Electrical connector and manufacturing method thereof

A technology of an electrical connector and a manufacturing method, which is applied in the direction of connection, fixed connection, and parts of the connection device, etc., can solve the problems of wasting time, rising cost, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

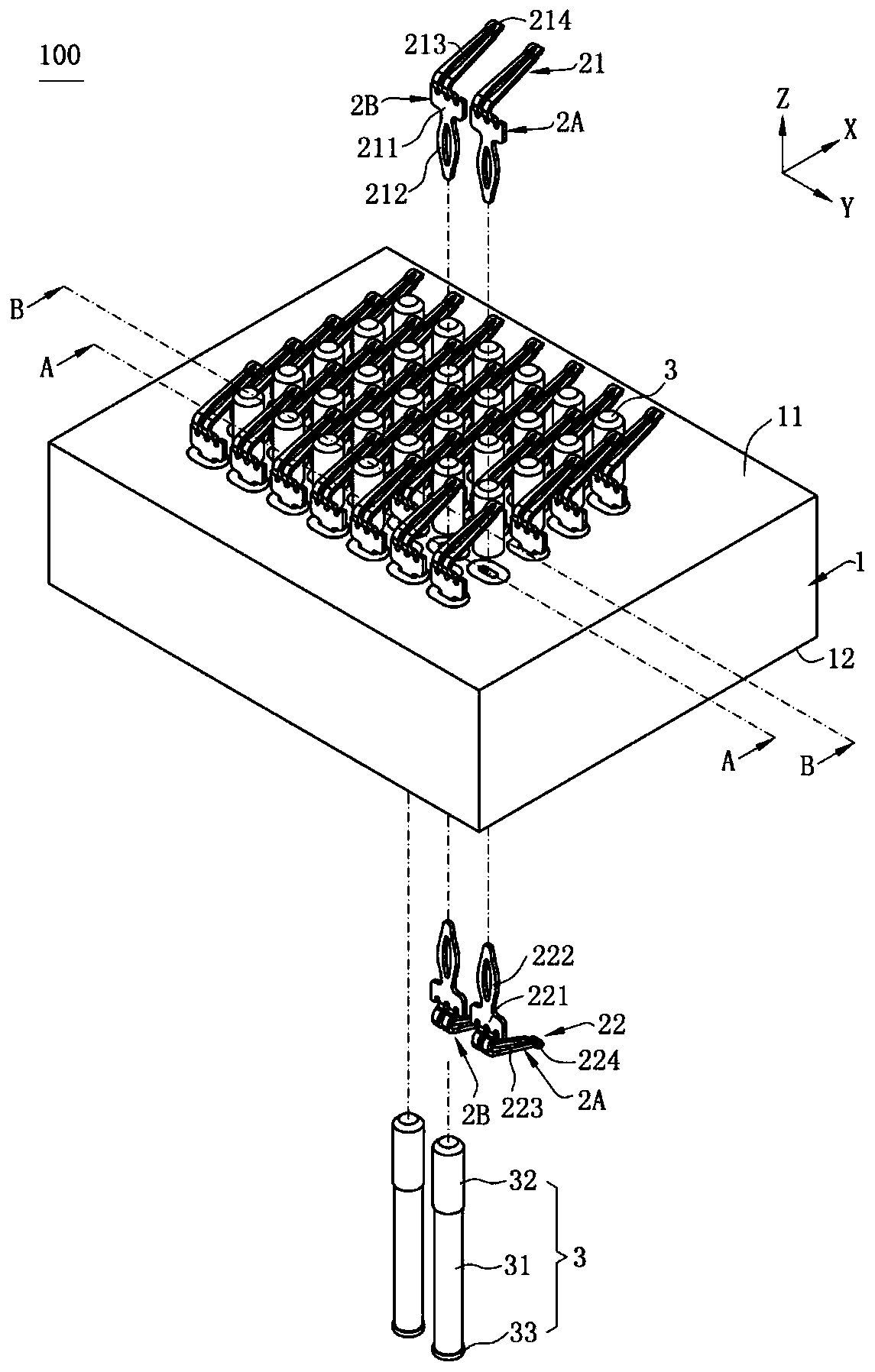

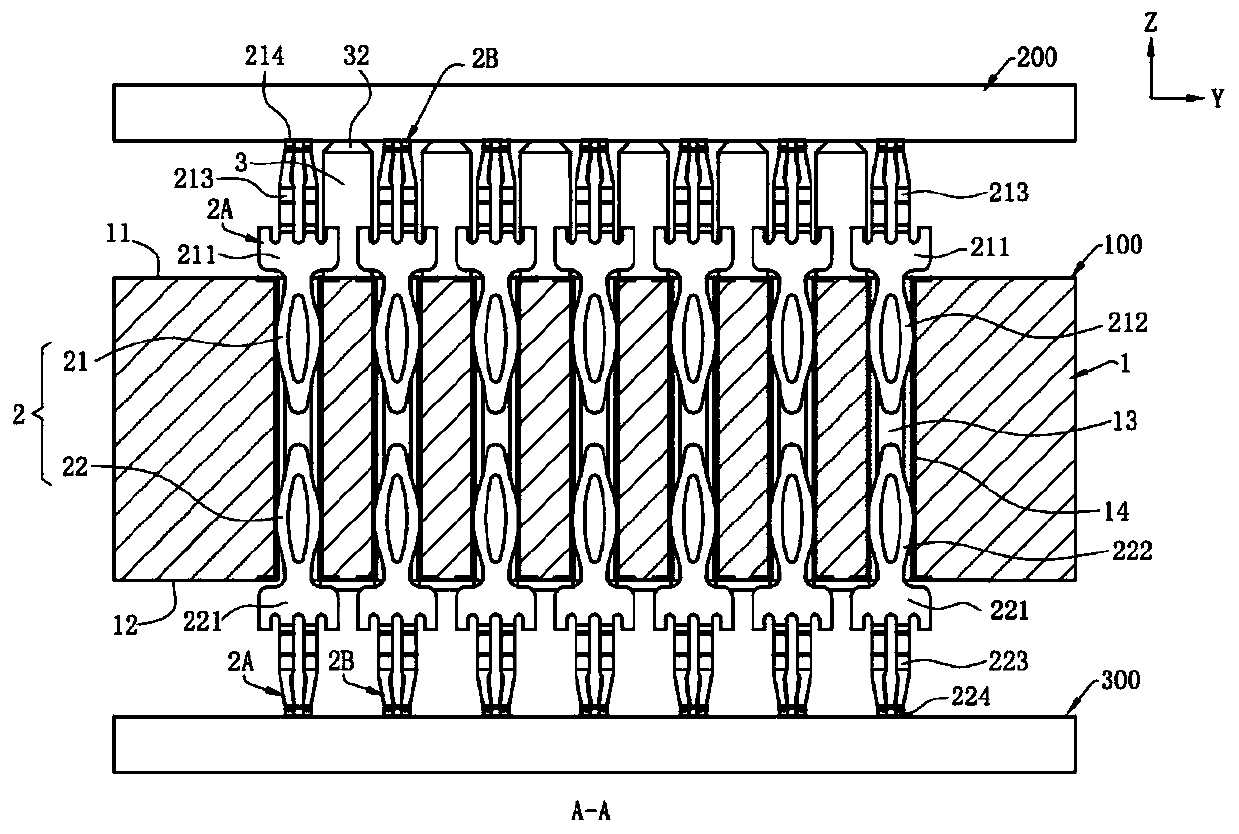

