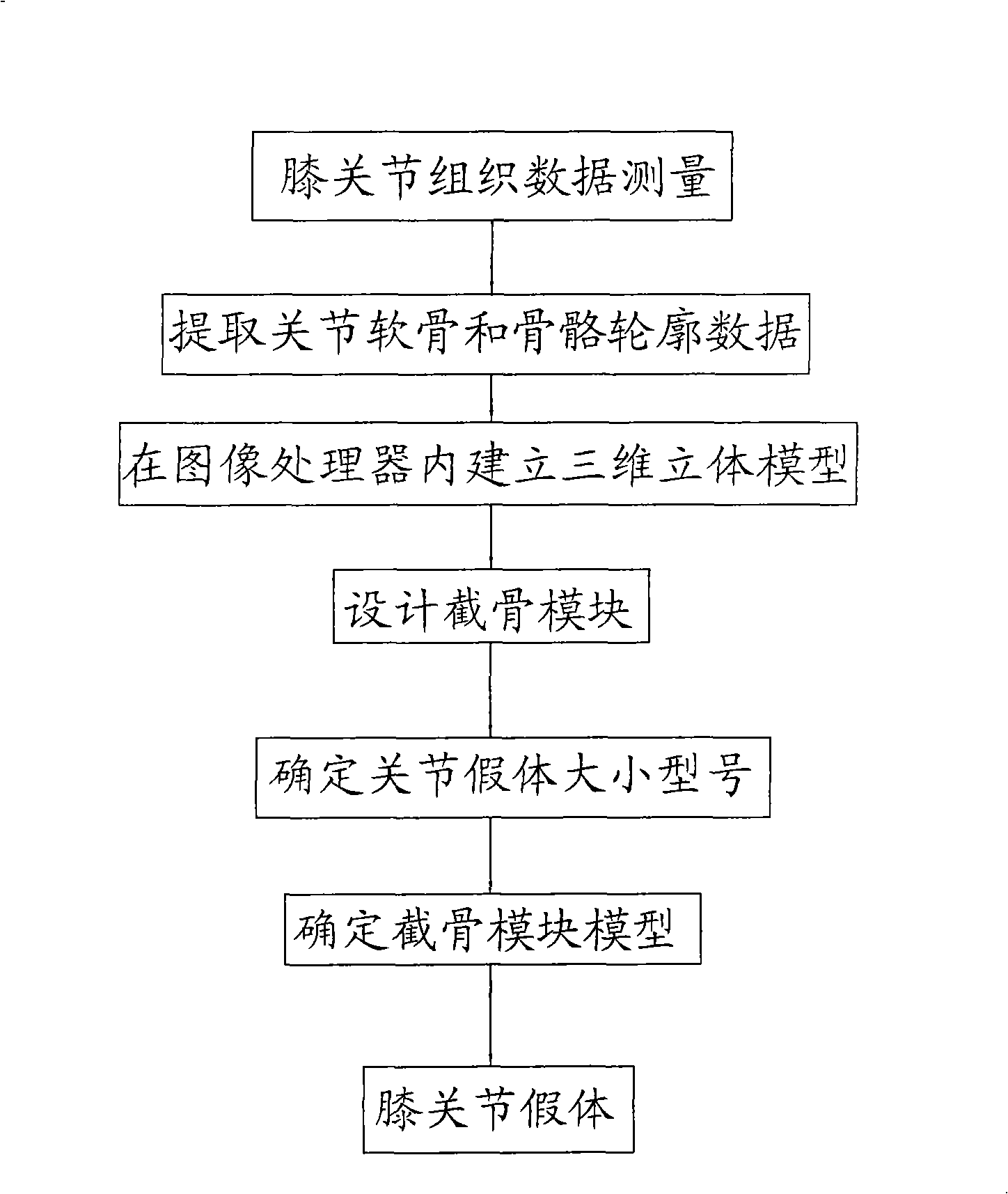

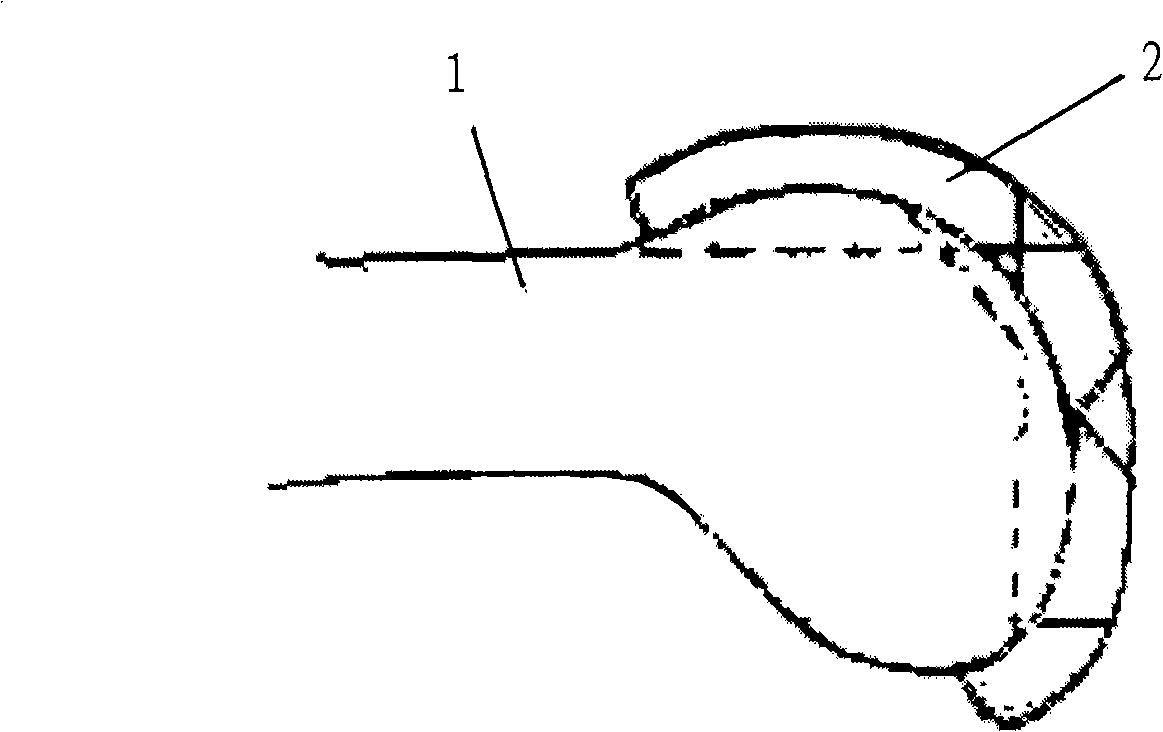

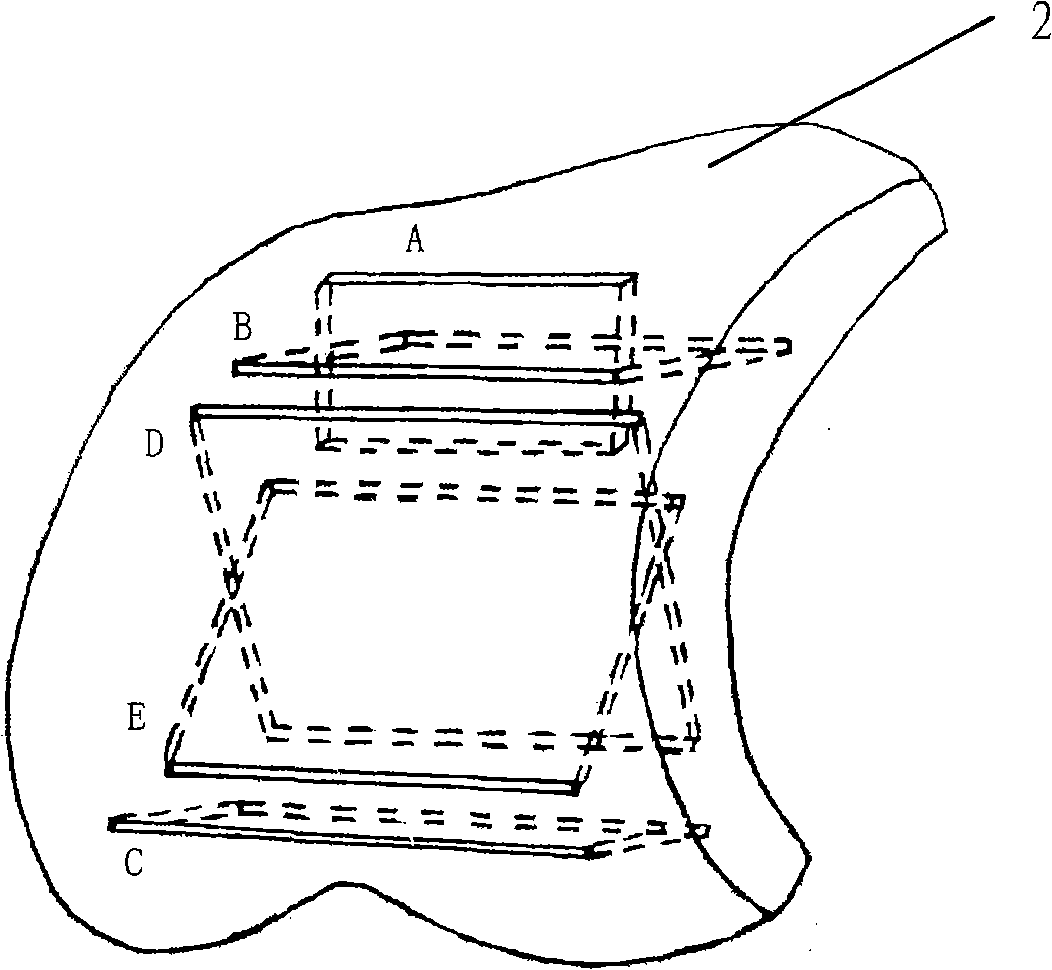

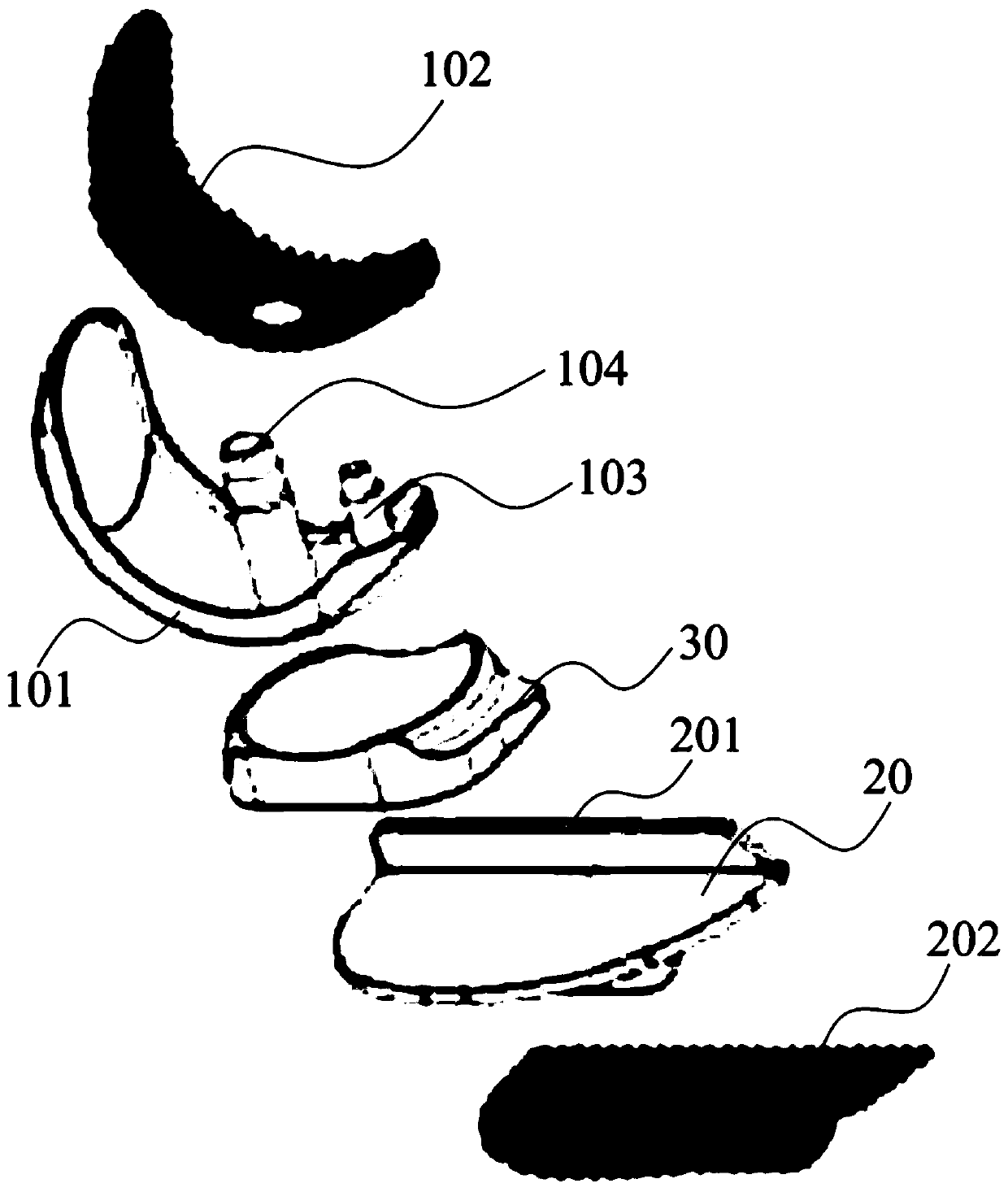

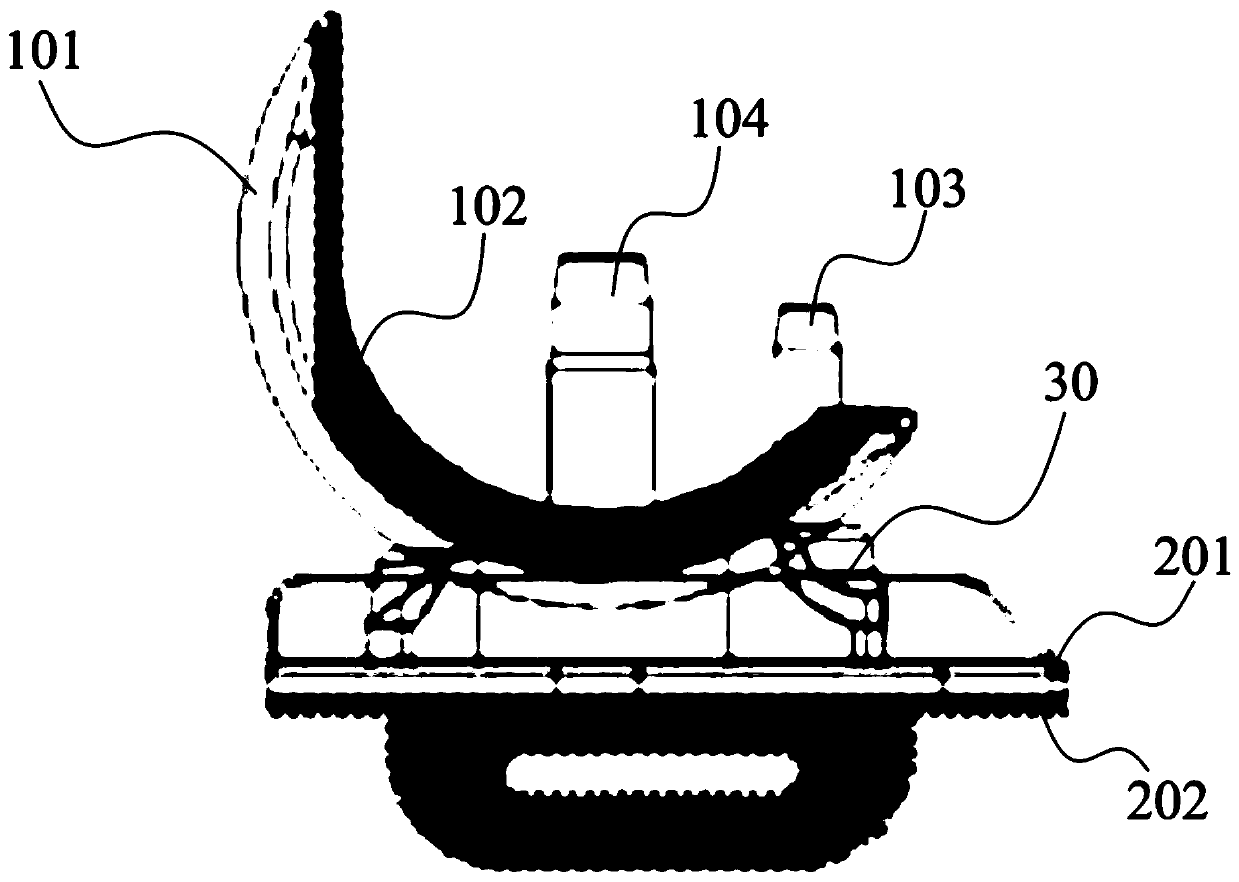

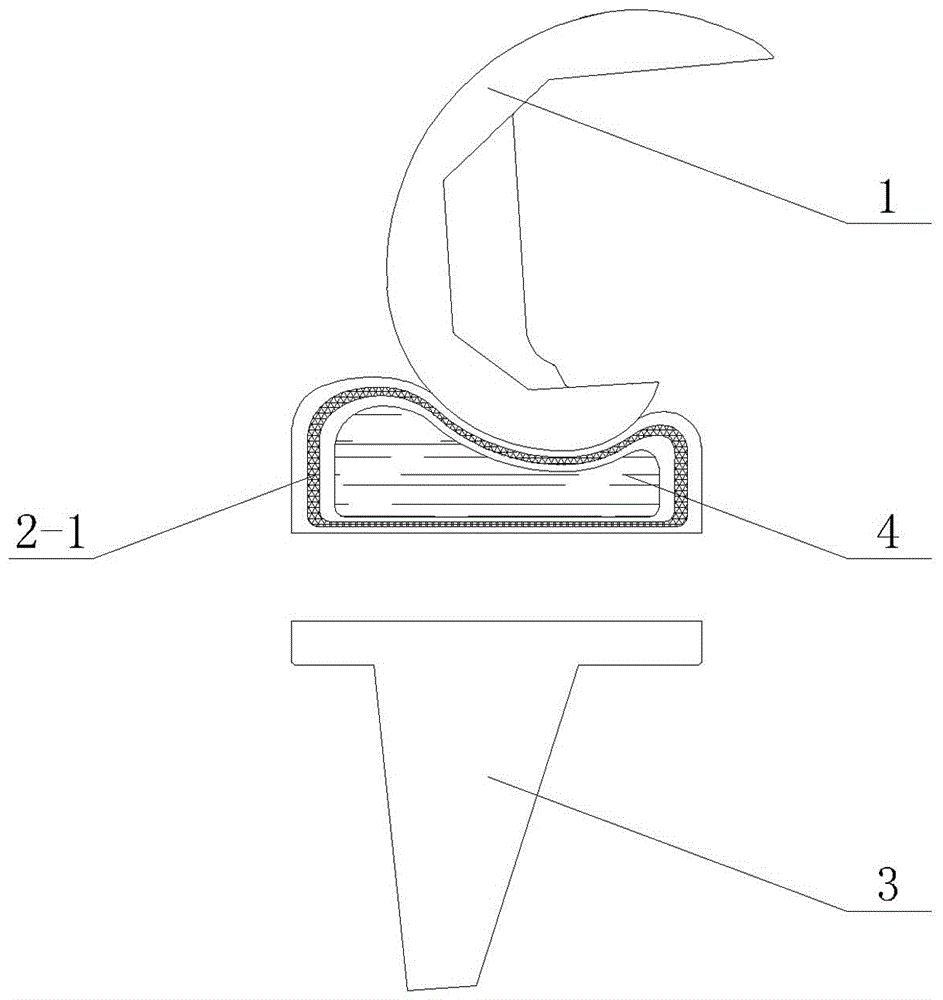

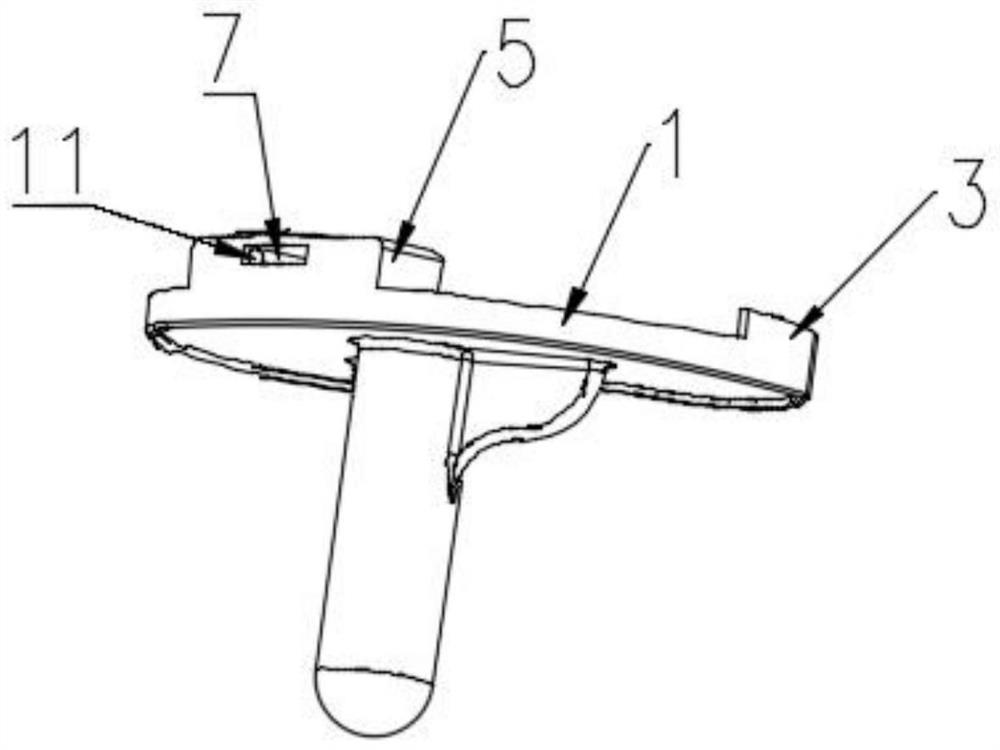

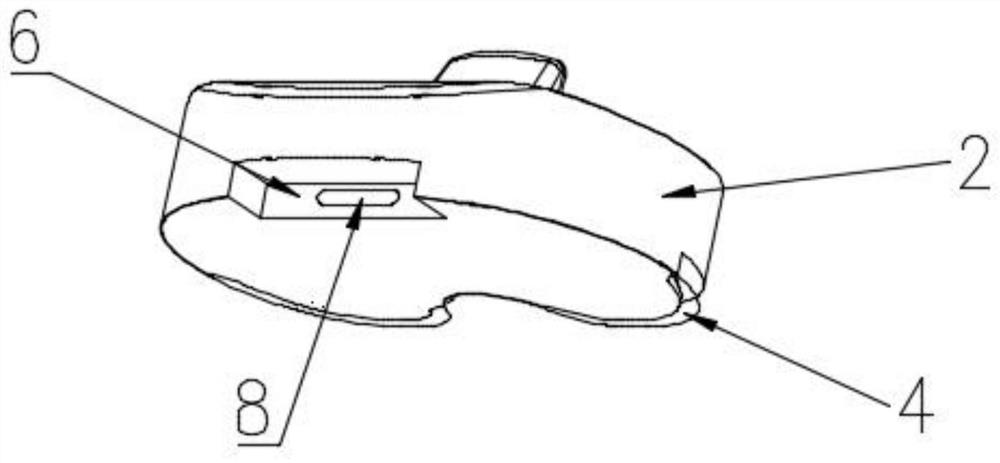

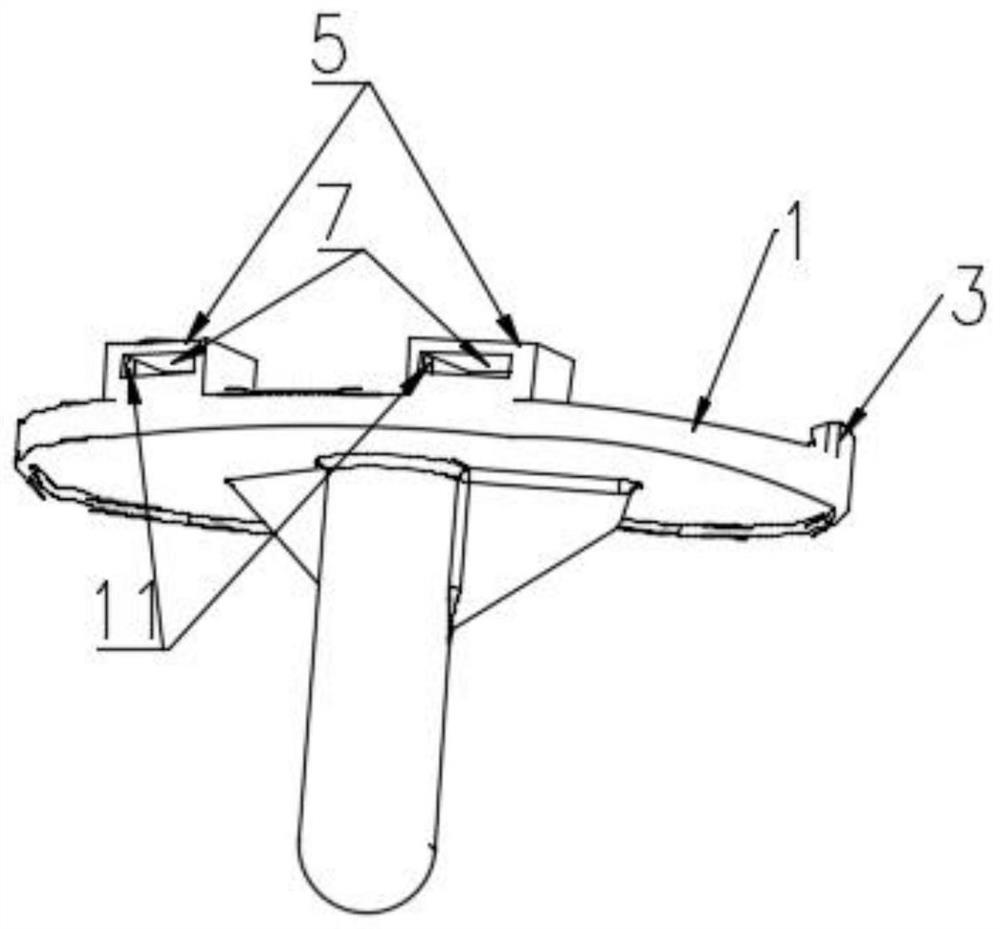

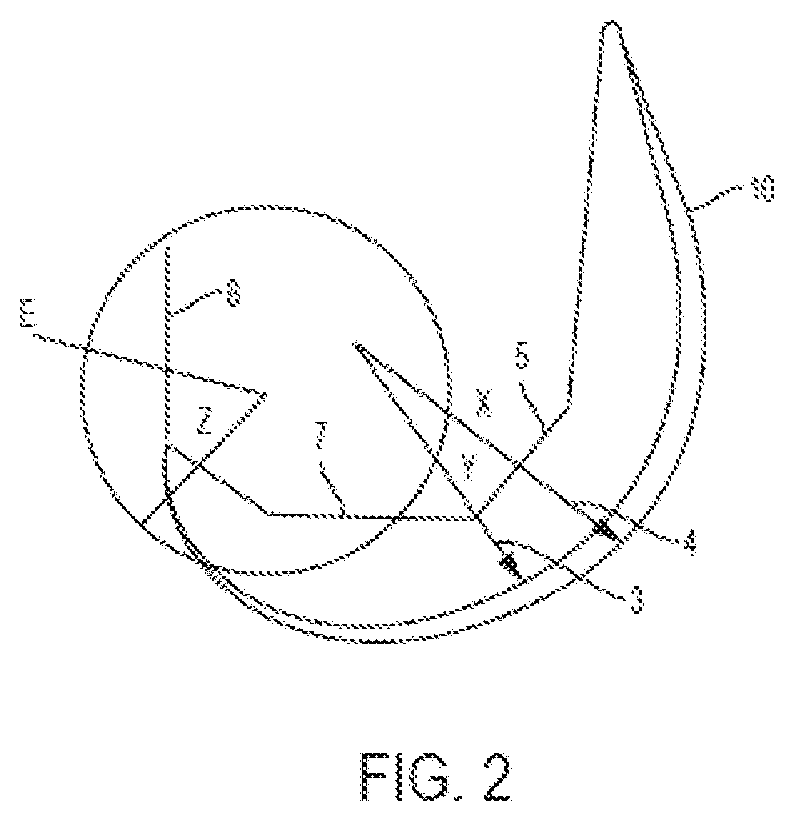

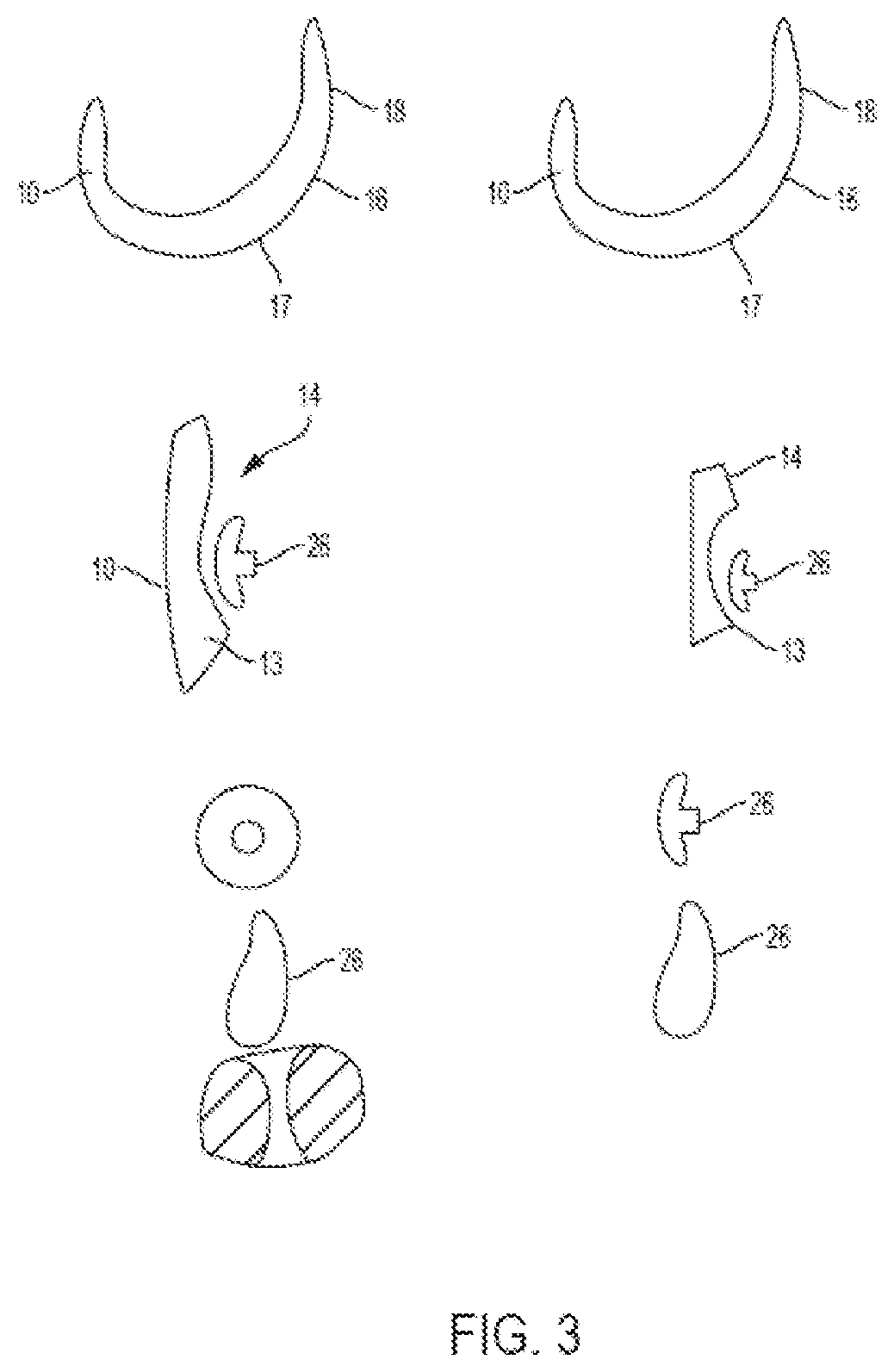

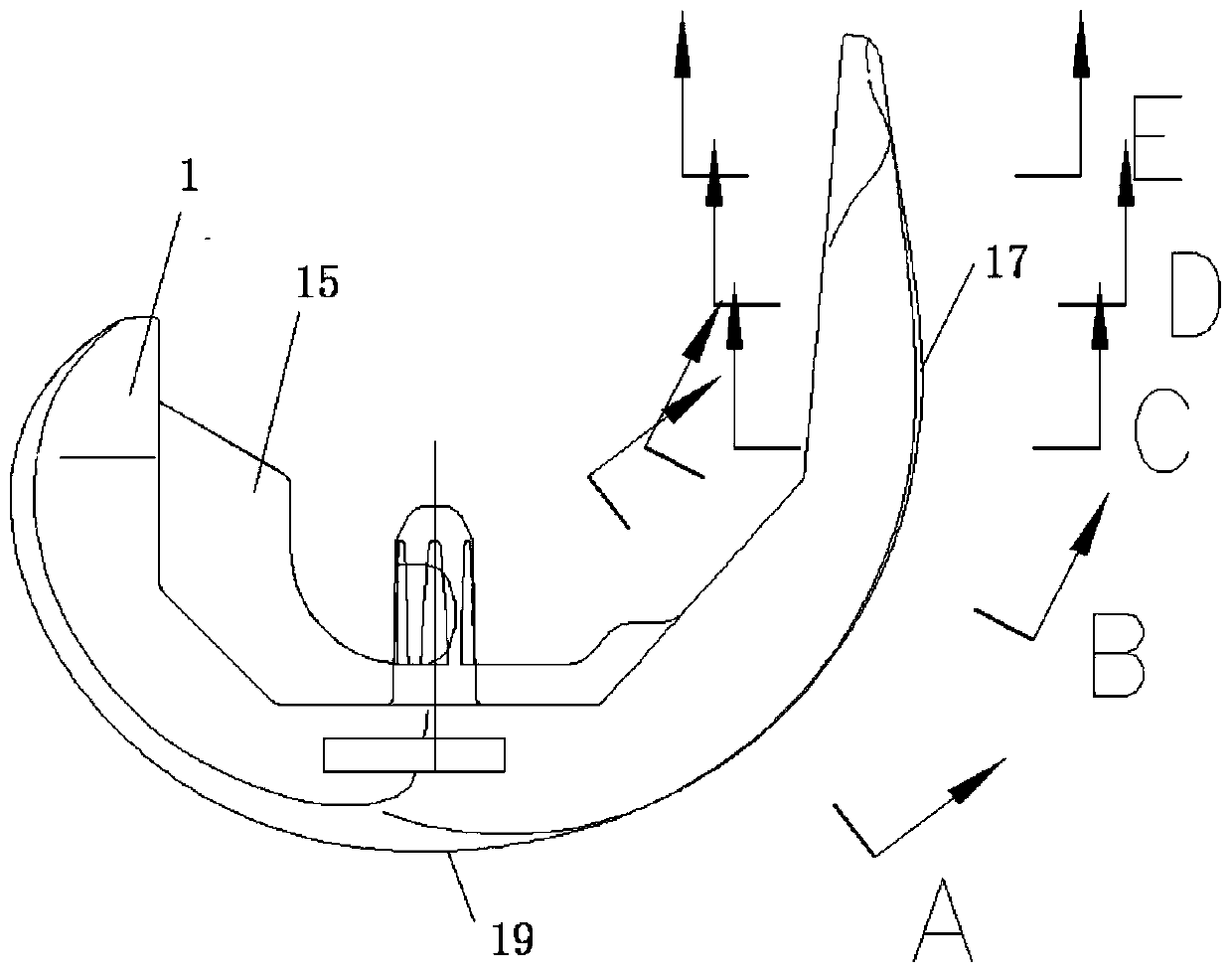

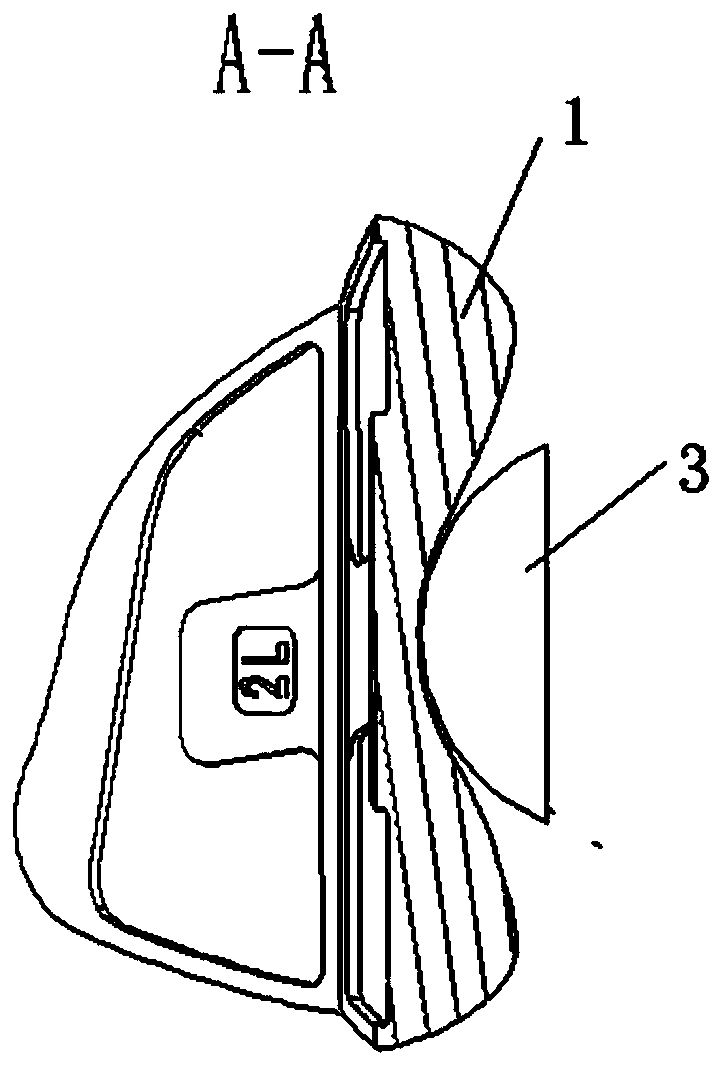

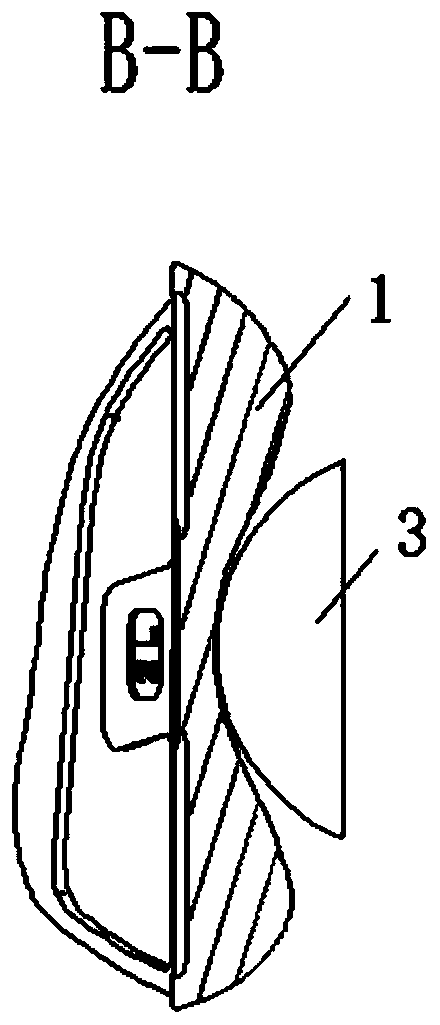

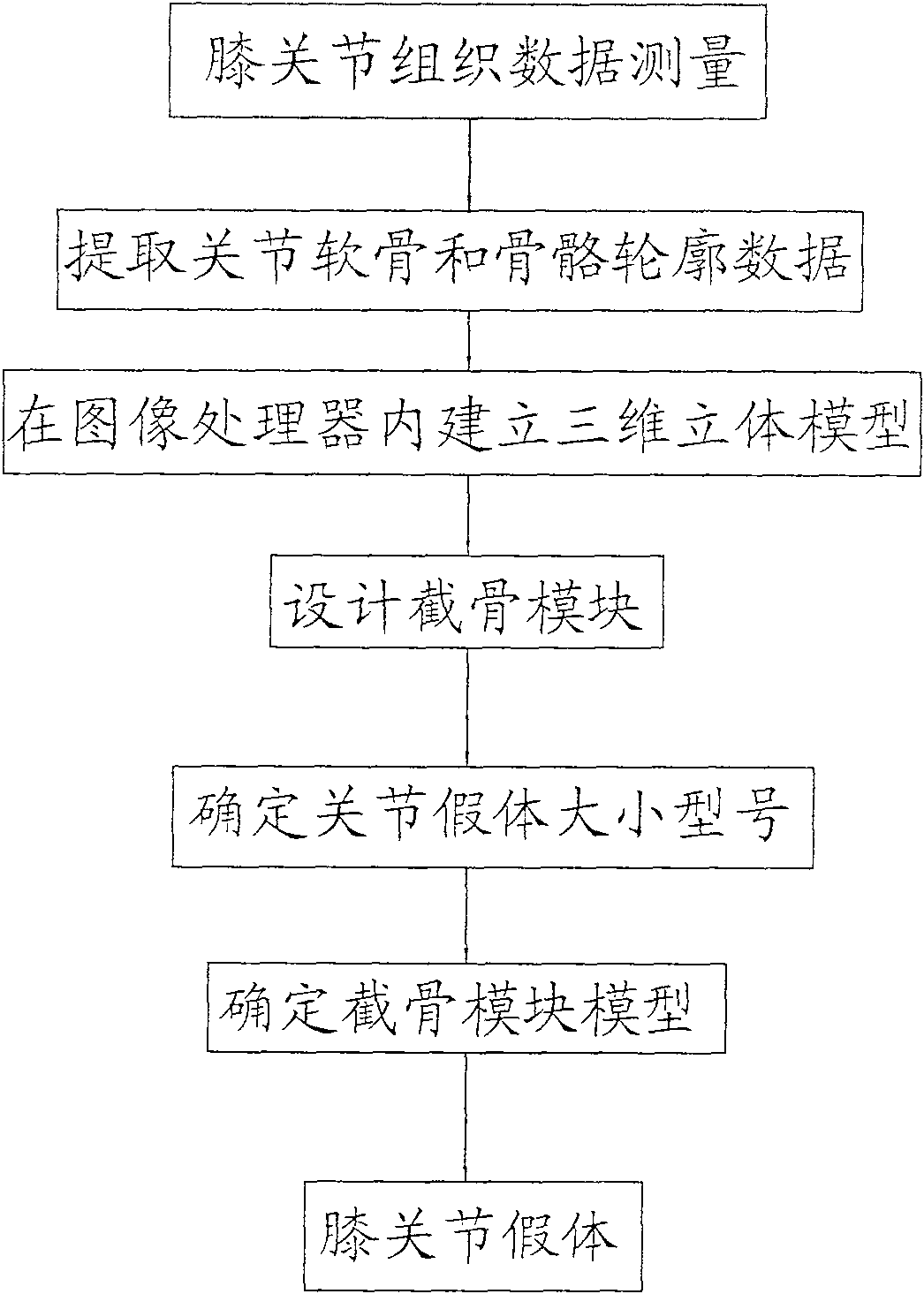

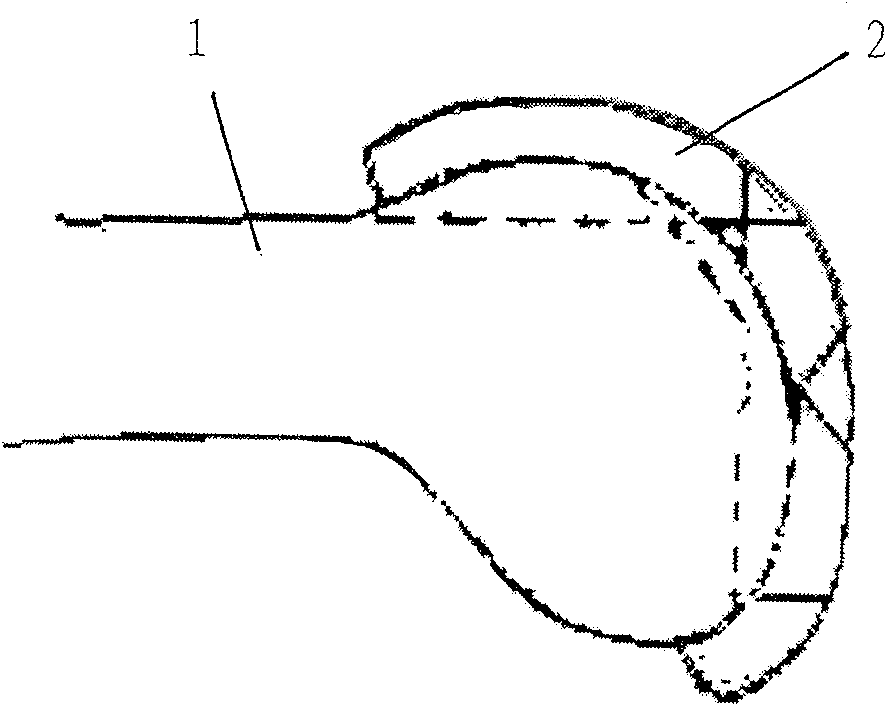

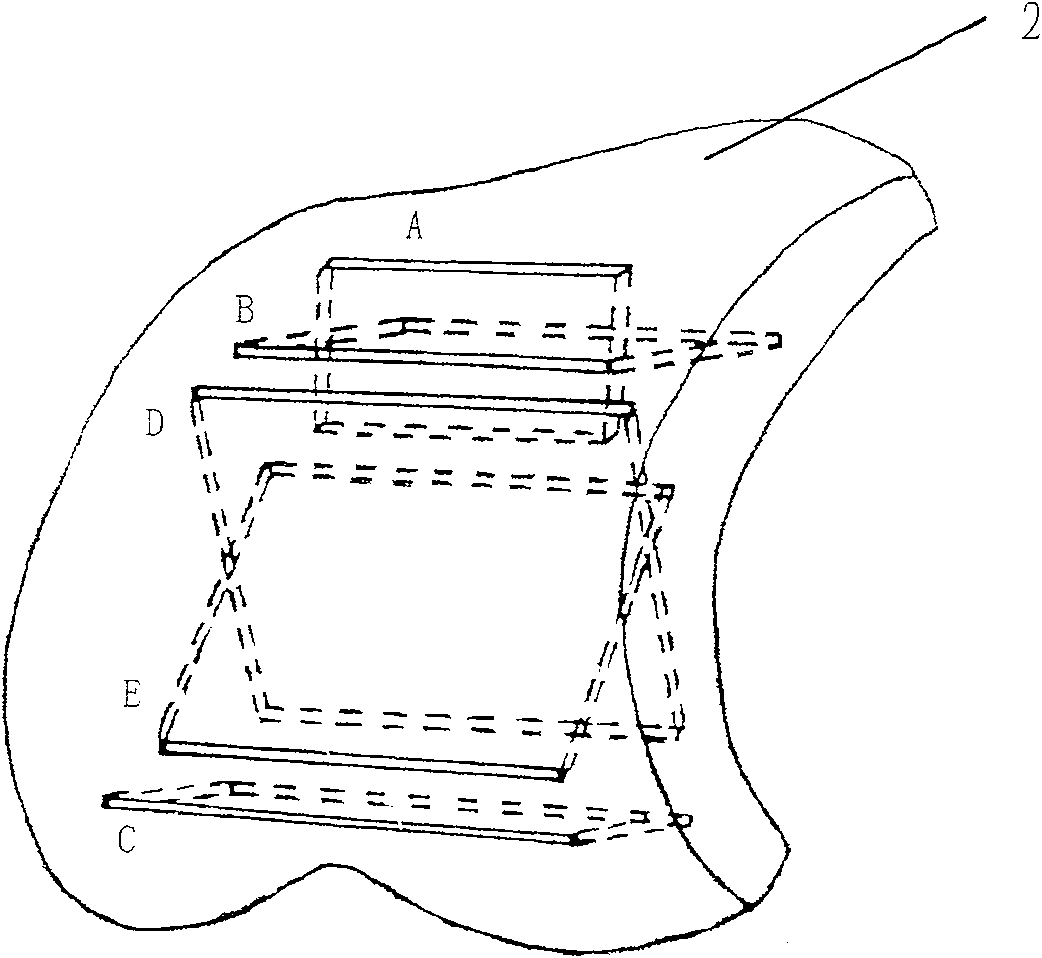

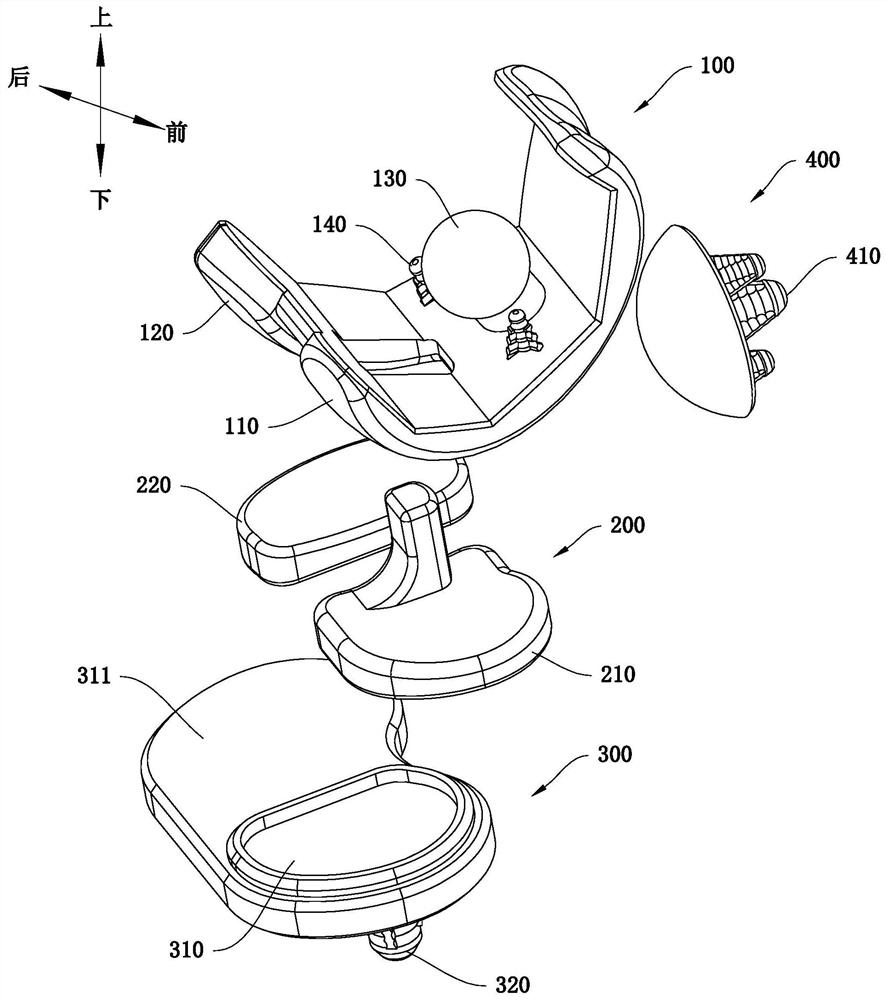

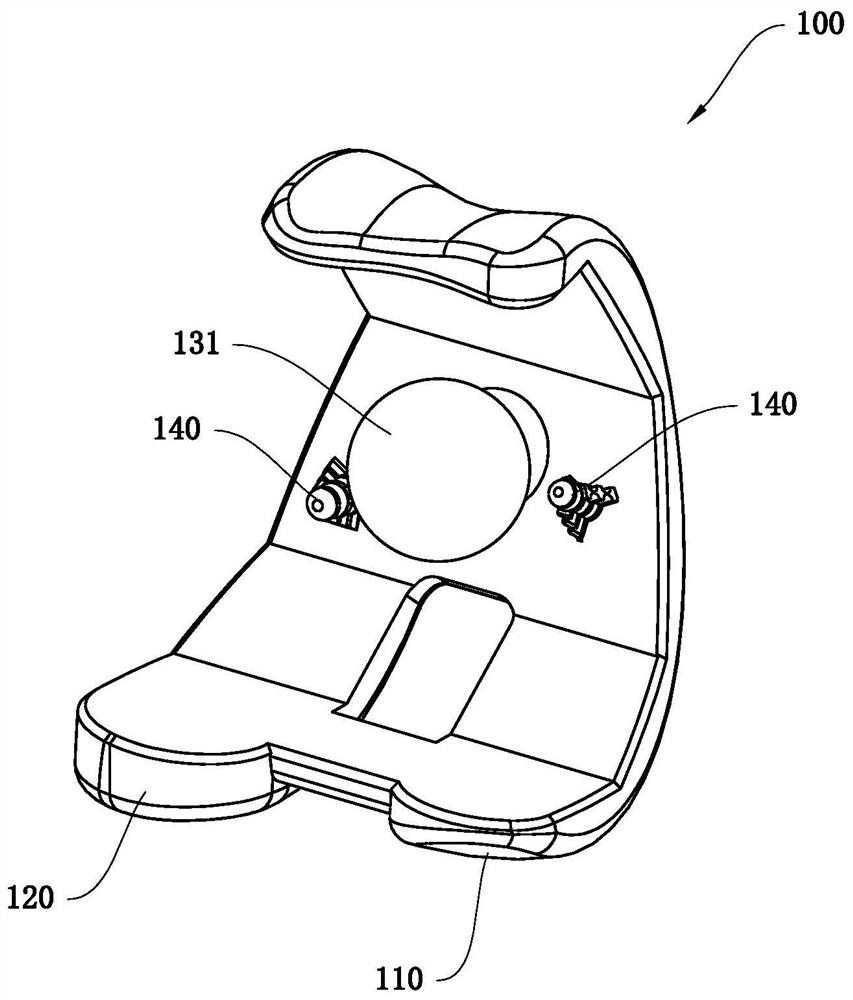

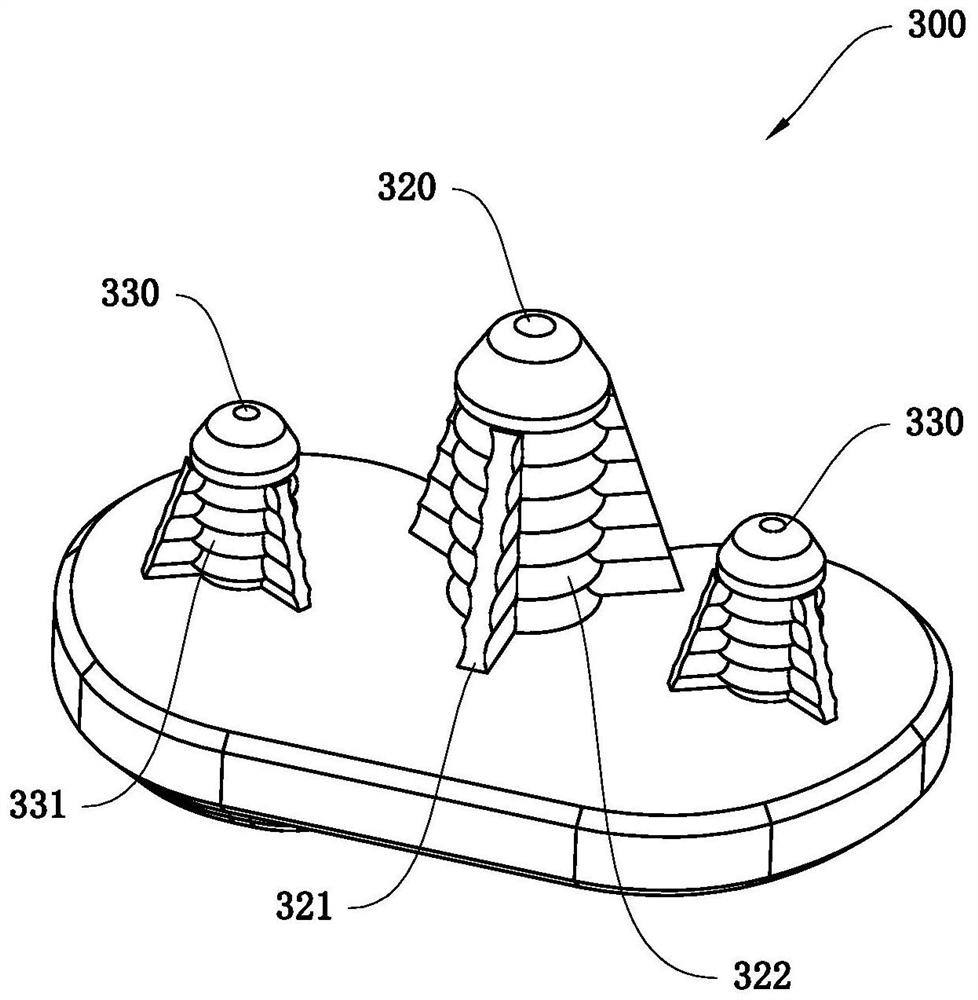

Knee-joint prosthesis implantation process, osteotomy module thereof and device thereof

InactiveCN101288597AConvenient osteotomyAvoid traumaSurgeryJoint implantsImplantation timeBone tissue

The invention discloses a knee prosthesis implantation method, an osteotomy module for usage and a using device, the knee prosthesis implantation method comprises the following steps of measuring the data of knee joint bone tissues, extracting the data of articular cartilage and the skeleton profile, establishing a three-dimensional model in an image processor, designing the osteotomy module, determining the size and the type of the used knee prosthesis