Patents

Literature

107 results about "Wear debris" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear debris is formed due to the abrasion and adhesion induced by sliding of a harder body (typically metal or ceramics) on the surface of the UHMWPE component.

Metal-ceramic composite articulation

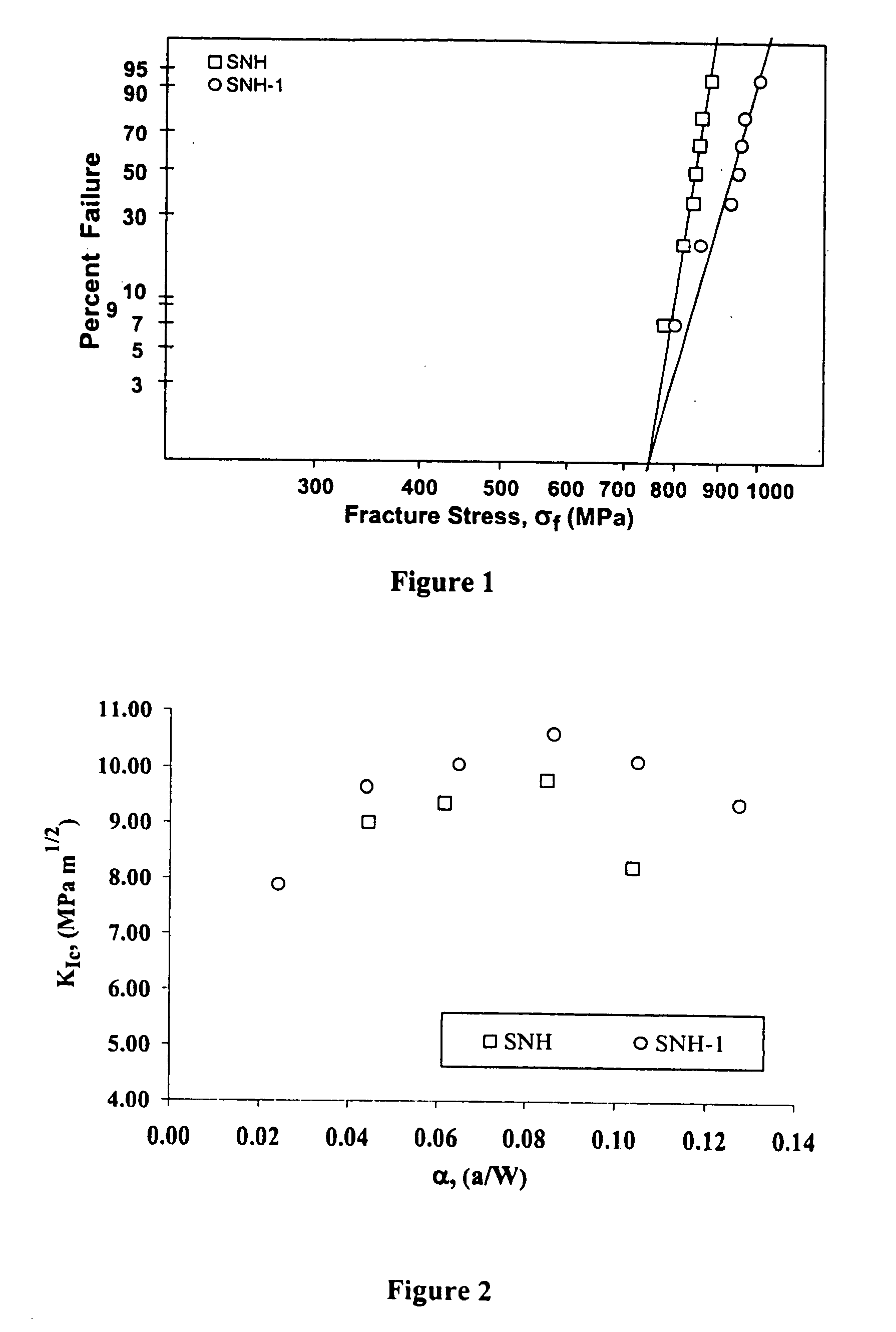

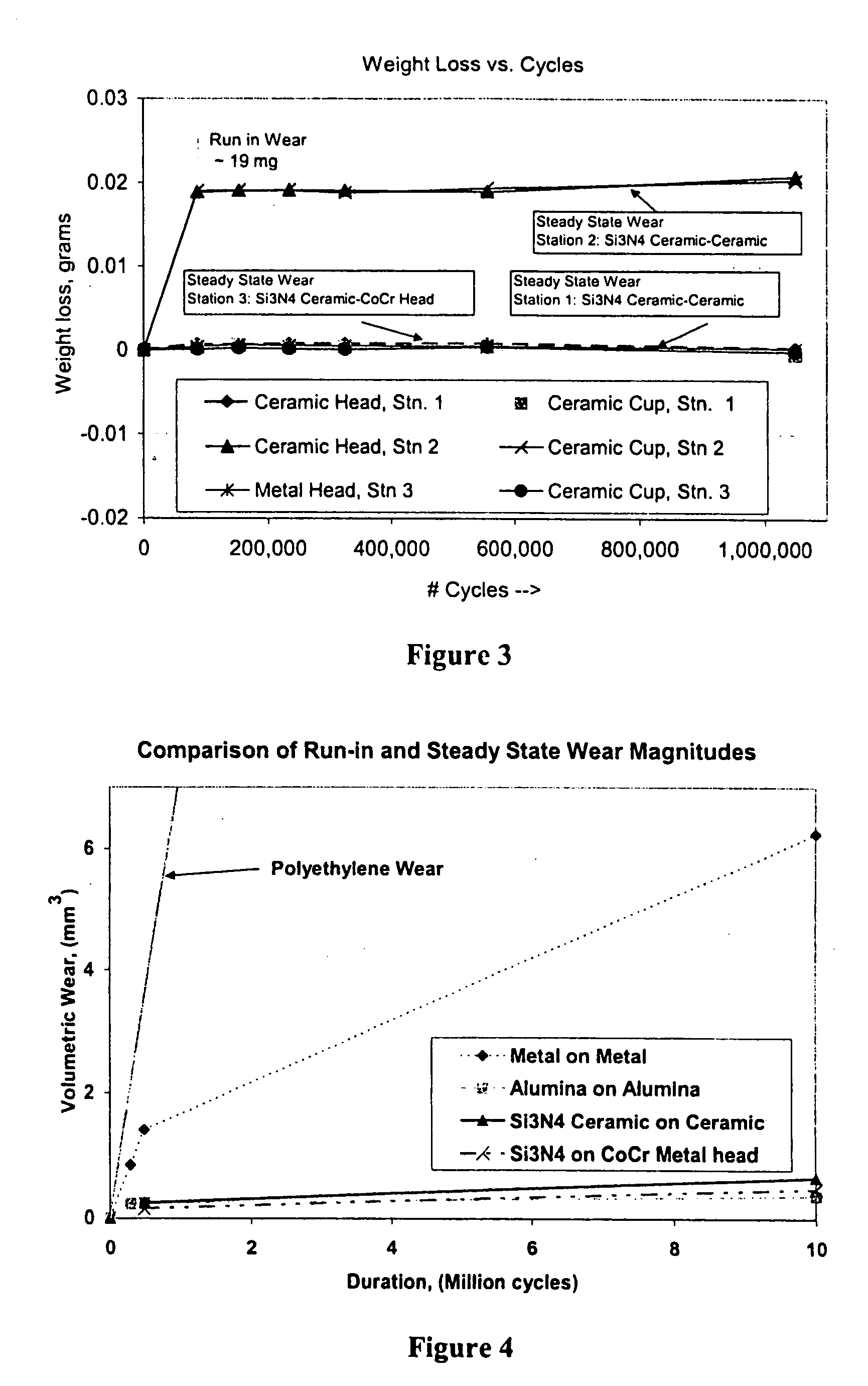

InactiveUS6881229B2Minimal productionImprove flexural strengthBone implantJoint implantsHigh fractureIn vivo

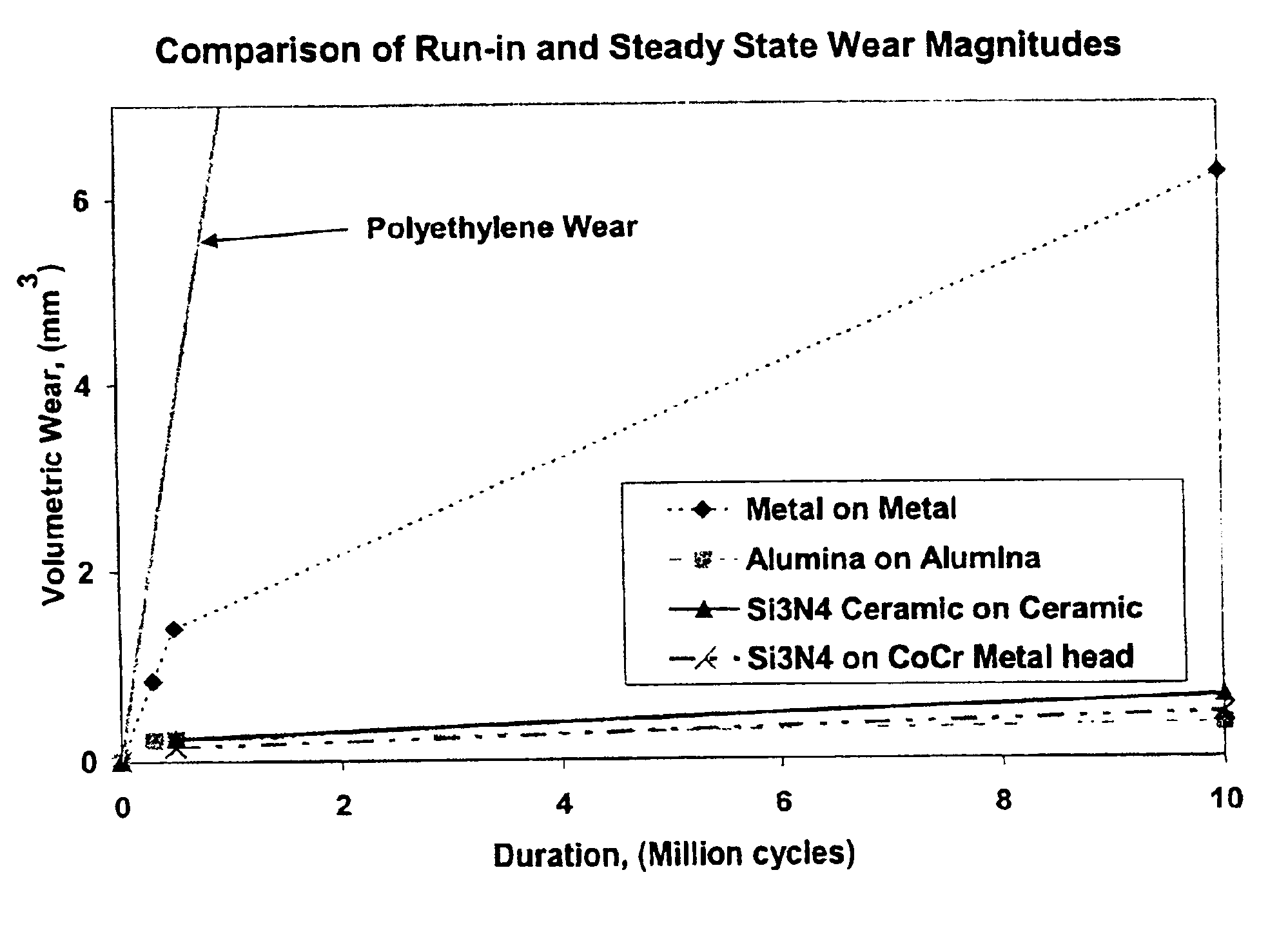

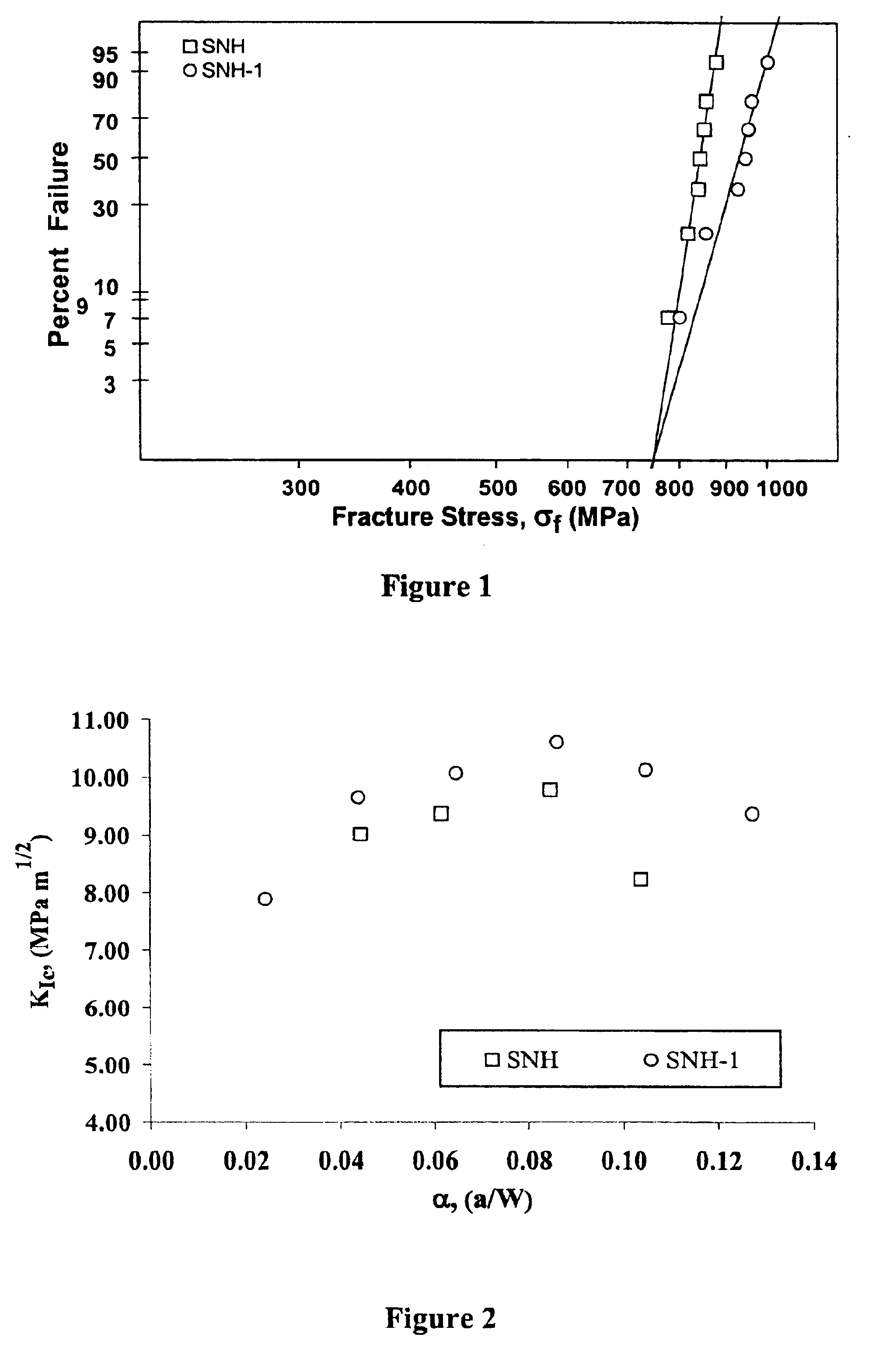

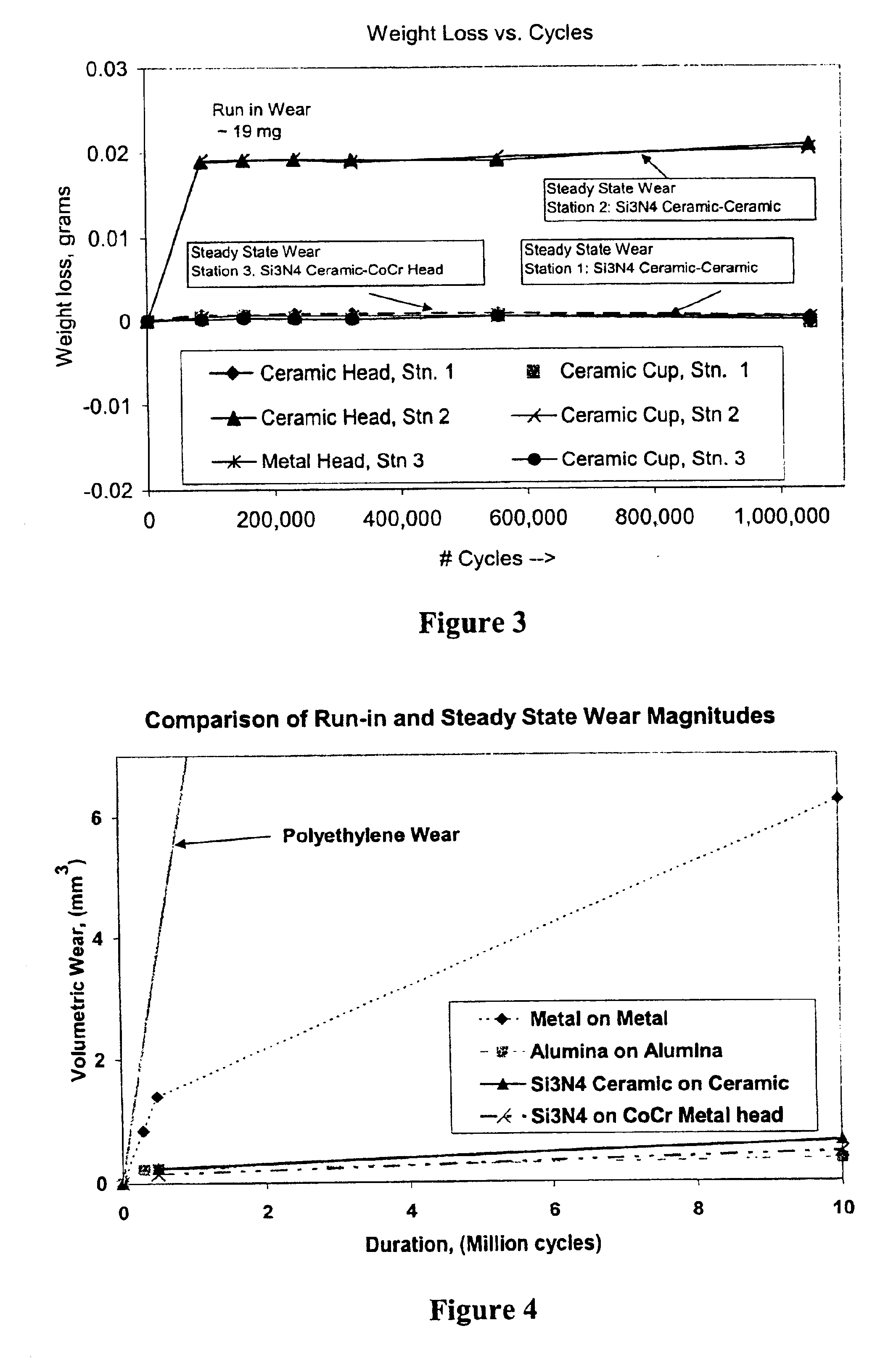

A ceramic-metal composite articulation is provided with substantial elimination of wear debris, wherein a ceramic material is provided with superior mechanical properties tailored for articulating with ceramic articulations having high flexural strength (greater than about 700 MPa), high fracture toughness (greater than about 7 MPa1 / 2) and a high Weibull modulus (greater than about 20), in comparison with presently available bio-ceramics such as alumina or zirconia. The mechanical property enhancement enables ceramic materials with greater reliability and significantly reduced in-vivo fracture risk to be obtained. Preliminary in-vitro wear performance, to several million cycles using established test protocols, of head / cup components in a prosthetic hip joint made from these ceramics also demonstrates the ultra low wear characteristics. These material properties substantially eliminate polyethylene (PE) wear debris mediated implant failures by offering an optimal combination of bio-mechanical safety and reliability with ultra low wear performance.

Owner:SINTX TECH INC

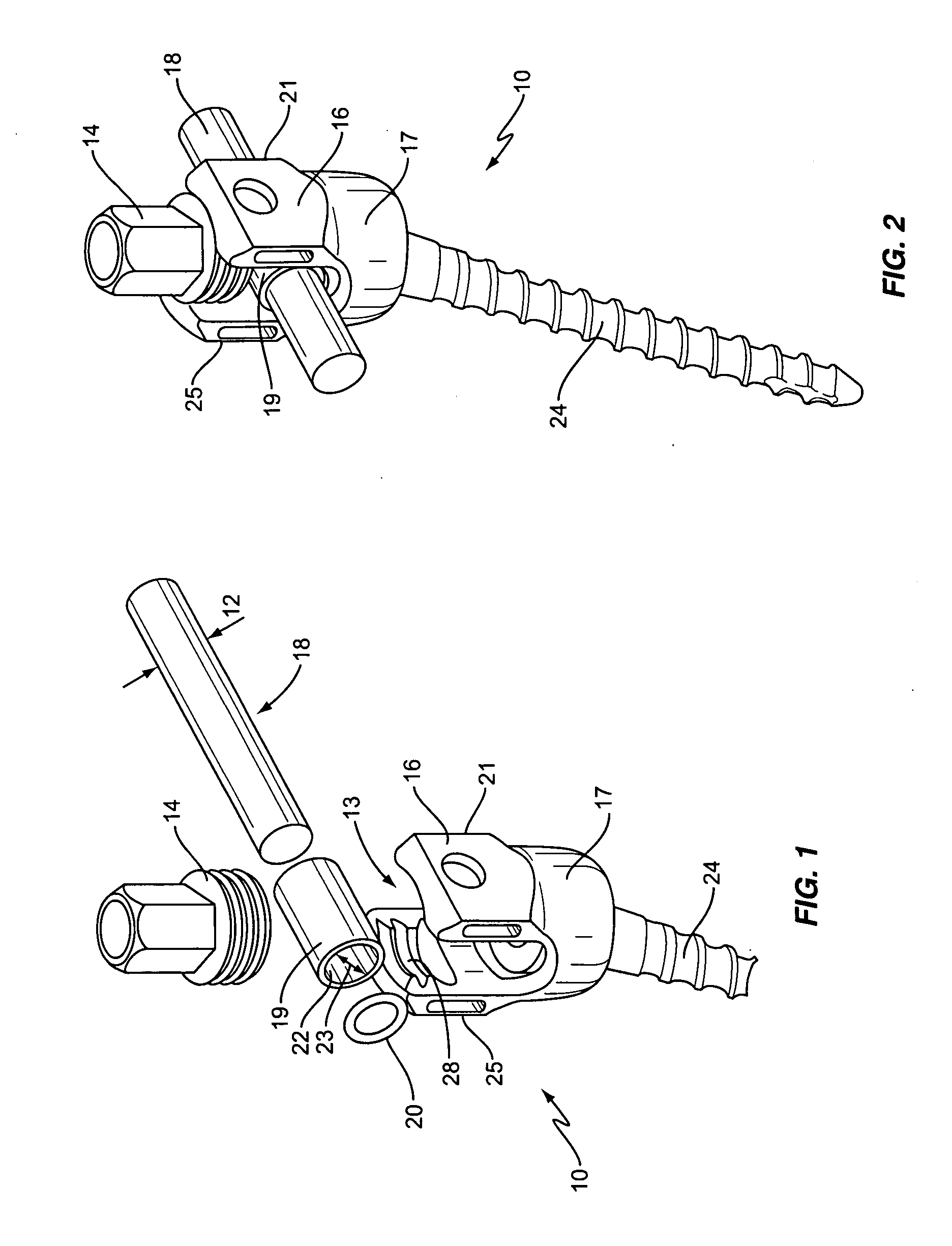

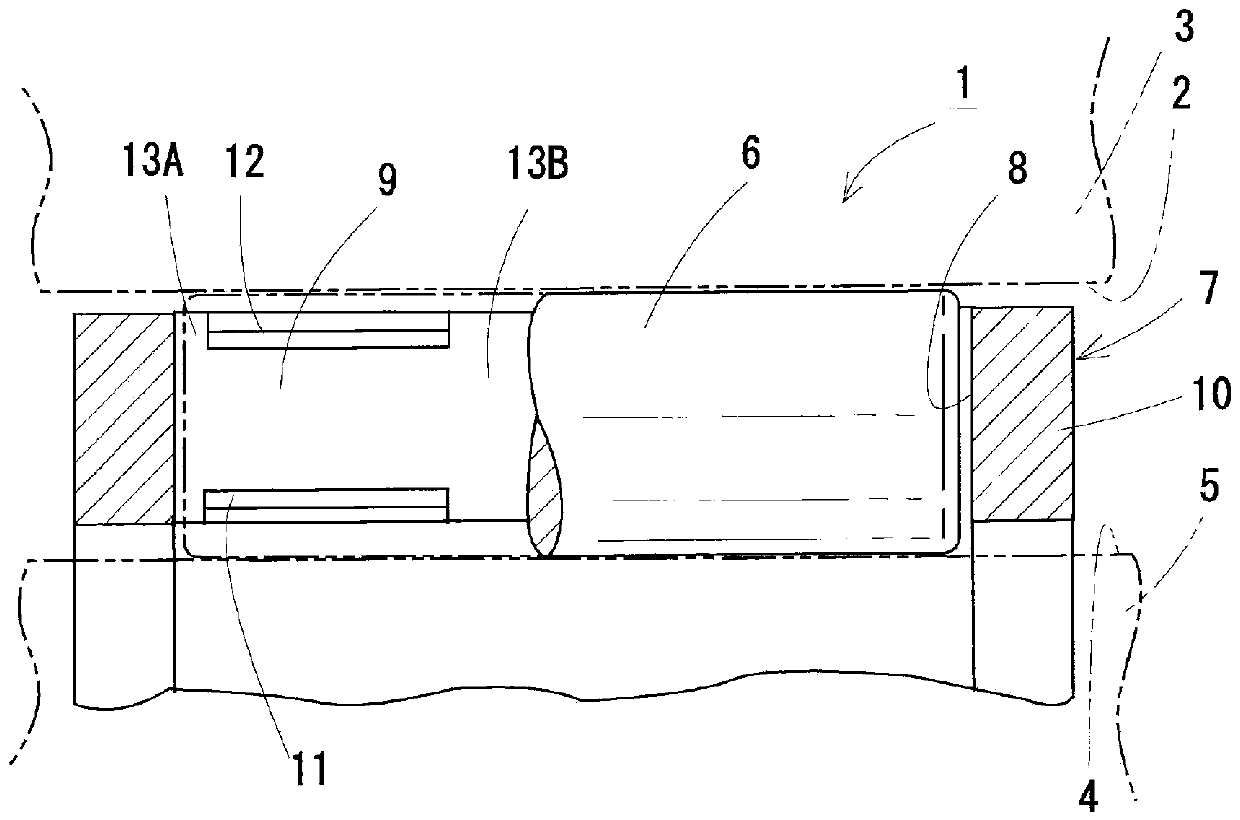

Spinal rod translation device

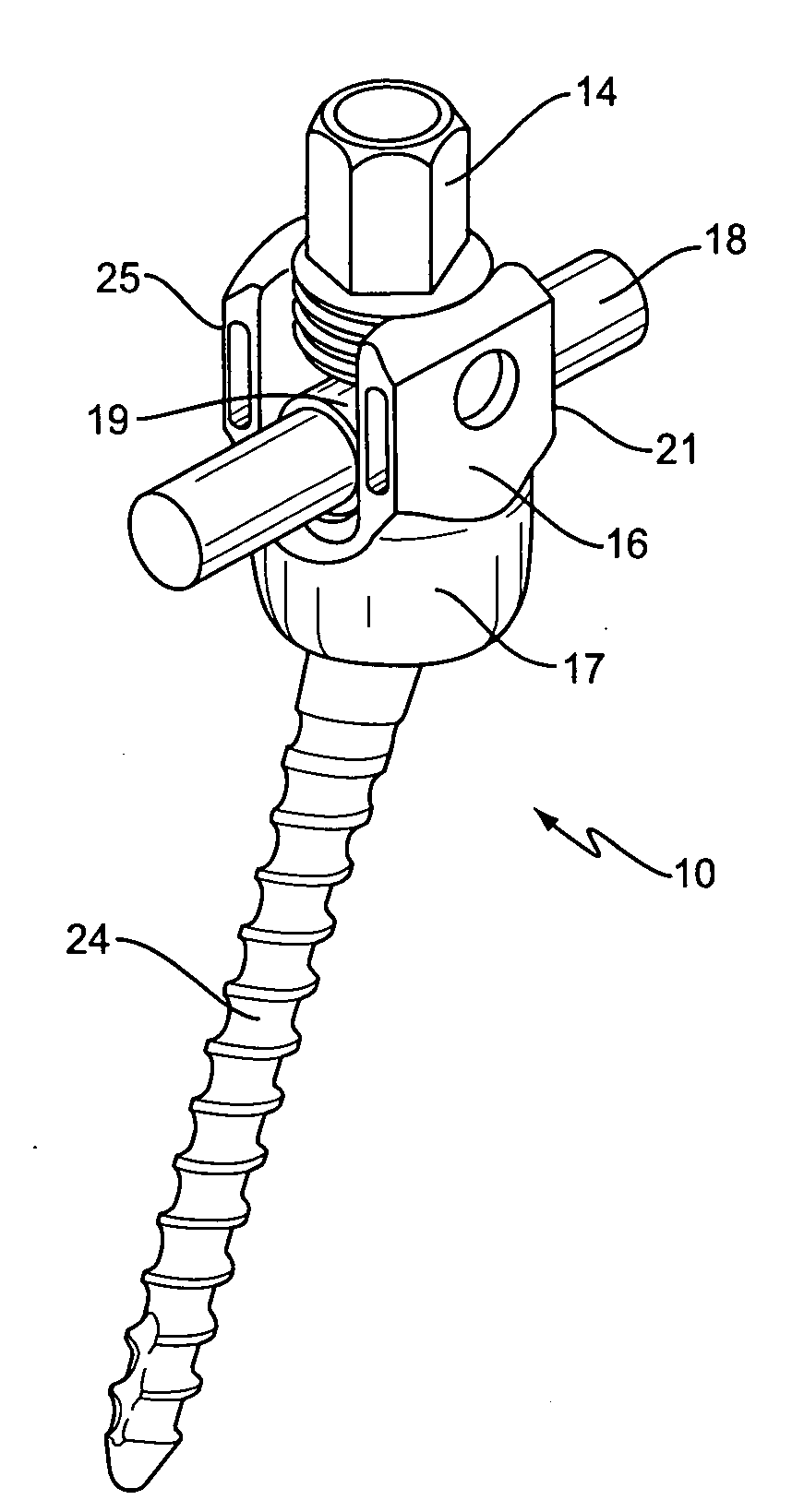

InactiveUS20100262190A1Reduce wearAvoid clamping forceSuture equipmentsInternal osteosythesisCompression memberIliac screw

A rod translation device is described that minimizes the wear between a spinal rod and a bone anchor in a spinal implant. In one embodiment, the rod translation device is a sleeve that is slid onto the outside diameter of the spinal rod. At least one compressible member, such as an O-ring, may be placed within the inside diameter of the sleeve to prevent direct contact of the outside diameter of the spinal rod to the inside diameter of the sleeve. Once the spinal rod is secured within the implant any translation of the spinal rod decreases wear debris between the outside diameter of the spinal rod and the pedicle screw.

