Fretting wear test device capable of conducting X-ray photoelectron spectroscopy analysis in situ

A photoelectron spectroscopy and fretting wear technology, which is applied in the direction of material analysis, measurement device, and material analysis using wave/particle radiation. The effect of reliable data support, reliable fretting service performance, and accurate evolution law

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

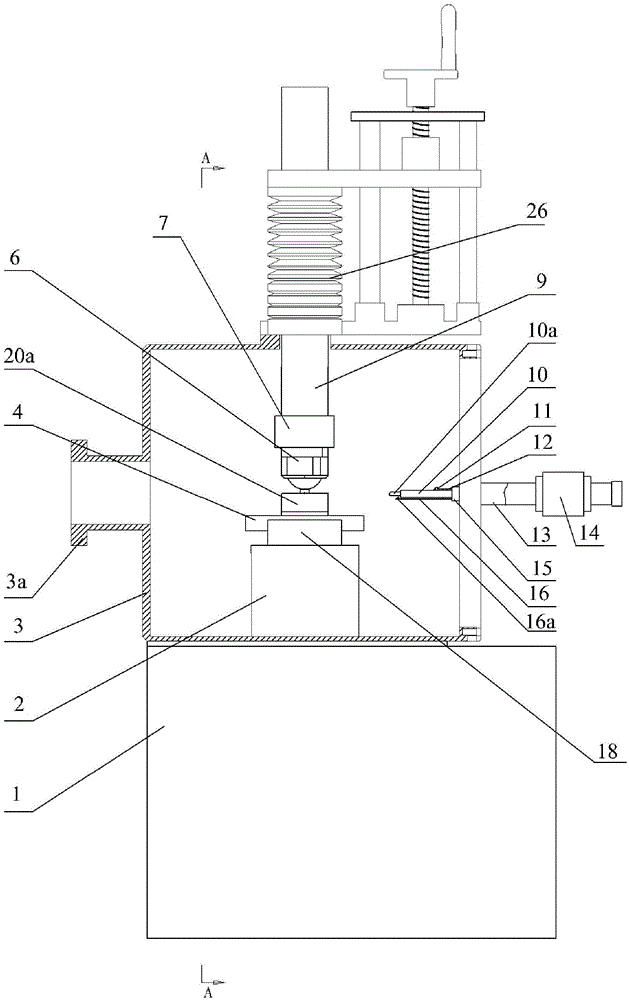

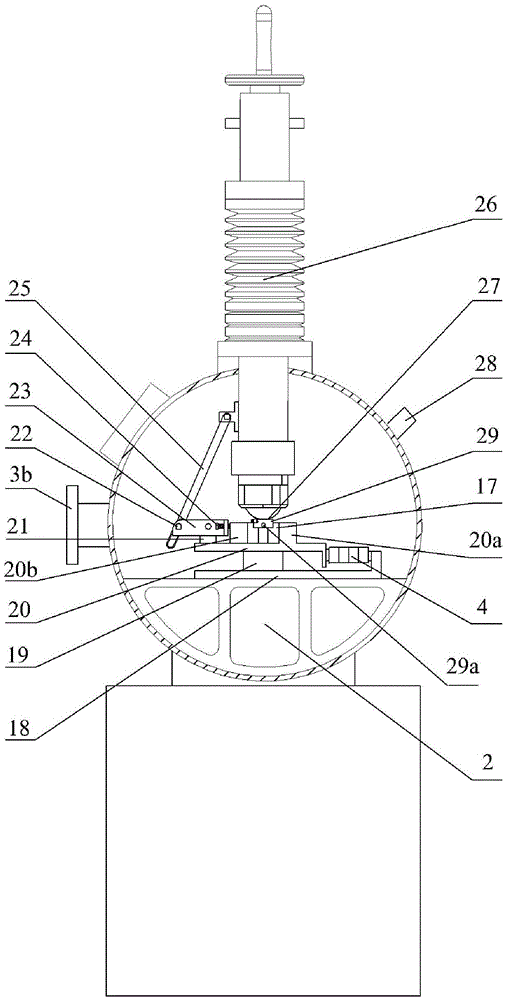

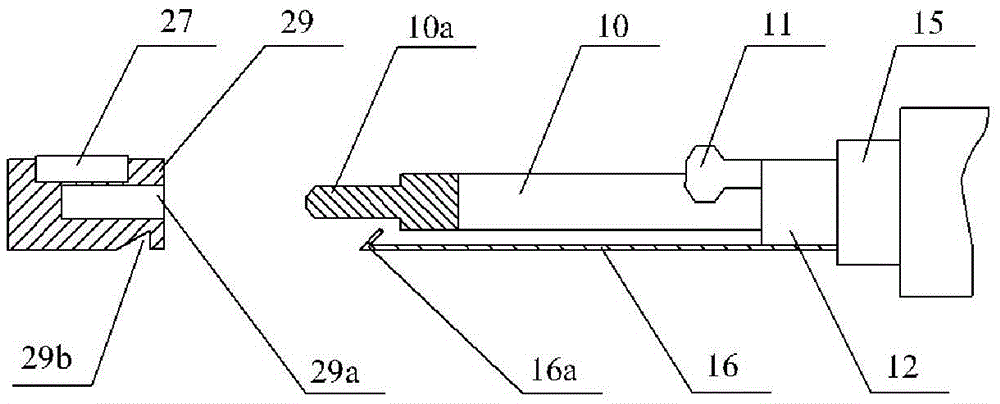

[0034] Figure 1-3 Shown, a specific embodiment of the present invention, a fretting wear test device that can perform X-ray photoelectron spectroscopy analysis in situ, including X-ray photoelectron spectroscopy analyzer, fretting wear testing machine, fretting wear tester The force applying rod 9, the three-dimensional force sensor 7, the upper clamp 6, the lower clamp 29 and the lower clamp fixing mechanism on the machine are characterized in that:

[0035]The middle and lower part of the force applying rod 9, the three-dimensional force sensor 7, the upper clamp 6, the lower clamp 29 and the fixing mechanism of the lower clamp are all sealed and wrapped in the vacuum chamber 3, and the bottom of the vacuum chamber 3 is installed on the box-shaped base 1 the top of;

[0036] Vacuum gauge 28 is installed on the described vacuum chamber 3, and the left part of vacuum chamber 3 is provided with horizontal connection pipe 3a, and connection pipe 3a is connected with the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com