and determining an osteotomy module model and the implantation of the knee prosthesis. The knee prosthesis implantation method of the invention can reduce the trauma of a patient, lower the cost, shorten the implantation time, reduce the risk of complications of a user of the knee prosthesis and have comparatively small error and higher precision.

Owner:周一新 +2

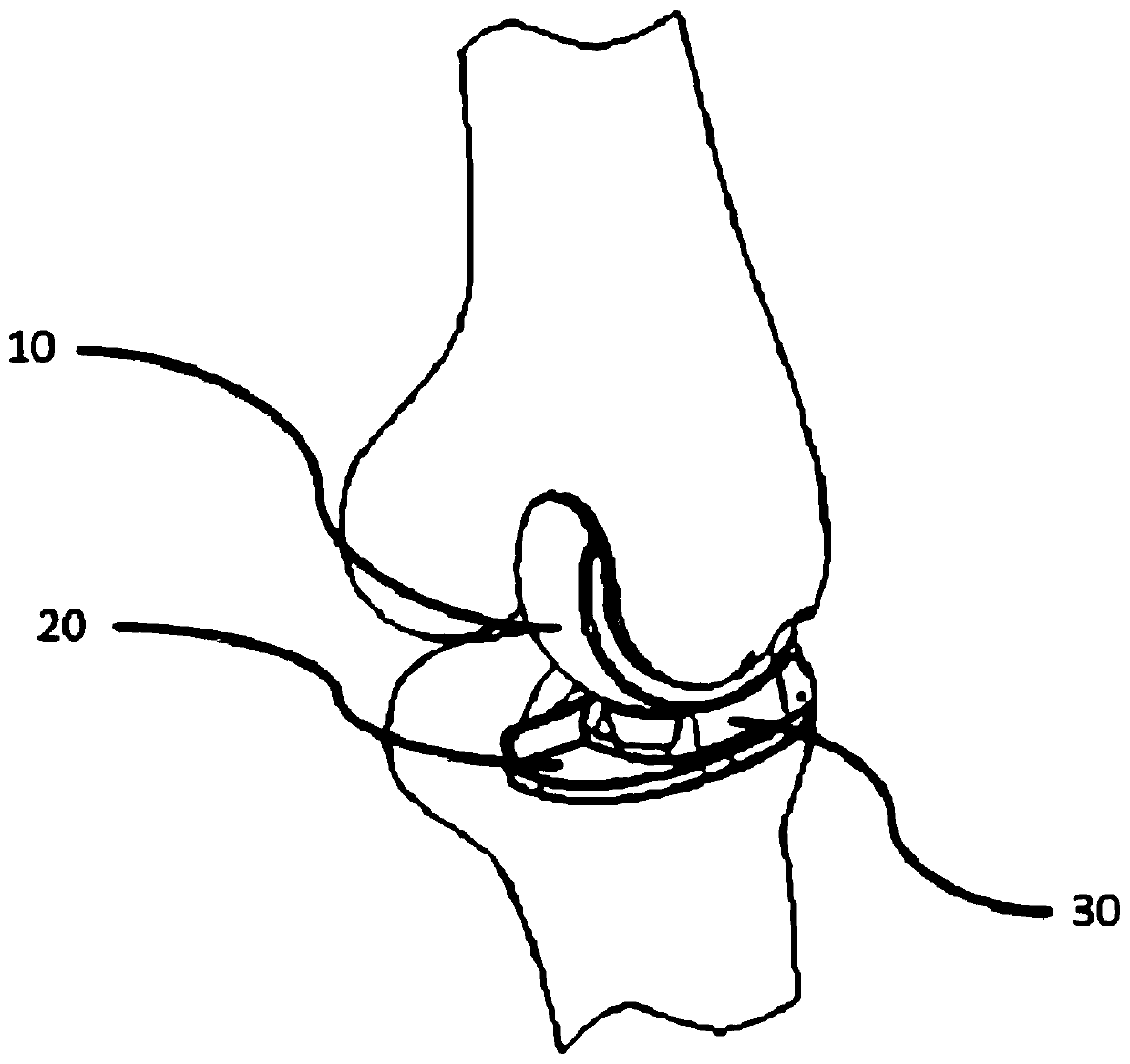

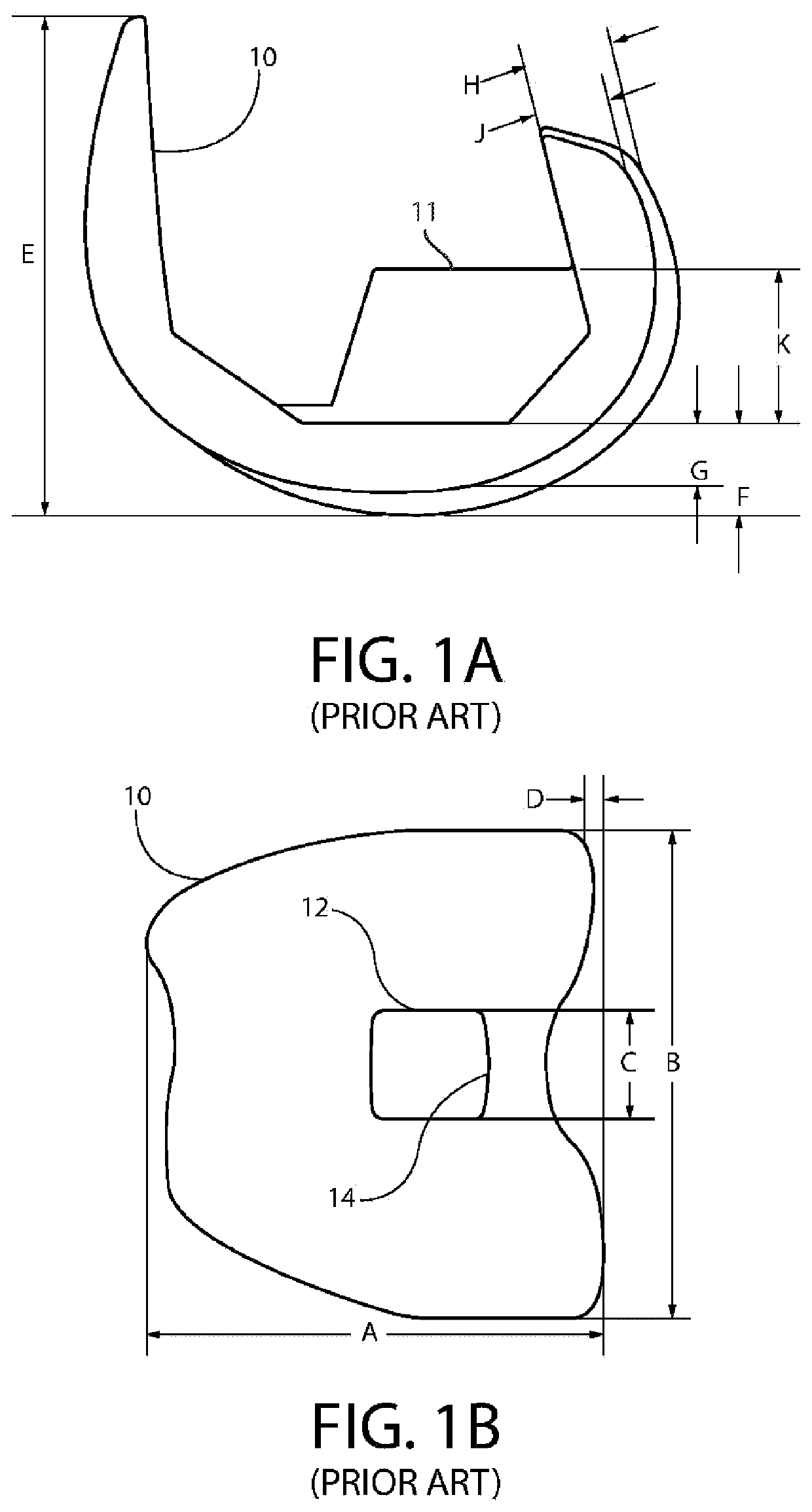

Femoral augments for use with knee joint prosthesis

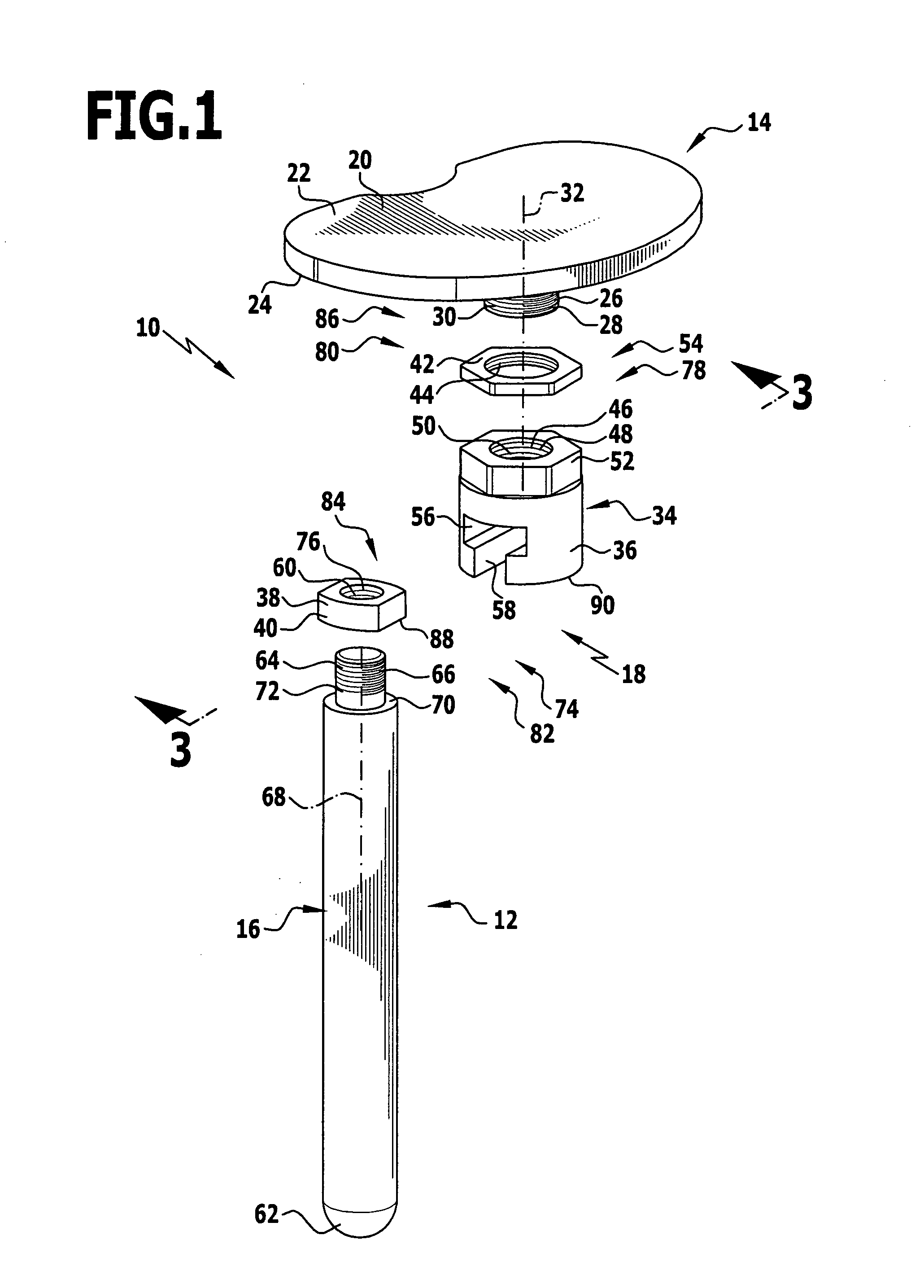

A femoral augment, or set of augments, for use with a knee joint prosthesis, where the femoral augment includes a main body portion, an aperture formed within the main body portion and extending in a generally distal / proximal direction, and a pair of legs extending outwardly from said main body portion in a generally posterior direction. In the preferred embodiment, the aperture is configured to receive a stem extension implant, and to allow it to pass through. Additionally, the legs of the femoral augment are preferably configured to be seated proximal of a proximal side of a pair of condylar portions of a femoral component of a knee joint prosthesis. The present invention is intended for situations in which the distal portion of the femur is defective, and it provides a method and devices that allow for preservation of healthy peripheral bone, while still providing the necessary augmentation to the distal portion of the femur.

