Patents

Literature

35 results about "Implantation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Most of the time, implantation occurs about nine days after ovulation, but it can occur as early as seven days or as late as 12 days after ovulation. Once implantation is complete, the cervix becomes closed with a mucus plug.

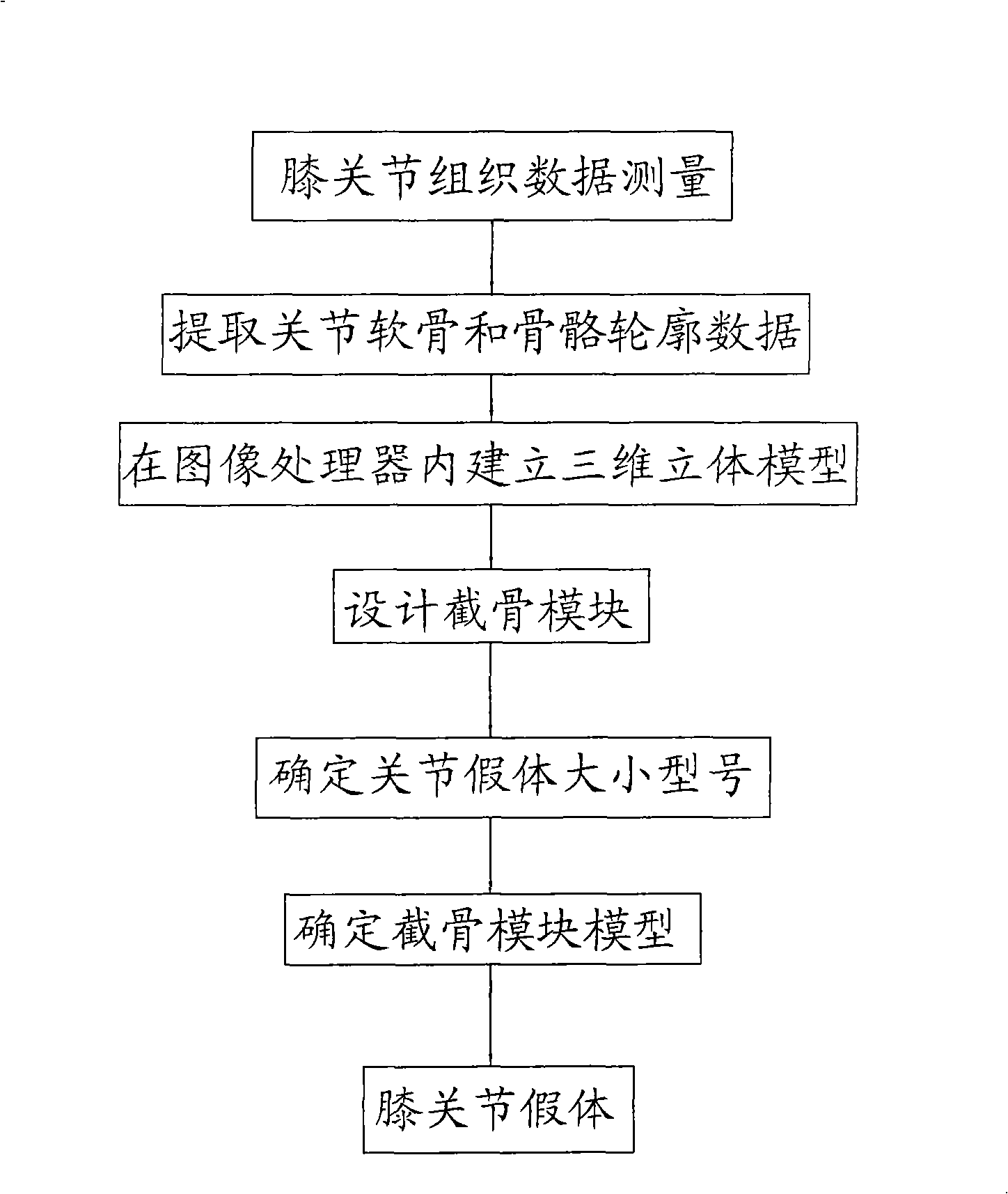

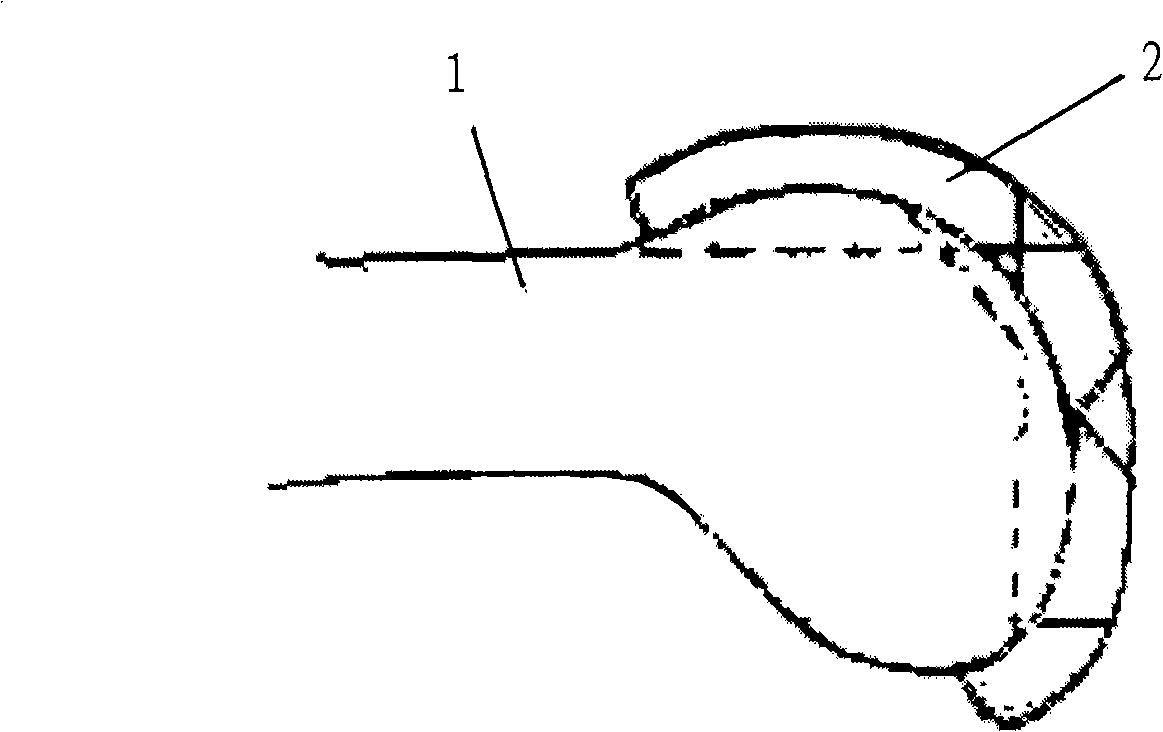

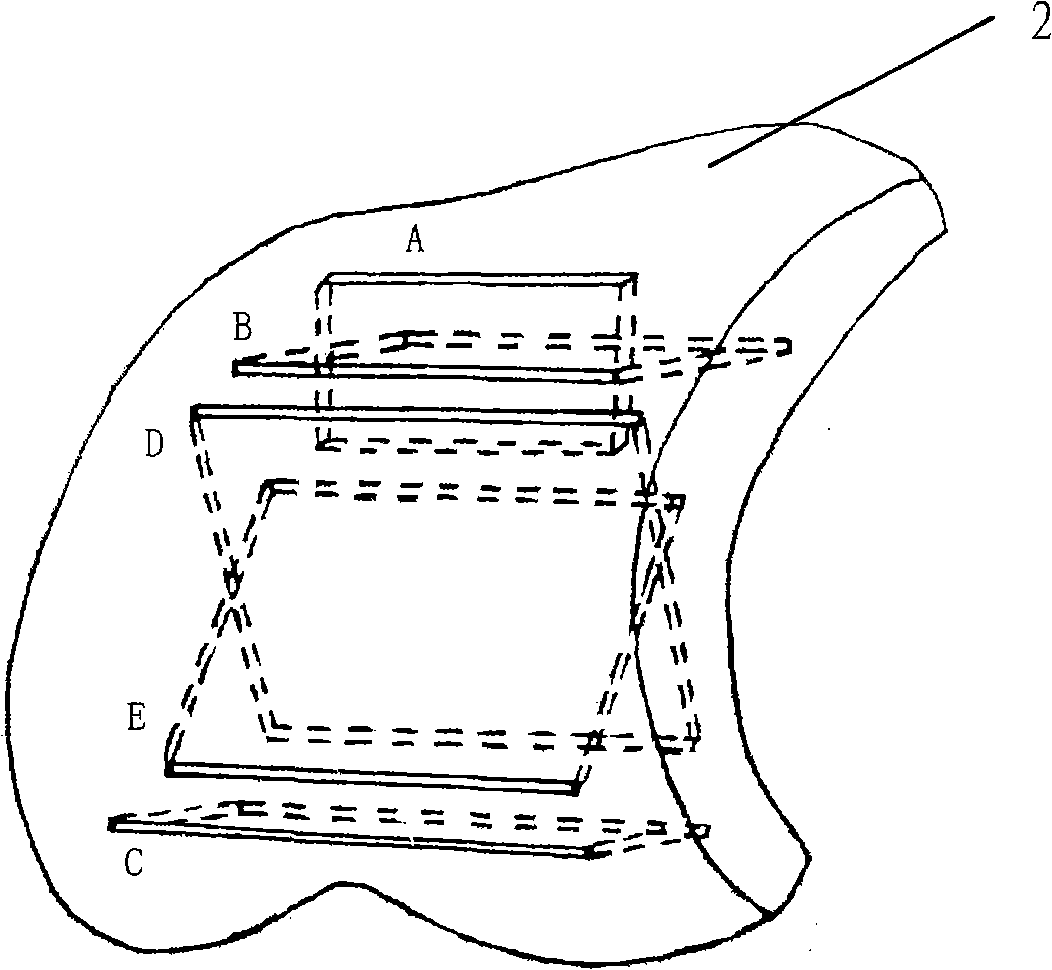

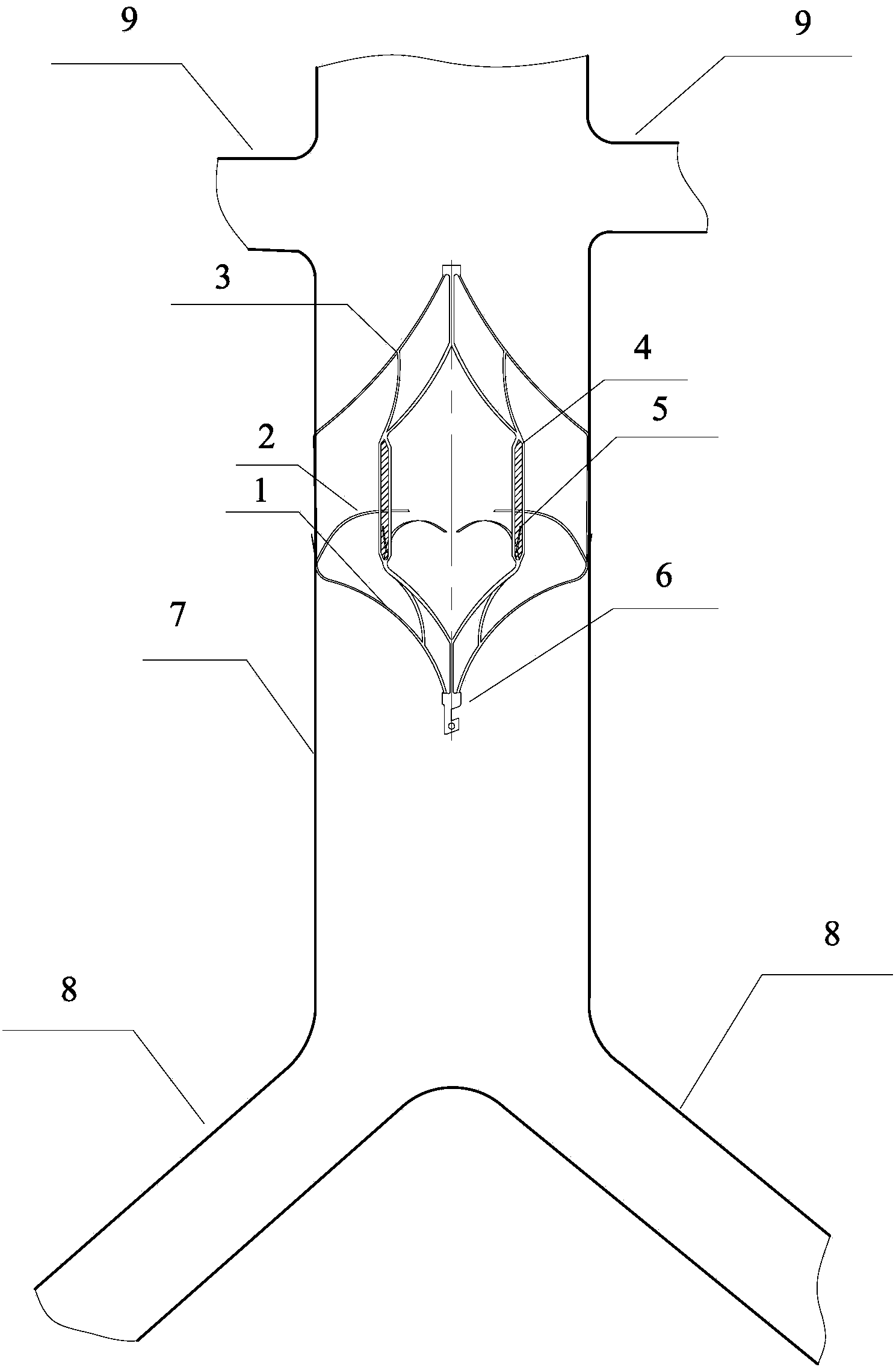

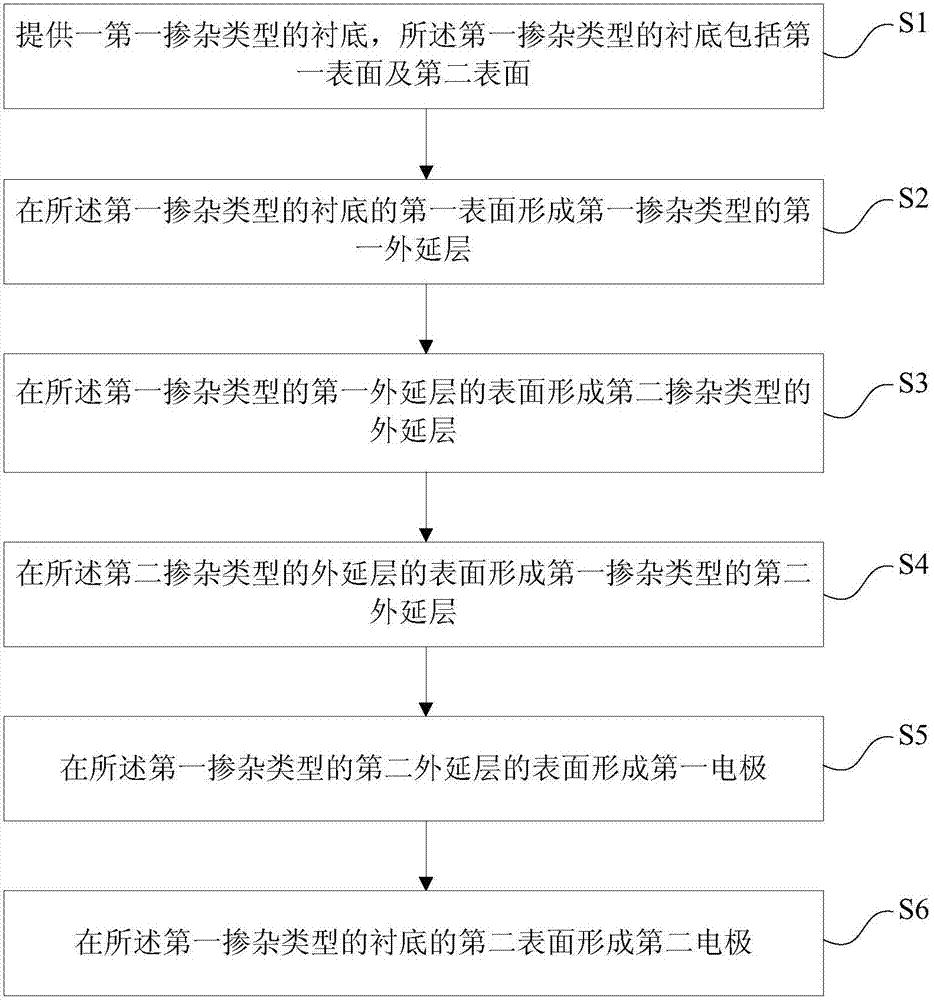

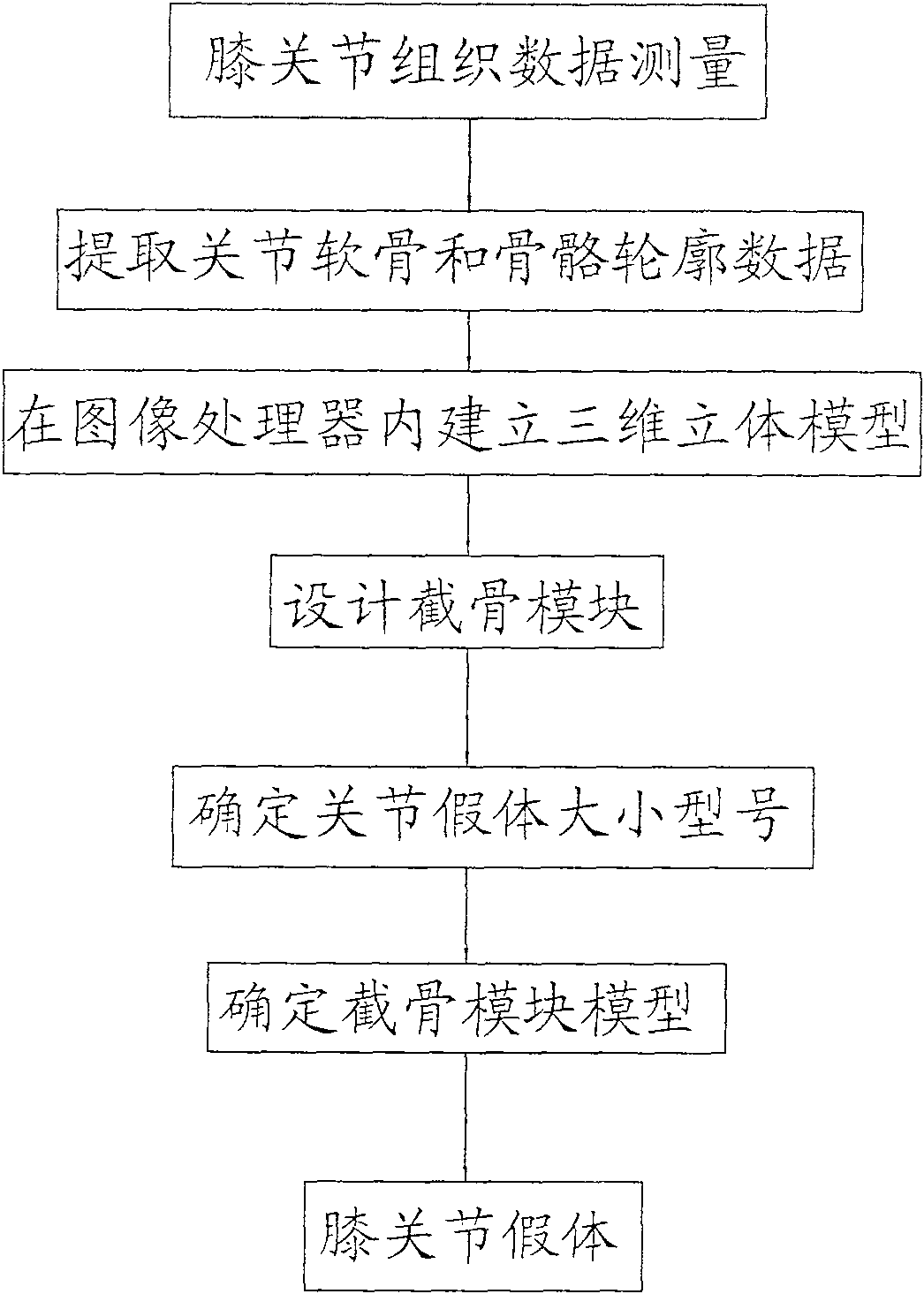

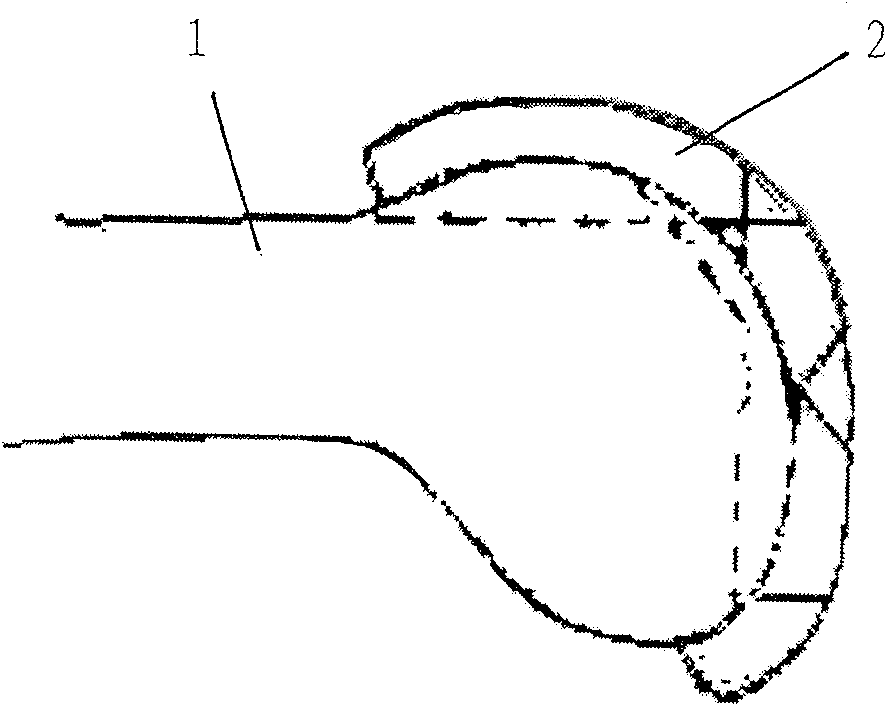

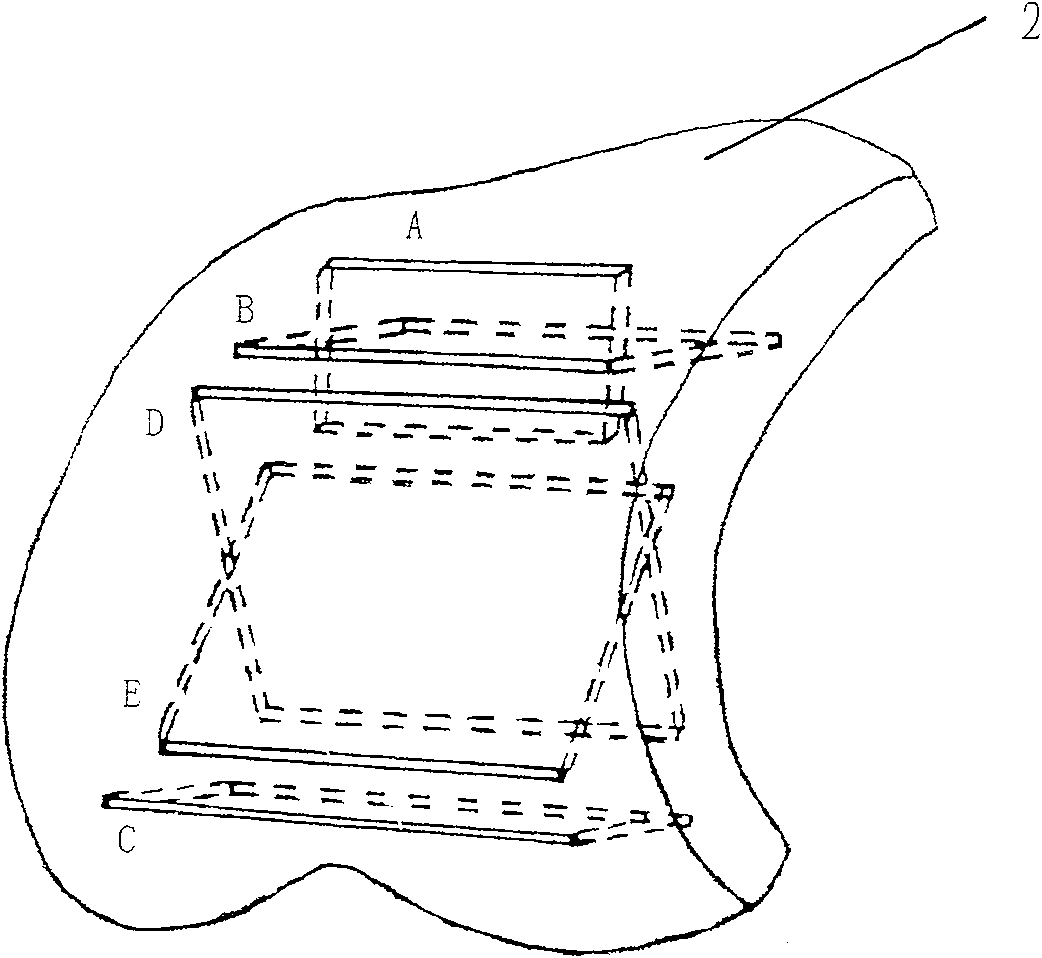

Knee-joint prosthesis implantation process, osteotomy module thereof and device thereof

InactiveCN101288597AConvenient osteotomyAvoid traumaSurgeryJoint implantsImplantation timeBone tissue

The invention discloses a knee prosthesis implantation method, an osteotomy module for usage and a using device, the knee prosthesis implantation method comprises the following steps of measuring the data of knee joint bone tissues, extracting the data of articular cartilage and the skeleton profile, establishing a three-dimensional model in an image processor, designing the osteotomy module, determining the size and the type of the used knee prosthesis and determining an osteotomy module model and the implantation of the knee prosthesis. The knee prosthesis implantation method of the invention can reduce the trauma of a patient, lower the cost, shorten the implantation time, reduce the risk of complications of a user of the knee prosthesis and have comparatively small error and higher precision.