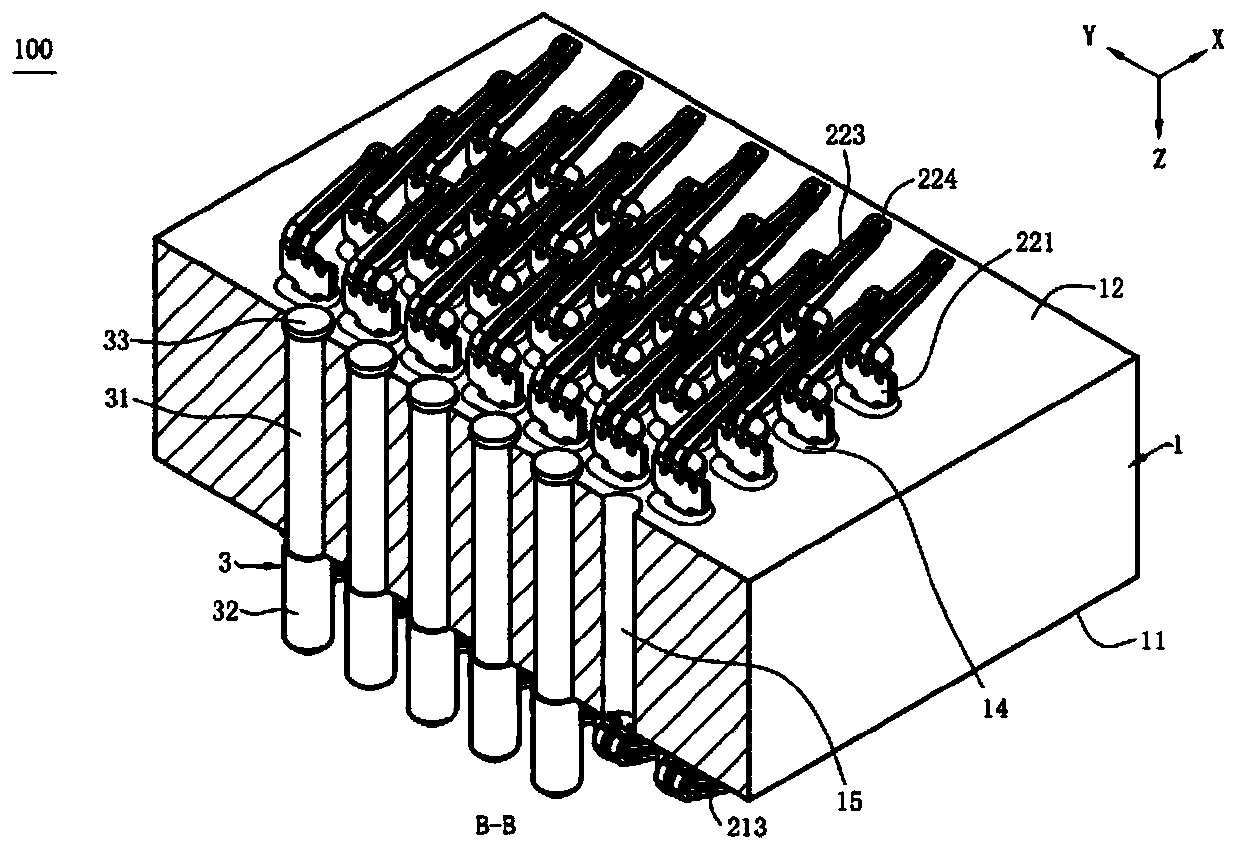

[0055] Such as figure 1 Shown is the first embodiment of the electrical connector 100 of the present invention. The electrical connector 100 defines an up-down direction Z, a front-back direction X and a left-right direction Y perpendicular to the up-down direction Z and perpendicular to each other.

[0056] Such as figure 1 with figure 2 As shown, the electrical connector 100 is used to connect a first docking element 200 and a second docking element 300, which mainly includes a substrate 1 and a plurality of conductive terminals 2 arranged on the substrate 1 and a plurality of the The support member 3, in this embodiment, the first docking element 100 is a chip module, the substrate 1 is a circuit board, and the second doc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com