Owner:ZIMMER INC

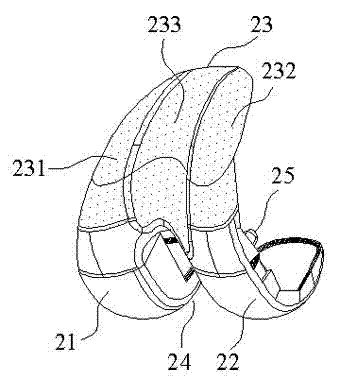

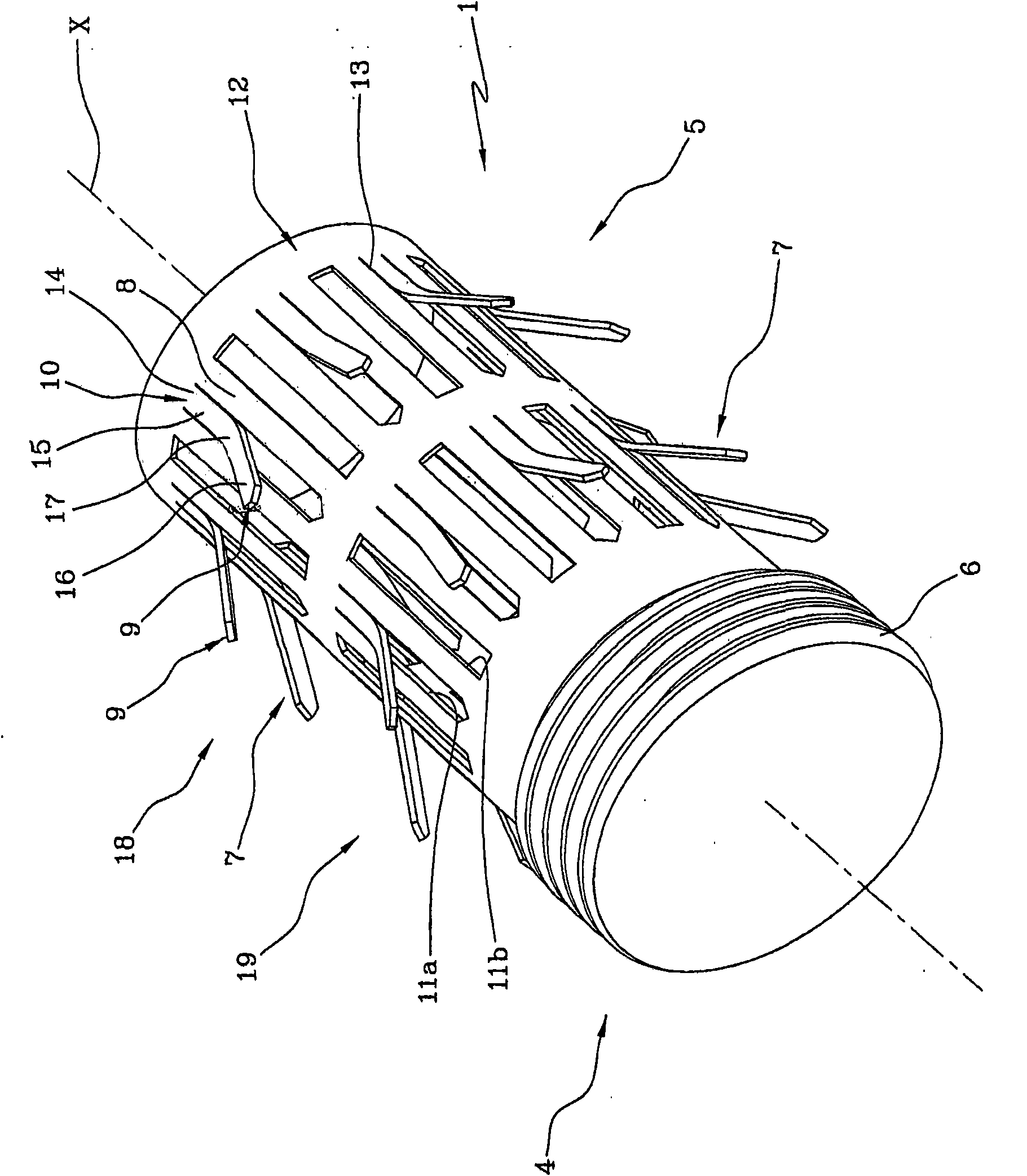

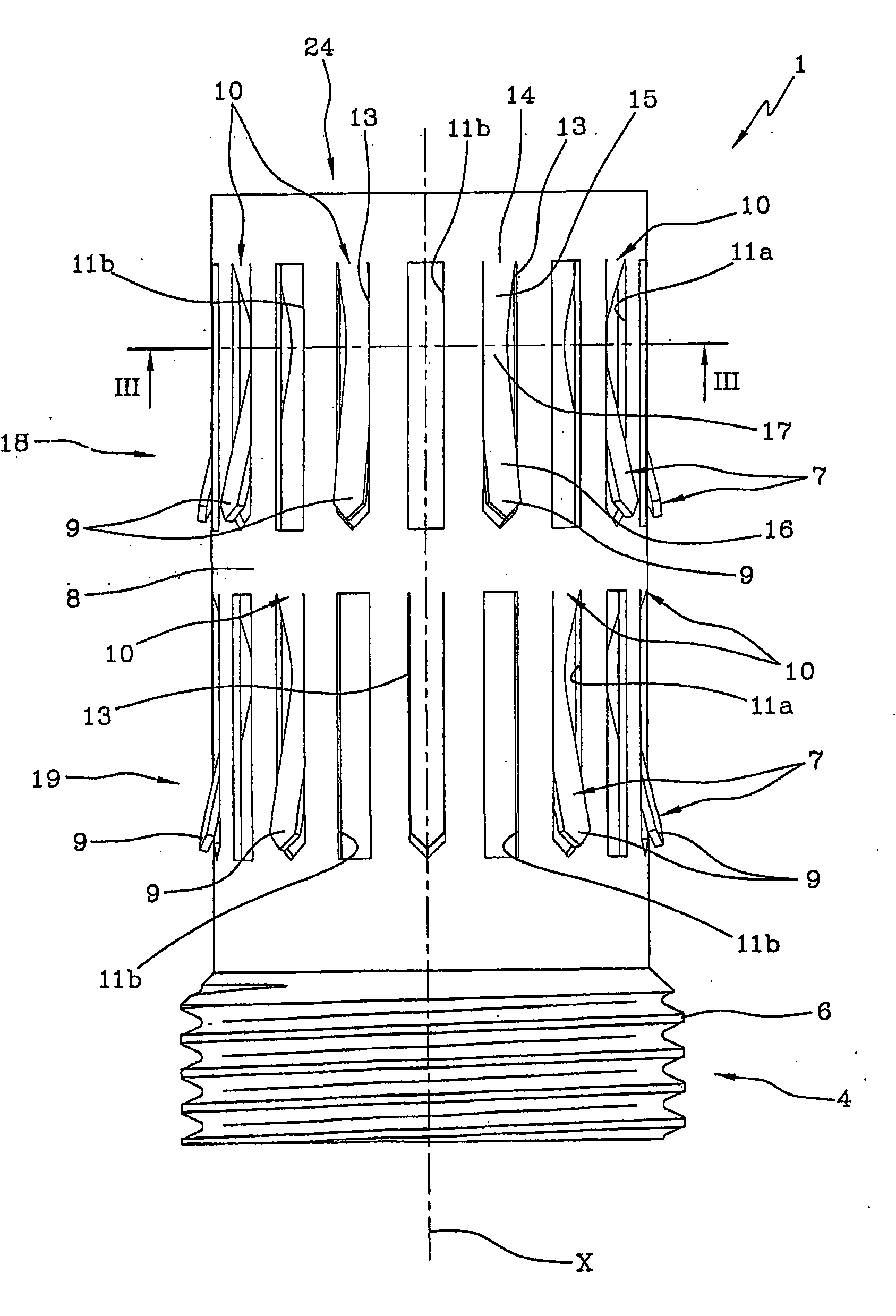

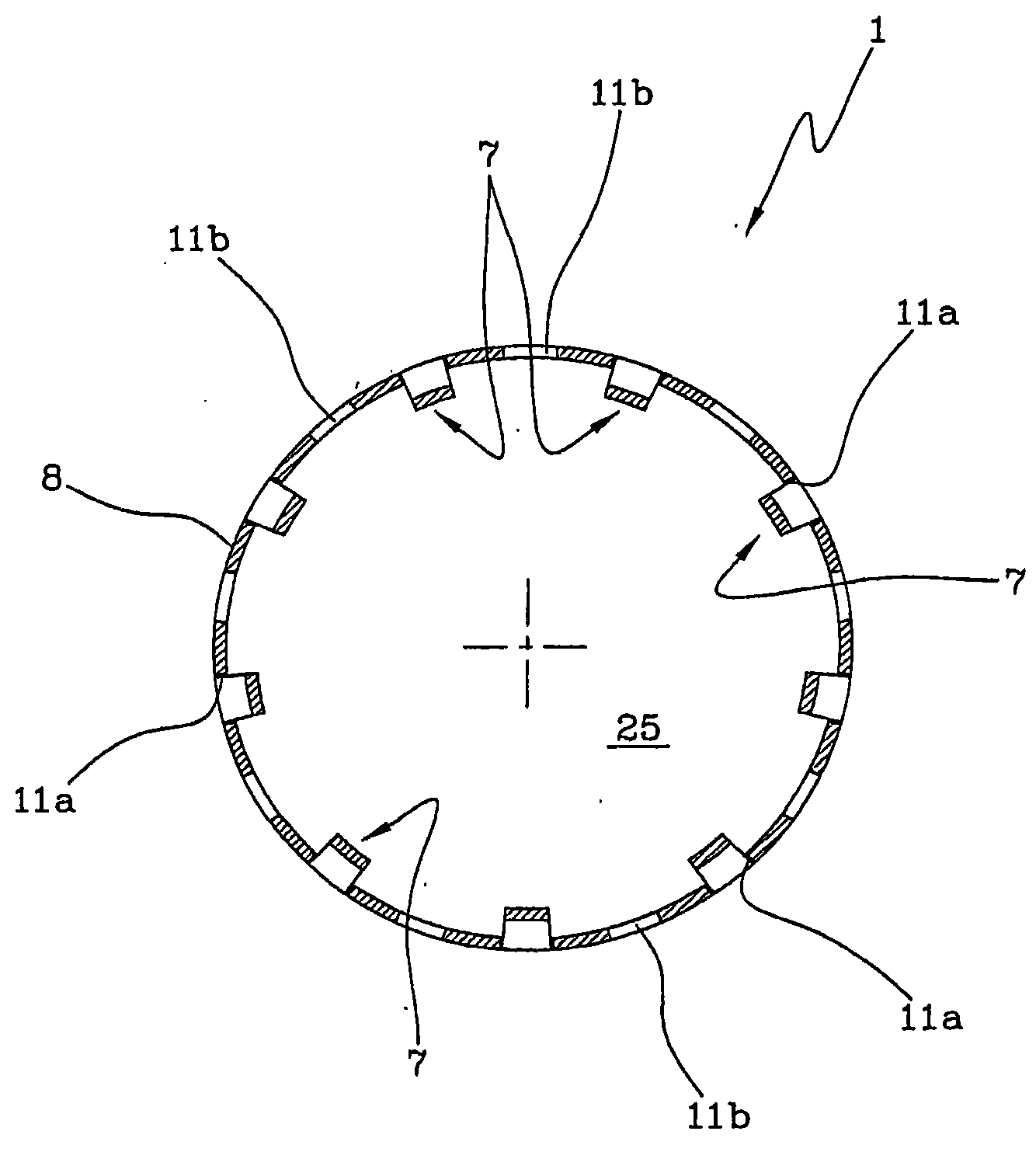

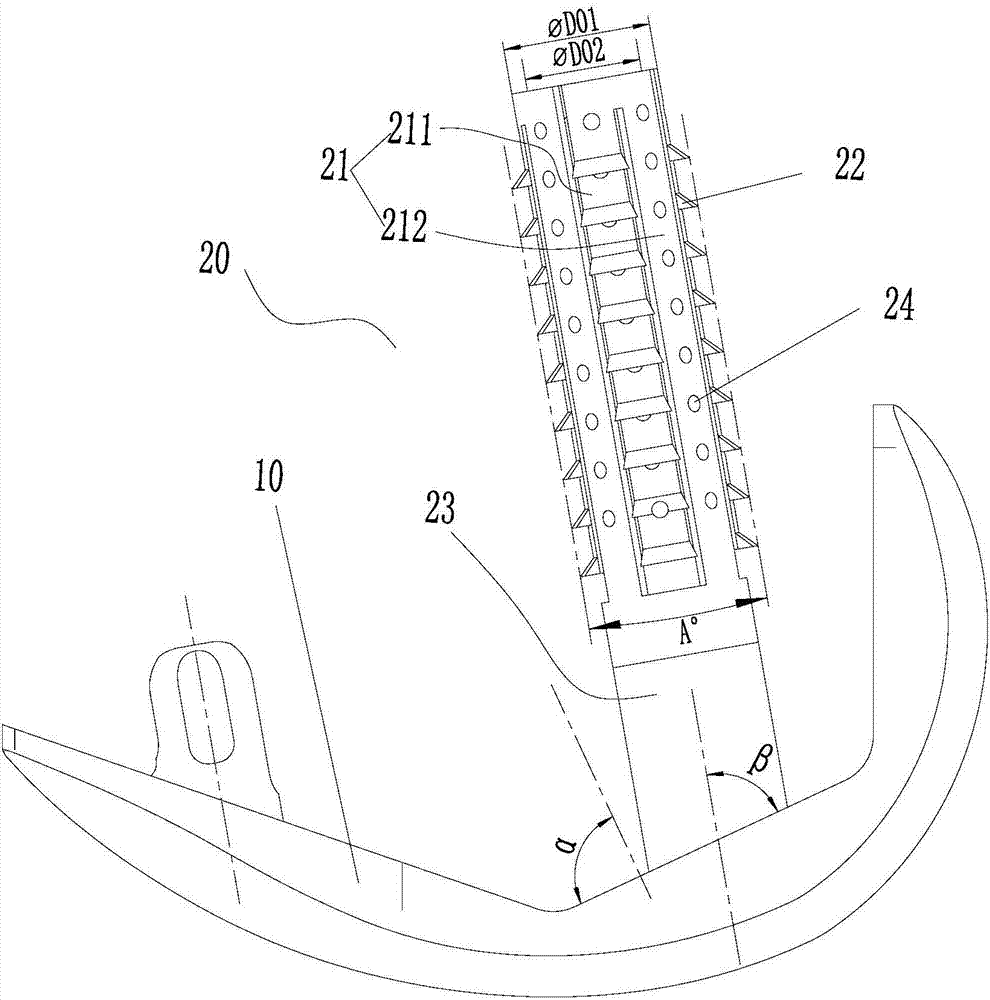

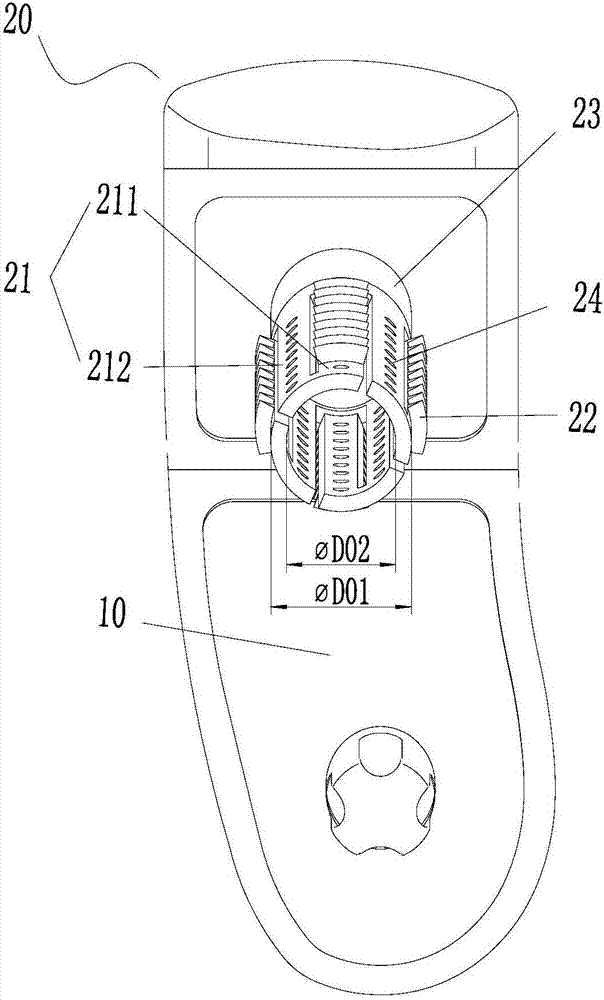

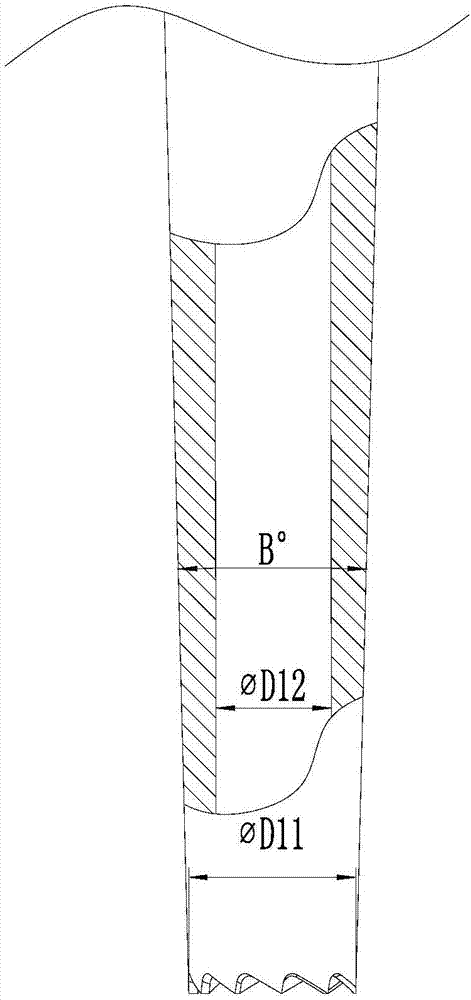

Modular implant part and knee joint prosthesis

ActiveUS8540775B2Reduces manufacturing complexity and thus costImprove facilitiesJoint implantsKnee jointsKnee JointProsthesis

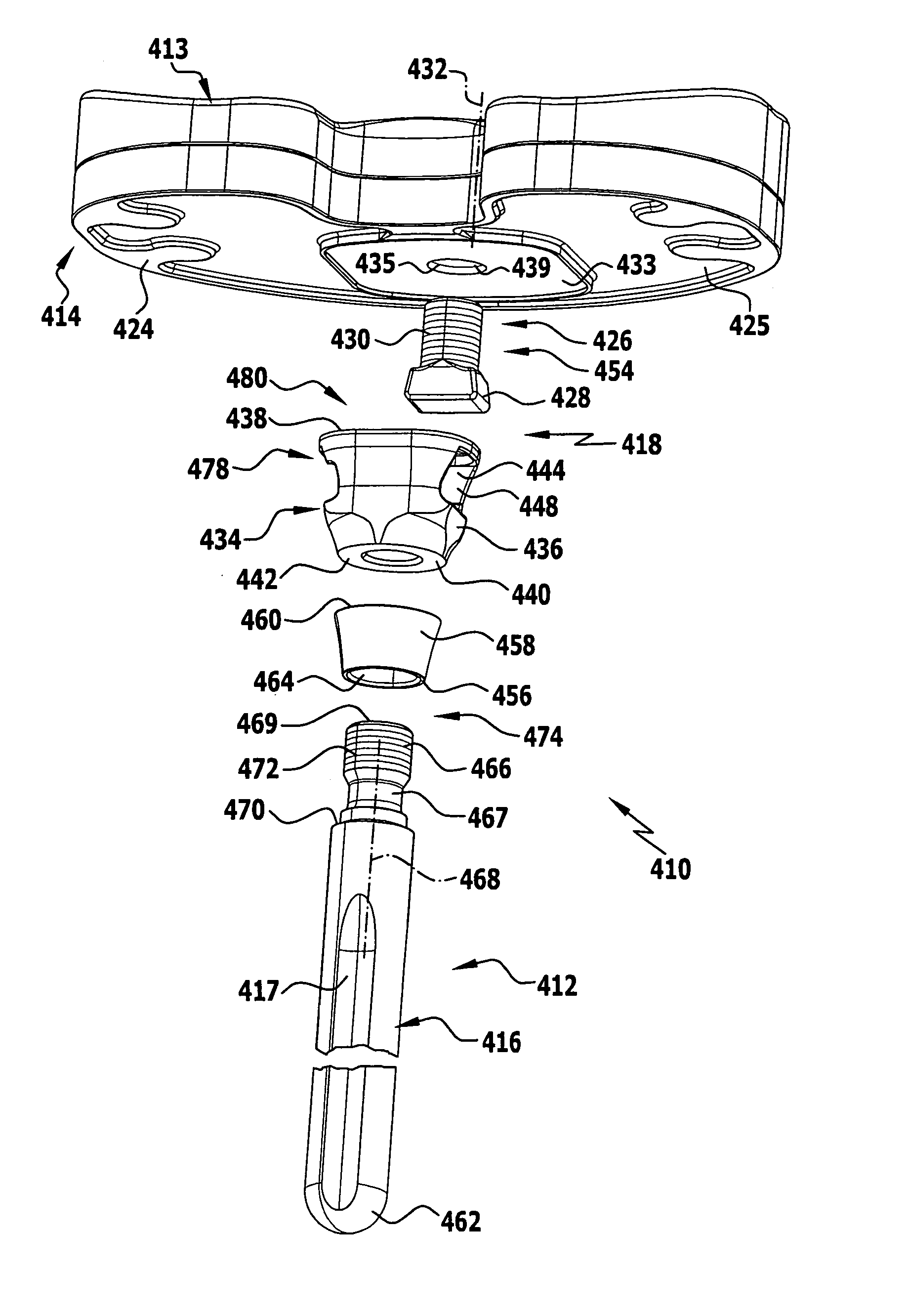

In order to improve a modular implant part for replacing a part of a natural knee joint with an implant component comprising a shaft extending away from the implant component and a connecting device for connecting the shaft to the implant component such that the shaft is adapted to be fixed to the implant component in a multiplicity of desired positions in a simple manner, it is proposed that the connecting device be formed in such a manner that, in a mounting disposition, the shaft is adapted to be moved into different translatory positions by a translatory movement in a direction transverse or substantially transverse to its longitudinal axis, and that, in an implantation disposition, the shaft is adapted to be fixed immovably to the implant component in one of the different translatory positions. Furthermore, an improved knee joint prosthesis is proposed.

Owner:AESCULAP AG

Artificial knee joint prosthesis

InactiveCN102727327AImprove wear resistanceReduce thicknessJoint implantsKnee jointsPatella prosthesisProsthetic graft

The invention relates to an artificial knee joint prosthesis which comprises a patella prosthesis and a femur prosthesis, wherein the patella prosthesis is made of metal and is 3-4mm, preferably 3.5mm in thickness; the femur prosthesis is provided with a tackle part which is made of metal; a polyethylene joint surface is arranged on the surface of the tackle part; and the polyethylene joint surface is gradually thickened from a near end to a far end and no gap exists between the polyethylene joint surface and the tackle part. The artificial knee joint has the following advantages: the patella prosthesis is made of metal, so that the wear resisting property is good, the thickness is thin, the patella cut amount is decreased, then the application scope of the existing knee joint prosthesis is enlarged, the postoperative fracture occurrence rate is reduced, benefit is brought to overhauling and the problem of uneven patella stress distribution is solved at the same time; the tackle part of the femur prosthesis is covered by a layer of ultra-high molecular polyethylene joint surface, so that the abrasion is reduced and the 'soft landing' of femur quadriceps tendon is realized; and no gap exists between the polyethylene joint surface and the metal backing and the polyethylene joint surface and the metal backing are integrally pressed and shaped, so that a polyethylene / metal friction surface is not added.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

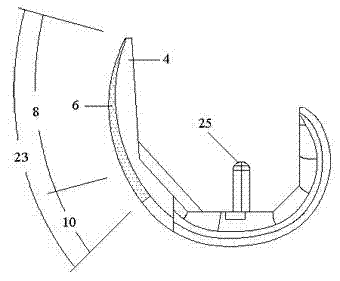

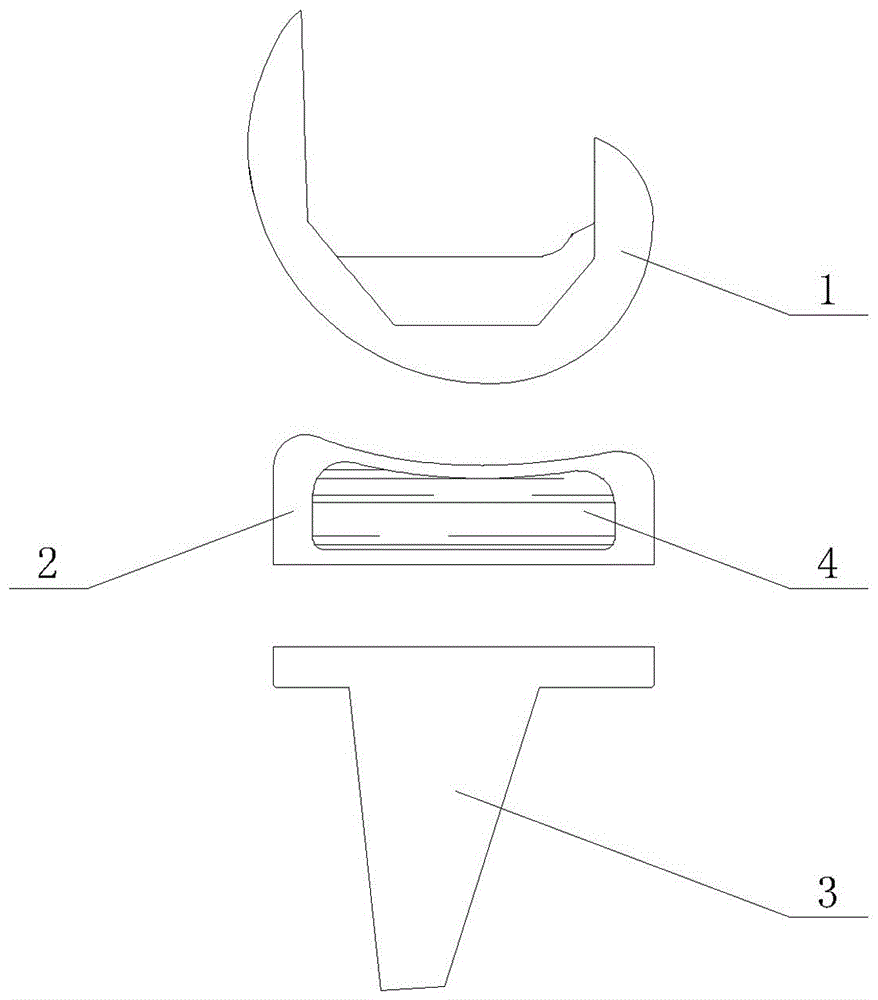

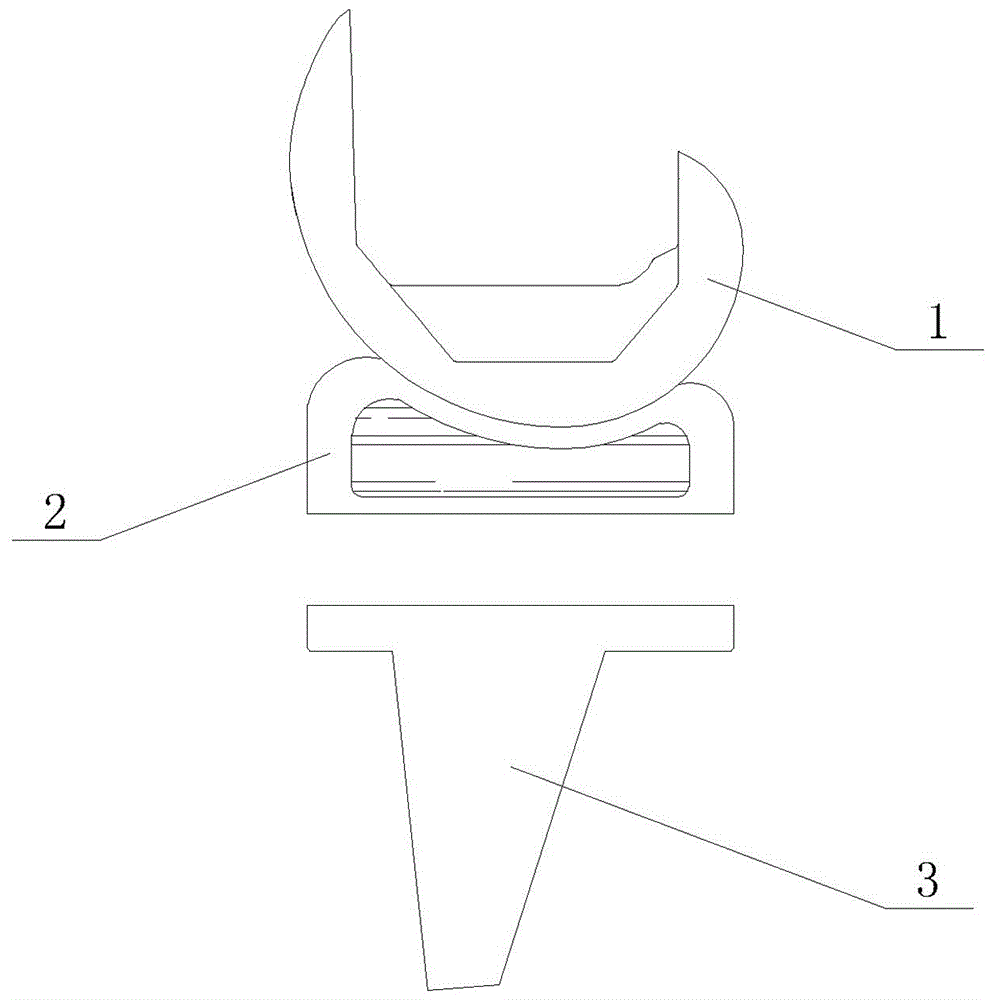

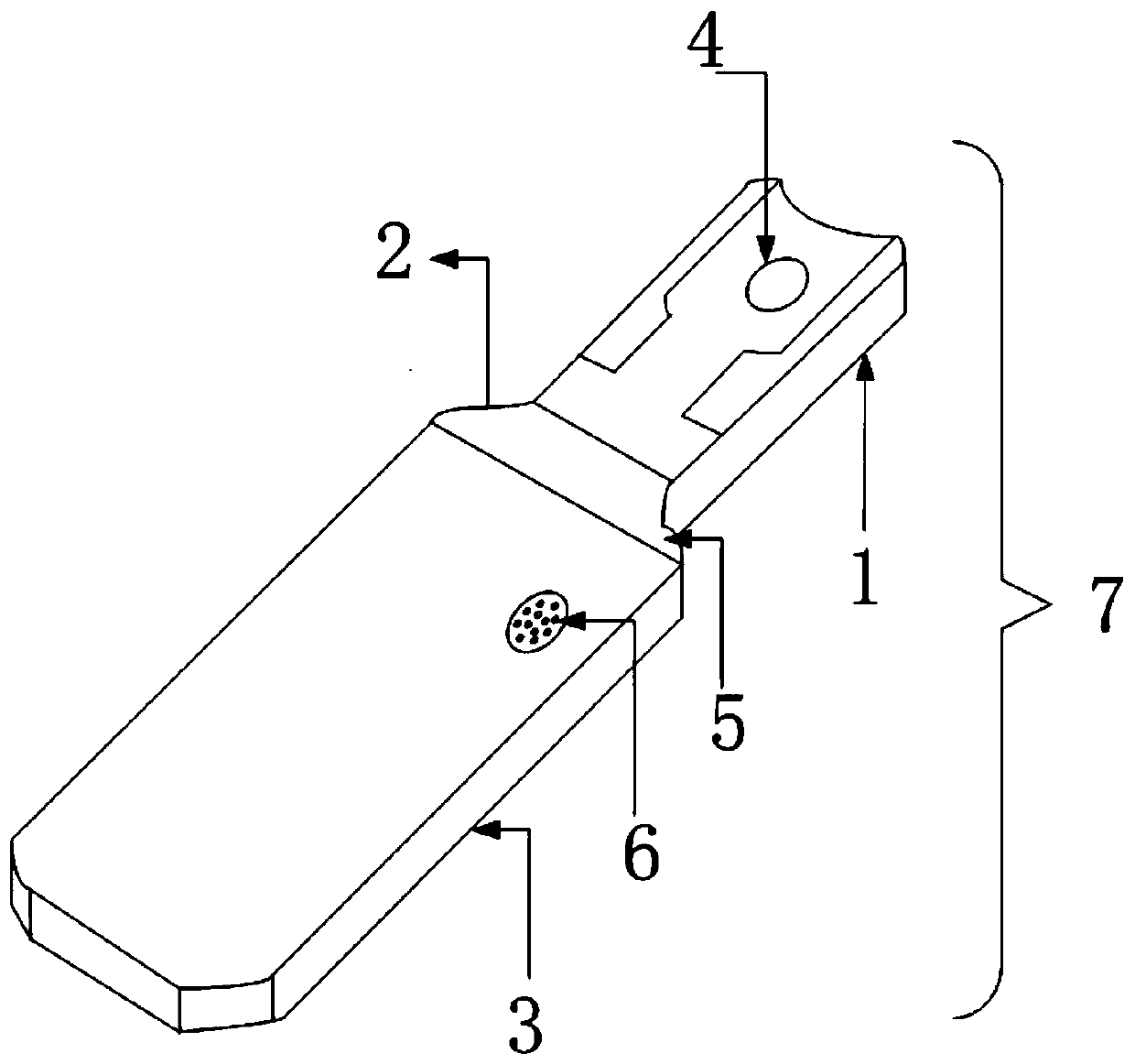

Tibial component and articular prosthesis for the knee comprising said tibial component

