Degradable biological hybrid high-strength hydrogel stent as well as preparation method and application thereof

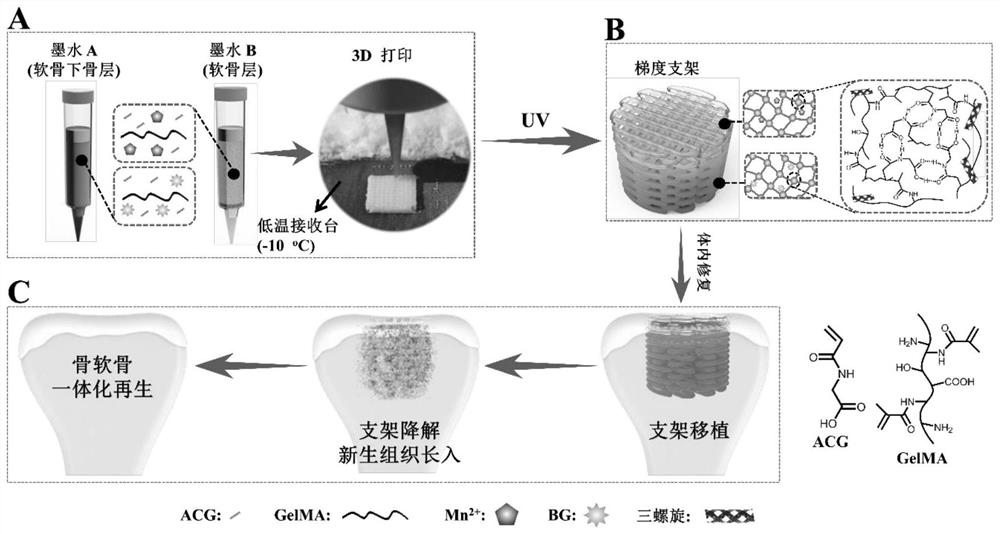

A bio-hybrid and hydrogel technology, used in tissue regeneration, medical science, prosthesis, etc., can solve the problems of inability to fully degrade, difficult to carry tissue engineering scaffolds, and inability to fully meet requirements, and achieve the effect of promoting tissue regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of bioactive glass (BG): solid-phase 1393-1.5B6Sr bioglass was prepared by melting method, and its molar composition was as follows: 6Na 2 O.8K 2 O.8MgO.16CaO.6SrO.27SiO 2 .27B 2 o 3 .2P 2 o 5 (mol%), the carbonates, phosphates, boric acids, etc. corresponding to the alkali metals and alkaline earth metals are fully mixed according to the proportioning ratio, and then the platinum crucible with the mixed raw materials is placed in a silicon-molybdenum furnace at 1100 ° C, melted After 2-4 hours, the melt is quenched to obtain bulk glass, and the glass block is ground and sieved to obtain a powder with a particle size of less than 40 μm, namely to obtain bioactive glass (BG).

