Polyether-ether-ketone material and surface modification method thereof

A polyetheretherketone and modification technology, which is applied in the field of surface modification of medical polymer materials, can solve the problems of unfavorable clinical medicine, poor biological activity, difficult bone tissue bonding, etc., and achieves improvement of initial adhesion and spreading conditions, The effect of improved alkaline phosphatase activity and simple and easy operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] After the pure polyetheretherketone of 10mm×10mm×1mm is polished, it is ultrasonically cleaned with acetone and deionized water in sequence, each time for 30 minutes, after cleaning, it is dried in an oven at 80°C and stored properly. Using the mixed gas of argon and water vapor as the ion source, plasma immersion ion implantation is carried out on the polyetheretherketone substrate, and the implanted modified polyetheretherketone material (AW-PEEK) is properly preserved. For the specific process parameters, see Table 2 shows.

[0045] Table 2 Argon water vapor mixed gas plasma immersion ion implantation parameters

[0046] Background vacuum (Pa)

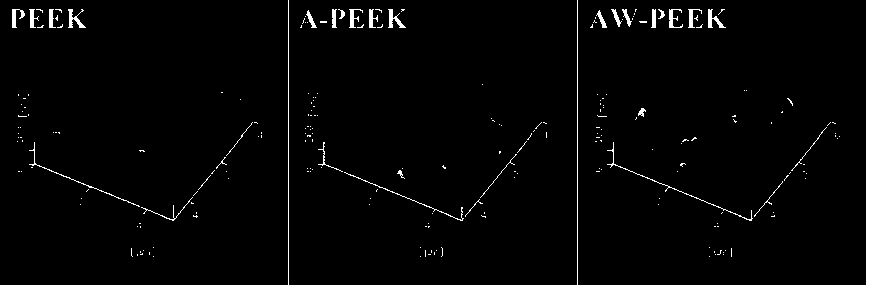

[0047] figure 1 (AW-PEEK) is the surface morphology diagram of the medical polyetheretherketone material obtained through the modification treatment of this example. The figure shows that the surface of the modified material has narrow and long groove-like nanostructures; figure 2 (AW-PEEK) is a three-dimensional...

Embodiment 2

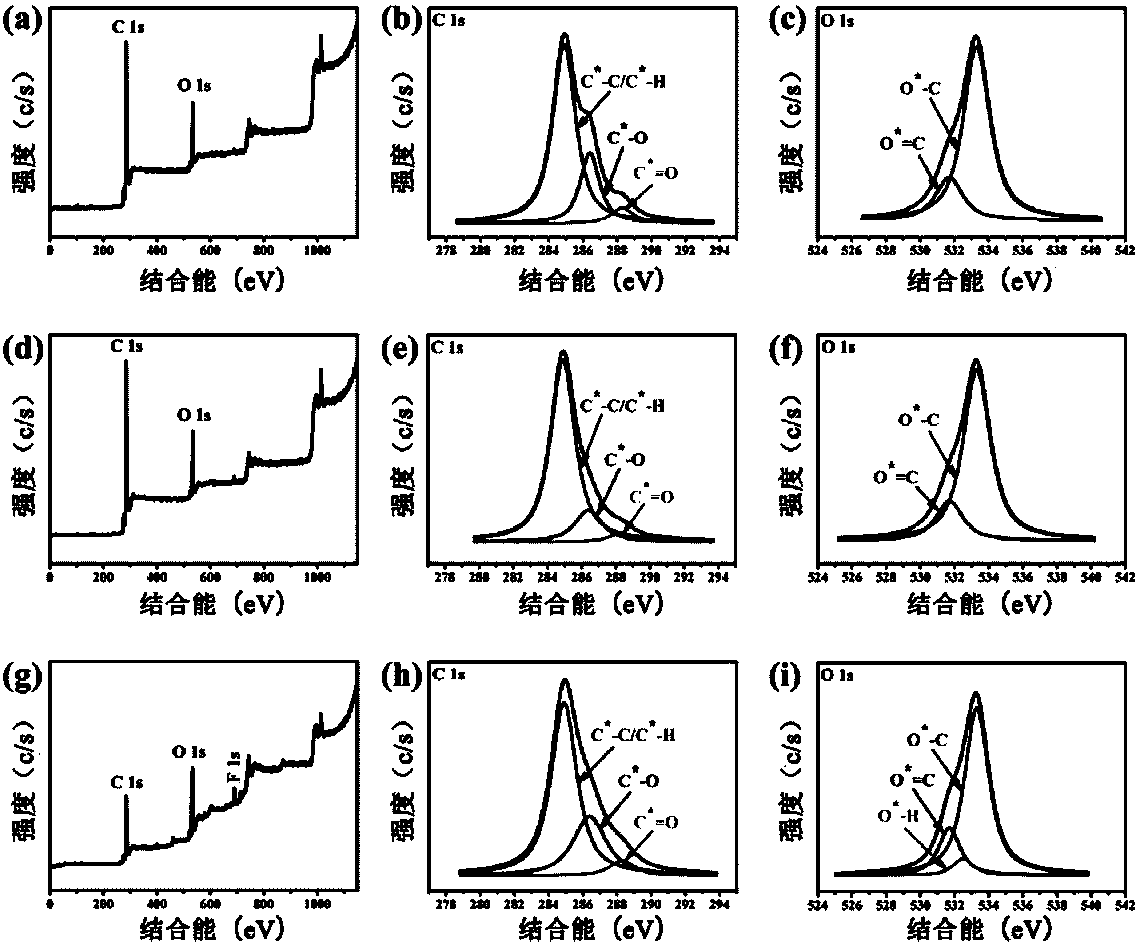

[0049] X-ray photoelectron spectroscopy (XPS) was used to evaluate the chemical state of the surface of the polyether ether ketone material obtained through the modification treatment of the above Comparative Example 1 and Example 1. The specific method is as follows: use a magnesium target Kα system (1253.6eV) ray source to measure the C1s and O1s high-resolution spectrum on the surface of the sample, and calculate the area percentage of each fitting peak in the high-resolution spectrum, and compare it with the measured sample The surface atomic percentages are listed together in Table 3. In addition, in order to qualitatively characterize the existence of hydroxyl groups on the surface of the material, a chemical derivatization method was used to label the hydroxyl groups as fluorine elements. Specifically, in the medium of pyridine and benzene, trifluoroacetic anhydride (TFAA) reacted with the hydroxyl groups on the surface of the sample to be tested (Analytical Chemistry 1...

Embodiment 3

[0055] The initial evaluation of the cytocompatibility of the polyether ether ketone material obtained through the modification of the above Comparative Example 1 and Example 1 was performed using the attachment and spreading of MC3T3 osteoblasts in the initial stage of in vitro culture. Methods as below:

[0056] 1) Put the sample sterilized with 75% ethanol into a 24-well culture plate, add 1 mL to each well with a density of 2×10 5 cell / mLMC3T3 cell suspension;

[0057] 2) Put the cell culture plate into 5% CO 2 Incubate at 36.5°C for 60 minutes in a cell culture incubator with saturated humidity;

[0058] 3) Aspirate the cell culture medium, wash the surface of the sample with PBS, move the sample to a new 24-well plate, add 2.5% glutaraldehyde solution to the sample to fix the cells, and the fixation time is not less than 4 hours;

[0059] 4) Aspirate the glutaraldehyde solution, add 30%, 50%, 75%, 90%, 95%, and 100% ethanol in sequence to dry and dehydrate the cells, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com