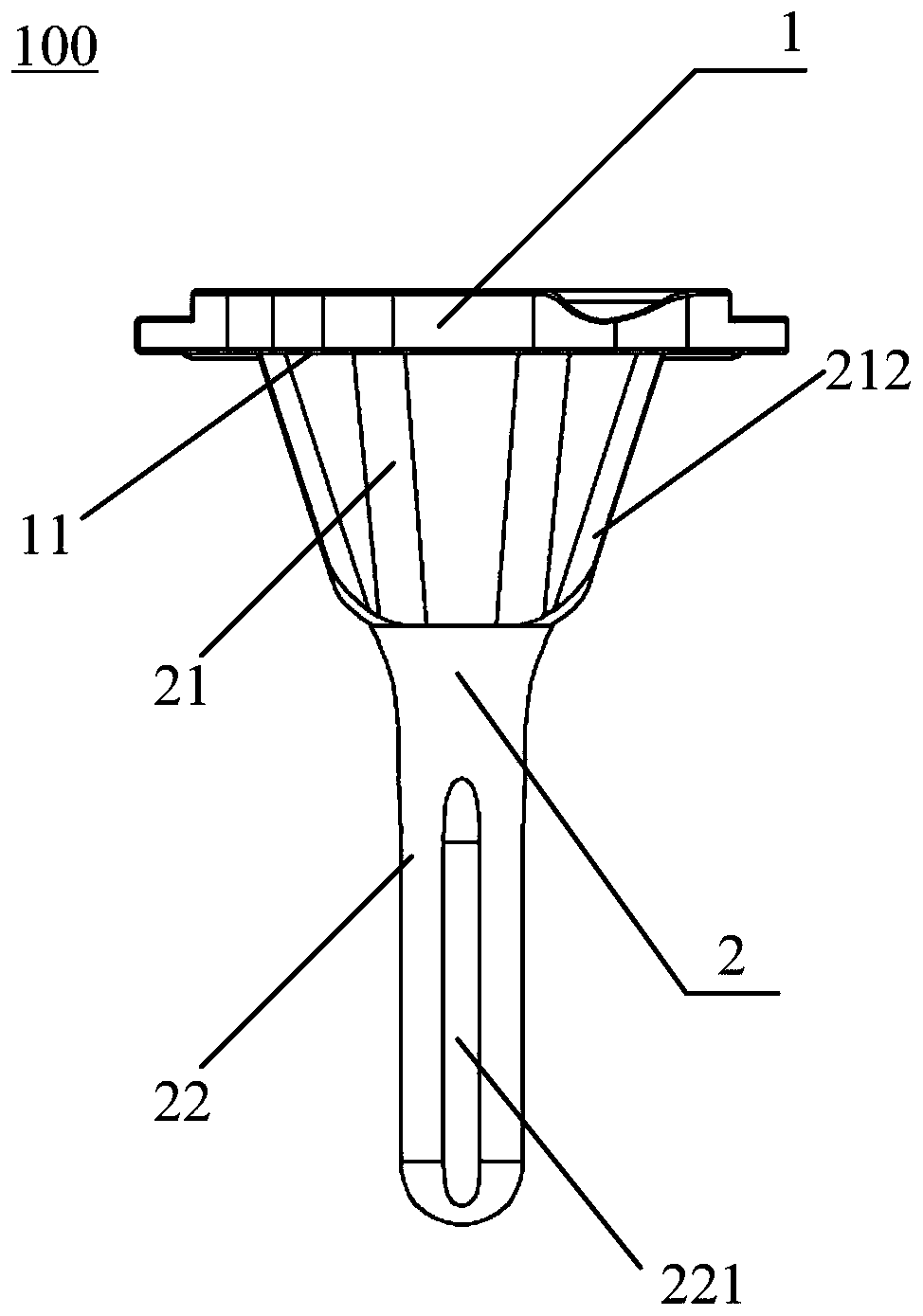

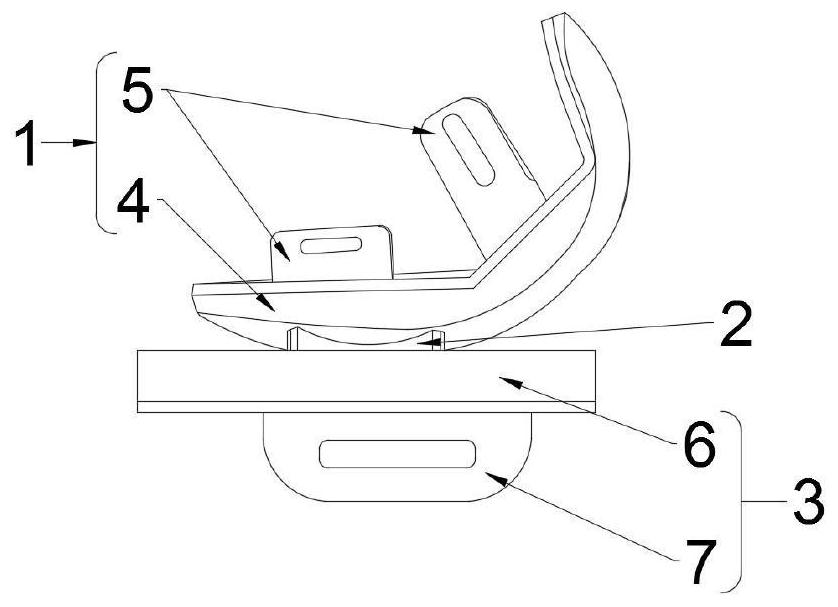

A pin for the anchoring of articular prostheses includes a connecting portion (4) with a prosthesis (2) and an engagement portion (5) in a hole obtained within a bone. The engagement portion (5) is at least partly deformable in a radial direction and in a resilient way, in order to allow the instantaneous blocking of the pin (1) in the hole and the primary fixing of the prosthesis (2) on the bone, so as to al low an easy primary fixing of the prosthesis by simply introducing with a pressure the connecting portion in the hole obtained within the bone itself.

Owner:FIN CERAMICA FAENZA

Single-compartment knee joint prosthesis and manufacturing method thereof

PendingCN111345921AGuaranteed to grow inAvoid coating peelingJoint implantsKnee jointsTibial boneKnee arthrodesis prosthesis

The invention relates to a single-compartment knee joint prosthesis. The single-compartment knee joint prosthesis comprises: a femoral condyle, wherein the inner side, facing the far end of the femoral head, of the femoral condyle is provided with a femoral condyle bone trabecula structure which is integrally formed through 3D printing fusion, and the inner surface of the femoral condyle bone trabecula structure is designed to be a spherical outline suitable for being in close press fit with the femur subjected to grinding treatment; a tibial plateau, wherein the lower side, facing the tibialosteotomy end, of the tibial plateau is provided with a tibial plateau bone trabecula structure which is integrally formed through 3D printing fusion; and a gasket, wherein the upper surface of the gasket is concave and fits the spherical outer side surface of the femoral condyle, and the lower surface of the gasket is a plane and fits the upper plane of the tibial plateau. The femoral condyle bone trabecula structure and the tibial plateau bone trabecula structure are formed by space-filling polyhedral unit cell structure in a topological mode, and have wire diameters or hole diameters whichare limited and randomized on the basis of set wire diameter or hole diameter parameters.

Owner:JIASITE HUAJIAN MEDICAL EQUIP (TIANJIN) CO LTD

Flexible knee joint prosthesis

InactiveCN105816259AReduce wearSlightly wornJoint implantsKnee jointsArticular surfacesArticular surface

The invention discloses a flexible knee joint prosthesis. The flexible knee joint prosthesis comprises a femoral condyle prosthesis and a tibial plateau, wherein a flexible gasket is arranged between the femoral condyle prosthesis and the tibial plateau and fixed to the tibial plateau, and the flexible gasket supports the femoral condyle prosthesis and deforms adaptively along with the rotation of the femoral condyle prosthesis to maintain surface contact with the femoral condyle prosthesis. Due to the fact that the flexible gasket is prepared from ultrahigh molecular weight polyethylene, the articular surface can deform to adapt to and conform to the flexion and rotation deformation of the femoral condyle prosthesis under pressure, and then abrasion of the tibial plateau is relieved remarkably.

Owner:BEIJING AKEC MEDICAL

Knee joint prosthesis

PendingCN111184598AAvoid transverse shear stressAddresses susceptibility to wear due to shear stressJoint implantsKnee jointsKnee arthrodesis prosthesisFEMORAL CONDYLE

The invention provides a knee joint prosthesis, which comprises a tibia platform, a femur condyle component and a spacer component, wherein the femur condyle component is positioned above the tibia platform and comprises an inner condyle joint surface and an outer condyle joint surface, and the inner condyle joint surface and an outer condyle joint surface have a height difference H; the spacer component is positioned between the tibia platform and the femur condyle part and comprises an inner side spacer cooperated with the inner condyle joint surface, and an outer side spacer cooperated withthe outer condyle joint surface; a position, which corresponds to the outer side spacer, on the upper surface of the tibia platform is provided with a first spherical convex surface; the outer side spacer is movably arranged on the prosthesis platform; and in addition, the lower surface of the outer side spacer is provided with a first spherical concave surface cooperated with the first sphericalconvex surface. According to the technical scheme of the invention, the problem in the relevant art that the knee joint prosthesis is likely to abrade can be effectively solved.

Owner:BEIJING AKEC MEDICAL

Novel knee joint prosthesis with locking mechanism

ActiveCN111616841ANo damageReduce the risk of surgical failureJoint implantsKnee jointsKnee arthrodesis prosthesisPhysical medicine and rehabilitation

The invention discloses a novel knee joint prosthesis with a locking mechanism. The knee joint prosthesis comprises a tibial platform support, wherein a tibial gasket is arranged at an upper end of the tibial platform support, a dovetail groove is formed in one side of the upper end of the tibial platform support, a dovetail protrusion is arranged on the tibial gasket at a position corresponding to the dovetail groove, a square protrusion is arranged at one end, opposite to the dovetail groove, of the tibial platform support, a square groove is arranged on the tibial gasket at a position corresponding to the square protrusion, a rectangular hole is formed in the square protrusion, an oblong hole is formed in the square groove at a position corresponding to the rectangular hole, and an insertion piece is arranged in the oblong hole and the oblong hole. The knee joint prosthesis greatly enhances connection strength between the tibial platform support and the tibial gasket, reduces fretting between the tibial platform support and the tibial gasket, reduces generation of tibial gasket debris, and reduces occurrence of osteolysis of a patient.

Owner:天衍医疗器材有限公司

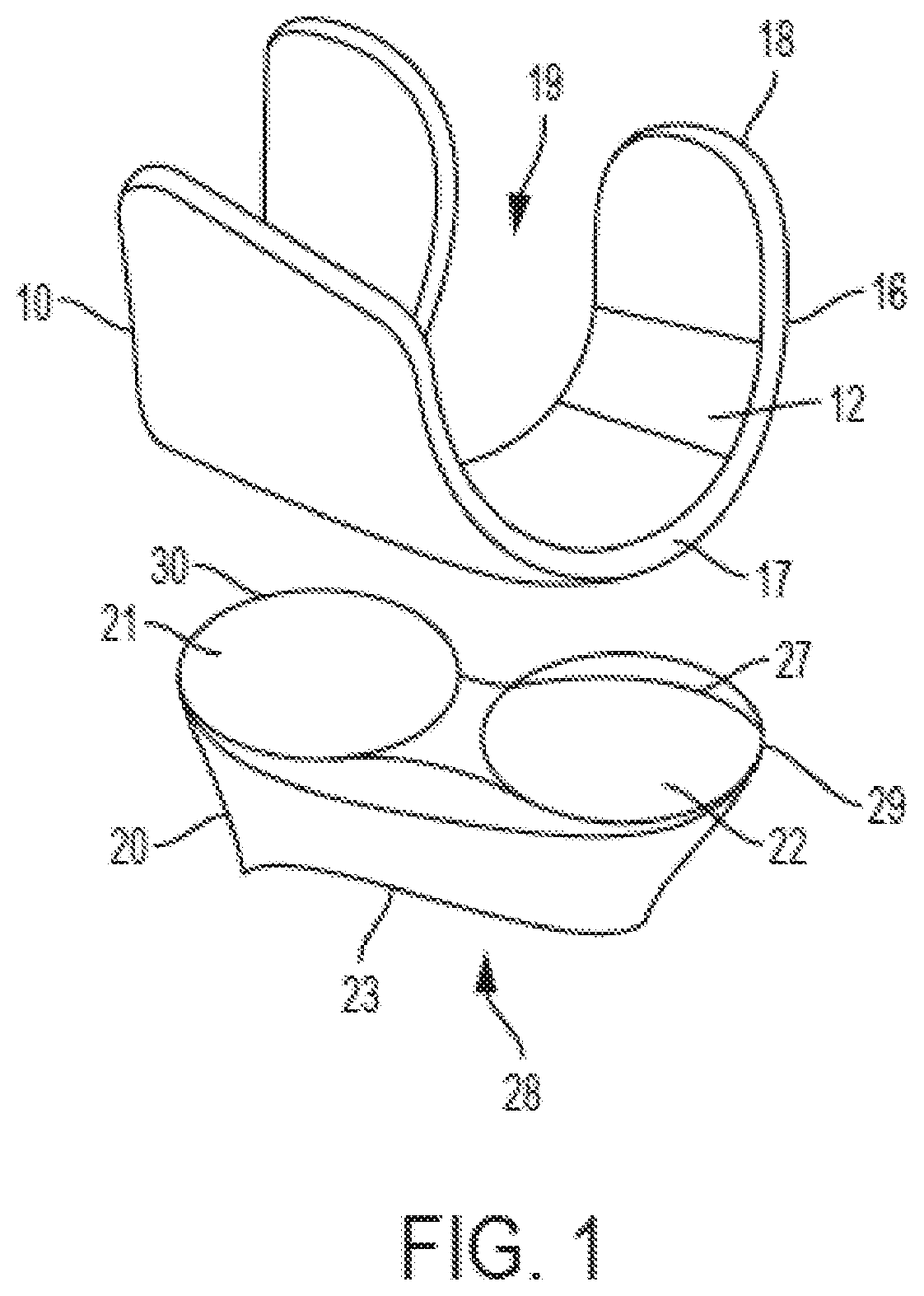

Lateral and medial pivoting knee prosthesis

PendingUS20200085583A1Improve efficiencyEasy to moveJoint implantsKnee jointsArthritisKnee joint movement

The present invention comprises an implantable knee prosthesis for the arthritic, aging, ligament-deficient knee having a femoral component, a tibial component and patella component forming three interactive knee compartments mainly the lateral, medial, and femoral patellar compartments articulating together with a variable axial pivot type of knee motion. This novel design accomplishes this motion pattern with four femoral component radii coacting with four reciprocal proximal tibial surface recesses. This occurs in a laterally congruent axial pivot fashion during the first half of knee flexion creating efficient external femoral rotation to align the femoral-patellar groove with the patella / quadriceps muscle complex.

Owner:HODGE WILLIAM ANDREW

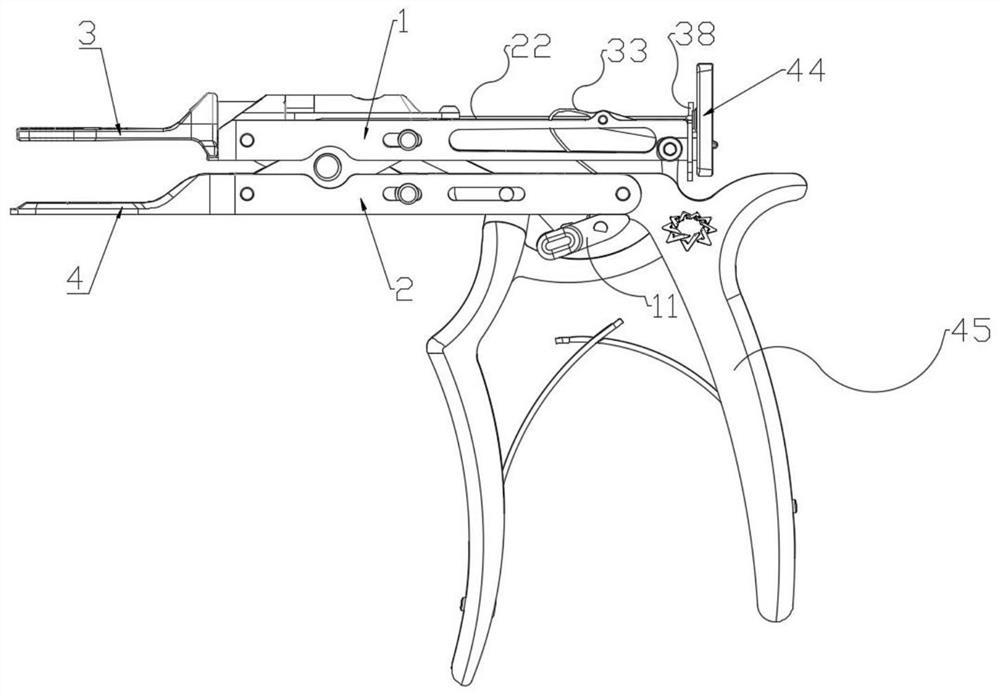

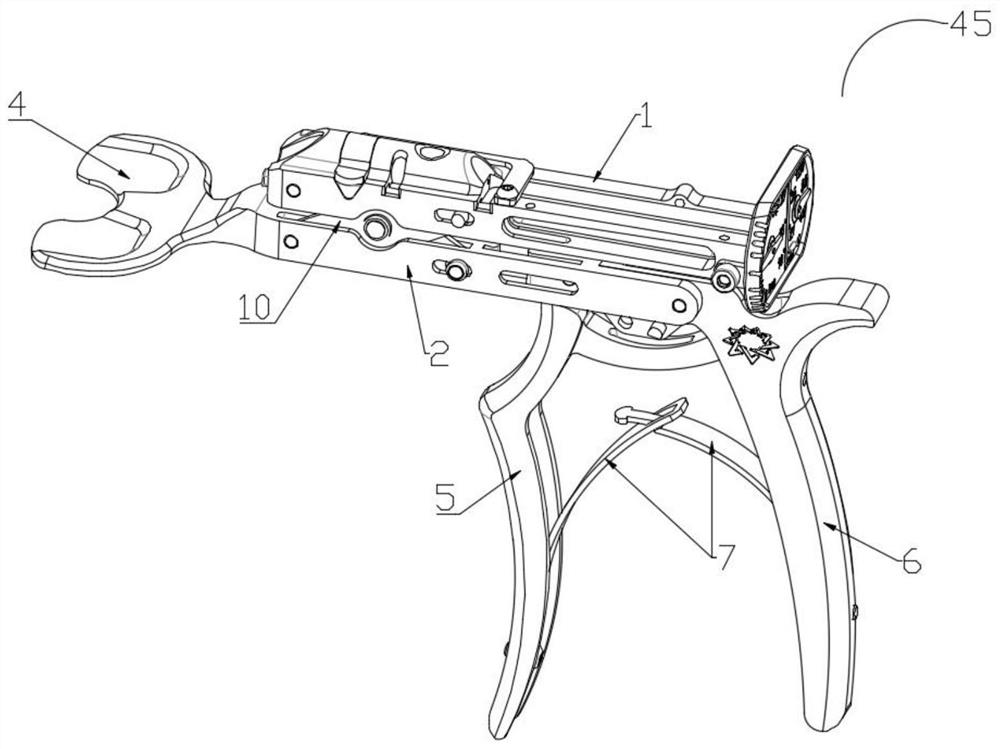

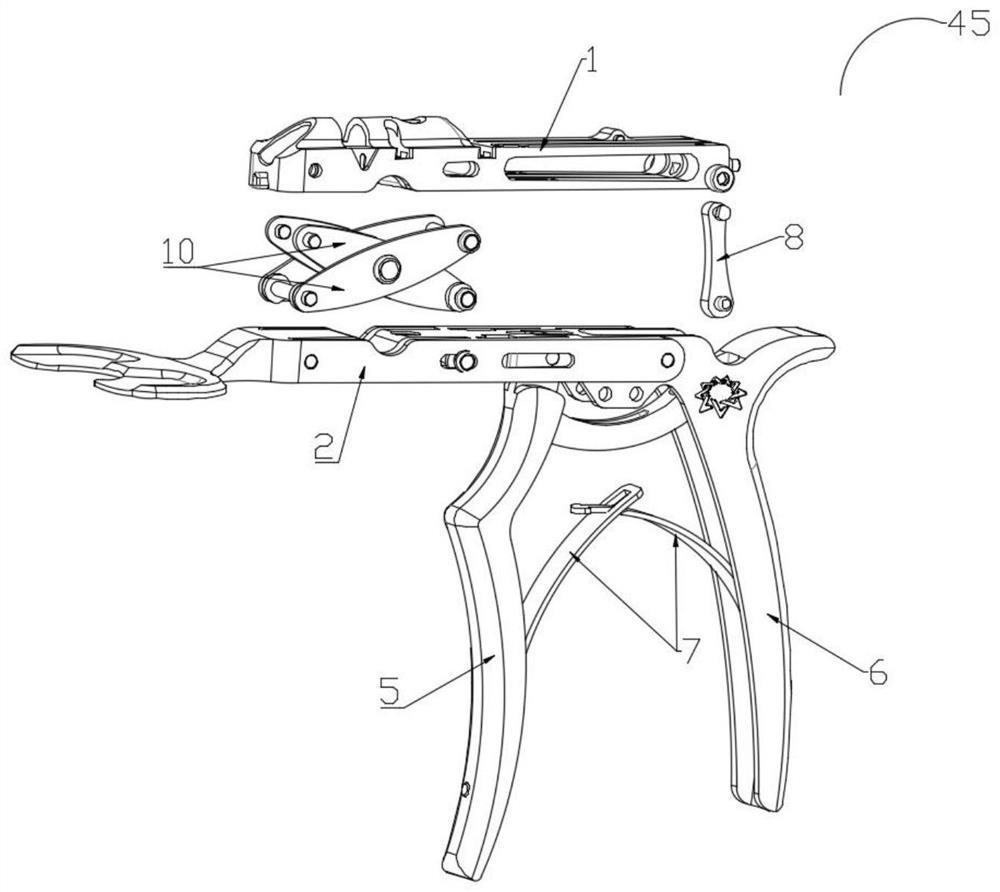

Gap balance measurer

ActiveCN113440317AEnsure balanceAvoid misjudgmentJoint implantsKnee arthrodesis prosthesisFemur osteotomy

The invention discloses a gap balance measurer, which comprises a femur spreading plate and a tibia spreading plate, wherein a femur osteotomy reference plate is arranged at one end of the femur spreading plate; a tibia osteotomy reference plate is arranged at one end of the tibia spreading plate; an indication surface plate is arranged at the end, which is far away from the femur osteotomy reference plate, of the femur spreading plate; a gap between the femur spreading plate and the tibia spreading plate can be adjusted through a gap adjusting mechanism; a locking mechanism is arranged on one side, which is far away from the femur osteotomy reference plate, of the tibia spreading plate; a balance angle indicating mechanism is arranged between the femur osteotomy reference plate and the indication surface plate; a gap indicating mechanism is arranged on one side of the indication surface plate; and a tension indication mechanism is also arranged on one side of the indication surface plate. According to the gap balance measurer disclosed by the invention, whether the balance of soft tissues at the knee joint is met in an osteotomy process or not can be verified in a plurality of steps in a knee joint operation process, the balance state of the soft tissues is quantified, and a doctor is assisted in finding and placing the most accurate knee joint prosthesis.