Owner:周一新 +2

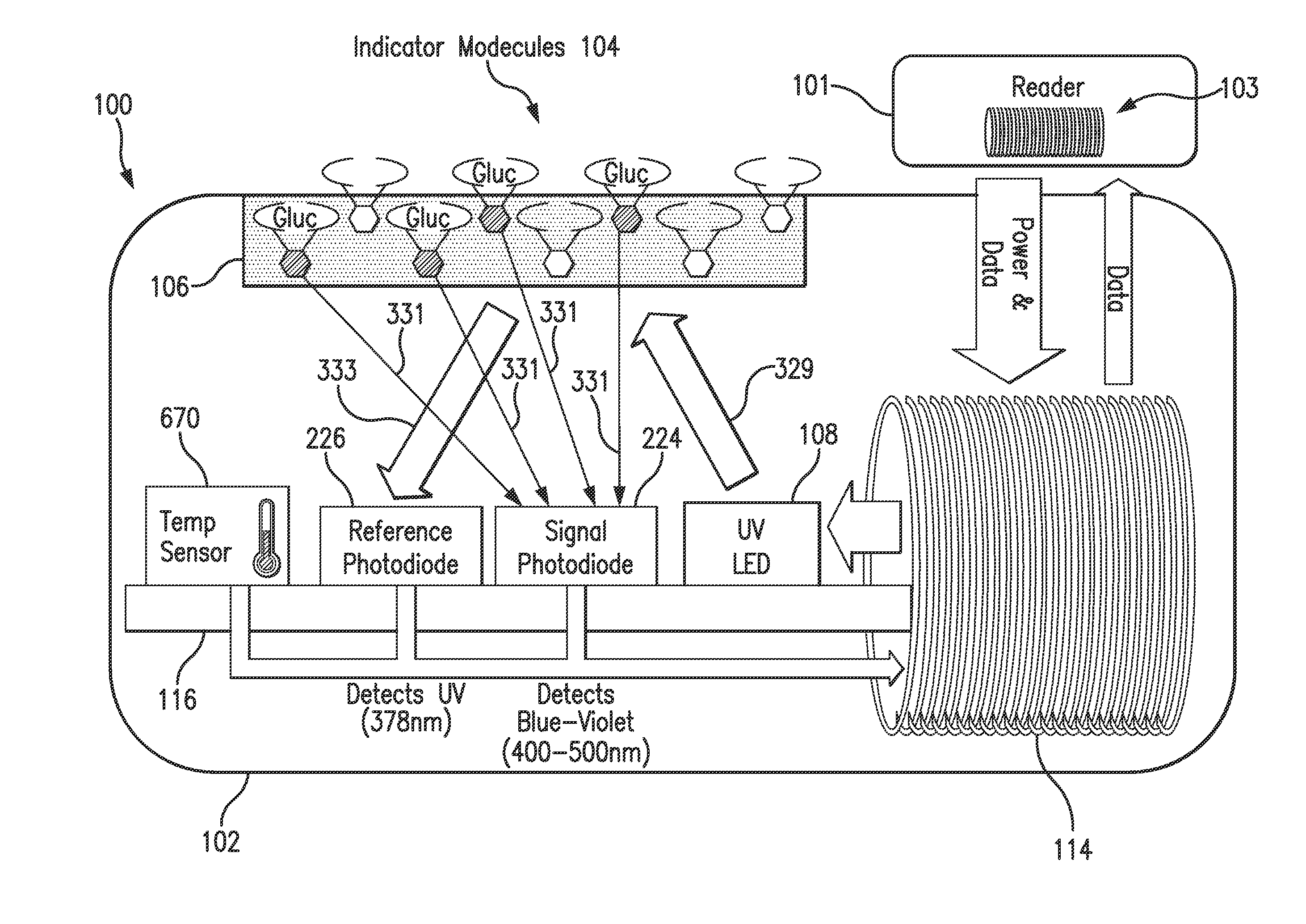

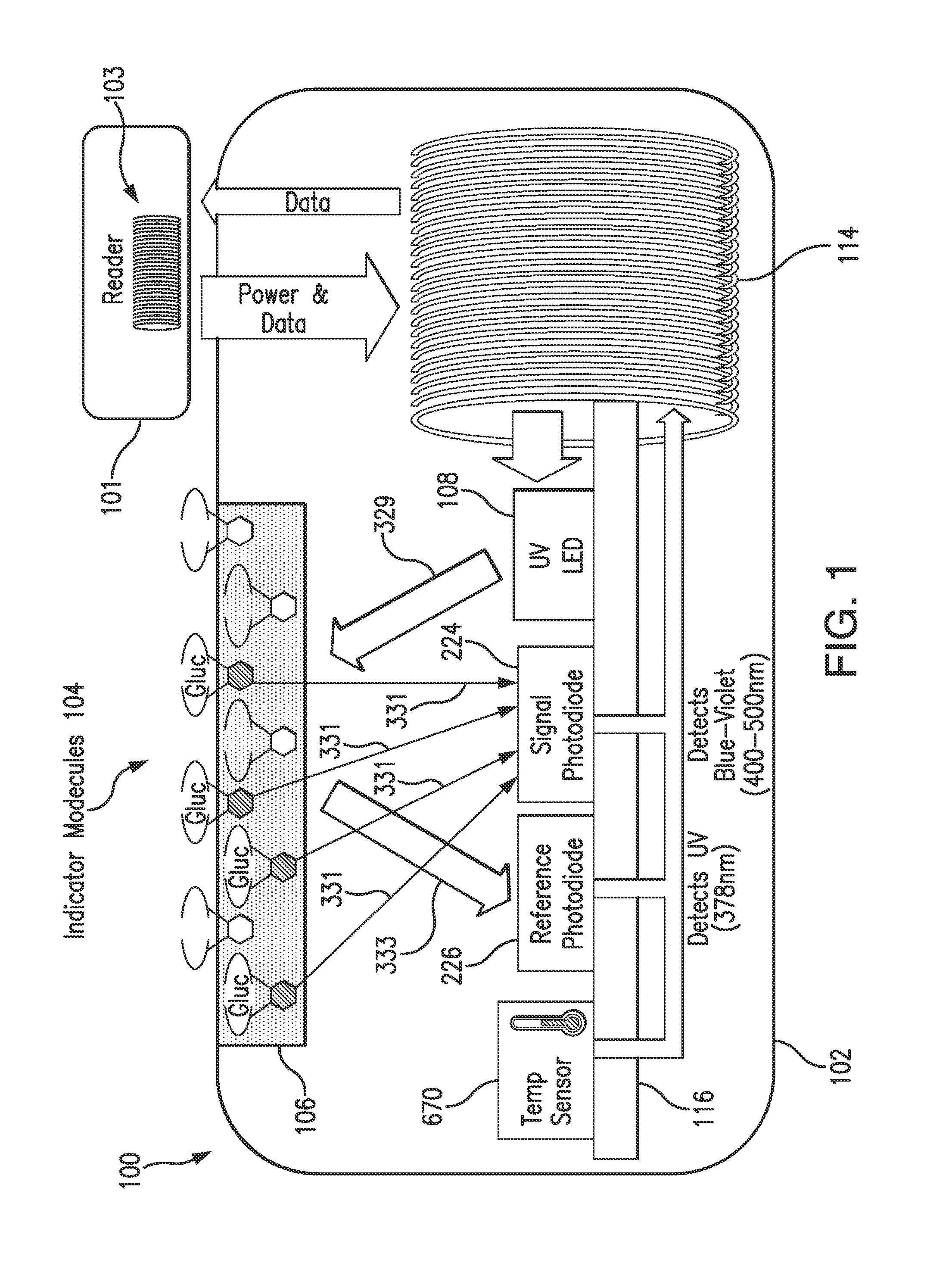

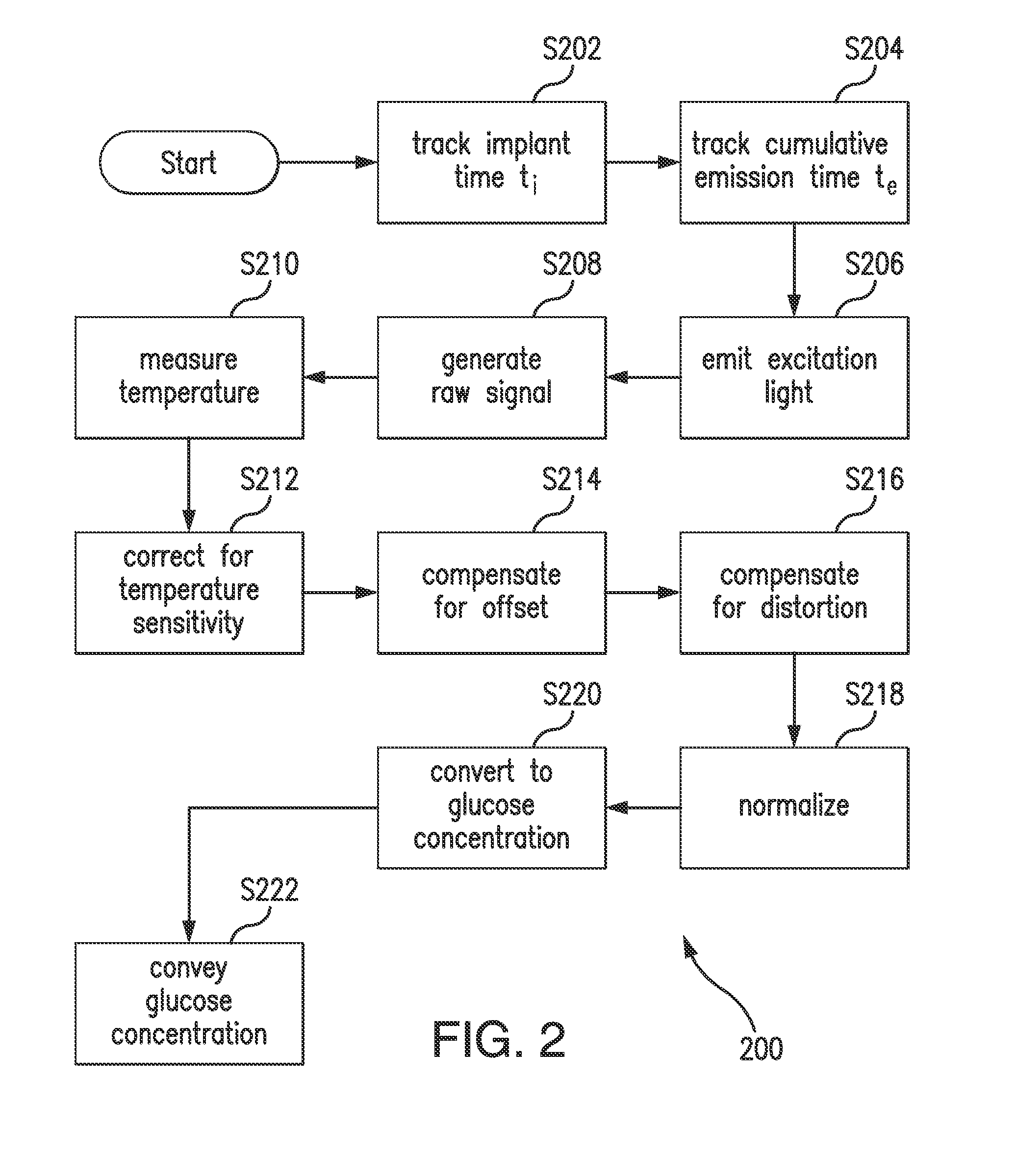

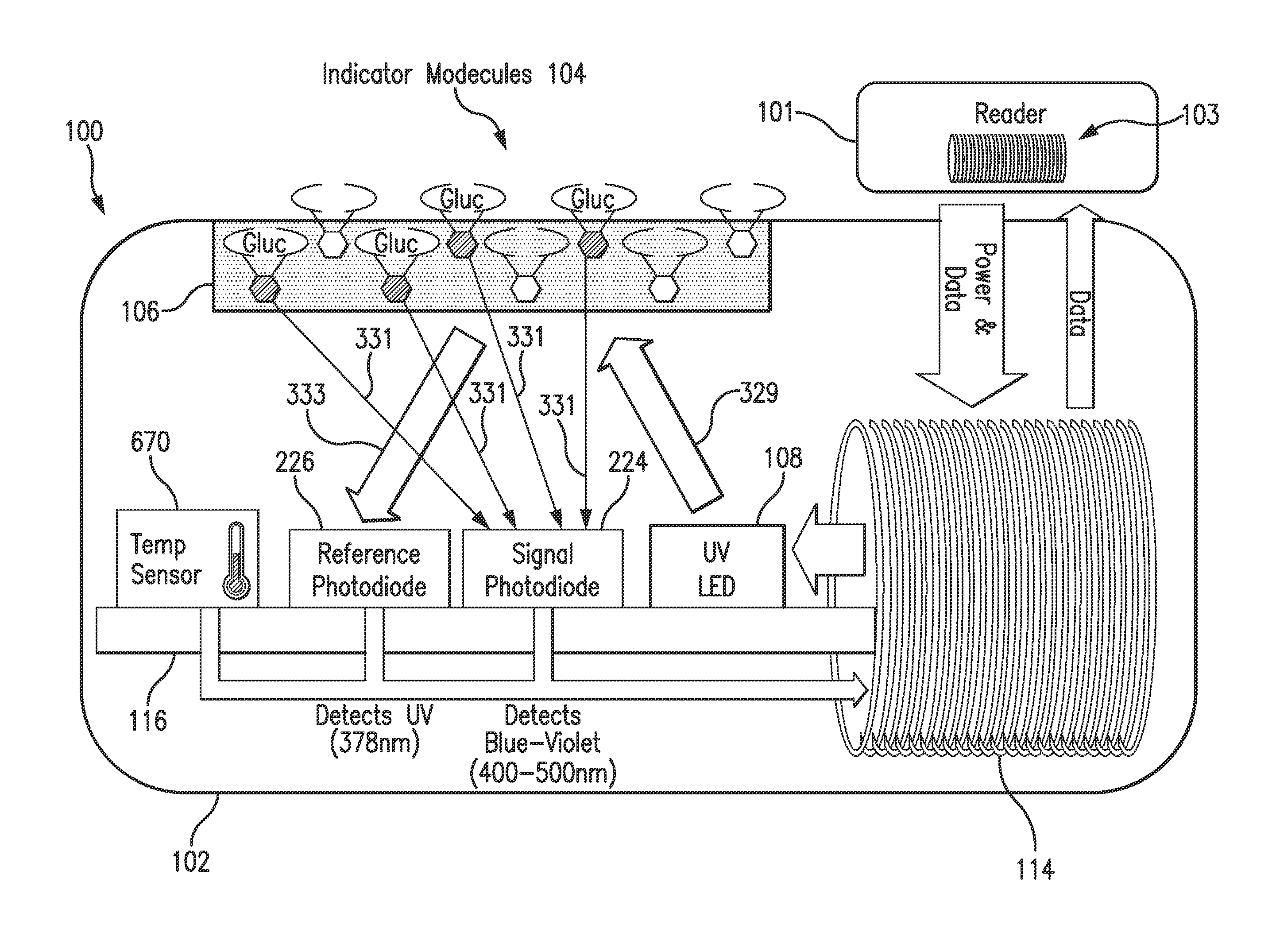

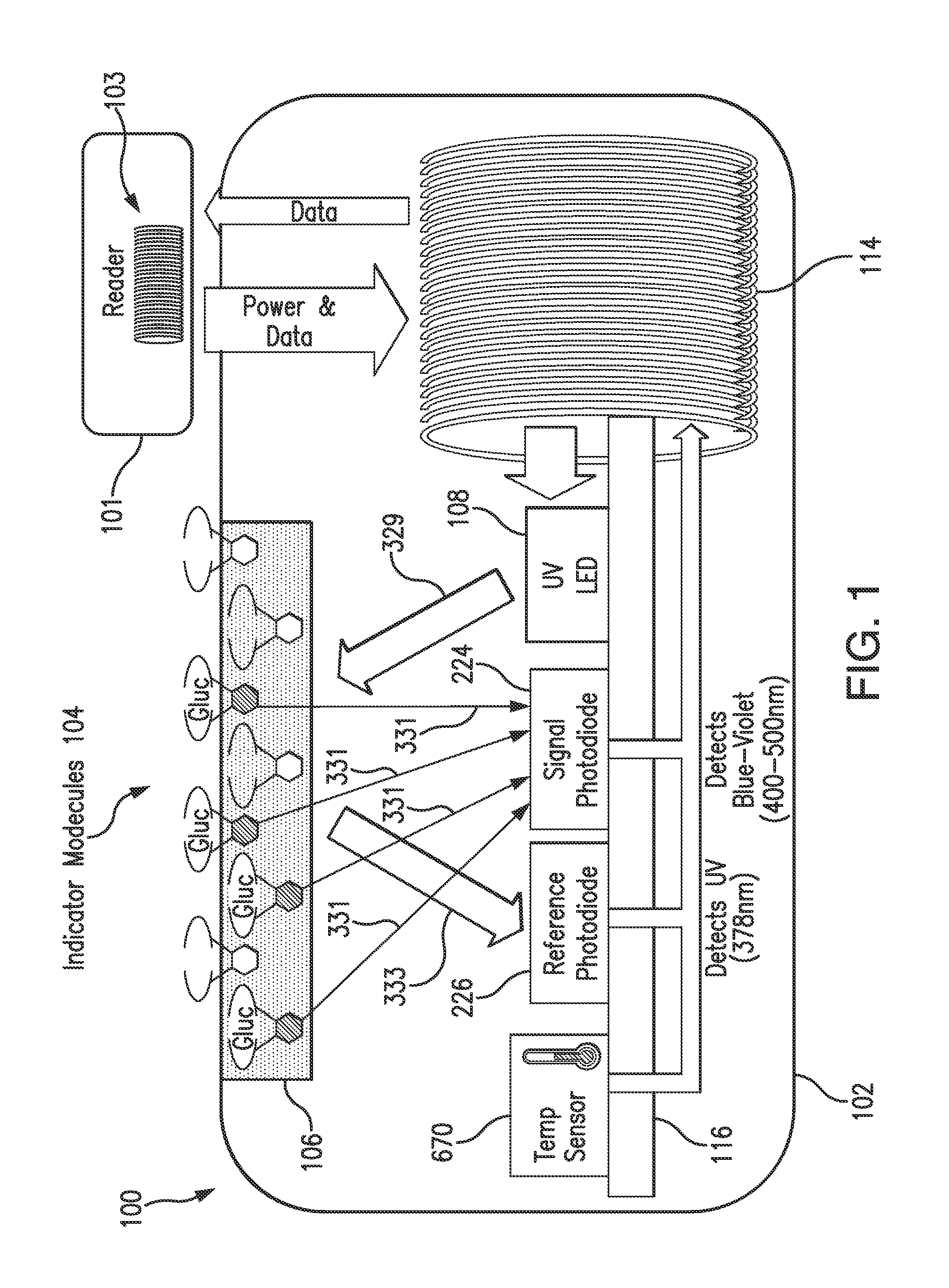

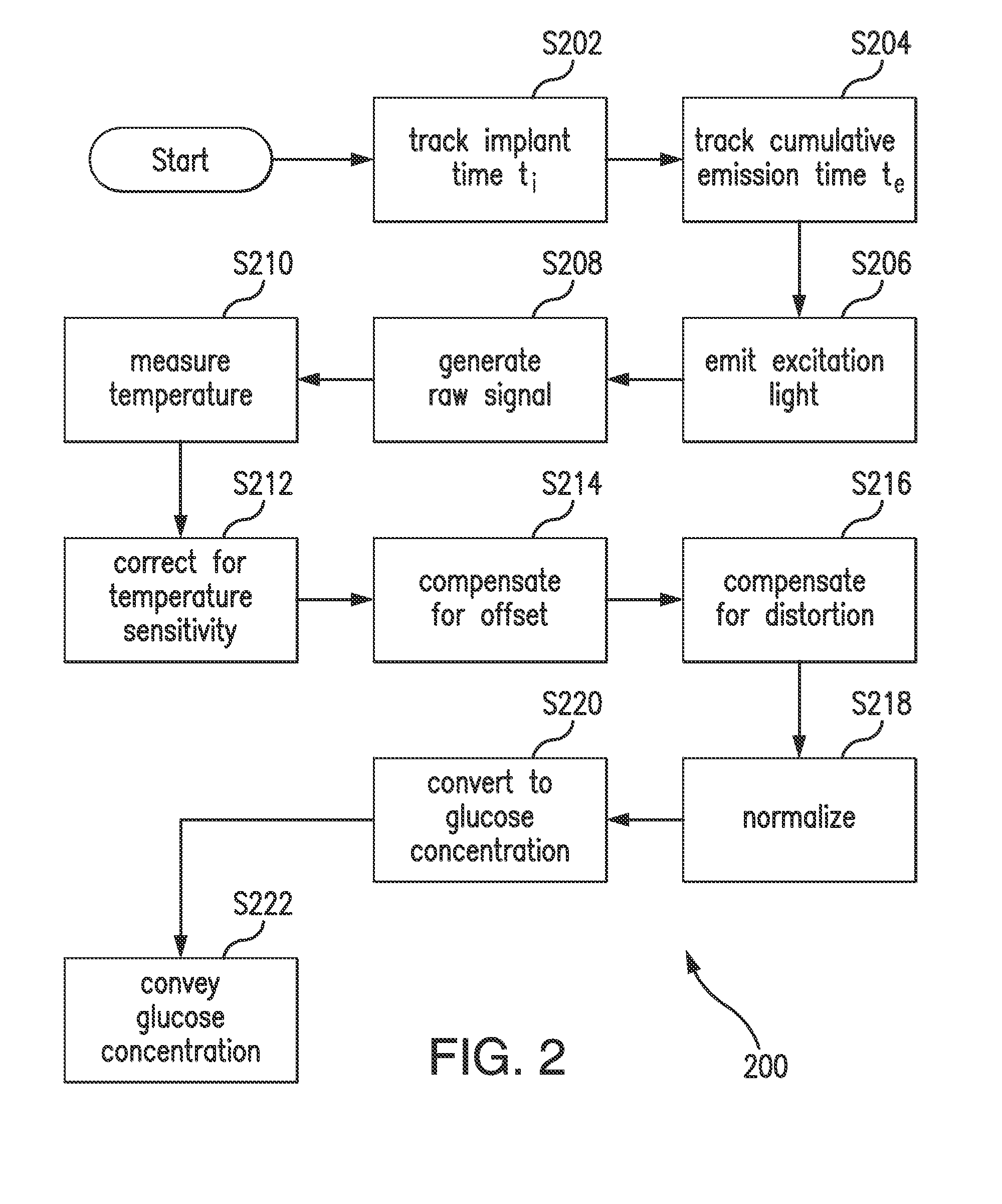

Purification of glucose concentration signal in an implantable fluorescence based glucose sensor

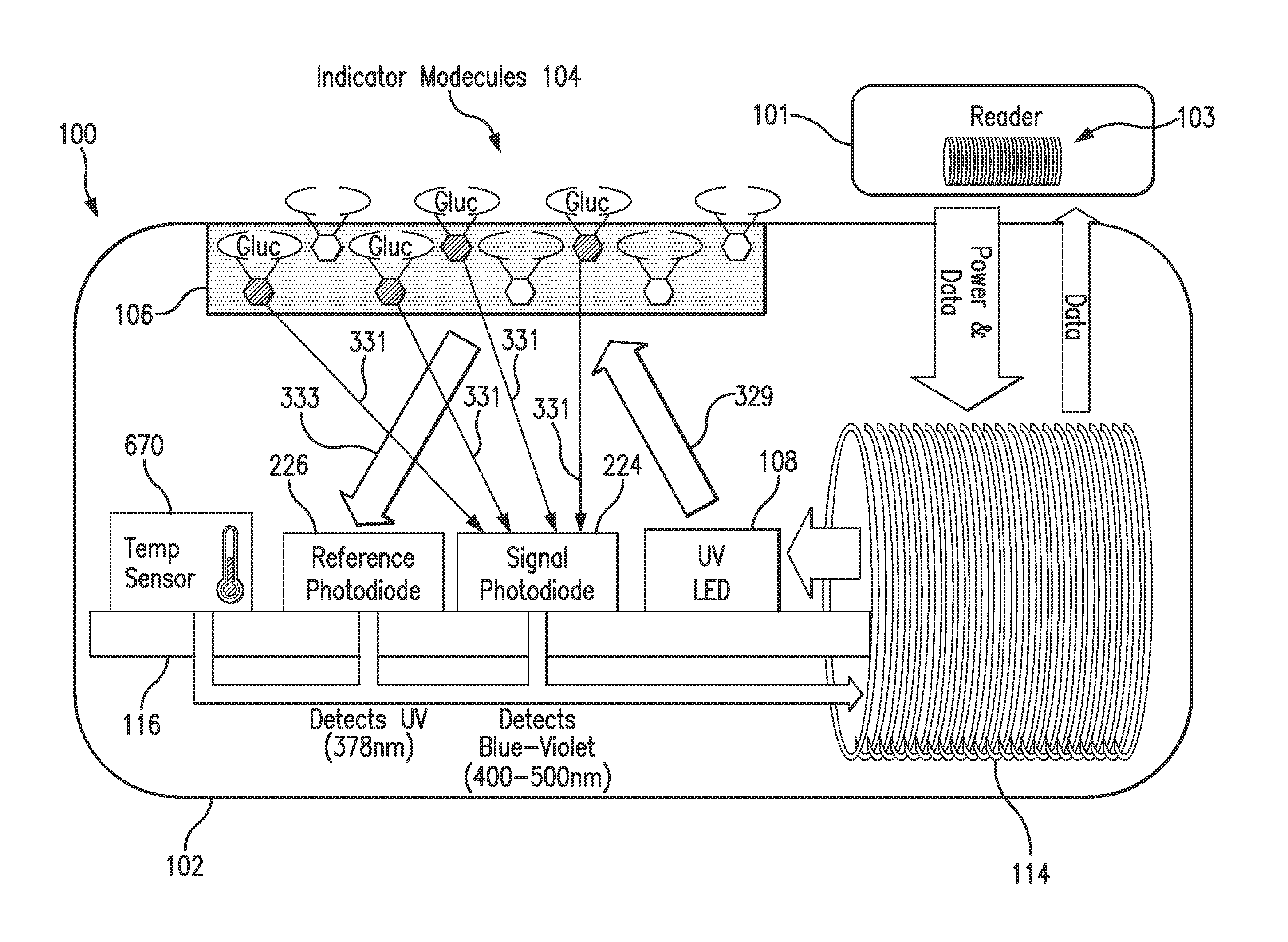

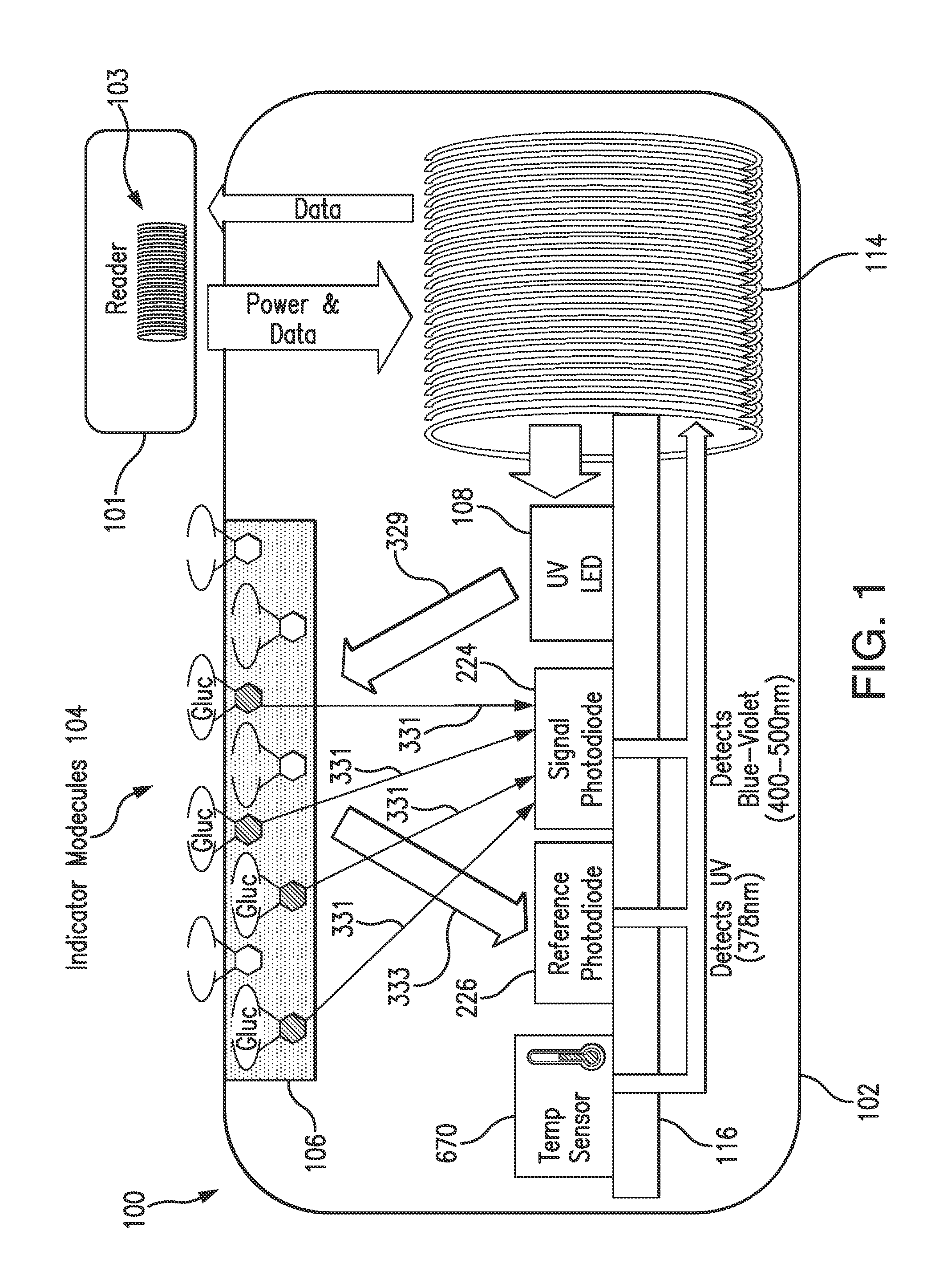

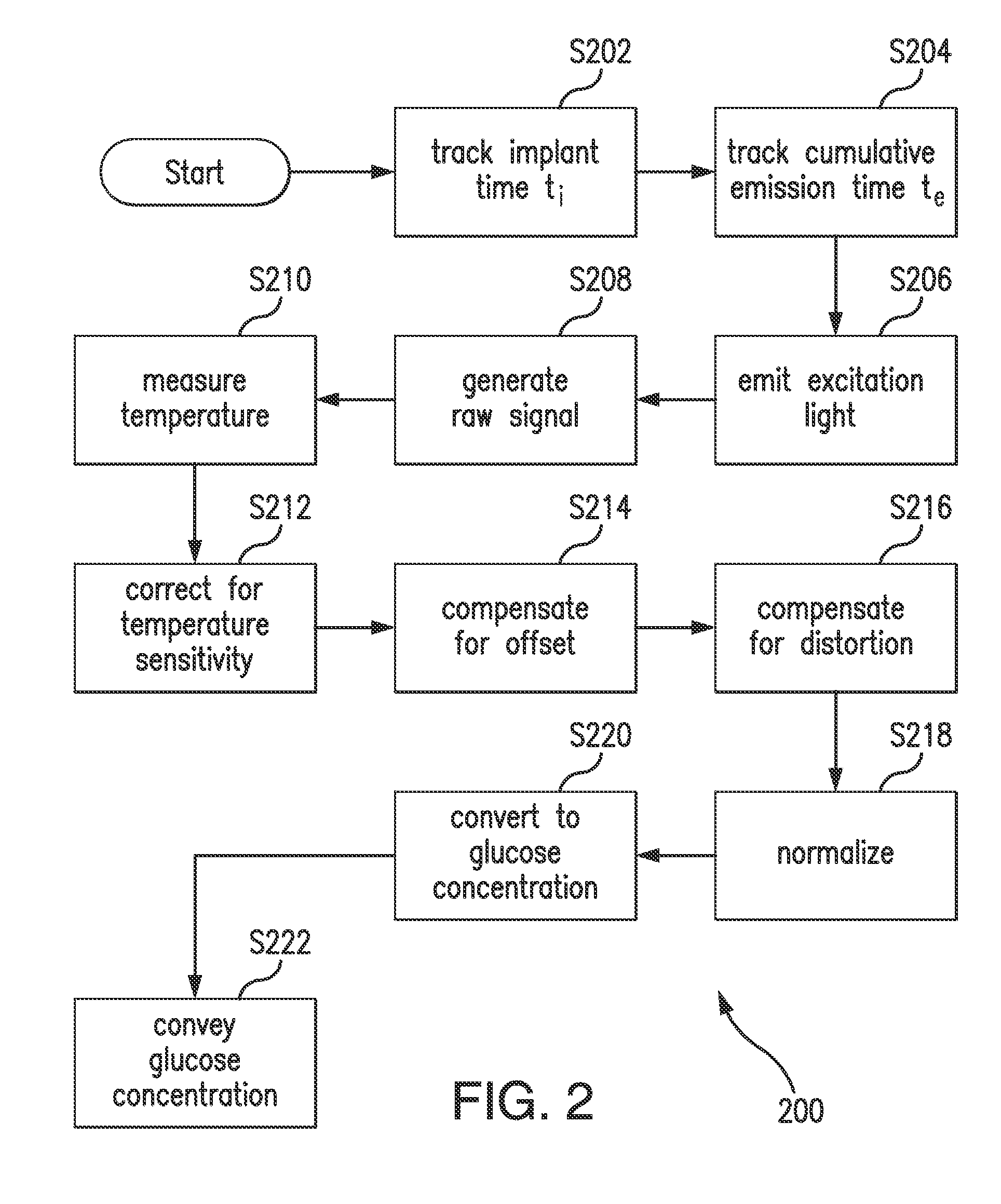

Methods, sensors, and systems for determining a concentration of glucose in a medium of a living animal are disclosed. Determining the glucose concentration may involve emitting excitation light from a light source to indicator molecules, generating a raw signal indicative of the amount of light received by a photodetector, purifying and normalizing the raw signal, and converting the normalized signal to a glucose concentration. The purification may involve removing noise (e.g., offset and / or distortion) from the raw signal. The purification and normalization may involve tracking the cumulative emission time that the light source has emitted the excitation light and tracking the implant time that has elapsed since the optical sensor was implanted. The purification and normalization may involve measuring the temperature of the sensor. The purification, normalization, and conversion may involve using parameters determined during manufacturing, in vitro testing, and / or in vivo testing.