Owner:WARSAW ORTHOPEDIC INC

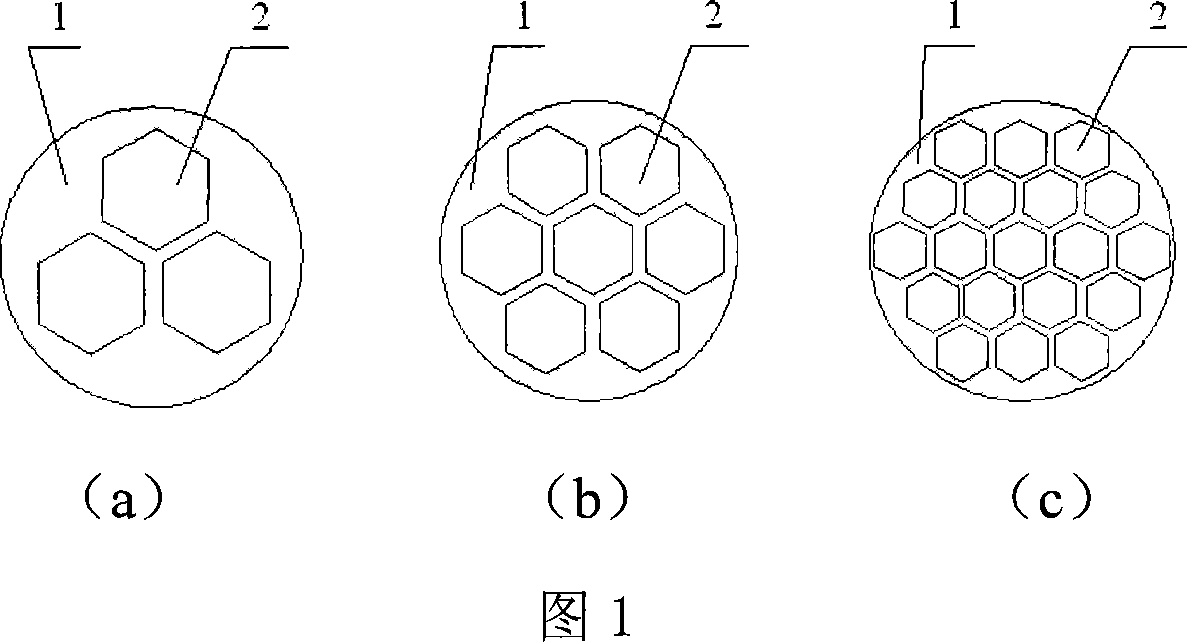

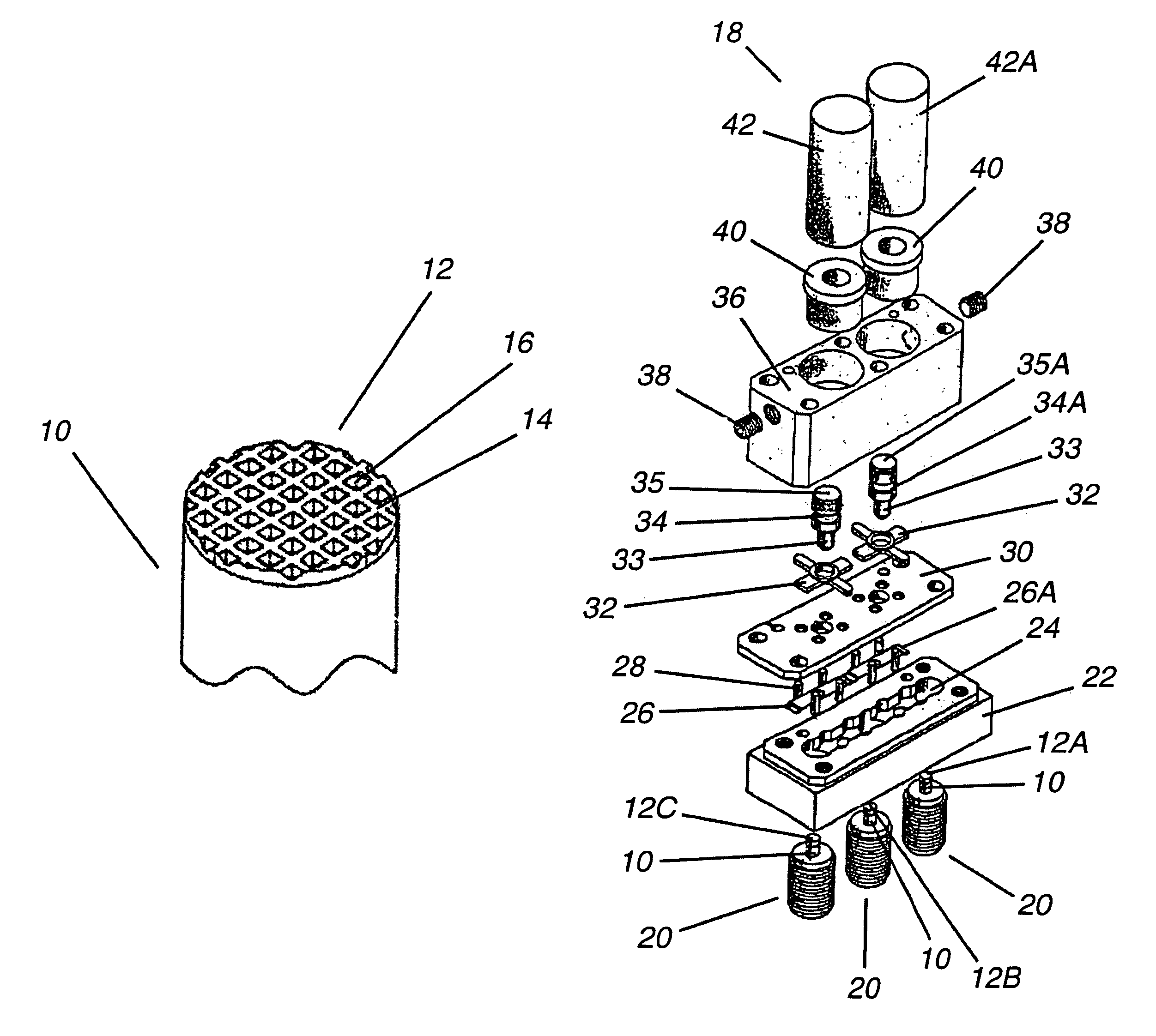

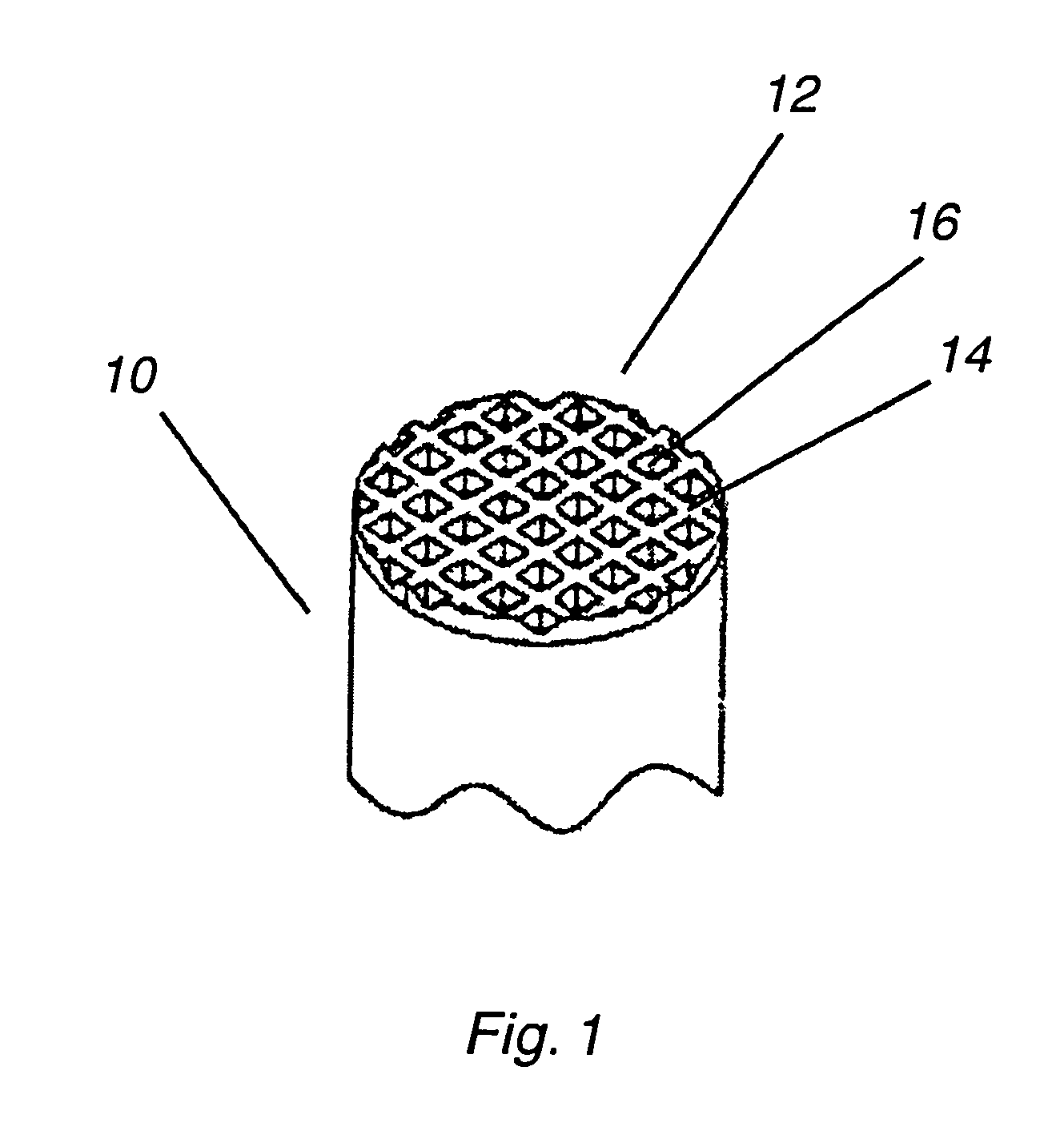

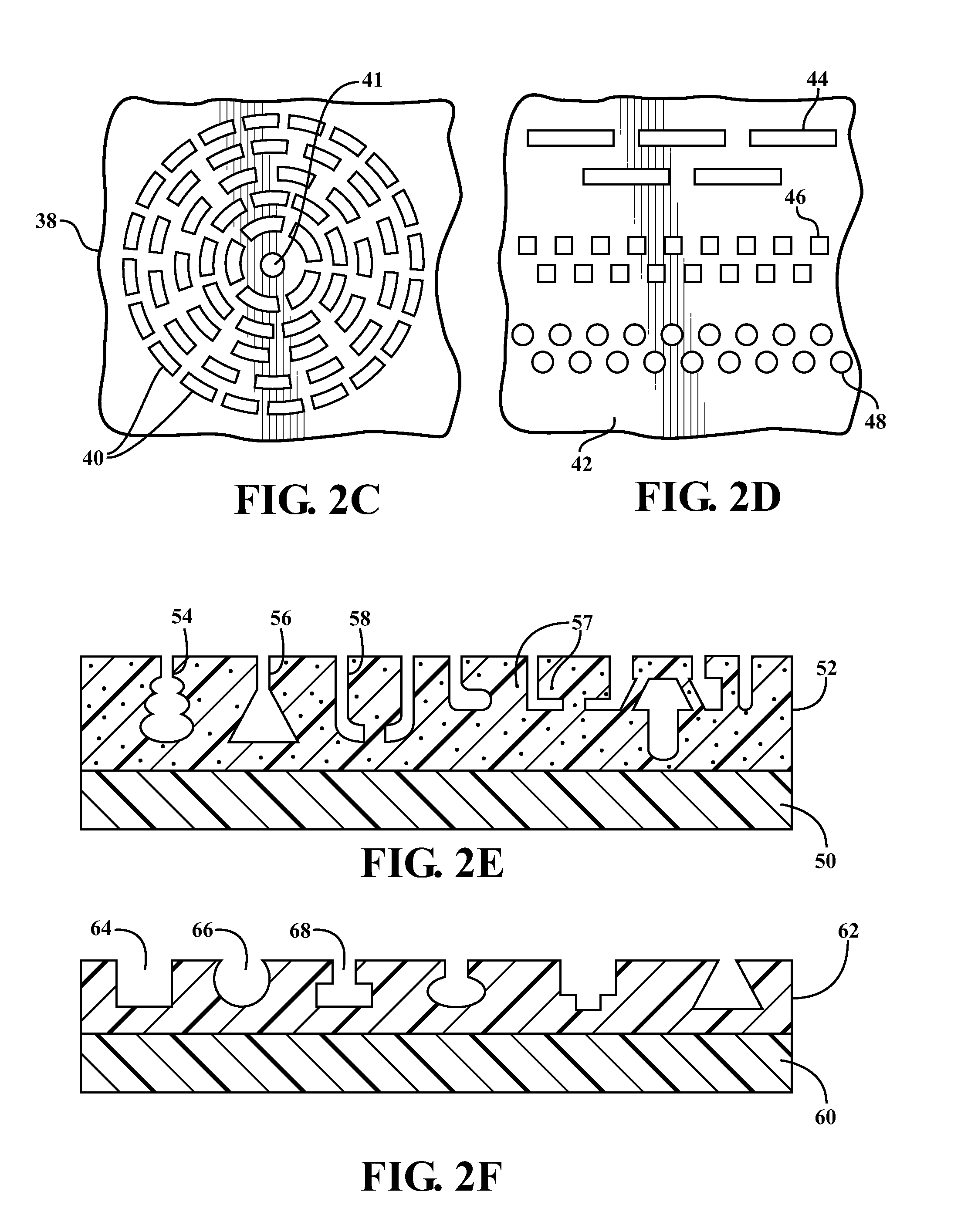

Production of optimized controllable arranged electroplating tool of three-dimensional abrasive laminated

InactiveCN101073882AImprove grinding performanceReduce manufacturing costElectrolytic coatingsGrinding devicesWear debrisAbrasive

The invention is concerned with a kind of milling stuff three-dimensional multi-layer controllable optimized collocation electroplated tools and its produce method, being the micro abrasive cluster optimized collocation and thickened composite plating mask. The micro abrasive cluster optimized collocation bases on the ratio to abrasive and air and the number of wear debris layer. This kind of tool has optimized designed surface abrasive cluster collocation and takes double layers of composite masks as plating mask. It adjusts the thickness of thickened composite plating mask to change the thickness of middle layer and controls the erode degree of middle layer and makes some hollow on it, and the shape of abrasive cluster formed by composite plating is like a foot pace. This abrasive tool and abrasive cluster optimized collocation are fit for discharging grinding bits, entering of grinding liquid and transfer of grinding heat to enhance the grinding capability of milling tool. It reduces the produce cost and the demand of machining precision to base stuff and assembly by adjusting the tool with multi-layer abrasive.

Owner:DALIAN UNIV OF TECH

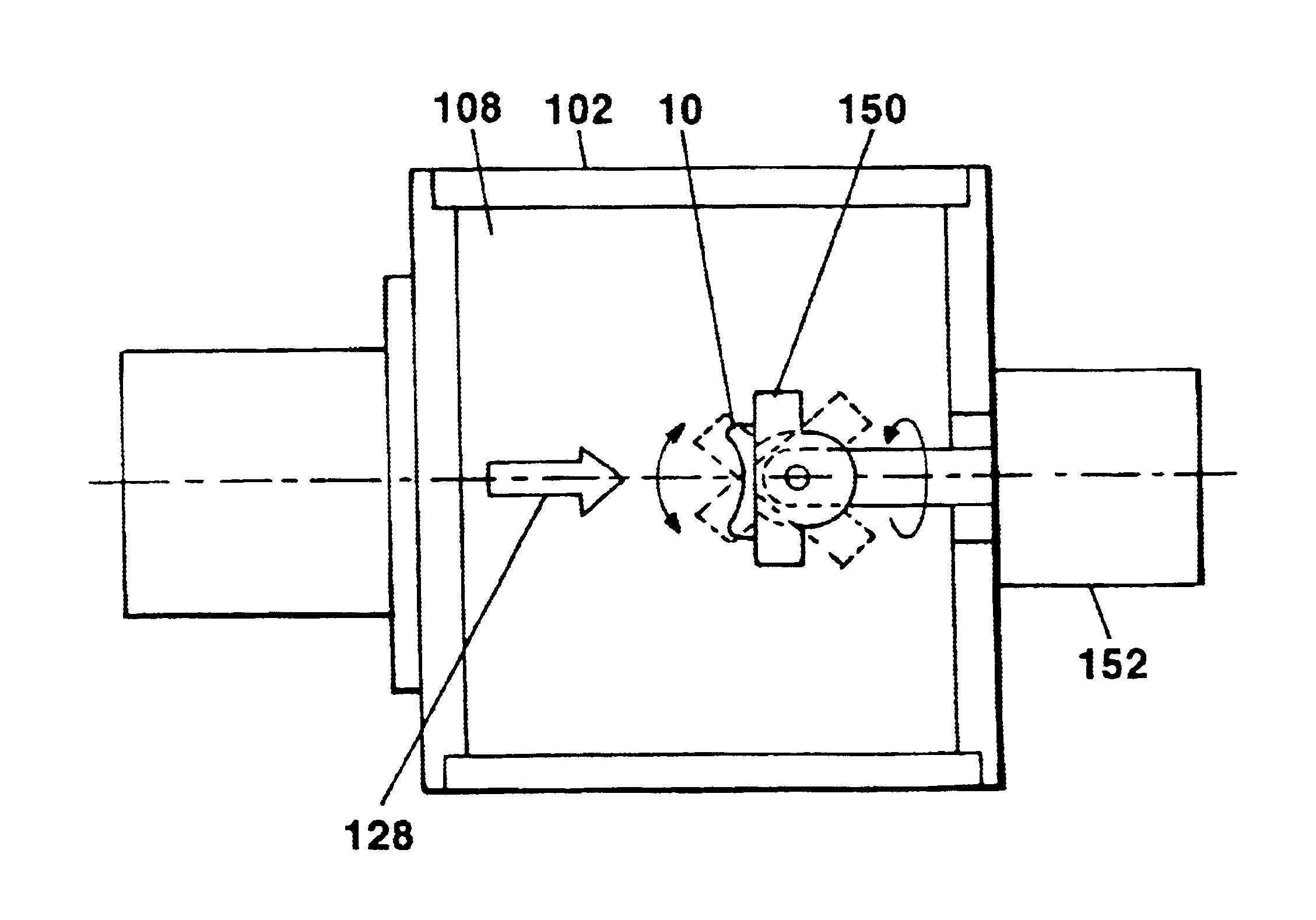

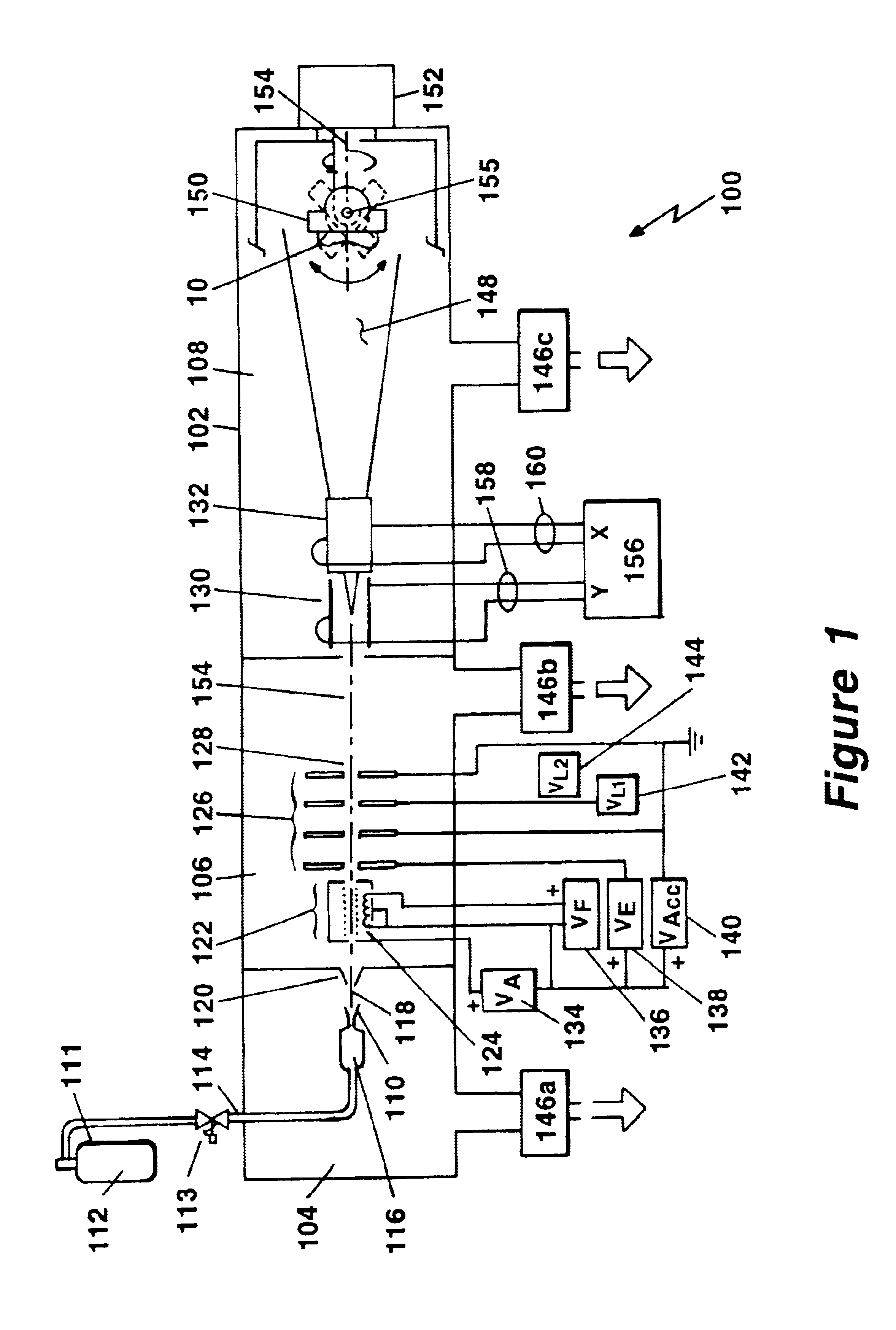

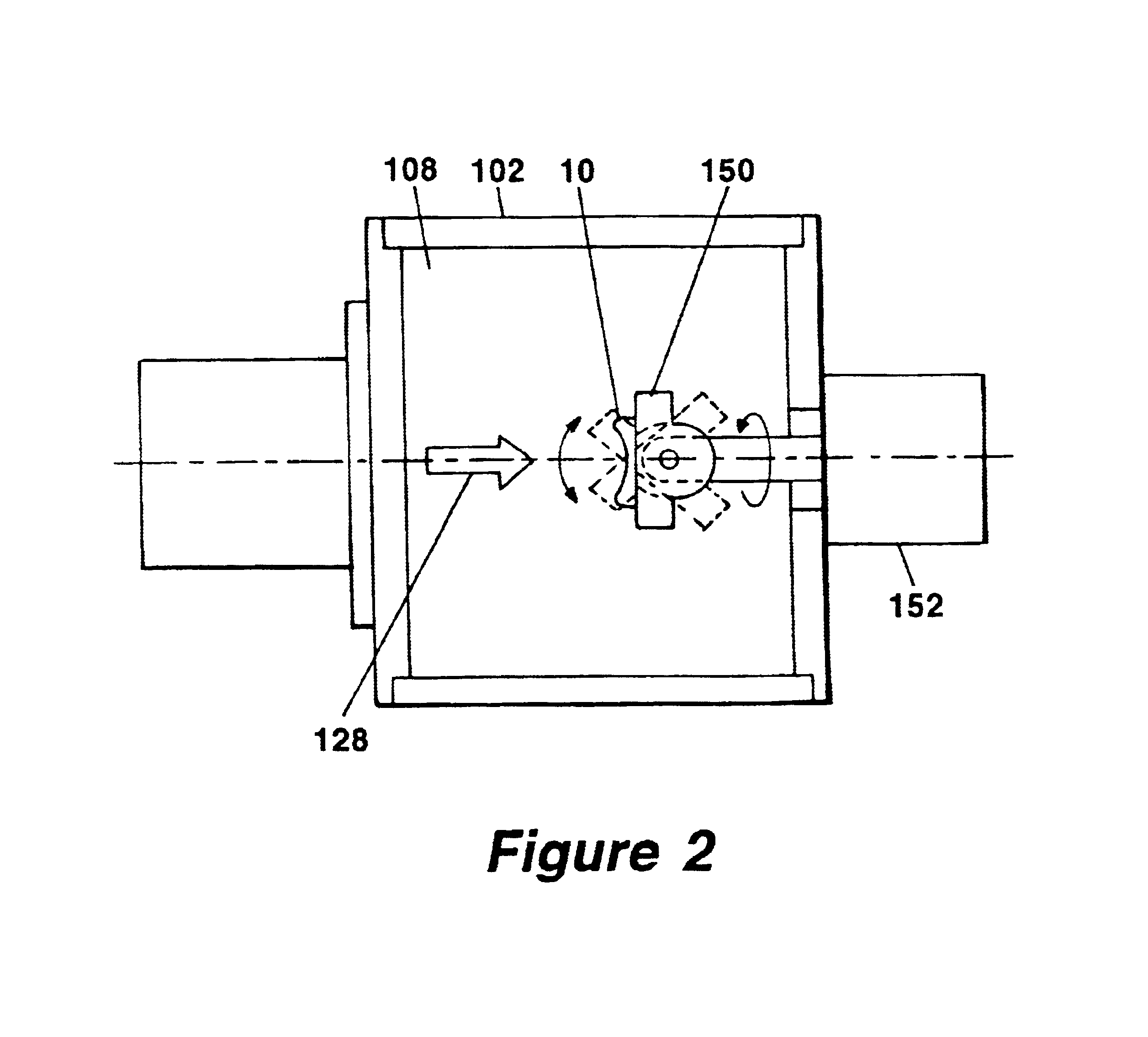

Method and system for improving the effectiveness of artificial joints by the application of gas cluster ion beam technology

InactiveUS6863786B2Minimize impactMinimize wear debrisCellsElectric discharge tubesSurface patternGas cluster ion beam

Regardless of the materials used in an artificial joint component design, the present invention applies gas cluster ion beam (GCIB) technology in order to modify the component's surface(s) so as to increase lubrication between contact surfaces, thereby substantially reducing wear debris, osteolysis complications, and accelerated wear failure. The approach of the surface modification comprises an atomic level surface patterning utilizing GCIB to apply a predetermined pattern to the surface(s) of the joint implant to reduce frictional wear at the interface of the surfaces. A reduction in wear debris by GCIB patterning on any surface(s) of a joint prosthesis reduces accelerated failure due to wear and osteolysis and results in a substantial cost savings to the healthcare system, and reduces patient pain and suffering.