Owner:天衍医疗器材有限公司

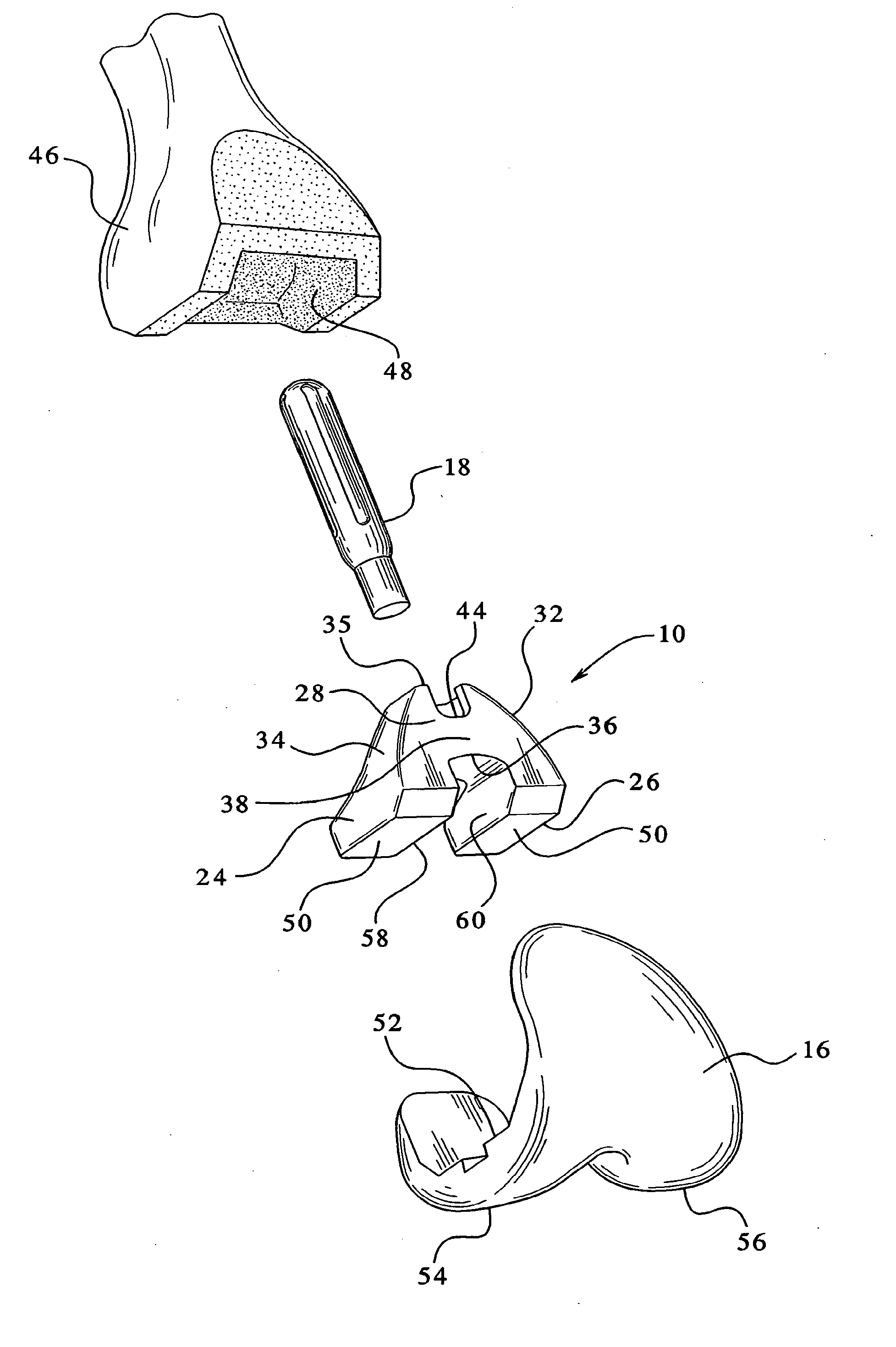

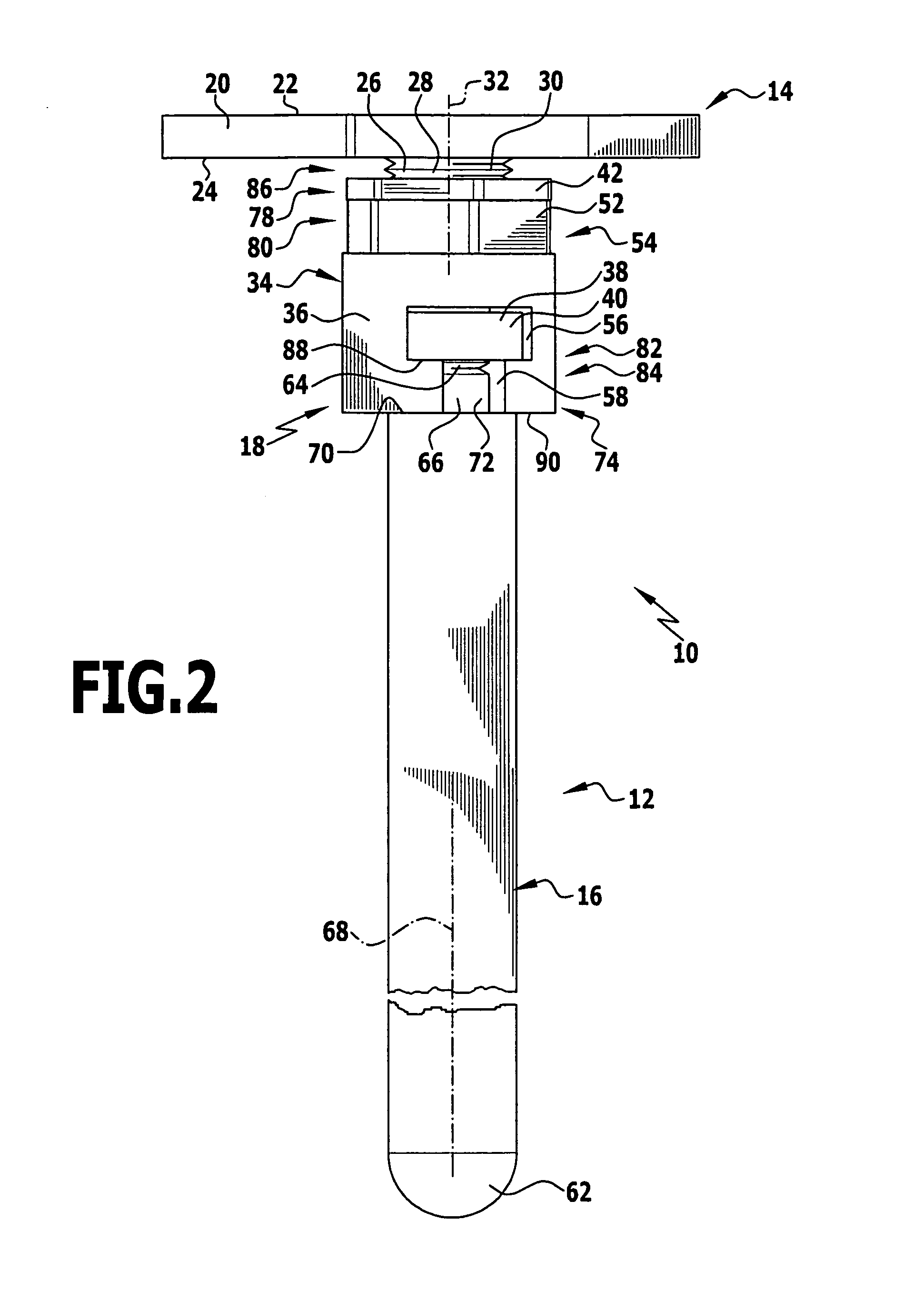

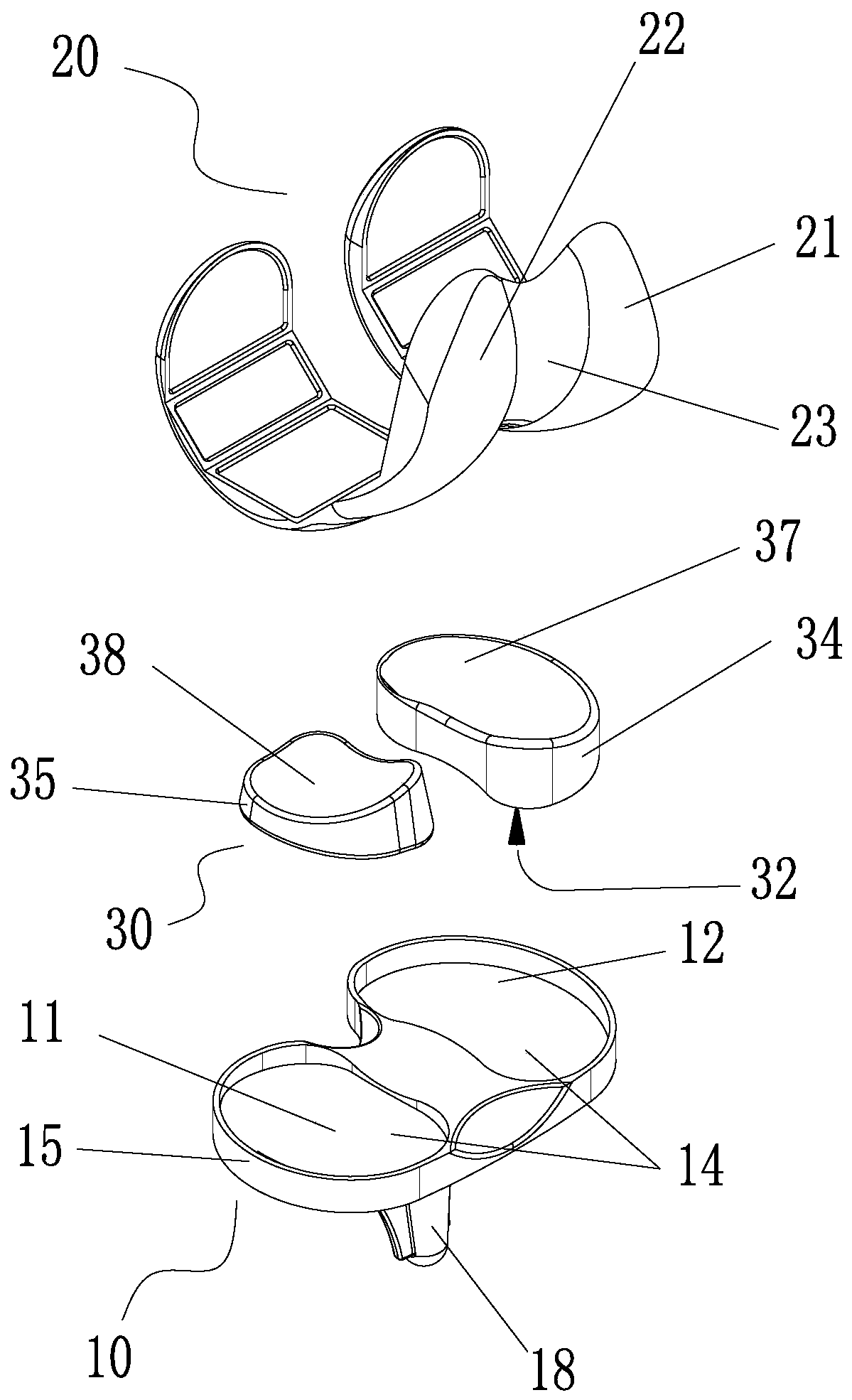

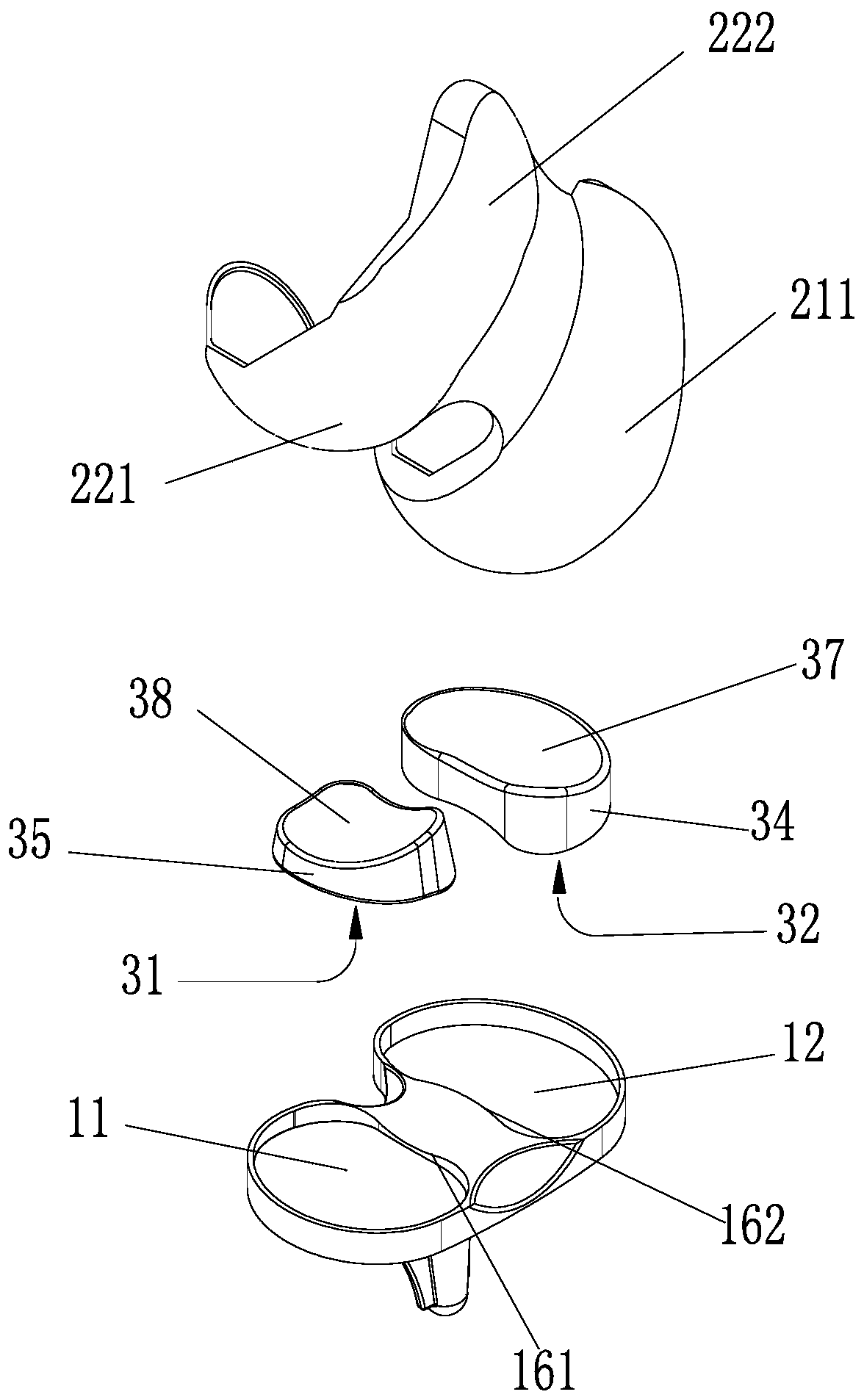

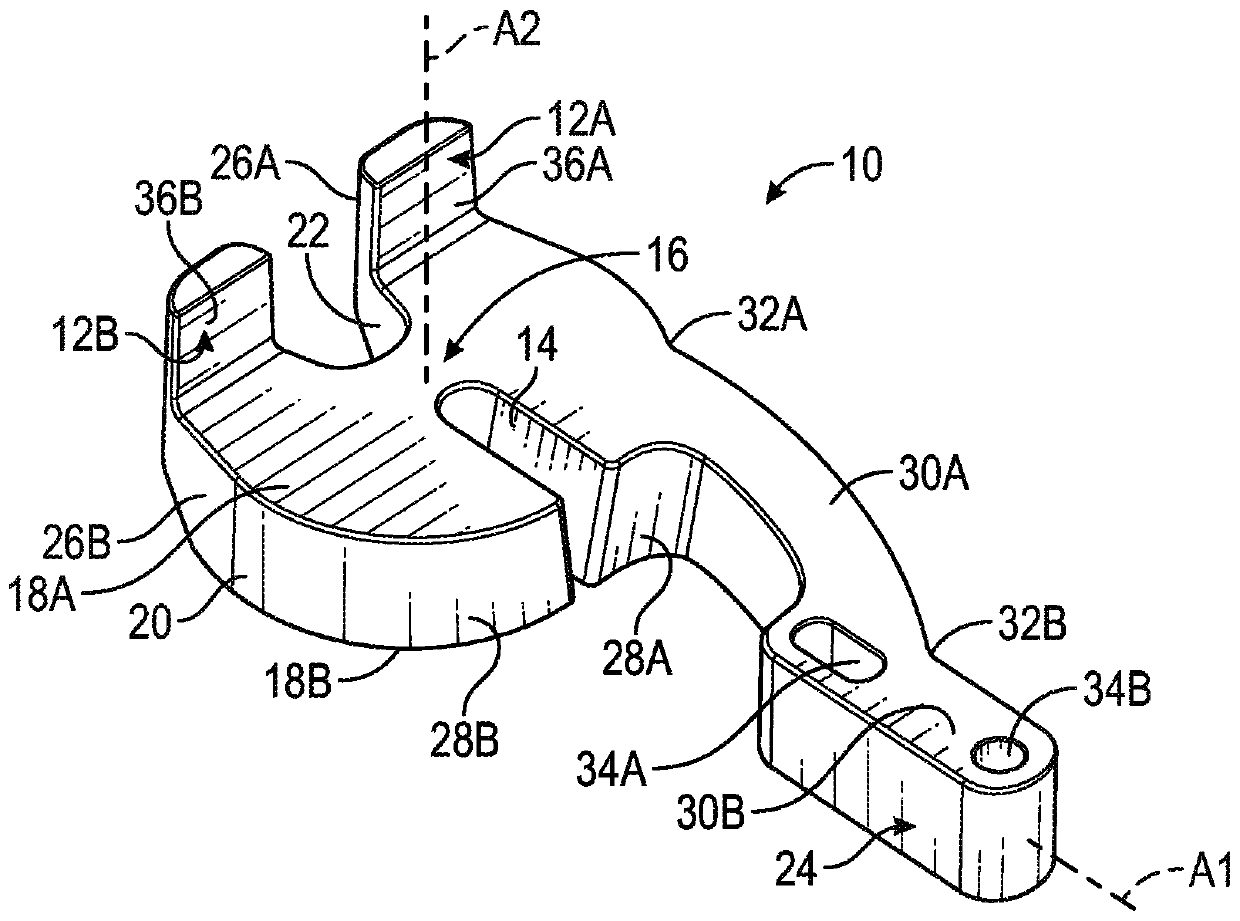

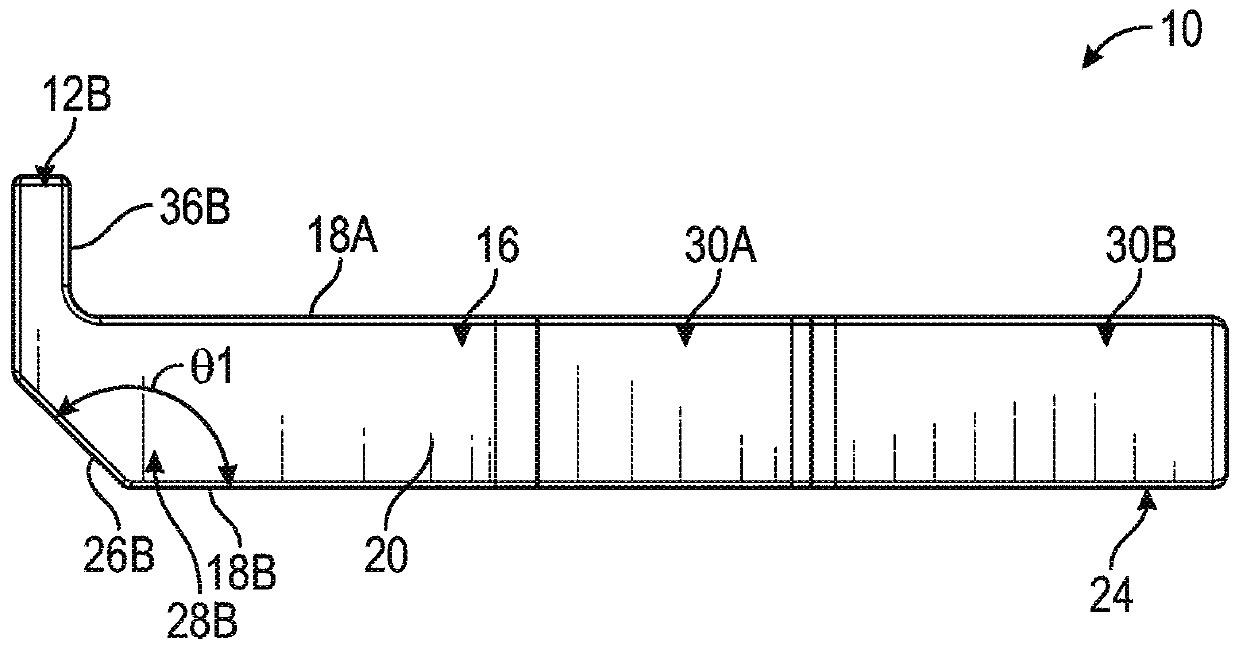

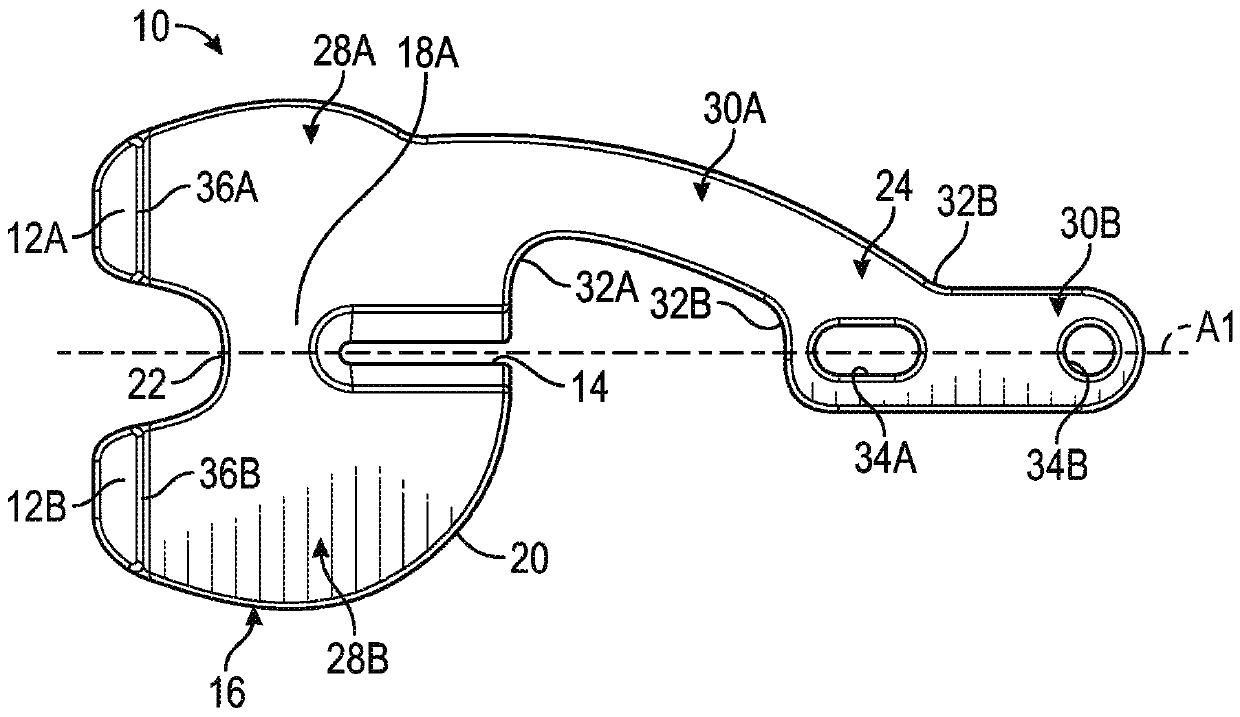

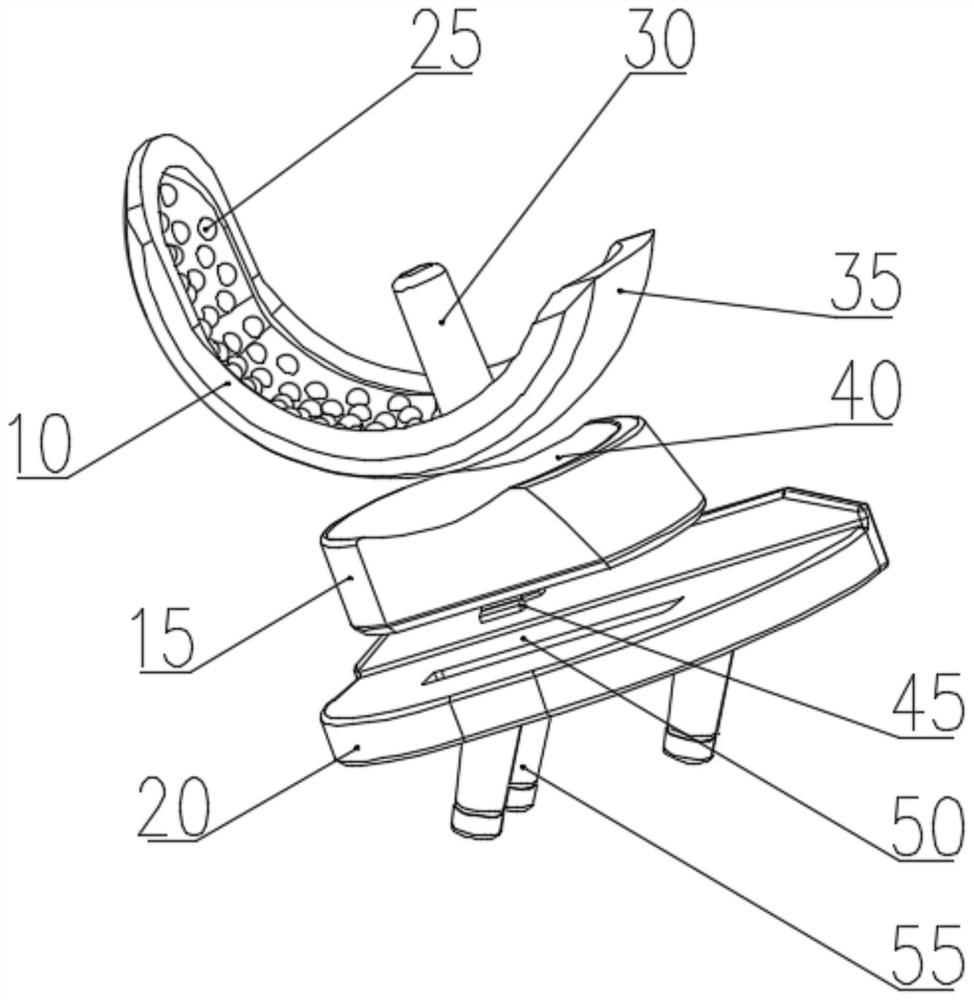

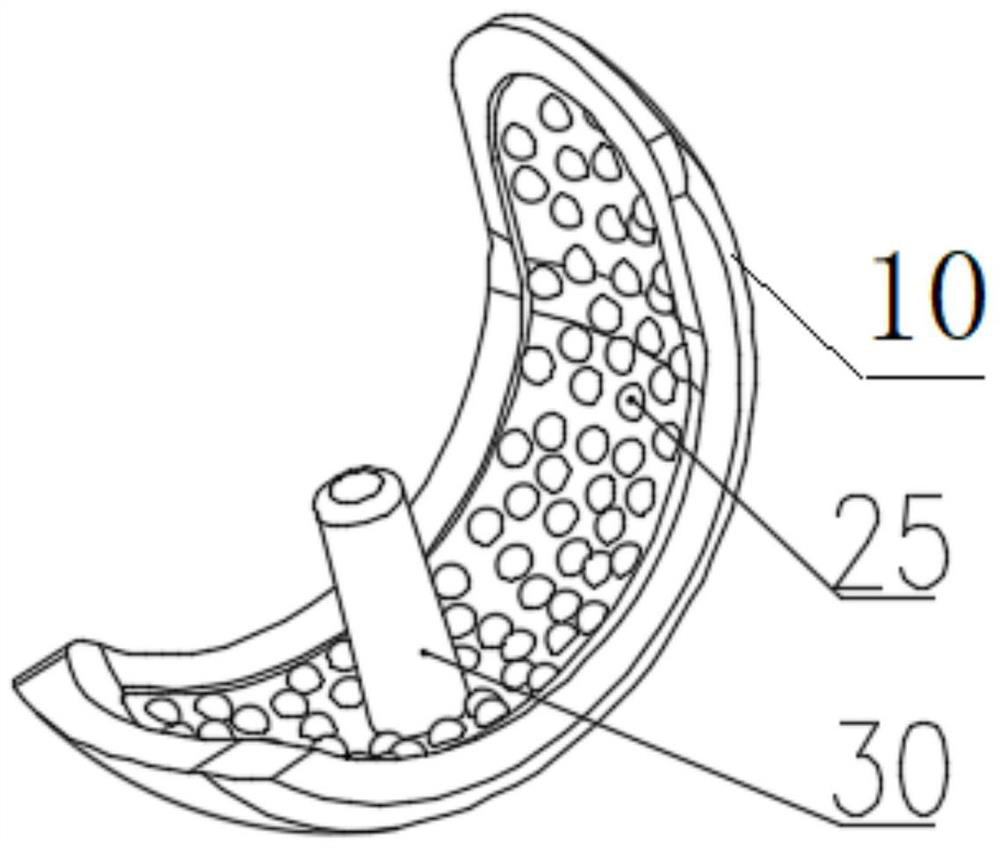

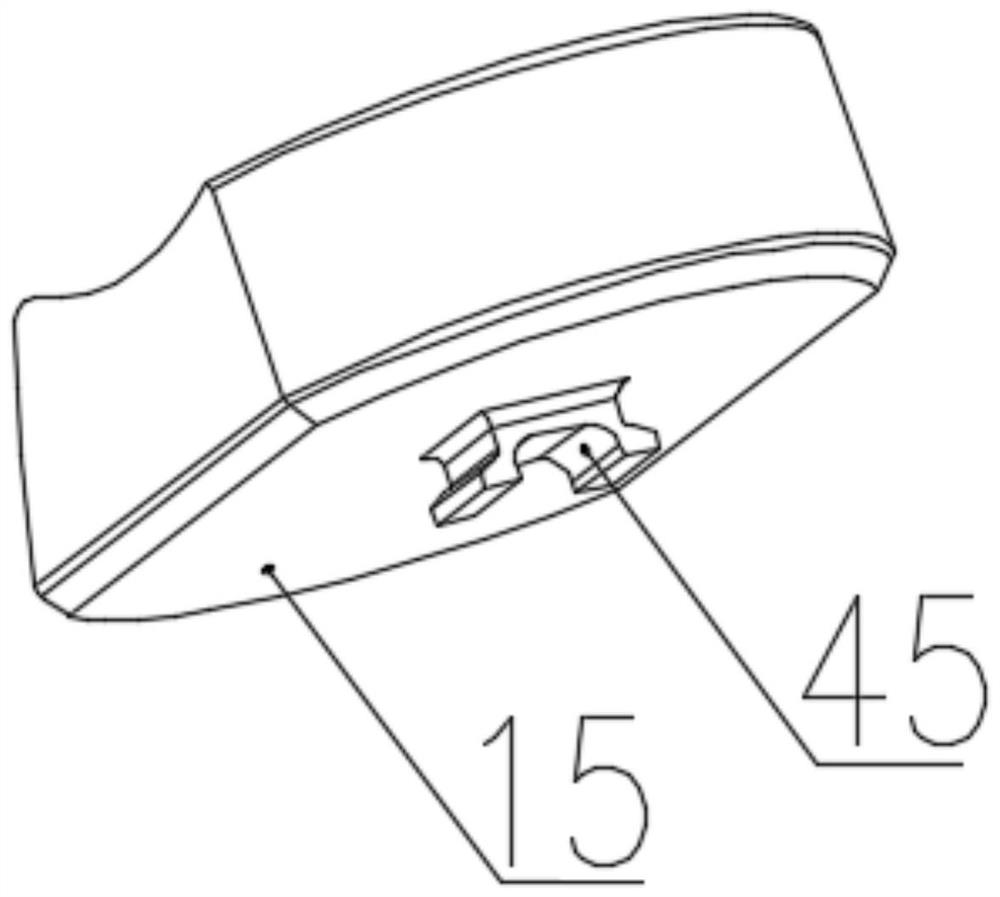

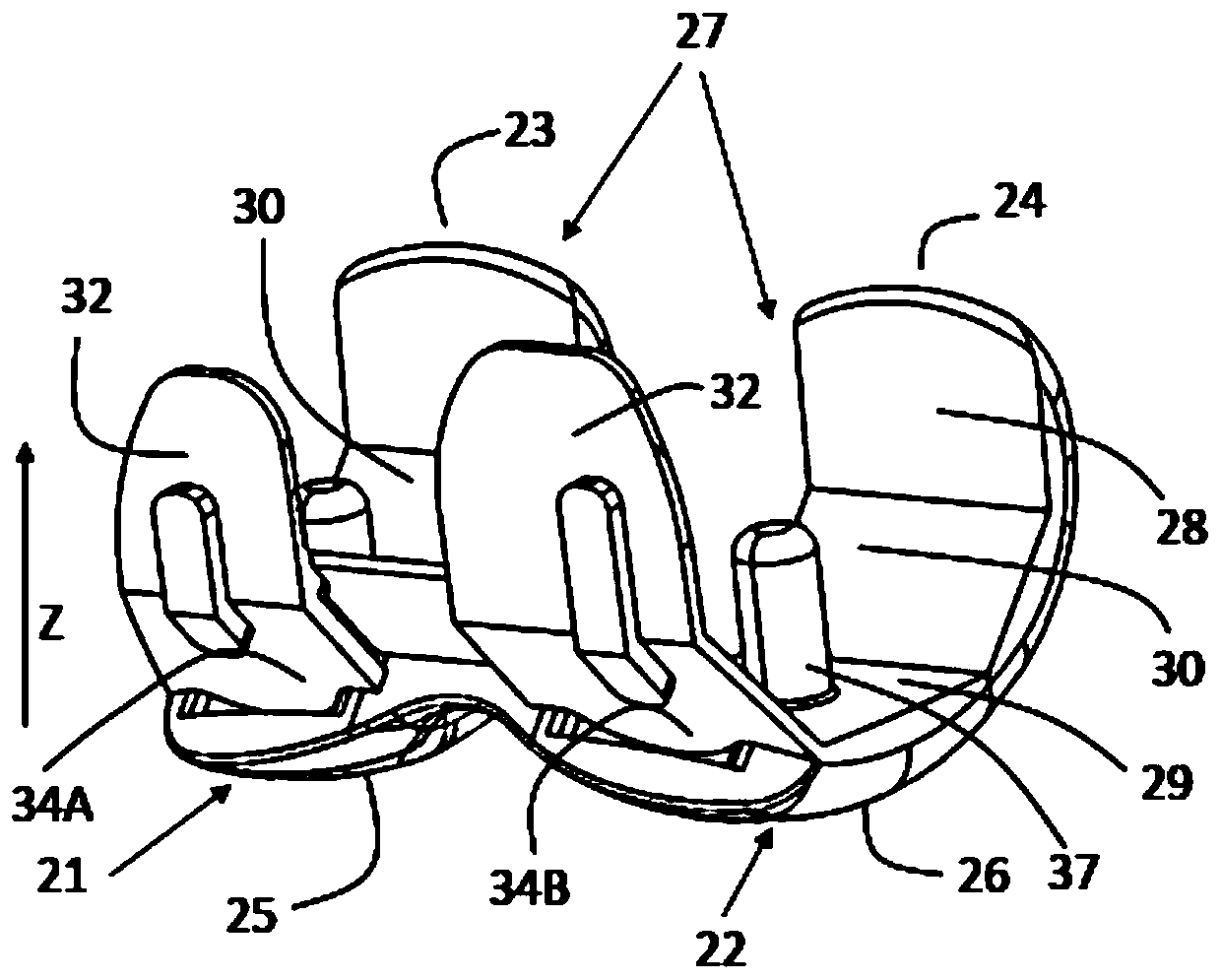

Prosthetic knee implant systems and methods with linked tibial rotation

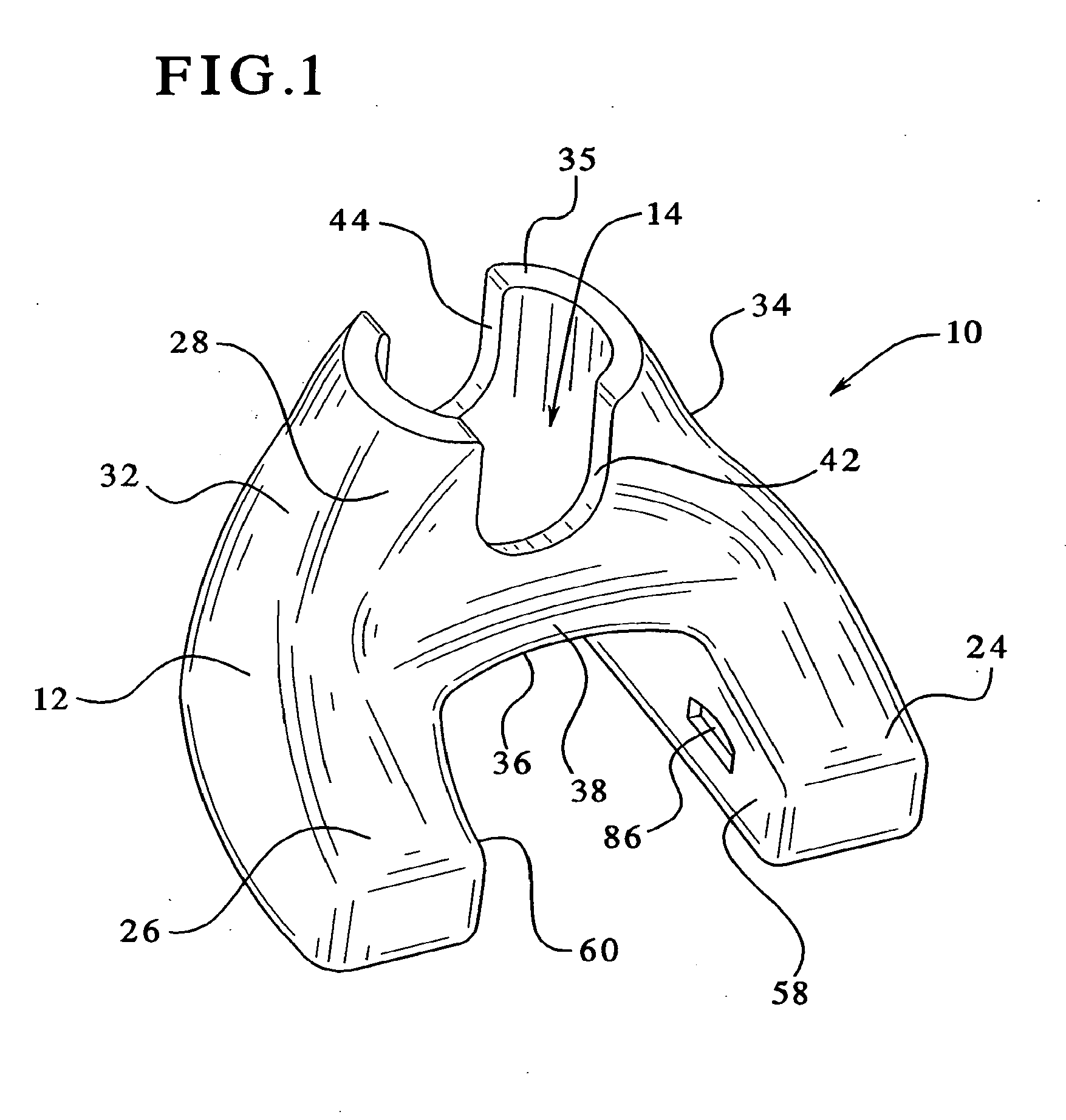

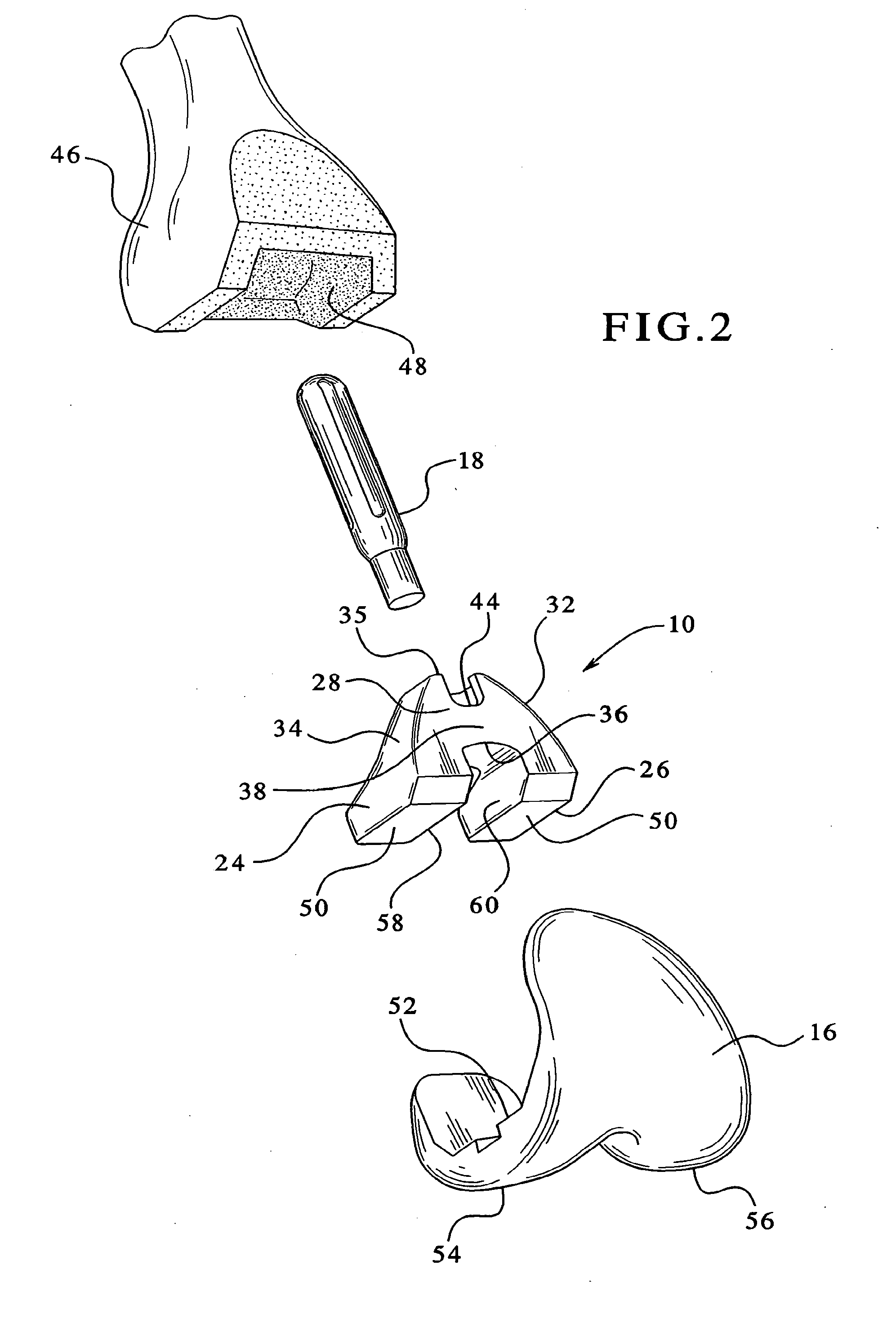

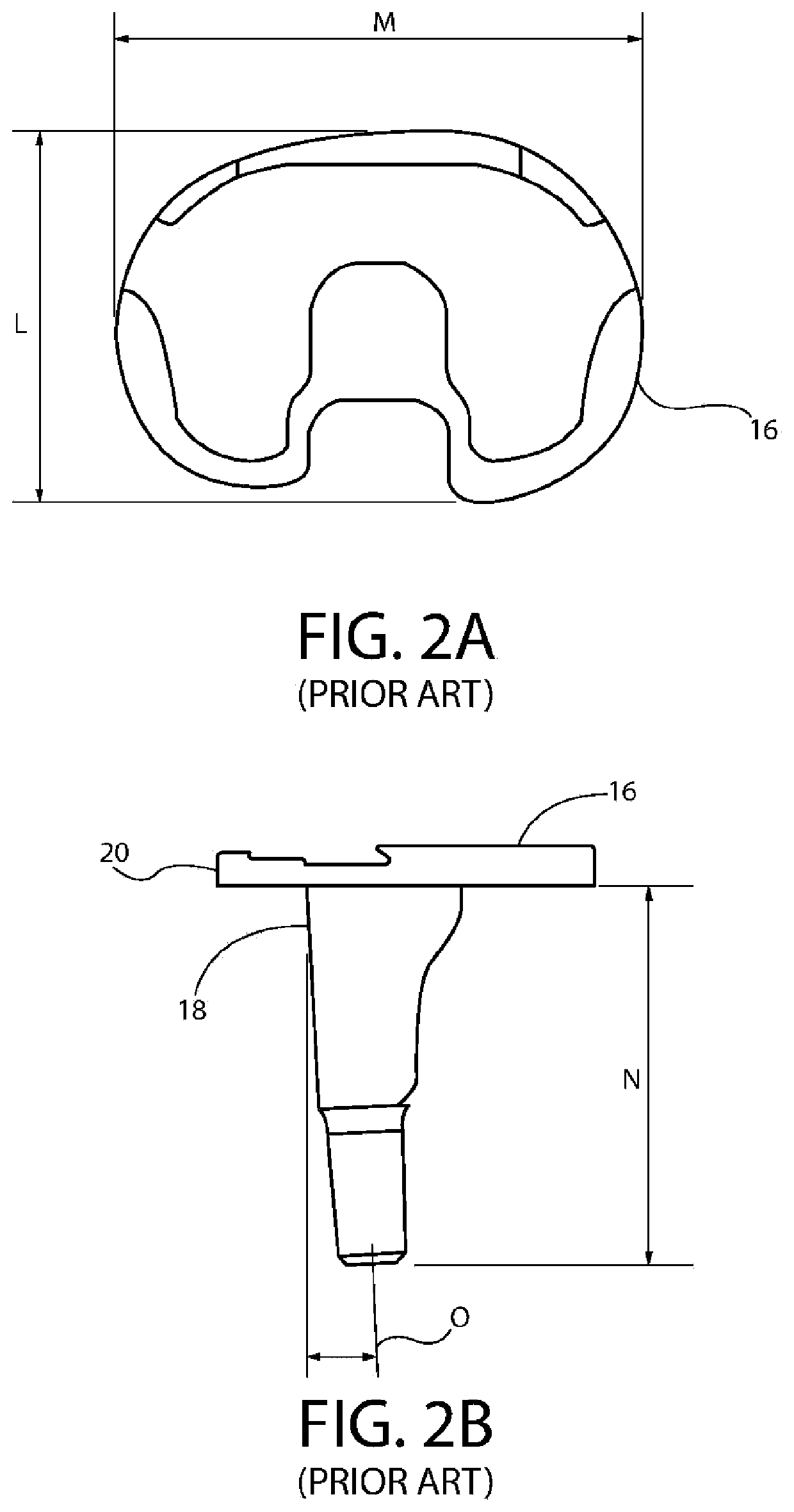

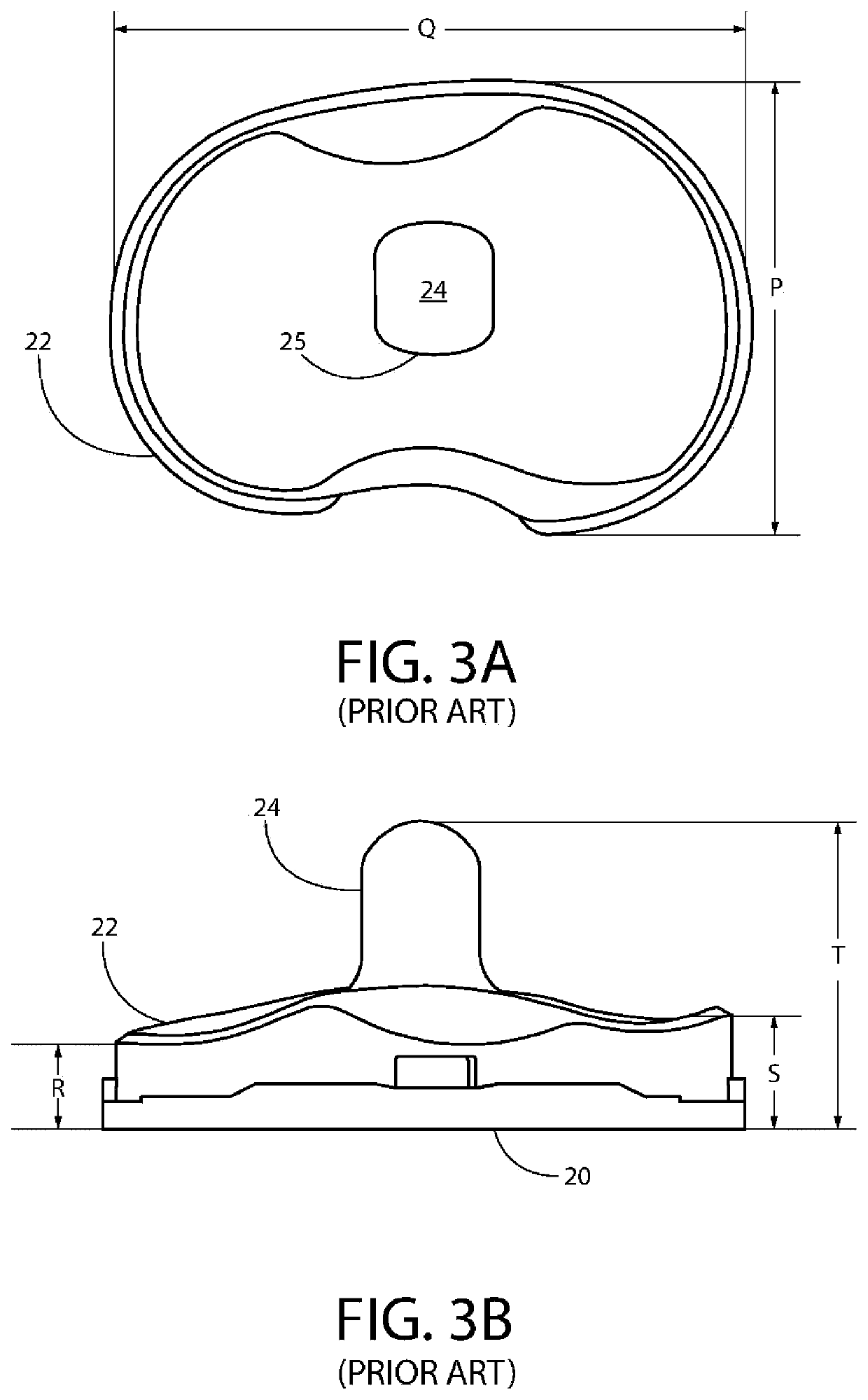

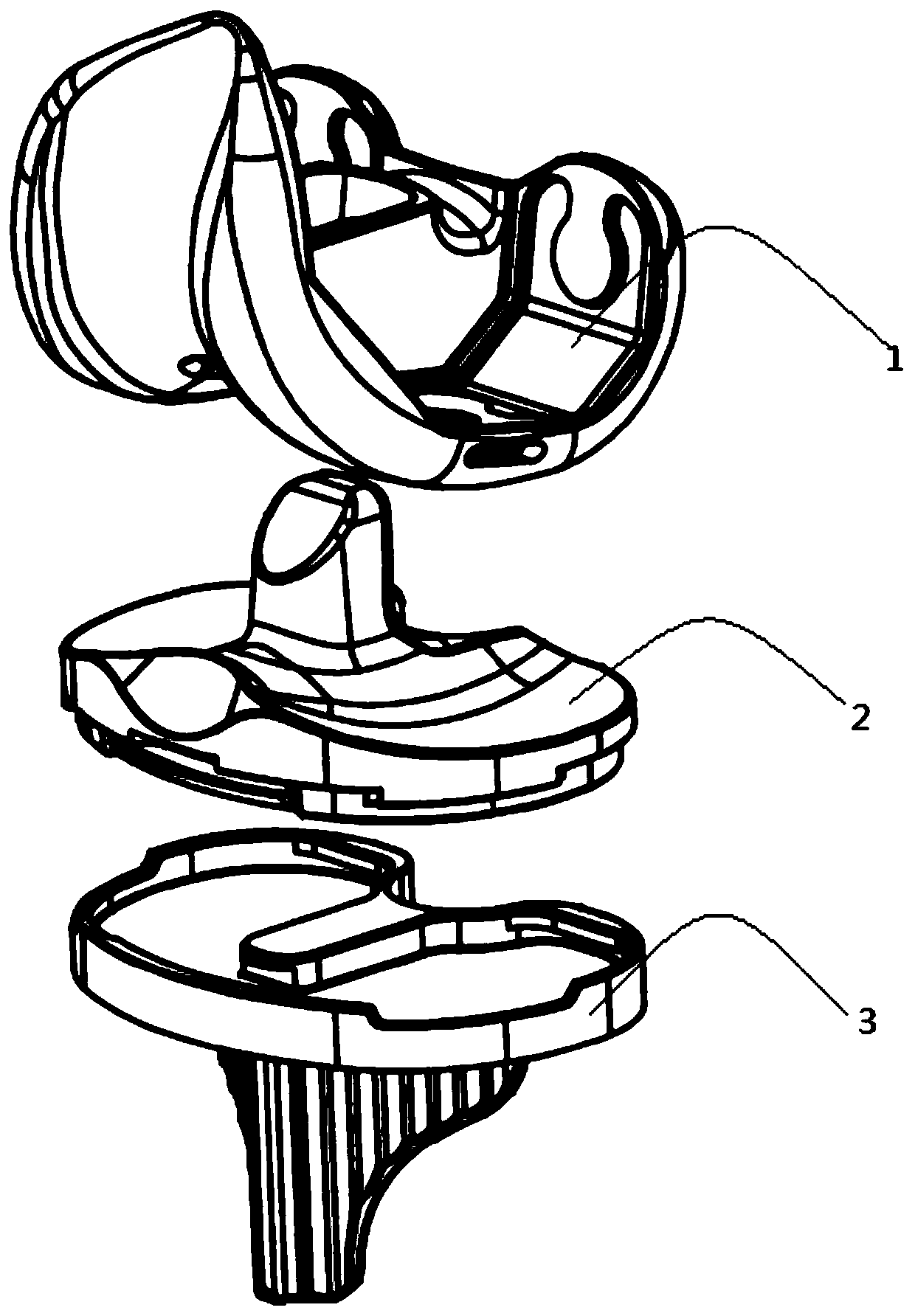

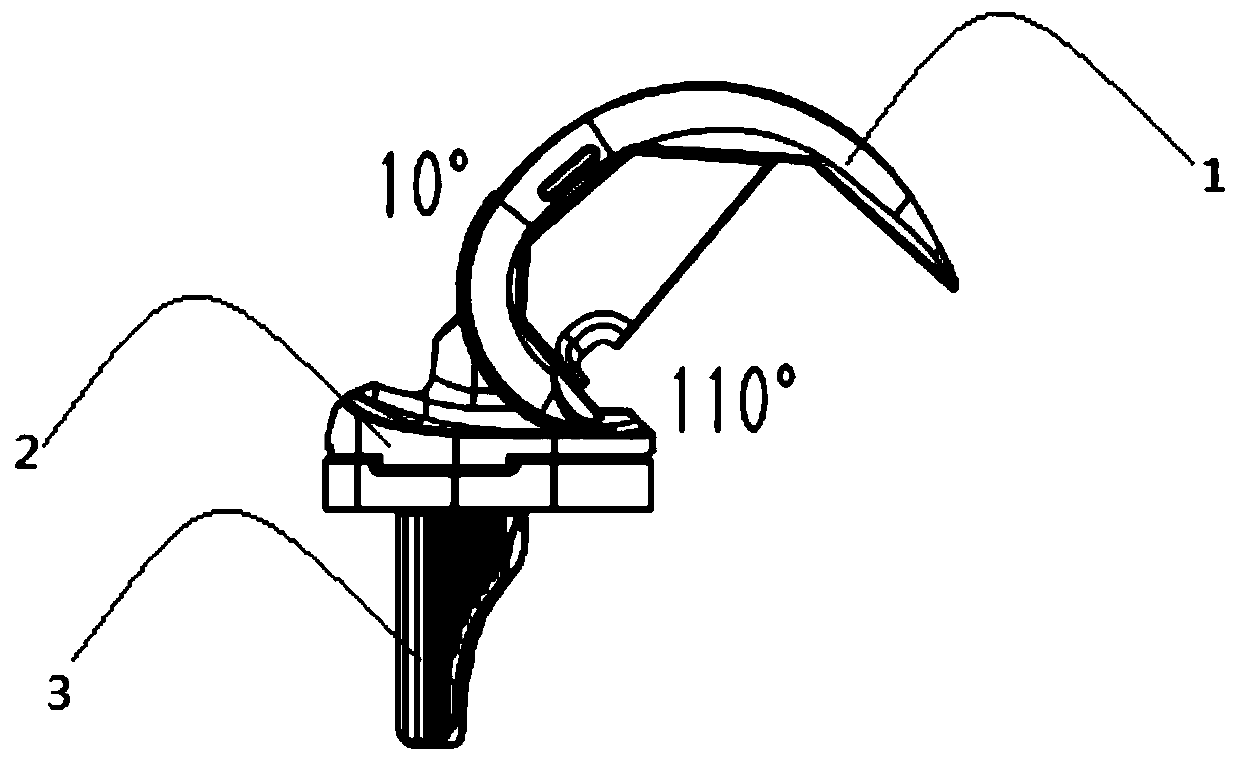

A tibial spacer paddle (10) comprises a spacer block (16) comprising opposing bearing surfaces (18A, 18B), an alignment slot (14) extending into the spacer block; and a handle extending from the spacer block. The spacer block can include feet (12A, 12B) for passively engaging the femur or pegs (112A, 112B) for actively engaging a femoral component so that the spacer block is linked to the femur while the tibia rotates. A tibial spacer system comprises a provisional component having an alignment tab (222) extending from a body and an alignment indicator located on the body, a femoral component(240) and a pin (264) extending from the femoral component. The pin can engage the alignment tab so that the provisional component is linked to the femur while the tibia rotates. In addition to or alternatively to the alignment tab and pin, the provisional component can include a tibial plate (30) that can be rotationally connected to the provisional component.

Owner:ZIMMER INC

Unicondylar knee joint prosthesis

InactiveCN112155800AGood articular fitLow sliding stabilityJoint implantsKnee jointsKnee arthrodesis prosthesisPhysical medicine and rehabilitation

The invention provides a unicondylar knee joint prosthesis. The unicondylar knee joint prosthesis comprises a femoral condyle, a tibia pad and a tibia support, wherein the femoral condyle is arrangedon the tibia pad, and the femoral condyle can rotate relative to the tibia pad; the tibia pad is connected with the tibia support through a sliding device, and can slide relative to the tibia support;and the tibia support plays a role in supporting the tibia pad, and besides, the problem that the tibia pad is easy to dislocate when sliding on the tibia support is solved. Through the sliding device, the tibia pad slides on the tibia support and cannot be separated from the tibia support, the dislocation phenomenon cannot occur, and the tibia pad is good in stability and small in abrasion loss.

Owner:BEIJING LIDAKANG TECH

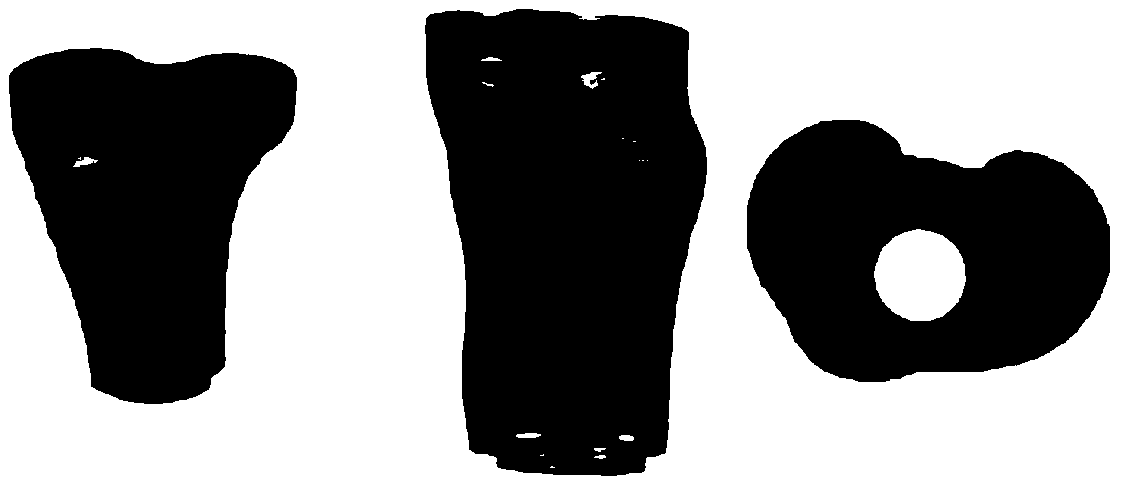

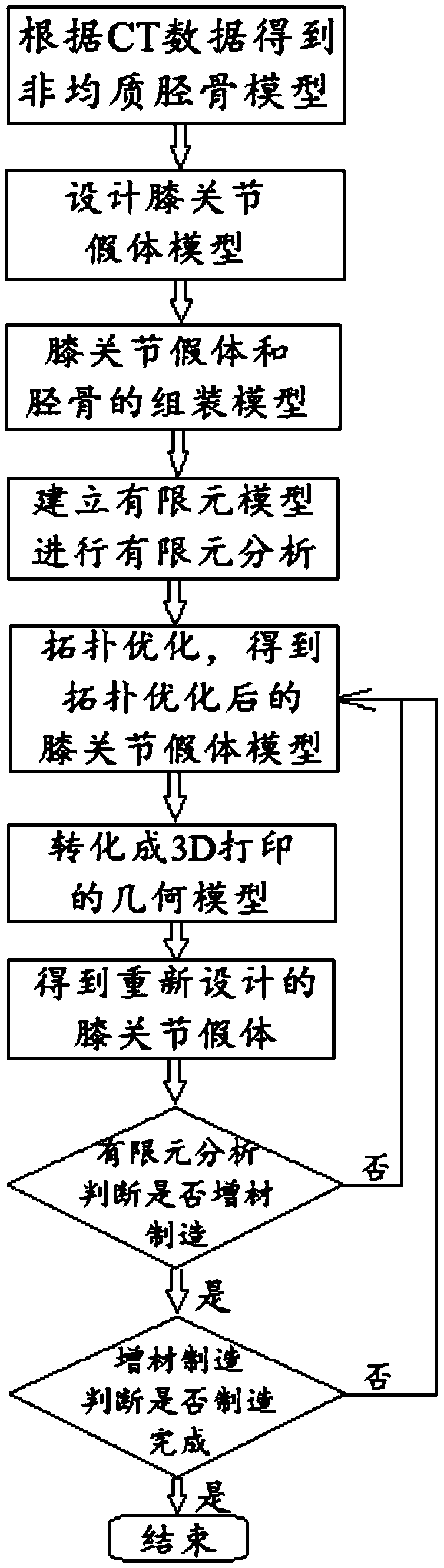

Manufacturing method of individualized customized knee joint bionic prosthesis based on 3D printing