Owner:SENSEONICS INC

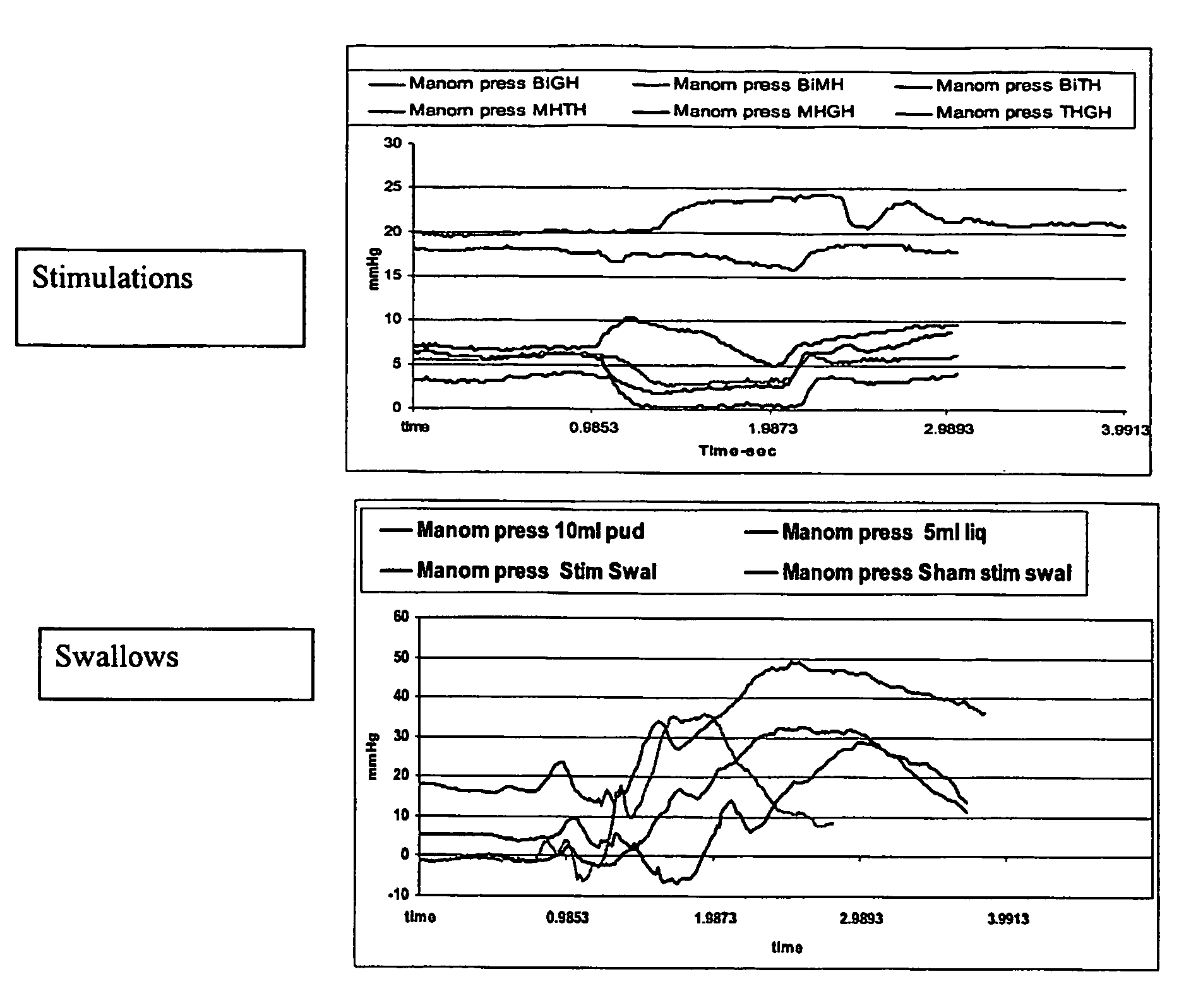

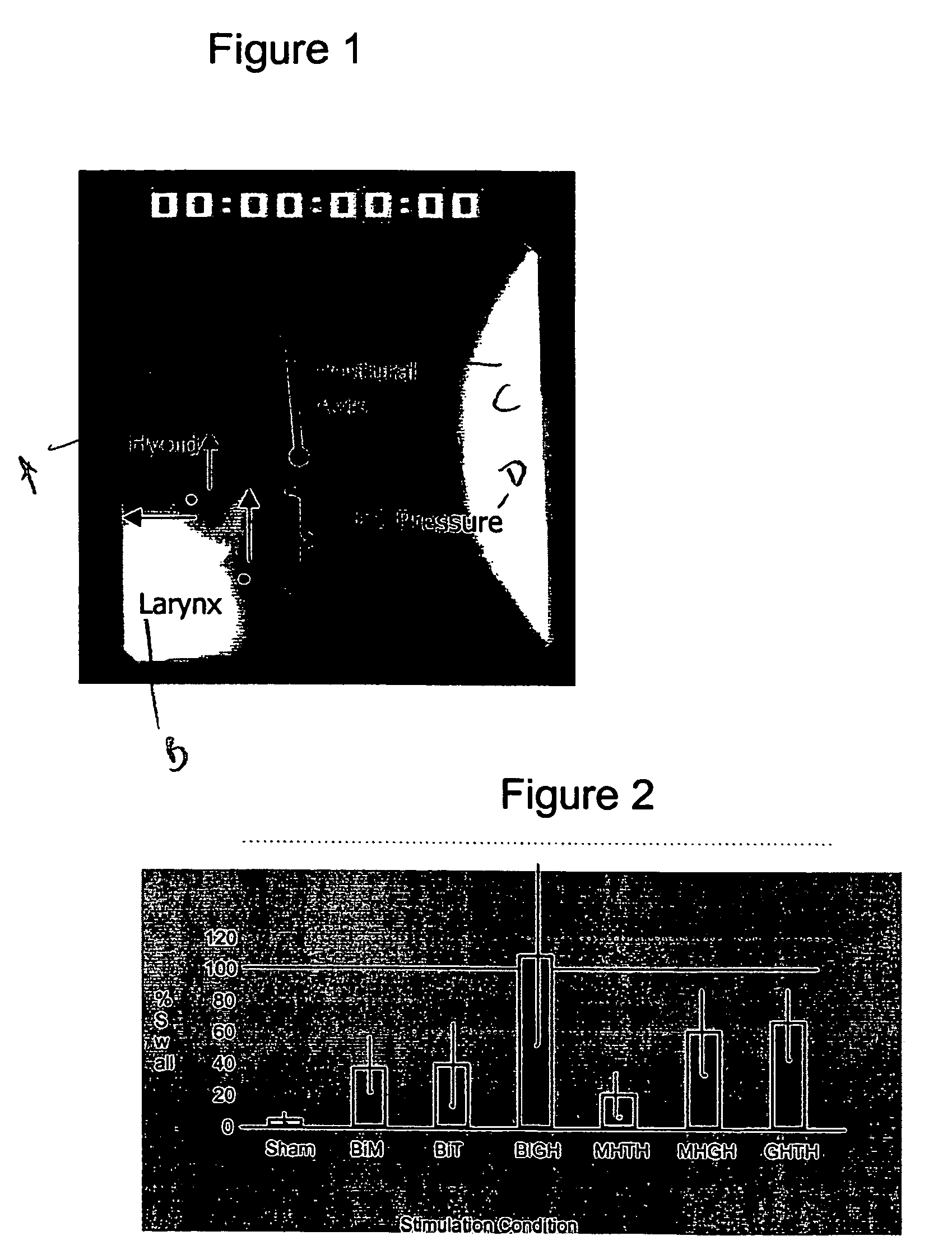

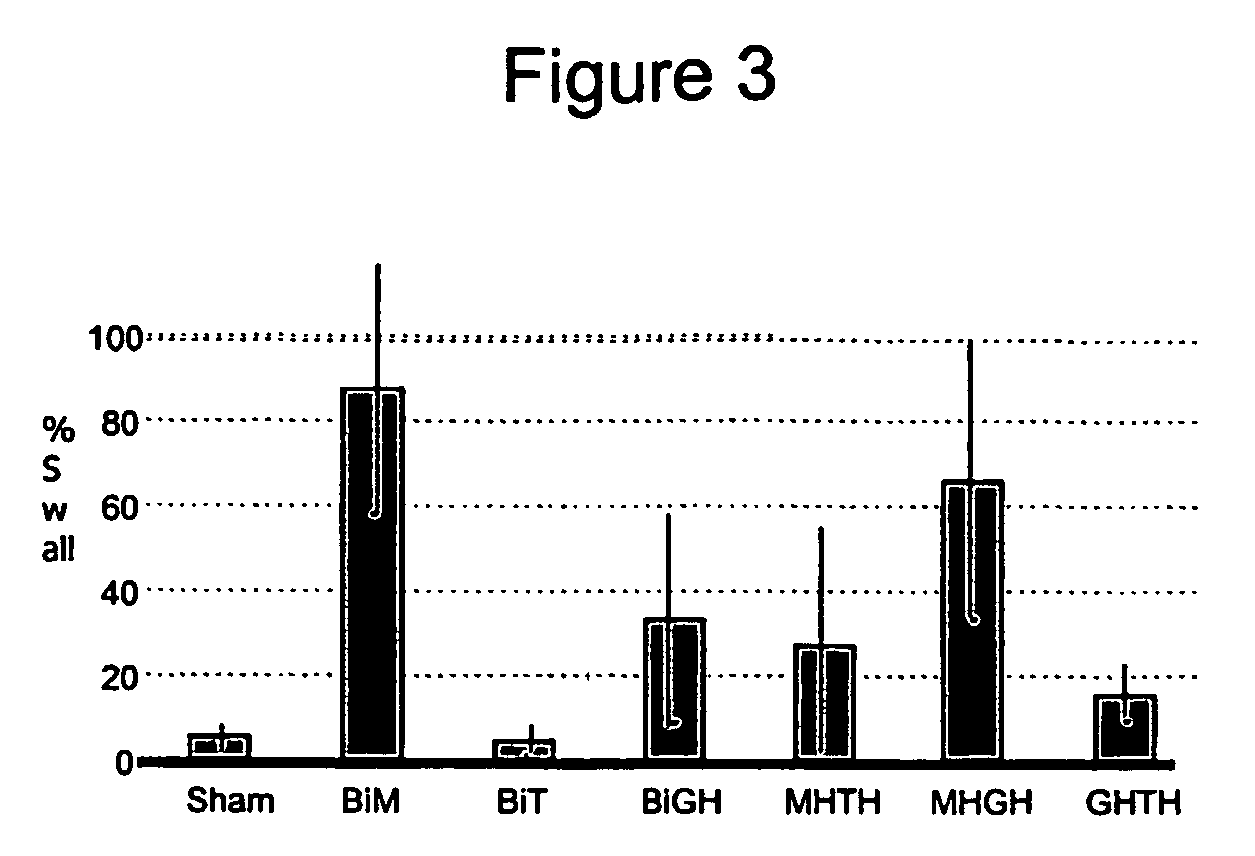

Methods and devices for intramuscular stimulation of upper airway and swallowing muscle groups

InactiveUS20070123950A1Avoid aspirationReduce disadvantagesElectrotherapyChiropractic devicesRespiratory muscleUpper esophageal sphincter

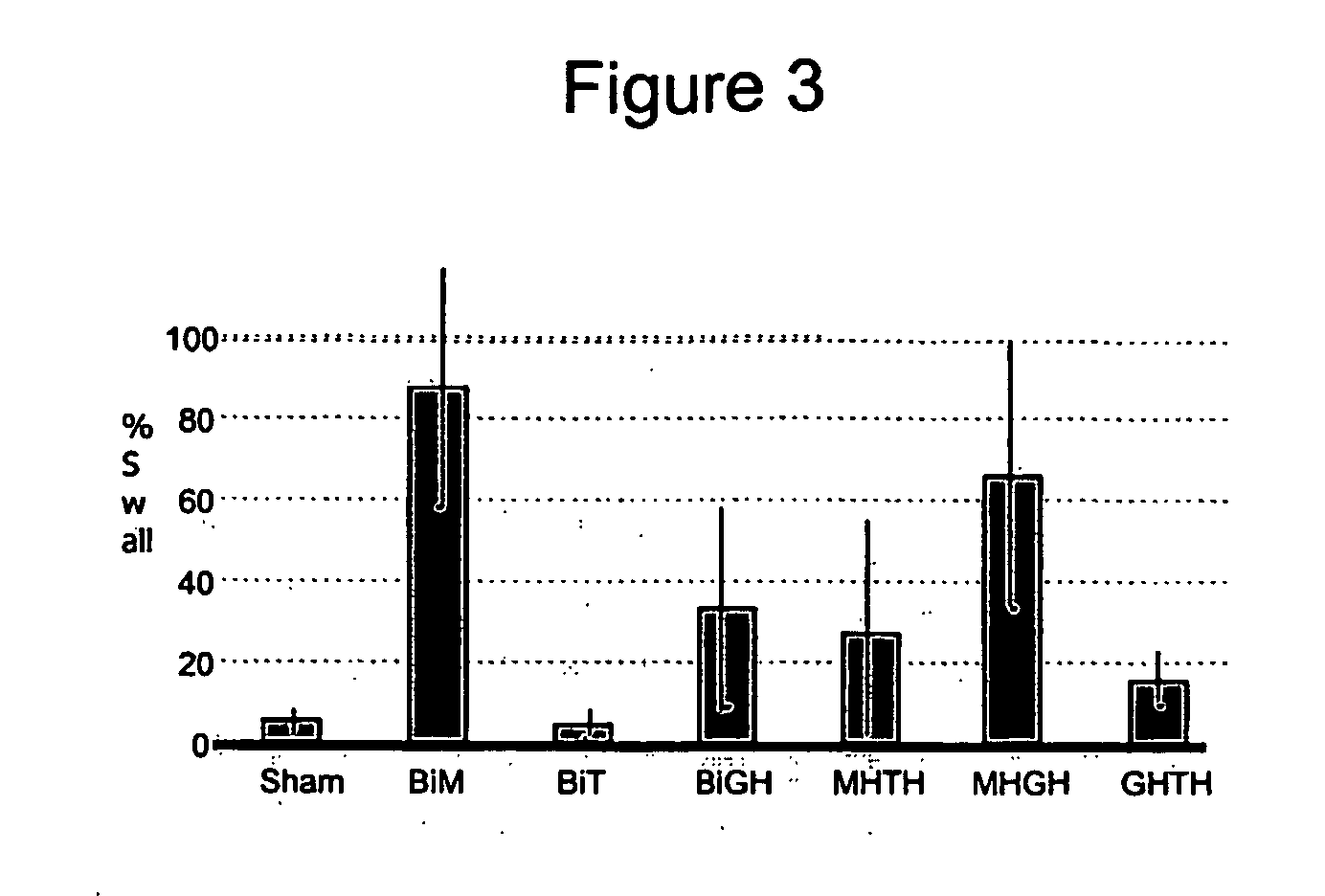

Devices and methods were discovered that successfully provided patient autonomous control of both hyolaryngeal elevation, anterior hyoid motion and opening of the upper esophageal sphincter for swallowing by intramuscular stimulation of two muscles. The technology allows patient self stimulation of swallowing and can return oral feeding to dysphagia patients. Indwelling electrode stimulation of only two muscles generated as much as 80 % of normal synergistic movement leading to swallowing. The devices and methods also are useful for control of other upper respiratory muscle groups involved in speech and voice. Calibration techniques may be used in combination for greater freedom in setting and using electrodes over extended implantation time periods. These methods and devices can control complex movements of body solids such as bone and cartilage and tissues by electro stimulation of a minimum set of muscles simultaneously.

Owner:UNITED STATES OF AMERICA

Purification of glucose concentration signal in an implantable fluorescence based glucose sensor

Methods, sensors, and systems for determining a concentration of glucose in a medium of a living animal are disclosed. Determining the glucose concentration may involve emitting excitation light from a light source to indicator molecules, generating a raw signal indicative of the amount of light received by a photodetector, purifying and normalizing the raw signal, and converting the normalized signal to a glucose concentration. The purification may involve removing noise (e.g., offset and / or distortion) from the raw signal. The purification and normalization may involve tracking the cumulative emission time that the light source has emitted the excitation light and tracking the implant time that has elapsed since the optical sensor was implanted. The purification and normalization may involve measuring the temperature of the sensor. The purification, normalization, and conversion may involve using parameters determined during manufacturing, in vitro testing, and / or in vivo testing.

Owner:SENSEONICS INC

Methods and devices for intramuscular stimulation of upper airway and swallowing muscle groups

Devices and methods were discovered that successfully provided patient autonomous control of both hyolaryngeal elevation, anterior hyoid motion and opening of the upper esophageal sphincter for swallowing by intramuscular stimulation of two muscles. The technology allows patient self stimulation of swallowing and can return oral feeding to dysphagia patients. Indwelling electrode stimulation of only two muscles generated as much as 80 % of normal synergistic movement leading to swallowing. The devices and methods also are useful for control of other upper respiratory muscle groups involved in speech and voice. Calibration techniques may be used in combination for greater freedom in setting and using electrodes over extended implantation time periods. These methods and devices can control complex movements of body solids such as bone and cartilage and tissues by electro stimulation of a minimum set of muscles simultaneously.

Owner:UNITED STATES OF AMERICA

Purification of glucose concentration signal in an implantable fluorescence based glucose sensor

Methods, sensors, and systems for determining a concentration of glucose in a medium of a living animal are disclosed. Determining the glucose concentration may involve emitting excitation light from a light source to indicator molecules, generating a raw signal indicative of the amount of light received by a photodetector, purifying and normalizing the raw signal, and converting the normalized signal to a glucose concentration. The purification may involve removing noise (e.g., offset and / or distortion) from the raw signal. The purification and normalization may involve tracking the cumulative emission time that the light source has emitted the excitation light and tracking the implant time that has elapsed since the optical sensor was implanted. The purification and normalization may involve measuring the temperature of the sensor. The purification, normalization, and conversion may involve using parameters determined during manufacturing, in vitro testing, and / or in vivo testing.

Owner:SENSEONICS INC

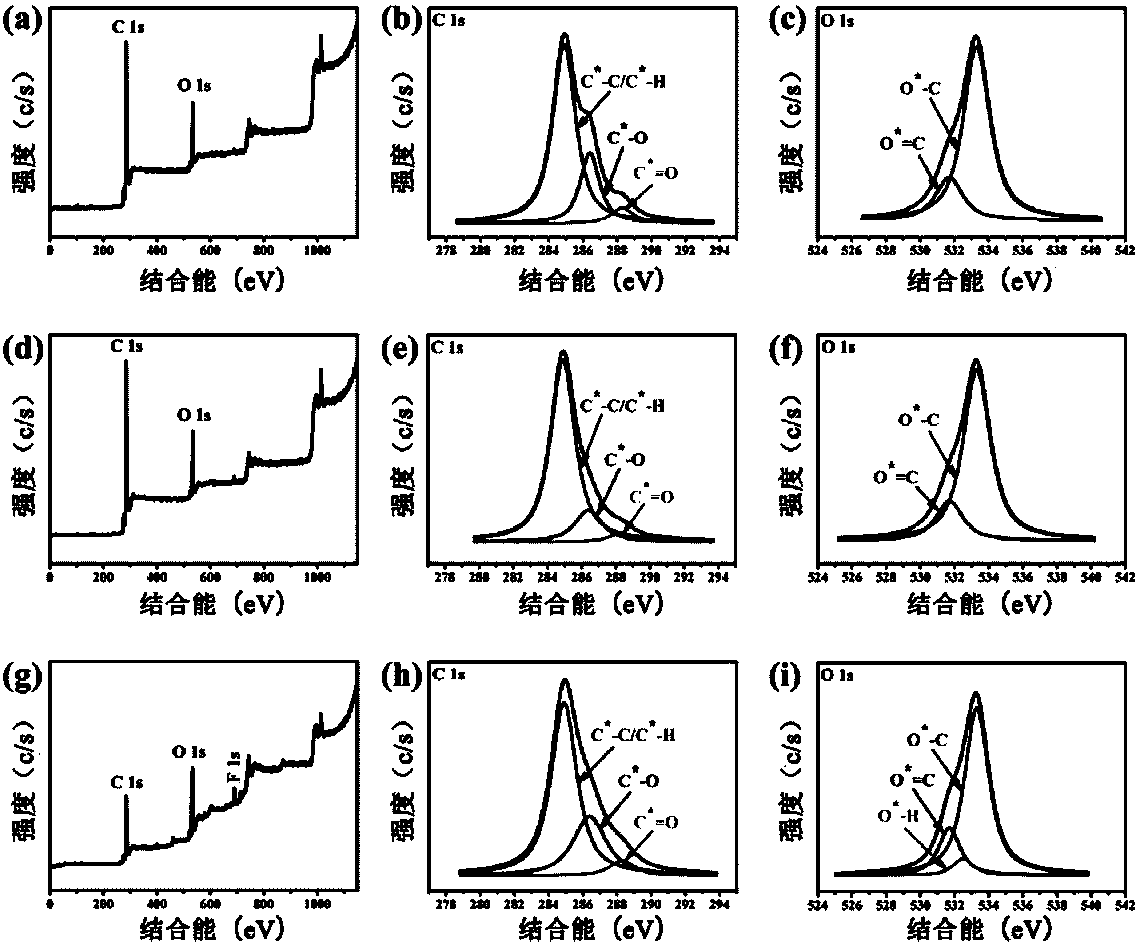

Polyether-ether-ketone material and surface modification method thereof

The invention relates to a polyether-ether-ketone material and a surface modification method thereof. The method comprises the step of carrying out plasma immersion ion implantation on a polyether-ether-ketone material by taking argon and water vapor as ion sources, wherein the process parameters of the plasma immersion ion implantation technique are as follows: the implantation voltage is 500-1000V, the argon flow is 15-60 sccm, the radio-frequency power is 300-500W, the base pressure is 5*10<-3> Pa, the duty ratio is 30%, the frequency is 30 kHZ, the implantation time is 30-90 minutes, the vacuum chamber temperature is 80-120 DEG C, and after the water vapor is fed, the vacuum chamber pressure is greater than 5*10<-3> Pa and smaller than 1*10<-2> Pa. The surface of the modified polyether-ether-ketone material is of a gully-shaped nanostructure, and the surface of the modified polyether-ether-ketone material is connected with a hydroxyl functional group.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

