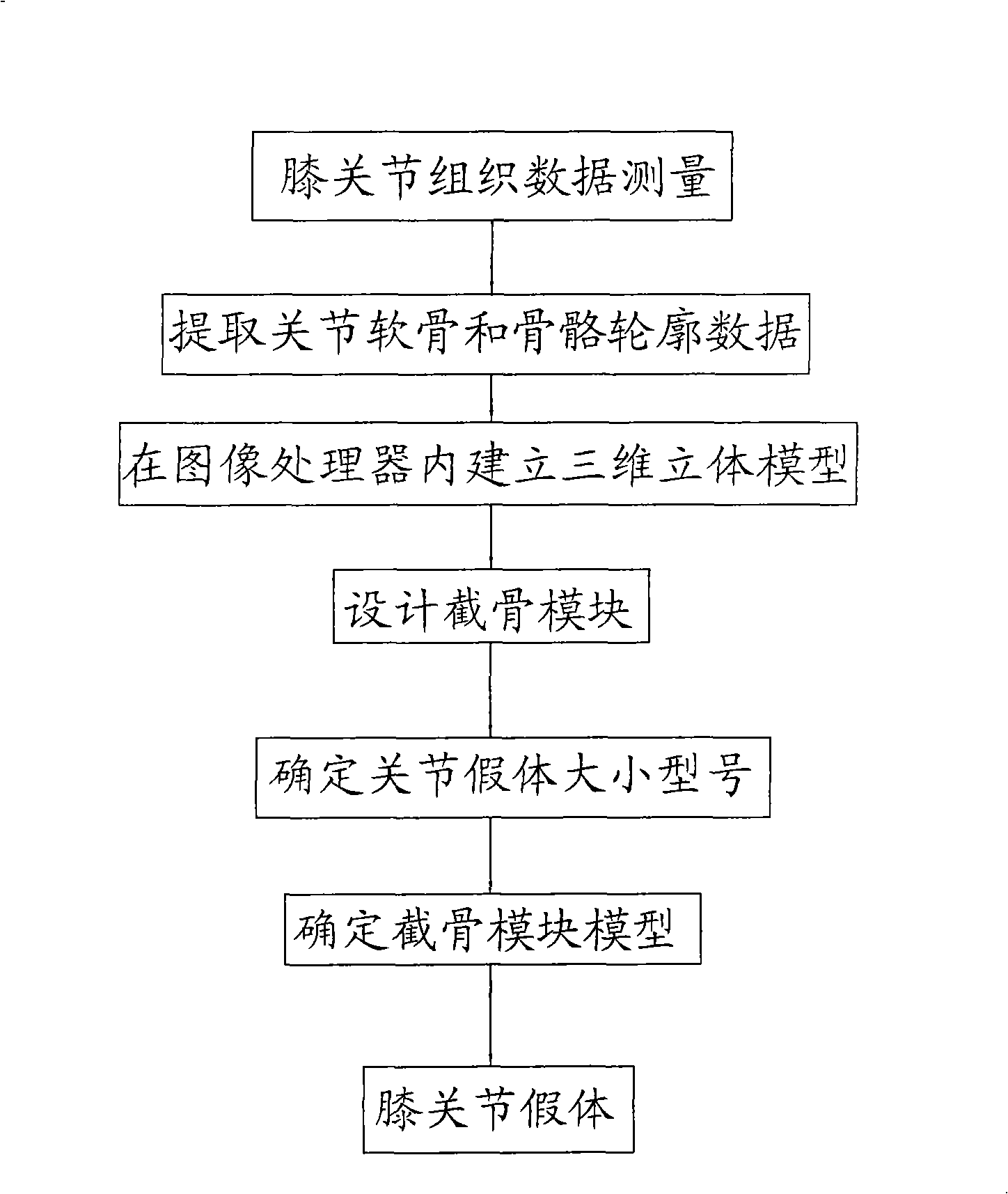

Knee-joint prosthesis implantation process, osteotomy module thereof and device thereof

A knee joint prosthesis, knee joint technology, applied in joint implants, joint implants, knee joints and other directions, can solve problems such as prolonging operation time, increasing the risk of complications and errors in patients, and achieving extended operation. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