ActiveCN110833472AUniform stress distributionGood biomechanical propertiesJoint implantsTomographyElement analysisKnee Joint

The invention discloses a manufacturing method of an individualized customized knee joint topological optimization bionic prosthesis based on 3D printing, which relates to the technical field of medical artificial joints. The problem that the manufacturing method is urgently needed to reduce prosthesis looseness or fracture around the prosthesis is solved, and the method comprises the steps: establishing and assembling a tibia model and a knee joint prosthesis model, and performing finite element analysis and topological optimization; carrying out fairing; designing a specific structure of themodel, optimally reserving an internal region by adopting a solid structure, optimally reserving an outer layer region and optimally removing the region by adopting a grid structure, and forming a gradient between the regions; introducing back an assembly state of a tibia model, performing finite element analysis, comparing with a first finite element analysis result, judging whether 3D manufacturing and application are performed or not, and performing topological optimization again if the 3D manufacturing and application cannot be performed. The prosthesis prepared by the invention reduces the problem of prosthesis looseness or prosthesis peripheral fracture, provides space for ligament stop point implantation and internal bone grafting, is light in weight, and is beneficial to bone tissue ingrowth.

Owner:JILIN UNIV

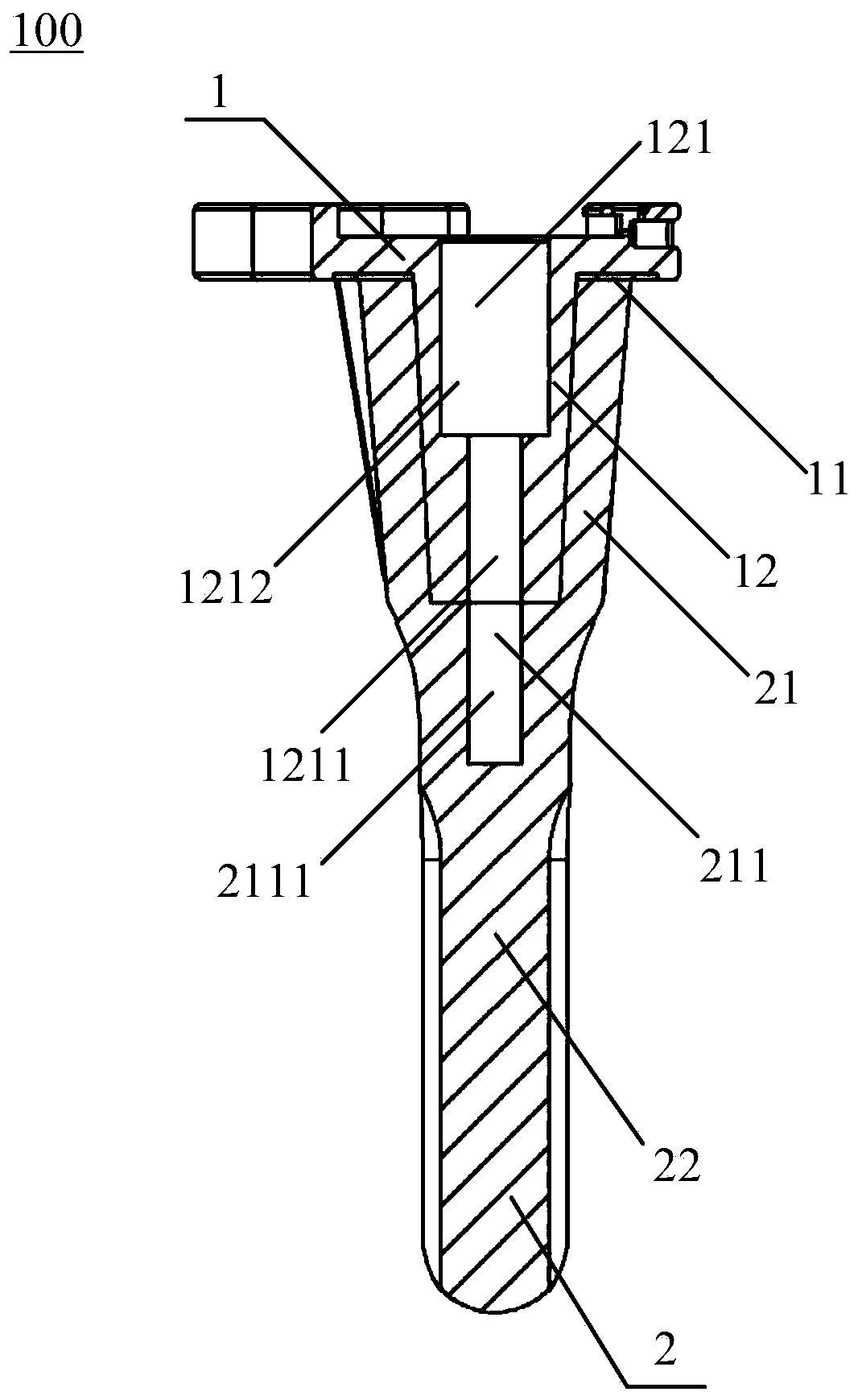

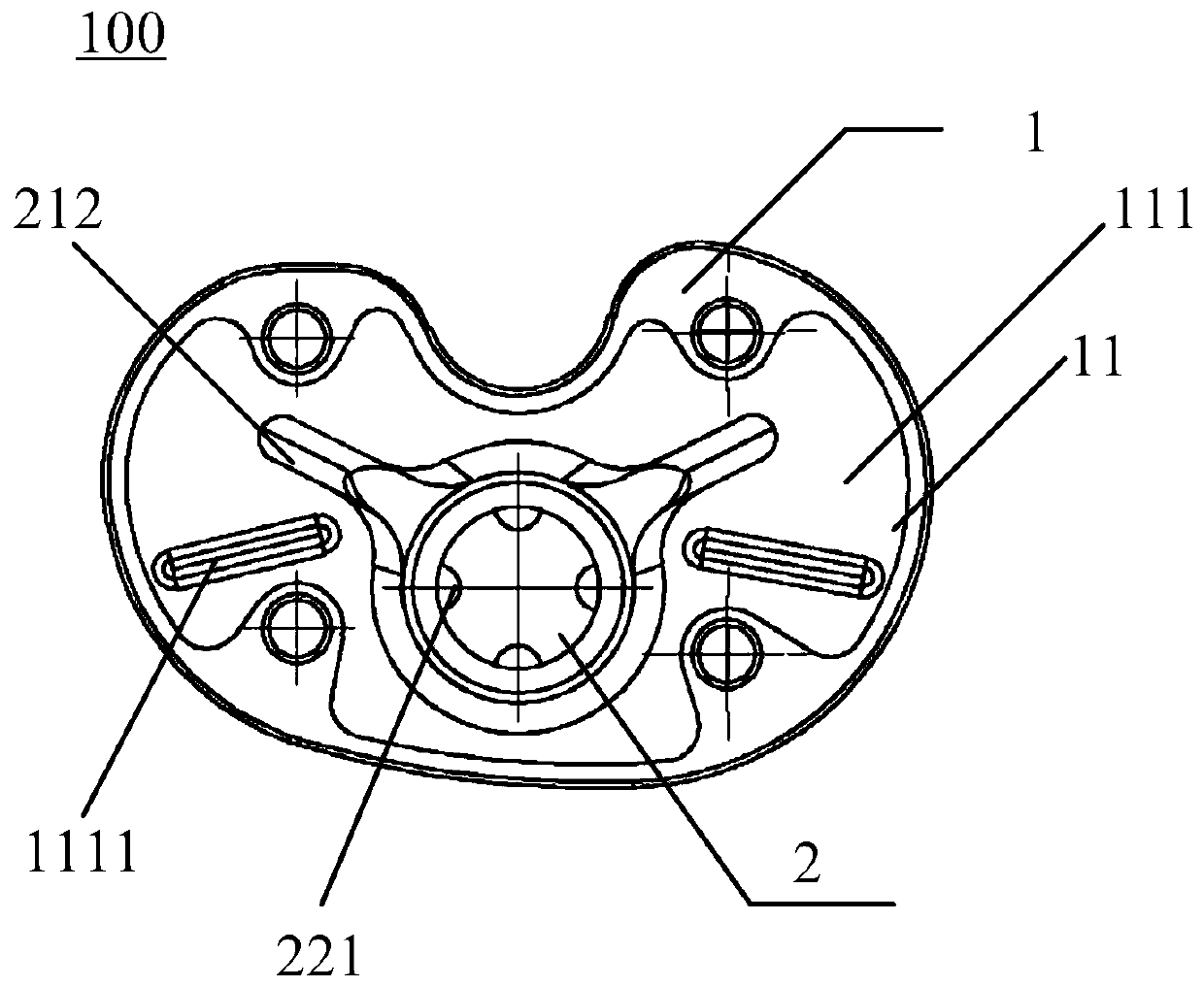

Tibial plateau assembly and knee joint prosthesis using tibial plateau assembly

PendingCN110786970AIncrease the lengthReduced risk of looseningJoint implantsKnee jointsKnee arthrodesis prosthesisAnatomy

The invention belongs to the field of medical apparatus, and discloses a tibial plateau assembly and a knee joint prosthesis using the tibial plateau assembly. The tibial plateau assembly includes a tibial plateau part and an extension part which is detachably connected with the tibial plateau part, wherein a connection column is formed on a first plane, which is used for being connected with a resected surface of a tibia, of the tibial plateau part and is perpendicular to the first plane; and the extension part includes a sleeving connection cylinder and an extension rod, wherein the sleevingconnection cylinder is used for being connected with the outer surface of the connection column in a sleeving mode, the extension rod is coaxially connected with the sleeving connection cylinder, andthe sleeving connection cylinder can rotate relative to the connection column and be fixed, so that rotation positions of the tibial plateau part relative to the extension part are adjusted and fixed. By adopting the tibial plateau assembly, loosening risks of a tibial plateau support can be effectively reduced, and meanwhile the universality of the tibial plateau support is enhanced.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