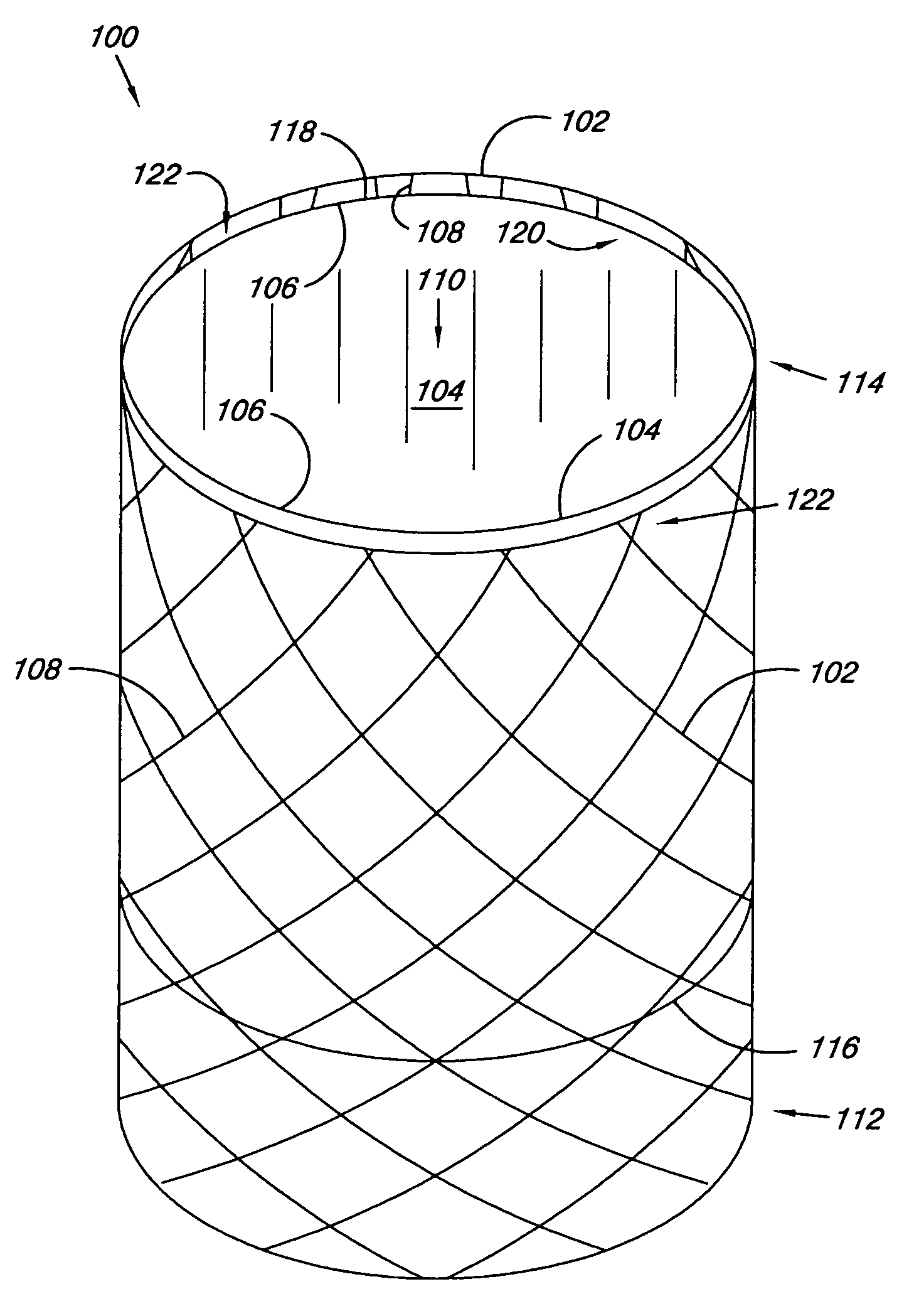

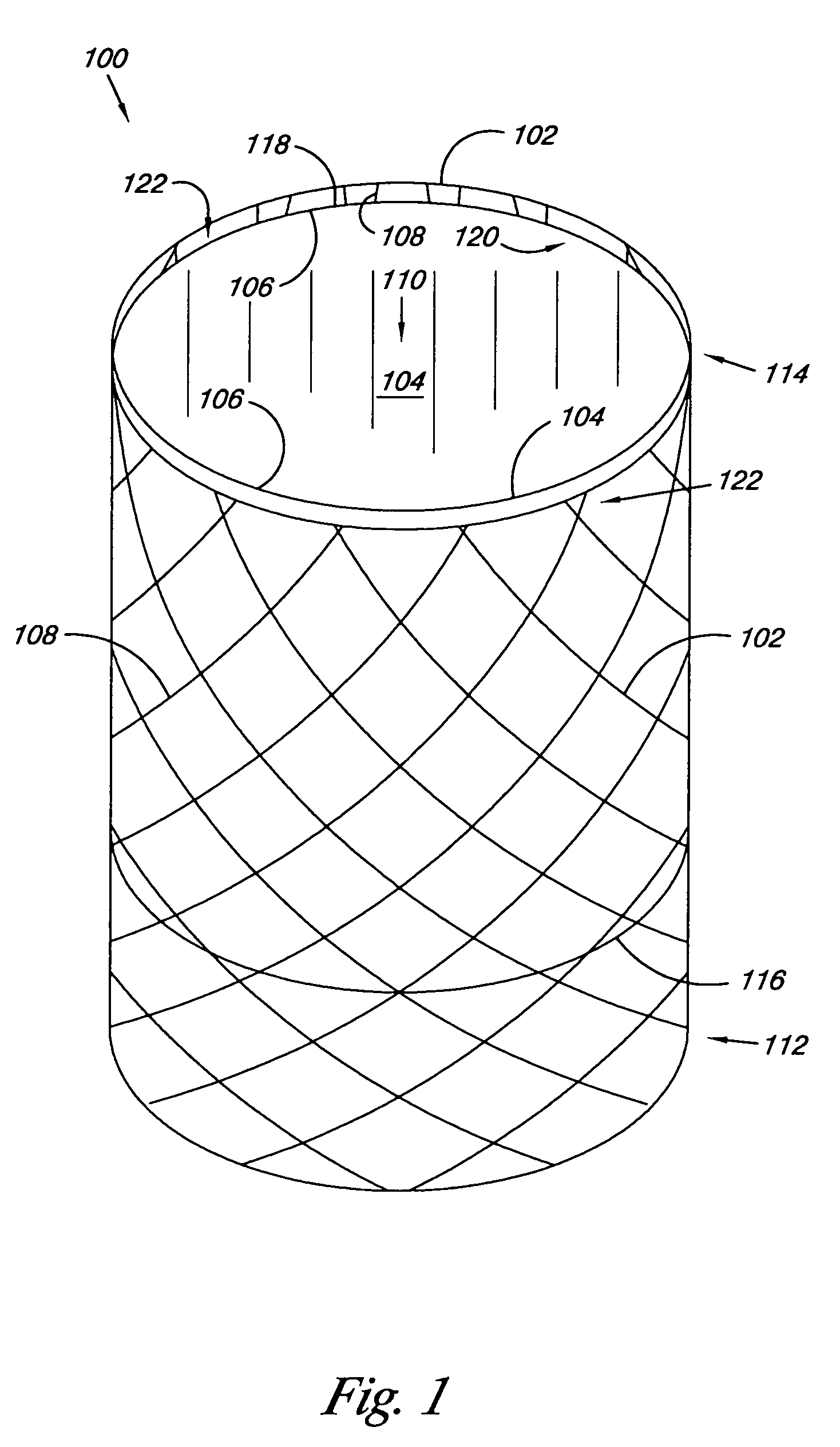

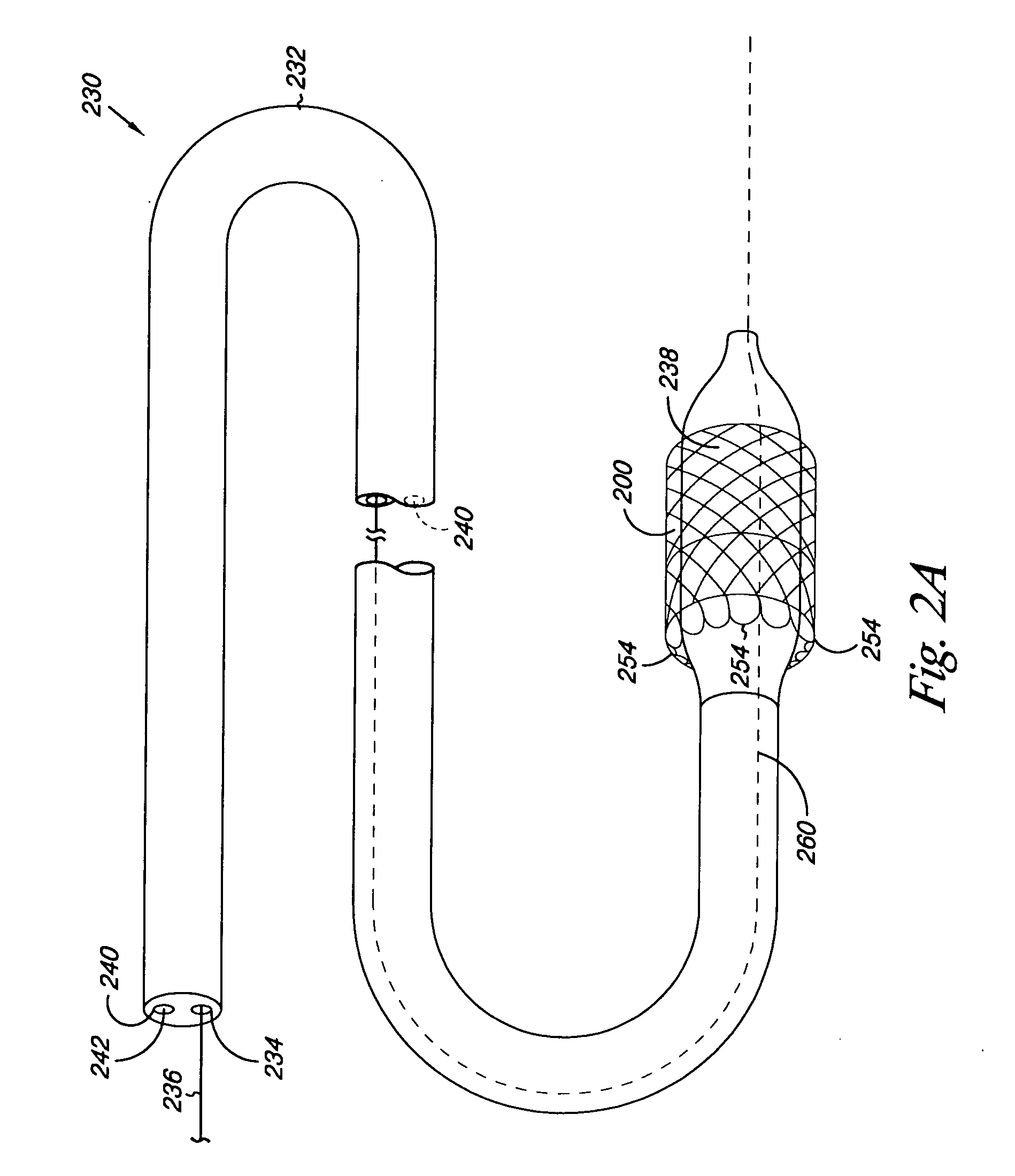

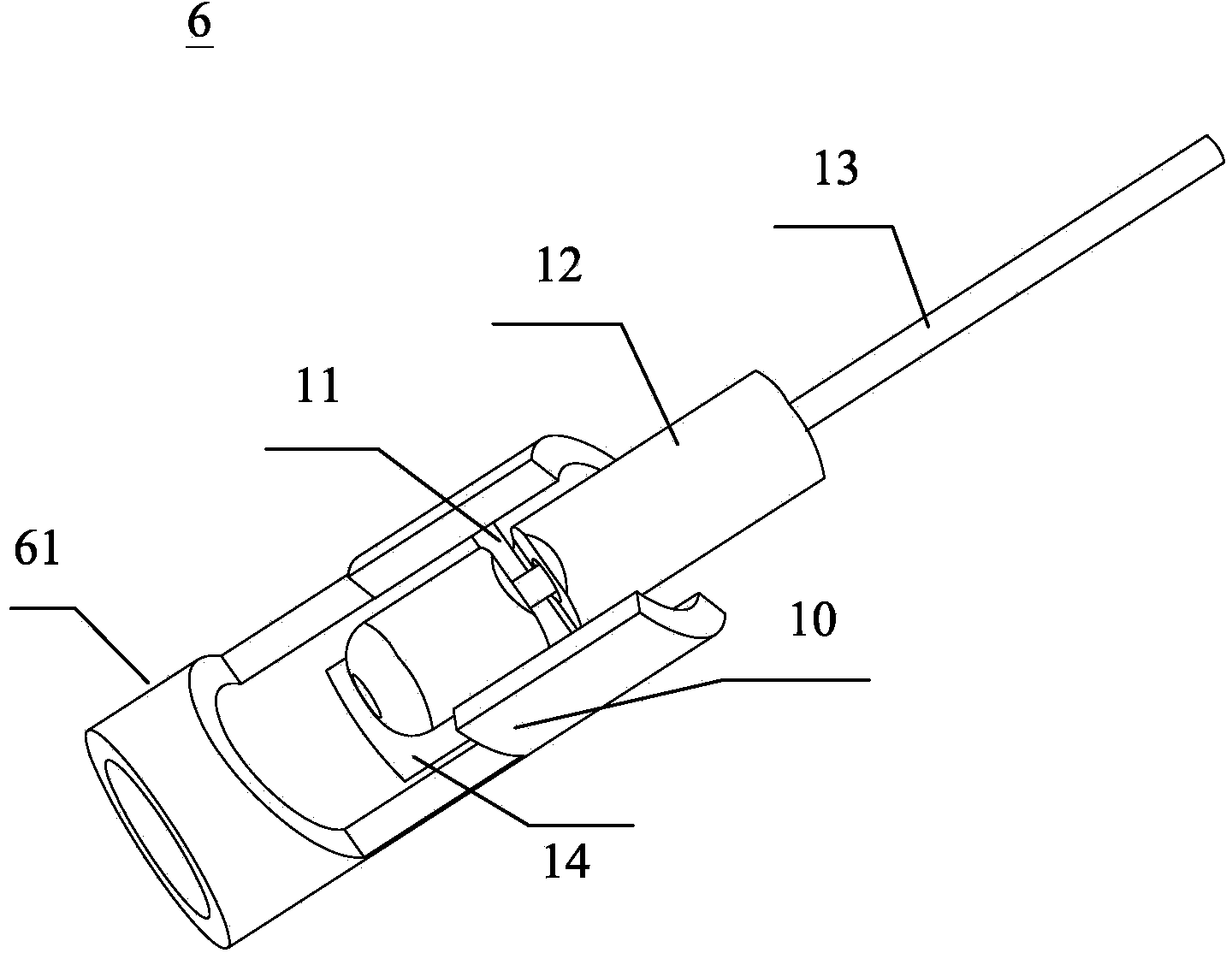

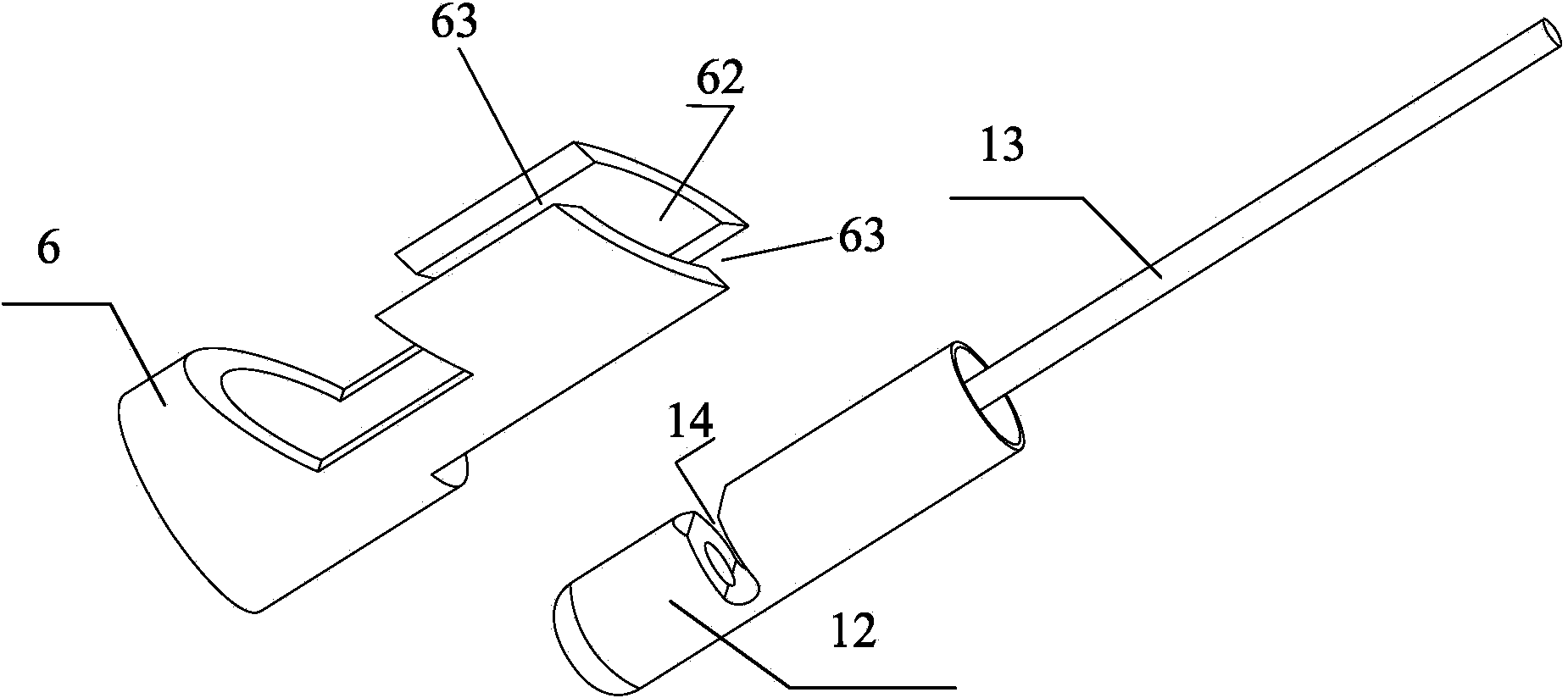

Valve with delayed leaflet deployment

A valve for use in a body lumen, where the valve includes a valve leaflet with delayed leaflet deployment relative an in vivo implant time. The valve includes a valve frame, a valve leaflet coupled to the valve frame. The valve leaflet includes a commissure that can reversibly seal for unidirectional flow of a liquid through the valve, and a biodegradable adhesive between the valve leaflet and the valve frame to hold at least the commissure of the valve leaflet in a static relationship relative the valve frame for a predetermined time once implanted in vivo.

Owner:BOSTON SCI SCIMED INC

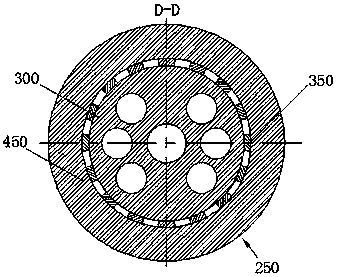

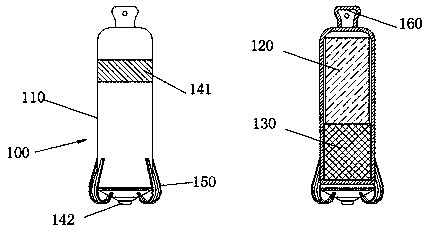

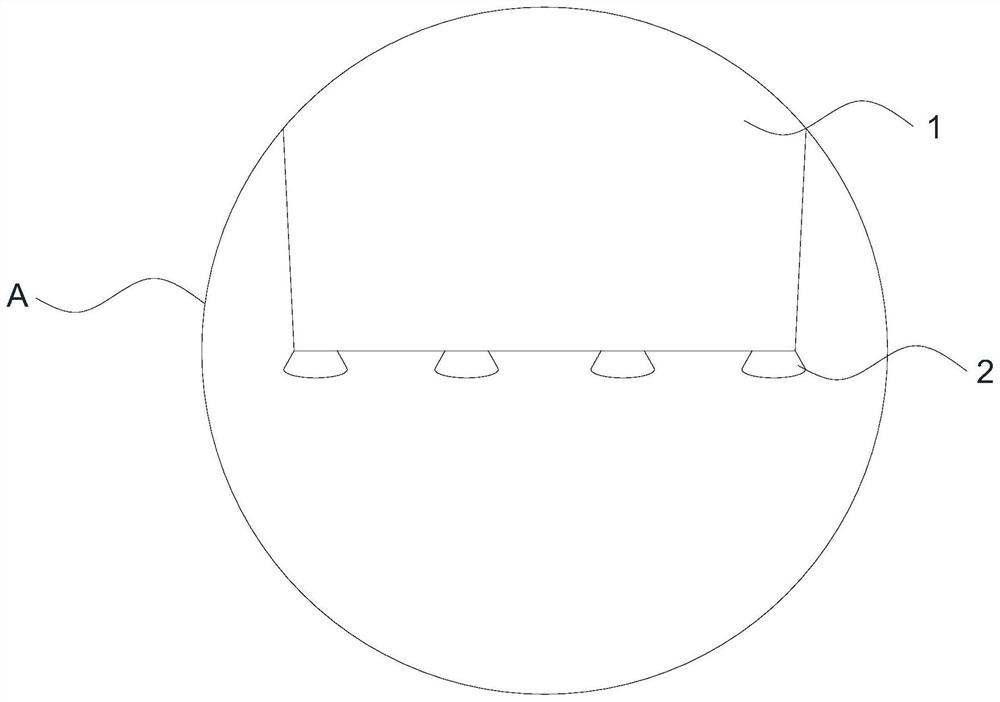

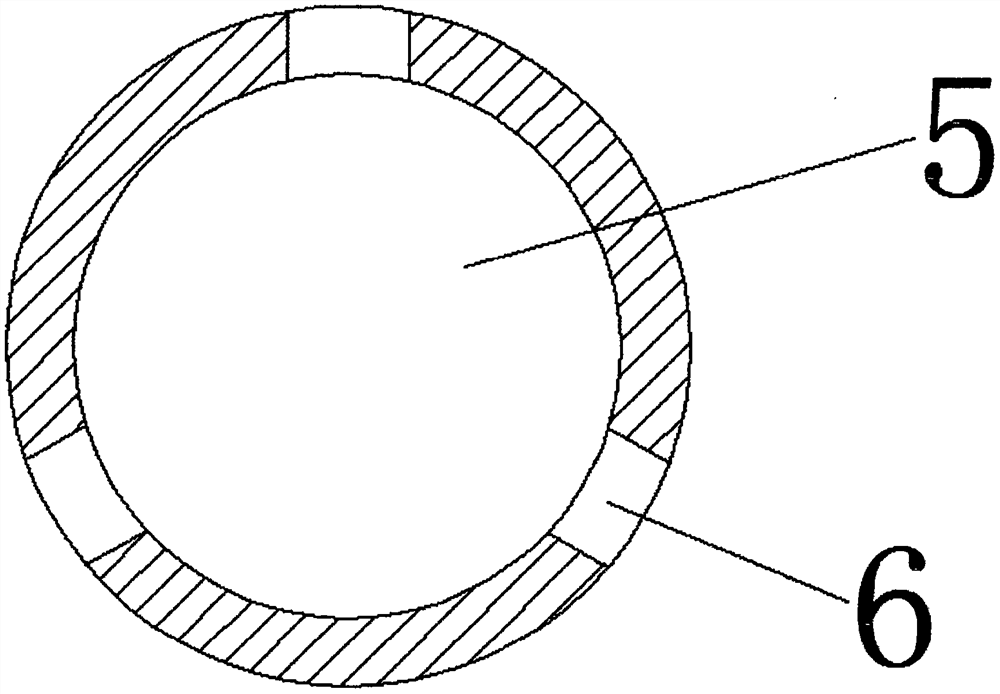

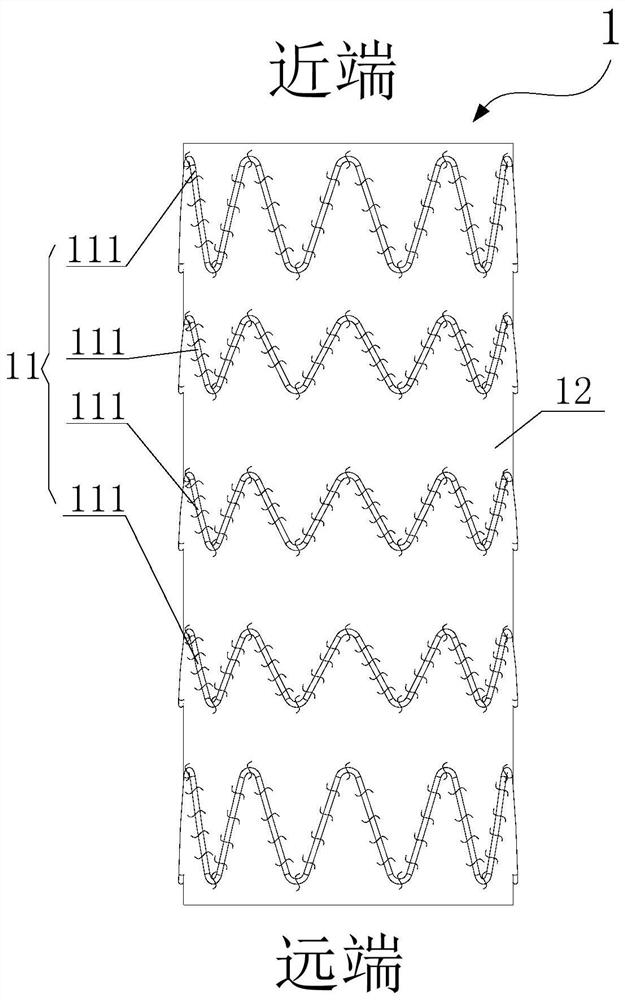

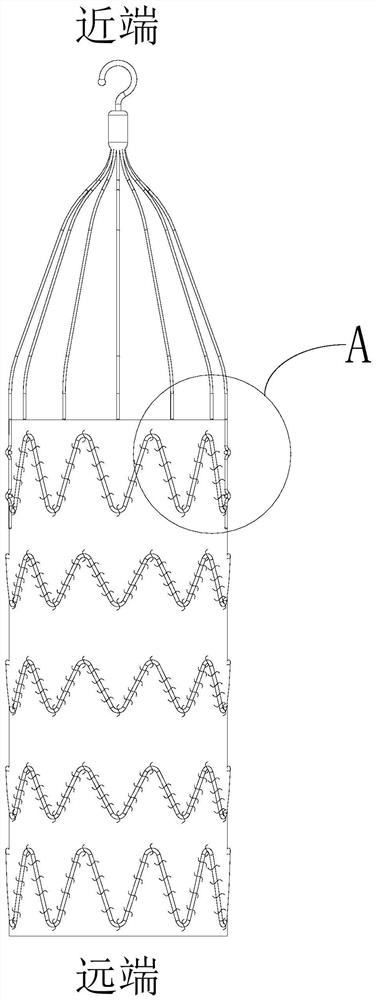

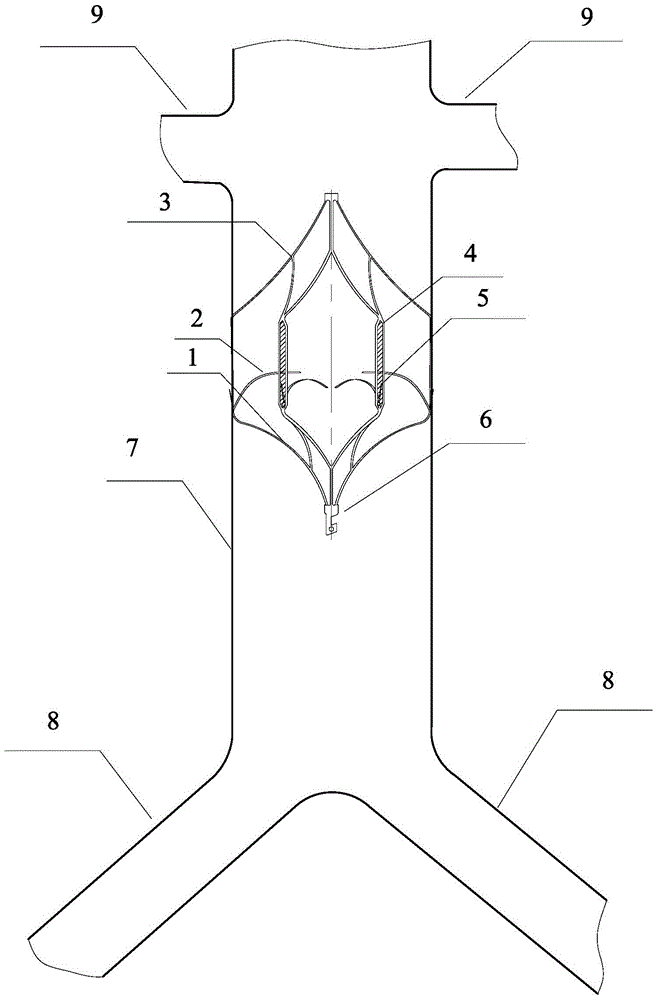

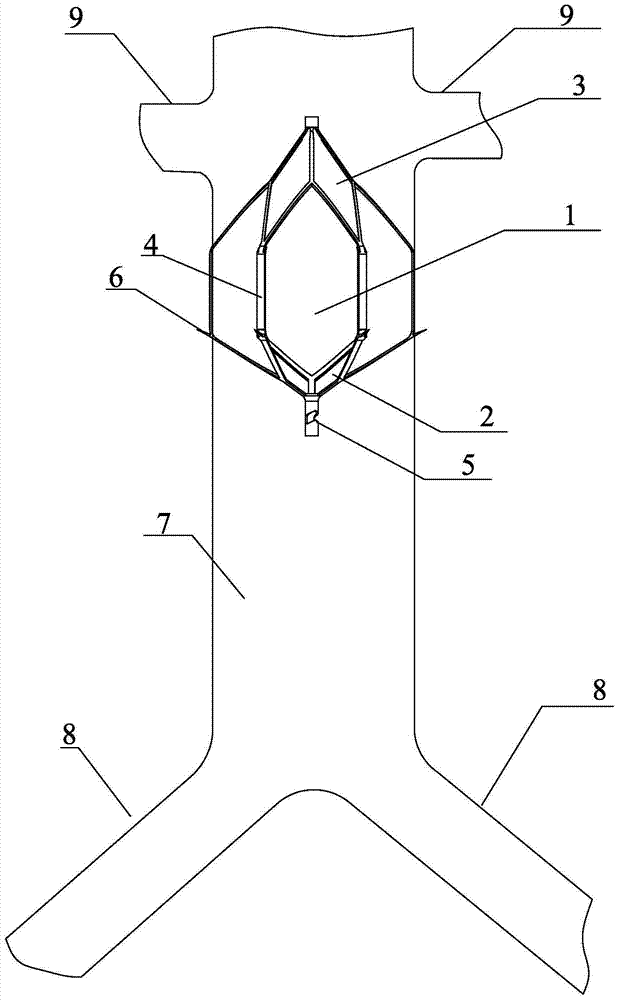

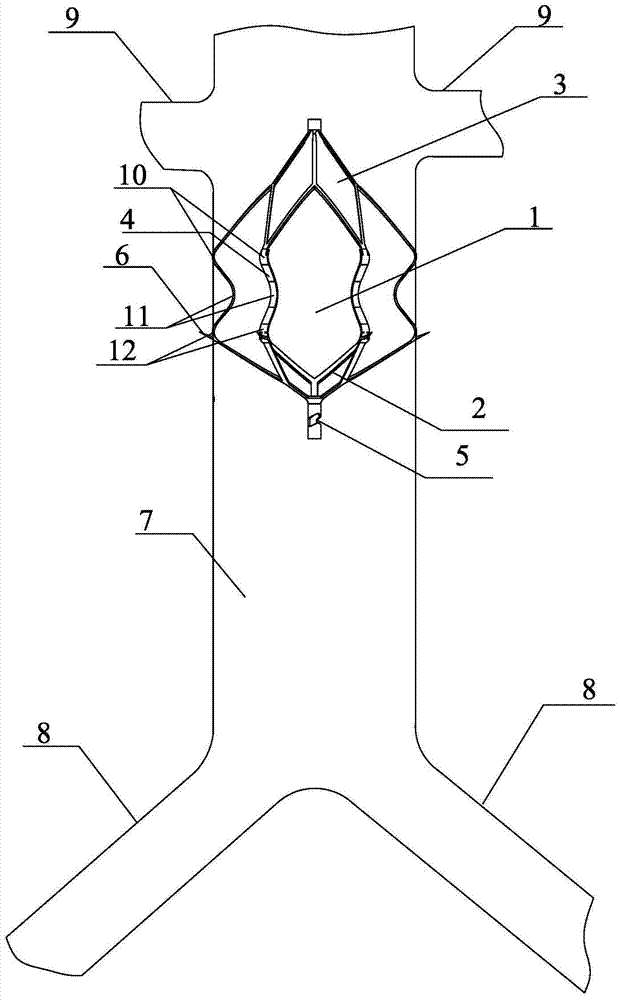

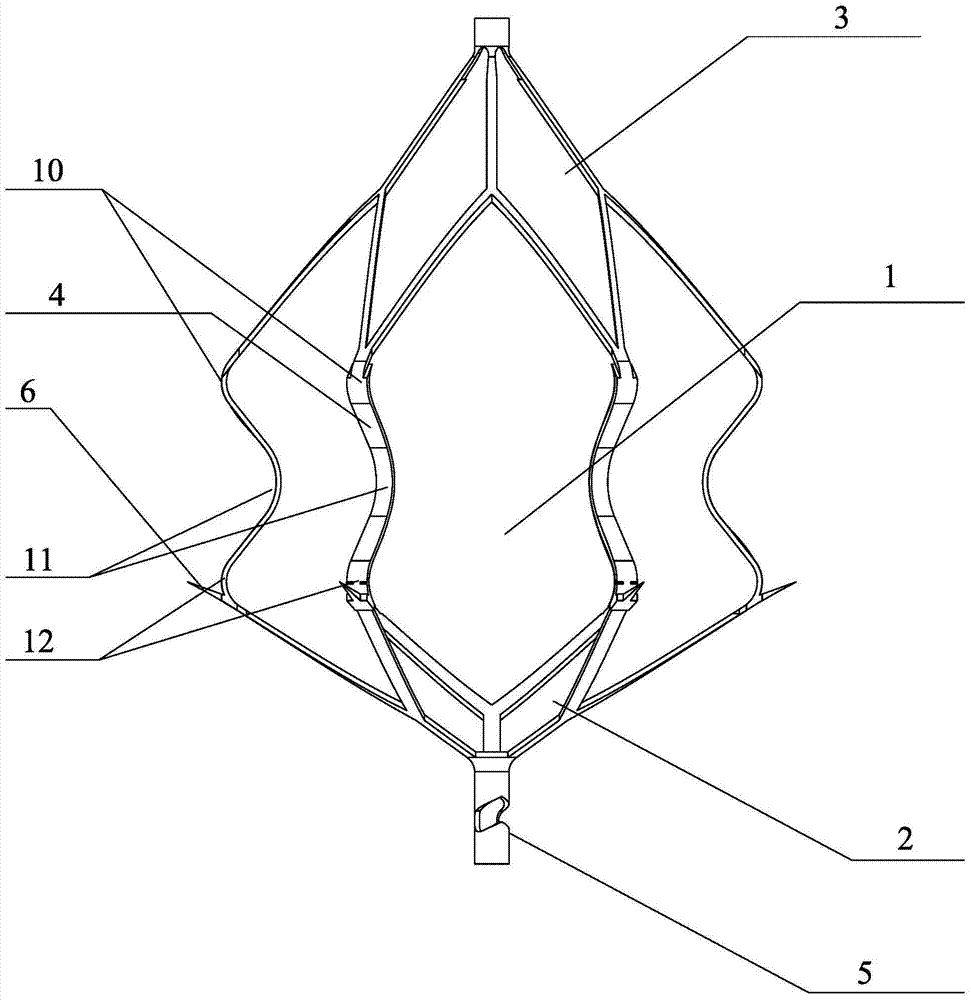

Vena cava filter

ActiveCN104352287AGood effect on filtering thrombusEasy to fixBlood vessel filtersImplantation timeAlloy

The invention discloses a vena cava filter which is placed at the position of an inferior vena cava between kidney venas and iliac venas, and is formed by integrally cutting a nickel-titanium alloy pipe with laser. The filter comprises connecting rods, a top layer filter screen, a middle layer filter screen and a bottom layer filter screen, wherein the top layer filter screen, the middle layer filter screen and the bottom layer filter screen are jointly formed in a cage-shaped structure, the middle layer filter screen is positioned between the top layer filter screen and the bottom layer filter screen, and is formed by inwards bending a plurality of branches which are cut; the top layer filter screen and the middle layer filter screen can capture and intercept larger thrombosis, and the bottom layer filter screen can capture and intercept smaller thrombosis; the surfaces of the filter screens of the three layers are wrapped with PTFE (poly tetra fluoro ethylene) films; the connecting rods are in contact with vascular walls, are connected with the cage-shaped structure, can be divided into more than two branches, are formed by expanding, and are wrapped with the PTFE films. The vena cava filter provided by the invention has the advantages that the effect of filtering the thrombosis is excellent, the vena cava filter can be repeatedly and firmly positioned, the implantation time can be prolonged, the vena cava filter can be recovered, and the endothelialization effect can be delayed.