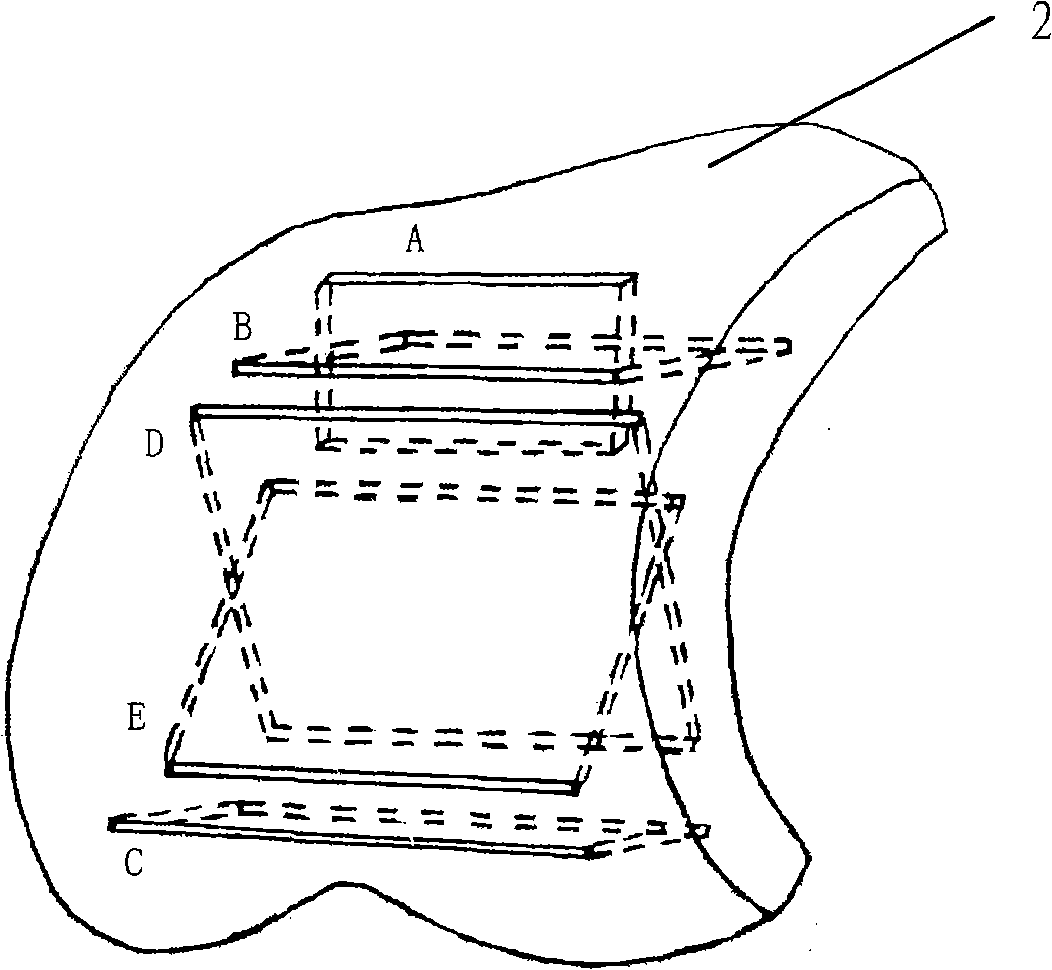

[0055] Example 1: For patients with varus deformity, please refer to Figure 5 , There is varus deformity in the tibia and femur, the femoral angle is 86°, and there is 2° varus. The tibial angle is 95° with 2° varus present. The measurement data of the femur are as follows: the anteroposterior diameter of the tibia is 6.13cm. The front face is 0.9cm thick. Genesis II5 prosthesis was selected. The femoral osteotomy block with perfect image preparation was designed for slotting. The groove at the distal end of the femur forms an angle of 84° with the mechanical axis of the femur, and an angle of 2° with the articular surface. Due to the presence of varus, the distance between the osteotomy groove and the distal end of the outer side is relatively large. Parallel to the line connecting the posterior condyle osteotomy groove and the posterior condyle, the distance from the anterior face osteotomy groove to the distal end is 9mm, the posterior condyle osteotomy distance is 9.3...

Embodiment 2

[0056] Embodiment 2: Valgus deformity patient, please refer to Figure 6According to the preoperative CT, MRI and X-ray measurements, both the femur and the tibia had valgus deformities. The femoral angle was 80°, with 4° valgus, and the tibial angle was 90°, with 3° valgus deformity. The anteroposterior diameter of the femur is 5.45cm, and the anterior face thickness is 0.6cm. The Genesis II No. 2 prosthesis is used, and the corresponding slot design is carried out. The groove at the distal end of the femur forms an angle of 84° with the mechanical axis of the femur, an angle of 4° with the articular surface, and is 10mm away from the most distal end of the articular surface. The groove of the posterior condyle of the femur is parallel to the line of the posterior condyle, the distance from the most distal end of the posterior condyle osteotomy is 13.5mm, and the bone volume of the anteroposterior diameter is 35mm (to ensure that it is suitable for the No. 5 Genesis II prosth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com