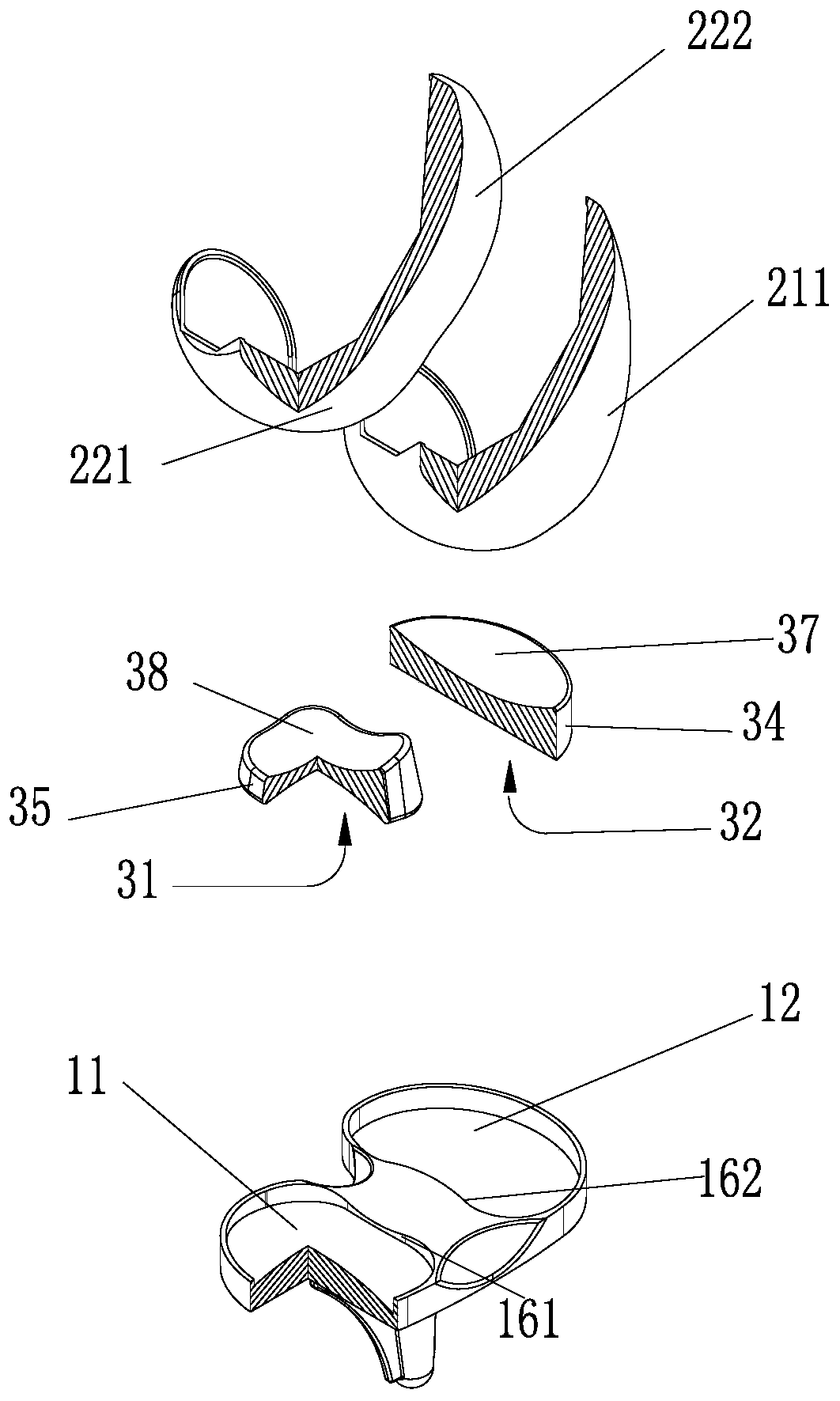

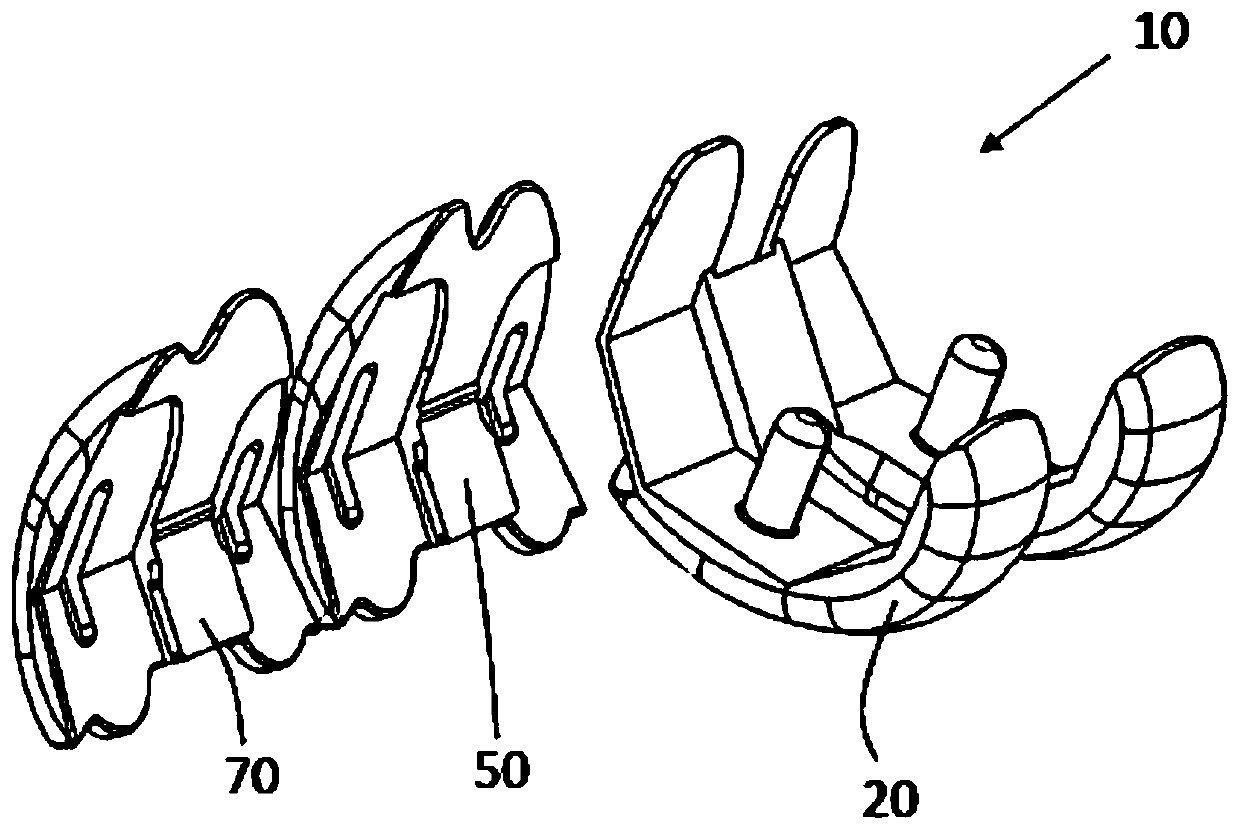

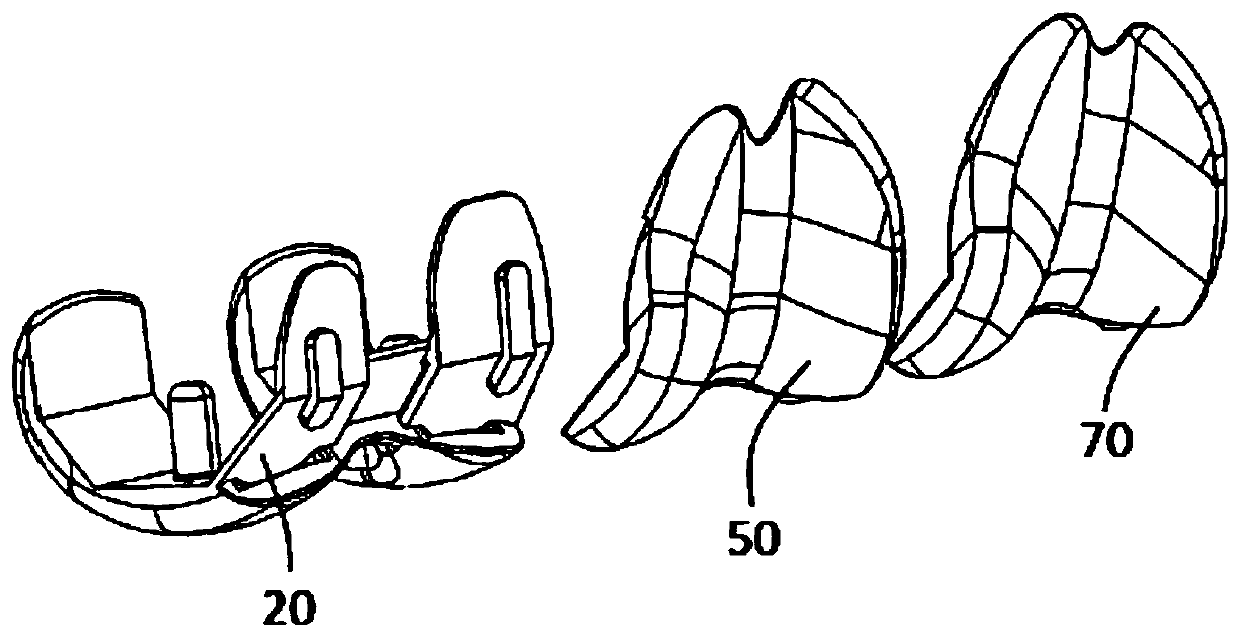

Modular knee prosthesis

The present invention relates to a modular knee prosthesis assembly kit (10) for replacement of resected articular surfaces of a distal femur of a first patient side. The kit (10) comprises (a) at least one bi-condylar component (20) sized and shaped to substantially replace resected posterior and distal condylar bone portions; and (b) at least a first trochlear groove component (50) and a secondtrochlear groove component (70), each sized and shaped to replace a resected trochlear groove bone portion. The first trochlear groove component (50) comprises a first patella articulation path defining a first trochlear groove direction angle. The second trochlear groove component (70) comprises a second patella articulation path defining a second trochlear groove direction angle. An assembly ofthe bi-condylar component (20) and one of the first and second trochlear groove components (50; 70) forms a substantially complete femoral knee prosthesis. The second trochlear groove direction angleis different from the first trochlear groove direction angle.

Owner:斯蒂芬埃格利

Total knee joint prostheses

InactiveCN111529138AReduce the probability of looseningIncrease contact areaJoint implantsFemurArticular surfacesKnee arthrodesis prosthesis

The invention provides a total knee joint prosthesis. The total knee joint prothesis comprises a femoral condyle prosthesis and a tibial pad prosthesis, and the femoral condyle prosthesis is installedon the tibial pad prosthesis; a patella groove is formed in an outer side of the femoral condyle prosthesis, and a femoral condyle articular surface is arranged at the bottom of the femoral condyle prosthesis; the depth of the patella groove extending downwards along the top of the outer side of the femoral condyle prosthesis is gradually increased; the femoral condyle prosthesis comprises a series of prostheses suitable for different crowds, and the femoral condyle articular surfaces of the series of prostheses are different in radius and center distance; a tibial pad prosthesis articular surface is arranged on the tibial pad prosthesis, the tibial pad prosthesis comprises a series of prostheses suitable for different crowds, and the tibial pad prosthesis articular surface are differentin radius and center distance; the contact area between the tibial pad prosthesis and the femoral condyle prosthesis is large, abrasion of pressure and polyethylene is reduced, and stability is high;the radiuses and the center distances of adjacent series of the femoral condyle prosthesis and the tibial pad prosthesis are similar, so that the shapes of articular surfaces of adjacent models are similar, and the probability of abrasion and looseness is reduced.

Owner:BEIJING LIDAKANG TECH

Cruciate replacing artificial knee

ActiveUS20200281732A1Joint implantsLigamentsKnee arthrodesis prosthesisPhysical medicine and rehabilitation

A knee joint prosthesis is capable of moving between an extended position and a flexion position. The knee joint prosthesis includes a femoral component that is configured to be mounted to a femur, a tibial component that is configured to be mounted to a tibia, a post fixedly connected to one of the femoral component and the tibial component, and a cam recess defined on the other of the femoral component and the tibial component that is configured to be engaged by the post in either the extended position or the flexion position of the knee joint prosthesis. The knee joint prosthesis may also include an artificial ligament that extends between the femoral component and the tibial component. The post and the ligament mimic one of the ACL and PCL.

Owner:GARINO JONATHAN P

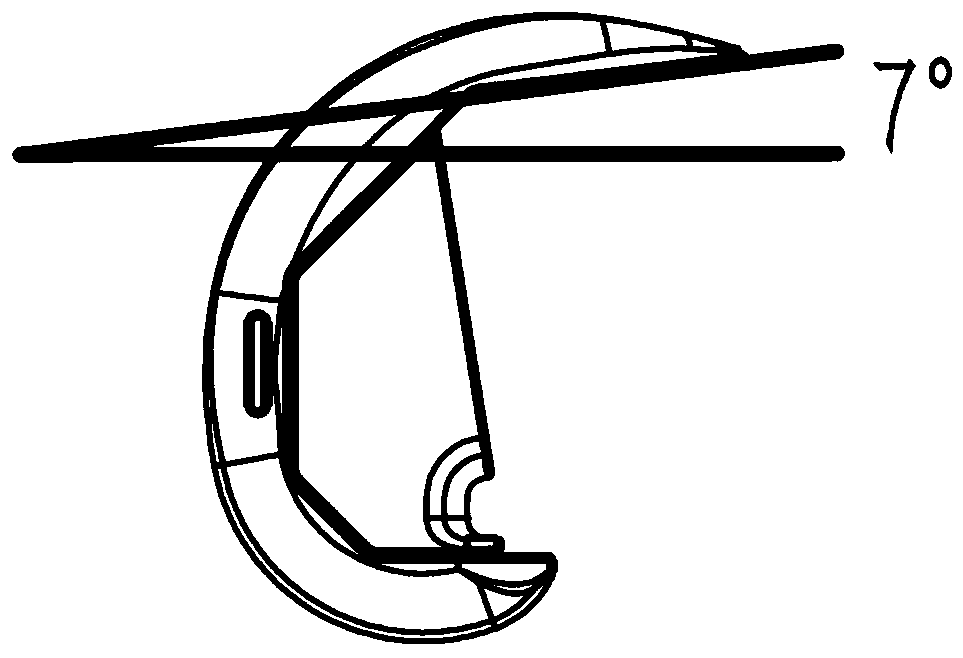

Knee-joint prosthesis

PendingCN110664519ASimple structureEasy to installJoint implantsKnee jointsKnee arthrodesis prosthesisFemoral bone

The invention belongs to the technical field of artificial bones, and particularly relates to a knee-joint prosthesis. The knee-joint prosthesis comprises a femoral condyle, a tibial plateau cushion and a tibial plateau support, and the upward angle of a front wing of the femoral condyle is seven degrees. According to the knee-joint prosthesis, when the upward angle of the front wing of the femoral condyle is implanted, a small thighbone can be elastically selected, implanting is more convenient and faster, and meanwhile, the situation that the implanted knee-joint prosthesis is embedded intoa supracondylar antero-lateral cortical bone is avoided; the knee-joint prosthesis is simple in structure, convenient to mount and good in stability, perfect fit between the plateau cushion and the plateau support and convenient mounting of the plateau cushion during an operation are ensured, the matching degree of covering of the plateau support and the bone surface of a cut tibia is further ensured, thus the implanted prosthesis is stable and firm, and abrasion is effectively reduced, and the service life of the knee-joint prosthesis is prolonged advantageously. The technical defects that inthe prior art, as for implanting of the knee-joint prosthesis, the structure is complex, mounting is inconvenient, and an implanted knee-joint prosthesis is low in flexion and poor in stability are overcome.

Owner:GUANGZHOU HUATAI 3D MATERIAL MFG TECH CO LTD

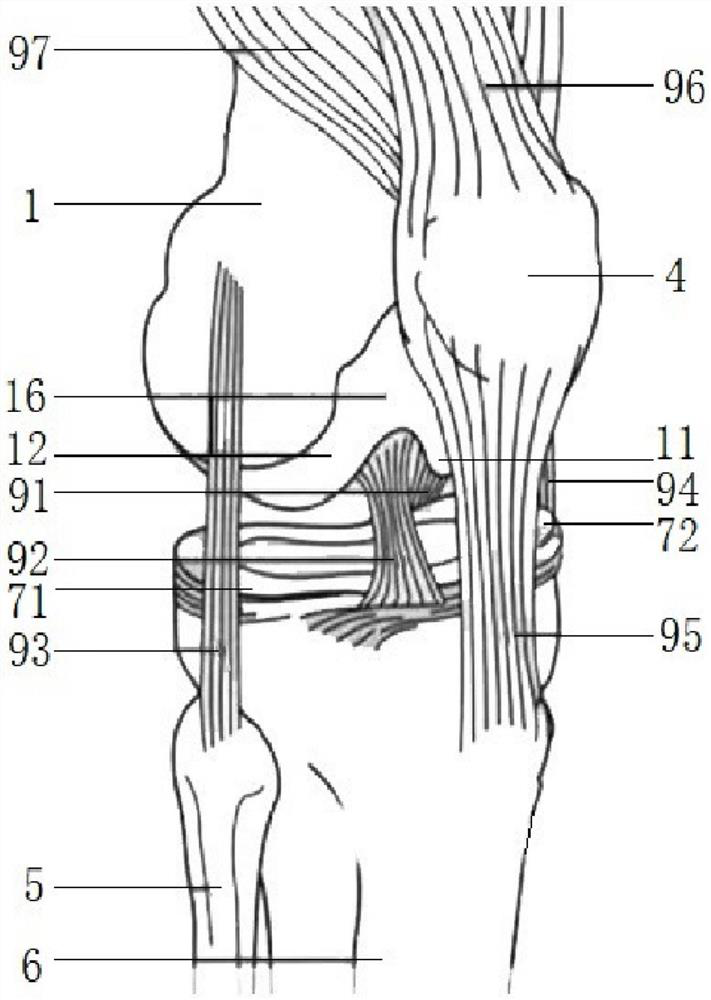

Anatomical form knee joint prosthesis with posterior cruciate ligament

PendingCN111616840ALock and stabilitySatisfy needsJoint implantsKnee jointsKnee arthrodesis prosthesisPosterior cruciate ligament

The invention belongs to the technical field of artificial joints, and particularly relates to a knee joint prosthesis with a posterior cruciate ligament. The anatomical form knee joint prosthesis with the posterior cruciate ligament comprises a femoral condyle and a tibial plateau pad, wherein the femoral condyle comprises entocondyle, lateral condyle and blocks, the entocondyle and the lateral condyle both are in the shape of C, and the intercondylar void is intercondylar fossa. The entocondyle and the lateral condyle are connected through the blocks, an inclined angle of the connecting lineof the lowest point of the entocondyle and the lowest point of the lateral condyle and the horizontal line is 3 degrees, and the tibial plateau pad comprises an entocondyle pit and a lateral condylepit to accommodate the entocondyle and the lateral condyle. According to the technical scheme, the pace of a postoperative patient is natural, the bending degree of the femoral condyle is increased, actions of going up and down stairs, deep squating, kneeling posture and the like are facilitated, and kneecap clicking and anterior knee pain can be reduced.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

Knee-joint prosthesis implantation process, osteotomy module thereof and device thereof

The invention discloses a kneed prosthesis implantation method, an osteotomy module used and a using device, the kneed prosthesis implantation method comprises the following steps of measuring the data of knee joint bone tissues, extracting the data of articular cartilage and the skeleton profile, establishing a three-dimensional model in an image processor, designing the osteotomy module, determining the size and the type of the used kneed prosthesis and determining an osteotomy module model and the implantation of the kneed prosthesis. The kneed prosthesis implantation method of the invention can reduce the trauma of a patient, lower the cost, shorten the implantation time, reduce the risk of complications of a user of the kneed prosthesis and have less error and higher precision.

Owner:周一新 +2

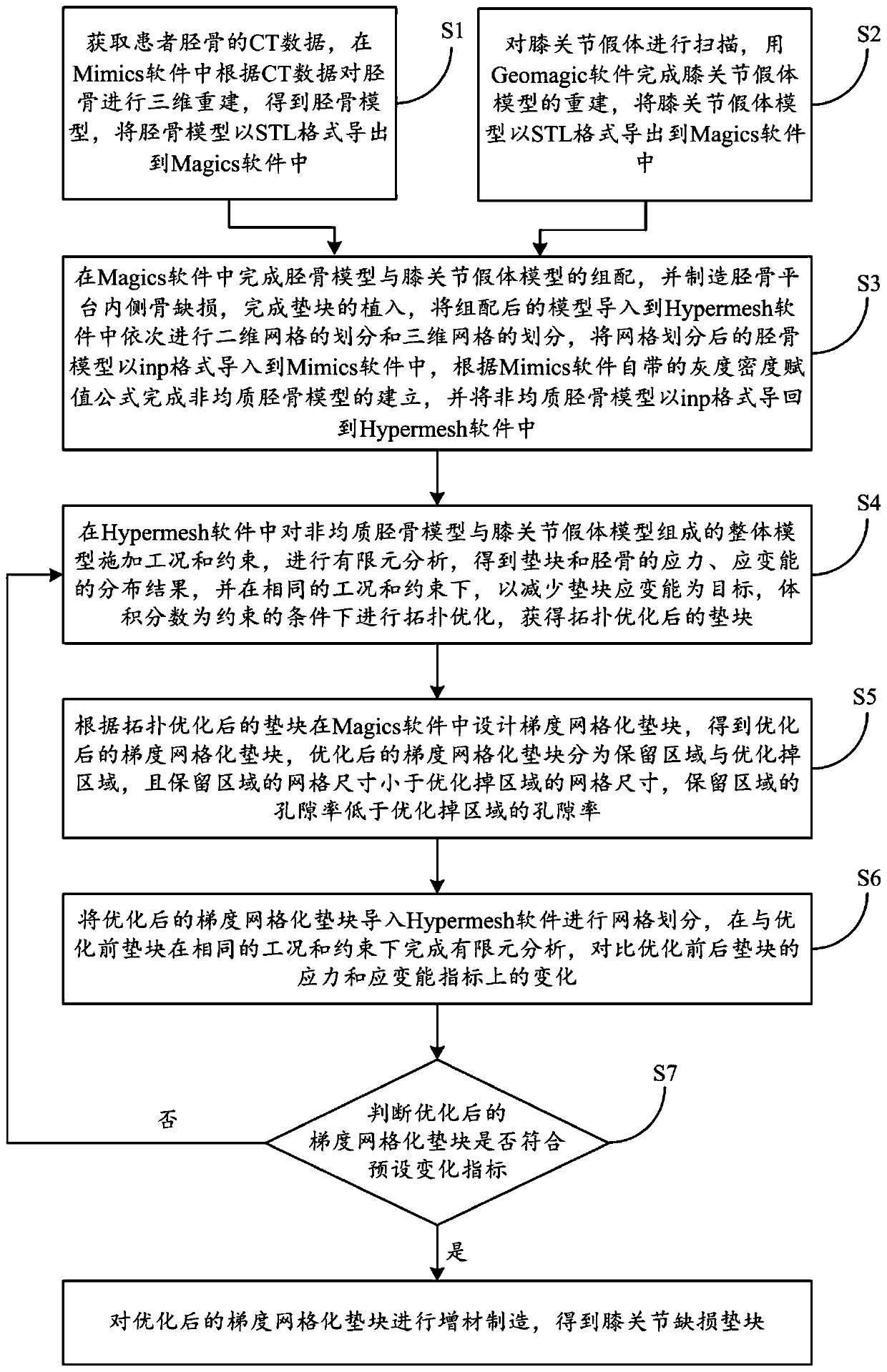

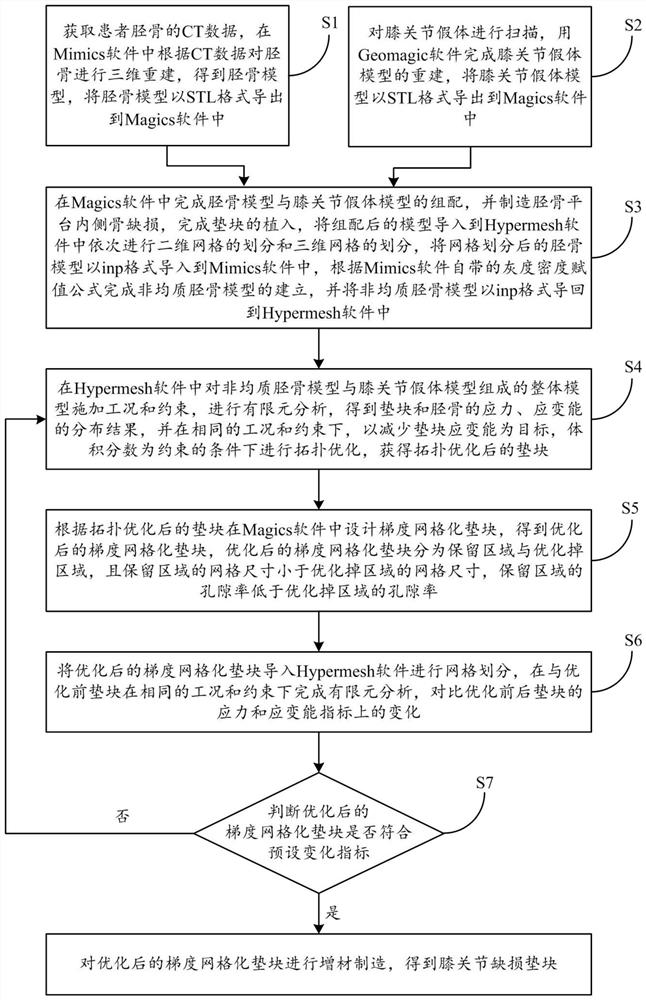

Knee joint defect cushion block and manufacture method therefor

ActiveCN111297524AReduce stress peaksReduced stress shielding effectJoint implantsOsseointegrationElement analysis

The invention relates to a knee joint defect cushion block and a manufacture method therefor. The method comprises the following steps: obtaining a tibia model, and exporting the tibia model into Magics software; rebuilding a knee joint prosthesis model and exporting the knee joint prosthesis model into the Magics software; completing matching of the tibia model and the knee joint prosthesis model, fabricating a medial bone defect of a tibia plateau, completing implantation of a cushion block and conducting meshing; applying working conditions and constraints on an overall model which is constituted of the heterogeneous tibia model and the knee joint prosthesis model in Hypermesh software and conducting finite element analysis; and carrying out topological optimization analysis, wherein ifthe optimized gradient-meshed cushion block satisfies preset changing indexes, additive manufacturing is carried out to obtain the knee joint defect cushion block. The knee joint defect cushion blockhas a mesh architecture as a whole, so that elastic modulus is further reduced, stress shielding is reduced, osseointegration between the cushion block and a tibia under the cushion block can be promoted, and stability of a knee joint prosthesis is enhanced.

Owner:JILIN UNIV

Knee joint prosthesis

PendingCN110840631AVersatileSolve non-universal problemsJoint implantsKnee jointsKnee arthrodesis prosthesisPhysical medicine and rehabilitation

The invention provides a knee joint prosthesis, which comprises a tibial platform part, an extension handle and a filling component, wherein the filling component is arranged between the tibial platform part and the extension handle to connect the tibial platform part and the extension handle; the filling component comprises a first adjusting part and a filling piece, the first adjusting part andthe filling piece are detachably connected, the first adjusting part is used for connecting with the extension handle, and the filling piece is used for connecting with the tibial platform part; and the filling piece comprises a second adjusting part, the second adjusting part comprises a telescopic part, and the telescopic part is movably arranged to increase the area of the outer peripheral surface of the second adjusting part by pushing the telescopic part to move, so as to enable the outer peripheral surface of the second adjusting part to be jointed and contacted with the bone defect position of the corresponding knee joint, and thus the effect of better matching of the second adjusting part with the bone defect position of the corresponding knee joint is achieved. Therefore, the kneejoint prosthesis can meet the bone defect situation at different knee joints and has good universality.

Owner:BEIJING AKEC MEDICAL

Knee joint prosthesis structure

PendingCN112869918AImprove long-term stabilityReduce the probability of looseningJoint implantsFemurSurgical RevisionKnee Joint

A knee joint prosthesis structure comprises a thighbone component, a cushion block component, a tibia component and a patella component, the thighbone component is provided with an intercondylar fixing block, the intercondylar fixing block is provided with a protruding part, the inner wall of the thighbone component is provided with a first coating used for bone ingrowth or bone growth, the cushion block component is located between the thighbone component and the tibia component, the outer wall of the lower end of the tibia component is provided with a second coating used for bone growth or bone length, the patella component is located in front of the thighbone component, and the inner wall of the patella component is provided with a third coating used for bone growth or bone length. The knee joint prosthesis structure is a biological type fixed prosthesis structure, various defects and complications caused by bone cement fixation can be avoided, harm to patients and surgical related medical staff due to current bone cement application is reduced, the long-term stability of the prosthesis is improved, the prosthesis loosening rate and the surgical revision rate are reduced, the cost is saved, and the cost is reduced. and the problem of precious medical observation is solved, and great social effect and economic benefit are achieved.

Owner:邬黎平

A knee joint defect pad and its manufacturing method

ActiveCN111297524BReduce stress peaksReduced stress shielding effectJoint implantsOsseointegrationElement analysis

The invention relates to a knee joint defect pad and a manufacturing method thereof, comprising: obtaining a tibial model, exporting the tibial model to Magics software; reconstructing a knee joint prosthesis model, and exporting the knee joint prosthesis model to Magics software; completing The tibial model and knee joint prosthesis model were combined, and the medial bone defect of the tibial plateau was manufactured, the spacer was implanted, and the mesh was divided; in the Hypermesh software, the heterogeneous tibial model and the knee joint prosthesis model were combined Working conditions and constraints are applied to the overall model, and finite element analysis is performed; topology optimization analysis is performed, and if the optimized gradient mesh pad meets the preset change indicators, additive manufacturing is performed to obtain a knee joint defect pad. The knee joint defect cushion block of the present invention has a grid structure as a whole, which further reduces the elastic modulus, reduces stress shielding, facilitates the osseointegration of the cushion block and the lower tibia, and improves the stability of the knee joint prosthesis.

