Engine flush process and composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

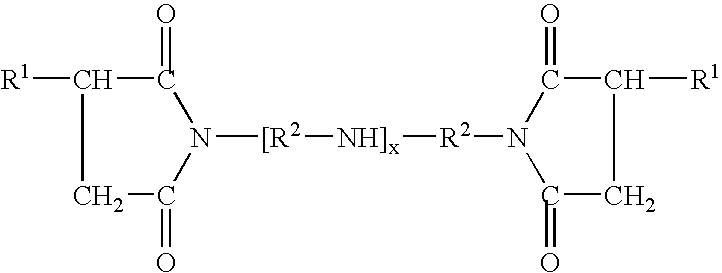

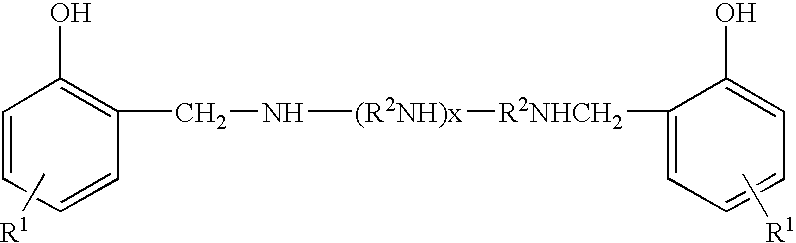

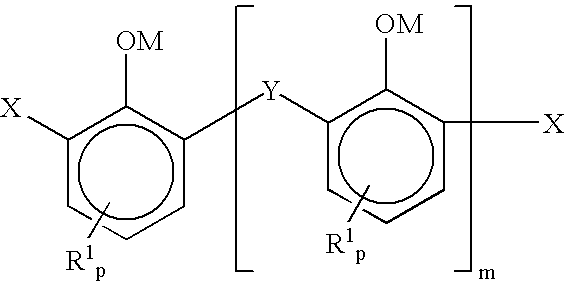

Method used

Image

Examples

example 1

[0065] A composition is prepared in a mixture of base oils (50% 400 N naphthenic oil and 50% 100 N API Group I oil), having a viscosity at 100° C. of 2.14 mm2 / s and 22% aromatic content, 5% of a succinimide dispersant, 1% of a hindered phenolic ester antioxidant, 1.4% overbased calcium and sodium sulfonate detergents, 1.4% zinc dialkyldithiophosphate, 0.4% trialkyl (relatively short chain) borate ester, 0.3% sulfurized olefin antioxidant, 0.1% alkyl sulfone and 10 ppm antifoam agent, all numbers on a diluent oil-free basis.

[0066] A 3.8 L six-cylinder gasoline engine is evaluated for high temperature poston deposits by the protocol set forth in ASTM Sequence IIIG Test Procedure Draft 2D prior to the flushing and cleaning of the present invention. Each piston is evaluated at the undercrown, second land, third land, piston skirt, 1st groove, 2nd groove, and 3rd groove positions. The weighted piston deposit result is determined by multiplying each rated area by the following weighting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com