Owner:SHENZHEN KYD BIOMEDICAL TECH CO LTD

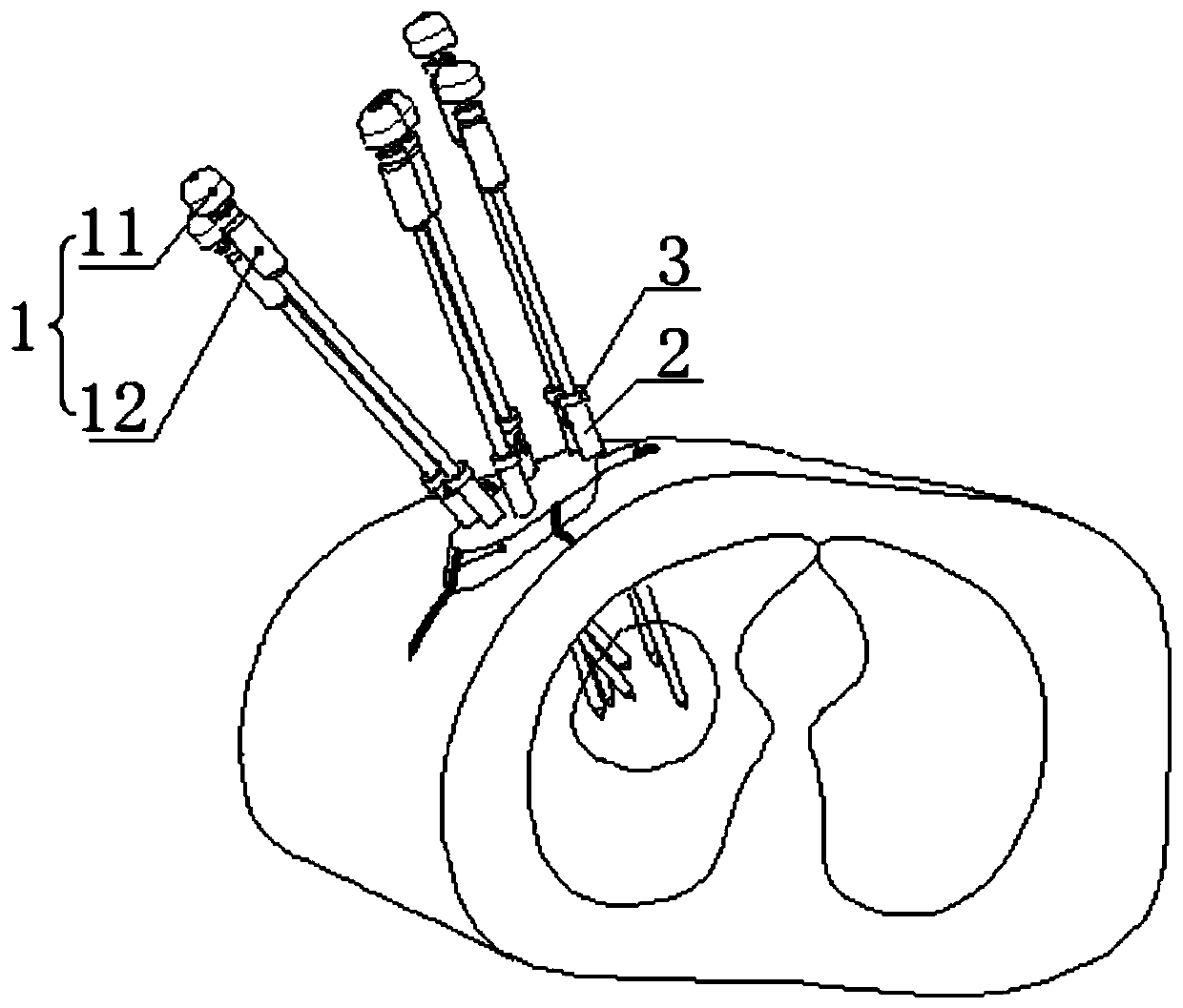

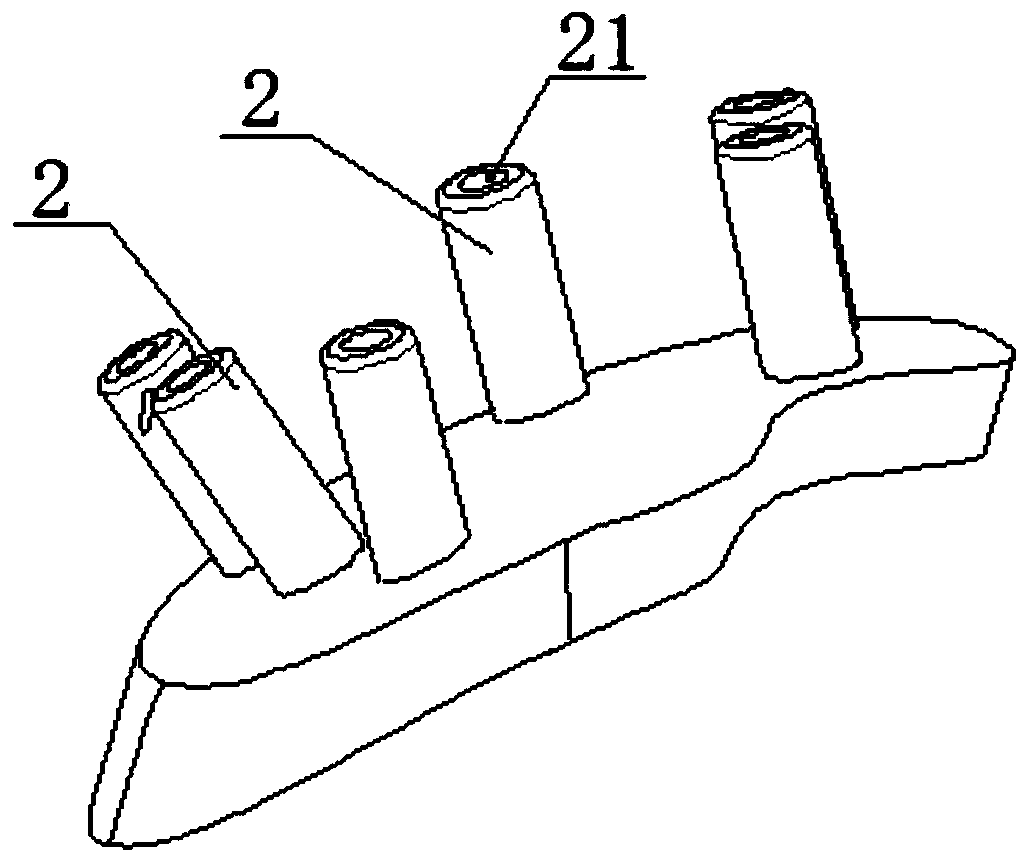

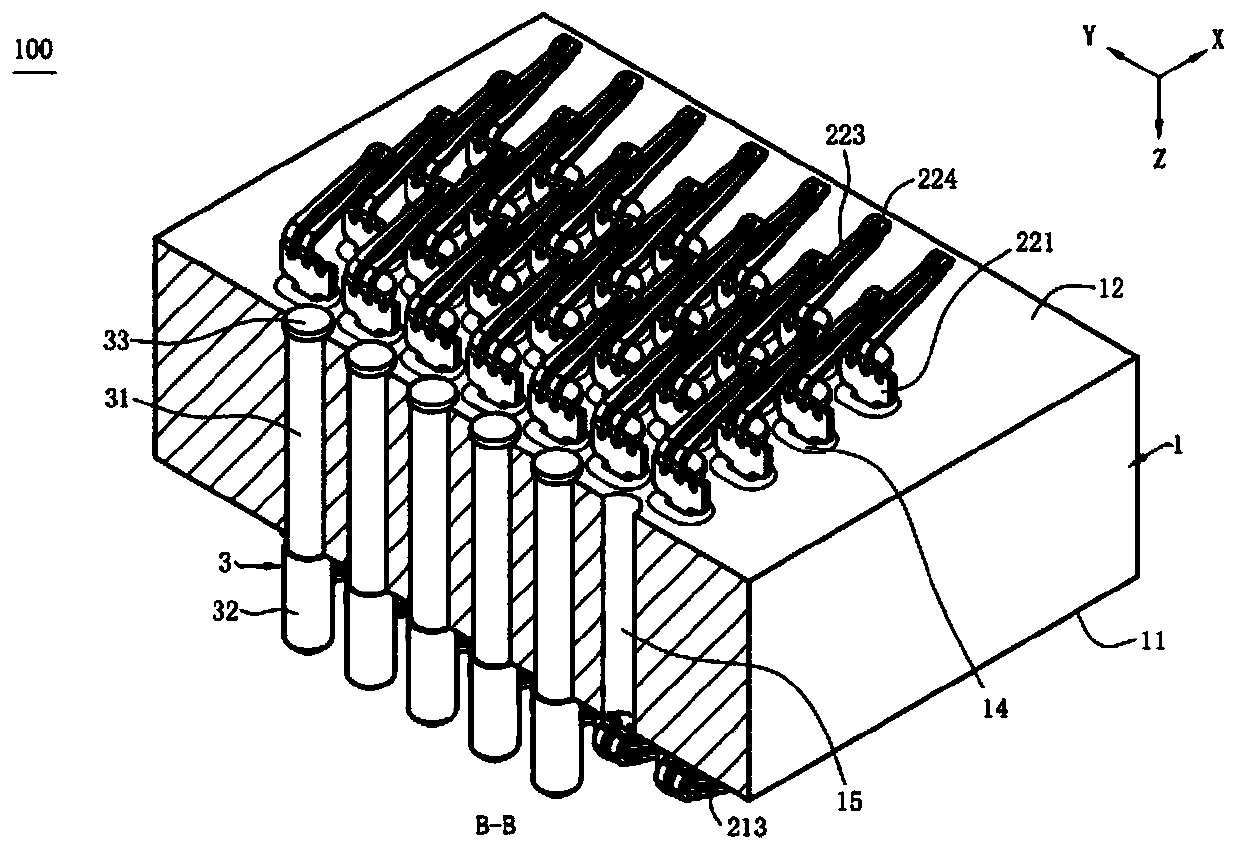

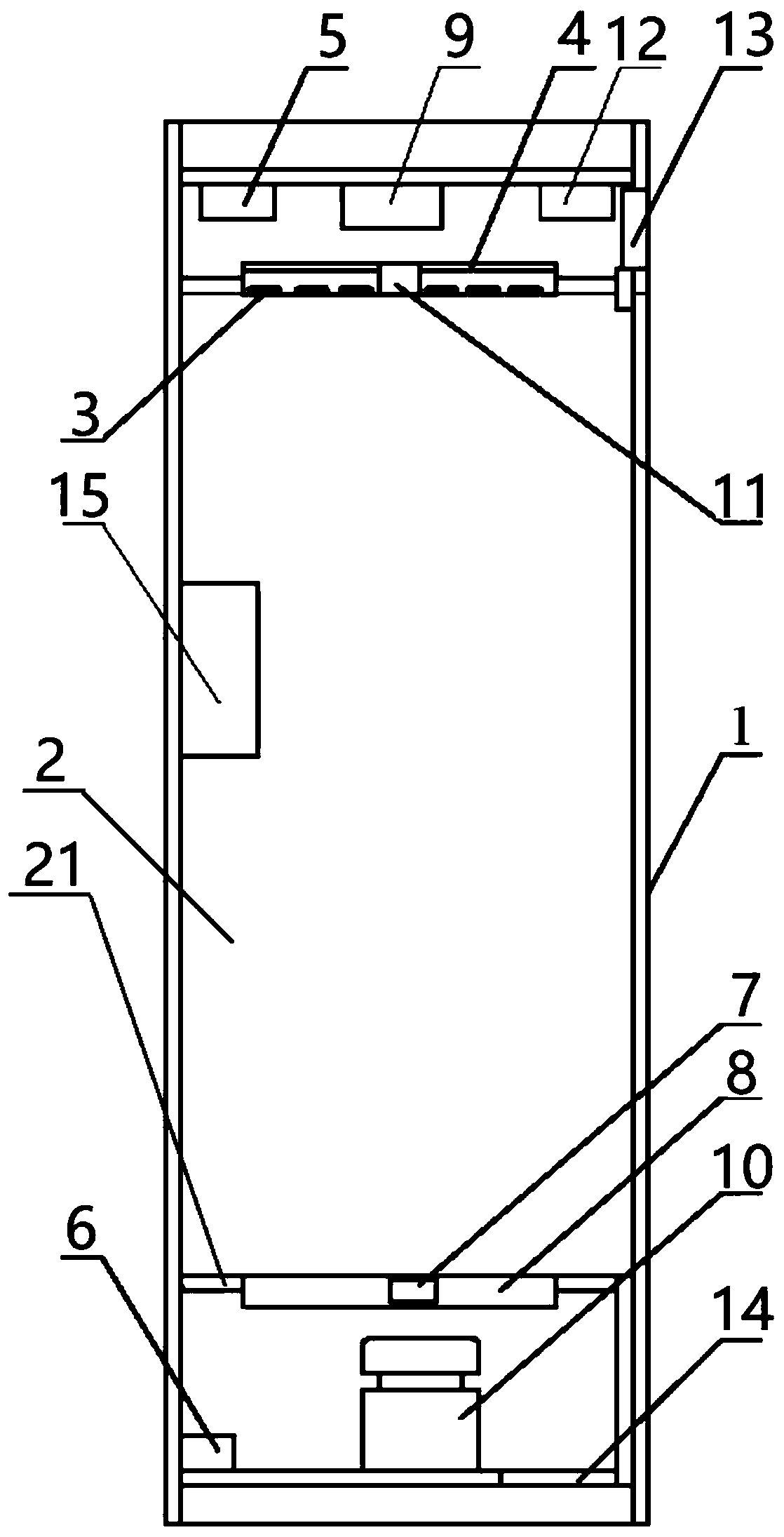

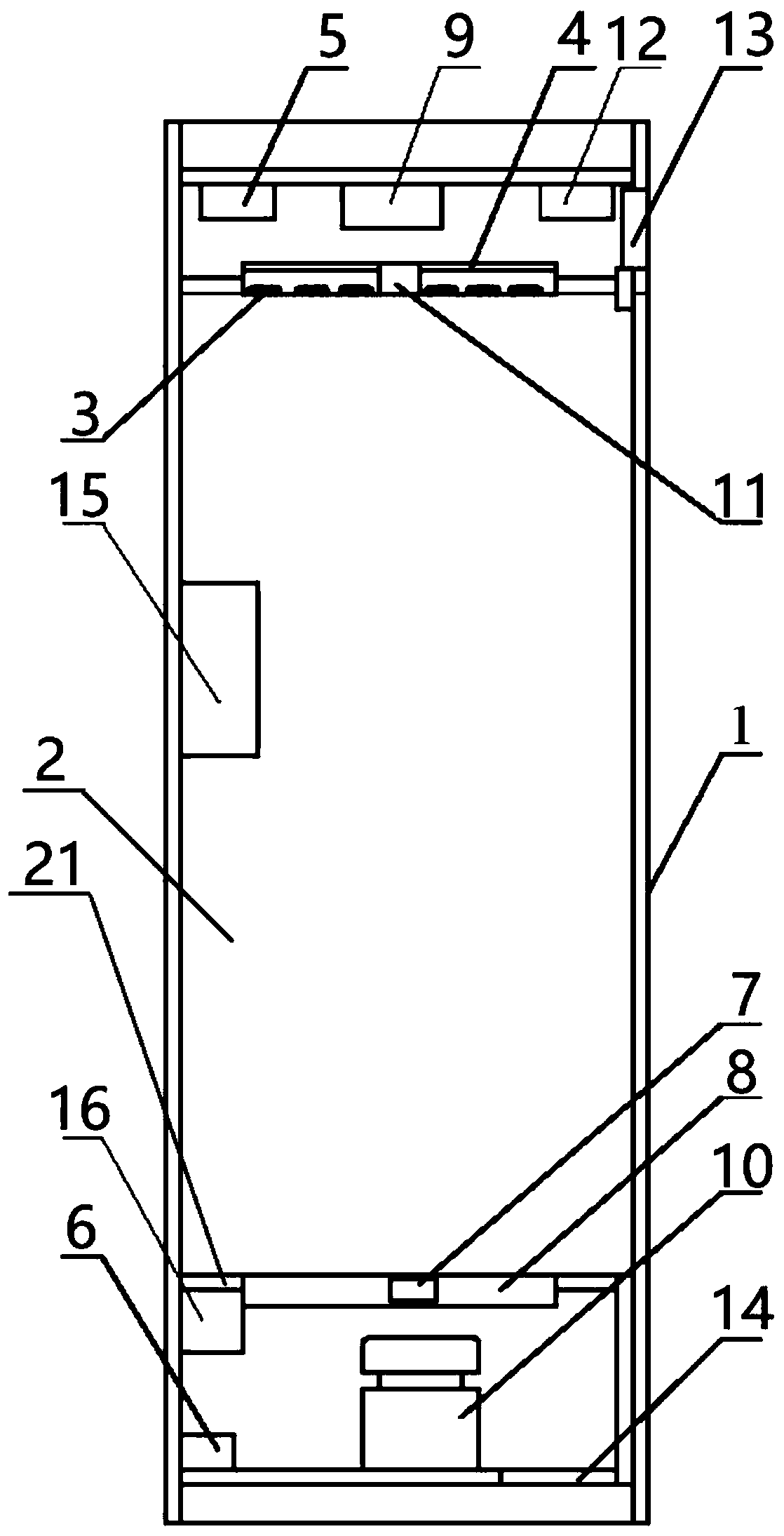

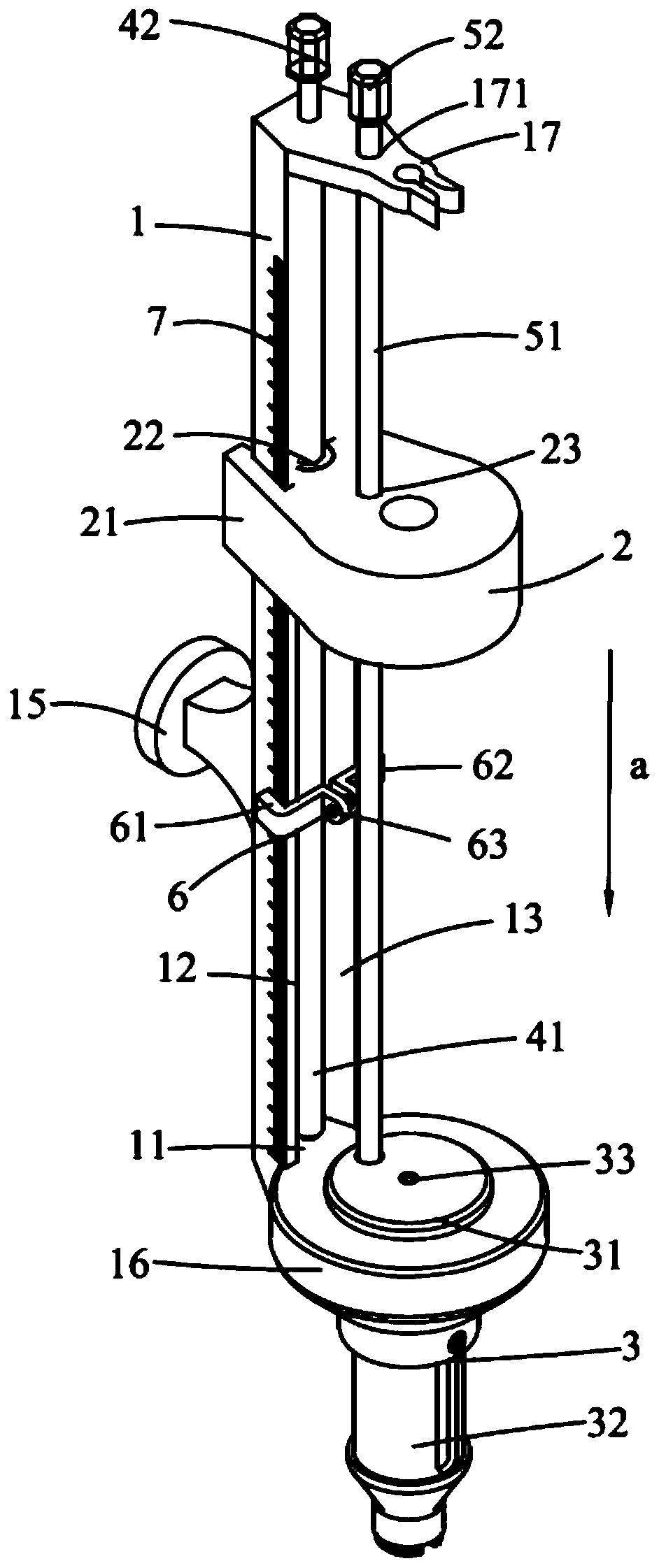

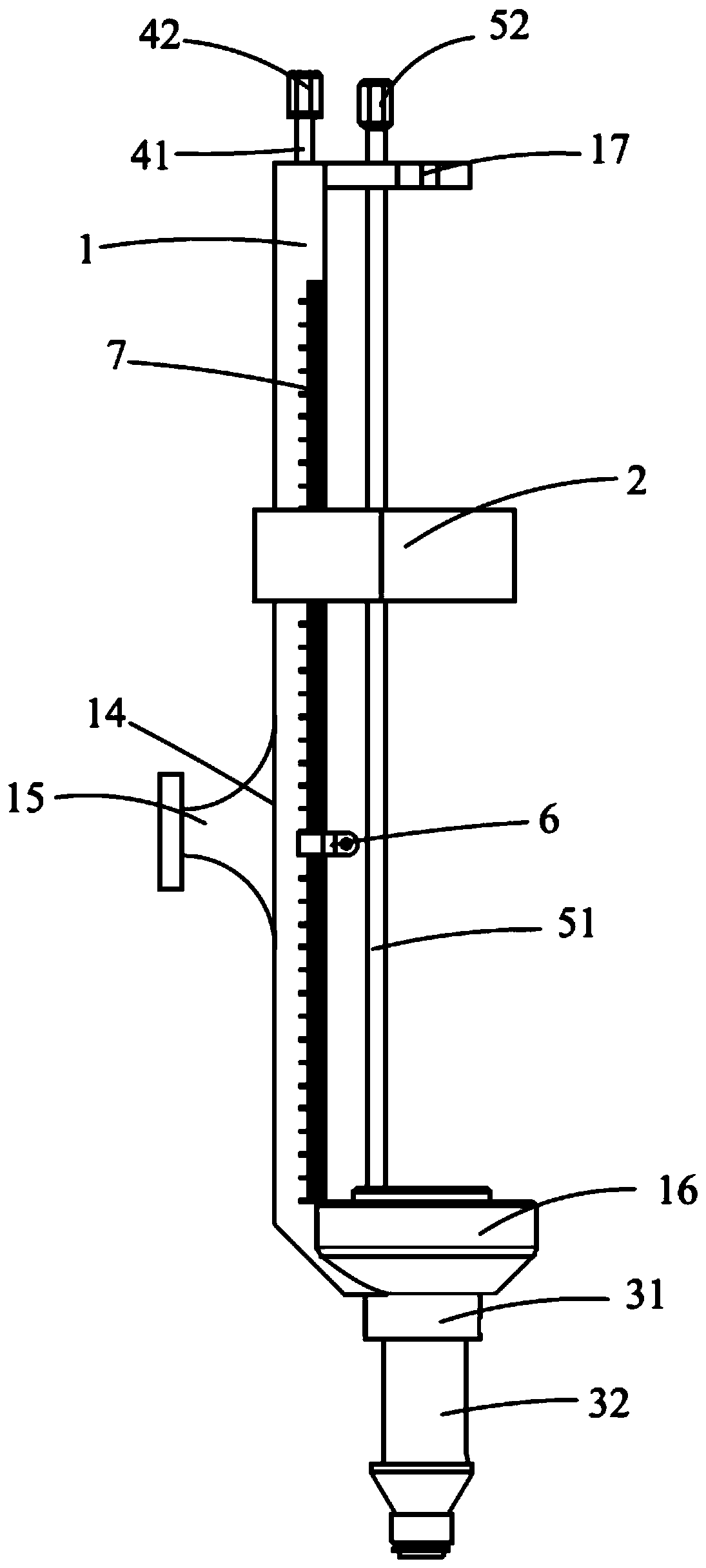

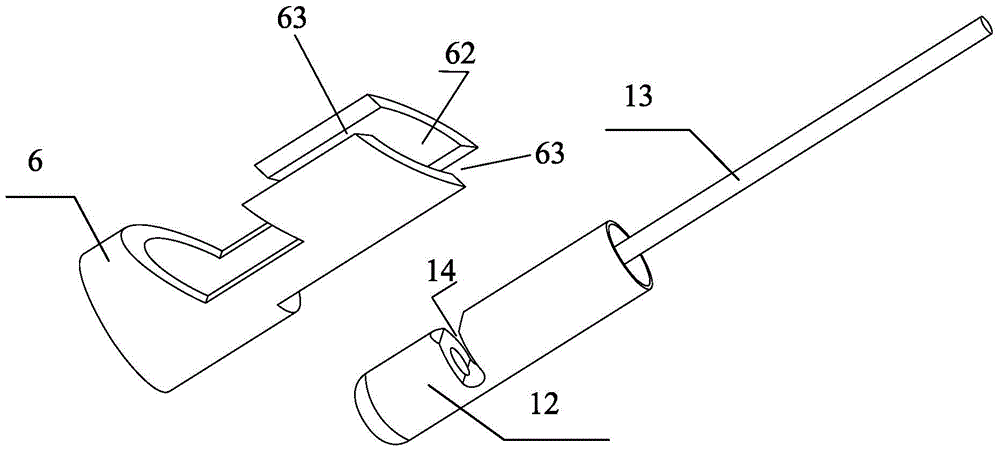

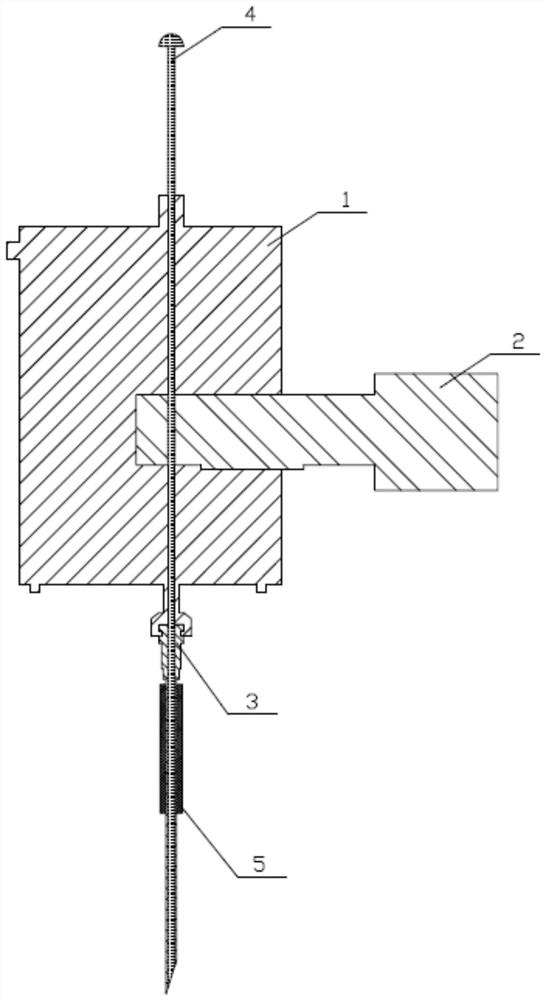

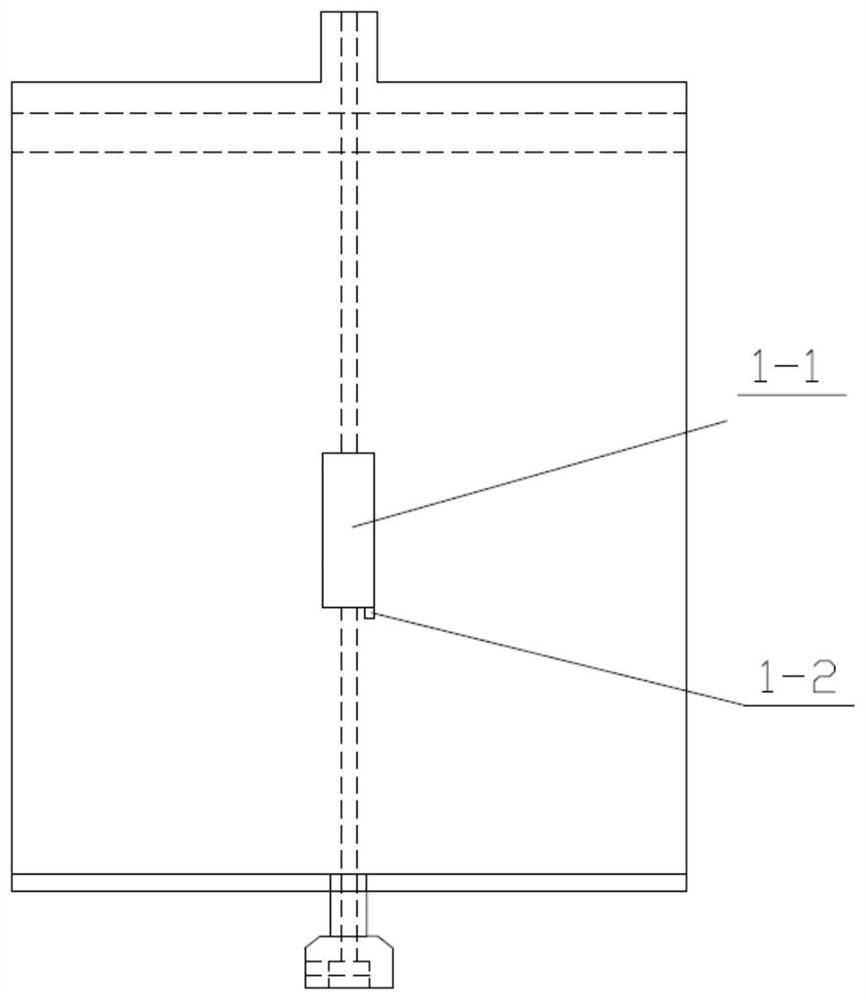

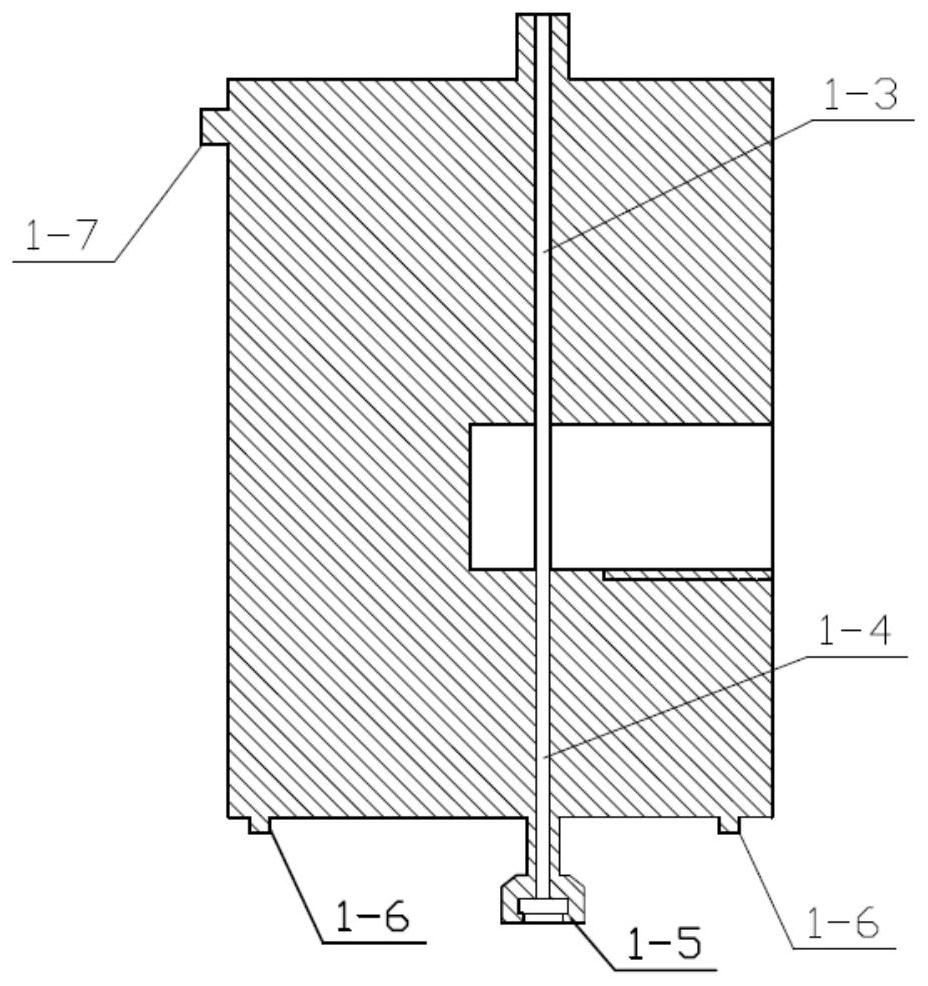

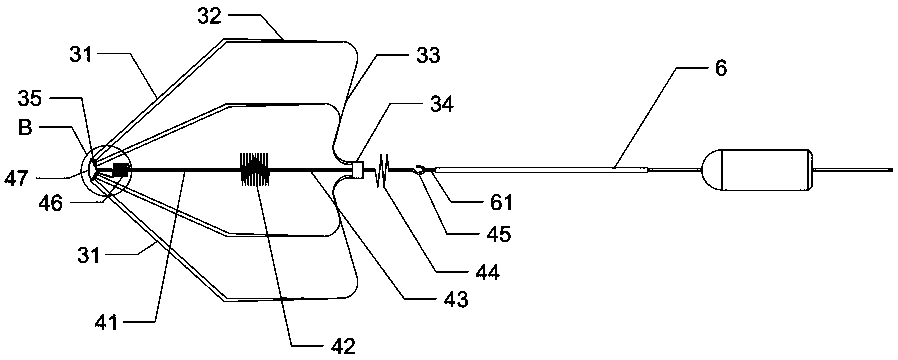

Image-lead after-loading interposition arthroplasty treatment system

PendingCN110237442ASimple structureReduce use costX-ray/gamma-ray/particle-irradiation therapyImplantation timeTarget tissue

The invention provides an image-lead after-loading interposition arthroplasty treatment system. The image-lead after-loading interposition arthroplasty treatment system comprises interposition arthroplasty needle bodies, wherein each interposition arthroplasty needle body comprises a needle wall for inserting into target area tissue and a regulating locking piece which is used for guiding the corresponding interposition arthroplasty needle body to insert and can lock the position of the corresponding interposition arthroplasty needle body. According to the image-lead after-loading interposition arthroplasty treatment system disclosed by the invention, the interposition arthroplasty position and the interposition arthroplasty angle of each interposition arthroplasty needle body can be adjusted and selected in advance through the corresponding regulating locking piece; in the interposition arthroplasty process, each interposition arthroplasty needle body is led to be inserted to the target tissue in the direction limited by the corresponding regulating locking piece, so that the operation steps are simplified, the implantation time of the needle wall is saved, and the accuracy of target treatment is improved; and in addition, the image-lead after-loading interposition arthroplasty treatment system is simple in structure, convenient to operate, low in using cost, and suitable for clinical large-range popularization and application.

Owner:SHINVA MEDICAL INSTR CO LTD

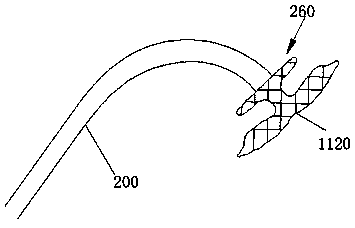

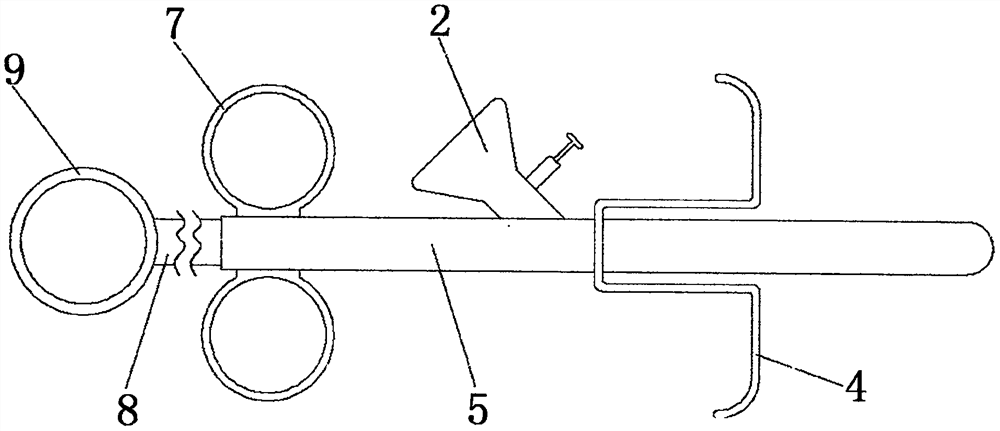

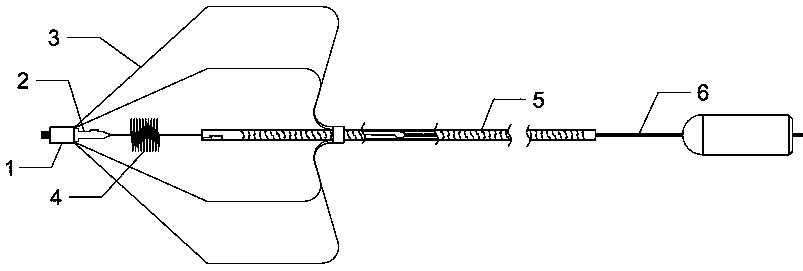

Wireless pacemaker conveying catheter device controlled to turn by using memory alloy wires and production method

InactiveCN108031006ARealize the bending functionOptimizing Implantation Path ParametersElectrotherapyMedical devicesImplantation timeControl system

The invention belongs to the field of interventional medical apparatuses, and particularly relates to a wireless pacemaker conveying catheter device controlled to turn by using memory alloy wires anda production method. The conveying catheter device structurally comprises a control handle, a conveying catheter, a specific device at a far end of the catheter and a control system. The wireless pacemaker conveying catheter device is mainly characterized in that electric currents passing through the memory alloy wires are integrally controlled through the handle; the change of a different lengthof each alloy wire is realized to realize a bending function of the conveying catheter; moreover, a bending angle is displayed on a display screen of the control system, so as to realize the digital control of the bending angle, wherein the control system has data recording and uploading function, and can be used for recording and uploading an implantation path of a medical device, so as to optimize the implantation path, wherein the conveying catheter is produced through a way of firstly gluing and then carrying out thermal shrinkage in the production method. The wireless pacemaker conveyingcatheter device can be used for accurately, conveniently and quickly realizing the digital control of the bending function of the catheter, is used for shortening an implantation time and improving implantation safety, and has a better application prospect in the conveyance of a wireless pacemaker.

Owner:张海军

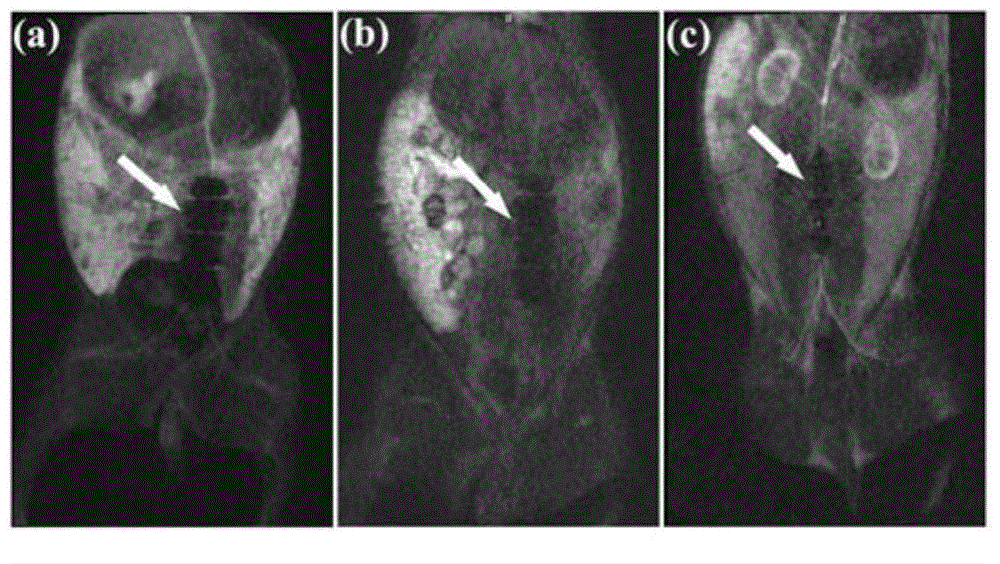

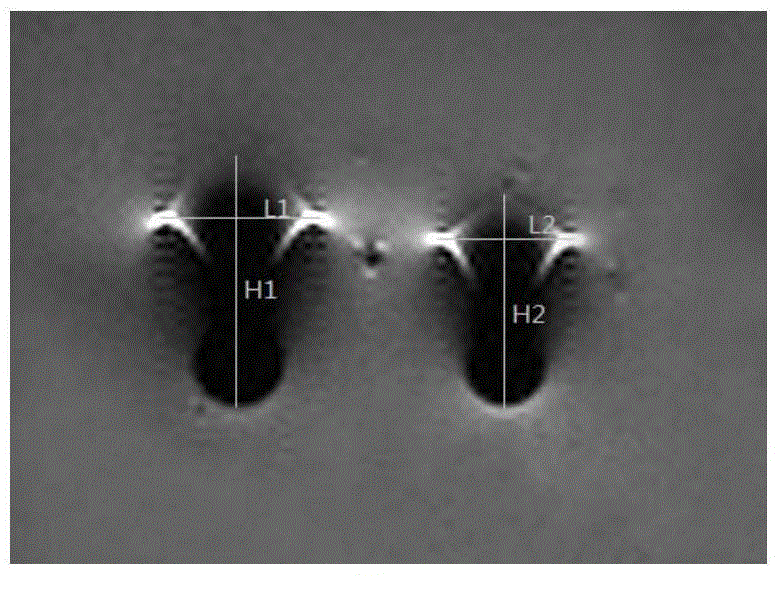

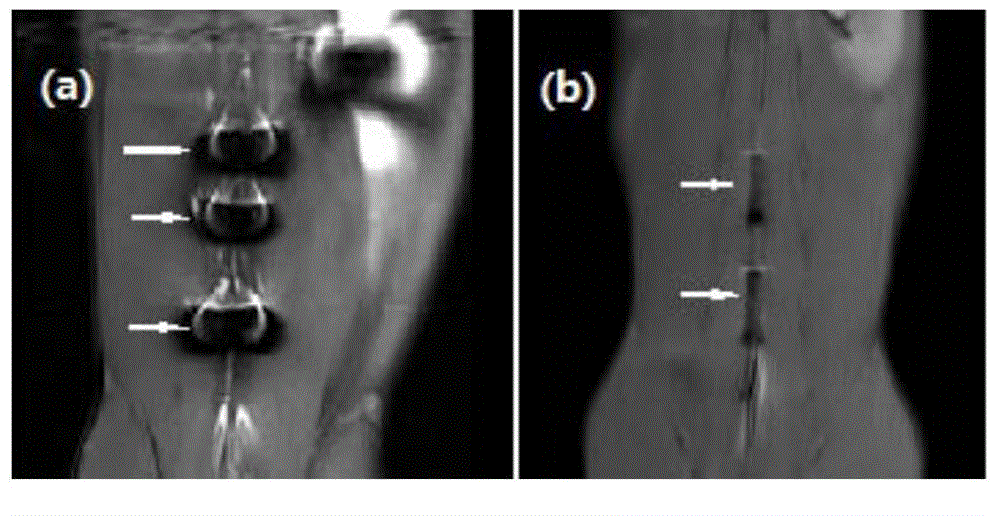

Method for monitoring corrosion degradation of bioabsorbable implant and for semi-quantification of relative weight loss ratio of corrosion product thereof

InactiveCN106323846AReduce in quantityReduce the burden onWeather/light/corrosion resistanceAnalysis using nuclear magnetic resonanceImplantation timeSemiquantitative Method