Owner:EXOGENESIS CORP +1

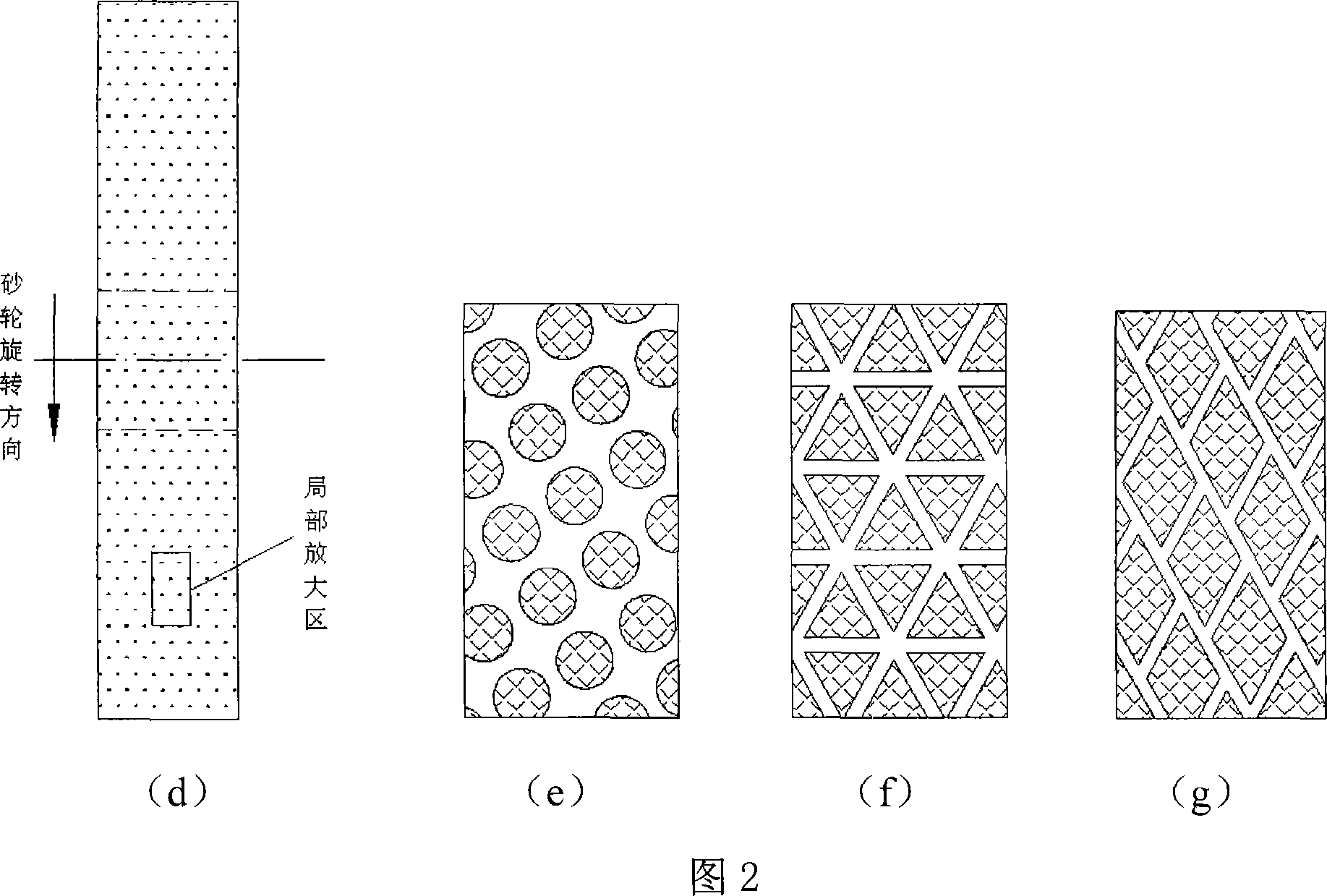

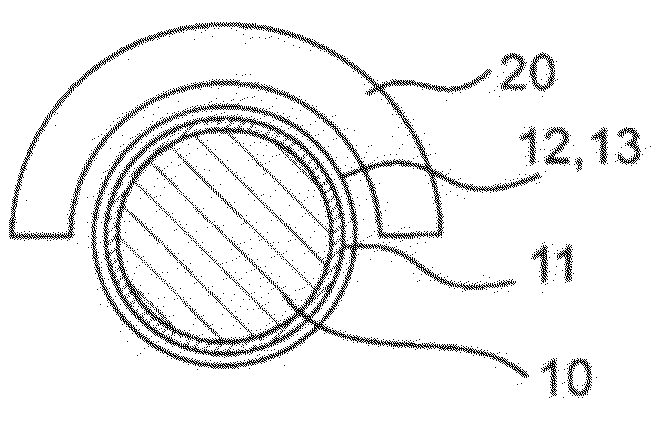

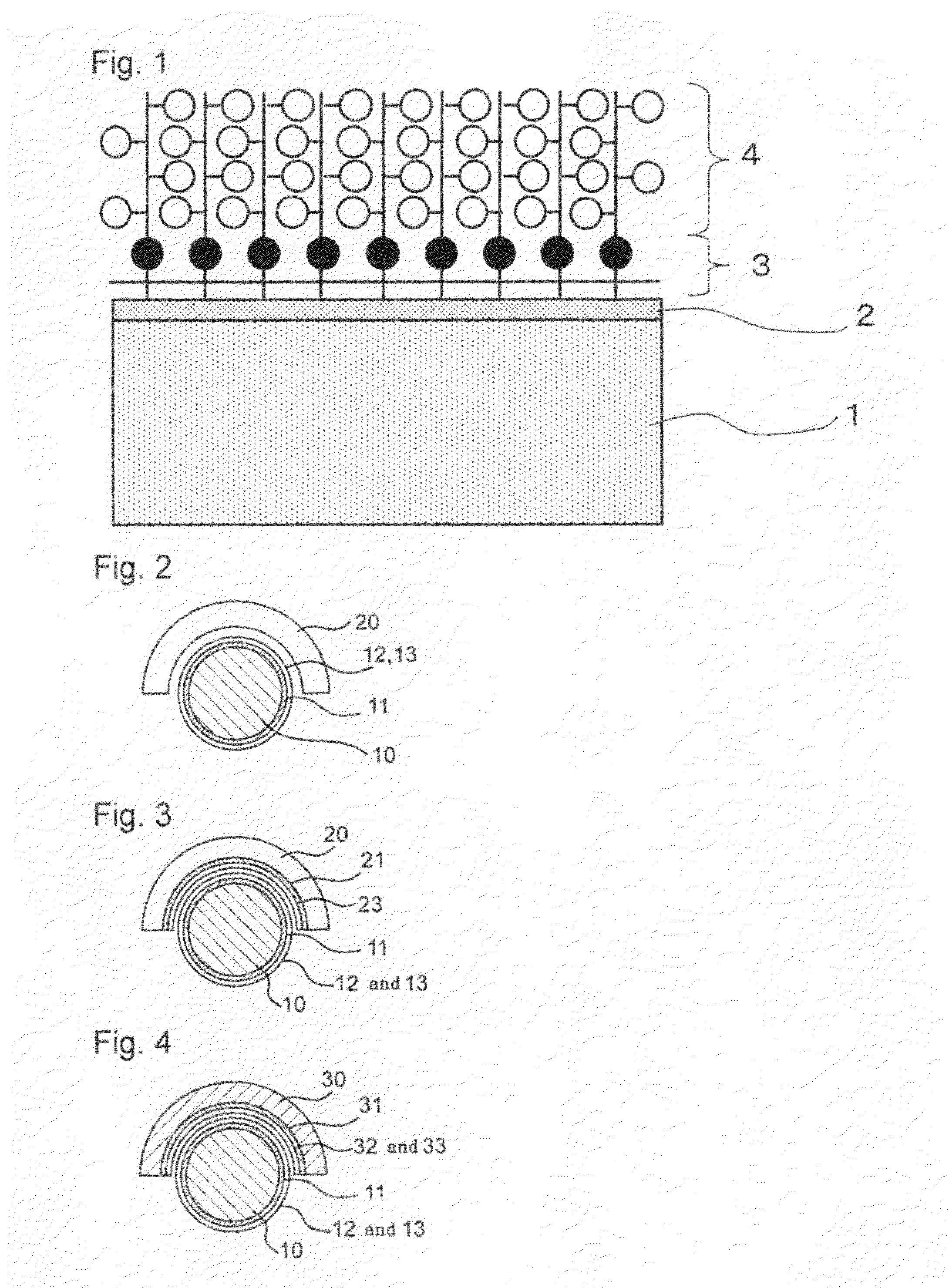

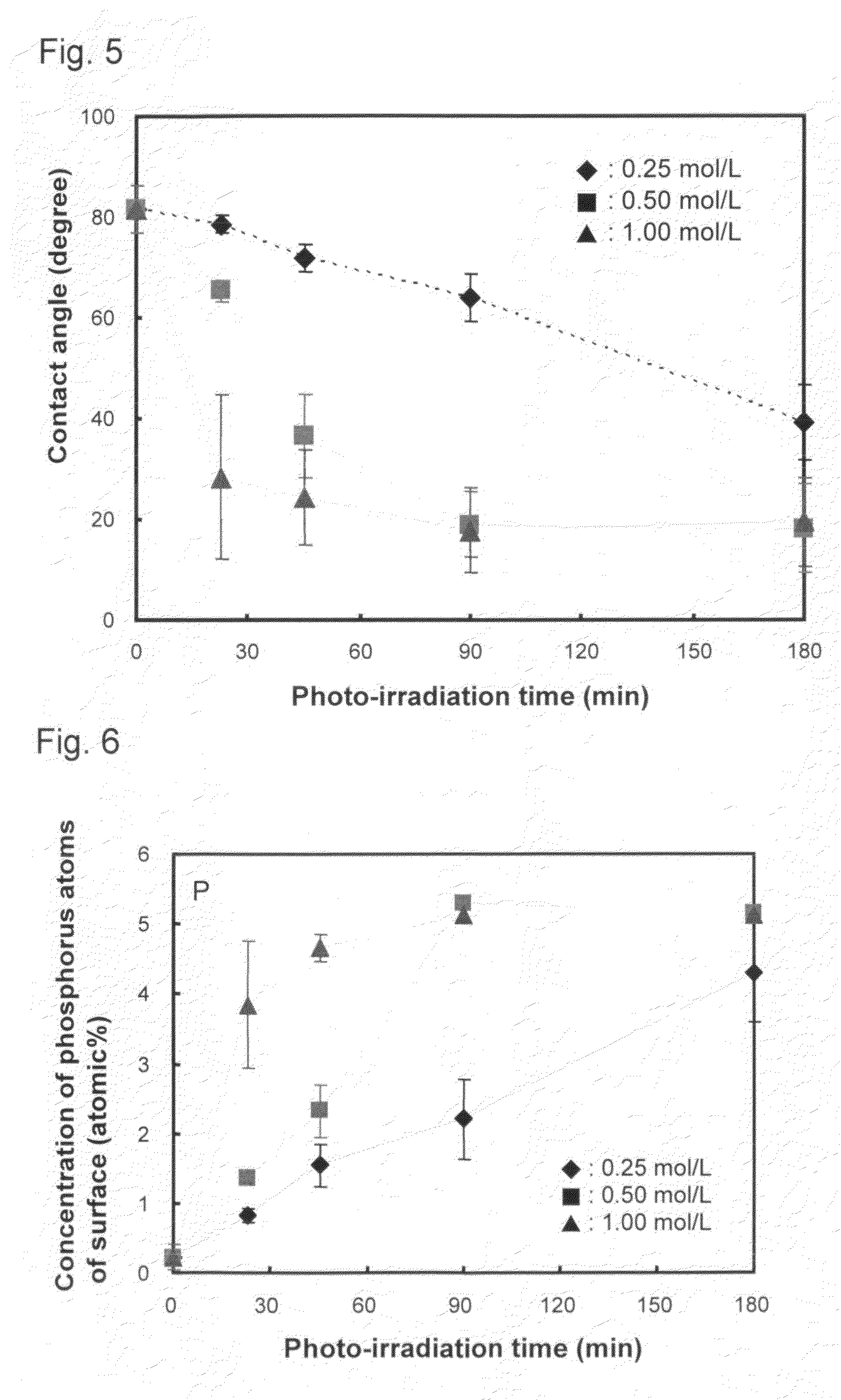

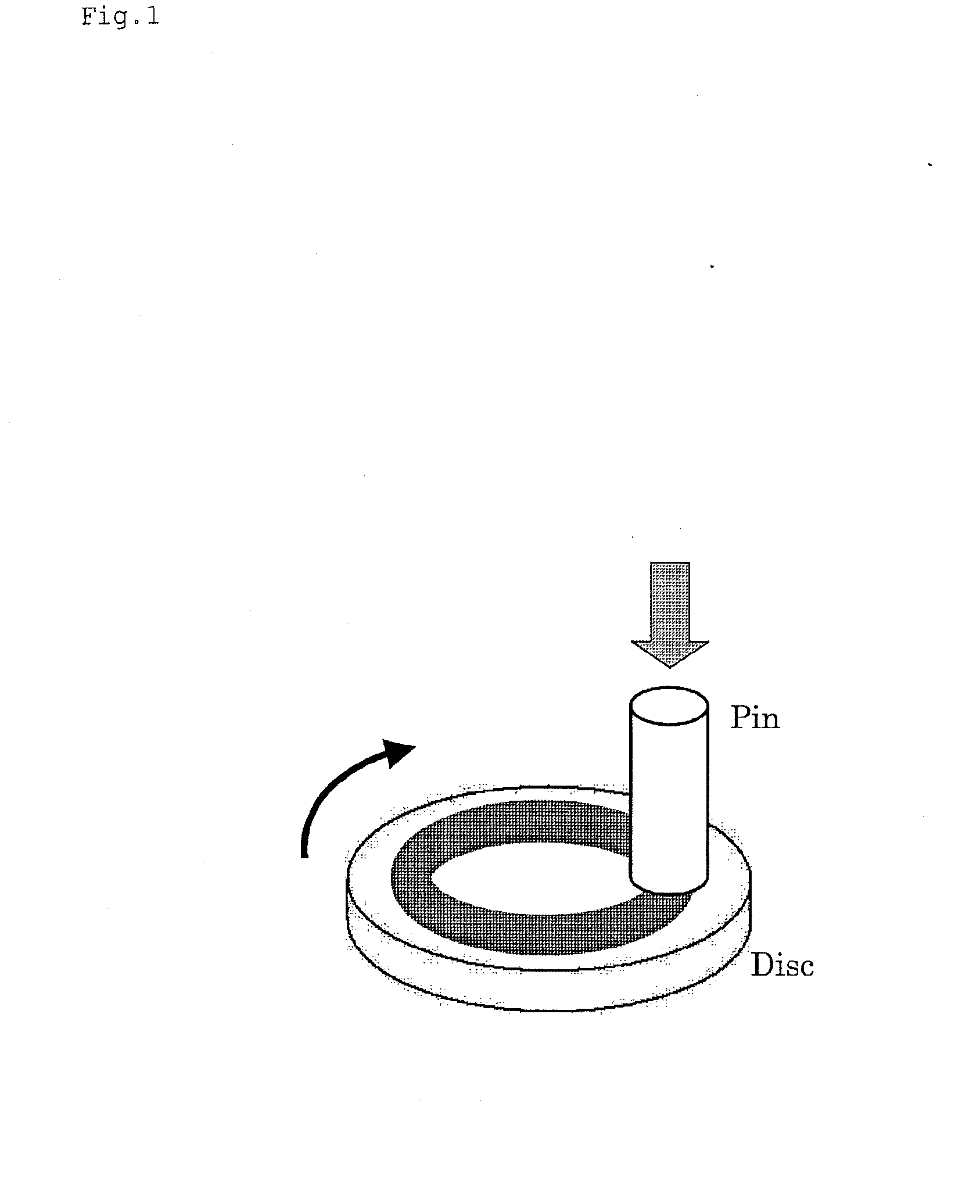

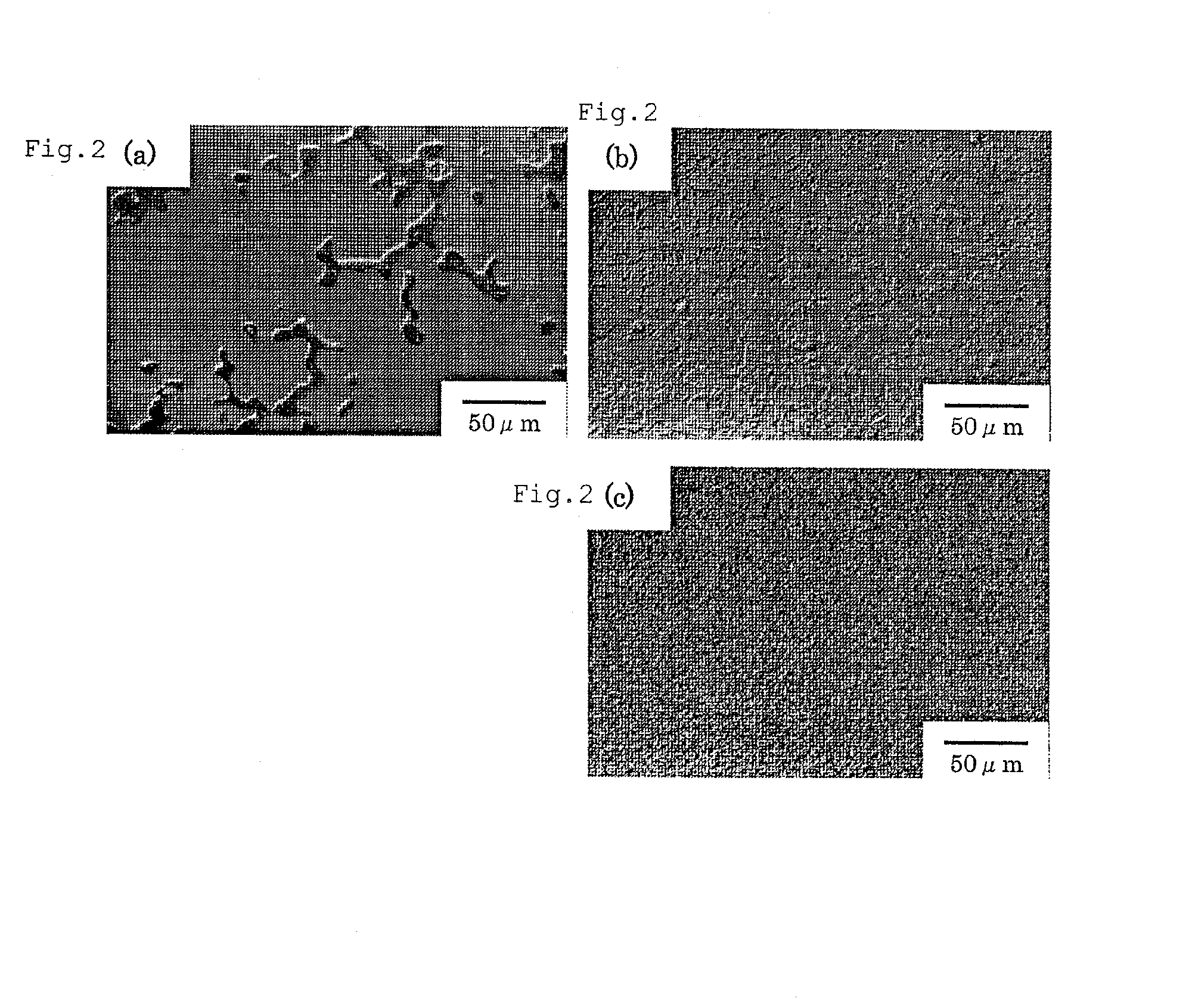

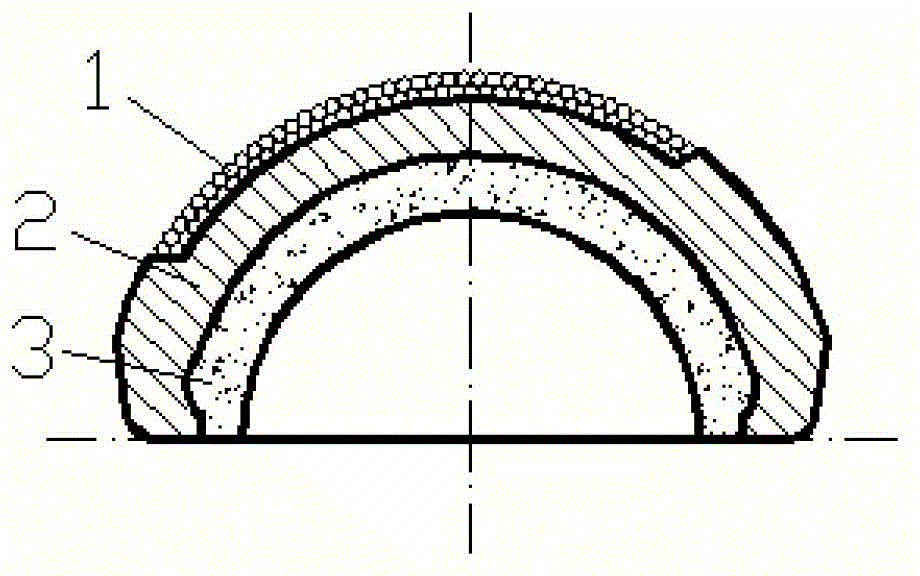

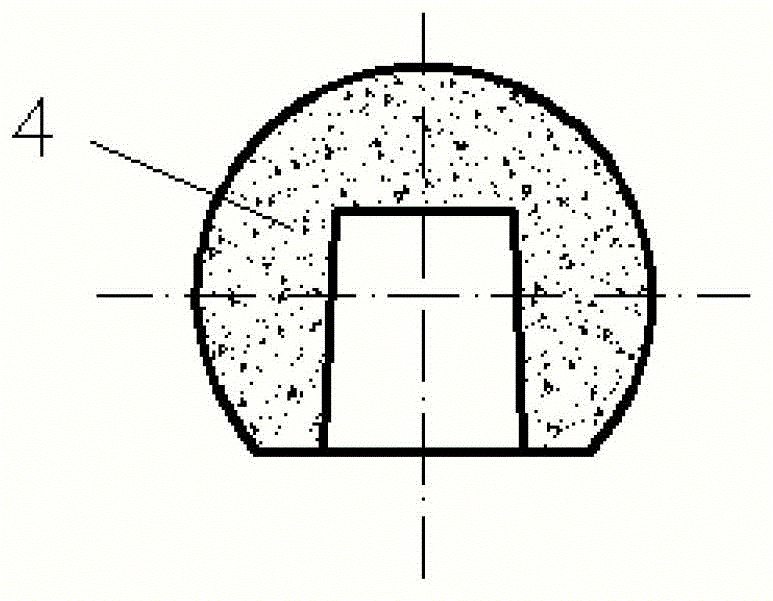

Biocompatible and low-abrasion member, and artificial joint using the same and method of producing the same

ActiveUS20120197413A1Firmly connectedSatisfactory mechanical characteristicImpression capsAnkle jointsArtificial jointsPhosphorylcholine

The object of the present invention is to provide a sliding member, a prosthesis and a method of producing the sliding member, which can suppress production of abrasive wear debris by suppressing friction of the sliding section, and also can maintain satisfactory mechanical characteristics in vivo. A sliding member comprising: a substrate 1 capable of forming hydroxyl groups; and a biocompatible material layer 4 laminated on appropriate sections of the substrate 1, wherein hydroxyl groups are formed on at least a required section of a surface of the substrate 1 by surface treating to form a surface-treated layer 2, while the biocompatible material layer 4 is formed from a polymer containing phosphorylcholine groups, and wherein the substrate 1 and the biocompatible material layer 4 are joined via a binder layer 3 formed from silica being covalently bonded with the hydroxyl groups and the biocompatible material, respectively.

Owner:KYOCERA CORP +1

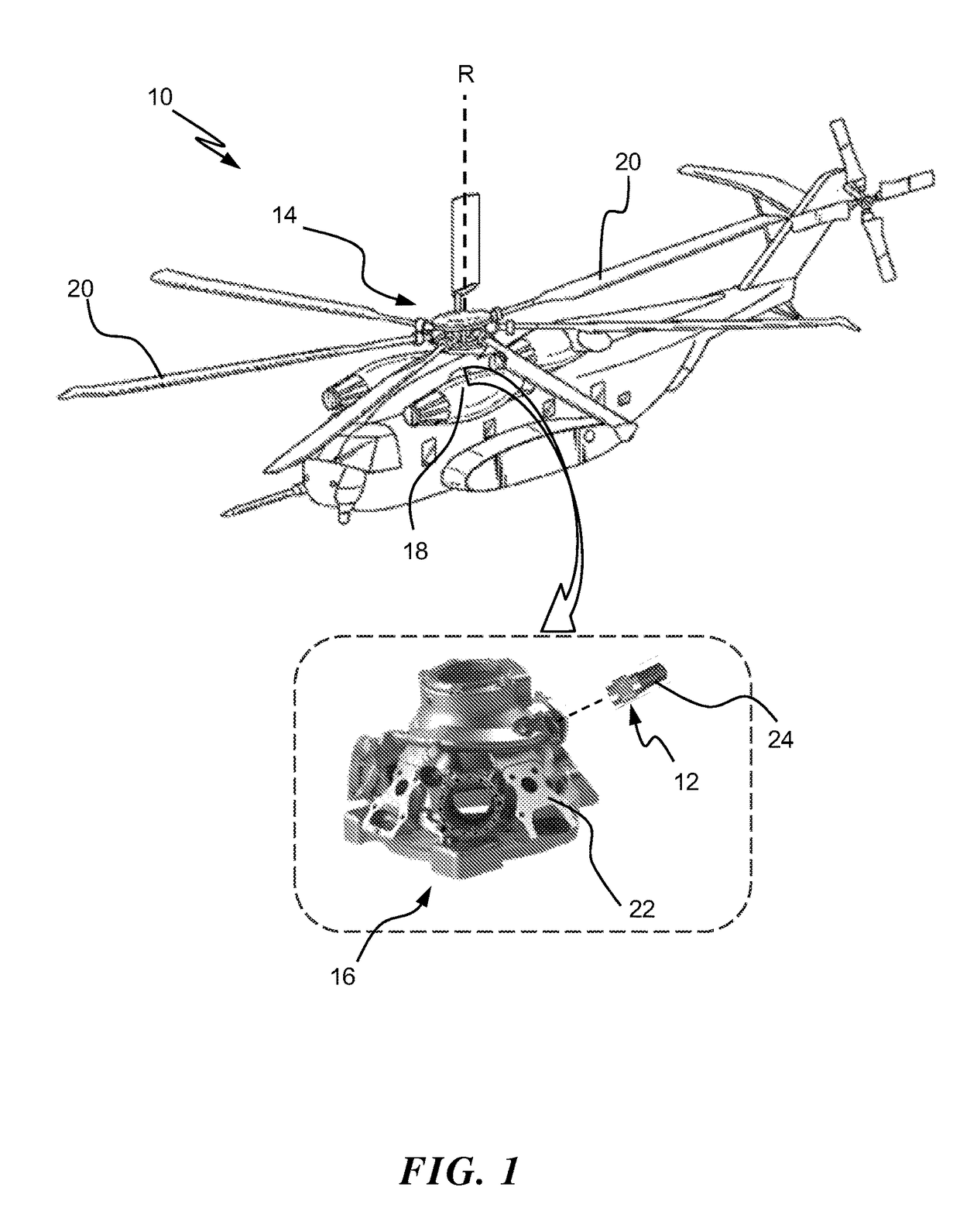

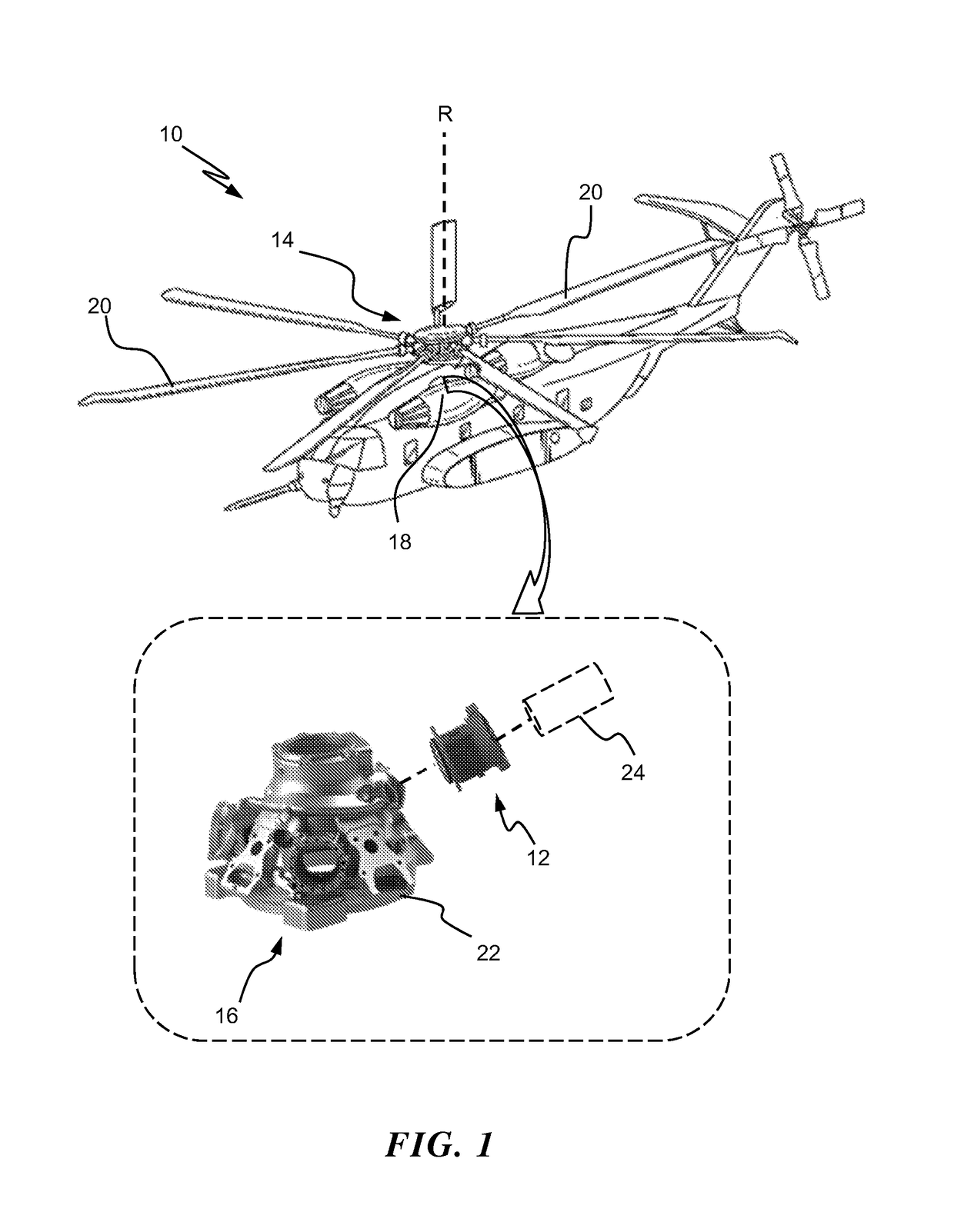

Lubricant condition assessment system

An apparatus for assessment of a fluid system includes a debris monitor to receive a first flow of a fluid, the debris monitor to determine wear debris information in the first flow of the fluid; and a fluid condition monitor to receive a second flow of the fluid, the fluid condition monitor being configured to determine fluid condition information in the second flow of the fluid.

Owner:SIKORSKY AIRCRAFT CORP

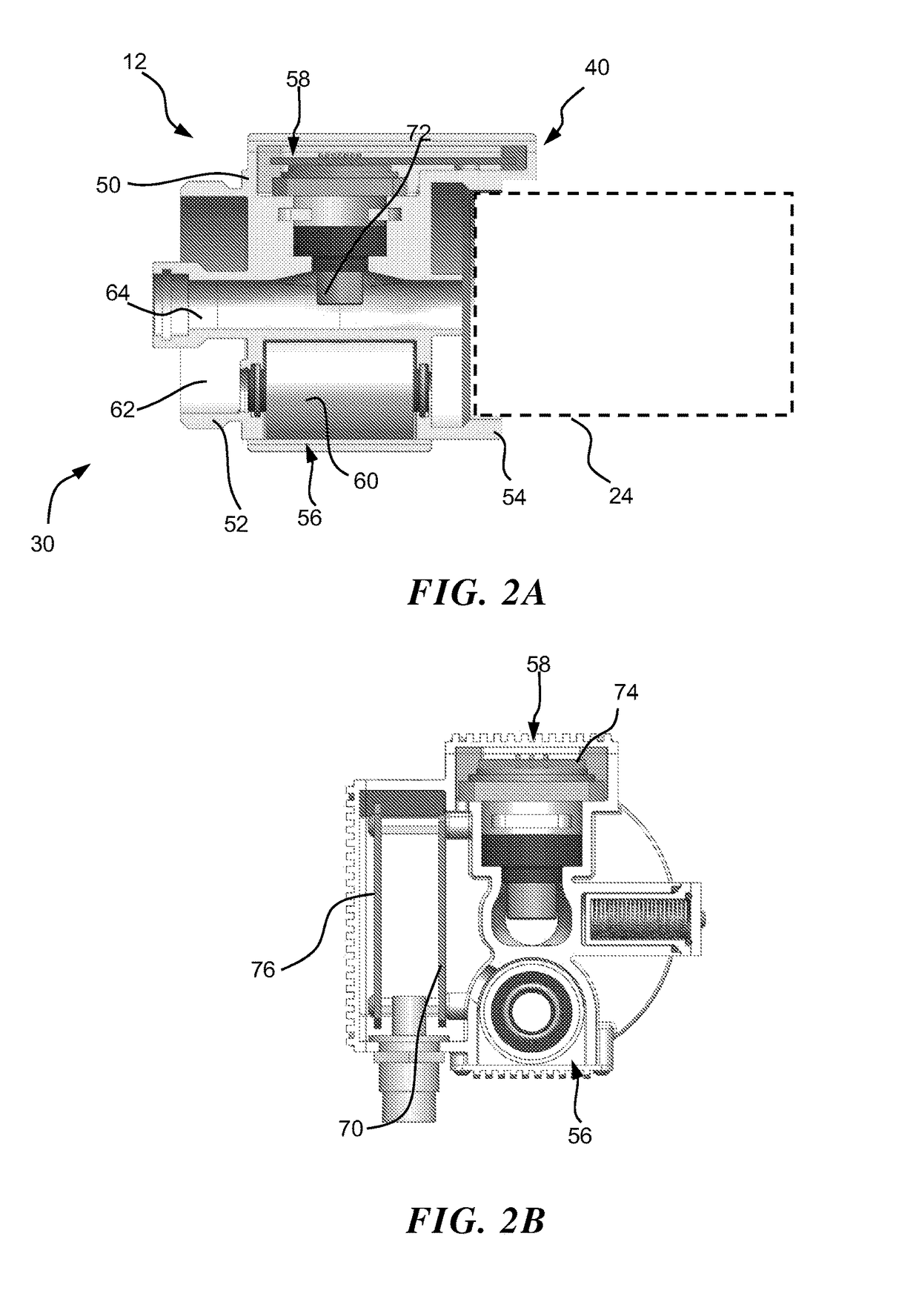

Metal-ceramic composite articulation

InactiveUS20050090903A1Minimal productionIncrease resistanceBone implantJoint implantsHigh fractureIn vivo

A ceramic-metal composite articulation is provided with substantial elimination of wear debris, wherein a ceramic material is provided with superior mechanical properties tailored for articulating with ceramic articulations having high flexural strength (greater than about 700 MPa), high fracture toughness (greater than about 7 MPam1 / 2) and a high Weibull modulus (greater than about 20), in comparison with presently available bio-ceramics such as alumina or zirconia. The mechanical property enhancement enables ceramic materials with greater reliability and significantly reduced in-vivo fracture risk to be obtained. Preliminary in-vitro wear performance, to several million cycles using established test protocols, of head / cup components in a prosthetic hip joint made from these ceramics also demonstrates the ultra low wear characteristics. These material properties substantially eliminate PE wear debris mediated implant failures by offering an optimal combination of bio-mechanical safety and reliability with ultra low wear performance.

Owner:SINTX TECH INC

High reliability microwave mechanical switch

ActiveUS7843289B1Improve operationImprove reliabilityCircuit-breaking switches for excess currentsContact mechanismsMicrowaveAlloy

An improved electromechanical switch designed to operate at frequencies from DC through microwave has terminal probe tips that are formed from an alloy of noble metal and contoured with a pattern of peaks and valleys in order to provide better contact wiping operation and capture of wear debris. The switch incorporates damper elements to reduce switching contact bounce, thus providing increased contact life as well as higher quality signal switching.