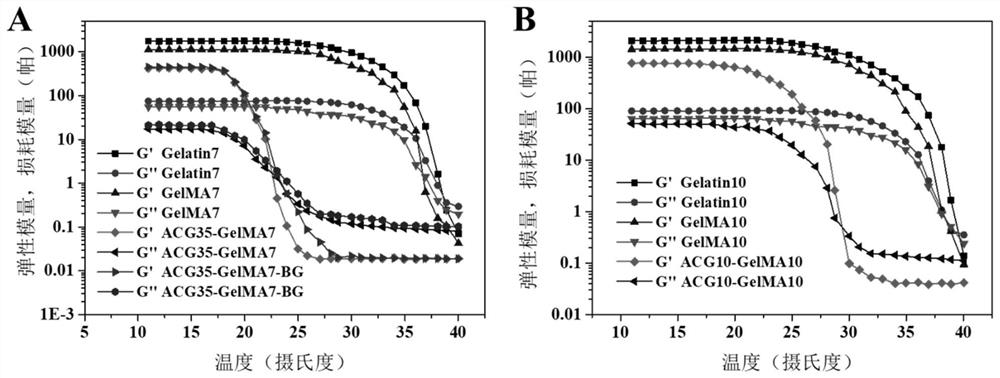

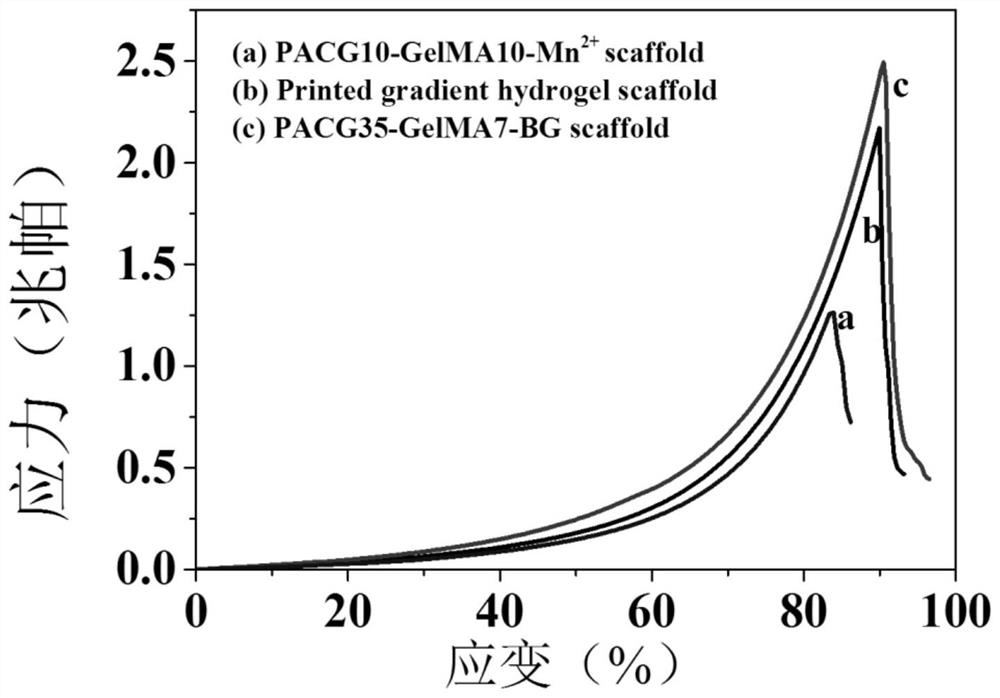

[0024] Taking methacrylylated gelatin (GelMA) with a mass fraction of 7%, N-acryloylglycine (ACG) with a mass fraction of 35%, and bioactive glass (BG) with a concentration of 3% of the total mass of the monomers as an example, in constructing a gradient scaffold The subchondral ...

Embodiment 2

[0028] Preparation of bioactive glass (BG): solid-phase 1393-1.5B6Sr bioglass was prepared by melting method, and its molar composition was as follows: 6Na 2 O.8K 2 O.8MgO.16CaO.6SrO.27SiO 2 .27B 2 o 3 .2P 2 o 5 (mol%), the carbonates, phosphates, boric acids, etc. corresponding to the alkali metals and alkaline earth metals are fully mixed according to the proportioning ratio, and then the platinum crucible with the mixed raw materials is placed in a silicon-molybdenum furnace at 1100 ° C, melted After 2-4 hours, the melt is quenched to obtain bulk glass, and the glass block is ground and sieved to obtain a powder with a particle size of less than 40 μm, namely to obtain bioactive glass (BG).

[0029] Taking methacrylylated gelatin (GelMA) with a mass fraction of 7%, N-acryloylglycine (ACG) with a mass fraction of 35%, and bioactive glass (BG) with a concentration of 5% of the total monomer mass as an example, the gradient scaffold was constructed The subchondral bone l...

Embodiment 3

[0033] Preparation of bioactive glass (BG): solid-phase 1393-1.5B6Sr bioglass was prepared by melting method, and its molar composition was as follows: 6Na 2 O.8K 2 O.8MgO.16CaO.6SrO.27SiO 2 .27B 2 o 3 .2P 2 o 5 (mol%), the carbonates, phosphates, boric acids, etc. corresponding to the alkali metals and alkaline earth metals are fully mixed according to the proportioning ratio, and then the platinum crucible with the mixed raw materials is placed in a silicon-molybdenum furnace at 1100 ° C, melted After 2-4 hours, the melt is quenched to obtain bulk glass, and the glass block is ground and sieved to obtain a powder with a particle size of less than 40 μm, namely to obtain bioactive glass (BG).

[0034] Taking methacrylylated gelatin (GelMA) with a mass fraction of 7%, N-acryloylglycine (ACG) with a mass fraction of 35%, and bioactive glass (BG) with a concentration of 1% of the total monomer mass as an example, the gradient scaffold was constructed The subchondral bone l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com