The invention provides a method for monitoring the corrosion degradation of a bioabsorbable implant and for the semi-quantification of the relative weight loss ratio of the corrosion degradation of the implant and a corrosion product of the implant. The monitoring method comprises the following steps: performing MR imaging of the implantation part of an individual with an implanted bioabsorbable implant at the predetermined at least two implantation time points respectively; and with the same imaging sequence, comparing the artifact sizes of the MRI images of the implant at the time points, wherein if the artifact size is gradually reduced along with the time increase, the corrosion degradation degree of the implant is deepened. The semi-quantification method comprises the following steps: with the same imaging sequence, performing MR imaging of the implant in the individual or a corrosion product thereof at different implantation time points; selecting an index plane, and establishing a function relation curve between the maximum artifact size value of the index plane and the weight loss ratio of the implant body or corrosion product thereof at the time points; and determining the relative weight loss ratio of the implant or corrosion product thereof according to the function relation curve and the monitored artifact size value of the implant or corrosion product thereof.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

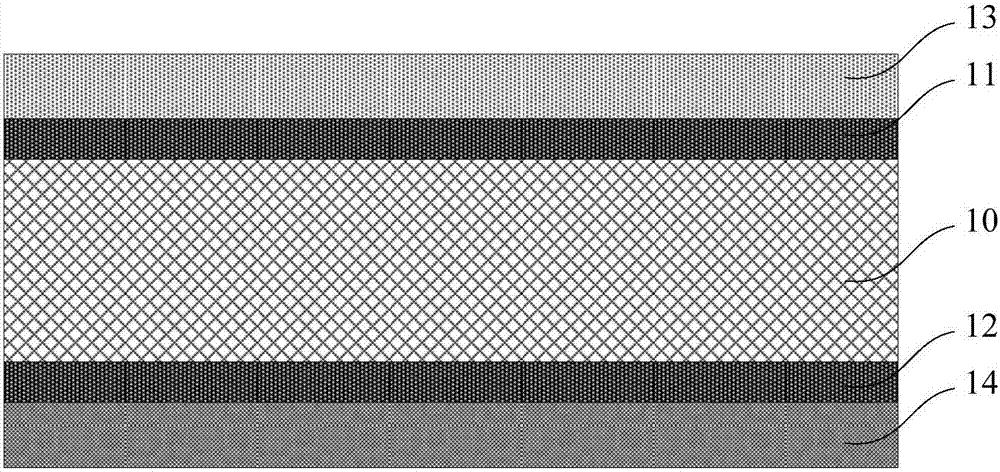

Bidirectional transient voltage suppressor diode and manufacturing method thereof

ActiveCN107346736ASimple preparation processUniform concentration distributionSemiconductor/solid-state device manufacturingSemiconductor devicesImplantation timeTransient voltage suppressor

The invention provides a bidirectional transient voltage suppressor diode and a manufacturing method thereof. The manufacturing method at least comprises the steps of: 1) providing a substrate of a first doping type, wherein the substrate comprises a first surface and a second surface; 2) forming a first epitaxial layer of the first doping type on the first surface of the substrate of the first doping type; 3) forming an epitaxial layer of a second doping type on the surface of the first epitaxial layer of the first doping type; 4) forming a second epitaxial layer of the first doping type on the surface of the epitaxial layer of the second doping type; 5) forming a first electrode on the surface of the second epitaxial layer of the first doping type; 6) and forming a second electrode on the second surface of the substrate of the first doping type. According to the manufacturing method, only the front surface of the substrate of the first doping type is processed, and the manufacturing process is simple; meanwhile, the number of epitaxial growing and implantation times of each epitaxial layer can be selected according to voltage withstand levels of the diode, so as to obtain uniform concentration distribution.

Owner:CHINA RESOURCES MICROELECTRONICS (CHONGQING) CO LTD

Knee-joint prosthesis implantation process, osteotomy module thereof and device thereof

The invention discloses a kneed prosthesis implantation method, an osteotomy module used and a using device, the kneed prosthesis implantation method comprises the following steps of measuring the data of knee joint bone tissues, extracting the data of articular cartilage and the skeleton profile, establishing a three-dimensional model in an image processor, designing the osteotomy module, determining the size and the type of the used kneed prosthesis and determining an osteotomy module model and the implantation of the kneed prosthesis. The kneed prosthesis implantation method of the invention can reduce the trauma of a patient, lower the cost, shorten the implantation time, reduce the risk of complications of a user of the kneed prosthesis and have less error and higher precision.

Owner:周一新 +2

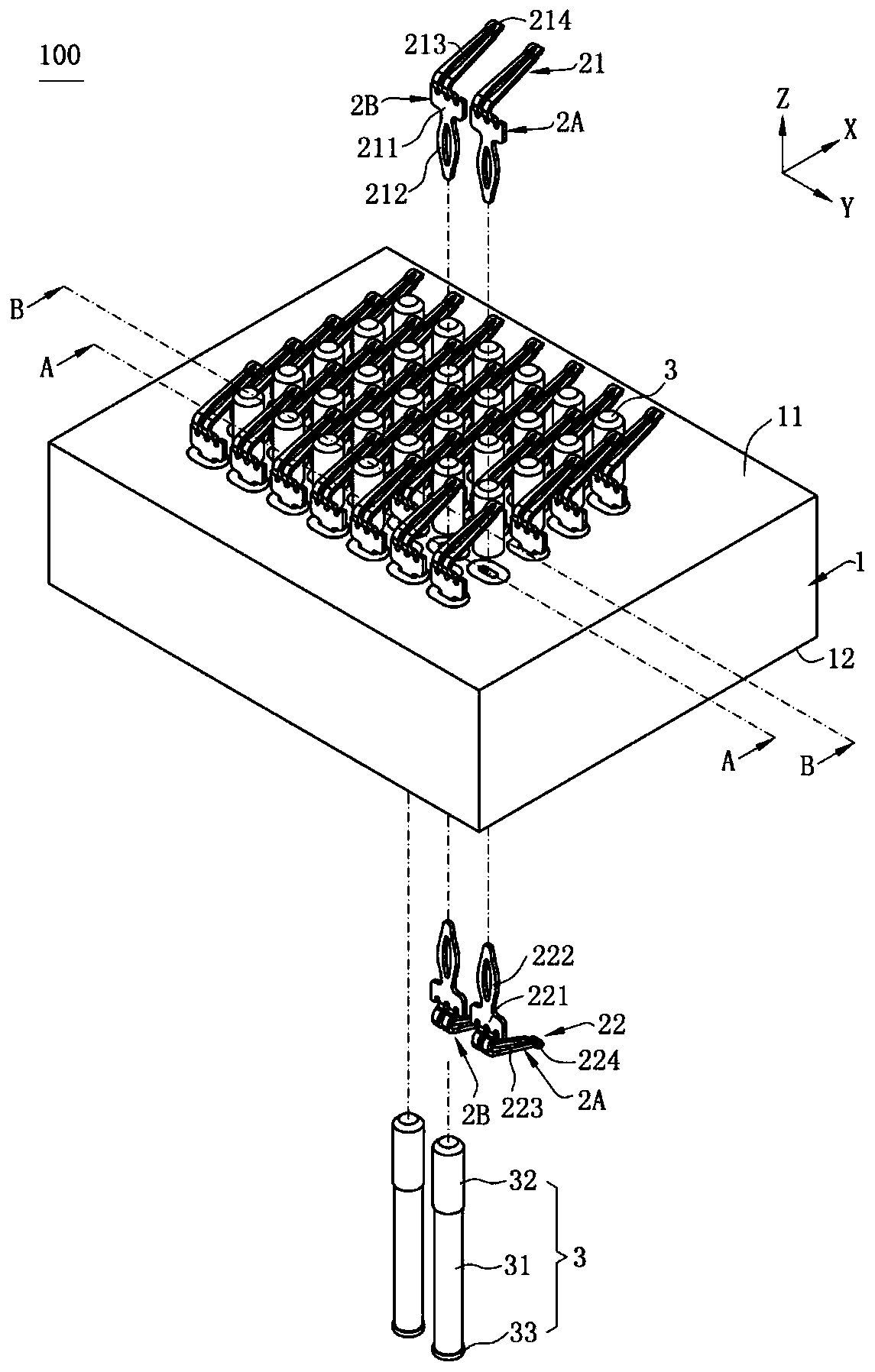

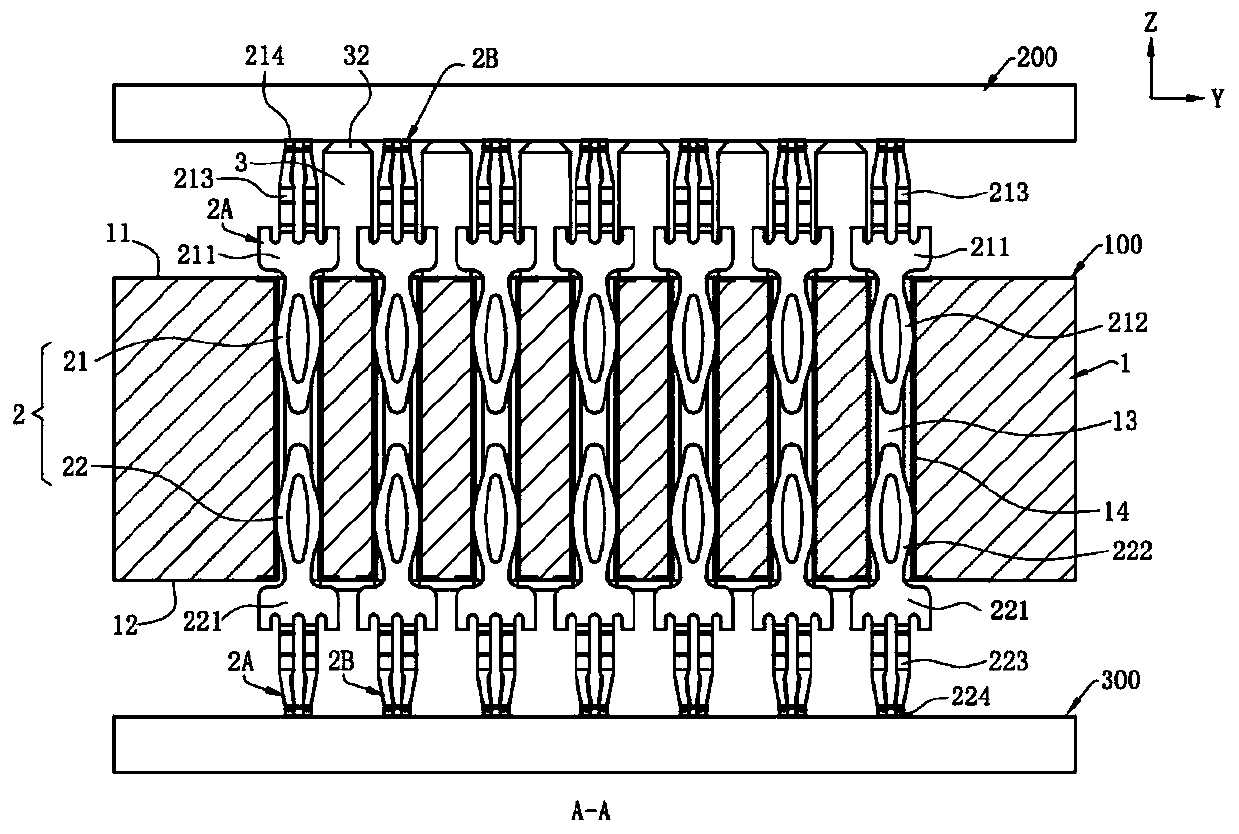

Electrical connector and manufacturing method thereof

ActiveCN109921221AShorten the timeLow costContact member assembly/disassemblyCoupling contact membersImplantation timeEngineering

The invention discloses a manufacturing method of an electrical connector. The manufacturing method comprises the following steps of: S1, providing a substrate, wherein the substrate is provided witha plurality of conductive parts and a plurality of through holes, and the through holes penetrate through the substrate up and down; S2, placing the substrate in a mold, injecting liquid plastic intothe mold, enabling the liquid plastic to flow into the plurality of through holes, and forming a connector and a plurality of supporting members integrally connected by the connector after the liquidplastic is cooled, wherein the supporting members are contained in the corresponding through holes and upwardly protrude out of the substrate, and the connector is located below the substrate; S3, taking the substrate, the plurality of supporting members and the connector out from the mold; and S4, forming a plurality of first terminals, wherein each of the first terminals is provided with a firstconduction part and a first contact part for upwardly conducting the first conduction part, the plurality of first guiding parts are downwardly and correspondingly conducted to a plurality of conductive parts, so that the electric connector is obtained. The supporting members are integrally formed on the substrate, so that the implantation time is saved, the cost is low and the working efficiencyis improved.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