Owner:SCI COMPONENTS

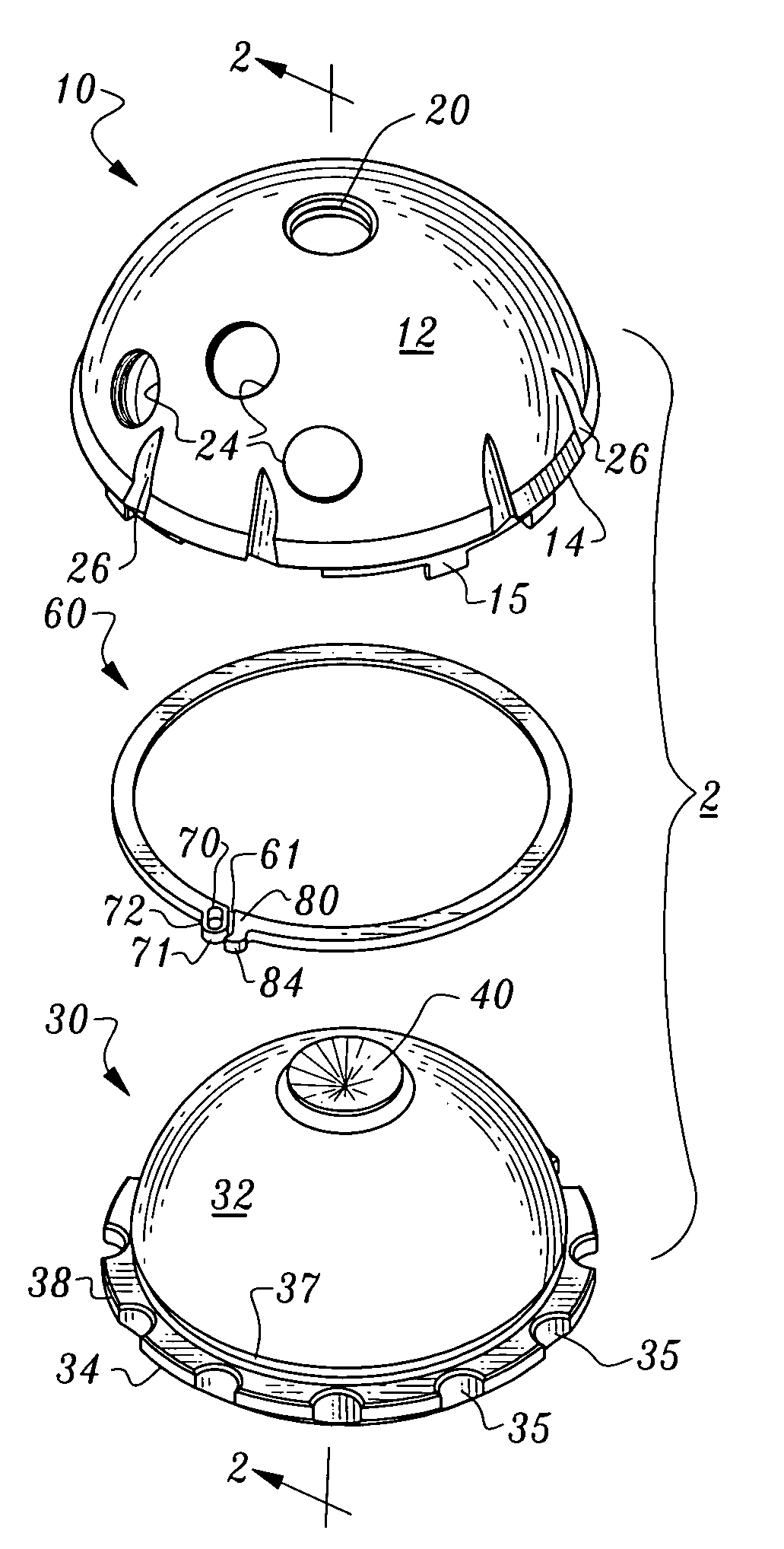

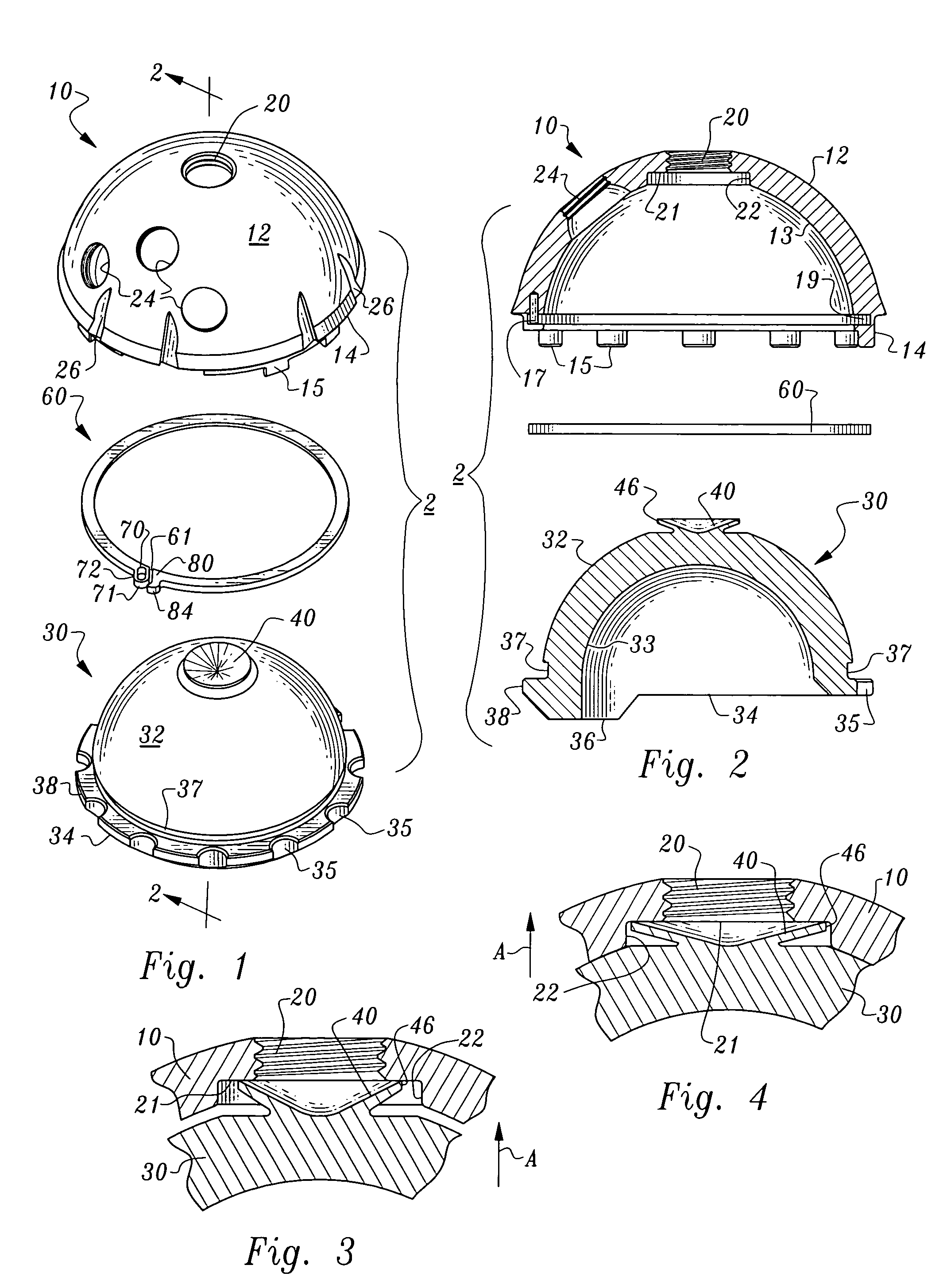

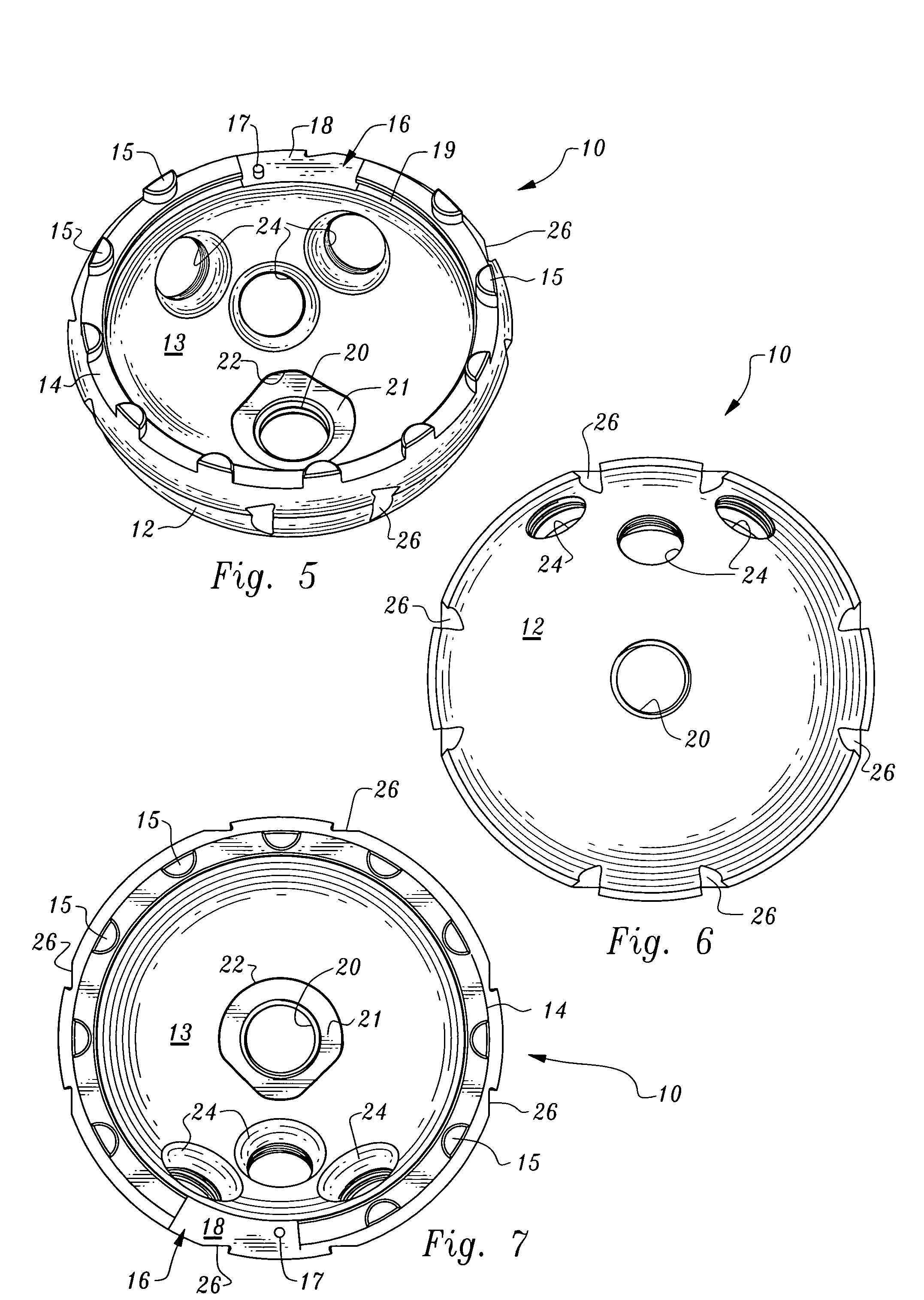

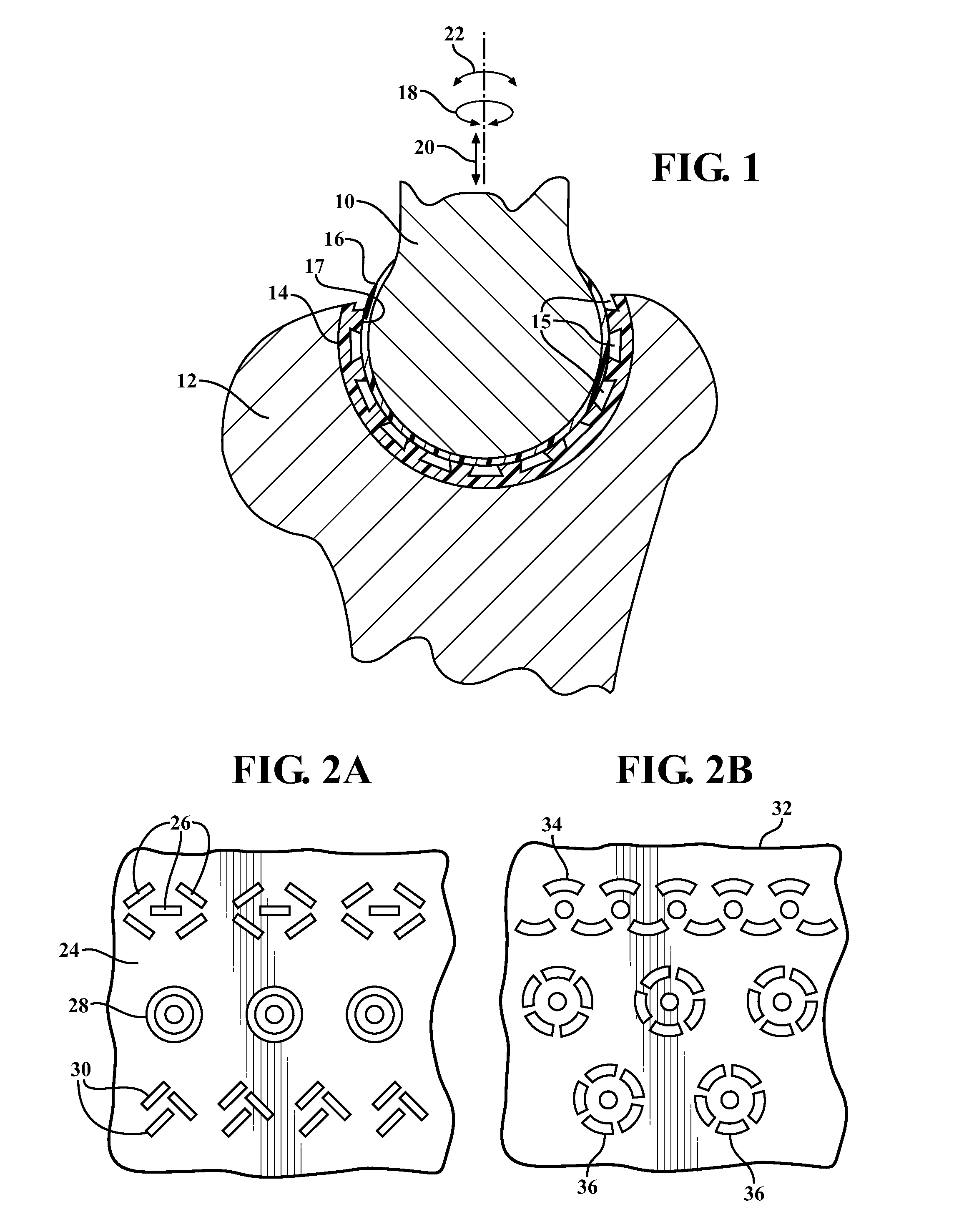

Liner for acetabular cup

InactiveUS7294150B1Inhibit migrationIncrease the diameterJoint implantsAcetabular cupsArtificial hip jointsCoxal joint

An artificial hip joint is provided featuring a liner with a deforming seal which quickly and easily seals a top bore in an acetabular cup of the artificial hip joint, such as to prevent the passage of fluid, wear debris or other material through the top bore in the acetabular cup. The acetabular cup is adapted to be secured to a hip bone and is generally hemispherical and sized to receive the generally hemispherical liner therein. The liner is secured to the acetabular cup by a locking ring which nests within both an acetabular groove in the annular cup and an annular seat in the liner. The liner provides a hemispherical bearing surface for a head at an upper end of a femur.

Owner:ORTHOPEDIC SOURCE

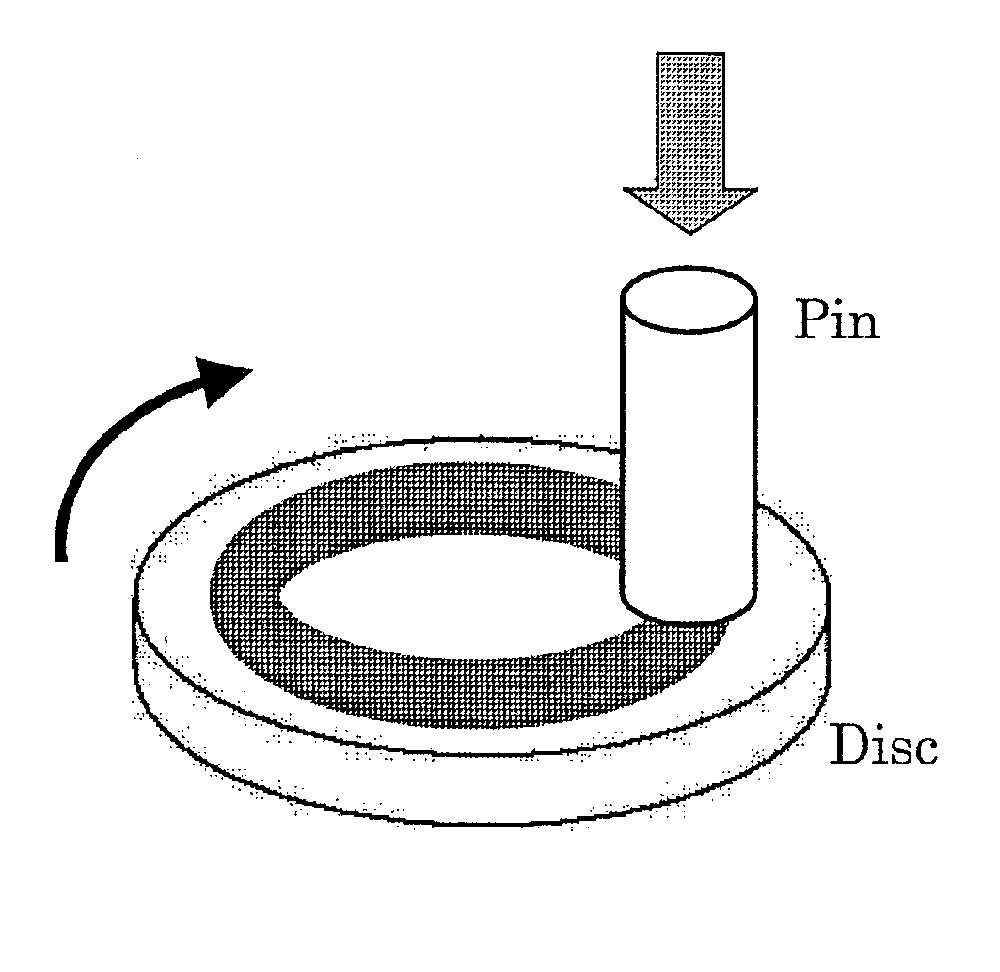

Co-Cr-Mo Alloy for Artificial Joint Having Excellent Wear Resistance

InactiveUS20080195214A1Small toxicityLong useful lifeJoint implantsArtificial hip jointsBiological body

In the field of biocompatible Co—Cr—Mo alloys for use in artificial joints or the like, the formation of wear debris in a living body is a matter of concern. The purpose of the invention is to provide a technique for improving the wear resistance of a Co—Cr—Mo alloy for use in an artificial joint to thereby prevent the formation of wear debris in a living body. The improvement in wear resistance of a Co—Cr—Mo alloy for use in an artificial joint can be achieved by finely dividing the crystal particles of the alloy, by preparing an alloy composition having a higher Mo content than any known standard Co—Cr—Mo alloy (e.g., Co-29Cr-6Mo alloy), by increasing the proportion of the σ phase that is dispersedly precipitated, by sintering an alloy powder produced by gas atomization technique to form pores on the surface of the alloy material, or the like. The Co—Cr—Mo alloy having high wear resistance is applicable to medical devices including artificial hip joints, artificial knee joints and the like which have less biotoxicity, namely which are safer and have a longer useful life.

Owner:IWATE UNIVERSITY

Integrated ultrasonic-inductive pulse sensor for wear debris detection

ActiveUS20140144216A1Material analysis using sonic/ultrasonic/infrasonic wavesParticle suspension analysisInlet channelUltrasonic sensor

An apparatus for detecting wear particles in a fluid includes an inlet channel and an outlet channel. An ultrasonic transducer creating an acoustic wave that defines an acoustic focal zone is located between the inlet and outlet channels. A flow path located between the inlet and outlet channel is shaped to restrict the flow of the fluid to be within the acoustic focal zone. An inductive pulse sensor includes a plurality of flow channels receiving the fluid and a plurality of planar coils wound around the flow channels. The inductive pulse sensor includes a detection system for the detection of wear particles passing through the flow channels based on a change in an electrical property of the planar coils. A single combined excitation signal is sent to all the planar coils at once and the detection system measures one single output measurement for the plurality of flow channels.

Owner:THE UNIVERSITY OF AKRON

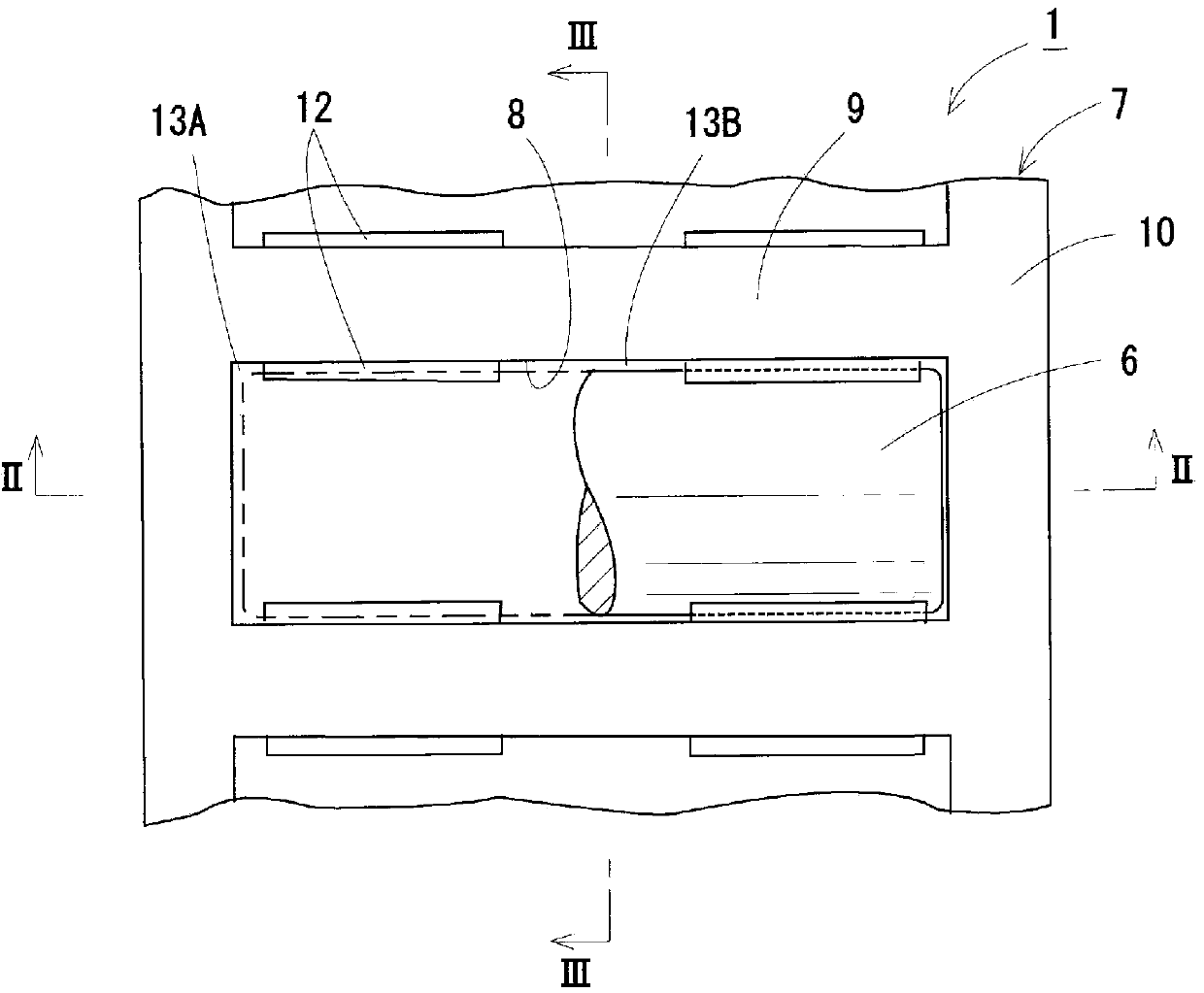

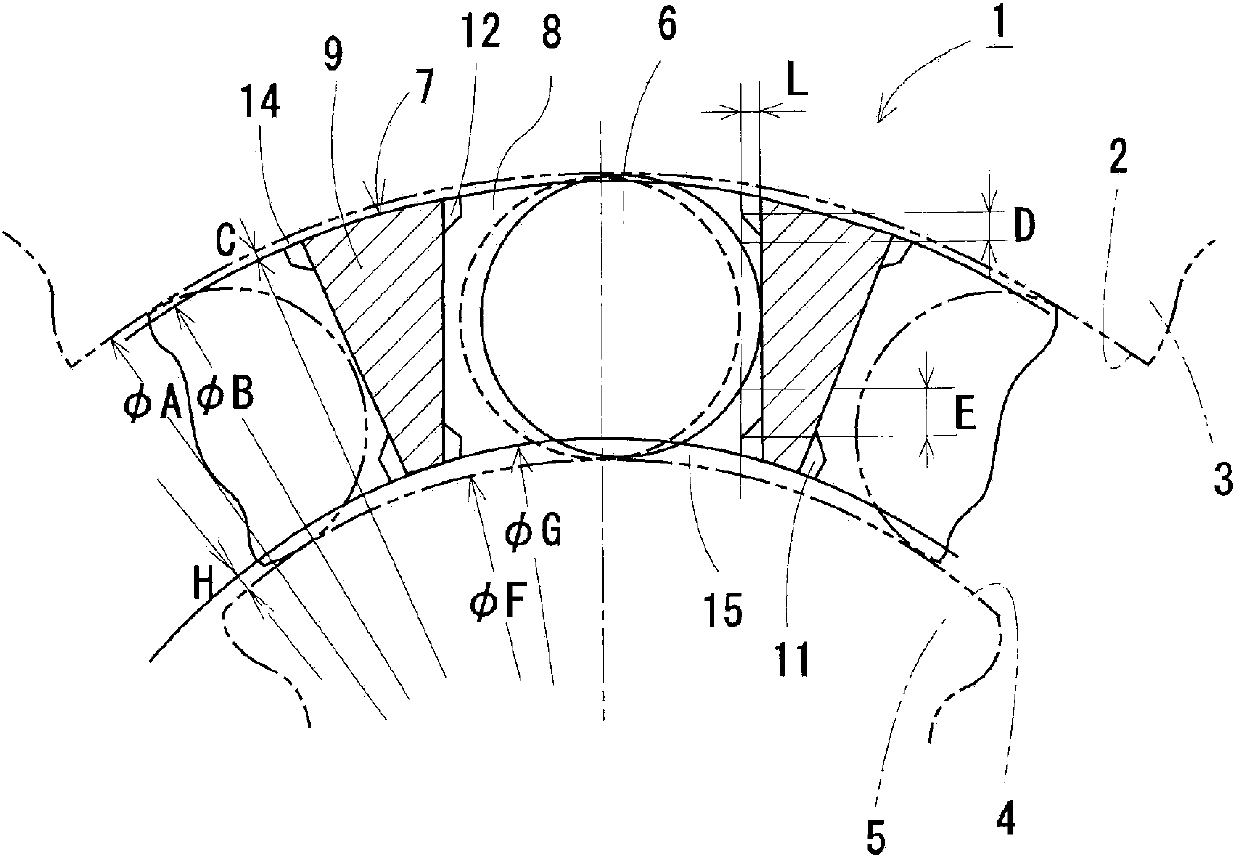

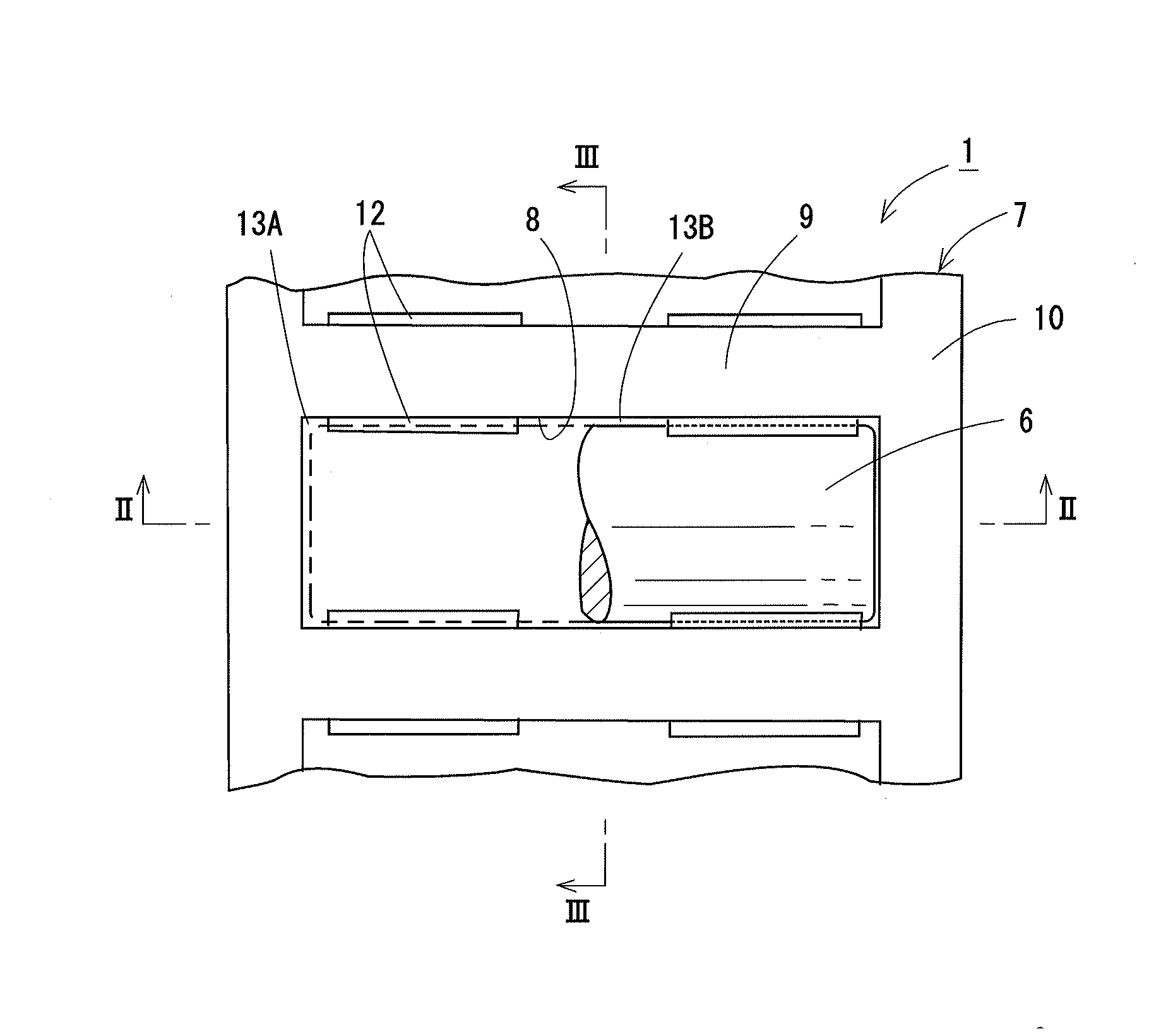

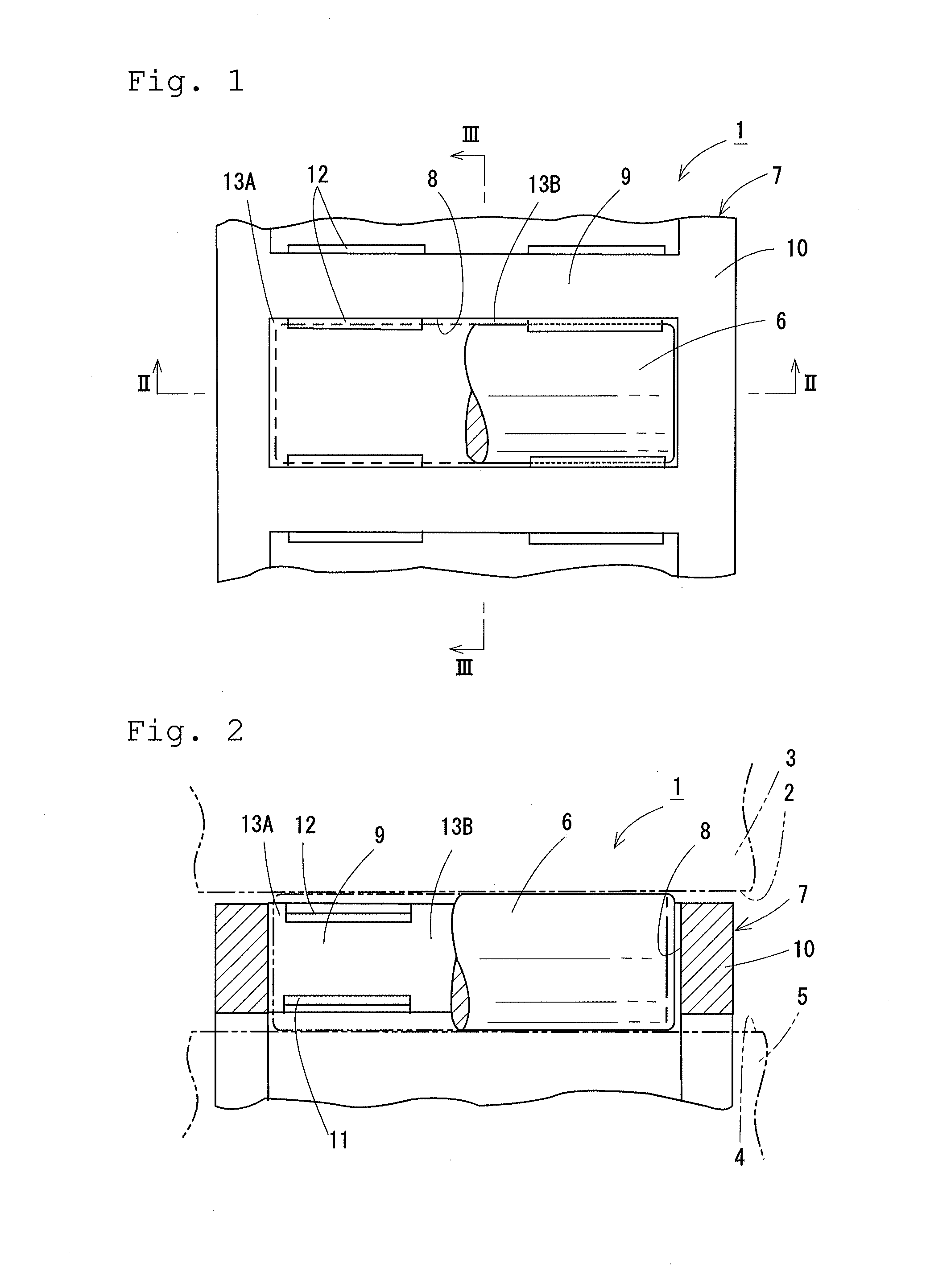

Roller bearing

ActiveCN103827528ASpeed up the flowAvoid breakingRoller bearingsShaftsMechanical engineeringRoller bearing

The problem addressed by the present invention is to increase service life by causing surface imprinting or an oil film shortage to not arise at a roller (6) by preventing the pinching and retention of wear debris in the pocket (8) of the holder (7) of a roller bearing (1). In the state of a roller (6) and a holder (7) being combined between an outer member (3) and an inner member (5), lubricating oil is caused to smoothly flow through the gap formed between the outer peripheral surface of the roller (6) and the cylindrical section (9) of the holder (7) by stipulating the position and dimensional relationship of the inner protrusion (11) and outer protrusion (12) of the cylindrical section (9), the diameter of an outer ring raceway (2), the diameter of an inner ring raceway (4), and the inner / outer diameters of the holder (7) in a manner so that the inner protrusion (11); and outer protrusion (12) that are for preventing the dropout of the roller (6) and are provided to the cylindrical section (9) of the holder (7) are constantly not touching the outer peripheral surface of the roller (6).