Owner:JILIN UNIV

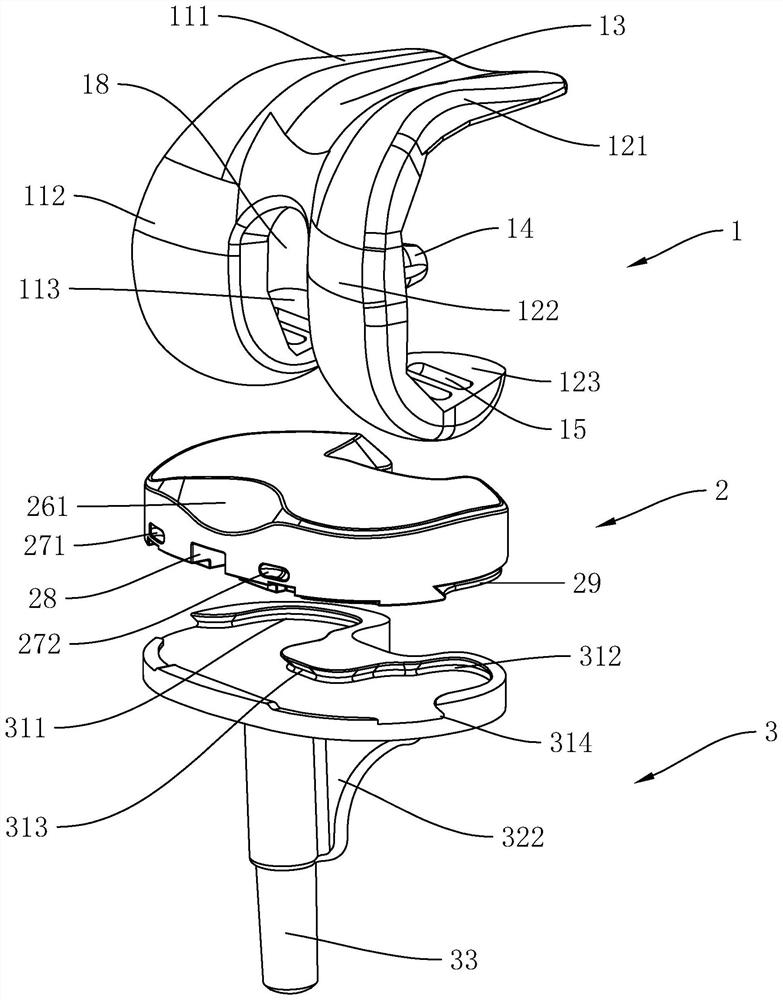

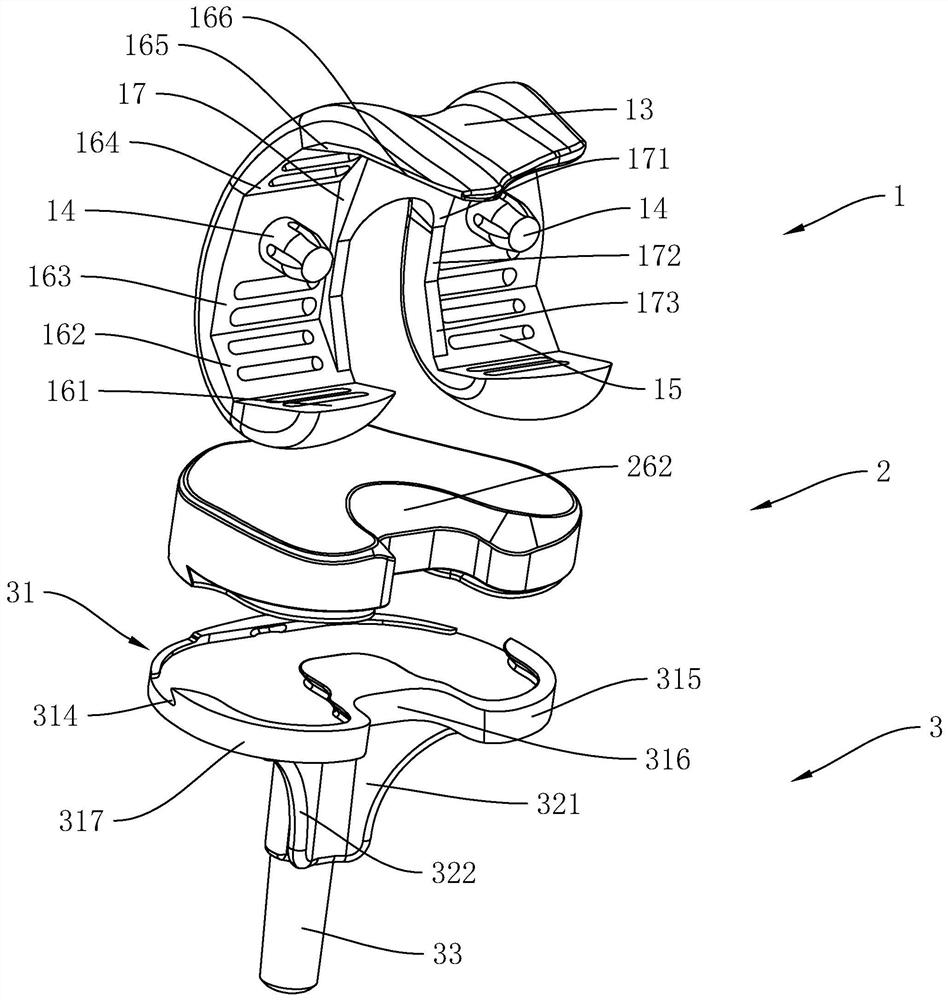

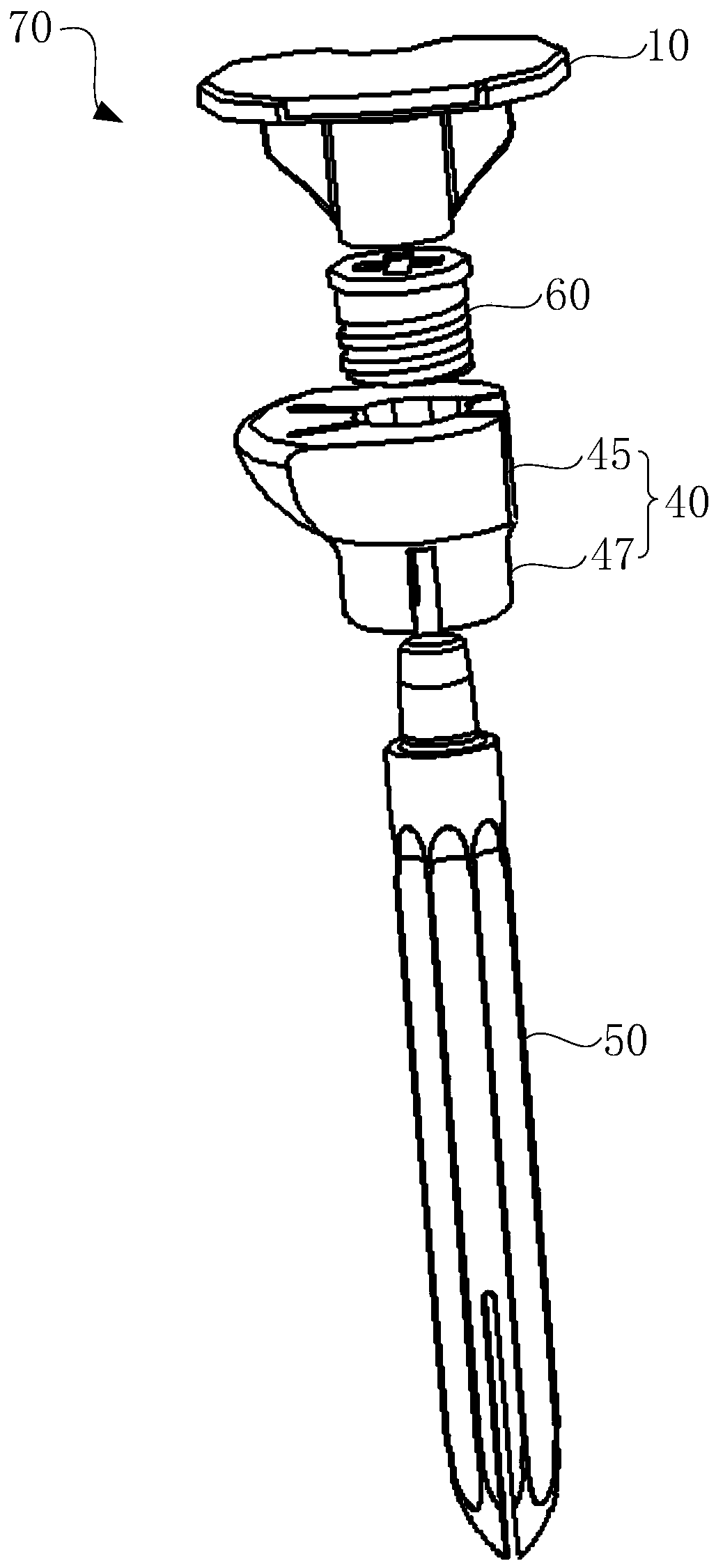

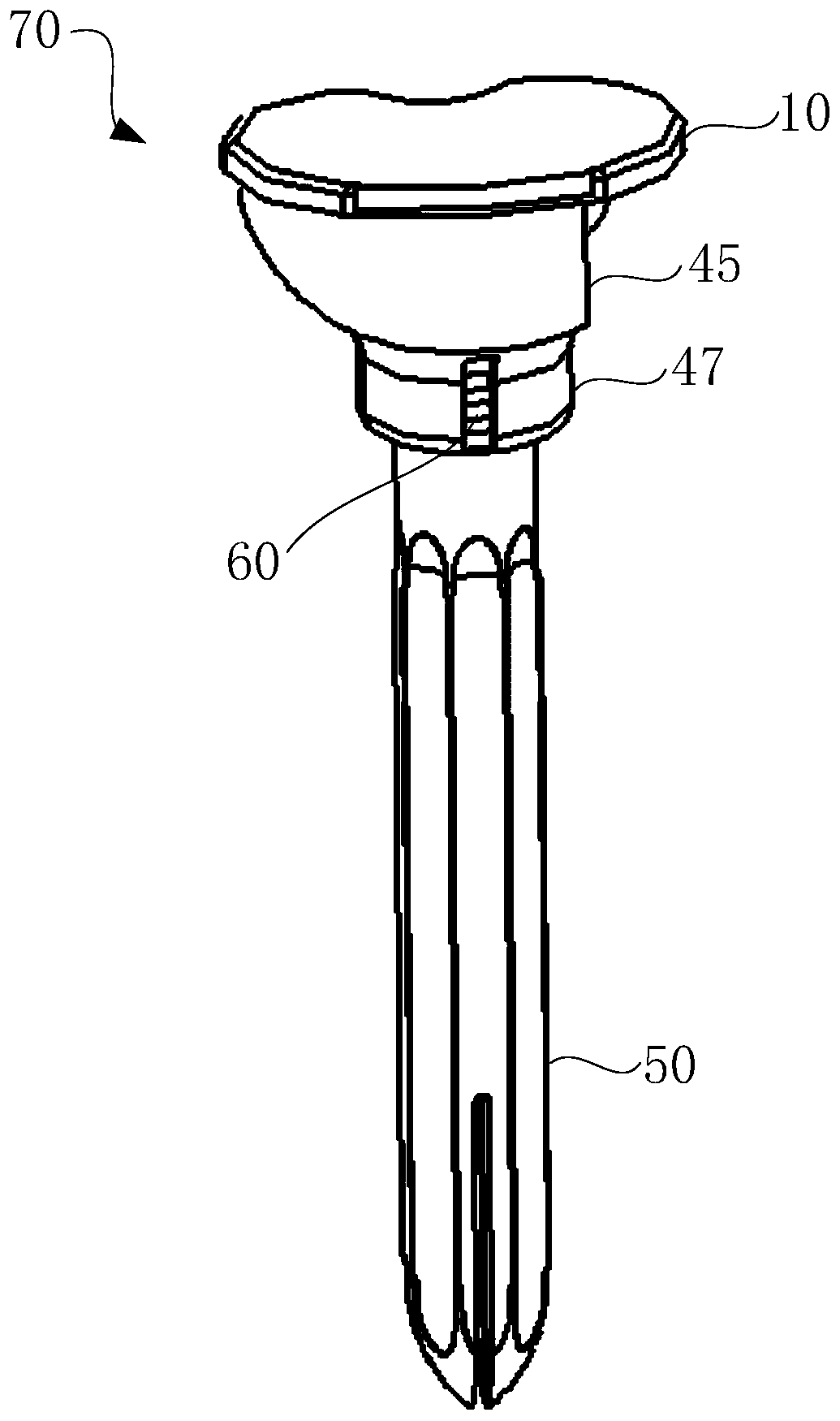

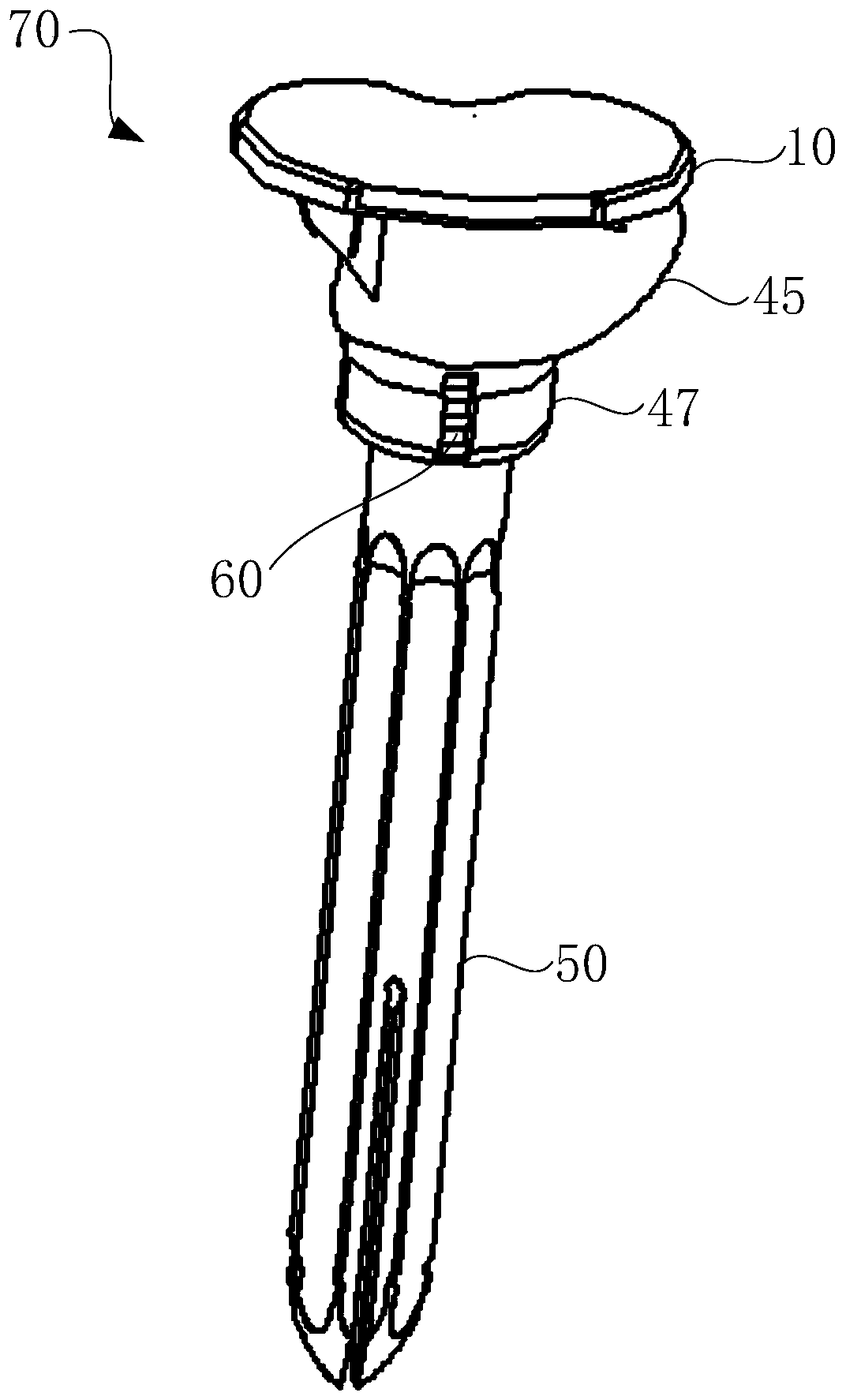

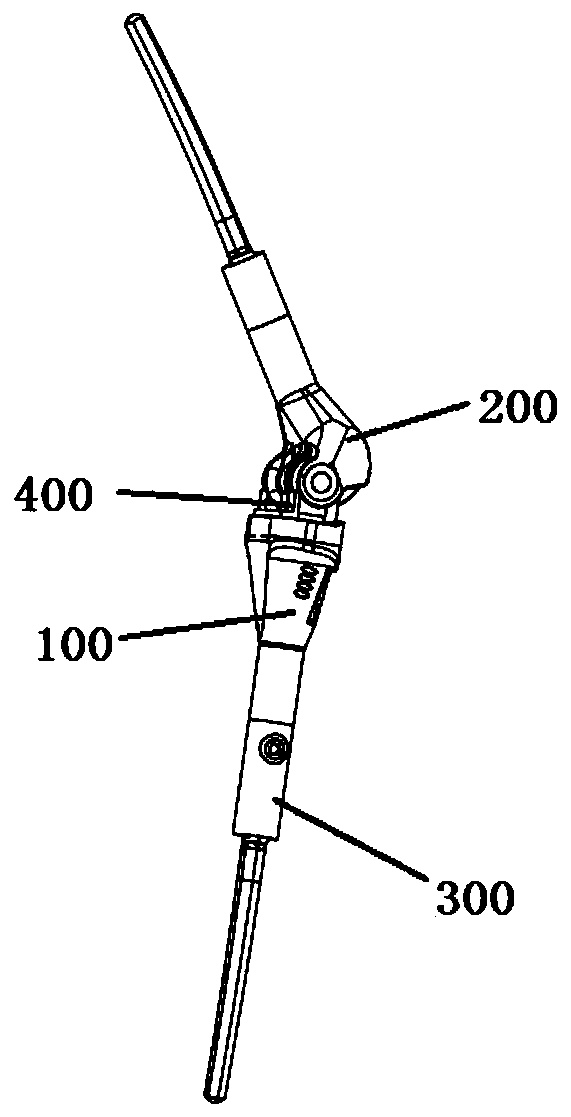

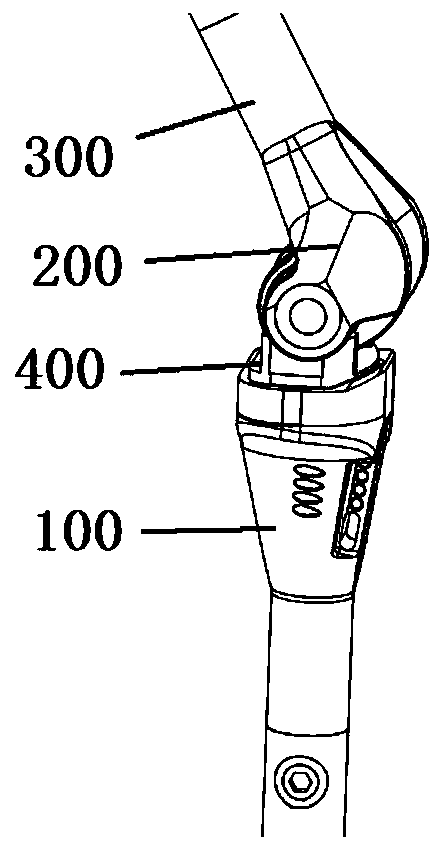

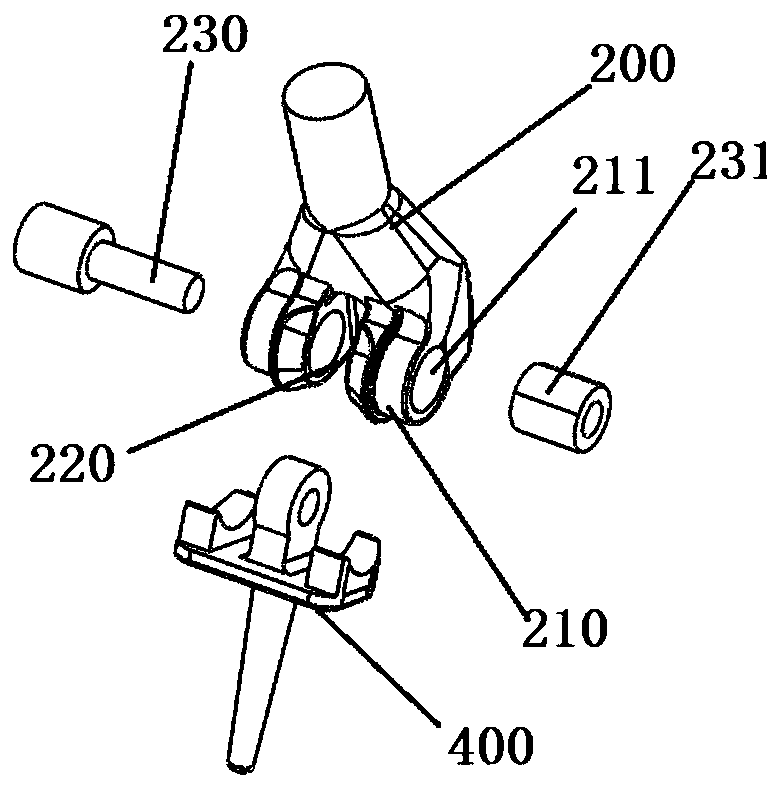

A tumor-type knee prosthesis

ActiveCN109199650BLock firmlyNo relative motionJoint implantsKnee jointsKnee arthrodesis prosthesisProsthesis

The invention discloses a tumor-type knee joint prosthesis, comprising: a tibia part, a femur part, a tibia liner and an extension handle; wherein the femur part and the tibia liner are connected through a hinge; and the femur part performs a hinge-centered rotational motion on the tibia liner. The tibial pad and the tibial part are connected to a third groove of the tibial part by a third protrusion below the tibial pad. The extension handle is connected to the femoral or tibial part by a conical connection and interference fit. The invention firmly locks the extension handle with the femur or the tibia to avoid the force deformation and the fracture of the connector. Another object of the present invention is that once the extension handle and the femoral or tibial portion are locked, relative movement between the components or wear debris is prevented from occurring, thereby avoiding osteolysis.

Owner:陕西四正医疗器械有限责任公司

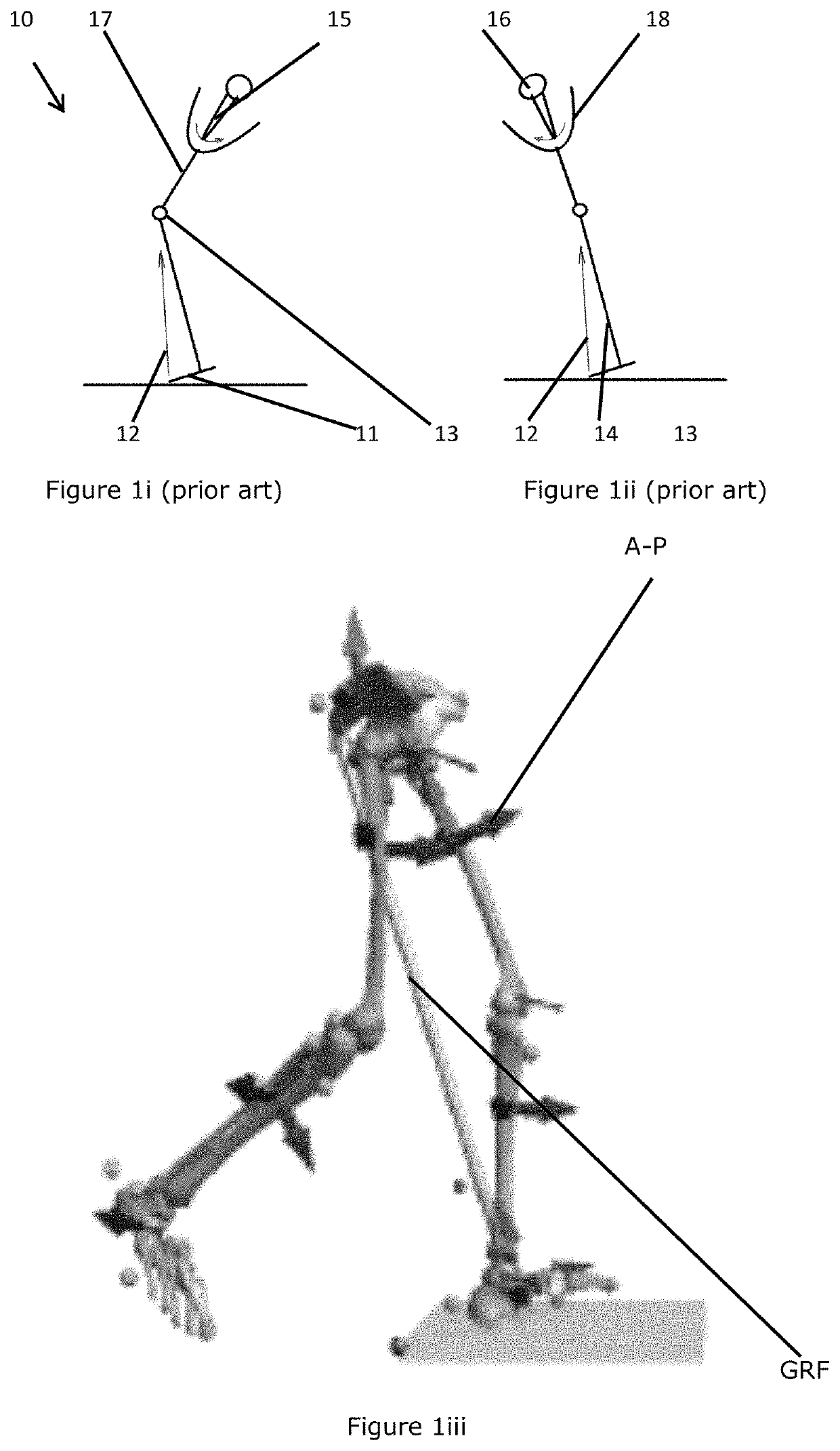

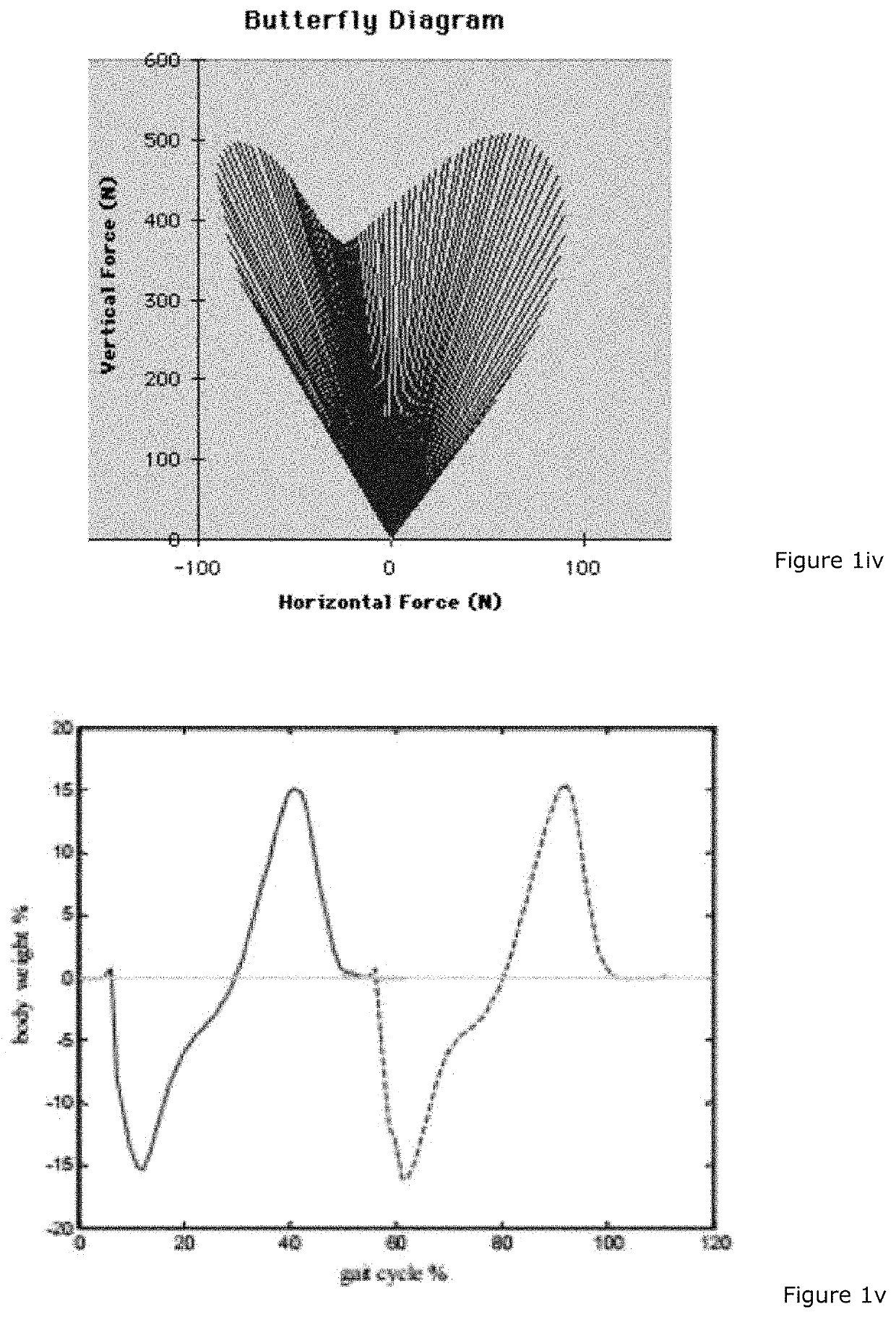

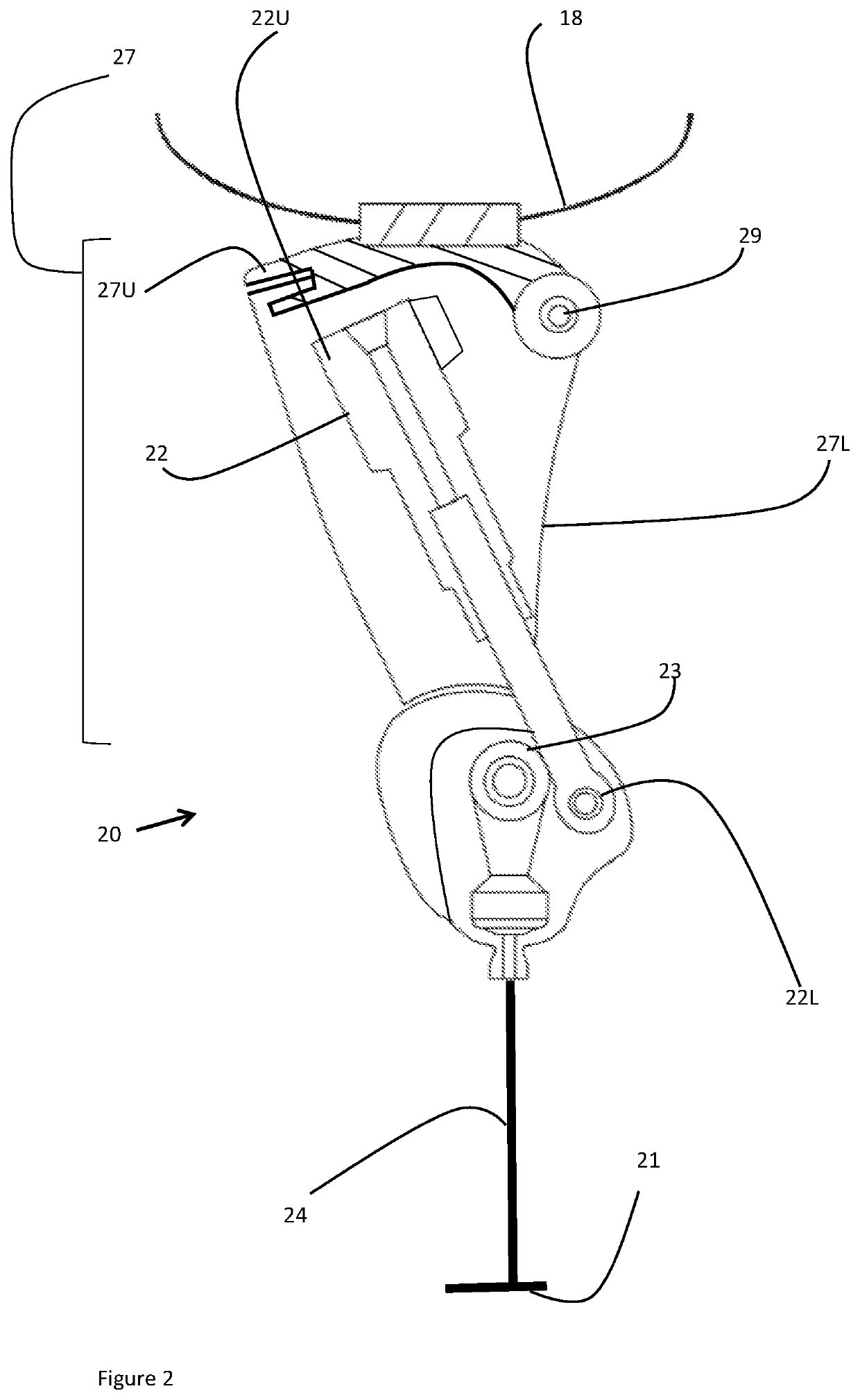

Prosthetic joints

The present invention relates to a prosthetic leg for those having a femoral amputee, namely those having an above the knee stump, where certain movements can be difficult to perform. Known prosthetic knee joints that are weight-activated cannot substantially assist short-stumped individuals. The weight placed on the toe will typically cause disengagement of any stance mode there otherwise might be. The invention provides a solution to the problems addressed above. The present invention seeks to provide an improved mechanically operated prosthesis for a femoral amputee. The invention also provides an improved electrically-operated prosthesis for a transfemoral amputee.

Owner:BOENDER JACOB QUINTUS LAURENCE ANTHONY +1

Device for measuring pressure and friction of single condyle of knee joint

The invention provides a device for measuring interface pressure and pull-out friction between single condylar femoral prosthesis and tibial prosthesis during the process of single condyle replacementof the knee joint. The device for measuring the interface pressure and the pull-out friction between the single condylar femoral prosthesis and the tibial prosthesis during the process of the singlecondyle replacement of the knee joint is mainly composed of a pressure measurement head, a pull-out friction measurement connection part, and a hand-held handle; a pressure sensor is arranged on an upper surface of the pressure measurement head, and can be used for measuring the interface pressure between the single condylar femoral prosthesis and the tibial prosthesis; the pull-out friction measurement connection part is provided with a tension sensor which is used for indirectly measuring dynamic friction when the pressure measurement head is pulled out; a microprocessor module, a wireless transmission module and a power supply module are arranged inside the hand-held handle; and the microprocessor module converts received analog electrical signals into digital signals. During operationof the single condyle replacement of the knee joint, after installation of the single condylar femoral prosthesis and the tibial prosthesis, the device for measuring the interface pressure and the pull-out friction provided by the embodiment of the invention is used for measuring the pressure and the friction between the single condylar femoral prosthesis and the tibial prosthesis so as to facilitate understanding the pressure and the friction of the joint space during operation by a doctor, thereby improving accuracy of meniscus pad size and material selection so as to ensure that force on the implanted knee prosthesis is balanced.

Owner:牛依芃

Unicompartmental knee joint prosthesis and manufacturing method thereof

PendingCN112472370AEasy to integrateImprove securityJoint implantsCoatingsKnee arthrodesis prosthesisBone tissue

The invention discloses a unicompartmental knee joint prosthesis and a manufacturing method thereof. The unicompartmental knee joint prosthesis comprises a femur condyle, a gasket and a tibial plateau, wherein a first porous structure is arranged on the inner surfaces, making contact with a host bone, of a femur connecting column and a femur condyle body, and a second porous structure is arrangedon the surfaces, making contact with the host bone, of a tibia connecting column and the tibial plateau body. The invention discloses a manufacturing method of the unicompartmental knee joint prosthesis. The manufacturing method comprises the steps of S1, additive manufacturing of a femur condyle, S2, hot isostatic pressing treatment of the femur condyle, S3, machining of the femur condyle, S4, additive manufacturing of a tibial plateau, S5, hot isostatic pressing treatment of the tibial plateau, S6, machining of the tibial plateau and S7, surface modification. According to the invention, theporous structure provides space for ingrowth of human bone tissue so as to improve stability of the prosthesis; the tibial plateau is endowed with a bioactive function through the in-situ membrane layer, so that bone induction and bone ingrowth of the tibial plateau can be rapidly achieved in the early stage of implantation; and the prosthesis is endowed with good mechanical properties through thehot isostatic pressing process, so that long-term safety and effectiveness of the prosthesis are facilitated.

Owner:天衍医疗器材有限公司

Femoral condyle and knee joint prosthesis with same

ActiveCN107951600AReduce back looseReduce loosenessJoint implantsFemoral headsKnee arthrodesis prosthesisKnee Joint

The invention provides a femoral condyle and a knee joint prosthesis with the same. The femoral condyle is arranged between a tibia and a femur and comprises a femoral condyle body arranged at the end, close to the tibia, of the femur and a fixing structure which is arranged on the side, in contact with the femur, of the femoral condyle body to make the femoral condyle body fixedly connected ontothe femur, wherein the fixing structure comprises a basal body and fixing teeth arranged on the basal body, and the fixing teeth can extend into the bone substance of the femur. According to the technical scheme, the problem is solved that in the prior art, a femoral condyle is likely to become loose and flake off.

Owner:BEIJING AKEC MEDICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com