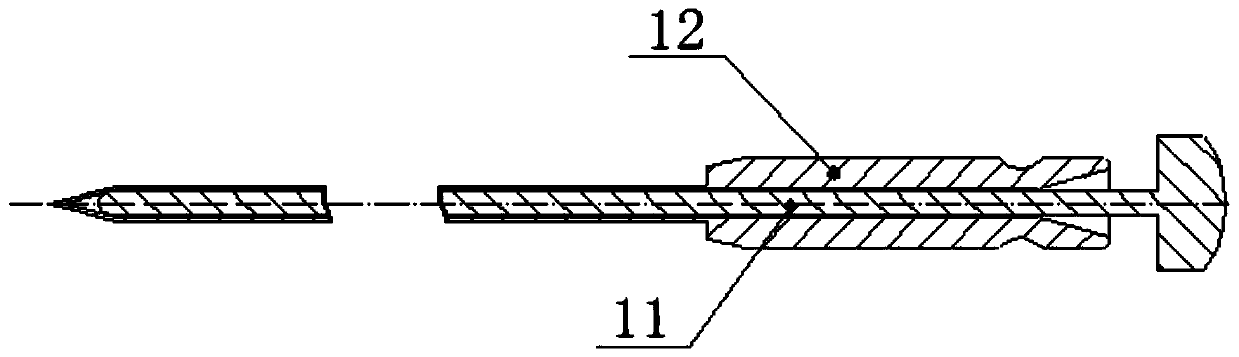

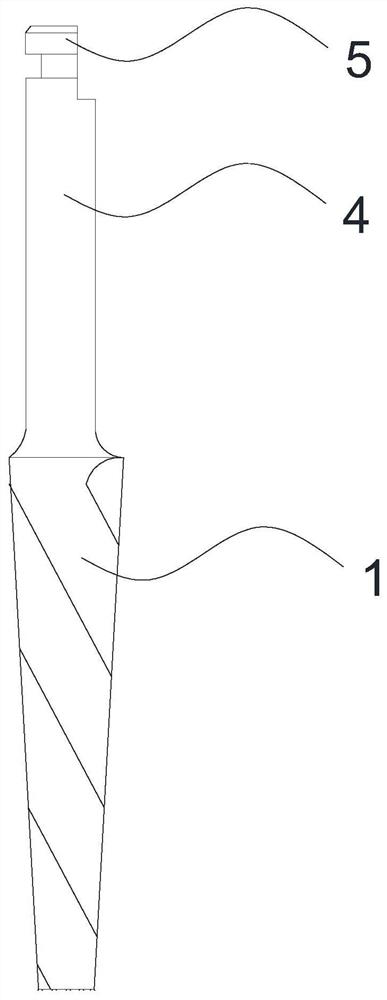

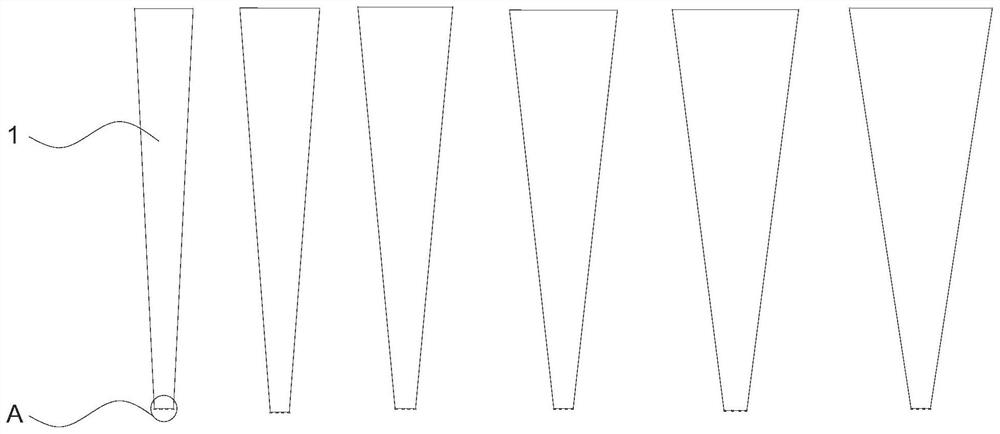

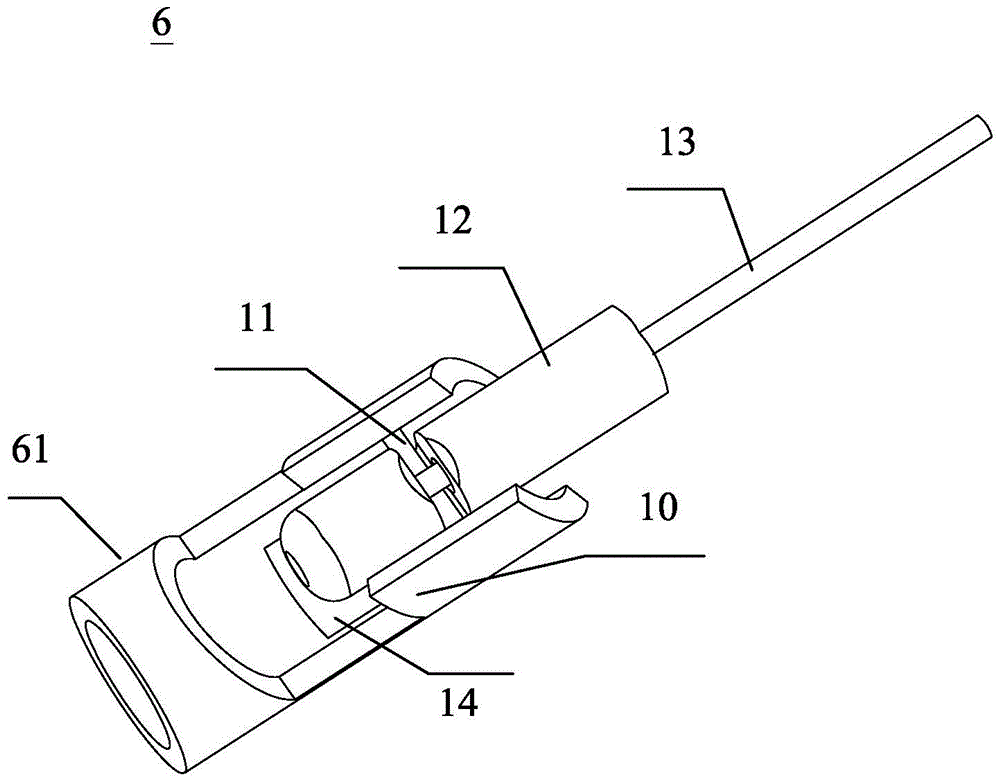

Drill point set for autologous tooth transplantation

ActiveCN113476154AShorten production timeShorten operation timeDental toolsImplantation timeDental transplantation

The invention relates to the technical field of dental medical instruments, in particular to a drill point set for autologous tooth transplantation, which comprises a pioneer drill, a ball drill and a split drill; the pioneer drill comprises a drill bit, a neck rod and a drill tail; the number of the pioneer drills is several; furthermore, the drill bit on each pioneer drill is of a circular truncated cone structure; the total length of each pioneer drill is 28 mm; the length of the drill bit is 16 mm; the diameter of the end, away from the neck rod, of the drill bit is 2 mm; the tapers of the drill bits are respectively 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 and 0.8; a cutting knife is arranged at the end, away from the neck rod, of the drill bit; the number of the cutting knives is several; the cutting knives are evenly distributed at the end of the drill bit; and a part of the cutting knife is positioned on the circumference of the end part of the drill bit. The drill point set can be used for rapidly preparing a tooth socket matched with a supplied tooth, so that the operation time of autogenous tooth transplantation is shortened, the trial implantation times of the supplied tooth are reduced, and the success rate of autogenous tooth transplantation is improved.

Owner:SICHUAN ACADEMY OF MEDICAL SCI SICHUAN PROVINCIAL PEOPLES HOSPITAL

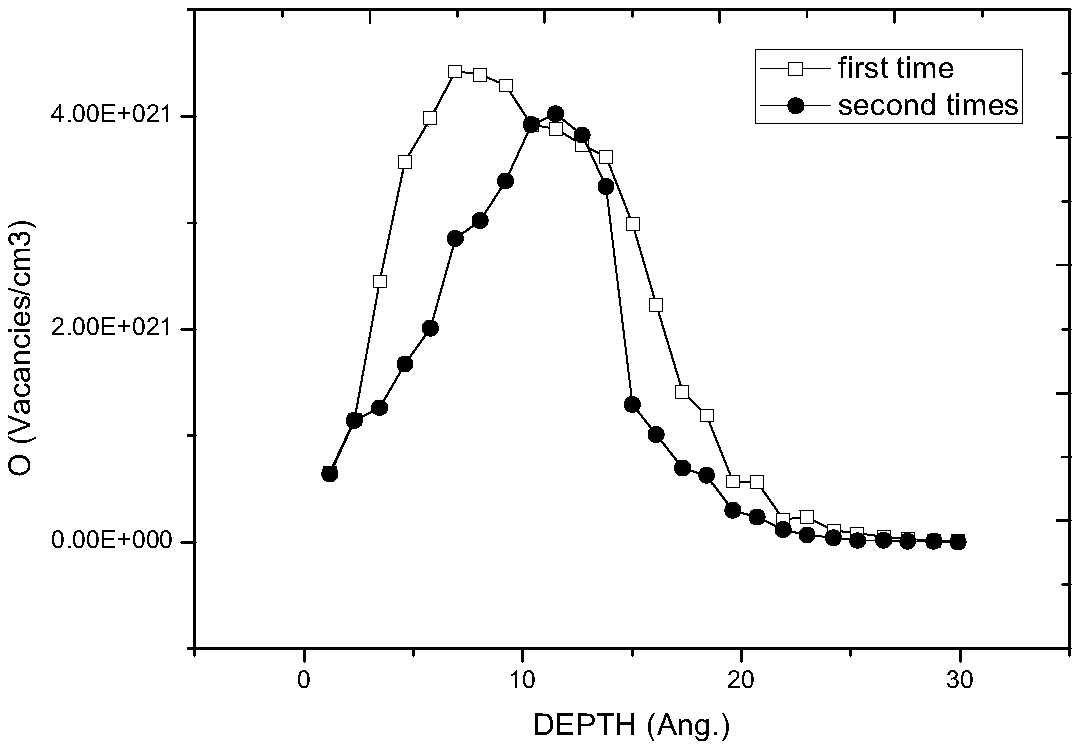

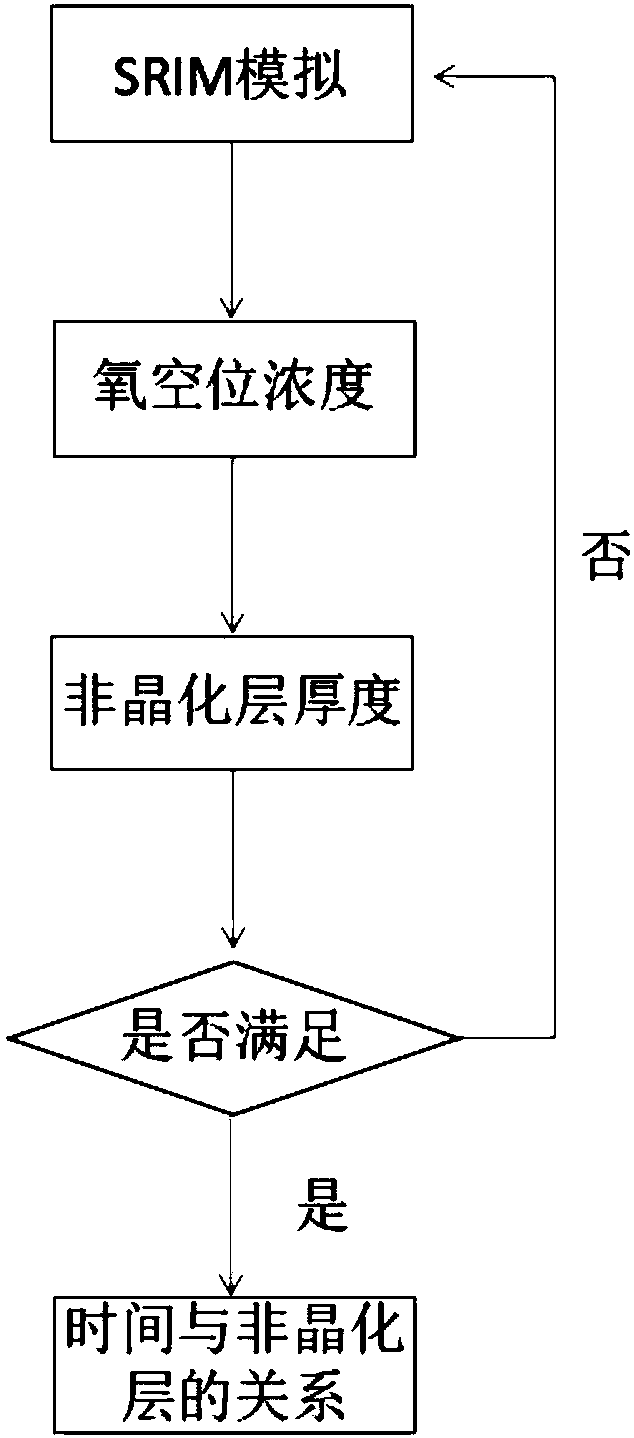

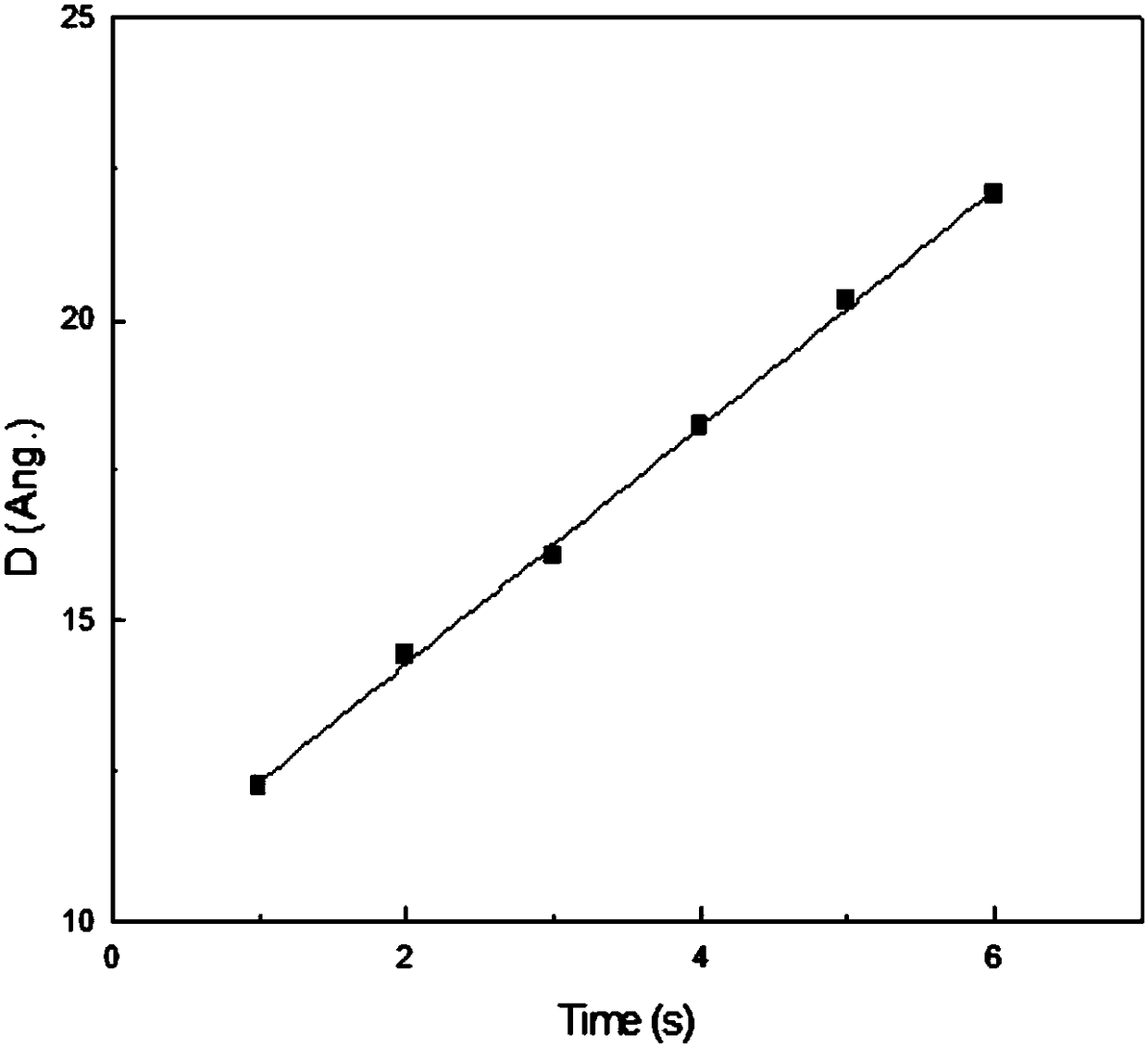

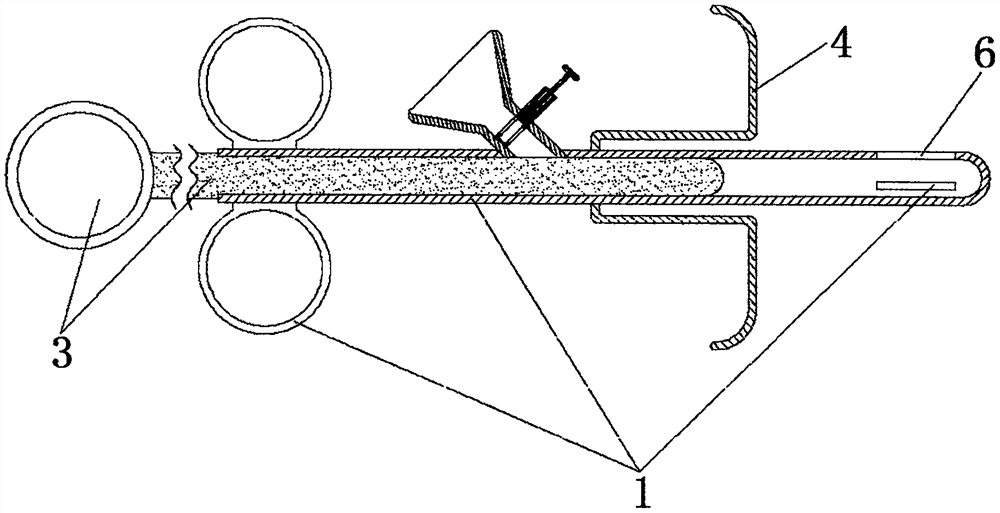

Method based on Monte Carlo stimulation to assist with control of ion implantation time

ActiveCN108517559ASolve the problem that the time parameter cannot be setInjection dose controlPolycrystalline material growthDiffusion/dopingOxygen vacancyLayer thickness

The invention belongs to the field of ion implantation application and specifically relates to a method based on Monte Carlo stimulation to assist with control of ion implantation time. According to the method disclosed by the invention, SRIM is utilized as foundation to simulate that argon ions are implanted into strontium titanate crystal, each unit time is utilized as a segment, repeated iterative computation is combined to control factors of ion implantation time, ion implantation dosage or the like to accurately control an oxygen vacancy concentration, and control time with experimental significance is obtained. Therefore, the problem that SRIM simulation cannot set time parameters is solved; time is divided into each unit time, so that solving is continuously promoted through the unit time; finally, a piece of time and non-crystallizing layer thickness relationship is obtained to assist with control of ion implantation dosage in an actual experiment process. The situation that implantation time is decided by only relying on experience of an experimenter in an experiment is avoided, and the method is a set of simulation calculation method with actual experimental significance.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

One-hand-operated bone powder implanting device

PendingCN114343930AImplantation time shortenedReduce work intensityJoint implantsImplantation timeBone dust

The invention discloses a one-hand-operated bone powder implanter which comprises a guide mechanism, a conical feeding sleeve, an implantation inner core mechanism, a positioner, a communication mechanism and a plugging mechanism, according to the one-hand-operated bone powder implanter, medical staff can complete bone powder implantation through one-hand operation, the working intensity of doctors and assistants is reduced, in addition, the device is convenient in operation step and high in practicability. The bone powder implanting device has the advantages that the bone powder implanting time is saved, the implanting operation is smooth, the operation is simple and reliable, the positioning function is added, the implanting position is more accurate, and in view of the defects, the one-hand operation bone powder implanting device is necessarily designed.

Owner:贝莱沃定州医疗科技有限公司

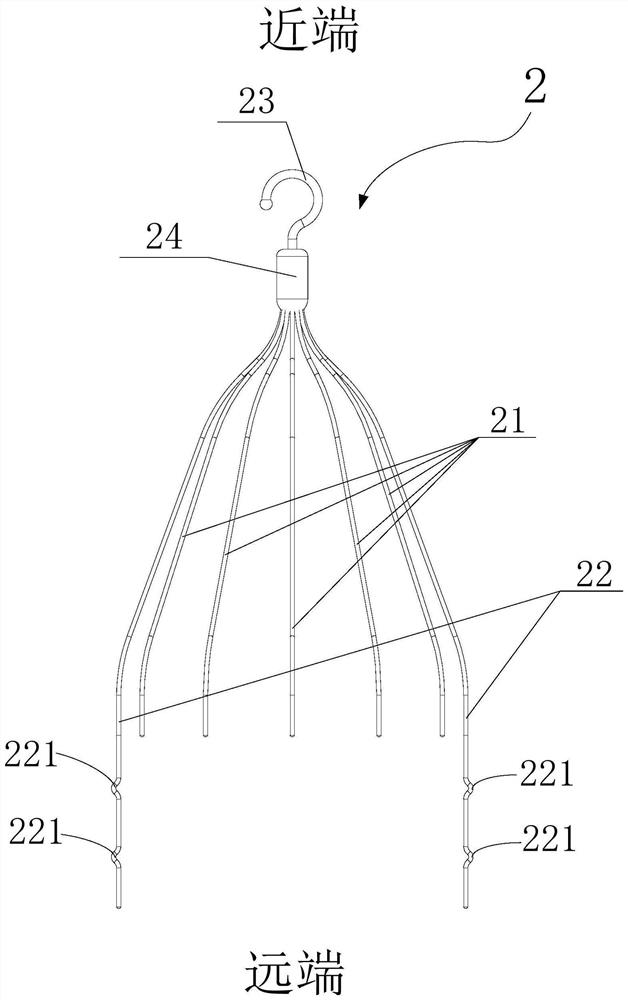

Vena cava filter

PendingCN113208772AAddress prone implant site bleedingResolution timeBlood vessel filtersImplantation timeVein

The invention provides a vena cava filter, and relates to the field of medical instruments. The vena cava filter comprises a support frame and a filter body, The filter body comprises a fixed arm, an anchoring arm and a recovery hook; the near end of the fixed arm and the near end of the anchoring arm are both connected to the opposite end of the hooking end of the recovery hook, and an anchoring part is arranged at the far end of the anchoring arm, and the anchoring part is anchored to the inner side face of the support frame; in a release state, the support frame is unfolded to be cylindrical, and the far end of the fixed arm and the far end of the anchoring arm are opened around, so that the fixed arm and the anchoring arm are unfolded to be of an umbrella shape; and the anchoring part can be separated from the support frame under the condition that the recovery hook is applied with an external force for dragging towards the near end. The vena cava filter solves the problems that in the prior art, after a vena cava filter is released in a blood vessel, the implanted position is prone to bleeding, the filter implantation time is short, and a filter is difficult to take out safely; and meanwhile, the shifting of the filter can be avoided after the vena cava filter is released in the blood vessel.

Owner:BEIJING PERCUTEK THERAPEUTICS CO LTD

Preparation process of quantum energy eyesight improving and refreshing liquid

InactiveCN110179983APromote absorptionImprove permeabilityOrganic active ingredientsSenses disorderImplantation timeMagnetization

The invention discloses a preparation process of quantum energy eyesight improving and refreshing liquid, including the following steps: (1) preparing raw materials according to the formula of the eyesight improving and refreshing liquid; (2) putting a mixture A into an emulsifying pot and heating to 85 DEG C, homogenizing for 6 minutes, and stirring for 10 minutes; putting a mixture B into a water pot and heating and stirring to 85 DEG C, after the mixture B is dissolved, pumping the mixture B into the emulsifying pot, stirring at constant temperature 85 DEG C for 10 minutes, cooling to 45 DEG C, adding a mixture C, stirring and dissolving evenly, sampling at 42 DEG C for comparison plate detection, and discharging after qualification to obtain unquantified eyesight improving and refreshing liquid; (3) sending the unquantified eyesight improving and refreshing liquid into a quantum energy chamber, starting a quantum energy generator for quantum implantation of the unquantized eyesightimproving and refreshing liquid to obtain the quantum eyesight improving and refreshing liquid, wherein the quantum implantation time is 2 to 7 days; (4) canning the quantized eyesight improving andrefreshing liquid, adding magnetic sheets for magnetization, and sealing. Molecular groups in the eyesight improving and refreshing liquid of the invention is micro-molecularized, so that the permeability is better and the absorption is more easy.

Owner:李波

Medical loading equipment

PendingCN111249006AQuick loading and unloadingReduce dependencySurgical navigation systemsSurgical manipulatorsSurgical riskImplantation time

The present application relates to medical loading equipment. The equipment is used to load medical devices, and the medical loading equipment includes a frame body, and a sliding main body and a guide device arranged on the frame body; the frame body extends in a first direction, the frame body has a first end located in the first direction, and the frame body is provided with a first guide partextending in the first direction; and the sliding main body is arranged on the first guide part, the guide device is arranged on the first end, and the medical devices are arranged between the guide device and the sliding main body. The sliding main body moves towards the guide device on the first guide part under the action of external pushing force to push the medical devices to reach a target position of a patient through the guide device, so that the equipment completes the quick loading and unloading of the medical devices through automatic machine operation, greatly reduces the risk of surgery, improves the accuracy of implantation, shortens the time of the implantation, and greatly reduces the degree of dependence of the surgery on a doctor; and at the same time, the equipment is fully compatible with magnetic resonance imaging and can understand the implantation status in real time.

Owner:SCENERAY

vena cava filter

ActiveCN104352287BGood effect on filtering thrombusEasy to fixBlood vessel filtersImplantation timeVein

The invention discloses a vena cava filter which is placed at the position of an inferior vena cava between kidney venas and iliac venas, and is formed by integrally cutting a nickel-titanium alloy pipe with laser. The filter comprises connecting rods, a top layer filter screen, a middle layer filter screen and a bottom layer filter screen, wherein the top layer filter screen, the middle layer filter screen and the bottom layer filter screen are jointly formed in a cage-shaped structure, the middle layer filter screen is positioned between the top layer filter screen and the bottom layer filter screen, and is formed by inwards bending a plurality of branches which are cut; the top layer filter screen and the middle layer filter screen can capture and intercept larger thrombosis, and the bottom layer filter screen can capture and intercept smaller thrombosis; the surfaces of the filter screens of the three layers are wrapped with PTFE (poly tetra fluoro ethylene) films; the connecting rods are in contact with vascular walls, are connected with the cage-shaped structure, can be divided into more than two branches, are formed by expanding, and are wrapped with the PTFE films. The vena cava filter provided by the invention has the advantages that the effect of filtering the thrombosis is excellent, the vena cava filter can be repeatedly and firmly positioned, the implantation time can be prolonged, the vena cava filter can be recovered, and the endothelialization effect can be delayed.

Owner:SHENZHEN KYD BIOMEDICAL TECH CO LTD

A composite explosive molding process

ActiveCN111454110BOrderly assemblyFlawlessExplosive working-up apparatusImplantation timeExplosive Agents

The invention discloses a composite explosive molding process. In order to solve the problem that the pouring explosives cannot realize the orderly assembly of particles, the invention adopts the method of mechanical implantation to implant oxidant, reducing agent particles or composite explosives into the mixed explosives to prepare high-energy pouring PBX explosives, pyrotechnics, and propellants Wait. While achieving the purpose of orderly assembly of particles, the invention solves the problem of air bubbles in mechanical implantation through a vacuum process; by controlling the implantation time, it ensures that there is no crack defect in the charge after implantation. The molding process disclosed by the invention is divided into five steps: determining the implantation time, preparing the implanted particles, preparing the matrix, implanting the particles, orderly assembling the particles, and curing at high temperature. The invention is mainly applied in the fields of explosives and explosives.