Owner:NTN CORP

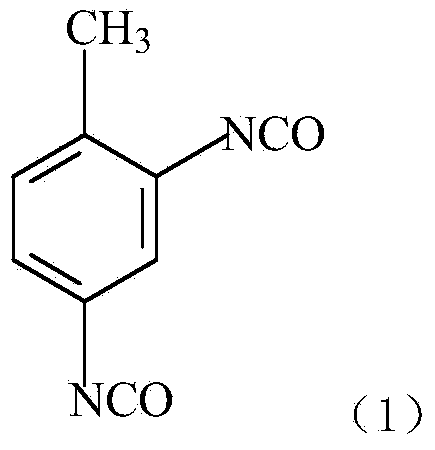

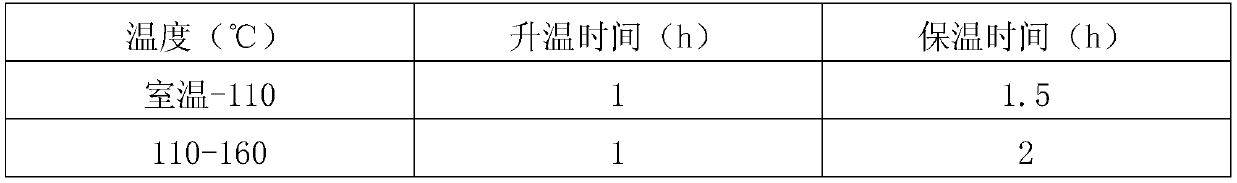

Method for preparing anti-oxidation anti-wear ultrahigh molecular weight polyethylene composite material

InactiveCN105713217AImprove antioxidant capacityGood biocompatibilityPolymer scienceBiocompatibility Testing

The invention specifically relates to a method for preparing an anti-oxidation and wear-resistant ultra-high molecular weight polyethylene composite material, which belongs to the technical field of polymer materials. It selects medical-grade ultra-high molecular weight polyethylene UHMWPE powder as the basic material, and combines it with single-layer graphene oxide GO to make a mixed powder. The mixed powder is added to the mold, and the UHMWPE / GO composite material is prepared by hot pressing. ; Subsequently, it is subjected to γ-ray irradiation crosslinking treatment, and then it is soaked with vitamin-E solution to finally obtain an anti-oxidation and wear-resistant ultra-high molecular weight polyethylene composite material. The present invention cross-links the UHMWPE / GO composite material through γ-ray irradiation with excellent wear resistance, and the two-dimensional structure of GO and excellent mechanical properties and biocompatibility not only reduce wear, reduce the amount of wear debris, but also reduce The degree of cellular adverse reaction caused by wear debris is reduced, and the addition of vitamin-E makes the composite material have excellent anti-oxidation and anti-aging properties.

Owner:JIANGNAN UNIV

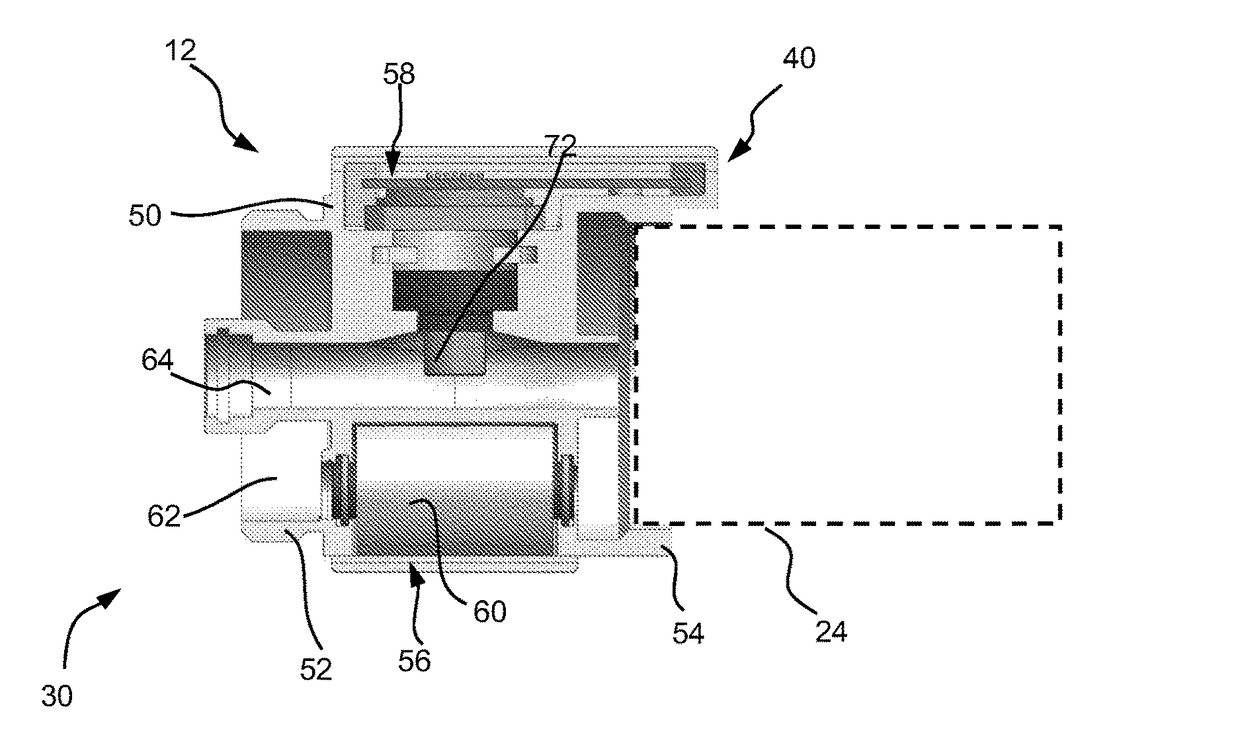

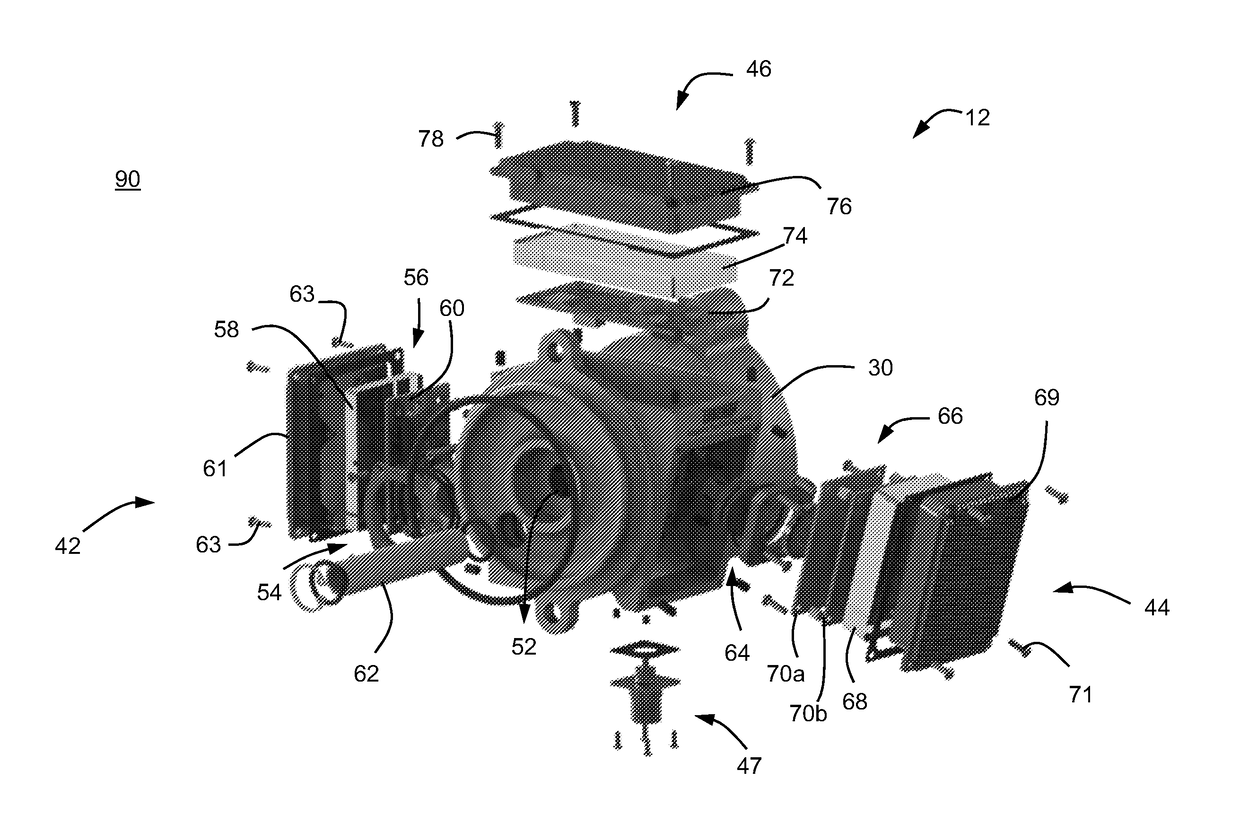

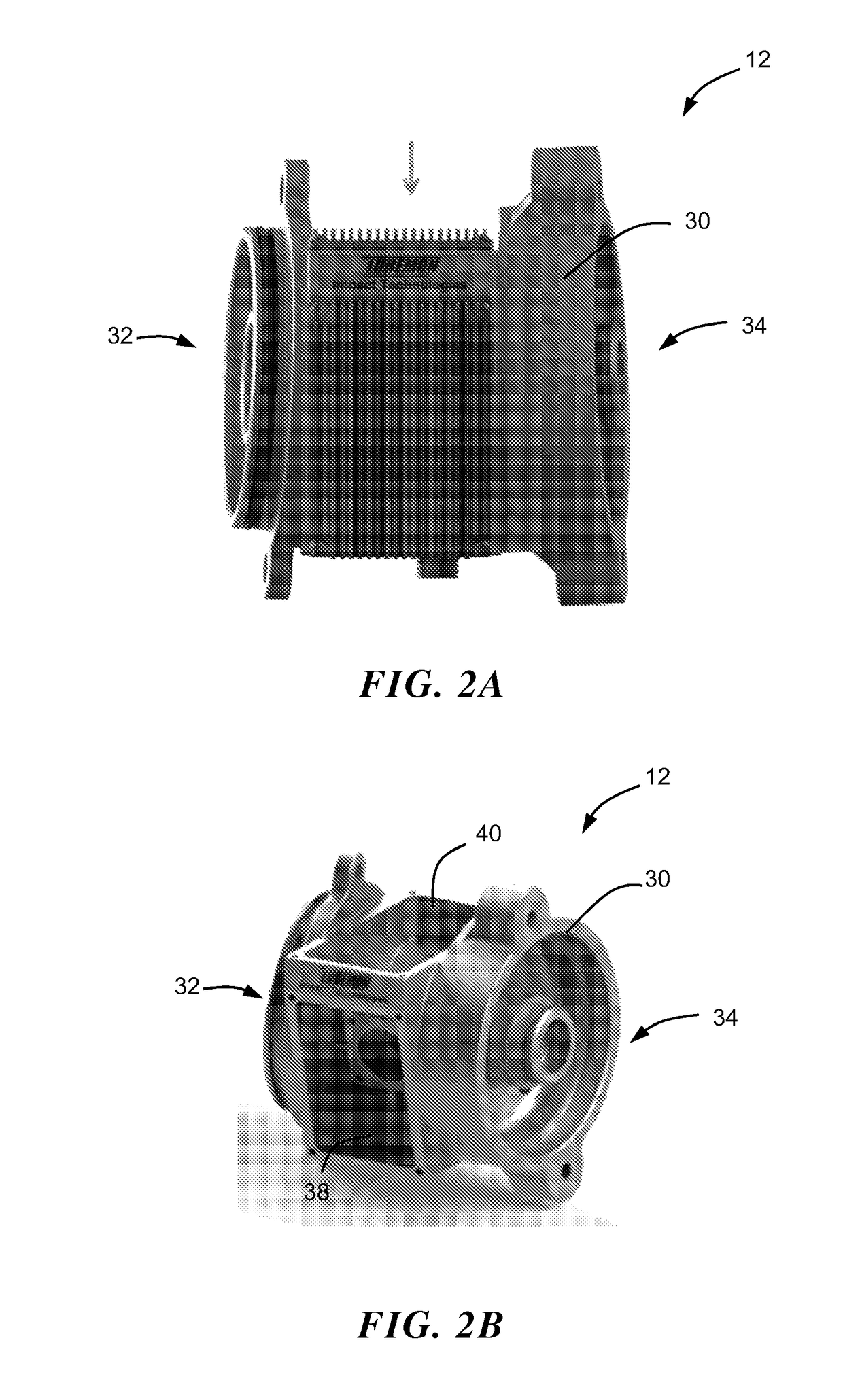

Modular packaging system for a lubricant condition monitor

An apparatus for assessment of a fluid system includes a scaffold housing with a plurality of internal cavities; a debris monitor module assembly to be selectively inserted into a first cavity of the plurality of internal cavities, the debris monitor module assembly to determine wear debris information in a lubricant; a lubricant condition monitor module assembly to be selectively inserted into a second cavity of the plurality of internal cavities, the lubricant condition monitor module assembly to determine lubricant condition information in the lubricant; and a processing module assembly that is configured to be selectively inserted into a third cavity of the plurality of internal cavities, the processing module assembly to provide communication to an external interface of at least one of the wear debris information and the lubricant condition information.

Owner:SIKORSKY AIRCRAFT CORP

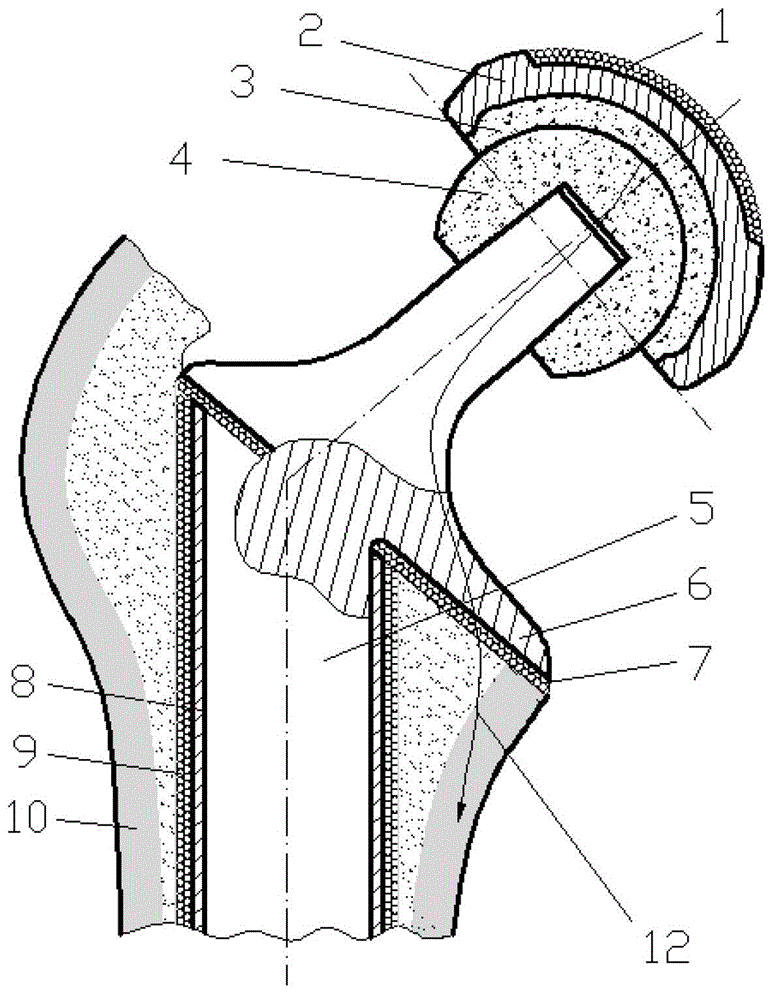

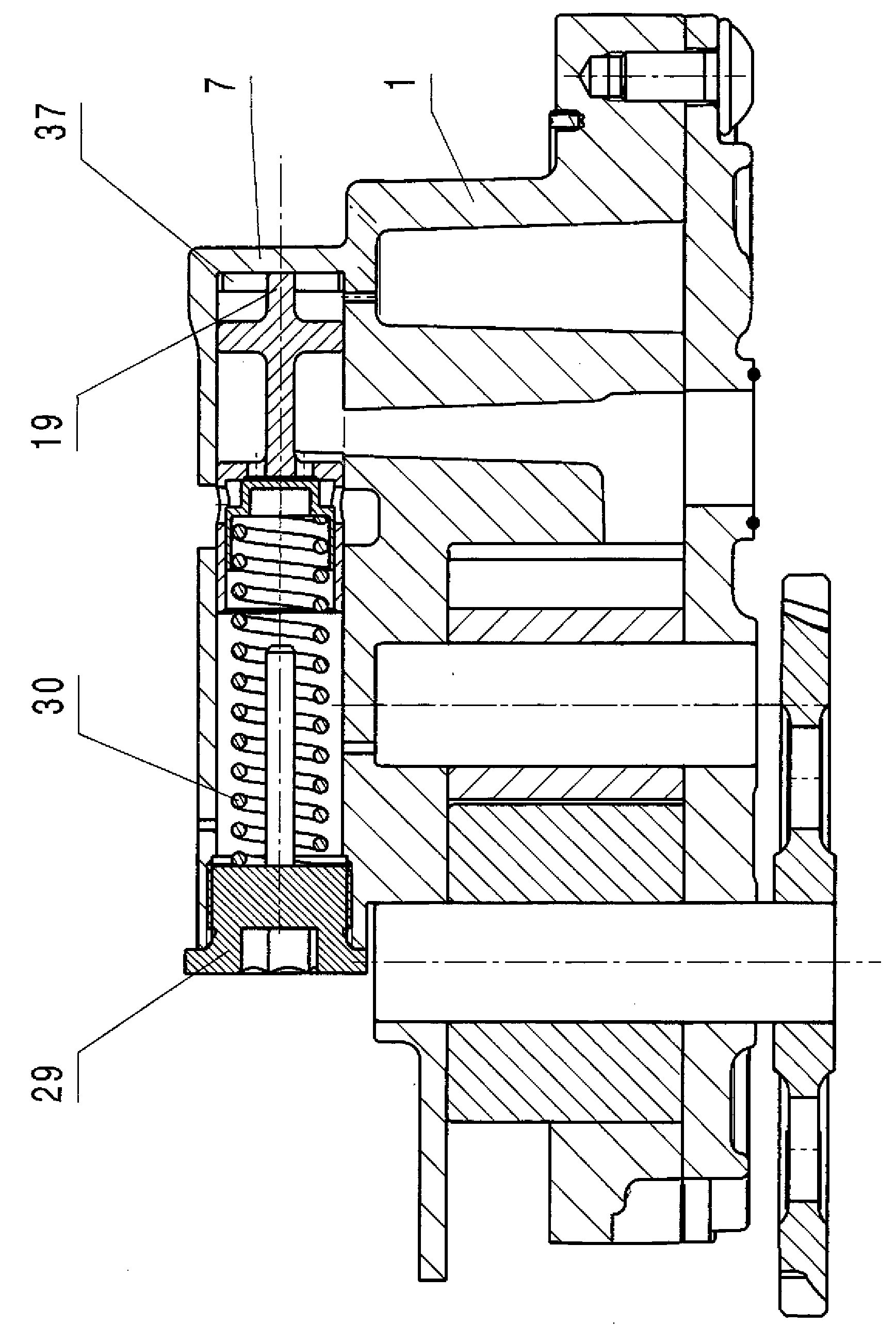

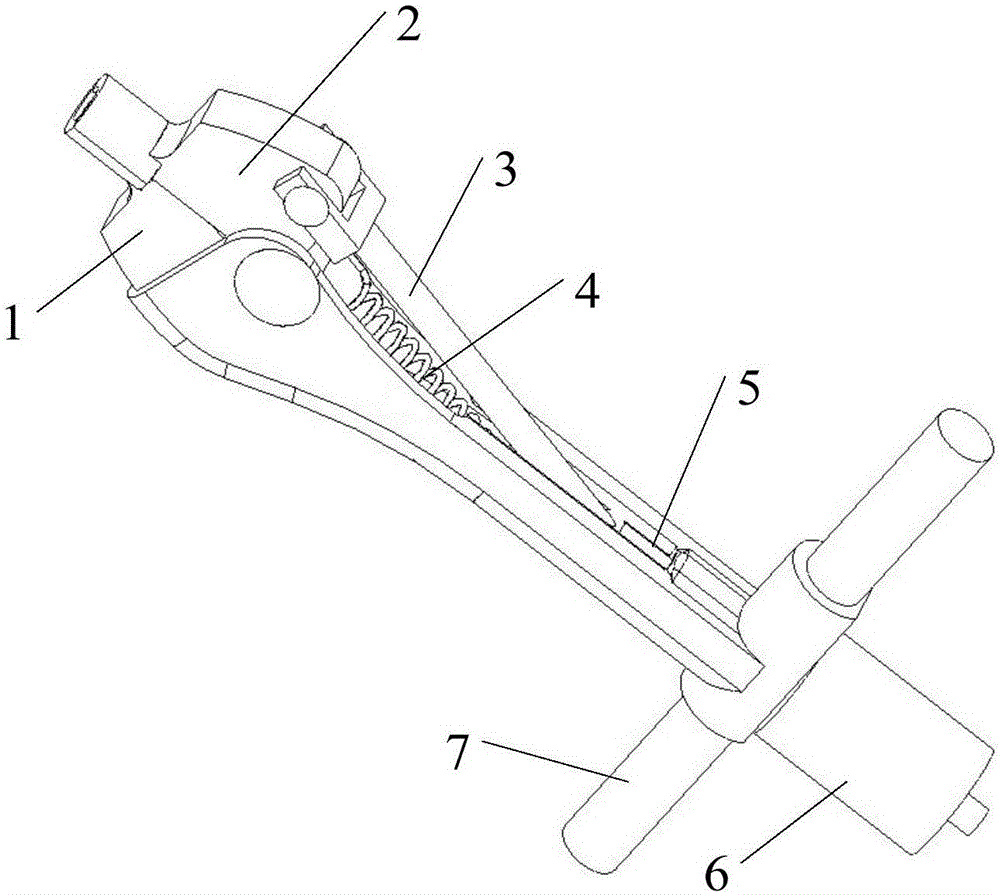

Novel artificial hip joint and manufacturing method thereof

ActiveCN102973335AReduce loosenessStress reliefJoint implantsHip jointsRight femoral headFemoral stem

The invention discloses a novel artificial hip joint and a manufacturing method thereof. The novel artificial hip joint comprises an advanced porous layer PCA (porous coated anatomic) spherical crown (1), an alloy acetabular cup (2), a metal ceramic acetabular lining (3), a metal ceramic femoral head (4), a metal handle (5), a collar (6), an advanced porous layer PCA plane ring (7), a metal handle guide pipe (8) and an advanced porous layer PCA net ring (9). According to the invention, the stress shielding of the artificial hip joint is removed and the proximal femoral osteopenia is prevented through femoral stem separation; the stress shielding on acetabular fossae is removed by increasing the pressure intensity; the osteolysis, the stem looseness and the femoral brittleness caused by wear debris are greatly reduced by using the metal ceramic acetabular lining and the femoral head with flexibility enhancement; and by improving the raw material selection and diffusion welding processes of the PCA structure part, the binding force of the PCA structure part and the bone tissues of a human body is increased, the postoperative problems of a patient are reduced, the comprehensive quality of the artificial hip joint is essentially improved, and the service life of the artificial hip joint is essentially prolonged to be longer than thirty or forty years at least.

Owner:刘昌星 +1

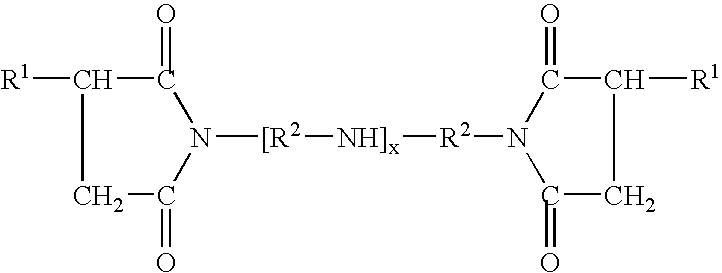

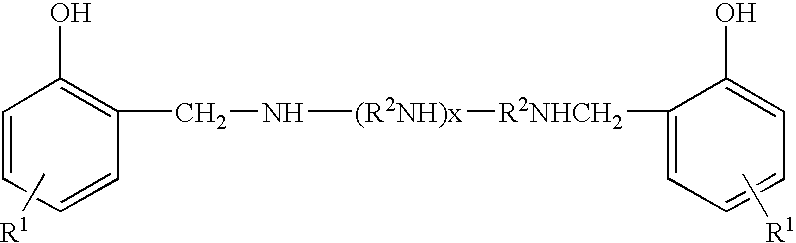

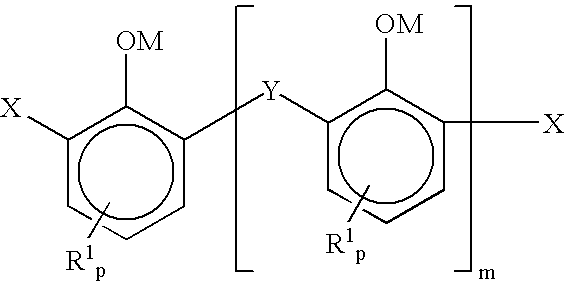

Engine flush process and composition

An internal combustion engine can be cleaned of sludge, deposits, or wear debris, by supplying to lubricated surfaces of said engine a composition having a kinematic viscosity of 1 to 10 mm2 / s at 100° C. comprising oil having at least 15% aromatics by ASTM D-2007; at least 2.5 weight percent of a nitrogen-containing dispersant; at least 0.6 weight percent of an overbased metal detergent; and at least about 0.5 weight percent of a metal salt of a phosphorus acid, circulating the composition through the engine and removing the composition from the engine.

Owner:THE LUBRIZOL CORP

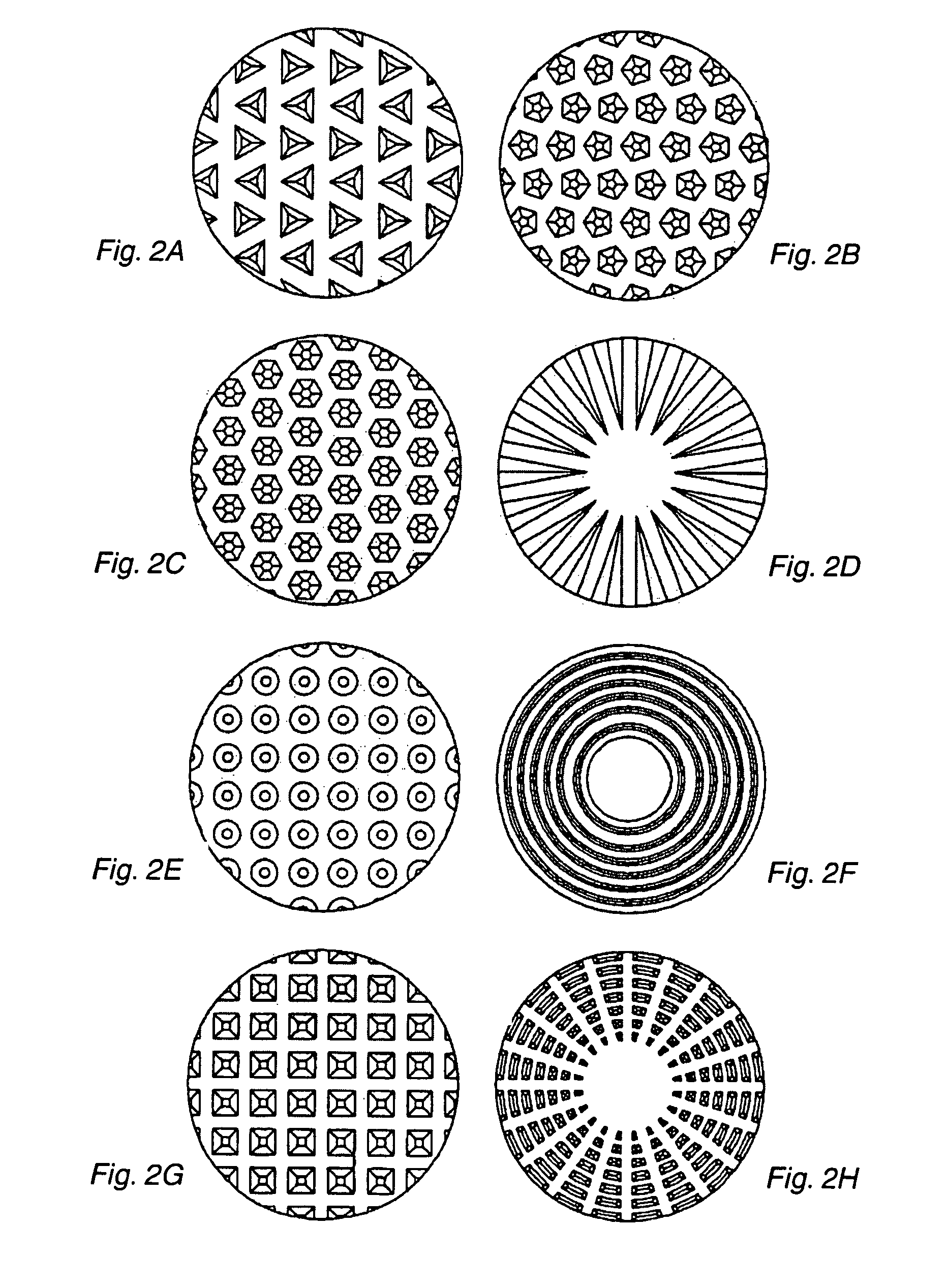

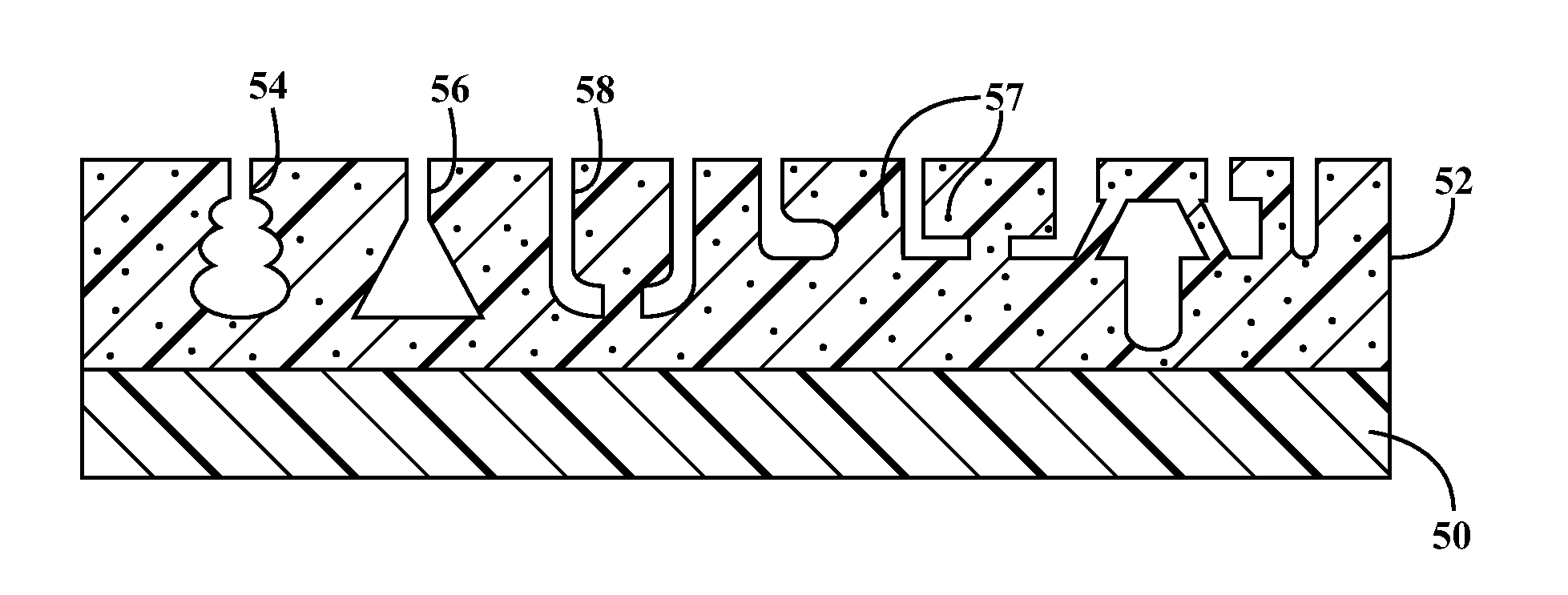

Joint assembly incorporating undercut surface design to entrap accumulating wear debris from plastic joint assembly

InactiveUS20100222892A1Optimize collectionImprove retentionBone implantLigamentsEngineeringNormal range

A layer applied to a joint defined surface including a general mat shape body exhibiting a plurality of recesses, such that abrading contact with an opposing joint surface creates debris which are entrapped within the recesses during a normal range of motion. The body can further exhibit a first harder plastic substratum and a second softer plastic surface. The recesses further incorporate undercut defined patterns selected from any of circular, linear and arcuate designs.

