Mass production method for calcium sulfate whisker

A calcium sulfate whisker, large-scale technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of low reaction concentration and inability to achieve large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

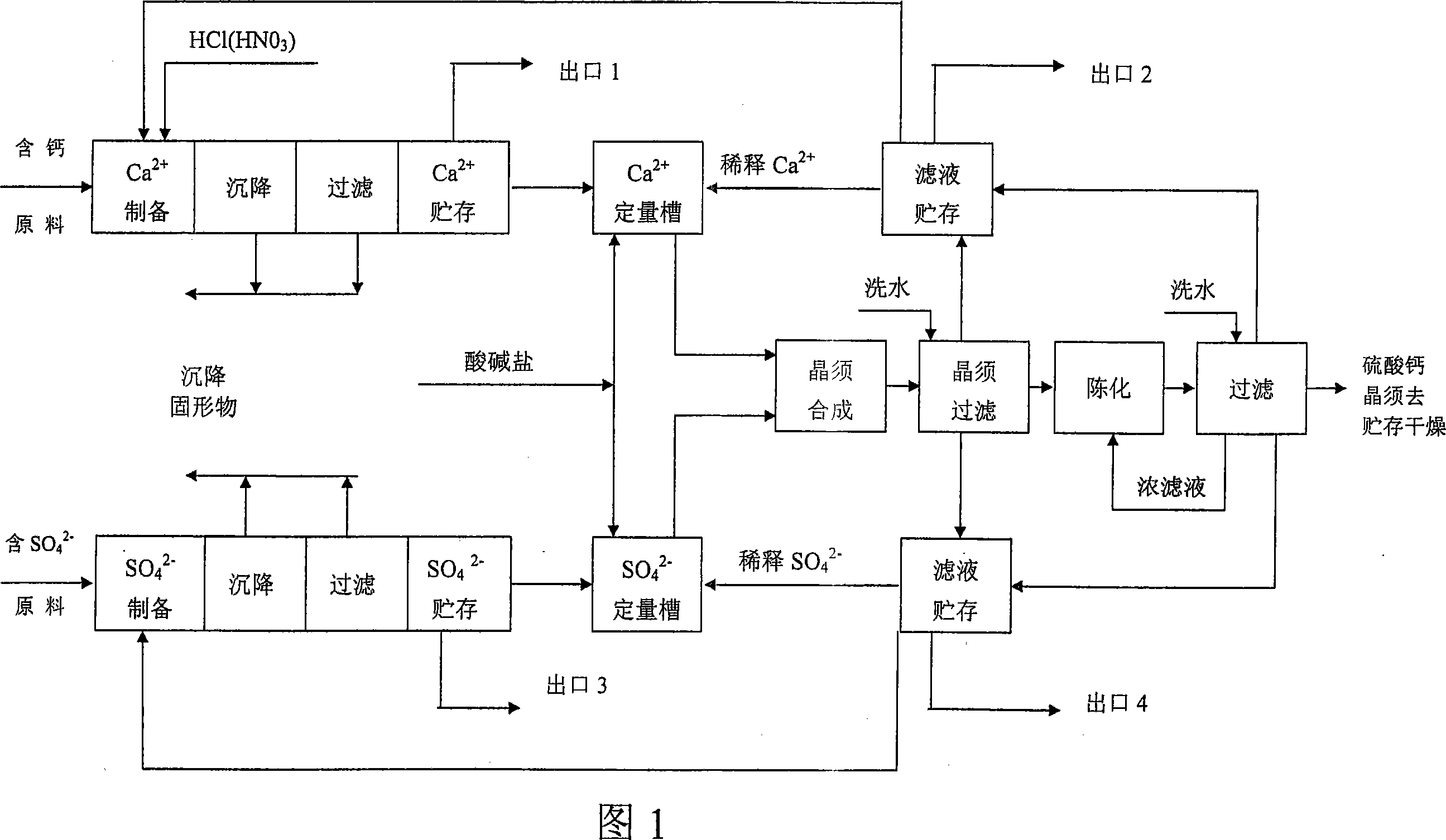

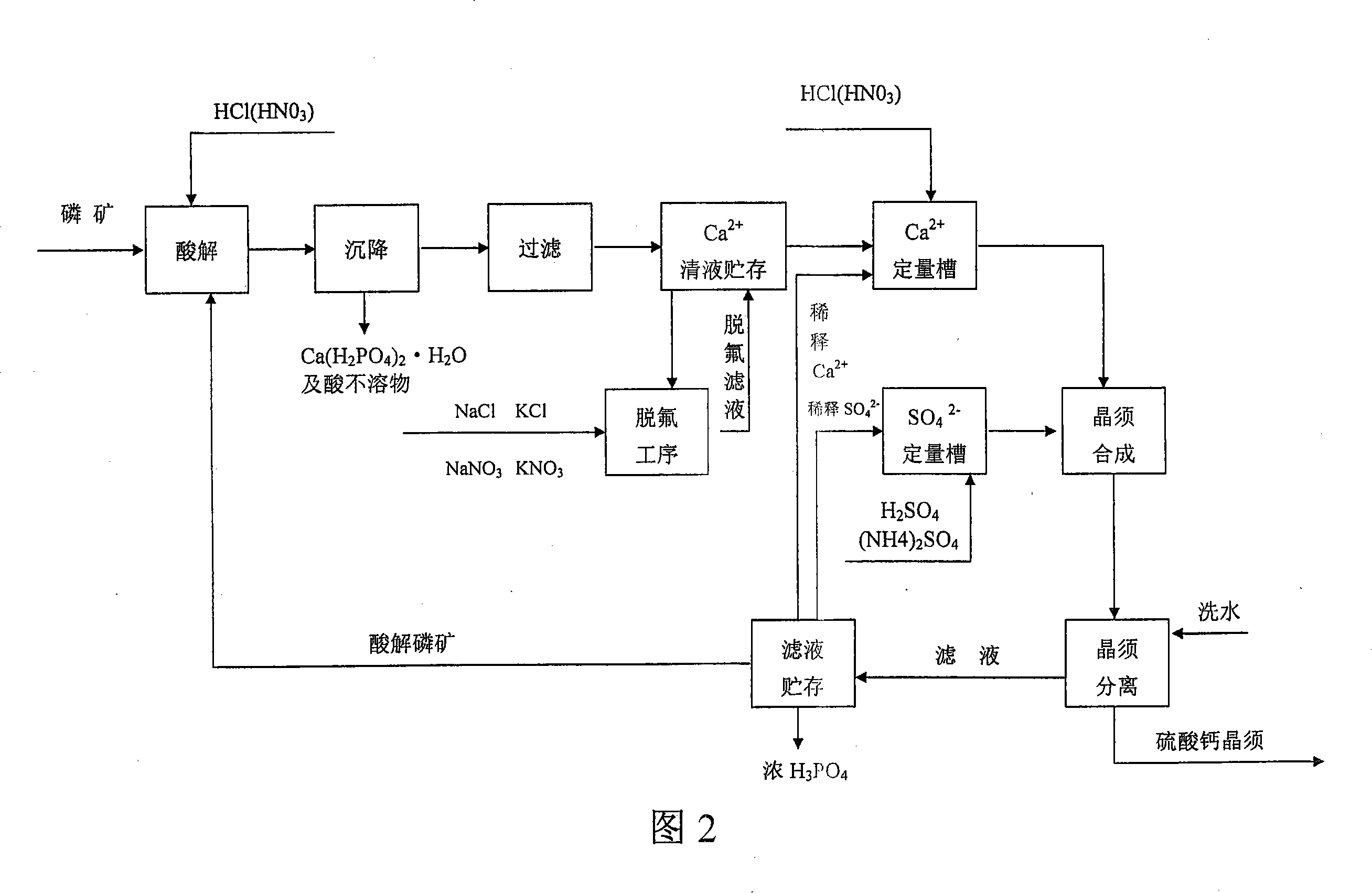

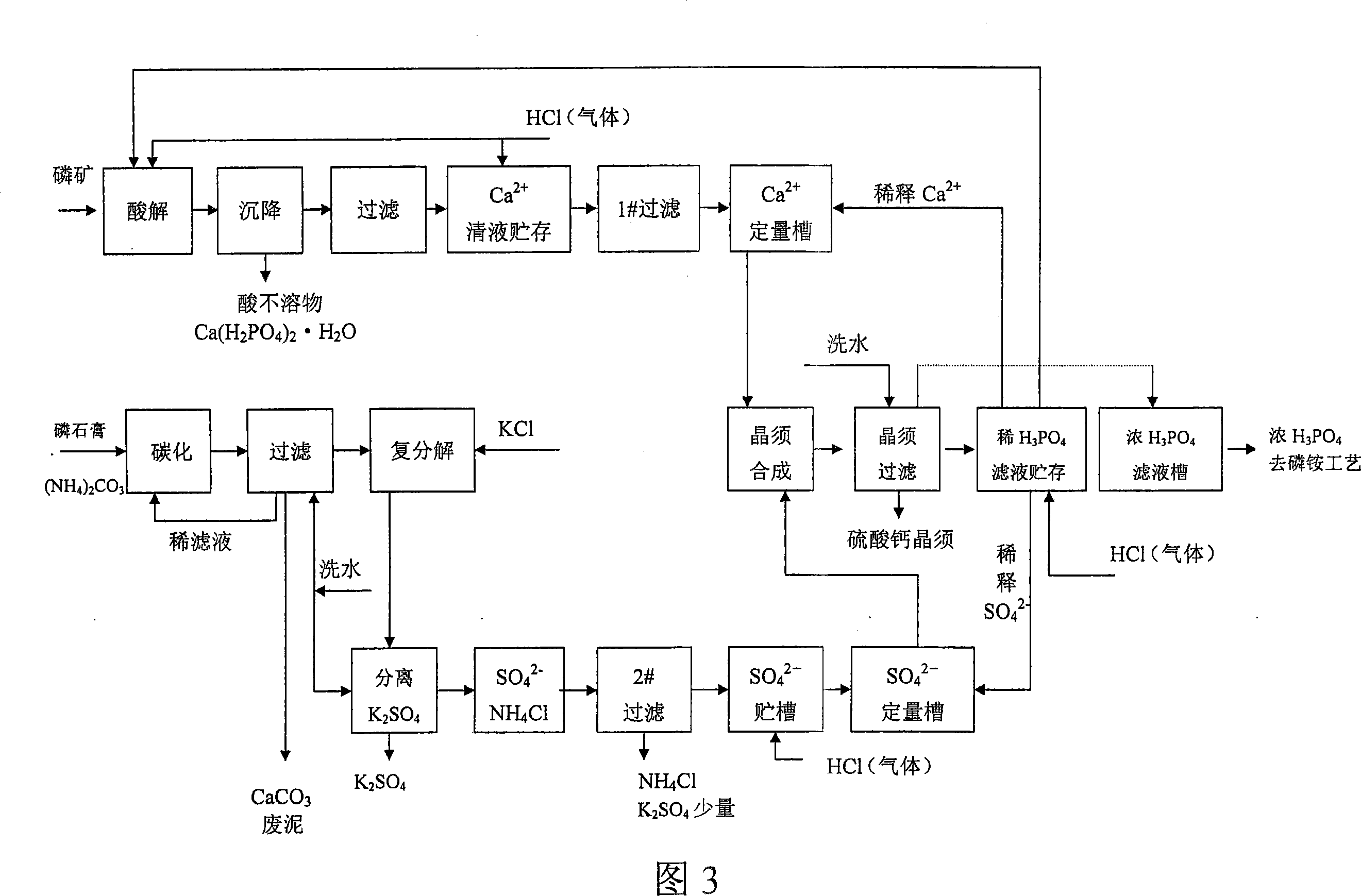

[0047] 1. Invention principle:

[0048] The methods provided by the background art all have one thing in common: that is, whether it is using raw gypsum or using Ca 2+ and SO 4 2- Ions are used as raw materials, no matter in alkaline (hydrothermal synthesis method), acidic and neutral, aqueous solution or organic solution, the essence of calcium sulfate whisker generation is to use Ca in solution. 2+ and SO 4 2- Under specific conditions and according to specific requirements, it can produce needle-shaped products of pure calcium sulfate, especially calcium sulfate hemihydrate whiskers with a diameter of 1-10um, a length of 50-800um, and an aspect ratio of 20-500. Practical and also easy to manufacture. Based on the application technology of 200510067111.5 and 200610149043.1 invention patents, the present invention uses a small-scale experimental process equipment with a daily output of 3 tons of calcium sulfate whiskers to verify the following whisker reaction principles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com