Owner:XIAN MODERN CHEM RES INST

retrievable thrombus filter

ActiveCN104970900BReduce contact areaShorten the timeBlood vessel filtersRenal veinNetwork connection

Owner:SHENZHEN KYD BIOMEDICAL TECH CO LTD

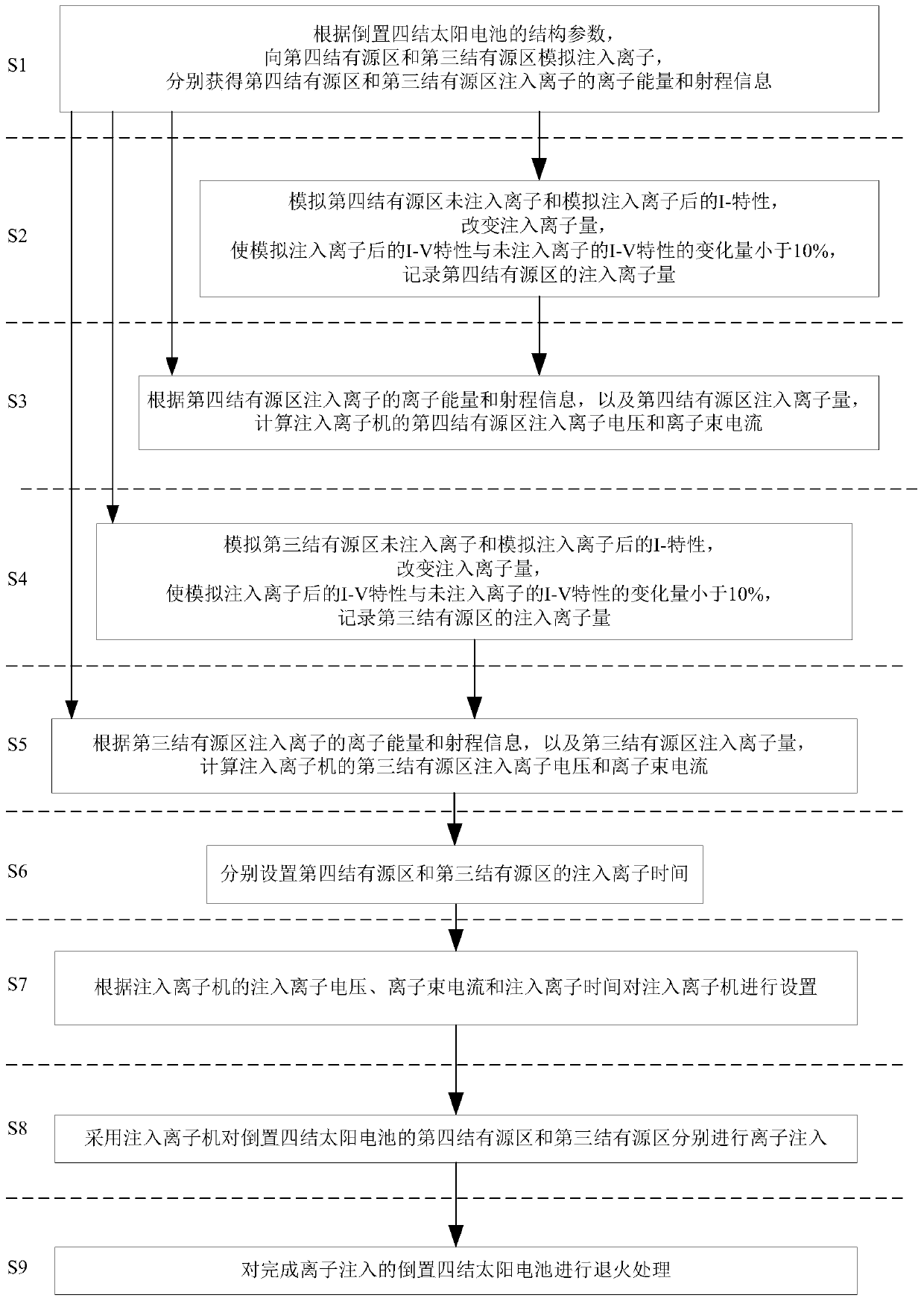

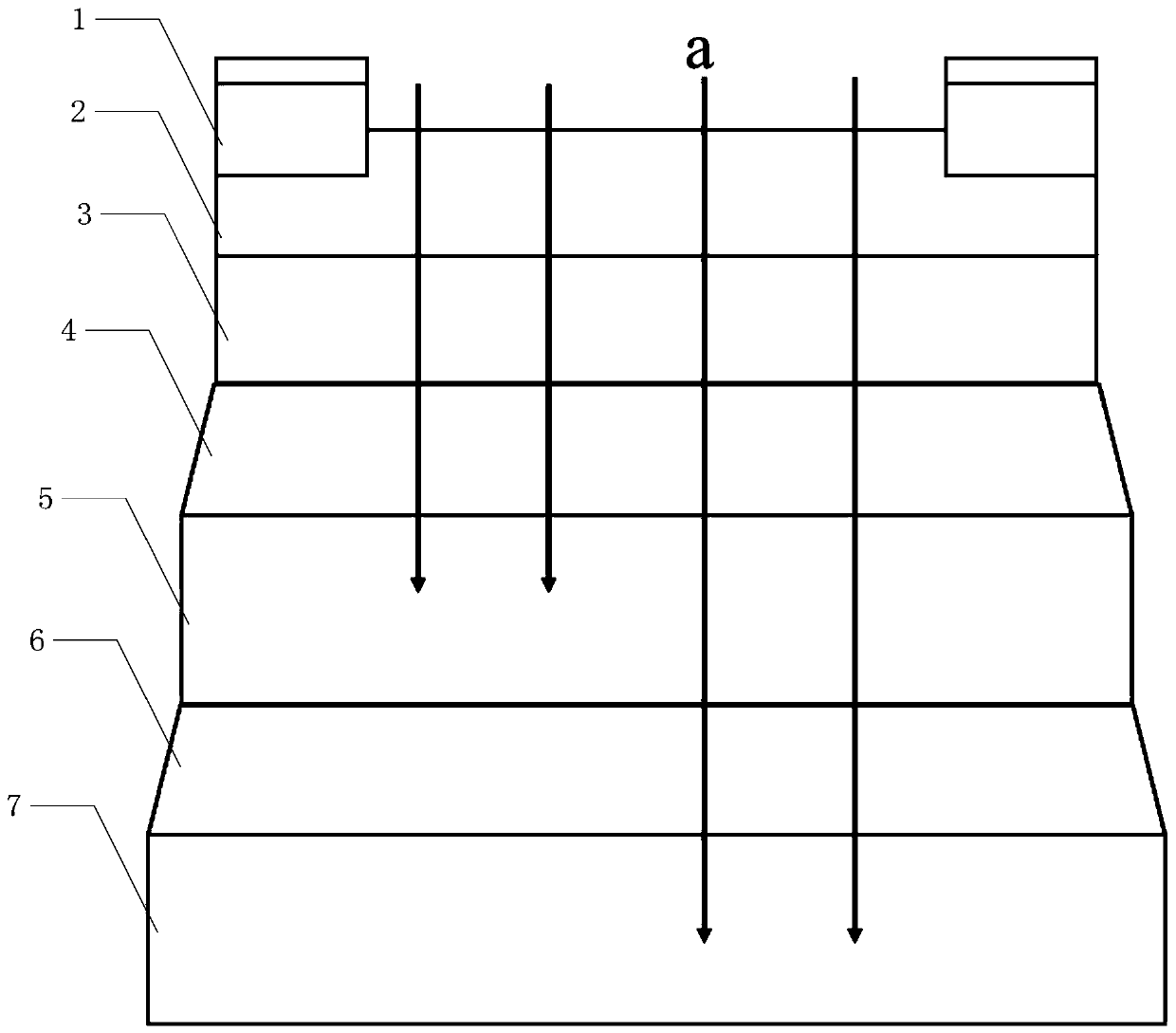

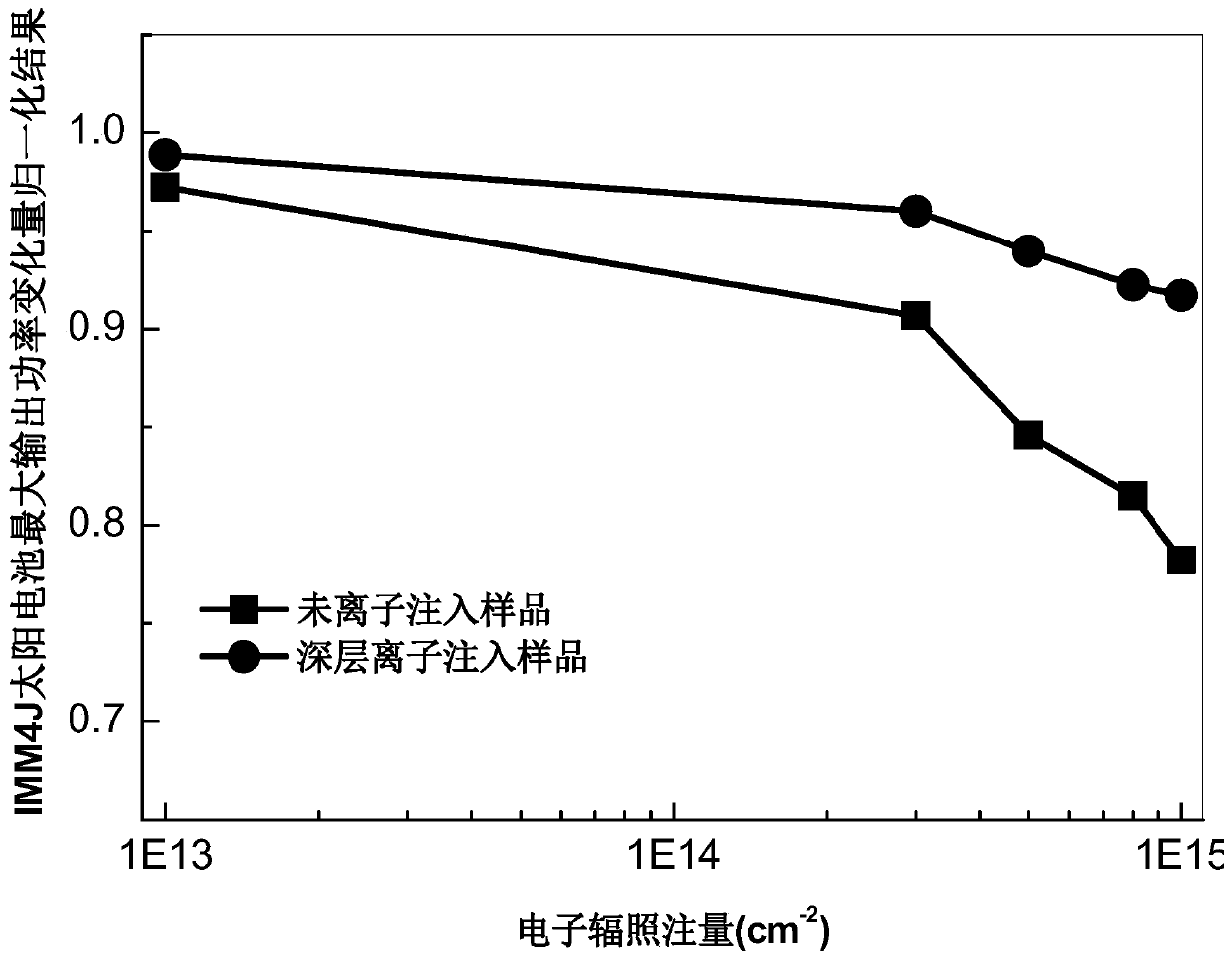

Inverted four-junction solar cell anti-displacement irradiation reinforcing method based on deep ion implantation mode

InactiveCN110491970AImprove radiation resistanceDisplacement Radiation Defect StabilizationFinal product manufactureSemiconductor/solid-state device manufacturingImplantation timeIon beam

The invention discloses an inverted four-junction solar cell anti-displacement irradiation reinforcing method based on a deep ion implantation mode, belongs to the technical field of microelectronics,and aims at solving the problems that existing inverted four-junction solar cells are poor in displacement irradiation resistance under the irradiation of space charged particles and are liable to generate displacement radiation damage, so that the performance parameters of the solar cells are seriously influenced. According to the method, ions are implanted into a fourth junction active region and a third junction active region of an inverted four-junction solar cell in a simulated manner; ion energy and range information are acquired; I-V characteristics are simulated; the ion implantationamount when the change amount of the I-V characteristics from those when ions are not implanted is less than 10% is recorded; the ion implantation voltage and the ion beam current are calculated; theion implantation time is set; ion implantation is performed by adopting the set ion implantation machine, and annealing treatment is performed on the inverted four-junction solar cell after ion implantation is completed. The method is used for carrying out anti-displacement irradiation reinforcement on the inverted four-junction solar cell.

Owner:HARBIN INST OF TECH

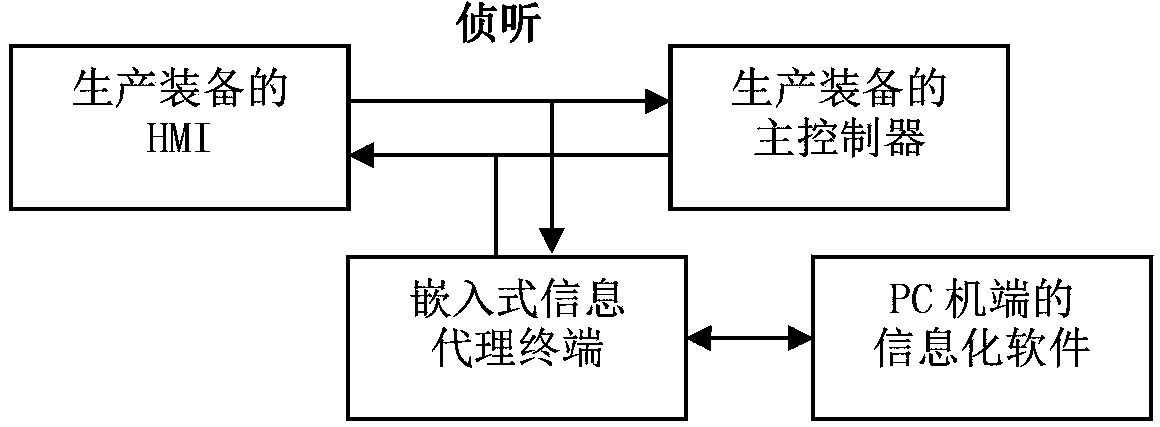

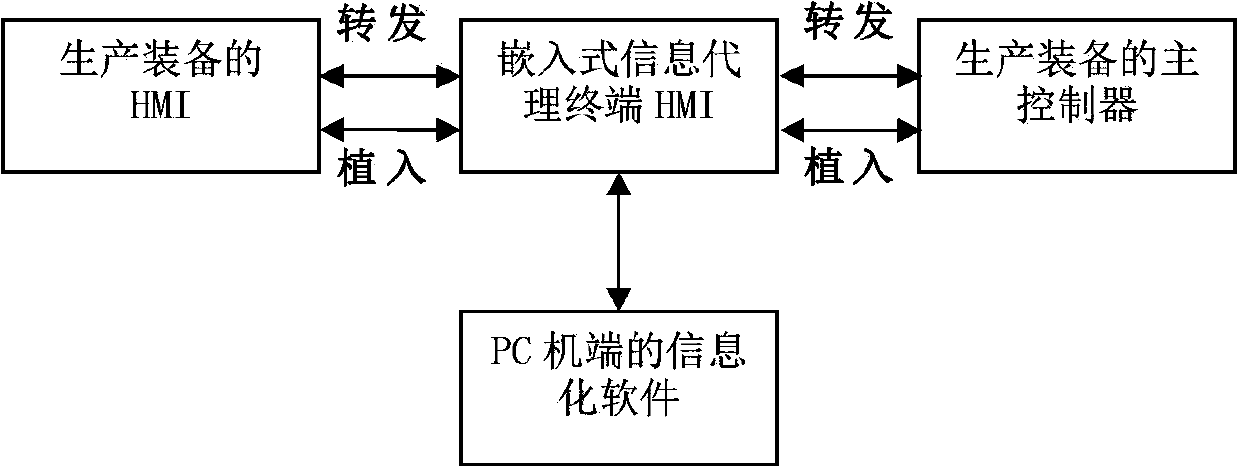

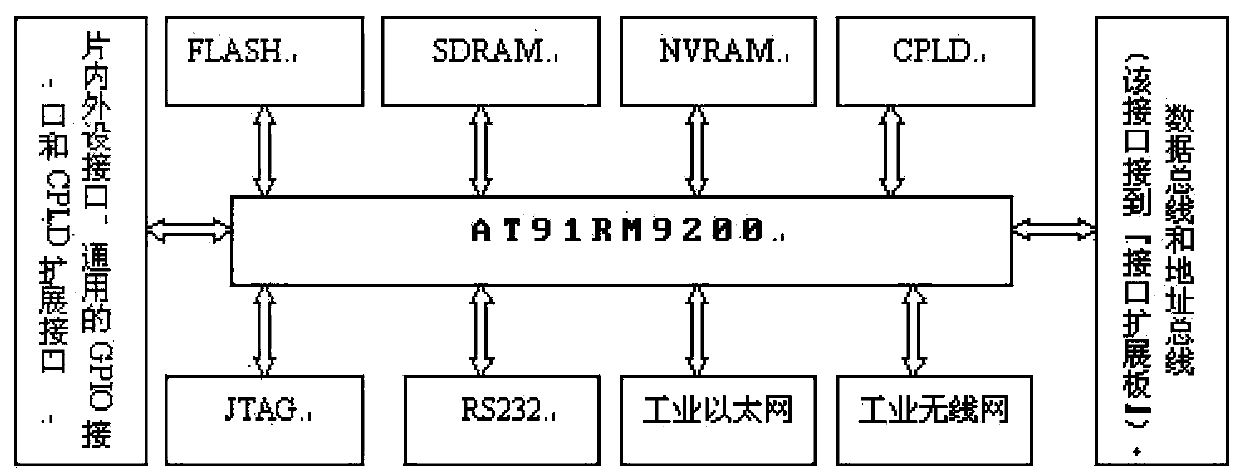

Implantation forwarding type data collecting method for production device

ActiveCN103389654AMinor changesImprove versatilityProgramme control in sequence/logic controllersImplantation timeHuman–machine interface

The invention discloses an implantation forwarding type data collecting method for a production device. The method includes the following steps that 1 an embedded information proxy terminal conducts implantation timing; 2 after timing is started, the embedded information proxy terminal enters a communication forwarding step, response communication data returned by a main controller aiming at forwarded communication is received and processed to extract A type data, and the response communication data is forwarded to a human-machine interface; 3 before the timed implantation time reaches the preset time, execution of the step 2 is kept; when the timed implantation time reaches the preset time, the embedded information proxy terminal enters a communication implantation step, and B type data is extracted; 4 after the embedded information proxy terminal finishes the communication implantation step, the timed implantation time is cleared, and the step 1 is returned. By means of the method, comprehensive work state data collection can be conducted on the production device with the human-machine interface, hardware modification on the production device is small, and the method is suitable for large-scale application.

Owner:GUANGDONG ELECTRONICS TECH RES INST

Method for utilizing ion implantation technology to modify serpentine

InactiveCN102583408BImprove adsorption capacityCause secondary pollutionMagnesium silicatesImplantation timeEngineering

The invention relates to a method for utilizing ion implantation technology to modify serpentine, which belongs to the technical field of physical technology material modification. The method is characterized in that serpentine powder is placed in an ion implantation machine, a cavity of the ion implantation machine is vacuumized, and the vacuum degree requirement is 1*10-3-1*10-6Torr. NH3 is injected in ion mode, ion implantation energy is 30-60kev, implantation flux is 1*1017cm-2, and the implantation time is 3 to 20min. Finally samples where ion is implanted are taken out to obtain serpentine samples with N element implantation.

Owner:SHANGHAI UNIV

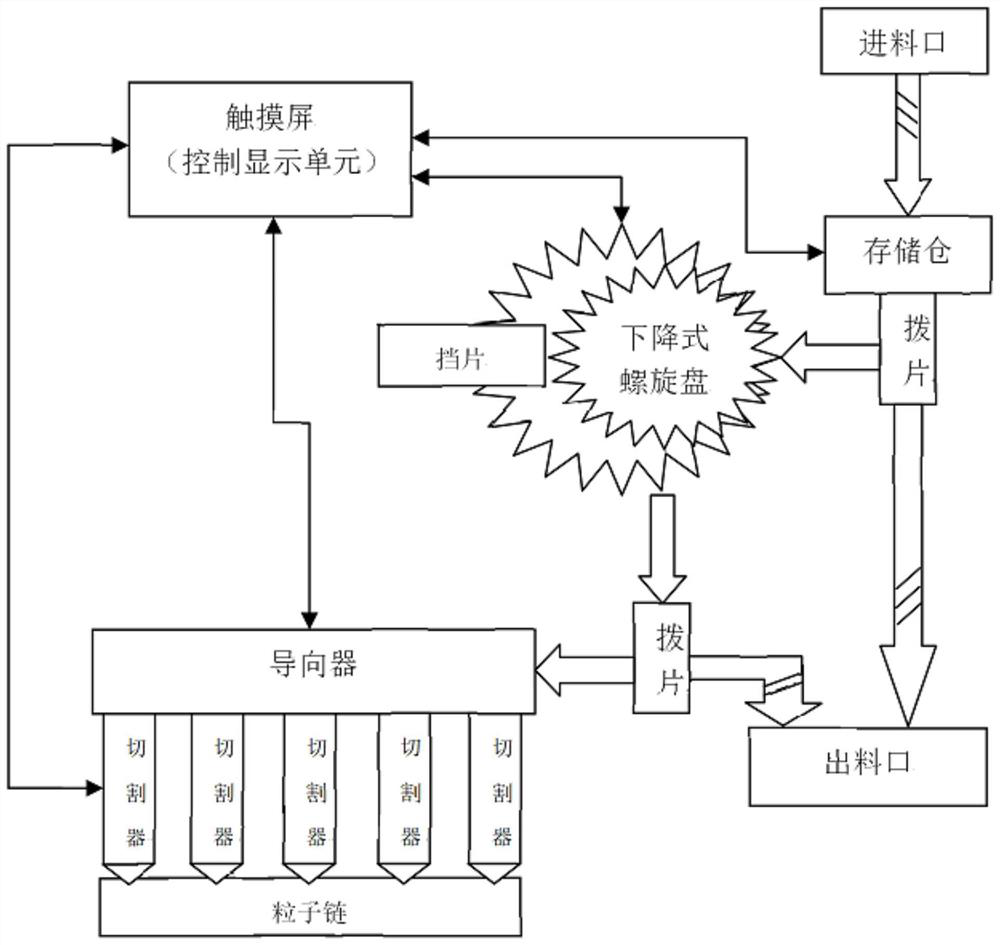

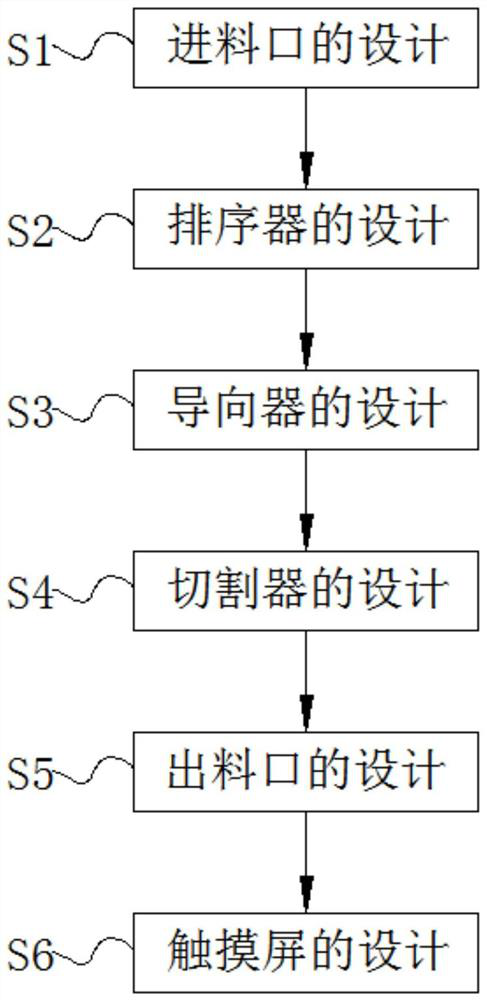

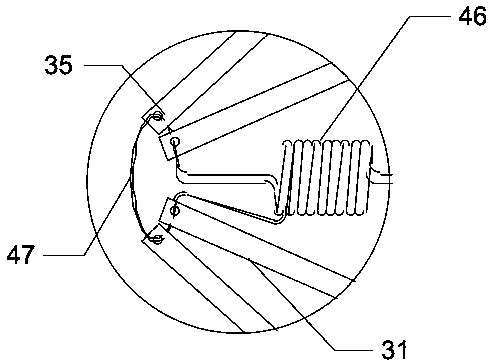

Method based on automatic radioactive particle loading machine

ActiveCN113895920APrevent leakageEasy to operateConveyorsNuclear energy generationTreatment effectEngineering

The invention discloses a method based on an automatic radioactive particle loading machine. The designed and produced automatic radioactive particle loading machine is composed of a feed port, a sequencer, a guider, a cutter, a discharge port and a touch screen, and the whole loading machine is covered and wrapped by a lead anti-radiation material to prevent radioactive leakage. The invention relates to the technical field of medical clinic. According to the method based on the radioactive particle automatic loading machine, the problems of storage, implantation, spacing, leakage and the like existing in a previous particle operation can be completely solved, radioactive contamination caused by particle exposure is avoided, the preoperative preparation time and the intraoperative particle implantation time are greatly shortened, the operation difficulty is reduced, the number of doctors needing to be allocated for operation is reduced, the distance between the particles completely meets the requirement of a preoperative treatment plan, therefore, the treatment effect is improved, and the pressure of storing, transporting and distributing the particles in a particle production plant is relieved.

Owner:山东卓业医疗科技有限公司

Removable recyclable cavity venous thrombosis filter

PendingCN110893128APrevent unsightly appearanceGood lantern balanceBlood vessel filtersSurgical operationVenous blood

The invention describes a removable recyclable cavity venous thrombosis filter consisting of a fixing nut, a fixing bolt, a stent main body, a disassembly guide wire, a recycling hose and a catcher. The cavity venous thrombosis filter is a lantern-type closed structure with a balance bar at the time of implantation. When the product is recycled, one end of the stent main body of the product can bedisassembled in vitro to turn the stent main body of the product into a conical open structure, so that the product has a lantern structure and good balance, is not liable to tilt, has no risk of puncture and has the characteristics that the conical structure has long implantation time and damage is small. In addition to tilt resistance, anti-puncture structure and prolonged implantation time ina patient body of the cavity venous thrombosis filter, the cavity venous thrombosis filter can also be recovered from the femoral vein of a patient after implantation, thereby reducing the risk of surgical operation, and preventing unsightly phenomenon that the neck wound of the patient form scars after healed.

Owner:SHANGHAI HOPE MEDICAL DEVICES CO LTD

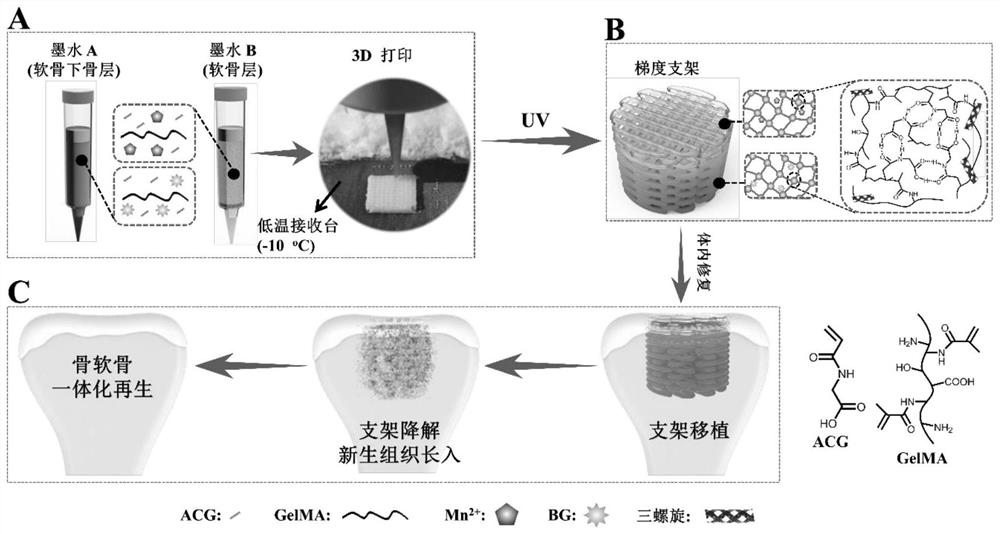

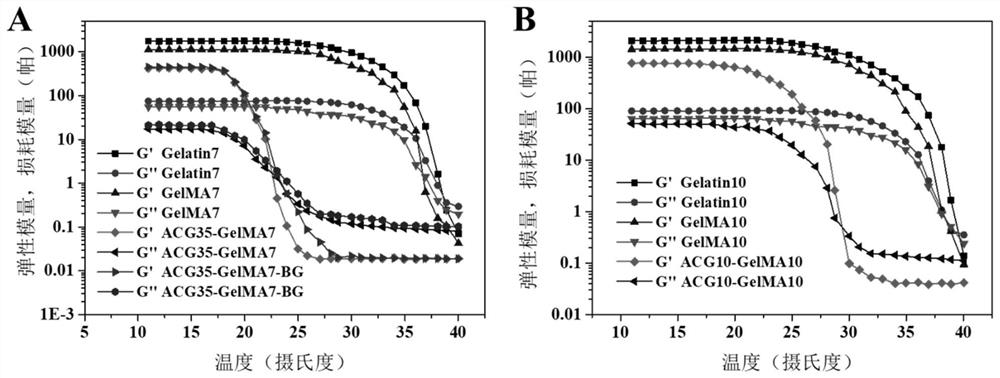

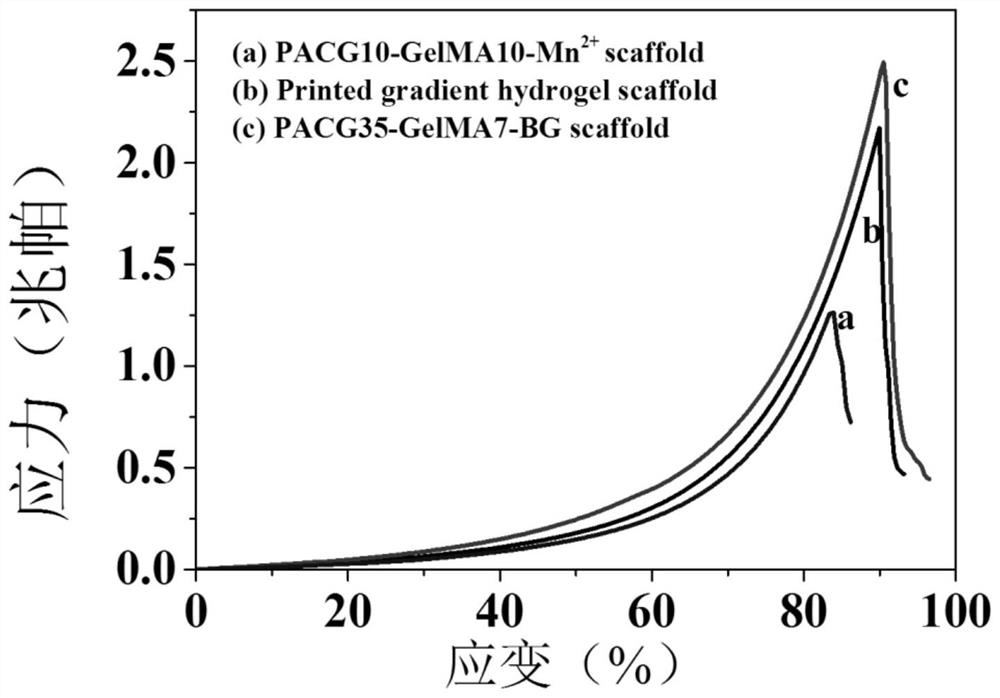

Degradable biological hybrid high-strength hydrogel stent as well as preparation method and application thereof

InactiveCN112107730APromote regenerationAdditive manufacturing apparatusTissue regenerationMeth-Chemistry

The invention provides a degradable biological hybrid high-strength hydrogel stent as well as a preparation method and application thereof. The hydrogel stent is constructed by taking methacrylated gelatin loaded with manganese ions or bioactive glass and an aqueous solution of an N-acryloylglycine monomer precursor as biological ink by a method of firstly performing 3D printing molding and then performing free radical polymerization. The stent is integrally formed, the formula is simple, the components are safe, the preparation conditions are mild, the problem of interface bonding of cartilage and subchondral bone layers is solved, and the hydrogel stent has two properties of high strength and degradability, can play a role in bearing at the initial stage of implantation of a defect part,and can be gradually degraded along with the extension of implantation time. Space is provided for growth of new tissues, and an osteochondral integrated repair effect is achieved.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com