Owner:LINARES MEDICAL DEVICES

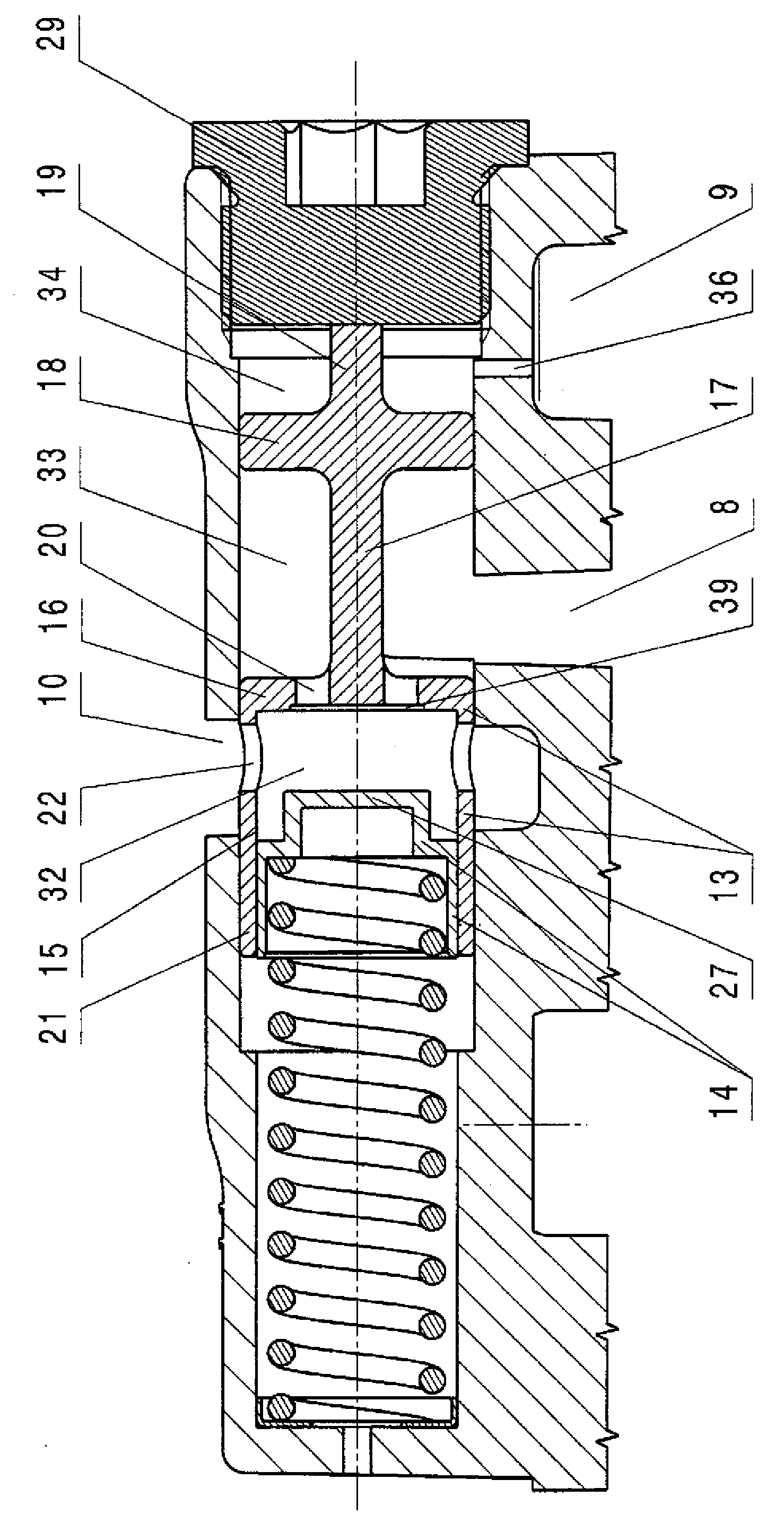

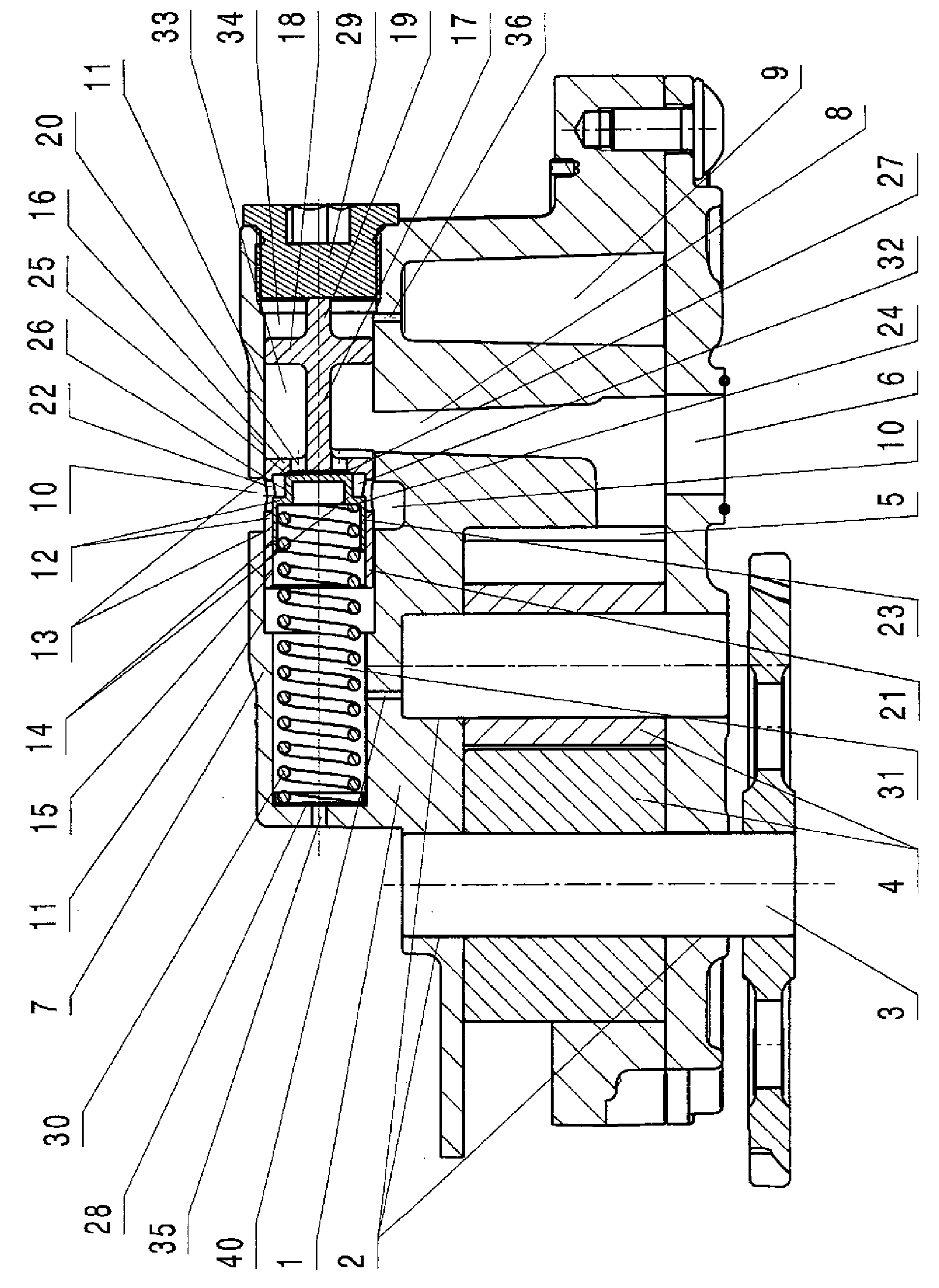

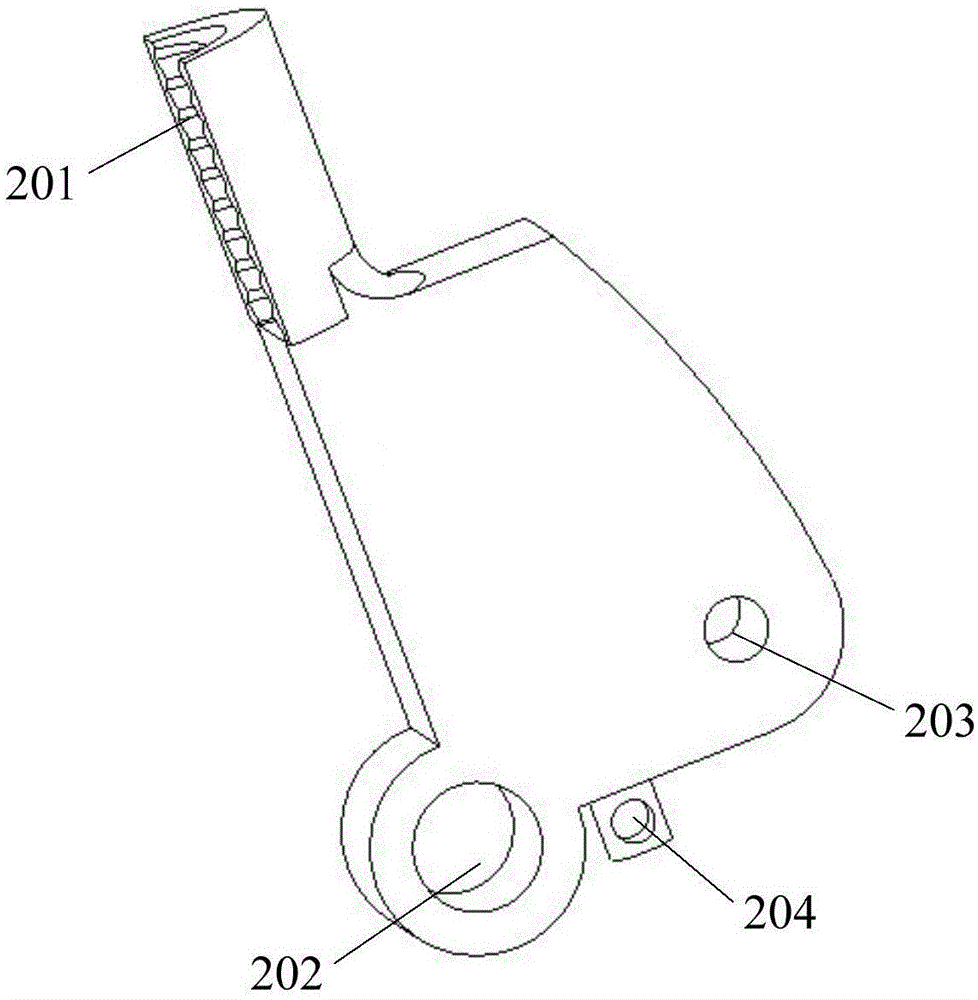

Lubricant valve for oil pumps of internal combustion engines

The invention relates to a lubricant valve for oil pumps of internal combustion engines, in order to supply the bearings and sliding surfaces of the engines with lubricant in an optimum manner in order to reduce the wear. The invention is based on the problem of developing a lubricant valve for oil pumps of internal combustion engines, which lubricant valve combines, in particular, the functions of a cold-start valve and those of a control valve within itself with a minimum amount of installation space and is constructed in such a way that it is insensitive with respect to the wear debris and / or foundry sand which is entrained by the lubricant, in the process makes high throughflow quantities possible, in addition is of inexpensive construction in terms of production and assembly technology and can be produced inexpensively, and, moreover, always operates robustly,; reliably and insusceptible to disruptions, even under extreme use conditions. The lubricant valve according to the invention for oil pumps of internal combustion engines is distinguished, in particular, by a double piston in a piston guide of a valve seat of the pump housing, the double piston consisting of a cold-start piston which is arranged in a control piston and is arranged in a cold-start piston guide which is arranged in the control piston, wherein, lying opposite the cold-start piston guide, a piston rod is arranged on the piston head of the control piston, on which piston rod, spaced apart from the piston head of the control piston, a working piston is arranged which the piston rod protrudes beyond in the form of a spacer rod, wherein, adjacent to the working piston, inflow holes are arranged in the piston head of the control piston and, adjacent to the piston head,; outflow holes are arranged in the cylinder wall of the cold-start piston guide of the control piston.

Owner:NIDEC GPM GMBH

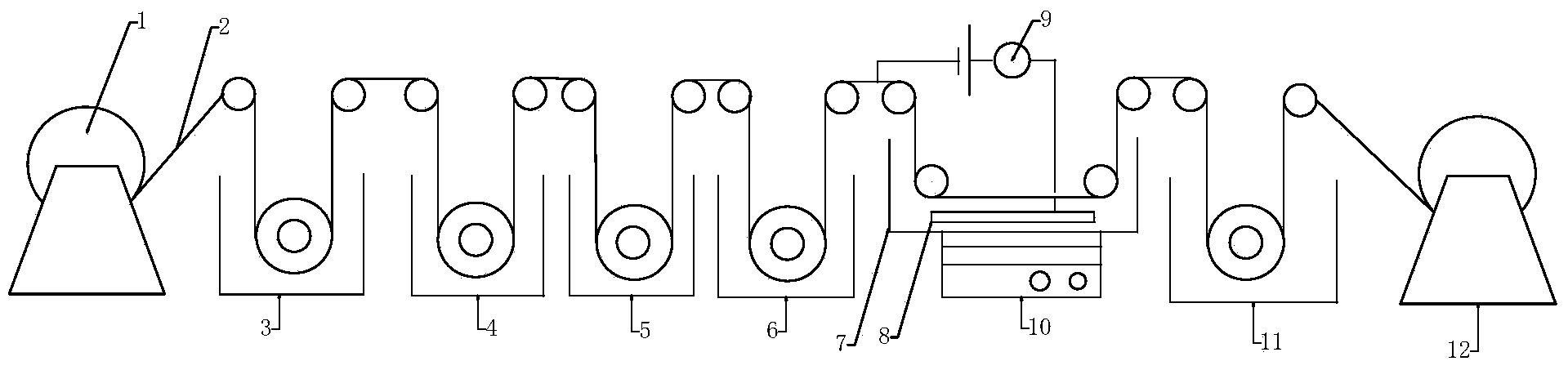

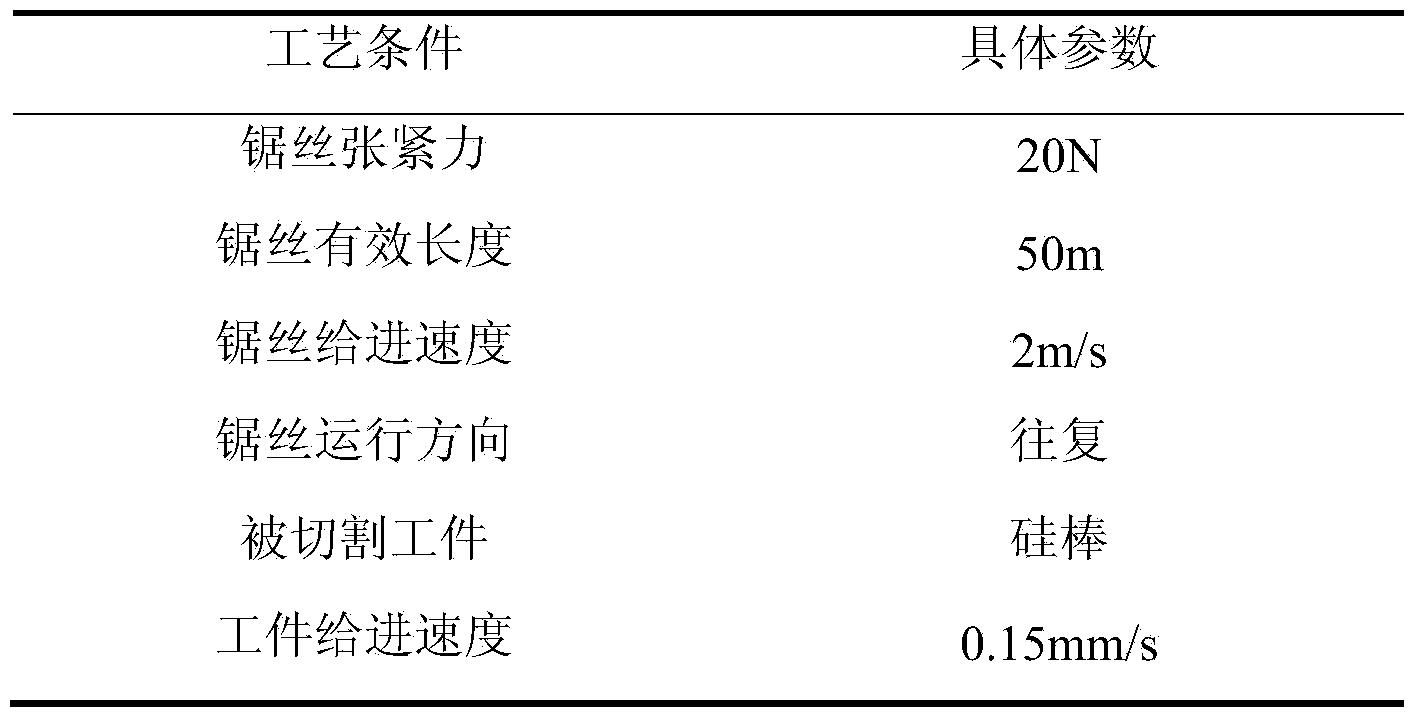

Preparation and superhigh-pressure processing method for cathode-electrophoresis-resin diamond scroll saw

ActiveCN104018207ALow unsealing temperatureHigh reactivityElectrolytic coatingsEmulsionPolymer science

The invention discloses preparation and a superhigh-pressure processing method for a cathode-electrophoresis-resin diamond scroll saw, and belongs to the field of preparation of diamond scroll saws. The diamond scroll saw is prepared by employing an electrophoresis method. The preparation method comprises: firstly preparing an emulsion of cathode electrophoresis resin, then adding diamond into the prepared emulsion, and employing an intermittent stirring manner to enable diamond to be uniformed suspended in the emulsion; and enabling a pretreated saw filament to pass through the diamond-containing emulsion in an electrophoresis way, and then performing pre-solidification, deep solidification, superhigh-pressure processing and the like, so as to finally prepare the diamond scroll saw. According to the prepared diamond scroll saw, the diamond usage amount is less, applied sand is uniform, the thickness of a resin layer is easily controllable, the resin layer is uniform, retention capability on wear debris, wear resistance and other aspects are better than those of diamond scroll saw coated with a resin binder.

Owner:SHANDONG UNIV OF SCI & TECH

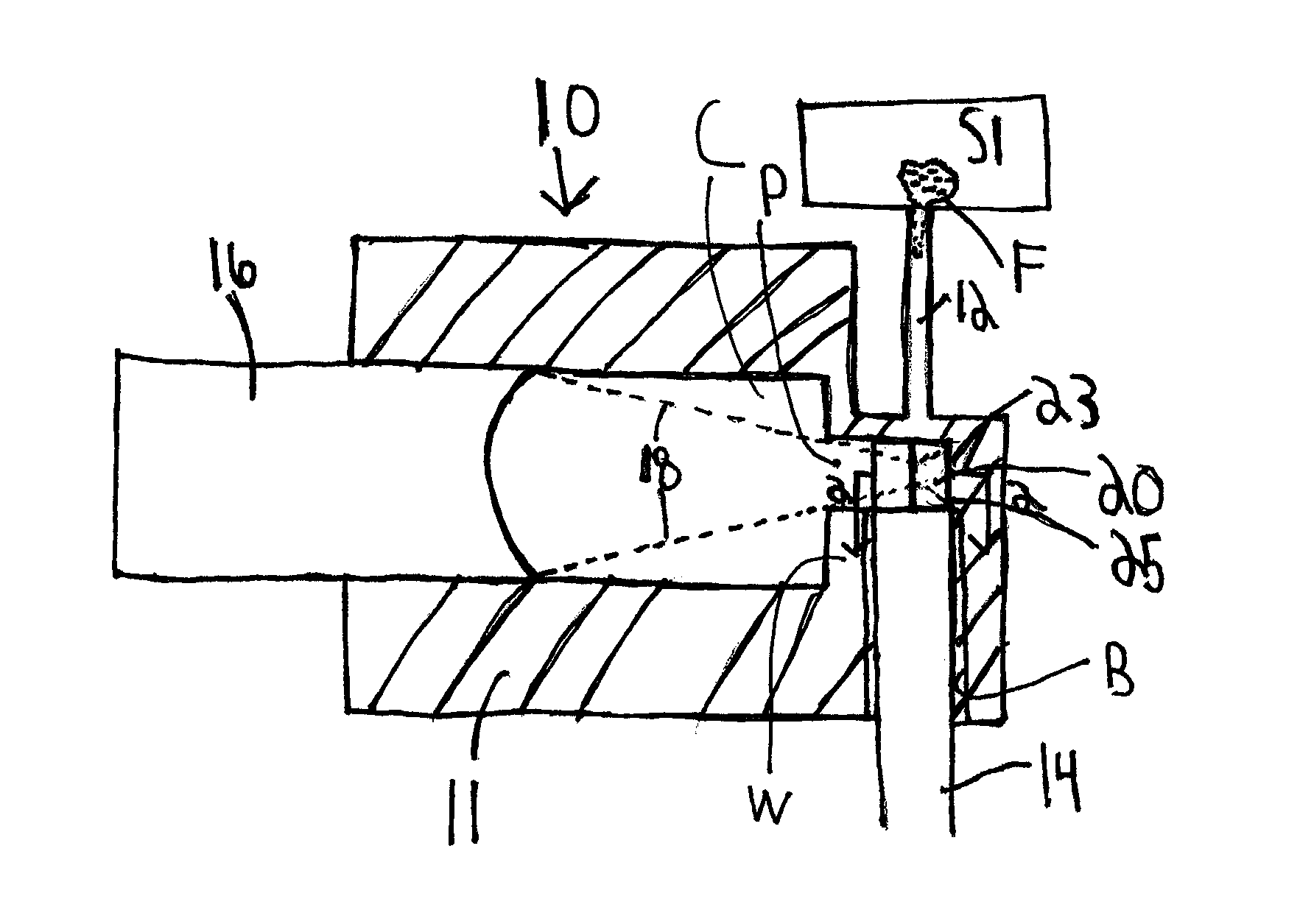

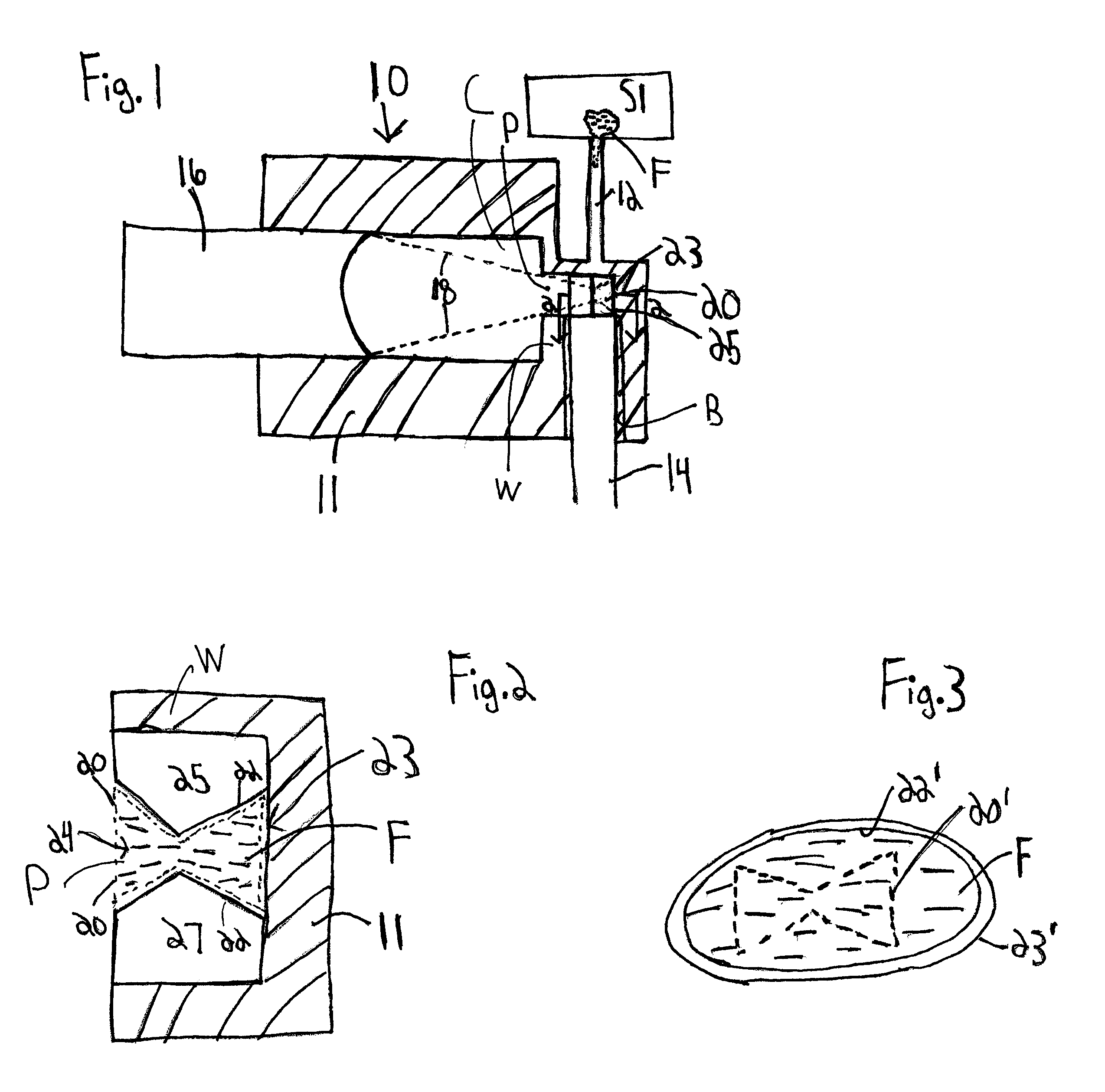

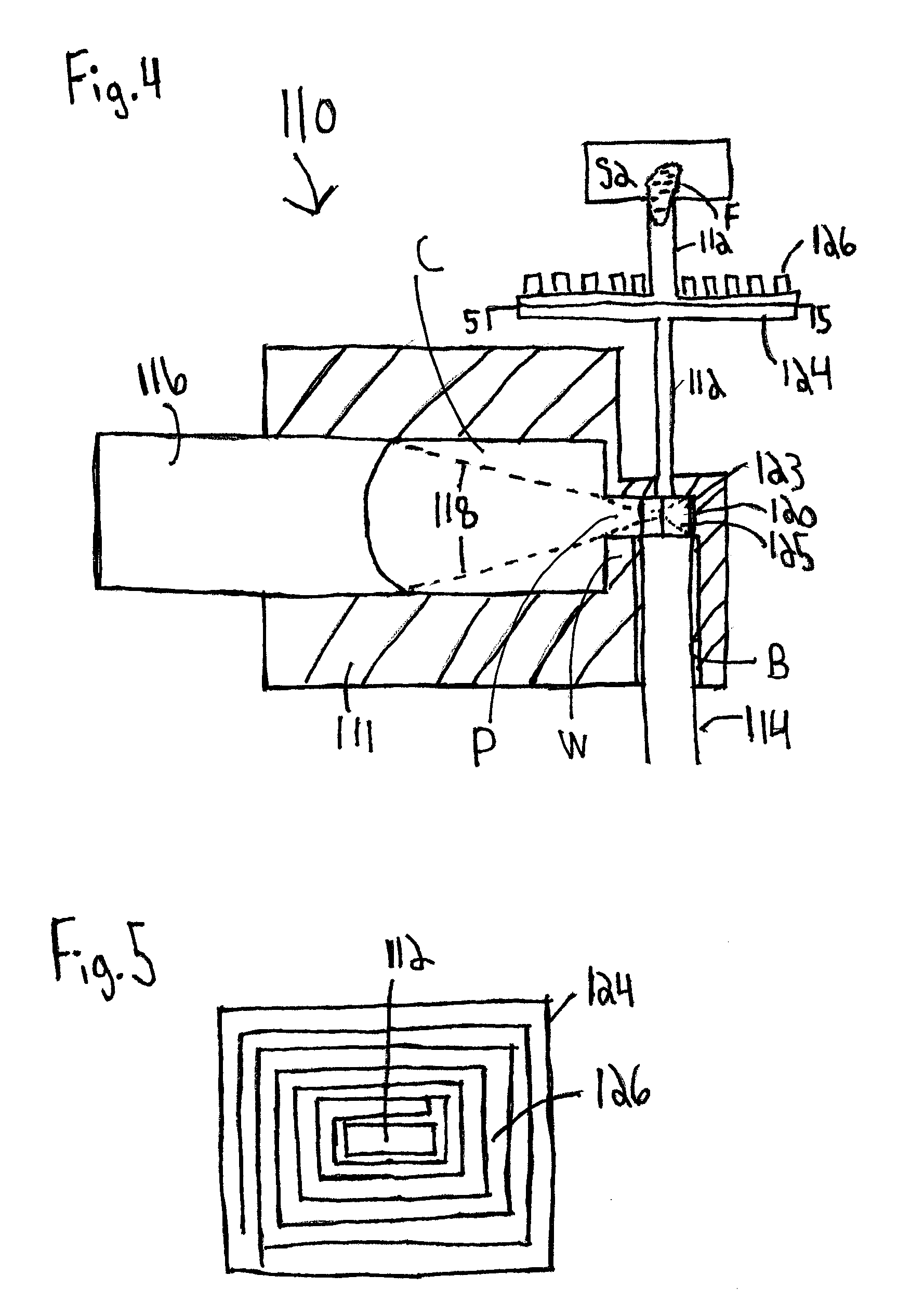

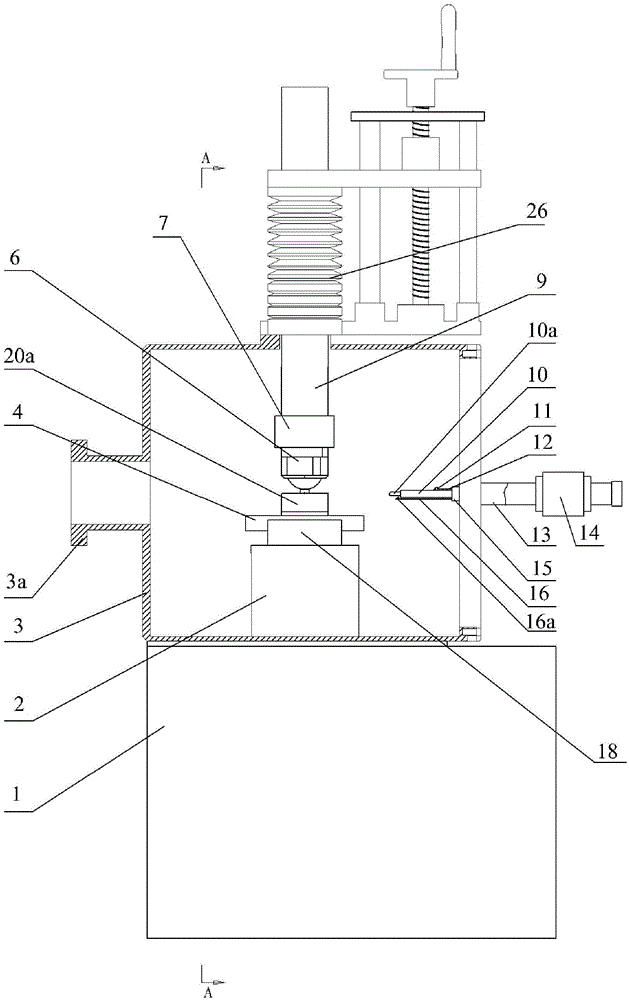

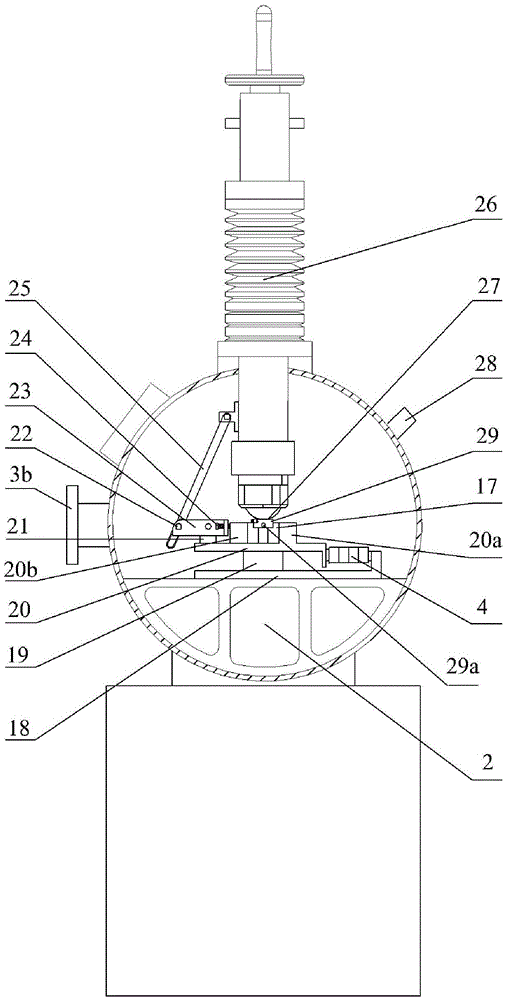

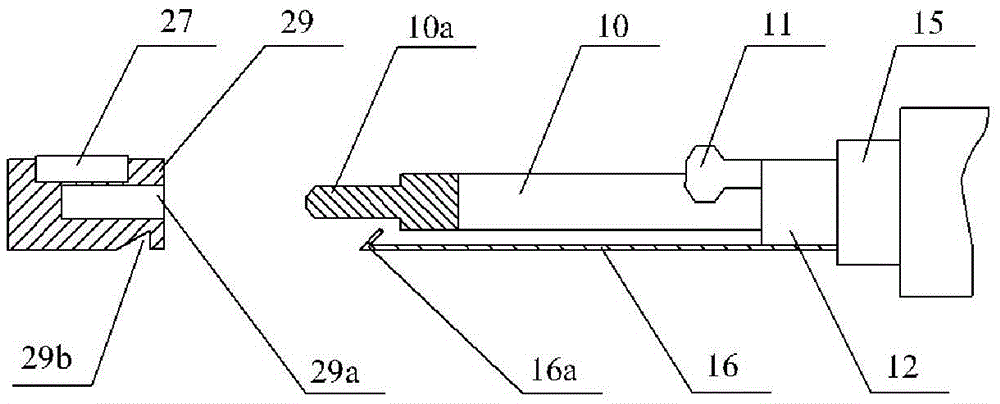

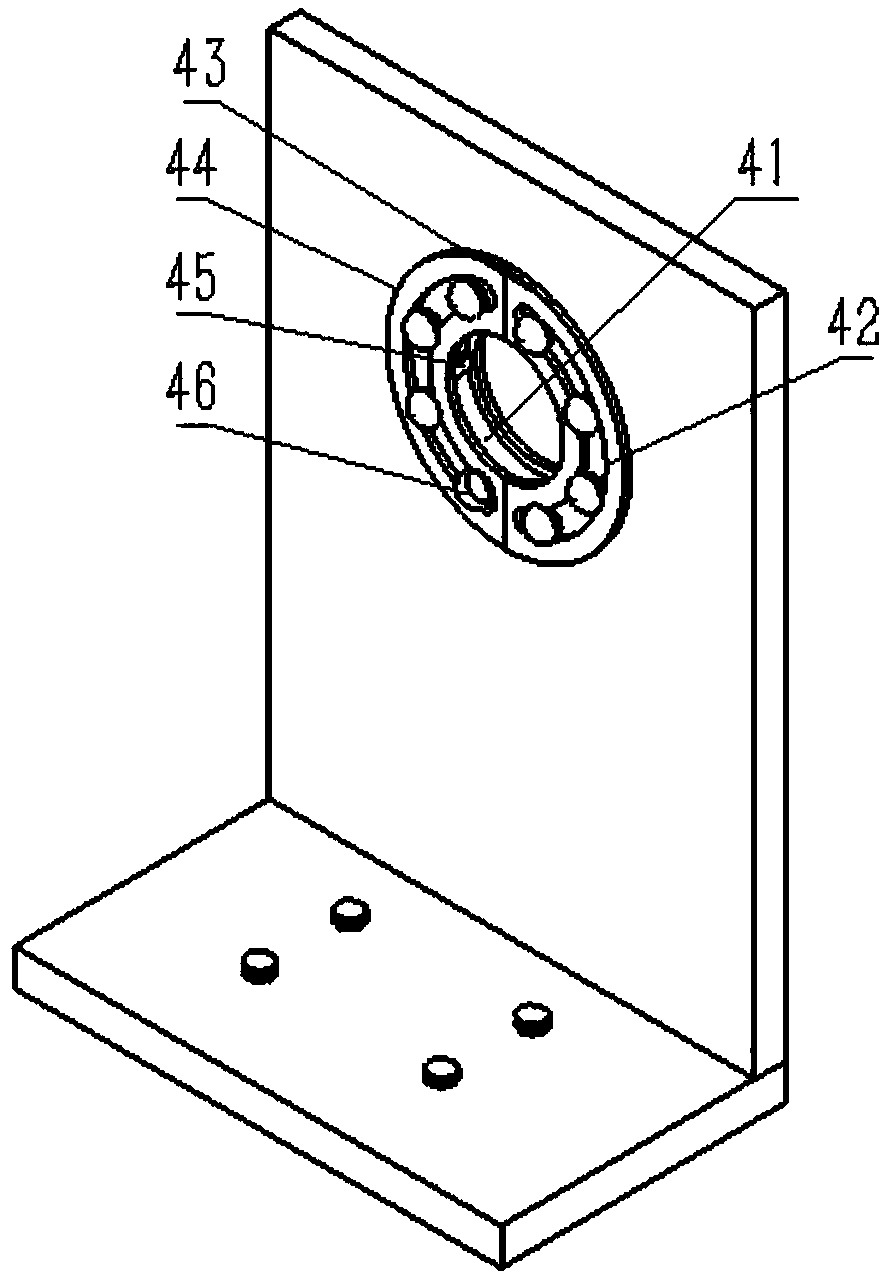

Fretting wear test device capable of conducting X-ray photoelectron spectroscopy analysis in situ

InactiveCN105606477AAccurately measure the composition of wear debrisAccurately measure its evolution lawMaterial analysis using wave/particle radiationInvestigating abrasion/wear resistanceX-rayEngineering

The invention relates to a fretting wear test device capable of conducting X-ray photoelectron spectroscopy analysis in situ. According to the main structure of the fretting wear test device, the lower middle portion of a force applying rod of a fretting wear test machine and all components below the lower middle portion are wrapped in a vacuum cavity in a sealed mode; a vacuum gauge is installed on the vacuum cavity, the left portion of the vacuum cavity is connected with a vacuum sample introduction cavity of an X-ray photoelectron spectroscopy analysis meter through a connecting pipe, the rear portion of the vacuum cavity is connected with a vacuum pump, and the right portion of the vacuum cavity is connected with a magnetic force rod in a sealed mode; a push rod is sleeved with an inner cavity of the magnetic force rod, and the peripheral face of the magnetic force rod is sleeved with a magnetic ring with magnetism; the right portion of the push rod has magnetism, and a clamping device capable of being clamped with a lower clamp of the fretting wear test machine is installed at the left end of the push rod. After a vacuum fretting wear test is completed, the fretting wear test device can immediately conduct in-situ X-ray photoelectron spectroscopy analysis on a wear crack surface and wear debris components in the same vacuum environment, and the fretting service performance and damage mechanism of materials in the vacuum environment can be obtained more accurately and reliably.

Owner:SOUTHWEST JIAOTONG UNIV +10

Recovery of lubricants from used cooling lubricants

In a method for recovering lubricant or lubricant concentrate from a used mixture containing lubricant, the mixture containing lubricant and which is substantially dewatered is subjected to short path distillation at a temperature of at least 150° C. and a pressure of less than 1.5 mbar, in order to obtain a lubricant concentrate which can be recycled into cooling lubricants and which is free of very finely wear debris, metal soaps and polymers.

Owner:HYDRO ALUMINIUM ROLLED PROD GMBH

Roller bearing

Surface indentation and oil film shortage on rollers is prevented and longer service life of a roller bearing is achieved, by preventing wear debris from being caught and accumulated in pockets of a holder of the roller bearing. Positions and dimensional relations of the diameters of inner and outer ring raceways, the inner and outer diameters of the holder, and inner and outer protrusions which are provided to pillar parts of the holder to prevent the rollers from coming off are defined such that the inner and outer protrusions of the pillar parts always do not come into contact with the outer circumferential surfaces of the rollers in the state where the rollers and the holder are incorporated between inner and outer members. As a result, lubricant oil is smoothly circulated in gaps formed between the outer circumferential surfaces of the rollers and the pillar parts of the holder.

Owner:NTN CORP

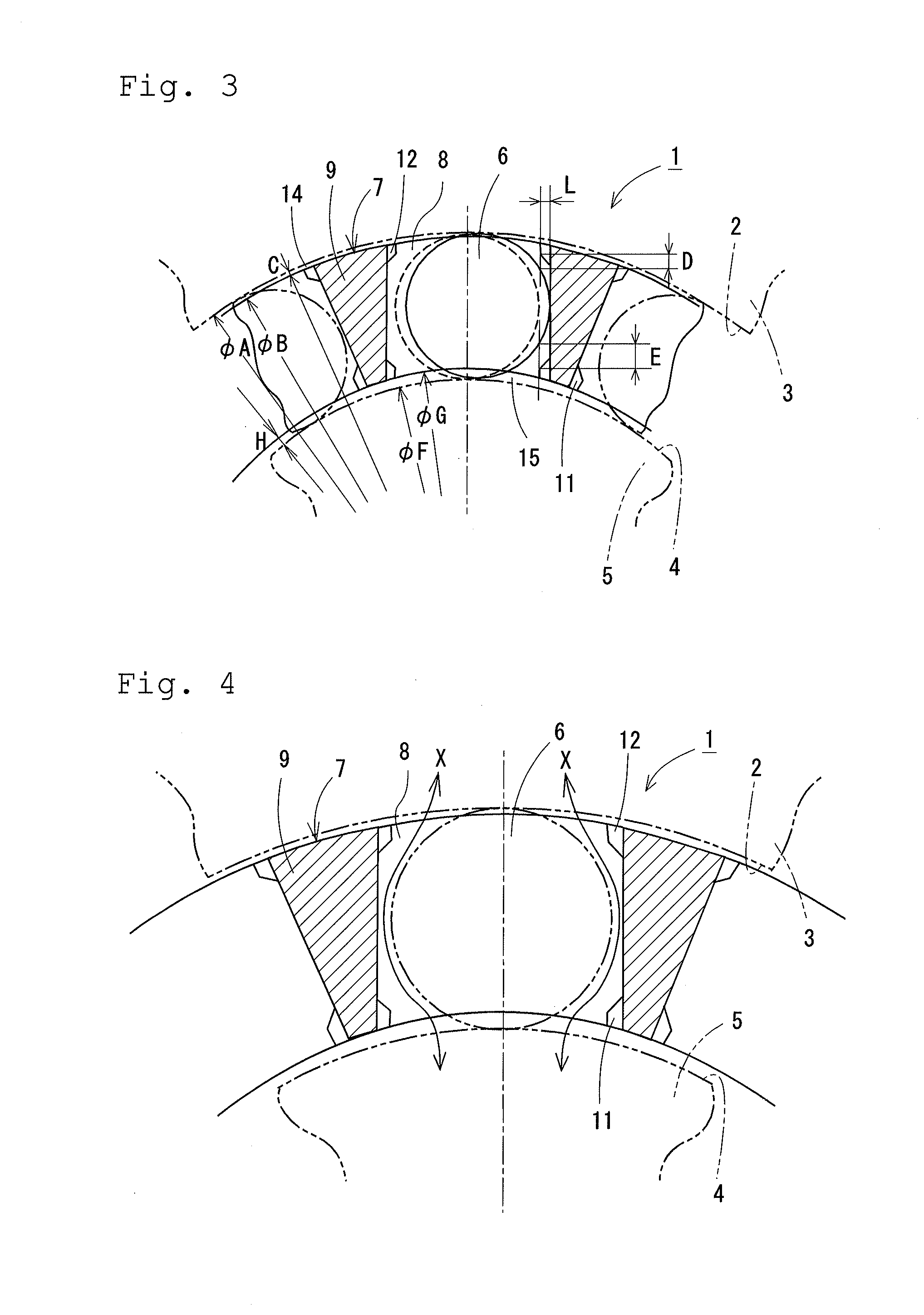

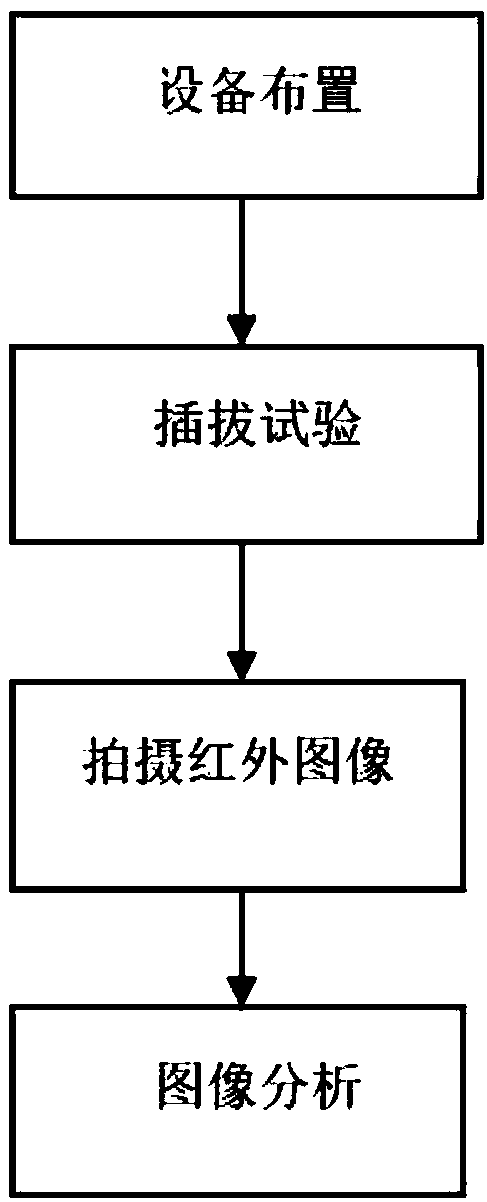

Electrical connector fretting wear detection system and method based on infrared thermography technology

PendingCN108535266AEasy to testPrecise positioningOptically investigating flaws/contaminationElectricityEngineering

The invention relates to an electrical connector fretting wear detection system and method based on an infrared thermography technology. The system comprises an insertion and extraction device used for making a to-be-detected electrical connector generate wear debris through an insertion and extraction test and a detection device used for obtaining an infrared thermogram in the insertion and extraction test of the to-be-detected electrical connector; the insertion and extraction device comprises a clamping unit; the clamping unit comprises a pin clamp used for clamping a pin without shell of the electrical connector and a jack clamp used for clamping a jack of the electrical connector, and the jack clamp and the pin clamp are installed in an aligned mode; the jack clamp is installed at thefront end of a mobile platform; the detection device comprises a direct current voltage and current stabilization source, a thermal infrared imager used for shooting the infrared thermogram in the insertion and extraction test of the to-be-detected electrical connector and a computer, the thermal infrared imager is connected with the computer, and the thermal infrared imager right faces the to-be-detected electrical connector. By means of the detection system, nondestructive real-time detection can be conducted on contact elements, and the wear debris distributing condition between the contact elements of the electrical connector can be visually, fast and accurately positioned.

Owner:HEBEI UNIV OF TECH

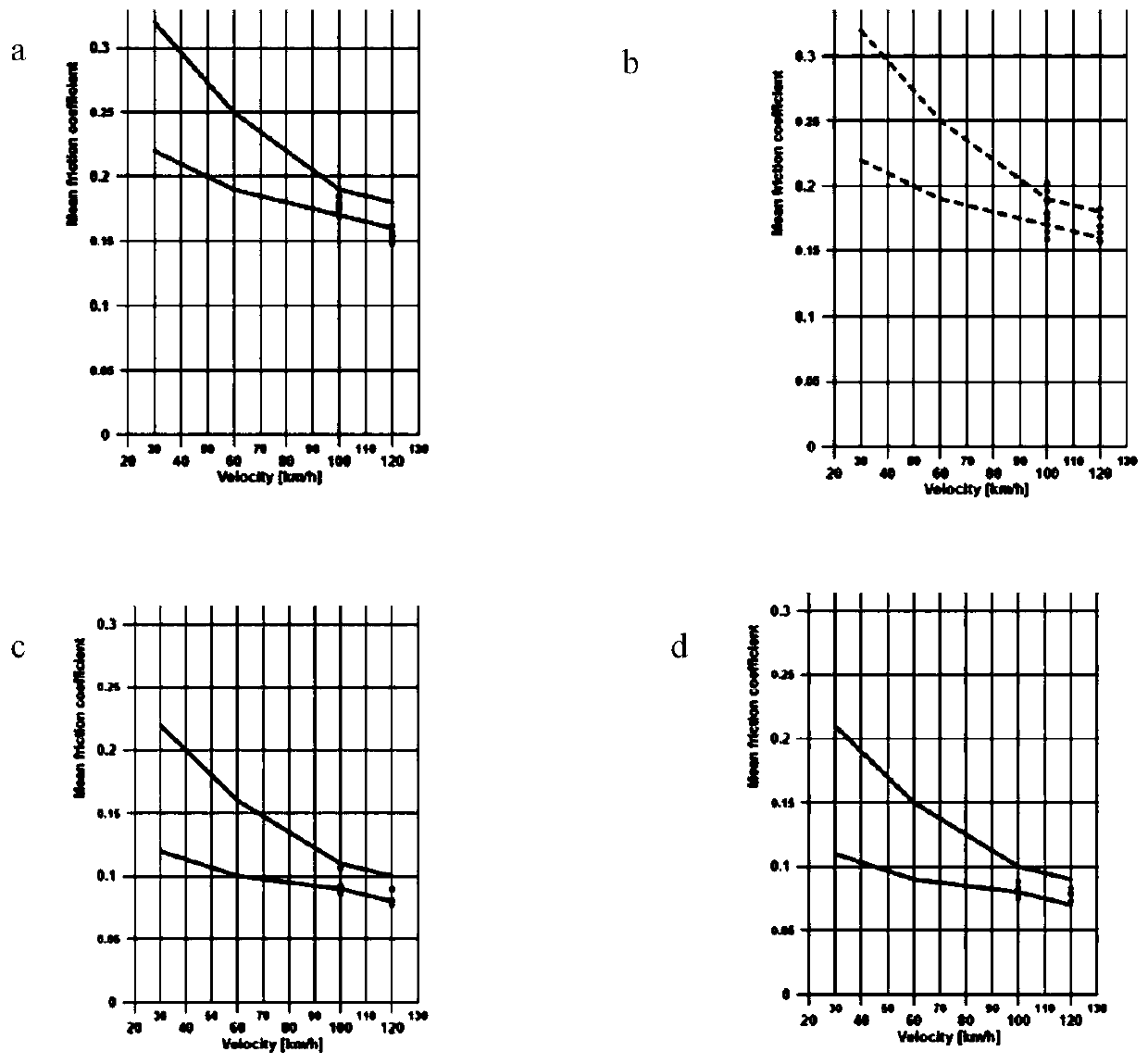

Ultralow-friction composite brake shoe for European freight train

ActiveCN109737157AReduce pollutionIncrease vibrationOther chemical processesBraking membersVulcanizationFreight trains

The invention aims to provide a composite brake shoe with the ultralow friction coefficient. The composite brake shoe can replace a cast iron brake shoe. The composite brake shoe comprises a frictionbody and a steel back. The friction body sequentially comprises, by mass percentage, 4%-8% of butadiene rubber, 4%-10% of steel fibers, 1.5%-3% of acrylic fibers, 1.5%-3% of aramid fibers, 4%-8% of liquid butadiene rubber, 18%-25% of modified phenolic resin, 20%-30% of graphite, 2%-6% of mica powder, 2%-5% of barium sulfate, 0.5%-2% of aluminum oxide, 1%-3% of iron powder, 3%-6% of calcium carbonate, 1%-2% of vulcanization accelerators and 5%-15% of other filling materials. The composite brake shoe has the ultralow friction coefficient, can fulfill the braking function instead of the cast ironbrake shoe under the condition that a braking unit is not changed, and reduces the pollution, caused by chemical components in the wear debris, to the environment.

Owner:北京浦然轨道交通科技股份有限公司 +1

Production method of maintenance-free joint shell

The invention discloses a production method of a maintenance-free joint shell, and is used for producing a ball joint shell with a ball socket which is applied to a steering pull rod of an automobile.The production method comprises the following steps of step 1, blanking; step 2, heating; step 3, forging and forming; step 4, normalizing; step 5, performing rough machining; step 6, tempering; step7, semi-finish turning; step 8, high-frequency quenching; step 9, low-temperature tempering; and step 10, swinging and grinding. According to the production method of the maintenance-free joint shell, an inner ball finish turning in the original process is changed into swing grinding, the ball joint shell is installed on a special tool, swinging and rotating at the same time, and the height of the center of a swinging shaft and the sphere center of the ball joint shell are kept consistent; a ball cubic boron nitride grinding wheel is used for grinding, and crossed meshes are formed on the ball surface; the functions of collecting, eliminating abrasion chippings and self-lubricating are achieved, production quality is stable, damage is not easy caused, maintenance is not needed, and the mechanical performance after final assembly is good; and meanwhile, the production process has the advantages of being high in production efficiency, free of the grinding wheel maintenance and saving incost.

Owner:宣城东海汽车转向部件有限公司

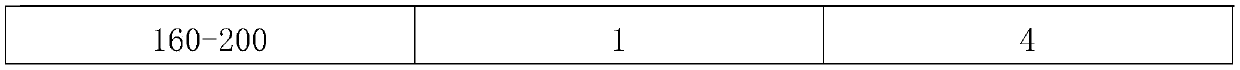

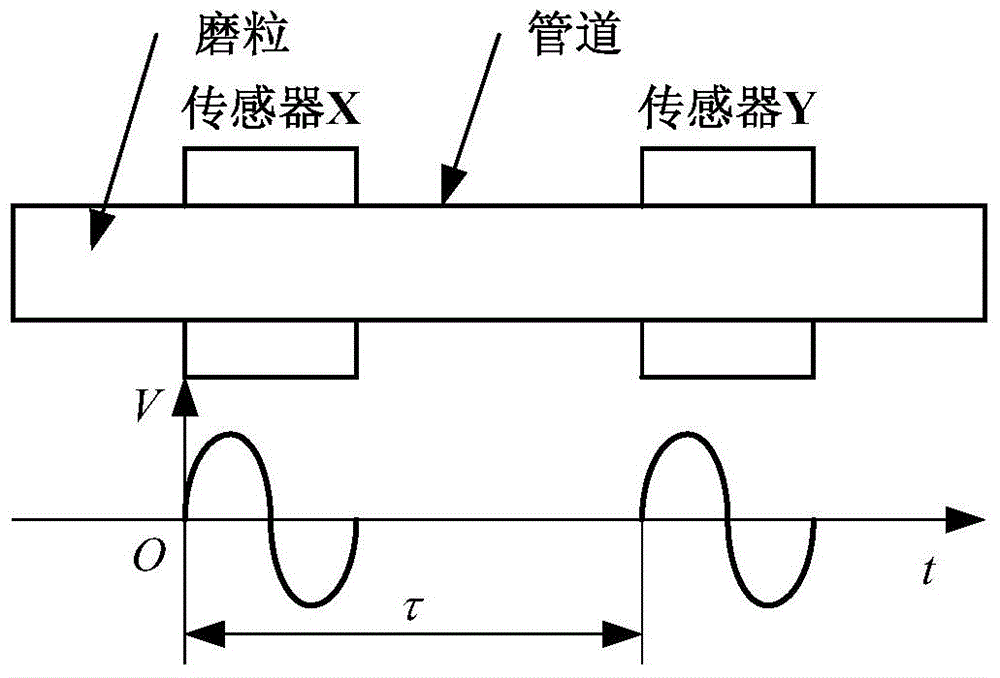

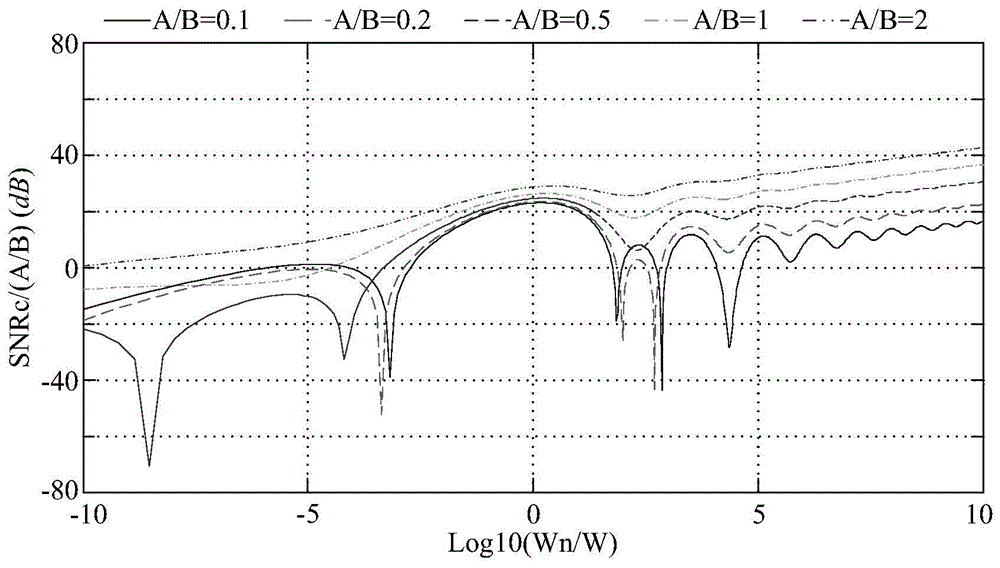

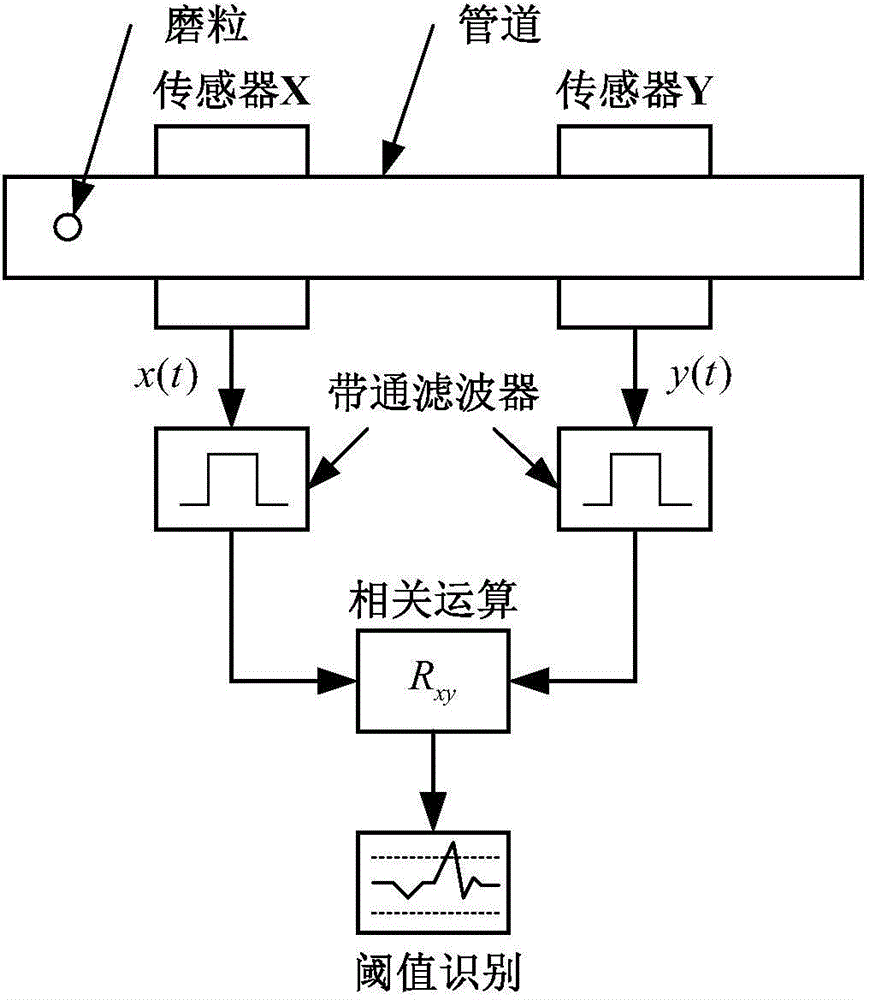

Wear debris sensor sensitivity increasing method based on combination of band-pass filtering and correlation operation

InactiveCN104792668AImprove signal-to-noise ratioAvoid local deteriorationMaterial analysisEngineeringFailure diagnosis

The invention discloses a wear debris sensor sensitivity increasing method based on combination of band-pass filtering and correlation operation to increase the signal sensitivity of existing wear debris sensors. On the basis of the existing inductive wear debris sensors, two sensors are connected in series and mounted in an oil pipeline, and the sensitivity of acquired signals of the two sensors can be increased by 2.76 times with the method, so that smaller wear debris can be detected, and the method is applied to failure diagnosis based on wear debris information.

Owner:BEIHANG UNIV

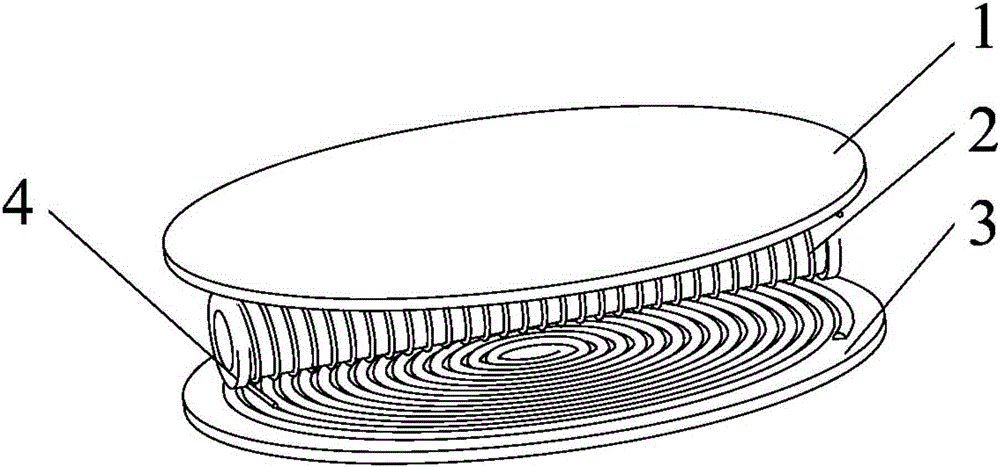

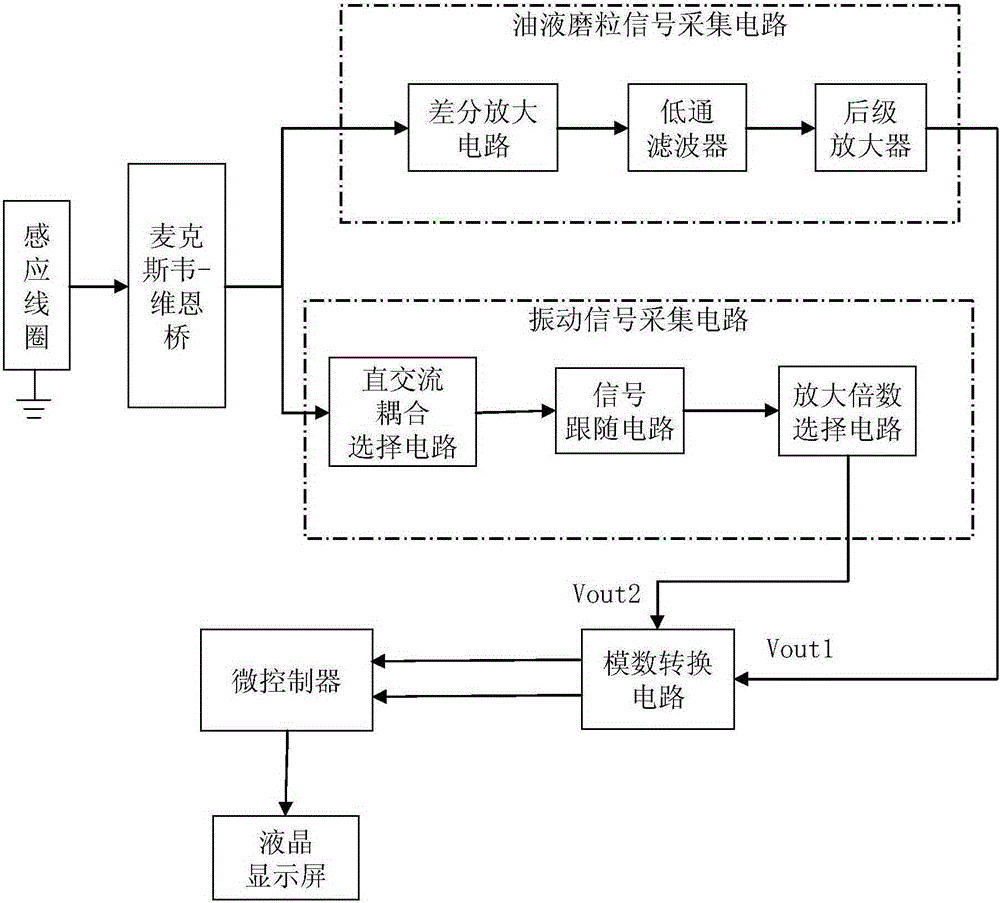

Oil wear debris monitoring sensor with vibration signal output characteristic and on-line oil monitoring system

ActiveCN105181534AReduce volumeRealize online fault monitoringInternal-combustion engine testingVibration testingMicrocontrollerLubrication

The invention provides an oil wear debris monitoring sensor with a vibration signal output characteristic and an on-line oil monitoring system. An induction coil of the monitoring sensor is located between two overlapped and parallel plane coils which are connected with a constant-current source, wherein the axis of the induction coil is parallel to the plane coils, and gaps are formed between the induction coil and the plane coils; the length of the induction coil is smaller than the outer diameter of each plane coil. The sensor of the on-line oil monitoring system is mounted in a lubrication circuit of a mechanical device, an output of the induction coil of the sensor is connected to a Maxwell-Wien bridge, outputs of the Maxwell-Wien bridge are connected with an oil wear debris signal acquisition circuit and a vibration signal acquisition circuit respectively and then connected to a microcontroller via an analog-digital conversion circuit; a comprehensive fault analysis module is arranged in the microcontroller which is connected with a display screen, metal wear debris signals and vibration signals are displayed on line, and the current fault information of the mechanical device is displayed. The mechanical fault can be judged timely and accurately, and the system is small in size and portable and can be mounted to a mobile device for on-line fault monitoring.

Owner:GUILIN UNIV OF ELECTRONIC TECH

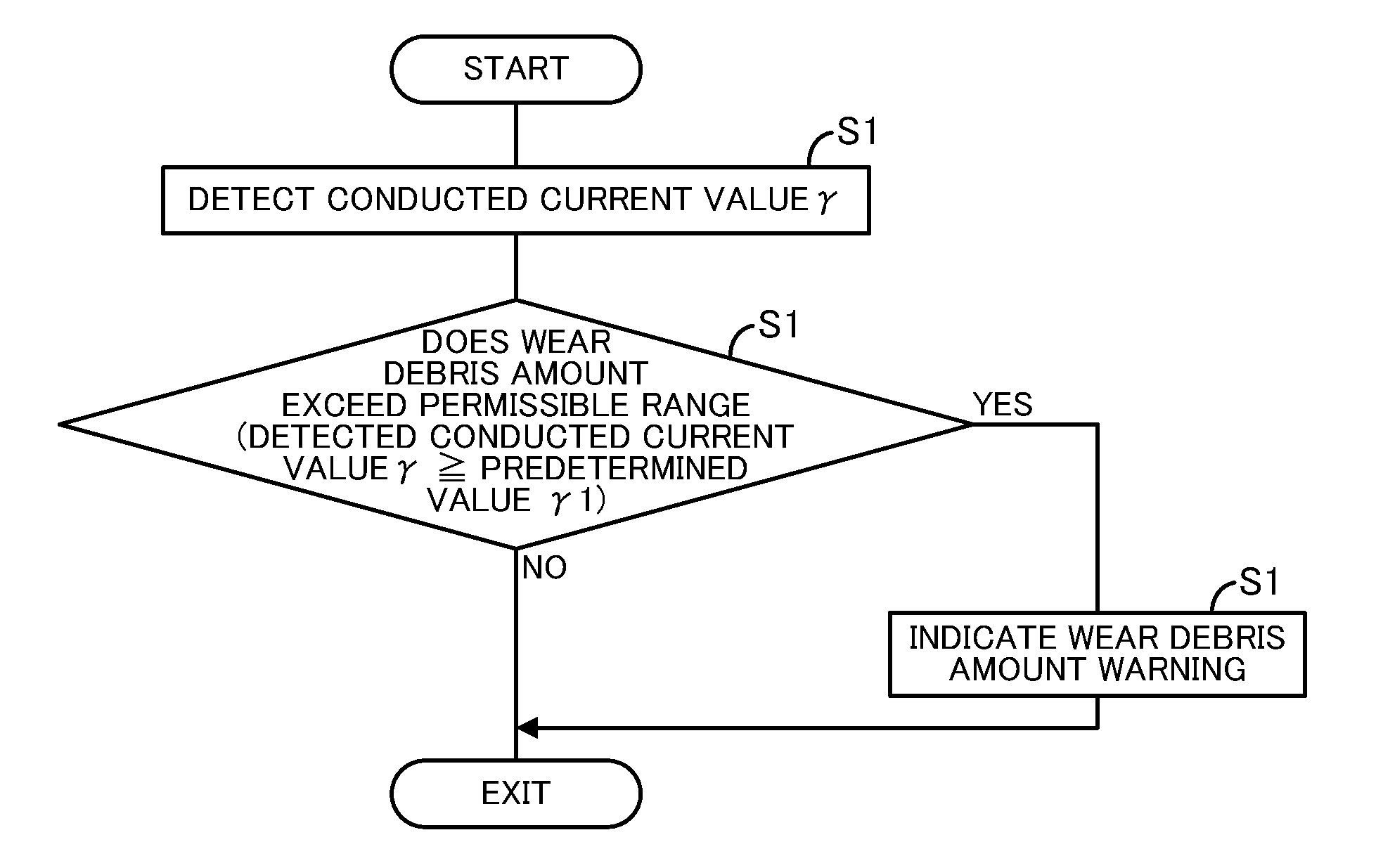

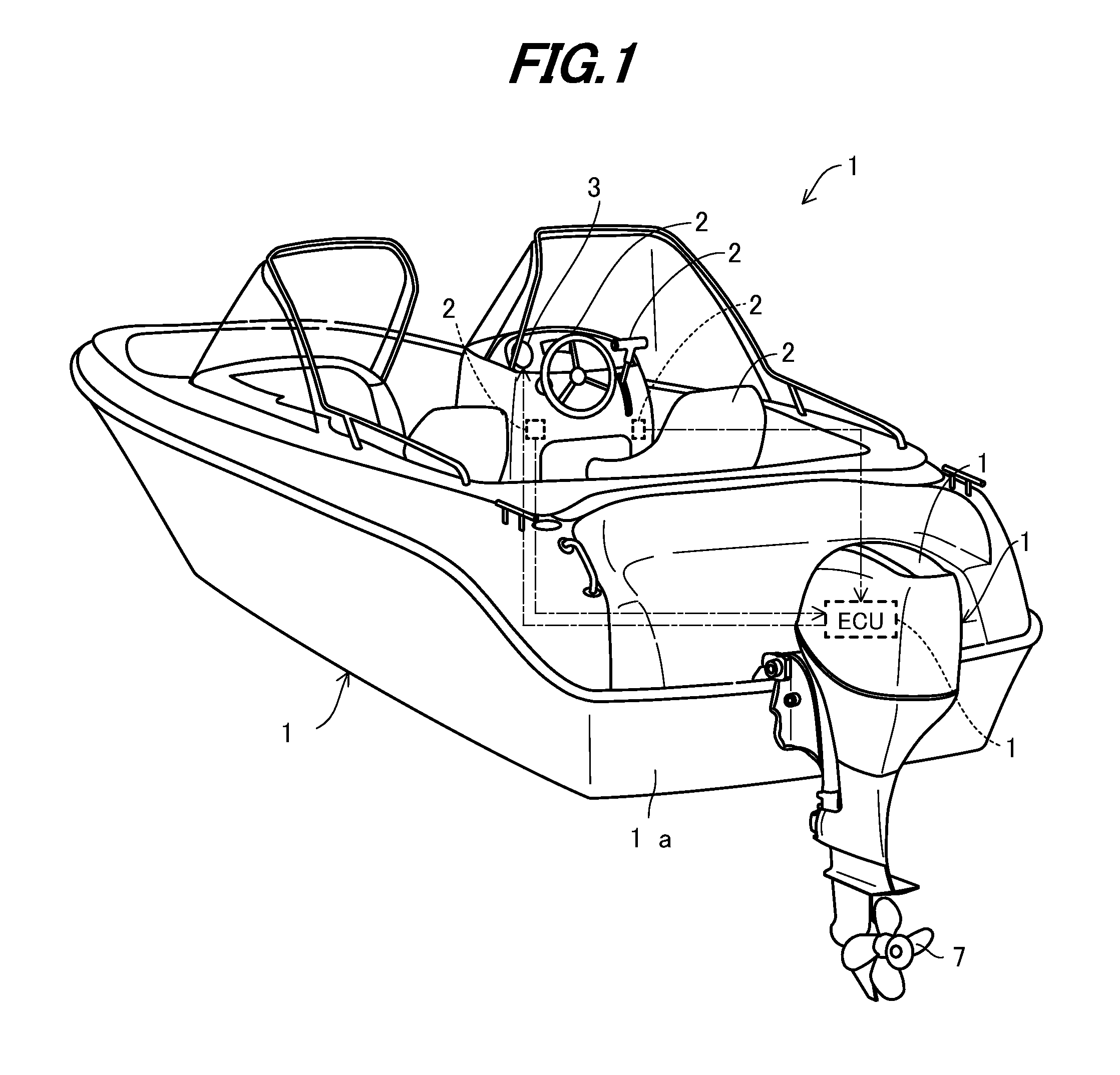

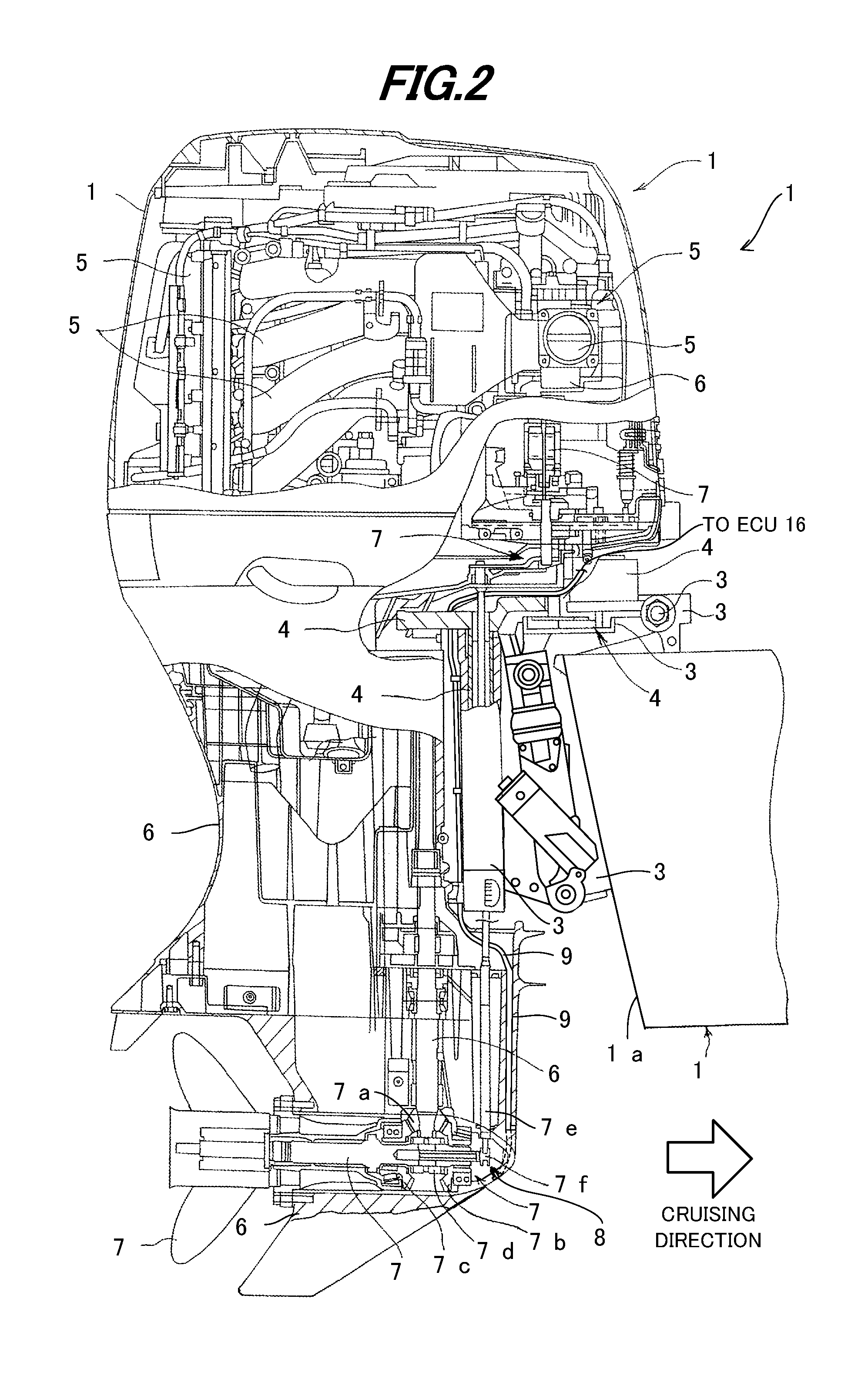

Outboard motor

InactiveUS20130130573A1Propulsion power plantsOutboard propulsion unitsElectrical resistance and conductanceElectrical conductor

In an outboard motor having a prime mover, a gear mechanism transmitting a driving force of the prime mover to a propeller, and a gear case housing the gear mechanism, it is configured to have a drain bolt fastened to a drain hole bored at the gear case and constituted as a magnetic member; a stacked portion provided at an exposed part of the drain bolt in an inside of the gear case and having a conductor, an insulator and a resistive element partially making contact with the conductor that are stacked in a gravitational direction; a current detector detecting a current value conducted from the conductor to the drain bolt under a condition where voltage is applied to the conductor; and a wear debris amount detector adapted to detect an amount of wear debris of the gear mechanism deposited at the drain bolt based on the conducted current value.

Owner:HONDA MOTOR CO LTD

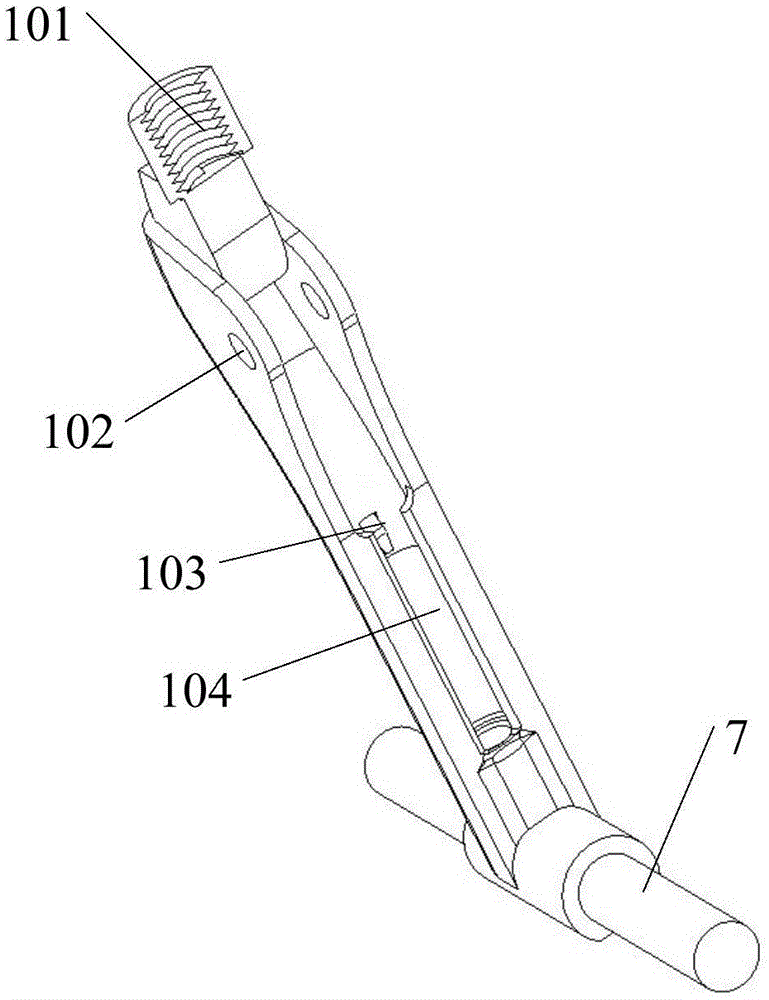

Stud assembly and disassembly tool

ActiveCN104999415APrevent slidingIncrease profitWork holdersMetal-working hand toolsEngineeringScrew joint

The invention belongs to the technical field of automobile parts, and provides a stud assembly and disassembly tool, which comprises an opening and closing mechanism and a driving mechanism for driving the opening and closing mechanism to be opened and closed, wherein the opening end of the opening and closing mechanism is provided with internal thread matched with external thread of the stud; and the stud is in screw joint with the internal thread and is clamped via the driving mechanism. Through arranging the opening and closing mechanism which is matched with the stud and the driving mechanism for driving the opening and closing mechanism, the internal thread of the opening and closing mechanism clamps the stud; as the internal thread and the external thread of the stud are matched and clamped via the driving mechanism, sliding of the stud and the opening and closing mechanism during the assembly and disassembly process can be prevented, thread of the stud can be protected, wear debris is not generated, the thread can be protected, the stud can be reused after assembly and disassembly, and the utilization rate of the element is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

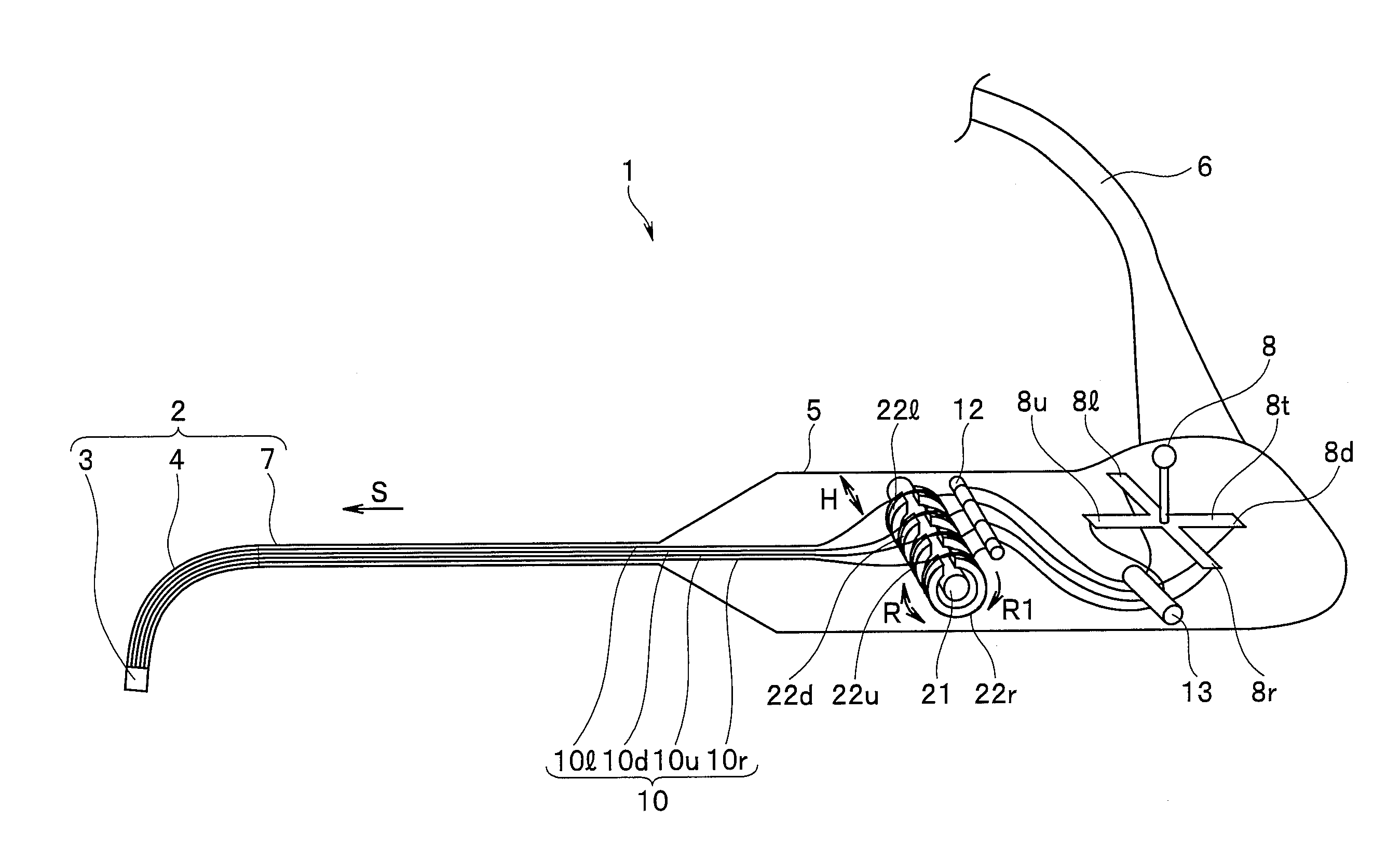

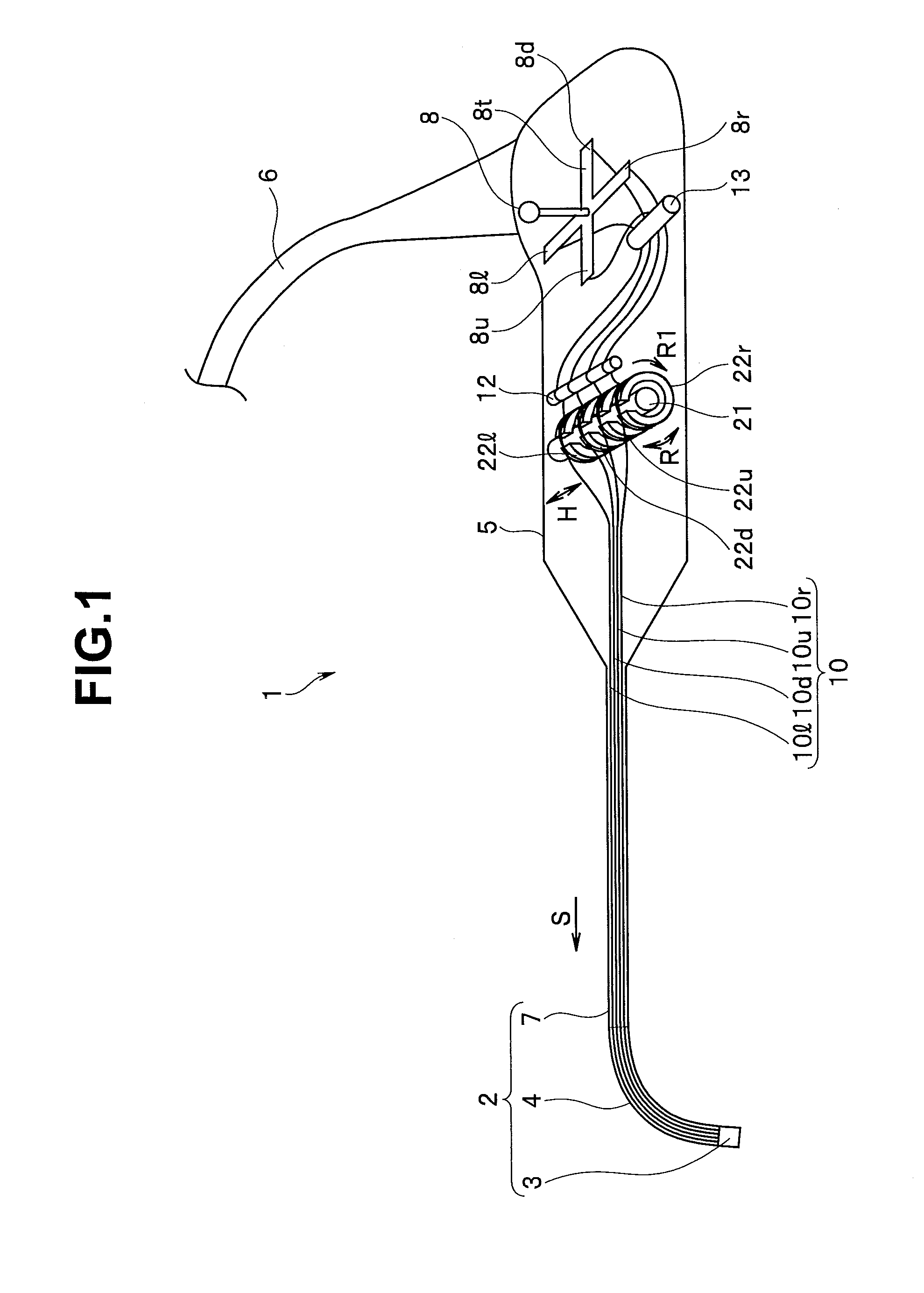

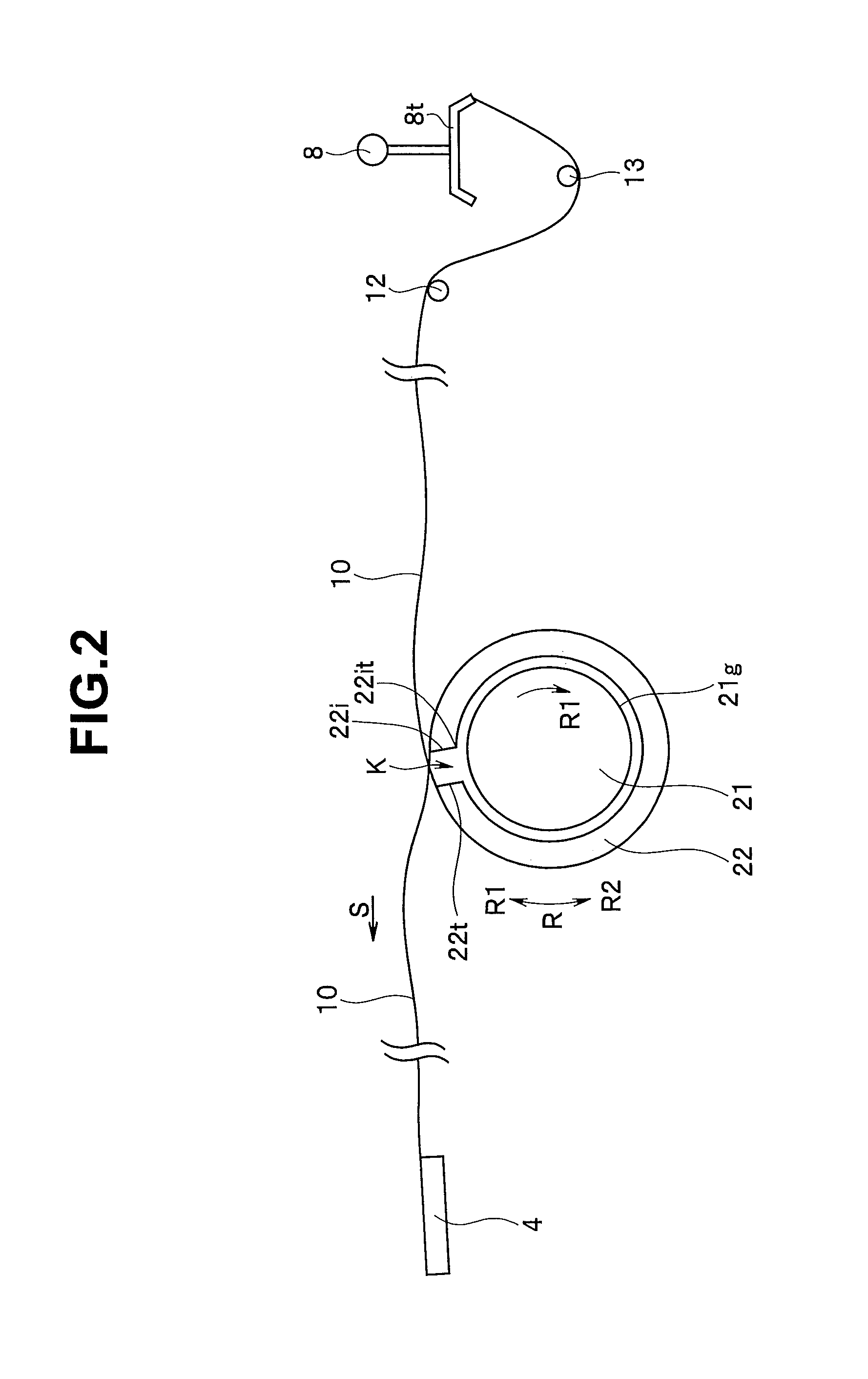

Insertion apparatus

An insertion portion, a bending portion, a joystick, a pulling wire, a pulley, a C-shaped ring, and an end portion of a cutout portion that is provided at the C-shaped ring, and removes wear debris that is scraped from the pulley with contact of the C-shaped ring to the pulley from the pulley are provided.

Owner:OLYMPUS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com